Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

258results about How to "Bonding strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

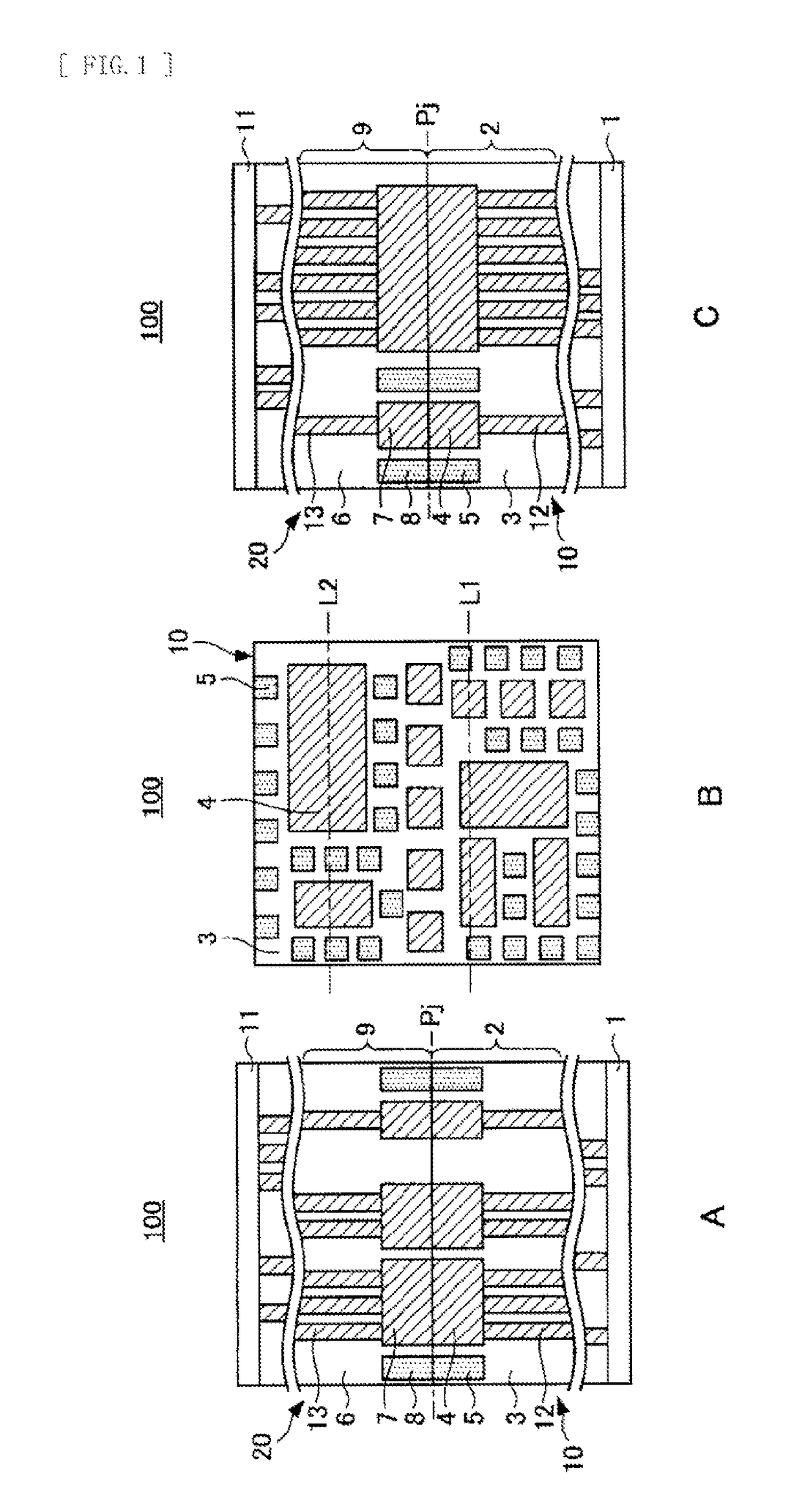

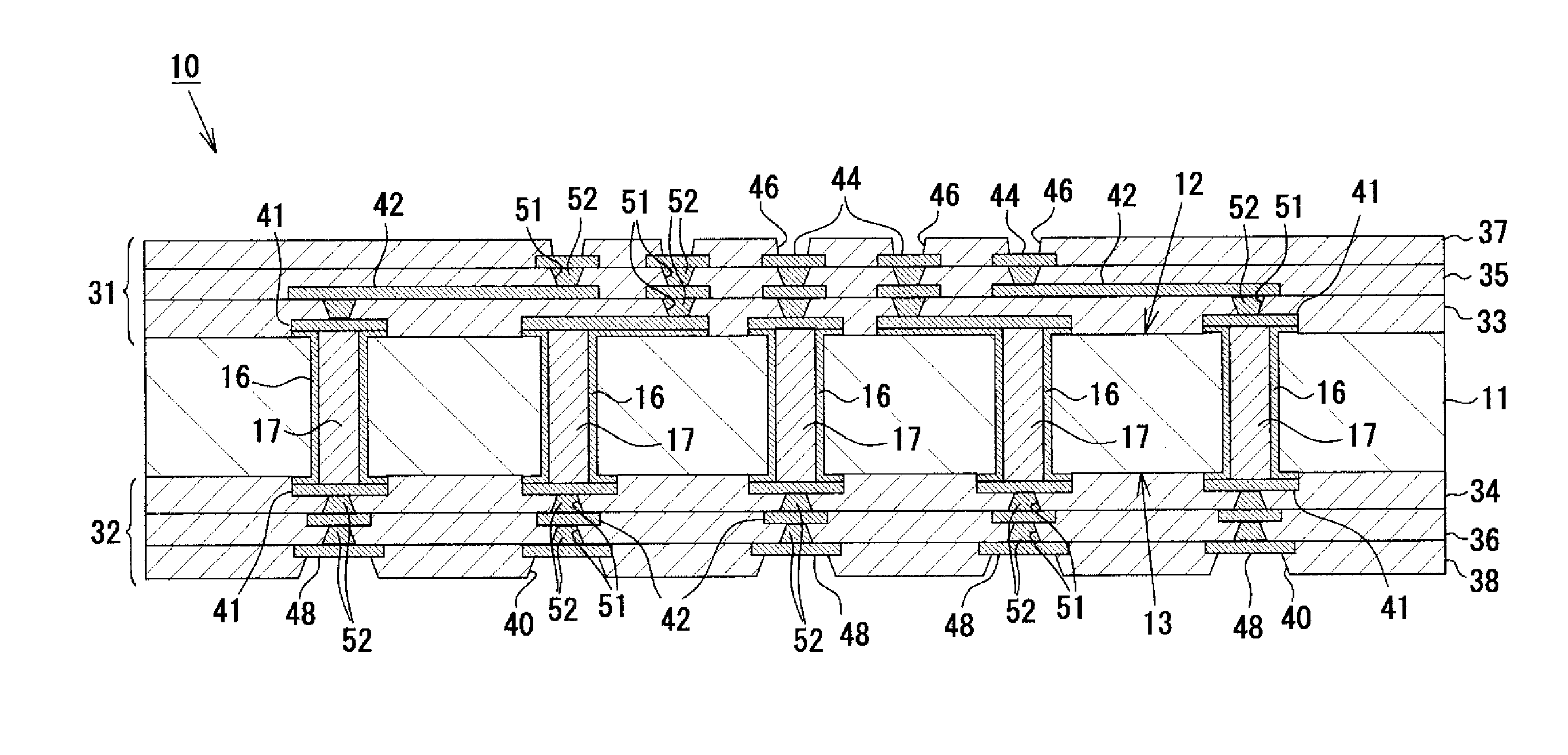

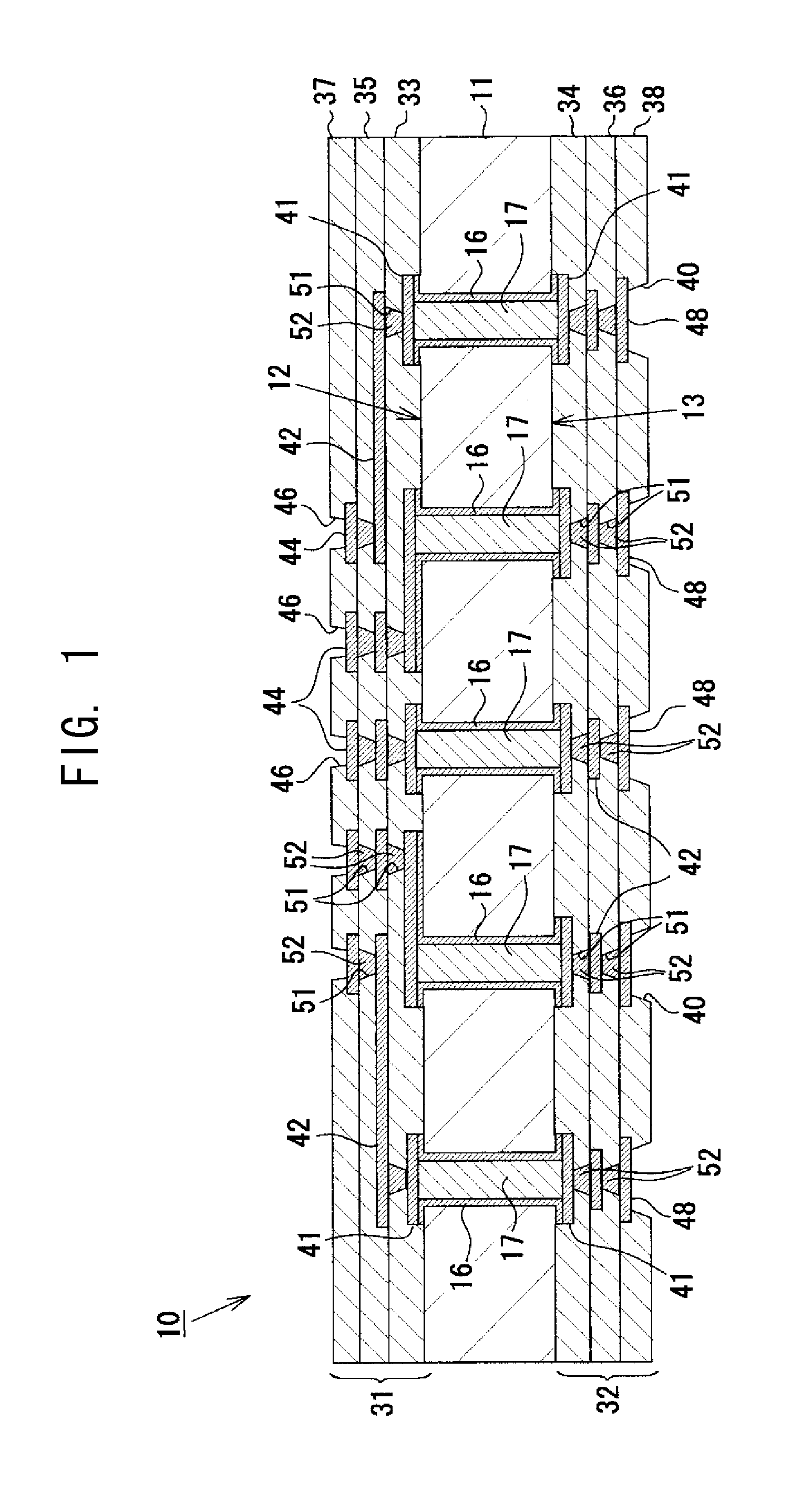

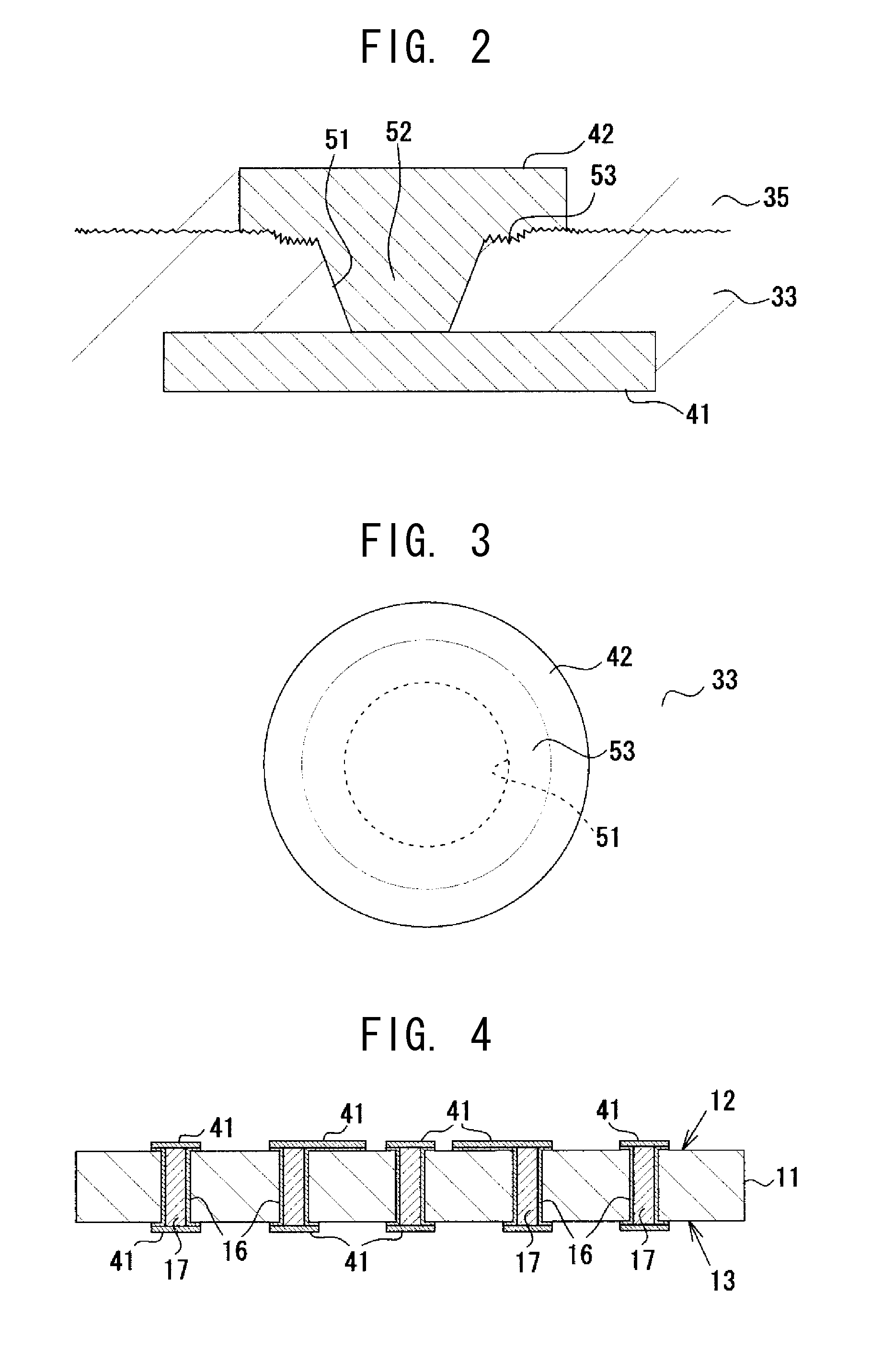

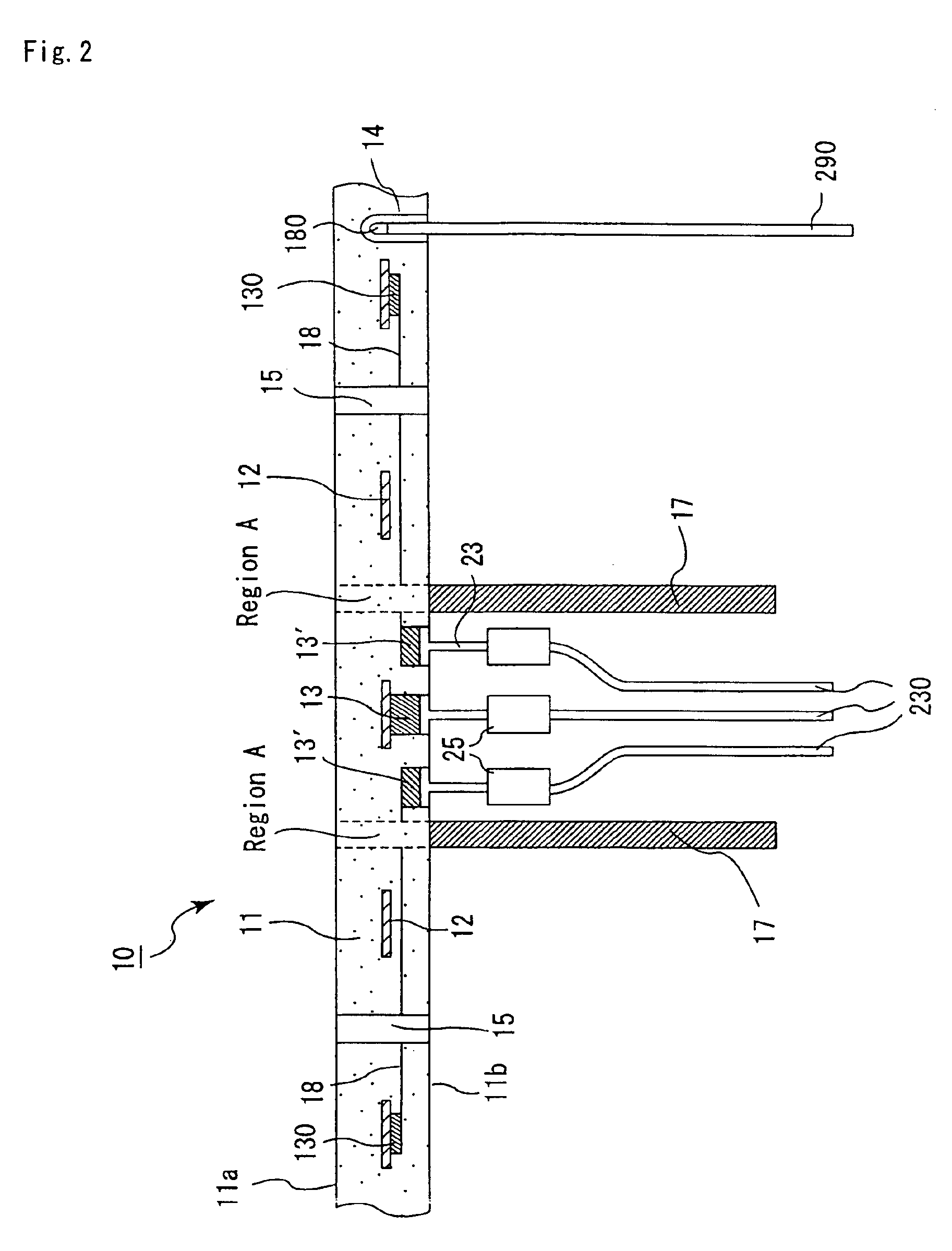

Semiconductor device

ActiveUS9799587B2Improve performanceReliable bonding surfaceSemiconductor/solid-state device detailsSolid-state devicesBond interfaceSemiconductor

A first semiconductor device includes: a first wiring layer including a first interlayer insulating film, a first electrode pad, and a first dummy electrode, the first electrode pad being embedded in the first interlayer insulating film and having one surface located on same plane as one surface of the first interlayer insulating film, and the first dummy electrode being embedded in the first interlayer insulating film, having one surface located on same plane as the one surface of the first interlayer insulating film, and being disposed around the first electrode pad; and a second wiring layer including a second interlayer insulating film, a second electrode pad, and a second dummy electrode, the second electrode pad being embedded in the second interlayer insulating film, having one surface located on same surface as one surface of the second interlayer insulating film, and being bonded to the first electrode pad, and the second dummy electrode having one surface located on same plane as the surface located closer to the first interlayer insulating film of the second interlayer insulating film, being disposed around the second electrode pad, and being bonded to the first dummy electrode. A second semiconductor device includes: a first semiconductor section including a first electrode, the first electrode being formed on a surface located closer to a bonding interface and extending in a first direction; and a second semiconductor section including a second electrode and disposed to be bonded to the first semiconductor section at the bonding interface, the second electrode being bonded to the first electrode and extending in a second direction that intersects with the first direction.

Owner:SONY CORP

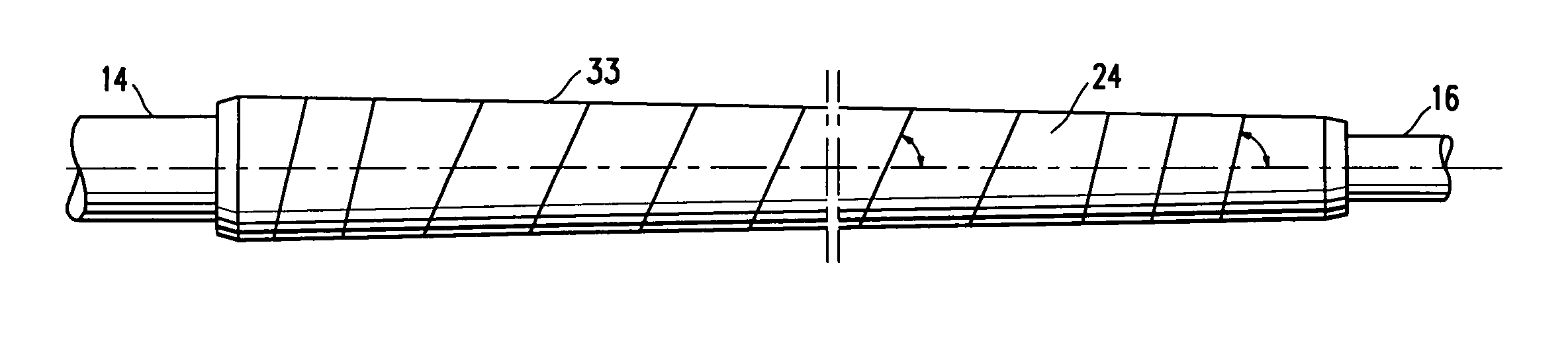

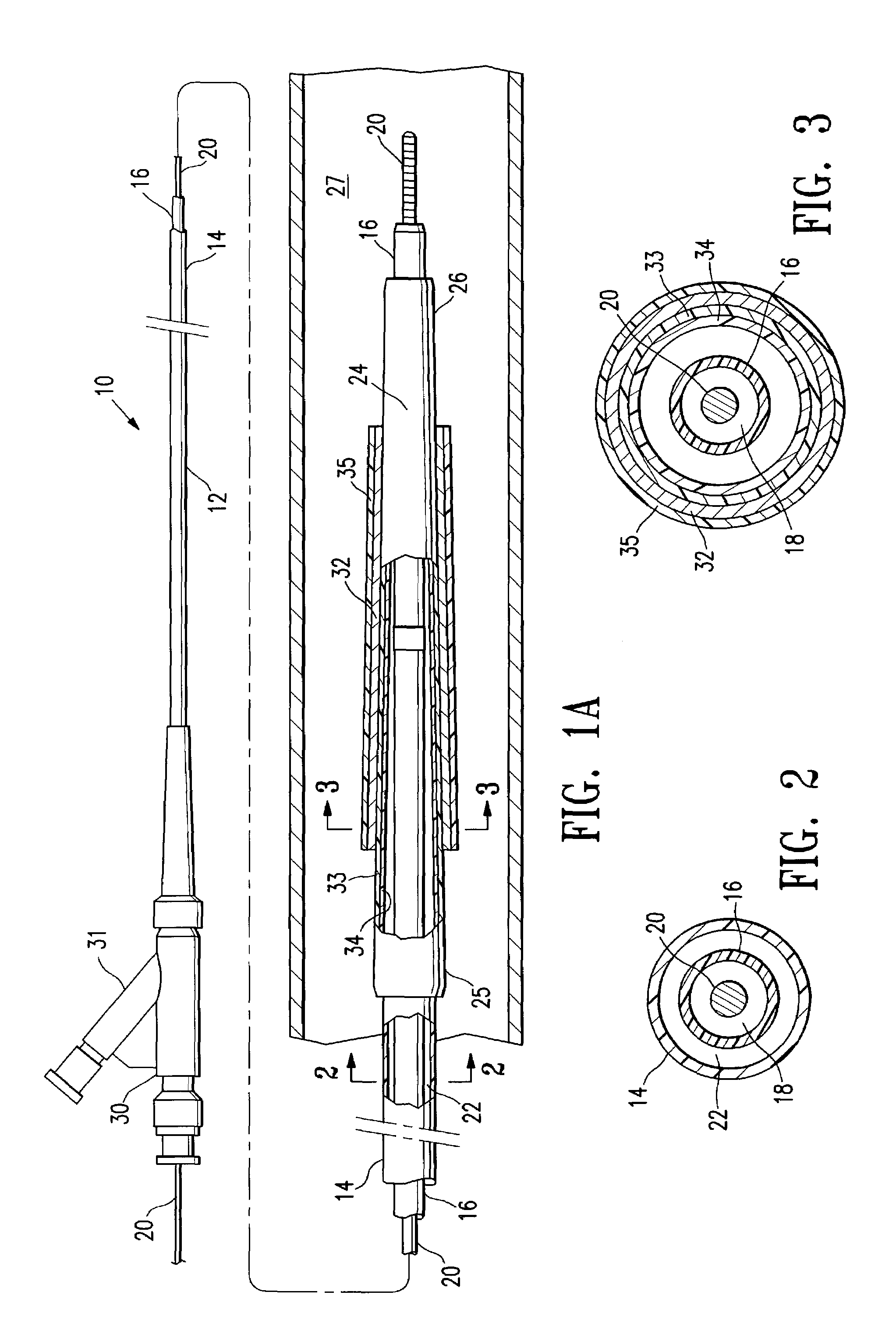

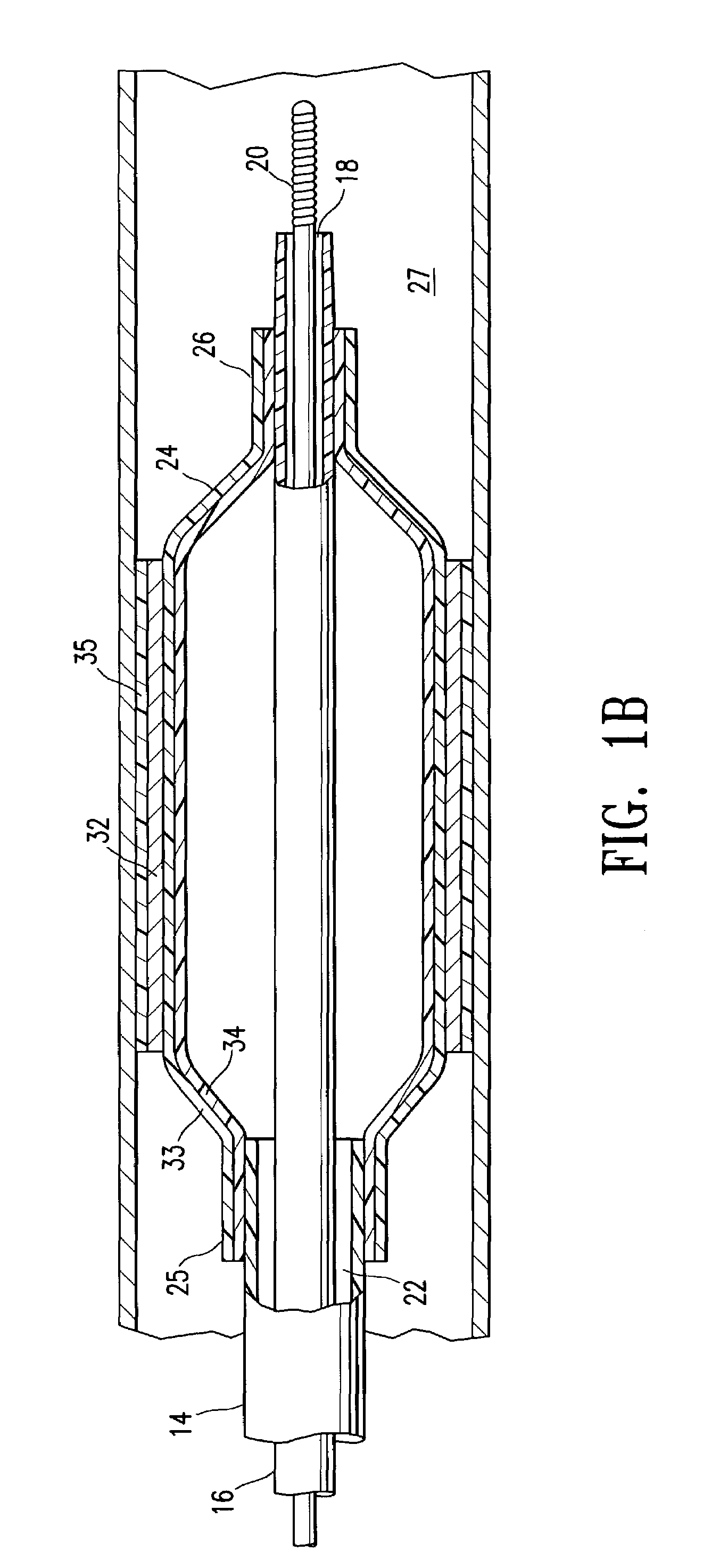

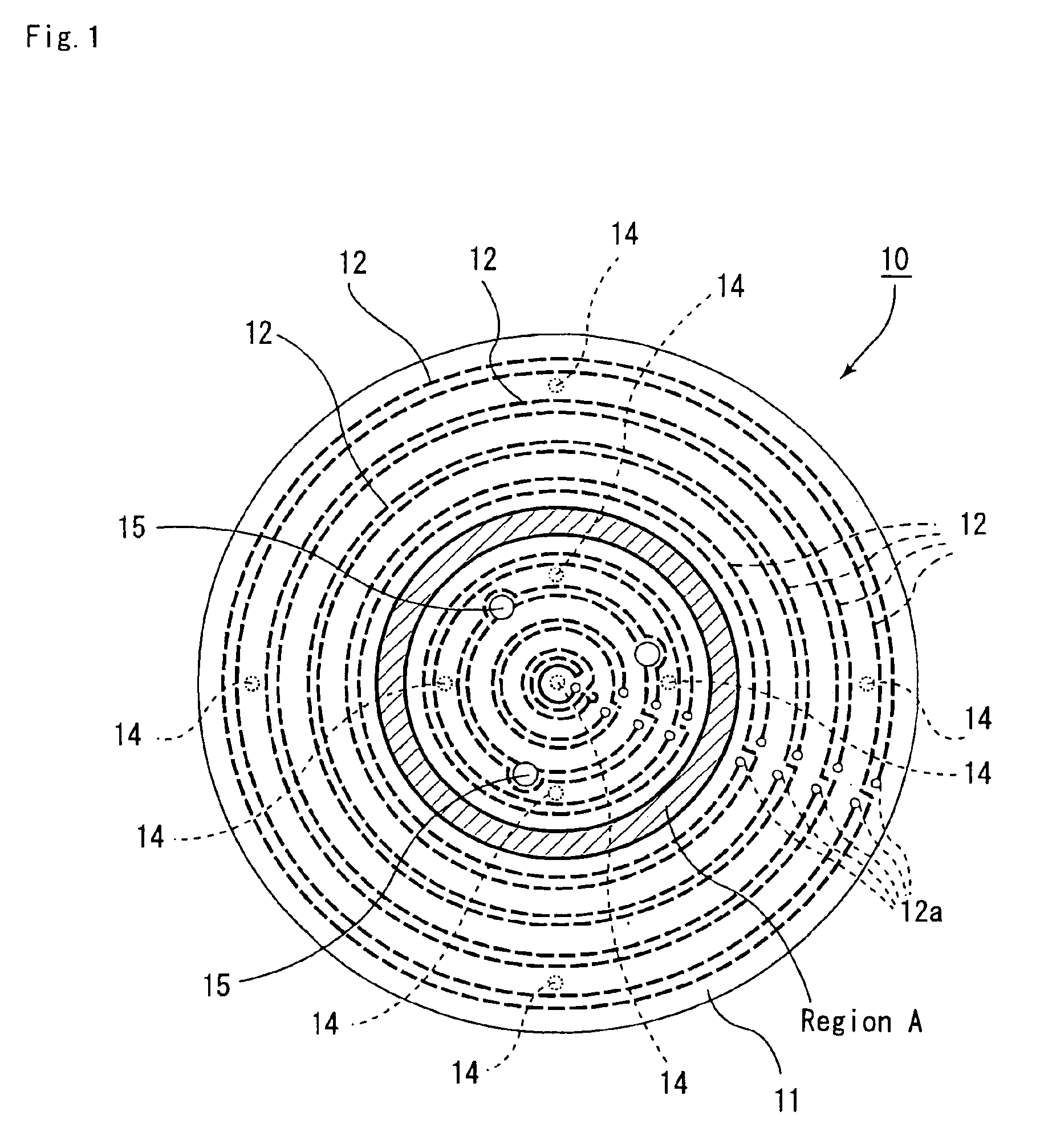

Catheter balloon

An expandable medical device or component thereof including a tubular body formed of a wrapped sheet of porous polymeric material fused together, the tubular body having a fused seam at an angle relative to the longitudinal axis of the tubular body which changes along the length of the tubular body from a first angle to a second angle greater than the first angle. The sheet of porous polymeric material is wound and then fused together such that the winding angle is less in a first longitudinal section of the tubular body compared with the winding angle in a second longitudinal section of the tubular body, in order to provide the second section with greater resistance to expansion (i.e., lower compliance) than the first section.

Owner:ABBOTT CARDIOVASCULAR

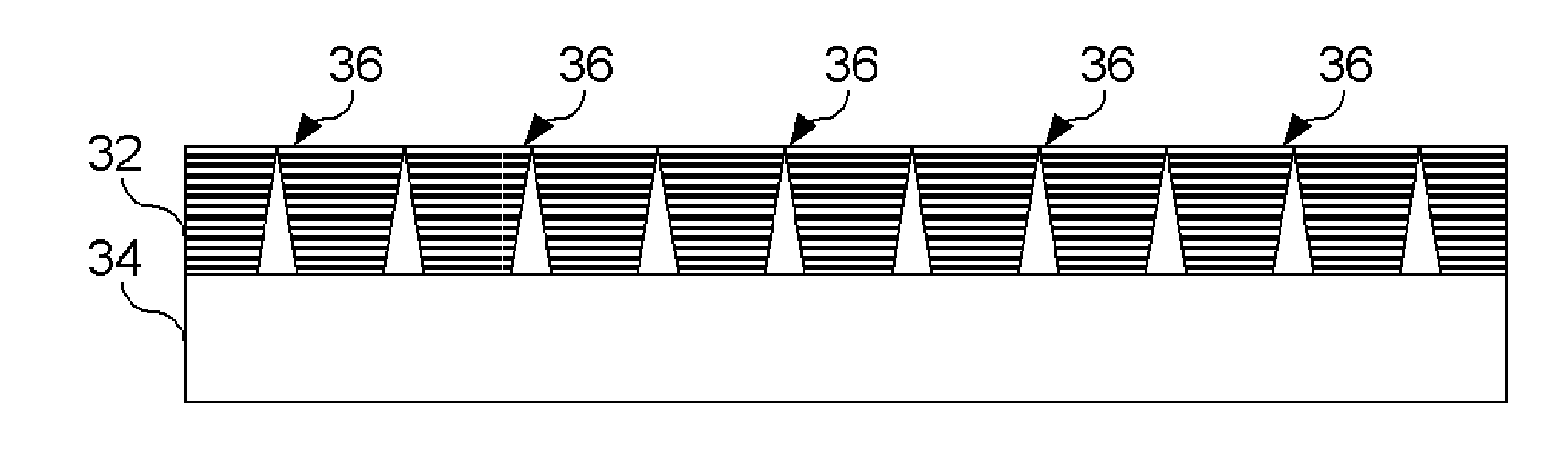

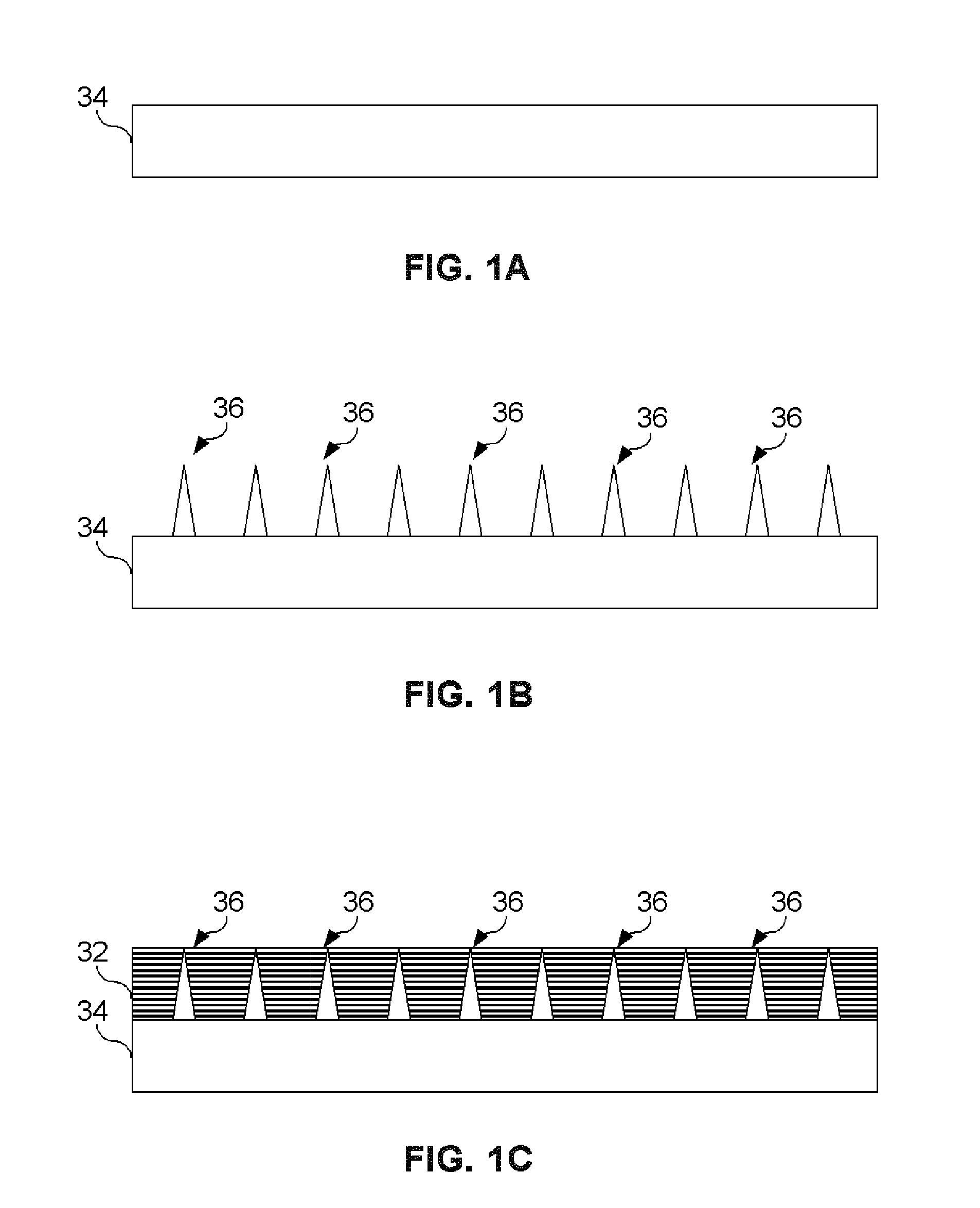

Metallic mini hooks for joining of metallic and composites

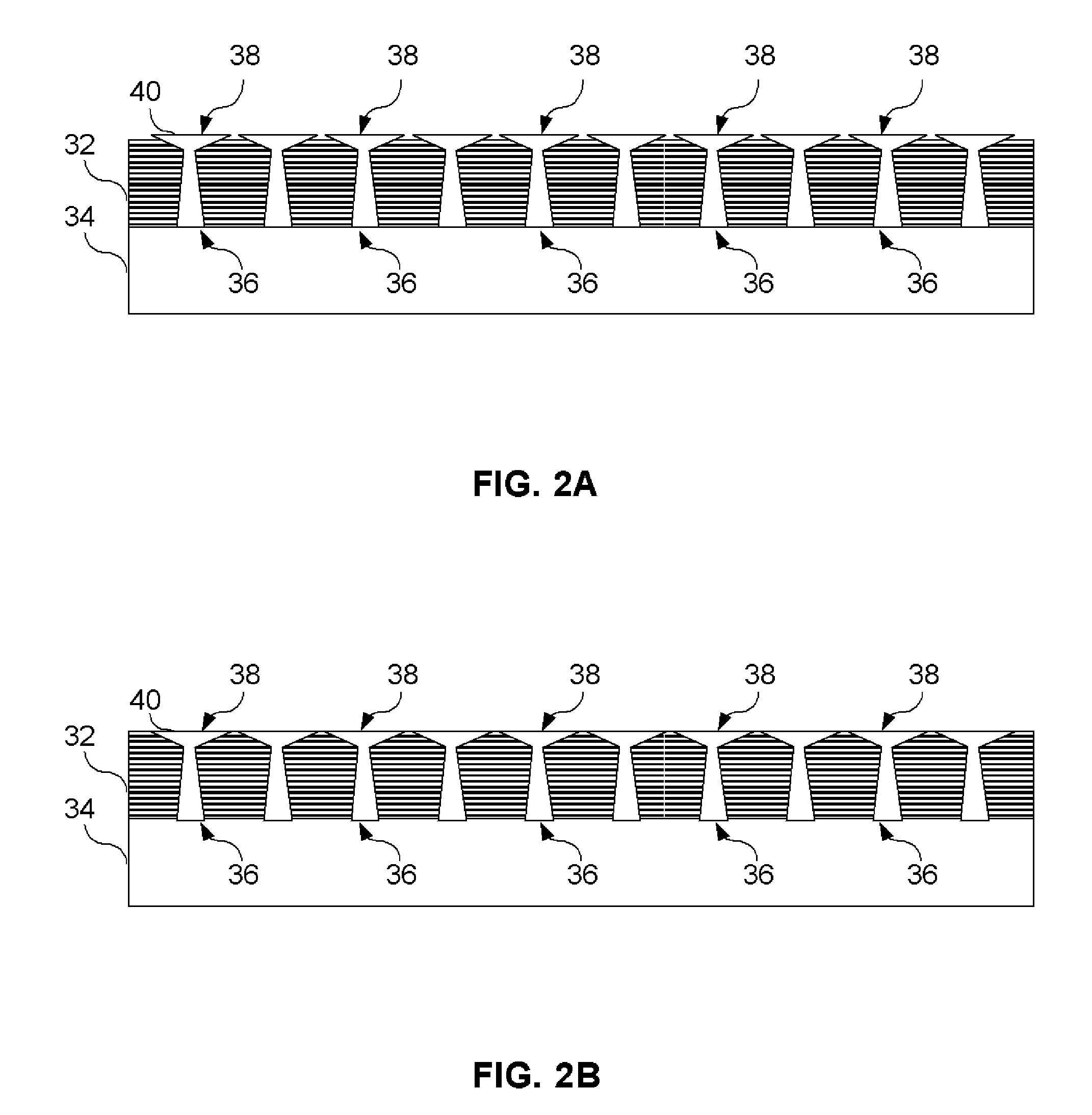

InactiveUS20080003401A1Bonding strengthGood mechanical bondLayered productsSheet joiningMetallic substrateMetal substrate

A method for joining a first structural member and a metallic substrate is provided. This method involves drawing projections from a metallic substrate using a Co-Meld or other like process. Individual plies of composite materials may be laid upon the metallic substrate and projections. These projections penetrate the individual ply or layers of the composite material. A mechanical feature that serves as a retaining device may be located at the distal end of the projections in order to prevent separation of the composite materials from the metallic substrate. The composite materials may be infused with a resin or other material to complete the formation of the composite material. Additionally, other layers of composite material may be placed over the mechanical features located at the distal ends.

