Dry quenching expansion joint firebrick structure construction technology

A construction process and technology of expansion joints, which are used in coke ovens, petroleum industry, coke cooling, etc., can solve problems such as inconvenience of expansion joints, and achieve the effect of reducing maintenance costs and shortening construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

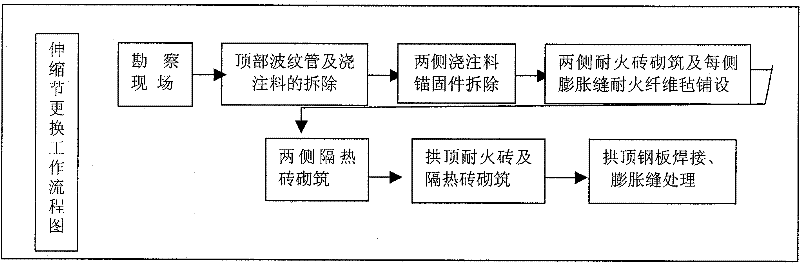

[0027] The CDQ expansion joint refractory brick structure construction process of the present invention can be constructed according to the flow chart of the main construction process for CDQ expansion joint maintenance listed in Table 1.

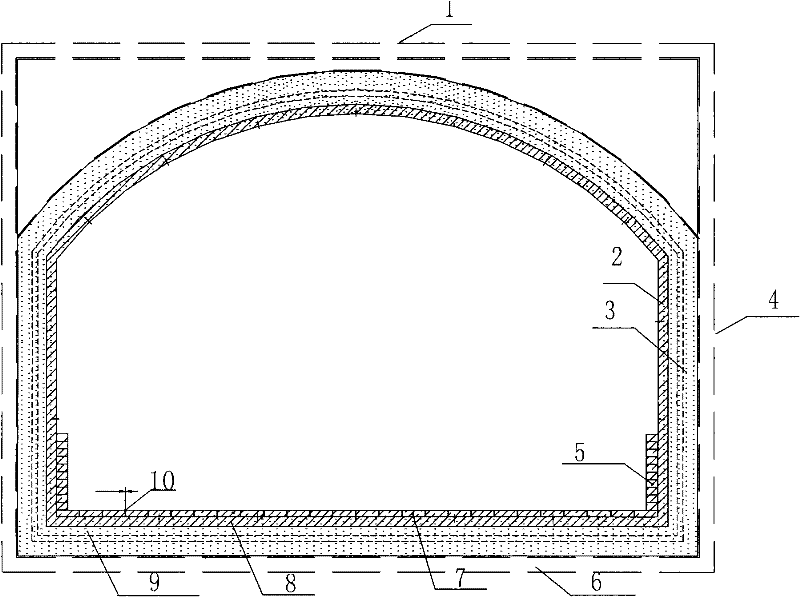

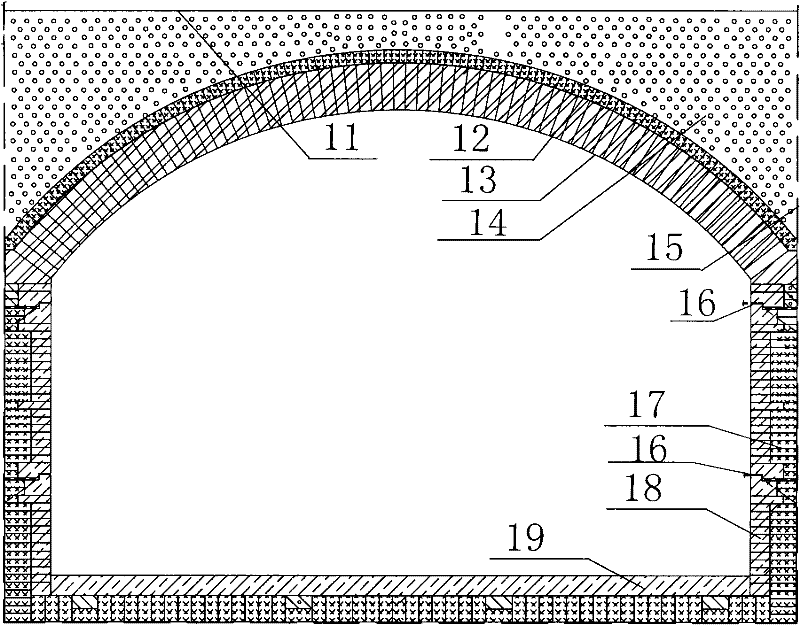

[0028] see now Figure 2 to Figure 4 , figure 2 Change the expansion joint of the present invention into a structural representation of refractory bricks, image 3 It is a schematic diagram of changing the section structure of the expansion joint side wall of the present invention, Figure 4 It is a structural schematic diagram of the refractory brick at the top of the expansion joint of the present invention. As shown in Table 1, when the CDQ expansion joint refractory brick structure construction process of the present invention is implemented, it is first necessary to survey the site, retain the bottom structure of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com