Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

473results about How to "Not easy to yellow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic silicon rubber encapsulating material for high-power LED

InactiveCN101747632AHigh light transmittance durabilityImprove temperature resistanceOther chemical processesSemiconductor devicesRefractive indexTackifier

The invention relates to an organic silicon encapsulating material for a high-power LED and a preparation method thereof. The organic silicon encapsulating material is prepared by mixing a component A containing vinyl polysiloxanes, a silicone resin component B, a component C containing hydrogen polysiloxane, a platinum catalyst component D, a component E of catalytic inhibitor of acetylene alcohols and a tackifier component F. The obtained encapsulating silicon rubber with different refractive indexes of level 1.4, level 1.5 and the like can be used for the encapsulation of various high-power LEDs and the encapsulation of other optical application. The organic silicon rubber encapsulating material for the high-power LED takes the silicone resin component B as a filling material, which not only enables that the silicone rubber has high transparency, high strength and high light transmittance, but also improves the temperature resistance, the yellowing resistance, and the durability of the high light transmittance of high-power LED products. The organic silicon rubber encapsulating material for the high-power LED can be prepared into two encapsulating forms of a single component and bi-component, which improves the adaptability and the encapsulating efficiency for encapsulating equipment and process procedures, and has the characteristics of reduced cost and convenient use.

Owner:陈俊光

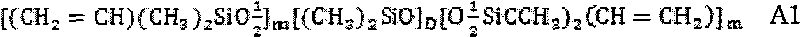

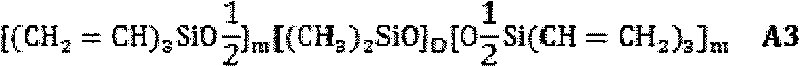

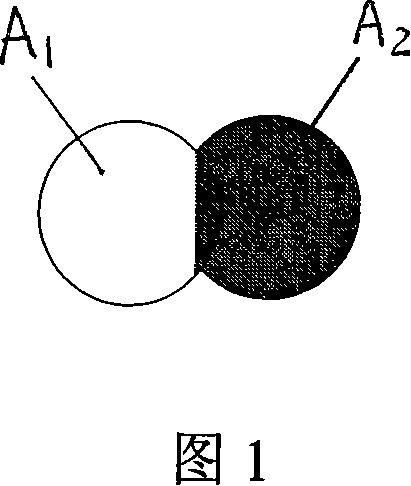

Elastic polyester fibre and preparation method thereof

InactiveCN101126180AIncrease elasticityConvenient careFilament/thread formingMonocomponent polyesters artificial filamentFiberPolymer science

The invention relates to a springy polyester fiber and the preparing method. The technical problem of the invention to be solved is that the invention provides a springy fiber and the preparing method to make up the disadvantages of the capability of the spandex and the applying arrange. The springy fiber of the invention adopts the method of the compound filature and uses two screw extrusion machines to respectively melt the two components, and the product is obtained through the extrusion of the compound filature component. The invention is characterized in that the components of the springy fiber comprise two of the following high polymers which have heat shrinking capability difference: the high fasculation PETP, the PET, the PBT, the PTT with the weight proportion of 30-70:50.

