Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

495 results about "Frequency dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Frequency dispersion is generally observable on seismic waves that propagate along the earth's surface but frequency dispersion is hardly ever perceptible on internally reflected waves. In seismic data processing, frequency dispersion is a nuisance and an embarrassment to process designers.

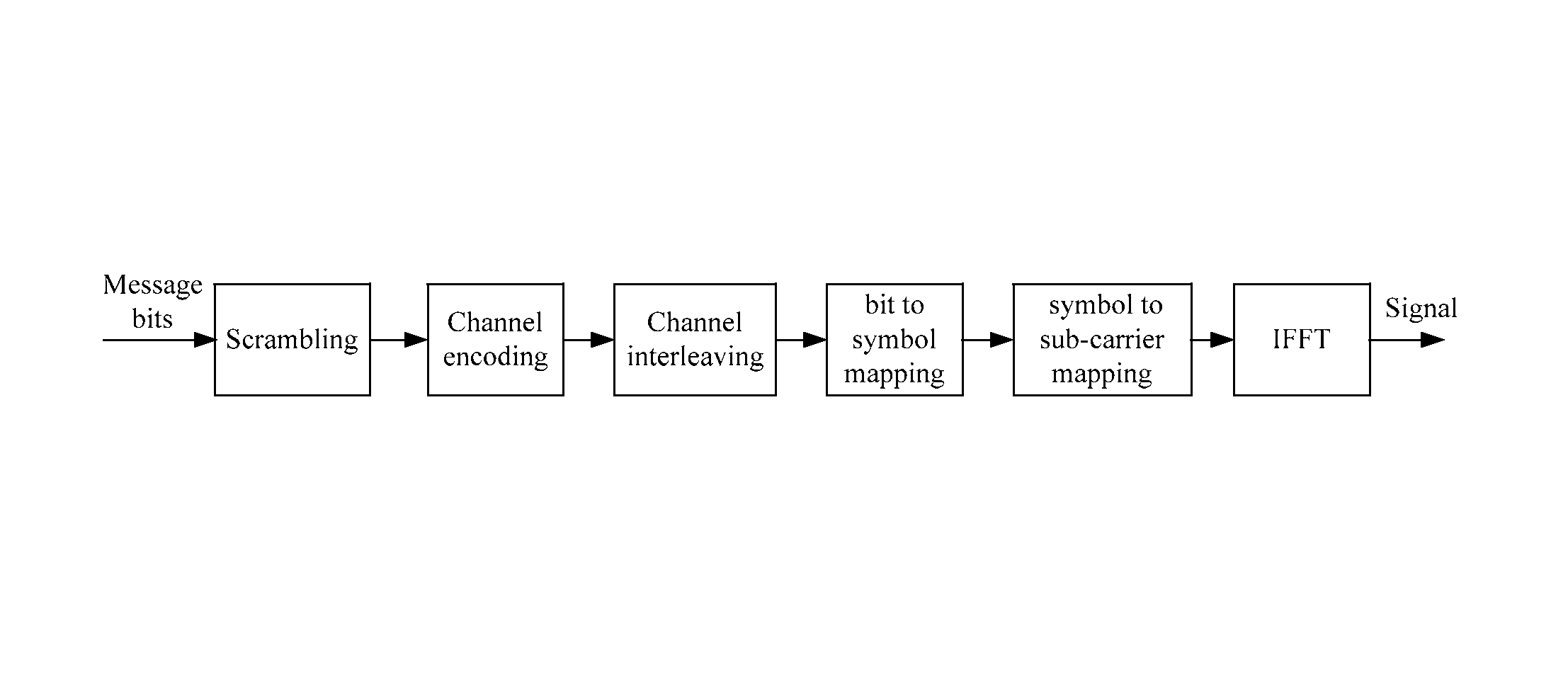

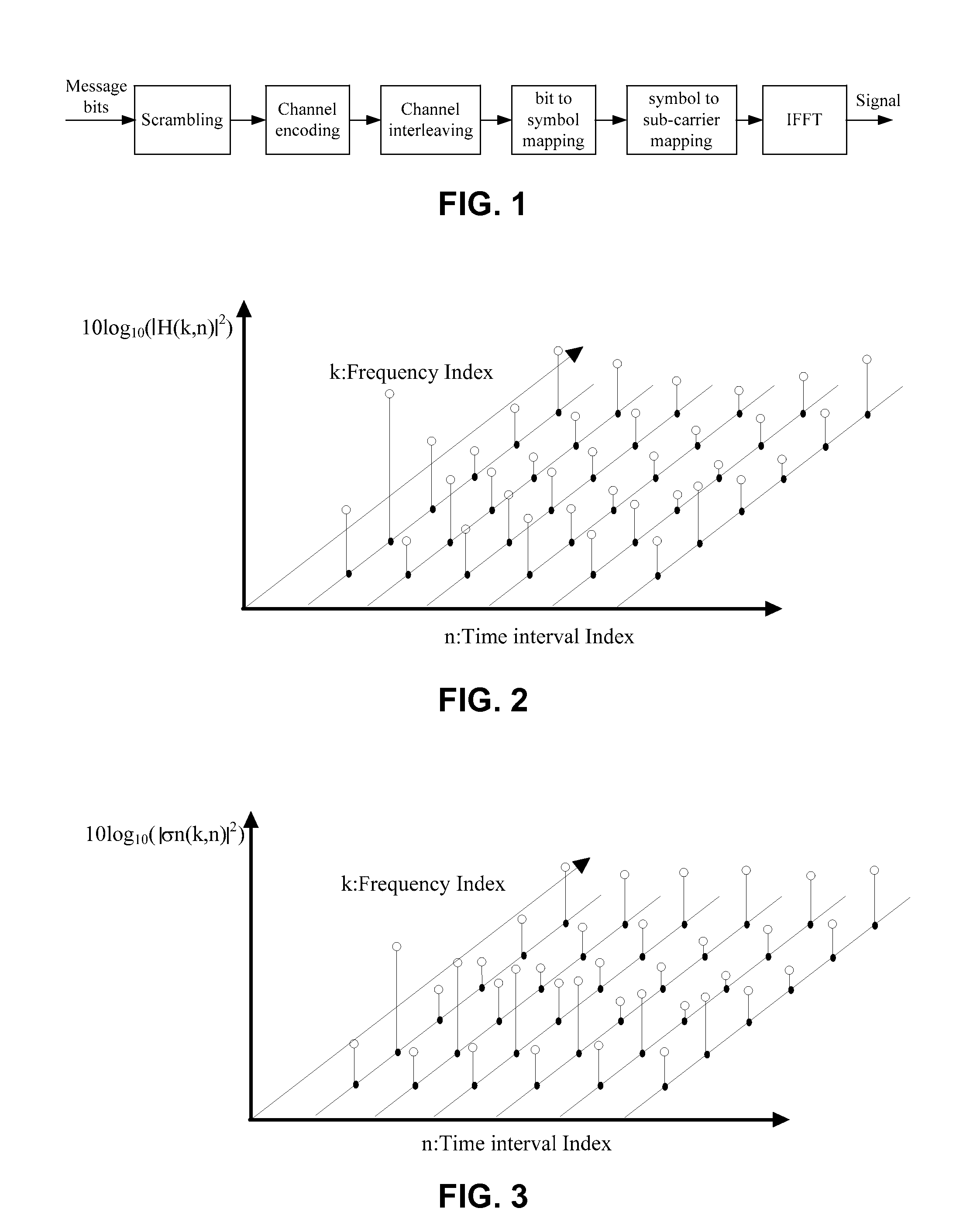

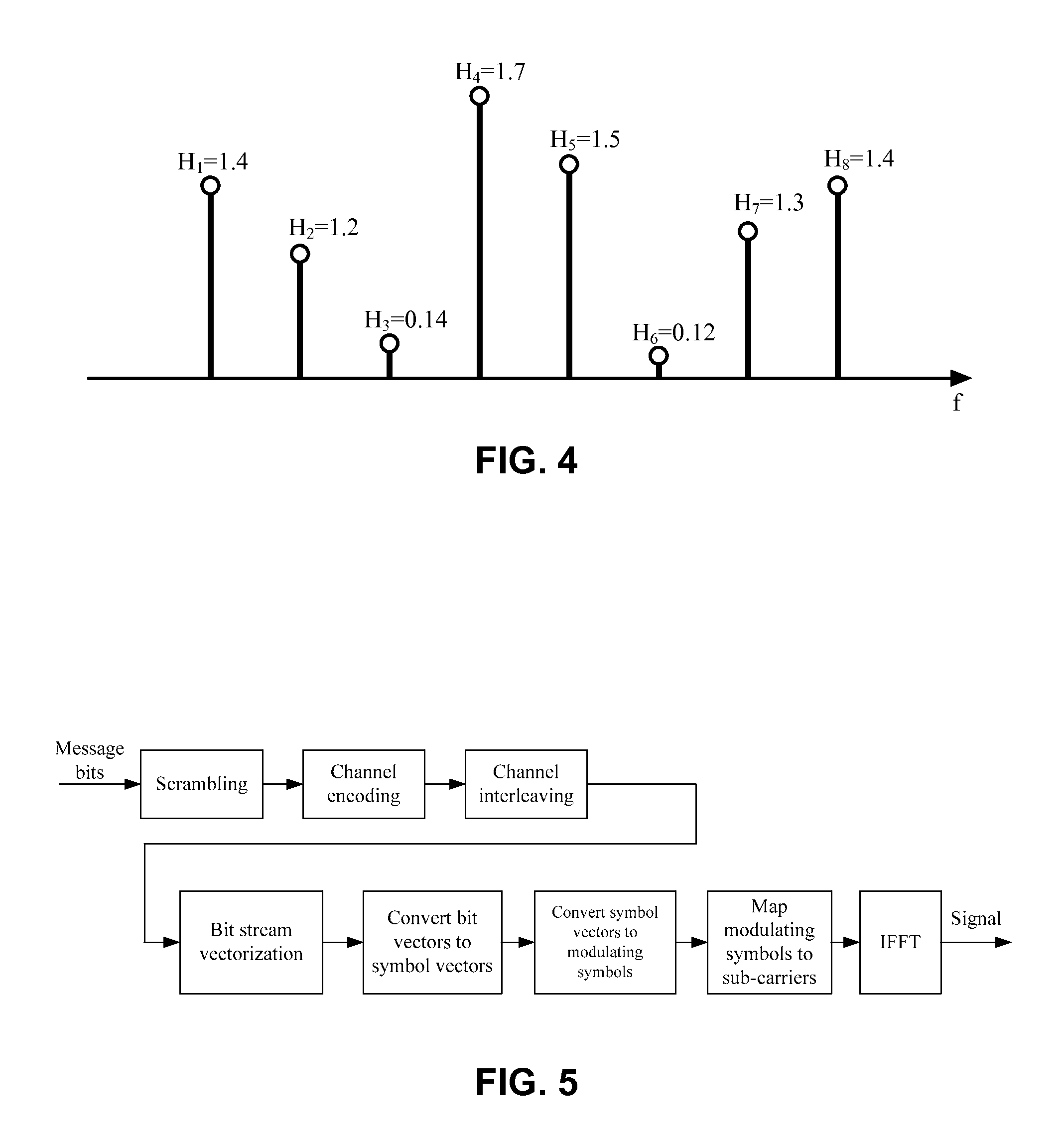

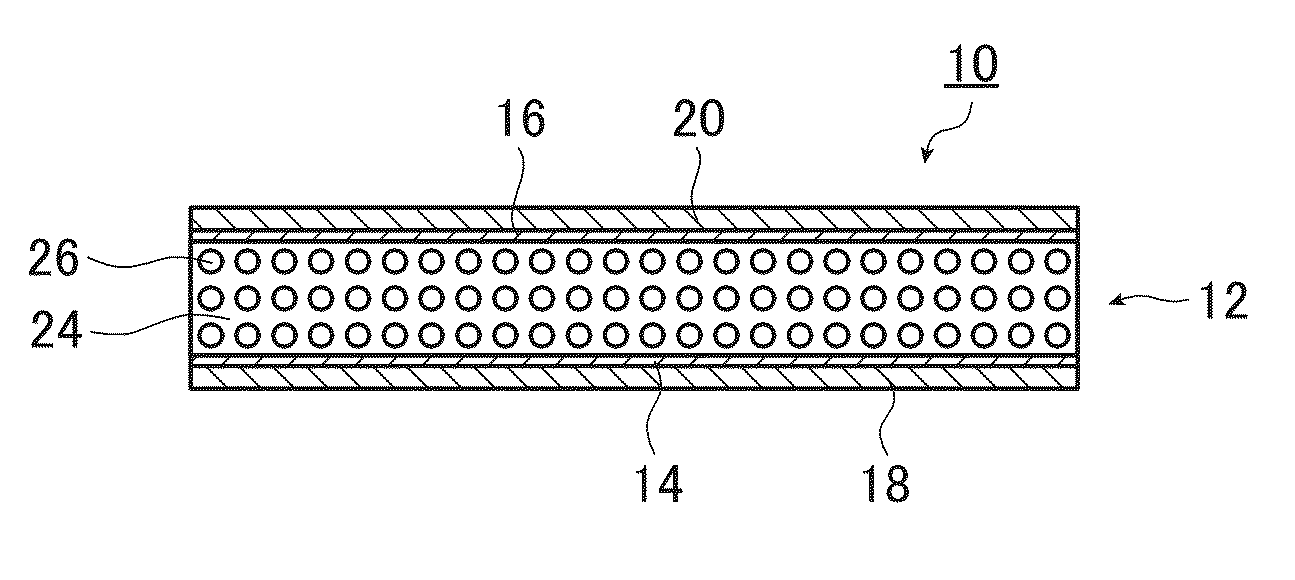

Signal transmission method and apparatus used in OFDMA wireless communication system

InactiveUS8289914B2Improve signal transmission stabilityImprove interferenceTransmission path divisionCriteria allocationLoading factorCommunications system

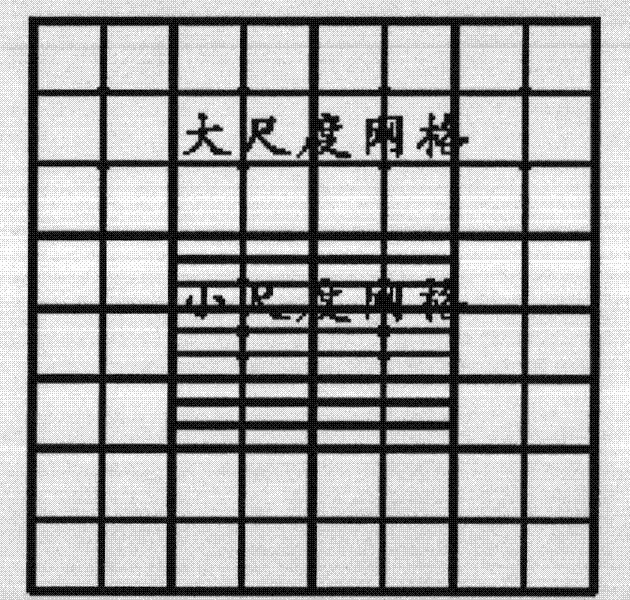

Embodiments of the present invention provide a signal transmission method and apparatus used in an Orthogonal Frequency Division Multiple Access (OFDMA) wireless communication system, to enhance stability of signal transmission and resist time-frequency dispersion. The signal transmission method used in the OFDMA wireless communication system provided by an embodiment of the invention includes: converting an L×1 symbol vector into an N×1 modulating signal vector according to a loading factor fed back by a receiving party, in which value of N is known, both L and N are natural numbers larger than one, N is larger than or equal to L, the loading factor is a ratio of L and N; mapping the N×1 modulating signal vector into N time-frequency grids; and converting the N time-frequency grids into a signal waveform and sending the signal waveform to the receiving party.

Owner:BEIJING XINWEI TELECOM TECH

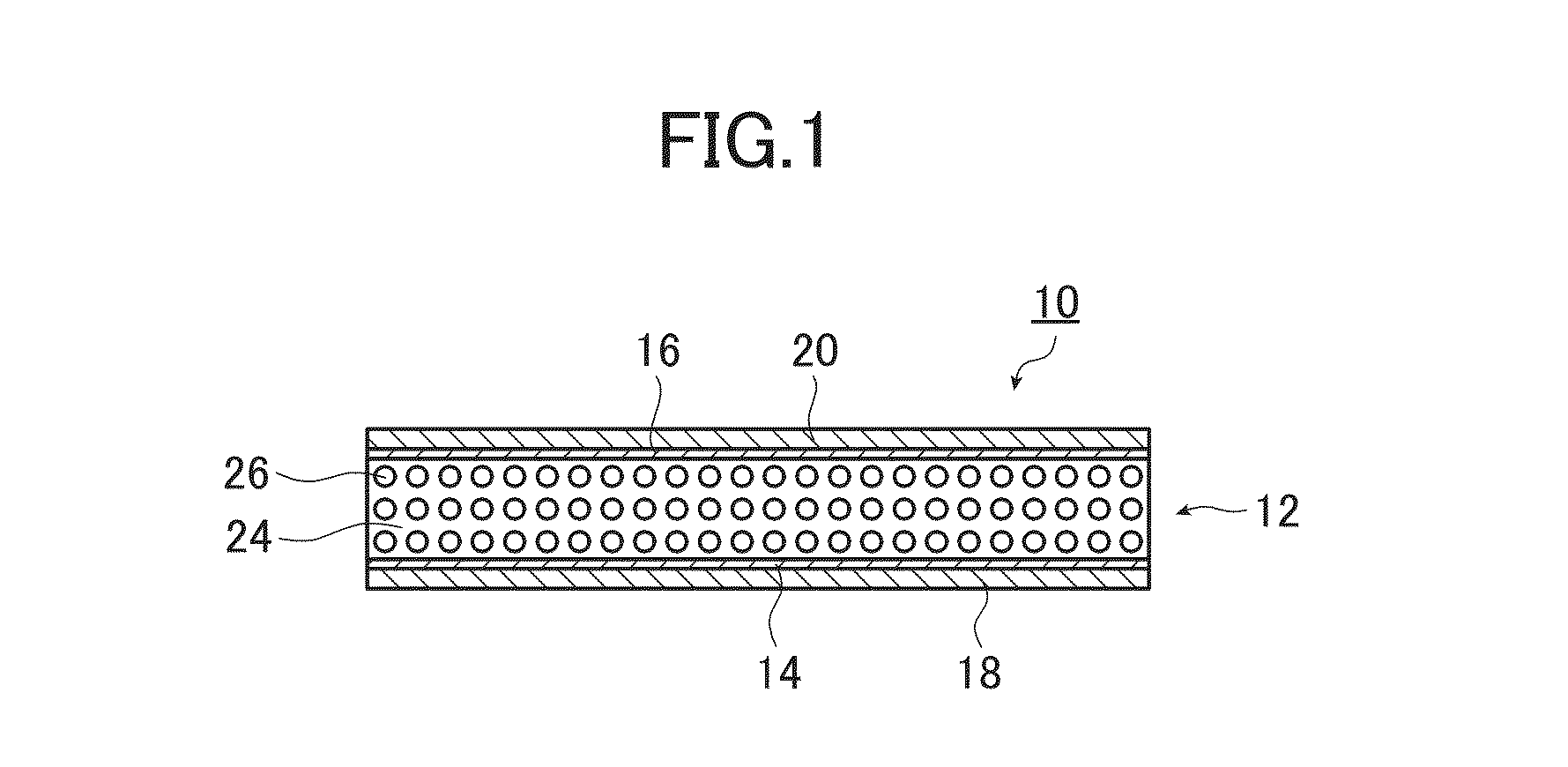

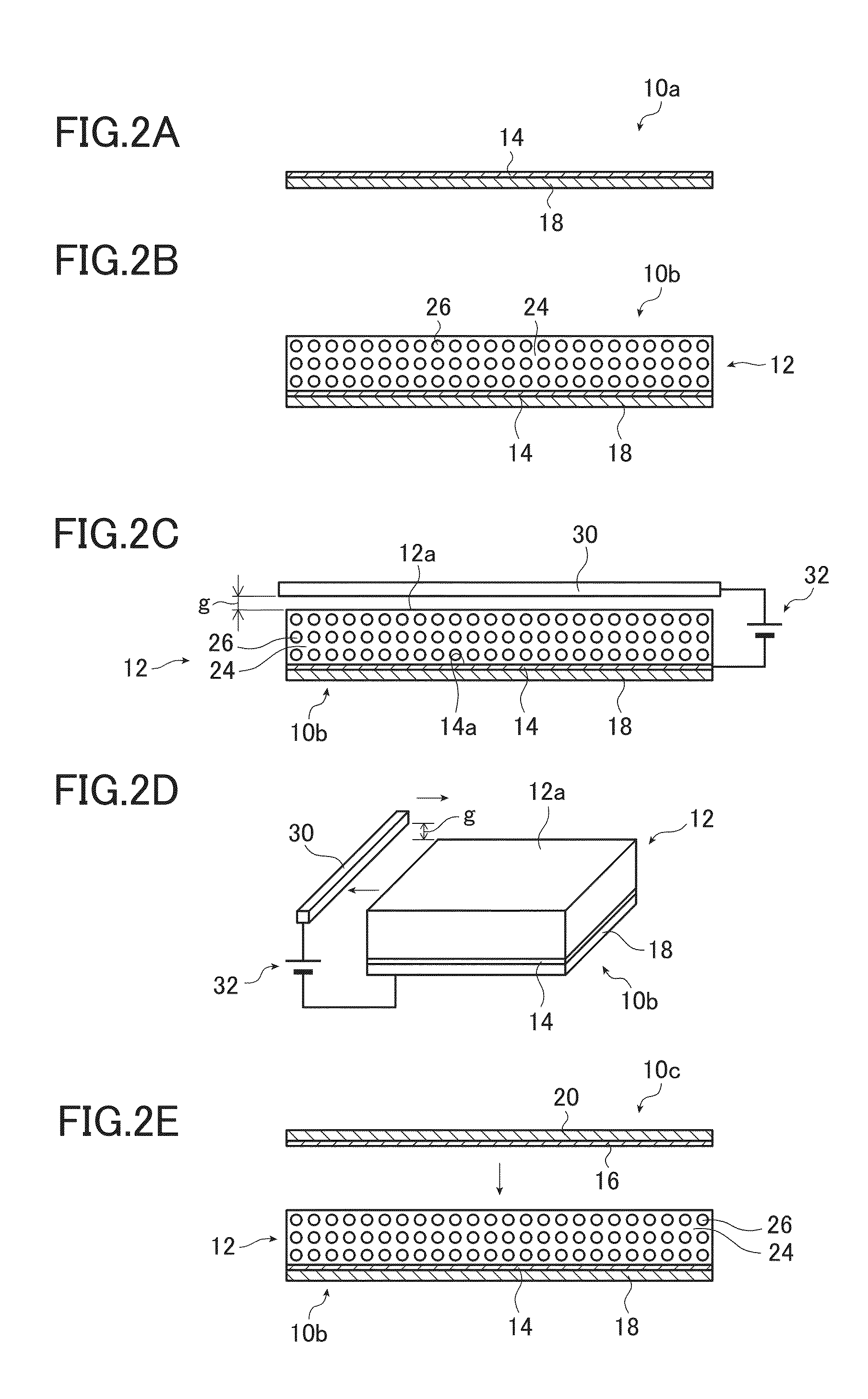

Electroacoustic converter film, flexible display, vocal cord microphone, and musical instrument sensor

ActiveUS20140210309A1Increase flexibilityExcellent acoustic characteristicsElectrophonic musical instrumentsPiezoelectric/electrostriction/magnetostriction machinesThin film electrodeDisplay device

Provided is an electroacoustic converter film including: a polymeric composite piezoelectric body having piezoelectric particles dispersed in a viscoelastic matrix which is formed of a polymer material exhibiting viscoelasticity at ordinary temperatures; thin film electrodes formed on both sides of the polymeric composite piezoelectric body; and protective layers formed on surfaces of the thin film electrodes. The electroacoustic converter film serves as a speaker capable of being integrated with a flexible display without impairing lightweightness or flexibility, and has considerable frequency dispersion in the storage modulus and also has a local maximum of the loss tangent around ordinary temperatures. A flexible display, a vocal cord microphone and a musical instrument sensor, in each of which the electroacoustic converter film is used, are also provided.

