Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2857results about How to "Small temperature difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

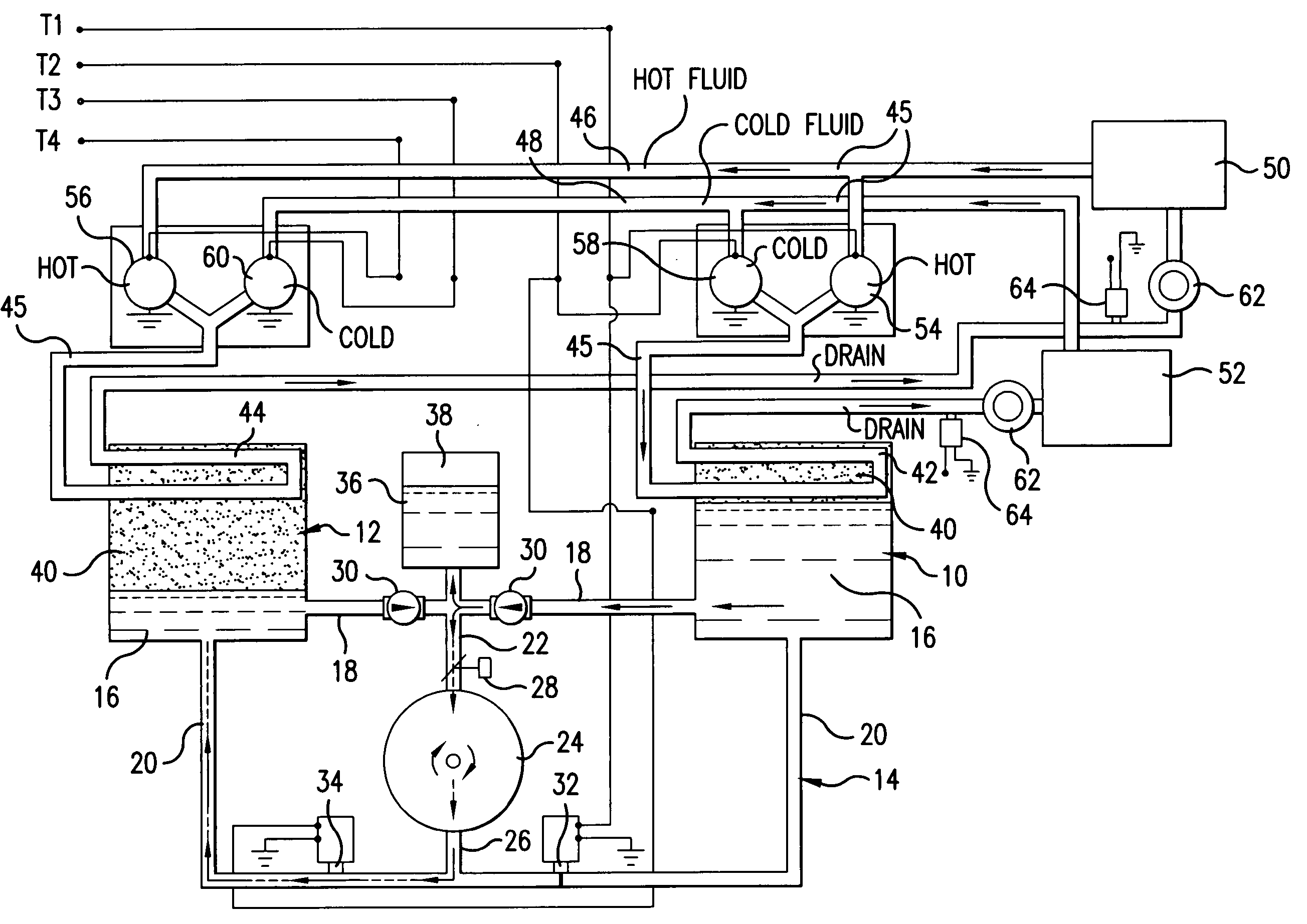

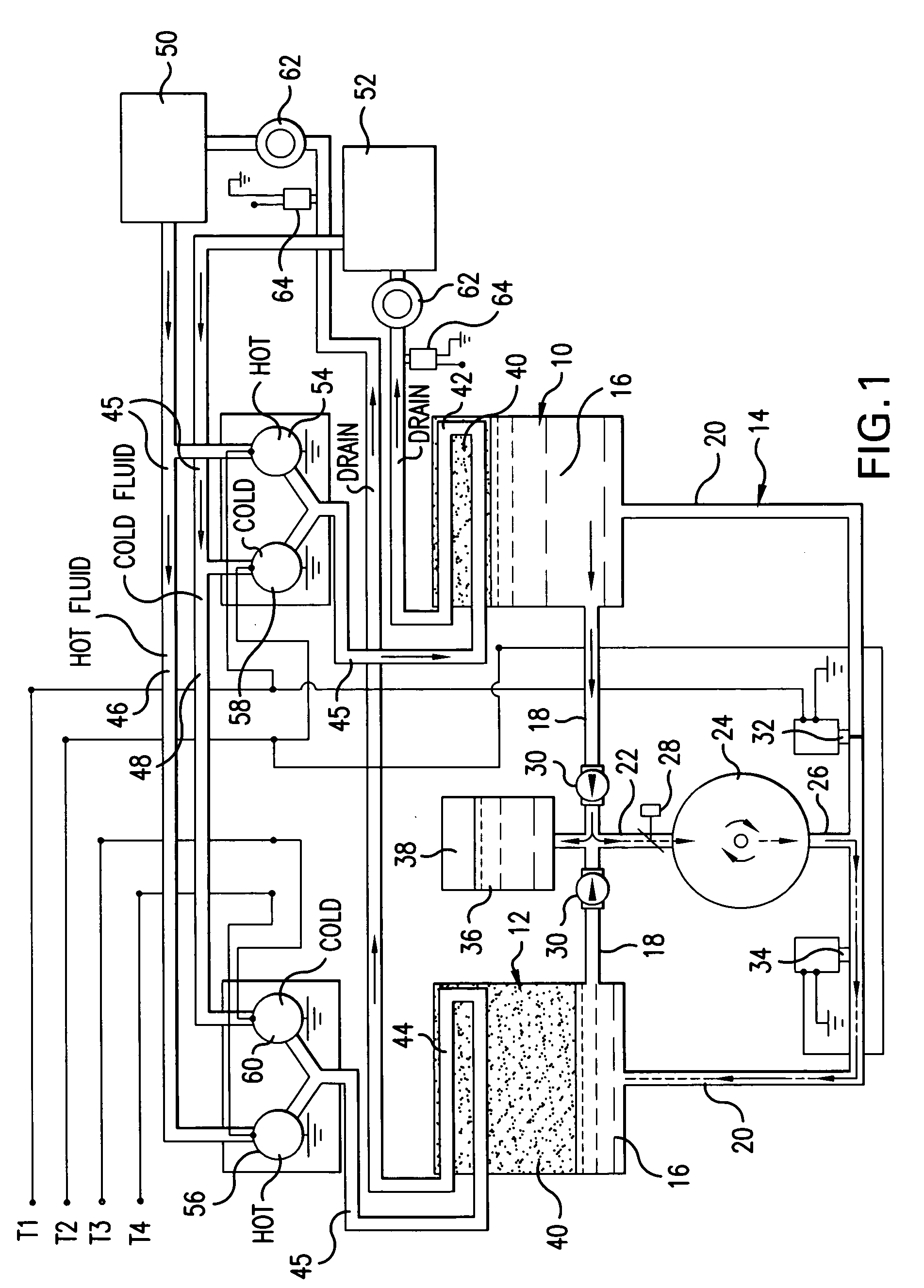

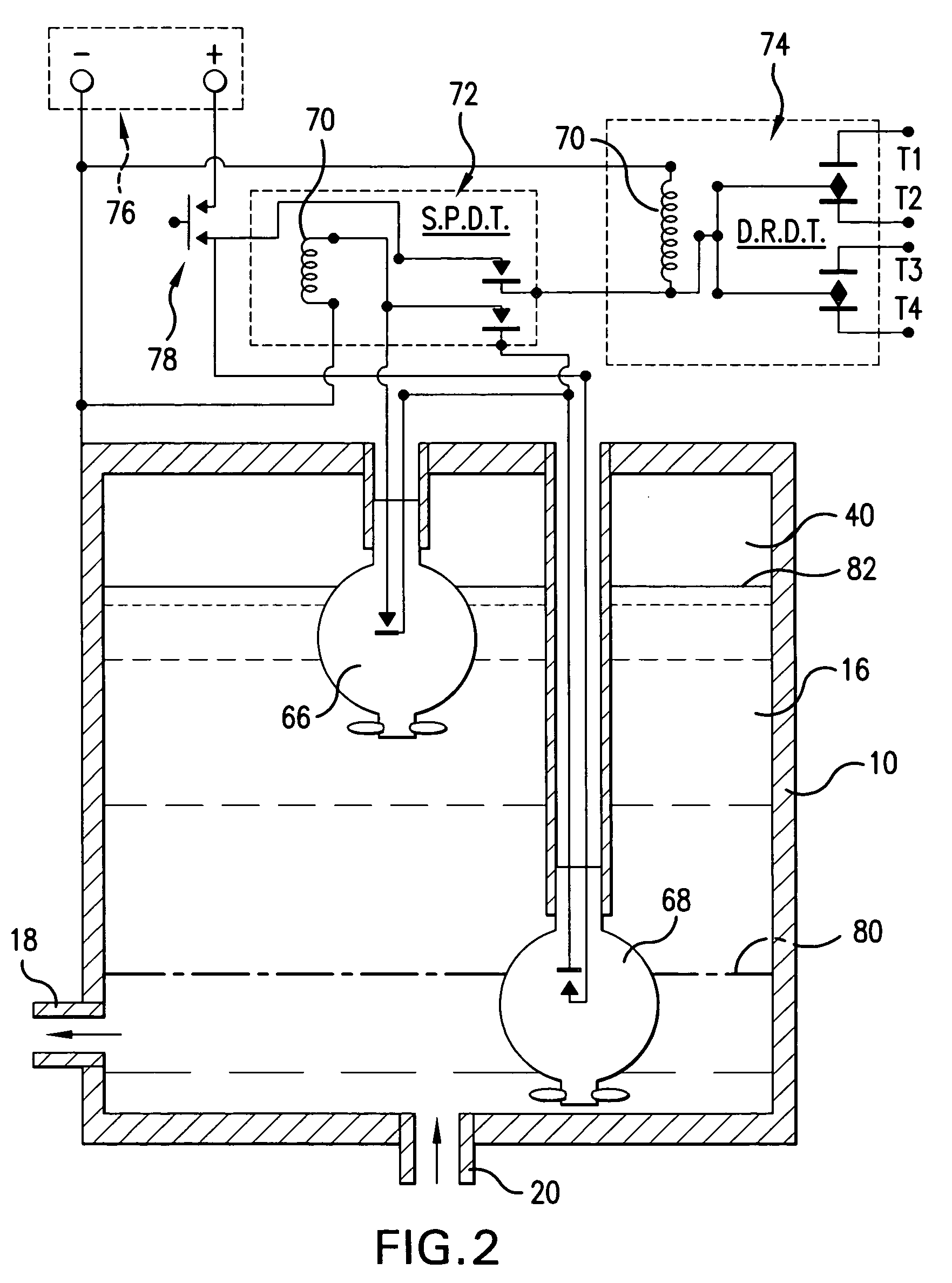

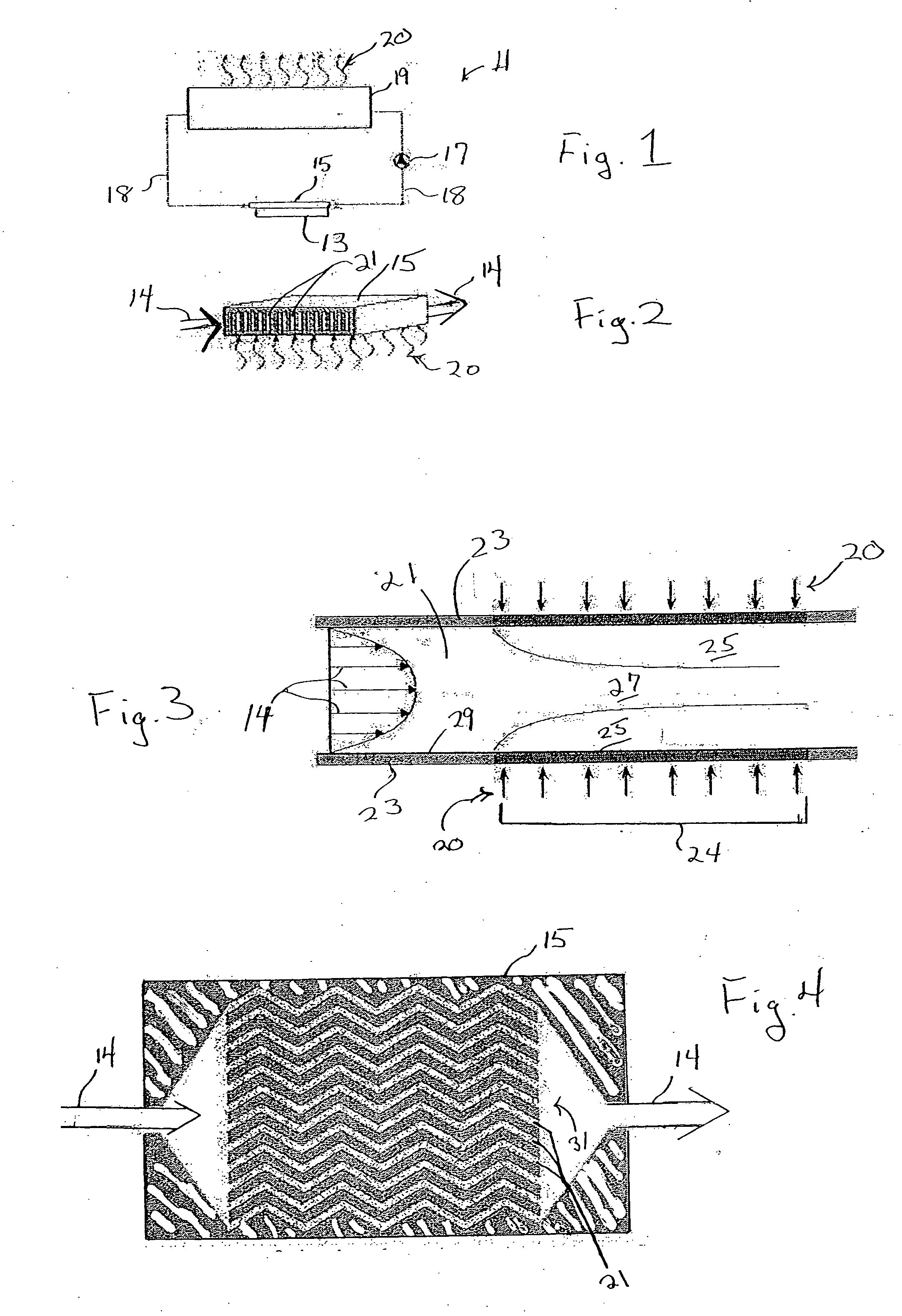

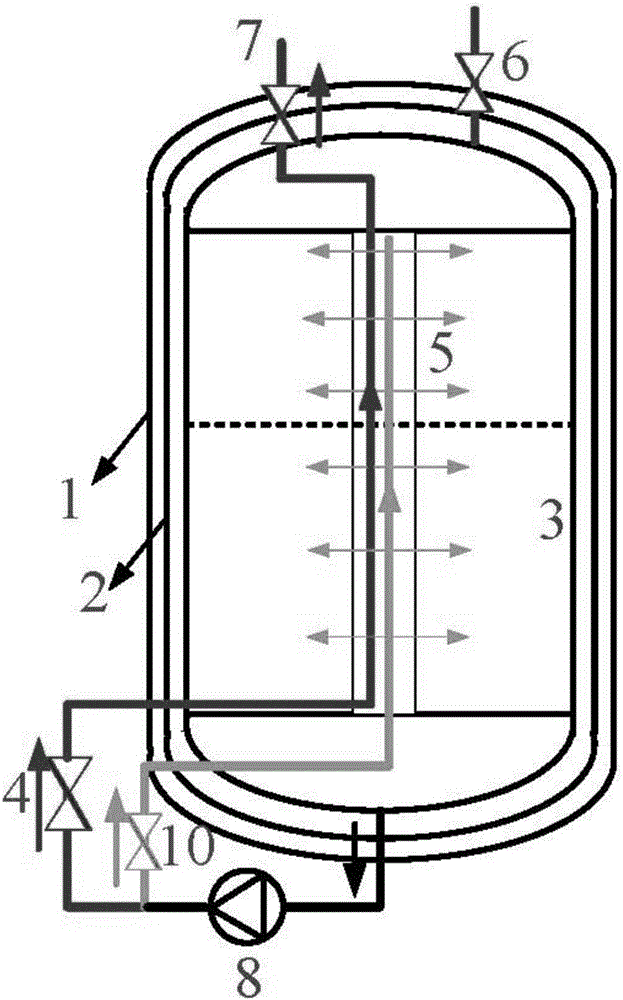

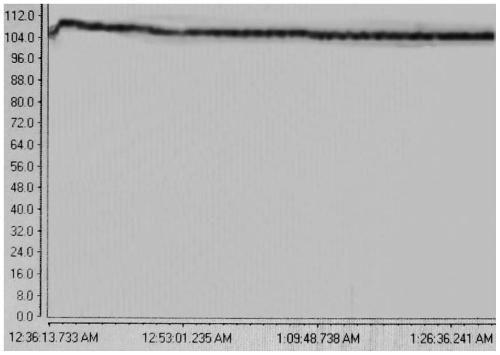

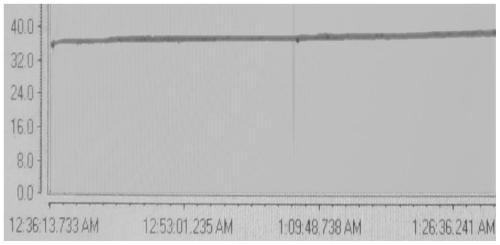

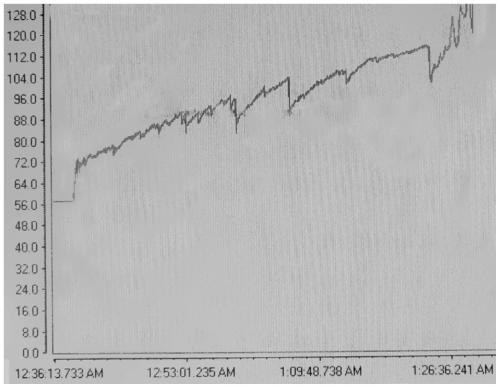

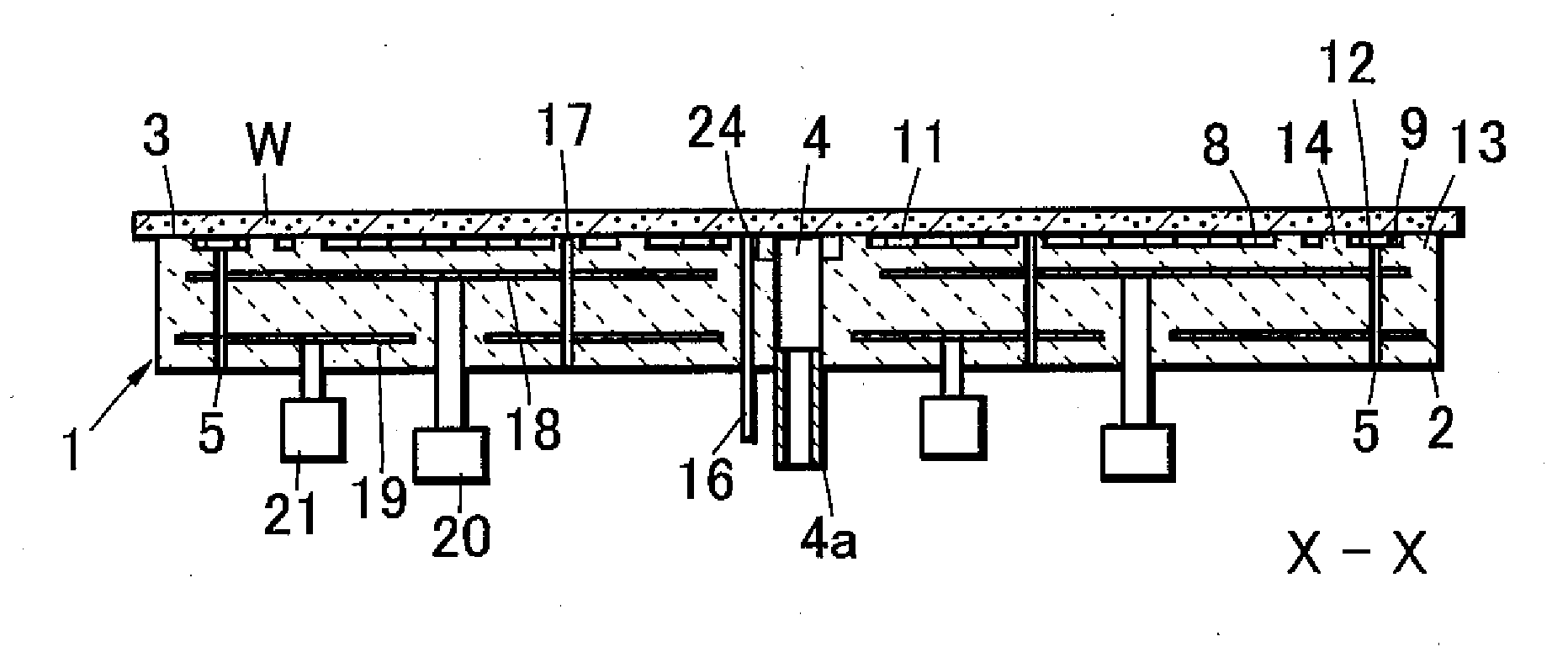

Vapor pump power system

InactiveUS20060059912A1Small temperature differenceIncrease pressureGas turbine plantsSteam engine plantsPower stationEngineering

A power plant with at least two pressure vessels containing a hydraulic fluid. A heat exchanging assembly is in heat transferring association with the pressure vessels. The hydraulic conduit is hydraulically connected with the pressure vessels. A power outlet device is in hydraulic association with the conduit between the vessels and is configured for outputing power from the flow of the hydraulic fluid. A controlling mechanism is operably associated with the heat exchanging assembly to cause the heat exchanging assembly to alternately increase the pressure in one of the pressure vessels compared to the other. Thus, hydraulic fluid is caused to flow through the power outlet device alternately between the pressure vessels to produce power from the power output device.

Owner:ROMANELLI PAT

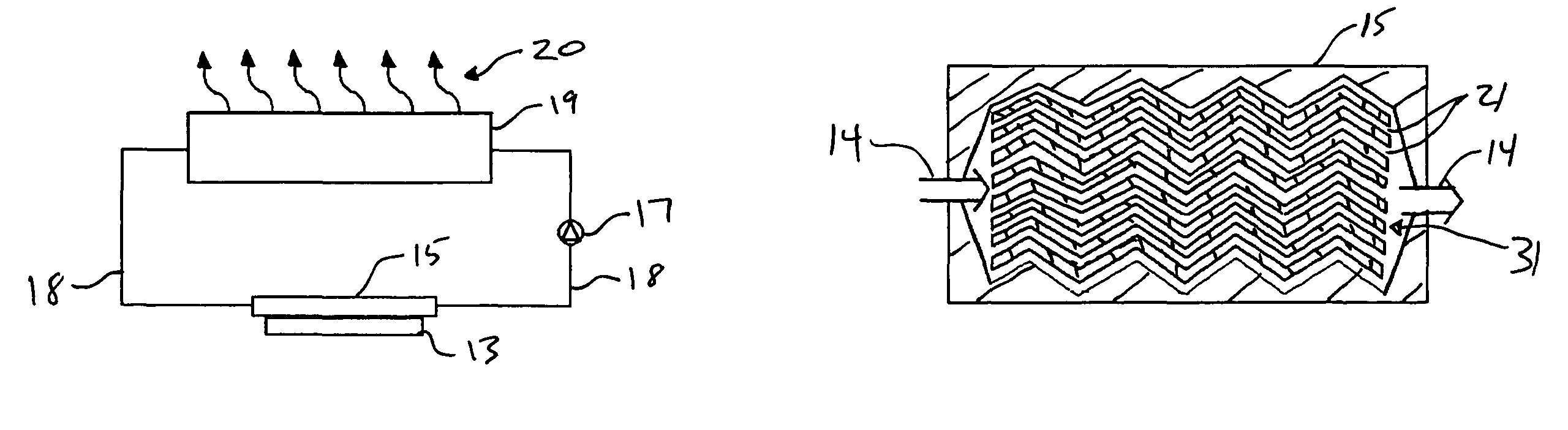

Microchannel heat exchanger with micro-encapsulated phase change material for high flux cooling

ActiveUS20060231233A1Improve cooling efficiencySmall temperature changeHeat storage plantsSemiconductor/solid-state device detailsParticulatesHigh flux

A microchannel cooler containing a slurry having a particulate liquid / solid phase change material is provided balancing the interdependent factors of microencapsulated particle size with microchannel size and shape and flow conditions for the removal of high heat flux with low space and low power requirements.

Owner:FARID MOHAMMED MEHDI +1

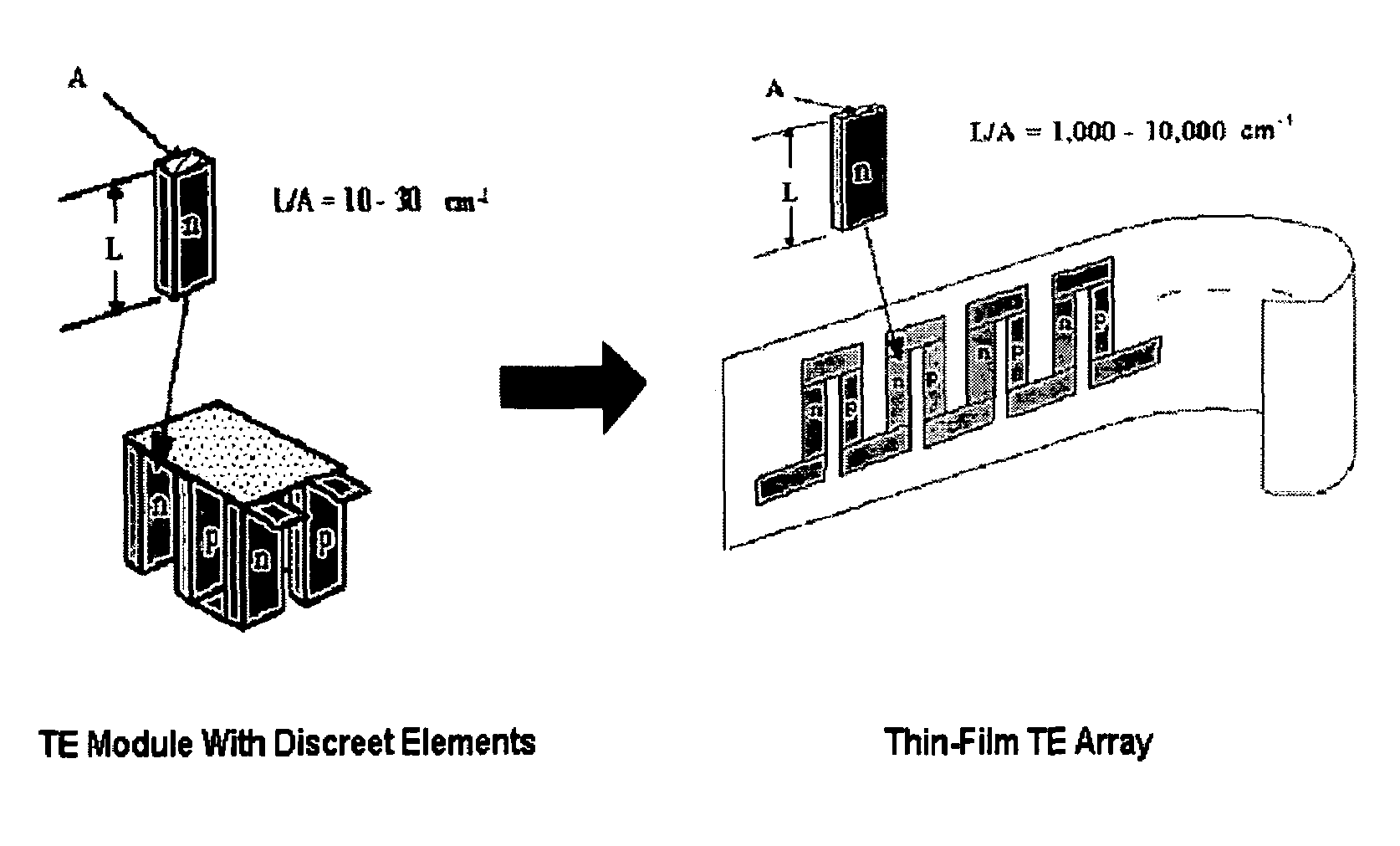

Thermoelectric power source utilizing ambient energy harvesting for remote sensing and transmitting

ActiveUS20050115600A1Reliable powerSmall temperature differenceThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermal energyElectrical devices

A method and apparatus for providing electrical energy to an electrical device wherein the electrical energy is originally generated from temperature differences in an environment having a first and a second temperature region. A thermoelectric device having a first side and a second side wherein the first side is in communication with a means for transmitting ambient thermal energy collected or rejected in the first temperature region and the second side is in communication with the second temperature region thereby producing a temperature gradient across the thermoelectric device and in turn generating an electrical current.