Owner:ZHEJIANG HENGYI GRP CO LTD

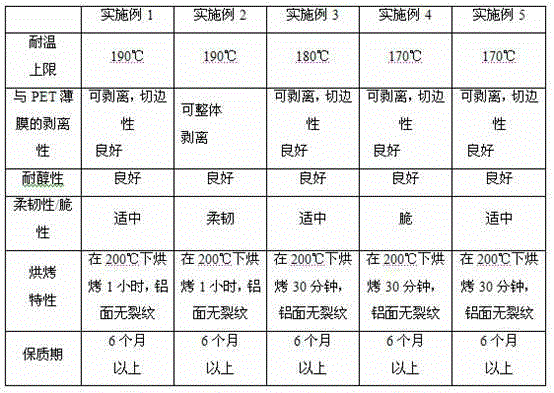

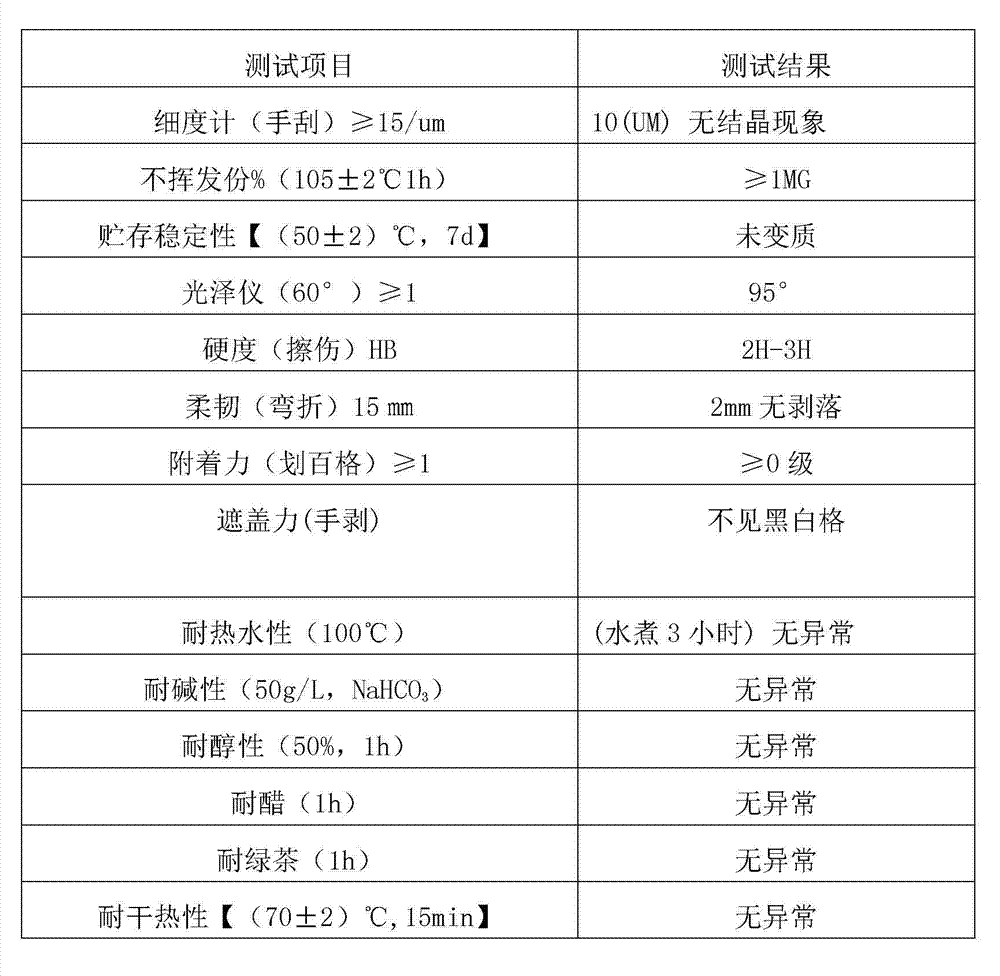

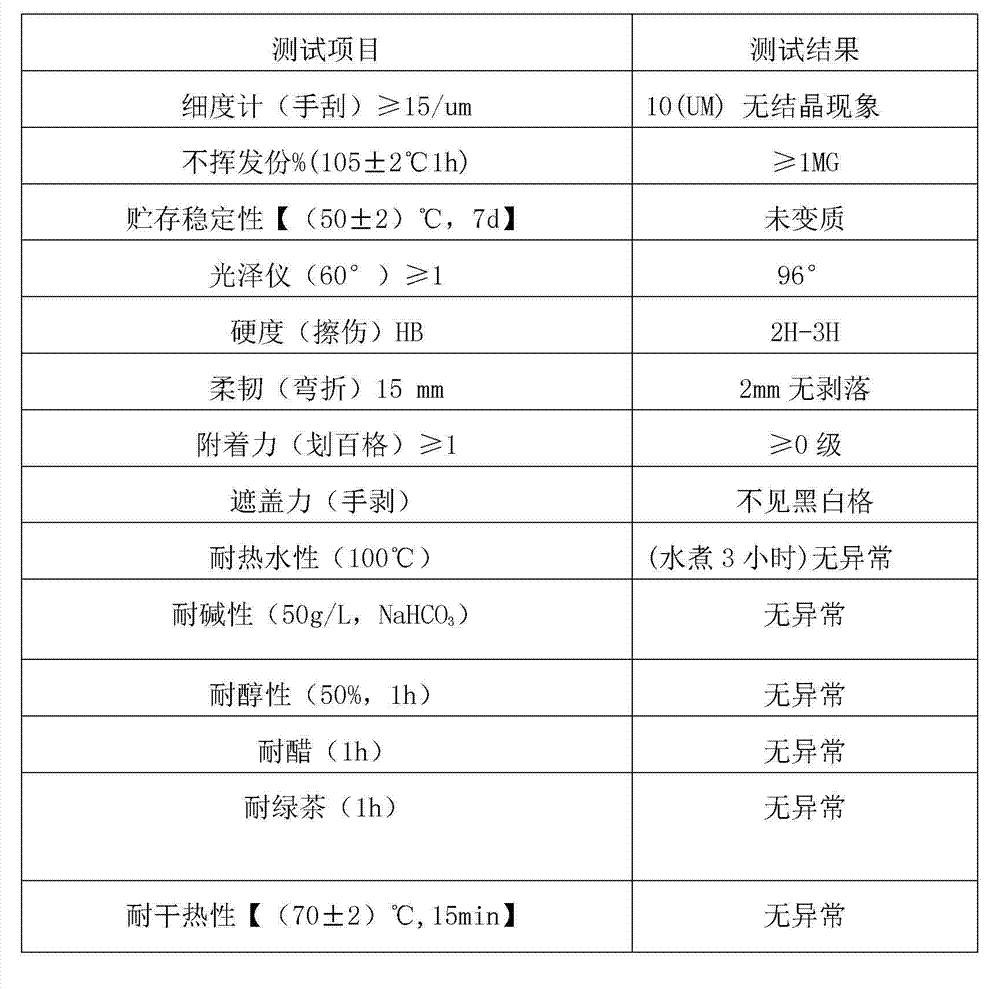

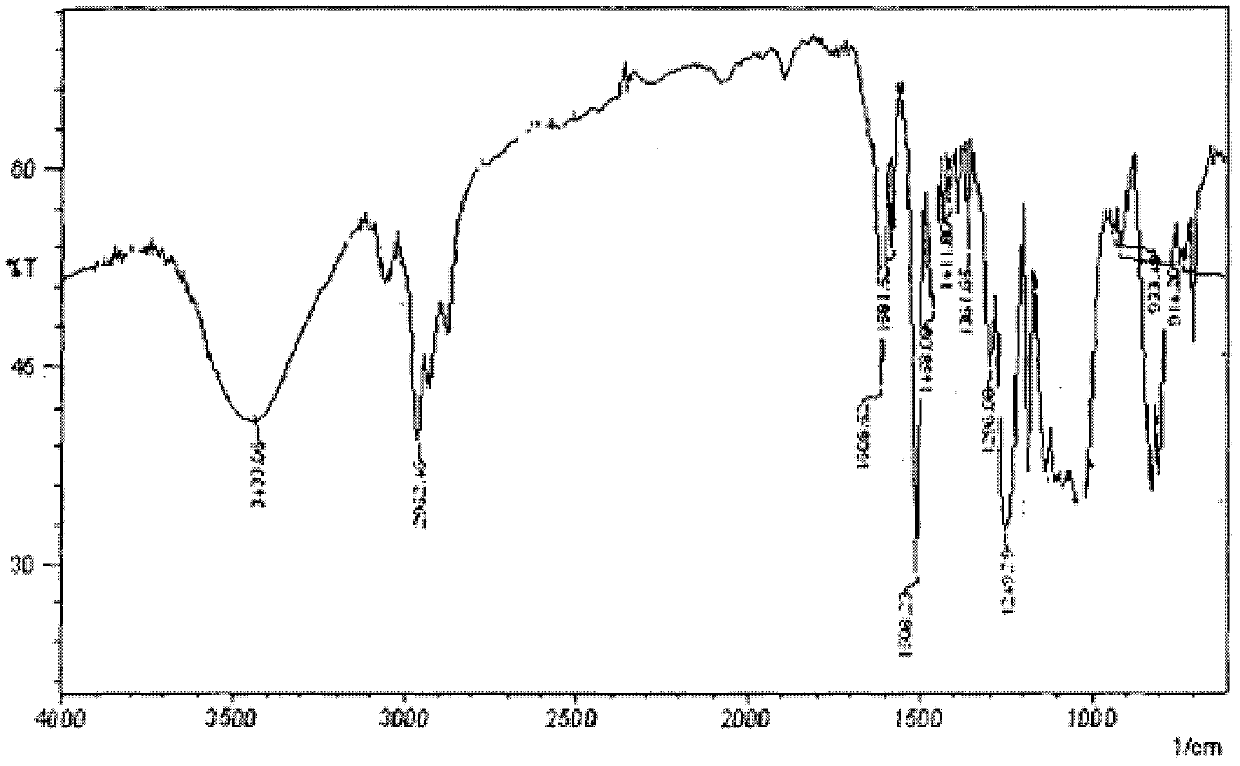

Water-based laser transfer coating for wine bottle glass baking paper, and preparation method thereof

The invention discloses a water-based laser transfer coating for wine bottle glass baking paper, and a preparation method thereof. The coating is prepared by mixing the following components in percentage by mass: 10-30% of water-based acrylic resin, 25-40% of water-based polyurethane resin, 0-8% of cosolvent, 20-45% of deionized water, 0-0.4% of water-based defoaming agent, 0.1-0.4% of base material wetting agent, and 0-0.2% of pH value regulating agent. The water-based laser transfer coating for the wine bottle glass baking paper is an environment-friendly laser transfer coating which meets national VOC detection standard by taking the water-based resin and deionized water as main raw materials. In addition, the composite water-based resin endows a curing film with good temperature resistance, aluminum adherence, strippability, alcohol resistance and the like, thus meeting the index requirement of the wine bottle glass baking paper.

Owner:三友(天津)高分子技术有限公司

Energy-saving insulated flame-retardant water-proof corrosion-proof functional coating and preparation method thereof

ActiveCN102746784AExcellent performanceGood compatibilityAnti-corrosive paintsPolyurea/polyurethane coatingsChemistryWetting

The invention discloses an energy-saving insulated flame-retardant water-proof corrosion-proof functional coating and a preparation method thereof. The functional coating is prepared from the following raw materials: an aqueous polyurethane dispersion, a flame retardant, a flame-retardant antismoke agent, a hollow glass bead, a wetting dispersant, an anti-settling agent, a thickening agent, water, a leveling agent and a de-foaming agent, has the functions of heat preservation, flame retarding, water prevention and corrosion resistance and the like, is unlikely to become yellow when in use, is safe and reliable, is excellent in performance, is good in compatibility with pigment dyestuff, is unlikely to damage the coated surface, is easy to modify, is nontoxic, is safe to use, does not pollute environment and is suitable for the fields of inner and outer wall coating, pipeline coating, wood furniture coating, decoration coating, chemical corrosion-proof coating and the like.

Owner:江苏瑞丰科技实业有限公司

White finish coat photocurable UV (ultraviolet) paint and preparation method thereof

ActiveCN103031034AHigh glossNot easy to yellowPolyurea/polyurethane coatingsEpoxy resin coatingsChemical industryReactive diluent

The invention belongs to the field of chemical industry, and particularly discloses white finish coat photocurable UV (ultraviolet) paint and a preparation method thereof. The photocurable UV paint comprises the following components in percentage by weight: 20-60% of epoxy acrylate, 20-60% of polyurethane acrylate, 2-5% of phenyl acetone photoinitiator, 0.2-1% of diphenyl phosphine oxide photoinitiator, 0.2-1% of dispersant, 0.2-1% of leveling agent, 1-40% of titanium white TiO2, 5-15% of two-functional-group reactive diluent and 5-30% of three-functional-group reactive diluent. The paint has the characteristics of favorable gloss, adhesive force and leveling property, thus ensuring that the white UV paint can be better applied.

Owner:AODA KOALA PAINT HUIZHOU

Polyimide and coating composition formed thereby

The present invention relates to a polyimide and a coating composition formed thereby, wherein the polyimide is represented by a formula (1), two ends of the polyimide respectively have two -COOH capping groups. The coating composition of the present invention comprises the polyimide and a hardener having two to six functional groups which can be reacted with the -COOH. A polyimide coating and a polyimide film formed by the coating composition of the present invention have excellent solution resistance and coefficient of thermal expansion (CTE), and can be applied to active (passive) assembly, optical materials, touch panels, copper clad laminates, flexible electronic materials, or protection materials of integrated circuit modules, or thin film base materials of glass thin film touch panels.

