Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

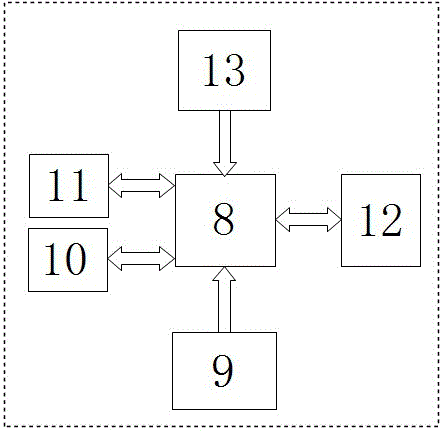

58results about How to "Strong anti-penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Torpedo tank lining gunning repairing material, preparation method and applications thereof

The invention discloses a torpedo tank lining gunning repairing material, a preparation method and applications thereof, wherein the torpedo tank lining gunning repairing material comprises, by weight, 60-67 parts of a Al2O3-containing fireproof material after-using regenerating material, 3-7 parts of fireproof clay, 2-5 parts of flaky graphite, 3-7 parts of silicon carbide, 10-15 parts of an alumina homogeneous material, 3-6 parts of kyanite, 2-5 parts of alpha-Al2O3 micro-powder, 3-11 parts of a binder, and 1.2-3.4 parts of an admixture. According to the present invention, the torpedo tank lining gunning repairing material has characteristics of low raw material cost, wide regeneration material source, convenient cold-hot state gunning repairing, excellent thermal shock stability, strong repairing layer interface bonding strength, strong slag iron corrosion resistance, high torpedo tank operation rate, long service life, and the like.

Owner:武汉钢铁有限公司

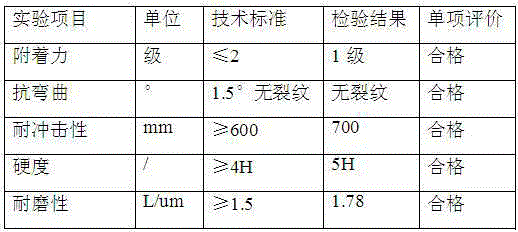

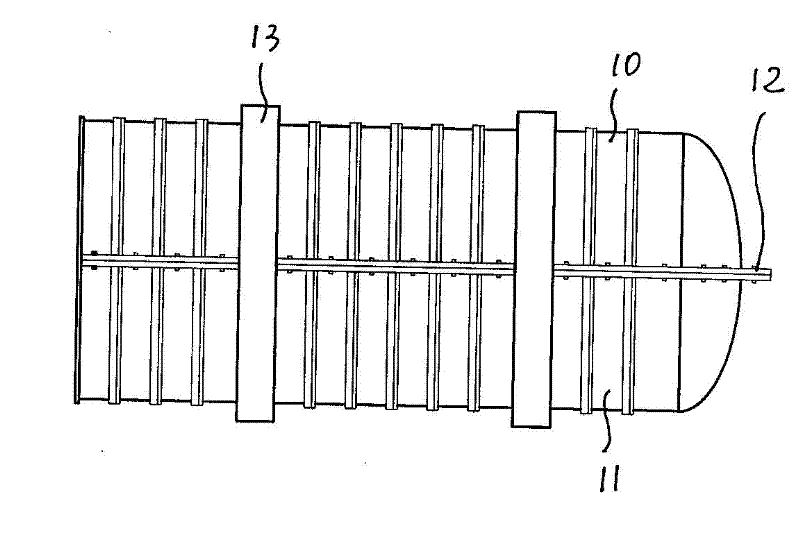

Heavy-anticorrosive epoxy finishing coat and preparation method thereof

ActiveCN103275598AImprove anti-agingEasy to cleanAnti-corrosive paintsEpoxy resin coatingsPolymer scienceFirming agent

The invention relates to heavy-anticorrosive epoxy finishing coat and a preparation method thereof. The heavy-anticorrosive epoxy finishing coat is a double-component system, wherein the component A comprises the following ingredients in parts by weight: 100 parts of hydrogenated bisphenol a expoxy resin, 10-30 parts of epoxy resin TDE 85, 5-20 parts of butyl titanate, 5-20 parts of fluorocarbon-containing silane coupling agent, 10-20 parts of an epoxy-containing silane coupling agent, 10-30 parts of other organic silicone precursor, 0.1-5 parts of a dispersing agent, 0.1-5 parts of a flatting agent, 0.1-5 parts of a defoaming agent, 0.1-2 parts of an accelerant and 50-150 parts of a solvent, and the component B is 30-20 parts by mass of an amine curing agent. The heavy-anticorrosive epoxy finishing coat mainly serves as outdoor heavy-anticorrosive finishing coat and has the advantages of excellent ultraviolet-resistance property, anti-yellowing property, good dispersion stability, excellent acid resistance, alkali resistance and salt-spray corrosion resistance, strong adhesive force, good wear-resisting property, self-cleaning property, room temperature curing, simple and convenient construction and the like.

Owner:STATE GRID CORP OF CHINA +2

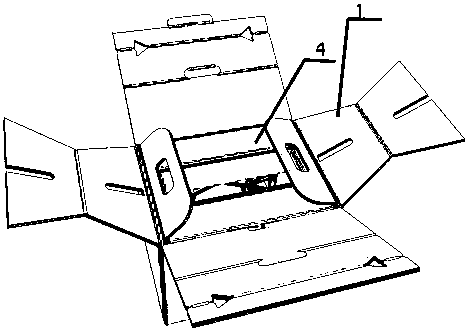

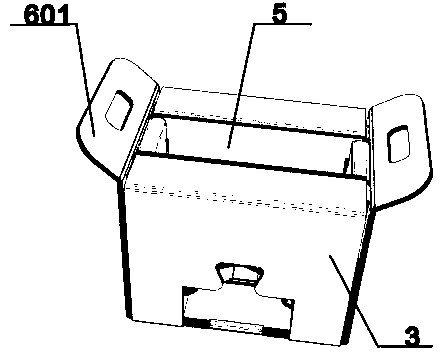

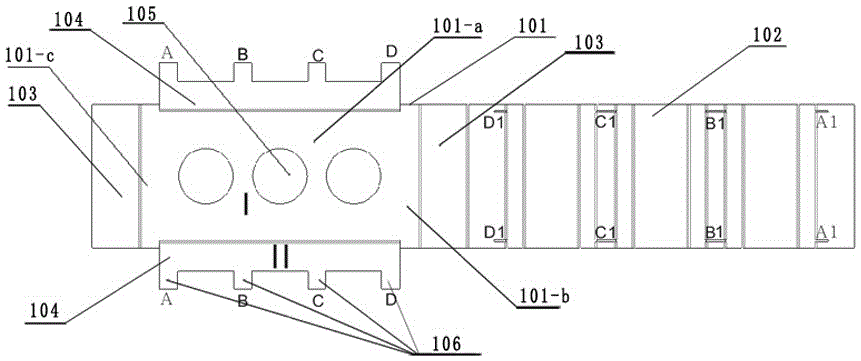

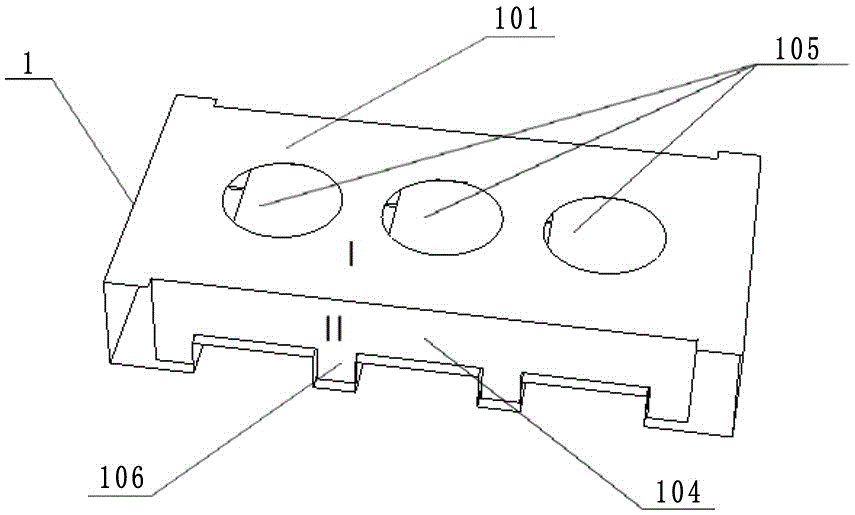

Shake-proof corrugated packaging box for electric rice cooker

InactiveCN103754451AUnique structureImprove seismic performancePackaging vehiclesContainers for machinesCushioningEngineering

A shake-proof corrugated packaging box for an electric rice cooker comprises an outer box body. Two L-shaped cushioning components I and a cushioning component II are arranged in the outer box body, the cushioning component II wraps the two cushioning components I to form a cushioning component group which is integrally cuboid, and the L-shaped cushioning components I and the cushioning component II encircle to form a cushioning cavity used for placement of the electric rice cooker. The shake-proof corrugated packaging box can bear certain pressure, and is elastic and good in cushioning effect; the shake-proof corrugated packaging box can be made into a liner or container in various shapes and sizes as required, and is more convenient and rapid than a plastic cushioning material; the shake-proof corrugated packaging box is low in impact of temperature, good in shading, good in self-adaptability, free of deterioration due to light and low in cost, can ensure the outer surface of the electric rice cooker not to be scratched, has compression resistance and stacking resistance and is resistant to breakage and puncture, vibration and various impacts.

