Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

521results about How to "Guaranteed high temperature performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

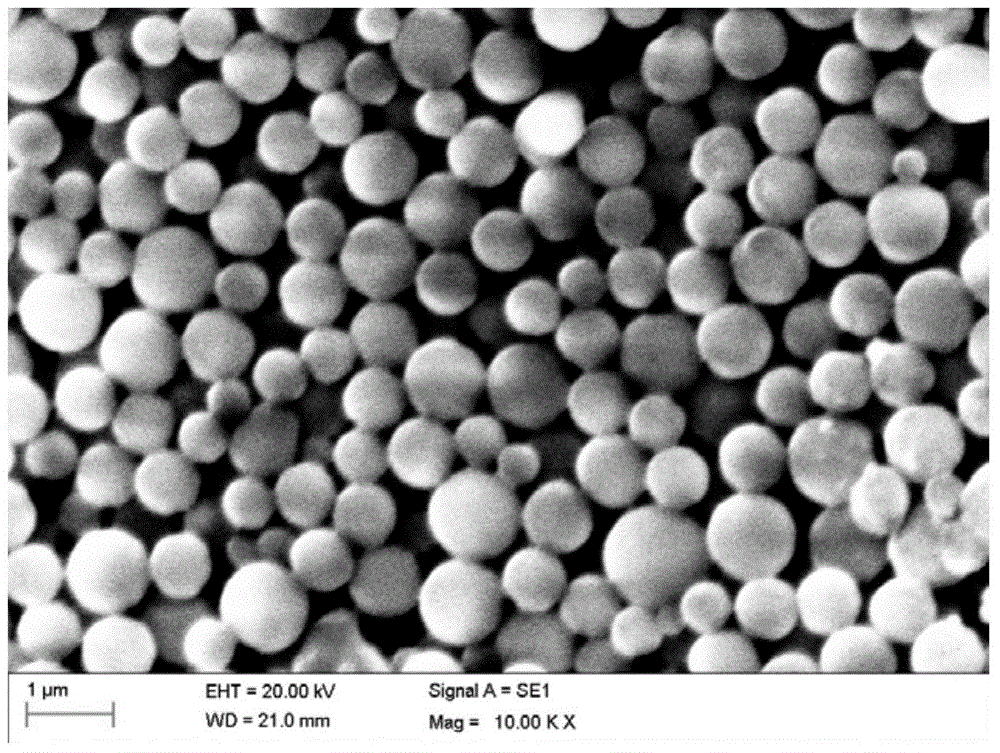

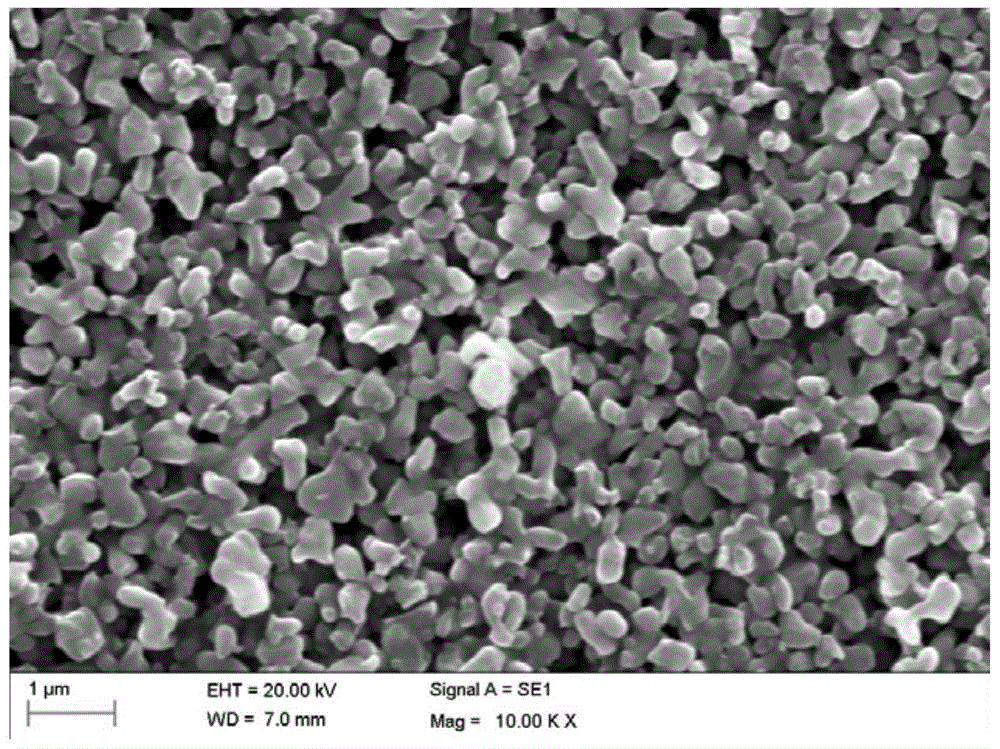

Lithium ion battery composite diaphragm and preparation method and application thereof

InactiveCN104157811AGood air permeabilityImprove securitySecondary cellsCell component detailsLithium electrodePolymer

The invention discloses a lithium ion battery composite diaphragm and a preparation method and an application thereof, belonging to the technical field of lithium ion batteries. The composite diaphragm comprises a polyolefin microporous membrane, a polymer microsphere based coating on one side surface of the polyolefin microporous membrane, and an inorganic ceramic-based coating on the other side surface of the polyolefin microporous membrane. The lithium ion battery composite diaphragm has good air permeability, liquid retaining capability and high-temperature resistance and can remarkably improve the security and the circulation property of the battery. The melting point or softening point of the polymer microsphere-based coating in the composite diaphragm is 90-140 DEG C, and when the temperature of the battery is increased, the polymer microsphere based coating is molten or swelled within a short time, then the apertures of the polyolefin microporous membrane are blocked rapidly, the thermal turn-off effect of the diaphragm is achieved, a lithium ion conveying channel is cut off, and short circuit inside the battery is prevented; meanwhile as ceramic grains inside the inorganic ceramic-based coating have the high-temperature resistance property, the polyolefin microporous membrane is effectively prevented from shrinkage, and the situation that positive and negative films directly come into contact to cause short circuit of the battery.

Owner:SHANGHAI FANNENG NEW MATERIAL TECH CO LTD

Polyvinylidene fluoride hollow fiber membrane and preparation method thereof

InactiveCN101954248AImprove anti-pollution performanceGuaranteed high temperature performanceSemi-permeable membranesFibre treatmentChemical industryDouble diffusion

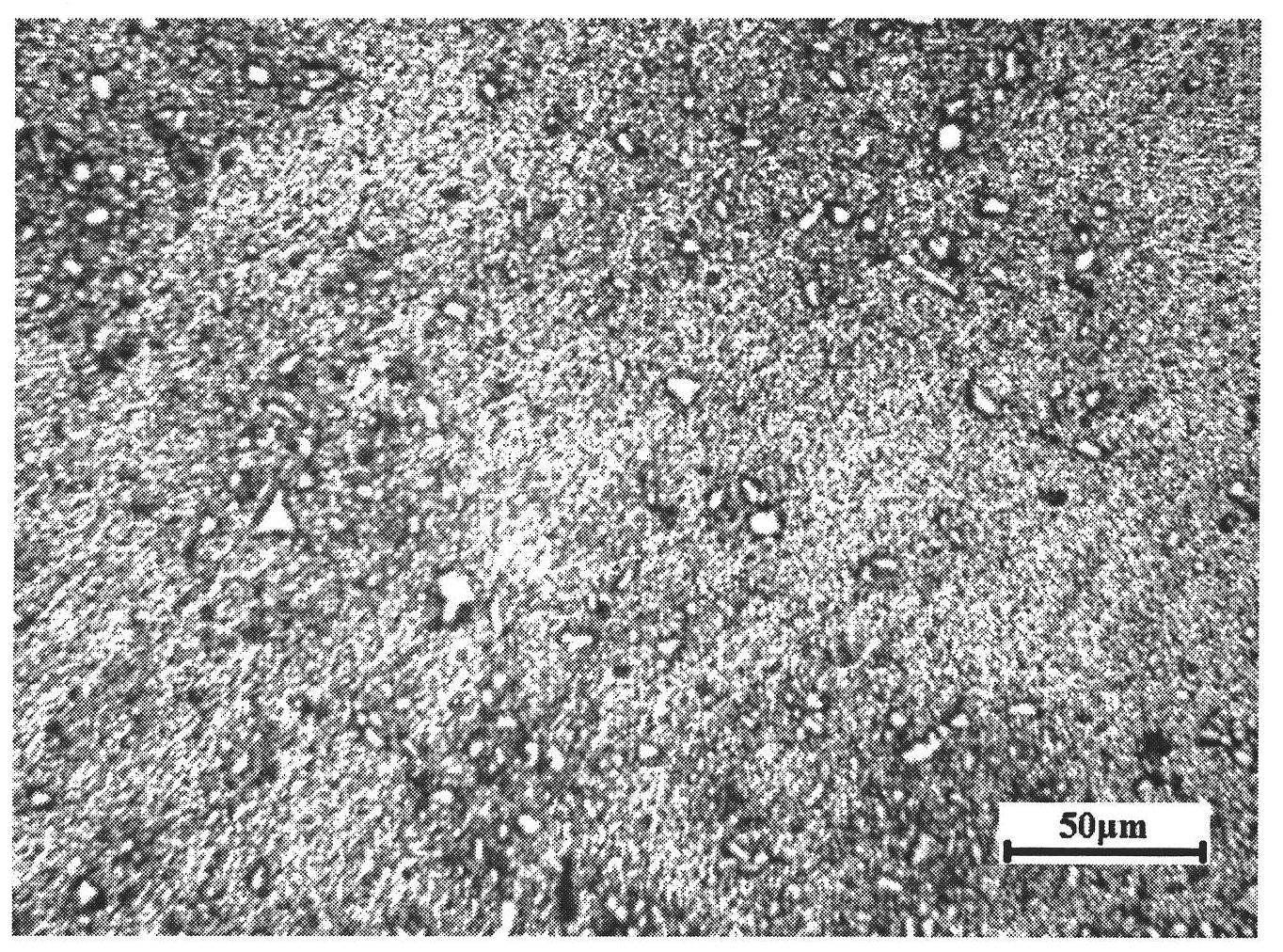

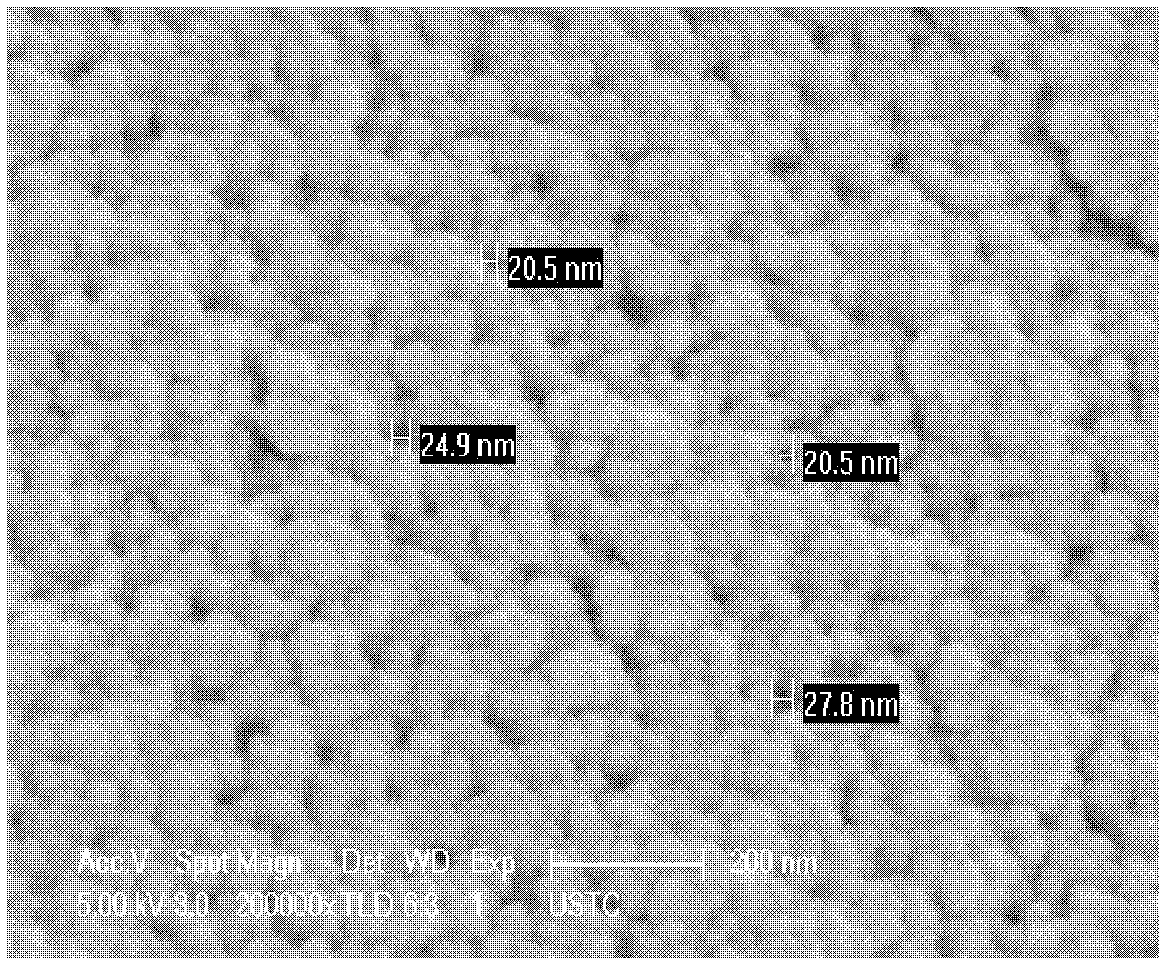

The invention relates to a polyvinylidene fluoride hollow fiber membrane and a preparation method thereof, belonging to the field of chemical industry. The pore size of the membrane is 0.02-0.5 micrometers, the thickness is 0.2-0.5 millimeters, and the external diameter of membrane wires is 1-2 millimeters. A membrane making liquid comprises the following components in percentage by weight: 15-30% of polyvinylidene fluoride resin, 1-10% of hydrophilic polymer, 0.5-5% of functional polymer or polymer monomer, 0.1-5% of surfactant, 0.1-15% of inorganic or organic polymer pore-forming agent, 0.1-5% of nano additive and 40-71% of solvent. The preparation method of the polyvinylidene fluoride hollow fiber membrane comprises the following step of: effectively controlling the interfacial tension between the membrane making liquid and a solidifying liquid and the double diffusion permeation speed of the solidifying agent and the solution on the interface by properly adjusting the ratio of all components and using the surface moistening and dispersing actions of the surfactant, the dispersing and thickening actions of the pore-forming agent and the hydrophilic action of the hydrophilic substance. Thus, the hydrophilic polyvinylidene fluoride hollow fiber membrane with high permeability is prepared.

