Fibrous support comprising a silicone coating

An organosilicon, polyorganosiloxane technology, applied in coating, fiber processing, transportation and packaging, etc., can solve problems such as roughness, high friction coefficient, passenger injury, etc., to achieve the effect of good possible performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

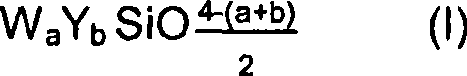

Method used

Image

Examples

Embodiment 1

[0161] Example 1 : Preparation of cross-linked emulsion R

[0162] Mentioned in Table 1 are various weight compositions (in g) of crosslinked emulsions:

[0163] Table 1

[0164] CR1 CR2 R3 R4 R5 POS A 27 27 27 27 27 Resin G 27 27 27 27 27 POS B 2.5 2.5 2.5 2.5 2.5 ECH 0.06 0.06 0.06 0.06 0.06 TA1 15 15 15 15 15 TA2 0 2 2 2 2 Filler (E) 0 0 50 25 75 Sorbic acid 0.02 0.02 0.02 0.02 0.02 water 28 28 28 28 28

[0165] CR1 and CR2 are comparative compositions.

[0166] TA1 and sorbic acid were introduced into an IKA laboratory reactor with scraper anchor stirrer and base (cooled by cold water circulation). Resin G was then poured over 170 min with stirring. Next, it takes 150 min to pour POS A in which ECH has been predispersed. An ultra-turrax (IKA) rotor-stator was then added and the emulsion was subjected to shear for 90 min, 20 min at 16000 rpm followed by 70 mi...

Embodiment 2

[0168] Example 2 : Preparation of Catalytic Emulsion C

[0169] The emulsion contained 53% by weight POS A, 28% by weight TA1, 0.45% by weight catalyst and 17.5% by weight water.

Embodiment 3

[0170] Example 3 : Preparation of Coated Fabrics

[0171] The fabric is a 470 dtex warp and weft polyamide fabric with 18 yarns per centimeter. Coated with a silicone inner layer (1) of Rhodorsil TCS 7510 from Rhodia Silicones having 65 g / m 2 surface density. The inner layer (1) has a thickness of 60 μm.

[0172] During the formation of the coating bath prior to application to the fabrics, the amounts of crosslinking and catalytic formulations described in Table 2 were mixed, optionally with dilution water, adjusted for the purpose of controlling the amount of silicone deposited on the fabrics The viscosity and concentration of the bath.

[0173] The coating bath was applied with a No. 3 Meyer rod to the fabric that had been coated with the silicone inner layer. Next, make the coated fabric enter the ventilated heating chamber according to the conditions specified in Table 2.

[0174] Characterization of coated fabrics

[0175] - Wetting: It is first evaluated visual...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com