Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

163 results about "Cumulative effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cumulative effect (plural cumulative effects) The state in which a series of repeated actions have an effect greater than the sum of their individual effects; noted especially in the repeated administration of drugs or repeated consumption of trace elements or chemicals that show no immediate effect.

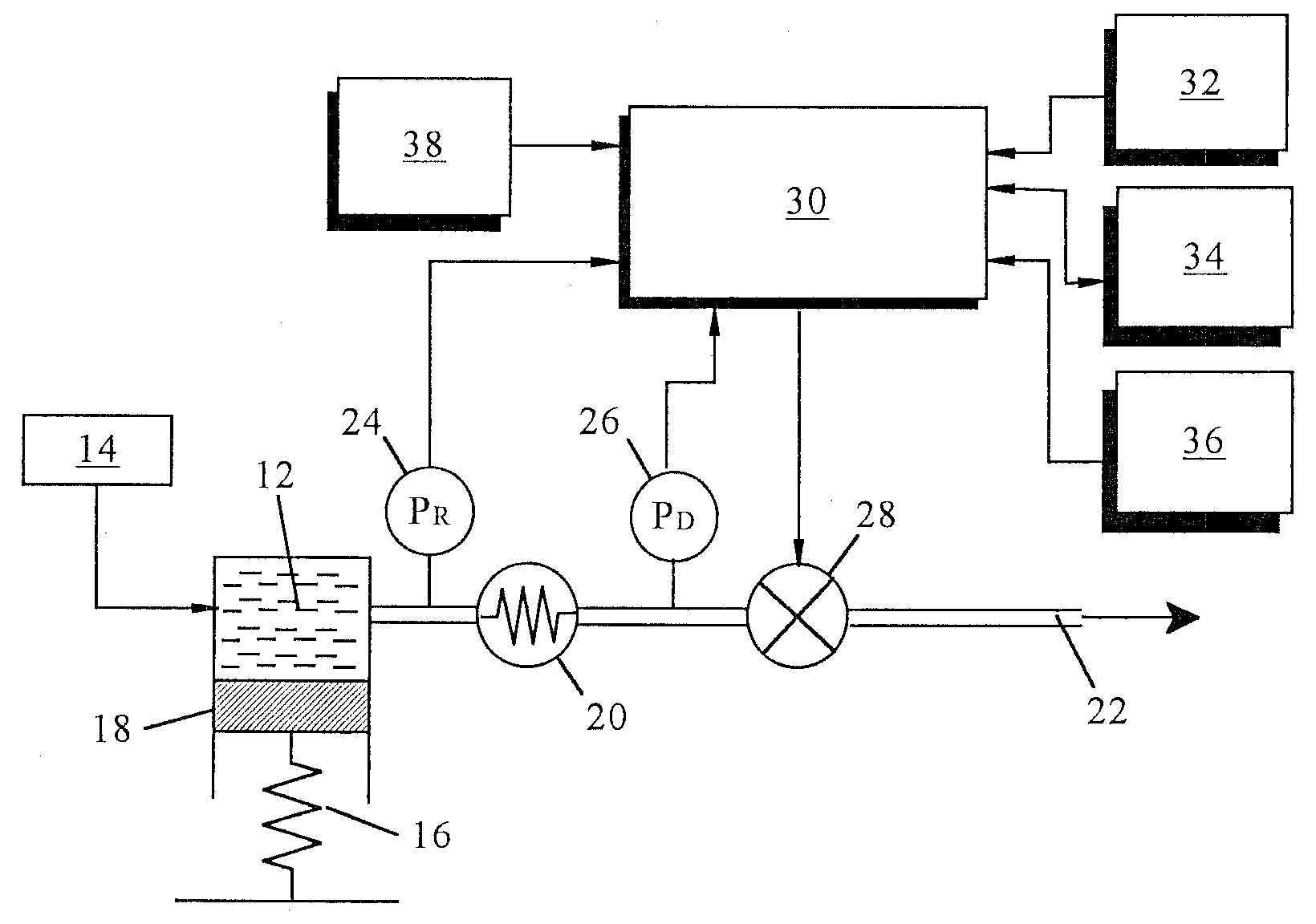

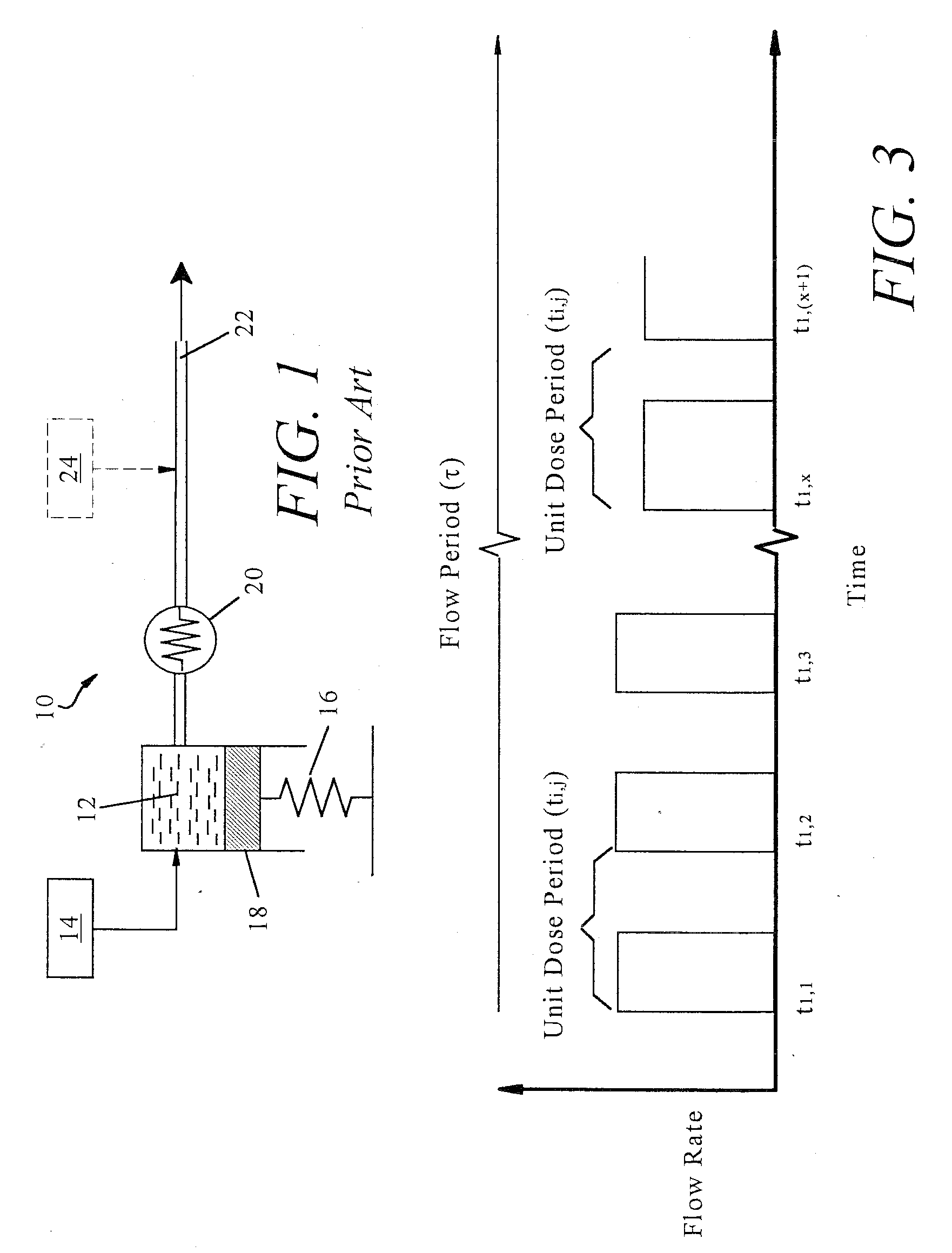

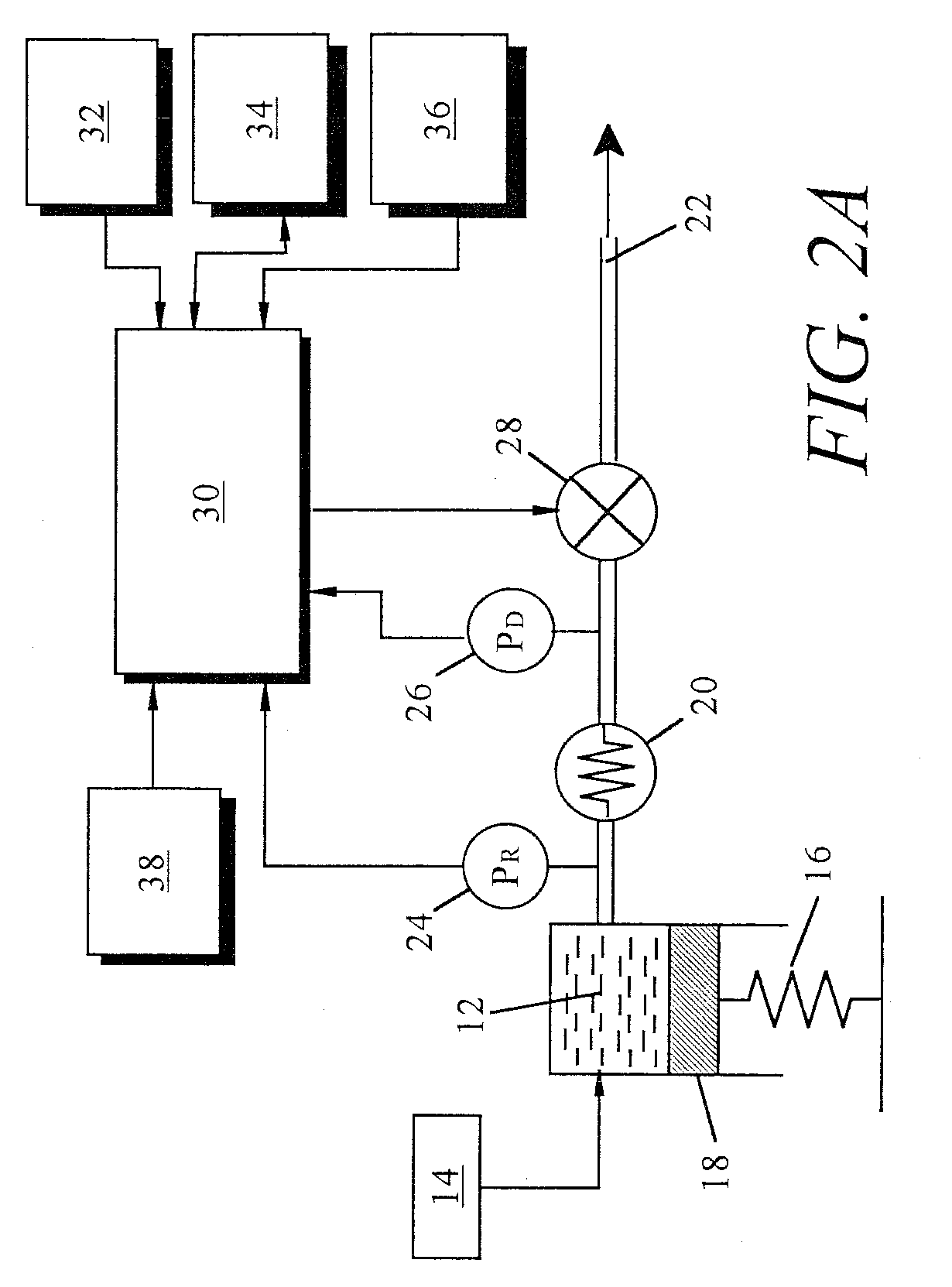

Non-constant pressure infusion pump

InactiveUS7338464B2Easy constructionPharmaceutical delivery mechanismMedical devicesPeriod effectsBiomedical engineering

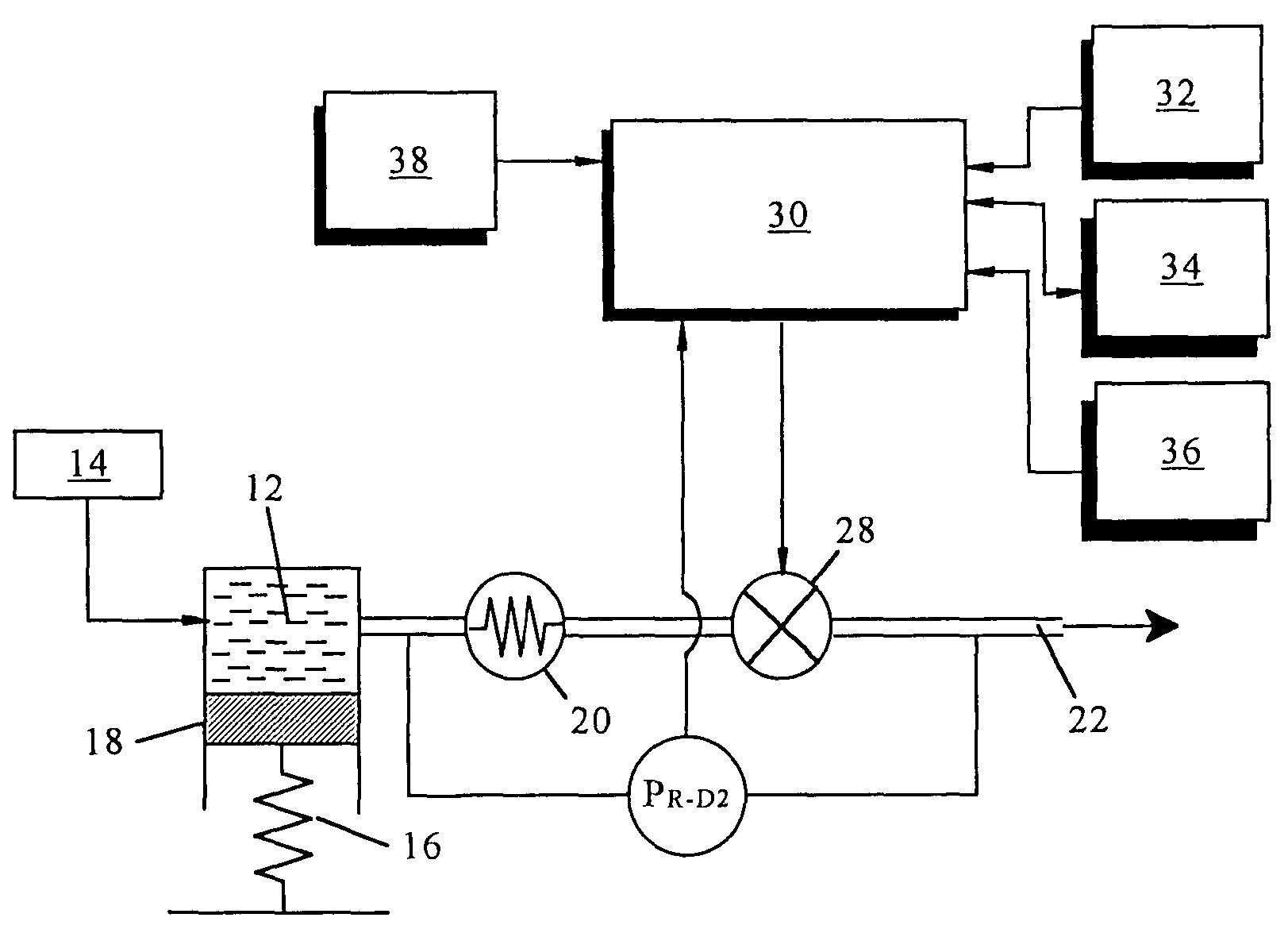

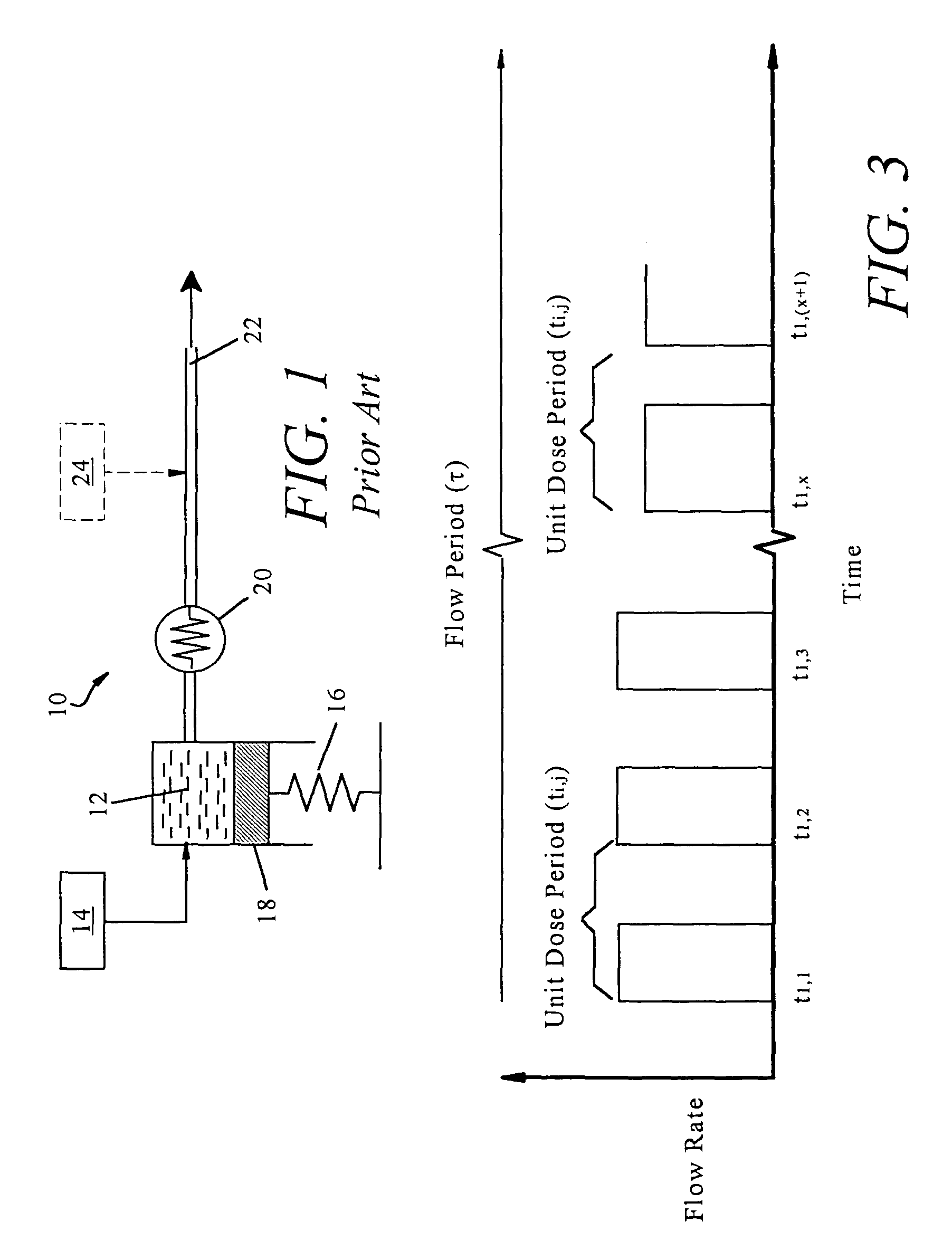

The present invention relates to an implantable infusion pump having a refillable infusate reservoir in fluid communication with a delivery site via a flow path. This flow path includes a flow resistance. The infusion pump includes a sensing device(s), positioned relative to the flow path, to provide data regarding a flow rate along the flow path. The infusion pump effects a division of a total flow period into at least a plurality of unit dose periods, each unit dose period effecting delivery of a unit dose of infusate. The cumulative effect of delivering the total number of unit dose periods is the delivery of a desired dose over the total flow period. The present invention permits a reservoir pressure to vary over any portion of total flow period but effects a constant-pressure state over each unit dose cycle.

Owner:ADVANCED NEUROMODULATION SYST INC

Multiprogrammable tissue stimulator and method

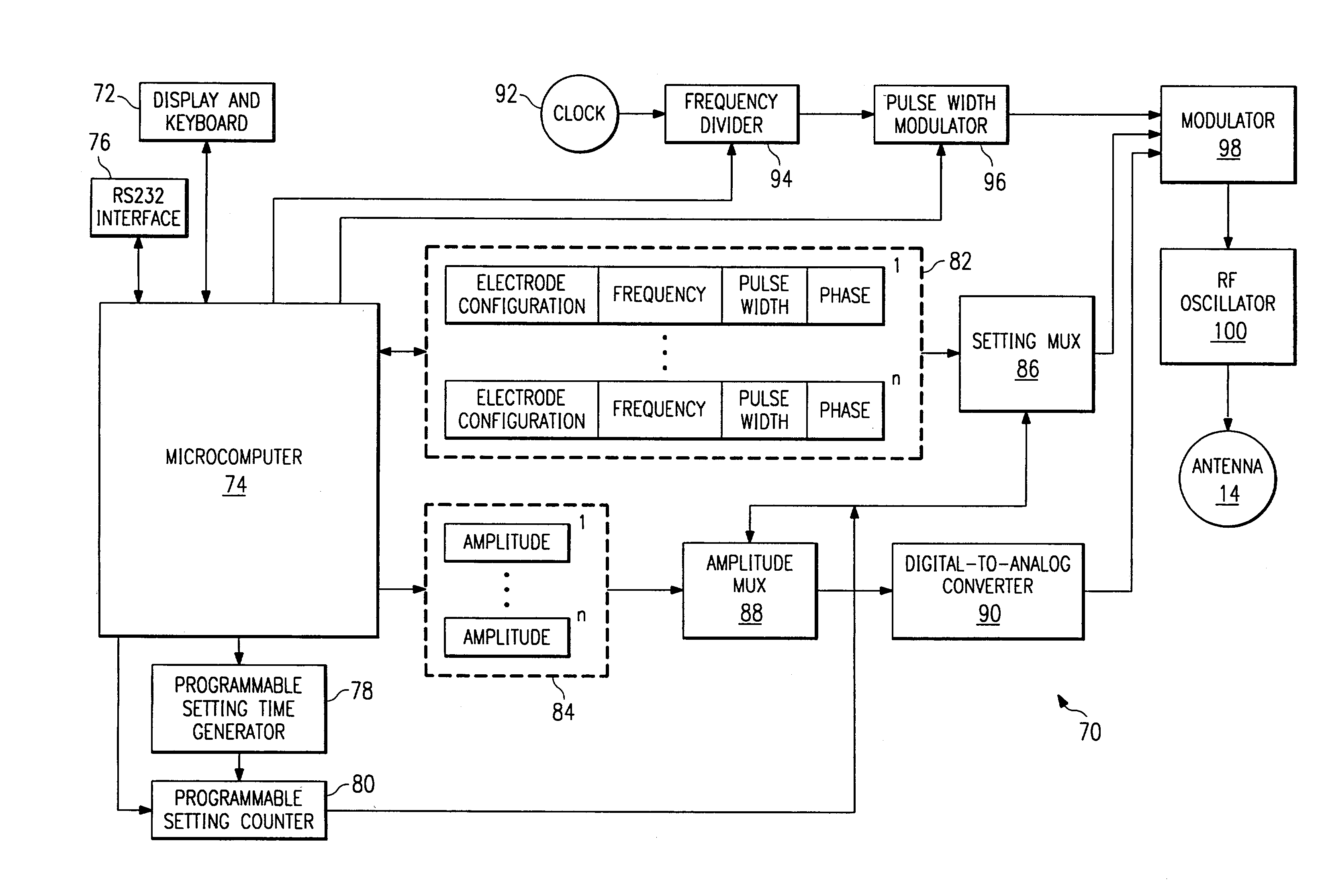

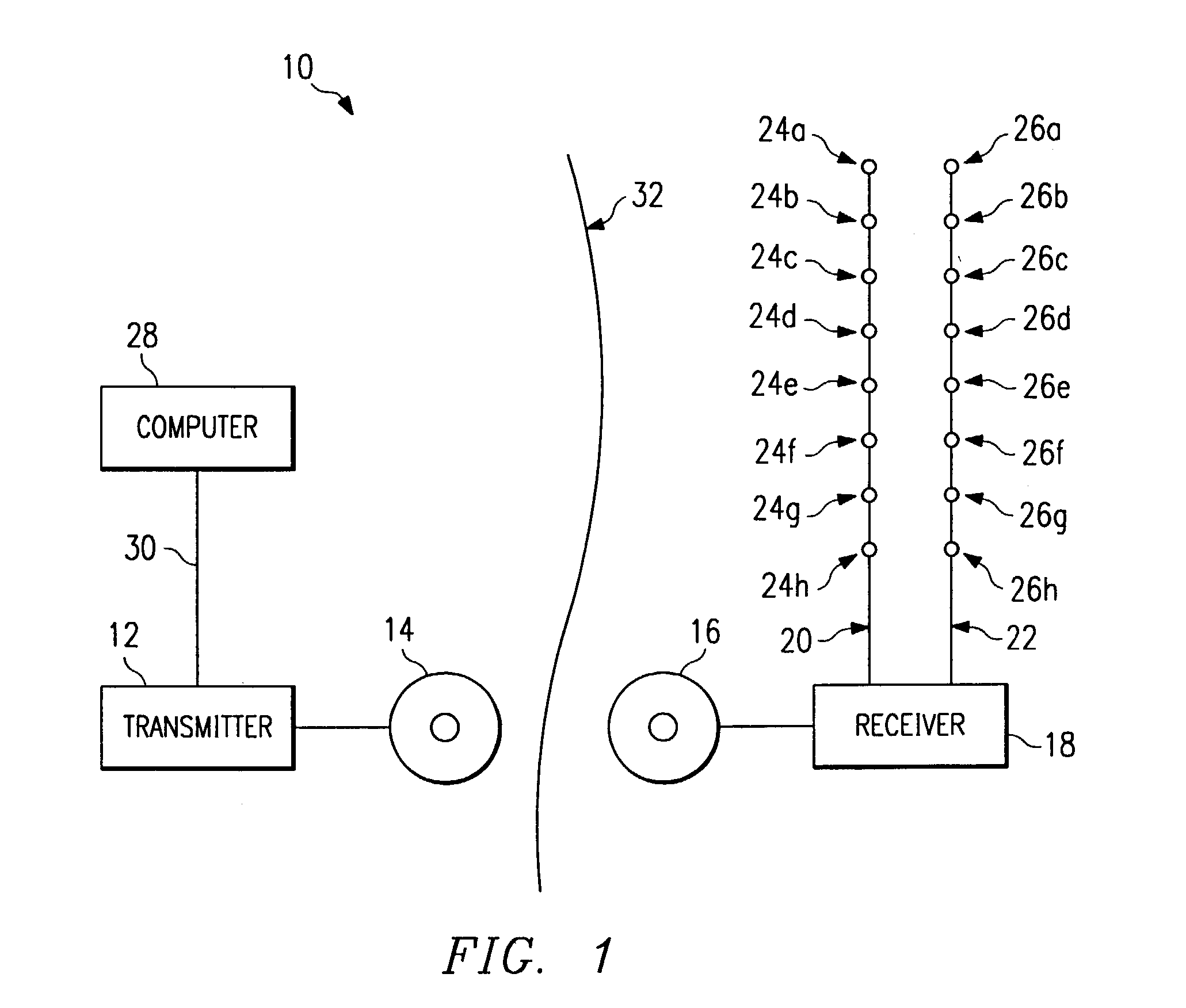

An electronic stimulation system is used to control pain over multiple regions of a patient's body. The system has one or more percutaneous leads, each having multiple electrodes, implanted within the patient's epidural space parallel to the axis of the spinal cord. The leads are connected to either a totally implanted system or a radio frequency system. The system is able to treat pain over different regions of a patient's body by “simultaneously” stimulating the patient with at least three different stimulation settings. “Simultaneous” stimulation involves sequentially stimulating the patient with the multiple stimulation settings such that the patient receives the cumulative effect of each stimulation setting, while not perceiving the transition from one stimulation setting to another.