Owner:LOCKHEED MARTIN CORP

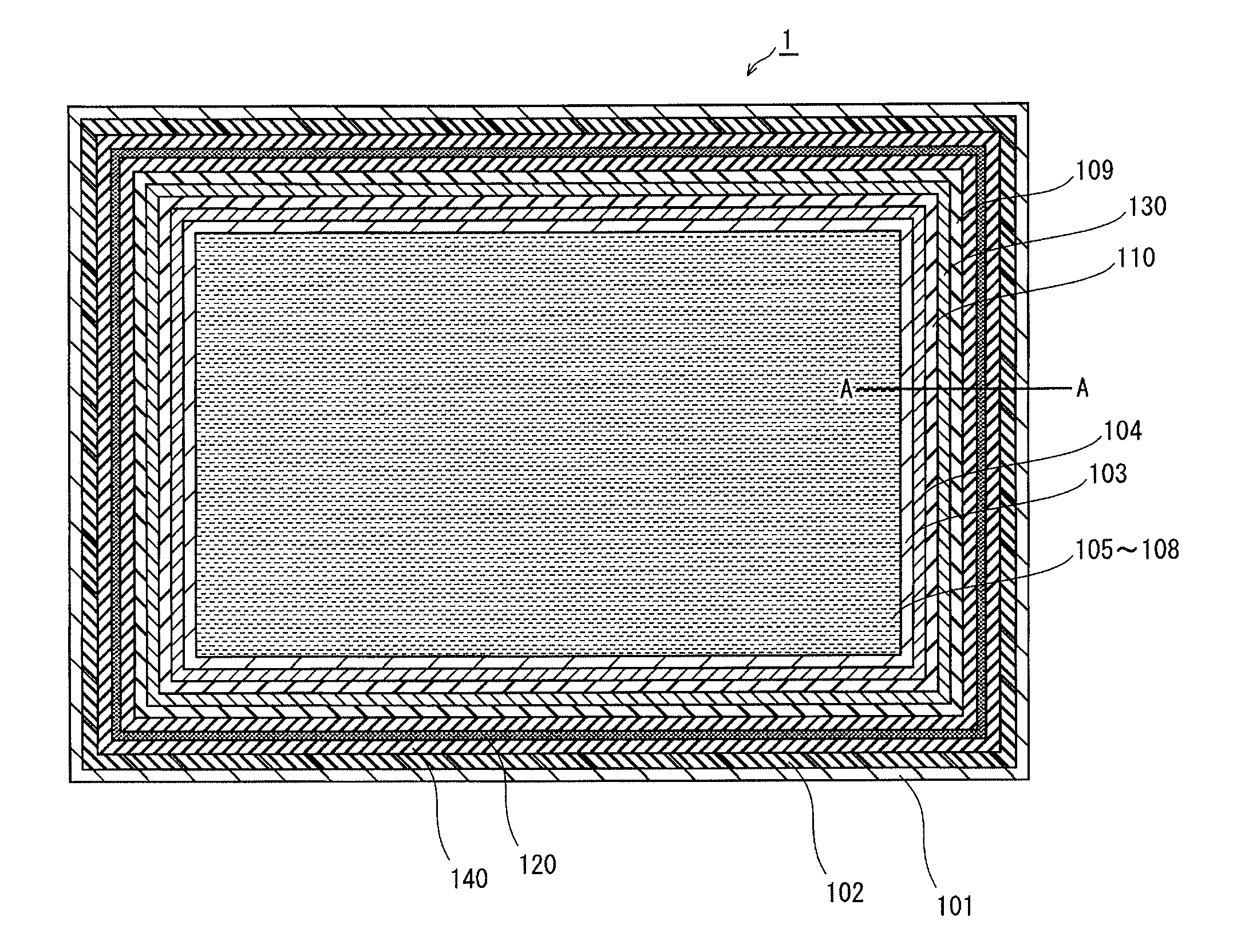

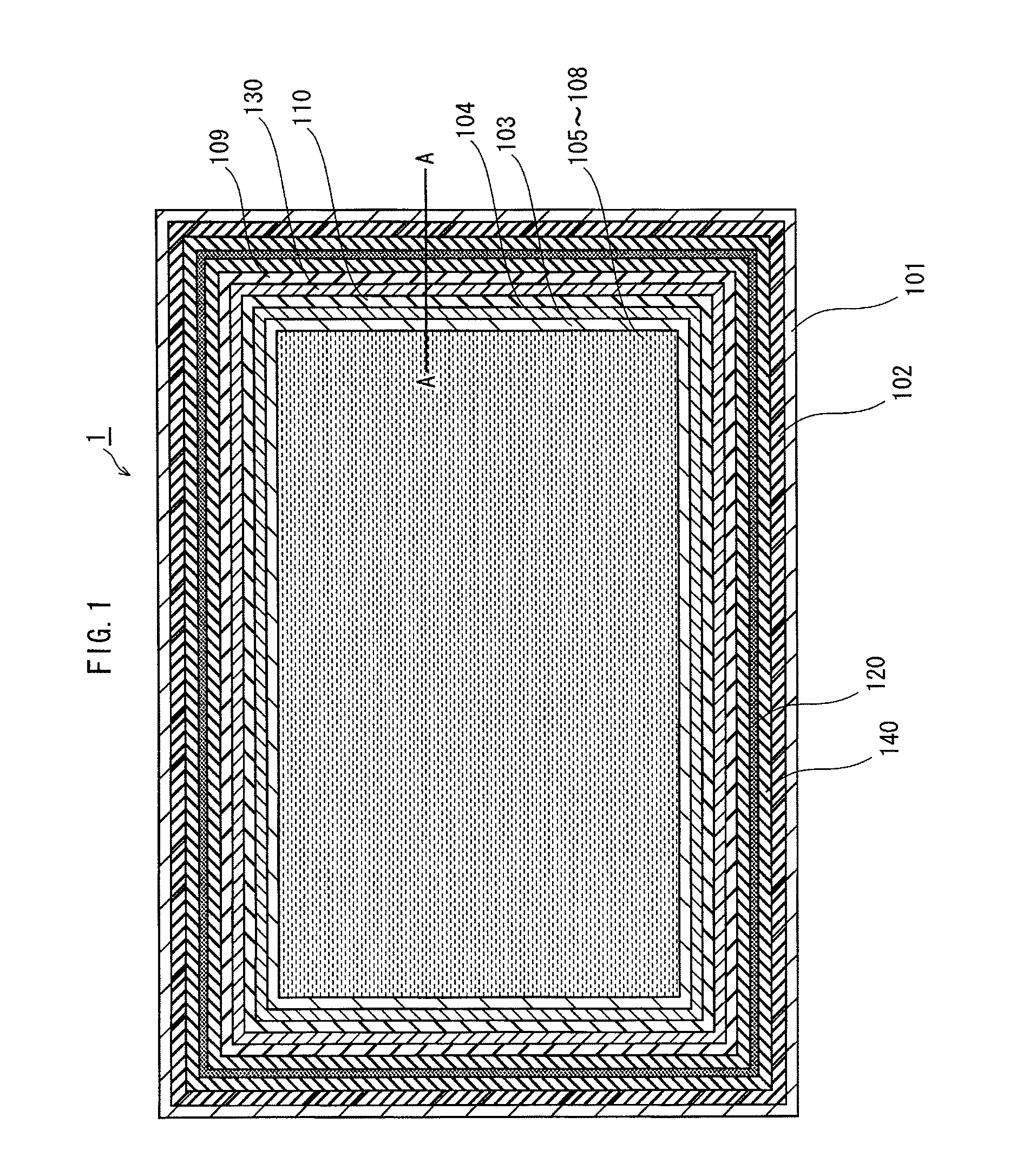

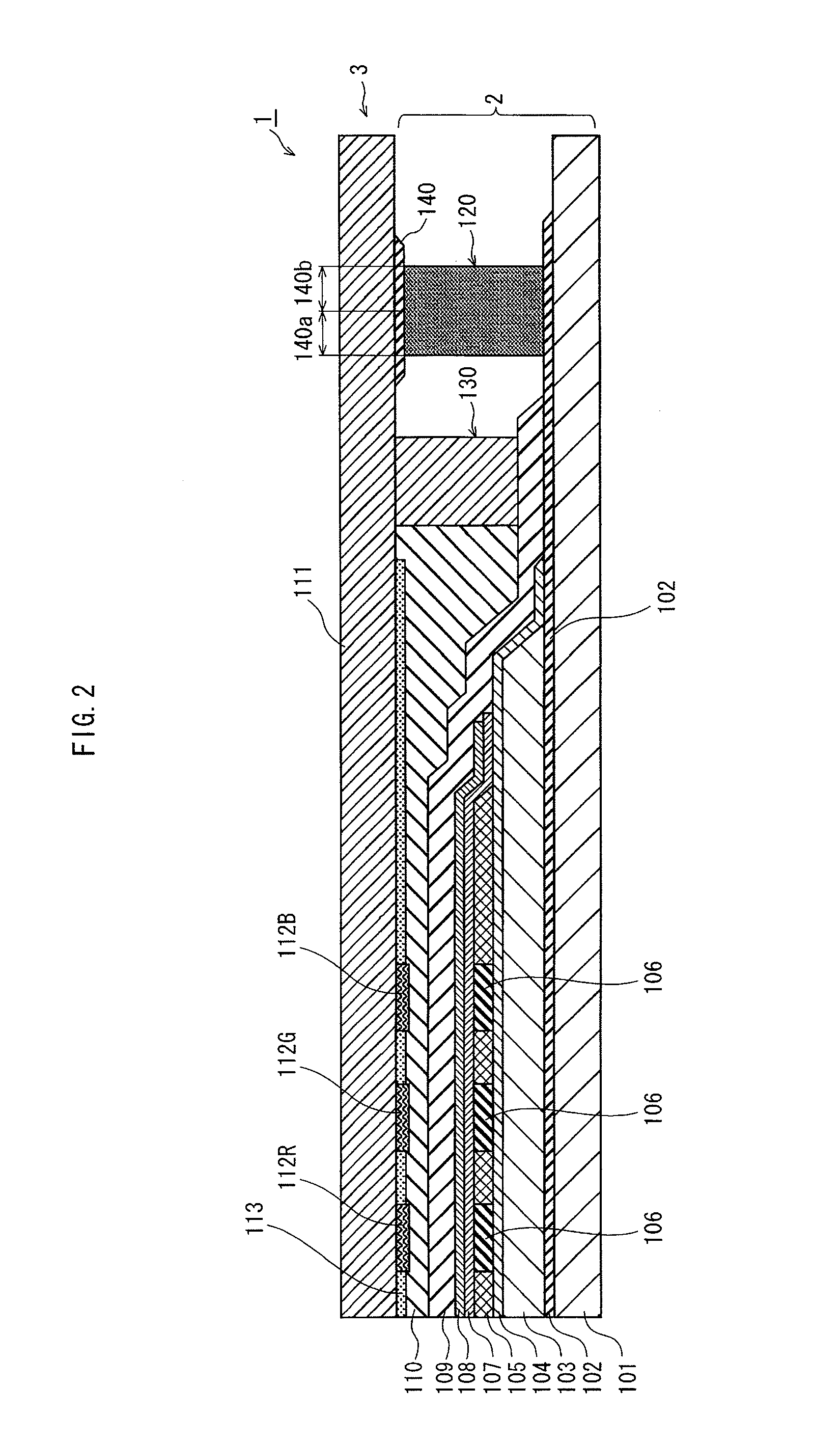

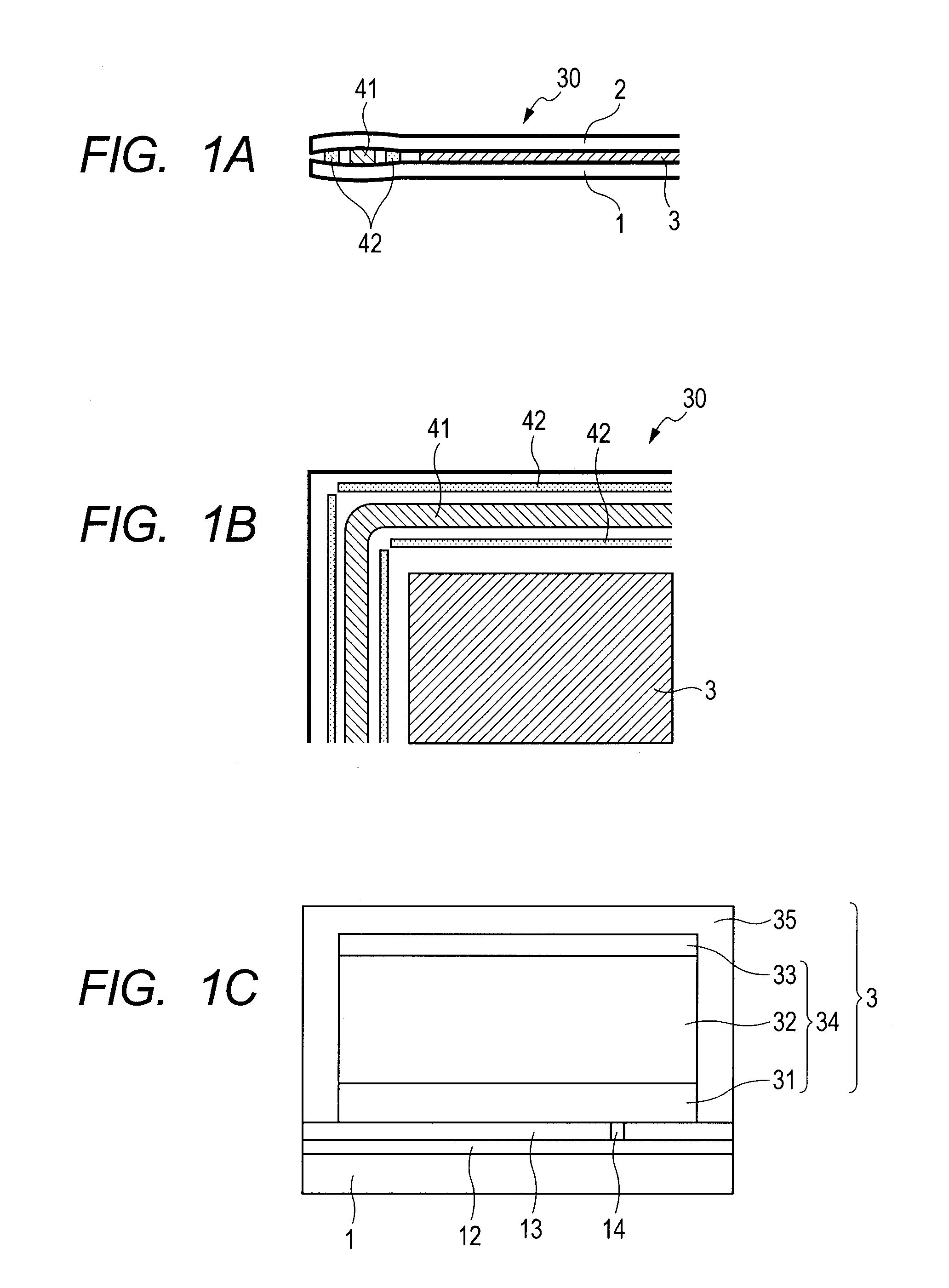

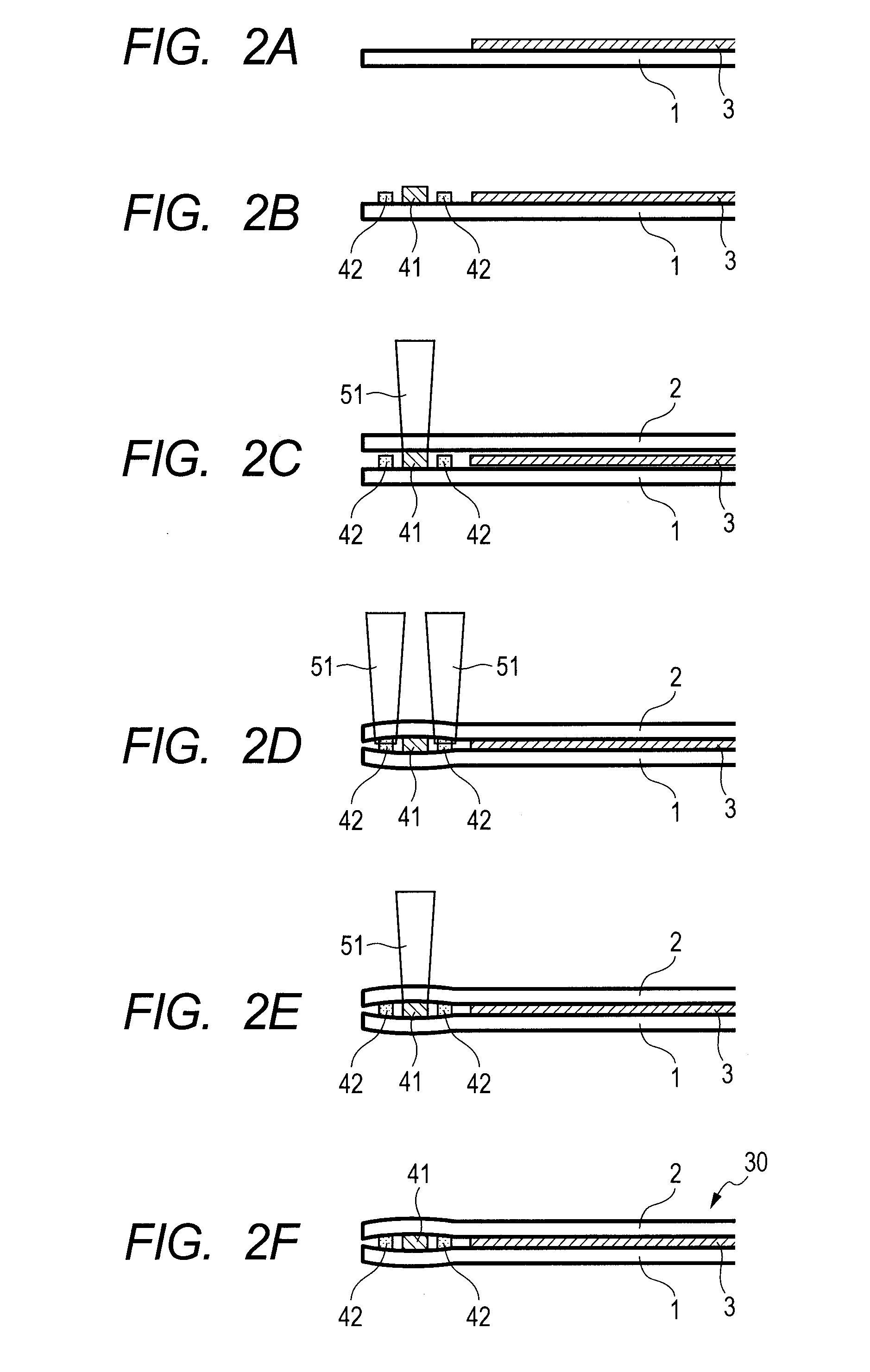

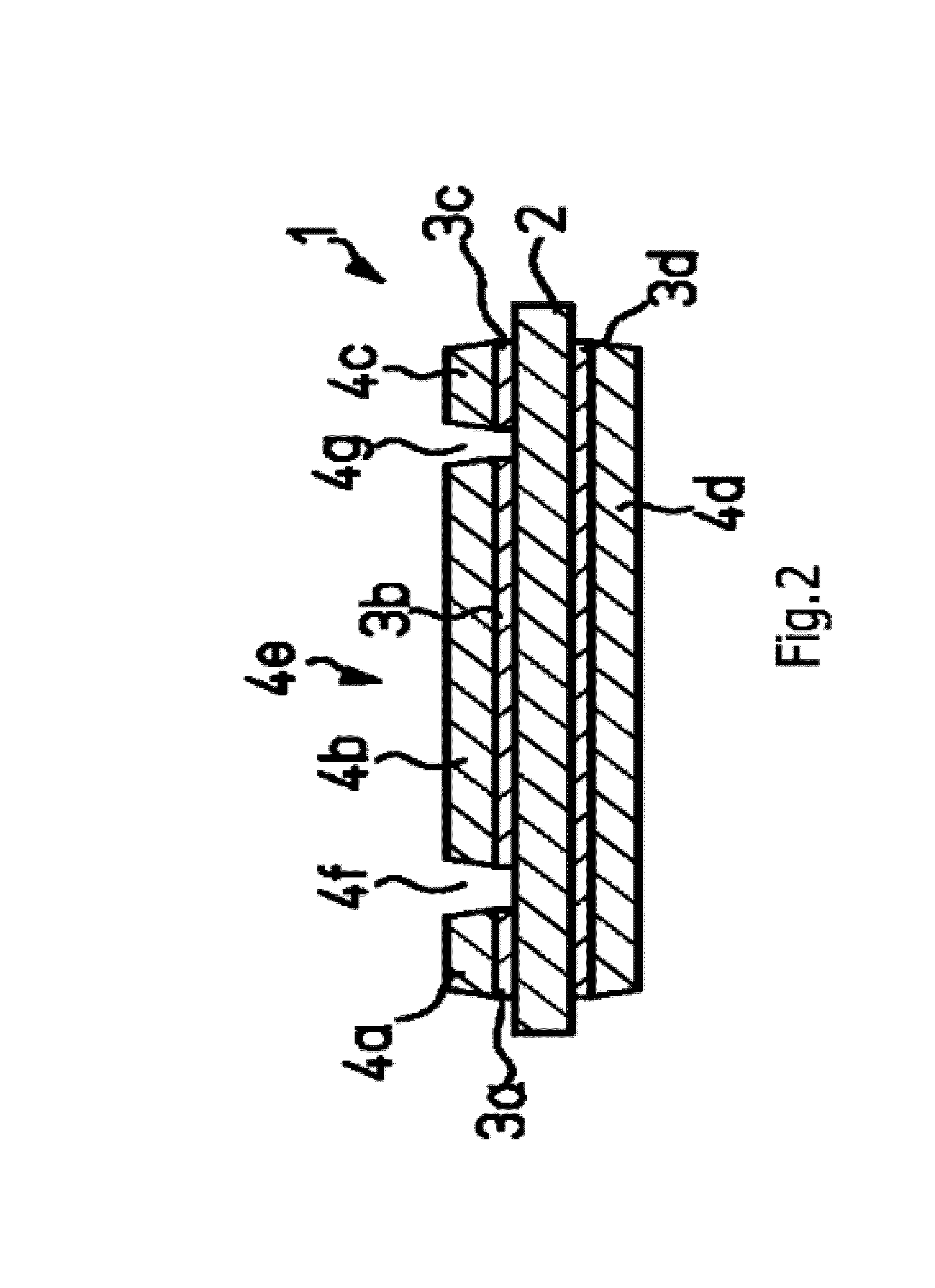

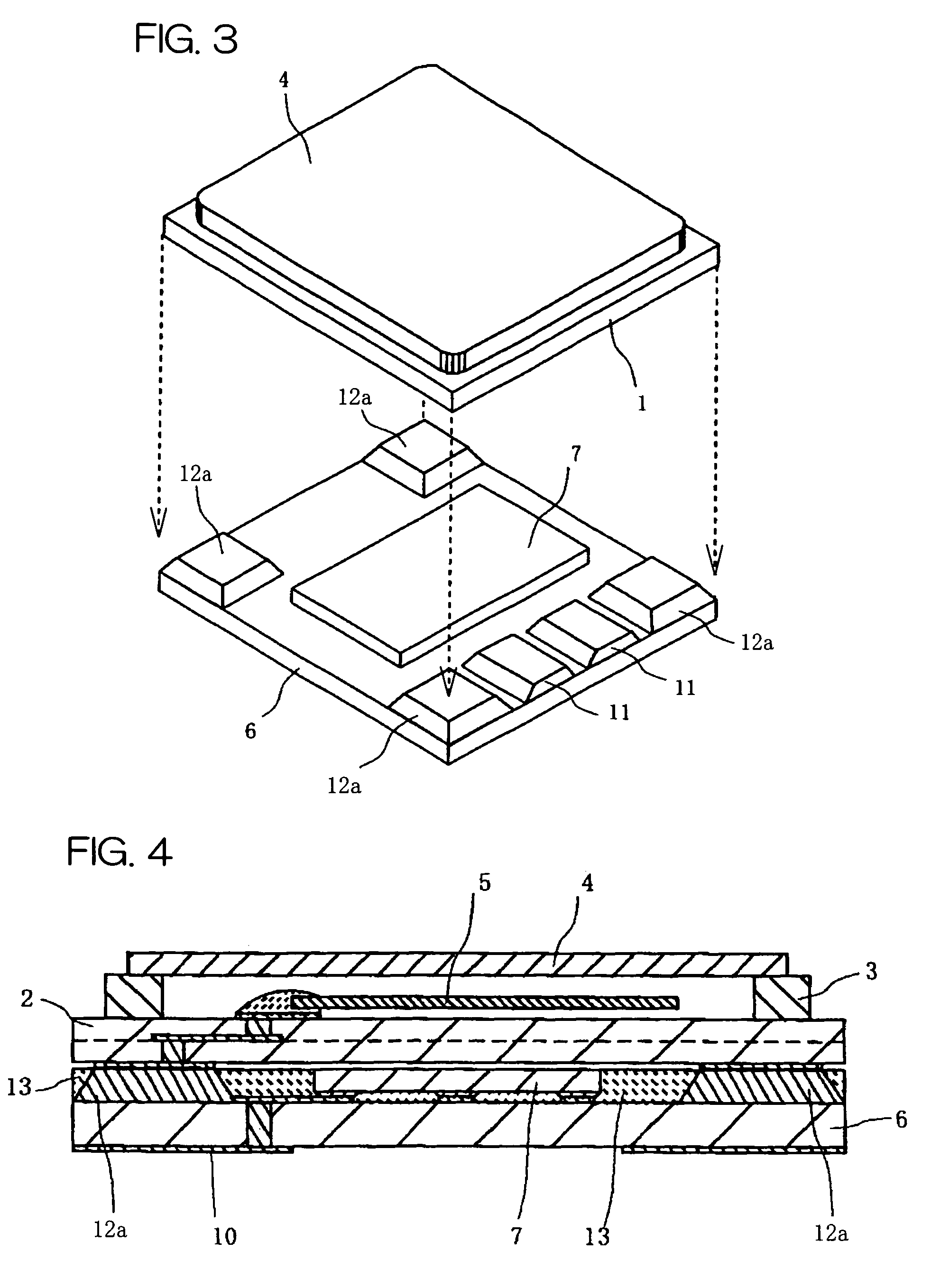

Display panel and production method thereof

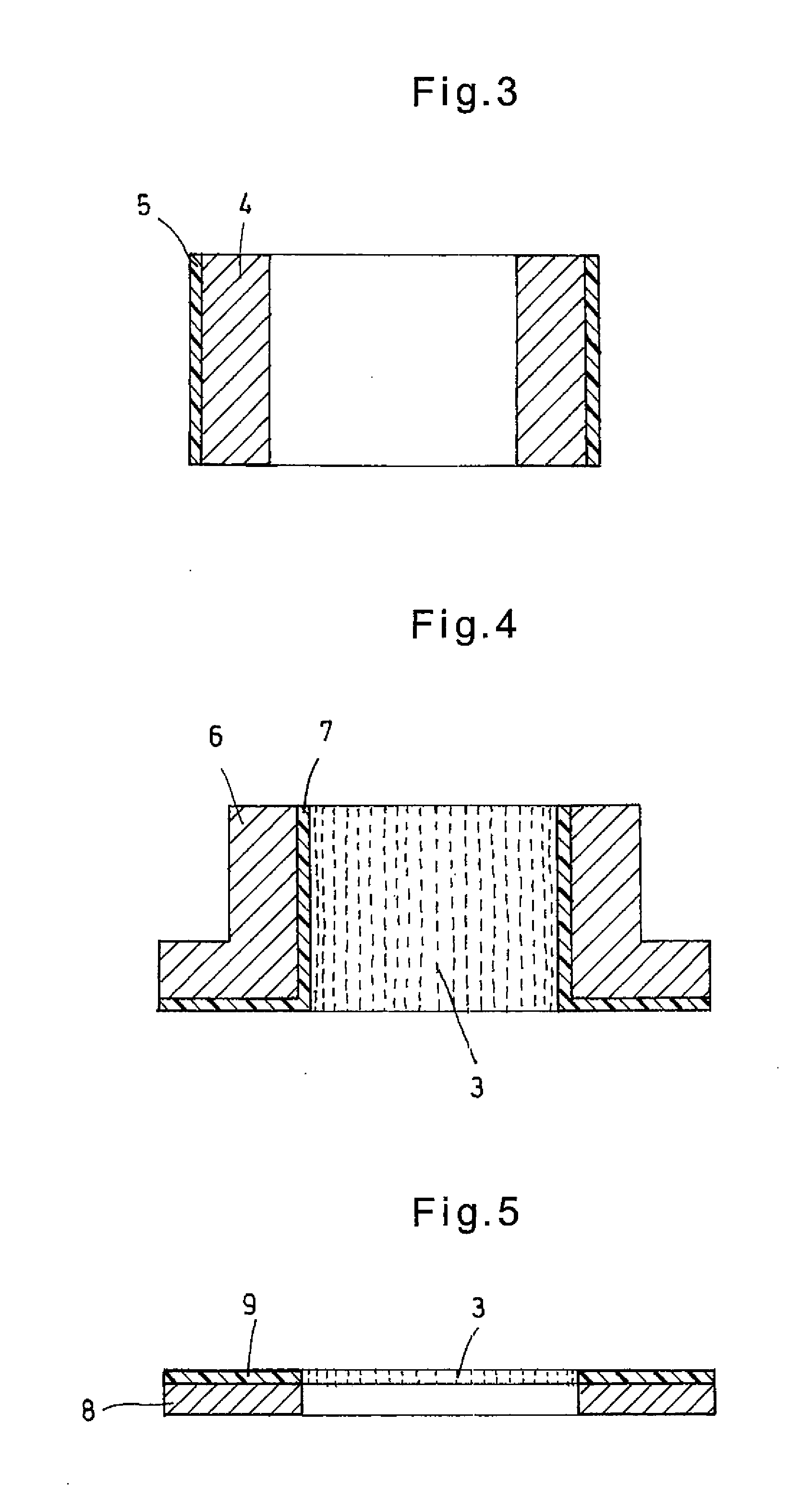

ActiveUS20120287026A1Improve deteriorationReduced Surface Flatness RequirementsLamination ancillary operationsStatic indicating devicesPhoto irradiationHermetic seal

A display panel includes: a first substrate; light-emitting elements on a region of the first substrate; a second substrate facing the first substrate with the light-emitting elements therebetween; a glass frit between the first substrate and the second substrate so as to surround the region of the first substrate in which the light-emitting elements are disposed, the glass frit providing a hermetic seal between the first substrate and the second substrate; and a light-shielding part formed on one of the first substrate and the second substrate so as to extend along the glass frit, the light-shielding part shielding light. The light-shielding part has a lower light-shielding property in a region corresponding to the outer region of the glass frit than in a region corresponding to the inner region of the glass frit. The glass frit has been irradiated with light through the light-shielding part.