Owner:ETERNAL MATERIALS CO LTD

Water-dispersible HDI-TDI mixed tripolymer curing agent and preparation method thereof

InactiveCN105949436ANo reduction in functionalityLow costPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a water-dispersible HDI-TDI mixed tripolymer curing agent and a preparation method thereof. The method comprises steps as follows: (1) diisocyanate monomers and a nonionic hydrophilic modifying agent are put into a round-bottom flask under the protection of nitrogen and heated to reach 50-70 DEG C for a thermal reaction; (2) after the mixture reacts for 2-4 h, a trimerization catalyst is added, the mixture is subjected to a thermal reaction continuously, a polymerization inhibitor is added after the percentage composition of -NCO of the system reaches the target, and the mixture is subjected to the thermal reaction for 0.5-1.5 h; (3) an anion hydrophilic modifying agent is added to a tripolymer obtained in the step (2), the mixture is continuously stirred and subjected to the thermal reaction at the temperature of 60-80 DEG C, a neutralizing agent is added after the mixture reacts for 5-7 h, and the mixture is stirred uniformly, subjected to the thermal reaction for 0.5-1.5 h and discharged after being cooled. The preparation method is simple, and the prepared curing agent has the advantages of good water dispersibility, good storage stability and good film water resistance and can be applied to a water-based bi-component polyurethane coating well.

Owner:SOUTH CHINA UNIV OF TECH

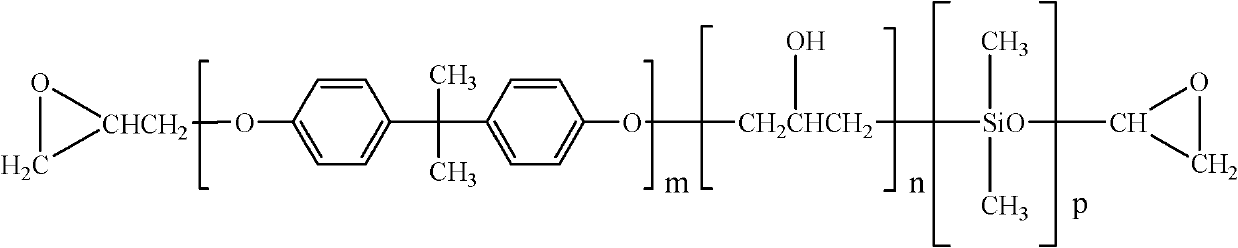

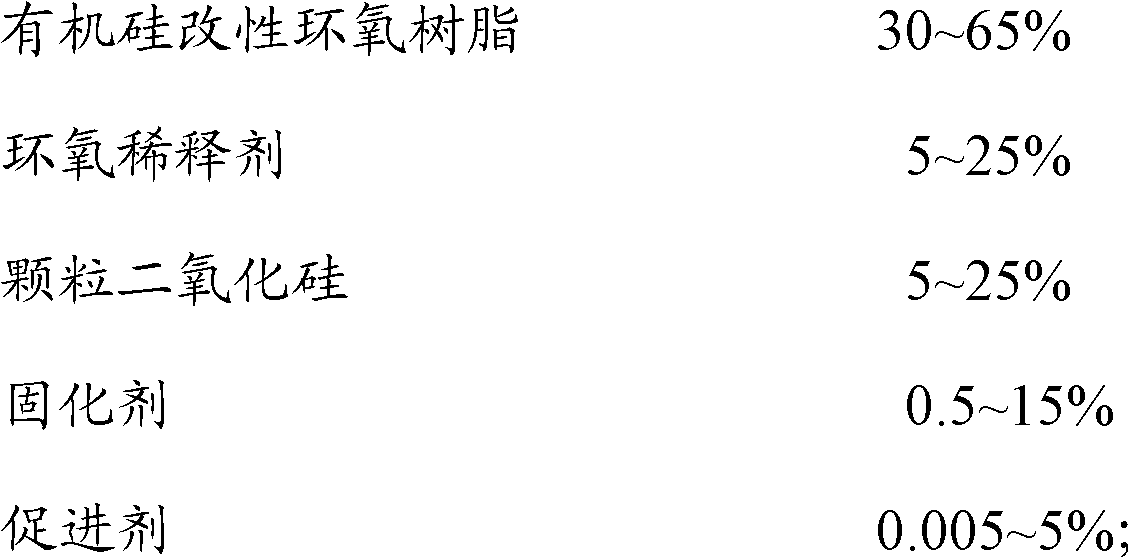

Organic silicon modified epoxy resin for packaging LED (Light Emitting Diode), and preparation method and application thereof

InactiveCN102516500AGood flexibilityGood weather resistanceGroup 4/14 element organic compoundsFilm/foil adhesivesWeather resistanceBackbone chain

The invention provides an organic silicon modified epoxy resin for packaging an LED (Light Emitting Diode), and a preparation method and an application thereof. According to the preparation method, an organic silicon monomer is directly polymerized with bisphenol A and epoxy chloropropane, for preparing the organic silicon modified epoxy resin with epoxy groups at the tail end and dimethyl silica chain links contained in a main chain. The organic silicon modified epoxy resin for packaging the LED is prepared; the flexibility, the weather resistance and the ultraviolet radiation resistance of the packaging materials are improved; and the organic silicon modified epoxy resin is difficult to yellow.

Owner:ZHEJIANG Z LIGHT OPTOELECTRONICS

Modified double-component epoxy resin paint

InactiveCN1704454AReduce volatilityLow viscosityEpoxy resin coatingsAntimony trioxideSilicon dioxide

The invention relates to a modified double-component epoxy resin paint, wherein the raw materials of the main ingredients includes bisphenol A epoxy resin, multiple functional group glycide amine epoxy resin and filler selected from silicon dioxide, titanium oxide, antimony trioxide, zinc oxide and calcium carbonate, the raw material of the curing agent includes modified aliphatic polyamines, organic diatomaceous soil and methyl ethylene glycol.

Owner:BEIJING HANTECH BUILDING MATERIALS TECH

Rattan bamboo plus material and preparation method thereof

InactiveCN101264679AWide range of usesImprove breathabilityLamination ancillary operationsCane mechanical workingUltravioletBiomedical engineering

The invention provides a cany bamboo fabric and preparation method, which comprises a cany skin layer or a bamboo skin layer (1) and a lapping cloth layer (2); wherein, the cany skin layer or the bamboo skin layer (1) are produced through the scraping and silking or drawing out and planishing treatments; the cany skin layer or the bamboo skin layer (1) are compounded with the lapping cloth layer (2) together. The cany bamboo fabric is characterized in that (a) the processes of degreasing, purifying, stewing, acid treatment and bleaching treatment are added between the process of silking or drawing out and the process of planishing, (b) the cany skin or the bamboo skin are weaved into the cany skin layer or the bamboo skin layer (1), and (c) the processes of softening finishing and hot compression and fixation are processed as the cany skin layer or the bamboo skin layer (1) are compounded with the lapping cloth layer (2) together. The cany bamboo fabric has the advantages of beautiful appearance, good performance of ultraviolet resistance, soft texture, uneasy to fold, free of yellowing, easy to clean, being applicable to the production of clothing, bedding articles, high grade car pad set, slipcover, window curtain, carpet, and shoes and hats, and versatility.