Owner:FUJIFILM CORP

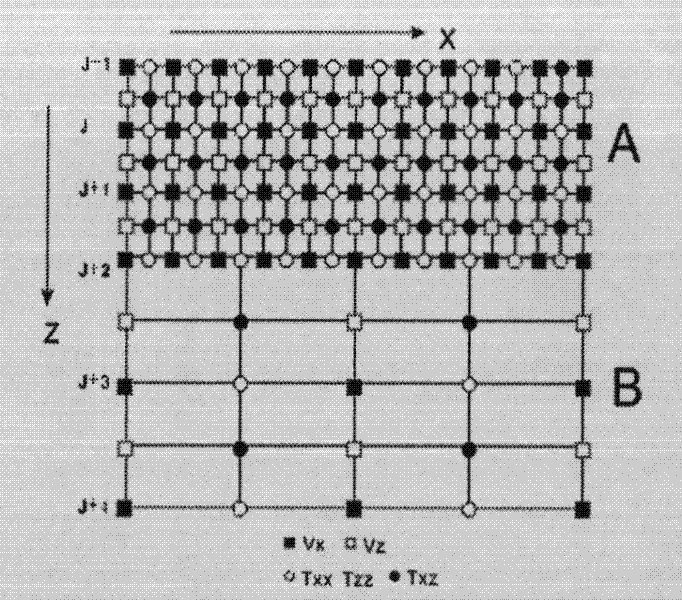

Elastic wave forward simulation technology based on space-time dual-variable grid

InactiveCN102183790AHigh precisionImprove reliabilitySeismic signal processingSeismology for water-loggingSpace constantPartial stability

The invention discloses an elastic wave forward simulation technology based on the space-time dual-variable grid, comprising the following steps: determining the stability conditions of the target area and the background area according to the speed parameter and the elasticity parameter of the underground medium aiming to the known earthquake geological model so as to calculate the size of the space grids with different dimensions and perform the discretization process to the speed field; obtaining the space arbitrary precision difference formula of the grid point variables with different dimensions by using the Taylor's formula and the finite difference technology, which is the arbitrary even order accuracy space difference formula of the space constant grid operator and the space variable grid operator, and calculating the wave field values of the precise division area, the rough division area and the middle transitional belt area by using the deduced space difference formula; in the wave field extrapolation process of the time layer, using different time sampling intervals to different grid division areas and meet the partial stability condition, obtaining the wave field value of the precise grid point in the precise time layer and the wave field value of the rough grid point in the global time layer; in each global time layer, transmitting the wave field value of the precise grid division area to the rough grid division area, thereby obtaining the space wave field value of the whole speed field at the said moment; performing the wave field extrapolation on each time layer by the said method and obtaining the forward simulation record of single cannon. The partial stability condition of the shallow layer can be met, so as to avoid the frequency dispersion noise.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

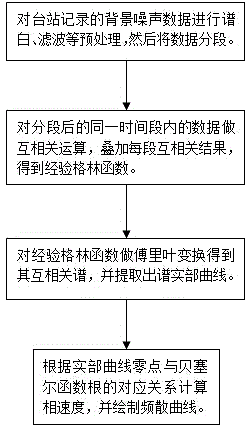

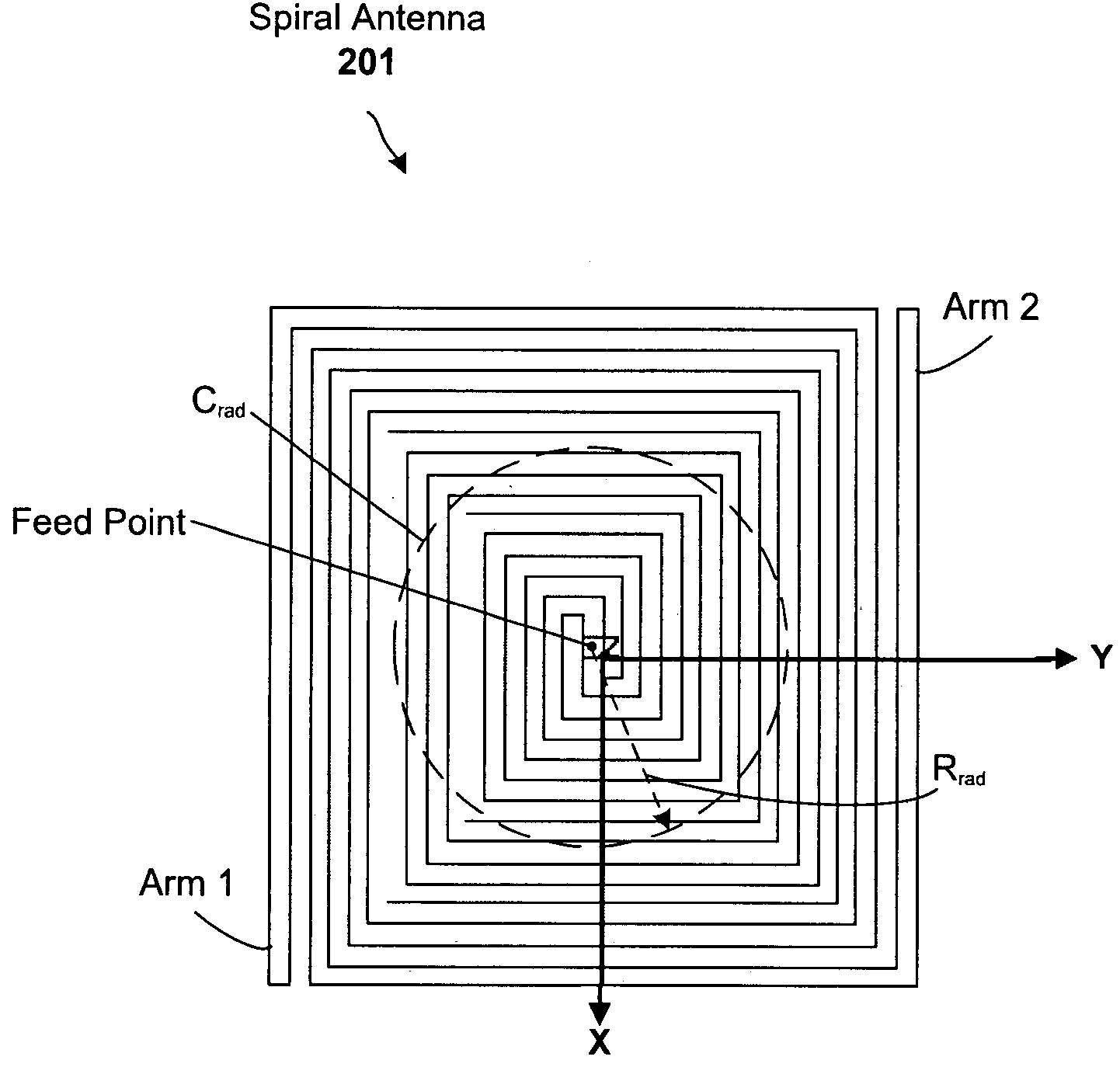

Method for extracting Rayleigh surface wave frequency dispersion curve

InactiveCN104678435AAvoid estimatesImprove accuracySeismic signal processingFrequency spectrumComputational physics

The invention discloses a method for extracting a Rayleigh surface wave frequency dispersion curve. The method comprises the following steps: a, performing Fourier transform on noise cross-correlation signals recorded by a seismometer pair which are spaced by R to obtain a frequency spectrum W(f); b, performing Gauss narrow-band filtering on the obtained frequency spectrum to obtain WG(f); c, extracting a real part curve of the WG(f), finding out null points of the real part curve, and recording fn as the frequency of the nth null point; d, finding out a root of a first-class zero Bessel function as Zn; e, solving a Rayleigh surface wave phase velocity value V(f) being equal to 2pifnR / Zn at a single frequency point according to the relation between a real part curve of a cross-correlation spectrum and the first-class zero Bessel function; f, connecting and drawing the solved phase velocities of single frequency points into a smooth curve as a frequency dispersion curve of Rayleigh surface waves. By using the relation between the Bessel function and the cross-correlation spectrum, the calculation efficiency of the frequency dispersion curve is effectively improved.

Owner:李欣欣 +1

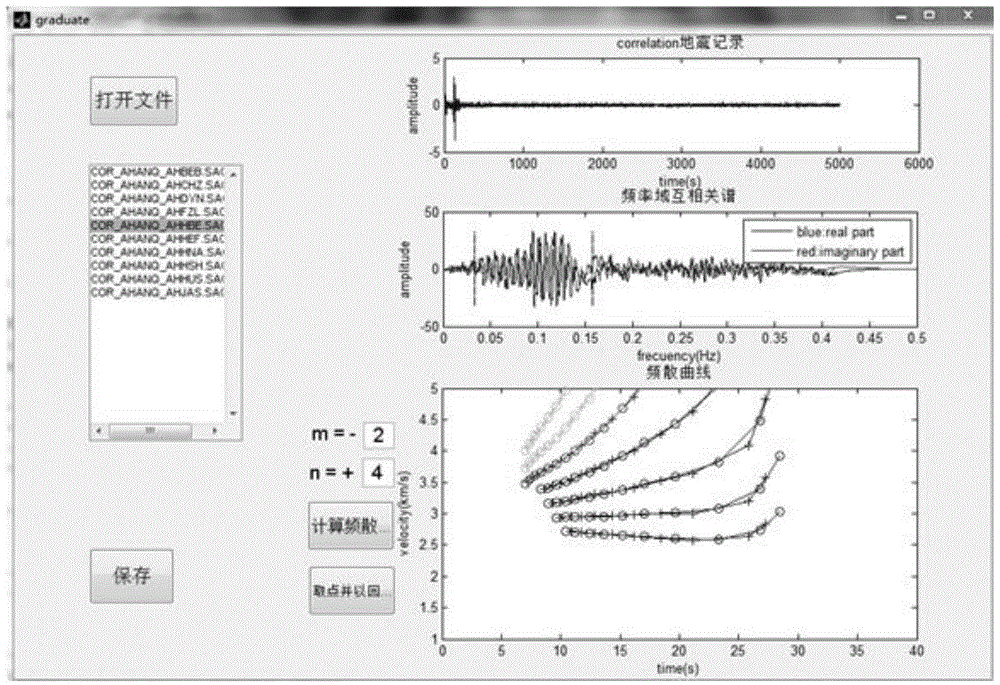

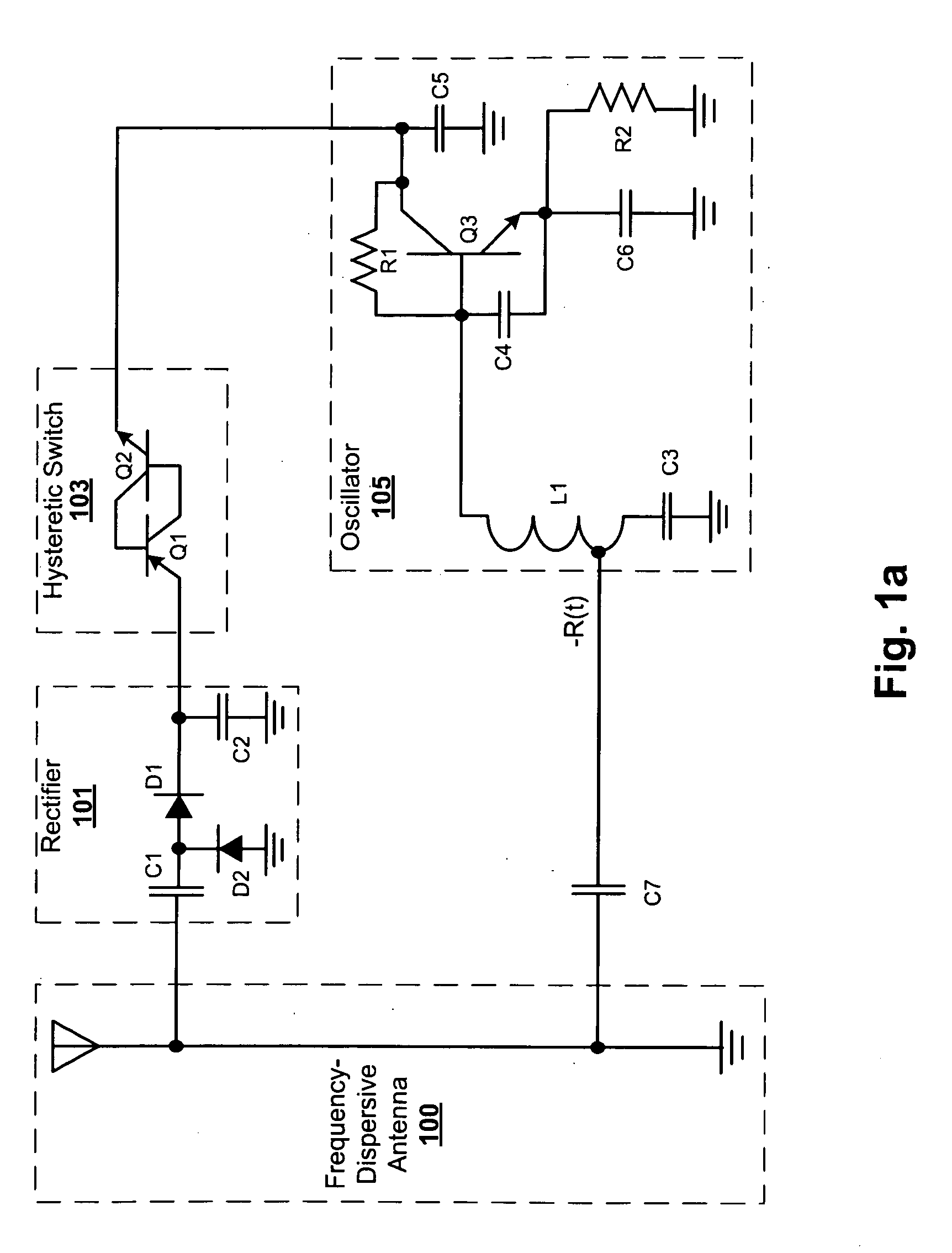

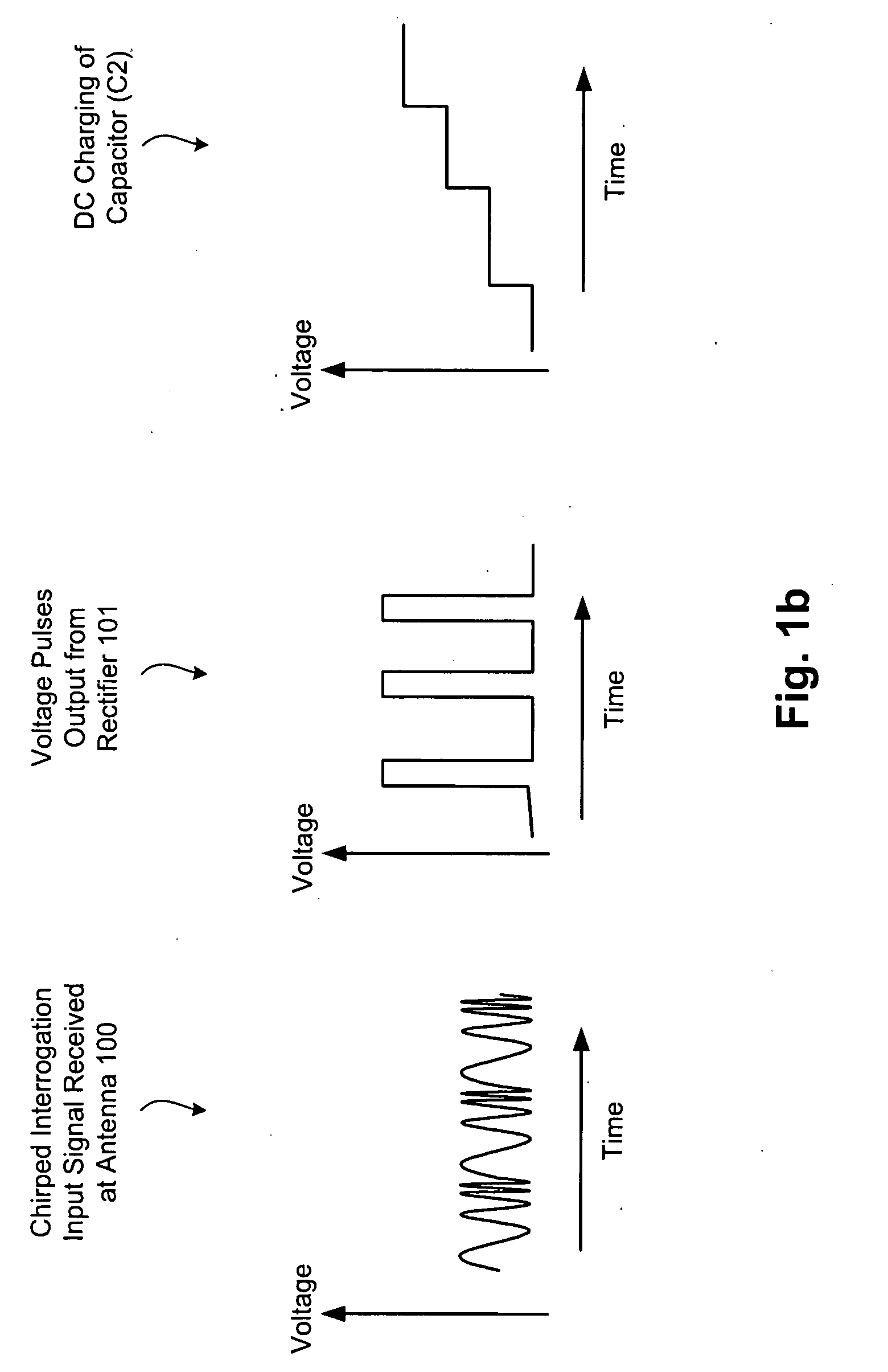

Dispersive antenna for RFID tags

ActiveUS20090284351A1Good dispersionMain station arrangementsNear-field transmissionWave shapeRectifier diodes

RFID tag designs and sensors are disclosed that include a dispersive antenna and exhibit greater detection ranges relative to conventional designs. The designs include, for example a transponder having including a rectifier, a radio-frequency identification (RFID) circuit for receiving and responding to interrogation signals, and a frequency dispersion element for receiving a multi-phase input signal and creating a pulse therefrom for input to the rectifier. Frequency-dispersive elements (e.g., antennas) and compatible interrogation waveforms can be used so that the rectifying diodes receive high peak voltage levels relative to the average voltage levels.

Owner:RADIOFIDO

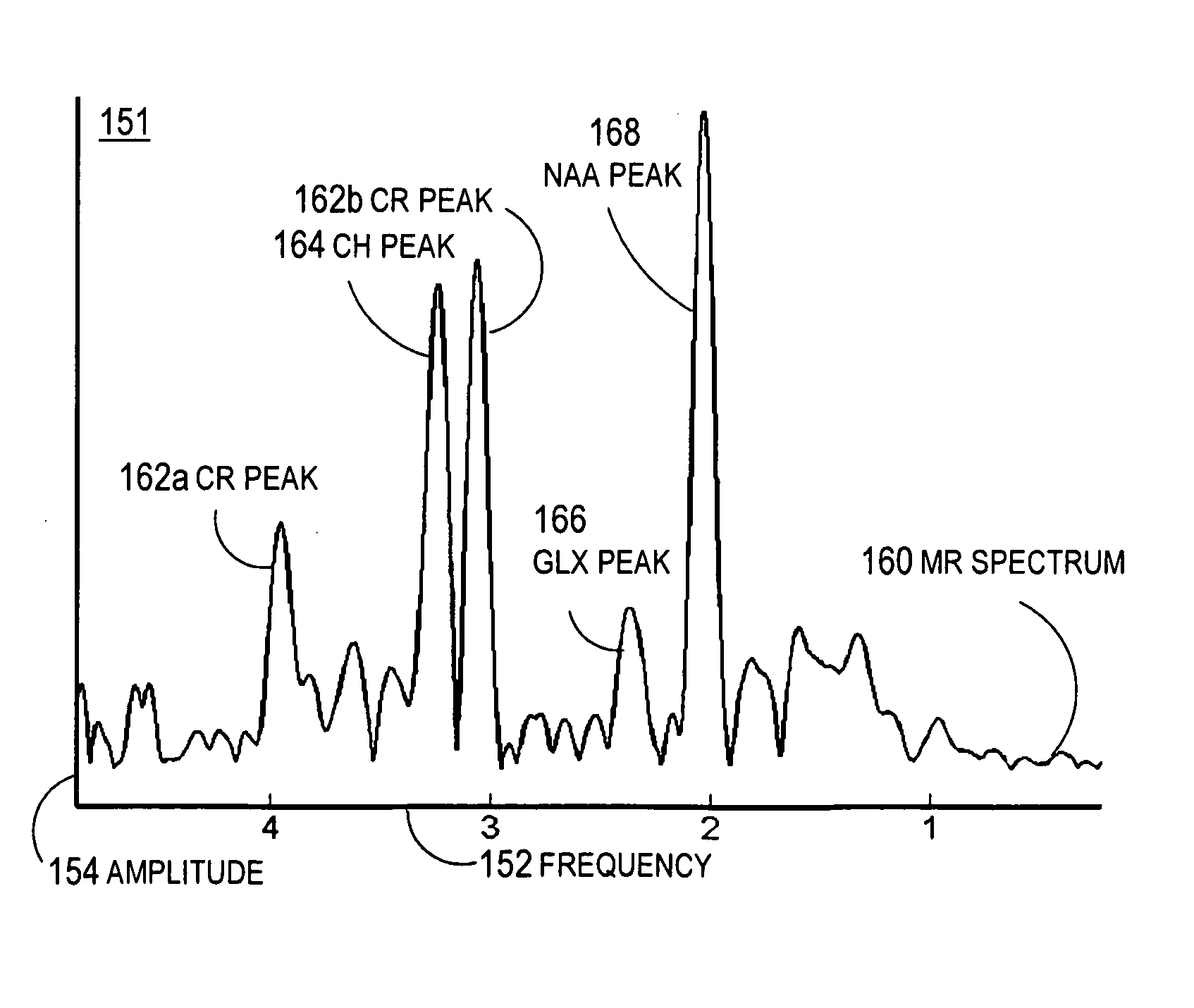

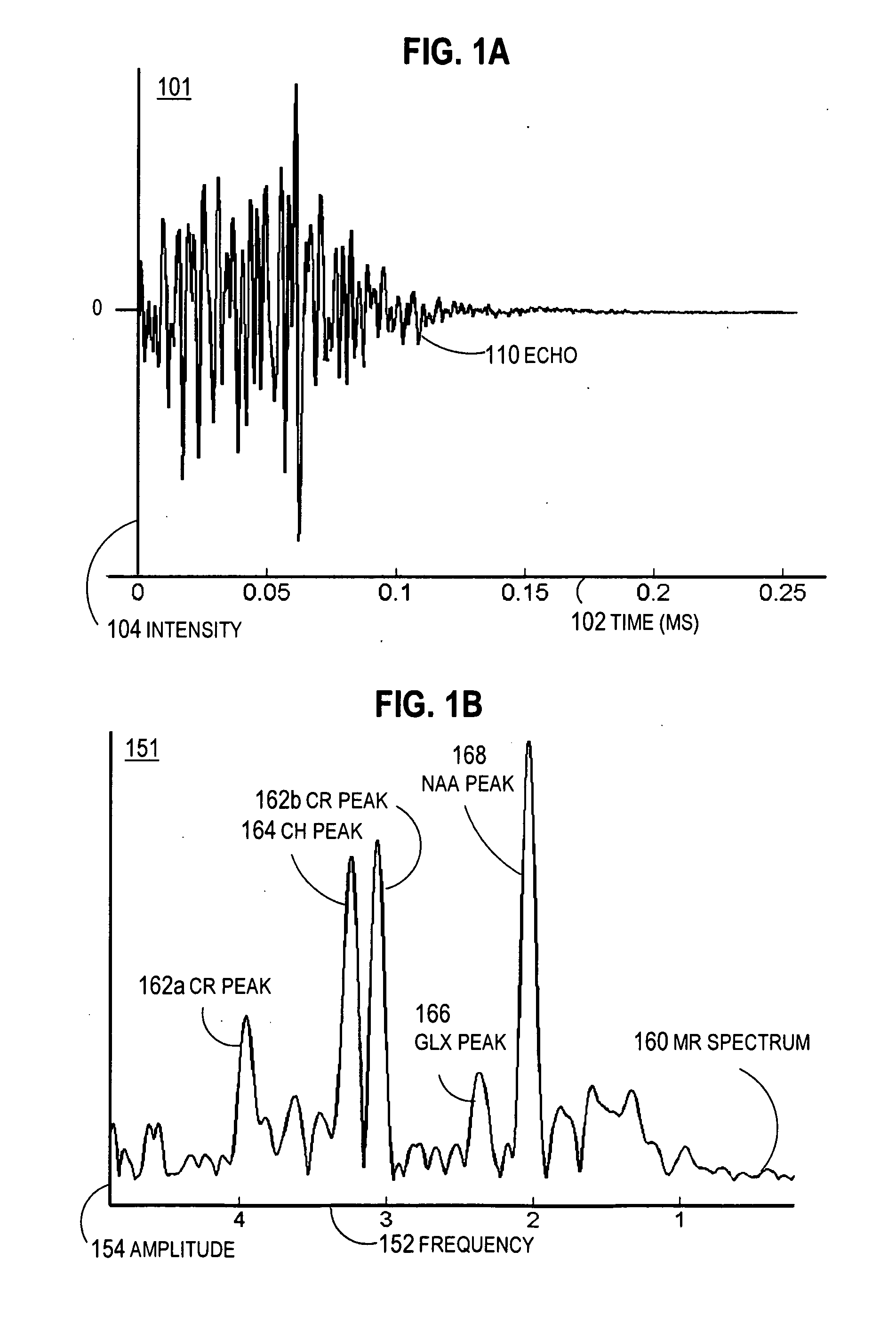

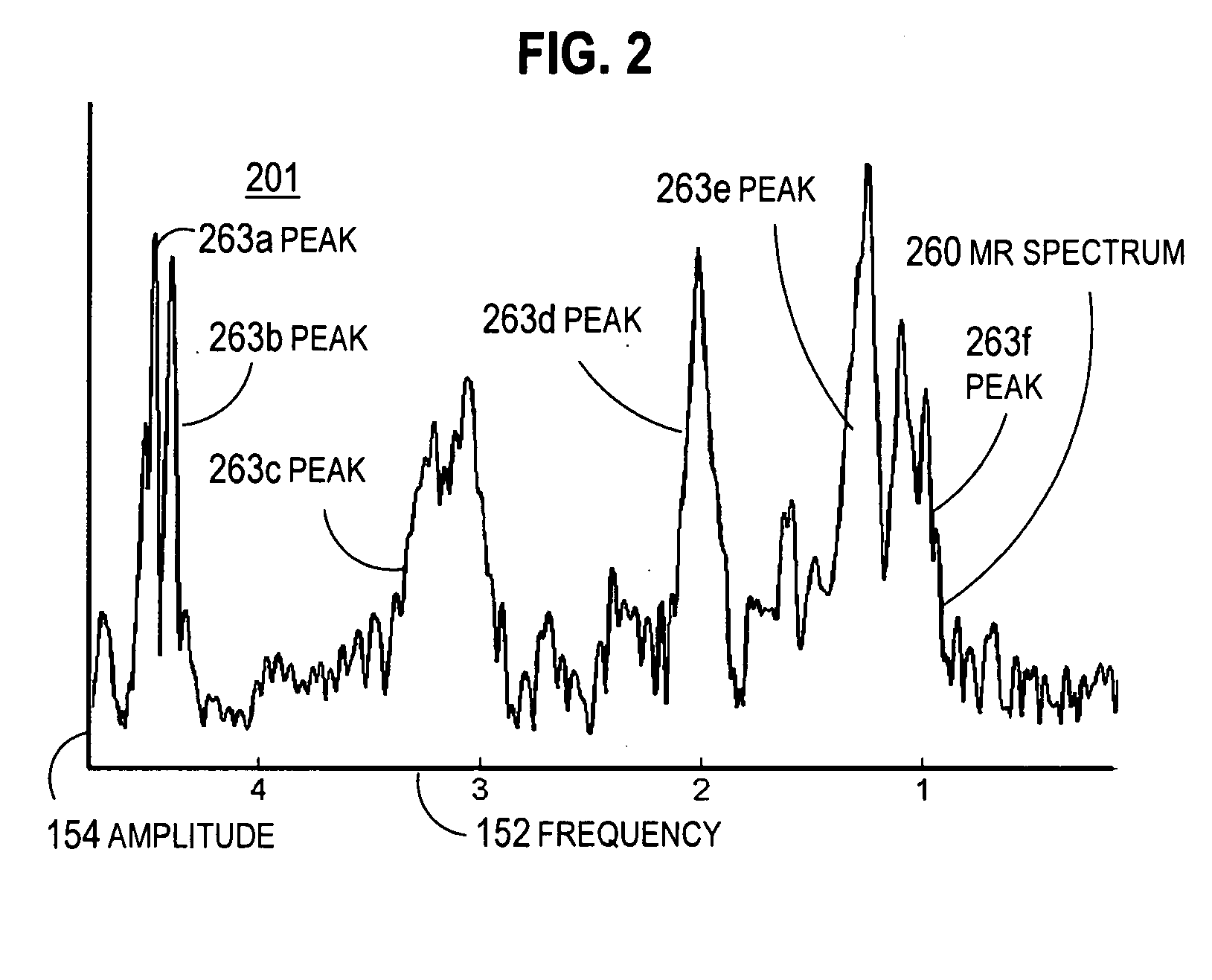

Spectral resolution enhancement of magnetic resonance spectroscopic imaging

InactiveUS20100085050A1Spectral broadeningMeasurements using NMR imaging systemsElectric/magnetic detectionTime domainMagnetic resonance spectroscopic

A method and apparatus for enhancing the spectral resolution of magnetic resonance spectroscopic (MRS) measurements include receiving time domain echo data from an MRS measurement for an MRS volume in a subject. Also received are high spatial resolution complex signal values within the MRS volume based on magnetic resonance imaging (MRI) measurements. Frequency-domain content is determined for the echo data based at least in part on the complex signal values. For example, in some embodiments, receiving complex signal values includes receiving high spatial resolution complex signal values within the MRS volume for each of two different echo time settings. The frequency-domain content of the echo data is corrected for a lineshape profile based on high resolution frequency dispersion values for the MRS volume determined from differences in the complex signal values for the two different echo time settings.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

