Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5469results about How to "Soft touch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

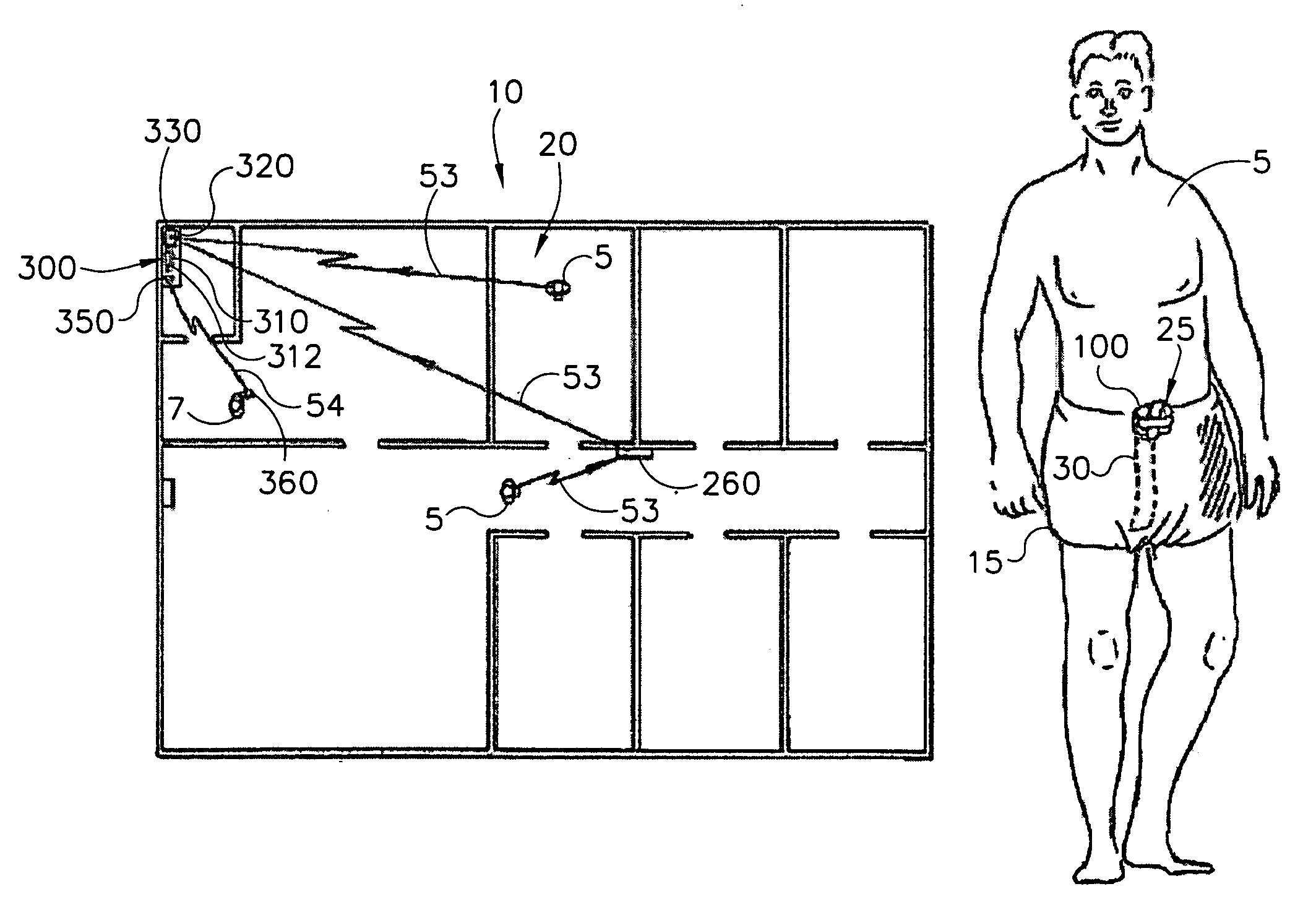

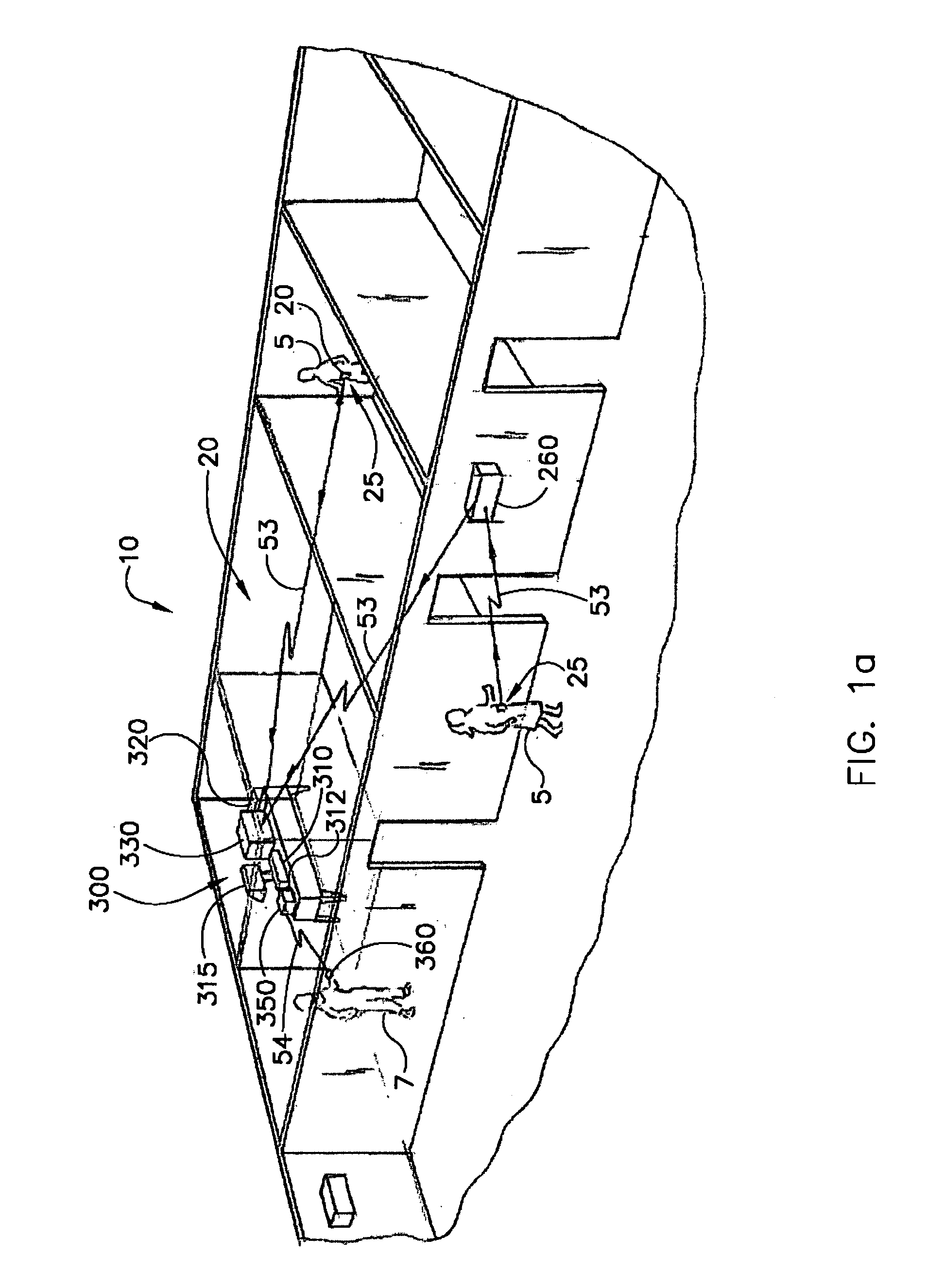

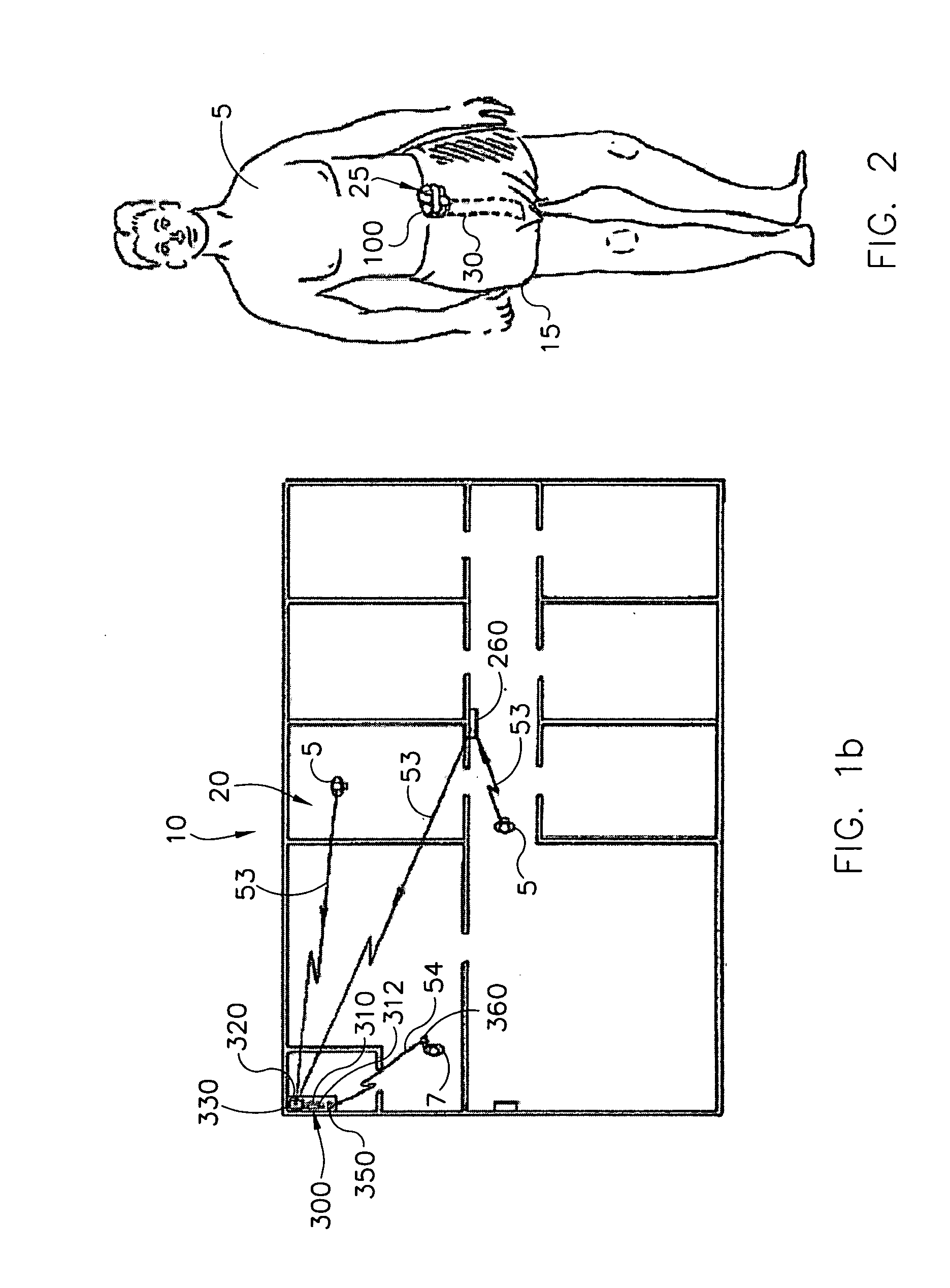

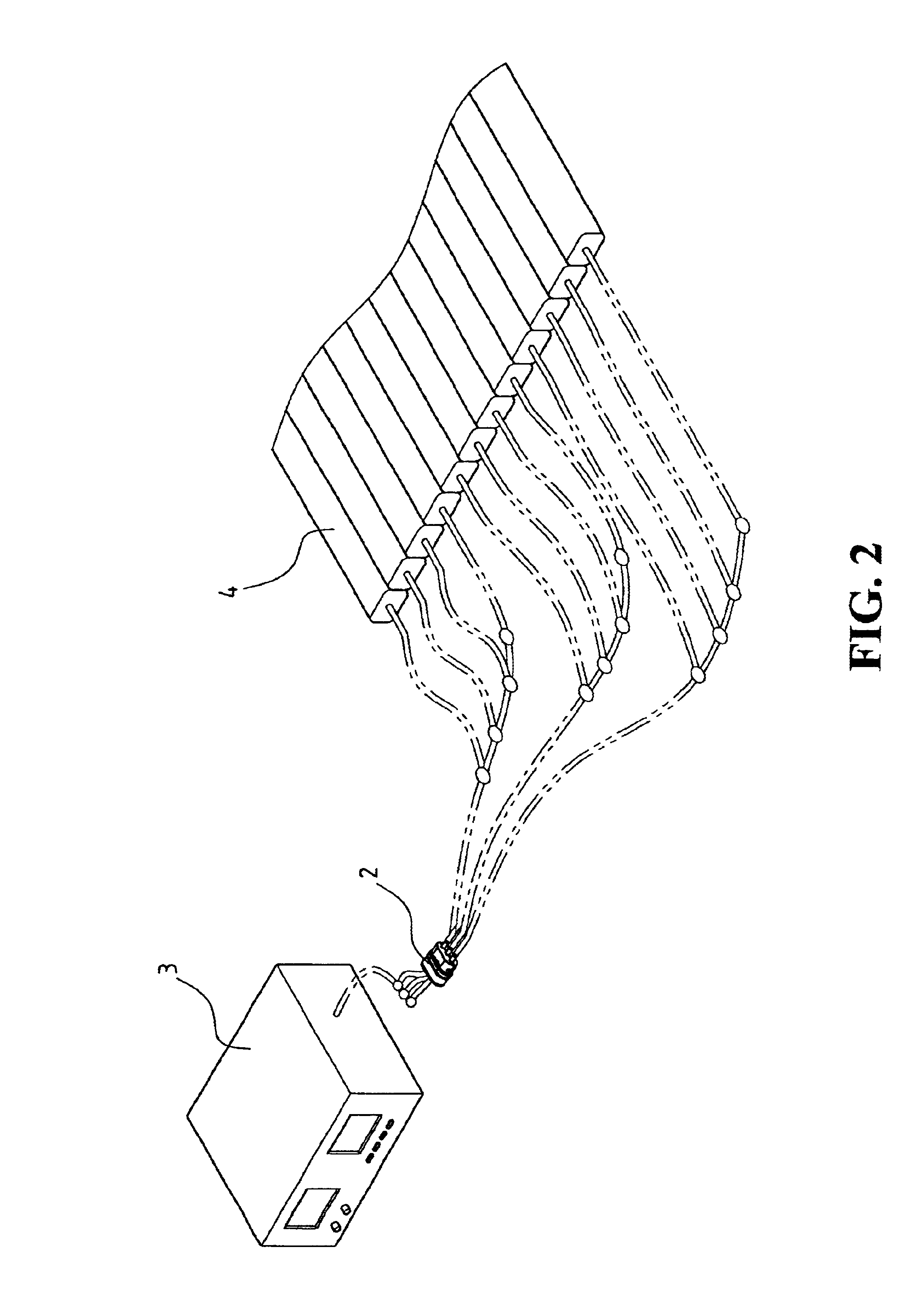

Wetness monitoring system

InactiveUS7250547B1Reduce operating costsLower annual operating costsBaby linensAlarmsData acquisitionMonitoring system

The present invention relates to a wetness monitoring system that includes a data collection device that sends wetness measurement data to a central computer that detects changes in wetness measurement data caused by the presence of urine or other dielectric fluids. The data collection device includes a semi-reusable sensor and reusable data collector that are worn on a garment of the person. The data collector includes an internal power source so that the person can live a normal ambulatory life. The data collector has an electrical circuit that uses the changing resistance characteristics in the sensor to gather wetness measurement data. The data collector periodically generates and transmits a signal containing the actual wetness measurement data. The signals are coded to identify the particular data collector or person sending the signal. The data collector is programmed to conserve power by sending signals less frequently during periods when the sensor is clearly dry. Signals are sent more frequently when the sensor is damp or a wetness event may have occurred. The central computer receives the signals containing the wetness measurement data and compares the measurement data to an adjustable wetness sensitivity level to determine if a wetness event has occurred. When the central computer determines that a wetness event has occurred, the computer displays the name of the particular person wearing the data collector and the approximate time that the wetness event occurred. The system then pages an appropriate healthcare worker to inform them that the particular individual needs attention and tracks the approximate response times to ensure that the patient is continuously receiving prompt care.

Owner:RF TECH

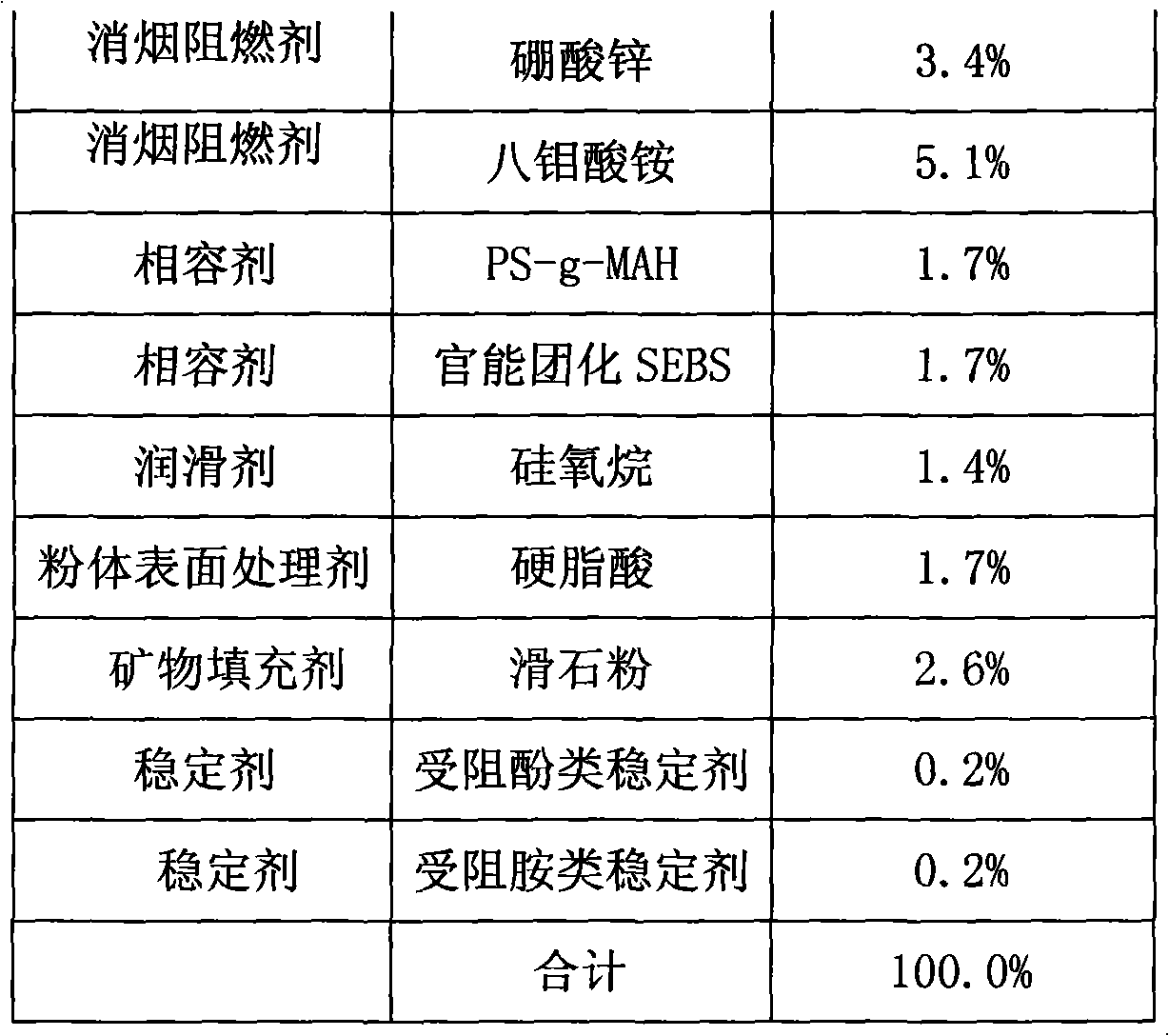

Halogen-free flame-retardant thermoplastic elastomer electrical cable material using polyphenylene ether as base material and preparation method thereof

InactiveCN101358028AGood compatibilityReduce stratificationInsulated cablesInsulated conductorsElastomerPolyphenylene oxide

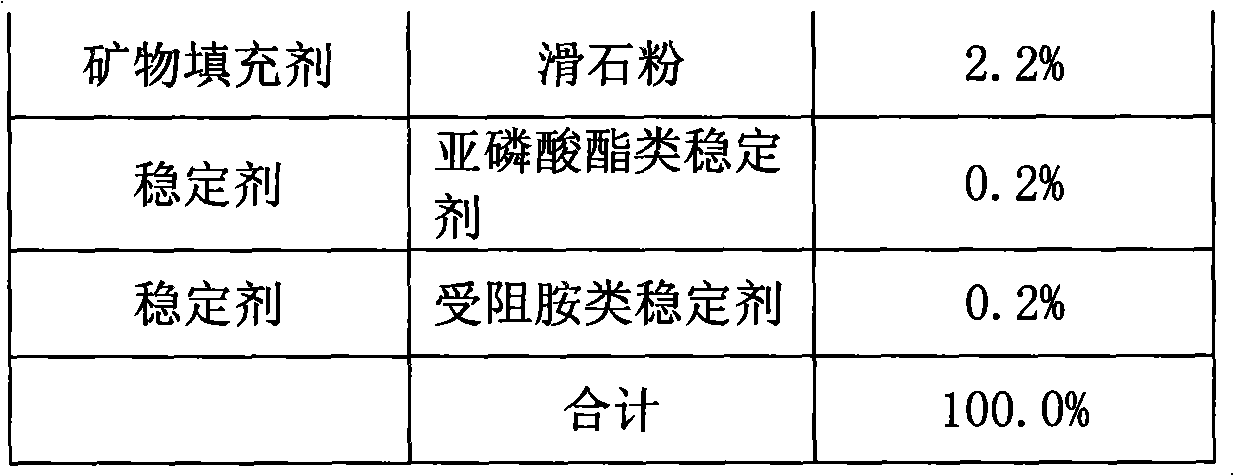

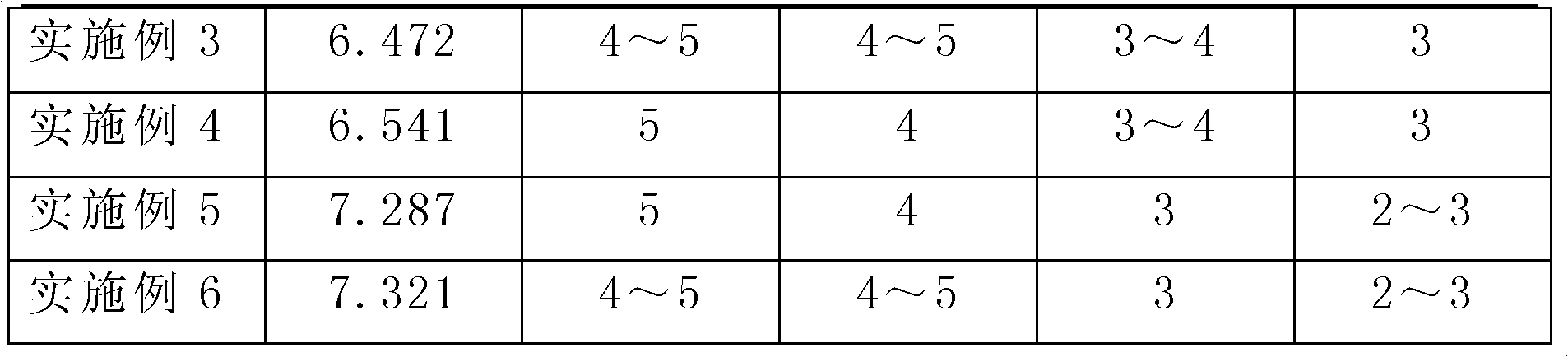

The invention discloses a halogen-free flame-retardant thermoplastic elastomer cable material with polyphenylether as the base materials and a preparation method thereof. The raw material of the cable material contains the components with the following weight percentage: 10 to 35 percent of matrix resin A; 5 to 15 percent of matrix resin B; 10 to 25 percent of elastomer; 5 to 25 percent of softening plasticizer; 8 to 15 percent of flame-retardant plasticizer; 20 to 40 percent of smoke-suppression flame retardant; 3 to 10 percent of compatilizer; 1 to 5 percent of lubricant; 1 to 5 percent of powder surface conditioner; 0 to 10 percent of mineral filler; 0.1 to 1 percent of stabilizing agent. The invention adds matrix resin, polyphenylether of strong polarity and functional group of styrene-ethylene / butylene-styrene segmented copolymer, which effectively improves the compatibility of non-polar elastomer with polyphenylether; the invention also adds plasticizer, which reduces the hardness of the material and increases the flexibility; and through the optimization and interaction of the softening plasticizer and the flame-retardant plasticizer, the invention reduces the hardness and improves the tactility of the material, and the flame retardant performance is excellent.

