Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Long working time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two-component polyurethane compound exhibiting a high early strength

InactiveUS20070129522A1Long working timeHigh early-strengthPolyureas/polyurethane adhesivesPrepolymerIsocyanate

The invention relates to a two-component compound in which the first component A comprises at least one type of polyurethane prepolymer A1 which contains isocyanate end-groups and is produced from at least one type of polyisocyanate and the second component B which comprises water and at least one type of polyaldimine B1 and is obtainable from at least one type of polyamine PA containing aliphatic primary aminogropus and at least one type of aldehyde ALD of formula (I) or formula (II). The inventive compound is outstanding by the fact of the long processing time and high early strength thereof, a fast setting time, nevertheless without bubble formation, in particular said compound is odourless or exhibits a very low odour before, during and after thermosetting.

Owner:SIKA TECH AG

Nano composite photocatalytic coating

InactiveUS20070000407A1Good anti-aging performanceNot perishableBiocideSolid waste managementAir cycleFungal microorganisms

A photocatalytic coating composition and method of coating articles, the composition containing solvents for rapid evaporation at room temperature, polyalkylphenylsiloxane, xylene, nano densified hydrophilic fumed silica, nanostructured composite photocatalyst powder and nano inorganic anti-bacteria powder. The coating may be applied by conventional coating methods to organic or inorganic structured surfaces where photocatalytic activity is desired, such as in a forced air-circulating environment. Once applied, the coating quickly dries to leave an adherent, flexible, durable, and long-lasting photocatalytic coating having a large surface area and exhibiting high surface activity against pathogens and pollutants such as bacteria, viruses, mold, fungi, and volatile organic compounds.

Owner:YORK INT CORP

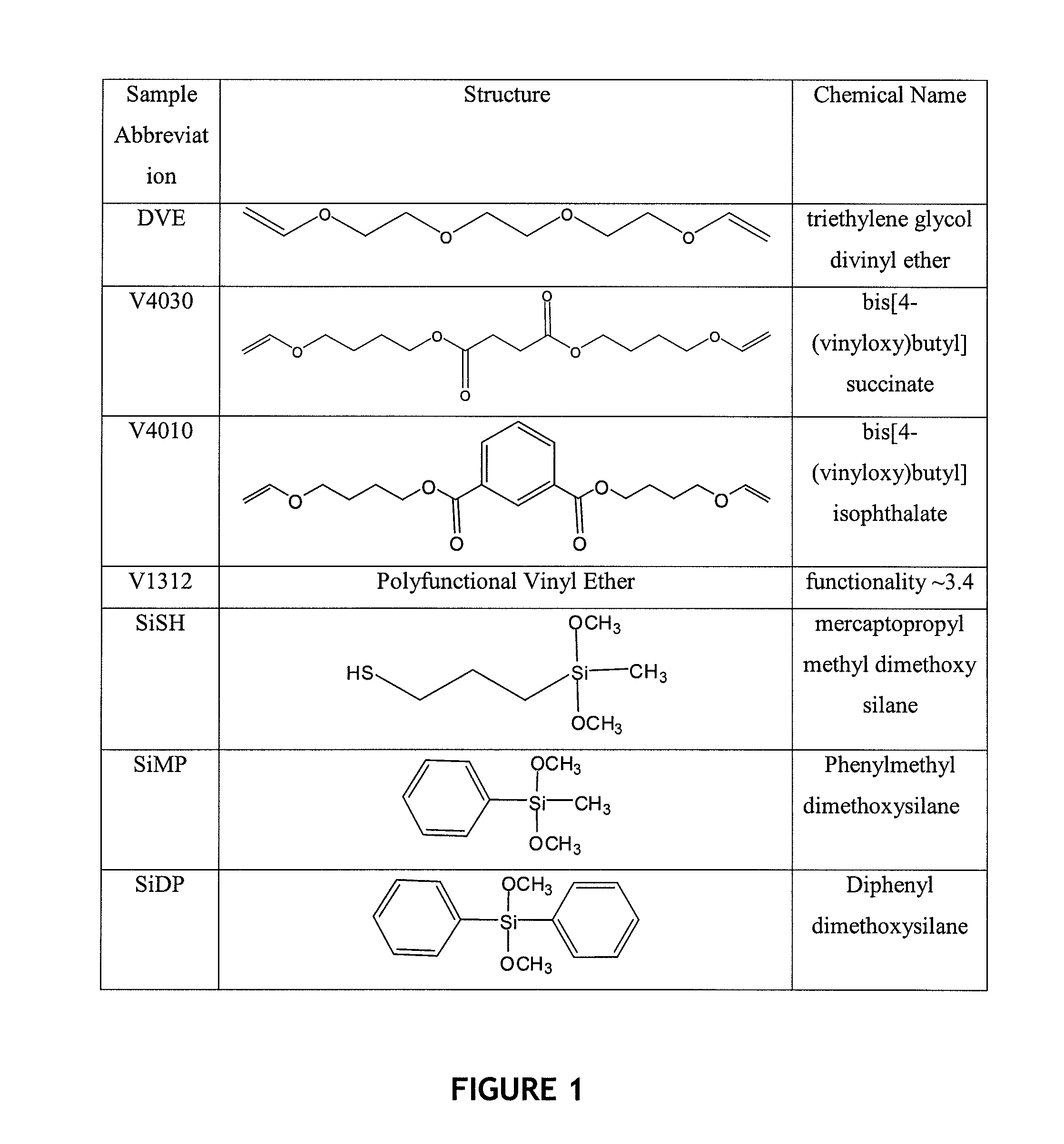

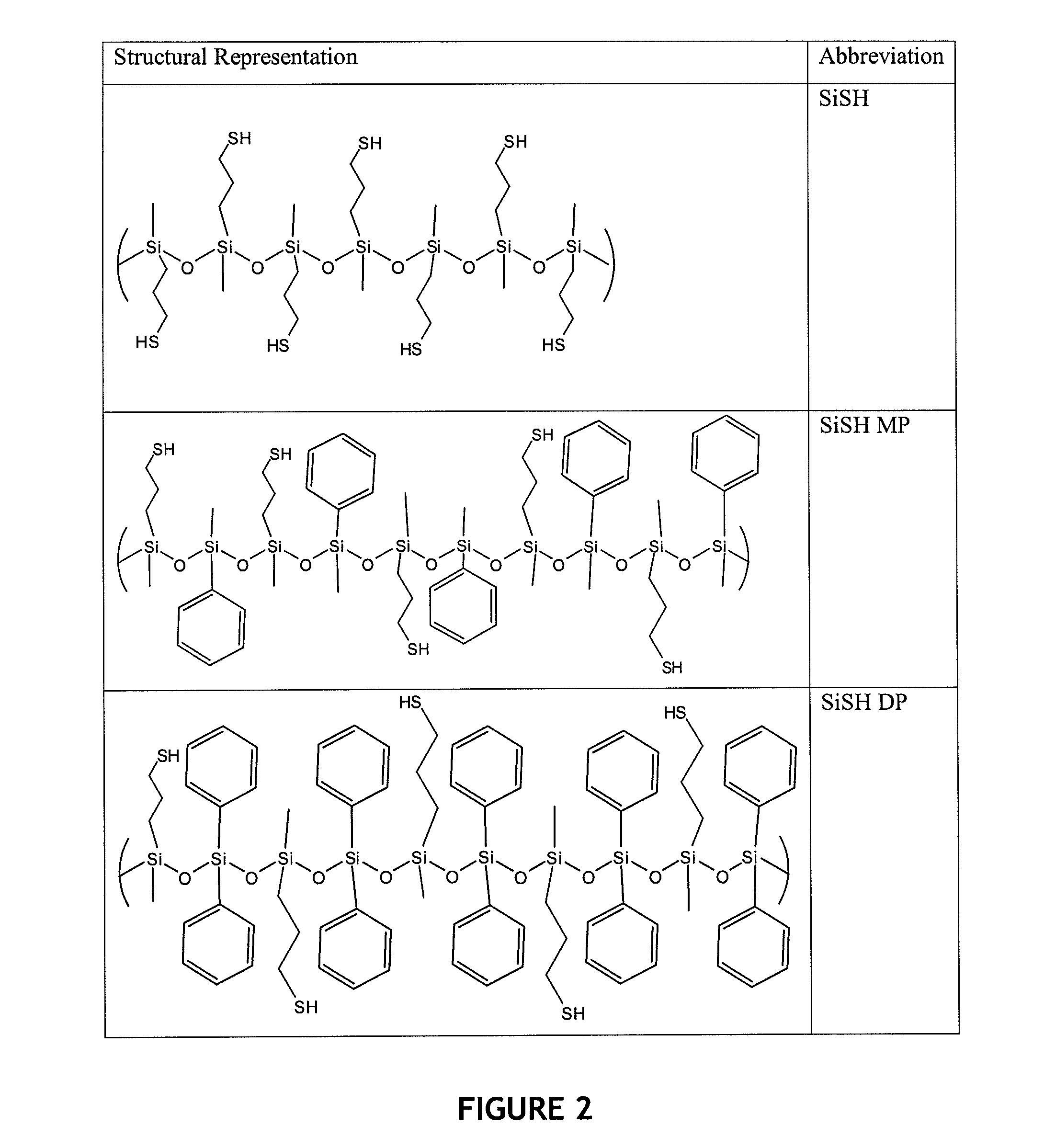

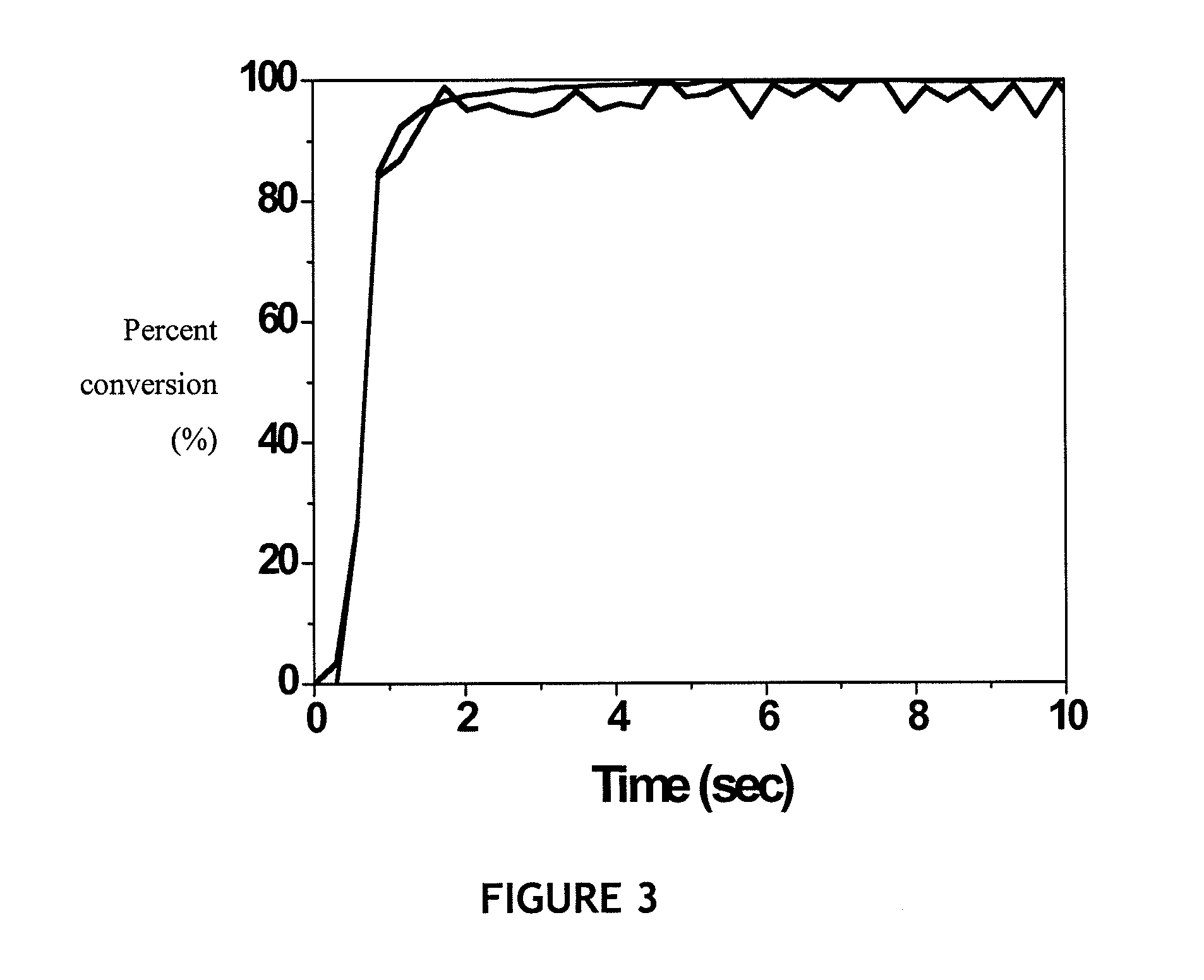

Polymer impression materials

InactiveUS20100304338A1Long working timeShort setting timeImpression capsDental articulatorsVoid ratioDental impression material

This invention relates to methods and compositions for single component photoinitiated dental impression materials. The impression material is workable in its pre-cured state, cures rapidly upon exposure to light, and exhibits desirable processing conditions such as short setting time, long working time, no void formation, good wettability, mechanical properties, and detail reproduction.

Owner:UNIV OF COLORADO THE REGENTS OF

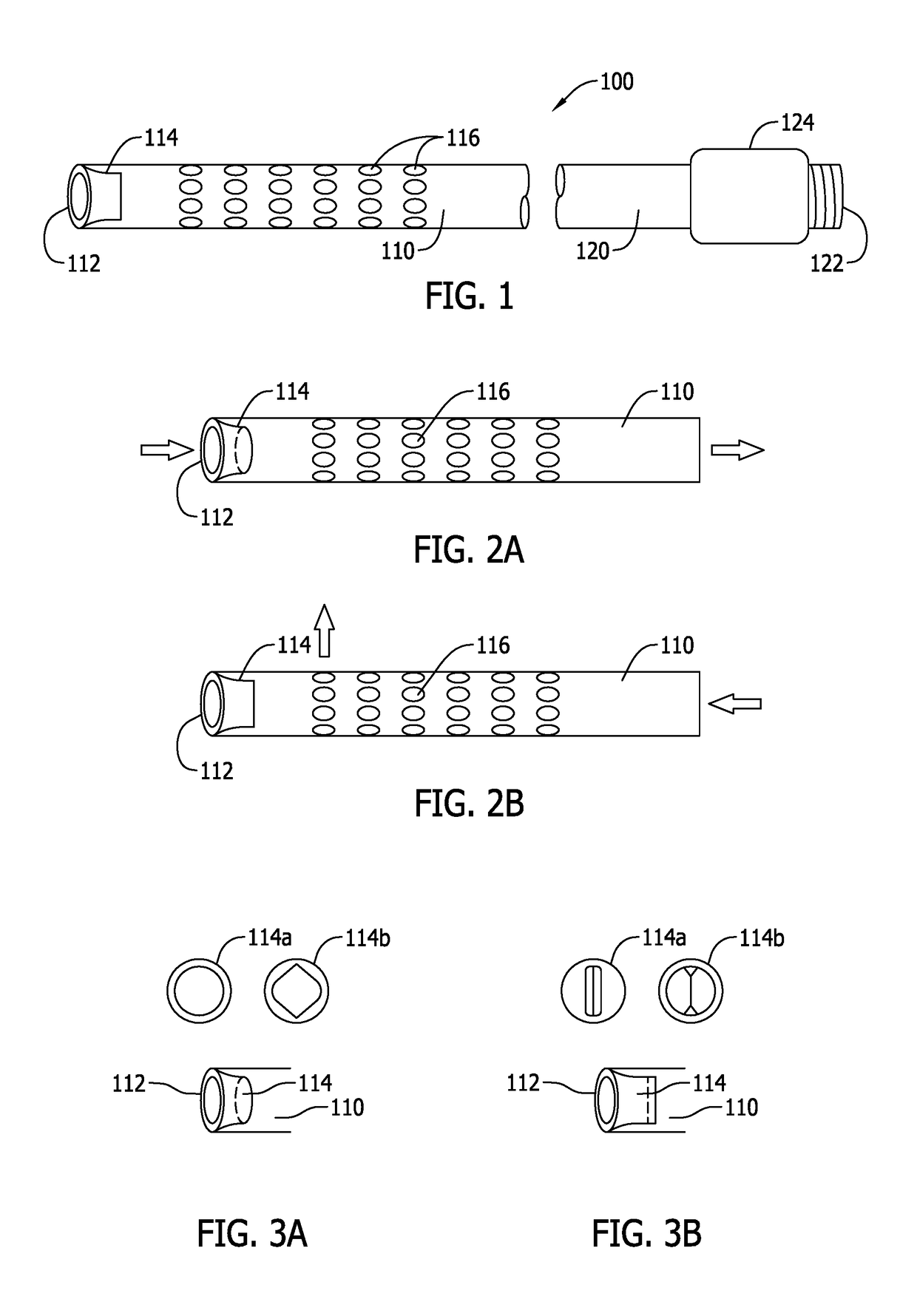

Blood Clot Aspiration Catheter

InactiveUS20180042623A1Many timesMore non-clotted bloodSurgeryMedical devicesDistal portionBlood vessel

A blood clot aspiration catheter includes an aspiration / flushing lumen having a distal portion that is insertable into a blood vessel of a patient, an aspiration device configured to create an aspiration phase to aspirate clot and blood into the aspiration / flushing lumen and a flushing phase to flush non-clotted blood from the aspiration / flushing lumen, a one-way valve configured to allow clot and blood to flow through the aspiration / flushing lumen during the aspiration phase and to block flow during the flushing phase, and filter valves configured to filter non-clotted blood to be flushed from the aspiration / flushing lumen.

