Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2191results about How to "Guaranteed verticality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

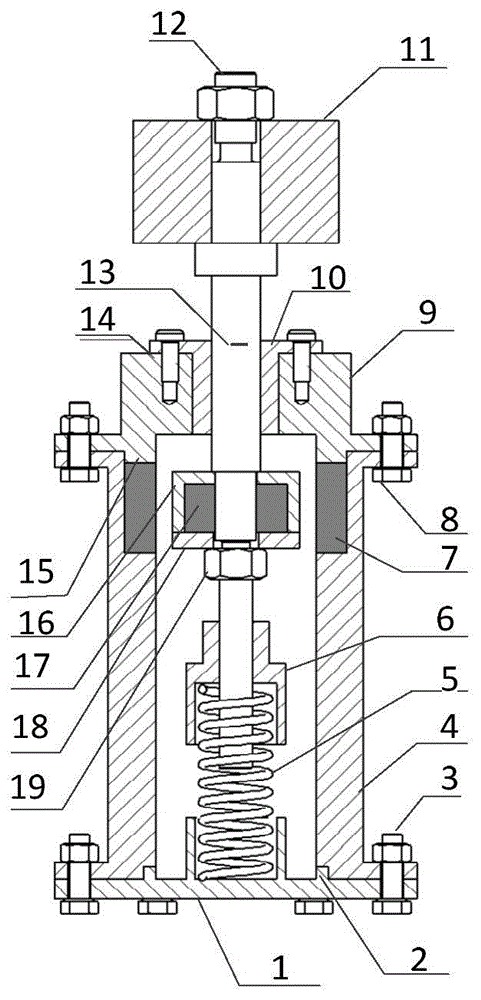

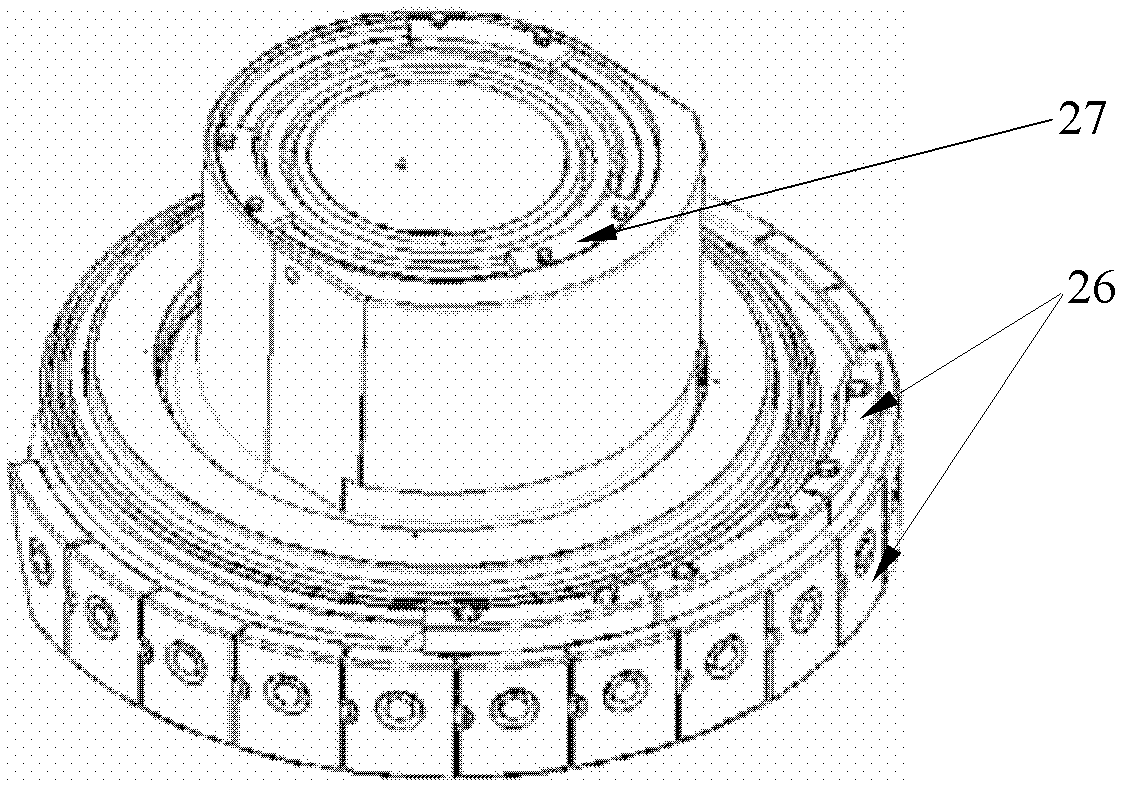

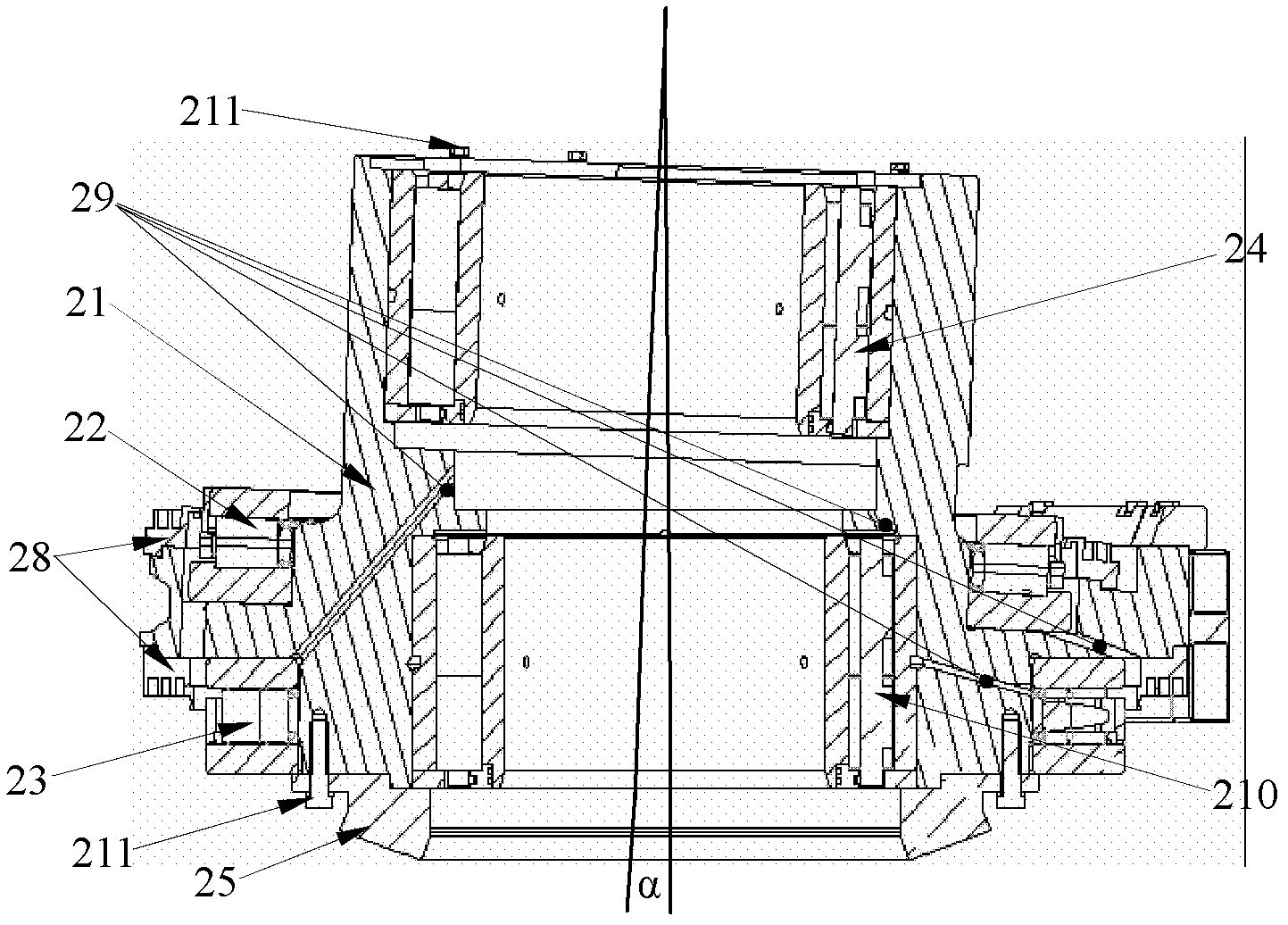

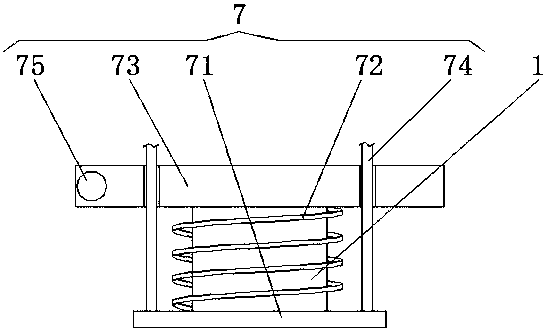

Quasi-zero stiffness vibration isolator with annular permanent magnets used for generating negative stiffness

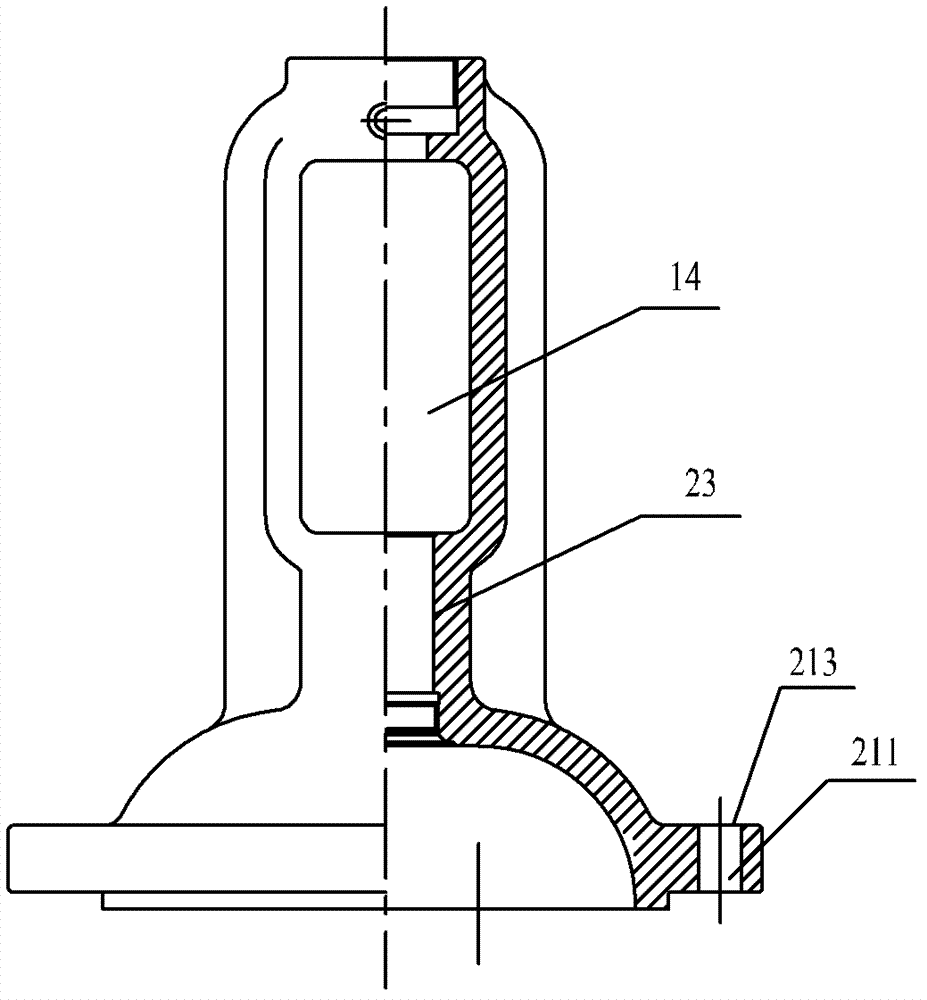

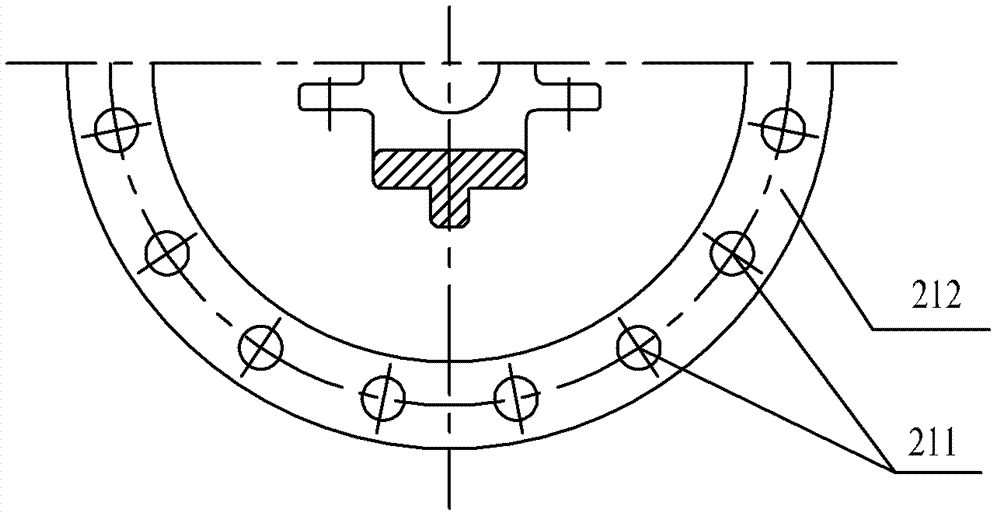

InactiveCN104455181ALarge negative stiffnessImprove uniformityMagnetic springsShock absorbersDynamic stiffnessNegative stiffness

A quasi-zero stiffness vibration isolator with annular permanent magnets used for generating negative stiffness comprises a base and an outer cylinder connected with the base, the outer permanent magnet is arranged in a top notch of the outer cylinder, an upper cover is connected with the outer cylinder, a sliding bearing is combined with a central hole of the upper cover in a sleeved mode, and a central shaft is sleeved with the sliding bearing and is in clearance fit with the sliding bearing. A sleeve and an adjusting sleeve are sequentially connected to the position, located on the lower portion of the sliding bearing, of the central shaft, and the inner permanent magnet is installed in the sleeve. A spring is arranged at the bottom of the central shaft in a sleeving mode, the bottom end of the spring is fixed to the base, and the top end of the spring is fixed to the adjusting sleeve. A mark line on the central shaft is used for representing the position of the inner permanent magnet relative to the outer permanent magnet. When the mark line coincides with the upper end face of the sliding bearing, the inner permanent magnet exactly faces the outer permanent magnet, and the isolator is in a normal working state. The quasi-zero stiffness vibration isolator has the advantages of being high in static stiffness and low in dynamic stiffness, basic stimulation with large amplitude can be isolated, and the mass of a vibration-isolated objected can be adjusted.

Owner:XI AN JIAOTONG UNIV

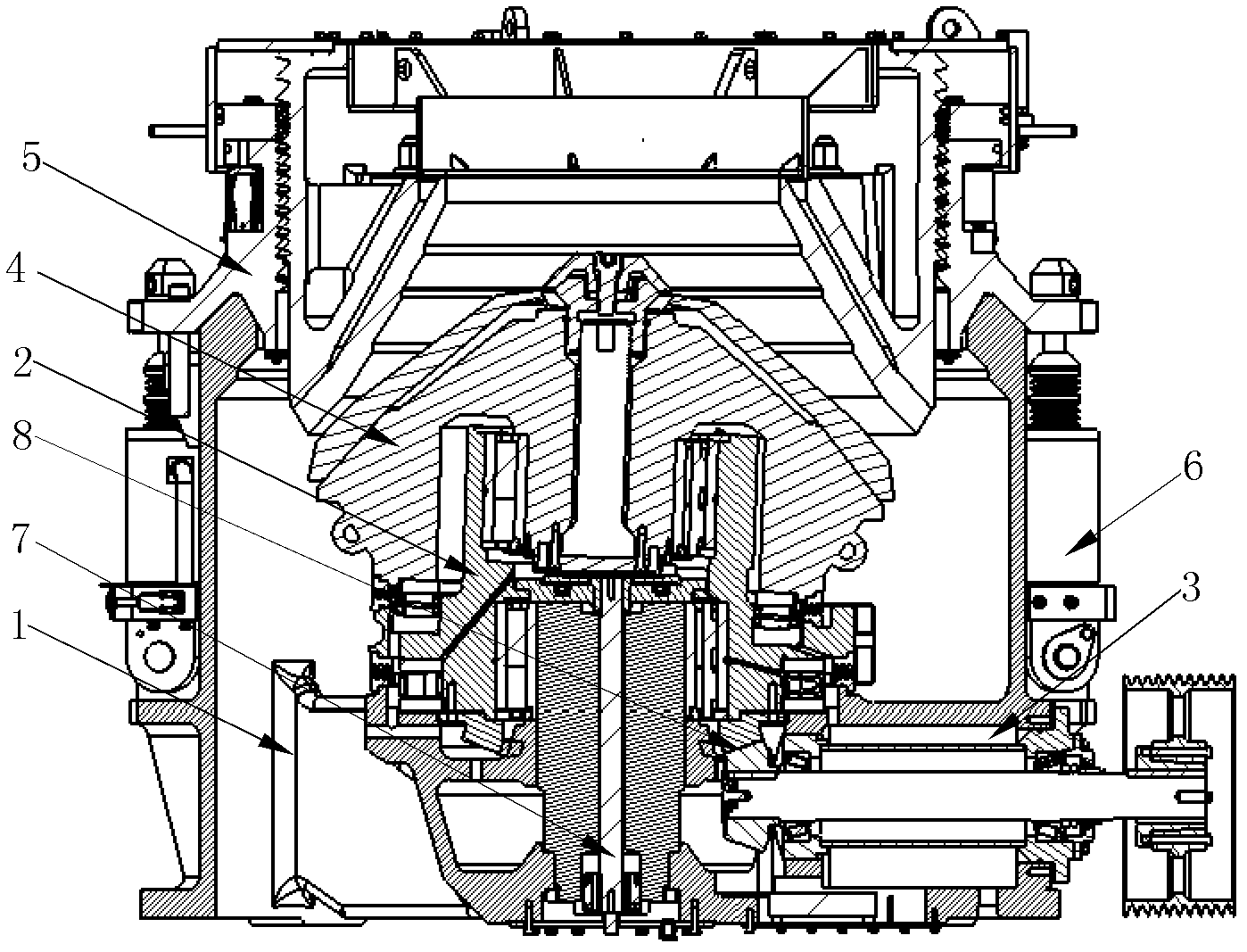

Multi-cylinder hydraulic antifriction bearing taper crusher

ActiveCN102357371AIncrease speedImprove crushing efficiencyGrain treatmentsRolling-element bearingWorking pressure

The invention discloses a multi-cylinder hydraulic antifriction bearing taper crusher, which comprises a lower machine frame, an eccentric sleeve mechanism, a transmission set, a movable tapper, an upper machine frame set and an iron passing and cavity clearing device. The upper machine frame set is arranged above the lower machine frame, the transmission set and the eccentric sleeve mechanism are both installed on the lower machine frame, the transmission set is connected with the eccentric sleeve mechanism where the movable tapper is arranged, the iron passing and cavity clearing device is directly installed on the lower machine frame and the upper machine frame set, the eccentric sleeve mechanism adopts an antifriction bearing type eccentric sleeve mechanism, the iron passing and cavity clearing device adopts a relief valve type iron passing and cavity clearing device, and a movable tapper body rotating-proof device is connected to the bottom of the movable tapper. The multi-cylinder hydraulic antifriction bearing taper crusher improves crushing efficiency and output of the taper crusher, and prolongs service life of a machine, reduces using cost of equipment. The iron passing and cavity clearing device can not only bear higher working pressure of a system, but also be safe and reliable, convenient to assemble and capable of controlling a tapper body to rotate according to certain direction, thereby improving production efficiency and saving energy.