Owner:周觉民

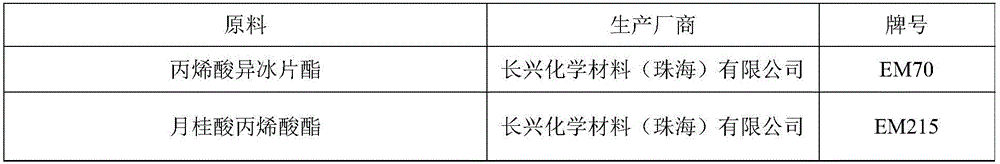

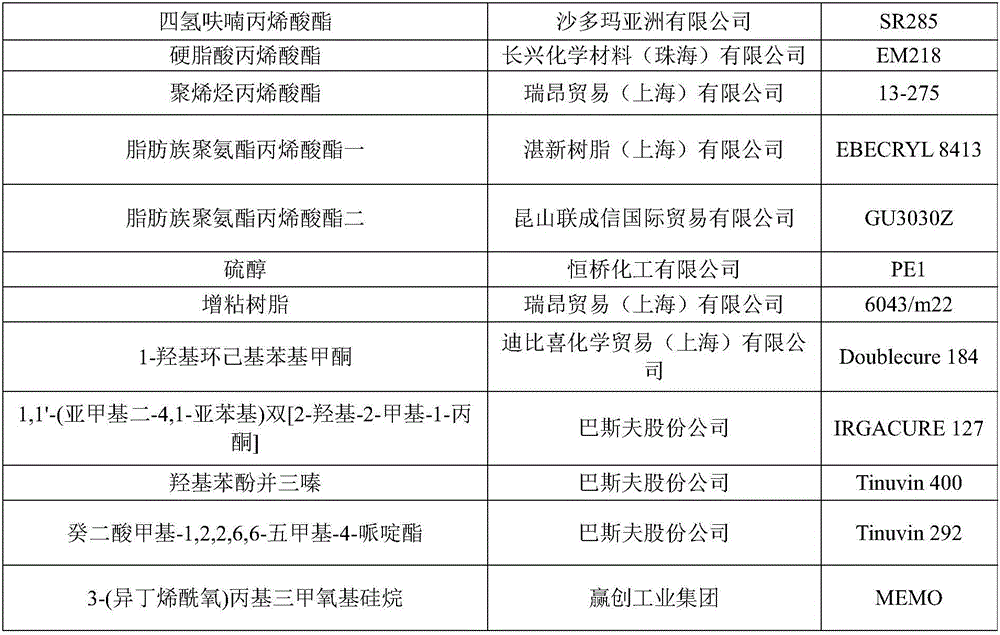

Ultraviolet-curing pressure-sensitive composition and pressure-sensitive adhesive

ActiveCN105969253AStrong weather resistanceNot easy to yellowPolyureas/polyurethane adhesivesPressure sensitive film/foil adhesivesPolyolefinWeather resistance

The invention provides an ultraviolet-curing pressure-sensitive composition and a pressure-sensitive adhesive. The ultraviolet-curing pressure-sensitive composition comprises low polymers, a reactive diluent and a photoinitiator, wherein the weight ratio of the reactive diluent to the low polymers is 40:60-60:40, and the weight content of the photoinitiator in the composition is 1-5%. The low polymers comprise the following components in parts by weight: 20-40 parts of polyolefin acrylate and 4-30 parts of polyurethane acrylate. The ultraviolet-curing pressure-sensitive composition can not result in pollution caused by solvent volatilization in the use process. The weight ratio of the monomer reactive diluent to the low polymers is controlled at 40:60-60:40, so that the bonding property of the pressure-sensitive adhesive is greatly enhanced. Furthermore, by using the polyolefin acrylate as the component of the low polymer, the olefin functional group can enable the pressure-sensitive adhesive formed by the ultraviolet-curing pressure-sensitive composition to have higher weather resistance and further have higher light transmission rate.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Preparation method of polyurethane raw liquid for high-speed spinning

ActiveCN103710786AIncrease productivityIncrease concentrationMonocomponent synthetic polymer artificial filamentPolyesterFiber

The invention relates to a preparation method of polyurethane raw liquid for high-speed spinning. The preparation method comprises the following steps: (1) adding a solvent and mixed polyester to a pre-polymerization tank; (2) accurately adding mixed diisocyanate according to a predetermined NCO / OH ratio so as to carry out prepolymefization reaction; (3) after ending prepolymefization reaction, transferring a prepolymer to a chain extension tank, adding a cleaning solvent, uniformly stirring, and cooling a refrigerant to about 0-20 DEG C; (4) slowly adding chain extension amine and a chain terminating agent solution, and reacting so as to form a polyurethane urea solution in the end; (5) transferring the obtained polyurethane urea solution to a storage tank, and adding multiple functional auxiliary materials and additives; and (6) fully and uniformly stirring, carrying out vacuum defoamation, and preparing polyurethane fibers by using polymerization raw liquid through dry spinning. The polyurethane raw liquid for high-speed spinning can be used for the spinning of fibers at the spinning speed of above 1000m / min. The new technology can be used for improving the spinning efficiency and reducing energy consumption and labor cost.

Owner:ZHEJIANG HUAFENG SPANDEX

Water radon-screening emulsion paint

A radon-screening water emulsoid paint used as decorative paint for preventing radon, benzene, xylene and formaldehyde from being educed from wall and adsorbing them contains water, hydroxyethyl cellulose, disperser, defoaming agent, levelling agent, light calcium carbonate, titanium oxide, bentone, talc powder, ethanediol, film forming agent, PVDF-acrylate copolymer and vinyl acetate-acrylate copolymer emulsion, and antibacterial mildew-proof agent.

Owner:陈伟常 +1

Self-emulsifying waterborne polyurethane curing agent and preparation method thereof

ActiveCN107082860AGood water dispersibilityStable storagePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsWater dispersibleAdhesive

The invention discloses a self-emulsifying waterborne polyurethane curing agent and a preparation method thereof. The self-emulsifying waterborne polyurethane curing agent takes micromolecule dihydric alcohol containing a sulfonic acid group with a molecular weight of 350 to 1,000 and diisocyanates as raw materials to prepare the sulfonic acid group modifying self-emulsifying waterborne polyurethane curing agent with a multifunctional NCO group on a terminal. The invention also discloses a preparation method of the self-emulsifying waterborne polyurethane curing agent. The self-emulsifying waterborne polyurethane curing agent has the advantages of good water dispersibility, good storage stability, good water resistance of coating film, high strength property and the like, and is suitable for mating with waterborne polyurethane dispersion, waterborne acrylic emulsion and waterborne alkyd resin and the like, prepared two-component polyurethane coatings and adhesives by the self-emulsifying waterborne polyurethane curing agent are especially suitable for some special performance requirements of waterborne products. The self-emulsifying waterborne polyurethane curing agent disclosed by the invention can also be used for mating with hydroxyl components of the solvent-type two-component coatings and the adhesives to produce a two-component solvent type and has a wide range of application.

Owner:FOSHAN JINGXIN HUIMING TECH CO LTD

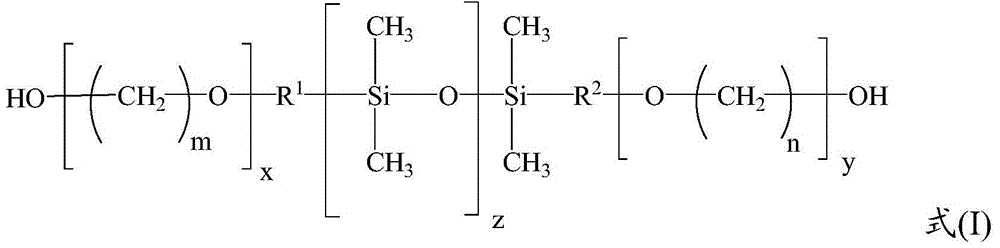

Preparation method of silane coupling agent and silicone sealant composition

ActiveCN103788122AGood adhesionHas yellowingGroup 4/14 element organic compoundsNon-macromolecular adhesive additivesSilanesStructural formula

The invention provides a novel silane coupling agent, of which the structural formula is alkyl amide alkyl alkoxy silane, wherein the general formula is R<1>CONHR<2>Si(OR3)<3>; R<1> is univalent or bivalent hydrocarbon group of which the carbon atom number is 1-12; R<2> is bivalent alkylene group; R<3> is alkyl of which the carbon atom number is 1-8, preferably, methyl or ethyl. The novel silane coupling agent provided by the invention is used as a tackifier, so as to prepare a transparent acid silicone sealant. The sealant has the advantages of being high in bonding strength, and free of damage, free of yellowing and the like after being poached at high temperature.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

High-viscosity yellowing-resistant explosion-proof film adhesive, adhesive tape and preparation method of adhesive tape

ActiveCN110527464ALight colorImprove antioxidant capacityNon-macromolecular adhesive additivesFilm/foil adhesivesIsooctyl acrylateEthyl acetate

The invention discloses a high-viscosity yellowing-resistant explosion-proof film adhesive. The explosion-proof film adhesive comprises the following components in parts by weight: 100 parts of acrylic acid adhesive, 5-10 parts of tackifying resin, 0.15-0.6 part of a curing agent and 50-90 parts of a solvent, wherein the acrylic acid adhesive is prepared by reacting the following components in parts by weight: 26-30 parts of isooctyl acrylate, 3-5 parts of acrylic acid, 0.5-1 part of hydroxyethyl acrylate, 5-10 parts of methyl acrylate, 53-65 parts of ethyl acetate and 0.5-1 part of azobisisobutyronitrile; the solvent is one or more selected from ethyl acetate, toluene and butanone; and the tackifying resin is hydrogenated resin. The invention also provides a high-viscosity yellowing-resistant adhesive tape prepared from the adhesive. The high-viscosity yellowing-resistant explosion-proof film adhesive has colorless transparent appearance, and can still ensure sufficient peeling forceaccording to different coating thicknesses. Under the condition of high-temperature aging, the explosion-proof film adhesive is not yellowing in appearance, and peeling force is basically not attenuated.