Owner:BATISTE STANLEY

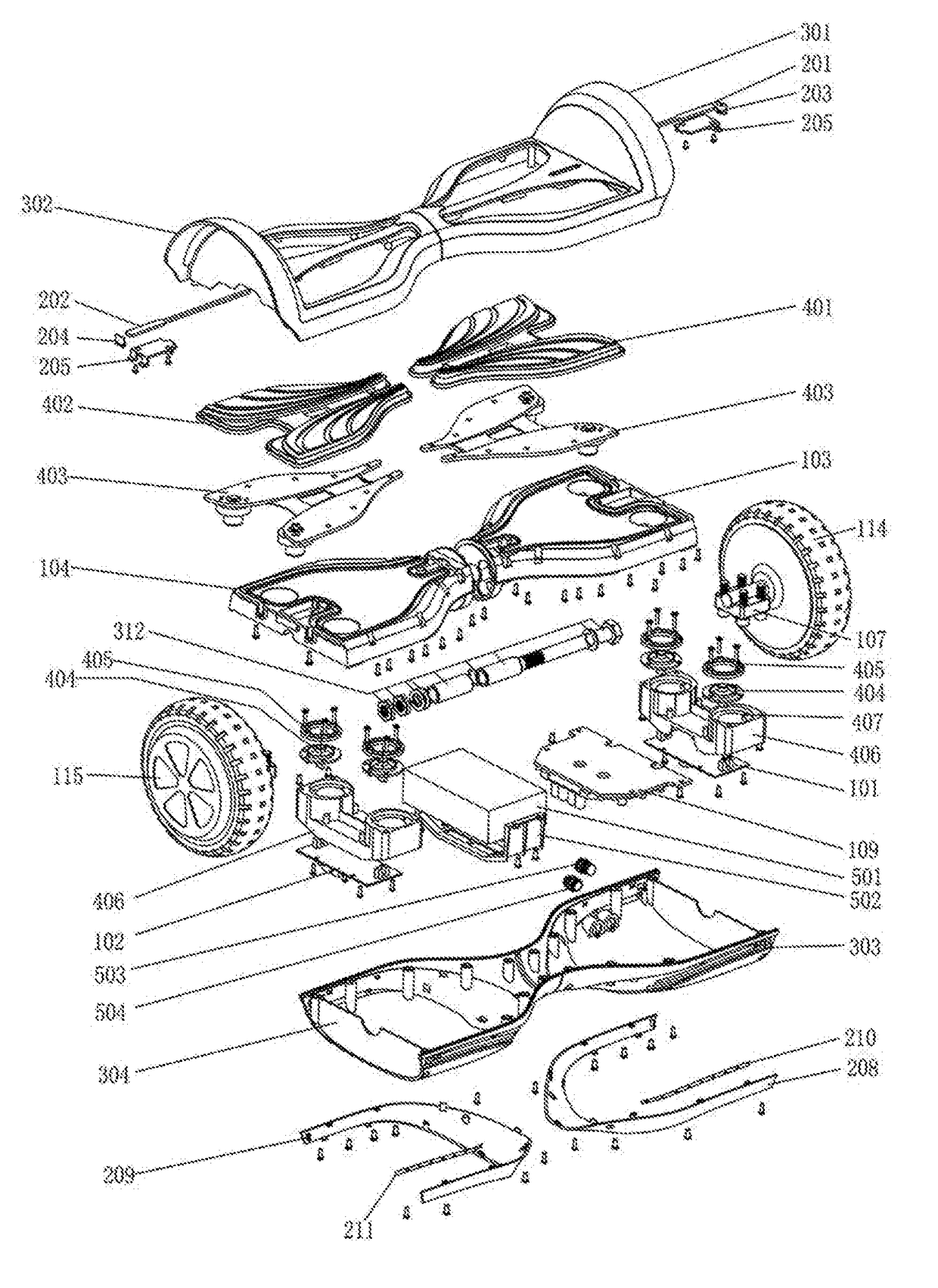

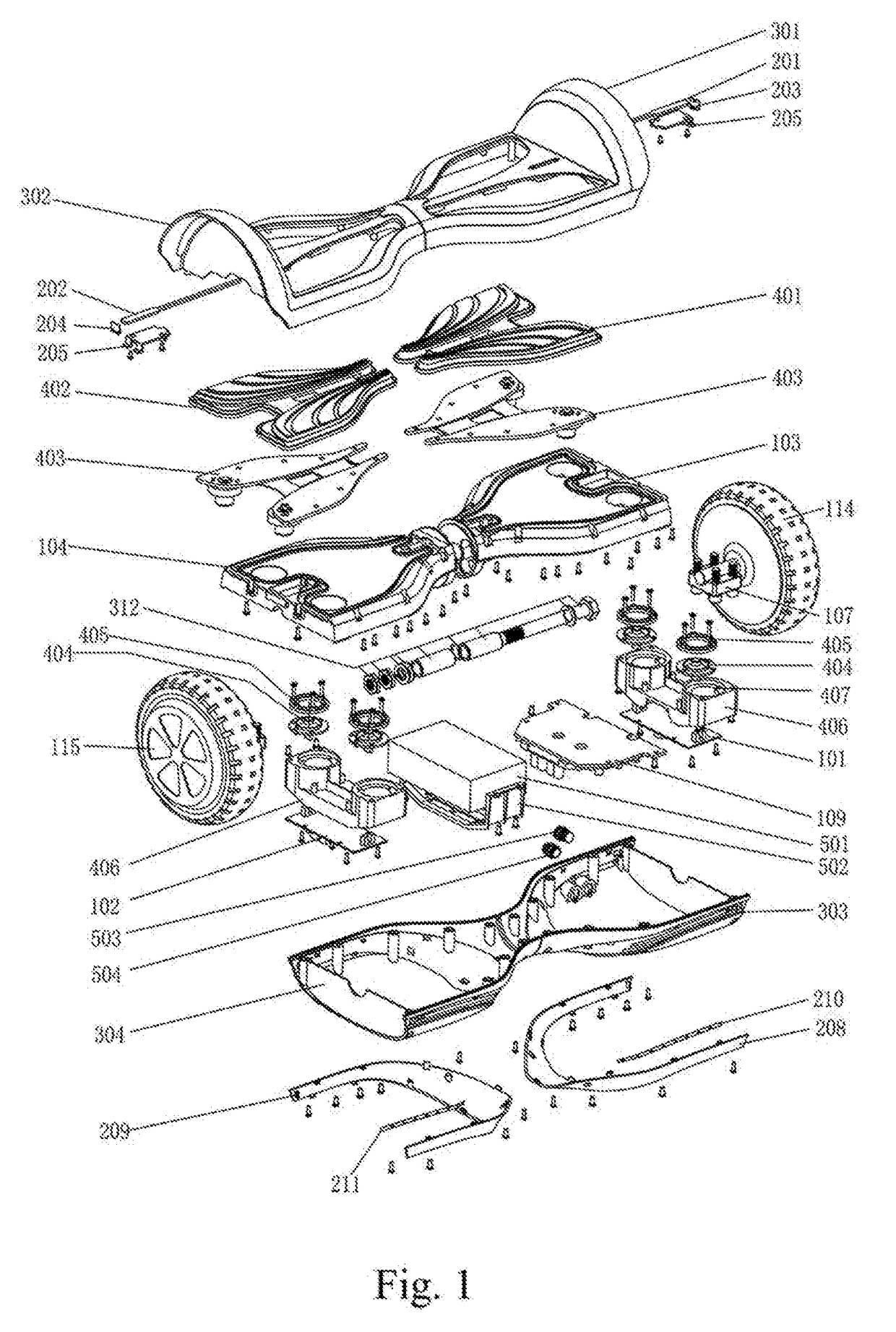

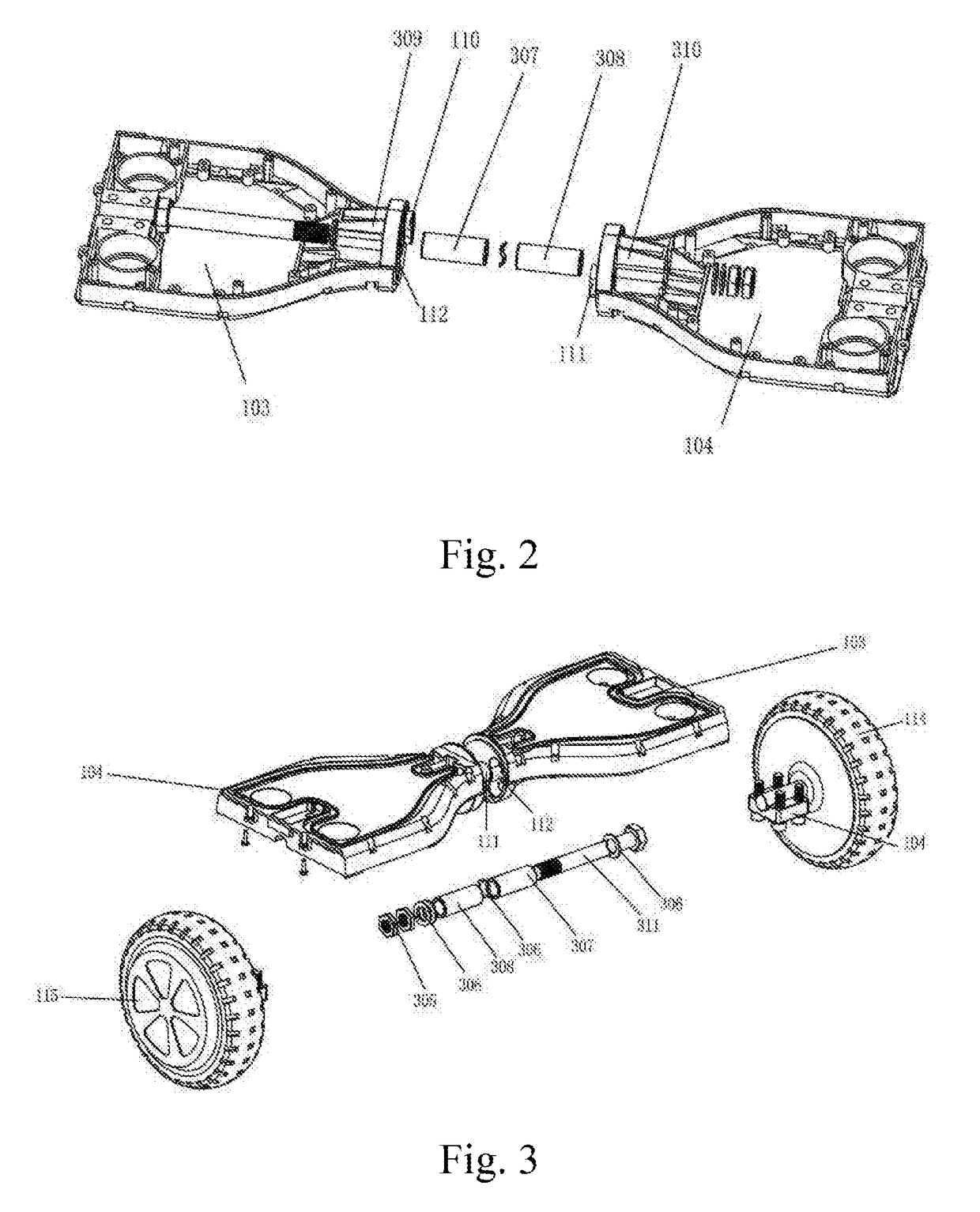

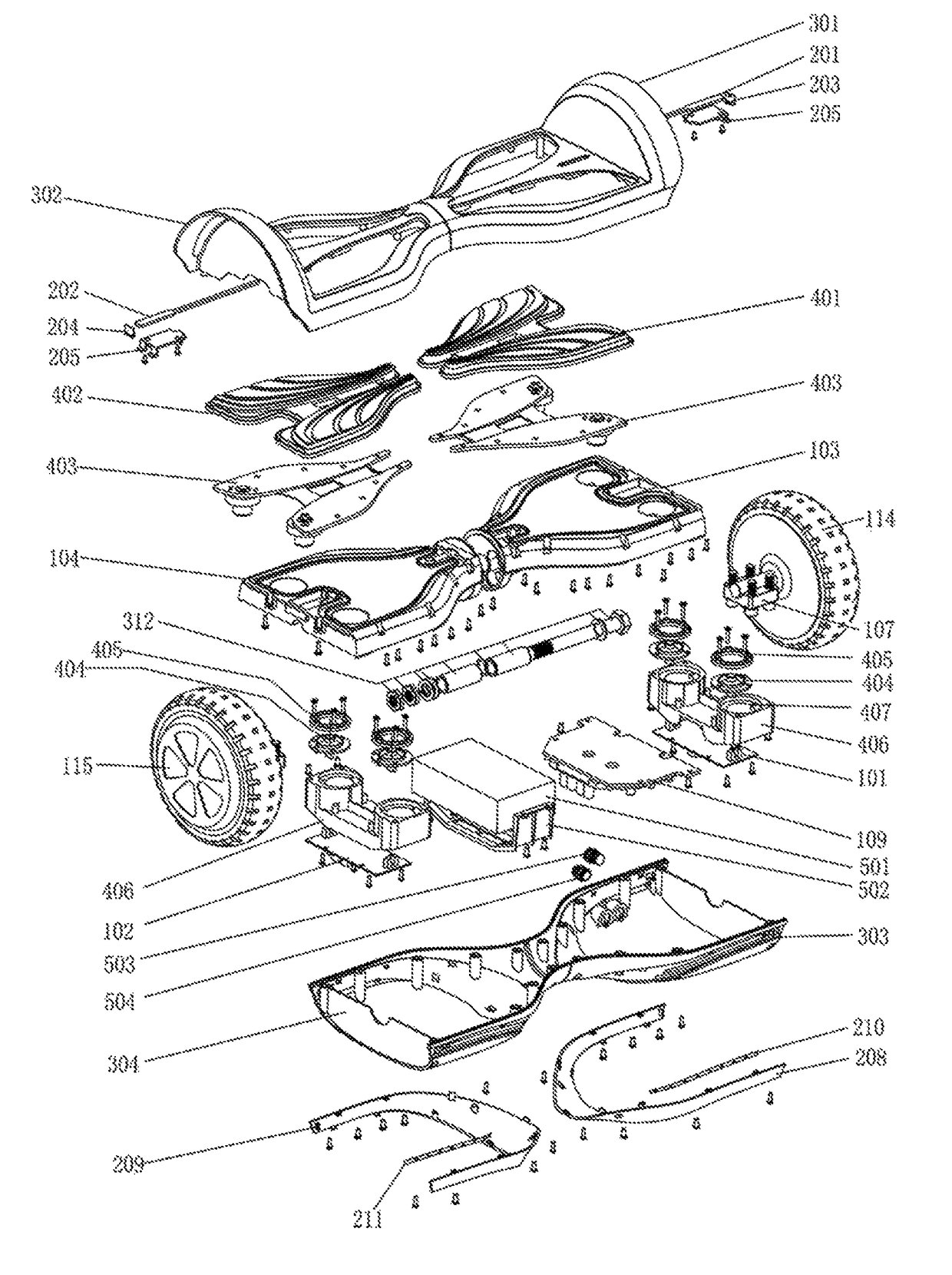

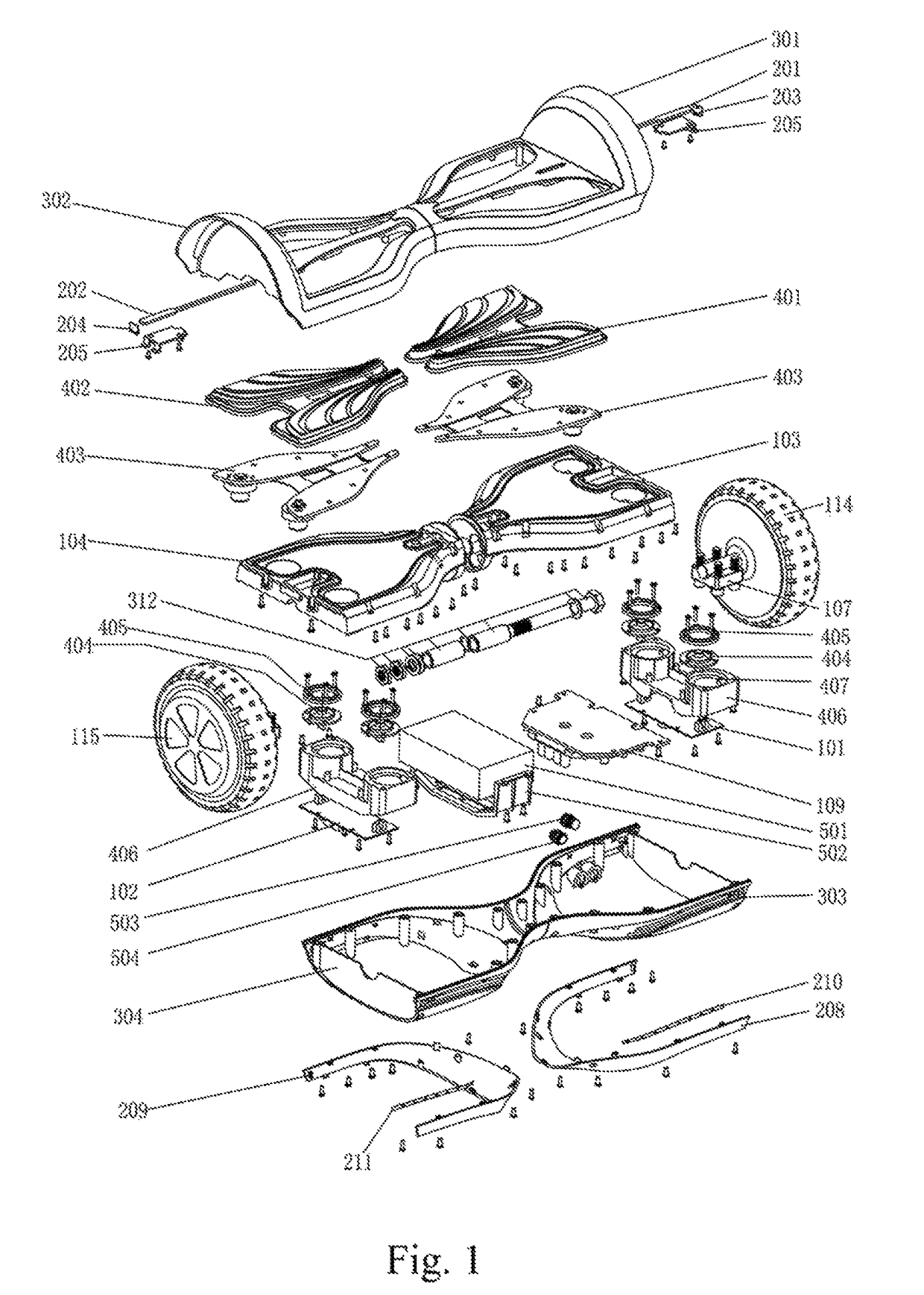

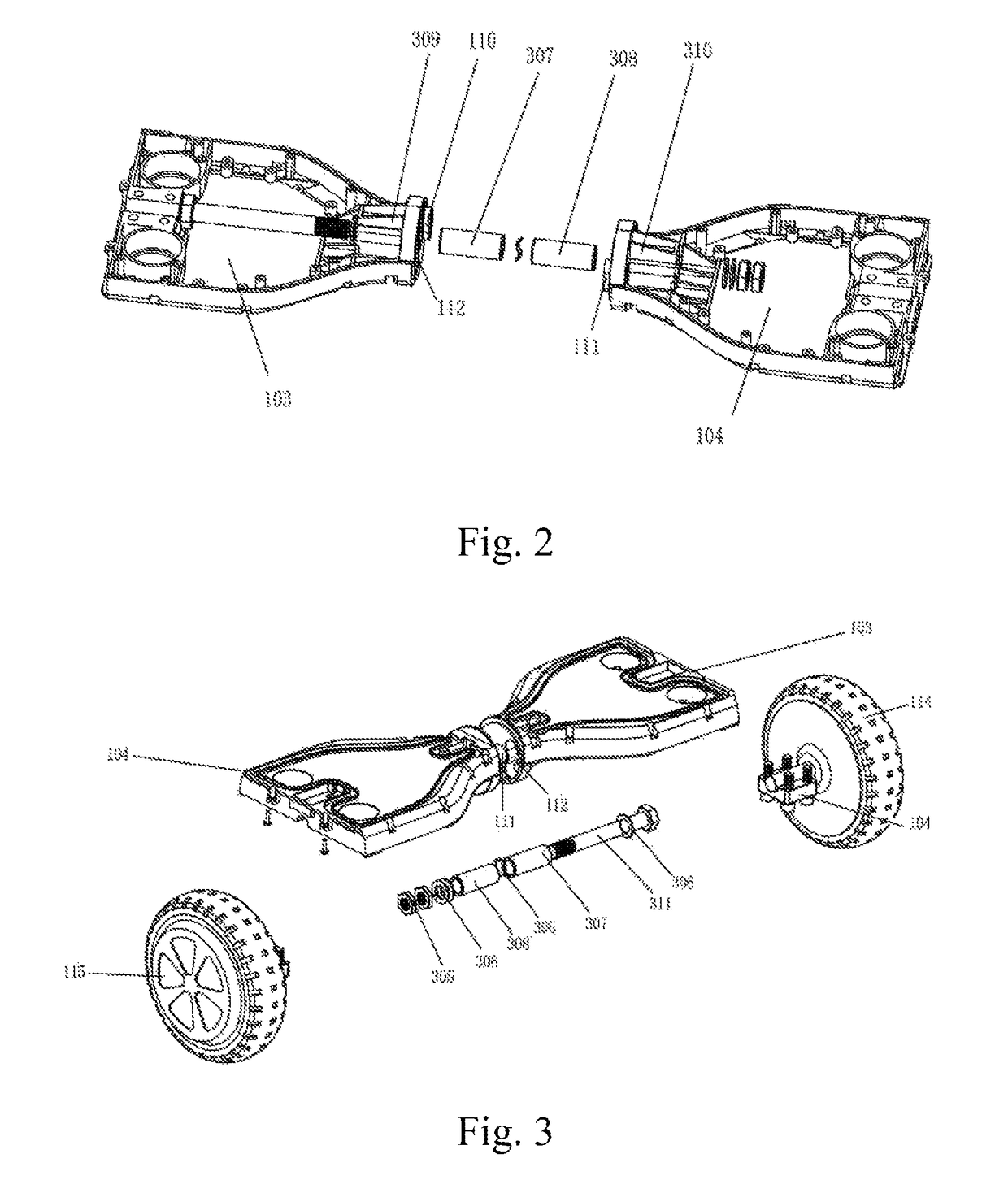

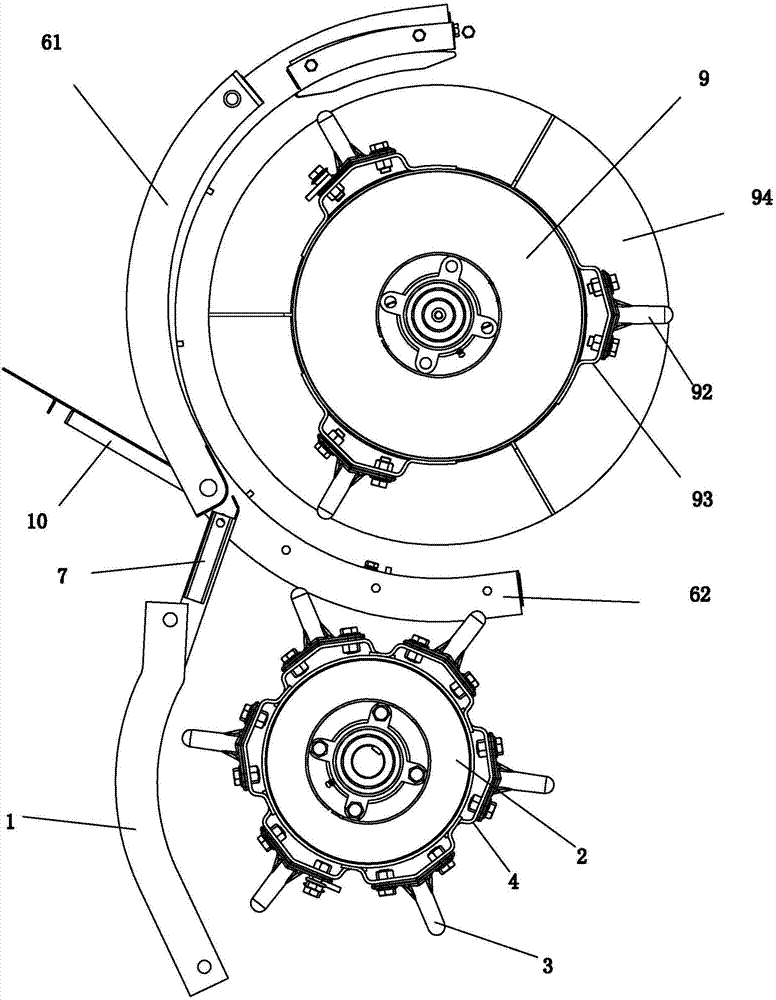

Smart balance wheel with bolt-shaft structure

InactiveUS20170183053A1Improve securityEasy to operateCharging stationsElectric propulsion mountingSafety controlEngineering

The present invention discloses a smart balance wheel with a bolt-shaft structure, comprising a fixedly connected bearing and shaft system, a balance control and drive system, a safety control and prompt system and a charging system. The fixedly connected bearing and shaft system comprises a main frame and a shaft system. The main frame comprises a left frame and a right frame symmetric to each other and rotating relative to each other. The shaft system passes through the left and right frames to realize relative rotation. The balance control and drive system is located under the fixedly connected bearing and shaft system. The present invention uses a bolt-shaft structure and a closed dustproof structure, realizes fixing of the left and right main frames, increases connection strength and bearing capacity of the frame, improves safety of balancing, controlling and driving and improves the service life.

Owner:GUANGDONG LONGXIN TECH CO LTD

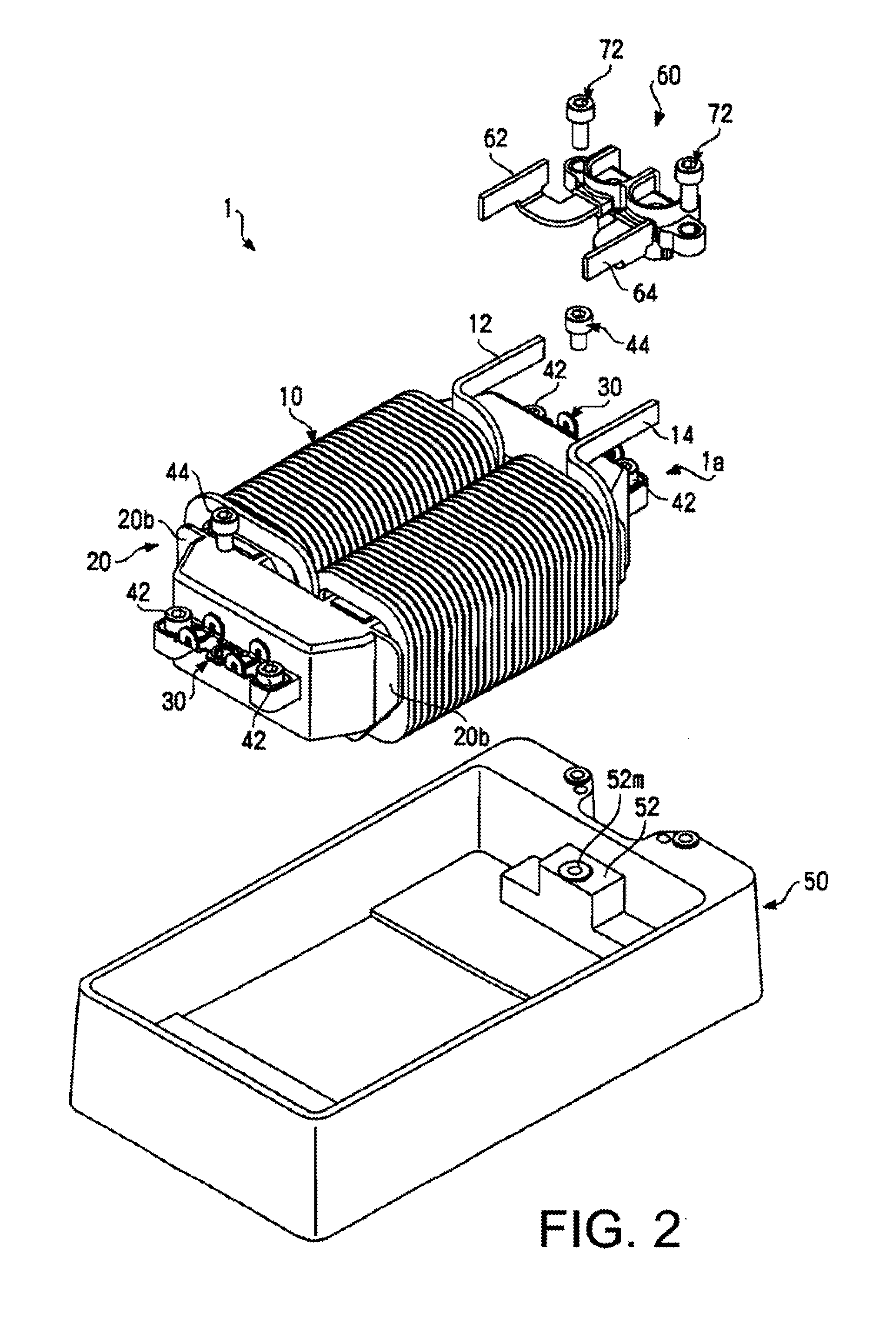

Core fixing member and coil device

ActiveUS20120194311A1Good installation accuracyLong working timeTransformers/reacts mounting/support/suspensionTransformers/inductances casingsEngineering

Owner:TAMURA KK

Smart balance wheel with bolt-shaft structure

InactiveUS9840302B2Improve securityEasy to operateCharging stationsElectric propulsion mountingSafety controlEngineering

