Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102results about How to "Good quick drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

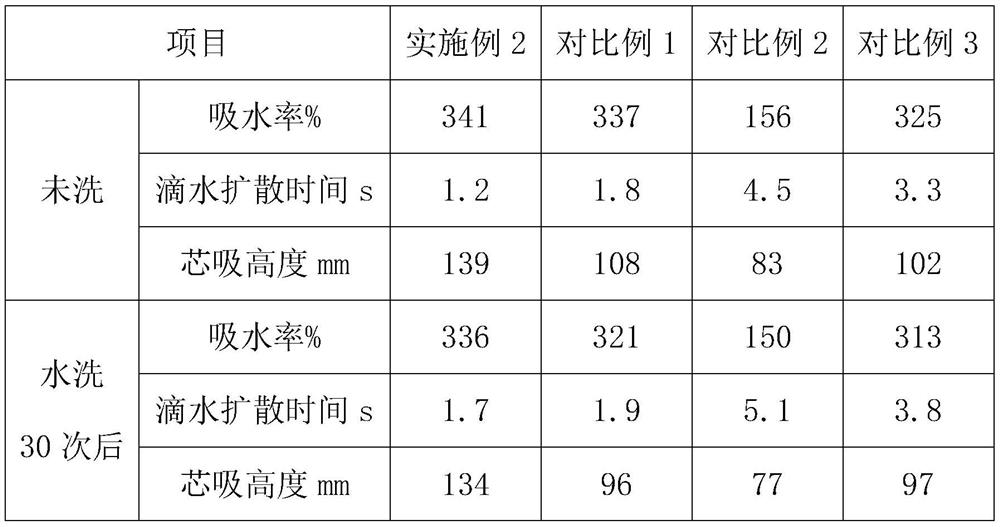

Wet-conduction quick-drying fabric

InactiveCN103147203AImprove water absorptionMany and small poresMulti-ply fabricsYarnCapillary Tubing

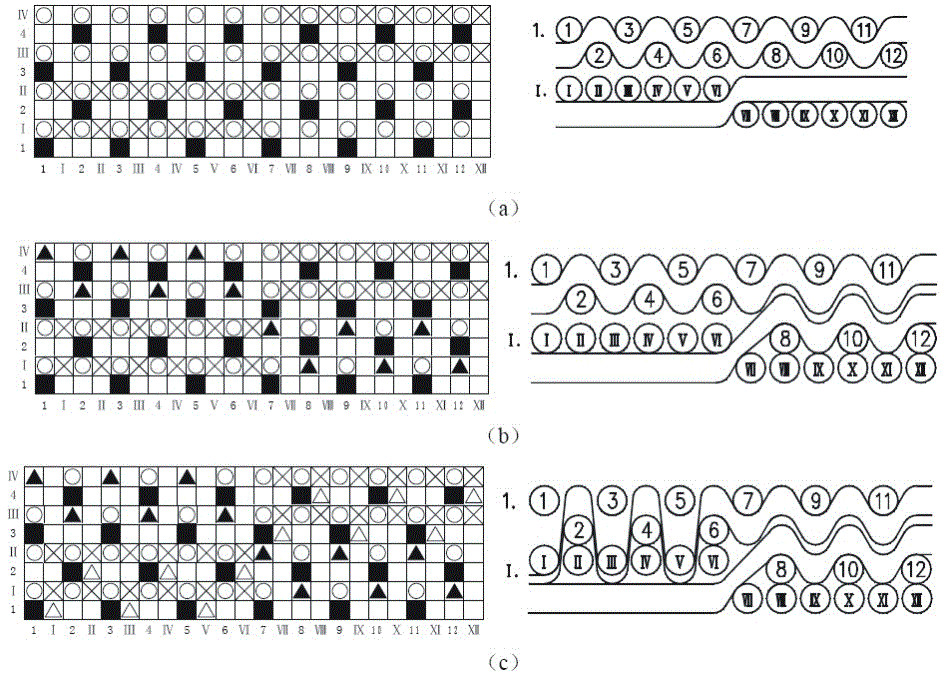

The invention relates to wet-conduction quick-drying fabric, which belongs to the technical field of textile. The fabric is a two-layer structure, a surface layer of the fabric is a plain structure, and an inner layer is a floating loosening structure. According to the two-layer fabric produced on the basis of plant moisture conduction effect, the floating loosening structure on the inner layer adopts a floating wire cluster structure, multiple yarns are concentrated together, interlacing points are few, the floating length is long, and pores are large; and the surface layer adopts the plain structure, interlacing is frequent, and the pores are small. A pore gradient structure which likes a trunk-stem structure of a plant is formed on the surface layer and the inner layer of the fabric, pressure difference is formed by utilizing different sizes of the pores when the water is conducted to produce a differential effect, the wet conduction capacity of a capillary pipe is obviously enhanced along with the variation of the size of capillary hoes of the fabric from the inner layer to the surface layer, and the wet conduction capacity can be realized. The surface layer is connected with the inner layer, so that better communication performance of the pores on the surface layer and the inner layer can be realized.

Owner:HENAN INST OF ENG

Ink jet recording process

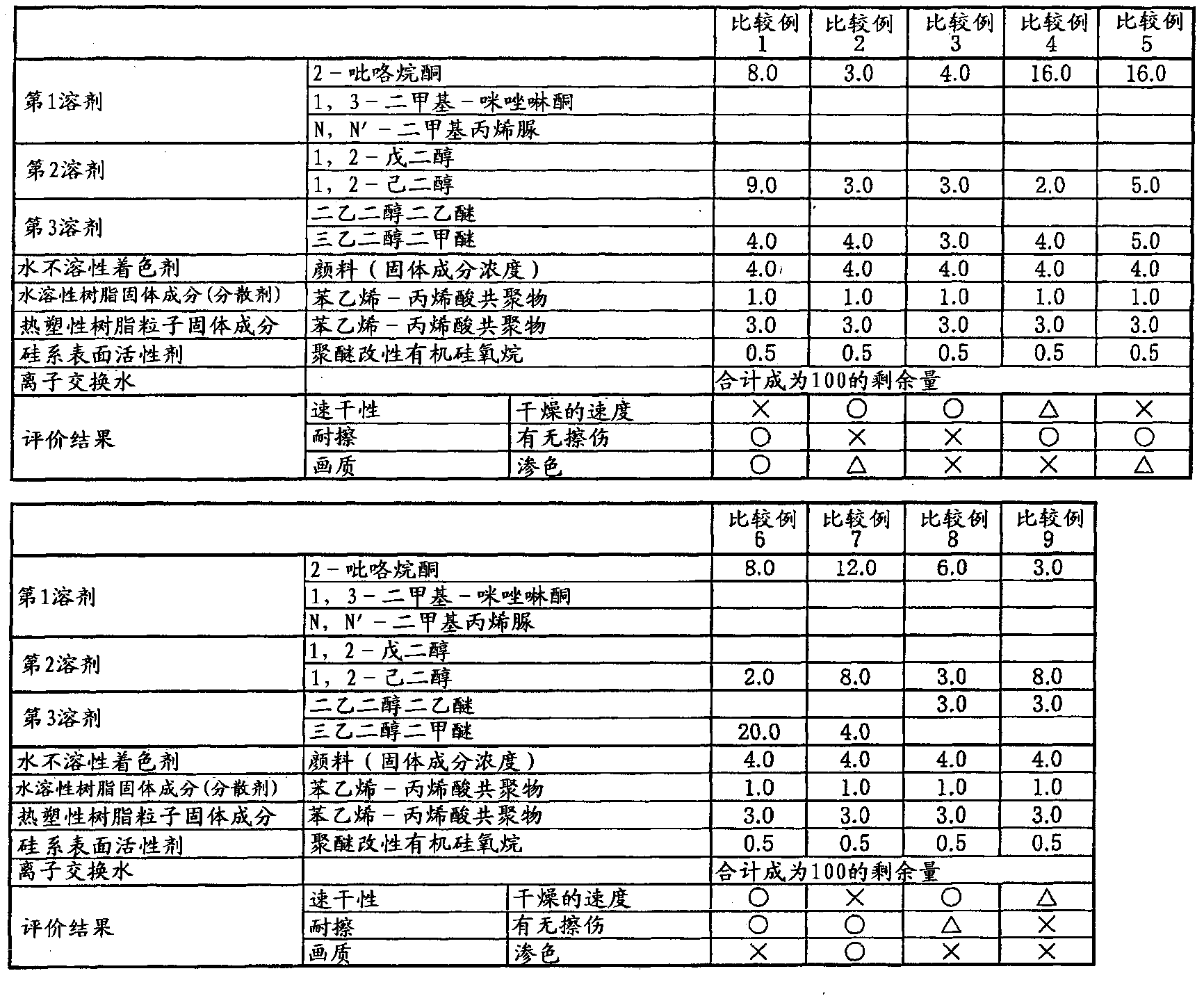

InactiveCN102233719AEfficient recordingGood quick dryingDuplicating/marking methodsInks2-PyrrolidoneSolvent

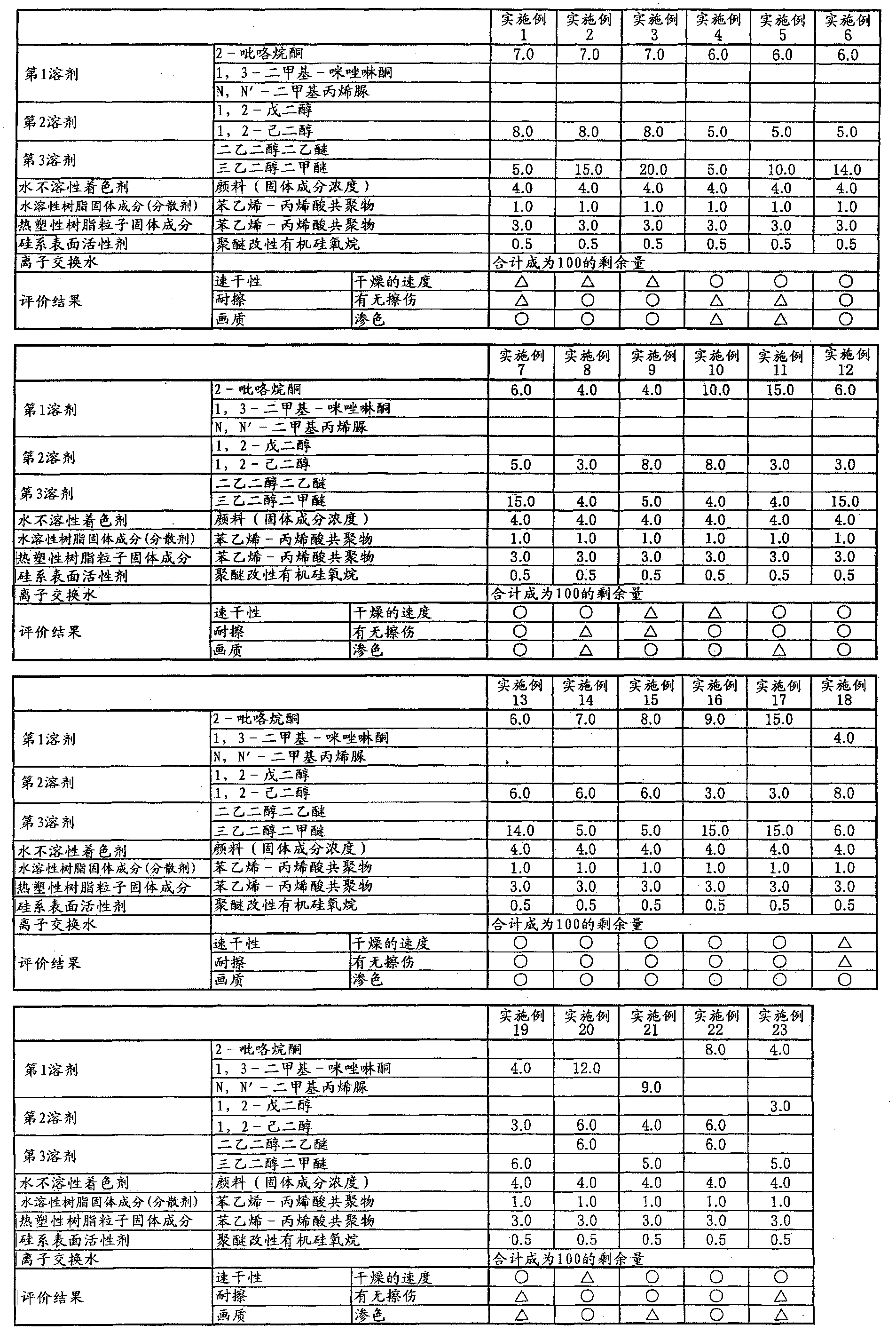

The invention relates to an ink jet recording process. Recording onto a non-ink-absorbing recording medium is performed using an aqueous ink composition containing a first solvent composed of at least one selected from 2-pyrrolidone, 1,3-dimethyl-imidazolidinone, and N,N'-dimethylpropylene urea, a second solvent composed of at least one selected from 1,2-hexanediol and 1,2-pentanediol, and a third solvent composed of at least one selected from glycol diethers and heating the non-ink-absorbing recording medium at 40 to 60 DEG C.