Owner:QINGDAO SEACON WATER SERVICE TECH

Wet process refractory mortar

The invention relates to wet process refractory mortar which comprises the following raw materials by weight: 25-50 parts of white fused alumina powder with the granularity of not more than 180 meshes, 40-65 parts of the white fused alumina powder with the granularity of not more than 320 meshes, 1-5 parts of phosphate binder, 1-4 parts of plasticizer, 1-3 parts of water retention agent, 0.1-1 part of resin type preservative, 0.05-0.5 part of preservative agent and 0-10 parts of Cr2O3 powder with the granularity of not more than 320 meshes, the wet process refractory mortar is prepared by uniformly stirring the raw materials, adding 12-18 parts of water, continuously uniformly stirring, and then loading into a plastic bag for sealing and preserving, and the preservation period is a year and a half to two years.

Owner:PUYANG REFRACTORIES GRP CO LTD

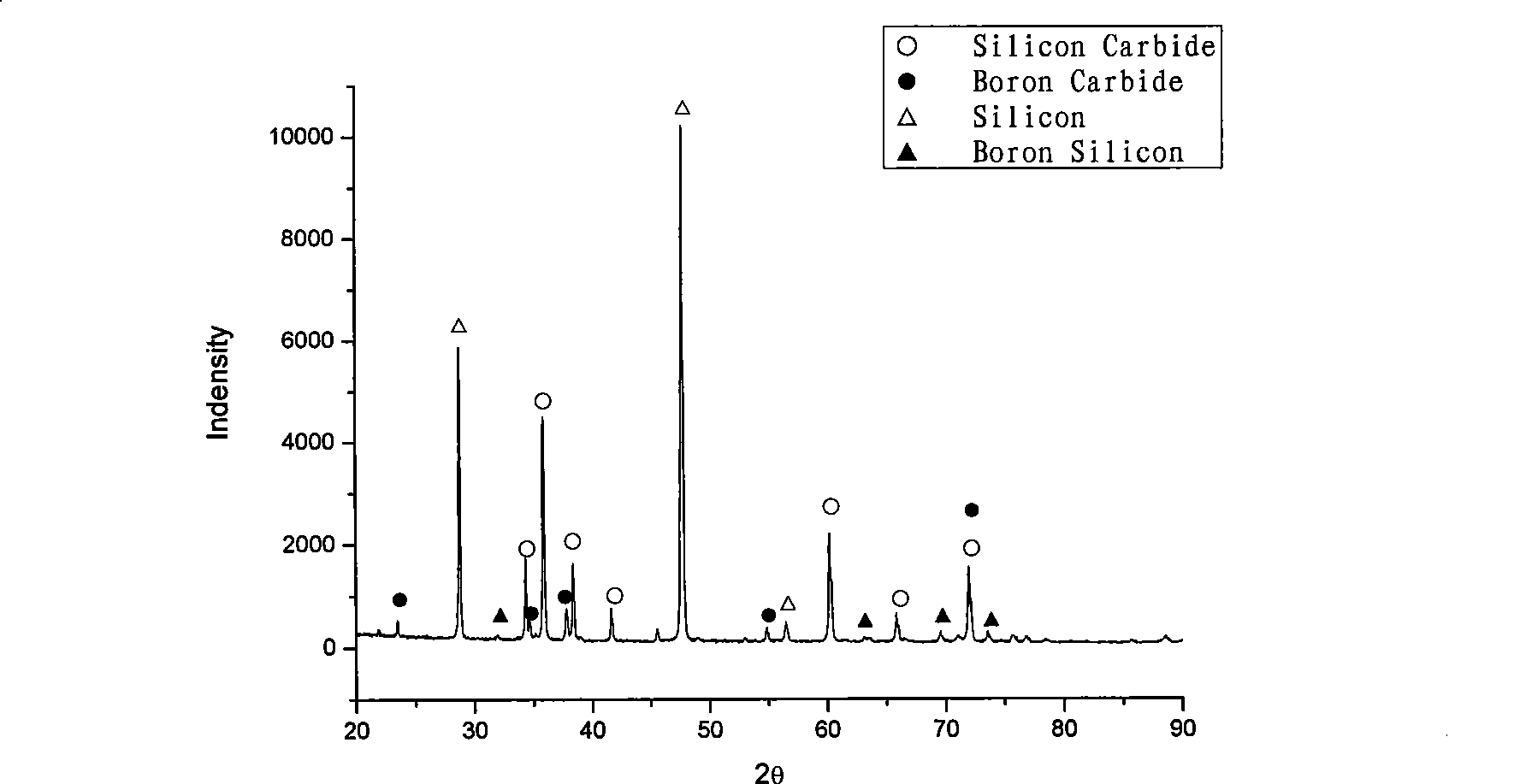

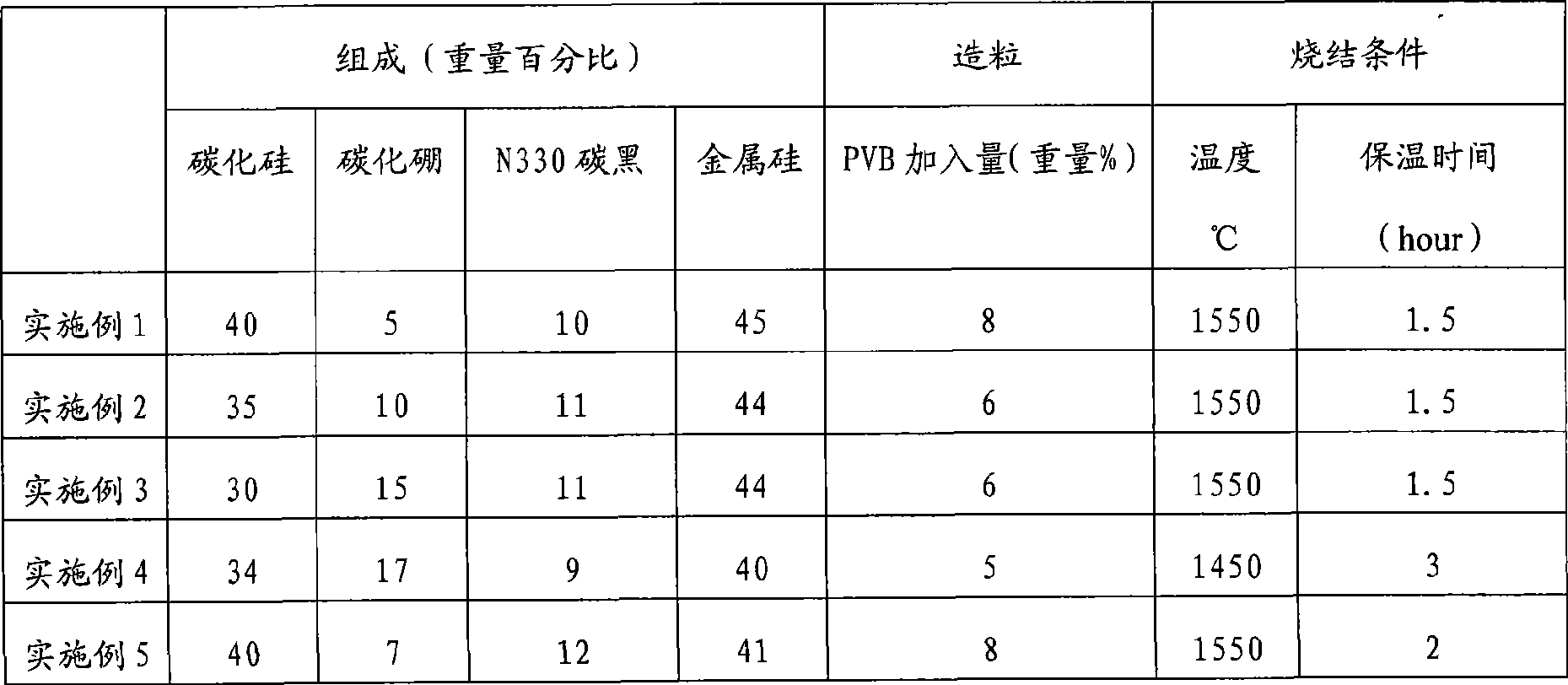

Silicon carbide based reinforced composite ceramic and preparation

The invention discloses a reinforced silicon carbide-based composite ceramic and a preparation method thereof. The composite ceramic is characterized by comprising the following components based on weight percentages: 30%-40% of silicon carbide powder, 5%-17% of boron carbide powder, 9%-12% of nano carbon black and 40%-50% of silicon metal. The method comprises the following steps: firstly, ball milling and wet mixing are performed on the silicon carbide powder, the carbon black and the boron carbide powder to obtain mixed powder, and a bonding agent PVB is added for granulation, die pressing is performed for forming; then the formed green compact is dried and put in an air furnace for binder removal; and finally, the obtained green compact is put into a graphite crucible with silicon powder, and siliconizing and sintering are completed after 1-3h heat preservation at 1450-1550 DEG C under a vacuum environment, thus obtaining a sintering body. The boron carbide particle reinforced reaction sintered silicon carbide composite ceramic prepared by the method can be widely used as a structural material under high-temperature atmosphere and corrosive atmosphere, a frictional wear material and the like; and as the composite ceramic has better obdurability and hardness, the ceramic can be used as a substitute material of the traditional reaction sintered silicon carbide.

Owner:珠海亿特立新材料有限公司

Corundum-silicon nitride-silicon carbide composite pouring material

The invention discloses a corundum-silicon nitride-silicon carbide compound castable used for a blast tuyere zone of an ironmaking blast furnace. The corundum, the silicon nitride, the silicon carbide, aluminate cement, aluminum powder, silicon metal, ultrafine silica powder, alumina powder and polypropylene fiber are mixed to form the castable. Residual brick of compound brown corundum refractory brick can be fast poured and repaired at the blast tuyere zone of the ironmaking blast furnace. When building a blast furnace, residual brick can be direct poured and formed to replace the compound brown corundum refractory forming brick and no high temperature is needed to fire during the production process; therefore, the invention is also an energy saving refractory for the blast tuyere zone of the ironmaking blast furnace and cast-place construction is not limited by space; fast pouring masonry is carried out and fast drying method is adopted, thereby being an inorganic nonmetal refractory applied to fast-drying quick furnace building and repairing during the blast furnace repairing and the tuyere zone of the newly-built blast furnace. The invention can normally furnace dry with the blast furnace.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