The present invention discloses a smart balance wheel with a bolt-shaft structure, comprising a fixedly connected bearing and shaft system, a balance control and drive system, a safety control and prompt system and a charging system. The fixedly connected bearing and shaft system comprises a main frame and a shaft system. The main frame comprises a left frame and a right frame symmetric to each other and rotating relative to each other. The shaft system passes through the left and right frames to realize relative rotation. The balance control and drive system is located under the fixedly connected bearing and shaft system. The present invention uses a bolt-shaft structure and a closed dustproof structure, realizes fixing of the left and right main frames, increases connection strength and bearing capacity of the frame, improves safety of balancing, controlling and driving and improves the service life.

Owner:GUANGDONG LONGXIN TECH CO LTD

Liquid Crystal Displays with Embedded Photovoltaic Cells

InactiveUS20110109853A1Improve energy efficiencyLong working timeVessels or leading-in conductors manufactureNon-linear opticsHigh energyDisplay device

Methods and apparatus for a liquid crystal display with embedded photovoltaic cells for high energy efficiency. The LCD with photovoltaic cell comprises a first linear polarizer, a second linear polarizer, a first and second substrate, a liquid crystal cell formed between two substrates, and a backlight unit at the backplane of the display. Further, the display device has many repetitive pixels in the LC cell, each pixel region comprises a transmissive region that can pass the light from the backlight, and another region that is backlight blocking. A photovoltaic cell is formed on the bottom substrate to substantially cover the backlight blocking region. In one embodiment, the LCD is a transflective display, and in another embodiment, the LCD is a pure transmissive display that relies on backlight for displaying images.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

