Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

228results about How to "Good waterproof performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

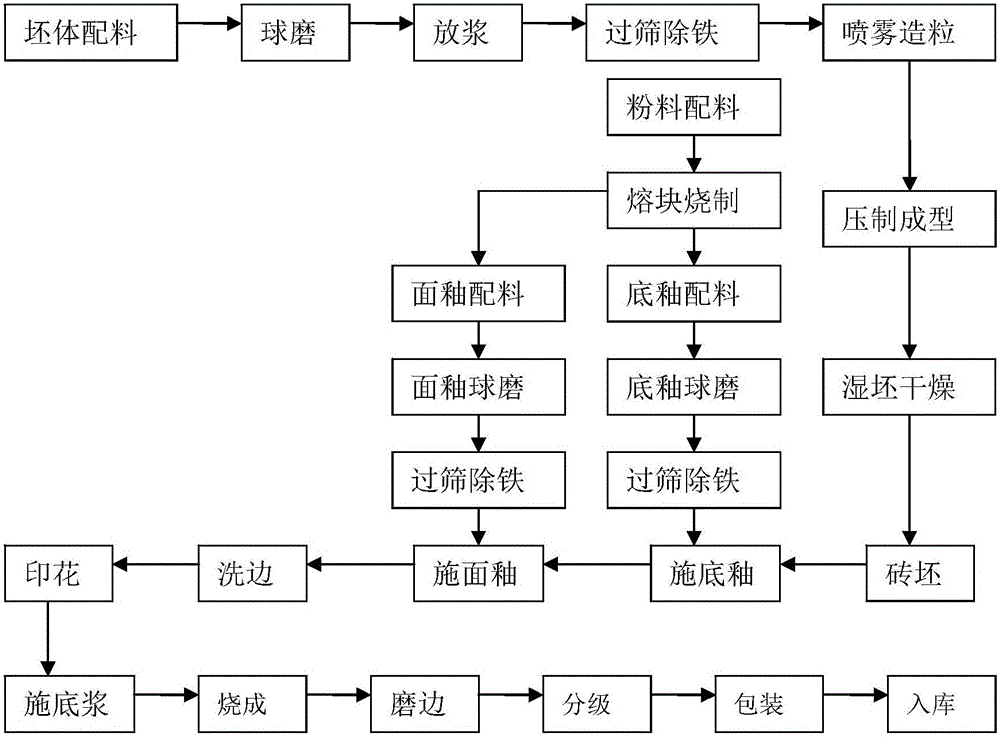

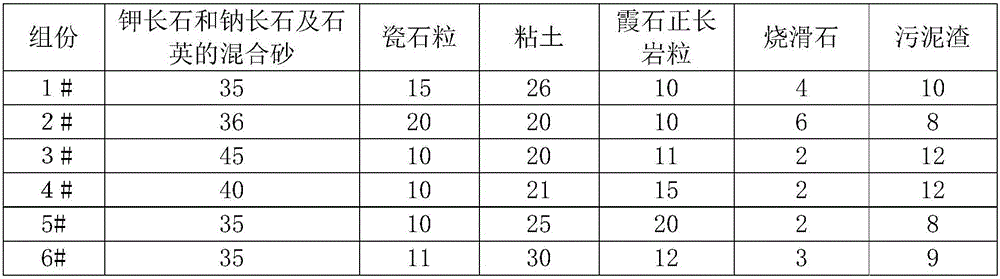

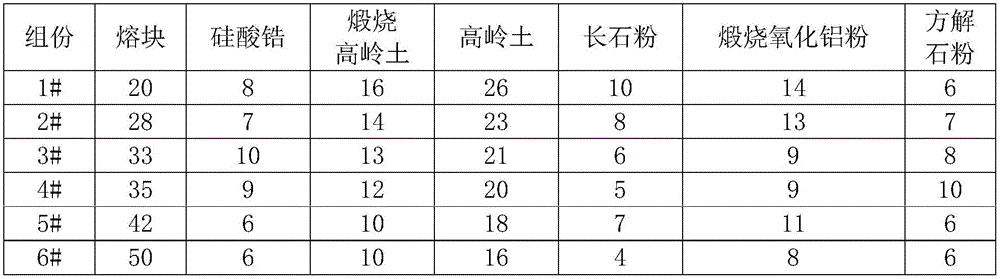

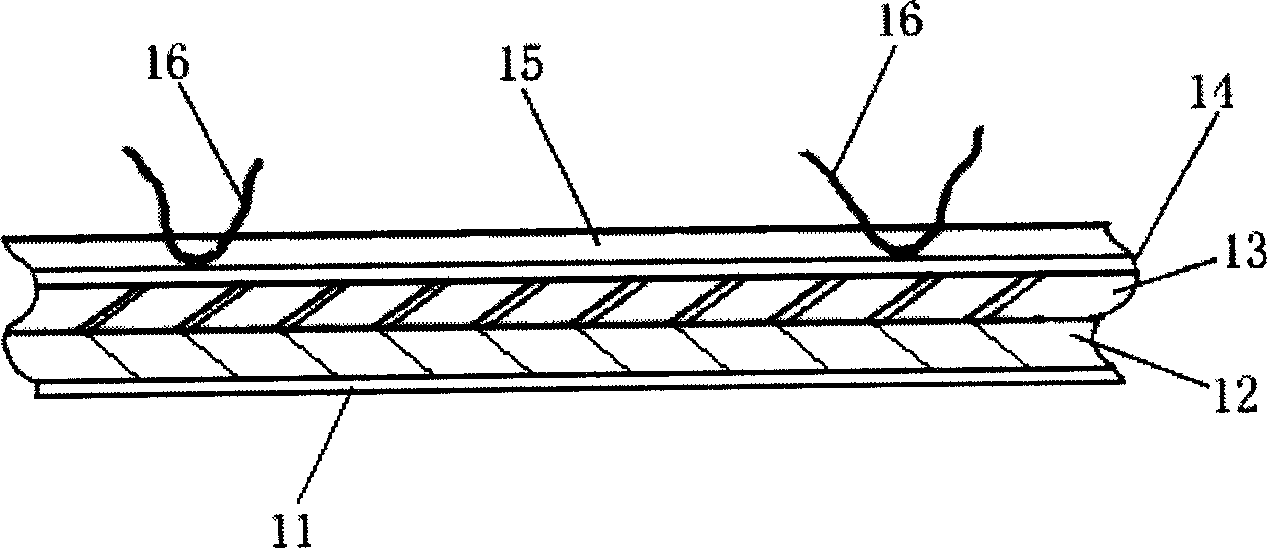

Resource-saving glazed ceramic tile having antiskid effect on surface and preparation method thereof

ActiveCN105837172AAchieve anti-slip effectGood quality glazeCeramic materials productionClaywaresBrickSludge

A resource-saving glazed ceramic tile having an antiskid effect on surface and a preparation method thereof. Without great change on production process of the glazed ceramic tiles, formula composition of a blank body, composition of ground and cover glaze frits and formula composition of ground and cover glaze are regulated and optimized focusedly, so that the glazed ceramic tile, which has excellent performance and the antiskid effect, can be prepared even large quantity sludge residue is added to the blank body. Through a high-magnification scanning electronic microscopy for observing the surface of glaze on the product, it is found that projects which are hard and needle-like and look like aluminum spinel crystal are formed on the surface, and the glaze is 0.8 in antiskid coefficient and is R12 in antiskid level when a less quantity of water is sprayed on the glaze. The glazed ceramic tile has good antiskid effect, can reach 4000 r / four grade in wear-resisting revolution through detection, and has good anti-wear performance, surface anti-fouling performance and water permeation resistance. The glaze has no defects such as needle pores, bubbles and the like, has clear decorative pattern grains and is highly stone-simulated. The technology has strong adaptability and is easy to promote in the field.

Owner:GUANGDONG WINTO CERAMICS +3

Wet coating self-adhering waterproof coiled material and producing method and construction method thereof

InactiveCN1888350AGood waterproof performanceHigh strengthLamination ancillary operationsRoof covering using flexible materialsSolventAsphalt

The present invention relates to a wet-stickable self-adhesive water-proof sheet material, its production method and construction method. It is characterized by that said invention uses butyl rubber and high-grade oxidated asphalt, makes them undergo the process of high-temperature mixing treatment, adds acryl water-absorbing resin, operation oil, filler and flow-resisting agent, makes them undergo the process of high-speed dispersion treatment so as to obtain self-adhesive seal water-proof material, dip-coating said self-adhesive seal water-proof material onto one surface of high-molecular water-proof sheet material carrier, then makes the above-mentioned material undergo the processes of calendaring, extruding and layering isolating layer as anti-adhesion layer, then makes a flexible protective layer be stuck on another surface of the above-mentioned high-molecular water-roof sheet material, so that the invented wet-stickable self-adhesive water-proof sheet material can be obtained.

