Combination outsole and friction sheet

a friction sheet and outsole technology, applied in the field of outsoles, can solve the problems of poor friction of the tread portion, difficult to have deep grooves in the thin outsole, and high cost of molds for making deeper tread portions, and achieve the effect of better friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

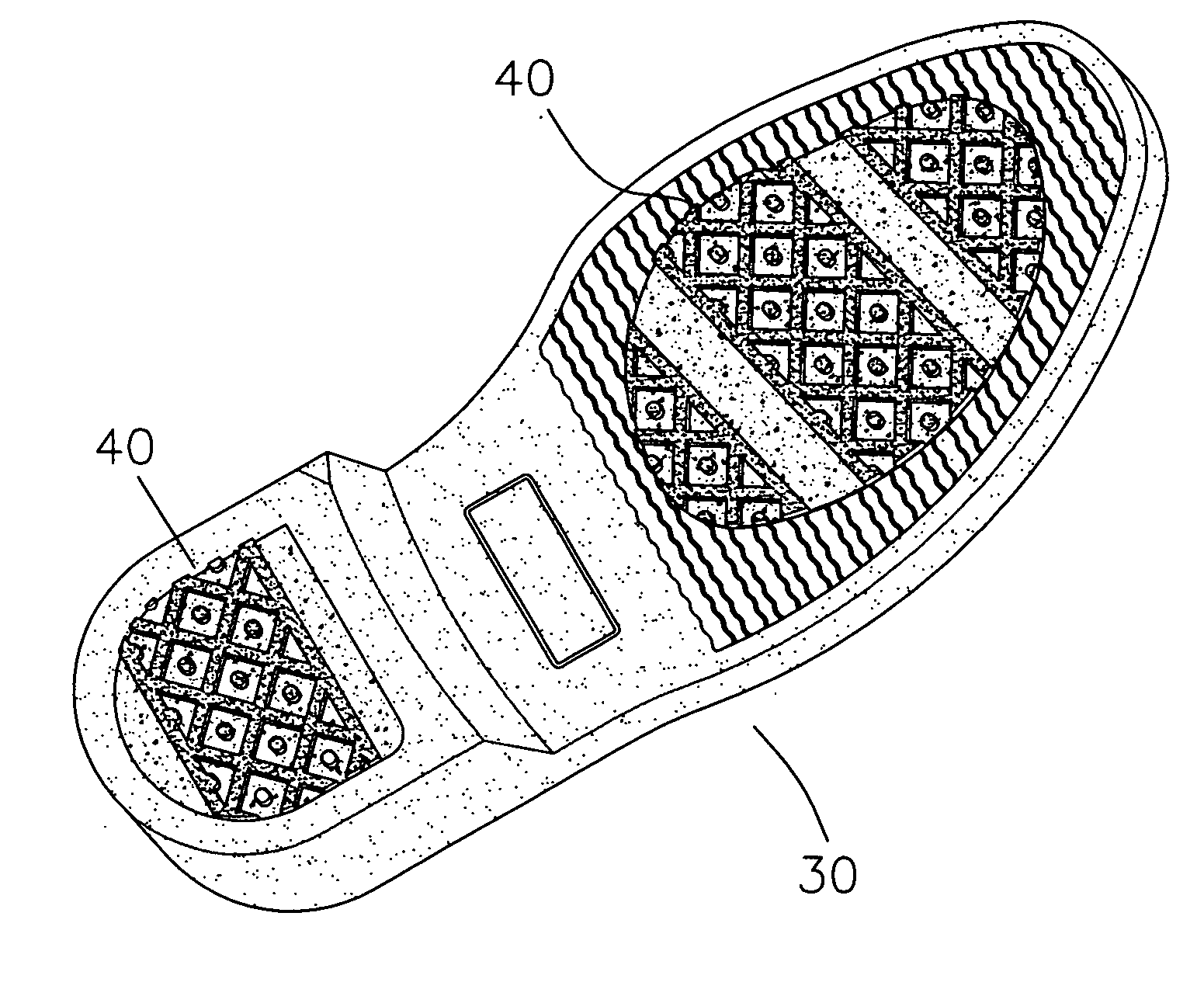

[0011] Referring to FIG. 1, the friction sheet 20 of the present invention comprises a fabric sheet 22 and a friction surface 22 is formed on a surface of the fabric sheet 22. The friction surface 22 may include ridges and grooves so as to provide sufficient friction with the roads and can be made by any proper material such as rubber. The fabric sheet 22 is made by non-woven fabric. The material of the friction surface 22 can be connected to the fabric sheet 22 by way of heat transferring so that the material is combined with the fabric sheet 22. The friction sheet 20 is attached to an outsole 10.

