Silicomethane coupling agent containing cyanide and secondary amino and its preparation process and application thereof

A technology of silane coupling agent and secondary amino group, which is applied in the field of silane coupling agent containing cyano group and secondary amino group and its preparation and application, and can solve the problems of strong amine smell, strong alkalinity, and yellowing of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

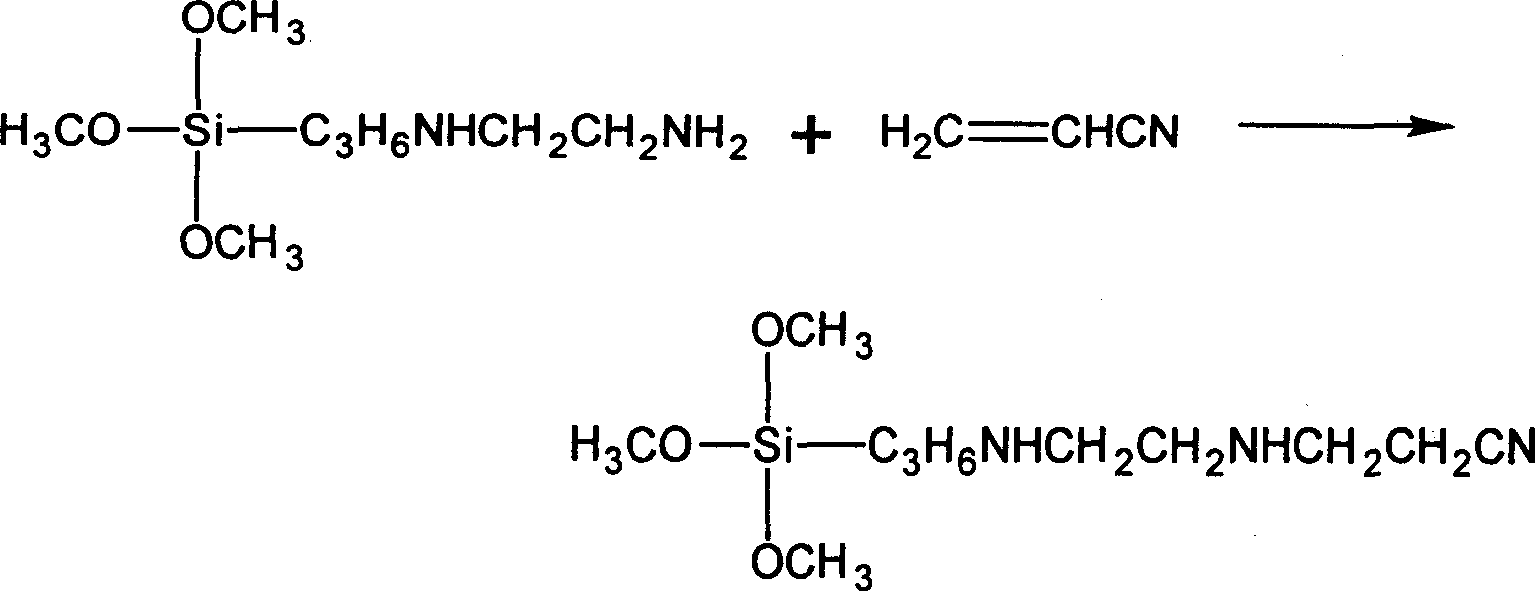

[0011] 1, 1.5, 2 moles of acrylonitrile were added to 1 mole of (MeO) 3 SiC 3 h 6 NHC 2 h 4 NH 2 (commercial brand is KH-792) in carrying out addition reaction, reaction formula is as follows:

[0012]

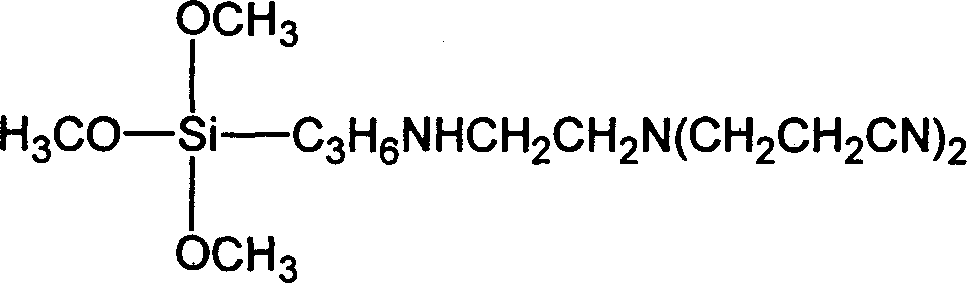

[0013] The name of the product is 7A for short, and the excess acrylonitrile will continue to react with the product to generate a small amount of dicyano substitute

[0014]

[0015] Product properties are shown in Table 1.

[0016] Acrylonitrile to KH-792 Ratio

Embodiment 2

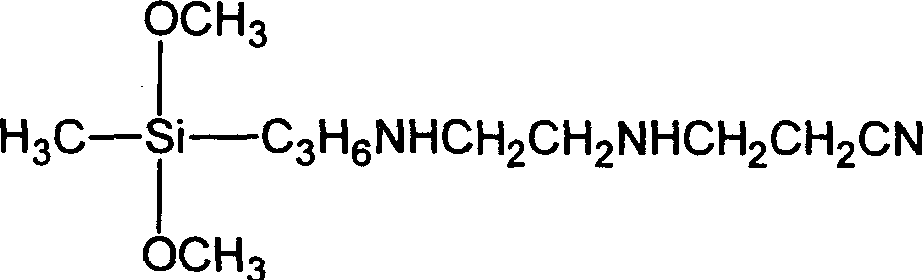

[0018] Prepare another silane coupling agent containing cyano and secondary amino groups in the same way, referred to as 6A, the difference is that 1, 1.5, 2 moles of acrylonitrile are added to 1 mole of (MeO) 3 CH 3 SiC 3 h 6 NHC 2 h 4 NH 2 (trade name is DL-602) in addition reaction, generate

[0019]

[0020] Excess acrylonitrile will also continue to react with the above-mentioned products to generate a small amount of dicyano substituents

[0021]

[0022] Its product performance is as shown in table 2

[0023] Acrylonitrile to DL-602 Ratio

[0024] As can be seen from Tables 1 and 2, the ratio of acrylonitrile and aminosilane is the key of the present invention. If the amount of acrylonitrile is too low, the reaction is not complete, the content of cyano group introduced on the aminosilane is low, and the polarity change is not obvious; if the amount of acrylonitrile is too high, it will continue to add hydrogen to the secondary ammonia on the amin...

Embodiment 3

[0026] Low-modulus, high-elongation silicone sealing materials are mainly composed of hydroxyl-terminated polyorganosiloxane, fillers, chain extenders, cross-linking curing agents, catalysts and plasticizers. Add an appropriate amount of silane to the system The coupling agent can not only effectively improve the mechanical properties of the silicone sealing material, greatly shorten its surface drying time, but also significantly improve its bonding strength to the substrate.

[0027] Mix 100 parts of hydroxyl-terminated polydimethylsiloxane, 100 parts of light calcium carbonate, 6 parts of chain extender, 5 parts of crosslinking curing agent and 0.1 part of catalyst, and stir evenly under vacuum, and add 1 part of silane coupling agent 7A at the same time , after the bubbles and some low-molecular substances generated in the reaction are removed, the silicone sealing material is prepared and sealed for preservation.

[0028] The other four silicone sealing materials were pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com