Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

718 results about "Void ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The void ratio of a mixture is the ratio of the volume of voids to volume of solids. It is a dimensionless quantity in materials science, and is closely related to porosity as follows: e=VV/VS=VV/(VT-VV)=ϕ/(1-ϕ) and ϕ=VV/VT=VV/(VS+VV)=e/(1+e) where e is void ratio, ϕ is porosity, VV is the volume of void-space (such as fluids), VS is the volume of solids, and VT is the total or bulk volume. This figure is relevant in composites, in mining (particular with regard to the properties of tailings), and in soil science.

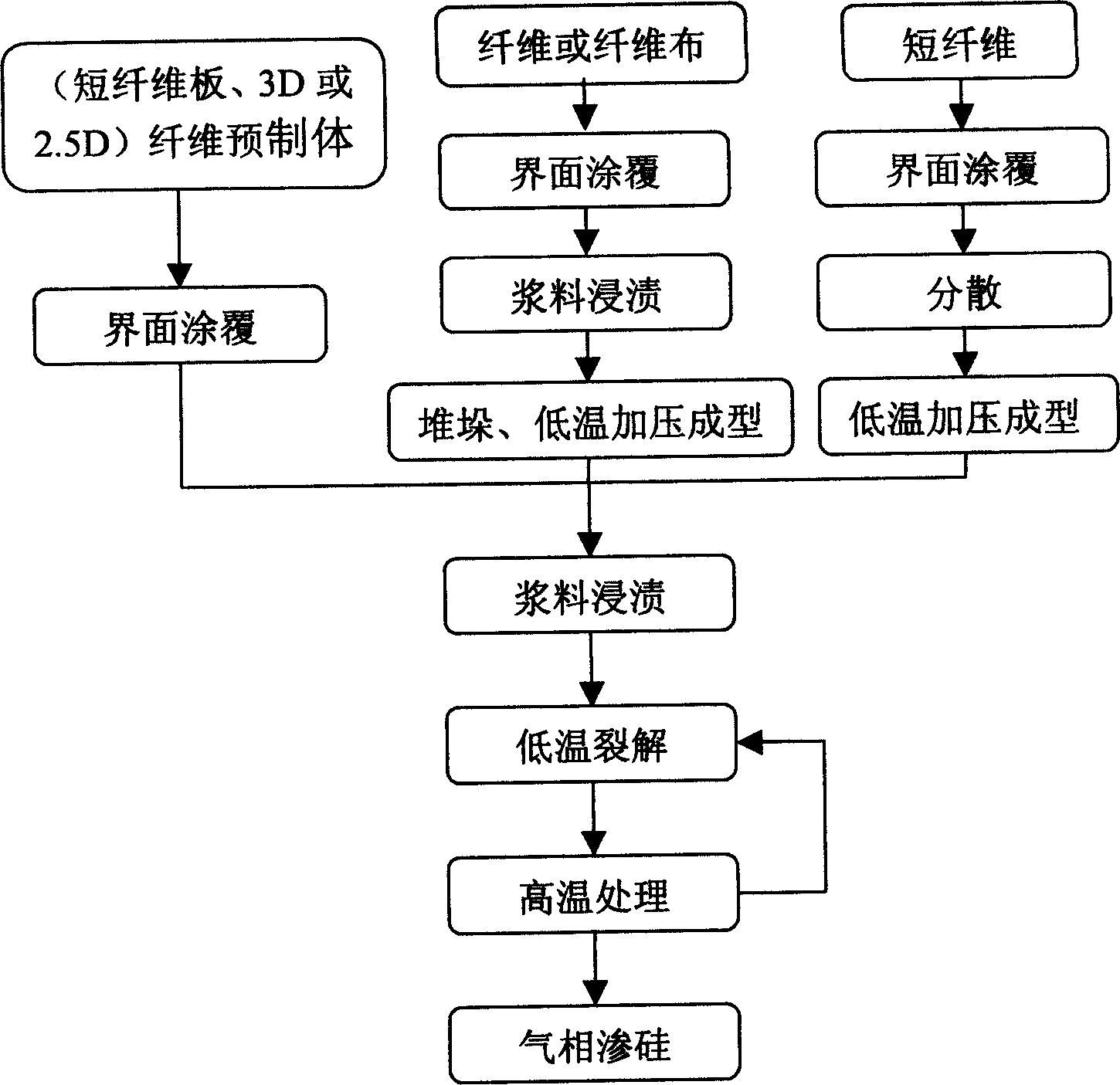

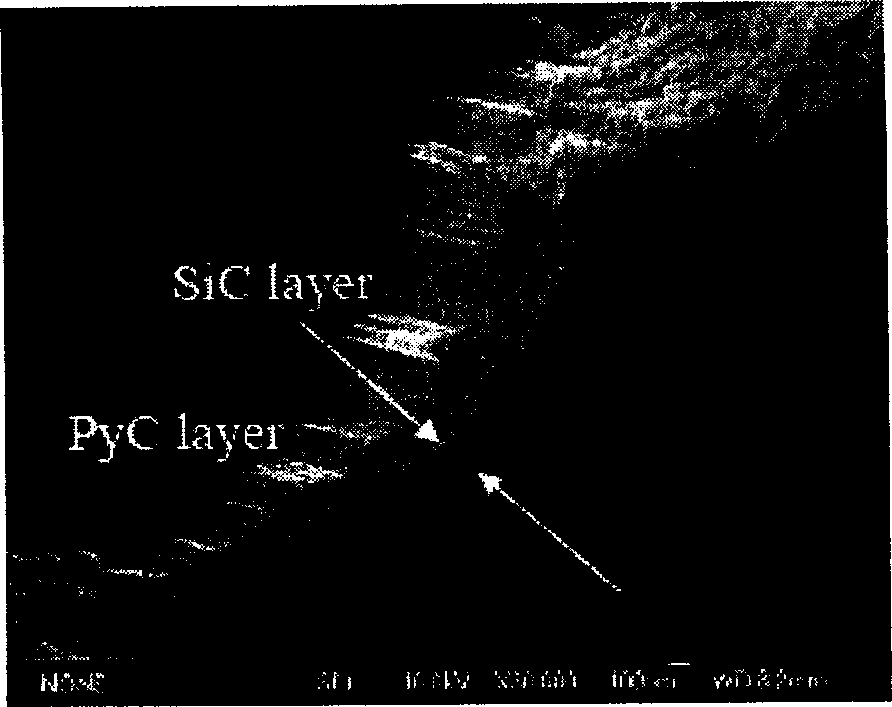

Method for preparing carbon-fiber reinforced silicon carbonate base composite by gas-phase siliconizing technology

This invention relates to preparation method gas phase siliconizing technique preparing high compact fiber reinforcement SiC group composite material. Protection layer interface is formed on fiber surface through gas phase or liquid phase, then they are dipped and cracked through nm SiC slime to make certain density precast body of fiber reinforcement SiC group. Carbon is added into the body through dipping and cracking way to form group body with certain pore, the group body penetrates inner part of the multi-hole body through gas phase silicon after it is high temperature treated, then it reacts with carbon and fills the pore to get compact basal body. The density of the material can reach 2.25-2.30g / cm3, open porosity is 3-6 percent; it is large more higher than traditional method of getting Cf / SiC material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

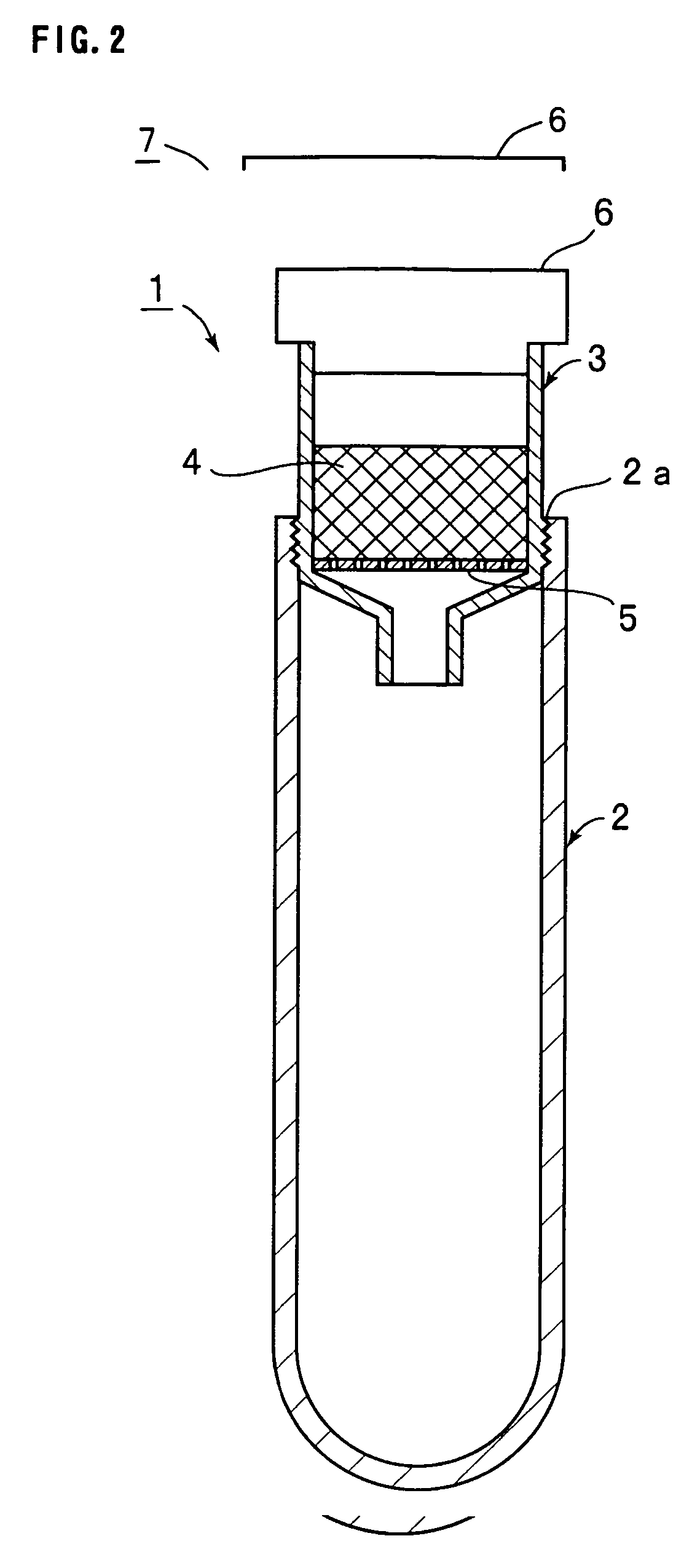

Plasma or serum separation membrane and filter apparatus including the plasma or serum separation membrane

ActiveUS20060029923A1Reliable rapid separationAvoid pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsVoid ratioBlood plasma

A Plasma or serum separation membrane that enables omitting centrifugal separation, is free from hemolysis attributed to destruction of red blood cells and realizes easy and rapid separation of plasma or serum from blood; and a filter apparatus including the plasma or serum separation membrane. In particular, a plasma or serum separation membrane being a membrane for separation of plasma or serum from blood and having a void ratio of 30% or below; and a filter apparatus comprising a filter member capable of attaining movement of plasma swifter than movement of blood cells and a plasma or serum separation membrane connected in series with a rear side of the filter member.

Owner:TOYO TOYOBO CO LTD +2

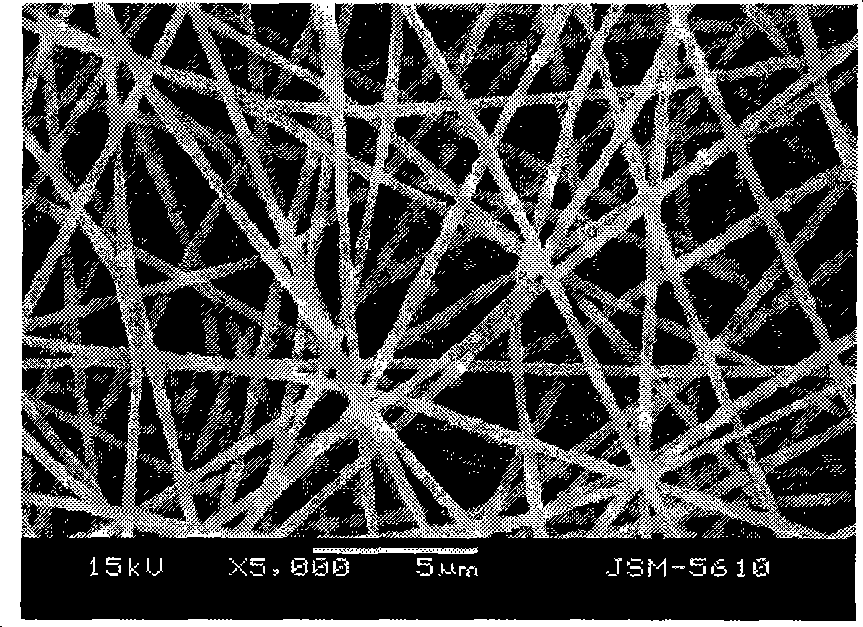

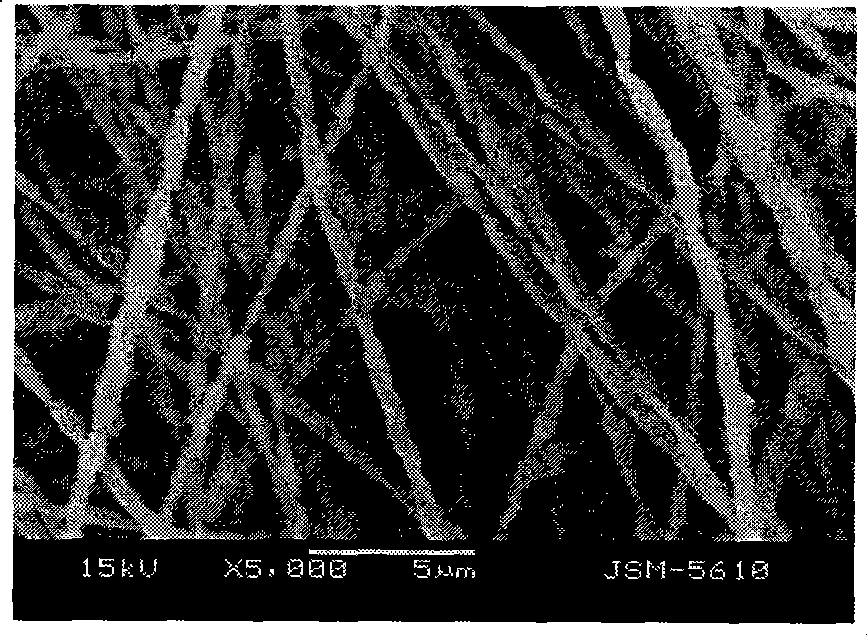

Preparation method of polytetrafluoroethylene superfine fiber porous membrane

InactiveCN101530750AUniform pore sizeHigh porositySemi-permeable membranesHigh concentrationVoid ratio

The invention discloses a preparation method of polytetrafluoroethylene superfine fiber porous membrane. In the method, high concentration polytetrafluoroethylene aqueous emulsion is mixed with matrix polymer uniformly to prepare spinning solution. With the effect of high voltage electric field, polytetrafluoroethylene / matrix polymer composite superfine fiber porous membrane with the diameter of 100 nm to 2 [mu]m is obtained by electrostatic spinning, and then polytetrafluoroethylene superfine fiber porous membrane is formed at the conditions of sintering temperature being 330 to 500 DEG C and the sintering time lasting 30s to 5min so that the aperture diameter is 100 nm to 10 [mu]m and the porosity is 50% to 80%. The polytetrafluoroethylene superfine fiber porous membrane prepared by using the method has uniform aperture diameter and high porosity, and can be widely applied to filter material. Compared with the existing technology, the preparation method has the characteristics of simple processing technology, short process and low cost.