Owner:北京中联天盛建筑工程有限公司

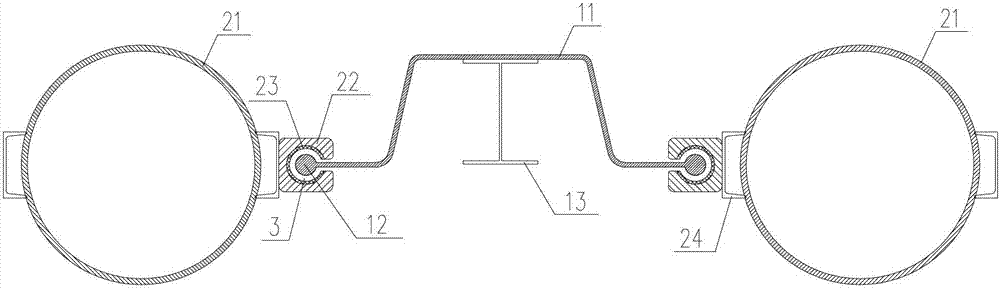

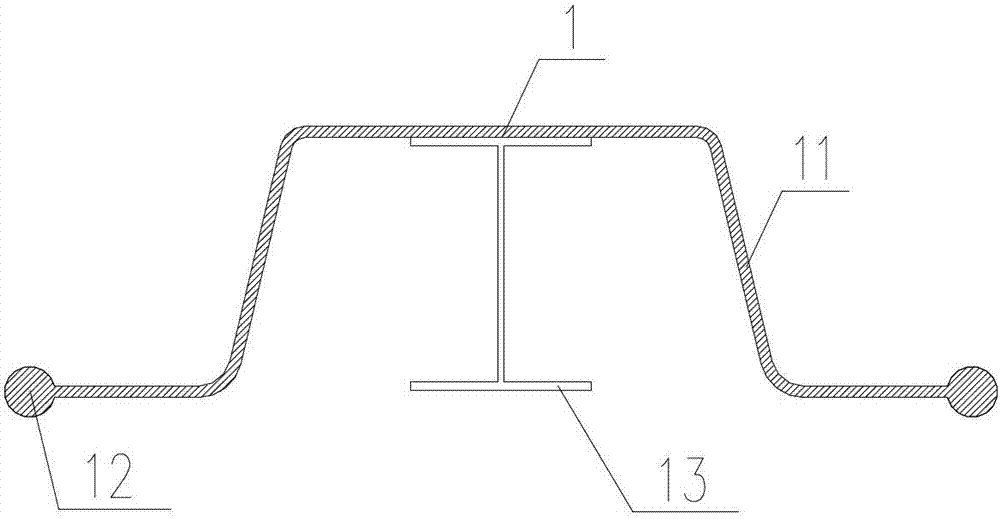

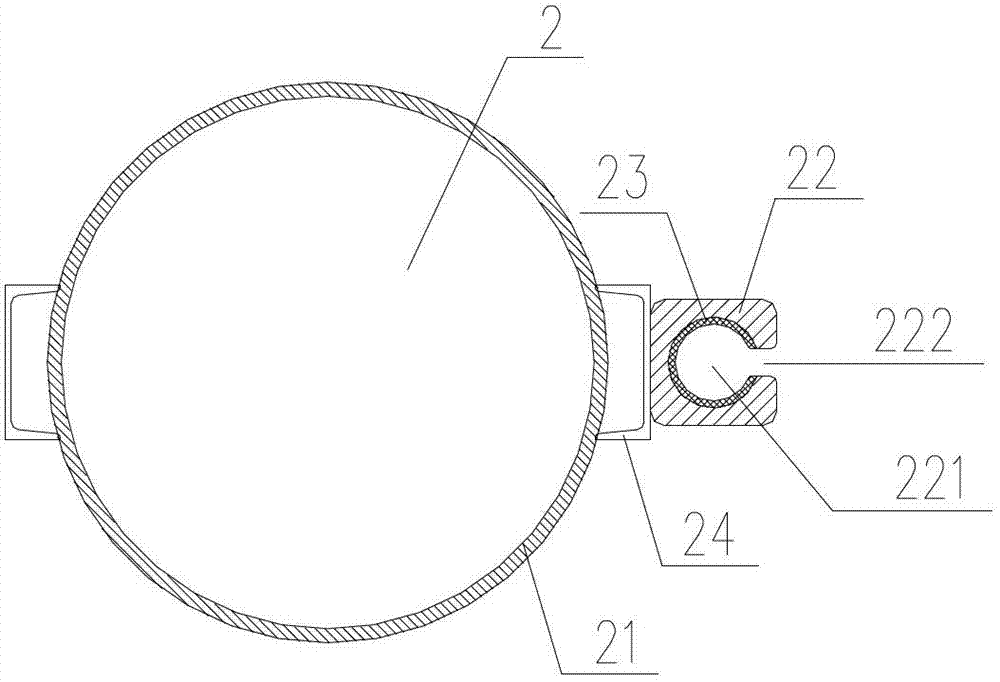

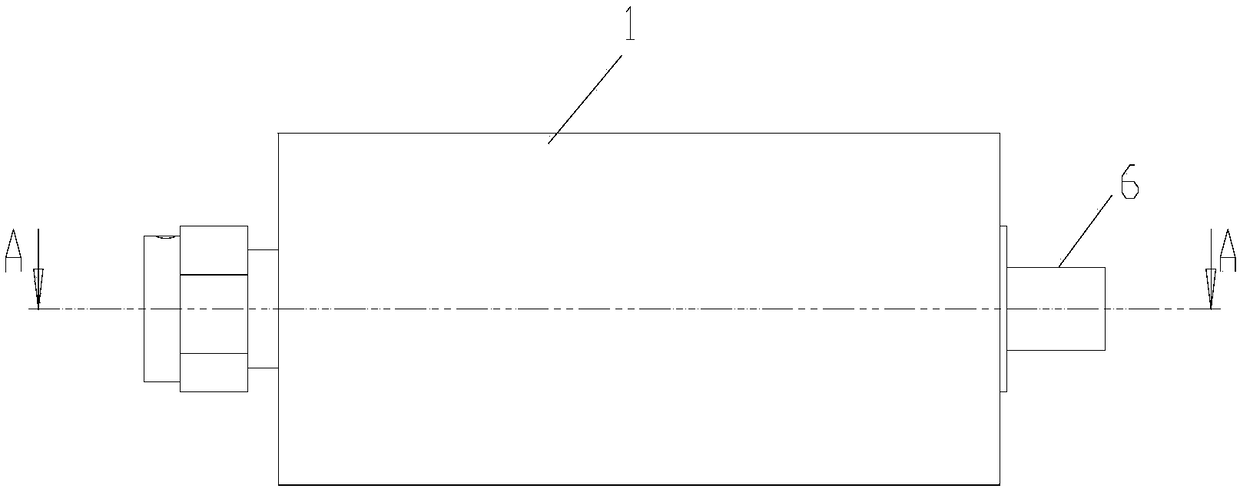

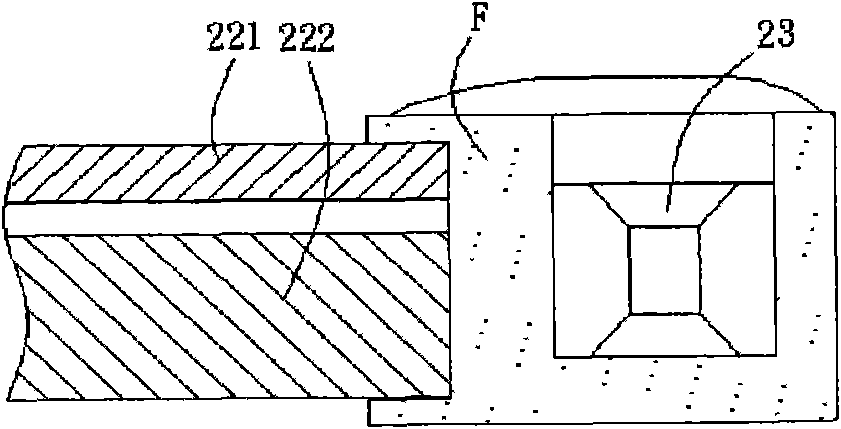

Double-isolating type charge interface structure of new energy car

ActiveCN104752886AGood waterproof performancePrevent water ingressCouplings bases/casesEngineeringElectric cars

The invention discloses a double-isolating type charge interface structure of a new energy car. The charge interface structure is outstanding in waterproof performance, can effectively prevent the problem that water enters a charge socket during long-term use to influence the normal use of the charge interface of the electric car and reduce the safety of the charging process of the car. The double-isolating type charge interface structure of the new energy car comprises a charge socket arranged on a car body, a charge interface box body which is arranged on an outer plate at the side of the car body and provided with an opening in the upper end, and a charge interface cover; the charge socket comprises a charge socket body, and a socket end cover which is hinged to the charge socket body and used for shielding an upper end port in the charge socket body; an avoiding gap is formed in the bottom surface of the charge opening box body; the upper end of the charge socket body passes through the avoiding gap to be positioned in the charge interface box body; the socket end cover is positioned in the charge interface box body; a first sealing ring is arranged at the side edge of an opening in the upper end of the charge interface box body; an inflating sealing structure is arranged between the charge socket body and the socket end cover.

Owner:XIAN ACTIONPOWER ELECTRIC

Knife coating type polyurea waterproof coating

ActiveCN101818018AExcellent mechanical properties of the coatingGood waterproof performancePolyurea/polyurethane coatingsSolventPrepolymer

The invention discloses a knife coating type polyurea waterproof coating comprising a main agent and a curing agent with the mass ratio of 1.0-1.5:1, wherein the main agent is an end NCO-based prepolymer obtained by reacting polyether polyol subjected to vacuum dehydration with polyisocyanate and contains 30-40 percent by weight of polyether glycol and 30-45 percent by weight of diisocyanate, the curing agent is formed by mixing an active hydride, a plasticizer and inorganic fillers subjected to vacuum dehydration with a catalyst, a defoamer and a dispersant disperser and contains 70-95 percent by weight of active substances. The knife coating type polyurea waterproof coating has the solid content of 100 percent, has the advantages of tastelessness, nontoxicity and no pollution in the construction process, and is not influenced by environmental dampness and moisture. A formed film layer has the advantages of excellent mechanical property and weatherability as well as favorable high-low temperature resistance, solvent resistance and corrosion resistance and has favorable bond property with materials such as cement products, steel products, wood products, glass fiber products, and the like.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

Fluoroalkyl-modified composite organosilicon water-proofing agent and preparing method and application thereof

ActiveCN105198274AGood waterproof effectGood waterproof performanceSilane couplingWeather resistance

The invention belongs to the field of water-proofing agents and discloses a fluoroalkyl-modified composite organosilicon water-proofing agent and a preparing method and application thereof. The fluoroalkyl-modified composite organosilicon water-proofing agent is prepared from, by mass, 10-15% of short-carbon-chain alkyl siloxane, 10-15% of long-carbon-chain alkyl siloxane, 40-45% of fluoroalkyl siloxane, 2-3% of complex emulsifier, 2-5% of polyvinyl alcohol, 1-5% of silane coupling agent, 1-3% of aluminum sulfate and the balance water. Short-carbon-chain alkyl siloxane, long-carbon-chain alkyl siloxane and fluoroalkyl siloxane are adopted for being used together to form a composite system, and it is ensured that the water-proofing agent has a good waterproof property and has excellent permeability and weather resistance; the water-proofing agent is W / O / W type pasty, and capable of being widely applied to the waterproof fields of concrete, bricks, mortar and the like, and the antifouling fields of glass and the like, and stability of the water-proofing agent is effectively achieved.

Owner:SOUTH CHINA AGRI UNIV

Graphene-based waterproof electrothermal film and production method thereof

ActiveCN106304435AThe preparation process is safe and environmentally friendlyGood waterproof performanceFibre treatmentHeating element materialsCvd grapheneHeating film

The invention relates to an electrothermal film, and provides a graphene-based waterproof electrothermal film and a preparation method thereof. According to the invention, the problem that the electrothermal film preparation process is not safe and not environmentally-friendly in the prior art is solved. The method comprises the following preparation steps: (1) dispersing graphene into water and mixing with resin emulsion and aids to obtain graphene-based waterborne electrothermal pulp; (2) dipping non-woven fabric into the graphene-based waterborne electrothermal pulp and drying to prepare electrothermal non-woven fabric; (3) adhering conductive copper foils to the two ends of the electrothermal non-woven fabric; (4) covering the upper surface and the lower surface of the electrothermal non-woven fabric, adhered with the conductive copper foils, with polyester plastic films, and hot-sandwiching the electrothermal non-woven fabric in the middle of the polyester plastic films.

Owner:福建久信科技有限公司

Combined steel pile cofferdam provided with water swellable waterproof rubber fore shaft

InactiveCN102900089AFast constructionGood waterproof performanceBulkheads/pilesStructural rigidityWater resistance

The invention discloses a combined steel pile cofferdam provided with a water swellable waterproof rubber fore shaft, which comprises cofferdam pegs and cofferdam long piles used for connecting two adjacent cofferdam pegs. Each cofferdam peg comprises a U-shaped steel sheet pile and a fore shaft sub-part, and the left and right ends of each U-shaped steel sheet pile are respectively and fixedly connected with one fore shaft sub-part. Each cofferdam long pile comprises a steel pipe pile, a fore shaft parent part arranged at the outer side of the steel pipe pile, and a water swellable rubber liner arranged in the fore shaft parent part; a tubular inner cylinder matched with each fore shaft sub-part and a notch connecting the interior of each tubular inner cylinder with the exterior of each tubular inner cylinder are arranged on the fore shaft parent part; each water swellable rubber liner is fixedly arranged on the inner wall of the corresponding tubular inner cylinder; each fore shaft sub-part is sleeved into the corresponding tubular inner cylinder; and bentonite compound filler is filled in a gap between each fore shaft sub-part and each water swellable rubber liner. By taking the combination of a rigid steel pile and a flexible steel pile to have complementary advantages, the combined steel pile cofferdam has good water resistance; the fore shaft is reliable in connection; the material of the combined steel pile cofferdam is easy to obtain; and the combined steel pile cofferdam is strong in integral structural rigidity and low in cost and is quick to construct.

Owner:SOUTHEAST UNIV

Novel expanded perlite insulation board and preparation method thereof

Provides are a novel expanded perlite insulation board and a preparation method thereof. The novel expanded perlite insulation board is mainly prepared by raw materials of 50%-80% of expanded perlite, 10%-40% of inorganic adhesive and organic adhesive, 0%-10% of fiber and 0%-10% of property-modifying additive. The novel expanded perlite insulation board uses a compression molding process and is high in production efficiency, good in size stability and low in production cost. The novel expanded perlite insulation board has excellent fireproofing safety to overcome shortcomings of poor fireproof performance, ageing resistant and environment pollution; and has excellent waterproofness and low thermal coefficients to overcome a shortcoming that a common inorganic insulation material is large in thermal coefficient and strong in water absorbability. The novel expanded perlite insulation board has excellent heat insulation performance, can achieve thermal insulation performance levels of the organic material, simultaneously has non-ignitable performance of the inorganic material, is good in durability and weather fastness, can achieve same service life of buildings, solves the problem that service life of an organic board is short, and is favorable for energy saving and environmental protection. The service life of the organic board can be asynchronous with the building.