Owner:ADVANCED NEUROMODULATION SYST INC

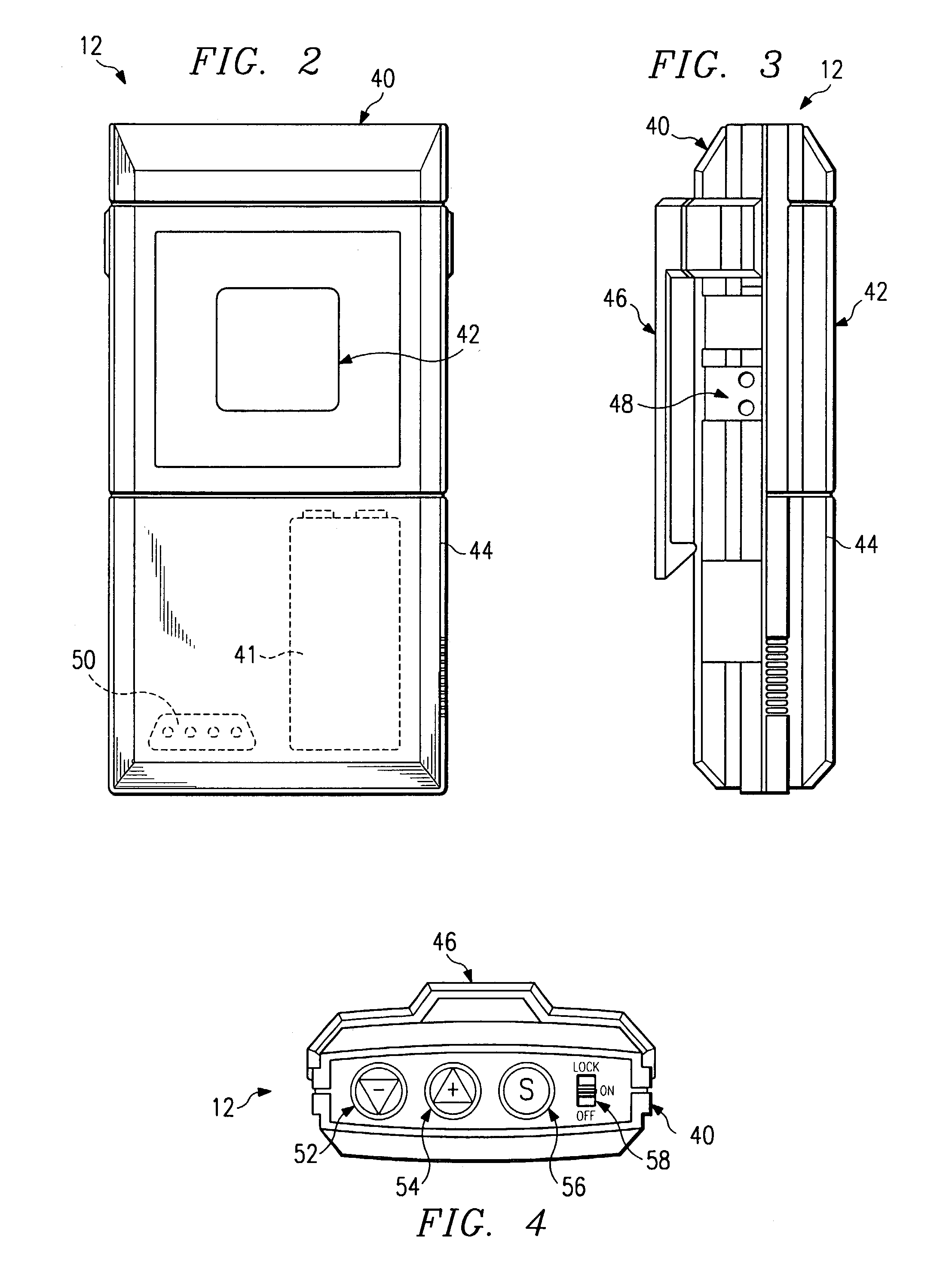

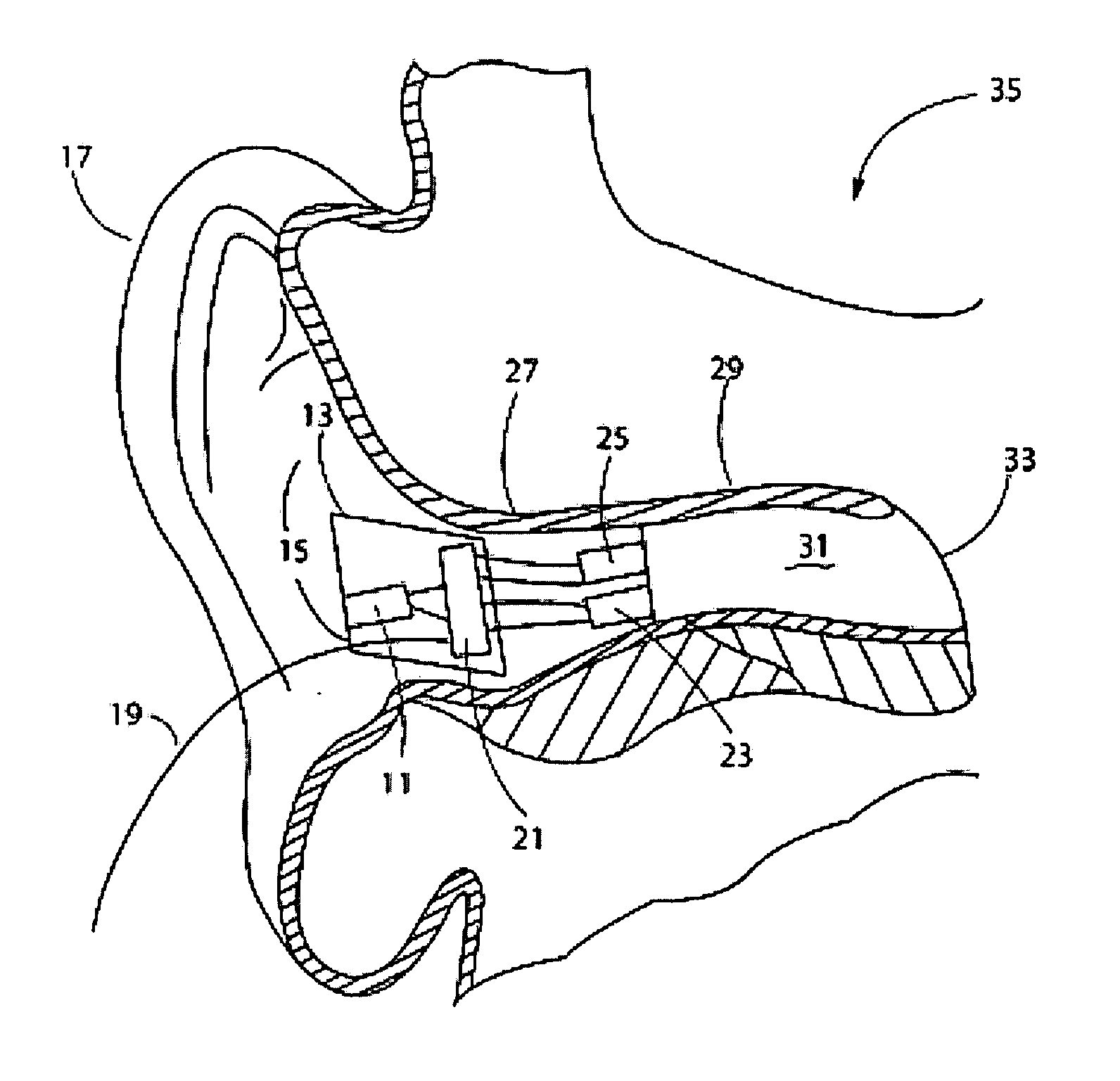

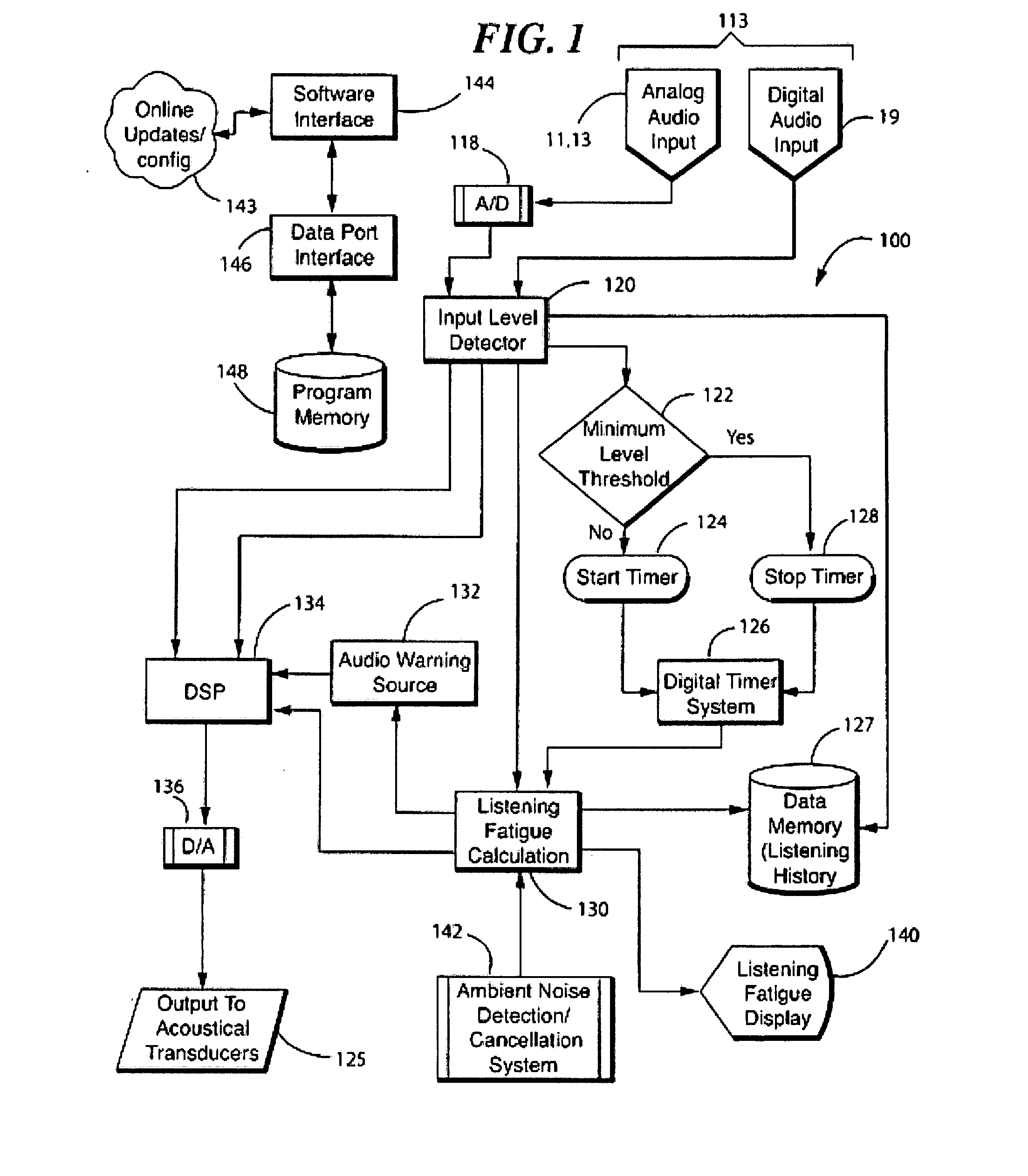

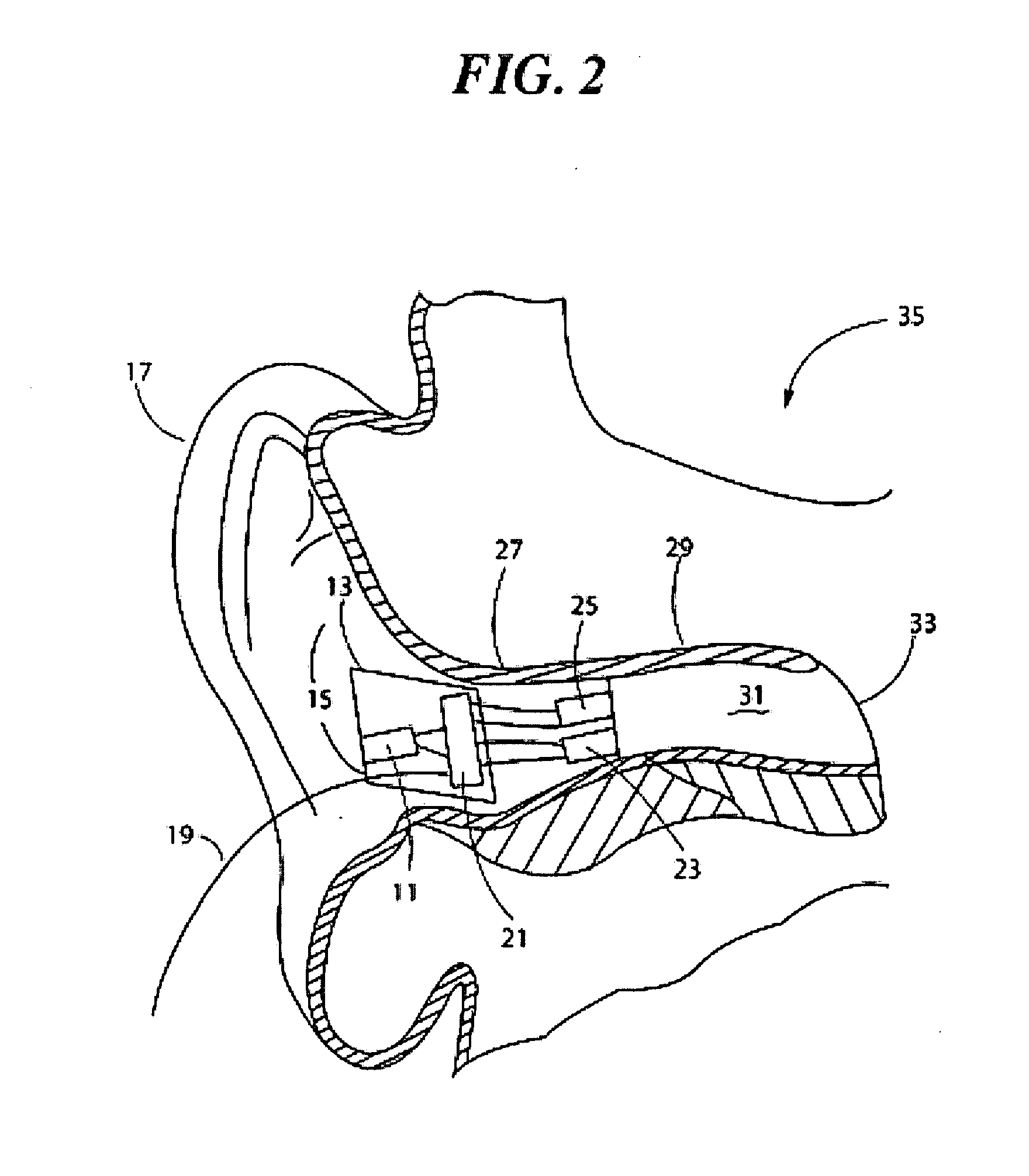

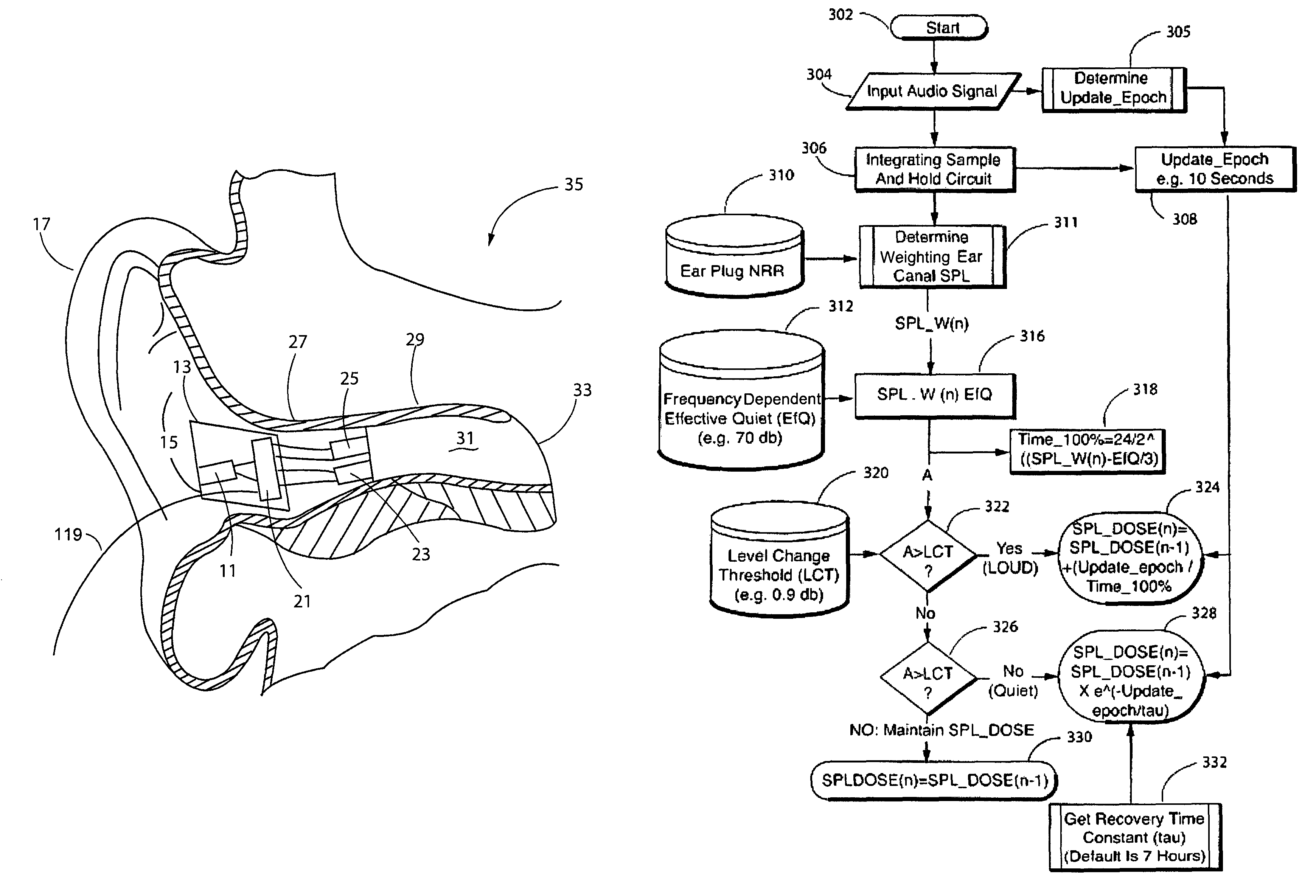

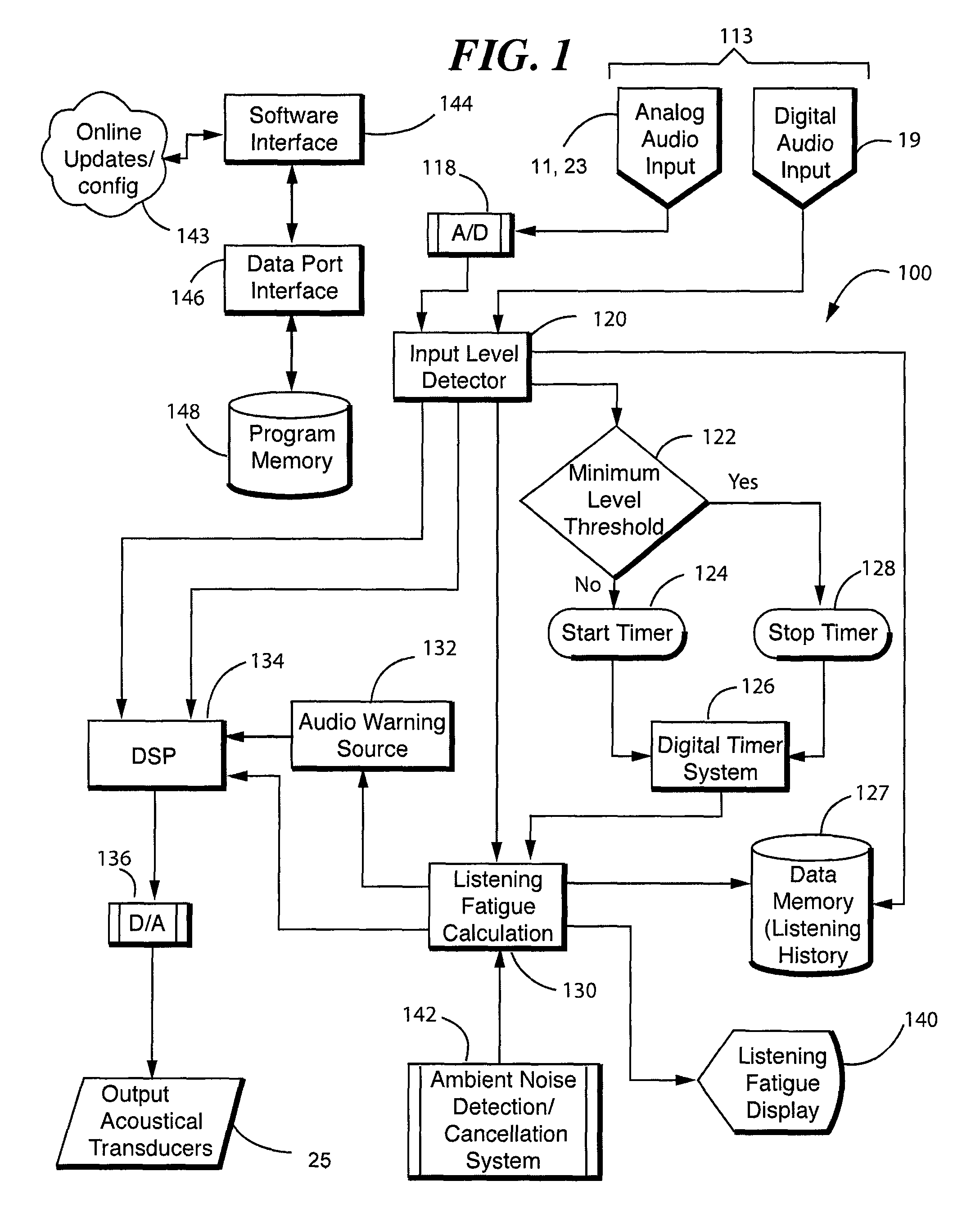

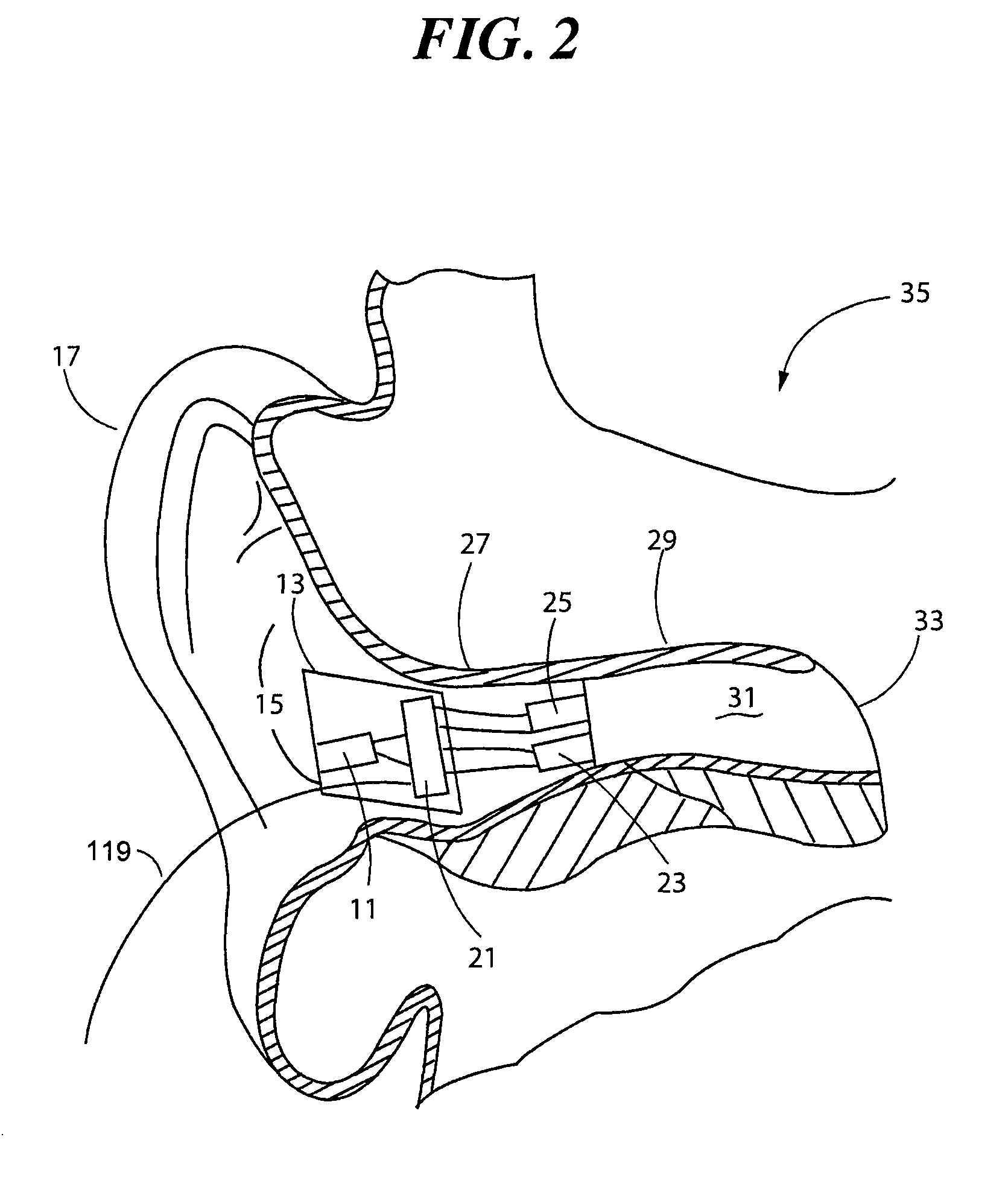

Ear input sound pressure level monitoring system

ActiveUS20080037797A1Vibration measurement in solidsOptical rangefindersTime segmentMonitoring system

At least one exemplary embodiment is directed to a system for monitoring a sound pressure level dose at an ear which includes an audio transducer adapted to be placed within an ear to receive sound at the ear. The audio transducer outputs a sound signal. A sound level threshold detector receives the sound signal and determines whether a sound pressure level of the sound signal is at a minimum level and outputs a sound pressure level signal corresponding to a sound pressure level of the sound pressure level when the sound pressure level is not at the minimum level. A clock calculates a time period during which the sound pressure level is not at the minimum threshold level. A listening fatigue calculator receives the sound signal and the time period and determines whether a cumulative effect of exposure to the sound at the ear over a monitored time period will cause harm to the ear. At least a portion of the system is disposed in situ at the ear.

