Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

517results about How to "Avoid insufficient friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

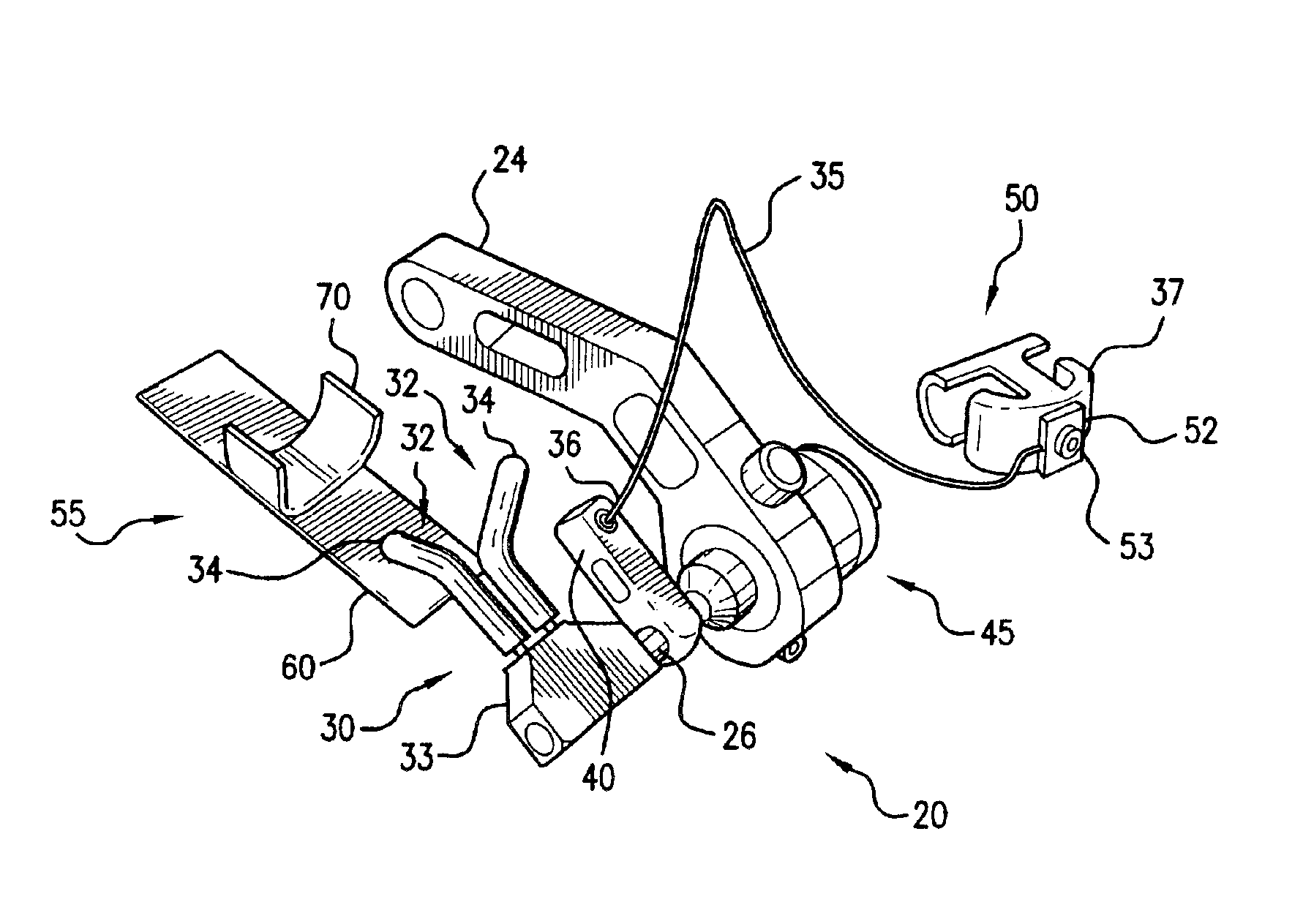

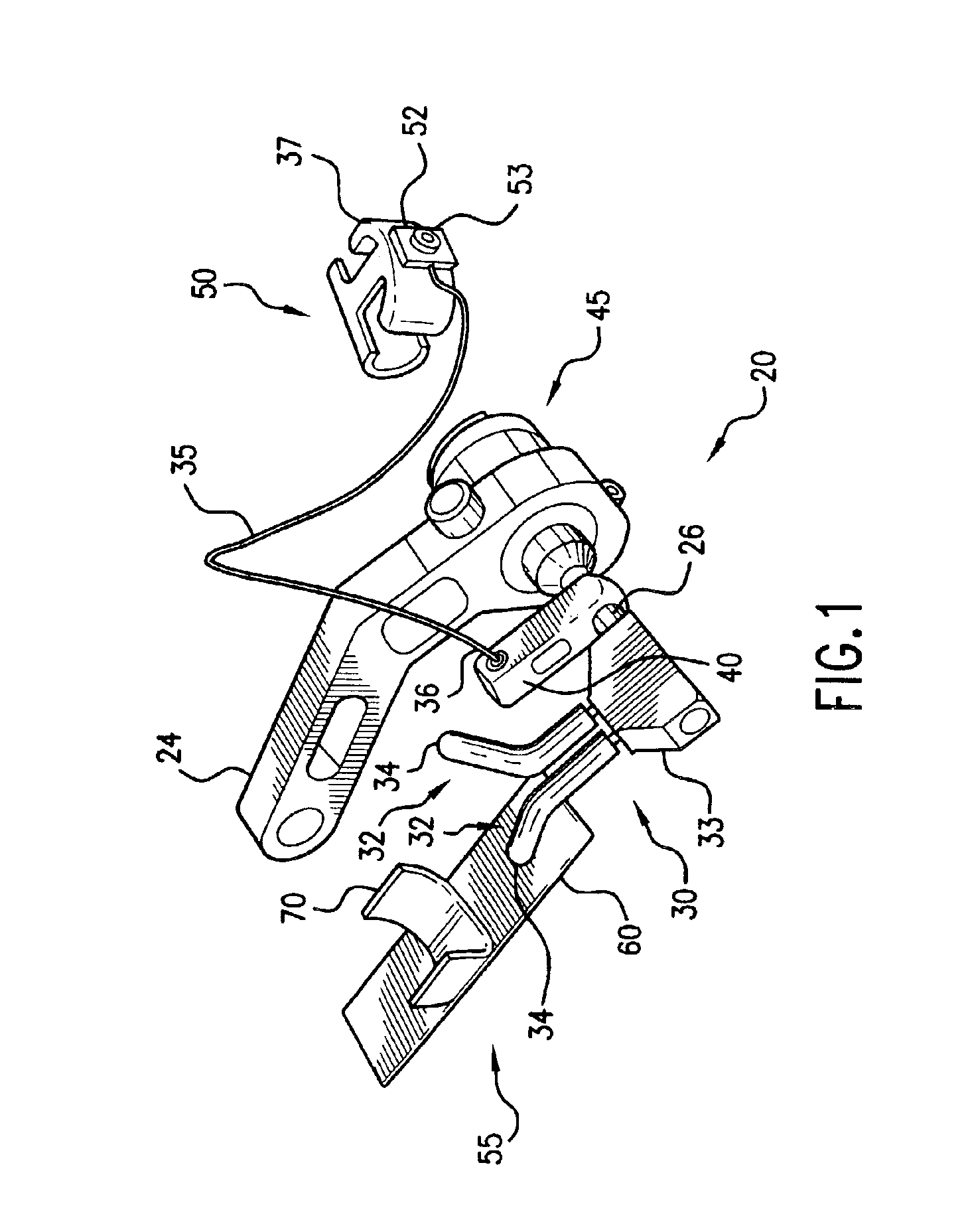

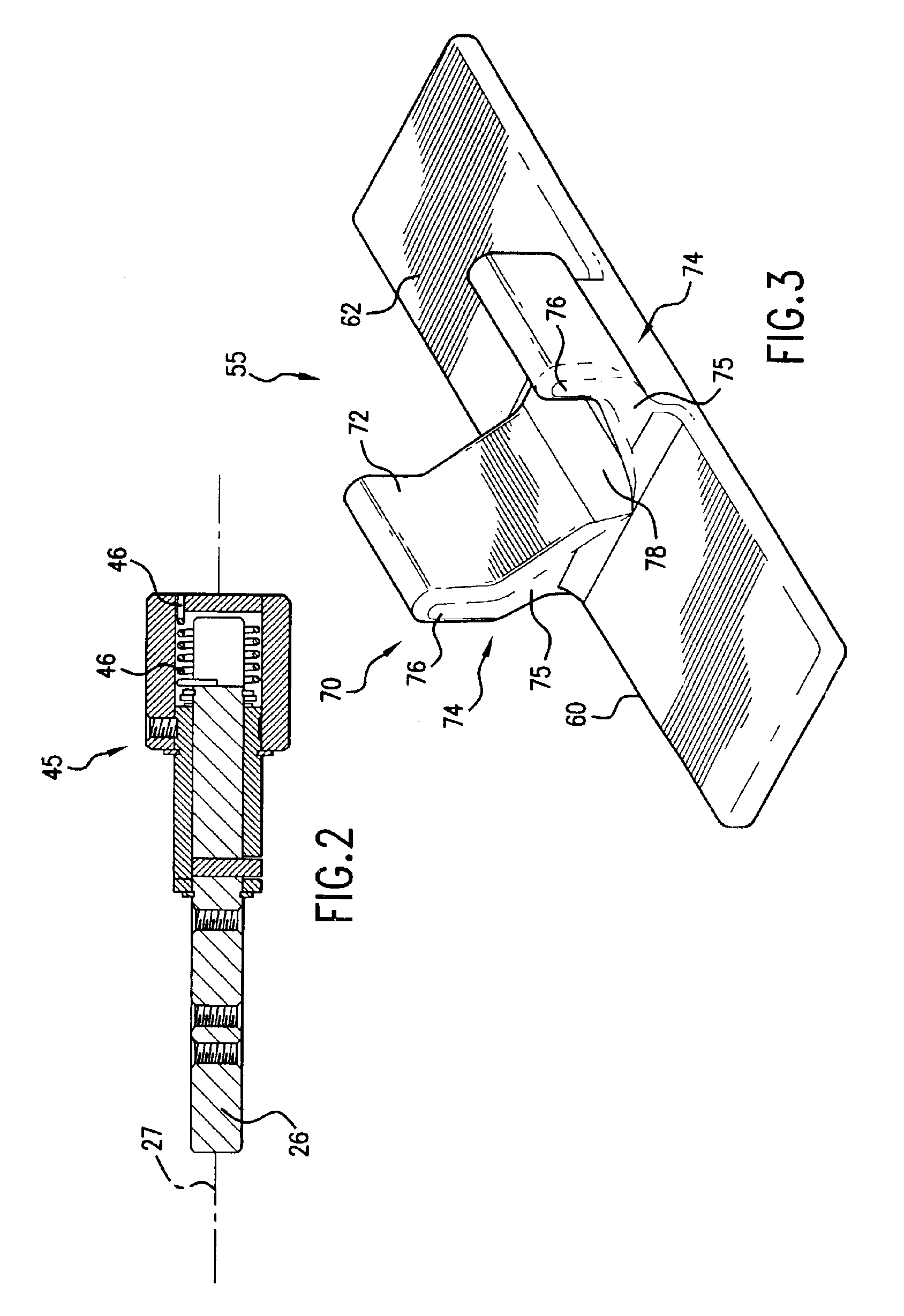

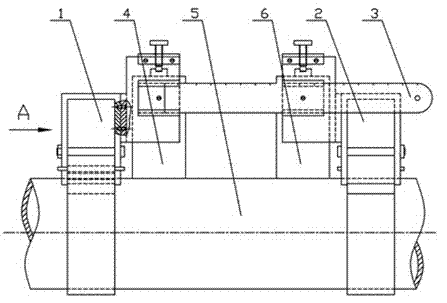

Power tong

InactiveUS6082224AEffectively grip a tubularPrevent slippingDrilling rodsWrenchesMechanical engineeringLoad force

A new power tong for rotating tubular members for make-up (connection) and break-out (disconnection) operations. In one aspect such a tong has at least one movable jaw with a smooth surface gripping element thereon and pre-load apparatus for applying a pre-load force to a movable jaw so that the jaw does not slip on a tubular to be rotated and so it does not mark or damage the tubular. In one aspect the pre-load apparatus includes a first pre-load device at one end of a movable jaw for breakout operations and a second pre-load device at another end of the jaw for make-up operations. In one aspect a power tong which has unique smooth surfaced jaw inserts made, e.g., of aluminum. In one aspect a single pivotable pre-load cylinder, fixed to rotary, pivots for pivotable connection to one jaw or the other. This can be done manually or a powered smaller piston / cylinder may be used to pivot the pre-load cylinder. In one aspect a jaw unit which comprises a jaw holder and a jaw movable with respect to said jaw holder, characterized in that said jaw is slidably mounted on said jaw holder.

Owner:WEATHERFORD TECH HLDG LLC

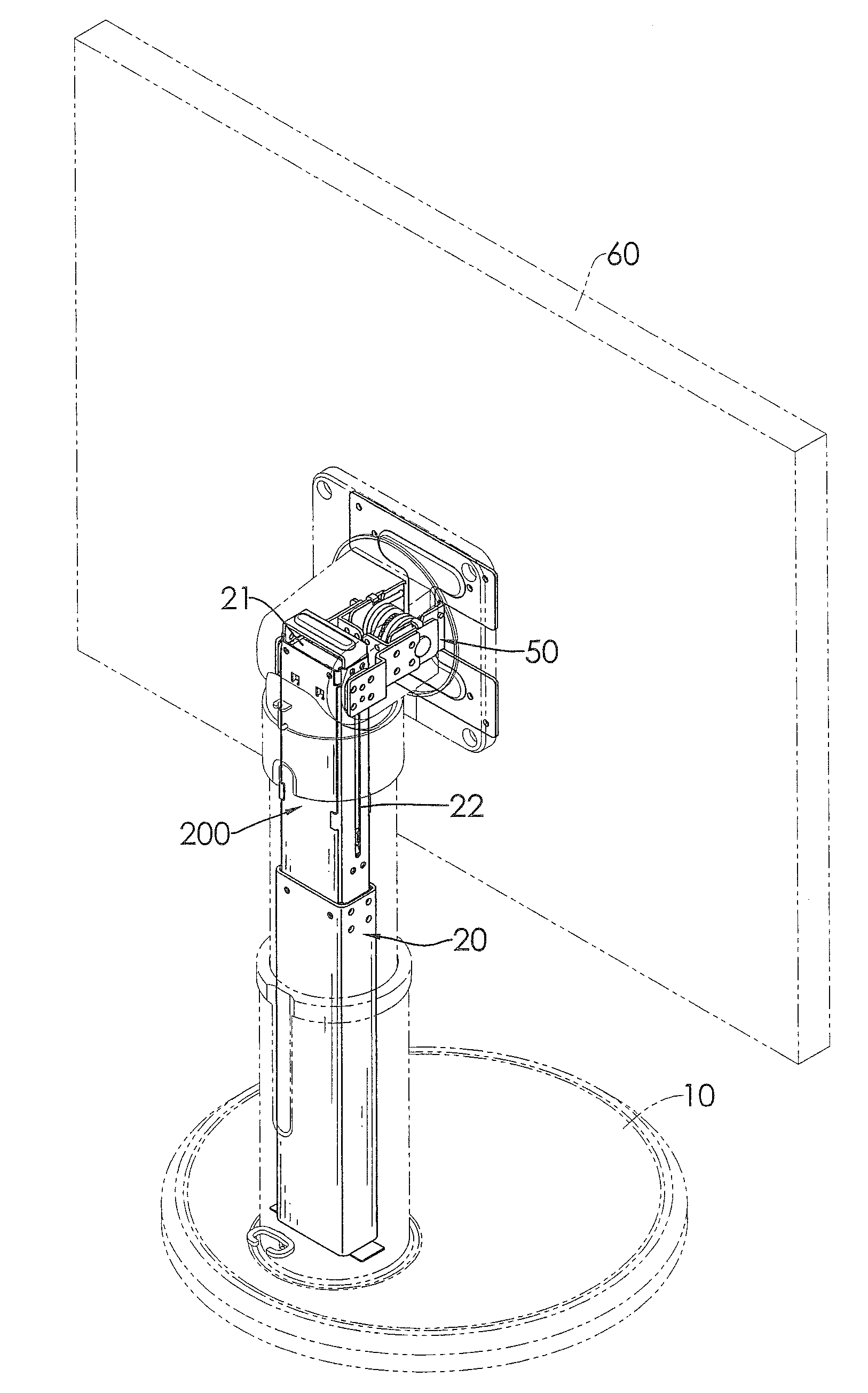

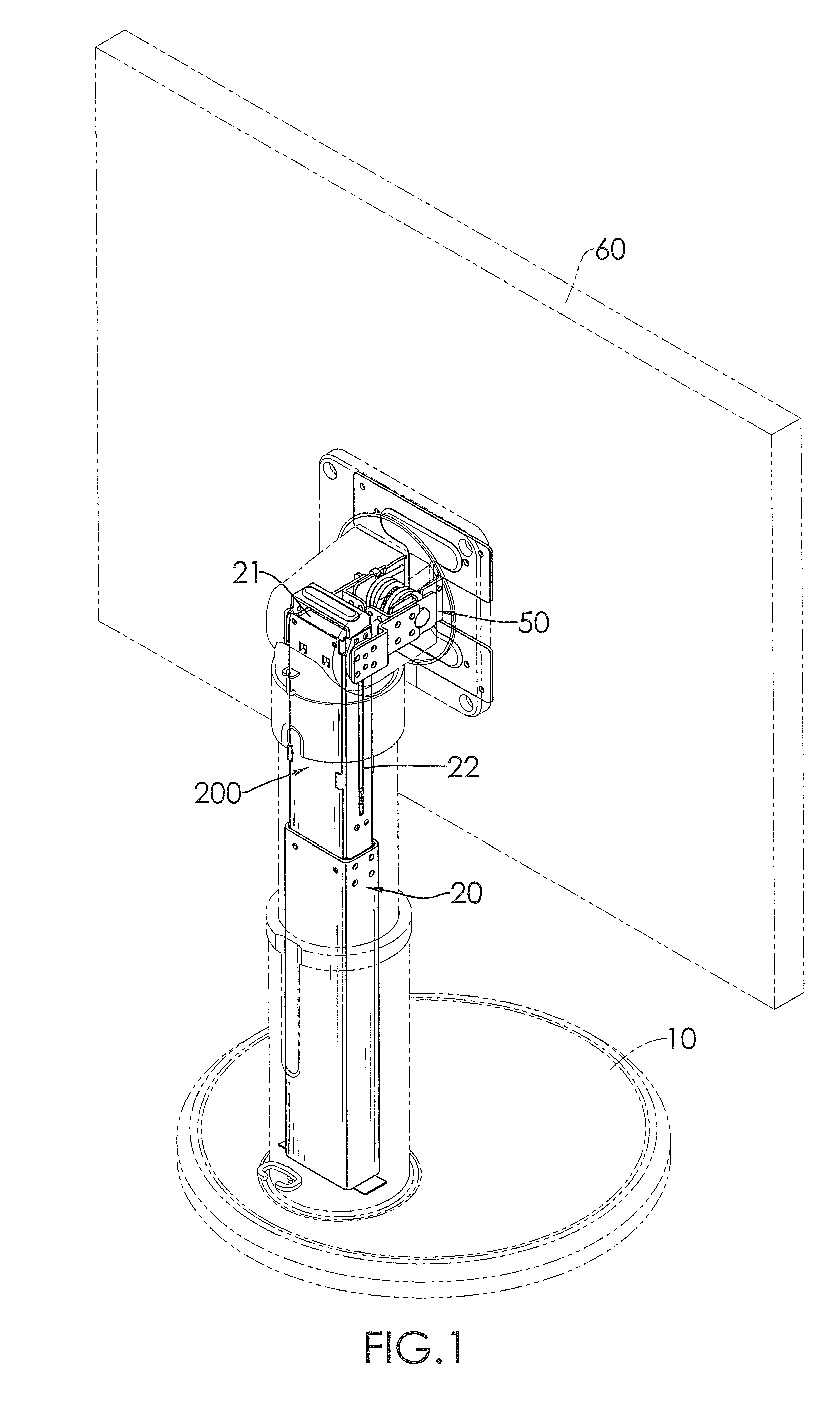

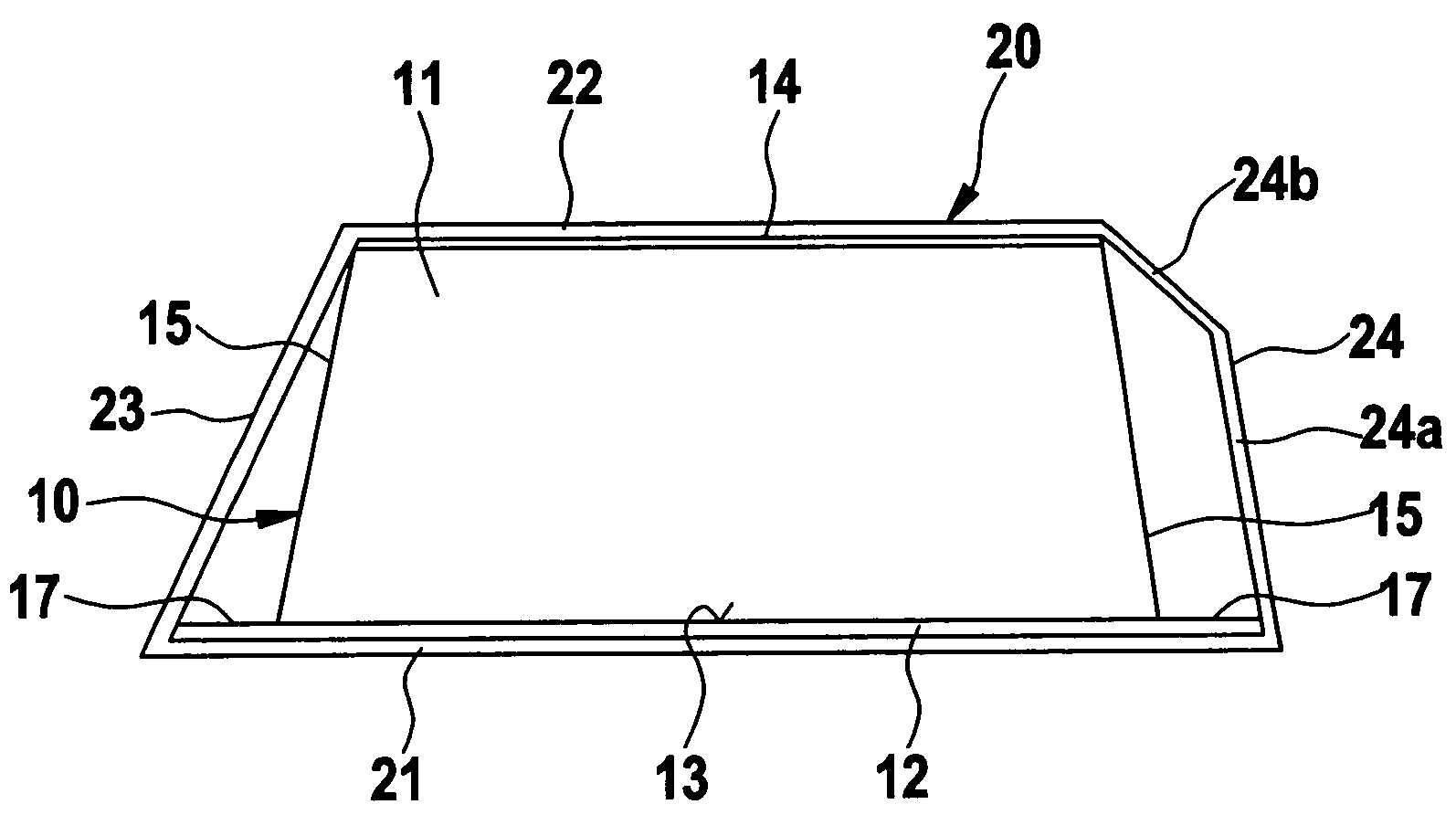

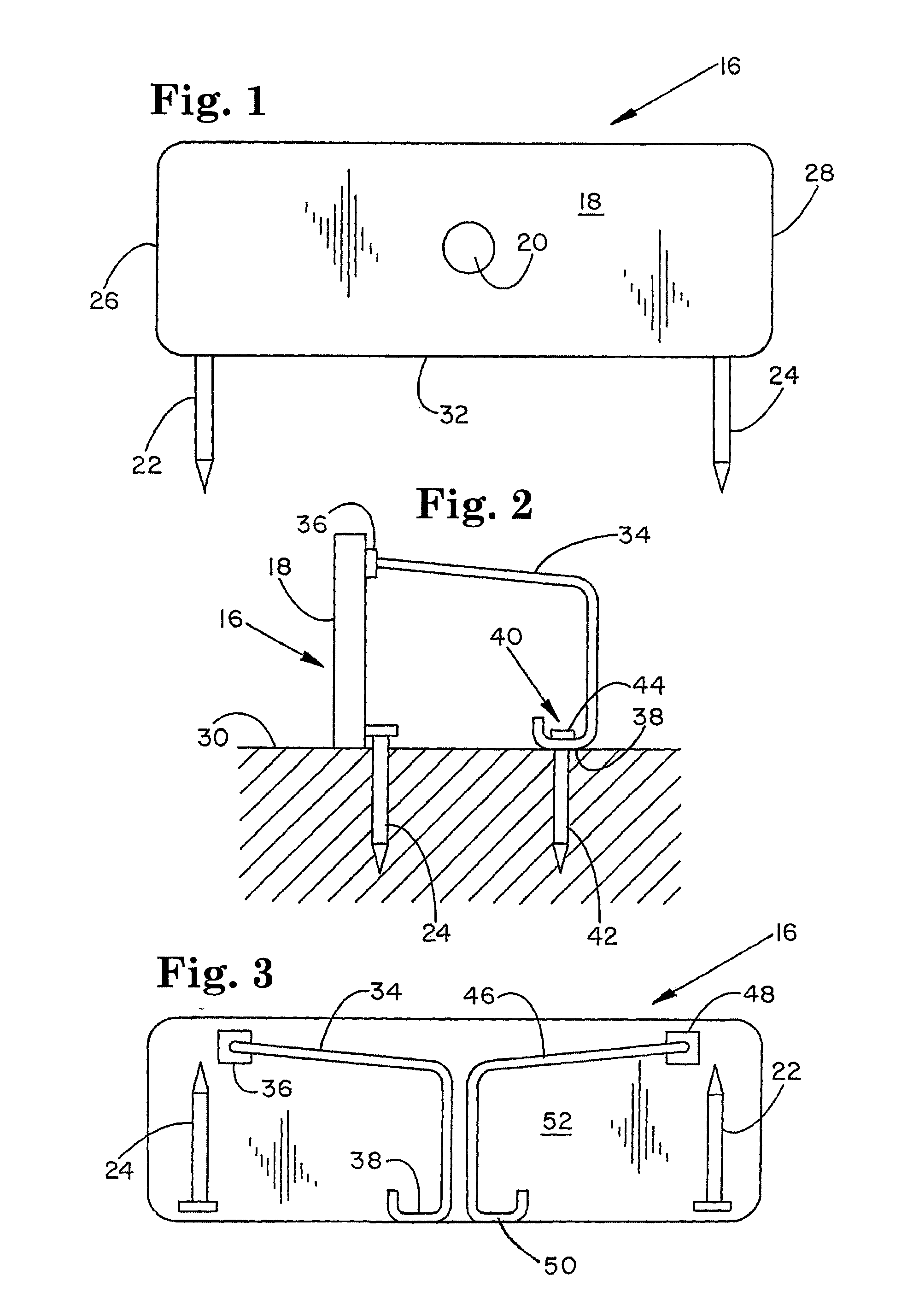

Flat panel display stand

InactiveUS7413150B1Avoid insufficient frictionEasy to displayPipe supportsDigital data processing detailsDisplay deviceCoil spring

A flat panel display stand has a base, a post, a resilient assembly and a holding bracket. The post is securely mounted perpendicularly on the base and has a channel defined inside the post and two guide slots formed through the post opposite to each other. The resilient assembly is mounted slidably in the channel of the post and has two friction feet and a coil spring. The friction feet are mounted respectively in the guide slots and generate adequate friction to hold the resilient assembly in place. The coil spring has an end secured in the channel and provides a resilient force to hold the resilient assembly in position. The holding bracket is connected to a flat panel display and is attached to the resilient assembly through the guide slots. The flat panel display stand is compact and facilitates adjustment of the position of the flat panel display.

Owner:SHIN ZU SHING

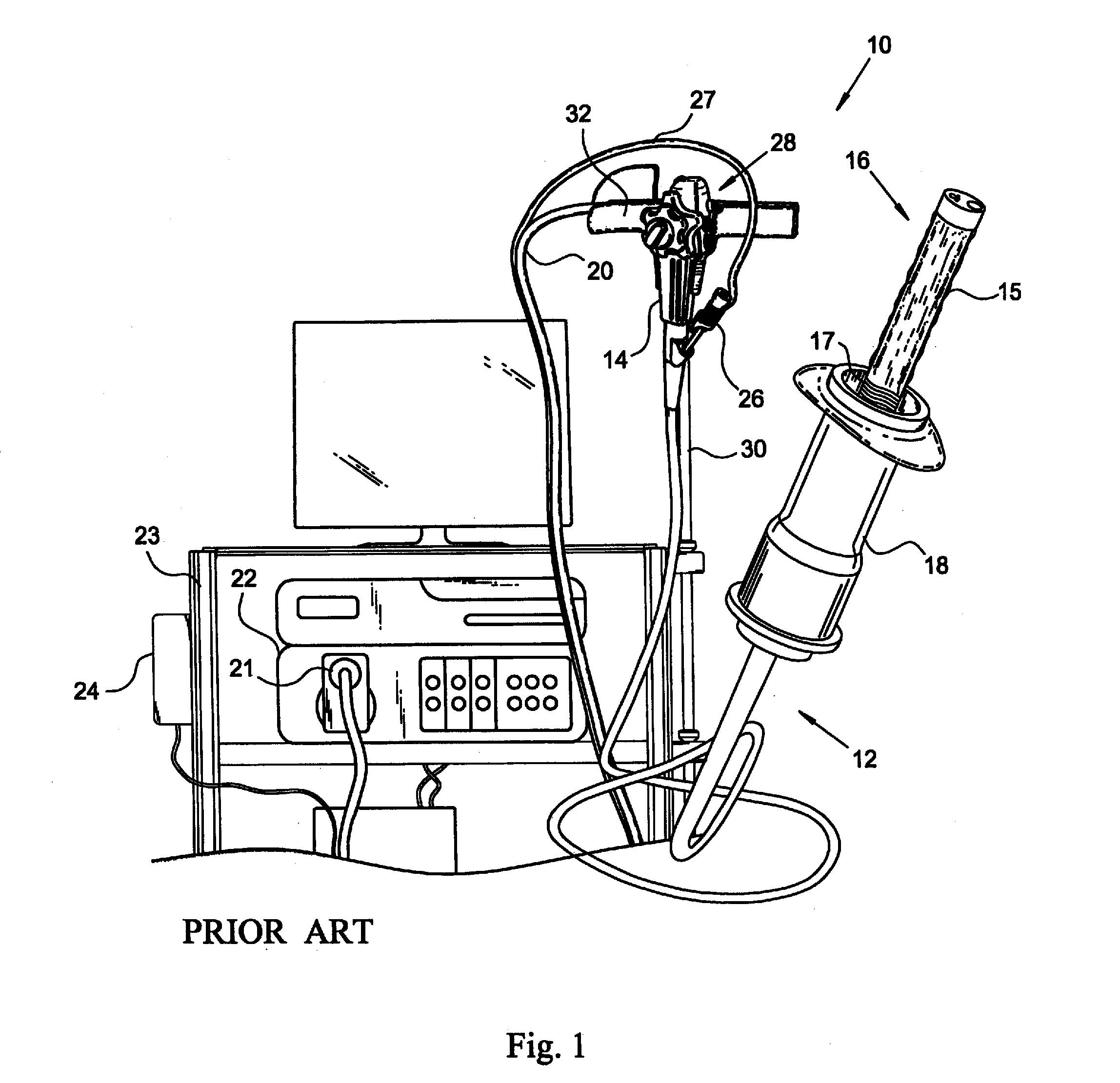

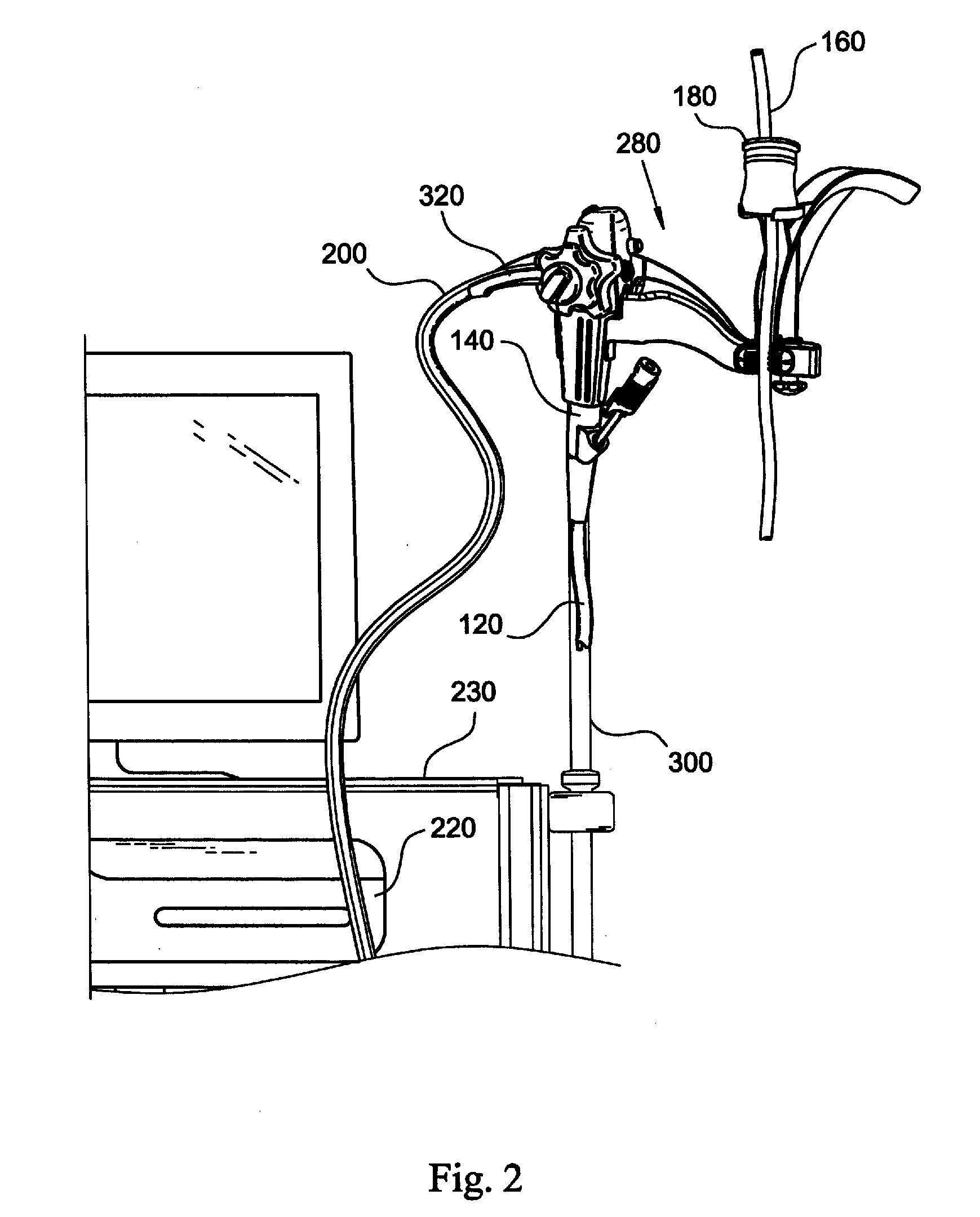

Endoscope Stand

InactiveUS20080183034A1Safe reliable hangingPrevent fallingGastroscopesEndoscopesEngineeringEndoscope

A stand for supporting at least an operating handle and an insertion tube of an endoscopic apparatus is disclosed. The stand includes a hanger member and a post member. Said hanger member has a first shoulder portion adapted for supporting an umbilical cord of the endoscopic apparatus, an intermediate portion adapted for supporting the operating handle, a carrier portion adapted for supporting the insertion tube and a second shoulder portion adapted for retaining a distal end of the insertion tube in an upright position.