Owner:BATTELLE MEMORIAL INST

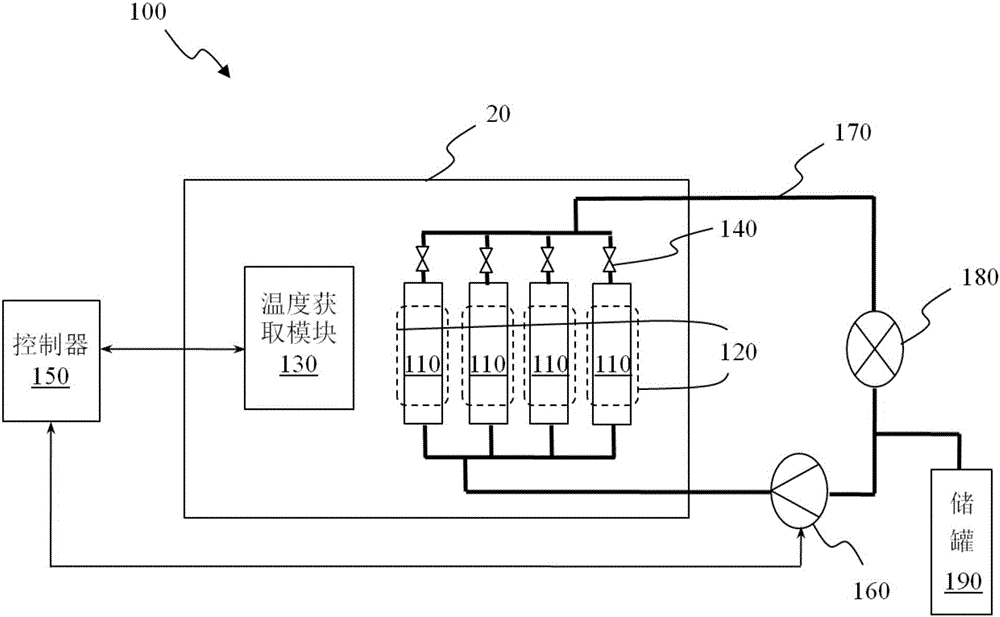

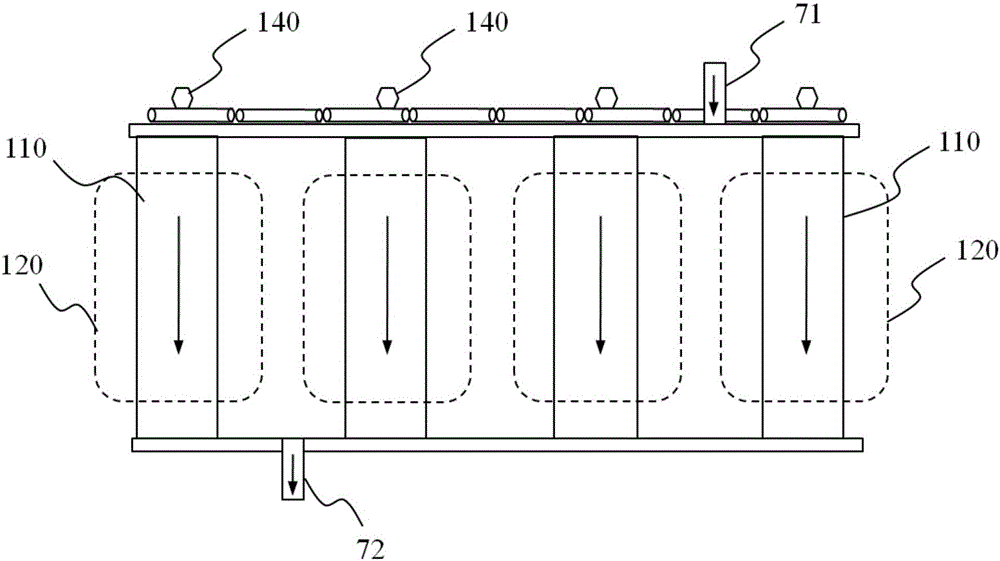

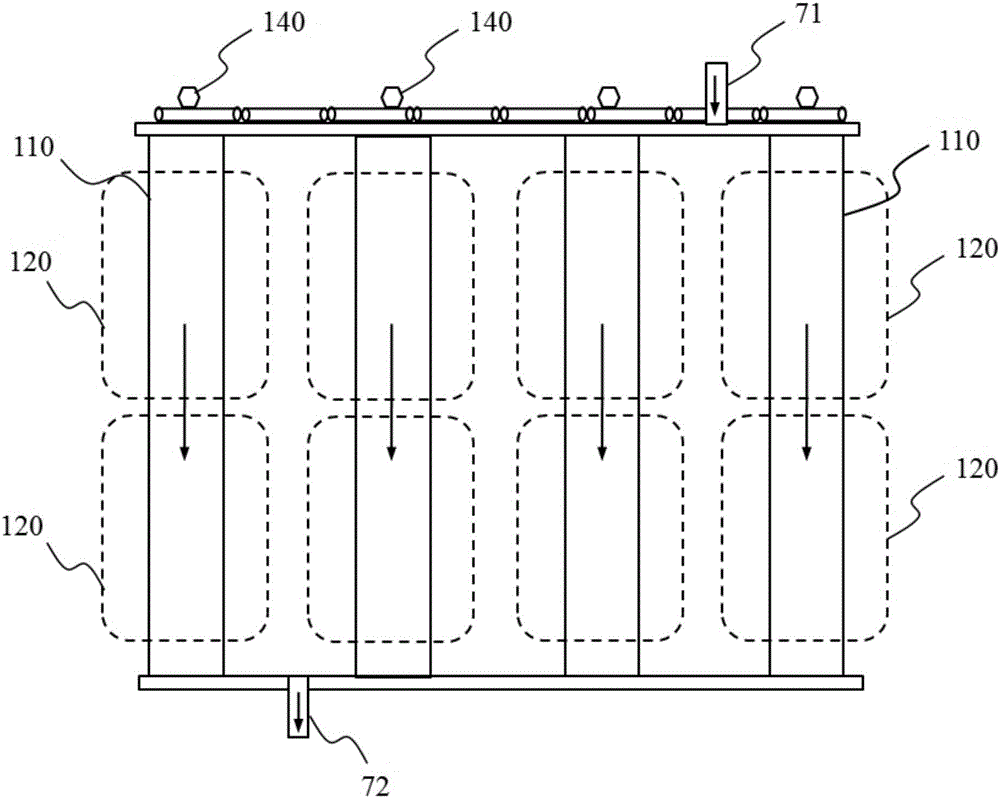

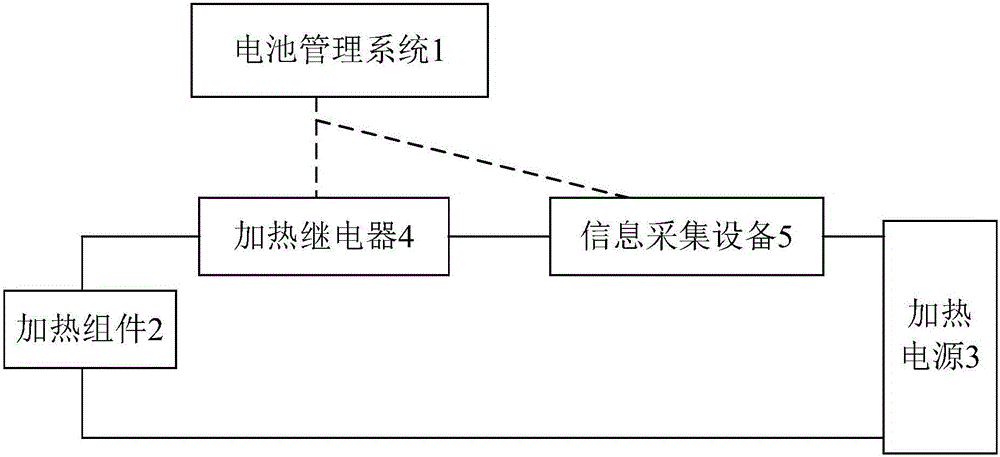

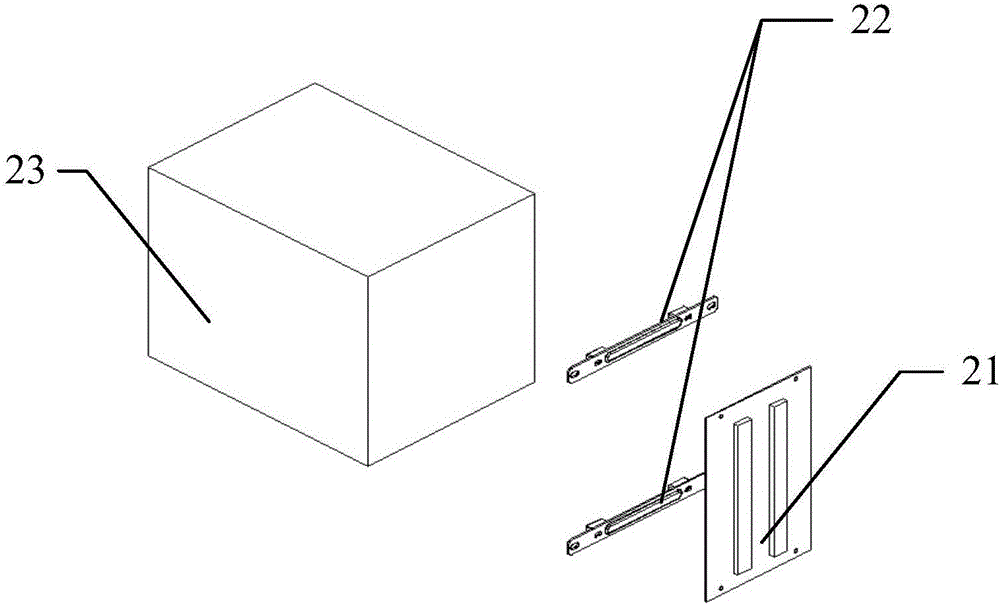

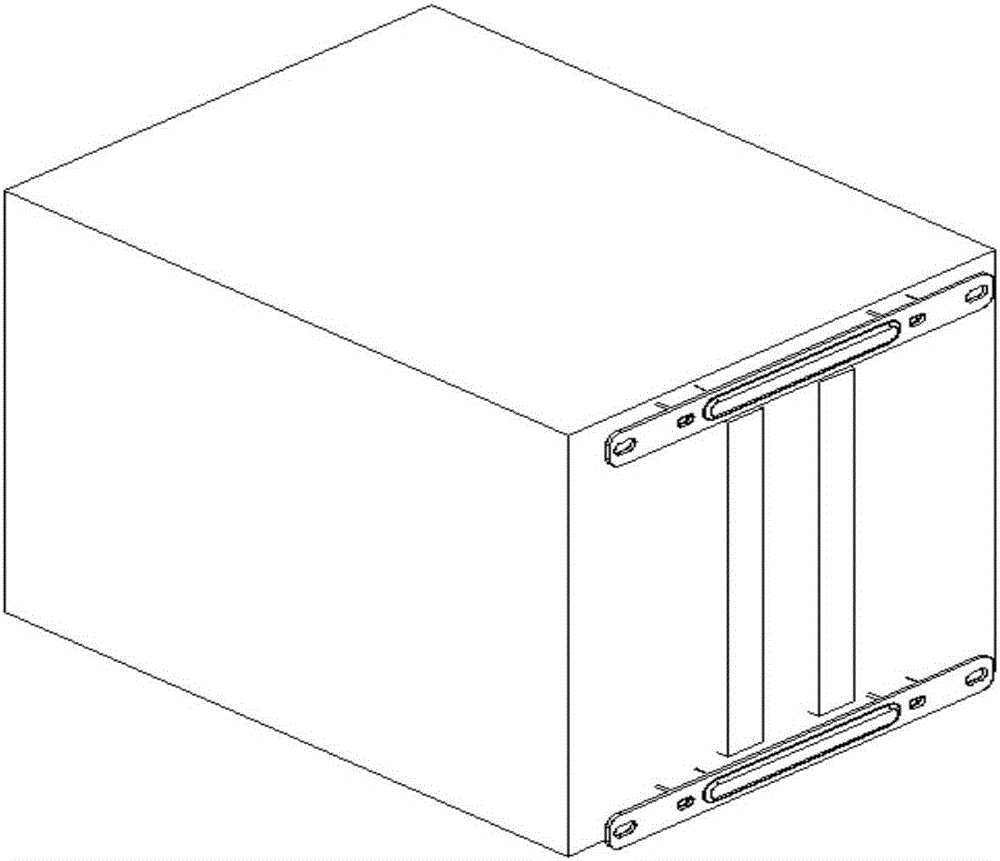

Thermal management system

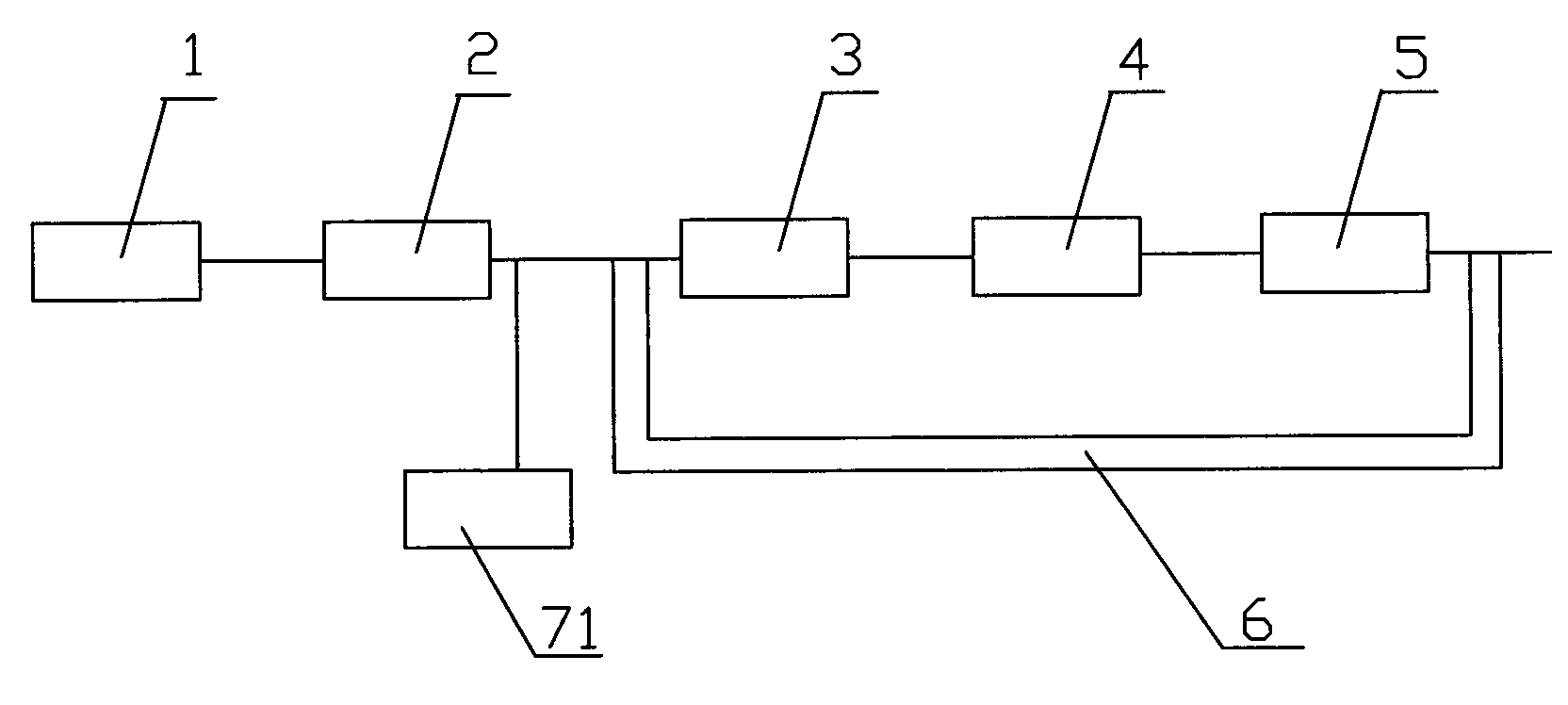

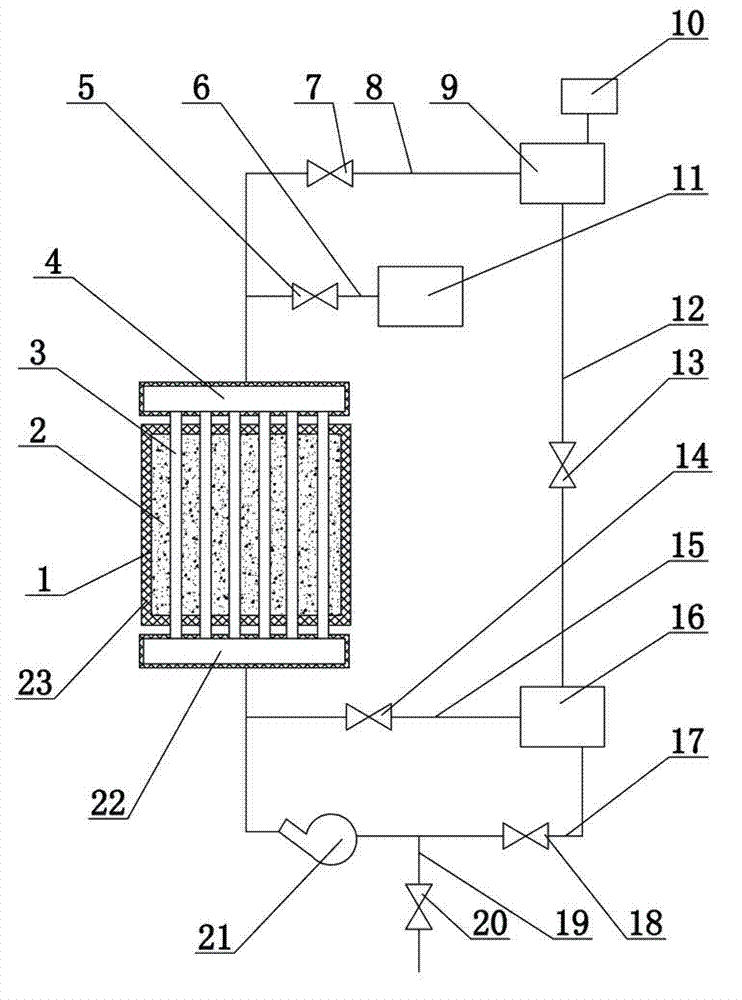

InactiveCN106785192ASmall temperature differenceAvoid excessive temperature differenceSecondary cellsPower batteryThermal management system

The invention provides a thermal management system and belongs to the field of electric vehicles and hybrid electric vehicles. The system comprises a plurality of cooling units corresponding to a plurality of battery modules respectively, a plurality of flow valves corresponding to the plurality of cooling units respectively, a temperature acquiring module and a controller, wherein each of the cooling units is configured to enable a cooling medium to circulate so as to cool the corresponding battery module, and the plurality of cooling units are used for receiving the cooling medium in a manner of parallel connection; the temperature acquiring module is used for acquiring the temperature of each of the battery modules; the controller is used for determining the opening of the flow valve of the corresponding cooling unit corresponding to each of the battery modules according to the temperature of the battery module and enabling each of the flow valves to open the corresponding opening. With the adoption of the scheme provided by the invention, as the flow rate of the cooling medium flowing through the corresponding cooling unit can be regulated through controlling the opening of the corresponding flow rate, the problem of larger temperature difference between the two adjacent battery modules is solved, so that the performance of power batteries are improved, and the service lives of the power batteries are prolonged.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

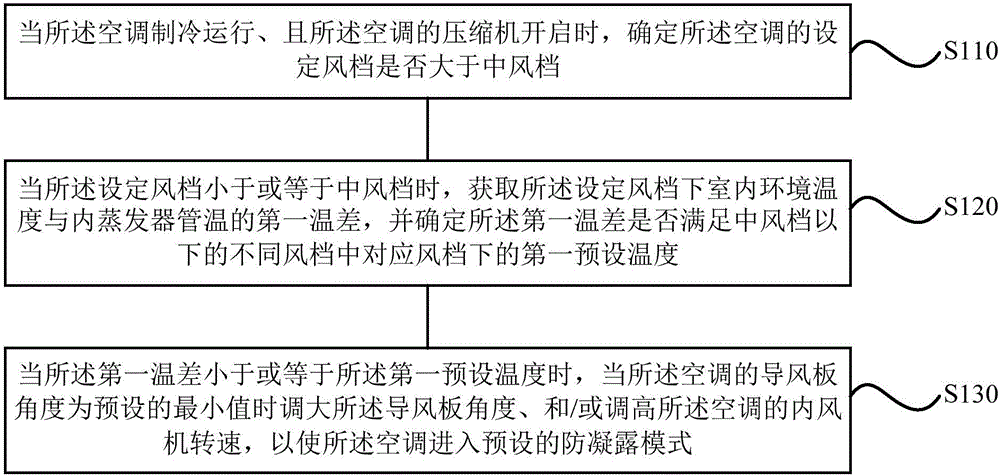

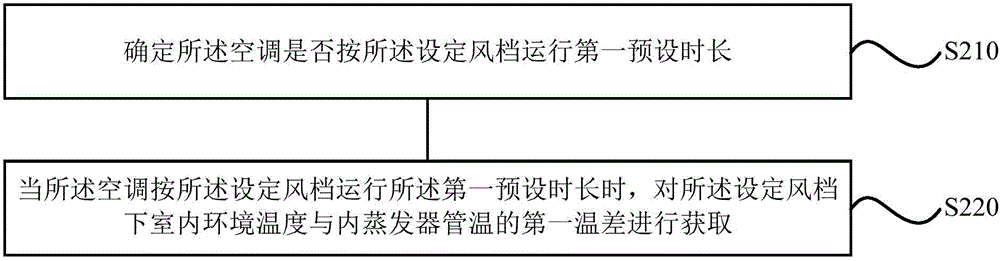

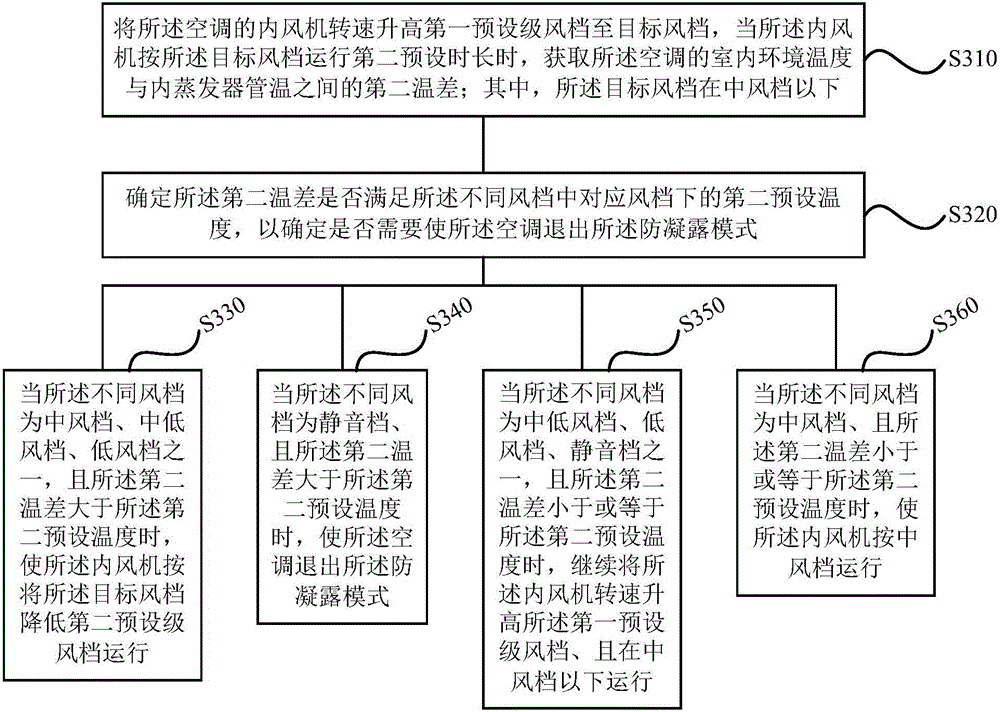

Control method and device for condensation prevention of air conditioner and air conditioner

ActiveCN106594958ACondensation is not easy to produceGuaranteed comfortMechanical apparatusCondensate preventionEngineeringTemperature difference

The invention discloses a control method and device for condensation prevention of an air conditioner and the air conditioner. The method comprises following steps: determining whether the wind level set by the air conditioner is higher than medium-speed wind level or not when the air conditioner operates in a cooling state and a compressor of the air conditioner is started; obtaining first temperature difference between indoor ambient temperature of the set wind level and inner evaporator tube temperature when the set wind level is less than or equal to the medium-speed wind level and determining whether the first temperature difference satisfies first pre-set temperature of corresponding wind level in different wind levels below the medium-speed wind level; increasing the angle of a wind guide plate, and / or rotating speed of an inner fan of the air conditioner when the first temperature difference is smaller than or equal to the first pre-set temperature and when the angle of the wind guide plate is the pre-set minimum value, and therefore the air conditioner is in the pre-set condensation prevention mode. The technical scheme provided by the control method and device for condensation prevention of the air conditioner and the air conditioner has following beneficial effects: defects in the prior art such as the proneness of generating condensation, bad environmental health and poor users' experience are solved; condensation is not easily generated; the environmental health is good; and users' experience is good.

Owner:GREE ELECTRIC APPLIANCES INC

Composite roller for high vanadium high speed steel and its production process

The invention offers the high V super-speed steel complex roller and its producing craft. The roller includes roller heart and roller shell, the roller heart uses low metal alloy steel or middle carbon steel to produce, the shell uses high V super-speed steel, whose main element is : C: 1.8--3.5A%, V: 7--12%, Cr: 4--5%, Mo: 2--4%, Ni: 0.5--1.5%, other is Fe. The producing craft is: melt and cast the heart and shell by responding heat way. The roller in the invention has good whet feature, high rate of feature and price, using safely. Fine roller, high strength of combination, no crush in use; it can reduce the stop times. It efficiently increase the roller tenacity and whet feature, solve the problems in the heart leaving foundry, and solve the problems of complicated craft and high cost.

Owner:HENAN UNIV OF SCI & TECH +1

Method for continuous casting, continuoccs rolling intermediate and thin sheet blanket

InactiveCN1483521ASmall temperature differenceImprove surface qualityMetal rolling arrangementsAutomatic controlThin slab

The production method of sheet billet conticasting tandem-rolling coil sheet is characterized by that said invention adopts the following technical measures: using conticasting machine and making pulling rate of casting blank low, and making the blank material have reasonable section; compactly arranging conticasting machine and heating furnace, making the conticasting blank output roller conveyer and inlet roller conveyer of heating furnace have double purpose, making inlet temp. of casting blank be above 900 deg.C; adopting double furnace and hating; and adopting small-cross charging and tapping process; two-high reversing rougher for three passes, four-high reversing rougher for one pass; and adopting thermal coiler box process of workpiece so as to raise coil sheet quality and reduce its production cost.

Owner:ANGANG STEEL CO LTD

Microchannel heat exchanger with micro-encapsulated phase change material for high flux cooling

ActiveUS8109324B2Improve cooling efficiencySmall temperature changeHeat storage plantsSemiconductor/solid-state device detailsParticulatesHigh flux

A microchannel cooler containing a slurry having a particulate liquid / solid phase change material is provided balancing the interdependent factors of microencapsulated particle size with microchannel size and shape and flow conditions for the removal of high heat flux with low space and low power requirements.