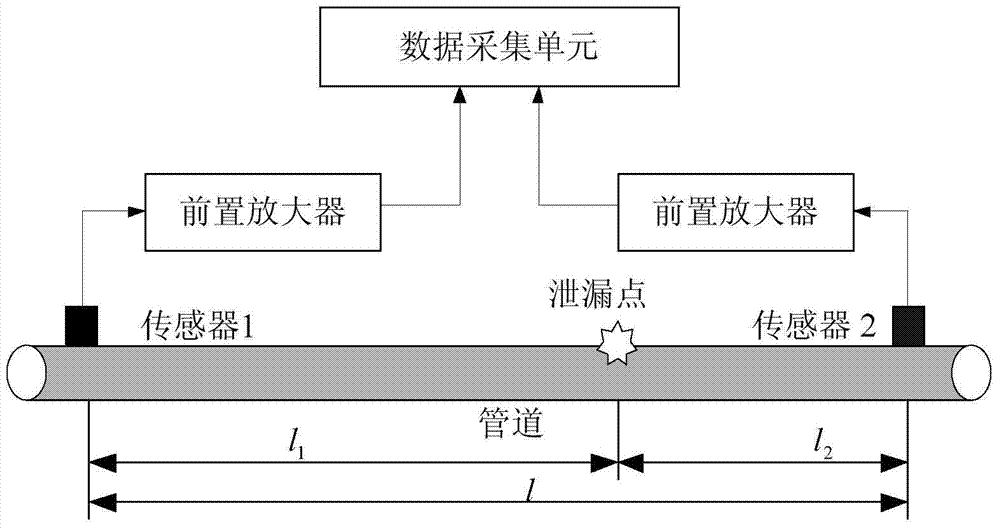

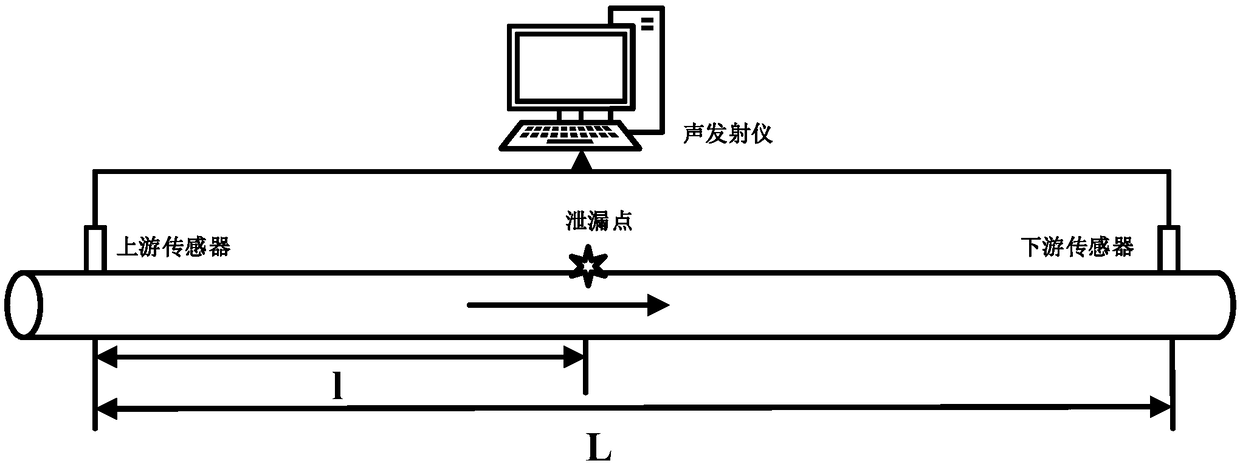

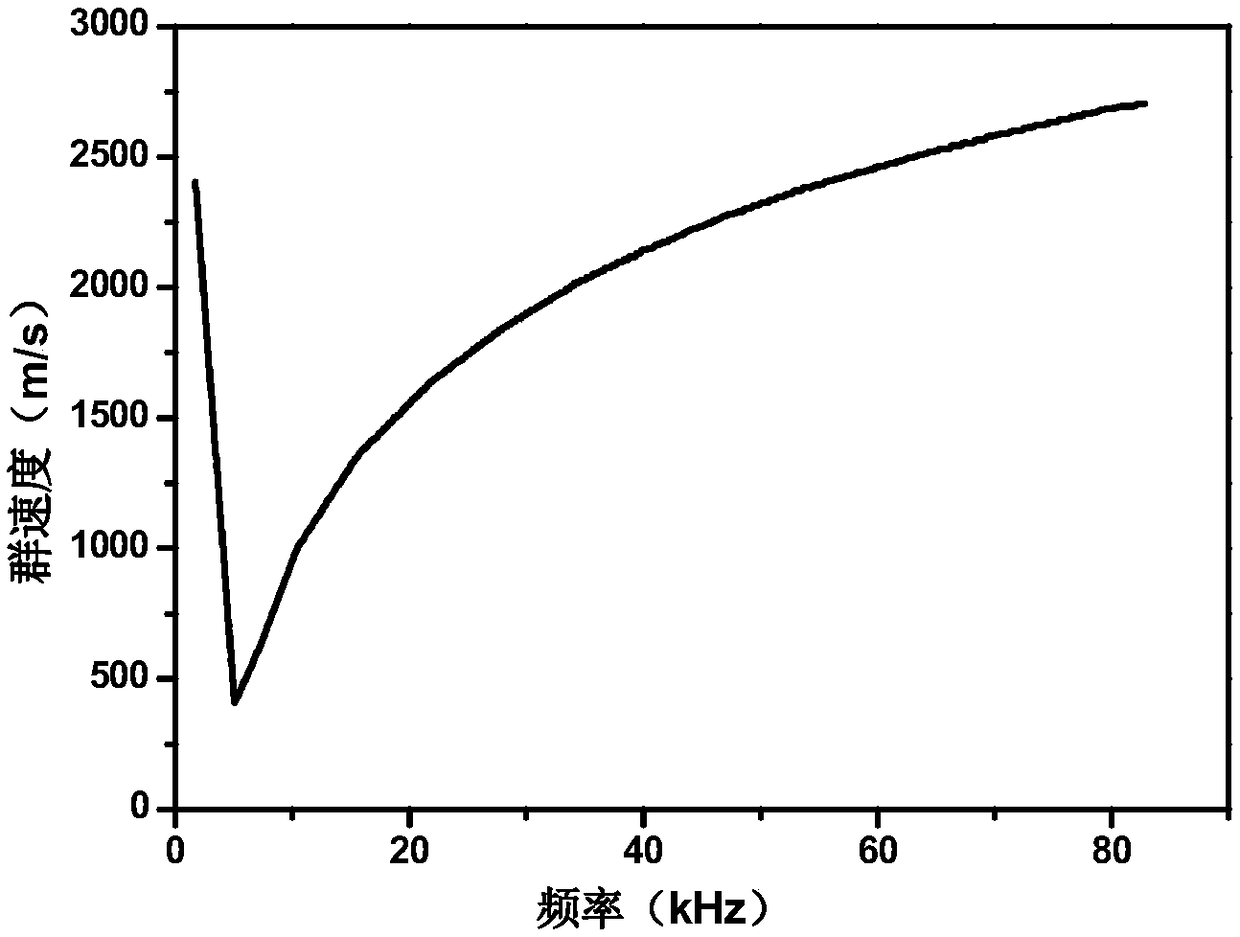

Fluid conveying pipe leakage acoustic emission time-frequency positioning method

ActiveCN104747912AImprove completenessSolve the problem of large leak location errorsPipeline systemsFrequency spectrumTime delays

The invention relates to a fluid conveying pipe leakage acoustic emission time-frequency positioning method. The fluid conveying pipe leakage acoustic emission time-frequency positioning method comprises the following steps of picking up acoustic emission signals through an acoustic sensor and a vibration sensor which are arranged at two ends of a pipe leakage point respectively and performing cross-correlation analysis on the acoustic emission signals which are picked up; performing time-frequency analysis on cross-correlation functions of the two channels of acoustic emission signals through smooth pseudo Wigner-Ville time-frequency distribution; extracting the time and frequency information corresponding to time-frequency spectrum peak values of the cross-correlation functions of the acoustic emission signals during pipe leakage; serving the time information corresponding to the peak values as the time delay of two observation signals and determining the transmission speed of the leakage acoustic emission signals along a pipe through table look-up on a frequency dispersion curve according to the frequency information of the peak values; determining the pipe leakage position through the time delay and the timely determined acoustic speed. The fluid conveying pipe leakage acoustic emission time-frequency positioning method can be used for performing accurate positioning on the leakage point under the conditions that the leakage acoustic emission frequency dispersion of the fluid conveying pipe is serious and the acoustic speed is difficult to be determined and meanwhile the correlation functions of the single frequency leakage signals are extracted for the time delay estimation and accordingly the degree of correlation of the leakage signals is enhanced and the leakage positioning error is further reduced.

Owner:重庆富世恒睿物联网科技有限公司

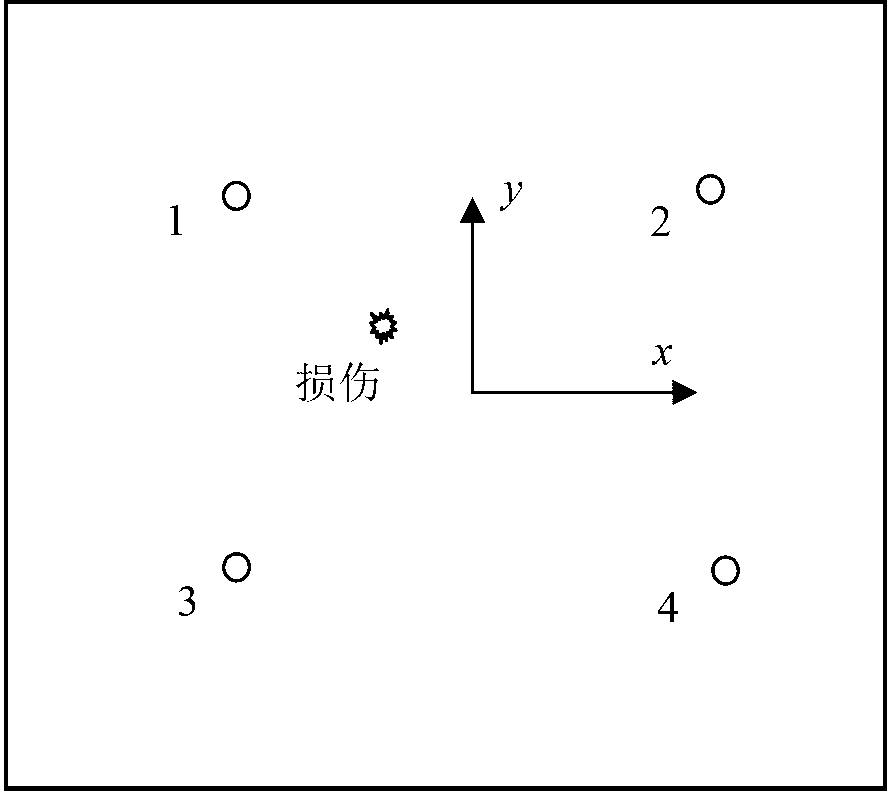

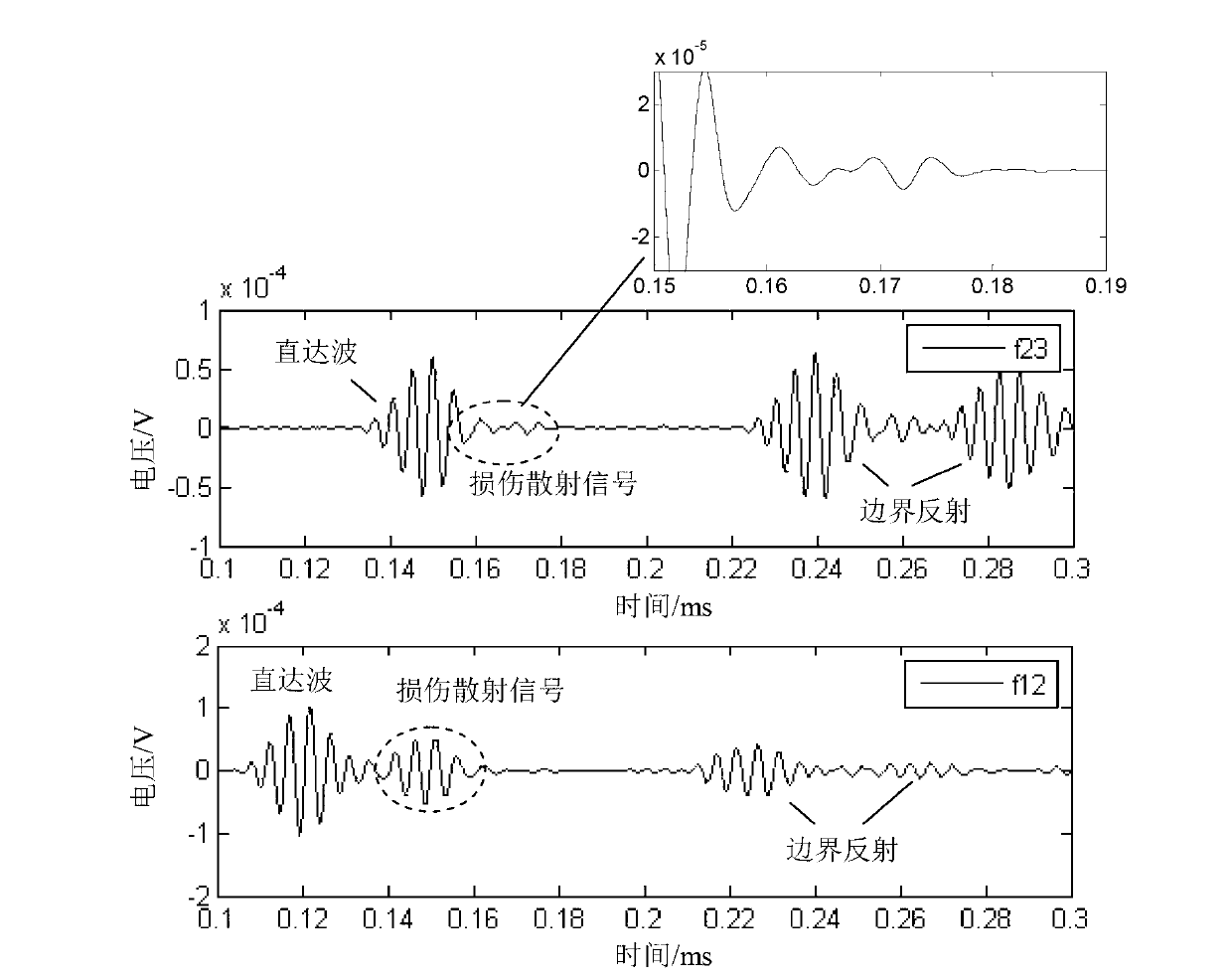

Monitoring method for time reversal damage to no-datum Lamb wave of engineering structure

InactiveCN102998370AAchieving focus reconstructionEliminate scalabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesEllipseEngineering

The invention discloses a monitoring method for time reversal damage to no-datum Lamb wave of an engineering structure. The monitoring method comprises the following steps of: distributing a group of excitation / sensing arrays on a structure to be monitored; building detection channels, and collecting Lamb wave response signals of all excitation / sensing channels; intercepting the response signals, and then conducting time reversal to obtain time reversal structure response signals; loading the time reversal structure response signals onto corresponding excitation, and collecting time reversal focusing structure response signals on the corresponding sensing; and in the time reversal focusing structure response signals of all the detection channels, extracting the occurrence time difference of focusing main wave crest and sidelobe signals, taking the occurrence time difference as a characteristic parameter, calculating to obtain the position and approximate range of the damage by adopting an ellipse positioning method, and analyzing and judging the health condition of the structure to be detected. With the method, the wave packet extension and signal aliasing caused by frequency dispersion can be eliminated, no-datum active positioning and detection to the Lamb wave can be realized, and the healthy monitoring practicalization of the structure can be benefited.

Owner:NANJING UNIV OF POSTS & TELECOMM

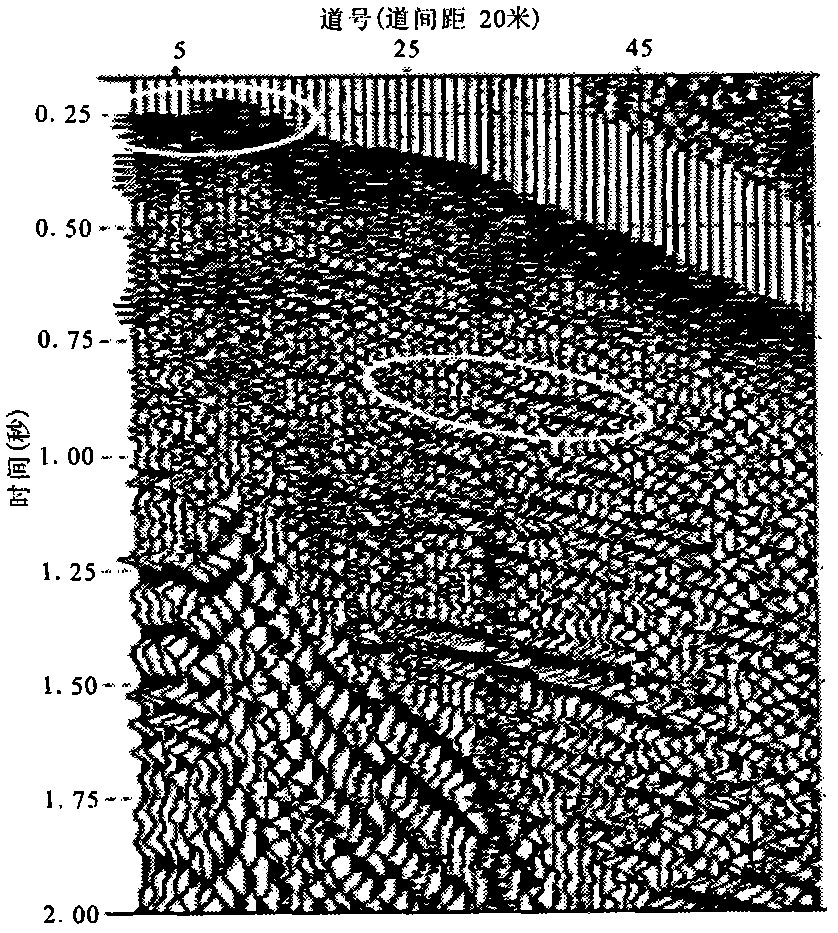

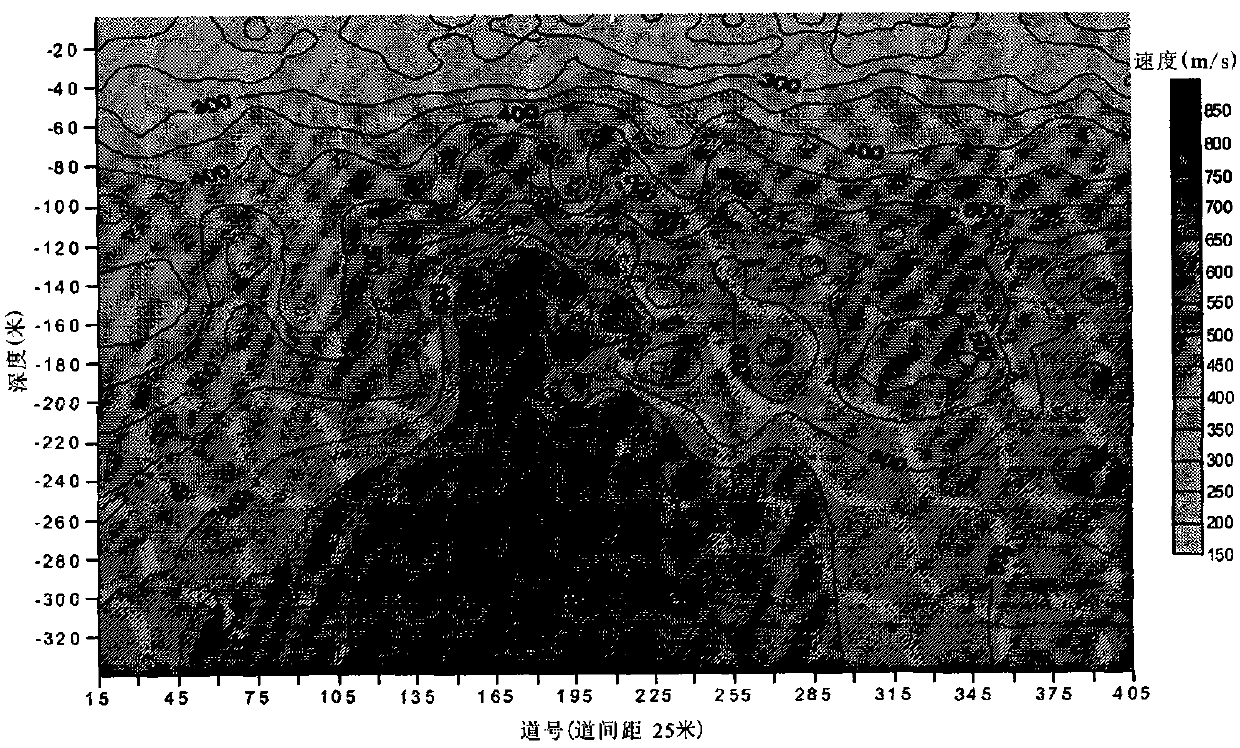

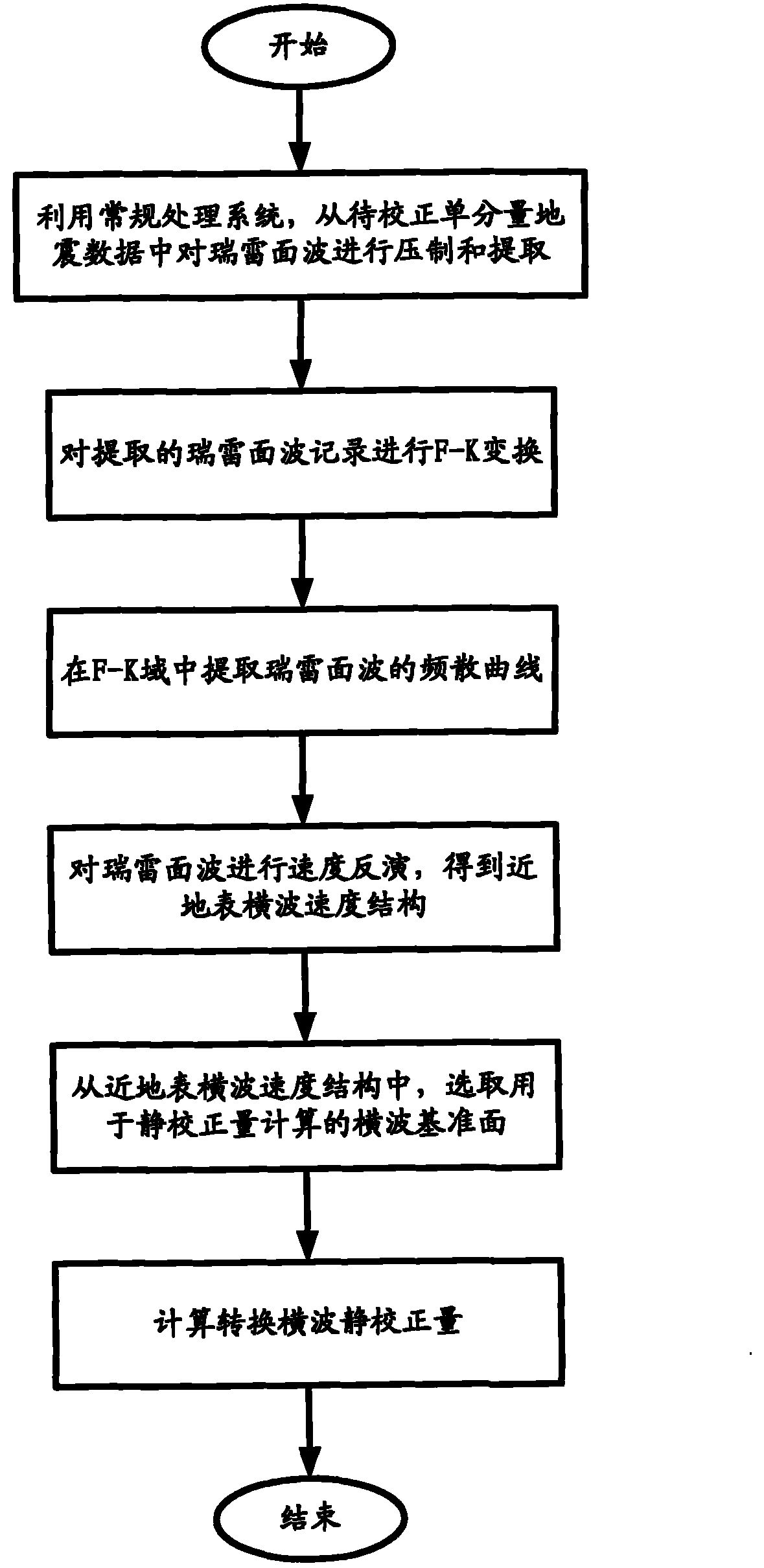

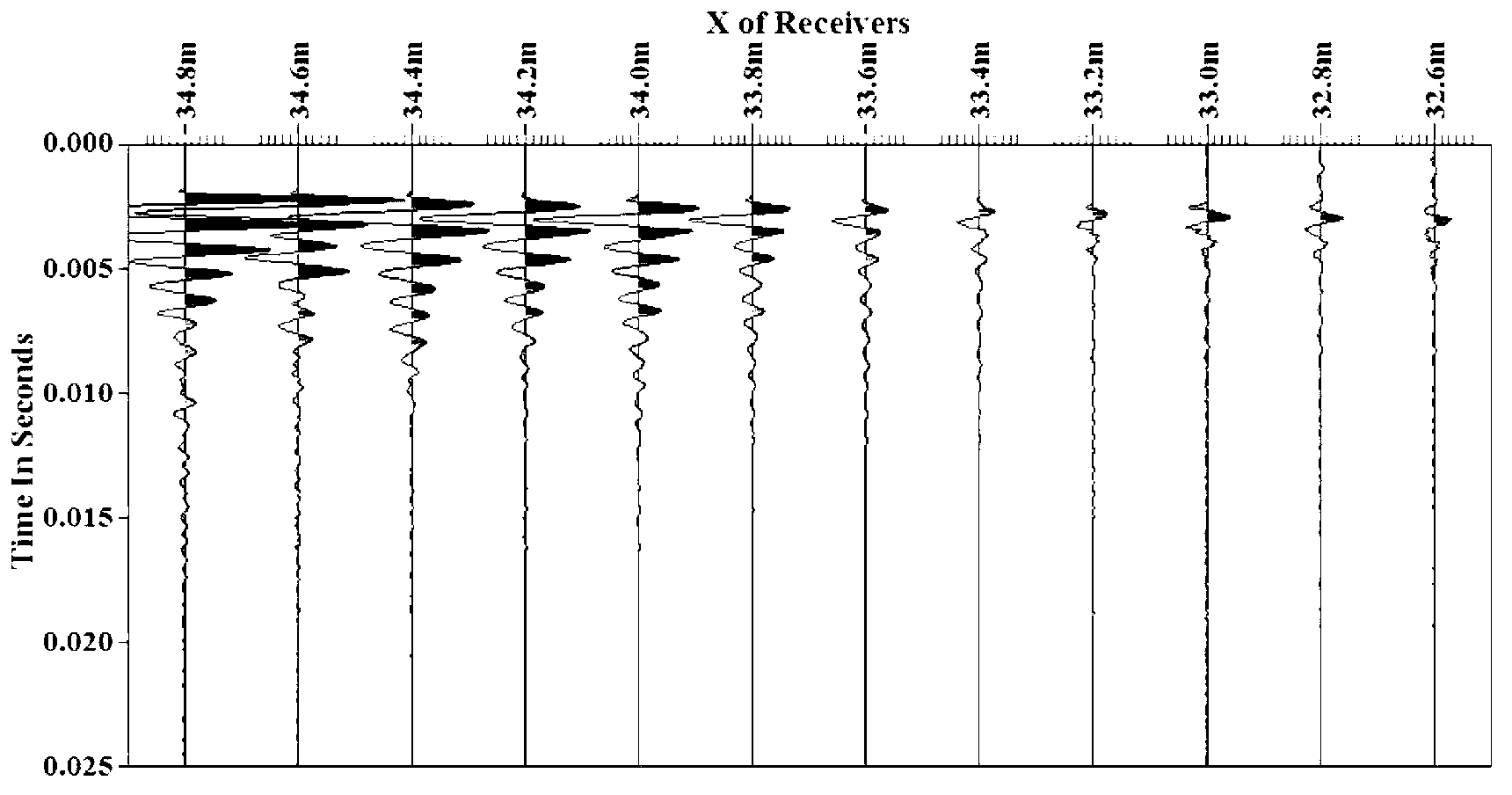

Multi-component converted wave static correction method by using surface waves

The invention relates to a multi-component converted wave static correction method by using surface waves, which comprises a step of solving stratigraphic classification and transverse wave velocity of a superficial layer through the extraction of the surface waves and the inversion of frequency dispersion curves based on Rayleigh surface waves in a shot record, so as to accurately calculate static correction quantity of detection points of converted waves. The test processing on two-dimensional three-component of a certain block in Daqing shows that a transverse velocity non-uniform body of the superficial layer generates a larger static correction time difference; and the processing on three-dimensional three-component data of a certain coal mine in Huainan shows that the static correction time difference of over 20 milliseconds can also occur due to the low and transversely non-uniform transverse wave velocity even in a flat plain terrain, and for a coalfield high-resolution seismic exploration to recognize minor faults of about 3 meters, the static correction time difference is a non-ignorable error. Application tests in three-component seismic data processing in two regions achieve a better processing effect and prove that the multi-component converted wave static correction method by using the surface waves is a feasible method.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI +1

