Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

337 results about "Silicone coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Article of manufacture and process for anodically coating an aluminum substrate with ceramic oxides prior to polytetrafluoroethylene or silicone coating

InactiveUS20050115840A1AnodisationElectrolytic inorganic material coatingCeramic coatingSilicone coating

Owner:HENKEL KGAA

Erosion-resistant silicone coatings for protection of fluid-handling parts

ActiveUS7033673B2Improve adhesionEconomy in coatingPretreated surfacesLiquid/solution decomposition chemical coatingSilanesSilanol

Owner:SS IND TECH LLC

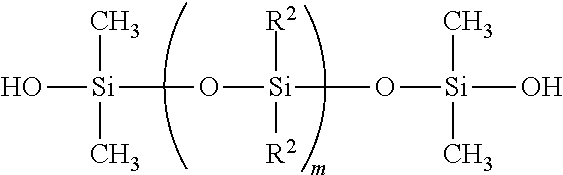

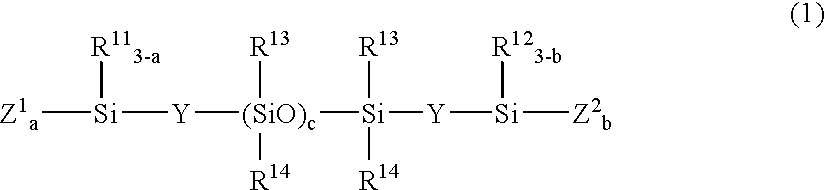

Release modifier and release coating organopolysiloxane composition

ActiveUS8933177B2Heavy release propertyLow viscosityLayered productsSkin careAlkoxy groupSilicone coating

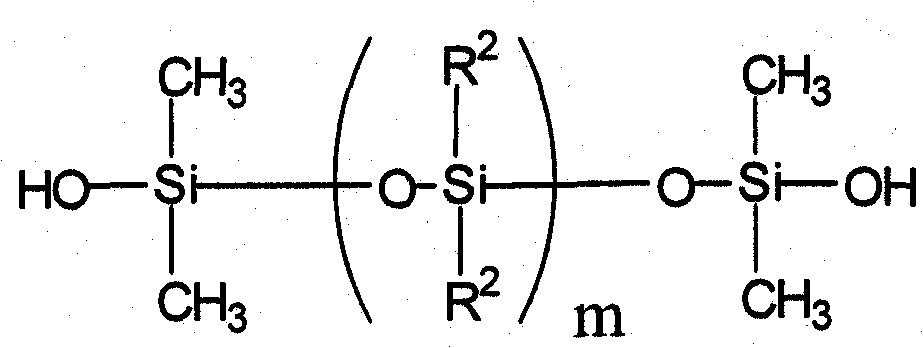

To provide a release modifier which provides a heavy release force to a cured release layer of silicone coating composition. The release modifier comprises an organopolysiloxane resin-organopolysiloxane condensation reaction product that is obtained by the condensation reaction of (a1) 100 weight parts of MQ-type organopolysiloxane resin in which the molar ratio of the M unit to the Q unit is 0.6 to 1.0 and the content of the hydroxyl group or alkoxy group is 0.3 to 2.0 weight % with (a2) 20 to 150 weight parts of chain-form diorganopolysiloxane that has an average degree of polymerization of 100 to 1000 and at least one hydroxyl group or alkoxy group; this organopolysiloxane resin-organopolysiloxane condensation reaction product preferably has a prescribed hydroxyl group content.

Owner:DOW TORAY CO LTD

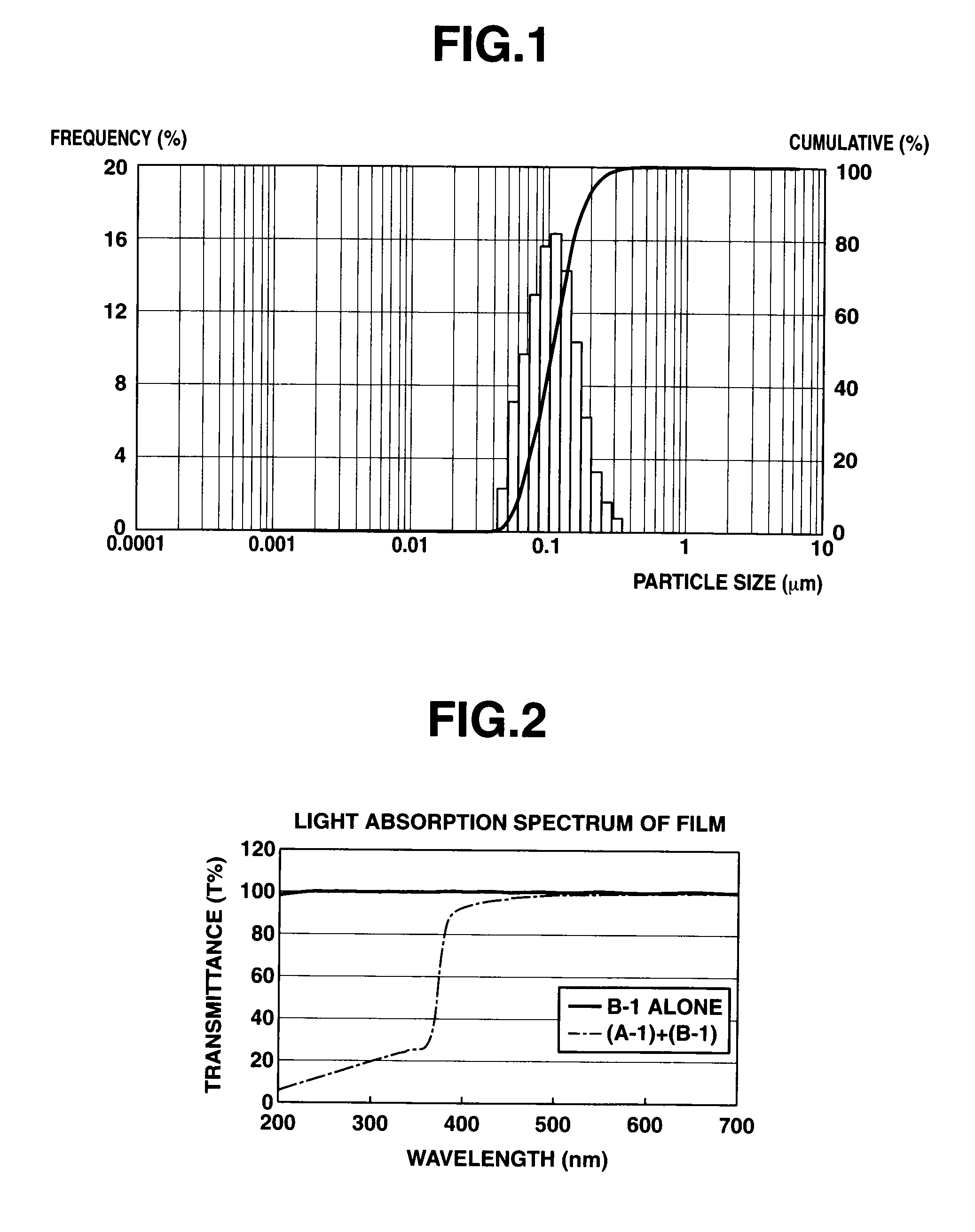

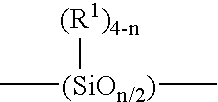

Uv-shielding silicone coating composition and coated article

ActiveUS20100221557A1Solve the lack of durabilitySolve the lack of resistanceLayered productsCoatingsUltravioletSolvent

A UV-shielding silicone coating composition comprises (A) a dispersion in a dispersing medium of composite zinc oxide nanoparticles which are obtained by coating zinc oxide nanoparticles with an oxide or hydroxide of Al, Si, Zr or Sn, the dispersion having a photocatalytic degradability of up to 25%, (B) a silicone resin, (C) a curing catalyst, and (D) a solvent, the solids content of composite zinc oxide nanoparticle dispersion (A) being 1 to 50% by weight based on silicone resin (B). The composition is transparent to visible light, mar resistant, UV-shielding, weatherable, and durable.

Owner:SHIN ETSU CHEM IND CO LTD

Erosion-resistant silicone coatings for protection of fluid-handling parts

ActiveUS20050019589A1Improve adhesionEconomy in coatingPretreated surfacesLiquid/solution decomposition chemical coatingSilanolSilicone coating

Owner:SS IND TECH LLC

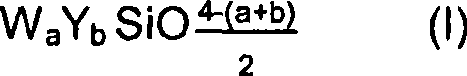

Silicone coating composition

ActiveUS20080196626A1Diffusion transfer processesPhotomechanical apparatusSilicone coatingPolymer chemistry

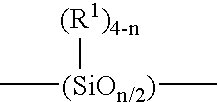

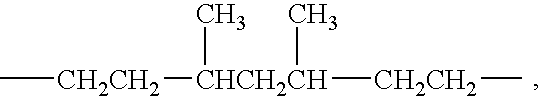

The present invention relates to a composition comprising:(a) a polymer having at least one repeating unit of formulawhere R1 is a non-hydrolysable group and n is an integer ranging from 1 to 3; and (b) a crosslinking catalyst. The composition is useful in forming low k dielectric constant materials and as well as hard mask and underlayer materials with anti-reflective properties for the photolithography industry.