Owner:CROWN TAICANG ADHESIVE PROD CO LTD

Anti-pilling finishing agent for pure cotton knitted fabrics and preparation method thereof

The invention relates to an anti-pilling finishing agent for pure cotton knitted fabrics and a preparation method thereof, in particular to the technical field of printing and dyeing accessory ingredients applied to spinning. The preparation method of the anti-pilling finishing agent for pure cotton knitted fabrics is characterized by adding melamine and isophorone in a container for heating and stirring, dripping mixed solution using isopropanol to dissolve isophorone diisocyanate, then adding catalyst to heat and mix evenly, adding the isopropanol, end-capping reagent, accelerant and water after cooling to sufficiently react, then rising the temperature to the normal temperature, and obtaining the anti-pilling finishing agent by continuously stirring. The anti-pilling finishing agent for pure cotton knitted fabrics is a novel printing and dyeing accessory ingredient and is lemon-yellow or water white solution which applies polyurethane on textile fibers by a lower baking temperature technology, thereby further expanding the application field of waterborne polyurethane in fabrics: the anti-pilling finishing agent has water-solubility, small grain diameter, even distribution, yellow-stain resistance, long storage period, no easy yellowing fabrics, good dispersivity by taking water as solvent without being dissolved by organic solvent, environment protection, favorable environment compatibility and no environment pollution.

Owner:JIANGNAN UNIV

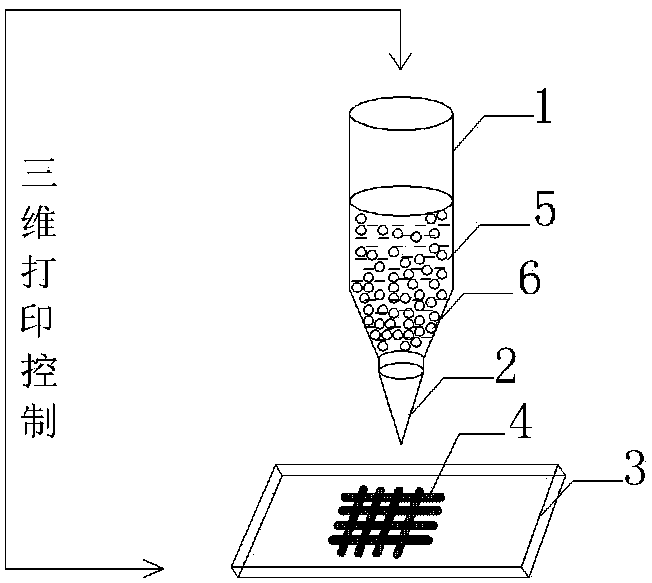

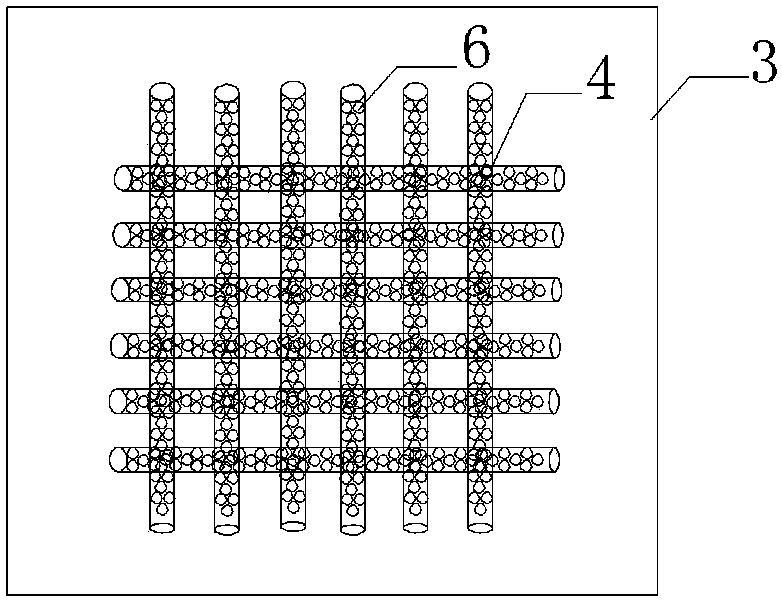

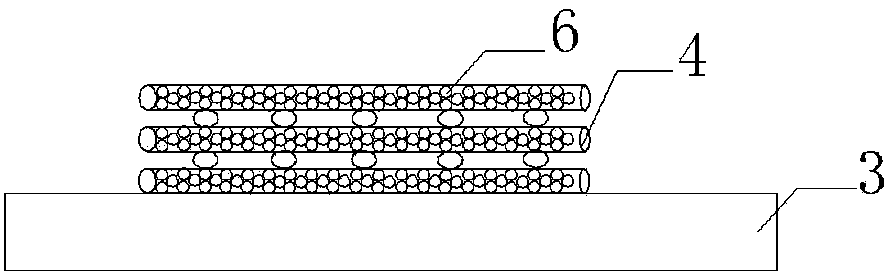

3D-printing wound dressing material based on silk microsphere bio-ink and preparation method thereof

ActiveCN107744601APromote recombinationGuaranteed mechanical propertiesAbsorbent padsMicrocapsulesWound dressingMicrosphere

The invention provides a 3D-printing wound dressing material based on silk microsphere bio-ink and a preparation method thereof. The preparation method includes the following steps: transferring silkmicrosphere bio-ink, which includes silk protein microspheres coating aspirin, silk protein water solution, ultraviolet initiator and polyvinyl alcohol ester, into a syringe of a 3D-printing machine;with a cotton gauze as a base printing cloth, printing the surface of the cotton gauze with the silk microsphere bio-ink according to a periodically circulated cross-network structure model; and rapidly curing and shaping the 3D-printing wound dressing material under ultraviolet irradiation. The product is based on 3D-printing technology, wherein the formed cross-network structure contains regularly arranged silk microspheres, and the silk microsphere bio-ink coating layer cures on the surface of the cotton gauze and does not completely penetrate through the cotton gauze. The 3D-printing wounddressing material has good mechanical performance and biocompatibility and excellent slow-release performance, can protect a wound for a long time and can accelerate healing of the wounding.

Owner:YANCHENG INST OF IND TECH

Silk screen printing ink

The invention relates to silk screen printing ink which comprises the following materials in parts by weight: 90-190 parts of a main body material and 15-25 parts of a curing agent. The silk screen printing ink provided by the invention can effectively enhance the adhesion property of the ink by adding an appropriate ratio of the curing agent into the ink. The silk screen printing ink is colorful and bright in color, stable in adhesion property, good in abrasion resistance and color fading resistance after being completely dried, and is not easy to be subjected to yellowing, discoloring and fading under radiation of intensive sunshine.