Owner:ZHEJIANG SCI-TECH UNIV

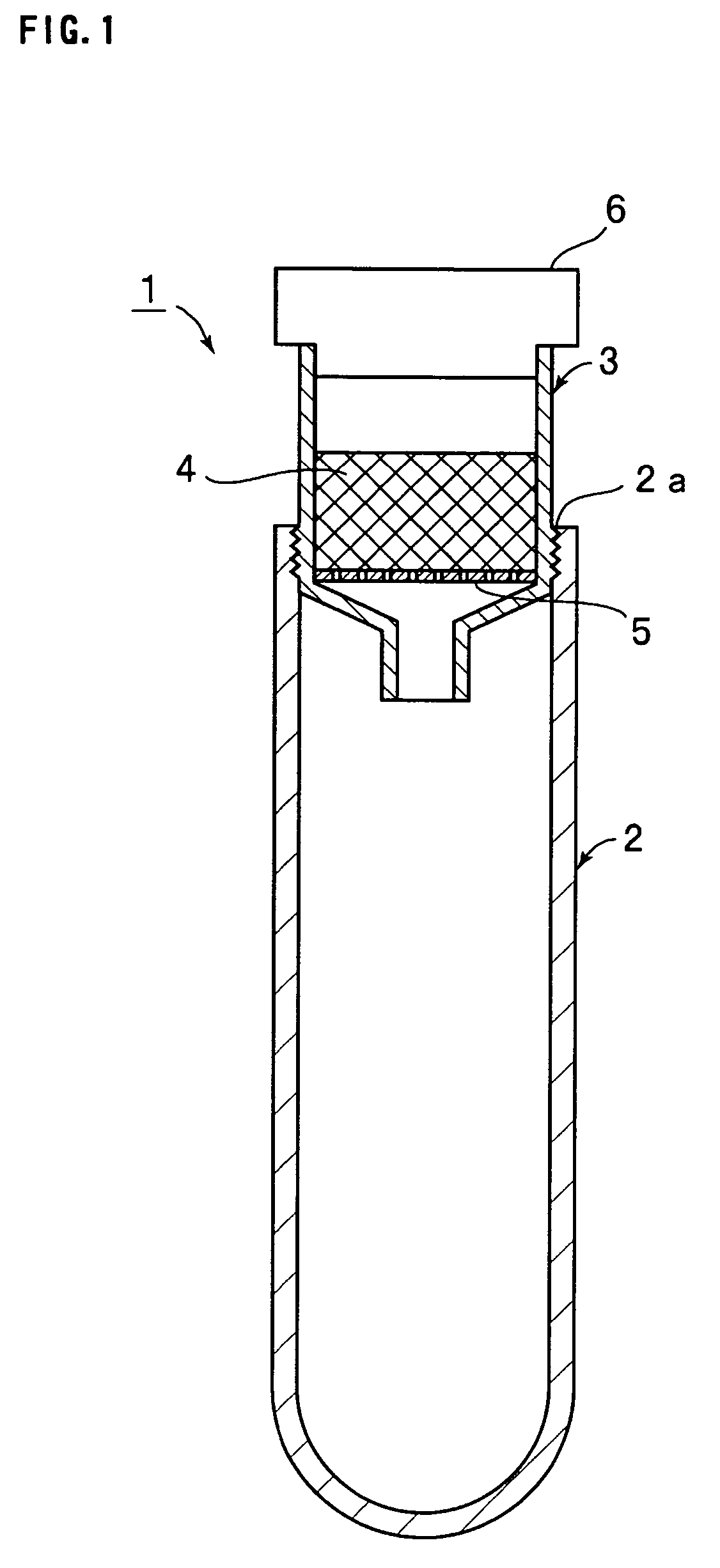

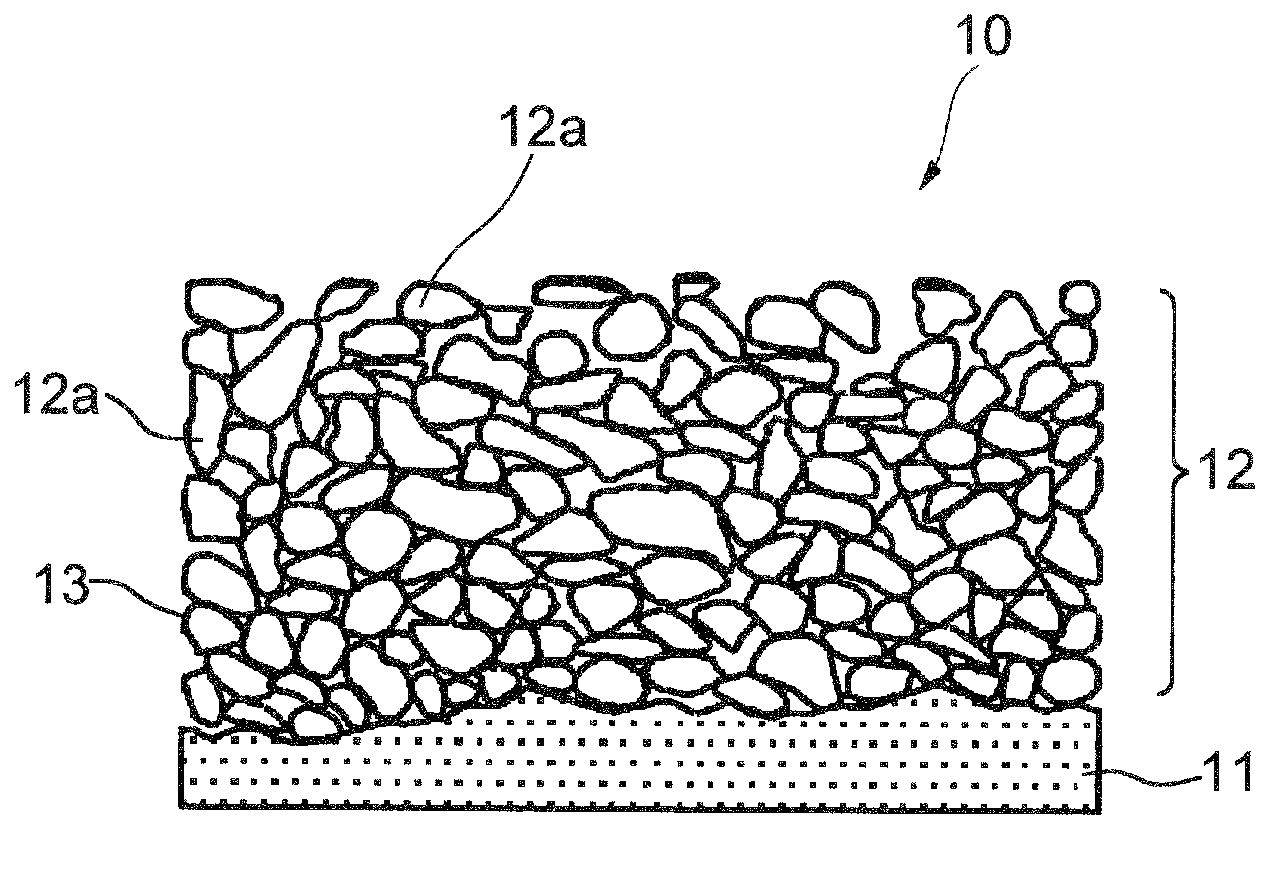

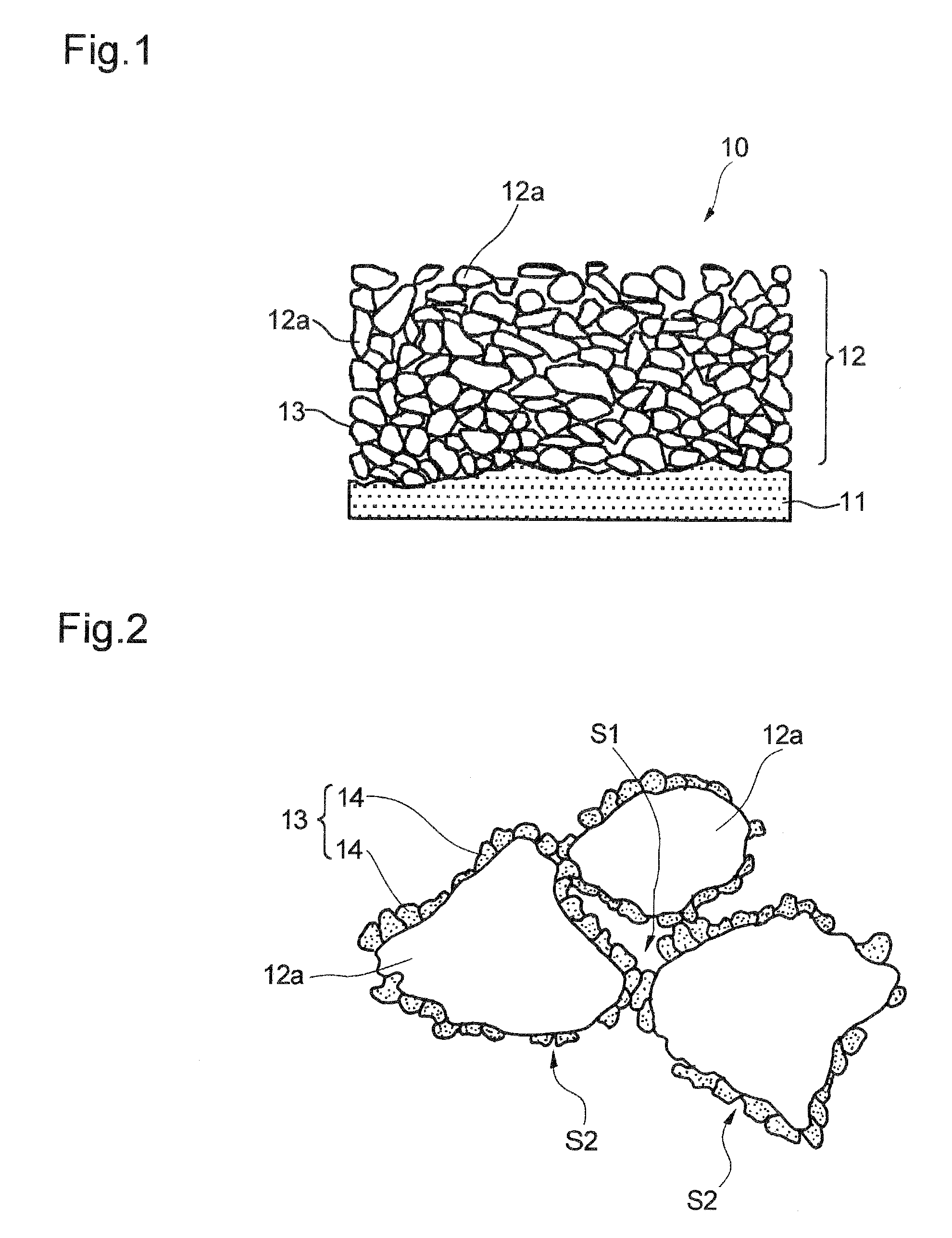

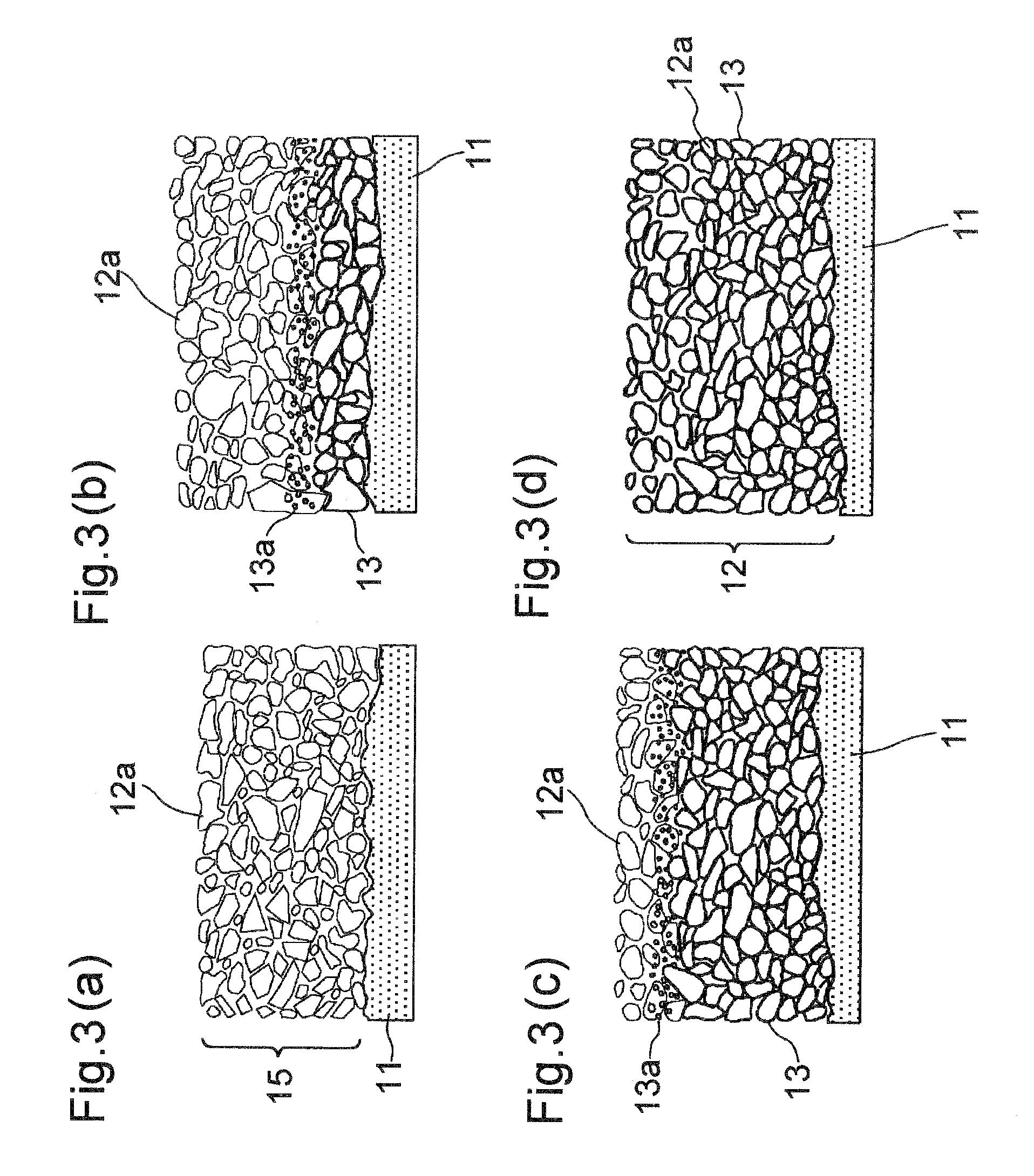

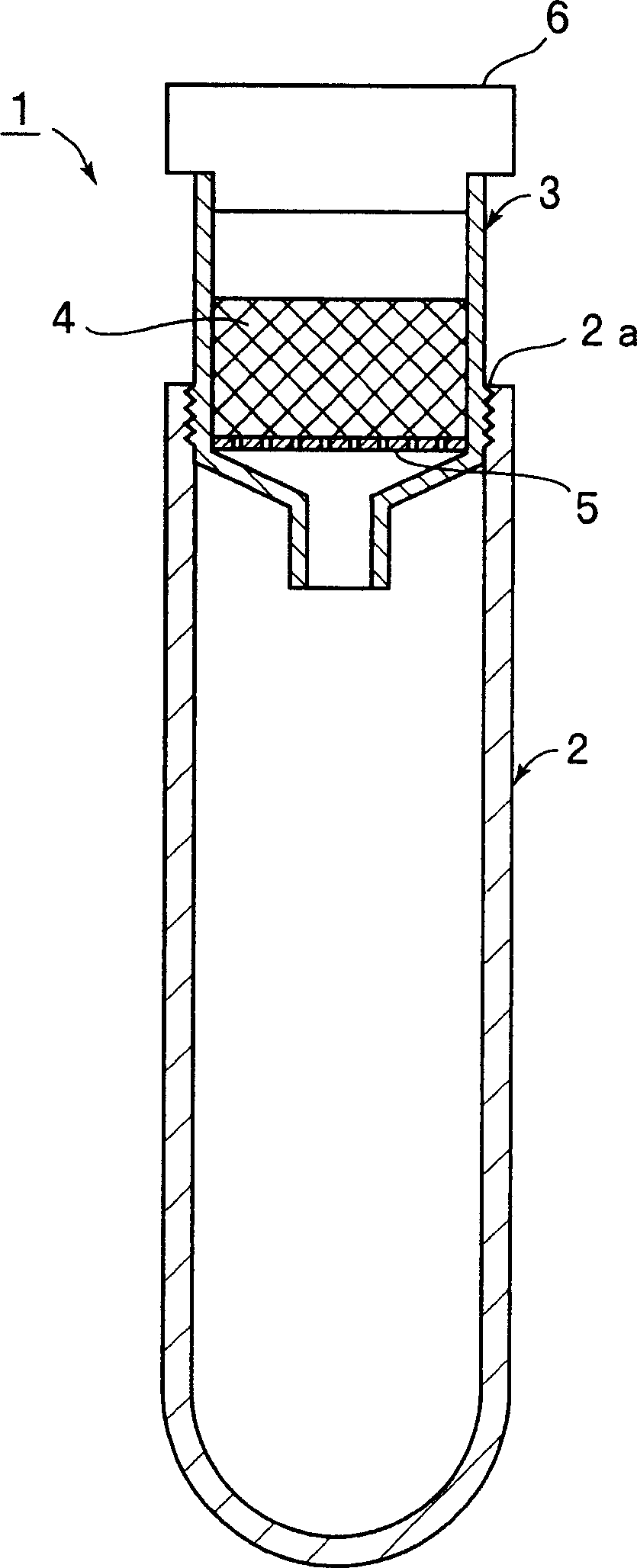

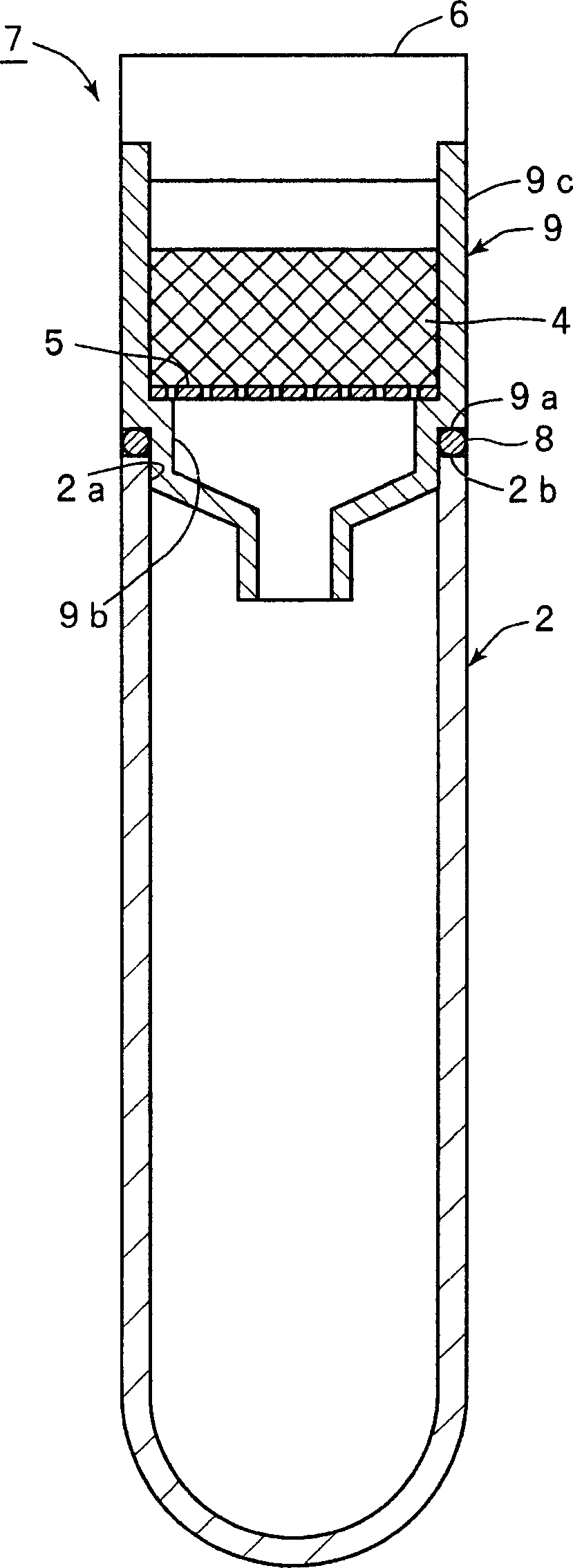

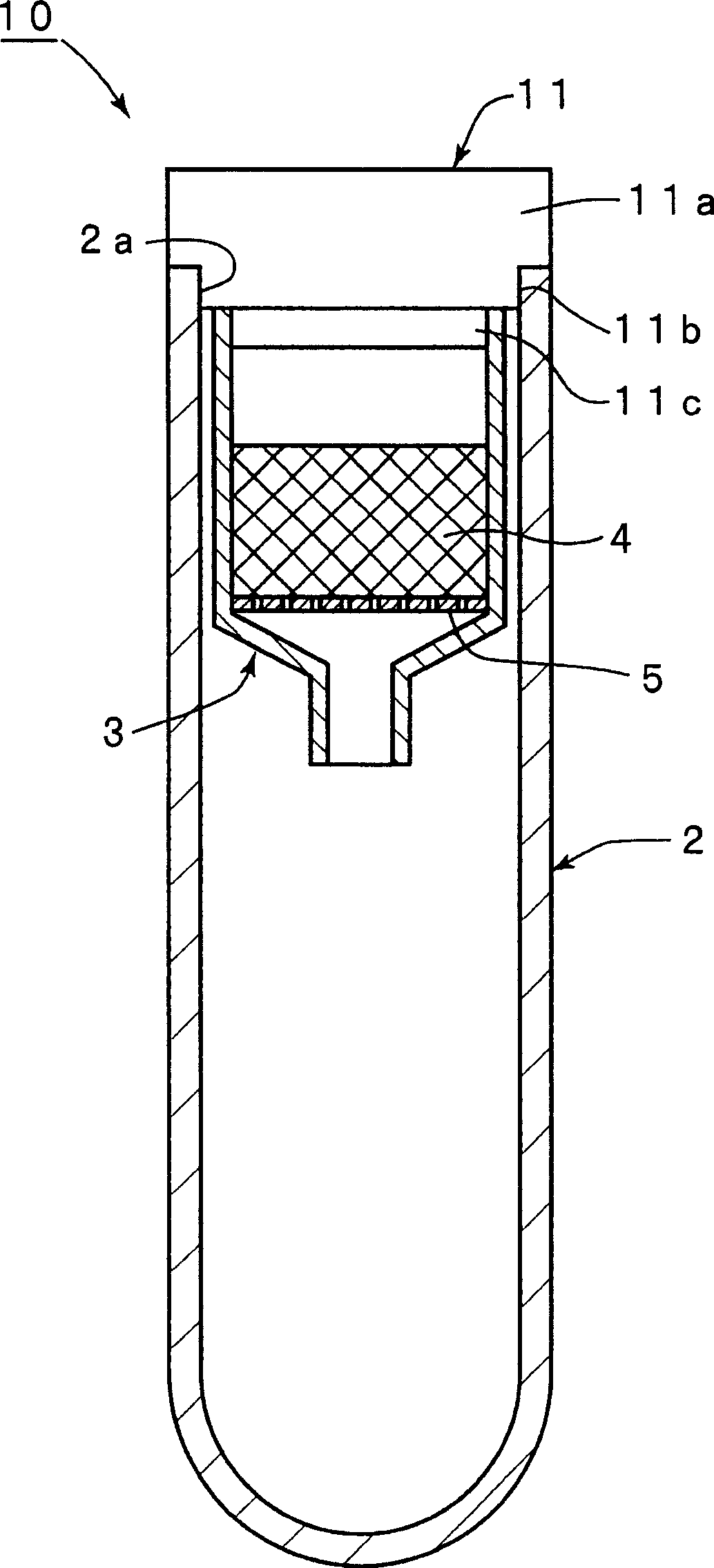

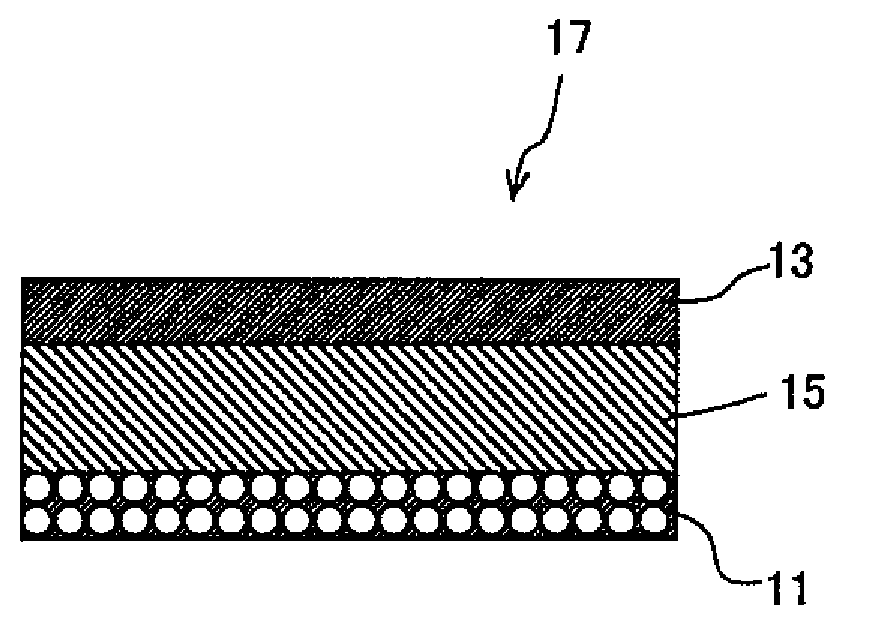

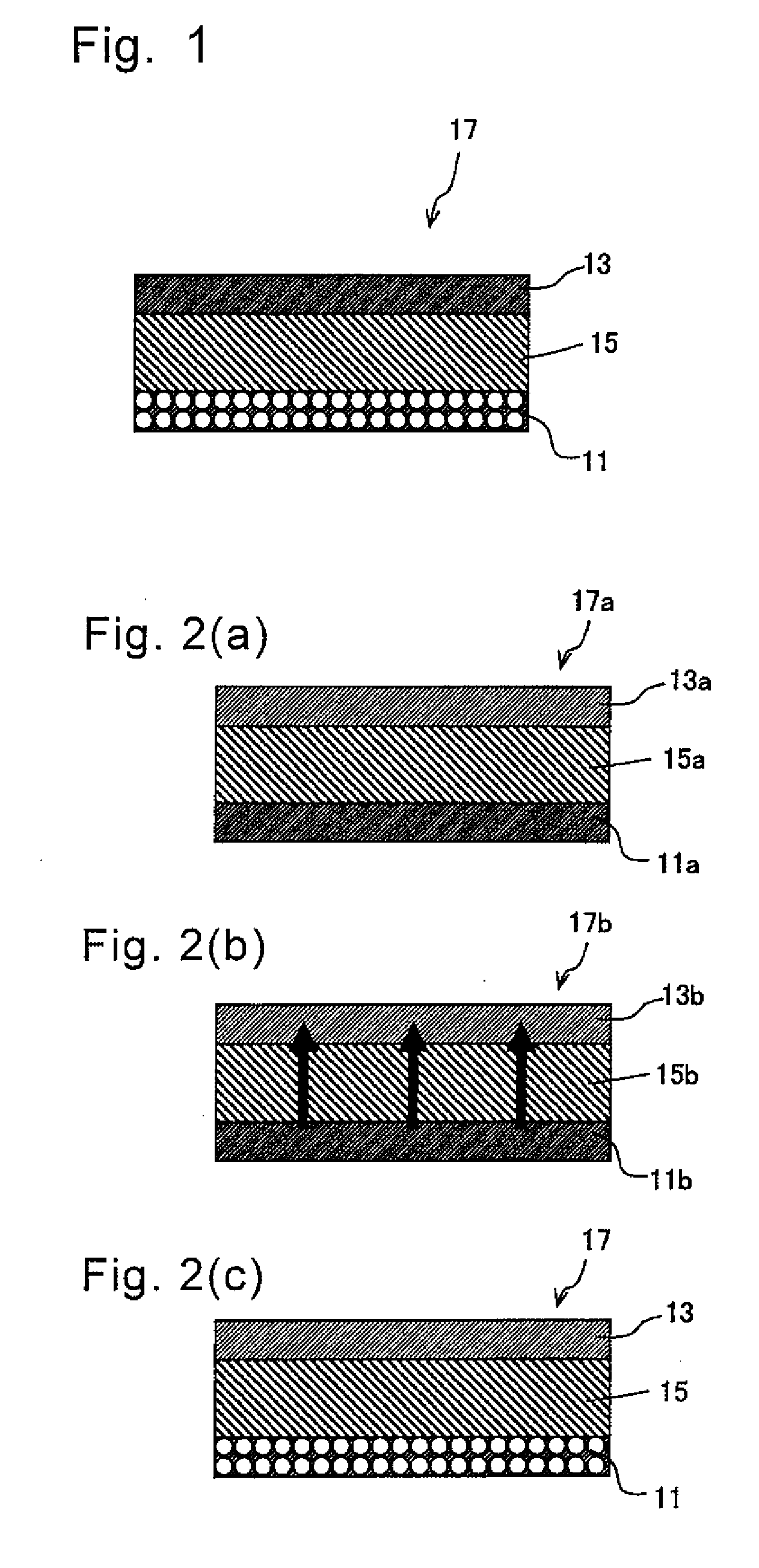

Negative electrode for nonaqueous secondary battery

InactiveUS20090202915A1Improve performanceNon-aqueous electrolyte accumulatorsActive material electrodesVoid ratioMetallic materials

A negative electrode (10) for use in a non-aqueous electrolyte secondary battery comprises an active material layer (12) containing a particle (12a) of an active material. At least a part of the surface of the particle (12a) is coated with a metal material (13) having a poor ability of forming a lithium compound. A void is formed between the particles (12a) that are coated with the metal material (13). The active material layer has a void ratio of 15 to 45%. Preferably, the metal material (13) is present over the entire area of such a part of the surface of the particle that extends in the thickness-wise direction of the active material layer. Also preferably, the particle (12a) of the active material is composed of a silicone material, and the active material layer (12) contains a conductive carbon material in an amount of 1 to 3% by weight relative to the weight amount of the particle (12a) of the active material.

Owner:MITSUI MINING & SMELTING CO LTD

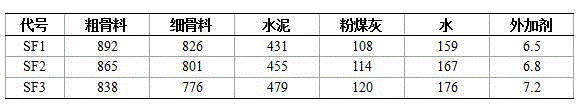

Design method for mixing proportion of self-compacting concrete mixture

ActiveCN105224727AQuick lockPrevent disengagementSpecial data processing applicationsParticulatesVoid ratio

The present invention belongs to the technical field of concrete construction and particularly relates to a design method for a mixing proportion of a self-compacting concrete mixture. The method comprises the steps of: determining a performance design target; determining mixing strength and a water-binder ratio; determining densest gradation (or a sand rate) of aggregates and void ratios of different packing states; determining the usage amount of binding materials and mixing water; determining the usage amount of the aggregates; determining the usage amount of additives; determining the actual adding amount of the mixing water; and the like. According to the method provided by the present invention, aimed at blindness of material selection during self-compacting concrete mixing proportion design in the prior art, based on a fundamental theory of particulate dense packing and a composition rule of reaching a densest packing state of solid particulate materials with different particulate diameters, a mixing proportion of different materials is determined by an actually measured densest packing state, and relationships are established between the material mixing proportions corresponding to different densest packing states and expected self-compacting performance grades of the mixture, so that the design method used for the mixing proportion of the self-compacting high-performance concrete mixture and based on a use performance as a target is constructed.

Owner:ZHENGZHOU UNIV

Polymer impression materials

InactiveUS20100304338A1Long working timeShort setting timeImpression capsDental articulatorsVoid ratioDental impression material

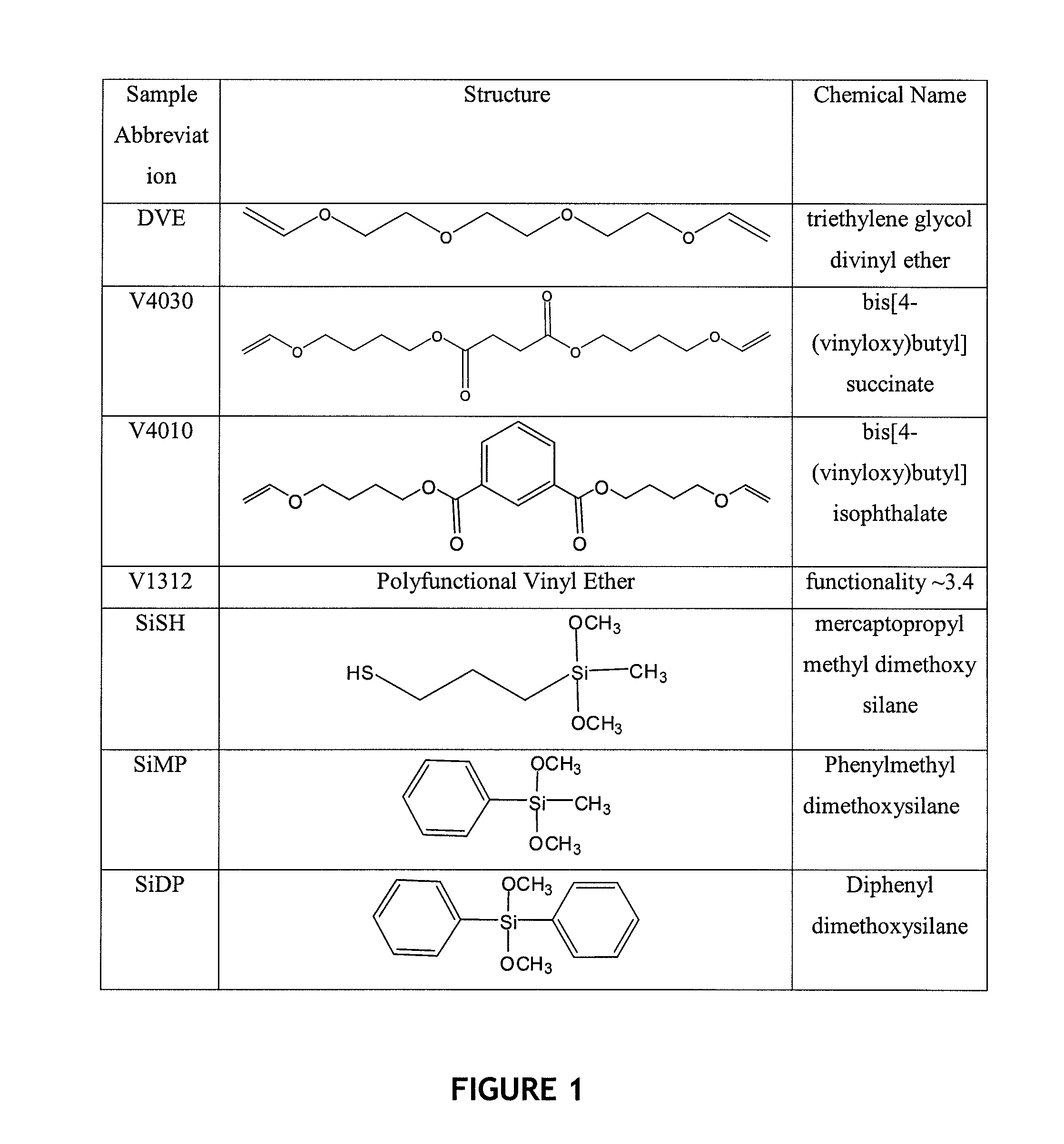

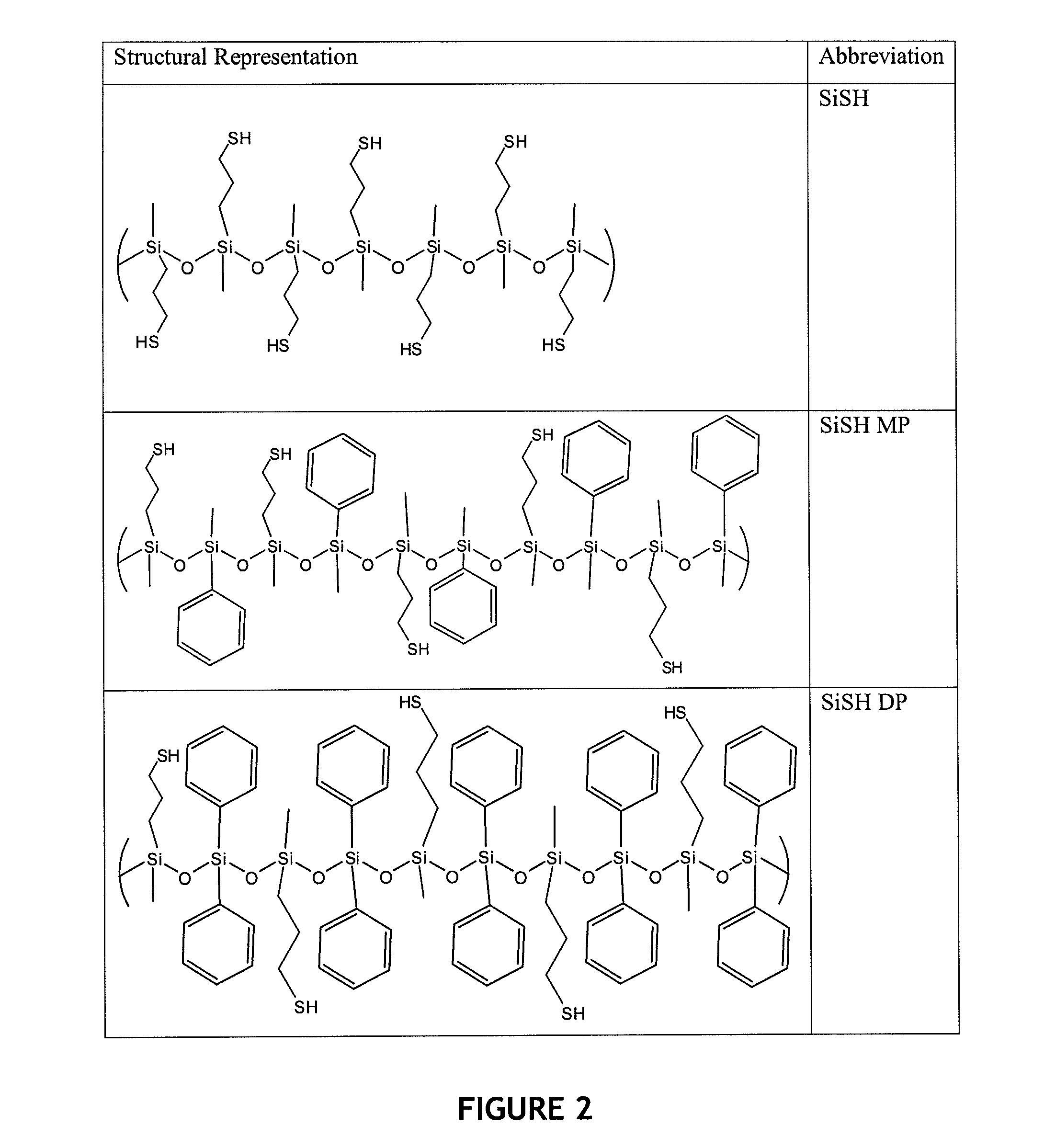

This invention relates to methods and compositions for single component photoinitiated dental impression materials. The impression material is workable in its pre-cured state, cures rapidly upon exposure to light, and exhibits desirable processing conditions such as short setting time, long working time, no void formation, good wettability, mechanical properties, and detail reproduction.

