A Construction Technology of High Precision Reinforced Concrete Reaction Wall

一种钢筋混凝土、施工工艺的技术,应用在建筑材料的处理、建筑、建筑物构造等方向,能够解决很难达到精度等问题,达到施工精度容易控制、减小误差、加快施工进度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

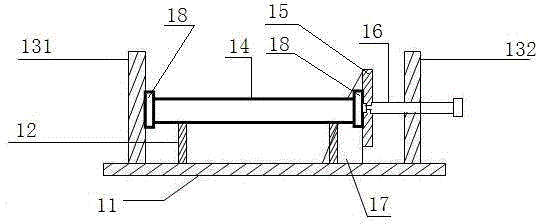

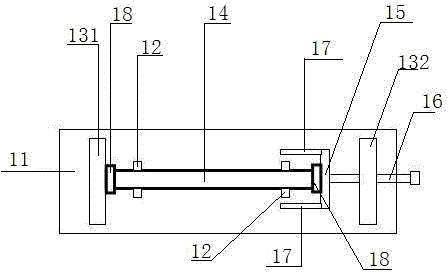

[0043] In an embodiment, a structural mechanics laboratory is selected with a building area of 720 square meters. The reaction wall pedestal is 14.9 meters wide from north to south, 22.6 meters long from east to west, and 1.8 meters thick. The storey height is 2.5 meters, the third storey height is 2.7 meters, the wall thickness is 1.2 meters, the total concrete consumption is 951.78 cubic meters, the steel bar is 460 tons, the formwork is 790 square meters, and the spacing of loading holes is 500mm.

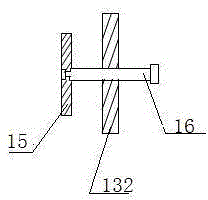

[0044] The vertical angle steel bracket is L80×50×8, the horizontal angle steel bracket is L50×4,

[0045] The design requirement error is:

[0046] The flatness of the loading groove surface is ≤3mm, and the axis offset is ≤1.5mm;

[0047] The flatness of the loading hole installation is ≤1.5mm, and the displacement of the center distance is ≤1.5mm;

[0048] The verticality deviation of the reaction wall is ≤5mm.

[0049] The specific construction process is as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com