Owner:NINGBO SHIP PLASTIC CO LTD

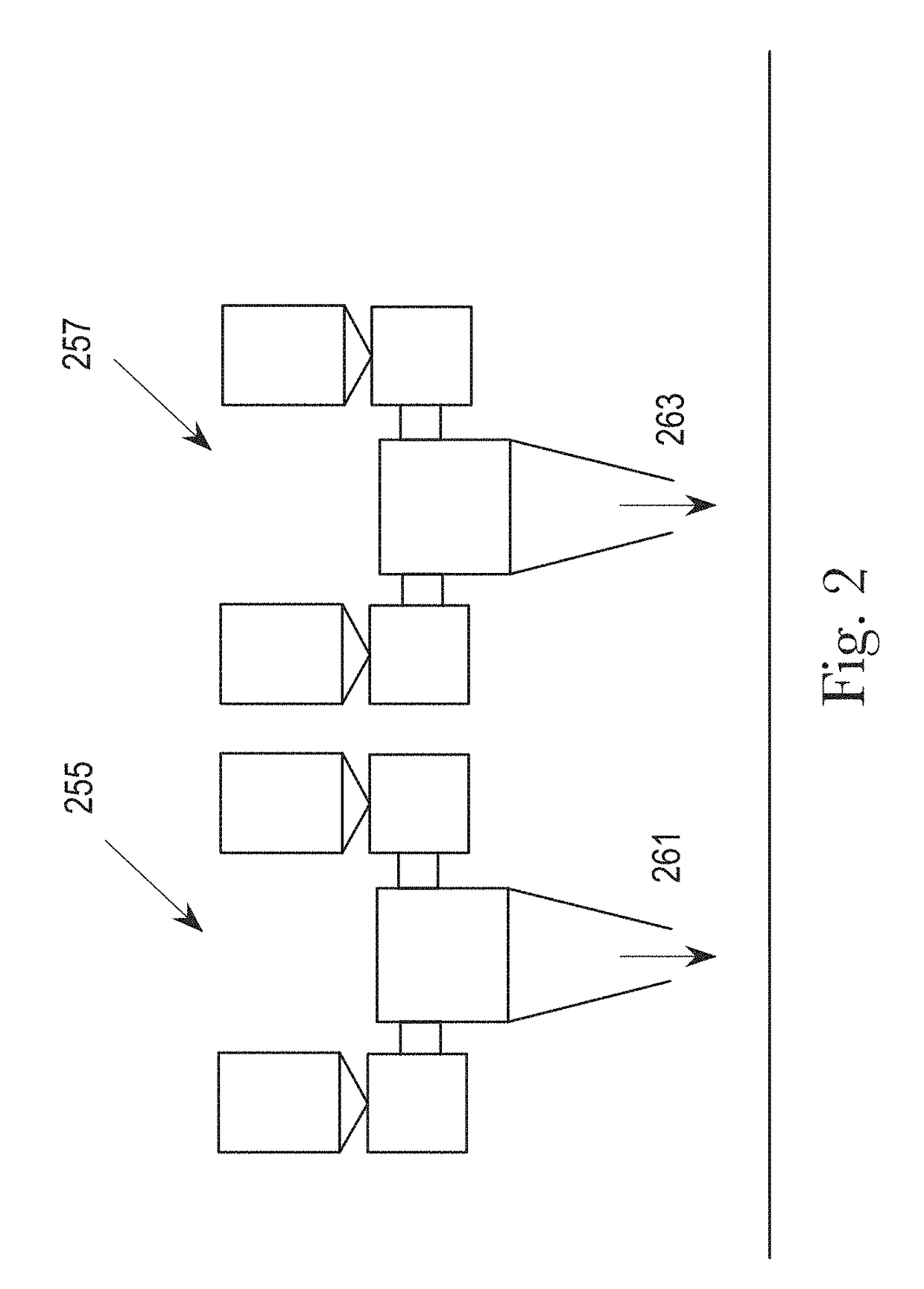

Fibrous nonwoven structure having improved physical characteristics and method of preparing

ActiveUS8017534B2Better sheet squarenessSoft touchLayered productsAbsorbent padsFiberMaterials science

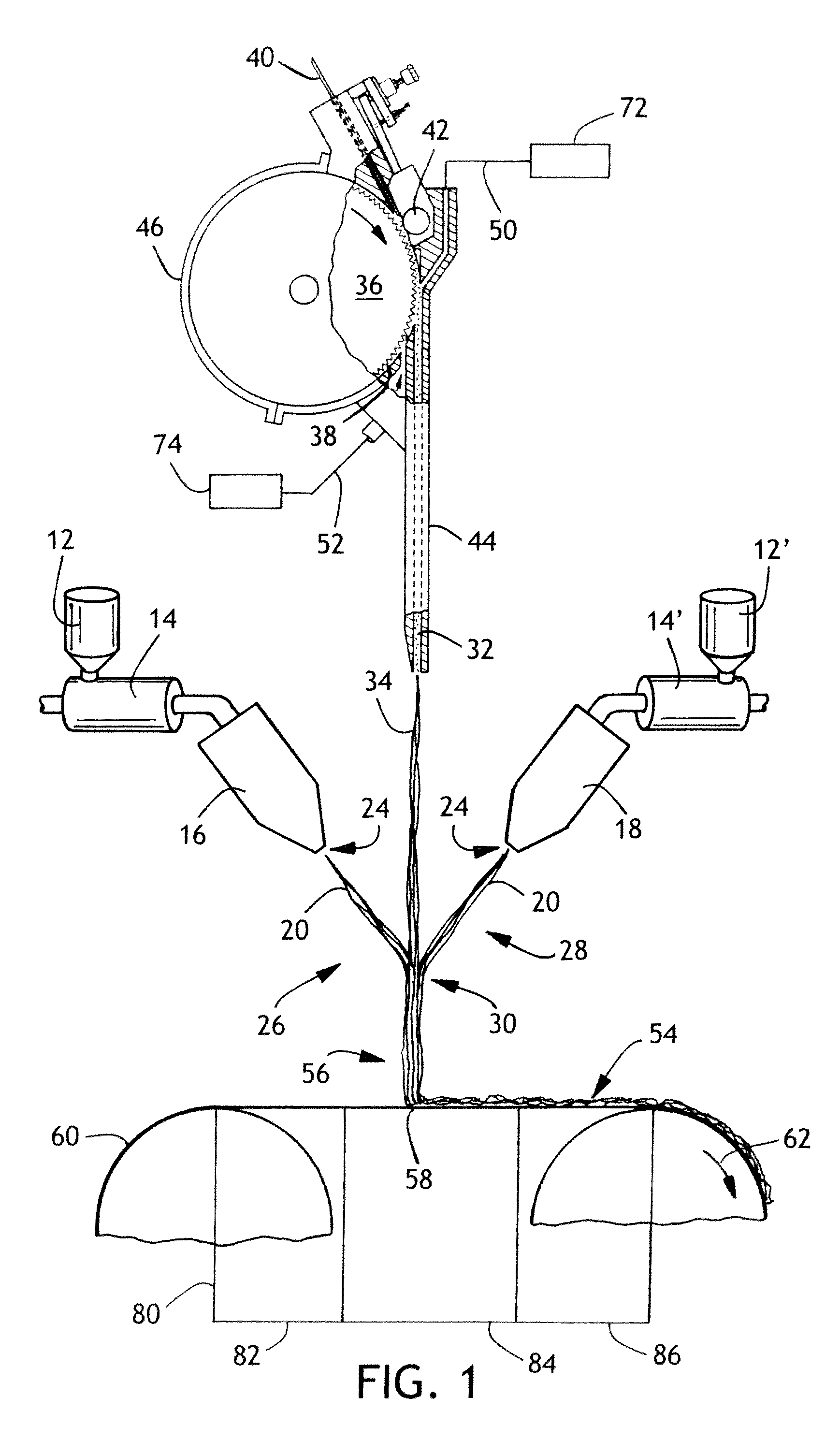

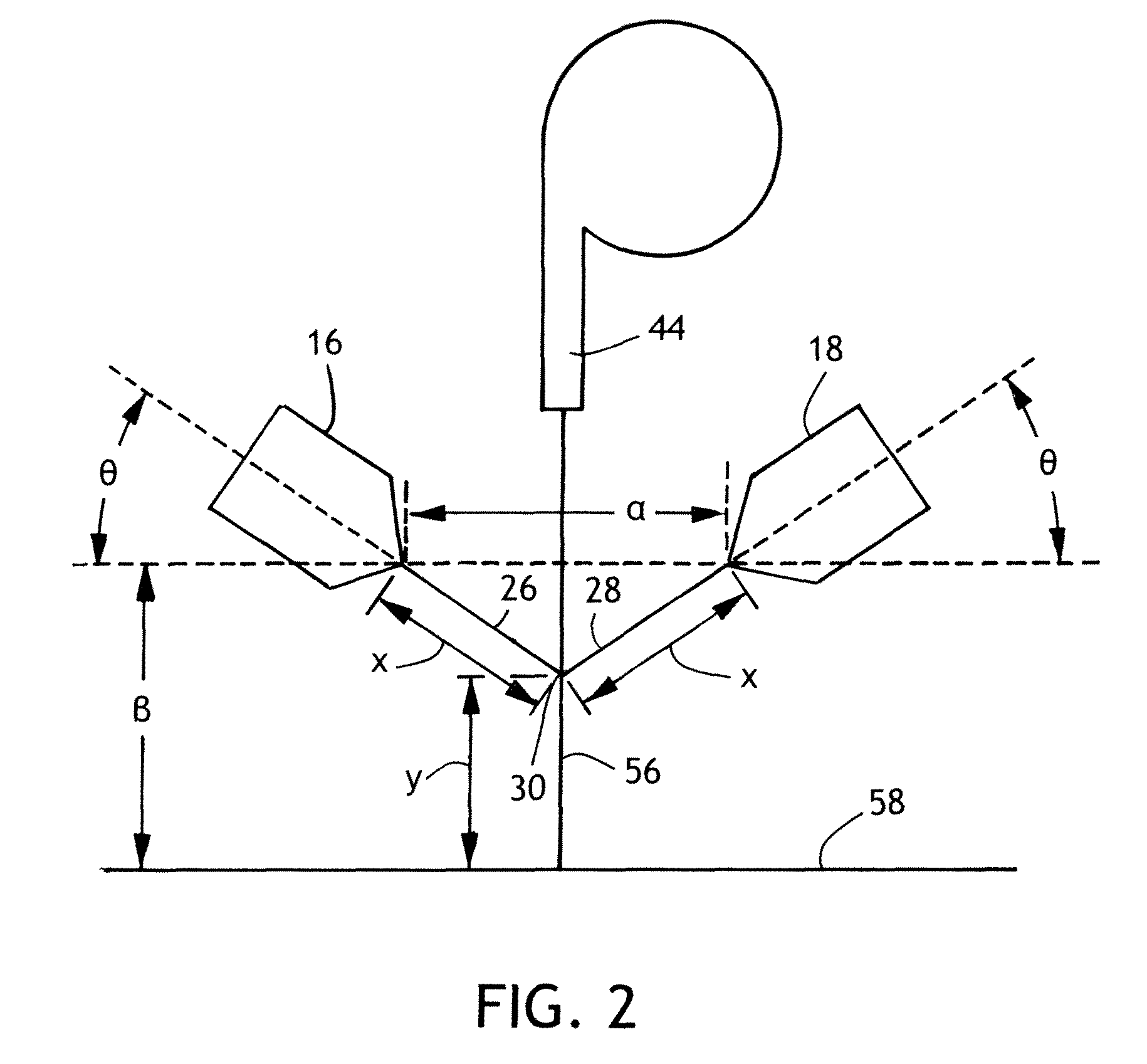

Disclosed is a fibrous nonwoven structure comprising meltblown fibrous materials and at least one secondary fibrous material and method of preparing. In one aspect, the fibrous nonwoven structure has a formation index of between 70 and 135. In another aspect, the fibrous nonwoven structure has an opacity that is greater than 72 percent at a basis weight of between about 35 and 55 grams per square meter. The fibrous nonwoven substrate may be utilized as a moist wipe.

Owner:KIMBERLY CLARK GLOBAL SALES LLC

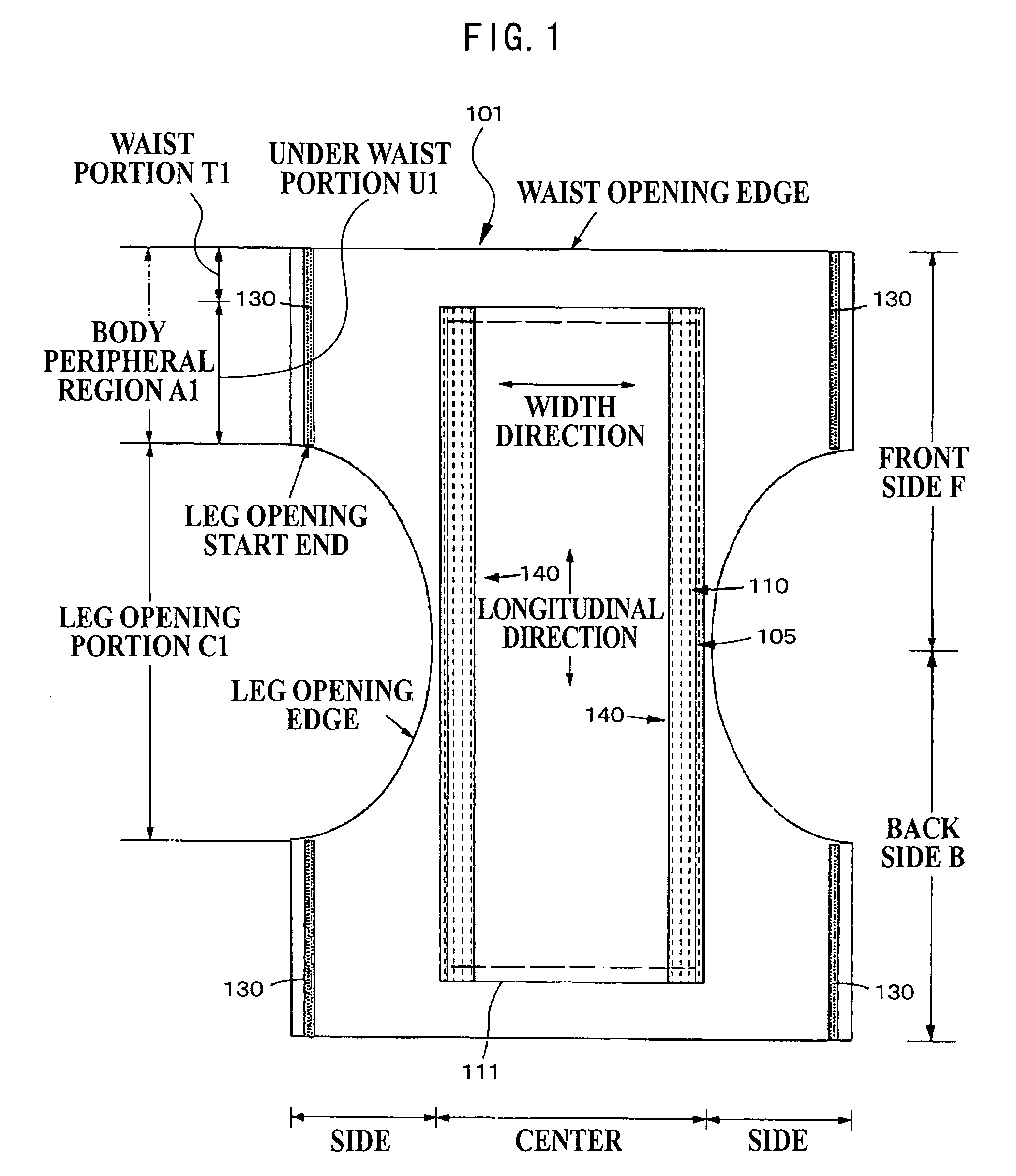

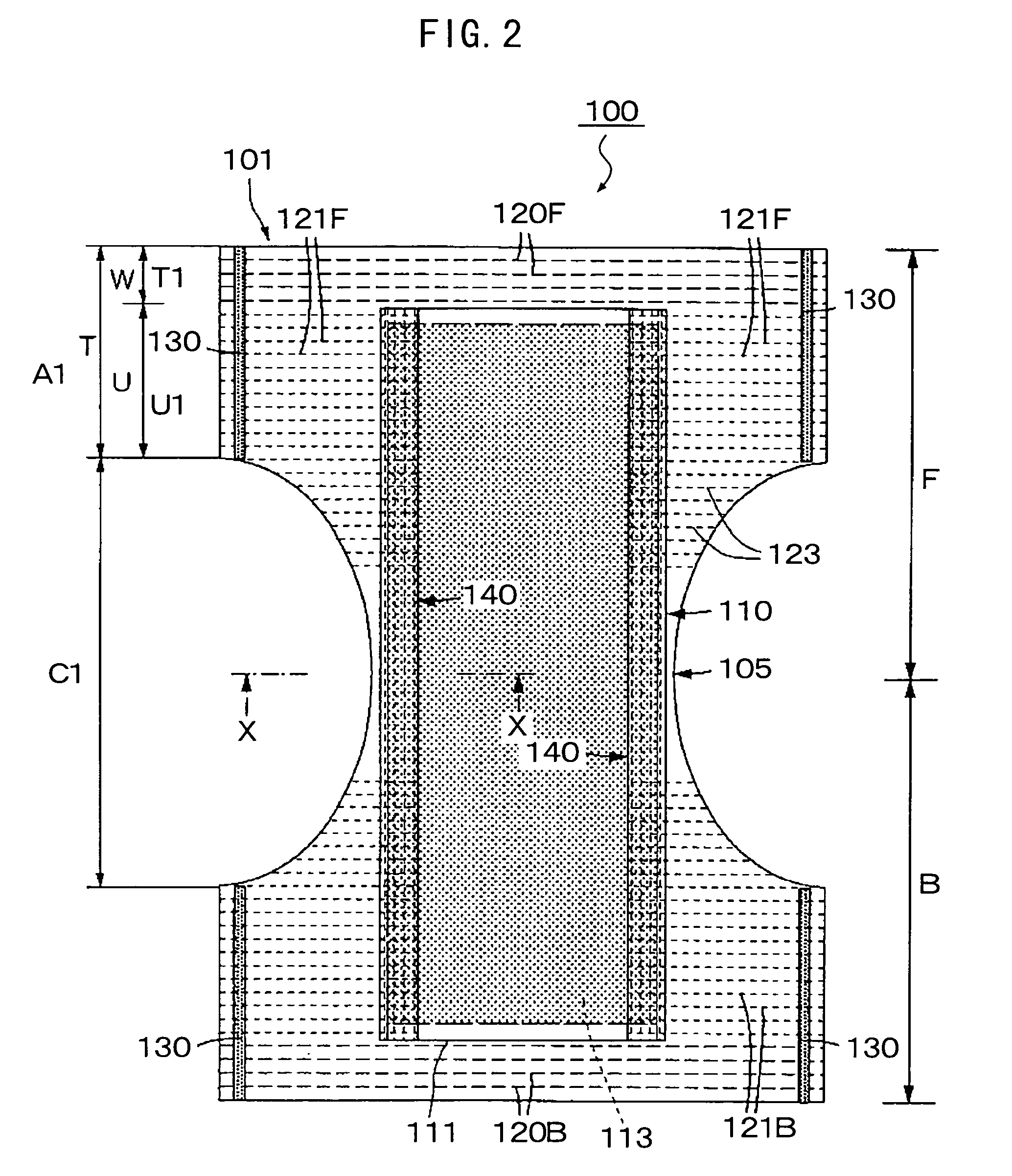

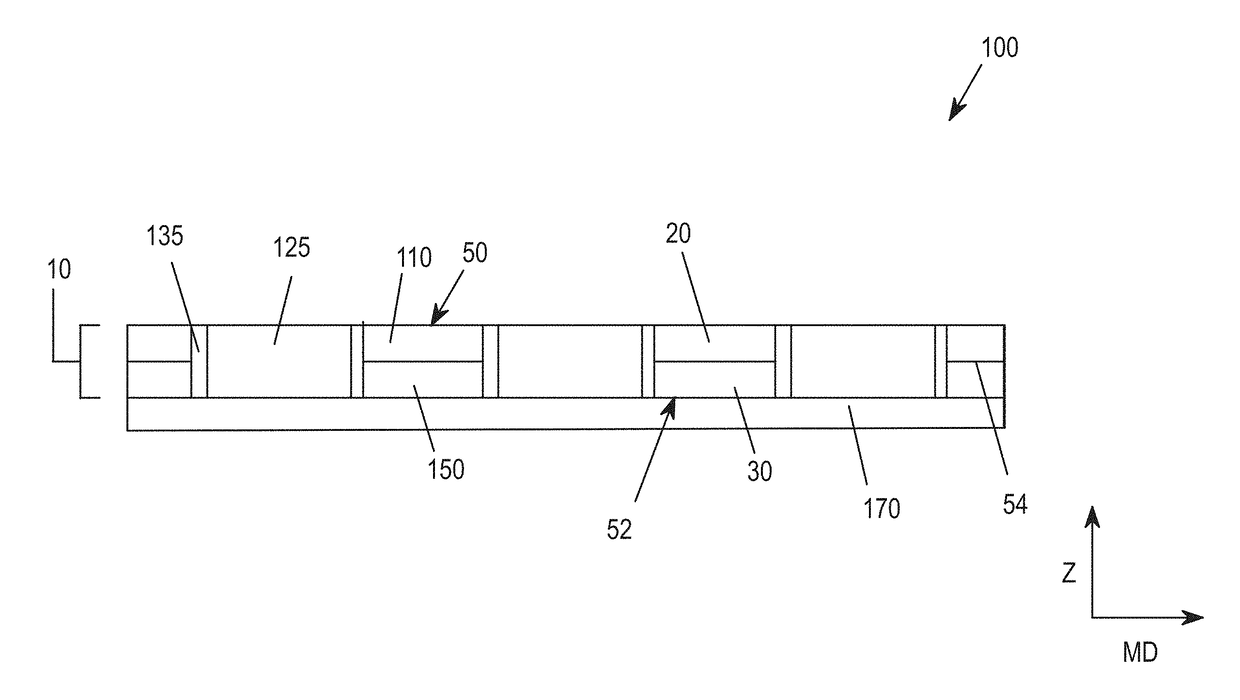

Paper diaper and method for manufacturing extensible sheet used in the diaper

InactiveUS7777094B2Reduce line pressureReduce positioningBaby linensTamponsEngineeringDisposable diaper

A disposable diaper having: an elastic portion where a plurality of elastic members is provided along a width direction with an interval of not more than 7.0 mm in a longitudinal direction, and a non-elastic portion wherein the non-elastic portion is in a center of at least one of a front side and a back side and the elastic portion is provided in a region including right-and-left side portions except the non-elastic portion, and a difference between a maximum product width obtained when the body peripheral region is extended to a limit of extension in a product width direction and a contracted product width obtained when the body peripheral region is in a non-extended contraction state is from 100 to 250 mm in a state where the front side and the back side are overlapped.

Owner:DAIO PAPER CORP +1

Thermoplastic elastomer composition

The present invention relates to a soft thermoplastic elastomer composition that is free of thermoplastic resin that can be utilized in manufacturing shoe sole inserts, seals, gaskets, wheels, and that can be overmolded on a hard substrate, such as a metal or a thermoplastic resin, for grips or handles on various household items. The present invention more specifically discloses a thermoplastic elastomer composition that is made by a process comprising: (1) mixing (A) a block copolymer comprising a first polymeric block that is comprised of repeat units that are derived from a vinyl aromatic monomer and a second block that is comprised of repeat units that are derived from a conjugated diolefin monomer, wherein the repeat units in the second block are hydrogenated, and wherein the repeat units in the second block are elastomeric in nature, (B) a crosslinkable elastomer, and (C) an oil, to produce an un-crosslinked three component blend; and (2) dynamically crosslinking the crosslinkable elastomer in the un-crosslinked three component blend during a thermo-mechanical mixing step; wherein the thermoplastic elastomer composition is void of thermoplastic resins.