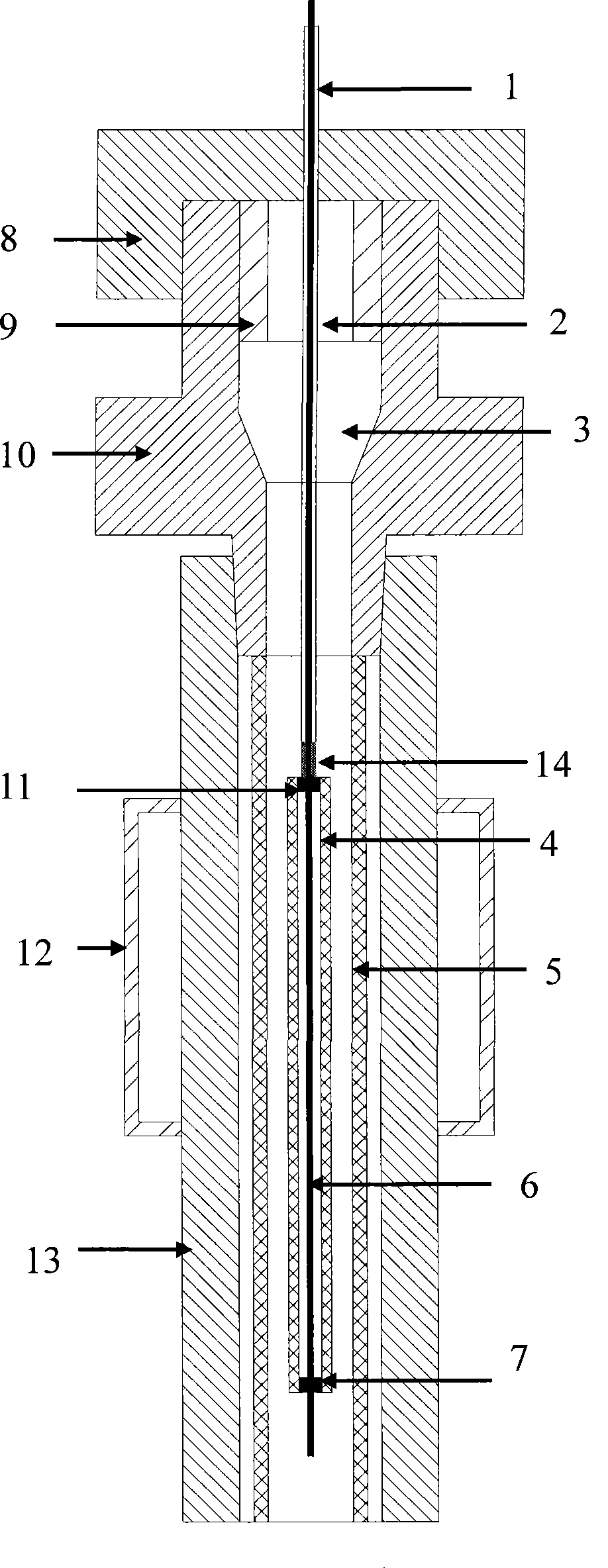

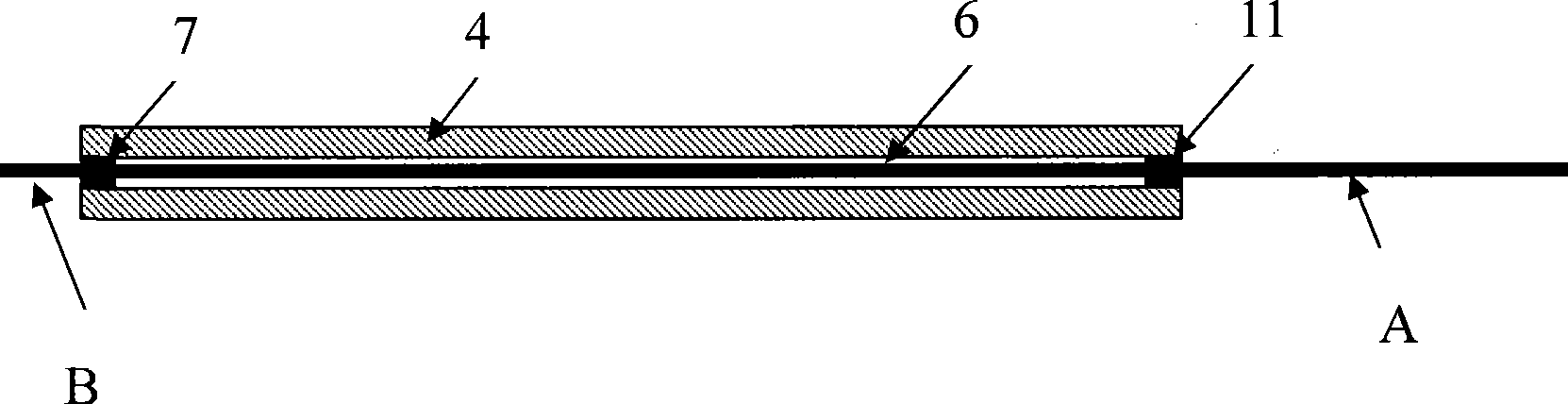

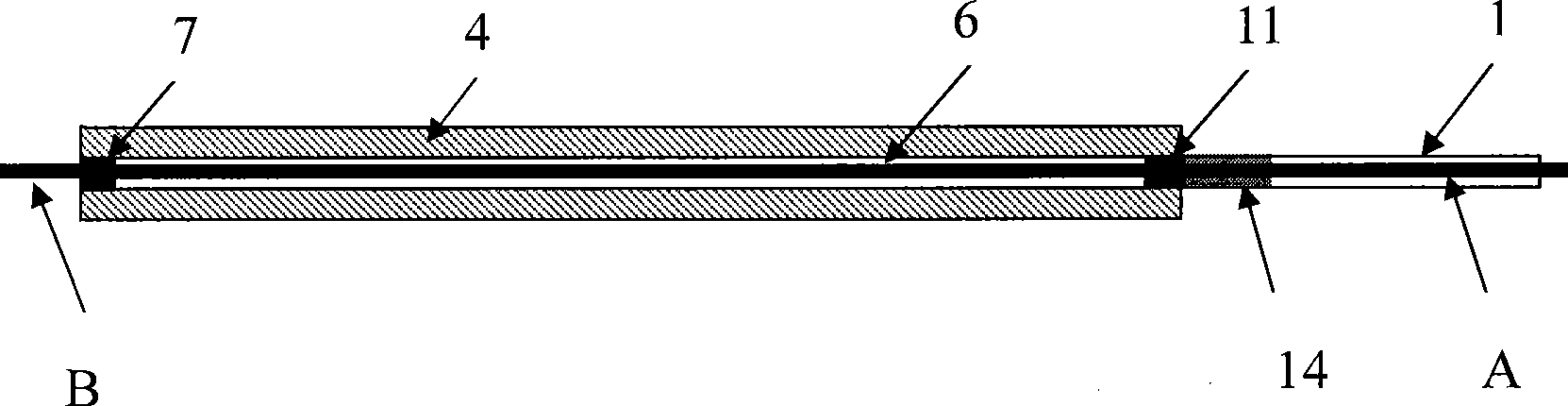

Working electrode for implementing electro-chemical test of high-temperature high-pressure water solution system

ActiveCN101470093AHigh temperature resistantGuaranteed high temperature performanceWeather/light/corrosion resistanceMaterial electrochemical variablesEpoxyCore component

The invention relates to a working electrode for realizing the electrochemical test of high temperature high pressure water solution system and a preparation technology thereof, belonging to the electrochemical test field of high temperature high pressure water solution. The working electrode is composed of a core component and a sealing component, wherein the insulation unit of the core component is composed of a high temperature part and a low temperature part; the high temperature part is made from corundum tube and is penetrated by a working electrode wire, and the port of the high temperature is sealed with the working electrode wire via high temperature glue; the low temperature part is made from polytetrafluoroethylene tube and is penetrated by a working electrode wire, the port of the low temperature part is sealed with the working electrode wire via high temperature epoxy resin; the high temperature part and the low temperature part are sealed by high temperature epoxy resin; the electrode and a high pressure autoclave are sealed of high temperature and high pressure via the sealing component. The electrode prepared by the technology has high sealing performance, resists high temperature and high pressure, and can be applied in the weak acidic, neutral and weak alkaline mediums for realizing electrochemical test of filamentous metal material in high temperature high pressure water solution system at room temperature to 350 DEG C and normal temperature to 20MPa.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-temperature resistant coating for refining crystal grains of casting and preparation method of high-temperature resistant coating

InactiveCN103100661AGuaranteed high temperature performanceGrain refinementFoundry mouldsFoundry coresAverage sizeCobalt aluminate

The invention relates to a high-temperature resistant coating for refining crystal grains of a casting. The high-temperature resistant coating comprises silica sol and white fused alumina powder as main components. The high-temperature resistant coating is characterized by also comprising cobalt aluminate as the main component, wherein the addition proportion of the cobalt aluminate to the silica sol to the white fused alumina powder is (0.07-0.15):1: (2.4-2.6). The high-temperature resistant coating provided by the invention has the advantages that fine grains of a casting crystal grain refiner are uniformly inlaid in the inner surface of a shell in the shell making process to play a role of catalyzing the formation of a condensation nucleus in the casting pouring, solidification and formation processes, so that the average size of the crystal grains of the casting can be up to 0.4-0.8mm, the grain size can be up to the first-level or third-level, and then, the aim of more conveniently and reliably refining the crystal grains is achieved.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

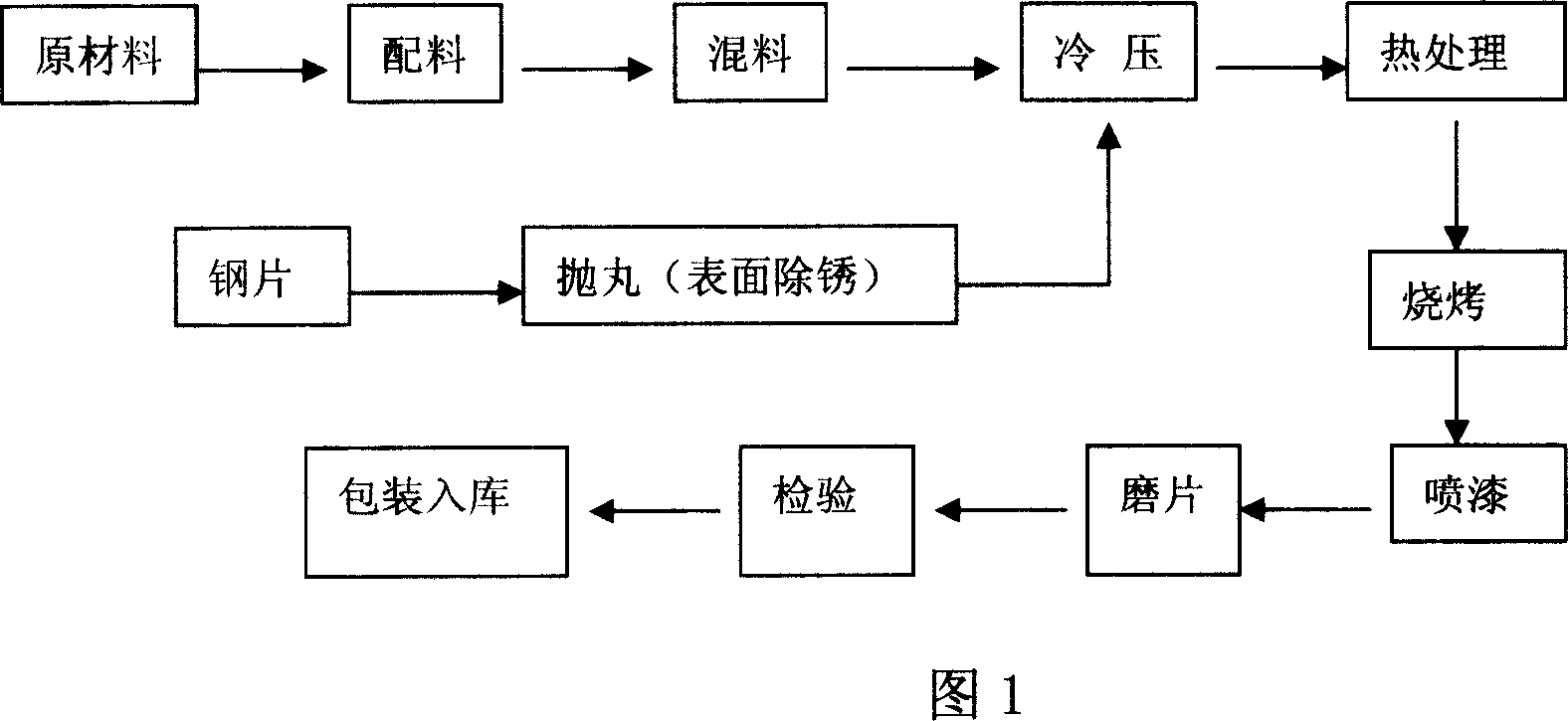

Asbestos-free non-metal friction material and preparation method thereof

The present invention relates to friction material for automobile brake disc, and is especially one kind of friction material reinforced with the mixture of aramid fiber and inorganic mineral fiber and its preparation process. The new non-metal friction material without asbestos consists of aramid fiber, LAPINUS inorganic mineral fiber, phenolic resin, butadiene-acrylonitrile rubber powder, inorganic stuffing and friction regulator. The organic-inorganic composite material reinforced friction material has raised comprehensive performance, stable friction performance and friction coefficient variation with temperature within 10 %. In addition, the present invention also provides high temperature fast curing process to ensure the heat resisting performance of the product and lowered power consumption.

Owner:浙江万赛汽车零部件股份有限公司

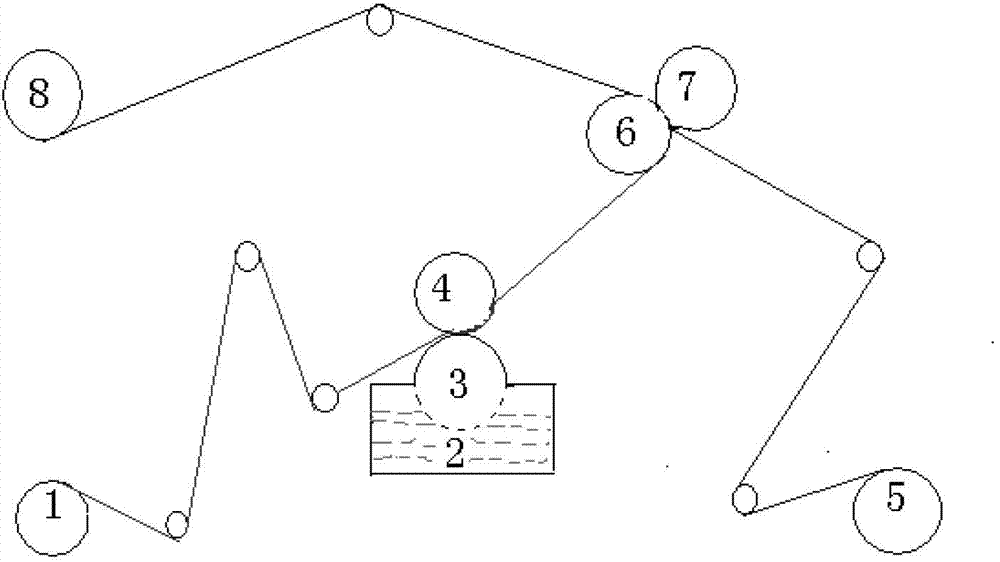

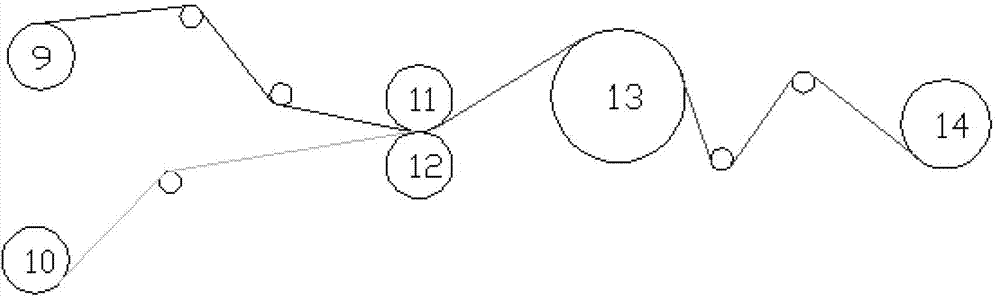

Ceramic particle reinforced aluminum-based gradient composite material and preparation method thereof and jetting precipitation device for preparing material

The invention belongs to the field of aluminum-based composite material and preparation technology thereof and in particular discloses a ceramic particle reinforced aluminum-based gradient composite material, a preparation method thereof and a device used by the method. The composite material uses aluminum alloy as a matrix; the volume fractions of ceramic particles serving as a reinforcement material in the surface layer and the bottom layer are between 30 and 40 percent and between 0 and 5 percent respectively; the ceramic particles perform continuous gradient variation from the surface layer to the bottom layer; and the preparation method comprises the following steps: introducing the ceramic reinforced particles to a high-pressure airflow channel by a discharge amount regulation device to form a solid phase flow and a gas phase flow; atomizing molten aluminum alloy liquid, mixing the molten aluminum alloy liquid and the ceramic particles of the solid phase flow and the gas phase flow, and precipitating the mixture on a deposition matrix to prepare a deposition billet; and controlling the discharge amount regulation device and output air pressure through a programmable logic controller according to the height information of the deposition billet to obtain the ceramic particle reinforced aluminum-based gradient composite material. The preparation method of the invention has convenient operation and high automation degree; and the prepared composite material has the advantages of light weight, high wear resistance and anticorrosion of the surface and the like.

Owner:HUNAN UNIV

Torpedo tank lining gunning repairing material, preparation method and applications thereof

The invention discloses a torpedo tank lining gunning repairing material, a preparation method and applications thereof, wherein the torpedo tank lining gunning repairing material comprises, by weight, 60-67 parts of a Al2O3-containing fireproof material after-using regenerating material, 3-7 parts of fireproof clay, 2-5 parts of flaky graphite, 3-7 parts of silicon carbide, 10-15 parts of an alumina homogeneous material, 3-6 parts of kyanite, 2-5 parts of alpha-Al2O3 micro-powder, 3-11 parts of a binder, and 1.2-3.4 parts of an admixture. According to the present invention, the torpedo tank lining gunning repairing material has characteristics of low raw material cost, wide regeneration material source, convenient cold-hot state gunning repairing, excellent thermal shock stability, strong repairing layer interface bonding strength, strong slag iron corrosion resistance, high torpedo tank operation rate, long service life, and the like.