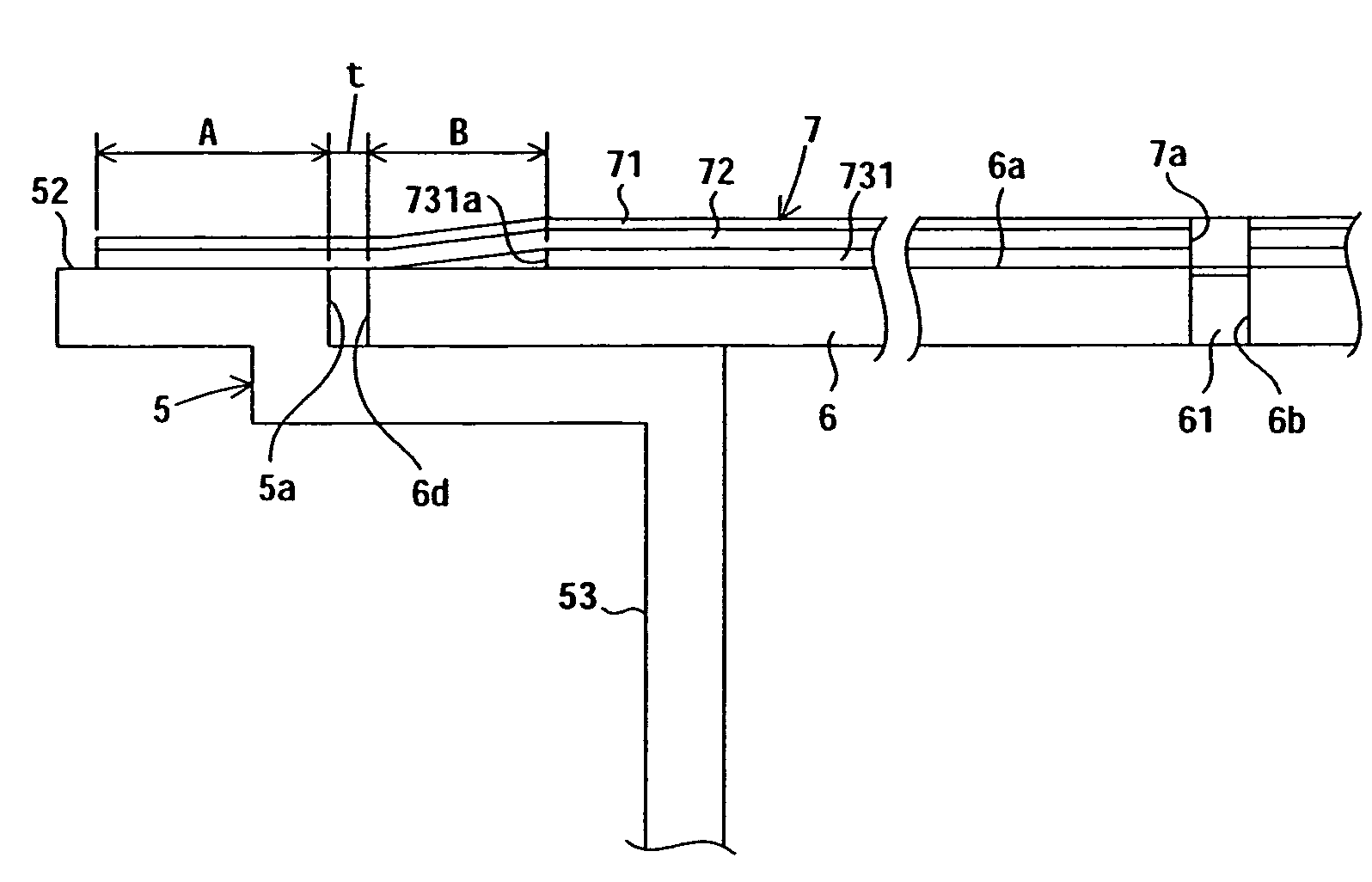

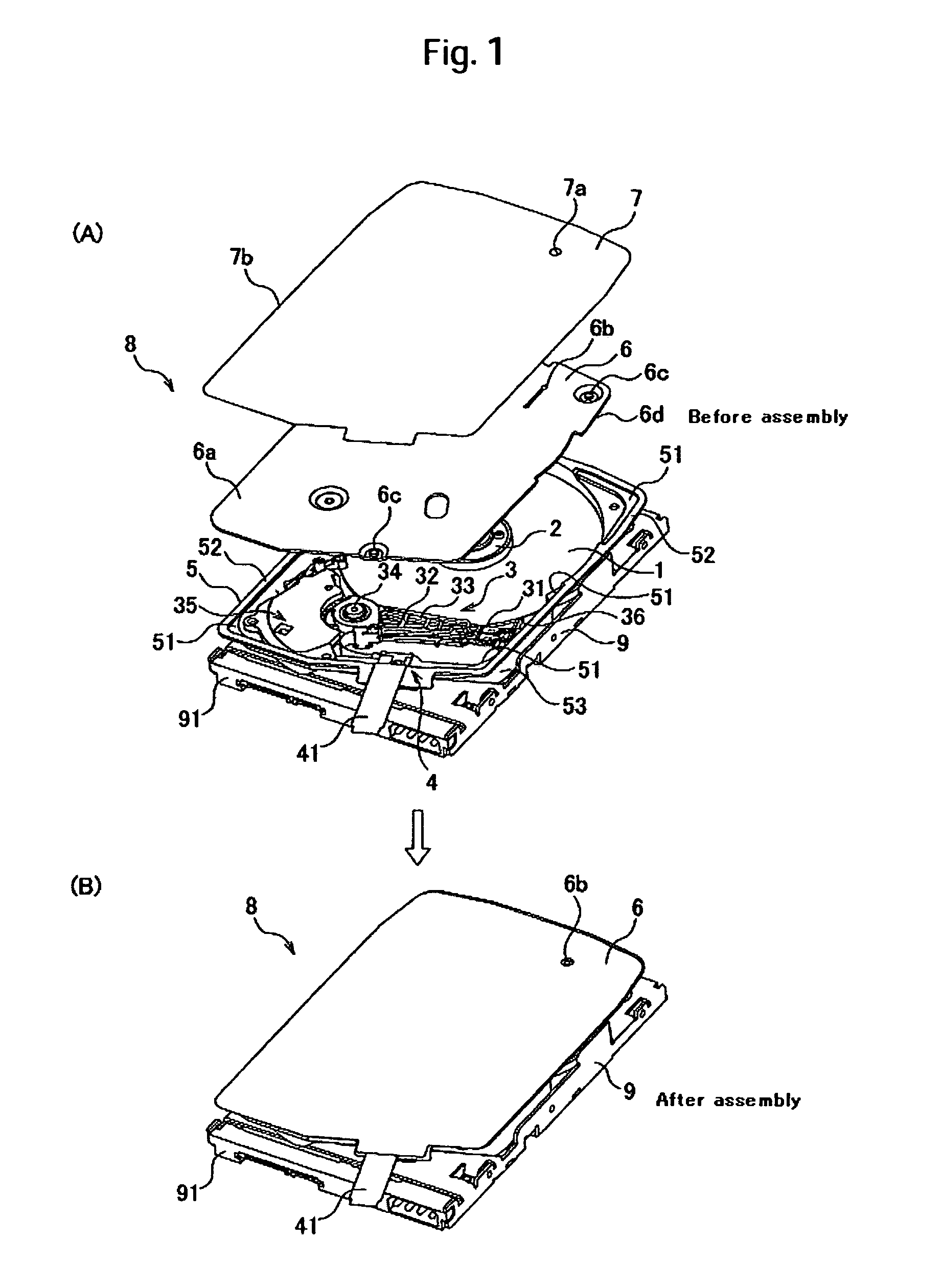

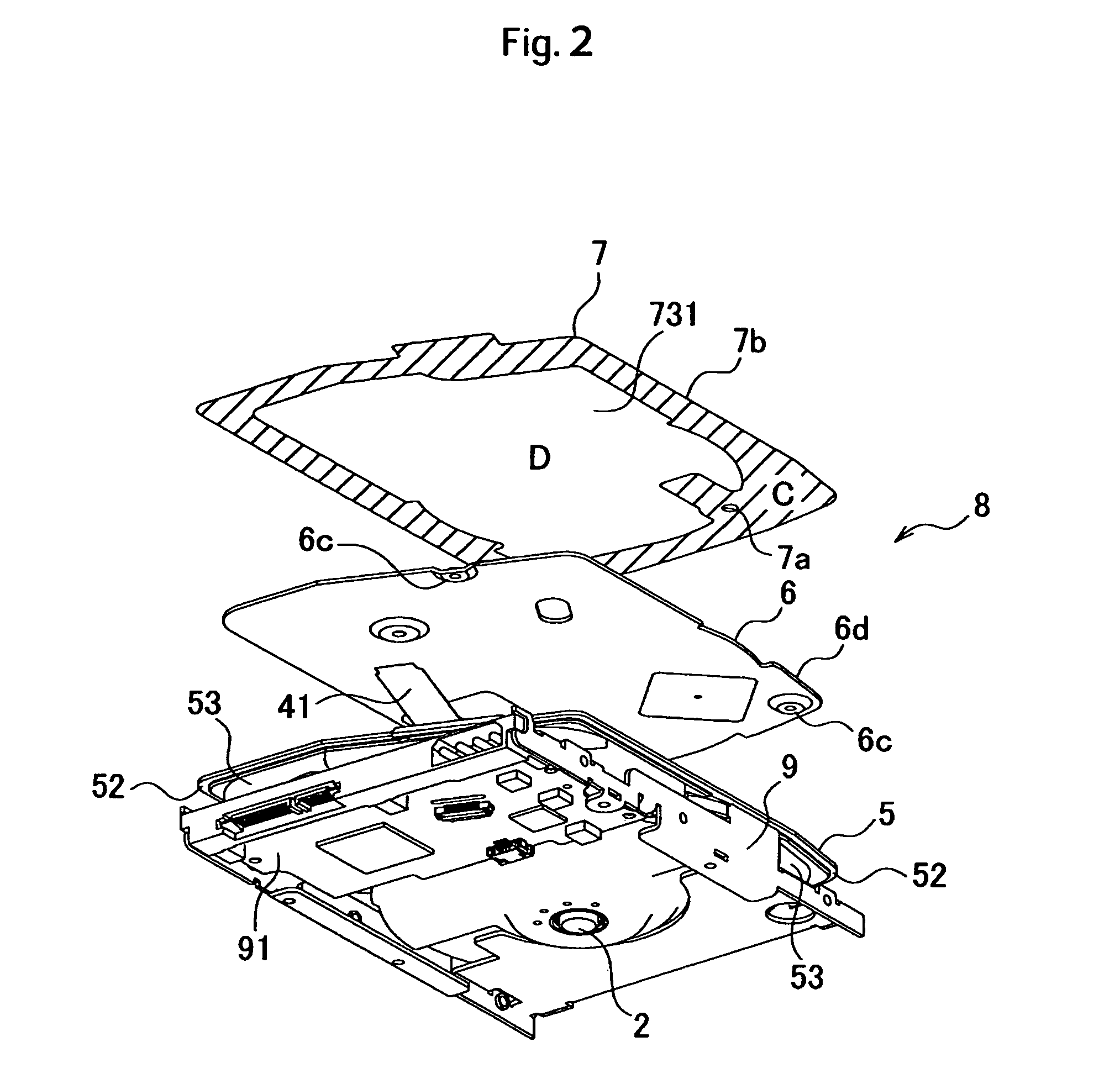

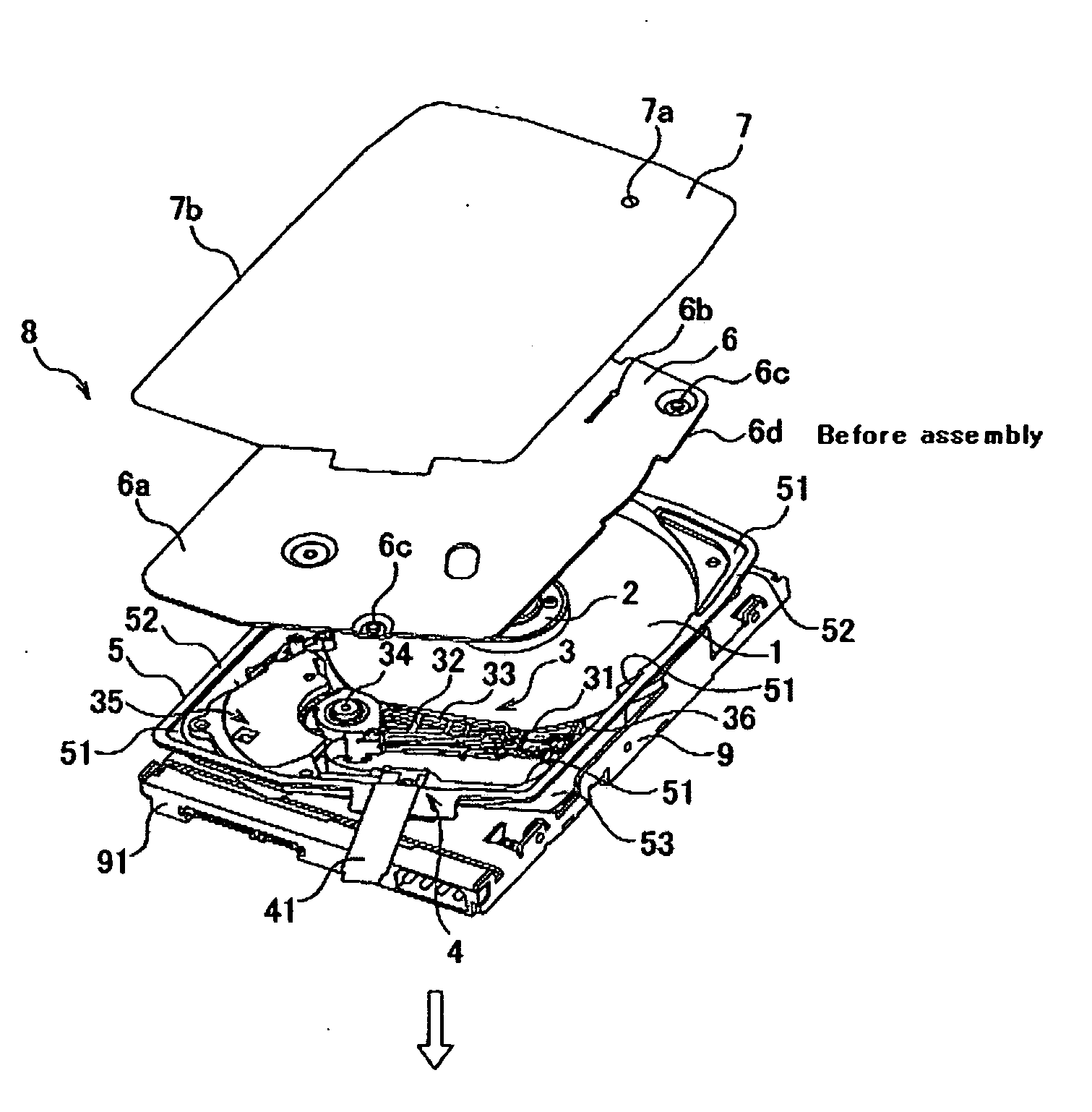

Magnetic disk drive with cover seal and method for fabricating same

InactiveUS7522375B2Long working timeAdditional drawbackApparatus modification to store record carriersUndesired vibrations/sounds insulation/absorptionWork timeElectrical and Electronics engineering

Owner:WESTERN DIGITAL TECH INC

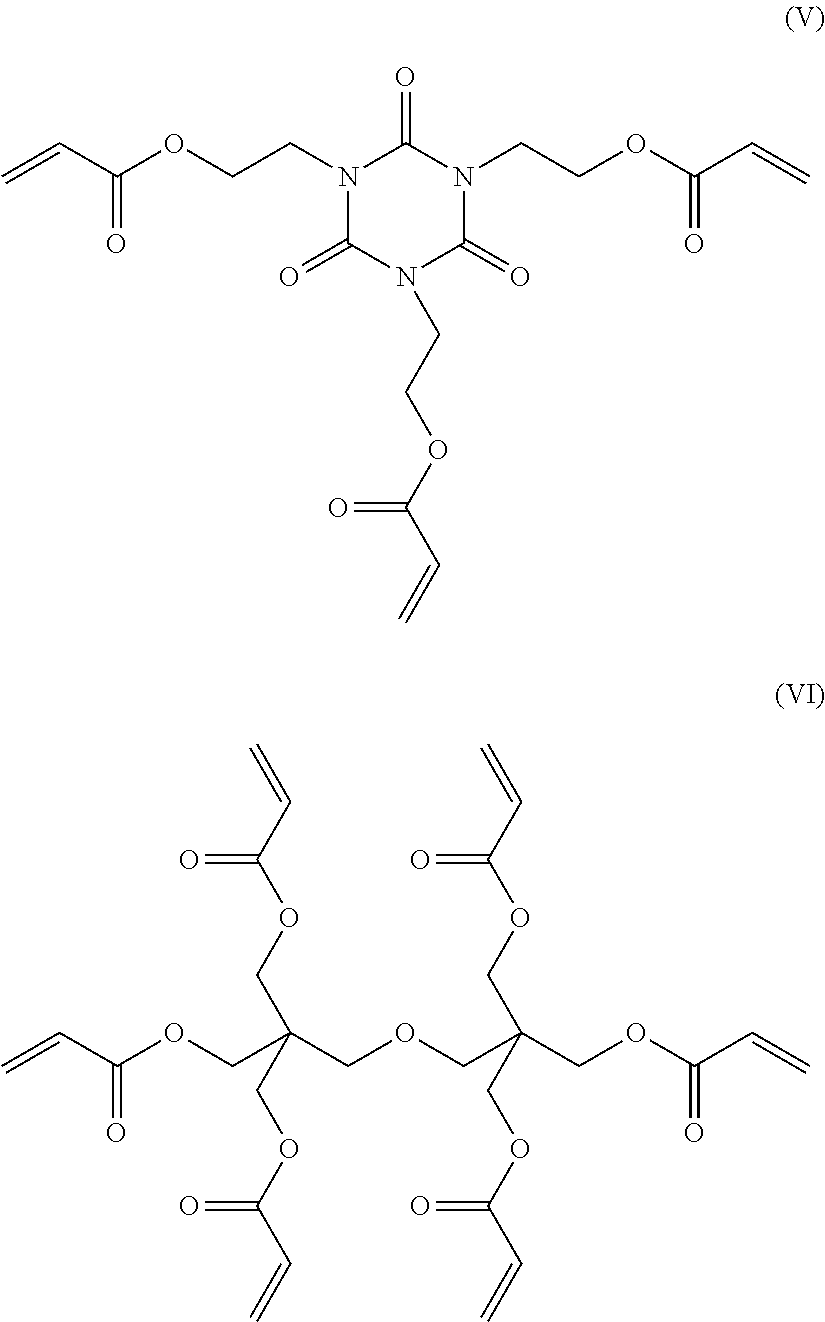

Easily removable dental curable composition

ActiveUS20110070563A1Prevent fallingEasily removable dentalCosmetic preparationsImpression capsMedicineChain length

An easily removable dental curable composition which prevents the fall or leakage of a temporary prosthetic appliance or a root canal filling material which is easily removed by bonding and adhering it to tooth, shows such high flowability that its operation is easy, has a long working time and excellent X-ray contrast properties and sealability and can be easily removed as required, and a filling kit.The dental curable compositon comprises (A) a polymerizable monomer mixture containing a polymerizable monomer having an acid group in the molecule and (B) a polymerization initiator, whereinthe component (A) contains (A′) a long-chain polymerizable monomer having a structure with a chain length of 17 or more atoms and / or the composition further comprises (D1) a soft resin material; andwhen the amount of the component (A′) based on 100 parts by weight of the component (A) is represented by [a′] and the amounts of the components (A), (B) and (D1) based on 100 parts by weight of the total of the components (A) and (B) are represented by (a), (b) and (d1), respectively, the following expressions (1) to (5) are satisfied:70≦(a)≦99.99 (1)0.01≦(b)≦30 (2)1≦[a′] / 5+(d1) / 1 (3)[a′]≦95 (4)(d1)≦250 (5).

