Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1582 results about "Polyurethane dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

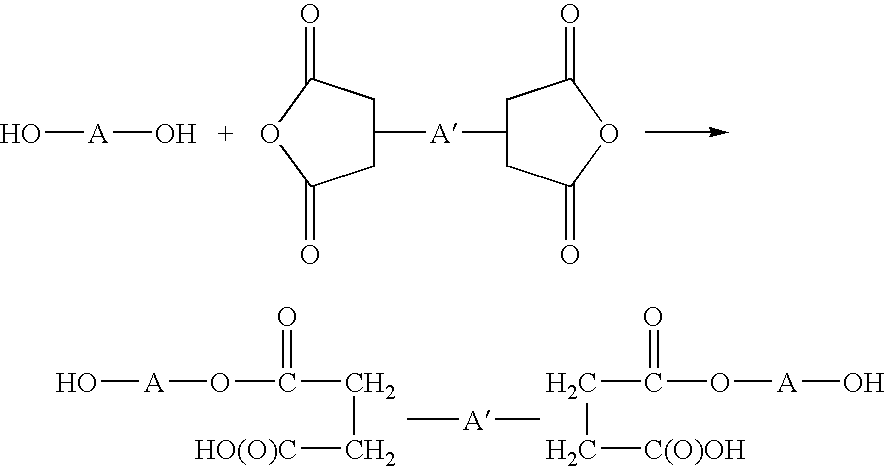

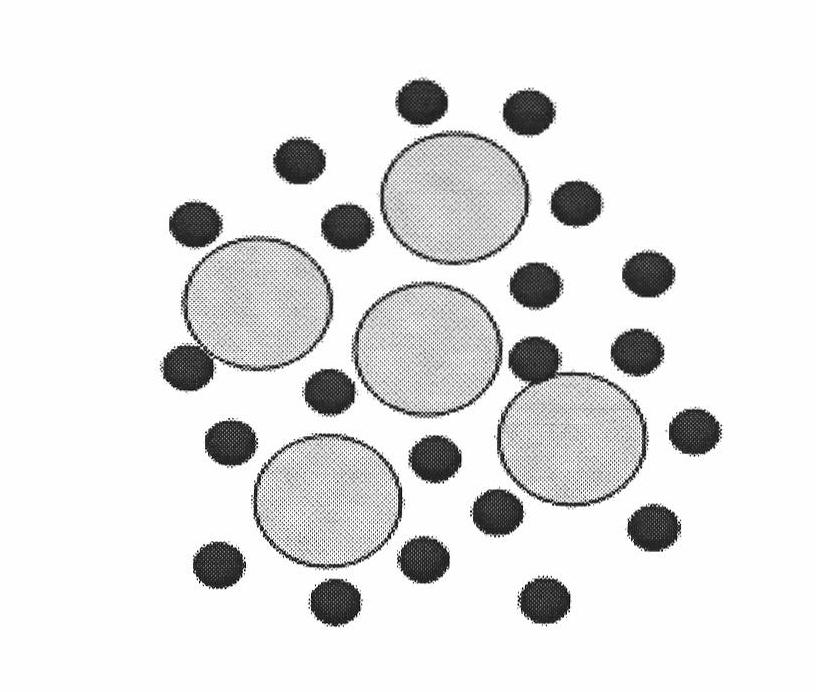

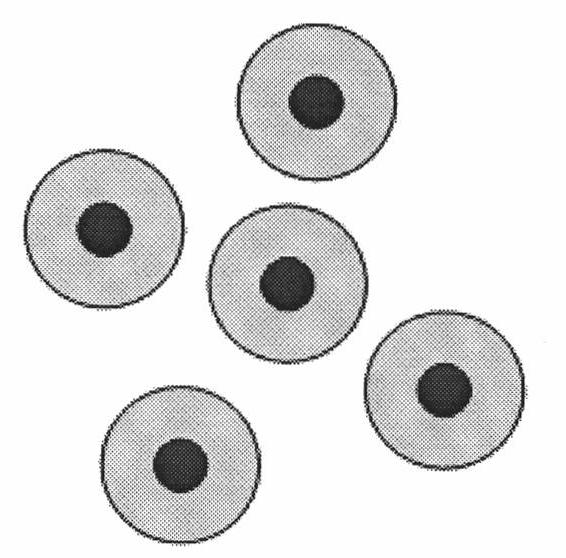

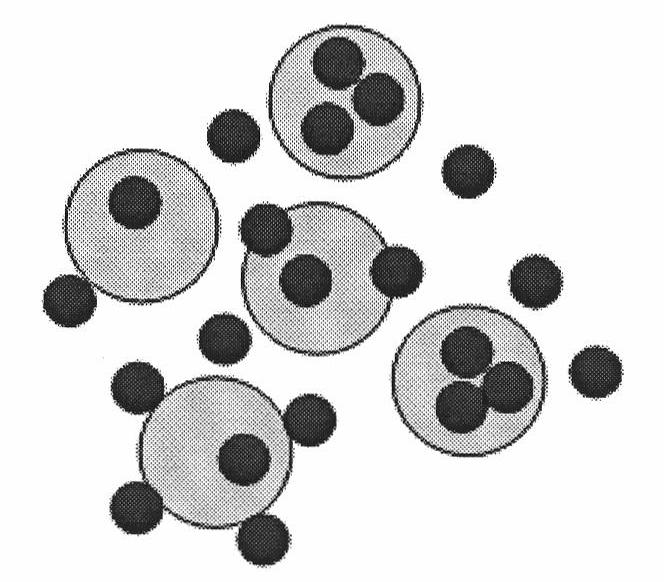

Polyurethane Dispersion, or PUD, is understood to be a polyurethane polymer resin dispersed in water, rather than a solvent. Its manufacture involves the synthesis of polyurethanes having carboxylic acid functionality or nonionic hydrophiles like PEG incorporated into, or pendant from, the polymer backbone.