Owner:SEIKO EPSON CORP

Waterborne marking paint and preparation method and construction method thereof

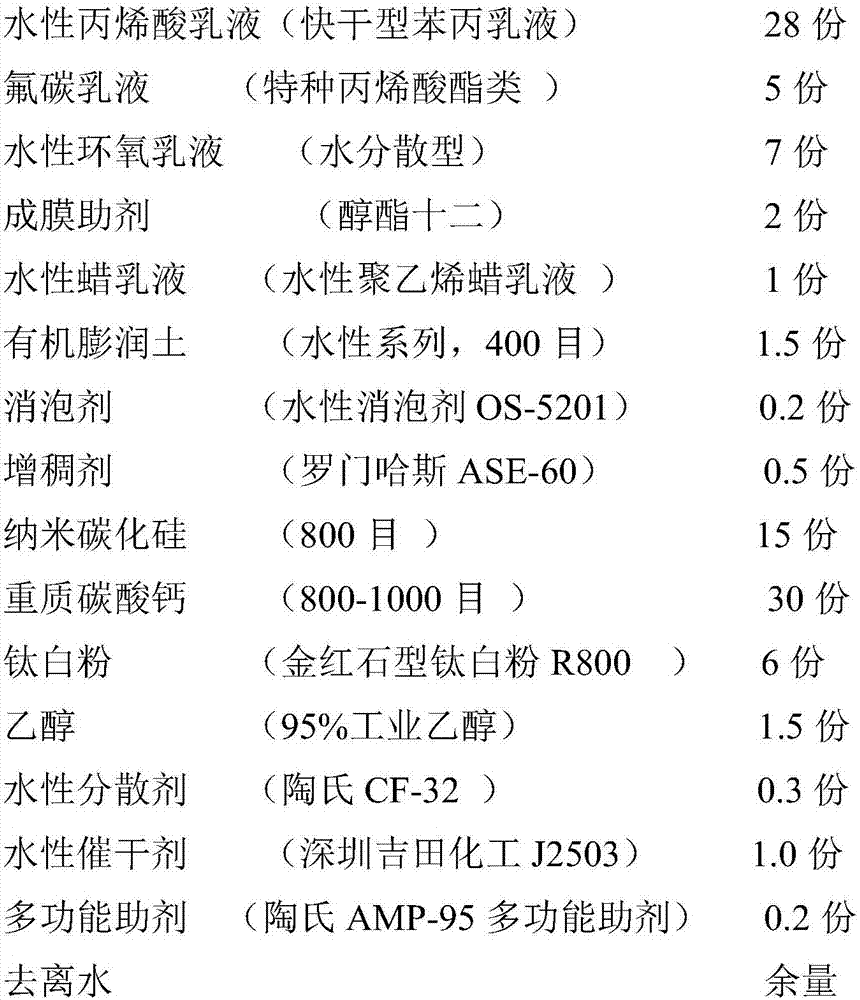

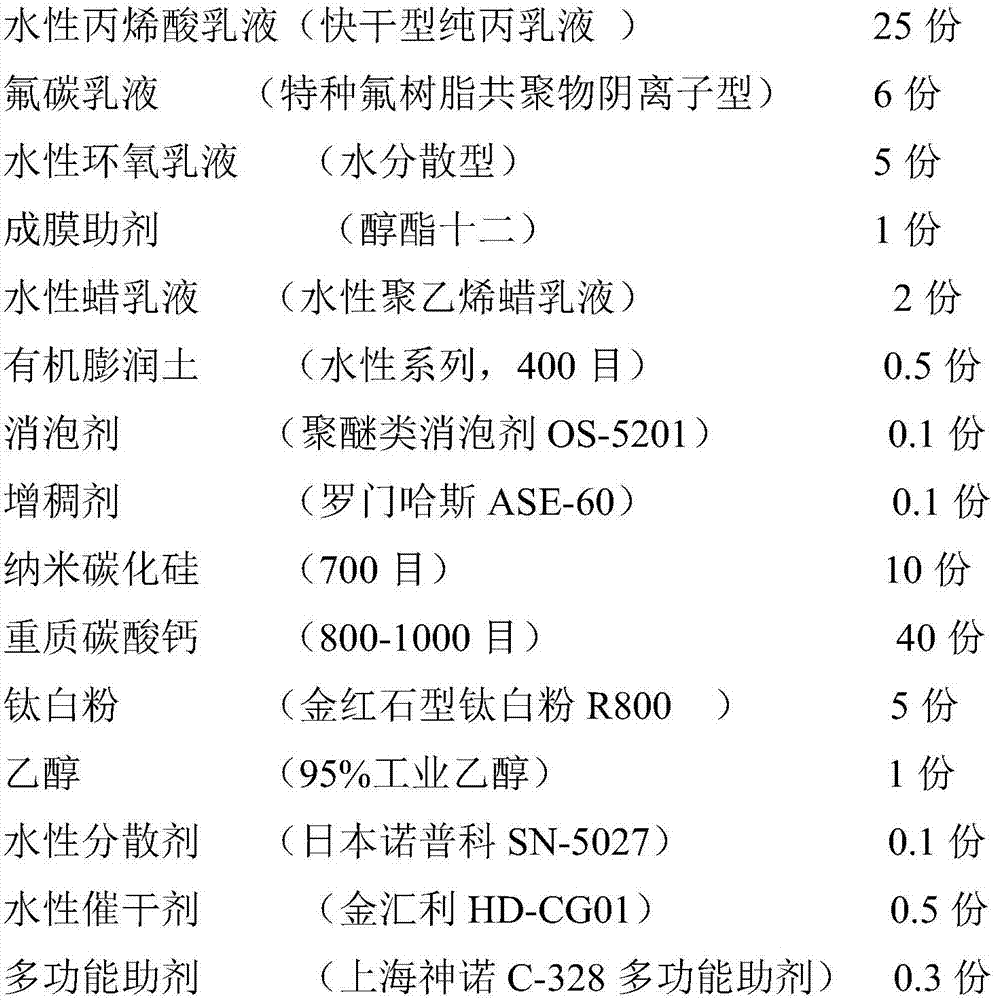

ActiveCN108003713AGood quick dryingImprove wear resistanceAntifouling/underwater paintsPaints with biocidesWaxWeather resistance

The invention provides waterborne marking paint and a preparation method and construction method thereof. The waterborne marking paint is prepared from, by weight, 15-35wt% of waterborne acrylic emulsion, 5-10wt% of fluorocarbon emulsion, 5-10wt% of waterborne epoxy emulsion, 1-3wt% of coalescing agent, 1-3wt% of waterborne wax emulsion, 0.5-5wt% of organic bentonite, 0.1-0.5wt% of antifoaming agent, 0.1-0.5wt% of thickener, 10-20wt% of nano-silicon carbide, 15-40wt% of heavy calcium carbonate, 5-10wt% of titanium dioxide, 1-3wt% of ethanol, 0.1-0.5wt % of waterborne dispersing agent, 0.5-1.5wt% of waterborne drier, 0.2-0.5wt% of multifunctional auxiliary agent and the balance deionized water; the particle size of silicon carbide is 600-900 nm. The waterborne marking paint has excellent quick-drying performance, abrasion resistance, weather resistance and stain resistance.

Owner:SUZHOU TOPOLINE TECH

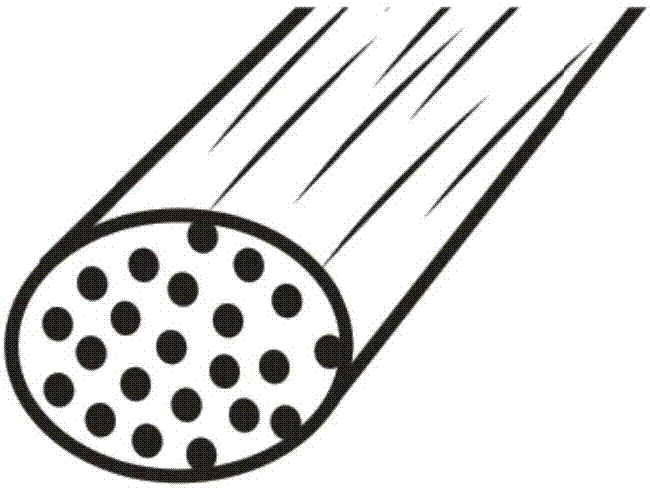

Water-absorbent rapid-dry impermeable profile mixed fiber terylen filament and method for producing same

The invention discloses a filament of fiber-mixing polyester and the producing method, which is water-absorption, drying quickly, anti-permeable and heteromorphic. The content of titania in the filament of fiber-mixing polyester is 1.5-3%. The filament of fiber-mixing polyester comprises heteromorphic and circle silks. The silk number ratio, namely heteromorphic silk / circle silk, is 1 to 2, the size ration, namely heteromorphic silk / circle silk is 0.8-1.2 and the heteromorphic degree of the silk, x, is 35-55%. The production method contains choosing polyester chip, passing through spinneret and winding the spinning silk. The invention is provided with good water-absorption and drying performance, and good anti-permeable effect. It is also provided with simple producing technology, easy operation so as to ensure the good performance of production.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

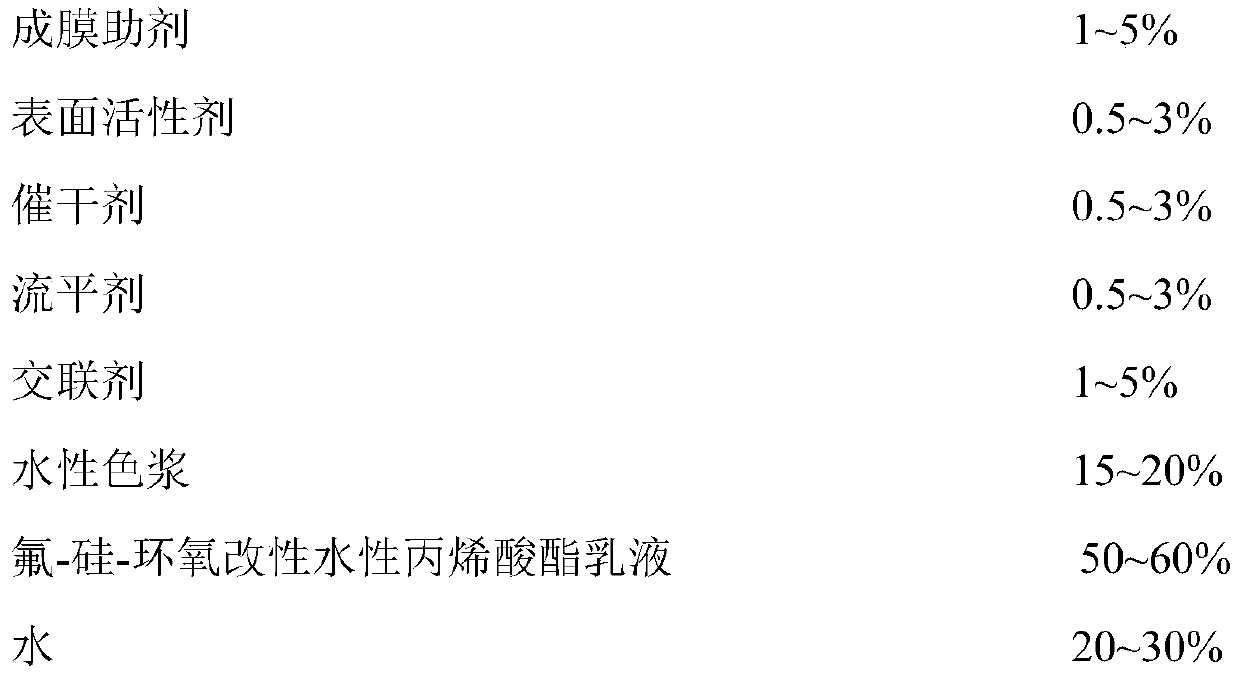

Fluorine-silicon-epoxy-modified aqueous acrylate emulsion ink special for PVC film and preparation method of ink

The invention discloses fluorine-silicon-epoxy-modified aqueous acrylate emulsion ink special for a PVC film and a preparation method of the ink. The ink consists of the following raw materials in parts by weight: 1-5% of a film forming additive, 0.5-3% of a surfactant, 0.5-3% of a drier, 0.5-3% of a leveling agent, 1-5% of a crosslinking agent, 15-20% of aqueous color paste, 50-60% of a fluorine-silicon-epoxy-modified aqueous acrylate emulsion and 20-30% of water. The fluorine-silicon-epoxy-modified aqueous acrylate emulsion ink takes the water as a solvent, so that the ink has no volatile odor; when the ink is applied to the PVC film, the wettability is good; an ink coating film with the thickness of 50 um can reach a surface drying state within 6 seconds at 50 DEG C, and the adhesion fastness reaches 99%; the ink can be scrubbed by 70% of an ethanol aqueous solution more than 100 times after curing completely, and the adhesion resistance reaches 95%; and the preparation process is simple, the production cost is low, and the ink is favorable for universal popularization and application.