Owner:STATON TECHIYA LLC

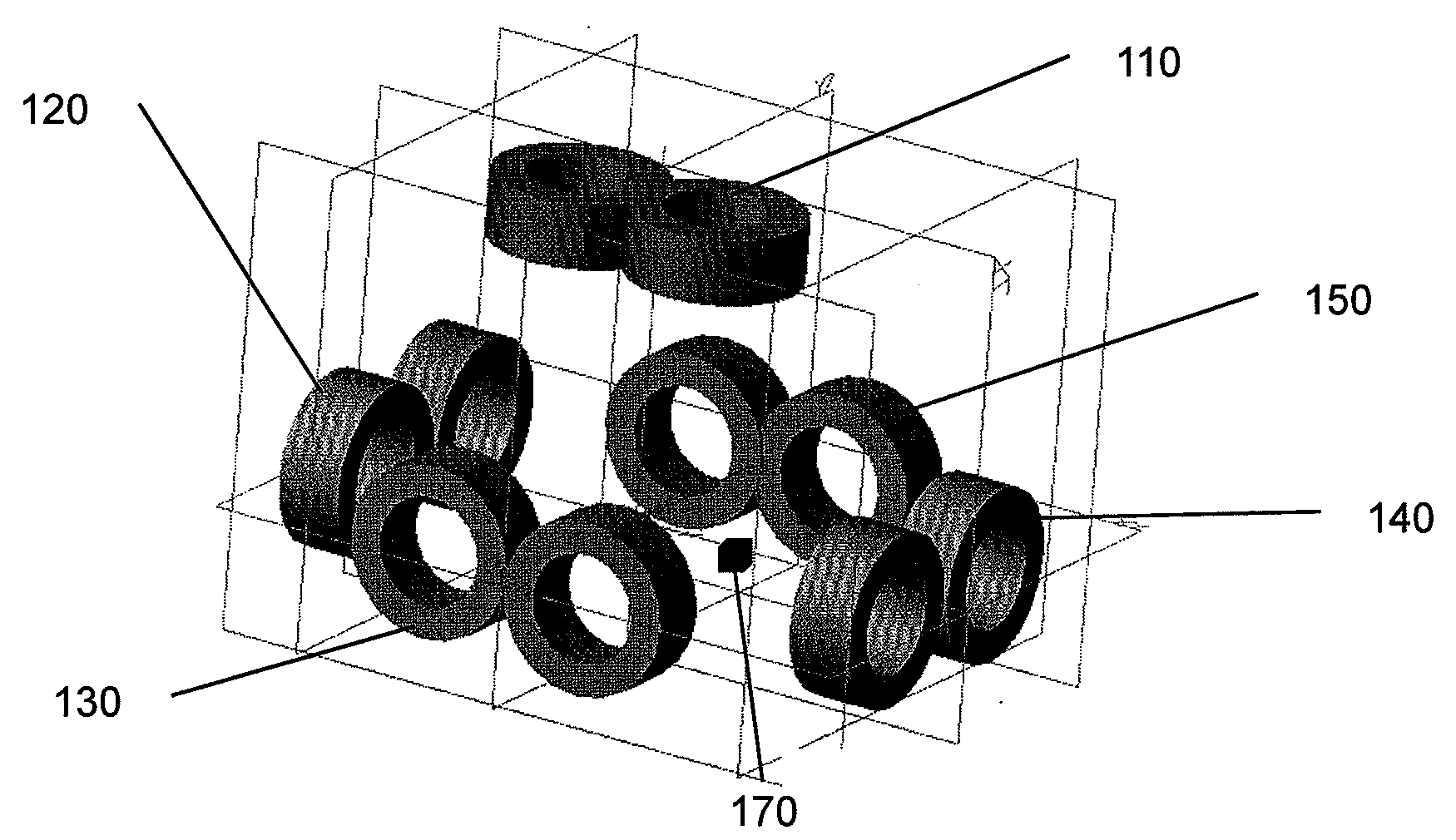

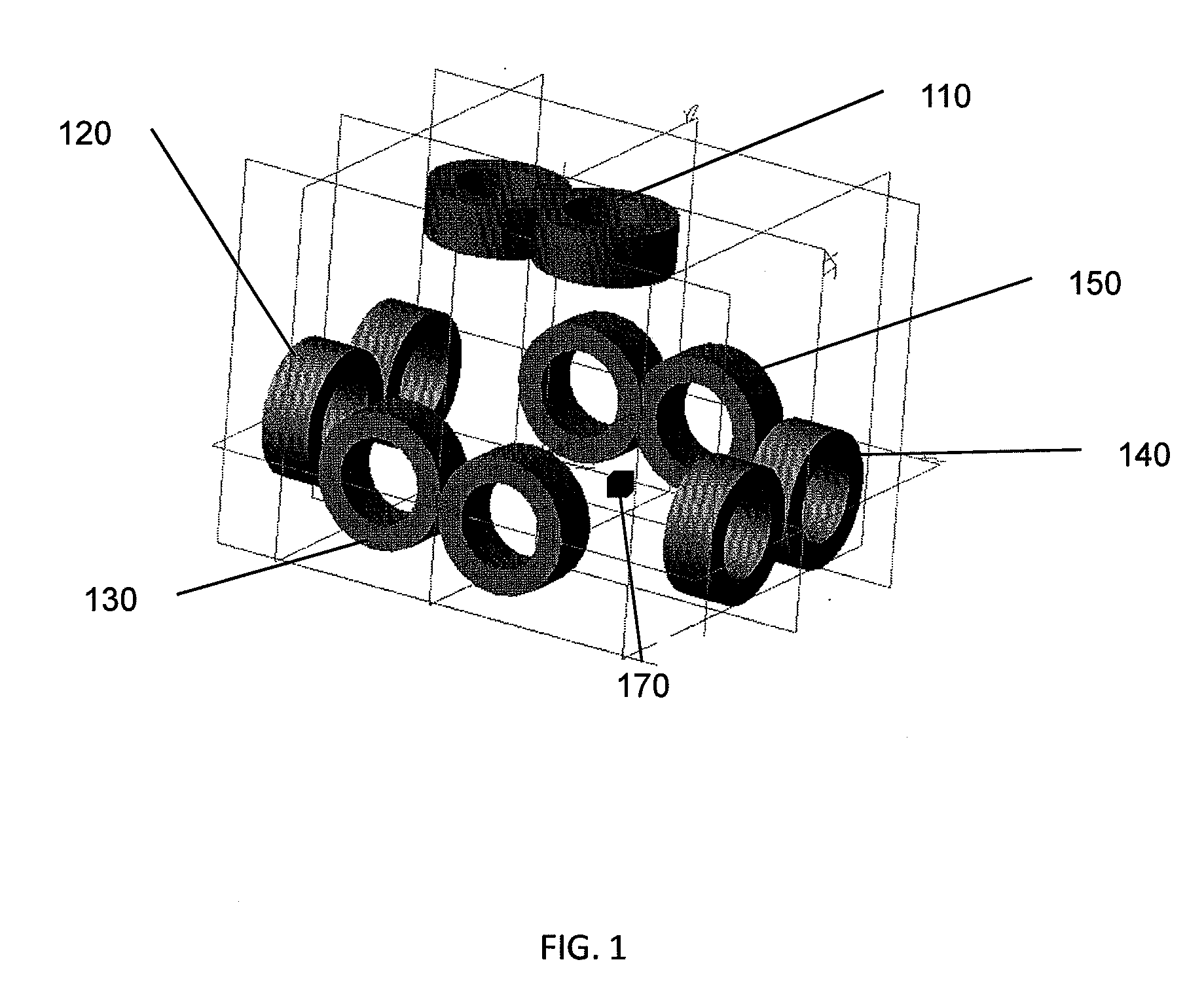

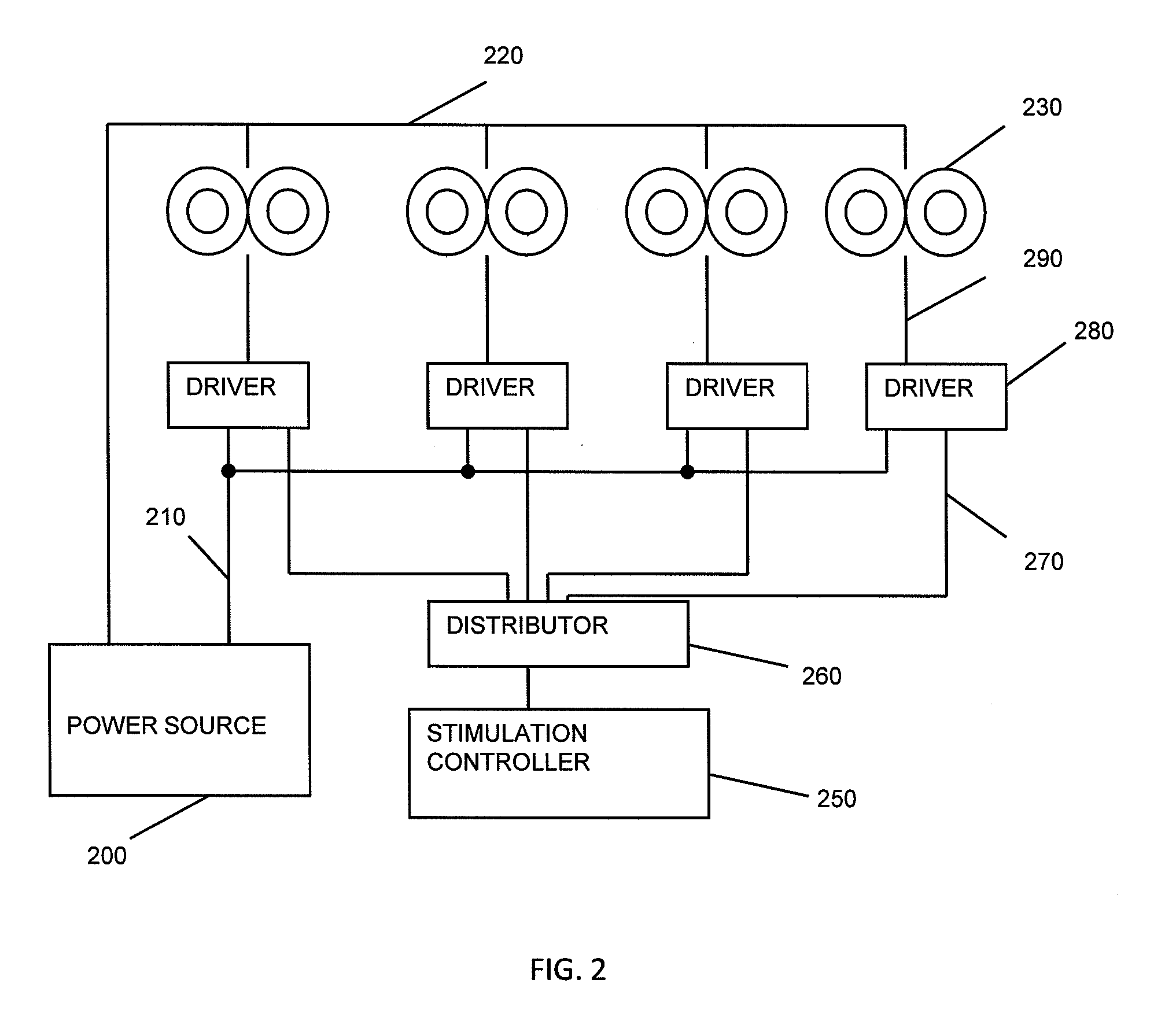

Firing patterns for deep brain transcranial magnetic stimulation

ActiveUS20100256438A1Maximally contributes to the overall intended effectFaster pulse rateElectrotherapyMagnetotherapy using coils/electromagnetsMedicinePulse sequence

Methods, devices and systems for Transcranial Magnetic Stimulation (TMS) are provided for synchronous, asynchronous, or independent triggering the firing multiple of electromagnets from either a single power source or multiple energy sources. These methods are particularly useful for stimulation of deep (e.g., sub-cortical) brain regions, or for stimulation of multiple brain regions, since controlled magnetic pulses reaching the deep target location may combine to form a patterned pulse train that activates the desired volume of target tissue. Furthermore, the methods, devices and systems described herein may be used to control the rate of firing of action potentials in one or more brain regions, such as slow or fast rate rTMS. For example, described herein are multiple electromagnetic stimulation sources, each of which are activated independently to create a cumulative effect at the intersections of the electromagnetic stimulation trajectories, typically by means of a computerized calculation.

Owner:BRAINSWAY

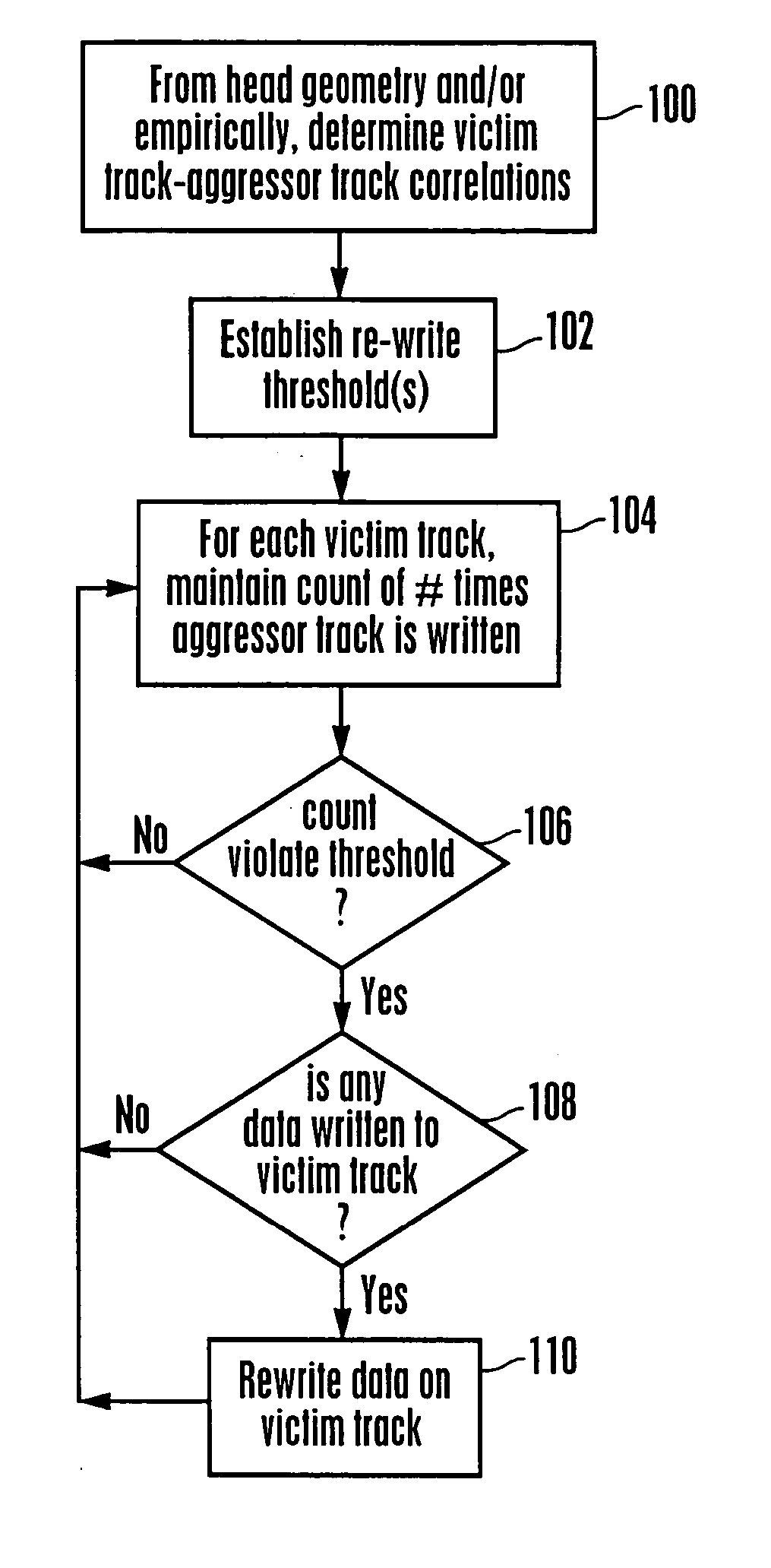

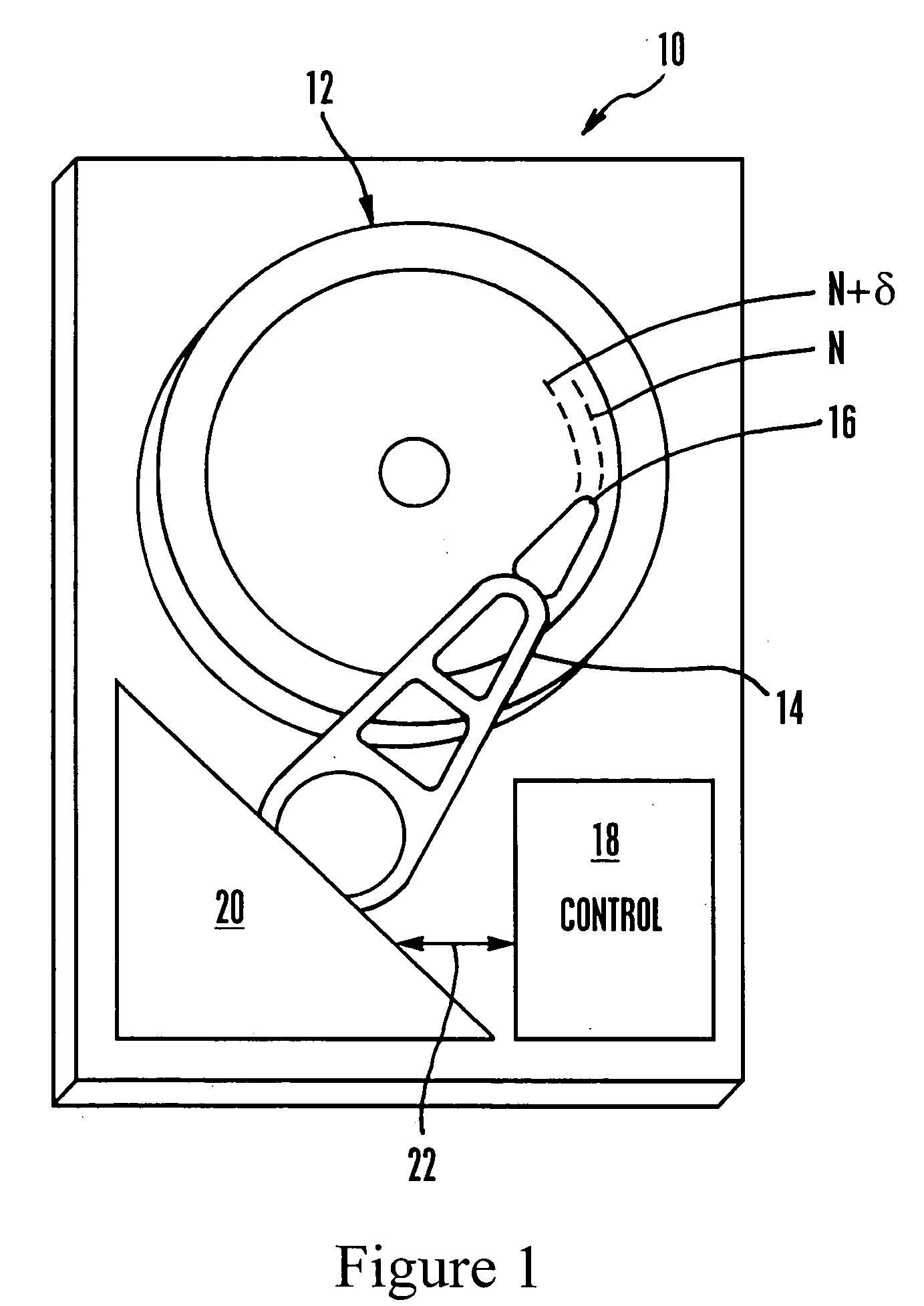

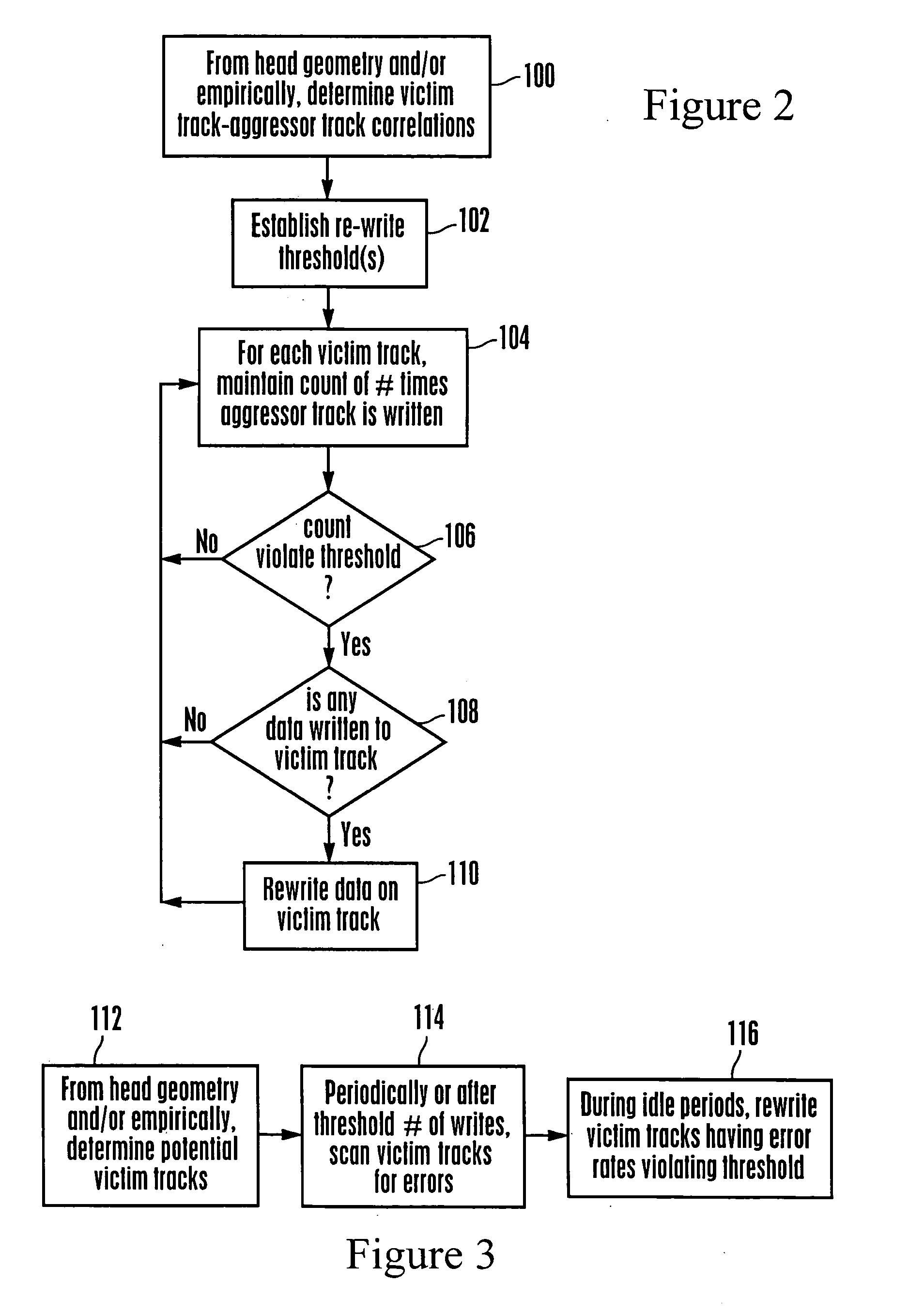

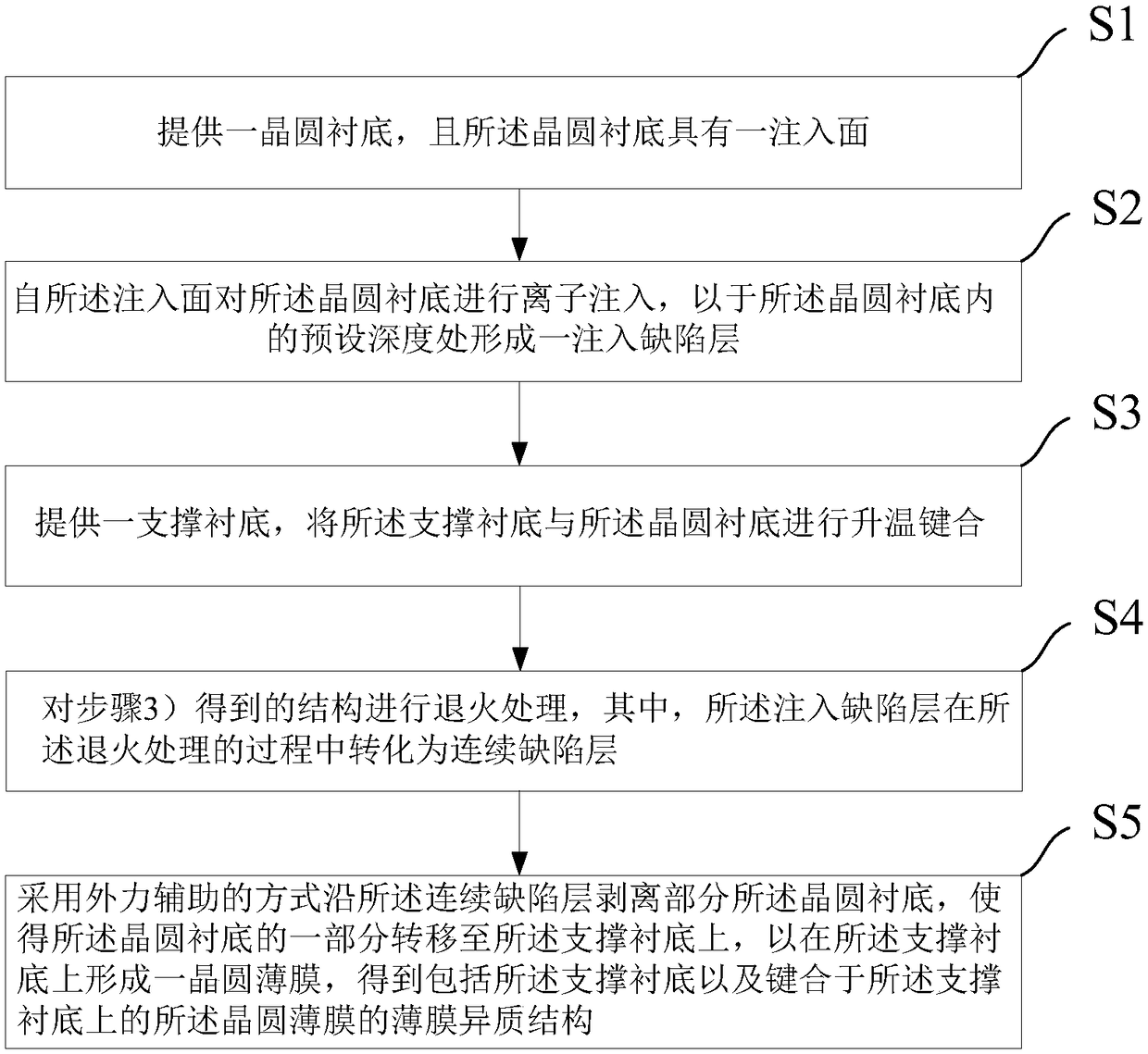

System and method for ameliorating the effects of adjacent track erasure in magnetic data storage device

To ameliorate the effects of ATE in a HDD, tracks that are potential victim tracks of an aggressor track by virtue of the victim tracks being exposed to a magnetic field associated with a write of the aggressor track are preemptively rewritten after an empirically-determined number of writes to the aggressor track, with the empirically-determined number of writes being selected to ensure that the cumulative effects of aggressor writes do not rise to the level that would be expected to result in a significant amount of lost data on the victim tracks. Alternatively, potential victim tracks can be scanned for error rates and if any error rates violate a threshold, the victim tracks can be rewritten when the disk is idle.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

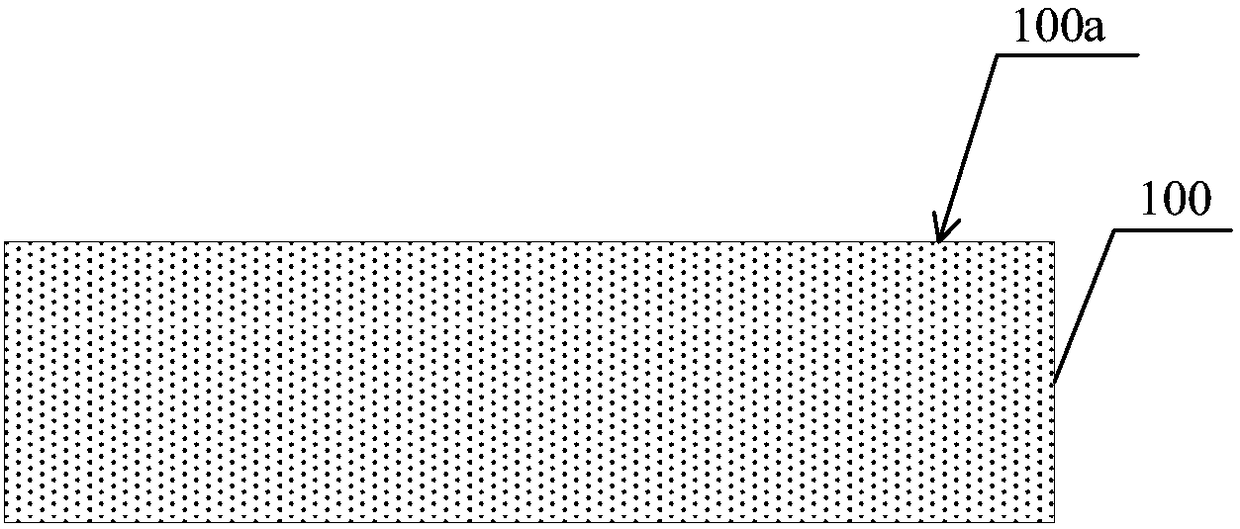

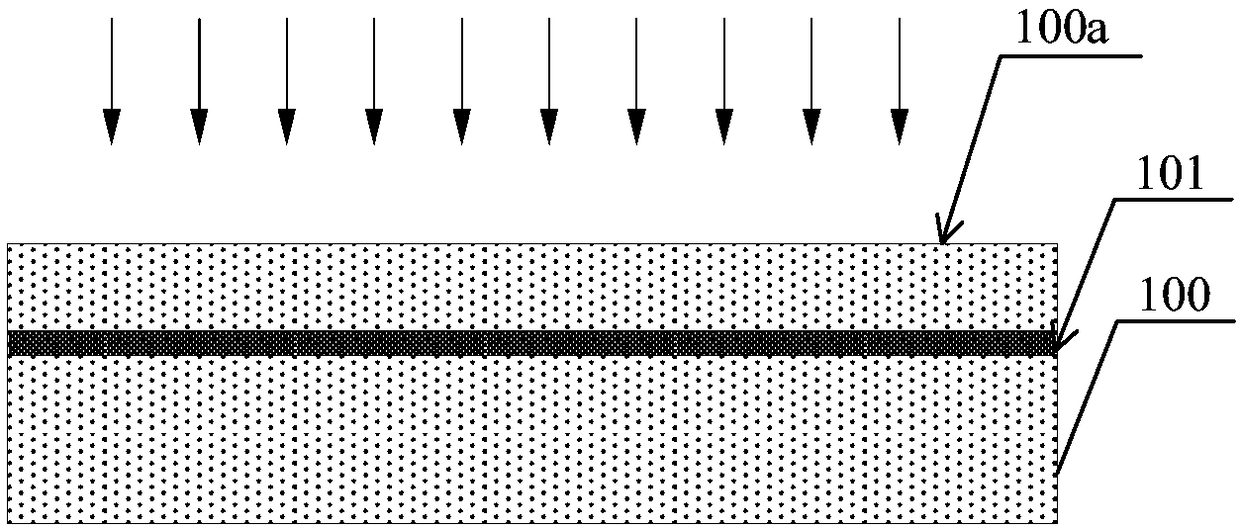

Method for preparing thin film heterostructure

InactiveCN108336219AReduce thermal strainAvoid chippingPiezoelectric/electrostrictive/magnetostrictive devicesOptoelectronicsIon implantation

The invention provides a method for preparing a thin film heterostructure. The method comprises the steps of providing a wafer substrate with an injection surface; conducting ion injection from the injection surface on the wafer substrate to form an injection defect layer at the predetermined depth of the wafer substrate; providing a support substrate, and performing temperature rising bonding onthe support substrate and the wafer substrate; annealing a obtained structure to form a continuous defect layer; stripping part of the wafer substrate through external force assisting, and forming wafer film on the wafer substrate to obtain a thin film heterostructure including the support substrate and the wafer film. The method can reduce the thermal strain of a bonding structure through the temperature rising bonding, so that the bonding structure remains stable and complete in the high-temperature process, and avoid the problem of film cracking caused by thermal mismatch in the stripping process, the bonding structure is separated from the continuous defect layer through the external force assisting method, so that no effect is caused on a bonding interface, and an external force assisting stripping method can reduce stripping temperature and stripping time, thereby reducing the cumulative effect of thermal stress in a piezoelectric crystal.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

