Asbestos-free non-metal friction material and preparation method thereof

A friction material and asbestos-free technology, which is applied in the field of friction materials and its preparation, can solve the problems of poor high temperature resistance of hybrid fiber reinforced materials, high density of semi-metallic friction materials, and easy damage to the dual disc, etc., to achieve good braking comfort , Stable thermal decay performance, high temperature resistance and performance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A new non-asbestos non-metallic friction material, the friction material is composed of the following components by weight percentage: 4% aramid fiber, 18% LAPINUS inorganic mineral fiber, 16% phenolic resin, 5% nitrile rubber powder, 25% barium sulfate , 10% calcium carbonate, 5% molybdenum disulfide, 8% artificial graphite, 8% coke, 1% alumina.

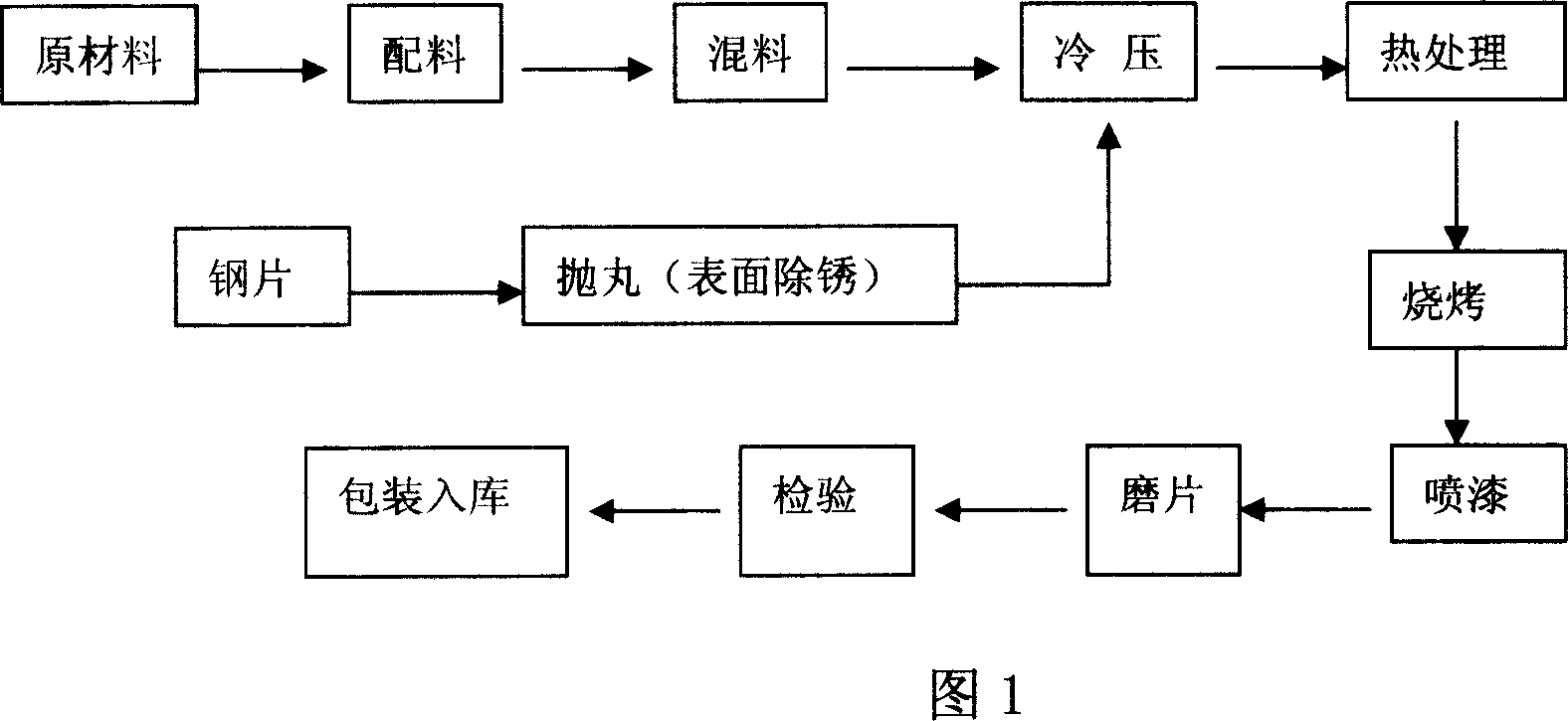

[0037] The preparation method of the above-mentioned novel asbestos-free non-metallic friction material, the method comprises the following steps:

[0038] A, mixing, uniformly mix the above-mentioned aramid fibers with artificial graphite and coke in a blender, so that the aramid fibers are in a uniformly dispersed state, then add other ingredients and mix evenly;

[0039] B. Cold pressing, the pressure is 50Mpa, the temperature is normal temperature, and the time is 1min;

[0040] C. Heat treatment, heat treatment in a single temperature section at 300°C for 1 hour;

[0041] D. Barbecue, the temperature is 600°C, and the ...

Embodiment 2

[0045] A new non-asbestos non-metallic friction material, the friction material is composed of the following components by weight percentage: 5% aramid fiber, 25% LAPINUS inorganic mineral fiber, 20% phenolic resin, 3% nitrile rubber powder, 20% barium sulfate , 10% calcium carbonate, 5% molybdenum disulfide, 5% artificial graphite, 6% coke, 1% alumina.

[0046] The preparation method of the above-mentioned novel asbestos-free non-metallic friction material, the method comprises the following steps:

[0047] A, mixing, uniformly mix the above-mentioned aramid fibers with artificial graphite and coke in a blender, so that the aramid fibers are in a uniformly dispersed state, then add other ingredients and mix evenly;

[0048] B. Cold pressing, pressure 50Mpa, temperature at room temperature, time 2min;

[0049] C. Heat treatment, heat treatment in a single temperature section at 300°C for 2.5 hours;

[0050] D. Barbecue, temperature 600°C, time 1.5min;

[0051] E. Surface tr...

Embodiment 3

[0054]A new non-asbestos non-metal friction material, the friction material is composed of the following components by weight percentage: 2% aramid fiber, 16% LAPINUS inorganic mineral fiber, 20% phenolic resin, 4.5% nitrile rubber powder, 25% barium sulfate , 10% calcium carbonate, 5% molybdenum disulfide, 8% artificial graphite, 8% coke, 1.5% alumina.

[0055] The preparation method of the above-mentioned novel asbestos-free non-metallic friction material, the method comprises the following steps:

[0056] A, mixing, uniformly mix the above-mentioned aramid fibers with artificial graphite and coke in a blender, so that the aramid fibers are in a uniformly dispersed state, then add other ingredients and mix evenly;

[0057] B. Cold pressing, pressure 50Mpa, temperature at room temperature, time 3min;

[0058] C. Heat treatment, heat treatment in a single temperature section at 300°C for 3 hours;

[0059] D. Barbecue, temperature 600°C, time 2min;

[0060] E. Surface treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com