Owner:SOUTH CHINA UNIV OF TECH

Self-cleaning water paint

InactiveCN107033747AGood lotus leaf dihydrophobicityImprove self-cleaningAntifouling/underwater paintsPaints with biocidesWater basedEpoxy

The invention discloses a self-cleaning water paint. The self-cleaning water paint is prepared from, by weight, 35-50 parts of water-borne-acrylic-modified epoxy emulsion, 5-20 parts of amino resin, pigment and assistants, wherein the pigment is prepared from, by weight, 3-20 parts of titanium dioxide, 1-9 parts of light expanding powder and 1-10 parts of organic silicone powder; the assistants are prepared from, by weight, 0.1-0.2 part of a PH adjusting agent, 0.1-0.2 part of an antifoaming agent, 2-5 parts of a silm forming assistant, 1-10 parts of an efficient lotus-leaf water repellent agent, 0.3-0.5 part of a wetting dispersant, 0.3-0.5 part of a base-material wetting agent, 5-10 parts of deionized water and 0.5-1.0 part of a thickening agent. The self-cleaning water paint is the ultralow-VOC water-based light-industry water paint, the hydrophobicity of a coating is improved for reducing the contact area between the coating and water and shortening contact time between the coating and water, and the aim of improving the waterproof performance of the coating is finally achieved. The invention also provides lamp-cover-or-metal-painting application of the self-cleaning water paint and the lamp cover; the lamp cover is coated with the self-cleaning water paint.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

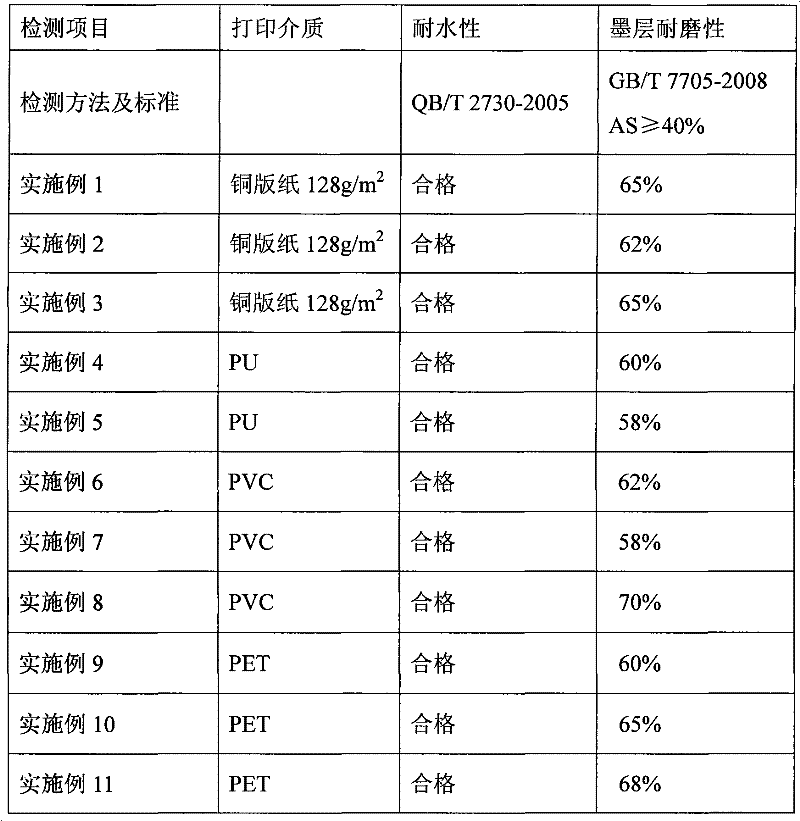

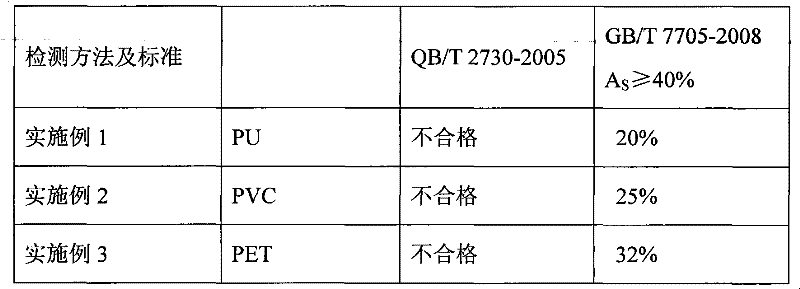

Aqueous inkjet ink for digital printing

InactiveCN102453378AImprove quality stabilityImprove water resistanceInksPolyethylene terephthalatePolyvinyl chloride

The invention discloses aqueous inkjet ink for digital printing, which comprises the following components according to the weight percentage: 0.2-10.0 percent of nano pigment, 2-20 percent of adhesion promoter, 2-20 percent of adhesive, 0.2-2 percent of surface tension regulator, 0.1-1 percent of fungicide, 0.1-2 percent of pH value regulator and the rest deionized water. The invention has the beneficial effects that: the ink can be applied to micro piezoelectric printers and thermal foaming printers; the ink has stability in quality and can be stored for a long time; and the ink can be applied to printing on copperplate paper, PP (polypropylene), PVC (polyvinyl chloride), PU (polyurethane), PET (polyethylene terephthalate) and other non-absorbent media, and also has good water resistance, abrasion resistance, quick-drying performance, color reproduction and color fastness.

Owner:HONGSAM DIGITAL SCI & TECH

Dual-component priming paint

The invention discloses a dual-component priming paint, which comprises the following parts: 5-40% hydroxy acryl resin, 0-5% pigment filler, 0.01-3% drier, 0.1-5% solvent and 0.05-2% hardener, wherein the priming paint adopts acrylic acid resin with low-hydroxy value and high-hydroxy activity, which has quick-drying effect through mating HDI tripolymer. The invention reduces roasting time and manufacturing cost, which improves manufacturing efficiency and perfects the property of the product.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

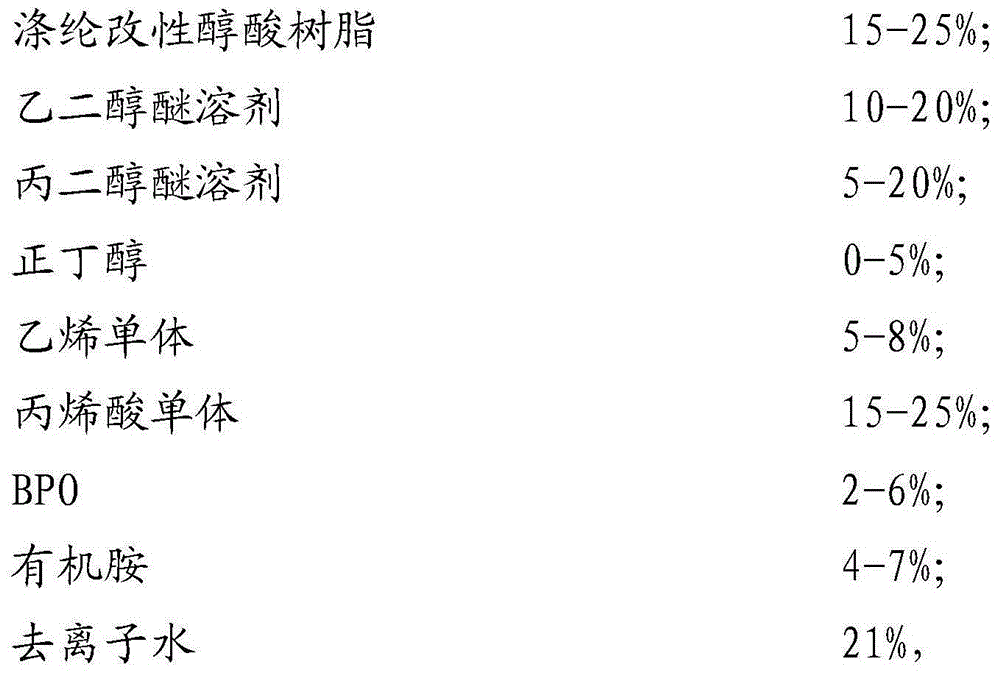

Water-borne acrylic-modified alkyd resin emulsion and preparation method thereof

ActiveCN104987468AGood mechanical propertiesGood color retentionAnti-corrosive paintsMaleic anhydrideChemistry

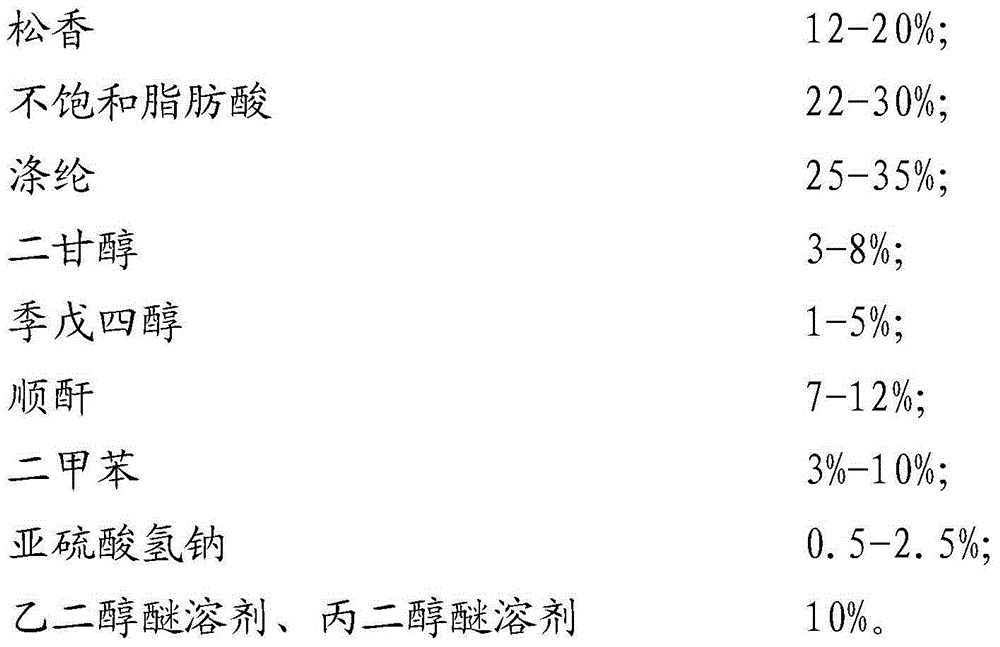

The invention provides water-borne acrylic-modified alkyd resin emulsion which comprises the following components in percentage by weight: 15-25% of polyester modified alkyd resin, 10-20% of a glycol ether solvent, 5-20% of a propylene glycol ether solvent, 0-5% of n-butanol, 5-8% of vinyl monomer, 15-25% of acrylic monomer, 2-6% of BPO, 4-7% of organic amine and 21% of deionized water, wherein the polyester modified alkyd resin comprises the following components: 12-20% of rosin, 22-30% of unsaturated fatty acid, 25-35% of polyester, 3-8% of diethylene glycol, 1-5% of pentaerythritol, 7-12% of maleic anhydride, 3-10% of xylene, 0.5-2.5% of sodium hydrogen sulfite and 10% of a glycol ether solvent and a propylene glycol ether solvent. Compared with the prior art, the water-borne acrylic-modified alkyd resin emulsion has the benefits of higher environment friendliness and better water solubility.