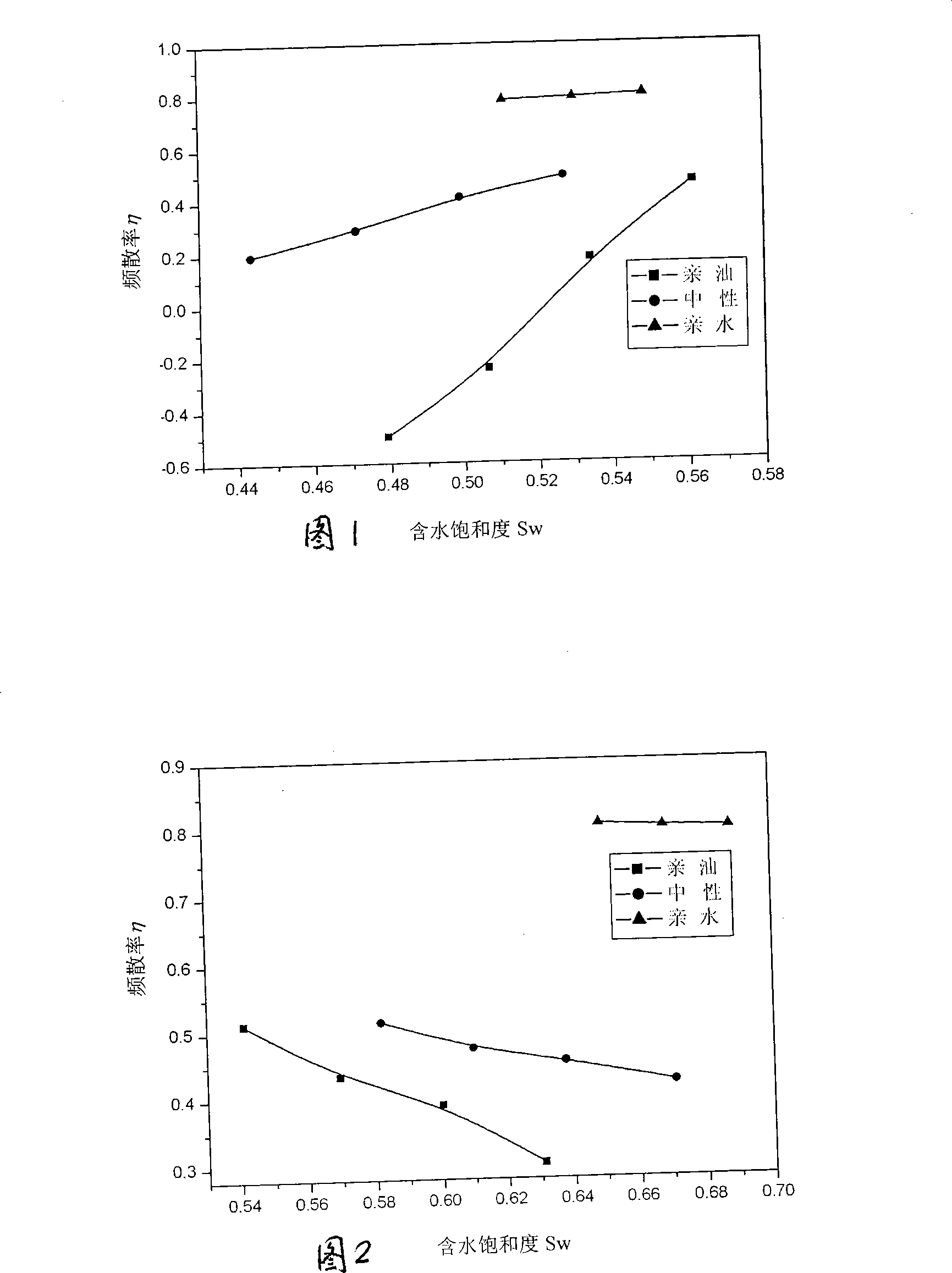

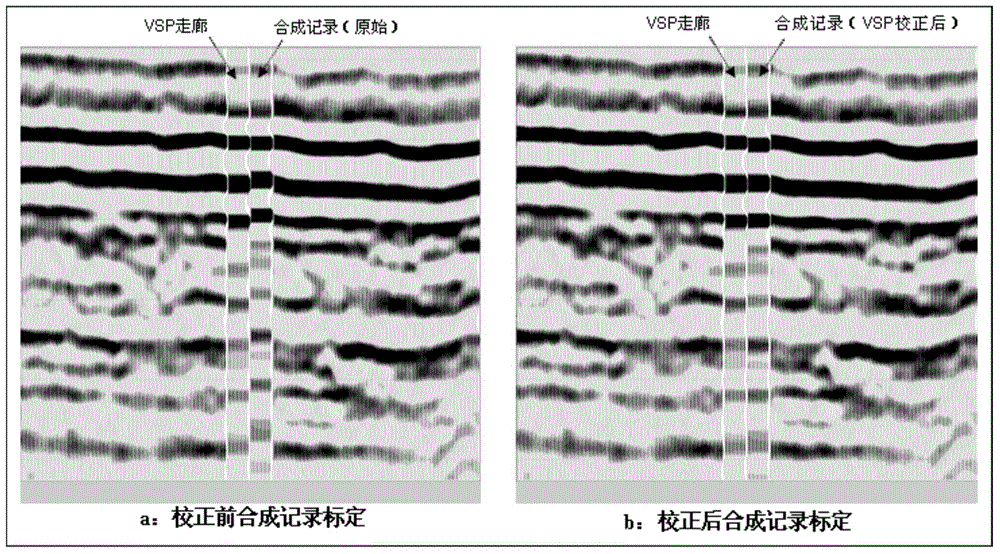

Appraisement method for rock wettability

InactiveCN101196460AEvaluation results are reliableThe experiment process is simpleSurface/boundary effectPermeability/surface area analysisOperabilityFrequency dispersion

The invention relates to a rock wettability evaluating method used for petroleum drilling and exploration, which utilizes the frequency dispersion character of rock electrical parameter to conduct reservoir rock wettability evaluating. The dispersion information of phase has closer relationship with the wettability comparing with the resistivity; therefore the evaluating result is more accurate and reliable. The method has the characters of being simple, visual and convenient, which doesn't need special experiment device and the experiment period is short, the maneuverability is strong, the experiment process is simple, and can be conducted under normal temperature and pressure, and which also can be conducted under stimulating the high temperature and pressure of reservoir condition.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

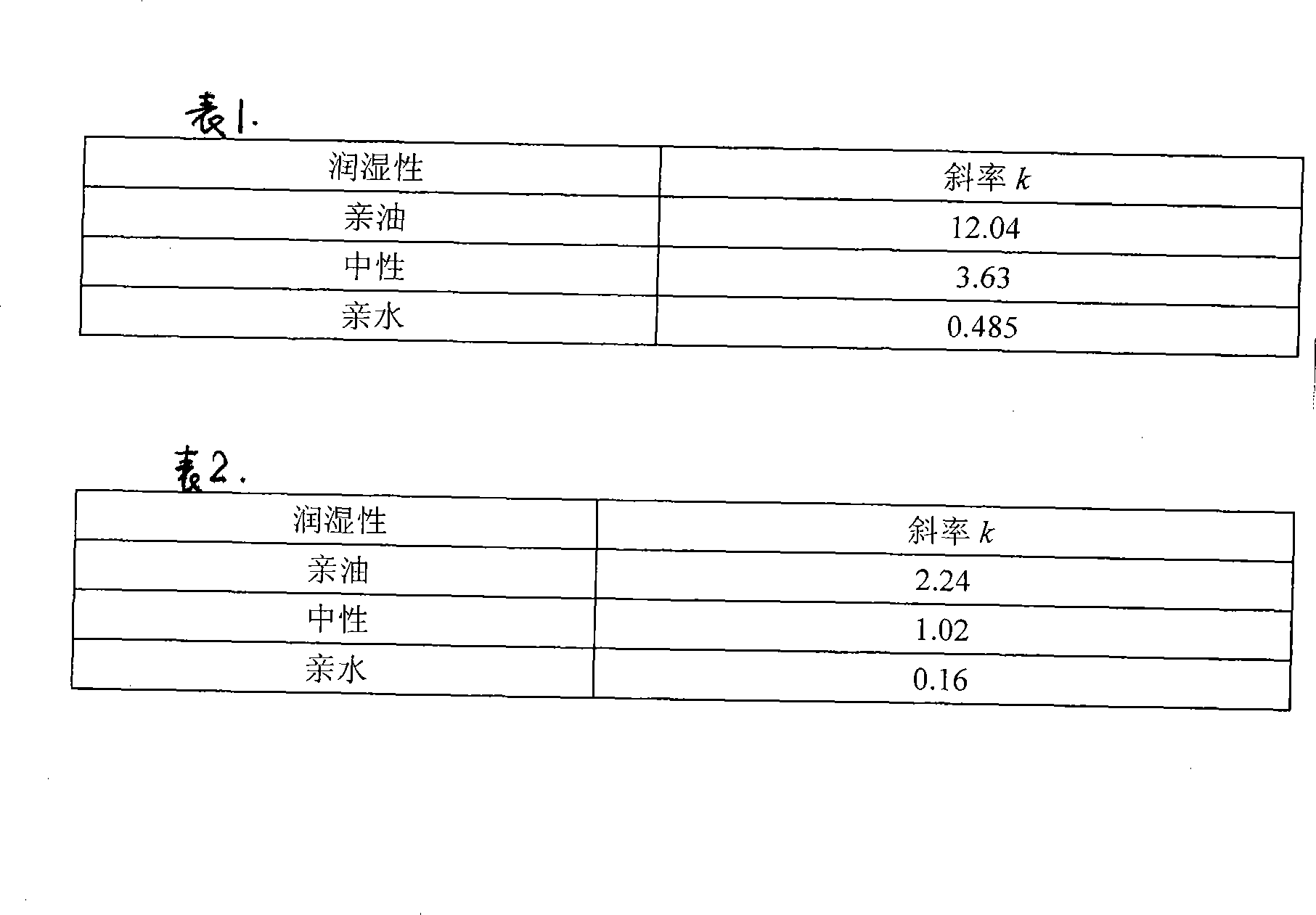

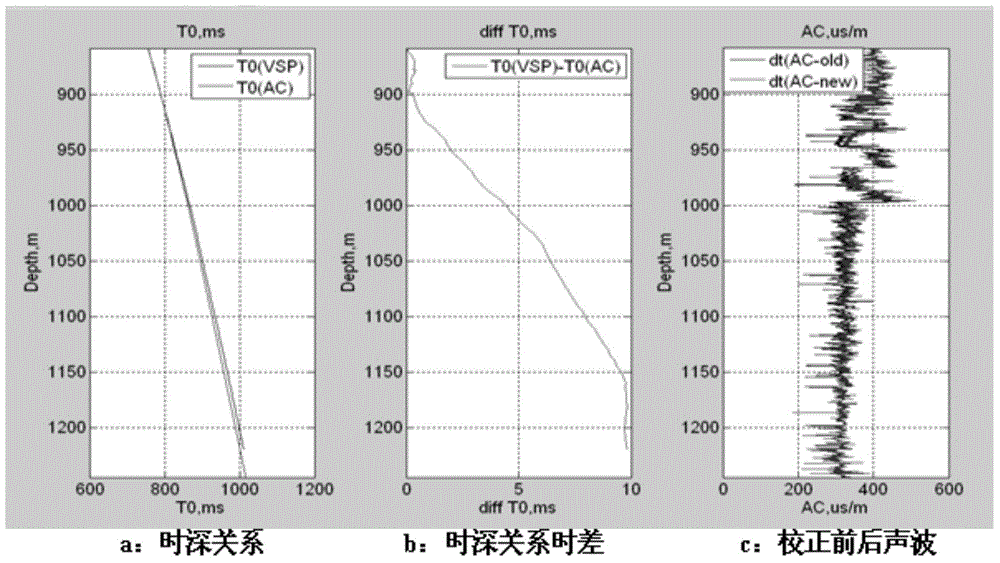

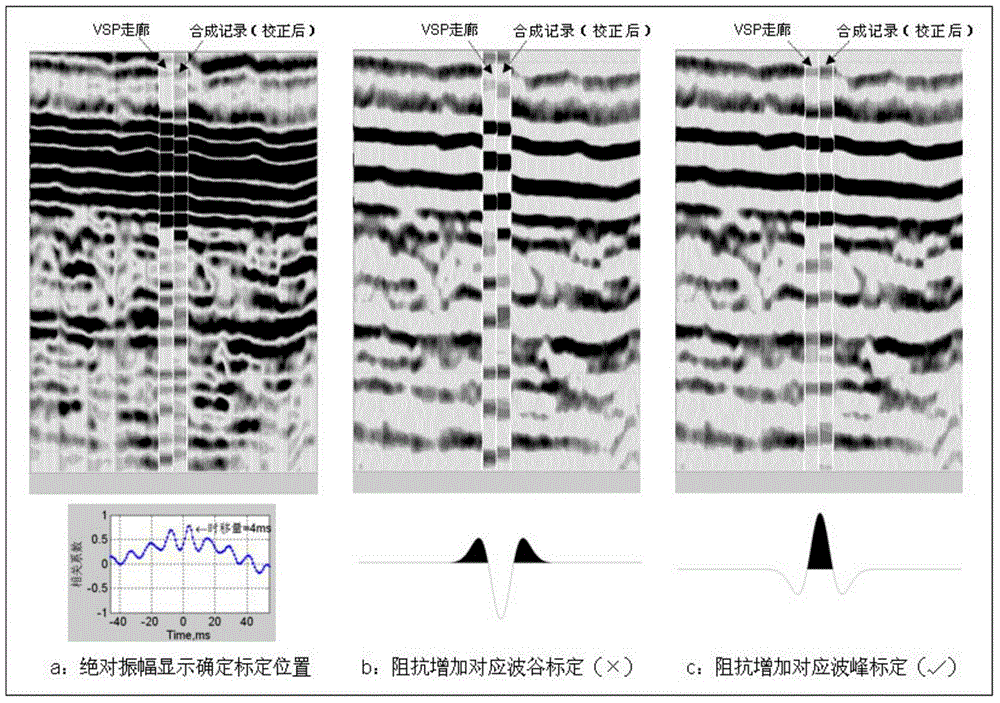

Seismic horizon calibration method utilizing vertical seismic profiling (VSP) and well-logging combination

The invention relates to a seismic horizon calibration method utilizing a vertical seismic profiling (VSP) and well-logging combination. The seismic horizon calibration method comprises the following steps: measuring and obtaining a longitudinal wave time-depth relationship and a corridor stacking profile according to zero offset data, performing well logging and obtaining acoustic well logging and density well logging data, calculating an acoustic wave time-depth relationship and a VSP time-depth relationship to get time difference, correcting an acoustic wave curve, obtaining a synthetic record through corrected well-logging curve and seismic wavelet convolution, making a horizon calibration chart after the time shift quantity of a VSP corridor and the correct polarity are determined and performing horizon calibration on a ground seismic profile according to known drilling geological stratification. According to the seismic horizon calibration method, the acoustic well logging error and the frequency dispersion effect are eliminated, the synthetic record making precision is improved, human factors in the calibration are reduced, and the calibration accuracy is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

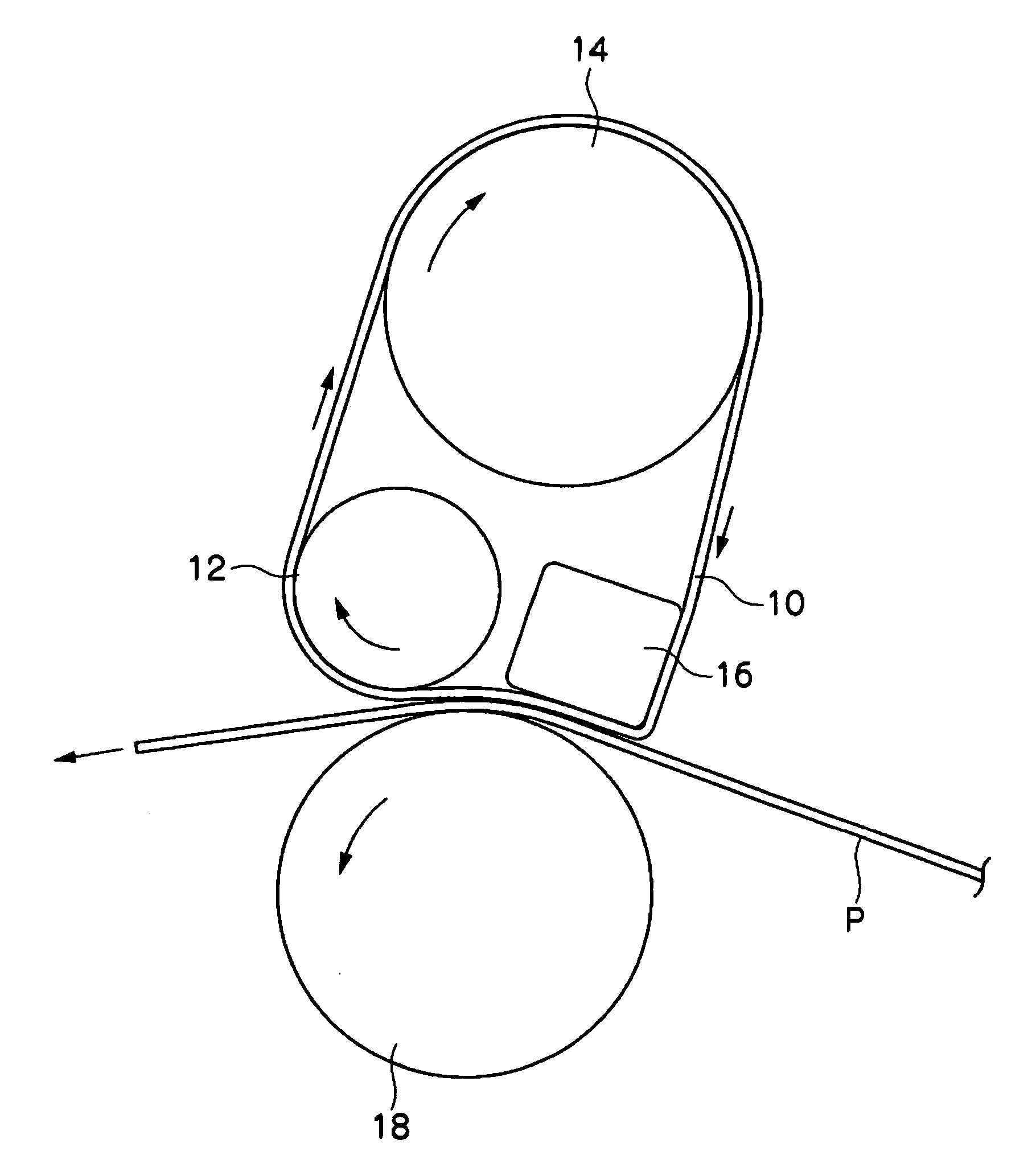

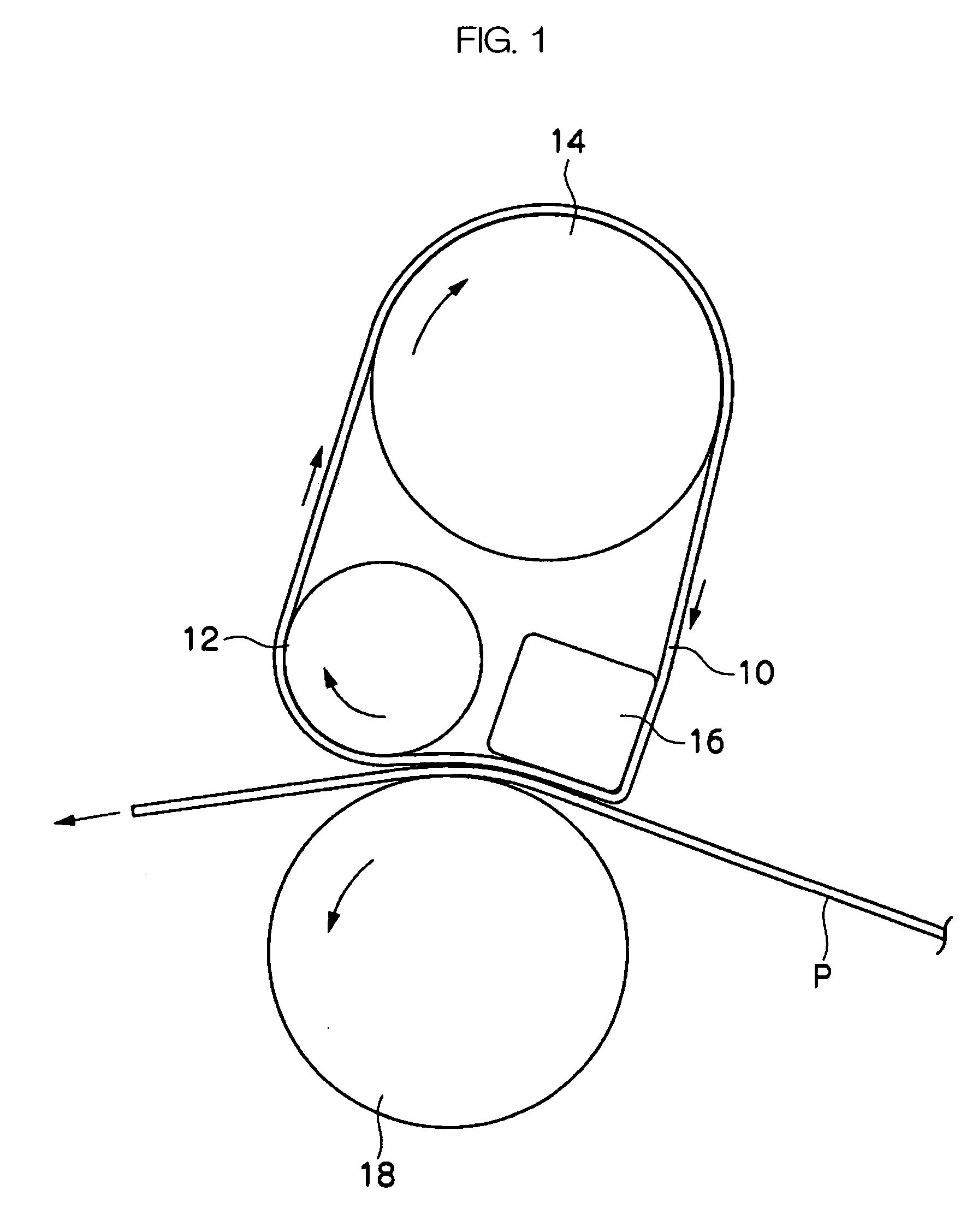

Electrostatic latent image developing toner and manufacturing method thereof

ActiveUS20060105258A1Good low temperatureLess in the warping (curling) properties of sheetDevelopersDynamic viscoelasticityLatent image

An electrostatic latent image developing toner including, as a binder resin, a crystalline resin and at least one kind of non-crystalline resin, wherein, in a dynamic viscoelasticity measurement by a sine wave vibration method, a minimum value of the relaxation elasticity H in a relaxation spectrum obtained from frequency dispersion characteristics measured at temperatures of 60 and 80 degrees centigrade with a measurement frequency set in the range of 0.1 to 100 rad / sec and measurement strain set in the range of 0.02 to 4.5% is in the range of 10 to 900 Pa / cm2, and a relaxation time λ corresponding to the minimum value is in the range of 1 to 10,000 sec.