Owner:MERCK PATENT GMBH

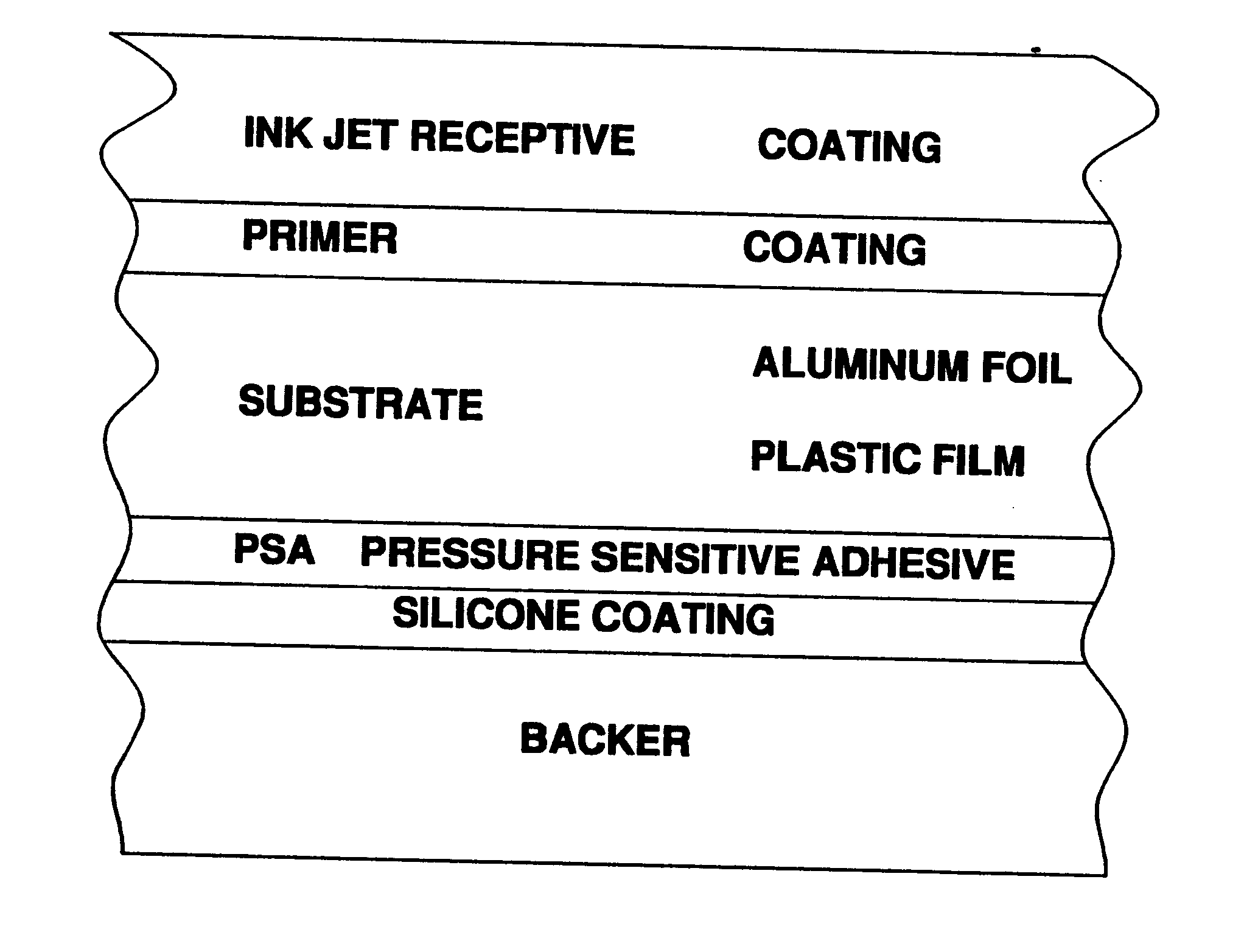

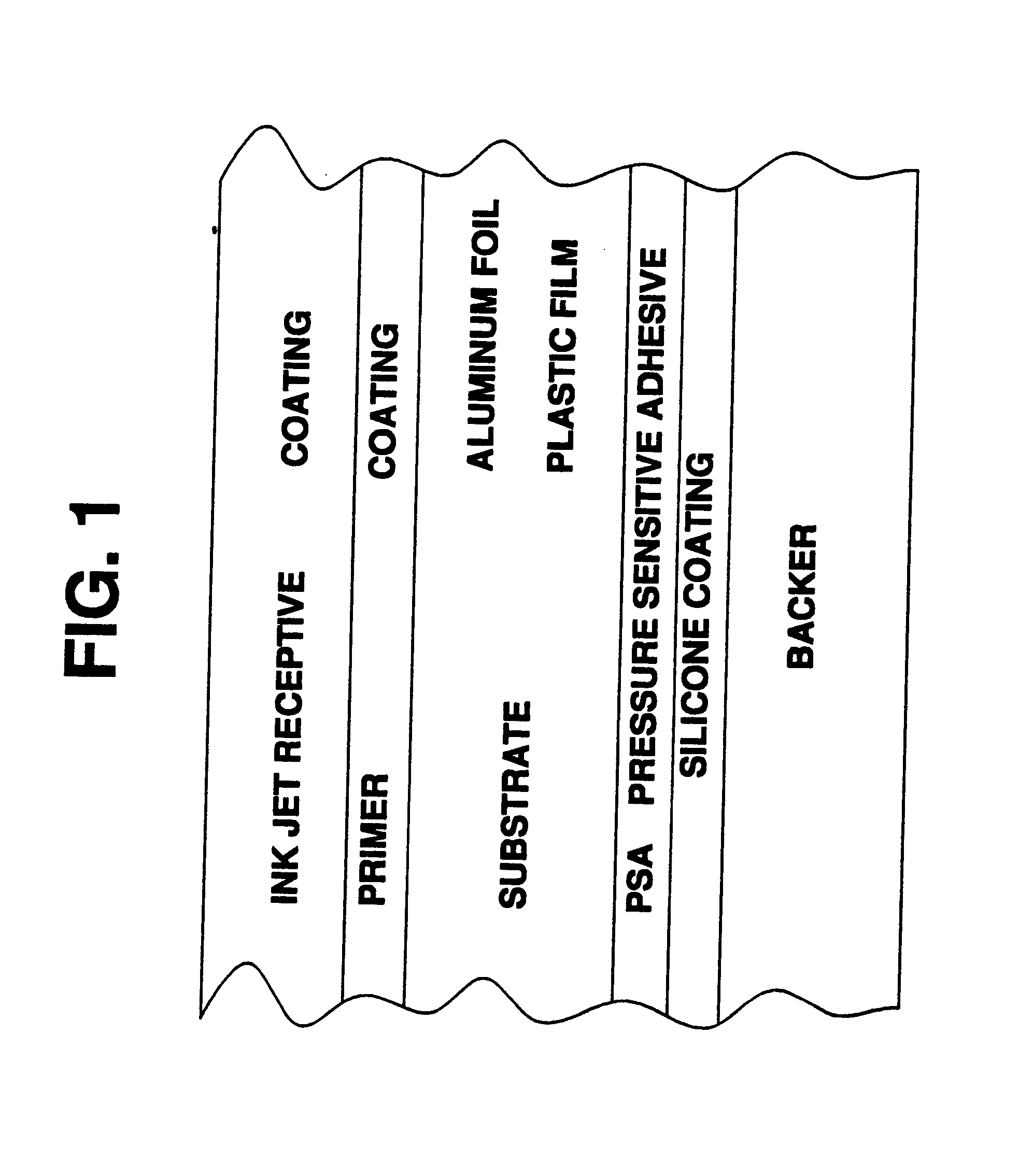

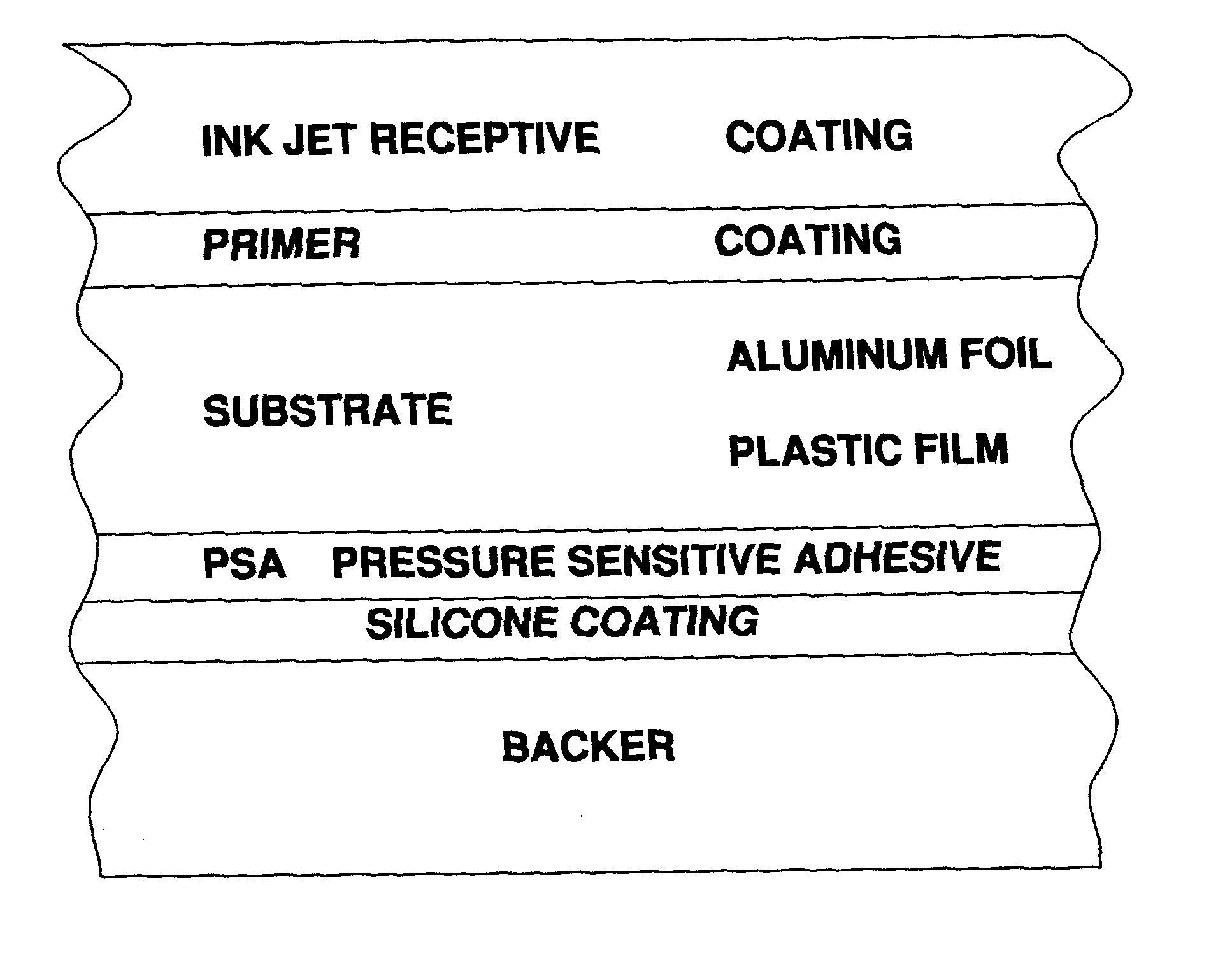

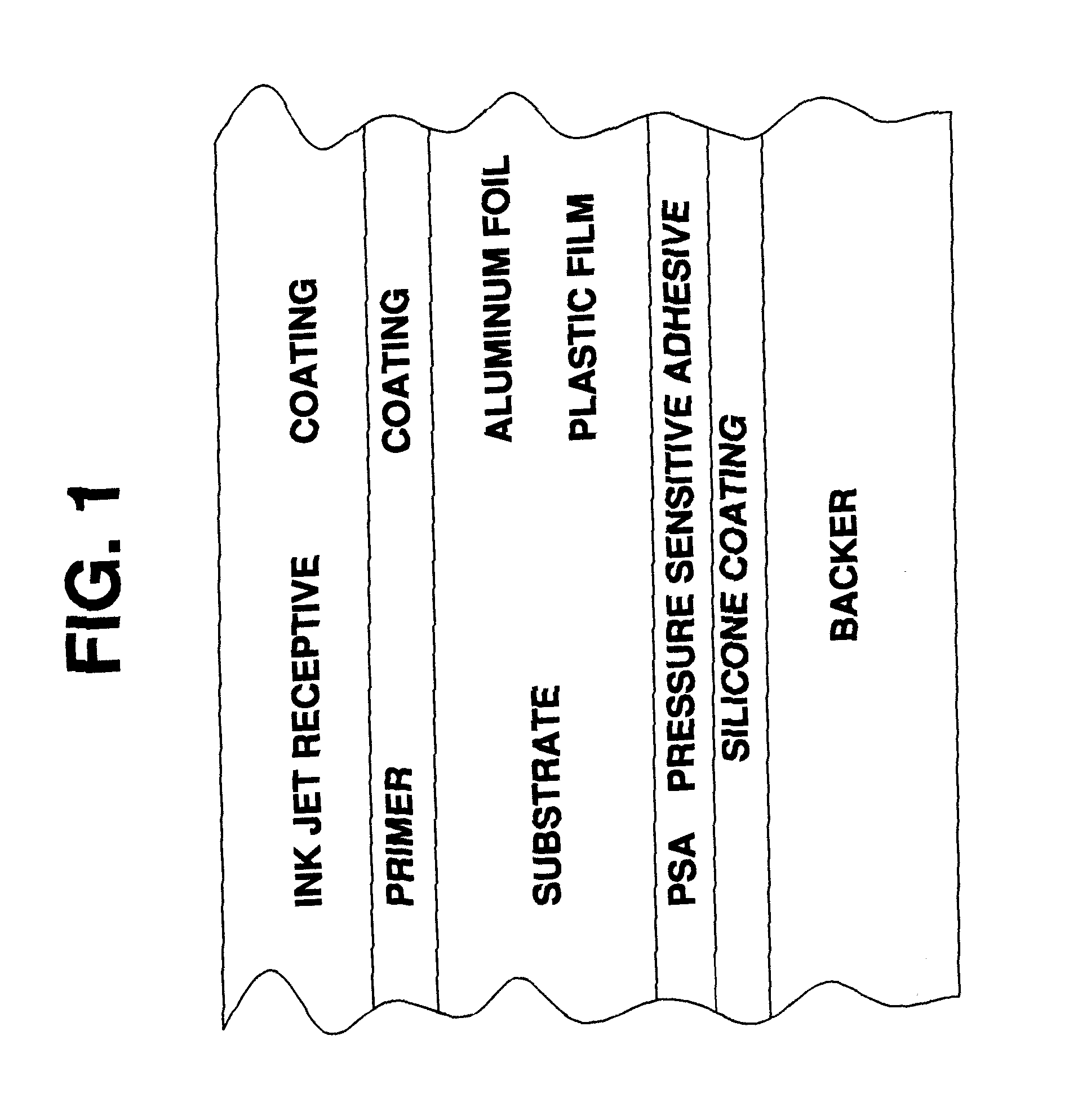

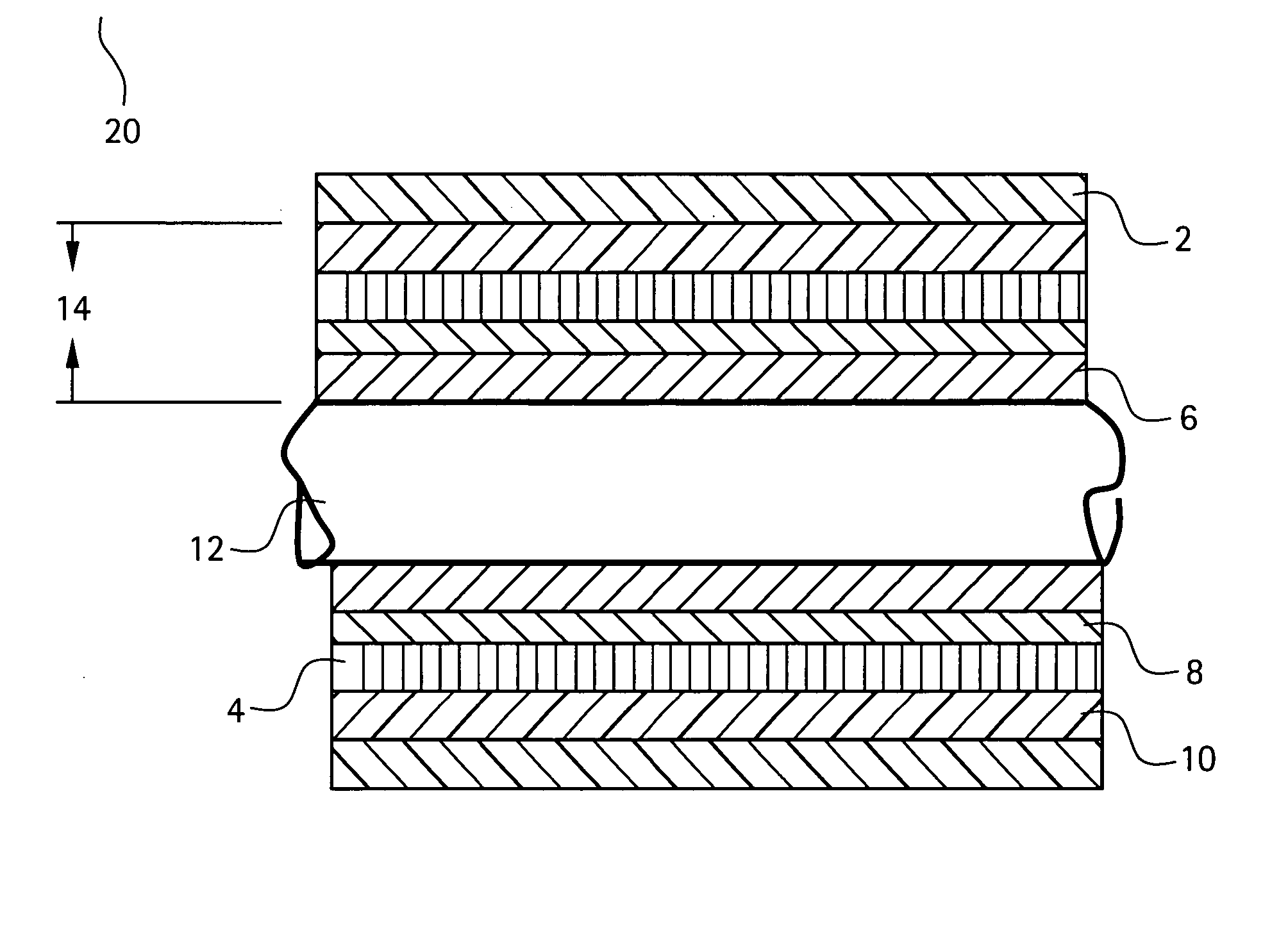

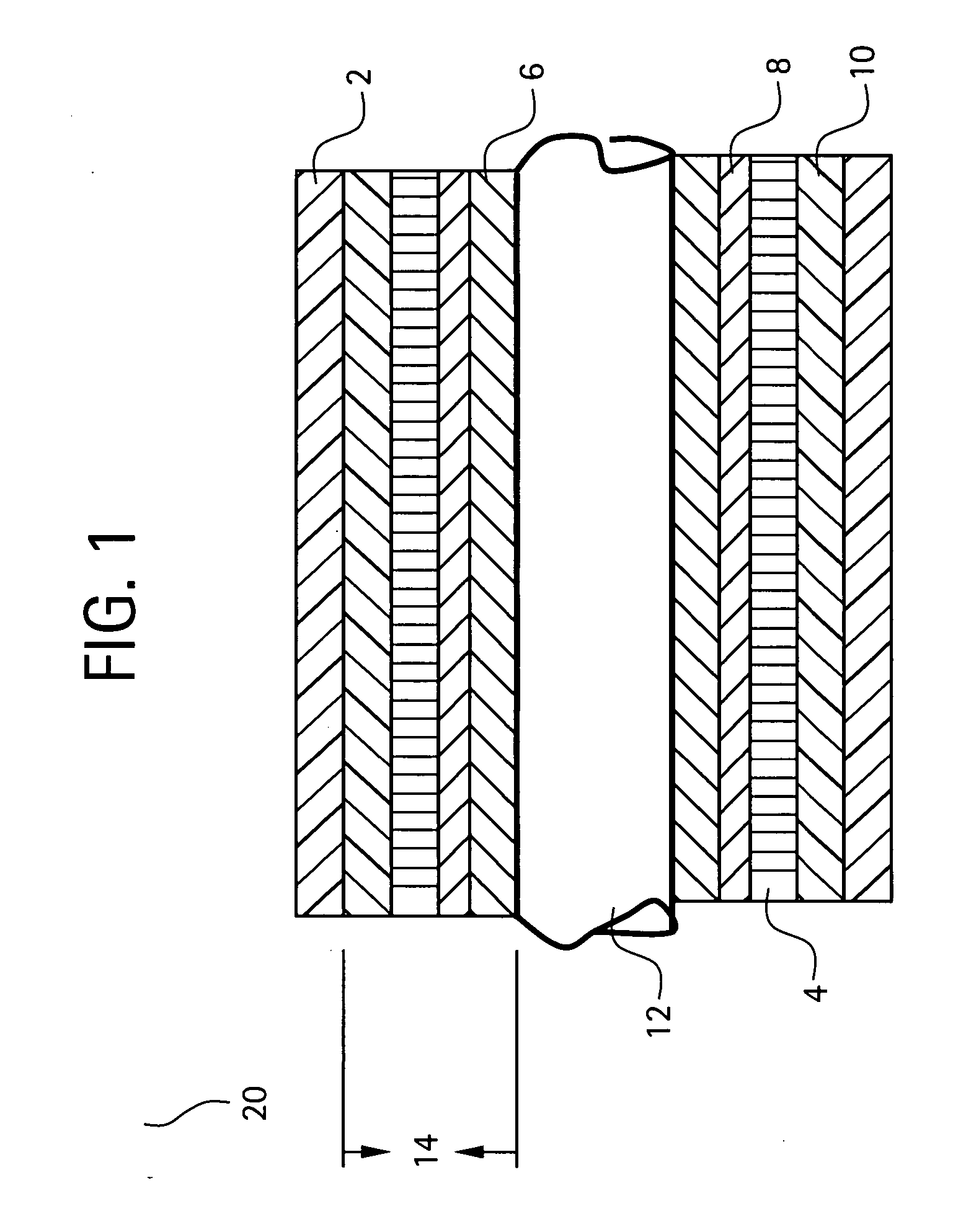

Pressure sensitive ink jet media for digital printing

InactiveUS6432501B1Efficient use ofMaximize absorptionLayered productsDuplicating/marking methodsPorous substrateCoated surface

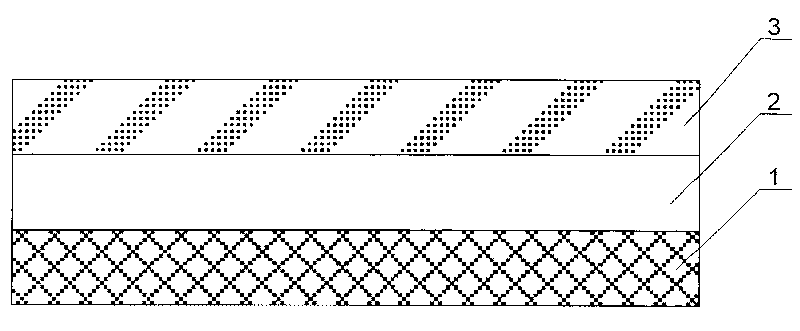

The problems of applying ink jet inks to various known coating surfaces so as to overcome smearing, poor resolution and attack by water etc., is overcome by the use of the new ink jet receptive media. The media comprises in combination: (1) a waterproof ink jet receptive coating, (2) a primer coating, (3) a non-porous substrate, (4) a pressure sensitive adhesive coating, (5) a silicone coating and (6) a backer layer. The receptive coating comprises the combination of: (1) binder, (2) charge control agent, (3) cross-linking agent, (4) adhesion enhancing agent and (5) dispersant. The absorption of the ink jet ink to the substrate is maximized, thus attracting and fixing the ink and providing a waterproofing effect.