Owner:ZHEJIANG ZHEKUANG HEAVY IND CO LTD

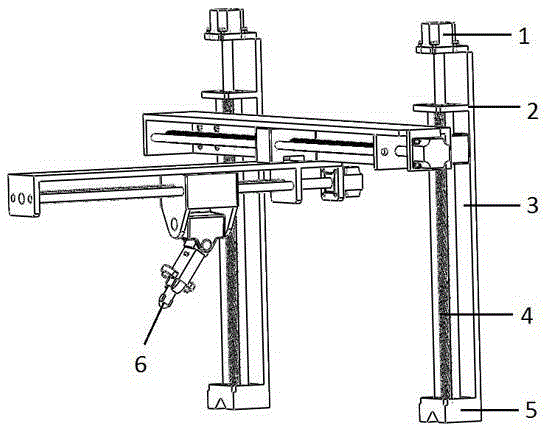

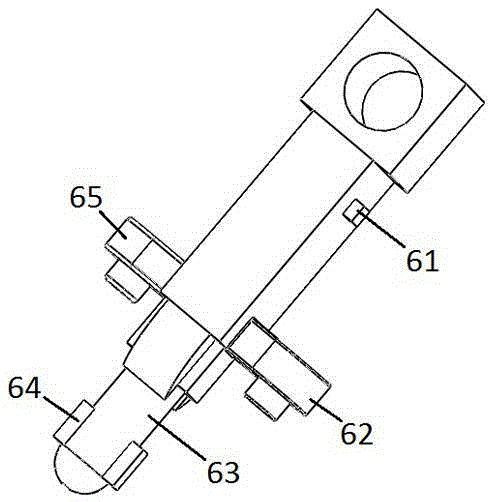

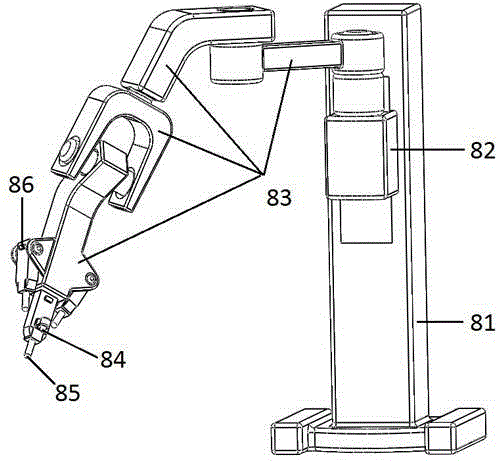

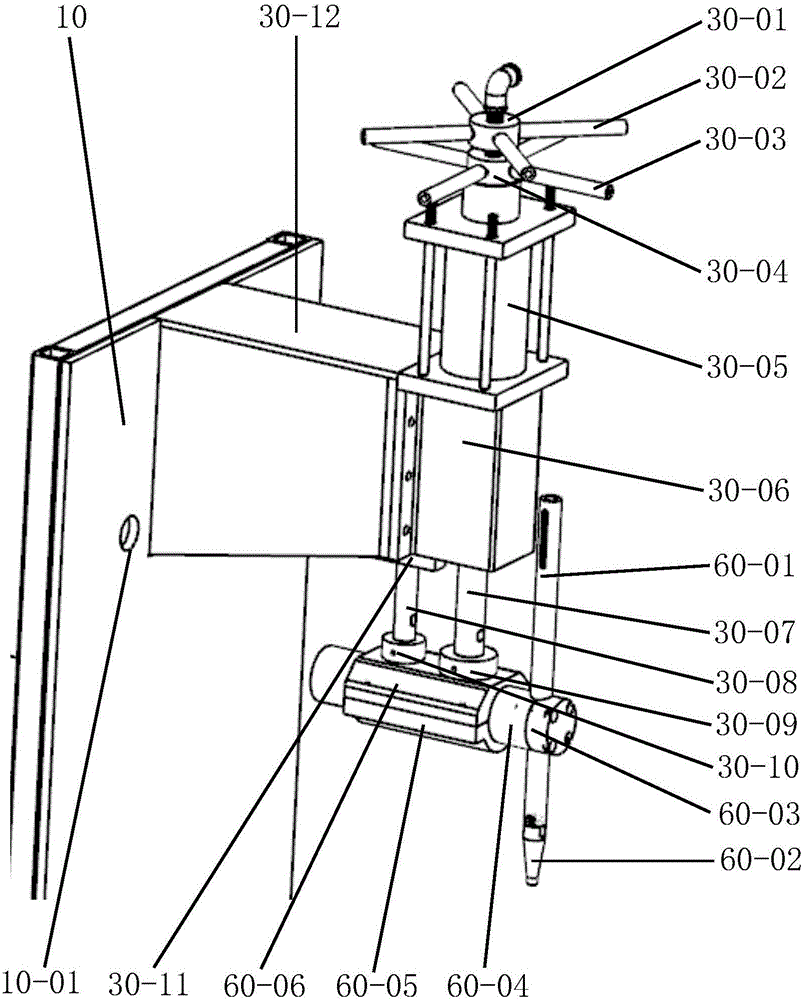

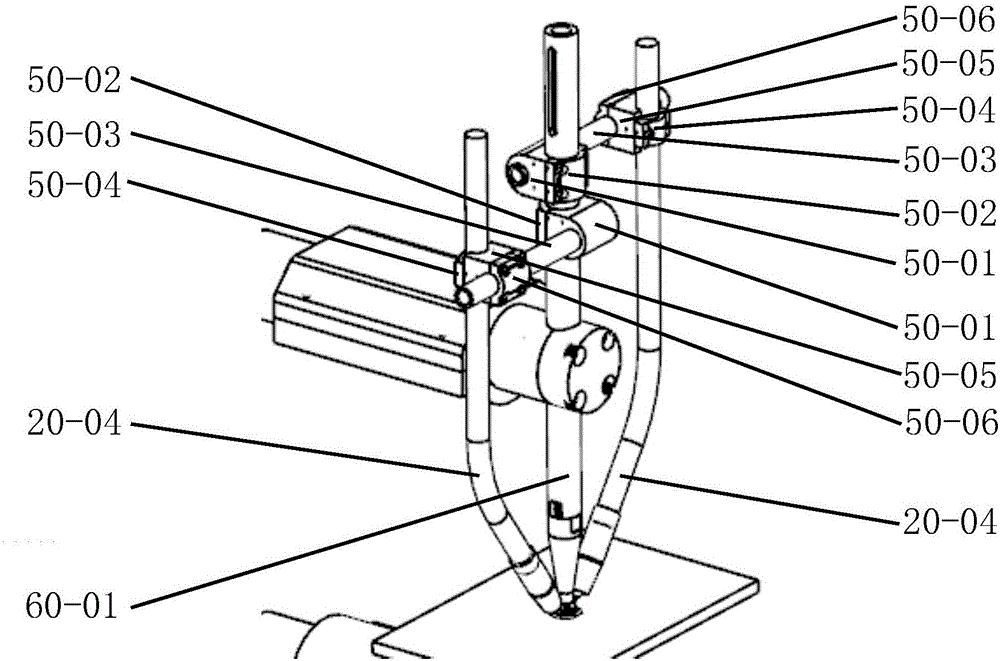

Skin laser treatment auxiliary robot and auxiliary method thereof

ActiveCN105288865AImprove accuracyEfficiencyProgramme-controlled manipulatorSurgical instrument detailsLaser probeEngineering

The invention provides a skin laser treatment auxiliary robot and an auxiliary method thereof. The skin laser treatment auxiliary robot comprises an accurate positioning mobile robot, a therapeutic instrument laser probe, a visual identification and control system, a range finding device and a safety device. The therapeutic instrument laser probe is installed at the front end of the tail position of the mechanical arm of the accurate positioning mobile robot. The range finding device is installed at the side surface of the therapeutic instrument laser probe. The CMOS probe of the visual identification and control system is installed at the other side surface of the therapeutic instrument laser probe. The safety device is installed at the front end of the therapeutic instrument laser probe. The measured value outputted by the range finding device and the sensing signal outputted by the safety device are connected with the input end of the visual identification and control system. Output of the visual identification and control system is connected with and controls the accurate positioning mobile robot. Manual operation on a skin laser therapeutic instrument is replaced by the accurate positioning mobile robot so that the skin laser treatment auxiliary robot and the auxiliary method thereof have advantages of high degree of automation and accurate positioning and movement, and high-curative-effect, high-efficiency, safe and reliable skin laser treatment can be guaranteed.

Owner:康健

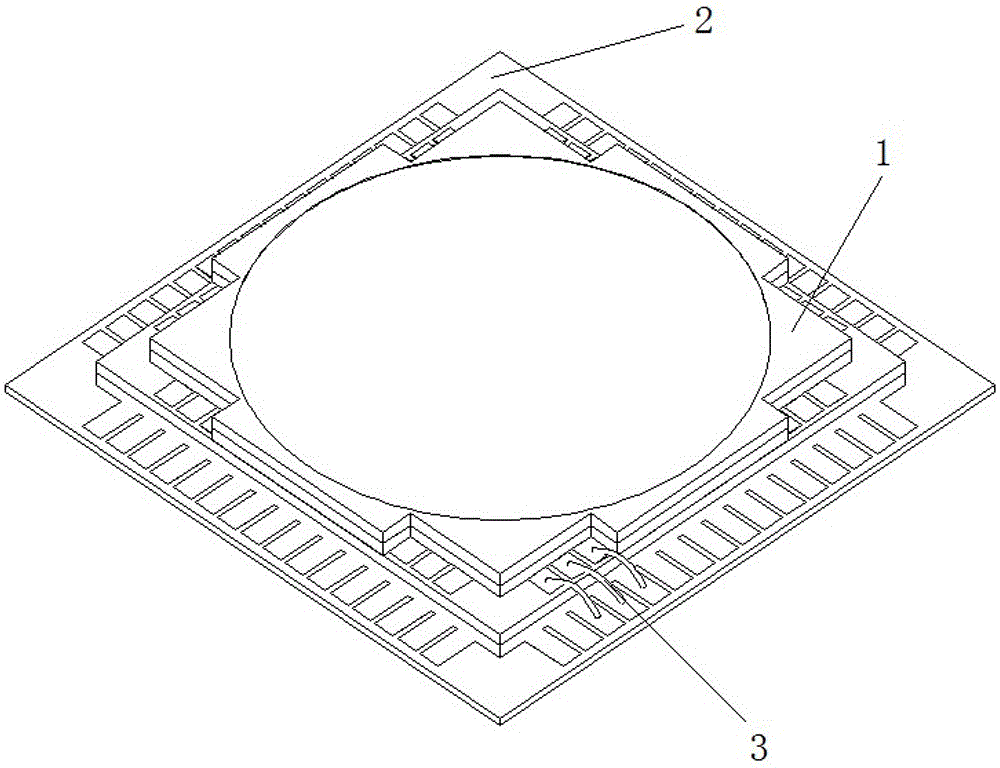

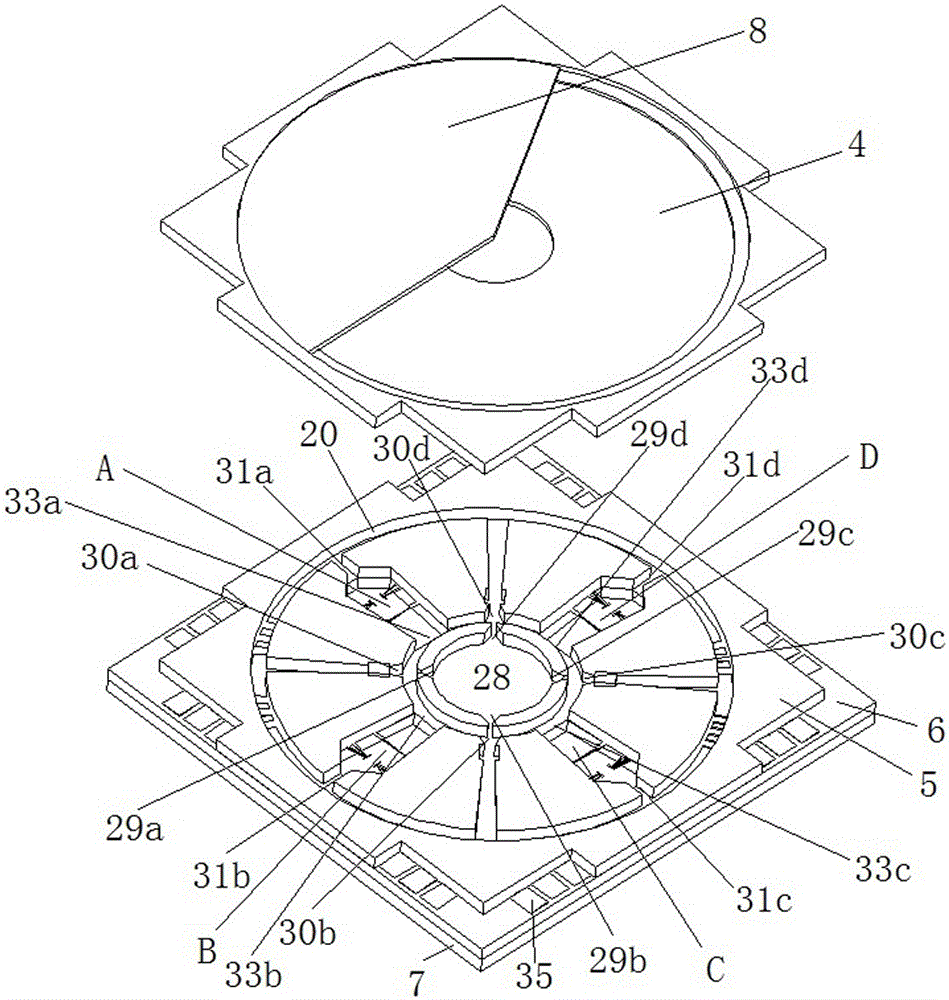

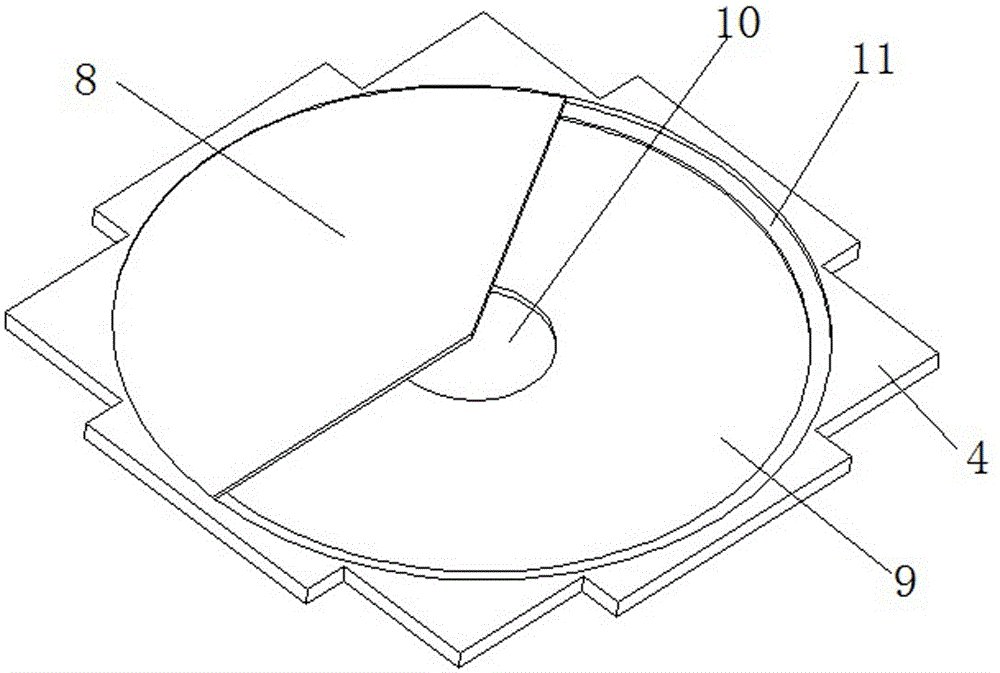

Miniature four-channel circular flow type triaxial silicon jet gyro

InactiveCN105091876AIncrease the areaImprove driving abilityTurn-sensitive devicesElectricityJet flow

The application exposes a miniature four-channel circular flow type triaxial silicon jet gyro; the jet gyro comprises a four-channel circular flow type triaxial angular velocity sensitive element and a PCB, and the sensitive element is electrically connected with the PCB, wherein the sensitive element comprises a PMMA upper cover, an upper silicon board, a lower silicon board, a PMMA bottom cover and a piezoelectric ceramic round oscillator; the piezoelectric ceramic round oscillator is embedded in the PMMA upper cover; the upper silicon board is provided with a jet network; the lower silicon board is provided with a jet network and a hot line; the PMMA upper cover, the upper silicon board, the lower silicon board and the PMMA bottom cover are successively bonded to form the sensitive element. The jet gyro adopts one piezoelectric ceramic round oscillator to drive four-channel circular flow, not only is simple in structure, long in life and low in power consumption, and implements deformation direction of the piezoelectric ceramic round oscillator and direction turning of jet flow network planes; the area of the piezoelectric ceramic round oscillator is large, the driving ability is strong, the jet velocity is high, and the jet gyro sensitivity is high; and angular velocities of three orthogonal directions can be sensitive at the same time, and multi-axis integration is achieved.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Method for architectural decoration plastering construction