Owner:THE GOODYEAR TIRE & RUBBER CO +1

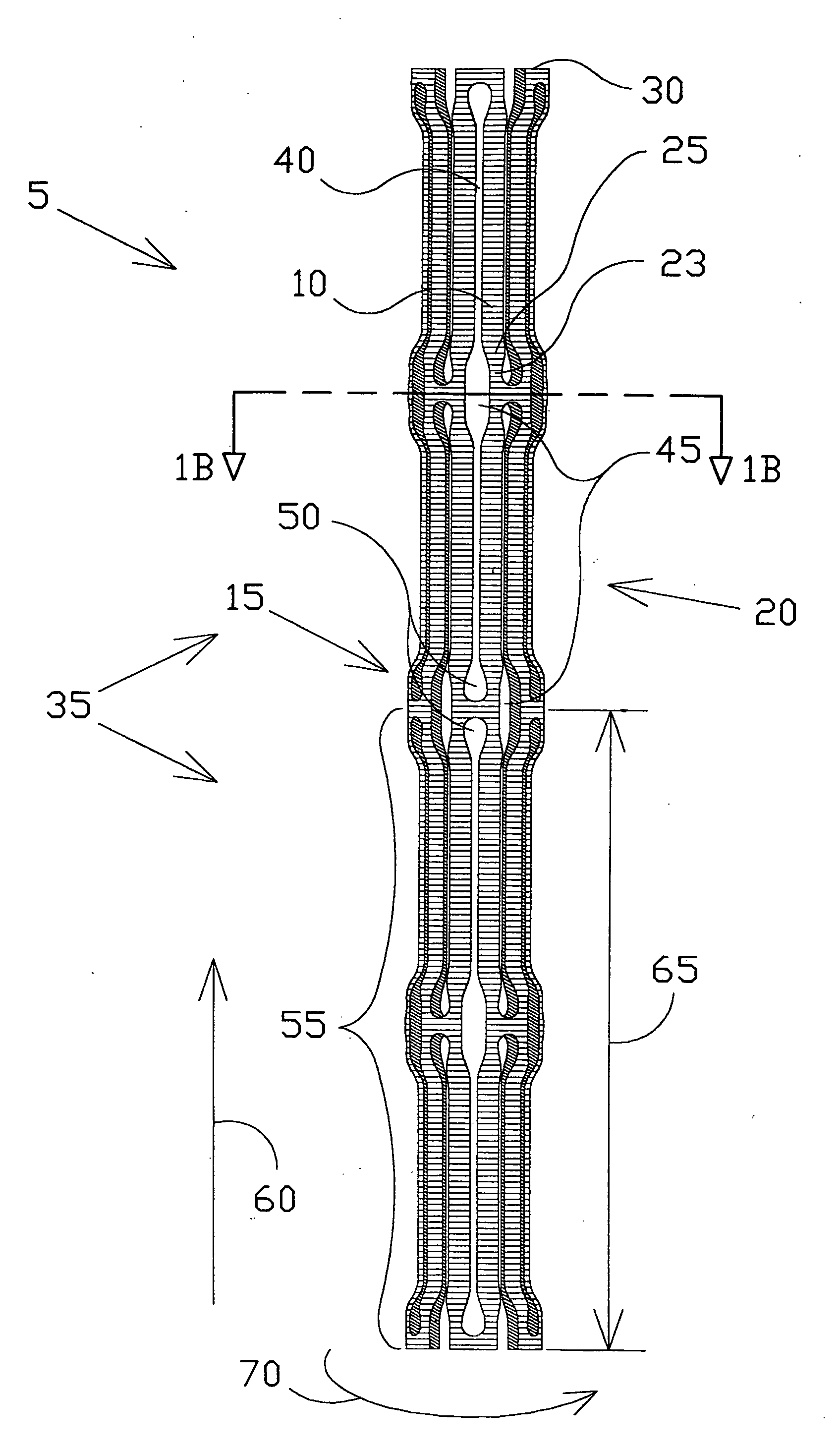

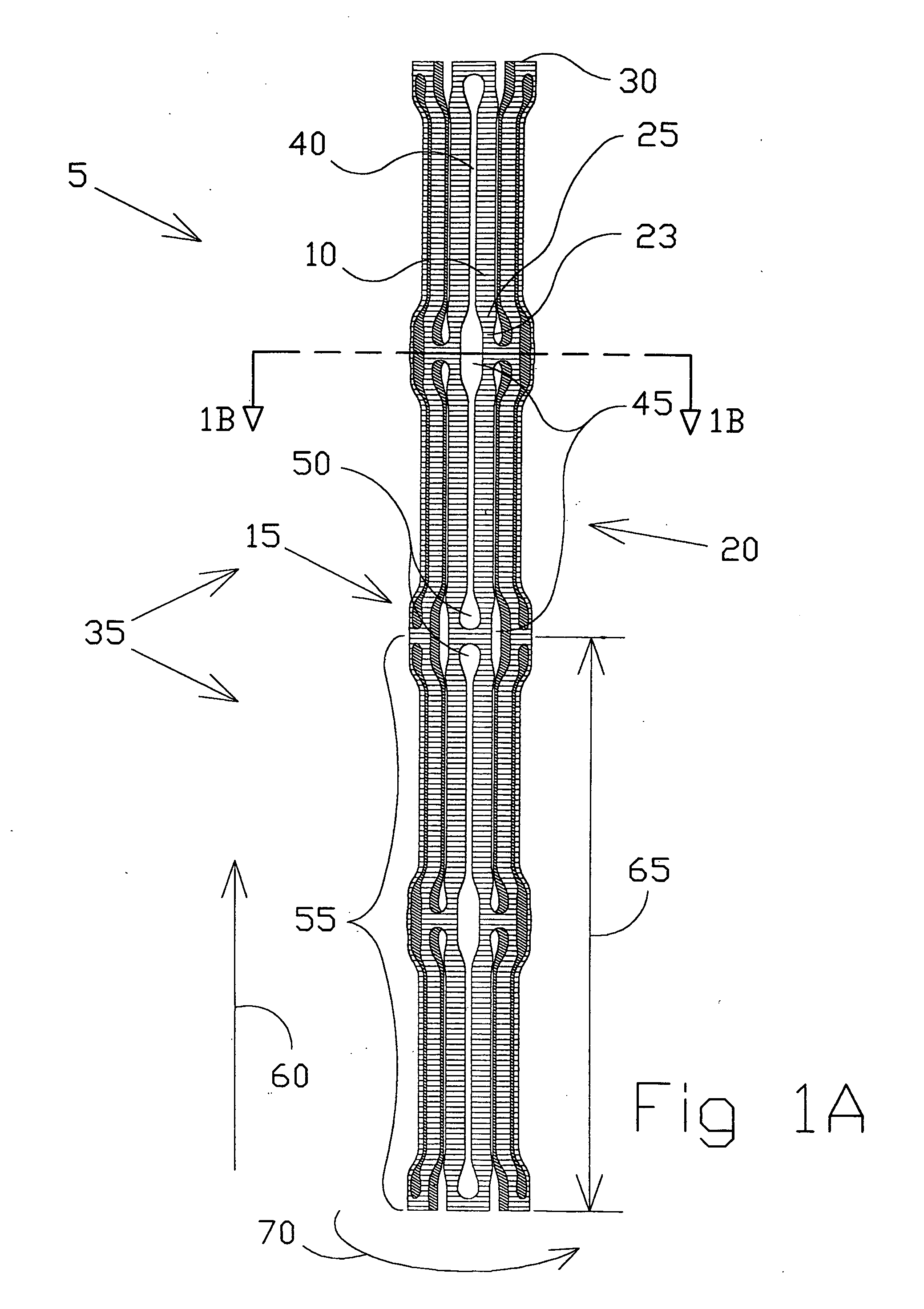

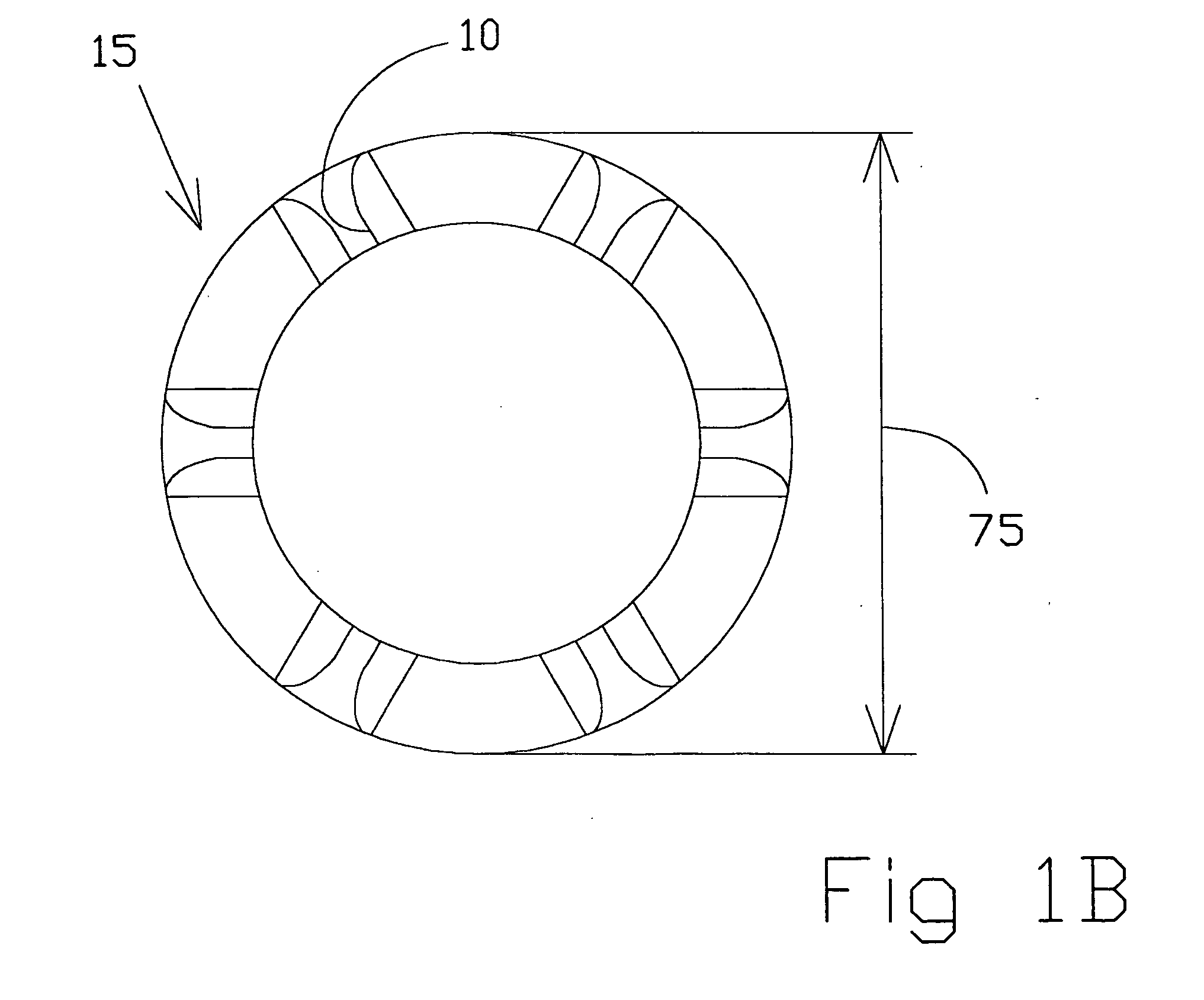

Intravascular hinge stent

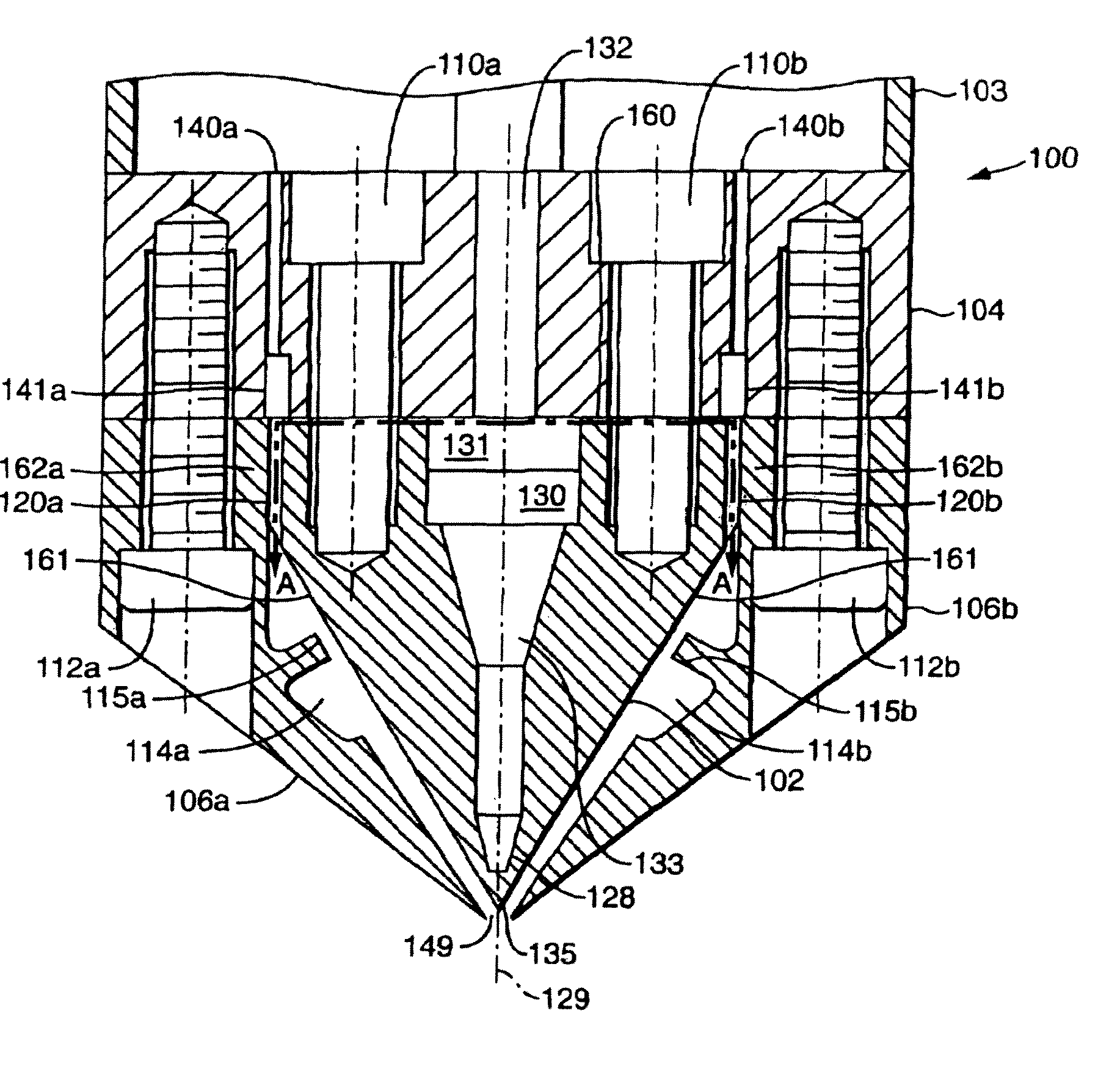

A balloon or self expandable endoprosthesis formed of a single or multiple joined stent sections. Each section has a node and strut structure extending throughout in order to uncouple expansion forces of the stent to hold a blood vessel outward from crush forces that resist the formation of an oval shape during crush deformation. The hinge can bend in the direction of a uniformly curved surface of the stent but not in the radial direction. The strut can bend in the radial direction but not in the uniformly curved surface of the stent. The widths, lengths, and radial dimensions of the hinges and struts provide a balloon-expandable hinge stent that is non-crushable. For a self-expanding stent the hinge and strut dimensions provide expansion forces that are controlled independently from crush forces. Expansion properties are determined by the hinge dimensions and crush properties are determined independently by strut dimensions.