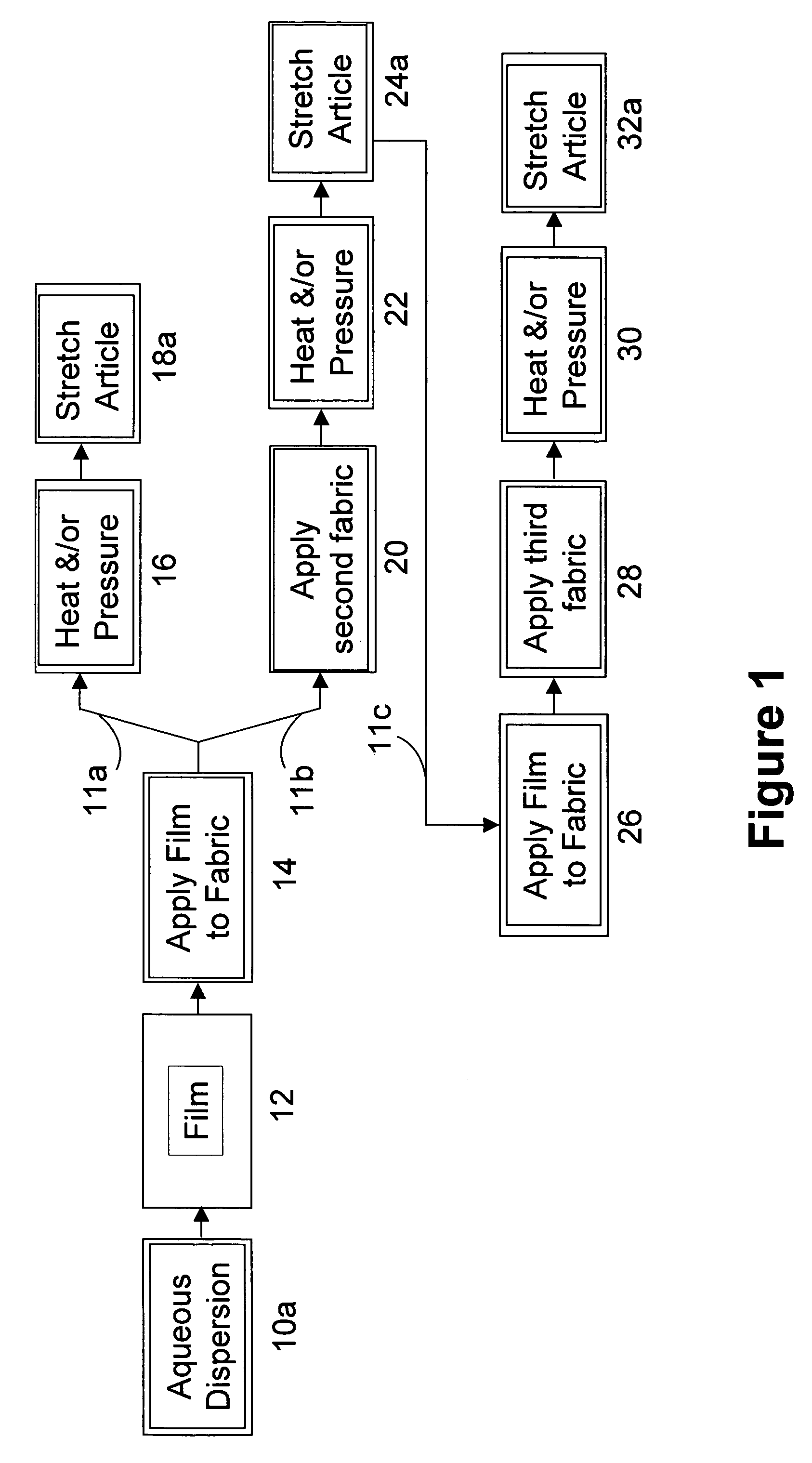

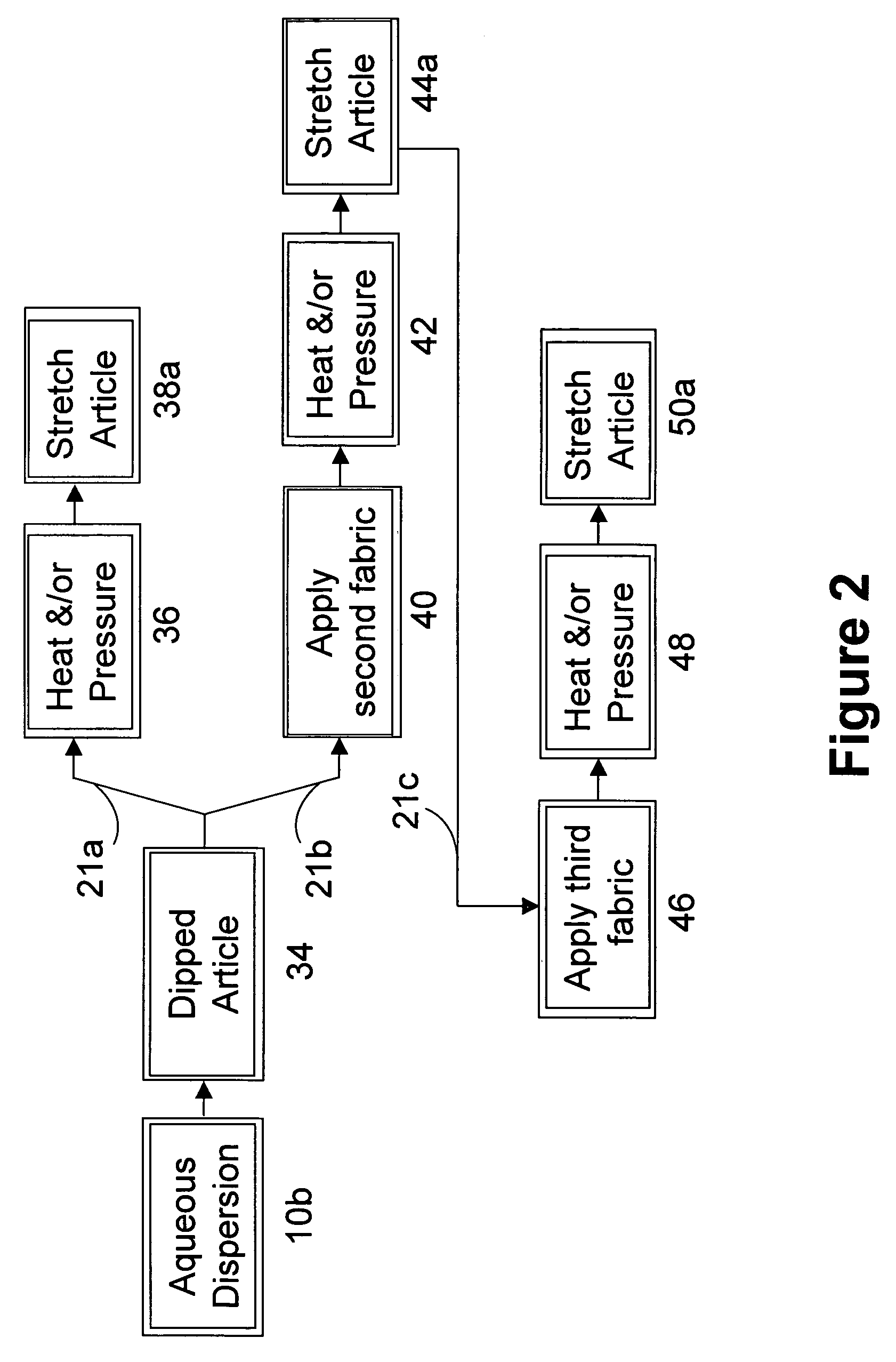

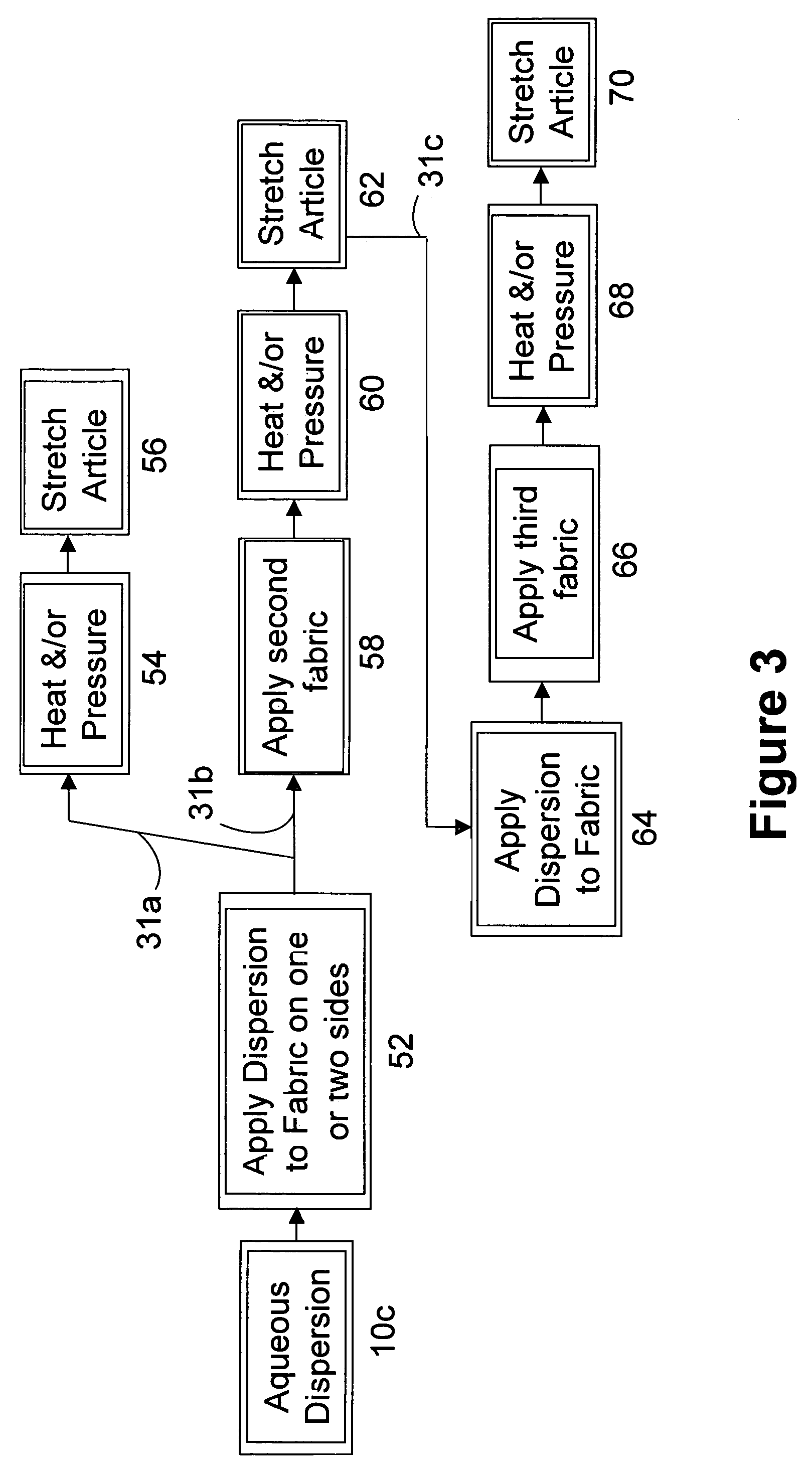

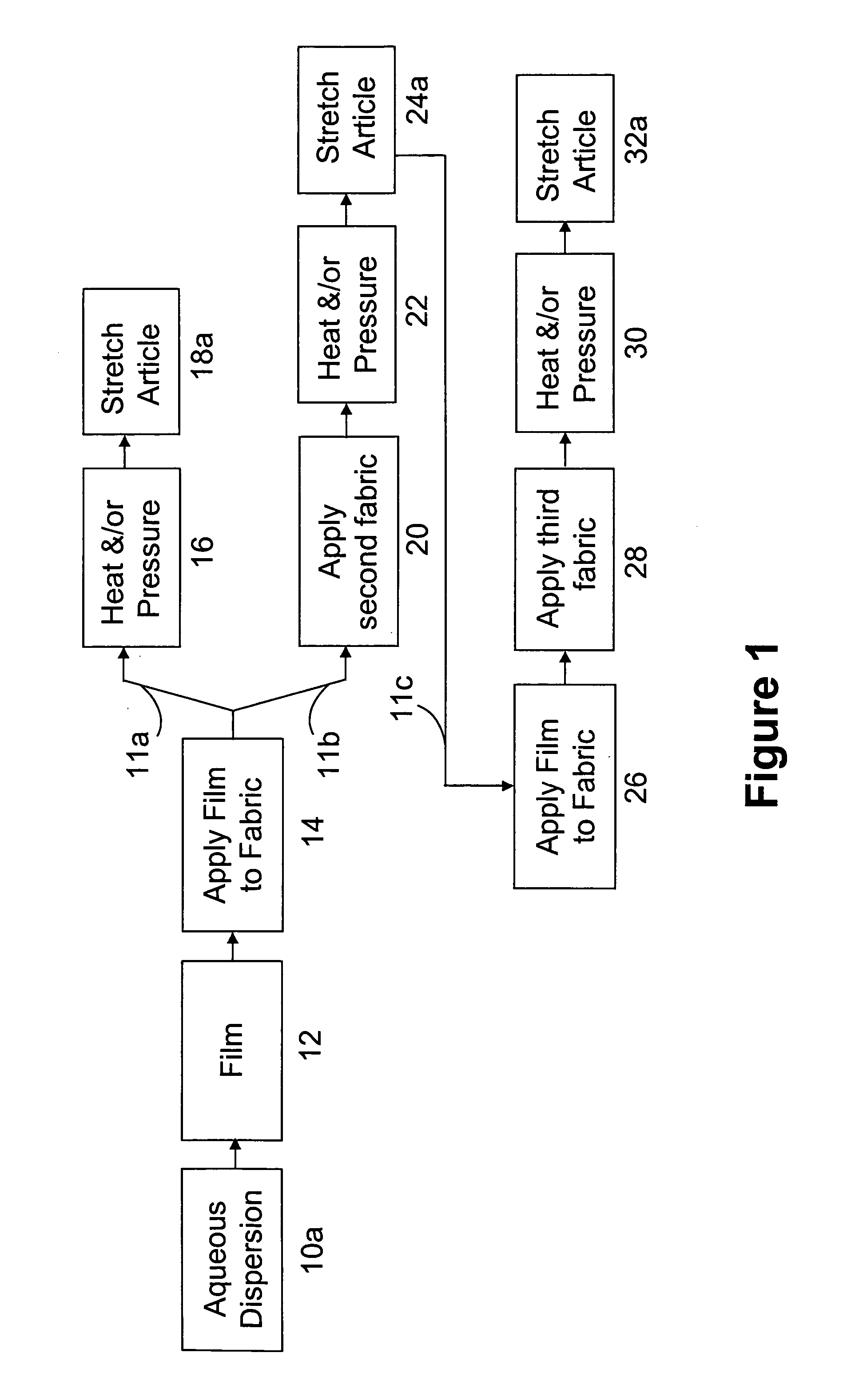

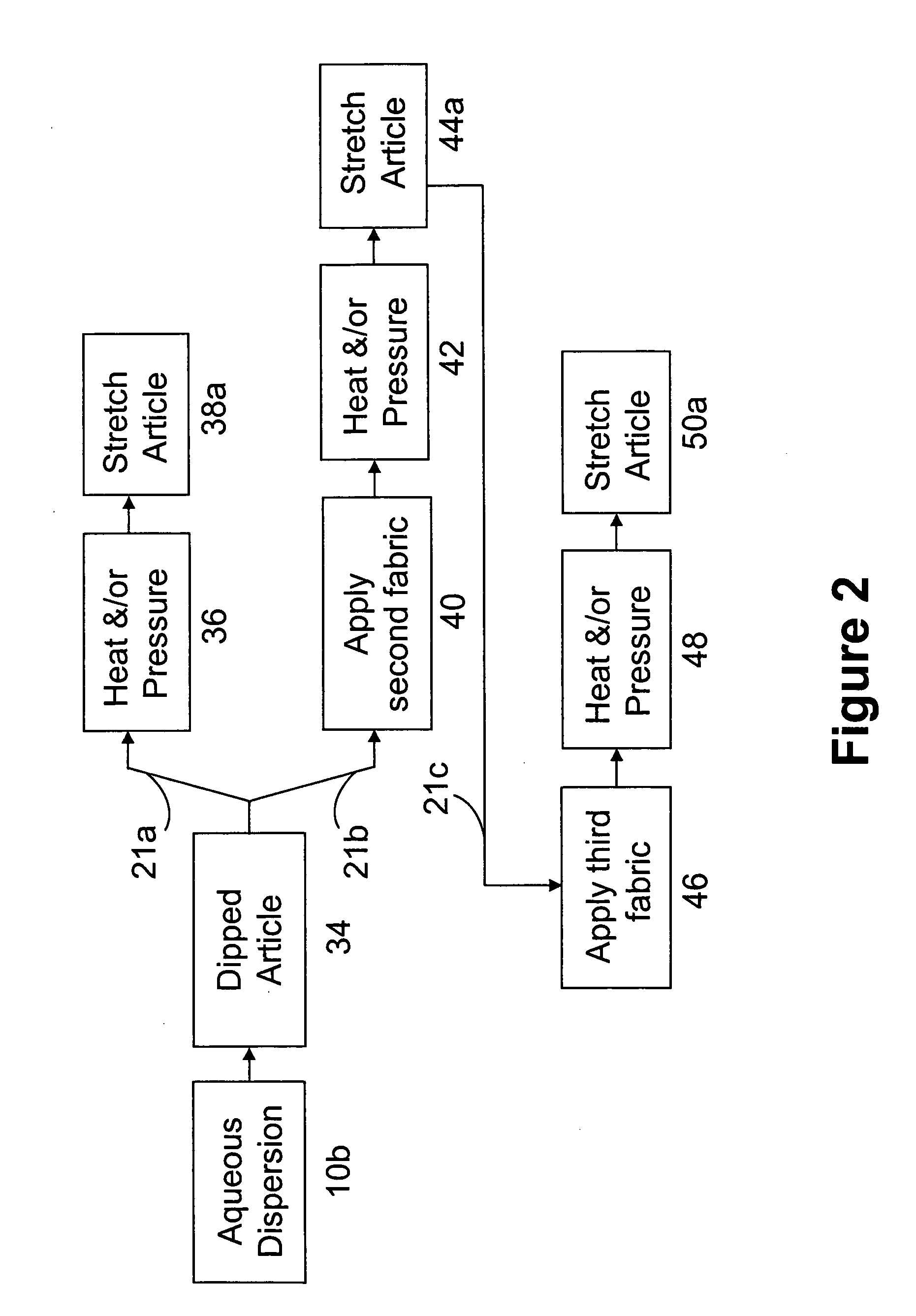

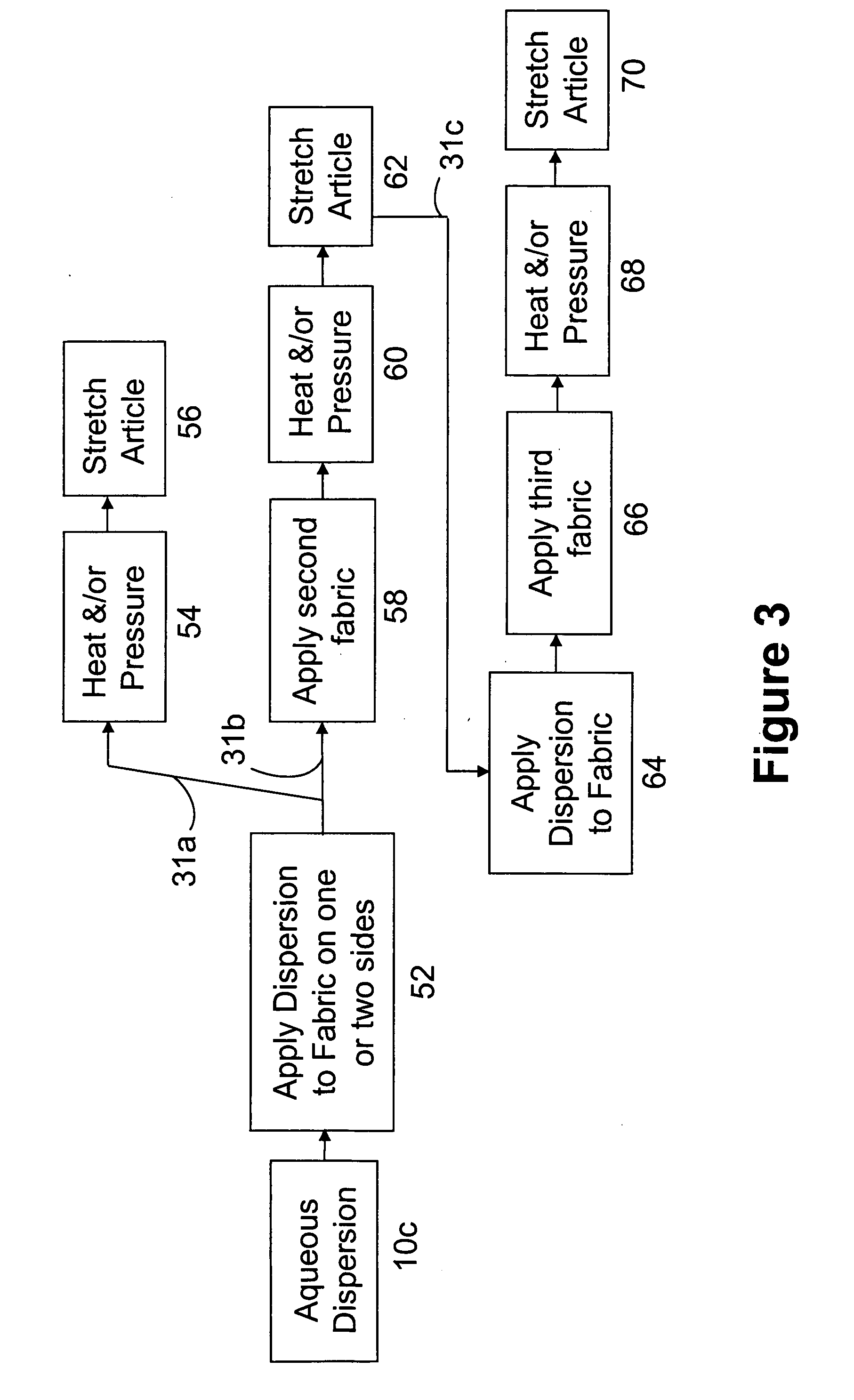

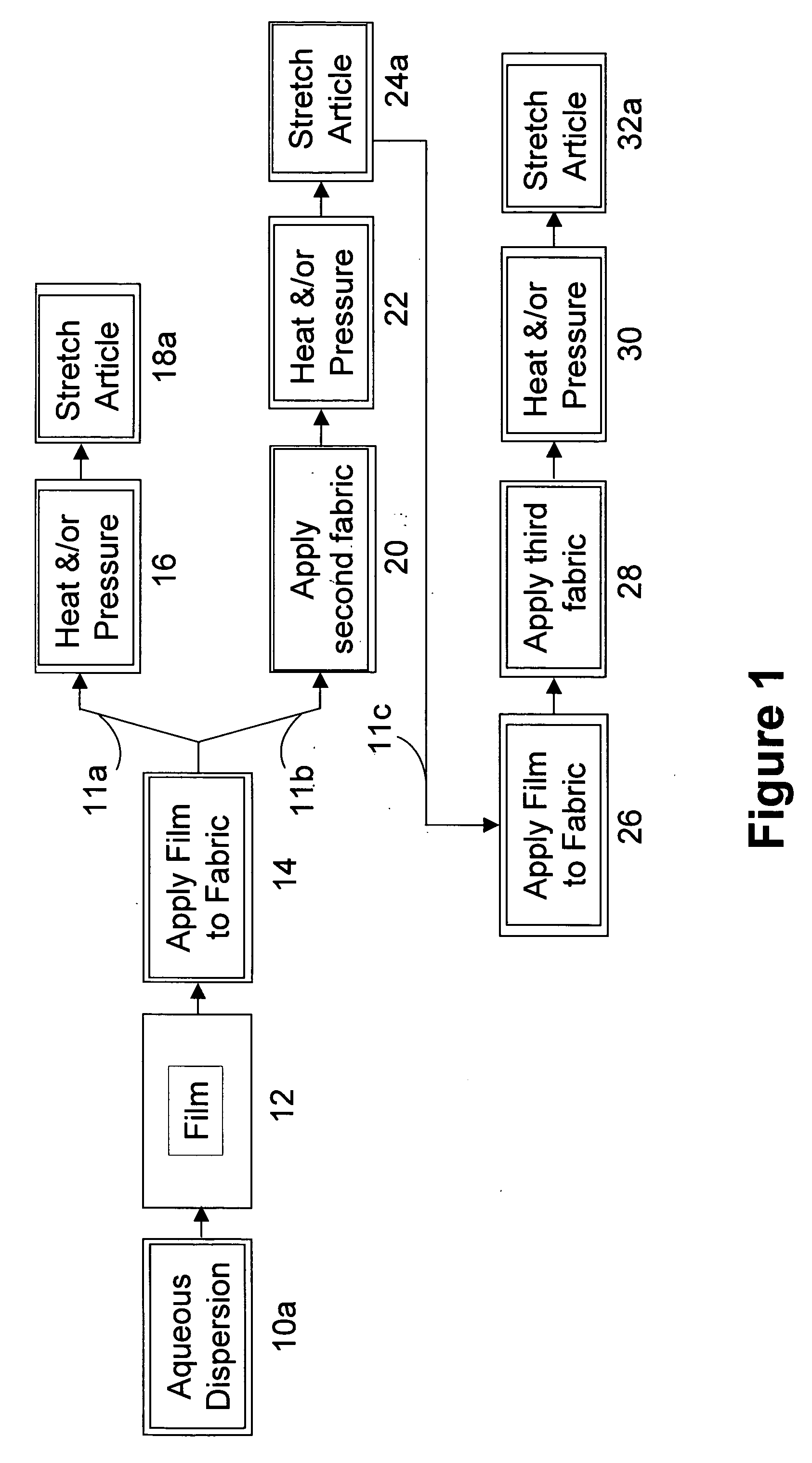

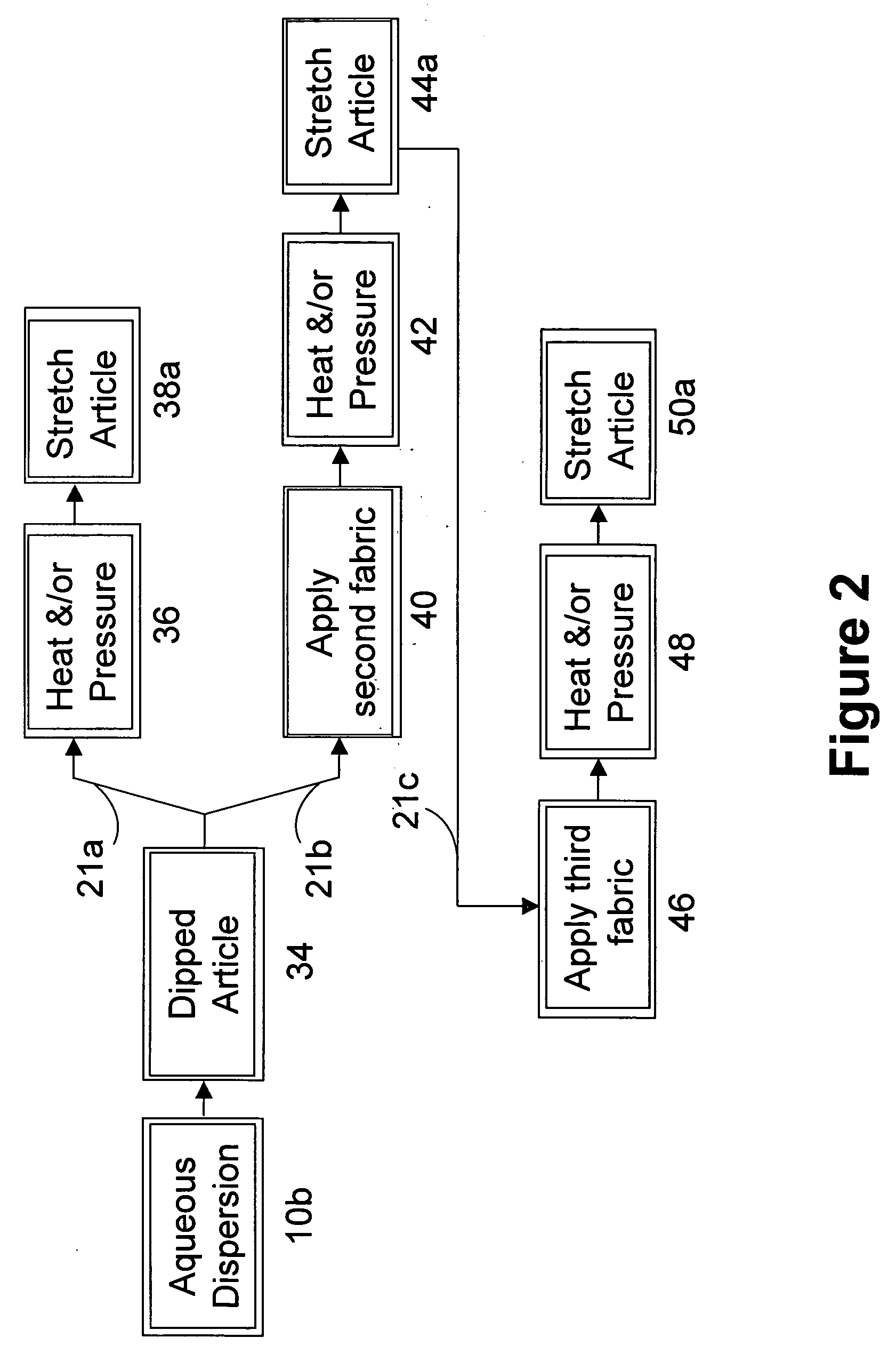

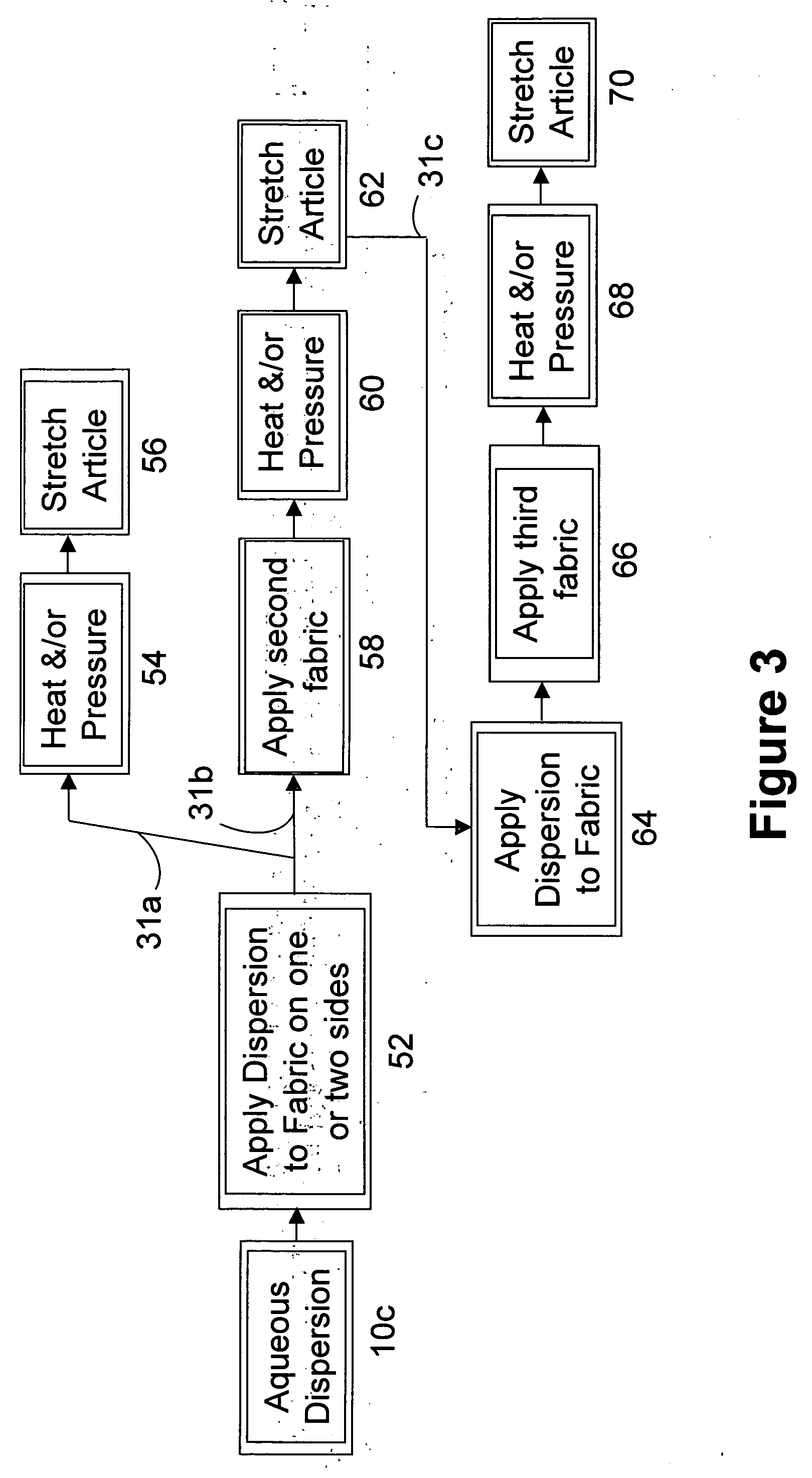

Solvent free aqueous polyurethane dispersions and adhesive films therefrom for stretch fabrics

Novel aqueous polyurethane dispersions and adhesive films formed therefrom are provided. The aqueous