Owner:STRYKER GI

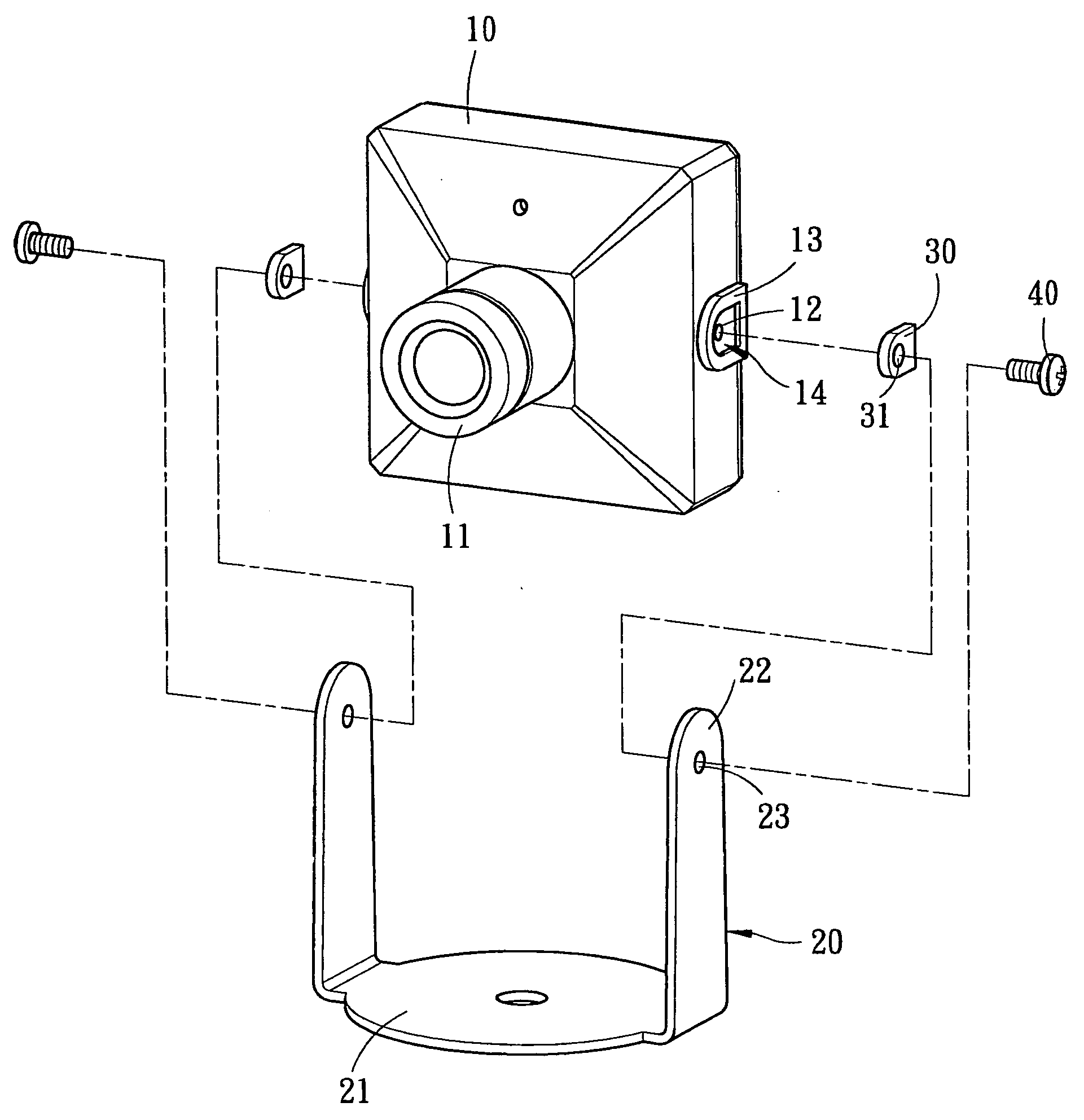

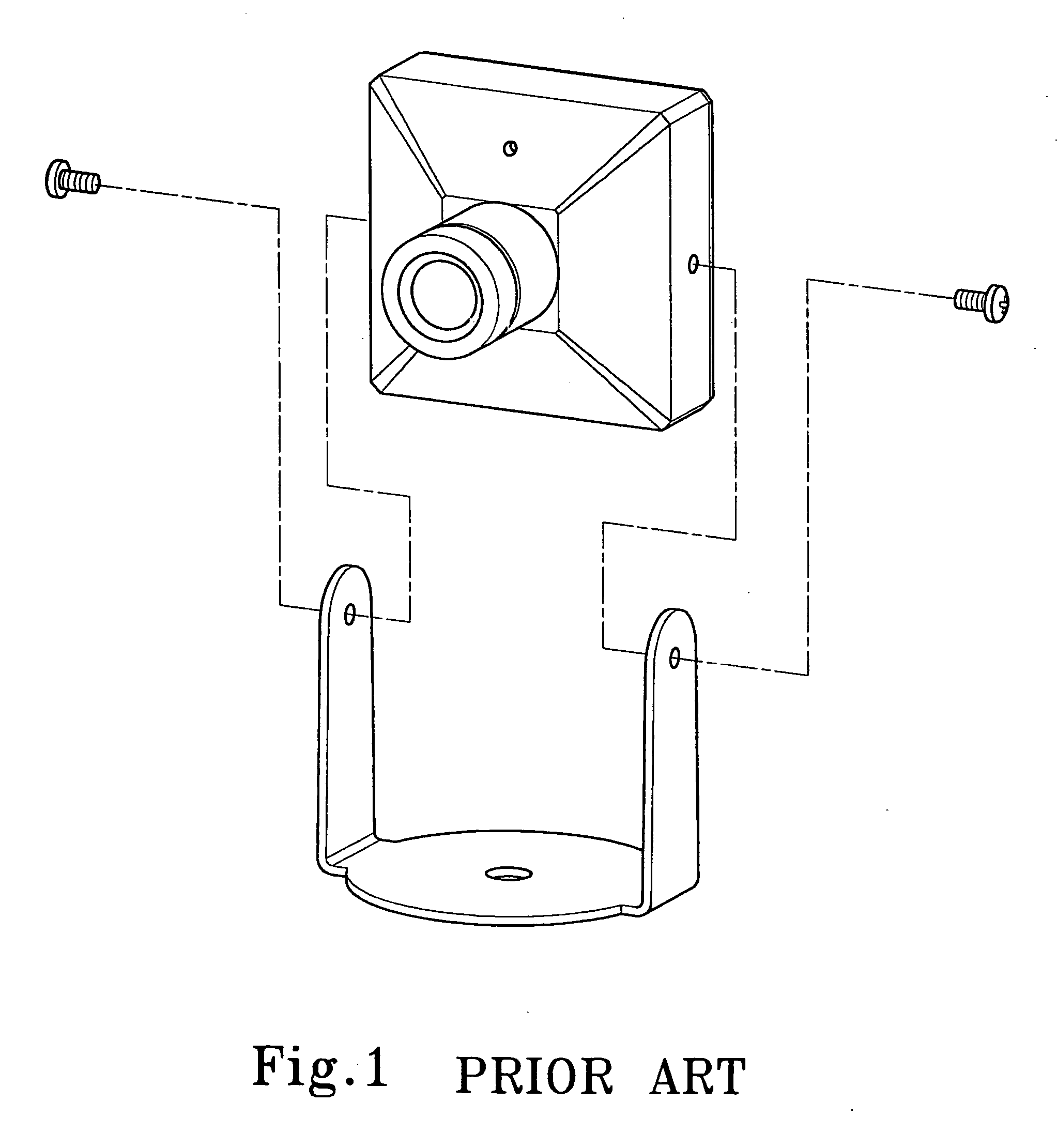

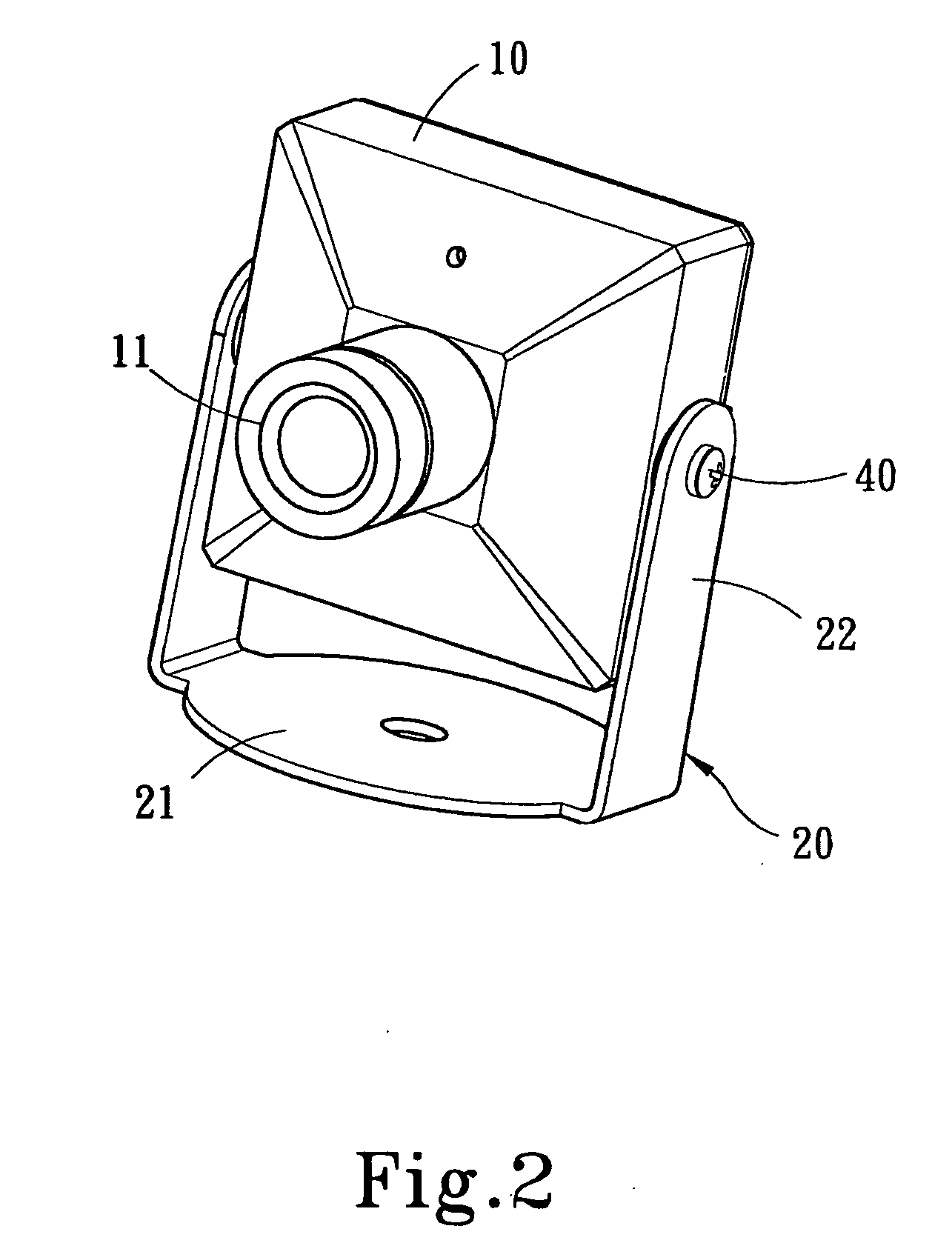

Mini-camera with an adjustable structure

InactiveUS20050212958A1Not damage connectionAdjustable structureTelevision system detailsColor television detailsCamera lensComputer graphics (images)

A mini-camera with an adjustable structure mainly includes a camera body, a support and at least one limiting element disposed at a connection between the camera body and the support. The limiting element provides the camera body with enough friction for adjusting the viewing angle of a camera lens relative to the support. A user can step-less adjust the view angle of the camera lens of the camera body, the user doesn't need disassemble the camera body or the support, and further the user cannot damage the connection between the camera body and the support for maintaining the outside beauty of the mini-camera.