Owner:CHARTPAK

Silicone coating compositions and coated articles

InactiveUS20050244659A1Eliminate coat crackingImprove balanceLayered productsCoatingsCrack resistanceArame

A silicone coating composition comprising (A) a silicone resin resulting from (co)hydrolytic condensation of an alkoxysilane or a partial hydrolytic condensate thereof, (B) an aromatic-free compound for curing the silicone resin, and (C) a solvent remains stable during shelf storage. It is applied and heat cured to a plastic substrate to form a protective coat having a high hardness, mar resistance, adhesion, toughness and crack resistance.

Owner:SHIN ETSU CHEM IND CO LTD

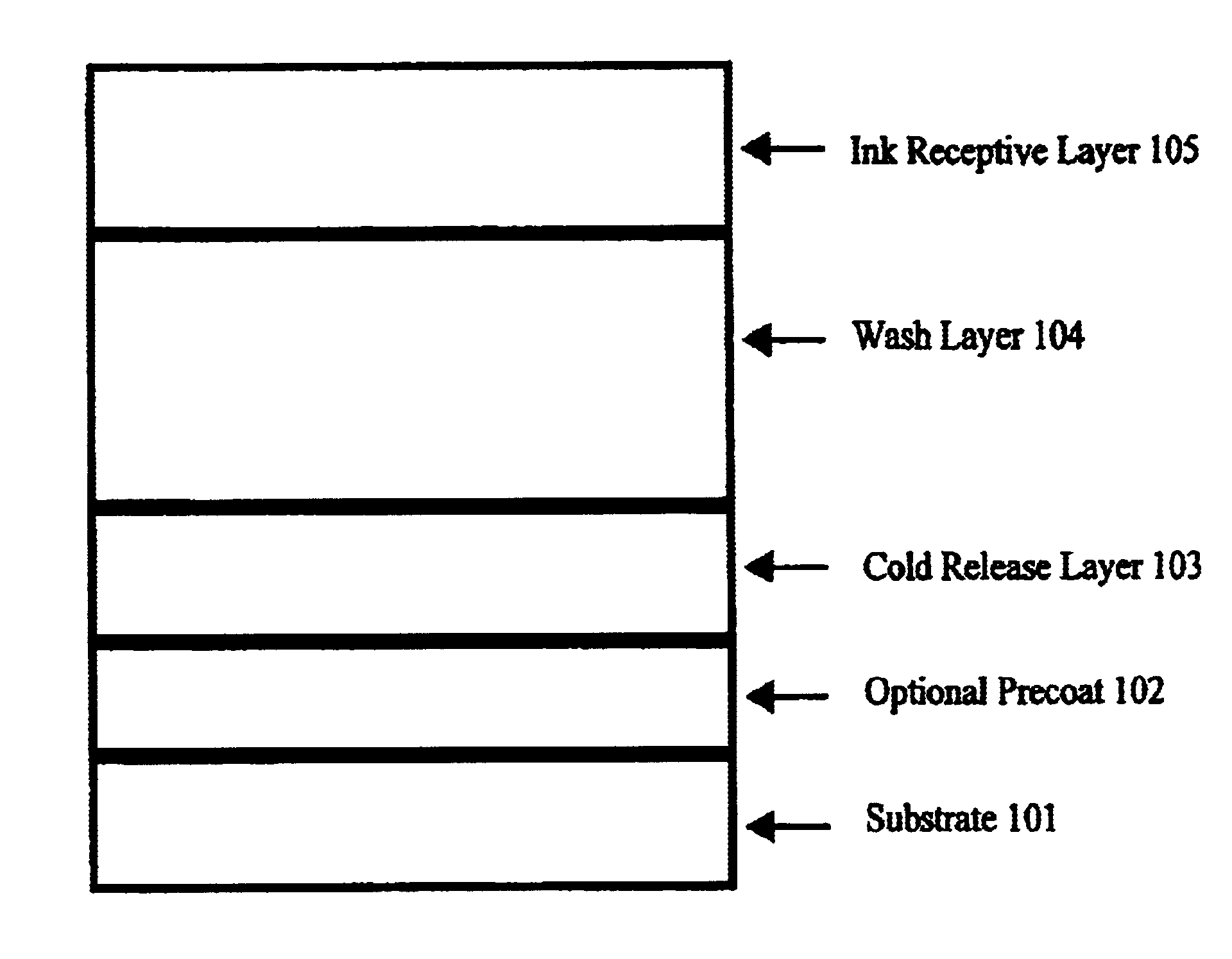

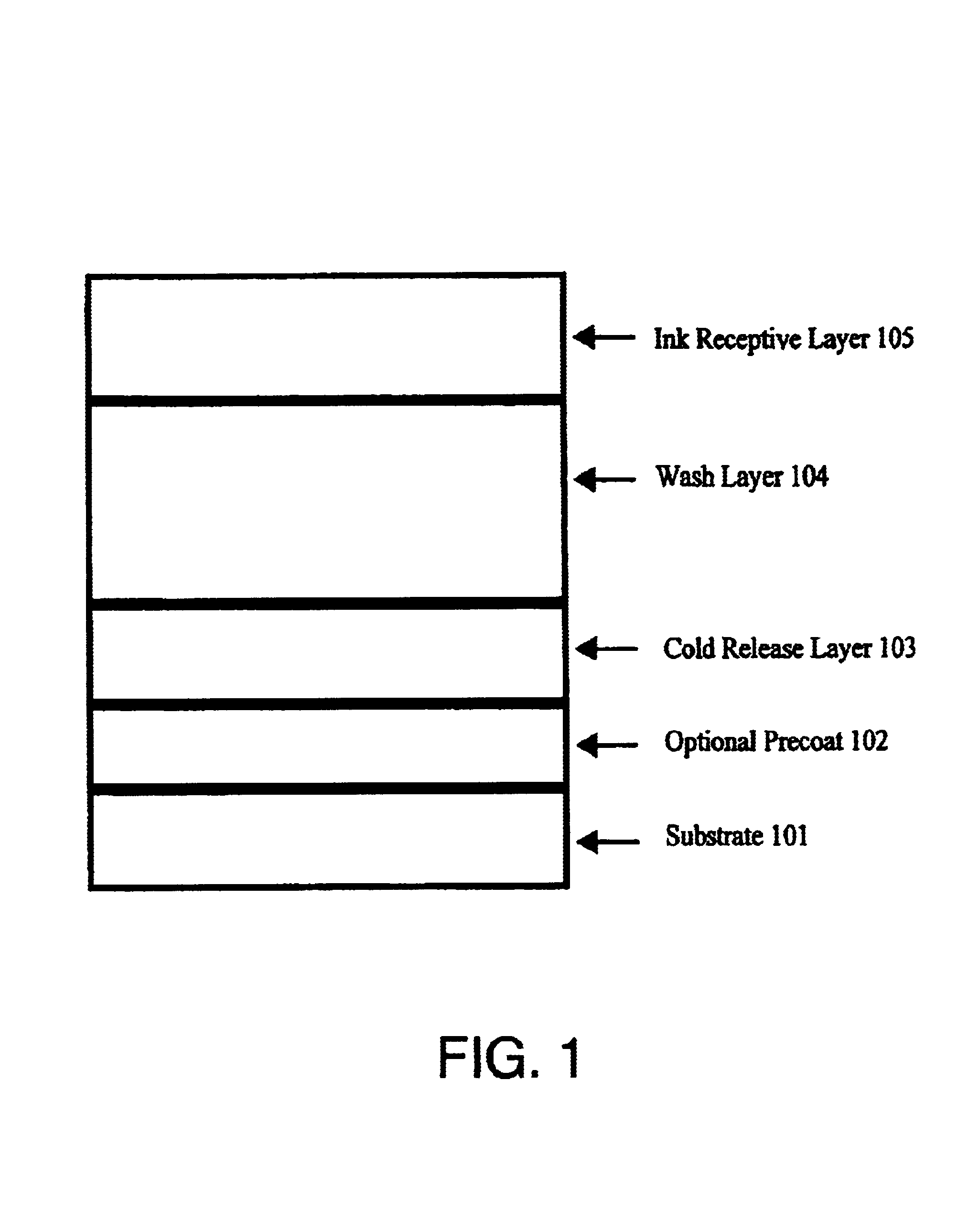

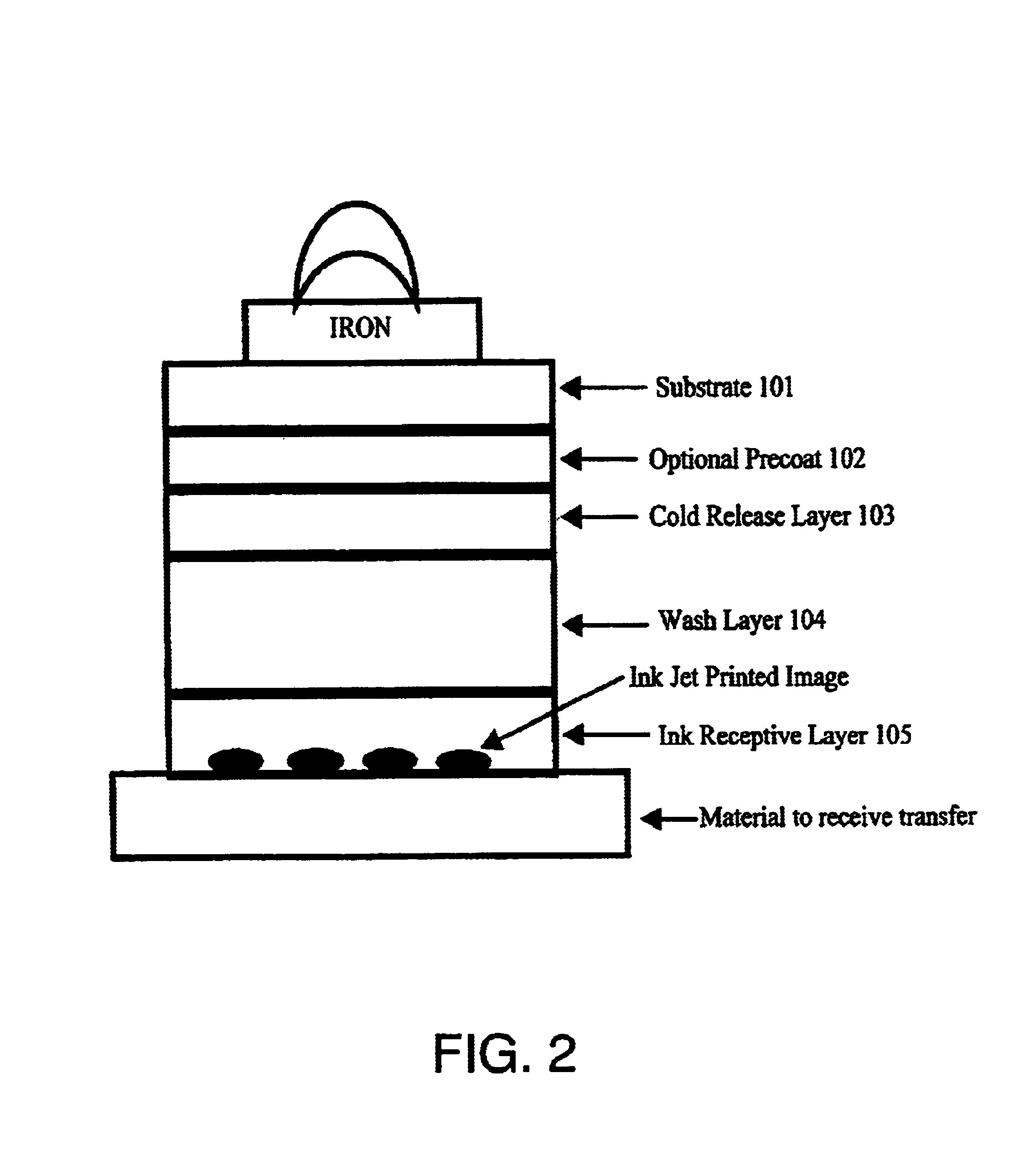

Ink jet printable heat transfer paper

InactiveUS6951671B2Quality improvementAbrasion excellentDecorative surface effectsTransfer printing processThermoplasticAntioxidant