polyurethane dispersions are provided in solvent-free systems of a prepolymer comprising at least one polyether or polyester polyol, a mixture of MDI isomers, and a diol. The adhesive films from such dispersions can be heat-activated for bonding, lamination, and adhesion of textile fabrics, including stretch fabrics.

Owner:THE LYCRA CO LLC

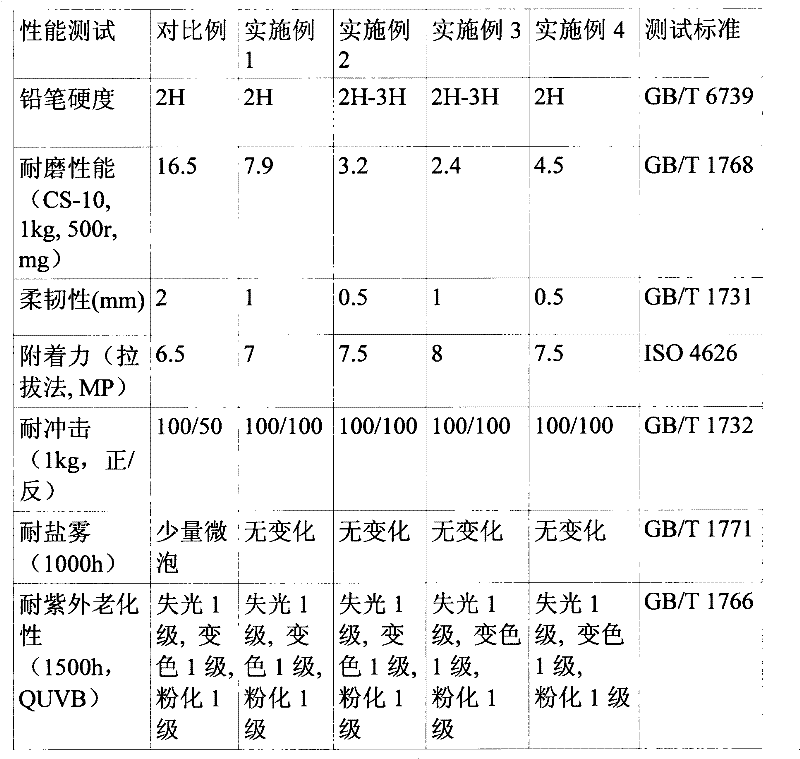

Preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents

InactiveCN101696262ASimple processEasy to operatePolyurea/polyurethane coatingsLeather surface finishingPolyesterSolvent