Owner:FARID MOHAMMED MEHDI +1

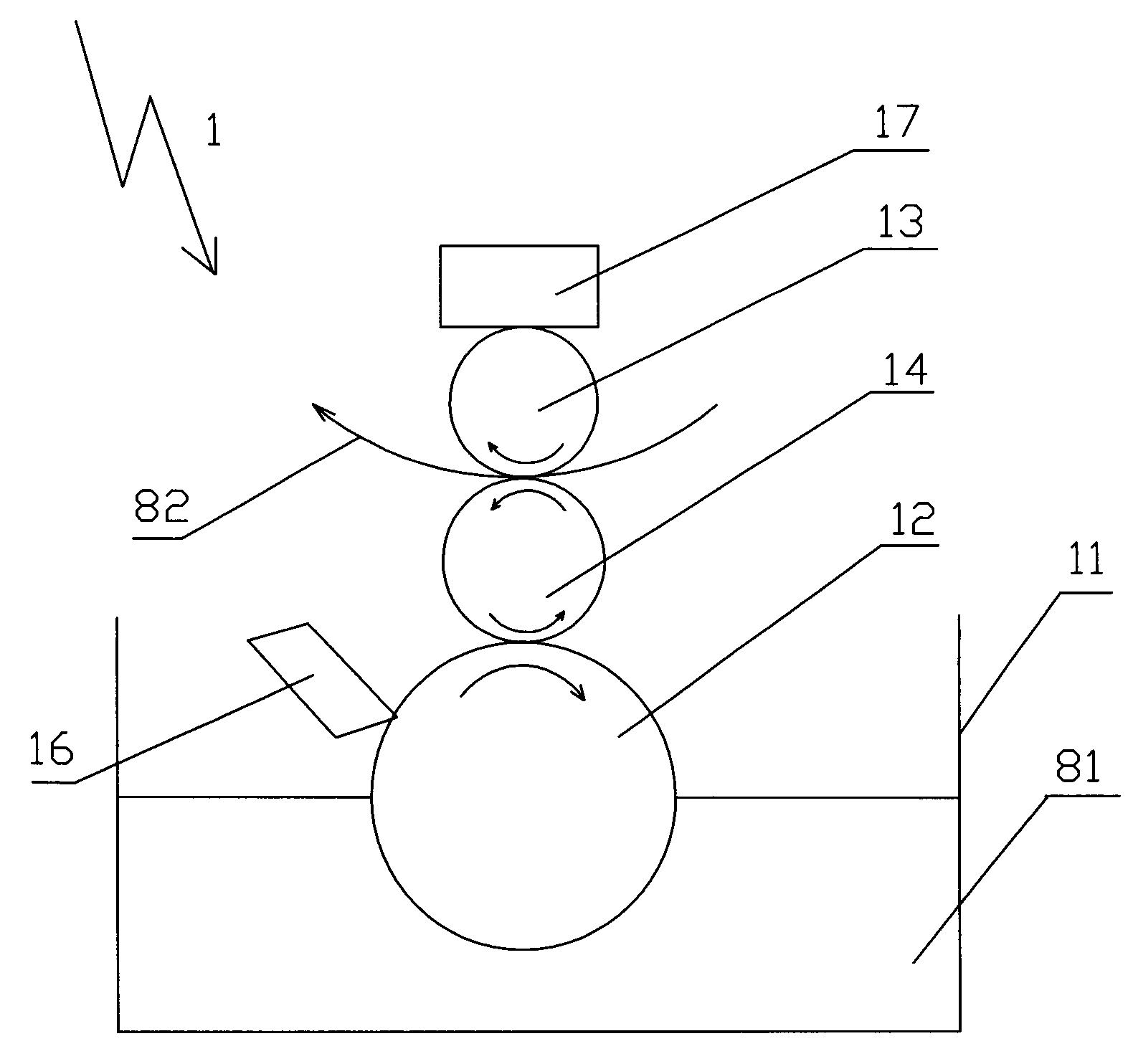

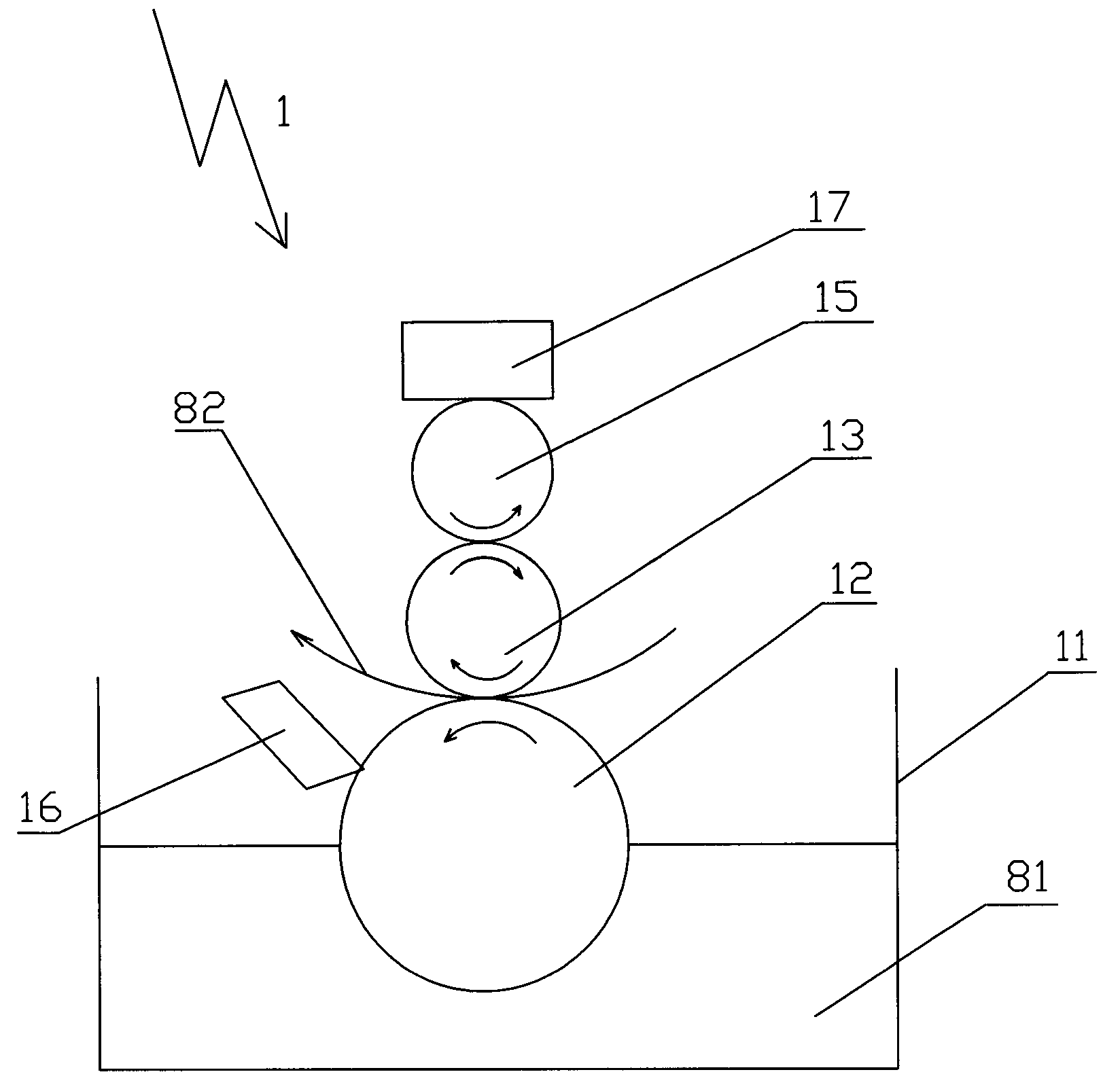

Apparatus for producing reflective membrane with microprism array structure

ActiveCN101672939AImprove work efficiencyImprove performanceOptical elementsUV curingHeat resistance

The invention relates to an apparatus for producing a reflective membrane with a microprism array structure and solves the defects in the prior art that the hardness, scratch resistance, heat resistance and solvent resistance of microprisms are disappointing, the product consistency is poorer, the production speed is lower, the work efficiency is not high, and the like. The apparatus comprises anannular strip-shaped mould, a heating membrane pressing device and a cooling device, wherein the annular strip-shaped mould is provided with an inner surface and an outer surface which is provided with a convex continuous precise microprism array structure. The apparatus also comprises a coating device, a drying device and a UV curing device. By adding the coating device, the drying device and theUV curing device, the microprism structure is formed after the UV curing of photosensitive resin, the hardness, scratch resistance, heat resistance and solvent resistance of microprism of the microprism structure are greatly improved, and the product consistency is fine. In addition, the apparatus can also obviously improve the production speed and the work efficiency.

Owner:ZHEJIANG DAOMING OPTOELECTRONICS TECH

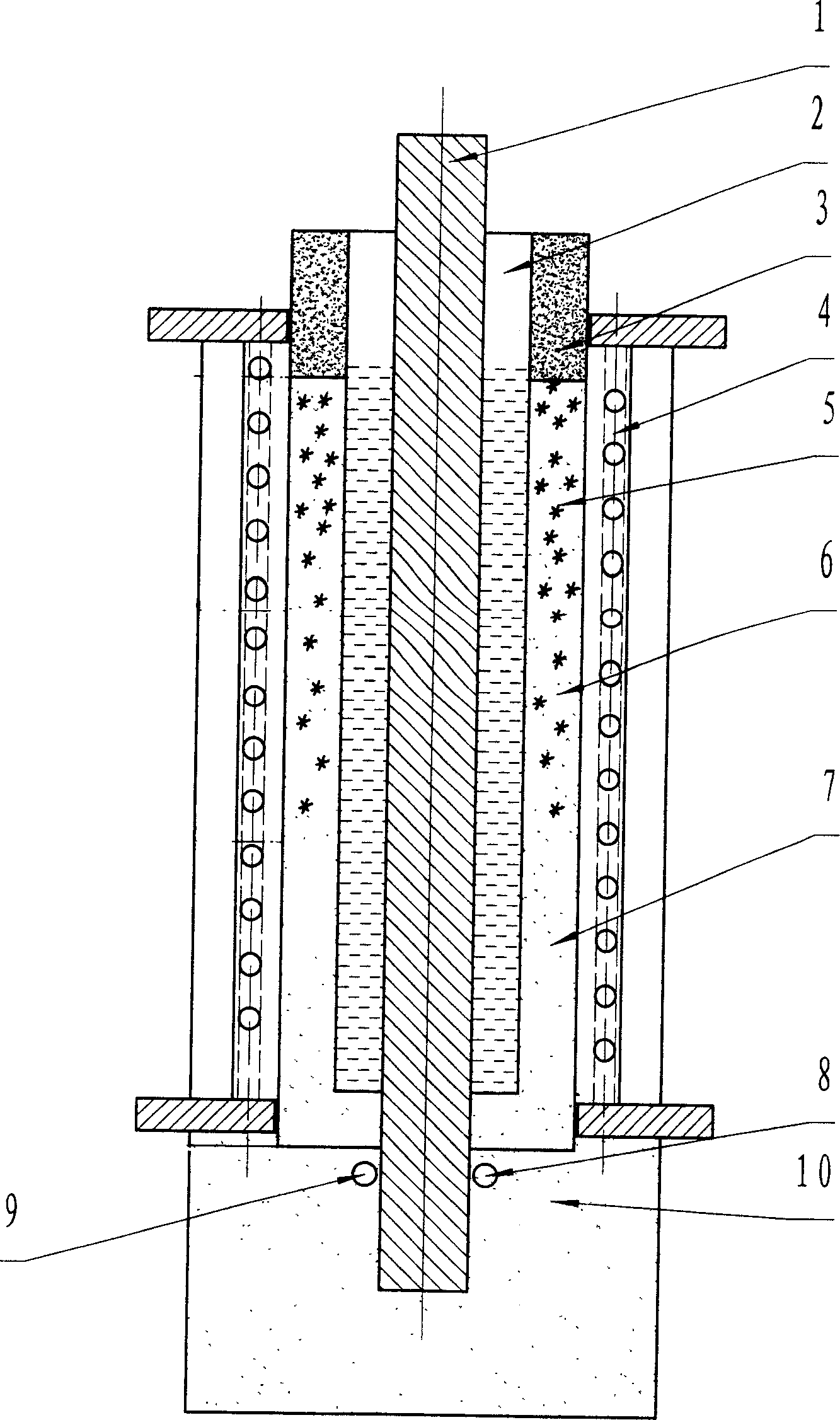

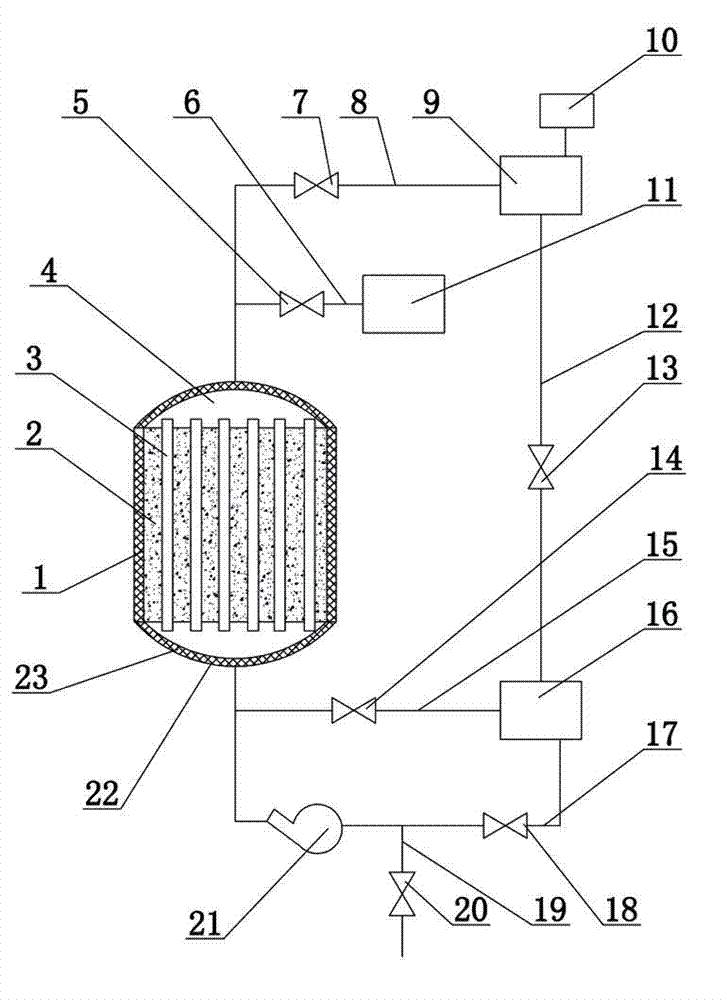

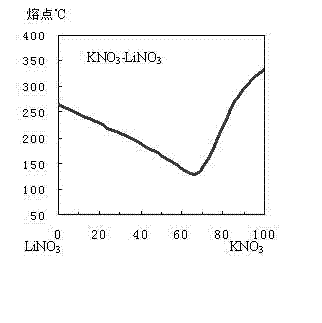

Phase change heat accumulation system for generating steam directly and preparation method of phase change heat accumulation agent

InactiveCN102777874AImprove efficiencyImprove heat transfer coefficientHeat storage plantsChemical industryPorous mediumToxic industrial waste

The invention relates to a phase change heat accumulation system for generating steam directly and a preparation method of a phase change heat accumulation agent. A phase change material is enhanced with graphite foam, and is absorbed in a porous medium of the graphite foam, so that a binary eutectic salt / graphite foam material is prepared and is used as a composite phase change material of a heat accumulation device, the composite phase change material is high in heat conduction coefficient, therefore under the same design condition, the phase change heat accumulation system provided by the invention is applied to systems of a focusing type solar thermal power generation system, an industrial waste heat recovery system and the like, and has the characteristics of high heat transfer efficiency, small volume, low cost and the like. In addition, the phase change heat accumulation system for generating steam directly can flexibly adopt a parallel connection or serial connection mode according to the temperature of high-temperature waste heat steam and the requirement of a steam user; and during serial connection, the binary eutectic salt / graphite foam composite phase change material can be combined in a cascaded manner according to a melting point, thus the efficiency of an energy accumulation system is increased, and the energy can be greatly accumulated.

Owner:ZHENGZHOU UNIV

Grain-refined extruded aluminum alloy tubular product with large wall thickness and preparation method thereof

The invention discloses a grain-refined extruded aluminum alloy tubular product with large wall thickness and a preparation method thereof. The tubular product comprises the following metallic substances in percentage by weight: 1.0-1.15% of Mg, 0.60-0.75% of Si, 0.20-0.35% of Cu, 0.35% of Fe, 0.10% of Mn, 0.05-0.08% of Cr, 0.15% of Zn, 0.10% of Ti and the balance of aluminum. The invention further discloses a preparation method of the grain-refined extruded aluminum alloy tubular product with large wall thickness. The grain-refined extruded aluminum alloy tubular product with large wall thickness provided by the invention solves the problem that the grains of the base and surface of a 6061 alloy extruded aluminum alloy tubular product with great wall thickness are thick and big, the deficiency of bulky crystal spots generated after anodic oxidation can be eliminated and indexes of the final product, such as inner welding quality and mechanical performance, can satisfy the GB / T6892-2006 standard requirement.

Owner:龙口市丛林铝材有限公司

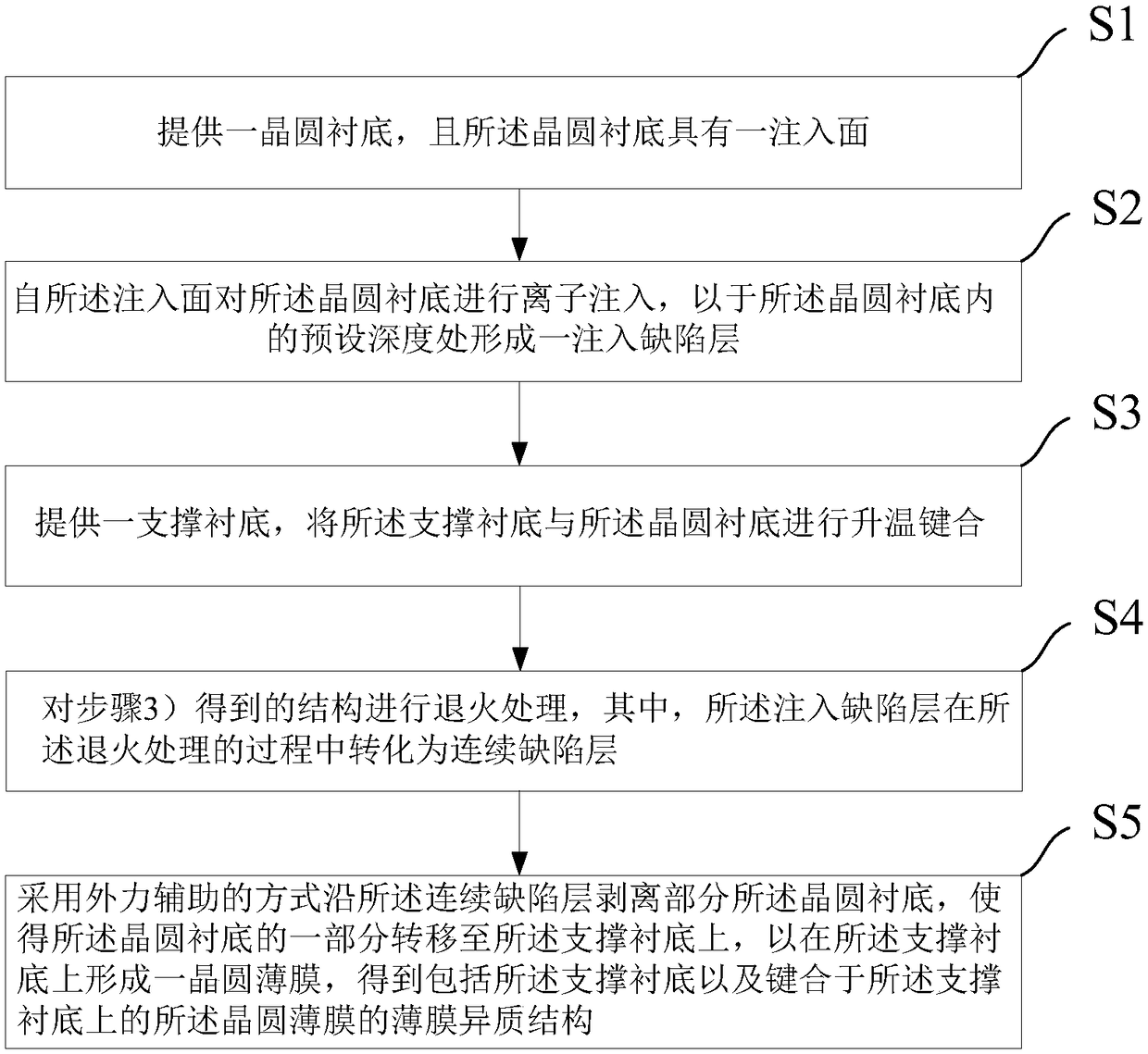

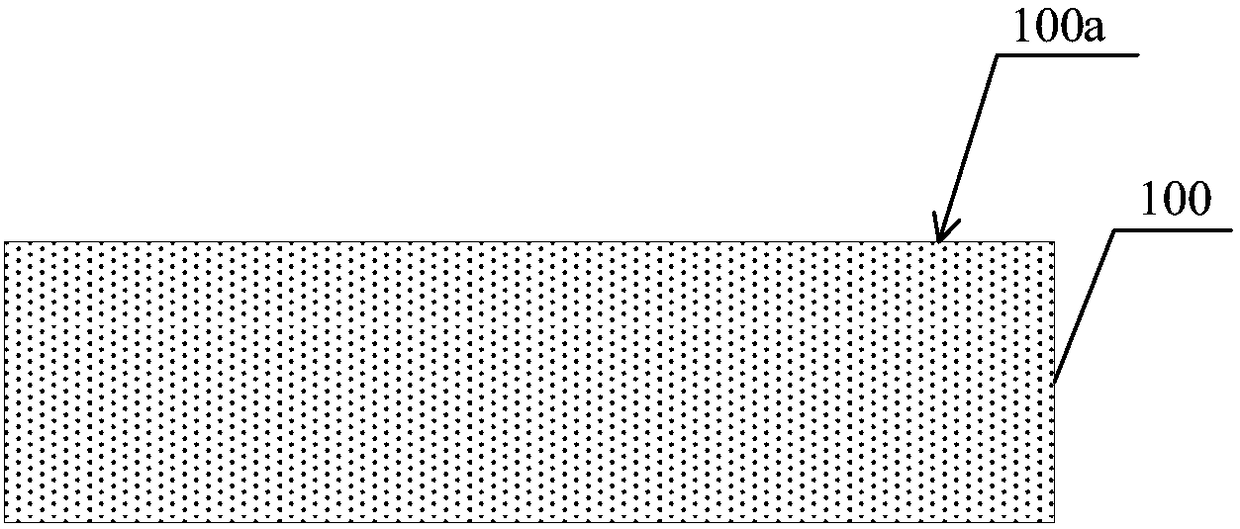

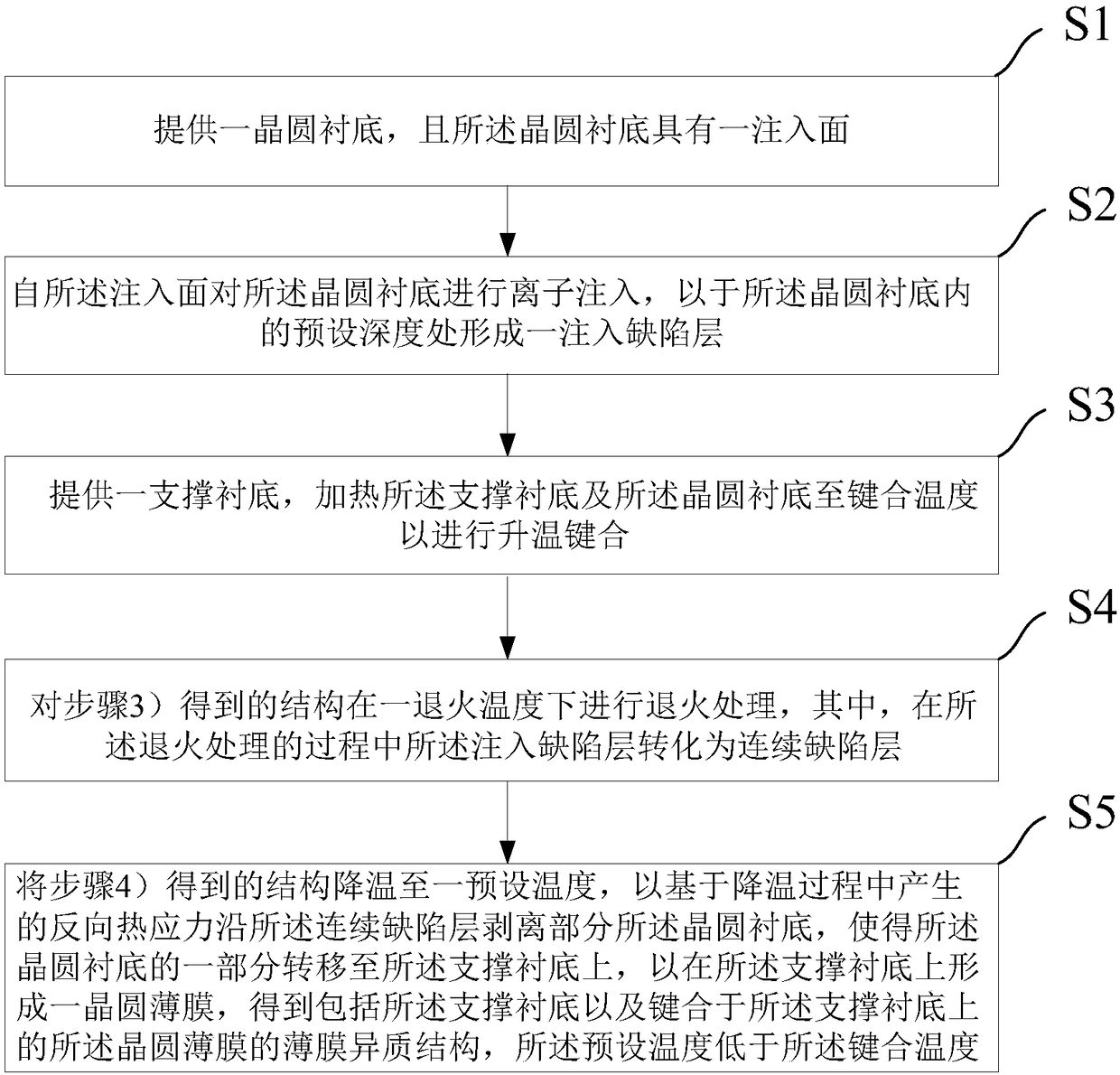

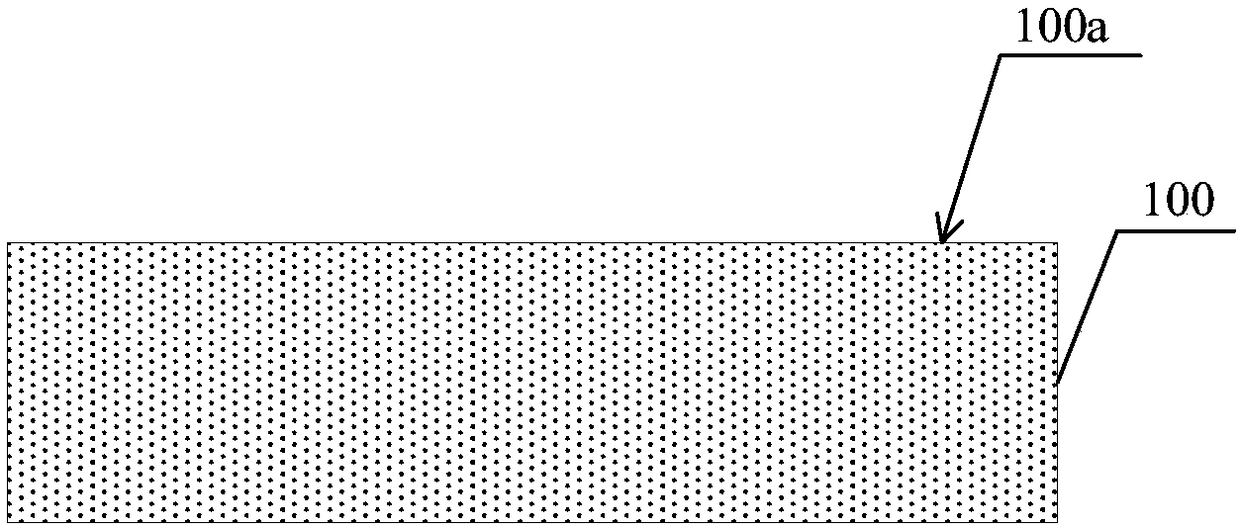

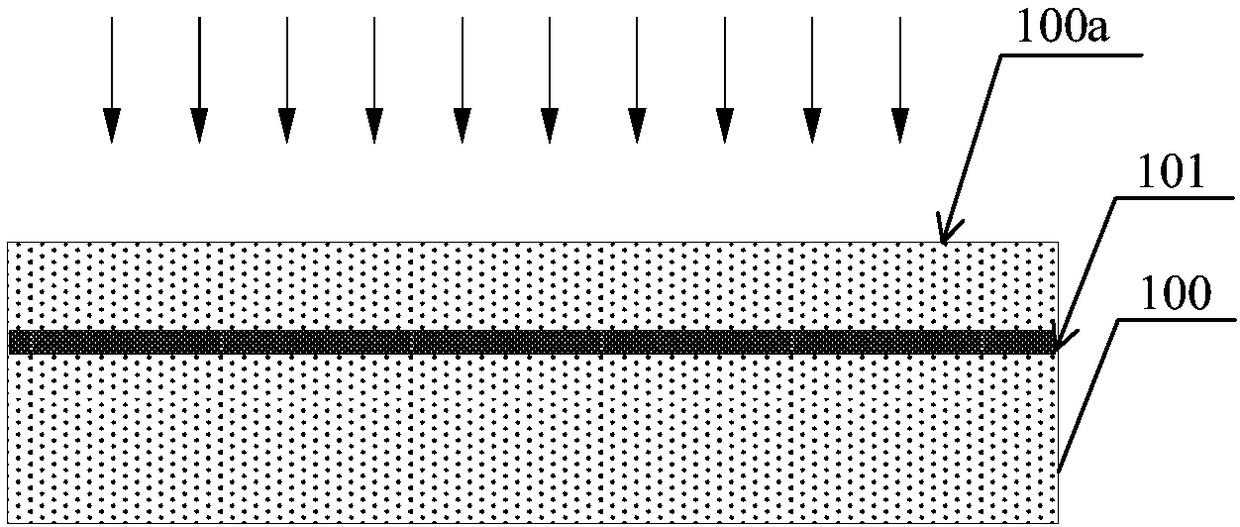

Method for preparing thin film heterostructure

InactiveCN108336219AReduce thermal strainAvoid chippingPiezoelectric/electrostrictive/magnetostrictive devicesOptoelectronicsIon implantation