Owner:UNIV OF COLORADO THE REGENTS OF

High-ductility polymer-rubber powder-honey-combed cement concrete road covering material and construction process thereof

InactiveCN101343162AReduce adverse effectsGood deformabilitySolid waste managementCeramicwarePorosityPolymer modified

Disclosed is a cover material of polymer modification rubber powder porous concrete with high toughness and a making technique thereof. Wherein, in per cubic meter of the concrete, the polymer is 20 to 75 kg, the cement is 200 to 400 kg, and the water to cement ratio is between 0.25 to 0.40 ; in aggregates, the amount of a fine aggregate is less than or equal to 20 percent, and the amount of a coarse aggregate is more than or equal to 80 percent; 0 to 5 kg of plasticizer and / or defoamer are / is added; rubber powder, whose volume fraction is not more than 50 percent, is used to replace the natural aggregate ; or the cement is replaced by mineral admixtures which are not more than 40 percent. The cover material is made by a small machine, a three-roller and an asphalt paver. The main technical parameters of the cover material are as follows: compressive strength is more than or equal to 15 MPa, flexural strength is more than or equal to 5 MPa, anti-skid structure depth is more than or equal to 2.0 mm, porosity is 18 to 22 percent, permeability coefficient is more than or equal to 1.5 mm / s, sound absorption coefficient is more than or equal to 0.30, and noise reduction effect is more than or equal to 5 dB. The cover material can comprehensively utilize the discarded rubber with the advantages of high toughness, sliding resistance and sound absorption and noise reduction. Thus, the cover material is applicable to the covers of the highway, the municipal road and the flat.

Owner:WUHAN UNIV OF TECH

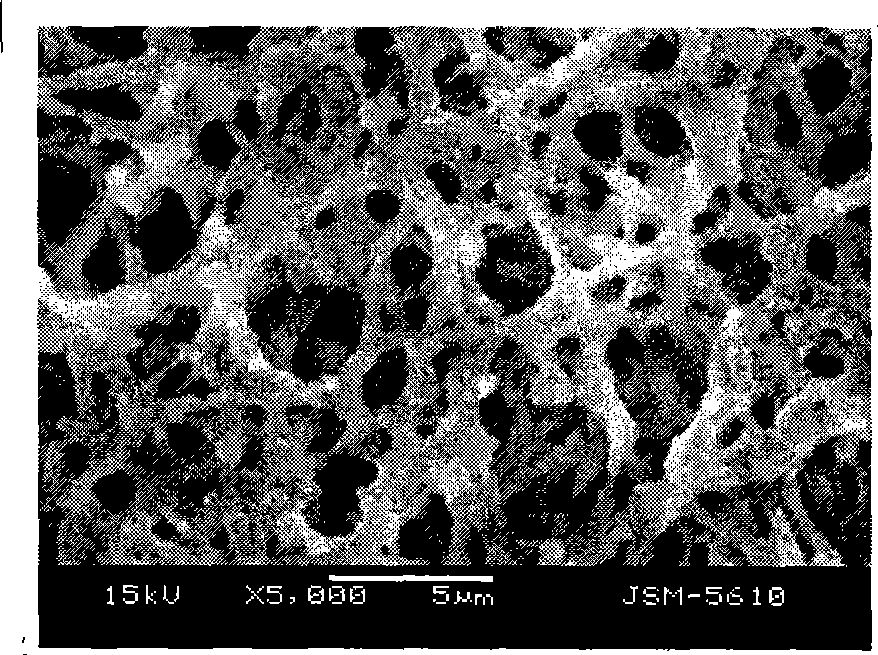

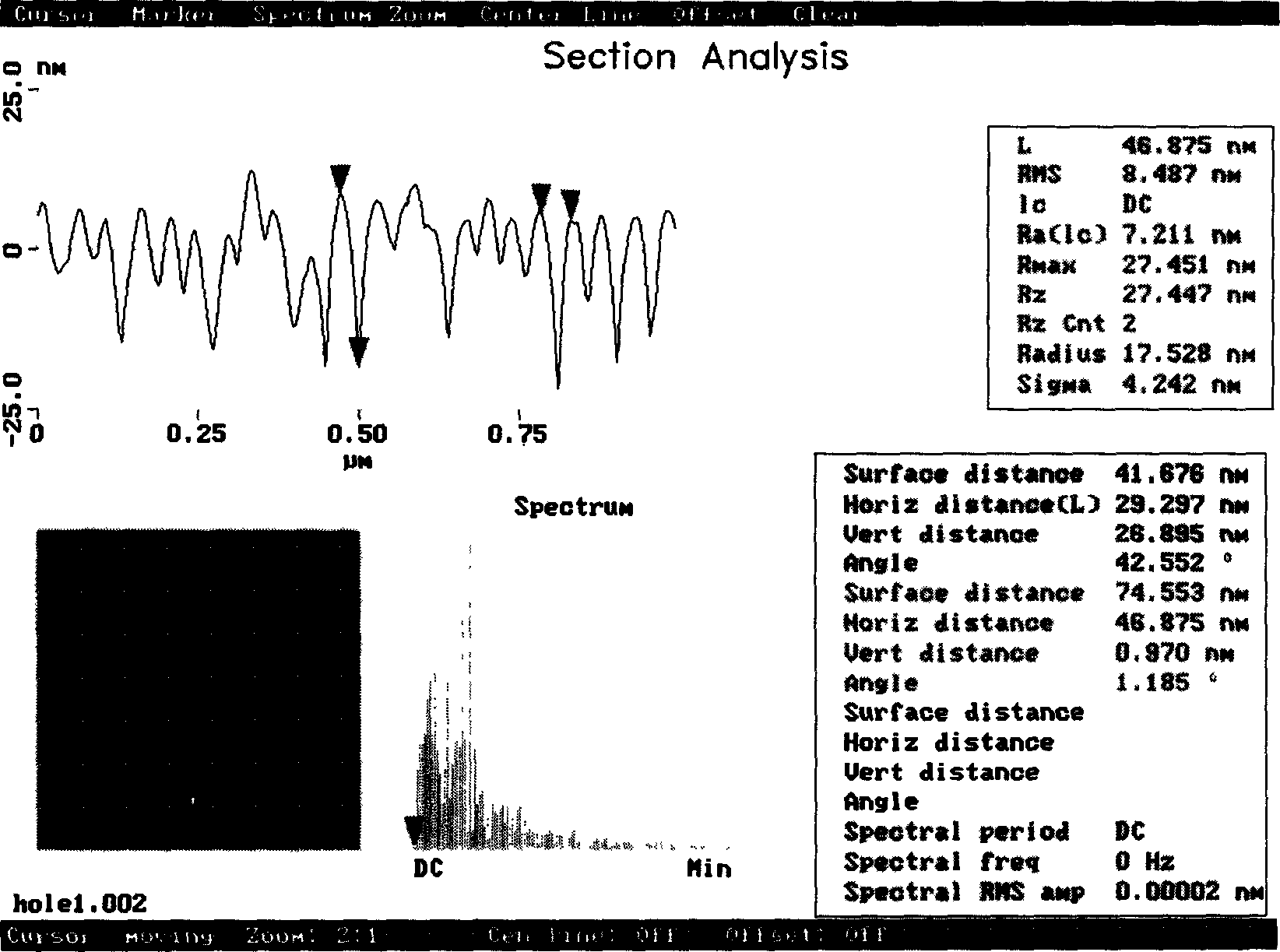

Process for producing ordered porous anodic alumina form

The present invention discloses one kind of ordered porous anode oxidized alumina template preparing process. Compared with available technology, the said process has the advantages of capacity one preparing great area highly ordered nanometer template, high template success rate and high template quality including raised nanometer pore arrangement orderliness, pore size homogeneity, depth uniformity and porosity.

Owner:DONGGUAN UNIV OF TECH

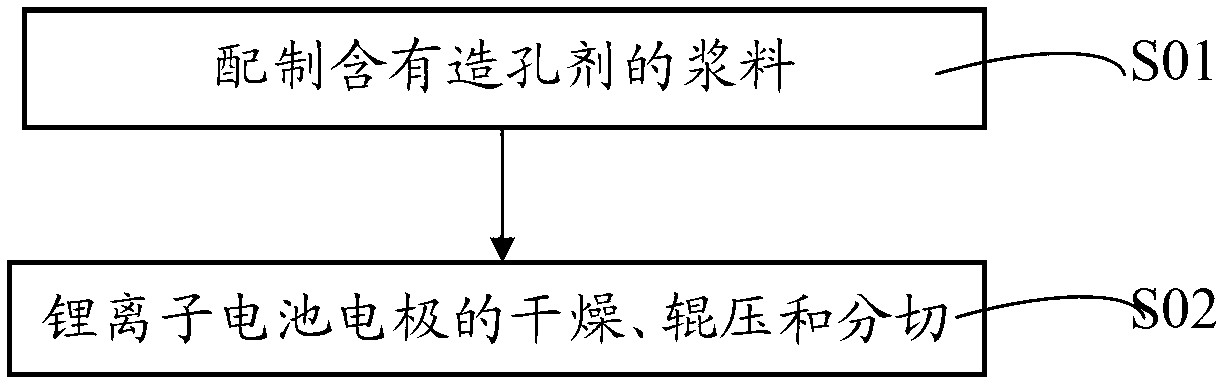

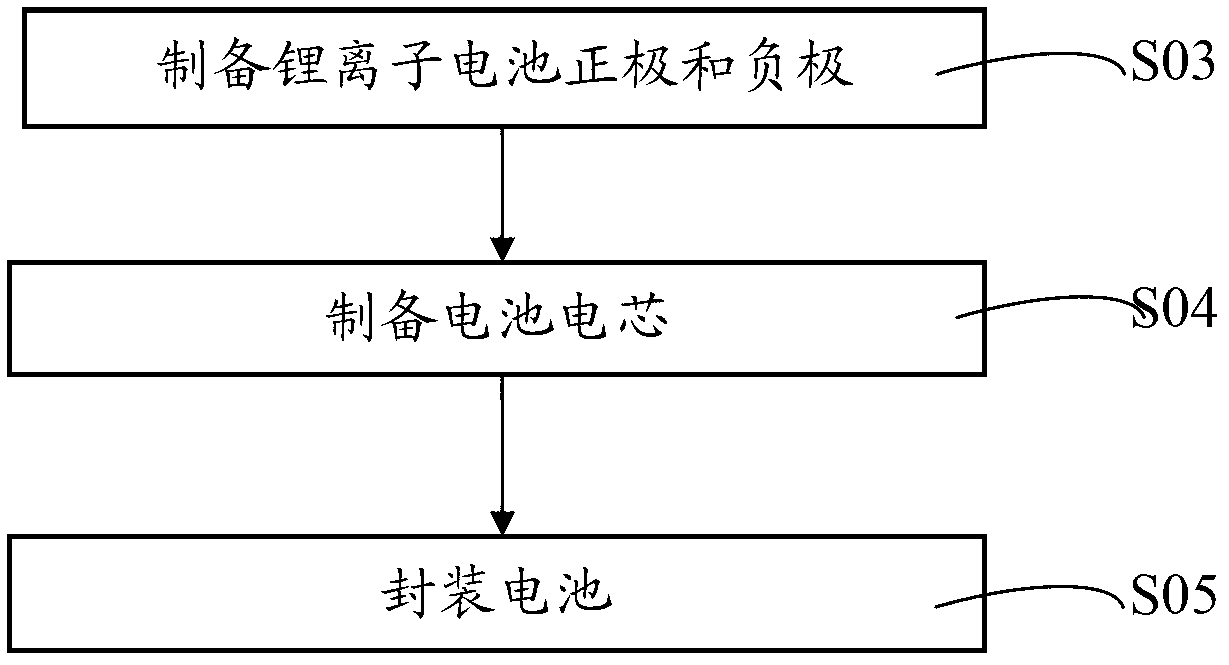

Lithium ion battery electrode, preparation method thereof and lithium ion battery

ActiveCN102931378AUniform porositySimple processSecondary cellsNon-aqueous electrolyte accumulator electrodesVoid ratioInternal resistance

The invention discloses a lithium ion battery electrode, a preparation method thereof, a lithium ion battery, and a preparation method and application of the lithium ion battery. The preparation method for the electrode of the lithium ion battery comprises a step of preparing slurry containing a pore forming agent and a step of drying, rolling and slitting the electrode of the lithium ion battery. The lithium ion battery comprises the lithium ion battery electrode prepared by the preparation method for the lithium ion battery electrode. The preparation method for the lithium ion battery electrode is simple, high in efficiency and suitable for industrial production, and conditions are easy to control. Voids in the prepared lithium ion battery electrode are uniformly distributed, and a void ratio is higher than that of an ordinary electrode. The lithium ion battery has low internal resistance, high cycle performance and high energy density, so that the application range of the lithium ion battery is widened.

Owner:DONGGUAN CHUANGMING BATTERY TECH

Plasma or serum separation membrane and filter apparatus including the plasma or serum separation membrane

ActiveCN1714292ASafe, reliable and fast separationDoes not cause ruptureBiological testingVoid ratioHemolysis

A plasma or serum separation membrane capable of omitting centrifugation, without hemolysis caused by red blood cell destruction, capable of conveniently and quickly separating plasma or serum from blood; and a filter comprising a plasma or serum separation membrane. In particular, a plasma or serum separation membrane is a membrane that separates plasma or serum from blood and has a void ratio of 30% or less; and a filter that includes a filter element capable of moving plasma faster than blood cells And the plasma or serum separation membrane sequentially connected with the rear side of the filter element.

Owner:SEKISUI MEDICAL CO LTD +2

Method for simultaneously removing phosphorous and nitrogen through synergistic effect of nanoscale-iron and microbes

ActiveCN103803703AEnriched nanovoidsTreatment with anaerobic digestion processesParticulatesFerric hydroxide

The invention provides a method for simultaneously removing phosphorous and nitrogen through the synergistic effect of nanoscale-iron and microbes. The method is characterized in that firstly limonite ore is broken and sieved so as to obtain particulate materials with the required particle size, the particulate materials mainly comprising nanoscale iron and having millimeter particle size and the porous structure characteristic are prepared through high temperature reduction under a hydrogen or carbon monoxide atmosphere, the nanoscale iron in the particulate materials slowly release nascent hydrogen atoms and hydrogen gas, and nitrate is chemically reduced; meanwhile, the particulate materials have relatively high void ratio, and abundant function anaerobic microbe denitrifying bacteria adhere to the inner parts and the outer surfaces of the particulate materials and reduce the nitrate by using hydrogen released through reaction between the nanoscale-iron and water as electron donors; adherent dependent nitrate iron-oxidizing bacteria also have the effect of reducing the nitrate; the nitrate in wastewater is removed under the chemical action of the nanoscale-iron and the synergistic effects of the anaerobic microbes; ferrous and ferric hydroxides are continuously formed on the inner surfaces and the outer surfaces of the porous particulate materials through the chemical reaction of the nanoscale-iron and water and the synergistic effect of the anaerobic microbes, so that the chemical adsorption of phosphorous in water is promoted, thus the effect of simultaneously removing phosphorous and nitrogen is achieved.

Owner:HEFEI UNIV OF TECH

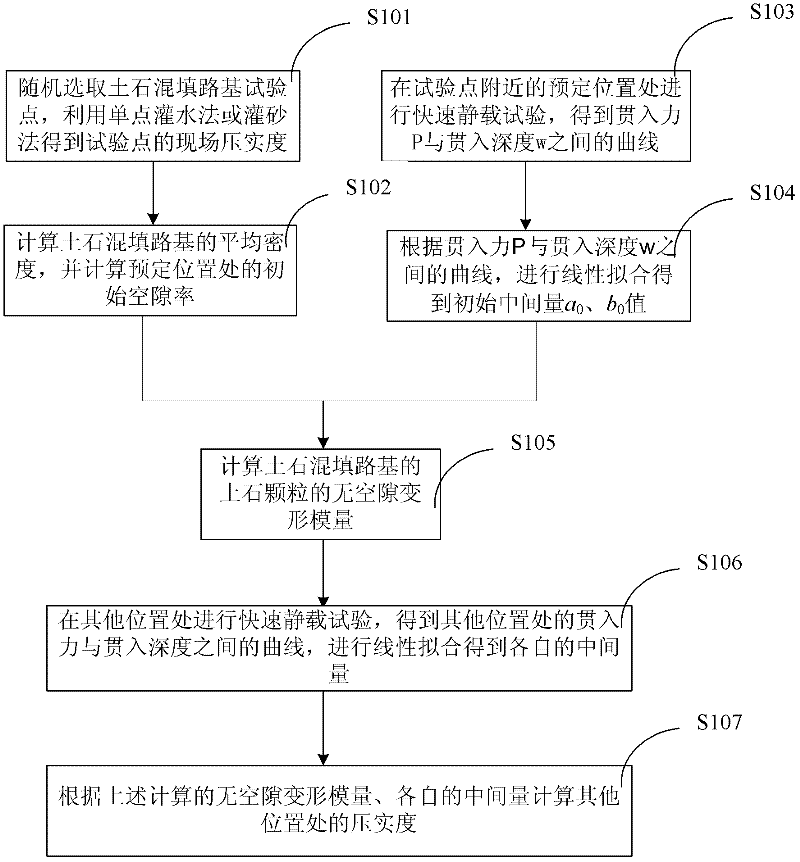

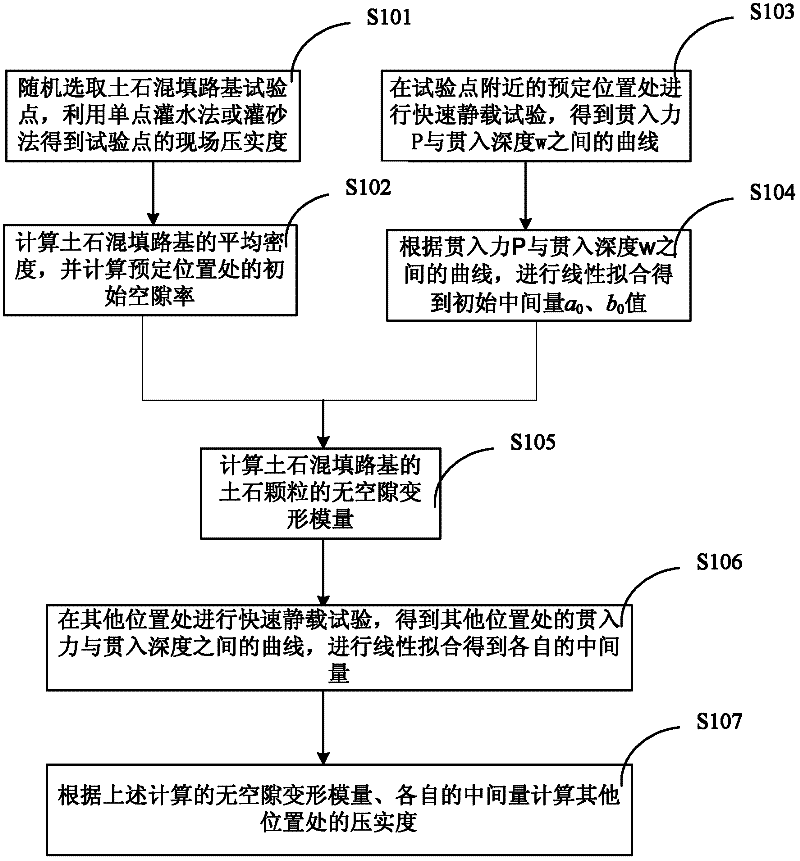

Soil and stone mixed filling roadbed compaction degree detecting method

The invention discloses a soil and stone mixed filling roadbed compaction degree detecting method, which comprises the steps of: randomly selecting a soil and stone mixed filling roadbed test site, and obtaining the site compaction degree by a single-point douche or a sand cone method; carrying out fast static test in a preset position near the test site and obtaining a curve between the penetration power P and the penetration depth w; calculating the average density Rhom of the soil and stone mixed filling roadbed and calculating the initial void ratio n0 in the preset position; carrying out linear fitting according to the curve between the penetration power P and the penetration depth w and obtaining the value of the initial intermediate quantity a0 and b0; calculating the void-free deformation modulus E0 of stone particles of the soil and stone mixed filling roadbed; and calculating the compaction degree of other positions, i.e. the compaction degree in the ordinary positions. The method can be used for fast, stably and accurately detecting the compaction degree of the soil and stone mixed filling roadbed and is suitable for any compaction process and roadbeds compacted by compaction machinery.