The invention provides a method for architectural decoration plastering construction. The method comprises the following steps: firstly, base treatment, secondly, screeding, thirdly, plastering, and fourthly, wall surface grinding; screeding in the second step means that construction positioning paying-off is performed according to required plastering height, screeding templates are longitudinally installed along a wall surface subjected to base treatment in the first step according to the paying-off height, and the lateral distance between adjacent screeding templates is 1.3 to 1.8 meters. Wall surface grinding in the fourth step means that the wall surface subjected to plastering in the third step is subjected to standing for 12 to 24 hours till plastering mortar on the wall surface is at a half-dried compact hardened state, and teeth of a saw blade are used for grinding the mortar along the two adjacent screeding templates through a rule till the mortar is even. Due to the method, the plastering construction efficiency can be improved, the construction quality is guaranteed, the large-area construction efficiency is further improved with the matching of mechanized construction, and the defects of low efficiency of traditional manual construction and high technical requirements on constructors are overcome.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

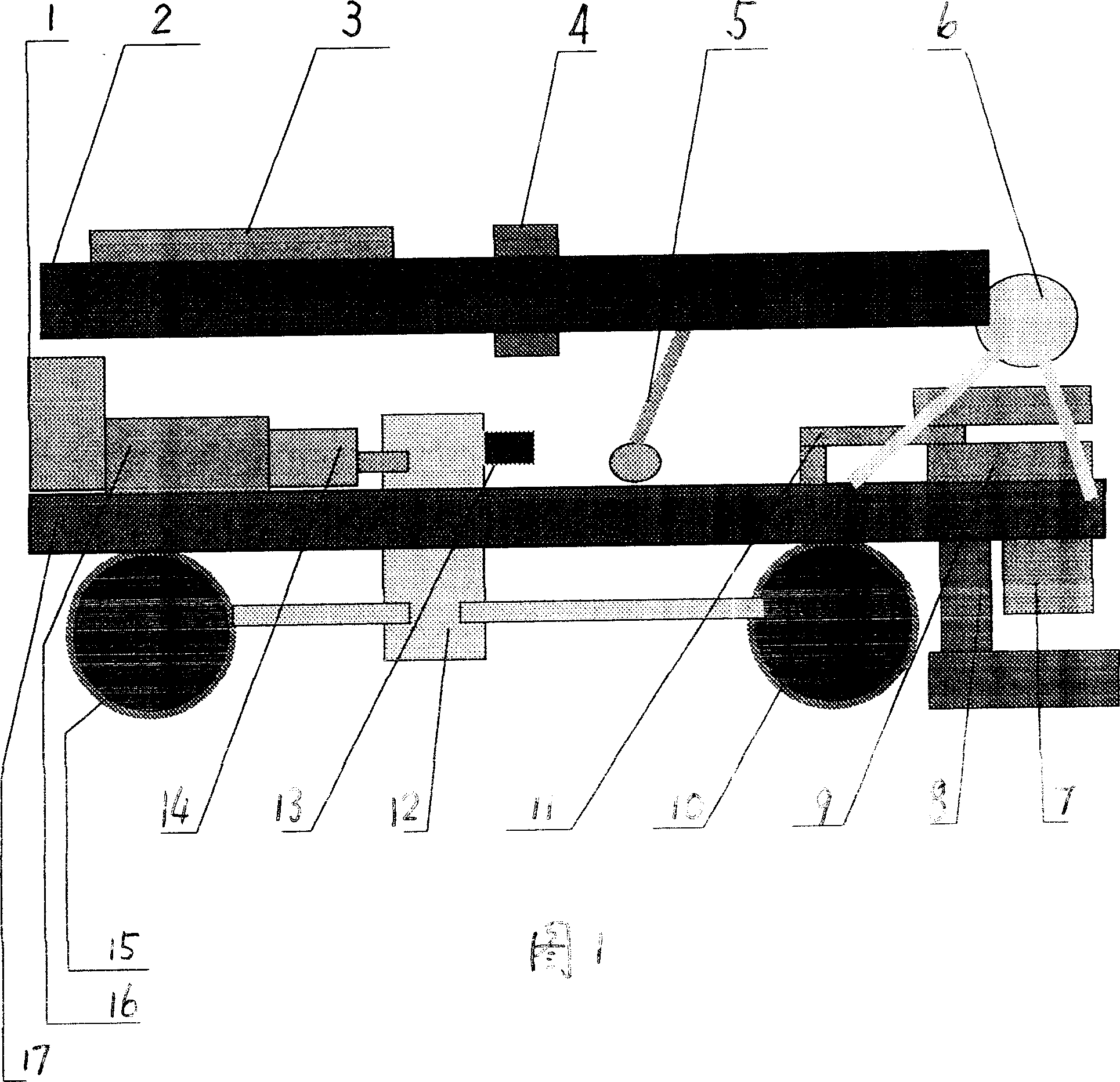

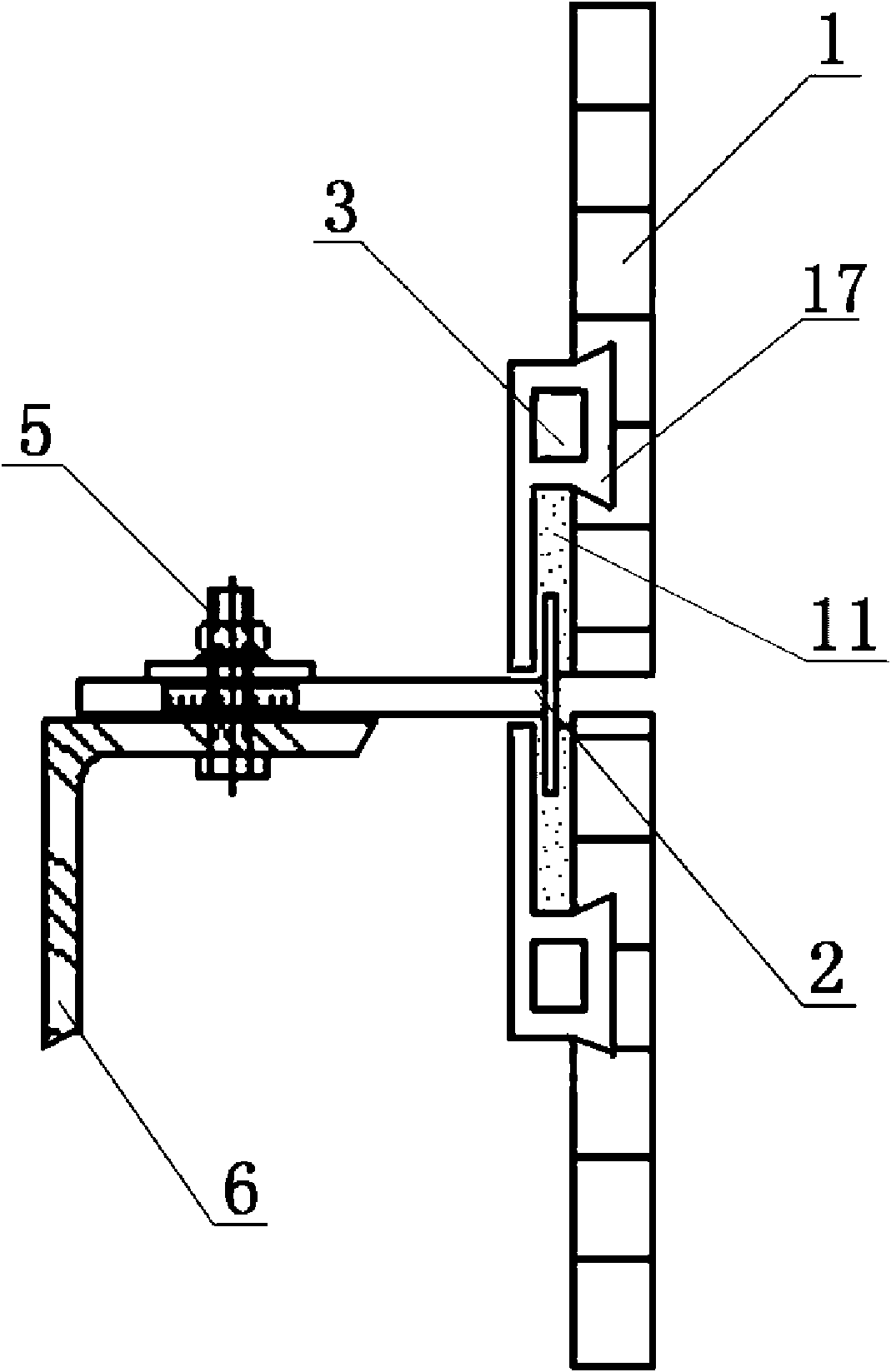

Drill floor well repairing machine without manual operation in well mouth

InactiveCN1920239AReduce labor intensityImprove workover efficiencyDrilling rodsDrilling casingsHydraulic cylinderVehicle frame

The invention relates to a workover device in drill floor type, used in non-manned operation under the oil well, wherein it is formed by driving control room 1, thick support post 2, discharge tube 3, lifter 4, amplitude-variable hydraulic cylinder 5, support post base 6, well-open hydraulic blowout preventer 7, drill floor hydraulic base 8, fixing hydraulic clamp disc 9, back tyre, back driving bridge 10, hydraulic clamper 11 with flexible sliding channel 11, hydraulic gear box 12, high-pressure gear pump 13, hydraulic torque converter 14, front tyre, front driving bridge 15, engine 16, frame and drill floor 17; the front part of frame 17 is arranged with driving control room 1, engine 16, hydraulic torque converter 14, hydraulic gear box 12 and high-pressure gear pump 13, while the back part has fixing hydraulic clamp disc 19, support post base 6, and hydraulic clamper 11; the support post base 6 is mounted with thick support post 2, discharge tube 3 and lifter 4. The invention can automatically set discharge tube and improve the working efficiency.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

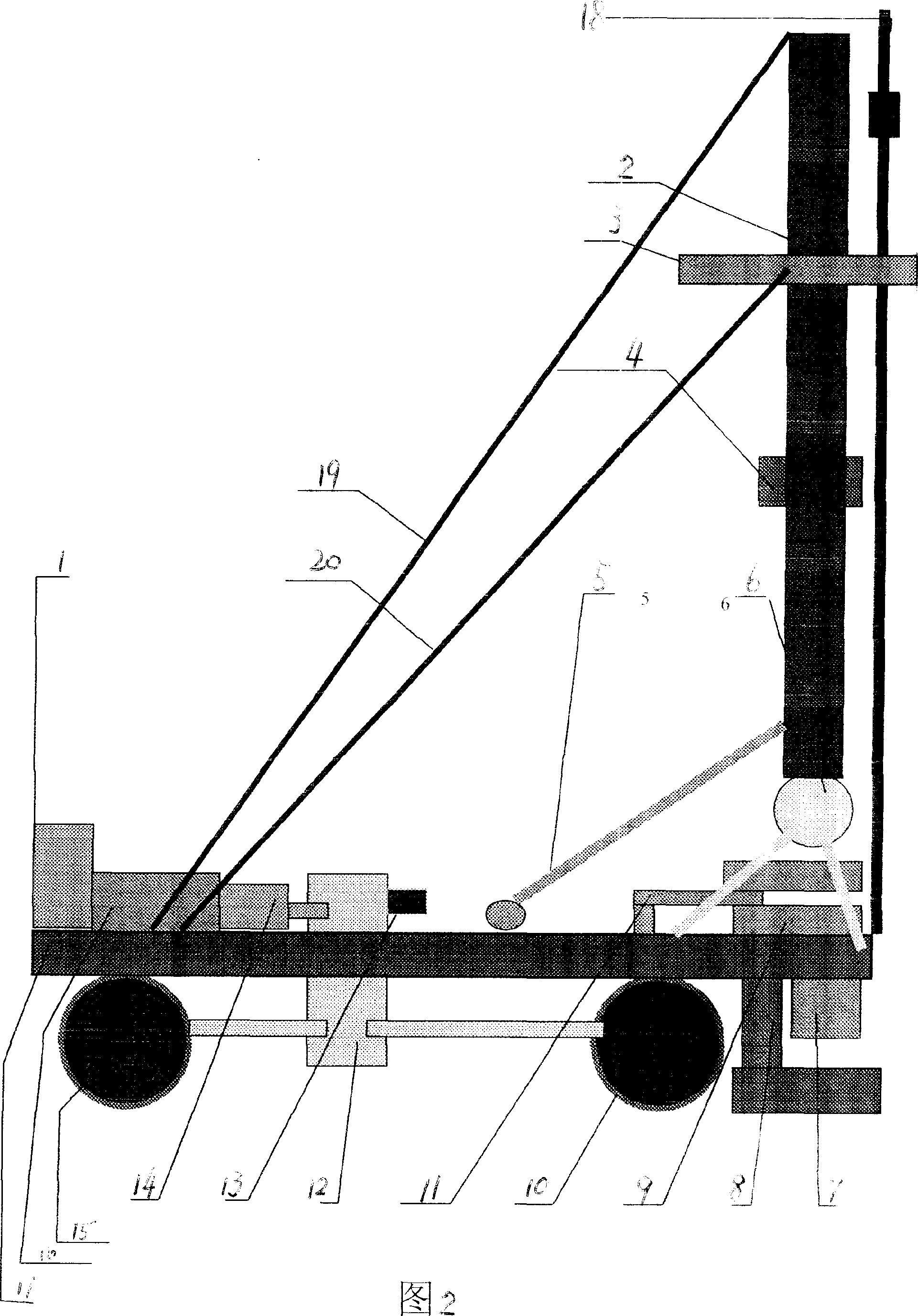

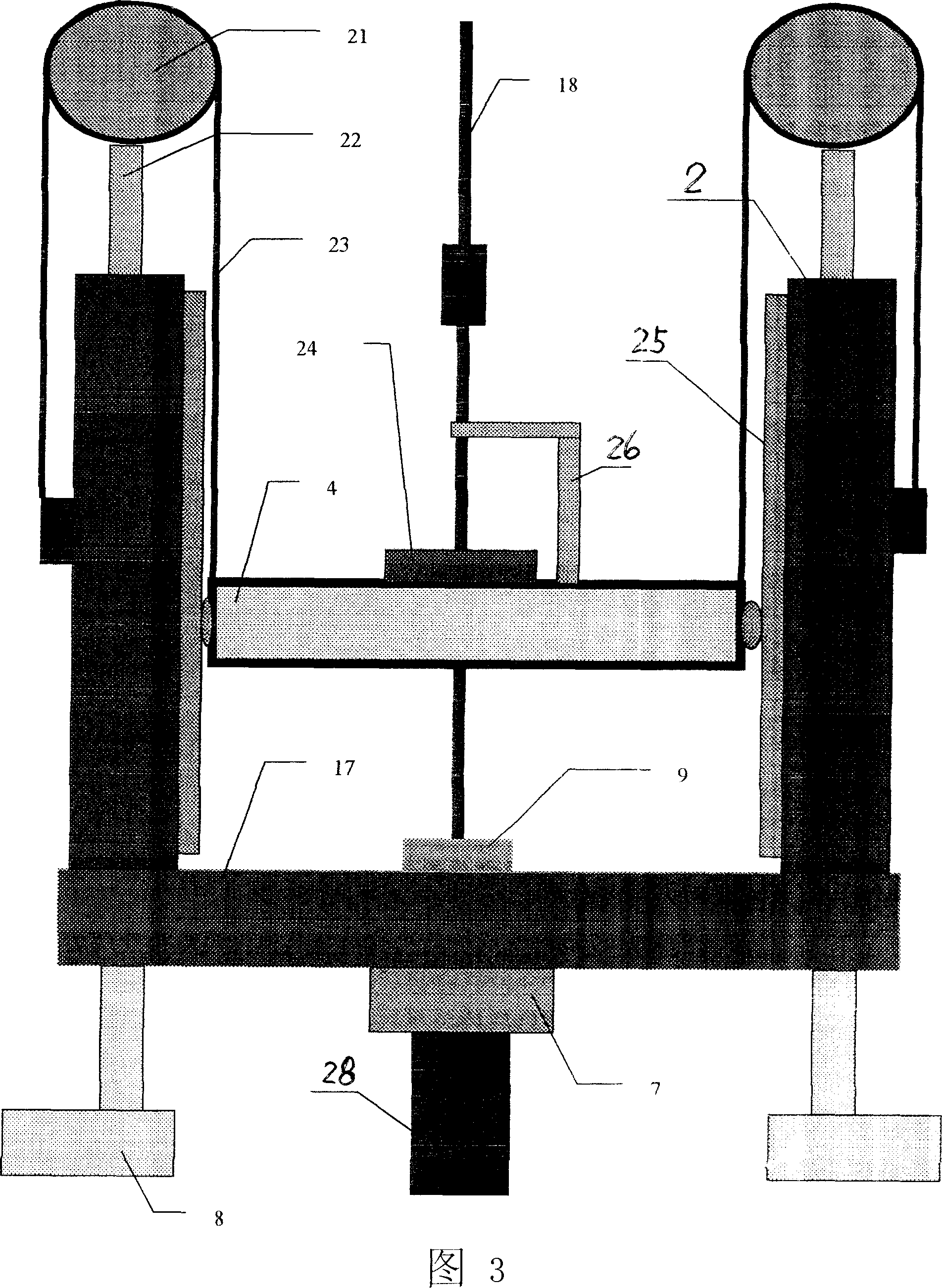

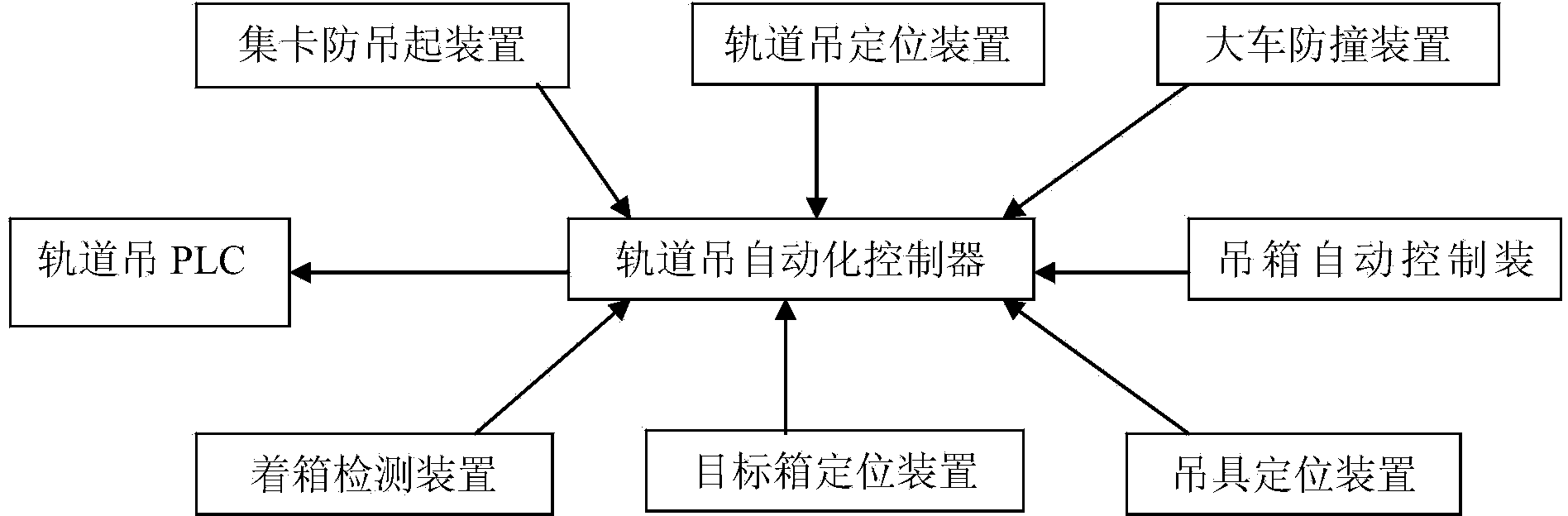

Rail-mounted gantry crane automatic yard operation control system and automatic loading and unloading method

ActiveCN103523675AImprove work efficiencyReduce labor costsSafety gearAutomatic controlControl system

The invention discloses a rail-mounted gantry crane automatic yard operation control system and an automatic loading and unloading method, and the control system and the automatic loading and unloading method can reduce investment for reconstruction and enables technological process to be simplified. The system comprises a rail-mounted gantry crane automatic controller, a rail-mounted gantry crane PLC controller, a hanger PLC controller, a container truck hoist-preventing device, a rail-mounted gantry crane positioning device, a container landing detection device, a hoisting box automatic control device, a target container positioning device and a hanger positioning device. The system refits a conventional rail-mounted gantry crane into an automatic rail-mounted gantry crane and can carry out container landing, locking, hanger rising, container dropping, unlocking, hanger rising and the like on containers through controlling by the automatic loading and unloading method, a cycle of operation can be automatically finished without intervention by a remote operator, so work efficiency is improved, labor cost is reduced and work cost is lowered down; moreover, equipment investment is small, and operation is simple and convenient.

