Non-constant pressure infusion pump

a non-constant pressure, infusion pump technology, applied in the direction of instruments, process and machine control, other medical devices, etc., can solve the problems of fluid flow rate such devices are susceptible to changes in ambient temperature and pressure, the propellant-reservoir pressure of conventional gas-driven infusion pumps is relatively large, and the use of battery power is relatively larg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]Various embodiments, including preferred embodiments, will now be described in detail below with reference to the drawings.

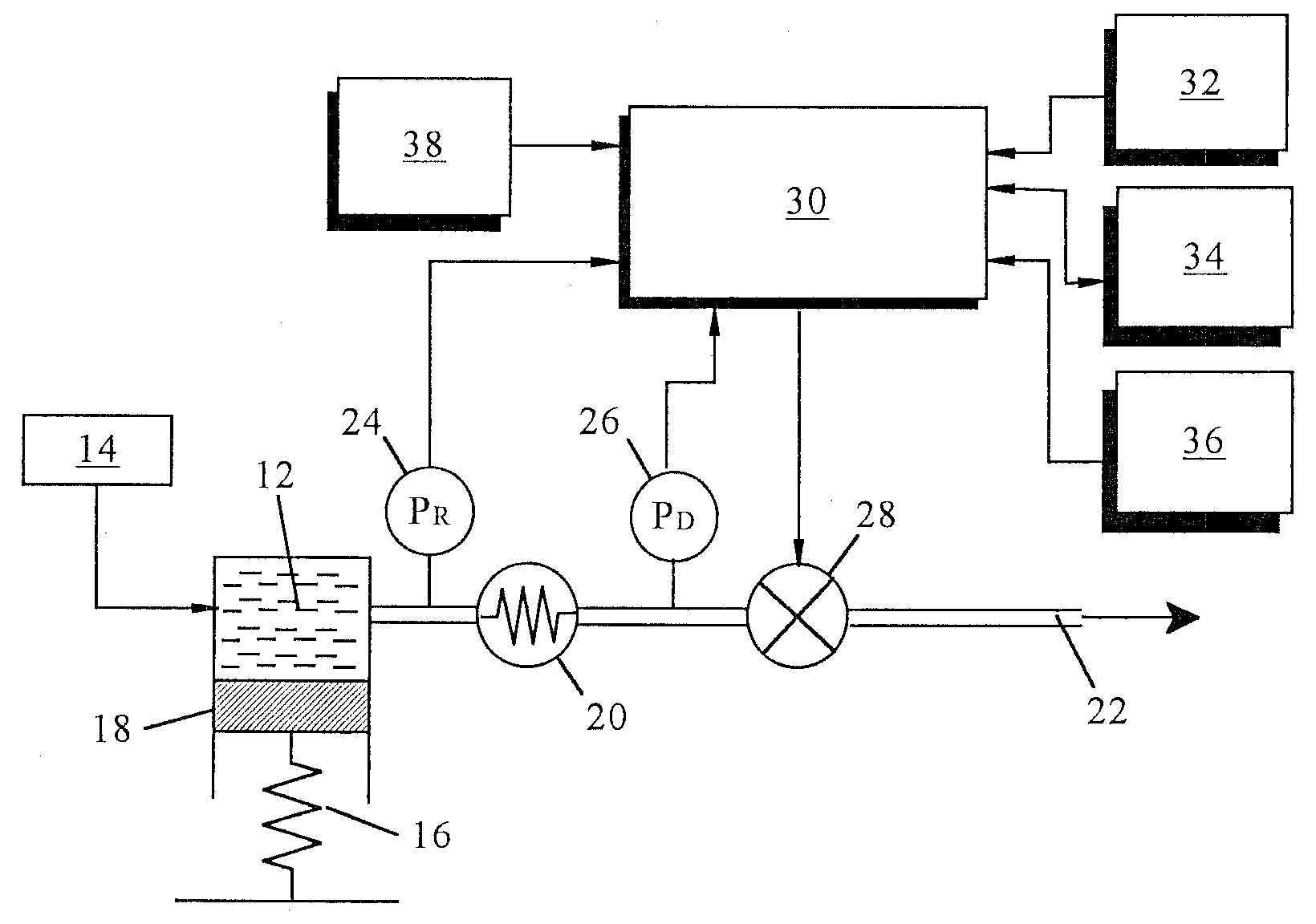

[0043]FIG. 1 illustrates a conventional, constant flow rate infusion device 10. The device 10 is characterized by an infusate reservoir 12 that is required to store a prescribed volume of infusate, e.g., insulin, medicament, pain relieving drugs, etc. The infusate reservoir 12 is of sufficient volume so as to provide a supply of infusate (i.e., a prescribed dose (D)) over a flow period (τ) at a (theoretically) constant flow rate. As but one possible example, the volume of the infusate reservoir 12 can be fixed at any prescribed volume to enable delivery of a precisely controlled volume of infusate from one day to more than three months. The infusate reservoir 12 can be refilled through a septum 14.

[0044]Infusate is pressurized and thereby driven from the infusate reservoir 12 by a drive source 16. The physical nature of the drive source 16 can be a two-pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com