Owner:ZIPPY TECH

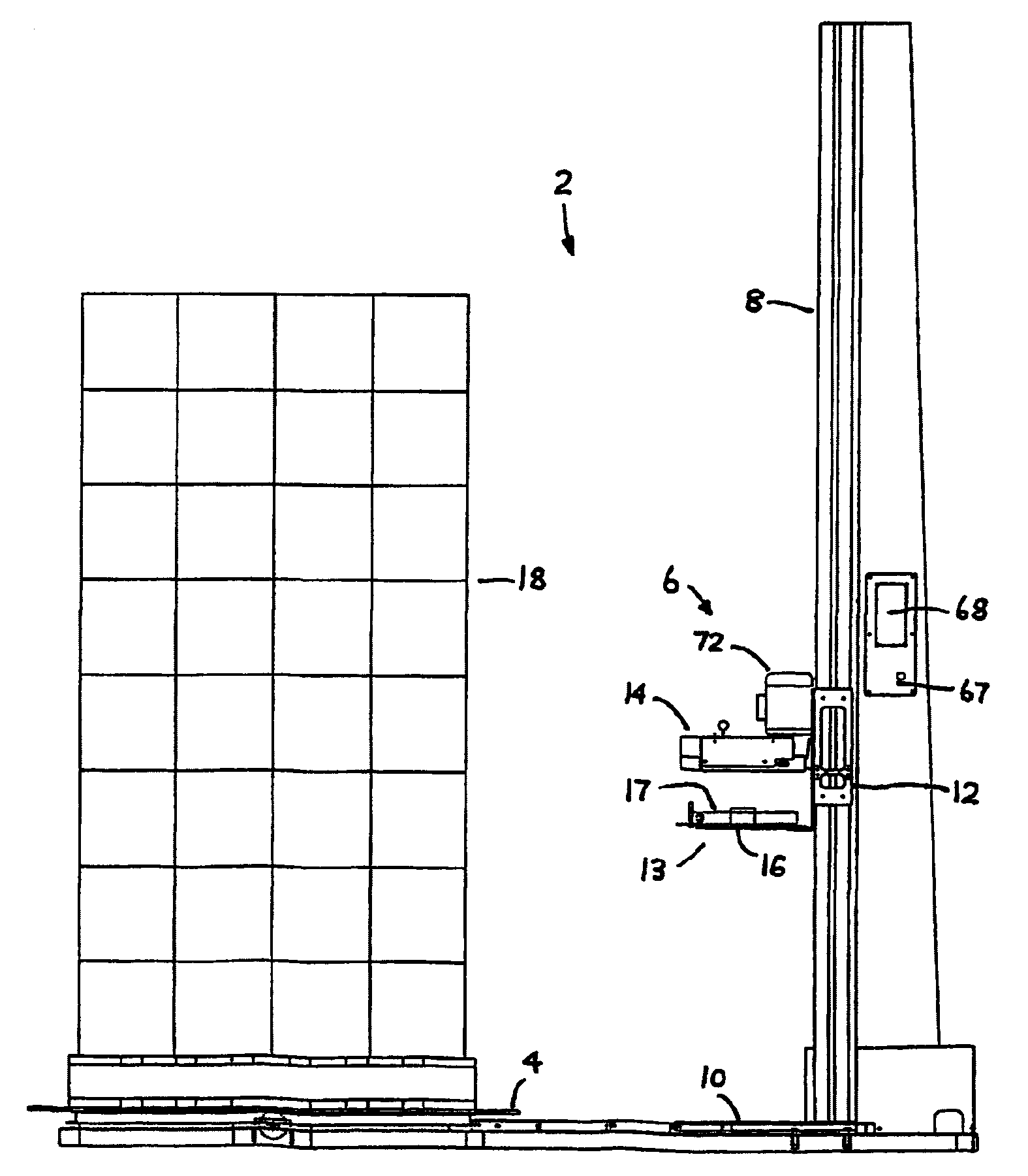

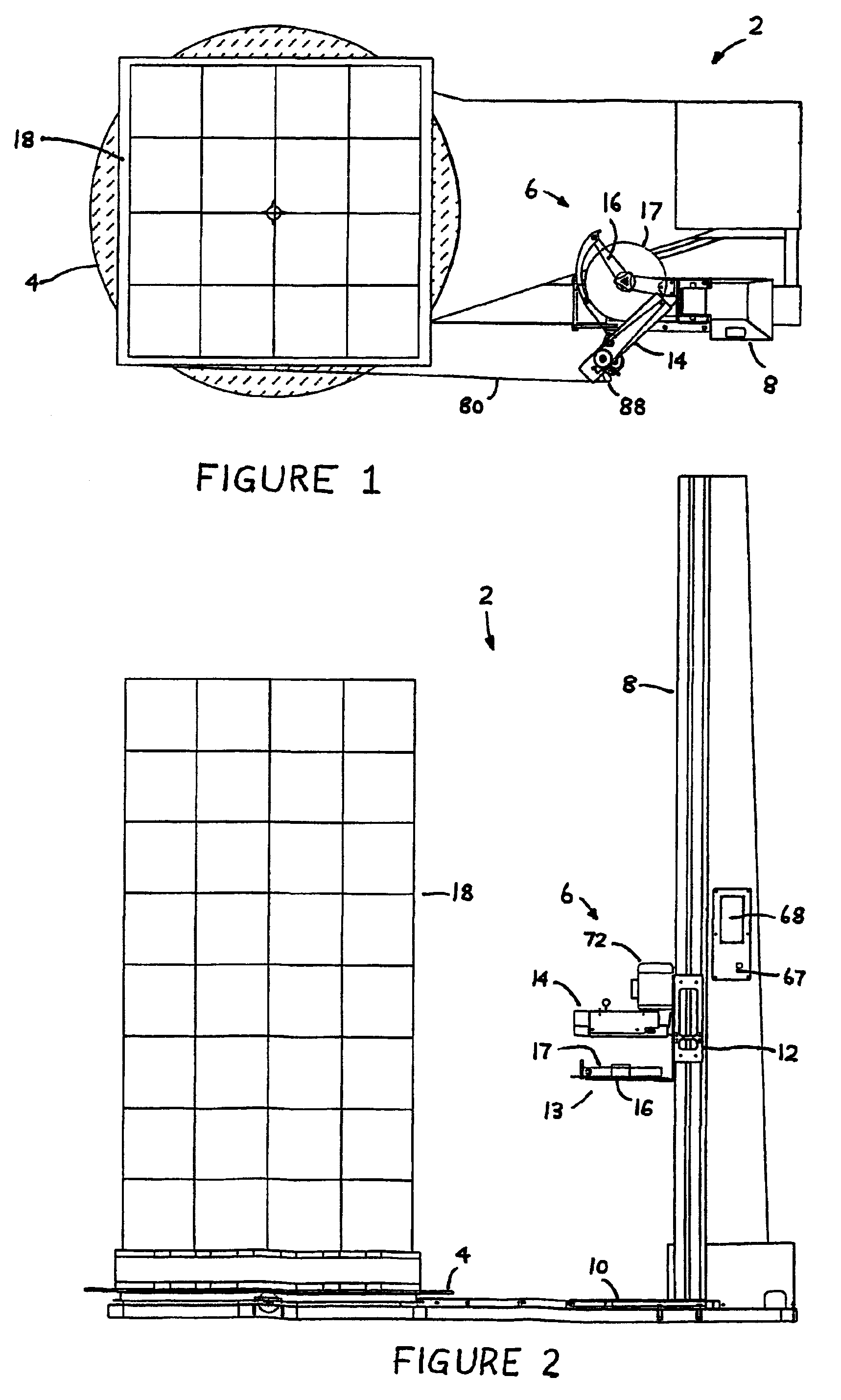

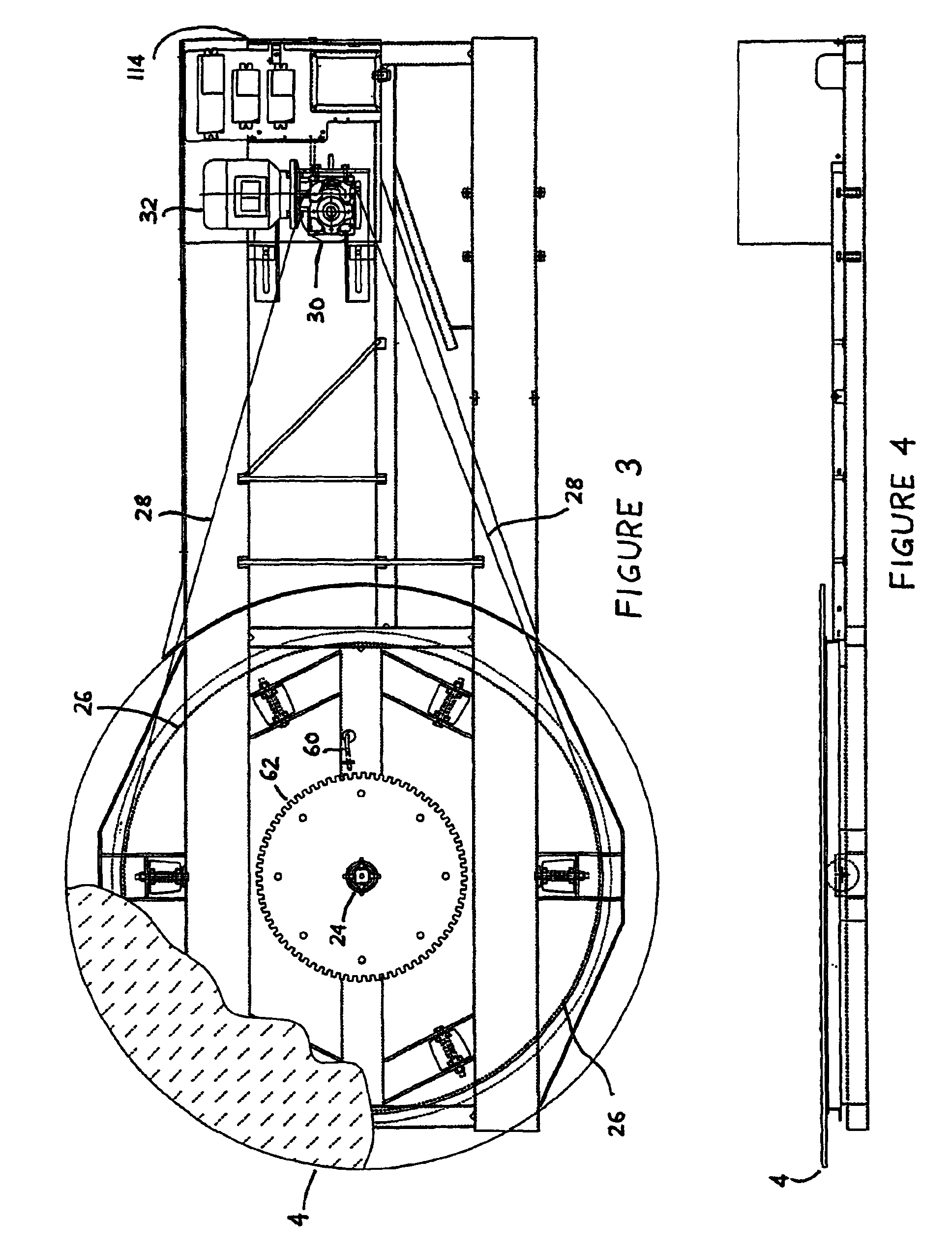

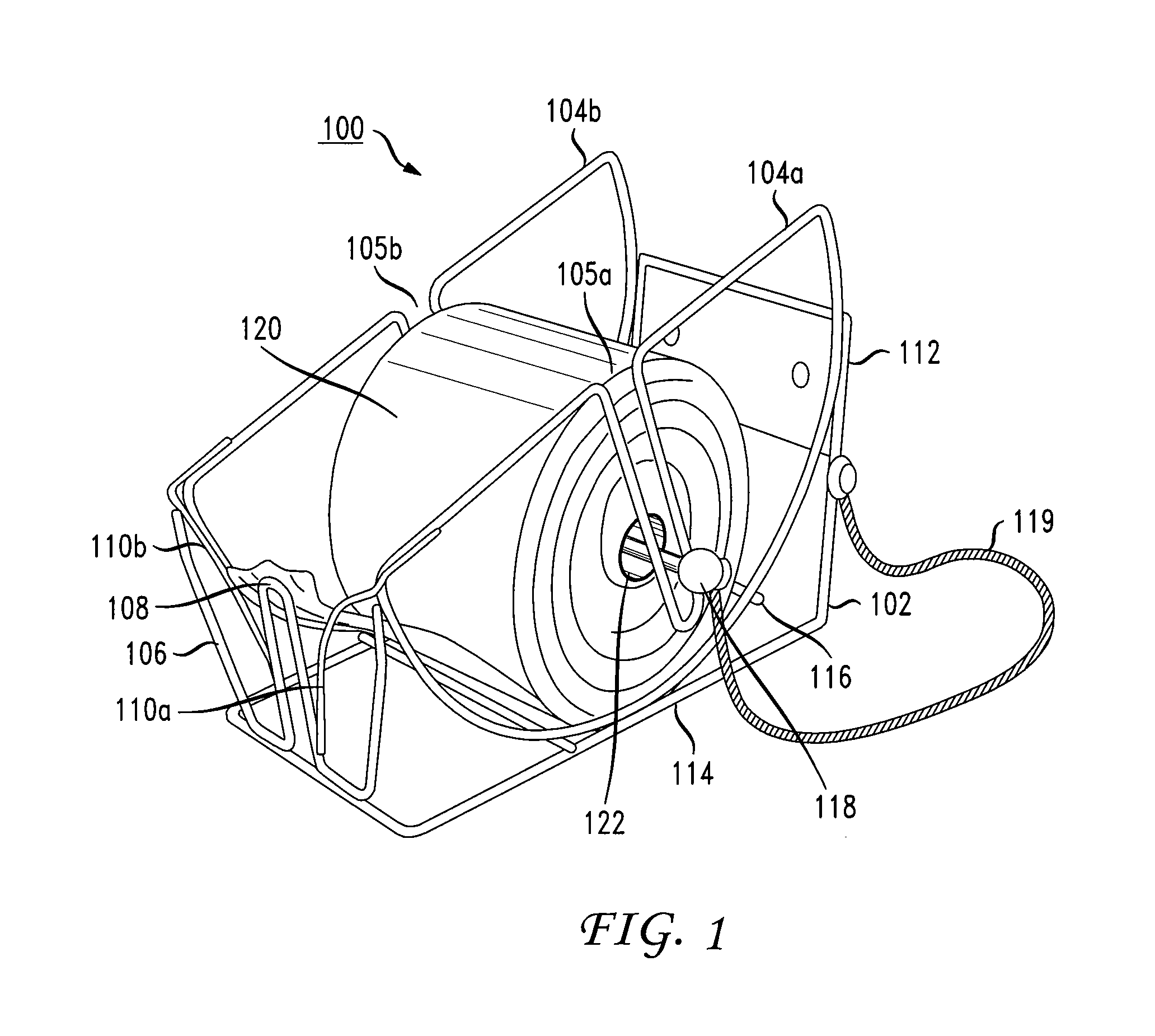

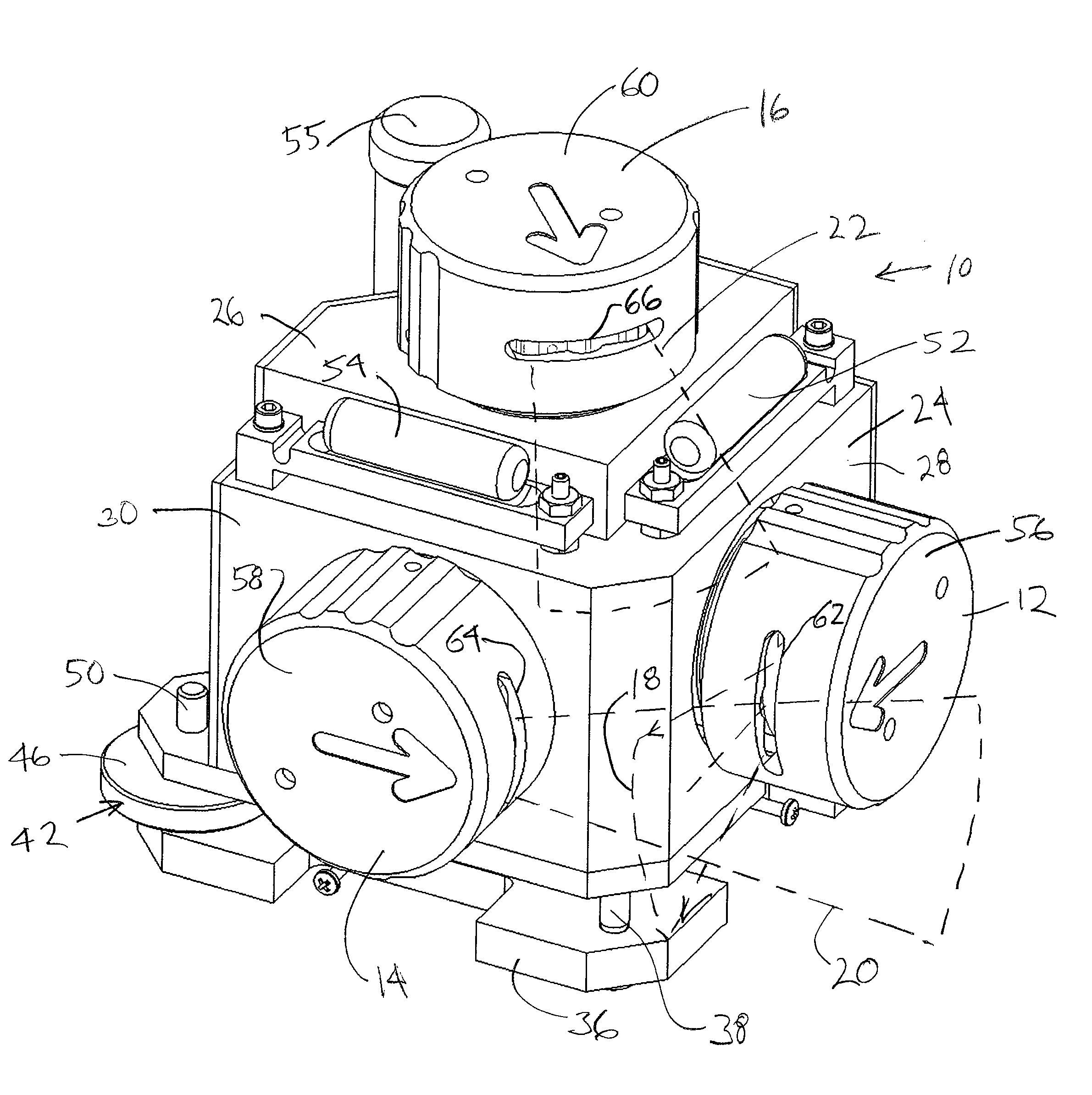

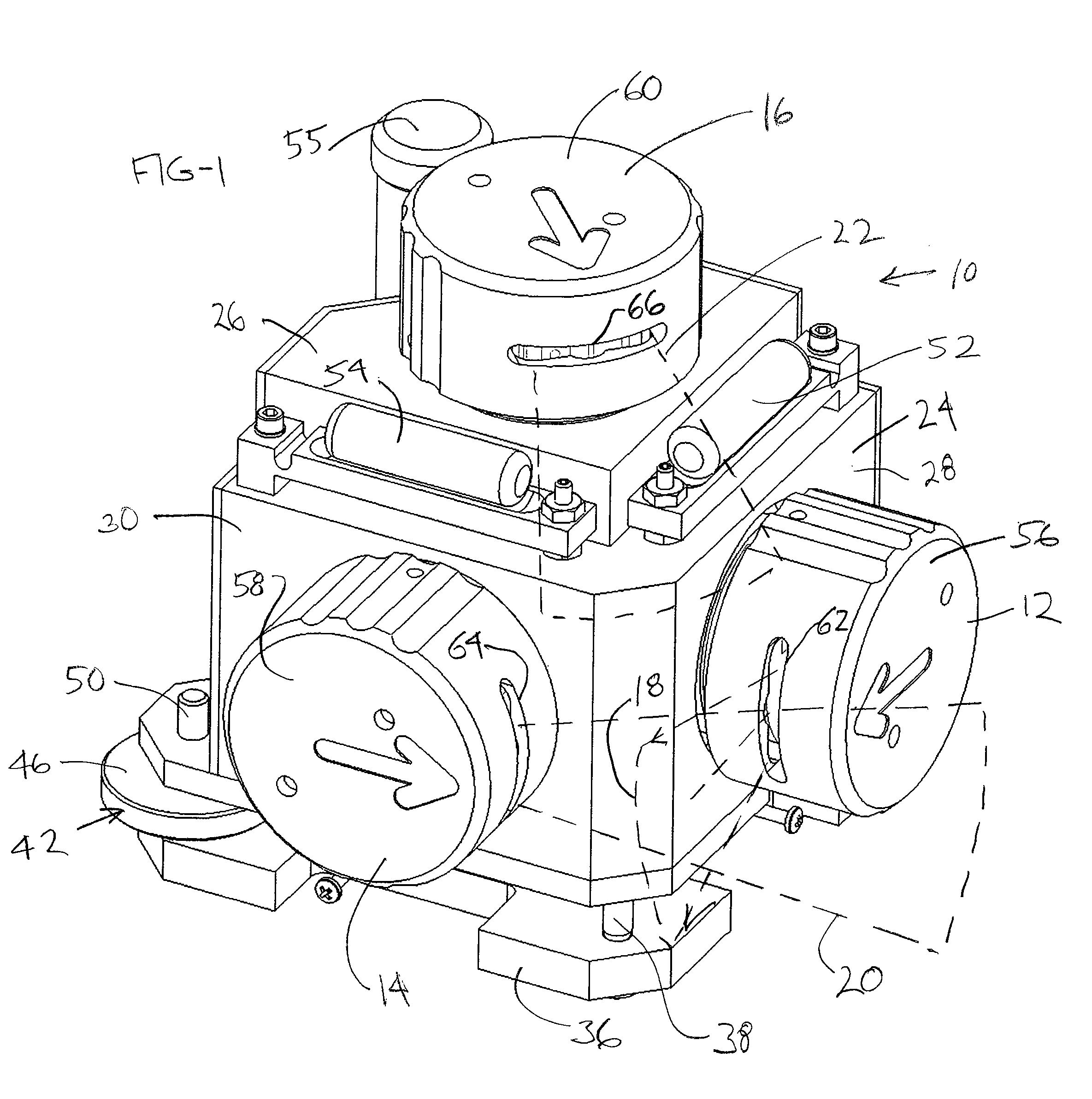

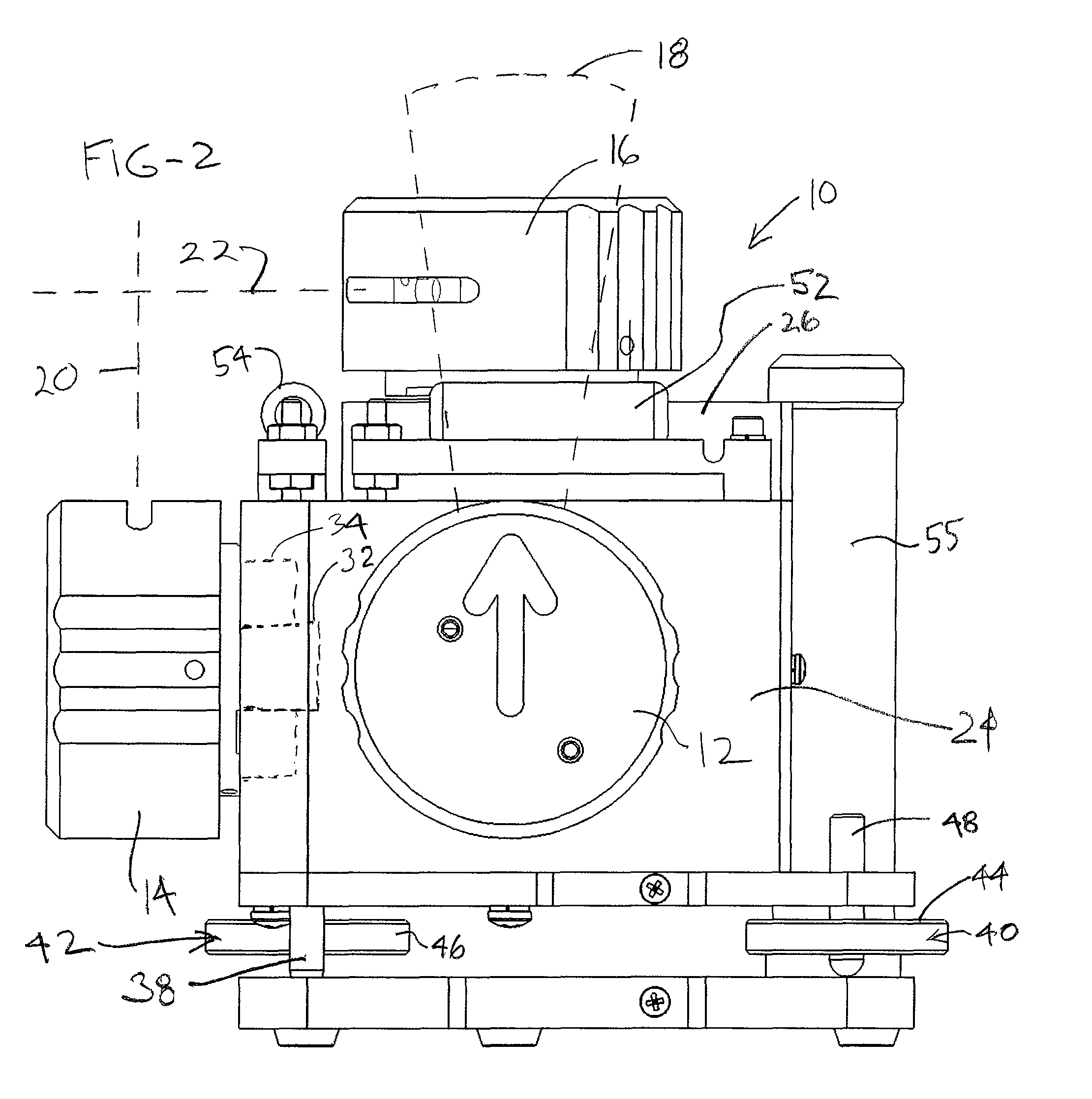

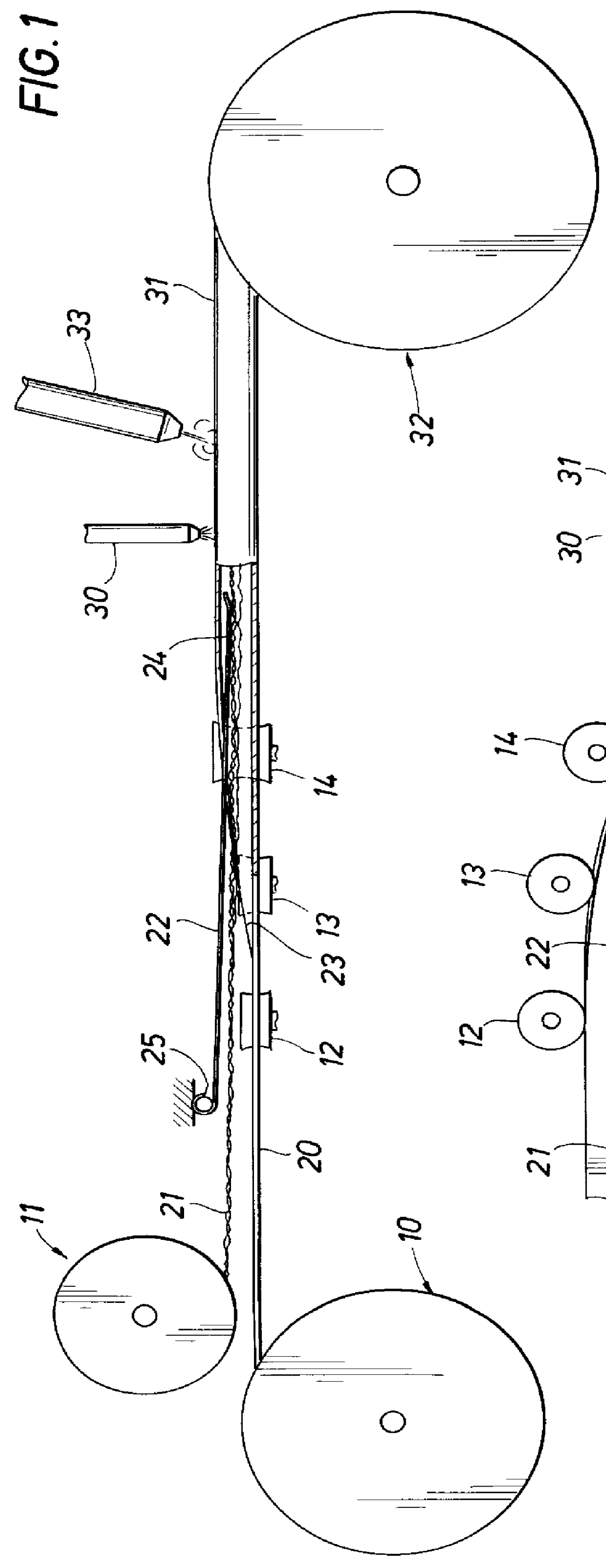

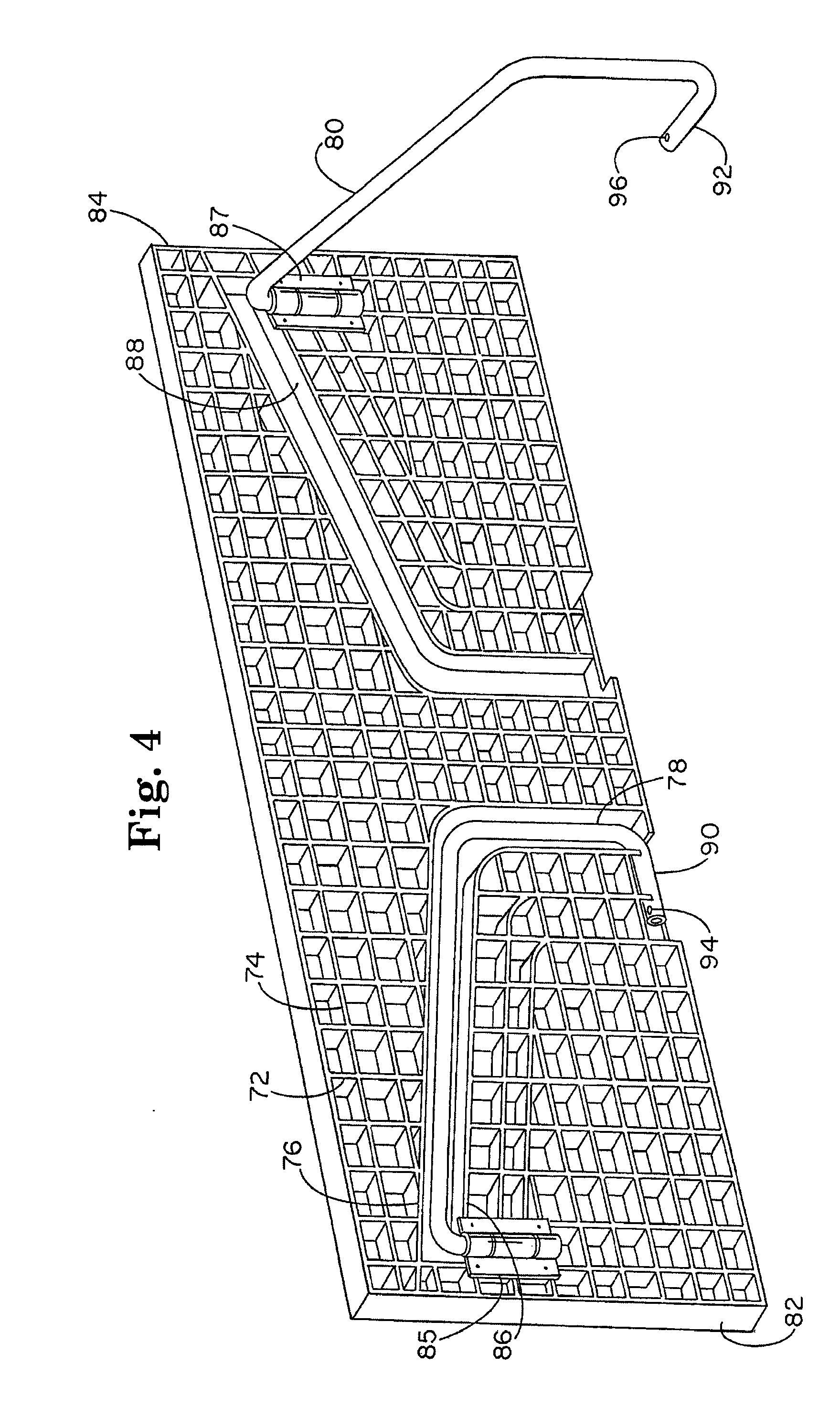

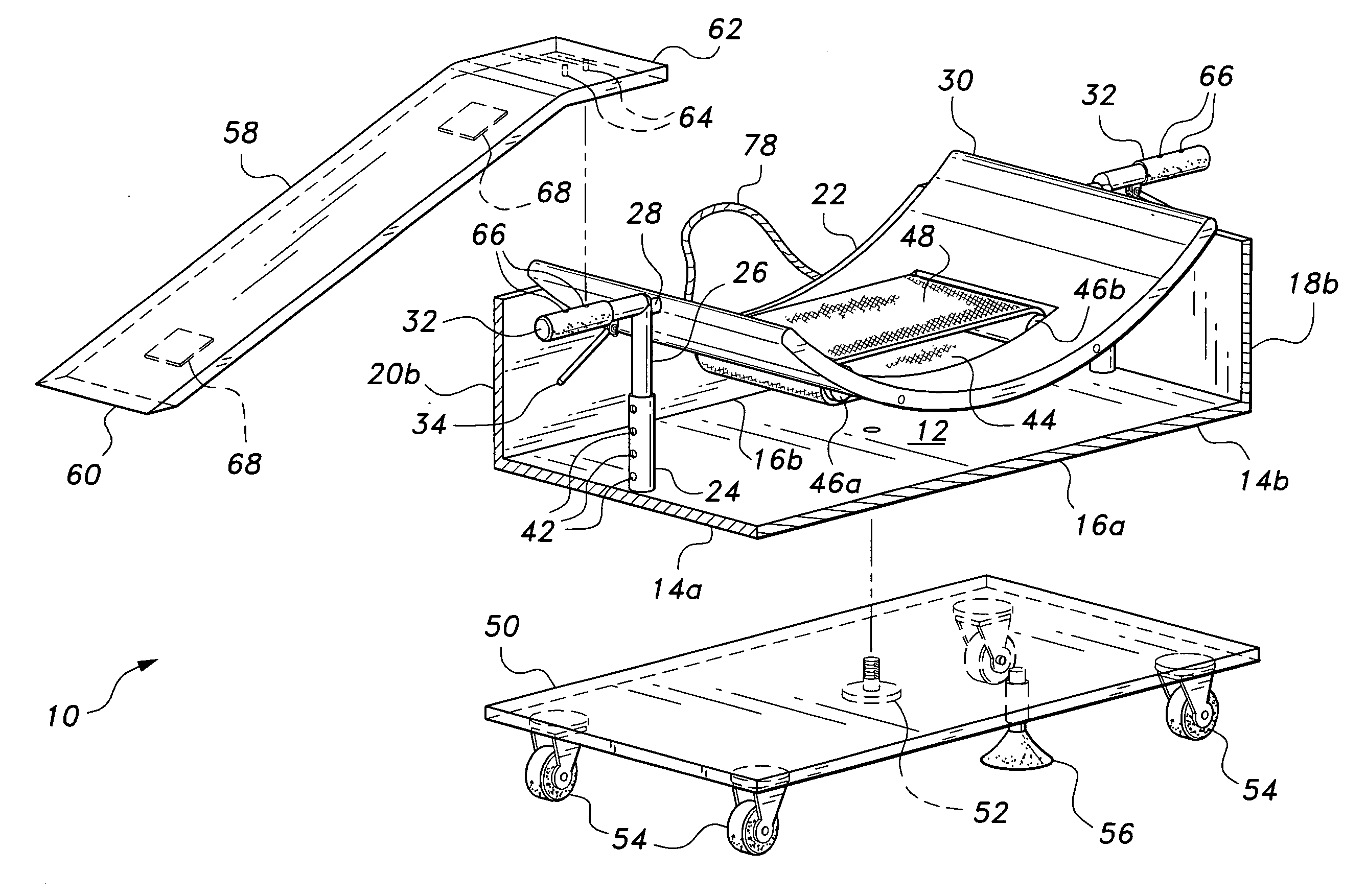

Method and apparatus for wrapping a load

InactiveUS7114308B2Minimal frictionAvoid insufficient frictionWrappers shrinkageBinding material applicationEngineeringMechanical engineering

Apparatus (2) for wrapping a load (18) placed on a turntable (4) having a mast assembly (8), a carriage assembly (12) adapted for vertical slideable movement along said mast assembly (8) and dispensing means (13) for dispensing tape material (80). The tape material (80) is transferred from the dispensing means (13) in response to rotation of the turntable (4) such that the tape material (80) wraps around the load (18) in a predefined pattern. The carriage assembly (12) and turntable (4) are configured for automated movement in response to a computer program stored in memory means (306) to enable wrapping of the load (18) with the tape material (80) in the predefined pattern. The carriage assembly (12) is positioned along the mast assembly (8) under control of the computer program in accordance with a rotational position of the load (18) to locate the tape material (80) at locations on the load (18). A pretensioning apparatus is also disclosed for pretensioning the tape material (80). Also disclosed is apparatus including adjusting the rate at which tape material (80) is payed out depending on a portion of the load (18) to be wrapped by the tape material (80). Also disclosed is tension adjustment apparatus (100) for varying the tension applied to the tape material (80).

Owner:SAFETECH PTY LTD

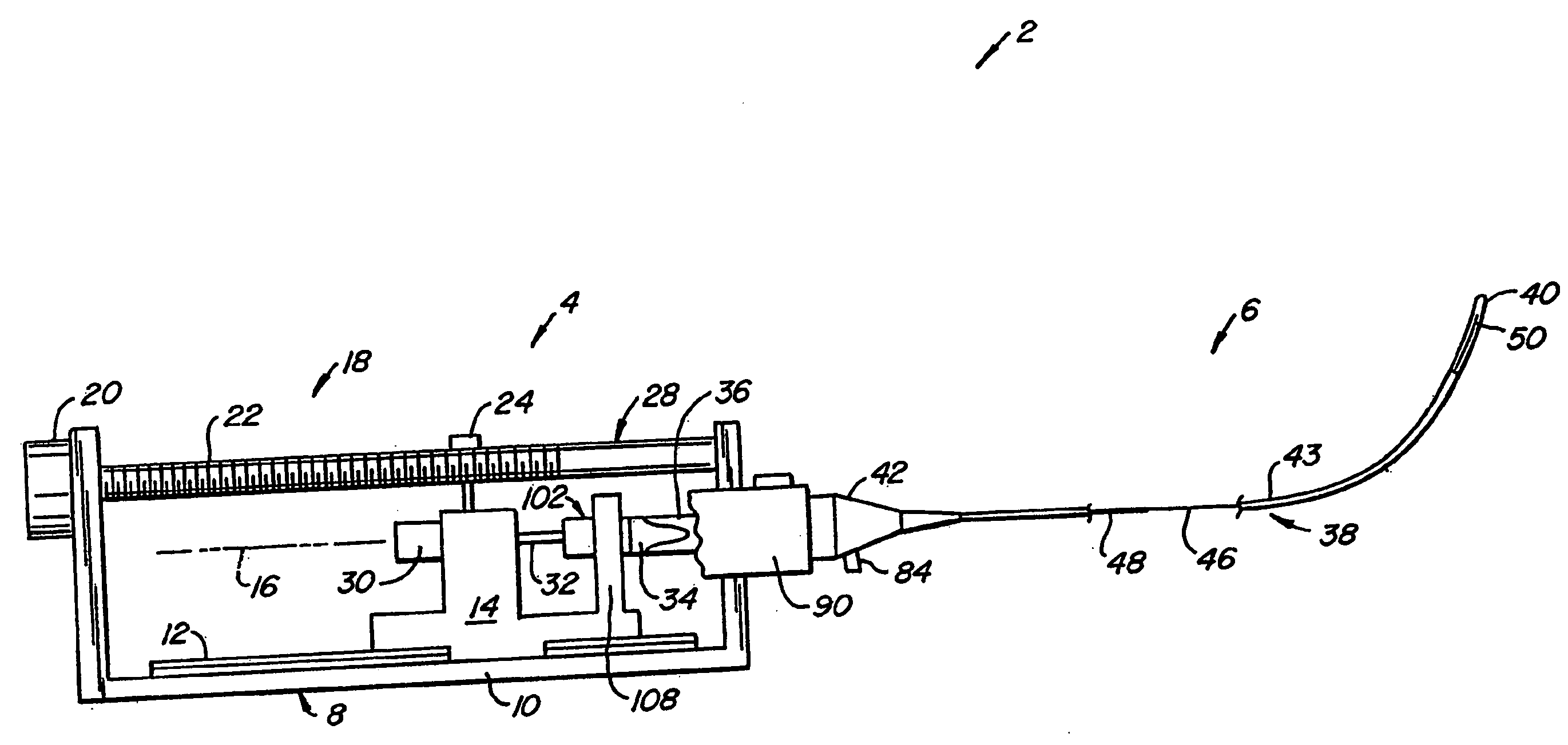

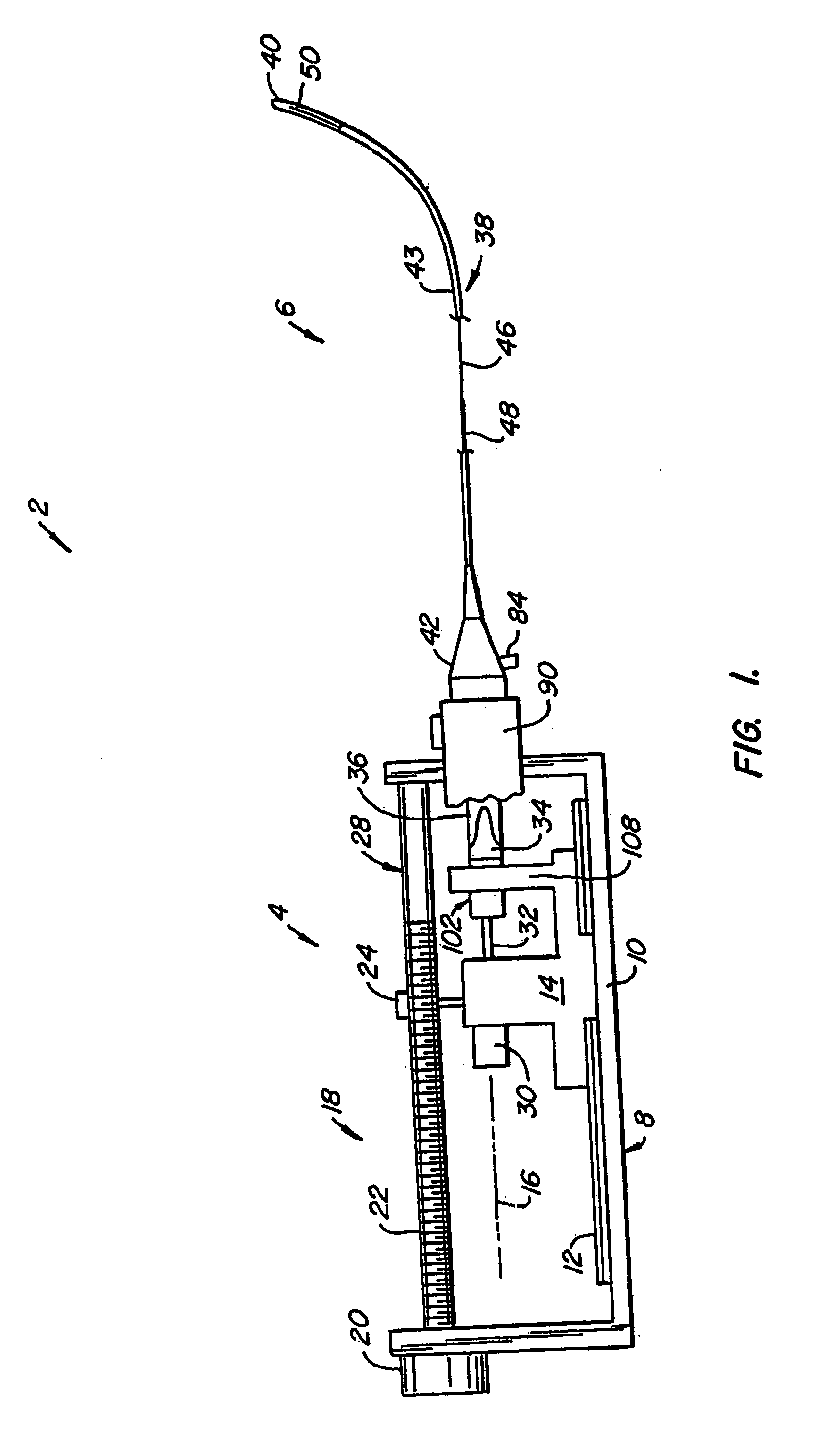

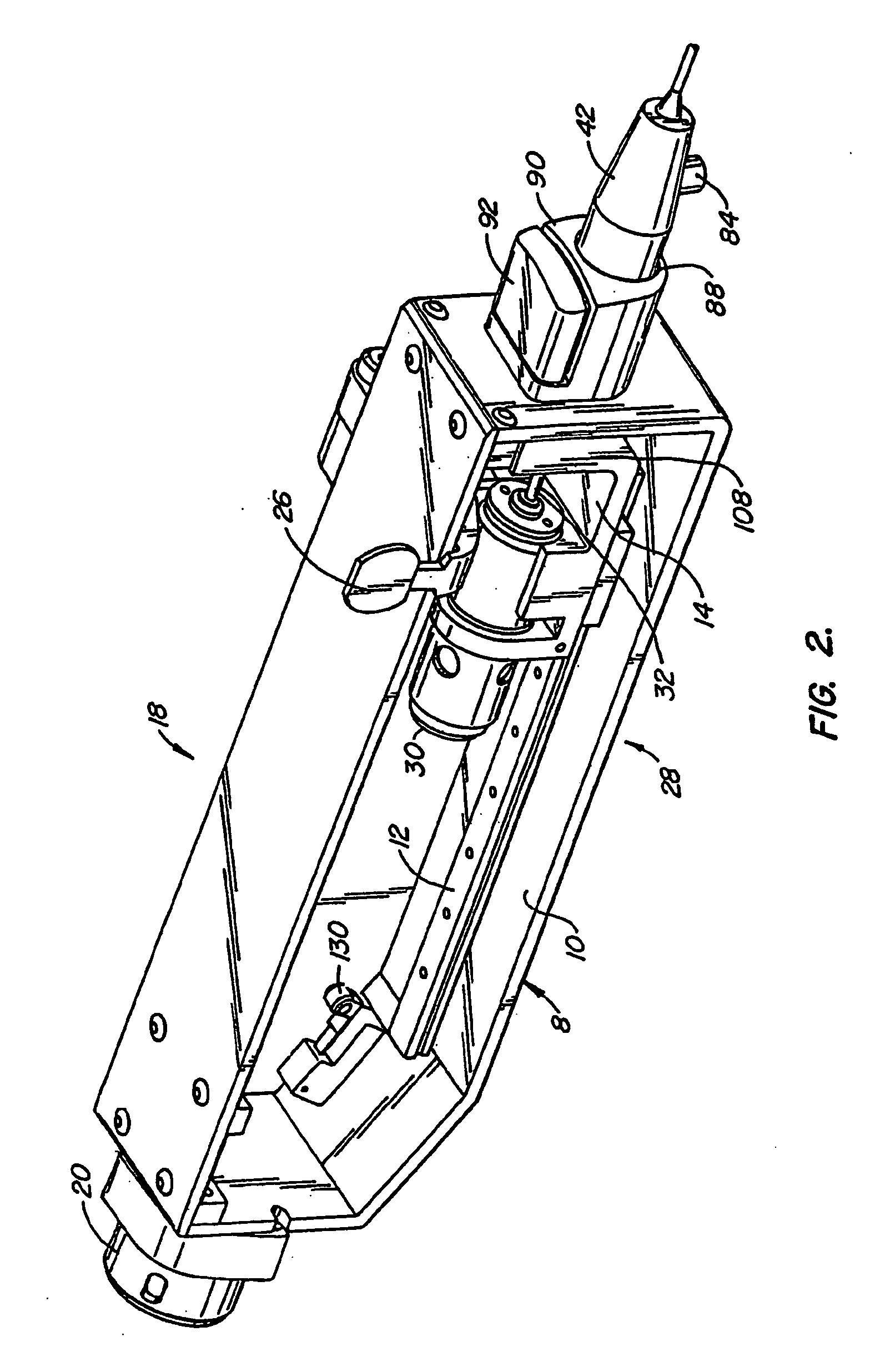

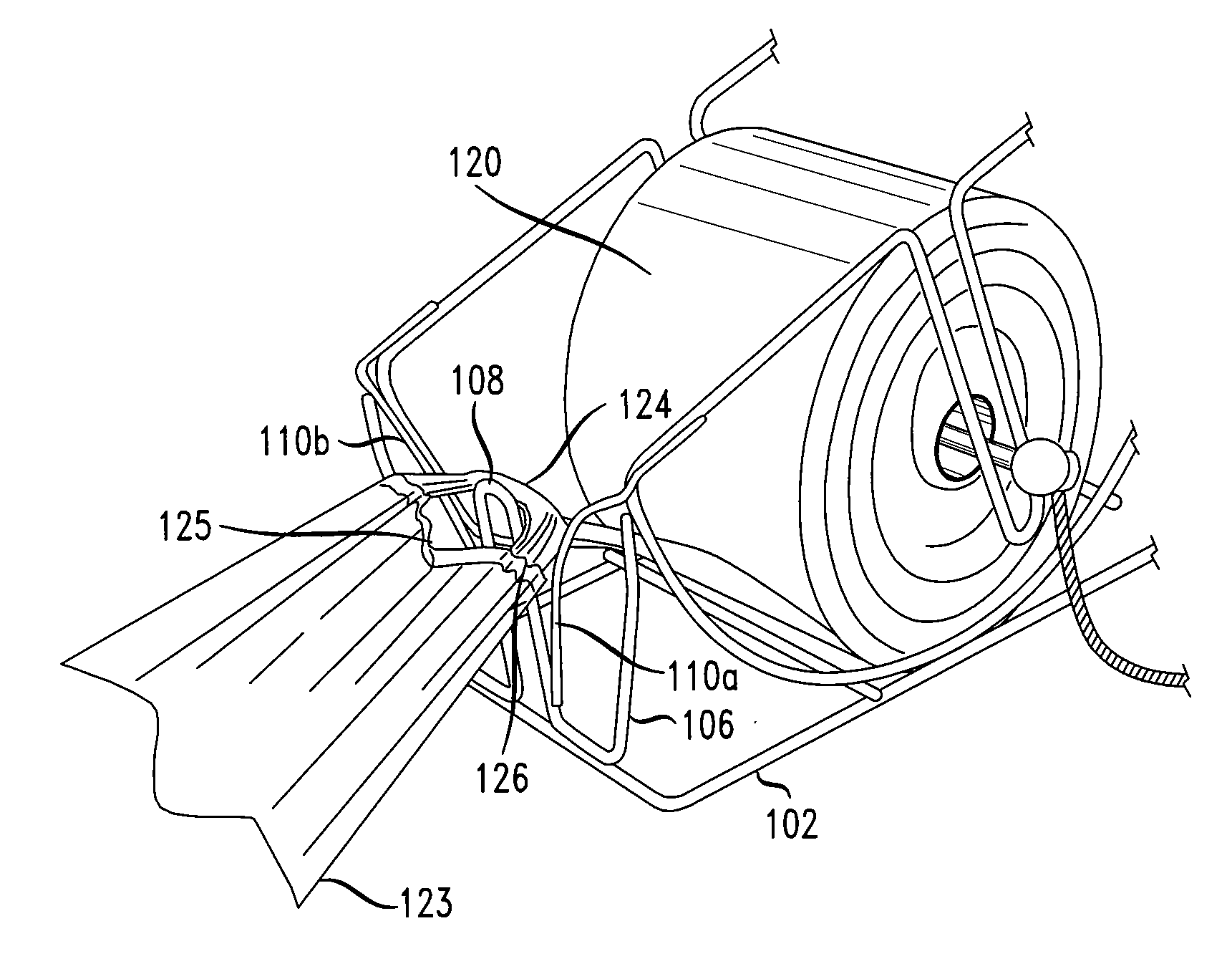

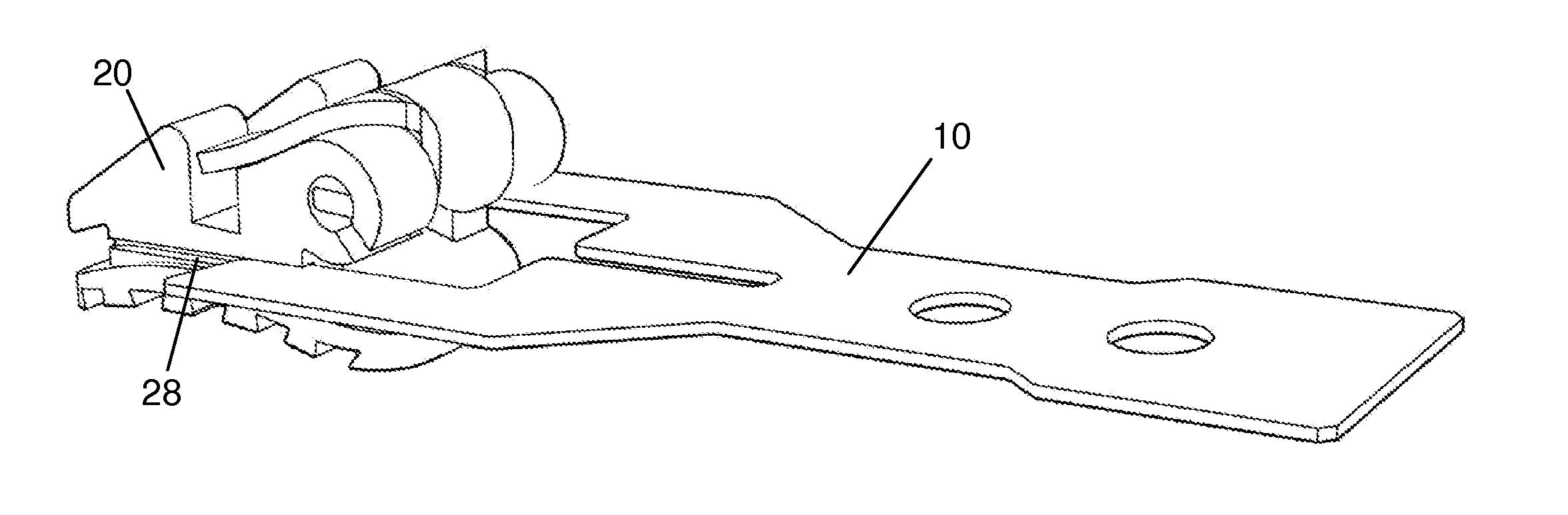

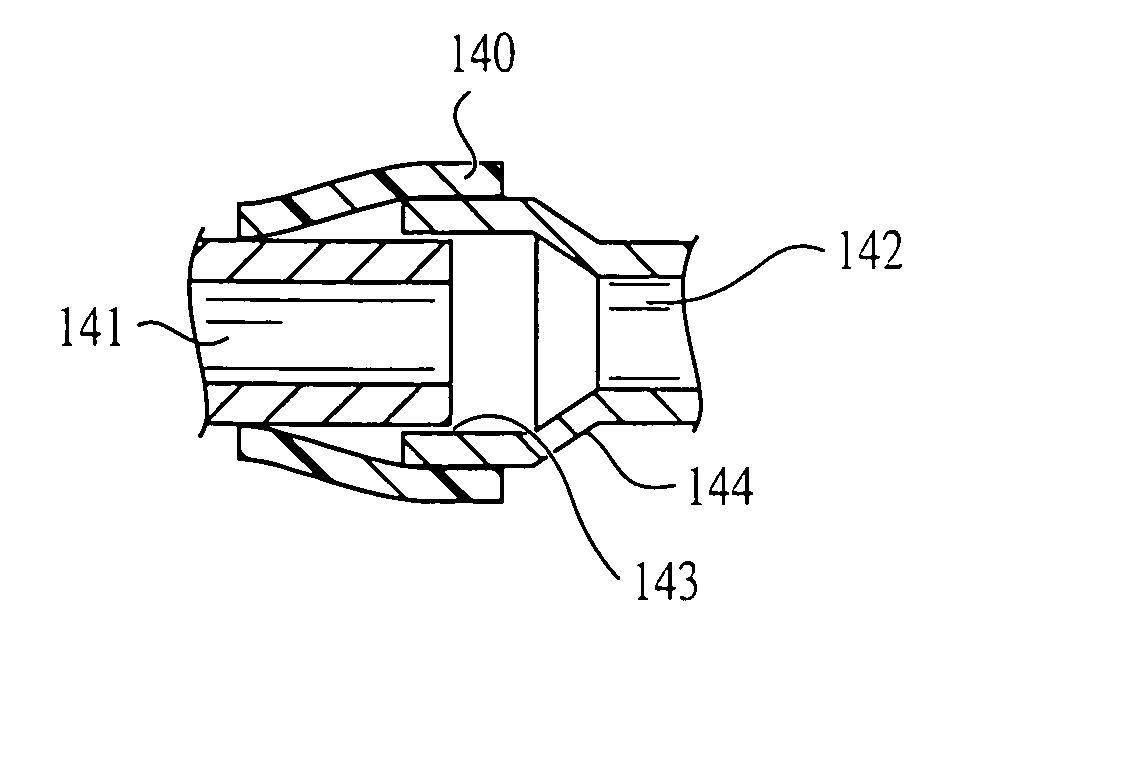

Automatic/manual longitudinal position translator and rotary drive system for catheters

InactiveUS20050043618A1Precise dockingAvoid insufficient frictionUltrasonic/sonic/infrasonic diagnosticsElectrotherapyCouplingEngineering

An automatic pullback catheter system (2) includes a disposable catheter assembly (6) mountable to a drive assembly (4). The drive assembly includes a body (8) to which a drive. chassis (14) is mounted for movement along a longitudinal path (16) by a motor (20) which rotates a longitudinal drive screw (22) selectively coupled to the drive chassis by a threaded clamp (24). A rotary drive motor (30), mounted to the drive chassis, rotates a first combined connector (34). The catheter assembly includes a hollow sheath (38) housing a rotatable and axially movable cable assembly (44). The sheath includes a proximal hub (42) mountable to the body. The cable assembly includes an elongate imaging cable (46) with a second combined connector (36) at its proximal end. The first and second combined connectors are blind matable connectors and provide for the longitudinal movement coupling, the rotary movement coupling and the data / information connection of the two connectors.

Owner:BOSTON SCI SCIMED INC

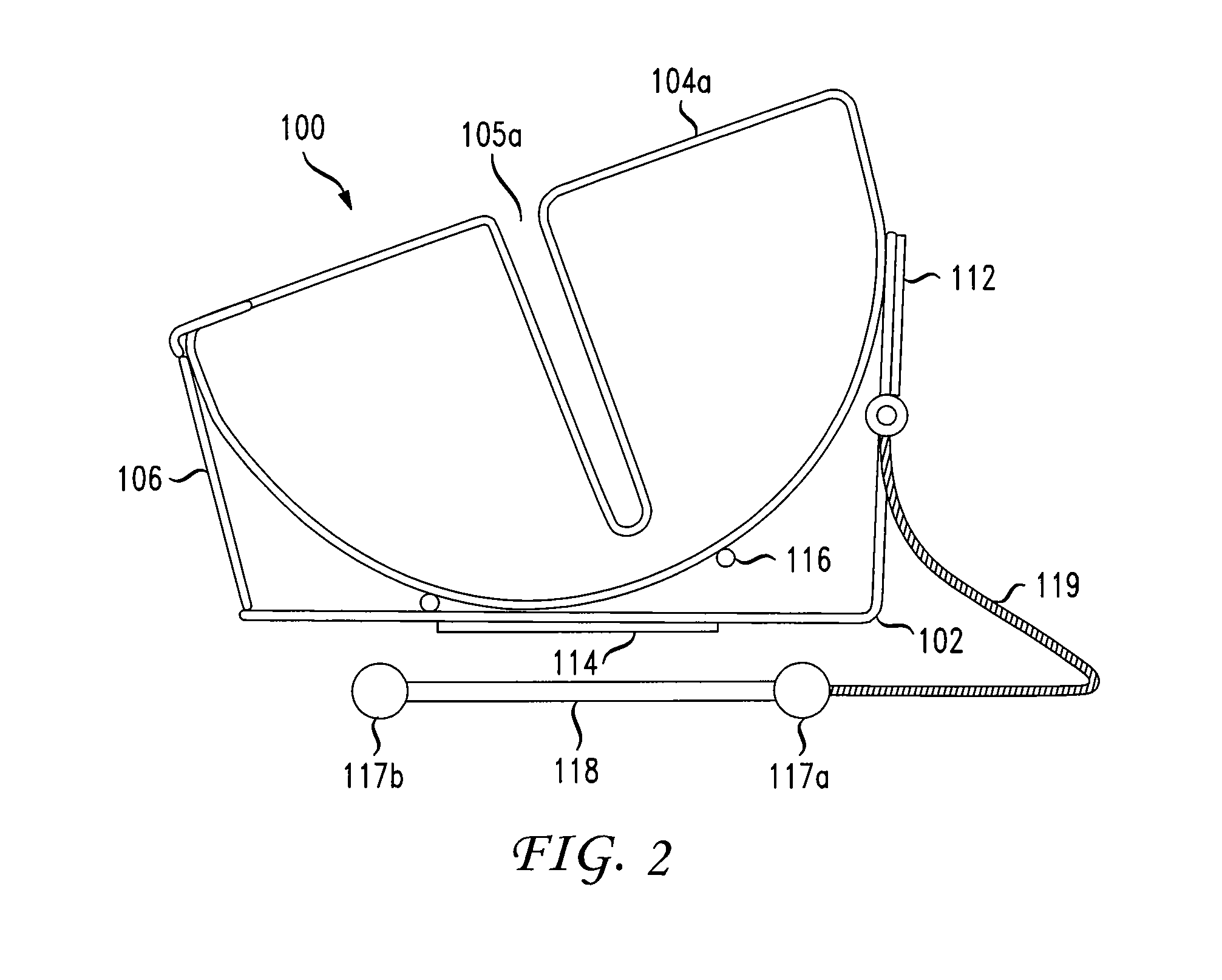

Apparatus for Dispensing Plastic Bags

InactiveUS20120125970A1Reduced footprintEasy to separateLike countersShop countersEngineeringMaterial Perforation