Owner:JOLED INC

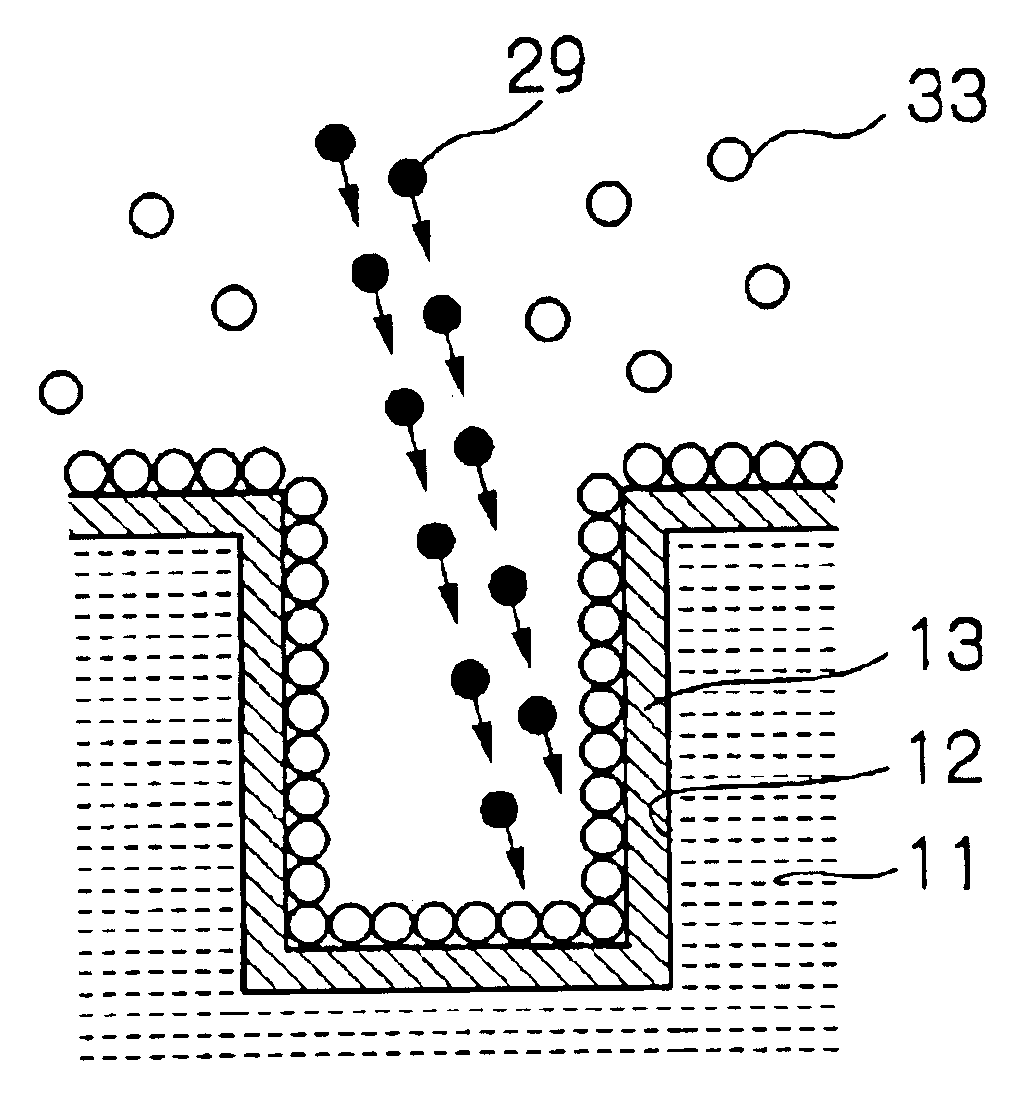

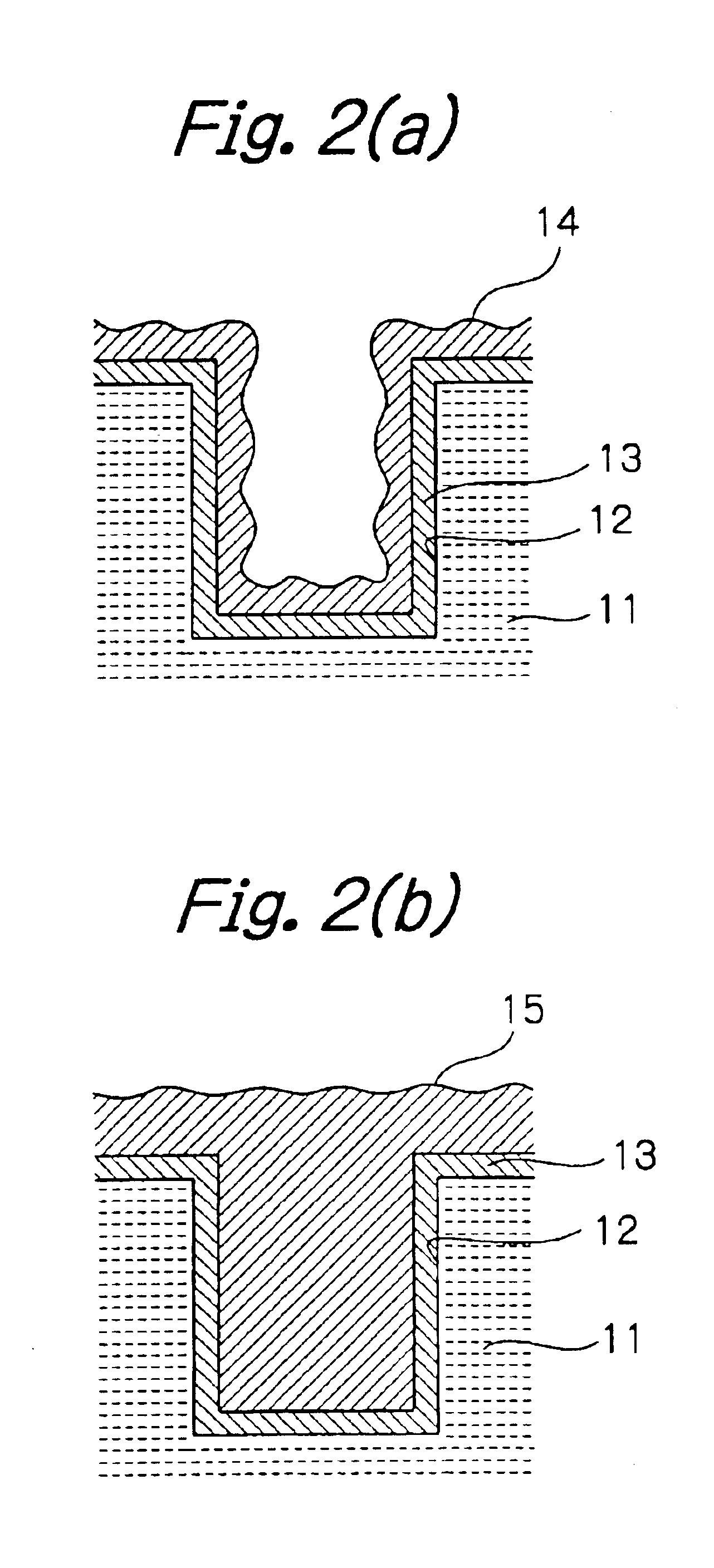

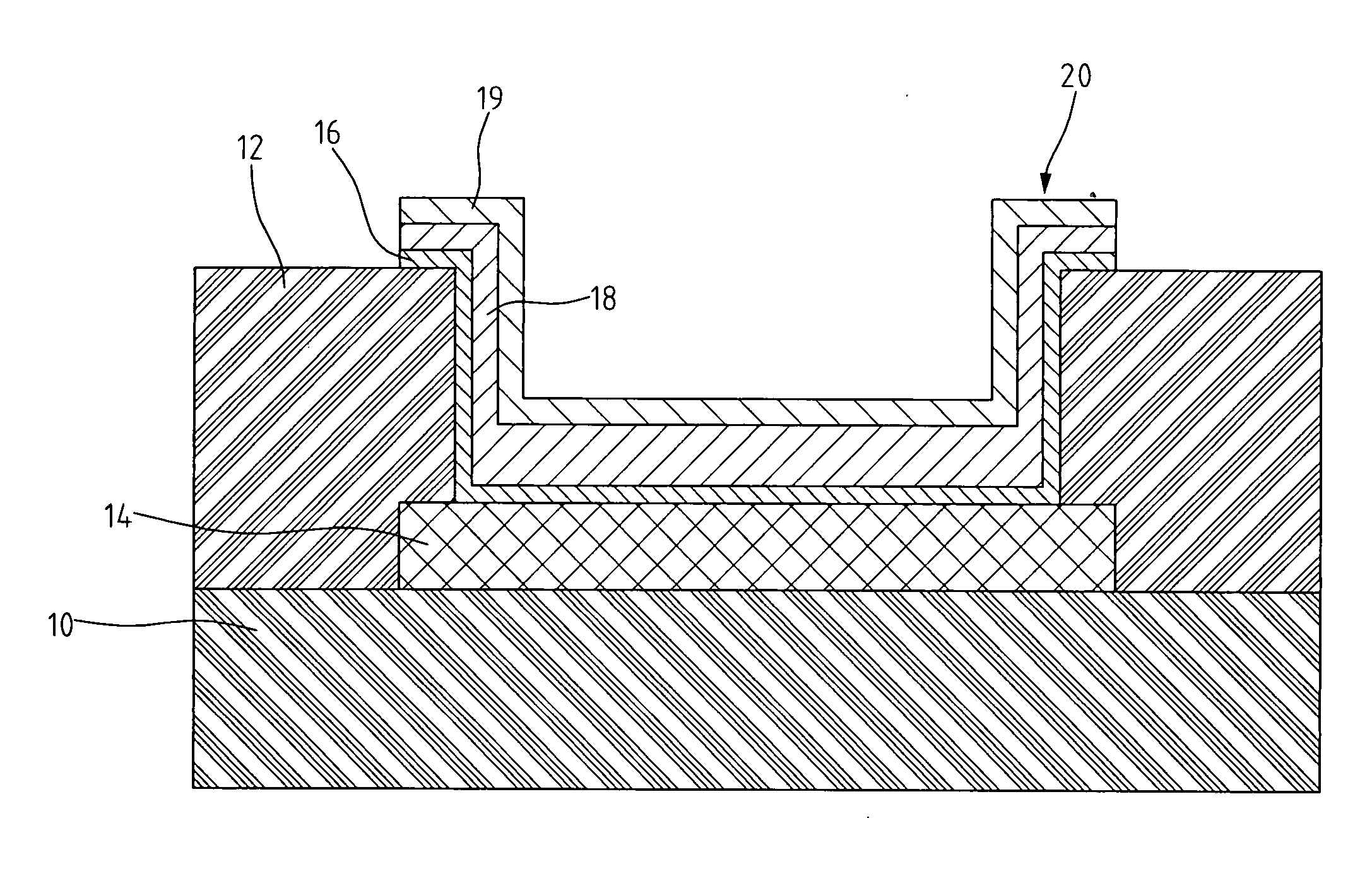

Coating, modification and etching of substrate surface with particle beam irradiation of the same

InactiveUS6921722B2Favorable adhesion (bond) strengthBonding strengthElectric discharge heatingElectric discharge tubesEtchingAtomic beam

There is provided a method of performing a surface treatment, such as coating, denaturation, modification and etching, on a surface of a substrate. The method comprises the steps of bringing a surface treatment gas into contact with a surface of a substrate, and irradiating the surface of the substrate with a fast particle beam to enhance an activity of the surface and / or the surface treatment gas, thereby facilitating a reaction between the surface and the gas. The fast particle beam may be selected from a group consisting of an electron beam, a charged particle beam, an atomic beam and molecular beam. For example, during a coating operation, chemical deposition of predetermined component elements of the gas onto the surface is effected and a predetermined portion of the surface of the substrate is irradiated with a particle beam to form a coating layer on the predetermined portion.

Owner:EBARA CORP

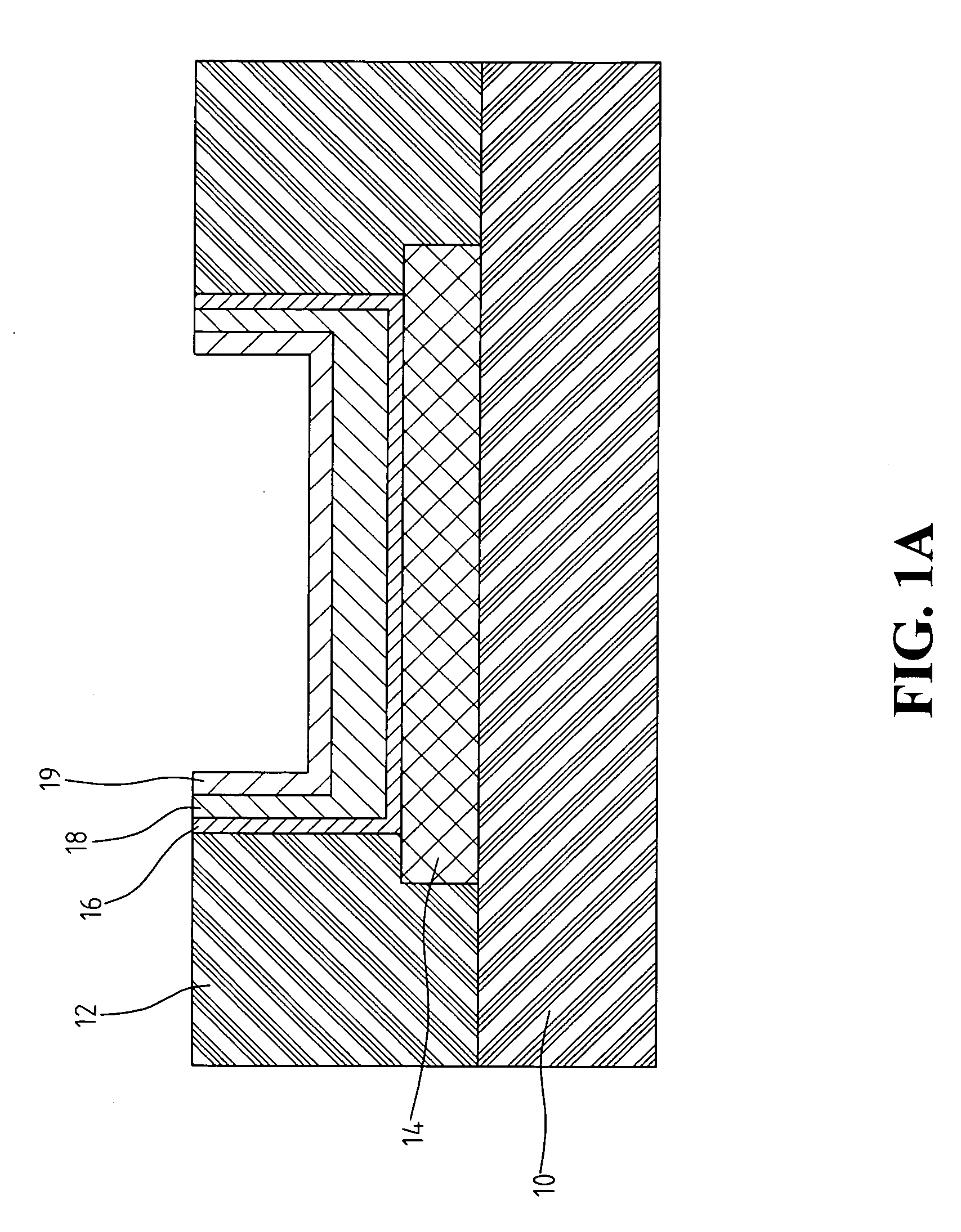

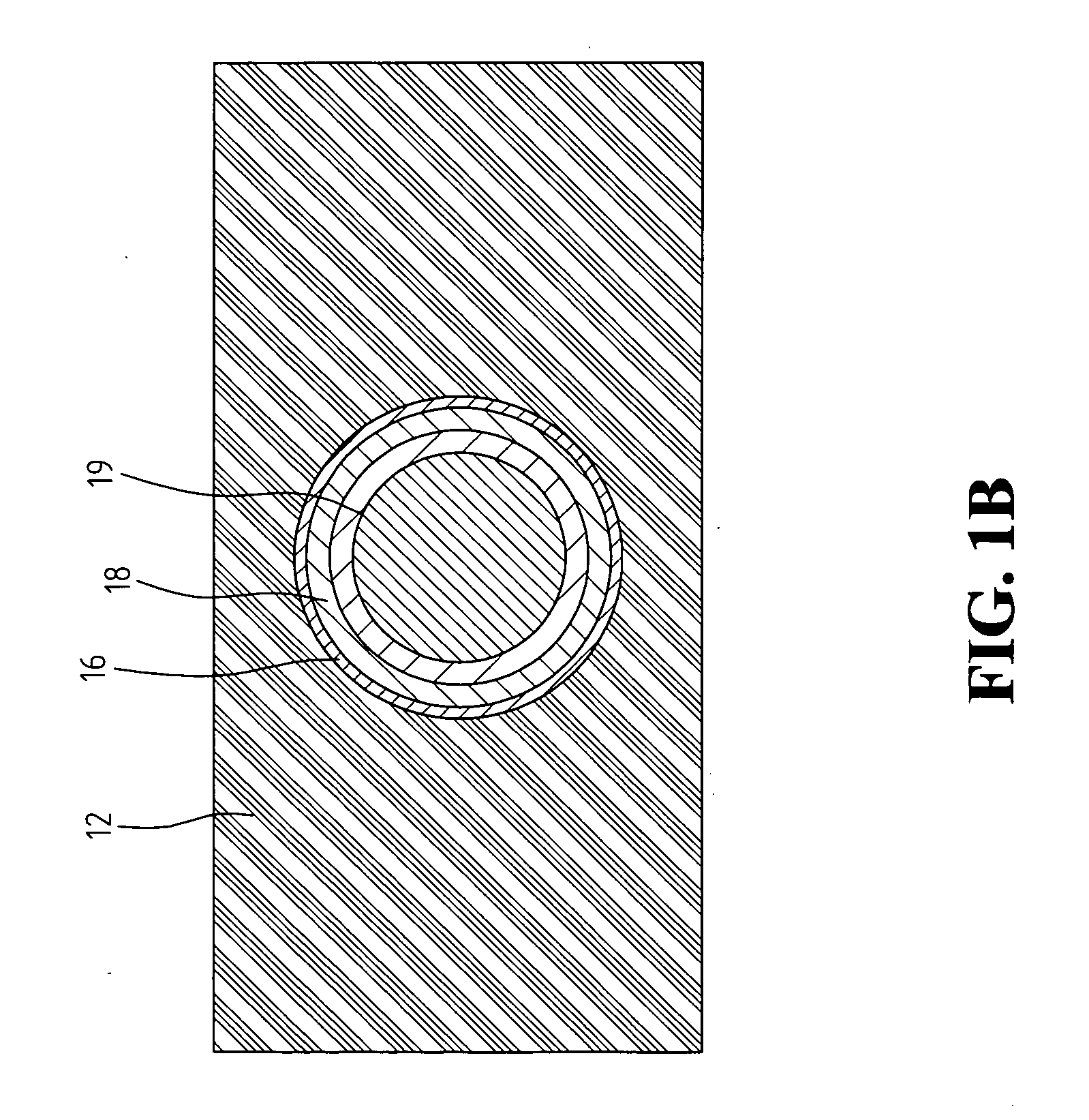

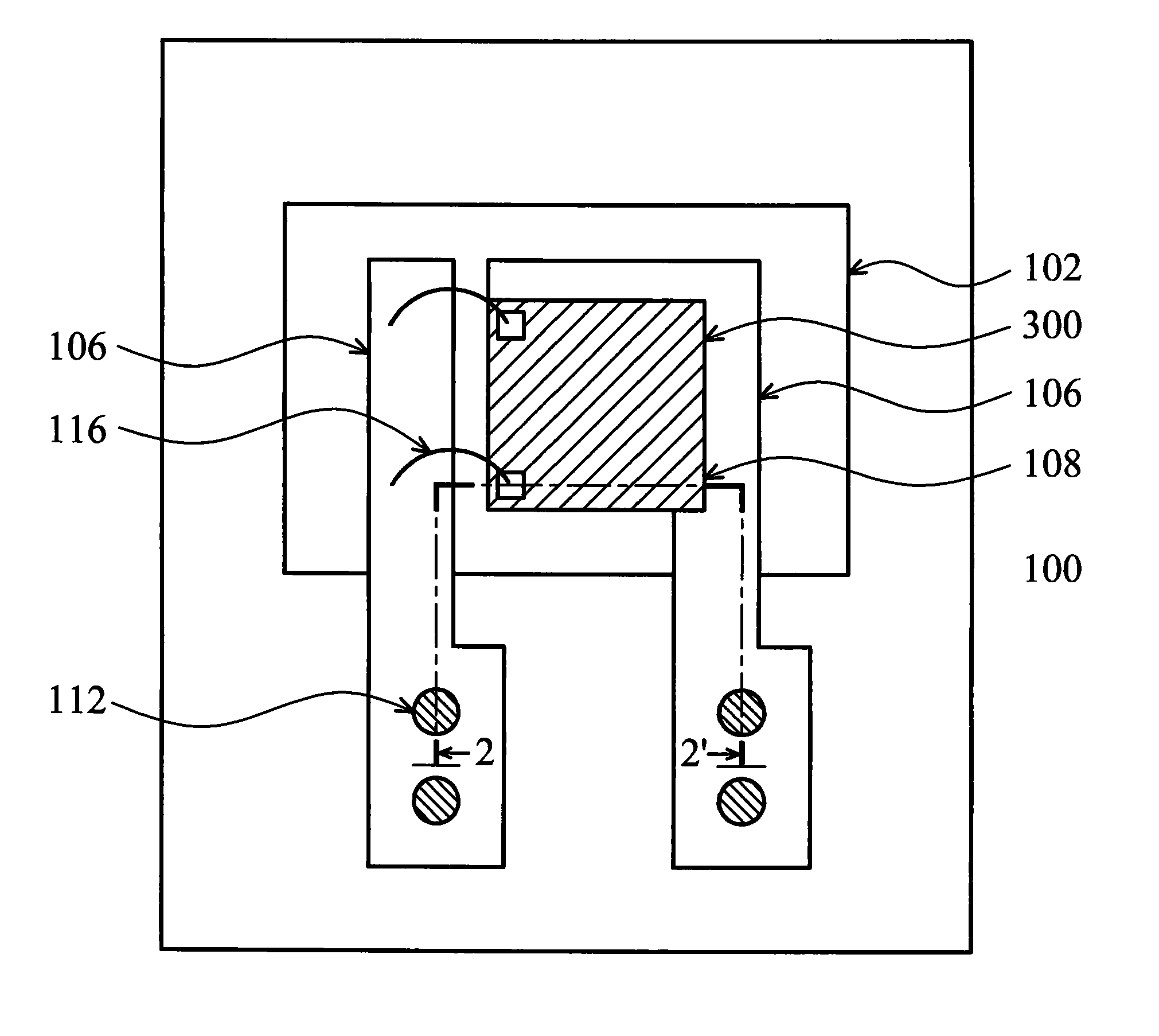

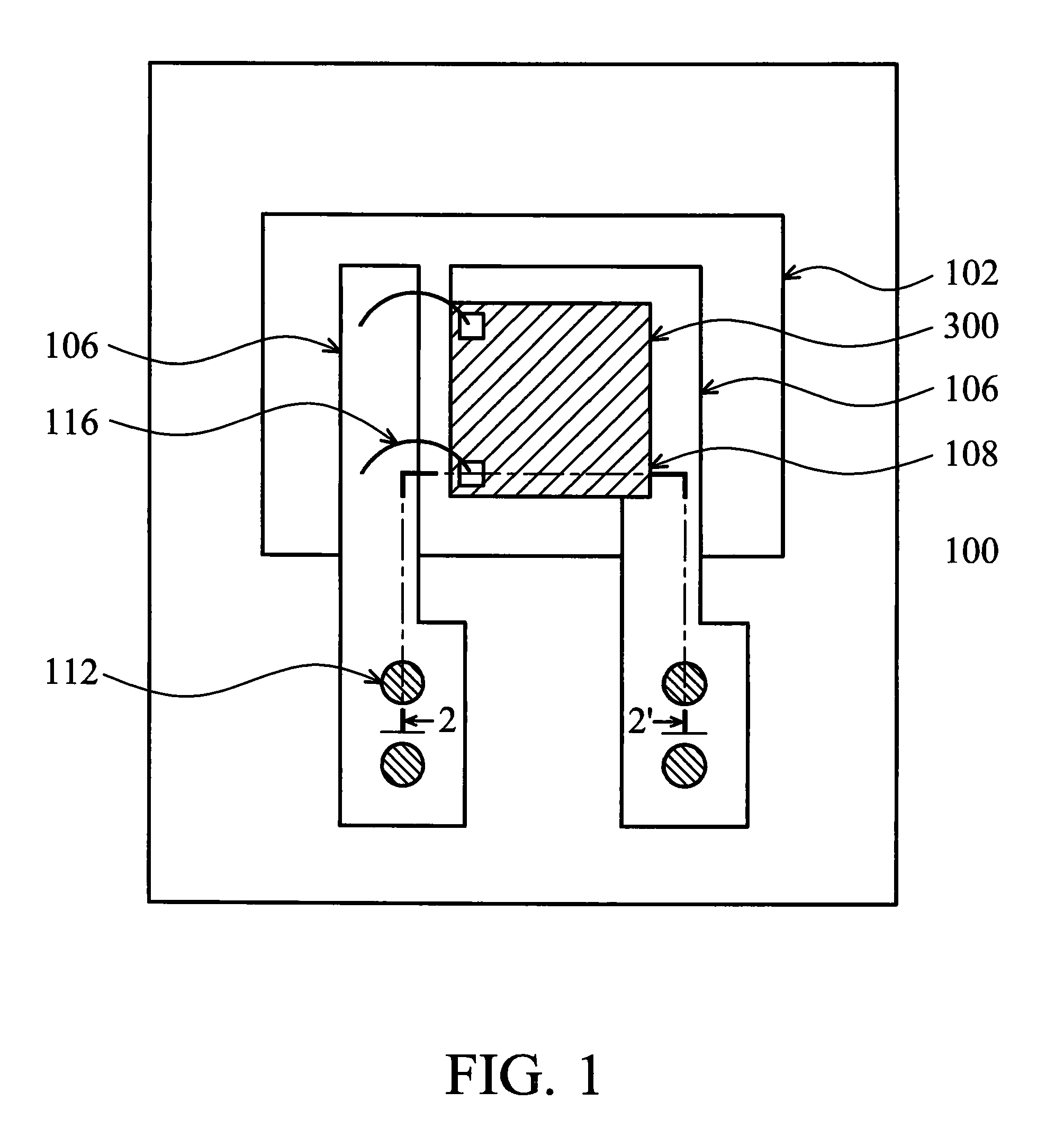

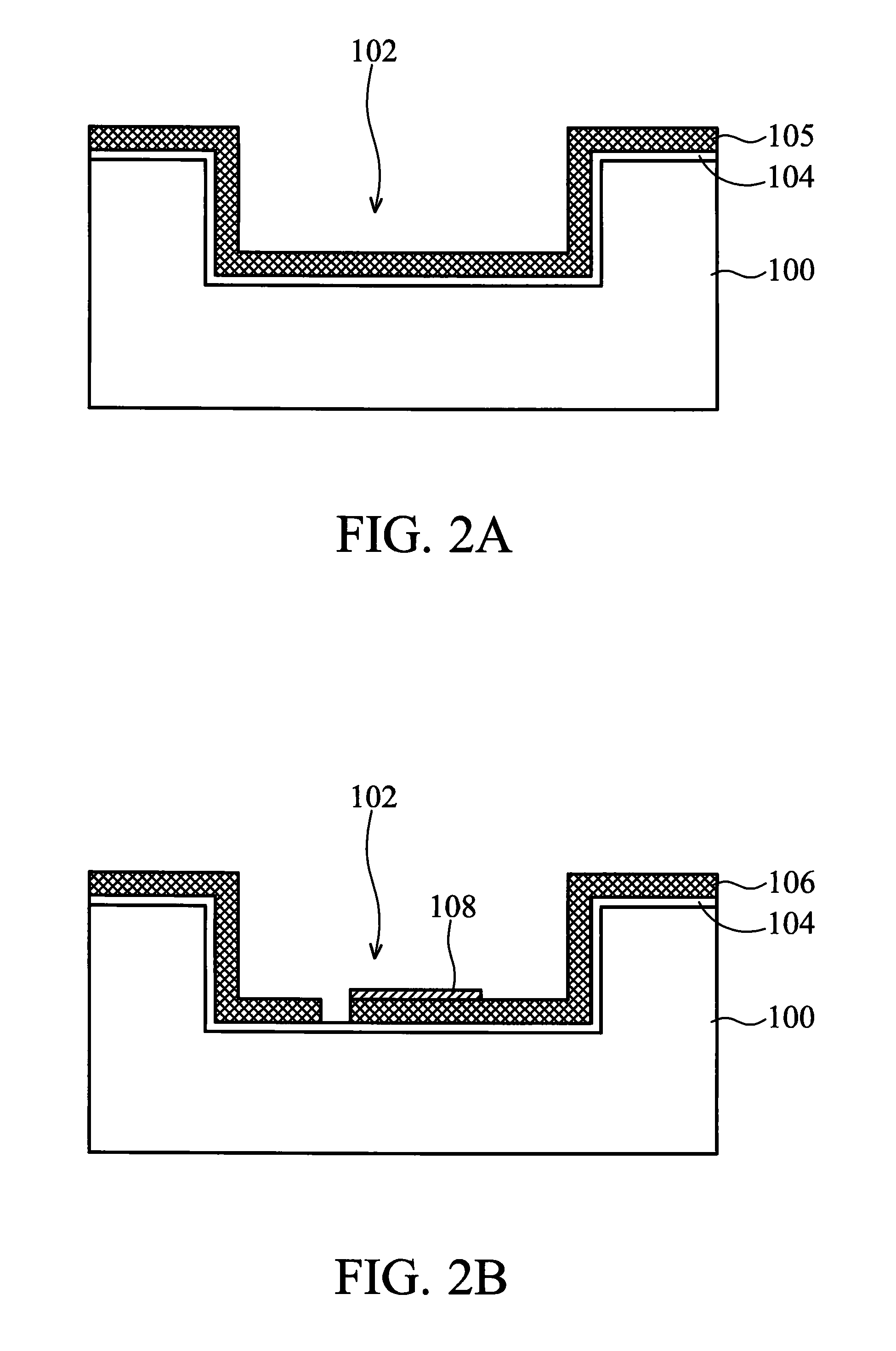

Bonding pad with high bonding strength to solder ball and bump

InactiveUS20070108619A1High bonding strengthBonding strengthSemiconductor/solid-state device detailsPrinted circuit aspectsSolder maskSolder ball

A bonding pad with high bonding strength to a solder ball and a bump includes a carrier, a wiring layer formed on the carrier, a protection layer formed on top of the wiring layer and a solder mask layer surrounded around the protection layer and the wiring layer to form a bonding pad opening. The protection layer is extended outside the bonding pad opening such that when solder are extended into the bonding pad opening, the solder balls engage with side faces defining the bump pad opening as well as the protection layer outside the bump pad opening and a bonding strength between the bonding pad and the solder performance is increased.

Owner:KINSUS INTERCONNECT TECH

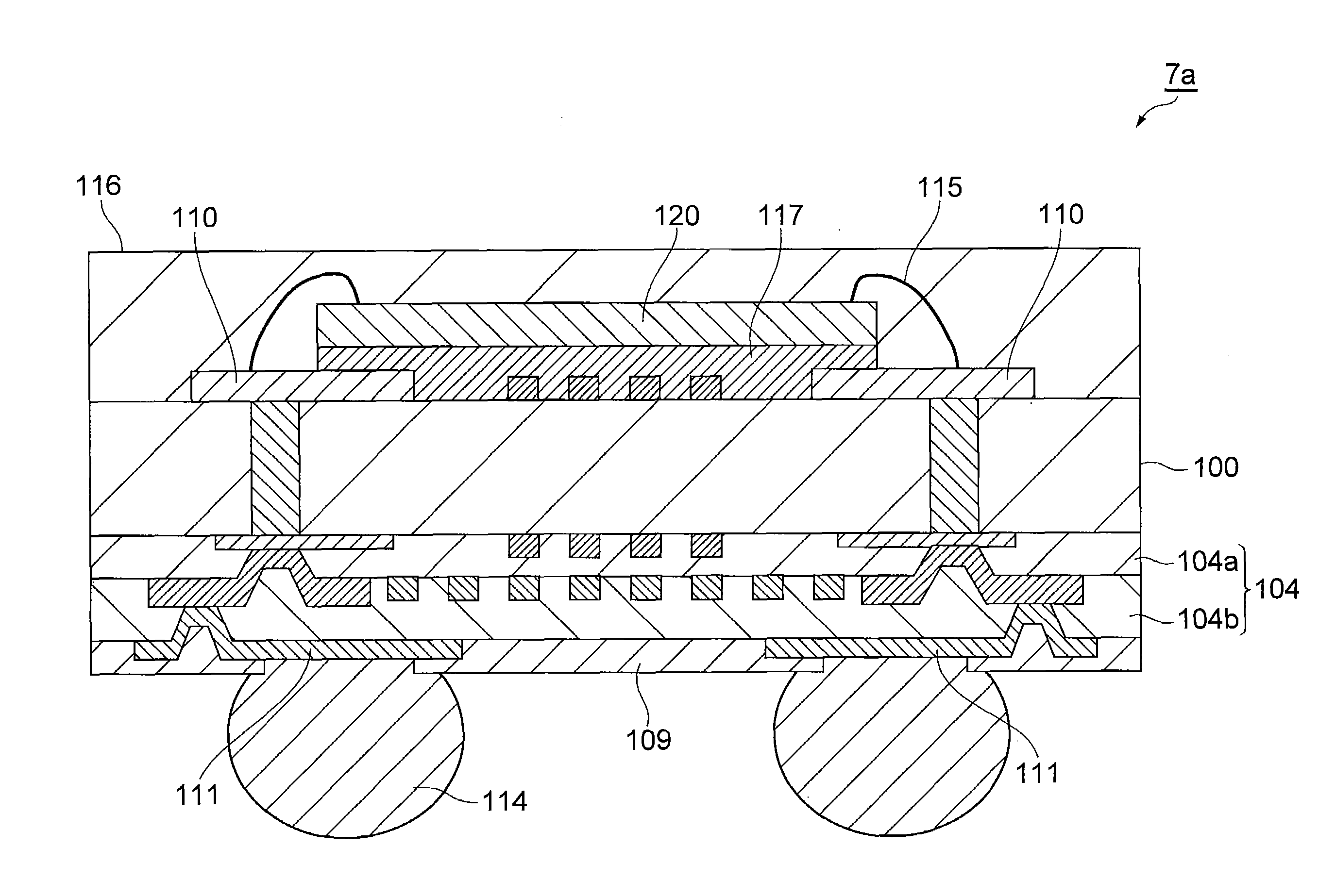

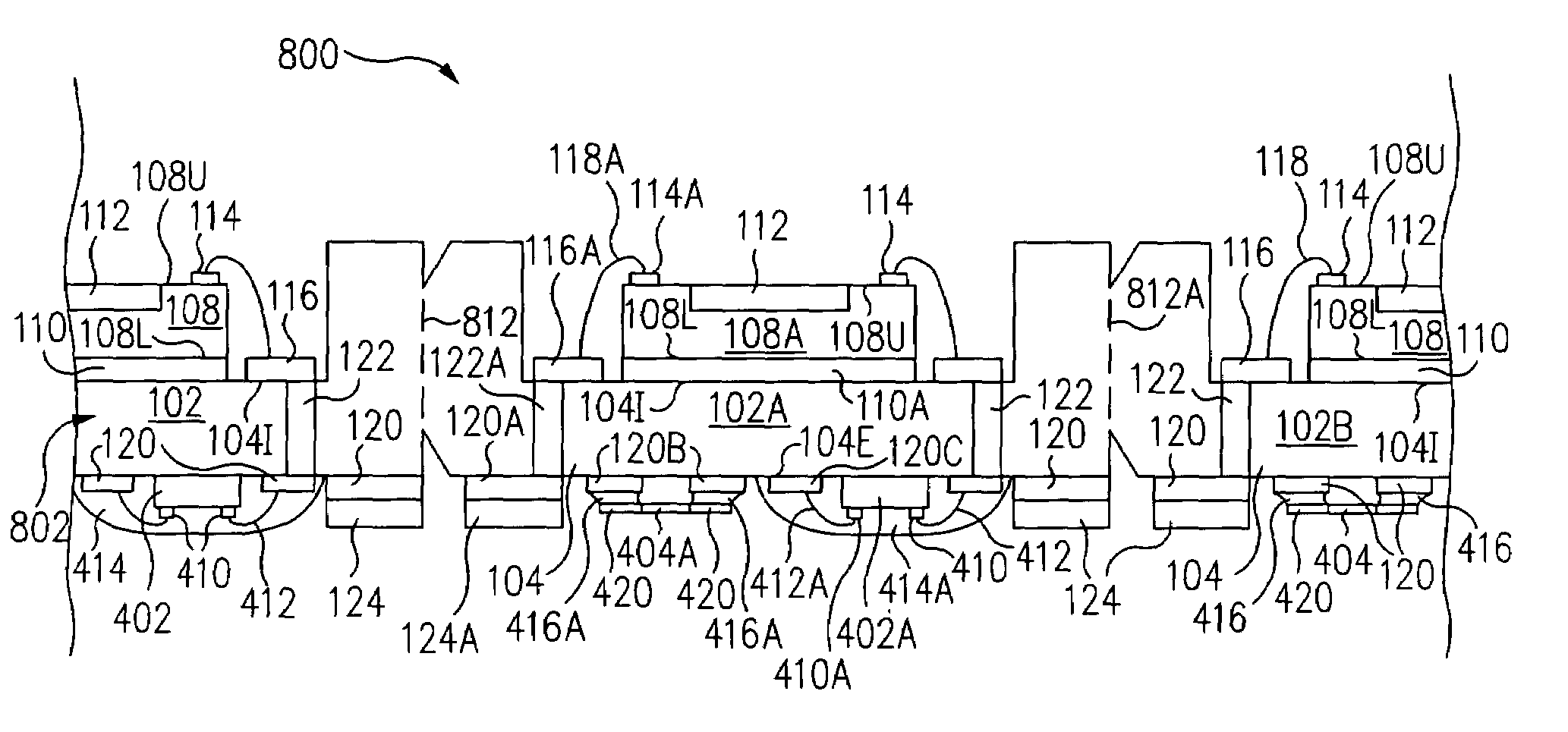

Connecting terminal, semiconductor package using connecting terminal and method for manufacturing semiconductor package

InactiveUS20100071940A1Improve connection reliabilityIncrease bonding strengthNon-insulated conductorsPrinted electric component incorporationElectrically conductiveElectroless plating

The connection reliability of connecting terminals with displacement gold plating films is improved by connecting terminals comprising a conductive layer, an electroless nickel plating film, a first palladium plating film which is a displacement or electroless palladium plating film with a purity of 99% by mass or greater, a second palladium plating film which is an electroless palladium plating film with a purity of at least 90% by mass and less than 99% by mass, and a displacement gold plating film, wherein the electroless nickel plating film, the first palladium plating film, the second palladium plating film and the displacement gold plating film are laminated in that order on one side of the conductive layer, and the displacement gold plating film is situated on the uppermost surface layer on the opposite side from the conductive layer.

Owner:HITACHI CHEM CO LTD

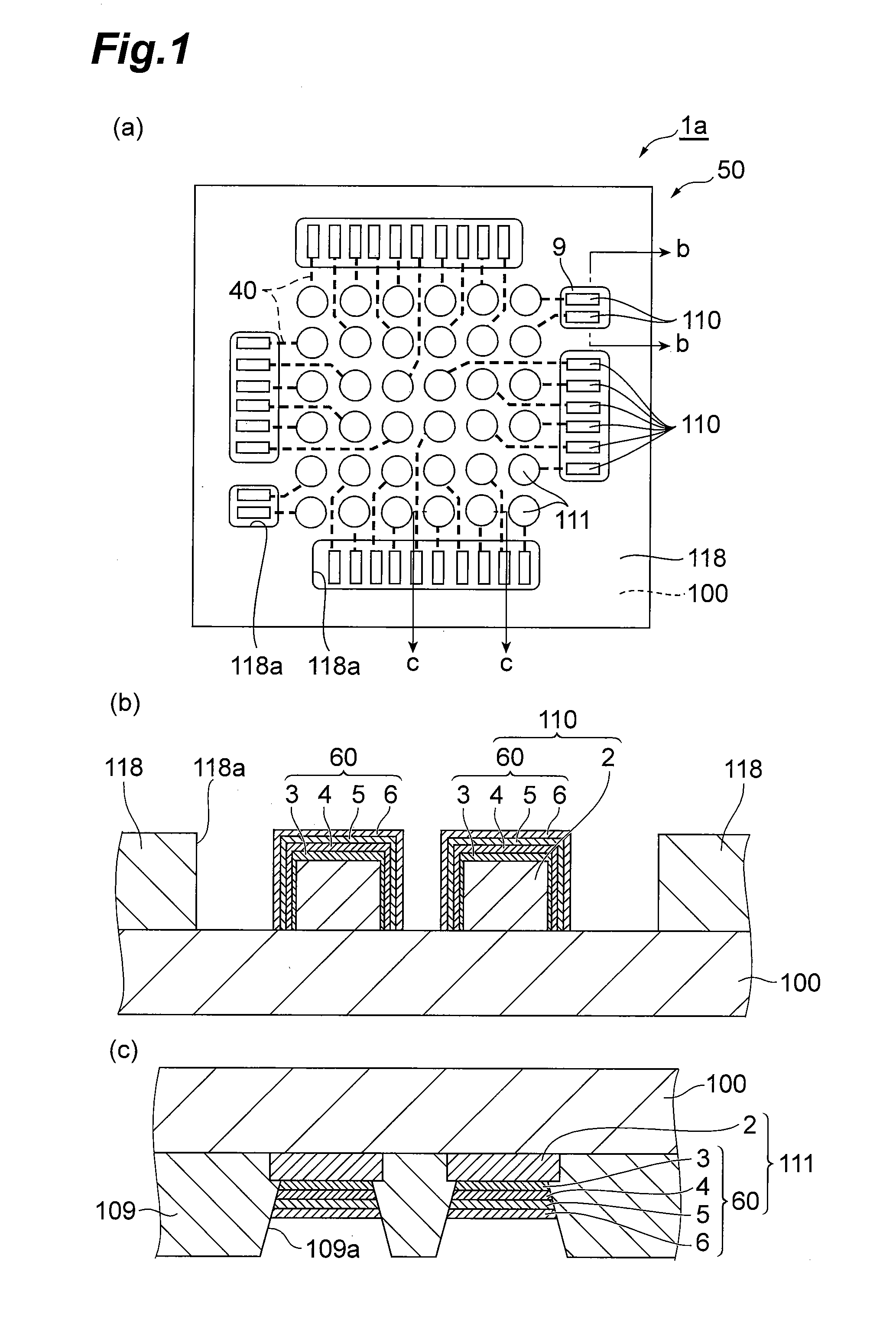

Multilayer wiring substrate and method of manufacturing the same

InactiveUS20120153463A1Avoid layeringDistribute pressureSemiconductor/solid-state device detailsPrinted circuit aspectsRough surfaceInsulation layer

To provide a multilayer wiring substrate in which the connection reliability of via conductors is enhanced, via holes are formed in a resin interlayer insulation layer which isolates a lower conductor layer from an upper conductor layer, and via conductors are formed in the via holes for connecting the lower conductor layer and the upper conductor layer. The surface of the resin interlayer insulation layer is a rough surface, and the via holes open at the rough surface of the resin interlayer insulation layer. Stepped portions are formed in opening verge regions around the via holes such that the stepped portions are recessed from peripheral regions around the opening verge regions. The stepped portions are higher in surface roughness than the peripheral regions.