The invention provides a method for preparing a thin film heterostructure. The method comprises the steps of providing a wafer substrate with an injection surface; conducting ion injection from the injection surface on the wafer substrate to form an injection defect layer at the predetermined depth of the wafer substrate; providing a support substrate, and performing temperature rising bonding onthe support substrate and the wafer substrate; annealing a obtained structure to form a continuous defect layer; stripping part of the wafer substrate through external force assisting, and forming wafer film on the wafer substrate to obtain a thin film heterostructure including the support substrate and the wafer film. The method can reduce the thermal strain of a bonding structure through the temperature rising bonding, so that the bonding structure remains stable and complete in the high-temperature process, and avoid the problem of film cracking caused by thermal mismatch in the stripping process, the bonding structure is separated from the continuous defect layer through the external force assisting method, so that no effect is caused on a bonding interface, and an external force assisting stripping method can reduce stripping temperature and stripping time, thereby reducing the cumulative effect of thermal stress in a piezoelectric crystal.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

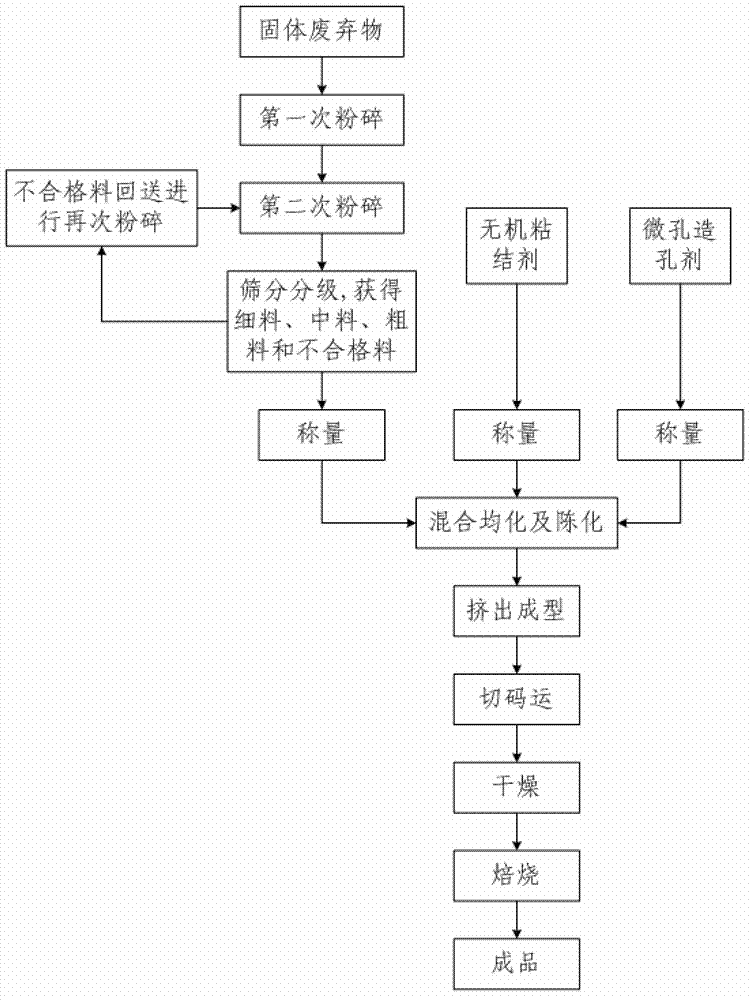

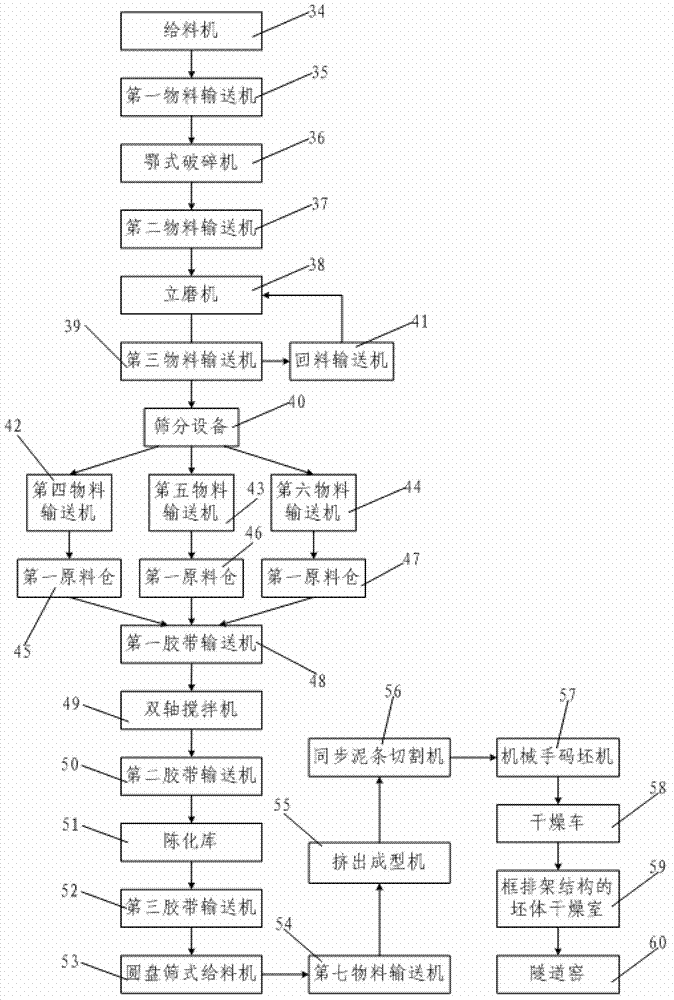

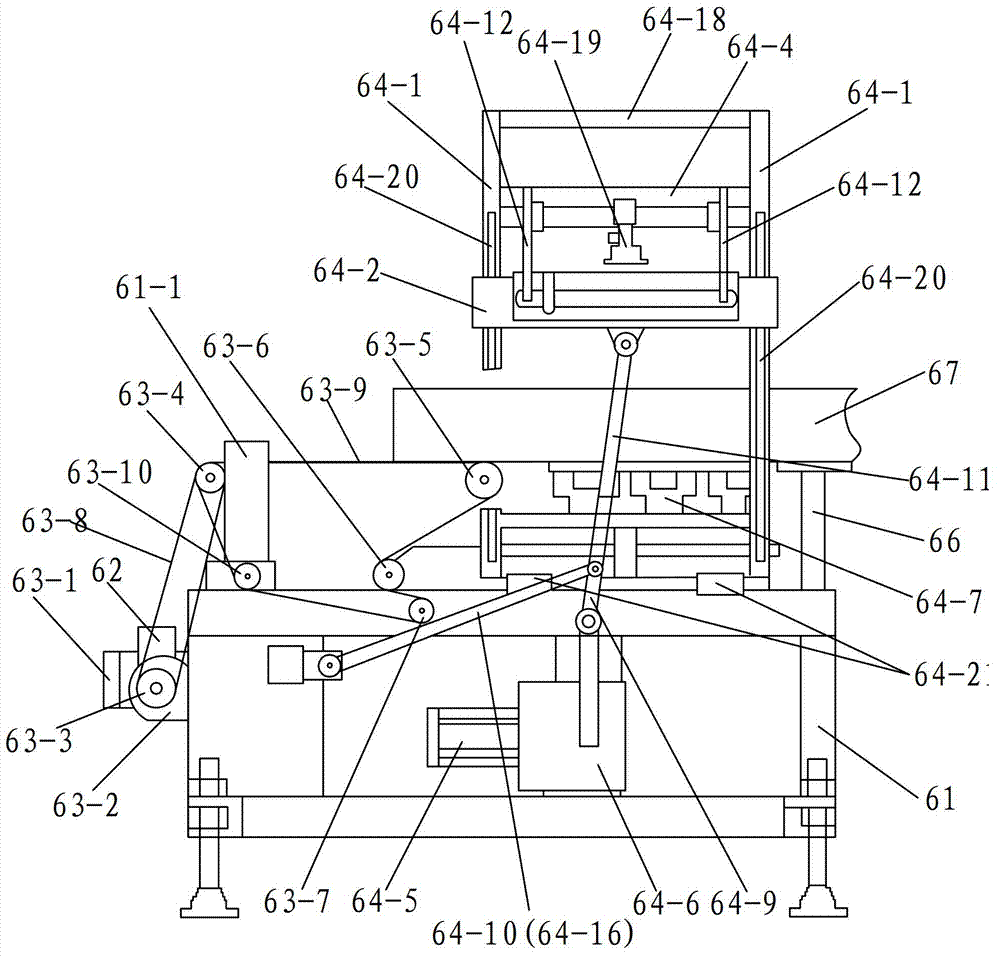

Porous sintering heat-insulating hollow block and manufacturing process thereof

ActiveCN102807390ASave resourcesPromote environmental protectionSolid waste managementCeramicwareSocial benefitsVoid ratio

The invention discloses a porous sintering heat-insulating hollow block and a manufacturing process thereof. According to the porous sintering heat-insulating hollow block, the void rate is 35 to 60 percent, the density is 700 to 1,000 kg / m<3>, and the coefficient of heat conductivity is less than or equal to 0.22 W / m.K. The porous sintering heat-insulating hollow block consists of the following ingredients in percentage by weight: 30 to 45 percent of solid waste, 45 to 55 percent of inorganic binder and 5 to 15 percent of micropore pore forming agent. The manufacturing process comprises the following steps of: 1, performing grain composition; 2, sieving for grading; 3, weighing raw materials; 4, mixing, homogenizing and aging; 5, extruding for forming; 6, cutting and stacking; 7, drying;and 8, sintering. The porous sintering heat-insulating hollow block is reasonable in design, convenient to realize, high in utilization rate of solid wastes, energy-saving, environment-friendly, highin void rate, low in density, high in thermal performance and strength, stable in size and difficult to crack, can be popularized and used in large areas, and has the excellent economic and social benefits.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

Intelligent fruit and vegetable controlled atmosphere carrier vehicle and implementing method thereof

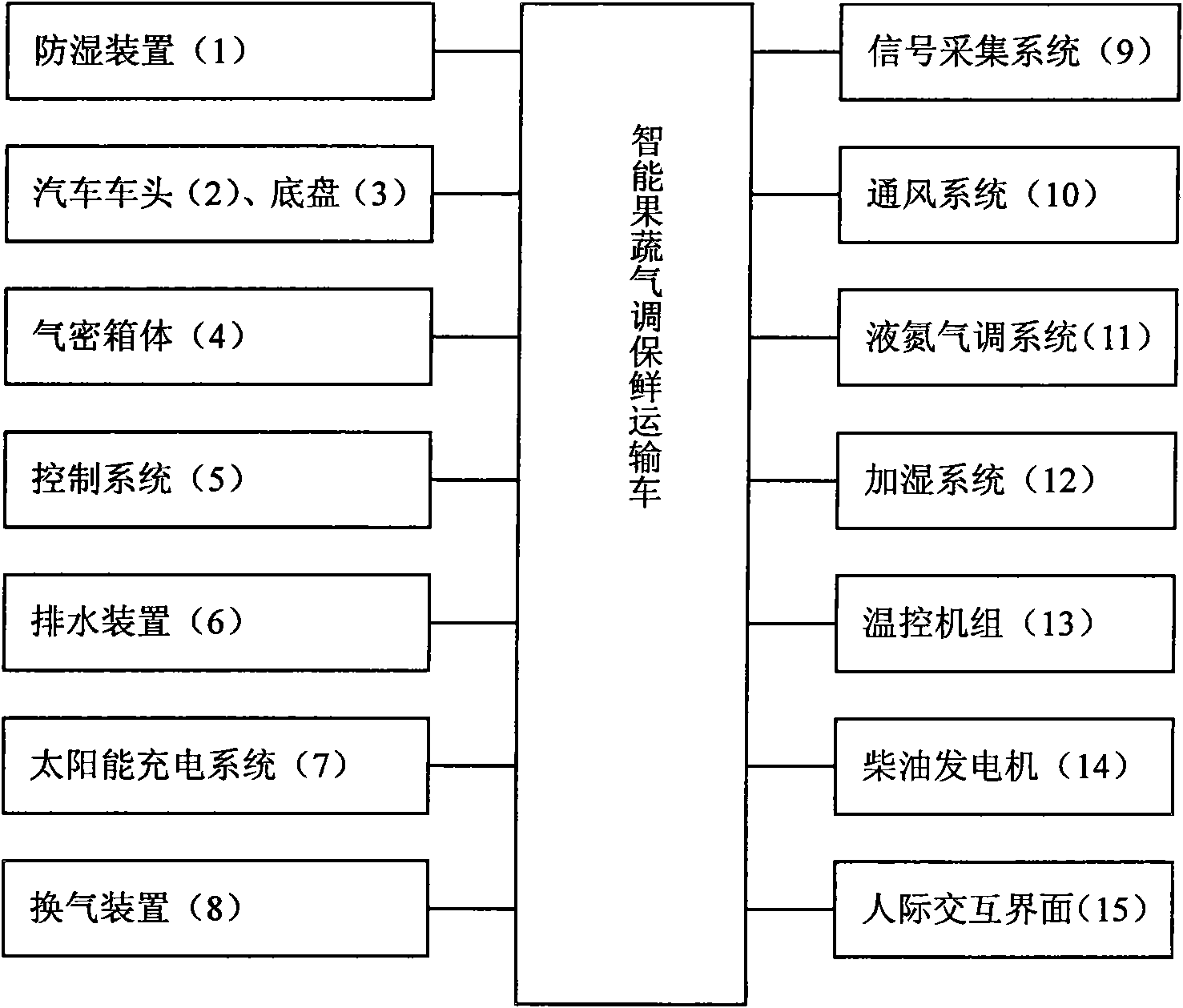

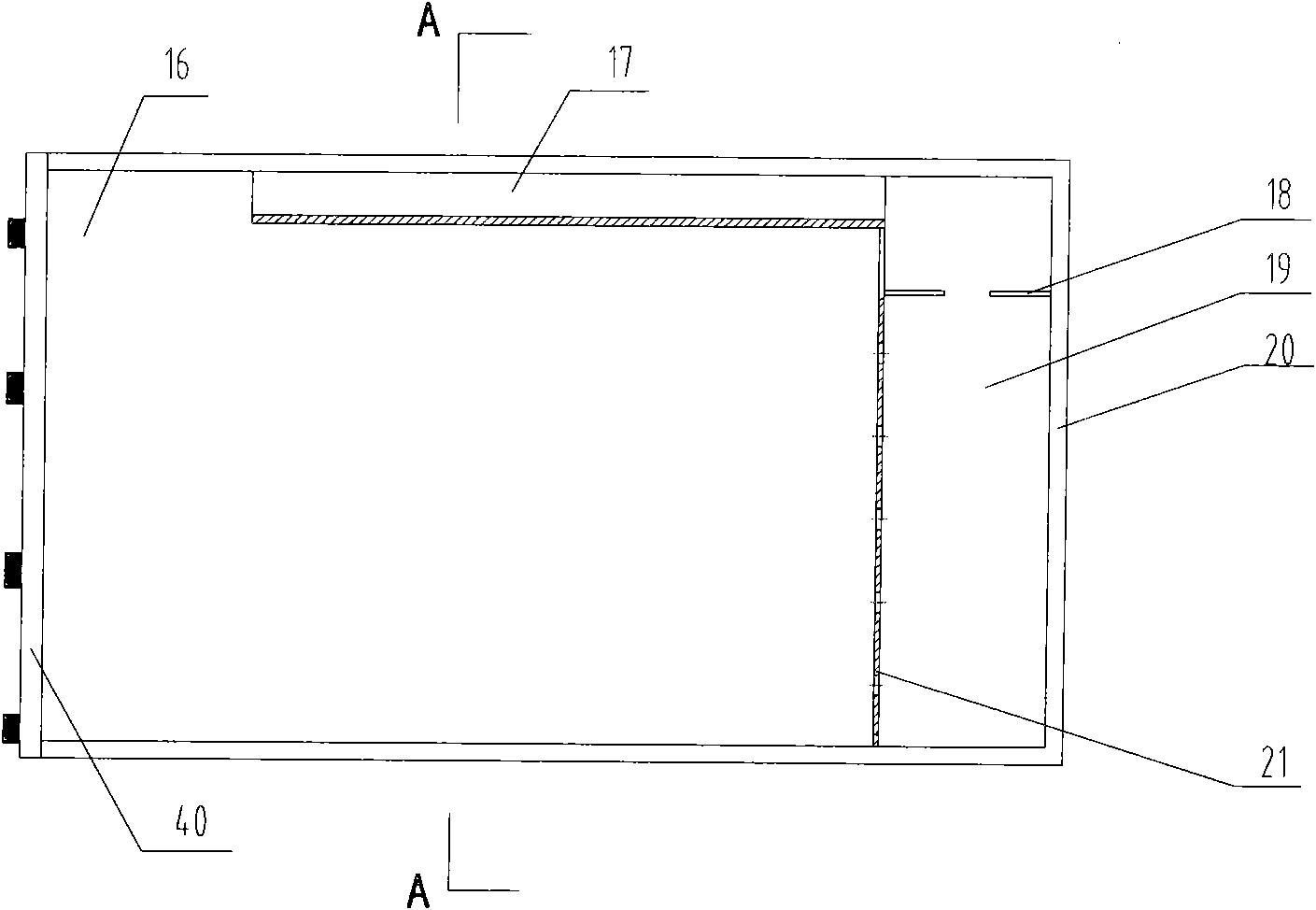

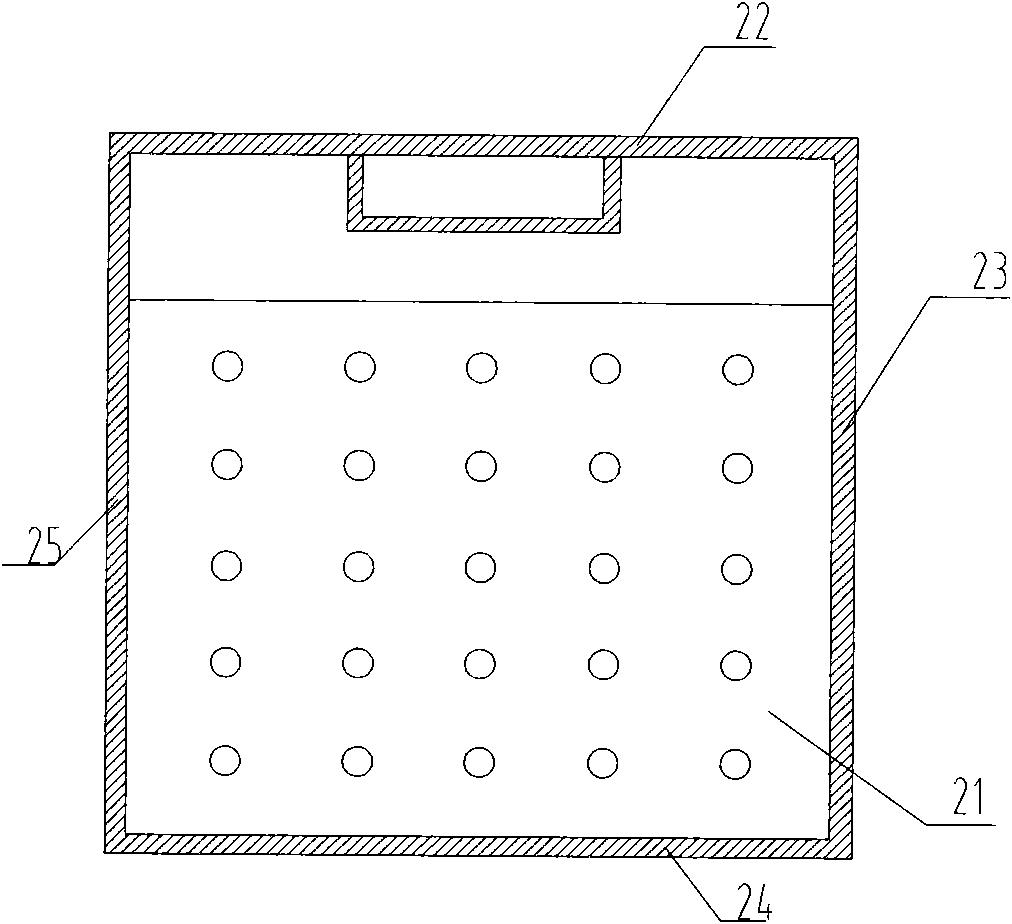

InactiveCN101961990AAccurate and uniform regulationImprove preservation qualityAir-treating devicesFruit and vegetables preservationTemperature controlControl system

The invention discloses an intelligent fruit and vegetable controlled atmosphere carrier vehicle, which comprises a headstock, a chassis, an airtight box and a human-computer interaction interface, and also comprises a control system, an air exchange device, a signal acquisition system, a ventilation system, a liquid nitrogen controlled atmosphere system, a humidifying system, a solar charging system, a temperature control unit, a diesel generator and a dampproof device, wherein the chassis is respectively connected with the headstock and the airtight box; the control system is respectively connected with the human-computer interaction interface, the air exchange device, the signal acquisition system, the ventilation system, the liquid nitrogen controlled atmosphere system, a humidifying system, the temperature control unit and the diesel generator; and the diesel generator is respectively connected with the control system, the ventilation system, the humidifying system, and the temperature control unit. The invention also discloses a method for implementing the carrier vehicle. The intelligent fruit and vegetable controlled atmosphere carrier vehicle and the method have the advantages of making the fruit and vegetable fresh-keeping environment more uniform, improving the quality of the fruit and vegetables, prolonging the fruit and vegetable fresh-keeping period and the like.

Owner:SOUTH CHINA AGRI UNIV

Air-conditioner self-adaptation control method and system

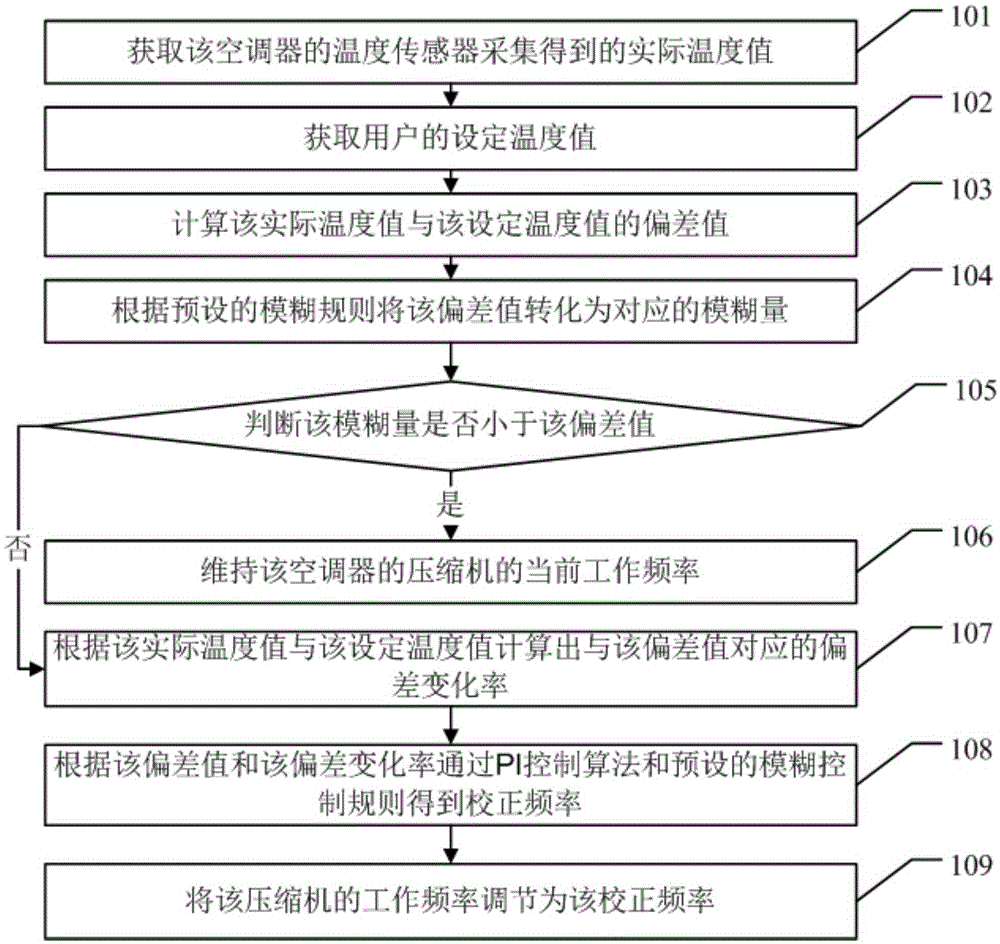

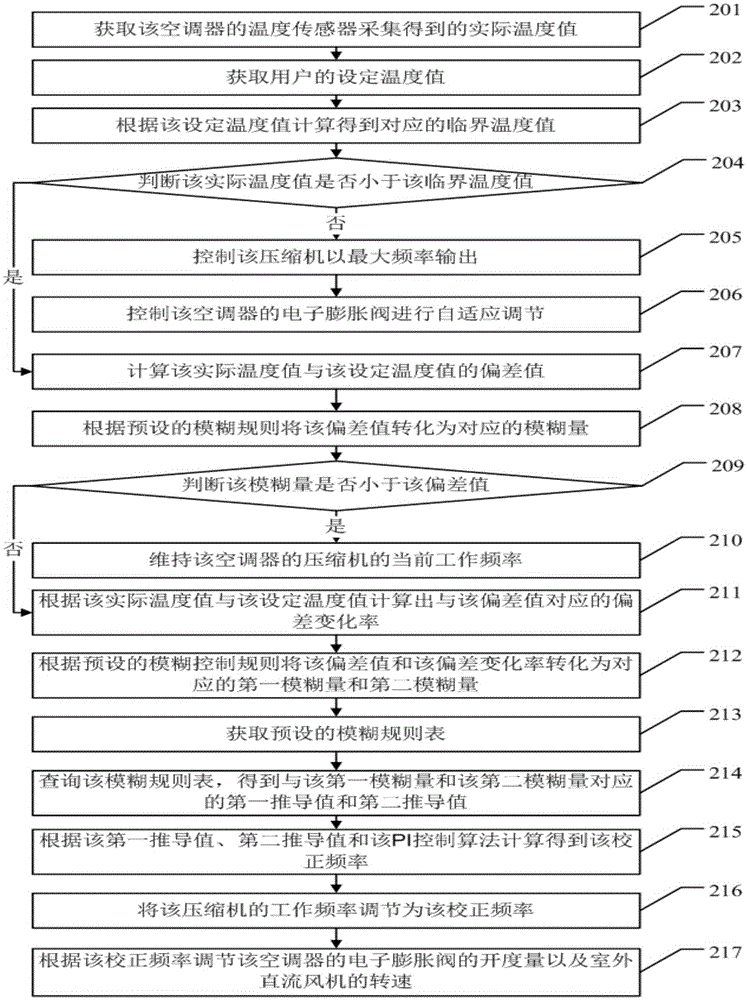

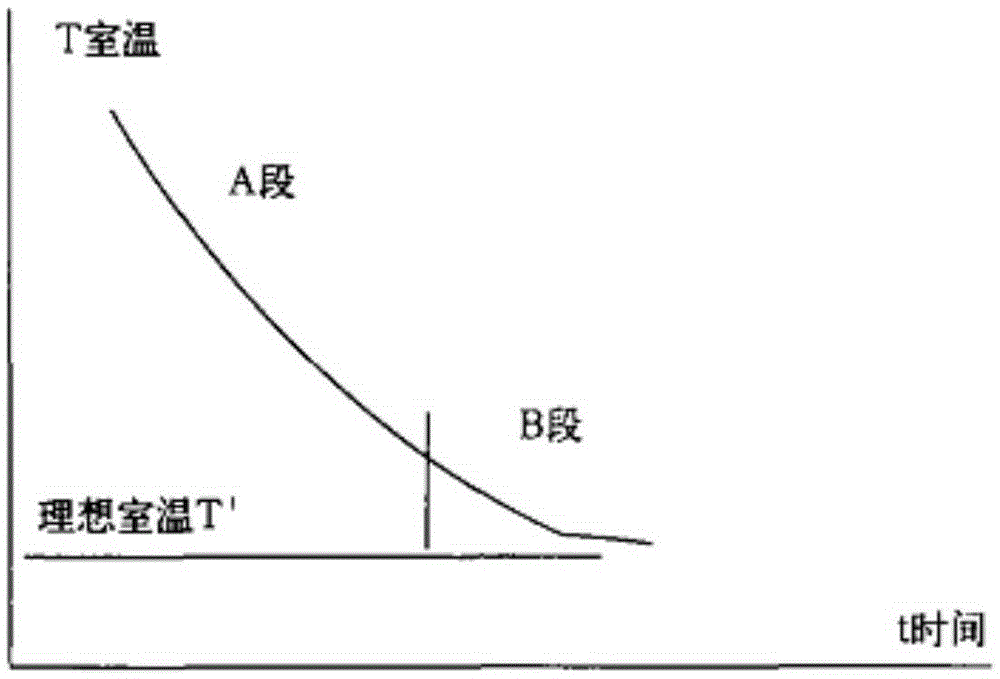

ActiveCN105402860AAvoid large temperature differencesSmall temperature differenceMechanical apparatusSpace heating and ventilation safety systemsSelf adaptiveFuzzy rule

The embodiment of the invention discloses an air-conditioner self-adaptation control method which is used for solving the problems of non-uniform temperature distribution of indoor areas and large temperature differences between some areas and a temperature set by a user, which are easily caused in a comfortable temperature control stage of a conventional air conditioner. The method provided by the embodiment of the invention comprises the following steps: calculating the deviation value between an actual temperature value and a set temperature value; converting the deviation value into a corresponding fuzzy quantity according to a preset fuzzy rule; judging whether the fuzzy quantity is less than the deviation value, if no, performing PID fuzzy control which comprises the following steps: calculating a deviation change rate corresponding to the deviation value according to the actual temperature value and the set temperature value; acquiring a calibration frequency through a PID control algorithm and the preset fuzzy rule according to the deviation value and the deviation change rate; and adjusting the working frequency of a compressor into the calibration frequency. The embodiment of the invention further provides an air-conditioner self-adaptation control system.