Owner:TIANJIN PORT CONTAINER TERMINAL

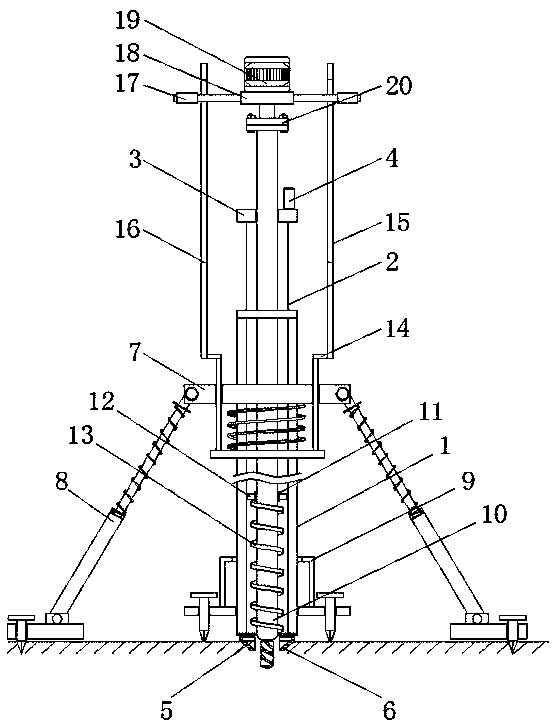

Convenient undisturbed soil taking device

InactiveCN105954059AGuaranteed original propertiesAvoid re-squeezingWithdrawing sample devicesEngineeringPiston

The invention discloses a convenient undisturbed soil taking device and relates to the technical field of soil taking tools. The undisturbed soil taking device comprises a base, a drilling pipe, a sampling pipe and a sample releasing device; the base is fixedly mounted on the ground to be sampled; the drilling pipe is clamped into the base, the top of the drilling pipe is provided with a handle for driving the drilling pipe to rotate, and the bottom of the drilling pipe is provided with sampling cutting edges which are vertically and spirally distributed; the sampling pipe is sleeved with the drilling pipe, and the sampling pipe can slide up and down along the inner wall of the drilling pipe; the sample releasing device comprises a sample releasing piston arranged at the top of the sampling pipe, and the sample releasing piston is provided with a sampling handle exposed out of the handle. The base plays a role of fixation, verticality of sampling is guaranteed, and labor intensity is lowered; a rotary-cut sampling mode is adopted, in the sampling process, soil is not or slightly disturbed, and the undisturbed feature of taken soil is guaranteed; by means of sample releasing design, secondary squeezing of taken soil by the sample releasing piston in a traditional sample releasing process is avoided.

Owner:QINGDAO AGRI UNIV

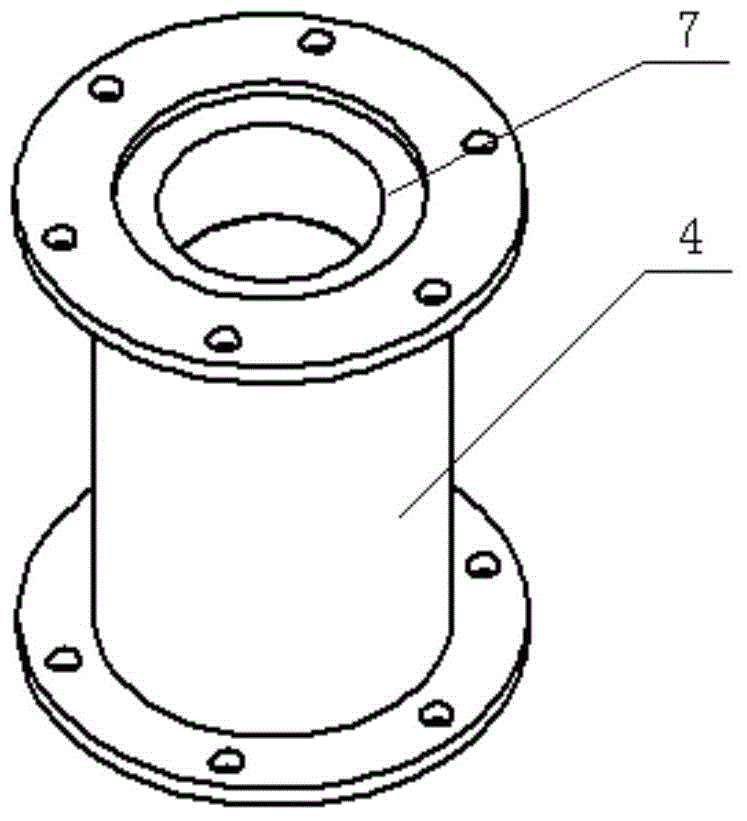

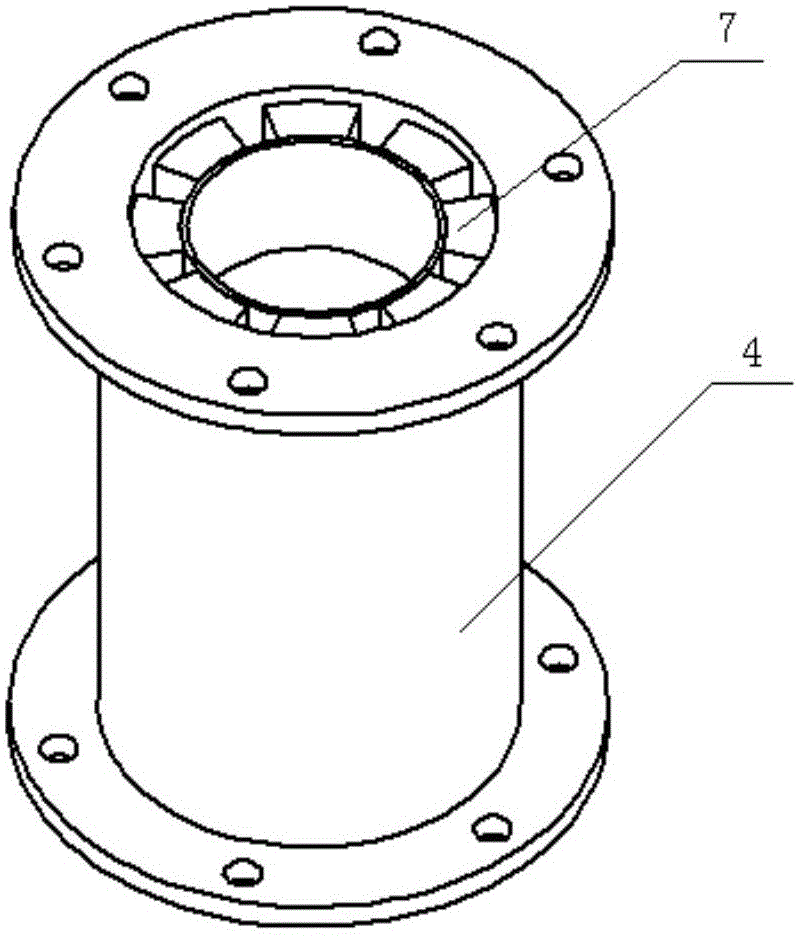

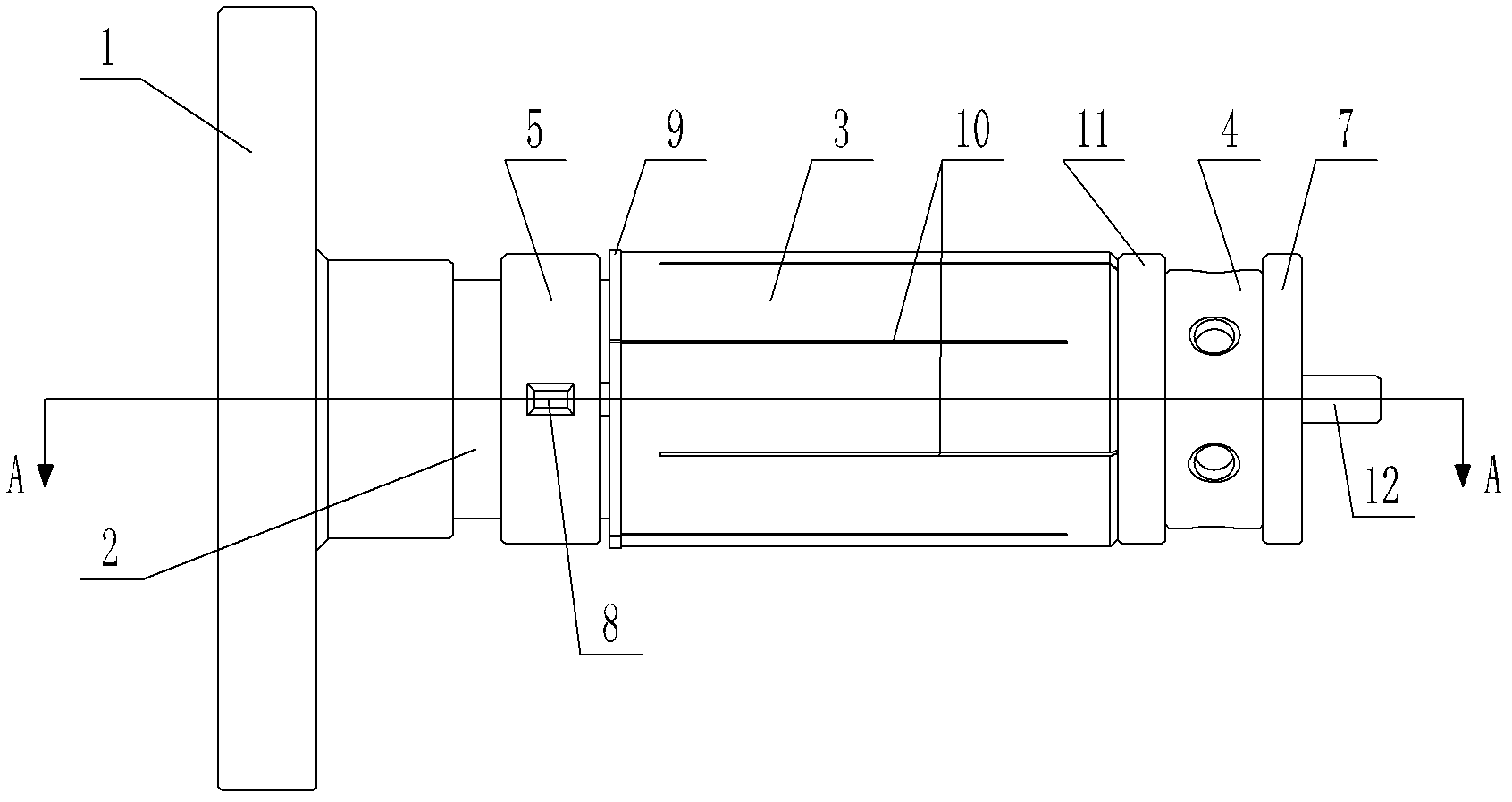

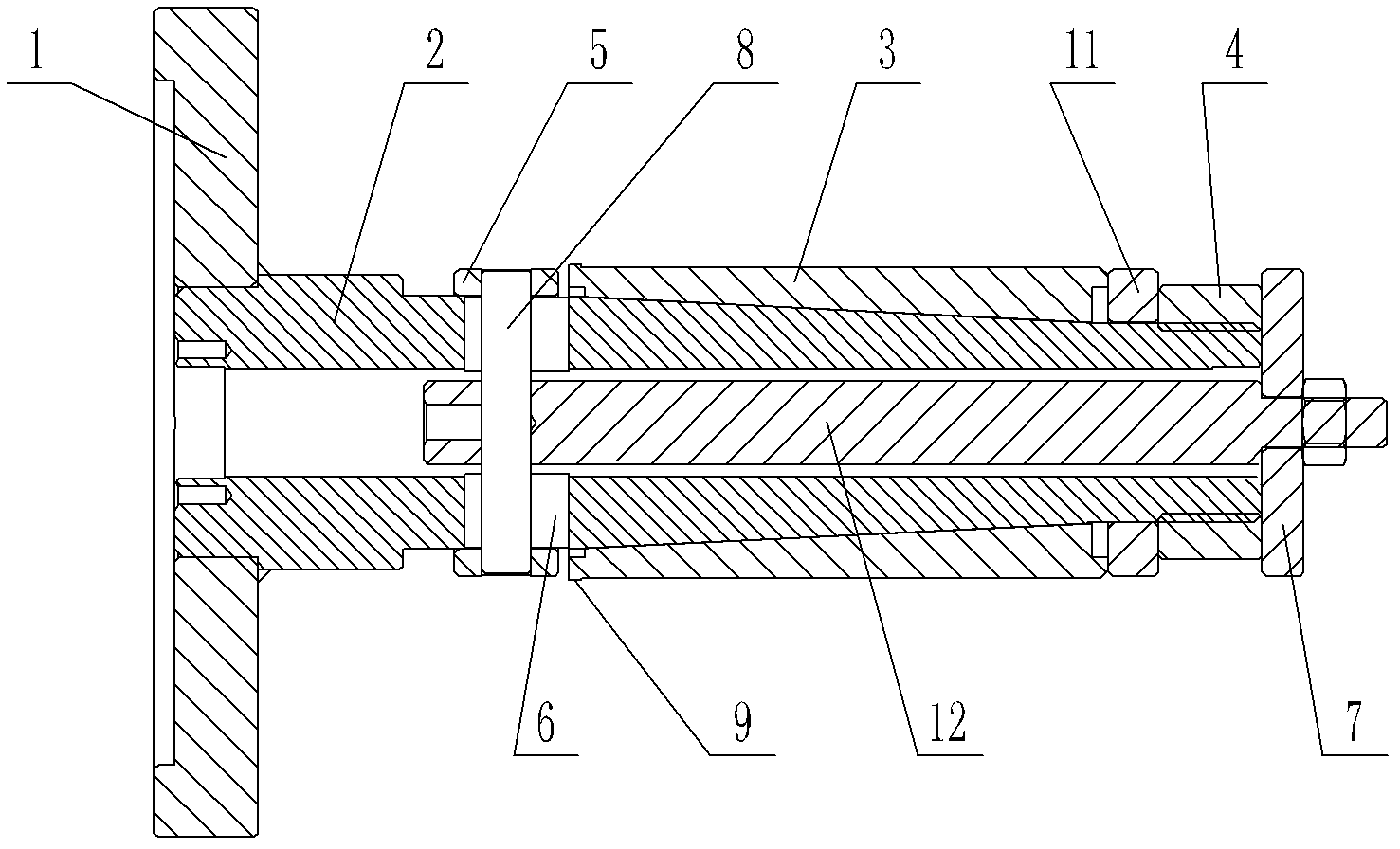

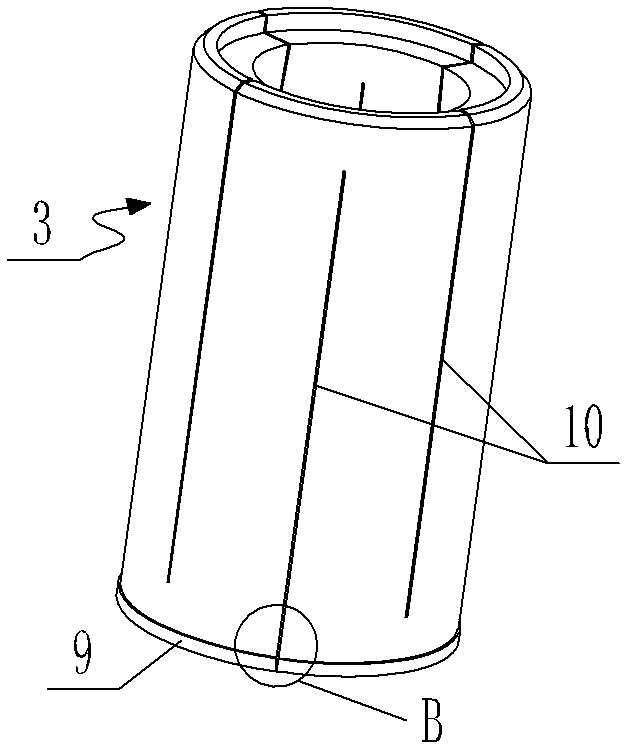

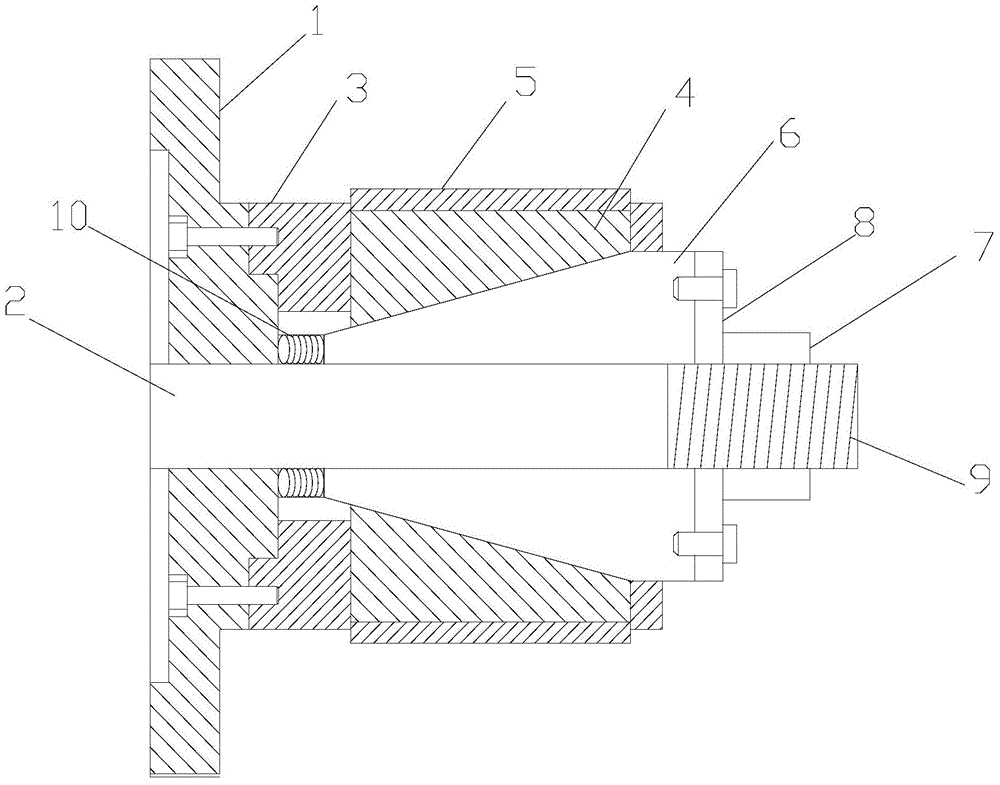

Self-centering fixture

InactiveCN102357826AEasy loading and unloadingGuaranteed concentricityPositioning apparatusMetal-working holdersExpansion jointCentring