Owner:HUNAN UNIV

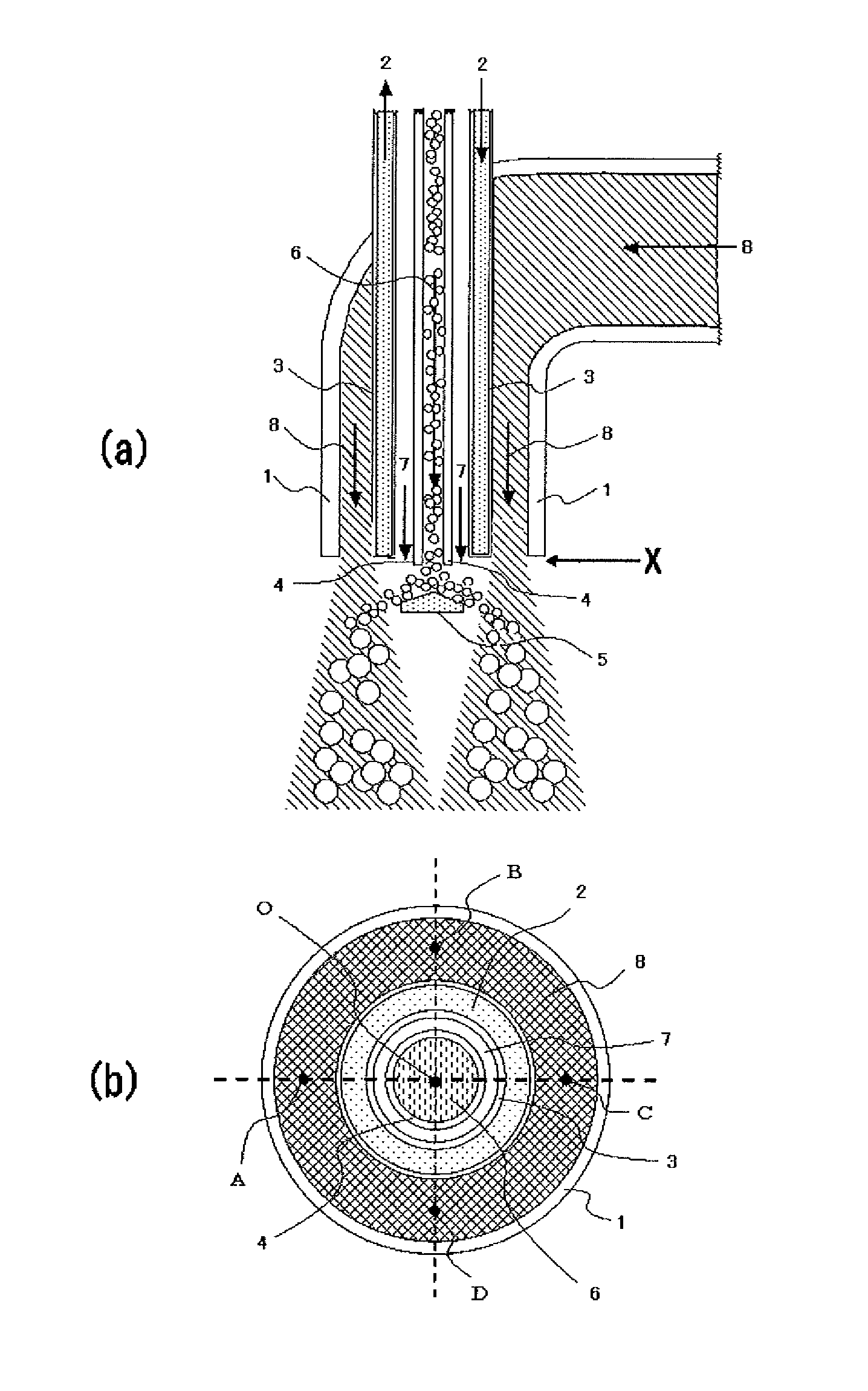

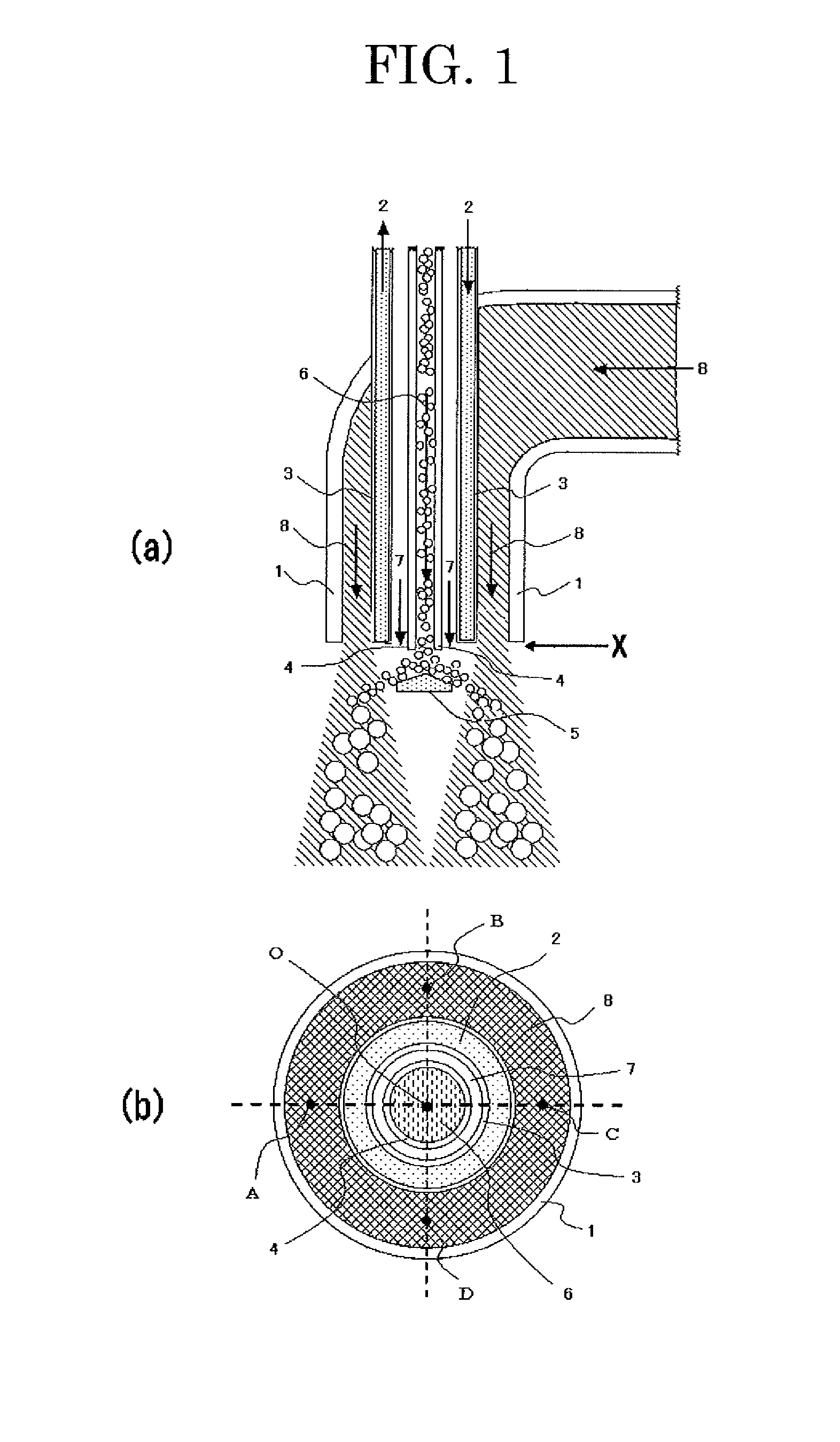

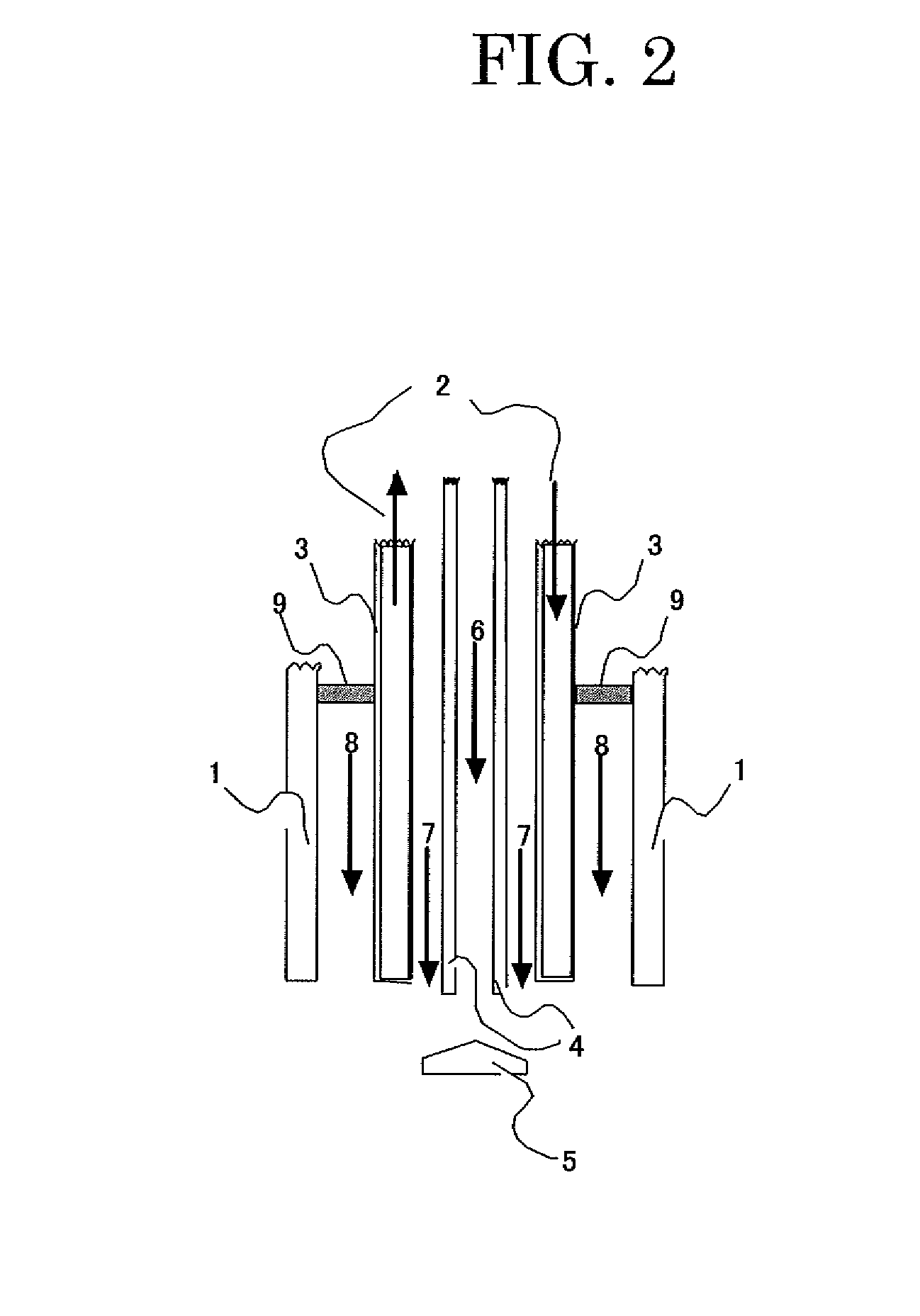

Packed bed bioreactor for biofouling control of reverse osmosis and nanofiltration membranes

ActiveUS20120193287A1Simpler design of equipmentEasy to operateMembranesWater treatment parameter controlVoid ratioSurface water

An installation and a method for removing dissolved biodegradable compounds as a biological treatment step up-stream of an equipment to be protected from biofouling being part of a ground water, surface water or tertiary wastewater treatment line, wherein said upstream biological treatment step is carried out in at least one packed bed bioreactor comprising a vessel or a tank filled with packing elements, characterized in that: iv) said packing elements of said packed bed show a void fraction of at least 70% and the flow velocity of water through said packed bed bioreactor is at least 20 m / h, so that said packed bed does not have a removal efficiency of suspended solids in water, if any, of more than 30%; v) said packing elements of said packed bed show a specific surface area of at least 750 m2 / m3; vi) said process does not require the use of any biocide or biostatic compound.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

Asphalt mixture fatigue test numerical simulation method based on random generation

InactiveCN106126820AImprove efficiencyImprove accuracyDesign optimisation/simulationSpecial data processing applicationsUnit sizeVoid ratio

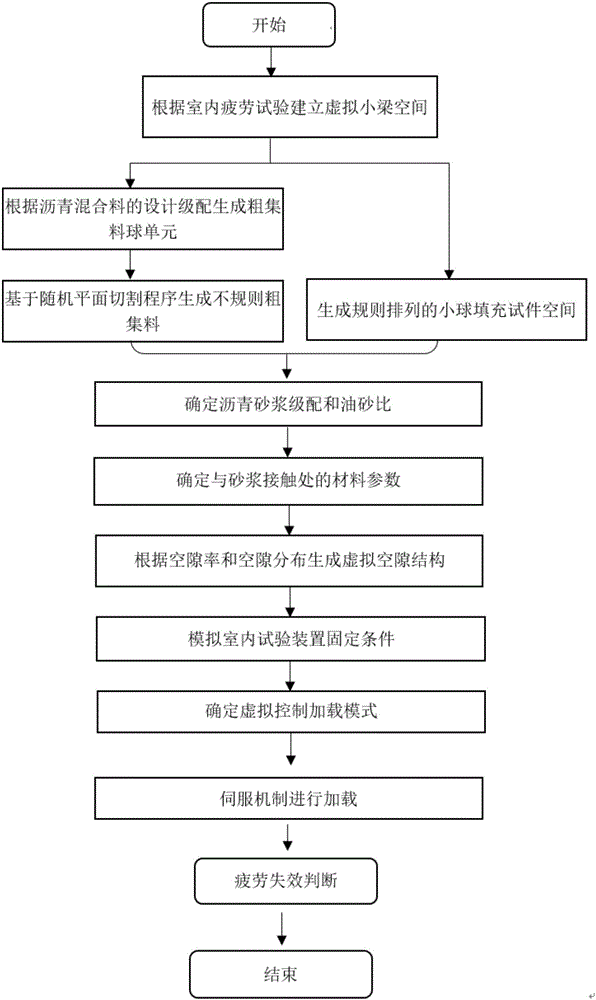

The invention discloses an asphalt mixture fatigue test numerical simulation method based on random generation. The method comprises the steps of randomly generating a test piece; determining the particle number, grading and irregular shape of coarse aggregates according to the test piece to be formed; determining that the coarse aggregates are not overlapped; generating irregular coarse aggregates; determining the minimum discrete unit size of bituminous mortar; filling the bituminous mortar; determining bituminous mortar grading and the dosage of asphalt in bituminous mortar according to the grading of an asphalt mixture; acquiring relative material parameters according to a bituminous mortar creep test and a spitting test; determining void ratio and void distribution and generating voids; conducting fatigue test numerical simulation; determining a virtual loading mode; conducting loading with a servo mechanism; conducting fatigue failure judgment. Through random test piece generation, three-dimensional configuration reconstruction of the asphalt mixture is achieved. By the adoption of the method, three-dimensional reconstruction of various grading levels, various void ratios and various asphalt mixtures can be achieved, and digital test piece reconstruction efficiency and accuracy are improved greatly.

Owner:SOUTHEAST UNIV

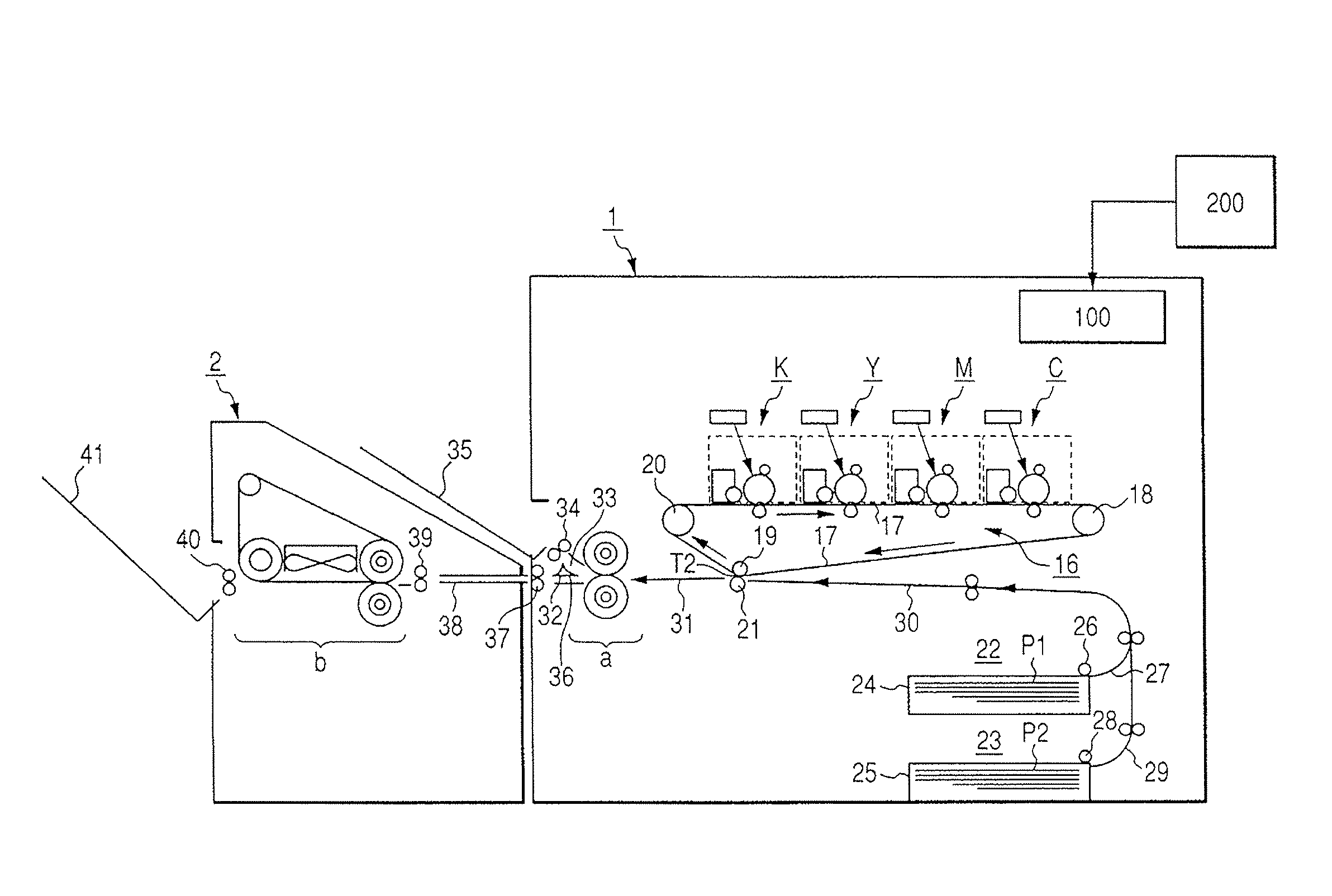

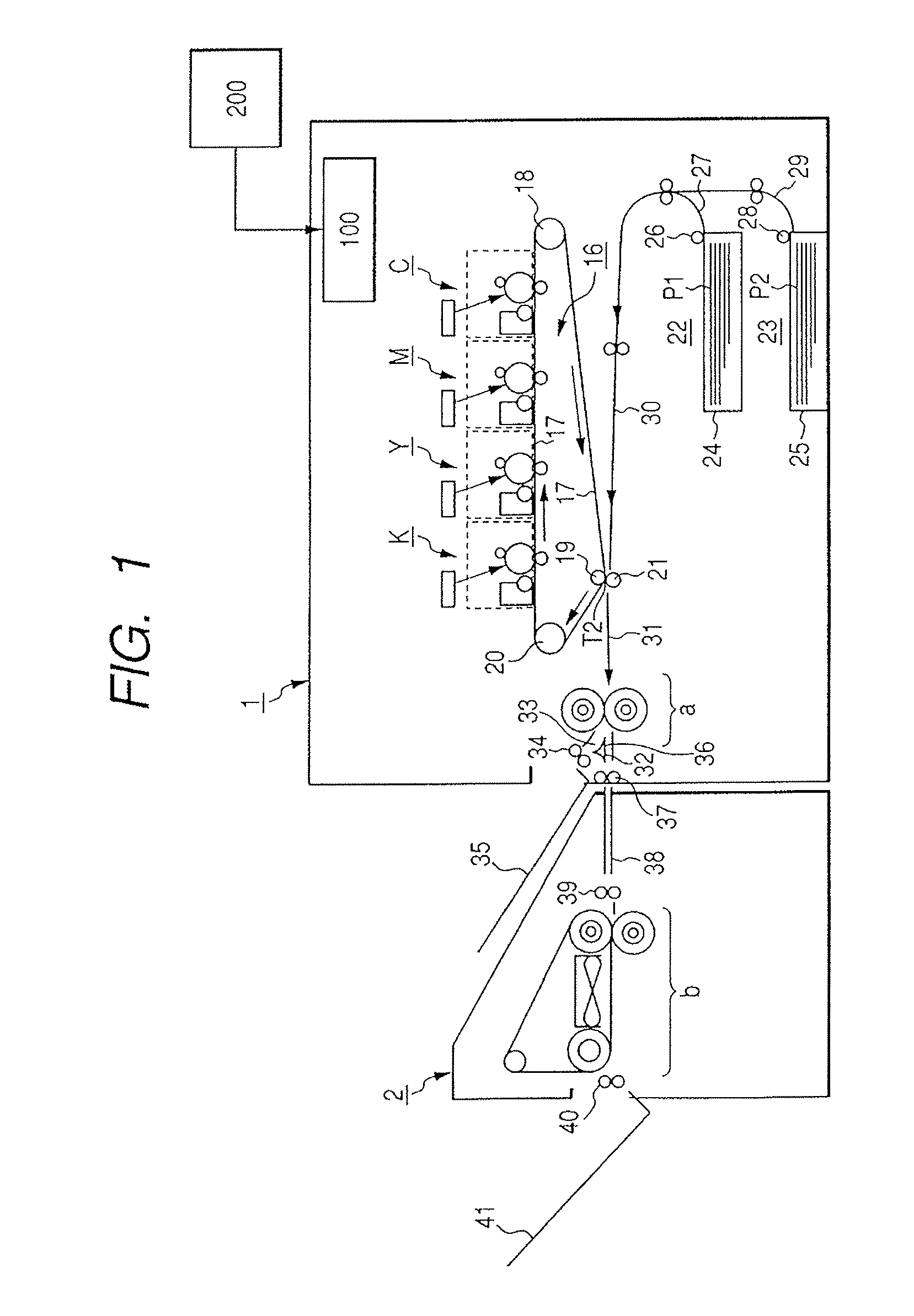

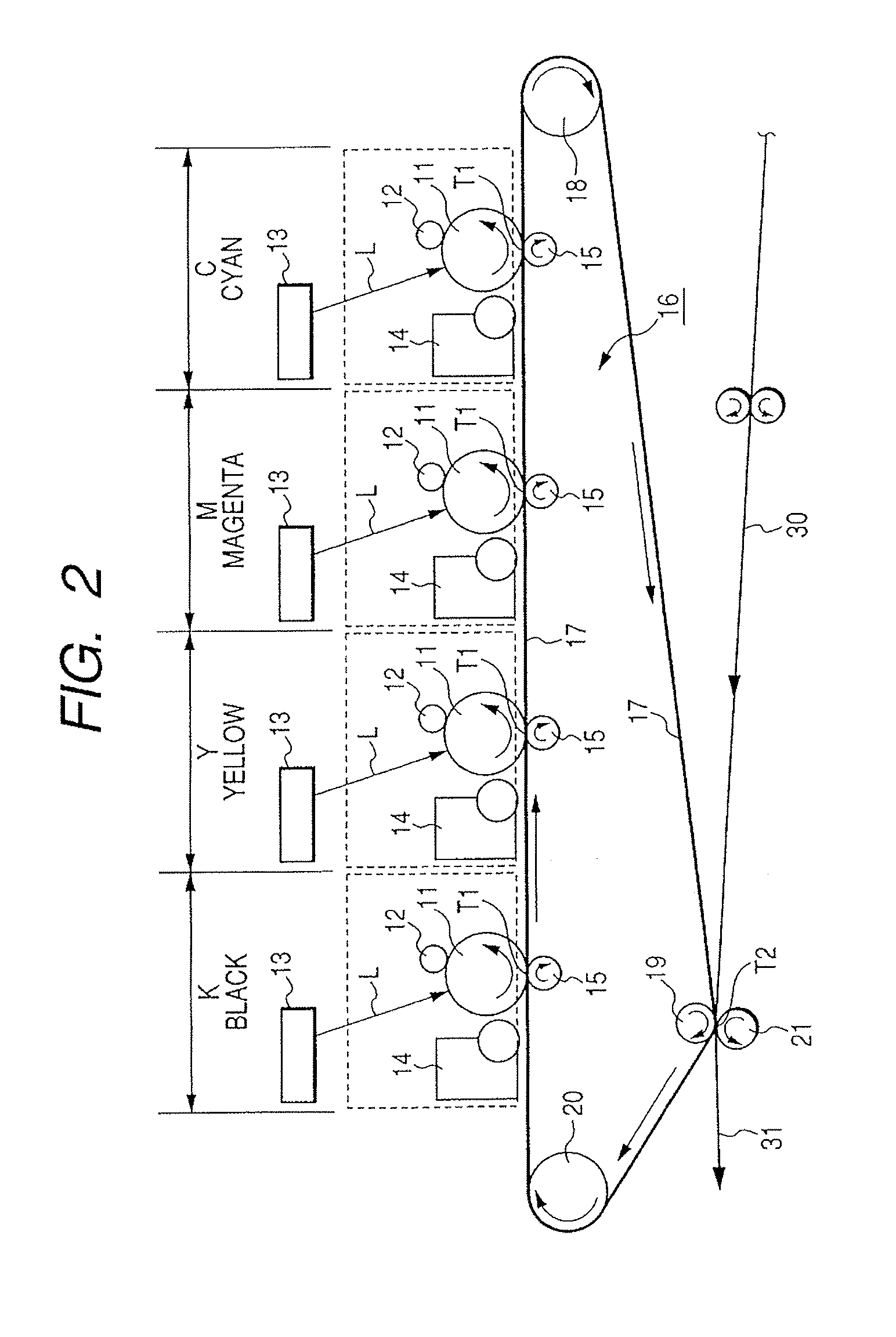

Image forming apparatus

InactiveUS7783242B2High-quality toner image excellent in glossinessExcellent glossinessElectrographic process apparatusVoid ratioImage formation