Owner:湖南天氟新材料有限公司

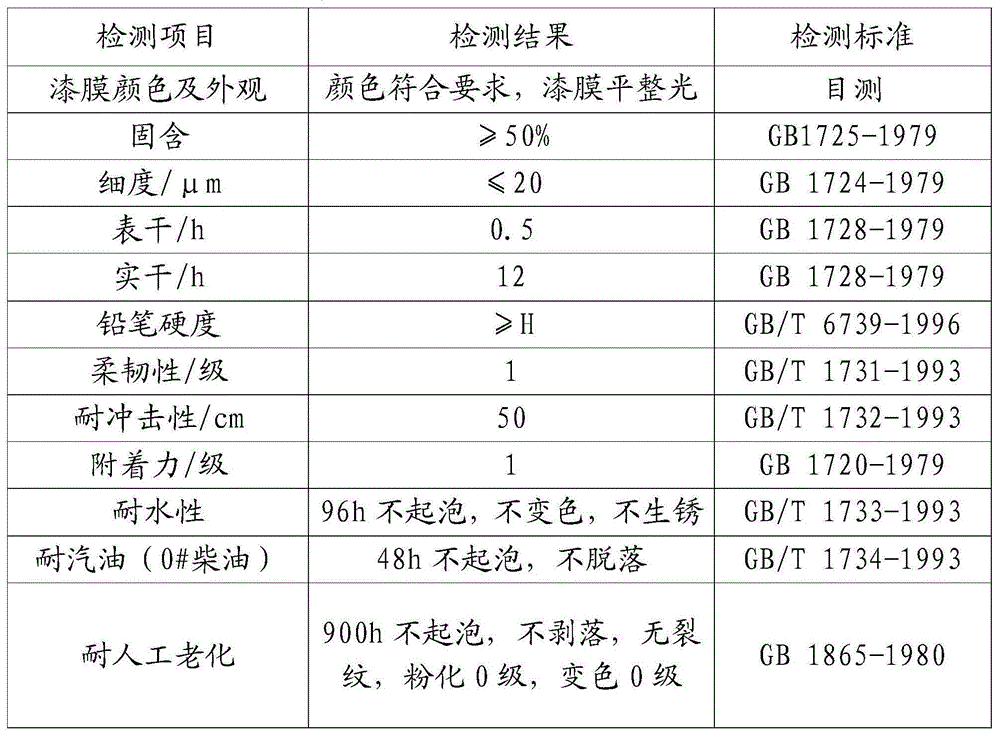

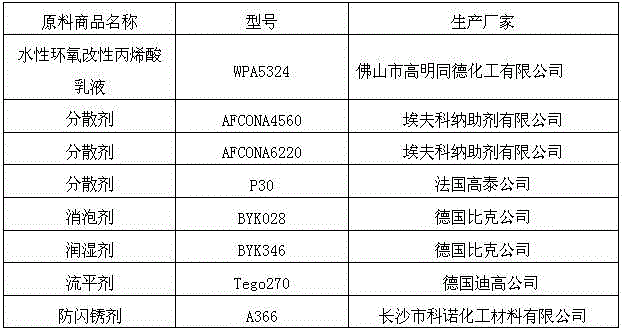

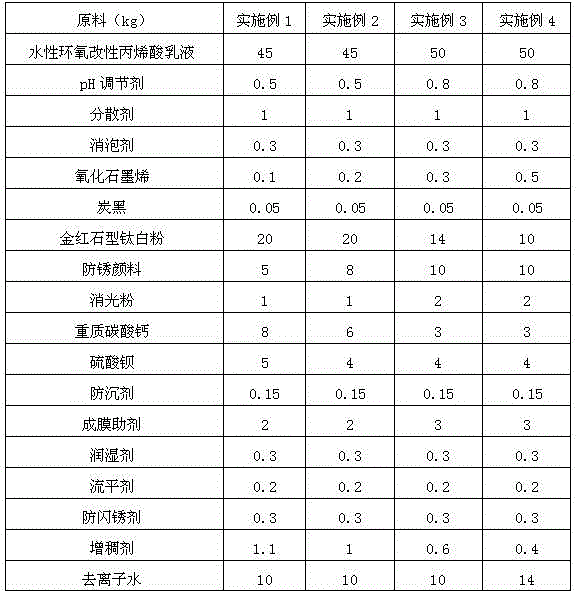

Acrylic water-based paint for motor shells and preparation method thereof

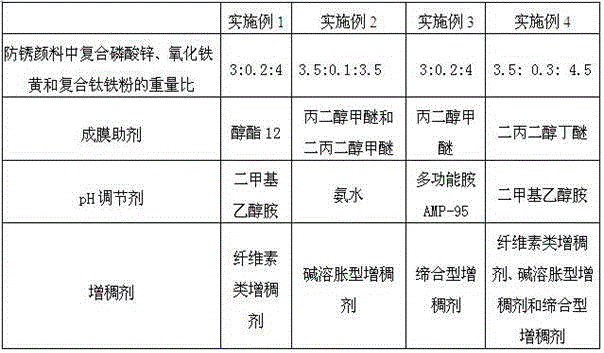

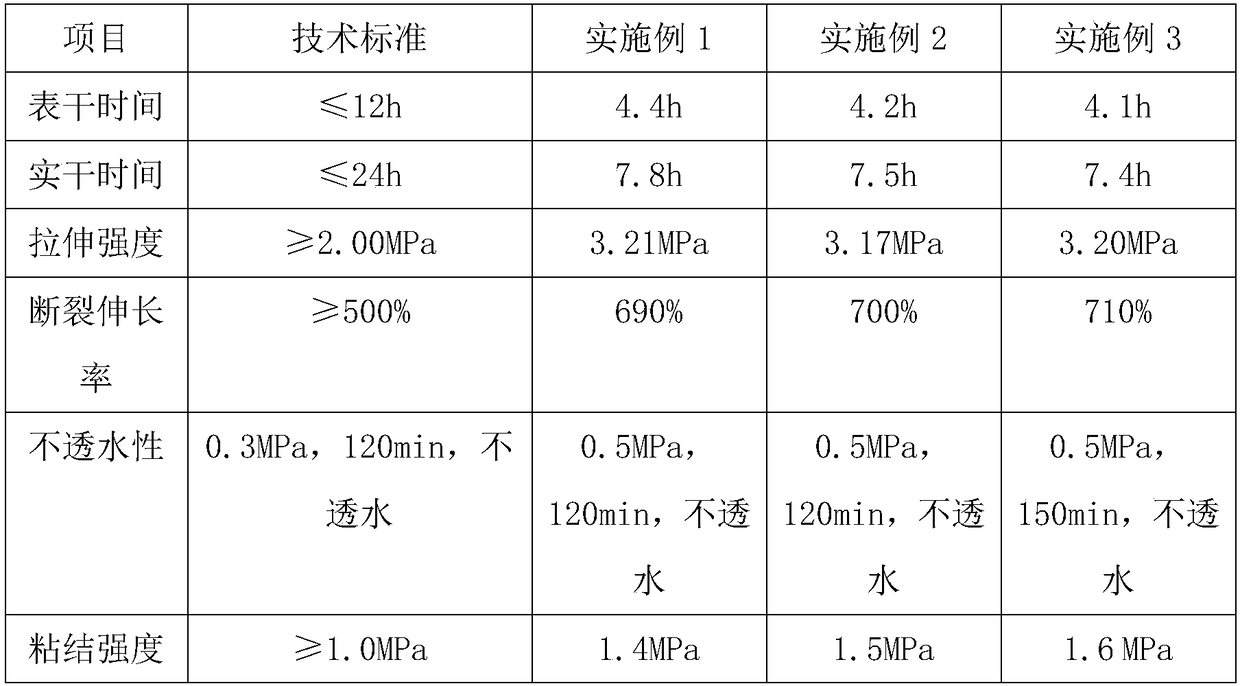

The invention discloses an acrylic water-based paint for motor shells and a preparation method thereof, relating to the technical field of metal water-based paints. The acrylic water-based paint for motor shells comprises the following raw materials in parts by weight: 45-50 parts of acrylic modified resin, 0.4-0.8 part of pH regulator, 0.6-1.5 part of dispersing agent, 0.3-0.5 part of defoaming agent, 0.01-0.5 part of graphene oxide, 0.05-3 parts of carbon black, 10-20 parts of rutile titanium white, 2-10 parts of antirust pigment, 0.5-4 parts of matting powder, 0.5-8 parts of ground calcium carbonate, 3-8 parts of barium sulfate, 0.05-0.15 part of anti-settling agent, 2-3 parts of film forming aid, 0.1-0.5 part of wetting agent, 0.1-0.5 part of leveling agent, 0.1-0.5 part of flash-rust inhibitor, 0.1-1.2 parts of thickener and 6-16 parts of deionized water. The water-based paint has the advantages of favorable antirust effect, quick air-drying, high adhesive force and high hardness; and by using water as the diluter, the water-based paint satisfies the environmental requirements, and is harmless to the human body.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Padding production process of single moisture conductive quick-drying shell fabric

InactiveCN101871155ASimple preparation processEasy to cutMercerising of sliversLiquid/gas/vapor removalTemperature resistanceAgricultural engineering

The invention relates to the technical field of cloth shell fabrics, in particular to a padding production process of a single moisture conductive quick-drying shell fabric. The process is characterized by comprising the following steps of: according to the principle of printing technology, placing prepared waterproofing agent, labberring agent and thickener in a padding groove, adjusting the PH to 8.0 by using ammonia, then placing knitwear and textile fabrics to be treated using a padding device, coating on the shell fabric, wherein the coating technology is screen scraper blade floating coating; then drying twice, wherein the drying temperature is 130 DEG C for 2-3 minutes after first coating, and the drying temperature at high temperature is 170 DEG C for second shaping, the padding speed is controlled at 20 meters / minute, and the whole cloth is stably finished within 1 minute. Compared with the prior art, the invention has the advantages of simple preparation processes, good quick-drying property which accelerates the moisture conductive speed of the shell fabric after absorbing moisture, high temperature resistance, convenient cutting and good comfort provided for the users.

Owner:陈昱达

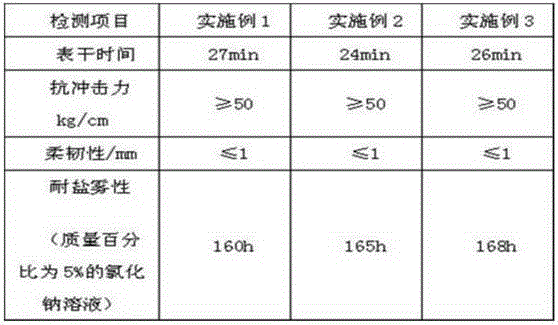

Environment-friendly anticorrosion quick-drying type primer-topcoat integrated air-dry paint and preparation method thereof

ActiveCN106634382AImprove quick-dry performanceGood water resistanceSiccativesAnti-corrosive paintsChemistrySalt resistance

The invention discloses environment-friendly anticorrosion quick-drying type primer-topcoat integrated air-dry paint and a preparation method thereof. The air-dry paint is characterized in that acrylic acid modified epoxy ester resin and styrene modified acrylic resin are jointly used as a film forming matter; a calcium and manganese naphthenate compound drier prepared from calcium naphthenate, manganese naphthenate and isobutanol is contained; various auxiliary agents and pigment fillers are added; an excellent air-dry effect can be achieved; good properties of water resistance, salt resistance, salt spray resistance and the like are realized. The air-dry paint provided by the invention has the advantages that the work efficiency is high; only once construction is needed; a large number of organic solvents are not contained; almost no pollution is caused on environment; heating is not needed in a work state; the energy consumption is reduced; the air-dry paint belongs to primer-topcoat integrated air-dry paint integrating environment protection, anticorrosion and quick drying.

Owner:珠海市立州水性涂料有限公司

Waterproof paint with improved hydrophobic property

InactiveCN108822714AImprove stabilityGood weather resistancePolyurea/polyurethane coatingsPolymer scienceStearic acid

The invention relates to the technical field of paints, specifically to a waterproof paint with an improved hydrophobic property. The waterproof paint with the improved hydrophobic property comprisesthe following components: amine-terminated polyether, hydroxyl terminated polyether, isocyanate, dioctyl phthalate, a chain extender, hydrophobic modified fillers, a catalyst, cyclohexane, a silane coupling agent and an auxiliary, wherein inorganic fillers contained in the hydrophobic modified filler are kaolin, a talcum powder and light calcium carbonate; the surfaces of the inorganic fillers aretreated by using a modifier with taking an organic silane coupling agent, stearic acid, ethylene glycol and acetic acid as main components so that the hydrophobic property of the inorganic fillers and the compatibility between the inorganic fillers and a polyurethane polymer are both improved. Therefore, the hydrophobic property of the modified waterproof paint is improved, and the stability andthe weather resisting performance of the material are improved.

Owner:合肥昂诺新材料有限公司

Aqueous dispersion of carbon black and method of producing the same

InactiveCN101233198AGood dispersionImprove wear resistanceInorganic pigment treatmentInksWater basedHydrogen atom

The invention discloses an aqueous dispersion of carbon black, which exhibits excellent dispersibility in an aqueous medium, and exhibits excellent wear resistance (quick drying), jetting stability, etc., and can be used as an inkjet printer Water-based black ink, etc. The carbon black aqueous dispersion includes an aqueous medium and carbon black dispersed in the aqueous medium, and the acidic groups formed by liquid-phase oxidation on the surface of the carbon black use basic amino acids and a base other than basic amino acids The neutralization of the acidic compound, the hydrogen atom of the acidic group is replaced by the basic amino acid and the basic compound. Also disclosed is a method for the preparation of an aqueous dispersion of carbon black, which comprises liquid-phase oxidation of carbon black, removal of reducing salts from the resulting slurry, neutralization of carbon black with basic amino acids and basic compounds other than basic amino acids, making The basic amino acid and basic compound replace the hydrogen atom of the acidic group, and the resulting product is purified.

Owner:TOKAI CARBON CO LTD

Waterborne two-component epoxy composition as well as preparation method and application thereof

ActiveCN111073461AGood quick dryingImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsPolymer scienceFirming agent

The invention provides a waterborne two-component epoxy composition as well as a preparation method and application thereof. The composition comprises a component A containing a waterborne epoxy resindispersion and a component B containing a waterborne epoxy curing agent, wherein the waterborne epoxy resin dispersion is a system formed by dispersing emulsified first epoxy resin into a water phase; and the waterborne epoxy curing agent is a polyethylene polyamine curing agent modified by second epoxy resin. According to the invention, the quick-drying waterborne two-component epoxy compositionis obtained, and a paint film obtained by using the composition has the advantages of low VOC, higher drying speed, better film-forming property, no cracking during thick coating and excellent corrosion resistance.

Owner:WANHUA CHEM GRP CO LTD +1

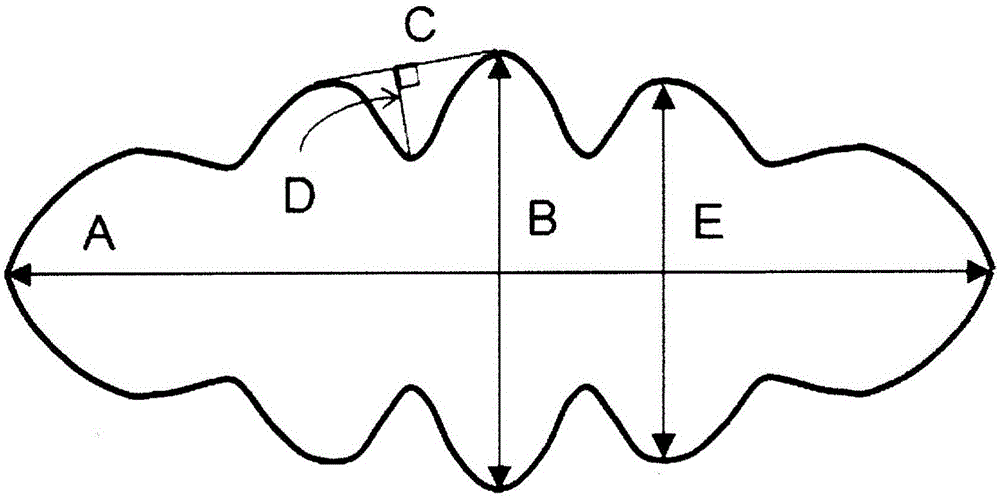

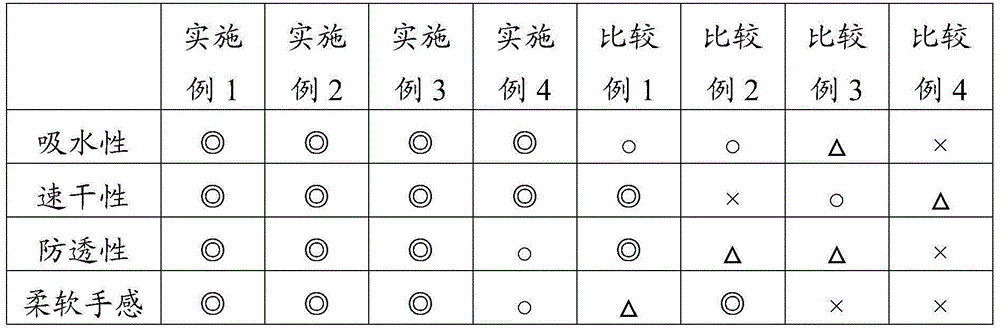

Spun yarn and woven or knitted fabric

ActiveCN105051275AHigh anti-penetration functionStrong water absorptionWeft knittingFilament/thread formingYarnPolyester

[Problem] To provide: a spun yarn which has not only a soft texture but also functions that cannot be attained by a natural or cellulosic fiber alone, namely high water absorption, quick drying property and non-see-through property, and which is suitable for clothing, particularly for inner shirts or sport shirts; and a woven or knitted fabric comprising the same. [Solution] A mixed spun yarn which comprises 20 to 80 mass% of a polyester-based fiber having a flat multi-lobe section and 20 to 80 mass% of a cellulosic fiber, wherein: the cross section of the polyester-based fiber has a flat shape which has six or more protrusions on the circumference; and the flatness degree and modification degree of the cross section are prescribed.

Owner:TORAY IND INC

Flame-retardant spray marking paint and preparation method thereof

InactiveCN111647328AImprove performanceImprove adhesionFireproof paintsRosin coatingsCellulosePolymer science

The invention belongs to the technical field of paint preparation, and particularly relates to flame-retardant spray marking paint and a preparation method thereof. The flame-retardant label sprayingpaint at least comprises the following components in parts by weight: 1-10 parts of thermoplastic acrylic resin, 1-10 parts of cellulose acetate butyrate, 5-10 parts of a pigment, 0.2-2 parts of a flame retardant and 60-120 parts of a solvent. The flame-retardant spray marking paint prepared by the preparation method disclosed by the invention is good in flame retardance, good in temperature resistance, capable of being normally used at 200 DEG C, good in quick-drying property, uniform in paint film, bright in color, good in weather resistance, free from the influence of air temperature and ultraviolet rays, and high in adhesive force; meanwhile, excellent dispersity is achieved, the problems of thickening, pigment sedimentation and the like cannot be generated after long-time storage, thefineness does not exceed 3 microns, a paint film is softened, use and spraying are smoother, a nozzle is not prone to being blocked, and excellent stability is achieved.