Owner:SUZHOU ANJIE TECH

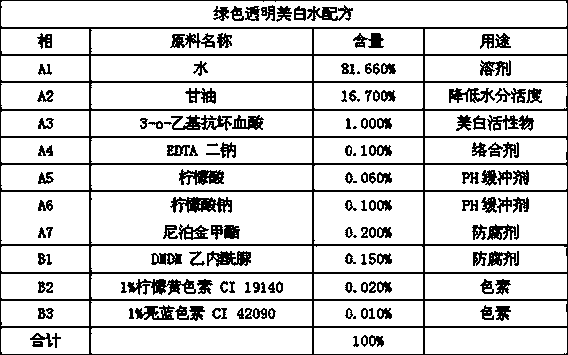

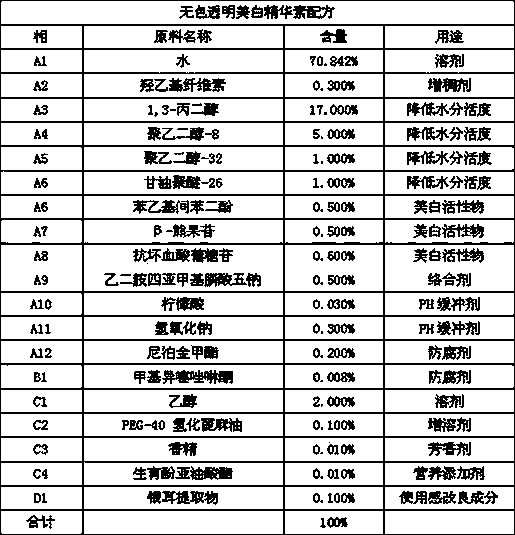

Method for inhibiting whitening cosmetics from yellowing

ActiveCN103385806AAvoid yellowingNot easy to yellowCosmetic preparationsToilet preparationsPolymer scienceSucrose

The invention relates to a method for inhibiting whitening cosmetics from yellowing. The method is characterized by comprising the steps of: adding an appropriate amount of an ingredient capable of inhibiting moisture activity to a cosmetic formula containing whitening active matters, so as to control the moisture activity of a product to be smaller than 0.87, wherein the ingredient capable of inhibiting moisture activity is one or a mixture or isomers of propylene glycol, dipropylene glycol, butanediol, pentanediol, hexanediol, glycerol, diglycerol, sorbitol, betaine, glucose, trehalose, sucrose, polyethylene glycol-8, polyethylene glycol-32, methyl glucitol polyether-10, methyl glucitol polyether-20, glycerol polyether-26 and poloxamer 184; adding 0.03-0.5wt% of complexing agent; and adding an appropriate amount of pH buffering agent so as to control the pH of the product to be 3.3-4.7. The method disclosed by the invention has the beneficial effect of inhibiting the whitening cosmetics from yellowing; and after the whitening cosmetics prepared by the method disclosed by the invention are stored for three years in cosmetic containers, the appearance of the products does not yellow, and the loss of the whitening active matters is small.

Owner:PROYA COSMETICS

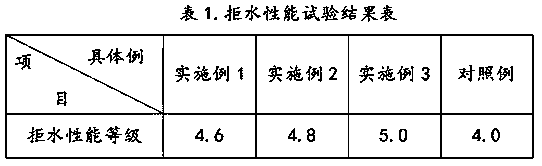

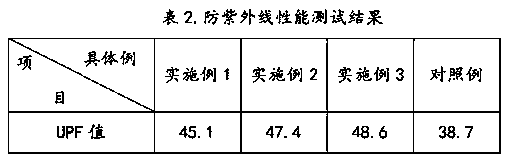

Umbrella cloth and manufacturing method thereof

InactiveCN107558231AImprove waterproof performanceNot easy to yellowFibre typesWoven fabricsPolyesterEmulsion

The invention discloses an umbrella cloth. The umbrella cloth comprises a fabric layer and a water-proof layer coating the fabric layer. The umbrella cloth is characterized in that the fabric layer isprepared by blending and weaving polyester fibers and acrylic fibers, wherein the water-proof layer is prepared from the following components in parts by weight: 35 to 45 parts of resin, 10 to 20 parts of silicone oil, 11 to 15 parts of cross-linking agent, 2.5 to 5.5 parts of adhesive and 1.5 to 4.5 parts of ultraviolet screening agent; the resin contains polyurethane emulsion and polyacrylate emulsion; the mass ratio of the polyurethane emulsion to the polyacrylate emulsion is 5 to 3; the silicone oil is prepared by mixing epoxy-modified silicone with polyether-modified silicone. The invention also aims at providing a method for manufacturing the umbrella cloth; the manufactured umbrella cloth has the advantages of good water-proof and ultraviolet-proof effects, light resistance and lowpossibility of yellowing while processing.

Owner:苏州雨维斯纺织纤维有限公司

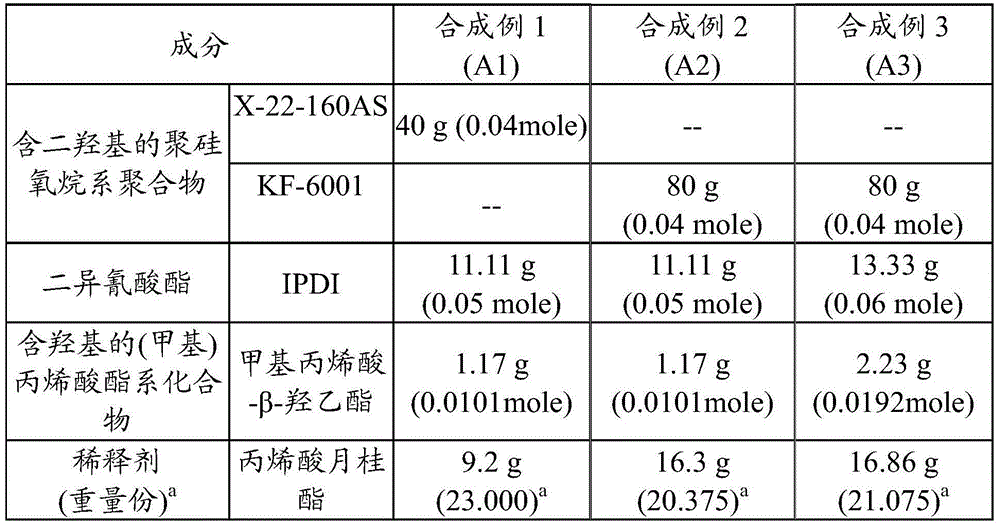

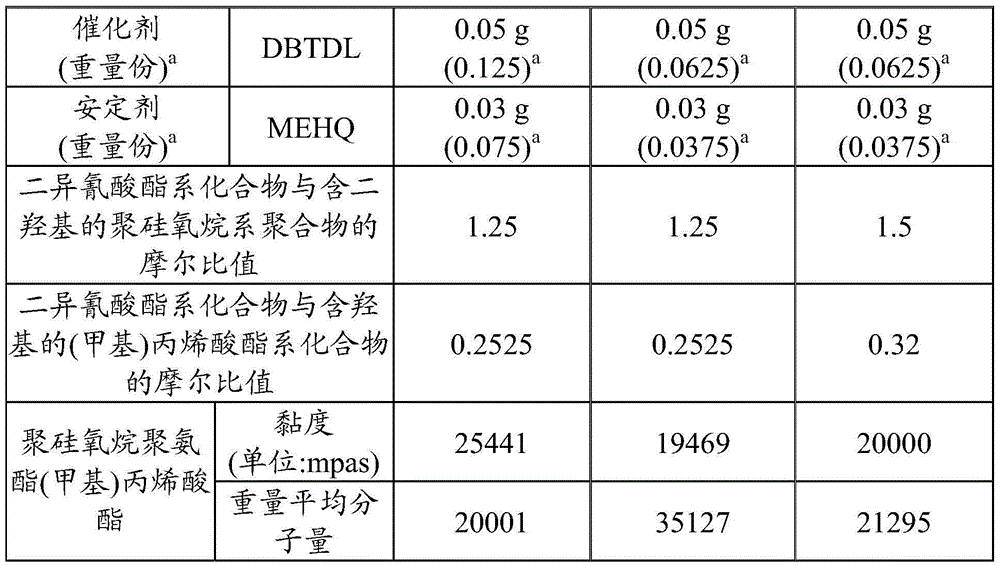

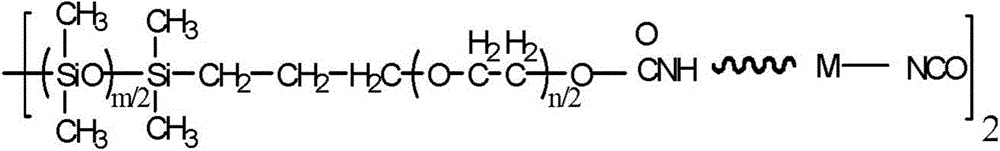

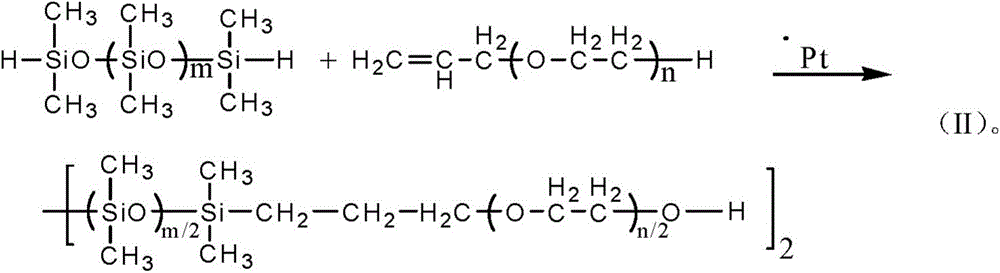

Photo-curable polysiloxane polyurethane (methyl) acrylate composition, adhesive and cured product