This patent describes an ink jet printable heat transfer material with cold release properties. The invention consists of multiple layers of coatings applied to a suitable substrate, typically paper. The first optional layer coating consists typically of a pigmented coating bound together with a synthetic or natural binder and is applied in sufficient quantity to level and densify the surface of a given substrate. The second coating is applied over the first and consists of a silicone coating with a controlled surface energy. The surface energy must be such that the subsequent aqueous coatings can be applied over top with good wetting and adhesion, but low enough for an easy removal from the heat transfer after cooling. A third or wash layer is applied over the silicone release layer. This layer must easily wet and adhere to the silicone release layer so the coating does not come off during subsequent coating passes and during handling by the user. The wash layer consists of one or more thermoplastic polymers including ethylene acrylic acid, waxes, and other polymers along with dispersions of non-water soluble plasticizers and antioxidants. An ink receptive layer consists of a low binder thermoplastic organic pigmented coating containing non-water soluble plasticizers and antioxidants along with water soluble and insoluble cationic polymers and / or cationic inorganic pigments. The non-water soluble cationic materials, either organic or inorganic, aid in the retention of the dyes and reduce the wet bleed and wash out of the dyes when the transfers get wet.

Owner:P H GLATFEITER +1

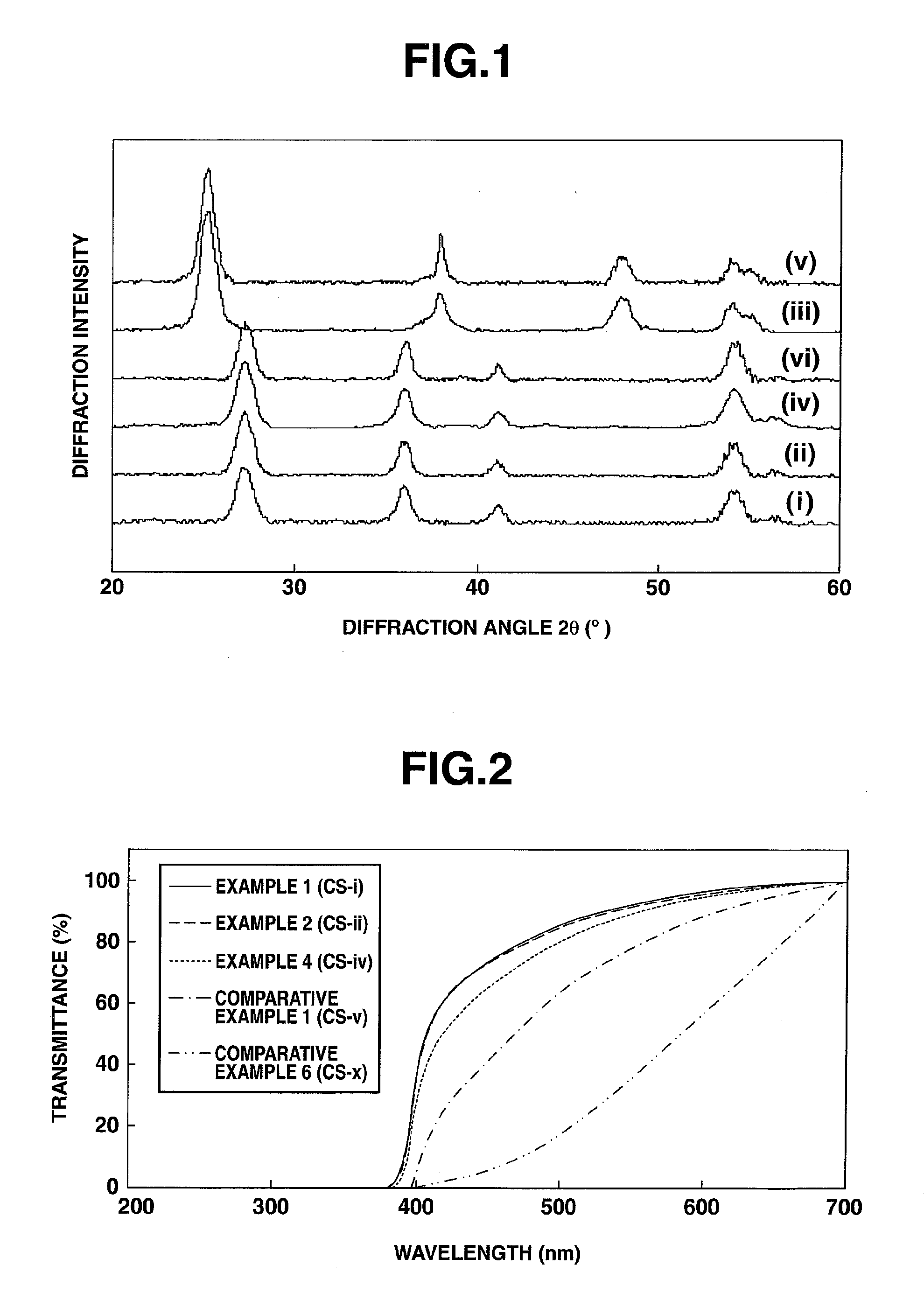

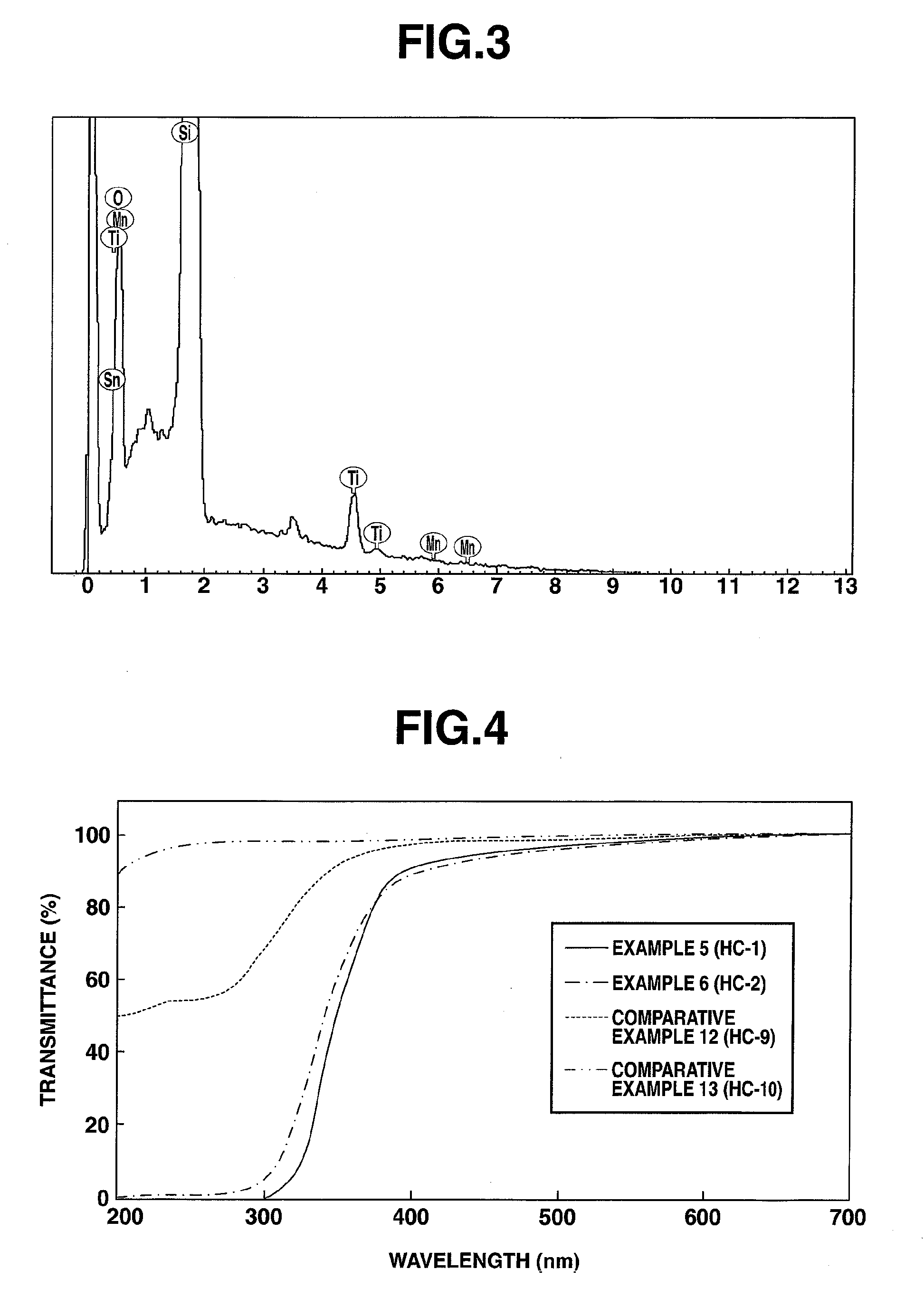

Core/shell type tetragonal titanium oxide particle water dispersion, making method, uv-shielding silicone coating composition and coated article

Core / shell type tetragonal titanium oxide particles consisting of a nanosized core of tetragonal titanium oxide having tin and manganese incorporated in solid solution and a shell of silicon oxide around the core are dispersed in an aqueous dispersing medium. The cores and the core / shell type titanium oxide particles have an average particle size of ≦30 nm and ≦50 nm, respectively. The amount of tin or manganese in solid solution is to provide a molar ratio Ti / Sn or Ti / Mn between 10 and 1,000.