Owner:上海维巳达实业有限公司

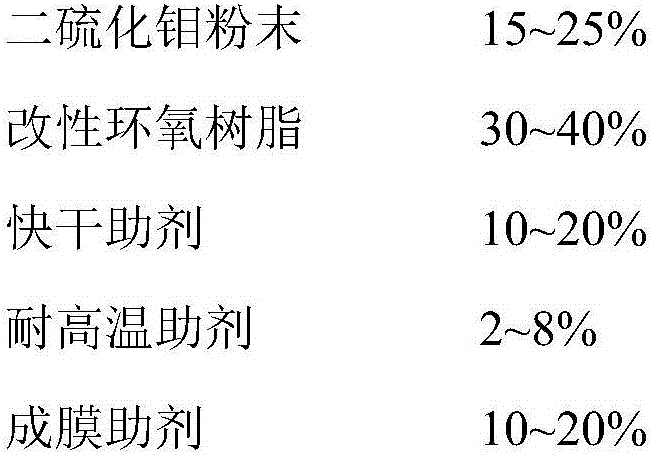

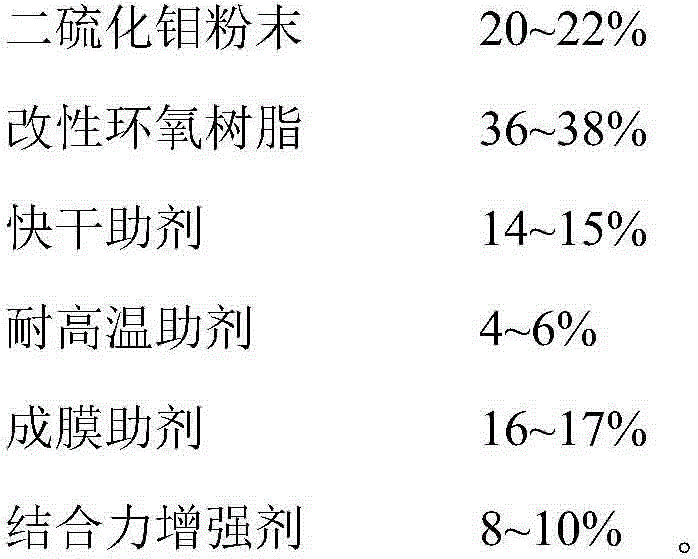

Molybdenum disulfide lubricating spray and preparation method thereof

ActiveCN105886074AEasy to useEasy to carryEpoxy resin coatingsLubricant compositionEpoxyWear resistance

The invention discloses a molybdenum disulfide lubricating spray. The molybdenum disulfide lubricating spray comprises components in percentage by weight as follows: 15%-25% of molybdenum disulfide powder, 30%-40% of modified epoxy resin, 10%-20% of a quick-drying auxiliary, 2%-8% of a high-temperature-resistant auxiliary, 10%-20% of a coalescing agent and 5%-15% of a binding force enhancer. The molybdenum disulfide lubricating spray is simple and convenient to use, has good quick-drying capacity and temperature tolerance, can be applied to the ultrahigh temperature environment and the ultralow temperature environment and has good lubricating property, abrasion performance and extreme pressure resistance, and the temperature tolerance range is 180-450 DEG C.

Owner:在邦润滑材料(上海)有限公司

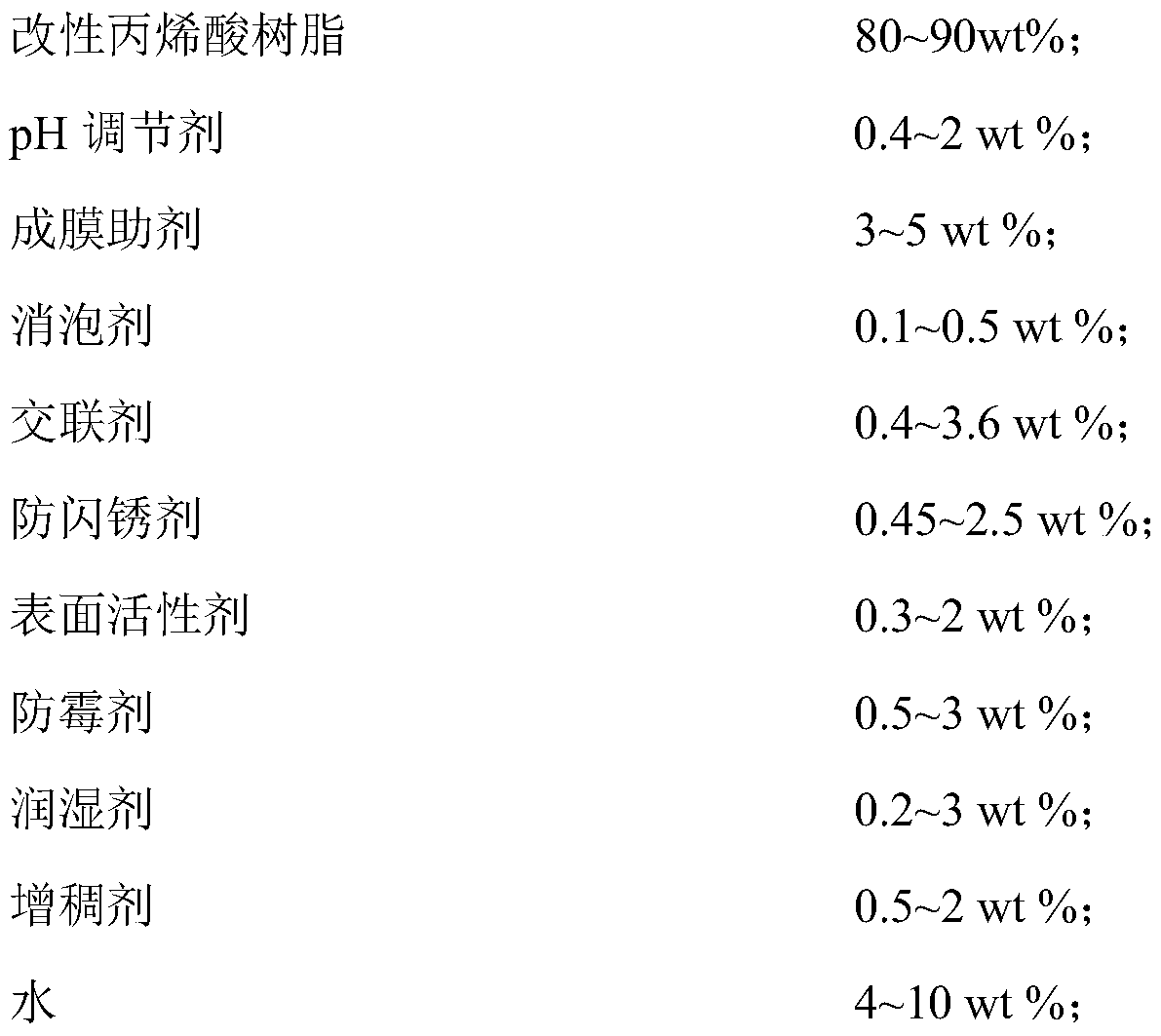

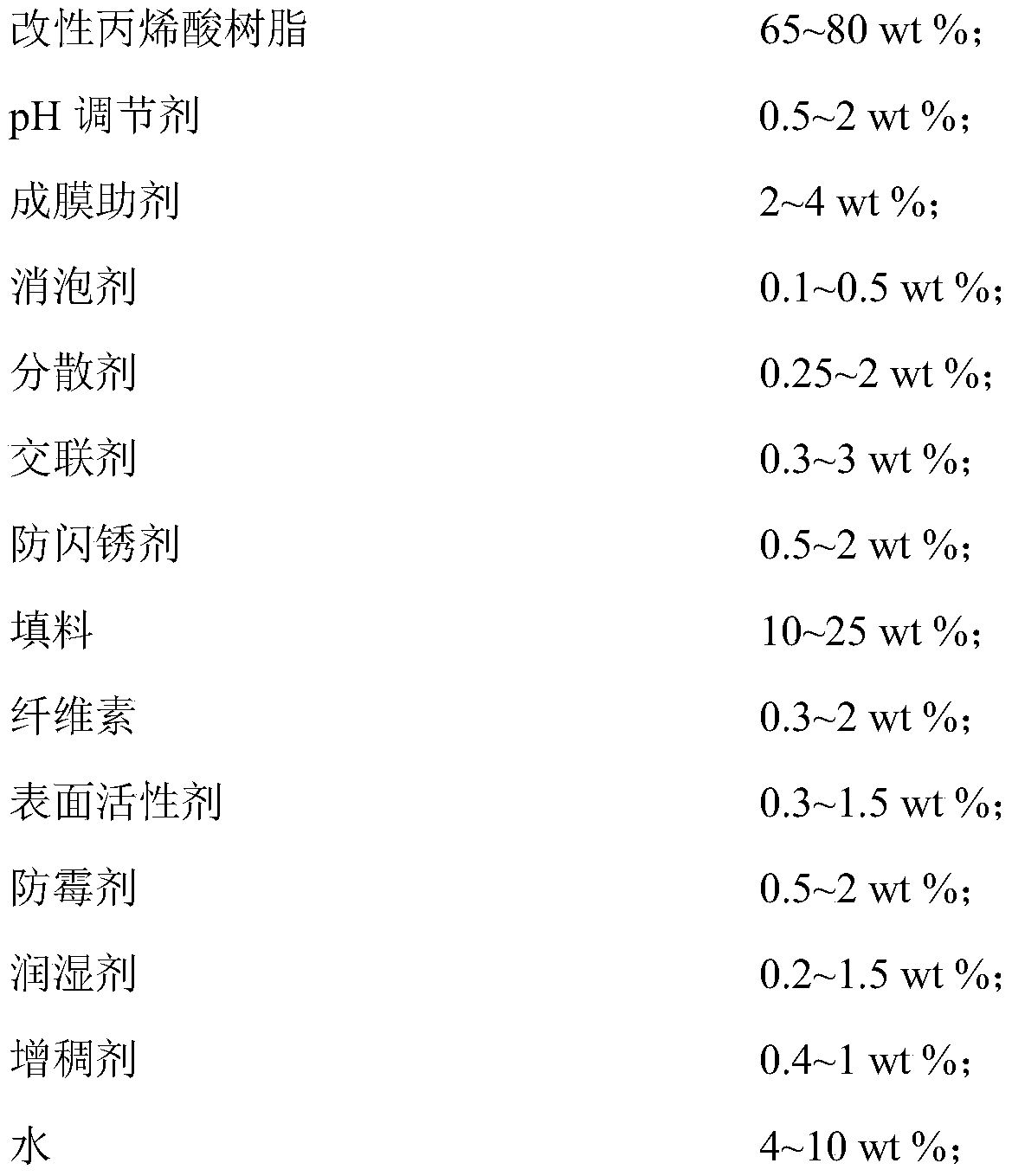

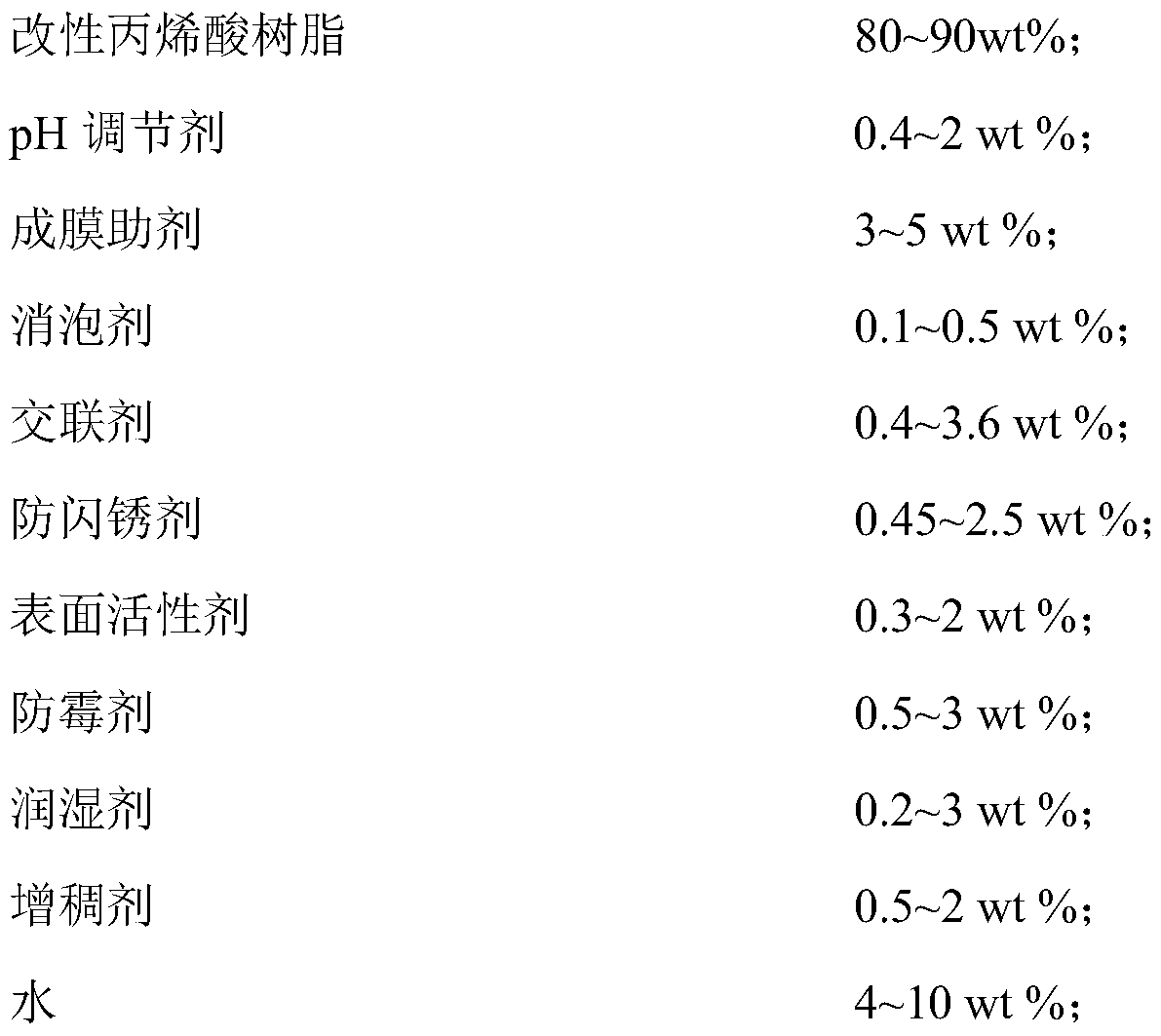

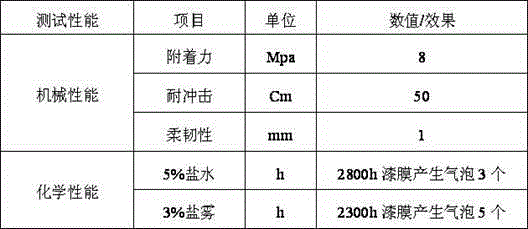

Water-based coil steel repair paint and preparation method thereof

ActiveCN109913072AGood alkali resistanceImprove corrosion resistanceAntifouling/underwater paintsPaints with biocidesWater basedAcrylic resin