Owner:CANON KK

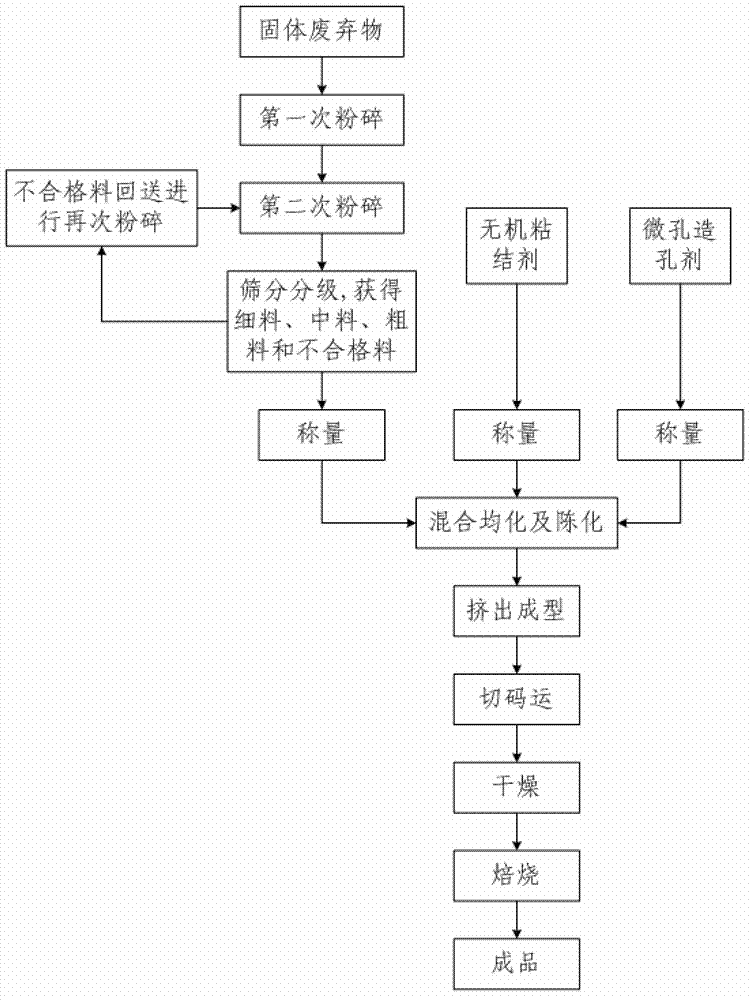

Porous sintering heat-insulating hollow block and manufacturing process thereof

ActiveCN102807390ASave resourcesPromote environmental protectionSolid waste managementCeramicwareSocial benefitsVoid ratio

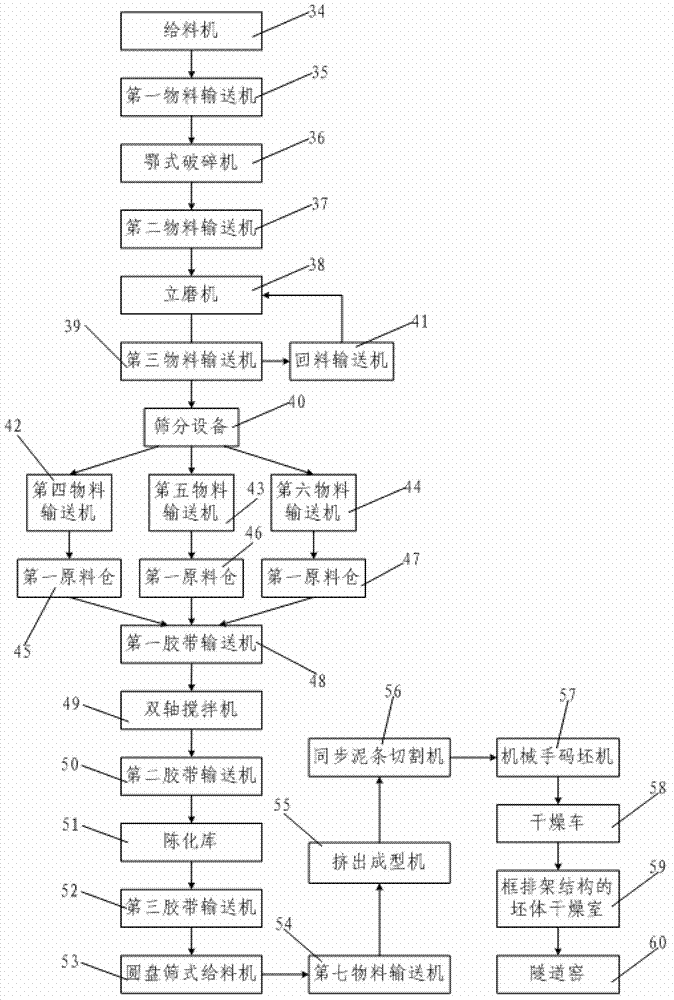

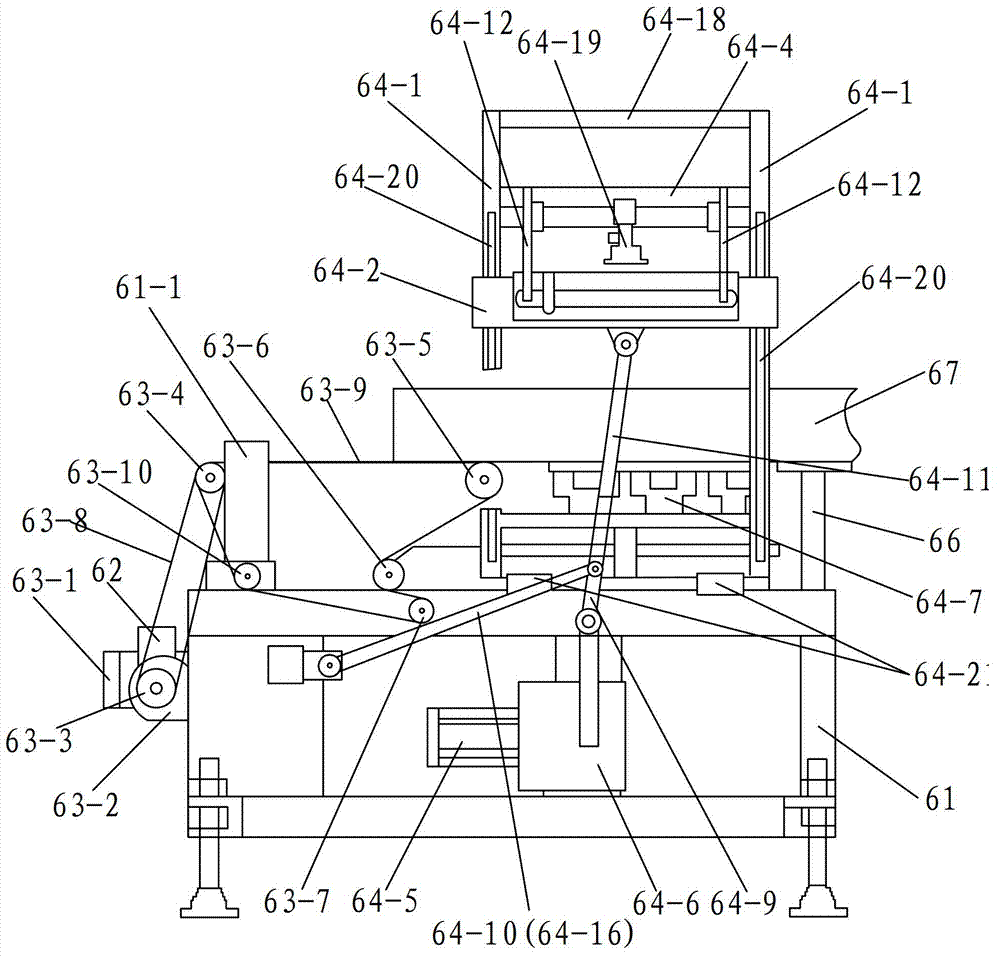

The invention discloses a porous sintering heat-insulating hollow block and a manufacturing process thereof. According to the porous sintering heat-insulating hollow block, the void rate is 35 to 60 percent, the density is 700 to 1,000 kg / m<3>, and the coefficient of heat conductivity is less than or equal to 0.22 W / m.K. The porous sintering heat-insulating hollow block consists of the following ingredients in percentage by weight: 30 to 45 percent of solid waste, 45 to 55 percent of inorganic binder and 5 to 15 percent of micropore pore forming agent. The manufacturing process comprises the following steps of: 1, performing grain composition; 2, sieving for grading; 3, weighing raw materials; 4, mixing, homogenizing and aging; 5, extruding for forming; 6, cutting and stacking; 7, drying;and 8, sintering. The porous sintering heat-insulating hollow block is reasonable in design, convenient to realize, high in utilization rate of solid wastes, energy-saving, environment-friendly, highin void rate, low in density, high in thermal performance and strength, stable in size and difficult to crack, can be popularized and used in large areas, and has the excellent economic and social benefits.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

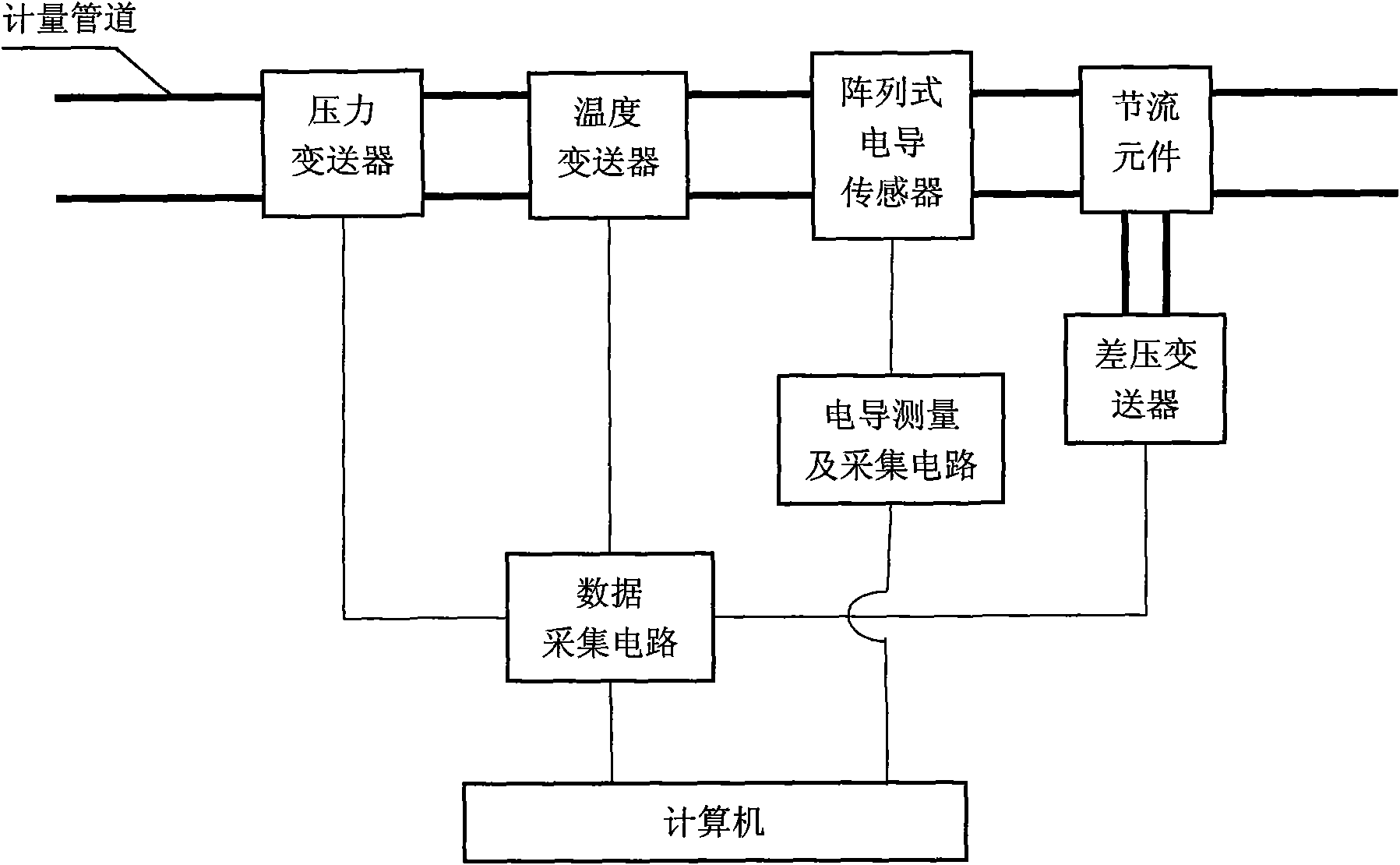

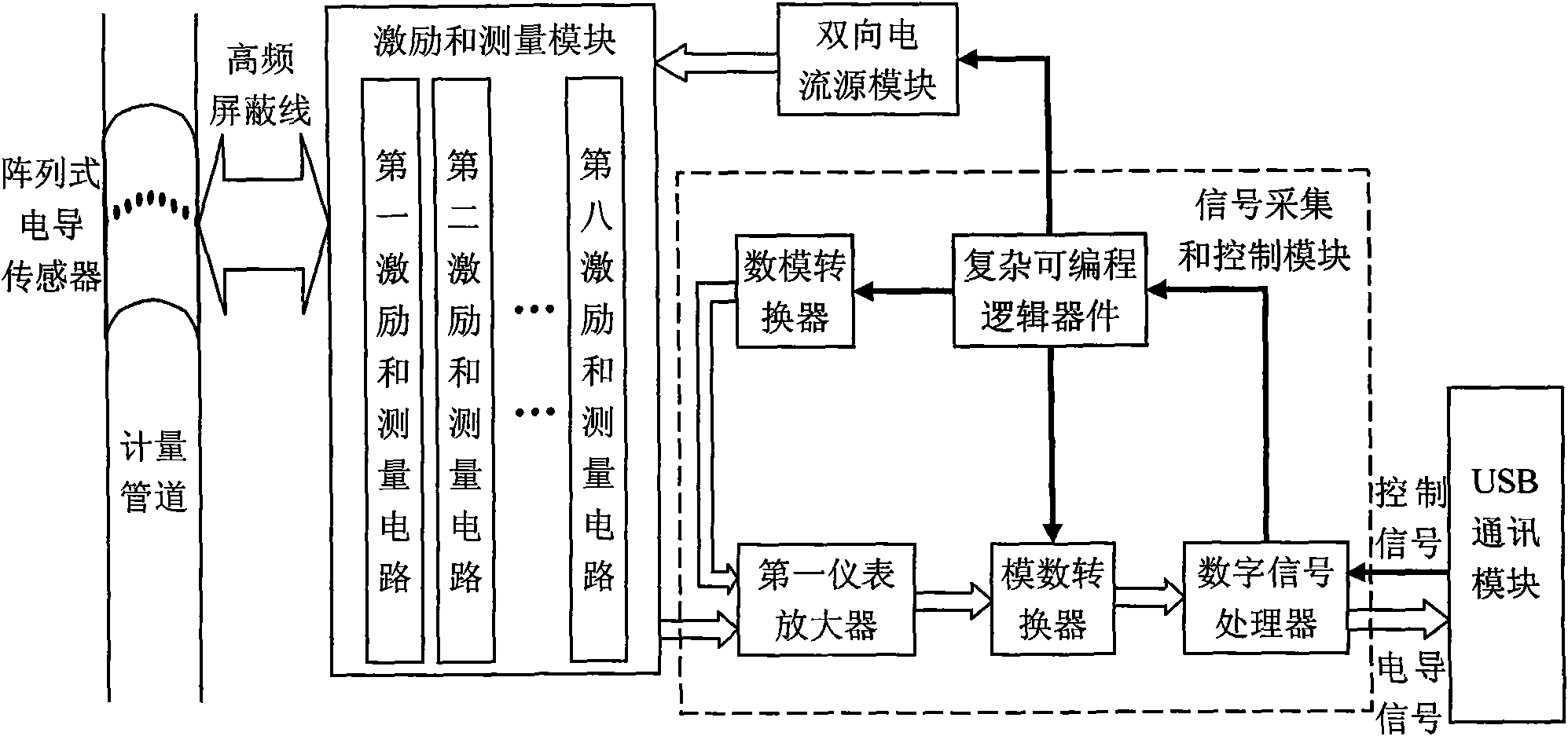

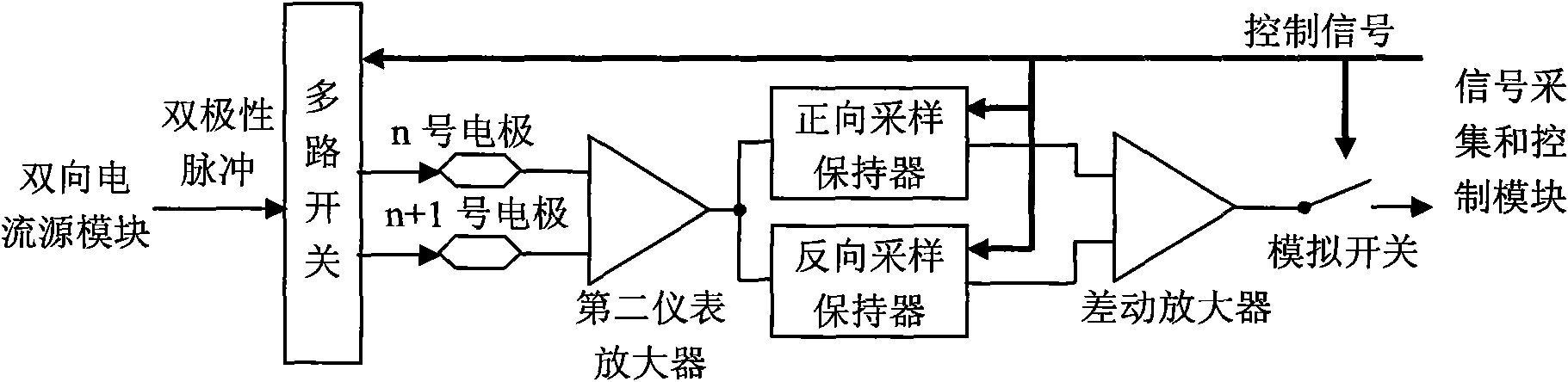

Gas-water two phase flow multiparameter measuring method and device

InactiveCN101556234ASolve online real-time measurement problemsSimple structureFlow propertiesVolume/mass flow by differential pressureVoid ratioDifferential pressure

The invention discloses a gas-water two phase flow multiparameter measuring method and a device thereof, wherein the device comprises a measuring pipe, a throttling element, a differential pressure transmitter, an array conductivity sensor, a pressure transmitter, a temperature transmitter, a conductivity measuring and collecting circuit, a data acquisition circuit and a computer; the array conductivity sensor is connected with the computer through the conductivity measuring and collecting circuit; and each transmitter is connected with the computer through the data acquisition circuit. According to the differential pressure obtained by the throttling element, the conductivity signal obtained by the array conductivity sensor, the pressure obtained by the pressure transmitter, and the temperature obtained by the temperature transmitter, a plurality of parameters such as flow pattern, void ratio, dryness, flow rate and the like of the gas-water two phase flow are obtained. In the measurement, according to the flow pattern judgement result, a corresponding measurement model or relational expression under the flow pattern is selected to calculate the void ratio, dryness and flow rate. The invention has simple structure, small loss of pressure, high reliability, low cost and wide range of application, and can be applied to the gas-water two phase flow measurement in the fields of energy, power, chemical engineering and the like.

Owner:ZHEJIANG UNIV

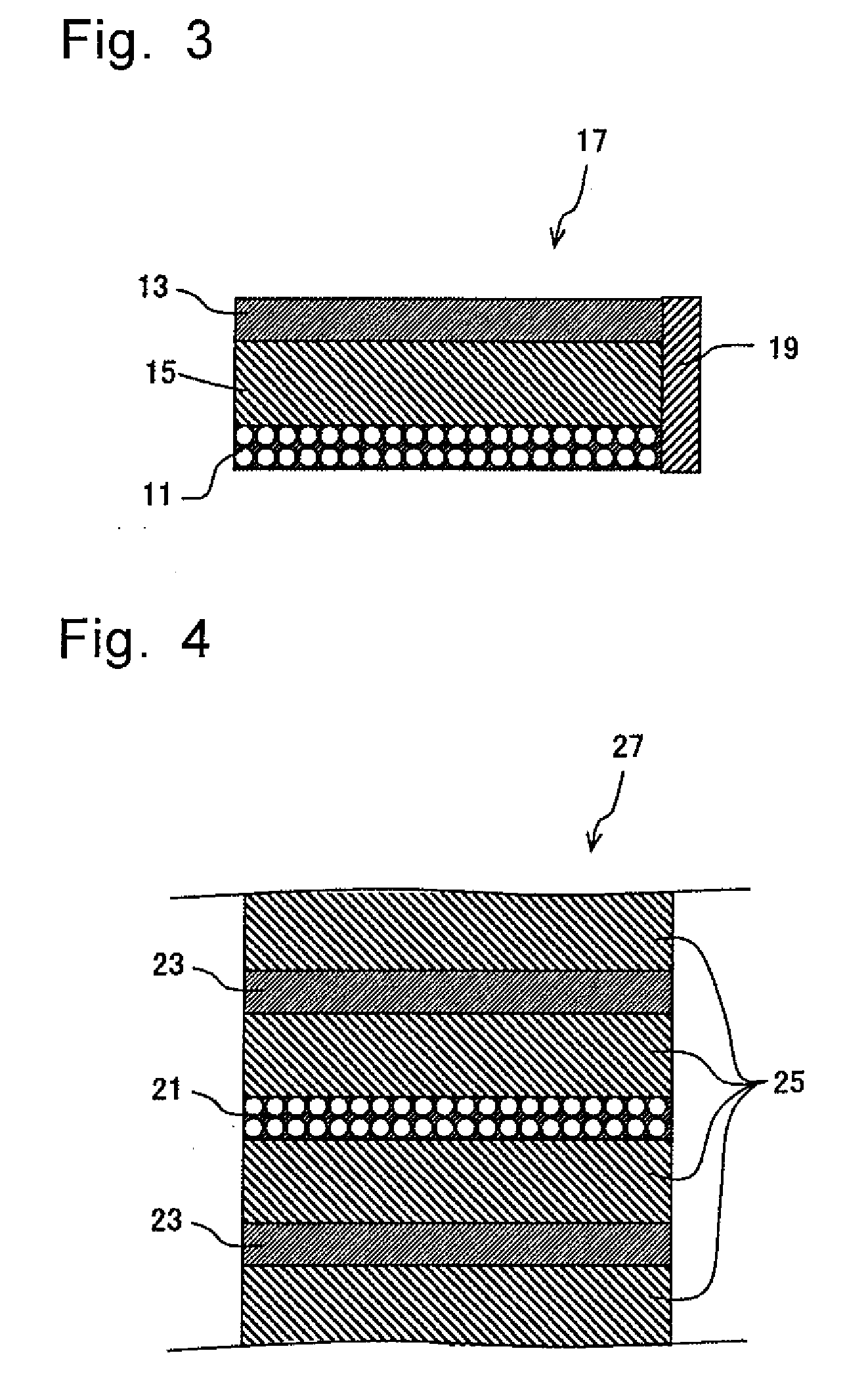

Method for Manufacturing Ceramic Member, and Ceramic Member, Gas Sensor Device, Fuel Cell Device, Multi-Layer Piezoelectric Device, Injection Apparatus and Fuel Injection System

InactiveUS20090162706A1Quality improvementHigh porosityPiezoelectric/electrostriction/magnetostriction machinesFuel cells groupingFuel cellsVoid ratio

A ceramic member in which the metal layers with high void ratio are sufficiently sintered to lower a residue of resin is produced.The method for manufacturing a ceramic member which comprises a step of forming a stacked compact from a plurality of metallic paste layers containing a metal component M1 that are stacked one on another via ceramic green sheets, and a step of firing the stacked compact, wherein at least one of plural metallic paste layers is formed as a second metallic paste layer that has the mass percentage X higher than that of the metallic paste layer that adjoin therewith in the stacking direction, the mass percentage X being the proportion of the metal component M1 to the total metal content in the metallic paste layer.