Owner:FUJIFILM BUSINESS INNOVATION CORP

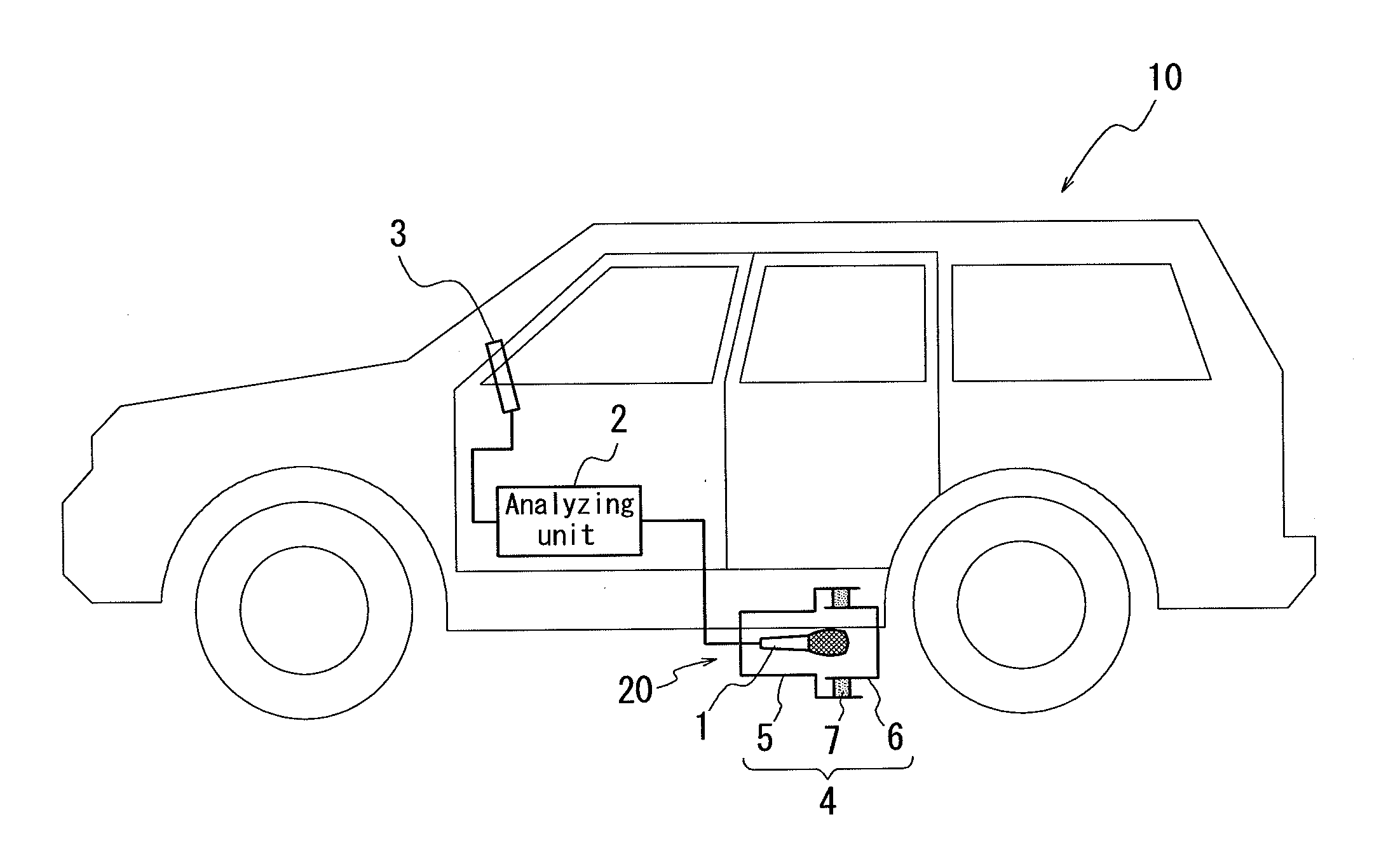

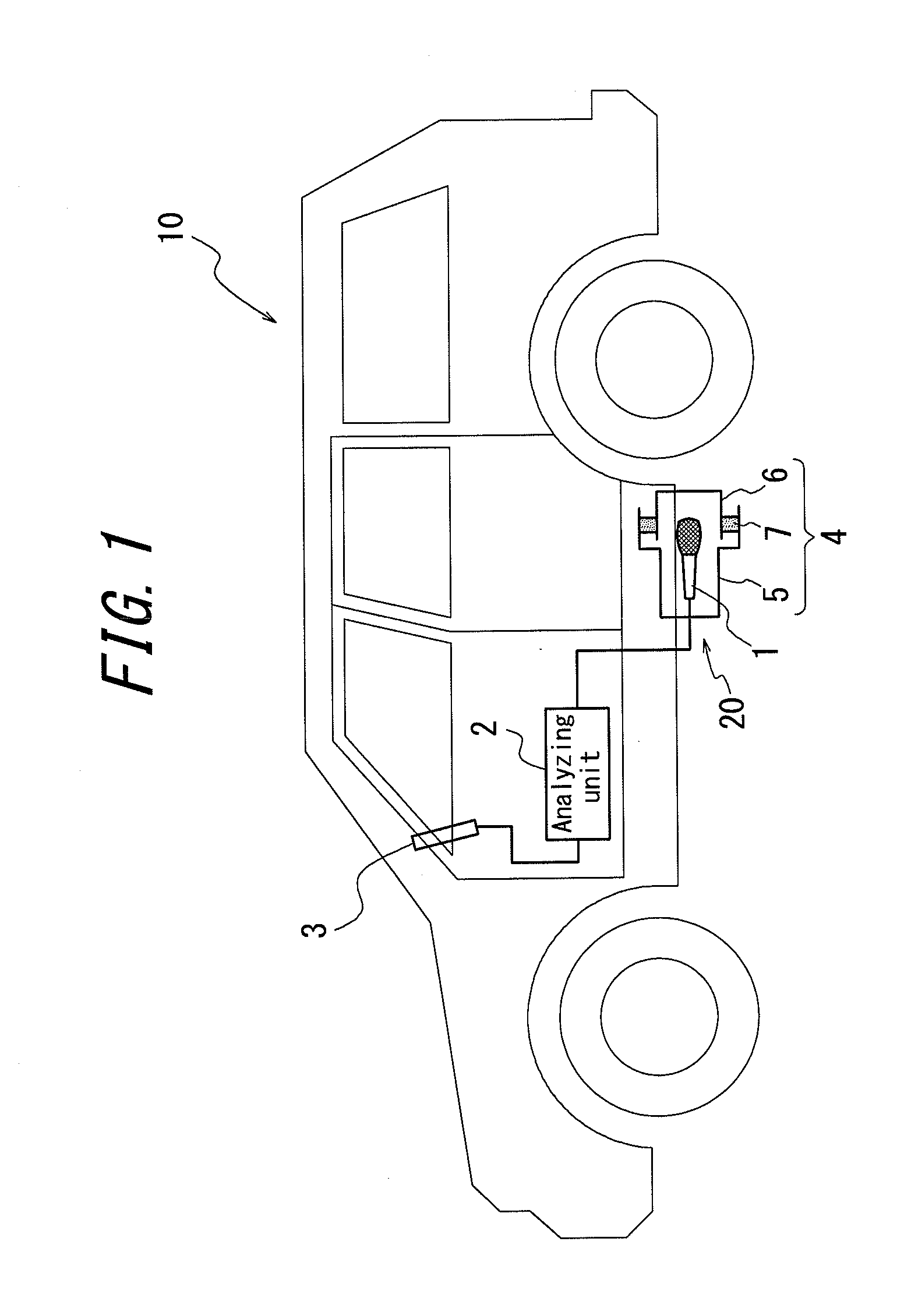

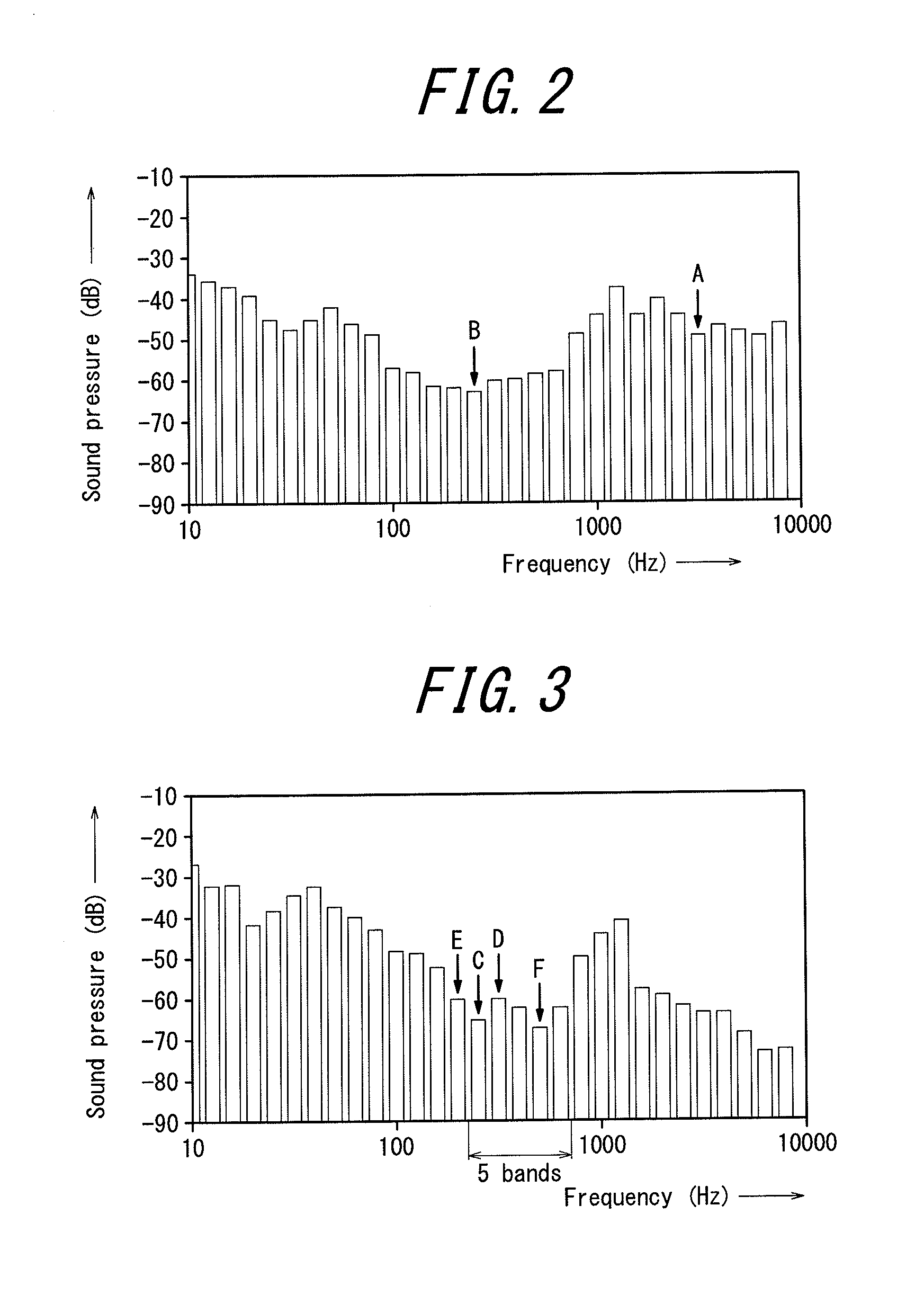

Method for estimating road surface state

ActiveUS20110200199A1Accurate estimateStatus accurateSubsonic/sonic/ultrasonic wave measurementElectrical apparatusGround contactSound detection

here is provided a method for determining a road surface state which can accurately estimate the road surface state on which a vehicle is running at one of finely classified road surface states based on a sound detection signal from a ground contact surface sound detection unit for detecting a sound in the vicinity of the ground contact surface of the tire of the running vehicle.The method calculates a wave profile of frequency dispersion by executing a 1 / N octave analysis of a detected sound signal from a sound detection unit 20 for estimating a road surface state. The state of the road surface on which the vehicle is running is determined whether the calculated wave profile of frequency dispersion satisfies predetermined determination conditions of the respective road surface states. A microphone housed in a container is used to detect said sound, and the determining step is adapted to apply the determination conditions to the measured wave profile including a resonance caused by the container.

Owner:BRIDGESTONE CORP

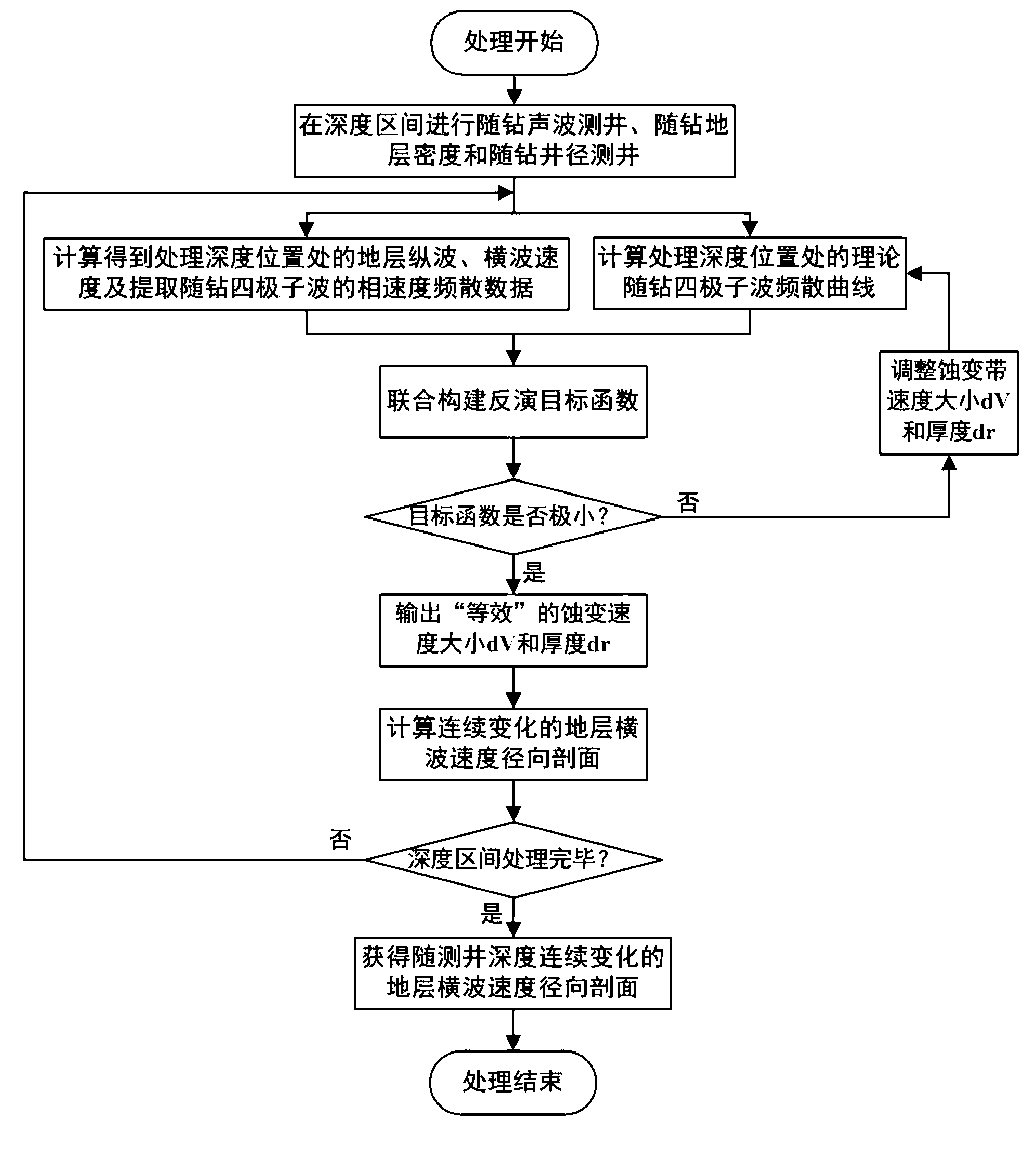

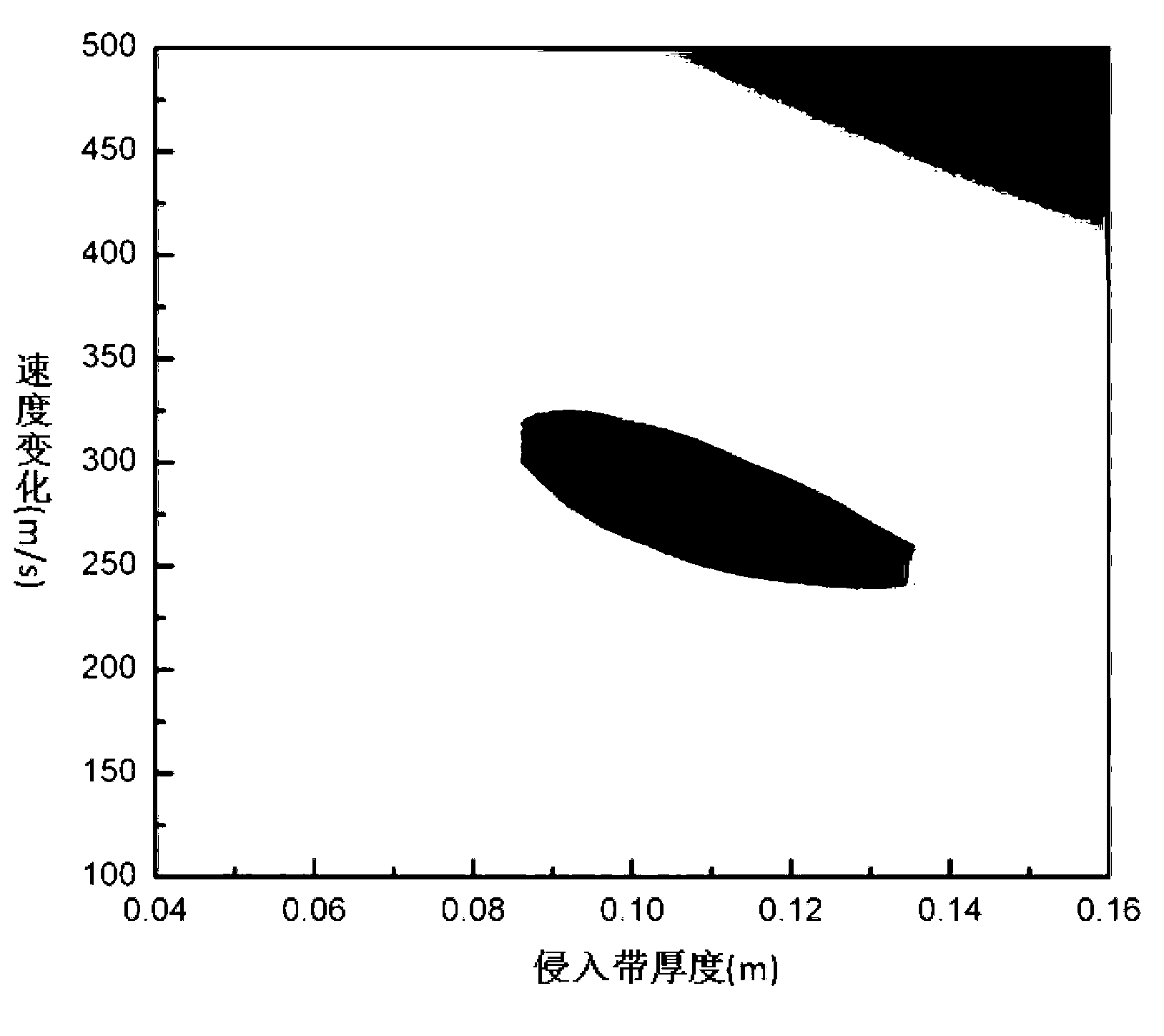

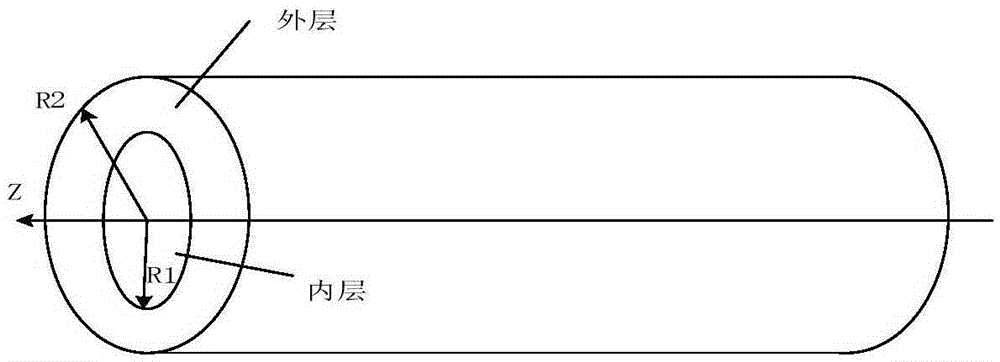

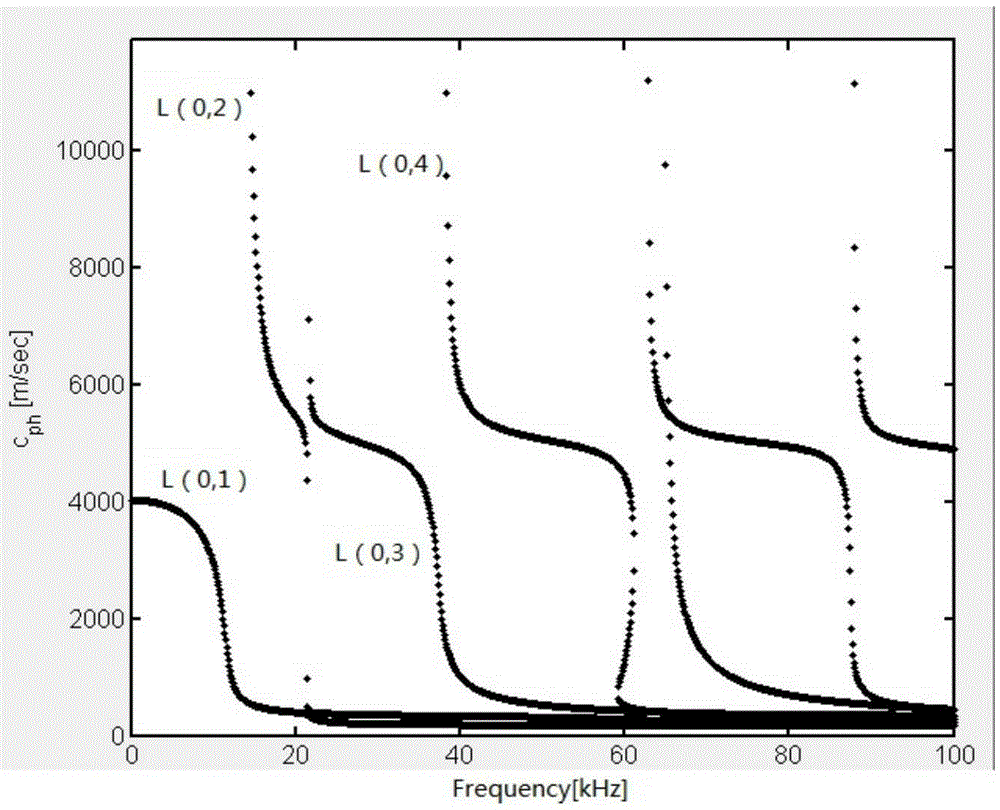

Inversion method of stratum shear wave velocity radial sections

ActiveCN103233727AObtain changes in mechanical/acoustic parameters in real timeObtain real-time changes in mechanical/acoustic parameters of the dominant mechanical/acoustic parameters near the wellBorehole/well accessoriesFull waveQuadrupole

The invention relates to an inversion method of stratum shear wave velocity radial sections. The inversion method includes: performing acoustic logging while drilling and while drilling stratum density and well diameter logging in a depth interval, and obtaining while drilling monopole and quadrupole array acoustic full wave train data, a while drilling stratum density logging curve and a while drilling well diameter logging curve; obtaining stratum longitudinal wave velocity and shear wave velocity at the position of processing depth through calculation, and extracting phase velocity frequency dispersion data of while drilling quadrupole wave; calculating a theoretical while drilling quadrupole wave frequency dispersion curve at the position of the processing depth; constructing an inversion objective function in a combined mode; outputting equivalent alteration velocity and thickness; calculating continuously variable stratum shear wave velocity radial sections; and repeating the steps until processing of the whole depth interval is finished, and obtaining the stratum shear wave velocity radial sections changing continuously along with logging depth. The inversion method of stratum shear wave velocity radial sections has the advantages of obtaining changes of mechanics / acoustic parameters nearby a well in real time, solving the problem of ununiqueness of inversion, and improving reliability of inversion results.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

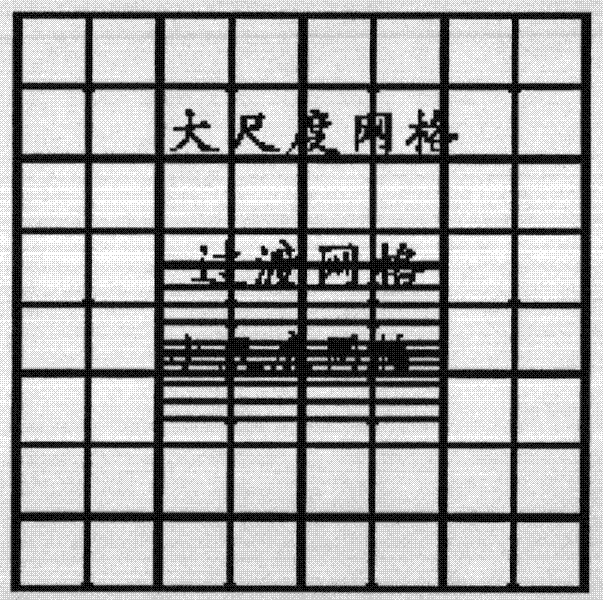

High-precision spatial and temporal arbitrary multiple variable grid finite difference forward modeling method

InactiveCN105277980AImprove computing efficiencyImprove calculation accuracySeismic signal processingSpecial data processing applicationsNODALDiscretization

The invention provides a high-precision spatial and temporal arbitrary multiple variable grid finite difference forward modeling method, which comprises the steps of: step 1, establishing a forward modeling speed model of an underground medium; step 2, subjecting the forward modeling speed model to two-dimensional grid discretization, and subjecting an acoustic wave field in the forward modeling speed model to two-dimensional grid discretization, wherein the acoustic wave field is located on grid nodes; step 3, subjecting a perfectly matched layer boundary condition to grid discretization; and step 4, conducting time-domain finite difference forward modeling simulation through an acoustic wave equation, wherein time sampling step lengths are variable step lengths at grids of different sizes. The high-precision spatial and temporal arbitrary multiple variable grid finite difference forward modeling method can effectively suppress forward modeling frequency dispersion, significantly increases signal-to-noise ratio, and greatly improves precision and efficiency of forward modeling simulation.

Owner:中石化石油工程地球物理有限公司胜利分公司

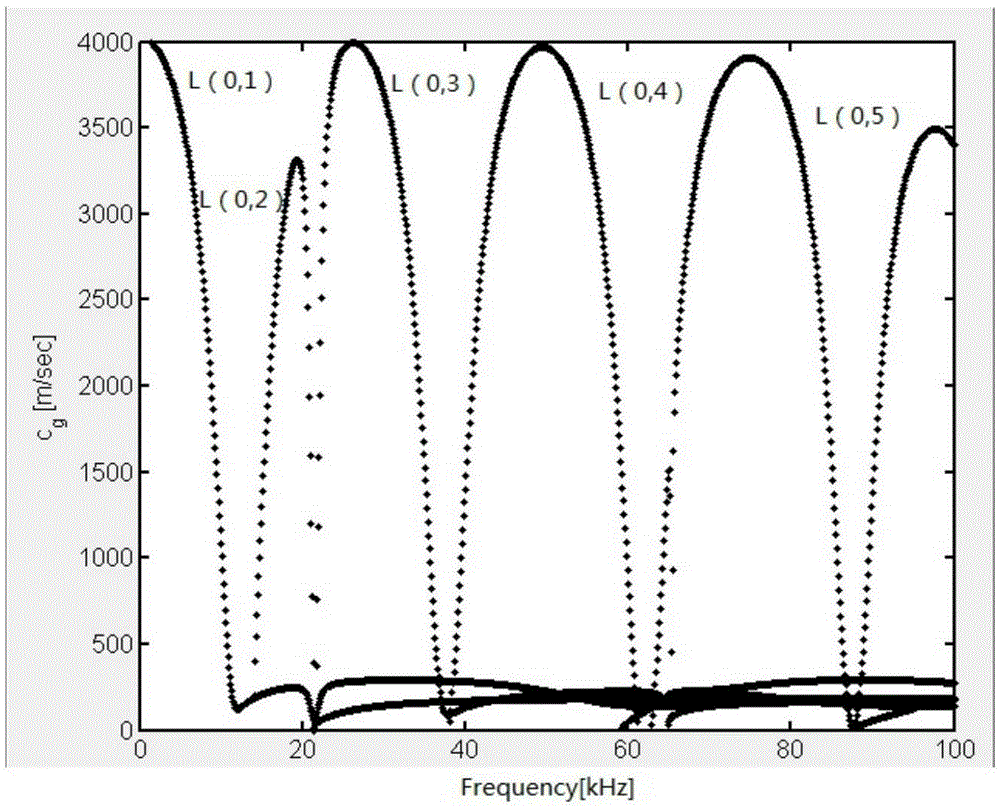

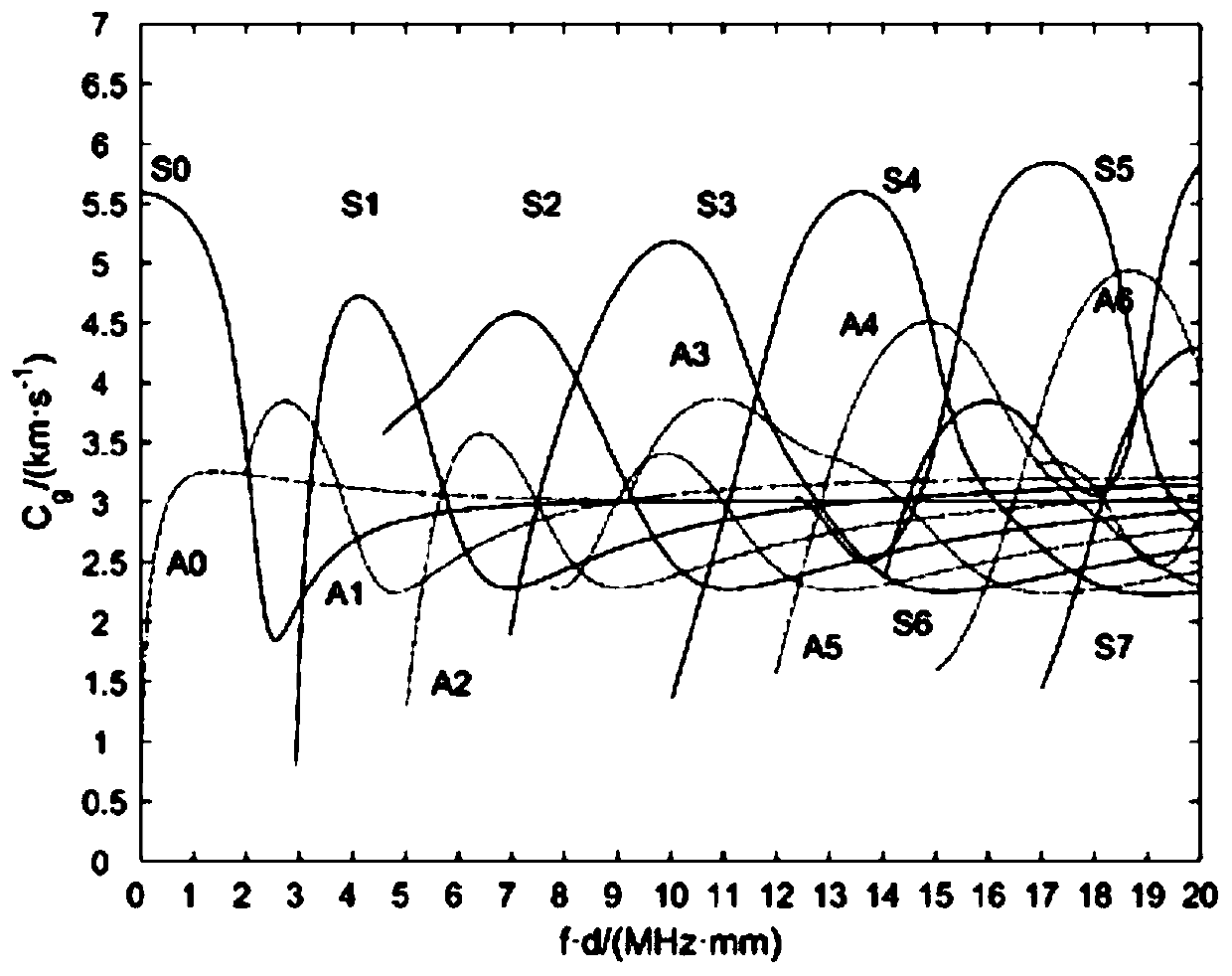

Ultrasonic guided-wave detecting system for defect of composite insulator and detecting method of ultrasonic guided-wave detecting system

InactiveCN105424802ALow costReduce sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesComposite insulatorsSonification

The invention discloses an ultrasonic guided-wave detecting system for the defect of a composite insulator. The ultrasonic guided-wave detecting system comprises a system master control computer, a signal generator, a power amplifier, a piezoelectric paster and a digital oscilloscope. The invention further discloses a detecting method applied to the ultrasonic guided-wave detecting system for the defect of the composite insulator. The detecting method comprises the following steps that 1, the frequency dispersion equation of propagation of guided waves in a composite insulator model is determined; 2, a corresponding frequency dispersion curve is obtained through insulator test piece related parameters tested through experiments; 3, stimulation guided wave frequency, periods and modal are determined according to a frequency dispersion curve conclusion; 4, stimulation and receiving points are selected, and defect detection of guided waves is achieved; 5, a guided wave detecting waveform is placed in a computer for data analysis processing, whether the defect exits or not it judged, and the size and type of the defect are judged. The detecting advantages of being accurate, fast, long in distance, large in range, low in cost and the like are achieved.