Owner:SUN MEDICAL

Powered hammer device

InactiveUS7331405B2Wear minimizationSmoothness of operation maximisedReciprocating drilling machinesPortable percussive toolsReciprocating motionEngineering

Owner:TERMINATOR IP II

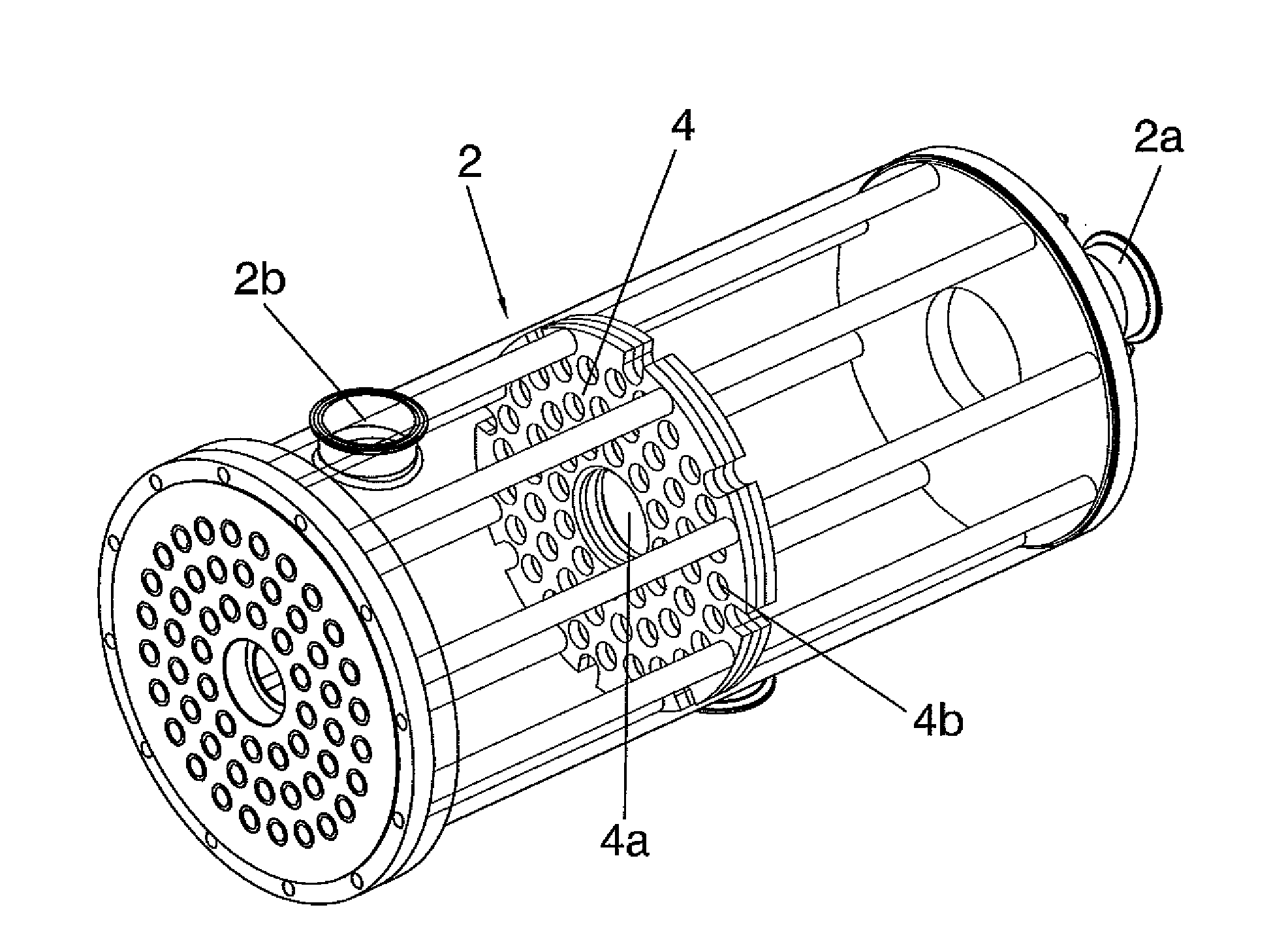

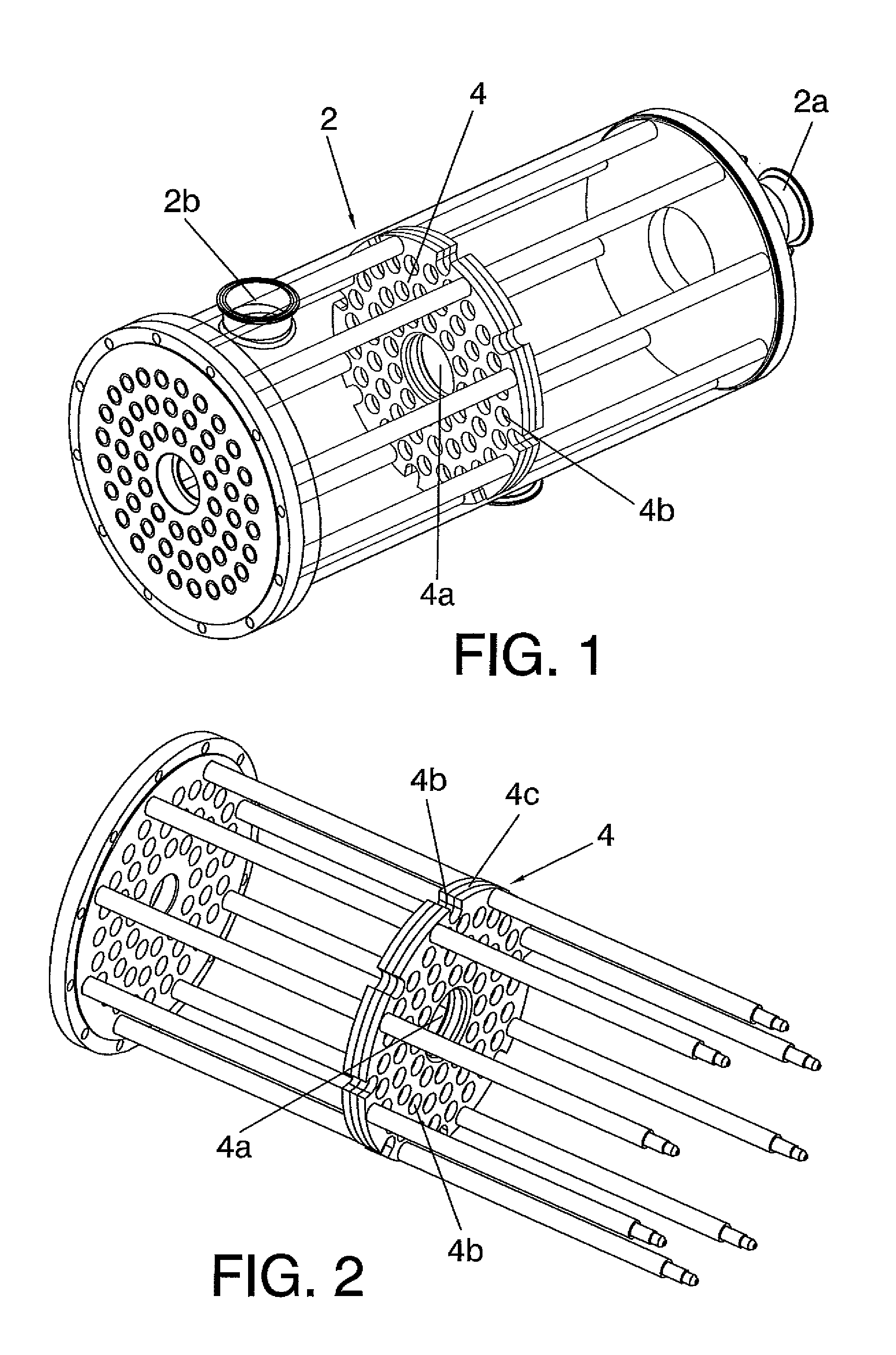

Tubular heat exchanger

InactiveUS20140110094A1Improve energy efficiencySmall sizeSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningPlate heat exchangerEngineering

The present specification describes a tubular heat exchanger (1) comprising a tubular sleeve (2); a first plurality of tubes (3a) carrying a heat transfer fluid which are located inside the tubular sleeve (2); at least one diaphragm (4) located inside the tubular sleeve (2) which divides the interior of the sleeve (2) into at least two chambers, where said diaphragm comprises a central hole (4a) configured for allowing the passage of the product, and where said diaphragm (4) comprises a plurality of holes (4b) configured for allowing the passage of the first plurality of tubes (3a); and a piston (5) comprising a tubular shaft (5a) and at least two plates (6) perpendicular to the tubular shaft (5a); where said tubular shaft (5a) is configured for performing a longitudinal reciprocating movement through the central hole (4a) of said at least one diaphragm (4); improving the heat transfer of the exchanger object of the invention.

Owner:AURUM FOODS

Magnetic disk drive with cover seal and method for fabricating same

InactiveUS20060176610A1Shorten timeEnhance reworkabilityApparatus modification to store record carriersUndesired vibrations/sounds insulation/absorptionMagnetic disksHead parts

Embodiments of the invention shorten a work time required for peeling off a cover seal during rework. In one embodiment, a magnetic disk drive includes: a base provided with a bonded surface around an opening edge and containing therein a head driving mechanism and a magnetic disk; a top cover to be fitted to the opening edge so as to be fixed to the base; and a cover seal including a liner disposed at an outside surface of the top cover, a sheet-like structure and an adhesive layer formed on the structure, the adhesive layer being laminated in such a manner as to face to the bonded surface and the outside surface of the top cover, at which the liner is disposed, to be thus fixed to the base.

Owner:WESTERN DIGITAL TECH INC

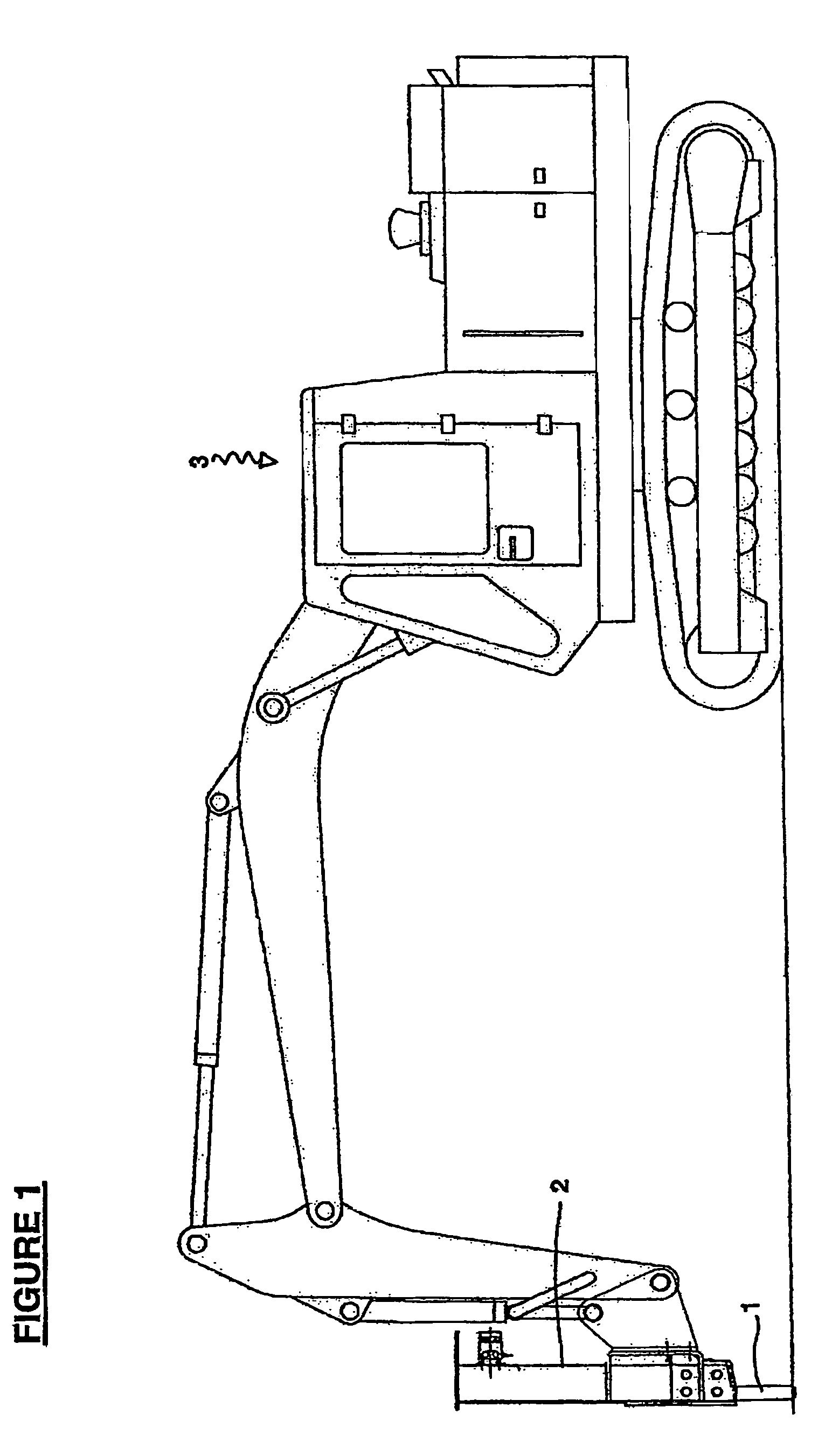

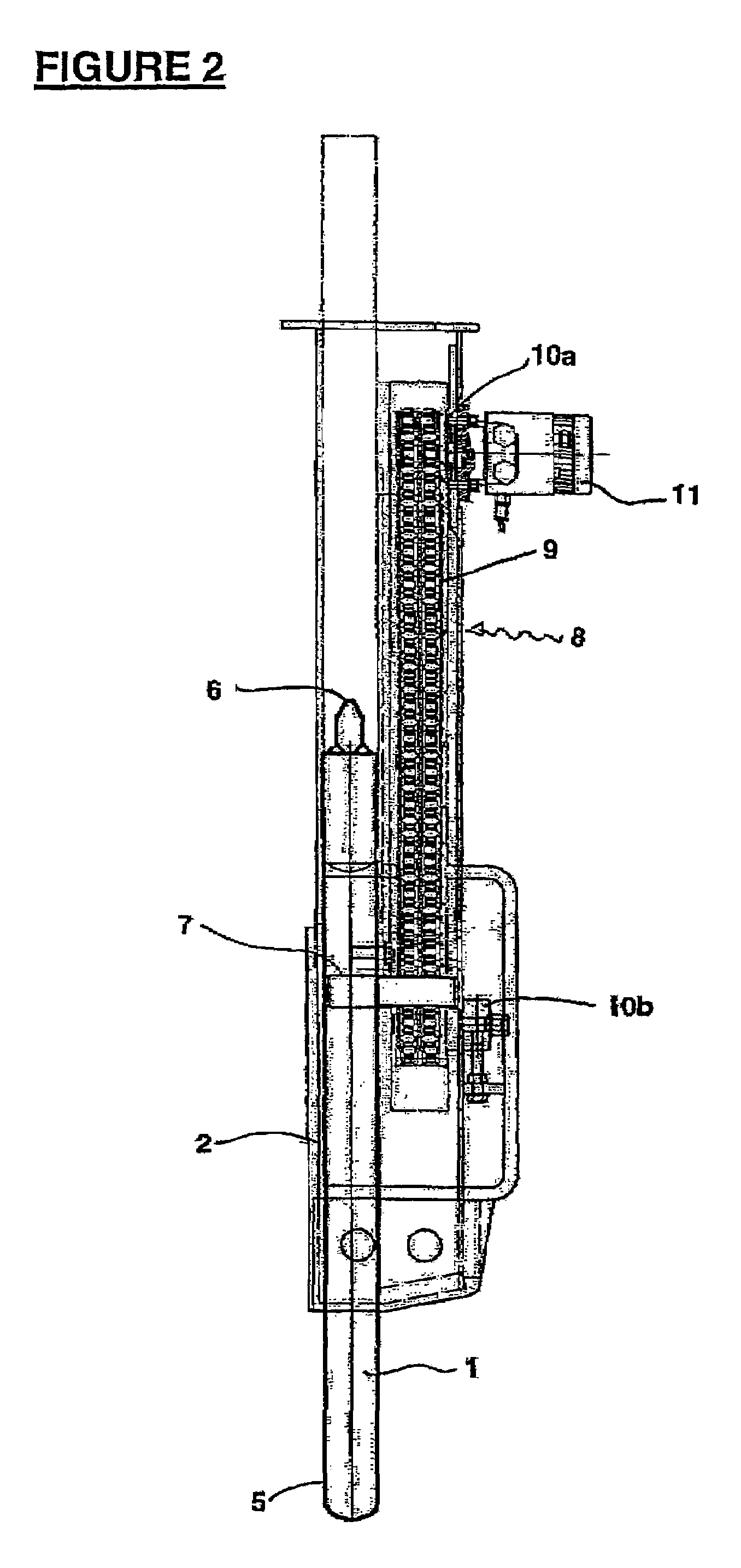

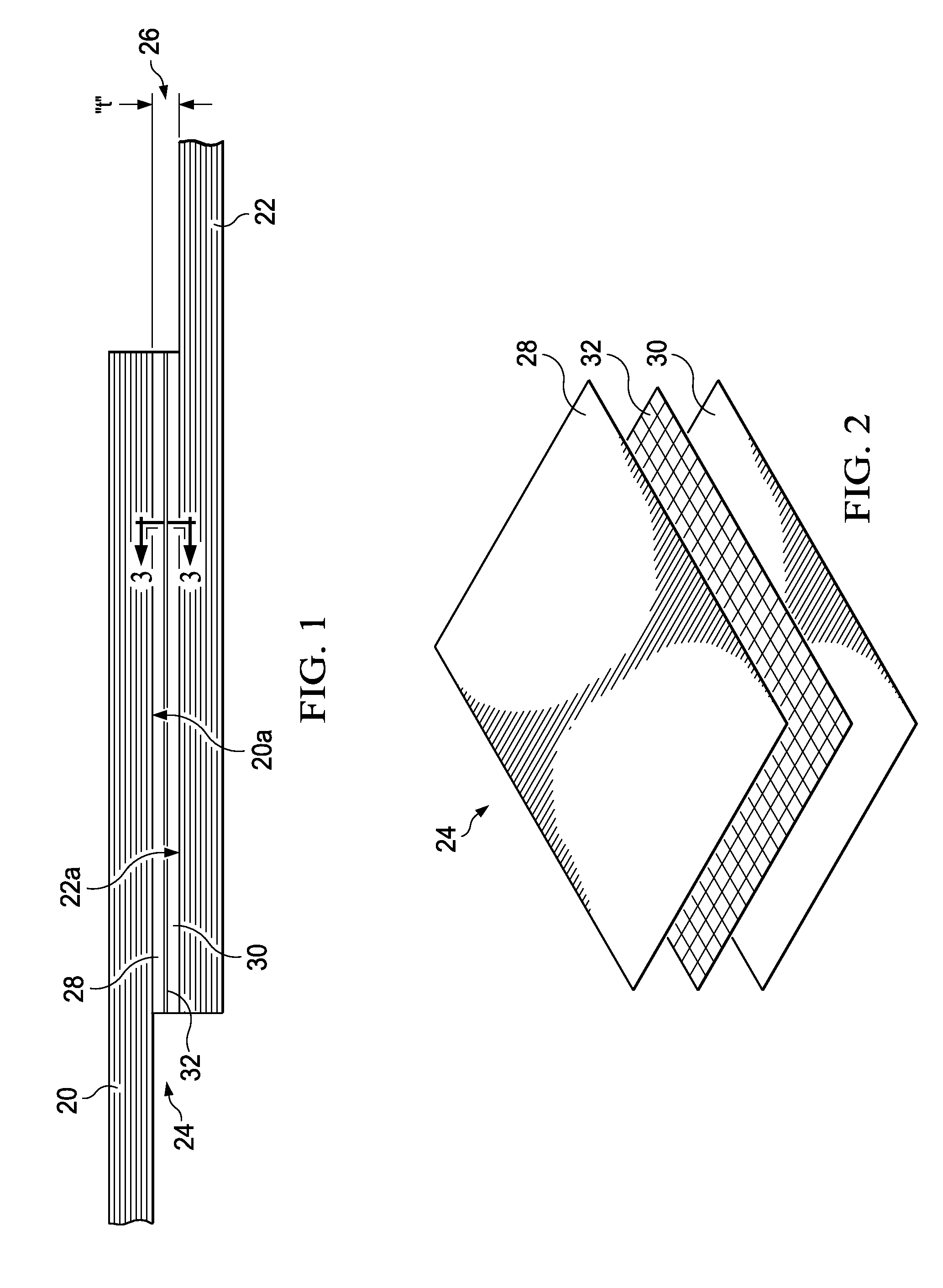

Systems and methods for reinforcing a pipe using fiber bundles and fiber bundle ribbon

InactiveUS20140356529A1Simple structureLong working timeLiquid surface applicatorsSpraying apparatusFiber bundleEngineering

Systems and methods for reinforcing a pipe. A robot is adapted for rotating in a pipe to apply resin and / or fiber to an inner surface of a pipe in a generally helical pattern. Application of resin and / or fiber to the pipe may be actively adjusted to achieve desired application. A rate at which the robot moves along the pipe per revolution of the robot can be may be adjustable. A rate at which fiber is advanced toward the inner surface of the pipe may be adjustable for application of the fiber to the inner surface of the pipe in a generally non-tensioned state.