Owner:HENAN UNIV OF SCI & TECH

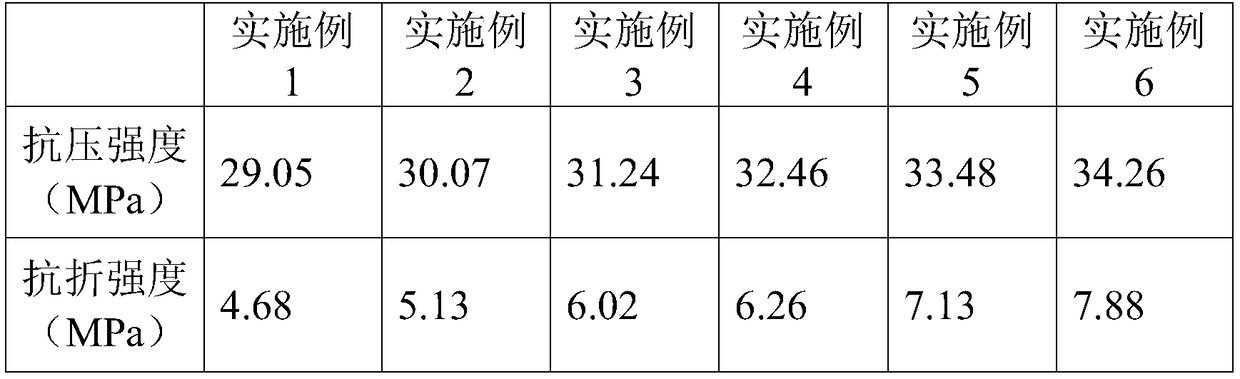

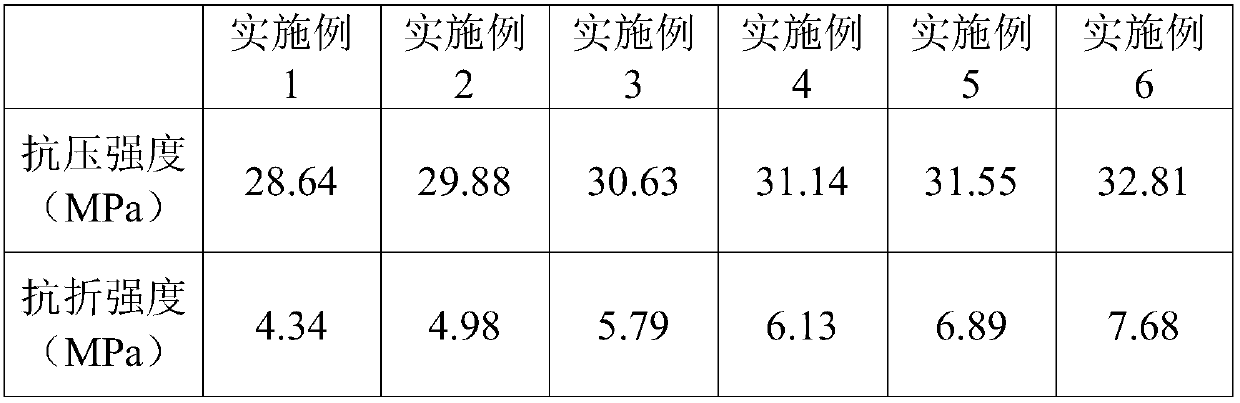

Nanometer inorganic stone slab using fly ash and production method thereof

The invention relates to a nanometer inorganic stone slab using fly ash and a production method thereof. The nanometer inorganic stone slab uses natural stone waste or quartz sand as aggregate, uses apolymer, produced by stimulating the fly ash by a sodium silicate solution, as an inorganic adhesive, and comprises main raw materials of the fly ash, nanometer active micropowder, an alkali silicatesolution, the stone aggregate, an inorganic pigment and the like. The preparation method comprises the following steps: firstly mixing the fly ash, the nanometer active micropowder, the stone aggregate and a toner uniformly by stirring, then adding the sodium silicate solution, stirring uniformly, then dispensing, vibrating under vacuum for compression moulding, curing, polishing, and siliconizing to finally obtain the nanometer inorganic stone slab. The nanometer inorganic stone slab provided by the invention not only has the decorative performance of resin-type artificial stone, but also isnon-toxic and environment-friendly, uses solid waste and is low in cost, resistant to acid and alkali corrosion and resistant to high temperature; in addition, the nanometer inorganic stone slab alsohas the advantages of no deformation, durability, ultraviolet resistance and the like, and is suitable to be used on outdoor occasions.

Owner:梁钟瑞

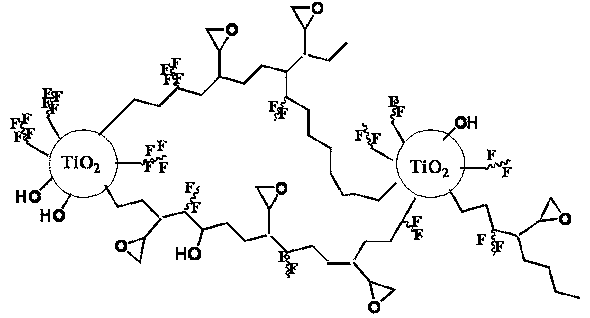

Nano titanium polymer inner wall anticorrosion oil pipe

ActiveCN103275601AExtended service lifeImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer

The invention relates to a nano titanium polymer inner wall anticorrosion oil pipe in the technical field of pipeline corrosion resistance. The technical scheme is as follows: the nano titanium polymer inner wall anticorrosion oil pipe comprises an oil pipe and an anticorrosion layer coated on the inner wall of the oil pipe. The anticorrosion layer is prepared by the following steps of: mixing and stirring 130-160 parts by weight of novolac epoxy resin, 20-40 parts by weight of nano-scale titanium powder and 10-30 parts by weight of diluent; sequentially adding 2-3 parts by weight of organosilicon leveling agent and 3-5 parts by weight of bentonite filler to adjust viscosity; screening with a sieve of 1,100-1,300 meshes to obtain an component A of a finished product; mixing and dispersing 15-18 parts by weight of curing agent, 4-6 parts by weight of titanate coupling agent and 6-8 parts by weight of butanone to obtain a component B of the finished product; and finally blending the component A and the component B by the diluent according to a ratio of (4.5-5.5):2:(1-2). Compared with other anticorrosion products, the product provided by the invention has unique advantages of static resistance, strong permission resistance and the like; and moreover, the construction equipment and technology are simple, and the product is easy to popularize.