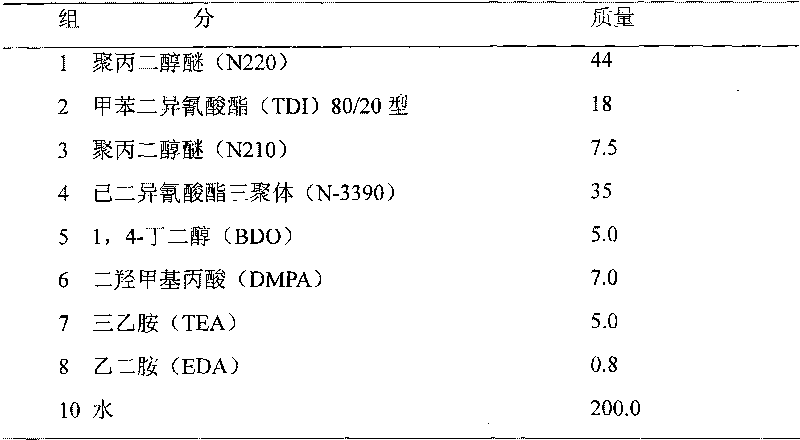

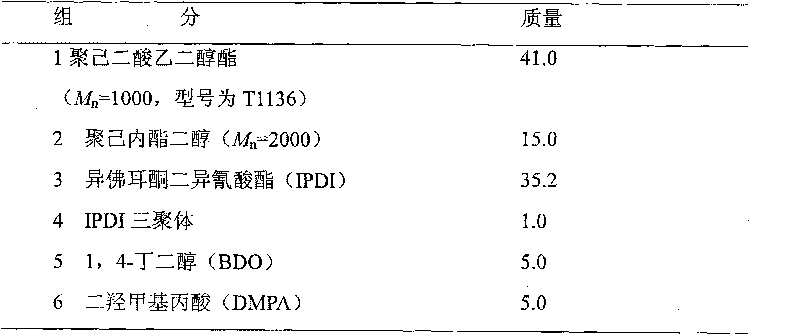

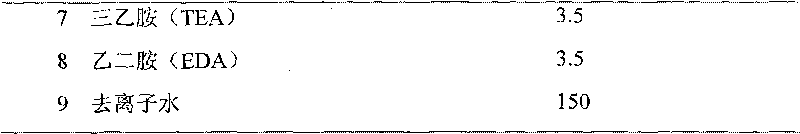

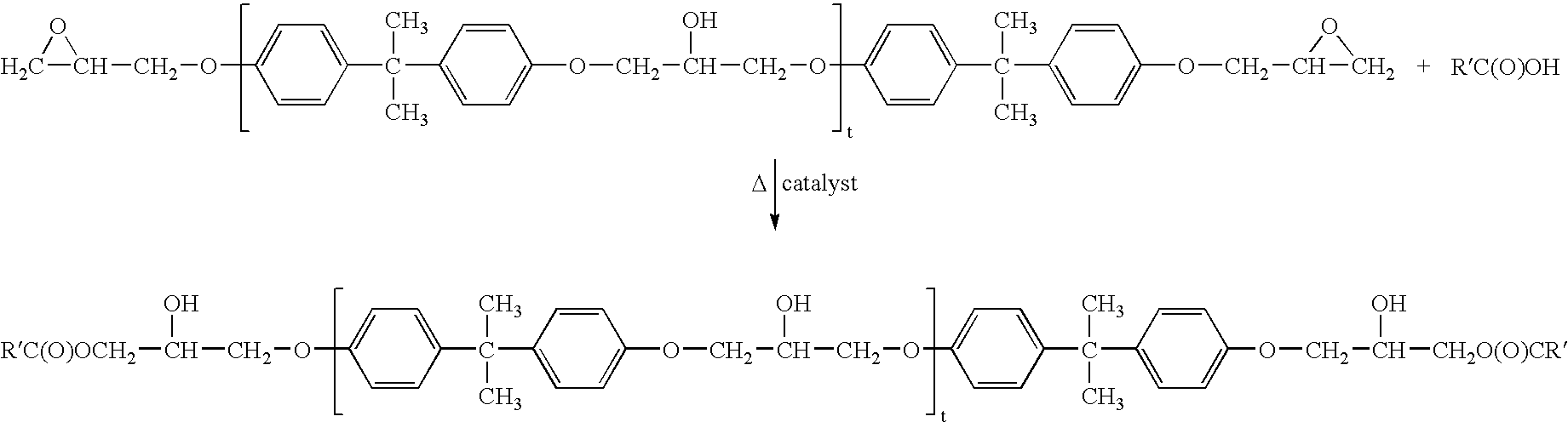

The invention discloses a preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents. The preparation method comprises the following steps of: carrying out prepolymerization reaction by using polyester polyol, vulcabond monomer and a polyisocyanate curing agent; reacting with a hydrophilic chain-extending agent and a micro-molecule chain-extending agent to obtain polyurethane prepolymer containing hydrophilic groups (carboxyl or sulfonic groups) and isocyanate(NCO)-terminated groups; neutralizing the polymer into salt, and then dispersing the salt into water; and preparing the modified polyurethane aqueous dispersions of the polyisocyanate curing agents by the chain extending of a polyamine chain-extending agent. The modified polyurethane aqueous dispersions of the polyisocyanate curing agents have self-crosslinking function at room temperature, and the self-crosslinking density is over 85%. Compared with non-modified polyurethane aqueous dispersions prepared under the same condition, the modified polyurethane aqueous dispersions have superior film forming property, water resistance, alcohol resistance, pollution resistance, cold resistance, dry / wet rubbing resistance and chemical solvent resistance; and coating films have especially high drying speed, high hardness increment speed and high final hardness.

Owner:SOUTH CHINA UNIV OF TECH

Aqueous polysiloxane-polyurethane dispersion, its preparation and use in coating compositions

InactiveUS6794445B2Feel goodImprove adhesionFibre treatmentThin material handlingPolyurethane dispersionAqueous dispersion

The invention relates to aqueous dispersions of polysiloxane-polyurethanes based on selected, substantially difunctional starting materials, to their preparation and use for preparing coating compositions, and to a coating composition comprising as substantial binder component polysiloxane-polyurethanes of the kind mentioned. The coating compositions of the invention are especially suitable for use as soft feel coatings.

Owner:EVONIK DEGUSSA GMBH

Coating compositions for glass substrates

InactiveUS20110045219A1Synthetic resin layered productsPolyurea/polyurethane coatingsPolyurethane dispersionPolyol

The present invention relates to an aqueous polyurethane coating composition comprising:1) 1 to 99 wt. % of the reaction product of:a) a polyol component, which is soluble or dispersible in water and is the reaction product of a polyisocyanate component containing 50 to 100 wt. % of an aliphatic diisocyanate, a polyol component containing one or more polyether polyols and having an OH number of 25 to 350 mg KOH / g solids and an isocyanate-reactive component containing at least one group capable of salt formation; andb) polyisocyanate component, which is soluble or dispersible in water, has blocked isocyanate groups and is the reaction product of one or more polyisocyanates having an isocyanurate group content of 2 to 30 wt. %, a reversible, monofunctional blocking agent for isocyanate groups, a nonionic hydrophilic component and a stabilizing component which has 1 to 2 hydrazide groups and a molecular weight of 70 to 300; and2) 1 to 99 wt. % of an aqueous polyurethane dispersion prepared from at least one polycarbonate polyol,wherein the total wt. % of components 1) and 2) add up to 100%.

Owner:COVESTRO LLC

Water-borne dispersions of oil modified urethane polymers

A composition comprising a self-crosslinkable aqueous dispersion of a polyurethane polymer having pendant auto-oxidizable functional groups is disclosed, said composition obtainable by reacting: (a) an organic polyisocyanate; (b) an isocyanate reactive compound containing pendant fatty acid unsaturation; (c) an isocyanate reactive polymeric polyol containing neutralizable pendant carboxylic acid groups; and (d) a reactive diluent containing at least two polymerizable, ethylenically unsaturated double bonds. The obtained polyurethane dispersion is suitable for application in self-curing coating compositions.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Preparation method of water-based polyacrylate modified polyurethane dispersion (PUD)

The invention discloses a new method for preparing water-based polyacrylate modified polyurethane dispersion (PUD), which mainly comprises the following steps: (a) preparing an acrylate polymer or copolymer emulsion; (b) preparing a polyurethane prepolymer with carboxyl, and neutralizing the carboxyl; and (c) under the condition of high-speed stirring or other mechanical mixing, adding a polyacrylate emulsion into the polyurethane prepolymer for carrying out dispersion and chain extension. If unsaturated acetoacetate-based compounds are added when the polyacrylate emulsion is prepared, the prepared water-based polyacrylate modified PUD has self-crosslinking property.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

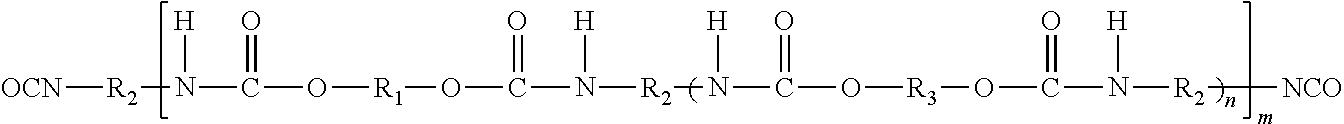

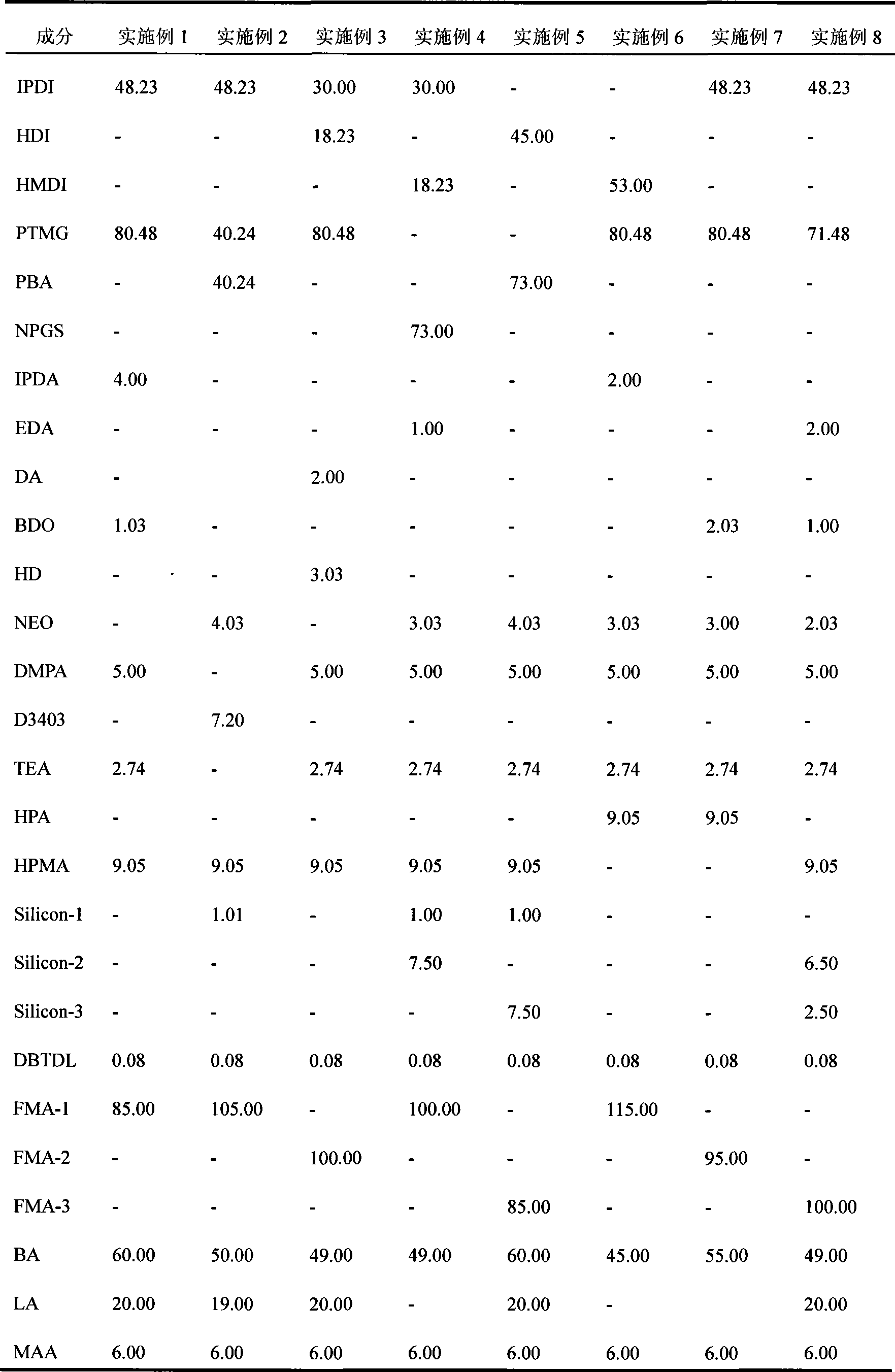

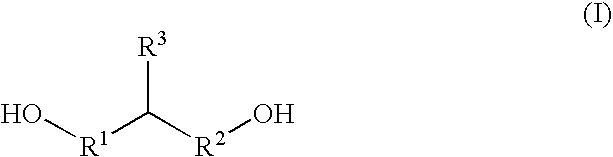

Polyurethane dispersions for use in personal care products

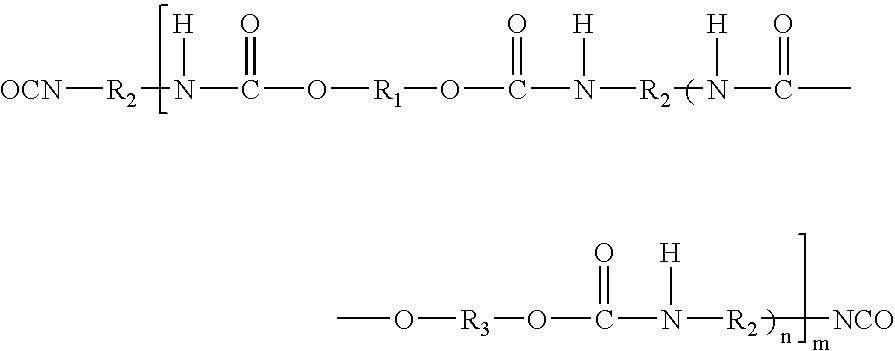

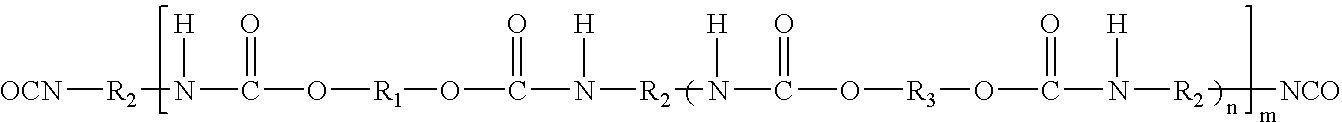

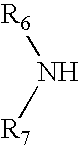

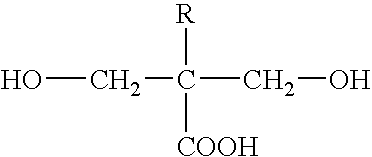

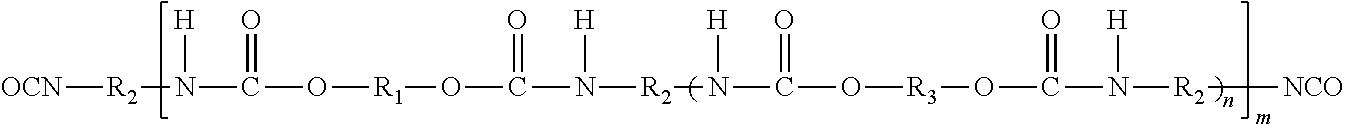

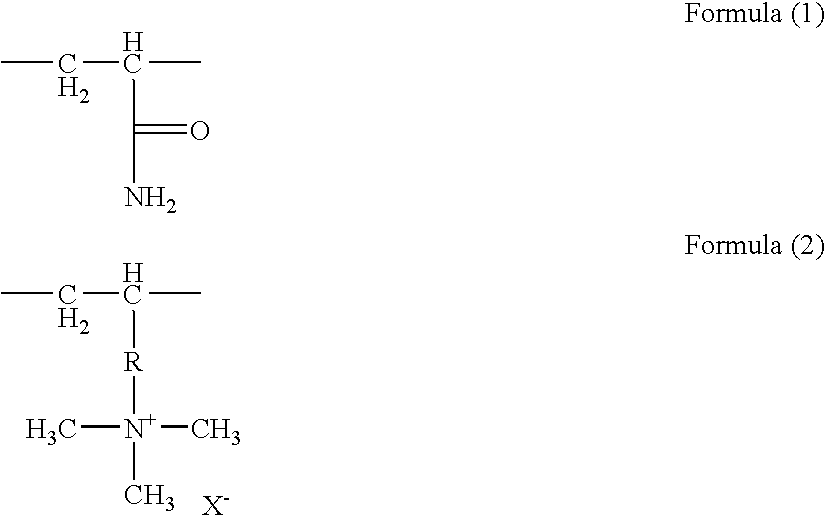

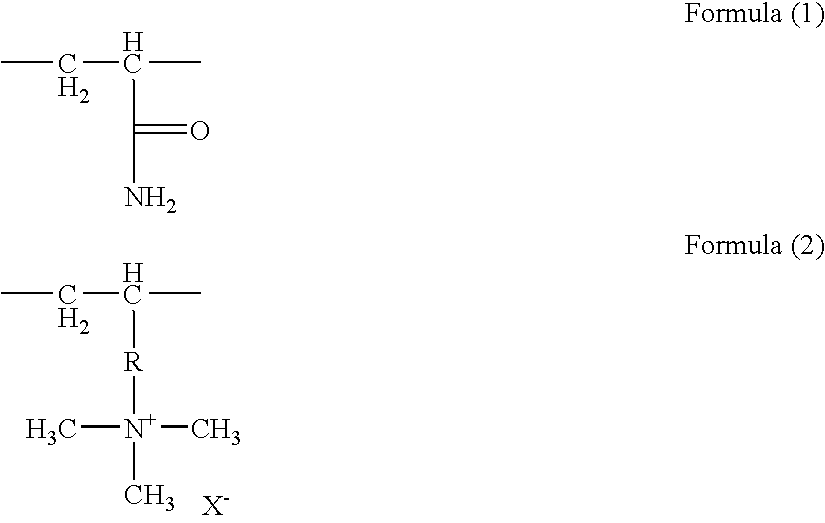

The invention relates to an aqueous polyurethane dispersion suitable for use in personal care products, the dispersed polyurethane comprising the reaction products of:A) a prepolymer according to the formula:whereinR1 represents a bivalent radical of a dihydroxyl functional compound,R2 represents a hydrocarbon radical of an aliphatic or cycloaliphatic polyisocyanate,R3 represents a radical of a low molecular weight diol, optionally substituted with ionic groups,n is from 0 to 5, andm is >1;B) at least one chain extender according to the formula:H2N—R4—NH2 wherein R4 represents an alkylene or alkylene oxide radical not substituted with ionic or potentially ionic groups; andC) at least one chain extender according to the formula:H2N—R5—NH2 wherein R5 represents an alkylene radical substituted with ionic or potentially ionic groups.