Owner:NGK SPARK PLUG CO LTD

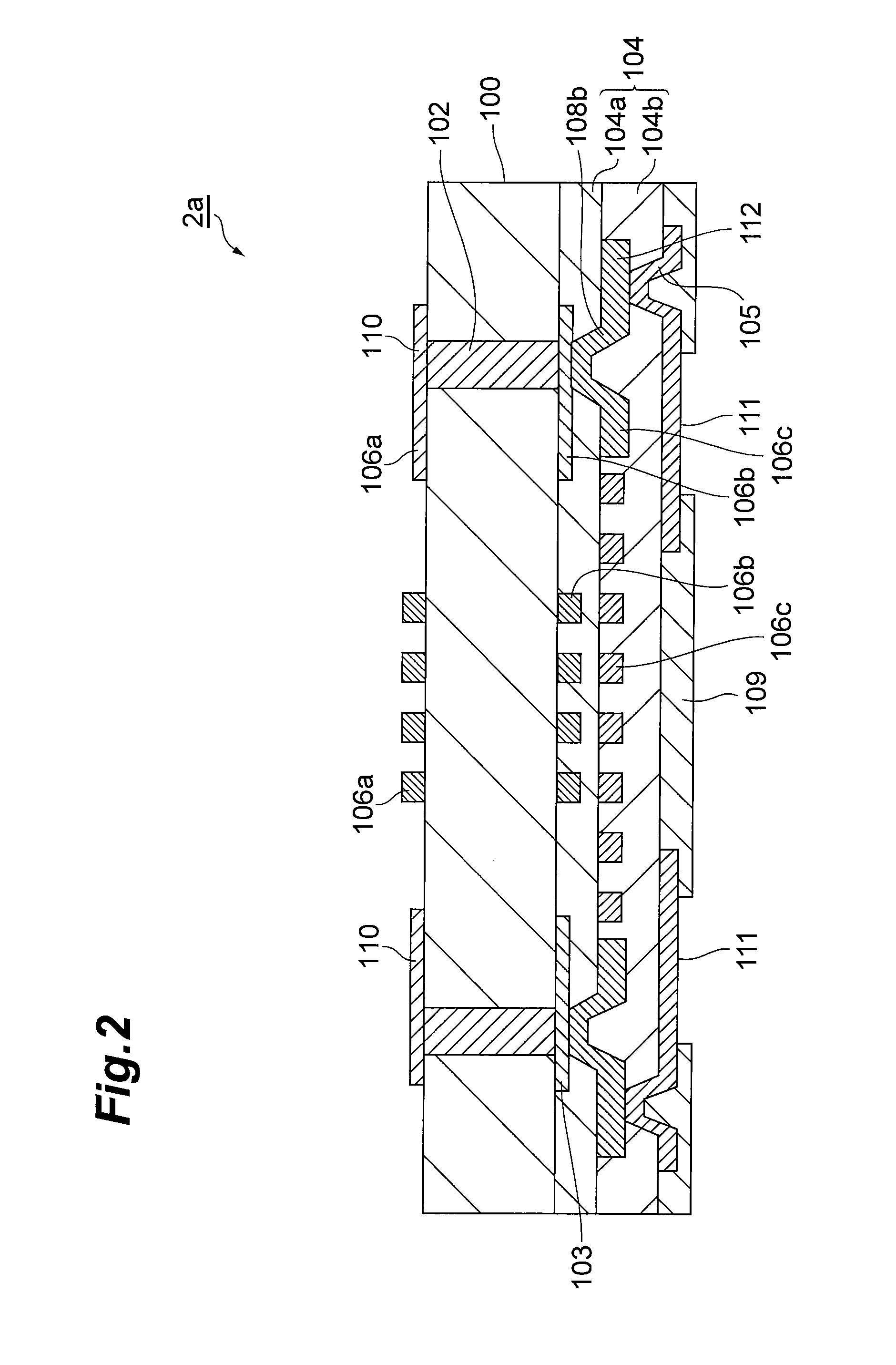

Hermetically sealed container, image display apparatus, and their manufacturing methods

InactiveUS20120248950A1Easy maintenanceImprove reliabilityLamination ancillary operationsSolid-state devicesHermetic sealImage display

Owner:CANON KK

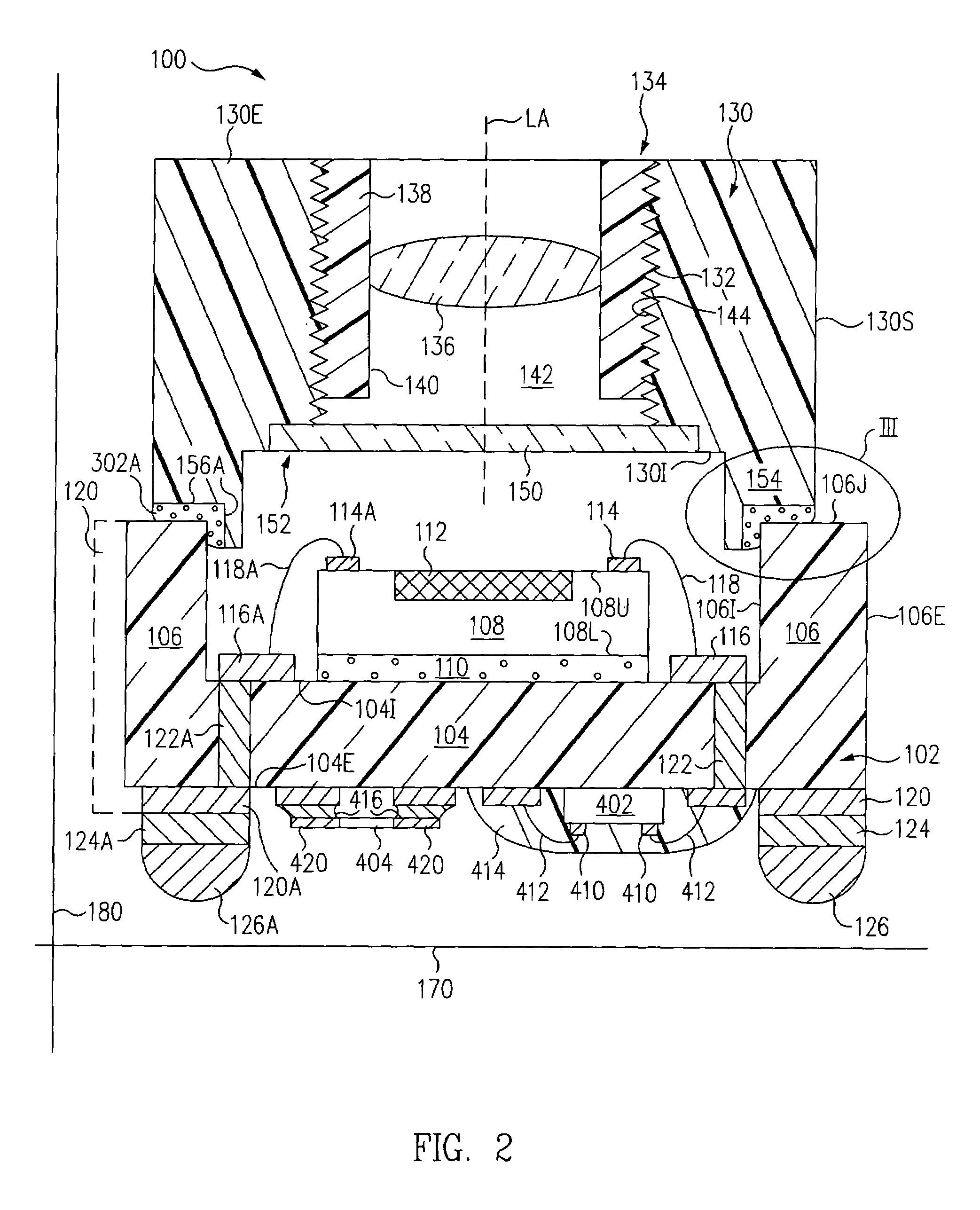

Optical module with lens integral holder fabrication method

InactiveUS7059040B1Improve protectionImprove reliabilityPrinted circuit assemblingTelevision system detailsCamera lensOptical Module

A method of forming an optical module includes mounting an image sensor to a base of a substrate and bonding a lens housing to a sidewall of the substrate. A mounting surface of the lens housing includes a locking feature having a horizontal surface and a vertical surface. The sidewall of the substrate includes a joint surface. To bond the lens housing to the sidewall of the substrate, a bond is formed between the horizontal surface of the locking feature of the lens housing and the joint surface of the sidewall. Further, a bond is formed between the vertical surface of the locking feature of the lens housing and an interior surface of the sidewall.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

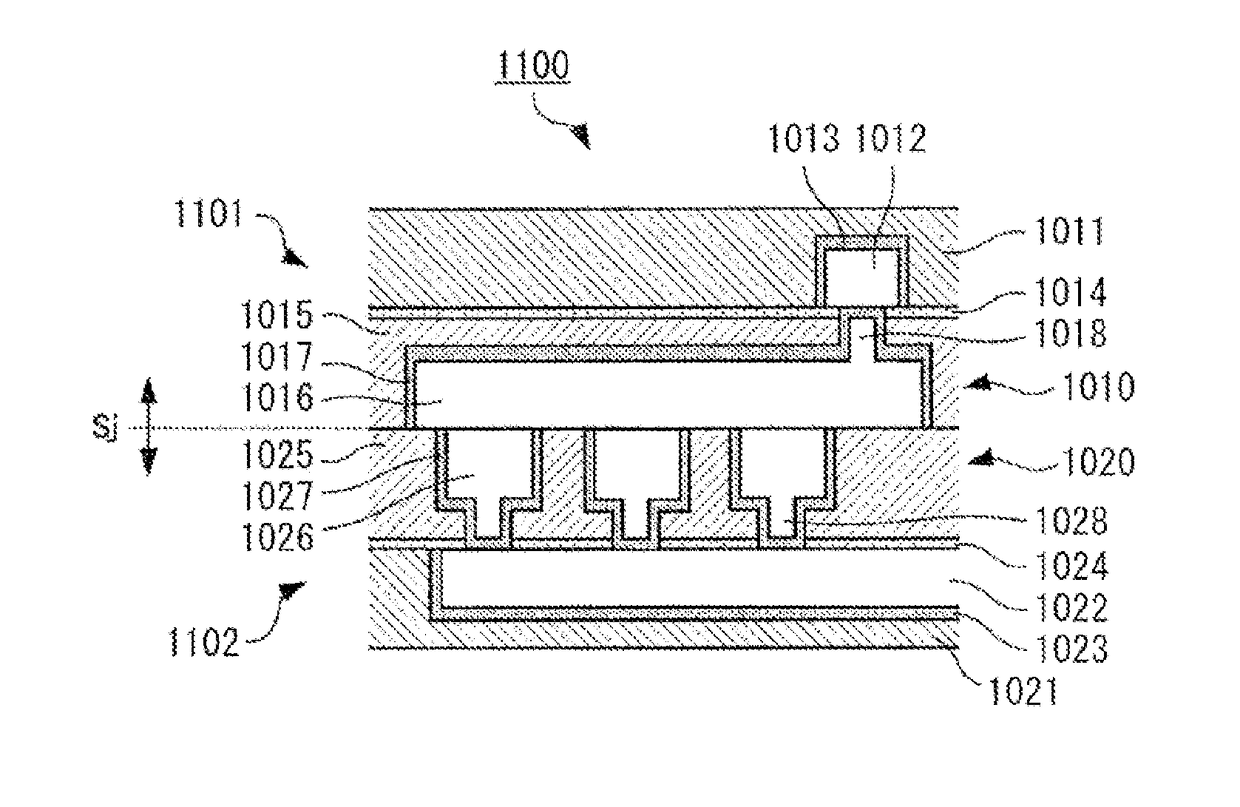

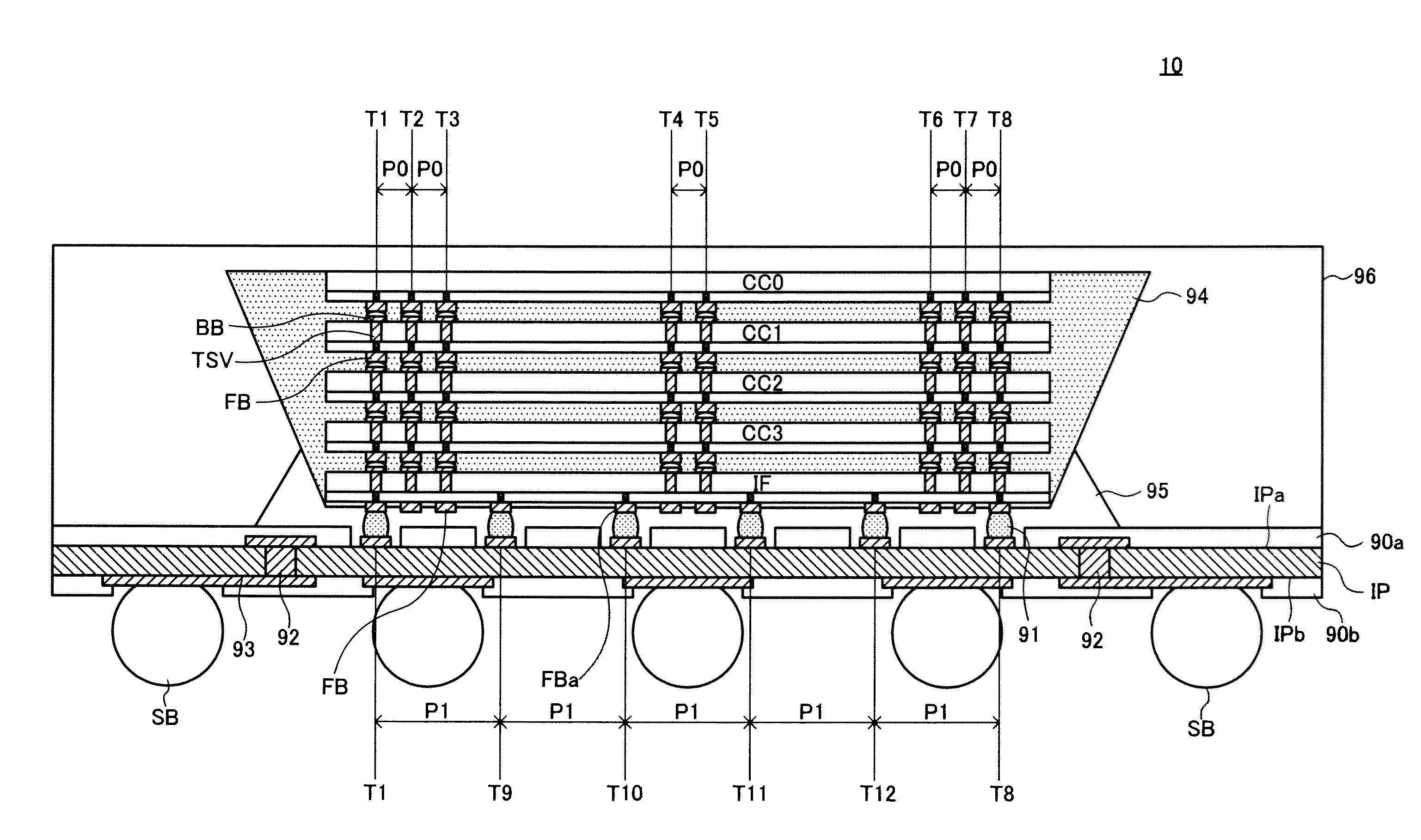

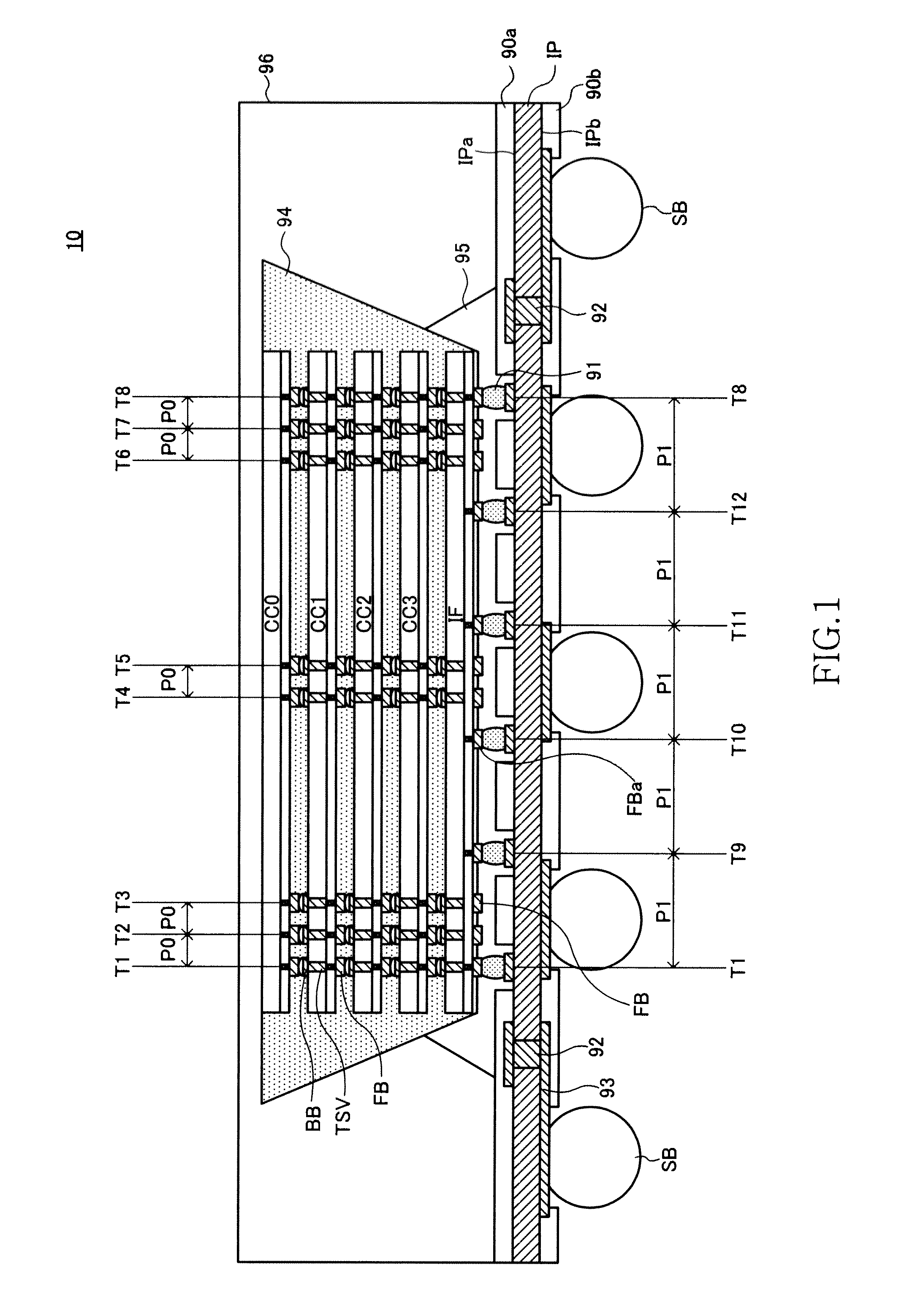

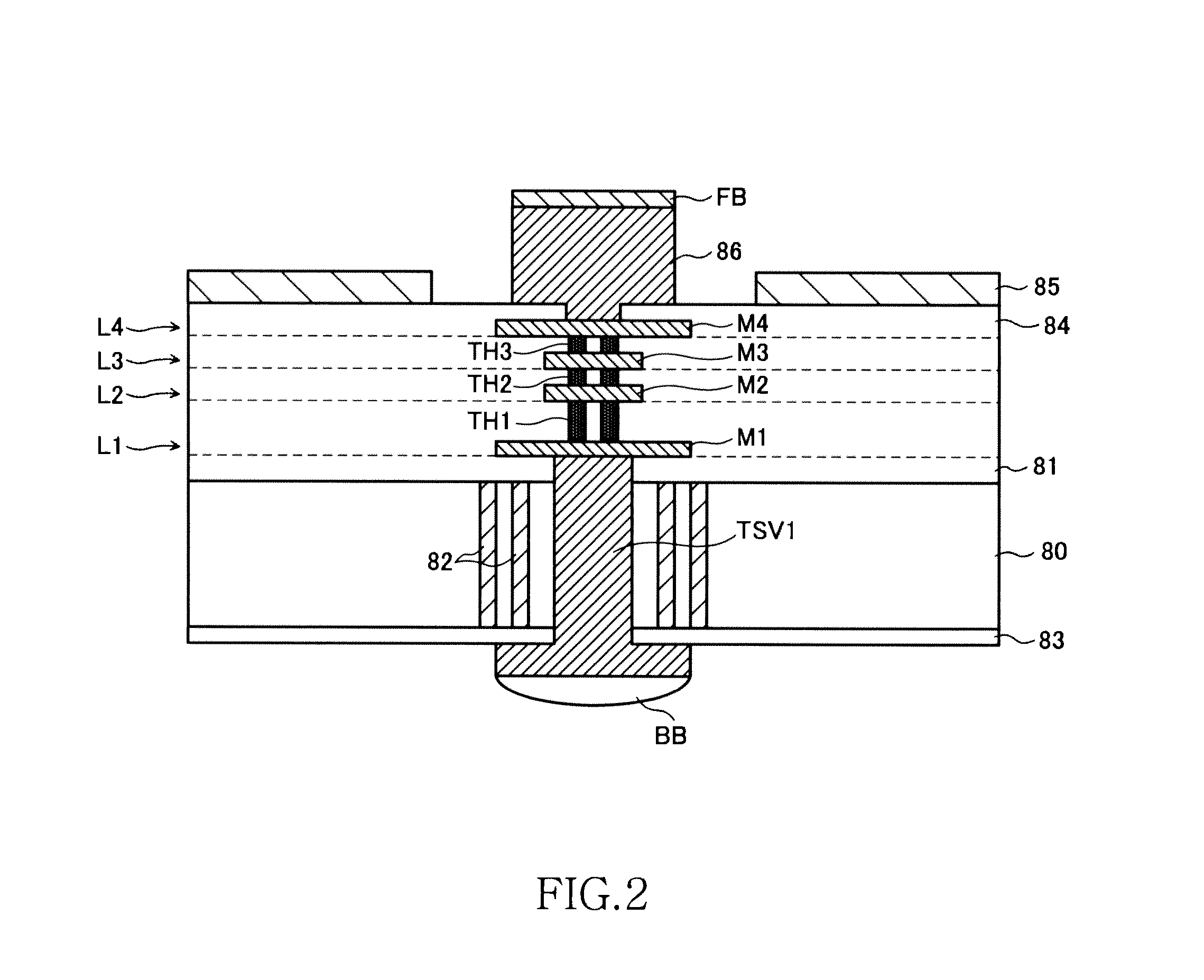

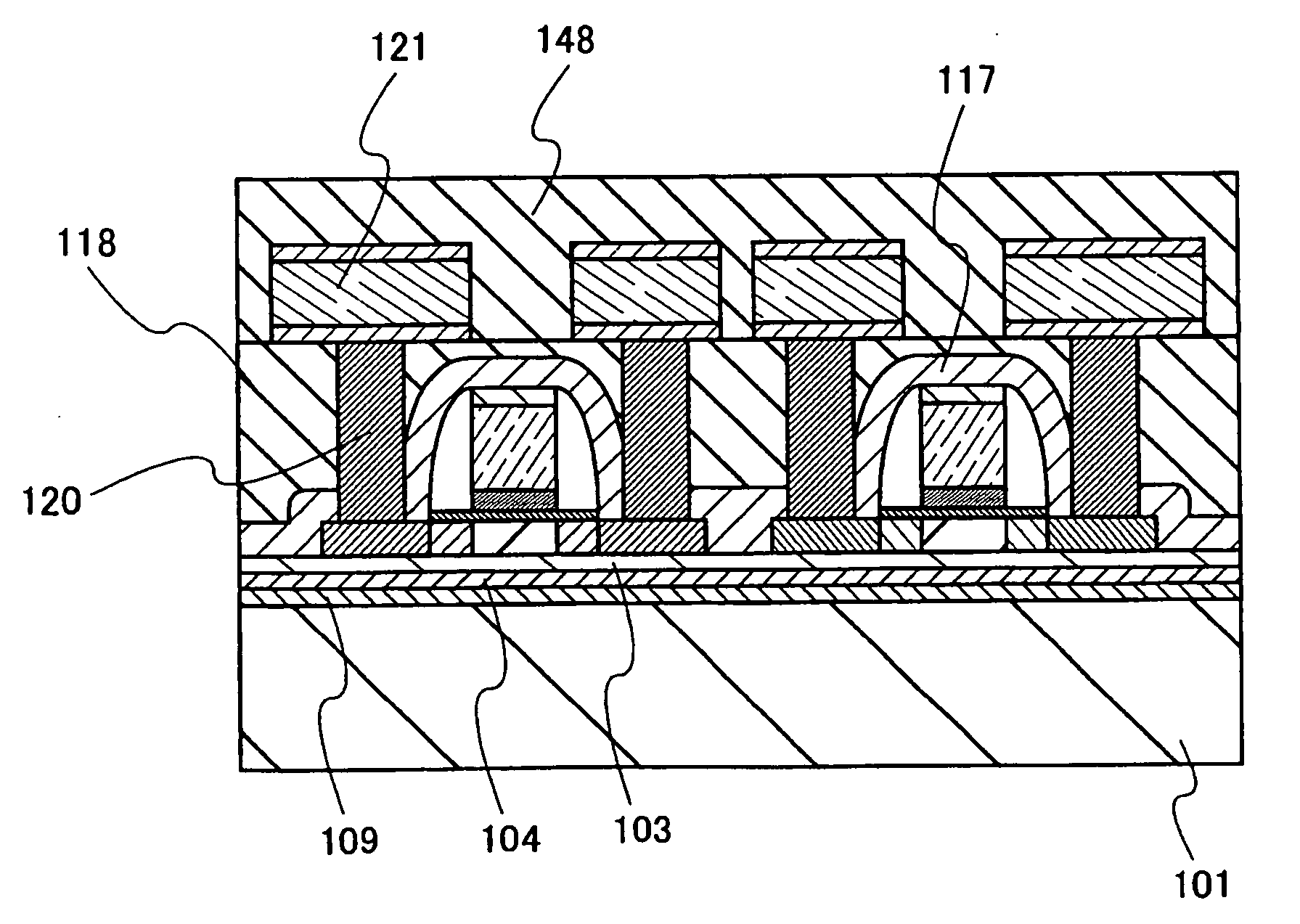

Semiconductor device having penetrating electrodes each penetrating through substrate

ActiveUS20130228898A1Bonding strengthImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesElectricityEngineering

Disclosed herein is a device that includes: a first semiconductor chip having a first internal circuit formed in a first substrate; and a plurality of penetrating electrodes each penetrating through the first semiconductor substrate. The plurality of penetrating electrodes includes first, second, third and fourth penetrating electrodes arranged along a first line. The first and second penetrating electrodes are in a floating state without electrically connected to the first internal circuit. The third penetrating electrode is electrically connected to a first power supply line that conveys a first power supply potential to the first internal circuit. The fourth penetrating electrode is electrically connected to a second power supply line that conveys a second power supply potential to the first internal circuit. The third and fourth penetrating electrodes are arranged between the first penetrating electrode and the second penetrating electrode.

Owner:LONGITUDE LICENSING LTD

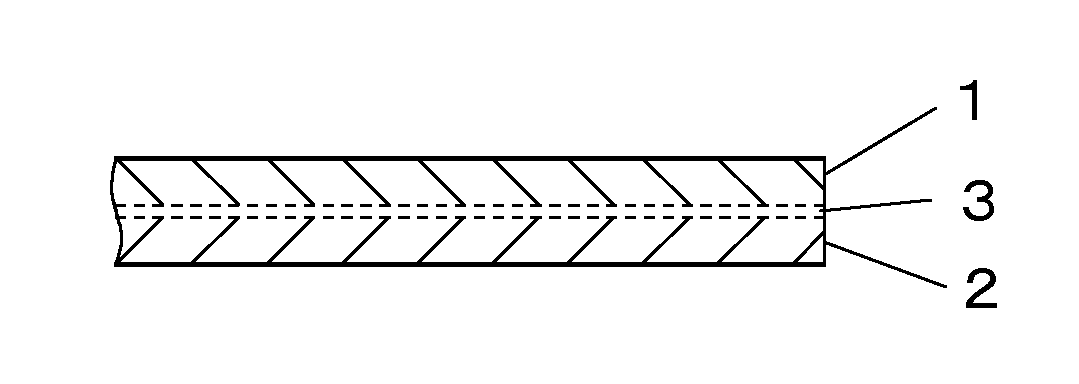

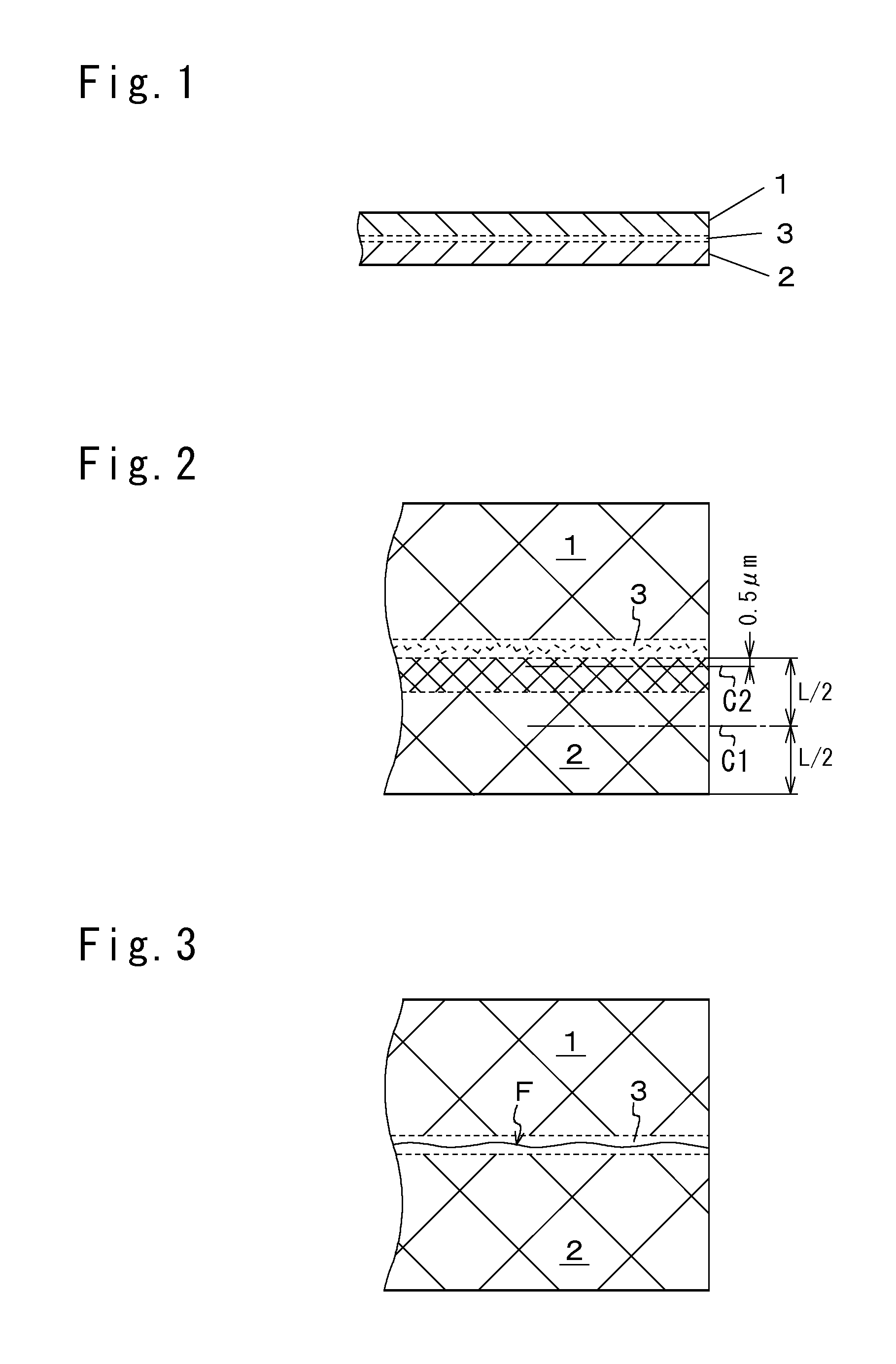

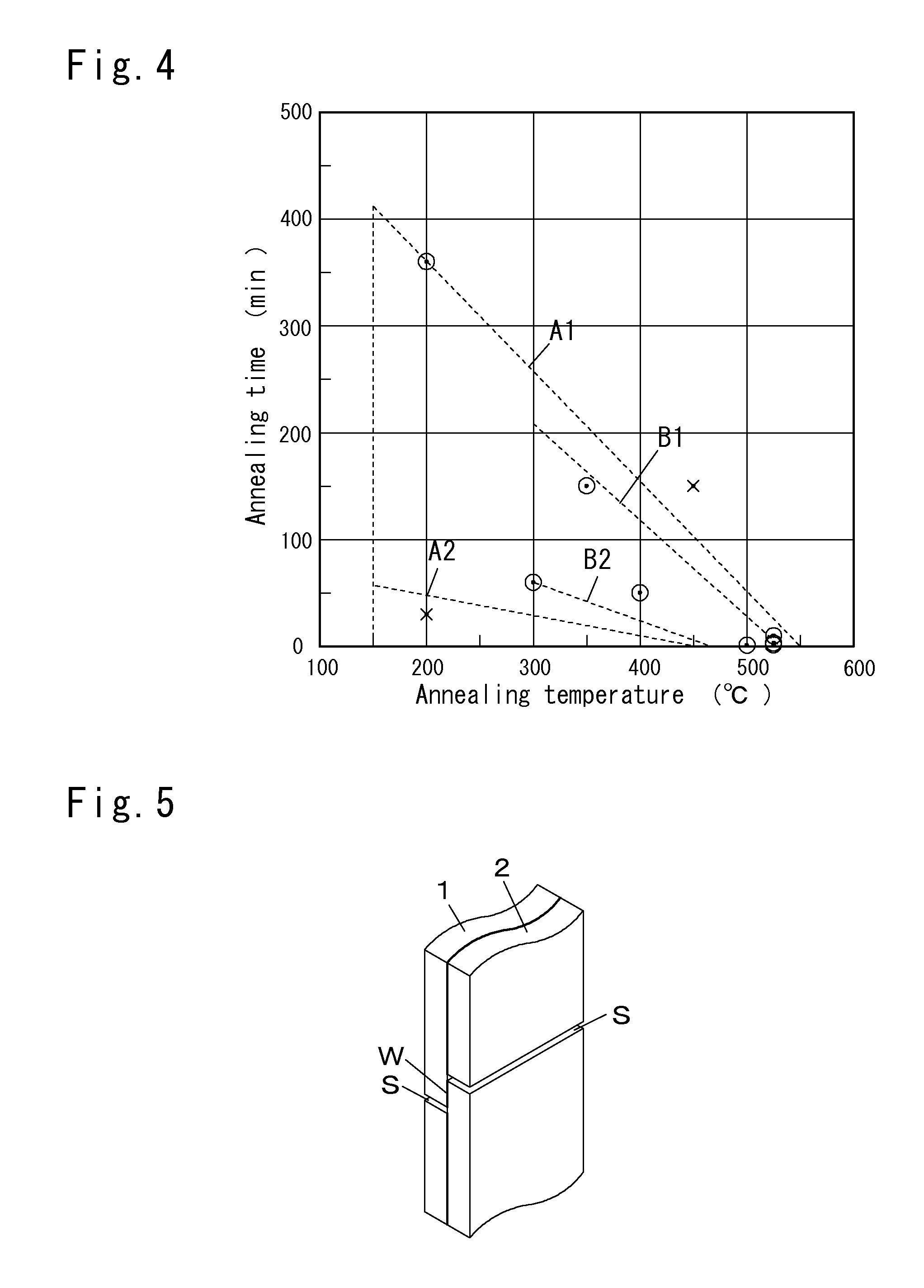

Aluminum copper clad material

InactiveUS20130071686A1Shorten the annealing timeImprove productivityFurnace typesHeat treatment process controlCopperBond strength

An aluminum copper clad material has excellent bonding strength and includes an aluminum layer and a copper layer that are bonded without a nickel layer interposed therebetween.The aluminum layer and the copper layer that are diffusion-bonded via an Al—Cu intermetallic compound layer. The copper layer satisfies Dcs≦0.5×Dcc, where Dcc represents the average crystal grain size of crystal grains in a central portion in the thickness direction of the copper layer, and Dcs represents the average crystal grain size of an interface adjacent portion C2 in the copper layer that is about 0.5 μm apart from the interface between the copper layer and the intermetallic compound layer. The intermetallic compound layer has an average thickness of about 0.5 μm to about 10 μm.