Owner:GUANGDONG CHIGO AIR CONDITIONING

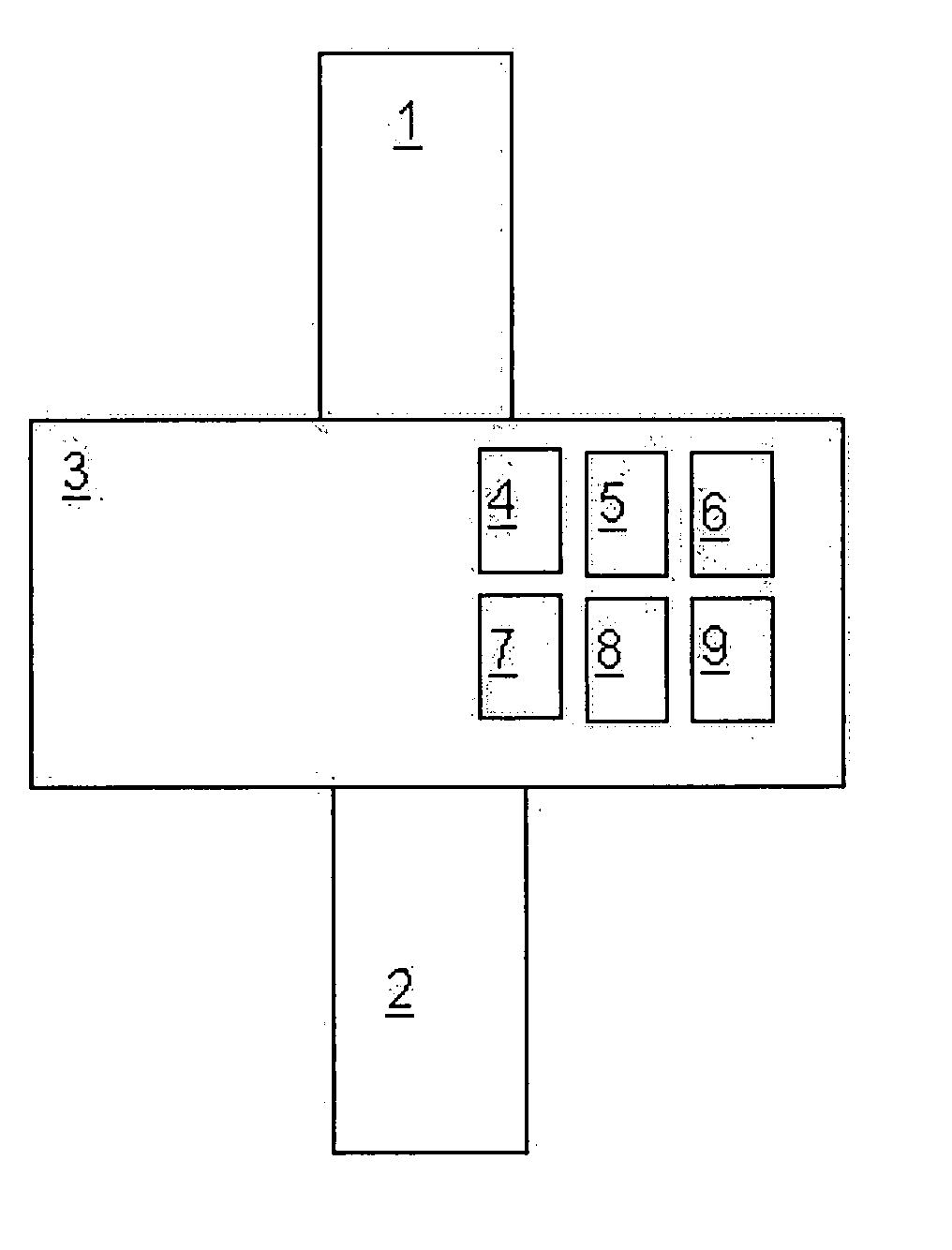

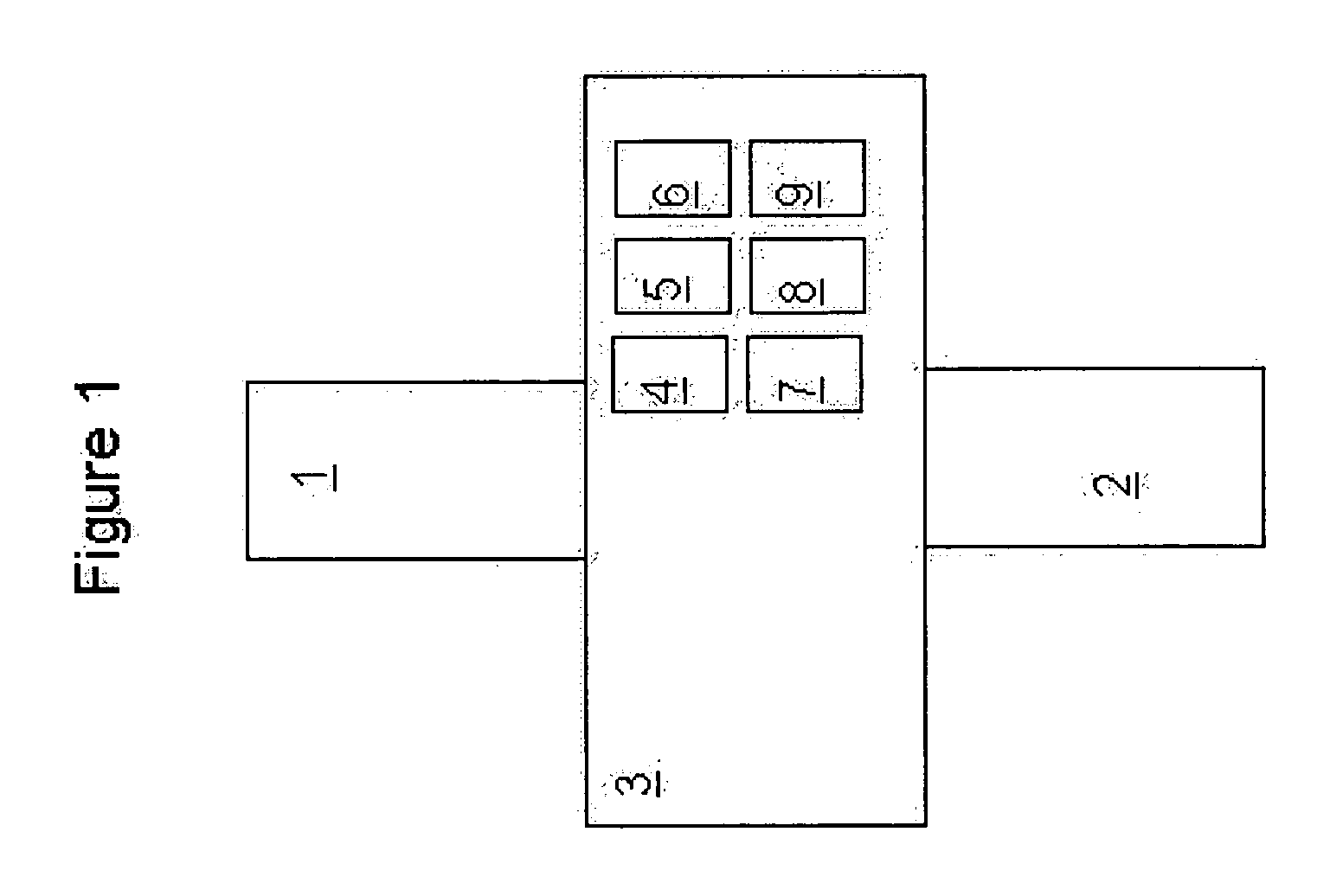

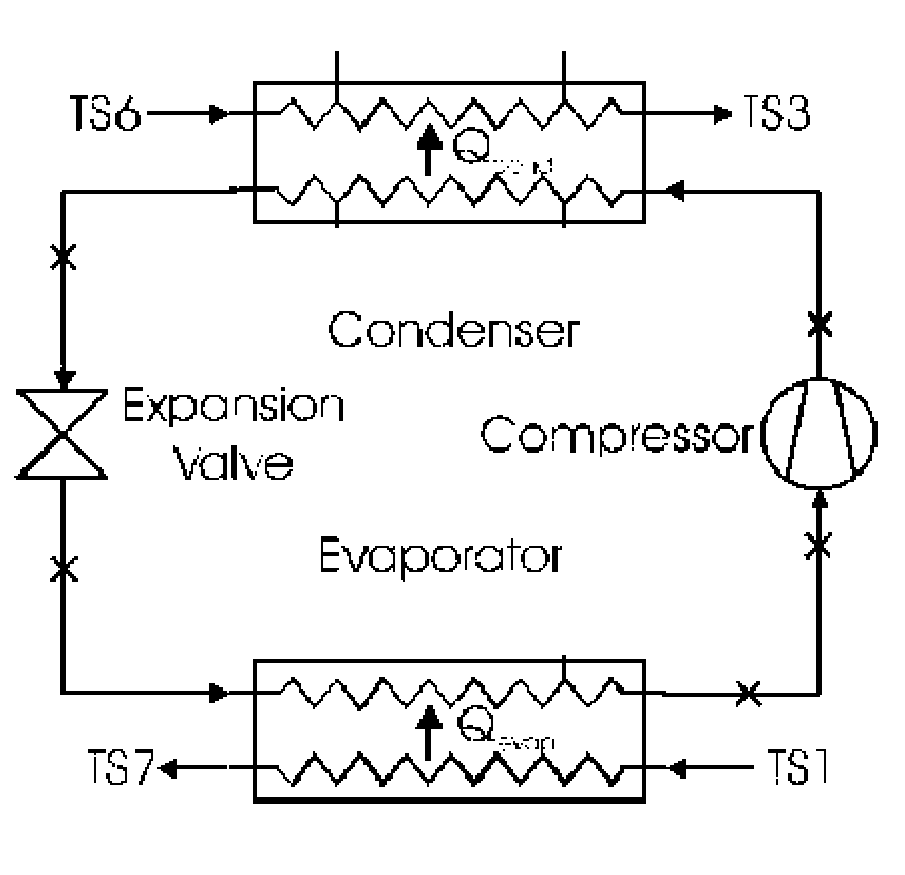

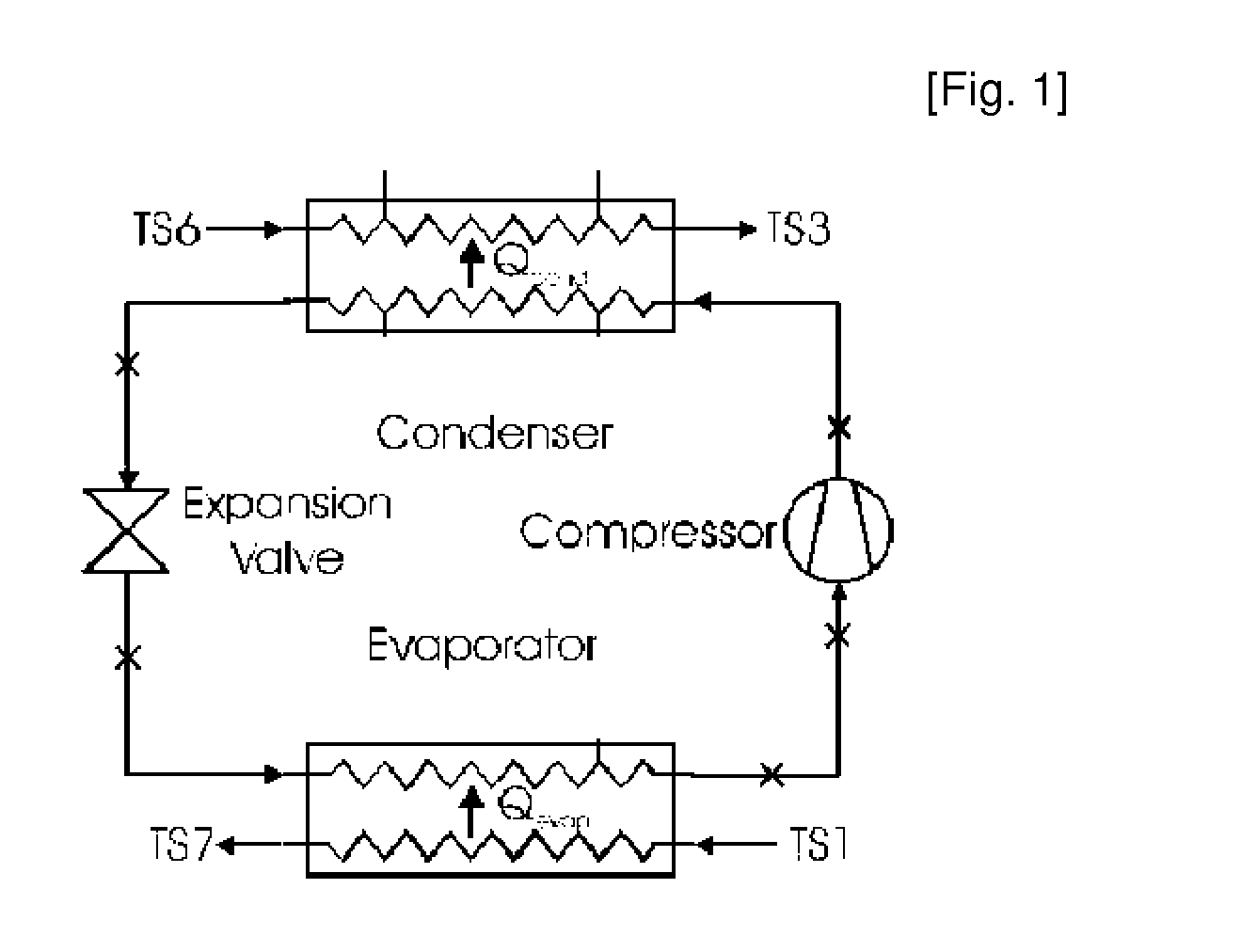

Freezer-refrigerator and cooling storage unit

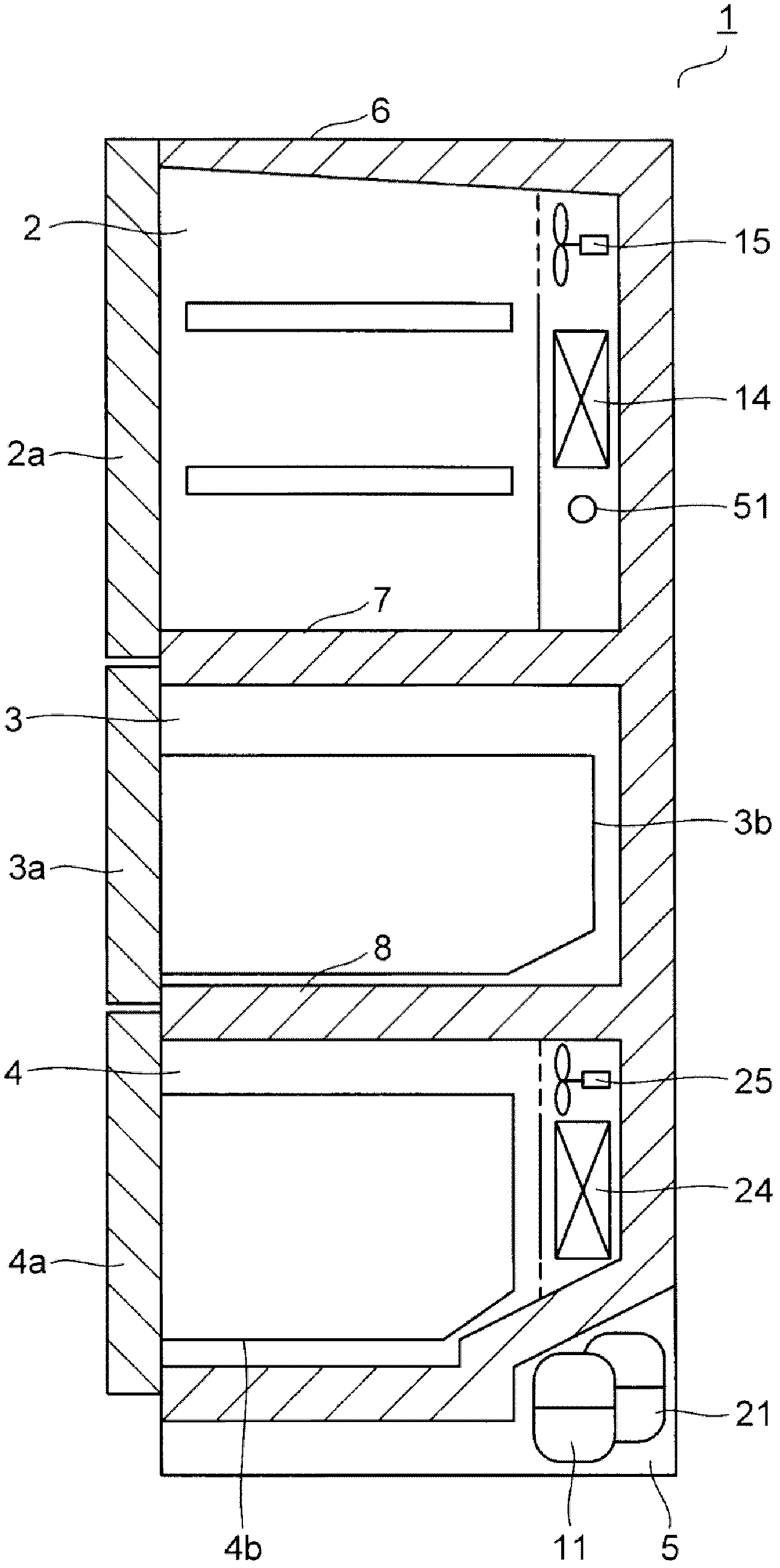

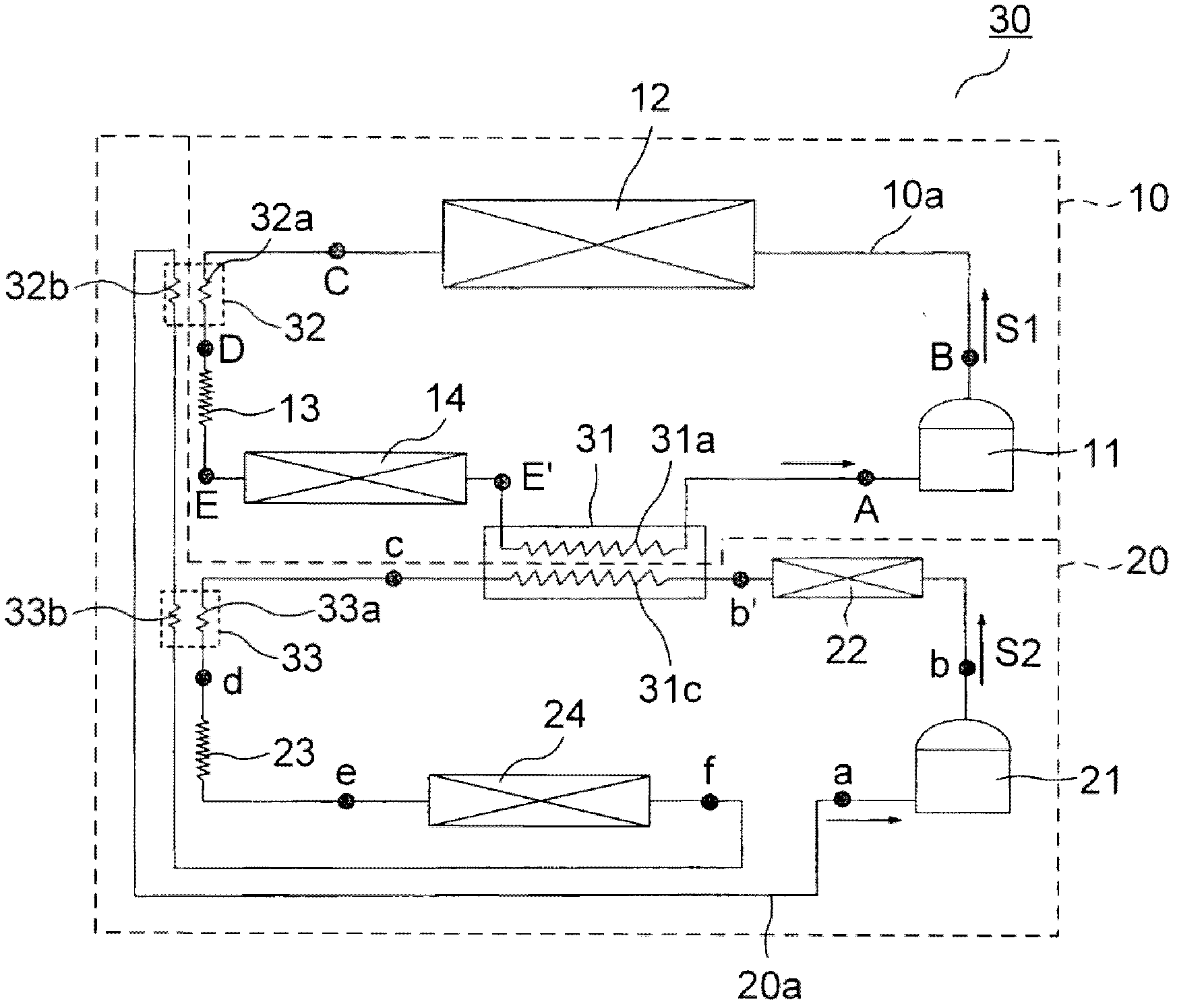

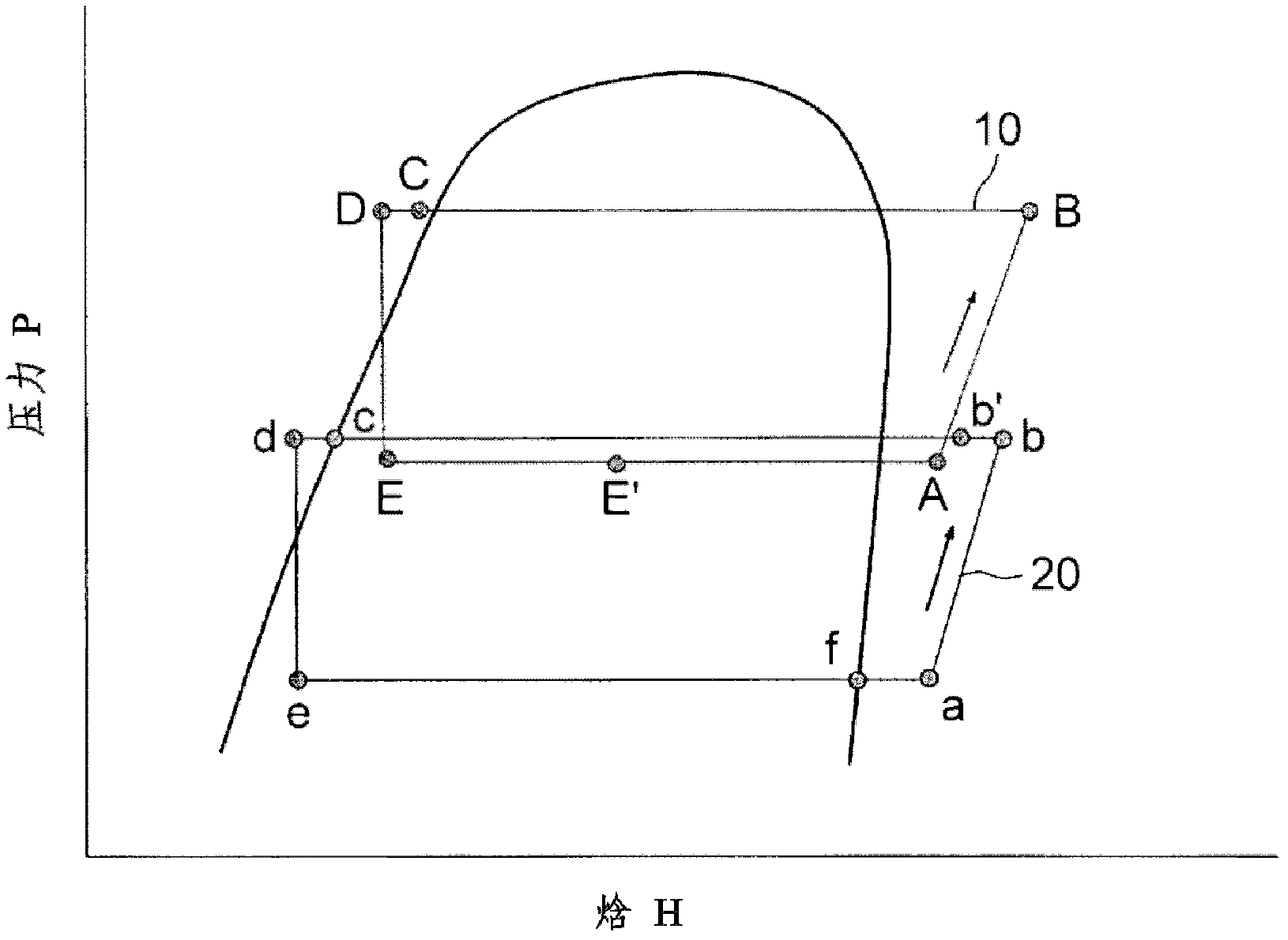

InactiveCN102395840AImprove COPLess power consumptionCompression machines with non-reversible cycleDomestic refrigeratorsIntermediate heat exchangerEngineering

A freezer-refrigerator comprising: a refrigeration compartment (2) for refrigerating and storing an object to be stored; a freezing compartment (4) for freezing and storing an object to be stored; a first compressor (11) for operating a first refrigeration cycle (10) in which a first refrigerant flows; a first heat dissipater (12) provided to a high-temperature section of the first refrigeration cycle (10); a first evaporator (14) provided to a low-temperature section of the first refrigeration cycle (10); a second compressor (21) for operating a second refrigeration cycle (20) in which a second refrigerant flows; a second evaporator (24) provided to a low-temperature section of the second refrigeration cycle (20); and an intermediate heat exchanger (31) for performing heat exchange between the low-temperature section of the first refrigeration cycle (10) and a high-temperature section of the second refrigeration cycle (20). The first evaporator (14) cools the refrigeration compartment (2), and the second evaporator (24) cools the freezing compartment (4).