Owner:SHENYANG JIANZHU UNIVERSITY

Waterproof acid and alkali resistant paint

ActiveCN103756473AGood acid and alkali resistanceGood waterproof performancePolyurea/polyurethane coatingsEmulsionRosin

The invention discloses a waterproof acid and alkali resistant paint. The waterproof acid and alkali resistant paint is prepared from the following raw materials in parts by weight: 15-40 parts of acrylic emulsion, 3-10 parts of polyurethane, 0.5-5 parts of rosin modified phenolic resin, 0.5-2 parts of triethoxyisobutylsilane, 5-10 parts of filler, 1-5 parts of hydroquinone, 10-30 parts of water, 2-4 parts of methyl isobutyl ketone, 0.5-2 parts of n-butyl acetate, 20-40 parts of heavy calcium carbonate, and 4-11 parts of expanded perlite micro powder. The waterproof acid and alkali resistant paint has acid and alkali resistance, good wear-resisting property, excellent waterproof performance and low cost.

Owner:ANHUI JINDUN PAINT

Waterproof paper-plastic compound bag and preparation method thereof

ActiveCN104925355AGood waterproof performanceGood biodegradabilityBio-packagingBagsChemistryOrganosilicon

The invention discloses a waterproof paper-plastic compound bag and a preparation method thereof. The waterproof paper-plastic compound bag comprises a plastic layer and a paper layer, wherein the plastic layer is arranged on the surface of the paper layer; the plastic layer comprises starch, polyvinyl alcohol, poly-beta-polyhydroxybutyrate, modified polyacrylate, high density polyethylene, dicumyl peroxide, polyisobutene, polyester fiber, lactose, glycerol, dimethyl phthalate and epoxy resin; the modified polyacrylate comprises a modifying agent and polyacrylate that are mutually compounded; and the modifying agent comprises one or more of organosilicon, organic fluorine and polyurethane. The preparation method of the waterproof paper-plastic compound bag is simple in step, and the raw materials are easy to obtain, so that large-scale industrial production of the waterproof paper-plastic compound bag can be conducted.

Owner:TONGLING FOUNDER PLASTICS TECH

Waterproof coiled material containing nano ceramic powder

InactiveCN105368077AGood waterproof performanceHigh tensile strengthBuilding insulationsUreaNatural rubber

The invention relates to a waterproof coiled material containing nano ceramic powder. The waterproof material containing the nano ceramic powder comprises a base material and a waterproof material dip-coated on the base material, the waterproof material comprises the following components in parts by weight: 80 parts of asphalt, 6 parts of nano ceramic powder, 0.3 parts of nano boron oxide, 2 parts of synthetic resin, 0.8 parts of modified starch, 1 part of a fire retardant, 0.2 parts of powder urea, 2 parts of linear polyethylene, 1.2 parts of polyurethane, 0.15 parts of dibutyltin dilaurate, 1.2 parts of swill-cooked dirty oil, 0.05 parts of lithium acetate, 0.5 parts of a stabilizing agent, 0.1 parts of oleamide, 0.8 parts of expandable graphite, 0.2 parts of potassium titanate whiskers, 5 parts of natural rubber powder, 0.6 parts of zinc fatty acid, and 0.5 parts of zirconium silicate powder. During preparation, the waterproof material is fused, and is dip-coated on the base material.

Owner:ANHUI YOUYANG WATERPROOF TECH CO LTD

Waterproof coating for water-based paperboards and preparation method thereof

InactiveCN104631207AGood waterproof performanceCost comparedWater-repelling agents additionPaper coatingSolventEmulsion

The invention discloses a waterproof coating for water-based paperboards and a preparation method thereof. The coating is mainly prepared from water, an acrylate emulsion, a paraffin emulsion, an epoxy resin, a film forming additive, a flatting agent and other additives. Through the compounding of the paraffin emulsion and the acrylate emulsion, the advantages of the two emulsions are integrated, so that the glossiness, adhesion, abrasion resistance and water repellency of the waterproof coating are maximally increased; due to the addition of the epoxy resin and a drier, the water repellency, coating hardness and surface drying time of the coating can be further improved; and the waterproof coating disclosed by the invention, as a water-based resin coating, is solvent-free, non-toxic, green and environment-friendly in the process of production, and therefore, the waterproof coating has important economical and social benefits.