Owner:DURATECH PLASTICS CORP

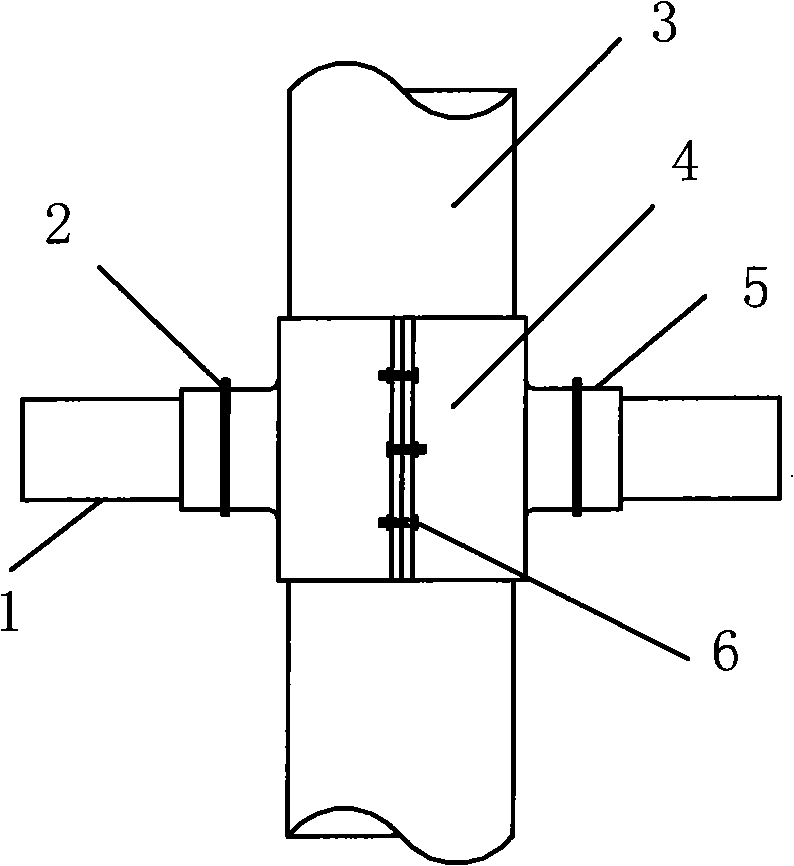

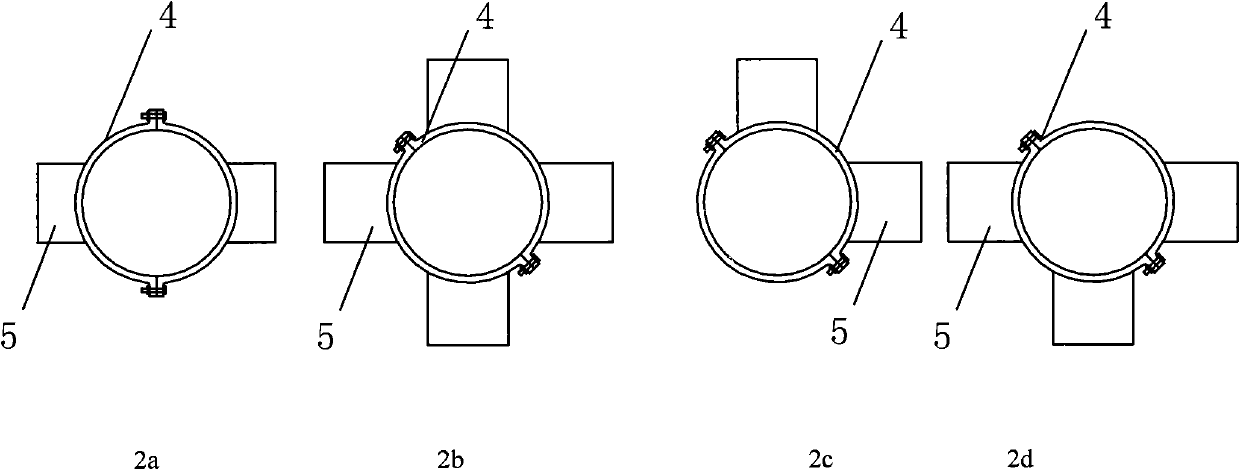

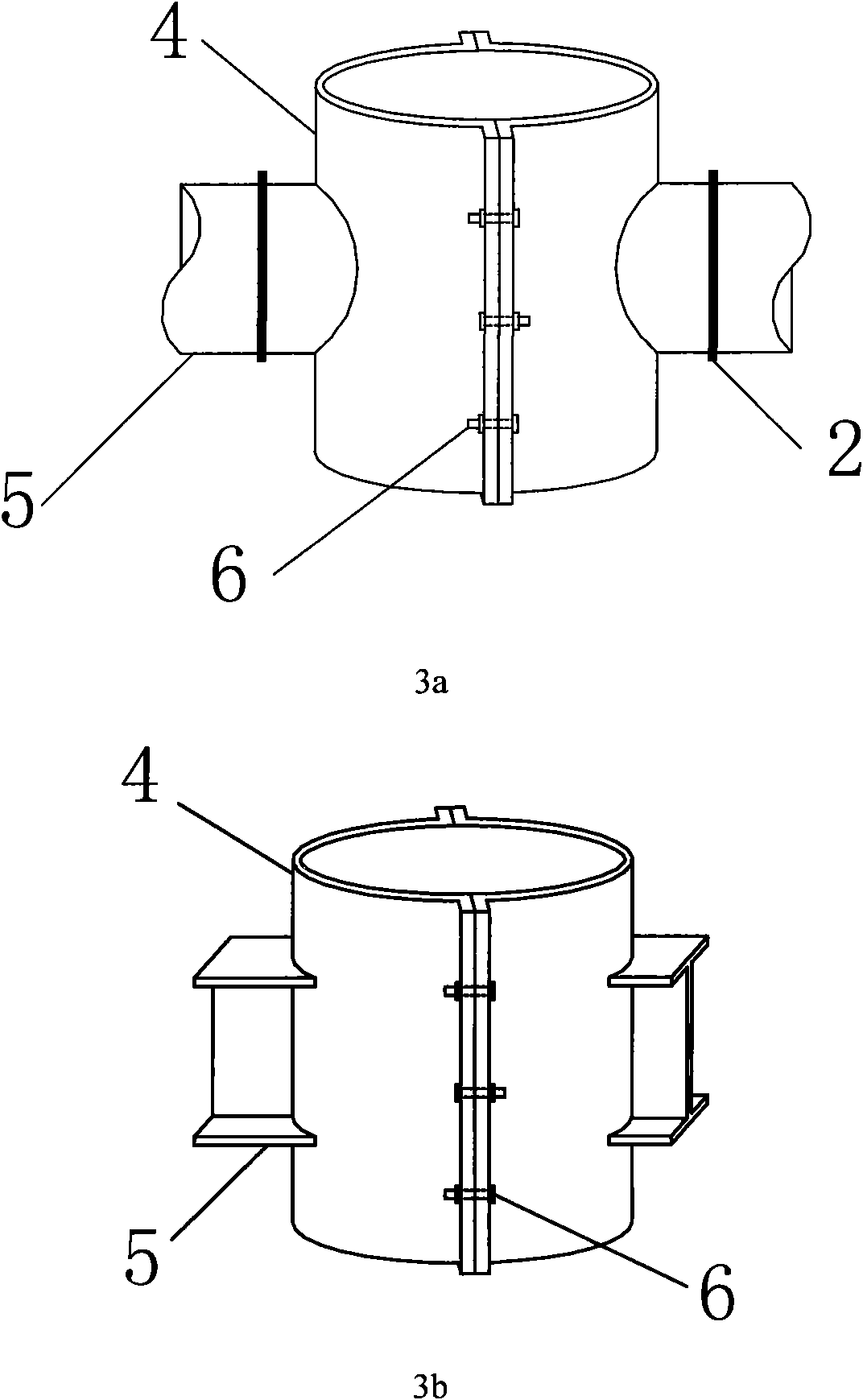

Circular steel tube concrete column and beam node connecting structure

InactiveCN101769011AFirmly connectedNode structure is simpleBuilding constructionsConcrete beamsEngineering

The invention discloses a circular steel tube concrete column and beam node connecting structure, which is characterized in that: the connecting structure comprises a node fastener, a bolt, a circular steel tube concrete column and a beam; the node fastener is composed of two sections of fastening rings and a joint, and the joint is in sleeve type and horizontally H-shaped type, the circular steel tube concrete column penetrates in the fastening rings and is fastened by the bolt, and the beam is connected by the joint on the fastener; the field installation is convenient without welding and the construction is rapid; the fastener is composed of two sections and is connected by the bolt after being fixed, and the circular steel tube concrete column is fixed by tightening force of the fastener; the circular steel tube concrete column is inserted in the sleeve type joint and is fixedly connected with the sleeve type joint by the bolt, and a concrete beam steel bar and a steel girder are welded with the horizontally H-shaped type joint; besides welding of the concrete beam steel bar and the horizontally H-shaped type joint, in the whole process, welding and complex distributed steel do not need, the construction is simple and rapid.

Owner:HOHAI UNIV

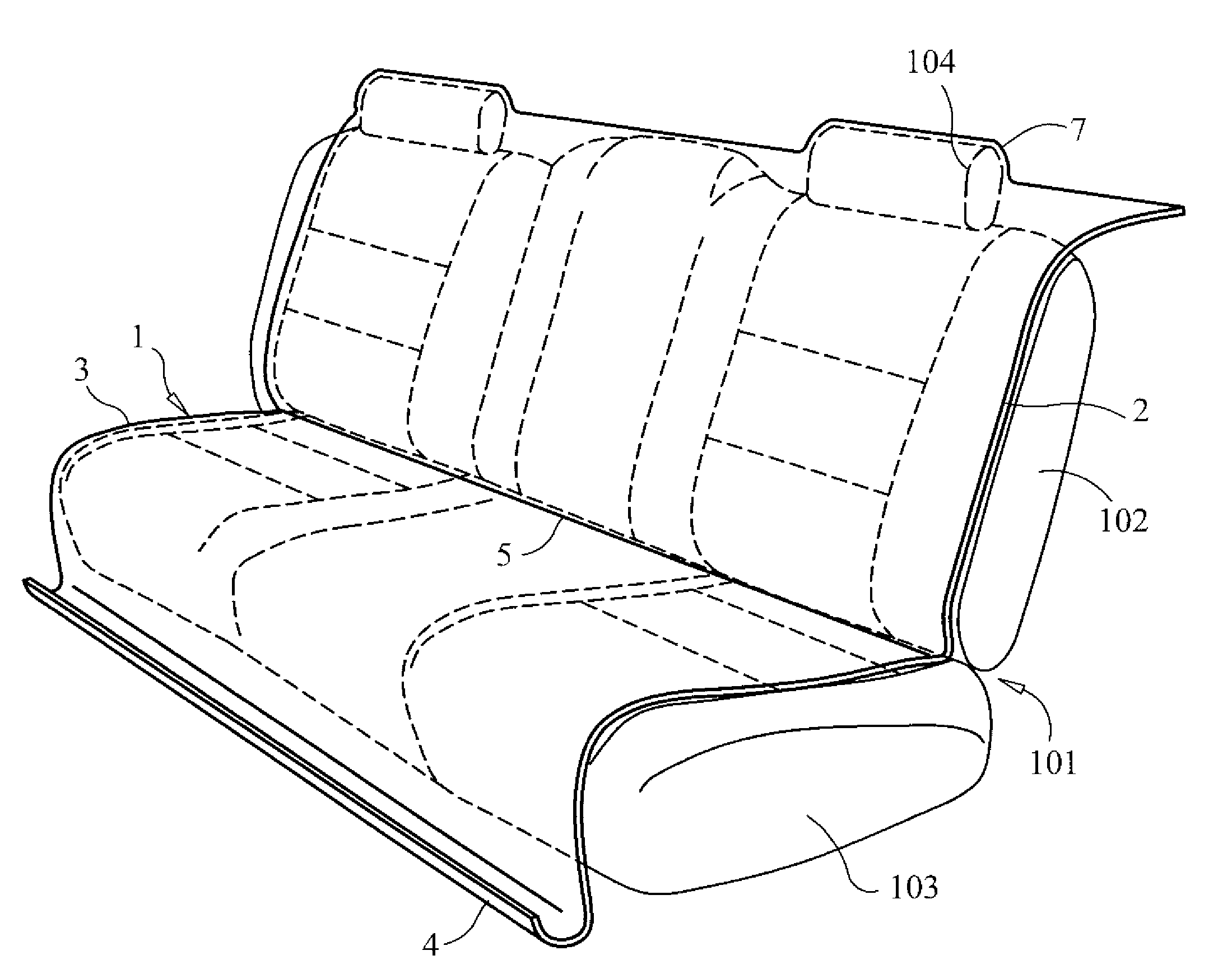

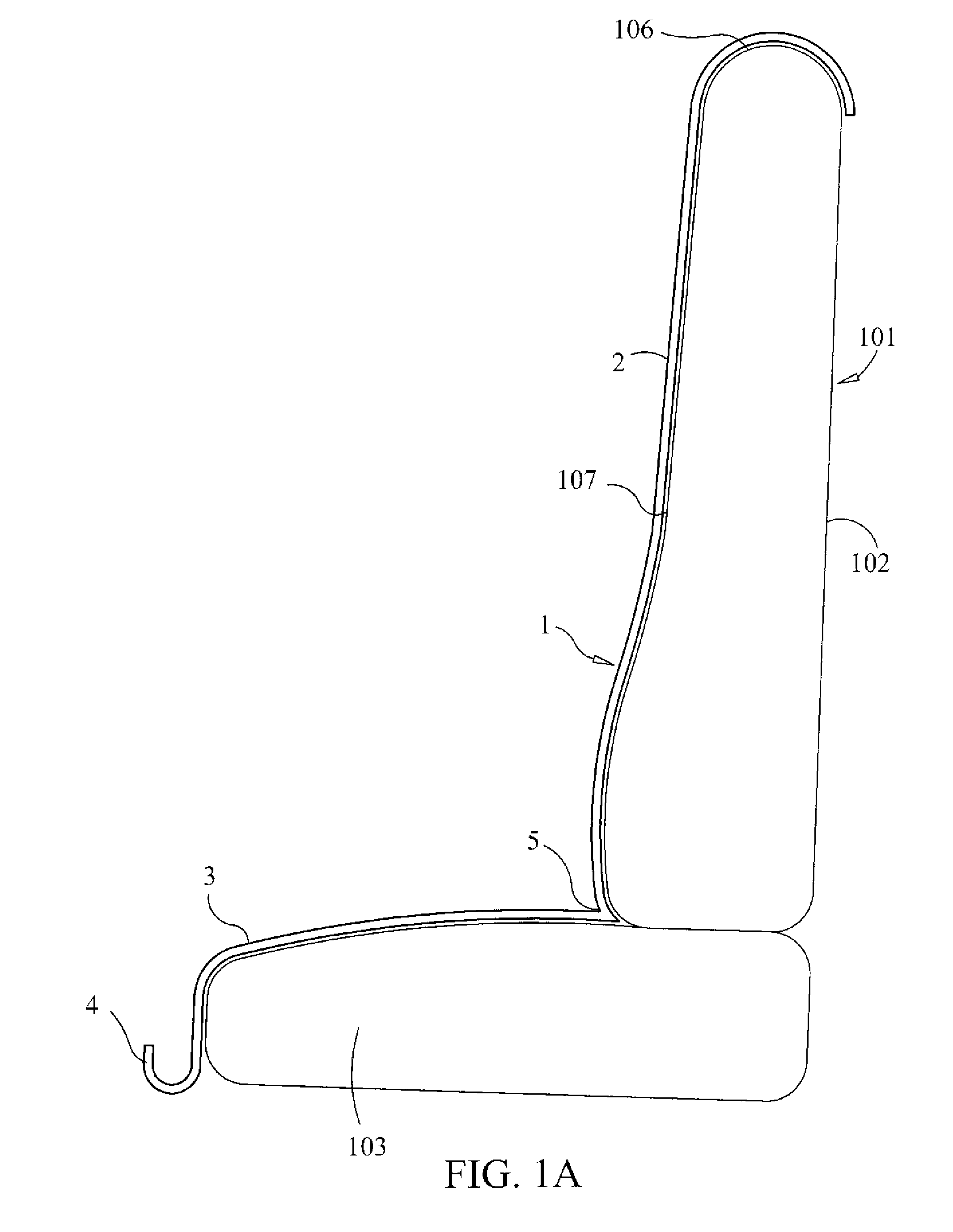

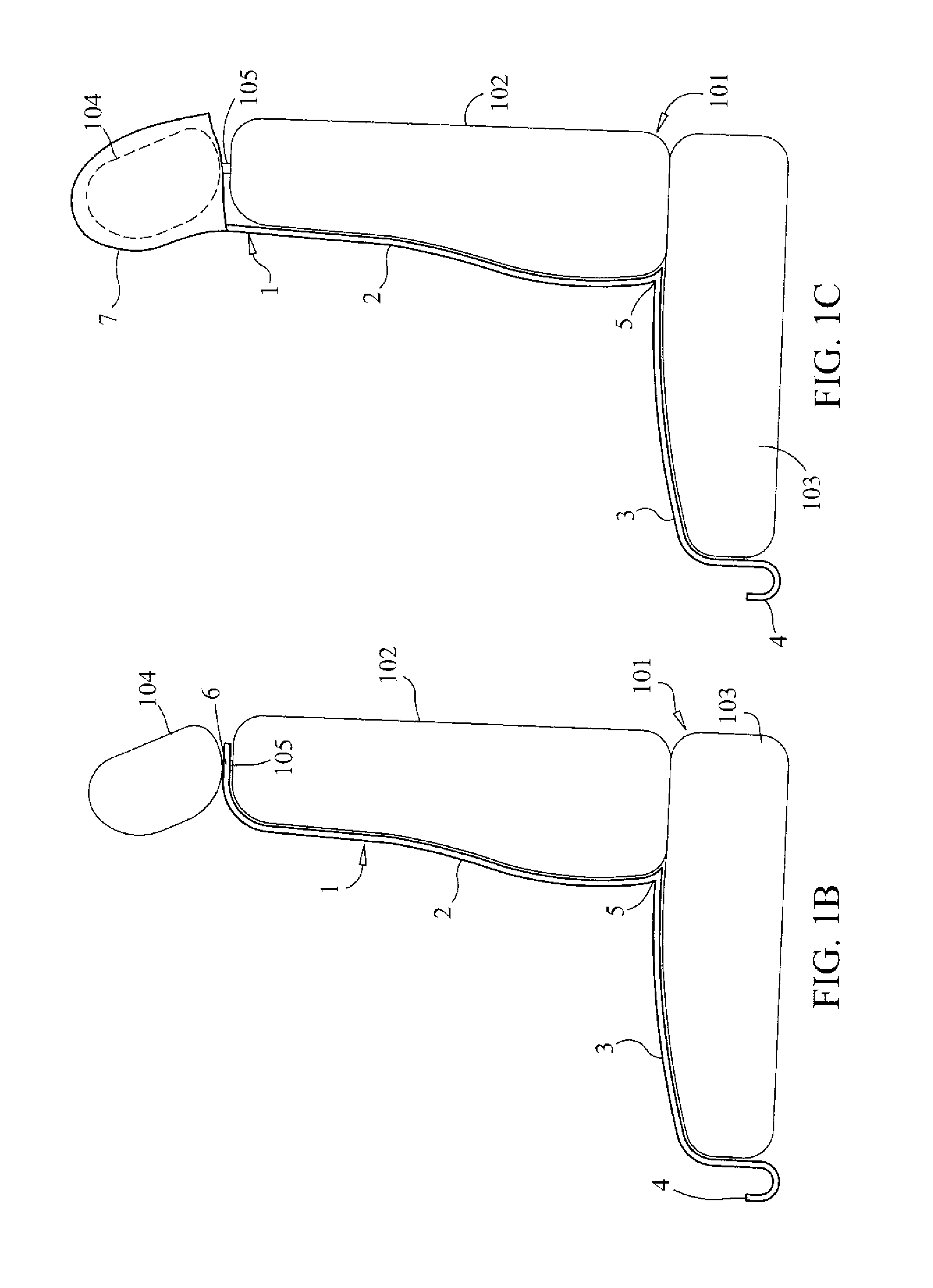

Mat Made of Flexible, Closed-Cell, Expanded Thermoplastic for Protecting a Car Seat from Pets

InactiveUS20080179926A1Protect childrenEasy to disassembleSeat coveringsStuffed mattressesThermoplasticCar seat

Owner:KUSHNER JAY

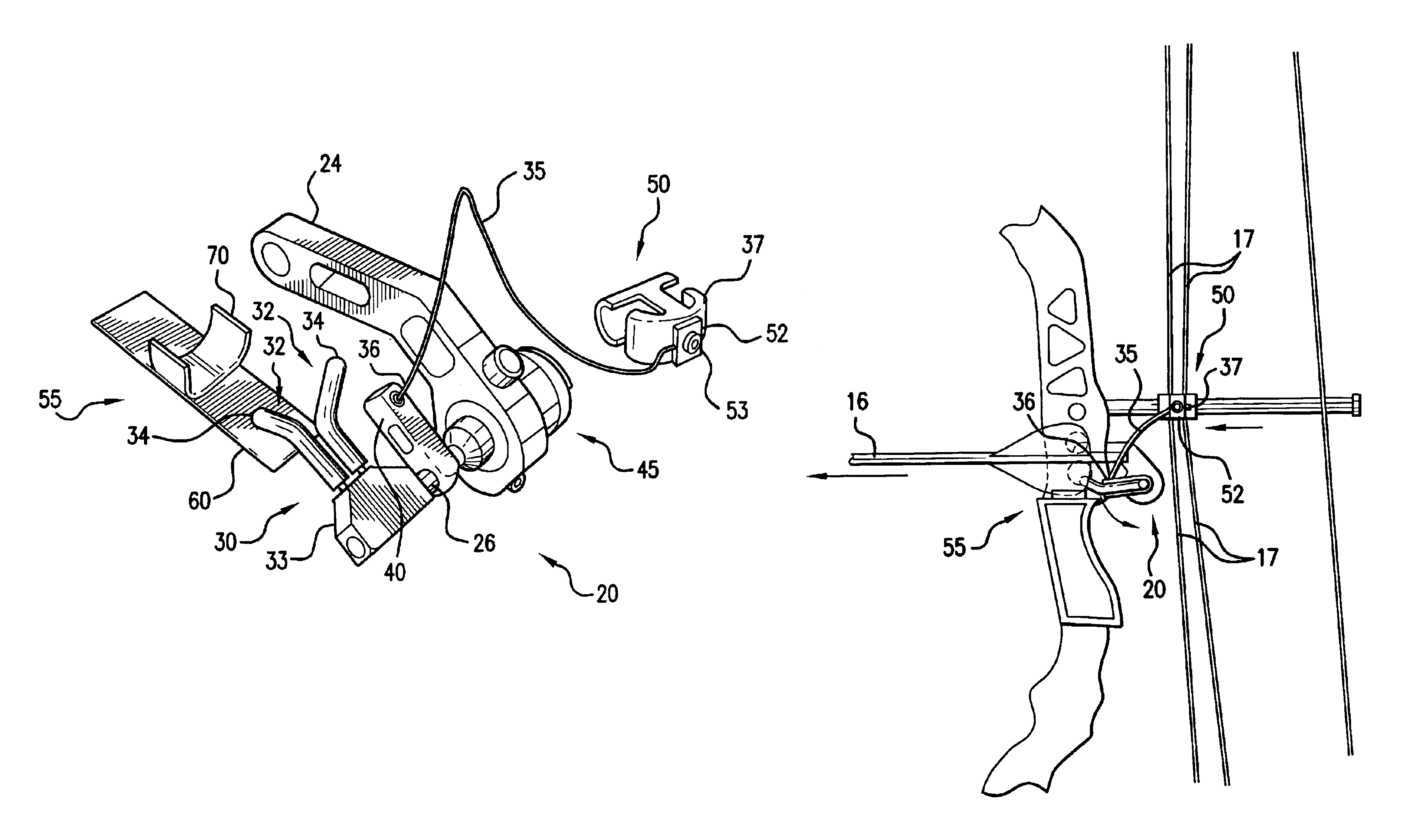

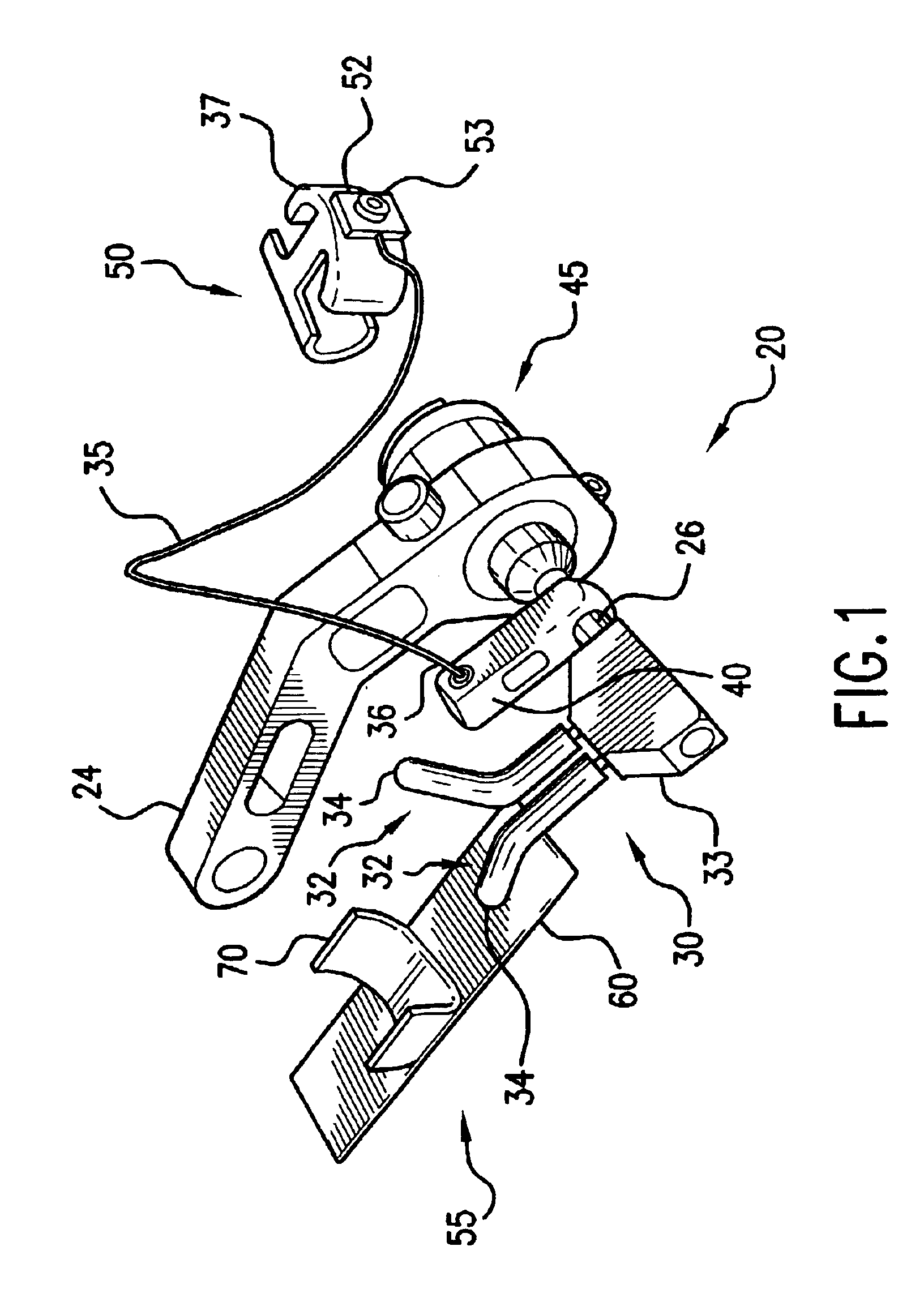

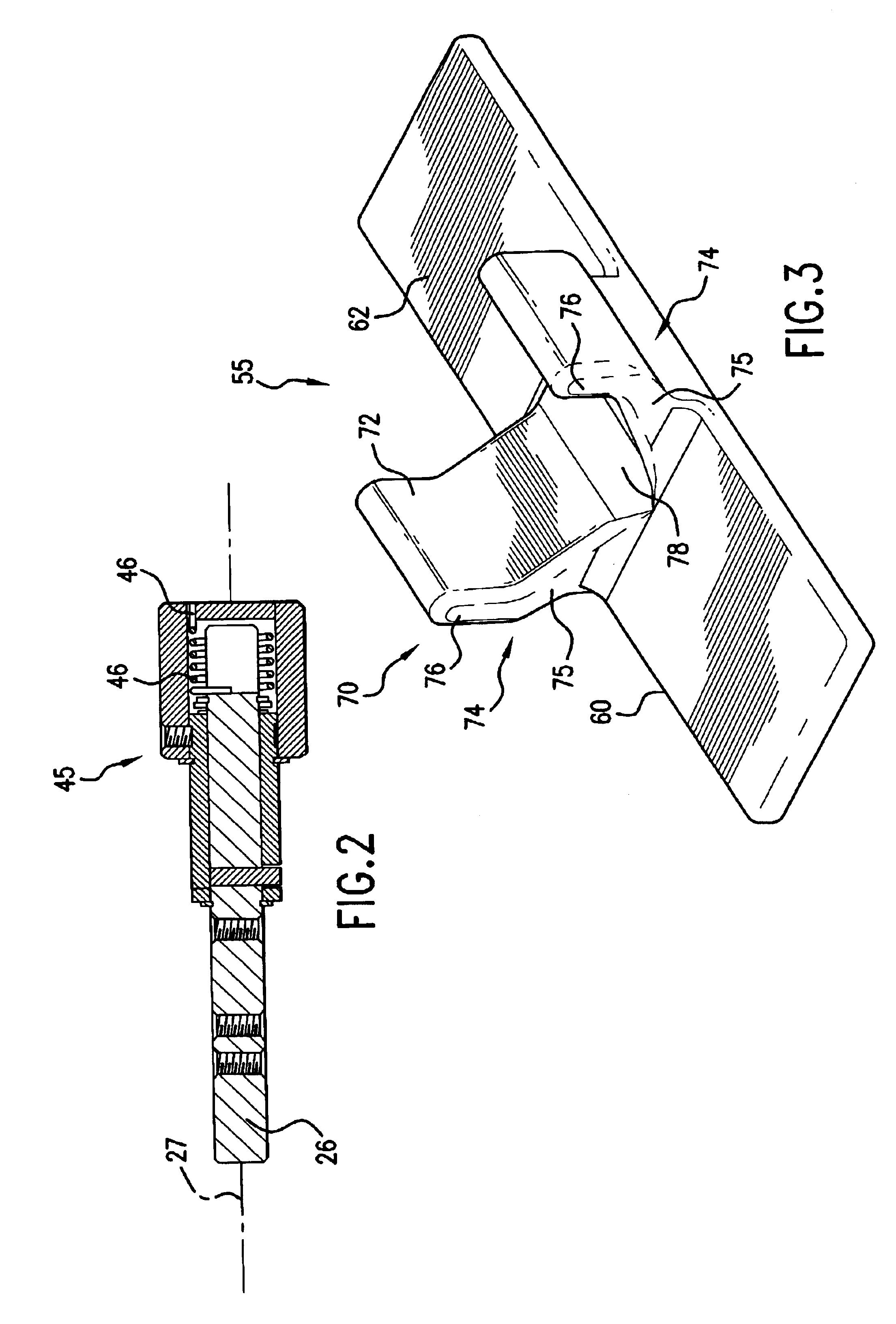

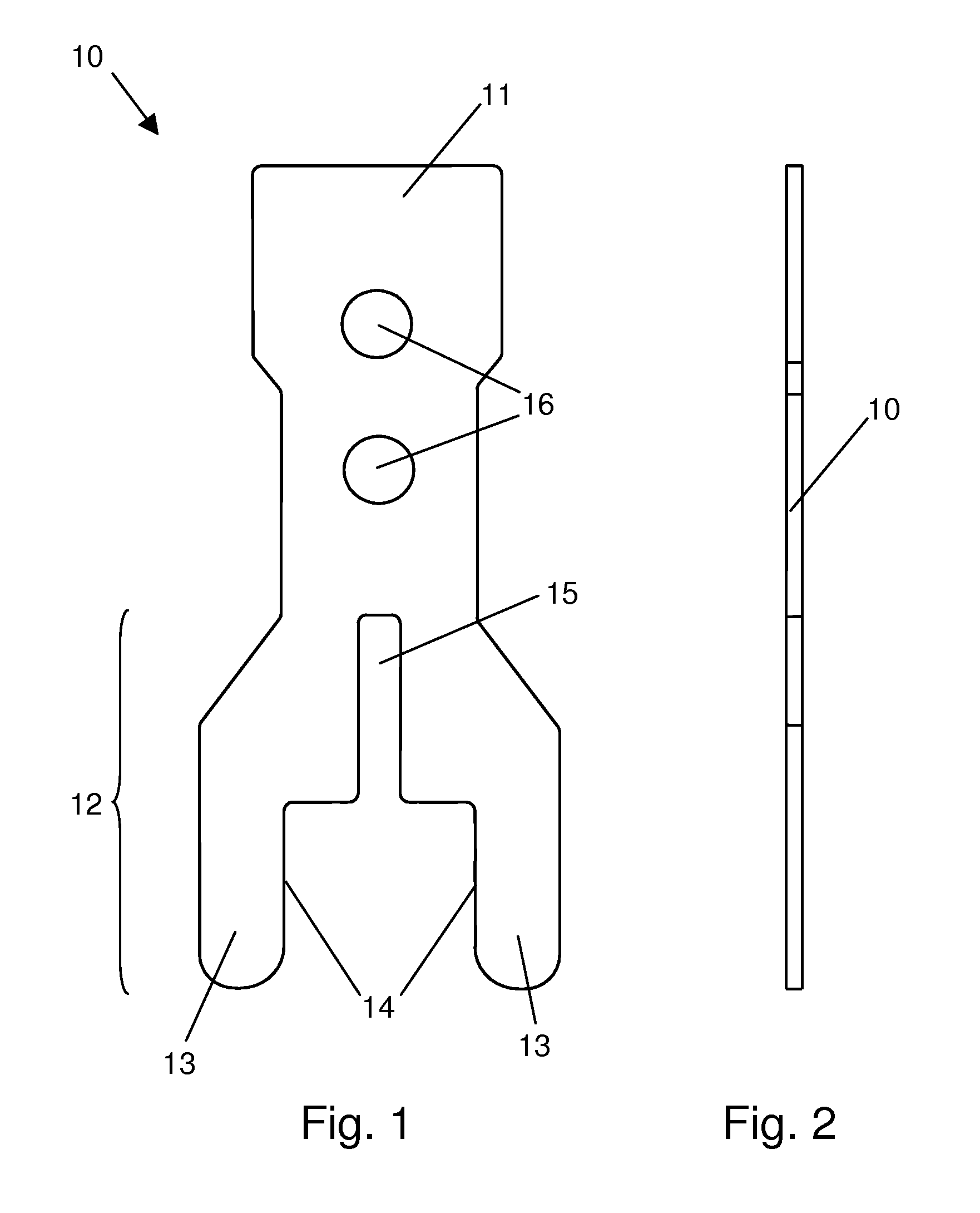

Move-away arrow rest

InactiveUS6782881B2Easily center arrow shaftSimply using gravity forcesBows/crossbowsCompressed gas gunsEngineeringMechanical engineering

Owner:NEW ARCHERY PRODS

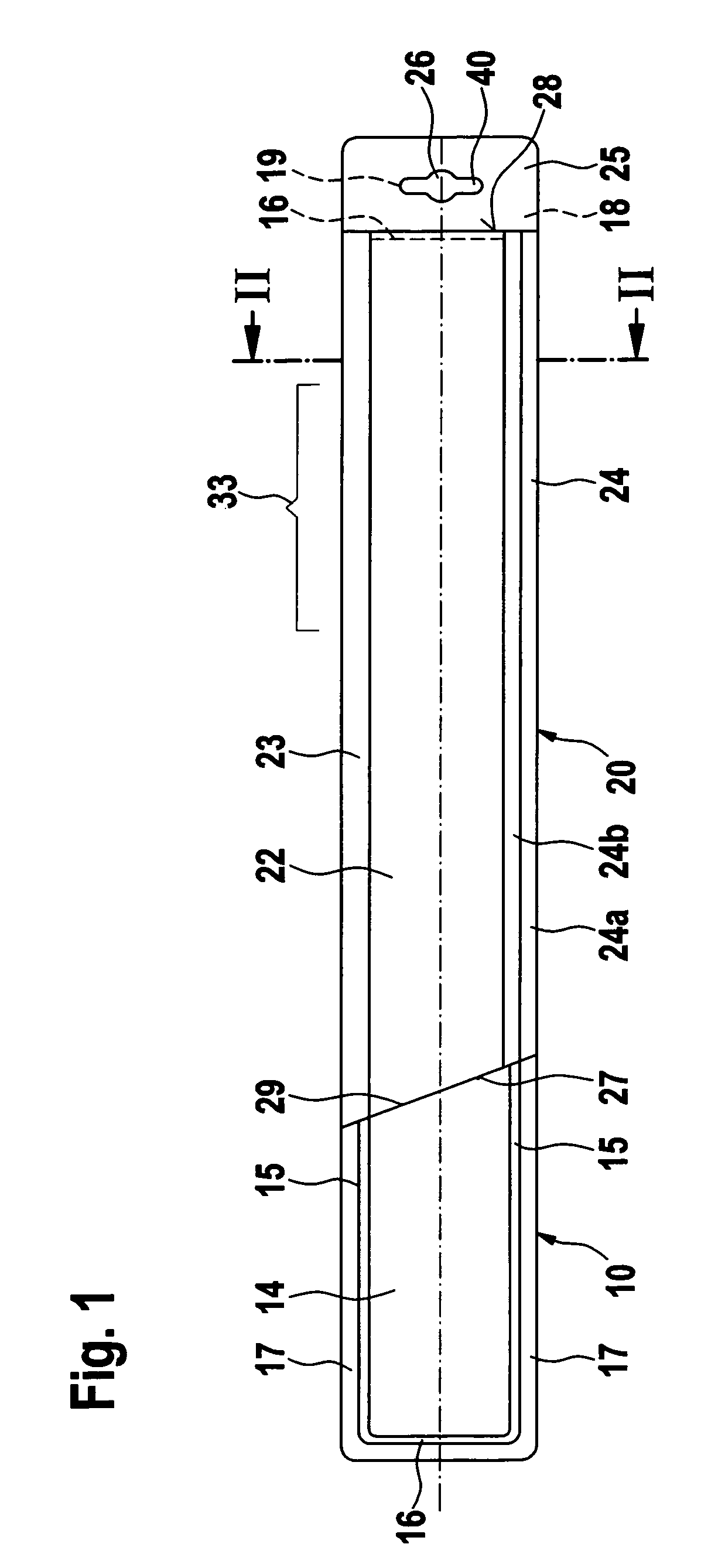

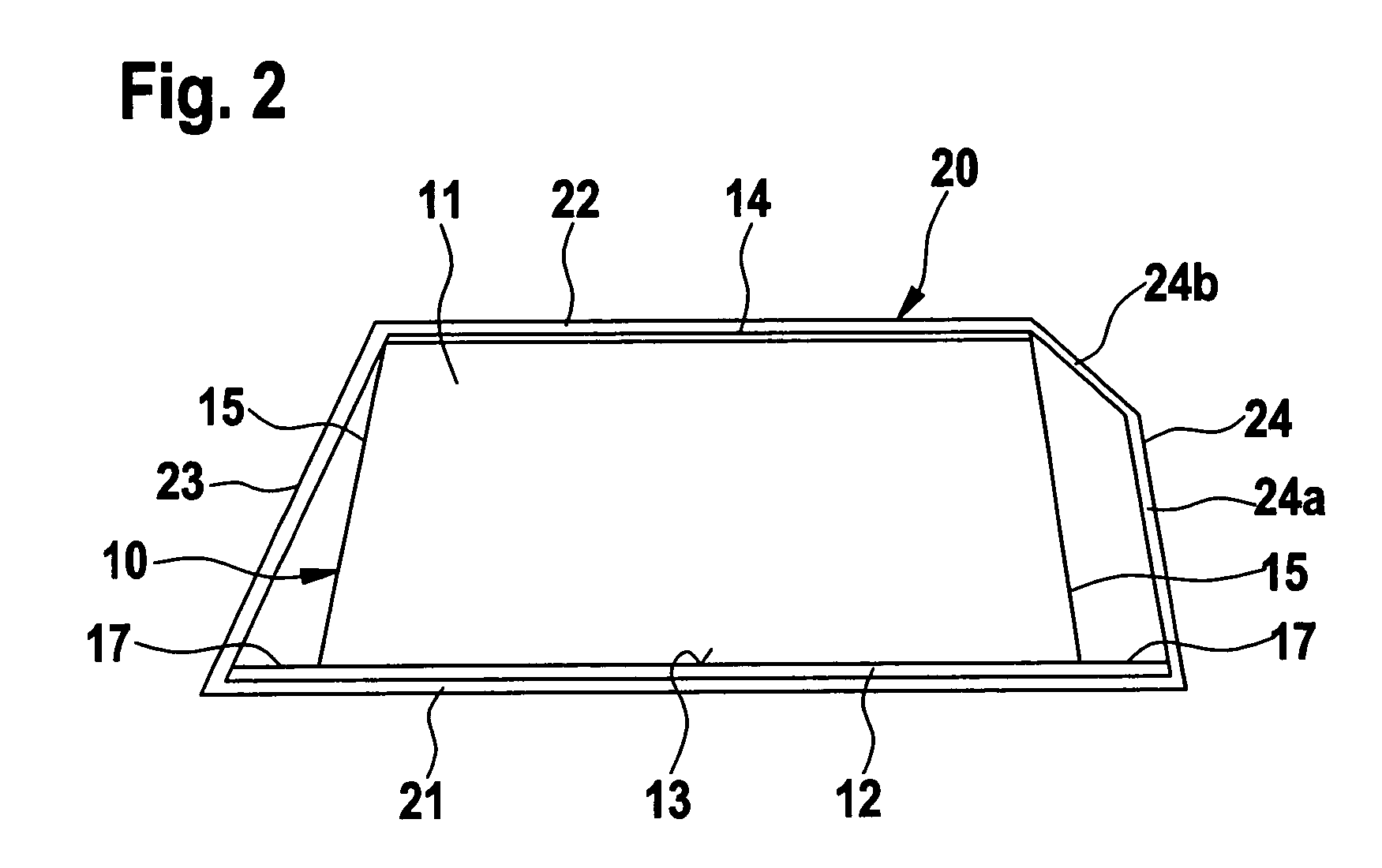

Packaging unit with slidable casing

ActiveUS7614499B2Preventing the slipping out of the containerAvoid insufficient frictionPackaging vehiclesContainers for machinesMechanical engineering