Owner:KYOCERA CORP

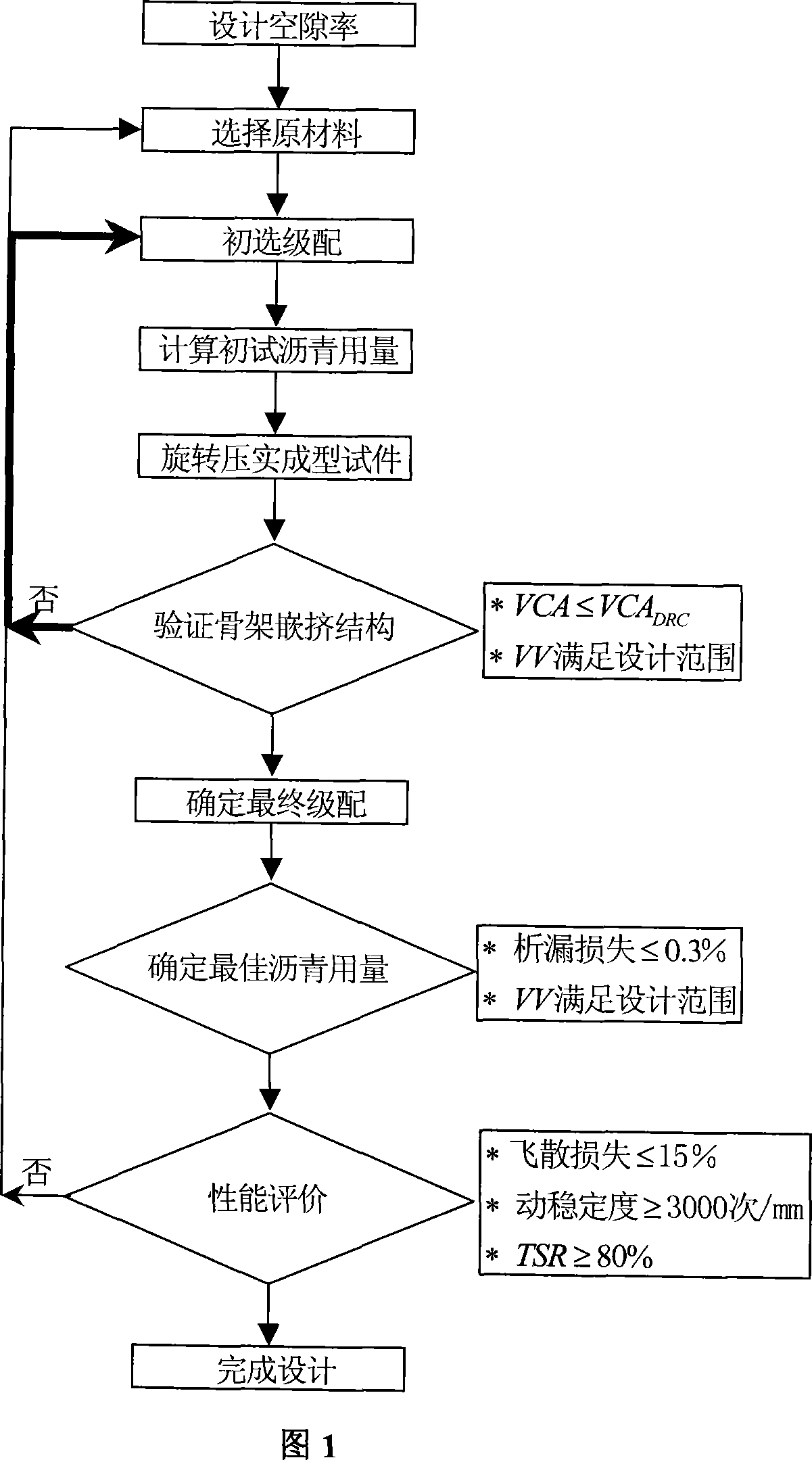

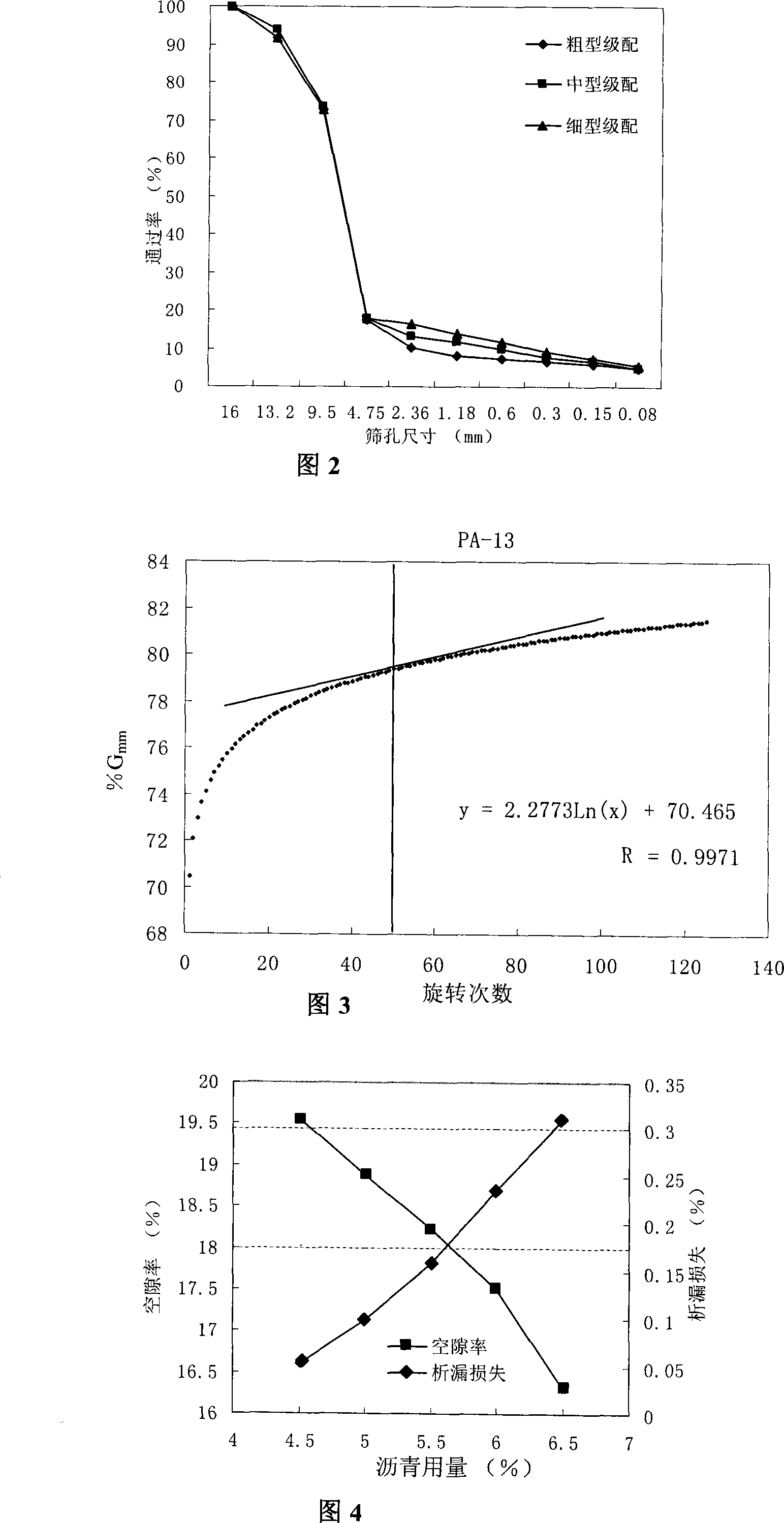

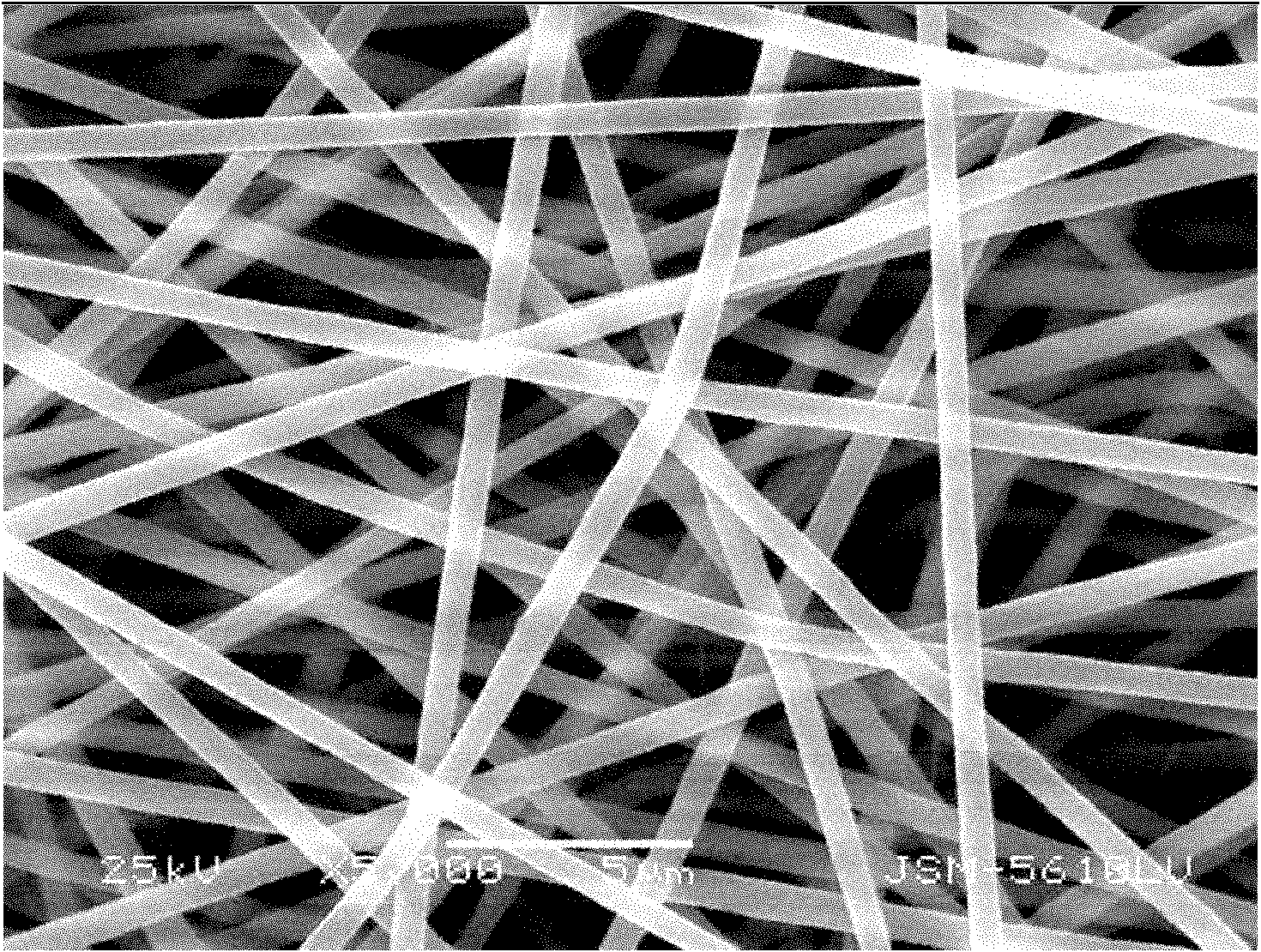

Drainage asphalt mixture material composition design method

The invention provides a composition design method for making porous asphalt mixture material, which includes steps: the porosity rate of the porous asphalt mixture material is defined according to the requirement of eliminating dynamic hydraulic and improving drainage performance; initial asphalt content is defined by the calculation method; frame embedding and extruding structure and porosity rate are regarded as the fundamental basis in extracting the final gradation of raw material; asphalt leakage loss and porosity rate are regarded as the main control index in defining the optimum asphalt content; fiber is used for increasing asphalt content on the basis of guaranteeing the porosity rate, and rotary specimen compacting and forming process is adopted to ensure the porous asphalt mixture material to own both the functionality and durability design requirements. The composition design method for making porous asphalt mixture material can satisfy the porosity rate design requirement and road-using property requirement of the porous asphalt mixture material, can ensure the functionality, road-using property of the porous asphalt road surface, and the stable compaction property and good drainage function in the later stage of using, and can improve the durability of the road surface, thus having the advantages of popularization and application.

Owner:WUHAN UNIV OF TECH

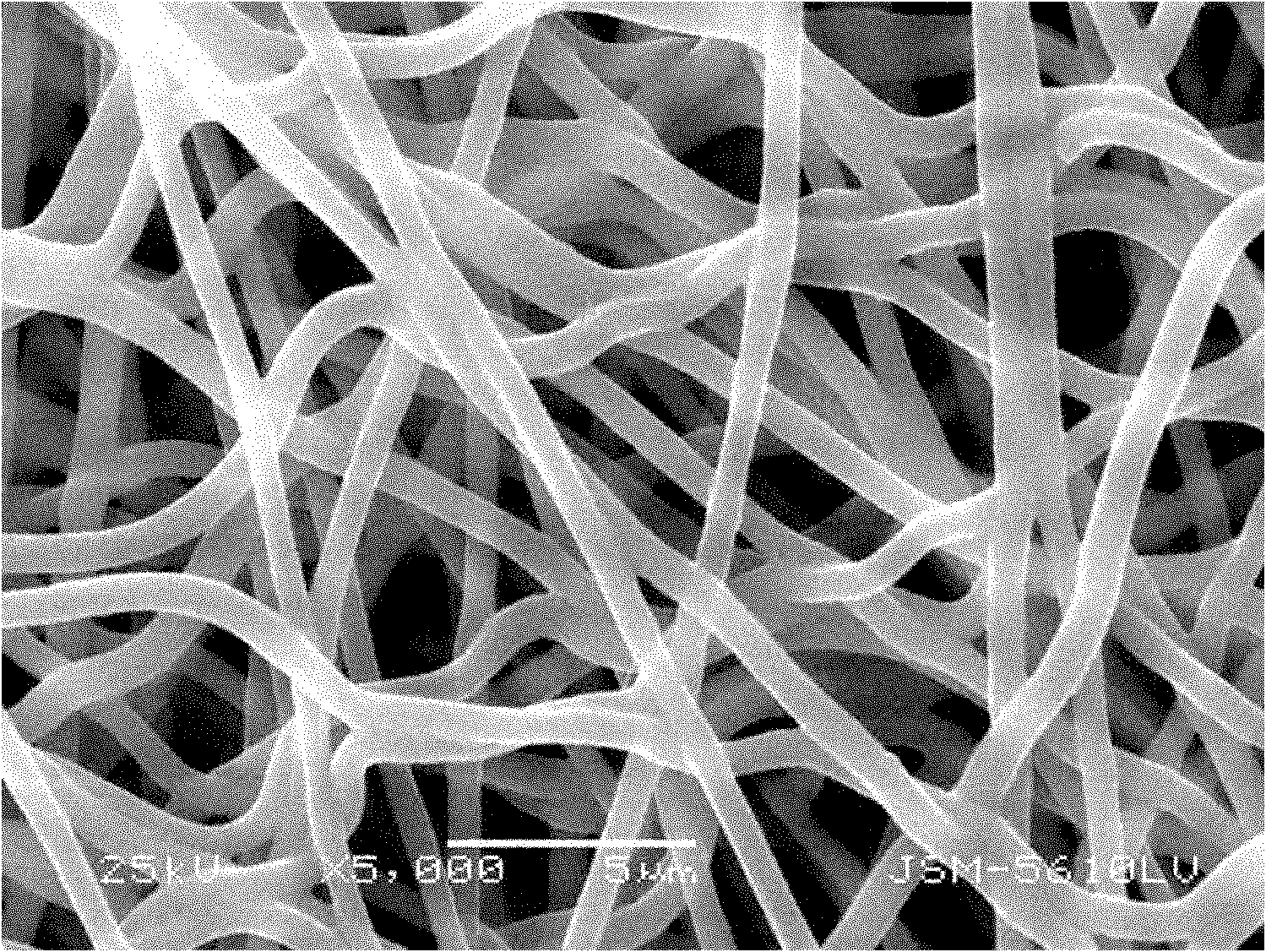

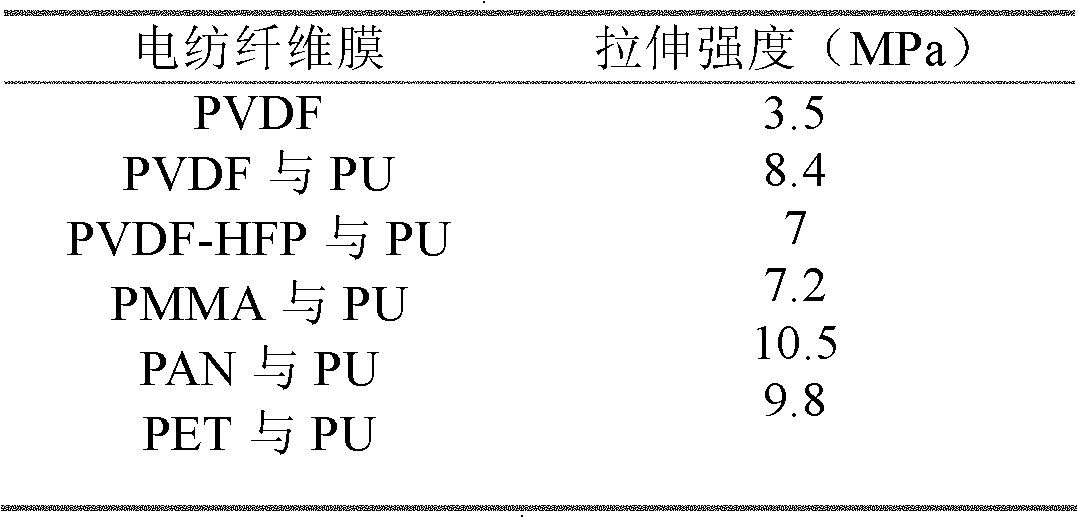

Enhanced bi-component nanofiber porous membrane and preparation method thereof

InactiveCN102140734AHigh porosityImprove wettabilityFilament/thread formingCell component detailsPolymer scienceVoid ratio

The invention relates to an enhanced bi-component nanofiber porous membrane and a preparation method thereof. The porous membrane is a lithium ion battery membrane with two components of polymer resin and polyurethane. The membrane is in a semi-interpenetrating network structure which has a void ratio of 60-80%, and the mechanical property is 2-3 times higher than a single-component porous membrane of polymer resin. The preparation method comprises the steps of: dissolving a polymer resin and polyurethane prepolymer bi-component composition in a solvent, and preparing a nonwoven membrane through an electrospinning technology; and putting the nonwoven membrane at room temperature to make -NCO in the polyurethane prepolymer react with the -OH bond of water in the air to produce polyurethanethrough crosslinking and autopolymerization. In the invention, the nanofiber in the nonwoven membrane binds to form the polymer resin and polyurethane bi-component compound membrane, and the mechanical strength of the fibrous membrane is improved greatly. The method is easy, and the prepared nonwoven membrane maintains the advantages of high void ratio, and good thermal stability of polymer resinof the membrane prepared by using the electrospinning technology, and the membrane has good ion permeability and electrolyte affinity.

Owner:WUHAN UNIV OF TECH

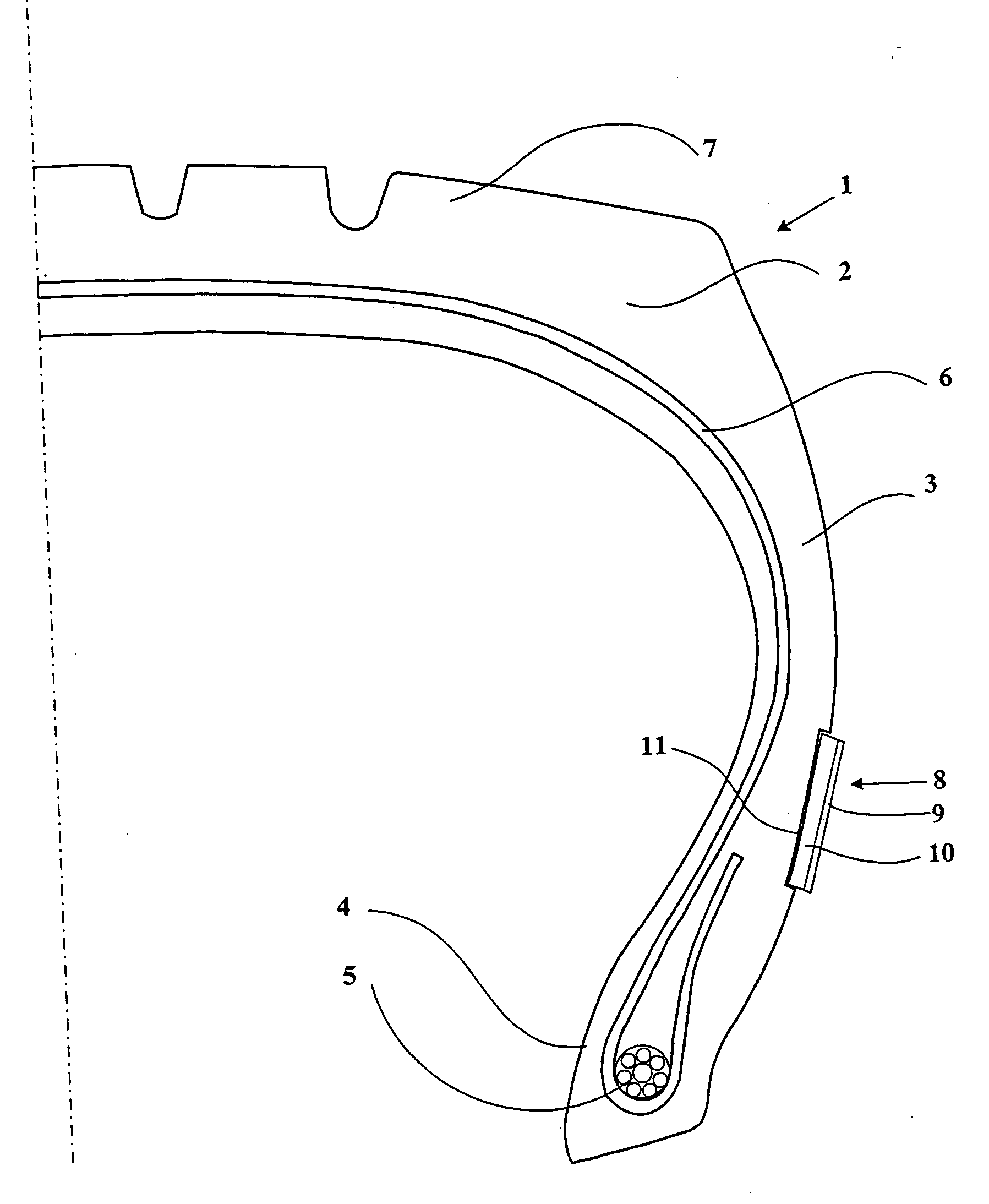

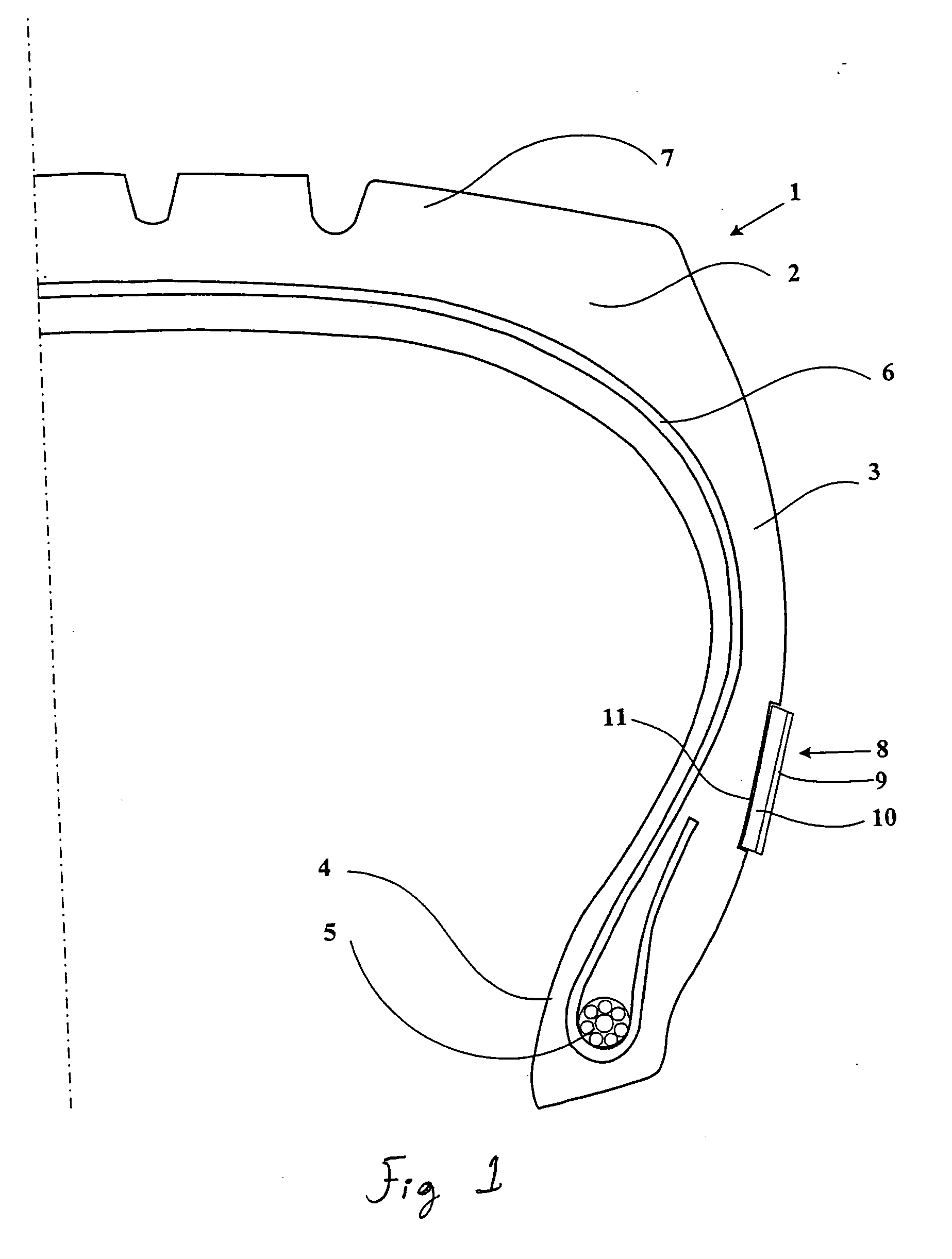

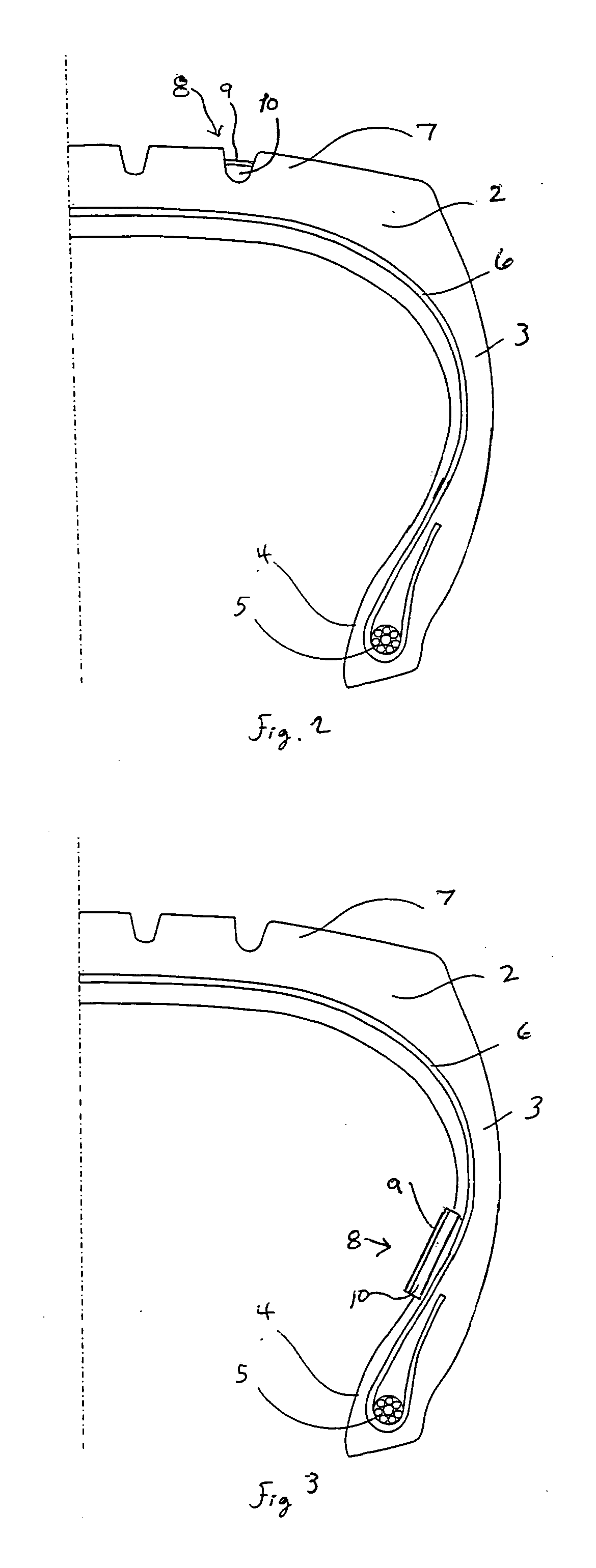

Tire having an element or covering attached to a surface thereof

ActiveUS20060016534A1Reduce and even eliminate of and brightnessMarking is durableTyresInflatable tyresVoid ratioEngineering