Owner:NEOMAX MATERIALS

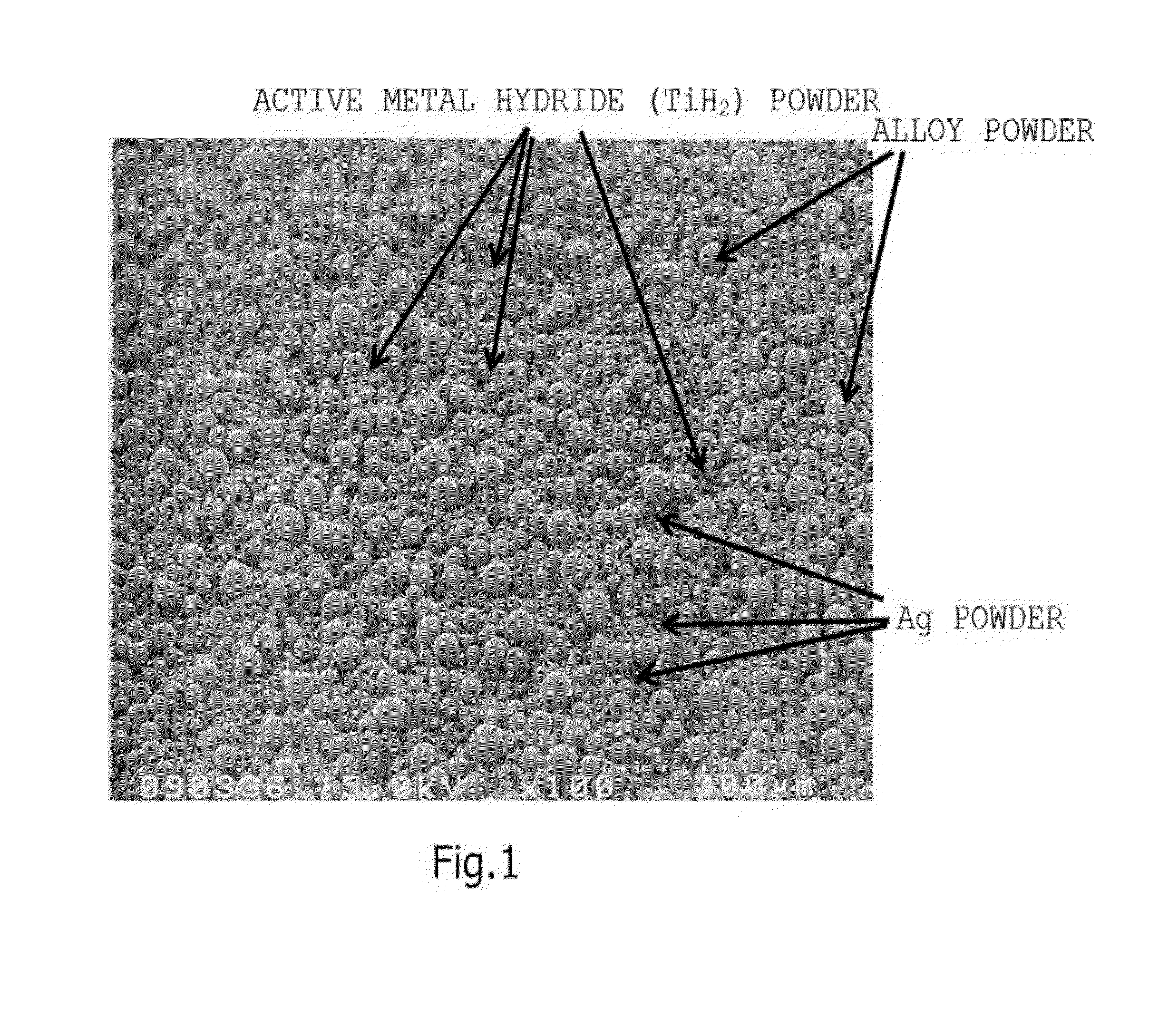

Brazing material, brazing material paste, ceramic circuit substrate, ceramic master circuit substrate, and power semiconductor module

ActiveUS20140126155A1Bonding strengthInsulating substrate metal adhesion improvementLayered productsPowder mixtureHemt circuits

To provide a brazing material for maintaining bonding strength between ceramic substrate and metal plate at a conventionally attainable level, while addition amount of In is reduced, and a brazing material paste using the same. A mixture powder provided by mixing alloy powder composed of Ag, In, and Cu, Ag powder, and active metal hydride powder, the mixture powder containing active metal hydride powder with a 10-to-25-μm equivalent circle average particle diameter by 0.5 to 5.0 mass %, the equivalent circle average particle diameters for the alloy powder, Ag powder, and active metal hydride powder having a relationship: alloy powder≧active metal hydride powder>Ag powder, and the powder mixture having a particle size distribution of d10 of 3 to 10 μm, d50 of 10 to 35 μm, and d90 of 30 to 50 μm, and in the frequency distribution, a peak of the distribution existing between d50 and d90.

Owner:HITACHI METALS LTD

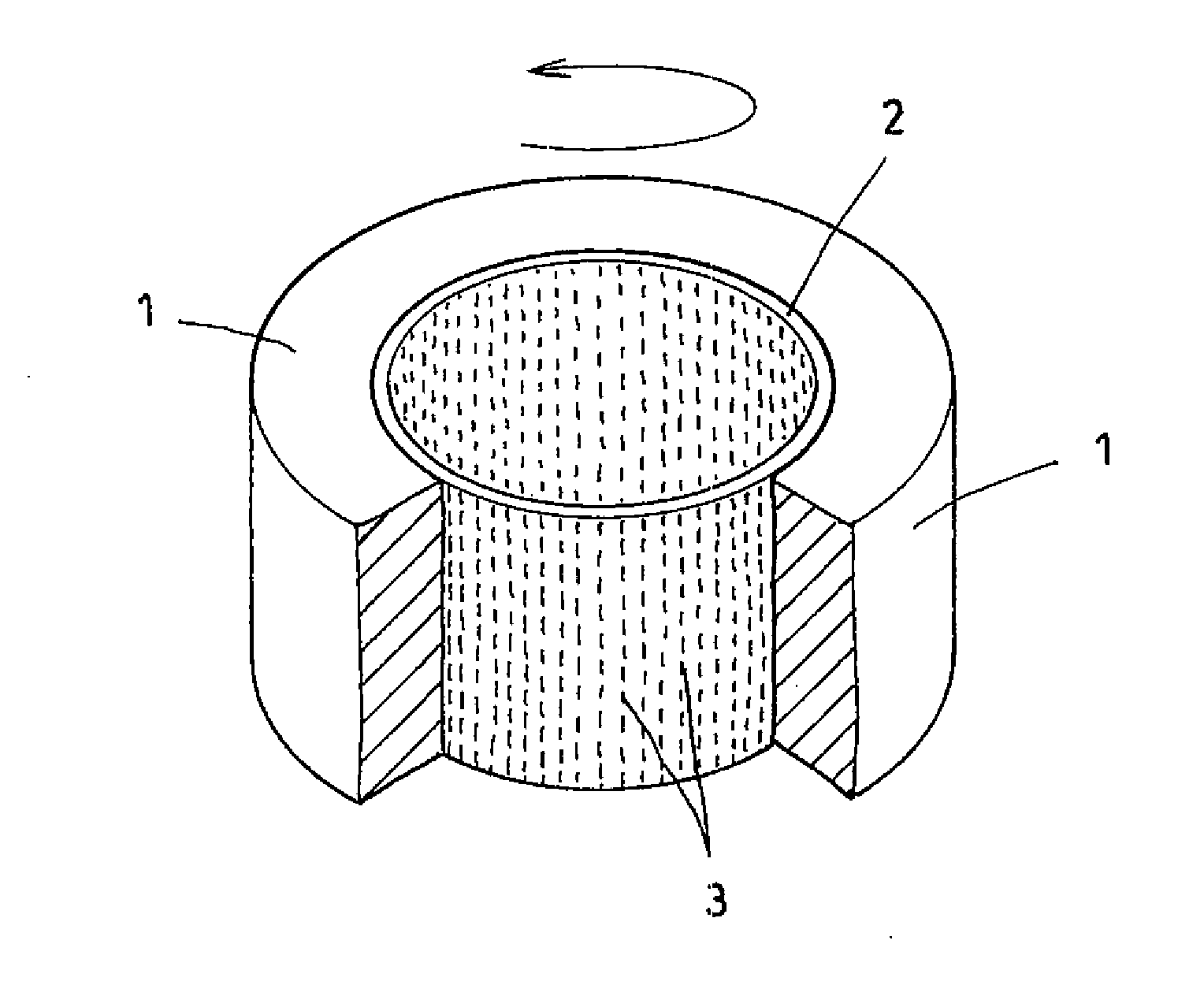

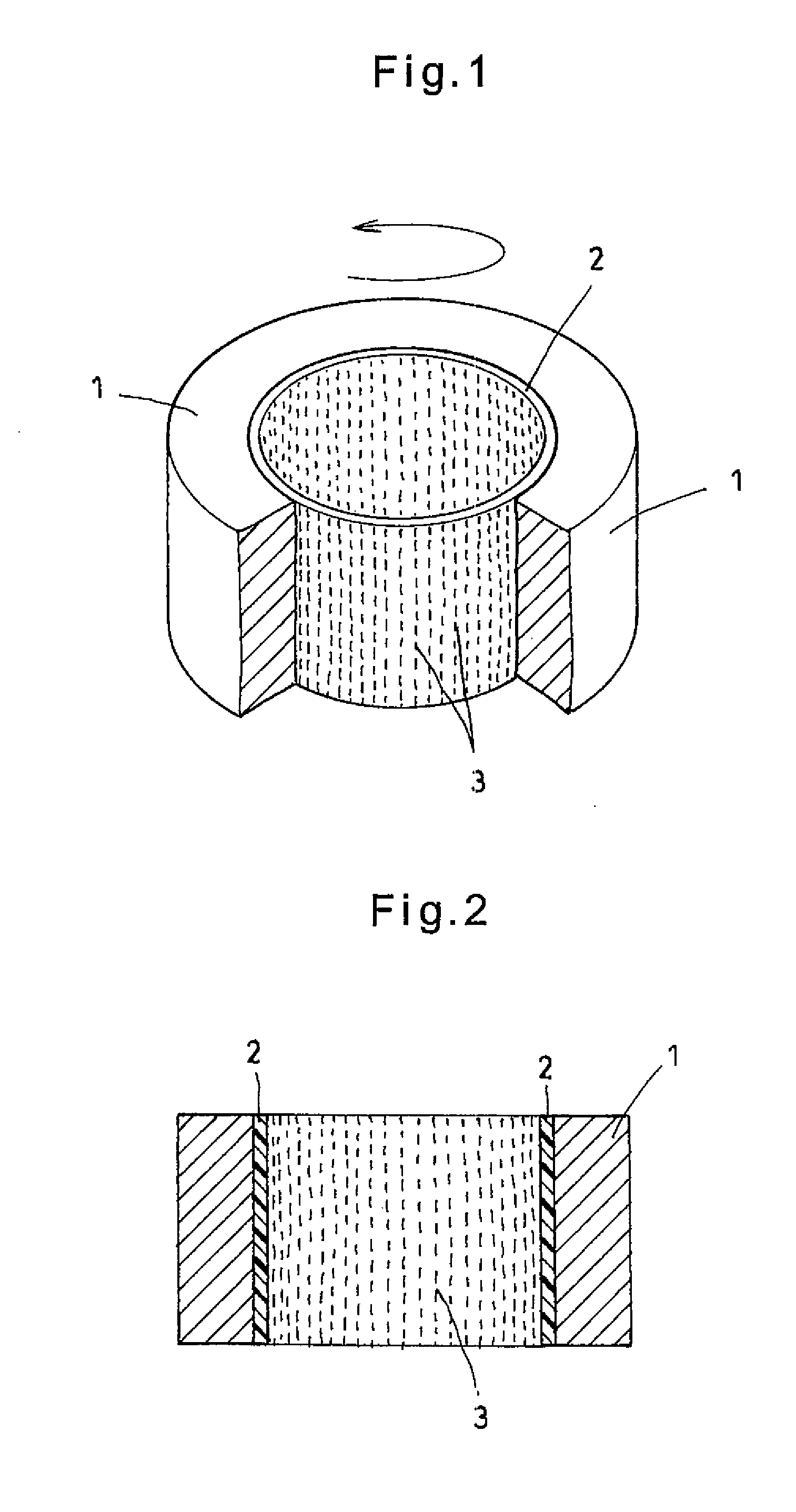

Composite slide bearing

A high-precision slide bearing is provided which includes a substrate of sintered metal and a synthetic resin layer. This bearing can be used e.g. for rotary shafts in compressors of room air-conditioners or in transmissions of motor vehicles and construction machines to support relatively large radial and axial loads. The resin layer is integrally superposed on the radially inner surface of the sintered metal substrate of the slide bearing, which is a cylindrical member. The resin layer is made of a resin composition of an aromatic polyetherketone resin containing a fibrous filler. The fibrous filler are made up of fibers dispersed in the resin layer and oriented such that their length directions intersect the rotational direction of the bearing at angles of 45 to 90 degrees. The resin layer has a thickness of 0.1 to 0.7 mm.

Owner:NTN CORP

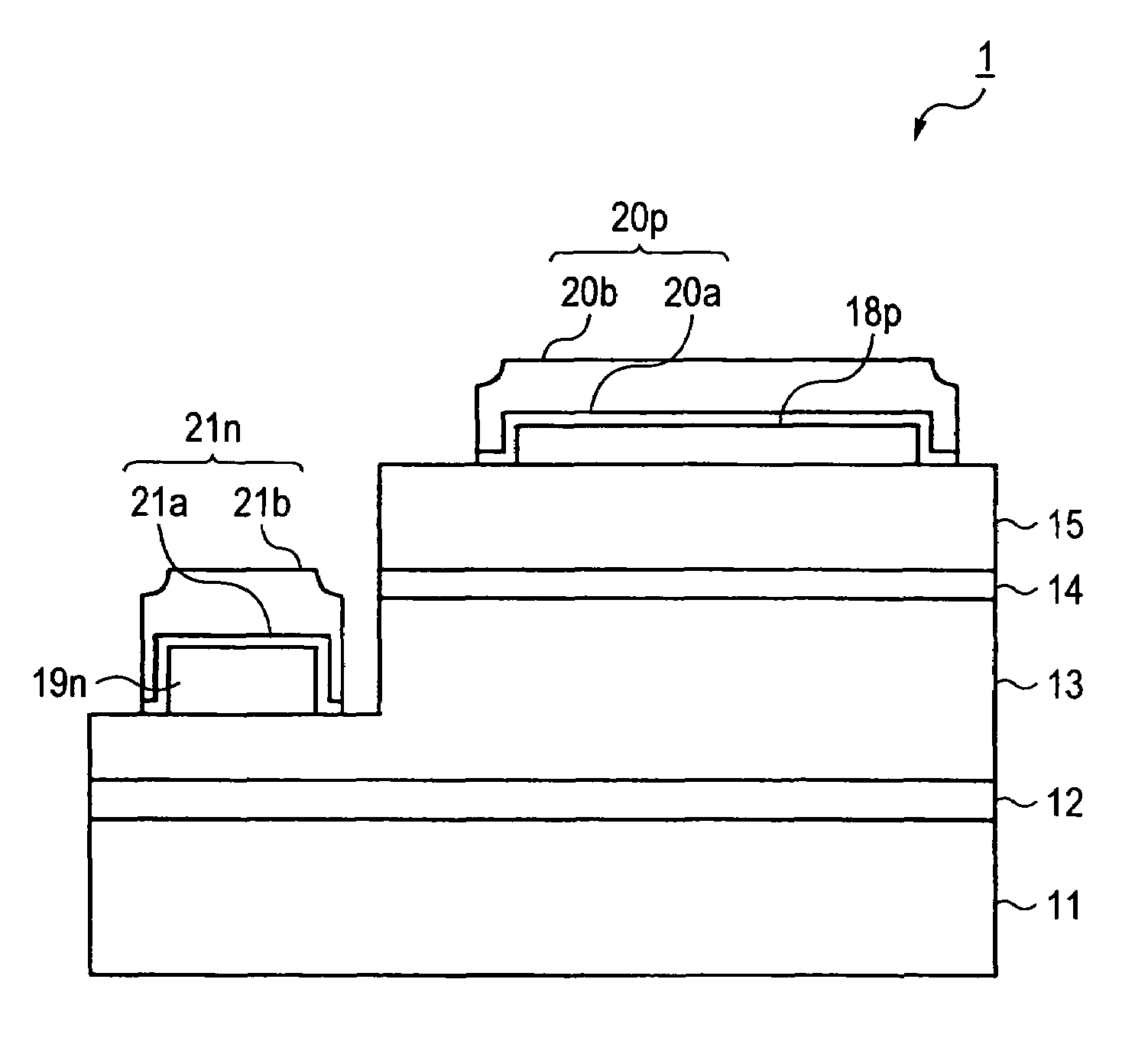

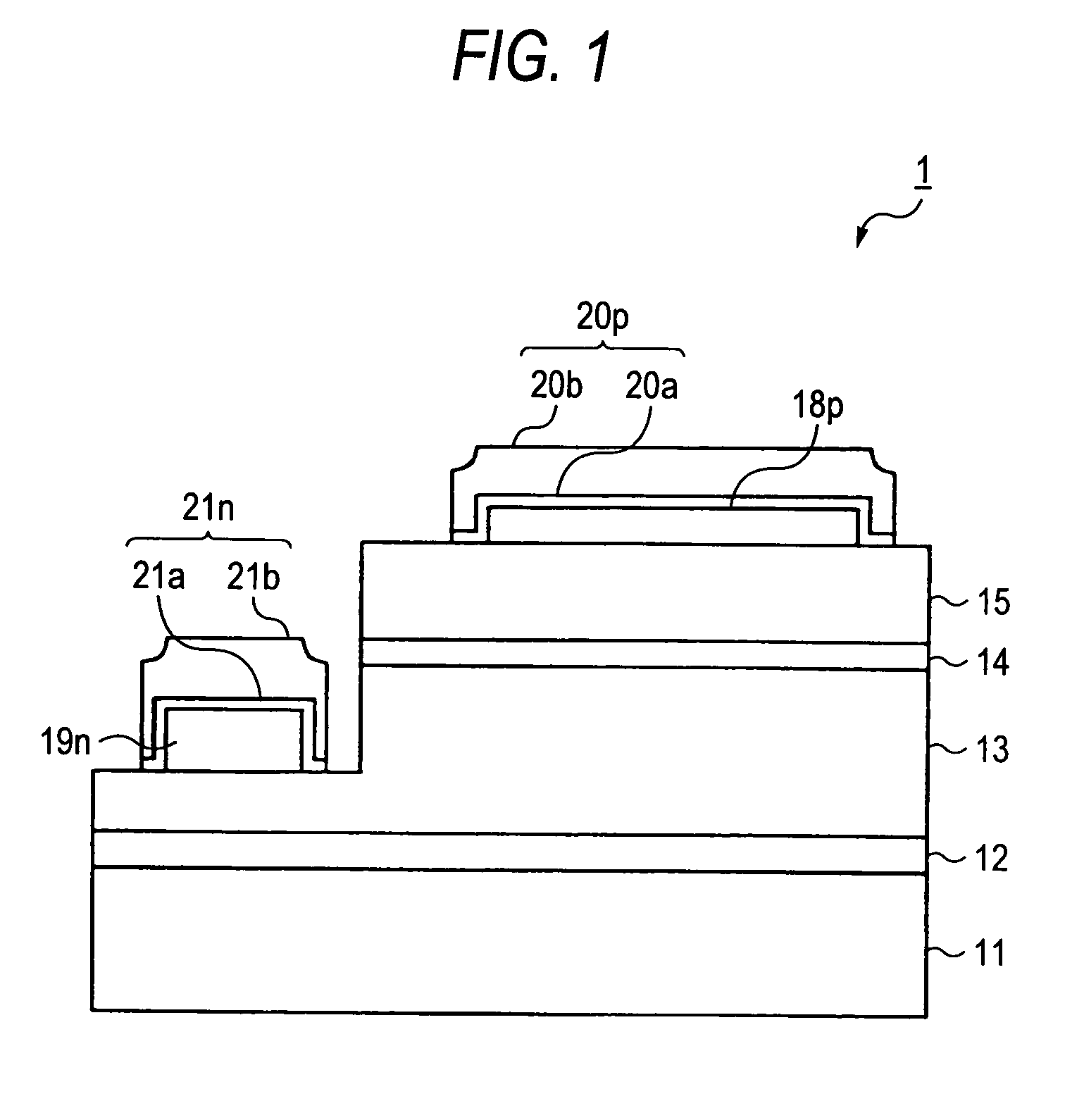

Group III nitride based semiconductor luminescent element

InactiveUS7005684B2Improve adhesionBonding strengthSemiconductor/solid-state device detailsSolid-state devicesNitrideCompound semiconductor

In a flip chip type Group III nitride compound semiconductor light-emitting element, an Au layer is provided on each of a surface of a p-side electrode and a surface of an n-side electrode with interposition of a Ti layer.

Owner:TOYODA GOSEI CO LTD

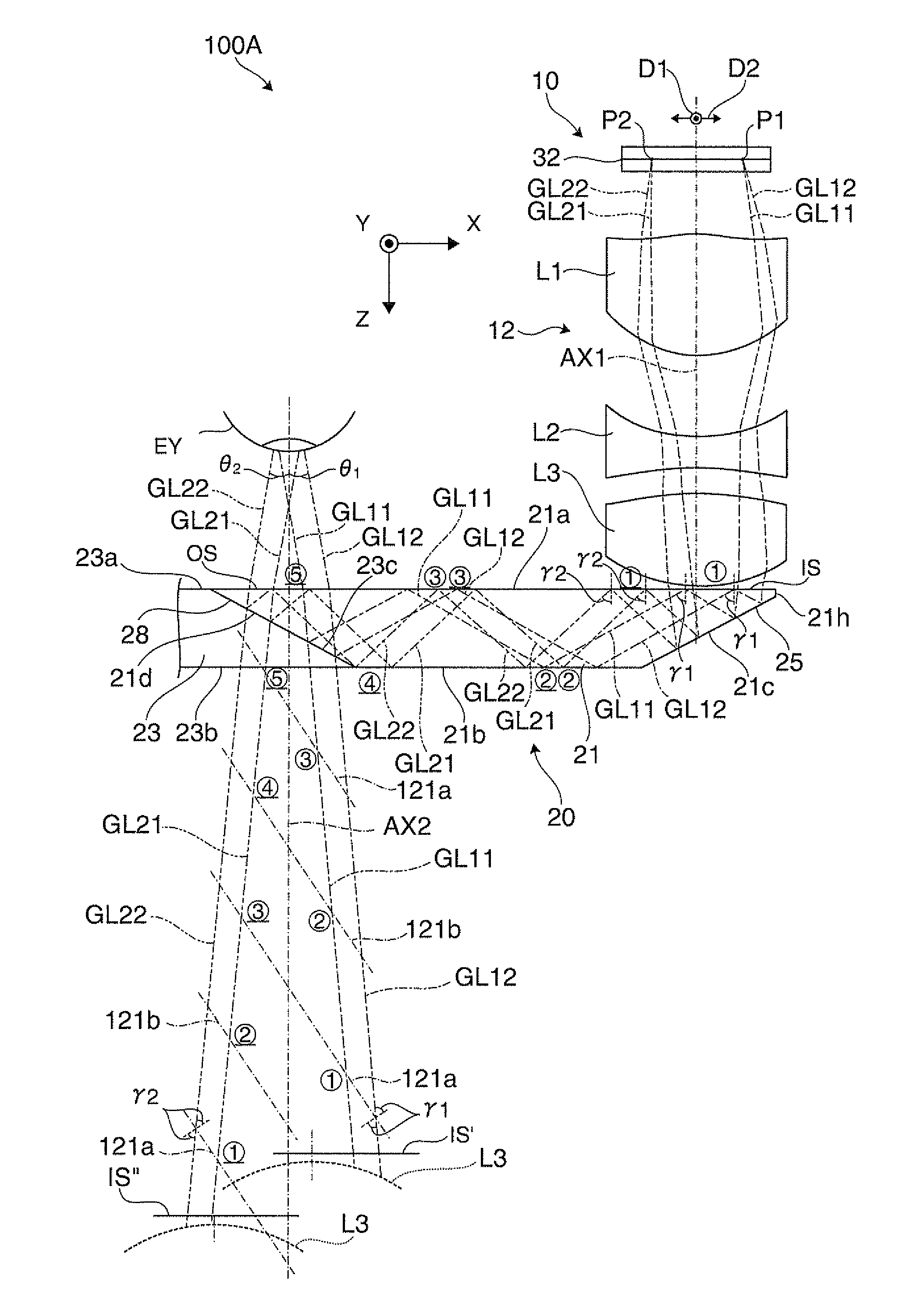

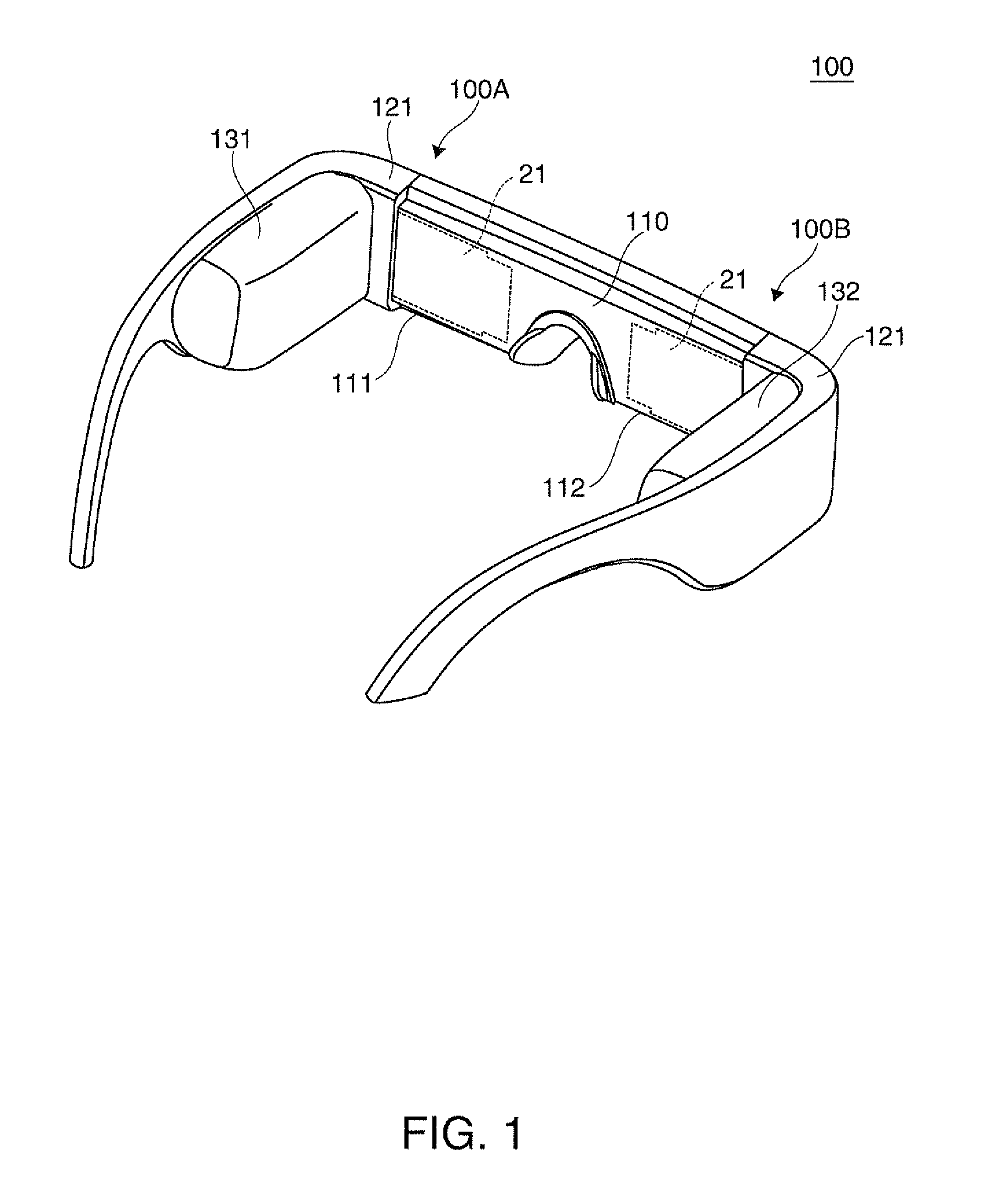

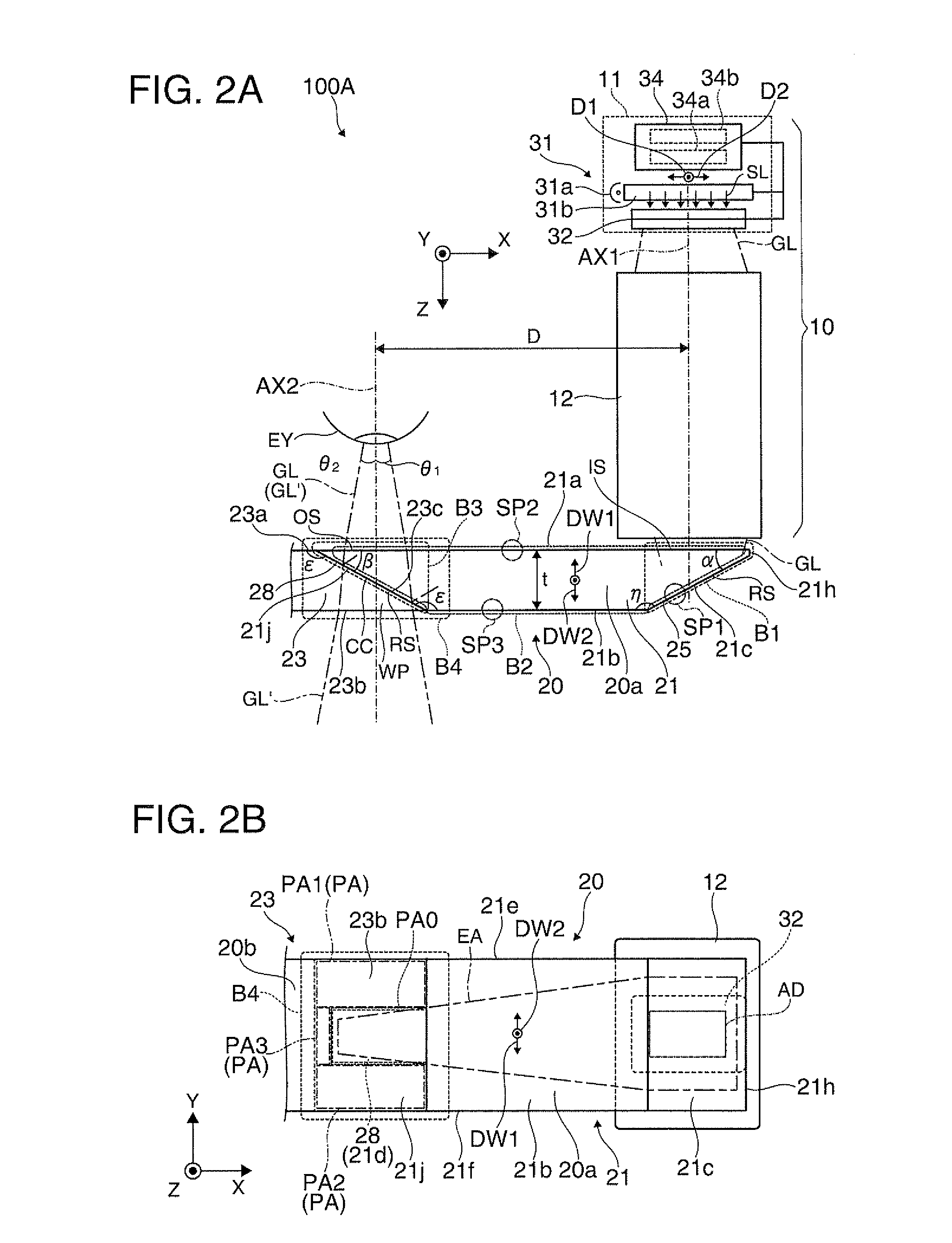

Virtual image display device

ActiveUS20130083404A1High strengthBonding strengthBundled fibre light guideLight guideDisplay device

A virtual image display device has a light guide device in which the half mirror layer (the semi-transmissive reflecting film) of the light guide member is formed on the partial area of the first junction surface, and the second junction surface of the light transmitting member is bonded to the first junction surface in at least the exceptional area. Therefore, it is possible to increase the bonding strength of the first junction surface and the second junction surface, namely the strength of the light guide device composed of the light guide member and the light transmitting member combined with each other even in the case in which the attachment force of the half mirror layer (the semi-transmissive reflecting film) with respect to the first junction surface is not sufficiently strong.