The invention discloses a self-centering fixture which comprises a mandrel and an expansion sleeve, wherein the mandrel is mounted on a machine tool through a flange; the expansion sleeve is sleeved on the outer circumference of the mandrel and can move axially; multiple expansion joints are arranged on the outer wall of the expansion sleeve; the outer wall of the mandrel and the inner wall of the expansion sleeve are matched conical surfaces; the mandrel is provided with an adjusting nut for driving the expansion sleeve to move along the mandrel; a pull rod and a stop ring are arranged between the mandrel and the expansion sleeve to pull the expanded sleeve to a shrinkage end; and through the expansion and shrinkage of the expansion joints, the outer diameter is controlled to increase / reduce so as to position / dismantle a workpiece. The fixture has a simple structure, is convenient to use and can realize self centering; and moreover, the processing accuracy of the workpiece is improved, the concentricity and verticality between the processed surface and an inner hole of the workpiece can be ensured, and the fixture deserves popularization and application in the fields realizing positioning and clamping by use of the inner hole of the workpiece.

Owner:JIANGSU FULIHUA GENERAL EQUIP

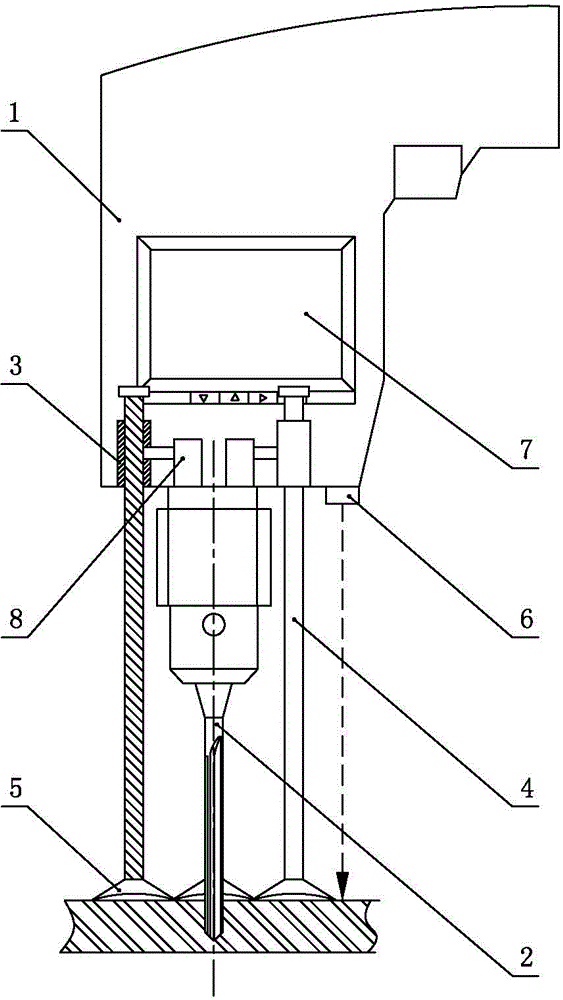

High-precision electric drill capable of conducting positioning

InactiveCN104526010AGuaranteed accuracyGuaranteed drilling accuracyDrilling/boring measurement devicesMeasurement/indication equipmentsDrill bitElectrical and Electronics engineering

The invention discloses a high-precision electric drill capable of conducting positioning. The high-precision electric drill comprises a shell, a drill bit, a motor and a transmission mechanism, wherein the motor and the transmission mechanism are arranged in the shell, the drill bit is connected with the motor in a transmission mode through the transmission mechanism, a sleeve is arranged on the shell, a positioning rod is arranged in the sleeve, the positioning rod and the sleeve are vertically connected in a sliding mode, and a positioning piece can conduct positioning on the surface of a workpiece is arranged at the lower end of the positioning rod. When the high-precision electric drill is used, the positioning rod is installed near a hole to be machined first, switch-on of a motor power supply is subjective to to-be-machine hole coverage achieved by the shallow, on the surface of the workpiece, of the drill bit, the sleeve arranged on the positioning rod in a sleeving mode plays a role in guiding the drill bit, and therefore the accuracy of the drilling position and the perpendicularity of a hole are ensured.

Owner:滁州用朴合金工具有限公司

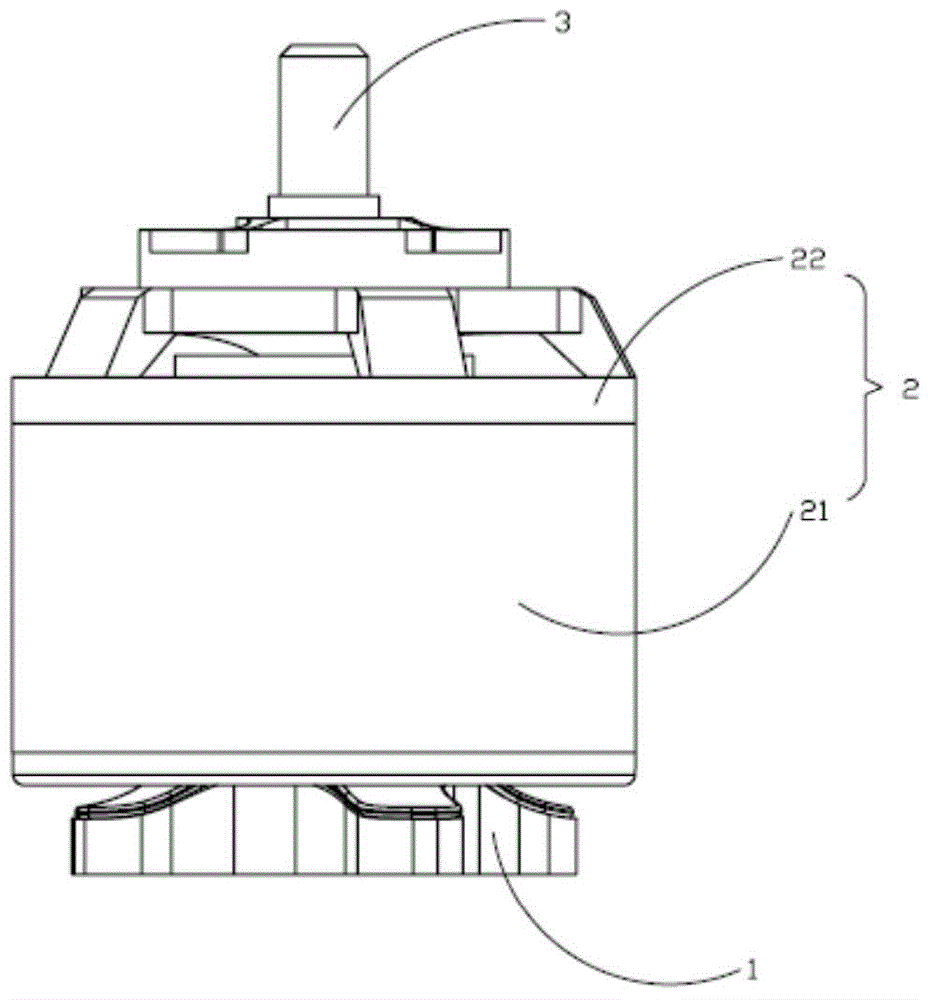

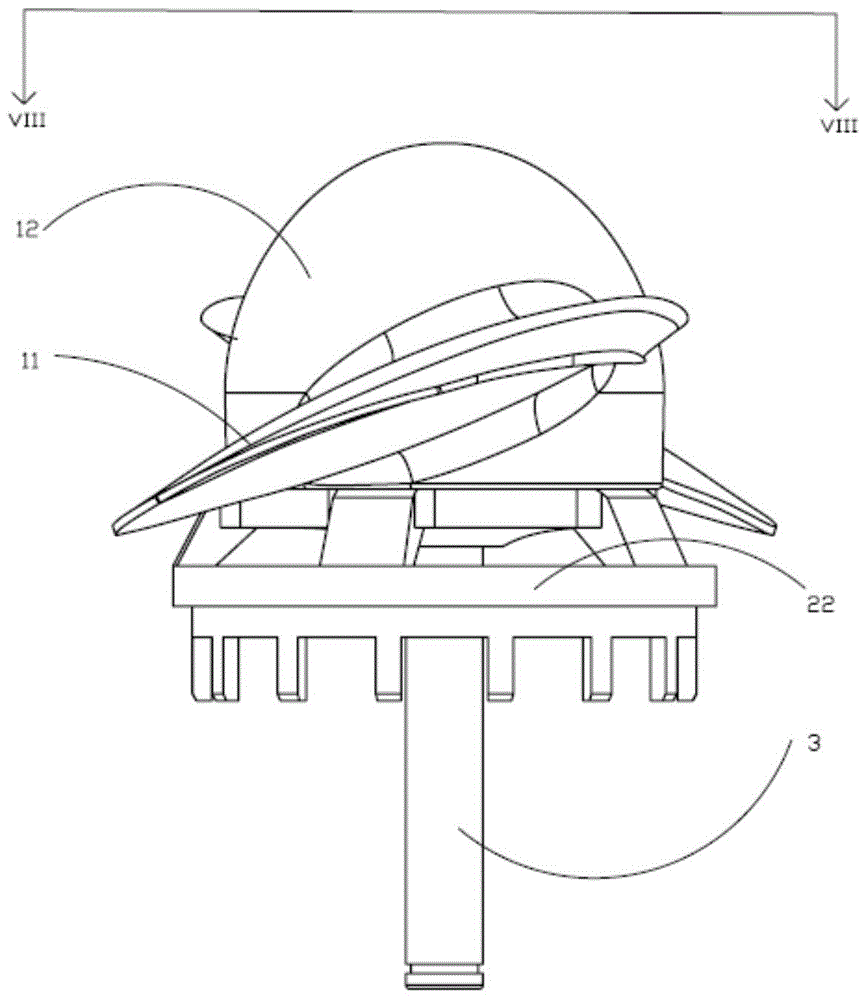

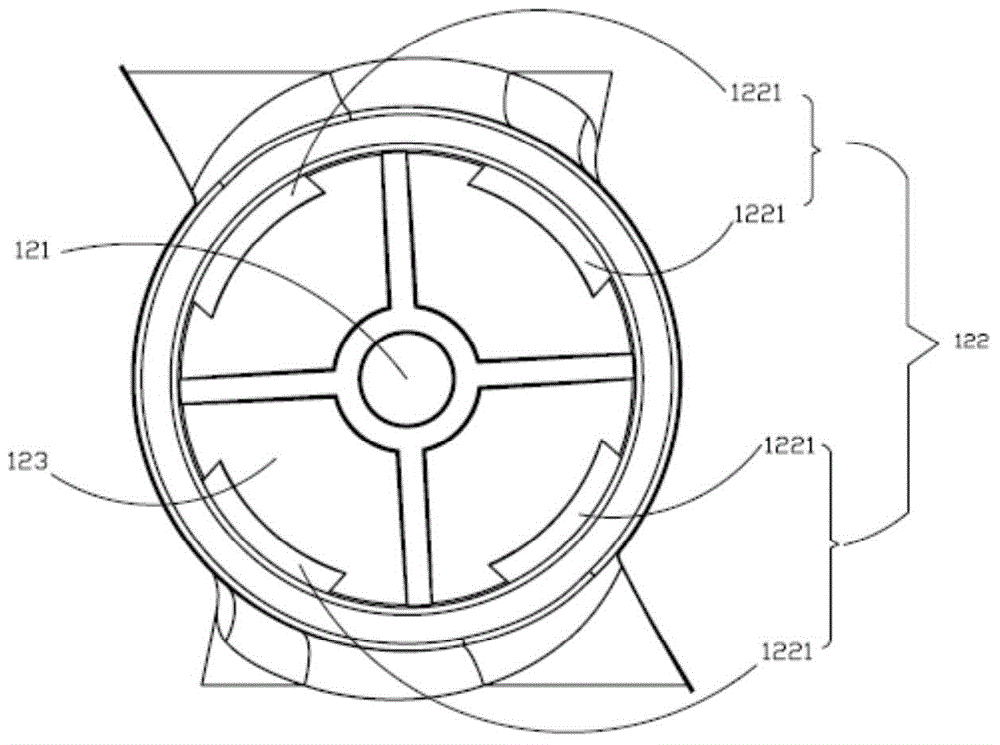

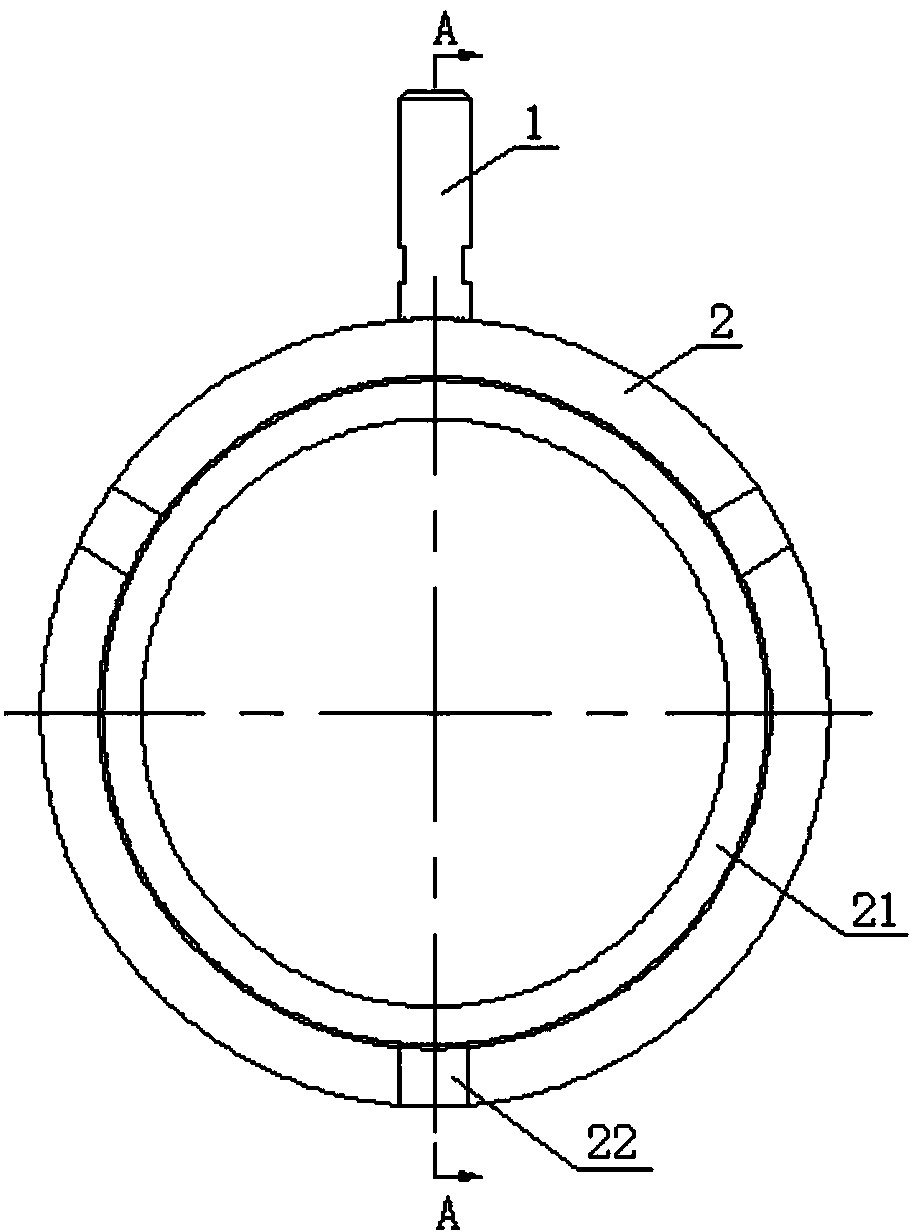

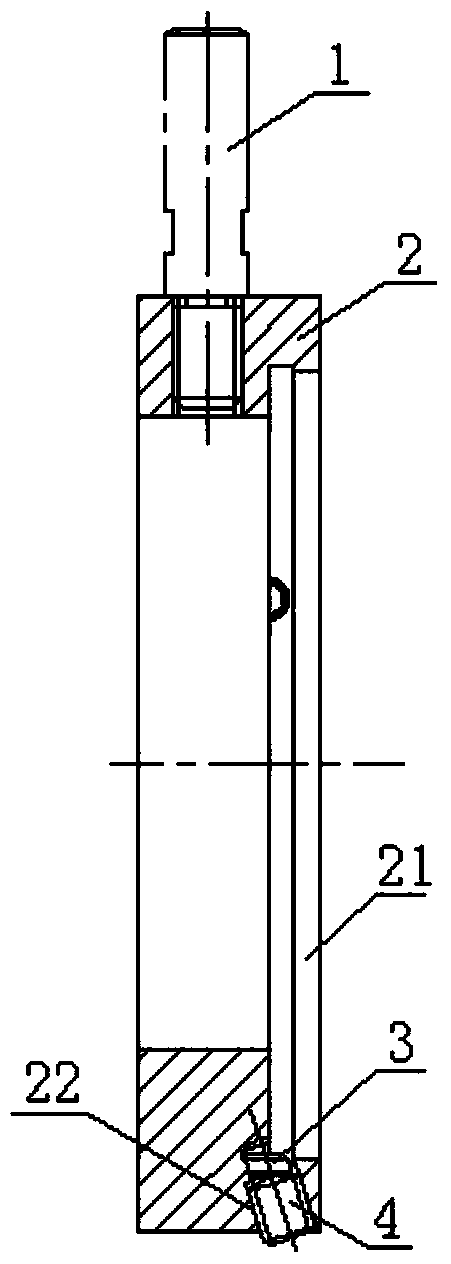

Power device and aircraft

ActiveCN104684805AEasy to assembleEasy to disassembleEfficient propulsion technologiesPower plant typePropellerPower apparatus

The invention provides a power device and an aircraft. The power device comprises a propeller and a motor, wherein the propeller comprises blades (11) and a propeller hub (12) and the motor comprises a stator component (1), a rotor component (2) and a rotating shaft (3). The rotor component (2) comprises a sleeve body (21) and a cover body (22). The propeller hub (12) is provided with a central hole (121) and a first clamping portion (122) and the cover body (22) is provided with a second clamping portion (221). The first clamping portion of the propeller hub and the second clamping portion of the cover body are in clamping fit and the rotating shaft cooperates with the central hole of the propeller hub, so that the propeller is fixed to the motor. According to the invention, the installation and detachment of the motor and the propeller in the power device of an aircraft can be completed conveniently and the concentricity and the perpendicularity of the motor and the propeller can be guaranteed to a certain extent.