Owner:武汉钢铁有限公司

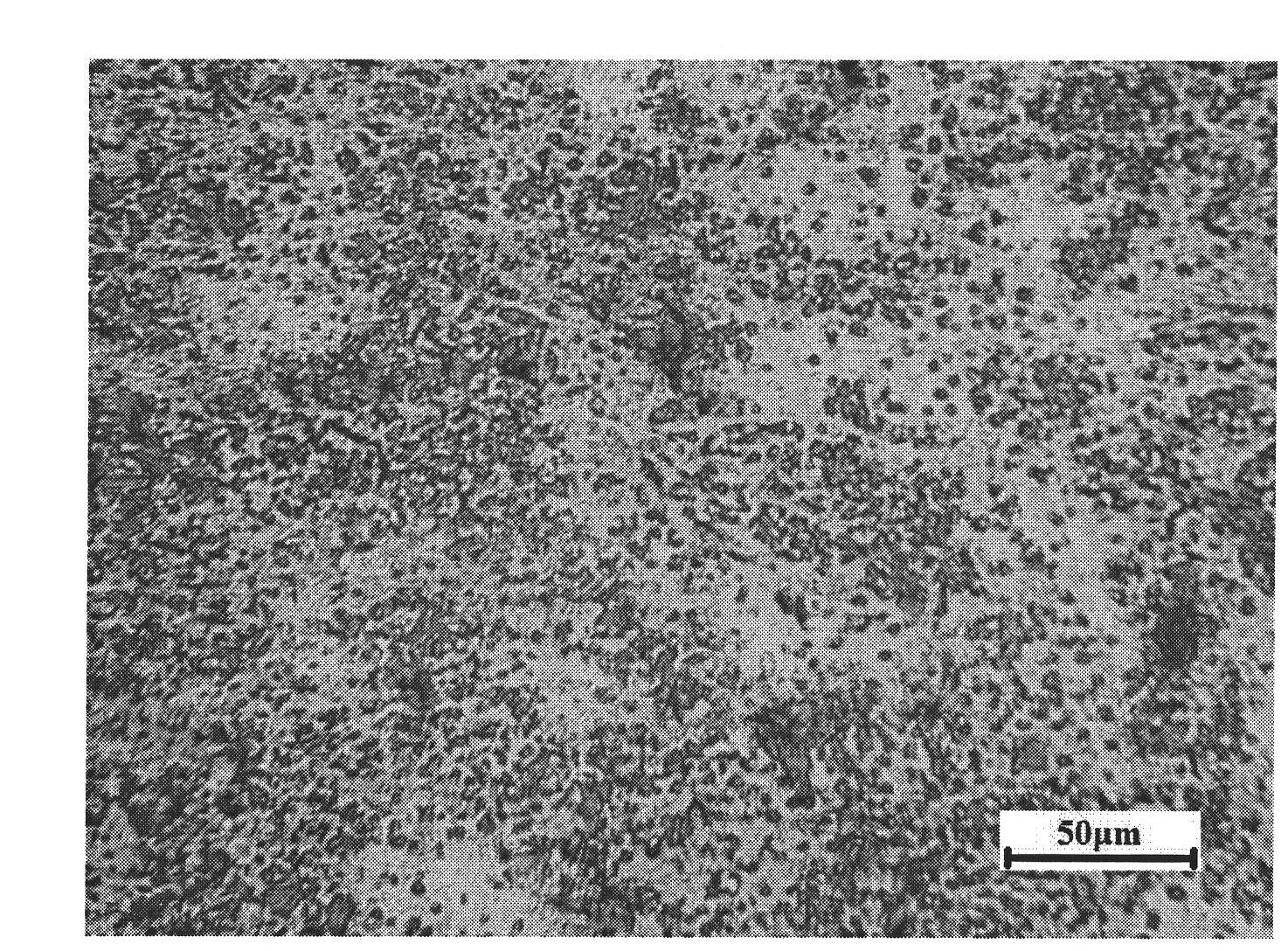

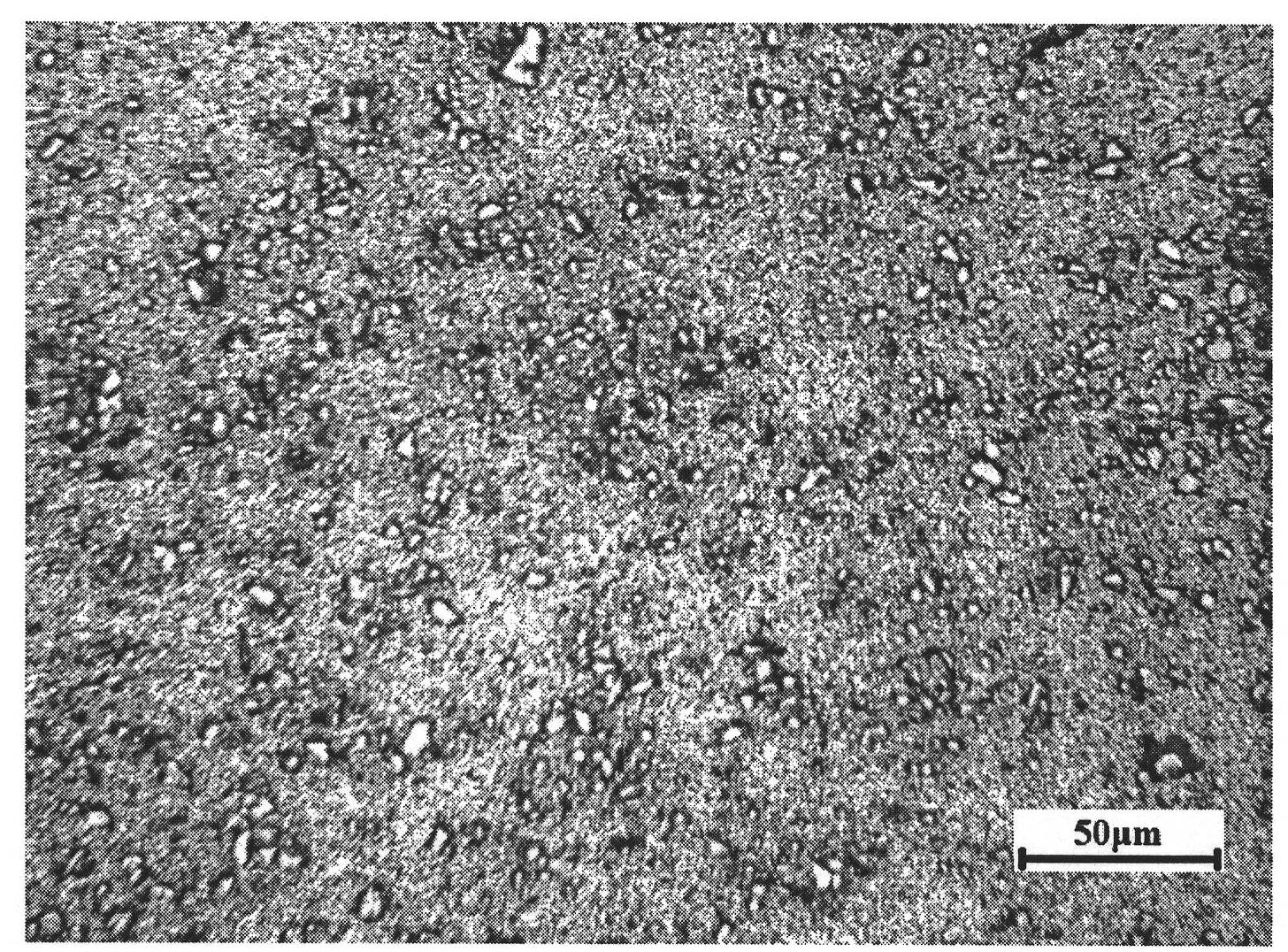

H13 die steel and preparation method thereof

The invention relates to H13 die steel and a preparation method thereof, and belongs to the technical field of wear-resistant materials. The H13 die steel comprises the following chemical elements in percentage by weight: 0.40 to 0.46 percent of C, 6.00 to 6.30 percent of Cr, 0.50 to 0.65 percent of V, 0.30 to 0.45 percent of Mo, 0.85 to 1.05 percent of Mn, 1.25 to 1.55 percent of Si, 0.12 to 0.25 percent of W, 0.008 to 0.018 percent of Nb, 0.008 to 0.015 percent of Ta, 0.08 to 0.12 percent of Ti, 0.003 to 0.006 percent of B, 0.08 to 0.15 percent of Al, 0.03 to 0.06 percent of N, 0.06 to 0.12 percent of Y, less than 0.025 percent of S, less than 0.030 percent of P and the balance of Fe. The H13 die steel has the advantages that: the content of precious alloy elements, namely molybdenum and vanadium is low, the H13 die steel is not required to be forged, and forging can be replaced by casting, so that the cost of the H13 steel is obviously reduced; the performance of the H13 steel can be obviously improved, and a tungsten slag iron alloy is recycled; a solidification structure can be obviously refined, and the mechanical property of the H13 steel is improved; and the H13 steel has high wear resistance and is used as a hot working die, and the service life is prolonged.

Owner:江苏环立板带轧辊有限公司

Composite battery diaphragm

ActiveCN103117369AGuaranteed high temperature resistanceGuaranteed low temperature closureCell component detailsPolyolefinHeat resistance

The application discloses a composite battery diaphragm comprising a nonwoven fabric layer and a polyolefin microporous membrane layer which are combined and fixedly connected to form the composite battery diaphragm. According to the composite battery diaphragm disclosed by the application, the non-woven fabric layer serves as a support body and ensures the high-temperature heat resistance of the composite battery diaphragm; and the polyolefin microporous membrane layer ensures the low-temperature close property of the composite battery diaphragm. The excellent air permeability and thermal contraction and a high membrane rupture temperature of the composite battery diaphragm are ensured on the basis of not changing the original characteristics and properties of the polyolefin microporous membrane; the low-temperature close property and the high-temperature heat resistance of the battery diaphragm are effectively coordinated; and the non-woven fabric is low in cost, so that the cost of the production process of the composite battery diaphragm is low.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

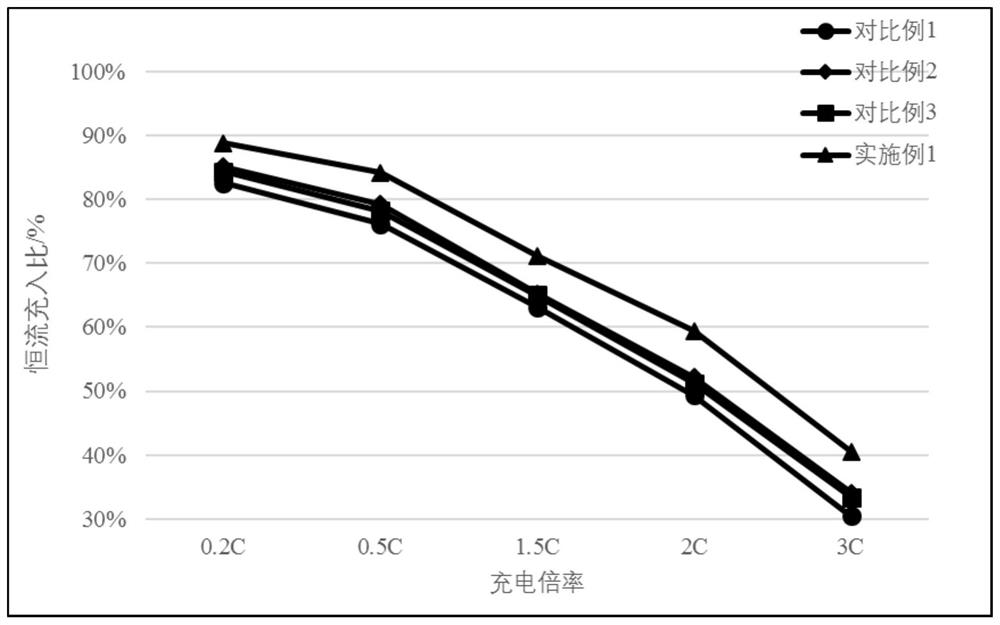

Positive plate and lithium ion battery comprising positive plate

InactiveCN111916665ALower internal resistanceImprove fast charge cycle performancePositive electrodesSecondary cells charging/dischargingInternal resistanceFast charging

The invention provides a positive plate and a lithium ion battery comprising the positive plate. The positive plate comprises a positive current collector, a first positive active material layer and asecond positive active material layer, wherein the first positive active material layer is arranged on the first surface of the positive current collector, and the second positive active material layer is arranged on the surface of the first positive active material layer; the first positive electrode active material layer comprises a first positive electrode active material, the second positiveelectrode active material layer comprises a second positive electrode active material, the first positive electrode active material is a positive electrode active material doped and / or coated with anMg element and an Al element, and the second positive electrode active material is a positive electrode active material doped and / or coated with an Al element. According to the positive plate, on theone hand, the high-temperature resistance and high-voltage resistance of positive active material particles on the surface of the positive plate can be ensured; on the other hand, the internal resistance of the positive plate is reduced, so the polarization in a quick charging process is reduced, and the quick charging cycle performance of the lithium ion battery is improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