Owner:SEIKO EPSON CORP

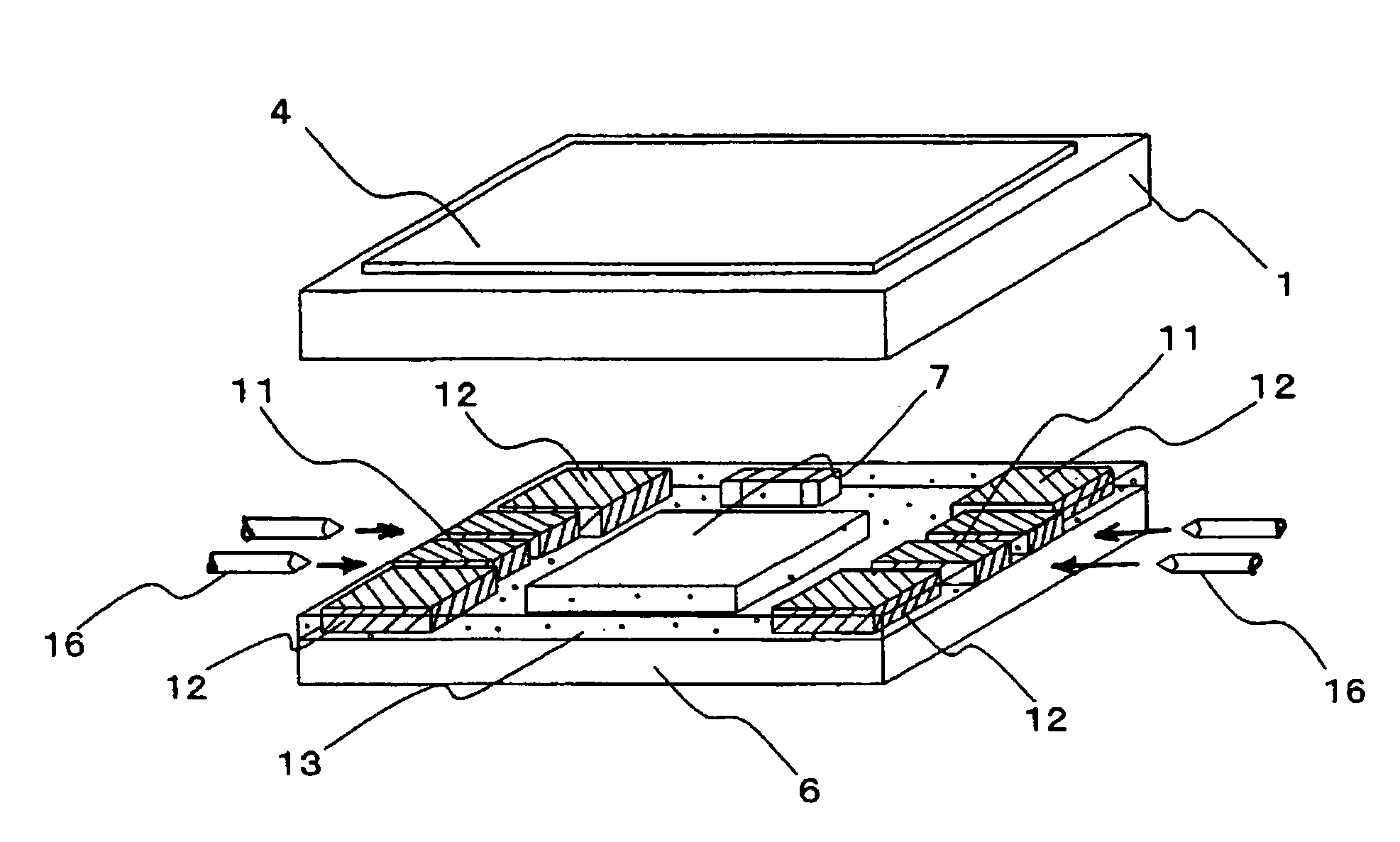

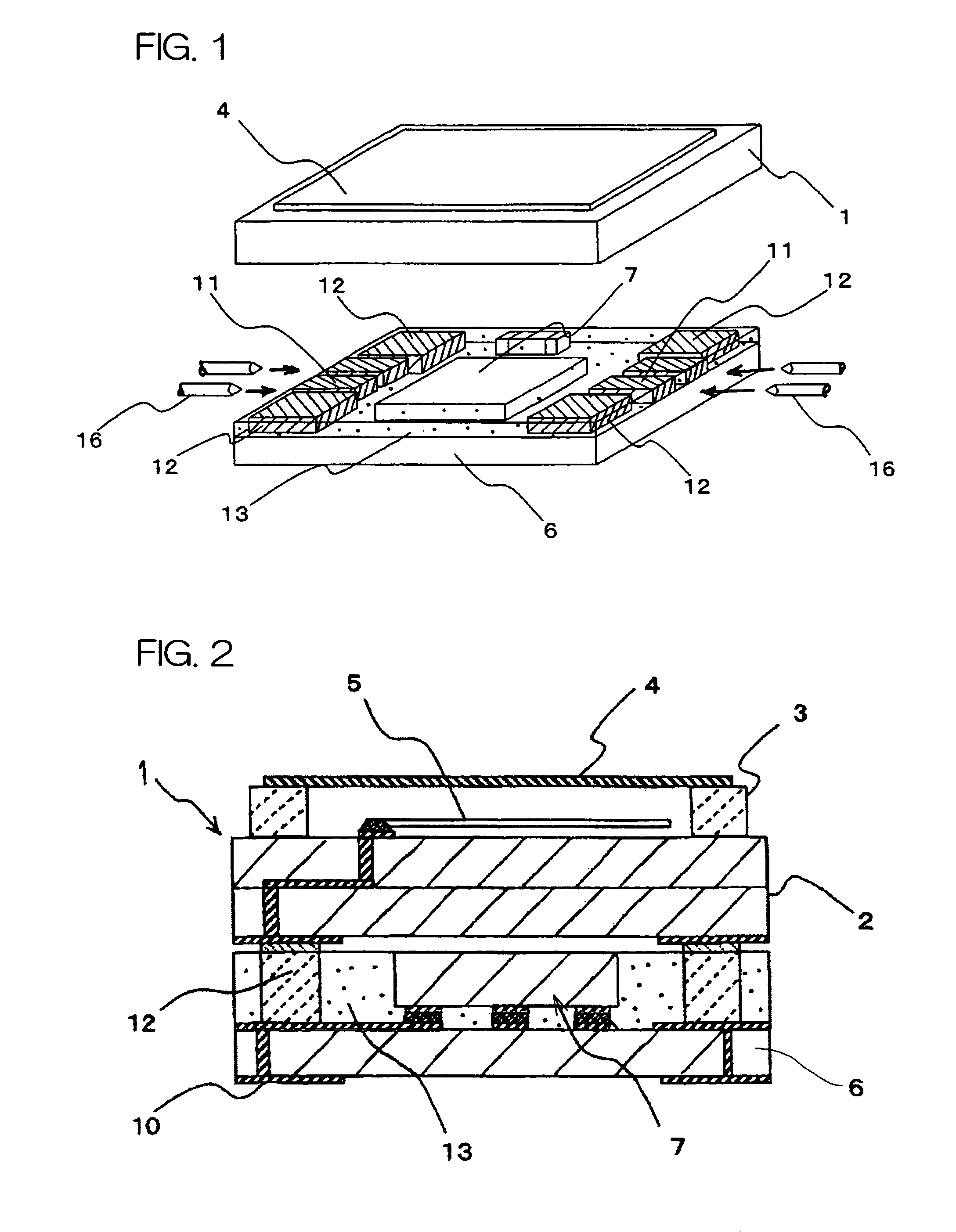

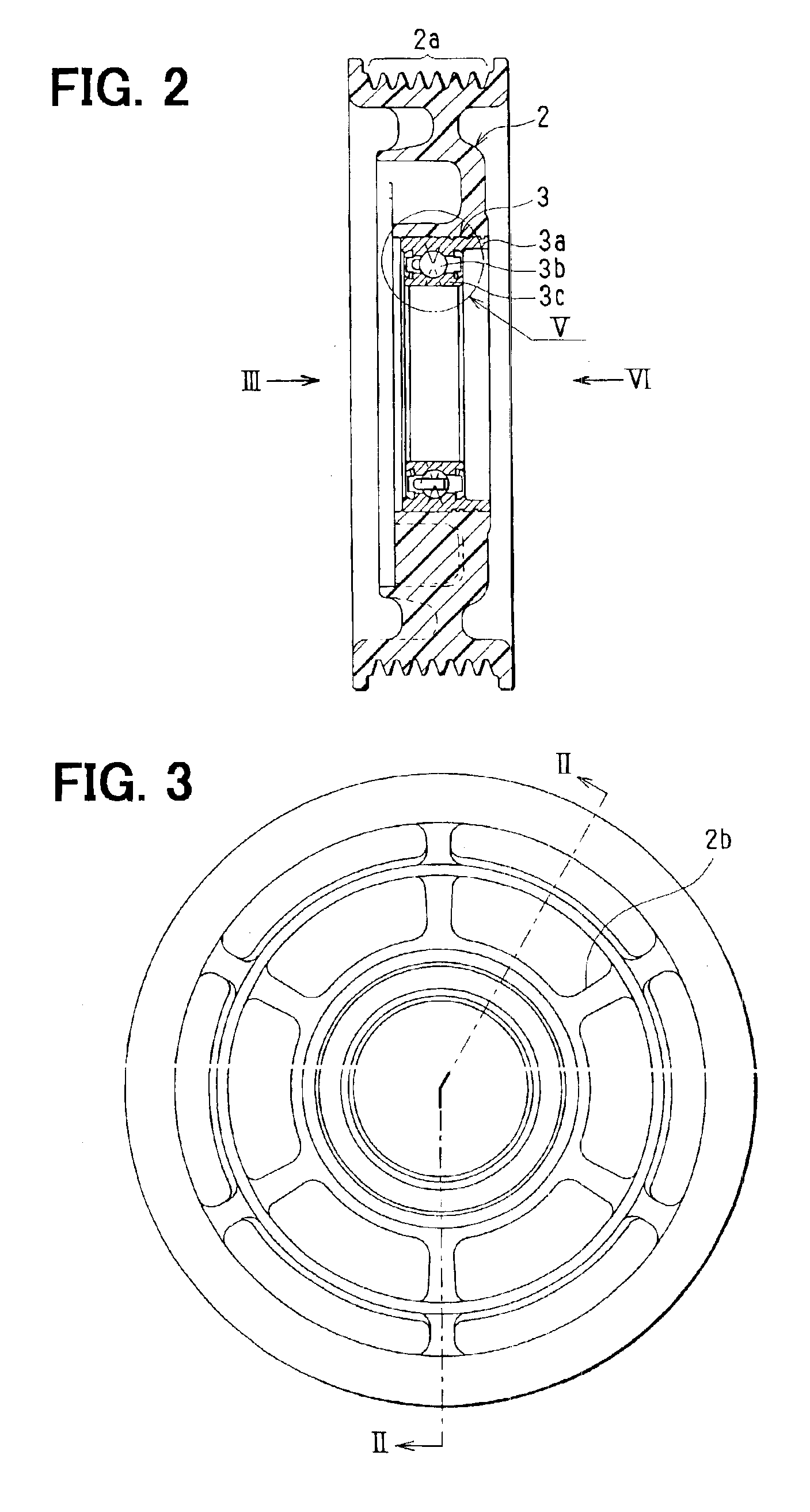

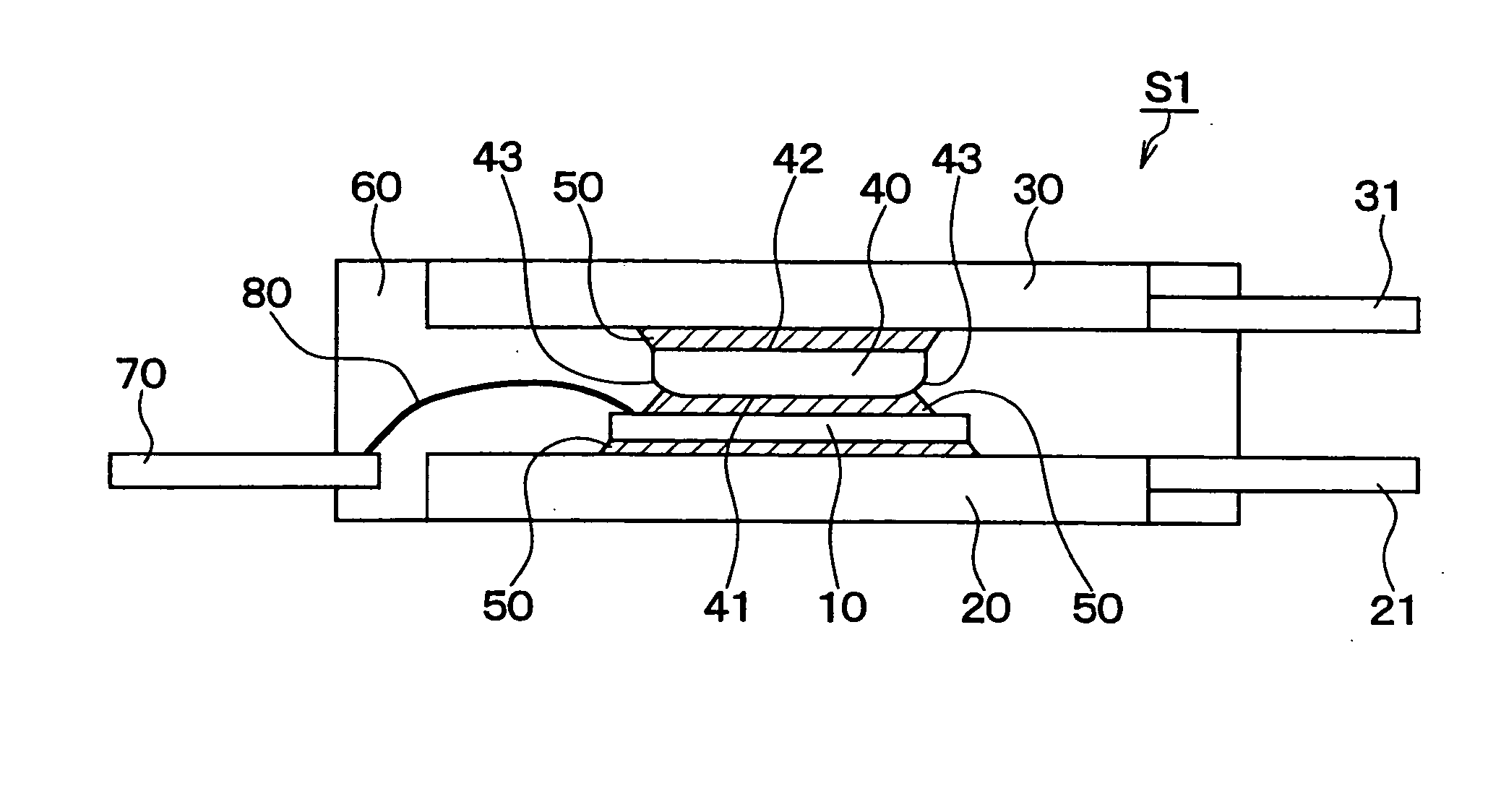

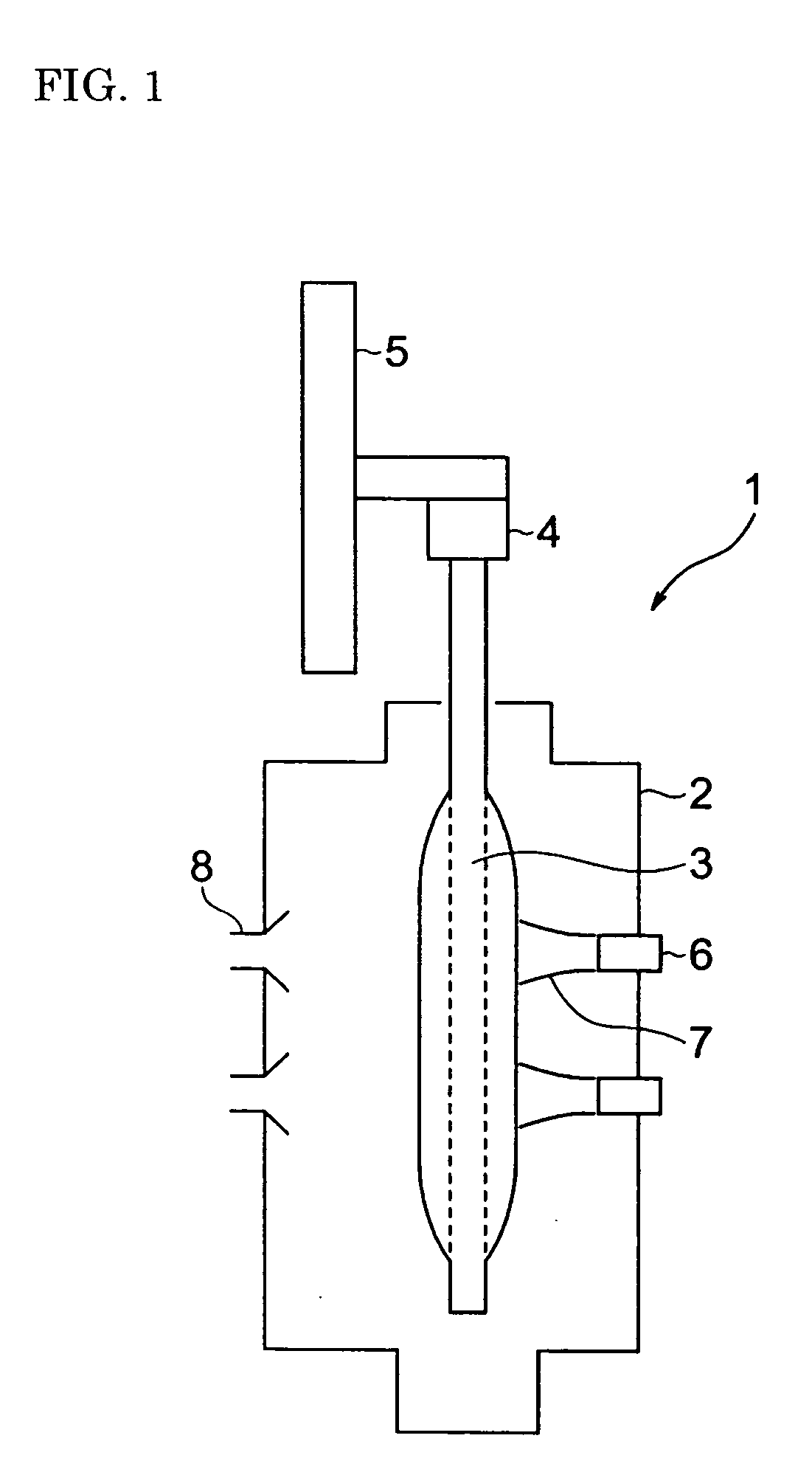

Piezoelectric oscillator

ActiveUS7098580B2Oxidative corrosion can be preventedImprove reliabilityImpedence networksPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsEngineering

A quartz-crystal oscillator has a configuration wherein a rectangular container 1 accommodating a piezoelectric oscillator device 5 therein is fixed to a rectangular supporting substrate 6 on which an IC device 7 is mounted via spacer members 12 formed of metal bodies. On the surface of the supporting substrate 6, part or all of the IC device 7 and side faces of the spacer members are coated with a resin material. When the quartz-crystal oscillator is implemented on a main board by soldering or the like, the problem that the solder for bonding the quartz-crystal oscillator to the main board is adhered to the spacer members 12, thereby causing a short-circuit can be effectively prevented.

Owner:KYOCERA CORP

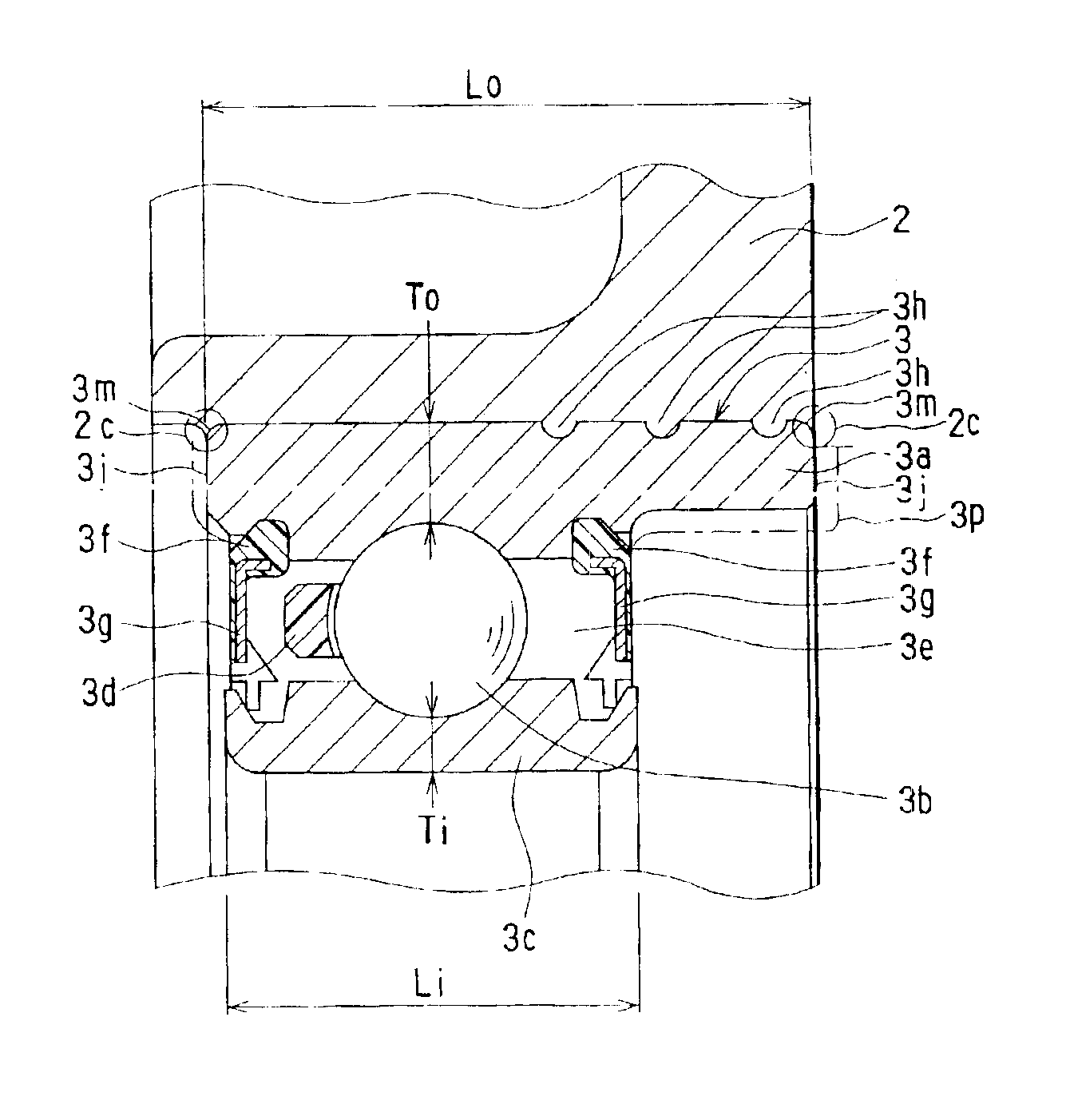

Rotator with bearing, and method for manufacturing the same

InactiveUS6860639B2Low production costLow costGearingBall bearingsRolling-element bearingEngineering

A pulley includes a radial rolling bearing and a pulley main body which are integrated to each other by an insert molding method. Therefore, a metal insert member is not required between the resin pulley main body and the radial rolling bearing, thereby reducing production cost of the pulley. Further, an axial dimension of an outer ring of the radial rolling bearing is set larger than an axial dimension of an inner ring thereof, so that a contact area between the radial rolling bearing and the pulley main body is increased. Therefore, a connection strength between the radial rolling bearing and the pulley main body is increased, and a surface area of the radial rolling bearing is increased, thereby improving heat radiation performance of the radial rolling bearing.

Owner:DENSO CORP

Ceramic joint body

InactiveUS6921881B2Occurrence can be suppressedAvoid warpingLayered product treatmentLaminationBond interfaceElectrical conductor

A ceramic joint body including a ceramic substrate and a ceramic body such as a cylindrical body firmly bonded to each other and excellent in corrosion resistance in the ceramic substrate for use for a semiconductor product producing / examining the step. The ceramic bonded body includes a ceramic substrate in which a conductor is provided, and a ceramic body bonded to a bottom face of the ceramic substrate. The ceramic bonded body has a region, where no conductor is formed, in at least a part of a region above a bonding interface between the ceramic substrate and the ceramic body.

Owner:IBIDEN CO LTD

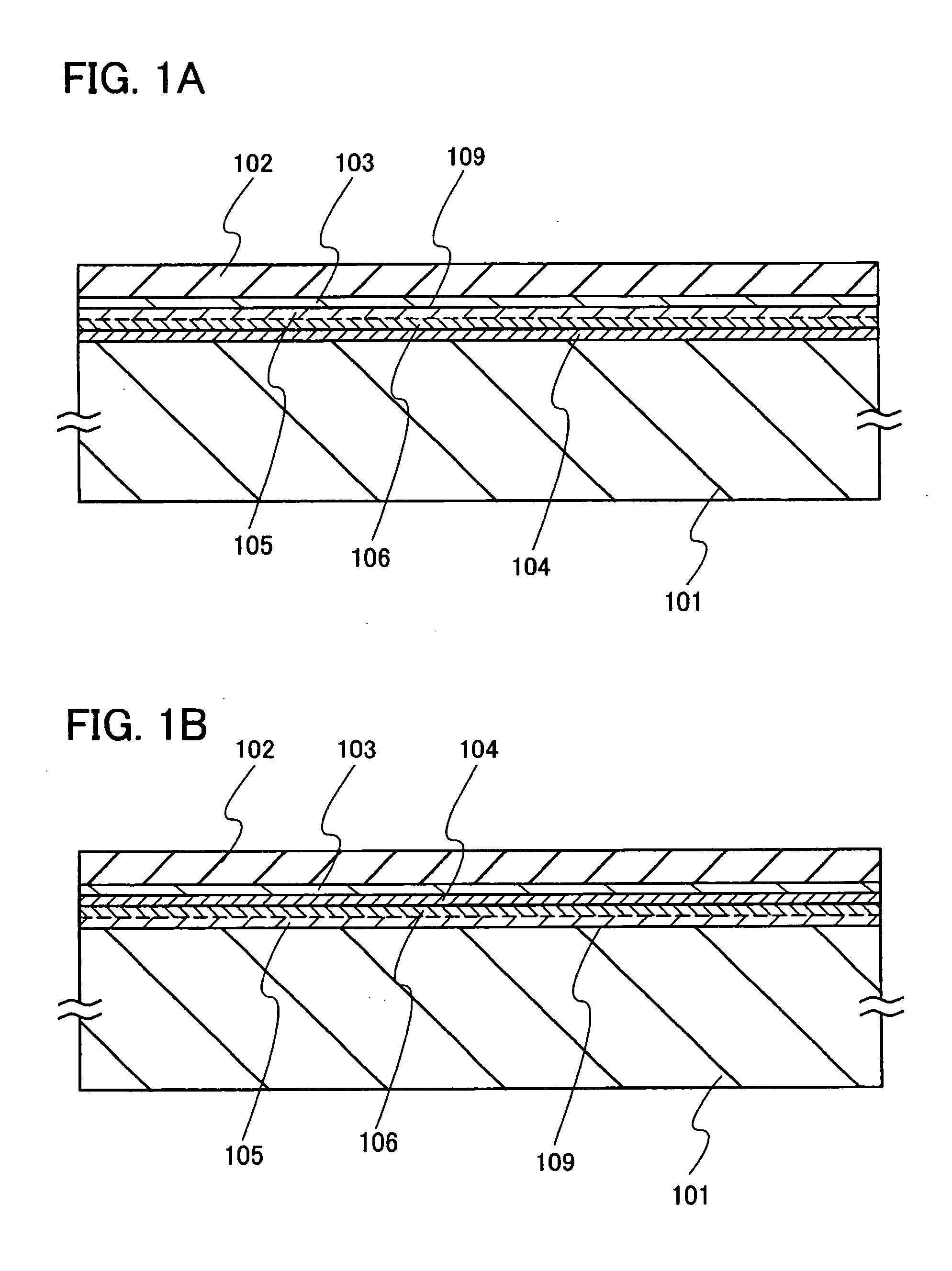

Semiconductor substrate, semiconductor device and manufacturing method thereof

InactiveUS20080283916A1Increase concentrationHigh concentrationTransistorSemiconductor/solid-state device detailsIonBonding strength

It is an object to provide a method for manufacturing a semiconductor substrate in which contamination of a semiconductor layer due to an impurity is prevented and the bonding strength between a support substrate and the semiconductor layer can be increased. An oxide film containing first halogen is formed on a surface of a semiconductor substrate, and the semiconductor substrate is irradiated with ions of second halogen, whereby a separation layer is formed and the second halogen is contained in a semiconductor substrate. Then, heat treatment is performed in a state in which the semiconductor substrate and the support substrate are superposed with an insulating surface containing hydrogen interposed therebetween, whereby part of the semiconductor substrate is separated along the separation layer, so that a semiconductor layer containing the second halogen is provided over the support substrate.

Owner:SEMICON ENERGY LAB CO LTD

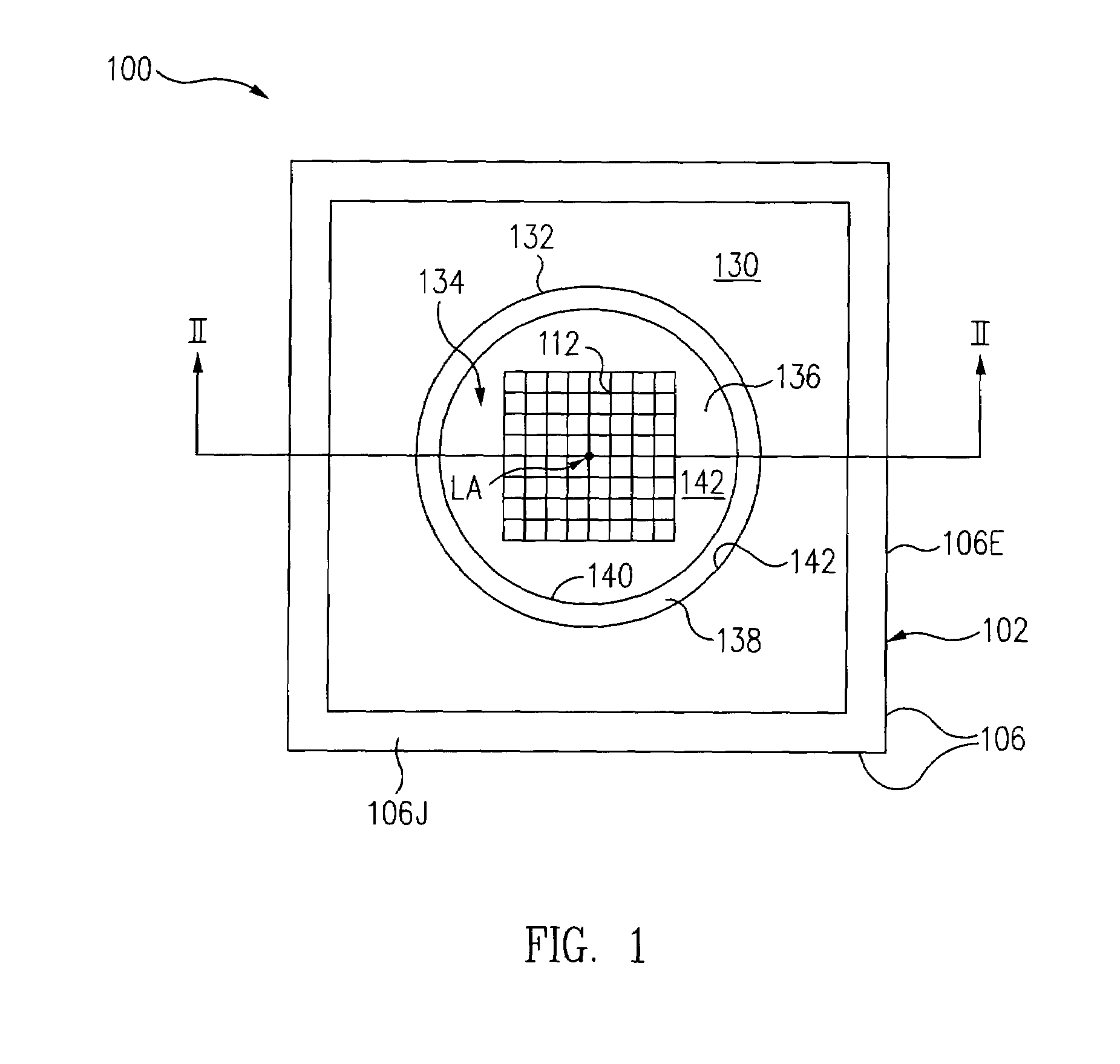

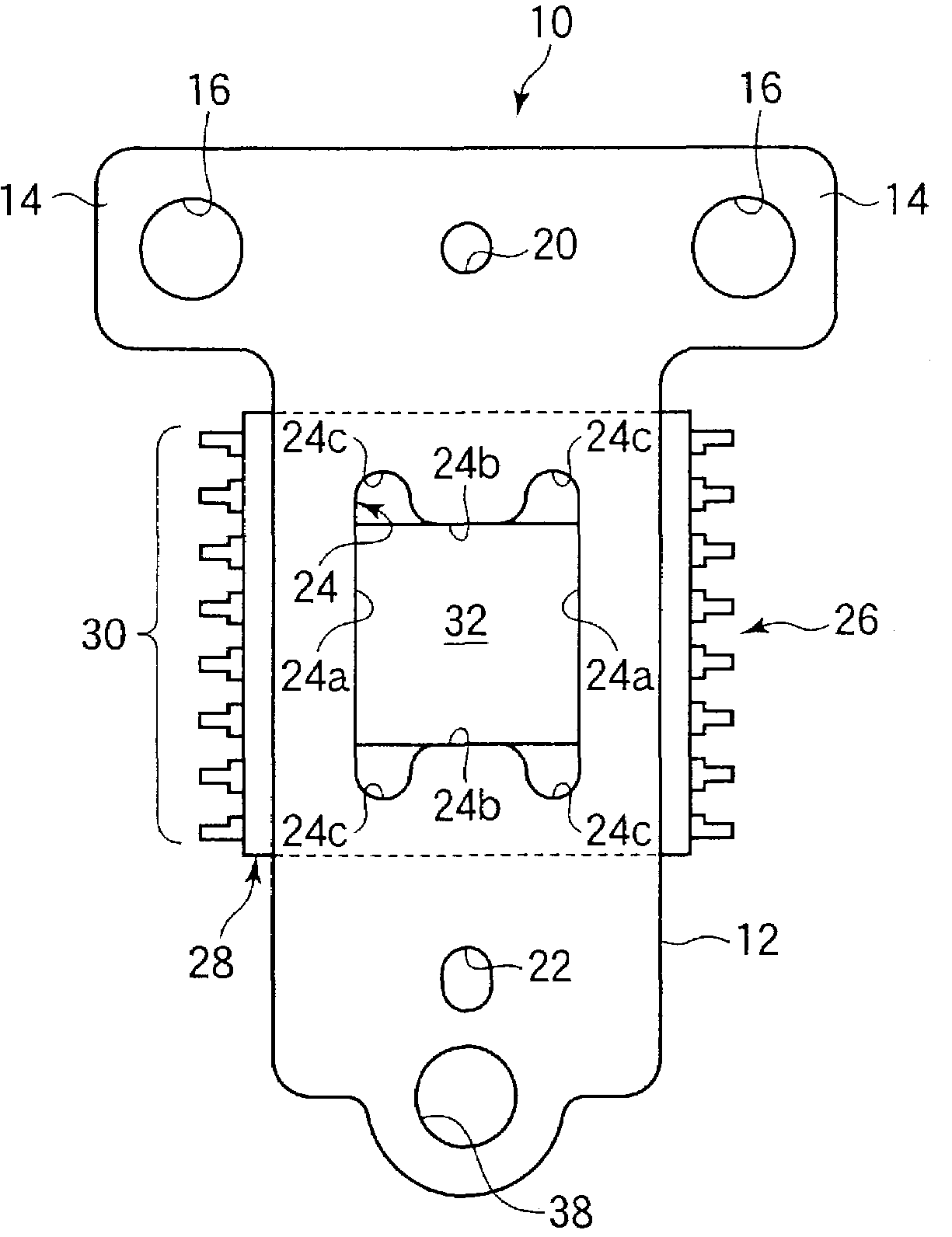

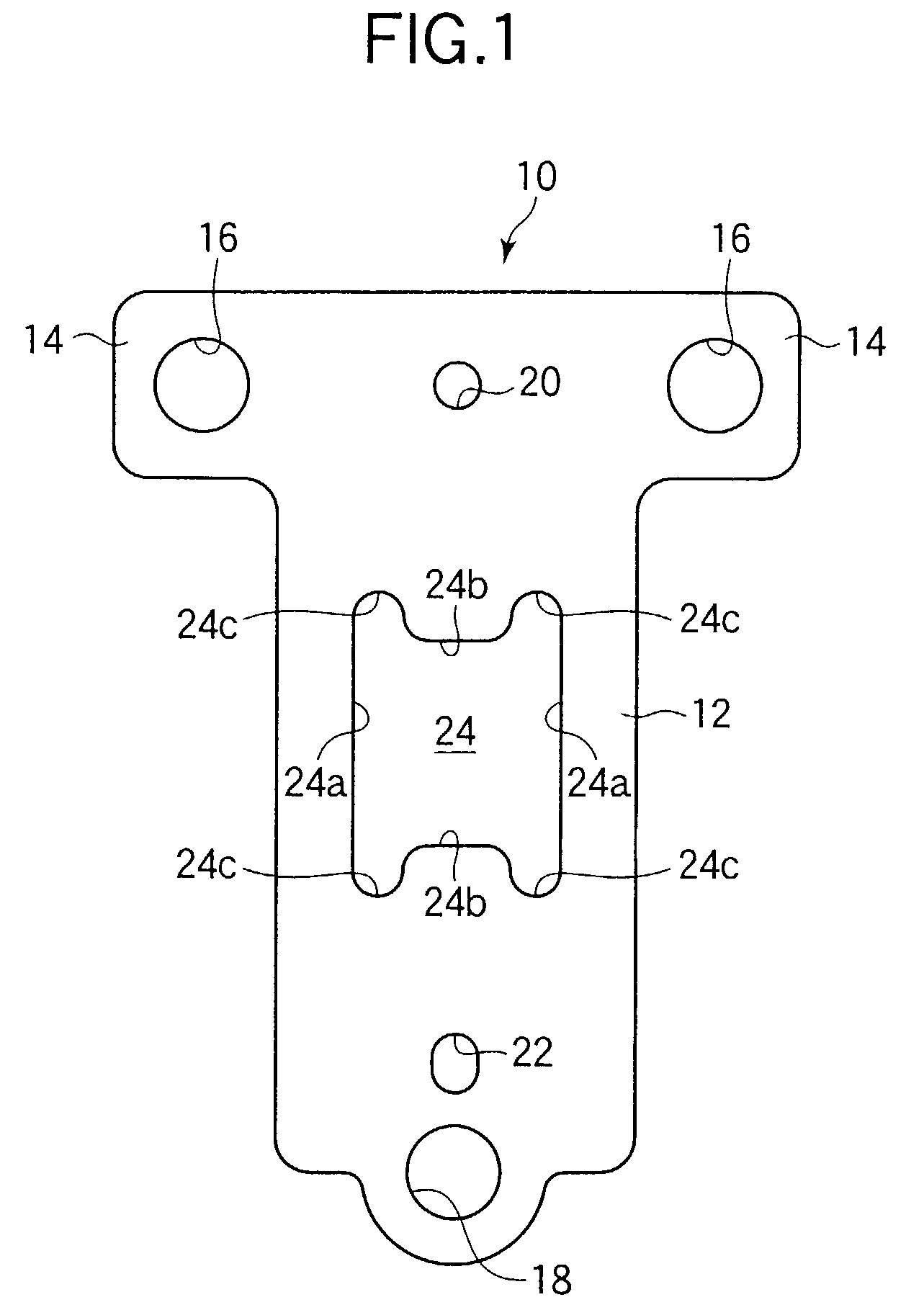

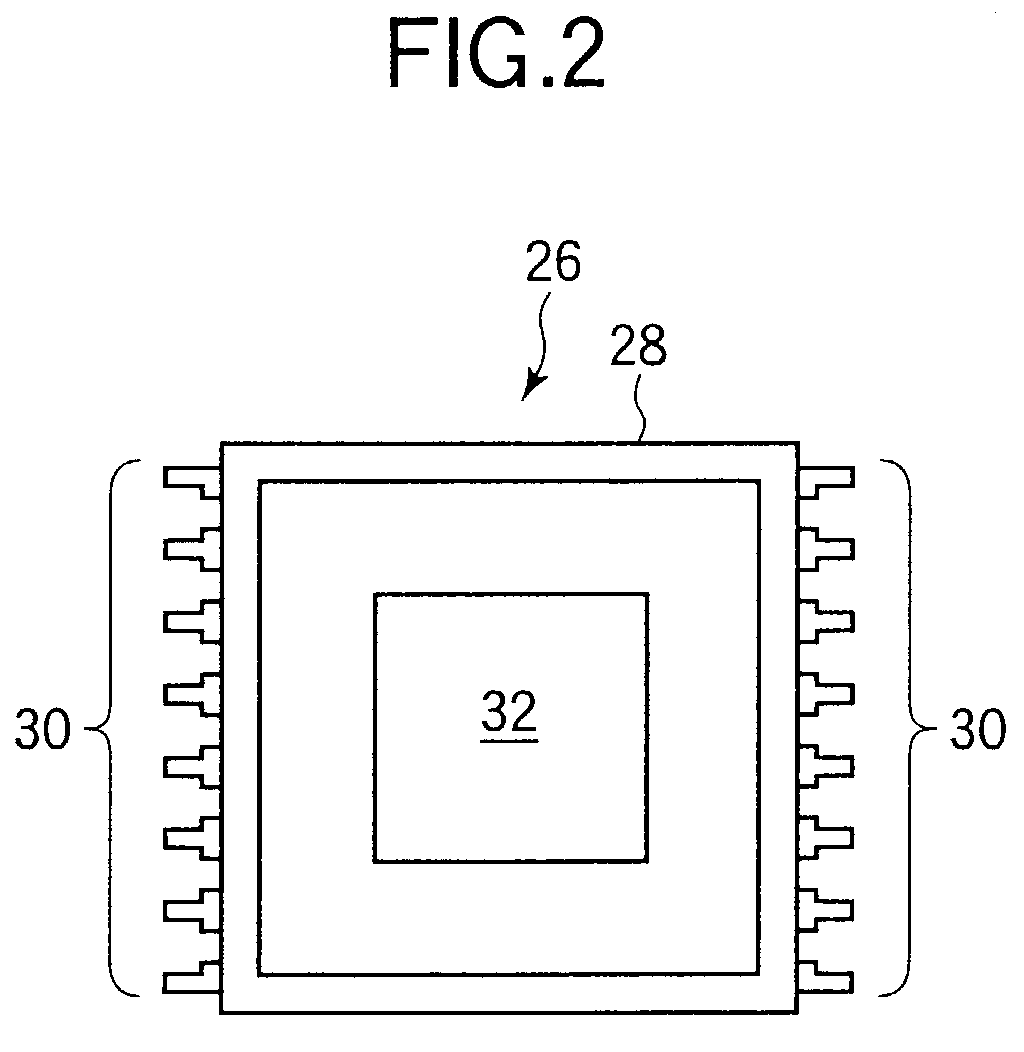

Mounting plate for solid-state imaging device and method for bonding solid-state imaging device to mounting plate

InactiveUS7436443B2Improve shapeProperly positionTelevision system detailsTelevision system scanning detailsSolid-stateEngineering

A mounting plate has an opening provided for bonding a solid-state imaging device thereto. The opening of the mounting plate comprises a first edge portion and a second edge portion. The first edge portion corresponds to a first side of part of the contour of a light receiving area of the solid-state imaging device. The second edge portion corresponds to a second side of part of the contour. The first and second edge portions function as reference lines for positioning the solid-state imaging device over said opening.