Owner:胜利油田金岛实业有限责任公司

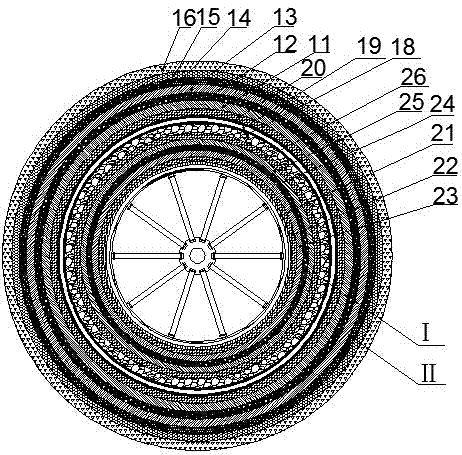

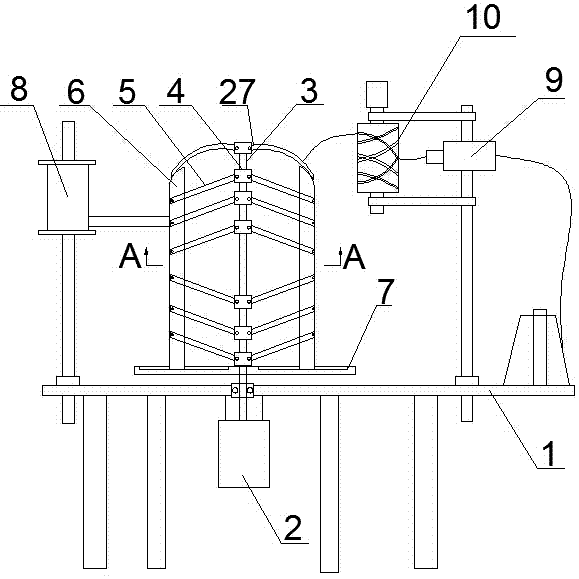

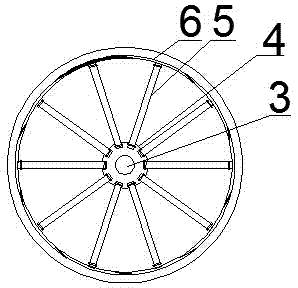

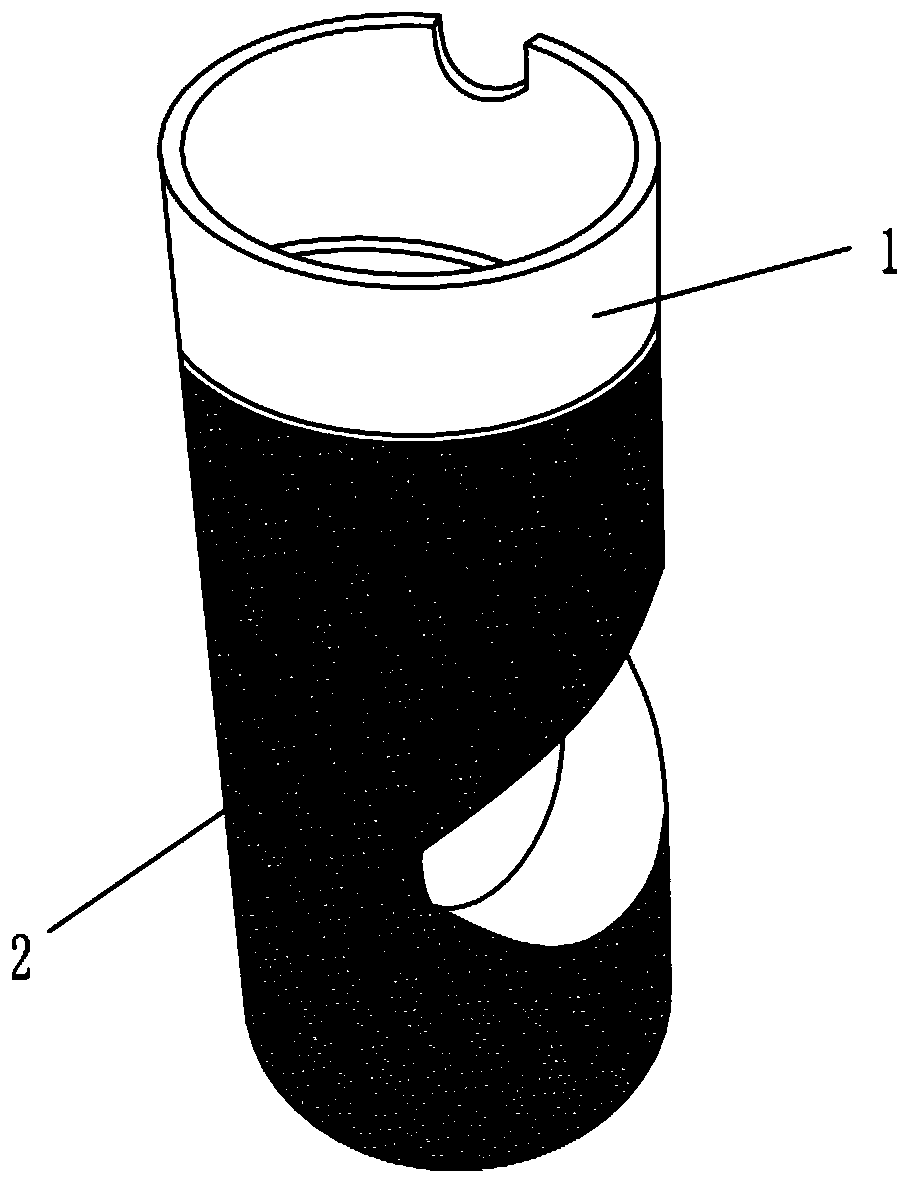

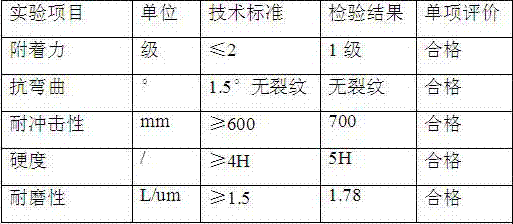

Dual-layer oil tank made of glass fiber, manufacturing method thereof and special mold

ActiveCN105437670AStrong anti-penetrationHigh mechanical strengthSynthetic resin layered productsDomestic containersYarnEnvironmental resistance

The invention discloses a dual-layer oil tank made of glass fiber, a manufacturing method thereof and a special mold. The dual-layer oil tank comprises a storage inner tank I made of glass fiber and a reinforcing tank II stuck to the outer surface of the storage inner tank made of glass fiber. A glass fiber sleeve adopted as a reinforcing rib concurrently is further stuck between the storage inner tank I made of glass fiber and the reinforcing tank II. First glass fiber non-twist fine mesh gauze capable of solidifying resin, a first S yarn picking layer, a first glass fiber short fiber layer, a first Z yarn picking layer, first glass fiber plying coarse mesh gauze and an anticorrosion solidification layer are sequentially stuck into the storage inner tank I from interior to exterior in a soaking mode. Second glass fiber plying coarse mesh gauze capable of solidifying resin, a second Z yarn picking layer, a second glass fiber short fiber layer, a second S yarn picking layer, second glass fiber non-twist fine mesh gauze, a modification polyethylene layer and an anti-aging white oil layer are sequentially stuck into the reinforcing tank II from interior to exterior in a soaking mode. The dual-layer oil tank achieves the effects of being high in safety and environment-friendly performance, low in cost and capable of preventing steam corrosion and electrolytic corrosion.

Owner:XINJIANG LIANCHENG HEAVY IND TECH CO LTD

Ecological texture artificial quartzite sheet material and preparation method thereof

The invention relates to quartzite, and discloses an ecological texture artificial quartzite sheet material and a preparation method thereof. The method comprises the steps of performing stirring, distributing, pressing, frame-drawing, thermocuring, thickness defining, cutting, polishing and inspecting on quartz sands, quartz powder, unsaturated resin, coupler, curing agent and pigment to prepare a finished product. The preparation process is simple and has high production efficiency and short pressing and stirring time, the production time can be reduced, production cost and product rejection can be effectively reduced, the color matching style is unique attractive and harmonious, and the texture types of quartzite can be greatly enriched; and the finished product has high density and strong infiltration resistance, and is easy to clean; and the manufactured quartzite sheet material has the advantages of no radioactive contamination, scratch prevention, burning prevention and recycling.

Owner:BENYEE NEW MATERIAL CO

Outer wall waterproof coating

InactiveCN103571298AStrong anti-penetrationGood waterproof performanceAnti-corrosive paintsDefoamerTemperature resistance

The invention discloses an outer wall waterproof coating. The outer wall waterproof coating is prepared from the following raw materials in parts by weight: 25-35 parts of silicon acrylate emulsion, 25-40 parts of filler, 1-8 parts of film forming additive, 1-5 parts of dispersant, 0.1-0.5 parts of thickener, 0.5-2 parts of flow agent, 1-5 parts of defoamer and 30-40 parts of dedeionized water. The outer wall waterproof coating is strong in the permeability resistance, obvious in the waterproofness, good in weatherability, and strong in acid-resisting, alkali-resisting and corrosion-resisting capability, has stronger high temperature resistance, does not have chemical odor which is harmful to a human body, is simply prepared and is an ideal outer wall waterproof coating.

Owner:GUILIN JINSHUIMU DECORATION DESIGN ENG

Packaging corrugated carton for transporting electric rice cookers

InactiveCN103754490AUnique structureStrong anti-shock and anti-pressure adjustment abilityRigid containersCardboardCarton

A packaging corrugated carton for transporting electric rice cookers is characterized in that buffer top covers and a buffer frame below the buffer top covers are arranged in an outer box, each of the buffer frame and the buffer top covers is made by folding one corrugated cardboard, and the buffer frame and the buffer top covers can bear certain pressure, are well elastic and have good buffering. The packaging corrugated carton can be made into cushions or containers with different shapes and sizes, and making is simpler and quicker than making with plastic buffer material; the packaging corrugated carton is less susceptible to temperature, good in shading performance, good in adaptability, capable of resisting deterioration caused by exposure to sunlight, capable of protecting the outer surfaces of electric rice cookers from scratches, low in cost, resistant to compression, tolerant to stacking, resistant to breakage or piercing, and resistant to vibration and various impacts.

Owner:HENAN UNIV OF SCI & TECH

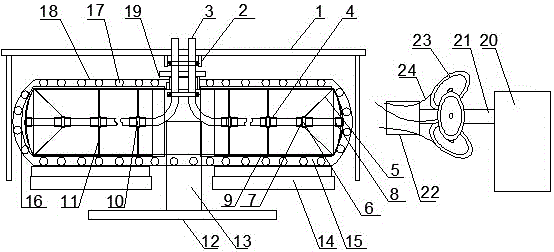

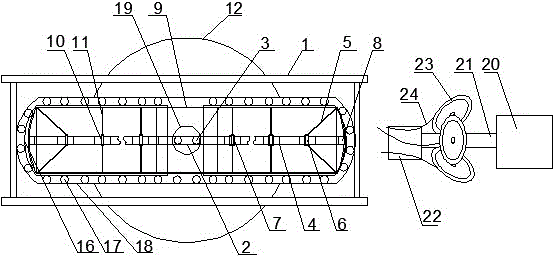

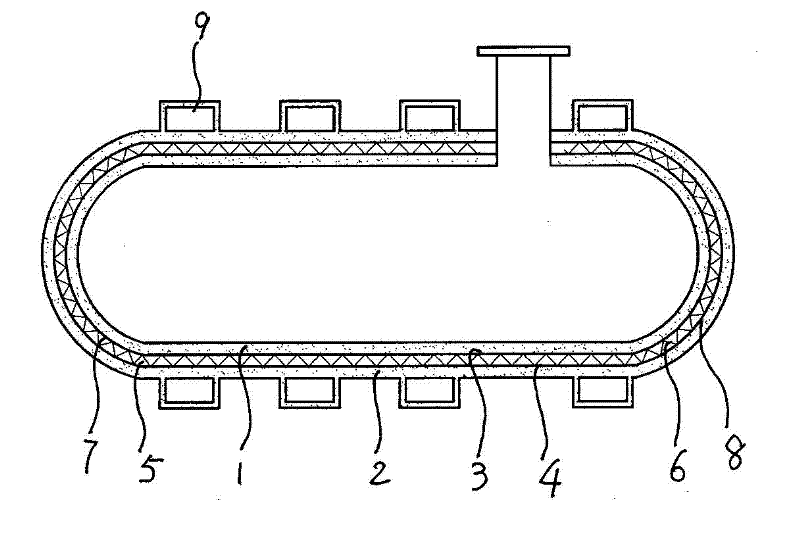

Glass fiber double-layer oil tank and production device as well as preparation method

ActiveCN105668063AImproves corrosion and aging resistanceHigh mechanical strengthLarge containersScrew jointEnvironmental resistance

The invention discloses a glass fiber double-layer oil tank which comprises two modified polyethylene ceramic double-layer half tanks in screw joint, wherein a glass fiber storage inner tank layer is adhered to the outer side of each modified polyethylene ceramic double-layer half tank, a glass fiber tube internally filled with a filler is wound on the outer wall of the glass fiber storage inner tank layer by a cloth winder, a glass fiber storage outer tank layer is adhered to the outer wall of the glass fiber tube, oil tank pipe orifices extending out of the glass fiber storage outer tank layer are formed at the upper parts of two extending shafts and the bottoms of the modified polyethylene ceramic double-layer half tanks, the lower parts of the two extending shafts are respectively provided with a base, and a hydraulic ejector rod capable of rotating along the base is arranged on the base; by adopting the structure, the effects of being high in safety, high in environment protection performance and low in cost and preventing moisture erosion and electrolytic etching can be achieved; and furthermore, the invention also discloses a device and a method for producing the glass fiber double-layer oil tank.