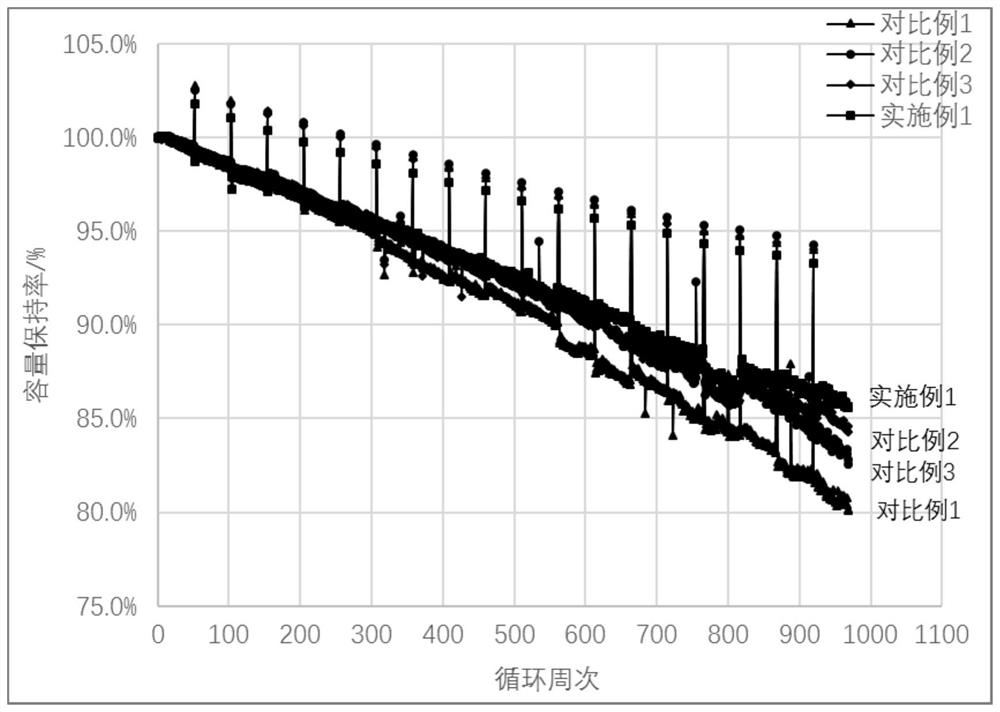

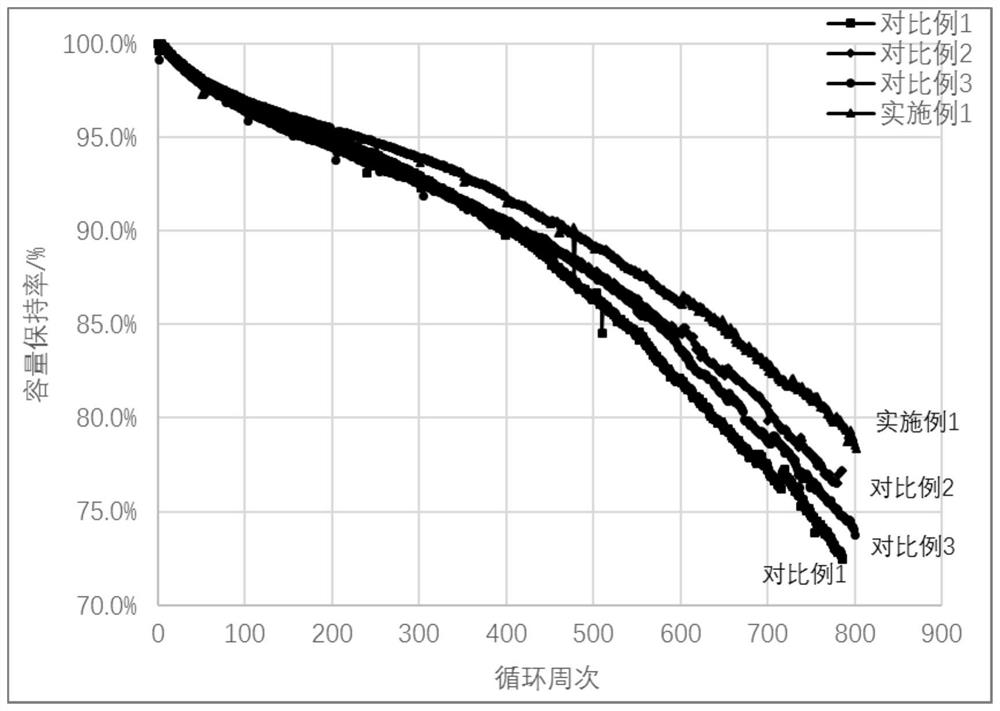

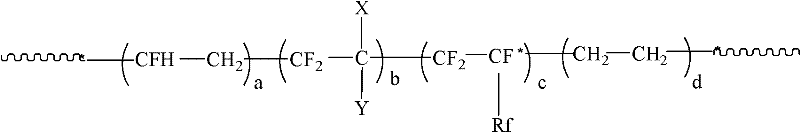

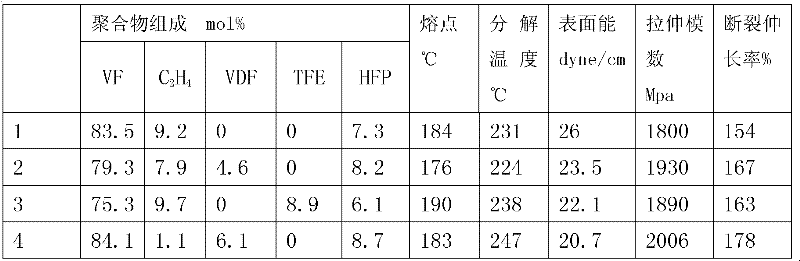

Melt-processable modified polyvinyl fluoride resin and preparation method thereof

The invention relates to a melt-processable modified polyvinyl fluoride (PVF) resin which is polymerized by vinyl fluoride, ethylene, one or more of CF2=CXY and one or more of CF2=CFRf. Reaction monomers are subjected to a copolymerization reaction under the action of an initiating agent in an aqueous phase or an emulsion, reaction temperature ranges from 40 DEG C to 100 DEG C, and reaction pressure ranges from 1 MPa to 10 MPa. According to the melt-processable modified polyvinyl fluoride resin, high-temperature performance of the PVF resin is kept, treatment temperature of the resin is reduced simultaneously, conventional melt processing can be used for processing the resin, and obtained thin-film materials have good combination properties.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

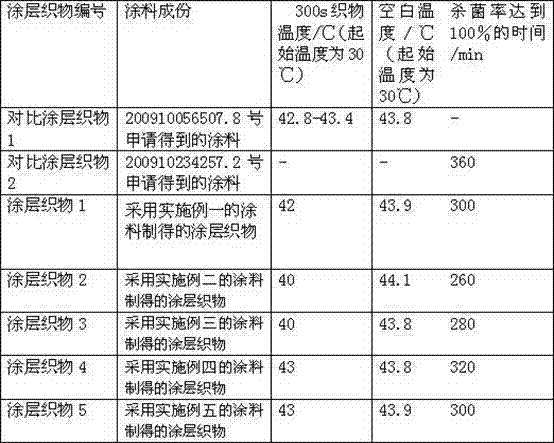

Antimicrobial thermal-insulation coating for fabrics and preparation method thereof

ActiveCN102733196ATo achieve the purpose of antibacterialGood heat insulationVegetal fibresThermal insulationPolyvinyl alcohol

The invention provides an antimicrobial thermal-insulation coating for fabrics and a preparation method thereof. The fabric coating has favorable thermal insulation property and is harmless to human bodies. The preparation method has the advantages of simple technique and low production cost, and is suitable for industrial production. The fabric with the composite coating is applicable to the fields of outdoor supplies, clothing, construction, military affairs and the like, and is widely applied to the occasions in need of heat preservation and thermal insulation. The coating comprises the following components in percentage by weight: 20-30% of ethanol, 5-10% of dioctyl phthalate, 0.6-0.9% of polyvinyl formal, 15-20% of zinc sulfide / magniferous aluminum oxide composite material, 5-12% of polyethyleneglycol and the balance of polyurethane.

Owner:NANTONG ABLE OUTDOOR PROD COMPANY

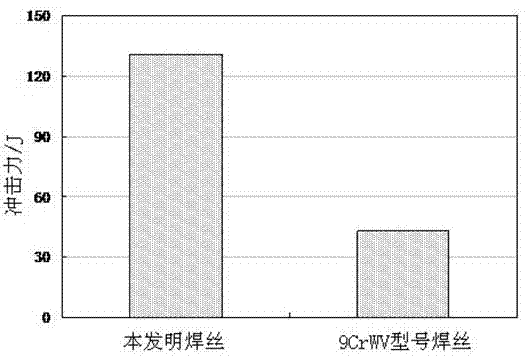

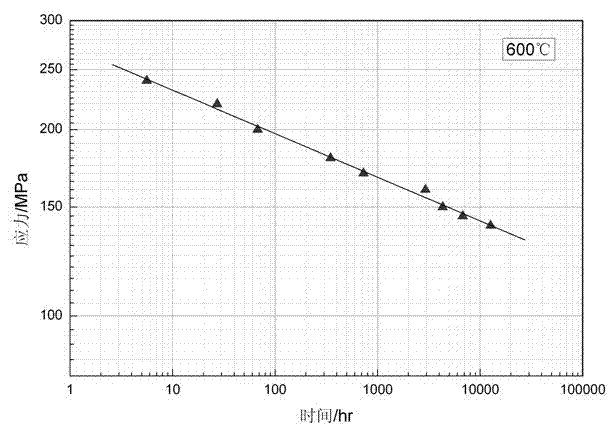

P92 steel submerged arc welding wire

ActiveCN102189352AImprove weld toughnessGuaranteed high temperature performanceWelding/cutting media/materialsSoldering mediaWeld seamSubmerged arc welding

The invention discloses a P92 steel submerged arc welding wire, which contains the following chemical components in percentage by mass: 0.06 to 0.08% of C, not less than 0.40% of Si, 0.4-1.0% of Mn, not less than 0.015% of P, not less than 0.015% of S, 9.0 to 10% of Cr, 0.3 to 0.6% of Mo, 0.15 to 0.25% of V, 1.5 to 2.0% of W, not less than 0.6% of Ni, 0.03 to 0.07% of Nb, 0.8 to 1.0% of Co, 0.001to 0.05% of B, 0.03 to 0.07% of N, and the balance of Fe. The welding wire is used in the submerged arc welding, on the premise of guaranteeing high temperature performance of a welding joint, the toughness of a weld seam is increased, and the application of a highly efficient welding method of the submerged arc in the boiler production is ensured.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

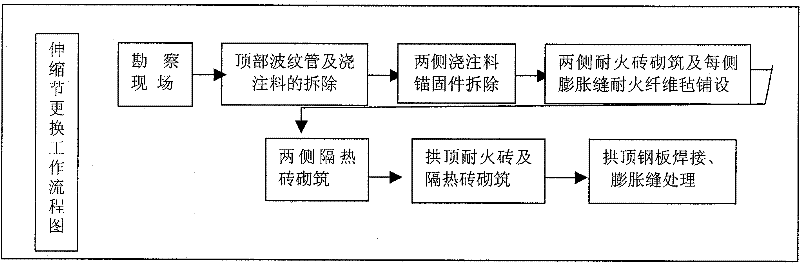

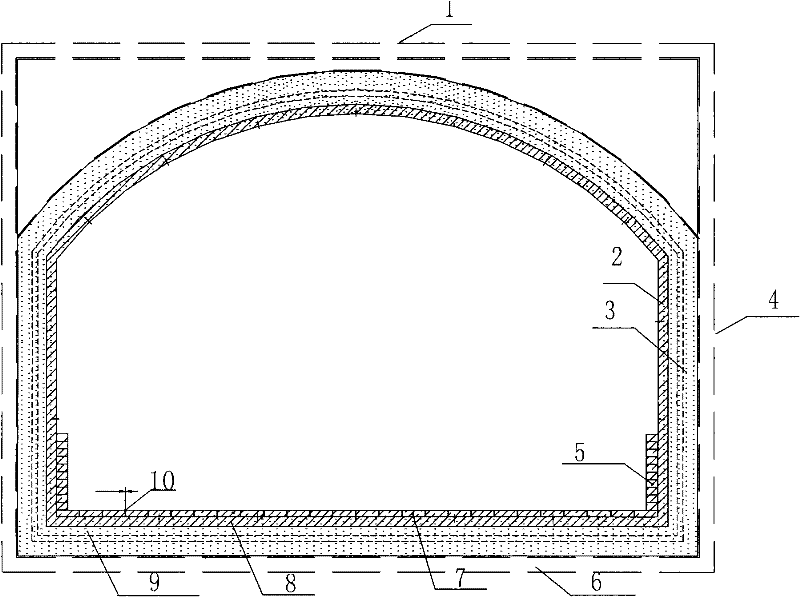

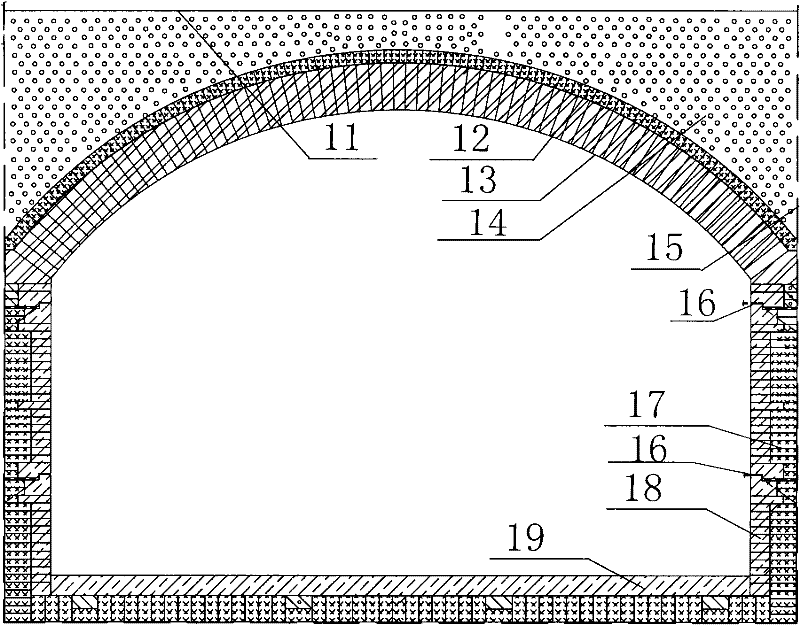

Dry quenching expansion joint firebrick structure construction technology

ActiveCN102241995AAdvantages of structural construction technologyAdvantages of construction technologyCoke quenchingAxial displacementBrick

The invention relates to a dry quenching expansion joint firebrick structure construction technology. According to the invention, a bottom structure and metal casings on the two sides are reserved, and a dry quenching expansion joint filling compound structure is changed into a firebrick structure. The construction technology is characterized in the following steps that: (a) arc bellows on the top of the expansion joint and rest filling compound are dismounted; (b) anchorages and filling compound on the two sides of the expansion joint are dismounted, until an expansion joint bottom level is reached; (c) dilatation joints (28) are arranged; (d) firebrick walls are constructed on the two sides of the expansion joint; (e) an arc firebrick structure and heat-insulating bricks are constructed on the top of the expansion joint; (f) a protection sleeve is welded. With the dry quenching expansion joint firebrick structure construction technology provided by the invention, dilatation joint dimension, air tightness and high temperature resistance of the expansion joint can be ensured; axial displacement of the expansion joint can be presented; thermal shock stability and air-flow scouring resistance of the inner refractory material lining of the expansion joint can be improved; service life of the expansion joint can be prolonged; maintenance cost can be greatly reduced; and construction time can be reduced.

Owner:MCC5 GROUP CORP SHANGHAI

Water-based alumium alloy releasing agent and preparing method thereof

ActiveCN105728639AGuaranteed high temperature performanceReduce environmental pollutionFoundry mouldsFoundry coresWaxIon

The invention discloses a water-based alumium alloy releasing agent. The water-based alumium alloy releasing agent comprises, by mass, 20-30 parts of long alkyl chain phenyl modified organic silicone oil, 100-150 parts of olein, 20-40 parts of oxidized polyethlene wax, 10-15 parts of glycerol mono-oleate, 700-850 parts of deionized water, 3-8 parts of isomeric alcohol ethoxylates and 5-10 parts of long-chain fatty alcohol-polyoxyethylene ether. According to the environment-friendly die casting releasing agent, the long alkyl chain phenyl modified organic silicone oil with the low proportion and plant oil with the high proportion serve as composite lubricating oil, the high-temperature performance of the releasing agent is guaranteed, and the environment pollution is greatly reduced. After composite emulsification is conducted on the environment-friendly die casting releasing agent through a composite surfactant, preparing is simple, and the obtained releasing agent is excellent in releasing effect.