Owner:HUNAN HUAWANG TECH

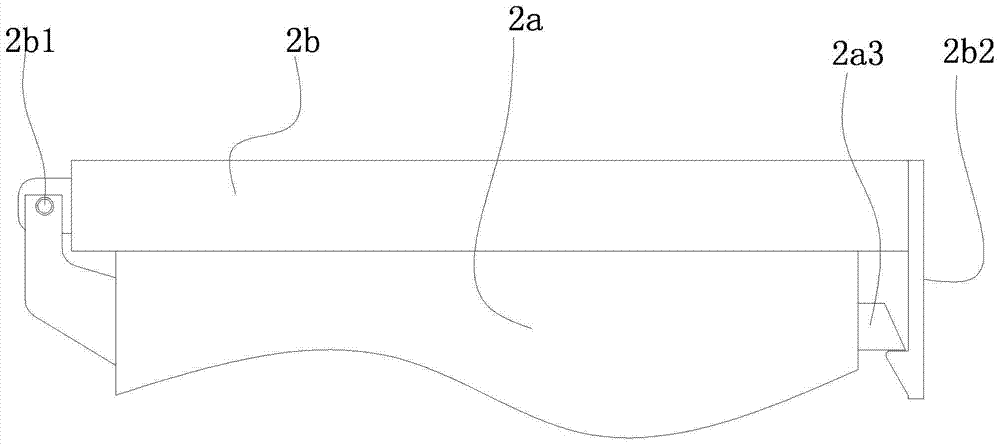

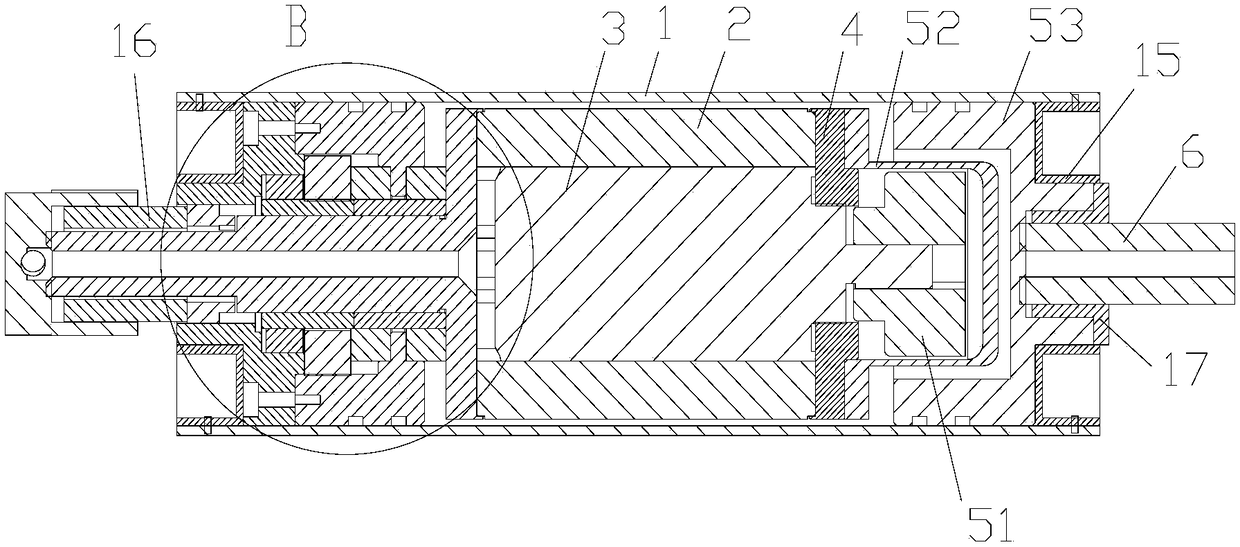

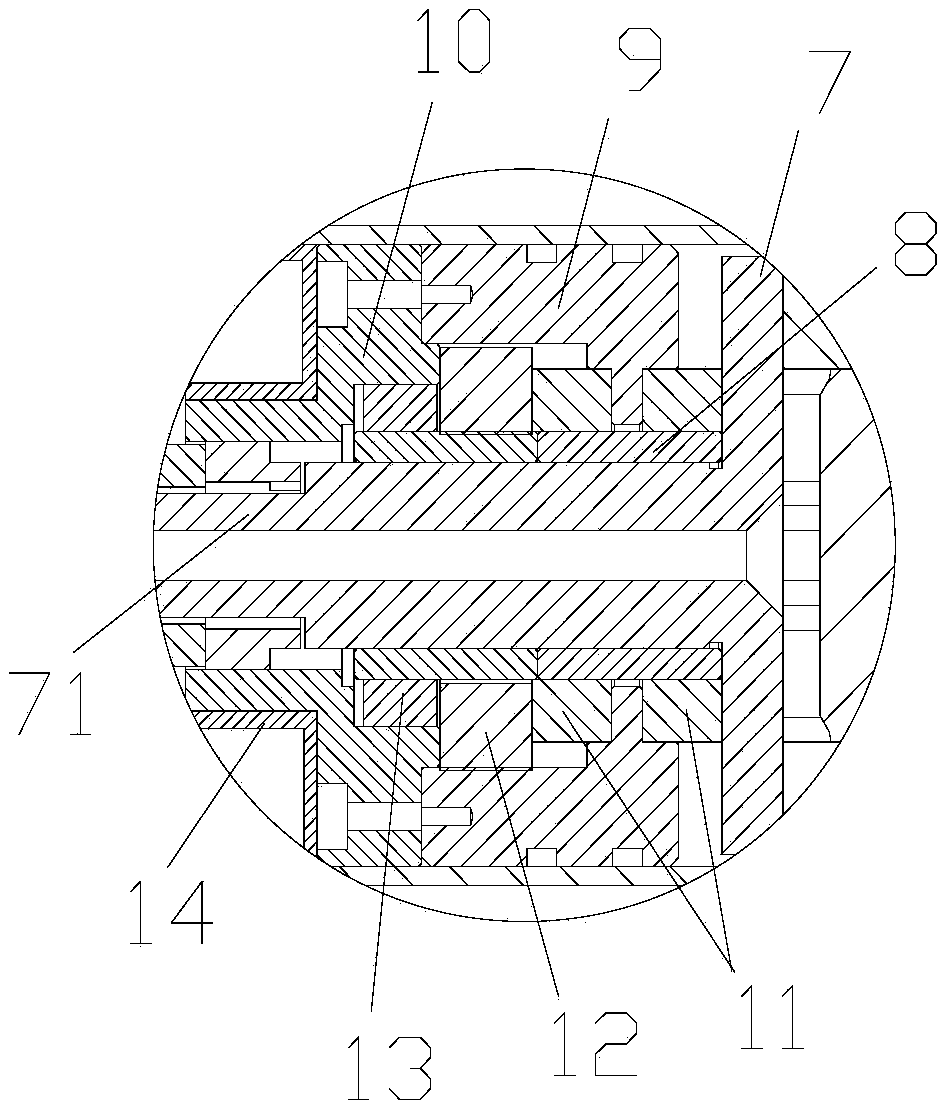

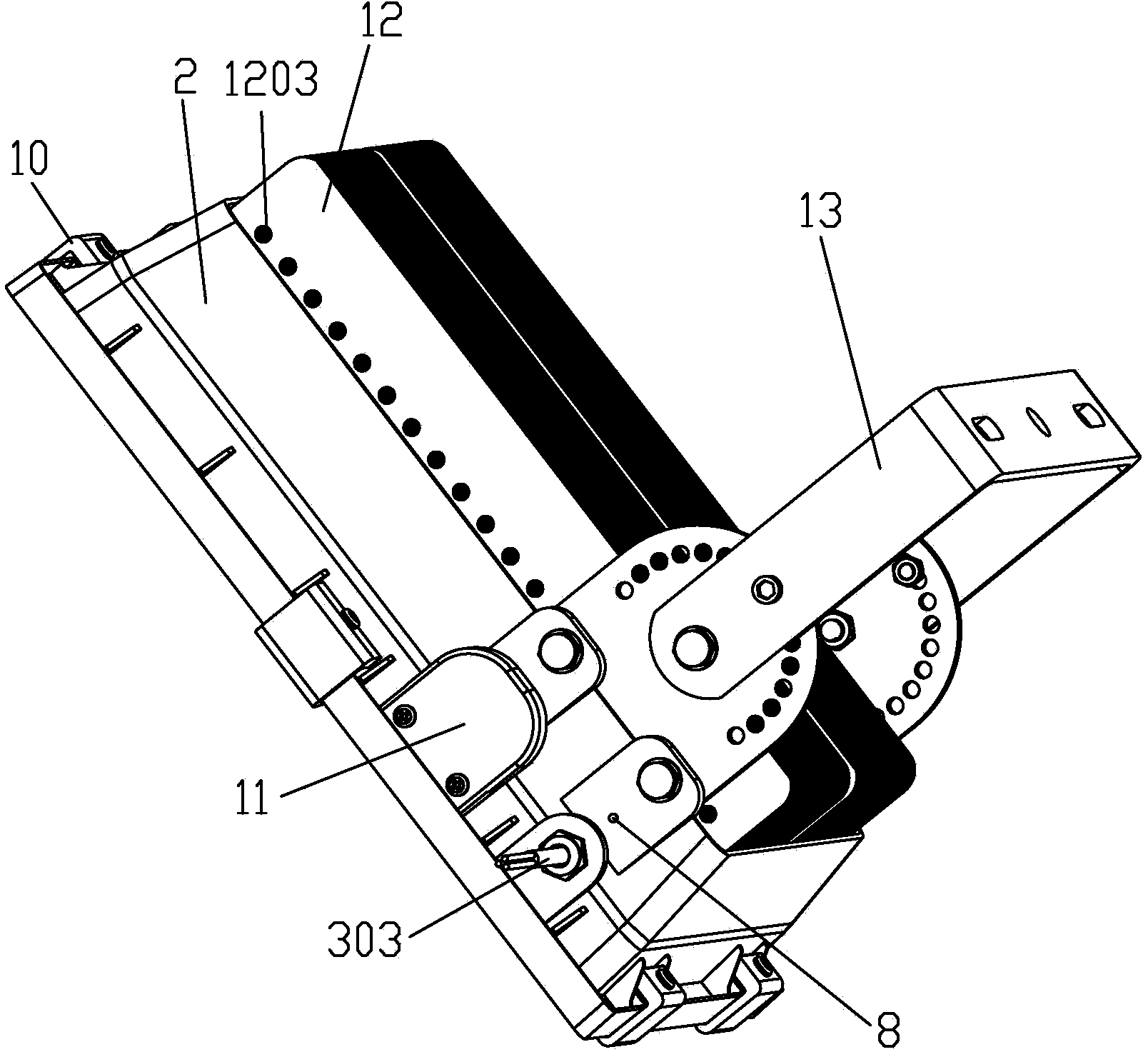

Driving roller

ActiveCN108506636AGood waterproof performanceIncrease contact areaEngine sealsShaftsPropellerEngineering

The invention discloses a driving roller. The driving roller comprises an outer cylinder and an inner cylinder arranged inside the outer cylinder, a motor is fixedly arranged inside the inner cylinder, the output shaft of the motor sleeves with a first rotating piece, and the outer peripheral surface of the first rotating piece is fixedly connected with the inner wall of the outer cylinder in a sealing mode; and the other end of the inner cylinder is provided with a second connecting piece, and the inner cylinder and the outer cylinder are rotationally connected together through the second connecting piece, wherein the second connecting piece is hermetically connected with the inner cylinder and the outer cylinder correspondingly. The driving roller has the beneficial effects that the motor is fixedly arranged inside the inner cylinder in a sealing mode, so that the waterproof performance is good; the inner cylinder and the outer cylinder are enabled to be connected rotationally through the first connecting piece and the second connecting piece, the outer cylinder is sleeved with the shell with spiral blades, when the roller of the robot is in contact with the inner wall or the sludge of the pipeline, friction is carried out by rotating of a spiral roller to the inner wall of the pipeline or the sludge to drive the pipeline robot to move forward, so that the contact area is large, and slipping is avoided; and when the roller of the robot is suspended in water, the spiral roller is equivalent to a propeller, the spiral roller rotates to be drained away water backwards and drives the pipeline robot to move forwards.

Owner:南京管科智能科技有限公司

Reacting polymer cement waterproof coating and preparing method thereof

InactiveCN1583915AGood waterproof performanceHigh strengthAntifouling/underwater paintsPaints with biocidesBenzenePlasticizer

This invention involves a kind of response type waterproof coaitng of polymer cement and prepares the method, this waterproof coating, include the aircrew one and there is no aircrew one, there is aircrew one from reacting type polyurethane cream, neighbor benzene two formic acid kinds of plasticizer and organic silicon is it steep pharmaceutical make up, have aircrew copy to made up of white cement and light body calcium carbonate to disapper. While using, the quality matching of one per group is: There are aircrew's shares: Response polyurethane 100 cream, neighbor benzene two formic acid kinds of 5 plasticizer, organic silicon is it steep 5 pharmaceutical to disappear; The weight matching of all raw material is when there is no aircrew one: white cement is 100. light body calcium carbonate is 40. The response type waterproof coating of polymer has already had the intersity of building inorganic material of cement high, able to bear it good advantage, have good high elasticity of high polymer material and waterproof performance.

Owner:陈伟忠

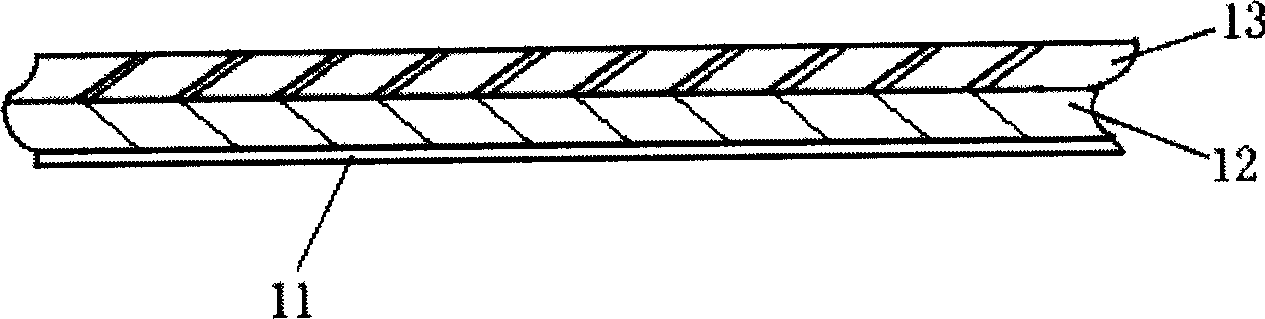

Modified asphalt waterproofing coiled material with self-adhering layer and preparation method thereof

ActiveCN104085145AGood waterproof performanceHigh tensile strengthMineral oil hydrocarbon copolymer adhesivesSynthetic resin layered productsAmmonium polyphosphatePolypropylene

The invention relates to a modified asphalt waterproofing coiled material with a self-adhering layer and a preparation method thereof and belongs to the technical field of building waterproofing coiled materials. The modified asphalt waterproofing coiled material comprises a polyester base, and an asphalt layer and a self-adhering layer which are formed by the polyester base in a dip-coating manner, wherein the self-adhering layer is prepared from the following ingredients in parts by weight: asphalt 90#, rubber powder, SBS (Styrene Butadiene Styrene block polymer), SBR (Styrene Butadiene Rubber), hydrogenated petroleum resin, naphthenic oil, rock flour, an ultraviolet absorbent and an antioxidant; the asphalt layer is prepared from the following ingredients in parts by weight: asphalt 10#, asphalt 90#, nylon powder, SBS, APP (Ammonium Polyphosphate), PP (polypropylene), cut 3 engine oil and rock flour. The modified asphalt waterproofing coiled material has the advantages of good waterproof performance, ageing resistance, high tensile strength, good extensibility and excellent low-temperature flexibility and heat resistance.

Owner:YUNNAN XINCHENG WATERPROOF SCI TECH

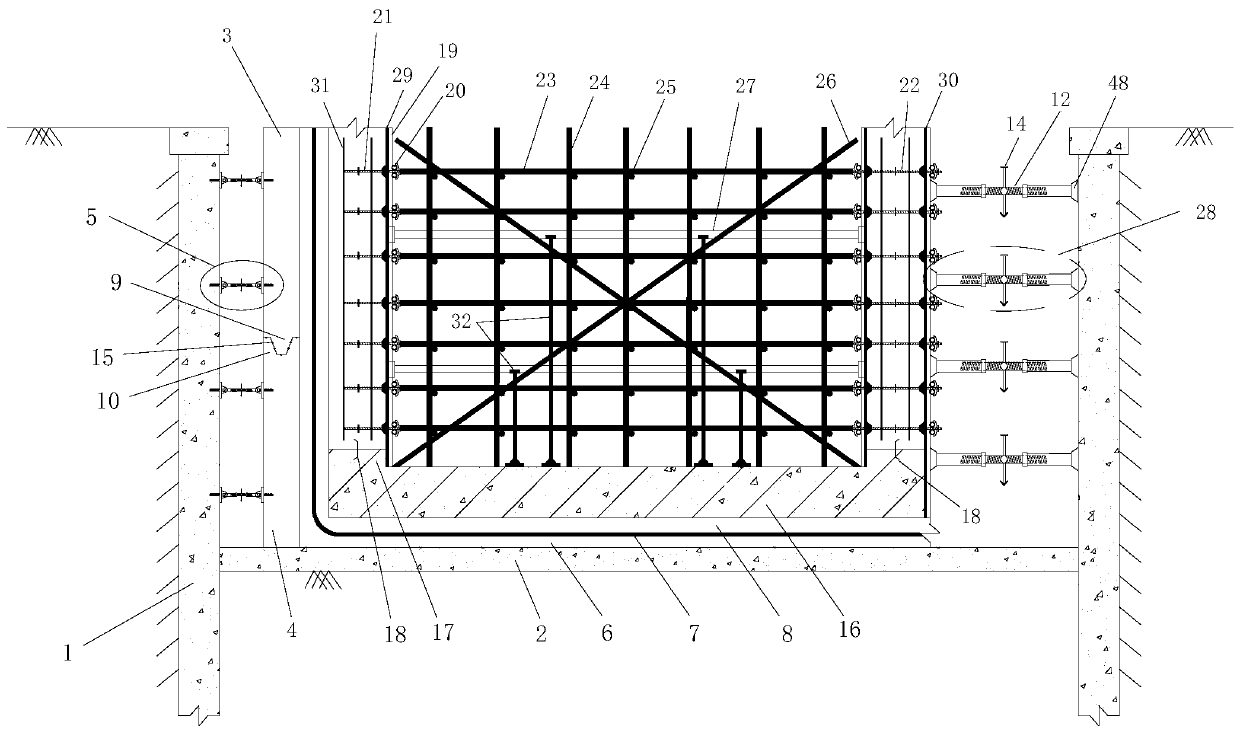

Construction method of composite unilateral formwork deep foundation pit basement exterior wall

ActiveCN109736353AImprove construction efficiencyGood waterproof performanceArtificial islandsProtective foundationFertilizerSteel tube

The invention relates to a construction method of a composite unilateral formwork deep foundation pit basement exterior wall. The construction method comprises the steps of: firstly, a composite waterproof layer of the deep foundation pit basement exterior wall is adopted for waterproof treatment of the basement exterior wall; secondly, a basement bottom plate and an outer wall guide wall are poured; thirdly, aiming at different working conditions with limited fertilizer tank space, three different unilateral formwork systems are adopted for carrying out unilateral formwork on the basement exterior wall, and each unilateral formwork system comprises an exterior wall frame opposite-supporting unilateral formwork system, an exterior wall steel pipe fastener inclined-supporting unilateral formwork system and an exterior wall profile steel support inclined-supporting unilateral formwork system; and fourthly, a basement exterior wall is poured. The method the following beneficial effects: aprotection wall adopts segmented prefabricated hoisting rear tenon type waterproof inserting connection to replace a traditional masonry or cast-in-place concrete structure; the construction efficiency is high, and the waterproof performance is good; and meanwhile, adjustable pull-connection pieces connected with the prefabricated protection wall sections are pre-buried in the foundation pit enclosure structure, so that the perpendicularity of the prefabricated protection wall sections is guaranteed, and the construction quality is high.