Owner:FYFE

Filter device for fluids and method for filtering fluids

ActiveUS7479219B2Extended service lifeLong operationWater/sewage treatmentSedimentation separationPressure controlFilter element

A filter device 10 for fluids, especially for motor oil, hydraulic oil, has a filter case 1 comprising one or two filter inlets 2 and one filter outlet 3. The filter case contains one filter 4 consisting of at least two ring-shaped filter elements 7, 8 which concentrically enclose a central tube 18 of the filter device. In a channel 14 between the two adjacent filter elements there is a duct 16 which is run in the form of a spiral around inner filter element 8 and is embedded in filter 4. In duct 16 there is a pressure-controlled regulating valve 9 which opens when a certain level of pressure is exceeded in the filtered oil.

Owner:RASSINGER GUENTHER

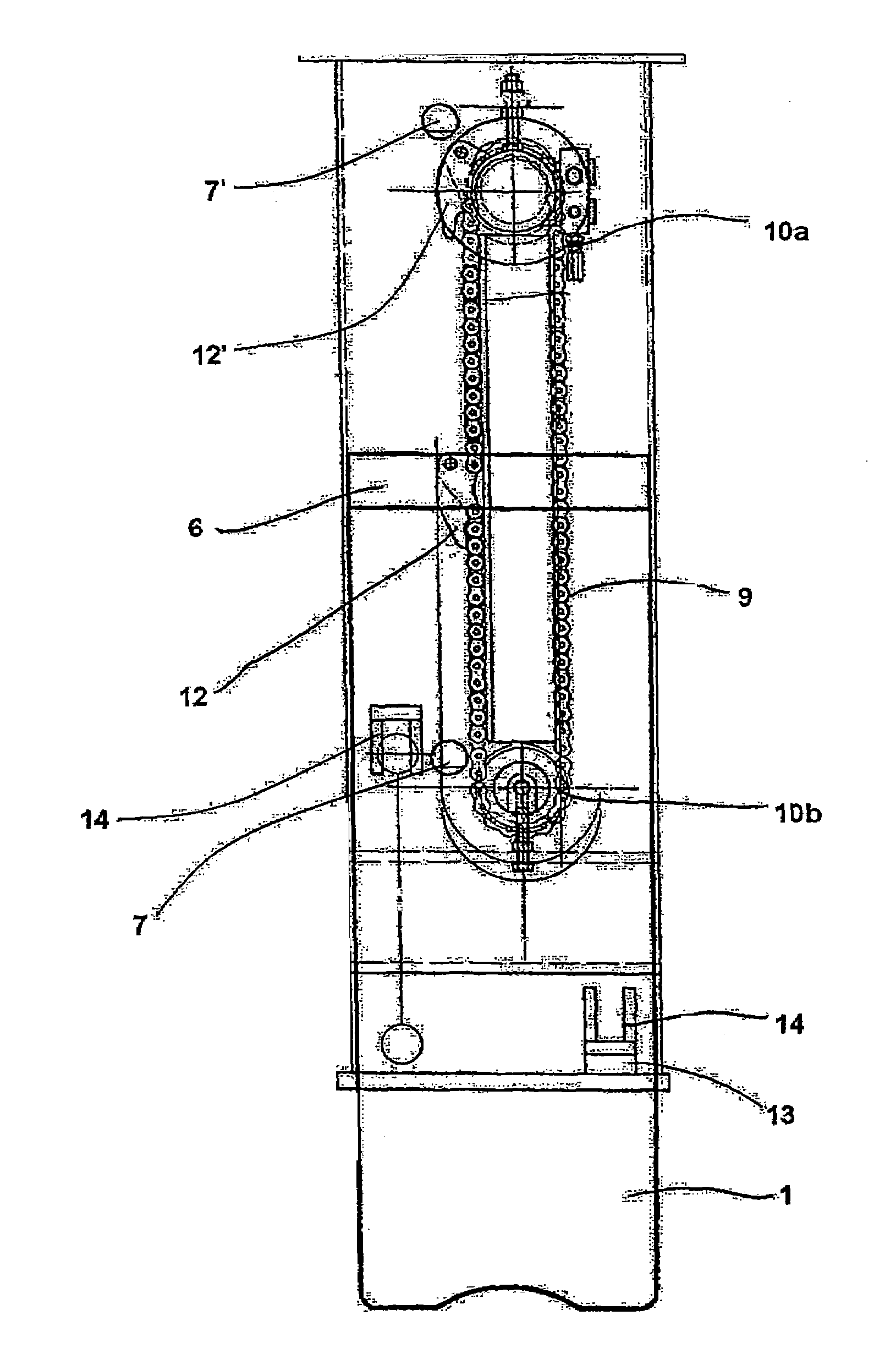

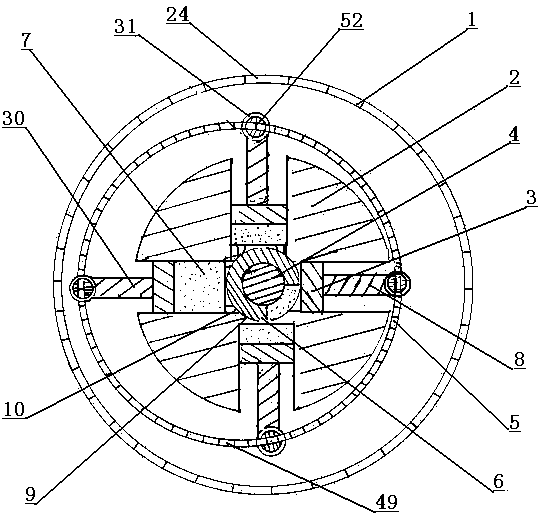

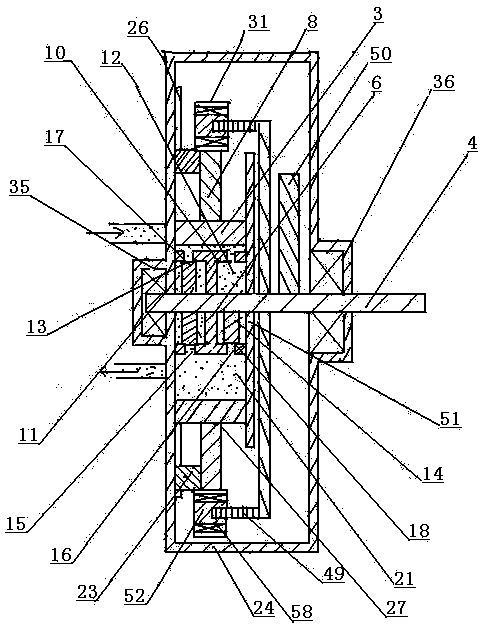

Fluid dynamic machine with rotating wheel piston speed change mechanism

InactiveCN104047638ALong working timeExtension of timeInternal combustion piston enginesRotary piston pumpsTop dead centerDrive shaft

The invention discloses a fluid dynamic machine with a rotary wheel piston speed change mechanism. The fluid dynamic machine is composed of a cylinder body (2), a piston (3), a sliding connecting rod (8), a transmission shaft (4), a rotary wheel transmission device (5) and an air distribution device (6), wherein a rotary wheel disc (51 )of the rotary wheel transmission device (5) of the rotary wheel piston speed change mechanism (1) is eccentrically arranged on the shaft body of the transmission shaft (4); a guide shaft (52) on the rotary wheel disc (51) and the sliding connecting rod (8) are linked with each other; the rotary wheel disc (51) rotates eccentrically; a piston (3) does decelerated motion along with the length change of the arm of force between the axis of the guide shaft (52) and that of the transmission shaft (4); under the driving of the sliding connecting rod (8), the piston (3) performs decelerated motion from a lower stop point (20) to an upper stop point (19) and performs accelerated motion from the upper stop point (19) to the lower stop point(20).

Owner:周觉明

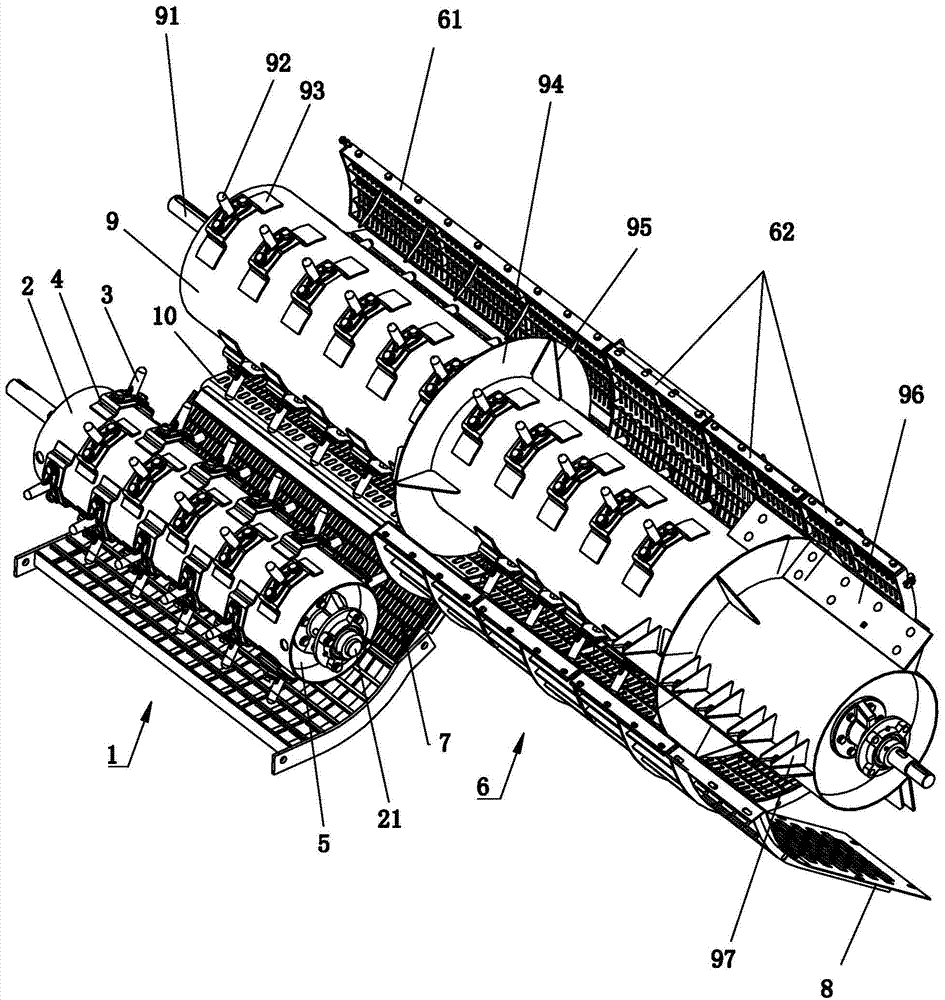

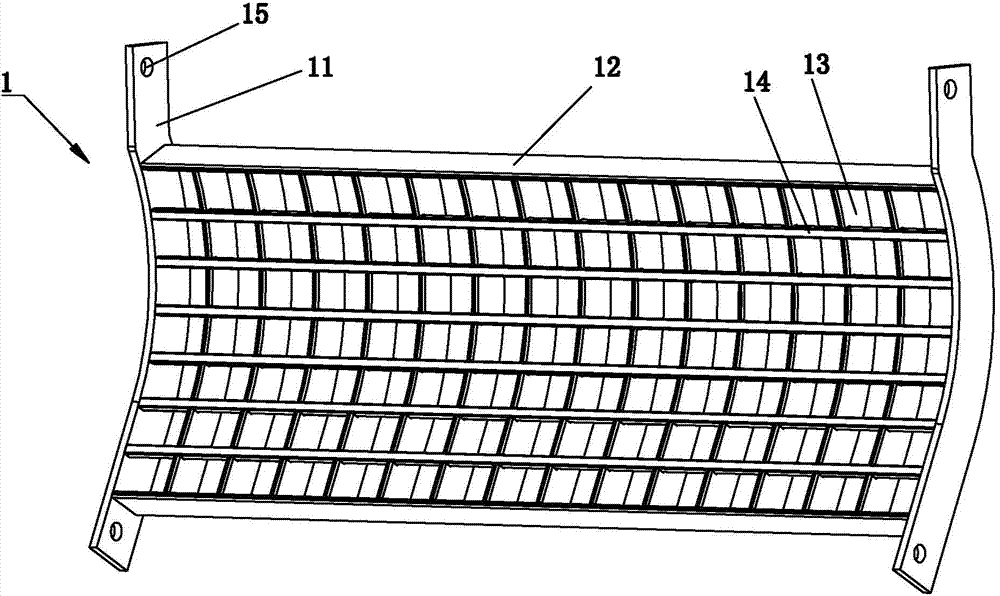

Corn kernel threshing and separating device

The invention discloses a corn kernel threshing and separating device which comprises a threshing roller with threshing teeth. Each threshing tooth comprises a tooth rod with a spherical top end, a threshing concave plate is arranged below the threshing roller and comprises a concave plate body, the concave plate body comprises two side plates, supporting plates are arranged between the two side plates, a longitudinal separation plate is arranged between the two supporting plates, separation bars are arranged on the longitudinal separation plate, and the separation bars and the longitudinal separation plate are flush with the side plates. A separation roller is arranged on one side of the flowing direction of crops, and separation teeth and separation plates are arranged on the separation roller in a staggered mode. A separation concave plate communicated with the threshing concave plate is arranged below the separation plate. Through rubbing between the threshing teeth and the threshing concave plate, threshing is achieved, power consumption is little, and cost is low. Through the threshing concave plate, while passing ability and screening efficiency are guaranteed, strength and use reliability are improved, and the crushing rate is lowered; meanwhile, through replacement of the corn kernel threshing and separating device, the effect of harvesting corn crops at the same time is achieved, and the use rate of a rice and wheat harvester is improved.