Owner:SUZHOU XINGYE MATERIALS TECH

Method for preparing SiO2 aerogel heat insulating composite through adhesive slip casting

The invention discloses a method for preparing a SiO2 aerogel heat insulating composite through adhesive slip casting,.The method comprises the following steps of: firstly, drying at normal temperature and normal pressure by taking tetraethoxysilane and methyltriethoxysilane as a co-precursor, absolute ethyl alcohol as a reaction solvent and DMF (Dimethyl Formamide) as a drying chemical control additive to obtain a mesoporous nanometer SiO2 aerogel material with uniform pore diameter distribution; then, carrying out flexibility modification by utilizing a polyurethane elastomer to prepare modified phenolic resin glue serving as an adhesive; and preparing the SiO2 aerogel heat insulating composite by using a slip casting method. The mechanical property of the aerogel is improved, and therefore, the SiO2 aerogel material has favorable toughness and mechanical property while playing a heat insulating role.

Owner:HEFEI UNIV OF TECH

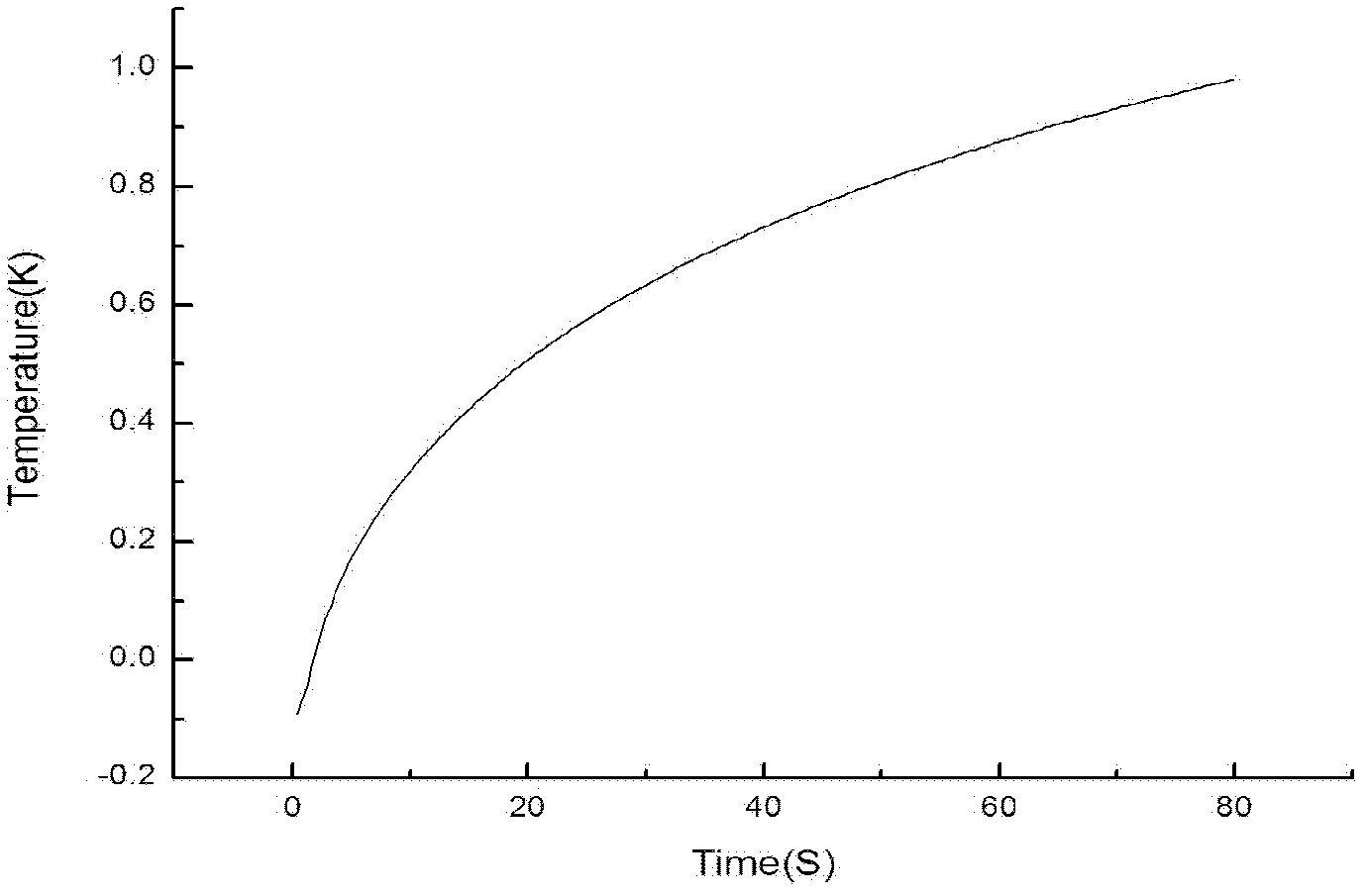

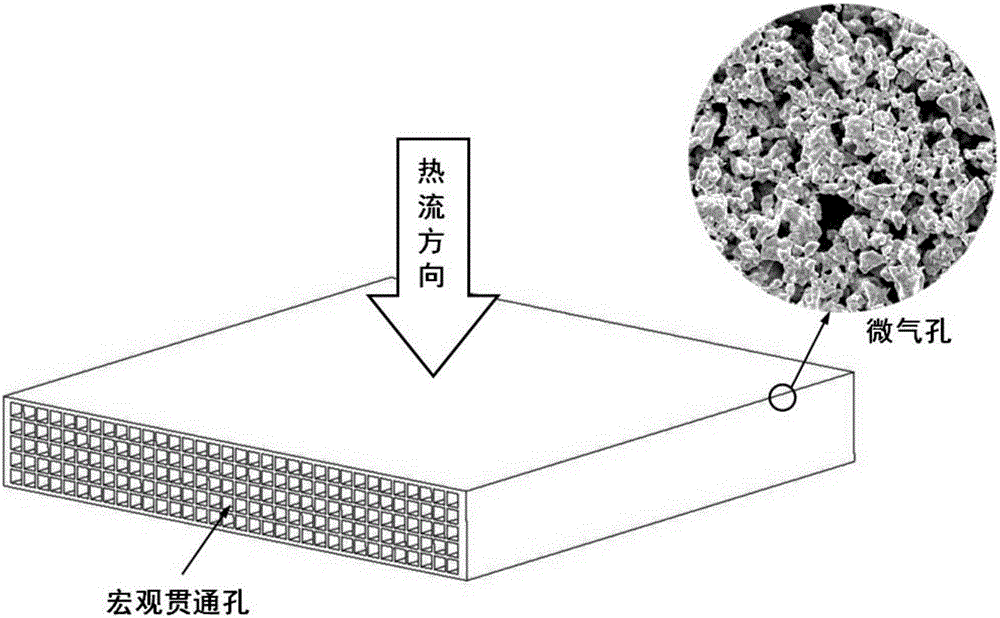

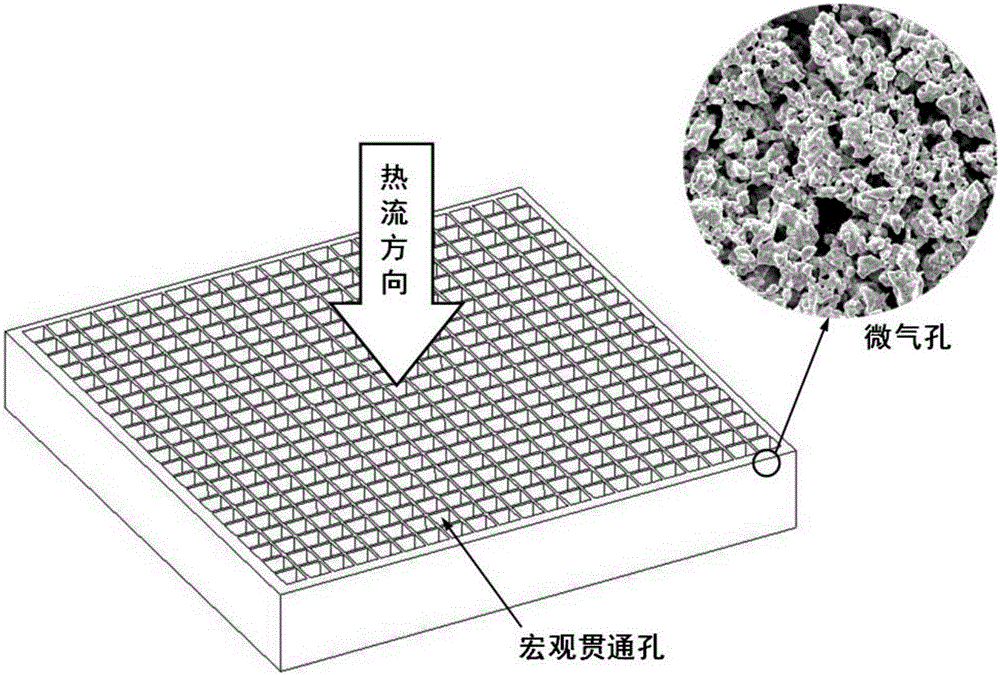

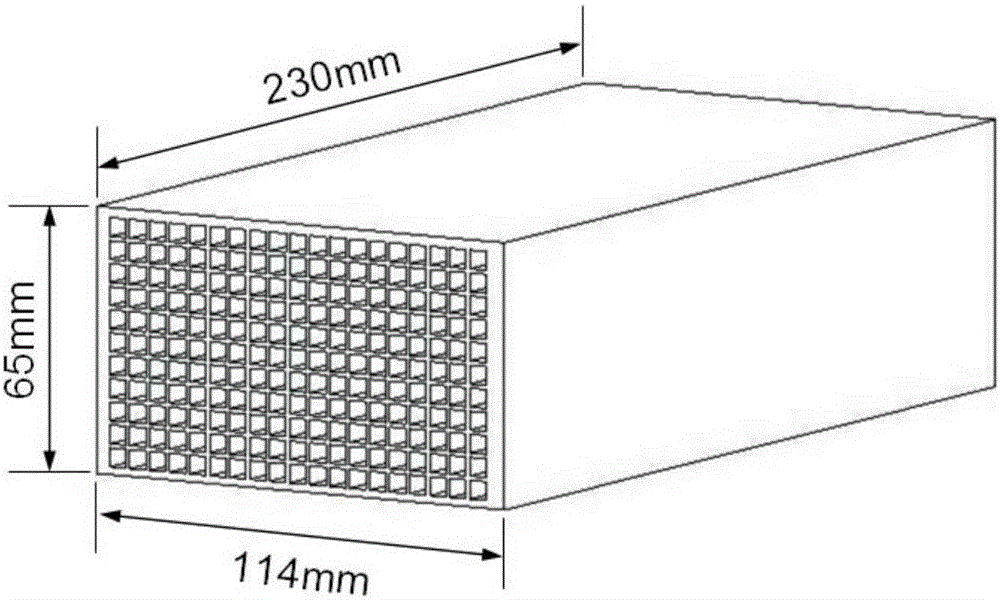

High-temperature-resistant lightweight heat-insulating material with dual pore structure and preparation method thereof

ActiveCN106220224AHigh strengthImprove high temperature creep resistanceCeramic extrusion diesCeramicwareUltimate tensile strengthSilicon dioxide

The invention discloses a high-temperature-resistant lightweight heat-insulating material with a dual pore structure and a preparation method thereof. The preparation method comprises the following steps: with alumina, silica and aluminosilicate powder as raw materials, adding a molding aid and a pore forming agent into the raw materials and carrying out uniform mixing under stirring; and then subjecting a mixture obtained in the previous step to extrusion molding and then to sintering so as to obtain the high-temperature-resistant lightweight heat-insulating material with the dual pore structure composed of macroscopic through hole channels and micropores, wherein a ratio of the total volume of through holes to the total volume of the micropores is 0.5-25: 1. According to the invention, through synergism of proper volumes of a micropore structure and the macroscopic through hole channels, the prepared material has improved energy conservation effect and thermal shock resistance, and substantially enhanced strength and high-temperature creep resistance while high temperature performance of the material is guaranteed.

Owner:NANJING WEINENG KILN TECH

Preparation method of oxide surface layer shell for titanium alloy precision casting

The invention discloses a preparation method of an oxide surface layer shell for titanium alloy precision casting. The preparation method comprises the steps of preparation of binders, preparation of surface layer powdery material, preparation of surface layer coating, preparation of a surface layer shell, shell dewaxing, shell roasting and the like; the preparation method has the beneficial effects that: the used raw material has low price and is easily available, the traditional process is improved, the using amounts of zirconium oxide and yttrium oxide are greatly reduced, the process is simplified, the preparation flow is shortened, and the labor and raw material costs are reduced; adhesive adopts silicon sol and zirconium acetate as main raw materials and is added with n-caprylic alcohol and polyvinyl alcohol, so that the surface layer coating has good coating property, can be uniformly coated on a wax mold and has good compactness; the adhesive is added with zirconium oxide fireproofing ingredient, therefore, the surface layer shell is capable of resisting high temperature; steam dewaxing is adopted to achieve the effect of no environment pollution; the prepared surface layer shell has no influence on human health, has wide application range, small interface reaction layer with thickness 0.018-0.02mm, high precision and excellent performance and is easy to realize post-finishing.