Owner:ROBERT BOSCH GMBH

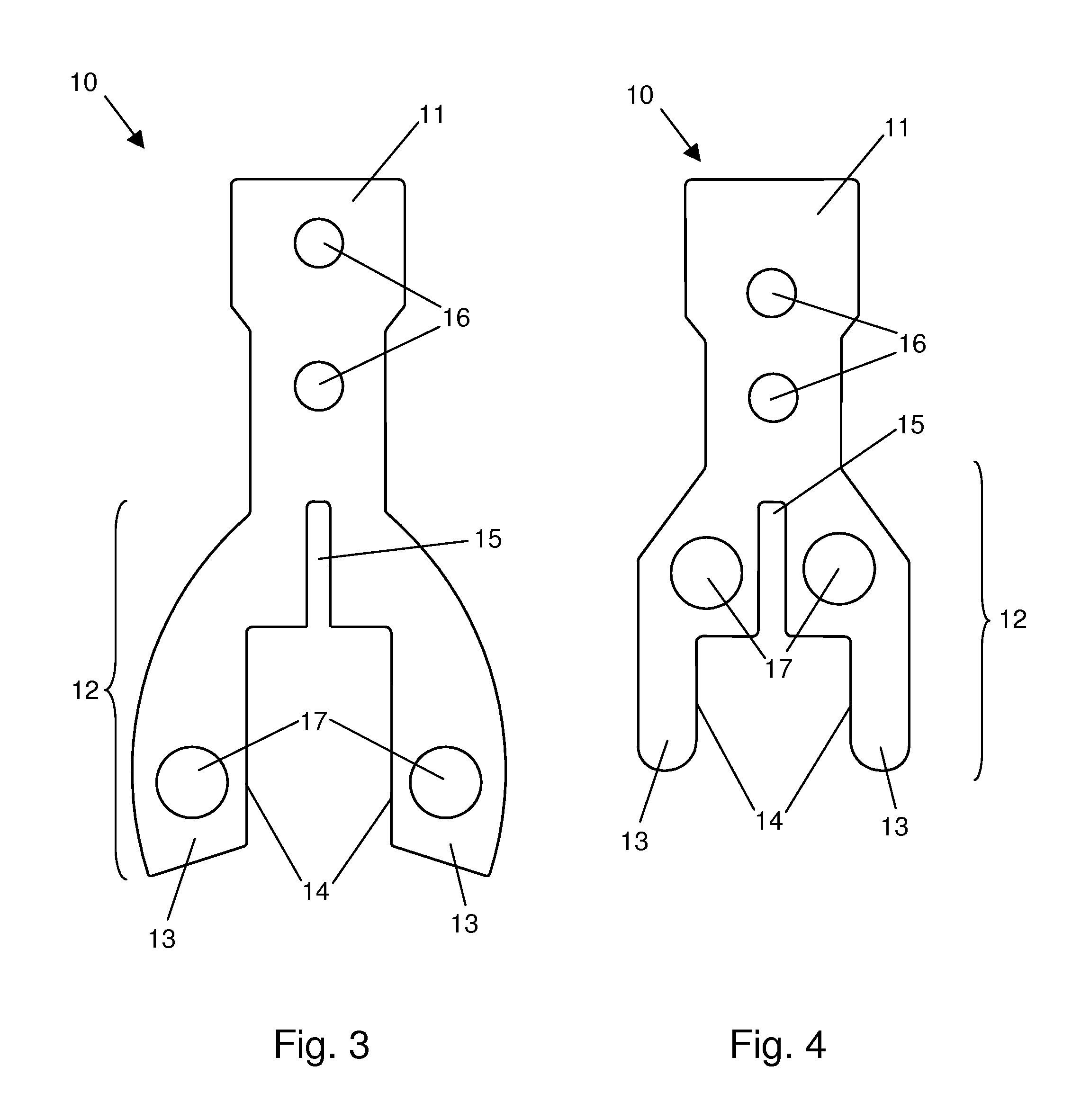

Apparatus for holding arrow

InactiveUS6913008B2Easily center the arrow shaftSimply using gravity forcesBows/crossbowsCompressed gas gunsEngineeringMechanical engineering

Owner:GOOD SPORTSMAN MARKETING LLC

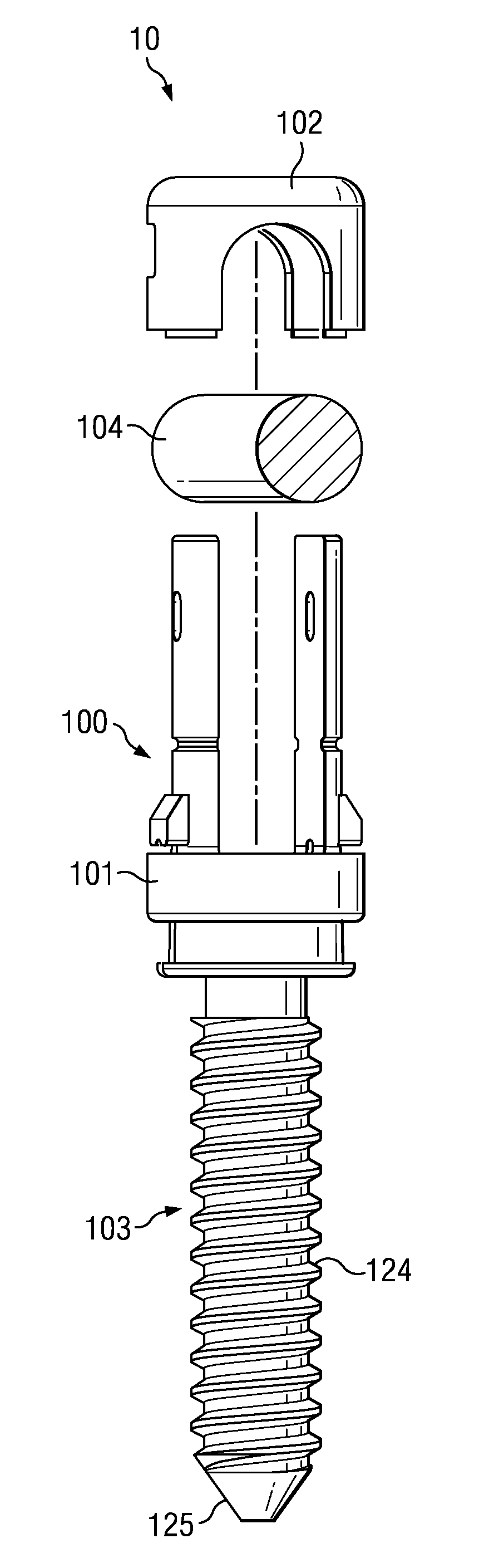

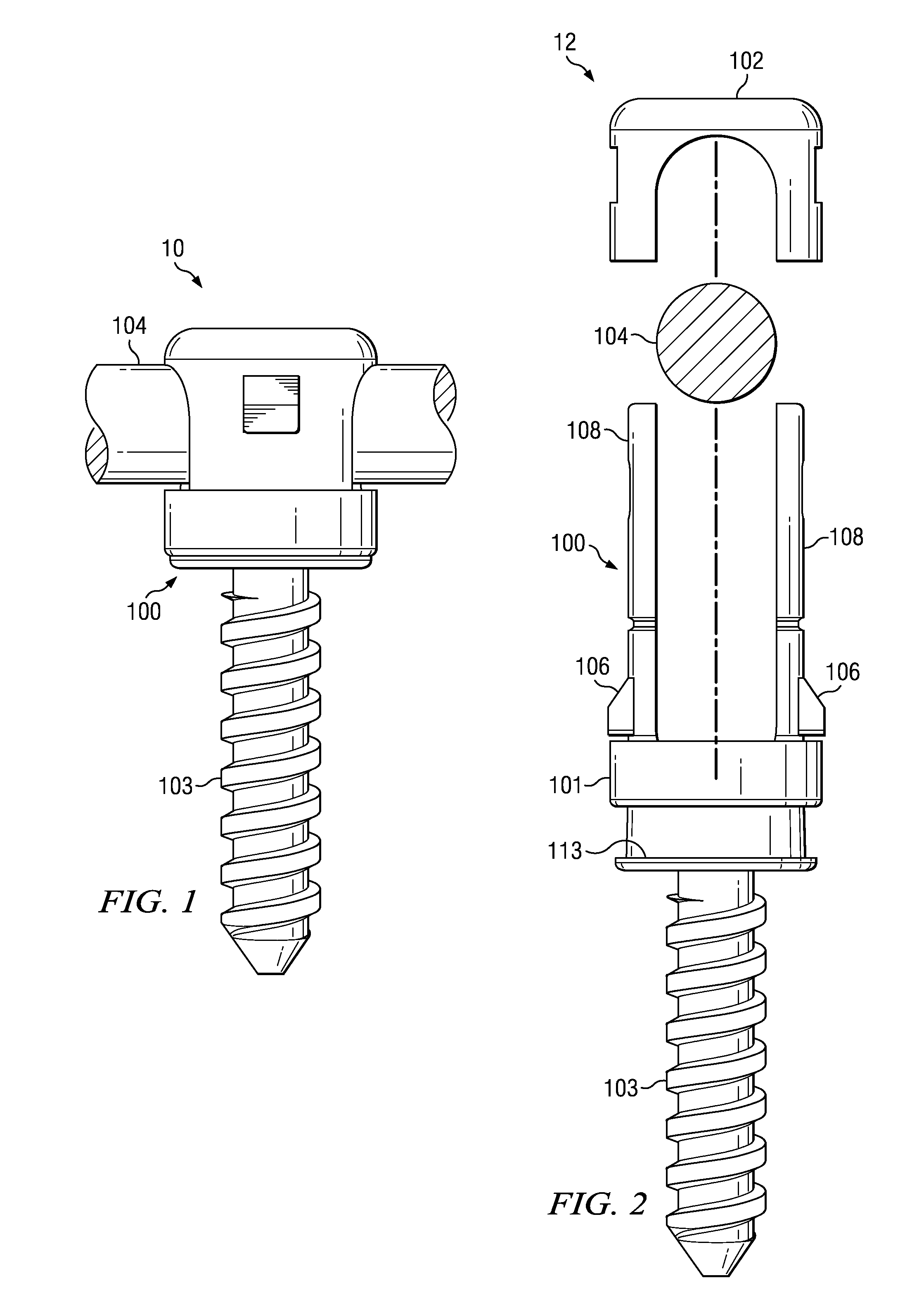

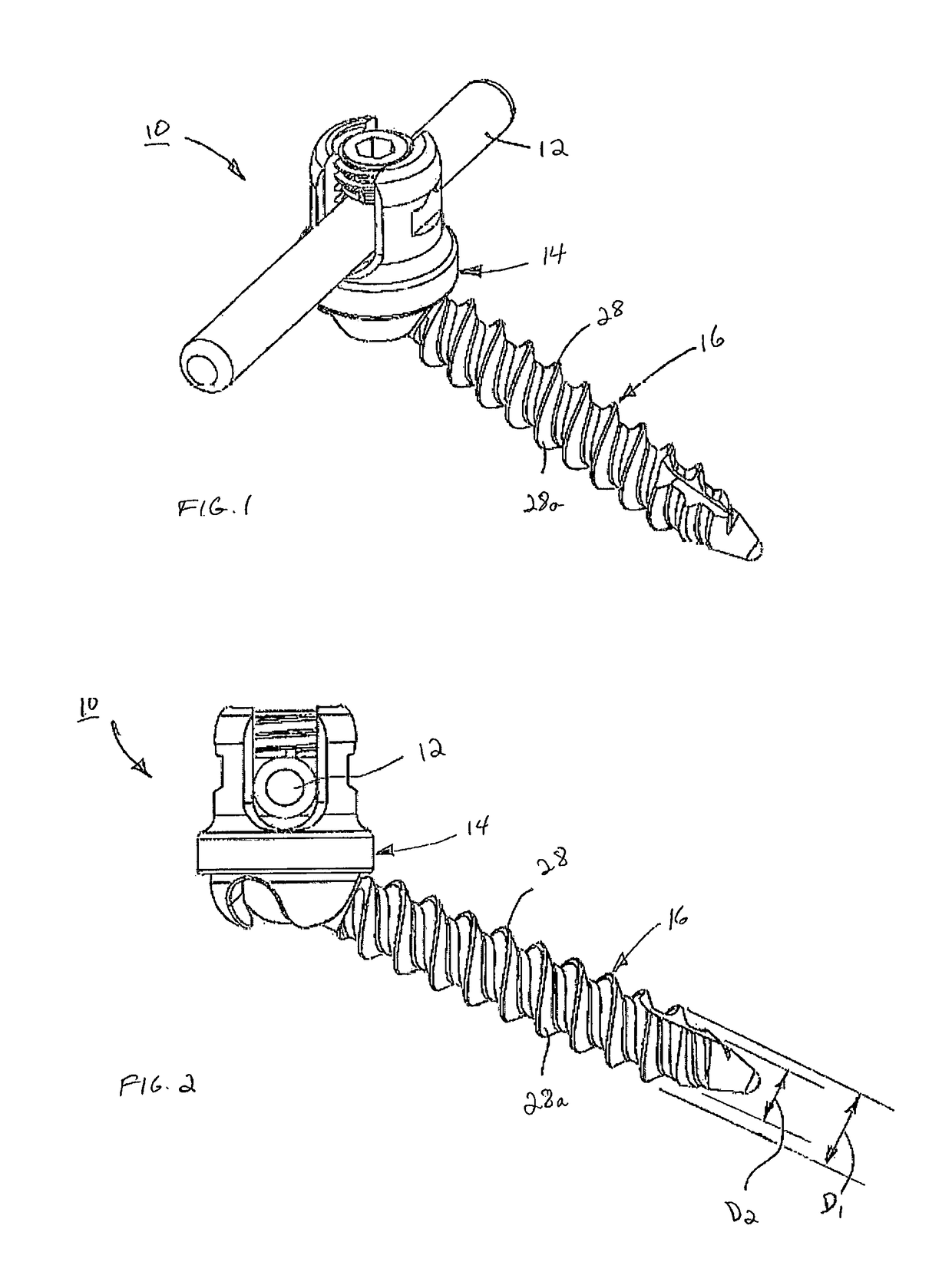

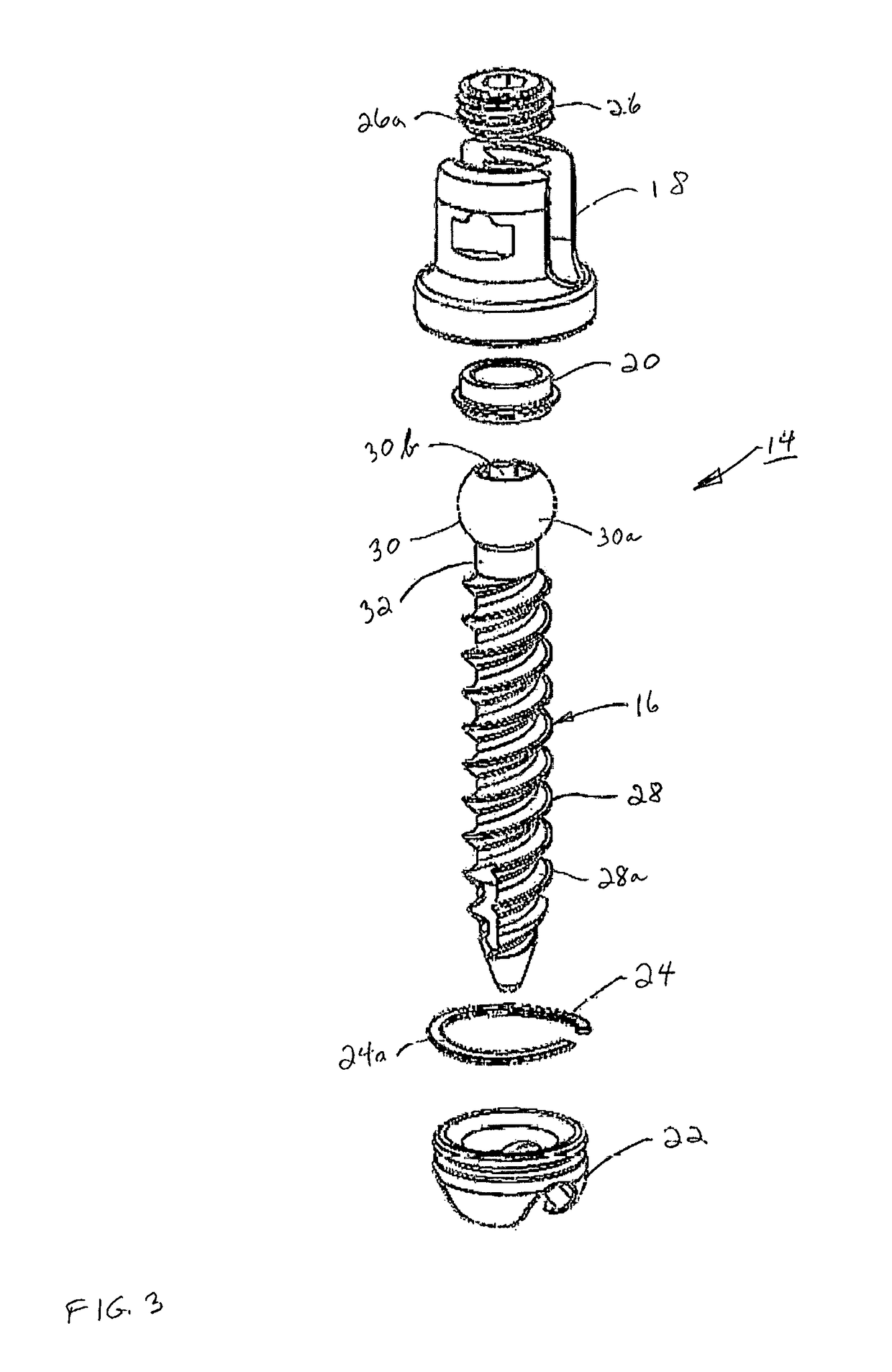

Spinal Implant

InactiveUS20110213419A1Avoid insufficient frictionSuture equipmentsInternal osteosythesisEngineeringSpinal implant

A screw and rod fixation assembly includes a body member including a screw seat for seating a screw head therein and a rod seat for seating a rod therein. An adjustable locking ring applies a locking force against the screw head seated in the screw seat and a locking cap adjustably applies a locking force against a rod seated in the rod seat. The adjustable screw locking ring and locking cap function independent of each other.A method of fixing the rod to the screw includes the steps of inserting a screw head into a screw seat in one end of a body member and inserting a rod into a rod seat in a second end of a body member and selectively and independently adjusting a locking force on both the screw head and the rod within the screw seat and rod seat, respectively.

Owner:INTELLIGENT IMPLANT SYST

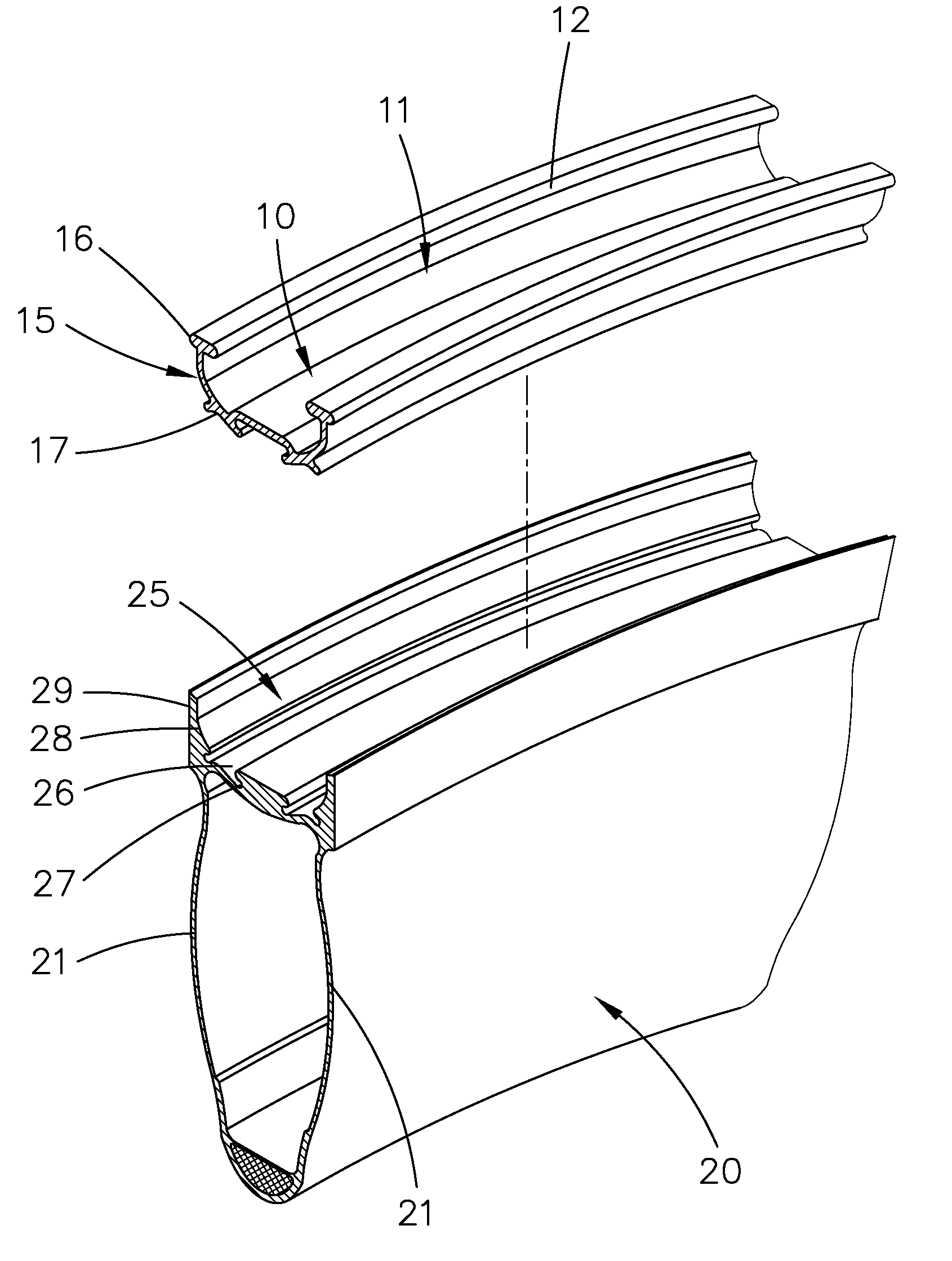

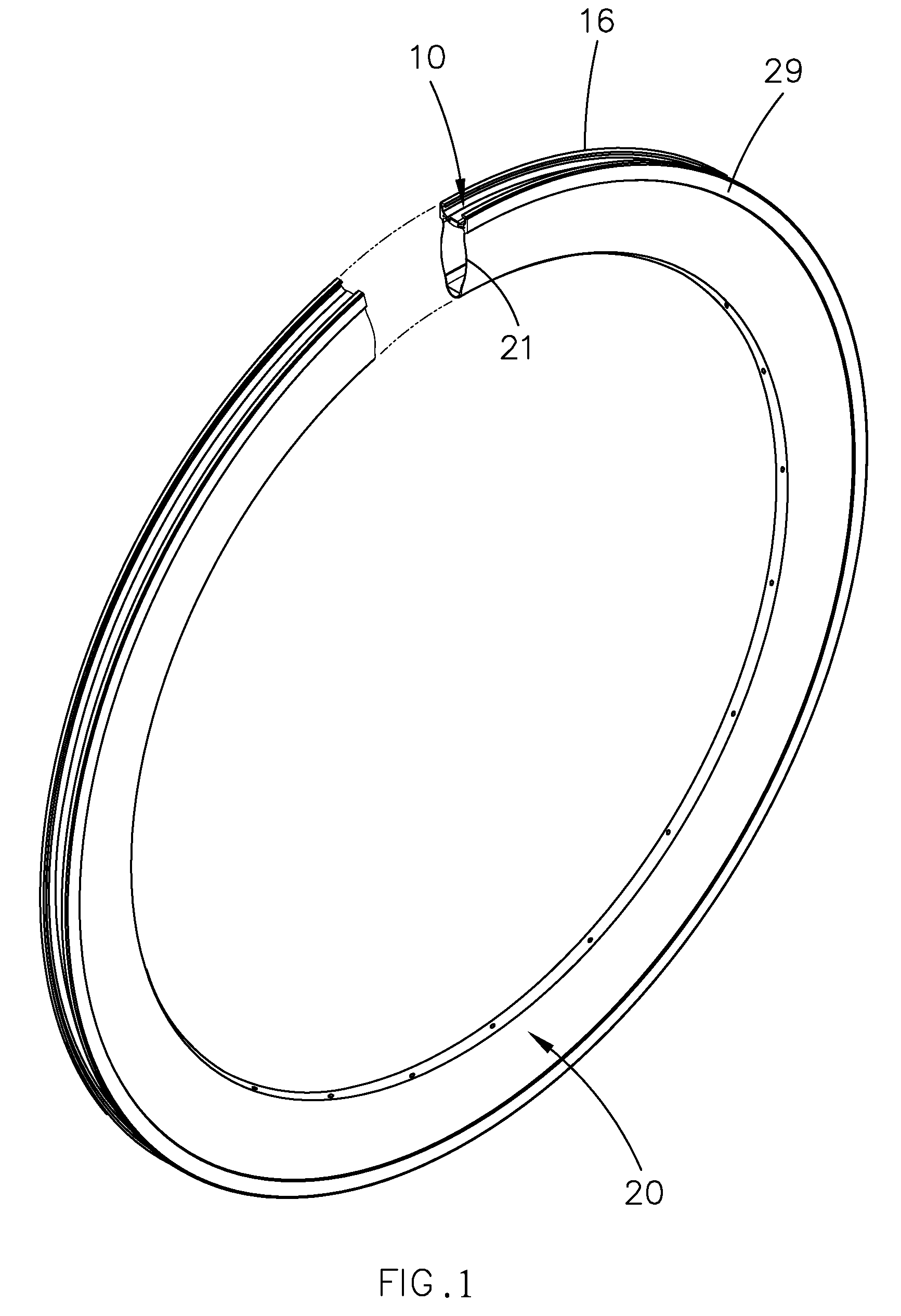

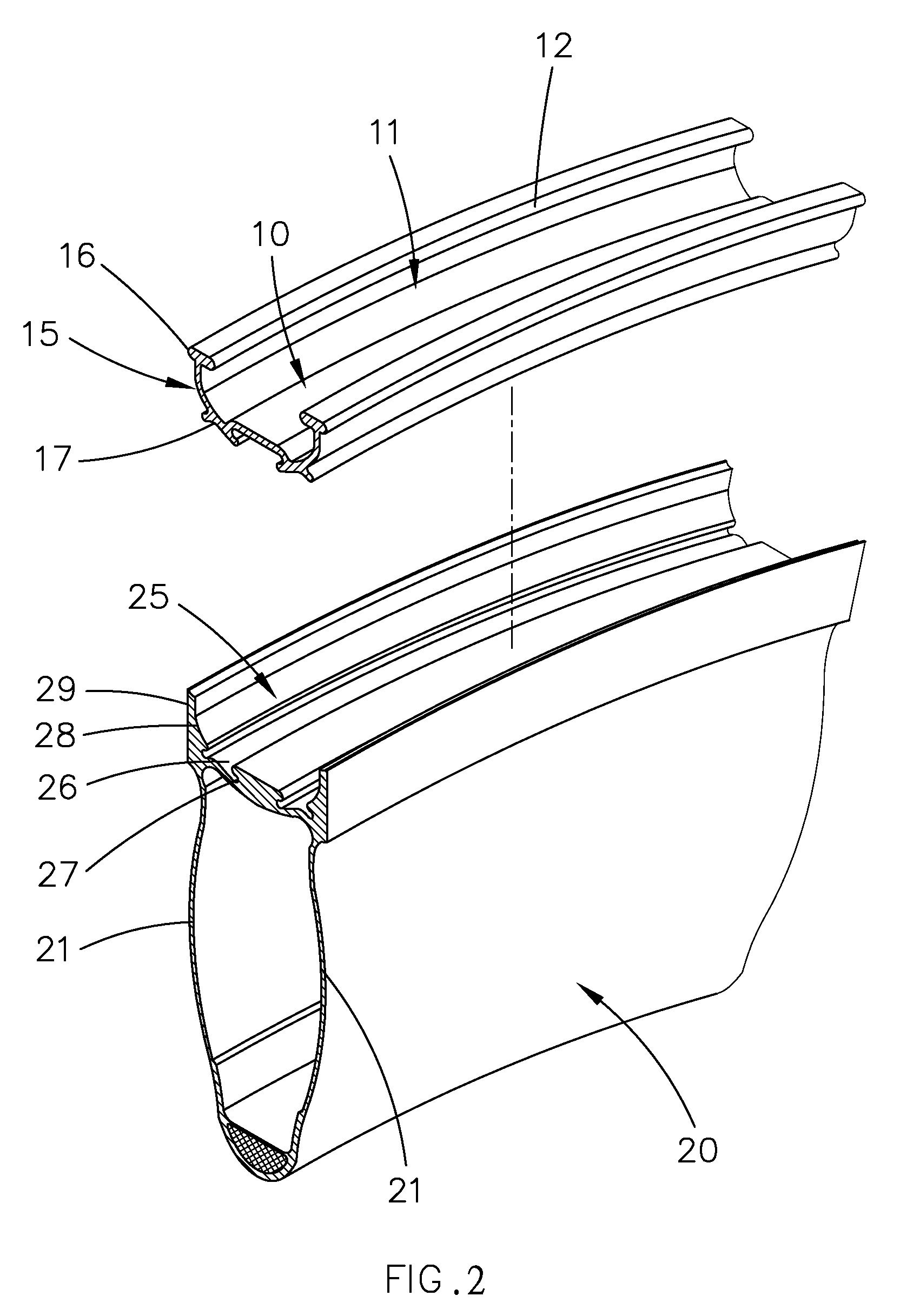

Composite rim

InactiveUS20080174168A1Avoid insufficient frictionRimsNon-metallic wheel bodyEngineeringMechanical engineering

A composite rim includes a tire-receiving ring made of metal and a spoke-connecting ring made of plastic. The tire-receiving ring includes at least one dovetail formed on the bottom thereof and two sidewalls formed thereon. The spoke-connecting ring includes two brake-contacting members located tightly outside the sidewalls of the tire-receiving ring, a cross member formed between the brake-contacting members and at least one dovetail groove defined in the cross member for receiving the dovetail.

Owner:YANG CHIH HSIANG

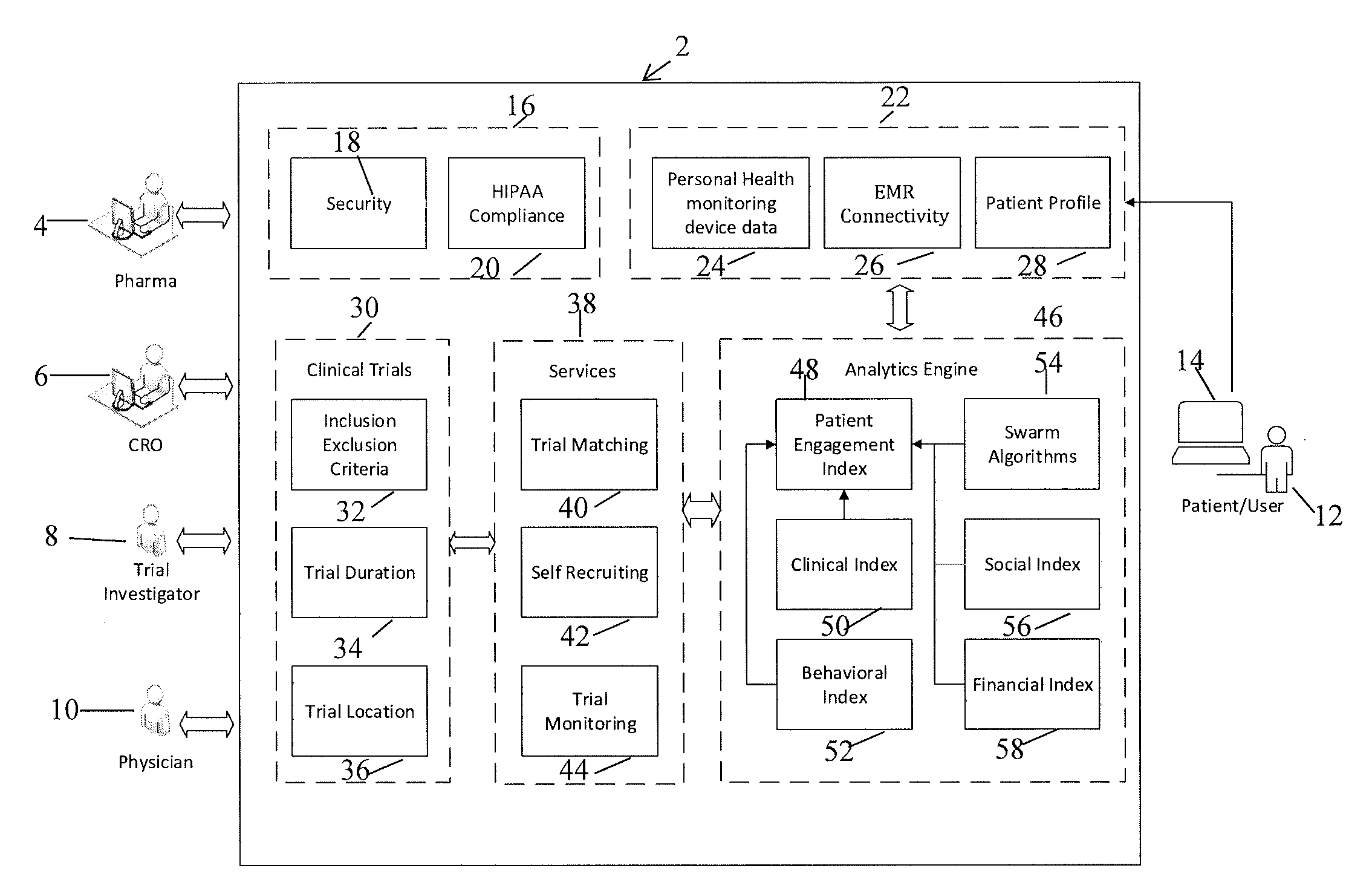

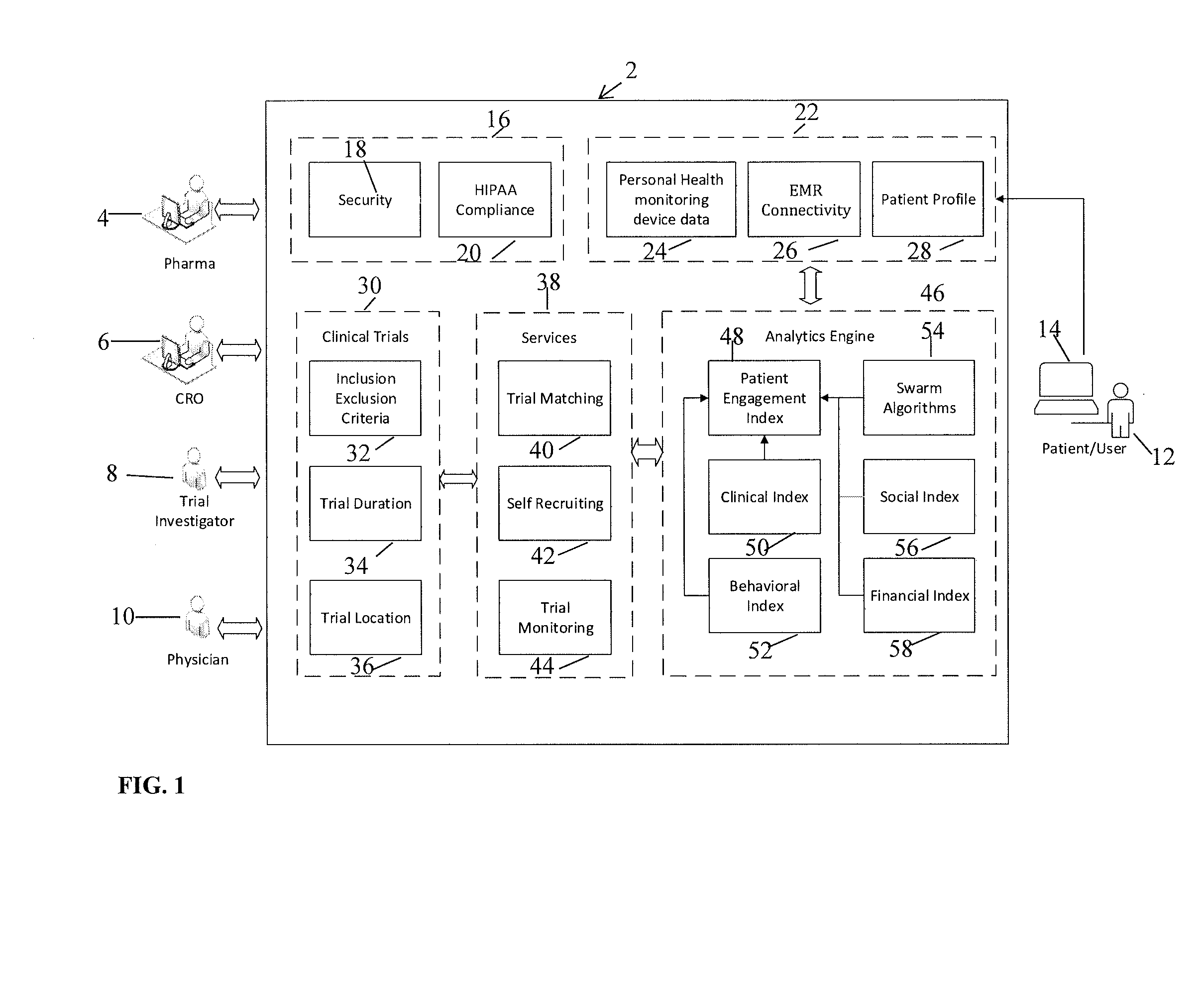

Method and apparatus for virtual clinical trial self-recruitment marketplace for patients based on behavioral stratification, patient engagement and patient management during clinical trials using behavioral analytics, gamification and cognitive techniques

InactiveUS20160357944A1Patient convenienceAvoid insufficient frictionFinanceComputer-assisted medical data acquisitionPatient managementApplication software

Method, Apparatus and non-transitory computer readable media that enhance patient-recruitment and participation in clinical trials preferably includes structure and / or steps whereby one or more APIs are used to interface at least one Cognitive Analytics Value Inference and Intelligence—Healthcare (CAVII-H) server with the patient(s), Pharma participant(s), Contract Research Organization(s), Trial Investigator(s), and Healthcare Providers (such as a physician). The at least one CAVII-H server preferably use at least one of stored trial data, user medical data, user behavioral date, user application collected data user registration data, healthcare professional data to guide patient participation. Preferably, information is obtained from the users through plural interactive algorithms designed to sharpen and perfect patient selection, preferably throughout the life of each trial. This creates a global clinical-trial patient engagement, recruitment and retention marketplace, which is open to patents and all trial stakeholders.