Owner:XINJIANG LIANCHENG HEAVY IND TECH CO LTD

Waterproof paint for exterior wall

ActiveCN104119757AStrong anti-penetrationImprove waterproof performanceCoatingsPotassiumAmmonium metavanadate

The invention discloses a waterproof paint for an exterior wall. The waterproof paint is prepared from the following raw materials in parts by weight: 53-60.2 parts of a silicone acrylic emulsion, 0.1-0.2 part of tantalum carbide, 0.3-0.7 part of copper 8-hydroxyquinoline, 0.1-0.3 part of fatty alcohol polyoxyethylene ether ammonium sulfate, 1-2 parts of potassium tetraborate, 0.4-0.6 part of ammonium metavanadate, 1-2 parts of polyurethane, 2-3 parts of polypropylene oxide glycol, 1.3-2 parts of sodium carboxymethylcellulose, 0.7-1 part of N, N-diethyl aniline, 0.1-0.2 part of trimethyl hexamethylene diamine, 4-6 parts of titanium dioxide, 8-10 parts of light calcium carbonate, 5-6 parts of coalescing agents and 10-15 parts of deionized water. The waterproof paint for the exterior wall is strong in seepage force resistance, remarkable in waterproof performance, good in weather resistance and strong in resistance to acid and base, has good high temperature resistance, is free from chemical odors which are harmful to human body and simple to operate, and is an ideal waterproof paint for the exterior wall.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

Efficient energy-saving magnesian ramming material prepared by recycling waste magnesite brick materials of cement plant and preparation technology

ActiveCN106316421AImproved thermal shock stabilityImprove corrosion resistanceBrickAdditive ingredient

The invention discloses an efficient energy-saving magnesian ramming material prepared by recycling waste magnesite brick materials of a cement plant and a preparation technology. The efficient energy-saving magnesian ramming material is prepared from the recycled waste materials of the cement plant through the preparation technology processes of waste material selecting, classifying, crushing, particle size screening, analyzing, ingredient synthesizing, inspecting, packaging, qualified product warehousing and the like. The MgO content of the prepared efficient energy-saving magnesian ramming material is higher than or equal to 85%, and the product has the advantages of being good in chemical stability, uniform in structure of a pre-reaction sintering layer, high in compactness, good in erosion resistance, high in permeating resistance, good in material impact and wear resistance, high in softening temperature and the like. No bonding agent or water needs to be added in the construction process, blowing-in can be quickly conducted after furnace building, and the service life is 3 times that of magnesite bricks when the efficient energy-saving magnesian ramming material is applied to the furnace bottom of an ore-smelting electric furnace with the power of 16,500. According to the efficient energy-saving magnesian ramming material, the preparation technology procedures are simple, the raw materials are selected from the waste materials of the cement plant, secondary utilization of the waste materials is achieved, the environmental protection and energy saving call of the state is responded, the waste materials can be effectively utilized, natural resources are greatly saved, and the extremely high industrial application value is achieved.

Owner:新化县腾宇炉料有限公司

Glassine base paper production method

ActiveCN103821026AStrong anti-penetrationReduce dosageNon-fibrous pulp additionSpecial paperSurface strengthFilm coating

The invention discloses a Glassine base paper production method, which comprises the following steps: a, bleached sulfate softwood pulp is selected and used as a raw material; b, an alkylketene dimmer synthetic glue and paper making special starch with a weight percentage of 5% are added in the bleached sulfate softwood pulp; c, a net part is formed via double-faced bidirectional dehydration, and positive contrast is reduced; d, press dewatering is performed after the formation; e, a front drying part performs drying after dewatering; f, a paper page enters a large roller radial pressing area and passes through a soaking solution, and a certain quantity of adhesive films cover the surface of the paper page; g, the drying part performs shaping and drying after film coating; h, the processed paper is further treated by a steel roller in high-temperature calendaring intermediate; y, the paper is cut and packed by a rewinding machine. Compared with the prior art, the Glassine base paper production method has the technical characteristics of strong infiltration resistance, reduction of the use amount of silicon oil, increment of the surface strength of the paper pages and low probability of linting, and can greatly improve the production efficiency.

Owner:ZHEJIANG HUACHUAN IND GRP

Granular sand for covering excreta and preparation process for granular sand

The invention discloses granular sand for covering excreta and a preparation process for the granular sand and relates to the technical field of covering of the excreta. The granular sand comprises the following ingredients in percentage by weight: 60%-80% of raw bamboo fibers, 3%-6% of bamboo pulp, 3%-4% of plant stalks, 1%-3% of pine needle meal, 8%-20% of organic matter base stock, 1%-3% of edible gelatin, 1%-3% of bamboo vinegar and 3%-6% of water. According to the granular sand, the dust is little, the pollution to air is reduced, the anti-seepage capability is very high, and the granularsand has relatively good caking and flavor absorbing functions. The granular sand directly sucks up urine, can be directly discarded into a toilet bowl for flush-out and has no need of excessive cleaning usually. The service life is long. Bamboo-fiber cat litter can achieve complete odor inhibiting substantially, a faint-scent flavor of raw bamboos is maintained, and thus, the granular sand is different from the traditional cat litter that urine off odors are covered by addition of flavoring essences.

Owner:杭州复耐吸科技有限公司

Corrosion-resistant coating and processing method thereof

InactiveCN106700934AFast curingHigh mechanical strengthAnti-corrosive paintsEpoxy resin coatingsAsphaltMaterials science

The invention relates to a corrosion-resistant coating and a processing method thereof and belongs to the technical field of reprocessed raw materials. The corrosion-resistant coating is prepared from components in percentage by weight as follows: 40%-60% of asphalt, 22%-43% of resin, 15%-25% of a curing agent and 2%-3% of filler. The processing method is applicable to processing of the corrosion-resistant coating, and the corrosion-resistant coating has the advantages of high corrosion-resistant effect and the like.

Owner:绍兴丰源节能科技有限公司

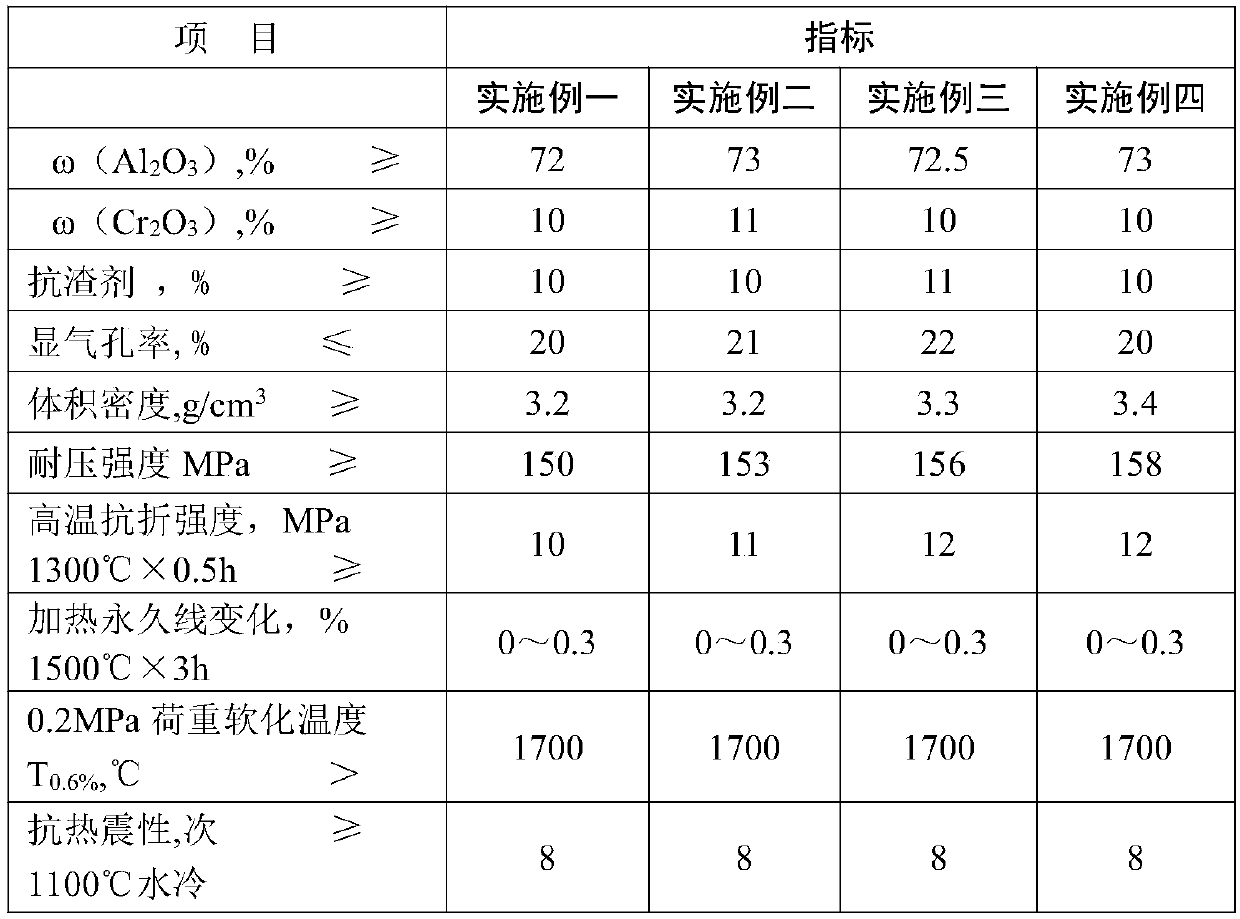

Fire resistant material for furnace wall mouth of nonferrous smelting furnace and preparing method thereof

The invention discloses a fire resistant material for a furnace wall mouth of a nonferrous smelting furnace. The fire resistant material is suitable for a furnace wall mouth position of the nonferroussmelting furnace and is prepared from electric smelting chromium corundum, chrome oxide and a gel binder. According to the fire resistant material, the electric smelting chromium corundum and the chrome oxide serve as raw materials, the content of MgO is reduced, so that related MgO dissolution and subsequent decomposition reactions which occur in the fire resistant material are greatly reduced,related thermal reactions are reduced, and the situation is avoided that the structure of the fire resistant material is damaged by frequent reactions. Due to the electric smelting chromium corundum,the fire resistant material is good in high-temperature performance, thermal vibration stability and corrosion resistance. Due to the chrome oxide, the penetration resistance of the fire resistant material is good.