Owner:SHIN ETSU CHEM IND CO LTD

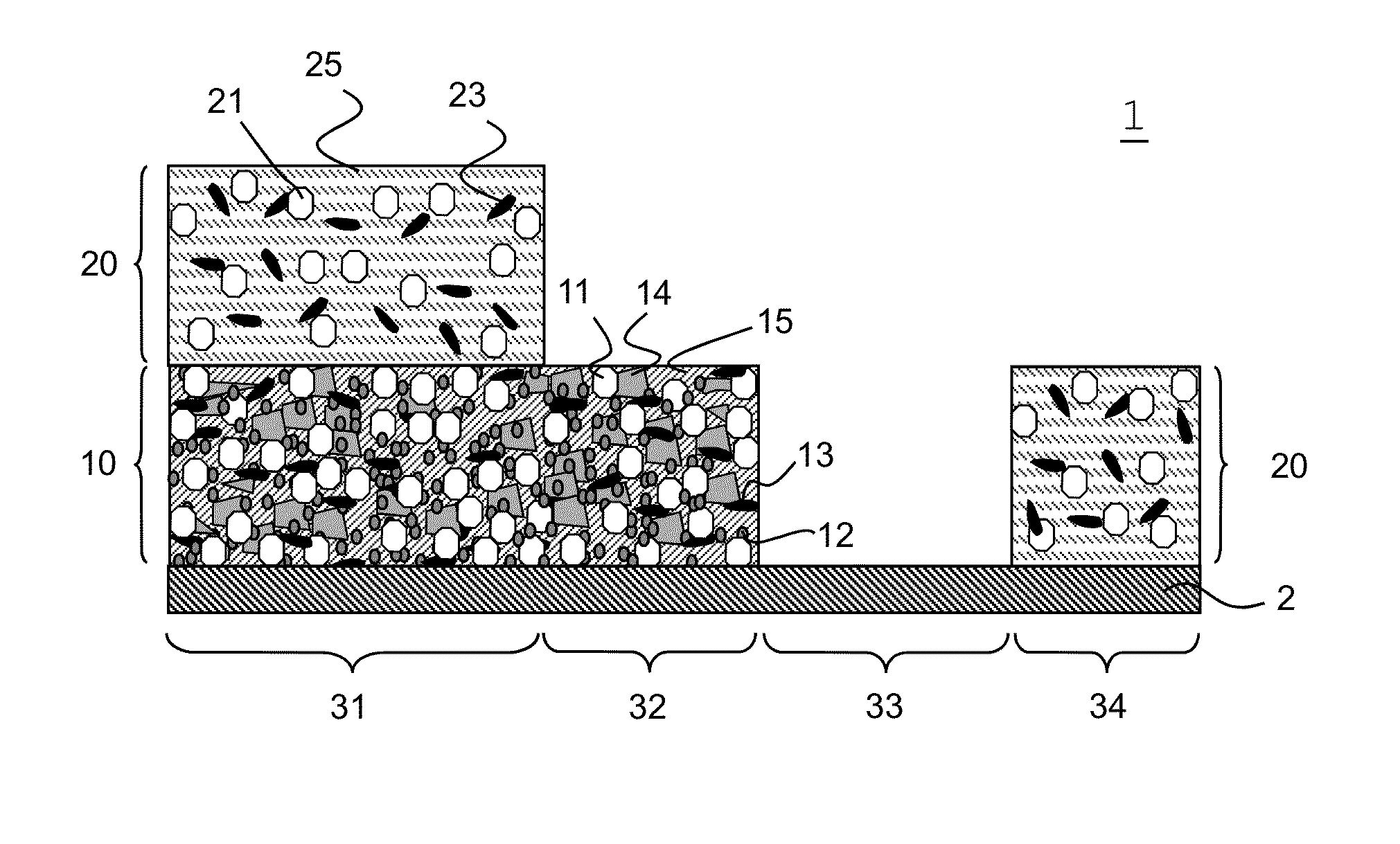

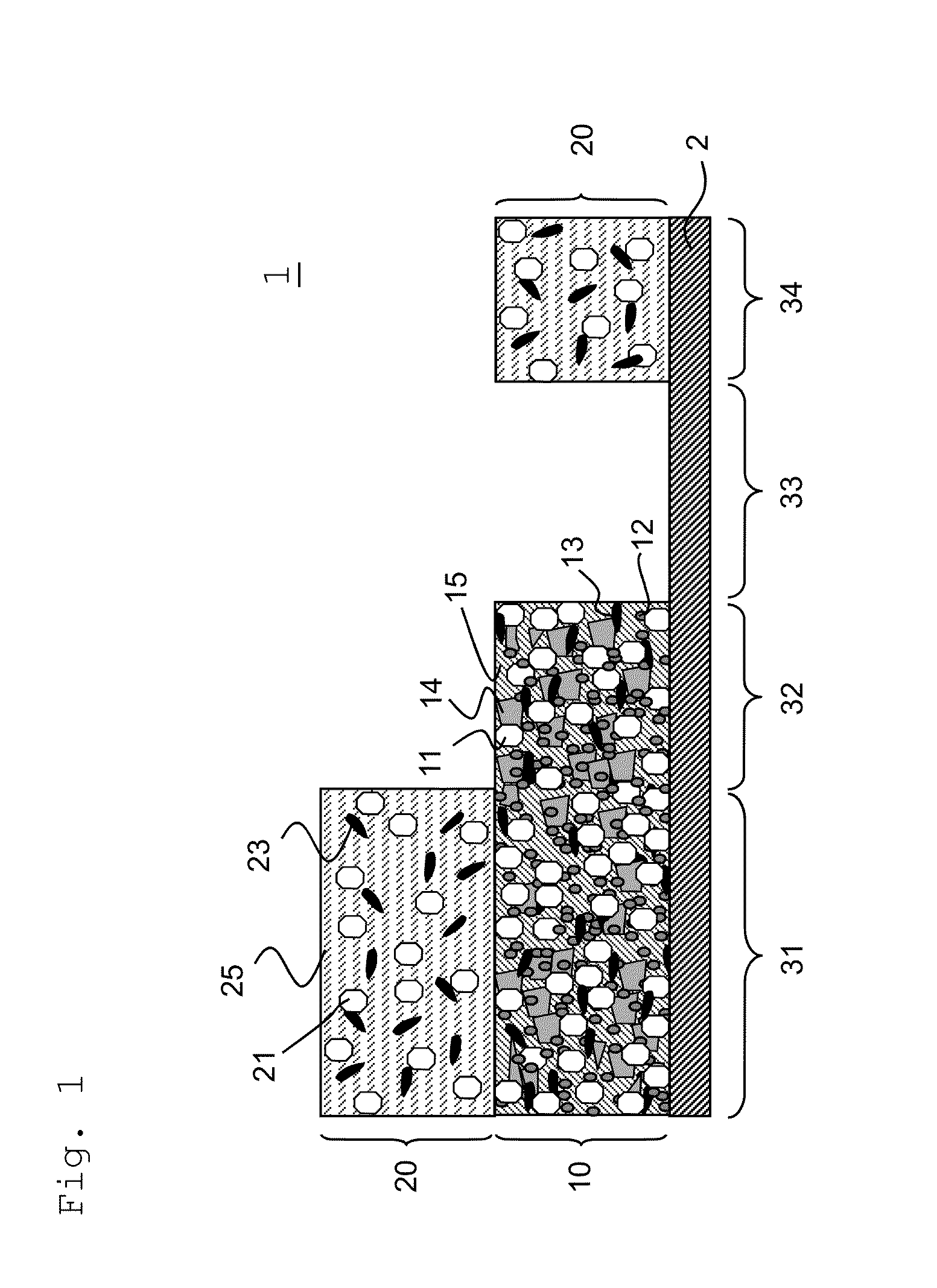

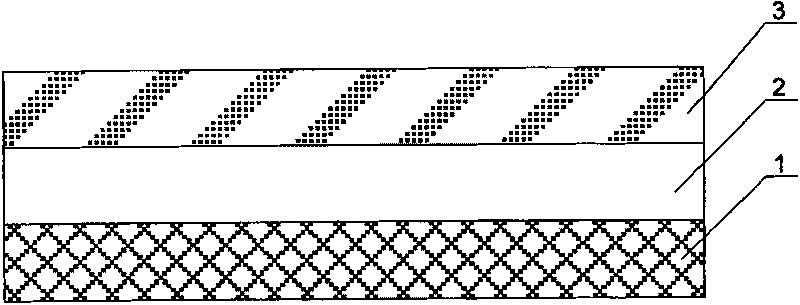

Fibrous support comprising a silicone coating

The present invention relates to a fibrous support comprising a silicone coating, consisting of at least two successive silicone-type layers. The first layer, that in contact with the fibrous support, is a layer based on an elastomeric silicone composition. The second layer, that in contact with the first layer, is a thin layer obtained by crosslinking an aqueous polyorganosiloxane emulsion crosslinkable by a polyaddition reaction, having a high filler content. The invention also relates to a process for manufacturing such coated fibrous supports, especially inflatable protective bags of the airbag type.

Owner:BLUESTAR SILICONES FRANCE SAS

Pressure sensitive ink jet media for digital printing

InactiveUS6461422B1High acceptanceHigh resolutionCosmetic preparationsStarch dervative coatingsPorous substrateCoated surface

The problems of applying ink jet inks to various known coating surfaces so as to overcome smearing, poor resolution and attack by water etc., is overcome by the use of the new ink jet receptive media. The media comprises in combination: (1) a waterproof ink jet receptive coating, (2) a primer coating, (3) a non-porous substrate, (4) a pressure sensitive adhesive coating, (5) a silicone coating and (6) a backer layer. The receptive coating comprises the combination of: (1) binder, (2) charge control agent, (3) cross-linking agent, (4) adhesion enhancing agent and (5) dispersant. The absorption of the ink jet ink to the substrate is maximized, thus attracting and fixing the ink and providing a waterproofing effect.

Owner:CHARTPAK

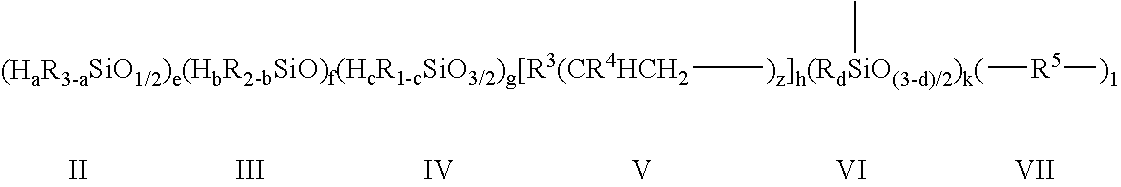

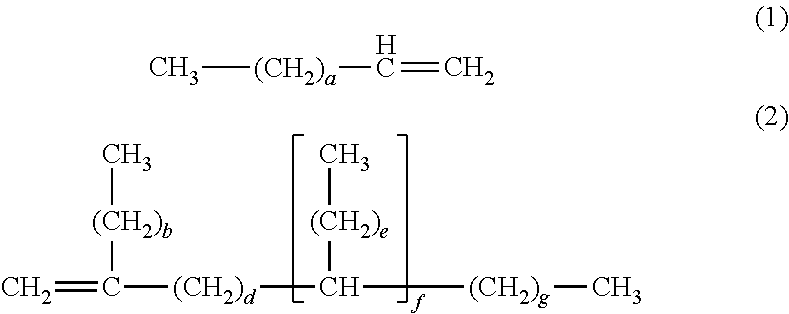

Branched siloxane polymers comprising alkenyl groups and used as antimisting additives for silicone coating compositions

Highly branched alkenyl-functional organopolysiloxane polymers are highly efficient antimisting additives for use in the preparation of silicone release coatings in high speed coating operations. The antimisting additives are miscible with the crosslinkable silicone coating components and produce storage stable compositions which can be used to provide coatings with good release properties.

Owner:WACKER CHEM GMBH

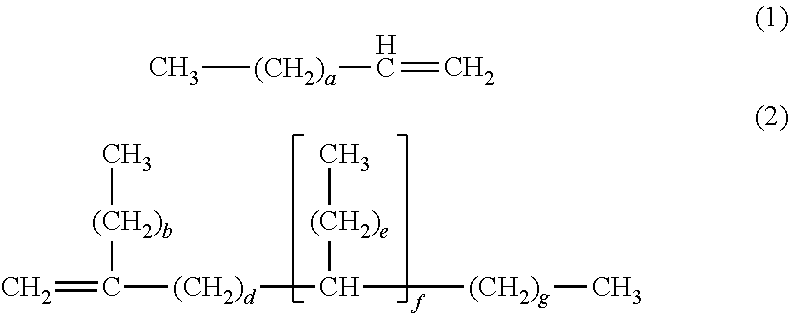

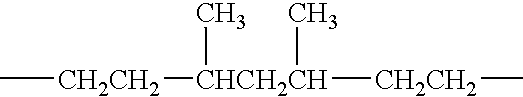

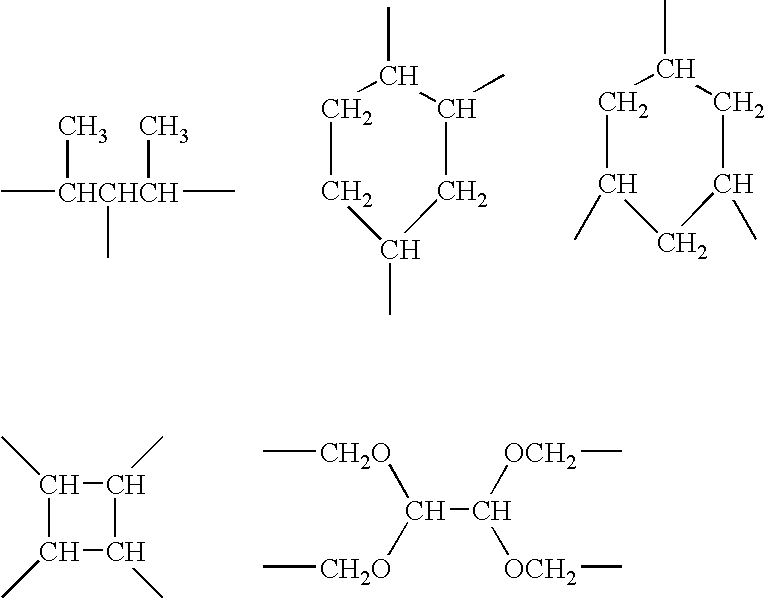

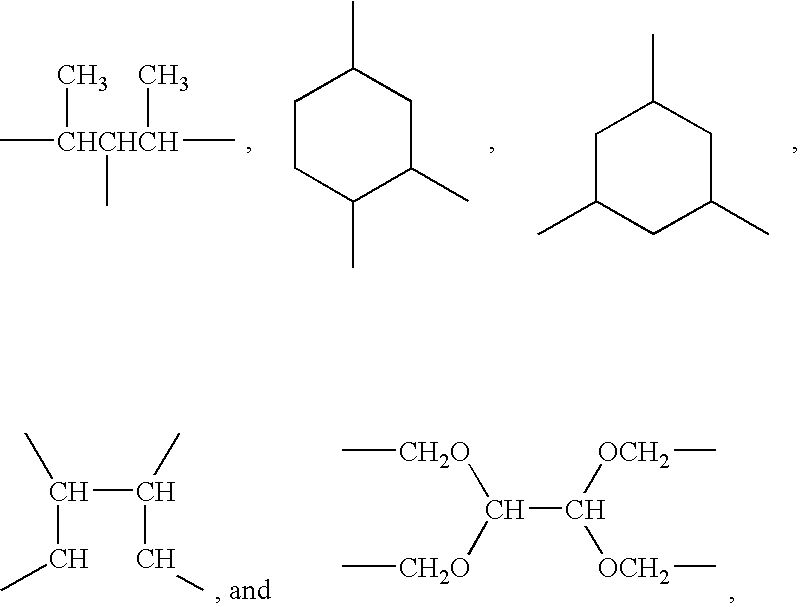

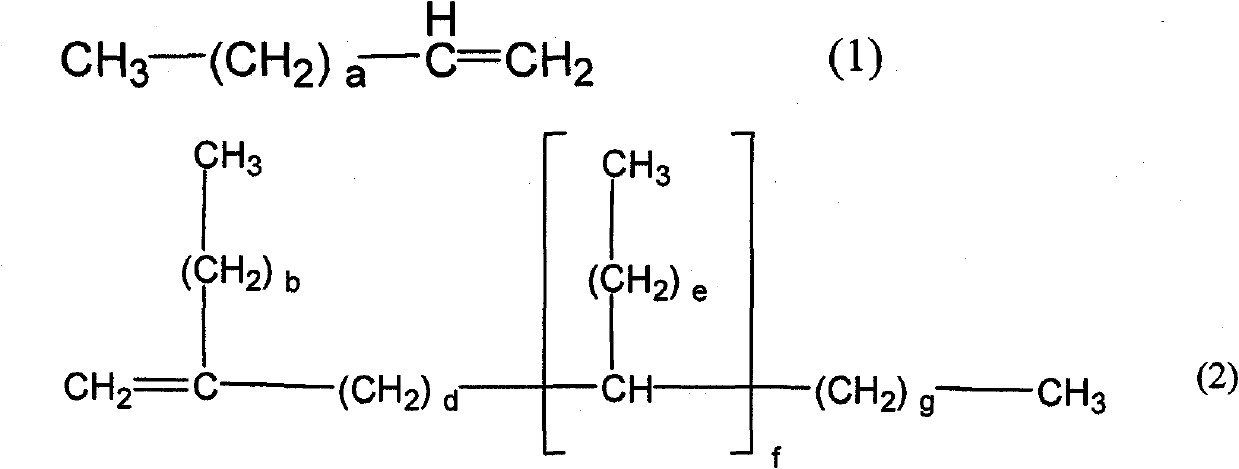

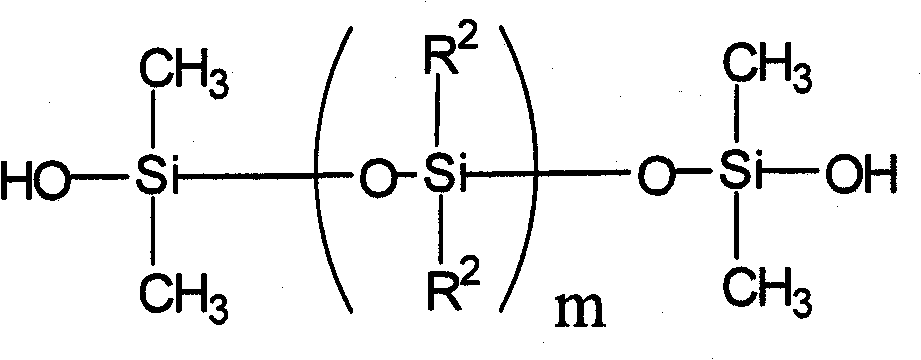

Alkenyl-functional siloxane copolymers as antimisting additives for silicone coating compositions

Antimisting additives are used in crosslinkable silicone coating compositions for reducing aerosol formation, the antimisting additives being alkenyl-functional siloxane copolymers prepared by reacting a hydrocarbon containing at least three aliphatic double bonds, and with an organosiloxane (2) having terminal Si-bonded hydrogen atoms in the presence of a hydrosilylation catalyst (3) at a ratio of Si-bonded hydrogen to aliphatic double bonds of from 1.3 to 10, and subsequently reacting the resulting SiH-containing hydrocarbon-siloxane copolymer with an α,ω-dialkenylsiloxane polymer (4) in the presence of a hydrosilylation catalyst (3) at a ratio of aliphatic double bonds to Si-bonded hydrogen of from 1.2 to 10, and optionally, in another step, equilibrating the resulting alkenyl-functional siloxane copolymers with an organopolysiloxane (5).