Owner:COVESTRO LLC

Aqueous polysiloxane-polyurethane dispersion, its preparation and use in coating compositions

InactiveUS20030198819A1Feel goodImprove adhesionLayered productsThin material handlingPolyurethane dispersionPolymer science

The invention relates to aqueous dispersions of polysiloxane-polyurethanes based on selected, substantially difunctional starting materials, to their preparation and use for preparing coating compositions, and to a coating composition comprising as substantial binder component polysiloxane-polyurethanes of the kind mentioned. The coating compositions of the invention are especially suitable for use as soft feel coatings.

Owner:EVONIK DEGUSSA GMBH

Primer coating for enhancing adhesion of liquid toner to polymeric substrates

ActiveUS7470736B2Improve adhesionImprove coating adhesionSpecial tyresInksWater basedPolyvinyl chloride

A primer coating is provided for use on polymeric substrates to enhance adhesion of liquid toner to the substrates for printing in an electrophotographic printing device. The primer coating is water-based and includes a dispersion of a copolymer of ethylene and acrylic or methacrylic acid, and a compatible adhesion enhancer selected from an aliphatic polyurethane dispersion, a hydrogenated hydrocarbon rosin or rosin ester dispersion, and an amorphous acrylic polymer dispersion. The coating may also include additives such as wetting agents, antiblocking agents, matting agents, and waxes. The primer coating may be applied to a variety of polymeric substrates including polypropylene, biaxially oriented polpypropylene, polyethylene terephthalate, and polyvinyl chloride.

Owner:MICHELMAN INC

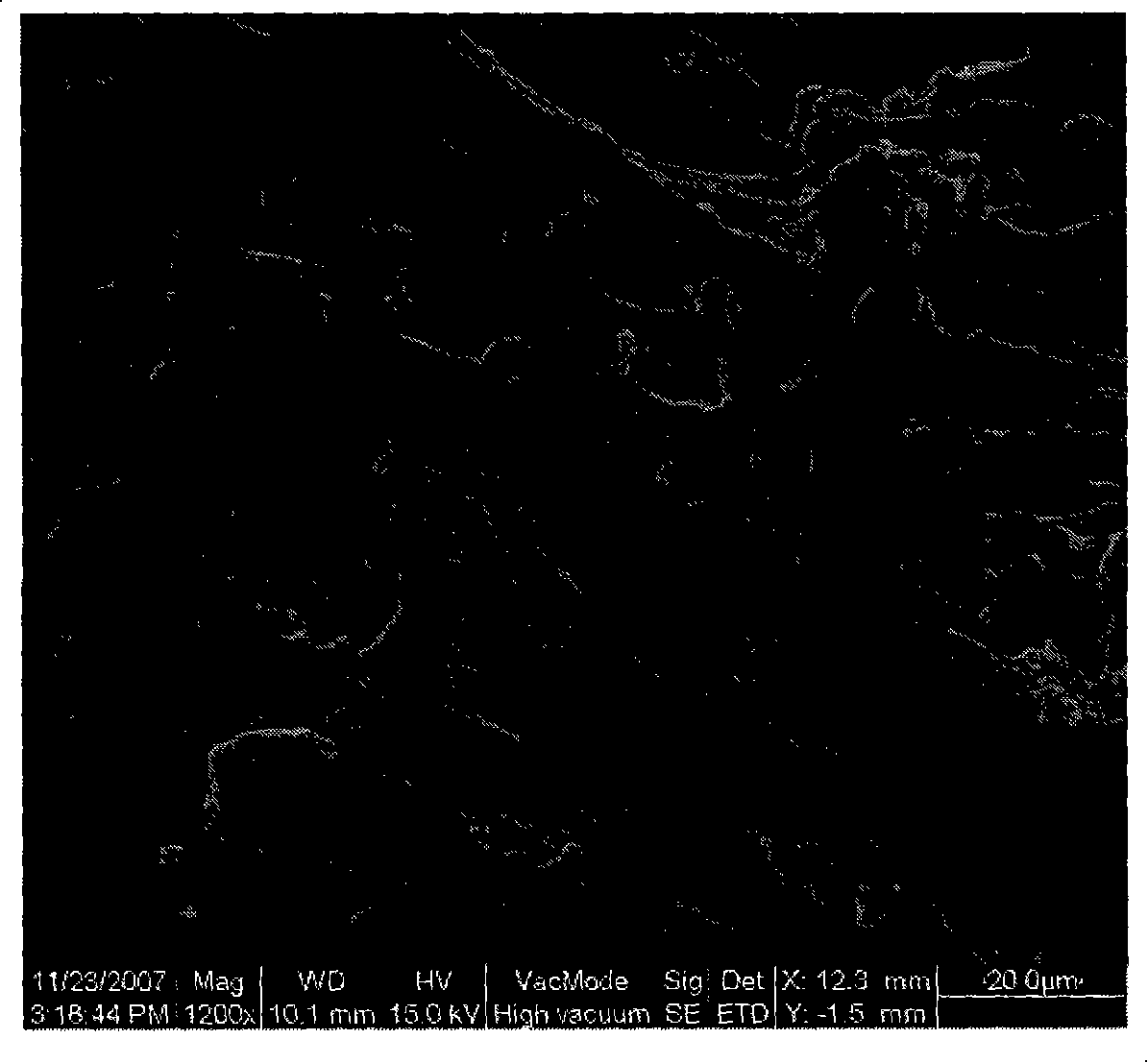

Water polyurethane electric conduction paint containing carbon nano-tube and preparation method thereof

InactiveCN101165127AImprove dispersion uniformityNo subsidencePolyurea/polyurethane coatingsEmulsion paintsPolyesterCarbon nanotube

The present invention belongs to the field of chemical technology, and is especially one kind of conducting water soluble polyurethane paint containing carbon nanotube and its preparation process. The conducting paint is prepared through the first modifying carbon nanotube chemically for the surface to carry hydroxyl group, carboxyl group or amino group; the subsequent introducing to polyester polyol or isocyanate terminated polyurethane pre-polymer through chemical bonding and self-emulsifying to prepare water soluble polyurethane dispersoid containing carbon nanotube; and final adding deionized water and assistants through high speed stirring to obtain the conducting paint. The conducting paint can form coating with volume resistivity of 1x10<-5>-4x10<-4. ohm.cm, surface resistivity of 1x10<-1>-2x10<2> ohm, adhesion of 0 grade, shielding effectiveness of 70-85 dB, and long term stability, and has wide application.

Owner:SHANGHAI SAFEGREEN TECH

Water-based coating and preparation method and application thereof

ActiveCN102533078AGood UV aging resistanceImprove wear resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedPolyurethane dispersion

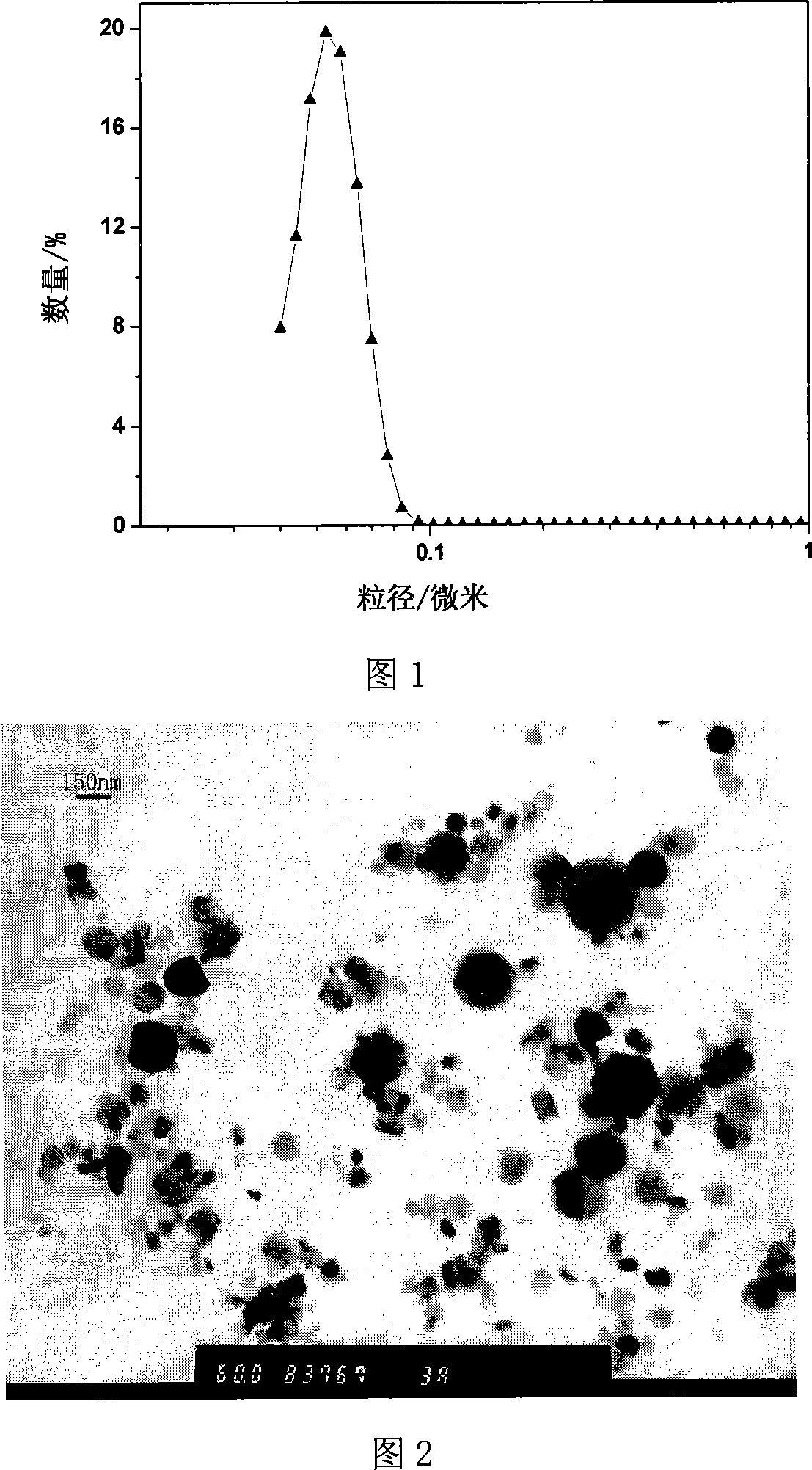

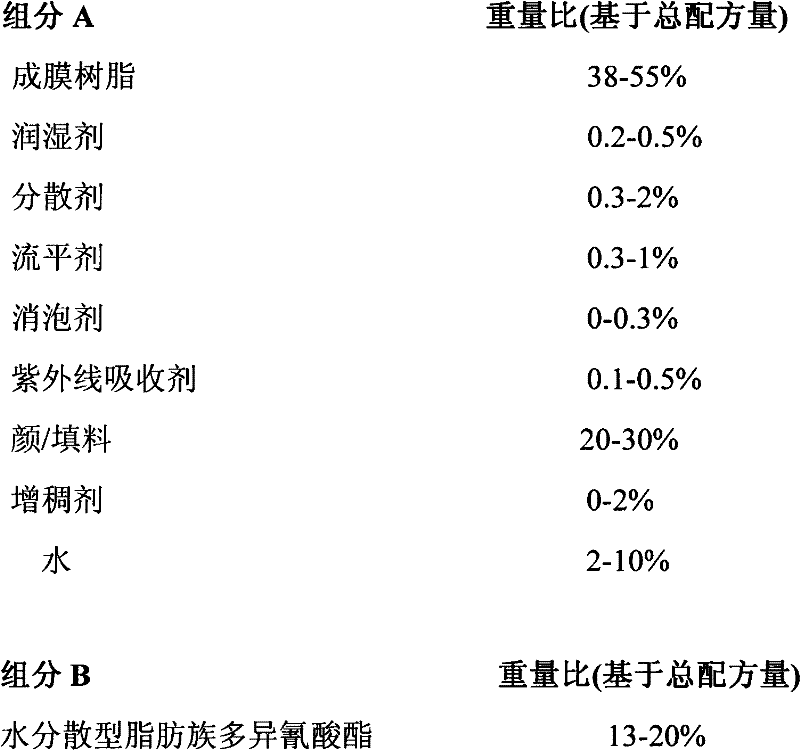

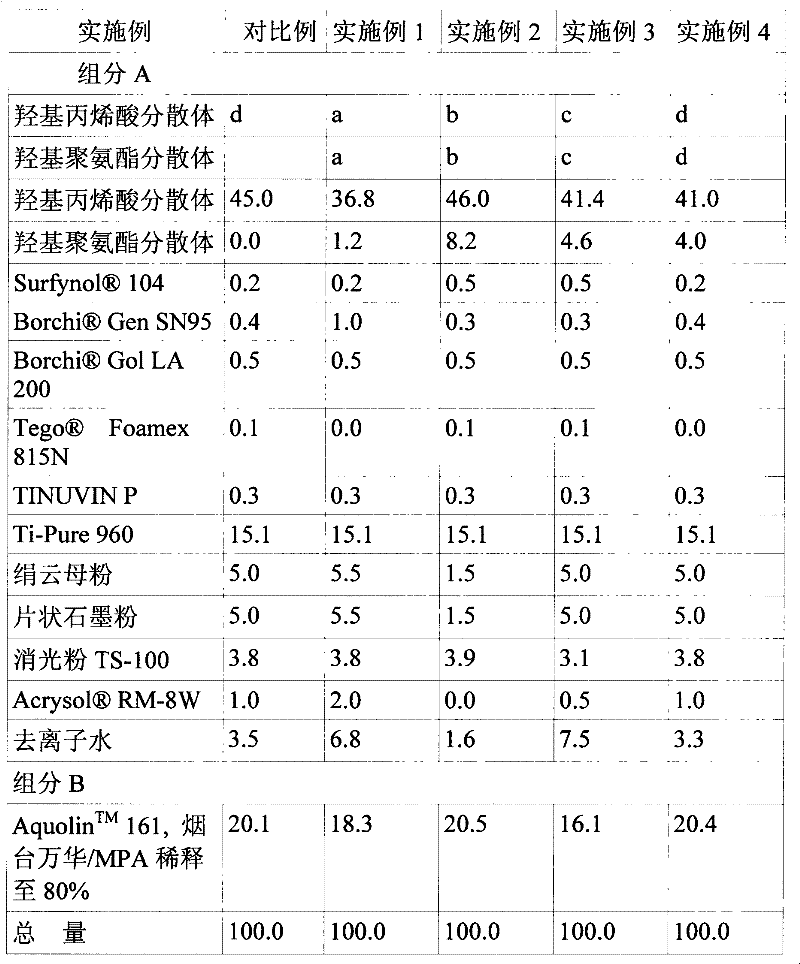

The invention discloses a water-based coating and a preparation method and an application thereof. The water-based coating belongs to a water-based two-component polyurethane coating for a wind turbine blade, and can be taken as priming paint and finishing paint. Film forming resin consists of a hydroxyl acrylic acid dispersion and a hydroxyl polyurethane dispersion; due to the adoption of a acrylic acid structure and a polyurethane structure, excellent ultraviolet ray resistance and high wear resistance can be provided respectively; and water-dispersible aliphatic diisocyanate is taken as a curing agent. The coating has excellent adhesive ability on the wind turbine blade, has excellent tolerance, and can be used for effectively prolonging the service life of wind power equipment.