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

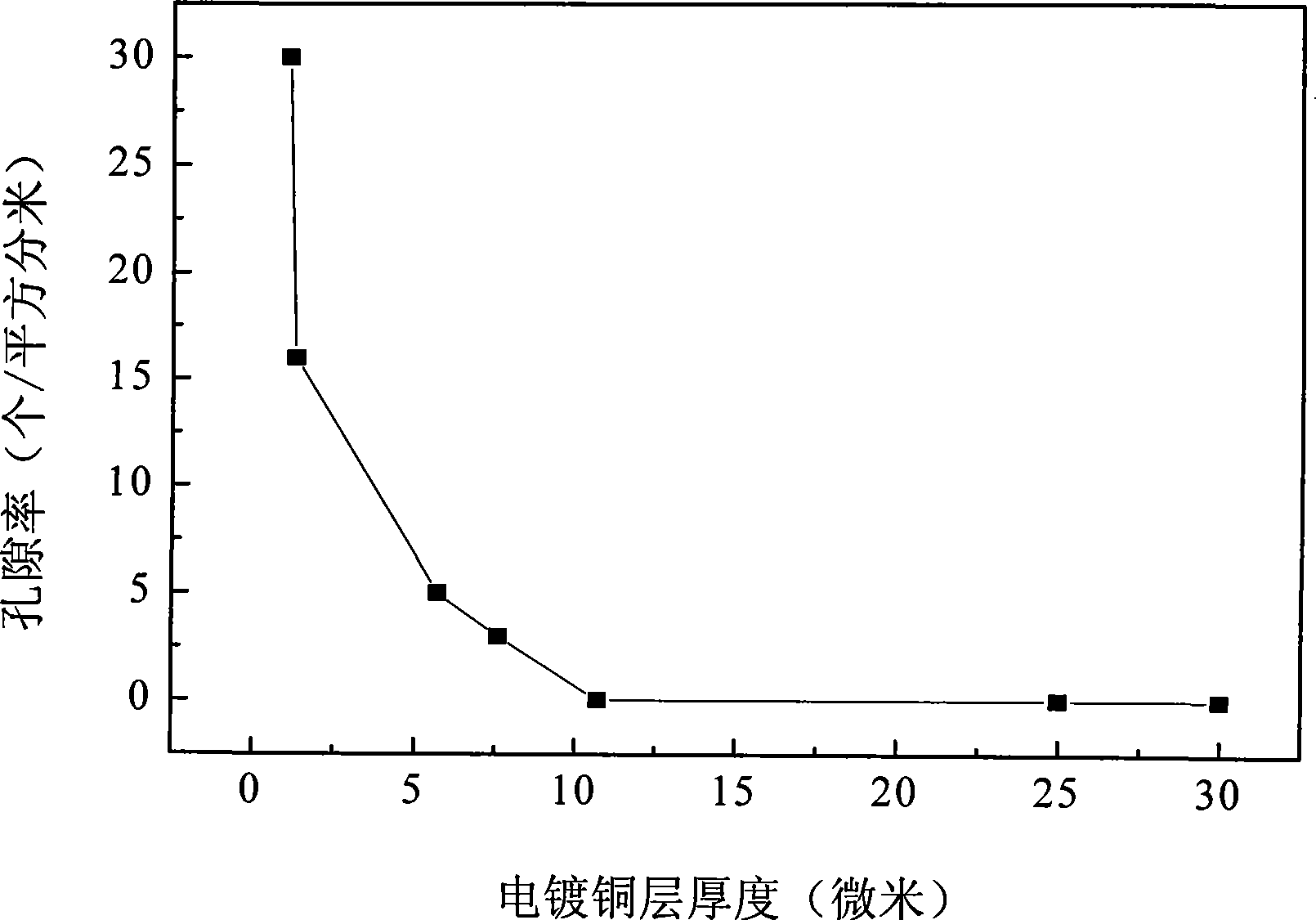

Cyanideless electro-coppering method for magnesium alloy casting parts

A method for no cyanide copper plating of a magnesium alloy casting relates to a method for the electro-coppering of a magnesium alloy. The invention solves the defects of the existing copper plating technique of the magnesium alloy of poor combining force of a plating coat, high void ratio and unstable plating bath. The method of the invention is as follows: first, alkaline cleaning; second, organic acid washing; third, activating in a magnesium alloy surface active agent under the condition of room temperature and water washing; fourth, soaking zinc alloy; fifth, plating in electro-coppering bath under the condition that the temperature is 20-50 DEG C and the intensity of cathode current is Dk=0.5-2.5A / dm<2>. The invention is not only used for strike copper plating of the magnesium alloy but also for thickening an electro-coppering coat. The copper plating coat has bright appearance, good combining force, low void ratio and convenient maintenance. The copper plating bath has good uniform coverage ability and covering power. The method has simple technique. The magnesium alloy casting that adopts the method to plate copper has wide application range and is applicable to the fields of electronic product, car and parts thereof, vessels, aerospace, etc.

Owner:HARBIN INST OF TECH

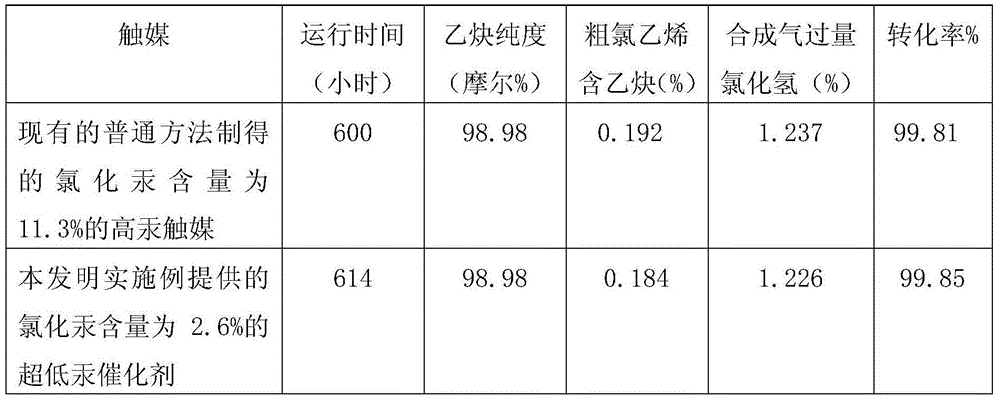

Composite metal chloride catalyst and its production process

ActiveCN1814345AReduce dosageThe dosage can be greatly reduced when theCatalyst activation/preparationMetal chlorideActivated carbon

This invention is a complex metal chloride catalyst. Its carrier is active carbon with void ratio>=0.56cm3 / g, specific surface area>= 1000m2 / g, mechanical strength>=90%, and it is made by absorbing mercuric chloride and zinc chloride under condition of 92-96 degree centigrade. Computing as weight percentage, the mercuric chloride is 2-8%, zinc chloride 1-15%. Its advantage is that 1. Mercuric chloride content is low, but activity and stability is boosted 5-20% and 10-20% comparing to existing mercuric chloride catalyst. 2. Mercuric chloride using level can be reduced according to the boost of activity and stability and the catalyst activity is not reduced, and catalyst producing cost is reduced, mercury resource consumption is reduced. Otherwise, catalyst useful life can be prolonged, its dosage can be reduced, and catalyst replacing time is economized, so vinyl chloride producing cost is reduced. 3. Catalyst consumption is few, mercury drain is few. So the damage of drained mercury to environment and product is lightened.

Owner:那风换 +1

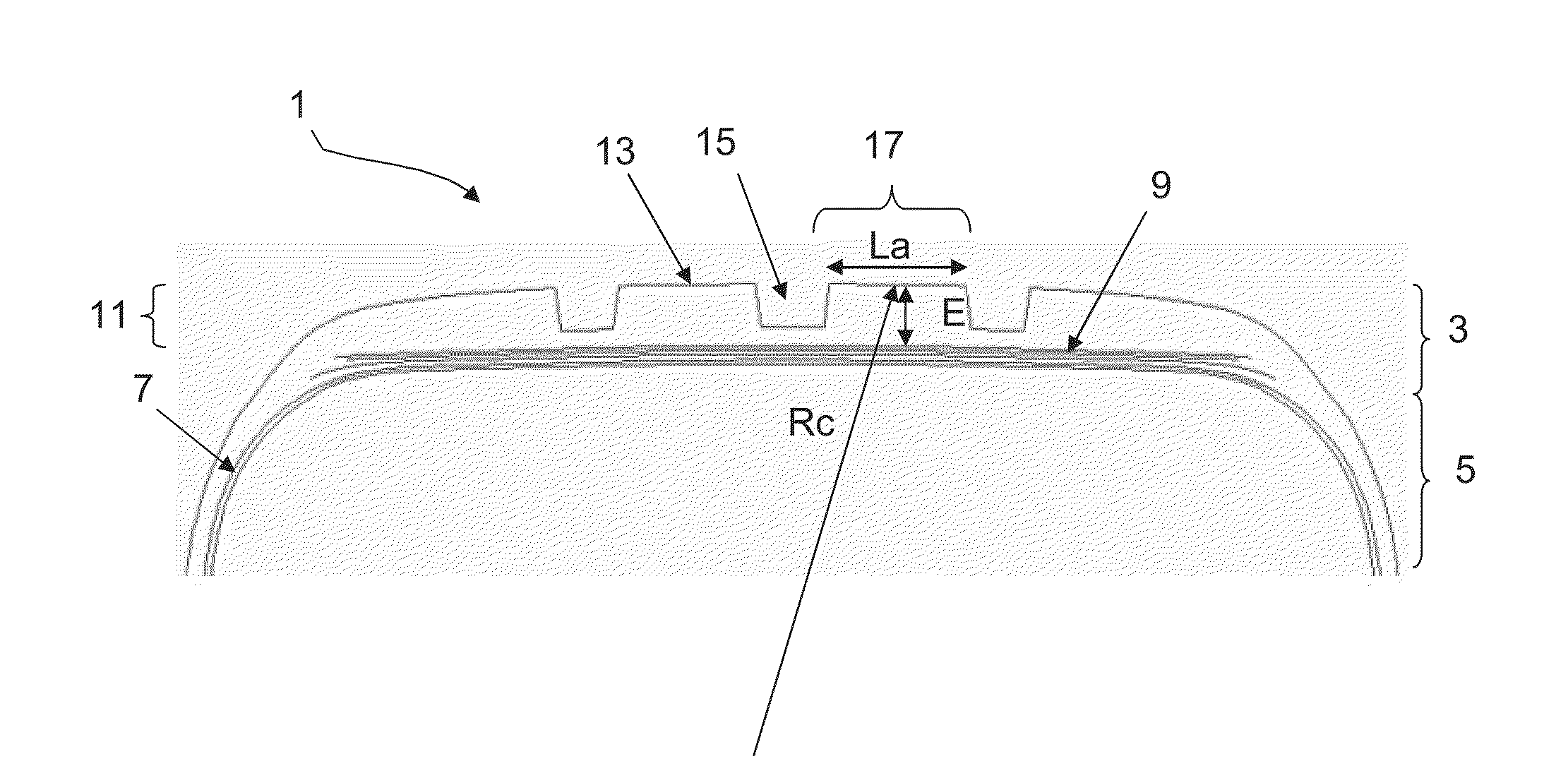

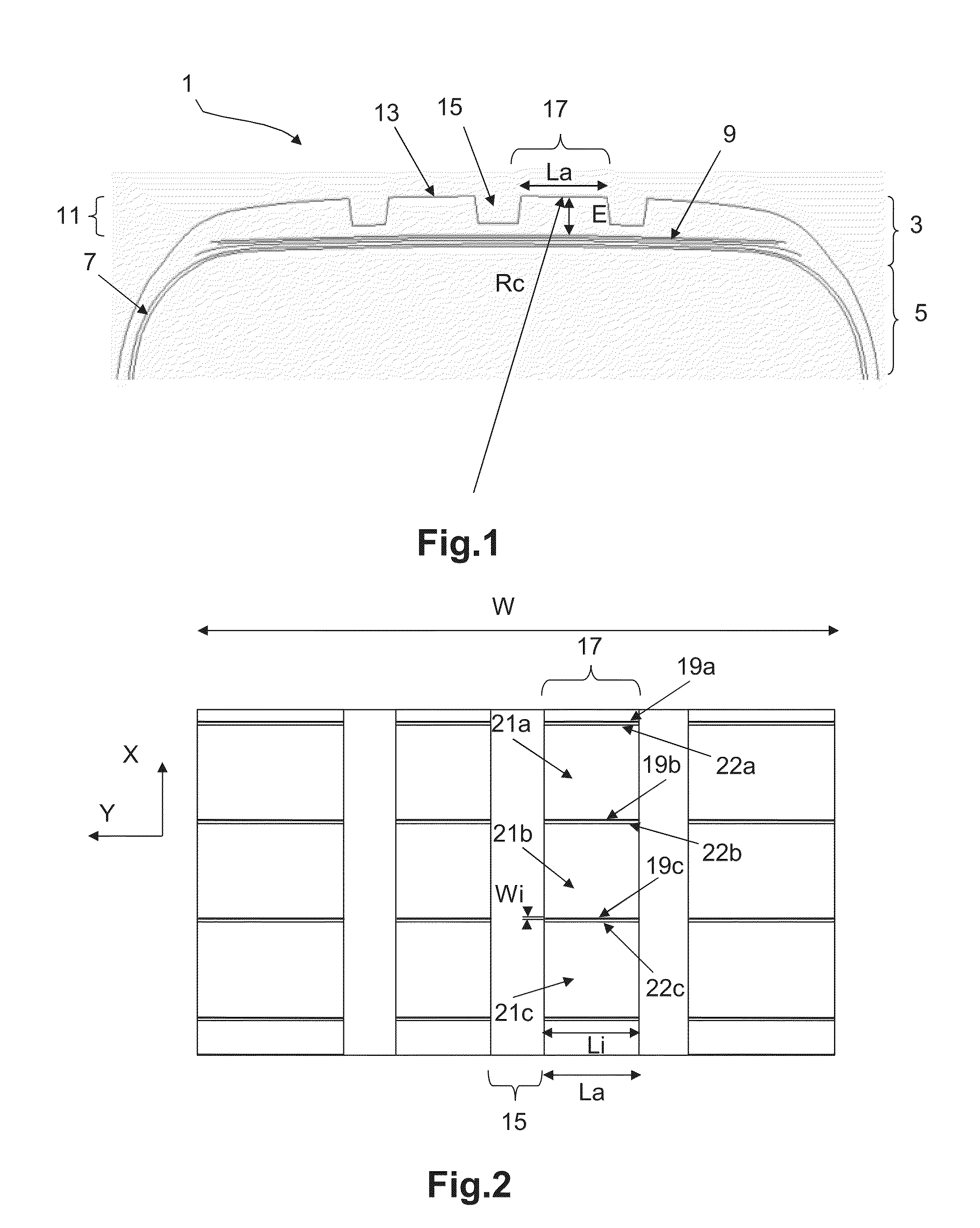

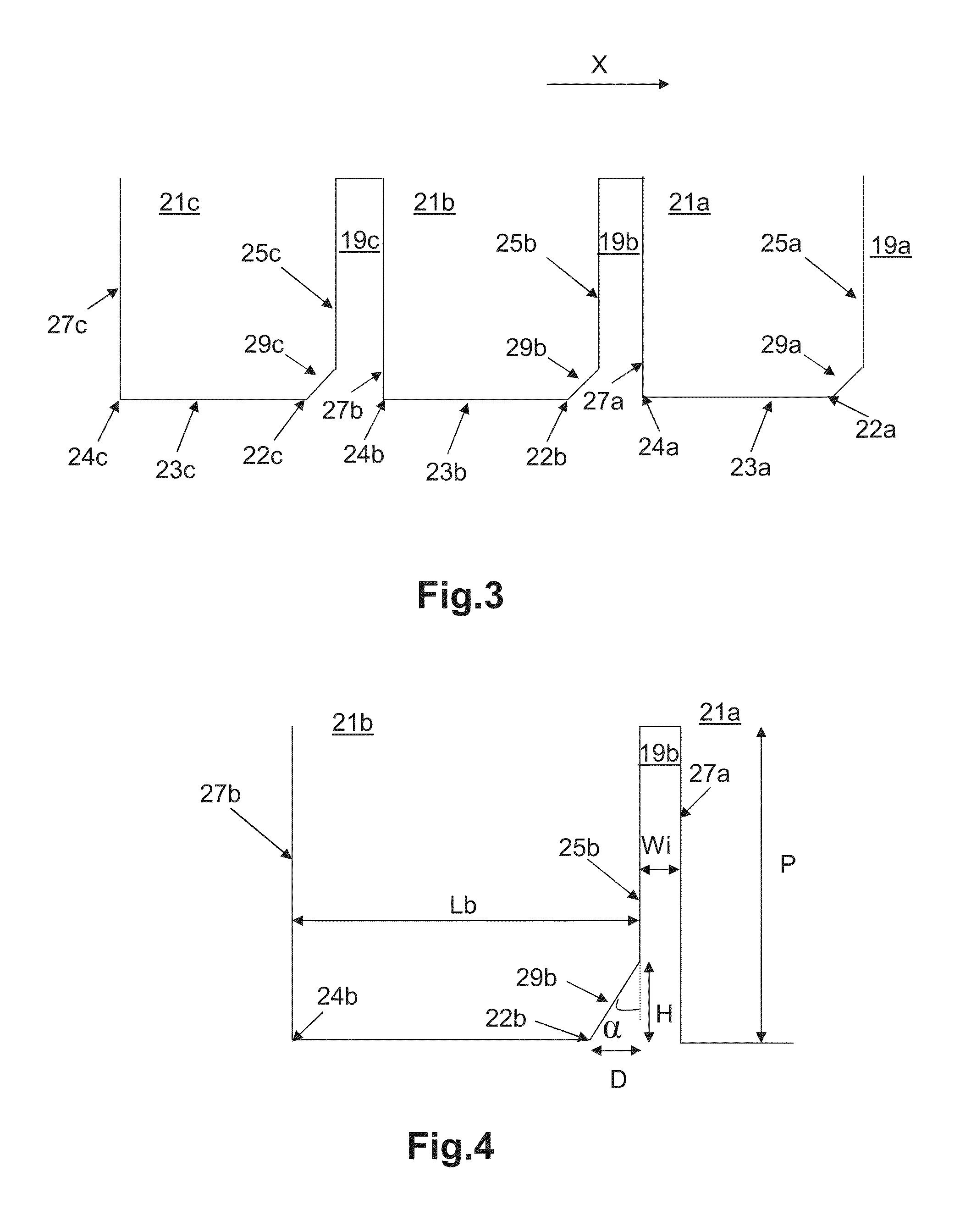

Pneumatic tire tread comprising a plurality of incisions

InactiveUS20130206298A1Easy to closeAvoid deformationTyre tread bands/patternsNon-skid devicesVoid ratioEngineering

A tread comprises a central zone with a width of between 70% and 80% of the width W of the tread. The central zone comprises one or more circumferential bands, each being delimited by two grooves of a width greater than or equal to 2 mm, and each comprising a contact surface intended to come into contact with the ground and a plurality of transverse sipes distributed evenly in the circumferential direction. Each sipe has, on the contact surface, a width less than 2 mm so as to define a mean circumferential void ratio, which is between 0.5 times and 1.5 times the ratio between a mean thickness (E) of the circumferential band to a mean circumferential radius of curvature (Rc) of the said circumferential band. The sipes divide the circumferential band into a succession of blocks, each having two edge corners intersecting the contact surface of the circumferential band, at least one of the edge corners of said block extending radially by an inclined part forming a chamfer. This inclined part connects the edge corner to a lateral wall of the block so as to generate an offset in the circumferential direction between the said edge corner and the lateral wall of the block.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

Ultralow-mercury catalyst and production process thereof

InactiveCN103551139AReduce manufacturing costLow in Mercury ChlorideCatalyst carriersPreparation by halogen halide additionVoid ratioPotassium

Owner:SHIJIAZHUANG KECHUANG ADDITIVES CO LTD

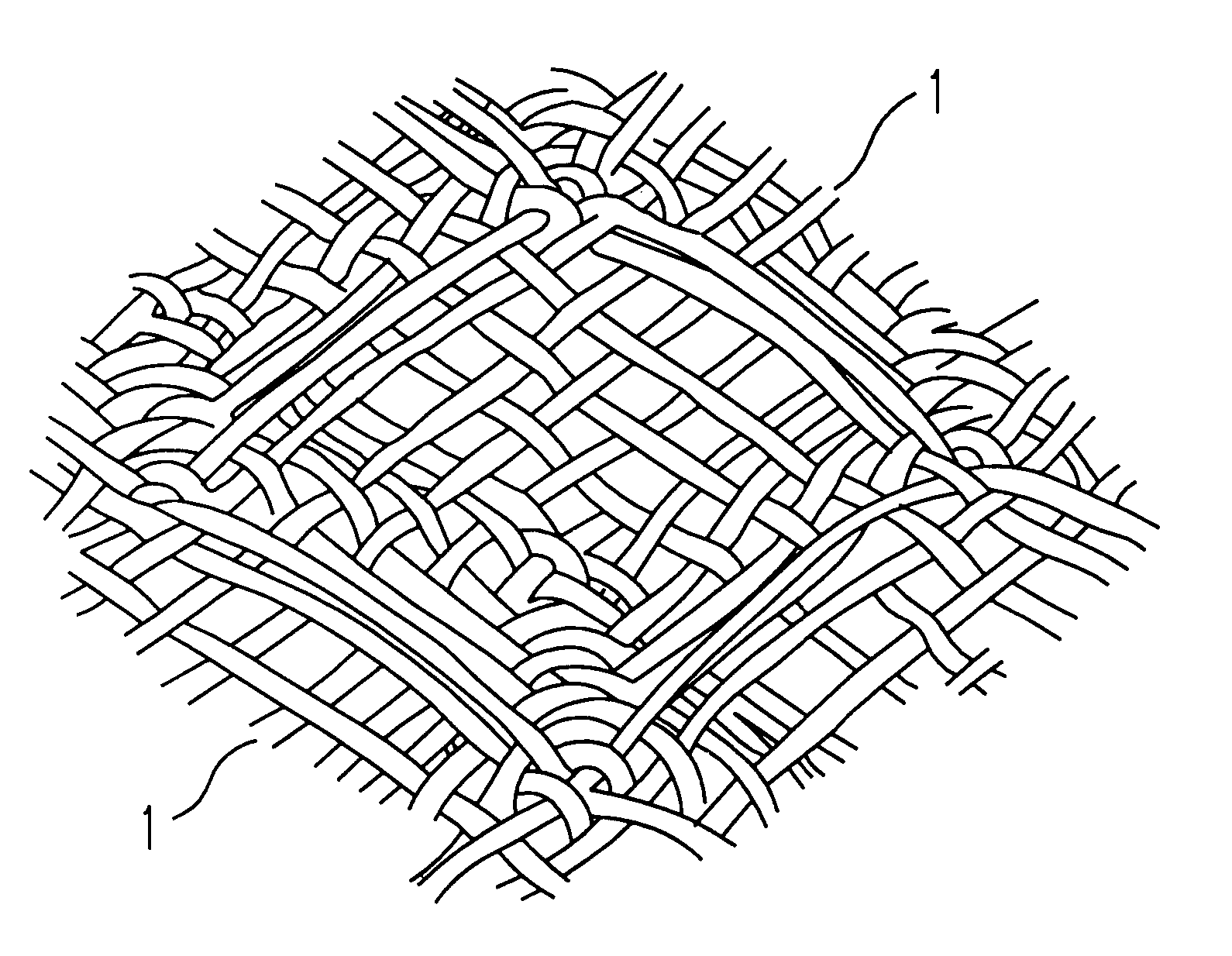

Adsorbent article with dust collecting function

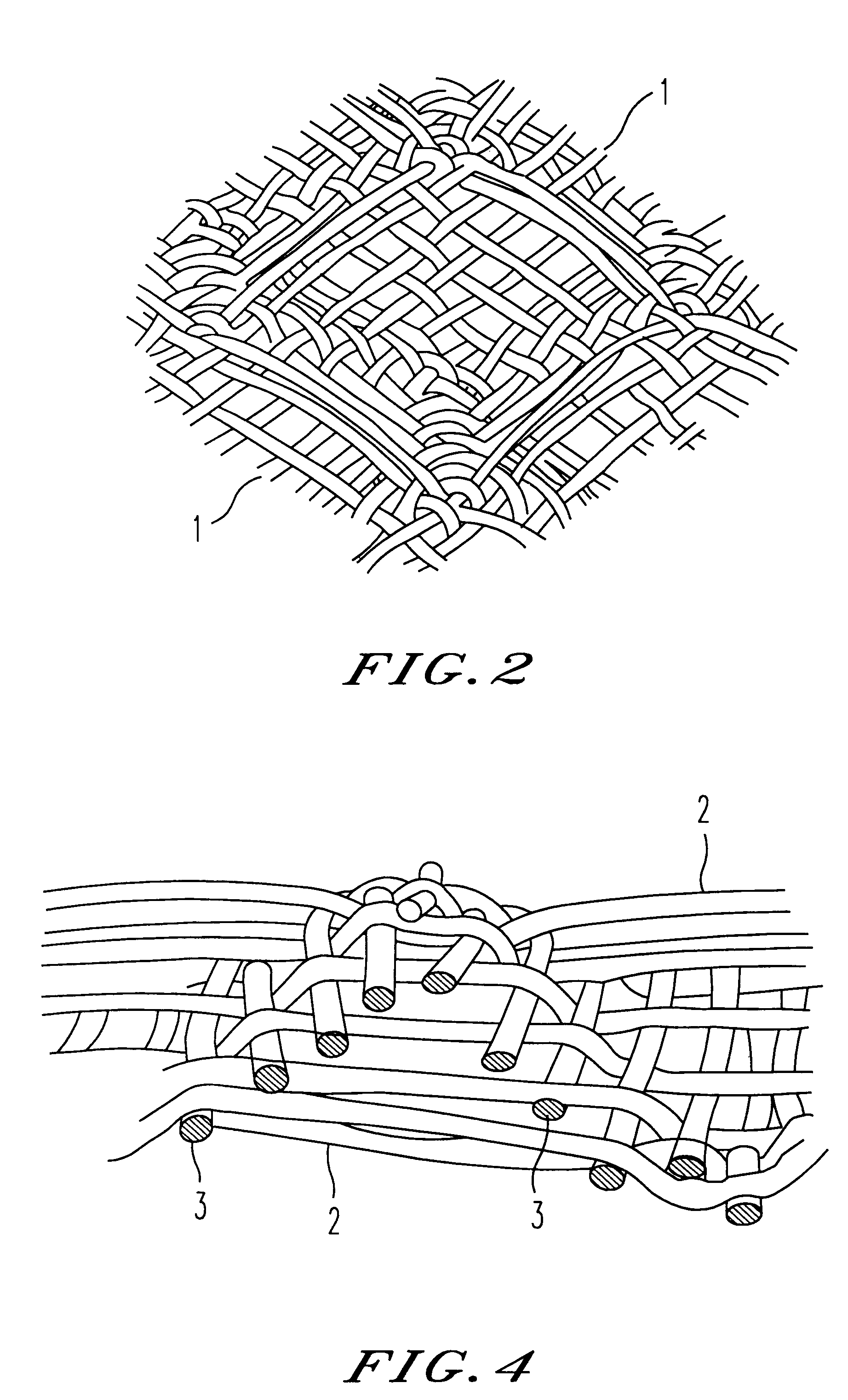

Preferably configured in ridge and recess irregularity, the inventive article provides adsorption of malodor components in air and also dust collecting function. It comprises woven sheet having coarse three dimensional structure whose areas of sheet surface as well as internal fiber structure allowable to contact to incoming outer air are formed with a binder layer made of latex or emulsion or non-solvent adhesive and such binder layer is adhered with activated carbon particles partially exposed. The process of adhereing activated carbon particles is conveniently performed by a fluidizing bed. The inventive sheet form fabric incorporates the particles with a high void ratio and uniformity and thereby exhibits high adsorptive rate and capacity, and exceedingly low pressure loss with such result that it is applicable regardless of high or air wind rate. Preferable use is a filter element of air-conditioner for cars.