Owner:SZ DJI TECH CO LTD

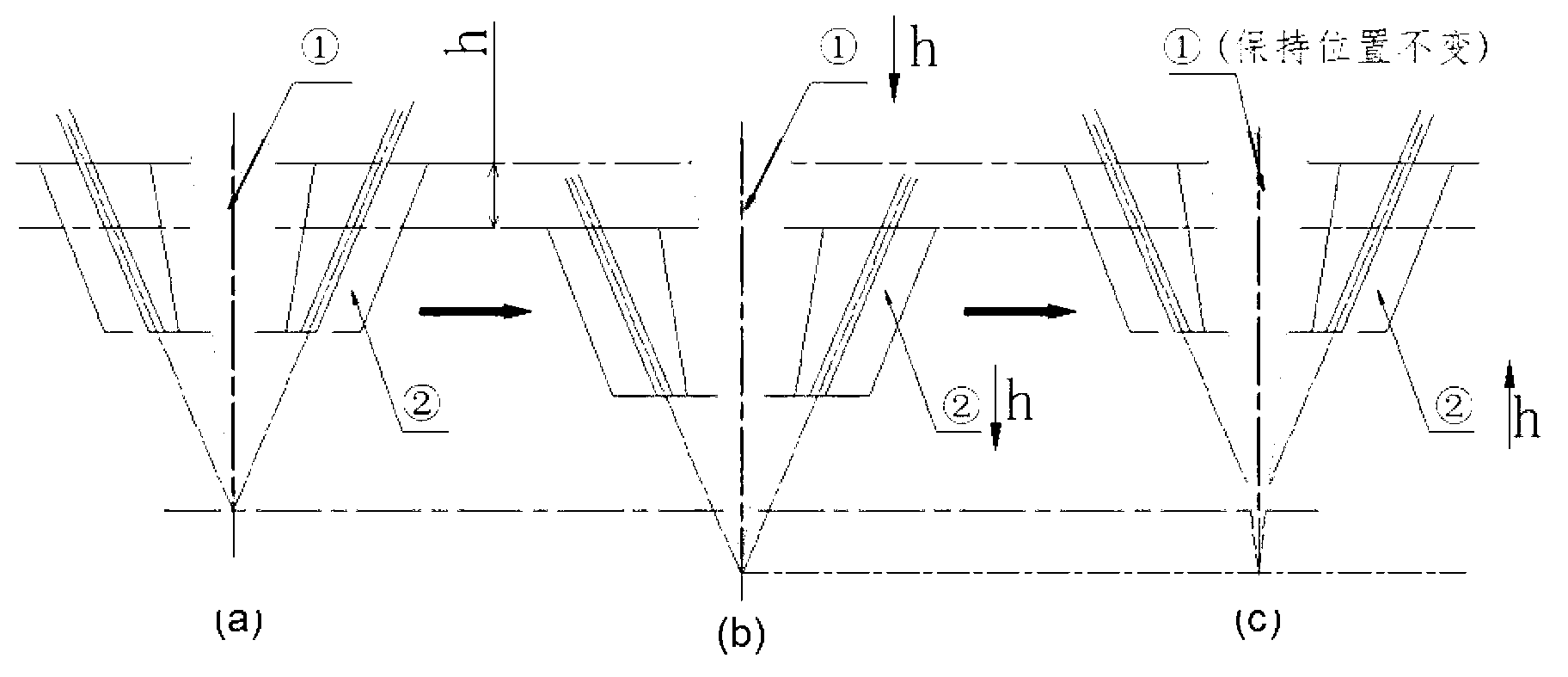

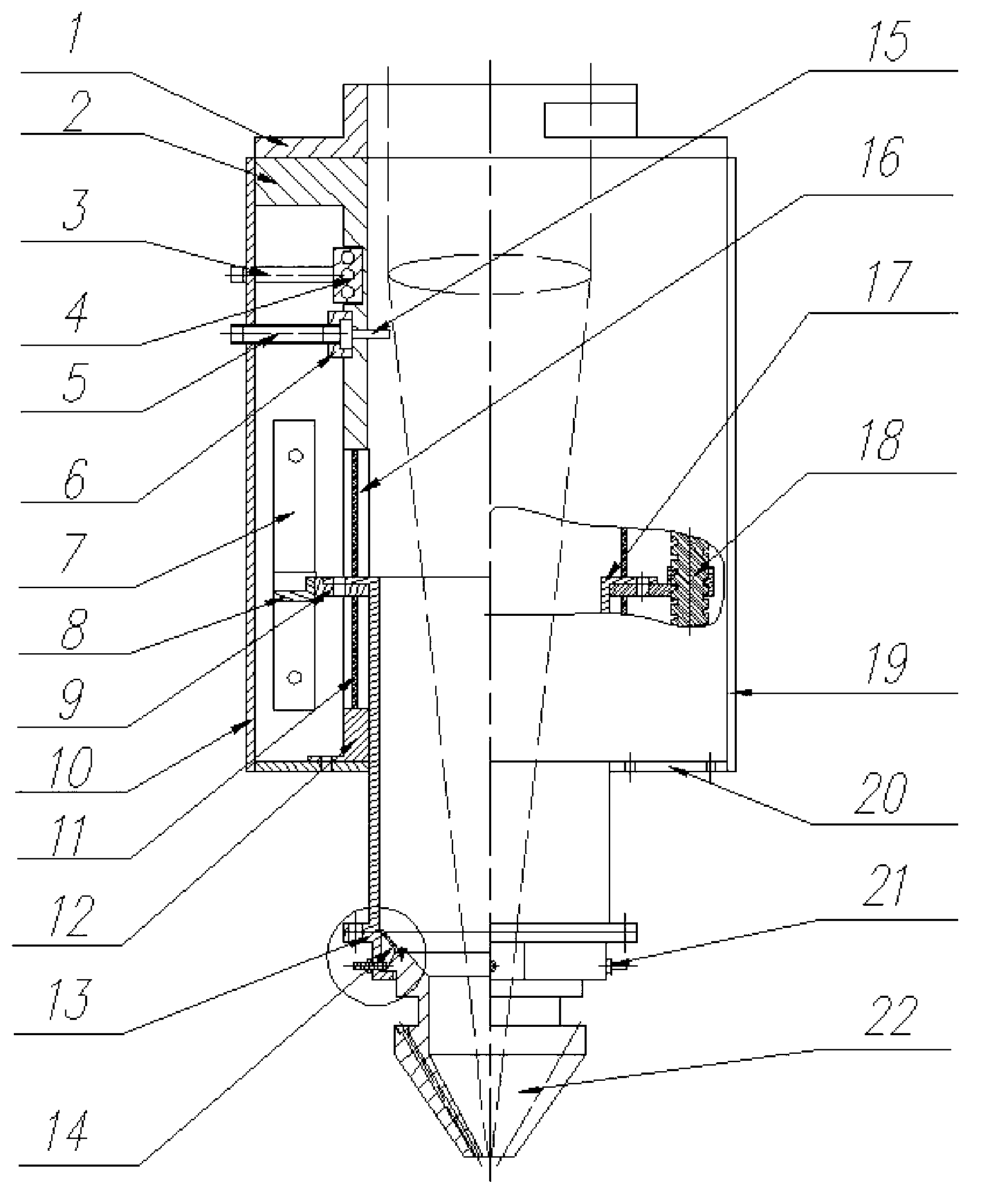

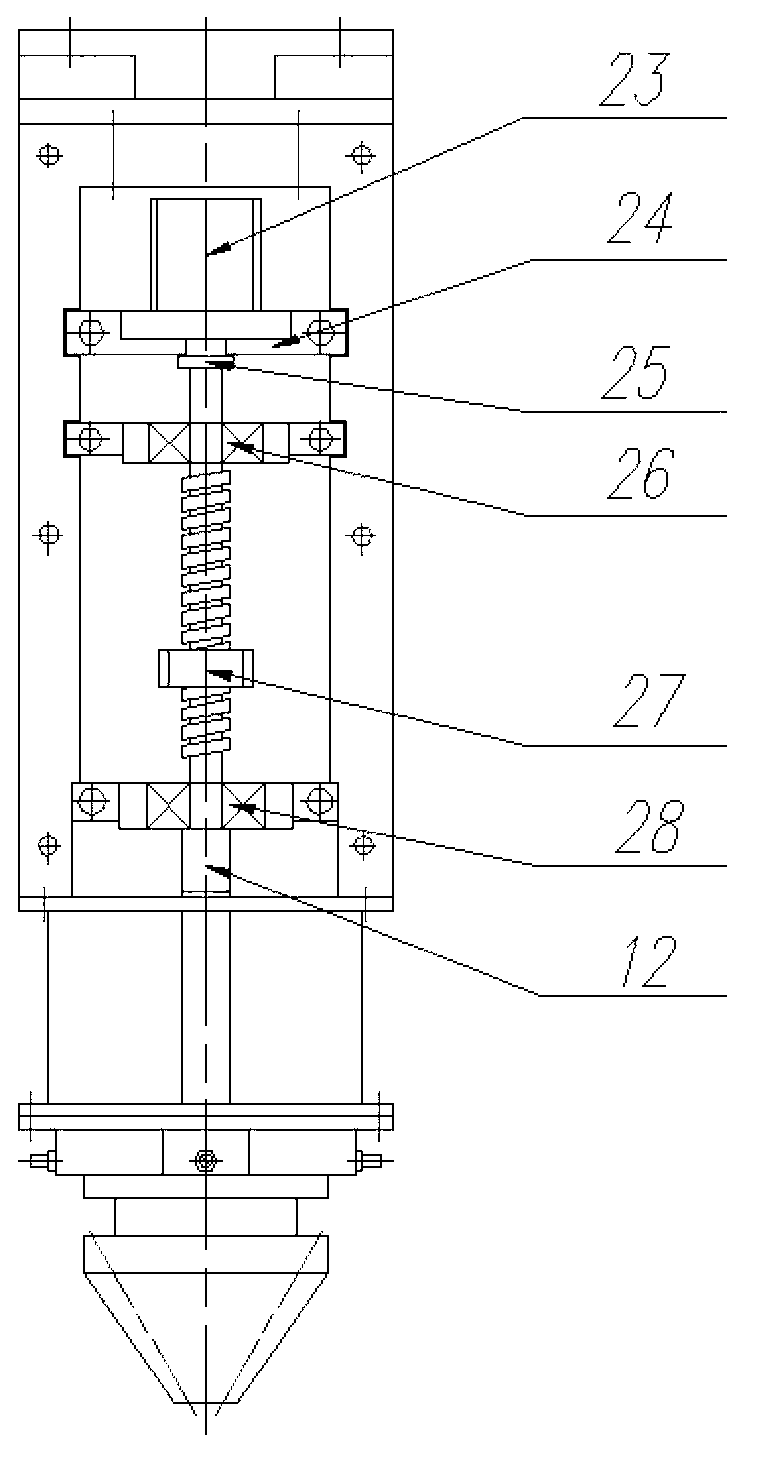

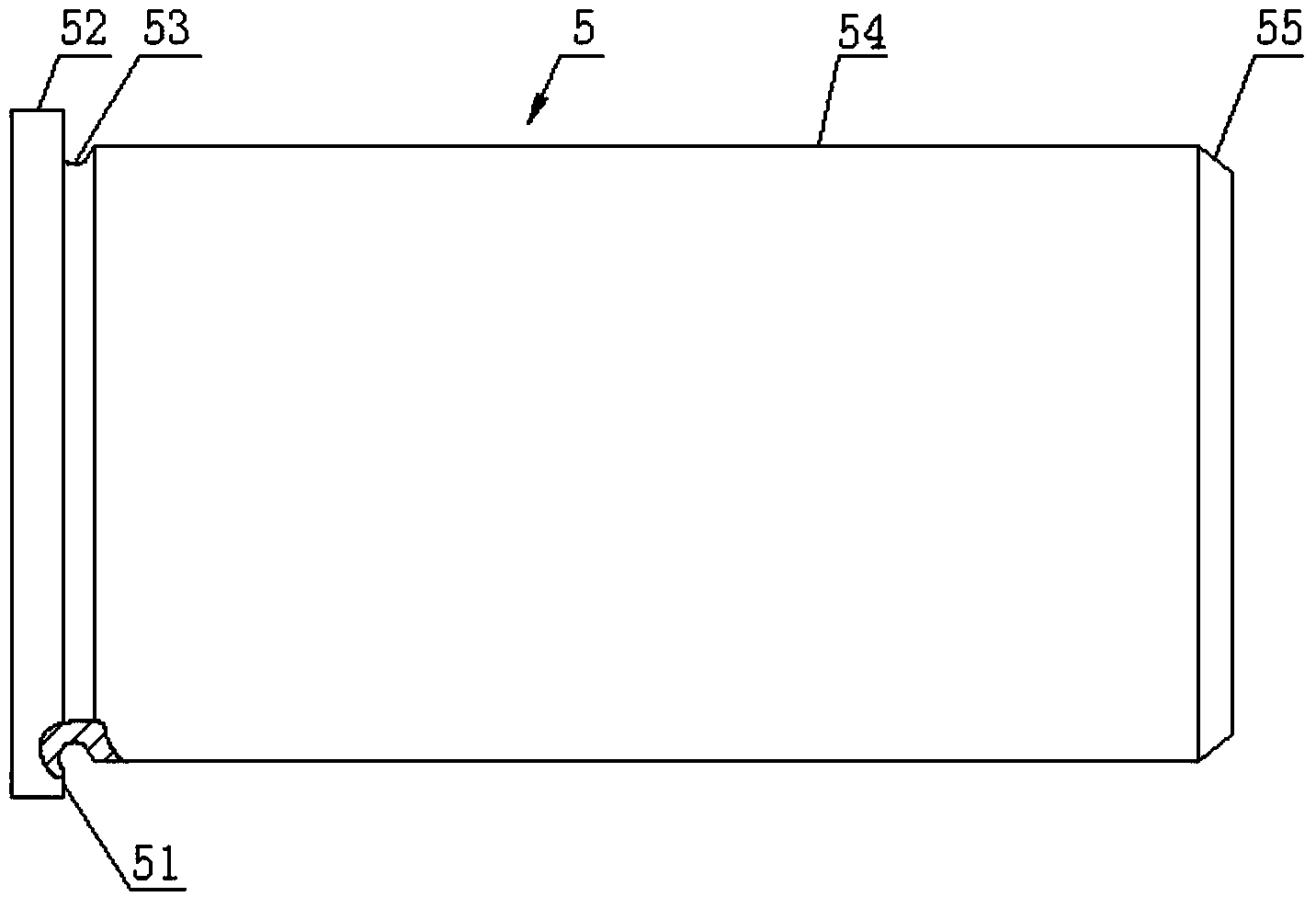

Coaxial powder delivery nozzle applied to variable spot technique

InactiveCN103060801APrecise automatic control of up and down moving distancePrecise guarantee of verticalityMetallic material coating processesLaser beam welding apparatusTemporary variableSpray nozzle

The invention relates to a coaxial powder delivery nozzle applied to a variable spot technique. The nozzle consists of three parts, wherein a first part is a structure for automatically regulating the collection position of powder in the nozzle in the vertical direction, and the part further comprises a cooling water loop and a gas protecting device; a second part is a structure for manually regulating the collection position of the powder in the horizontal diameter direction; and a third part is a powder delivery sprayer structure. The coaxial powder delivery nozzle disclosed by the invention is applicable to the field of material increase manufacturing, and especially applicable to an application place adopting a defocusing manner to realize temporary variable spot formation of laser for realizing both formation efficiency and precision. The coaxial powder delivery nozzle disclosed by the invention can also be applied to the field of laser welding.