Owner:PENTAX RICOH IMAGING CO LTD

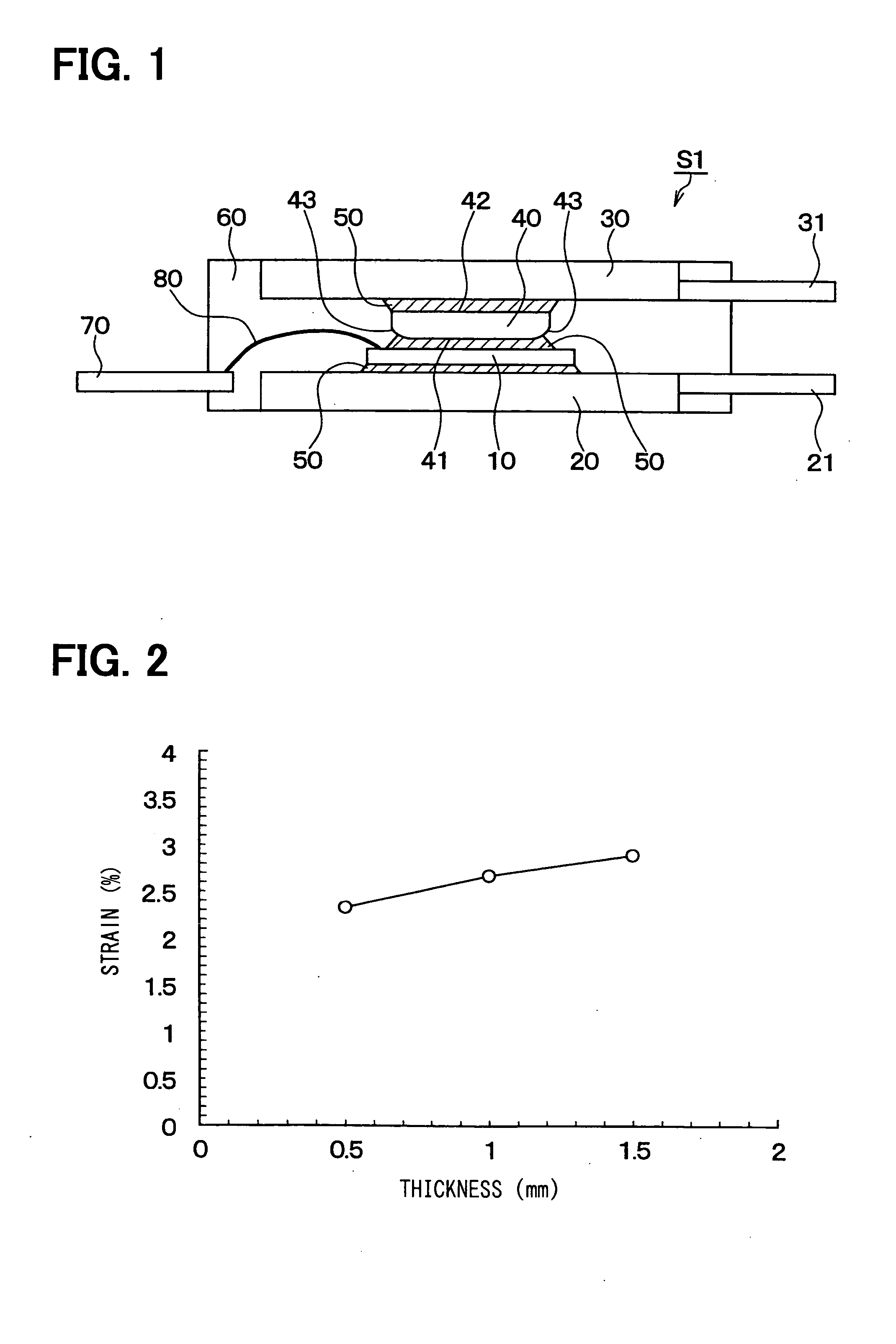

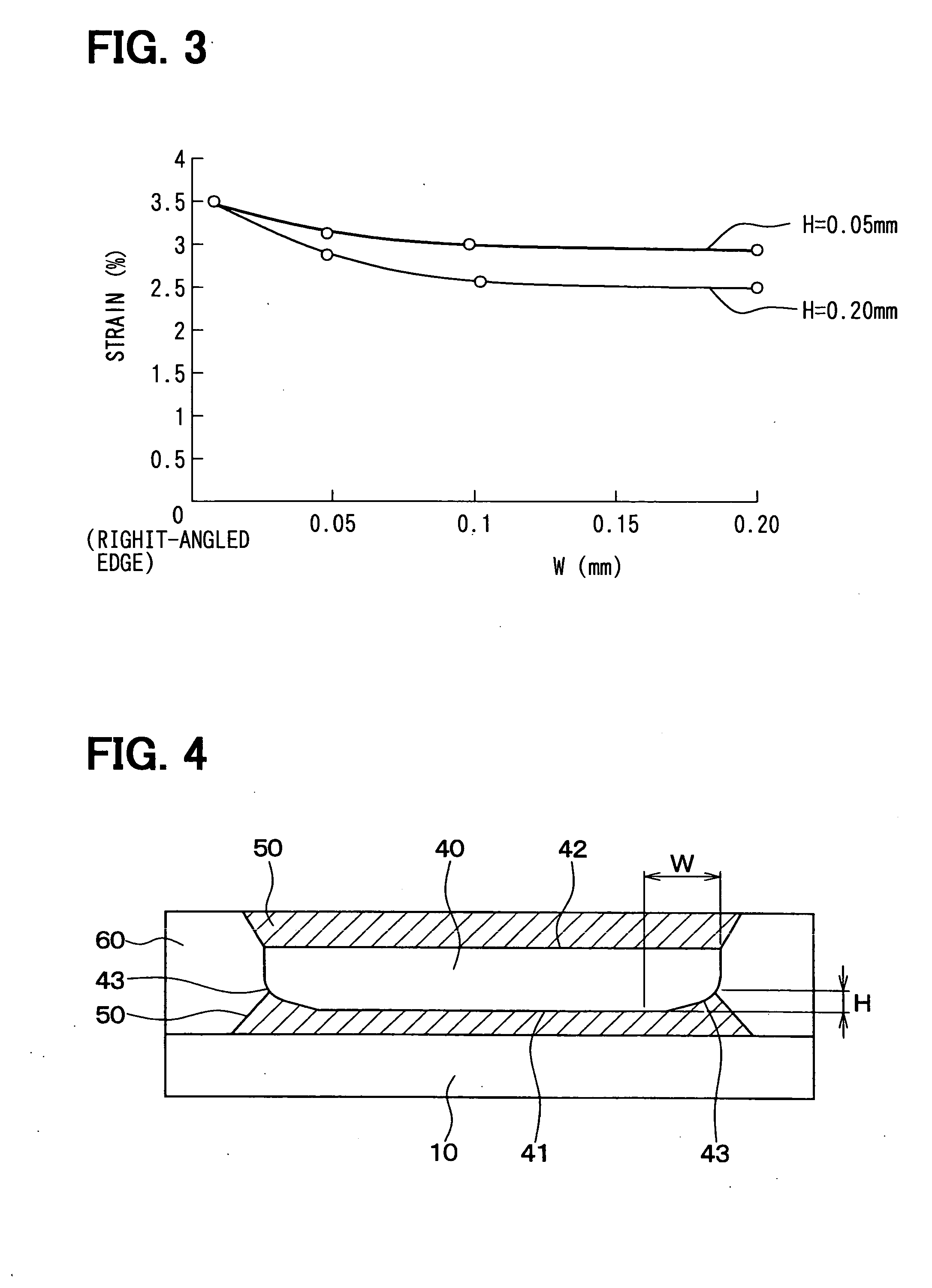

Semiconductor device having heat radiation plate and bonding member

ActiveUS20050077617A1Avoid crackingHigh bonding strengthSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A semiconductor device includes a heat generation element; a bonding member; first and second heat radiation plates disposed on first and second sides of the heat generation element through the bonding member; a heat radiation block disposed between the first heat radiation plate and the heat generation element through the bonding member; and a resin mold. The heat radiation block has a thickness in a range between 0.5 mm and 1.5 mm. The semiconductor device has high reliability of the bonding member.

Owner:DENSO CORP

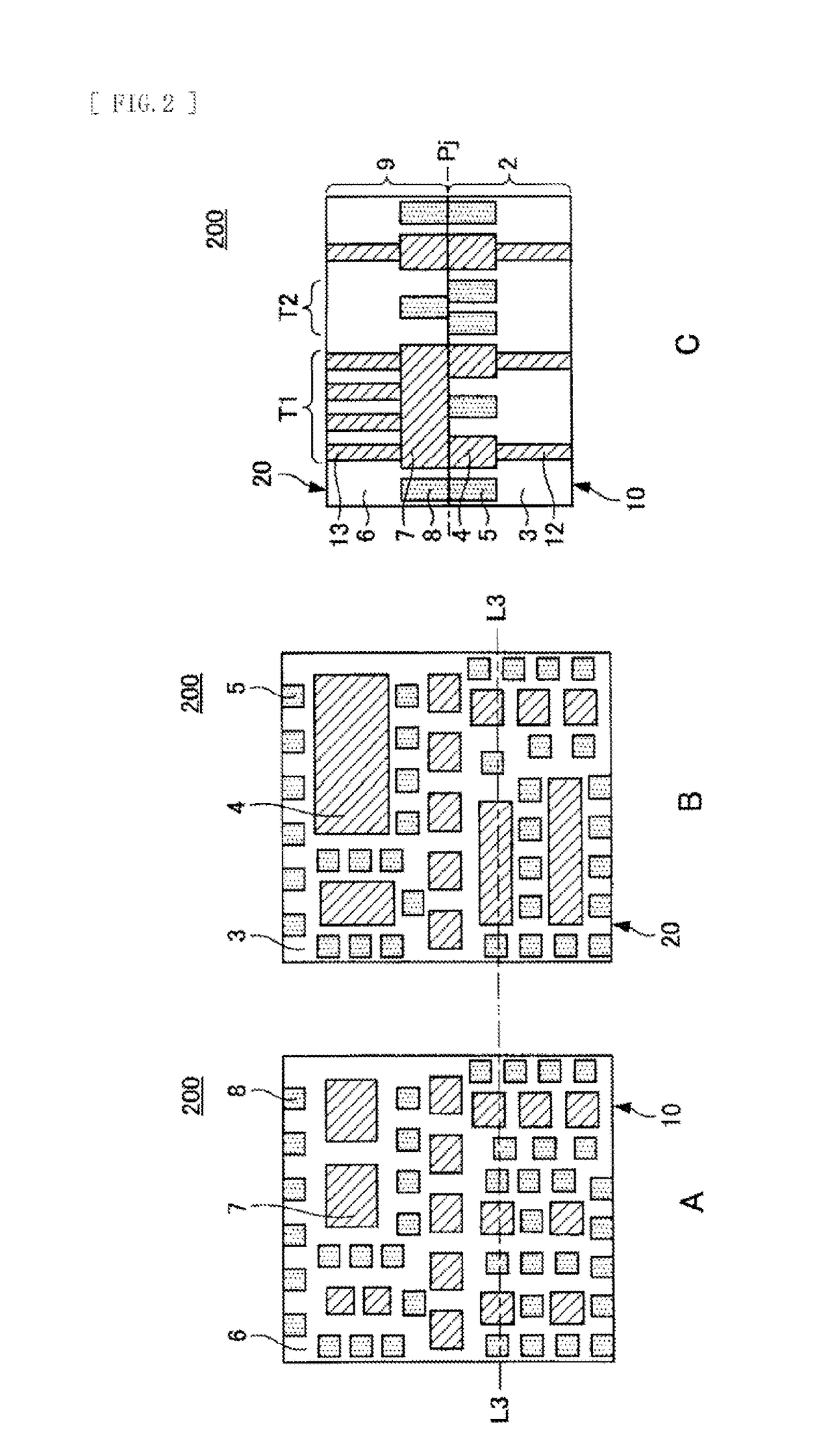

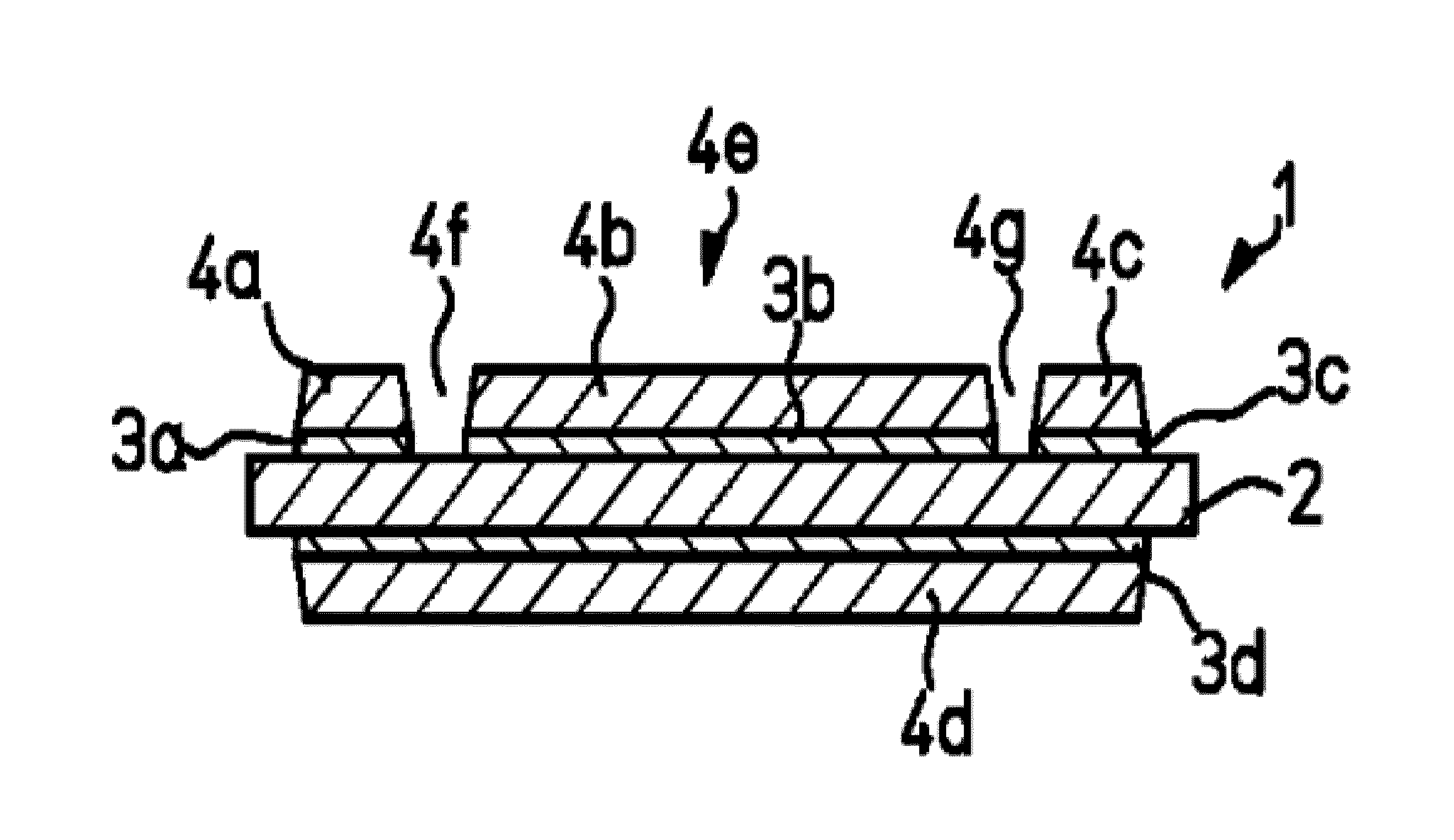

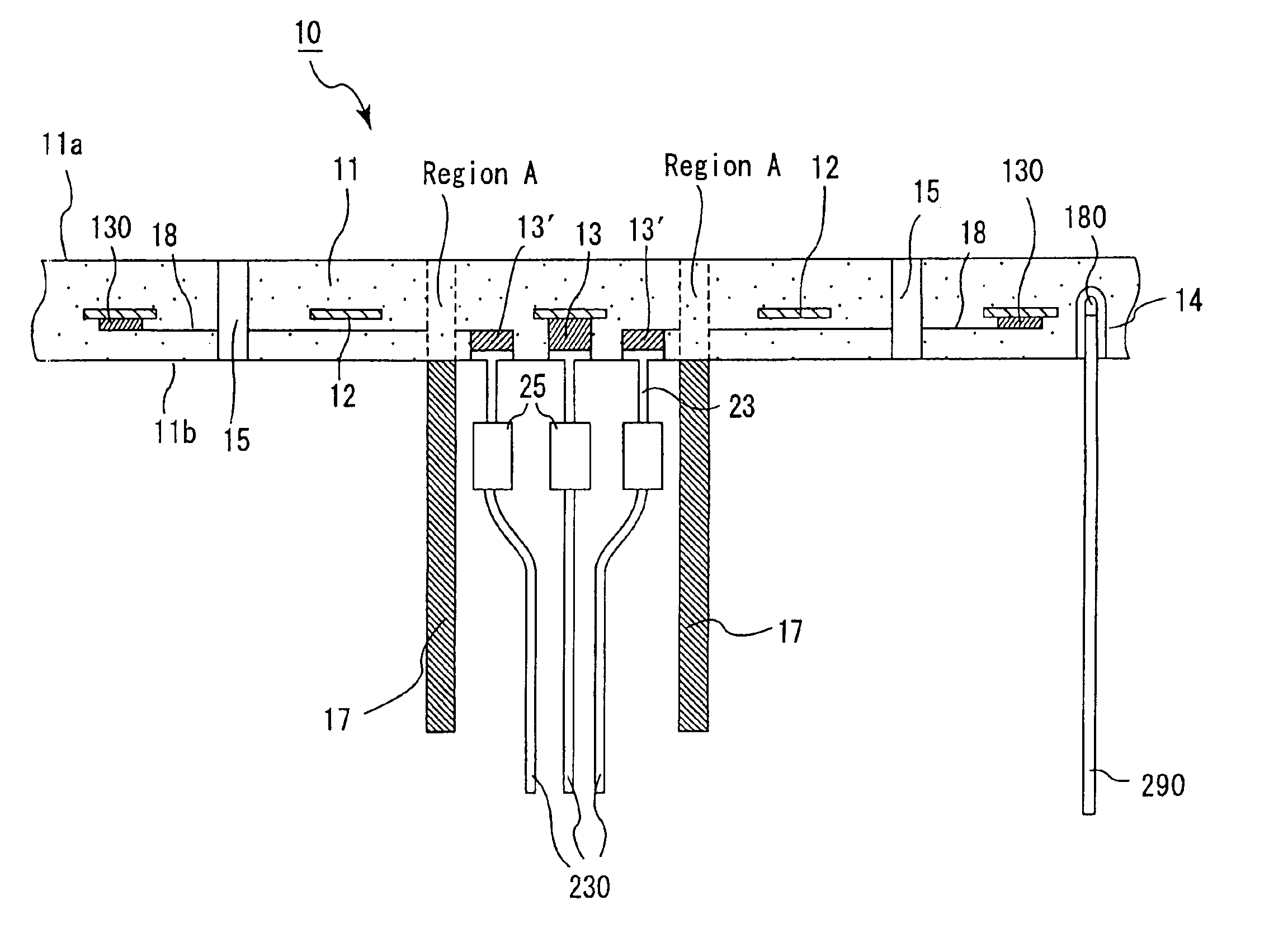

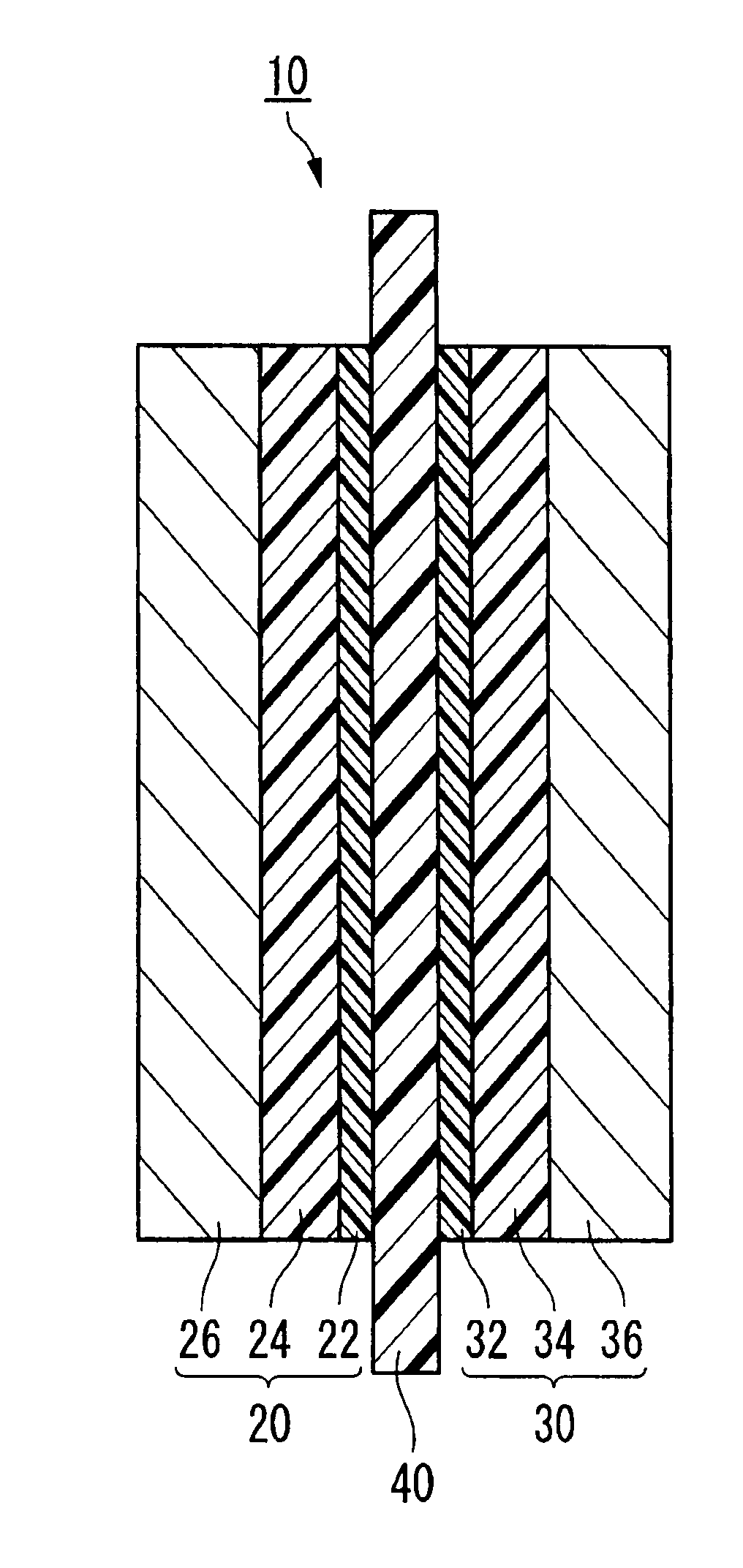

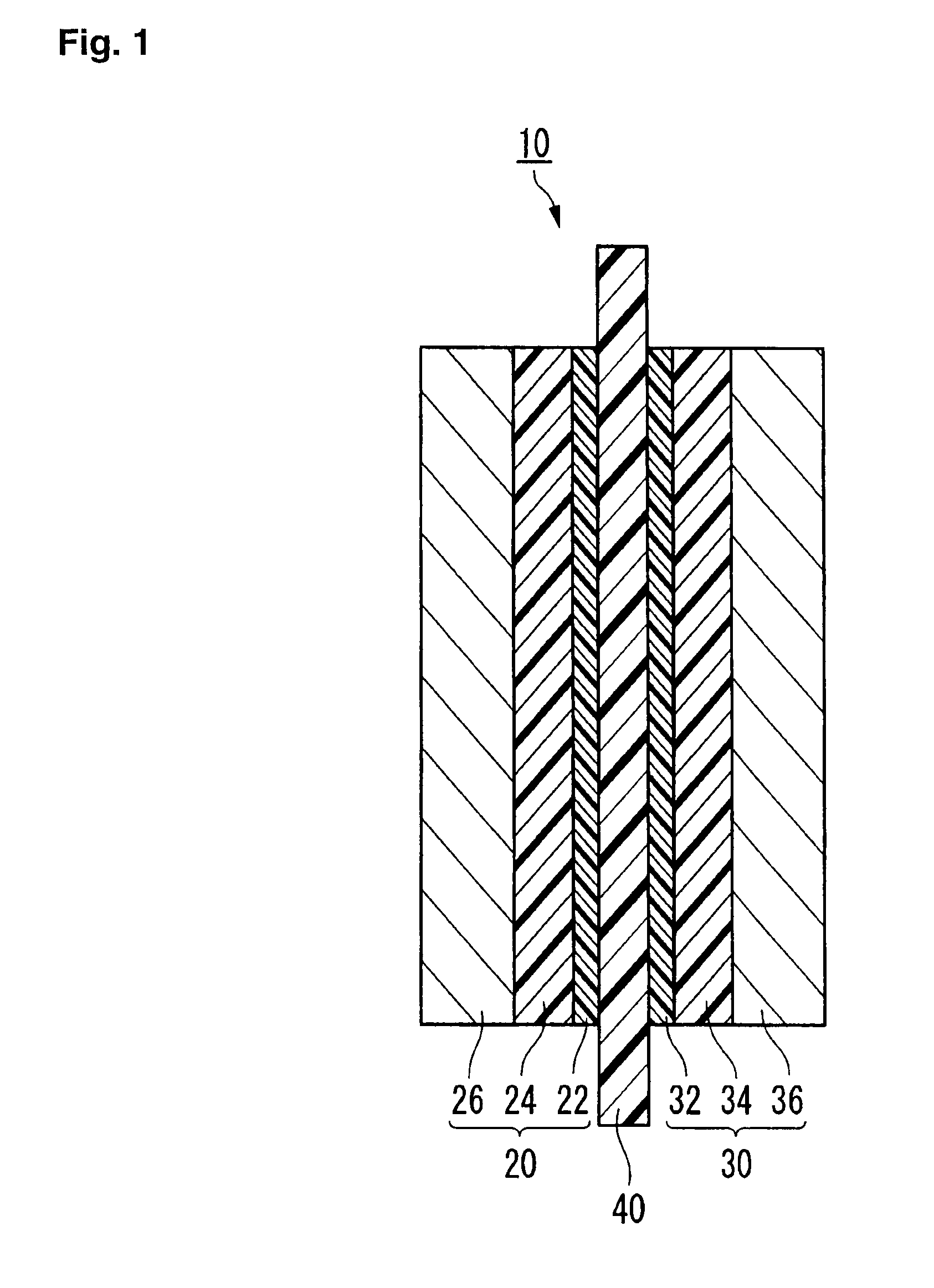

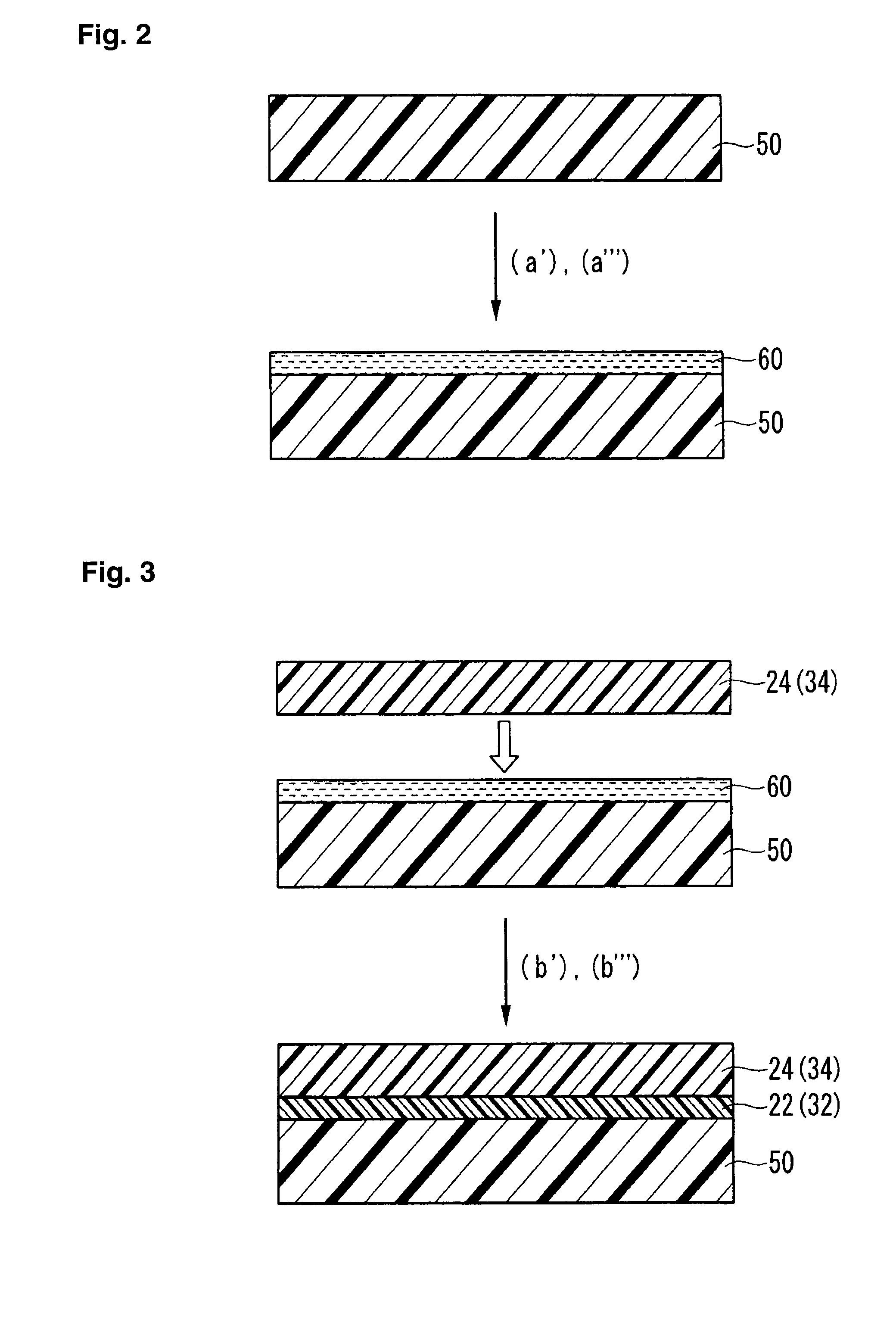

Process for forming catalyst layer, and process for producing membrane/electrode assembly for polymer electrolyte fuel cell

ActiveUS20100043954A1High bonding strengthBonding strengthLamination ancillary operationsFinal product manufactureLiquid layerPolymer electrolytes

To provide a process for forming a catalyst layer whereby defects such as cracks are scarcely formed in the catalyst layer, and the bond strength is high at the interface between the catalyst layer and a reinforcing layer and at the interface between the catalyst layer and a polymer electrolyte membrane; and a process for producing a membrane / electrode assembly for a polymer electrolyte fuel cell, which is capable of exhibiting high power generation performance even under a low humidity condition and has sufficient mechanical strength and dimensional stability and which has excellent durability even in an environment where humidification and drying, etc. are repeated.In the production of a membrane / electrode assembly 10, a first catalyst layer 22 (a second catalyst layer 34) is formed by a process comprising steps (a) and (b). (a) A step of applying a coating fluid comprising a catalyst and an ion-exchange resin, on a substrate to form a coating fluid layer. (b) A step of disposing a reinforcing layer 24 (34) on the coating fluid layer formed in the step (a) and then, drying the coating fluid layer to form a first catalyst layer 22 (a second catalyst layer 34).

Owner:ASAHI GLASS CO LTD

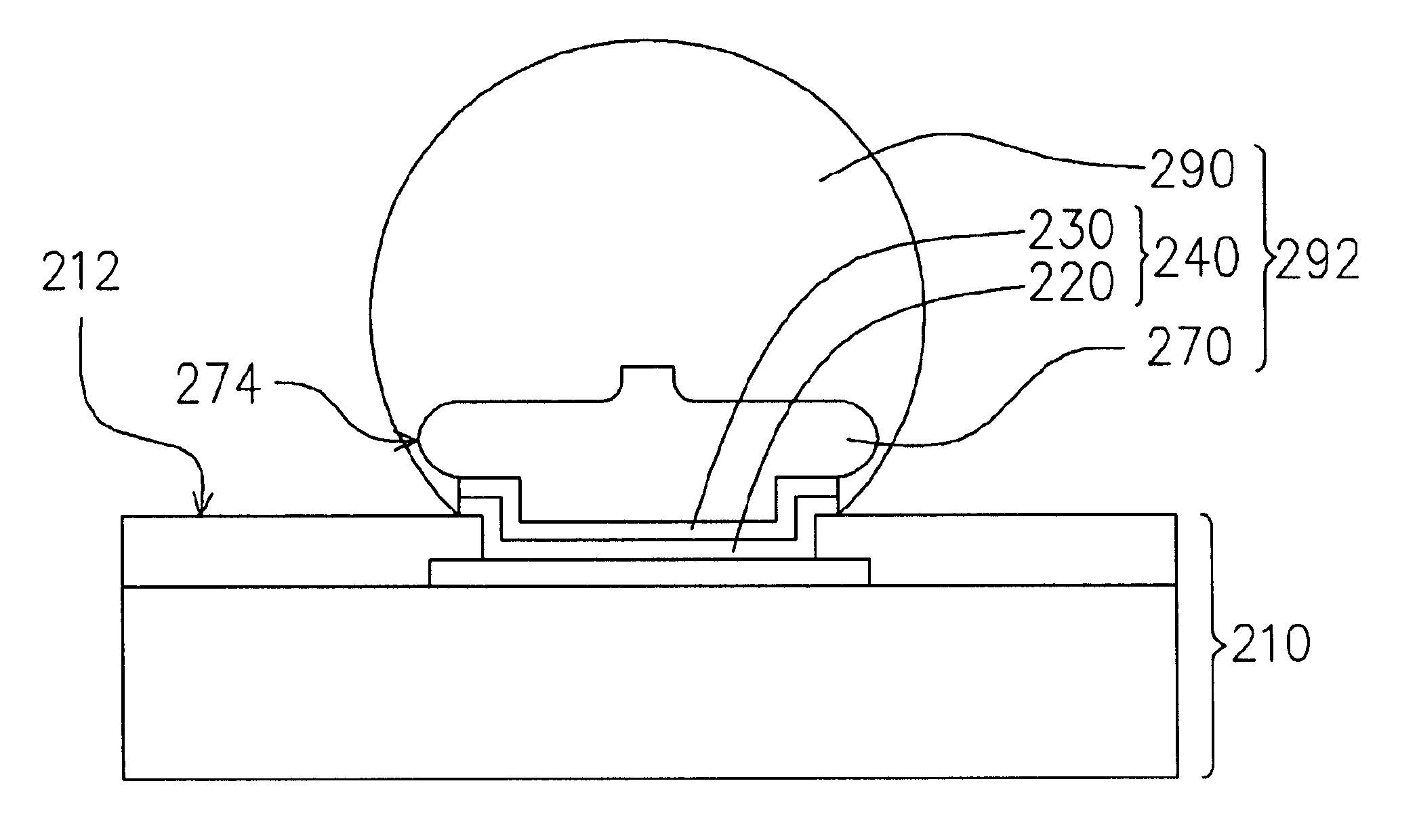

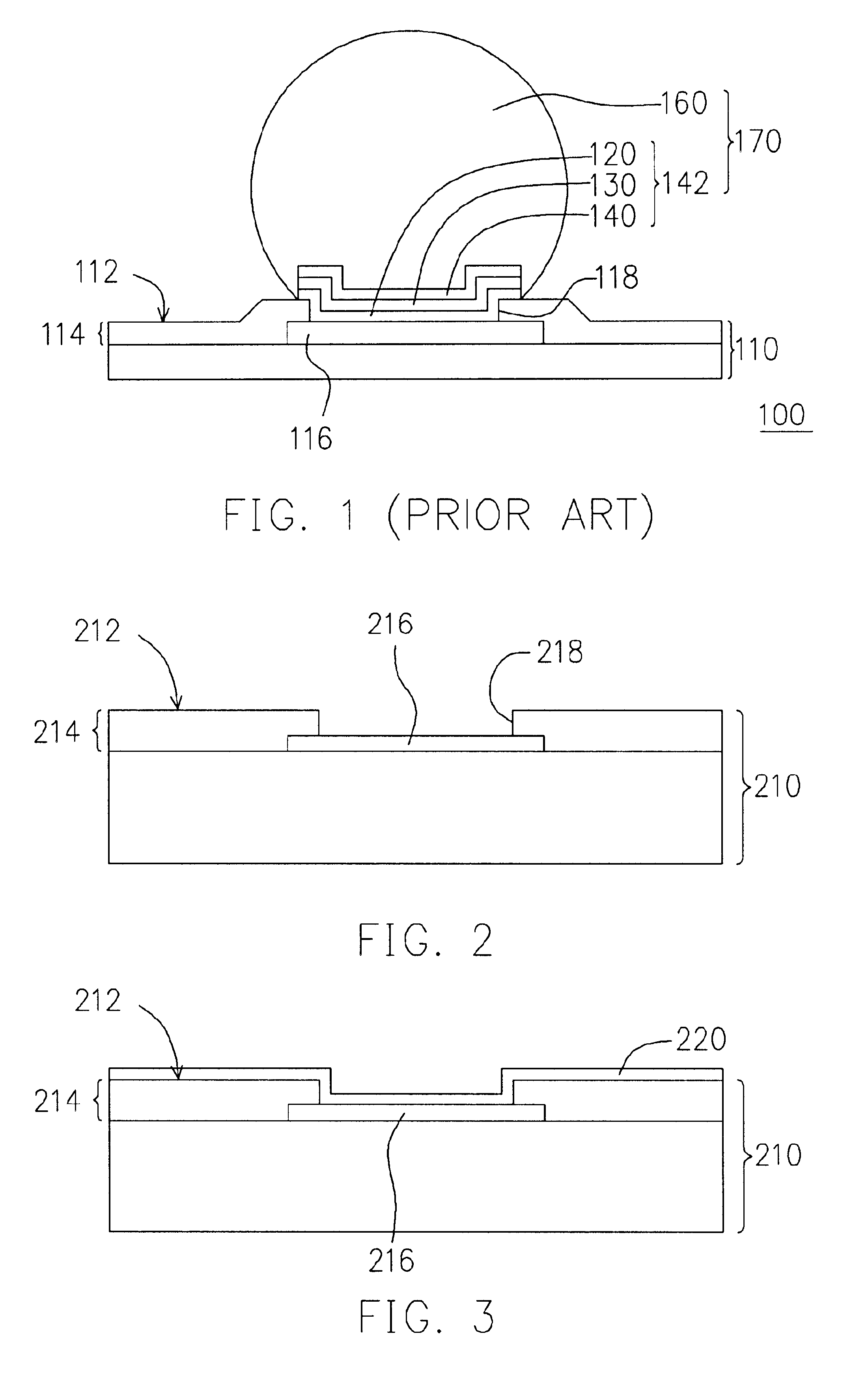

Bump and fabricating process thereof

ActiveUS6864168B2High mechanical strengthPrevent peelingSemiconductor/solid-state device detailsSolid-state devicesContact padBonding process

A bump structure on a contact pad and a fabricating process thereof. The bump comprises an under-ball-metallurgy layer, a bonding mass and a welding lump. The under-ball-metallurgy layer is formed over the contact pad and the bonding mass is formed over the under-ball-metallurgy layer by conducting a pressure bonding process. The bonding mass having a thickness between 4 to 10 μm is made from a material such as copper. The welding lump is formed over the bonding mass such that a sidewall of the bonding mass is also enclosed.