Owner:DRASLER WILLIAM JOSEPH +1

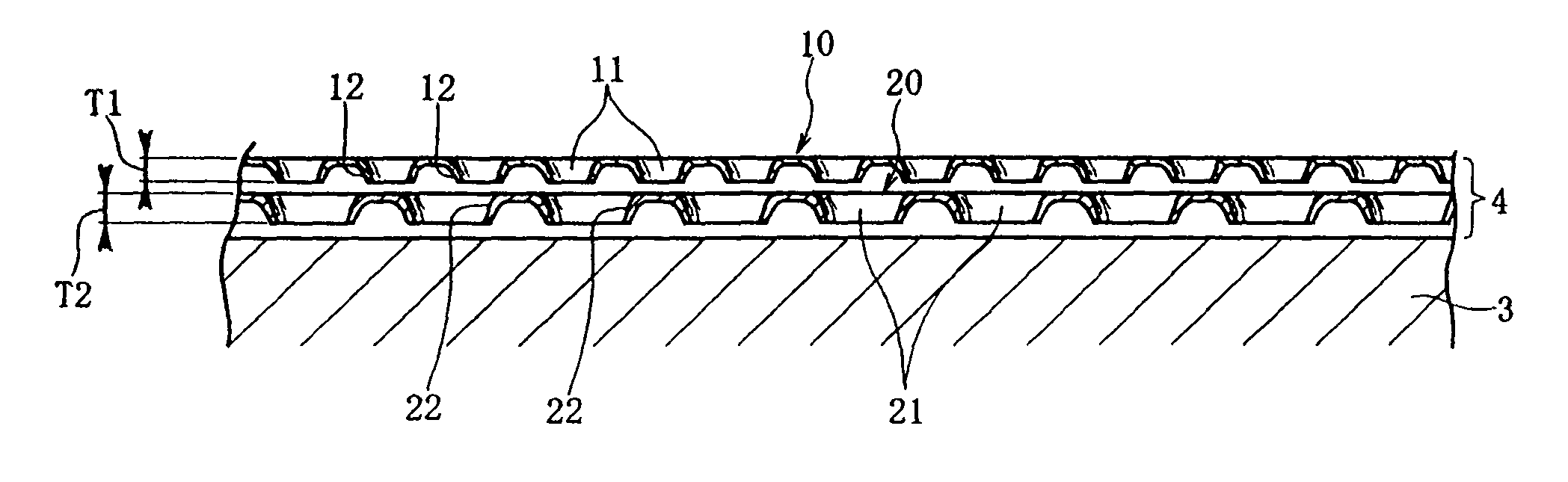

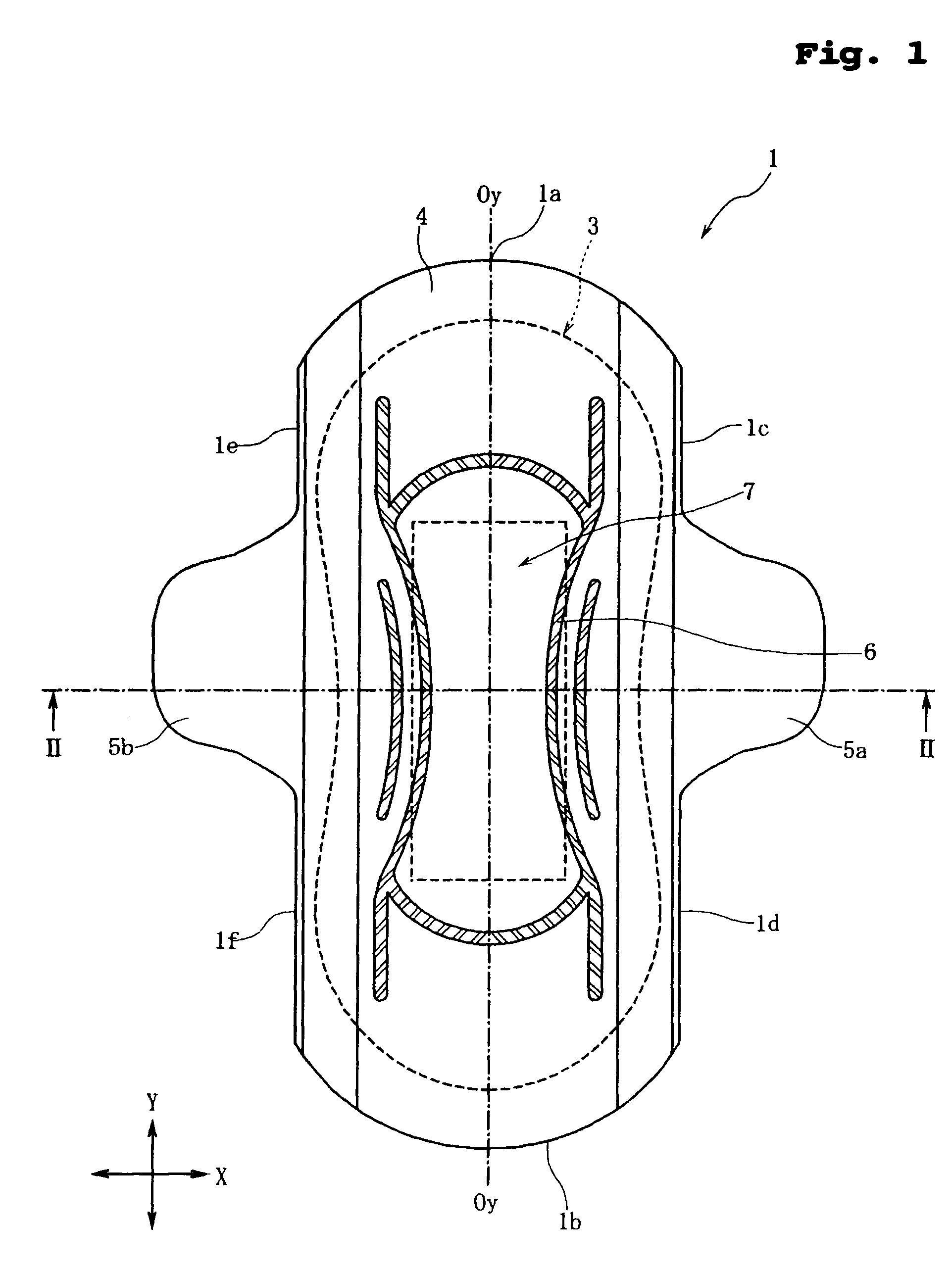

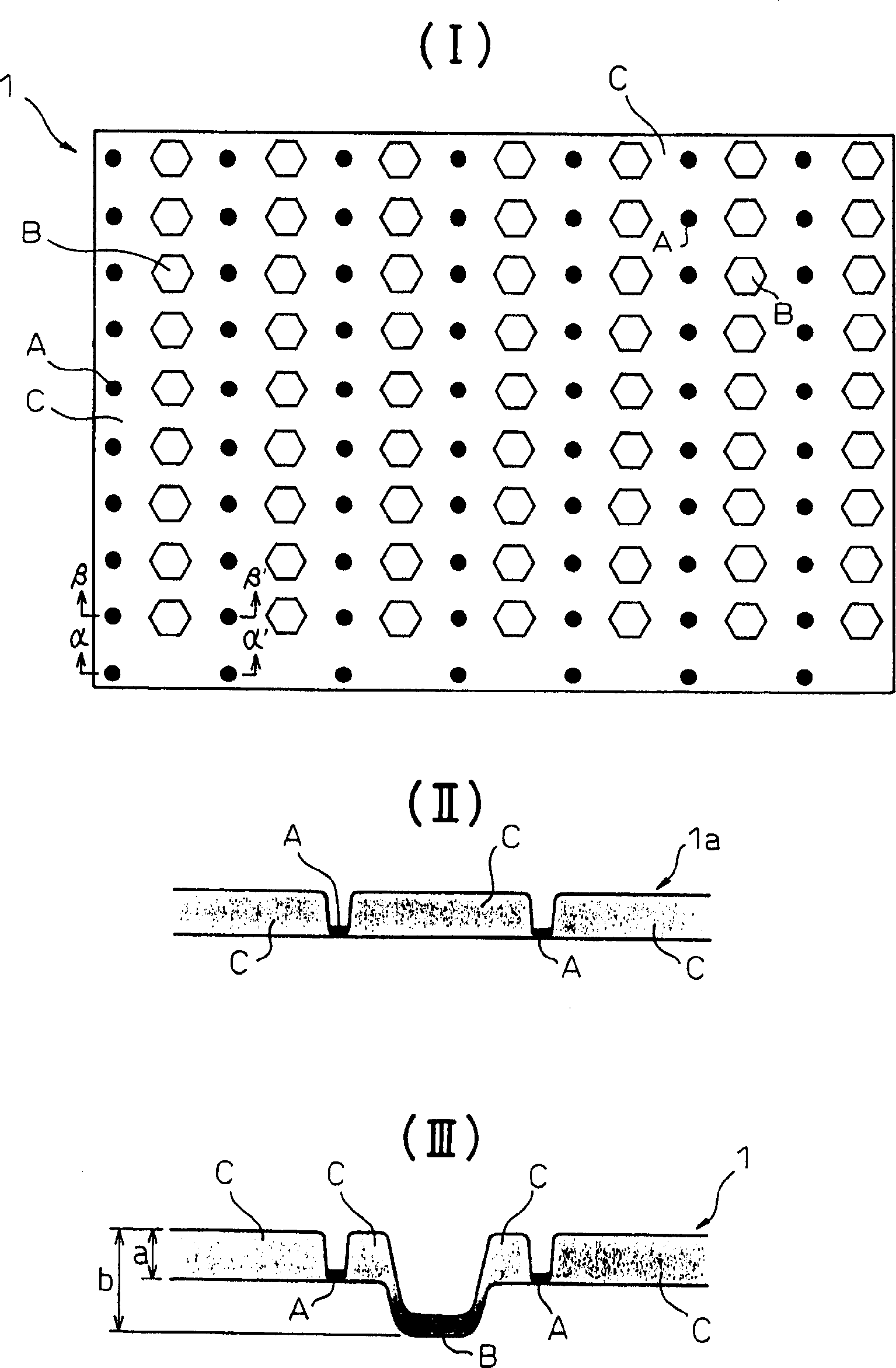

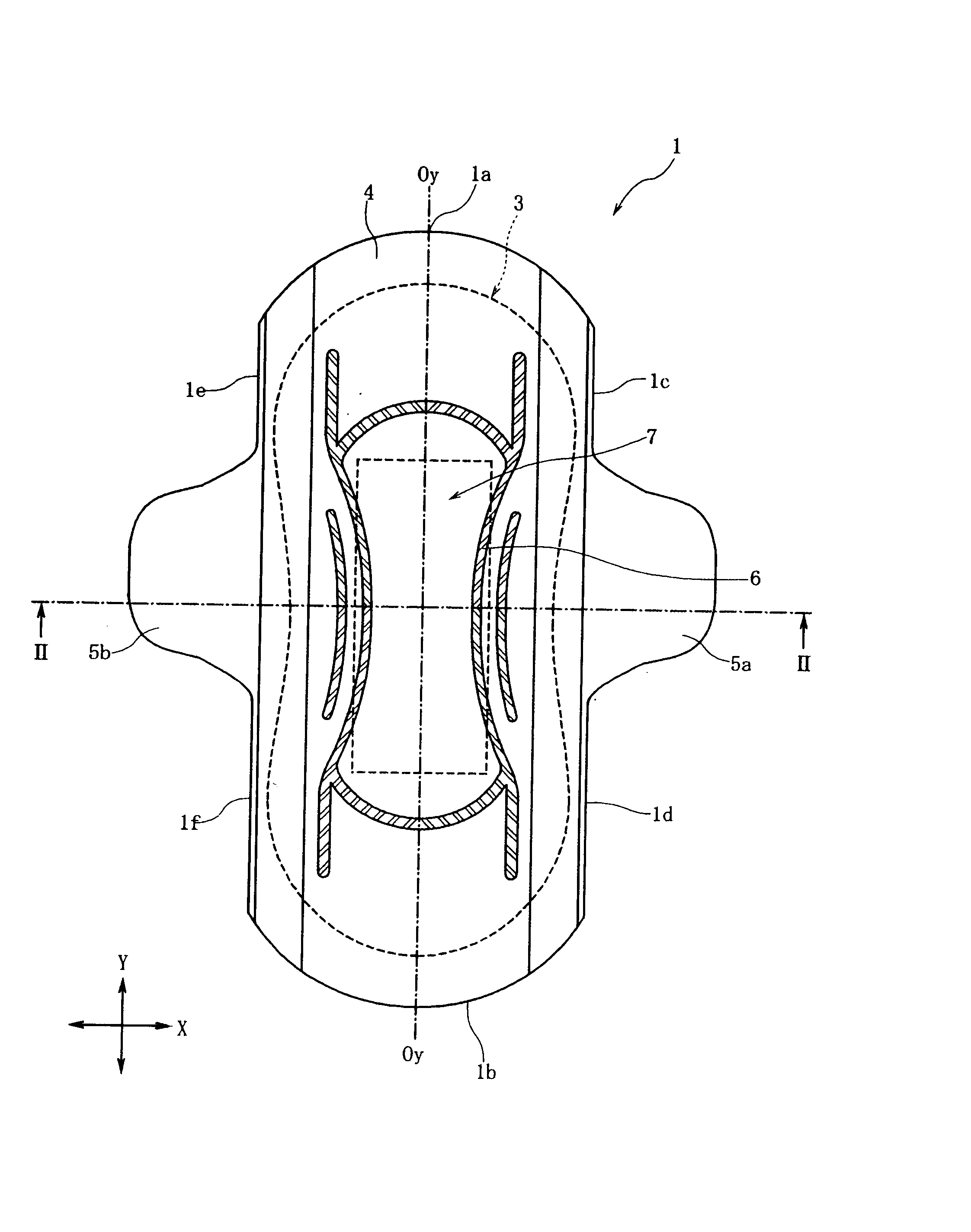

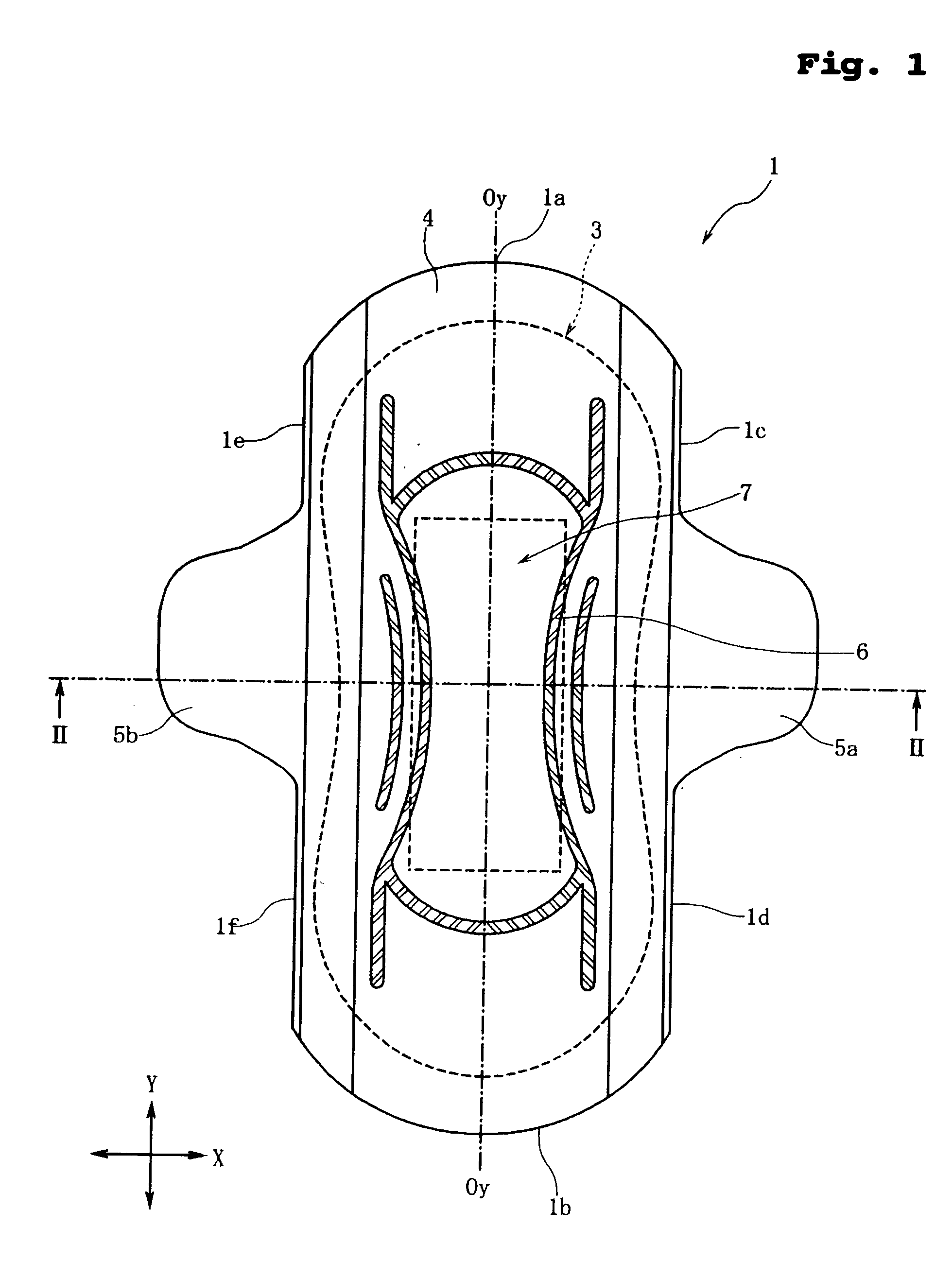

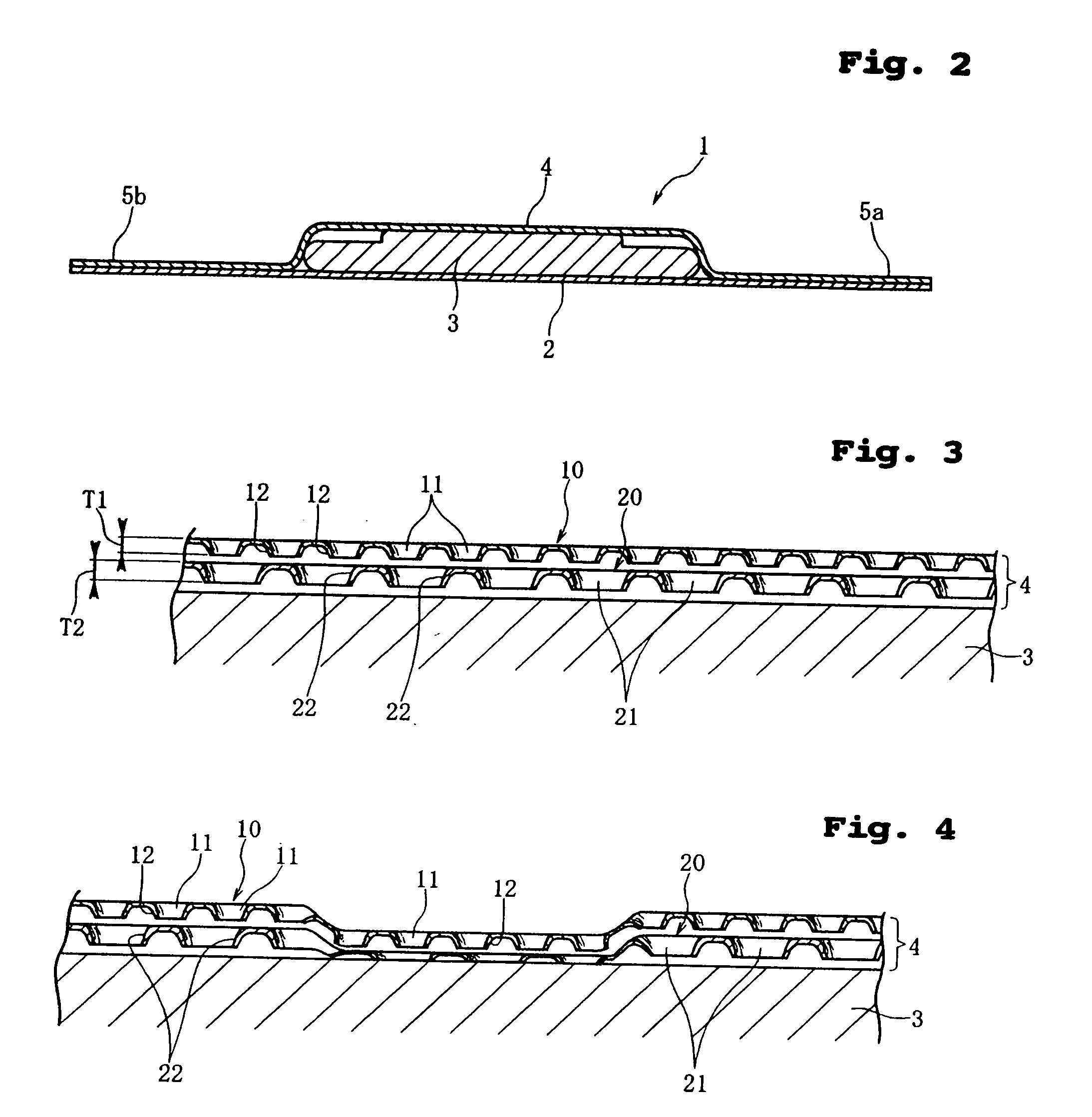

Absorbent article

InactiveUS7858842B2Easy transferLess irritating to the wearer's bodyLayered productsBaby linensCompressibilityElectrical and Electronics engineering

Disclosed is an absorbent article including a liquid absorbent layer for absorption and retention of liquid and a liquid passage layer located on a liquid-receiving side of the liquid absorbent layer. The liquid passage layer includes a first passage layer and a second passage layer disposed between the first passage layer and the liquid absorbent layer. The first passage layer and the second passage layer are resin films formed with a plurality of liquid passage apertures. The individual liquid passage apertures are defined by a peripheral wall projecting toward the liquid absorbent layer to provide the first passage layer and the second passage layer with thicknesses greater than a thickness of the resin film itself. Under a load in a thickness direction, the second passage layer has a greater compressibility than the first passage layer.

Owner:UNI CHARM CORP

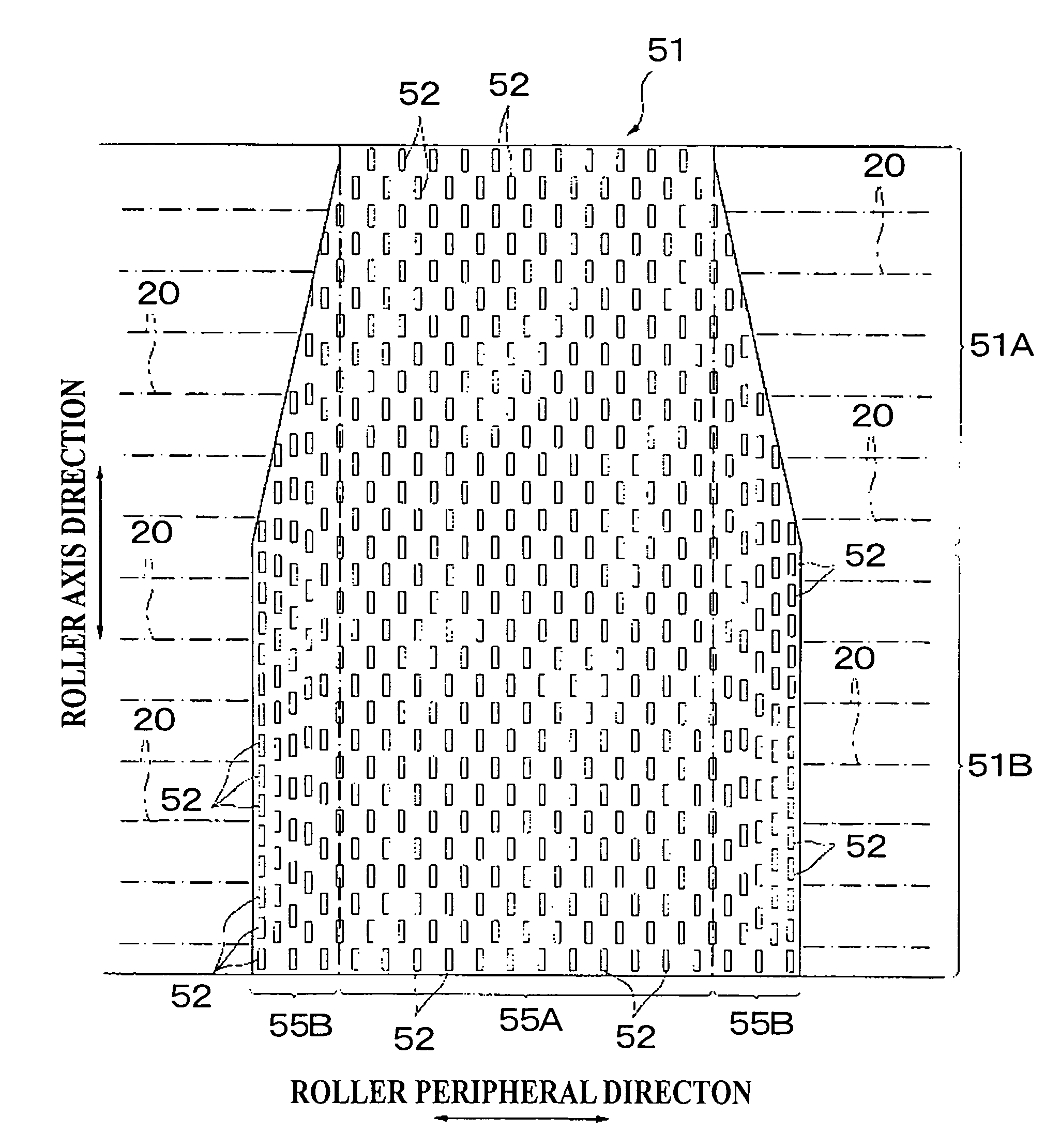

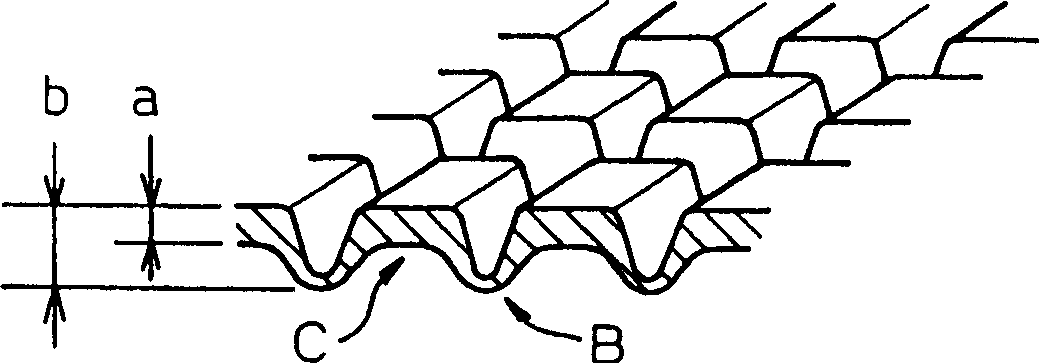

Spun-bonded nonwoven fabric and sanitary supplies

A spun-bonded nonwoven fabric constituted of a web of continuous filaments of thermoplastic synthetic fibers, the structure of which fabric is set by a pattern composed of areas which are produced by partially fusing the fibers by hot pressing and pierce through the fabric and concavely and convexly embossed patterns on the surfaces of the fabric which patterns are composed of high-density concave and convex areas of unbonded fibers respectively and the bulkiness of which fabric is 100 to 400 % in terms of the ratio of the thickness of the fabric inclusive of the convexly embossed pattern surface to the thickness of the low-density areas of the fabric. The application of a hydrophilic agent to the nonwoven fabric gives sanitary supplies such as disposable diaper.

Owner:ASAHI KASEI KK

Absorbent Articles

InactiveUS20170258651A1Soft touchEasy accessElectro-spinningSanitary towelsEngineeringMechanical engineering

Owner:THE PROCTER & GAMBLE COMPANY

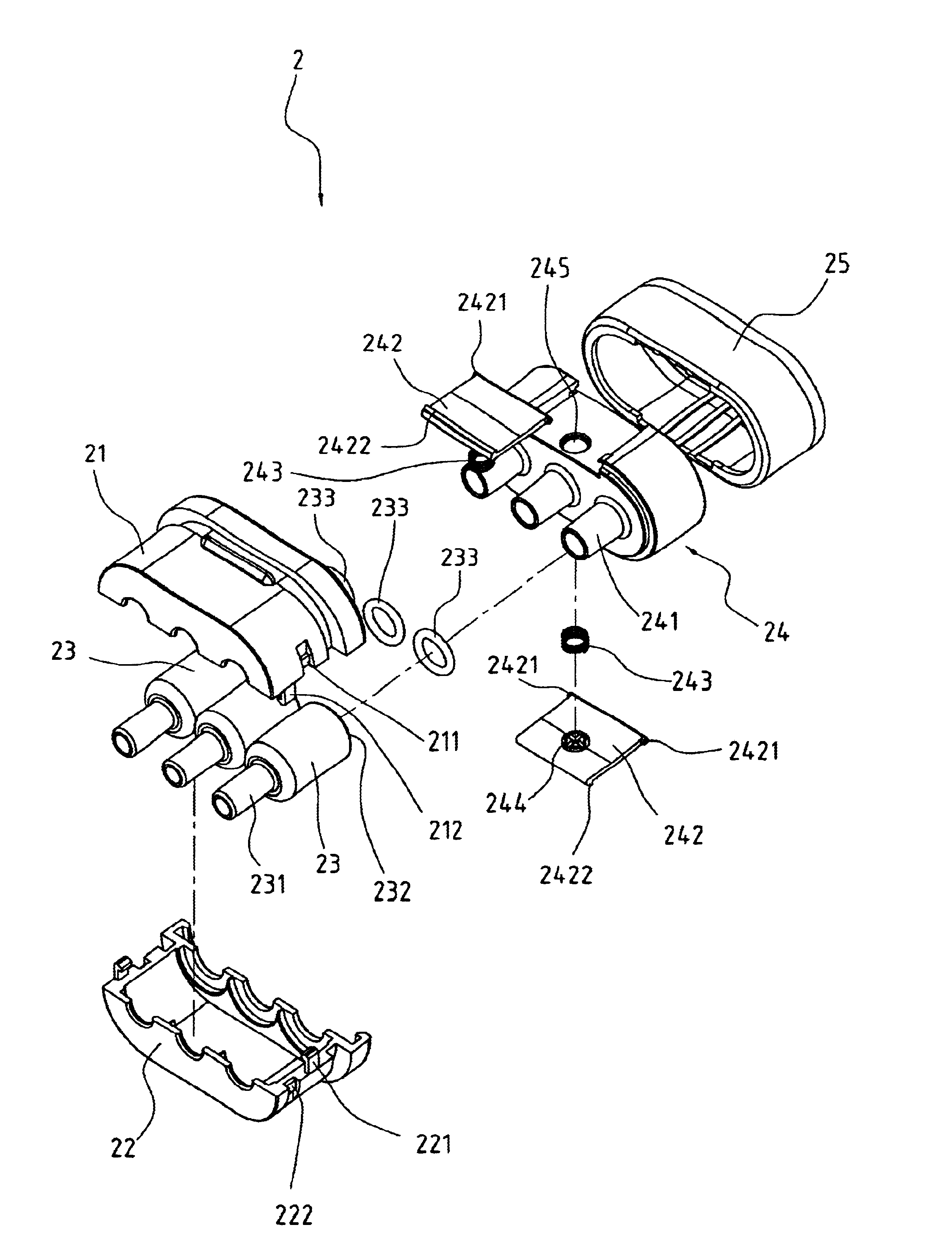

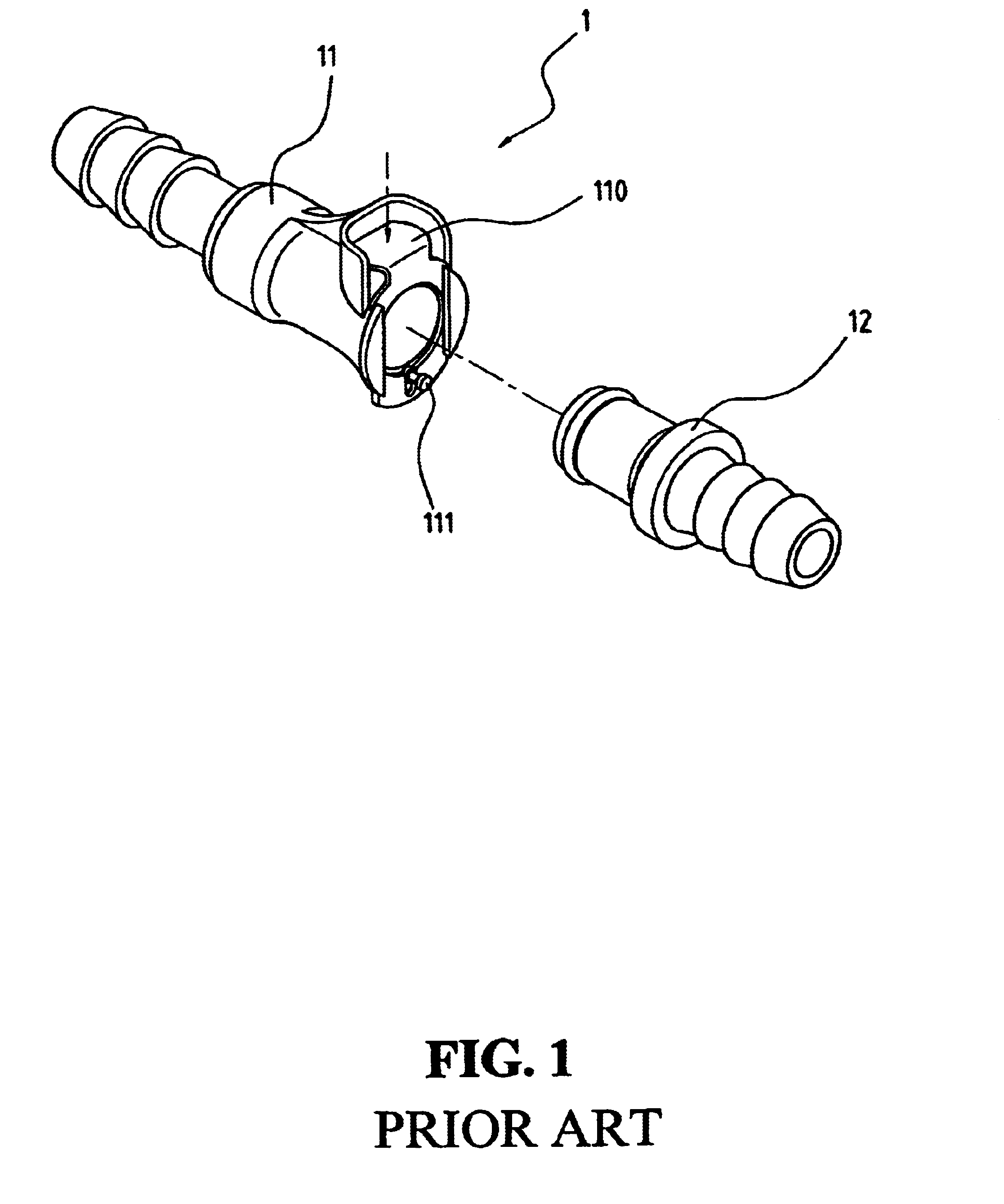

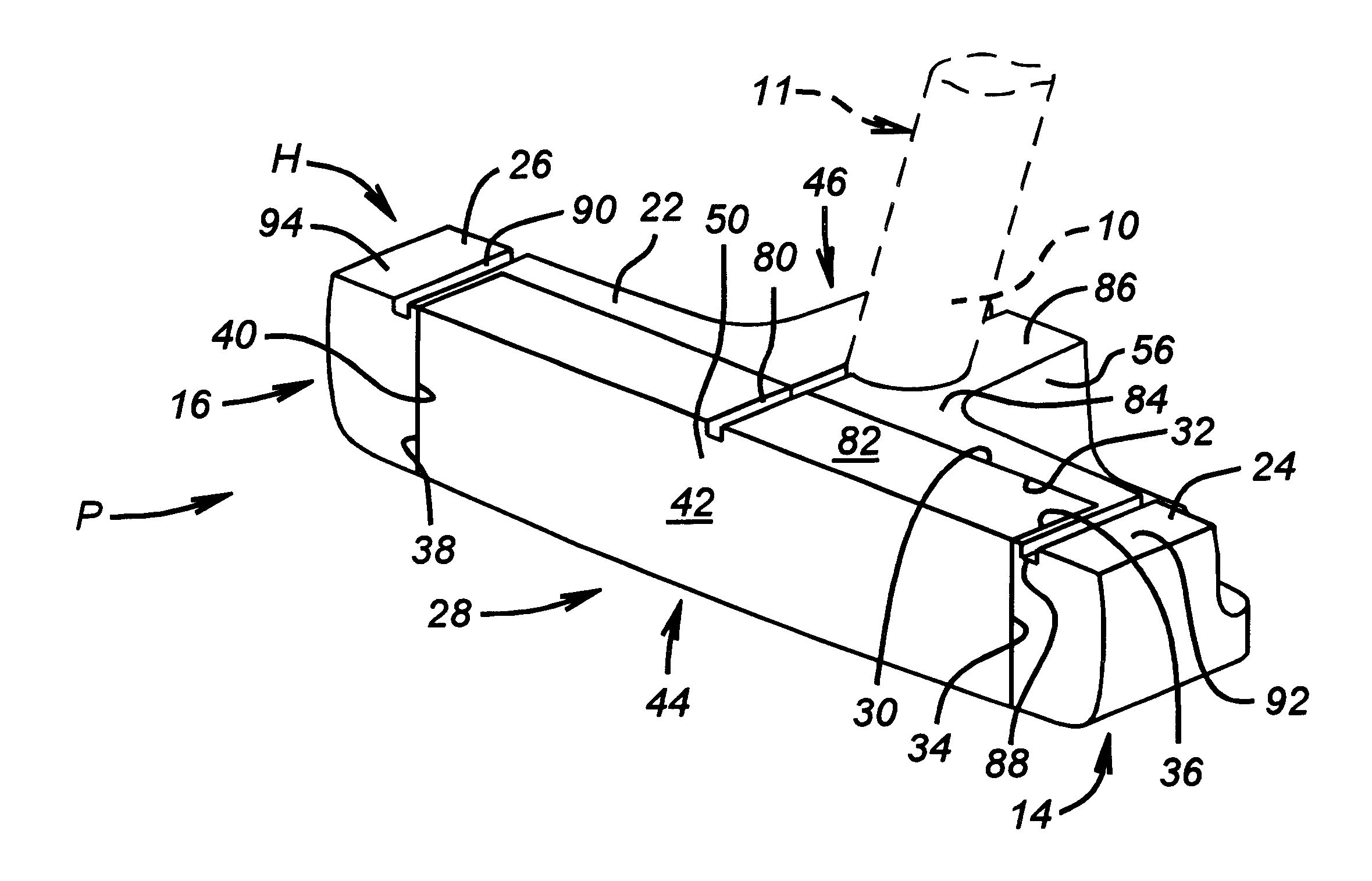

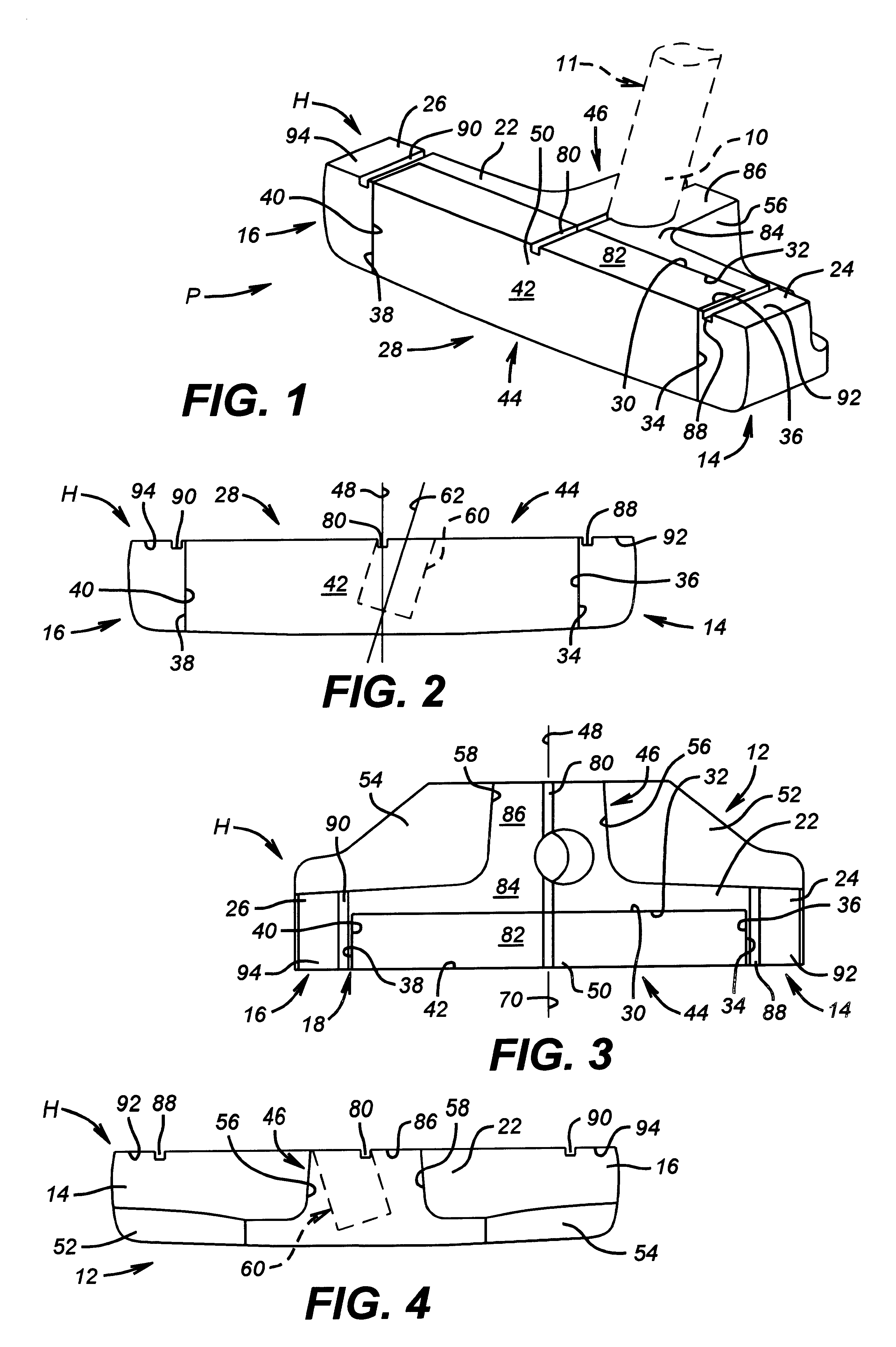

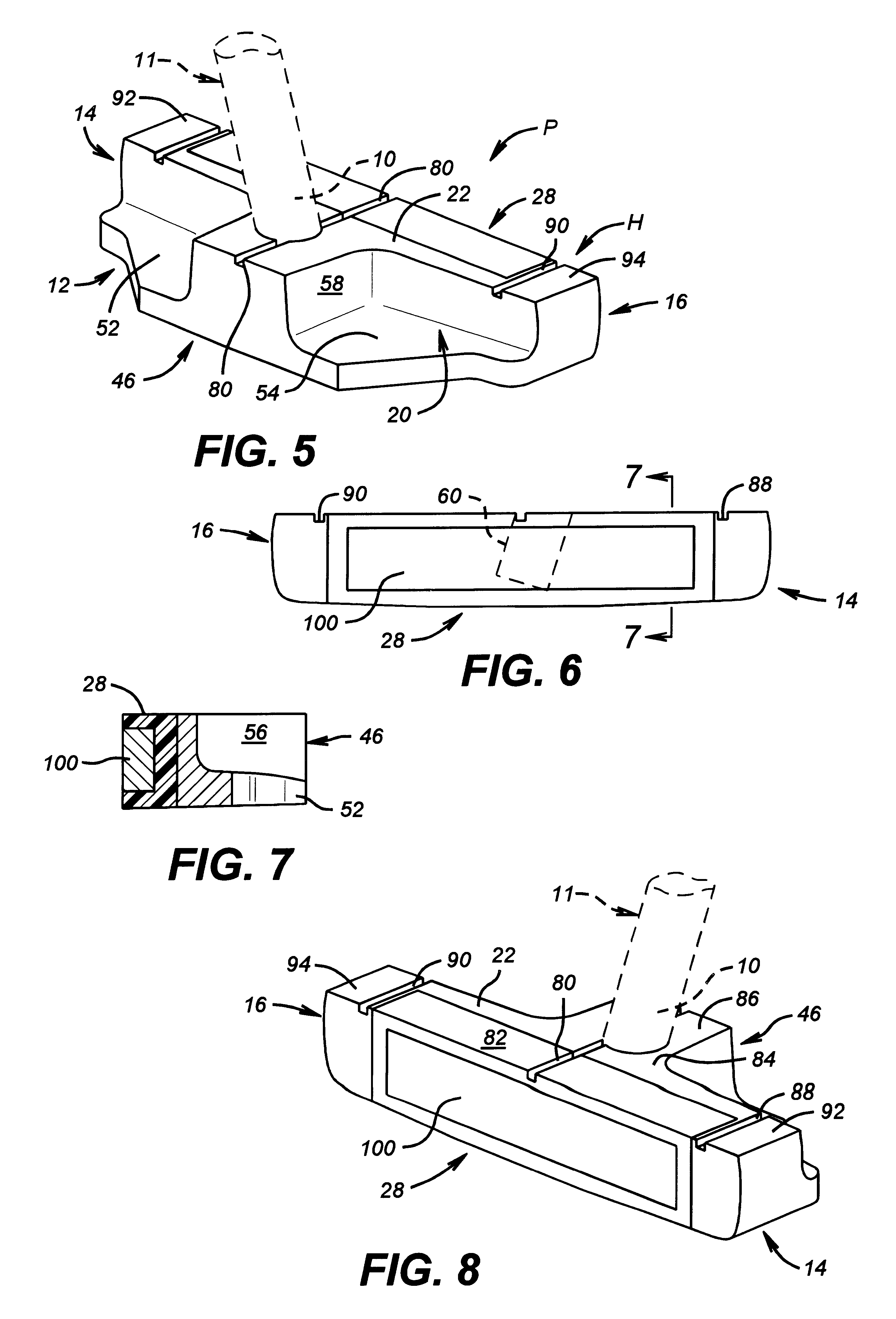

Apparatus for quick connection

InactiveUS6926311B2Eliminate disadvantagesSoft touchSleeve/socket jointsEngine sealsEngineeringMechanical engineering