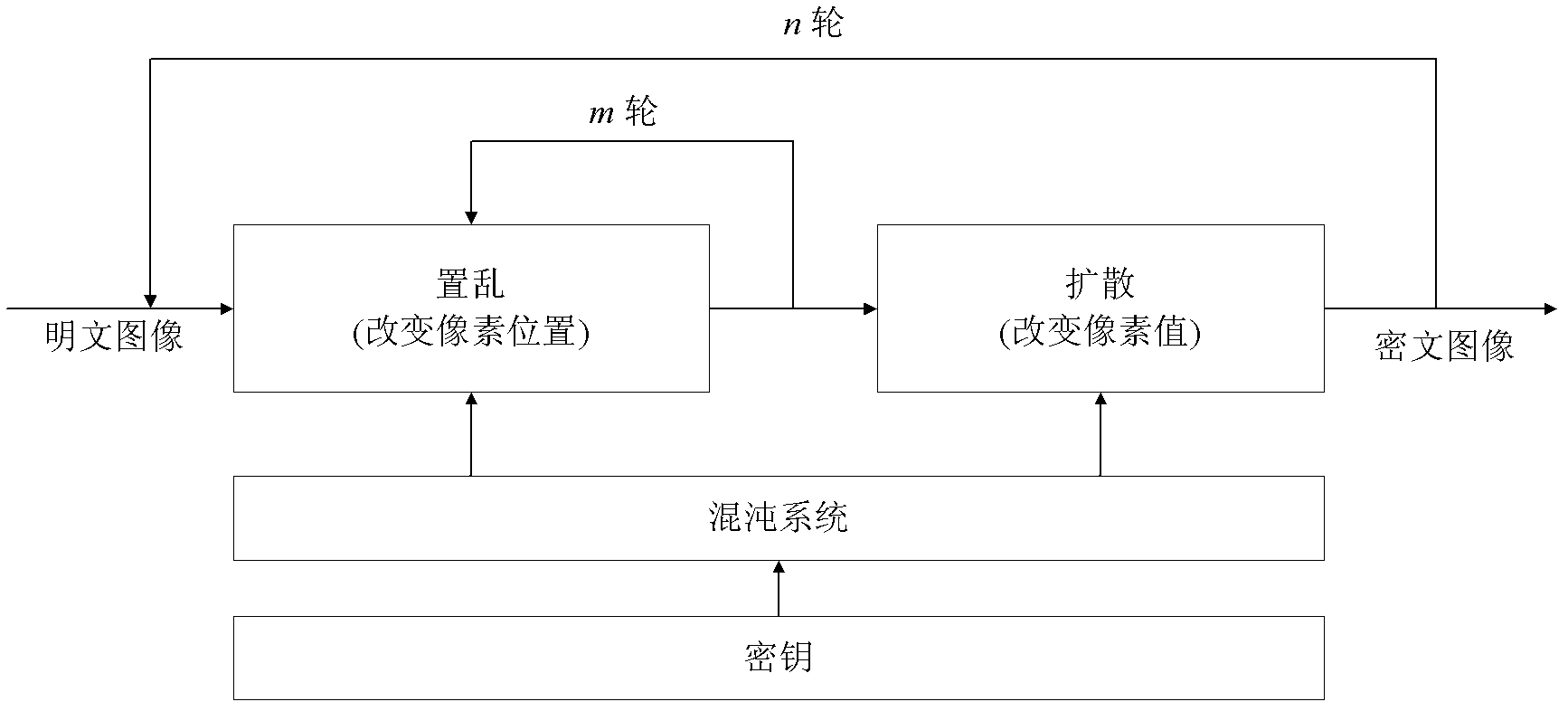

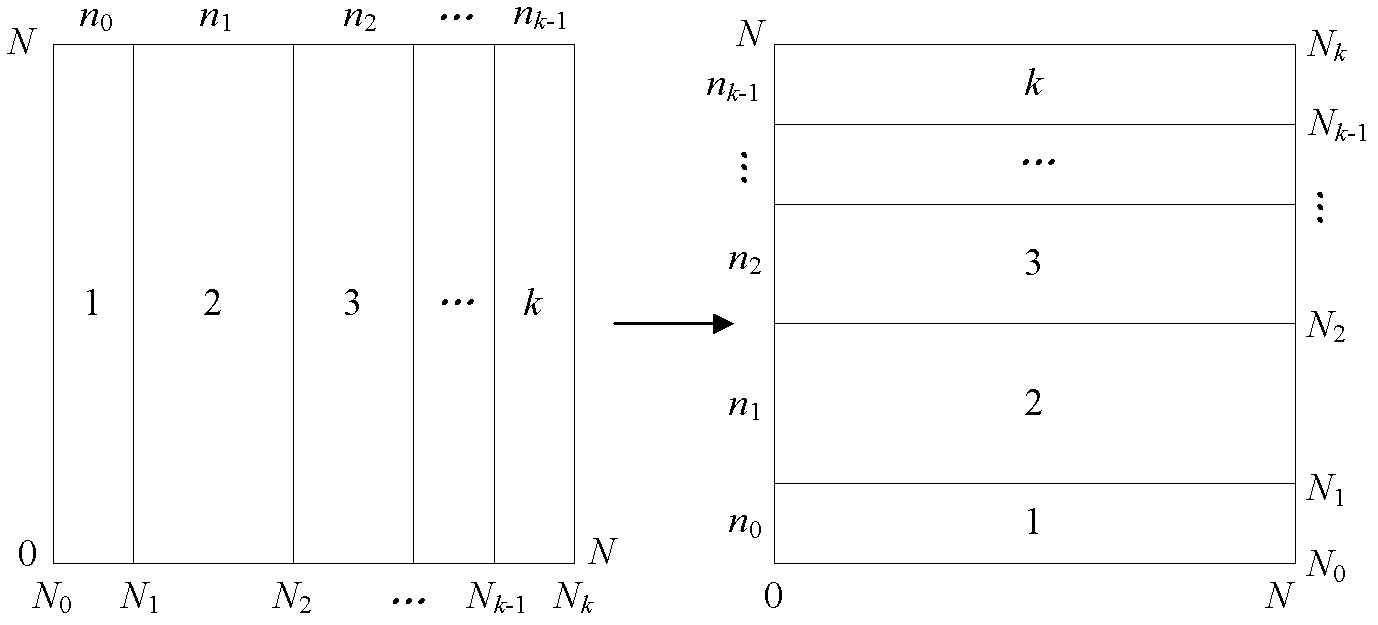

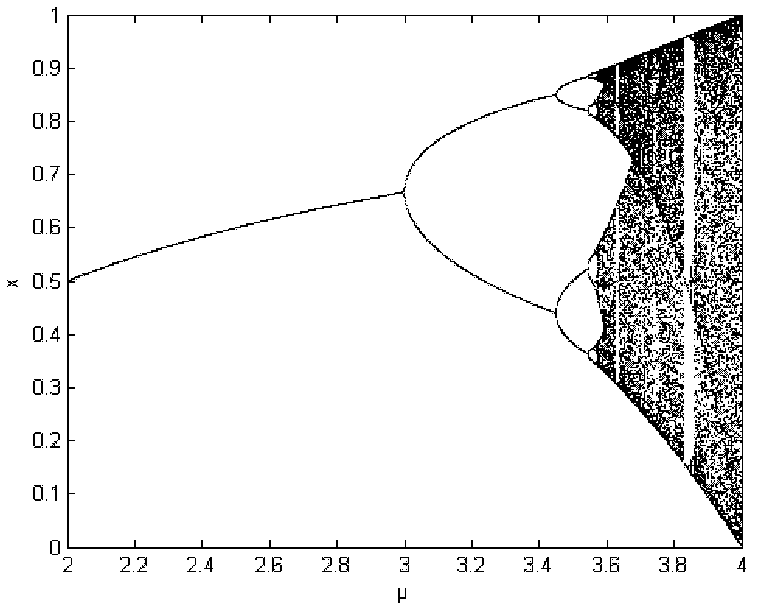

Digital image encryption method based on chaotic orbit perturbation

InactiveCN102360488AImprove diffusion abilityImprove abilitiesImage data processing detailsMultiple encryptionPlaintext

The invention relates to a digital image encryption method based on chaotic orbit perturbation and relates to the field of encryption systems. The method comprises the following steps of: scrambling a plaintext image by adopting a generalized discrete Baker mapping-based method; diffusing the scrambled image by adopting a Logistic mapping-based method, and changing the pixel value of each point in the image; and performing multiple encryption according to the requirement on encryption strength. According to the method, a key flow is related to a key and a plaintext by introducing a chaotic orbit perturbation mechanism related to the plaintext, so that the diffusing effects of an encryption system are effectively improved, and the known plaintext resistance is obviously improved. Certain pixel value is changed in the diffusion process depending on the cumulative effect of all the encrypted pixel values before the pixel, so that the tiny change of one pixel value can be effectively diffused to all the subsequent pixels in the image. The method has short encryption time.

Owner:付冲 +1

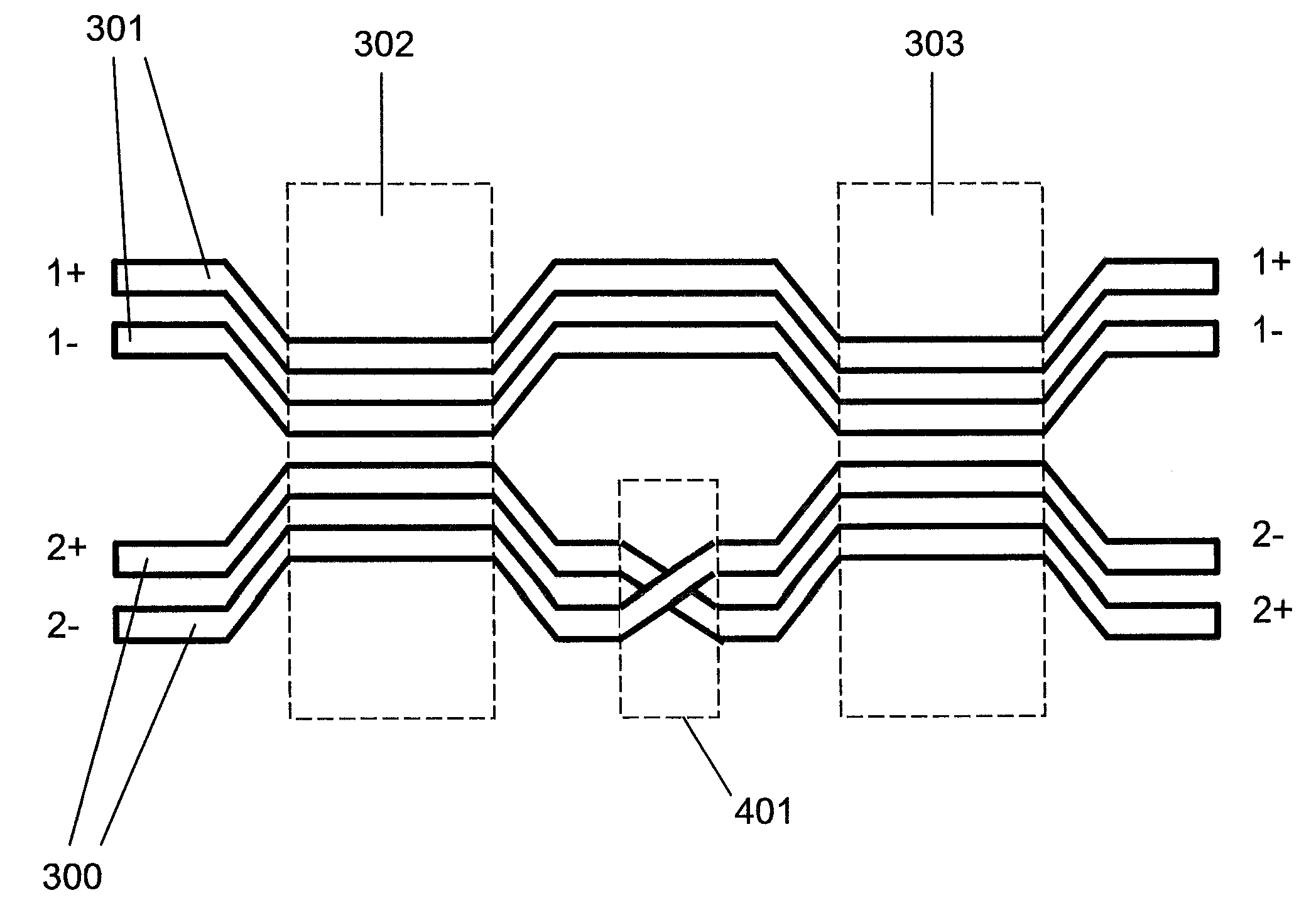

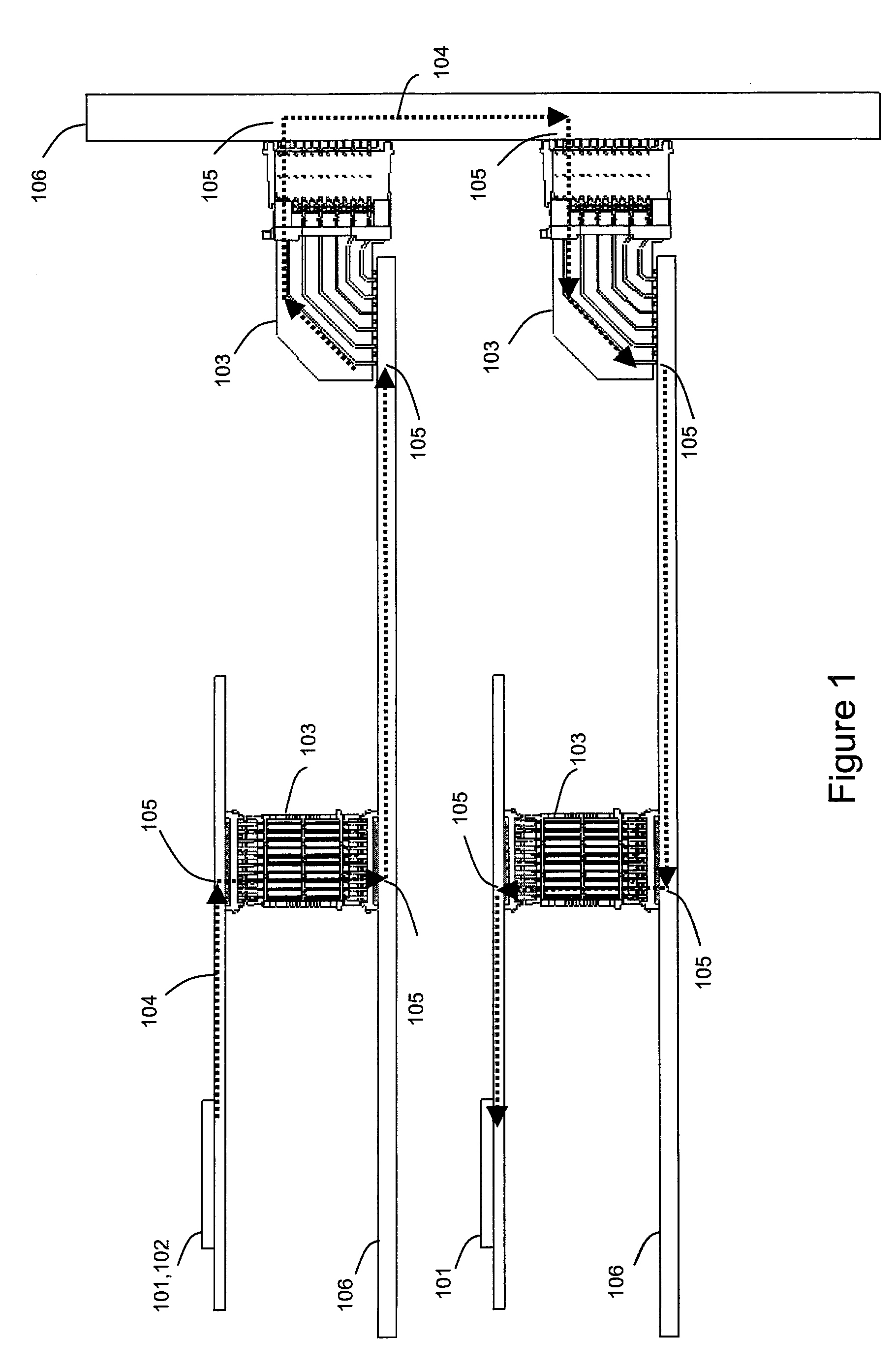

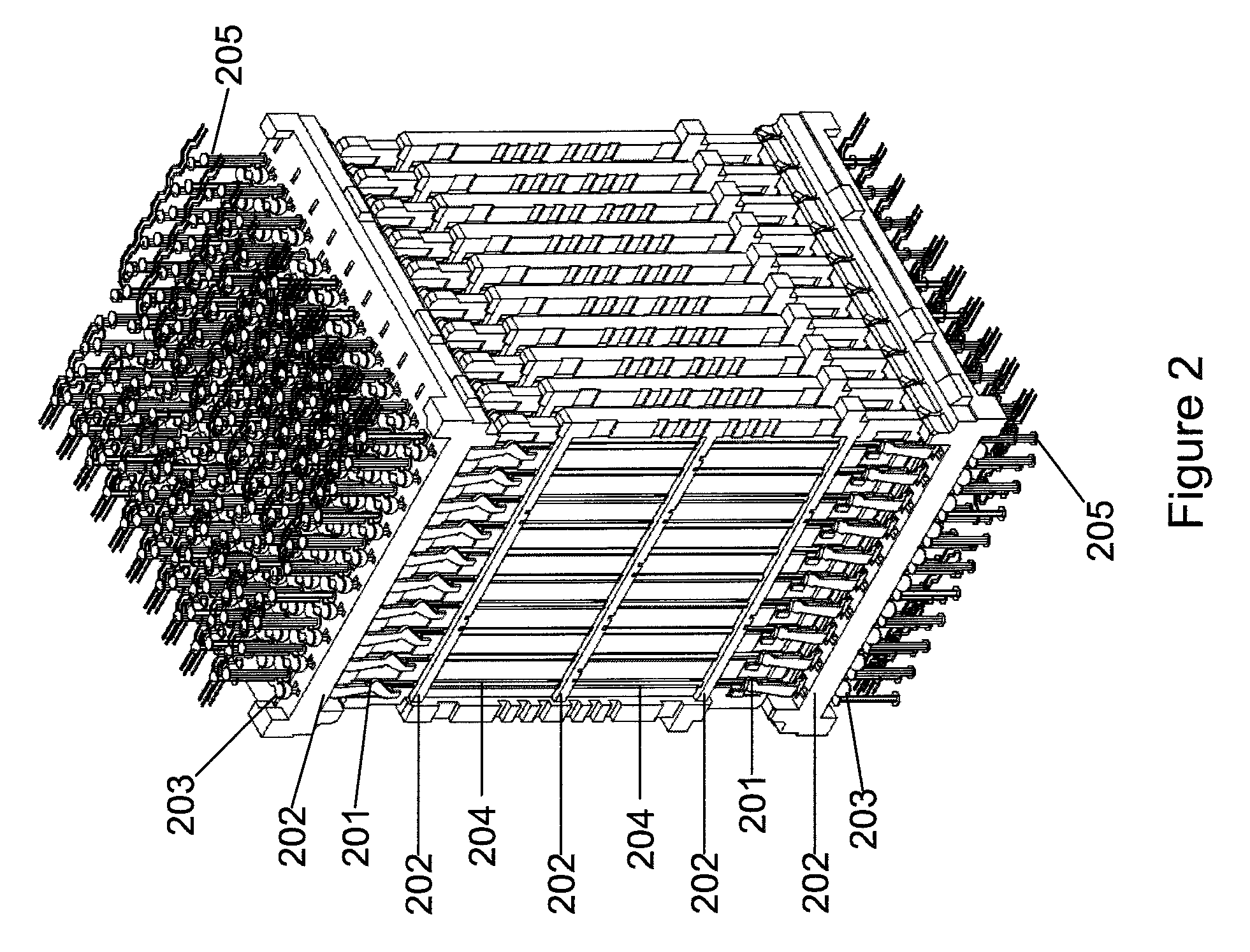

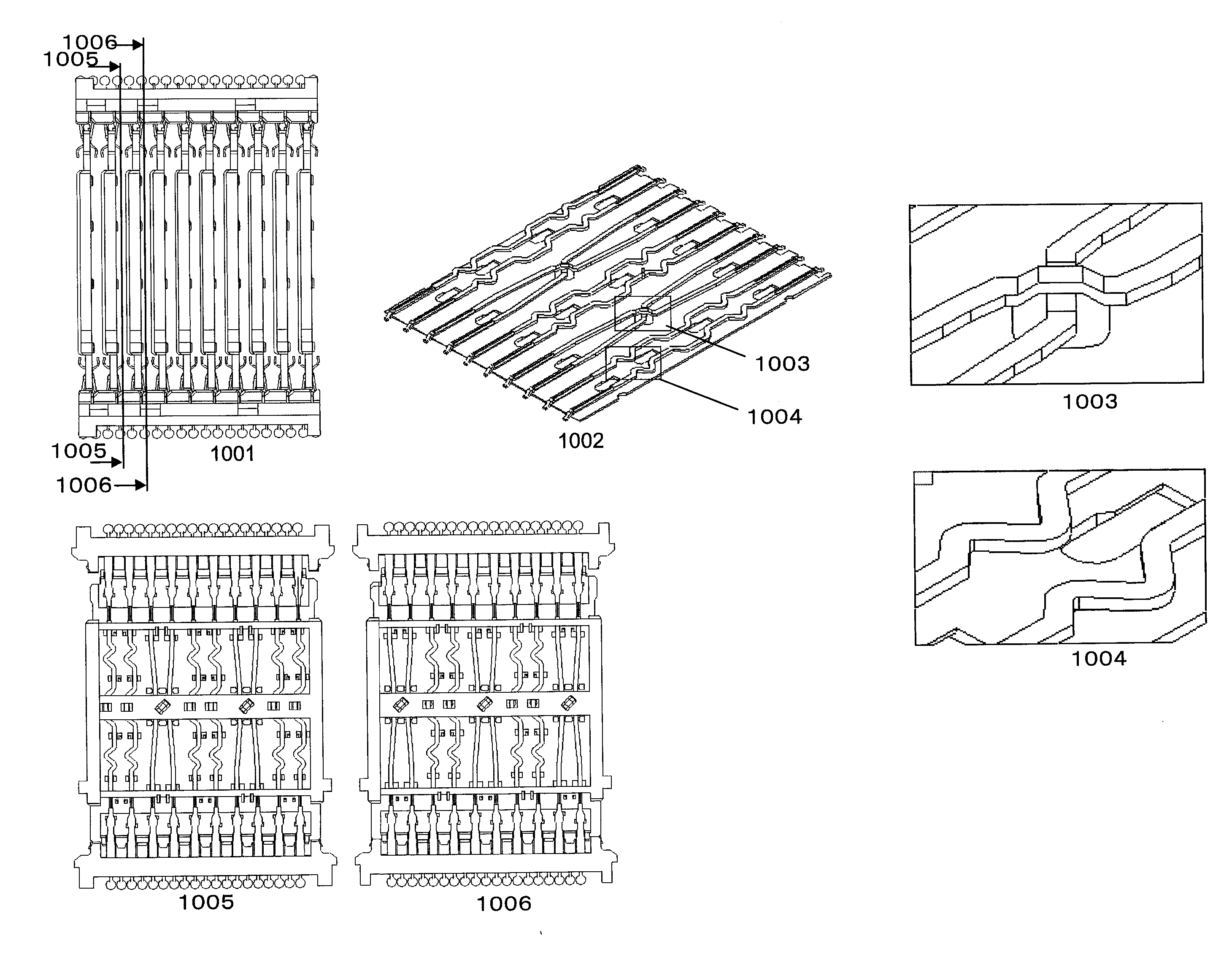

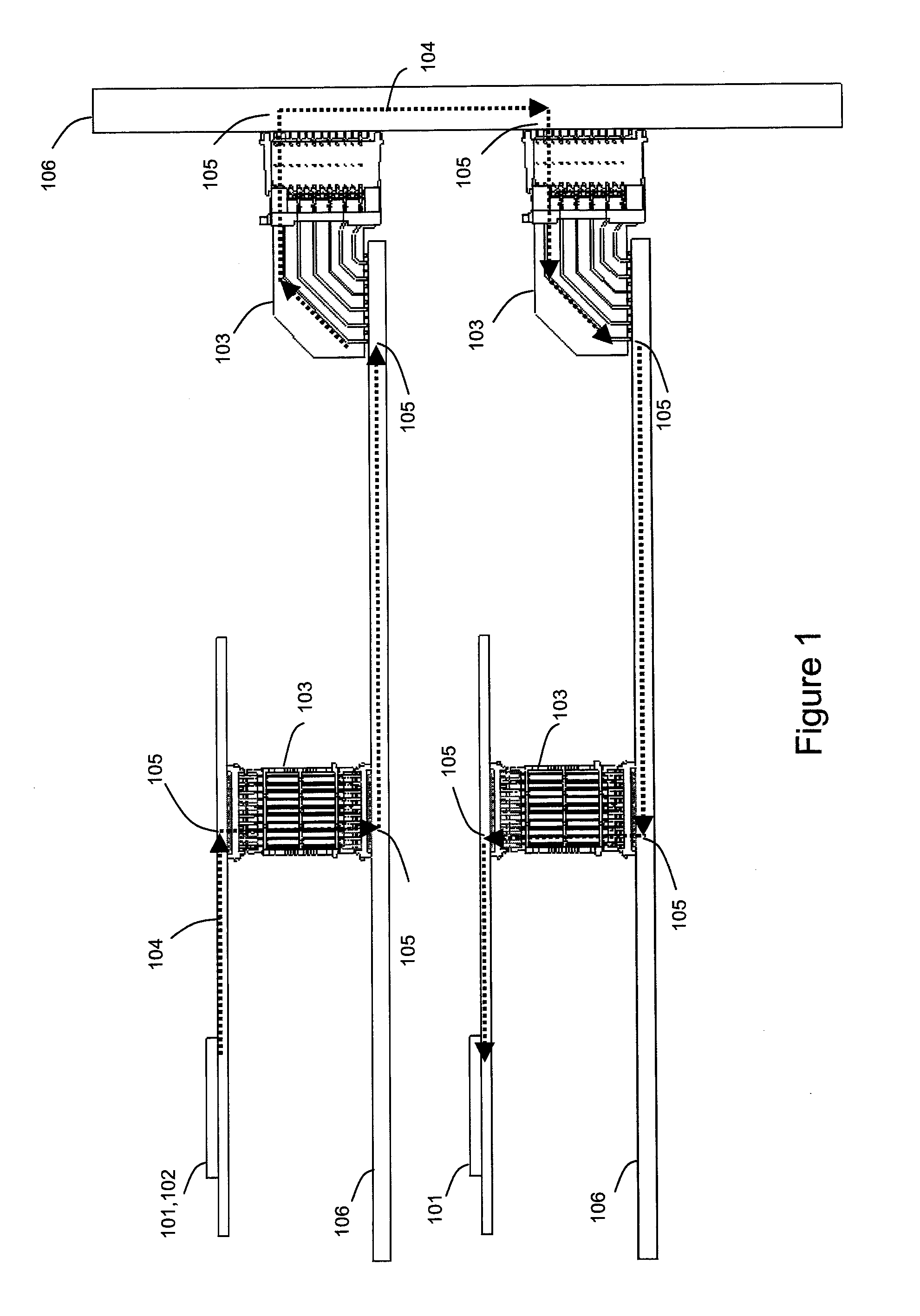

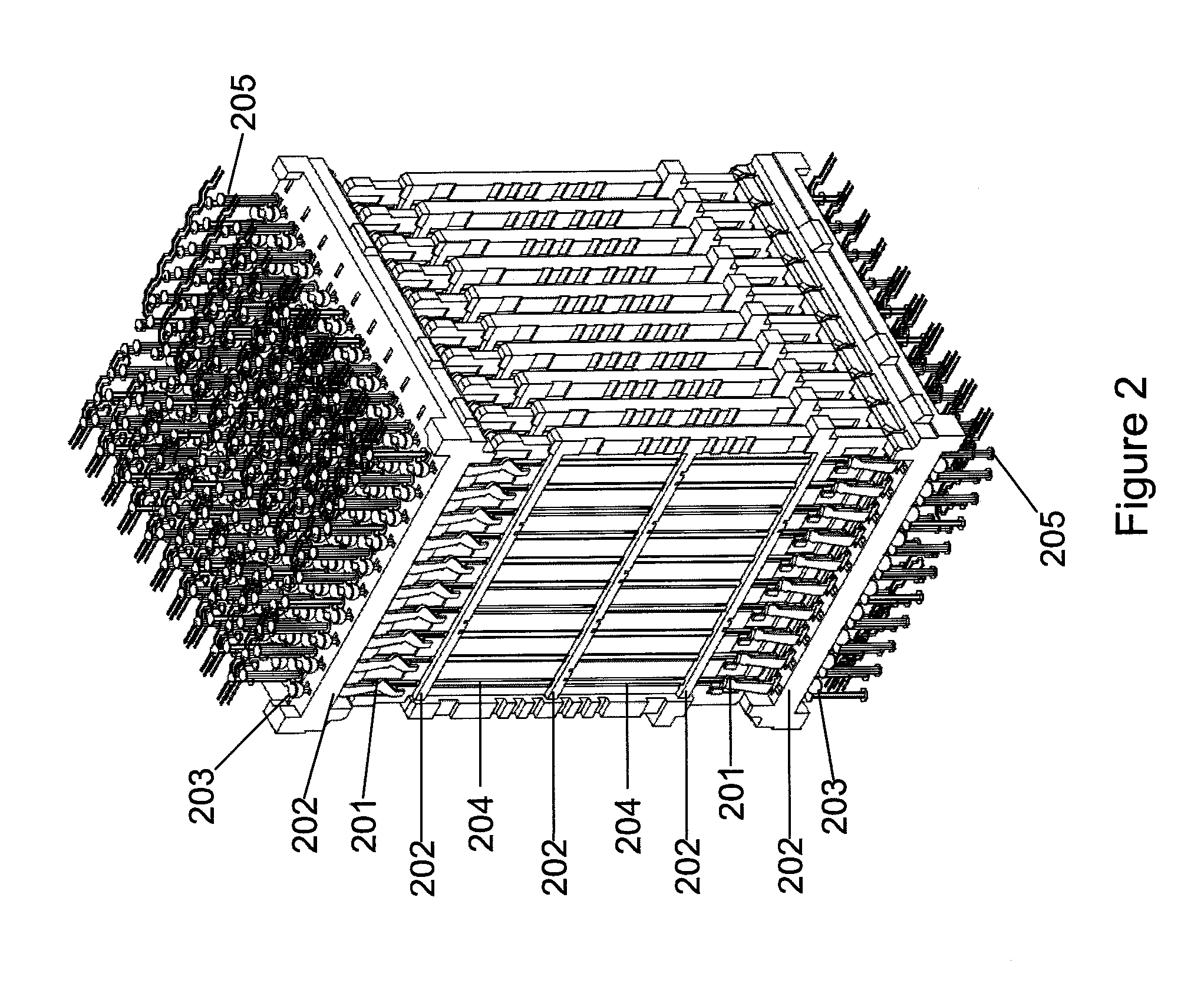

Reducing far-end crosstalk in chip-to-chip communication systems and components

InactiveUS20100183141A1Big improvements in total FEXTCancel improvementSubstations coupling interface circuitsInterconnection arrangementsCommunications systemElectrical polarity

The present invention involves chip-to-chip communication systems for reducing Far-End Crosstalk (FEXT) through the use of novel polarity swapping to negate the cumulative effect of FEXT. Skew adjustment is used to improve the FEXT cancellation from polarity swapping. The polarity reversal location or locations among FEXT sources are optimized to achieve maximum FEXT cancellation. The novelty polarity swapping technique can be applied to a wide variety of systems that can benefit from FEXT reduction.

Owner:HIROSE ELECTRIC GROUP

Reducing far-end crosstalk in electrical connectors

ActiveUS20100184307A1Big improvements in total FEXTCancel improvementInterconnection arrangementsSubstations coupling interface circuitsElectricityElectrical polarity

The present invention involves connectors for reducing Far-End Crosstalk (FEXT) through the use of novel polarity swapping to negate the cumulative effect of FEXT. Skew adjustment is used to improve the FEXT cancellation from polarity swapping. The polarity reversal location or locations among FEXT sources are optimized to achieve maximum FEXT cancellation. The novelty polarity swapping technique can be applied to a wide variety of connectors, such as mezzanine connectors, backplane connectors, and any other connectors that can benefit from FEXT reduction.

Owner:HIROSE ELECTRIC GROUP

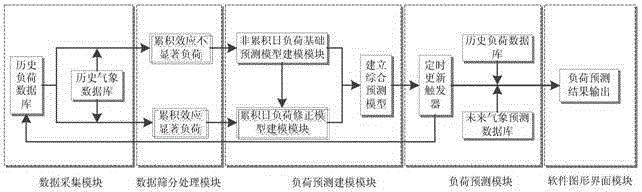

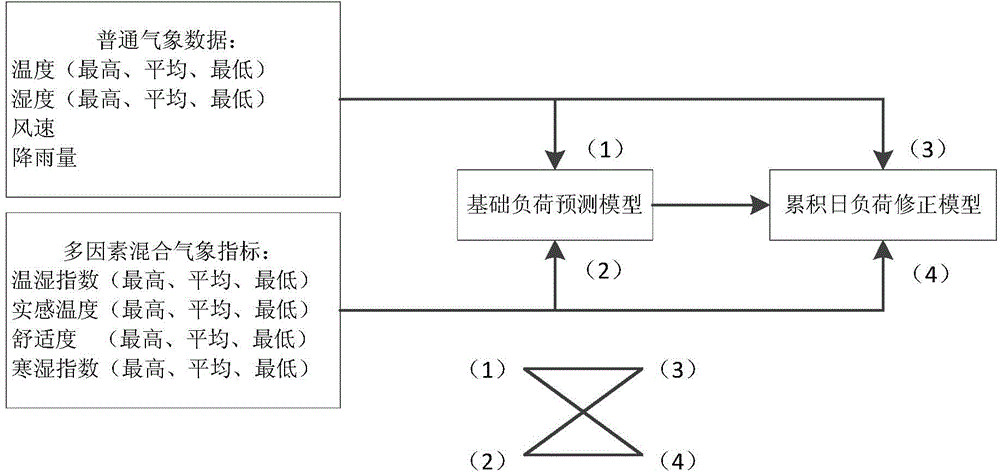

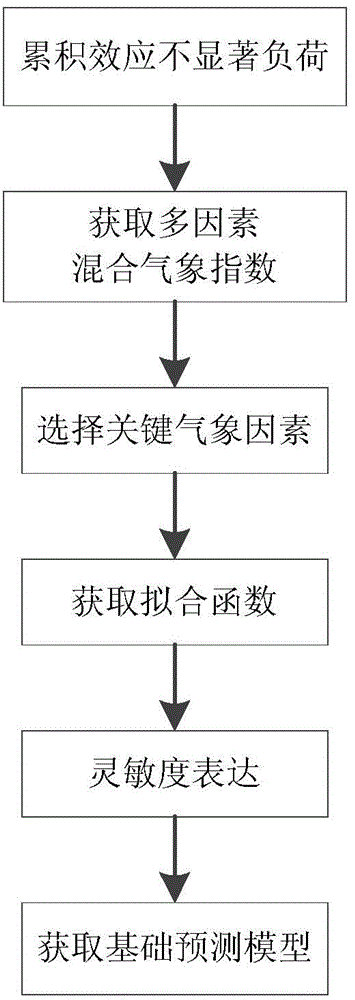

Maximum daily load prediction system and method of electric system considering meteorological accumulative effect

The invention discloses a maximum daily load prediction system and method of an electric system considering the meteorological accumulative effect. The meteorological and load data is read in a system by a data acquisition module; the load data is divided into two parts by a data screening and processing module: one part contains no accumulative effect and the other part is of significant accumulative effect and the key meteorological index influencing the network load is determined; a non-accumulative daily load basic prediction model is firstly established in the load prediction modeling module, on the basis, an accumulative daily load modified model is established so as to generate a comprehensive prediction model; finally in the load prediction module, the modeling module result and the meteorological and load database are linked to obtain a load predicted value, which is input into a software diagram interface to be supplied to a user. The maximum daily load prediction system and method can reflect the influences of meteorological conditions on the timeliness and accumulation of the network load, helps grid operating personnel accurately master the variation regulation of load, timely predict the maximum daily load change according to the weather conditions on the basis of weather forecasts, so as to improve the accuracy of short-term load prediction.