Owner:SOUTH CHINA UNIV OF TECH

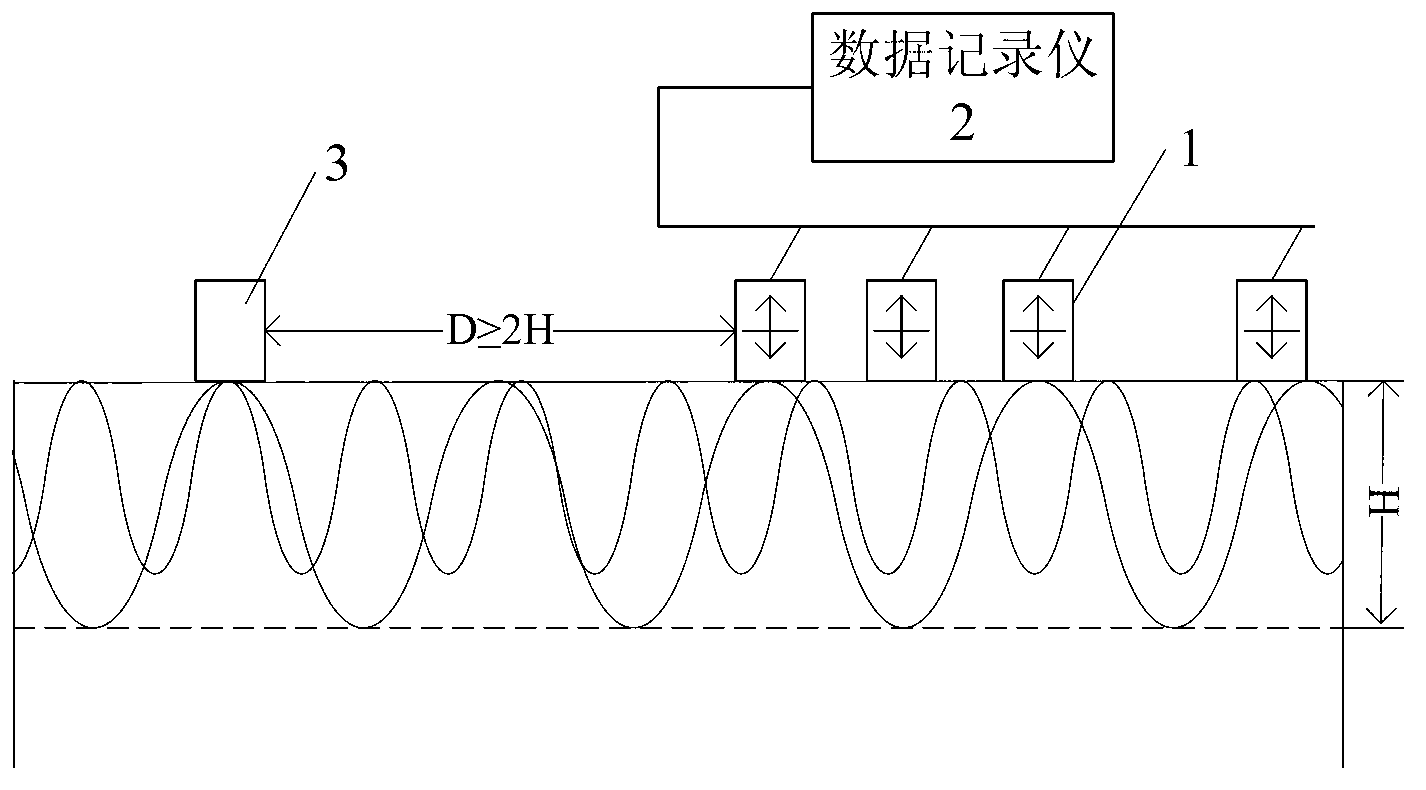

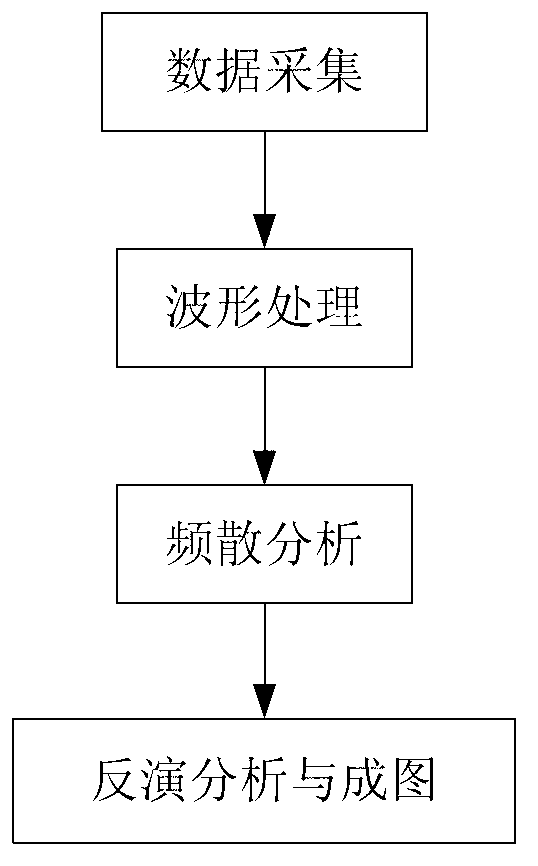

Surface wave-based nondestructive testing method and system for internal concrete state

InactiveCN103018337ASimple methodGood precisionAnalysing solids using sonic/ultrasonic/infrasonic wavesDetector arrayComputer module

The invention relates to a surface wave-based nondestructive testing method and a nondestructive testing system for internal concrete state. The method comprises the steps of: 1) setting a measuring line on the surface of concrete to be tested, and setting n testing points on the measuring line; 2) setting a detector array on a straight line taking a first testing point as the center, and setting an elastic wave triggering device; 3) trigging an elastic wave through the elastic wave triggering device, acquiring the elastic wave through the detector, and transmitting the elastic wave to a data recorder through a cable; 4) moving the central point of the detector array to a next testing point, and repeating the step 3) till the testing is accomplished; 5) carrying out waveform processing on the data, and extracting and displaying a frequency dispersion curve of the surface wave; and 6) converting the frequency dispersion curve into a cross-section diagram so as to obtain the internal concrete state. The system comprises a data acquisition module, a data analysis module and a data visualization processing module which are connected in sequence. Compared with the prior art, the device and the method have the advantages of good precision, high efficiency, high detection degree, low cost and the like.

Owner:SHANGHAI JIAO TONG UNIV

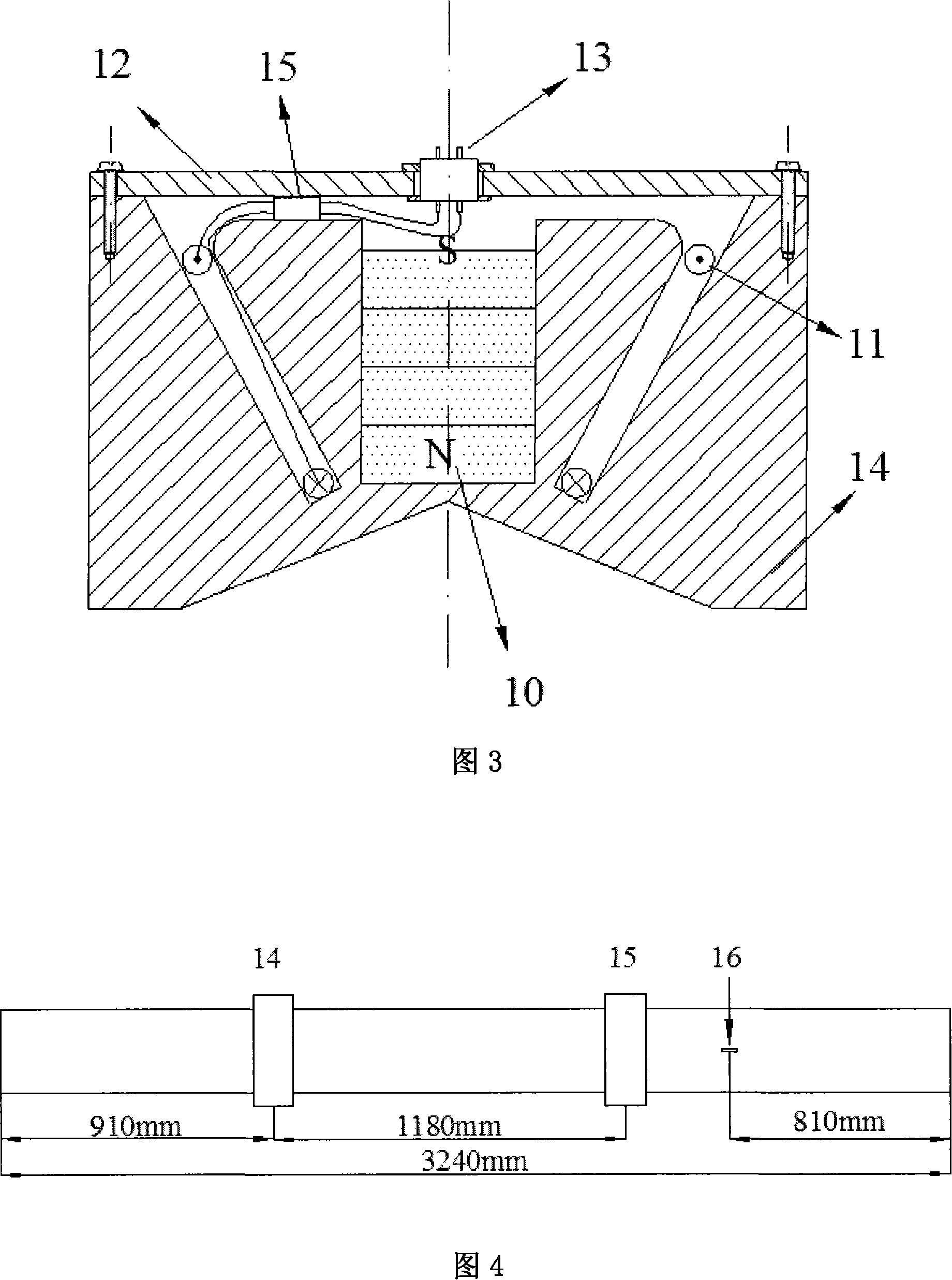

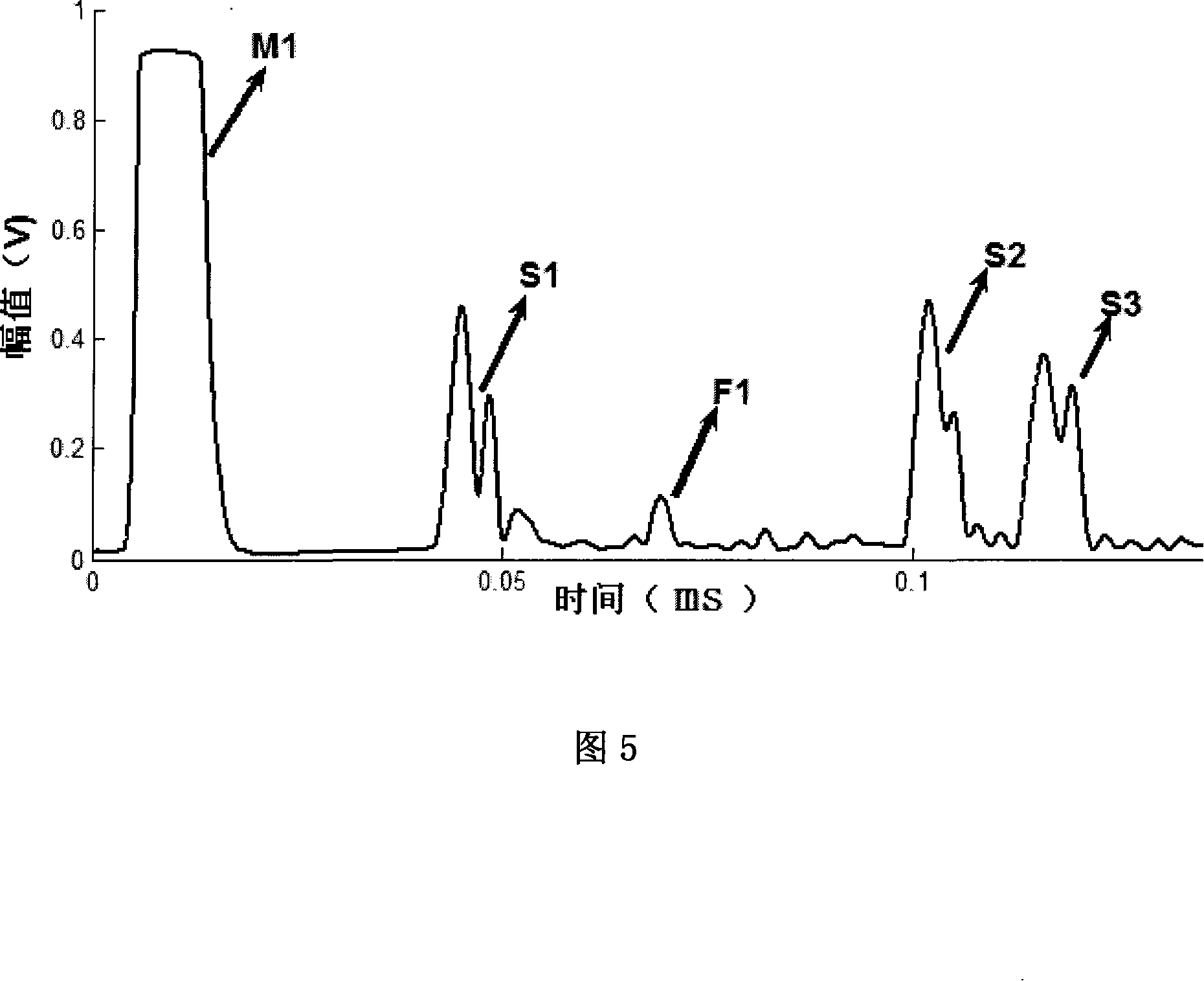

Device detecting magnetic conduction component defect based on magnetic striction torsion wave

InactiveCN101140266ALittle outside influenceGood motivationAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using acoustic emission techniquesUltrasound attenuationAudio power amplifier

A device to detect defects of magnetic conducting structures based on magnetoconstriction torsional waves belongs to an ultrasonic nondestructive detector, which overcomes shortcomings of high guide wave attenuation of vertical mode and remarkable frequency dispersion effect. During detection, it is unnecessary to process surfaces of the structure. The present invention comprises a pulse signal generator, a power amplifier, a magnetoconstriction torsional wave sensor, a signal preprocessor, an A / D converter and a computer. Wherein, the magnetoconstriction torsional wave sensor is composed of an excitation unit and a receiving unit. The computer controls generation of pulse signals. The pulse signal is amplified by the power amplifier and then generates torsional waves in the structure through the excitation unit. The receiving unit receives the torsional wave from the structure, which is processed by the signal preprocessor and then converted into digital signals by the A / D converter. The computer obtains defect information of the structure. The present invention can conveniently excite and receive torsional waves, detect defects along axis of the structure and adapt to long-distance detection of clad pipes and cables with PE jacket.

Owner:HUAZHONG UNIV OF SCI & TECH +1

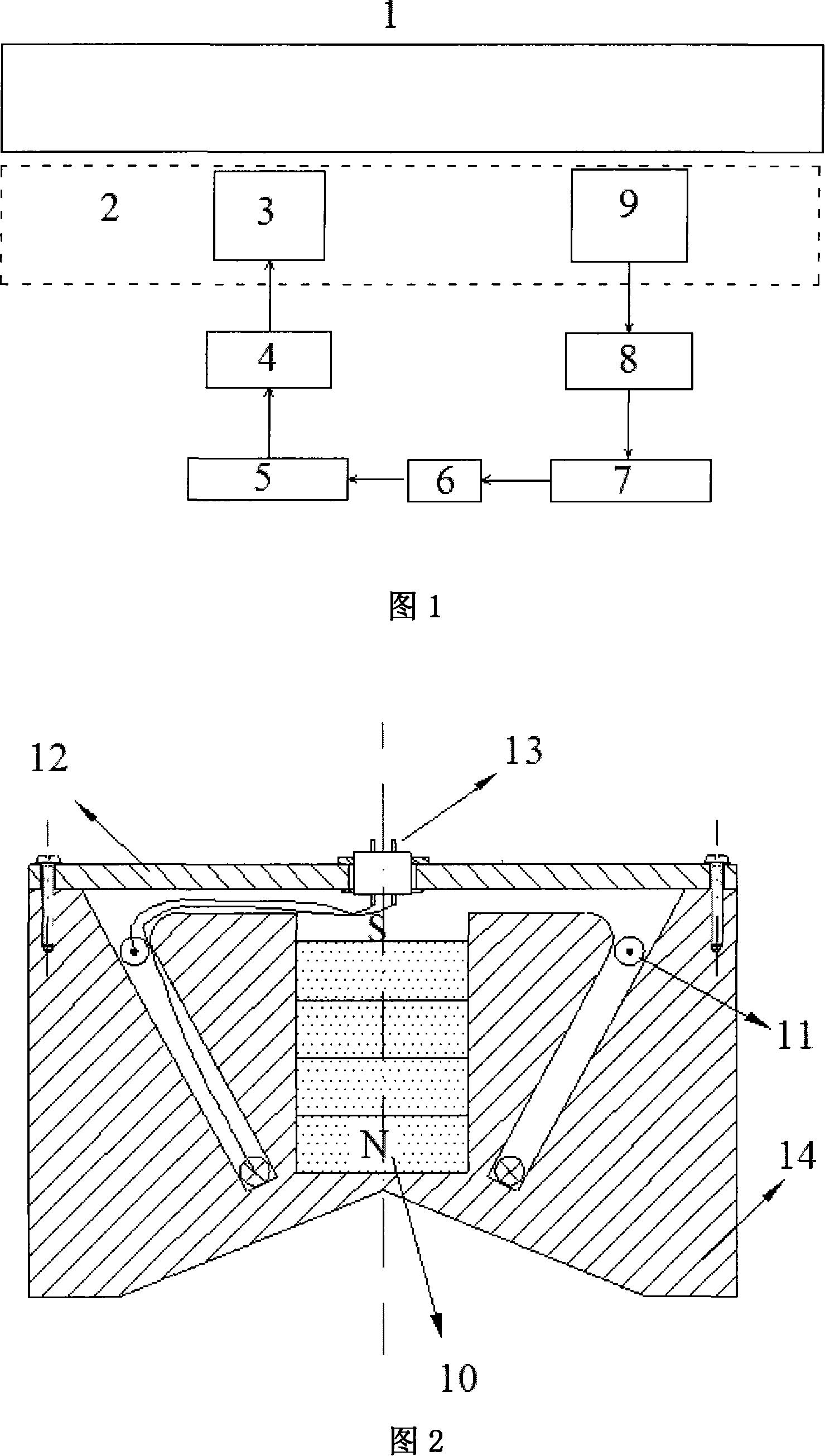

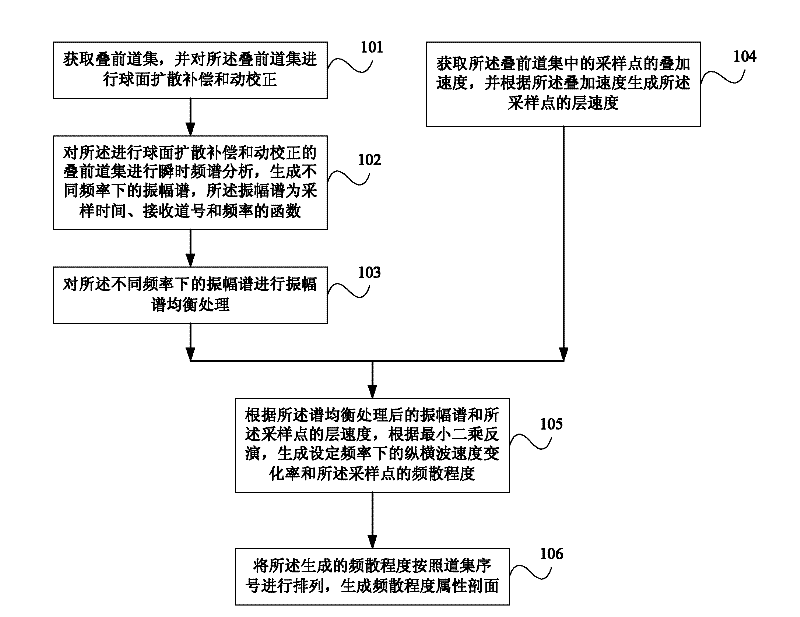

Inversion method of frequency dispersion amplitude versus offset (AVO)

ActiveCN102478667AEliminate the effects ofImprove mining efficiencySeismic signal processingFrequency spectrumInterface waves

The invention discloses an inversion method of frequency dispersion amplitude versus offset (AVO). The inversion method comprises the following steps: acquiring a pre-stack trace gather; carrying out spherical diffusion compensation and dynamic correction on the pre-stack trace gather, and carrying out instant spectrum analysis on the pre-stack trace gather, so as to generate amplitude spectra under different frequencies; carrying out amplitude spectrum balancing on the amplitude spectra; acquiring a stacking velocity of sampling points in the pre-stack trace gather; generating a layer velocity of the sampling points according to the stacking velocity; generating speed variation rate of the velocity of vertical and horizontal waves under a set frequency and frequency dispersion degree of the sampling points according to the amplitude spectra after amplitude spectrum balancing, the layer velocity of the sampling points, and least square inversion; and ranking the generated frequency dispersion degree according to the trace gather serial number, so as to generate an attribute section of the frequency dispersion degree. By utilizing the inversion method of frequency dispersion AVO provided by the embodiment of the invention, the influence of a strong amplitude energy group caused by impedance difference of an elastic interface wave can be eliminated, and the false 'frequency abnormality' caused by the stacking when post-stack seismic data spectrum is analyzed can be avoided, so that the obtained result is more reliable.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

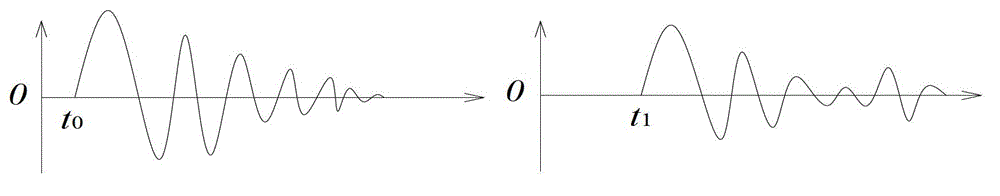

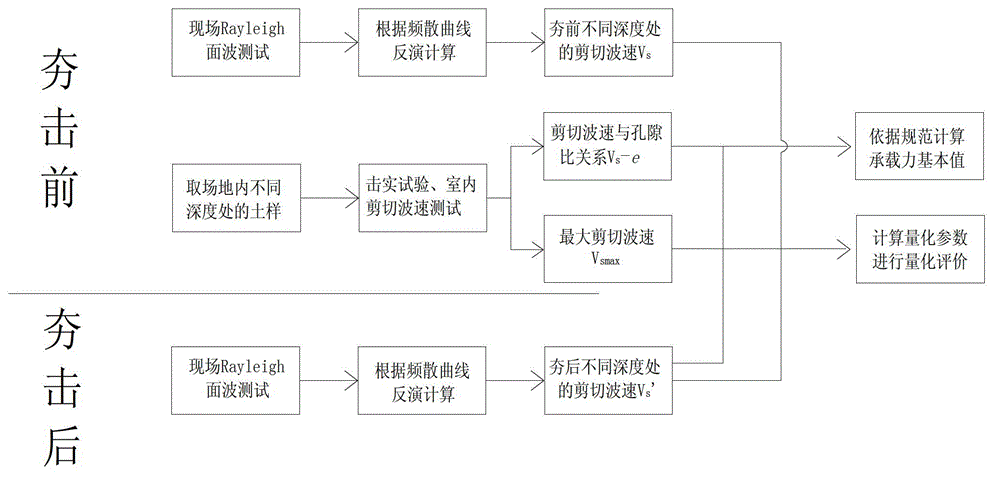

Quantitative analysis method for evaluating dynamic compaction reinforcement effect of foundation by utilizing Rayleigh surface waves

ActiveCN102943461AThe results of the effect analysis are specificThe effect analysis results are accurateIn situ soil foundationDynamic compactionVoid ratio

The invention discloses a quantitative analysis method for evaluating a dynamic compaction reinforcement effect of foundation by utilizing Rayleigh surface waves. The method comprises compacting pretreatment and compacting post-treatment, namely before compacting, performing field Rayleigh surface wave test according to frequency dispersion curve back calculation, so as to obtain a shear wave velocity Vs at different depths before compacting, performing a compacting test on a soil sample at different depths in the field, and finishing an indoor shear wave velocity test, wherein the testing result comprises a relationship Vs-e between the shear wave velocity and a void ratio, and the maximum shear wave velocity Vsmax; and after compacting, performing field Rayleigh surface wave test according to frequency dispersion curve back calculation, so as to obtain a shear wave velocity Vs' at different depths after compacting, and finally, calculating the compaction degree delta according to the parameters, and realizing evaluation on the dynamic compaction reinforcement effect according to the compaction degree delta. Compared with the prior art, the method has the advantages that the quantization parameter, namely the compaction degree delta, of the dynamic compaction reinforcement effect of the foundation is evaluated due to introduction of quantitative analysis, an evaluation effect of the dynamic compaction reinforcement effect can be quantitatively analyzed, and the method is specific and accurate.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