Owner:中钢洛耐科技服份有限公司

Burst-proof non-toxic protective layer for valve core of water faucet

InactiveCN110746171AExtend your lifeAchieve explosion-proofValve arrangementsEnvironmental engineeringMechanical engineering

The invention belongs to the technical field of equipment and materials of kitchens and bathrooms and particularly relates to a burst-proof non-toxic protective layer for a valve core of a water faucet. The burst-proof non-toxic protective layer for the valve core of the water faucet, provided by the invention, has the advantages that the valve core of the water faucet can be prevented from bursting and the surface of the valve core is prevented from corrosion. The burst-proof non-toxic protective layer for the valve core of the water faucet comprises a water faucet valve core and a protectivelayer, wherein the water faucet valve core is smeared with the protective layer; and the protective layer is prepared from the following raw materials in percentage by mass (100%): 10% of gypsum powder, 10% of talcum powder, 5% of blockage preventer, 25% of glass glue, 0.5% of strengthening agent and 49.5% of iron sand. The burst-proof non-toxic protective layer achieves the effects of preventingbursting, preventing corrosion and prolonging the service life of the valve core.

Owner:苏连吉

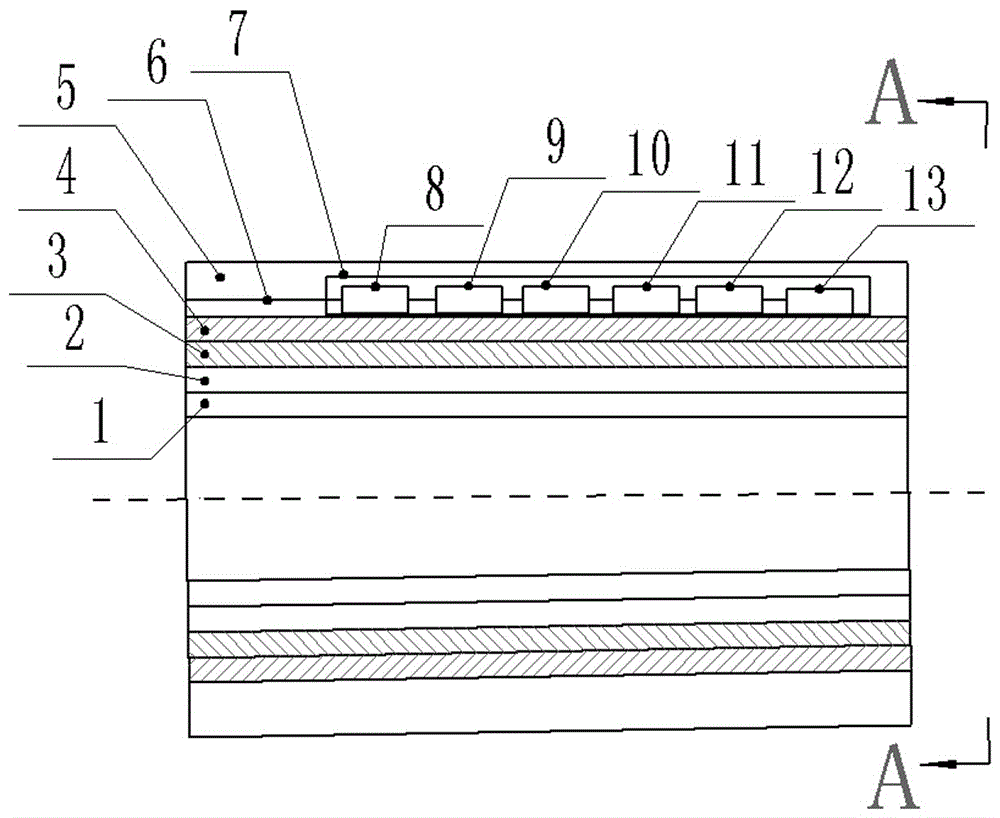

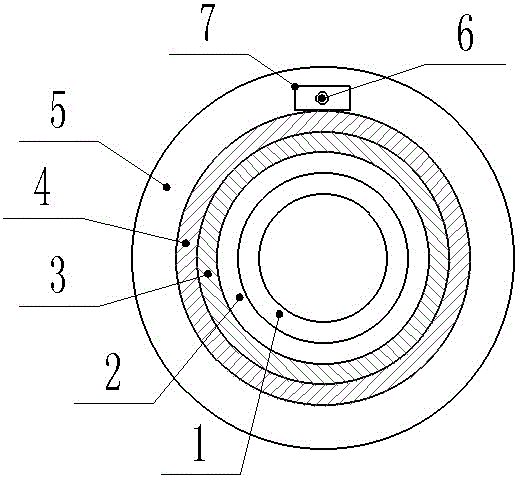

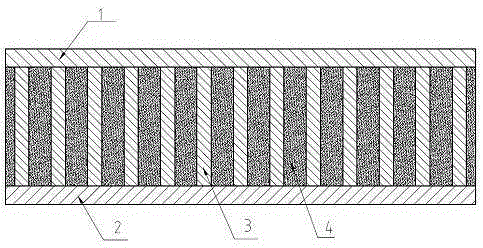

Continuous flexible reinforced adhesion-type composite tube

PendingCN106838494AHigh strengthExtended service lifePipe heating/coolingPipeline systemsPhysical chemistryOil field

The invention relates to a composite tube used for an oil field, in particular to a continuous flexible reinforced adhesion-type composite tube. The composite tube comprises a lining layer, an anti-permeation layer, a compression-resistive reinforced layer, a tensile reinforced layer and an outer protective bush layer. The composite tube is characterized in that the anti-permeation layer, the compression-resistive reinforced layer, the tensile reinforced layer and the outer protective bush layer are sequentially arranged on the outer surface of the lining layer; a power line and a control module are arranged on the outer surface of the tensile reinforced layer. The composite tube has the advantages that the adhesion-type structure is good in integrality, the anti-permeation capacity is high, and ring stiffness and an axial tensile property are good; the composite tube can bear high pressure and is small in deformation caused by pressing, allows local heating, further has quite high functions of information collecting and monitoring alarming, and is convenient to use, suitable for delivering water, natural gas, petroleum oil and others from a long distance and particularly suitable for deeply passing through roads, villages and other working conditions that the composite tube can not be laid through ditching at a long distance.

Owner:康红艳 +1

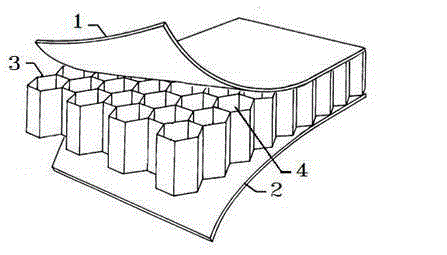

A continuous fiber reinforced thermoplastic polymer tempering panel

ActiveCN104290372BNo leakageHigh strengthSynthetic resin layered productsLaminationSpecific modulusHeat fusion

A continuous-fiber reinforced thermoplastic polymer temperature-adjusting plate comprises a surface plate, a bottom plate, a honeycomb core layer and a phase-change energy-storage material packed in the honeycomb core layer. The surface plate, the bottom plate and the honeycomb core layer are prepared from a sheet of a continuous-fiber reinforced thermoplastic polymer composite material filled with a modified heat-conduction filler, the honeycomb-core-layer phase-change energy-storage material is packed in multiple mutually-independent chambers in the honeycomb core layer, and the surface plate and the bottom plate are respectively combined with the upper surface and the lower surface of the honeycomb core layer through heat fusion. By blending a high-heat-conductivity substance with the polymer, the high-heat-conductivity continuous-fiber reinforced thermoplastic polymer plate, which is prepared by employing a double-face film coating method, has high specific modulus and specific strength. The honeycomb core layer employs a material same to that of the surface plate, and the honeycomb core layer and the surface plate are firmly bonded through fusion. Honeycomb holes are filled with the phase-change material, the addition amount is large and the problem that the phase-change material precipitates is effectively avoided. The continuous-fiber reinforced thermoplastic polymer temperature-adjusting plate has an expanded application field and is especially applicable to decoration of indoor decoration furred ceilings and wall surfaces.

Owner:BEIJING UNIV OF CHEM TECH

Anti-erosion zirconium-containing andalusite brick and preparation method thereof

The invention discloses an anti-erosion zirconium-containing andalusite brick and a preparation method thereof. The anti-erosion zirconium-containing andalusite brick is mainly composed of the following raw materials: andalusite of 5-3mm, andalusite of 3-1mm, andalusite of 1-0mm, andalusite of 200 meshes, a zirconium source and clay. In addition, a binding agent is added. The method comprises the following steps: firstly, uniformly mixing the andalusite of 5-3mm, 3-1mm and 1-0mm, then adding the binding agent, and performing uniform mixing to obtain a mixed material A; uniformly mixing 200-mesh andalusite, the zirconium source and the clay to obtain a mixed material B; and adding the mixed material B into the mixed material A, uniformly mixing, carrying out compression molding on the obtained total mixed material, performing drying, and finally performing sintering and cooling to obtain the product. The product prepared by the method has excellent erosion resistance, permeation resistance and thermal shock resistance, is suitable for rotary kilns and oversize cement kilns for co-processing hazardous wastes, and has a service life of more than 15 months.

Owner:TONGDA REFRACTORY TECH CO LTD +1

Microwave-excitation-based self-broken concrete as well as preparation method and application thereof

The invention relates to microwave-excitation-based self-broken concrete as well as a preparation method and application thereof. The concrete contains the following components in parts by weight: 250-300 parts of sulfur, 100-150 parts of Portland cement, 150-200 parts of fine aggregates, 350-500 parts of coarse aggregates, 10-20 parts of paraffin, 30-50 parts of a microwave absorbent and 20-30 parts of a mineral filler; and the density of the concrete is 1850kg / m<3>-2900kg / m<3> after being mixed and blended. By virtue of the interaction and cooperation of the components, the concrete has thecharacteristics of high strength, corrosion resistance, permeation resistance and high hardening speed of existing sulfur concrete and further has the advantages of lightness and high heated volume swelling speed of light aggregate concrete. The concrete is reasonable in design, low in cost and easy in preparation process. A component prepared from the concrete has good mechanical properties. Whenbeing dismounted, the component can be automatically cracked and broken under an external microwave field, so that the difficulty of dismounting construction is reduced, and the popularization and use are promoted.