Owner:WANHUA CHEM GUANGDONG +2

Mascara containing aqueous dispersion of polyurethane and a hard wax

The invention relates to a composition comprising aqueous polyurethane dispersions and at least one hard wax.

Owner:LOREAL SA

Solvent free aqueous polyurethane dispersions and adhesive films therefrom for stretch fabrics

Novel aqueous polyurethane dispersions and shaped articles formed therefrom are provided. The aqueous polyurethane dispersions are provided in solvent-free systems of a prepolymer comprising at least one polyether, polyester, or polycarbonate polyol, a mixture of MDI isomers, and a diol. The shaped articles from such dispersions can be heat-activated for bonding, lamination, and adhesion of substrates, including stretch fabrics.

Owner:INVISTA NORTH AMERICA R L

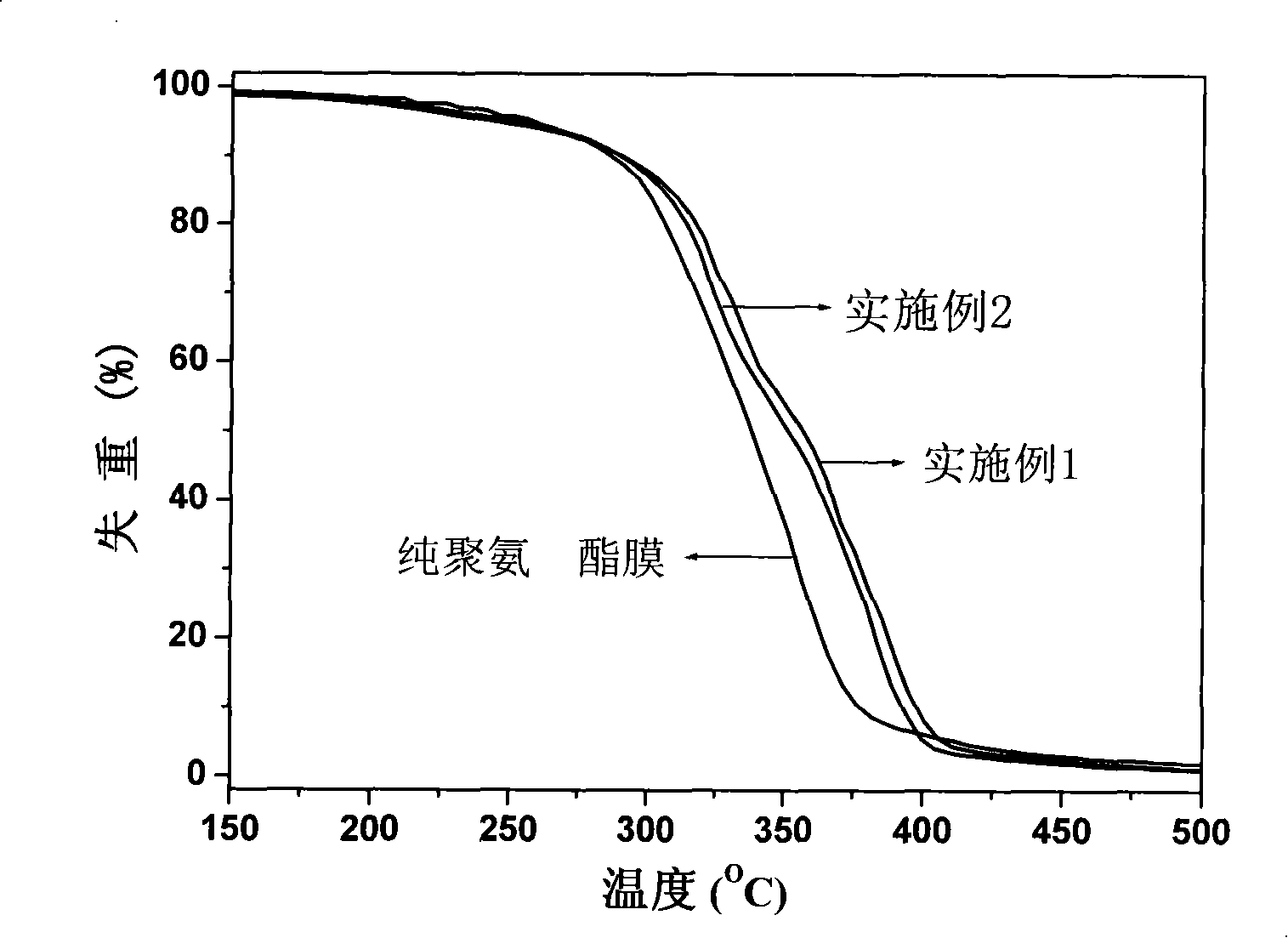

POSS/polyurethane aqueous composite paint and preparation method thereof

ActiveCN101250375ANo subsidenceEasy to storePolyurea/polyurethane coatingsEmulsion paintsPolyurethane dispersionHeat resistance

The invention relates to a POSS / polyurethane water compound paint and the process for preparation, the water compound paint is prepared by the following process, firstly, preparing POSS which is not capped with a hydrolysis method, secondly, adopting silane coupling agent KH-550 to cap and get a POSS which contains amido group, and finally, chemically compounding POSS and water polyurethane dispersion to prepare a POSS / polyurethane water compound paint. The water compound paint of the invention has the advantages of excellent indoor temperature storage property, degree of hardness and waterproof property, and fire-resisting property and anti-ultraviolet light property are excellent. The process for preparation of the invention has the advantages of convenient and simple technique, high film coating quality, low production cost and extend application prospect and the like, which has no pollution to environment, the water paint is a new generation environmental-friendly high-performance chemical product, which can be applied in the fields such as automobile coating, wood coating, construction, office furniture, leather, textile finishing, pigment printing and mechanical equipment.

Owner:SUZHOU JIREN HIGH TECH MATERIAL CO LTD

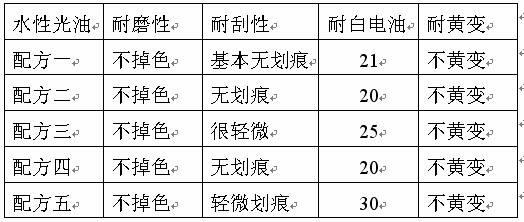

Water-based matte touch gloss oil and preparation method thereof

The invention discloses a water-based matte touch gloss oil and a preparation method thereof. The water-based matte touch gloss oil is prepared from the following raw materials in percentage by mass: 65-80% of water-based polyurethane dispersion, 10-20% of modified acrylic elastic emulsion, 1-3% of flatting agent, 3-5% of coupling agent, 3-5% of hand touch wax slurry, 1-3% of matting agent, 0.1-0.5% of defoamer, 0.5-2% of hand touch scratch-resistant agent, and 0-3% of water. The water-based matte touch gloss oil prepared from the materials is low in matte degree, and employs water as a diluent and contains no organic solvent or heavy metal; and the water-based matte touch gloss oil is natural and soft in color and luster without whiting, and good in color reveal property. Furthermore, the water-based matte touch gloss oil is suitable for surface coating treatment of high-quality paper, so that the coated paper feels like cotton, silk and velvet, and the paper finished product is good in matte degree and high in white gasoline resistance; the level of product packaging is greatly improved; and the water-based matte touch gloss oil is mainly applied to leatherette paper, imitation leather, calendered paper and some coated paper.

Owner:GUANGDONG YINGKE GRP CO LTD

Polyurethane water dispersion and its preparing method

InactiveCN1425726APrevent flocculationAvoid layeringPolyurea/polyurethane coatingsPolyurethane dispersionPolyol

The present invention relates to paint and is especially aqueous polyurethane dispersion and its preparation process. The preparation process includes: vacuum dewatering of polyol at 90-120 deg.c vacuum degree 0.05-0.1 MPa for 1.0-2.0 hr before cooling; adding polyol and diisocyanate monomer, heating to 60-100 deg.c for 1.0-2.0 hr, adding small molecular dibasic alcohol as chain expander, reaction at 60-80 deg.c until reaching required NCO group content, adding hydrophilic chain expander and reaction at 50-70 deg.c to unchanged NCO group content to obtain polyurethane prepolymer; cooling the prepolymer, neutralizing with neutralizing agent, transferring the product to emulsifying reactor, high speed emulsifying while adding deionized water, adding amine to expand chain, adding NCO group collecting agent and defoaming agent for stabilizing treatment, and eliminating acetone.

Owner:SOUTH CHINA UNIV OF TECH

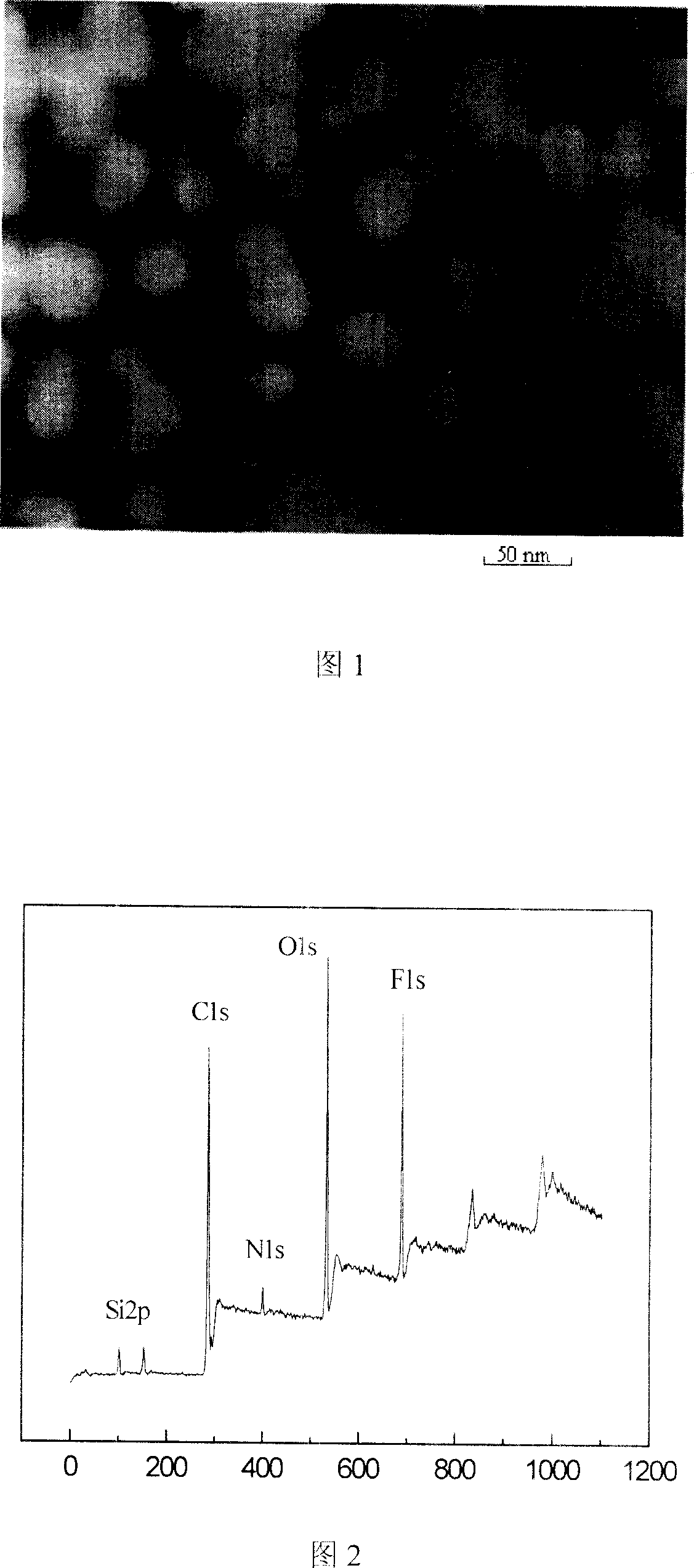

Fluorin-silicon modified core-shell structure polyurethane-acrylate emulsion preparation method

InactiveCN1951968AImprove water resistanceGood oil resistancePolyurea/polyurethane coatingsPropanoic acidPolydimethyl siloxane

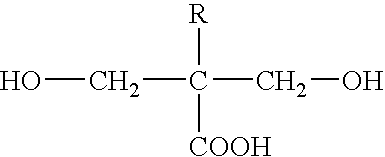

The invention discloses a preparing method of fluorosilicate-composite emulsion with polyurethane-acrylate as nuclear shell structure, which is characterized by the following: dehydrating the composite liquid of macromolecular diatomic alcohol and dihydroxy-terminated polydimethyl siloxane; adding diisocyanate; adding dimethylol propionic acid, diatomic alcohol chain-extending agent and catalyst (disilicon acid dibutyl tin); cooling; emulsifying; extending chain in the water through polyamine chain-extending agent; obtaining the aqueous polyurethane dispersion modified by organic silicon as seed; dripping the fluorine acrylate monomer to do emulsion polymerization.

Owner:UNIV OF SCI & TECH OF CHINA +1

Aqueous polyurethane adhesive and preparation thereof

InactiveCN101348703ASmall molecular weightSolve process problemsFilm/foil adhesivesPolyureas/polyurethane adhesivesPolyurethane dispersionPolyurethane adhesive

The invention discloses a waterborne polyurethane adhesive which comprises the following compositions in mass portion: 100 portions of waterborne polyurethane dispersoid, 0.08 to 0.25 portion of thickener, 0.08 to 0.25 portion of flatting agent, 0.02 to 0.05 portion of antifoaming agent and 0.02 to 0.05 portion of antioxidant. The invention also discloses a method for preparing the adhesive. The preparation method is to drip multi-amine compound into the waterborne polyurethane dispersoid, to react for 15 to 30 minutes at a temperature of between 10 and 25 DEG C, to remove organic solvent in the waterborne polyurethane dispersoid, to add the thickener, the flatting agent, the antifoaming agent and the antioxidant again, to uniformly mix the materials, and then to obtain the waterborne polyurethane adhesive. The preparation method disclosed by the invention has a simple technology, and the waterborne polyurethane adhesive prepared has the characteristics of high solid content, quick drying speed, large bonding strength, large tensile strength, good elasticity, and superior water resistance, solvent resistance and high and low temperature resistance.