Owner:SHANGHAI UNIV OF ENG SCI +1

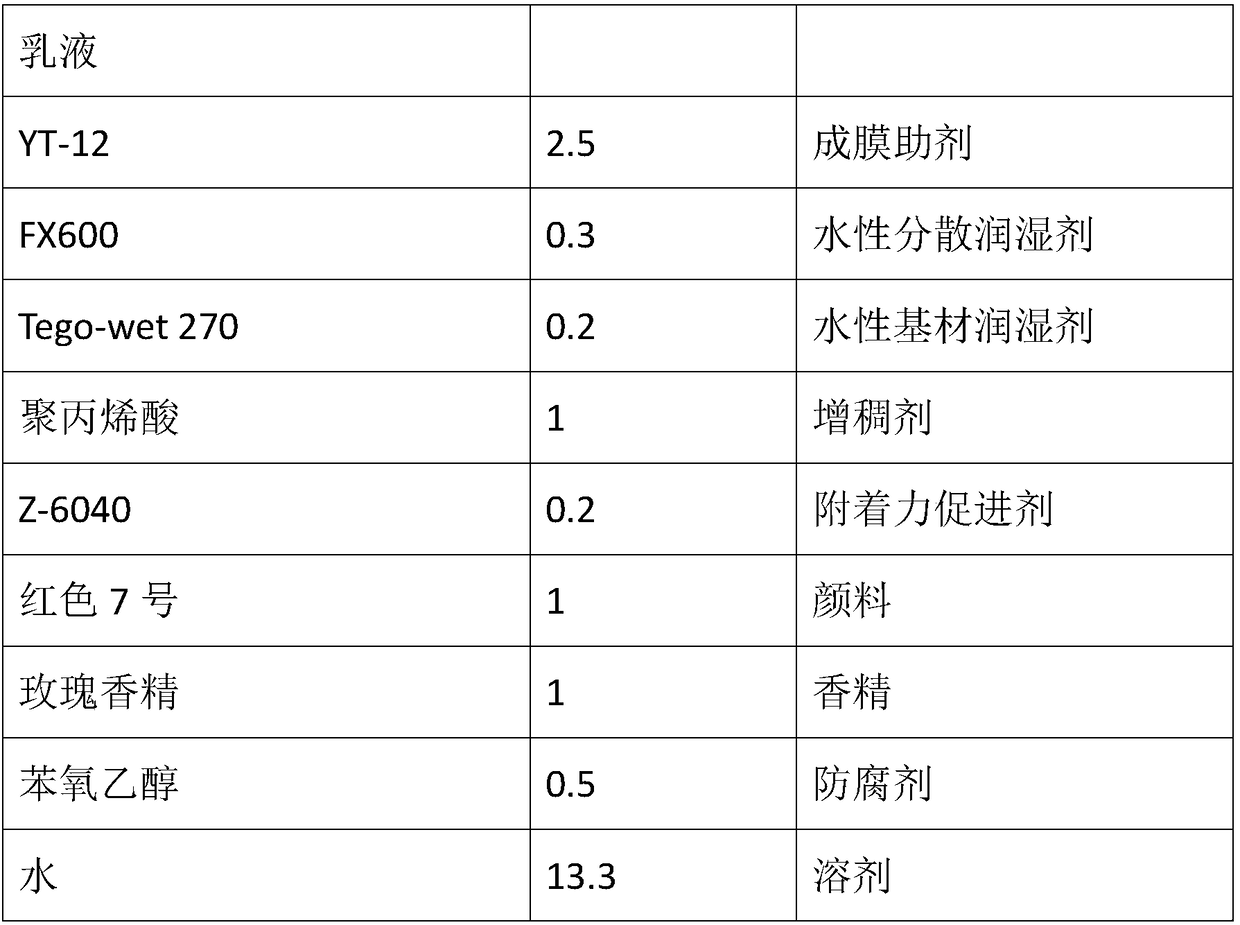

Water-soluble nail polish and preparation method thereof

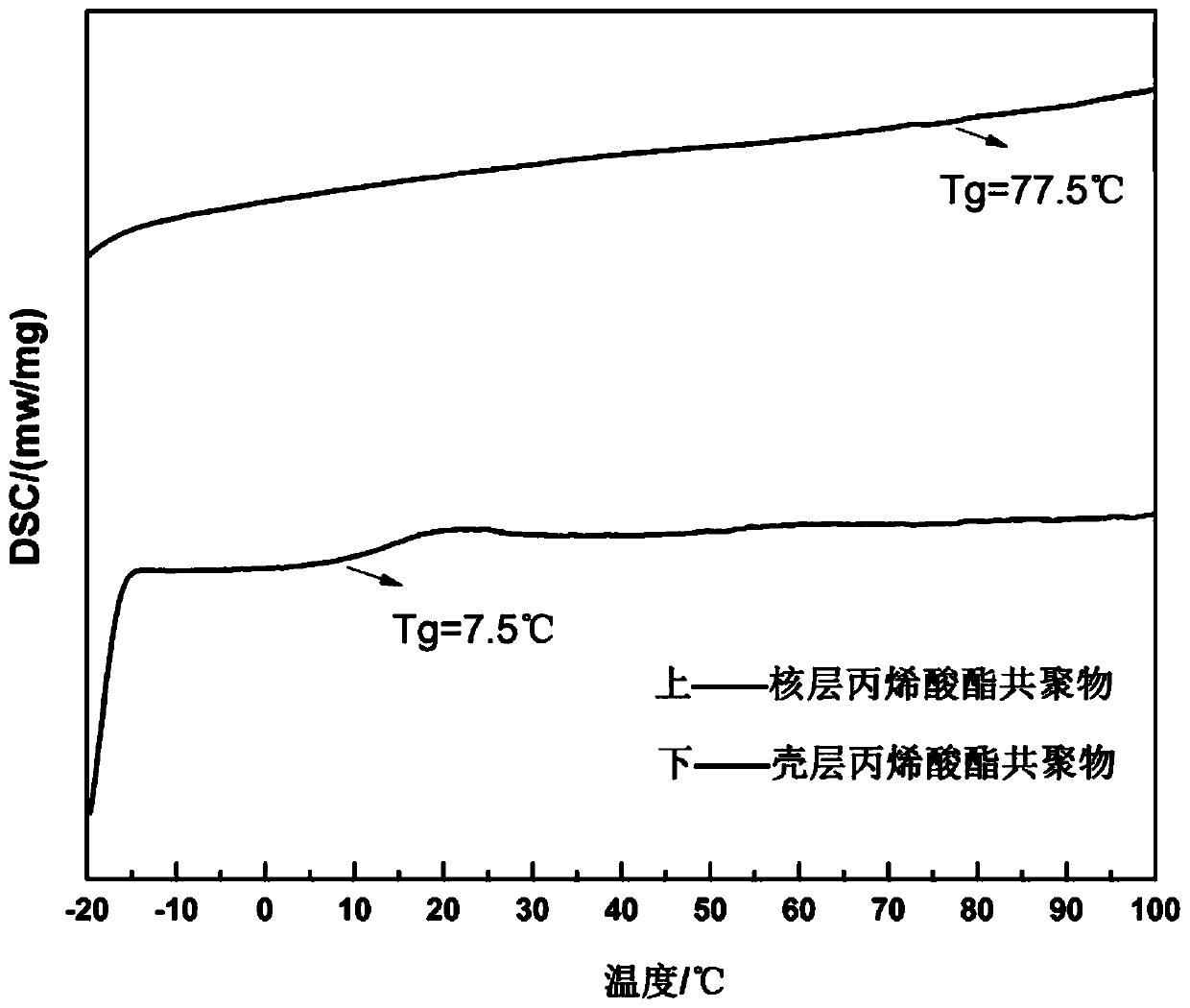

InactiveCN108272656AStrong adhesionImprove adhesionCosmetic preparationsToilet preparationsEmulsionWater soluble

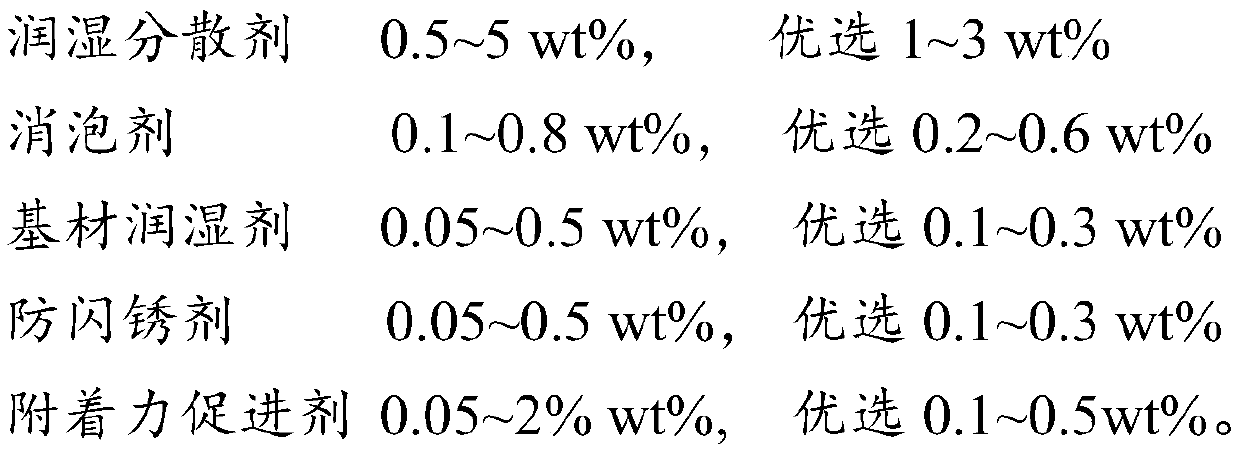

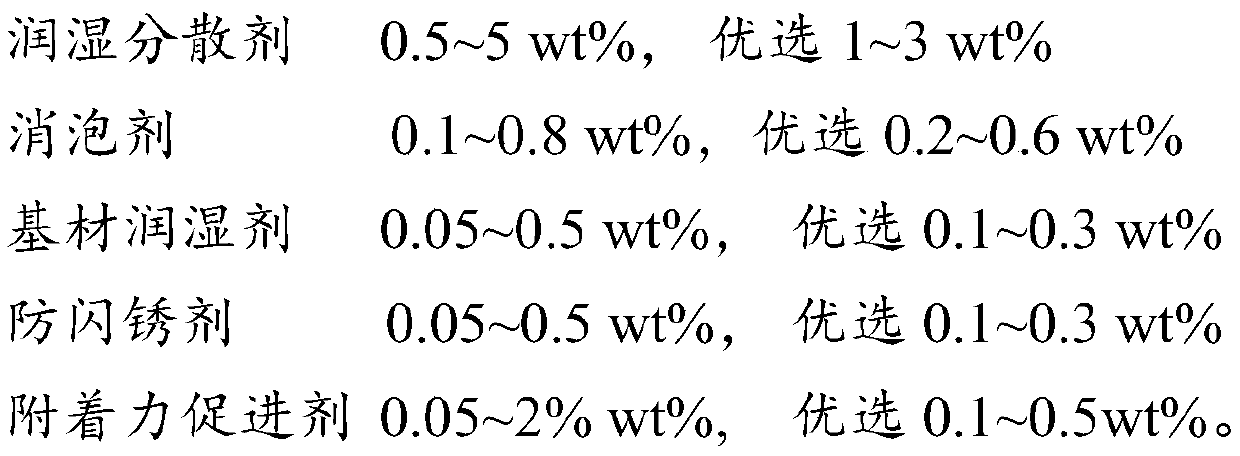

The invention provides water-soluble nail polish and a preparation method thereof. The water-soluble nail polish comprises a waterborne polyurethane-modified acrylic composite emulsion, a film formingaid, a waterborne wetting dispersant, a waterborne substrate wetting agent, a thickening agent, an adhesion promoter, a pigment, other auxiliaries and water. The preparation method comprises the following steps: adding the waterborne polyurethane-modified acrylic composite emulsion at a rotating speed of 800-900 r / min, adding the film forming aid at a speed of 6-8 L / h, dispersing for 25-30 minutes, then adding the waterborne wetting dispersant and the waterborne substrate wetting agent, continuously dispersing for 10-15 minutes, then adding the pigment, the adhesion promoter and the other auxiliaries, uniformly stirring, adjusting the viscosity with the thickening agent and the balance of water, and filtering and packaging with a 150-mesh filter screen. The water-soluble nail polish provided by the invention uses the waterborne polyurethane-modified acrylic core-shell composite emulsion with a special structure and is fine in particle size, optimal in film-forming property, strong inadhesive force, high in water resistance, high in glossiness and strong in after tackiness resistance.