Owner:QINGDAO RUNQIAN HI TECH CO LTD

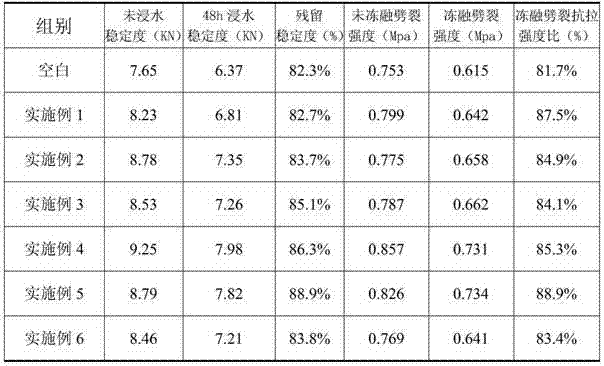

Organic composite warm asphalt mixture and preparation method thereof

ActiveCN104761191AReduce the temperatureLess componentsClimate change adaptationPerformance indexEthylene bis

The invention discloses an organic composite warm asphalt mixture. The mixture is prepared from 4-6wt% of asphalt, 90-92wt% of aggregate, 1-2wt% of ore powder, 1-2wt% of an inorganic filler and 0.1-0.2wt% of an organic composite warm mixing agent, wherein the organic composite warm mixing agent comprises one or more of ethylene bisstearamide, octadecanamide, oleamide and ethylene bisoleamide. The organic composite warm asphalt mixture substantially reduces the mixing and compacting temperature of the warm asphalt mixture, greatly saves energy, reduces the discharge of waste gas, effectively guarantees that the high temperature, the water stability and other pavement performance indexes of the warm asphalt mixture approach or are better than those of routine asphalt mixtures, and meets practical engineering standard requirements. The organic composite warm asphalt mixture disclosed in the invention has the characteristics of few components, simple preparation technology and low cost. The invention also provides a preparation method of the organic composite warm asphalt mixture.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +2

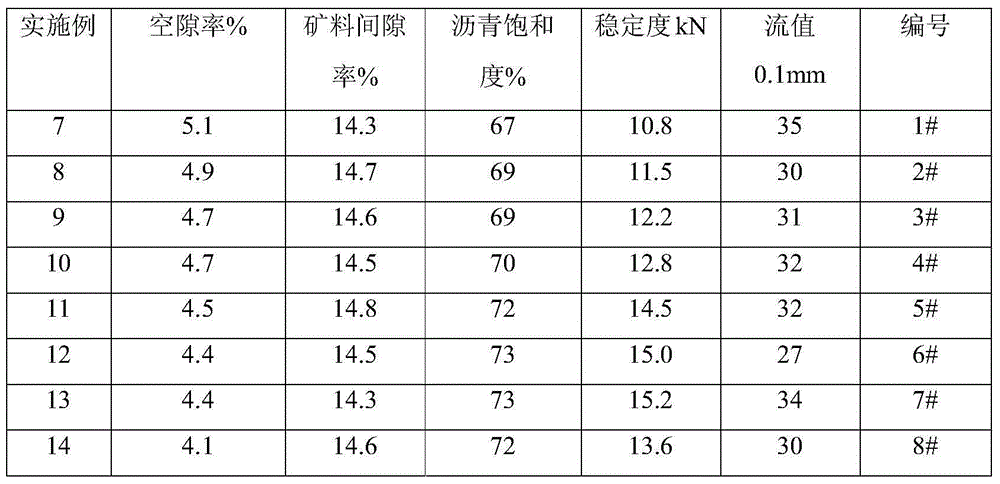

Bituminous mixture using DVS (direct vat set) high-adhesion modifier and preparation method thereof

ActiveCN104693821AControl "Secondary Pollution"Low costBuilding insulationsBulk chemical productionCrack resistancePolymer science

The invention relates to a bituminous mixture using a DVS (direct vat set) high-adhesion modifier and a preparation method thereof. The bituminous mixture is prepared from aggregates, a DVS high-adhesion bituminous mixture modifier and matrix asphalt by mixing, wherein the modifier is prepared from high-desulfurization-degree reclaimed rubber, modified high-temperature coal tar pitch and a skeleton proppant by stirring and extruding. Waste rubber is deeply activated under the high temperature and high shearing action of a twin screw extruder, so that the high-desulfurization-degree reclaimed rubber is obtained; then, the mixture of the modified high-temperature coal tar pitch modified by rubber pyrolysis oil, the high-desulfurization-degree reclaimed rubber and the skeleton proppant is fully mixed by using a screw, and then extruded and granulated so as to obtain the DVS high-adhesion bituminous mixture modifier; and finally, the modifier, the aggregates and the matrix asphalt are mixed so as to obtain a DVS high-adhesion bituminous mixture. The bituminous mixture disclosed by the invention has excellent water damage resistance, good high-temperature rutting resistance and low-temperature crack resistance.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

High-temperature-resistant easy-collapsibility precoated sand for casting

ActiveCN103521676AGuaranteed high temperature performanceGuaranteed collapsibilityFoundry mouldsFoundry coresElectrical conductorDecomposition

The invention discloses high-temperature-resistant easy-collapsibility precoated sand for casting. The precoated sand comprises the following components in parts by weight: 97 to 98 parts of original sand, 2 to 2.5 parts of phenolic resin, 0.3 to 0.4 part of urotropine, 0.15 to 0.2 part of calcium stearate, and 0.1 to 0.3 part of anhydrous copper sulfate. The high-temperature-resistant easy-collapsibility precoated sand for casting is prepared by employing the specific components and content, especially, the contained anhydrous copper sulfate has high decomposition temperature which is required to be a high temperature of 650 DEG C or more; when a pouring temperature reaches 1400 DEG C, because the precoated sand is a poor heat conductor, the decomposition temperature is relatively appropriate, and the high temperature resistant performance and the poured collapsibility performance of the precoated sand can be guaranteed. At the same time, the invention also discloses a preparation method of the precoated sand. The method adopts specific steps and a charging sequence, and can quickly obtain the high-temperature-resistant easy-collapsibility precoated sand.

Owner:LIUZHOU LIUJING TECH CO LTD

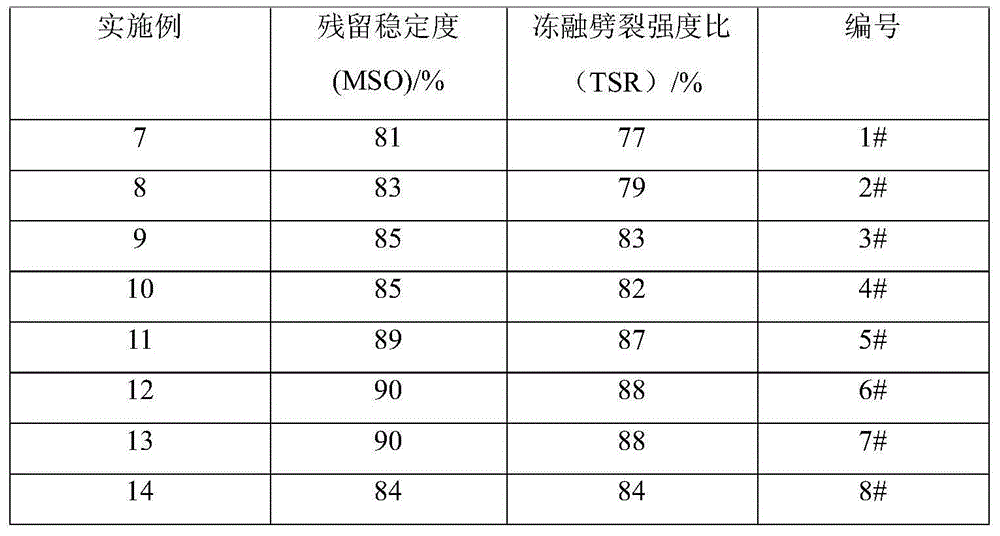

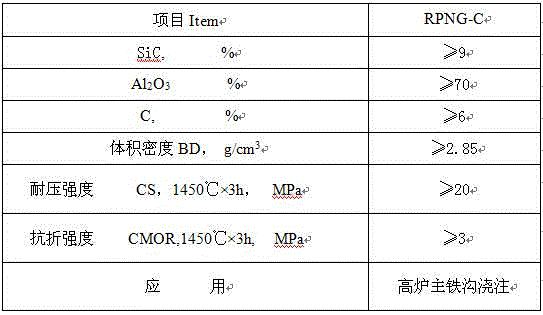

Special casting material for main iron runner of iron-making blast furnace

The invention discloses a special casting material for a main iron runner of an iron-making blast furnace. The special casting material is prepared from brown fused alumina granules, white alundum granules, white alundum powder, plate corundum micro powder, chromium concentrate, silicon carbide granules, silicon carbide powder, spherical asphalt, activated aluminum oxide, silica powder, pure calcium aluminate cement, metal silicon powder, metal aluminum powder, additives, anti-explosion fiber, carbon composite micro powder and the like according to a certain ratio. The special casting material has the advantages that aiming at problems that a main iron runner casting material of the blast furnace is generally poor in furnace slag corrosion resistance, slag lines are easy to deteriorate, the operation and the yield of the blast furnace can be affected, and the like, a refractory material which is good in slag corrosion resistance and good in abrasion and flushing resistance is compounded. According to the scheme, co-ground composite micro powder which is not easy to infiltrate by molten iron and slag is introduced, the silicon carbide granules, powder materials, plate corundum micro powder and chromium concentrate are introduced to improve the abrasion and flushing resistance, and by optimizing a binding agent and the additives, the comprehensive high temperature properties of the casting material for the main iron runner is ensured.

Owner:REWELL REFRACTORY ZHENGZHOU CO LTD

Preparation method of proton exchange membrane and polyimide perfluorosulfonic acid resin proton exchange membrane obtained thereby

InactiveCN102477162AEvenly distributedThe content is easy to controlCell component detailsFuel cell detailsAcetic anhydridePolyamide

The present invention provides a preparation method of a proton exchange membrane. The method comprises dispersing perfluorosulfonic acid resin in an organic solvent with a high boiling point of 140-205 DEG C to obtain a perfluorosulfonic acid resin solution; adding an organic thermal stabilizer and aromatic diamine into the perfluorosulfonic acid resin solution, and adding aromatic dianhydride to obtain a polyamic acid perfluorosulfonic acid resin solution; coating the polyamic acid perfluorosulfonic acid resin solution on a glass plate, and drying to obtain a polyamic acid perfluorosulfonic acid resin composite membrane; and soaking the composite membrane in a mixed solvent containing acetic anhydride and pyridine, and allowing cyclodehydration reaction at a room temperature to obtain a polyimide perfluorosulfonic acid resin proton exchange membrane. The prepared proton exchange membrane has high electrical conductivity and good high-temperature resistance, and it is free of through holes, to thereby improve safety of batteries.

Owner:BYD CO LTD

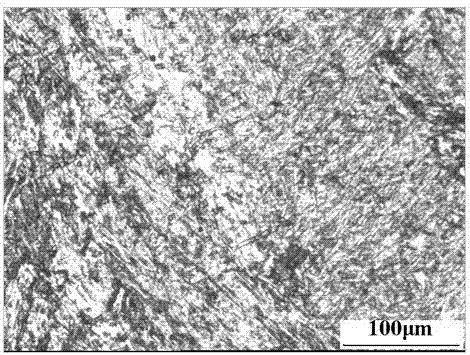

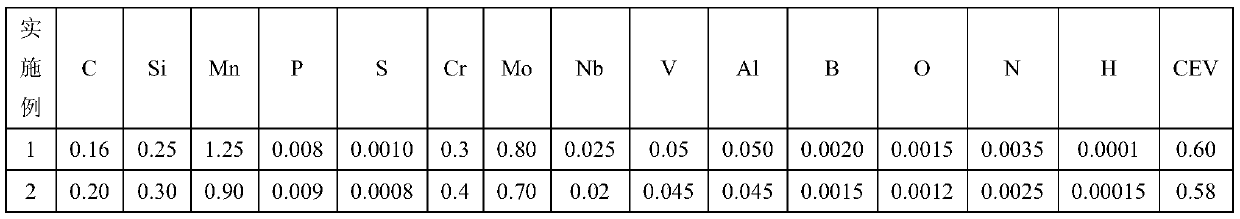

High-temperature-resistant 400 HB wearproof steel plate and production method thereof

The invention relates to a high-temperature-resistant 400 HB wearproof steel plate. The high-temperature-resistant 400 HB wearproof steel plate is prepared from chemical components including 0.15%-0.25% of C, 0.10%-0.40% of Si, 0.8%-1.30% of Mn, 0.010%-0.040% of Nb, 0.030%-0.060% of V, smaller than or equal to 0.010% of Ti, 0.03%-0.06% of Al, smaller than or equal to 0.1% of Ni, smaller than or equal to 0.1% of Cu, 0.10%-0.50% of Cr, 0.50%-1.00% of Mo, 0.001%-0.005% of B, 0.0010%-0.0050% of Ca, smaller than or equal to 0.010% of P, smaller than or equal to 0.0015% of S, smaller than or equal to 0.0015% of O, smaller than or equal to 0.0035% of N, smaller than or equal to 0.0002% of H, larger than or equal to 0.55 or smaller than or equal to 0.65 of the carbon equivalent CEV and the balanceFe and inevitable impurity elements, wherein CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. In a production process, controlled cooling is carried out after rolling is completed, grains are refined, and fine Martensite lathes are obtained for following offline quenching. High-temperature tempering is adopted after quenching is completed, under the combined effect of Cr / Mo / V precipitates, it is guaranteed that the microstructure of the high-performance performance finished steel plate of the steel plate is uniform tempered sorbite, and the grains are fine; and the size is smaller than or equal to 20 micrometers, fine uniform precipitates are dispersed on a ferrite matrix, and the precipitates are carbide.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