Owner:SHARP KK

Intelligent temperature control cup

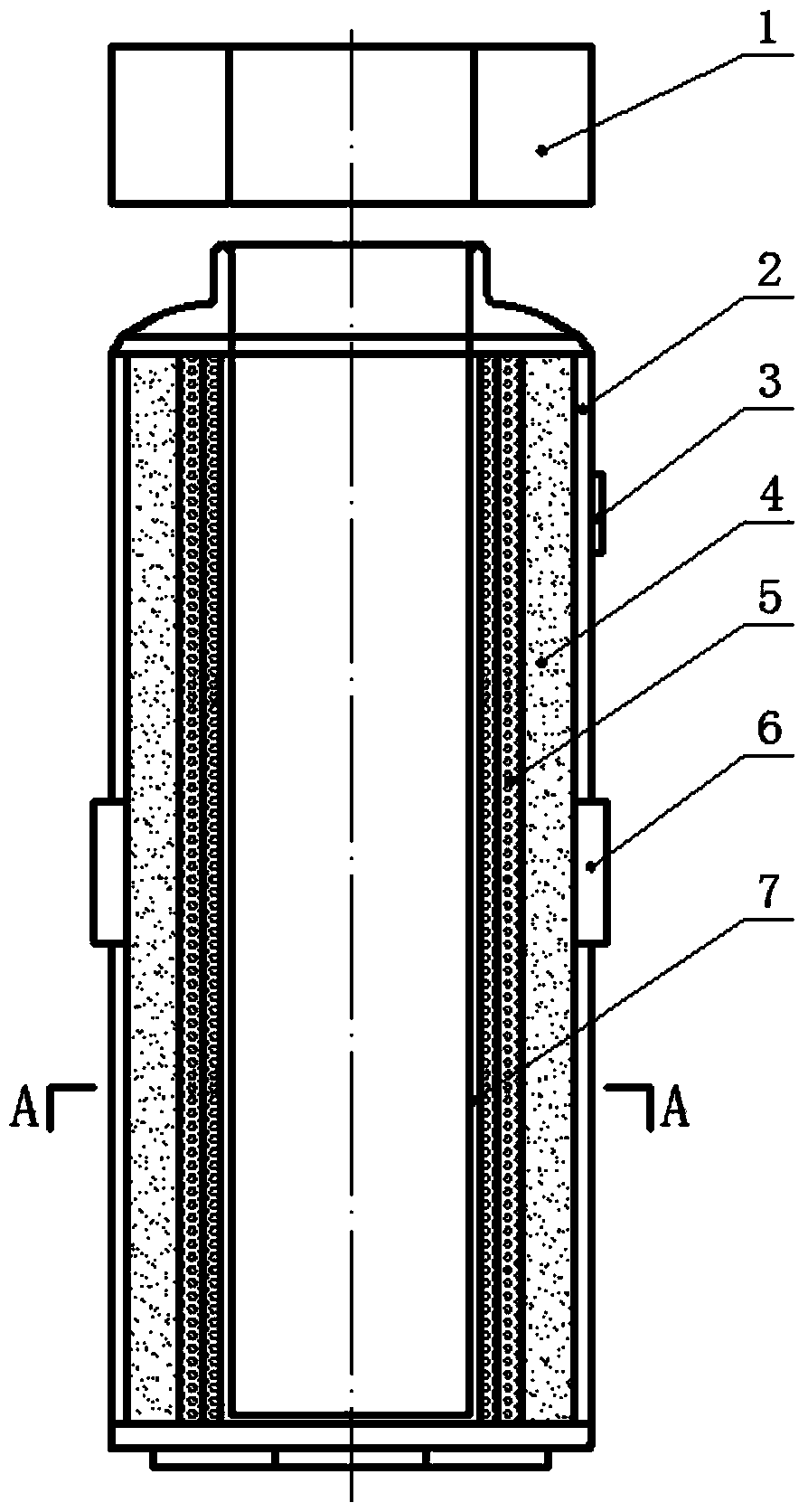

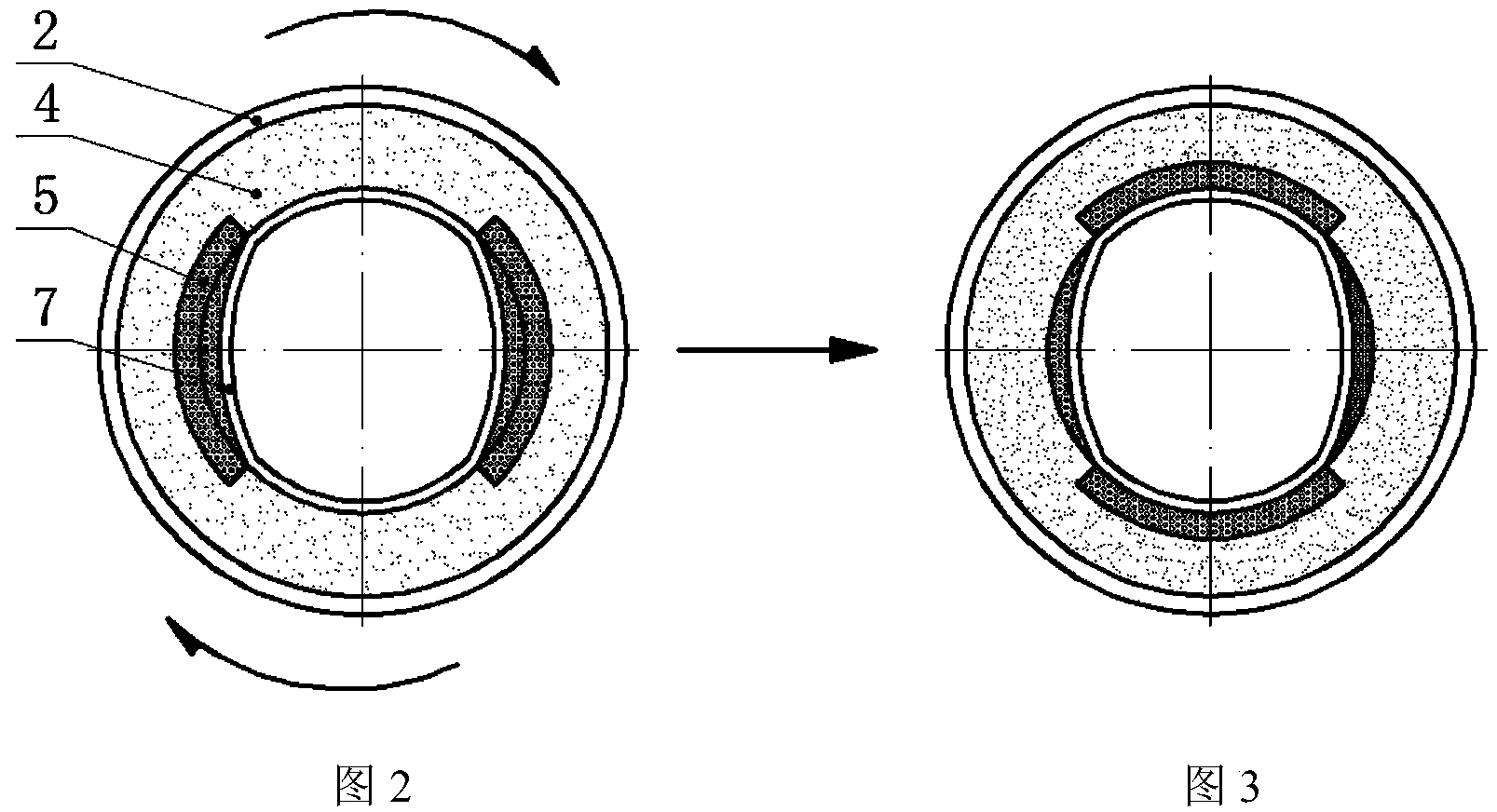

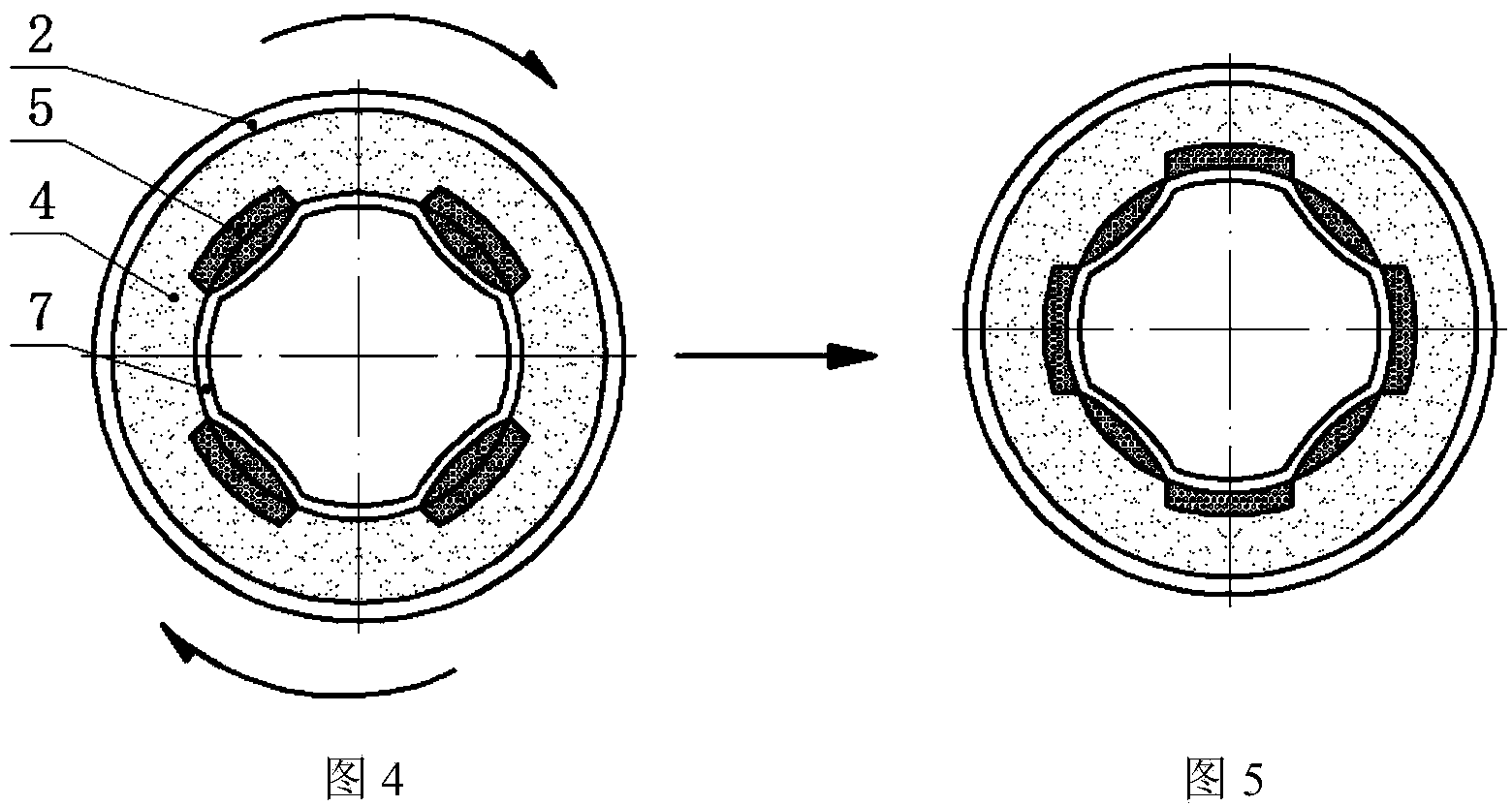

ActiveCN104161430AAccurate temperature controlSmall temperature differenceDrinking vesselsEngineeringPhase-change material

The invention relates to an intelligent temperature control cup which comprises a cup body and a cup cover. The cup body is sealed by the cup cover. The cup body comprises an inner container and an outer shell. Heat insulation materials and phase-changing materials are arranged between the inner container and the outer shell. Grooves are formed in the outer wall of the inner container in the radial direction at intervals. Each groove is filled with heat insulation materials. A phase-changing material layer is arranged between the inner container and the outer shell in a sleeved mode. Grooves are evenly distributed in the radial direction of the inner edge column face of the phase-changing material layer at intervals. Each groove is filled with heat insulation materials. A rotating ring is coaxially and fixedly arranged on the outer edge column face of the phase-changing material layer. According to the rotating ring, the phase-changing material layer rotates in the axial direction, and when the phase-changing material layer rotates to the position where the heat insulation materials arranged in the phase-changing material layer grooves in a filling mode and the heat insulation materials arranged in the inner container grooves in a filling mode are crossed and are not overlapped, the heat insulation materials can right seal and surround the inner container. According to the temperature control cup, temperature controlling and preservation can be carried out at multiple points and multiple time periods, and the intelligent, convenient, quick and human-friendly designing concept is reflected.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Thin film heterostructure preparation method

ActiveCN108493334ALow annealing temperatureShorten process timePiezoelectric/electrostrictive/magnetostrictive devicesOptoelectronicsHigh-temperature corrosion

The invention provides a thin film heterostructure preparation method. The method comprises steps: a wafer substrate with an injection surface is provided; ion implantation is carried out on the wafersubstrate from the injection surface, and an injection defect layer is formed at a preset depth in the wafer substrate; a support substrate is provided, and the support substrate and the wafer substrate are subjected to temperature rise bonding; the obtained structure is subjected to annealing treatment to form a continuous defect layer; the temperature of the obtained structure is reduced to a preset temperature, reverse thermal stress generated based on temperature reduction strips part of the wafer substrate along the continuous defect layer, and a thin film heterostructure comprising thesupport substrate and the wafer thin film is obtained, wherein the preset temperature is lower than the bonding temperature. In the temperature rise bonding mode, the thermal stress of the bonding structure can be reduced, the bonding structure can keep stable and complete in a high temperature process, the problem of wafer crack generated by thermal mismatch in the stripping process can be effectively solved, and through the reverse thermal stress assisting method, the bonding structure is separated at the continuous defect layer and a bonding interface is not influenced.

Owner:上海新硅聚合半导体有限公司

Active evaporation control method applicable to long-term on-orbit storage of cryogenic propellant

The present invention relates to an active evaporation control method applicable to long-term on-orbit storage of a cryogenic propellant. According to the method, an active evaporation control device that comprises a composite thermal insulating layer, a steam cooling shield, a heat exchanger, a throttling assembly, a circulating pump, a bypass valve and a steam cooling shield exhaust valve is installed for a propellant storage tank. According to the present invention, with the developed active evaporation control method for a cryogenic propellant, discharge of a small amount of simple gaseous propellant can be achieved under the circumstance of uncertain gas-liquid position under microgravity condition, and pressure control on the cryogenic propellant storage tank and control on evaporation of the cryogenic propellant may be effectively realized under dual action by fully using thermodynamic enthalpy of the discharged cryogenic propellant after being throttled; and the method can allow effective reduction of evaporation loss of the cryogenic propellant in on-orbit use, thus prolonging the on-orbit mission time of a spacecraft.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

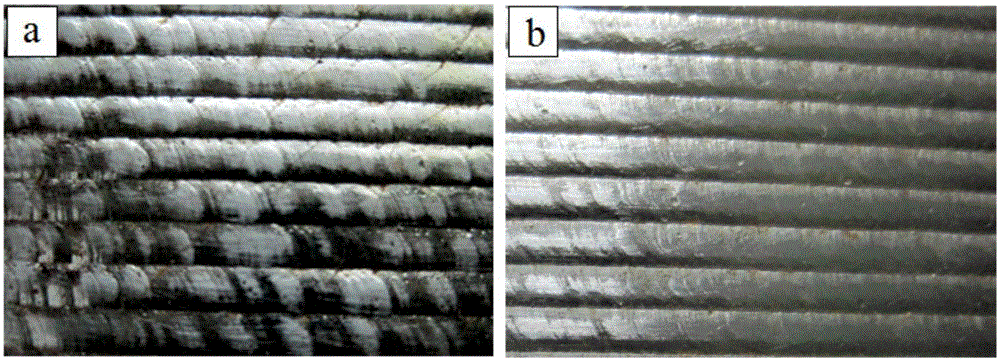

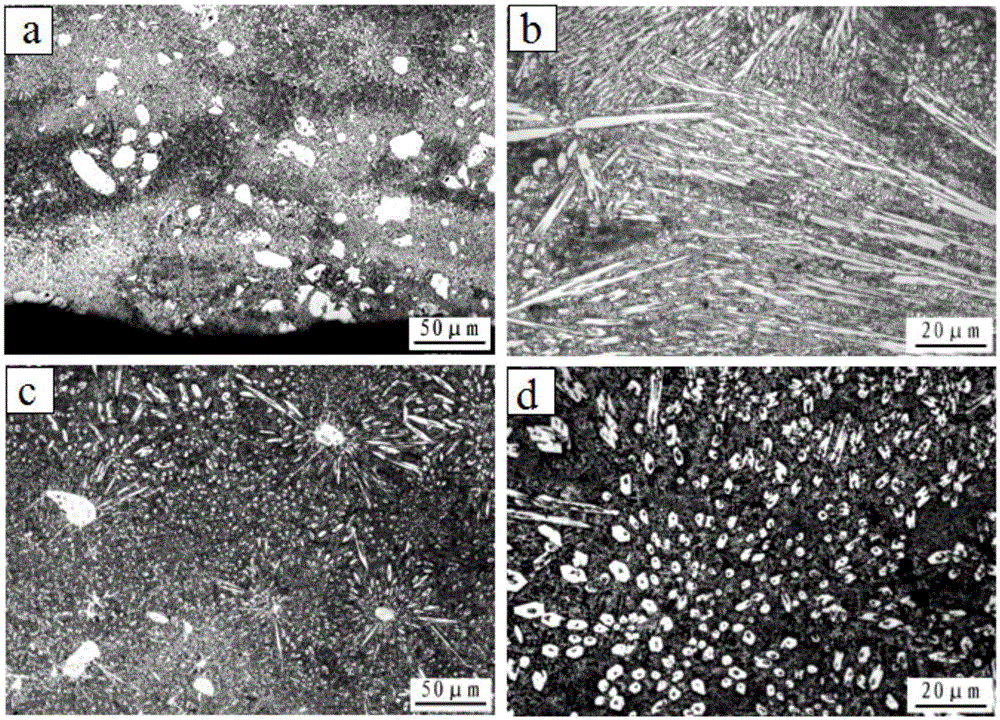

Iron-based Cr3C2 laser-cladding coating added with CeO2 and preparation method of coating

ActiveCN105112909AHigh hardnessImprove wear resistanceMetallic material coating processesAlloyHardness

The invention discloses an iron-based Cr3C2 laser-cladding coating added with CeO2 and a preparation method of the coating, and belongs to the technical field of surface modification. The coating is prepared by uniformly mixing the following components in percentage by mass for laser-cladding: 65-73% of iron-based self-fluxing alloy powder, 26.5-34% of Cr3C2 alloy powder and 0.5-1% of CeO2 powder. The preparation method comprises the following steps: powder preparation; uniform mixing and drying; preparation and post-treatment of the coating. Through adoption the technical scheme, the rigidity, abrasion resistance and high-temperature oxidation resistance of the coating can be improved; besides, the forming quality and cladding property of the coating can be remarkably improved to inhibit and eliminate bubbles and cracks.

Owner:ANHUI MA STEEL SURFACE TECH CO LTD

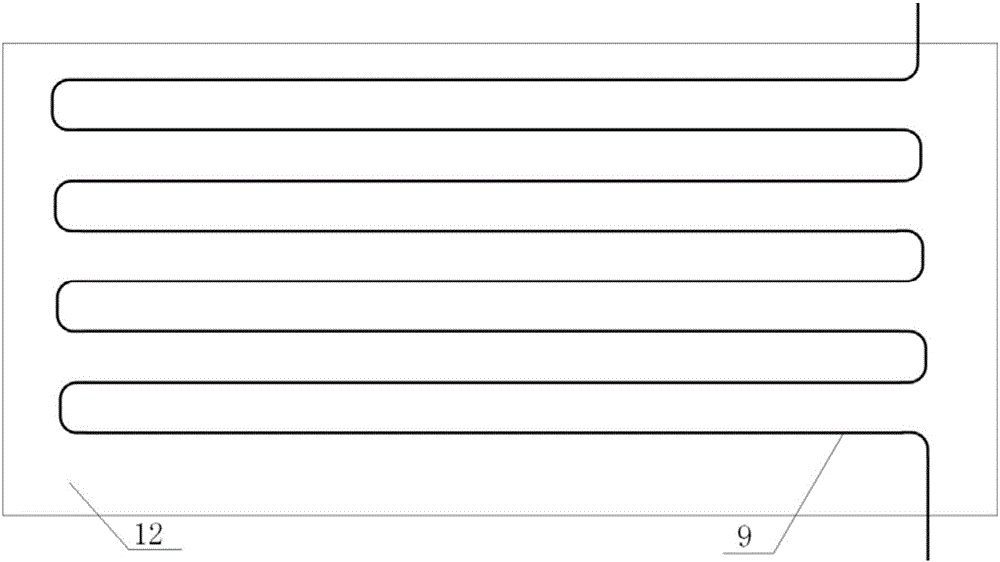

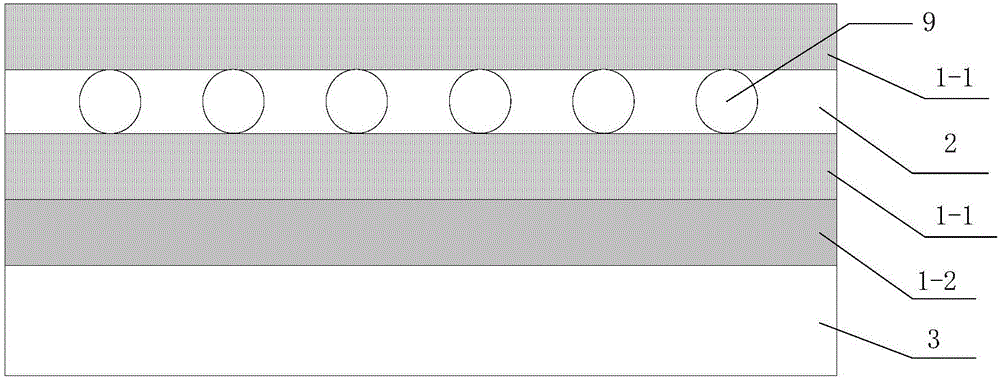

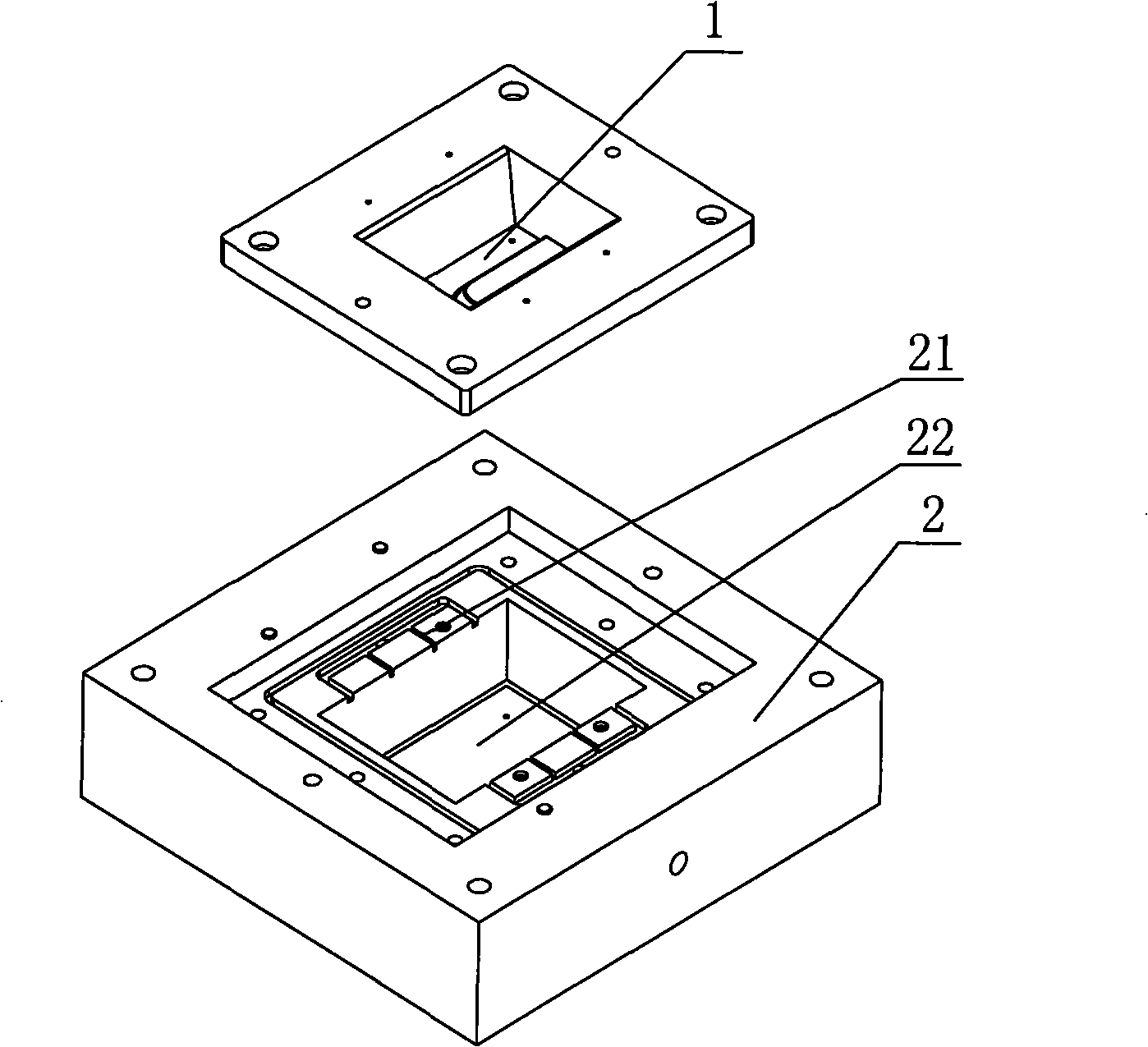

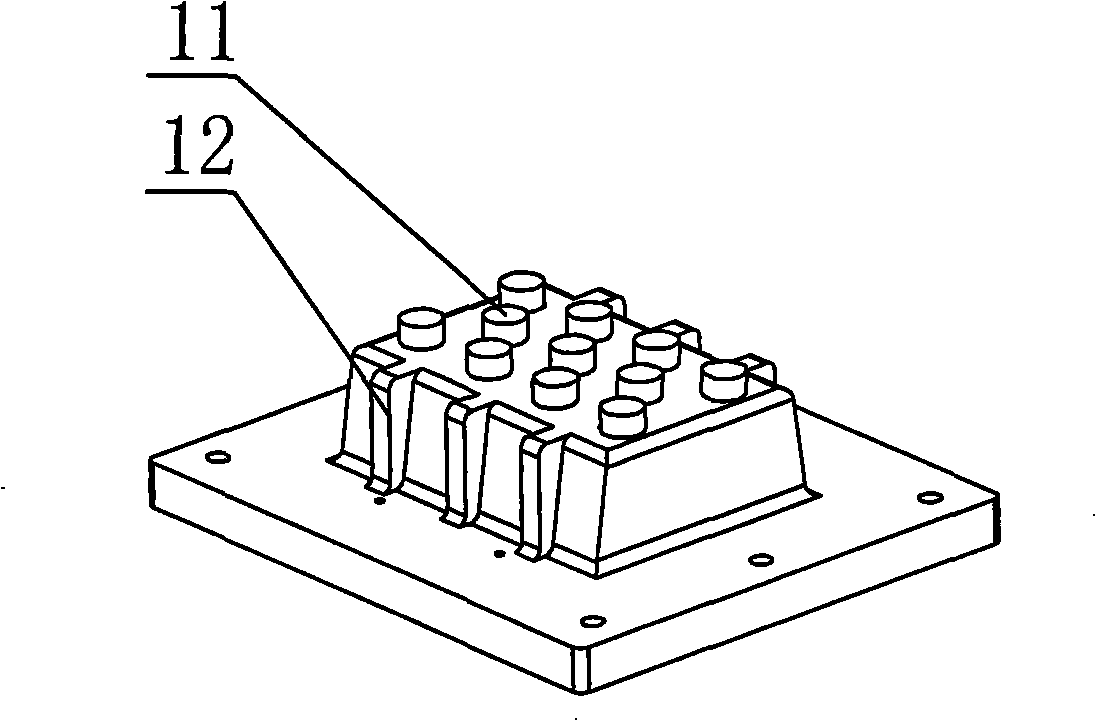

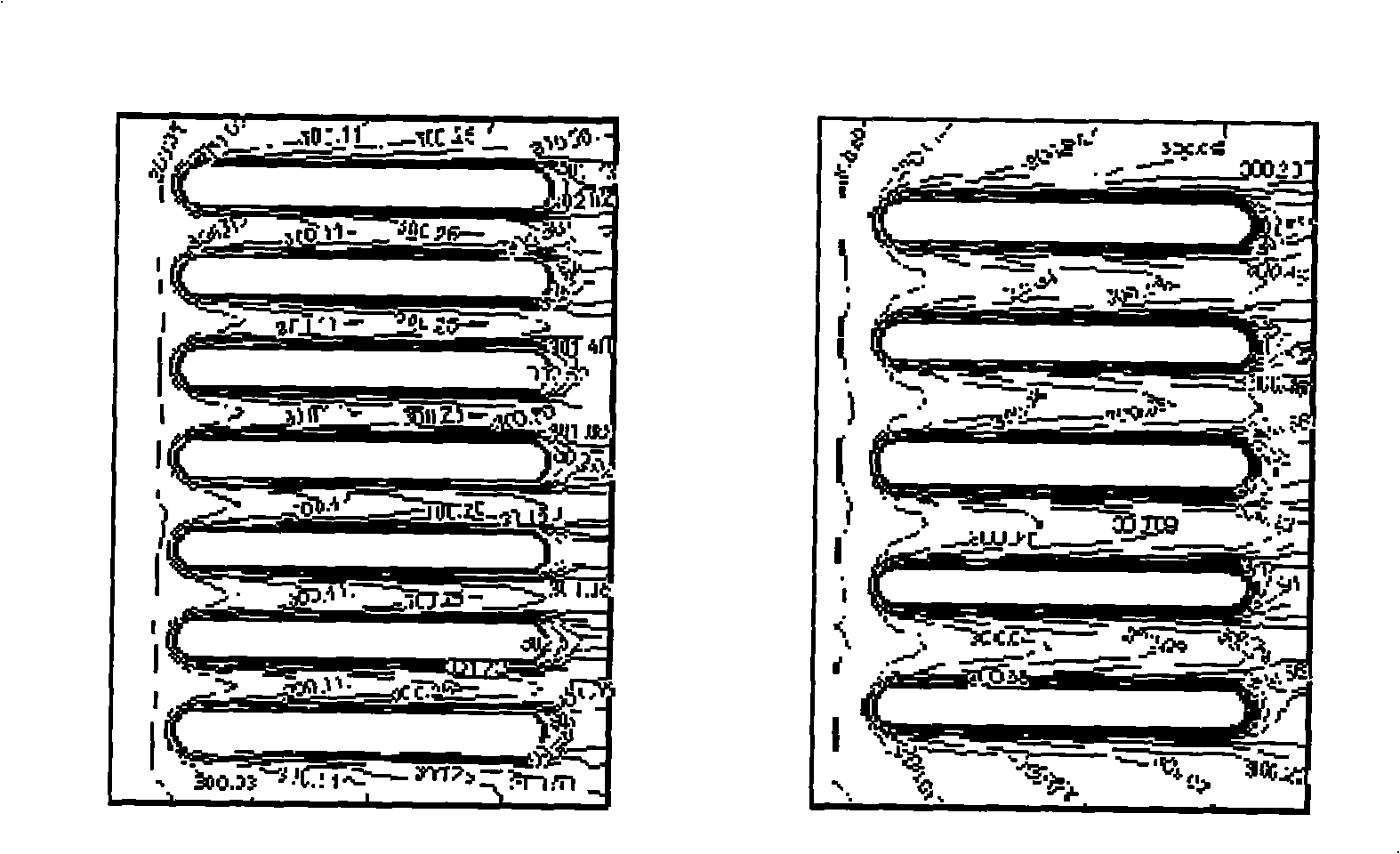

Cooling system of ultra-high strength steel hot stamping forming die

InactiveCN101288890AImprove cooling effectWarranty Strength RequirementsShaping toolsHot stampingSheet steel

The invention discloses a cooling system used for an ultra-high strength steel plate thermal die cutting and forming die. The die comprises a concave die and a concave die seat; a water chamber is arranged between the concave die and the concave die seat; the water chamber is communicated with a water inlet and a water outlet. The water chamber is arranged between the concave die and the concave die seat of the invention; after cooled water is inlet in the water chamber, a steel plate workpiece can be quickly cooled by the thermal conduction between the die and the steel plate so as to meet the quenching condition of the steel plate. Especially, the water chamber is also internally provided with a supporting column; the upper end of the supporting column is contacted with the lower bottom surface of the concave die; the lower end of the supporting column is contacted with the upper bottom surface of the concave die seat; therefore, the structural strength of the concave die is ensured, the flowing direction of the water flow can be guided, flow perturbation conditions can be provided, meanwhile, the heat transfer area is increased, and the heat exchange efficiency between the cooled water and the die is improved.