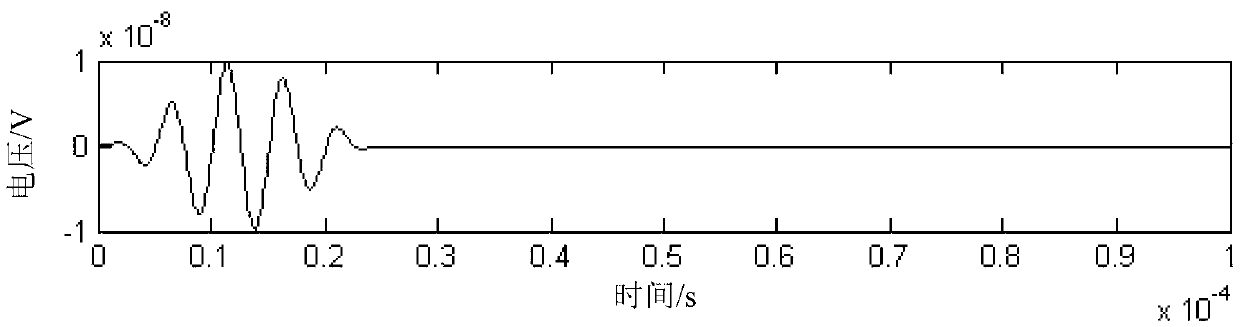

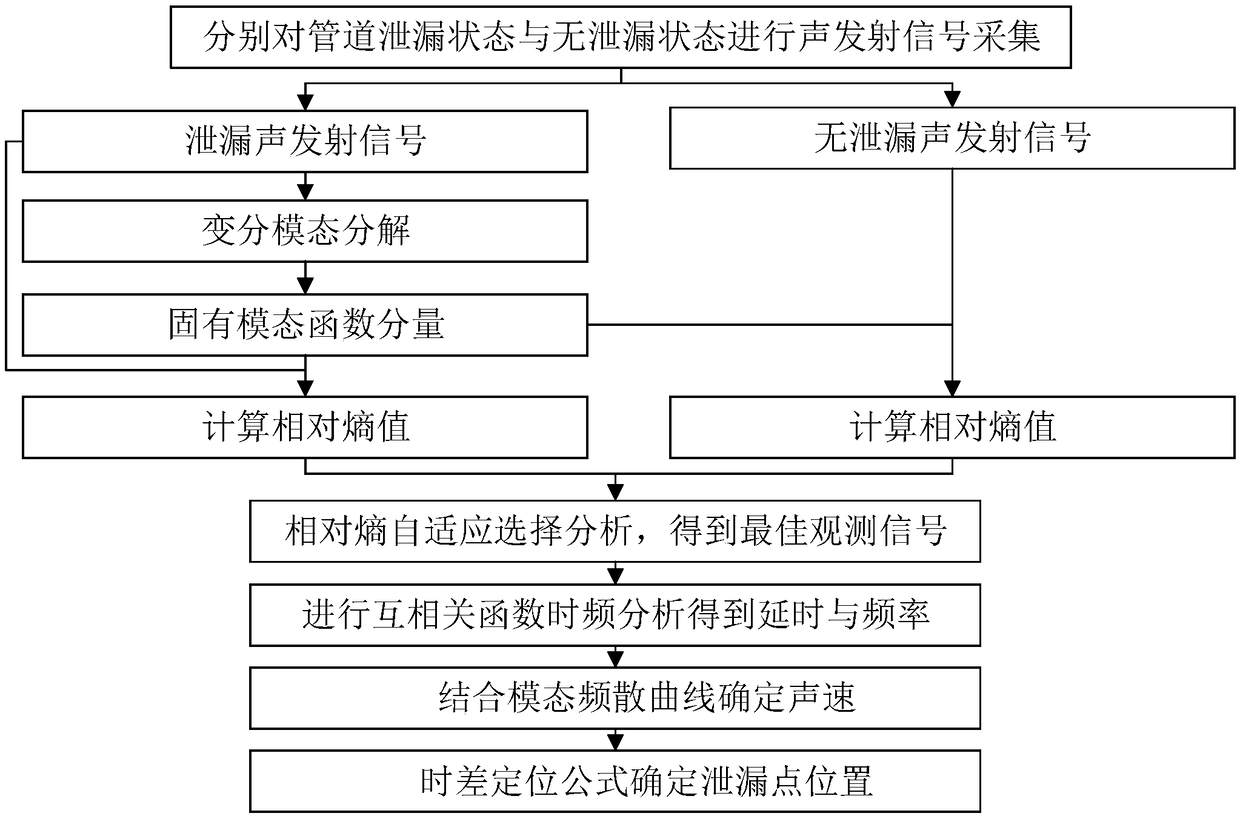

Pipeline leakage positioning method based on VMD component relative entropy analysis

ActiveCN108644618ASolve the problem of large leak location errorsEfficient extractionDetection of fluid at leakage pointPipeline systemsTime–frequency analysisEngineering

The invention provides a pipeline leakage positioning method based on VMD component relative entropy analysis. A VMD is applied to treat a leakage sound emission signal, an IMF component is obtained,the component is combined with the leakage sound emission signal and a non-leakage sound emission signal to calculate relative entropy value, the relative entropy value is subjected to self-adaptationoption analysis, the IMF component corresponding to a signal containing leakage characteristics is extracted for signal reconstruction, and an optimal observation signal is obtained; time-frequency analysis is used for obtaining observation signal delay and frequency, the obtained frequency is combined with a modal frequency dispersion curve to determine a signal sound speed, and finally, throughthe time difference positioning principle, the pipeline leakage position is obtained. Through contrastive analysis of the non-leakage signal and leakage signal IMF component relative entropy value, an interference signal and a virtual component are removed, extraction of an effective leakage signal is achieved, and in joint with the time-frequency analysis and the modal frequency dispersion curve, the problems that the leakage signal is hard to extract, and due to the dispersion property, the leakage positioning error is large are solved.

Owner:CHANGZHOU UNIV

Metal plate micro-defect detection method based on nonlinear Lamb waves

PendingCN111044613AEffective representationCharacterize the flaws of the metal sheet under test for efficient characterizationAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalNon linear waveNonlinear ultrasound

The invention provides a metal plate micro-defect detection method based on nonlinear Lamb waves. The metal plate micro-defect detection method comprises the following steps of: S1, acquiring a phasevelocity frequency dispersion curve and a group velocity frequency dispersion curve of a metal plate; S2, acquiring an excitation frequency, Lamb waves of a specific mode and an incident angle of theLamb waves of the specific mode as model parameters according to the phase velocity frequency dispersion curve and the group velocity frequency dispersion curve; S3, deriving a relative nonlinear coefficient beta' according to the Lamb waves of the specific mode in the S2, wherein the relative nonlinear coefficient beta' is used for representing the depth of a defect; S4, establishing a nonlinearultrasonic test system according to the model parameters; and S5, testing the metal plate according to the nonlinear ultrasonic test system established in the step S4, judging whether the relative nonlinear coefficient beta' is reliable or not, and if so, representing the defects of the tested metal plate by utilizing the relative nonlinear coefficient beta'. According to the metal plate micro-defect detection method, the relative nonlinear coefficient beta' represents the defects of the tested metal plate, the defects of the metal plate can be effectively represented, and the detection precision is improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

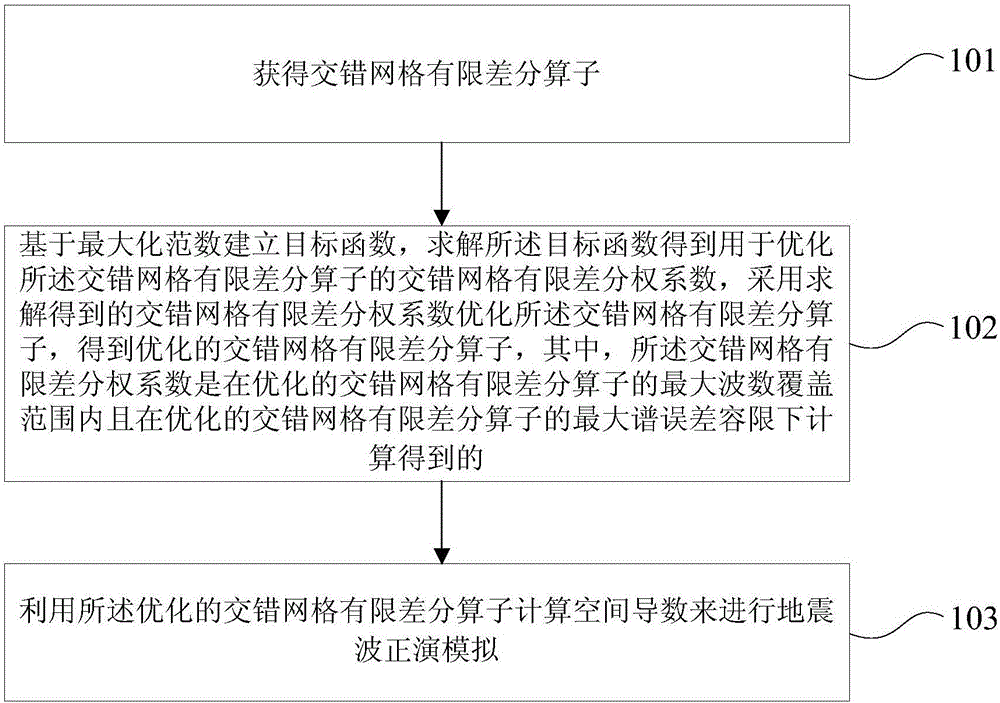

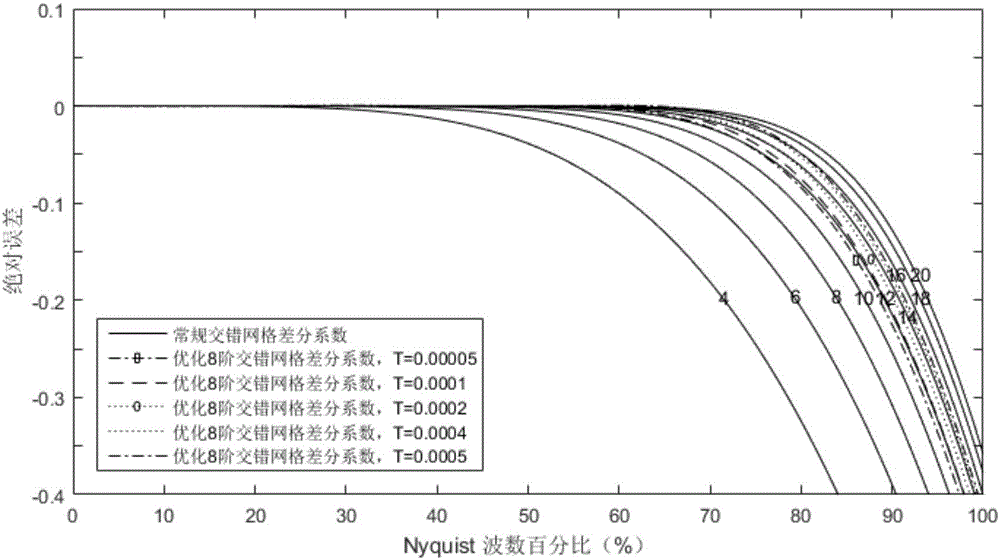

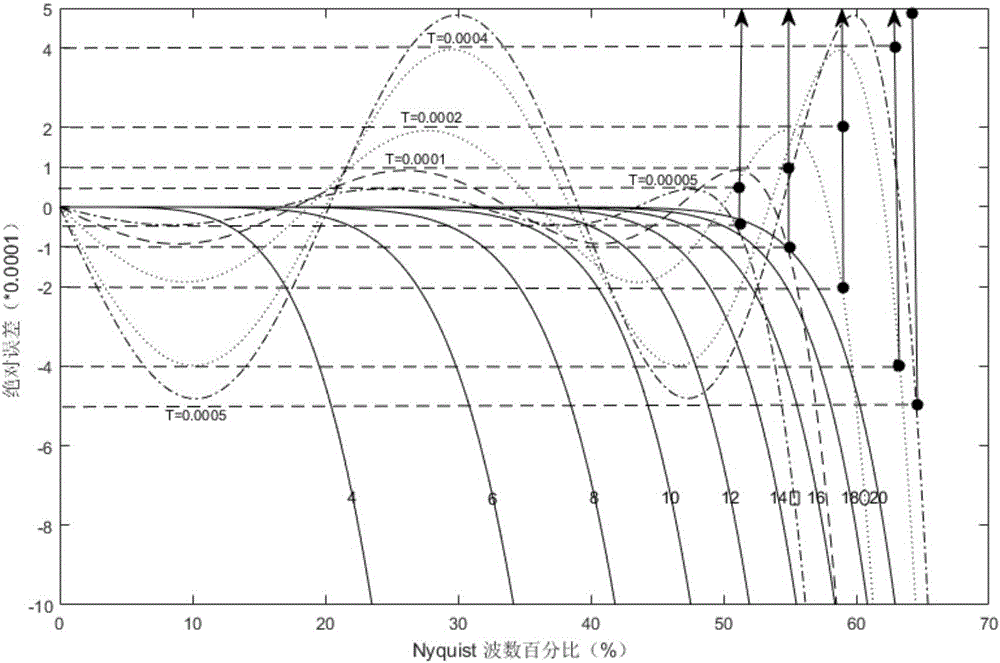

Globally optimized staggered mesh finite-difference forward simulation method and device

InactiveCN106842306AFlexible processControlling Absolute Spectral ErrorSeismic signal processingGlobal optimizationFrequency dispersion

The embodiment of the invention provides a globally optimized staggered mesh finite-difference forward simulation method and device. The method comprises the steps that a staggered mesh finite-difference operator is obtained; a target function is established based on a maximized norm and is calculated to obtain a staggered mesh finite-difference decentralization coefficient for optimizing the staggered mesh finite-difference operator, wherein the staggered mesh finite-difference decentralization coefficient is calculated in the maximum wave number coverage range of the optimized staggered mesh finite-difference operator and under the maximum spectrum error margin of the optimized staggered mesh finite-difference operator; the calculated staggered mesh finite-difference decentralization coefficient is adopted to optimize the spatial staggered mesh finite-difference operator, and forward simulation of seismic waves is performed. By adopting the scheme, absolute spectrum errors of the optimized staggered mesh finite-difference operator are more flexibly controlled, numerical value frequency dispersion is more effectively constrained, and the seismic simulation precision is improved.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

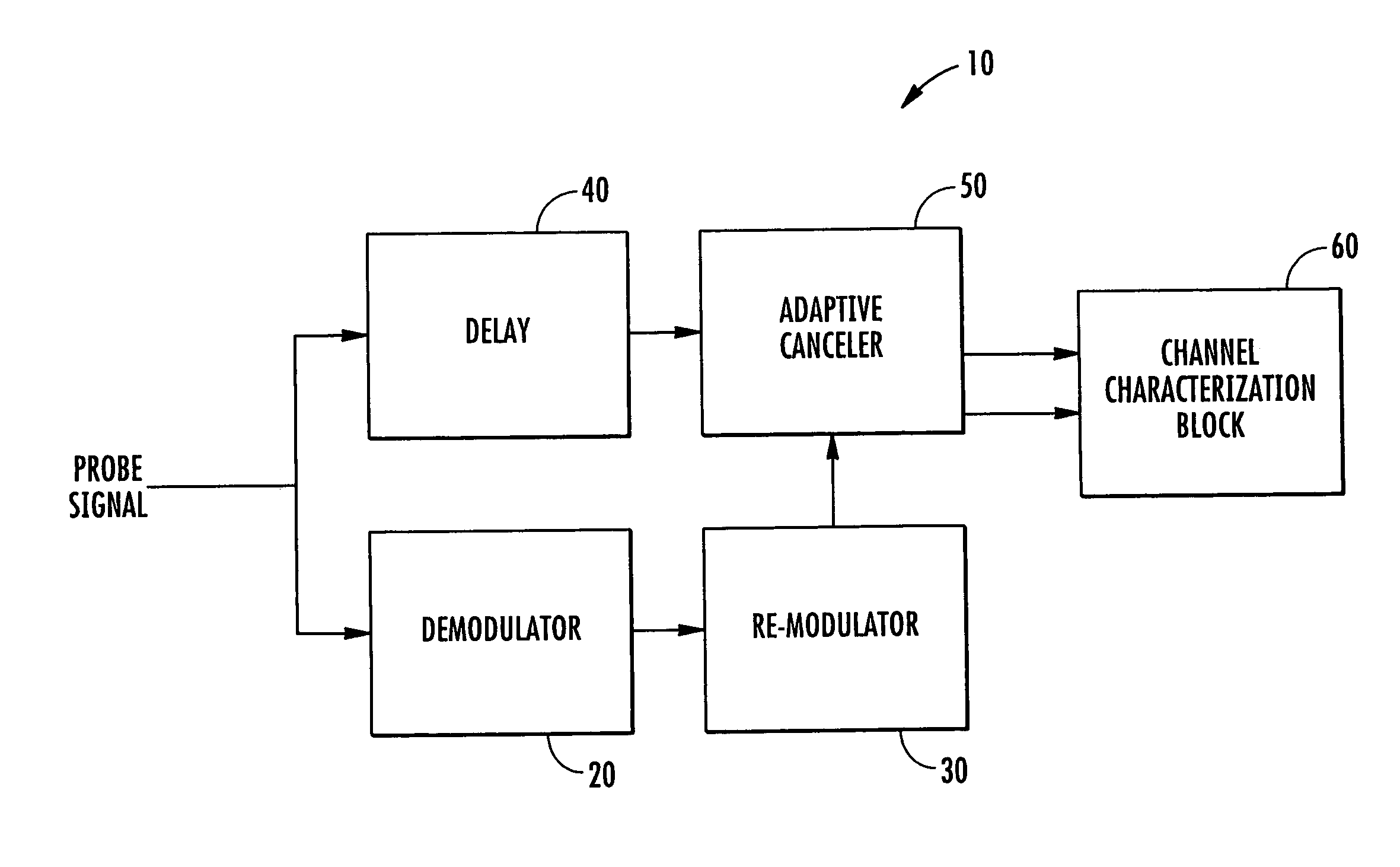

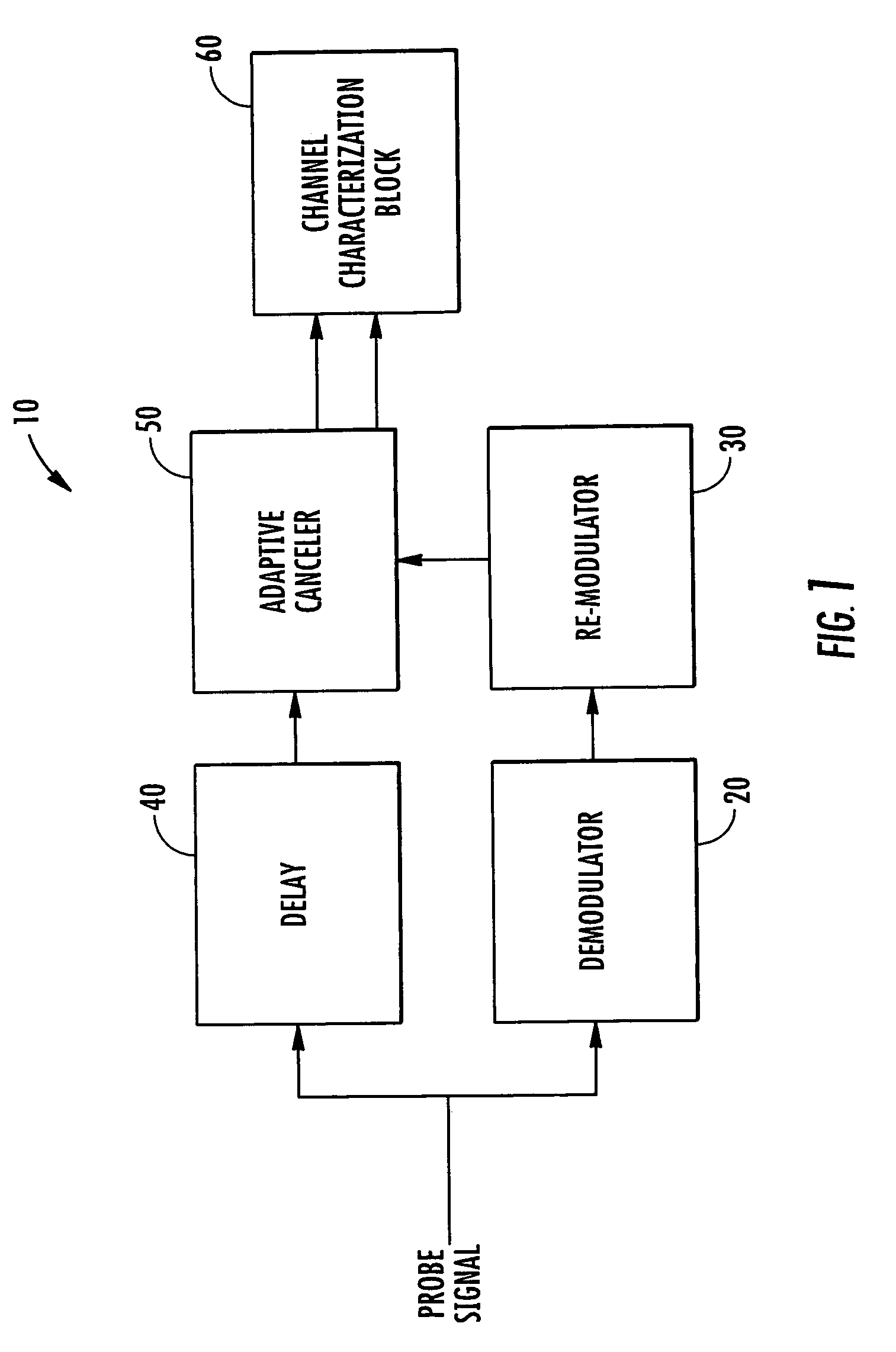

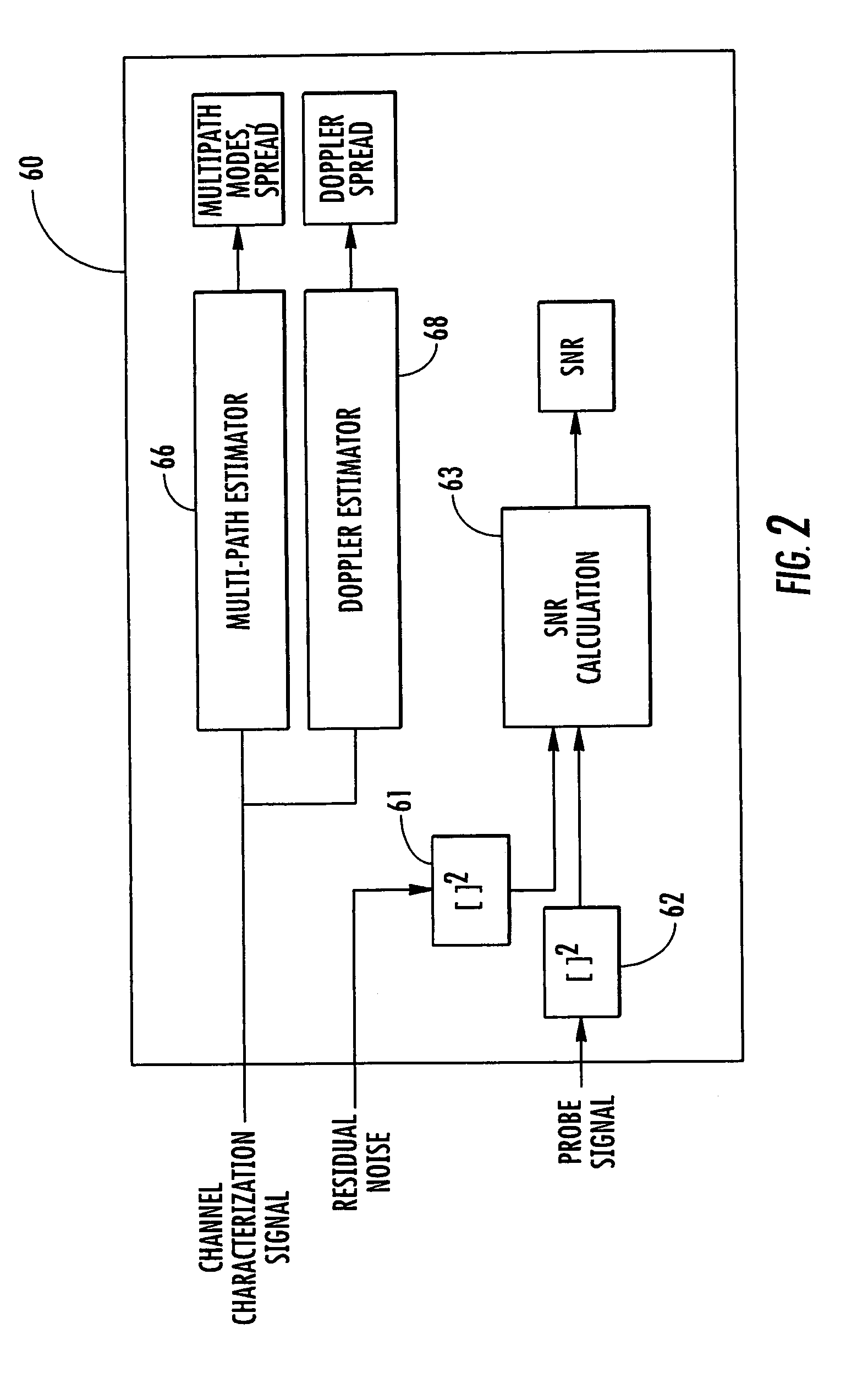

Communications channel characterization device and associated methods

ActiveUS7085539B2Error detection/prevention using signal quality detectorTransmission monitoringDoppler spreadSignal-to-noise ratio (imaging)

The system and method characterize a communications channel with respect to signal-to-noise ratio (SNR), time dispersion or multi-path, and frequency dispersion or Doppler spread. A probe signal demodulator receives a probe signal transmitted on a wireless communication channel and generates a demodulated probe signal, and a probe signal re-modulator generates a replica probe signal. A delay unit generates a delayed probe signal, and an adaptive canceller receives the delayed probe signal and the replica probe signal, and generates a residual noise signal and a channel characterization signal. A channel characterization block receives the channel characterization signal and the residual noise signal to generate channel measurements of the wireless communication channel.