Owner:IYER GIRI +2

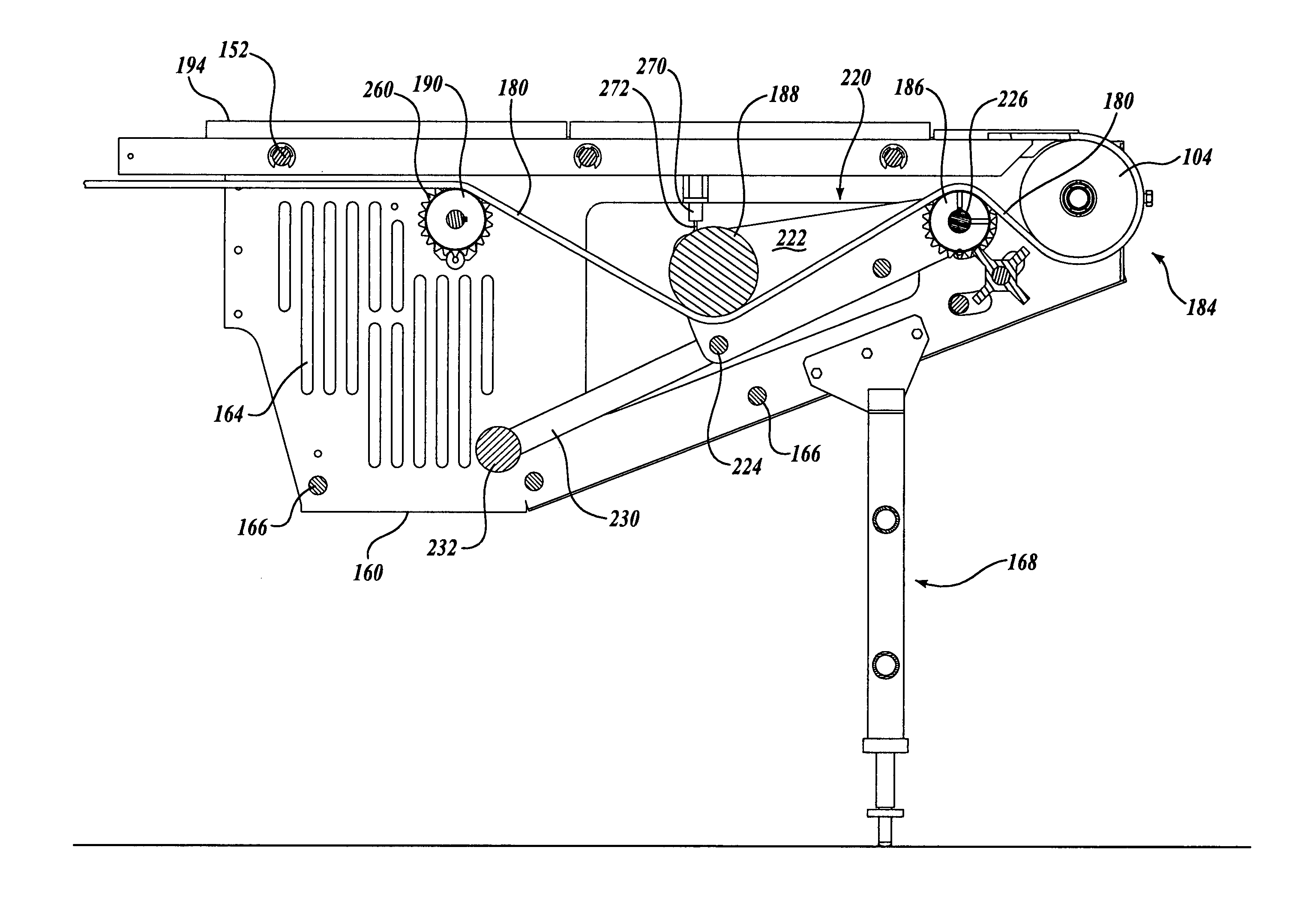

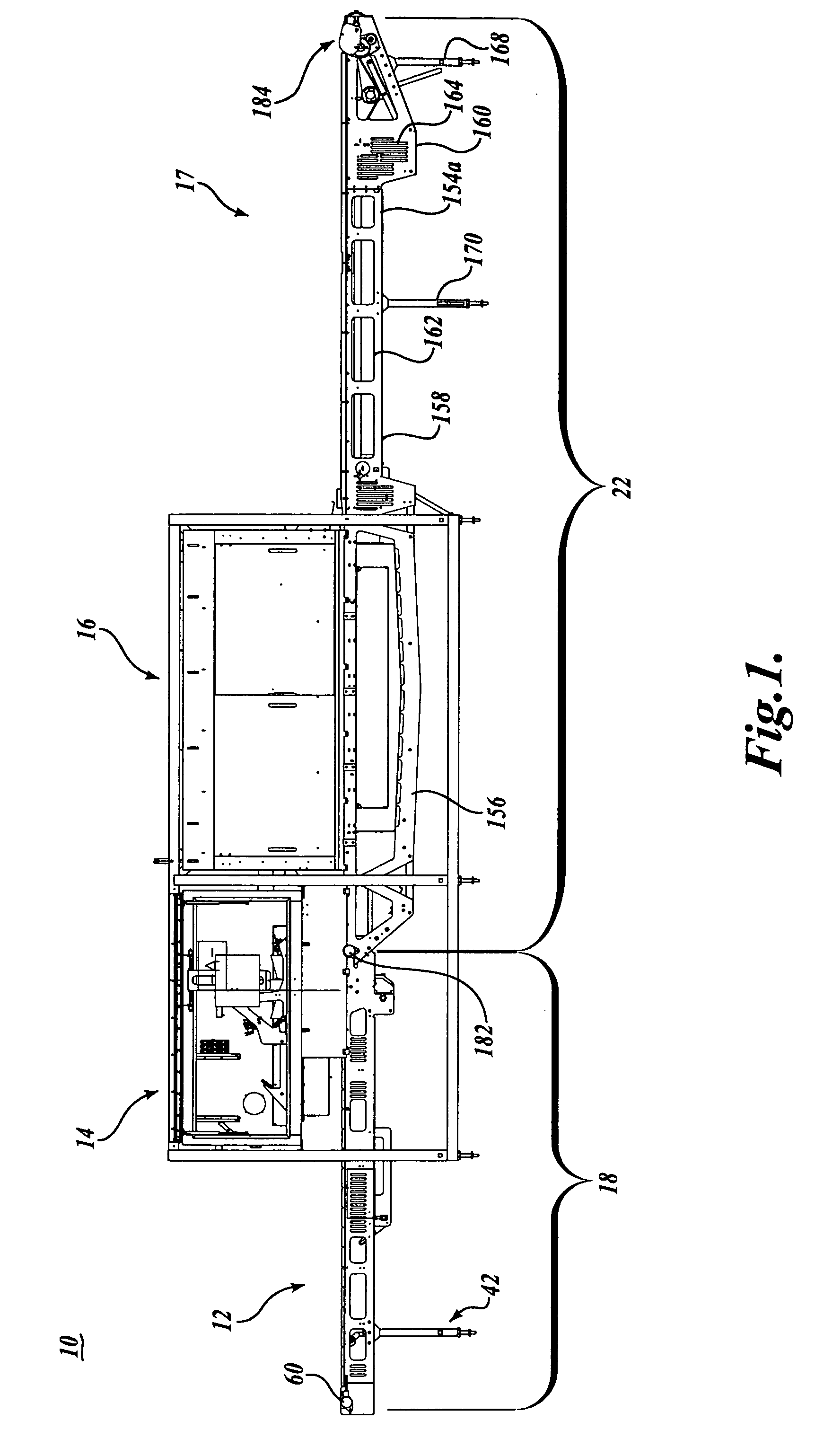

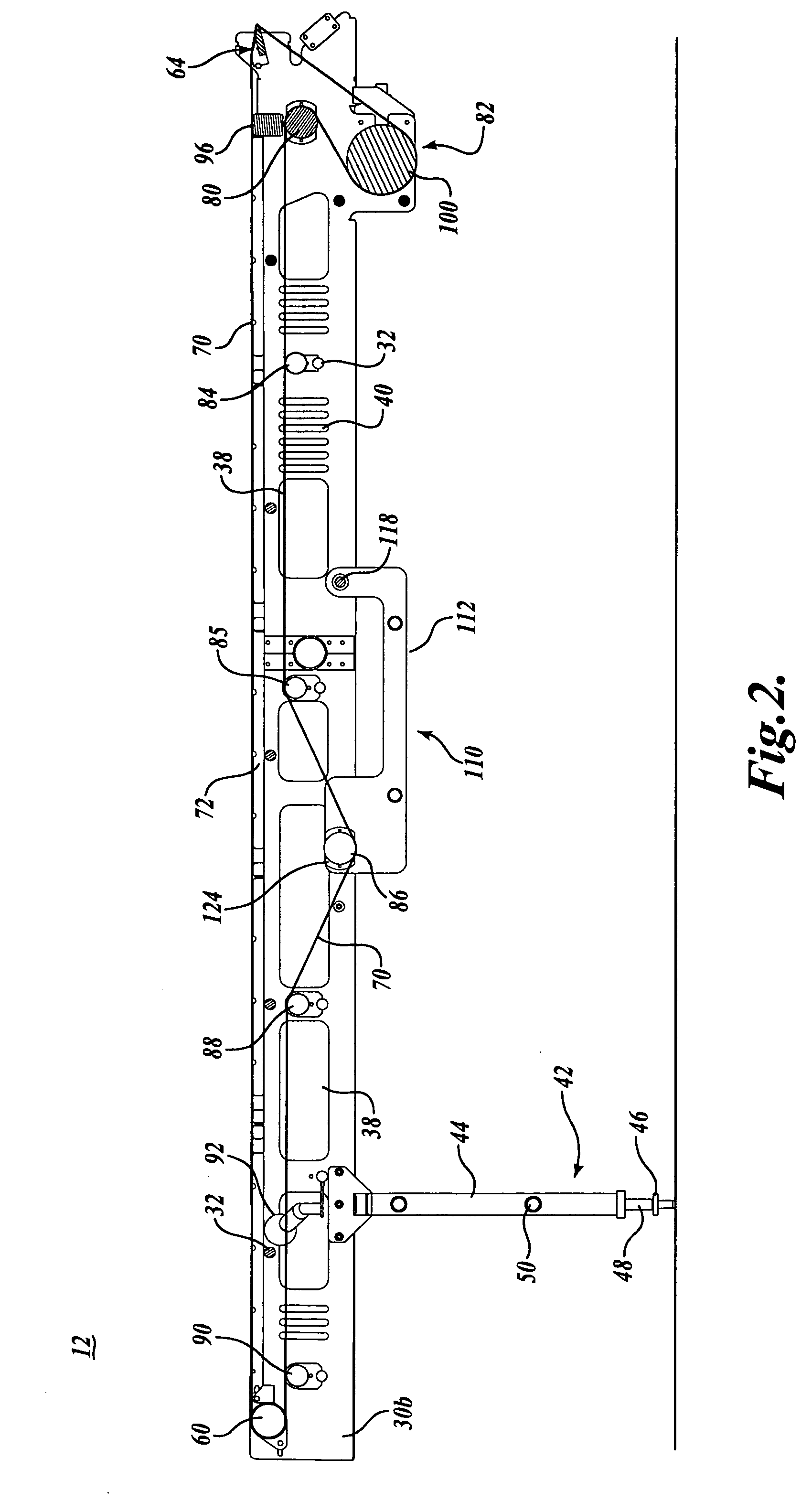

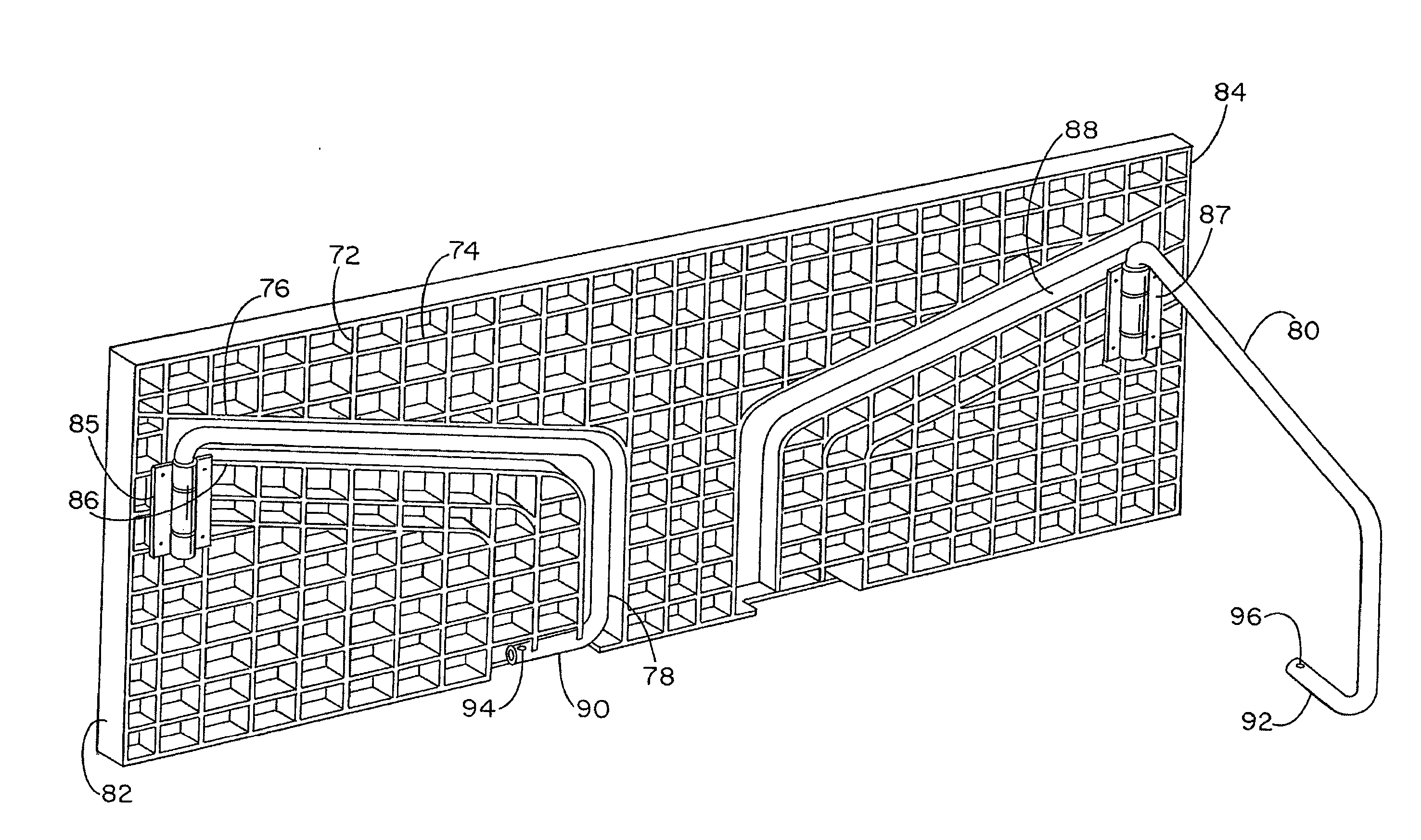

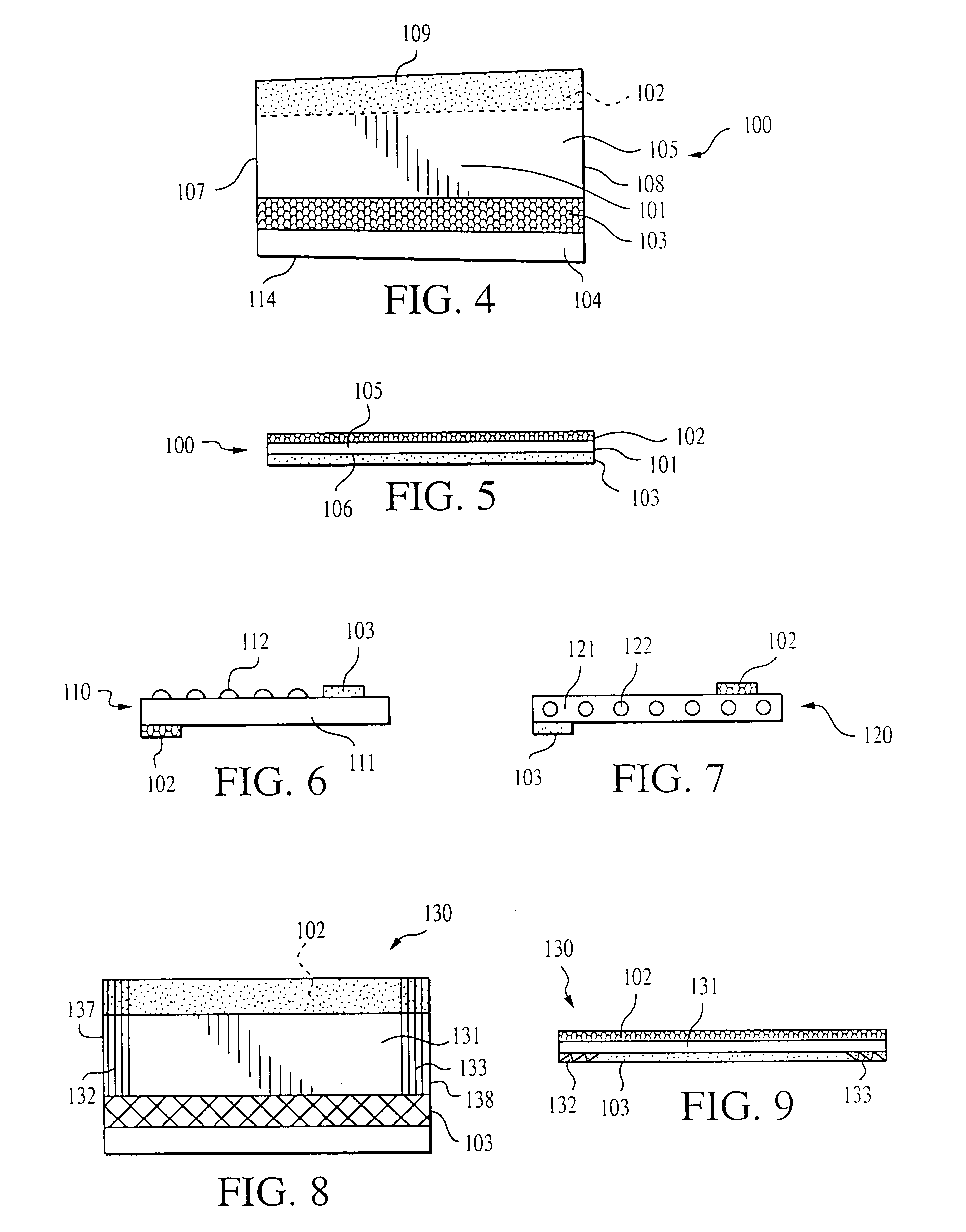

Friction drive conveyor

InactiveUS20050077152A1Avoid insufficient frictionReduce vibrationMetal sawing devicesAutomatic control devicesEngineeringFriction drive

A conveyor 12 includes an infeed / scanning section (18) and a cutting / outfeed section (22). Both sections have an endless belt (70) and (180) each driven by a friction drive roller (100) and (200). Adequate frictional load is applied between the endless belts and corresponding drive rollers by tension assemblies, each having a tensioning roller (86), (188) rotatably mounted on a pivot frame structure (112), (220) allowing the weight of the tensioning roller to be applied to the return run of the endless belts. Dampeners (130) (270) are integrated with the tensioning rollers (86) (188) to dampen vibrations in the endless belts (70) (180).

Owner:JOHN BEAN TECH CORP

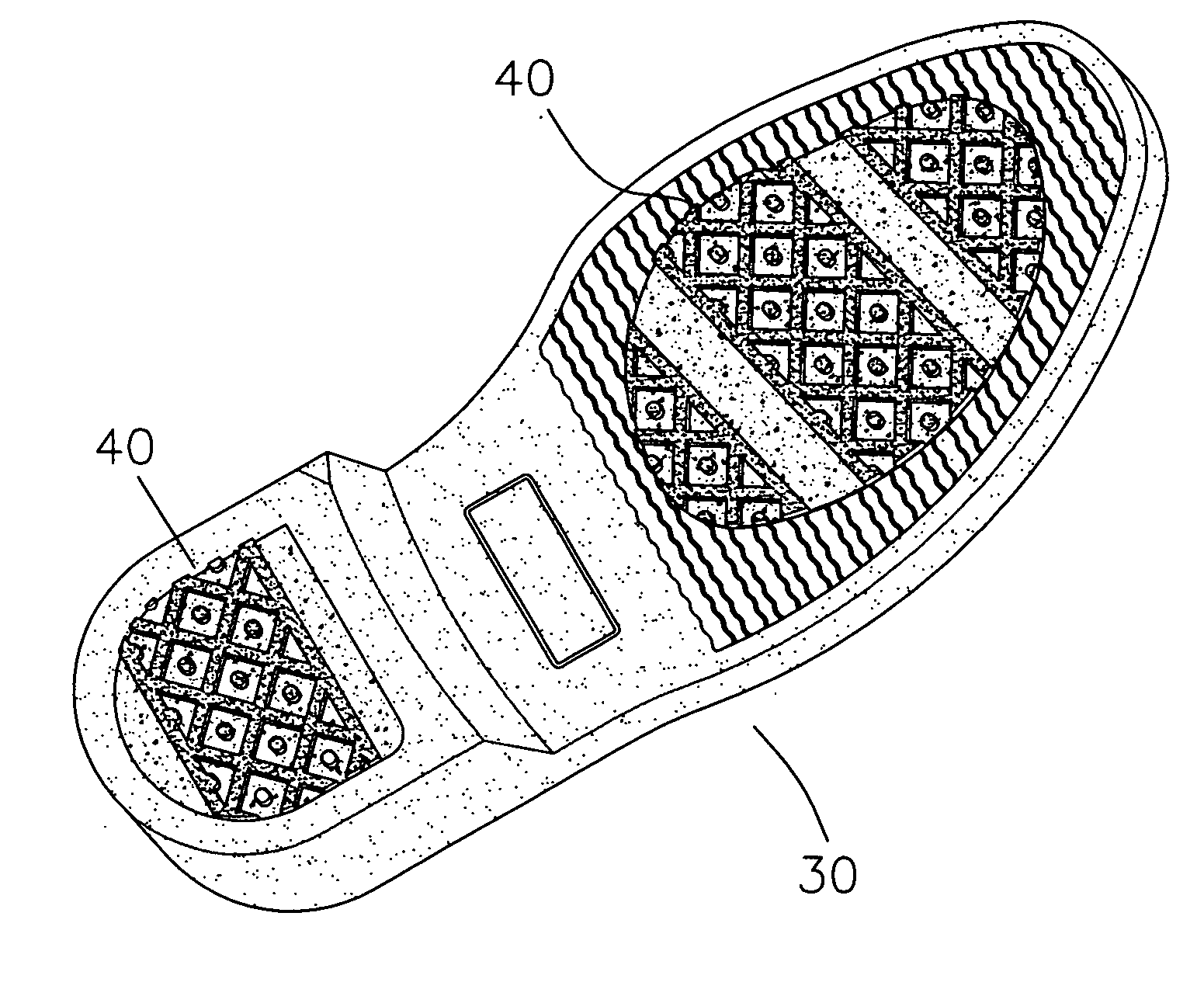

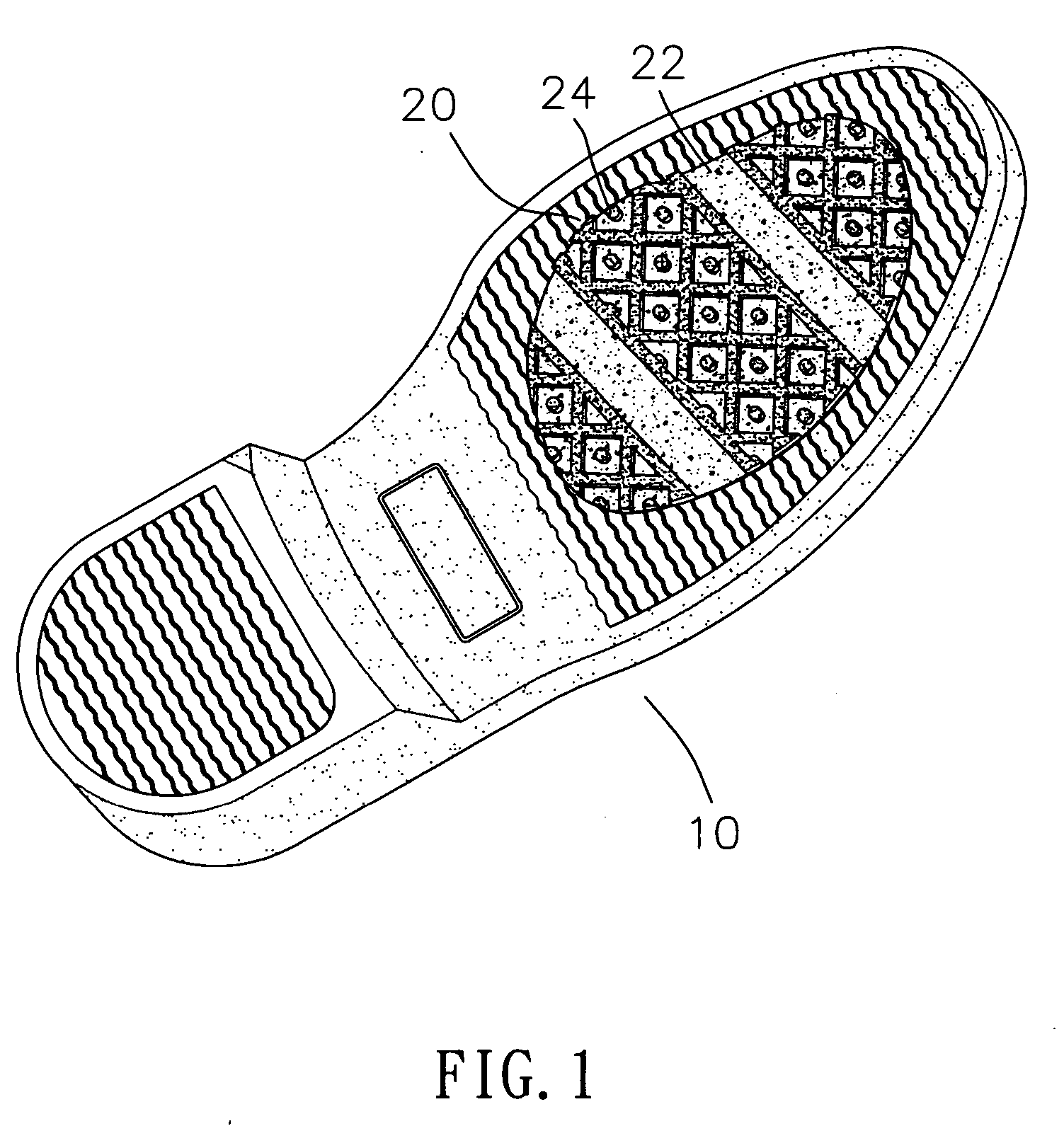

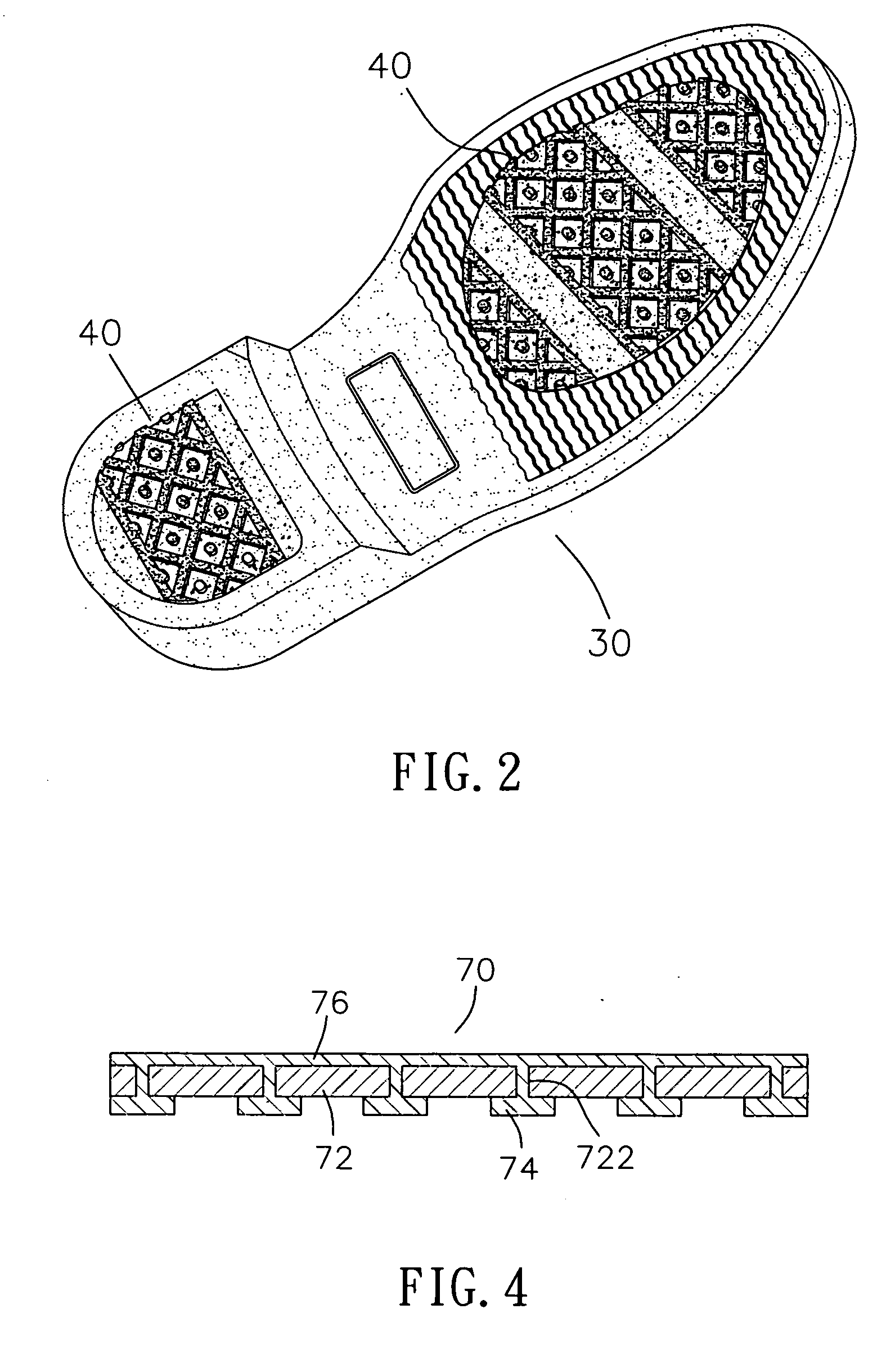

Combination outsole and friction sheet

InactiveUS20070130801A1Increase frictionAvoid insufficient frictionSolesUpperEngineeringMechanical engineering

Owner:WU KUN HO

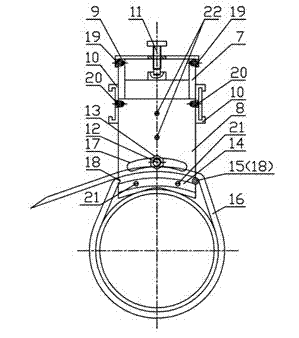

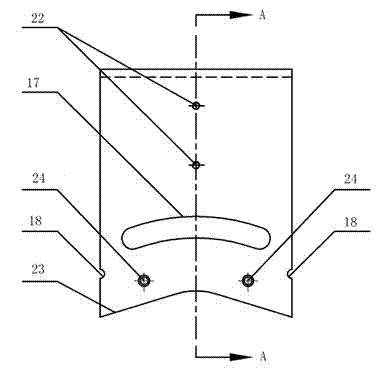

Device for installing externally-clamping probes of portable ultrasonic flow meter

ActiveCN102359802AEasy to installGuaranteed coincidenceVolume/mass flow measurementMechanical engineeringPortable ultrasound

Owner:SHANGHAI JIAO TONG UNIV +1

Reference beam generator and method

InactiveUS7992310B2Avoid insufficient frictionImprove the level ofUsing optical meansReference line/planes/sectorsLight beamLaser light

A reference beam generator has first, second, and third projection turrets for projecting first, second, and third fan beams of laser light, respectively. The first, second, and third fan beams of laser light are oriented normal to each other. The turrets may be rotated such that each of said fan beams can each be rotated about an axis that is normal to the plane in which the fan beam is projected. The generator may be used to project a number of reference points and lines on multiple surfaces.

Owner:SPECTRA PRECISION (USA) LLC

Mounting Arrangement with Mounting Aid and Orthodontic Bracket

InactiveUS20110250556A1Easy to fixImprove scalabilityBracketsDental toolsEngineeringOrthodontic brackets

Owner:HEISER WOLFGANG

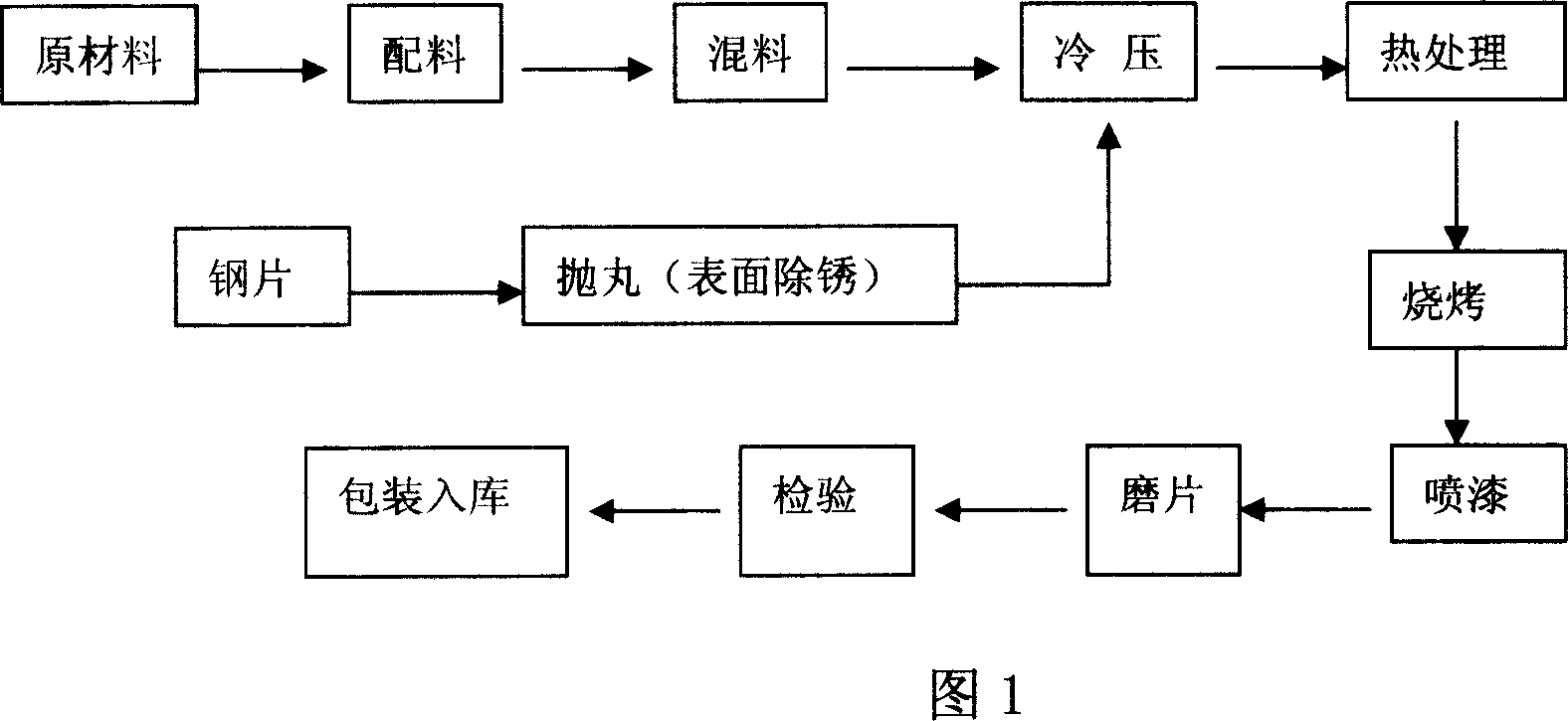

Asbestos-free non-metal friction material and preparation method thereof

The present invention relates to friction material for automobile brake disc, and is especially one kind of friction material reinforced with the mixture of aramid fiber and inorganic mineral fiber and its preparation process. The new non-metal friction material without asbestos consists of aramid fiber, LAPINUS inorganic mineral fiber, phenolic resin, butadiene-acrylonitrile rubber powder, inorganic stuffing and friction regulator. The organic-inorganic composite material reinforced friction material has raised comprehensive performance, stable friction performance and friction coefficient variation with temperature within 10 %. In addition, the present invention also provides high temperature fast curing process to ensure the heat resisting performance of the product and lowered power consumption.