Owner:JINHUA MINGSHI TECH

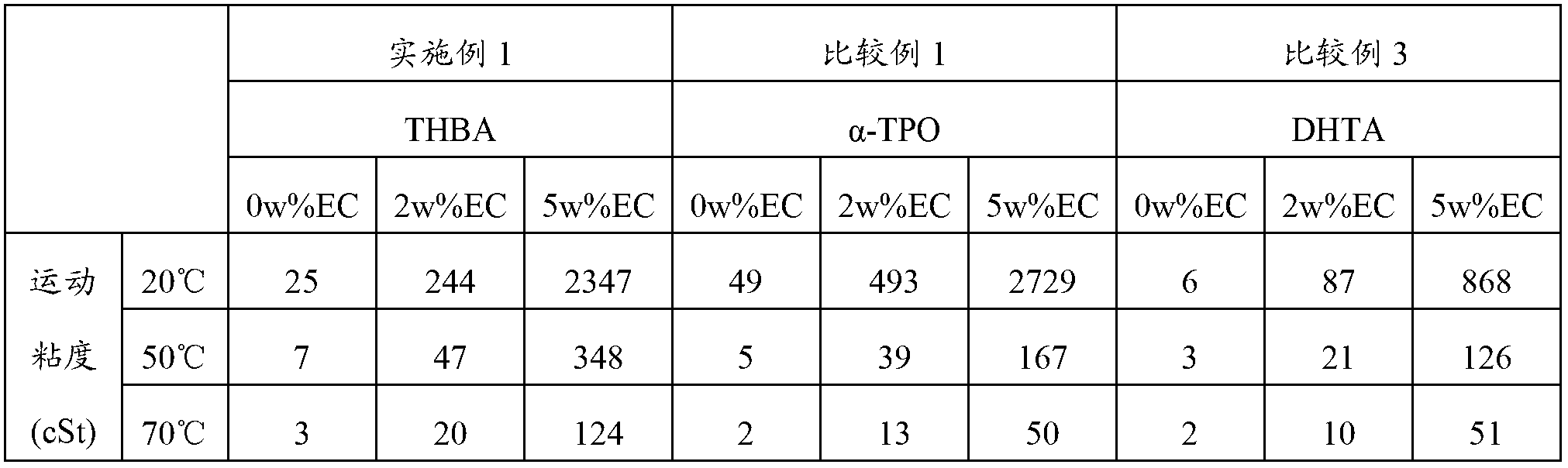

Solvent or solvent composition for printing

InactiveCN102827508AExcellent pattern retentionGood quick dryingTransistorFinal product manufactureLetterpress printingBENZYL ALCOHOL/WATER

The invention provides a solvent or solvent composition which is used in printing ink of electronic component patterns formed by a printing method. The solvent or solvent composition gives excellent stencil misplacing property at printing and excellent pattern maintenance and quick-drying property at high temperature and dry to the printing ink. The solvent or solvent composition for printing the electronic component patterns is used for the electronic component patterns through the printing method, and contains at least more than 10 % by weight of 1,2,5,6-tetrahydro benzyl alcohol in the total weight (100 %) of the solvent or solvent composition. The printing method is preferably selected from at least one of an inkjet method, a screen printing method, a letterpress printing method, an offset printing method, a gravure printing method, a micro-contact printing method and a nano-imprinting method.

Owner:DAICEL CHEM IND LTD

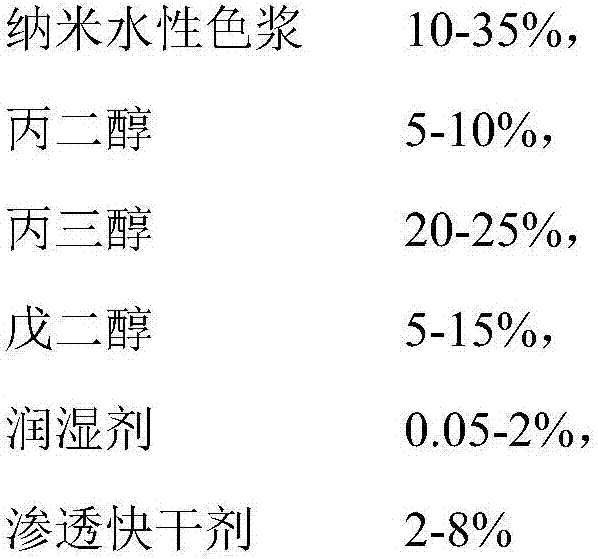

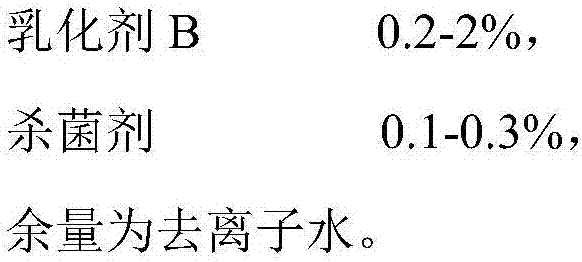

Waterborne Single-pass Kyocera high-speed ink-jet printing heat transfer ink and preparation method thereof

ActiveCN107987612AInkjet smoothGood standby performanceTransfer printingInksEnvironmental resistanceSalt free

The invention provides a waterborne high-speed ink-jet printing heat transfer ink for a Single-pass Kyocera nozzle. The waterborne high-speed ink-jet printing heat transfer ink is prepared from the following raw materials of nanometer color paste, polyhydric alcohols, a wetting agent, a penetration quick-drying agent, an emulsifier B, a sterilant and deionized water, wherein the color paste is prepared from the following raw materials of salt-free refined superfine dispersive dye color powder, a dispersant, an emulsifier A, glycerin, a sterilant, a defoamer and deionized water. The waterborneKyocera high-speed ink-jet printing heat transfer ink has the advantages that the waterborne high-speed ink-jet printing heat transfer ink is suitable for Single-pass high-speed ink-jetting printing of Kyocera KJ4B-600DPI nozzle, the printing is smooth, the standby property is good, the quick-drying property is good, the printing property is stable, and the wire drawing is avoided; the color stability and reduction property are good, the register and color are conveniently matched in the printing process, the printing quality is high, the consistency of the finished product is good, the comprehensive cost is low, the waste of dye ink is avoided, and the resource is saved; the physical and chemical properties are excellent, namely that the level of water washing property is 4 to 5, the level of dry and wet scratching property is 4 to 5, and the sun-resistant property is 3.5 to 5; the environment-friendly effect is realized, and the poison and harm are avoided; in the printing process, the platemaking is not needed, the wastewater and waste gas are not produced, and the high-efficiency and environment-friendly effects are realized.

Owner:珠海东昌色彩科技有限公司

Brown undertone canvas

InactiveCN104890437ABright appearanceNot easy to decolorizeOther artistic work equipmentsVegetal fibresChemistryCoating

The invention discloses a brown undertone canvas. A preparation method of the brown undertone canvas includes the steps: (1) coating gel resin on the surface of a fabric, and then drying the gel resin in an oven at the temperature of 100-120 DEG C to obtain a gel resin layer; (2) coating prime paint on the surface of the gel resin layer, and drying the prime paint in the oven at the temperature of 90-100 DEG C to form a prime paint layer; (3) coating colorant paint on the surface of a bottom layer, and drying the colorant paint in the oven at the temperature of 90-100 DEG C to form a colorant layer; (4) finally, coating brown undertone top paint on the colorant layer, and drying the brown undertone top paint in the oven at the temperature of 70-85 DEG C. The speed of the fabric penetrating the oven is 6-7 meters per minute. The brown undertone canvas is fine in waterproof performance, saturation and drape effect, bright in color, colorful and not easy to fade.

Owner:WUXI PHOENIX ARTIST MATERIALS

Waterborne self-drying anticorrosion priming paint for construction crane and preparation method thereof

ActiveCN104031533AImprove corrosion resistanceGood value for moneyAnti-corrosive paintsPolyester coatingsPolymer scienceSilicon dioxide

The invention discloses a waterborne self-drying anticorrosion priming paint for a construction crane and a preparation method thereof. The priming paint comprises, by weight, 10 to 30% of a resin, 25 to 45% of an auxiliary agent, 2 to 15% of a thickening thixotropic agent, 0.8 to 6% of an antirust pigment, 2 to 4% of silica and 15 to 25% of an auxiliary material. The preparation method for the waterborne self-drying anticorrosion priming paint comprises the following steps: step (1), mixing the resin and the auxiliary material according to a ratio of 4: 6; step (2), putting the resin and the auxiliary material into an agitator for stirring and dispersing, wherein a stirring speed is 400 to 700 r / min; step (3), adding the prepared thickening thixotropic agent, antirust pigment and silica into the agitator for uniform mixing under stirring; and step (4), adding the auxiliary material and carrying out stirring for 40 to 55 min.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

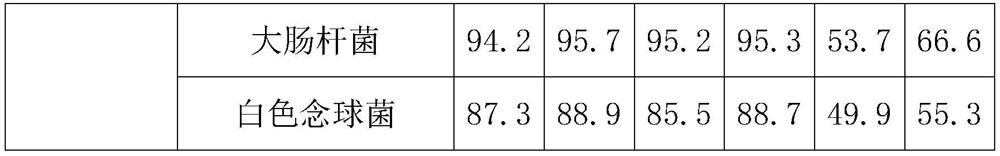

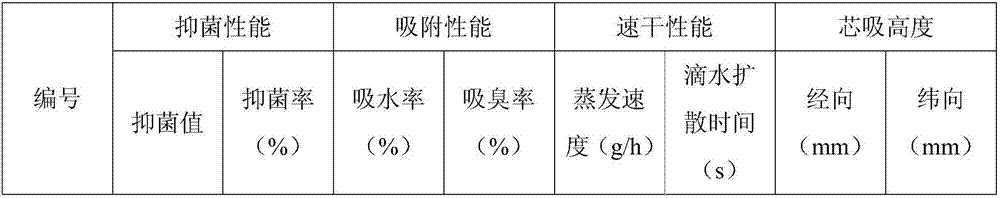

Production method of antibacterial moisture-absorbing and quick-drying fabric

InactiveCN111926440ASimple production processGood antibacterialBiochemical fibre treatmentFibre typesCotton fibreDyeing

The invention provides a production method of antibacterial moisture-absorbing and quick-drying fabric. The production method comprises the following steps that S1, sea-island fiber is used as first warp yarn, polyester long fiber of 300D is used as second warp yarn, and weaving is carried out to obtain warp yarn; S2, the warp yarn is immersed in a sodium hydroxide solution, modified with polyquaternium-7 and propylene glycol monolaurate, then immersed in a functional modification solution for modification, taken out, and dried to obtain modified warp yarn; S3, cotton fiber is used as first weft, the polyester long fiber of 300D is used as second weft, and weaving is carried out to obtain weft; S4, a group of modified warp yarn and two groups of weft are used to weave to obtain a quick-drying fabric blank; and S5, dyeing, wet scutching, shaping and drying of the quick-drying fabric blank are carried out to obtain the antibacterial moisture-absorbing and quick-drying fabric. The production method is simple in production process, and the produced fabric is good in antibacterial property, moisture absorption and moisture conductivity, soft and comfortable in texture, and superior in quick-drying performance.

Owner:李庆

One-component epoxy aluminum-rich coating for steel structure, and preparation method thereof

InactiveCN105315834AWith cathodic protectionImprove adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyBound property

The invention discloses a one-component epoxy aluminum-rich coating for steel structure, and a preparation method thereof. The coating comprises, by mass, 30-40% of one-component epoxy resin, 40-50% of aluminum powder, 5-10% of a solvent and 1-5% of an assistant. The coating has the advantages of excellent binding property, chemical corrosion resistance, wear resistance, quick drying property, water penetration resistance, flame resistance, realization of a long-term anticorrosion effect, and can be specially used to protect the steel structure.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