Owner:LOVOL HEAVY IND CO LTD

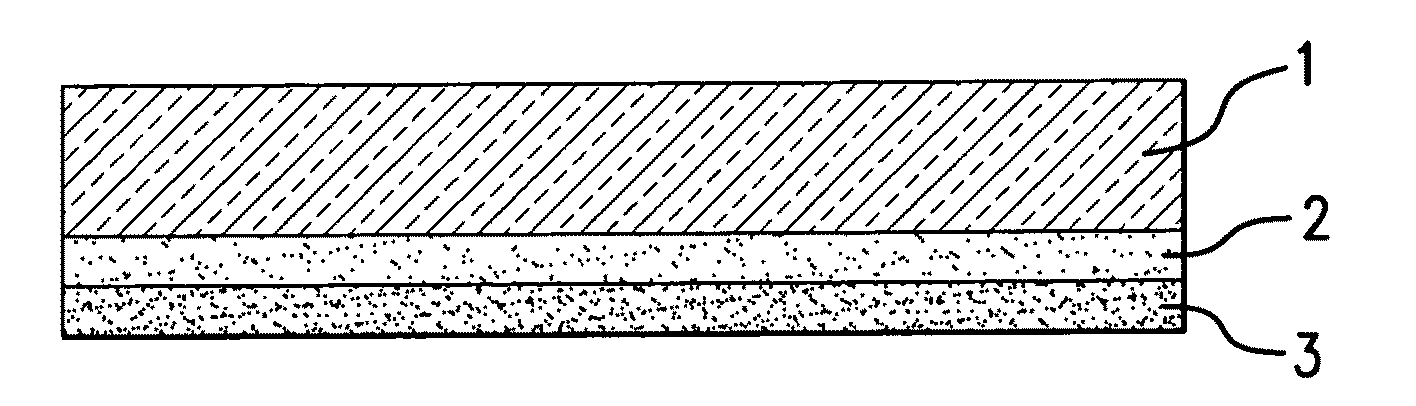

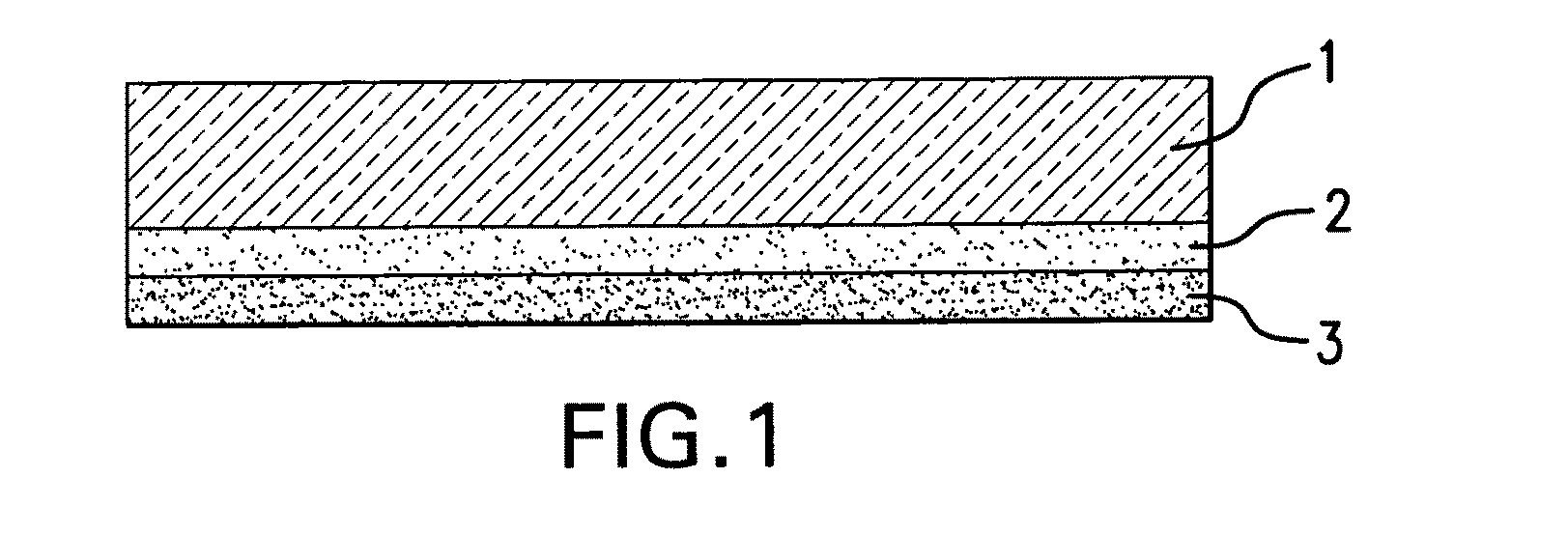

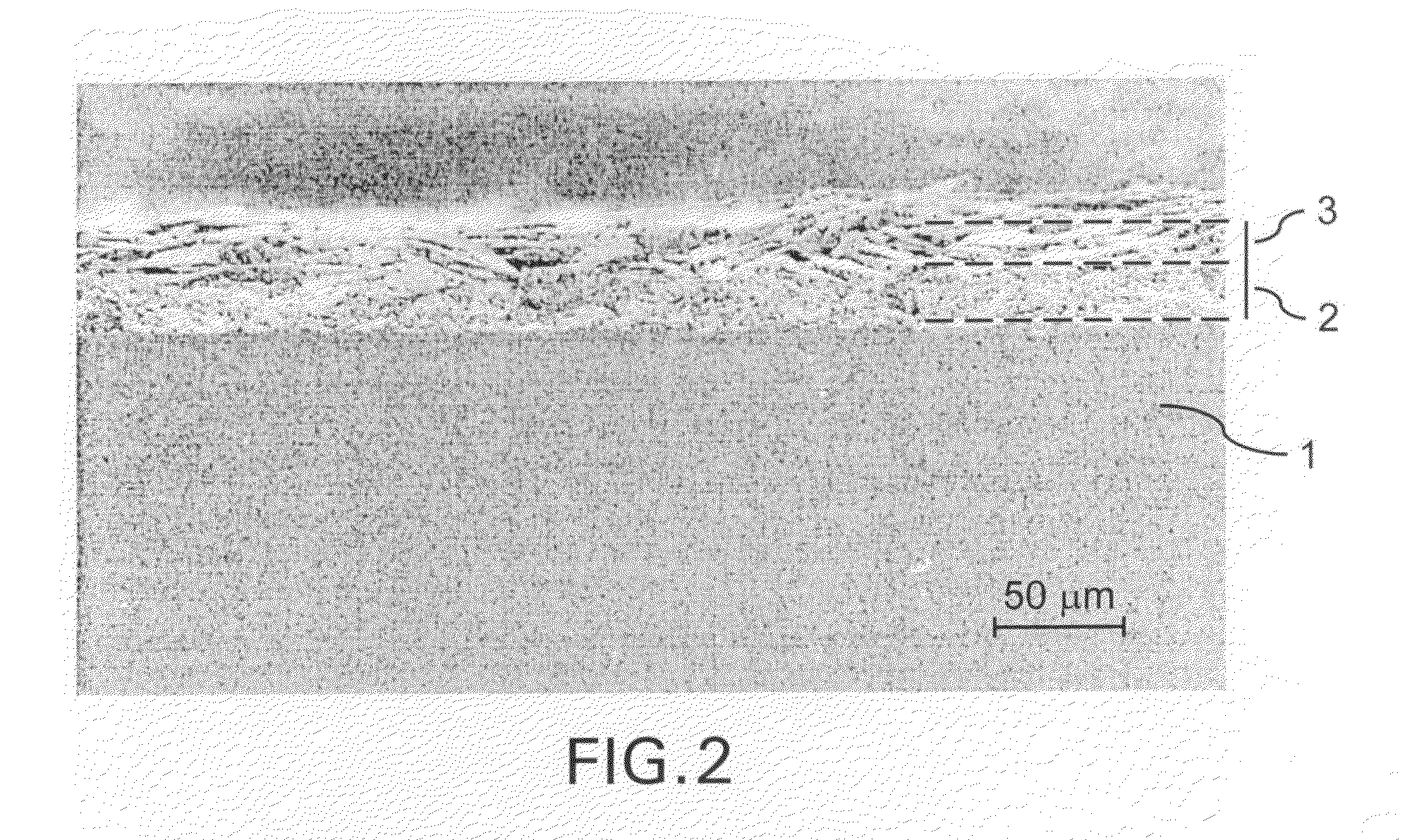

Scratch-resistant silicone coating for cooktops made of glass or glass ceramic

InactiveUS20100167035A1Improve substrate strengthHigh bonding strengthSynthetic resin layered productsGlass/slag layered productsColloidal silicaSilicone coating

A functional element, in particular a cooktop or control panel, having a flat substrate composed of or of glass or glass ceramic, in which a coating that contains a crosslinked polysiloxane is applied to the substrate. In order to improve the scratch resistance of such a coating, according to this invention, a covering layer that contains an uncrosslinked polysiloxane is applied to the coating.

Owner:SCHOTT AG

Thermally Curable Bonding Film Adhesive with Uniform Thickness

InactiveUS20140299268A1Improve mechanical propertiesLong working timeNon-macromolecular adhesive additivesLamination ancillary operationsMetal particleMaterials science

Owner:THE BOEING CO

Advanced heat insulation compressed air energy storage system with electric heating heat preservation sleeves

InactiveCN109488573AImprove working abilityLong working timeHeat storage plantsCombination enginesElectric heatingPower grid

The invention discloses an advanced heat insulation compressed air energy storage system with electric heating heat preservation sleeves. The advanced heat insulation compressed air energy storage system comprises a compressor unit, an expansion machine unit, a compressed air storage tank, a cold storage tank, a heat storage tank, the electric heating heat preservation sleeves, a power generator,a motor and an external power grid; and the compressor unit is connected to the compressed air storage tank, the compressed air storage tank is connected to the expansion machine unit, a first heat exchanger is arranged between every two adjacent stages of compressors, a second heat exchanger is arranged between every two adjacent stages of expanding machines, a pipe between the compressed air storage tank and the first-stage expansion machine and a pipe between the second heat exchanger and the later-stage expansion machine are sleeved with the electric heating heat preservation sleeves, andthe electric heating heat preservation sleeves are connected with the external power grid. According to the advanced heat insulation compressed air energy storage system, the power capability of the expansion machines can be improved, the air flow in the energy release stage can be increased to increase the turbine output power, and the acting efficiency and the output power of an AA-CAES system are greatly improved.

Owner:CHONGQING UNIV

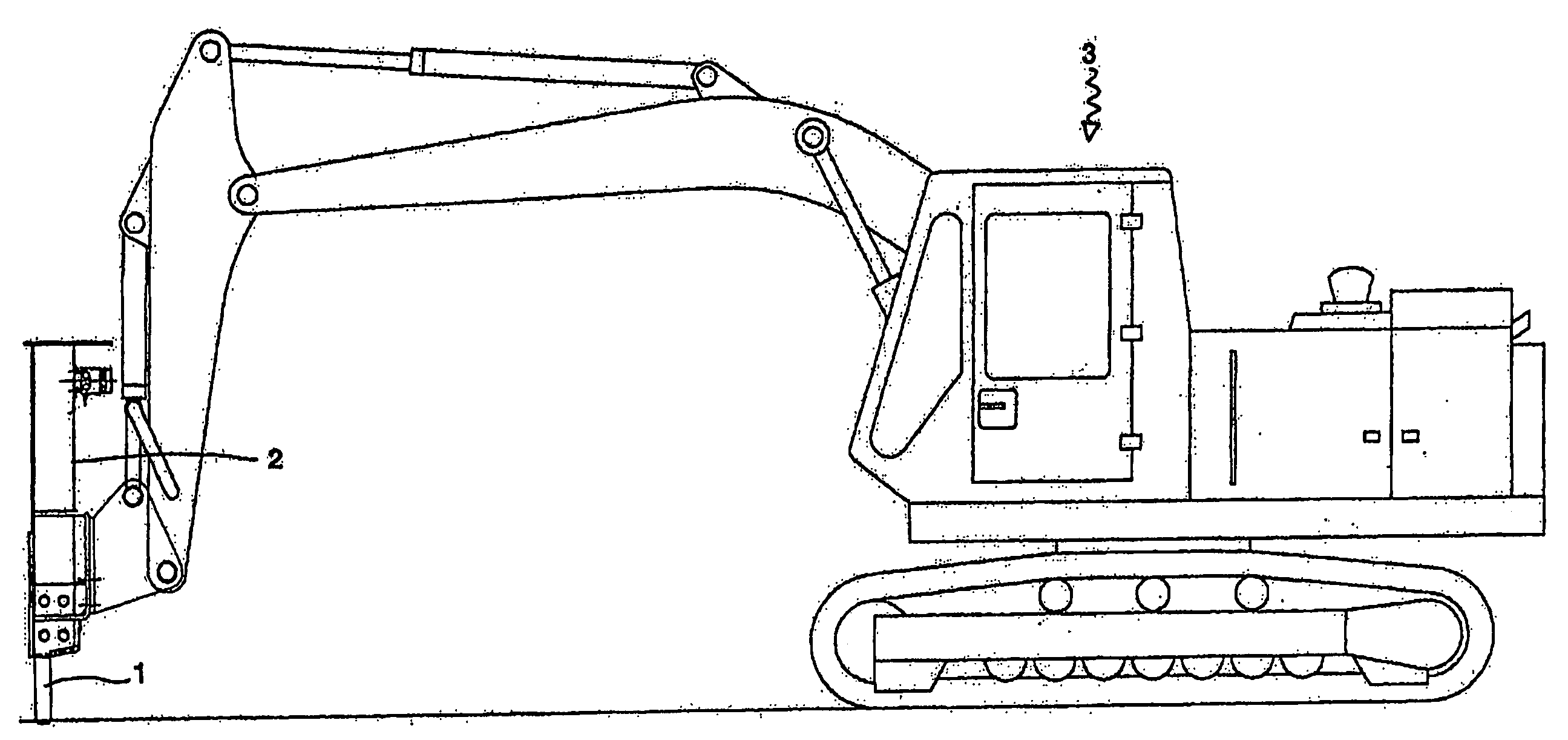

Smart cutting tool system for use in precision cutting

InactiveUS20190358709A1Increase speedImprove accuracyAutomatic control devicesAuxillary equipmentCouplingComputer module

A smart cutting tool system for use in precision cutting, comprising a cutting insert (1), an upper cutter arbor (2), a lower cutter arbor (3), a first pressure sensor (4), a second pressure sensor (5), a signal processing module (6), a Bluetooth® transmission module (7), and a power supply (8), wherein the cutting insert (1) is fixed to a front end of the upper cutter arbor (2), the cutting insert (1) is provided at its rear end with a microgroove, in which the first pressure sensor (4) and the second pressure sensor (5) are inserted. The cutting tool system solves the problem of mutual coupling of various cutting forces, and has higher sensitivity.

Owner:GUANGDONG UNIV OF TECH

Powered hammer device

InactiveUS20050254904A1Long working timeWear minimizationReciprocating drilling machinesPortable percussive toolsEngineeringCanis lupus familiaris

Owner:TERMINATOR IP II

Enclosure for modular construction systems

InactiveUS20170130474A1Simpler and fast solutionLong working timeWallsSpecial buildingTransverse grooveModularity

A simple and fast solution over the current modular construction techniques does not require welding or having to plaster the heads of the connecting elements, while allowing the increase and reinforcement of their resistance to the wind in locations with exposure to extreme winds. An enclosure includes a number of panels formed by at least one multilayer outer piece, a multilayer inner piece, and an intermediate air chamber, wherein the outer pieces of each panel have transverse grooves and recesses located at the side edges thereof. The enclosure includes bracing metal bars coupled to the groove of the outer pieces. The enclosure further includes supporting metal bars coupled vertically in correspondence with the recesses of the outer pieces.

Owner:SUSTAINABLE ENERGY&HOUSING SL

Curable organopolysiloxane compositions

Artificial stone having excellent mechanical and weatherability properties is prepared from a highly filled crosslinkable organosilicon composition where the filler comprises at least 20 weight percent of coarse fillers, the organosilicon component contains silicon-bonded alkoxy and or hydroxyl groups, with a catalyst containing a metal compound and an amidine or guanidine.

Owner:WACKER CHEM GMBH

Corn grain threshing and separating device and combine harvester with separating device

The invention discloses a corn grain threshing and separating device and a combine harvester with the separating device. The corn grain threshing and separating device comprises a threshing roller which is provided with threshing teeth with ball-headed top ends, wherein a threshing concave plate is arranged below the threshing roller and is arranged on a mounting rack, and multiple columns of staggered elliptical holes are formed in the threshing concave plate; a stone collecting tank is arranged at one side, close to a corncob source, of the mounting rack, and a stone collecting tank cover plate is arranged above the stone collecting tank. Through the threshing teeth, grains are prevented from being crushed, and the threshing effect is enhanced; the threshing teeth are matched with the threshing concave plate, so that under the condition of guaranteeing low grain crushing rate, high threshing performance, screening performance and passing characteristic, the working strength, reliability and stability are improved through the mounting rack, and mounting and repair / maintenance are facilitated; the stone collecting tank is closed by the stone collecting tank cover plate, so that corncobs are prevented from falling into the stone collecting tank; meanwhile, through replacing a threshing and separating attachment, on the basis of realizing rice / wheat harvesting, the effect of harvesting corn crops is realized, and the use ratio of the harvester is increased.

Owner:LOVOL HEAVY IND

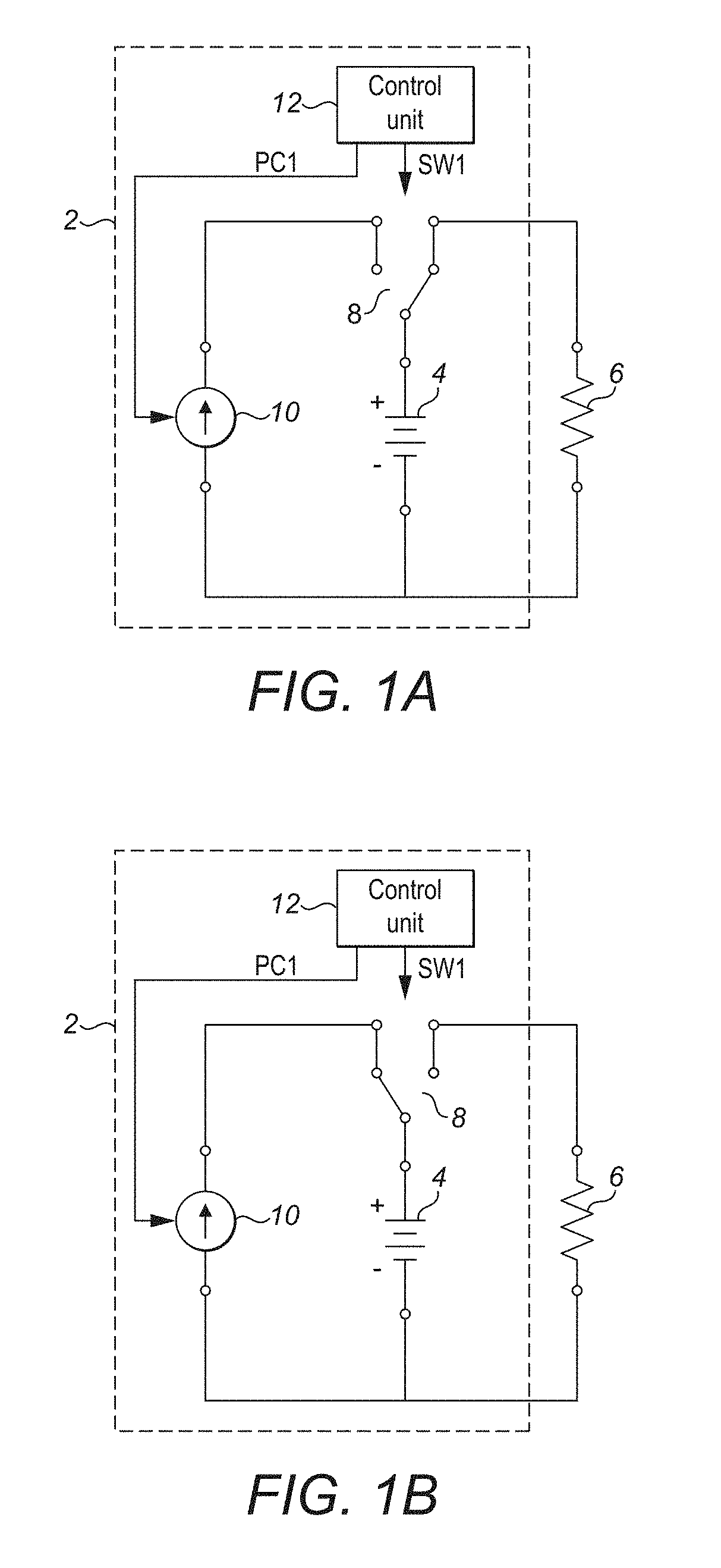

Power supply system

ActiveUS20160315485A1Improve efficiencyOptimize working timeParallel/serial switchingElectric powerElectricityCharge current

A power supply system for supplying an electrical load using a pulse discharge arrangement. The power supply system comprises a first electrical battery for supplying said electrical load, a control unit configured to control the first electrical battery for periodically switching between a discharge state of the first electrical battery and a rest state of the first electrical battery, said control unit being further configured to control a power source for supplying a first charging current to the first electrical battery during a rest period when the first electrical battery is in the rest state.