Owner:APEX MEDICAL CORPORATION

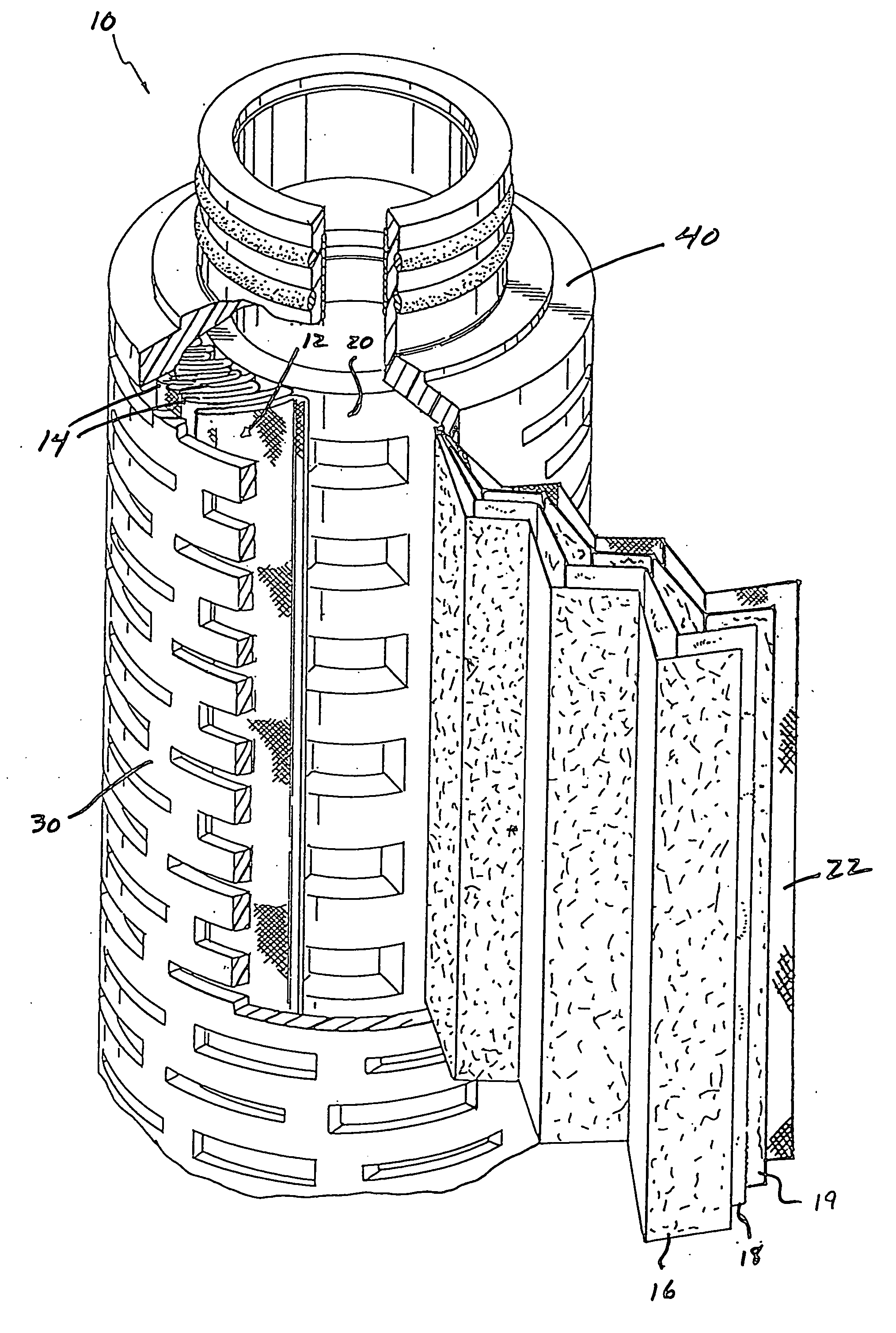

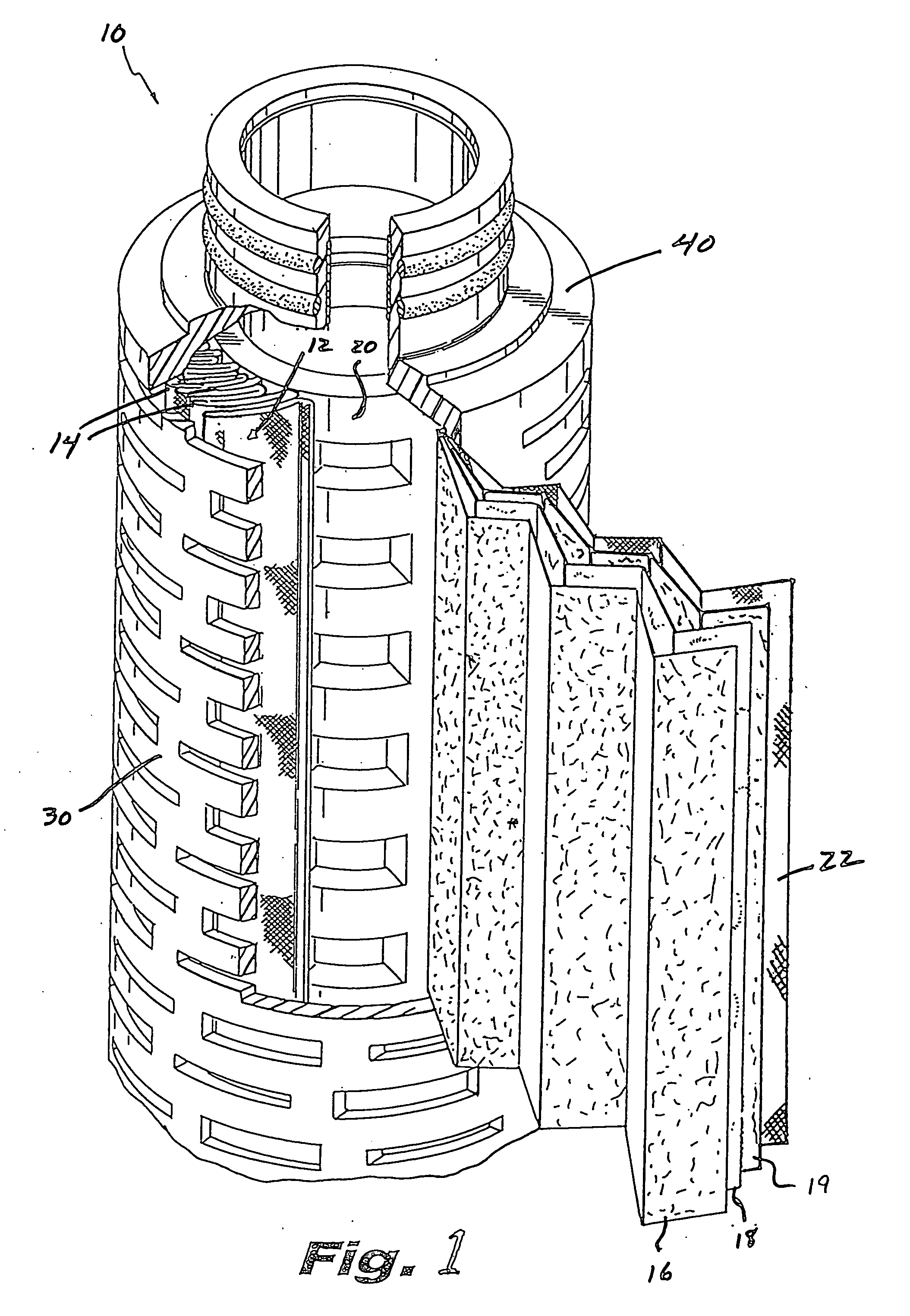

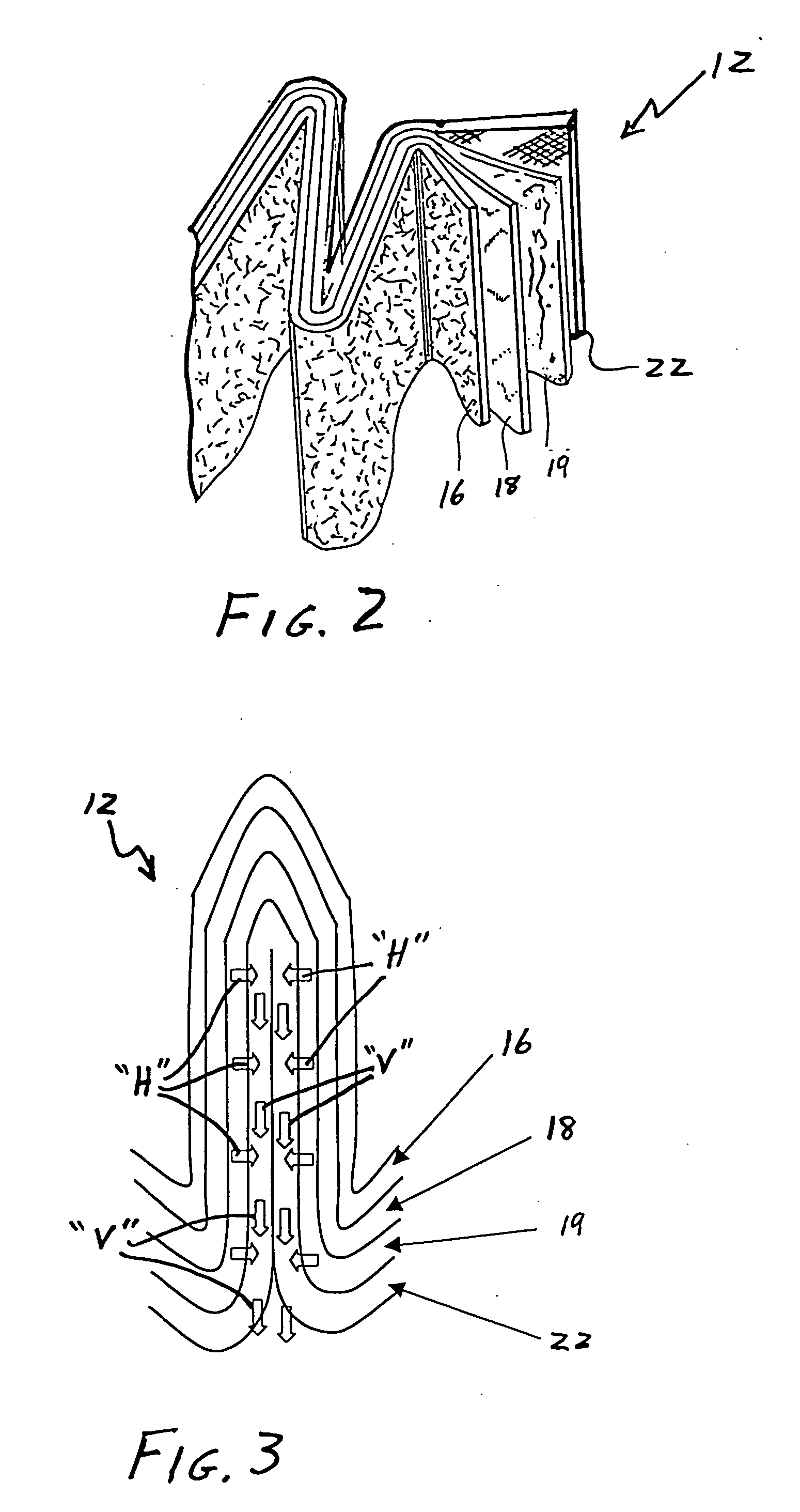

Multi-layer pleat support filter construction

InactiveUS20040060858A1Superior filtration performanceImprove flowSemi-permeable membranesMembrane filtersEngineeringStreamflow

A filter element is disclosed that includes a filtration media, an upstream pleat support and a multi-layer downstream pleat support. The multi-layer downstream support includes a first downstream support layer and a second downstream support layer. The first downstream support layer is in contact with the filtration media and is interposed between the filtration media and the second downstream layer. The first downstream support layer is fabricated so as to minimize points of surface contact with the filtration media, thereby enhancing fluid flow away from the filtration media. The second downstream support layer is in contact with the first downstream support layer and is fabricated so as to facilitate lateral fluid flow relative to the multi-layer downstream pleat support. The disclosed filter element may be utilized in filter cartridges of various designs to provide enhanced filtration performance, e.g., by way of increased media area and improved flow / throughput.

Owner:3M INNOVATIVE PROPERTIES CO

Golf putter

A golf putter improves a golfer's ability to consistently impart a smooth putting stroke on the ball. The putter has an elastomer insert extending over a ball striking surface formed on the head of the club head. An inertial mass or ballast is formed at a rear central portion of the club head, with center portions of the ballast mass aligned with the vertical center line of the ball striking surface. The shaft portion of the putter is connected to the club head so that the longitudinal axis of the shaft intersects the center line of the club head and the inertial mass. The club head also has a base plate portion to assist the golfer in club grip and alignment during "set up" before the actual putting stroke.

Owner:WRIGHT VERNON V

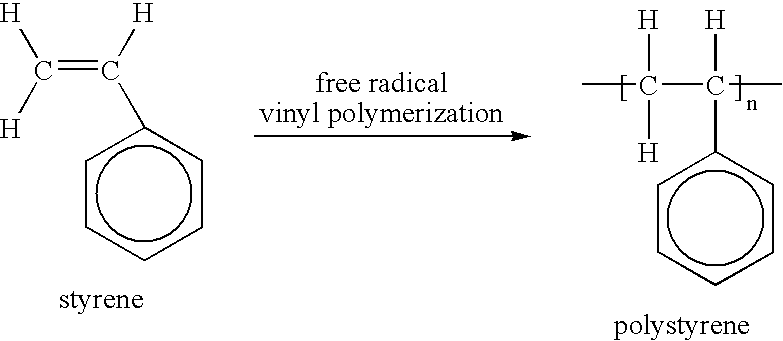

Thermoplastic elastomer composition

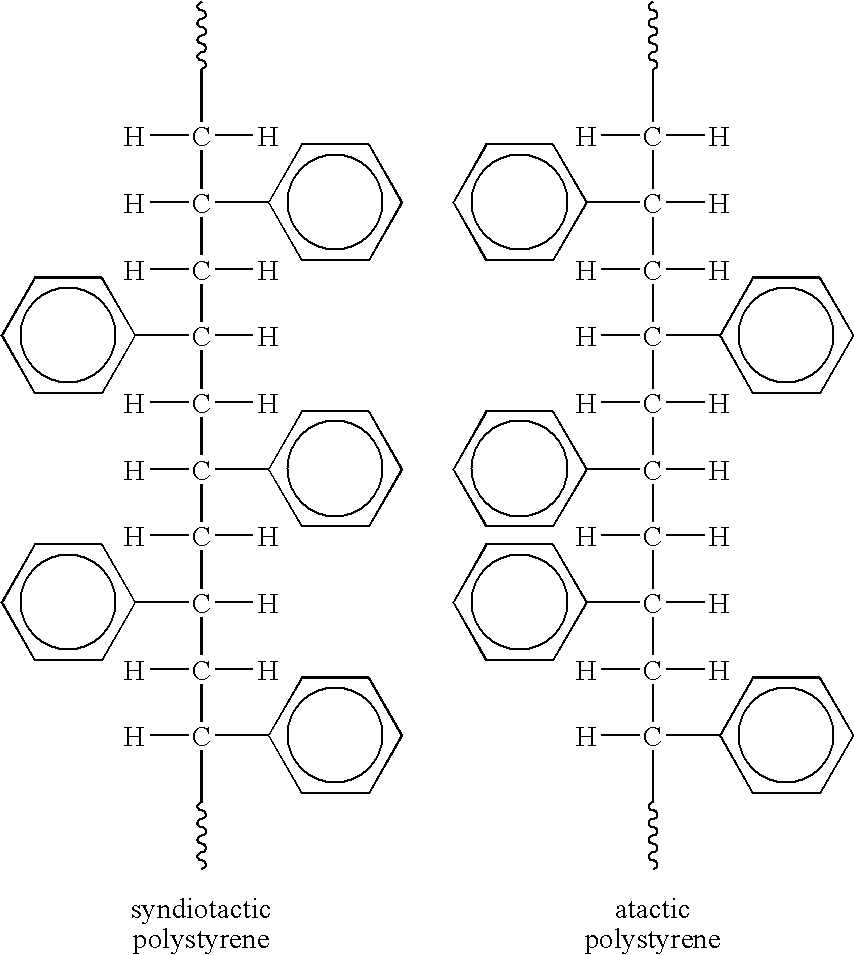

InactiveUS20050288393A1Low costGood oil resistanceFilm/foil adhesivesCoatingsThermoplastic elastomerPolystyrene

A thermoplastic elastomer composition comprised of (a) a thermoplastic resin selected from the group consisting of polyphenylene ether, polypropylene, polyethylene, and polystyrene, (b) a block copolymer selected from the group consisting of styrene-ethylene butylene-styrene, styrene-ethylene propylene-styrene, hydrogenated polybutadiene, hydrogenated polyisoprene, hydrogenated styrene-isoprene random copolymer, styrene-ethylene propylene block copolymer, styrene-ethylene ethylene propylene-styrene and hydrogenated styrene-butadiene random copolymers, (c) a core-shell polymer comprised of a polymeric core and a polymeric shell with the proviso that the polymeric core and / or the polymeric shell may be crosslinked, and (d) an oil.