Owner:TONGJI UNIV +1

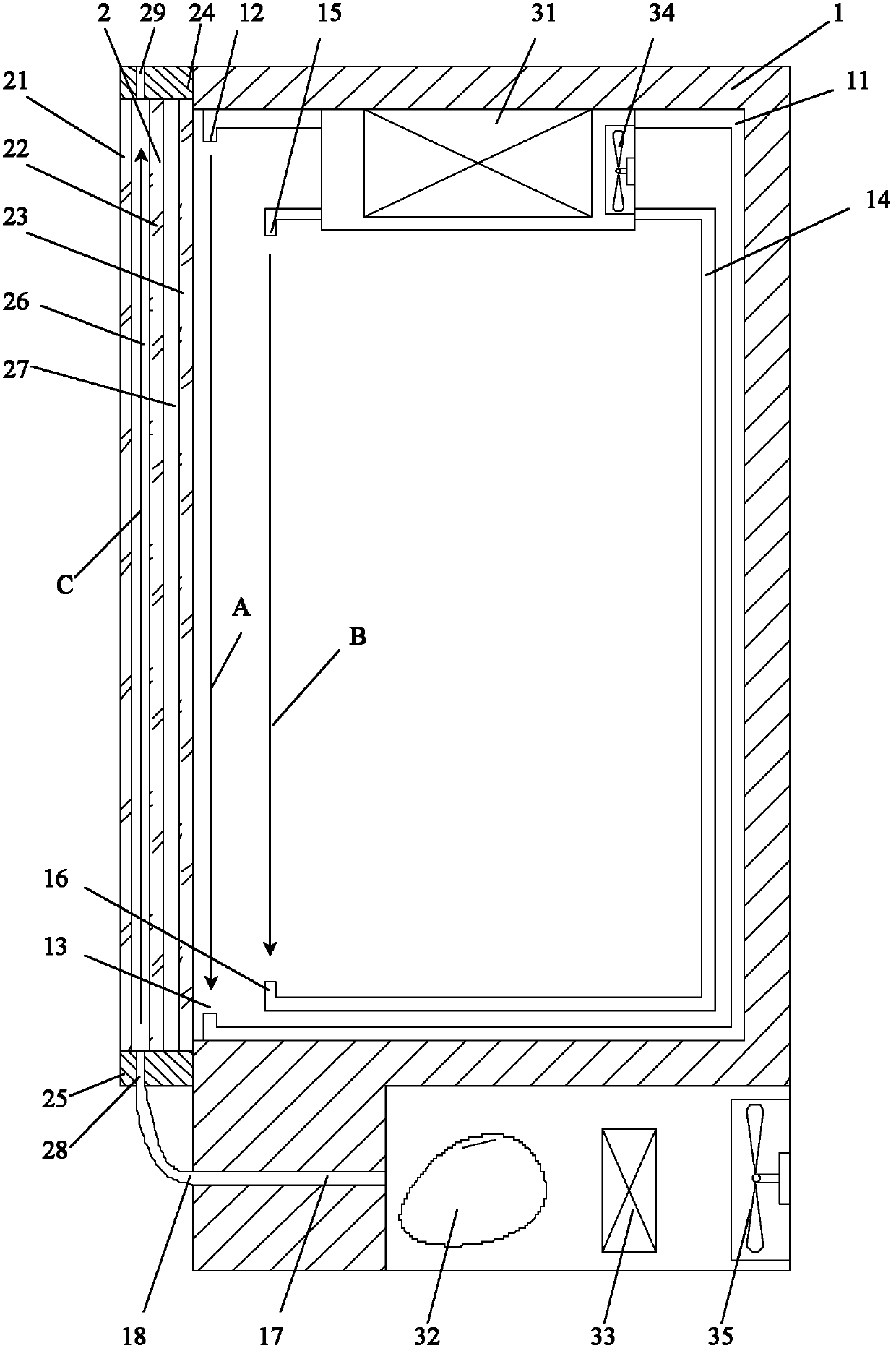

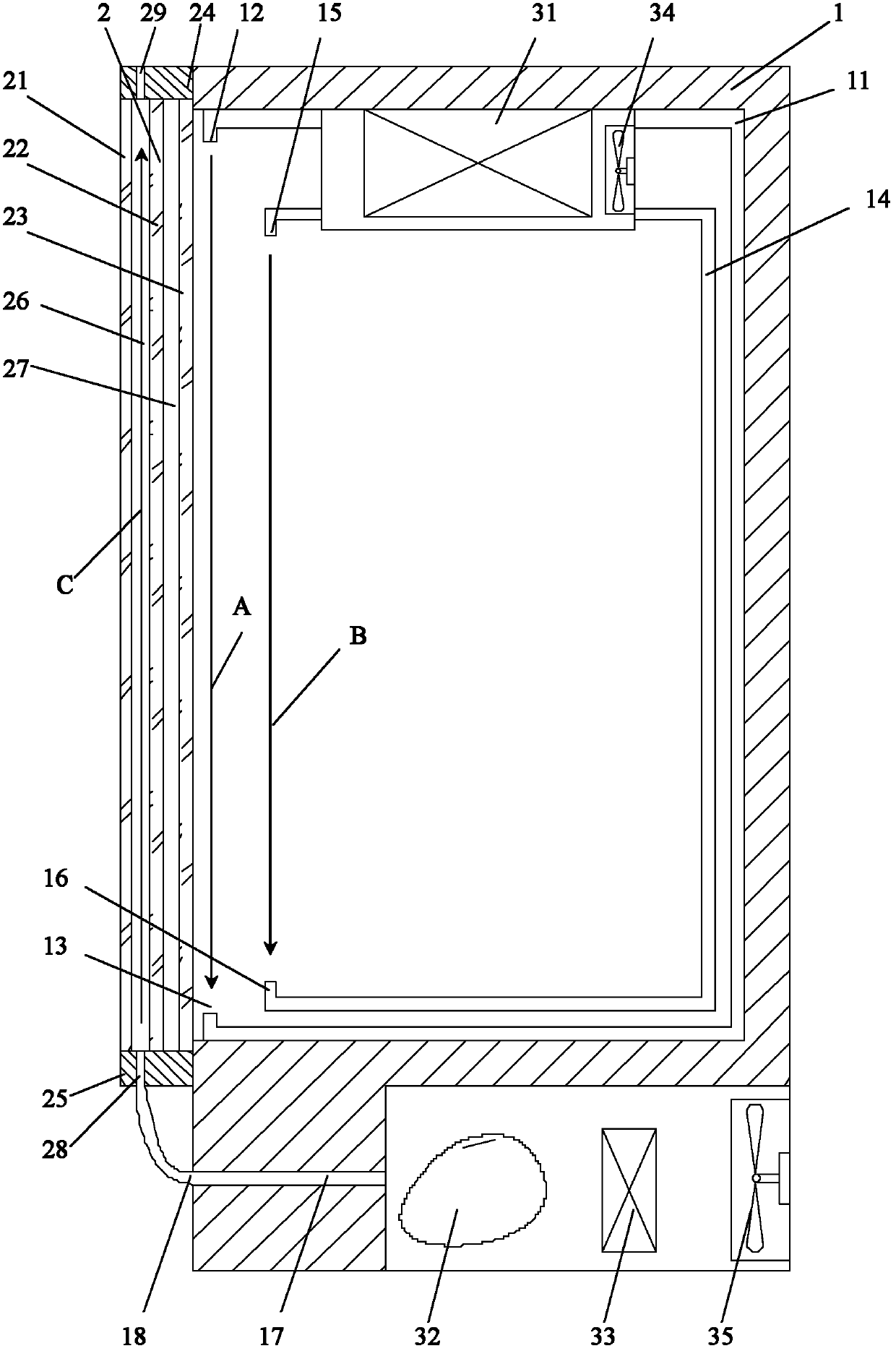

Anti-condensing closed-type display cabinet

ActiveCN102379580AImprove cooling effectSmall temperature differenceShow cabinetsLighting and heating apparatusCold airEngineering

The invention relates to an anti-condensing closed-type display cabinet, which comprises a box body and a glass cabinet door. The glass cabinet door is installed on door frames. The door frames are fixedly connected with the box body. A refrigerating system is installed in the box body. An outer cold air duct and an inner cold air duct are installed in the box body. The first cold air duct outlets of the outer cold air duct are arranged in the box body at positions adjacent to the glass cabinet door, and the first cold air duct outlets and first cold air duct inlets are relatively arranged vertically to form an outer cold air curtain; and the second air duct outlets of the inner cold air duct are arranged in the box body at positions adjacent to the outer cold air curtain, and the second air duct outlets and second air duct inlets are relatively arranged vertically to form an inner cold air curtain. The invention provides the anti-condensing closed-type display cabinet which has a good refrigerating effect and can effectively prevent condensate from occurring on the external surface of the glass cabinet door at the same time.

Owner:YINDU KITCHEN EQUIP

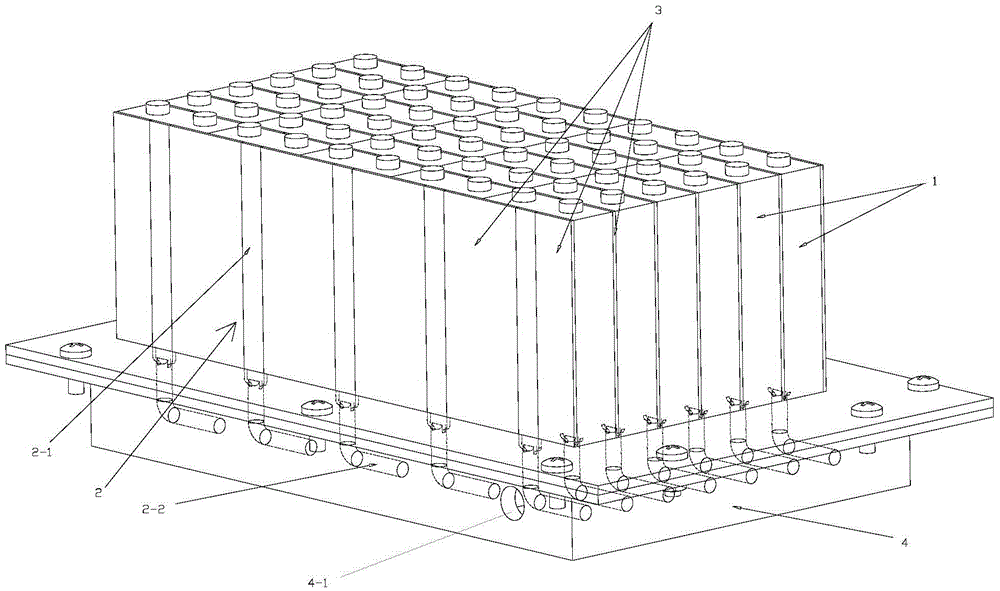

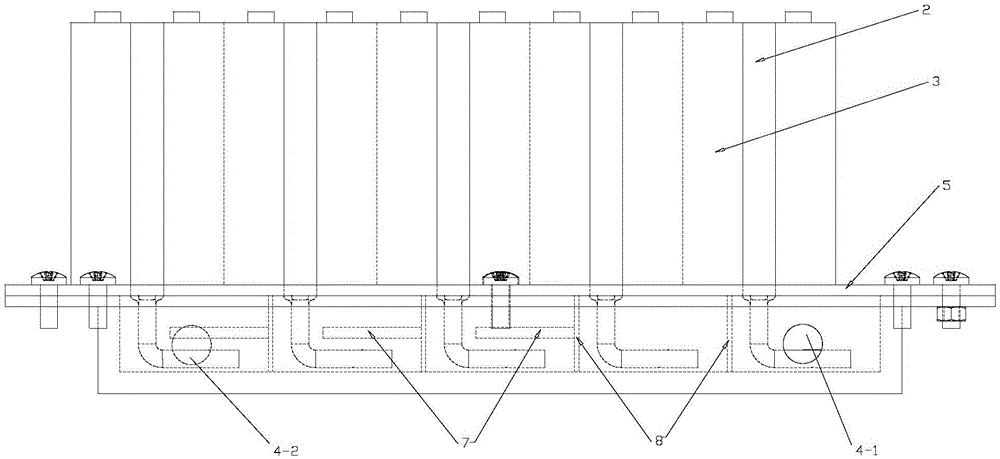

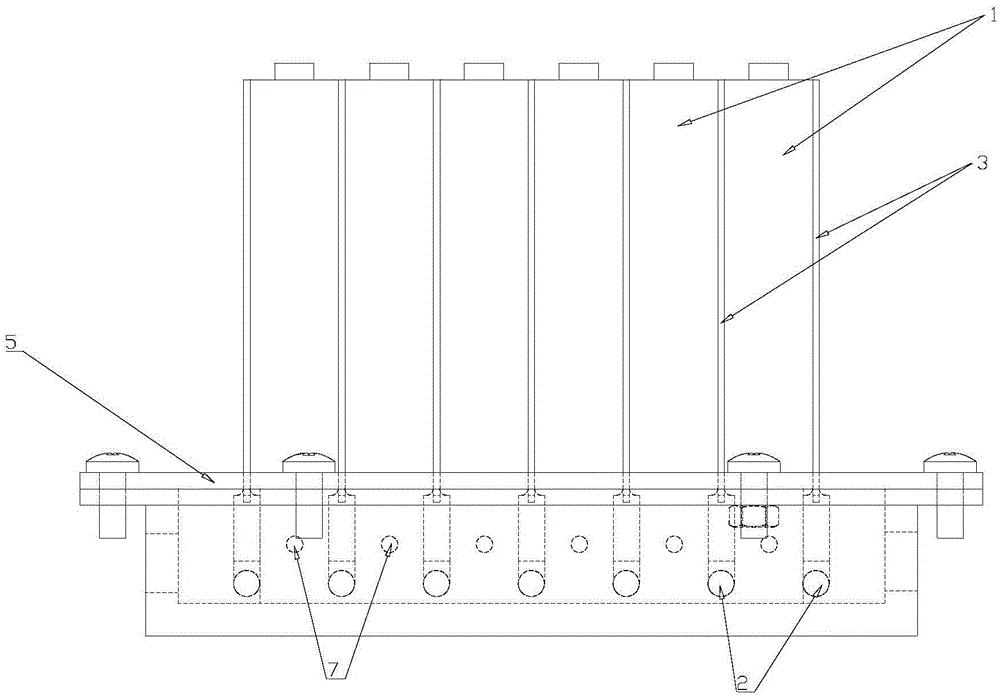

Power battery composite heat management system and method thereof

ActiveCN105633509AImprove thermal conductivityReduce weightSecondary cellsPower batteryHeat management

The invention discloses a power battery composite heat management system and a method thereof. The power battery composite heat management system comprises a water tank filled with a circulating fluid, a circulating pump, a sealing cover plate of the water tank, and a battery pack array which is fixedly mounted above the sealing cover plate and is composed of a plurality of battery cells, wherein a temperature equalizing plate and a heat pipe are adhered onto the surface of each battery cell respectively, and cooing sections of the heat pipes pass through the sealing cover plate to be arranged in the circulating fluid in the water tank; a circulating fluid inlet is formed in one side end of the water tank, a circulating fluid outlet is formed in the other side end of the water tank, and a circulating fluid turbulent flow structure is arranged inside the water tank, so that the circulating fluid flows into the circulating fluid outlet from the circulating fluid inlet of the water tank in a curve flowing manner. The system and the method thereof can solve the technical problems such as heat dissipation, battery pack temperature difference reduction, battery preheating and heat cyclic utilization under different working conditions of batteries; and meanwhile, the system is compact and simple in structure and convenient in installation and maintenance, accords with the development tendency of battery heat management systems and electric automobiles, and has good application prospects.

Owner:SOUTH CHINA UNIV OF TECH

Method for controlling cleanliness of molten steel, and smelting control method capable of preventing molten steel gap from nodulation during sulphur and aluminum contained steel pouring

The invention discloses a method for controlling cleanliness of molten steel, and a smelting control method capable of preventing a molten steel gap from nodulation during sulphur and aluminum contained steel pouring, and belongs to the field of smelting. The method for controlling cleanliness of the molten steel comprises the following steps that blast furnace molten iron without desulfuration issubjected to converter smelting, and during converter tapping, deoxygenation, alloying and tapping wash heat are carried out in sequence for carrying out inclusion removal treatment. Through an LF furnace, converter tapping is subjected to refining under the condition that acid soluble aluminum is not adjusted, that is, during tapping, a slagging constituent is added for controlling refining slagcomposition, and after the slag is dissolved, deoxygenation is carried out through a deoxidizing agent. Through the process, the content of sulphur in the molten steel is monitored, ferrous sulfide is used for adjusting the content of sulphur in the molten steel to the first target value, an RH furnace is used for refining LF furnace tapping, in the process, according to the content of the acid soluble aluminum of LF furnace tapping, selective aluminum feeding is carried out to adjust the content of the aluminum to the second target value, and after RH furnace refining is finished, calcium treatment is carried out. According to the process, the cleanliness of the molten steel can be improved, the nodulation problem during molten steel pouring can be avoided, and the stopper bar curve rising can be controlled.

Owner:SGIS SONGSHAN CO LTD

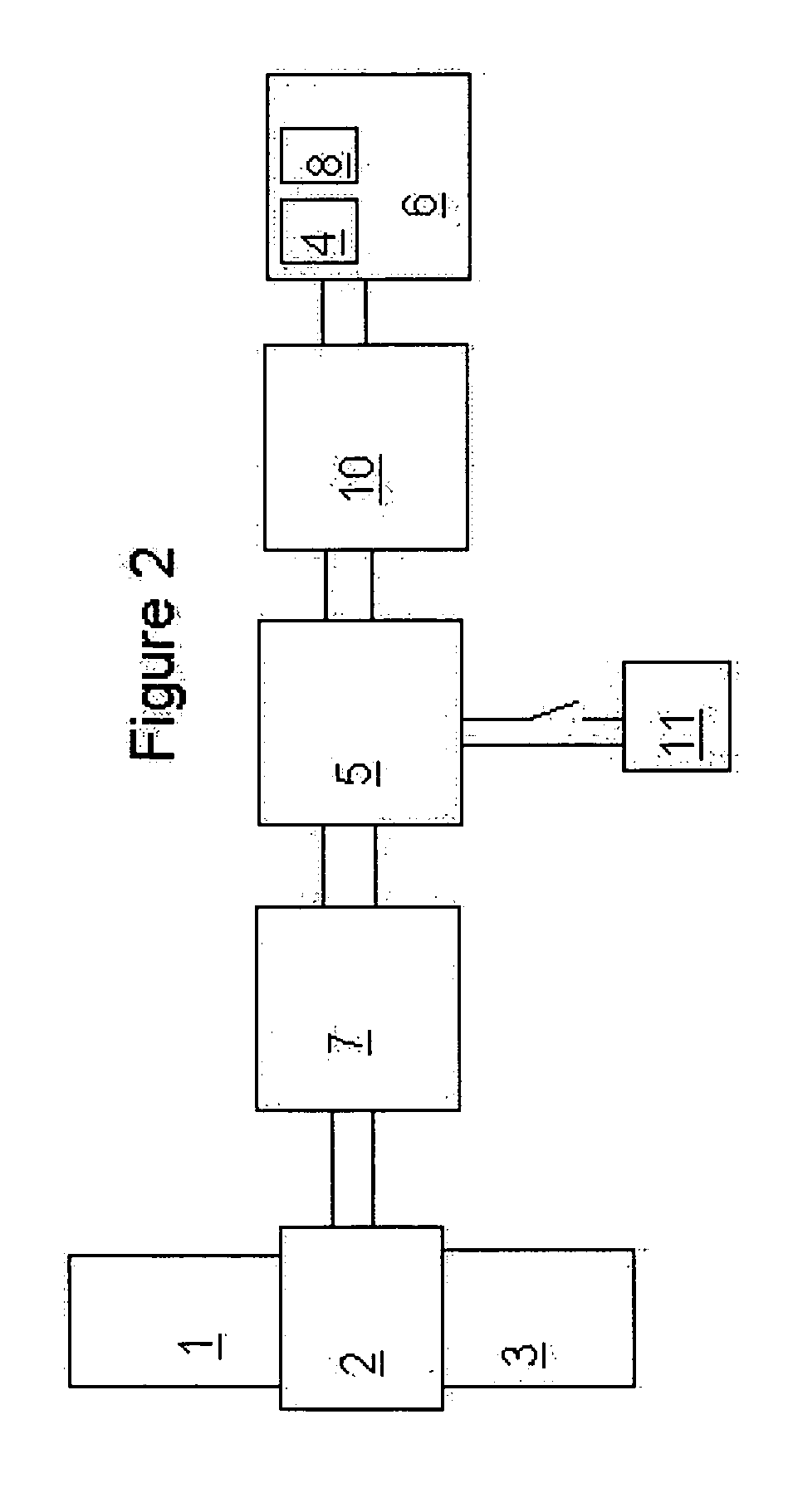

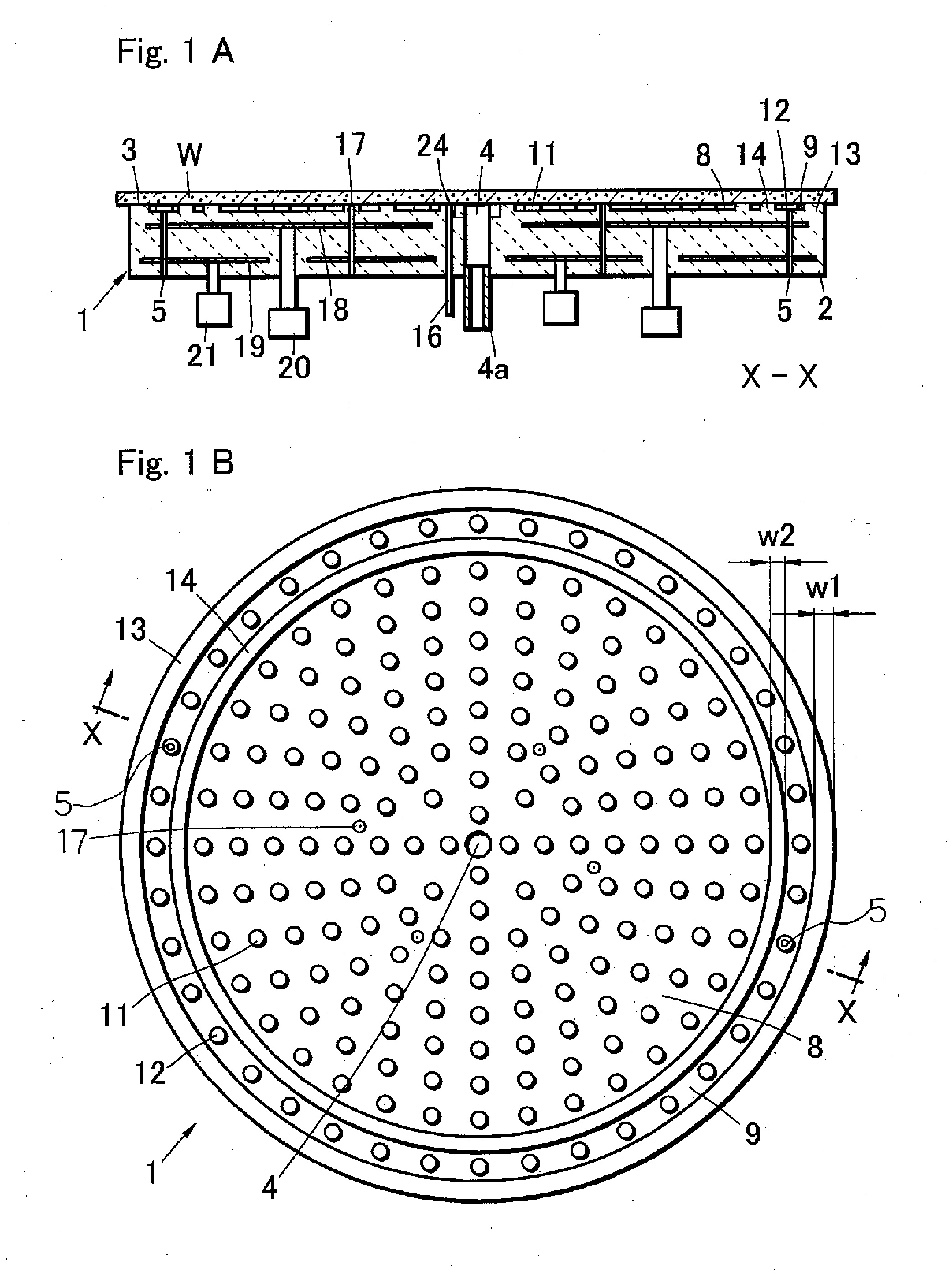

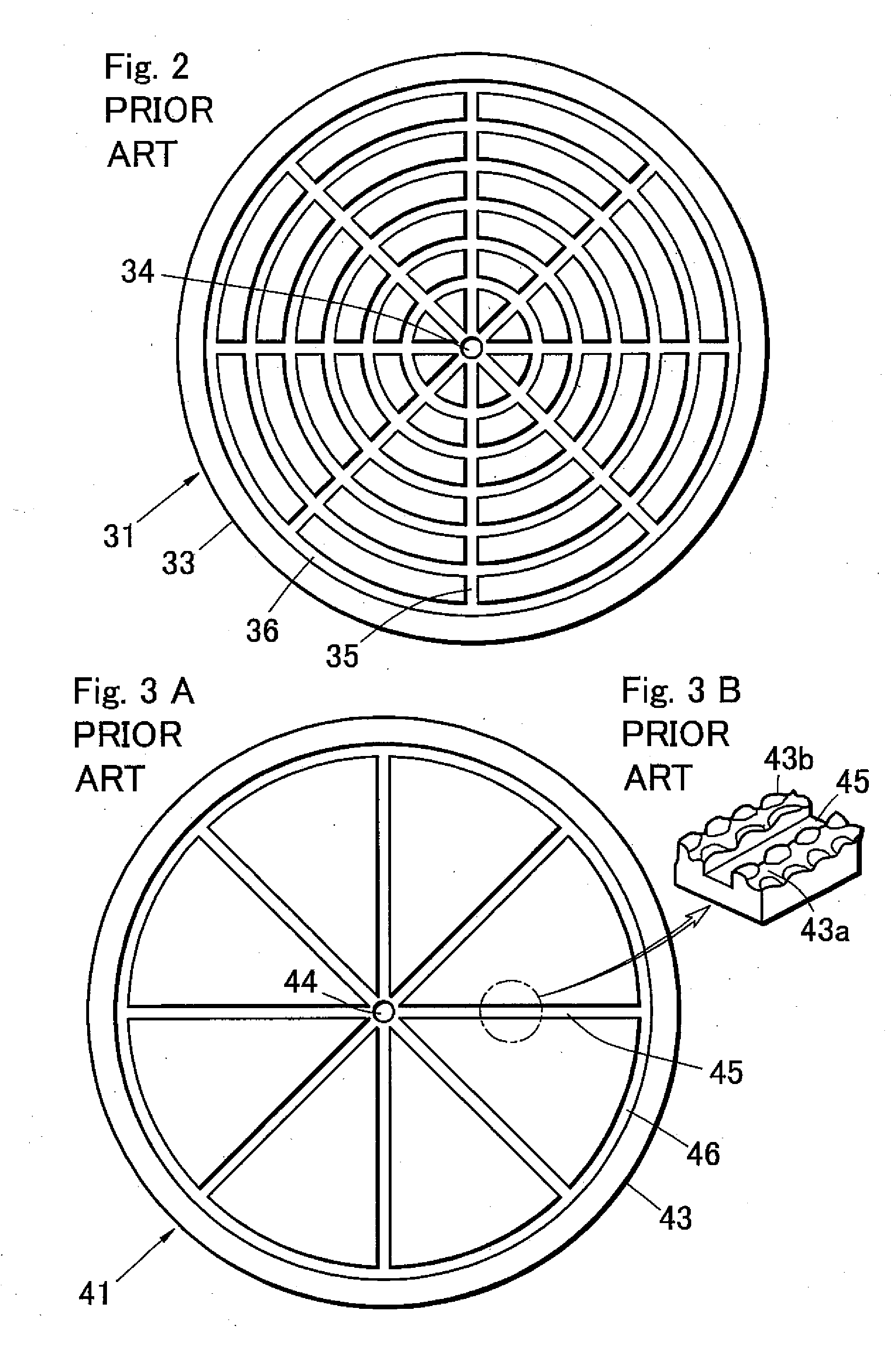

Electrostatic Chuck

ActiveUS20070247779A1Small temperature differenceShorten the timeSleeve/socket jointsSemiconductor/solid-state device manufacturingIn planeEngineering

An electrostatic chuck is provided which includes a circular ceramic plate having an electrostatic attractive electrode, a mounting surface for supporting a wafer which is formed on one of the main surfaces of the circular ceramic plate, an annular gas groove formed on the periphery of the mounting surface in the form of concentric circles with a gas inlet communicating with the annular gas groove, and a circular gas recess formed inside the ceramic plate and surrounded by the annular gas groove with a gas inlet communicating with the circular gas recess, wherein the annular gas groove and the circular gas recess are independently separated from each other by an annular rib protrusion, with a plurality of dotted protrusions being formed within both the annular gas groove and the circular gas recess. This arrangement makes it possible to achieve a smaller in-plane temperature difference on the wafer placed on the mounting surface of the electrostatic chuck and a shorter saturating time into a predetermined constant temperature.