Owner:SHENZHEN JIANAN GRP

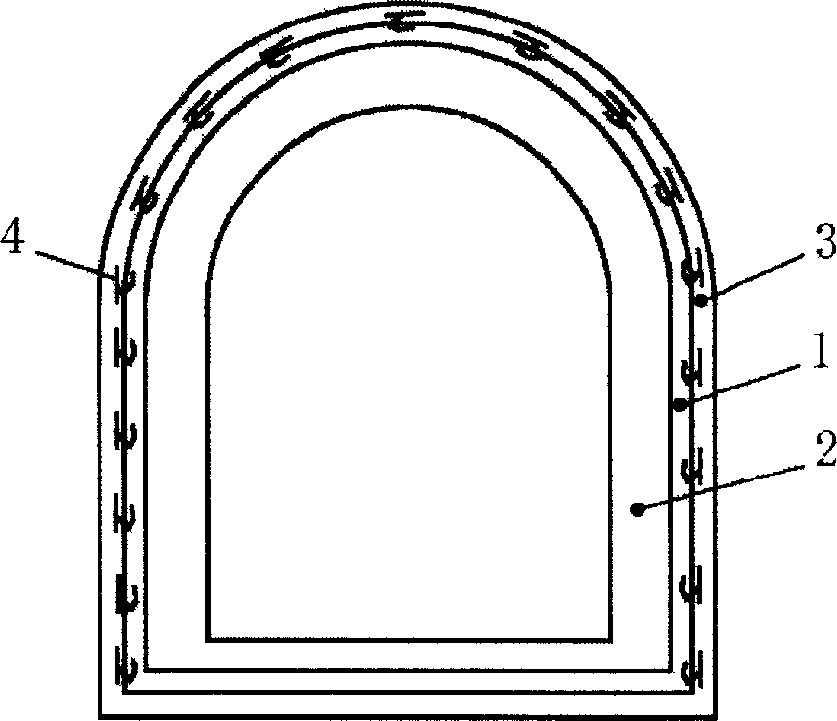

Double-frequency transmitting monopole antenna for portable high-frequency ground wave radar

InactiveCN102904024AGood waterproof performanceSolve outdoor waterproofingSimultaneous aerial operationsAntenna supports/mountingsPhysicsMonopole antenna

The invention discloses a double-frequency transmitting monopole antenna for portable high-frequency ground wave radar. The double-frequency transmitting monopole antenna consists of an antenna upper section, a wave trap, an antenna lower section, a feed base and a ground network, wherein a conductor on the antenna upper section is h1 high and a conductor on the antenna lower section is h2 high. When the wavelength lambda 2 corresponding to the radar signal frequency f2 meets a formula of h2=k lambda2 / 4, the wave trap makes resonance oscillation so as to equivalently isolate the antenna upper section and ensure that the antenna upper section becomes a typical quarter-wave vertical monopole on the ground and has a major lobe of a radiation directional diagram along the ground surface. When the radar signal frequency is far lower than f2, the wave trap is in dissonance, so that the whole height of the antenna is equivalently increased to h3, and therefore the whole antenna forms a quarter-wave monopole with resonance being in lower frequency f1, meets a formula of (h1+h2+h3)=k Lambda 1 / 4 and has a major lobe of a radiation directional diagram along the ground surface as well. The double-frequency transmitting monopole antenna disclosed by the invention can work on two frequency bands respectively taking f1 and f2 as central frequencies conveniently, and both the two frequency bands have major lobes of directional diagrams along the ground surface. Besides, the adopted feed base realizes favorable waterproof structure design.

Owner:WUHAN UNIV

Waterproof waste-stone-powder dry-mixed mortar

The invention provides waterproof waste-stone-powder dry-mixed mortar. A powder waterproof agent and waste stone powder are added into the dry-mixed mortar formula. The waterproof waste-stone-powder dry-mixed mortar comprises, by weight, 28 parts of cement, 16 parts of waste stone powder, 39 parts of sand, 5 parts of powder waterproof agent, 4 parts of redispersible rubble powder, 1 part of polyvinyl alcohol, 1 part of naphthalene water reducer, 4 parts of cellulose fibers and 2 parts of polypropylene fibers; the powder waterproof agent comprises, by mass, 48% of calcium stearate, 35% of zinc stearate, 7% of organosilicone powder water repellent agent and 10% of calcium hydroxide; the waste stone powder is a mixture of one or two of waste marble powder and waste granite powder and comprises, by mass, 35% of waste stone powder with the grain size smaller than 100 microns and 65% of waste stone powder with the grain size of 100-500 microns. According to the dry-mixed mortar, as the powder waterproof agent is added, the waterproof performance is good; as the industrial-waste waste stone powder is added, cost is reduced, and the dry-mixed mortar can be applied to constructional engineering.

Owner:TIANJIN YUFENGYUAN ENVIRONMENTAL PROTECTION TECH

Fiber bragg grating osmometer

InactiveCN101625273AGood waterproof performanceImprove measurement accuracy and measurement reliabilityFluid pressure measurement using elastically-deformable gaugesConverting sensor output opticallyElectromagnetic interferenceOsmometer

The invention discloses a fiber bragg grating osmometer which comprises a shell, a pressure bar, grating and a transmission optical fiber, wherein the shell is provided with a pressure inlet hole and an optical fiber lead hole, and the pressure inlet hole is provided with a filter screen; the shell is provided with a membrane which can directly sense the pressure at the pressure inlet hole; the two ends of the pressure bar are connected with the membrane, the grating is buried inside the pressure bar, and the transmission optical fiber is led out through the optical fiber lead hole. When in use, pore water enters into the osmometer through the pressure inlet hole and acts on the membrane to lead the membrane have deflection deformation; meanwhile, the pore water is transformed into concentrated force and acts on the pressure bar, and external force is applied on the pressure bar to lead the pressure bar to stretch; when the grating is under the pressure, the central wavelength is changed. At this time, a fiber bragg grating demodulation device is used for detecting the central wavelength of the grating, and software can be used for acquiring and storing data, so that osmotic pressure detection can be realized. The fiber bragg grating osmometer has the advantages of high measuring accuracy, small volume, electromagnetic interference resistance, good waterproof performance, capability of long-term monitoring, etc.

Owner:SHANDONG UNIV

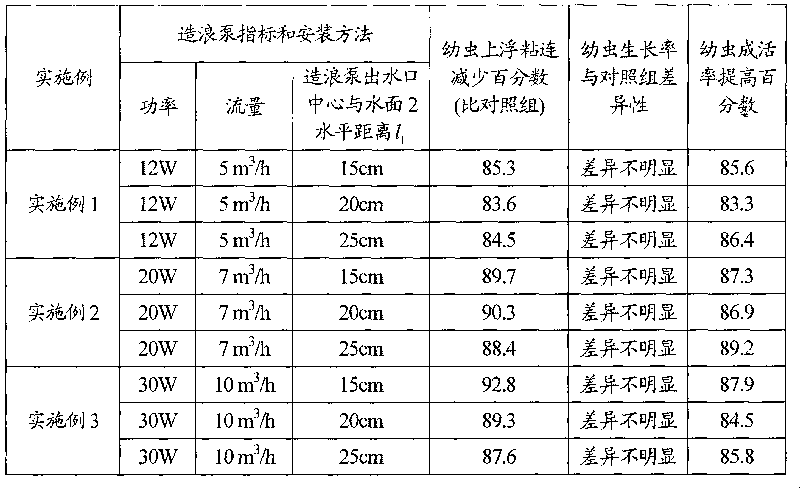

Method for preventing pinna pectinata larvae from floating upwards and adhering

ActiveCN101720704AGood waterproof performanceHigh dielectric strengthClimate change adaptationPisciculture and aquariaAdverse effectOffspring

The invention relates to aquaculture bivalve offspring seed production, in particular to a method for preventing pinna pectinata larvae from floating upwards and adhering. Two wave-making pumps are arranged in a diagonal shape on the pond wall of a culture pond in a width direction; waves and water flows which are generated by the wave-making pumps are used for dispersing the pinna pectinata larvae so that the pinna pectinata larvae are uniformly distributed in the culture pond, thus the pinna pectinata larvae are prevented from floating upwards and adhering; 24 hours after pinna pectinata fertilized ovums are incubated into D-shaped larvae, when the D-shaped larvae float upwards and are adhered, the wave-making pumps are installed; the proper power of the wave-making pumps is 12-30 W, the proper flow rate is 5-10 m3 / h, the proper distance horizontally kept between the water outlet centers of the wave-making pumps and a water surface is 15-25 cm, and the proper distance between the water outlet centers of the wave-making pumps and the adjacent pond wall of the culture pond is 20-40 cm. The invention can reduce upward floating and adhesion ratio matched groups of the pinna pectinata larvae more than 80 percent, enhance the survival rate by 80 percent without obvious adverse effect on the growth of the larvae and achieve the culture density of the larvae by 4-5 / ml, thereby effectively enhancing the survival rate and the culture efficiency of the pinna pectinata larvae.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