Owner:浙江万赛汽车零部件股份有限公司

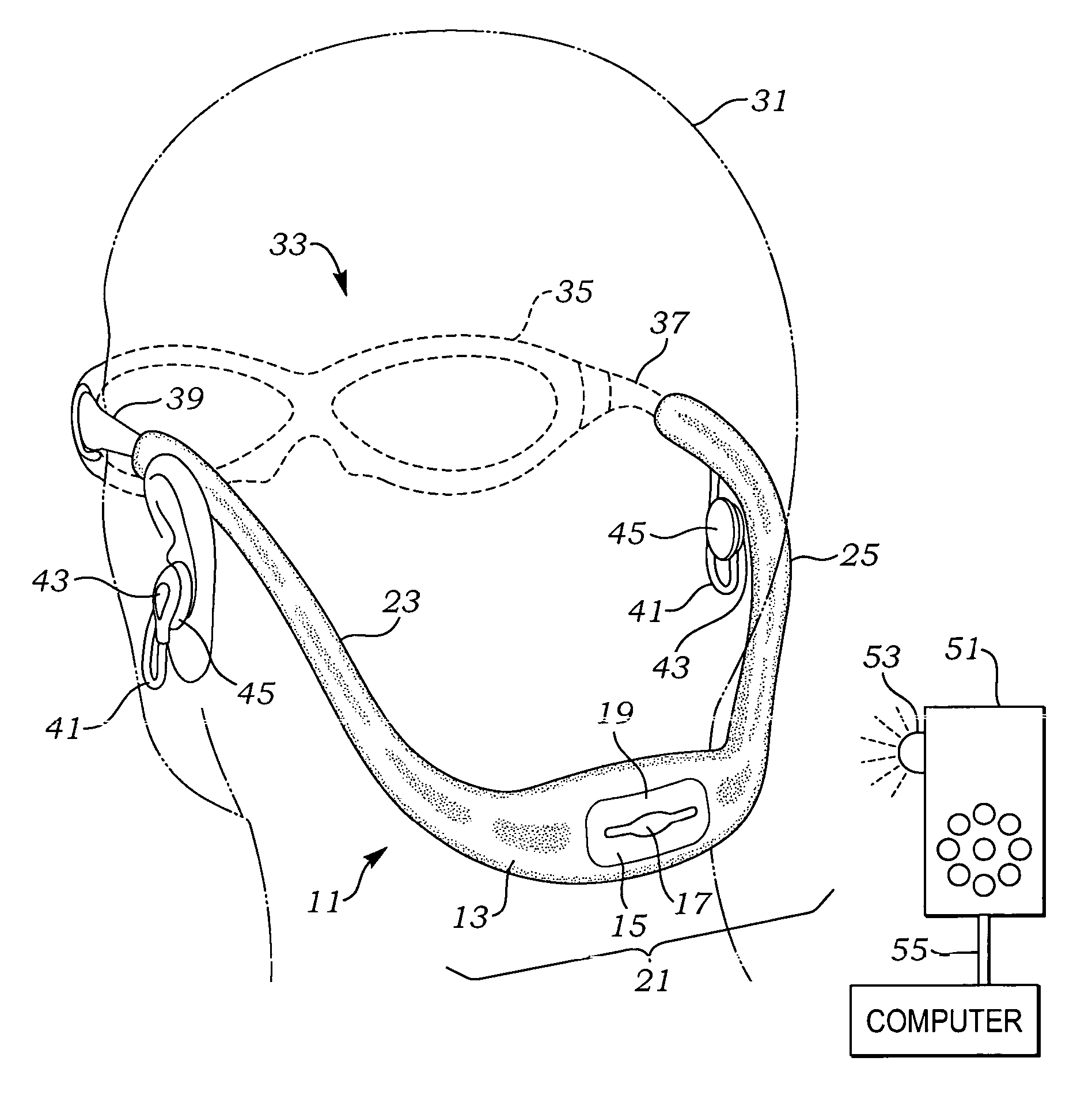

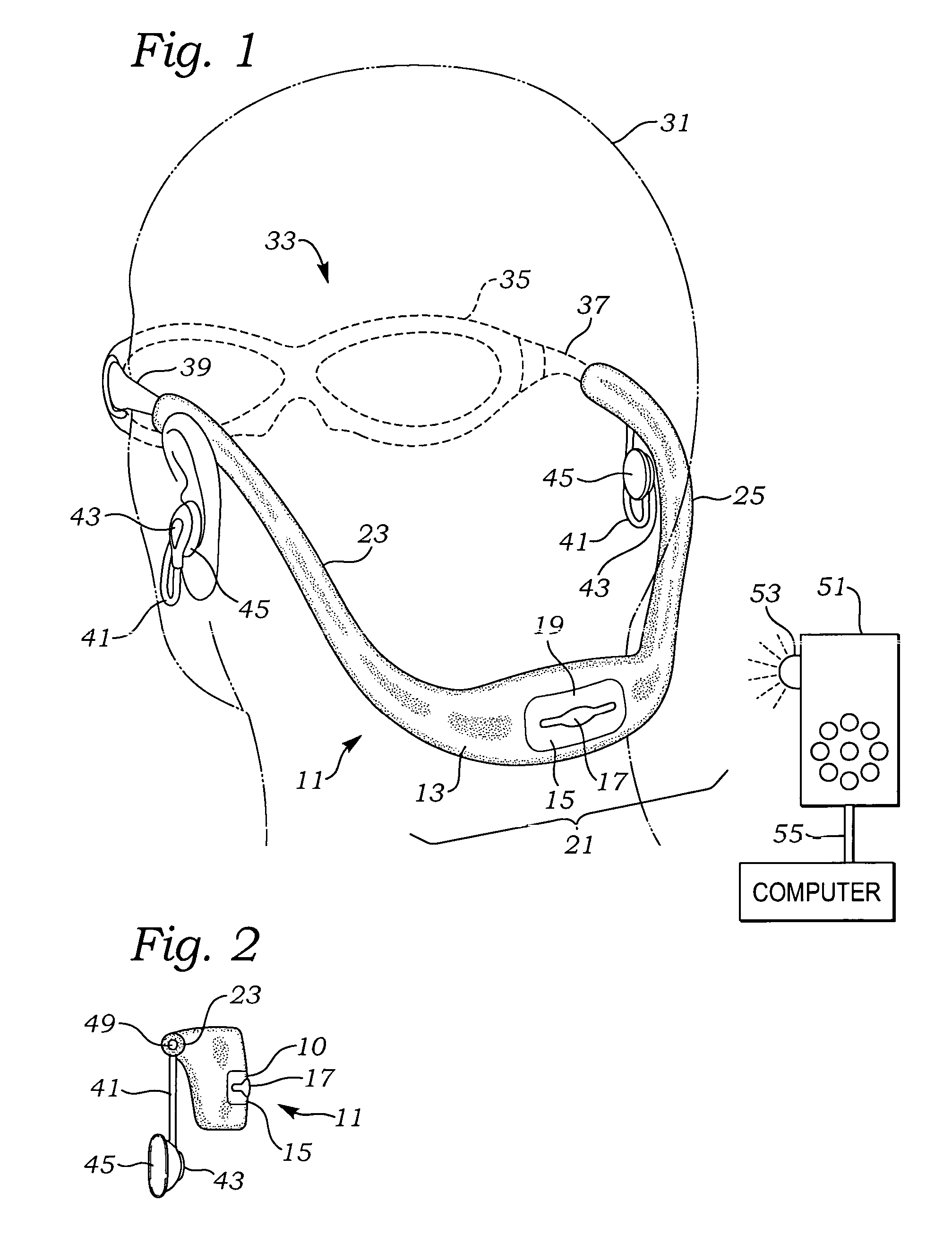

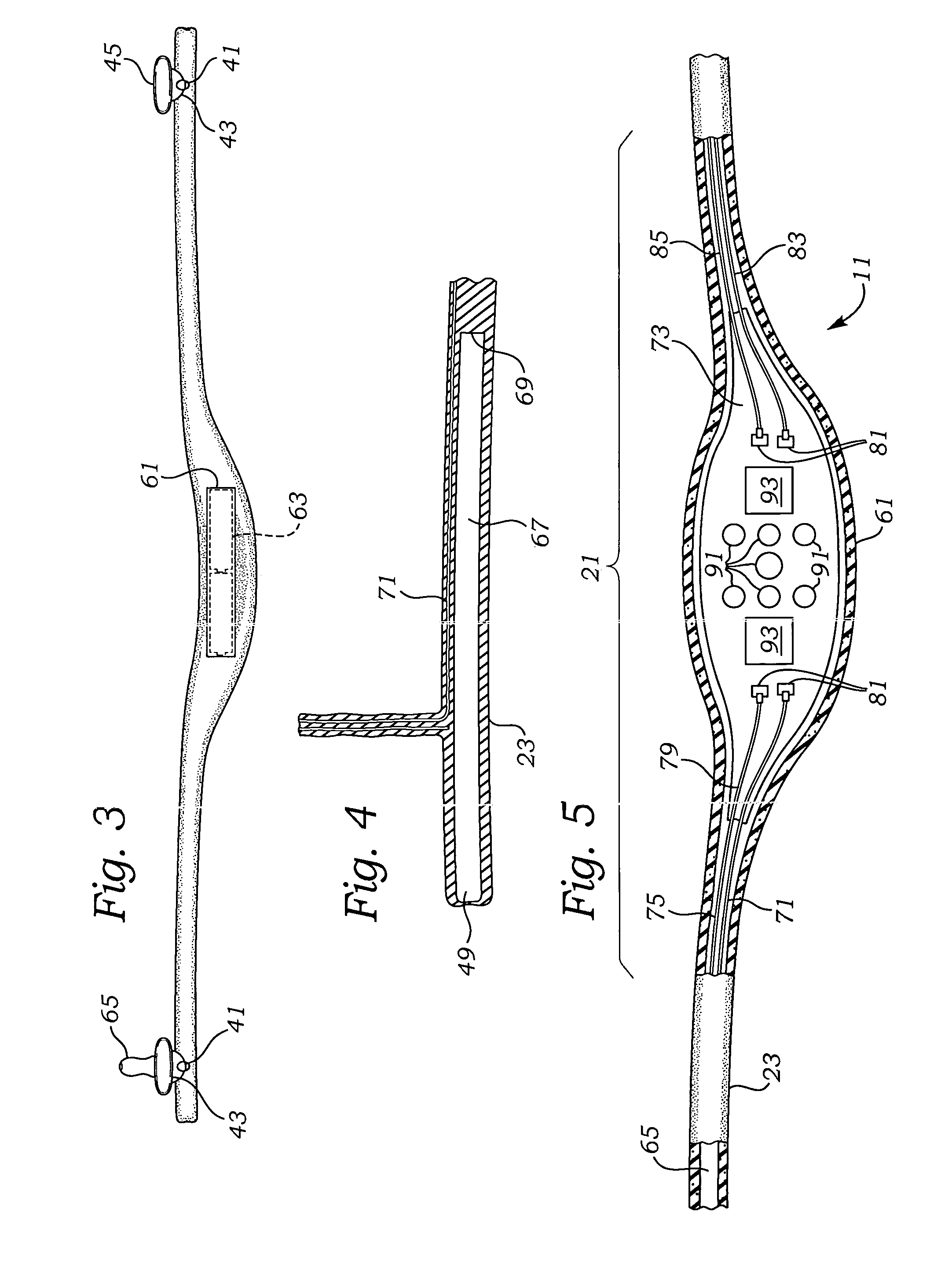

Audio lanyard

InactiveUS7226162B2Avoid insufficient frictionIncrease surface areaNon-optical adjunctsTransmissionEngineeringElectronics

An audio lanyard audio device provides a number of advantages not seen with earlier devices, including, (1) a pair of soft openings to accept the ear pieces of conventional eyewear in a manner that supports and engages several inches of the ear pieces of conventional eyewear with sufficient surface area and friction to hold the conventional eyewear securely, (2) provision of a length of softer foam material for fitting both the lanyard and convention eyewear ear pieces between the ear and head, (3) formation of a balanced combination when worn with conventional eyewear, and (4) the location of the controls and main electronics and battery at the rear for balance and easy reach by a user.

Owner:DAKA RESEARCH INC

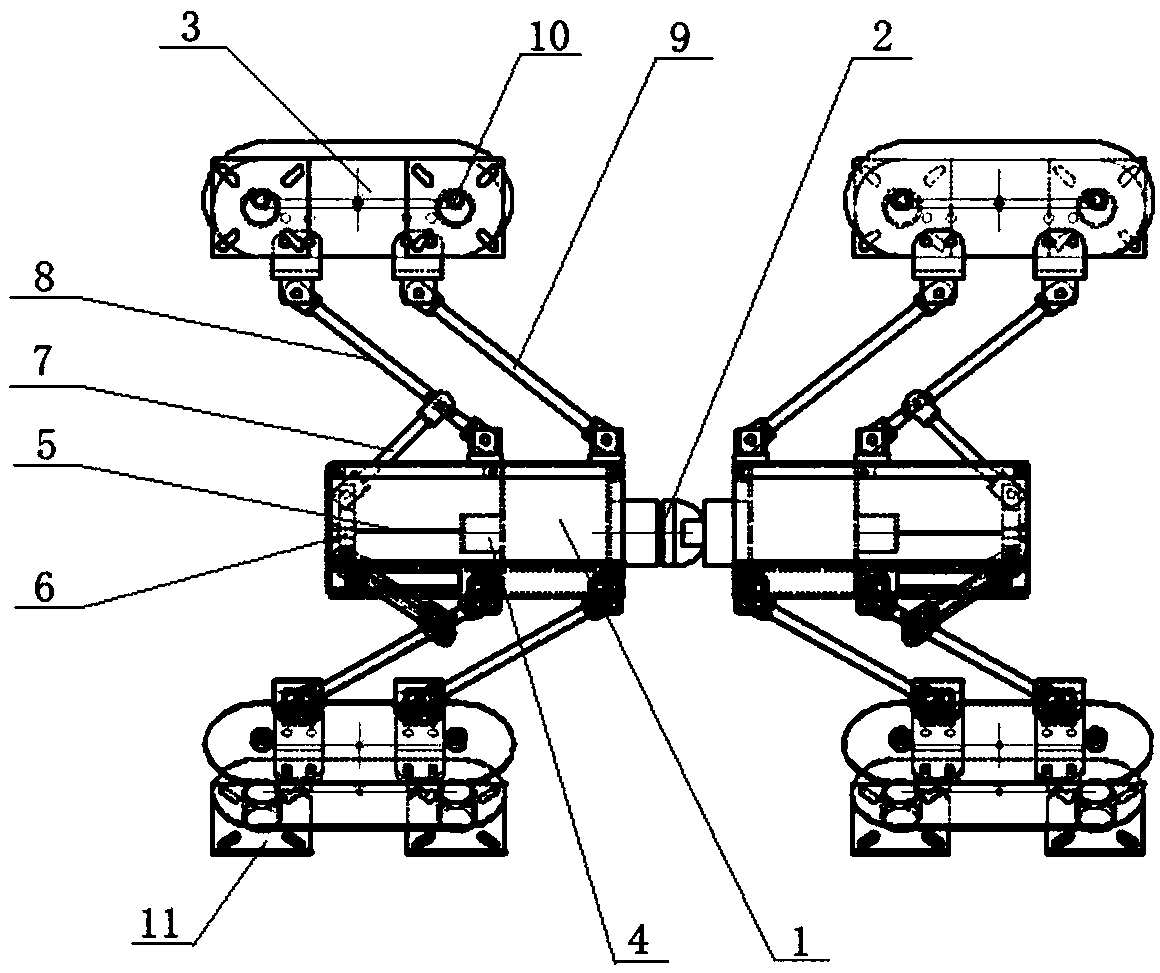

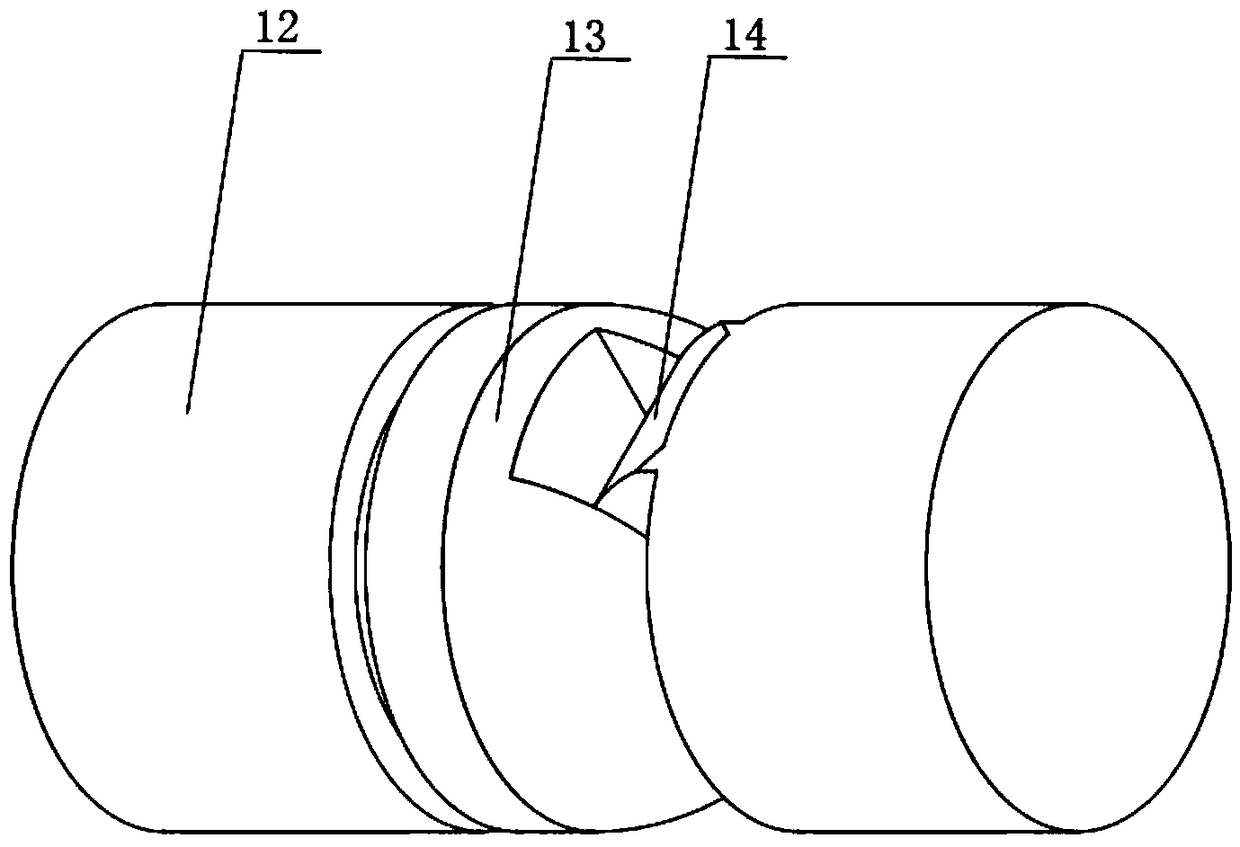

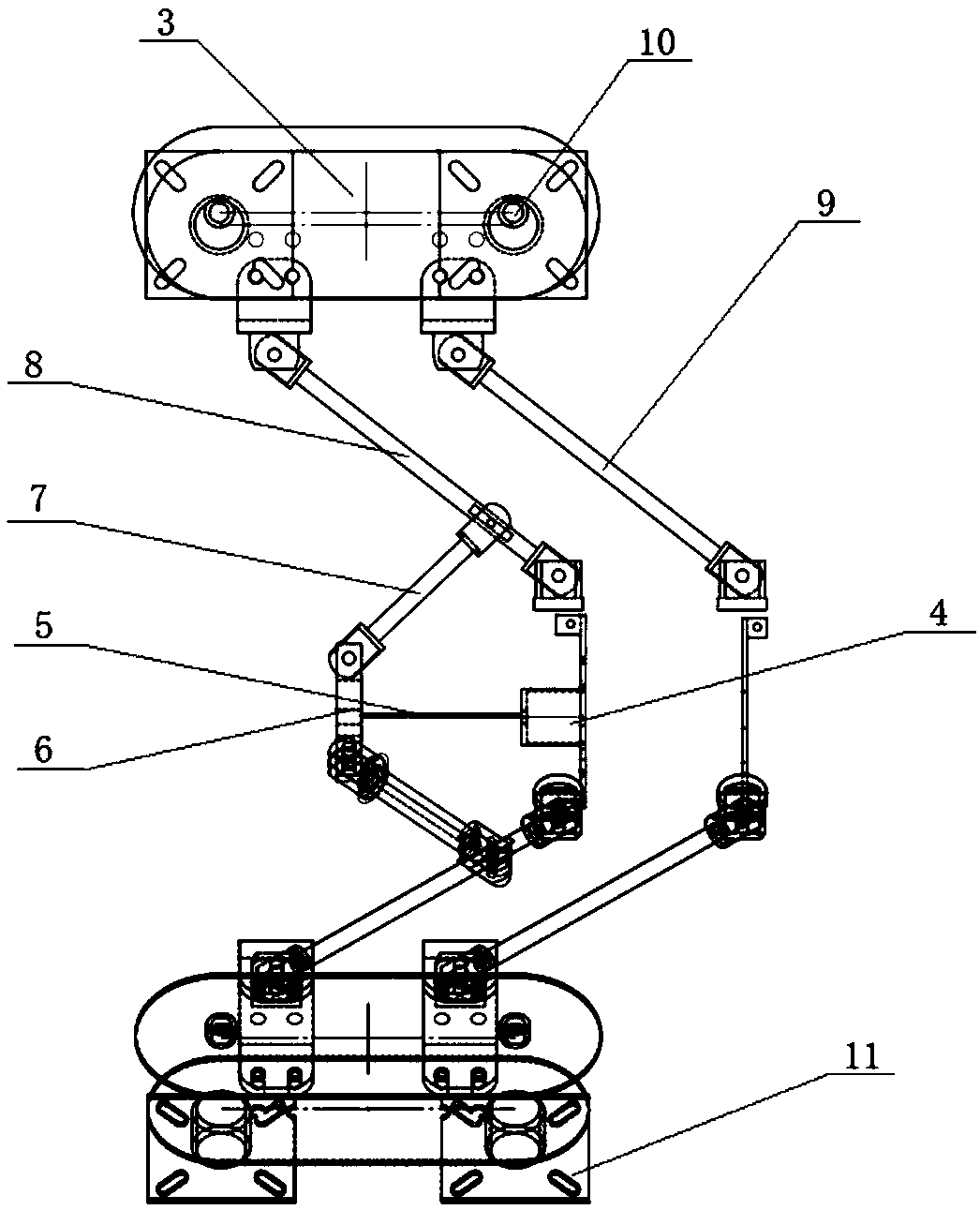

Novel pipeline robot

The invention discloses a novel pipeline robot. The robot is composed of two robot bodies which are the same in structure and are in mirror symmetry connection through a universal rotating module connector. Each robot body comprises a robot main body of a prismoid, three crawler-type walking mechanisms evenly arranged in the circumferential direction of the robot main body, and a connecting mechanism connected with the robot main body and the walking mechanisms. Each connecting mechanism is further connected with a stepping motor through a lead screw nut and a lead screw, and the stepping motors rotate to control the expanding degree of crawler belt feet. The novel pipeline robot has the beneficial effects that the pipeline robot can go straight and turn in a pipeline and can also move ina horizontal-to-vertical pipeline. The expanding angles of the crawler belt feet can be adjusted at any time by adjusting the connecting mechanisms to meet the walking needs of different pipe diameters. The crawler-type walking mechanisms are high in road holding force, the multiple motors carry out independent driving, the robot can adapt to various pipeline environments, and the whole equipmenthas the function of preventing water and corrosion.

Owner:DATANG ENVIRONMENT IND GRP

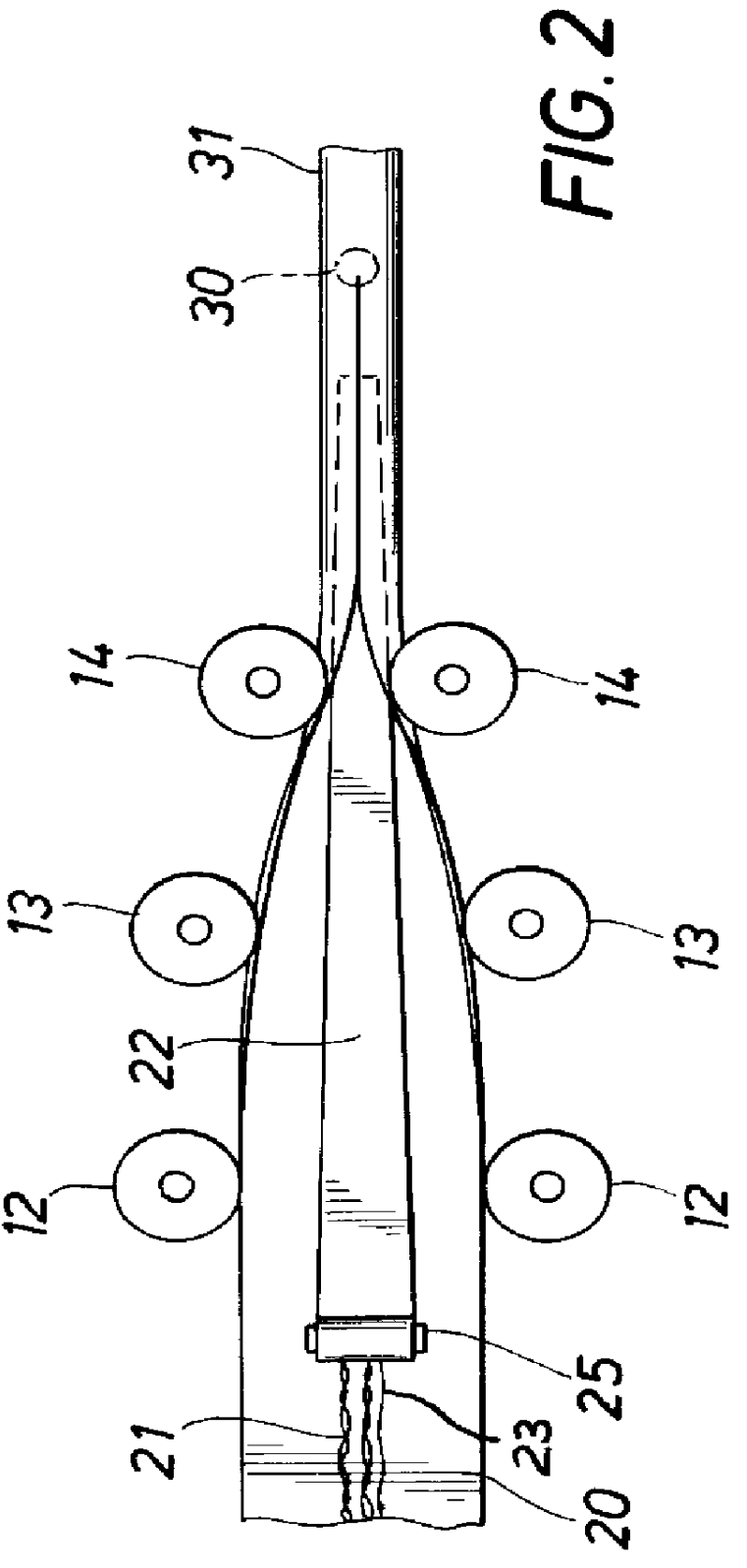

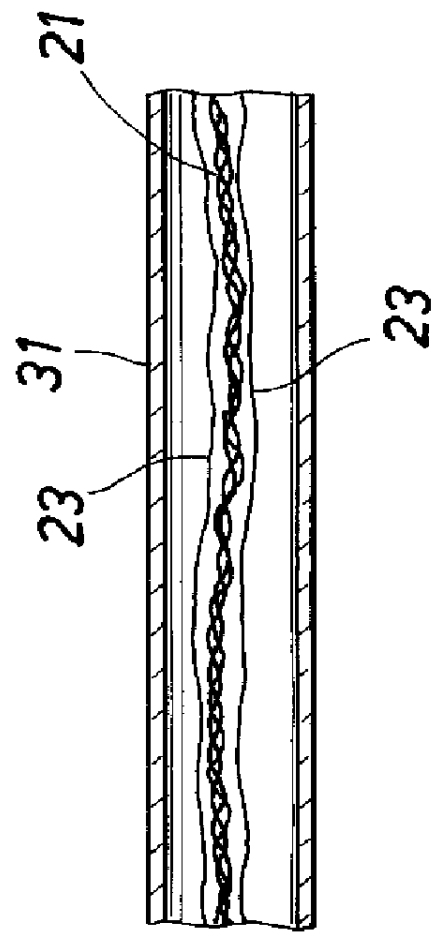

Temperature compensated wire-conducting tube and method of manufacture

InactiveUSRE36833E1Simple to manufactureHeat damageDrilling rodsRigid-tube cablesEngineeringElectrical conductor

A method and apparatus for manufacturing a continuous metal tube having a plurality of electrical conductors disposed therein, by using a spring member to depress the electrical conductors while a flat metal strip is formed into a tubular member and welded to enclose the electrical conductors. The spring member functions to protect the electrical conductors from heat damage. The welding occurs completely downstream of the spring member in order to avoid excessive heat buildup in the spring member.

Owner:QUICK CONNECTORS

Indoor/outdoor ball control training device

InactiveUS20080261727A1Fixed securityAvoid insufficient frictionGymnastic exercisingBall sportsEngineeringSupport surface

Owner:SNYDER GREGORY P

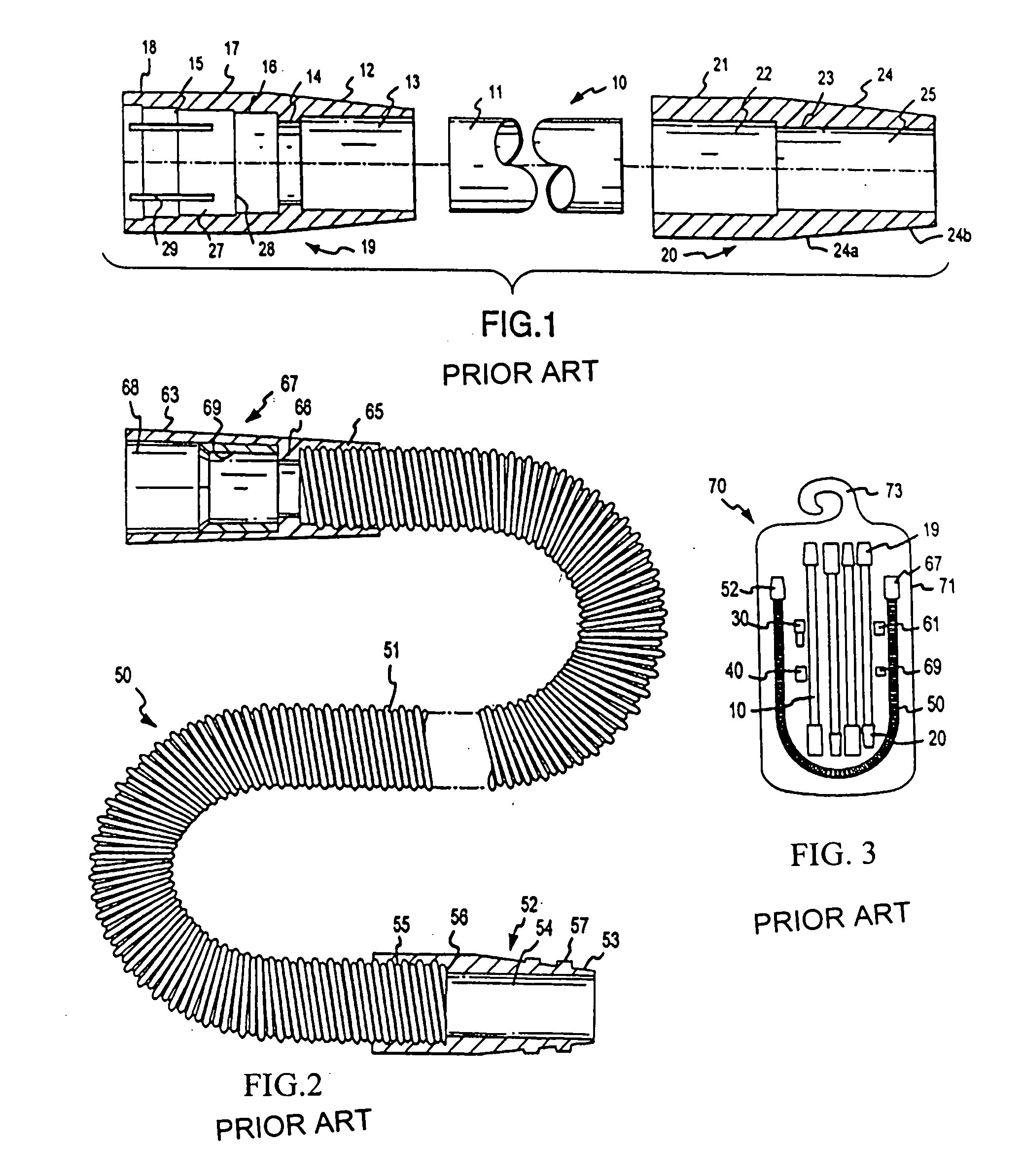

Elastic coupling for universal vacuum extension kit

InactiveUS20050134037A1Large amount of adjustmentExtensive controlSleeve/socket jointsSuction hosesCouplingEngineering

A quick-release, fluid impervious elastic coupling with hook and loop strips conforms to the shape of conduit ends to join, seal and secure together conduits that can have different diameters. The elastic sheet can be a single or multiple layers and can be reinforced with strengthening ribs or cords and / or provided with gripping ridges to assist securing and sealing the conduits against leakage.