Owner:WACKER CHEM GMBH

Silicone coating as a sealing layer for a decoration layer

InactiveUS20130266781A1Fulfil requirementsSimple and fast productionStoves/ranges topsGlass/slag layered productsMetallurgySolid particle

A glass or glass ceramic article is provided that has a glass or glass ceramic substrate with a decorative coating. The decorative coating includes a decoration layer and a sealing layer. The decoration layer is applied to at least some surface portions of the glass or glass ceramic substrate, and the sealing layer is applied to at least portions of the decoration layer. The decoration layer is a cured sol-gel coating having inorganic solid particles, and the sealing layer is a cured silicone coating comprising inorganic solid particles. Methods for producing such glass or glass ceramic articles are also provided.

Owner:SCHOTT AG

Mar resistant surface film-forming silicone coating compositions and coated articles

InactiveUS20060083936A1Increase flexibilityHigh hardnessSynthetic resin layered productsCoatingsCrack resistancePliability

Silicone coating compositions comprising a silicone resin which is obtained by cohydrolytic condensation of (A) an organosilicon compound, and (B) an alkoxysilane and / or (C) a fluorine-containing organosilicon compound form mar resistant surface-protecting films having a hardness, flexibility, crack resistance and weather resistance.

Owner:SHIN ETSU CHEM IND CO LTD

Composite coatings for ground wall insulation in motors, method of manufacture thereof and articles derived therefrom

InactiveUS20050016658A1Windings insulation materialWindings insulation shape/form/constructionBobbinSilicone coating

An article comprises a bobbin wire; an electrically insulating backing disposed upon the bobbin wire; a mica paper disposed upon the electrically insulating backing and wound around the backing; and a silicone coating disposed upon the electrically insulating backing. A method of manufacturing an article comprises disposing an electrically insulating backing upon a bobbin wire; disposing mica paper upon the electrically insulating backing; and coating the mica paper with a silicone coating.

Owner:GENERAL ELECTRIC CO

Alkenyl-functional siloxane copolymers as antimisting additives for silicone coating compositions

Antimisting additives are used in crosslinkable silicone coating compositions for reducing aerosol formation, the antimisting additives being alkenyl-functional siloxane copolymers prepared by reacting a hydrocarbon containing at least three aliphatic double bonds, and with an organosiloxane (2) having terminal Si-bonded hydrogen atoms in the presence of a hydrosilylation catalyst (3) at a ratio of Si-bonded hydrogen to aliphatic double bonds of from 1.3 to 10, and subsequently reacting the resulting SiH-containing hydrocarbon-siloxane copolymer with an alpha,omega-dialkenylsiloxane polymer (4) in the presence of a hydrosilylation catalyst (3) at a ratio of aliphatic double bonds to Si-bonded hydrogen of from 1.2 to 10, and optionally, in another step, equilibrating the resulting alkenyl-functional siloxane copolymers with an organopolysiloxane (5).