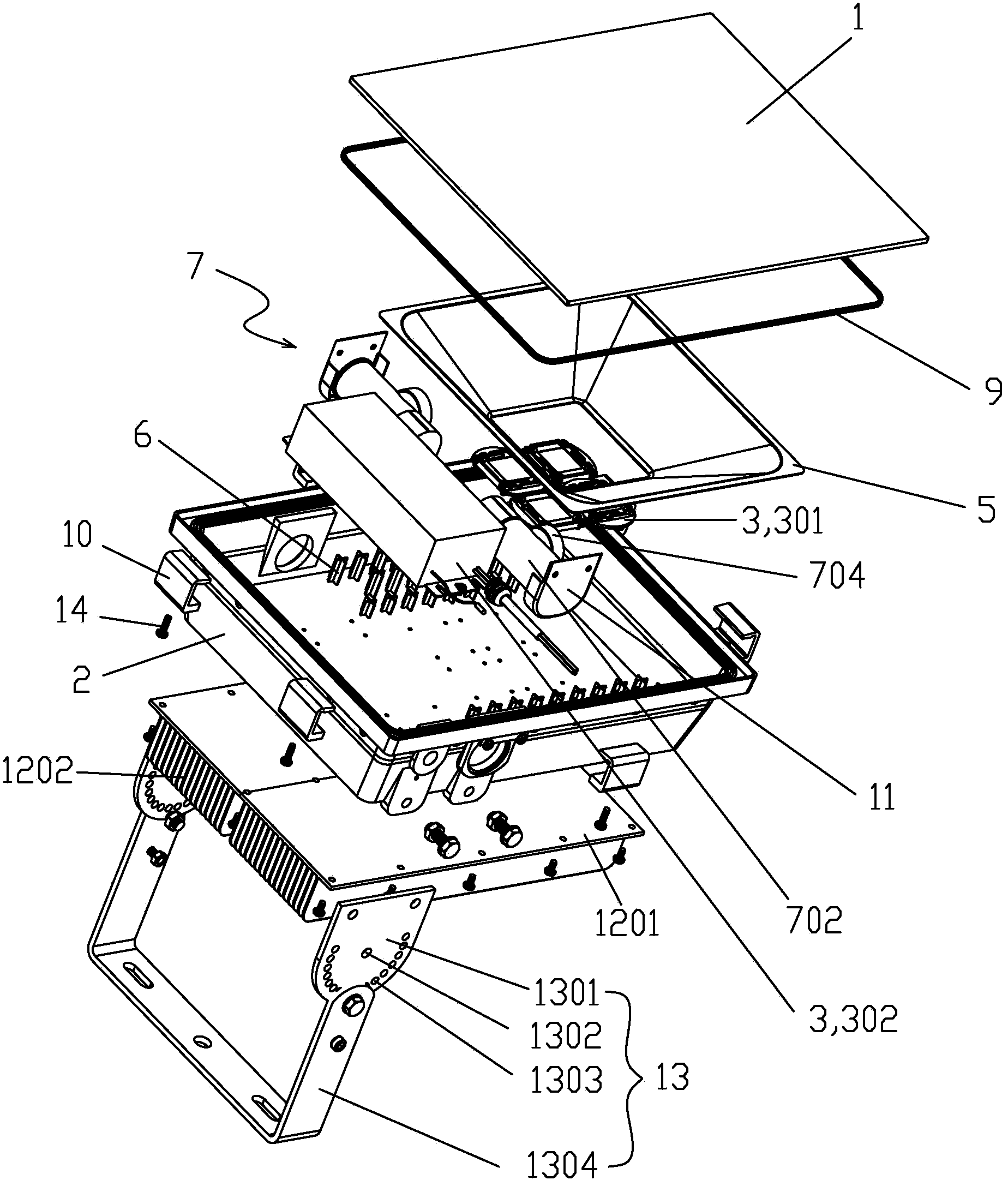

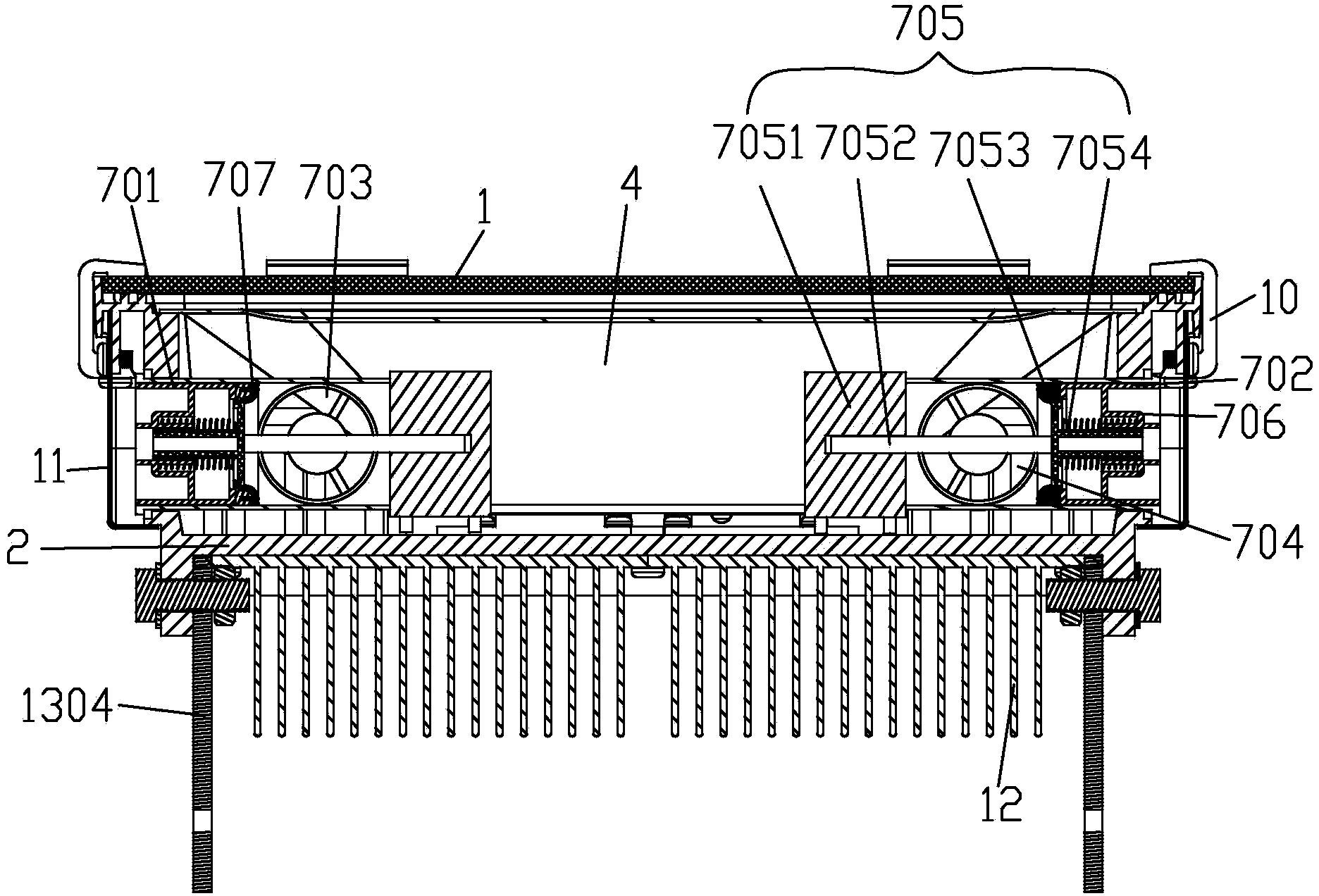

Novel LED (light emitting diode) projection lamp

ActiveCN104235804AImprove cooling efficiencyGood waterproof performanceLighting support devicesPoint-like light sourceEngineeringElectromagnetic valve

The invention discloses a novel LED (light emitting diode) projection lamp which comprises a rear lamp housing, wherein an opening is formed in the front end of the rear lamp housing; the front end of the rear lamp housing is provided with a front lamp cover in a butting manner, and a lamp cavity is formed in the front lamp cover; a luminous assembly and a reflection cover for reflecting light are arranged in the lamp cavity; the novel LED projection lamp is characterized in that a rainwater temperature control probe for detecting whether raining occurs outside is arranged on the outer wall of the rear lamp housing; an air cooling device is arranged in the lamp cavity outside the reflection cover and comprises an air inlet pipe and an air exhaust pipe which are oppositely arranged on two inner sides of the rear lamp housing and are communicated with the outside; an air suction fan which is connected with the air inlet pipe and is used for blowing external air into the lamp cavity and an air exhaust fan which is connected with the air exhaust pipe and is used for exhausting hot air in the lamp cavity are respectively arranged at the bottom of the rear lamp housing; electromagnetic valves for controlling the air inlet pipe and the air exhaust pipe to be switched on and switched off are arranged in the air inlet pipe and the air exhaust pipe. Due to the arrangement, the novel LED projection lamp is high in heat dissipation performance and waterproofing performance.

Owner:广东恒辰光电科技有限公司

Restaurant robot

PendingCN107756419AGood waterproof performanceGood shock resistanceManipulatorAgricultural engineeringEngineering

The invention discloses a restaurant robot which comprises a stand, a tableware containing device and a vibration buffer device; the tableware containing device comprises a holding platform and a collecting tank for containing tableware; a hollow part is arranged on the holding platform; the tank bottom of the collecting tank penetrates through the hollow part; the tank top of the collecting tankexpands outwards and bears the holding platform; a gap is formed between the external tank wall of the collecting tank and the internal wall of the hollow part; the tableware containing device is arranged on the stand through the vibration buffer device; the vibration buffer device comprises elastic pieces; the first ends of the elastic pieces are connected to the stand; and the second ends of theelastic pieces are connected to the holding platform. The restaurant robot solves the technical problem that the restaurant robot in the existing is not water-proof or vibration-proof, the meal taking and delivery quality is improved, and the use experience of the restaurant robot is improved.

Owner:GEER TECH CO LTD

High-temperature-resistant paint for hydraulic cylinder and preparation method thereof

ActiveCN104789116AStrong adhesionNot easy to fall offRubber derivative coatingsAnti-corrosive paintsPhosphorous acidPolymer science

The invention discloses a high-temperature-resistant paint for a hydraulic cylinder and a preparation method thereof. The high-temperature-resistant paint for the hydraulic cylinder is prepared from the following constituents in parts by weight: 58-60 parts of modified epoxy organic silicon resin, 22-24 parts of hydrogenated acrylonitrile butadiene rubber, 27-29 parts of bisphenol A epoxy resin, 12-14 parts of mica powder, 10-13 parts of butyl rubber, 5-7 parts of polydimethylsiloxane, 12-14 parts of phenylmethylsilane resin, 3-5 parts of dioctyl phthalate, 2-4 parts of copper powder, 2-4 parts of rutile type titanium dioxide, 1-3 parts of ceramic powder, 20-25 parts of deionized water, 2-4 parts of triethylene tetramine, 5-7 parts of triphenyl phosphite, and 1-3 parts of an auxiliary.

Owner:SUZHOU TONGMING MACHINERY

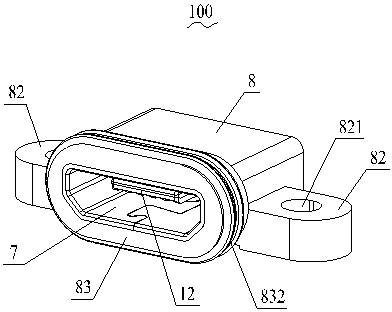

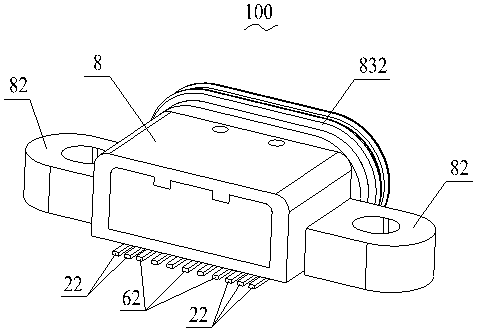

Waterproof connector and manufacturing method thereof

ActiveCN103986011AGood waterproof performanceImprove waterproof performanceLine/current collector detailsCouplings bases/casesEngineeringElectrical and Electronics engineering

The invention discloses a waterproof connector comprising a first terminal module, a second terminal module, and a shielding shell covering the first terminal module and the second terminal module. The first terminal module comprises a first insulating body and a plurality of first terminals which are embedded into the first insulating body. The second terminal module comprises a second insulating body which is inserted and installed into the first insulating body and a plurality of second terminals which are embedded into the second insulating body. The waterproof connector further comprises an injection moulding element which is formed on the outer side of the first terminal module, the second terminal module and the shielding shell through injection moulding after the assembly of the first terminal module, the second terminal module and the shielding shell is completed. The injection moulding element is used to seal joints between the first terminal module and the second terminal module and seal joints between the shielding shell and the first insulating body, so the advantage of good waterproof performance can be realized on the whole. The invention further discloses a manufacturing method of the waterproof connector.

Owner:KUNSHAN JIAHUA ELECTRONICS

Cold water fast dissolving rubber powder for buildings

InactiveCN102618187AGood waterproof performanceGood bond strengthStarch adhesivesCellulose adhesivesHydroxypropylmethyl celluloseMethyl cellulose

The invention relates to an adhesive for buildings, in particular to cold water fast dissolving rubber powder for buildings. The cold water fast dissolving rubber powder is characterized by mainly comprising the following substances in percentage by weight: 30-60 percent of pre-gelatinized starch, 15-50 percent of cold water fast dissolving polyvinyl alcohol powder and 10-40 percent of hydroxy ethyl cellulose or hydroxypropyl methyl cellulose. During production, the compositions are directly mixed proportionally, stirred uniformly, and packaged. During construction, 30-100 times of water is added for mixing and stirring uniformly. The cold water fast dissolving rubber powder has the advantages of low cost, environmental friendliness, fast dissolubility in cold water, easiness for constructing, high adhesion, increase in adhesion strength and smoothness, and convenience for storing and transporting, can be mixed with cement, talc powder, nature calcium carbonate, gypsum products, water-proof materials and the like or used separately, and has tackifying property and water retention property.

