Waterborne self-drying anticorrosion priming paint for construction crane and preparation method thereof

An anti-corrosion primer and crane technology, which is applied in anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problems that engineering cranes cannot be used for coating, engineering cranes occupy a large area, and cannot set up independent spraying workshops, etc., to achieve excellent Adhesiveness, increase production efficiency, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

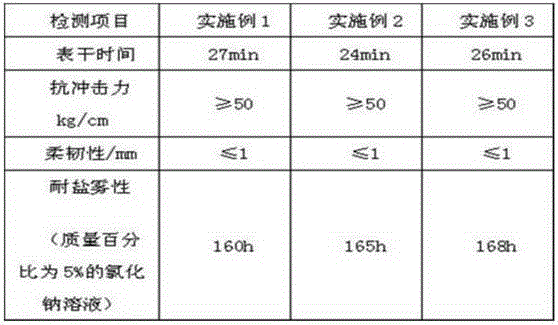

Embodiment 1

[0024] A water-based self-drying anti-corrosion primer for engineering cranes provided in this embodiment, the primer consists of resin: 20%, additives: 30%, thickening thixotropic agent: 15%, anti-rust pigment: 6%, carbon dioxide Silicon: 4%, auxiliary material: 25%; auxiliary agent is initiator: 15%, dispersant: 15%, defoamer: 10%, emulsifier: 60%; auxiliary material is titanium dioxide: 30%, mica powder : 35%, light stabilizer: 25%; resin is 0814 water-based polyester resin; silicon dioxide is A380, light stabilizer is light stabilizer 292, thickening thixotropic agent is FLU 600 anti-settling thickening thixotropic agent, The antirust pigment is 313 mica iron oxide; the initiator is polyacrylamide, the dispersant is pigment dispersant, BOK-5406, the defoamer is silicone defoamer, and the emulsifier is sodium dodecylbenzenesulfonate. The preparation method of water-based self-drying anticorrosion primer is carried out as follows:

[0025] Step (1): First configure 0814 wat...

Embodiment 2

[0030] A water-based self-drying anti-corrosion primer for engineering cranes provided in this embodiment, the primer consists of resin: 30%, additives: 40%, thickening thixotropic agent: 5%, anti-rust pigment: 5%, carbon dioxide Silicon: 3%, auxiliary material: 17%; auxiliary agent is initiator: 10%, dispersant: 25%, defoamer: 10%, emulsifier: 65%; auxiliary material is titanium dioxide: 25%, mica powder : 35%, light stabilizer: 40%; resin is 0814 water-based polyester resin; silicon dioxide is A380, light stabilizer is light stabilizer 292, thickening thixotropic agent is FLU 600 anti-settling thickening thixotropic agent, The antirust pigment is 313 mica iron oxide; the initiator is polyacrylamide, the dispersant is pigment dispersant, BOK-5406, the defoamer is silicone defoamer, and the emulsifier is sodium dodecylbenzenesulfonate. The preparation method of water-based self-drying anticorrosion primer is carried out as follows:

[0031] Step (1): First configure 0814 wate...

Embodiment 3

[0036]A water-based self-drying anti-corrosion primer for engineering cranes provided in this embodiment, the primer is composed of resin: 28%, additives: 42%, thickening thixotropic agent: 5%, antirust pigment: 5%, carbon dioxide Silicon: 3%, auxiliary material: 17%; auxiliary agent is initiator: 10%, dispersant: 25%, defoamer: 10%, emulsifier: 65%; auxiliary material is titanium dioxide: 30%, mica powder : 30%, light stabilizer: 40%; resin is 0814 water-based polyester resin; silicon dioxide is A380, light stabilizer is light stabilizer 292, thickening thixotropic agent is FLU 600 anti-settling thickening thixotropic agent, The antirust pigment is 313 mica iron oxide; the initiator is polyacrylamide, the dispersant is pigment dispersant, BOK-5406, the defoamer is silicone defoamer, and the emulsifier is sodium dodecylbenzenesulfonate. The preparation method of water-based self-drying anticorrosion primer is carried out as follows:

[0037] Step (1): First configure 0814 wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com