Release modifier and release coating organopolysiloxane composition

A technology of polysiloxane and polysiloxane resin, which is applied in coating, transportation and packaging, and thin material processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0123] Hereinafter, the present invention will be specifically described using examples and comparative examples; however, the present invention is not limited to the following examples. In the following examples, parts mean parts by weight in all cases and viscosities are values measured at 25°C. In each formula, M is represented by (CH 3 ) 3 SiO 1 / 2 or (CH 3 ) 2 (OH)SiO 1 / 2 Monofunctional siloxane unit represented by; M Vi Because (CH 3 ) 2 (CH 2 =CH)SiO 1 / 2 Monofunctional siloxane unit represented by; M OH by (CH 3 ) 2 (OH)SiO 1 / 2 Represented monofunctional siloxane unit; D is represented by (CH 3 ) 2 SiO 1 / 2 A difunctional siloxane unit represented by ; and Q is composed of SiO 2 Represented tetrafunctional siloxane units. The following methods were used to evaluate the curing rate of the organopolysiloxane composition forming a release coating, the adhesion of the cured coating formed from the composition to the substrate, and the performance of the cu...

Synthetic example 1

[0137] [Manufacture of peeling improver (1)]

[0138] The following materials were fed into a 2-liter separable flask equipped with a thermometer, condenser and stirrer, and stirred for 30 minutes.

[0139] (a1-1) Methyl polysiloxane resin:

[0140] m 0.74 Q 1 (OH content = 0.74%) 300g

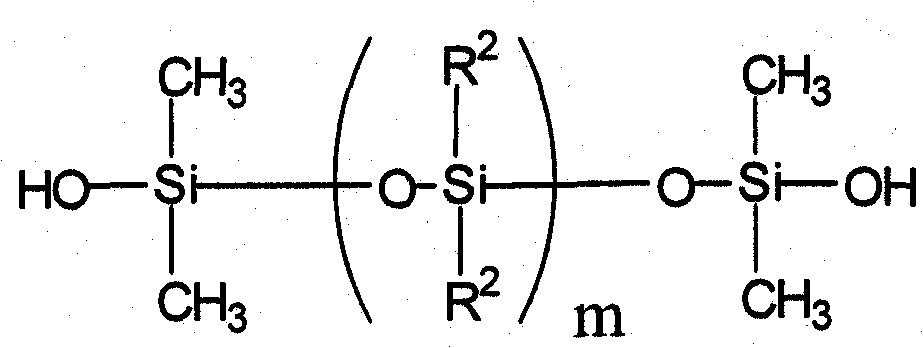

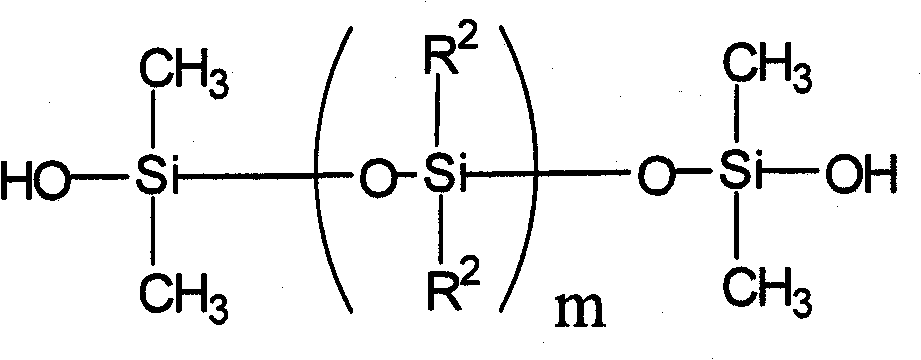

[0141] (a2-1) Linear dimethylpolysiloxane with chain terminated by hydroxydimethylsiloxy groups at both ends of the molecular chain:

[0142] m OH D. 330 m OH 128g

[0143] Xylene 444g

[0144] After the raw materials were mixed until uniform, the temperature was raised to 40° C.; 5 g of 28% ammonia solution (a3) was added; and the reaction was carried out for about 5 hours. Thereafter a water trap is installed; the temperature is raised to 140°C; condensed water and ammonia are removed over 2 hours; subsequent cooling to room temperature produces a peel modifier comprising a methylpolysiloxane resin-dimethylpolysiloxane condensate (1) xylene solution. ...

Synthetic example 2

[0147] [Manufacture of peeling improver (2)]

[0148] By producing in the same manner as the peeling modifier Synthesis Example 1, but in this case using 256 g as the component (a2-1) in Synthesis Example 1 (ie, M OH D. 330 m OH ), thereby obtaining a xylene solution of the stripping modifier (2). In addition, in order to adjust the viscosity, 556 g of linear dimethyl polysiloxane (M Vi D. 60 m Vi ) was added to the xylene solution of the stripping modifier (2). After mixing until homogeneous in about 30 minutes, xylene was removed by steam stripping to obtain a dimethyl polysiloxane solution of peel modifier (2) (peel modifier (2) content = 50% by weight).

[0149] Table 1 shows the hydroxyl group (silanol group) content of the release modifier (2). Also shown in Table 1 are the viscosities of the dimethylpolysiloxane solutions of the release modifier (2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com