ActiveCN103937437AStrong penetrating powerNot easy to yellowPolyureas/polyurethane adhesivesThiolMethyl group

A photo-curable polysiloxane polyurethane (methyl) acrylate composition comprises polysiloxane polyurethane (methyl) acrylate, a compound containing ethylenic-bond unsaturated functional groups, a photoinitiator and a thiol compound. The polysiloxane polyurethane (methyl) acrylate comprises polymerization products obtained by polymerization reaction of reactants, the reactants of the weight-average molecular weight of less than 5000 have polysiloxane polymers having dyhydroxy, diisocyanate compounds and (methyl) acrylate compounds having hydroxyl. The mole ratio of diisocyanate compounds to the (methyl) acrylate compounds having hydroxyl is from 1.05 to 1.45. The cured product formed by the composition has a tensile failure length of more than 680% and a volume shrinkage of less than 1.95%.

Owner:DAXIN MATERIALS

Luminous fiber Raschel blanket production process

The invention discloses a luminous fiber Raschel blanket production process. The luminous fiber Raschel blanket production process comprises the steps of (1) yarn selection, (2) knitting, (3) bleaching, (4) dyeing or printing, and (5) after-finishing. The luminous fiber Raschel blanket produced by use of the production process is soft in hand feeling, good in comfort, high in product quality, luminous at night, high in technological content and added values, advantageous for product structure optimization and product grade improvement, and extremely wide in market prospect; the process conditions of the bleaching are optimized and improved, so that the whiteness of the semi-finished product of the single-layer luminous fiber Raschel blanket can be at the optimal level under the premise of the lowest damage on the luminous fiber deformed yarns, and consequently, the single-layer luminous fiber Raschel blanket is not easy to yellow and good in stability, and has excellent wettability and hand feeling.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

Production technology of anti-yellowing resin imitation diamond with high light transmittance and high weatherability

InactiveCN102166806AGood weather resistanceNot easy to yellowCoatingsEpoxyHeat deflection temperature

The invention relates to a production technology of an anti-yellowing resin imitation diamond with high light transmittance and high weatherability, and belongs to the field of resin processing technology. The production technology includes the steps of using a high-quality rhinestone or zircon imitation diamond as a mold base, sticking the mold base on the surface of a piece of glass or a metal plate, and then covering a high-quality silica gel or plastic cement to obtain a product mould after solidification; making a special-purpose resin glue raw material by evenly mixing the special-purpose epoxy resin glues, A and B, at a ratio of 1:1; injecting the glue into the cavity of the resin mould artificially or via an automatic glue-dripping machine for solidification; obtaining a finished product after moulding. The color performance can be realized by the methods of spraying base color, plating base color and adding color concentrates into glue. The resin prepared by the technology of the invention is good in weatherability and is not easy to become yellow. Besides, the resin has a light transmittance which is over 90%, a thermal deformation temperature which is over 80 DEG, and a Shore hardness which is over 80.

Owner:DONGGUAN NANYU RESIN HARDWARE

Preparation method of blocked organosilicone waterborne polyurethane anti-fluffing-and-pilling agent

InactiveCN105693989AHigh film strengthImprove compactnessLight resistant fibresGrip property fibresHydrogenPolymer science

The invention discloses a preparation method of a blocked organosilicone waterborne polyurethane anti-fluffing-and-pilling agent. The preparation method includes following steps: preparing terminated hydrogen group modified silicone oil; preparing terminated hydroxyl blocked silicone oil; preparing the blocked organosilicone waterborne polyurethane anti-fluffing-and-pilling agent. The preparation method is simple in process, and the agent prepared by the method is high in film forming strength, compactness and continuity; fabric finished by using the agent is not clammy and free of adhesion with a roller in the process of application, anti-fluffing-and-pilling effect is improved obviously, and the fabric after being finished is good in hand feeling.

Owner:南通曙光染织有限公司

Adhesive for light-reflecting particles and preparation method thereof

ActiveCN101698788AFeel goodSoft touchPolyureas/polyurethane adhesivesFunctional monomerPolymer science

The invention discloses adhesive for light-reflecting particles and a preparation method thereof, which belongs to the technical field of adhesive preparation. The adhesive comprises a component A and a component B which are mixed in a weight ratio of 100:5-9, wherein the component A comprises the following raw materials in percentage by mass: 30 to 55 percent of acrylate soft monomer, 0.2 to 5 percent of functional monomer containing carboxyl or hydroxyl groups, 0.5 to 10 percent of crosslinking monomer containing hydroxyl groups, 40 to 60 percent of non-alcohol solvent, 0.2 to 5 percent of oil-soluble initiator and 0.05 to 0.2 percent of thiol chain transfer agent; and the component B adopts low-molecular polymer with the content of NCO between 10 and 14 percent. The crosslinking monomer containing hydroxyl groups in the component A of the adhesive undergoes crosslinking reaction with NCO in the component B to increase the cohesive energy and polarity of an adhesive system, thereby increasing the adhesive bonding action of the system on base materials and inorganic light-reflecting particles.

Owner:NANTONG GAOMENG NEW MATERIAL

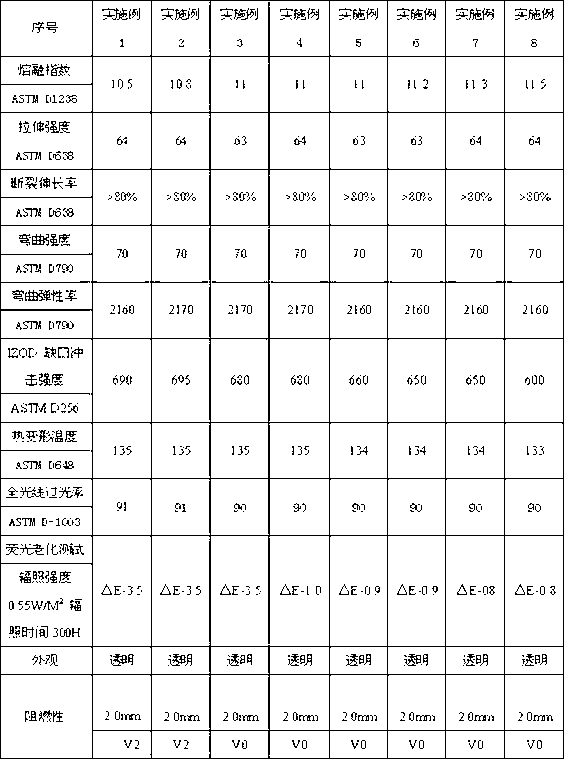

High light-transmittance and high flame-retardant polycarbonate material and preparation method of polycarbonate material

ActiveCN102702716AHigh light transmittanceImprove flame retardantGlobesOxidation resistantFire retardant

The invention relates to the technical field of polycarbonate material, particularly to high light-transmittance and high flame-retardant polycarbonate material. The polycarbonate material contains the following constituents and materials by weight: 94.8-99.5% of polycarbonate, 0.1-0.3% of fire retardant A, 0.1-3.5% of fire retardant B, 0.1-0.3% of antioxidant A, 0.1-0.3% of antioxidant B, 0.1-0.2% of a lubricating agent and 0-0.6% of light stabilizer, and the sum of the weight percentages of the constituents is 100%. The preparation method comprises the steps of putting the constituents except for the polycarbonate into a high-speed mixer to uniformly agitate, putting the polycarbonate and uniformly mixed material into the high-speed mixer to carry out three-segment agitation, and putting the material into a double-screw extruder to extrude and pelletize. The polycarbonate material disclosed by the invention has the advantages of high light transmittance and high fire resistance and the like, can meet the requirements of a lampshade for outdoor illumination, and is simple in process and beneficial for generalization and application.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

Heat insulated anticorrosive coating for coiled material, and fabricating method

InactiveCN1760292AGood heat insulationReduce indoor temperatureAnti-corrosive paintsPolyester coatingsCross-linkHigh resistance

A paint for the coiled insulating and anticorrosion material is prepared from special polyester resin, high etherified cross-linking resin and pigment, functional insulating filler, special chemical assistant and solvent through proportional mixing, dispersing, grinding, adding insulating filler, etc. Its advantages are no poison and pollution, high flame-retarding and insulating effect, and high resistance to ageing and corrosion.