Owner:GUANGXI POWER GRID CORP +1

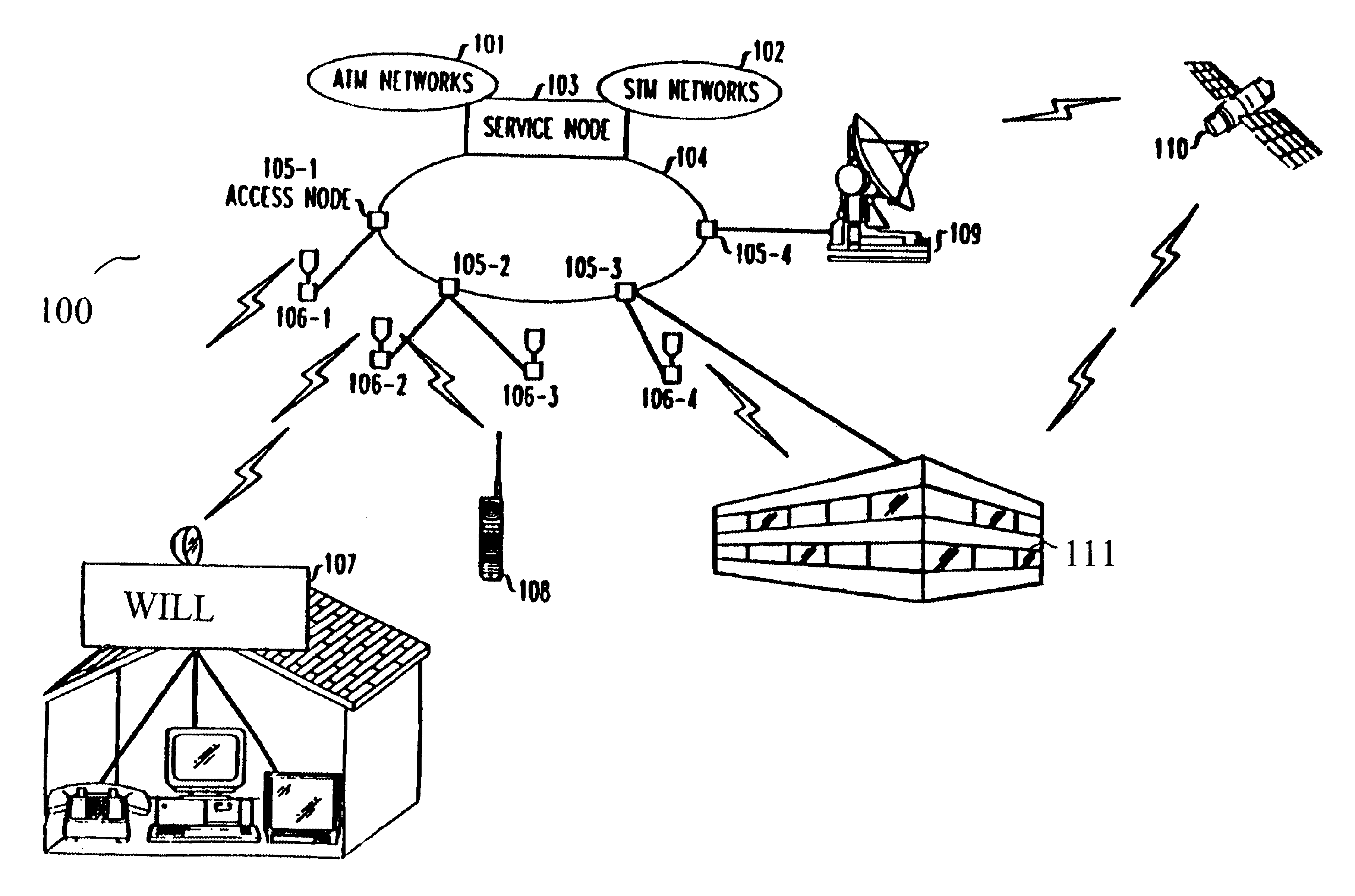

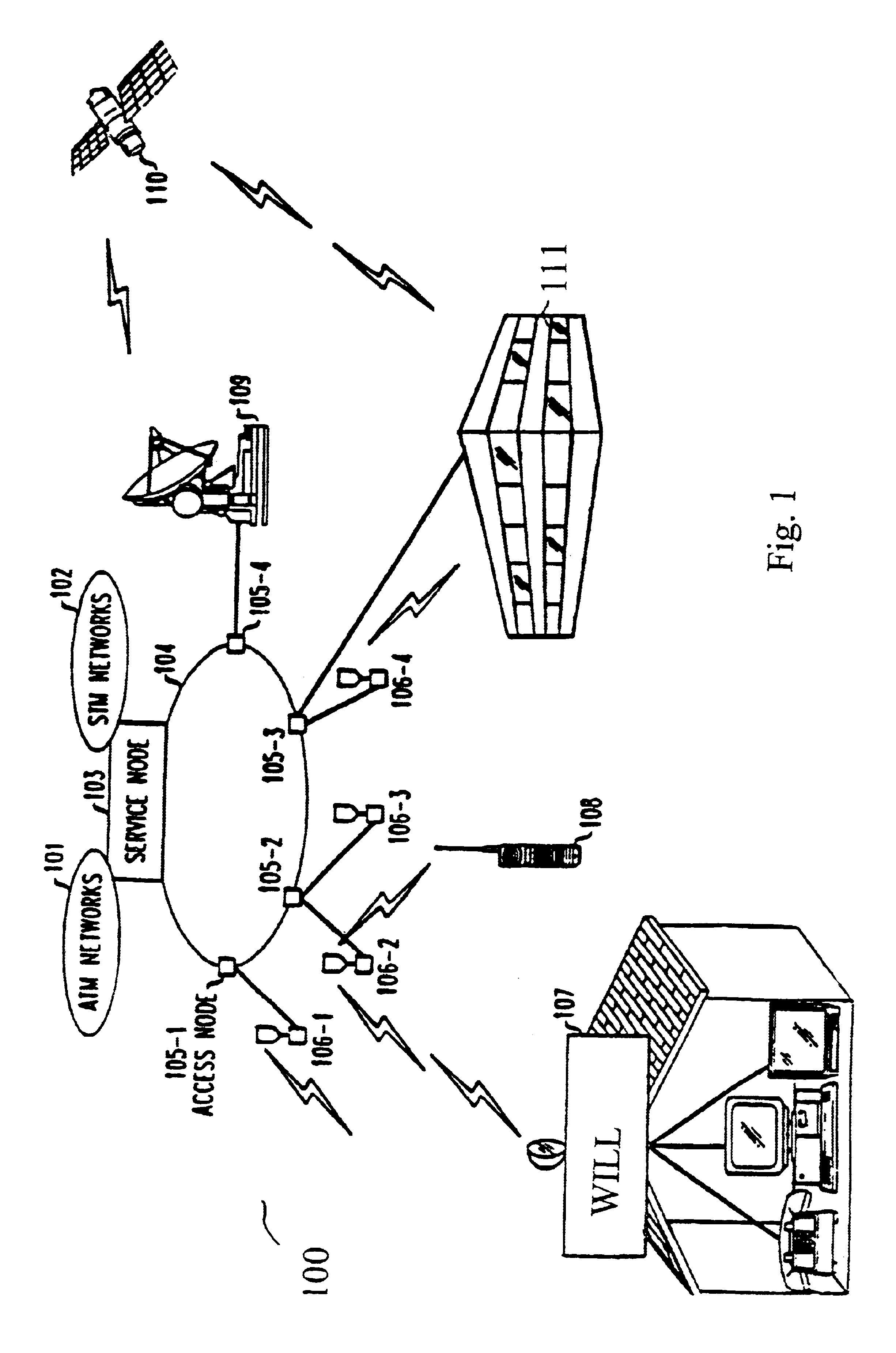

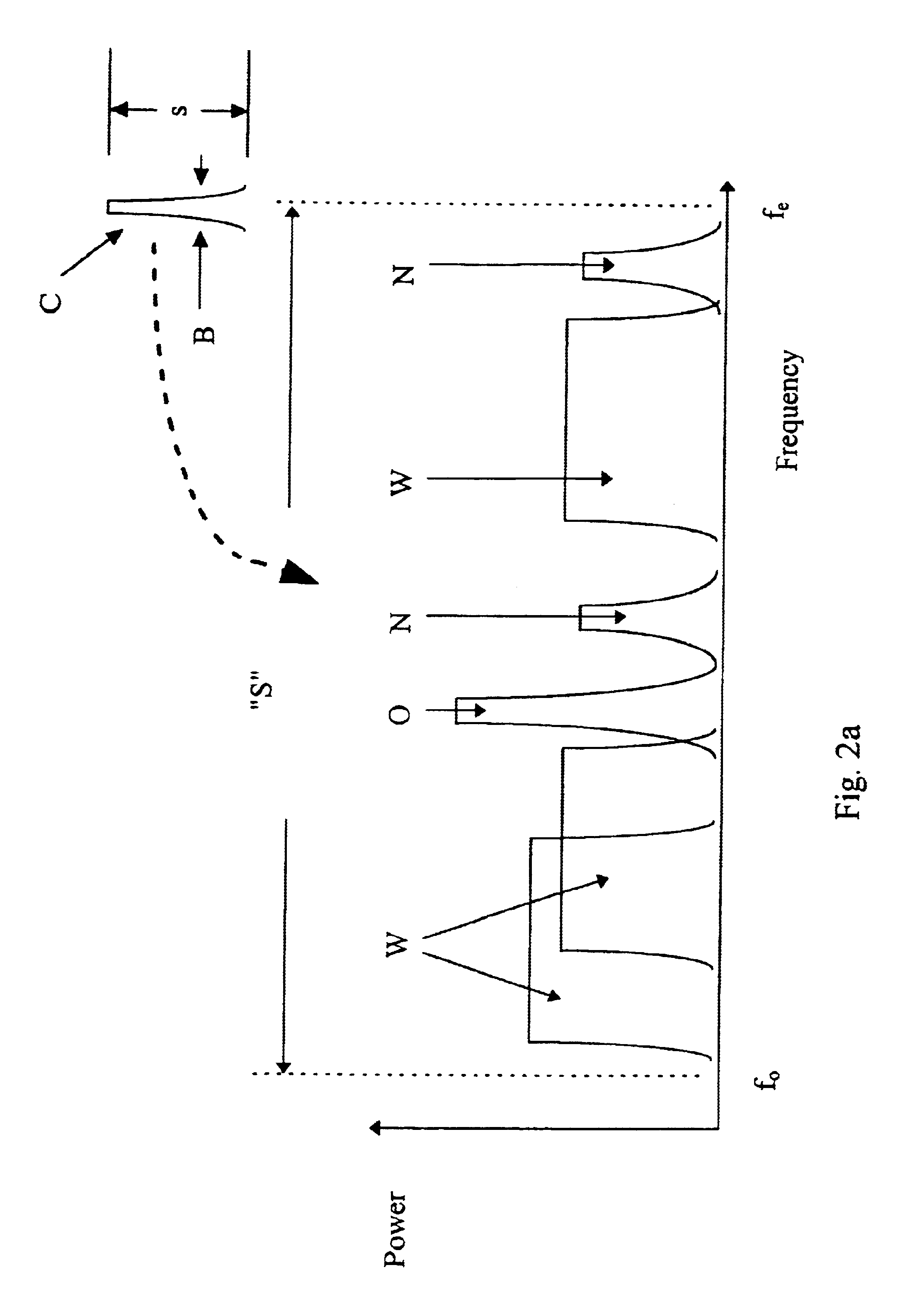

Method and apparatus for allocation of a transmission frequency within a given frequency spectrum

A method / apparatus for use of the power / frequency characteristics of the candidate transmission for which the frequency must be allocated, the method / apparatus providing a power spectrum of the cumulative effect of the power / frequency characteristic of at least a portion of the existing transmission at a plurality of center frequencies within the frequency spectrum at the time of allocation, calculating allocation based on a first function of a combination of the power spectrum and the power / frequency of the candidate transmission, the first function being determined at different frequencies at the time of allocation, selecting a center frequency for the candidate transmission from the frequency spectrum based on a minimum value among the calculated allocation values or based on a calculated allocation value being below a first threshold value.

Owner:MICROSOFT TECH LICENSING LLC

Combustion online optimizing method of boiler

InactiveCN102679391AImprove economyImprove stabilityCombustion regulationCombustionMathematical model

The invention discloses a combustion online optimizing method of a boiler. The combustion online optimizing method comprises the following steps of: monitoring real-time operation parameters of the boiler through a unit, recording and determining the real-time operation parameters; then comparing the real-time operation parameters, providing an optimal value curve guidance; then establishing a combustion characteristic optimization mathematical model of the boiler by adopting an artificial intelligent neutral network technology; optimizing the combustion characteristic of the boiler by using a genetic algorithm or simulated annealing method; and finally, storing the combustion optimization parameter as a long-term trend data, and carrying out accumulated monitoring and storing on a parameter with an accumulation effect. Through the mode, according to the invention, the economy of the operation of the boiler can be improved, the NOx discharge can be reduced by 20-30 percent after the combustion optimization technology is adopted, the exhaust gas temperature is reduced, the unburned carbon in flue dust is lowered, the efficiency of the boiler is increased, various kinds of loss are reduced, and the efficiency of the whole unit is increased.

Owner:CHANGZHOU XINGANG THERMOELECTRICITY

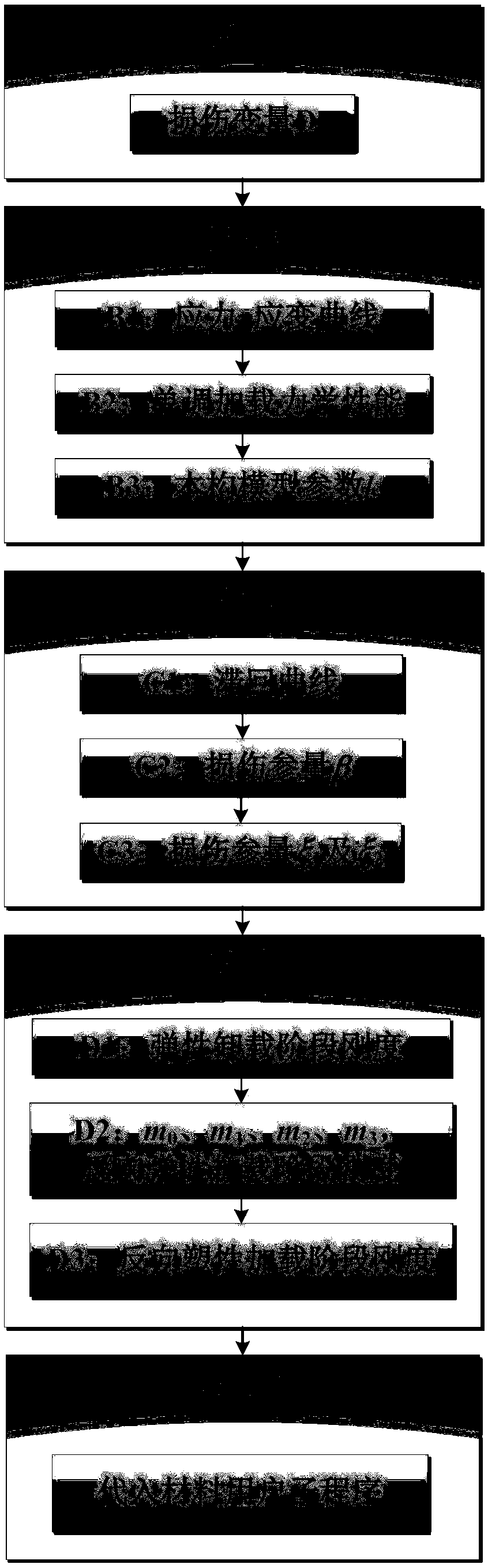

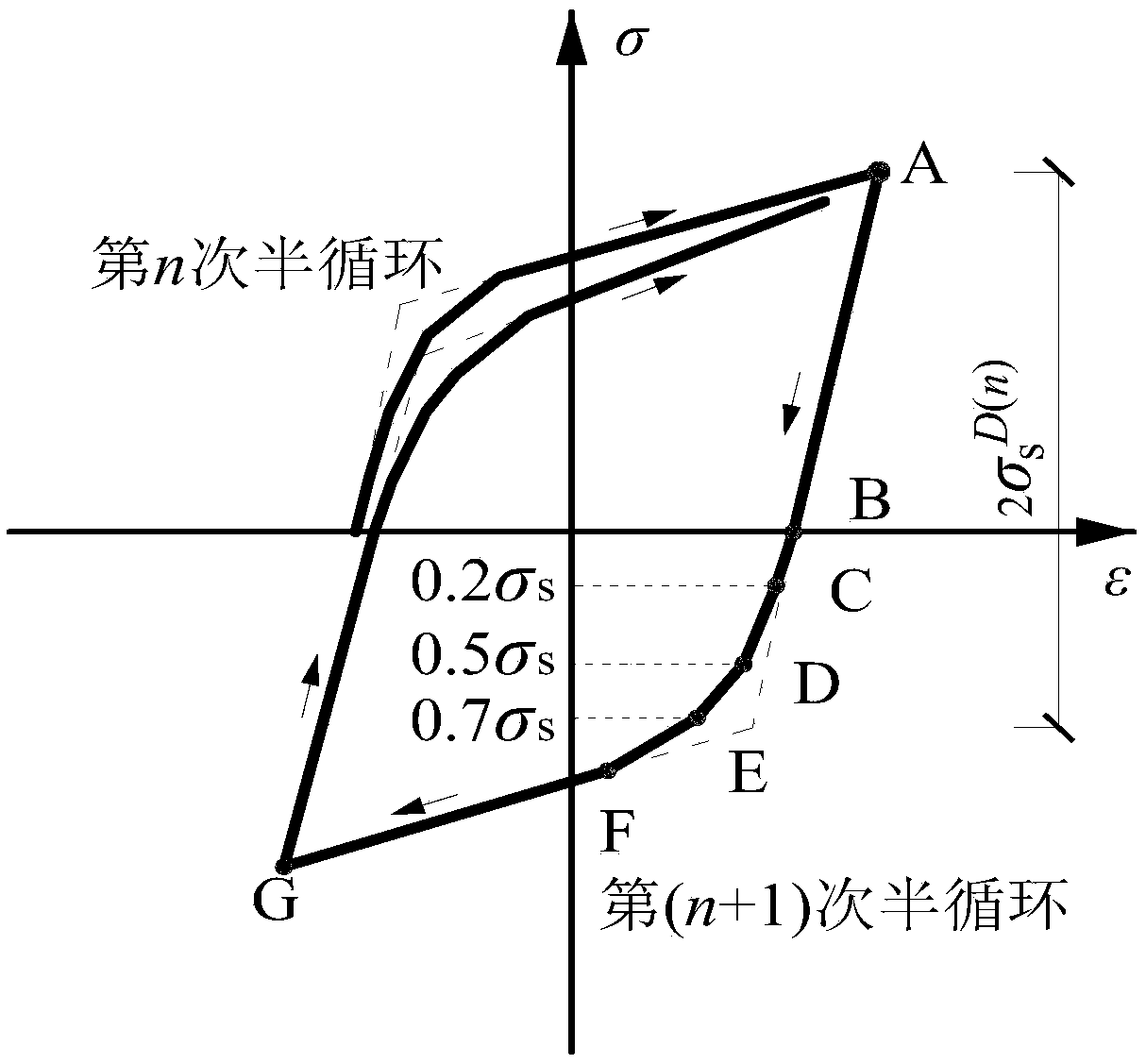

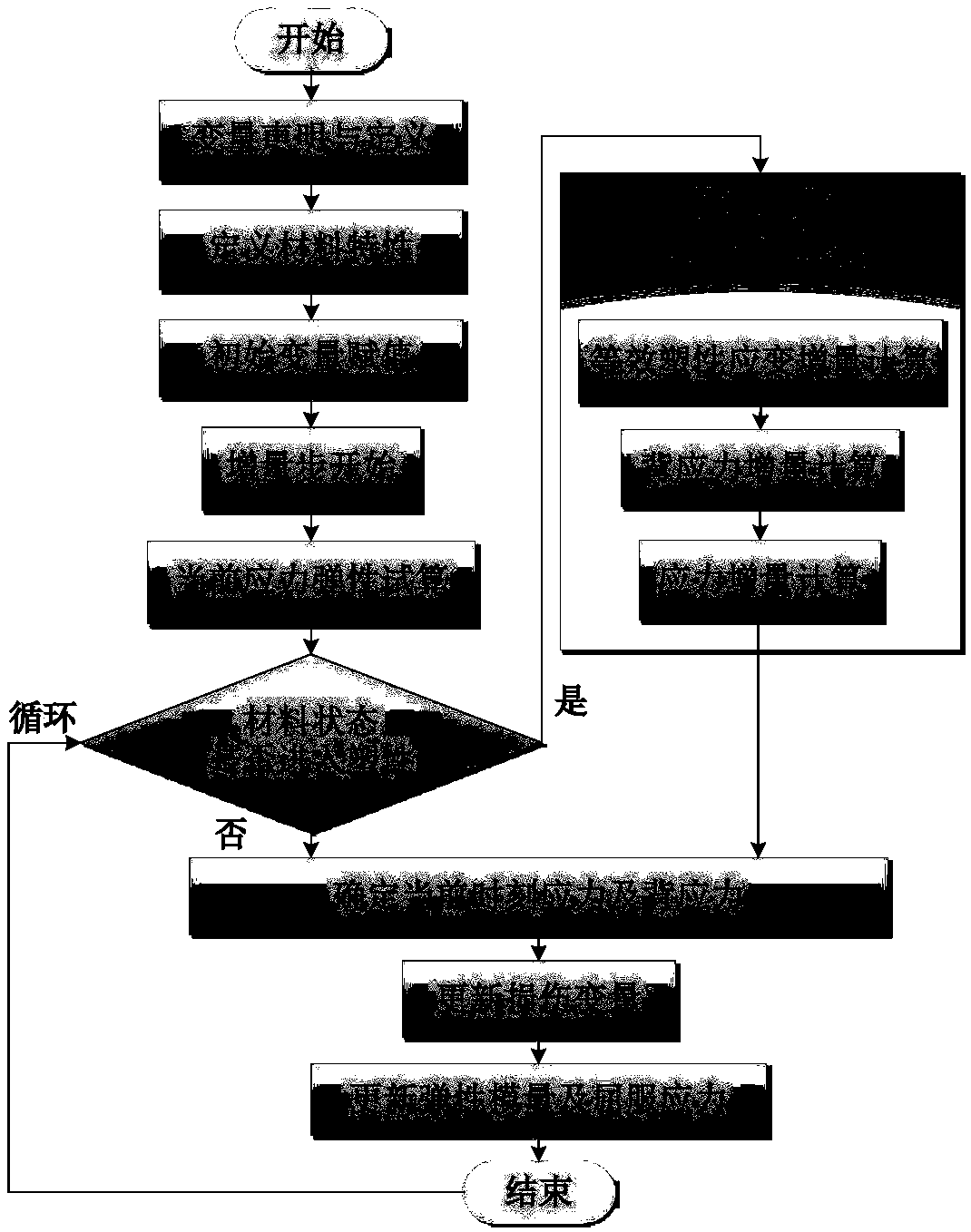

Material constitutive model numerical analysis method taking damage accumulation effect into consideration

ActiveCN108920739AImprove usabilityImprove versatilityGeometric CADDesign optimisation/simulationStress–strain curveEngineering

The invention discloses a material constitutive model numerical analysis method taking damage accumulation effect into consideration. The method includes: step A, defining damage variable D; step B, acquiring material monotonic loading mechanical performance according to a stress-strain curve of a material; step C, calculating damage parameters beta, zeta 1 and zeta 2 according to a hysteretic curve of a material different in strain amplitude; step D, acquiring undetermined parameters m0, m1, m2 and m3 according to the hysteretic curve of the material, and building a material circulation constitutive model taking damage accumulation effect into consideration; step E, through ABAQUS finite element software, substituting related parameters of the material into a material user subprogram VUMAT to accurately simulate damage of the material under circulation load action. By the method, difficulty of accumulation damage model application at the present stage can be solved effectively, damageparameters can be specified, calculation accuracy can be improved, application of the material constitutive model taking damage accumulation effect in the finite element software is realized, and damage to the material under the circulation load action can be simulated accurately.