Owner:KURARAY CHEM CORP

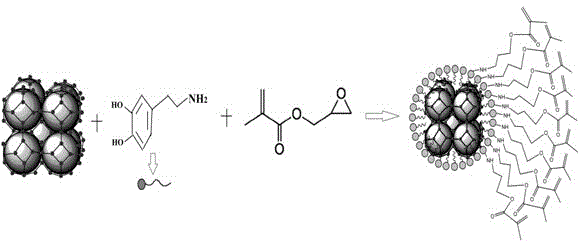

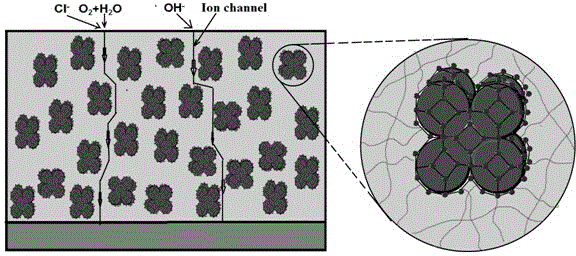

Preparation method of metal organic framework/ water-borne anti-corrosive coating

ActiveCN104861822ASolve the disadvantages of mechanical performance declineEliminate the disadvantages of the decline in anti-corrosion effectAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses a preparation method of a metal organic framework / water-based anti-corrosive coating. The composite coating is formed by compounding a coordination compound of a metal organic framework (MOFs) and water-borne epoxy resin. As a novel organic hybrid material, the coordination compound of a metal organic framework (MOFs) has high void ratio and adjustability of hole dimension and shape; when the material gets the outside stimulation (such as pressure, light, chemical stimulation of a guest molecule), the framework shape can be changed. The preparation method introduces the metal organic framework material to an anti-corrosive coating system, thus the crosslinking density of the coating can be added, the corrosive particles can be absorbed; besides, the preparation method overcomes the shortcoming of poor barrier property and short anti-corrosive cycle which are generally existed in the water-borne anti-corrosive coating at present, and greatly improve the anti-corrosive performance of the anti-corrosive coating.

Owner:CHANGCHUN SHUNFENG XINCHENG BUILDING MATERIAL CO LTD

Thermally expanded microspheres and a process for producing the same

ActiveUS20090280328A1Improve efficiencyImprove liquiditySynthetic resin layered productsCellulosic plastic layered productsVoid ratioMicrosphere

The present invention provides heat-expanded microspheres having high packing efficiency, and a production method thereof. The heat-expanded microspheres are produced by expanding heat-expandable microspheres, which comprise shell of thermoplastic resin and a blowing agent encapsulated therein having a boiling point not higher than the softening point of the thermoplastic resin and have an average particle size from 1 to 100 micrometer, at a temperature not lower than their expansion initiating temperature, and the heat-expanded microspheres result in a void fraction not higher than 0.70.

Owner:MATSUMOTO YUSHI SEIYAKU

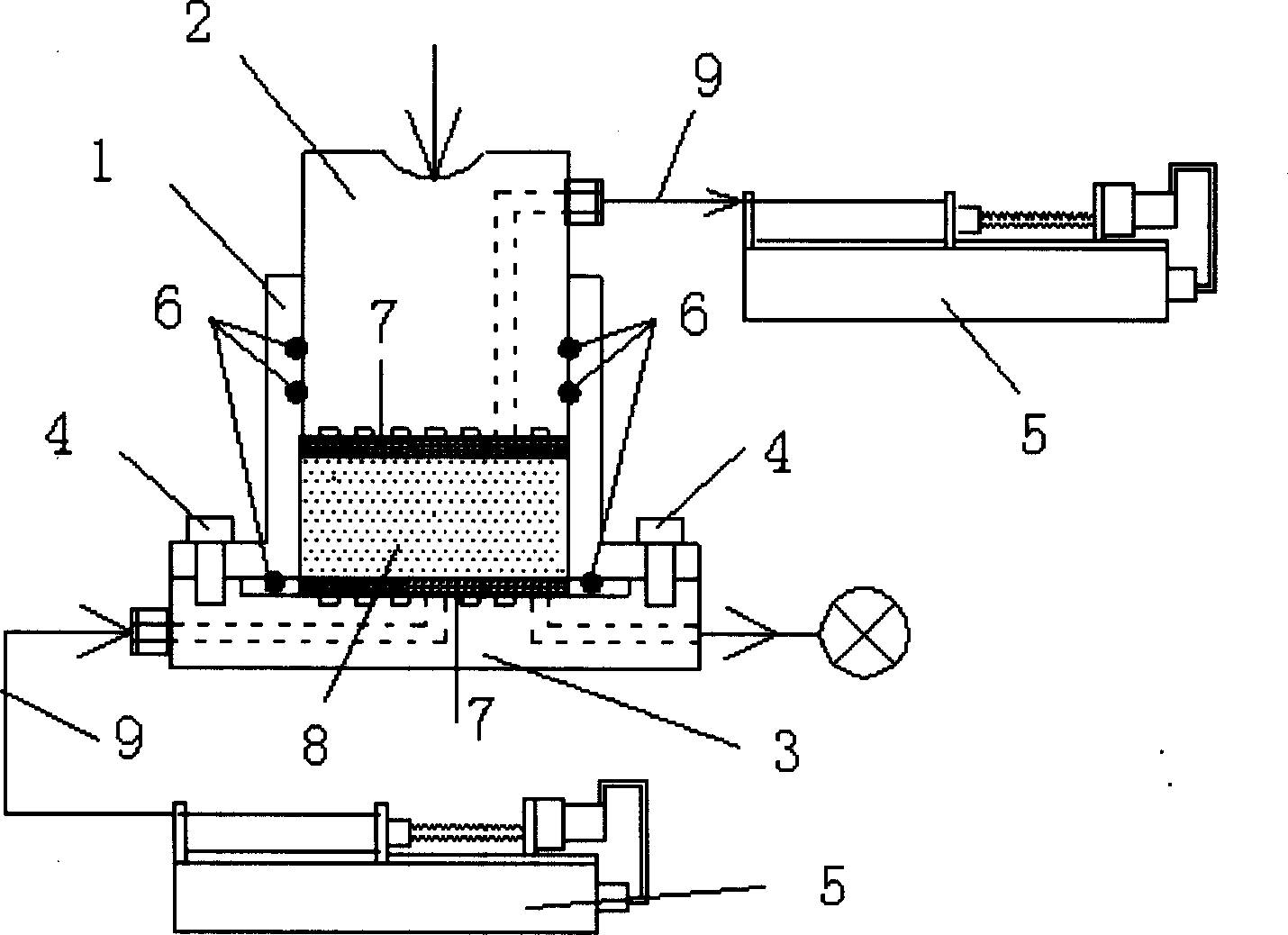

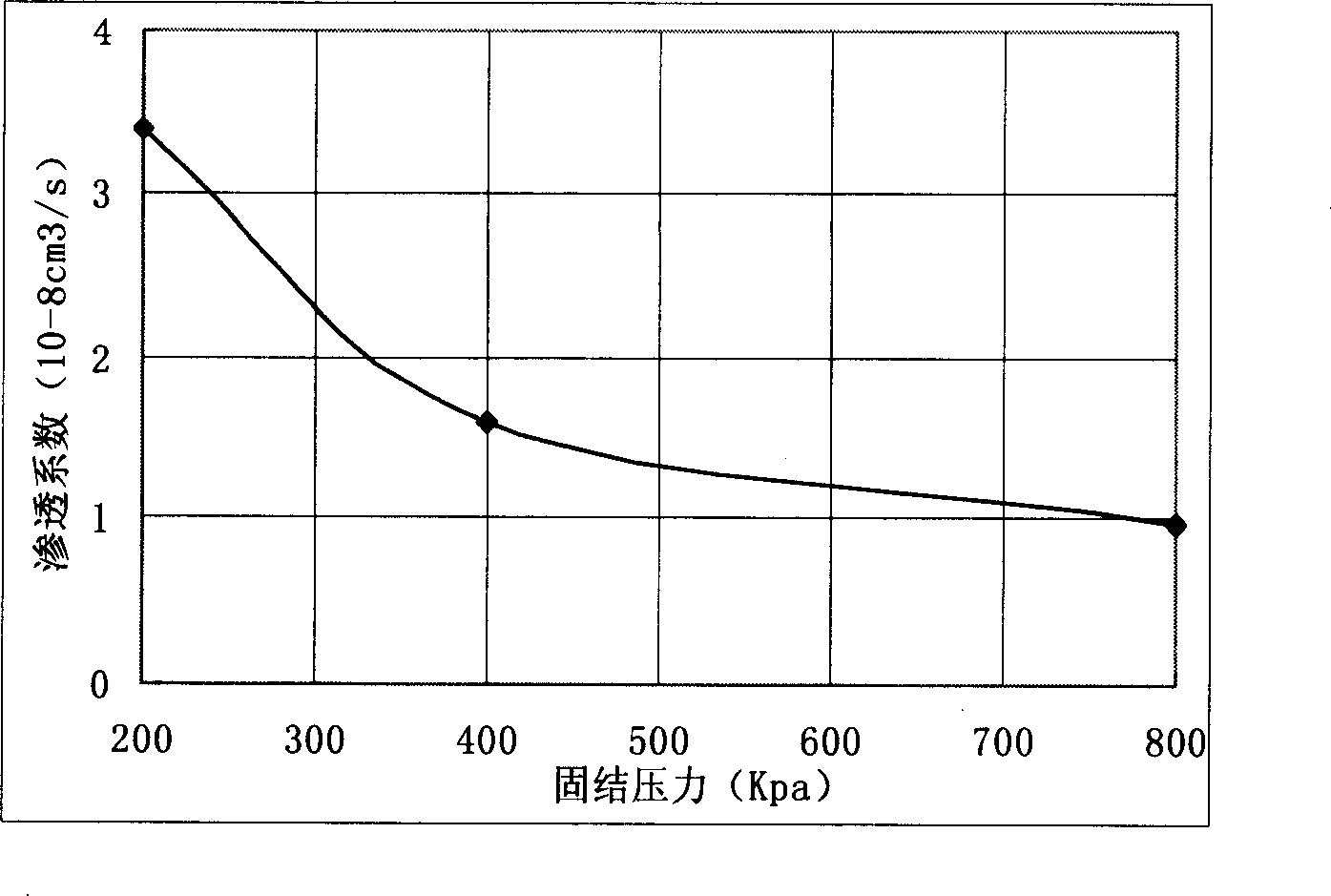

Soil permeameter

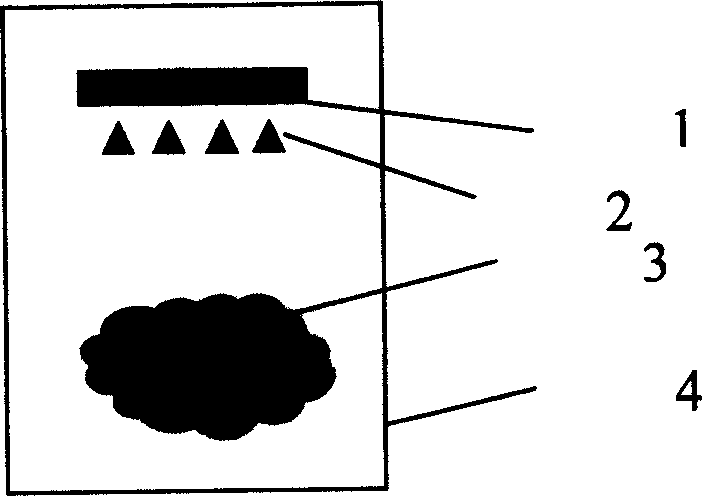

The related permeameter to measure soil permeability comprises: a soil sample ring (1), a loading piston (2) with an exhaust channel in (1) for up-down slide, a base (3) with and air inlet and exhaust channel on two sides. Wherein, both exhaust channels of (2) and (3) connect with self GDS pressure controller (5) through high-pressure plastic pipe (9). This invention can obtain the soil permeability on different void ratio and stress.

Owner:TONGJI UNIV

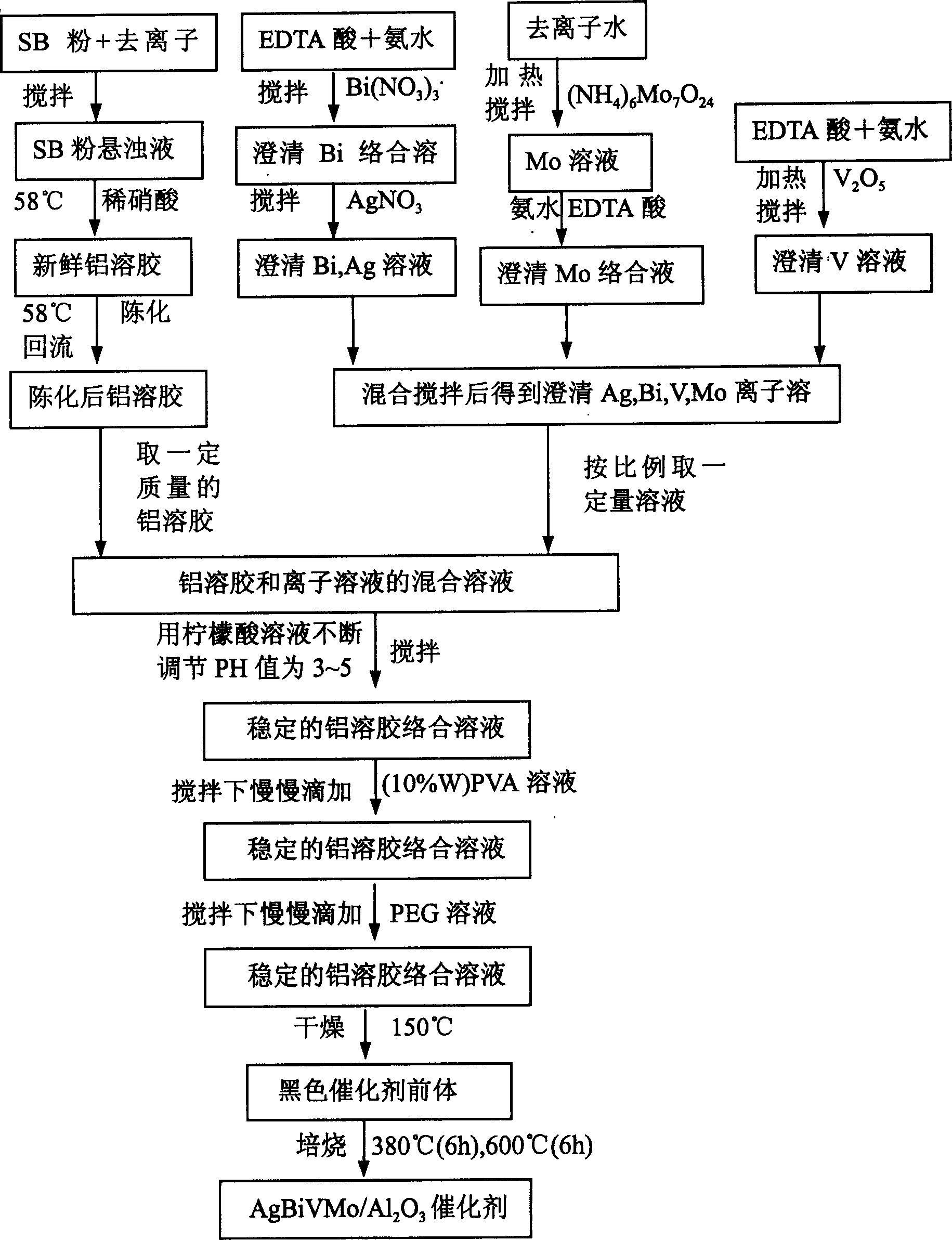

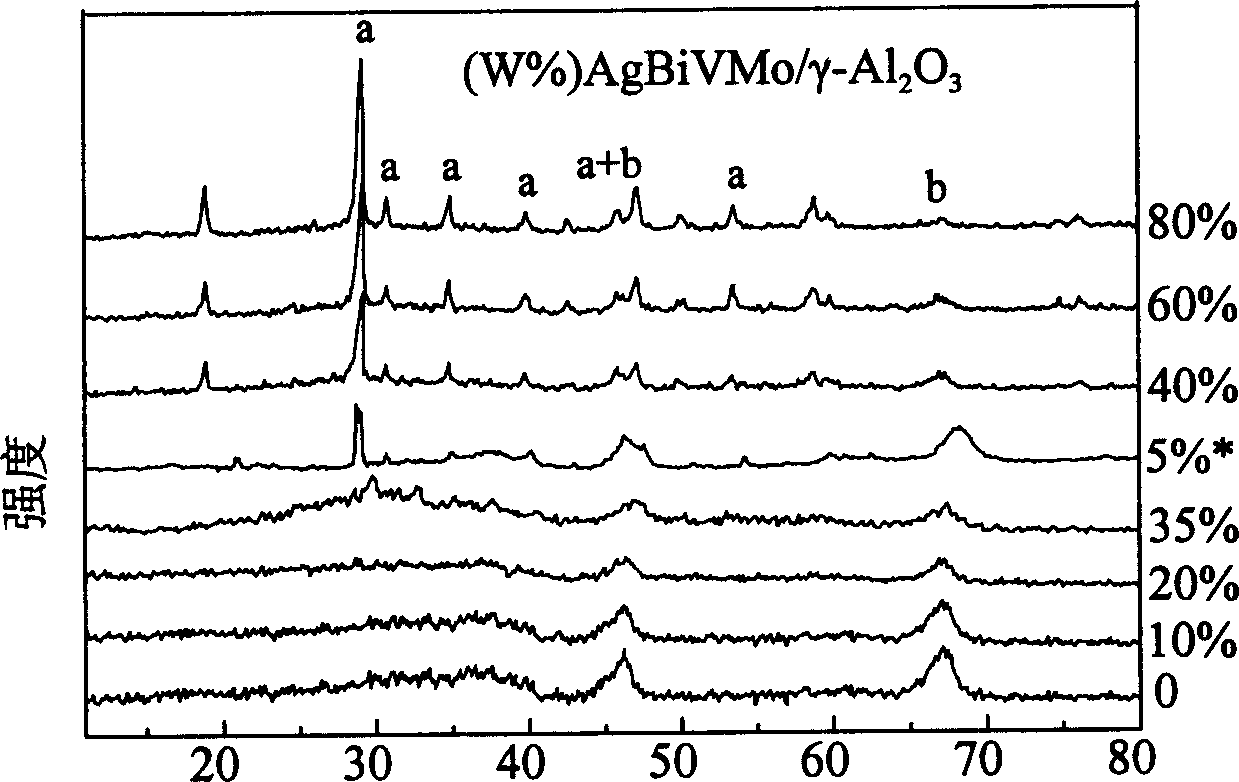

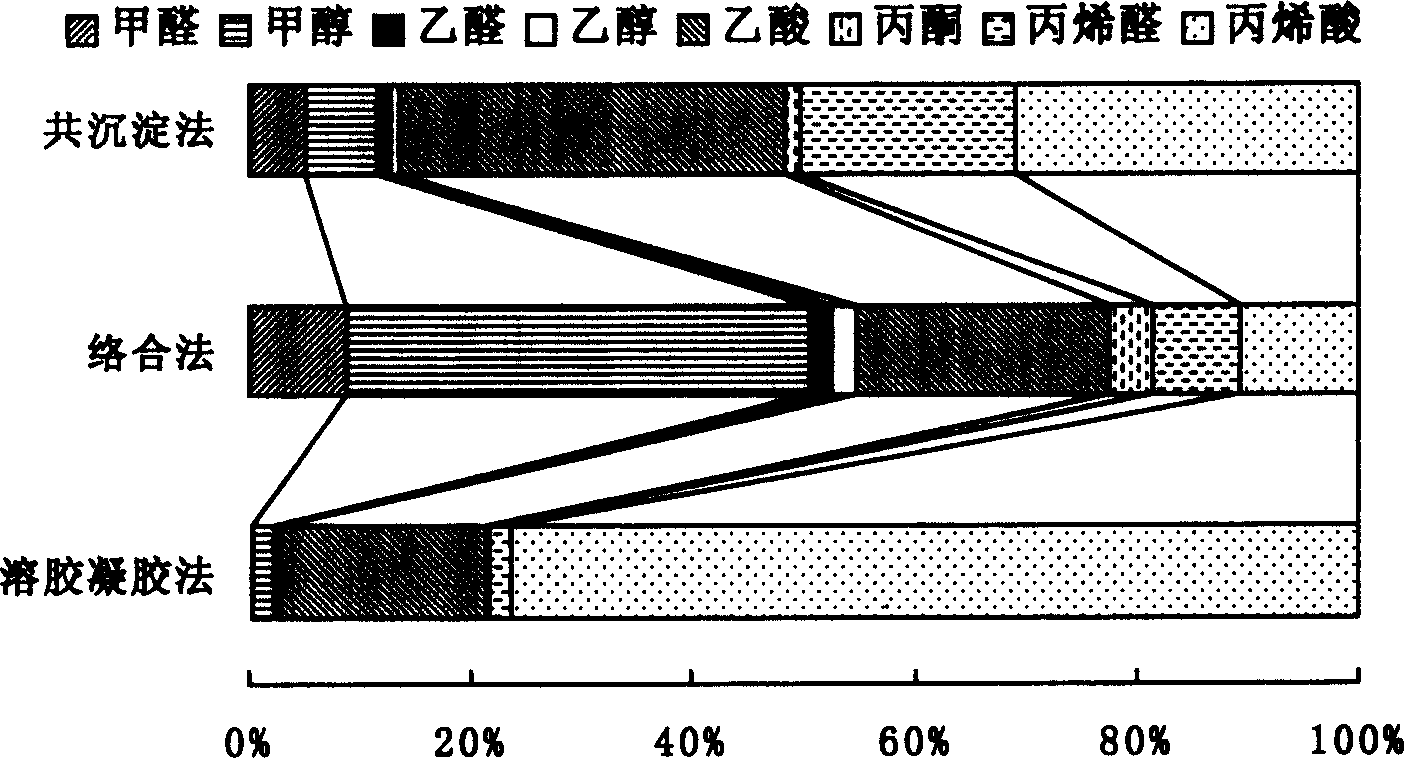

Composite oxide catalyst and its preparing method and use

InactiveCN1473654AIncrease the areaLarge porosityCatalyst activation/preparationPartial oxidationVoid ratio

The present invention provides a kind of composite oxide catalyst for partial oxidation of propane to prepare acrylic acid. The preparation process includes following steps: dissolving or peptizing active catalyst component precursor to prepare homogeneous dispersion; dissolving or peptizing catalyst carrier component precursor to prepare homogeneous dispersion; mixing the two kinds of dispersion obtained in the previous steps to obtain stable mixed sol; drying; and roasting the composite oxide precursor to prepare the composite oxide catalyst. The composite oxide catalyst has great specific surface area, large void volume and homogeneous dispersion of the active component inside the carrier compound.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com