Elastic polyester fibre and preparation method thereof

An elastic fiber, composite elastic fiber technology, applied in fiber processing, single-component polyester rayon, filament/thread forming and other directions, can solve the problems of unseen fiber composition, manufacturing process, description, etc. Good recovery, smooth cloth surface, soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

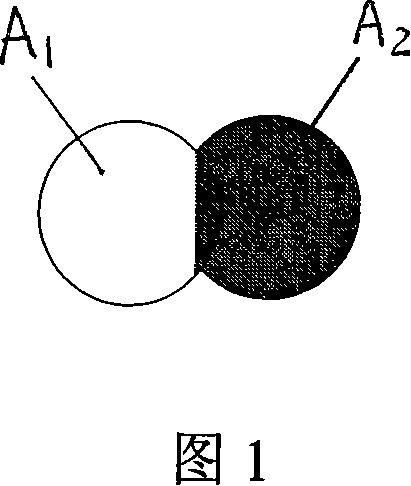

[0016] The side-by-side composite elastic fiber uses two independent screws to melt two kinds of high polymers A which form the side-by-side composite fiber. 1 、A 2 , with a weight percentage of 30:70, which are transported to the spinning box through their respective melt pipelines, and then the melt is quantitatively sent to the side-by-side spinning assembly by the metering pump for extrusion, cooling, oiling, stretching, After shaping and winding, the finished side-by-side composite elastic fibers can be obtained, the cross-section of which is shown in Figure 1. The spinning temperature is 278-283°C, the winding speed is 2500 m / min, the side blowing wind speed is 0.28-0.35 m / s, the stretching temperature is 85-90°C, the setting temperature is 125-130°C, and the draw ratio is 2.5 to 3.5 times, the main indicators of FDY are shown in the attached table.

Embodiment 2

[0018] The side-by-side composite elastic fiber uses two independent screws to melt two kinds of high polymers A which form the side-by-side composite fiber. 1 、A 3 , whose weight percentage is 40:60, is transported to the spinning box through its own melt pipeline, and then the melt is quantitatively sent to the side-by-side spinning assembly by the metering pump for extrusion, cooling, oiling, stretching, After shaping and winding, the finished side-by-side composite elastic fiber can be obtained. The spinning temperature is 265-275°C, the winding speed is 1200 m / min, the side blowing wind speed is 0.25-0.30 m / s, the stretching temperature is 82-88°C, the setting temperature is 123-129°C, and the draw ratio is 3.5 to 4.0 times, the main indicators of the spun FDY are shown in the attached table.

Embodiment 3

[0020] The side-by-side composite elastic fiber uses two independent screws to melt two kinds of high polymers A which form the side-by-side composite fiber. 1 、A 4 , with a weight percentage of 50:50, which are transported to the spinning box through their respective melt pipelines, and then the melt is quantitatively sent to the side-by-side spinning assembly by the metering pump for extrusion, cooling, oiling, stretching, After shaping and winding, the finished side-by-side composite elastic fiber can be obtained. The spinning temperature is 267-276°C, the winding speed is 1800 m / min, the side blowing wind speed is 0.27-0.33 m / s, the stretching temperature is 83-88°C, the setting temperature is 123-128°C, and the draw ratio is 2.8~3.5 times, the spun FDY

[0021] See the attached table for the main indicators.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com