Owner:THE GOODYEAR TIRE & RUBBER CO

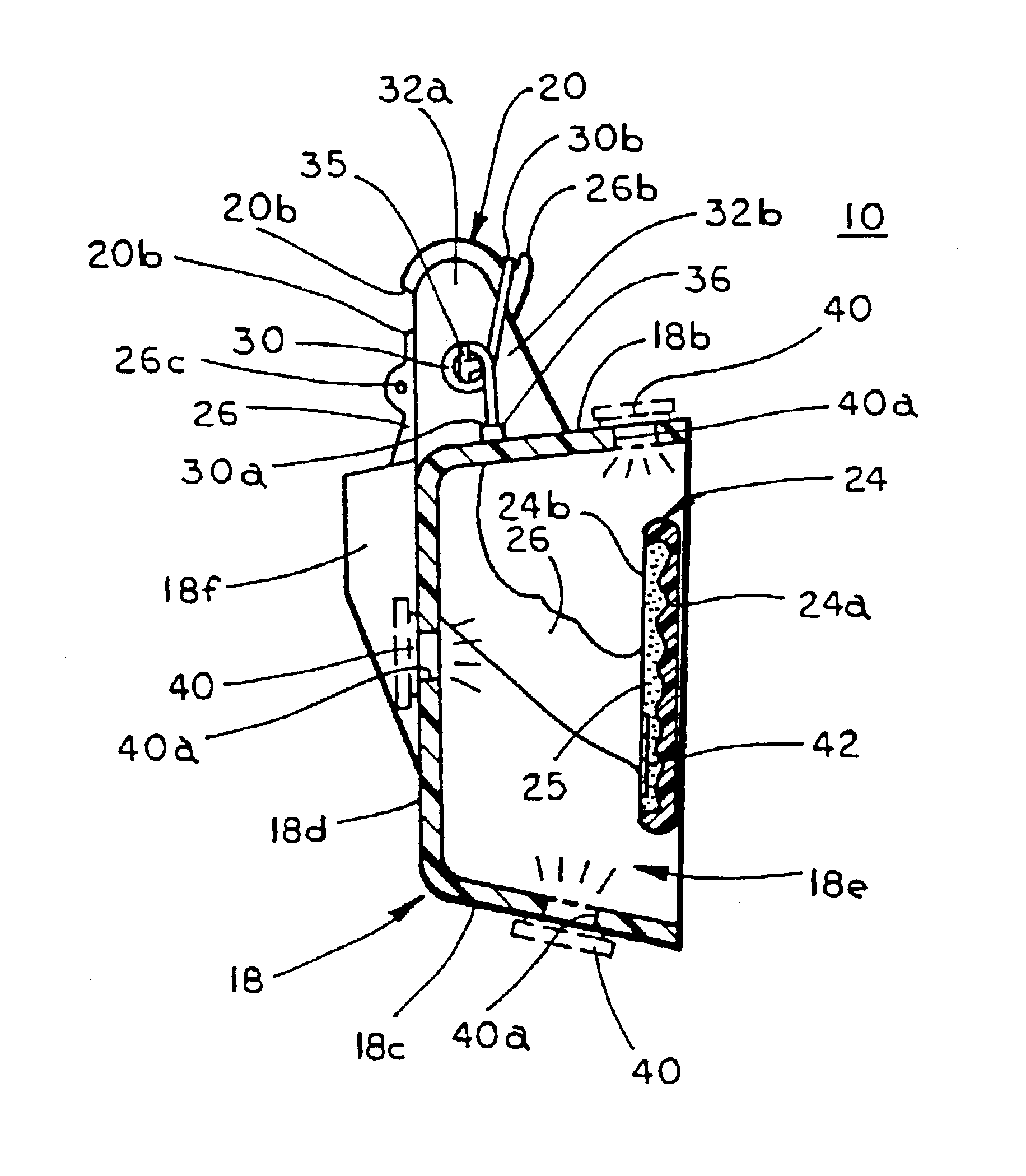

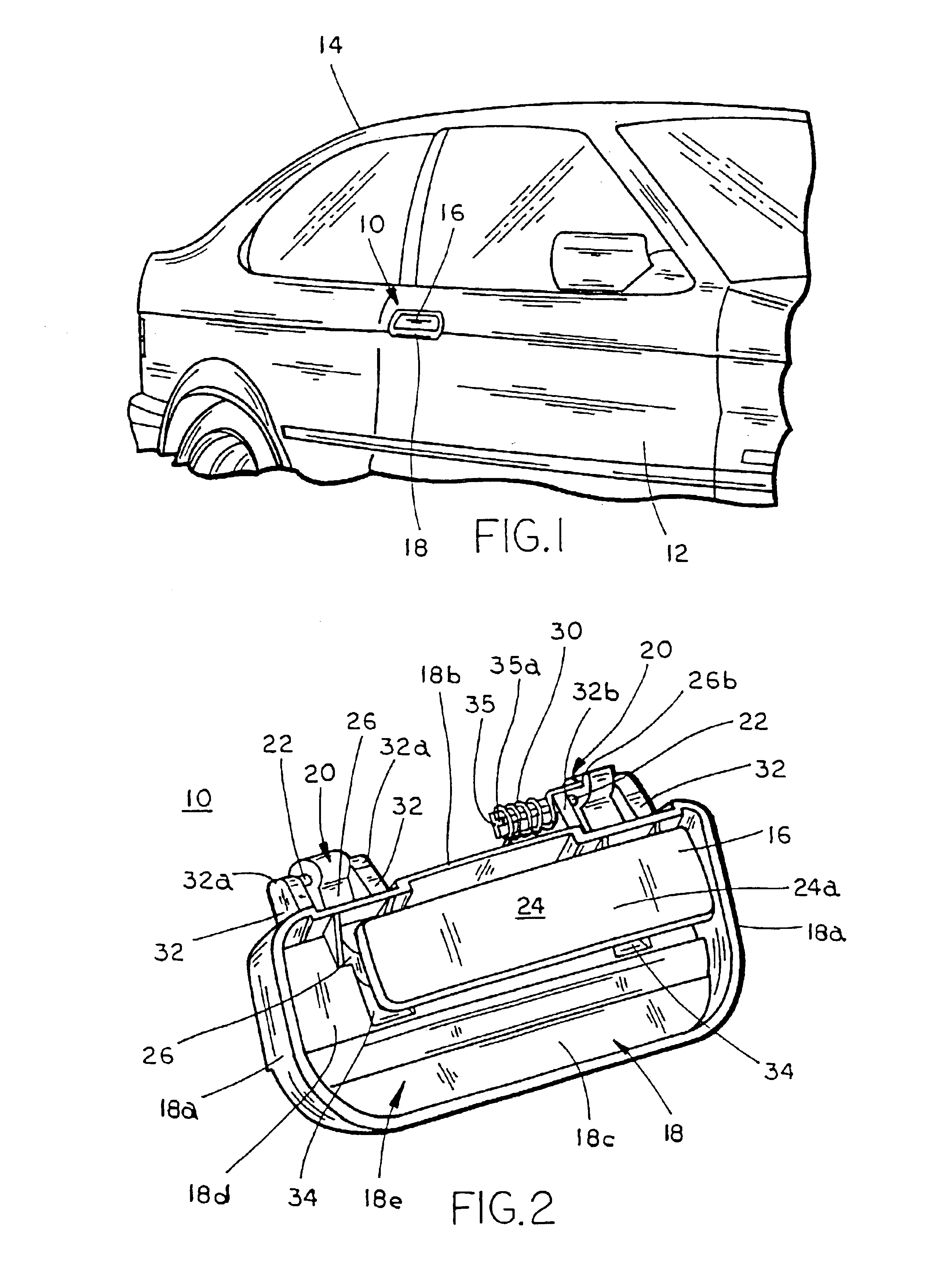

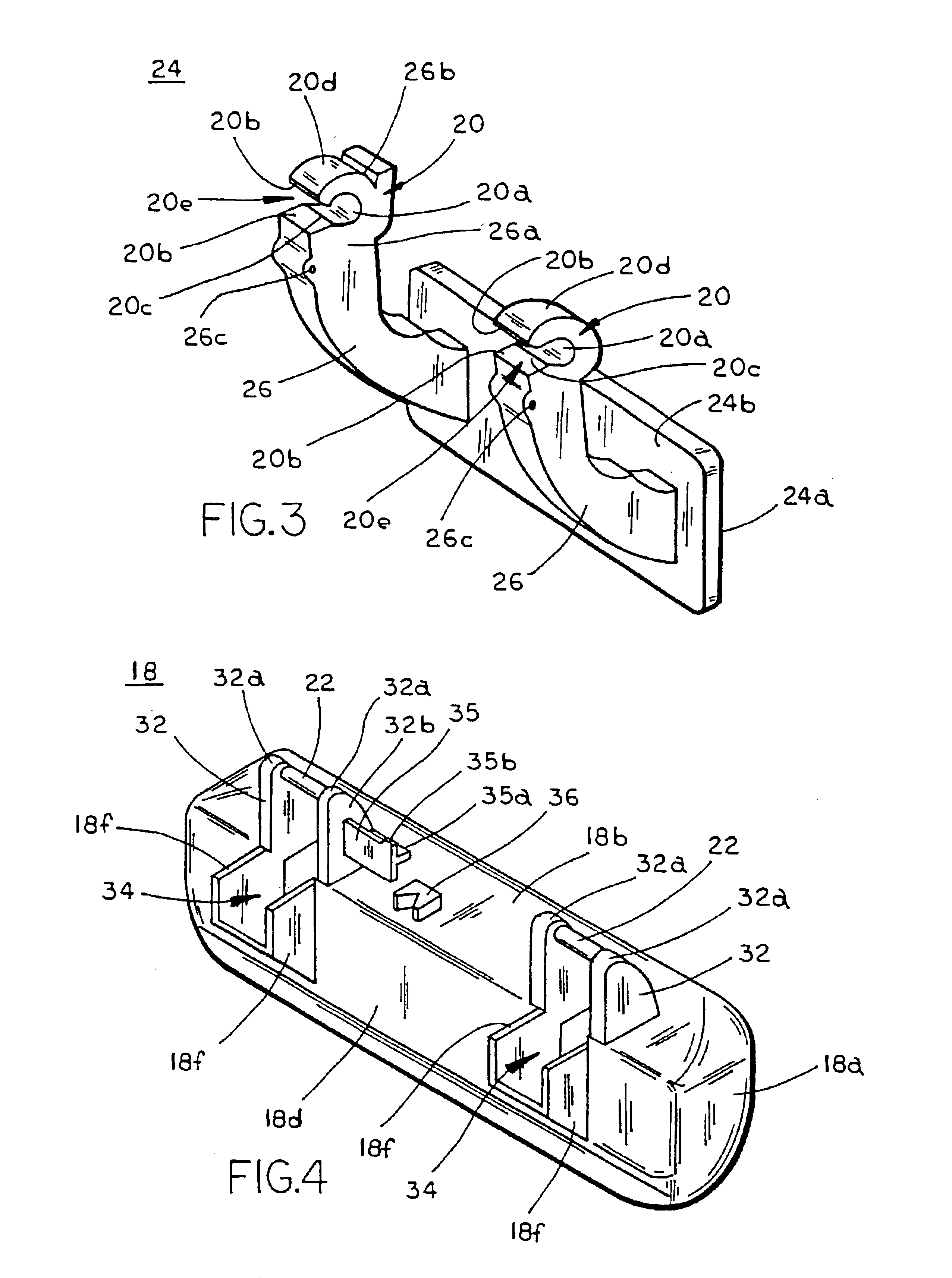

Vehicle door handle

A vehicle door handle assembly for opening a door of a vehicle includes a base which is mountable at the door of the vehicle and a handle portion which is operable to open the door via movement of the handle portion relative to the base. The handle portion includes a first portion having a first material hardness and a second portion having a second material hardness. The first material hardness is greater than the second material hardness, such that the second portion provides a softer feel to a user of the door handle assembly when opening the door of the vehicle. The door handle assembly may further include an illumination source for illuminating the handle portion and / or a heating element for heating the handle portion.

Owner:DONNELLY CORP

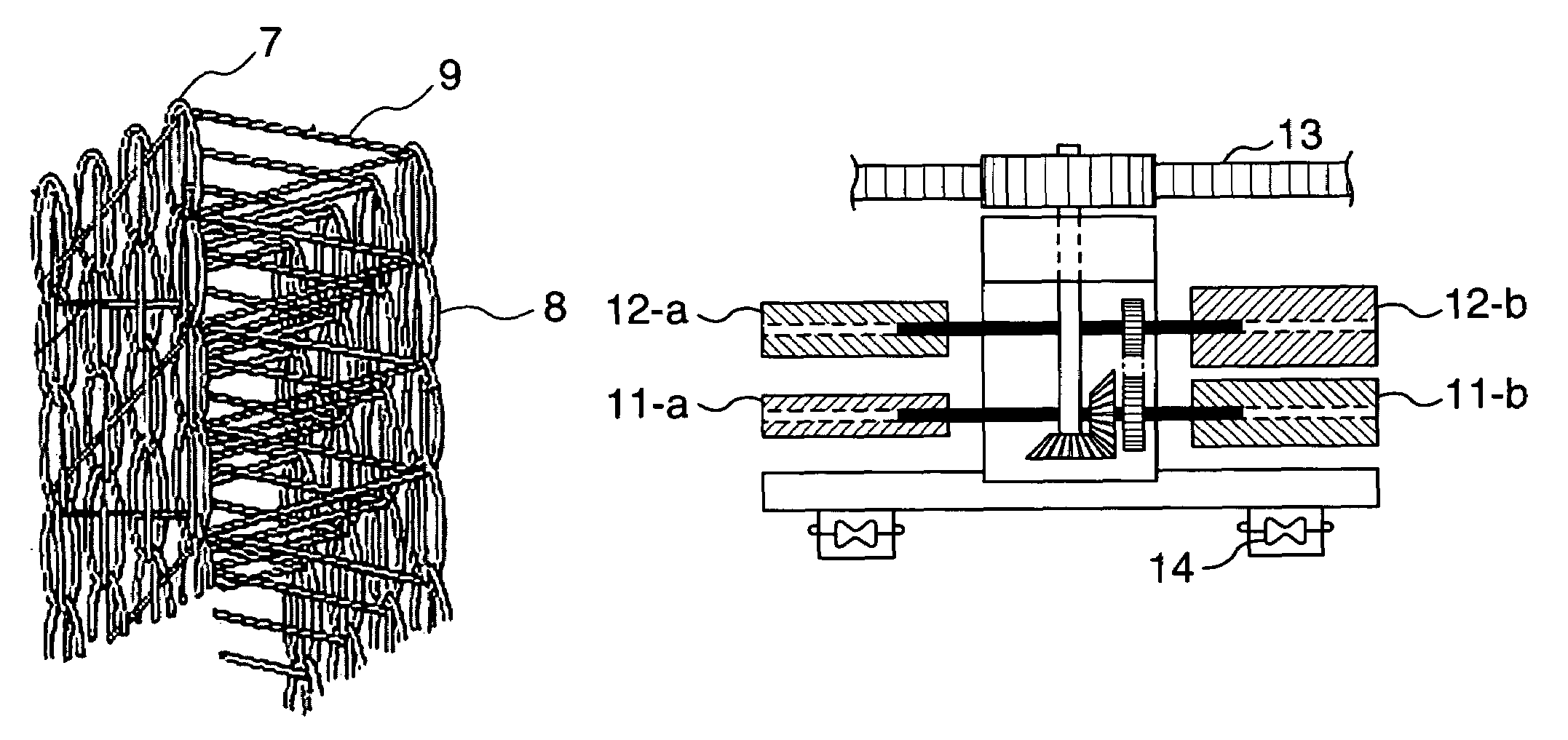

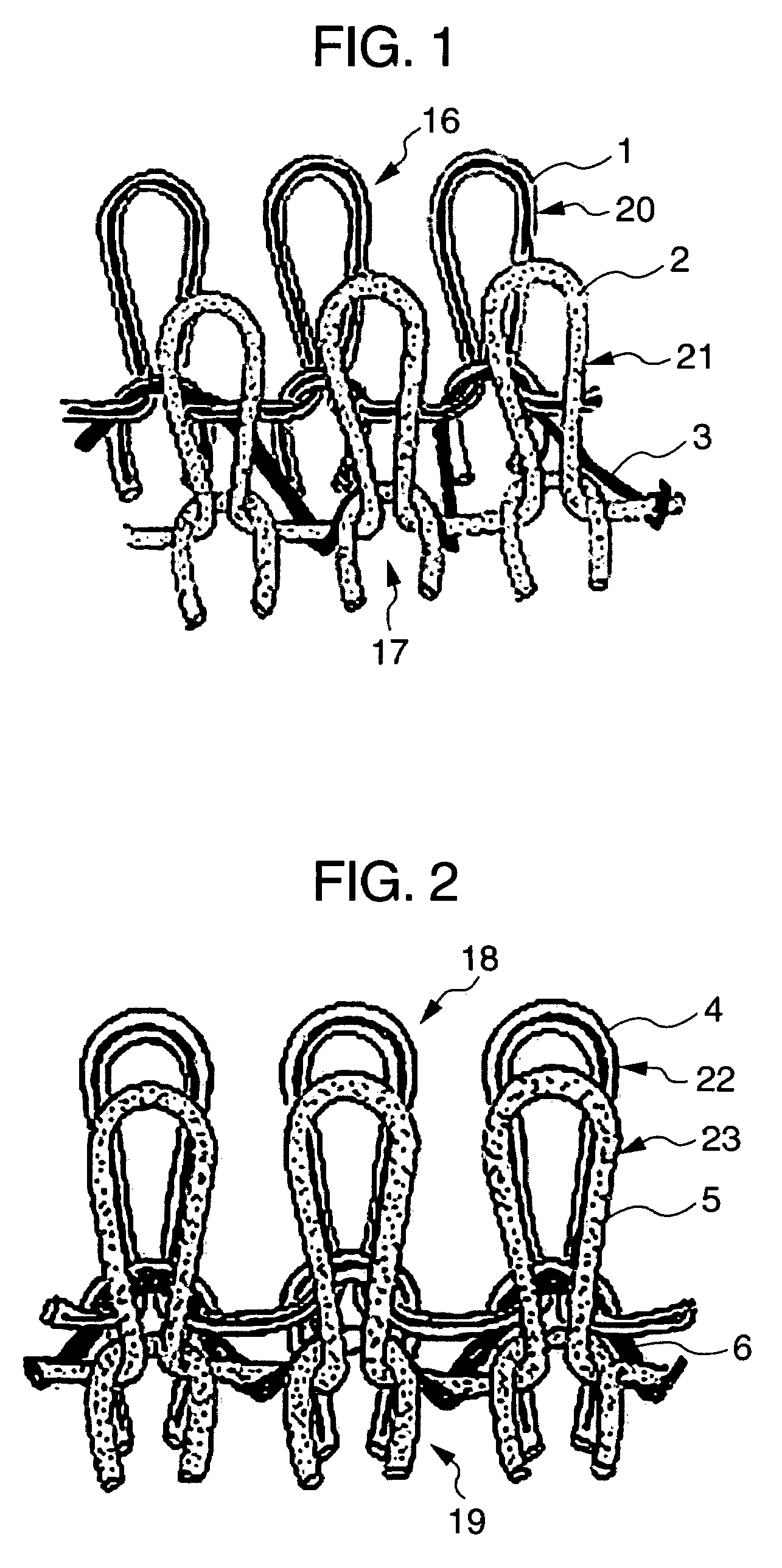

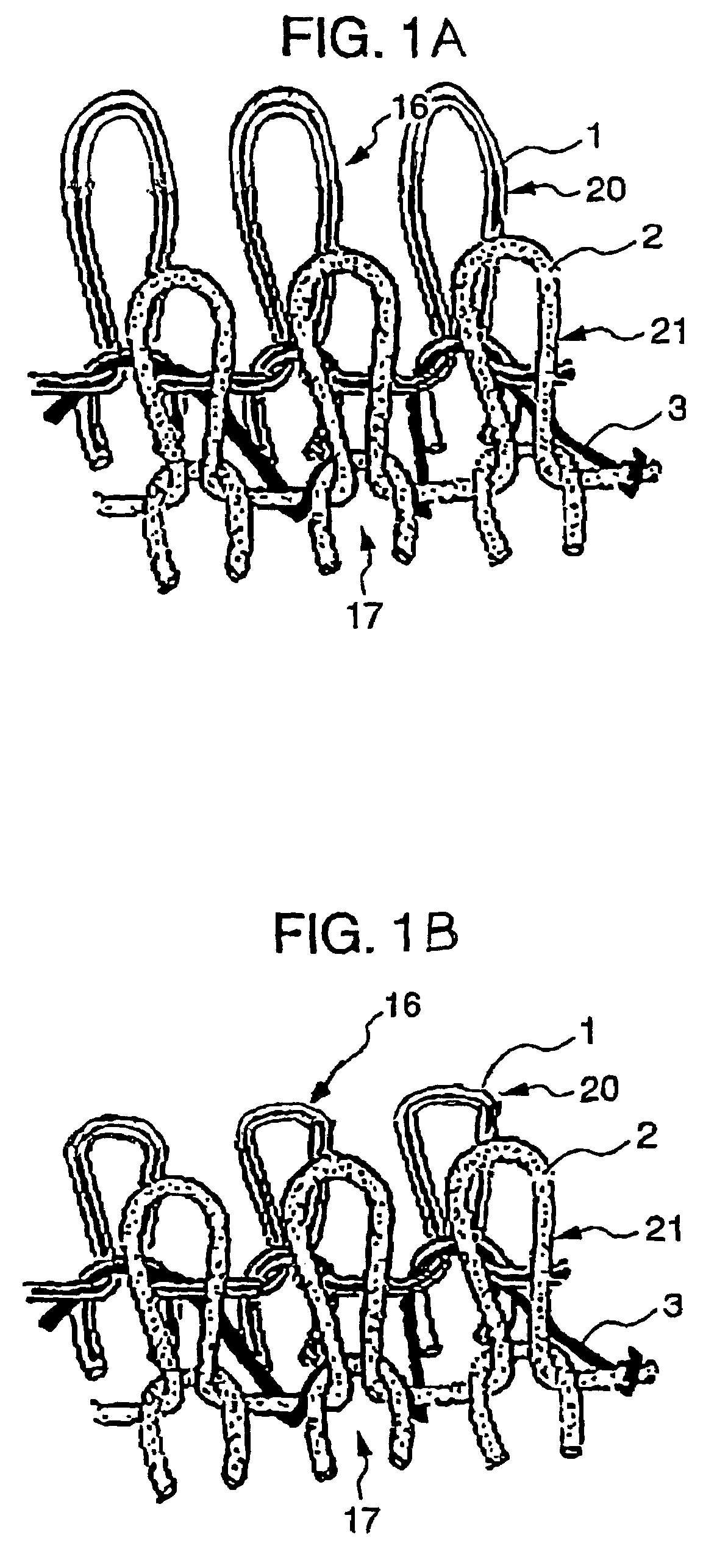

Elastic knitting fabric having multilayer structure

InactiveUS7240522B2Improve tensile propertiesImproved shape stabilityOrnamental textile articlesStraight-bar knitting machinesFiberElastic fiber bundle

An elastic knitted fabric having a multilayer structure, made by binding separate front and back two-layer ground knitted fabrics together, wherein the above described two-layer ground knitted fabrics are bound together with only a bare string(s) of polyurethane based elastic fibers of 17 to 3000 decitexes.

Owner:ASAHI KASEI FIBERS CORPORATION

High-strength stretch-proof flame-retardant textile

InactiveCN101748549ASolve the difficulty of weavingSolve not easy to dyeWoven fabricsYarnCompound aEngineering

The invention provides a high-strength stretch-proof flame-retardant textile. The flame-retardant textile is formed by weaving a flame-retardant composite yarn, wherein the flame-retardant composite yarn is formed by compounding a core yarn and a leather yarn and is one of a covering yarn and a fasciated yarn; the core yarn adopts a flame-retardant filament yarn as a raw material; the leather yarn adopts a flame-retardant short fiber as a raw material; and the weight ratio of the flame-retardant filament yarn to the flame-retardant short fiber is 30-90:10-70. Compared with the conventional flame-retardant textile, the high-strength stretch-proof flame-retardant textile has higher strength and overcomes the defects of difficult weaving, difficult dyeing and uncomfortableness of the high-strength fiber; the high-strength stretch-proof flame-retardant textile has permanent flame retardance which cannot decrease after the textile is washed, and better textile strength; the textile has soft and comfortable handfeel, rich color and good strength, meets the requirements of various flame-retardant clothes and related standards; the product has rich and varied appearances and is durable; and the combustion performance of the textile can meet the national standards of flame-retardant products.

Owner:汕头市奥山服饰有限公司

One step hair coloring using salts

InactiveUS20060137111A1Superior lift and dyeing propertyHigh levelCosmetic preparationsHair cosmeticsSalt contentAmmonium carbonate

Owner:UNILEVER HOME & PERSONAL CARE USA

Golf ball cover stocks and golf balls

Owner:BRIDGESTONE SPORTS

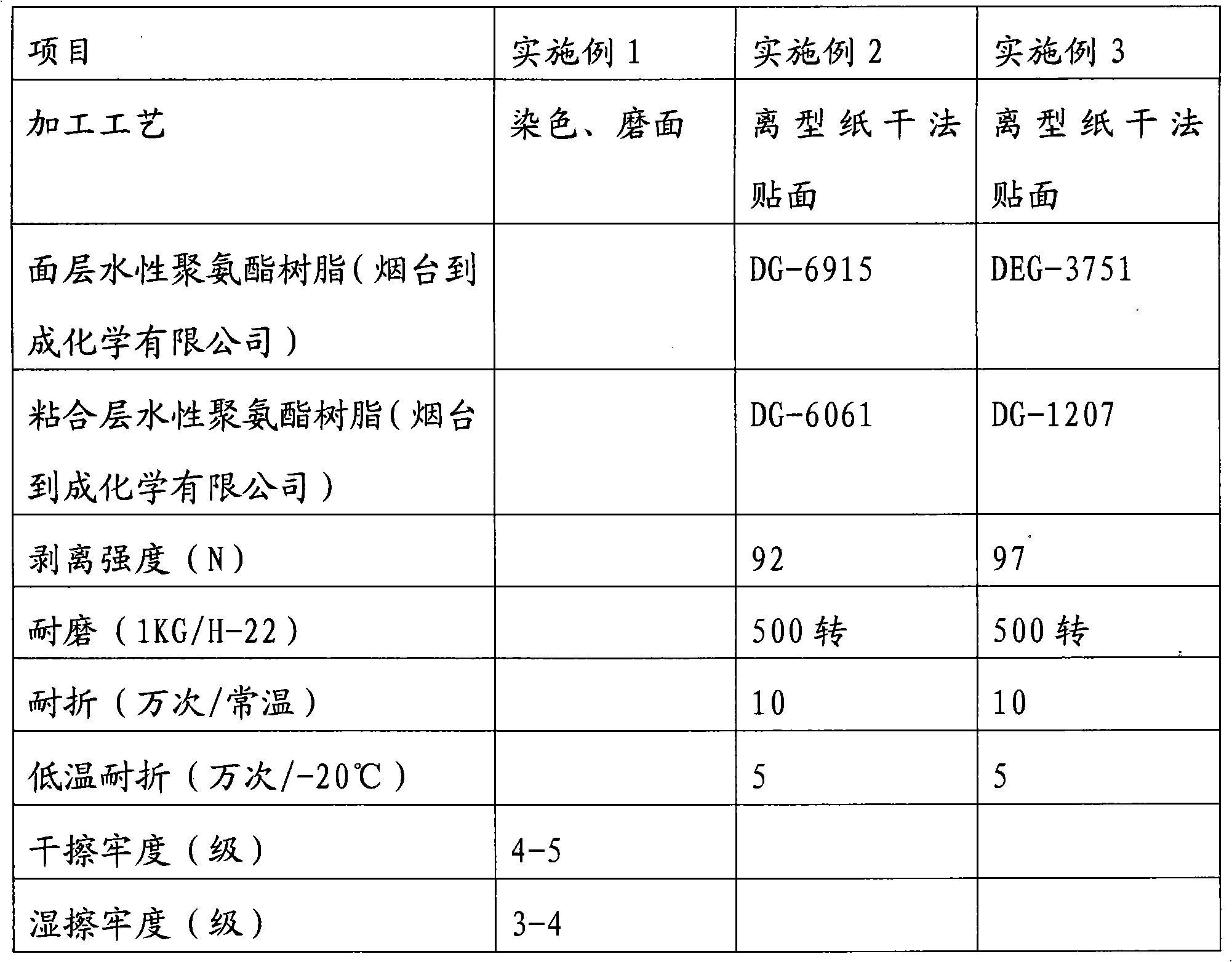

Aqueous polyurethane superfine fiber synthetic leather and preparation method thereof

The invention relates to aqueous polyurethane superfine fiber synthetic leather and a preparation method thereof. The preparation method comprises the following steps of: firstly, adding the following components according to parts by weight, i.e. 2-5 parts of foaming agents, 50-200 parts of water, 2-3 parts of foam stabilizers and 0-3 parts of waterborne colorants, into 100 parts of aqueous anionic polyurethane dipping sizing agents, and stirring the components and the sizing agents uniformly at high speed by using a blender so as to prepare a sizing agent; secondly, dipping non-woven fabricsin the sizing agent, scrapping the surface of the fabrics and keeping partial cells; thirdly, solidifying aqueous polyurethane on the dipped non-woven fabrics through aqueous coagulating liquid so asto form cells; fourthly, carrying out water scrubbing after aqueous polyurethane resin is completely solidified, and drying the aqueous polyurethane resin by an infrared drying oven so as to obtain base cloth; fifthly, treating the dried base cloth through an alkali reducing process; sixthly, treating the base cloth treated through the alkali reducing process through an postprocessing process; and seventhly, preparing the obtained base cloth into the synthetic leather. The aqueous polyurethane superfine fiber synthetic leather is prepared by the method.