Owner:KYOCERA CORP

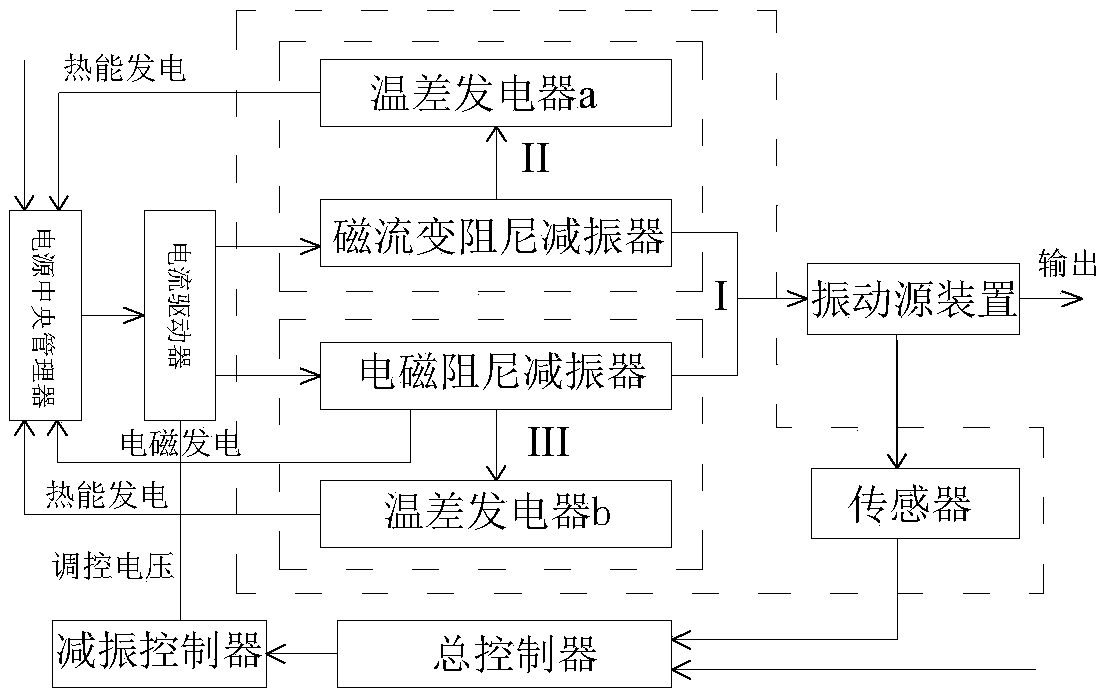

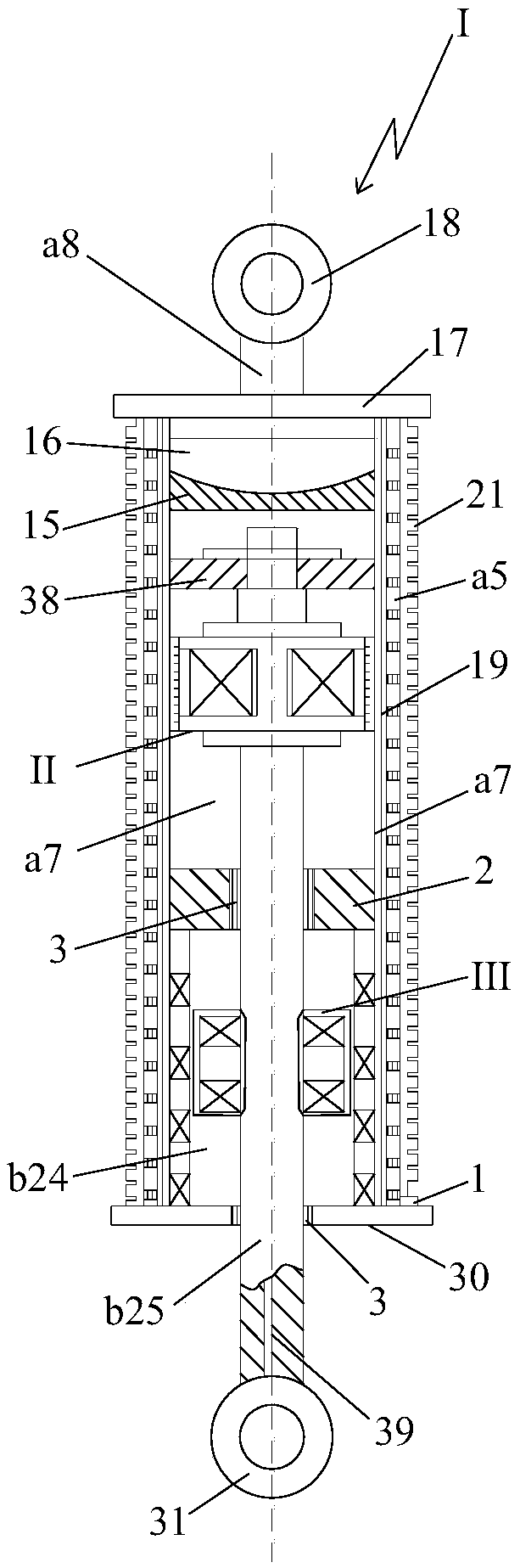

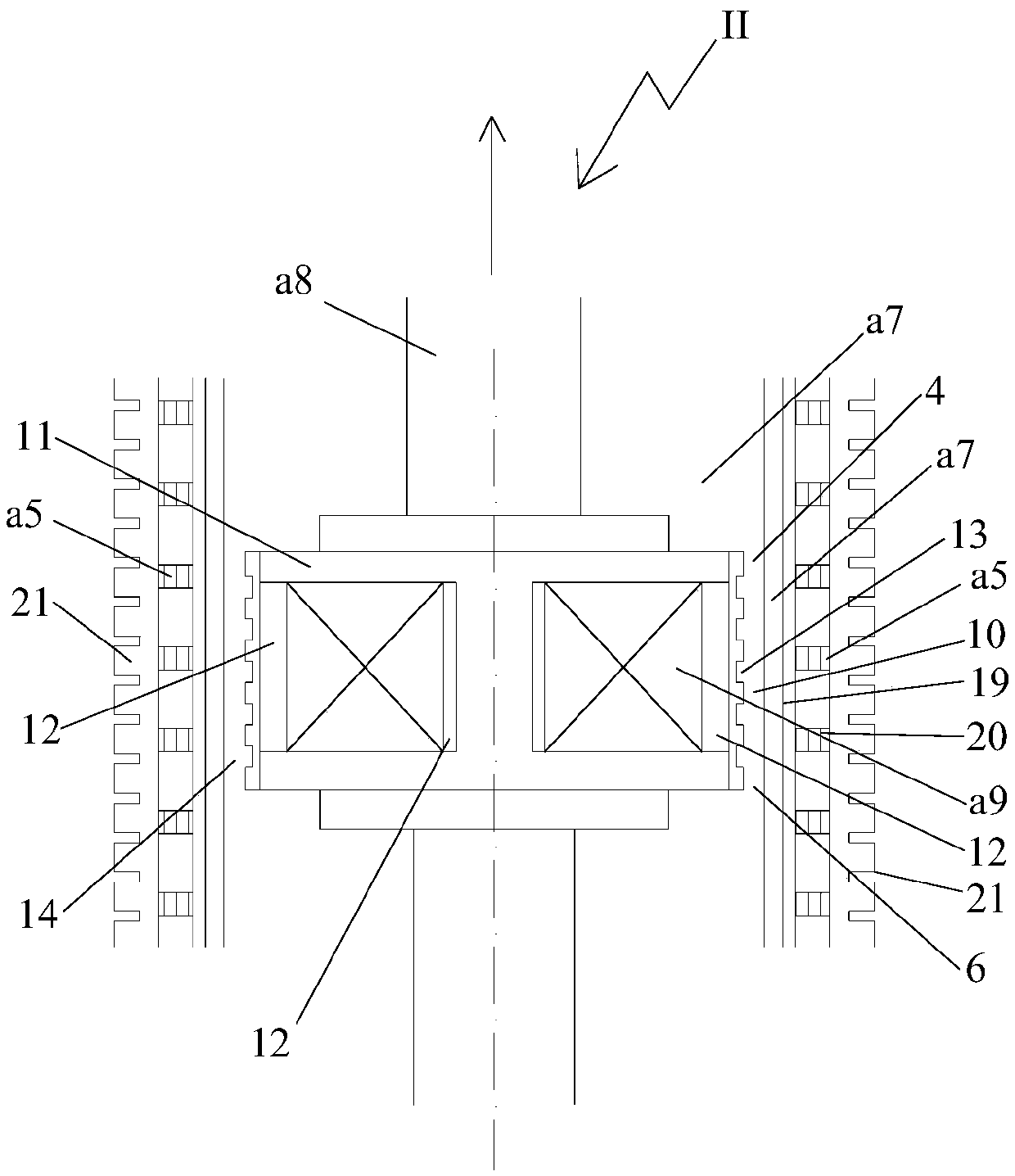

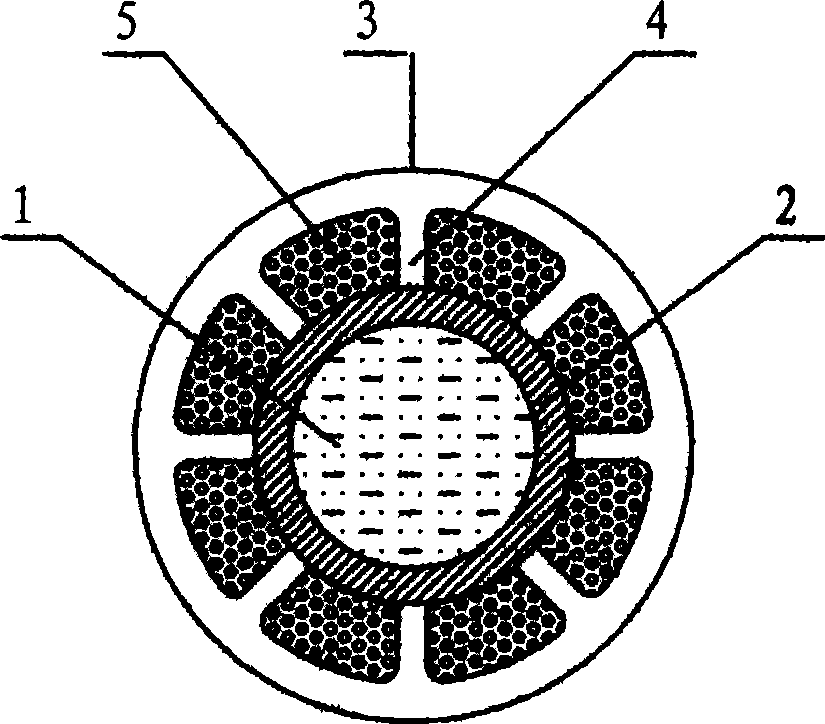

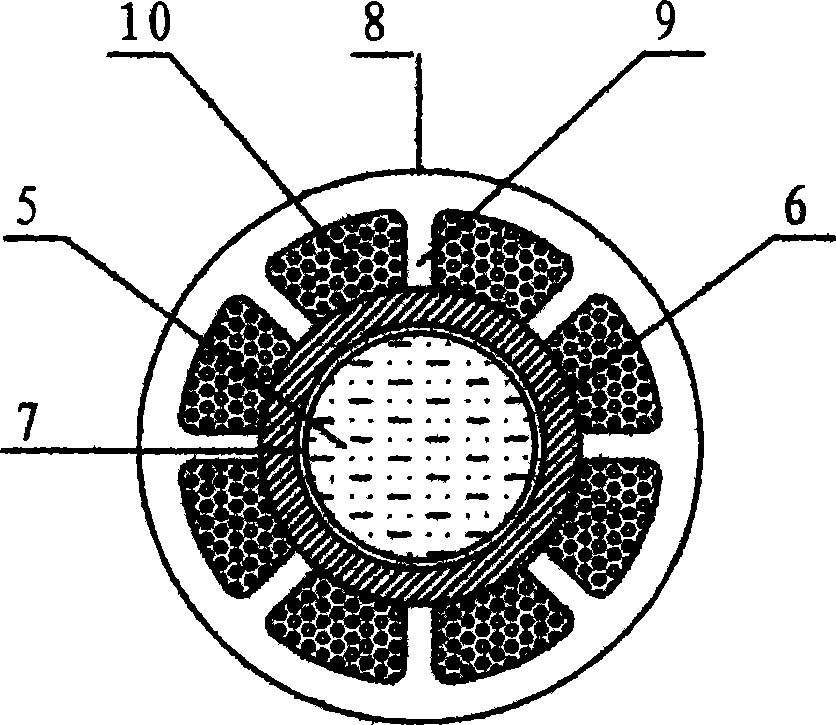

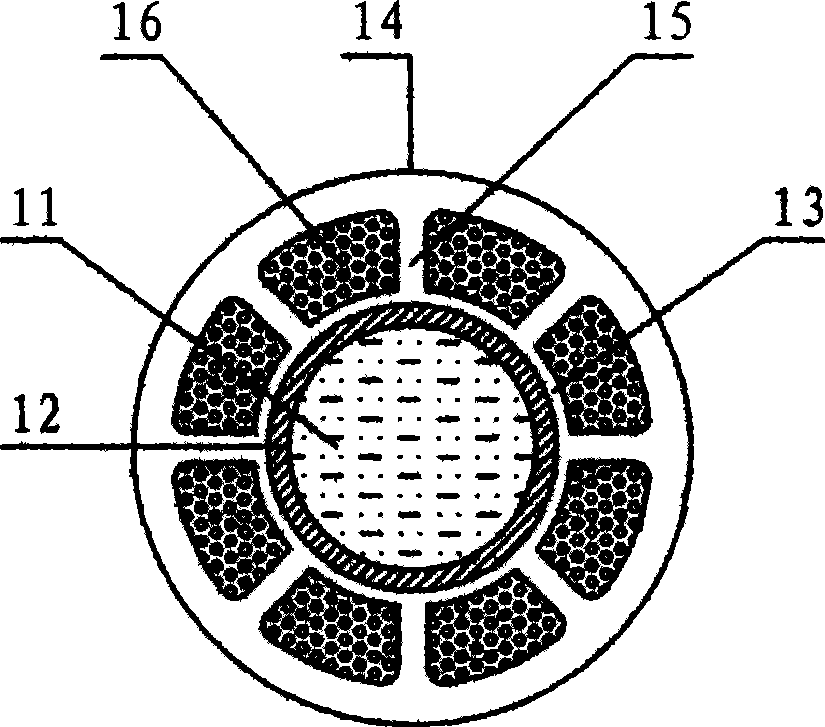

Dual-damping and dual-power-generating combined damping device

InactiveCN105508487ADisturbing forceEfficient recovery and storageBatteries circuit arrangementsNon-rotating vibration suppressionTemperature differenceControl theory

The invention relates to a dual-damping and dual-power-generating combined damping device comprising a magnetorheological damping temperature difference power generating type damper and an electromagnetic damping temperature difference power generating type damper which are spaced by a magnetic isolating material and a sealing material to form working spaces independent from each other. The magnetorheological damping temperature difference power generating type damper and an electromagnetic damping temperature difference power generating type damper form a synergistic dual-damping damping and synergistic dual-power-generating working mode. The device is of a novel device structure formed by integration, the objective of optimizing and improving comprehensive performance of the device is achieved, and the device is applicable to damping of automobiles, trains, ships, tanks, airplanes, machinery, projects and bridges and vibrating energy recycling for power generation.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Phase-transition energy-storage constant-temperature compound infusion tube

The invention relates to a phase-transition energy-storage constant-temperature compound infusion tube, which comprises an infusion tube, an energy-storage material and a protective insulating tube, wherein a phase-transition energy-storage material is arranged between the infusion tube and the protective insulating tube or the phase-transition energy-storage material is arranged in a radial plate cavity between the infusion tube and the protective insulating tube.

Owner:王广武

Thermoelectric power source utilizing ambient energy harvesting for remote sensing and transmitting

ActiveUS7834263B2Small temperature differenceThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermal energyElectrical devices

A method and apparatus for providing electrical energy to an electrical device wherein the electrical energy is originally generated from temperature differences in an environment having a first and a second temperature region. A thermoelectric device having a first side and a second side wherein the first side is in communication with a means for transmitting ambient thermal energy collected or rejected in the first temperature region and the second side is in communication with the second temperature region thereby producing a temperature gradient across the thermoelectric device and in turn generating an electrical current.

Owner:BATTELLE MEMORIAL INST

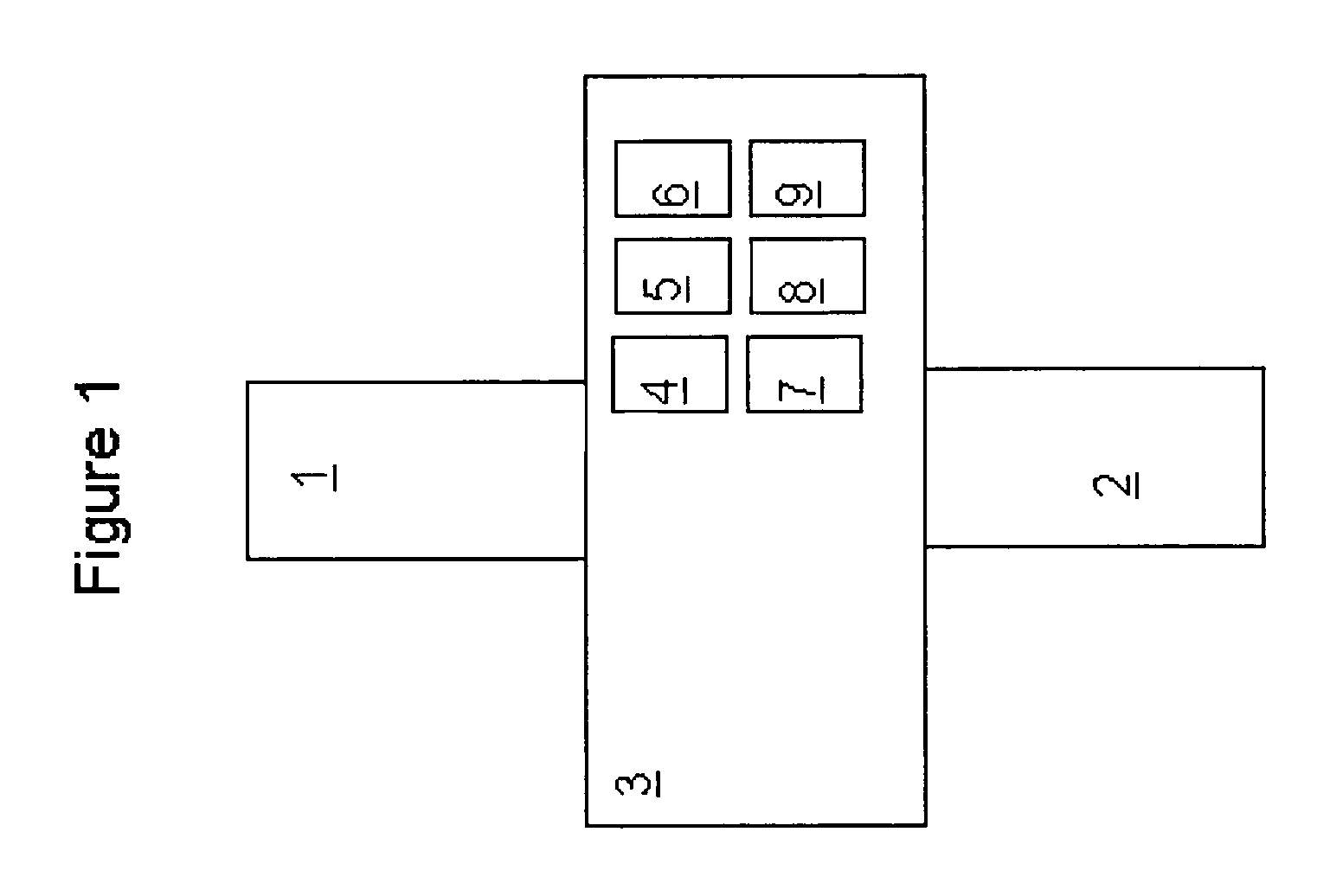

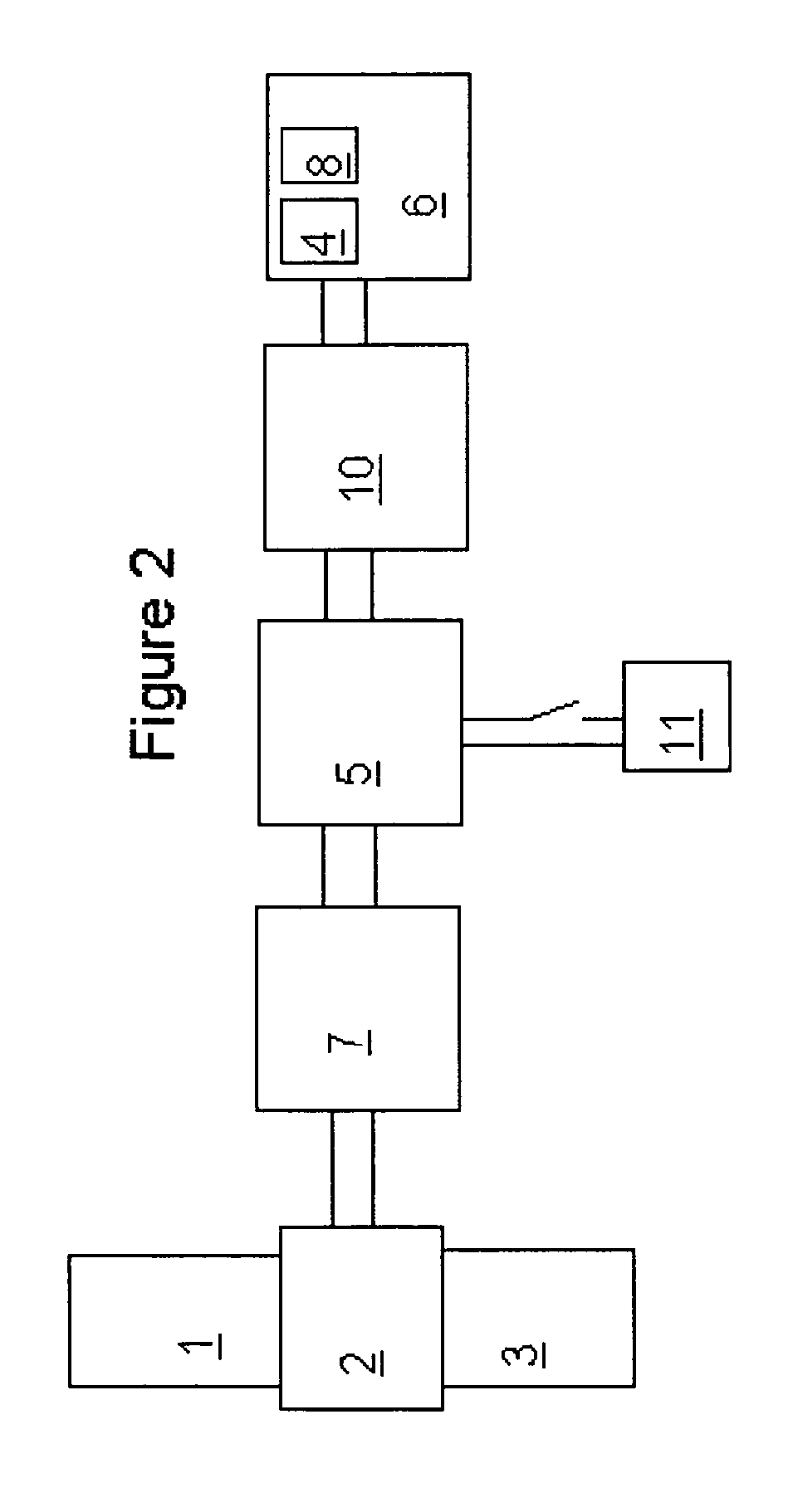

Power battery low-temperature charging heating system

InactiveCN105870542AImprove performanceImprove cycle lifeSecondary cells testingPower batteryElectrical battery

The invention provides a power battery low-temperature charging heating system which comprises a battery managing system, a power battery module, a heating power source, a heating assembly, a heating relay and an information collection device. The battery managing system, the heating relay and an information managing system form a control loop of the heating system. The heating assembly, the heating relay, the information collection device and the heating power source are in hard connection through a wire harness or a copper bar to form a heating loop of the heating system. The heating assembly can provide heat for the power battery module for heating when the power battery module is in a low-temperature environment. The battery managing system accurately adjusts the heating power of the heating assembly according to current, voltage, temperature and other information collected by the information collection device, the internal environment temperature of a power battery is rapidly improved, it is ensured that the power battery module is evenly heated, and the effect of lowering the temperature difference of the power battery module and parts is achieved, so that the performance of the power battery is improved, and the cycle life of the power battery is prolonged.

Owner:深蓝汽车科技有限公司

R502, R12 or R22 Substitute Mixed Refrigerant and Refrigeration System Using Thereof

InactiveUS20090261289A1Avoid destructionShorten the timeHeat-exchange elements1,1-DifluoroethaneEngineering

The present invention relates to a refrigerant mixture for substituting R502, R22 or R12 used in a vapor compression refrigerator or air conditioner and a refrigeration system using the same. More specifically, the present invention relates to a refrigerant mixture comprising a combination of two or three components, which is capable of being used without causing ozone layer destruction and global warming and at the same time, without replacement of the existing refrigeration system, wherein the components are selected from the group consisting of propylene, propane, 1,1,1,2-tetrafluoroethane, pentafluoroe thane, 1,1,1-trifluoroethane, 1,1-difluoroethane, dimethylether and isobutane; and a refrigeration system using the same.

Owner:HAM YOON SIK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com