Owner:XI AN JIAOTONG UNIV +1

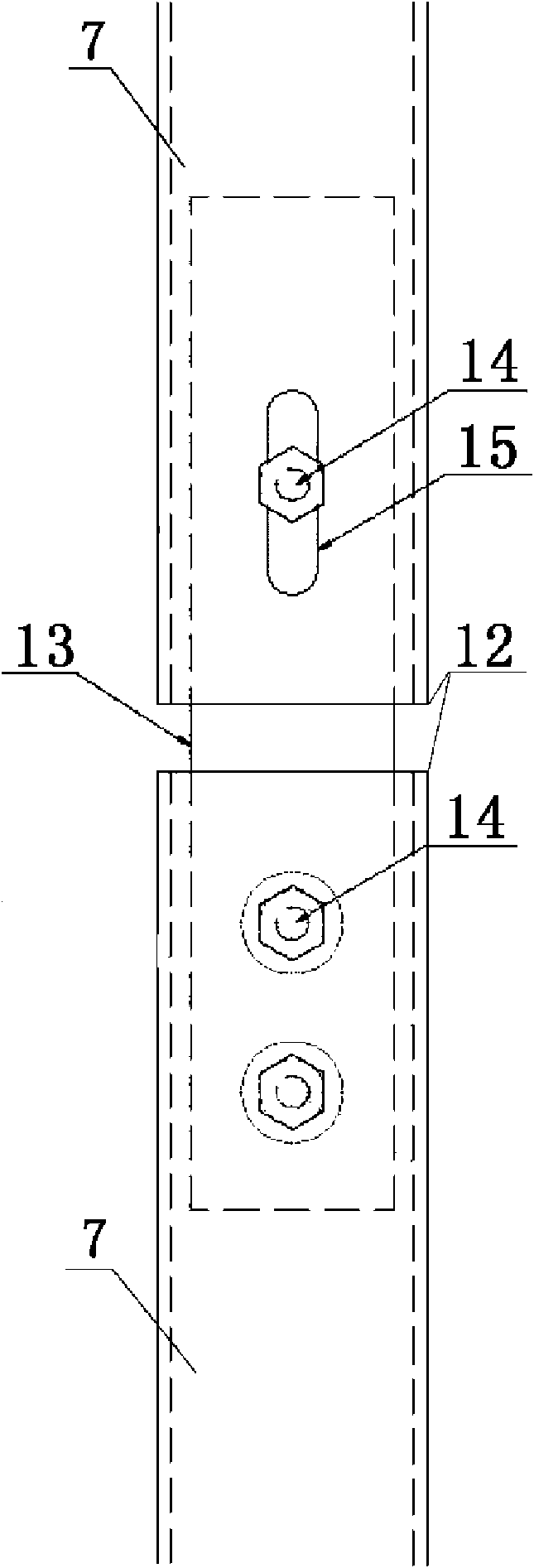

Drily hung vitrolite wall surface decoration system and construction method thereof

InactiveCN101824895ASatisfy self-expanding deformationFulfil requirementsCovering/liningsWallsKeelHigh rise

The invention relates to a drily hung vitrolite wall surface decoration system and a construction method thereof. A main building wall body is connected with a preembedded piece; the preembedded piece is connected with vertical keels through floor connecting pieces; the vertical keels are vertically connected with a transverse keel; the transverse keel is provided with a dilatation joint at each floor; a steel lock pin is inserted between the two vertical keels of the upper part and the lower part of the dilatation joint, one end of the steel lock pin is fixedly connected with a vertical keel through bolts, and the other end is in flexible connection with an oblong hole of the other vertical keel; the back of the vitrolite is provided with at least a pair of dovetail grooves; the dovetail grooves are connected with anchoring pieces in an embedded mode; the heads of the anchoring pieces are clamped into the dovetail grooves at the back of the vitrolite; a cavity for penetrating and anchoring the head of a T-shaped hanging piece is formed between an anchoring plate and the back of the vitrolite; the head of the T-shaped hanging piece extends to the cavity; the cavity is filled with epoxide resin anchoring glue; and a pectoral plate of the T-shaped hanging piece is fixedly connected with the transverse keel through a stainless steel bolt. The invention solves the problem of dry hanging vitrolite wall surface decoration systems on high rise buildings.

Owner:BEIJING CONSTR ENG GRP CO LTD

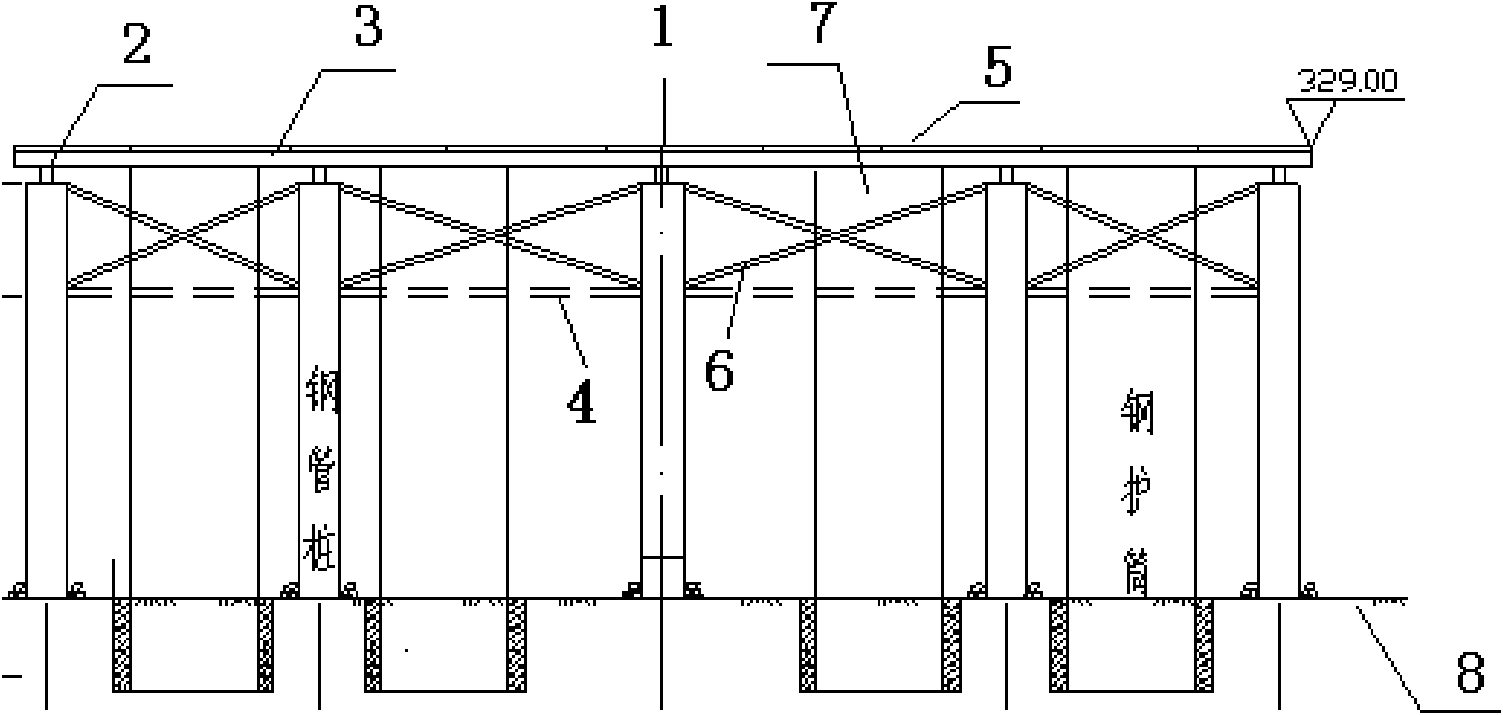

Abrupt slope bare rock drilling platform and technology in huge reservoir

ActiveCN101666081AGuaranteed stabilityFix stability issuesArtificial islandsUnderwater structuresBridge engineeringSteep slope

The invention relates to bridge engineering, in particular to an abrupt slope bare rock drilling platform and a technology in a huge reservoir and used for bridge construction. The invention is characterized in that an abrupt slope bare rock drilling device in a huge reservoir comprises steel pipe piles, a cross beam, a longitudinal beam, cross struts and a steel casing, wherein the steel pipe piles are arranged on the riverbed in a longitudinal and transverse spacing manner; the longitudinal and transverse spaces of the steel pipe piles are connected through a braced plane frame, the longitudinal cross strut and the transverse cross strut; the space surrounded by the four steel pipe piles is internally provided with the steel casing the height direction of which is parallel to the steel pipe piles; and the diameter of the pile foundation steel casing is 280cm, and the steel casing is made by rolling an A3 steel plate with the thickness of 14mm. The construction technology of the platform has 14 steps, and the invention provides the abrupt slope bare rock drilling platform and the technology in the huge reservoir, which can ensure the platform safety, easily heighten or lower the steel pipe piles, ensure the accurate in-position of a drilling machine and the pile foundation verticality, and is convenient to controlling the axial plane position of the pile foundation.

Owner:中交二公局第六工程有限公司

Expansion fixture suitable for blank surfaces

The invention relates to an expansion fixture suitable for blank surfaces. The fixture comprises a flange, a mandrel fixed in the center of the flange, and a retainer connected with the flange through a bolt. A plurality of sliders are evenly distributed in the circumference direction of the retainer, a cushion block is fixed to each slider, a conical expansion sleeve is further arranged between the retainer and the mandrel, the conical expansion sleeve is tightly connected with the sliders, a spring is connected between the front end of the conical expansion sleeve and the flange, and the tail end of the conical expansion sleeve is provided with a fastening nut arranged on the mandrel in a sleeving mode. The expansion fixture has the advantages of being simple in structure, capable of improving production efficiency, capable of being used for machining the blank surfaces with different diameters and the like.

Owner:CHANGZHOU YINBAO NICKEL NETWORK

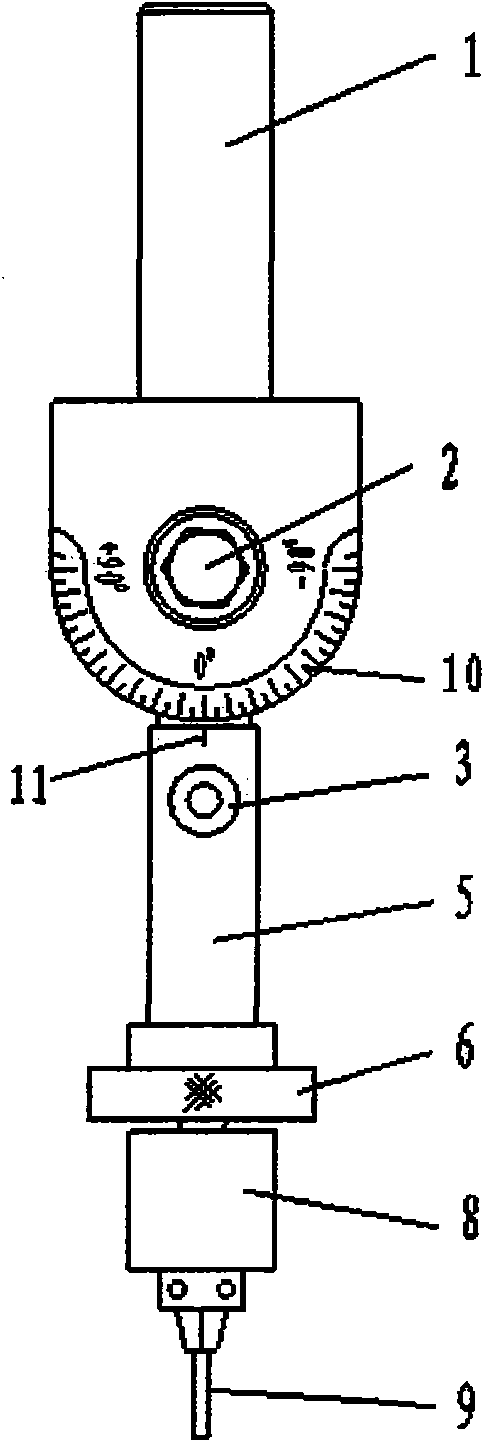

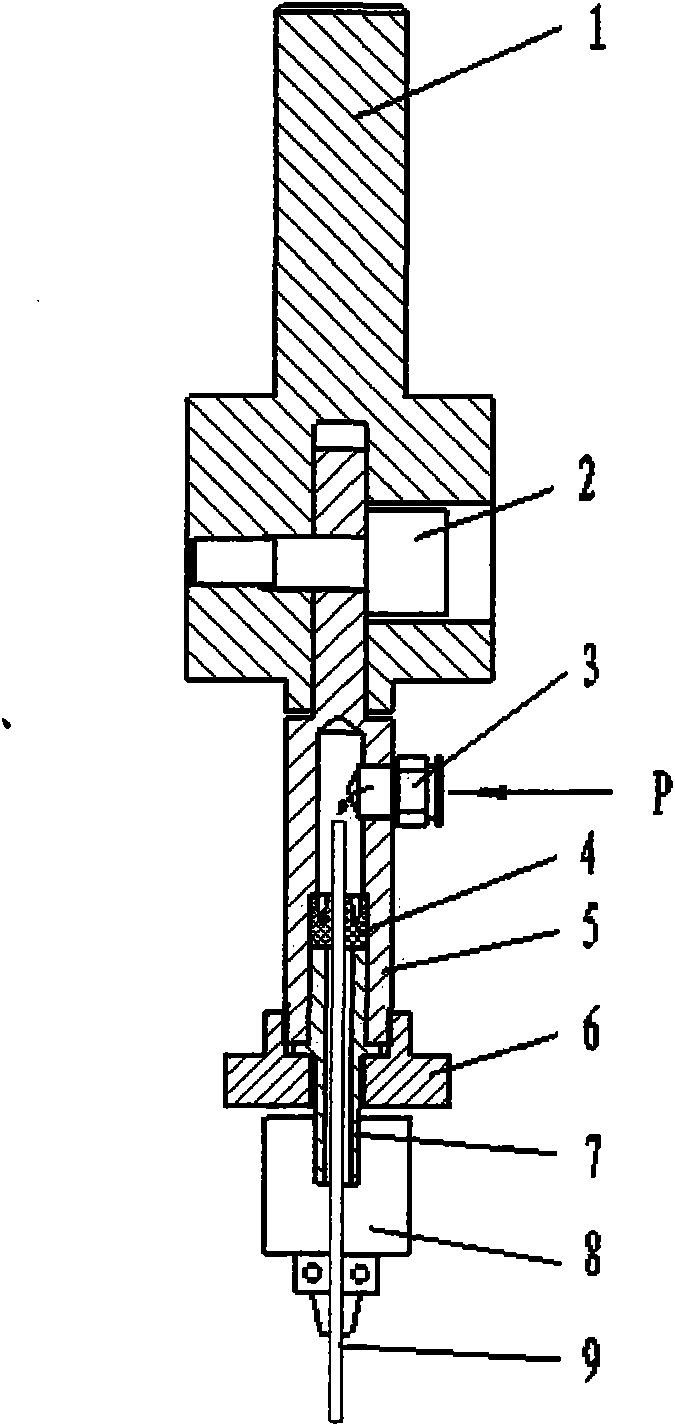

Inclined hole electrosparking processing device and method for adjusting position and angle of electrode

The invention relates to an inclined hole electrosparking processing device, comprising a joint body, an electrode deflection shaft, a positioning clamping screw, a tightening screw cap, a positioning shaft and a hollow small hole electrode. A connecting rod of the electrode deflection shaft is located in a rectangular slotted hole of the joint body; an equal-diameter end of a positioning shaft is located in a shaft hole of the electrode deflection shaft and is tightened up; a rubber sealing piece is located in the shaft hole of the electrode deflection shaft and the hollow small hole electrode penetrates through a drill chuck and is placed into the positioning shaft. In the invention, according to the inclined angle between the inclined hole and the X axis or Y axis and degree scale on the joint body, the inclined angle beta between the electrode and the X axis or the Y axis is initially adjusted, and the electrode is moved along the negative direction of Z axis or the positive direction of the X axis to obtain the actual inclined angle beta between the electrode and the X axis or the Z axis. In addition, the corresponding position of the inclined hole electrode and the inclined hole center C is identified to obtain coordinates of the Z axis and X axis of a machine tool, so that the problems of the existing small hole electrosparking processing device such as high cost, long cycle, difficult positioning of the electrode and low positional precision of processing holes and the like are solved and 0-90-degree inclined hole electrosparking processing is realized.

Owner:NANTONG ZHONGLING INSULATION MATERIALS +1

Fourth-axis rotary indexing processing device for special processing center of valve body

ActiveCN109176145AAchieve pre-lockingComplete deadlockAutomatic control devicesPrecision positioning equipmentProcessing accuracyEngineering

The invention provides a fourth-axis rotary indexing processing device for a special processing center of a valve body. The fourth-axis rotary indexing processing device comprises a rotary motor. An installation base is arranged on the rotary motor. An installation vertical plate is arranged perpendicular to the installation base. A centering component, a clamping component and a first correctingcomponent are arranged on the installation vertical plate. The device further comprises an auxiliary mechanism arranged on the installation vertical plate. The auxiliary support is carried out by utilizing a first support ejector rod and a second support ejector rod. An operator can lift the valve body to the installation vertical plate through a hoisting machine and then pre-lock the valve body by centering the valve body through the centering assembly, and meanwhile in cooperation with the work of the clamping component and the first correcting component, the complete locking of the valve body is automatically realized in the process of correcting the levelness of the valve body, so that the technical problem of automatic installation of the valve body is solved, the manpower is reduced,meanwhile accurate installation and locking of the valve body are realized, and the processing precision is improved.

Owner:ZHEJIANG ZHONGDE AUTOMATIC CONTROL VALVE

Bonnet support processing method and clamp and processing equipment for bonnet support

ActiveCN103240567AAvoid Machining PrecisionAvoid Processing RequirementsOther manufacturing equipments/toolsLarge fixed membersProduct processingLubrication

The invention discloses a bonnet support processing method and clamp and processing equipment for a bonnet support. The bonnet support processing method includes fixing a bonnet support through the special clamp to enable the central line of the bonnet support to be coaxial with the processing equipment; cutting a flange plane and an end face of a valve rod nut through the processing equipment; changing a cutter, rough-boring or fine-boring a valve rod nut hole, assembling a seal seat and a gland box; changing a cutter to enable the cutter to be coaxial with the processing equipment, rotating a rotation disc at 180 degrees, and finish-milling a thread of the valve rod nut; changing a cutter to enable the cutter to be coaxial with the processing equipment, rotating the rotation disc at 180 degrees, and drilling a flange hole; rotating the rotation disc at 90 degrees, and drilling an eyelet bolt hole and a lubrication hole of the valve rod nut on the support; changing a cutter, rotating the rotation disc at 90 degrees, scraping reversely and facing the back end face of the flange hole; and after finishing processing the back end face of the flange hole, disassembling the bonnet support. By the bonnet support processing method, processing on components can be finished through being clamped only once, and product processing accuracy and quality are improved.