Owner:TIANJIN UNIV

Laser power regulating method based on model features

InactiveCN107599382ASmall amount of calculationEasy to operateAdditive manufacturing apparatus3D object support structuresClassical mechanicsLaser additive manufacturing

The invention belongs to the technical field of laser material additive manufacturing, and particularly relates to a laser power regulating method based on model features. The laser power regulating method comprises the following steps that a special region with a complex structure in a model is obtained, slicing processing is conducted on the workpiece model, and preprocessing is conducted on thesplice contour of a special region in the contour data of each layer, the laser power of the point needed to be adjusted is calculated point-by-point; and the slice contour of a non-special region ineach layer contour data is filled in a conventional filling mode; and the process is repeated until layer processing of all slices of the workpiece model is finished, and finally the laser printing path data of the workpiece model is generated. According to the laser power regulating method based on the model features, the heat accumulation effect generated by excessively intensive scanning and printing of in the local region of the laser is utilized, and the laser power of the progressive contour ring filling path in the region is adjusted dynamically, so that adverse effects caused by the heat accumulation effect is avoided, and the fact that the temperature of a material molten pool is stable in the melting temperature range of powder materials all the time is guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

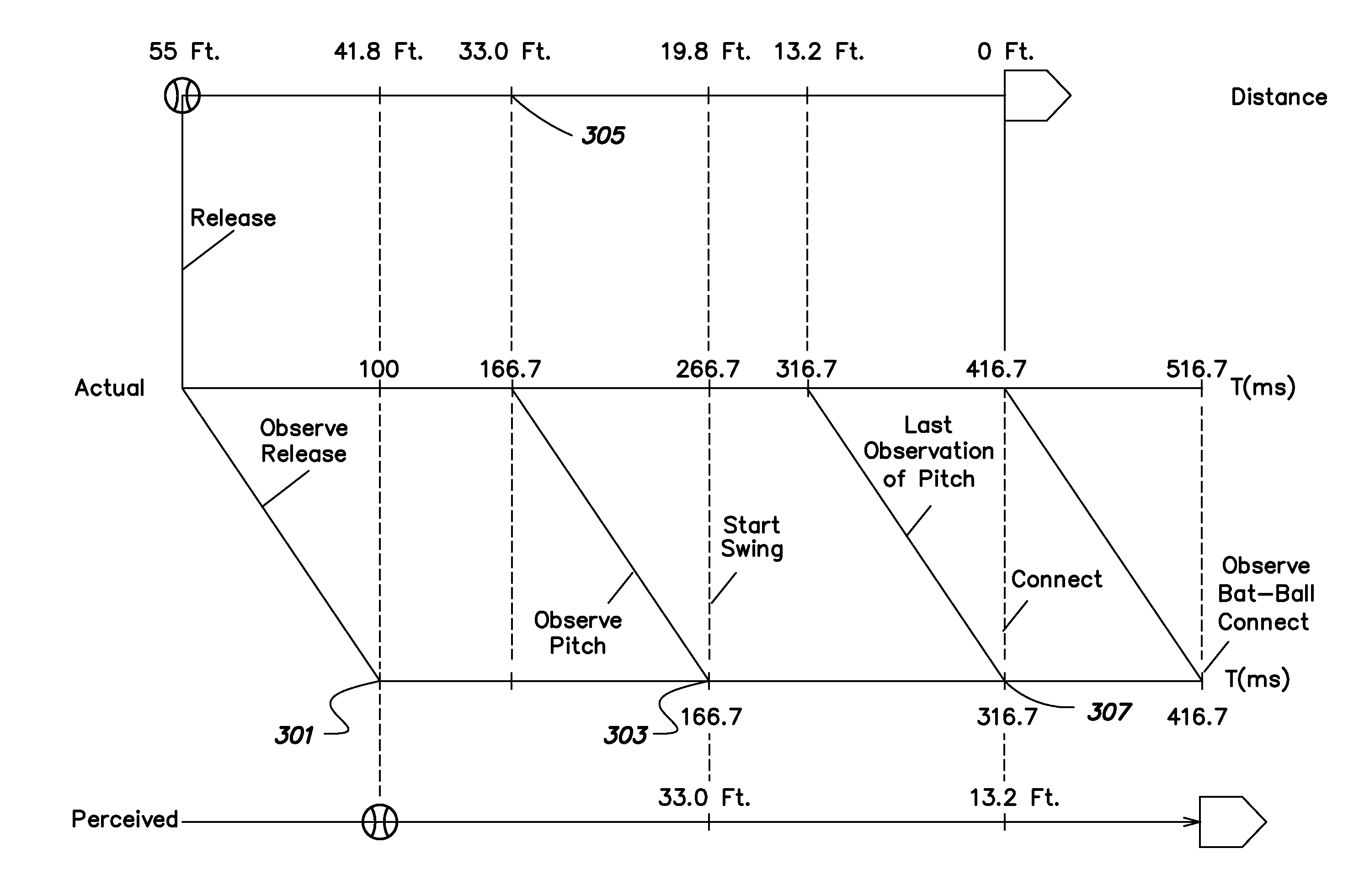

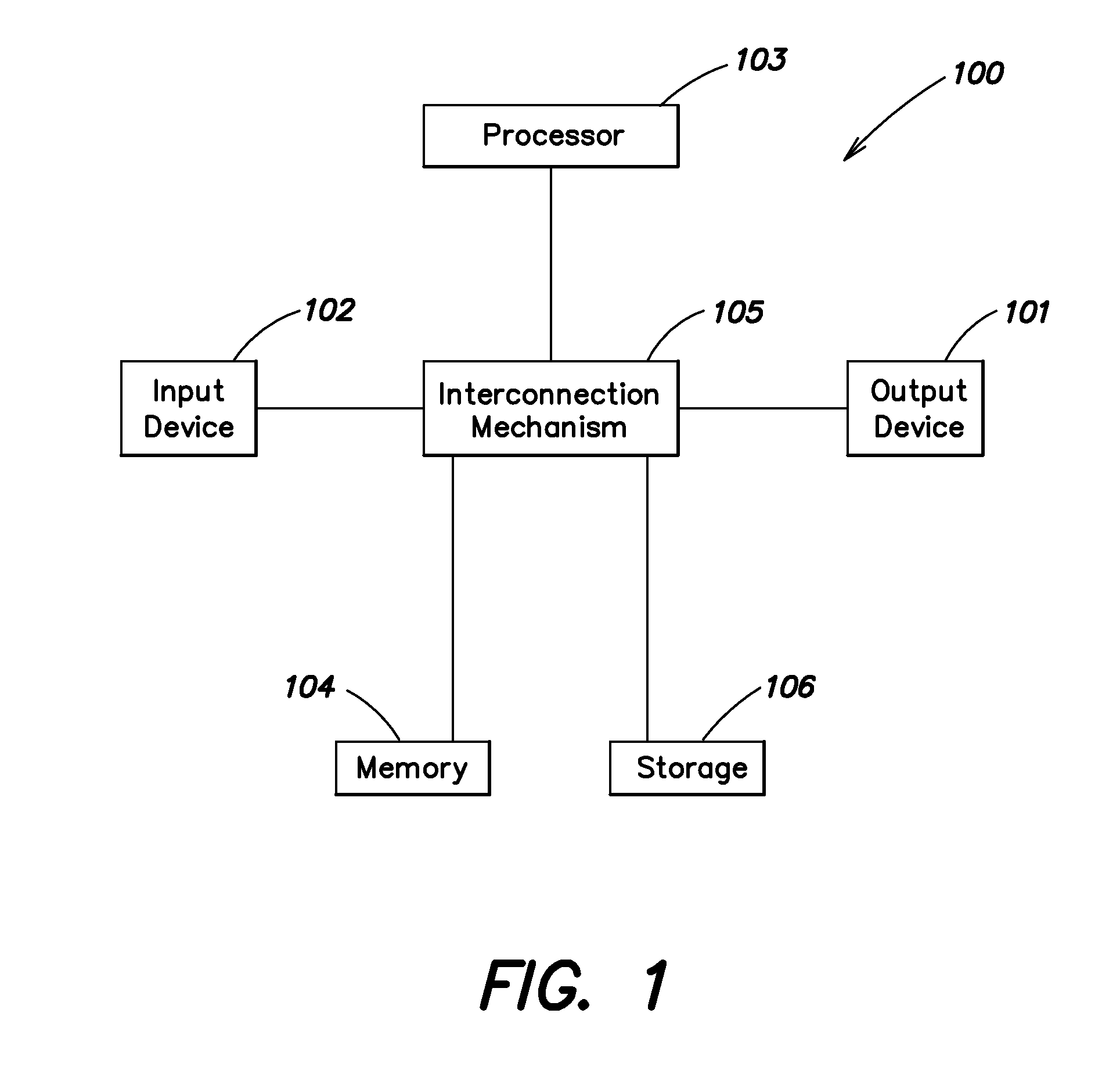

Baseball event outcome prediction method and apparatus

ActiveUS20100298958A1Improve performanceGymnastic exercisingBall sportsStatistical databaseOutcome prediction

A computer-implemented method of predicting outcomes of hypothetical events which can occur during a game of baseball, includes: accumulating and storing in a computer memory a statistical database of the cumulative effects of latency and engrams specific to an individual batter having individual batter capabilities and an individual pitcher having individual pitcher capabilities; selecting a pitch, by a user, from amongst pitches compatible with the individual pitcher capabilities; selecting a swing, by a user, from amongst swings compatible with the individual batter capabilities; computing in a computer processor a statistical performance of the individual pitcher of the selected pitch; computing in a computer processor a statistical performance of the individual batter of the selected swing; and matching in a computer processor the statistical performance of the individual pitcher with the statistical performance of the individual batter so as to compute an outcome.

Owner:DREAM BIG BASEBALL

System and method for assessing cumulative effects of a failure

ActiveUS20150019187A1Ease of evaluationEasy to identifyTesting/monitoring control systemsDesign optimisation/simulationFailure analysisWorkload

A failure-effect validation system includes an effects modeler configured to develop a cumulative effects model for failure modes of the complex system, and by which a model of the complex system is extendible to form an extended complex-system model. The effects modeler is also configured to develop search targets each of which includes logical expressions of notable hazards and other factors that contribute to the cumulative effects, such as crew workload, safety margin and / or physiological effects. A model analysis system is configured to perform an automated analysis using the extended complex-system model and search targets, and in which the automated analysis includes a graph search of possible states of the extended complex-system model to locate search targets. And the effects assessment system is configured to selectively generate a layout of failure analysis data including at least a portion of the extended complex-system model and results of the automated analysis.

Owner:THE BOEING CO

Short-term load forecast method based on artificial neural network

InactiveCN103093285AReduce the numberIncrease training speedBiological neural network modelsForecastingHuman bodyLoad forecasting

The invention relates to a short-term load forecast method based on an artificial neural network and belongs to the technical field of electric system load forecasts. The method comprises a network structure improved method and an output result correcting method. The network structure improved method mainly improves an input variable choice. The input variable considers six aspect factors, wherein the six aspect factors respectively are a date type W, a temperature exponent T, a comfortable degree exponent of human body D, an accumulative effect exponent A, a load data L and an economy increasing exponent E. The output result correcting method considers the load increasing or increasing influence brought by atypia day time influence and correct output results. The short-term load forecast method based on the artificial neural network improves load susceptibility to weather exponents, optimizes network nonlinear function fitting parameters, fastens network training speed and improves load forecast accuracy rate.

Owner:TSINGHUA UNIV +1

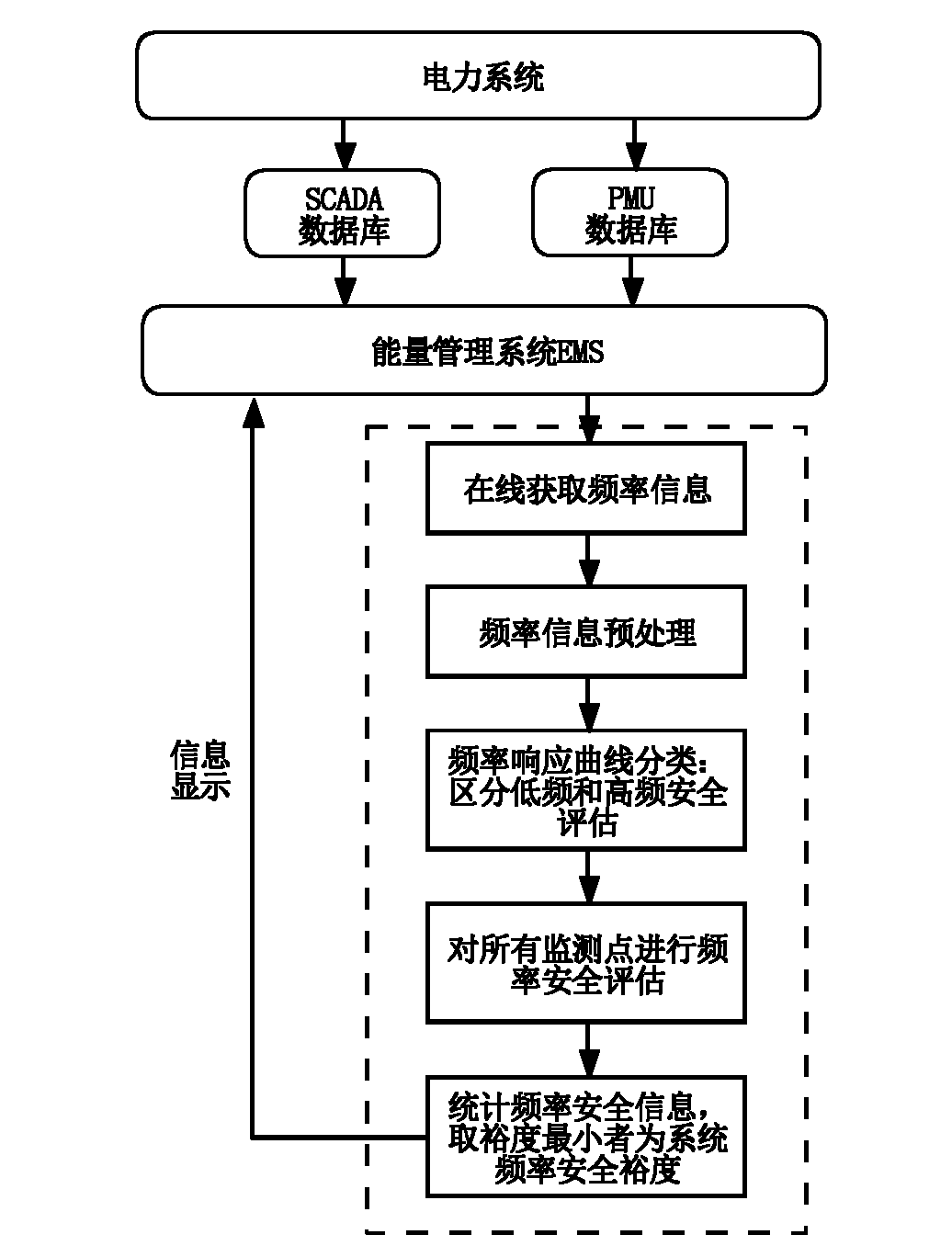

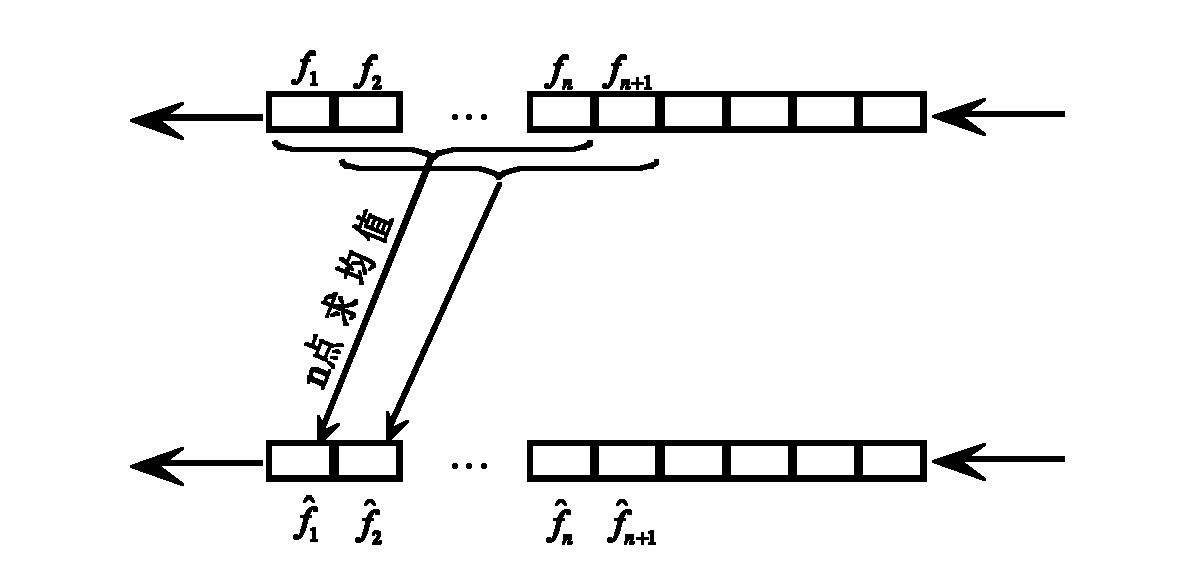

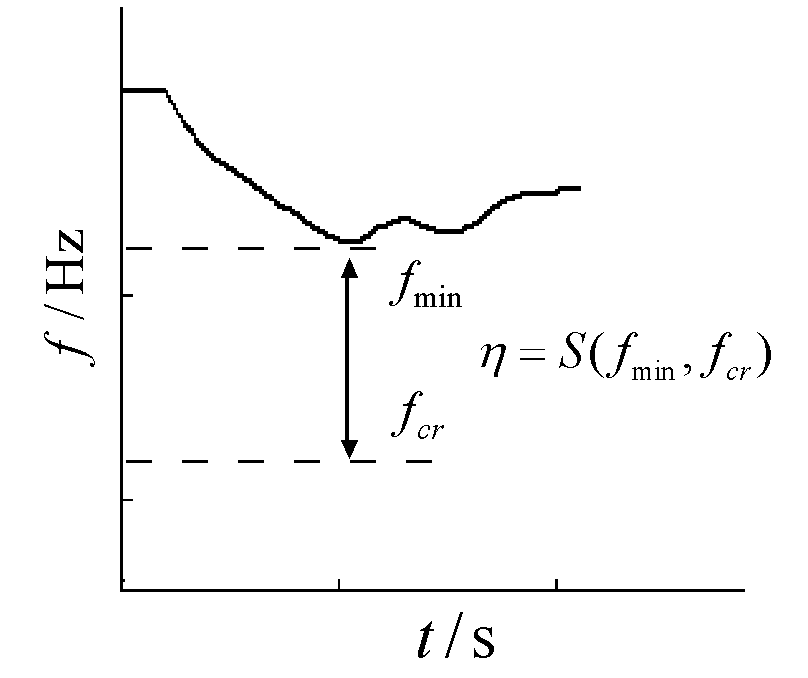

Frequency safety online monitoring and assessment method of power system

ActiveCN101917006ADefine a unified formImprove smoothnessData processing applicationsAc network circuit arrangementsMoving averageElectric power system

The invention relates to a frequency safety online monitoring and assessment method of a power system, which comprises the following steps: (1) setting a transient frequency safety binary table (fcr, fcr); (2) acquiring real-time frequency data of all monitoring points of the power system from an energy management system (EMS); (3) filtering the dynamic frequency data of all the monitoring points on the basis of a moving average method; (4) primarily analyzing the frequency data; (5) analyzing every group of dynamic frequency data, and calculating a frequency safety margin index according to the relationship between a frequency curve and the binary table (fcr, fcr) by the following three conditions: (1) tb = 0; (2) 0 < tb < tcr; and (3) tb > tcr, wherein tb is time that the frequency curve in an observation window deviates from fcr, and a frequency safety quantitative assessment method which takes frequency deviation cumulative effect is applied to the frequency safety margin calculation; and (6) comprehensively analyzing the frequency safety margin calculation results of all the monitoring points, taking the minimum margin value as a system frequency safety margin, and feeding back the system frequency safety margin to the energy management system for information display.

Owner:SHANDONG UNIV

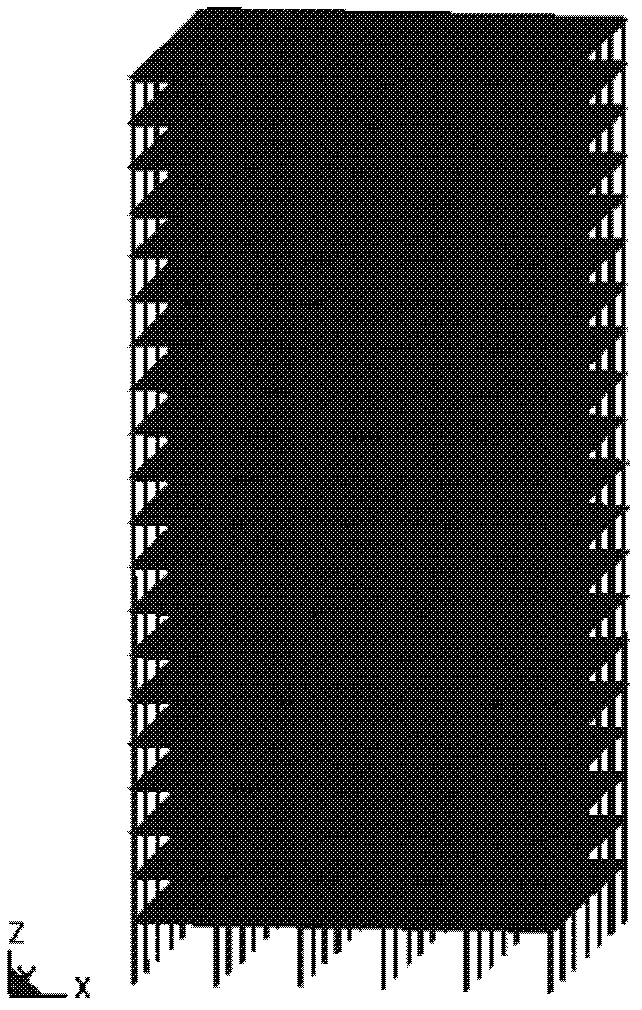

Earthquake collapse analysis method for high-rise steel frame structure

ActiveCN102385663AMeet the needs of practical applicationsSpecial data processing applicationsDynamic equationEngineering

The invention discloses an earthquake collapse analysis method for a high-rise steel frame structure, which comprises the following steps: obtaining the dynamic equation of the high-rise steel frame structure under the earthquake action; according to a central difference method and the dynamic equation, solving the speed and the acceleration of the displacement differential of the high-rise steel frame structure within time interval delta t; according to the Von Mises yield condition and a corrected K&K model, obtaining unit stress sigma t at the t time; defining a failure criterion corresponding to the K&K model; according to the failure criterion, judging whether a unit fails or not; if so, deleting the failed unit; if not, according to a geometric equation and the displacement u(t+delta t) of the high-rise steel frame structure, obtaining the strain increment d epsilon of the unit; according to a damage evolution equation, obtaining the accumulated damage value D of the unit; according to the accumulated damage value D of the unit, calculating the layer damage value of the high-rise steel frame structure; obtaining the stress sigma t+delta t of the t+delta t time unit; and updating time t to t+delta t. According to the earthquake collapse analysis method, the whole collapse damage process of the high-rise steel frame structure under the earthquake action by considering the damage accumulation effect can be precisely simulated.

Owner:扬中市冠捷科创有限公司

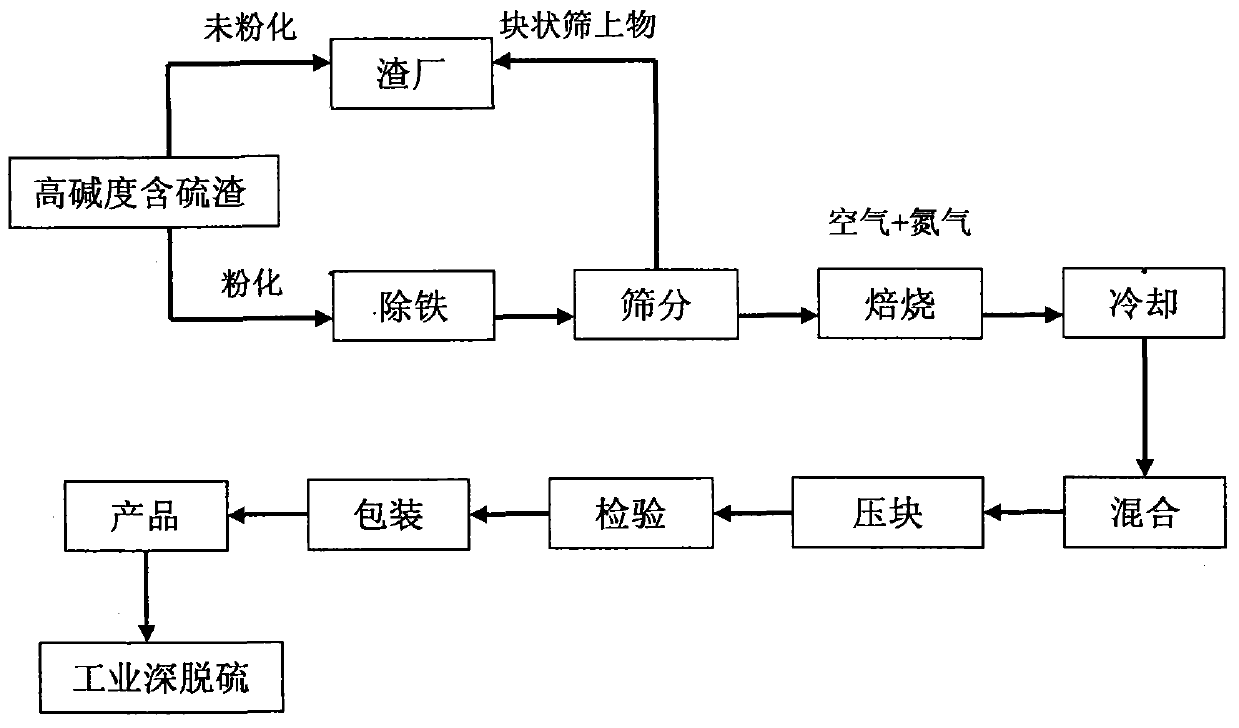

Method for utilizing sulfur-containing refining waste residue for refining slag

InactiveCN101717843AGive full play to the maximum utility valueImprove cleanlinessProcess efficiency improvementCalcium/strontium/barium oxides/hydroxidesCalcium hydroxideSlag

The invention relates to a method for recycling sulfur-containing refining waste residue generated in the process of liquid steel refining for refining slag, which is characterized by taking cooling pulverization pretreatment fine powders, roasting the sieving fine powders in the weak oxidizing atmosphere that an oxygen partial pressure is between 0.08 and 0.15atm at a temperature of more than or equal to 1100 DEG C to convert a harmful component CaS to an effective component CaO so as to remove sulfur impurities, and decomposing calcium hydroxide. In the method, the recycling of the sulfur-containing refining waste residue is directly used for reusing the refining slag with high utilization value, and the maximum utility value of the abandoned sulfur-containing refining slag is fully exerted. Compared with the conventional technology application, the invention can increase the value added for each ton of the abandoned sulfur-containing refining slag by more than 800 RMB. Moreover, the sulfur in the sulfur-containing refining waste residue is removed by a simple oxidizing and roasting process to guarantee the cleanliness of the recyling product, the liquid steel resulfurization can not be caused in the recycling process of carrying out the liquid steel desulfuration, the cumulative effect of the sulfur can not be generated in the metallurgy process, and a novel way of recycling the sulfur-containing refining slag is developed.

Owner:NORTHEASTERN UNIV +1

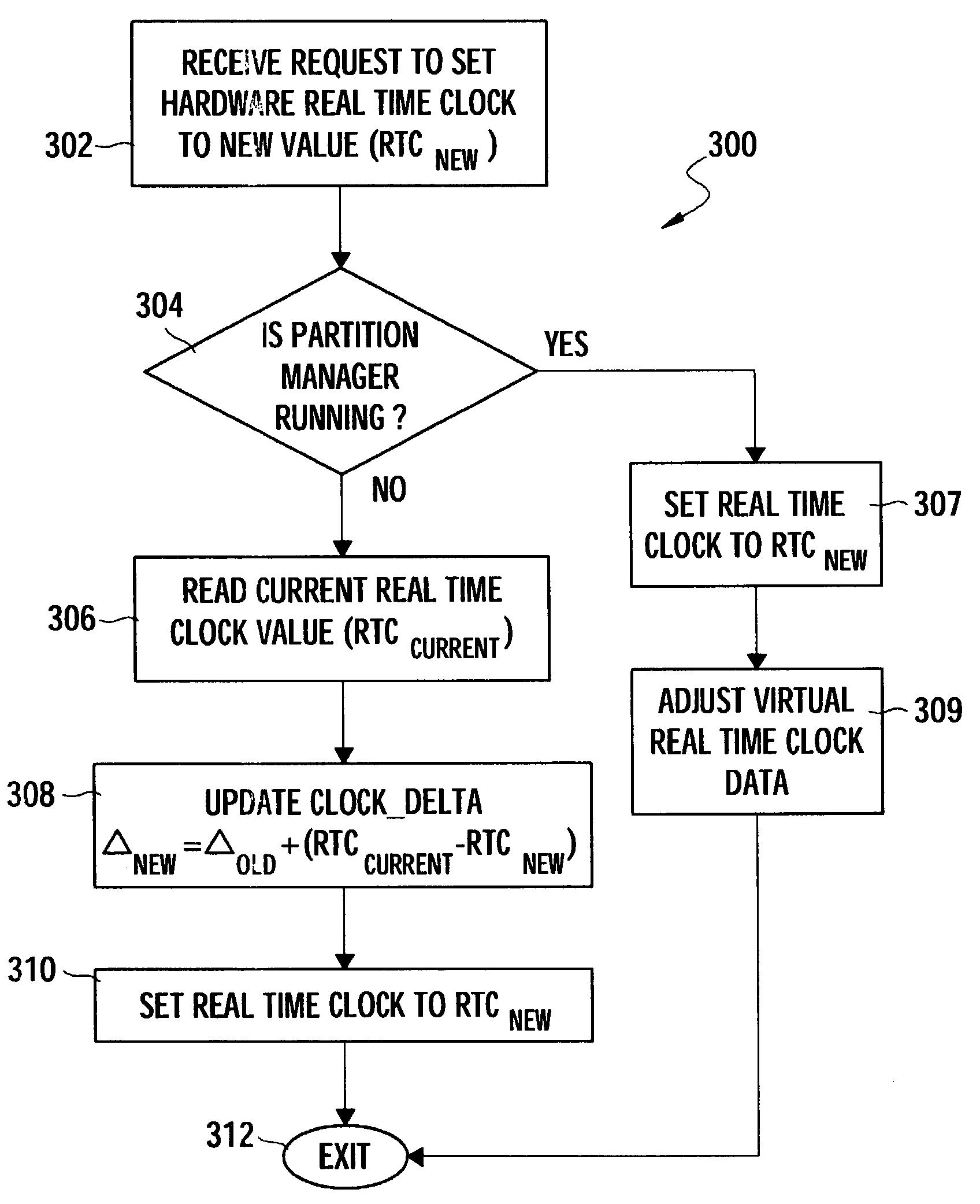

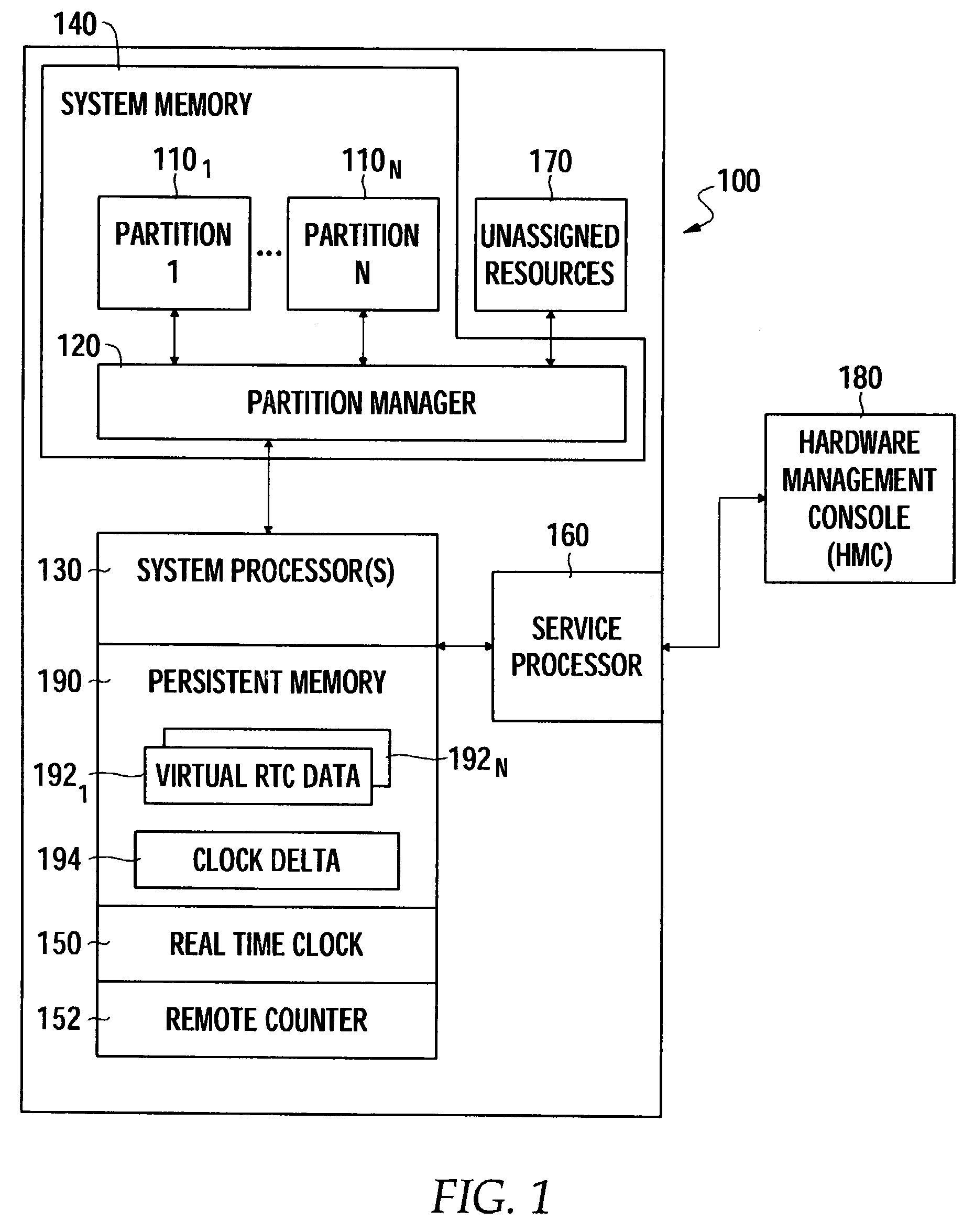

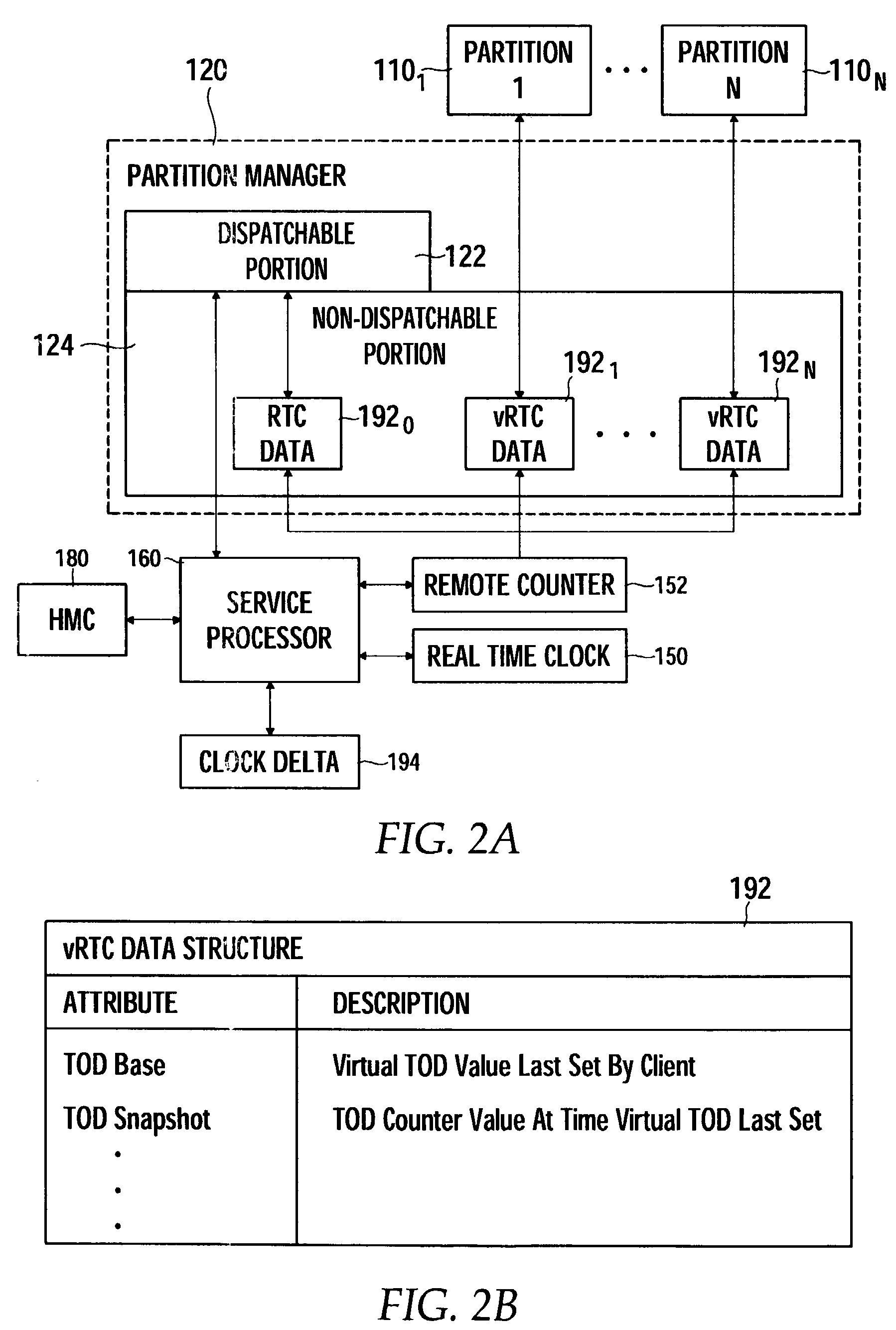

Virtual real time clock maintenance in a logically partitioned computer system

InactiveUS7155629B2Multiprogramming arrangementsGenerating/distributing signalsReal-time clockComputerized system

Methods, apparatus, systems, and articles of manufacture for maintaining virtual real time clocks (virtual RTCs) in a logically partitioned computer system are described. Changes made to a hardware real time clock (hardware RTC) while a partition manager is not running (or is not fully operational) are tracked. The cumulative effect of these changes on the hRTC value may be captured in a clock delta variable. For some embodiments, a service processor may be configured to track the changes to the hRTC while the partition manager is not running and generate the clock delta. Upon loading, the partition manager may utilize this captured clock delta to make adjustments to vRTCs, in an effort to preserve their integrity by compensating for the changes made to the hRTC while the partition manager was not running.