Owner:SUN YAT SEN UNIV

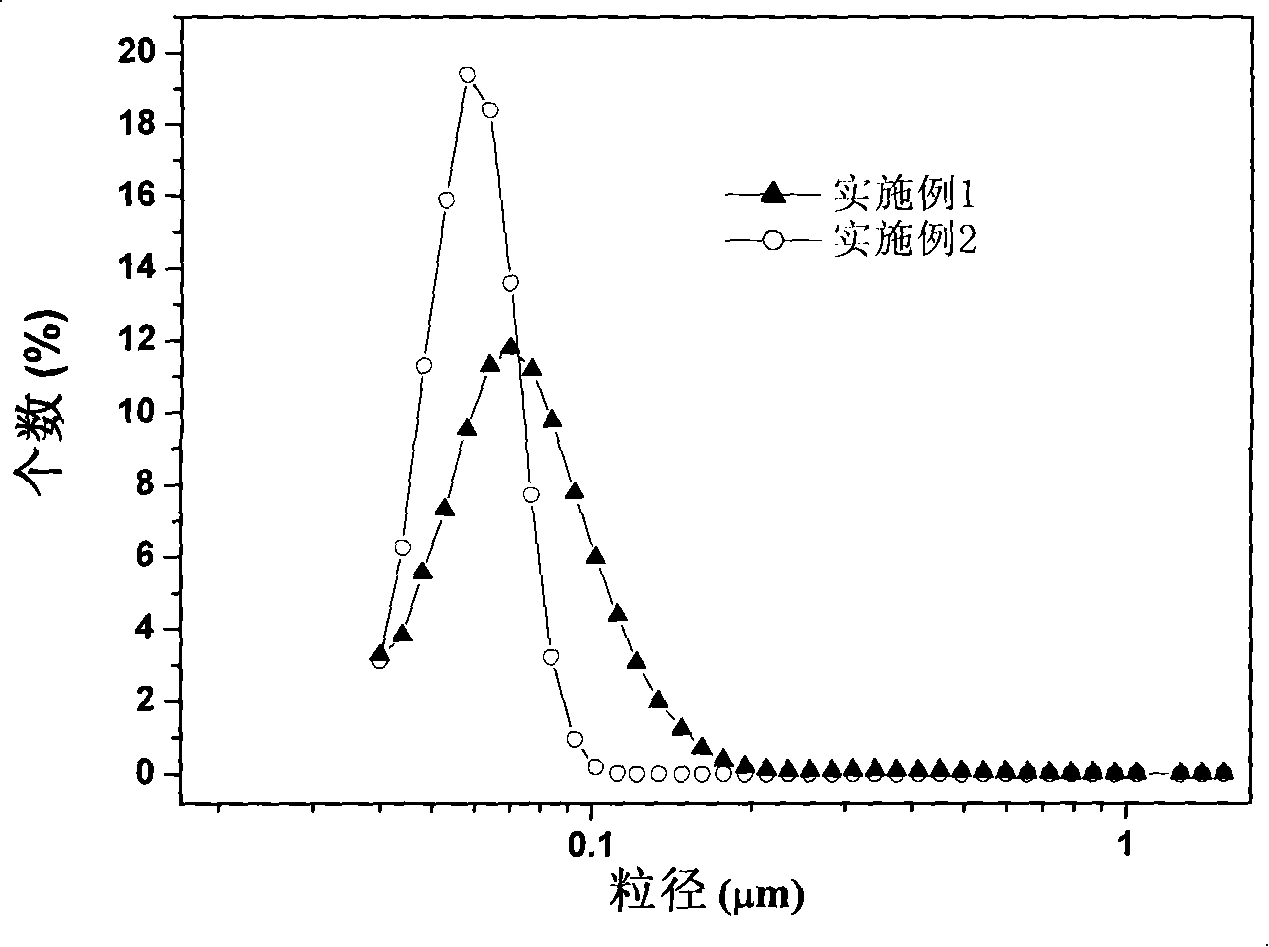

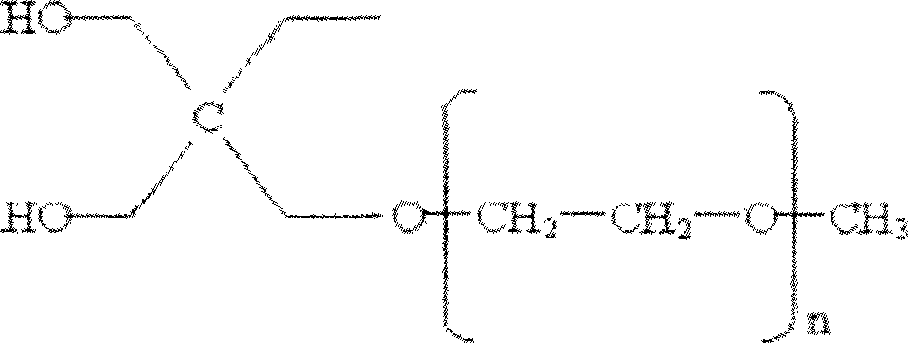

Hybrid polyurethane-polyacrylacid ester dispersion containing fluorine and/or siloxane and preparation method thereof

InactiveCN101362815AGood oil proofImprove waterproof performanceCoatingsDouble bondPhysical property

The invention provides a hybrid polyurethane-polyacrylate dispersoid containing fluorine and siloxane and a preparation method thereof, wherein, an interpenetrating network structure and a nuclear shell structure exist in a dispersoid particle simultaneously. The hybrid polyurethane-polyacrylate dispersoid is polymerizing a polyurethane dispersoid containing double bonds (10-20 percent), a fluorine-containing monomer (5-15 percent), a fluorine-free monomer (10-30 percent), an initiating agent (0.1-2.0 percent), an emulsifying agent (0.5-5 percent), a chain transfer agent (0.01-0.5 percent) and deionized water (50-70 percent) by emulsion. The dispersoid is white lacteal liquid, contains no organic solvent, and has a solid content of 30-50 percent, a molecular weight of 10,000-100,000, a pH value of 7-9, a viscosity of 30-300cp and a stationary phase of more than 1 year. Paint films prepared by the dispersoid have good physical property and relatively low surface energy and can be applied to providing surface coatings with excellent water-proof / antifouling performance.

Owner:大连振邦氟涂料股份有限公司

Composition containing an aqueous dispersion of polyurethane and an oil-soluble polar modified polymer

The invention relates to a composition comprising at least one aqueous polyurethane dispersion, at least one oil-soluble polar modified polymer, and at least one polyamine compound having at least two amine groups.

Owner:LOREAL SA

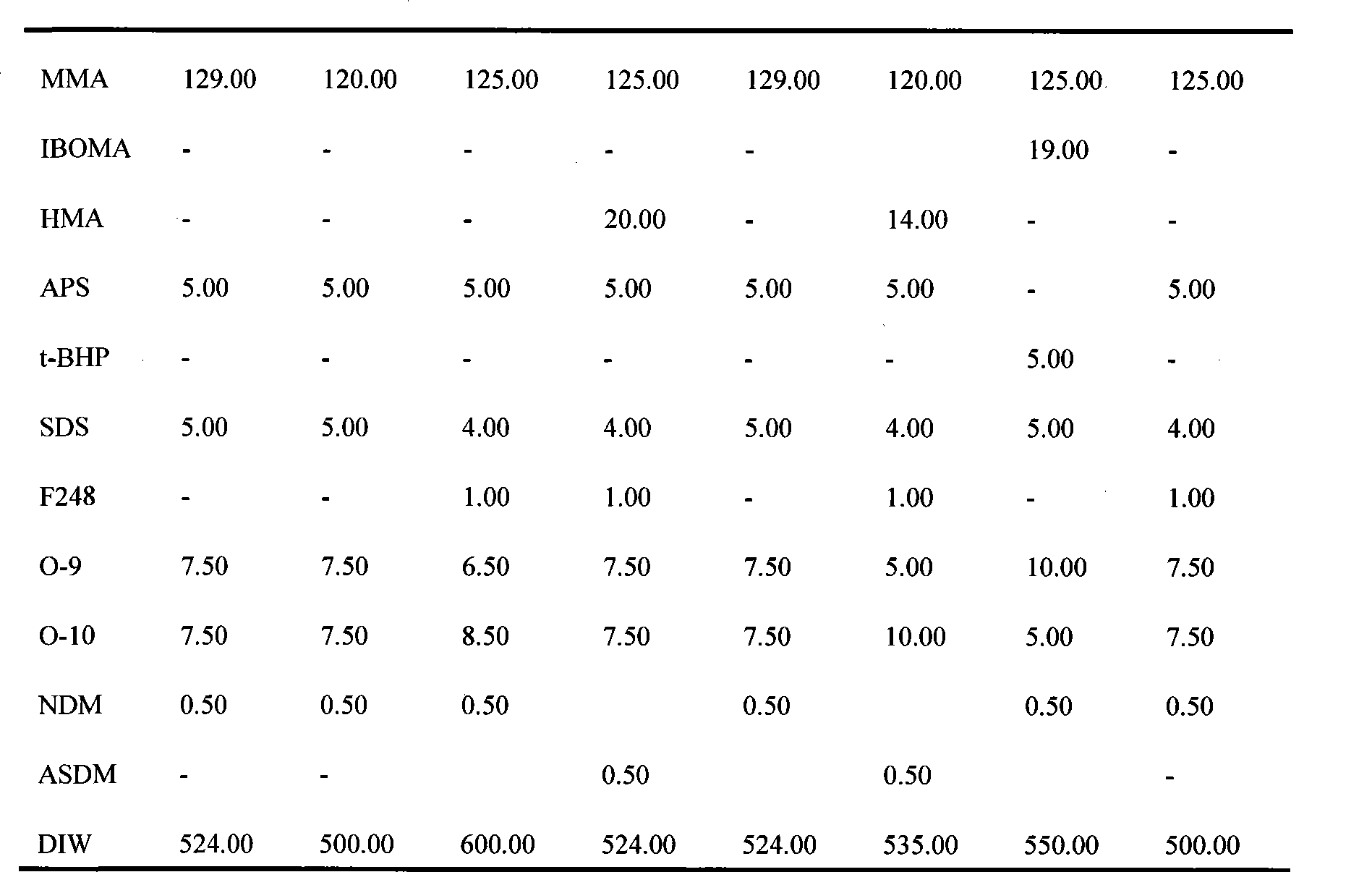

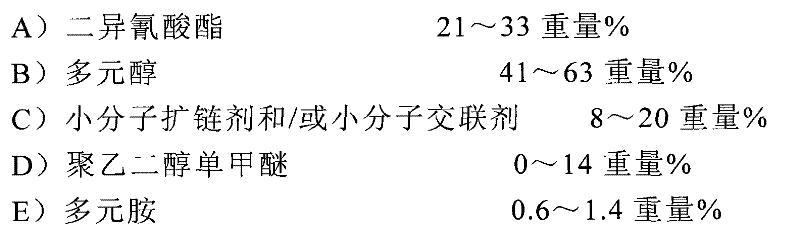

Nonionic waterborne polyurethane dispersoid and preparation method thereof

InactiveCN102690404AWide range of usesGood acid and alkali resistancePolyurethane dispersionPolymer science

The invention discloses a nonionic waterborne polyurethane dispersoid and a preparation method thereof. The dispersoid is mainly made from raw materials of A) diisocyanate, B) one or more than two polyols containing at least two hydroxy groups, wherein number average molecular weight of the polyols is 1000-4000, C) a small molecule chain extender and / or a small molecule cross-linking agent, D) methoxy polyethylene glycol with medium-low molecular weight, and E) one or more than one polyamines with number average molecular weight smaller than 500. According to the invention, the prepared dispersoid is with a small particle size, has long storage time and has great stabilities of acid tolerance, alkali tolerance and salt tolerance, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environmentally-friendly high-performance water-based woodware paint and using method thereof

ActiveCN102051096AGood weather resistanceGood quick dryingPolyurea/polyurethane coatingsDiethylene glycol monobutyl etherWater based