Owner:SHENYANG JIANZHU UNIVERSITY

Self-crushing concrete based on magnetocaloric excitation, preparation method and application thereof

The invention provides self-crushing concrete based on magnetocaloric excitation, and preparation method and application thereof. The self-crushing concrete contains, by weight, of the components of 250-300 parts of sulfur, 100-150 parts of Portland cement, 150-200 parts of fine aggregate, 350-500 parts of coarse aggregate, 10-20 parts of paraffin, 30-50 parts of magnetic powder and 20-30 parts ofmineral filler; the density is 2050-2850 kilograms per cubic metre after the components are mixed. With the coordination and synergy of the components, the self-crushing concrete based on the magnetocaloric excitation has the advantages of having not only the characteristics of high strength, corrosion resistance, penetration resistance and rapid setting of existing sulphur concrete but also theadvantages of light weight and rapid expansion of heat volume of lightweight aggregate concrete, and being reasonable in design, low in cost and simple in preparation process. Furthermore, members made of the concrete have the advantages of being good in mechanical properties and capable of self expanding and crushing under the action of an external alternating magnetic field during demolition, reducing the difficulty of demolition construction, and being suitable for popularization.

Owner:上海隧港建筑材料有限公司

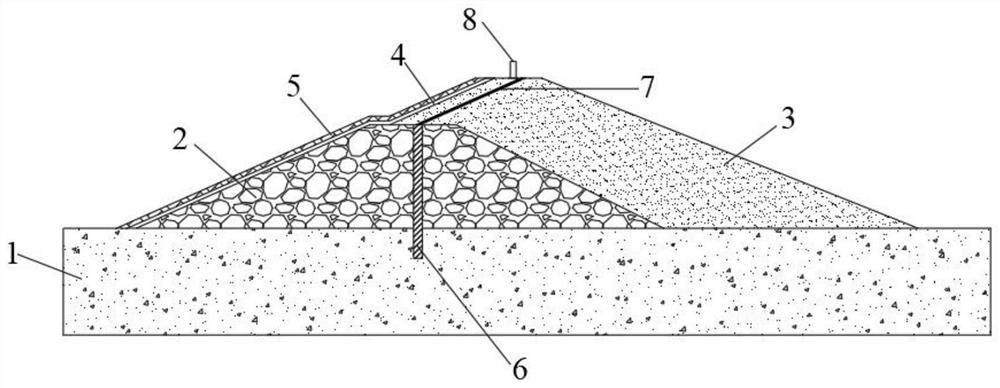

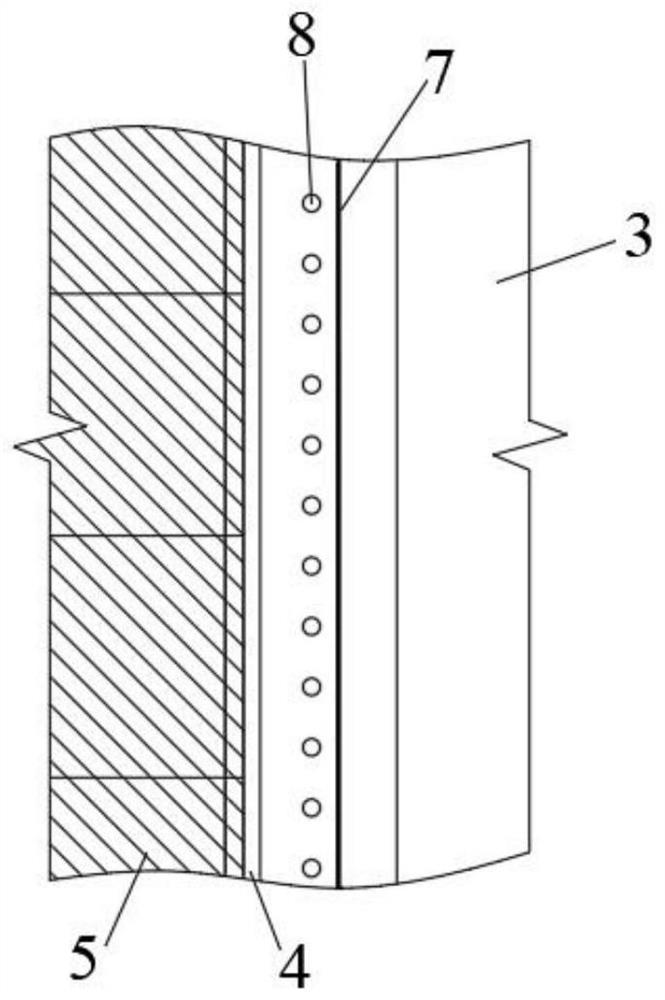

Anti-seepage stable cofferdam structure and construction method thereof

PendingCN113585303AIncrease in sizeLower the altitudeCoastlines protectionFoundation engineeringGeomembraneCofferdam

The invention provides an anti-seepage stable cofferdam structure and a construction method thereof. The cofferdam structure comprises a cofferdam foundation, and further comprises a berm and a cofferdam body which are sequentially arranged from the upstream face to the downstream face; the cofferdam foundation is filled with the berm; the berm and the cofferdam foundation are filled with the cofferdam body; sand cushion layers are laid on the upstream face of the berm and the upstream face of the cofferdam body; mold bag concrete protection slopes are laid outside the sand cushion layers; an anti-seepage wall is arranged in the berm; a composite geomembrane is buried in the cofferdam body; the lower end of the composite geomembrane is connected to the upper end of the anti-seepage wall in a pouring manner; and the berm and the anti-seepage stable cofferdam structure are each of a trapezoid structure. According to the anti-seepage stable cofferdam structure and the construction method thereof, the stability of the cofferdam structure can be maintained without increasing the height of a cofferdam or decreasing the gradient of the cofferdam, the size of the cofferdam structure is reduced, the situation that the work amount of the cofferdam structure is sharply increased is avoided, and the project cost is remarkably reduced.

Owner:江西省港航建设投资集团有限公司 +1

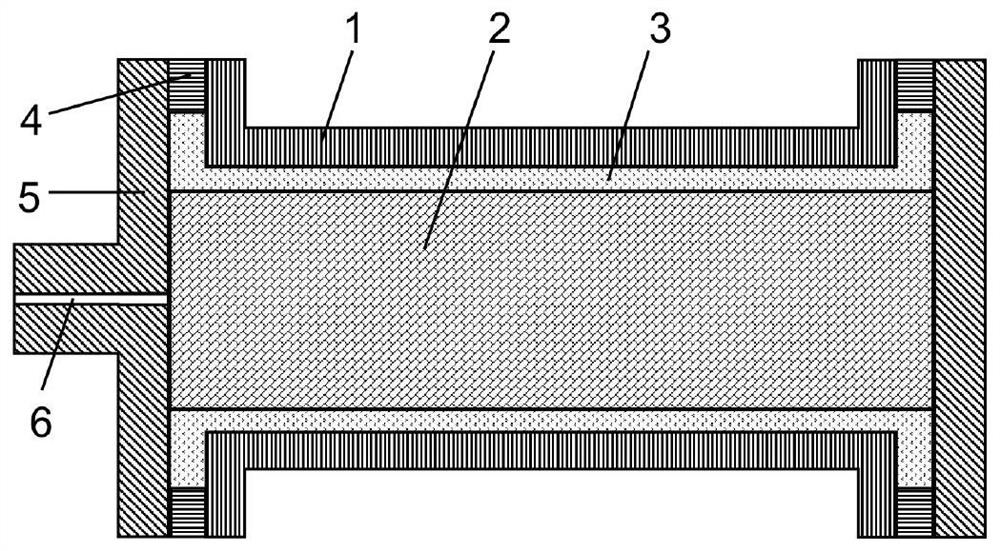

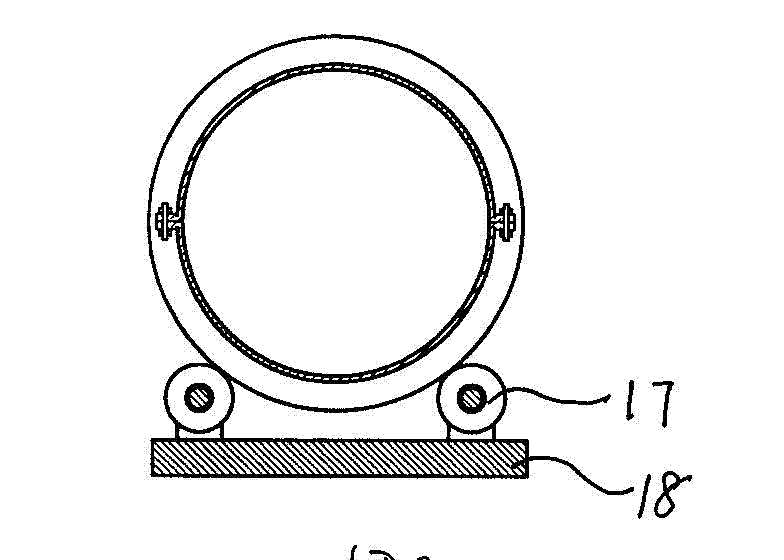

Isobaric preparation process for polytetrafluoroethylene lining of pipeline

The invention belongs to the technical field of pipeline linings, and discloses an isobaric preparation process for a polytetrafluoroethylene lining of a pipeline. The process comprises the followingsteps of filling polytetrafluoroethylene powder between the inner wall of the pipeline and a rubber bag soft mold, sealing, putting into an autoclave, equally increasing the water pressure in a rubberbag and the autoclave to a specific high pressure, and expanding the rubber bag to compact polytetrafluoroethylene, so that forming the uniform and compact lining on the inner wall of a steel pipe. Compared with a traditional compression molding method, the isobaric molding process has the advantages that equipment and molds used are simple, operation is convenient, and the yield is high; the pressures inside and outside the pipeline are equal in the machining process, and the steel pipe is not damaged; and the lining is uniform and compact and low in shrinkage rate due to everywhere equal high pressure. The specific technological process comprises the steps of A, steel pipe inner surface treatment, B, rubber bag soft mold loading, C, polytetrafluoroethylene powder adding, D, sealing, E,water injection and pressurization in the autoclave, F, pressure relief and part taking, G, rubber bag soft mold removal, H, sintering and I, inner filler removal.