Owner:IBM CORP

Non-constant pressure infusion pump

InactiveUS20080125702A1Easy constructionMedical devicesPharmaceutical delivery mechanismPeriod effectsReservoir pressure

Owner:ADVANCED NEUROMODULATION SYST INC

Method for forecasting ecological risks of pollutant in surface water environment on living beings

ActiveCN102737156AOvercome spaceTesting waterSpecial data processing applicationsEnvironmental resource managementEcological toxicology

The invention discloses a method for forecasting ecological risks of pollutant in surface water environment on living beings. Combined with a non-constant water environment module and a water ecology toxicology comprehensive module, the invention discloses a method for assessing the ecological risks in the surface water environment, which comprises a long-term ecological risks assessing method and an acute ecological risks assessing method. The long-term ecological risks assessing method emphasizes the long-term accumulation effect of the pollutant and also takes the ecological toxicology effect and hydrodynamic and water quality space-time trends characteristics into consideration, which is a comprehensive ecological risk assessment method; and the acute ecological risks assessing method emphasizes the acute ecological risk assessment for the pollutant and provides methodology support for rapid ecological risk assessment in surface water pollution events.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

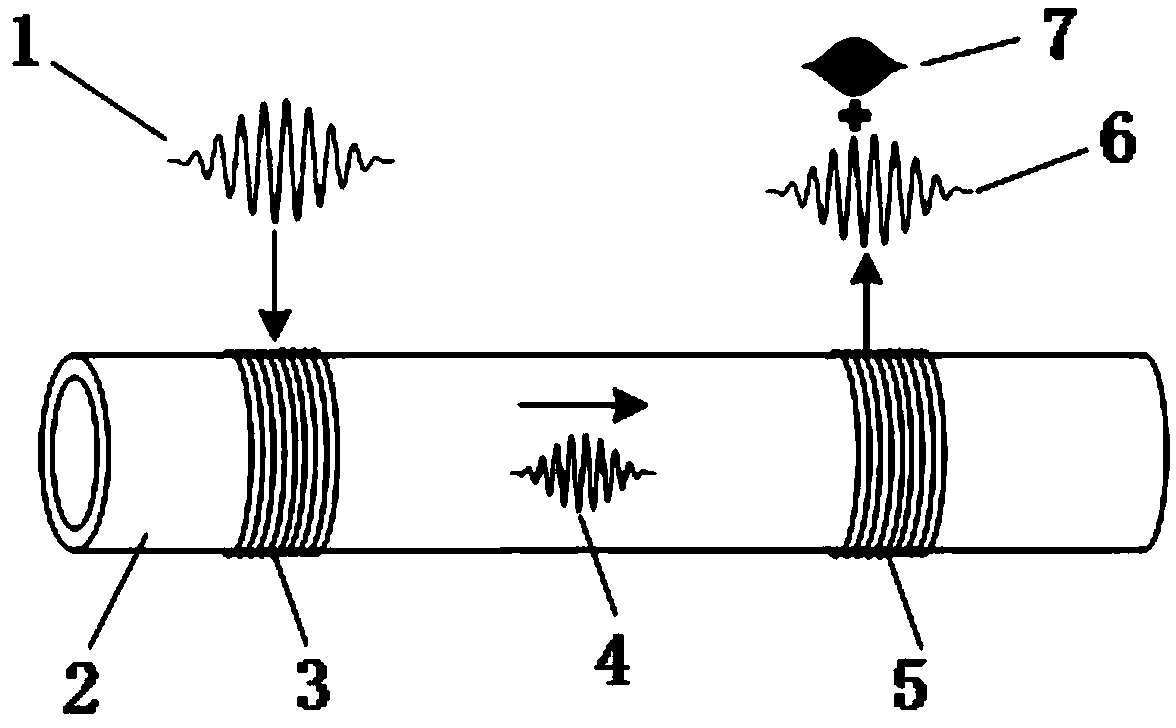

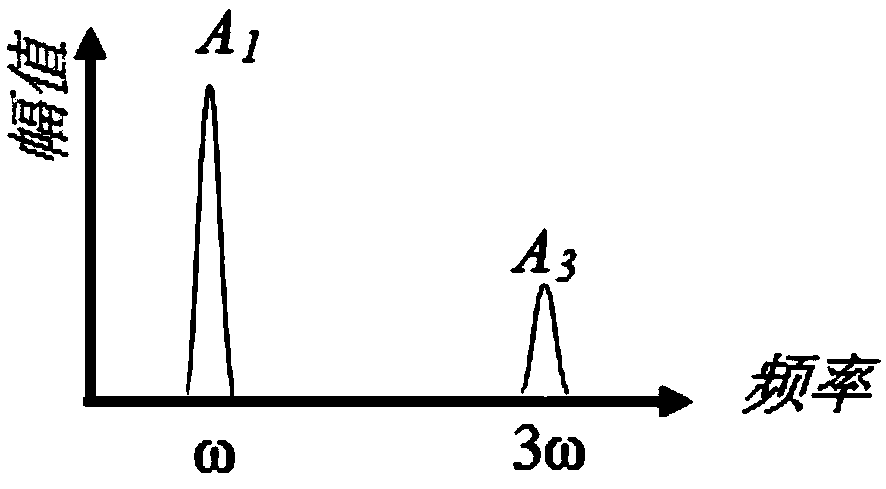

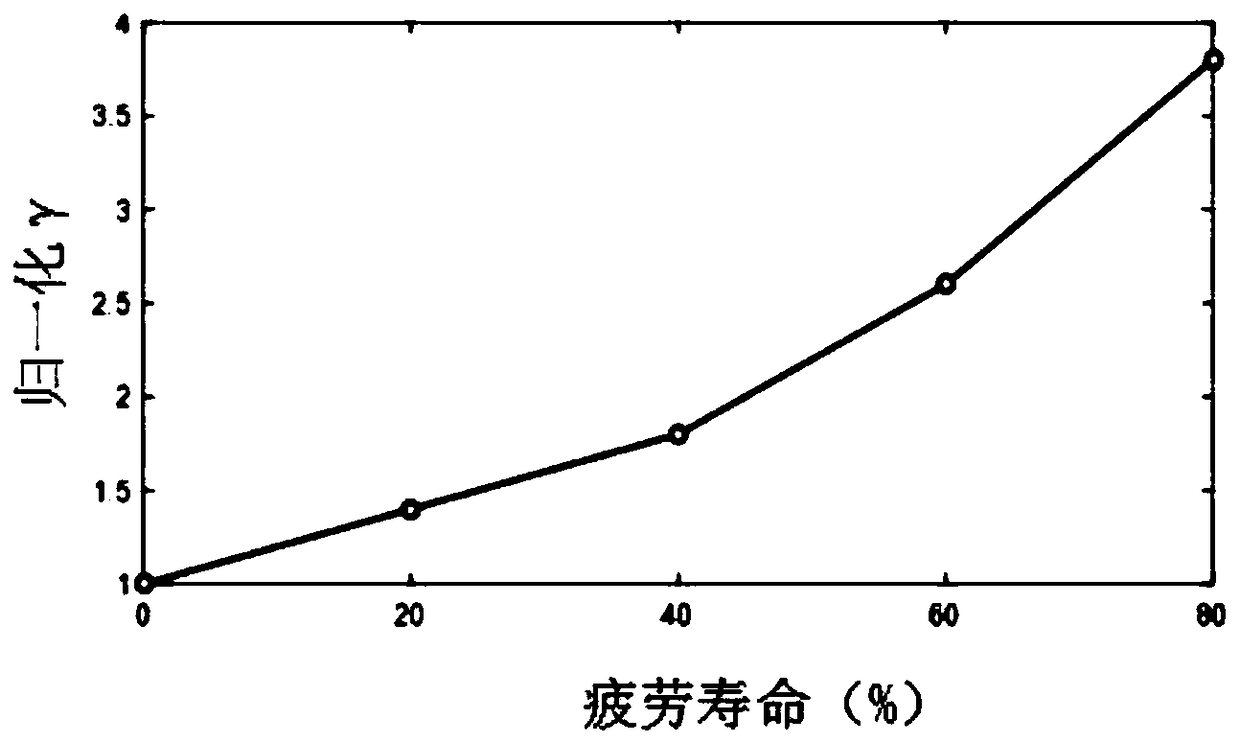

Nonlinear torsion modal ultrasonic guided-wave method used for evaluating metal circular tube microdamage

ActiveCN108872378AEffective evaluationHas a cumulative effectAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalNonlinear ultrasoundThird harmonic

The invention discloses a nonlinear torsion modal ultrasonic guided-wave method used for evaluating metal circular tube microdamage. Through a stimulation energy converter, single torsion modal ultrasonic guided-wave is stimulated in the circular tube; when the torsion modal ultrasonic guided-wave is spread in the circular tube, the torsion modal ultrasonic guided-wave and the microdamage of the circular tube mutually act to generate third harmonic with an accumulation effect; through a receiving energy converter, a fundamental frequency signal and third harmonic generated by the tube microdamage are received; an amplitude A1 and a third harmonic amplitude A3 of the fundamental frequency signal are obtained, an equivalent three-order nonlinear sound parameter [gamma'] is calculated, and the nonlinear ultrasonic guided-wave evaluation of the microdamage of the circular tube is evaluated. The nonlinear torsion modal ultrasonic guided-wave has a third harmonic accumulation effect on any point on a frequency dispersion curve, and therefore, the restriction that nonlinear longitudinal modal guided-wave only has the accumulation effect on certain points on the frequency dispersion curveis overcome. The damage states of circular tube construction members / materials can be effectively detected and evaluated, detection speed is high, detection cost is low, and detection accuracy is high.

Owner:XIAN UNIV OF SCI & TECH

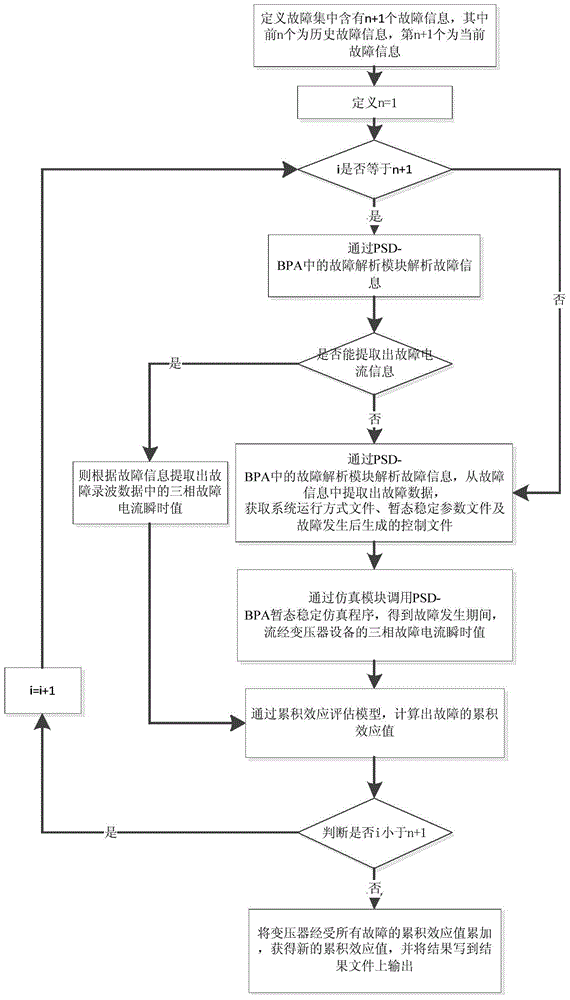

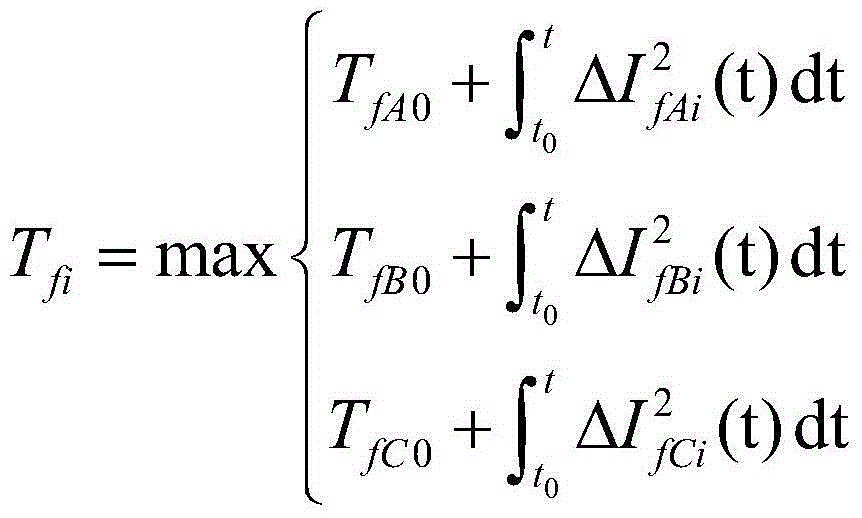

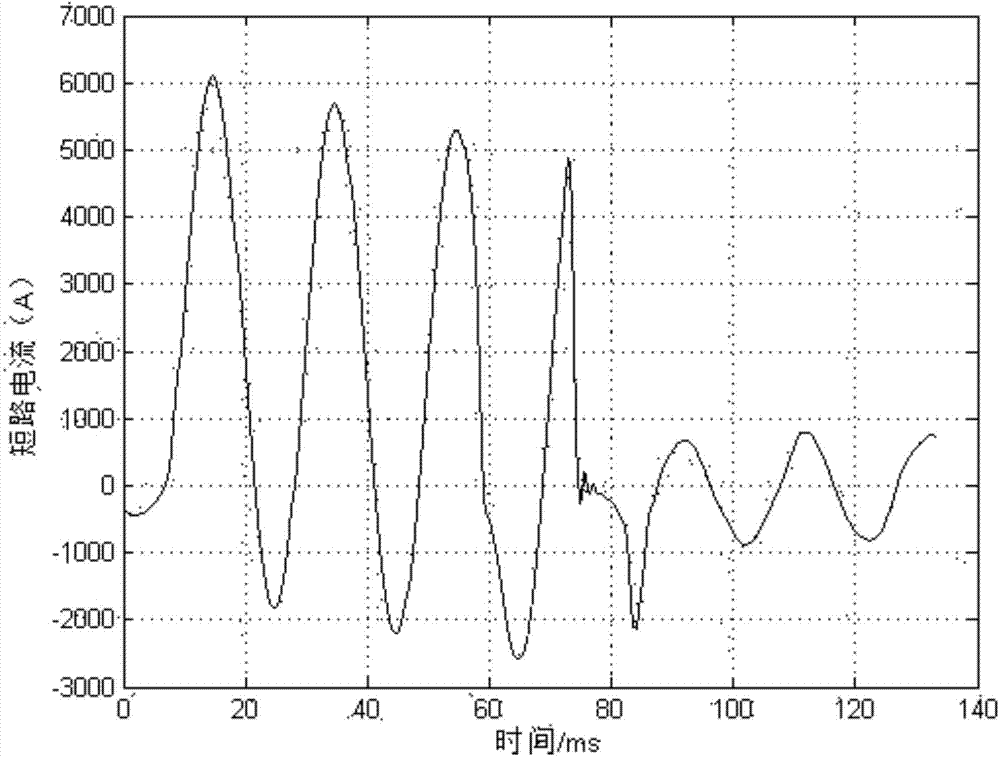

Fault cumulative effect assessment method for PSD-BPA-based batch processing transformer

ActiveCN104978482AImprove processing speedImprove accuracySpecial data processing applicationsGraphicsBatch processing

The present invention discloses a fault cumulative effect assessment method for PSD-BPA-based batch processing transformer and proposes the concept of fault cumulative effects. After the power system has the fault of short-circuit, calculating the cumulative effect on the equipment according to the obtained fault information and finally showing in graphical form so as to improved efficiency of using fault data; A cumulative effect value obtained from calculation can be ordered based on historical fault current transformer effect to provide transformer condition warning and equipment maintenance priority strategy so as to improve the stable working condition of network equipment and function as reference data of scheduling maintenance personnel making maintenance plan, thereby making maintenance plan become more directional and targeted so as to improve the processing speed and accuracy of information, reduce the manual costs and largely avoid human mistakes and errors.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +3

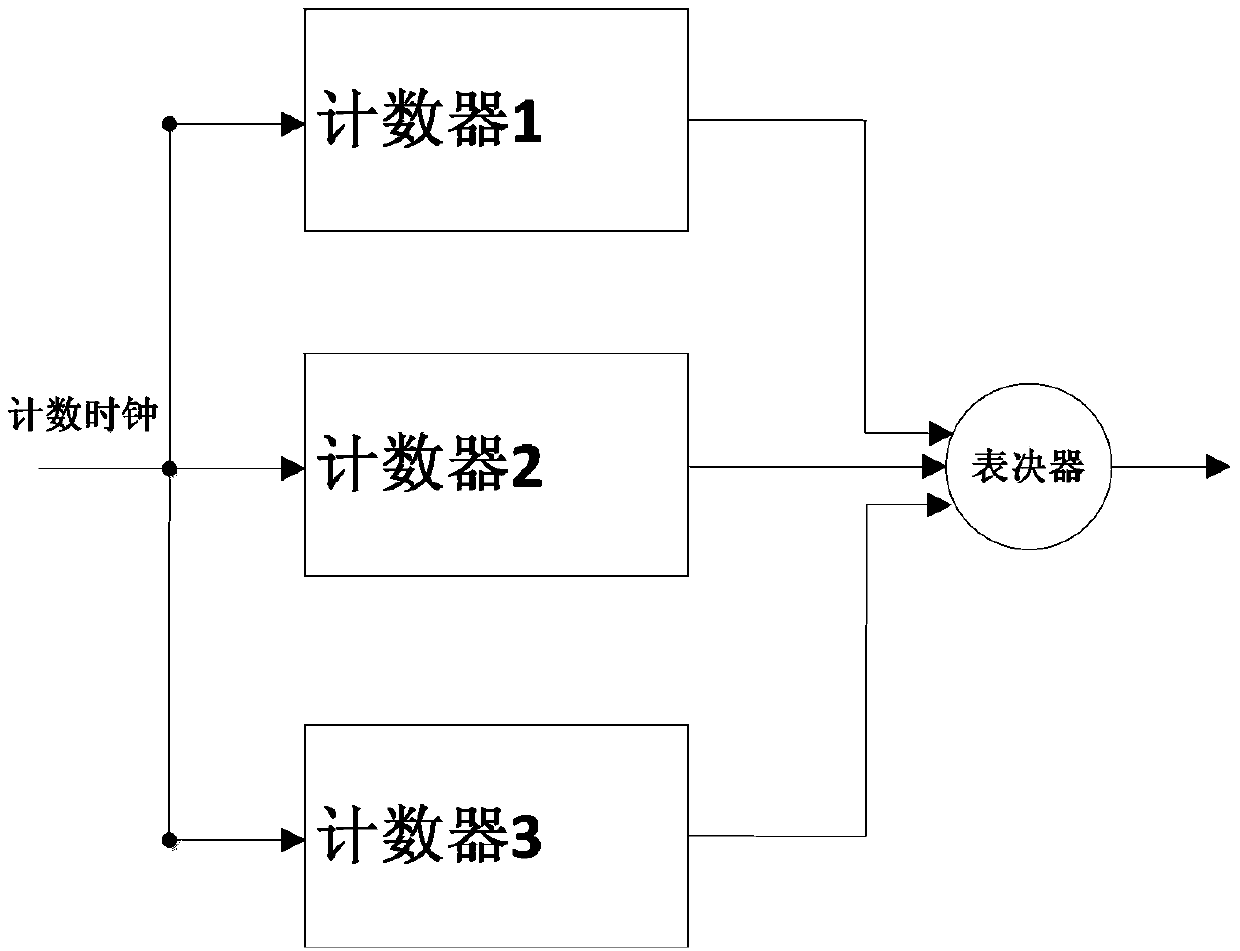

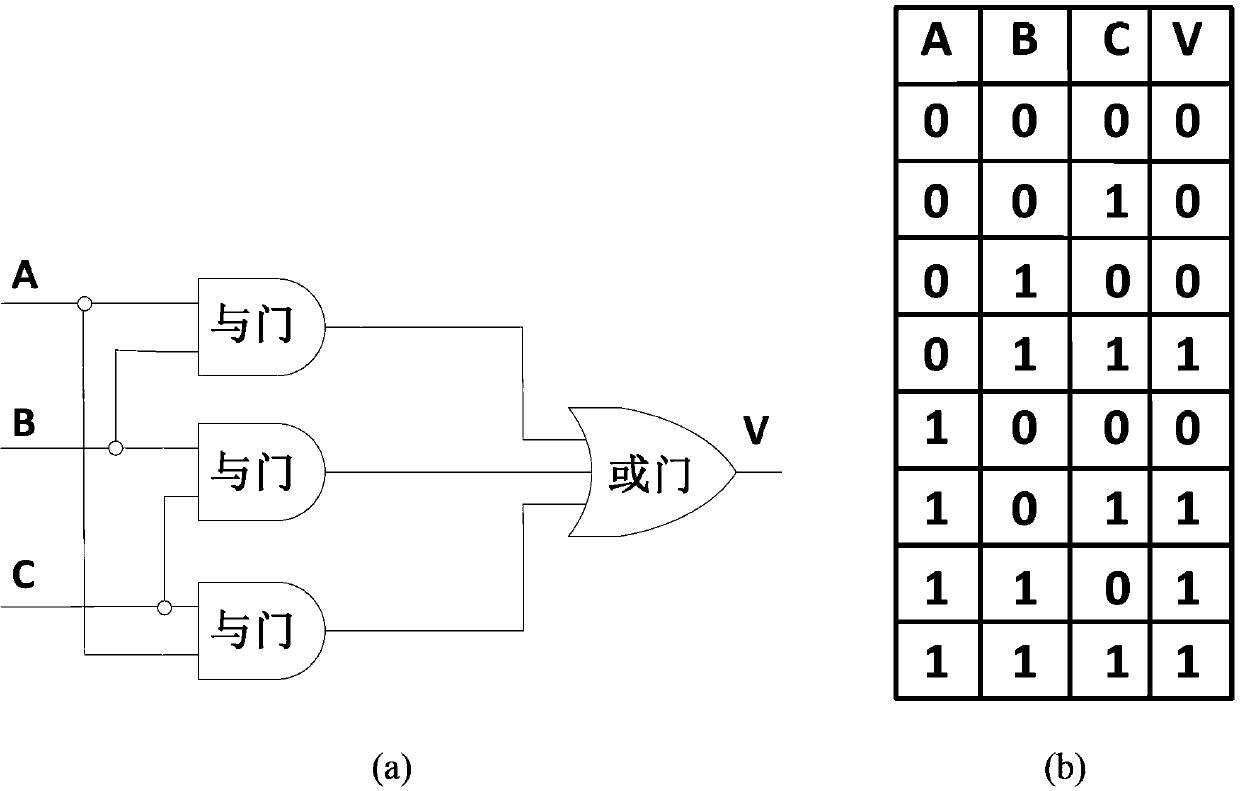

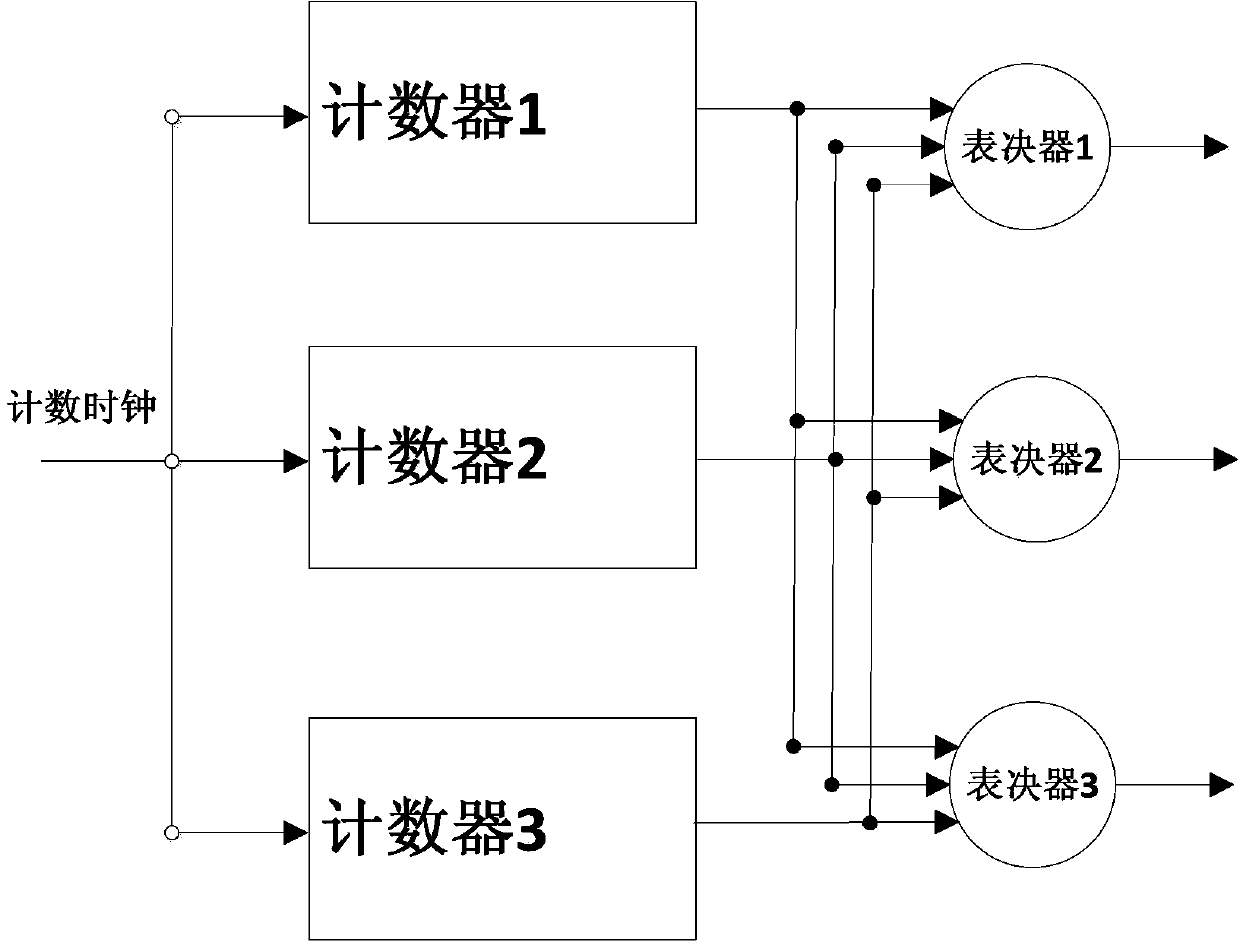

Self-refreshing triple-modular redundancy counter

InactiveCN103389892AGuaranteed to workEliminate the cumulative effect of errorsComputations using residue arithmeticComputer scienceTriple modular redundancy

The invention discloses a self-refreshing triple-modular redundancy counter, which comprises three counters J1, J2 and J3 and three voters B1, B2 and B3, which are mutually connected. According to the triple-modular redundancy counter disclosed by the invention, by feeding back results of the voters to the counters, the counting results of the counters can be refreshed timely, and accordingly the error cumulative effect of the counters can be eliminated; as long as two of the three counters do not go wrong simultaneously, the whole triple-modular redundancy counter can continue to normally work.