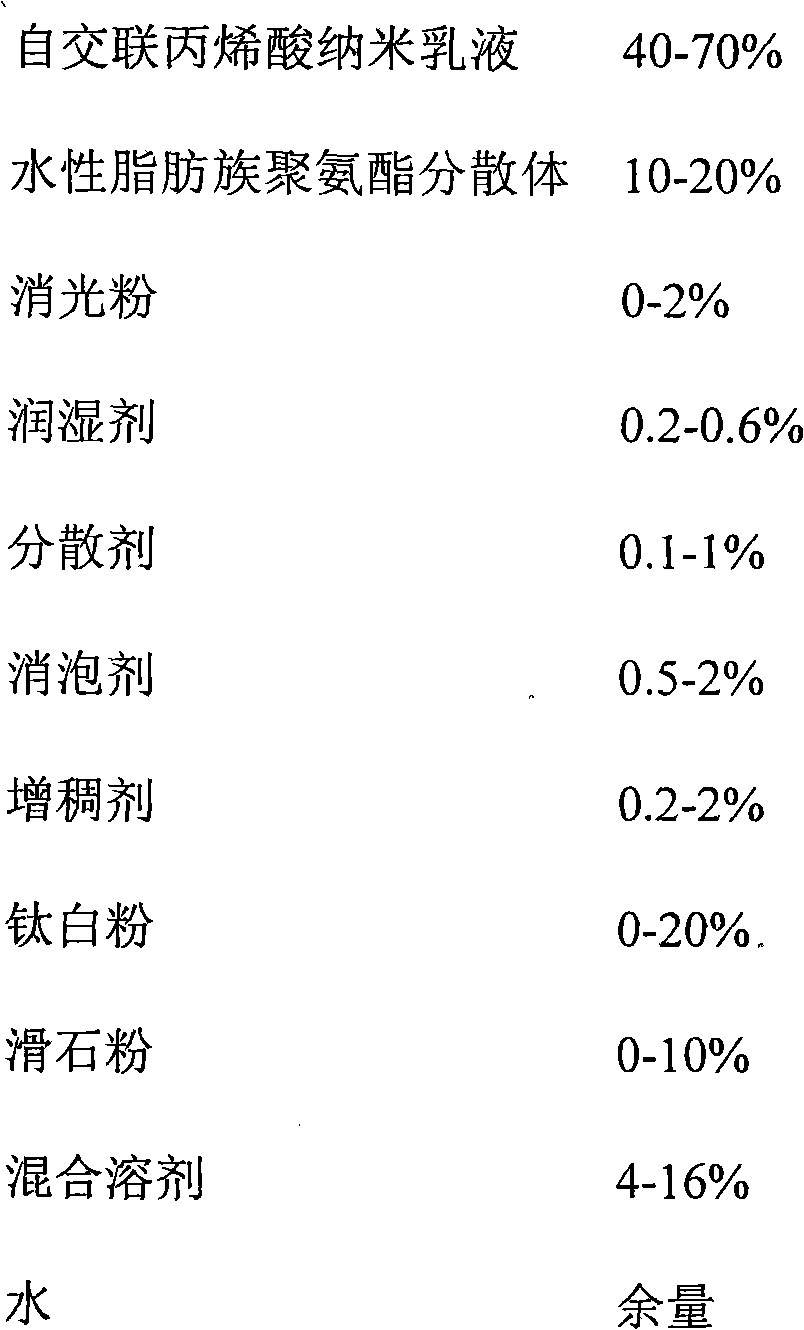

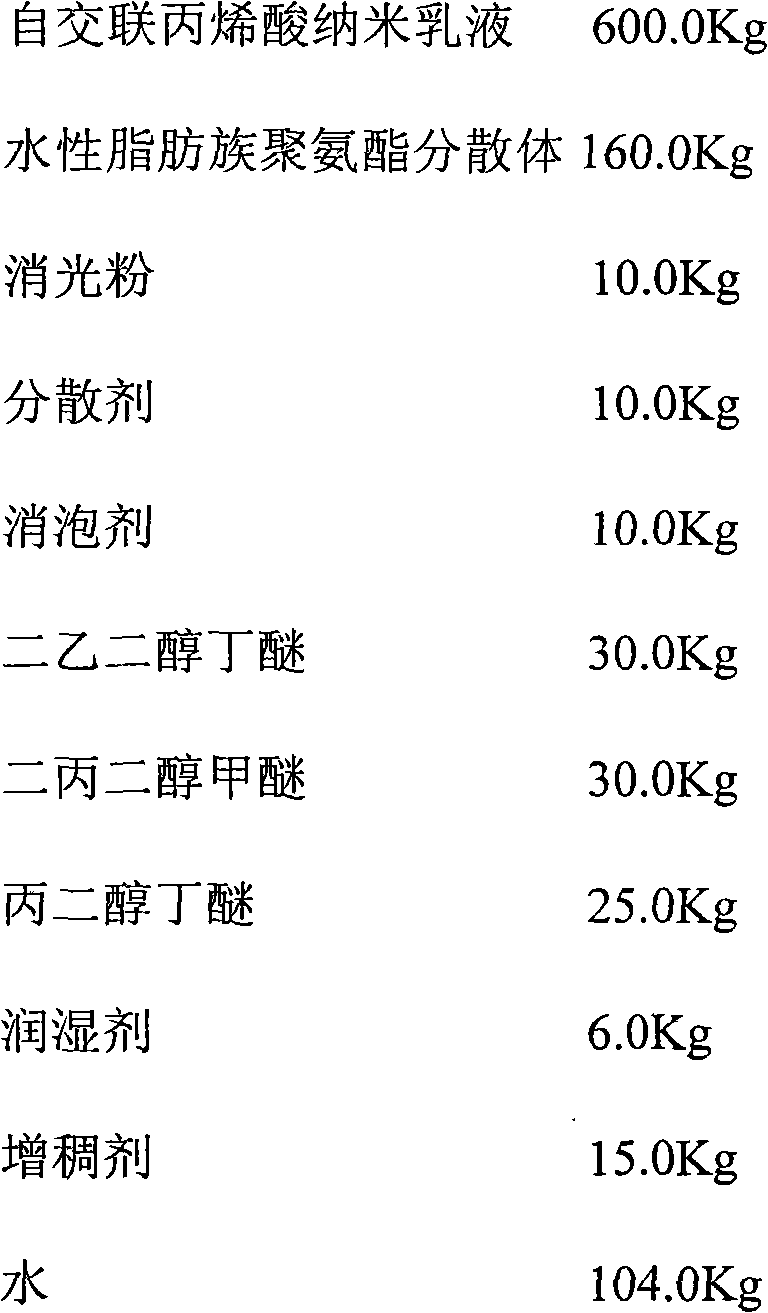

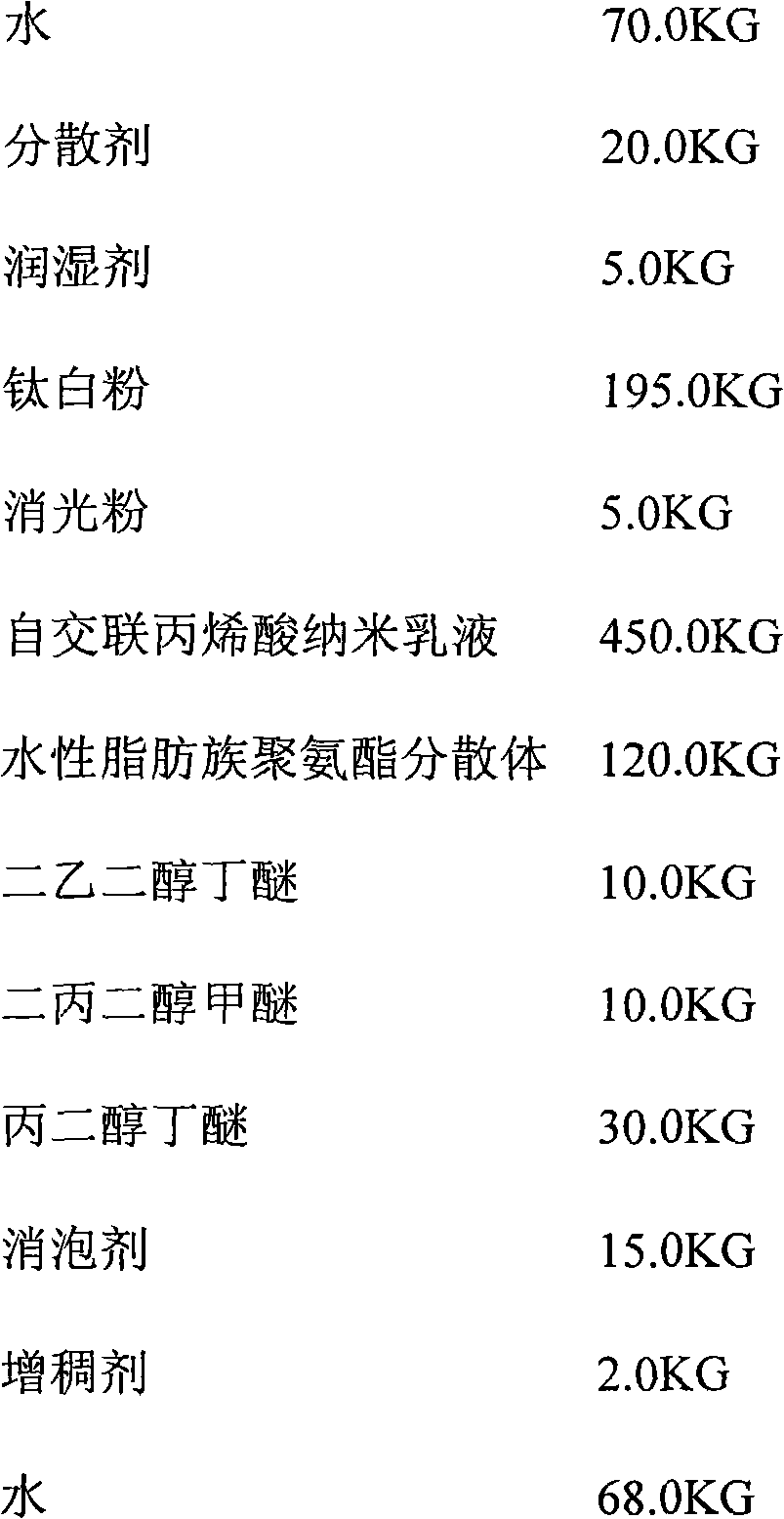

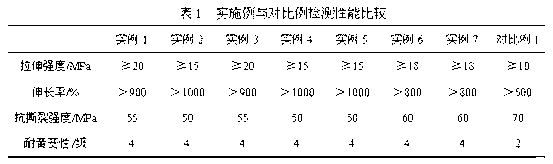

The invention discloses an environmentally-friendly high-performance water-based woodware paint and a using method thereof. The environmentally-friendly high-performance water-based woodware paint comprises 40 to 70 weight percent of self-crosslinking acrylic nano-emulsion and 10 to 20 weight percent of water-based aliphatic polyurethane dispersion. The water-based woodware paint is mainly prepared from the self-crosslinking acrylic emulsion with high triglyceride (Tg) content and weather resistance, so that a paint film has high quick-drying property, chemical resistance and weather resistance, and economy; the self-crosslinking acrylic emulsion is compounded with castor oil modified aliphatic polyurethane dispersion, so that the paint film has high adhesion, hardness, fullness, weather resistance, dry heat resistance and block resistance; and diethylene glycol monobutyl ether is matched with dipropylene glycol methyl ether and propylene glycol monobutyl ether, so that the film forming property of the paint film is ensured, and high drying property is achieved.

Owner:BAUHINIA PAINTS SHANGHAI CO LTD

Primer coating for enhancing adhesion of liquid toner to polymeric substrates

ActiveUS20050245651A1Enhanced liquid toner adhesionImprove adhesionSpecial tyresInksWater basedPolymer science

A primer coating is provided for use on polymeric substrates to enhance adhesion of liquid toner to the substrates for printing in an electrophotographic printing device. The primer coating is water-based and includes a dispersion of a copolymer of ethylene and acrylic or methacrylic acid, and a compatible adhesion enhancer selected from an aliphatic polyurethane dispersion, a hydrogenated hydrocarbon rosin or rosin ester dispersion, and an amorphous acrylic polymer dispersion. The coating may also include additives such as wetting agents, antiblocking agents, matting agents, and waxes. The primer coating may be applied to a variety of polymeric substrates including polypropylene, biaxially oriented polpypropylene, polyethylene terephthalate, and polyvinyl chloride.

Owner:MICHELMAN INC

Watersoluble polyurethane adsorption agent containing sulfhydryl group for removing hydrargyrum and preparation method thereof

InactiveCN101293196AImprove film qualityQuality improvementOther chemical processesWater/sewage treatment by sorptionHigh concentrationCross-link

The present invention pertains to the technical field of wastewater treatment, in particular to hydrophilic polyurethane absorbent containing sulfhydryl for removing Hg and a preparation method thereof. The present invention takes water and volatile non-water solvent as the mixed solvent, introduces chloromethyl thiirane monomer as the cross linking agent into hydrophilic polyurethane dispersion dope and finally carries out coating and solidification, thus obtaining the hydrophilic polyurethane absorbent containing sulfhydryl. The present invention has the advantages of simple and convenient technique, high production efficiency, high product quality and low cost. The composition of the prepared absorbent is controllable with the size of 50 to 250mm, the prepared absorbent has the advantages of large specific surface area, strong Hg-ion absorption capacity and rapid absorption rate. In addition, the present invention with excellent high-concentration Hg-ion absorption capacity and trace Hg-ion absorption capacity, good mechanical property and damage ratio lower than 0.5 percent after being used for a plurality of times can be applied to Hg, lead, cadmium and other heavy metal industrial wastewater treatment within a more extensive concentration range.

Owner:TONGJI UNIV

Aqueous polyurethane dispersoid for coating yellowing-resistant leather and preparation method thereof

InactiveCN102924683AGood yellowing resistanceEasy to preparePolyurea/polyurethane coatingsLeather surface finishingPolyurethane dispersionPolymer science

The invention discloses an aqueous polyurethane dispersoid for coating yellowing-resistant leather. The aqueous polyurethane dispersoid is prepared through the following steps: performing reaction on polyalcohol, a diisocyanate mixture and a crosslinking agent to generate a prepolymer with -NCO terminal group, wherein the diisocyanate mixture consisting of dicyclohexylmethane diisocyanate and isophorone diisocyanate is taken as a starting material; adding a hydrophilic chain extender into the prepolymer, further reacting and extending the chain by micromolecular dihydric alcohol; and neutralizing by using triethylamine and dispersing into water to obtain the aqueous polyurethane dispersoid. According to the aqueous polyurethane dispersoid prepared by the method, the yellowing-resistant level can reach more than level 4, the tensile strength is more than or equal to 15 MPa, the elongation ratio is more than or equal to 800 percent and the tearing strength is more than or equal to 50 MPa. The coated leather has soft and natural luster and plump and moist handfeel.

Owner:山西省应用化学研究所

Solvent free aqueous polyurethane dispersions and adhesive films therefrom for stretch fabrics

ActiveUS20060183852A1Polyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterPolyurethane dispersion

Novel aqueous polyurethane dispersions and adhesive films formed therefrom are provided. The aqueous polyurethane dispersions are provided in solvent-free systems of a prepolymer comprising at least one polyether or polyester polyol, a mixture of MDI isomers, and a diol. The adhesive films from such dispersions can be heat-activated for bonding, lamination, and adhesion of textile fabrics, including stretch fabrics.

Owner:THE LYCRA CO LLC

Aqueous Coating Systems Based On Physically Drying Urethane Acrylates

InactiveUS20100210757A1Polyureas/polyurethane adhesivesEster polymer adhesivesPolyurethane dispersionPolymer science

The invention relates to radiation-curable coating systems based on aqueous polyurethane dispersions, to a process for their production, to the use of the coating systems as lacquers and / or adhesives, and also to articles and substrates provided with these lacquers and / or adhesive.

Owner:COVESTRO DEUTSCHLAND AG

Polyurethane foams for wound management

InactiveUS20070270730A1Improve mechanical propertiesIncrease chanceAbsorbent padsDermatological disorderPolyurethane dispersionWound dressing

The invention relates to a process for producing polyurethane foams for wound management. These polyurethane wound dressing foams are prepared by a process comprising frothing and drying of a foam foaming composition, which comprises a polyurethane dispersion and specific coagulants.

Owner:BAYER MATERIALSCIENCE AG

N-methylpyrrolidone-free polyurethane dispersions based on dimethylolpropionic acid

InactiveUS20060240264A1Synthetic resin layered productsPolyurea/polyurethane coatingsPolymer sciencePropanoic acid

The present invention relates to aqueous polyurethane dispersions that are free from N-methylpyrrolidone and other solvents and wherein the polyurethanes are the reaction products of A) a mixture of 25% to 90% by weight of 1-isocyanate-3,3,5,-trimethyl-5-isocyanatomethylcyclohexane (IPDI) and 10% to 75% by weight of 4,4′-diisocyanatodicyclohexylmethane, wherein the preceding percentages are based on the weight of component A), with B) one or more polyols having average molarcular weights (Mn) of 500 to 6000, C) one or more compounds which have at least one OH— or NH-functional group and contain a carboxyl and / or carboxylate group, wherein at least 50 mol % of the acid groups, based on the total moles of acid incorporated into the polyurethane, are incorporated by dimethylolpropionic acid, D) one or more polyols and / or polyamines having average molecular weights (Mn) of below 500, and E) optionally one or more monoalcohols and / or monoamines. The present invention also relates to a process for preparing the aqueous polyurethane dispersions and to the use of the polyurethane dispersions for preparing coatings or adhesives.

Owner:BAYER MATERIALSCIENCE AG

Production of polyurethane wound dressing foams

InactiveUS20070254974A1Fast and high absorbenceSuitable permeabilityAbsorbent padsBandagesPolyurethane dispersionPolymer science

The invention relates to a process for producing polyurethane wound dressing foams comprising frothing and drying polyurethane foam compositions which comprise anionically hydrophilicized aqueous polyurethane dispersions.

Owner:BAYER MATERIALSCIENCE AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com