Owner:HUADA CHEM GRP CO LTD

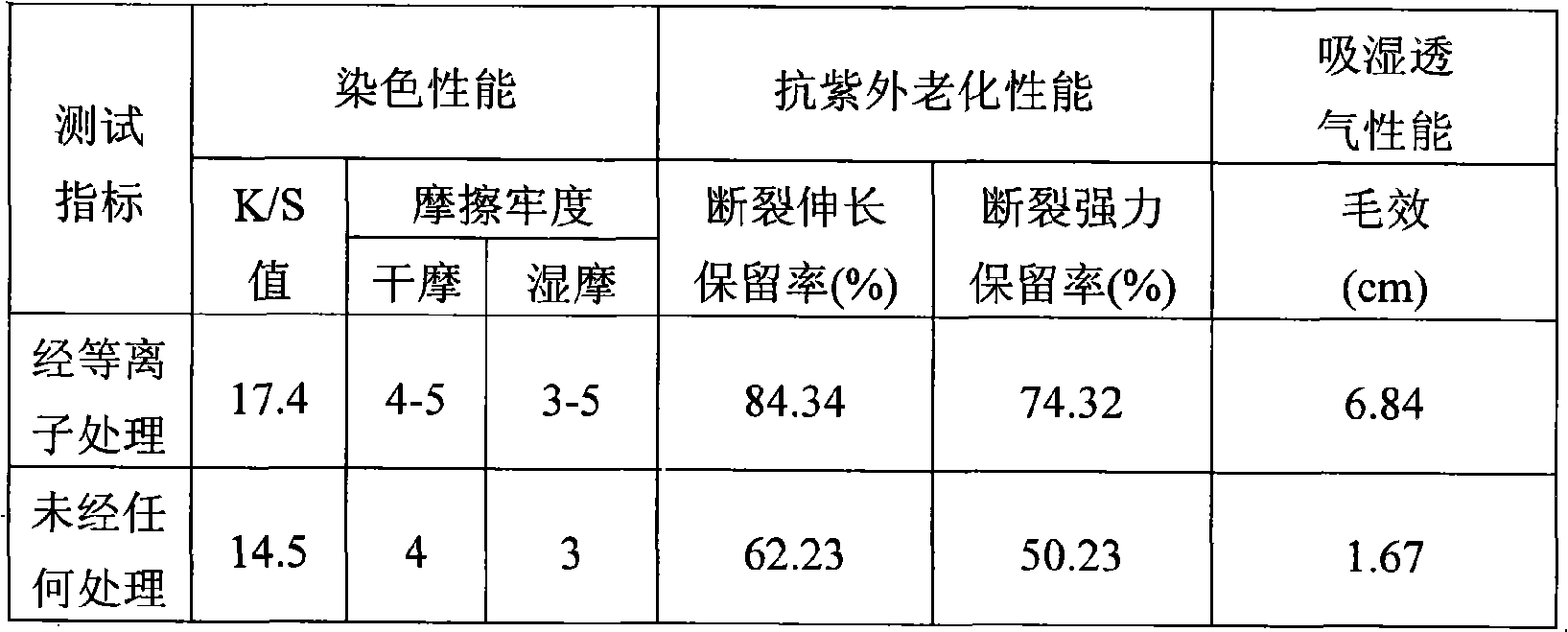

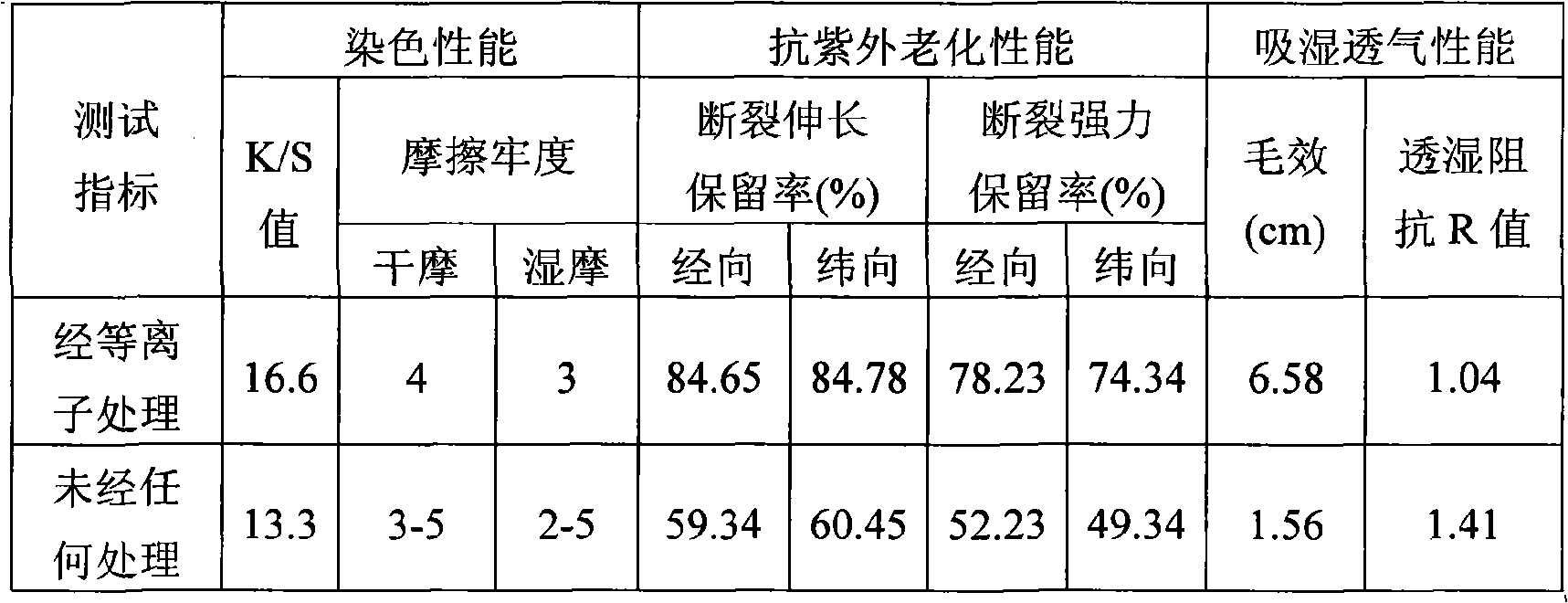

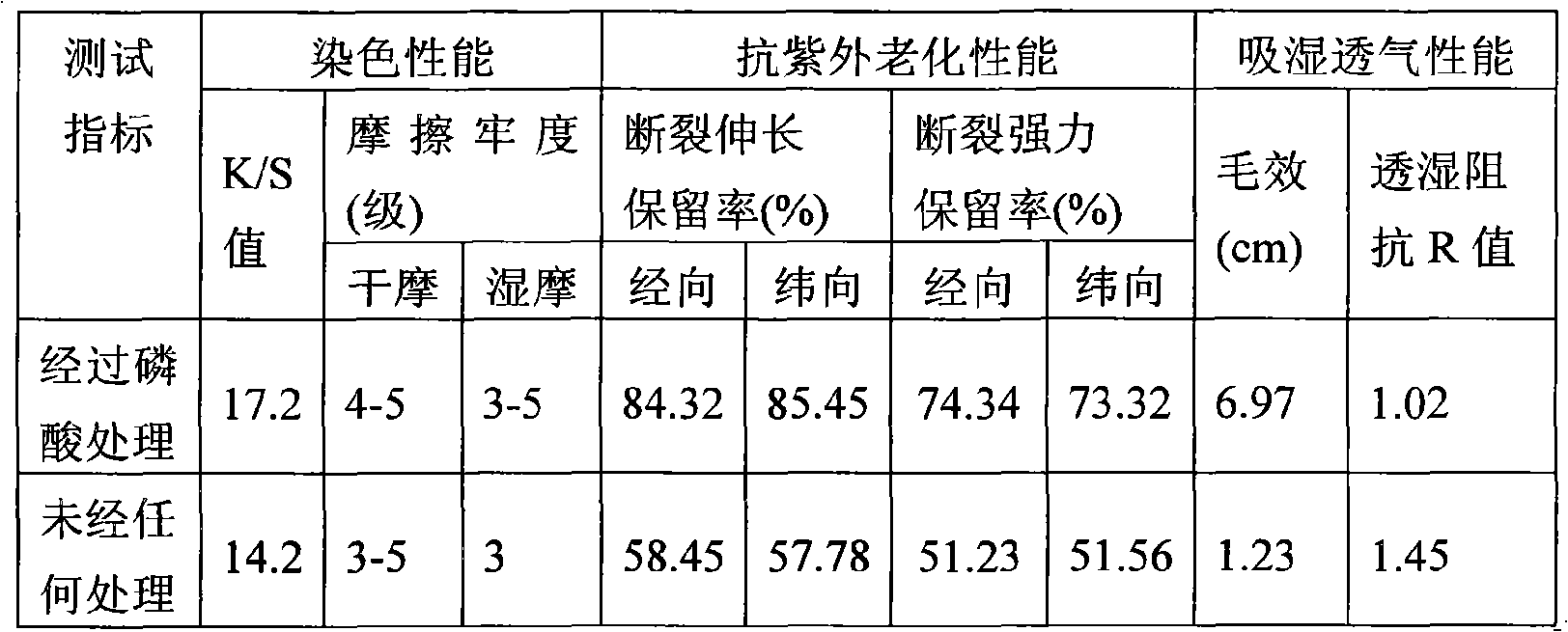

Method for modification, dyeing and multifunctional composite finishing of aramid fiber

InactiveCN101570940ALittle impact on physical and mechanical properties such as strengthEnhanced interactionPhysical treatmentDyeing processChemical industryMoisture permeability

The invention discloses a method for modification, dyeing and multifunctional composite finishing of aramid fiber, and belongs to the technical field of textile chemical industry. Through surface physical and chemical modification for the aramid fiber, the method improves the physical and chemical states of the aramid fiber surface and is favorable for the dyeing and after finishing of the aramid fiber. The specific process flow comprises the following steps of cleaning before the dyeing of the aramid fiber, pretreatment of the aramid fiber, dyeing of the aramid fiber, and multifunctional composite finishing of the aramid fiber. Not only the dyeing property of the aramid fiber treated by the method is remarkably improved, but also the dyeing fastness is good, the aramid fiber has good moisture permeability particularly, and simultaneously the aramid fiber is endued with good anti-ultraviolet ageing function. Moreover, the aramid fiber is subjected to composite finishing by adopting a nano composite sol, and the method has wide applicability, simple process, relatively low treatment cost, and low requirements on the applied technology and equipment.

Owner:JIANGNAN UNIV

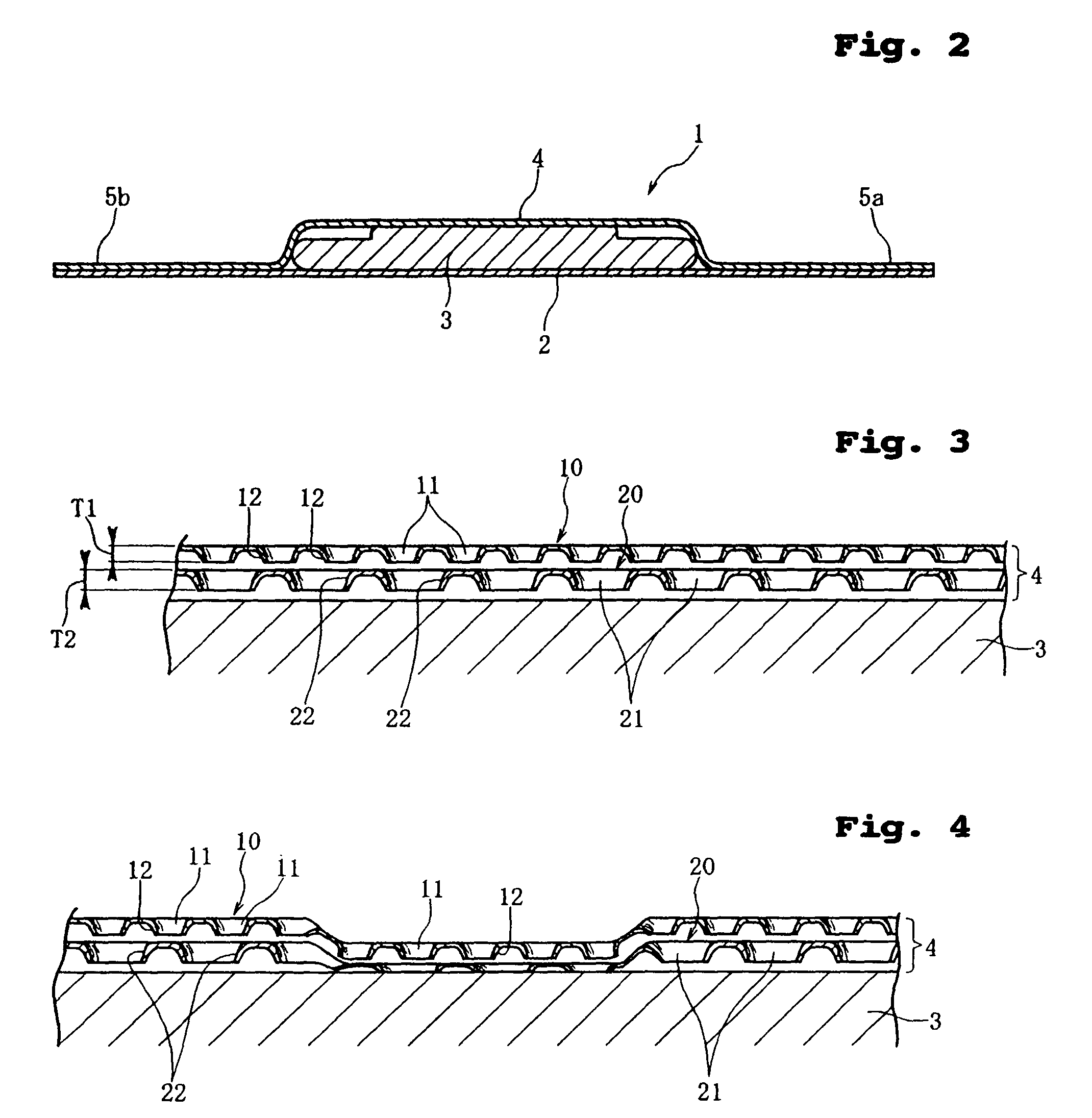

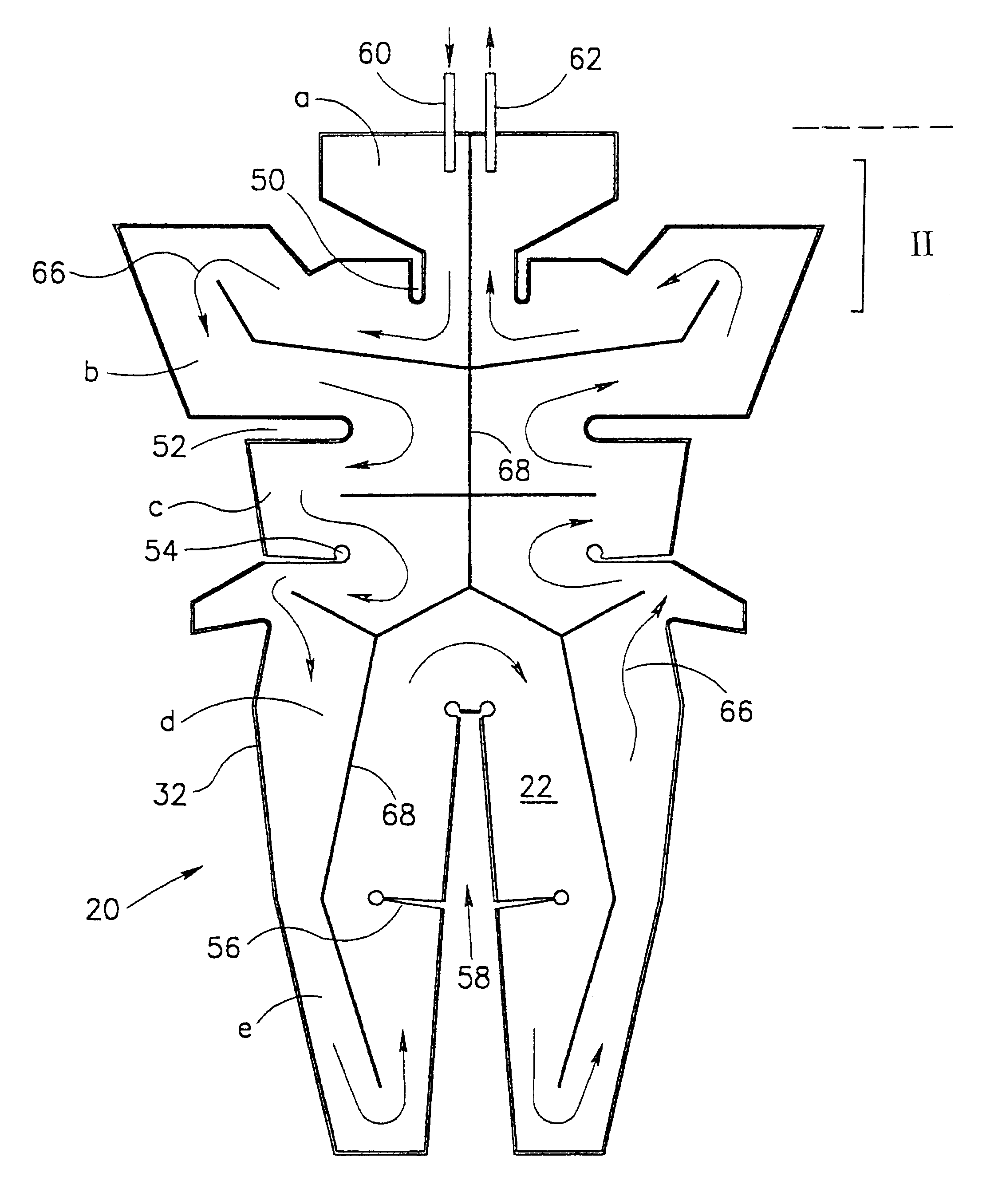

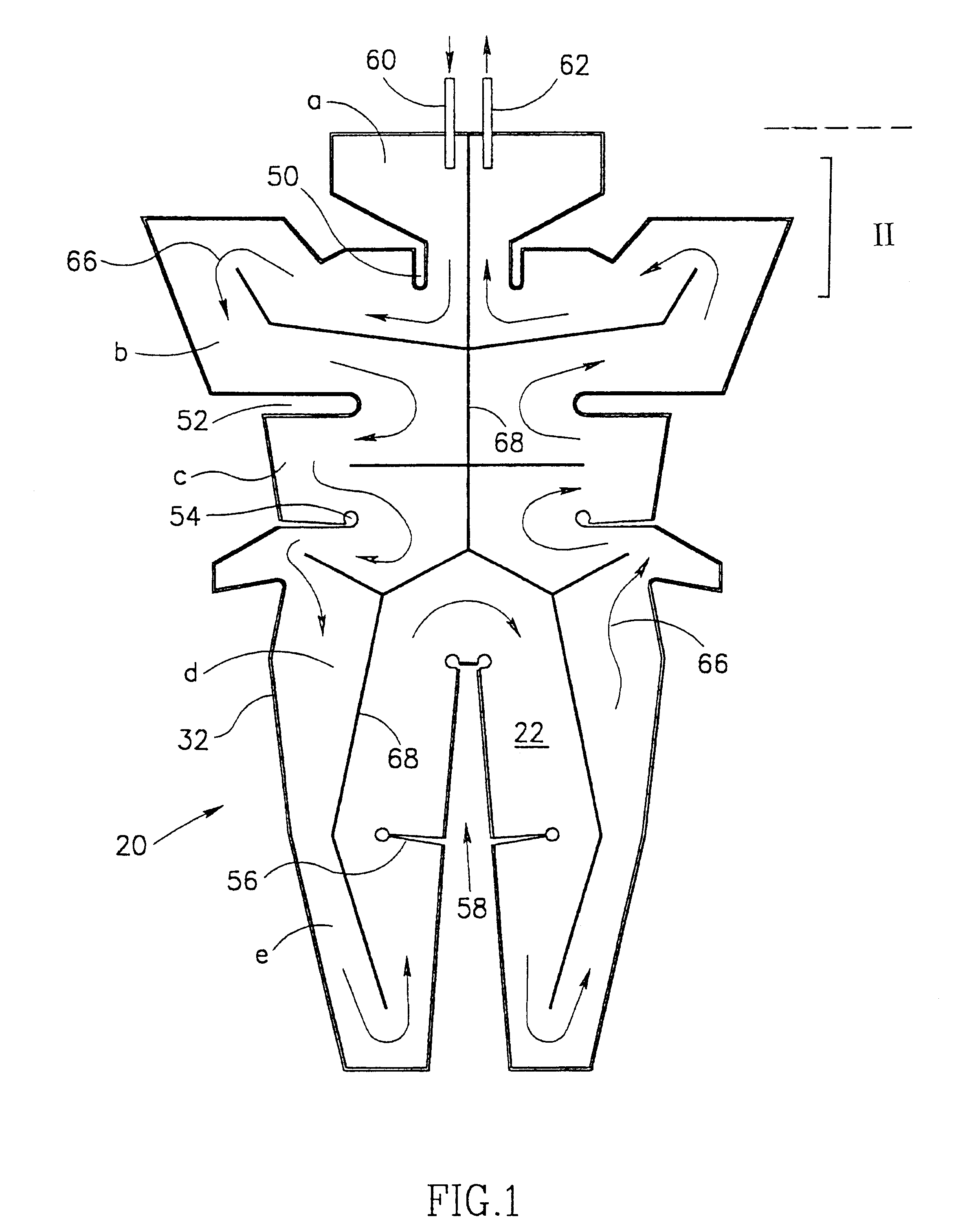

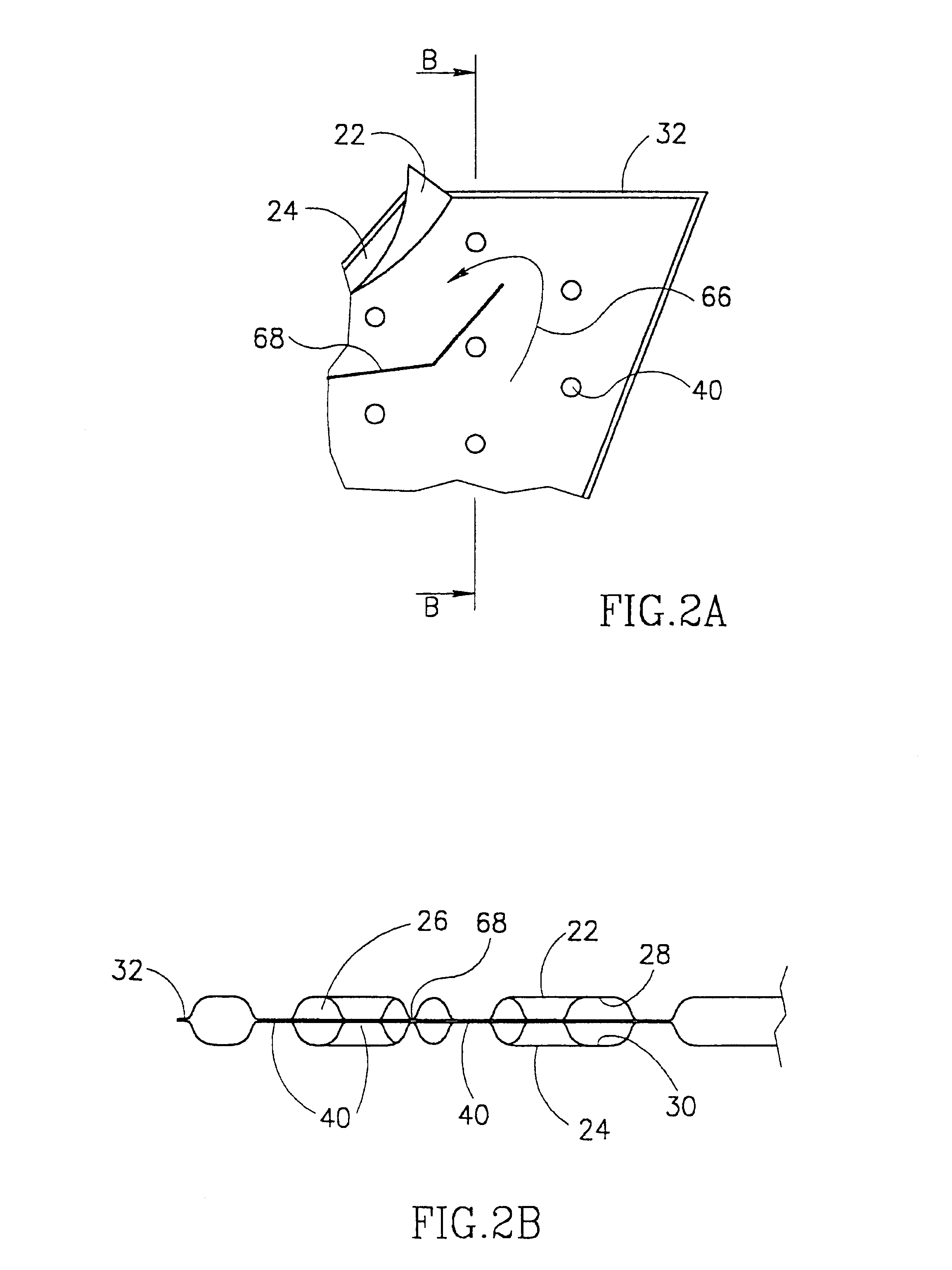

Heat exchanger garment

InactiveUS6500200B1Improved patient 's comfortSoft touchHeat exchange apparatusTherapeutic coolingBody regionControl subjects

A heat exchanger for use in controlling subject's body temperature during a medical procedure comprises a flexible garment adapted for enveloping portions of the subject's body surface with dedicated sections for enveloping different body parts. Defined within the garment is a continuous, fluid tight space, wherein a flow path for heat-control fluid is defined between fluid inlet and fluid outlet. The inner faces of the garment's internal and external layers are made of a heat-weldable material and are point-welded to one another at a plurality of locations throughout the garment with a distance between two adjacent points being between about 8 to about 20 mm.

Owner:CAPITAL ONE NAT ASSOC AS AGENT

Foaming synthetic leather manufacturing technology based on waterborne polyurethane (WPU)

ActiveCN102409554AFeel plumpSoft touchSynthetic resin layered productsTextiles and paperManufacturing technologyMicrosphere

The invention provides a foaming synthetic leather manufacturing technology based on waterborne polyurethane (WPU). In the manufacturing technology, the WPU is taken as a main raw material, and a hollow microsphere foaming agent is taken as a foaming material; and the technology can be widely used for manufacturing synthetic leathers such as clothing leathers, luggage leathers, shoe upper leathers, sofa leathers, home interior trim leathers and the like. The content of volatile organic compounds (VOC) in the finished leather is lower than 2mg / kg (leather), and the air permeability and moisture penetrability are good, thus meeting the EU (European Union) requirements for the ecological synthetic leather; and in addition, the foaming synthetic leather has the advantages of moderate foaming multiplying power, uniform and compact foaming holes, bulky and firm hand feel as well as good comprehensive performance which is equivalent to or superior to that of a solvent-borne product. The foaming synthetic leather manufacturing technology based on the WPU provided by the invention has the beneficial effects that by adopting the WPU instead of the traditional solvent-borne PU, organic pollution is eliminated from a source, organic solvent resources are saved, the comprehensive energy consumption is lowered, the employment environment of laborers is improved, and the ecological grade of the synthetic leather and the international market competitiveness of the product are enhanced, thus achieving obvious innovativeness and remarkable social and economic benefits.