Owner:HARRIS GLOBAL COMM INC

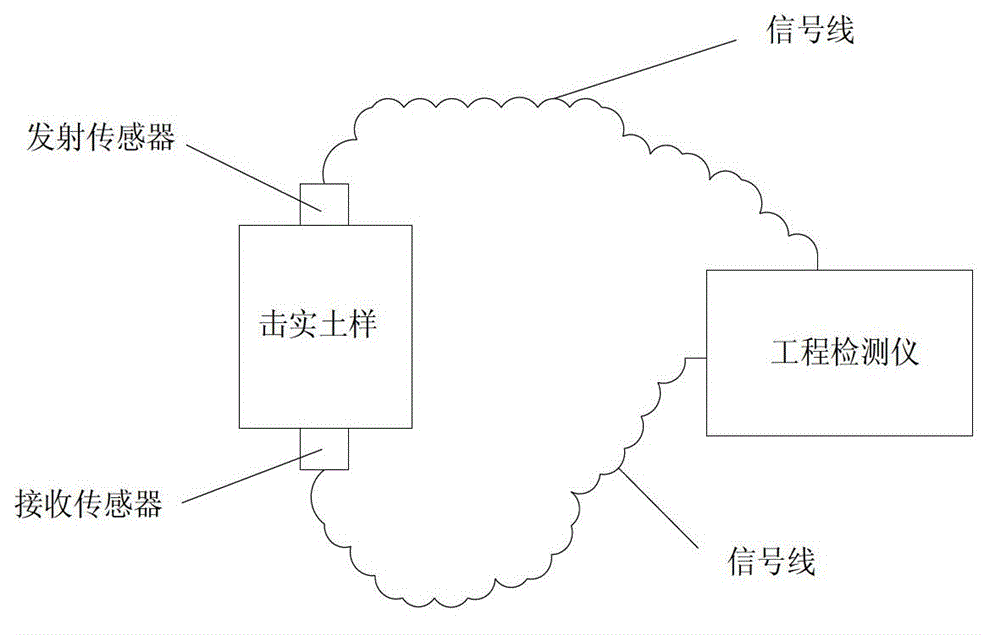

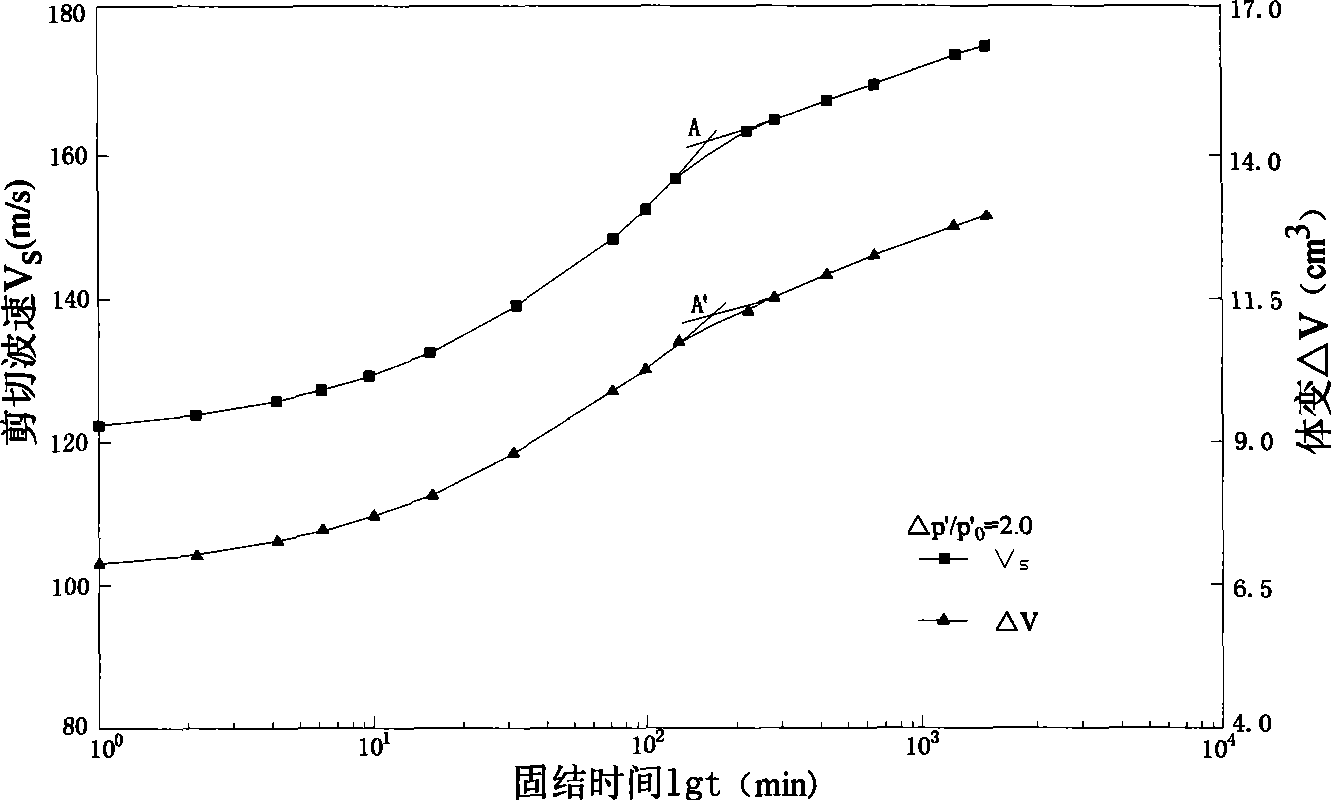

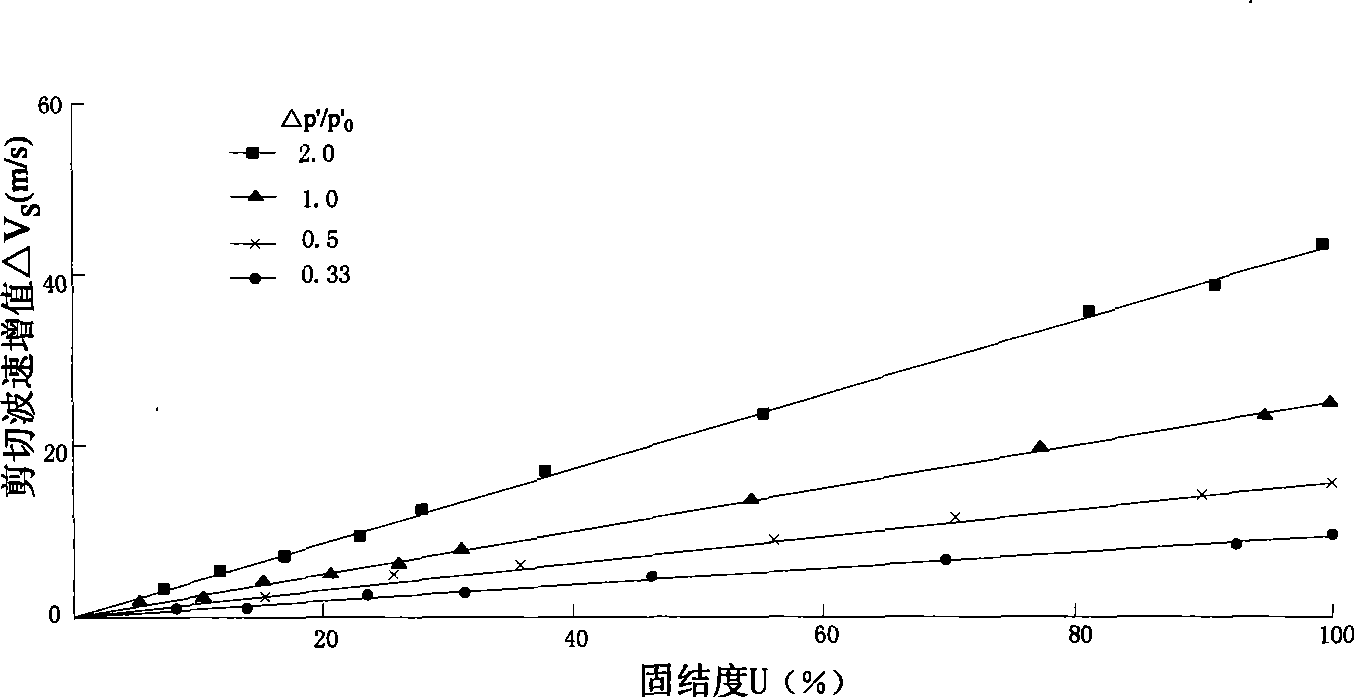

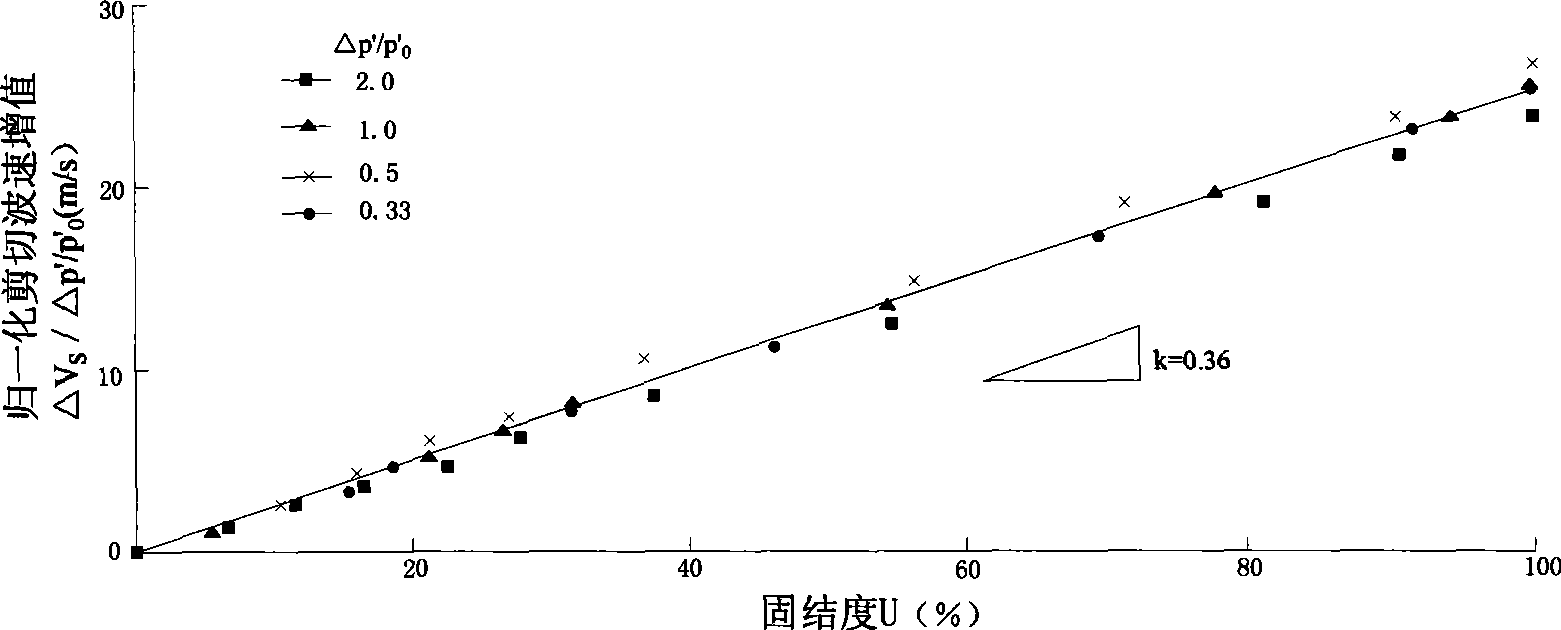

Testing method for consolidation degree of soft soil foundation

InactiveCN101520440ALow costThe testing process is simpleAnalysing solids using sonic/ultrasonic/infrasonic wavesPore pressure gradientFrequency dispersion

The invention discloses a testing method for consolidation degree of soft soil foundation in the field of engineering construction, which comprises the following steps: acquiring a frequency dispersion curve by utilizing the frequency dispersion characteristics when Reyleigh waves are transmitted in a layered medium, and correlationship of the spread velocity of the Reyleigh waves and the physical-mechanical property of a soil body; calculating the wave velocity of the Reyleigh waves of a soft foundation soil layer according to the frequency dispersion curve of the Reyleigh waves; and finally, calculating the consolidation degree by combining a parameter k calculated according to the relation between a normalized shear wave velocity increment of the tested soil layer and the consolidation degree obtained by indoor resonant column tests. Compared with the prior method for calculating the consolidation degree through pore pressure, the testing method is more simple, convenient, effective and economic. The pore pressure is not needed to be tested, so the testing time is greatly saved; moreover, the prior method is easy to fail because of high requirement on the laying of a pore pressure gauge, and the results obtained by the testing method are more accurate.

Owner:HOHAI UNIV

Two-way time reversal damage imaging method based on ultrasonic guided-wave

ActiveCN105510444AIncrease signal amplitudeImprove signal-to-noise ratioAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationElement model

The invention discloses a two-way time reversal damage imaging method based on ultrasonic guided-wave. The method comprises the following steps: carrying out active stress wave detection on a damaged object by the use of a modulated excitation signal, and synchronously acquiring signals at a transmission end and a reflective end of a detected area; carrying out frequency dispersion compensation separation on the acquired signals, and separating longitudinal mode guided wave and bending mode guided wave; extracting the longitudinal mode guided wave in the separated signals, carrying out time reversal treatment, and amplifying the reversed signal; carrying out simulation reversal by importing the reversed signal into a finite element model, extracting displacement values of all point clouds and moments in the model, and carrying out time and space focusing treatment to obtain a vibration cloud map; and defining a space curve to convert the vibration cloud map into a three-dimensional color map, and carrying out damage imaging by three-dimensional color point cloud. According to the method, characteristics of damages are analyzed from an overall perspective, and different mode guided waves are innovatively extracted to carry out time reversal analysis of transmission and reflective ends simultaneously. The method of the invention has important academic value and practical significance.

Owner:SOUTH CHINA UNIV OF TECH +1

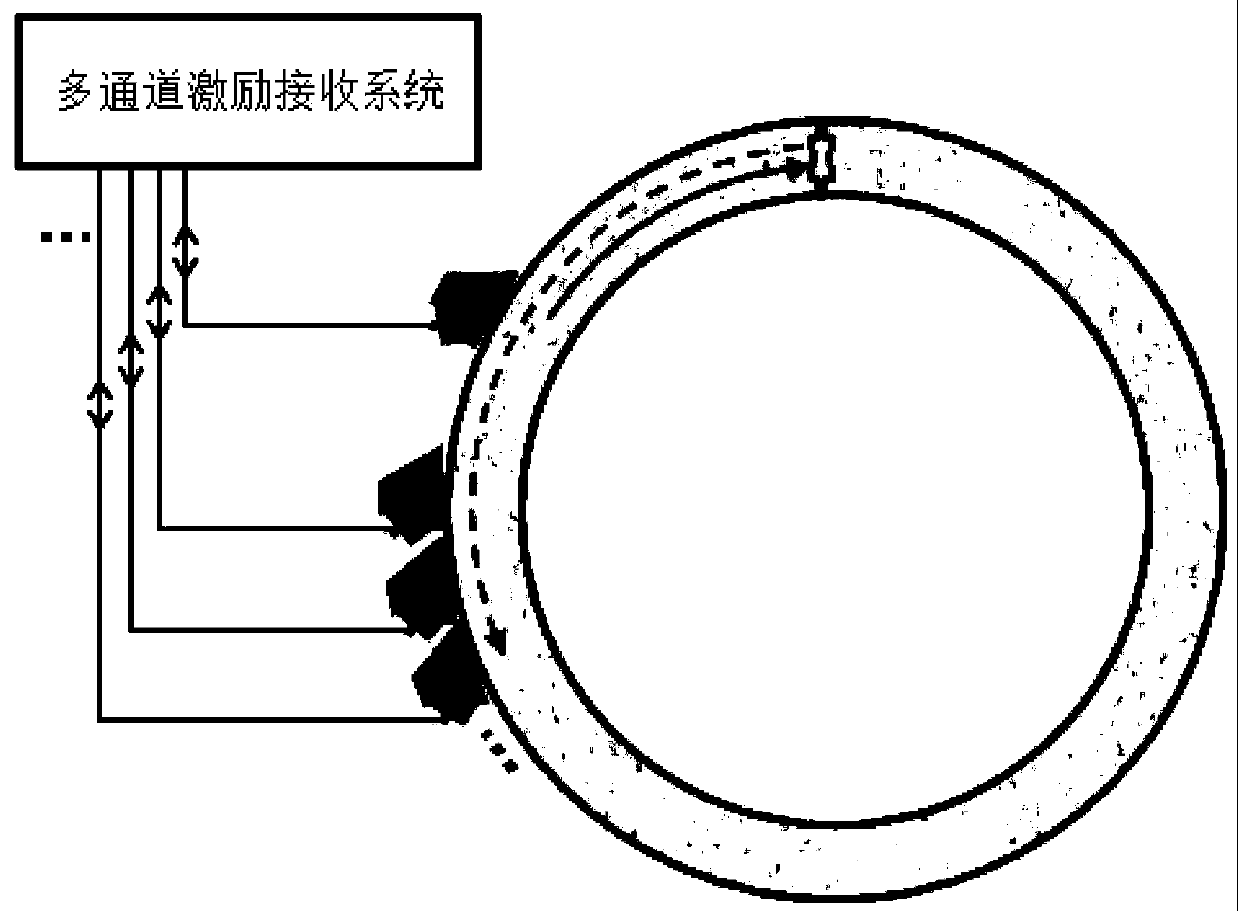

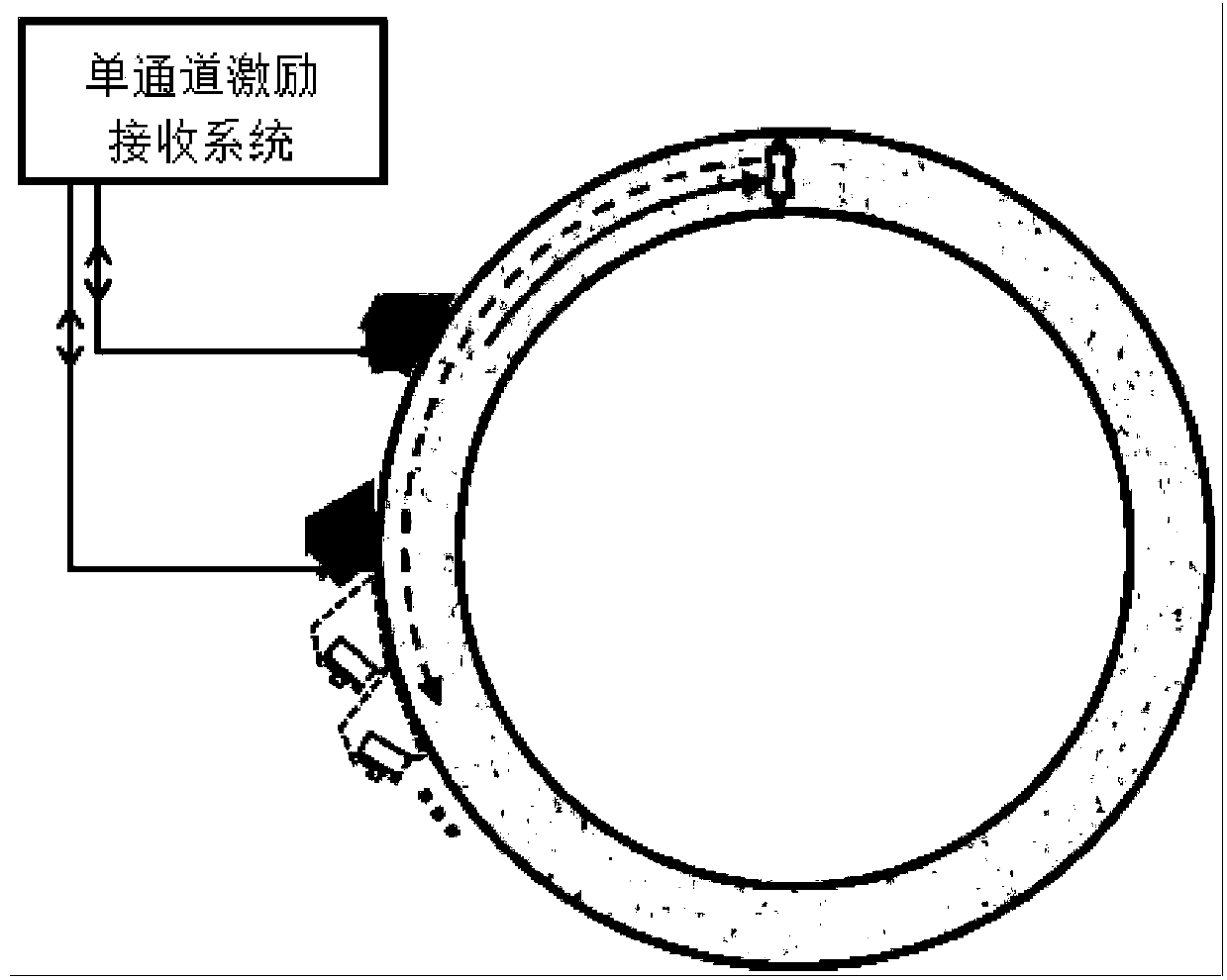

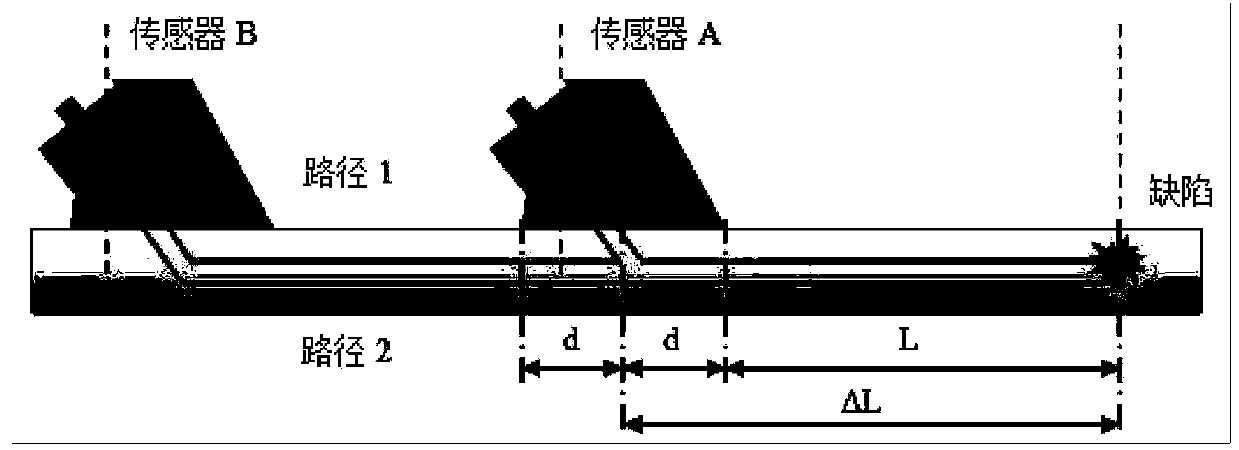

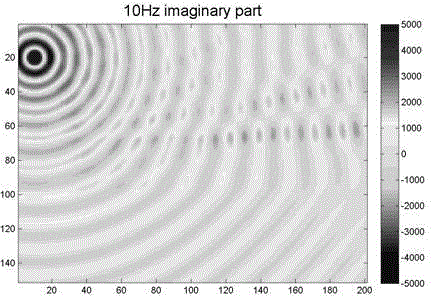

Large-caliber thick-wall pipeline defect location method based on time-reversal circumferential Lamb waves

ActiveCN103389339AAchieving Adaptive FocusRealize detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalSensor arrayThick wall

The invention relates to a large-caliber thick-wall pipeline defect location method based on time-reversal circumferential Lamb waves. According to the method, a defect in a pipeline is regarded as a wave source, and scattered signals generated by interaction of the circumferential Lamb waves and the defect are regarded to be sent by the wave source. The scattered signals are secondarily excited by a multi-channel sensor after the scattered signals are accepted, intercepted and inverted by the multi-channel sensor, thereby achieving detection of small defects in a large-caliber thick-wall pipeline. Bu utilization of the time-reversal focusing principle, the signals surely focus on the position of the wave source (namely the defect), and therefore defect echo signals with high amplitudes are generated, and existence of the defect can be determined based on the defect echo signals. Meanwhile, according to compensation characteristics of time reversal to circumferential Lamb wave frequency dispersion and multimoding effects, the direct signals will focus partly, and defect circumferential location of the large-caliber thick-wall pipeline is achieved by using the time for direct signal focusing as the time reference. The process can be achieved by two manners as follows: detection by utilization of a sensor array and a multichannel signal excitation reception system; and detection by utilization of a pair of sensors and a single-channel signal excitation reception system. The method solves problems, namely difficulty in finding the time reference, difficulty in locating defects, and the like, in time-reversal ultrasonic detection.

Owner:BEIJING UNIV OF TECH

Frequency domain optimization mixture staggered grid finite difference forward modeling method

InactiveCN103823239AHigh precisionReduce anisotropySeismic signal processingFourier transform on finite groupsMesh optimization

Owner:中国石油集团西北地质研究所有限公司

Color image forming method and color toner forming method

ActiveUS20060275679A1High glossStable high glossinessDevelopersElectrographic process apparatusColor imageDynamic viscoelasticity

The invention provides a color image forming method including charging, developing, transferring and fixing. The fixing includes thermally fixing a toner image to paper by using a heating body and a pressurizing member which is positioned opposite to the heating body via a film-like member. The color toner includes a toner particle containing a crystalline resin and a non-crystalline resin. When the color toner is subjected to dynamic viscoelasticity measurement employing a sine wave vibration method, a minimum value of the relaxation elasticity H in a relaxation spectrum obtained from frequency dispersion characteristics when a measurement frequency measured at 60 and 80° C. is 0.1 to 100 rad / sec and a measurement strain at a frequency of 6.28 rad / sec is 0.1 %, is in a range of about 10 to 900 Pa / cm2. A relaxation time λ corresponding to the minimum value is in a range of about 1 to 10,000 sec.

Owner:FUJIFILM BUSINESS INNOVATION CORP

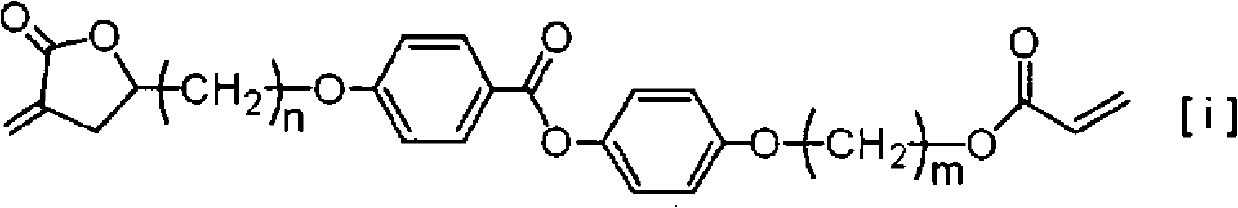

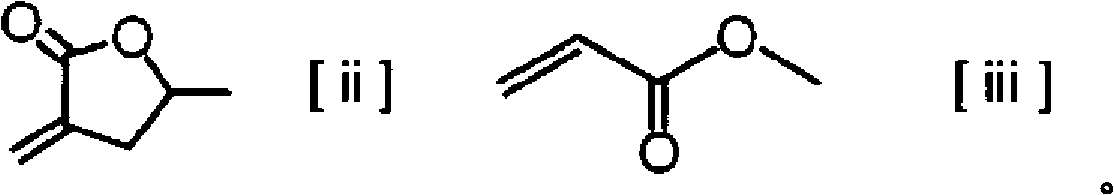

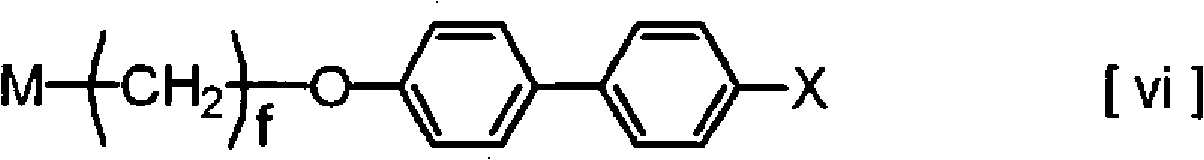

Polymerizable liquid crystal compound, polymerizable liquid crystal composition and oriented film

ActiveCN102159560AHigh optical anisotropyShow chemical resistanceLiquid crystal compositionsOrganic chemistryCrystallographyWavelength

Polymerizable liquid crystal compounds represented by formula (i) and polymerizable liquid crystal compositions that contain the polymerizable compounds can provide optically anisotropic films that have excellent optical anisotropy, that stably maintain retardation values and transparency even at high temperatures, and that additionally have excellent retardation value frequency dispersion characteristics. (In the formula, n represents an integer of 3-10, and m an integer of 4-8.).

Owner:NISSAN CHEM IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com