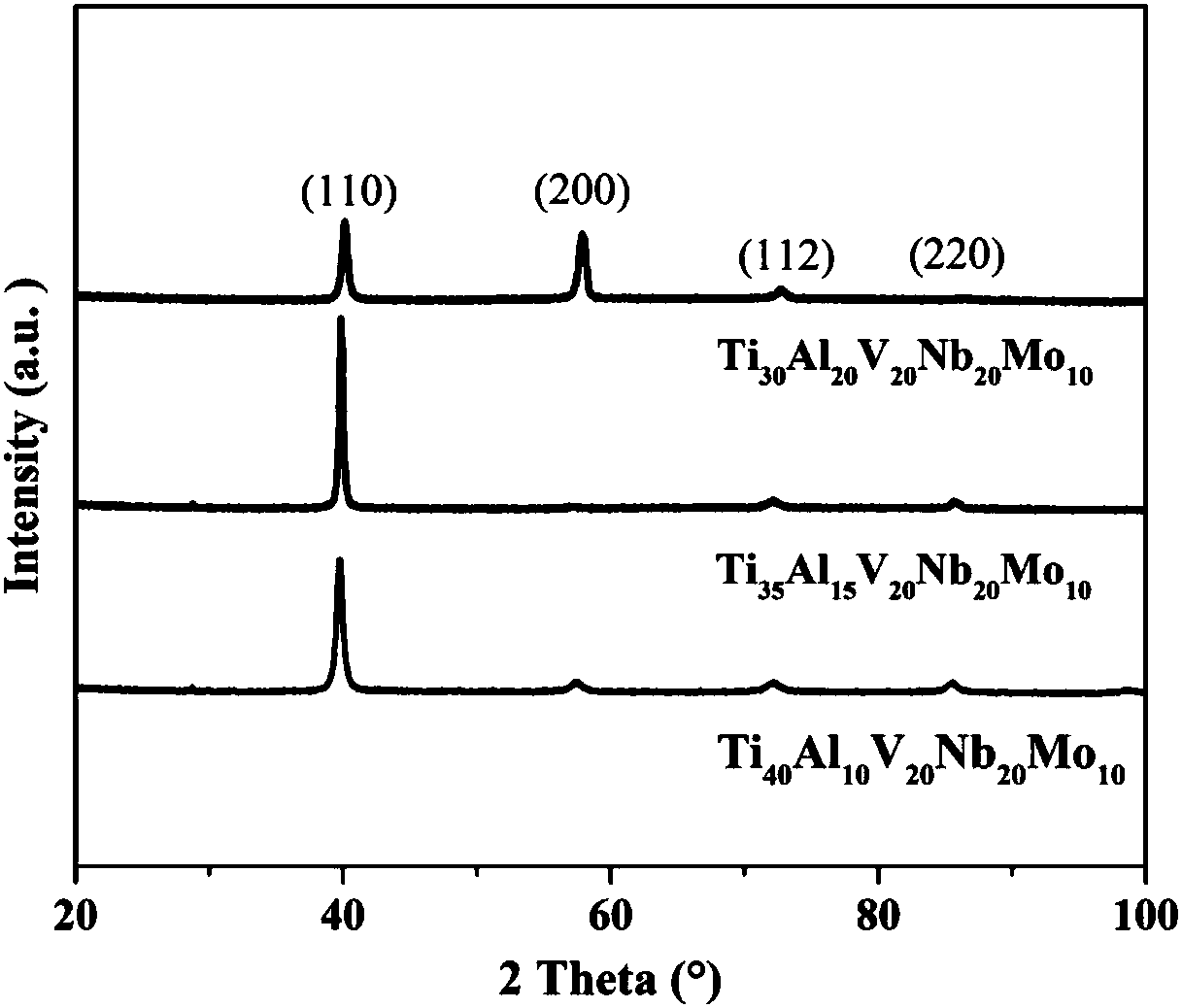

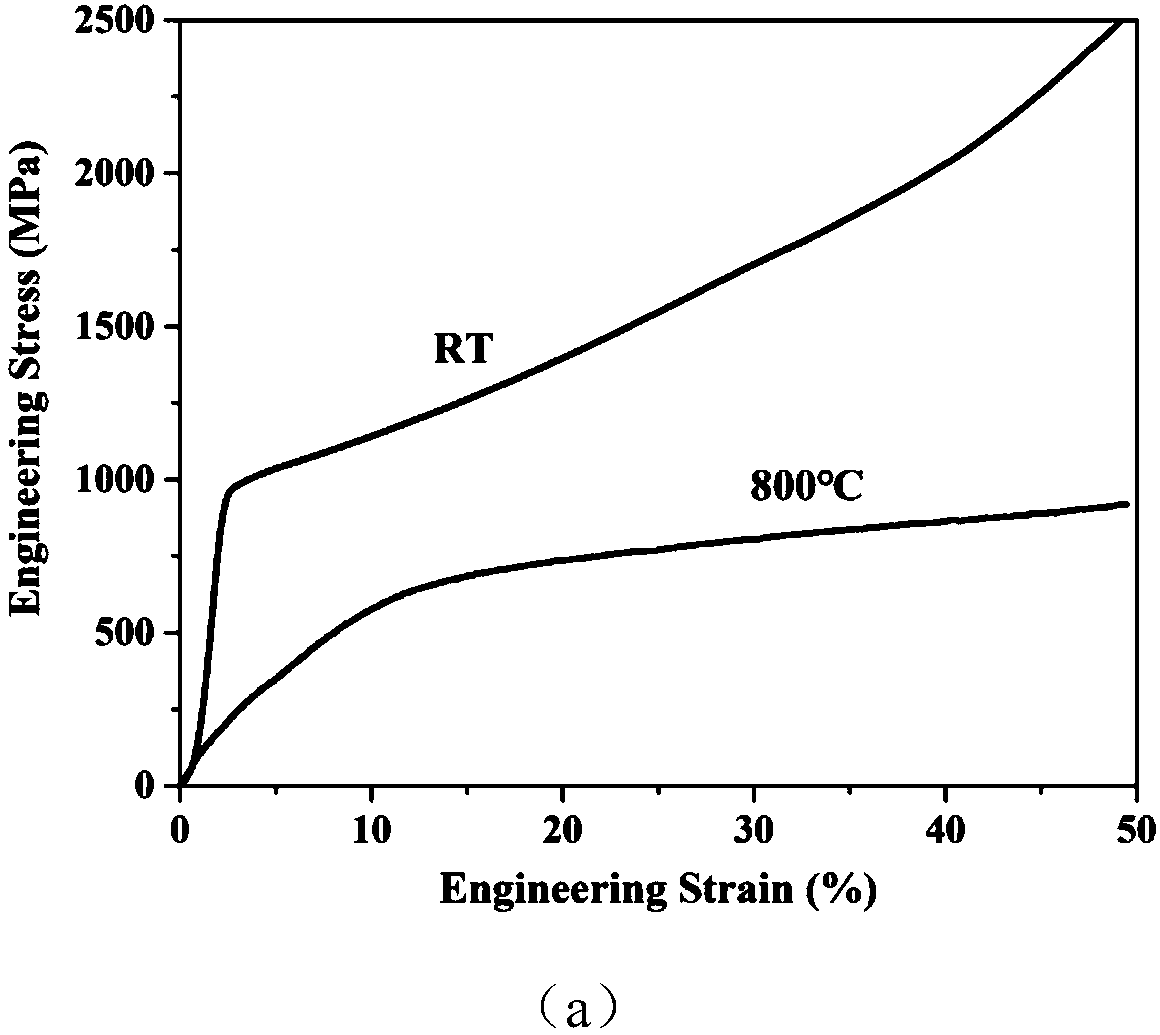

Low-density high-entropy alloy material oriented for high temperature applications and preparation method of low-density high-entropy alloy material

The invention relates to a low-density high-entropy alloy material oriented for high temperature applications and a preparation method of the low-density high-entropy alloy material, in particular toa TiAlNbVMo-system low-density high-entropy alloy material and a preparation method thereof, and belongs to the field of high-entropy alloys. In order to possessing characteristics of both low densityand high strength, the novel alloy consists of Ti, Al, V, Nb and Mo, and a mother alloy button ingot is obtained through electric arc melting. The alloy is of a single phase BCC (body-centered cubic)structure; the novel alloy is high both in strength and tenacity, has very well mechanical property, can exceed 1000MPa in as-cast compressive yield strength, and cannot crack in a compression process; meanwhile, the density of the alloy is from 5.5 g / cm<3> to 6.1 g / cm<3>, and is relatively low; and the novel alloy is high in specific strength, still relatively high in strength at high temperature, and can exceed 700MPa at 800 DEG C and exceed 200MPa at 1000 DEG C in compressive yield strength.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Polyaryletherketone nano composite material and preparation method thereof

The invention discloses a polyaryletherketone nanocomposite material and a preparation method thereof. The polyaryletherketone nanocomposite material is prepared from 0.2-20 parts of nano fillers, 100 parts of 4,4-DFBP or paraphthaloyl chloride, and a phenol monomer or a diphenyl ethermonomer with equal molar weight to the 4,4-DFBP or paraphthaloyl chloride in in-situ polycondensation reaction. The nano fillers are layered expanded graphite, graphene, graphene oxide or carbon monofluoride; the phenol monomer is phenol, xenol, bisphenol A, o-methylhydroquinone or 3,3',5,5'-tetramethyl biphenol. The polyaryletherketone nanocomposite material not only has good thermodynamic property and decay resistance, simultaneously has high wear resistance, is applicable to the molding technologies such as injection, mold pressing and the like, and can meet the operating requirements under severe conditions such as high temperature, high pressure and the like, and the preparation method is reliable in principle, simple in process, convenient to operate, easy to control, and free of toxic and side products, and has a broad market prospect.

Owner:四川天策聚材科技有限公司

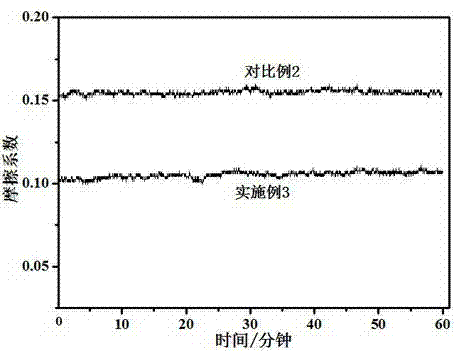

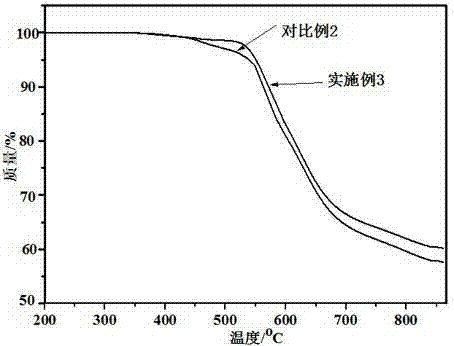

Long-service-life iron runner castable for hot repair

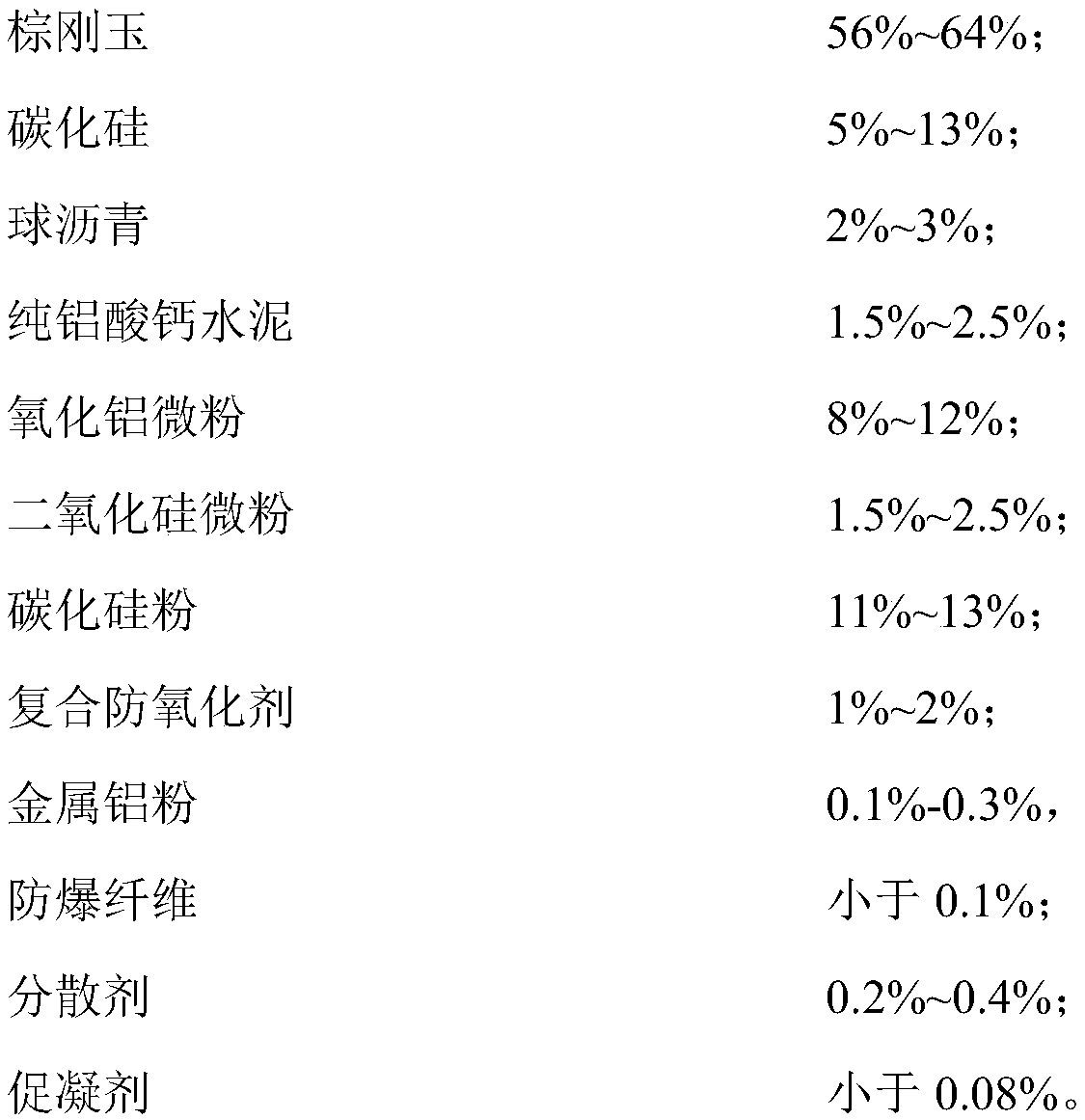

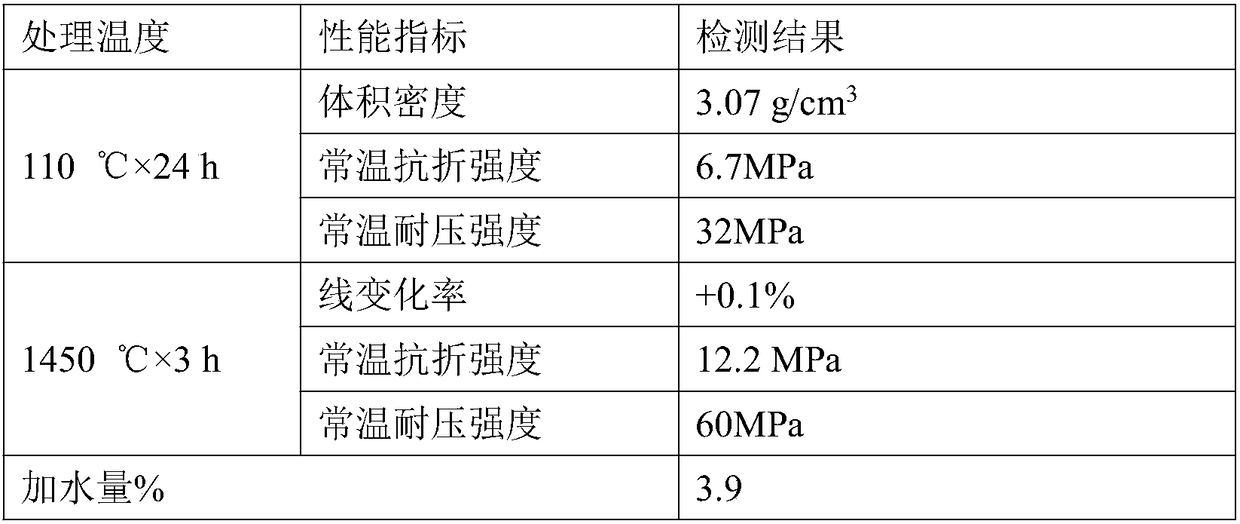

The invention discloses a long-service-life iron runner castable for hot repair. The long-service-life iron runner castable for hot repair comprises the following components in percentage by mass: 56%-64% of brown fused alumina, 5%-13% of silicon carbide, 2%-3% of ball pitch, 1.5%-2.5% of calcium aluminate cement, 8%-12% of alumina micro-powder, 1.5%-2.5% of silicon dioxide micro-powder, 11%-13% of silicon carbide powder, 1%-2% of a composite antioxidant, 0.1%-0.3% of metal aluminum powder, less than 0.1% of explosion-proof fibers, 0.2%-0.4% of a dispersing agent and 0.08% of a coagulant. Thenovel coagulant is used for the iron runner castable, thus, the metal aluminum powder in the iron runner castable produces hydrogen ahead of time, the gas is generated to open an exhaust hole when thecastable is not cured, then, the castable is matched with the suitable metal aluminum powder and the low-melting-point explosion-proof fibers, and it ensures that the castable has excellent high-temperature usability while meeting the condition of construction.

Owner:中冶武汉冶金建筑研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com