Owner:BRUNO FR L +1

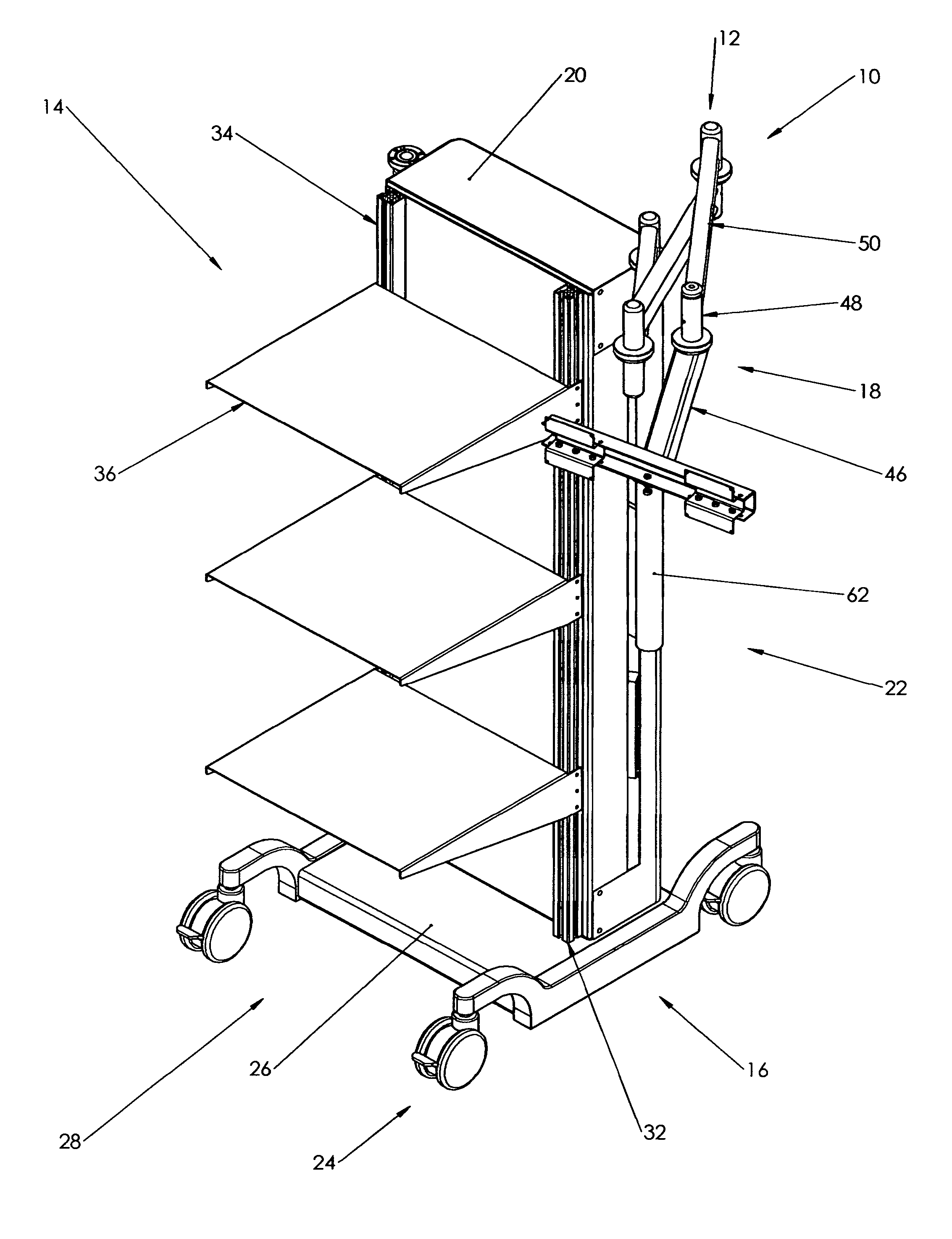

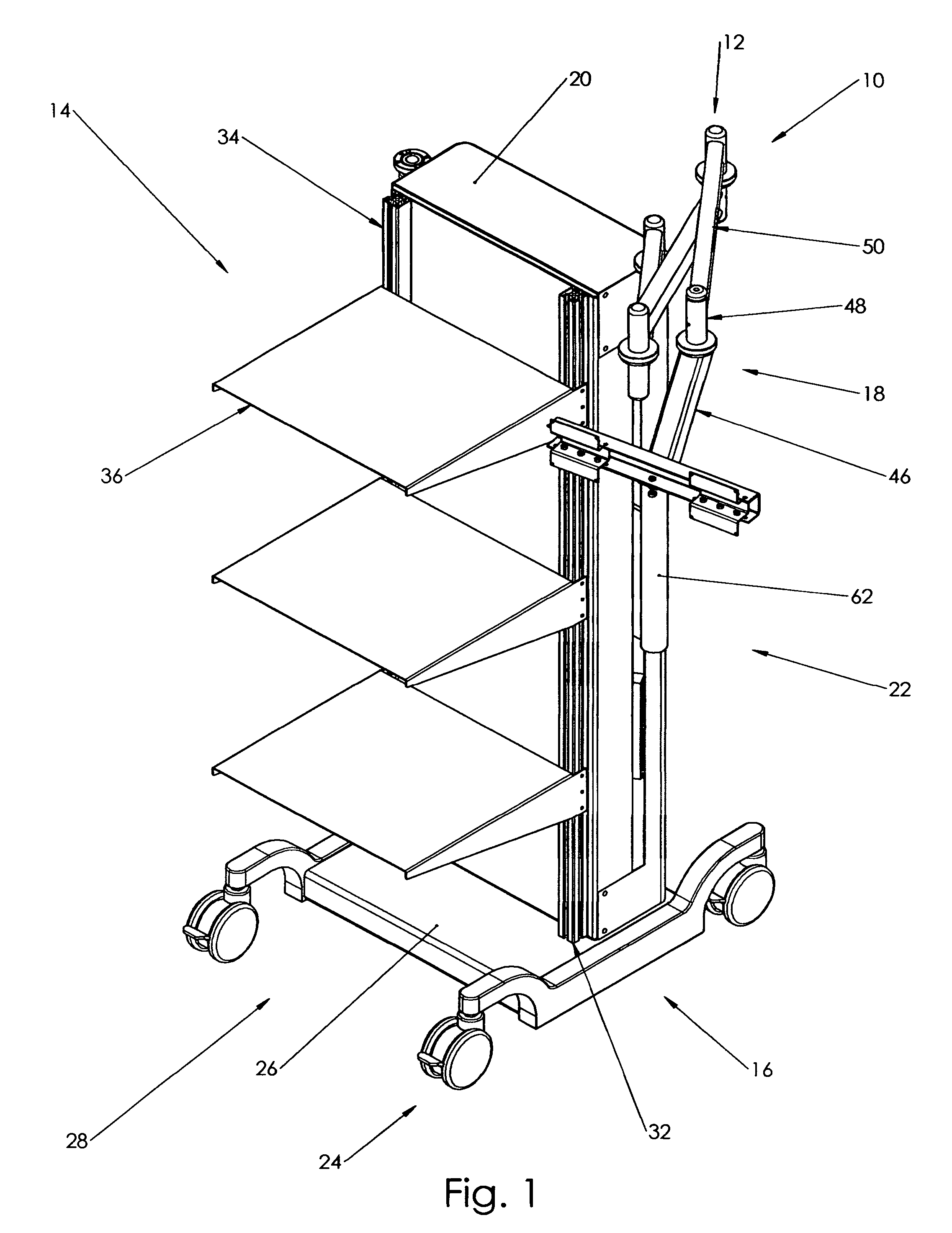

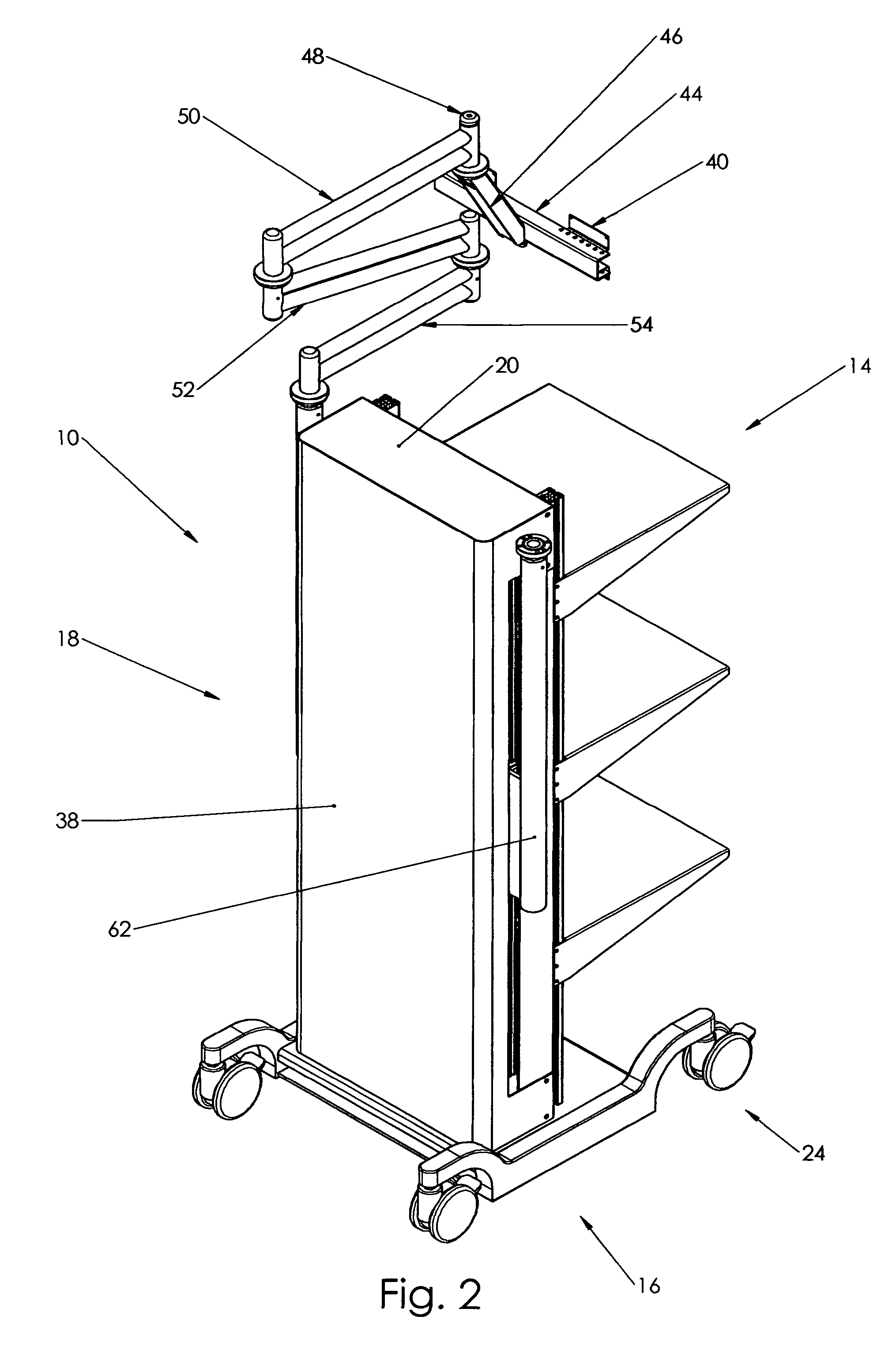

Mobile support cart for adjustable holding equipment

ActiveUS8474835B1Easy to adjustAvoid insufficient frictionSledge wheelsHand carts with one axisEngineeringNeutral buoyancy

A mobile support cart has one or more extendable and foldable arms to position one or more monitors or devices mounted to the extendable arm. The arm is mounted to a vertical column that is supported by a linear rail system providing vertical guidance. An adjustable counterweight carriage rides on a second rail set and is connected to each column through a chain and pulley. Each chain and pulley is fully redundant with two chains attached to discrete mounting points on each counterweight carriage and to each column. The amount of counterweight applied can be adjusted within a given load range by adding additional plates / ballast to the counterweight carriage. When the load on the arm(s) are fully offset by ballast on the counter weight carriage the arms and payloads reach a “neutral buoyancy” condition. The system maintains the position once an operator has released them.

Owner:ROSSI REMO J

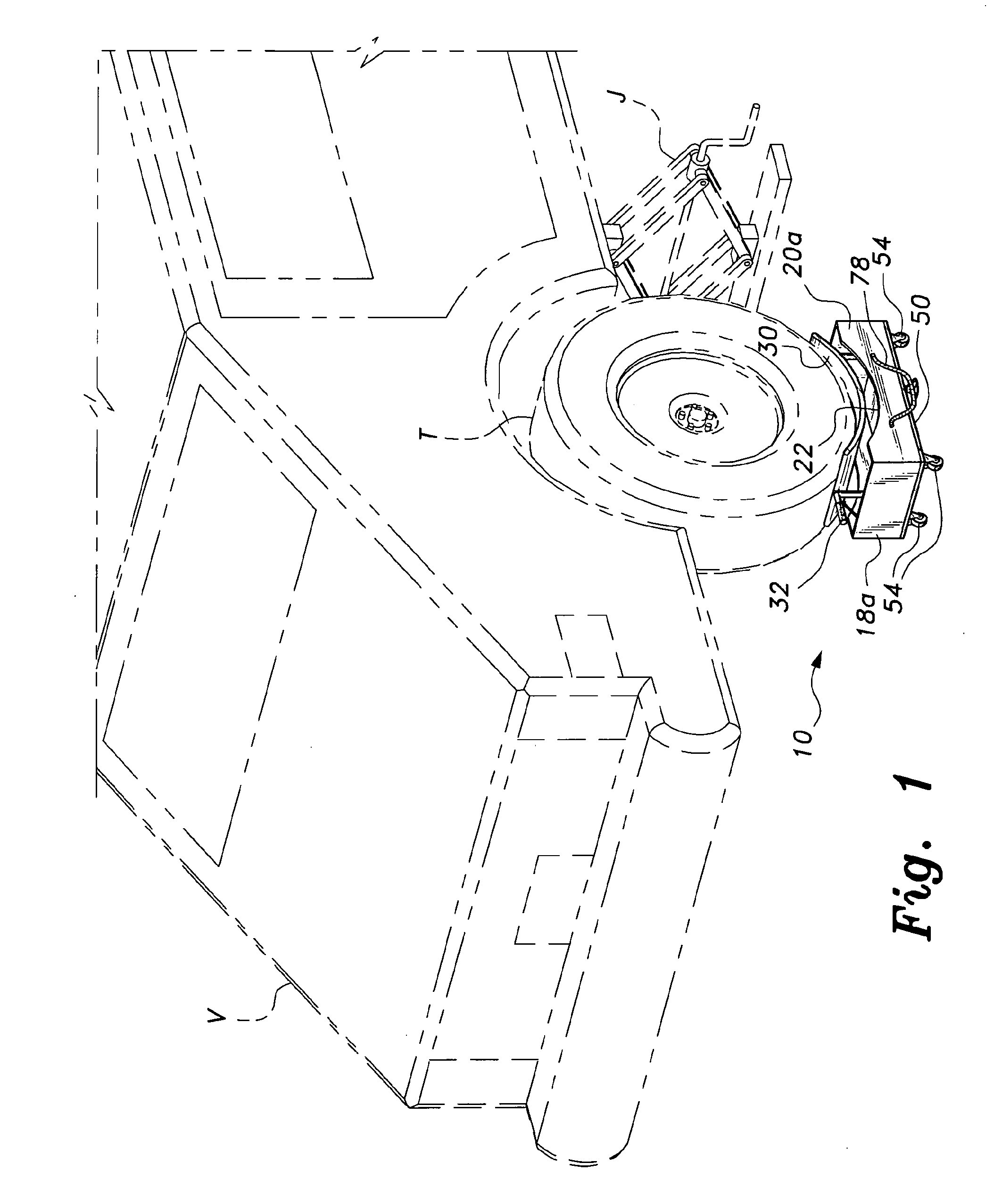

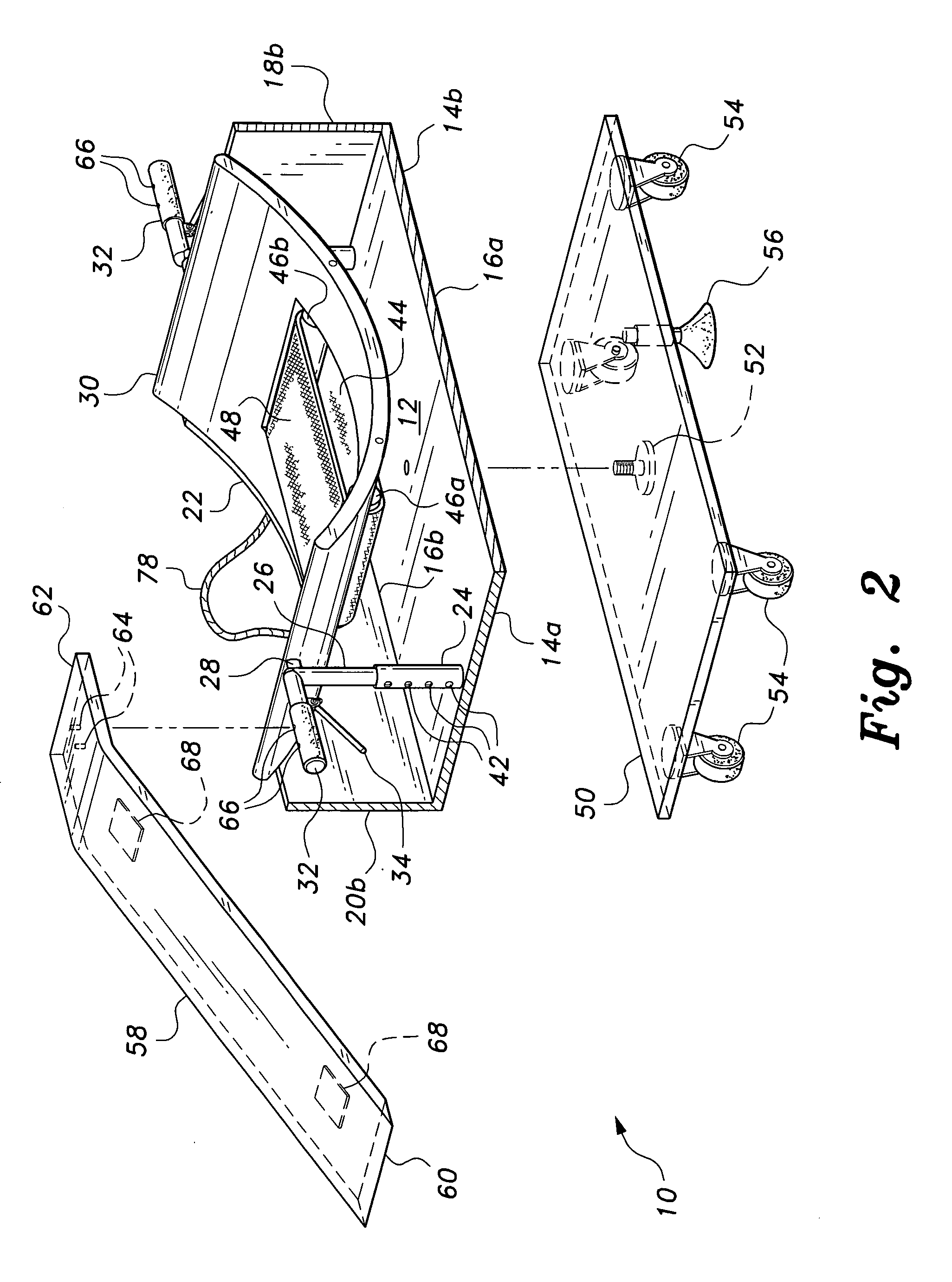

Tire-handling device

InactiveUS20100092270A1Easy to carryClearance can be providedStatic/dynamic balance measurementTyresMobile vehicleMotorized vehicle

The tire-handling device (10) is a compact, lightweight tool for carriage within a motor vehicle trunk or storage compartment to facilitate handling of a tire (T) during a tire change or similar operation. The device includes a tire support cradle (30) supported by opposed vertically adjustable handles (32). The handles (32) and cradle (30) therebetween may be adjusted to position the cradle (30) beneath a tire (T) on a raised axle during a tire change, or for aligning a fresh tire with the wheel mounting studs of the wheel hub. Two mutually opposed tire support belt rollers are disposed within the cradle (30). A tire support belt extends between the rollers, allowing a tire (T) resting thereon to be rotated for alignment with the mounting studs of the vehicle wheel hub.

Owner:ADAMS SKY A

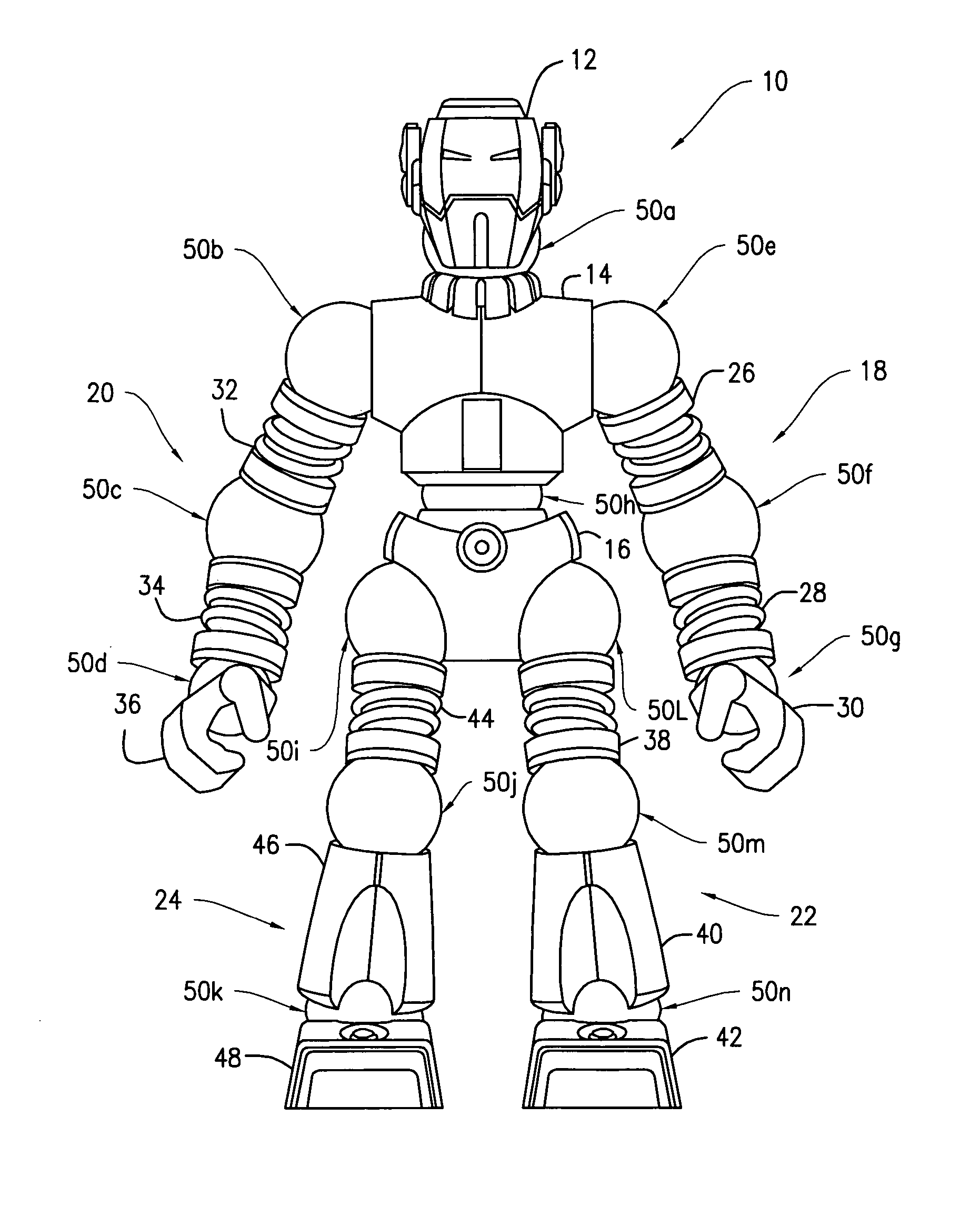

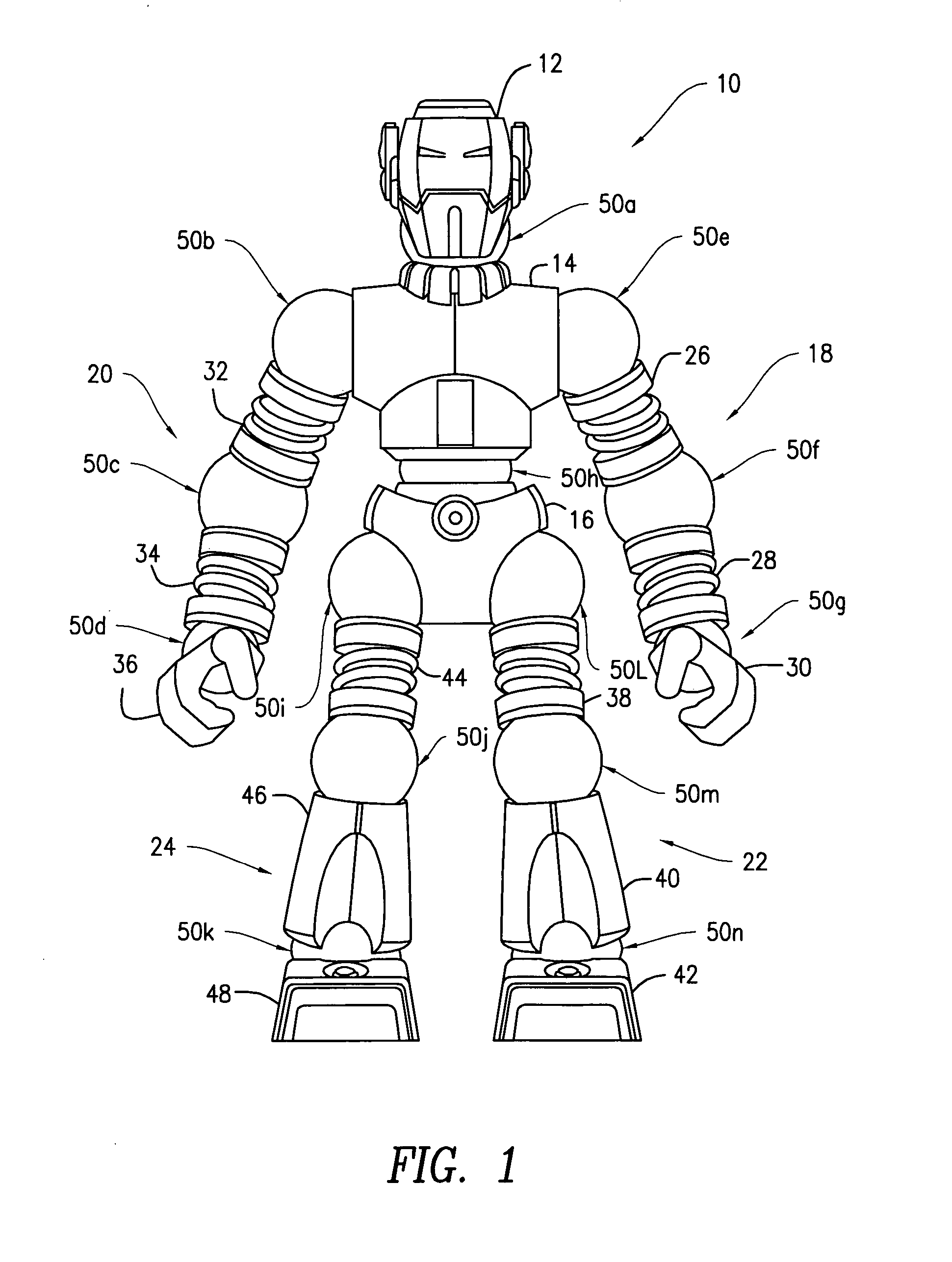

Magnetic joints and toy figurines made therefrom

InactiveUS20060178081A1Easily and quickly assembleQuick and convenient assembly and disassemblyDollsMagnetEngineering

Owner:MEGA BRANDS INT R L LUXEMBOURG ZUG BRANCH

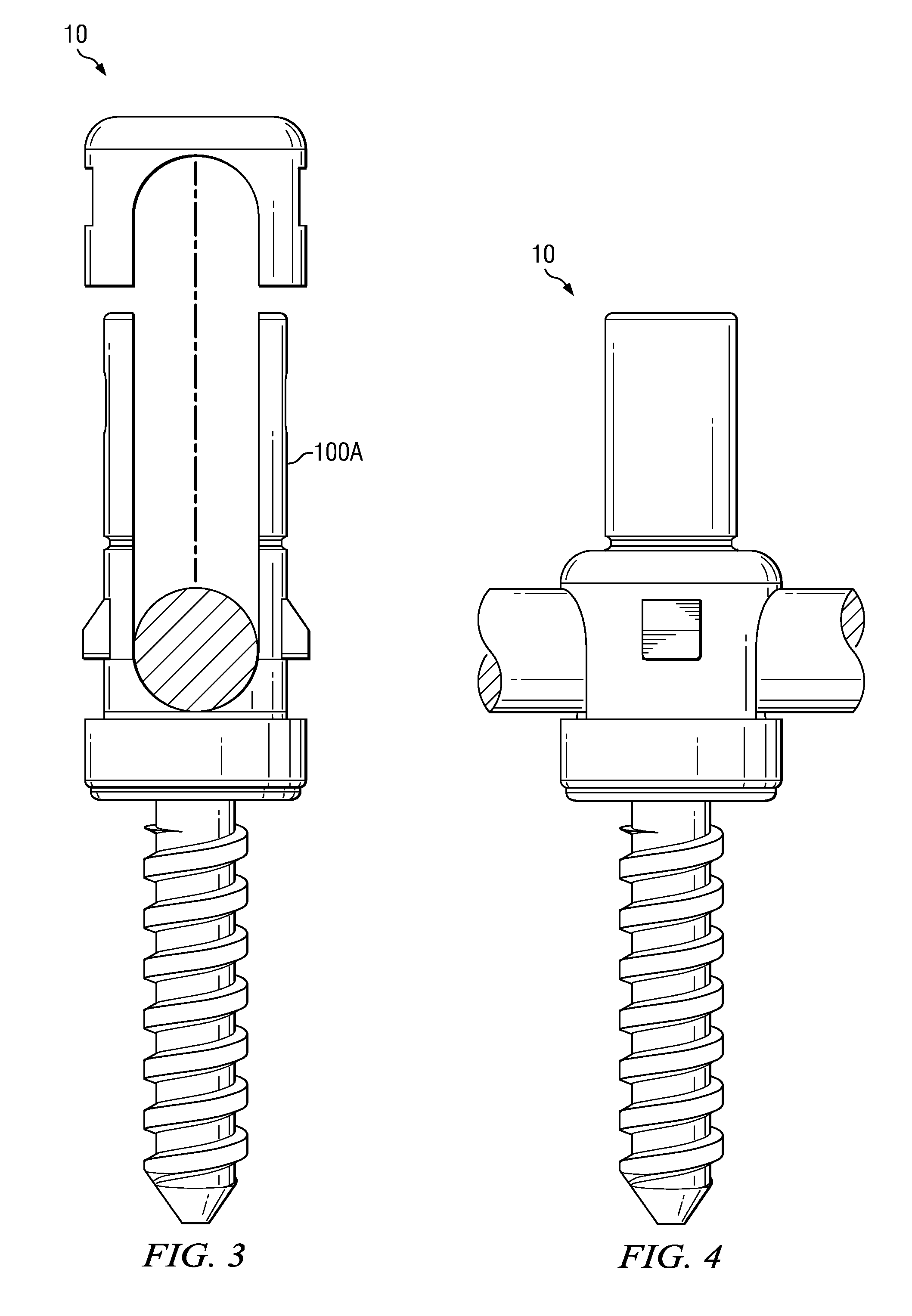

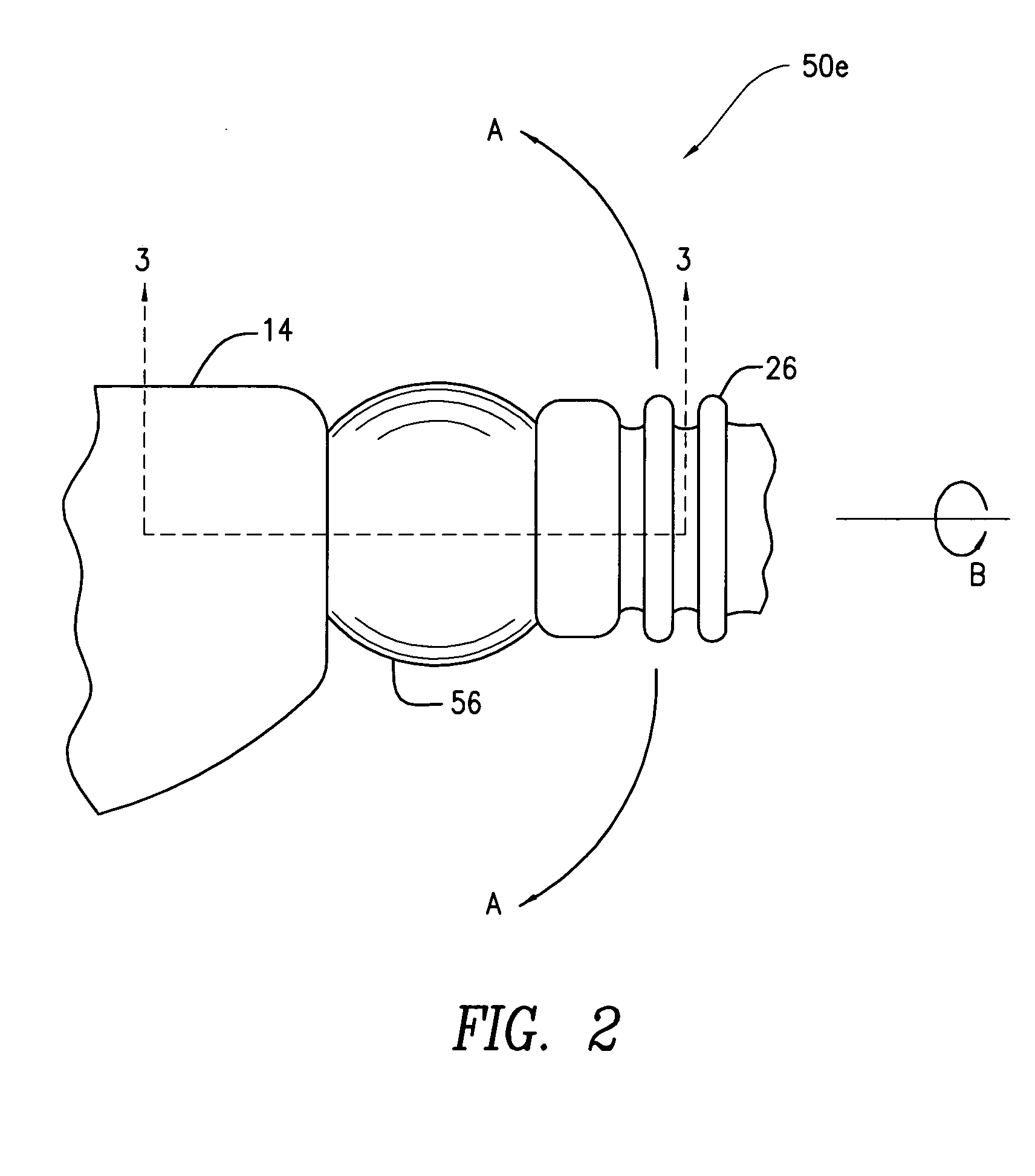

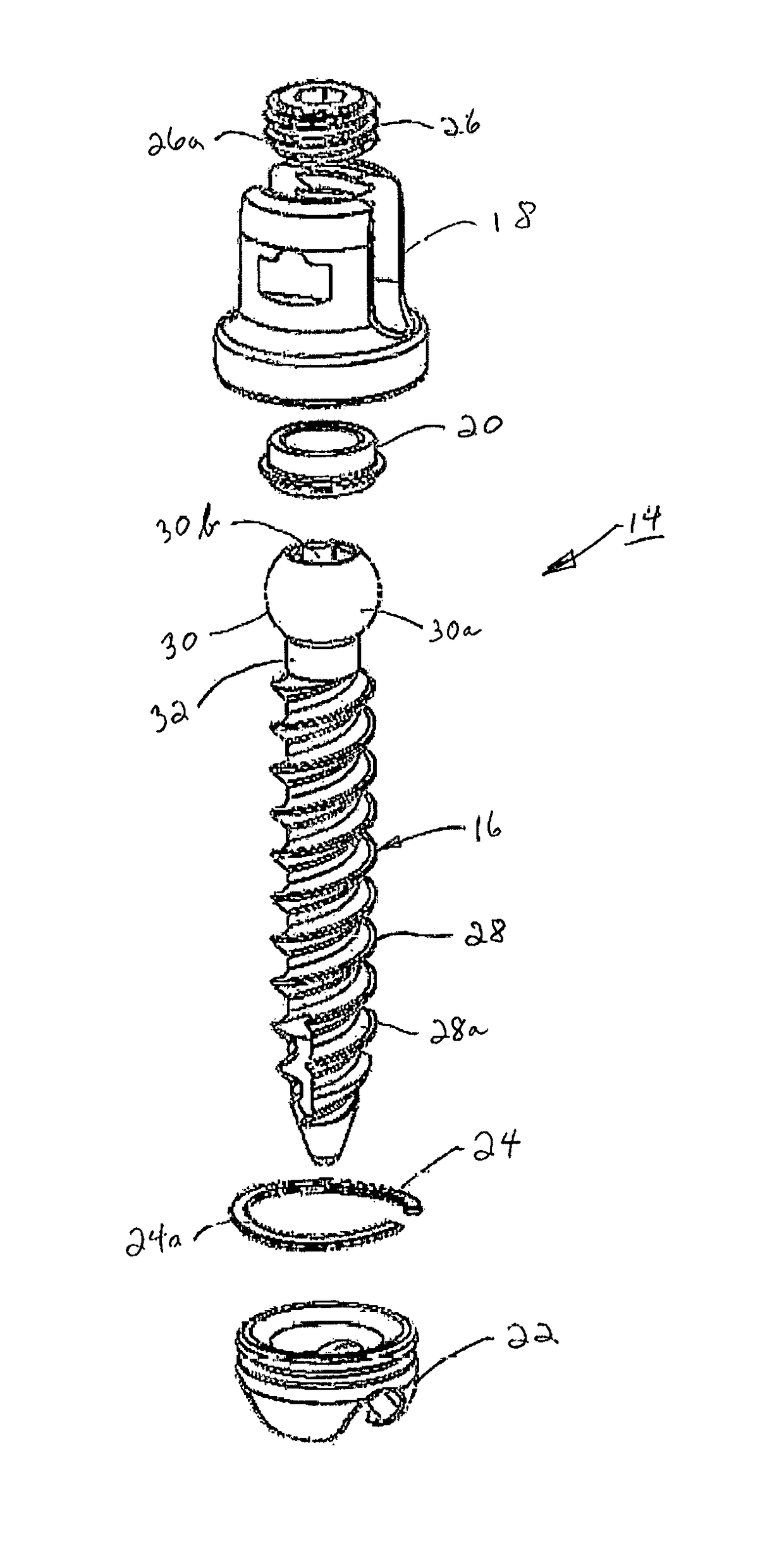

Polyaxial bone screw

ActiveUS9763700B1Avoid insufficient frictionHigh degree of angulationInternal osteosythesisFastenersSet screwBiomedical engineering

A polyaxial bone screw for attaching a rod to a vertebra comprises a fastener having a threaded shank and a head. A yoke has a rod receiving channel for receiving the rod. A screw support rotatably attached to the yoke has a cavity articulatingly and rotatably supporting the fastener head, a hole receiving the threaded fastener shank therethrough, and a plurality of slots for maximum screw angulation. A crown has an upper rod receiving surface, a lower surface in contact with the fastener head and a projecting surface in contact with the yoke. A biasing element between the screw support and the yoke applies biasing forces among the fastener, the crown, and the yoke to provide sufficient friction to retain the yoke in a manipulable position relative to the fastener. A set screw is supported by the yoke overcome the bias and to rigidly secure the components.

Owner:SPINEWAVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com