Owner:ZHEJIANG UNIV

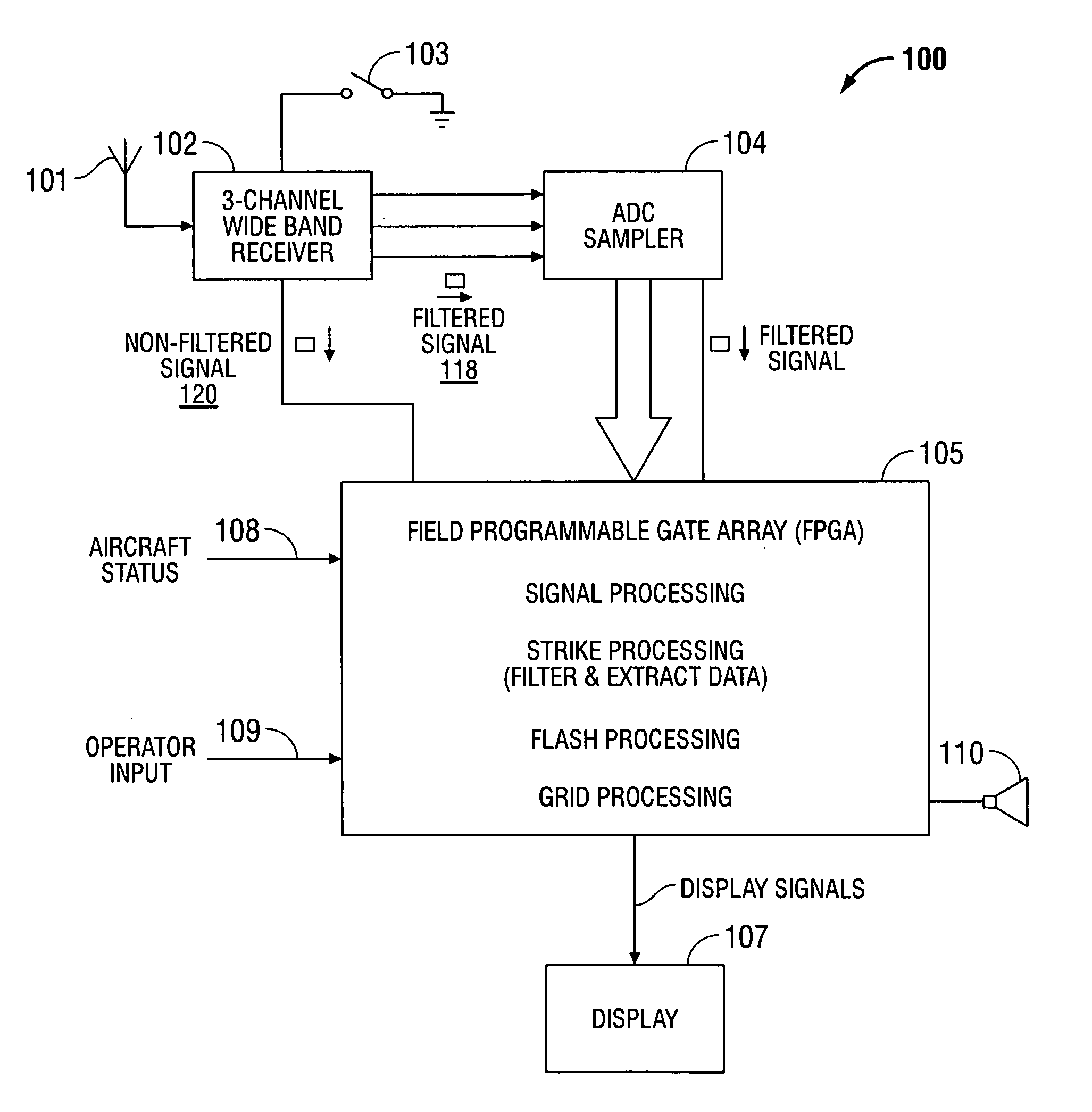

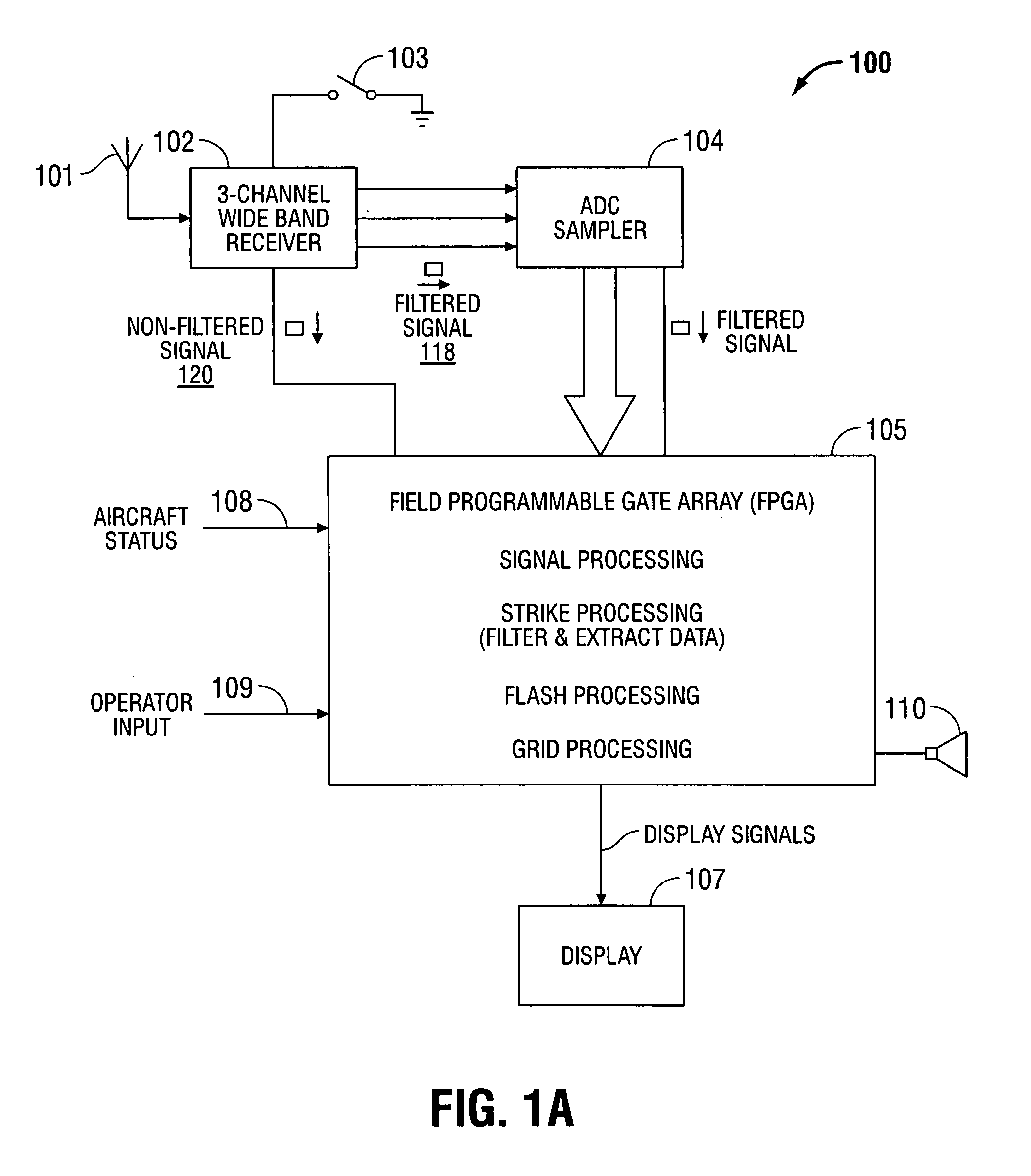

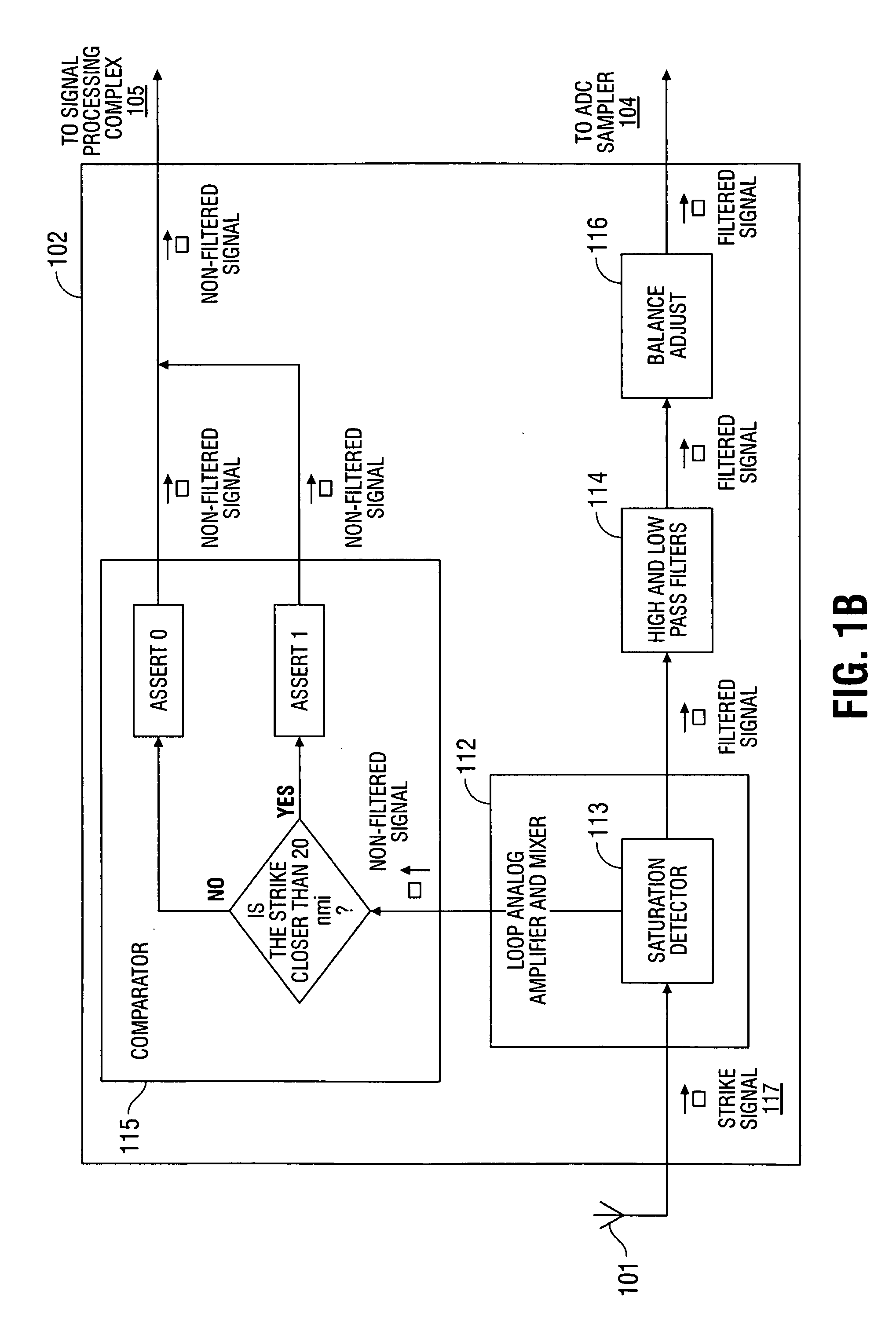

Ultra wideband receiver for lightning detection

InactiveUS20090164124A1Electromagentic field characteristicsSpecial data processing applicationsUltra-widebandLightning strike

The present invention relates to a system and method for detecting lightning activity. When a lightning strike is close enough to a receiver, the strength of the signal received will cause the receiver to saturate. In such a situation, a non-filtered signal is used to calculate a range and bearing. In one specific embodiment, a receiver detects energy emitted by a lightning strike and separates the lightning strike to a filtered signal and non-filtered signal. A saturation detector determines if the filtered signal is saturated prior to the filtered signal being filtered. In response to the filtered signal being saturated, a processor processes the non-filtered signal from the receiver, estimates locations of the detected lightning strike relative to the system, determines a cumulative effect of the lightning strike spaced in distance and time, and generates display signals to illustrate the cumulative effect with respect to a grid.

Owner:AVIDYNE CORPORATION

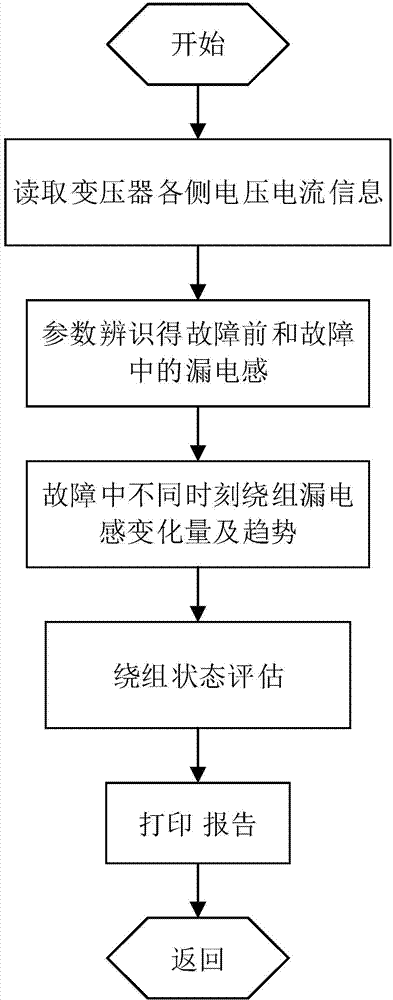

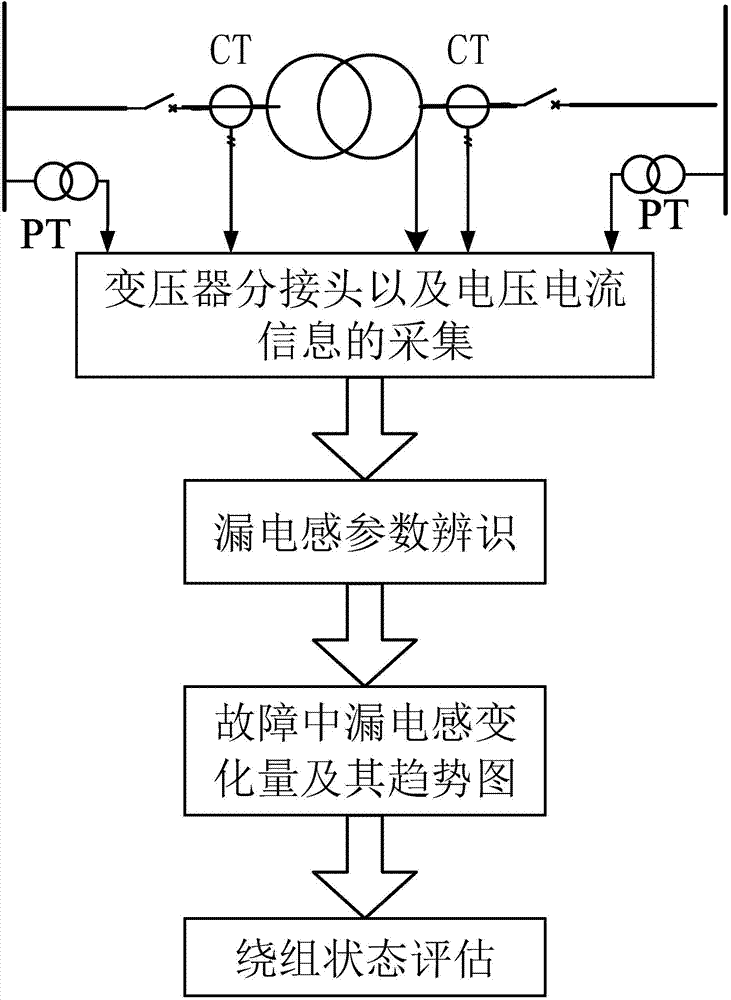

Winding state evaluation method in the condition of transformer external fault

InactiveCN104330689ARealize monitoringElectric winding testingInformaticsEngineeringLeakage inductance

The invention discloses a winding state evaluation method in the condition of a transformer external fault. According to the method, current flows through a transformer winding conducting wire, the magnitude of the electromagnetic force is proportional to the square of passing current, in the condition of high fault current, the electromagnetic force born by a winding is hundred times of that in a normal condition, winding formation happens when winding strength is insufficient, elastic deformation is partly recovered after fault elimination, however the cumulative effect of the winding deformation causes a large accident in the next fault condition. According to the method, the collected current data of two sides of a transformer before and in the fault is used, an appropriate numerical algorithm is utilized, the values of leakage inductance of the transformer before and in the fault are identified and obtained, the deviation of winding leakage inductance in each time in the fault is calculated and analyzed, the tendency chart of the deviation is made with time as a horizontal ordinate, and the shock to the transformer winding by the fault and the state of the winding are evaluated according to the deviation tendency chart.

Owner:STATE GRID CORP OF CHINA +3

Ear input sound pressure level monitoring system

ActiveUS8311228B2Vibration measurement in solidsVibration measurement in fluidMonitoring systemTransducer

Systems and methods for monitoring a sound pressure level dose at an ear are provided. A system includes an audio transducer which outputs a sound signal is placed within an ear to receive sound at the ear. A sound level threshold detector determines whether a sound pressure level of the sound signal is at a minimum level and outputs a sound pressure level signal corresponding to the sound pressure level when the sound pressure level is not at the minimum level. A time period is calculated during which the sound pressure level is not at the minimum threshold level. A listening fatigue calculator determines whether a cumulative effect of exposure to the sound signal at the ear over the time period will cause harm to the ear. At least a portion of the system is disposed in situ at the ear.

Owner:STATON TECHIYA LLC

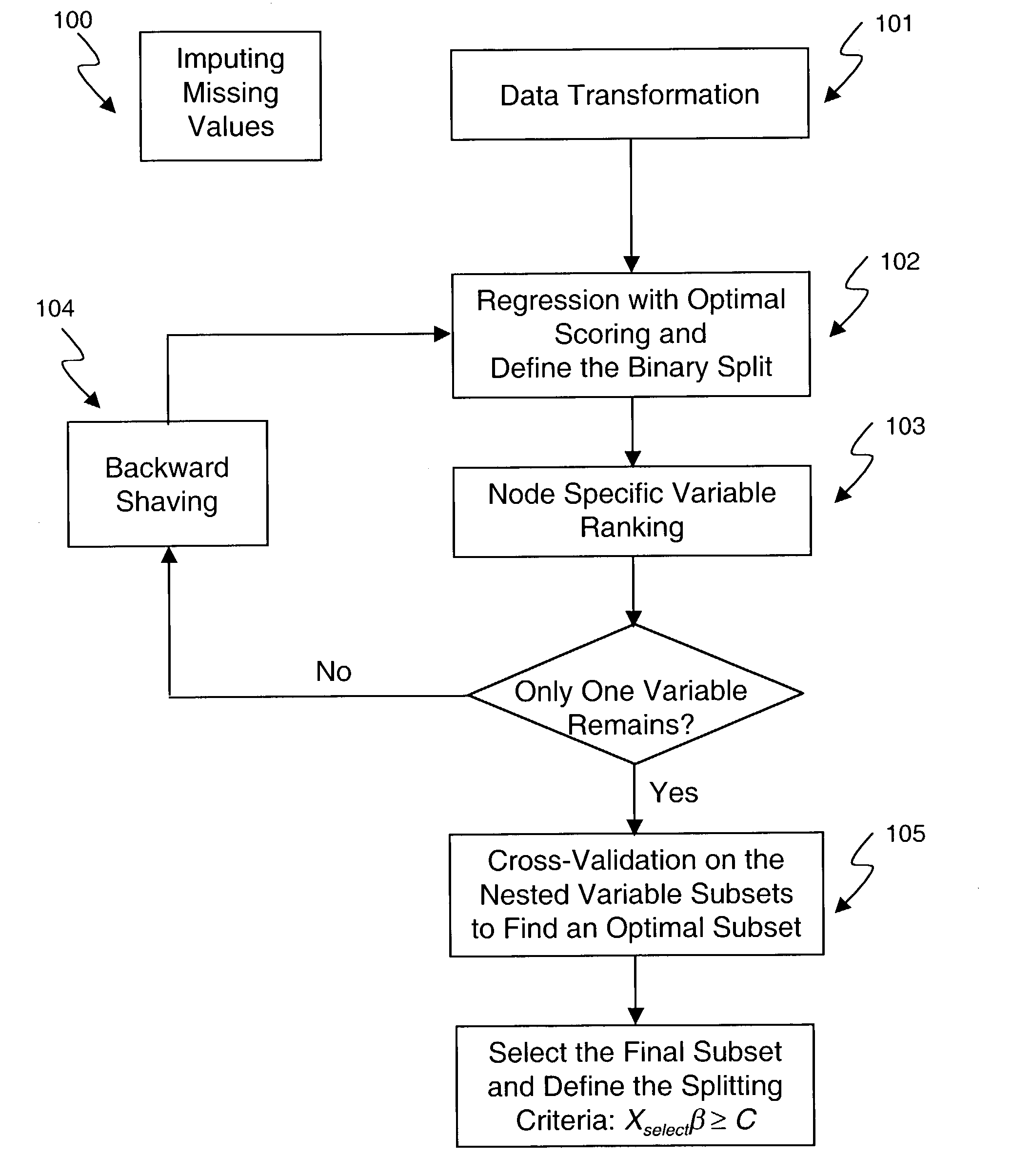

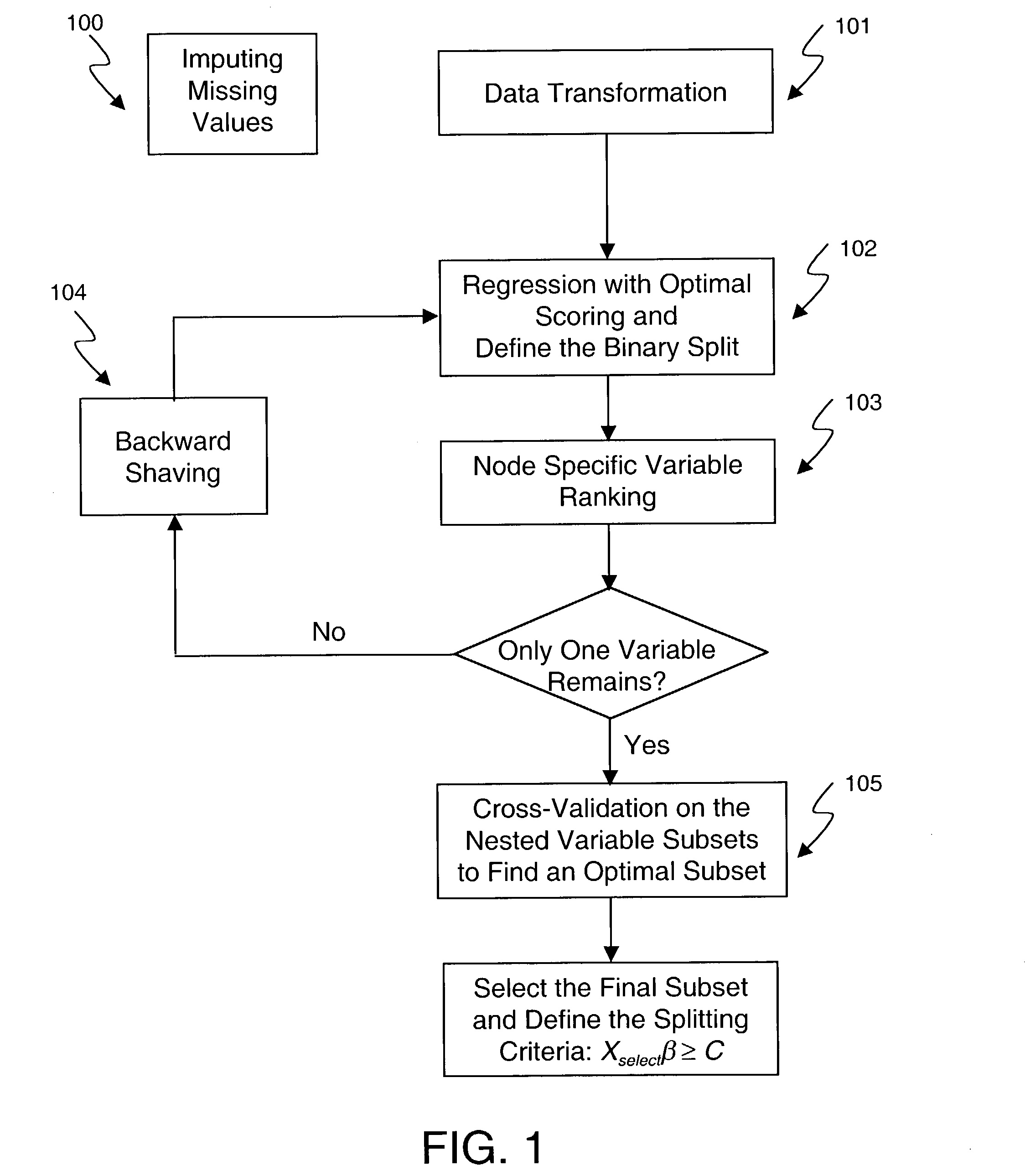

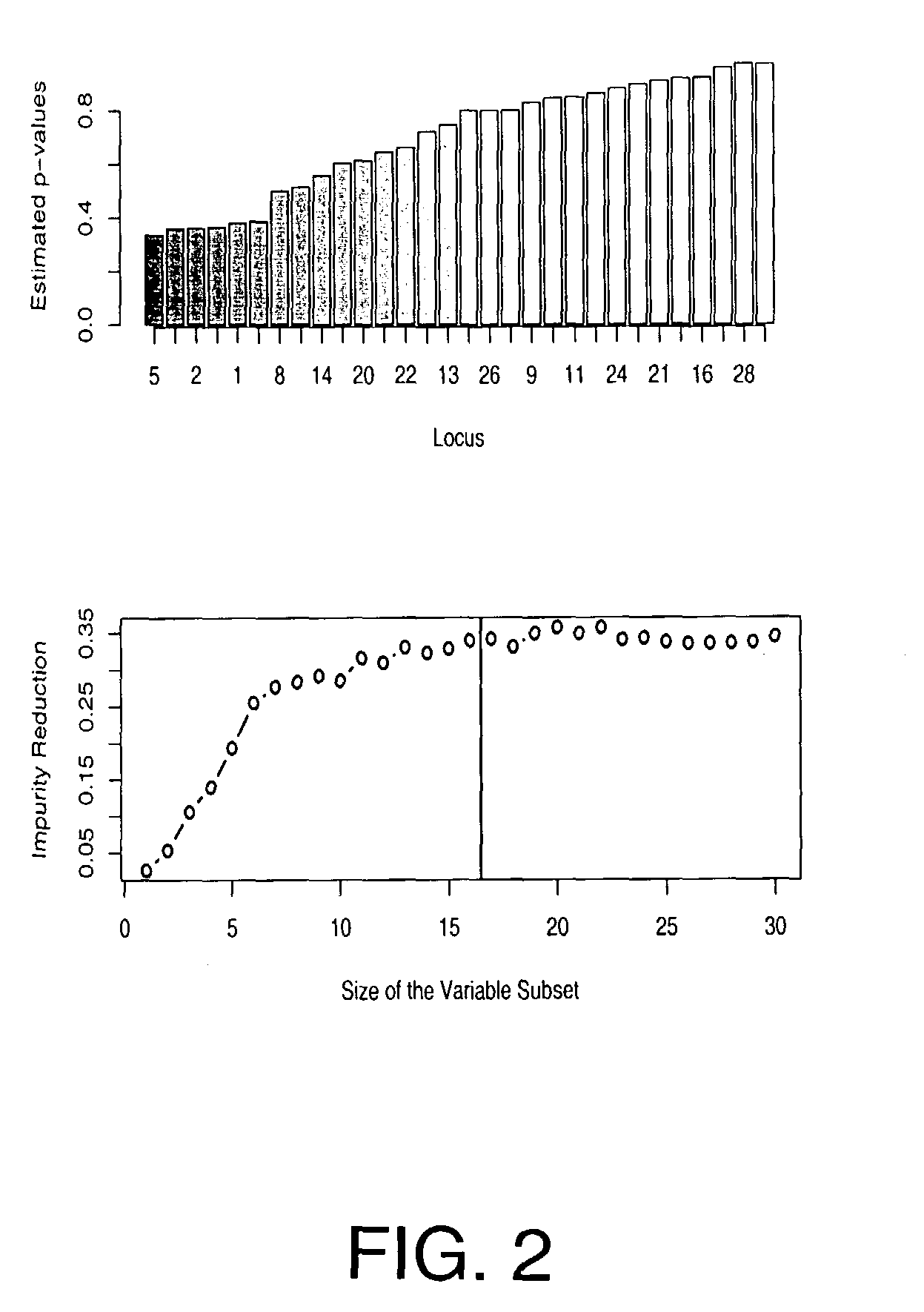

Binary tree for complex supervised learning

InactiveUS7133856B2Improve performanceMedical data miningDigital data processing detailsData setPolygenic disease

The present invention provides a powerful and robust classification and prediction tool, methodology, and architecture for supervised learning, particularly applicable to complex datasets where multiple factors determine an outcome and yet many other factors are irrelevant to prediction. Among those features which are relevant to the outcome, they have complicated and influential interactions, though insignificant individual contributions. For example, polygenic diseases may be associated with genetic and environmental risk factors. This new approach allow us consider all risk factors simultaneously, including interactions and combined effects. Our approach has the strength of both binary classification trees and regression. A simple rooted binary tree model is created with each split defined by a linear combination of selected variables. The linear combination is achieved by regression with optimal scoring. The variables are selected using backward shaving. Cross-validation is used to find the level of shrinkage that minimizes errors. Using a selected variable subset to define each split not only increases interpretability, but also enhances the model's predictive power and robustness. The final model deals with cumulative effects and interactions simultaneously.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com