Owner:倪建东

Composite connection construction technology for steel reinforced spirally wound polyethylene drainage pipe

The invention discloses a hot melting extrusion welding composite heat shrinking sleeve connecting technology. The hot melting extrusion welding composite heat shrinking sleeve connecting technology is adopted and includes the steps that a welding interface is treated, the connecting end of the draining pipe is polished to be flat before welding, and a surface is cleaned; before heat shrinking sleeve connection, the draining pipe and the surface of a heat shrinking sleeve material are cleaned; welding parameters are controlled, during hot melting extrusion welding connection, the walking speed of a weld gun is 3 cm / s and the welding width of a pipe joint is about 4+ / -0.5 mm; and during heat shrinking sleeve connection, the flame walking height is 15+ / -2 cm, the flame walking speed ranges from 10 cm / s to 12.5 cm / s, and the temperature is controlled to ranges from 110 DEG C to 120 DEG C. By means of the hot melting extrusion welding composite heat shrinking sleeve connecting technology, hot melting extrusion welding connection is firstly conducted, and then a heat shrinking belt is adopted for connection; and a polyethylene pipeline connector connected by adopting the technology has high tensile strength which can reach 16.56 MPa, water permeability resistance is good, the water pressure of 0.4 MPa can be borne, acid, alkali and salt corrosion resistance is achieved, the strength is not obviously reduced after 28 d corrosion immersion, and ductility is good during damage.

Owner:SINOHYDRO BUREAU 7 CO LTD

Corrosion resistant paint for hydraulic cylinder and preparation method of corrosion resistant paint

InactiveCN104804642AStrong adhesionNot easy to fall offAnti-corrosive paintsEpoxy resin coatingsCross linkerTrichloroethylene

The invention discloses corrosion resistant paint for a hydraulic cylinder and a preparation method of the corrosion resistant paint. The corrosion resistant paint for the hydraulic cylinder, provided by the invention includes the following components in parts by weight: 60-63 parts of epoxy-modified organic silicone resin, 40-45 parts of trichloro ethylene, 20-30 parts of bisphenol A epoxy resin, 12-14 parts of mica powder, 10-13 parts of an amino resin cross-linking agent, 7-9 parts of polydimethylsiloxane, 12-14 parts of silicone resin, 3-5 parts of rust-proof lubricating oil, 5-7 parts of copper powder, 2-4 parts of clay, 1-3 parts of ceramic powder, 2-5 parts of beryllium oxide, 1-3 parts of triethylene tetramine, 5-7 parts of zirconium oxide and 3-5 parts of auxiliaries.