Owner:WACKER CHEM GMBH

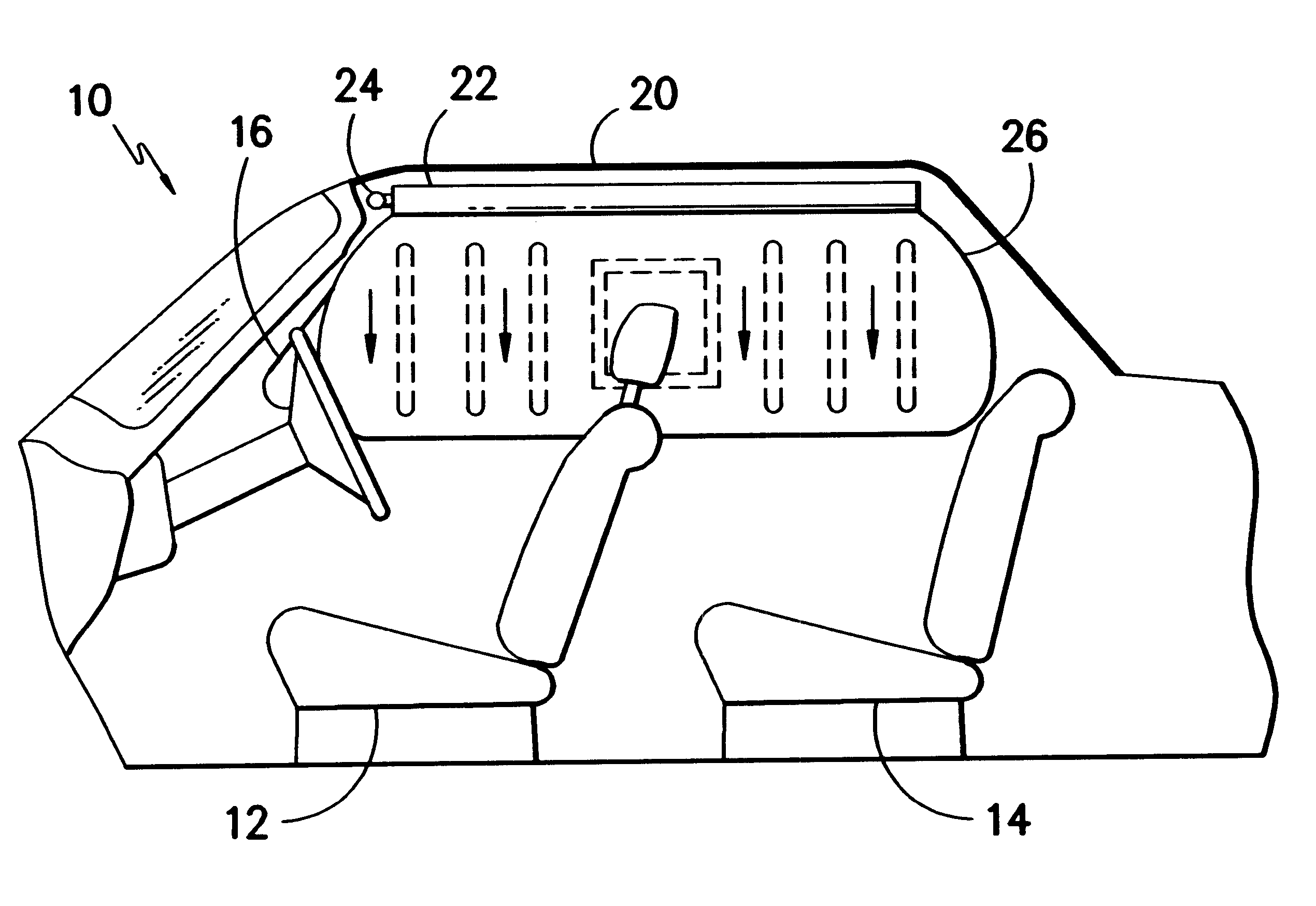

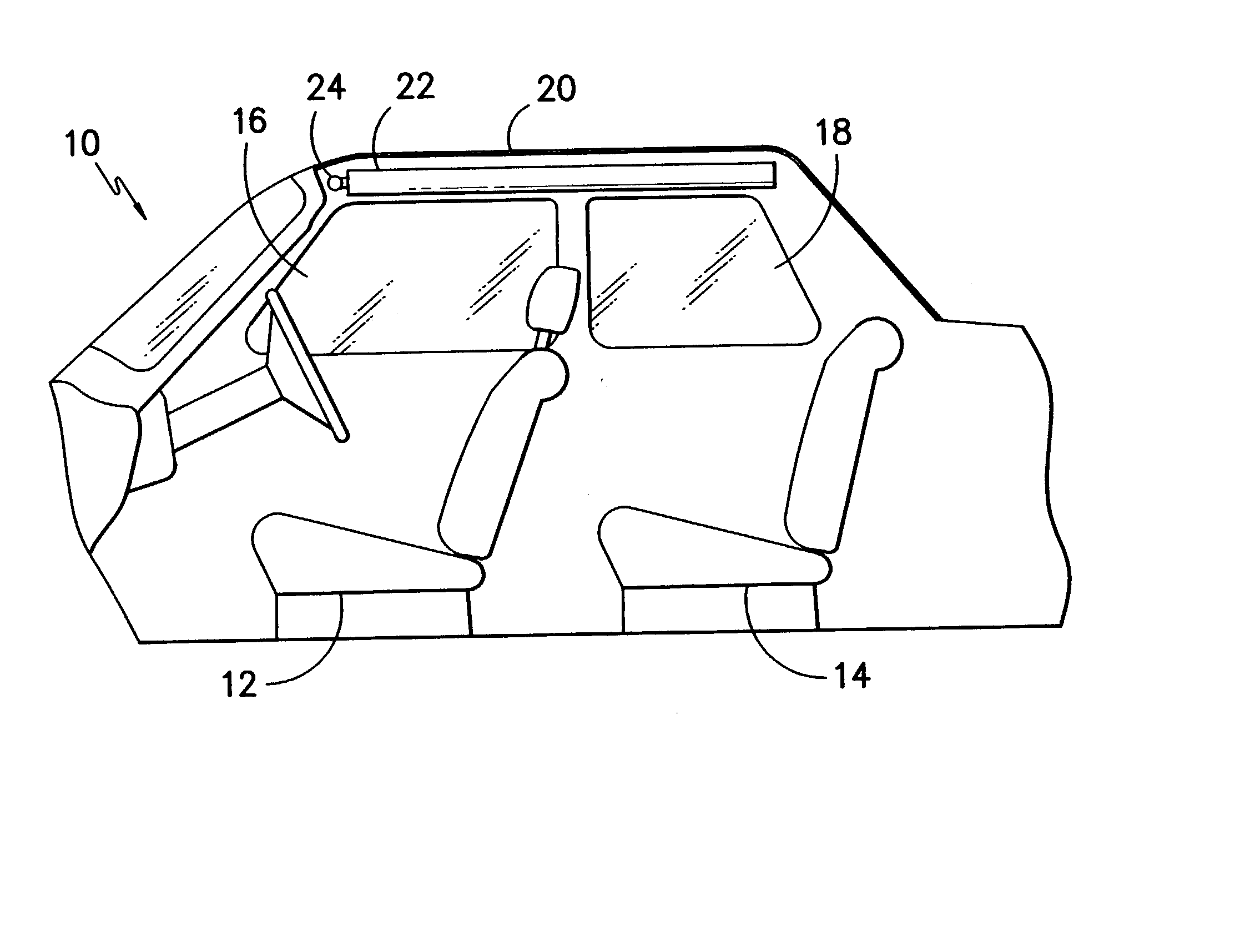

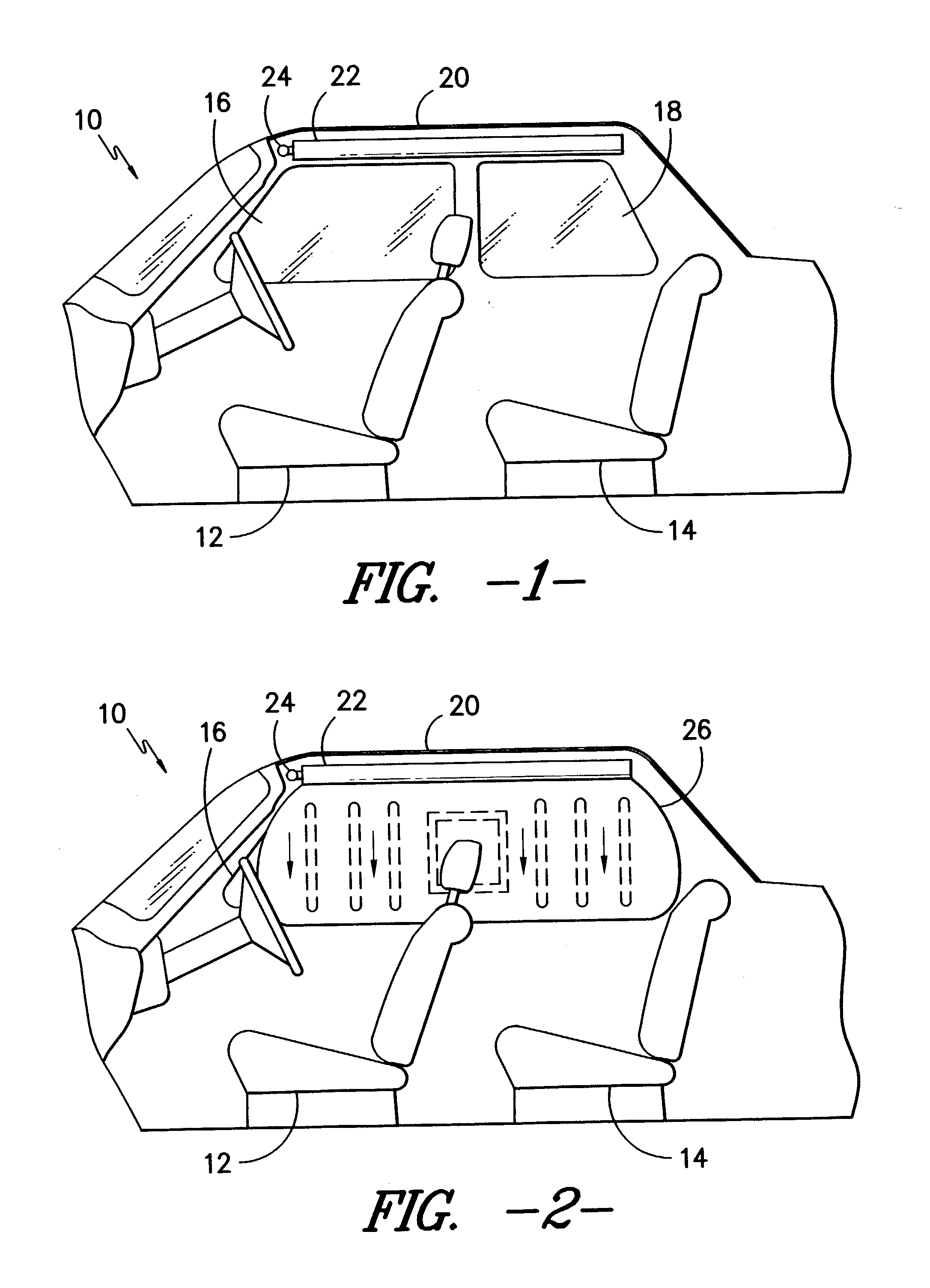

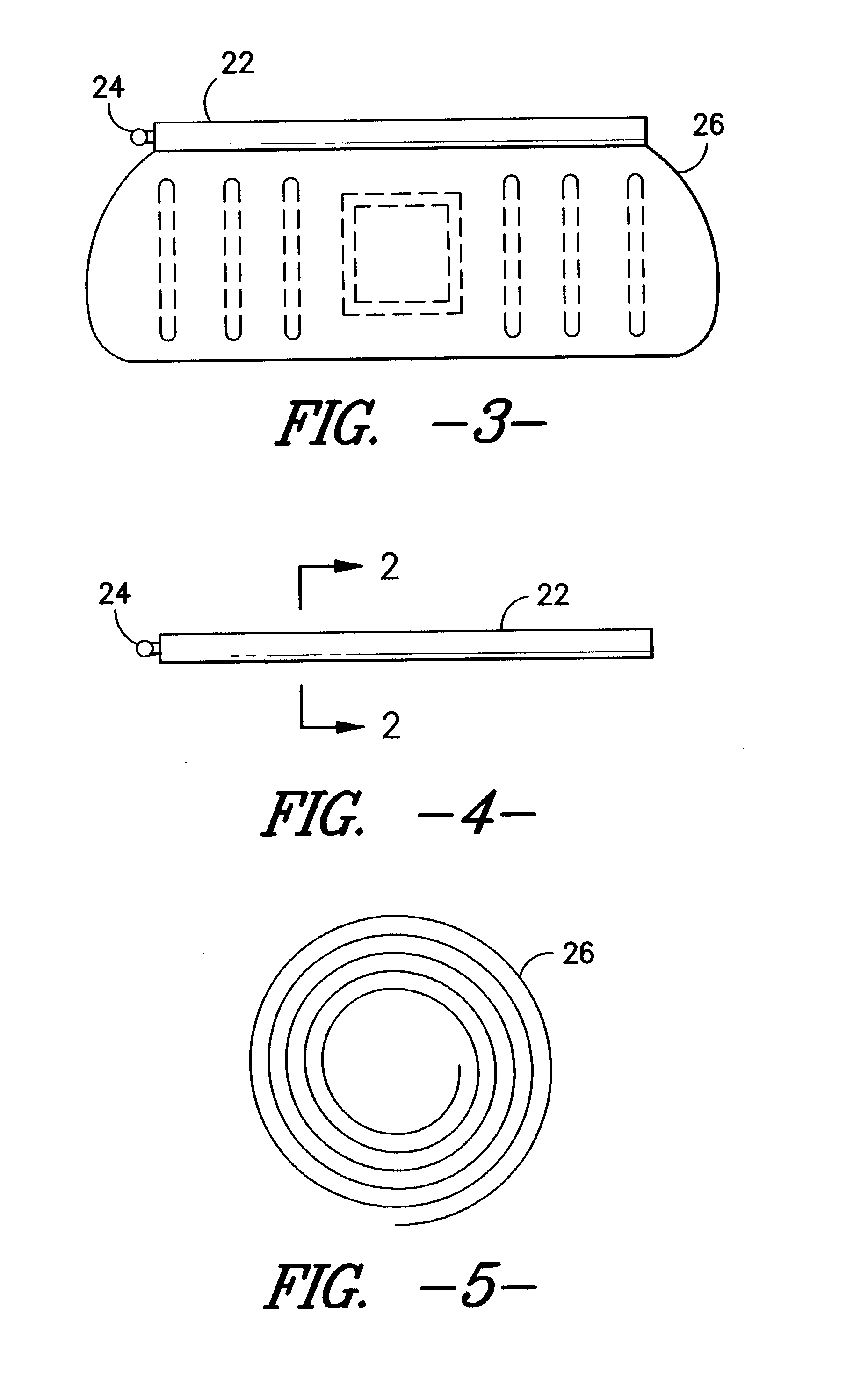

Low permeability airbag cushions having extremely low silicone-based coating levels

InactiveUS6569788B1Reduced packaging volumeHigh leak-down timePretreated surfacesPreformed elementsEngineeringNeoprene

Coated inflatable fabrics and more particularly concerns airbag cushions to which very low add-on amounts of silicone-based coating have been applied and which exhibit extremely low air permeability are provided. The inventive inflatable fabrics are primarily for use in automotive restraint cushions that require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones, and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin, substantially uniform silicone coating to provide such necessarily low permeability levels. Thus, the inventive coating comprises at least a single layer comprising a majority of silicone-based material, wherein the total thickness of the single layer is at most about 3.0 ounces per square yard as applied to a target fabric surface. The inventive airbag exhibits a characteristically long leak-down rate as compared to other coated airbags.

Owner:MILLIKEN & CO

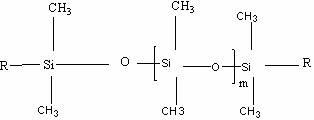

Release modifier and release coating organopolysiloxane composition

ActiveCN102089356APromote migrationExcellent peeling propertiesCoatingsThin material handlingAlkoxy groupSilicone coating

To provide a release modifier which provides a heavy release force to a cured release layer of silicone coating composition. The release modifier comprises an organopolysiloxane resin-organopolysiloxane condensation reaction product that is obtained by the condensation reaction of (a1) 100 weight parts of MQ-type organopolysiloxane resin in which the molar ratio of the M unit to the Q unit is 0.6 to 1.0 and the content of the hydroxyl group or alkoxy group is 0.3 to 2.0 weight% with (a2) 20 to 150 weight parts of chain-form diorganopolysiloxane that has an average degree of polymerization of 100 to 1000 and at least one hydroxyl group or alkoxy group; this organopolysiloxane resin-organopolysiloxane condensation reaction product preferably has a prescribed hydroxyl group content.

Owner:DOW CORNING TORAY CO LTD

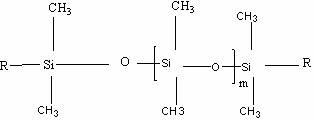

Terminal modified organic silicone coating flatting agent and preparation method thereof

The invention relates to a coating flatting agent, in particular to a preparation of polyether terminal modified polydimethylsiloxane and an application of the polyether terminal modified polydimethylsiloxane serving as the flatting agent in coatings. The structural formula of a terminal modified organic silicone coating flatting agent is shown as follows, wherein m is equal to 0-100; and R is equal to - (CH2) 3-O-(C2H4O) x (C3H6O) y-R', wherein the x is equal to 0-100, the y is equal to 0-100, and R' is hydrogen (H) or alkyl, acetoxy group and epoxy group with one to ten carbon atoms. The flatting agent has the advantages that the surface tension of the coatings is reduced, the wettability of substrates is improved, the flowing and flatting of the coatings are increased, the surface defects are eliminated, the smoothness is improved, the surface friction coefficient of the coatings is lowered, and the scrath resistance and anti-blocking are improved.

Owner:RUNHE ORGANICSILICONE NEW MATERIAL

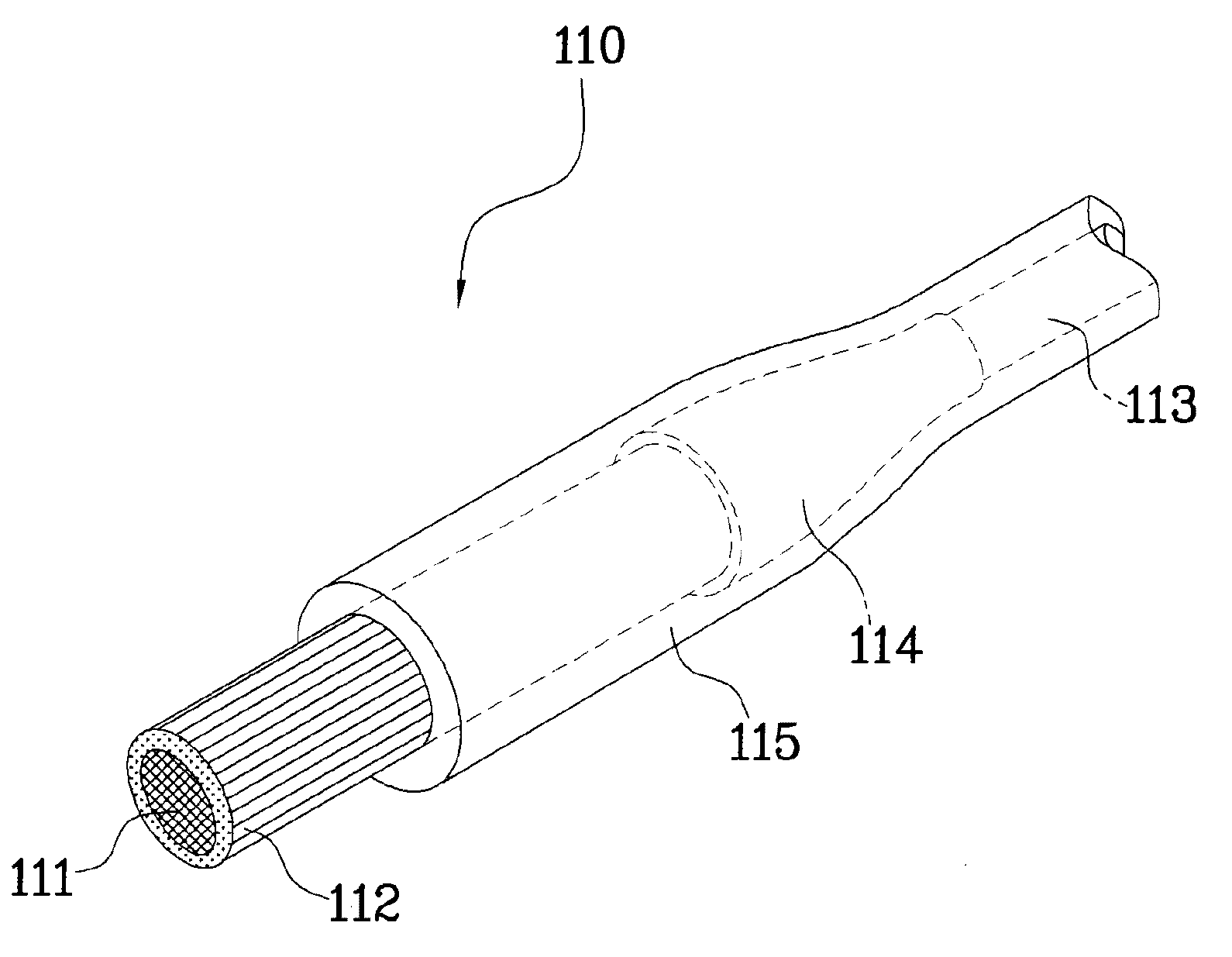

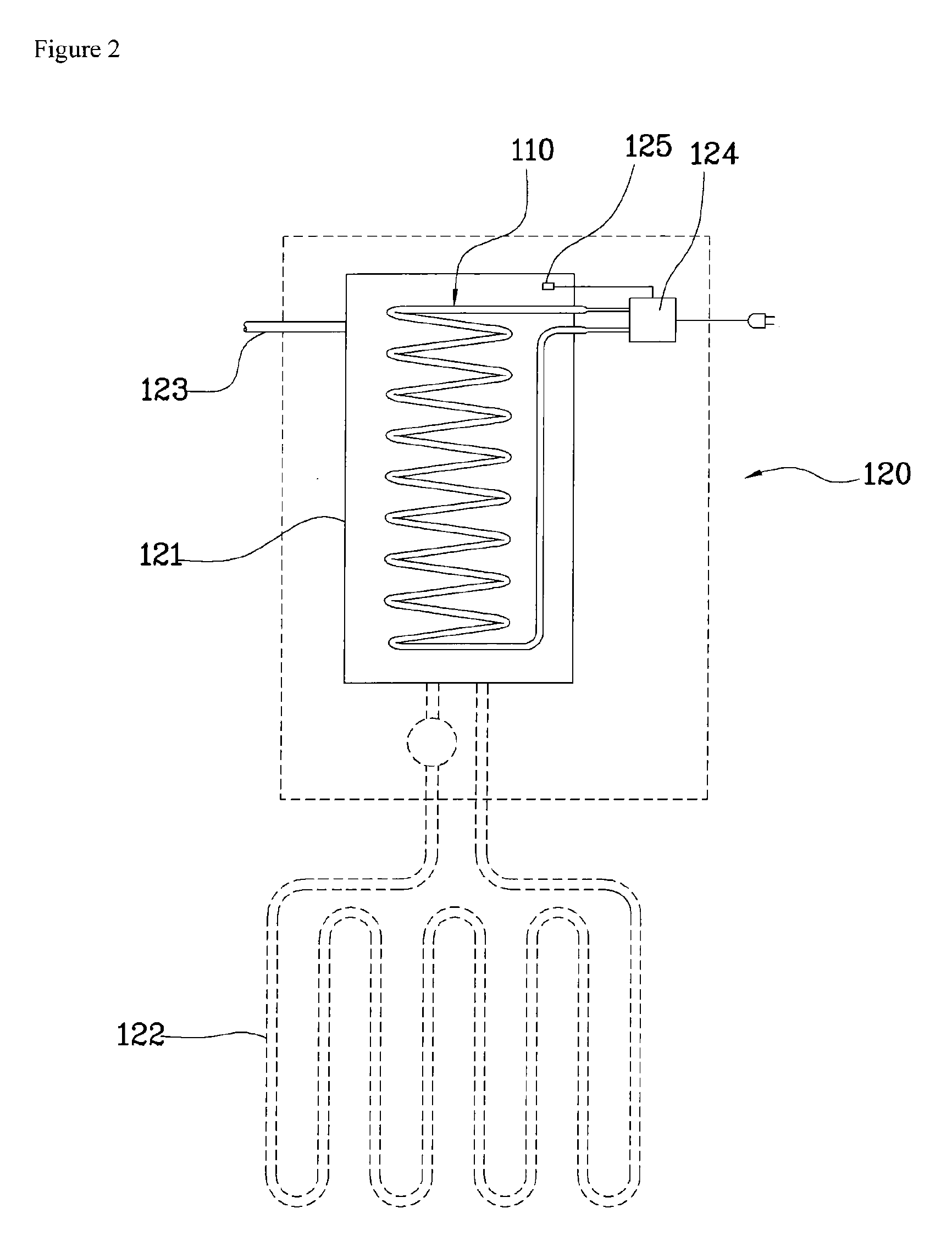

Carbon fiber heating source and heating system using the same

InactiveUS20100282458A1High tensile strengthReduce power consumptionElectric heating systemEnergy efficient heating/coolingGlass fiberFiber

A carbon fiber heating source includes a bundle of carbon fibers combined with glass fibers. The bundle is surrounded with a silicone coating layer and has high tensile strength responsive to bending and tension while emitting heat at high temperature. The carbon fiber heat emitting source includes heat emitting fibers formed by combining carbon fibers with glass fibers. Connection terminals are formed at both ends of the heat emitting fibers so that electricity can be applied thereto. A coating member coats the surfaces of the heat emitting fibers and the connection terminals. The coating member may be a silicone coating layer formed on the heat emitting fibers and the connection terminals. The coating member may be a quartz pipe that is filled with LPG and hydrogen and receives and seals the heat emitting fibers such that only a portion of the connection terminals is exposed from the both ends.