Owner:JIANGSU JIN FU LONG ANTICORROSION EQUIP CO LTD

Anticorrosive paint used for inner wall of oil pipe and oil pipe having inner wall sprayed with anticorrosive paint

ActiveCN105176315AHigh temperature resistantStrong anti-penetrationAnti-corrosive paintsEpoxy resin coatingsHigh concentrationMass ratio

The invention discloses an anticorrosive paint used for an inner wall of an oil pipe and the oil pipe having the inner wall sprayed with the anticorrosive paint. The anticorrosive paint comprises a component A and a component B, wherein the component A comprises modified phenolic resin, a mixed solvent, auxiliary agents and auxiliary materials; the mixed solvent comprises xylene and butanone; the auxiliary agents comprise a de-foaming agent, an anti-sagging agent and a film forming auxiliary agent; the auxiliary materials comprise heavy calcium carbonate, kaolin and titanium dioxide; the component B comprises an accelerant and a solvent; the accelerant is a mixture of CYD-128 epoxy resin and bisphenol A, and the solvent is butanone; the mass ratio of the component A to the component B is (3-7) to (0.5-2). The anticorrosive paint has unique advantages of high temperature resistance, strong permeation resistance and the like, can be used for a long period under weak acid and weak alkali environments, and expresses the unique superiority in special mine wells containing hydrogen sulfide and having high concentration of carbon dioxide; anti-corrosion and scale formation capabilities of the mine wells also can be improved, leaked-point-free spraying can be realized through a specific mass ratio and the spraying thickness is uniform.

Owner:胜利油田金岛实业有限责任公司

Used for anti-corrosion paint on the inner wall of the oil pipe and the oil pipe with the inner wall sprayed with anti-corrosion paint

ActiveCN105176315BHigh temperature resistantStrong anti-penetrationAnti-corrosive paintsEpoxy resin coatingsXylyleneKaolin clay

The invention discloses an anticorrosive paint used for an inner wall of an oil pipe and the oil pipe having the inner wall sprayed with the anticorrosive paint. The anticorrosive paint comprises a component A and a component B, wherein the component A comprises modified phenolic resin, a mixed solvent, auxiliary agents and auxiliary materials; the mixed solvent comprises xylene and butanone; the auxiliary agents comprise a de-foaming agent, an anti-sagging agent and a film forming auxiliary agent; the auxiliary materials comprise heavy calcium carbonate, kaolin and titanium dioxide; the component B comprises an accelerant and a solvent; the accelerant is a mixture of CYD-128 epoxy resin and bisphenol A, and the solvent is butanone; the mass ratio of the component A to the component B is (3-7) to (0.5-2). The anticorrosive paint has unique advantages of high temperature resistance, strong permeation resistance and the like, can be used for a long period under weak acid and weak alkali environments, and expresses the unique superiority in special mine wells containing hydrogen sulfide and having high concentration of carbon dioxide; anti-corrosion and scale formation capabilities of the mine wells also can be improved, leaked-point-free spraying can be realized through a specific mass ratio and the spraying thickness is uniform.

Owner:胜利油田金岛实业有限责任公司

Glass fiber reinforced plastics twin-wall oil tank, preparation method and special mould thereof

ActiveCN101948038BHigh mechanical strengthStrong anti-penetrationLarge containersGlass fiberEngineering

Owner:青岛澳科仪器有限责任公司 +1

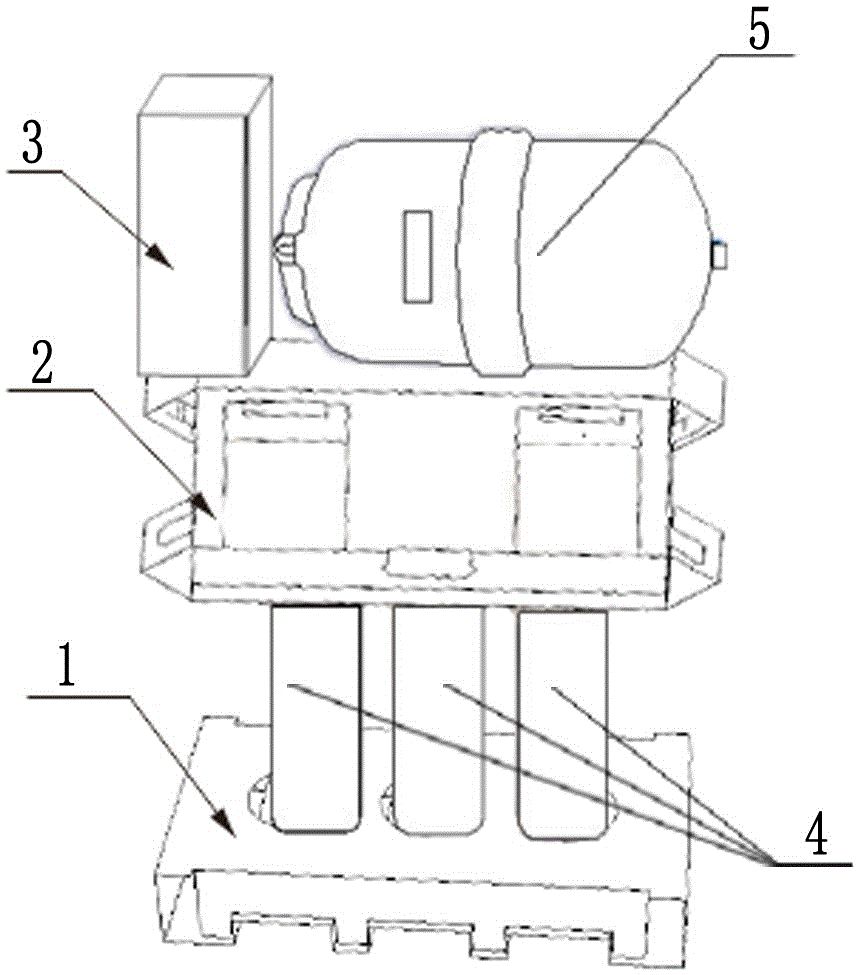

Corrugated paper based kitchen water purification machine cushion-packaging structure and production method thereof

Disclosed is a corrugated paper based kitchen water purification machine cushion-packaging structure. The corrugated paper based kitchen water purification machine cushion-packaging structure comprises an outer packaging box, a bottom lining body, a main lining body and an accessory box; the space between the bottom lining body and the main lining body is used for clamping a filter drum and a main engine, and the accessory box and a pressure drum are placed at the top of the main lining body. By the design that a plurality of reverse-folded triangular-prism cushion structures are arranged on the periphery of the main lining body in the cushion packaging structure, characters which are stable and less prone to deformation, of a triangular are fully utilized, shock absorption can be achieved when the packaging box is shocked, protective effect on key cushion of the periphery of the main engine is realized, and internal products can be observed through windows formed in side walls of the main engine through the reverse-folded triangular-prism cushion structures. The lining structure is integrally highly resistant to knocking, protruding, penetrating and shocking, self-adaptability and safety reliability are good, and resources are saved.

Owner:HENAN UNIV OF SCI & TECH

Manufacturing method for waterproof color coating used for exterior walls

InactiveCN106167663AStrong anti-penetrationGood weather resistanceFireproof paintsMulticolor effect coatingsEmulsionWeather resistance

The invention discloses a method for manufacturing a colored waterproof paint for exterior walls, which comprises the following steps: first, the ingredients are prepared according to the following parts by weight: 15 parts of water, 0.2 parts of preservative, 60 parts of pure acrylic emulsion, 0.4 part of dispersant, 3 parts of toner, 0.8 part of color paste, 25 parts of heavy calcium carbonate powder, 0.2 part of defoamer, 1.8 part of film-forming aid, and 0.6 part of thickener; then, mix water, preservative, and pure acrylic emulsion Stir evenly to prepare mixture A; then add dispersant, toner, and color paste to the prepared mixture A in sequence and mix and stir to obtain mixture B; finally add heavy calcium carbonate to the prepared mixture B in sequence Powder, defoamer, film-forming aid, and thickener are fully stirred and evenly prepared into a finished coating. The coating produced by the method provided by the invention has strong anti-penetration ability, remarkable waterproof performance, good weather resistance, strong acid and alkali resistance, good high temperature resistance, no chemical smell harmful to human body, simple preparation and good weather resistance , service life up to 8-10 years.