Owner:广东创想现代产业科技有限公司

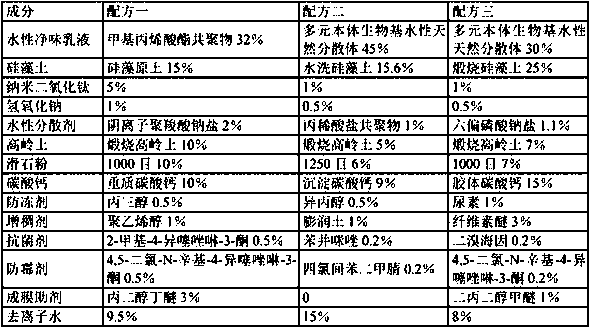

Multifunctional environment-friendly water-based nanometer diatom ooze and preparation method thereof

InactiveCN108219559AHigh catalytic activityChemically stableAntifouling/underwater paintsPaints with biocidesIonEmulsion

The embodiment of the invention provides multifunctional environment-friendly water-based nanometer diatom ooze and a preparation method thereof. The multifunctional environment-friendly water-based nanometer diatom ooze is prepared from the following ingredients in percentage by mass: 30 to 45 percent of waterborne odor removal emulsion, 15 to 25 percent of kieselguhr, 1 to 5 percent of nanometertitanium dioxide, 20 to 32 percent of filling materials, 0.5 to 1 percent of sodium hydroxide, 1 to 2 percent of waterborne dispersing agents, 0.5 to 1 percent of anti-freezing agents, 1 to 3 percentof thickening agents, 0.2 to 0.5 percent of antibacterial agents, 0.2 to 0.5 percent of mildew preventives and 8 to 15 percent of deionized water. A coating formed by coating the multifunctional environment-friendly water-based nanometer diatom ooze provided by the invention onto the surface of a base body has the effective protection effects of high sealing performance, anti-corrosion performance, scratching and friction resistance and anti-impact performance and also has the advantages that the decoration performance is high; the antibacterial and mildewproof effects are realized; the functions of adsorbing and decomposing harmful substances such as formaldehyde, benzene and ammonia gas in the air in a long-effect way, regulating the humidity and the like can be realized; the service life is long; the effect is obvious.

Owner:深圳光天建材有限公司

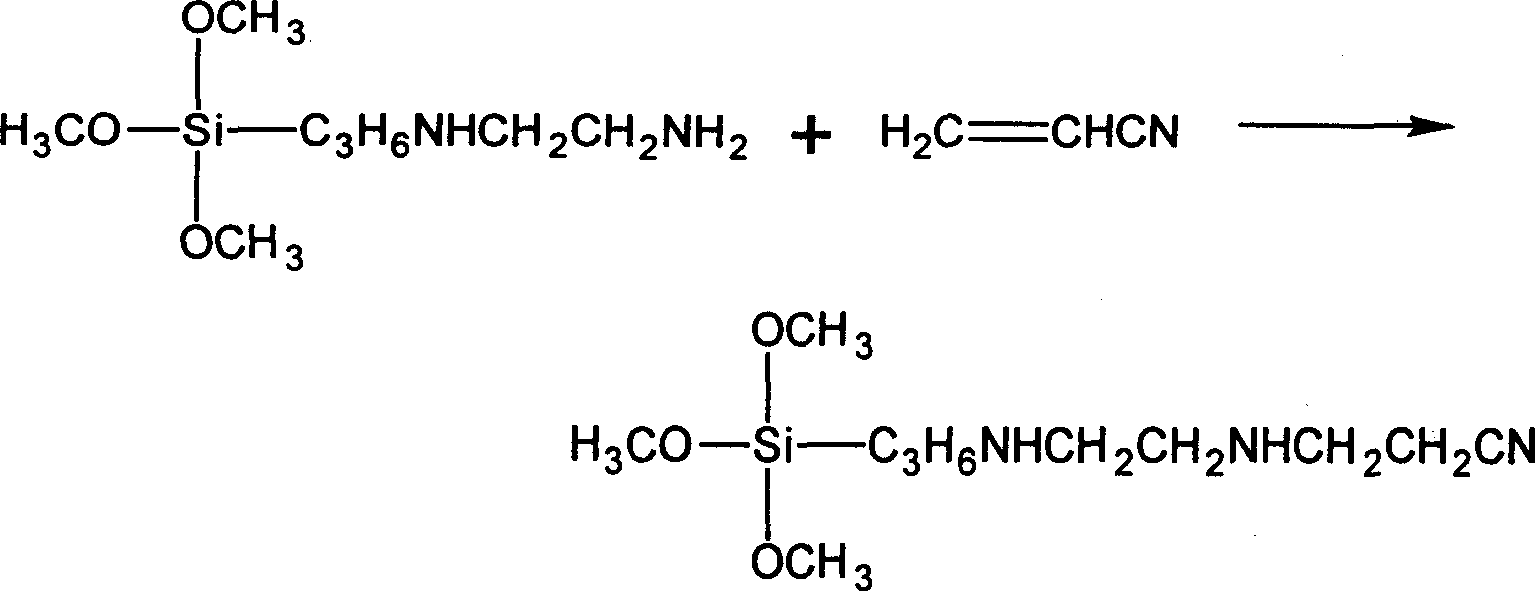

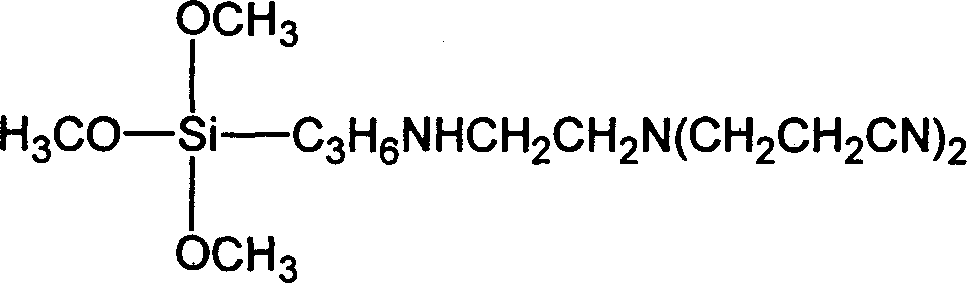

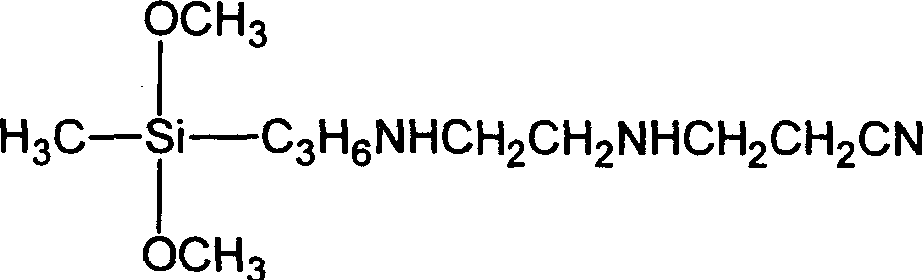

Silicomethane coupling agent containing cyanide and secondary amino and its preparation process and application thereof

InactiveCN1793207AHigh bonding strengthGood storage stabilityAldehyde/ketone condensation polymer adhesivesEpoxy resin adhesivesCyanideSilanes

The invention discloses a method to make silane coupler that contains cyan and secondary amino group. The molecular structure is (R1O)3-xSiR2xR3NHR4NHy(C2H4CN)z that is made up from the reaction of 1-2mol acrylonitrile and 1mol amino silane that has the molecular of (R1O)3-xSiR2xR3NHR4NH2. Comparing to traditional amino silane coupler, it has good restoring stability could be make into other coupler. The mechanical property and strength of bond to the base material would be greatly improved.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com