Construction technology for converting floor-type scaffold to cantilevered scaffold

A construction technology and scaffolding technology, which is applied to the accessories of scaffolding, building structure support, building structure support, etc., to achieve the effects of saving time and workload, simple conversion methods, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

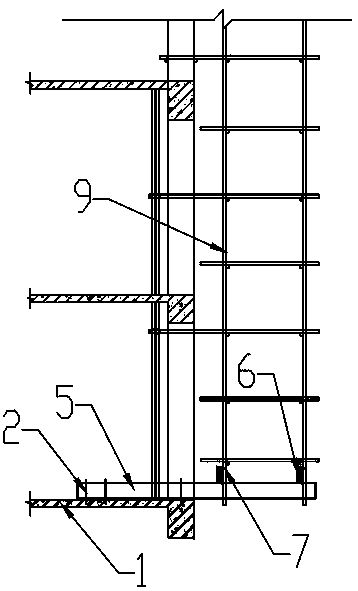

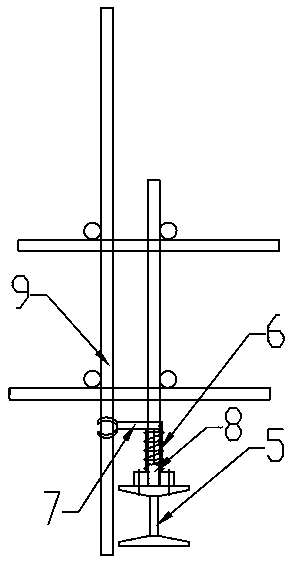

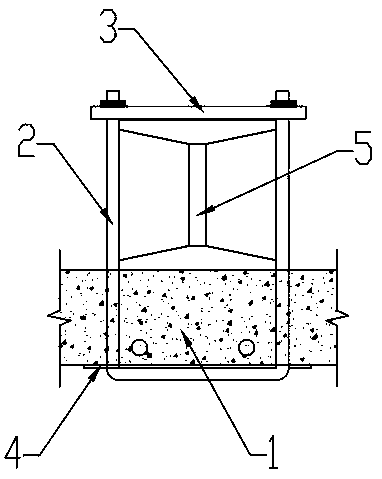

[0025] The construction technology of floor-to-ceiling scaffold to cantilever-type scaffold provided by this embodiment includes the following steps: S1, draw the bottom support structure diagram of cantilever-type scaffold according to the span of floor-to-ceiling scaffold; S2, according to the cantilever-type scaffold in S1 According to the design requirements of the I-beam 5 in the bottom support structure diagram, the corresponding number and length of the I-beam 5 are cut out, and a plurality of vertical poles are welded on one of the webs of the I-beam 5 according to the distance between the vertical poles 9 of the floor-standing scaffold. Reinforcement pipe 8, the spacing and quantity of the vertical reinforcement pipe 8 are corresponding to the spacing and quantity of the vertical pole 9 of the floor-standing scaffold (such as Figure 4 shown); S3, install the I-beam 5 according to the support structure diagram at the bottom of the cantilevered scaffold in S1, and place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com