Owner:MANODYA LTD +1

Scratch-resistant silicone coating for cooktops made of glass or glass ceramic

InactiveUS8734935B2Good storage stabilityLong working timeSynthetic resin layered productsGlass/slag layered productsSilicone coatingGlass-ceramic

A functional element, in particular a cooktop or control panel, having a flat substrate composed of or of glass or glass ceramic, in which a coating that contains a crosslinked polysiloxane is applied to the substrate. In order to improve the scratch resistance of such a coating, according to this invention, a covering layer that contains an uncrosslinked polysiloxane is applied to the coating.

Owner:SCHOTT AG

Power supply system

ActiveUS10110023B2Improve efficiencyOptimize working timeParallel/serial switchingSingle network parallel feeding arrangementsElectricityCharge current

A power supply system for supplying an electrical load using a pulse discharge arrangement. The power supply system comprises a first electrical battery for supplying said electrical load, a control unit configured to control the first electrical battery for periodically switching between a discharge state of the first electrical battery and a rest state of the first electrical battery, said control unit being further configured to control a power source for supplying a first charging current to the first electrical battery during a rest period when the first electrical battery is in the rest state.

Owner:MANODYA LTD +1

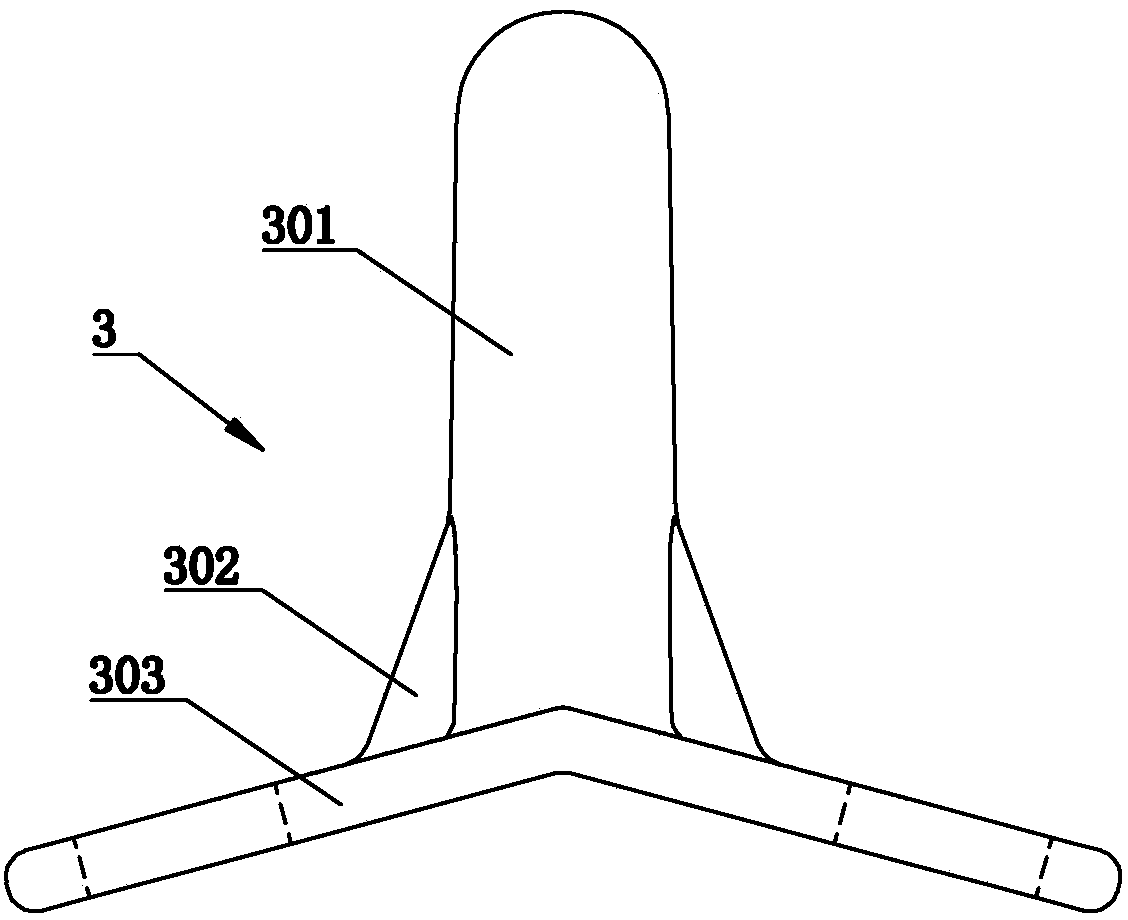

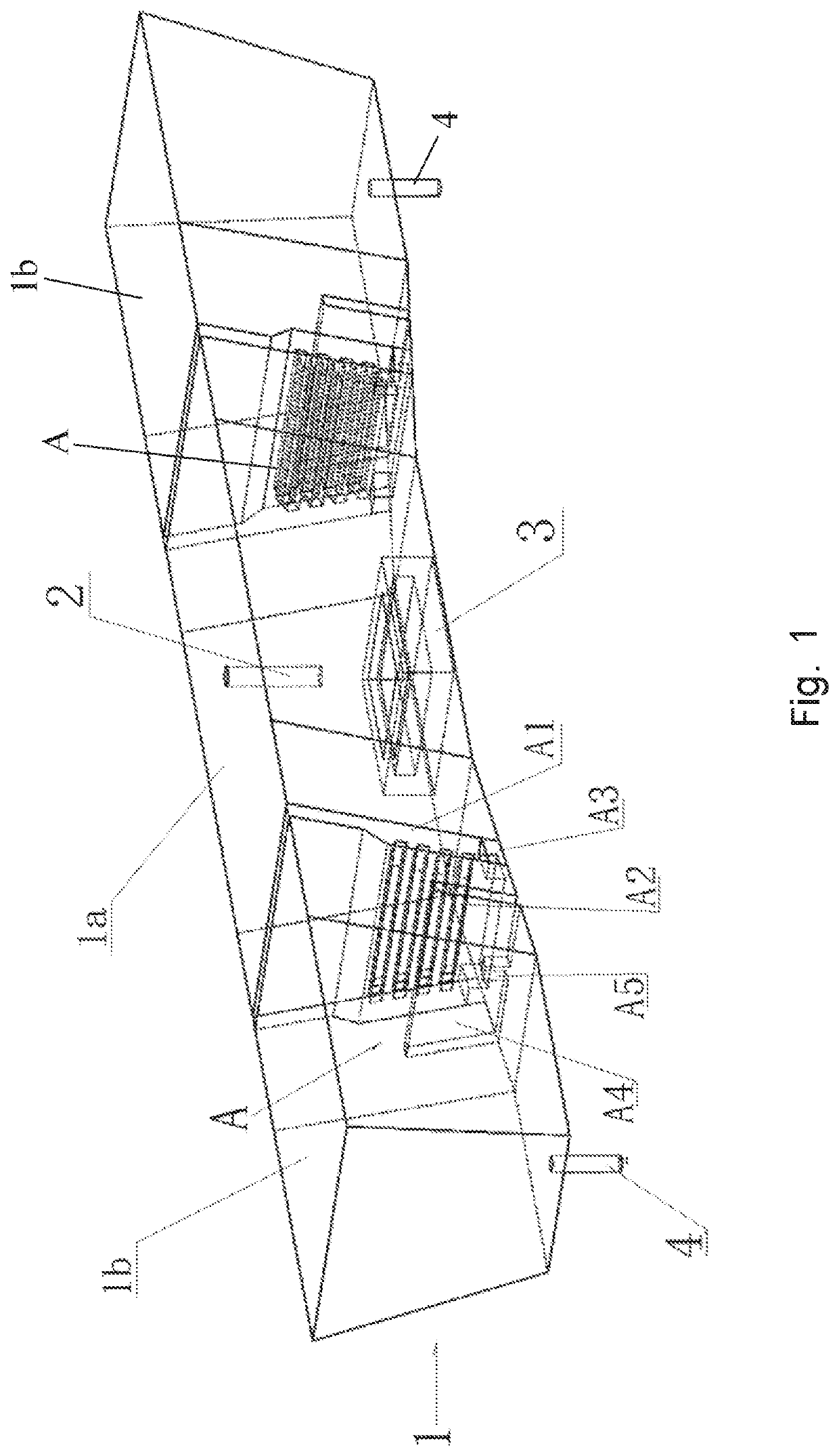

Flow-controllable tundish structure capable of filtering inclusions in molten steel

ActiveUS20210016346A1Reduce in quantityPromote growthMelt-holding vesselsCasting cleaning apparatusLiquid steelMechanics

Disclosed is a flow-controllable tundish structure capable of filtering inclusions in molten steel. The tundish structure comprises a tundish (1), the tundish being divided into three separated cavities which comprise an impact zone cavity (1a) in the middle and pouring zone cavities (1b) at two sides thereof. A long nozzle (2) for pouring is vertically arranged in the center of the impact zone cavity, and molten steel flows down out of the long nozzle for pouring and is injected into the impact zone cavity; and a turbulence suppressor (3) directly facing the long nozzle for pouring is arranged on the cavity bottom under the long nozzle for pouring, and the molten steel flowing down out of the long nozzle for pouring impacts on the turbulence suppressor and is then buffered and mixed. Filter assemblies (A) are respectively arranged between the impact zone cavity and the pouring zone cavities at the two sides, and the buffered and mixed molten steel in the impact zone cavity is filtered by the filter assemblies and is then delivered into the pouring zone cavities at the two sides. Discharge ports (4) are respectively arranged in the bottom of the pouring zone cavities, and the molten steel filtered by the filter assemblies flows into the pouring zone cavities and then flows out from the discharge ports. The flow-controllable tundish structure has the advantages of a simple structure, easy building and lower cost, and has a good liquid steel purification effect.

Owner:BAOSHAN IRON & STEEL CO LTD

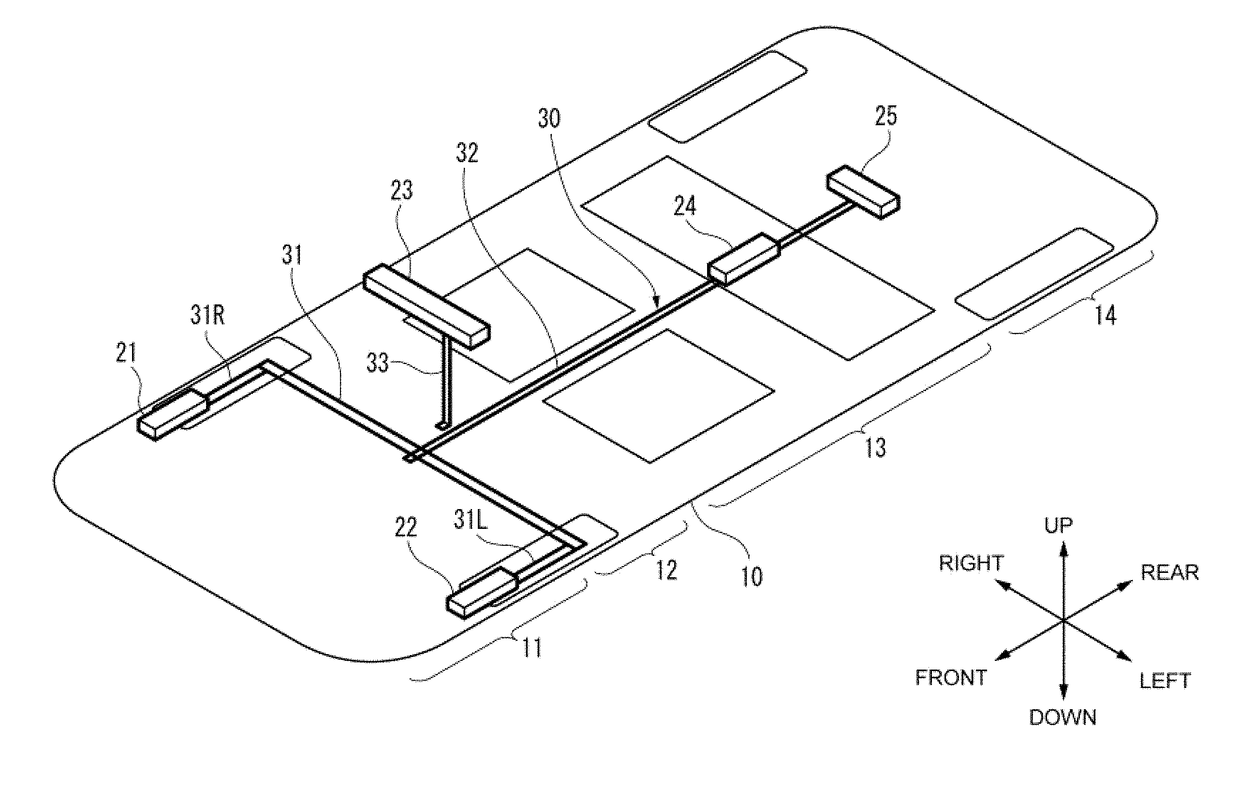

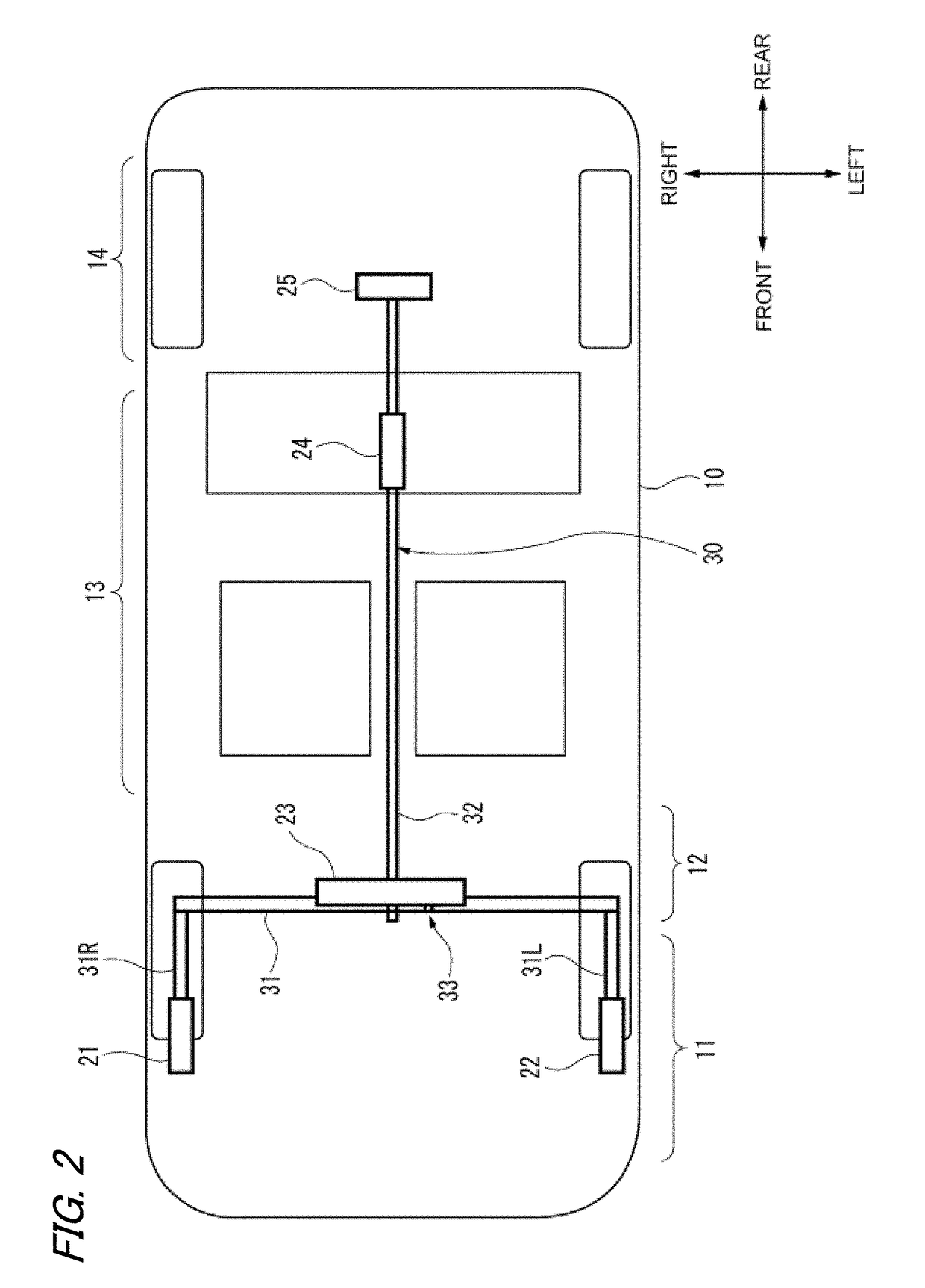

Circuit for vehicle and circuit routing system for vehicle

ActiveUS20180334113A1Long working timeWeight increaseElectrical apparatusElectric/fluid circuitEngineeringControl unit

This vehicle circuit routing system as a whole has a backbone-like routing structure, said system being provided with a plurality of backbone JB structures, wherein the vehicle circuit bodies of the backbone JB structures are connected to each other by means of a backbone main line. Each vehicle circuit body is provided with a power supply circuit that is connected to a main power supply on the vehicle, a plurality of connection parts to which a plurality of branch lines having a power supply line are connected, and a control unit that controls the distribution of power from the power supply circuit to the branch lines.

Owner:YAZAKI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com