Owner:广州欧耐克建材有限公司

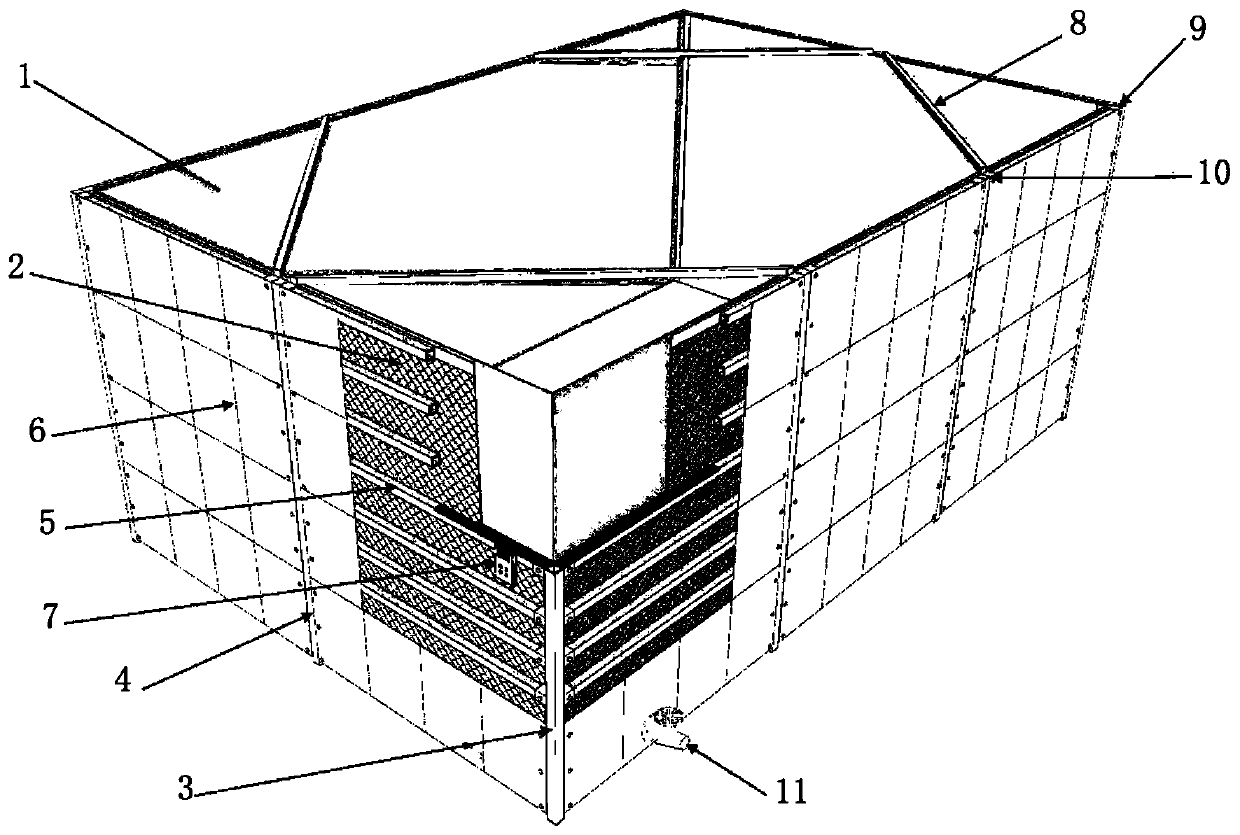

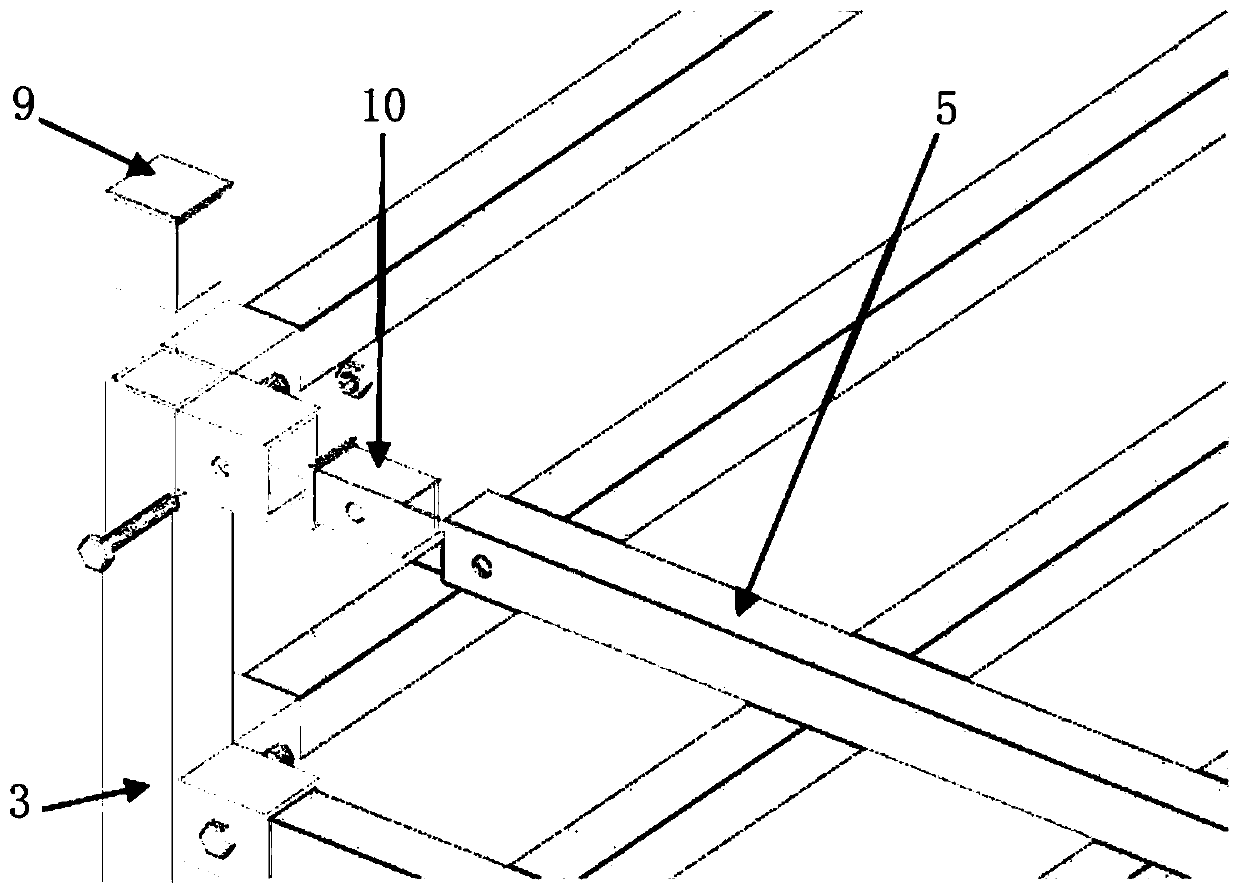

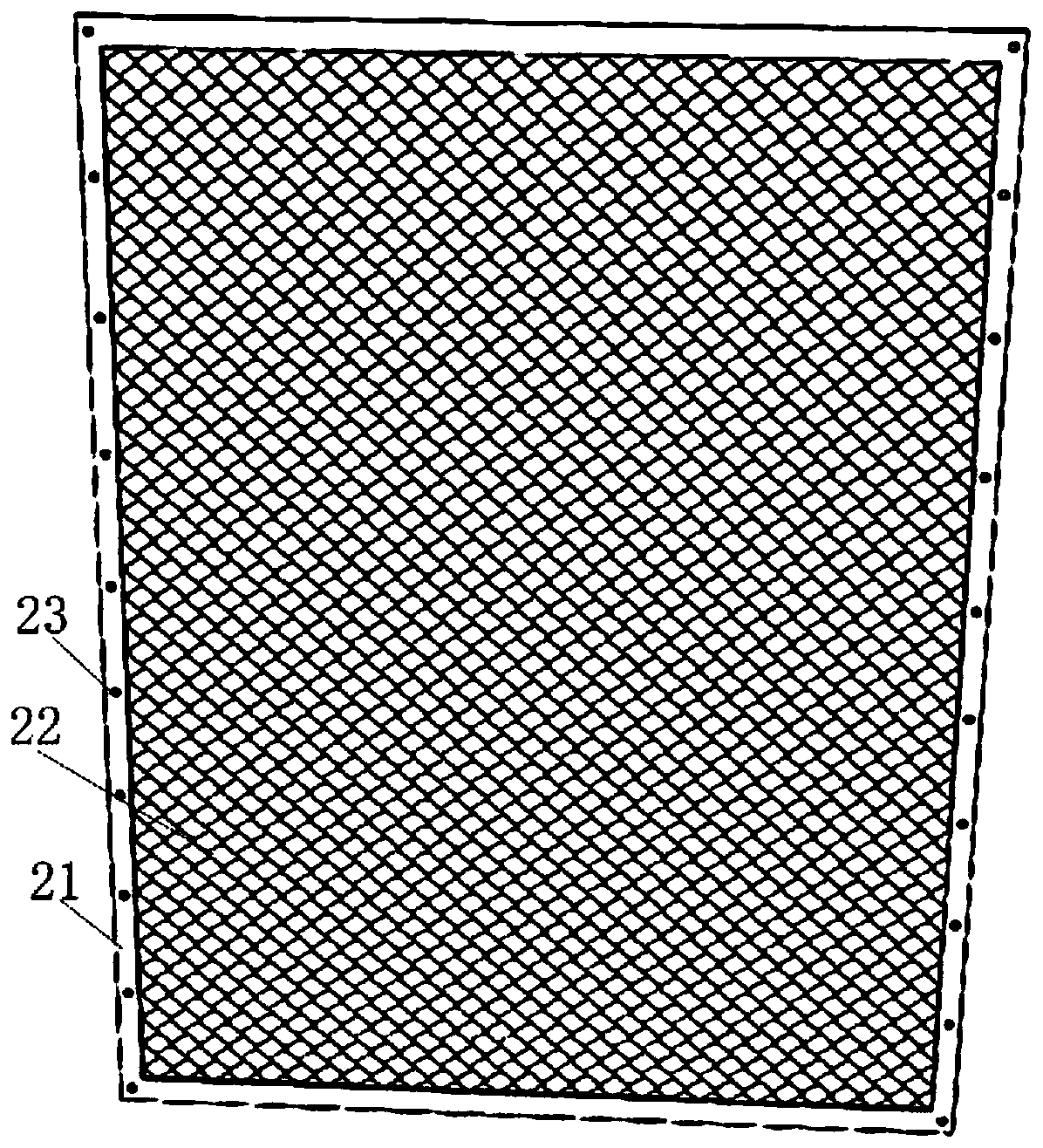

Low-cost quick assembly type intelligent irrigation water storage tank for mountainous area

InactiveCN111456518AShort assembly timeLow costSewerage structuresGeneral water supply conservationWater storage tankEngineering

The invention discloses a low-cost quick assembly type intelligent irrigation water storage tank for a mountainous area. The low-cost quick assembly type intelligent irrigation water storage tank comprises a ring-shaped water storage tank framework which is of a detachable structure, wherein a waterproof film is spread in the water storage tank framework, and a water level meter is mounted on thewater storage tank framework; the water storage tank is composed of a water storage tank framework and the waterproof film, and constituent parts can be detachably removed; the waterproof film sleevesthe water storage tank framework just like that a basin is used as a water containing container which can be used for directly receiving water to store on rainy days, so that use is convenient and auser can know water level from time to time through the water level meter, and therefore, water resources can be reasonably arranged and utilized. The low-cost quick assembly type intelligent irrigation water storage tank has the advantages of being short in assembly time, small in needs on manpower and material resources, capable of being dismounted and carried, strong in anti-osmosis ability, capable of knowing the water level conveniently, and the like, and further has characteristics of easily controlling the capacity size, being capable of sufficiently utilizing rainwater resources, beingcapable of solving the engineering water shortage problem very well, being small in loss while parts are used, and being free of any pollution on an environment.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com