Owner:ECO CARBON ENERGY

Low permeability airbag cushions having extremely low silicone-based coating levels

InactiveUS20030124929A1High leak-down timeReduce penetrationLayered productsPedestrian/occupant safety arrangementNeopreneEngineering

Coated inflatable fabrics and more particularly concerns airbag cushions to which very low add-on amounts of silicone-based coating have been applied and which exhibit extremely low air permeability are provided. The inventive inflatable fabrics are primarily for use in automotive restraint cushions that require low permeability characteristics (such as side curtain airbags). Traditionally, heavy, and thus expensive, coatings of compounds such as neoprene, silicones, and the like, have been utilized to provide such required low permeability. The inventive fabric utilizes an inexpensive, very thin, substantially uniform silicone coating to provide such necessarily low permeability levels. Thus, the inventive coating comprises at least a single layer comprising a majority of silicone-based material, wherein the total thickness of the single layer is at most about 3.0 ounces per square yard as applied to a target fabric surface. The inventive airbag exhibits a characteristically long leak-down rate as compared to other coated airbags.

Owner:PIONEER HI BRED INT INC

Production technology of medical fabric

ActiveCN107299540ASoft touchImprove tear resistanceMedical preparationsCoatingsEngineeringResin coating

The invention discloses a production technology of a medical fabric. The technology comprises the following steps of grey fabric weaving, desizing, drying, splashing and sizing, calendering treatment, and coating of a double-sided coating, wherein the calendered surface of the fabric is coated with a PU resin coating with water pressure resistance; the PU resin coating is divided into a PU polyether two-component base material and a PU one-component fabric for separate coating; after the calendered surface is coated, the fabric is dried through high-temperature oven until being rolled up, and the other side of the fabric is coated with an organic silicone coating, and high-temperature drying is carried out to obtain the medical fabric. The tissue style characteristics of the woven fabric are integrated, and coating finishing is carried out on the front and reverse sides of the fabric, so that the fabric has the characteristics of being waterproof, easy to decontaminate and high in tenacity, and the production technology is suitable for the medical fabric.

Owner:HUAMAO (XIAMEN) WEAVING DYEING & FINISHING CO LTD

Superconductivity copper foil tape

The invention provides a superconductivity copper foil tape, which has good ultra-high conductivity and direct welding capacity, is applied to key parts of ultra-precision electrical and electronic components, and is not easily oxidized. The superconductivity copper foil tape is characterized in that a conductive self-adhesive layer is attached on the upper surface of anti-sticking silicone-coating oil paper, and tin-plated copper foil is attached on the upper surface of the conductive self-adhesive layer. The copper foil tape which is coated with a conducive adhesive with ultra-low resistance leads the copper foil to be convenient to be bended and crimped, has ultra-high conductivity and direct welding capacity, is not easily cracked, and is suitable for electronic components and punching type processing.

Owner:东莞市富邦科技应用材料有限公司

Release Modifier And Release Coating Organopolysiloxane Composition

ActiveUS20110160376A1Heavy release propertyLow viscosityCoatingsThin material handlingAlkoxy groupSilicone coating

To provide a release modifier which provides a heavy release force to a cured release layer of silicone coating composition. The release modifier comprises an organopolysiloxane resin-organopolysiloxane condensation reaction product that is obtained by the condensation reaction of (a1) 100 weight parts of MQ-type organopolysiloxane resin in which the molar ratio of the M unit to the Q unit is 0.6 to 1.0 and the content of the hydroxyl group or alkoxy group is 0.3 to 2.0 weight % with (a2) 20 to 150 weight parts of chain-form diorganopolysiloxane that has an average degree of polymerization of 100 to 1000 and at least one hydroxyl group or alkoxy group; this organopolysiloxane resin-organopolysiloxane condensation reaction product preferably has a prescribed hydroxyl group content.

Owner:DOW TORAY CO LTD

Process For The Production Of Silicone Coatings and Silicone Moldings From Photocrosslinkable Silicone Mixtures

Silicone coatings and moldings are produced from a photocrosslinkable silicone mixture which contains(A) a polyorganosiloxane containing at least two carbon-carbon multiple bonds,(B) an organosilicon compound containing at least two SiH functions, and(C) a cyclopentadienyl-platinum complex catalyst be activatable by light of 200 to 500 nm,wherein the mixture is heated to 40° C. to 250° C., and then irradiated with light of 200 to 500 nm wavelength.

Owner:WACKER CHEM GMBH

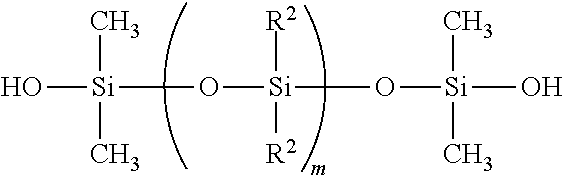

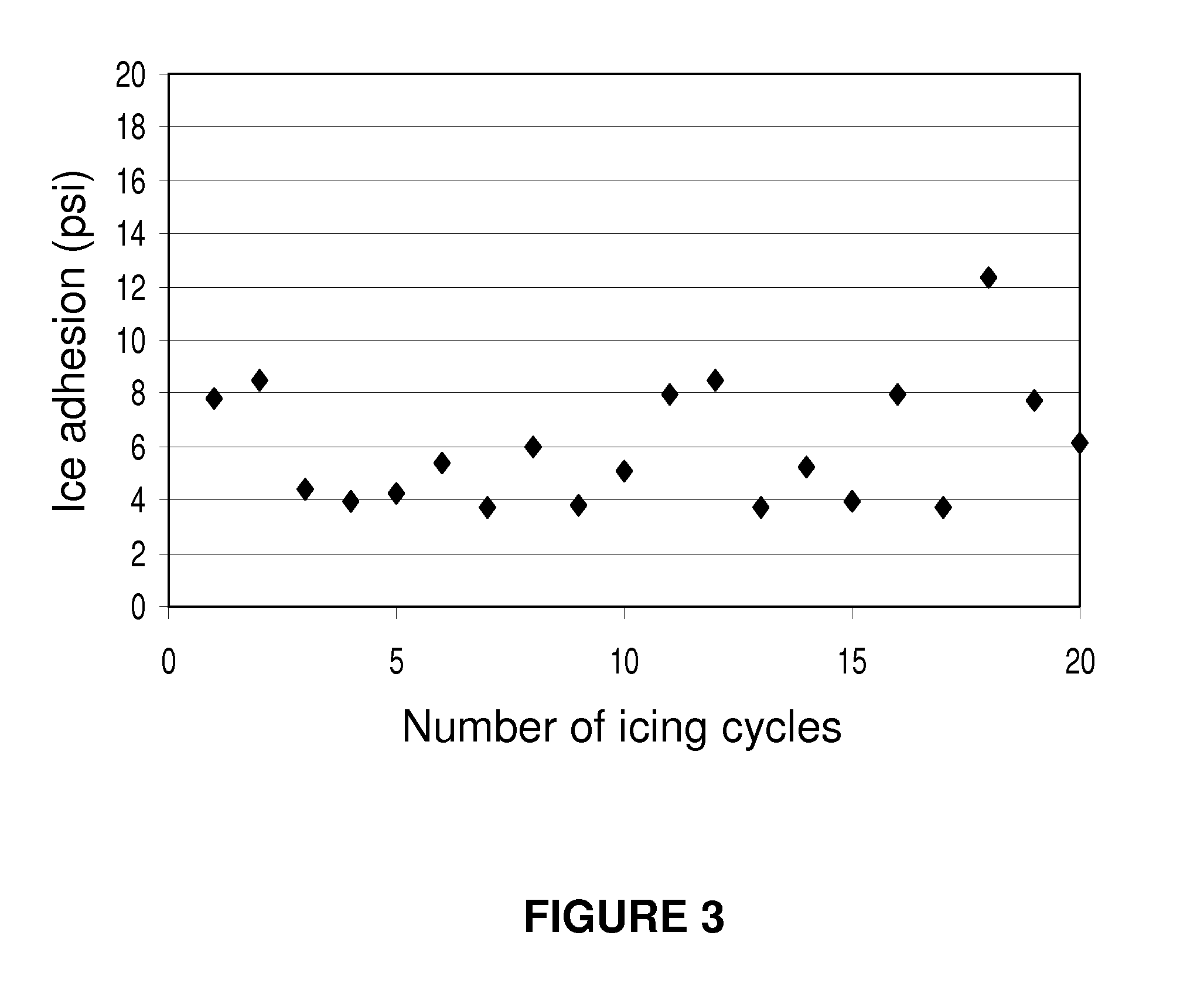

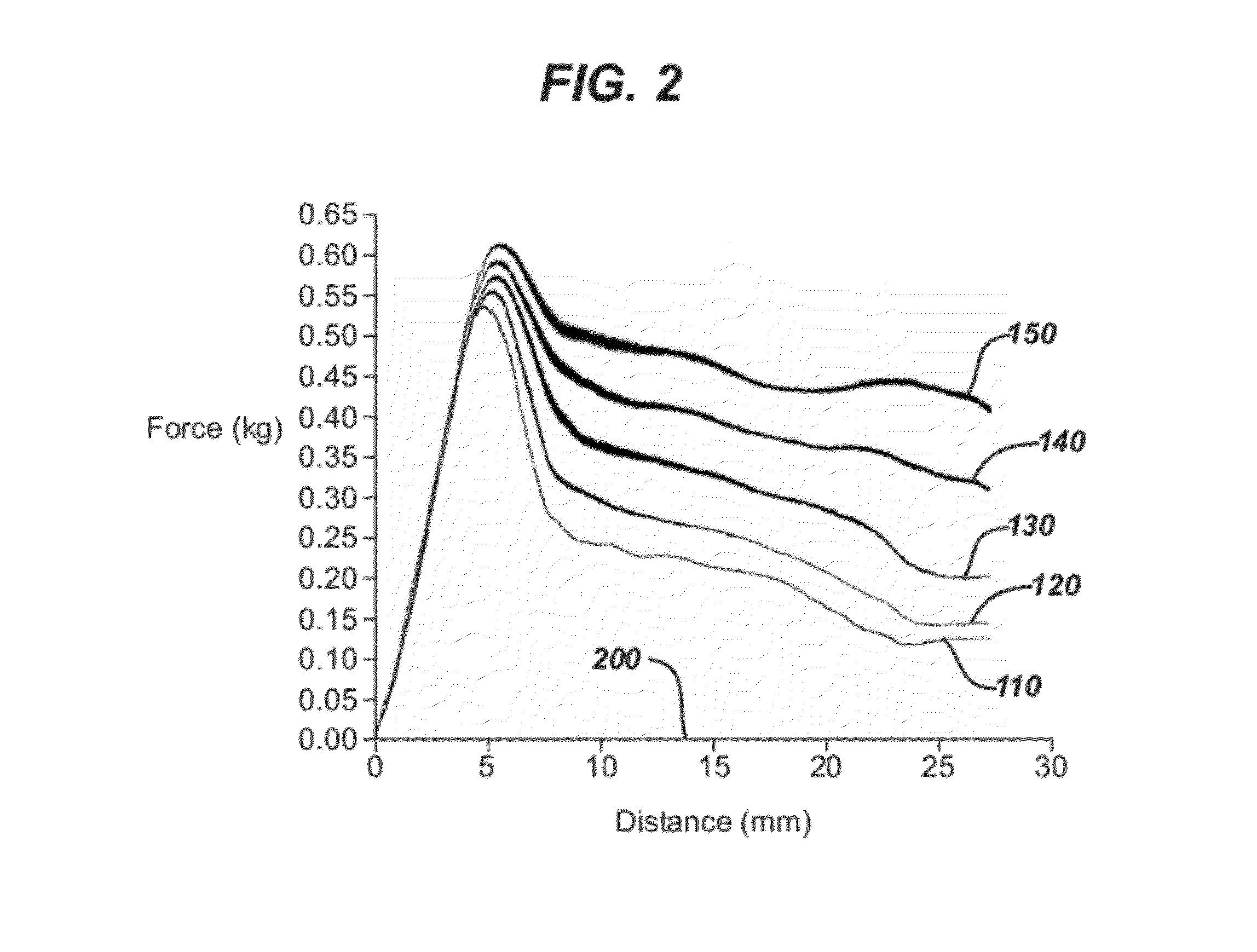

Articles comprising a weather resistant silicone coating

InactiveUS20110143148A1Reduced adhesion strengthResistant to harsh environmentsPlastic/resin/waxes insulatorsLayered productsSilyleneRoom temperature

An article comprises a weatherable surface exposed to precipitation or airborne debris; and a weather resistant coating disposed on the weatherable surface, wherein the coating comprises component A, a one- or two-part room temperature vulcanizable polyorganosiloxane composition; and component B, an ice release-enhancing proportion of at least one polyorganosiloxane comprising one or more silanol or alkoxy-silyl groups and comprising from about 10 weight percent to about 85 weight percent of at least one hydroxy-terminated or alkoxy-terminated polyoxyalkylenealkyl radical; and any reaction products thereof. In another embodiment, an article comprises a weatherable surface exposed to precipitation or airborne debris; and a weather resistant coating disposed on the weatherable surface, wherein the coating includes a one- or two-part addition curable polyorganosiloxane composition comprising a resin polymer and a crosslinker, wherein the resin polymer and / or crosslinker comprises an ice release-enhancing proportion of covalently bound hydrophilic functionality that contributes from about 0.5 weight percent to about 40 weight percent of the coating composition; and any reaction products thereof.

Owner:GENERAL ELECTRIC CO +1

Process for anodically coating an aluminum substrate with ceramic oxides prior to polytetrafluoroethylene or silicone coating

An article of manufacture and a process for making the article by the anodization of aluminum and aluminum alloy workpieces to provide corrosion-, heat- and abrasion-resistant ceramic coatings comprising titanium and / or zirconium oxides, and the subsequent coating of the anodized workpiece with polytetrafluoroethylene (“PTFE”) or silicone containing coatings. The invention is especially useful for forming longer life PTFE coatings on aluminum substrates by pre-coating the substrate with an anodized layer of titanium and / or zirconium oxide that provides excellent corrosion-, heat- and abrasion-resistance in a hard yet flexible film.

Owner:HENKEL KGAA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com