Owner:ADVANCED SEMICON ENG INC

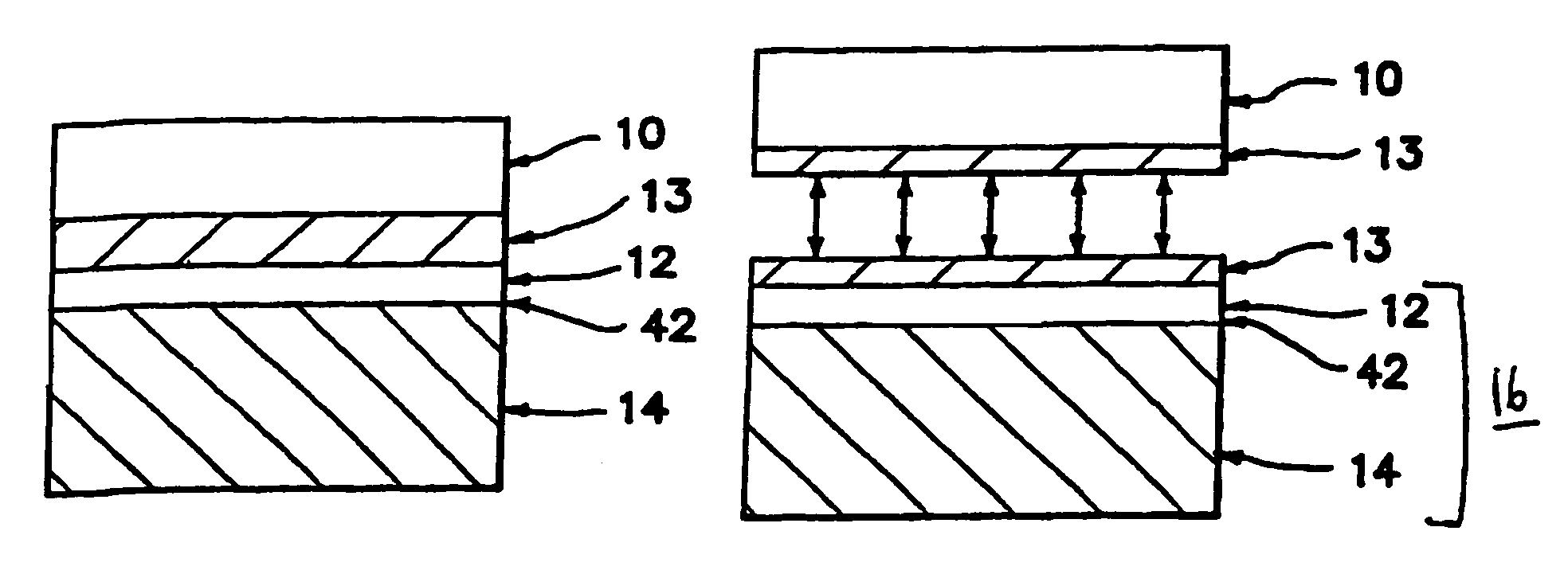

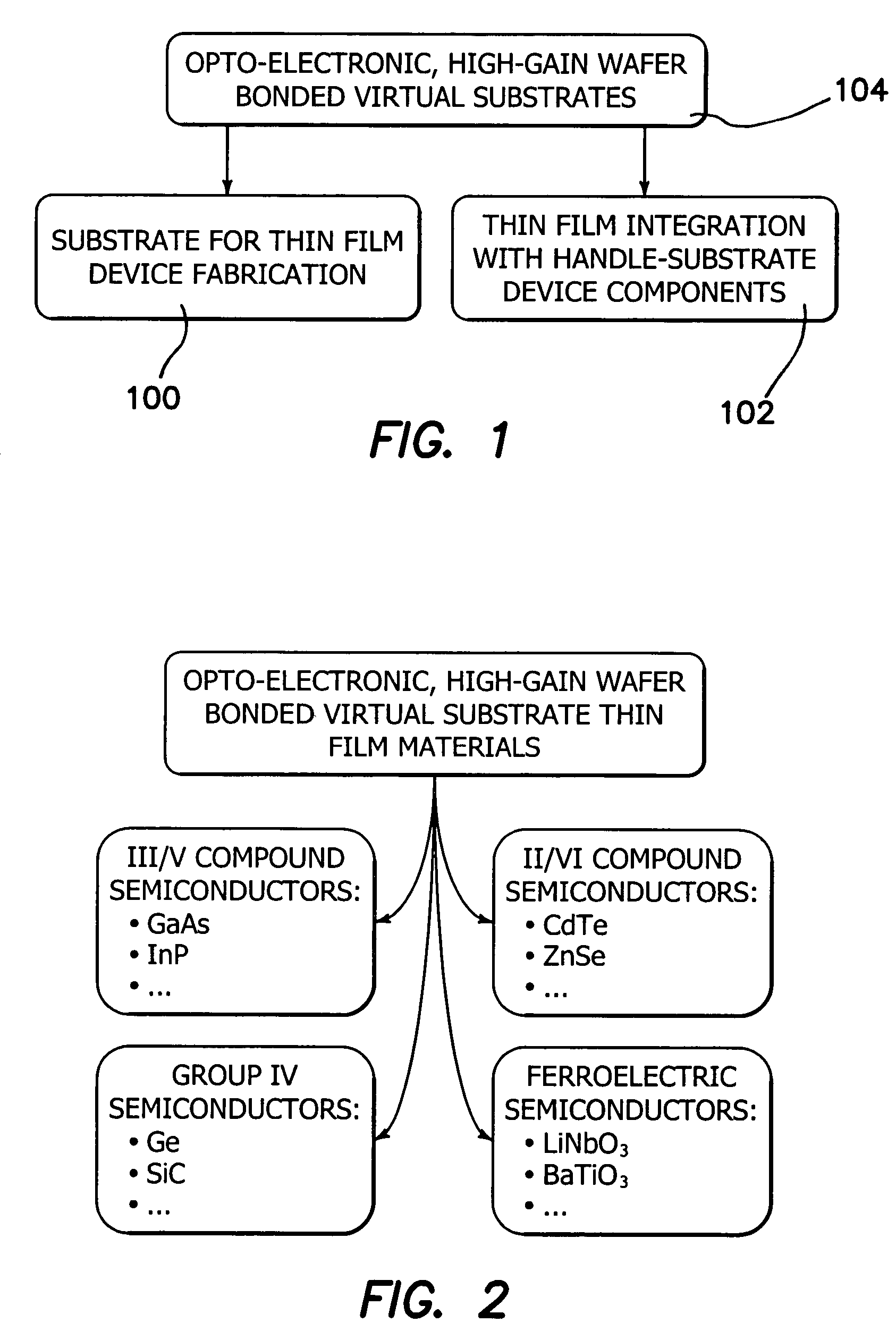

Wafer bonded virtual substrate and method for forming the same

InactiveUS7238622B2Improving and increasing mechanical strength of bondBonding strengthSemiconductor/solid-state device manufacturingPhotovoltaic energy generationEngineeringSingle crystal

A method of forming a virtual substrate comprised of an optoelectronic device substrate and handle substrate comprises the steps of initiating bonding of the device substrate to the handle substrate, improving or increasing the mechanical strength of the device and handle substrates, and thinning the device substrate to leave a single-crystal film on the virtual substrate such as by exfoliation of a device film from the device substrate. The handle substrate is typically Si or other inexpensive common substrate material, while the optoelectronic device substrate is formed of more expensive and specialized electro-optic material. Using the methodology of the invention a wide variety of thin film electro-optic materials of high quality can be bonded to inexpensive substrates which serve as the mechanical support for an optoelectronic device layer fabricated in the thin film electro-optic material.

Owner:CALIFORNIA INST OF TECH

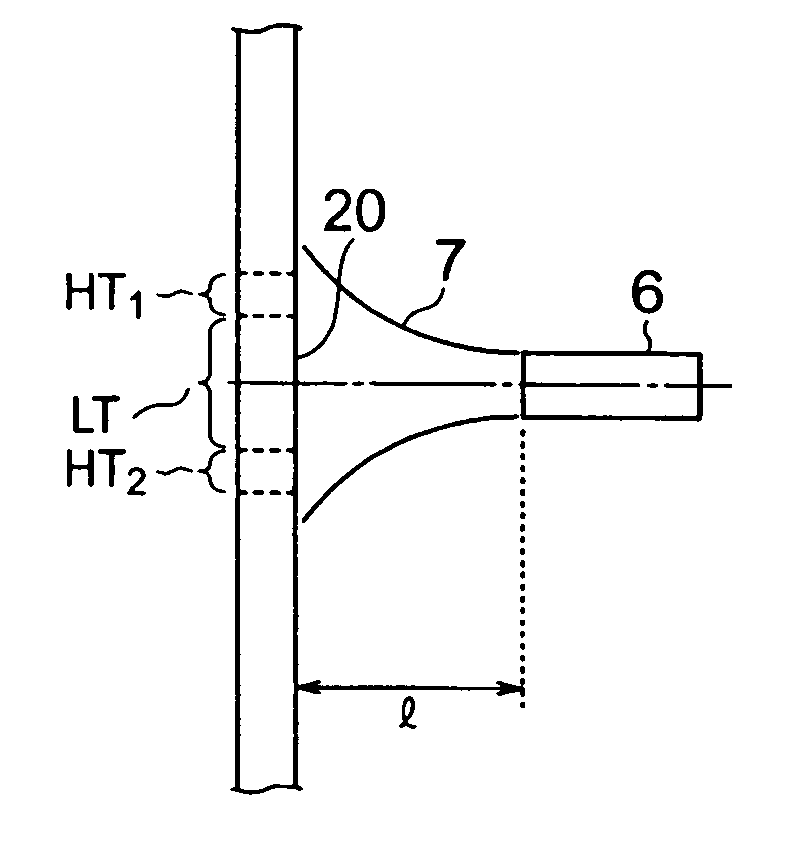

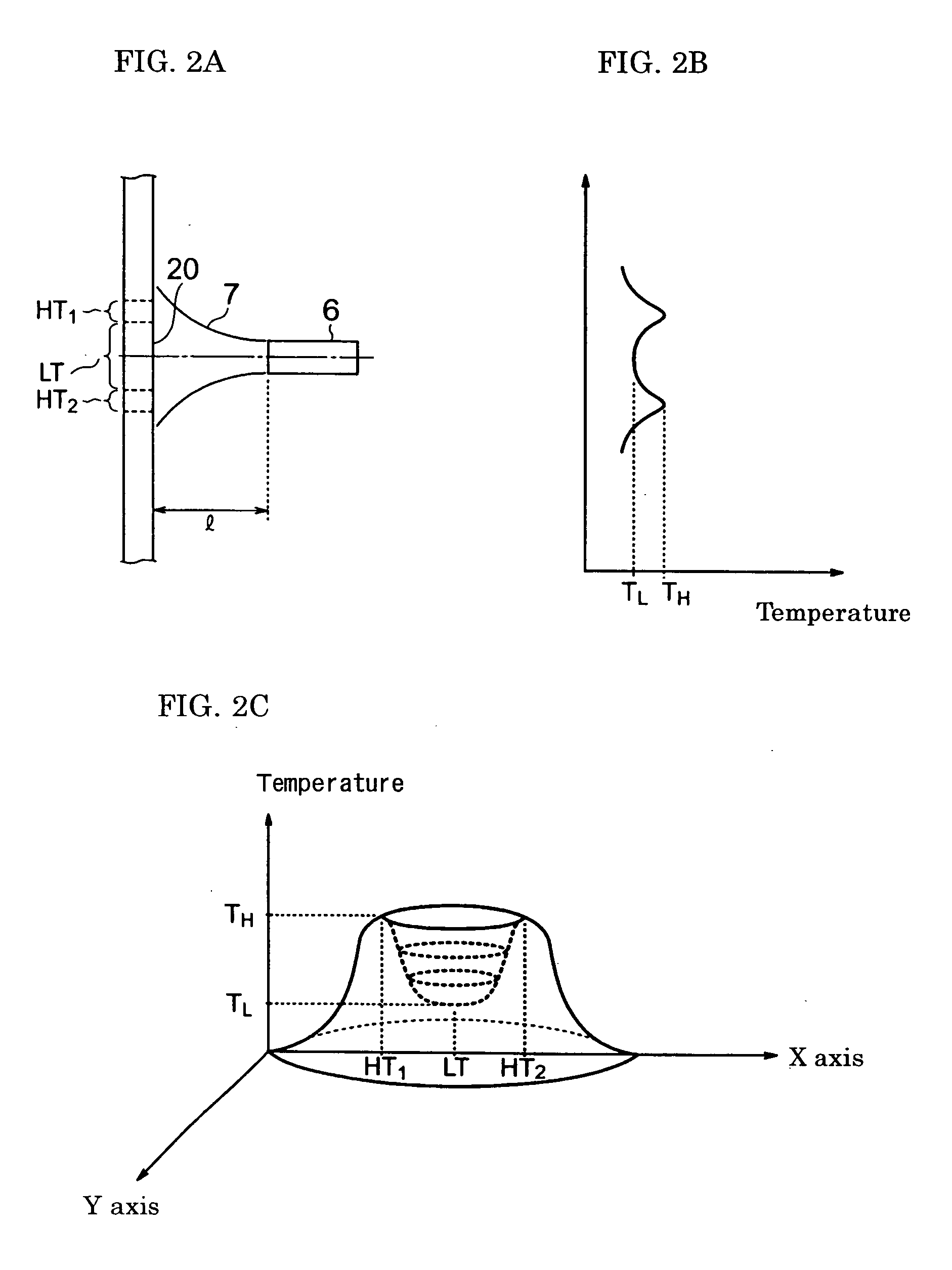

Method of producing porous glass-particle-deposited body and burner for synthesizing glass particles

InactiveUS20040182114A1Efficiency of the deposition of the glass particles on the surface of the starting member isImprove efficiencyGlass shaping apparatusGlass deposition burnersCombustorGlass particle

A method of producing a porous glass-particle-deposited body by effectively depositing the glass particles synthesized by a burner for synthesizing glass particles on a starting member with increased bonding strength between the deposited glass particles and decreased possibility of developing cracks and other problems, and a burner to be used for the production method. In the method of producing the deposited body by depositing the glass particles synthesized by a burner on the surface of the starting member, the glass particle deposition surface has (a) a region that is hit by the center portion of the flame issuing from the burner and (b) another region that has a temperature higher than that of the region hit by the center portion of the flame and that is located at the outside of the region hit by the center portion of the flame.

Owner:SUMITOMO ELECTRIC IND LTD

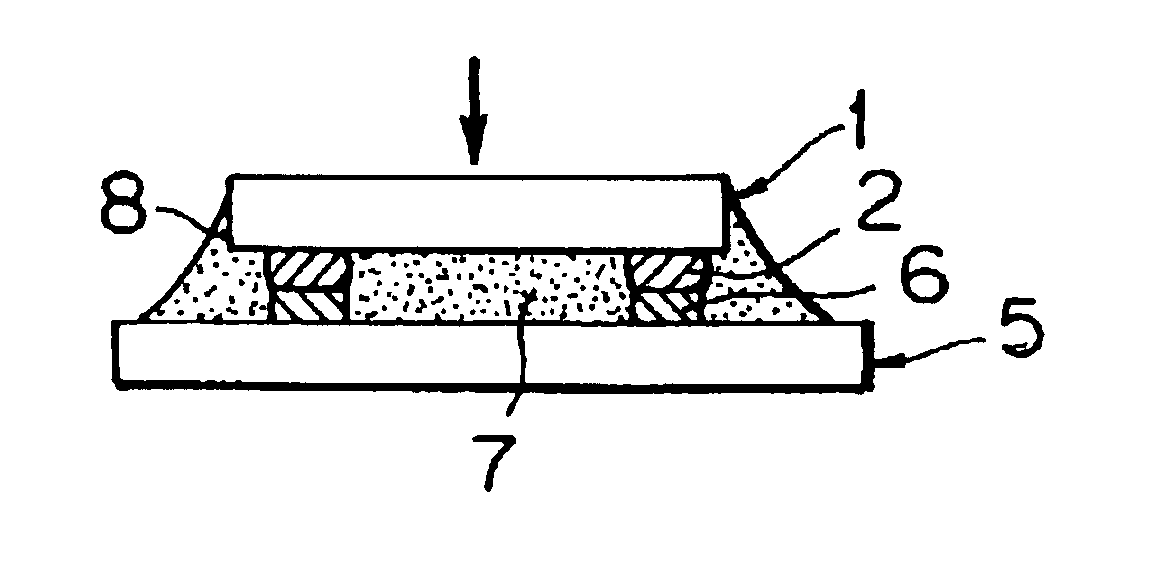

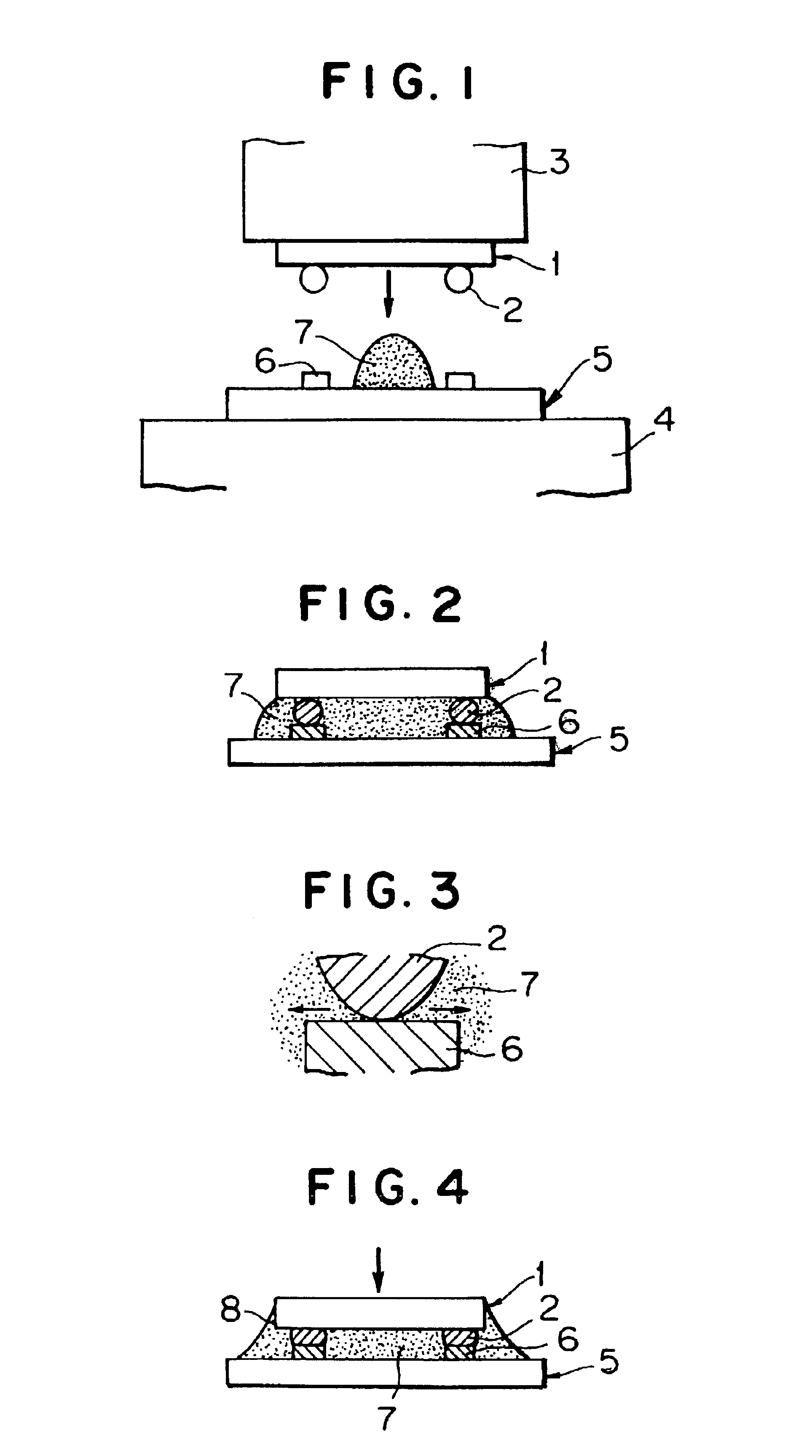

Chip mounting method

InactiveUS6796481B2Bonding strengthImprove insulation performancePrinted circuit assemblingSolid-state devicesEngineeringElectrical and Electronics engineering

A method for mounting a chip on a substrate includes applying the underfill agent onto at least one of the substrate and the chip and moving the chip to the substrate to bring the bump into contact with the electrode. The method also includes steps to distribute the underfill agent in a space between the chip and the substrate, to around the bump and the electrode, heating the bump or electrode in the state that the bump is buried in the underfill agent to melt the bump or electrode so as to weld the bump to the electrode.

Owner:TORAY ENG CO LTD

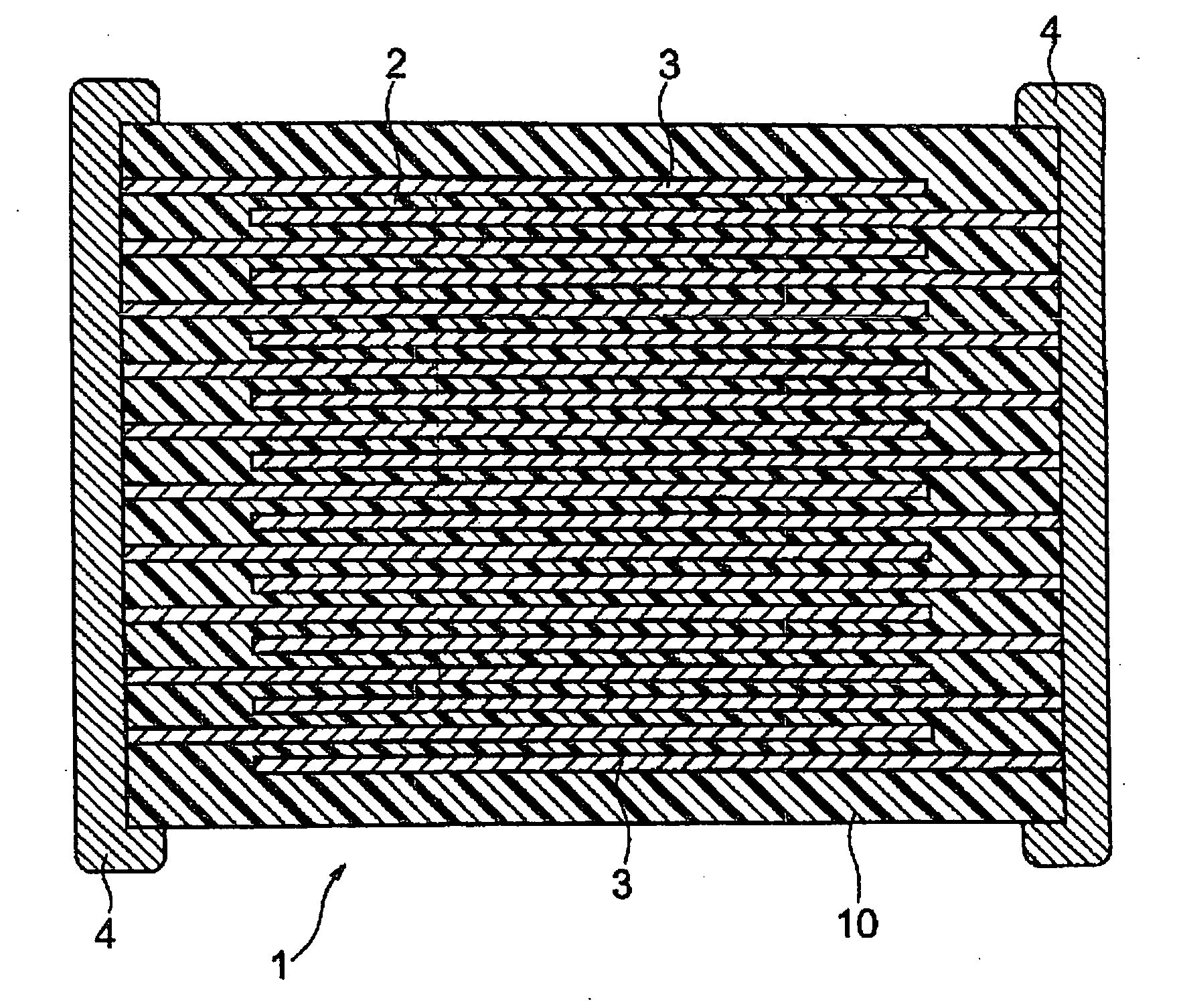

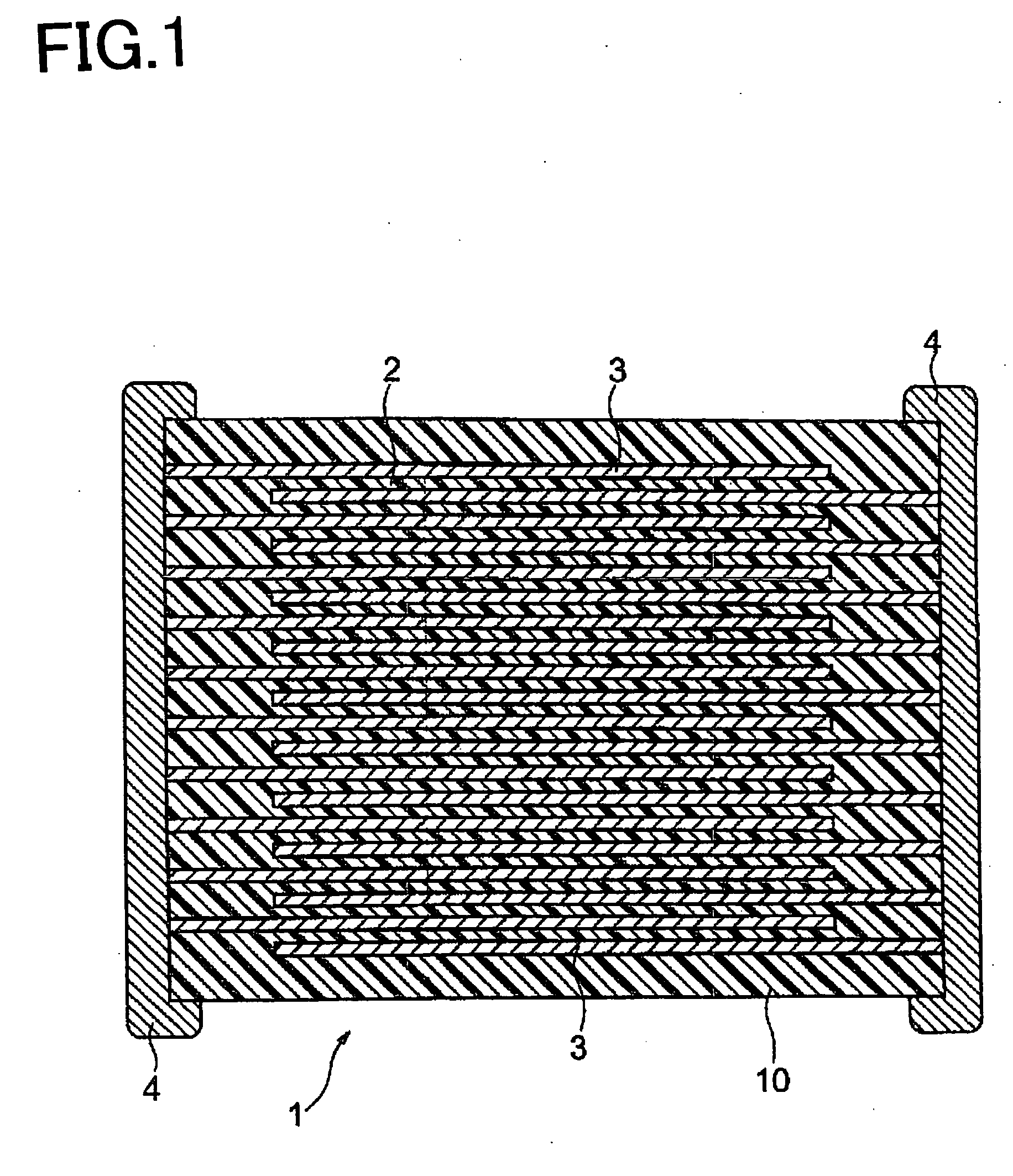

Production method of multilayer ceramic electronic device

InactiveUS20070074806A1Prevent spheroidizationAvoid crackingFixed capacitor dielectricStacked capacitorsCapacitanceMetallurgy

By a production method for producing a multilayer ceramic electronic device including dielectric layers and internal electrode layers comprising the steps of forming a green sheet to be said dielectric layer after firing, forming a pre-fired electrode layer to be said internal electrode layer after firing in a predetermined pattern on said green sheet by using a conductive material paste, forming a green chip by successively stacking said green sheets and said pre-fired electrode layers, and firing said green chip: wherein the conductive material paste for forming said pre-fired electrode layer is composed at least of conductive material particles, a first common material composed of ceramic powder and a second common material composed of ceramic powder having a larger average particle diameter than that of said first common material; an average particle diameter of said first common material is 1 / 20 to ½ of an average particle diameter of said conductive material particles; and the average particle diameter of said second common material is 1 / 10 to ½ of an average thickness of said internal electrode layers after firing; a multilayer ceramic electronic device, such as a multilayer ceramic capacitor, wherein arising of cracks is effectively prevented, having a low short-circuit defect rate, a low voltage resistance defect rate and high capacitance is produced.

Owner:TDK CORPARATION

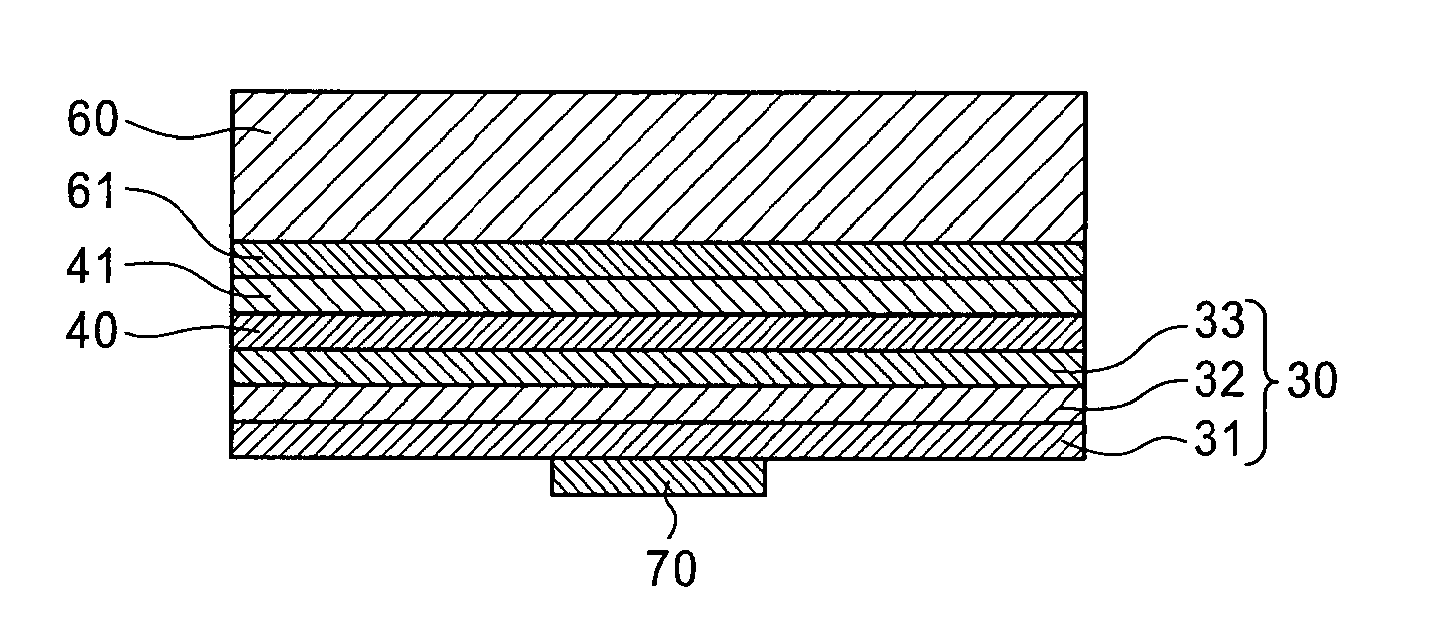

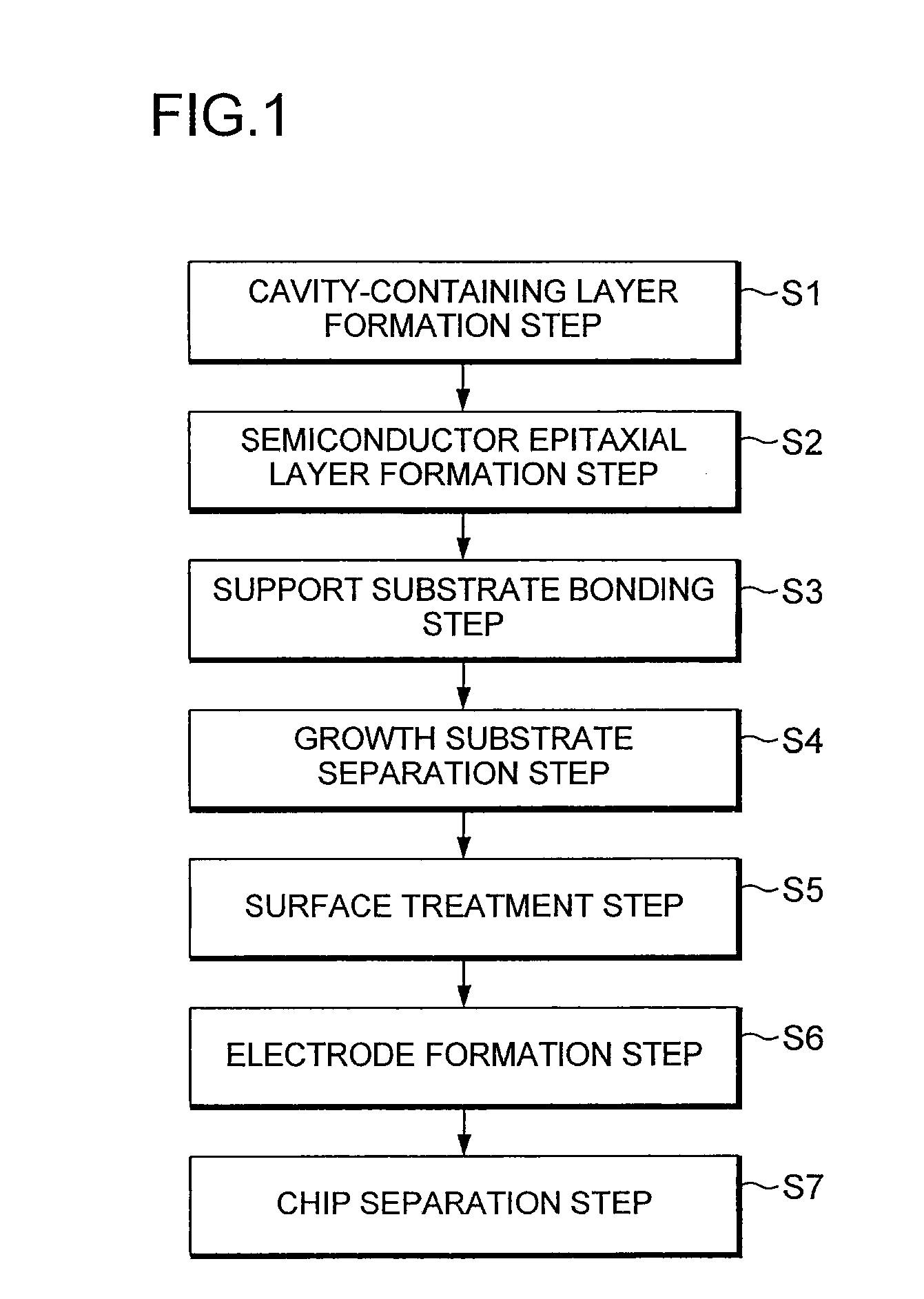

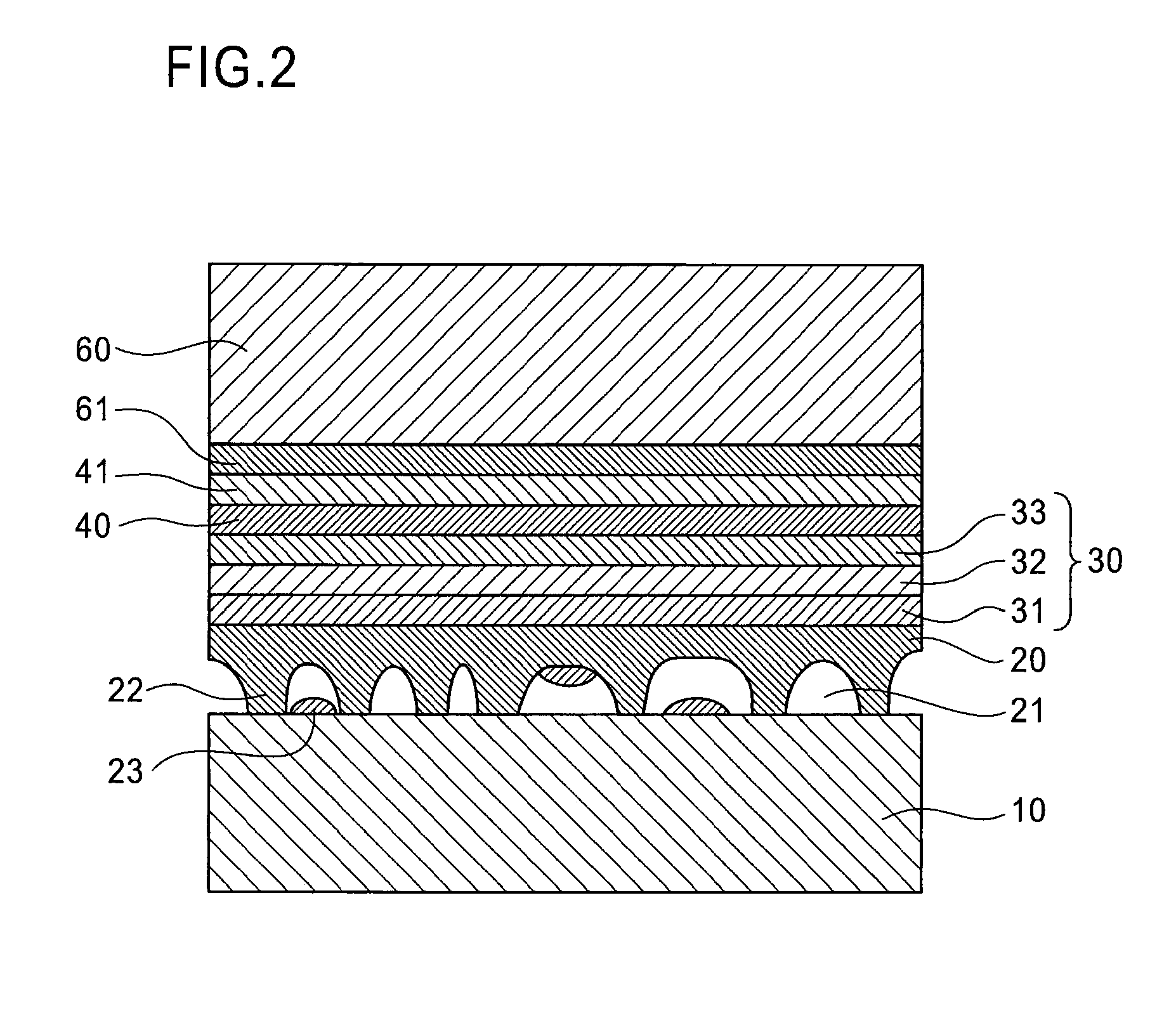

Semiconductor device and method for manufacturing semiconductor device

ActiveUS20100155740A1Bonding strengthLow costSemiconductor/solid-state device manufacturingSemiconductor devicesNitrideSemiconductor

A cavity-containing layer having a plurality of cavities is formed on a growth substrate by carrying out in alternating fashion a plurality of cycles of a first and second growth steps of growing a group III nitride at growth rates different from each other. The semiconductor epitaxial layer is subsequently formed on the cavity-containing layer, after which a support substrate is bonded to the semiconductor epitaxial layer. The growth substrate is separated from the cavity-containing layer.

Owner:STANLEY ELECTRIC CO LTD

Light-emitting diode package

InactiveUS20110101405A1Improve cooling effectImprove reliabilitySolid-state devicesSemiconductor devicesLight-emitting diodeElectrically conductive

A light-emitting diode package is provided. The light-emitting diode package comprises a substrate and a first metal layer disposed over the substrate. A solder layer is disposed on the first metal layer and a light-emitting diode chip is disposed on the solder layer, wherein the light-emitting diode chip comprises a conductive substrate and a multilayered epitaxial structure formed on the conductive substrate, and wherein the conductive substrate is adjacent to the solder layer.

Owner:SEMILEDS OPTOELECTRONICS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com