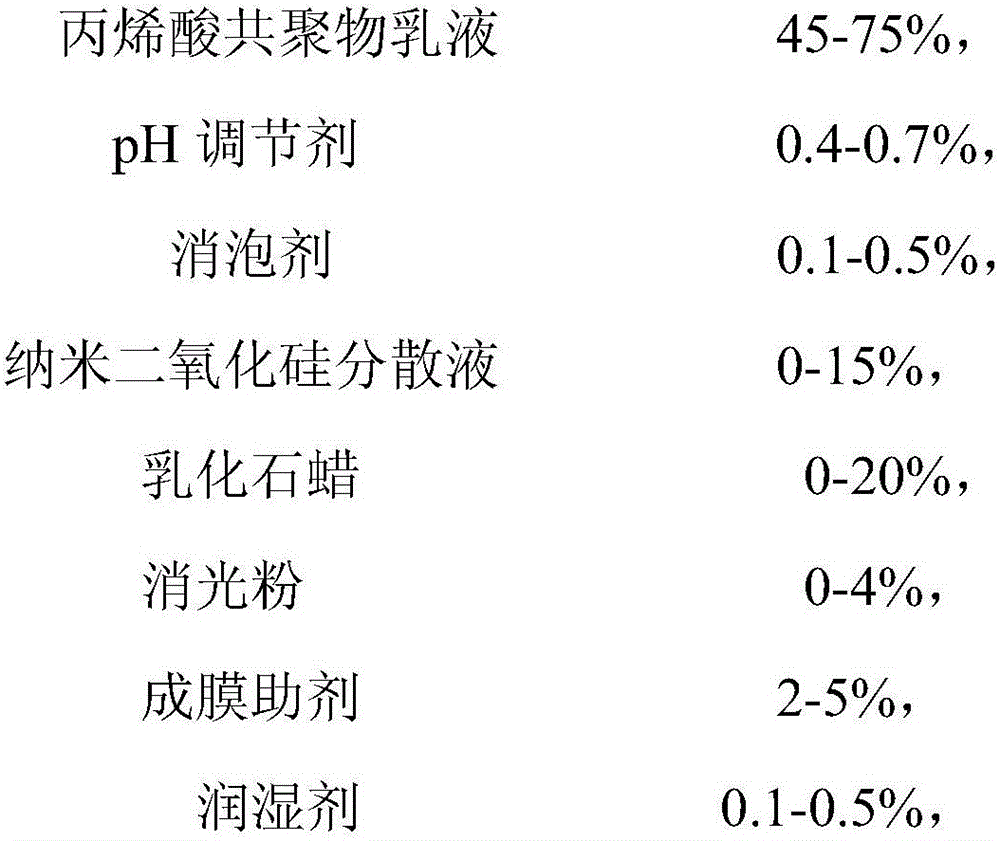

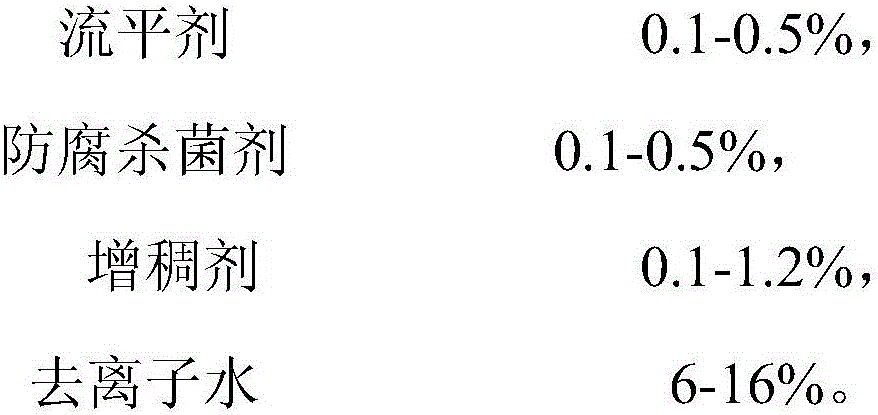

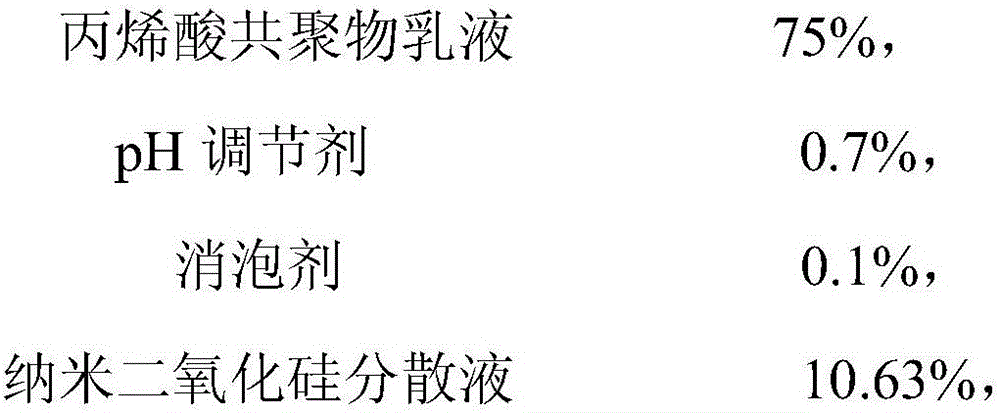

Water paint for paper materials and preparation method thereof

The invention discloses water paint for paper materials and a preparation method thereof, wherein the water paint for the paper materials comprises following components by weight: 45-75% of acrylic copolymer emulsion, 0.4-0.7% of a pH regulator, 0.1-0.5% of a defoaming agent, 0-15% of nano silica dispersion, 0-20% of emulsion paraffin, 0-4% of matting powder, 2-5% of a film forming assistant, 0.1-0.5% of a wetting agent, 0.1-0.5% of a leveling agent, 0.1-0.5% of an antisepsis and sterilization agent, 0.1-1.2% of a thickening agent and 6-16% of deionized water. The water paint has the advantages of easy increase of film thickness, good transparency, smooth surface, good hardness, excellent corrosion resistance, powdering resistance, wear resistance and good printability.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Coffee carbon fiber and preparation method thereof

PendingCN107385549ASimple processLow costMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterCarbon fibers

The invention discloses a coffee carbon fiber and a preparation method thereof. The preparation method of the coffee carbon fiber comprises the following steps: (1) roasting coffee beans into coffee carbon at a temperature of 800-1200 DEG C; (2) grinding the obtained coffee carbon into coffee carbon particles with a mesh number of 900-2000; (3) mixing the coffee carbon particles with polyester fiber primary pulp by stirring to obtain coffee carbon primary pulp; and (4) adopting a high-pressure spinneret machine for jetting the coffee carbon primary pulp into coffee carbon fibers. The invention provides the preparation method of the coffee carbon fiber. The method is simple in process, is relatively low in cost, and is not high in requirement on equipment; and the prepared coffee carbon fiber has the advantages of being good in antibacterial activity, strong in adsorption capacity, high in moisture regain, good in quick drying performance, high in negative ion emitting ability and good in uniformity.

Owner:宁波汉方家居科技有限公司

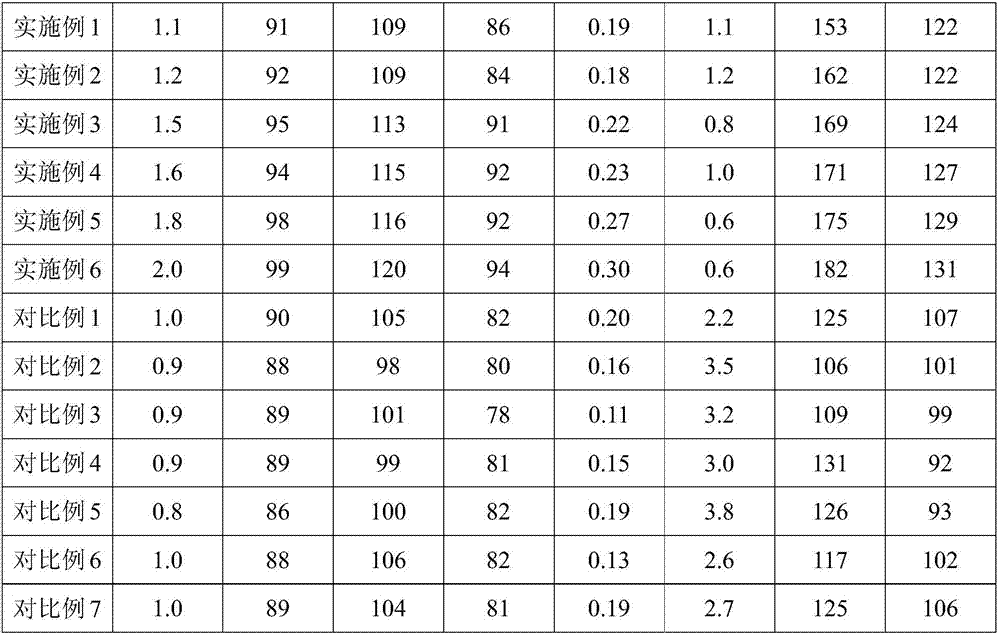

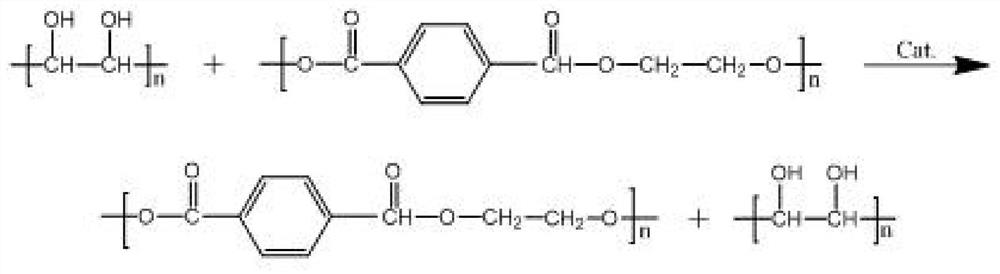

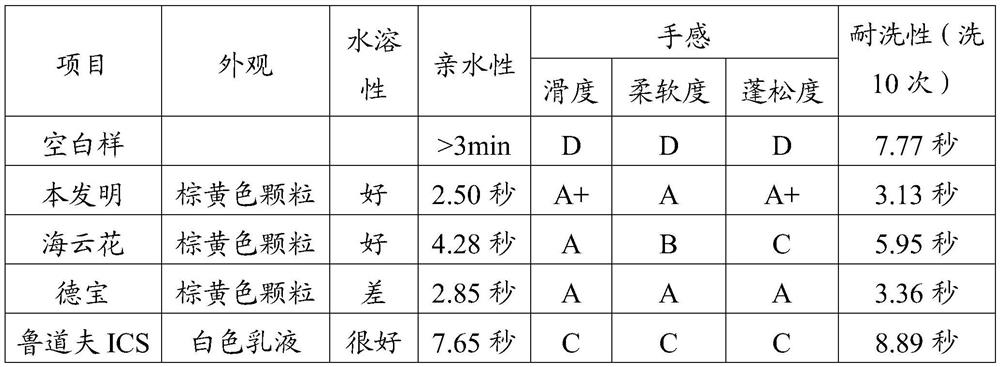

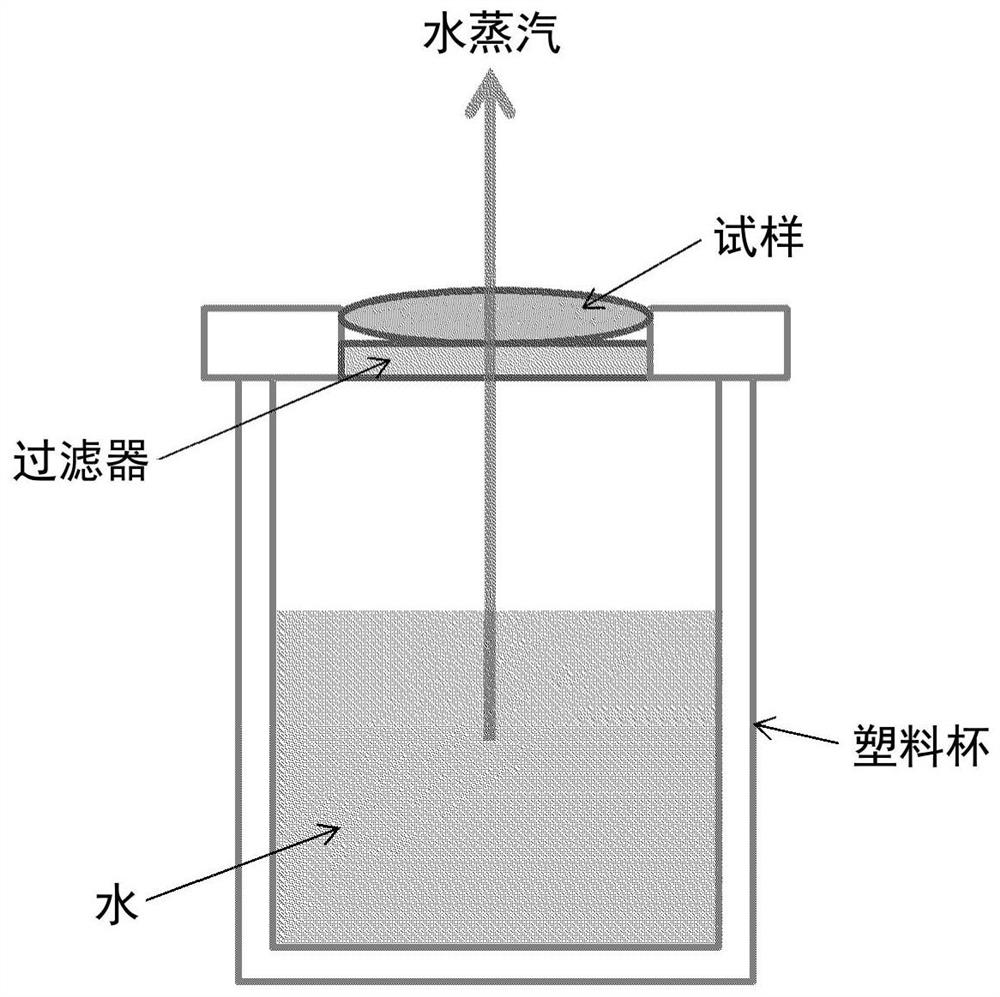

Multifunctional moisture absorption and sweat releasing finishing agent and preparation method therefor

ActiveCN111705511AStrong water absorptionGood moisture permeabilityGrip property fibresPolymer sciencePolyethylene terephthalate glycol

Owner:湖南金全立生物科技股份有限公司

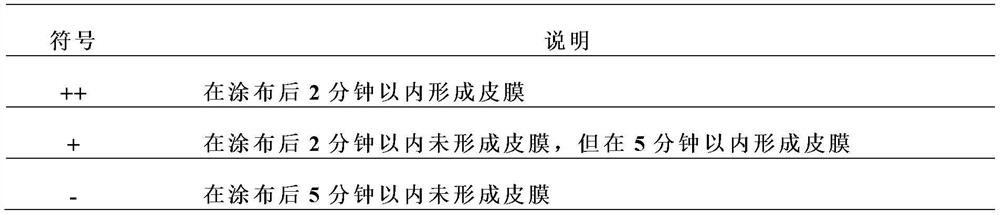

Skin composition

PendingCN113382769ALess irritatingReduce viscosityCosmetic preparationsAerosol deliveryEczematous rashChronic hand eczema

The present invention addresses the problem of providing a coating-forming-type skin composition (coating-type skin protective agent, coating-type skin topical agent, or the like) that does not contain a lower monovalent alcohol such as ethanol and isopropanol, that has excellent quick-drying ability and water resistance, and that is less sticky and provides excellent sensation when being used. The present invention pertains to a coating-forming-type skin composition characterized by containing a specific acrylic polymer, a plasticizing agent, and water, but substantially not containing a lower monovalent alcohol such as ethanol and isopropanol. The composition according to the present invention is extremely useful in the therapy of chronic skin diseases, etc., represented by hand eczema, atopic dermatitis, or the like (i.e., skin diseases with reduced skin barrier function).

Owner:MARUHO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com