Owner:SUZHOU JIN YUAN OIL MACHINERY

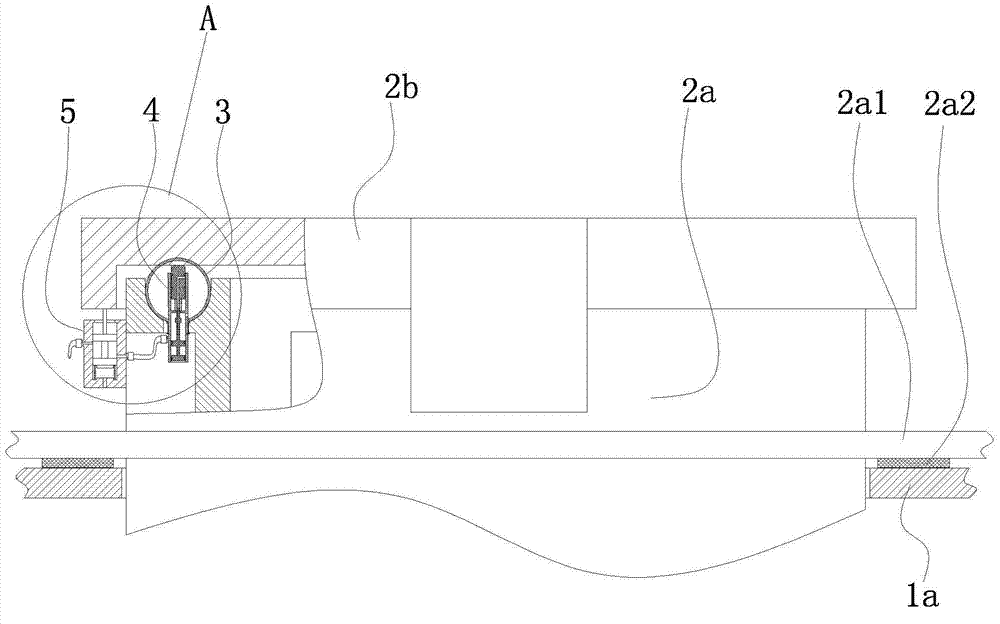

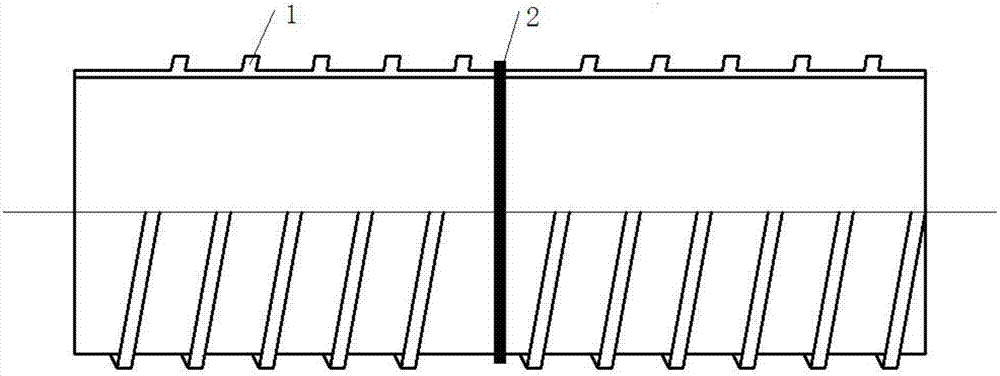

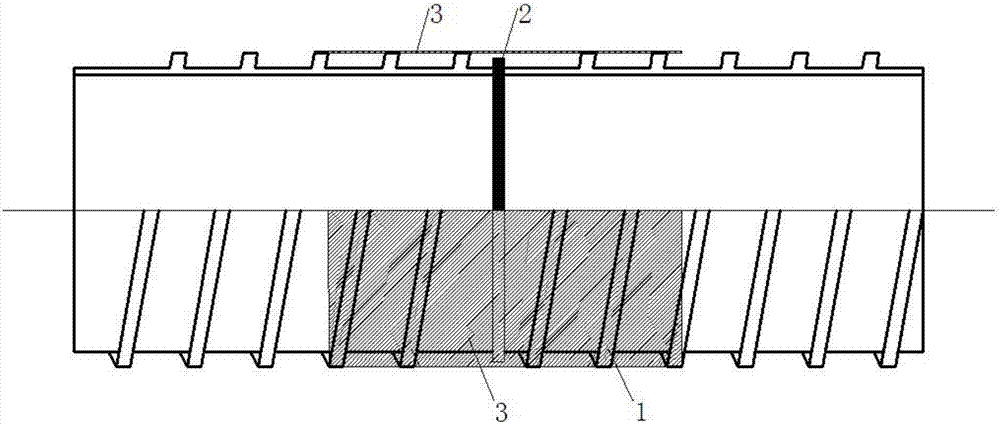

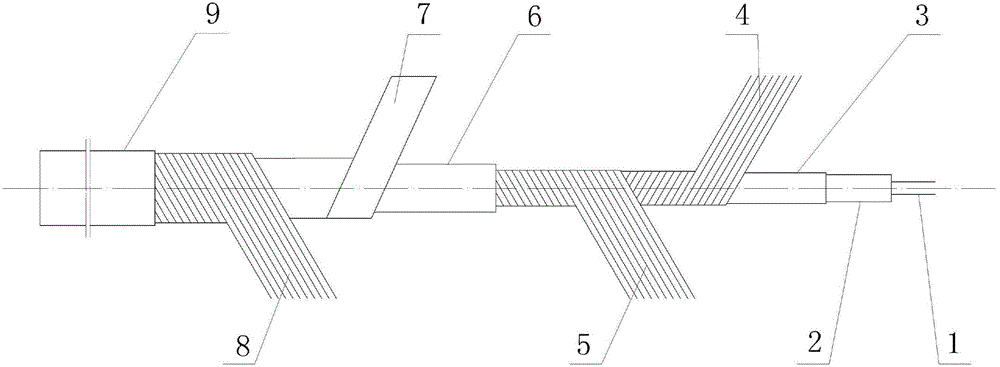

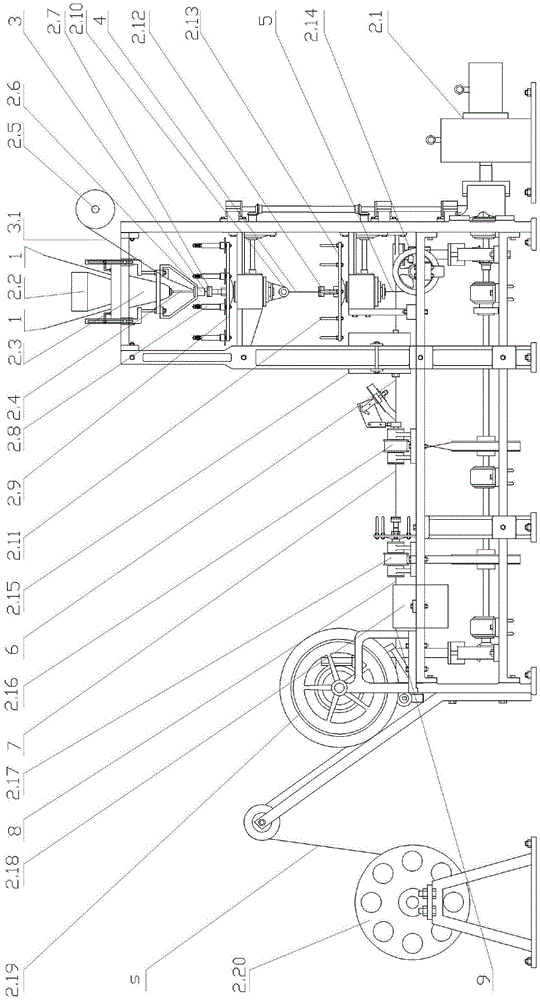

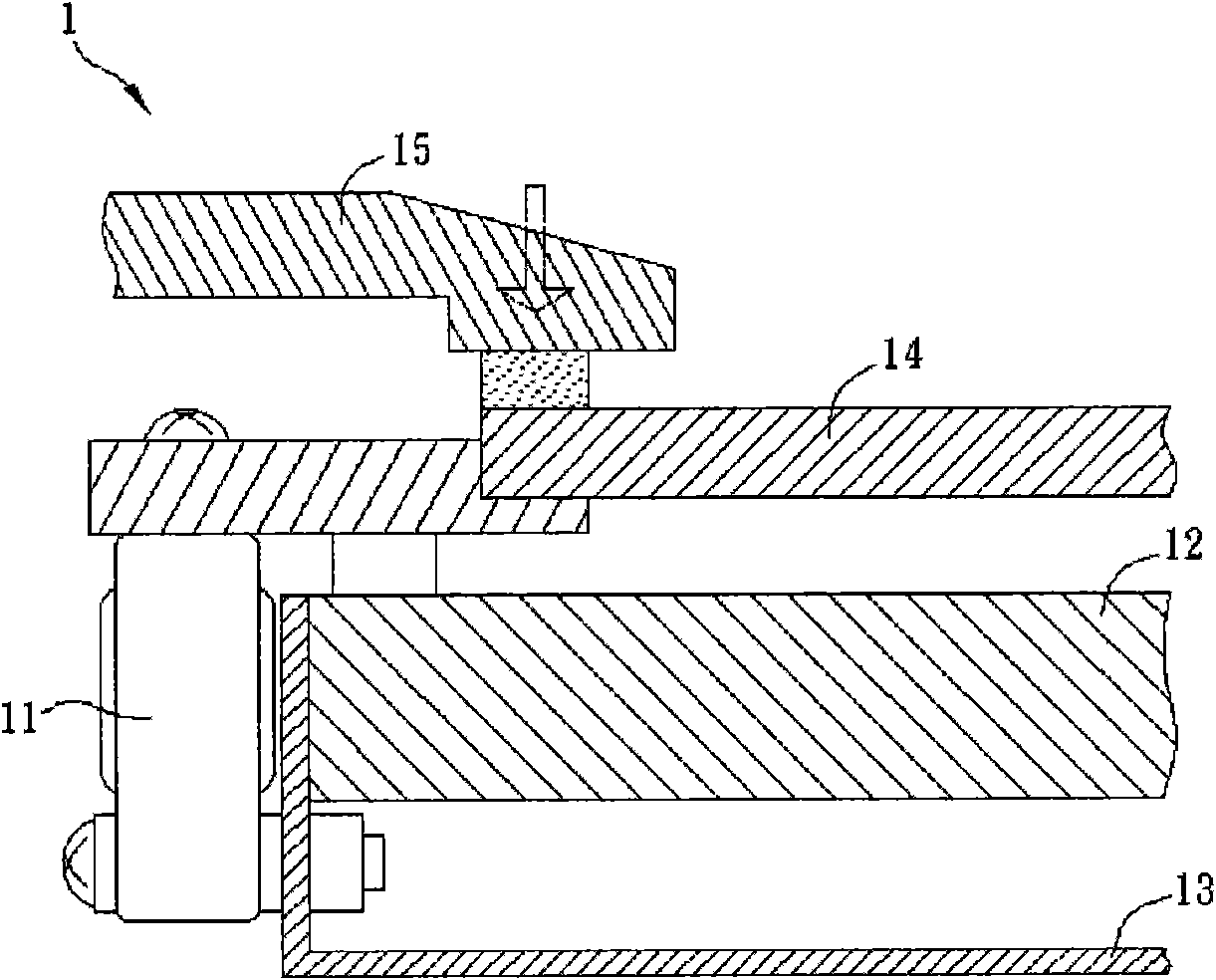

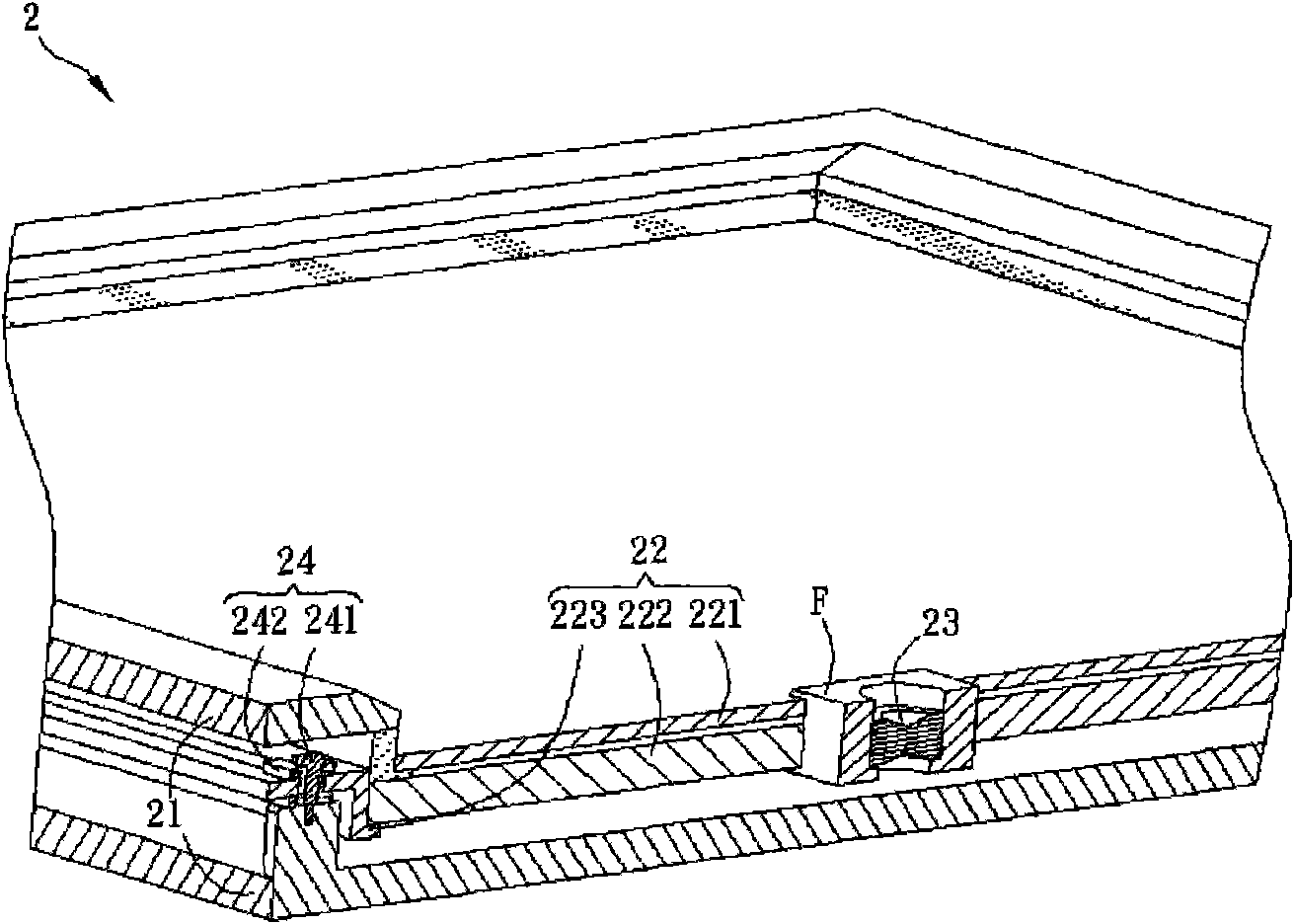

Environment-friendly type common cotton thread detonating cord

ActiveCN104829402AGood waterproof performanceDoes not pollute the airFuse detonationPolypropyleneCotton thread

The invention discloses an environment-friendly type common cotton thread detonating cord, relating to the technical field of detonating cords. The environment-friendly type common cotton thread detonating cord comprises a core wire 1, a Taian powder core 2, a detonating cord body 3, a polypropylene flat filament layer 4, a cotton yarn layer 5, a water-proof environment-friendly coating layer 6, an external blasting fuse paper strip layer 7, an outer cotton yarn layer 8, and an outer coating layer 9; the detonating cord adopts the water-proof environment-friendly paint instead of pitch to serve as a moisture-proof coating layer, has good moisture-proof and water-proof properties, is non-toxic and odorless, does not need to be heated, cannot pollute air and environment, and cannot harm the body health of operators; the environment-friendly type common cotton thread detonating cord is innovatively improved based on the common cotton thread detonating cord production process, the environment-friendly type common cotton thread detonating cord is good for the civil explosive industry, the energy is saved, the air is purified, the environment is purified, the body health level of the operators in the civil explosive industry is improved, and the comprehensive economic benefit is remarkable; and the environment-friendly type common cotton thread detonating cord can be widely applied to all the detonating cord production enterprises.

Owner:HUBEI SHUAILI CHEM

Outer wall waterproof coating

InactiveCN103571298AStrong anti-penetrationGood waterproof performanceAnti-corrosive paintsDefoamerTemperature resistance

The invention discloses an outer wall waterproof coating. The outer wall waterproof coating is prepared from the following raw materials in parts by weight: 25-35 parts of silicon acrylate emulsion, 25-40 parts of filler, 1-8 parts of film forming additive, 1-5 parts of dispersant, 0.1-0.5 parts of thickener, 0.5-2 parts of flow agent, 1-5 parts of defoamer and 30-40 parts of dedeionized water. The outer wall waterproof coating is strong in the permeability resistance, obvious in the waterproofness, good in weatherability, and strong in acid-resisting, alkali-resisting and corrosion-resisting capability, has stronger high temperature resistance, does not have chemical odor which is harmful to a human body, is simply prepared and is an ideal outer wall waterproof coating.

Owner:GUILIN JINSHUIMU DECORATION DESIGN ENG

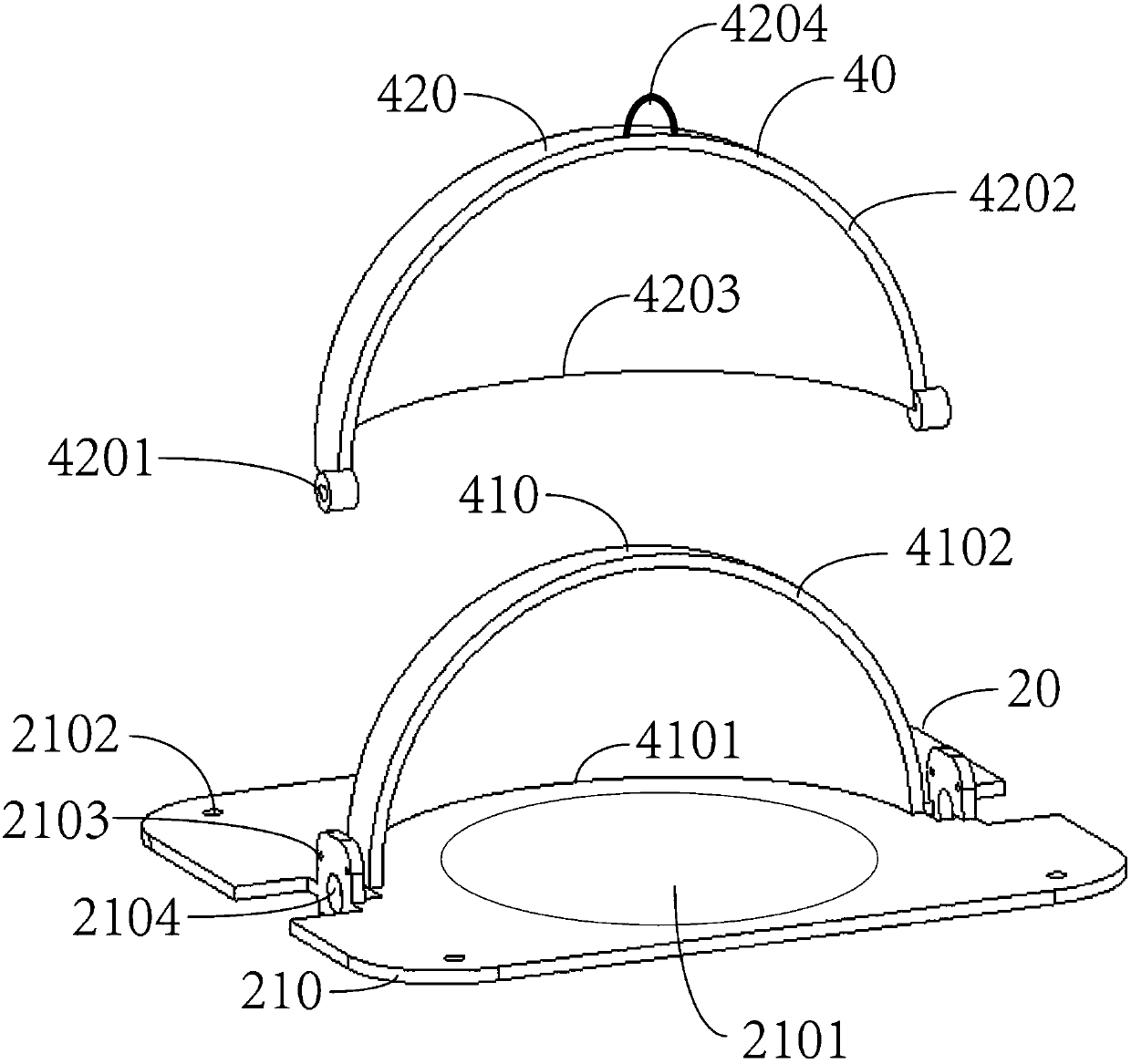

Touch device

InactiveCN102467280AGood waterproof performanceGood tactile feedbackInput/output for user-computer interactionGraph readingTouch panelRotary actuator

The invention discloses a touch device, which comprises a shell, a touch module and at least one non-rotary actuator, wherein the touch module is arranged in the shell and provided with at least one touch panel; and the non-rotary actuator is connected with the shell or the touch module. The touch device provided by the invention has an excellent tactile feedback effect and can be used for producing a sound.

Owner:DELTA ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com