[0012] The color, shape and sizes of the friction sheets 20 can be made to meet different requirements so that the friction sheet 20 can also attract people's attention when walking or jogging.

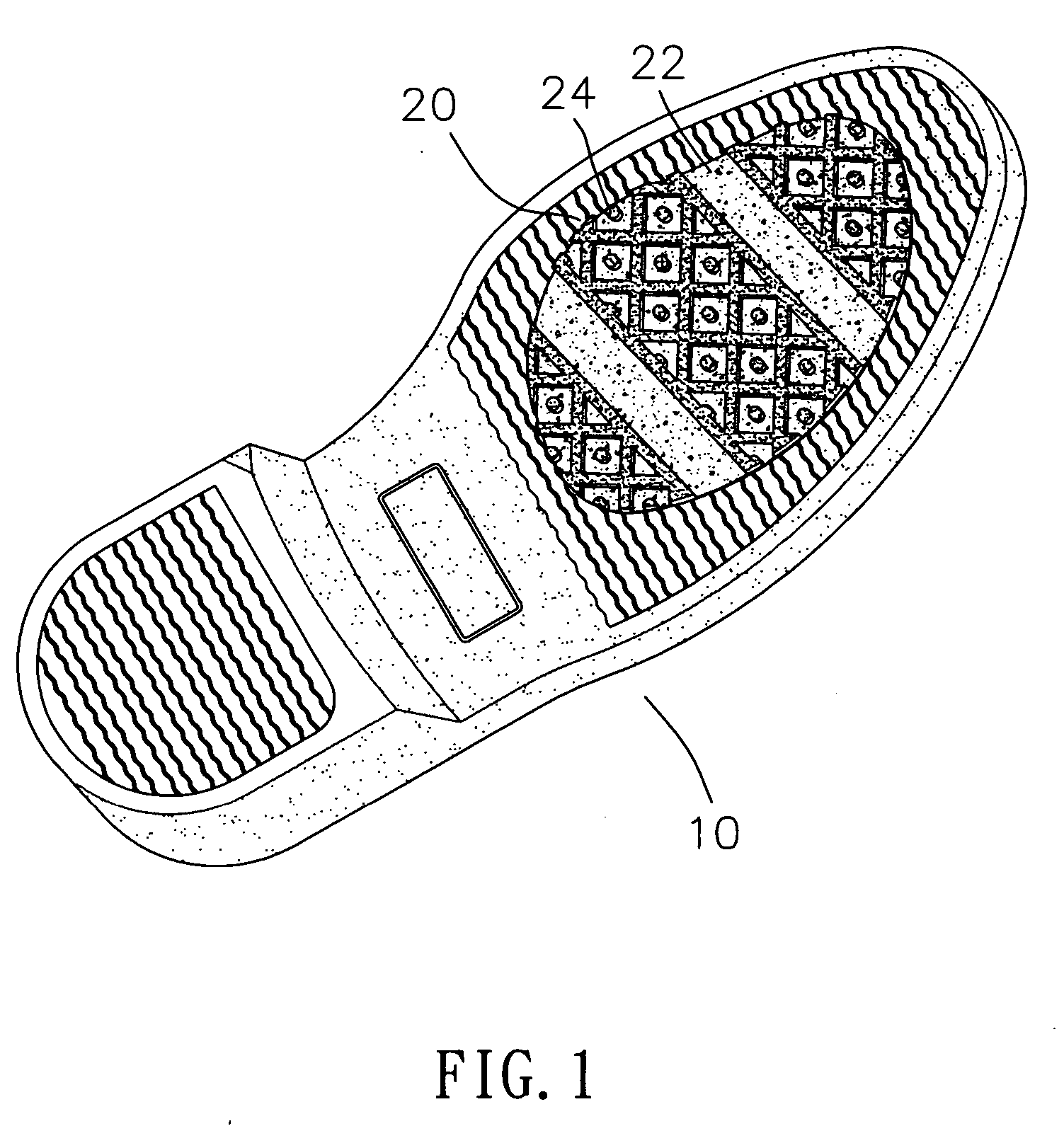

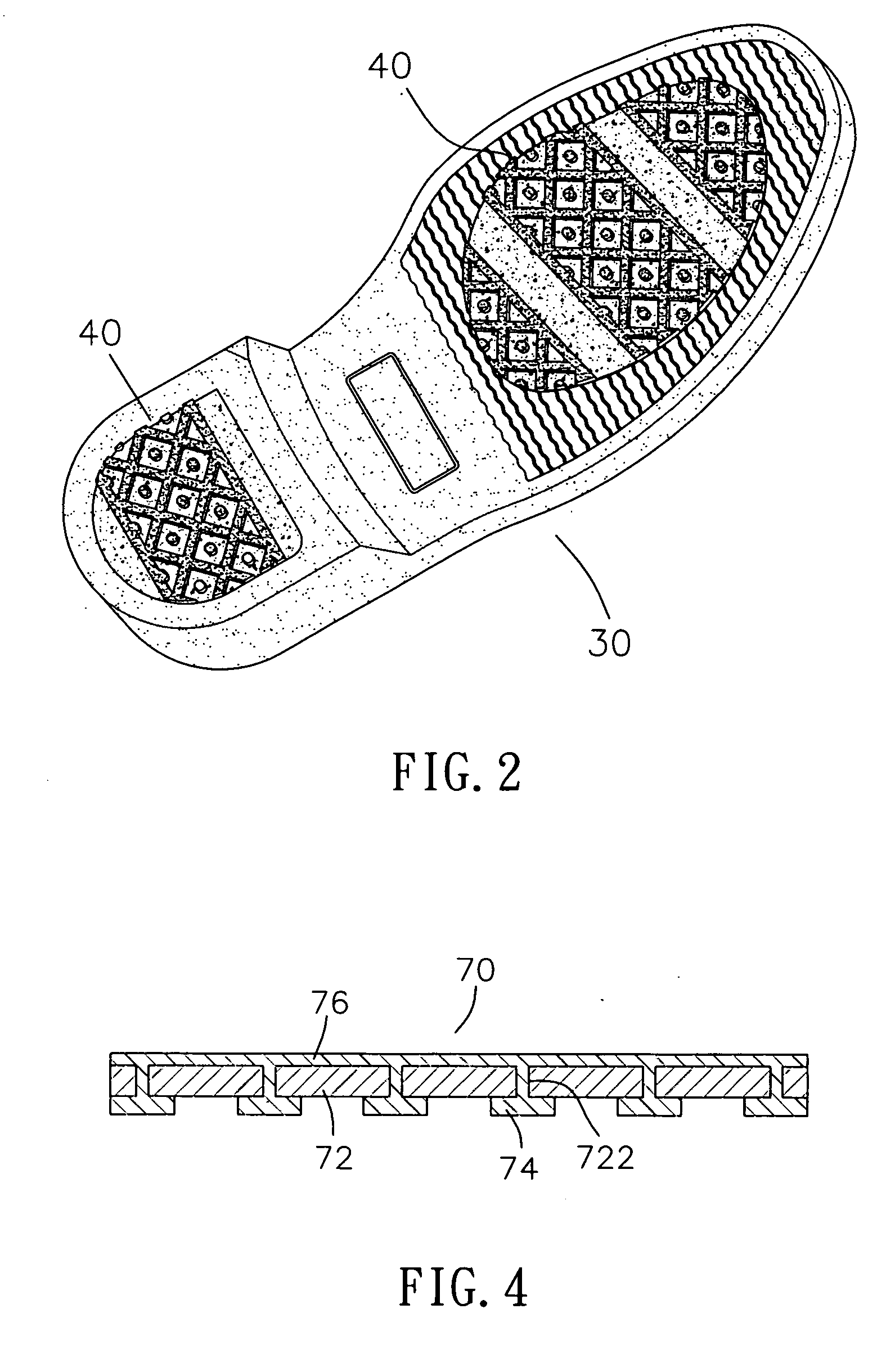

[0013] As shown in FIG. 2, a shoe may be cooperated with two friction sheets 40 which are attached to the outsole 30 and the heel.

[0014]FIG. 3 shows that the outsole 50 includes a recess 52 define...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com