Owner:DONGTAI FUAN SYNTHETIC MATERIAL CO LTD

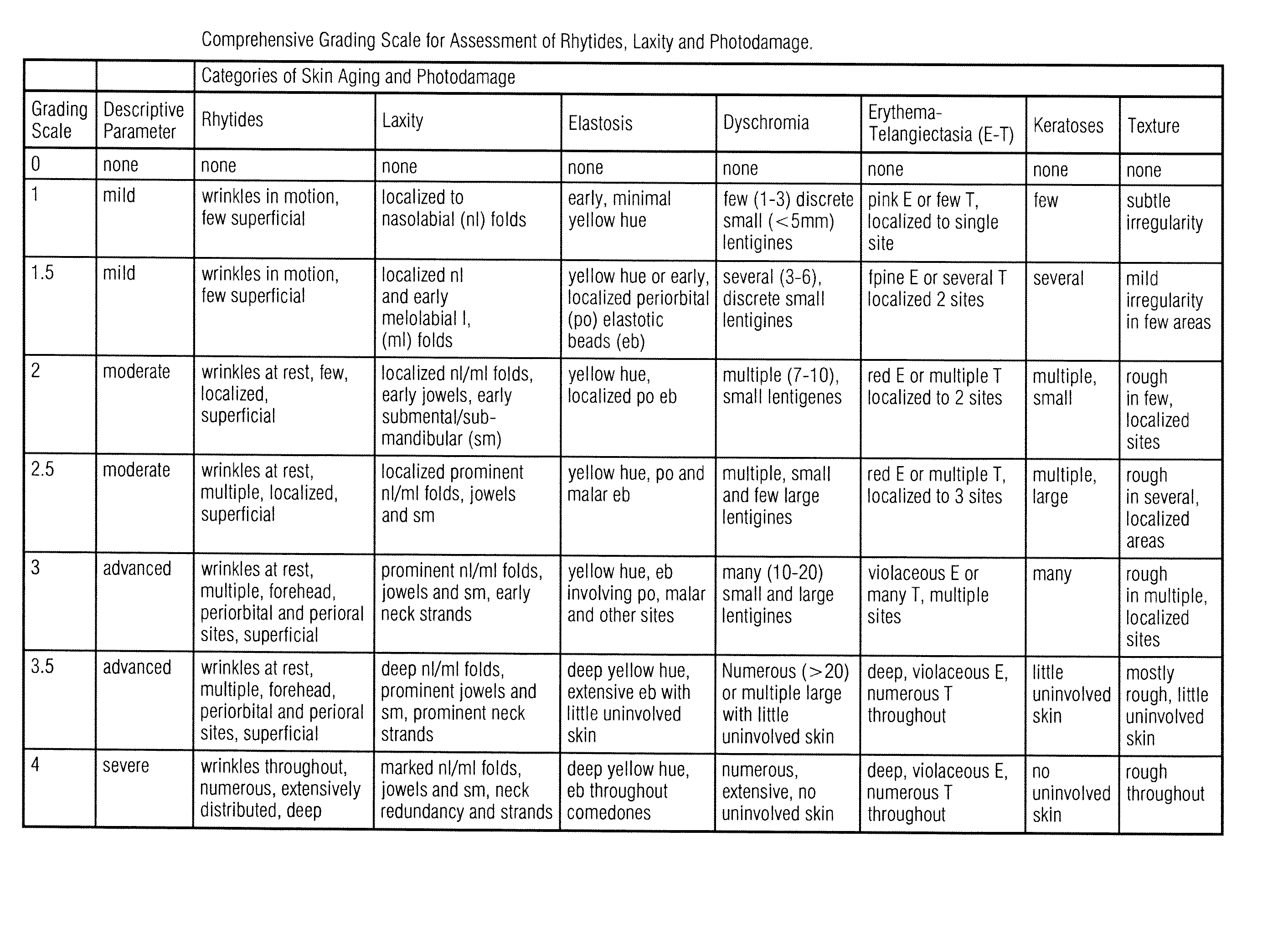

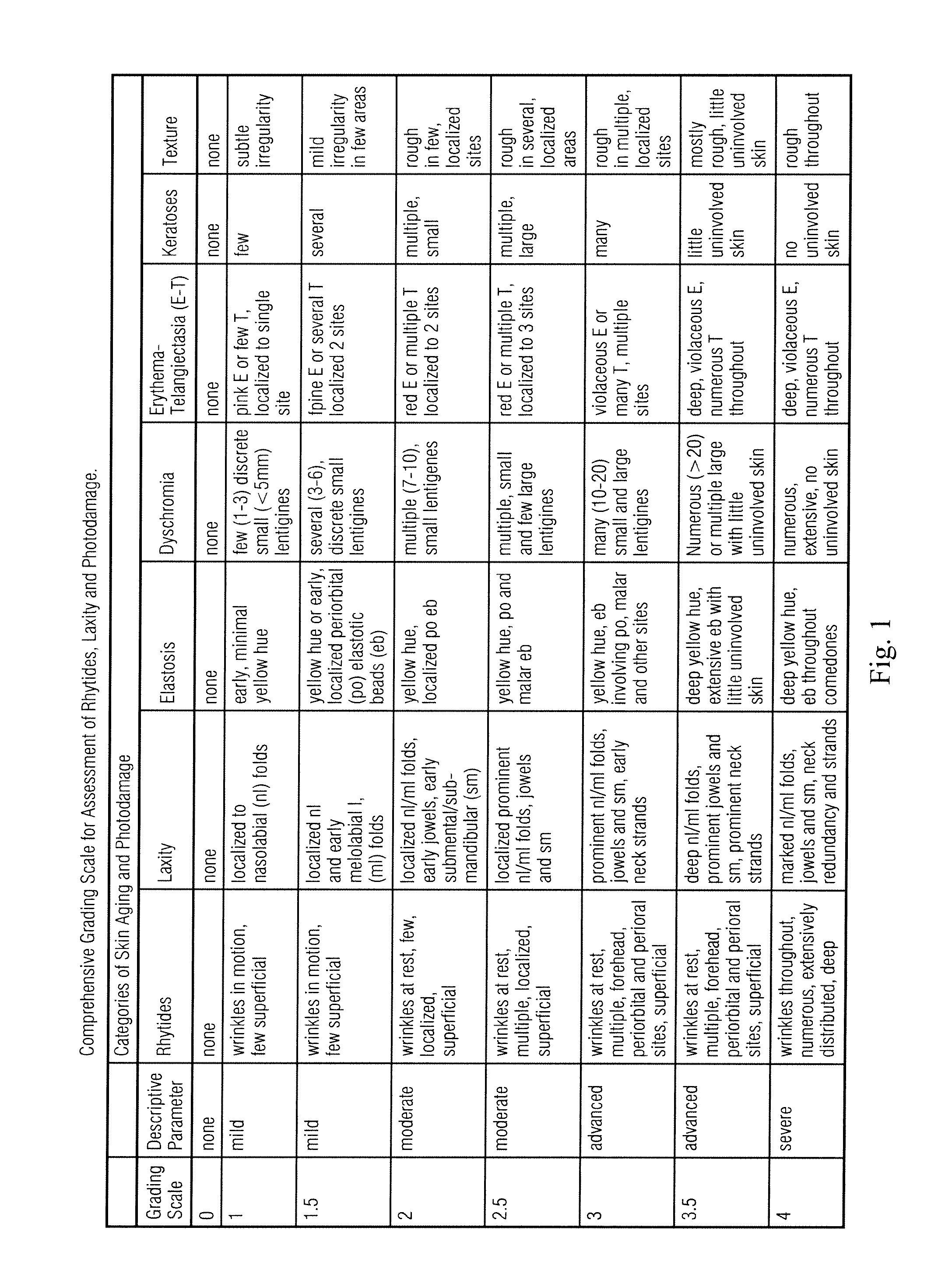

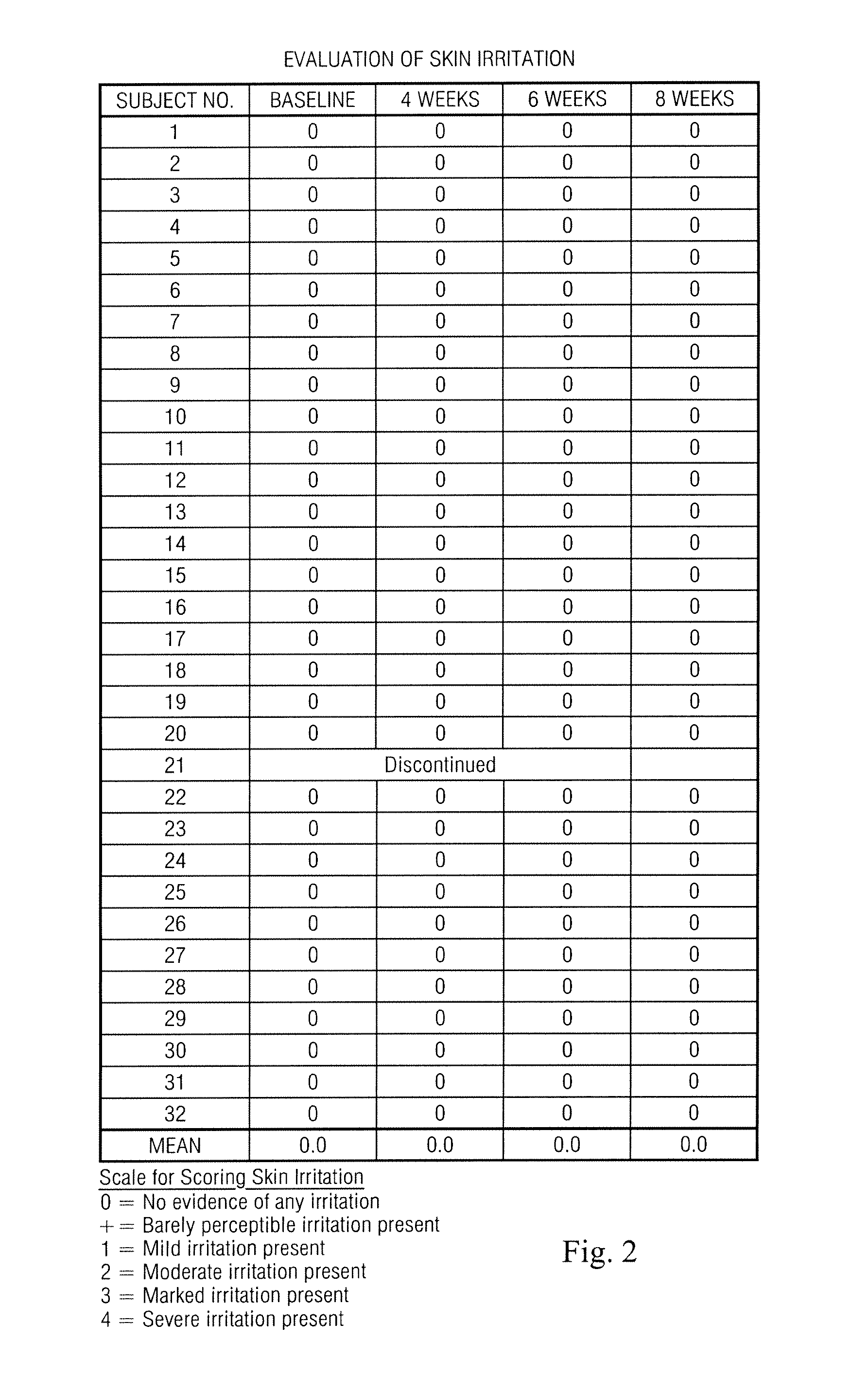

Multi-Active Microtargeted Anti-Aging Skin Cream Polymer Technology

InactiveUS20110305737A1Reduction in signWithout exacerbating acneCosmetic preparationsBiocideCosmetic creamLotion

A comprehensive, single agent cosmetic cream or lotion containing a high number of ingredients that target anti-aging in a defined manner. The cream or lotion contains a high number and variety of active substances that demonstrate excellent safety and efficacy in all of the various defined categories of skin aging, including but not limited to wrinkles, abnormal pigment or brown spots due to aging of the skin and an unexpectedly high efficacy in the reduction of redness and acne and rosacea blemishes.

Owner:MACRENE ACTIVES LLC

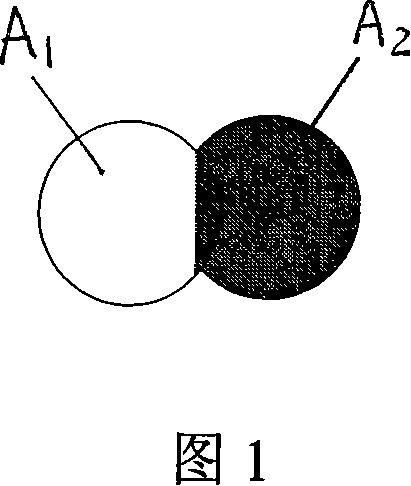

Elastic polyester fibre and preparation method thereof

InactiveCN101126180AIncrease elasticityConvenient careFilament/thread formingMonocomponent polyesters artificial filamentFiberPolymer science

The invention relates to a springy polyester fiber and the preparing method. The technical problem of the invention to be solved is that the invention provides a springy fiber and the preparing method to make up the disadvantages of the capability of the spandex and the applying arrange. The springy fiber of the invention adopts the method of the compound filature and uses two screw extrusion machines to respectively melt the two components, and the product is obtained through the extrusion of the compound filature component. The invention is characterized in that the components of the springy fiber comprise two of the following high polymers which have heat shrinking capability difference: the high fasculation PETP, the PET, the PBT, the PTT with the weight proportion of 30-70:50.

Owner:ZHEJIANG HENGYI GRP CO LTD

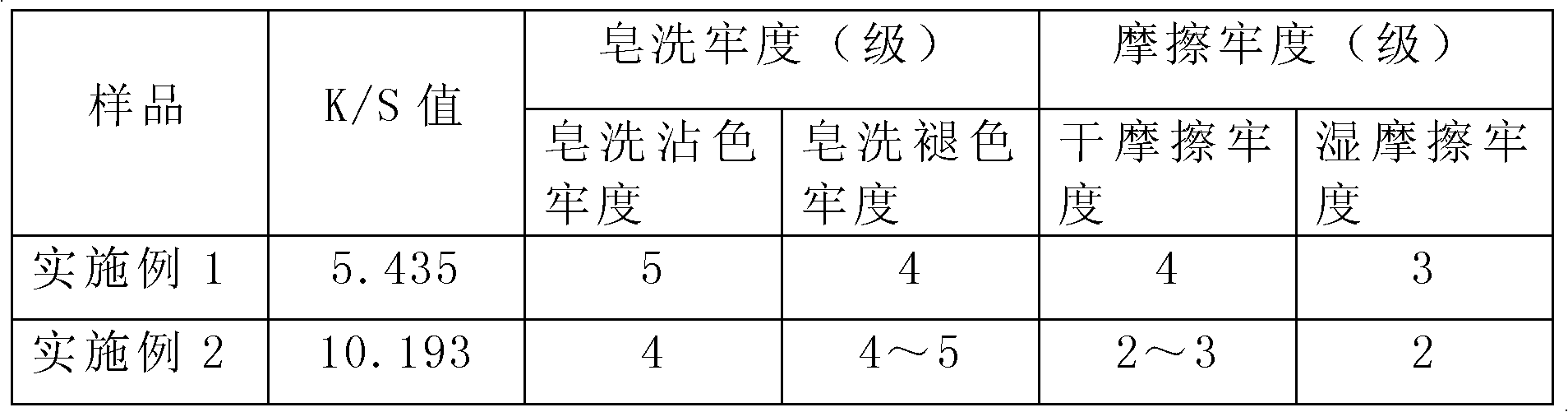

Method of dyeing fabric by using dye

ActiveCN102535194ASoft touchImprove washing fastnessBiochemical fibre treatmentDry-cleaning apparatus for textilesTextile printerEngineering

The invention provides a method for dyeing fabric by using a dye, belonging to the technical field of textile printing and dyeing and aiming to the solve the problems of complex process, low dyeing rate, poor dyeing uniformity and poor color fastness and hand feel of dyed fabric of the existing method for dyeing the fabric by using the dye. The method comprises the following steps of: desizing the fabric, scouring, bleaching and mercerizing; adding the dye, a cationic modifier, a leveling agent, a dispersant, an alkaline reagent and a wet rubbing fastness enhancer to water, and mixing uniformly to prepare a dyeing solution; soaking the fabric into the dyeing solution, and controlling temperature and liquor ratio to dye; steaming the dyed fabric for colour fixation, washing by water and drying to finish dyeing the fabric by using the dye. The method for dyeing the fabric by using the dye is simple, ensures the high dyeing rate and the uniform dyeing, and ensures that the dyed fabric has good washing fastness and rubbing fastness and a soft feel.

Owner:台州东海翔染整有限公司

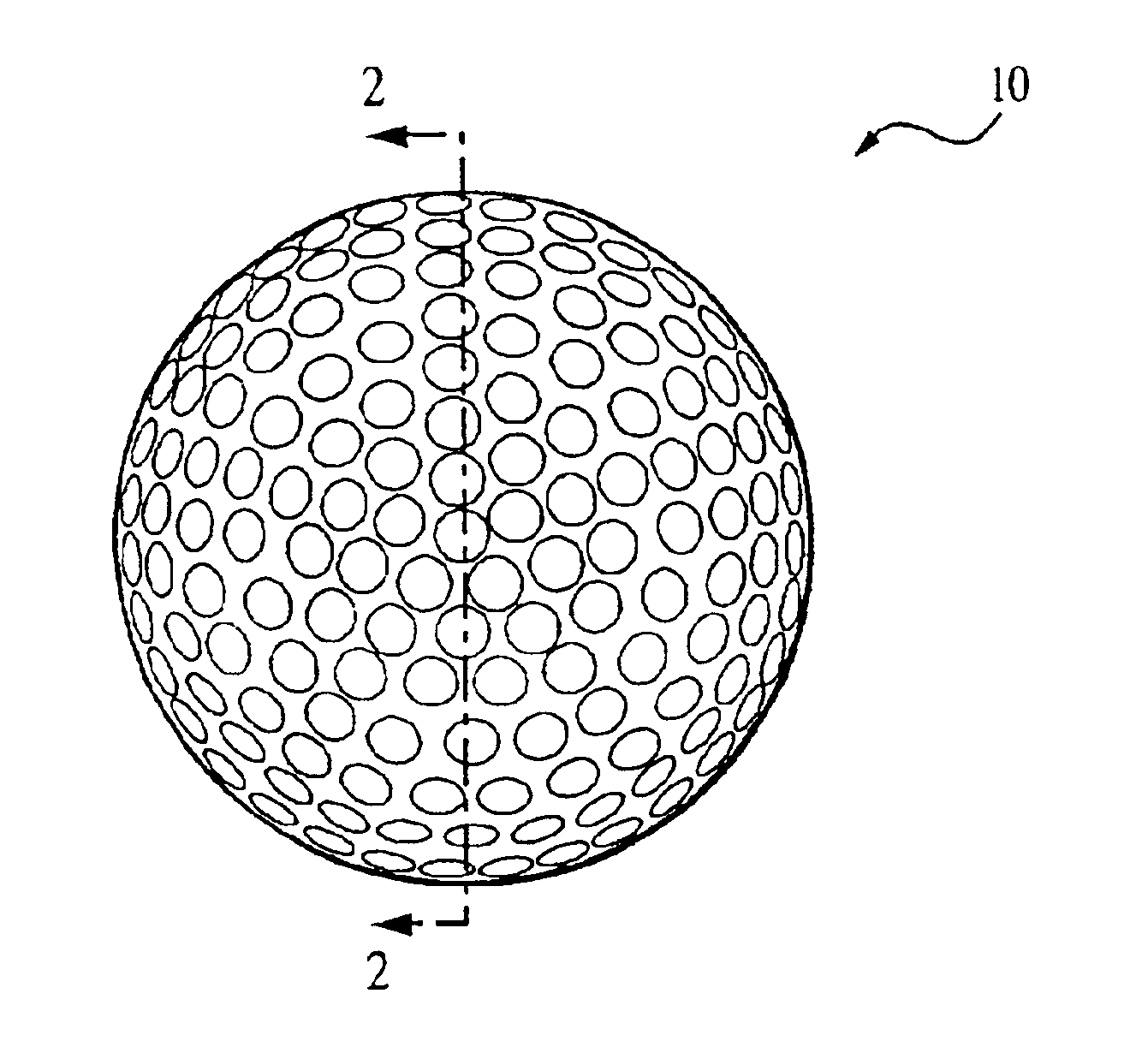

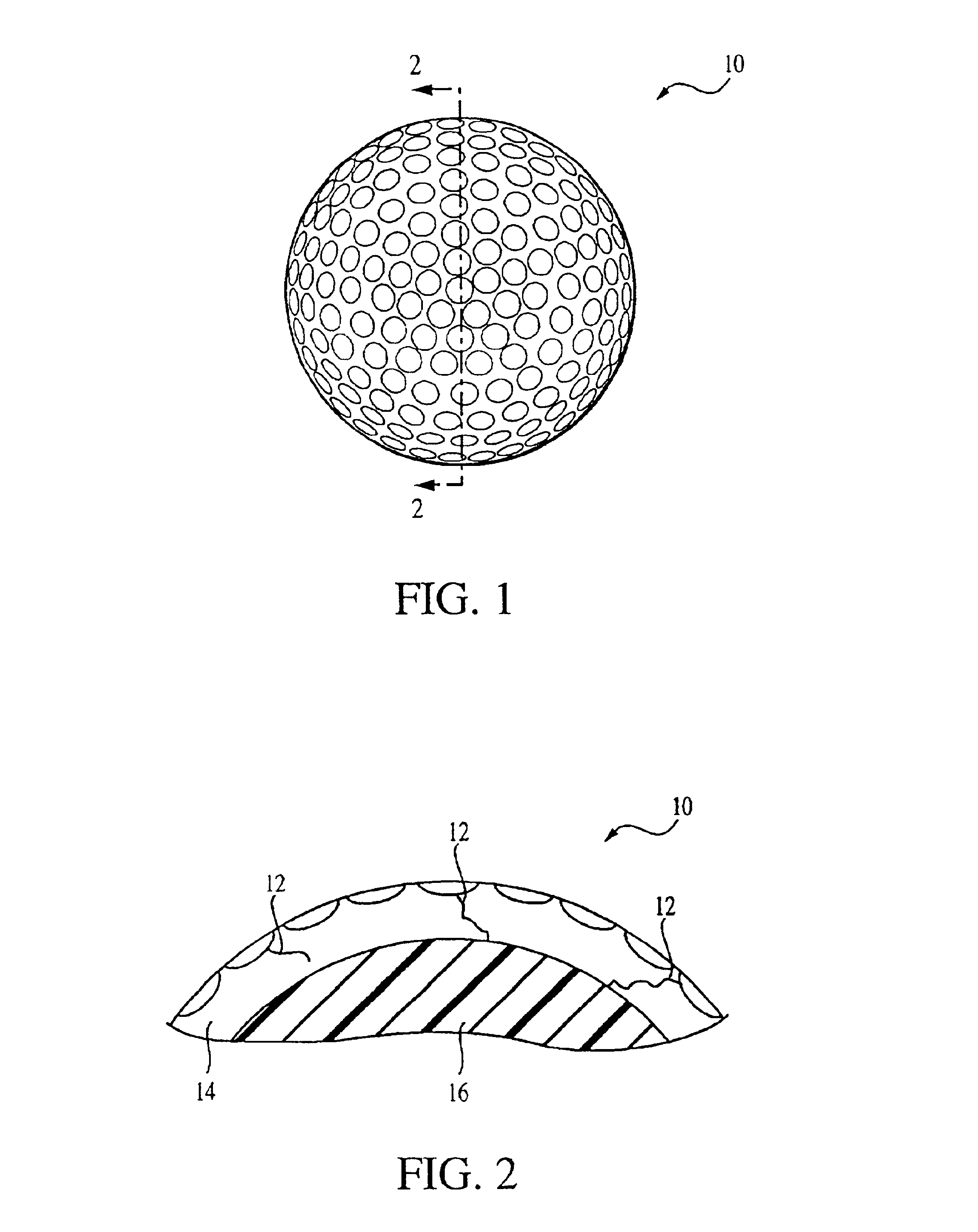

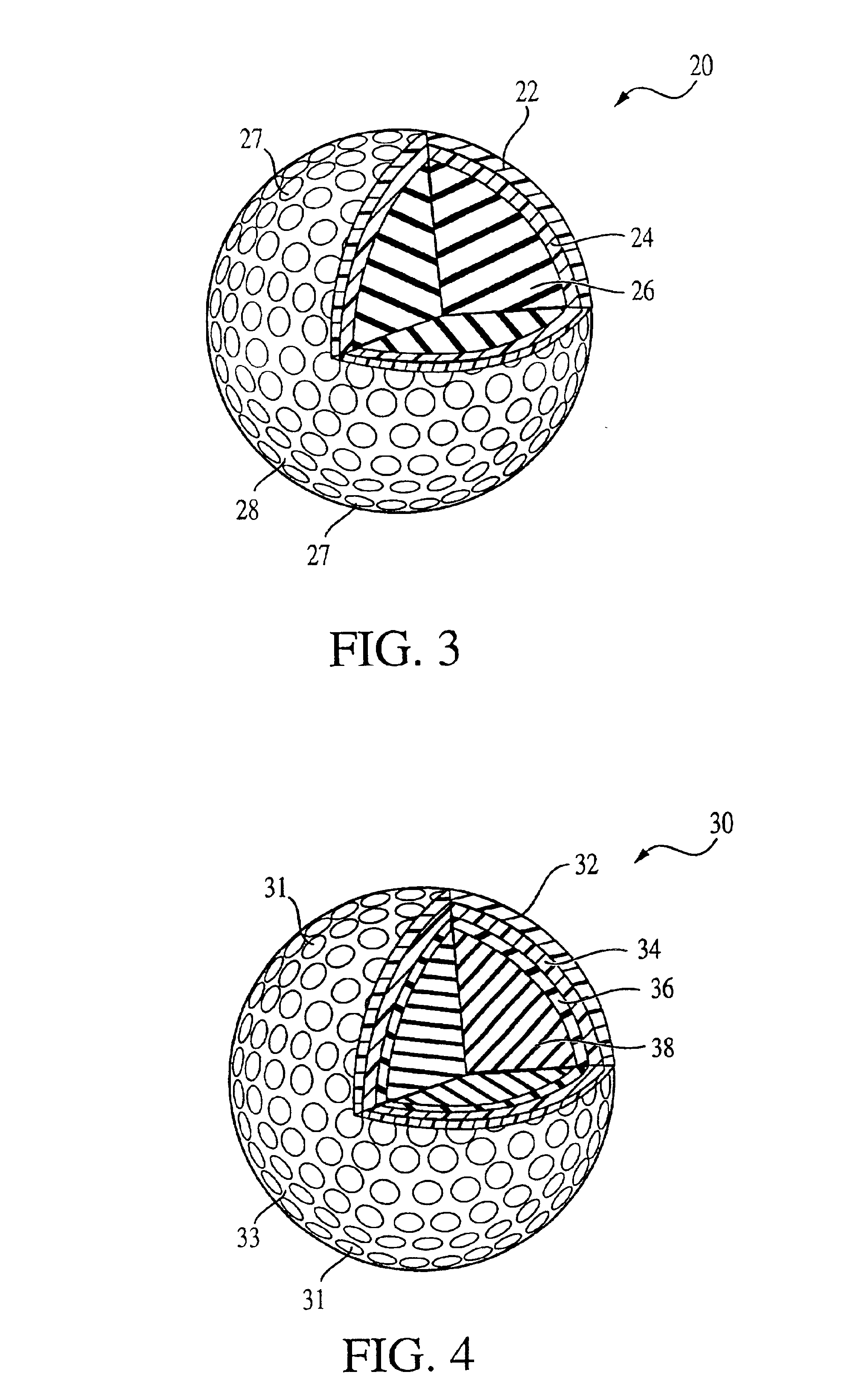

Golf ball with multi-layer cover

InactiveUS6837805B2Increased durabilityLow densityGolf ballsSolid ballsCoefficient of restitutionEngineering

A golf ball is described having a core with a multi-layer cover with a thickness of at least 3.6 mm (0.142 inches) and a Shore D hardness of at least 60. The combination of a core, preferably soft core, with a thick, relatively hard multi-layer cover results in a ball having better distance than conventional golf balls having a comparable coefficient of restitution.

Owner:TOPGOLF CALLAWAY BRANDS CORP

An environment-friendly digital ink-jet direct printing textile ink and method for preparing same

ActiveCN101531848ASolve problems such as easy to cause pollution to the environmentSolve problems such as pollutionInksDyeing processUltra fineEngineering

An environment-friendly digital ink-jet direct printing textile ink and method for preparing same, the digital ink-jet direct printing textile ink composed of components as follows: pigment paste, connection materials, cross-linking agent, softening agent, solvent, surfactant, bactericide, pH regulating agent, and deionized water. The pigment paste is a mixture of the following components: pigments, ultra-dispersing agent, wetting agent, and deionized water. The preparation method includes: a. mixing the pigments, ultra-dispersing agent, wetting agent, and deionized water into a pigment paste, mixing the pigment paste at high-speed and then grinding it in an ultra-fine nano-grinding machine, to obtain the nano stage ultrafine grain paste; b. mixing the proportioning mixture with the grinded nano stage ultrafine grain paste, high-speed stirring and then filtering to obtain a finished environment-friendly digital ink-jet direct printing textile ink. The inventive printing textile ink does not contain formaldehyde, can be direct digital printed wtihtout plate-making when in use, and has rich color, soft hand feeling, and capability of allowing the digital ink-jet printing textile materials to meet the high environmental and quality requirements.

Owner:深圳市墨库图文技术有限公司

Method for manufacturing high-breathability non-woven wallpaper body paper and product

The invention discloses a method for manufacturing high-breathability non-woven wallpaper body paper and a product. The existing non-woven wallpaper has the disadvantages that the hand feel thereof is not soft enough, the principal plane stereoscopic impression is not strong and the opacity degree is low. The method of the invention comprises the following steps: beating plant fiber containing chemical wood pulp until the beating degree is 20-30OSR, and mixing with non-plant fiber containing chemical fiber; adding chemical addition agent into the mixed fiber; manufacturing the mixed fiber containing the chemical addition agent into body paper semi-finished products by utilizing a fourdrinier wire or inclined wire paper machine; mixing pigment, chemical addition agent and adhesive to form coating liquor, carrying out dip coating on the body paper semi-finished products inside or outside the machine; and drying and finishing the body paper subject to dip coating, and rolling the body paper to form finished paper of body paper, thus obtaining non-woven wallpaper which contains continuous fiber, has high breathability, and can be directly printed. The principal plane has natural lines; and the finished paper has the advantages of soft hand feel, good processability, excellent shape stability, rich color, distinct image and strong stereoscopic impression.

Owner:ZHEJIANG WINBON SPECIALTY PAPER +1

Fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof

ActiveCN102021819AExcellent water repellencyBasic physical and mechanical propertiesSilicon compoundsVegetal fibresOrganic solventHYDROSOL

The invention relates to a fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof. The finishing agent is prepared by the following steps of: (1) mixing a precursor, an anionic surfactant and water and stirring violently at the temperature of between 20 and 50 DEG C; and (2) slowly adding ammonia water serving as a catalyst dropwise, stirring, adding long-chain alkylsiloxane serving as a modifier and stirring continually so as to obtain modified SiO2 hydrosol. The finishing agent has a stable property, avoids the pollution of an organic solvent and has high water repellency when used for performing superhydrophobic finishing on textiles.

Owner:DONGHUA UNIV +1

Absorbent article

InactiveUS20050256475A1Facilitate transfer of liquidLess irritatingLayered productsFlexible pipesEngineeringCompressibility

Disclosed is an absorbent article including a liquid absorbent layer for absorption and retention of liquid and a liquid passage layer located on a liquid-receiving side of the liquid absorbent layer. The liquid passage layer includes a first passage layer and a second passage layer disposed between the first passage layer and the liquid absorbent layer. The first passage layer and the second passage layer are resin films formed with a plurality of liquid passage apertures. The individual liquid passage apertures are defined by a peripheral wall projecting toward the liquid absorbent layer to provide the first passage layer and the second passage layer with thicknesses greater than a thickness of the resin film itself. Under a load in a thickness direction, the second passage layer has a greater compressibility than the first passage layer.

Owner:UNI CHARM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com