Owner:SHANGHAI HONGGONG MASCH TECH CO LTD

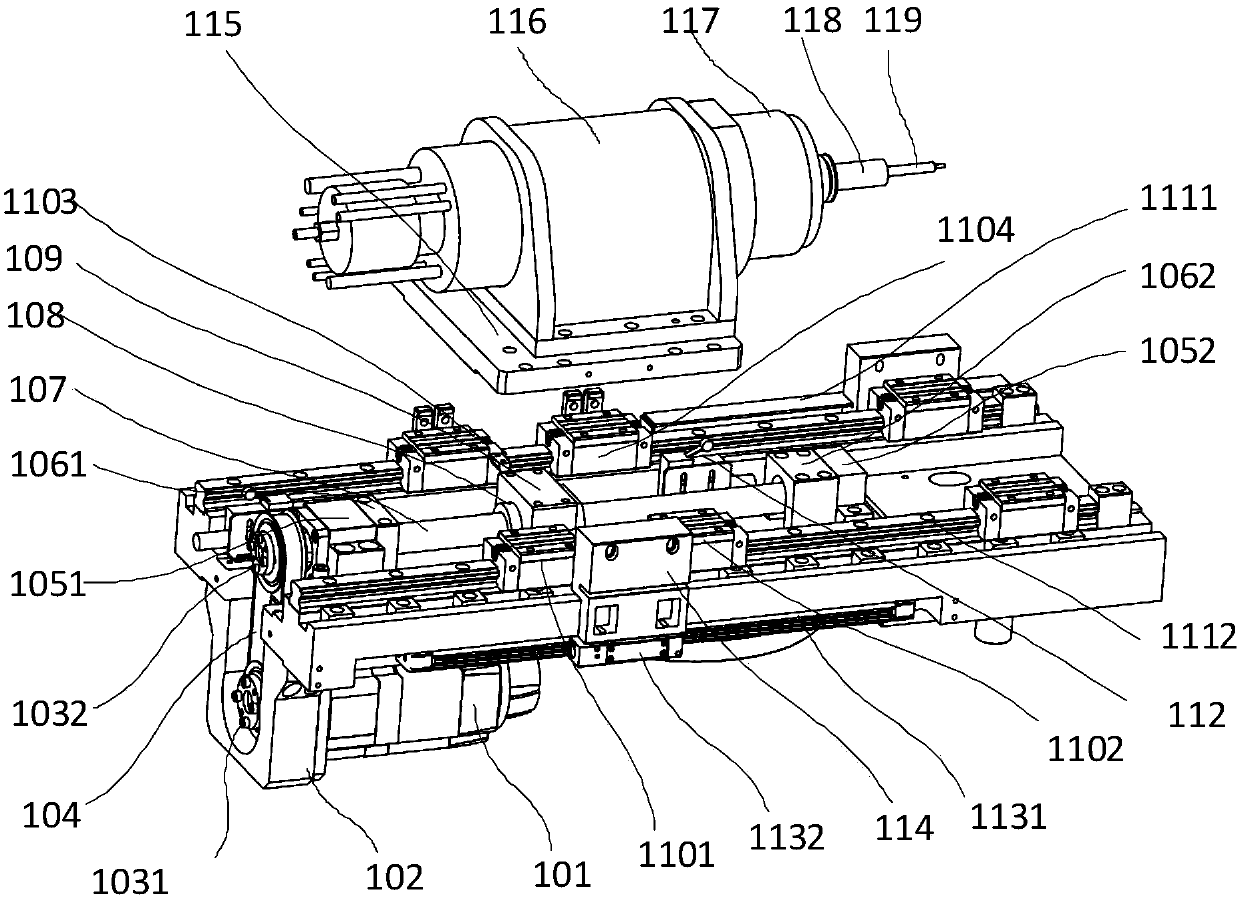

End executor used for high-precision drilling and dimpling of robot and measurement method

ActiveCN108015312ACompact structureImprove measurement reliabilityAutomatic control devicesGripping headsMeasurement deviceEngineering

The invention provides an end executor used for high-precision drilling and dimpling of a robot. The end executor comprises a spindle, a feeding unit of the spindle, a normal measuring device, a driving unit of the normal measuring device, a datum hole visual positioning unit and a guide rail installation plate. The spindle and the feeding unit of the spindle are installed on the guide rail installation plate. The normal measuring device is installed at one end of the guide rail installation plate. The datum hole visual positioning unit is installed on the back side of the guide rail installation plate. The end executor is compact in structure and comprises a plurality of function modules including a displacement detection module, a normal measuring module and a datum hole visual positioning module, and the measurement reliability is improved. The displacement detection module can detect the tool feeding amount and deformation amount of a workpiece when the workpiece is clamped and machined, and compensate for the deformation amount. The normal measuring device is small in size, multifunctional and high in measurement precision. The end executor is installed on an end flange plateof the industrial robot, and the drilling perpendicularity can be guaranteed.

Owner:SHANGHAI TOPNC NUMERICAL CONTROL TECH CO LTD

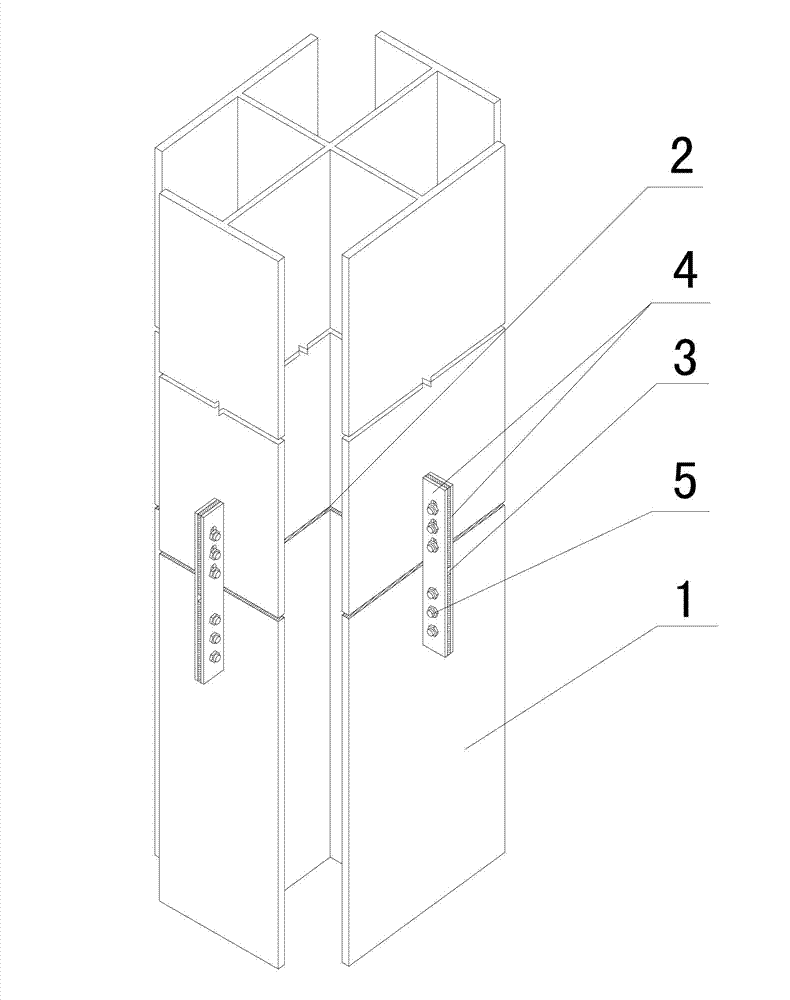

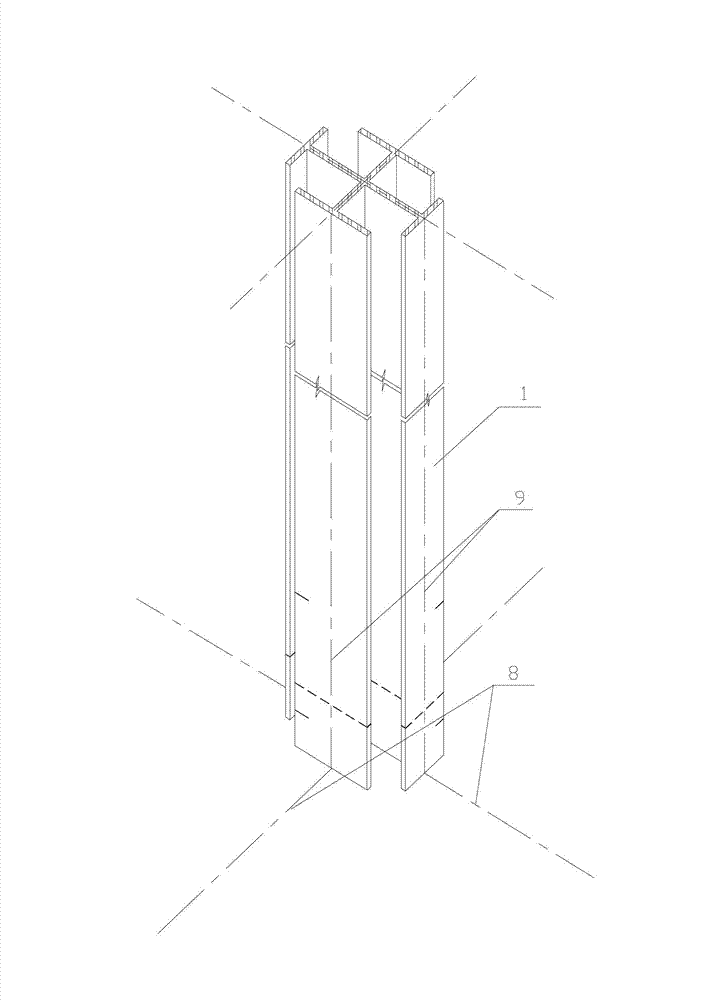

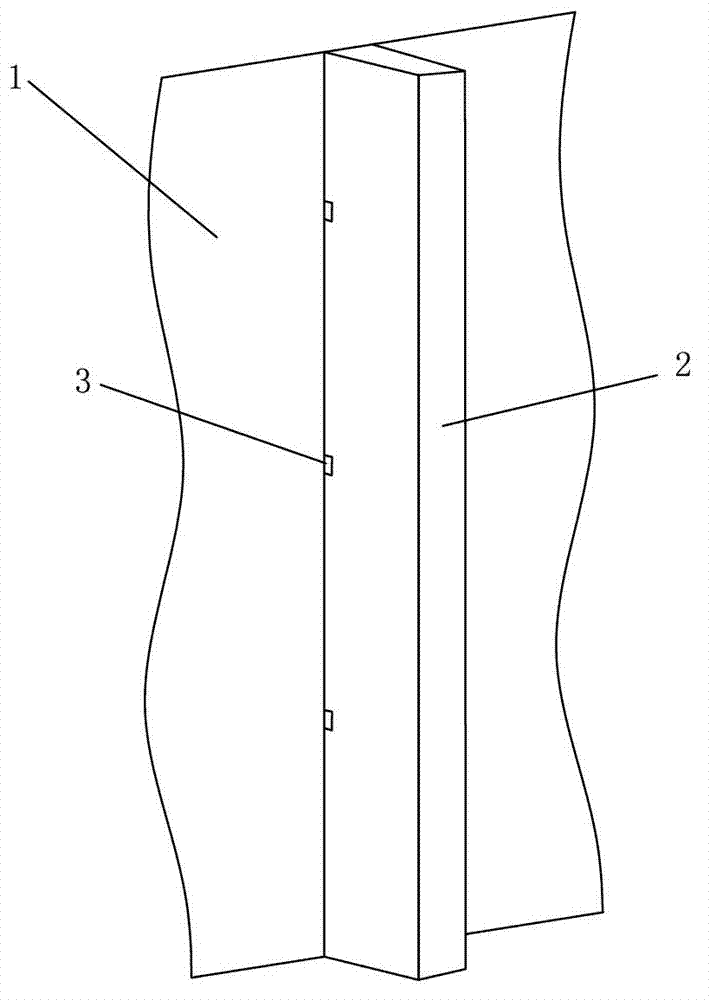

Section steel column for high-rise building section steel concrete combination structure, and construction method thereof

ActiveCN102733545AGuaranteed section sizeGuaranteed lengthStrutsBuilding material handlingConnection typeEngineering

The present invention discloses a section steel column for a high-rise building section steel concrete combination structure, and a construction method thereof. The section steel column comprises a plurality of column sections, wherein the column sections are sequentially connected from bottom to top, an interface position of two optionally adjacent column sections is provided with an inner sleeve interface, and an outer side wall of a connection position of the two adjacent column sections is provided with a buckle fixation type assembly. The construction method comprises that: the insert-connection type initial positioning of the two adjacent column sections is achieved through the inner sleeve interface; the cross extending line and the buckle fixation type assembly are combined to carry out positioning correction on the column; a scale measurement method is adopted to carry out column scale height adjustment; and the cross extending line and the buckle fixation type assembly are combined to carry out verticality correction on the full length of the column sections. With the section steel column of the present invention, the model of one construction interface in each floor of the traditional section steel column can be increased to the model of one construction interface in every two floors or three floors, such that more than half of the construction interfaces of the section steel column can be saved, the probability of deviation error due to construction interface operation can be greatly reduced, and the guarantee degree of installation quality can be improved.

Owner:广东中城建设集团有限公司 +1

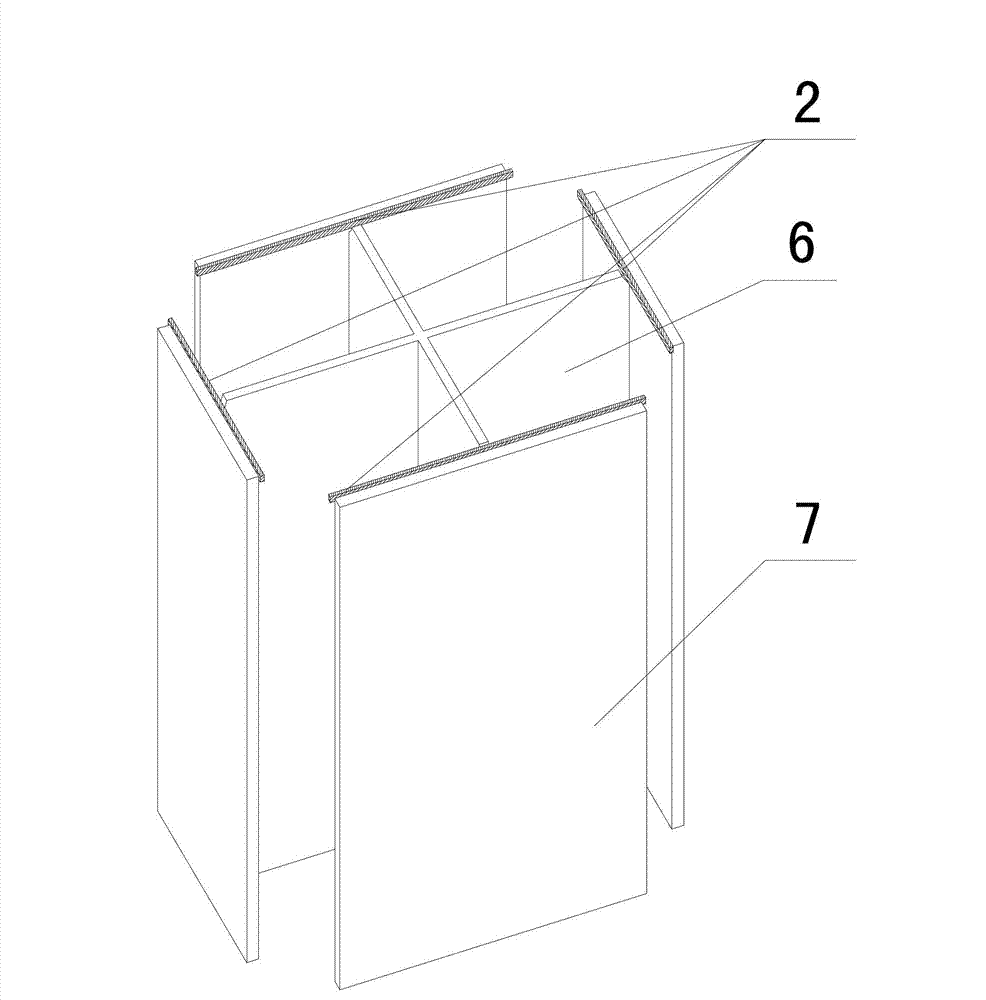

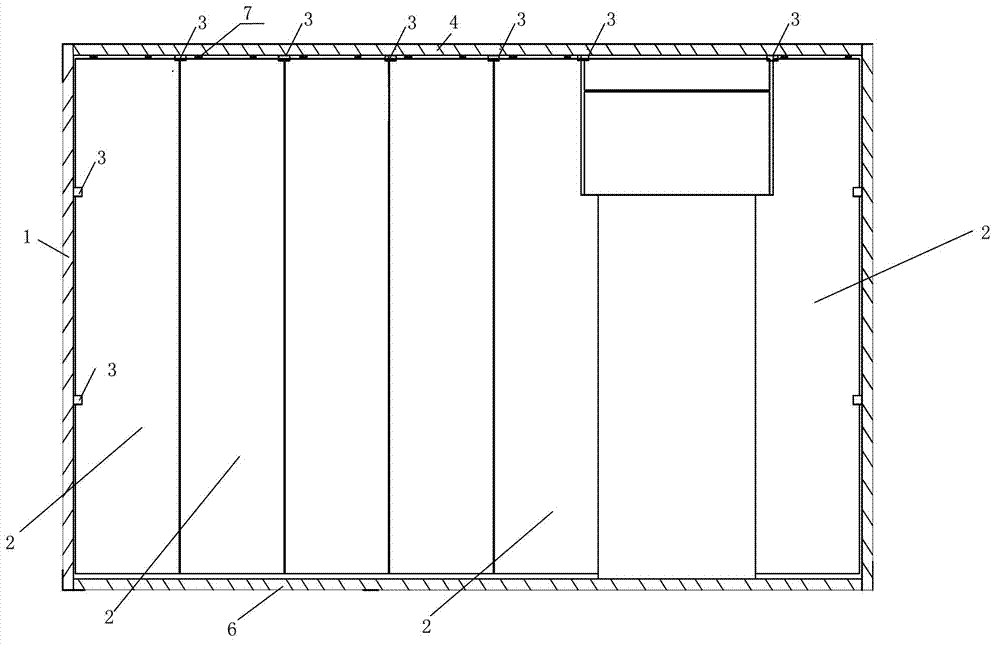

Installation technology of inner separation wall body

InactiveCN102777041ARapid positioningGuaranteed flatnessWallsBuilding material handlingStructural engineeringEngineering

Owner:中山建华墙体材料有限公司

Hydraulic lifting self-ascending template system of intelligent independent unit structure

ActiveCN102587646AAdjust pouring height at willSave moneyForms/shuttering/falseworksScaffold accessoriesSupporting systemControl system

The invention provides a hydraulic lifting self-ascending template system of intelligent independent unit structure. The hydraulic lifting self-ascending template system comprises a supporting system, a steel truss system arranged on the supporting system, an operating platform system and a template system which are hung on the steel truss system, a lifting system, a total electric control system, and a touch screen total control panel; wherein the lifting system, the total electric control system and the touch screen total control panel are applied to lift the operating platform system and the template system and adjust the balance of the operating platform system and the template system, and are sequentially in communication connection with each other; the supporting system comprises a plurality of main upright posts, and a plurality of supporting legs and guiding legs arranged on the main upright posts; each main upright post comprise an outer square pipe and an inner square pipe capable of moving opposite to each other; a self-ascending prompting system, an independent electric control system and an independent touch screen control panel which are sequentially in communication connection with each other for realizing the independent self-ascending of each main upright post, are arranged on the outer square pipe; and each supporting system can ascend independently by itself, in this way, the problems of security risks caused by the reduction of supporting points on the wall of the upper steel truss system due to the fact that multiple supporting systems ascend by themselves at the same time are solved.

Owner:TABLE CONCRETE FORMWORK & SHORING SHAANXI

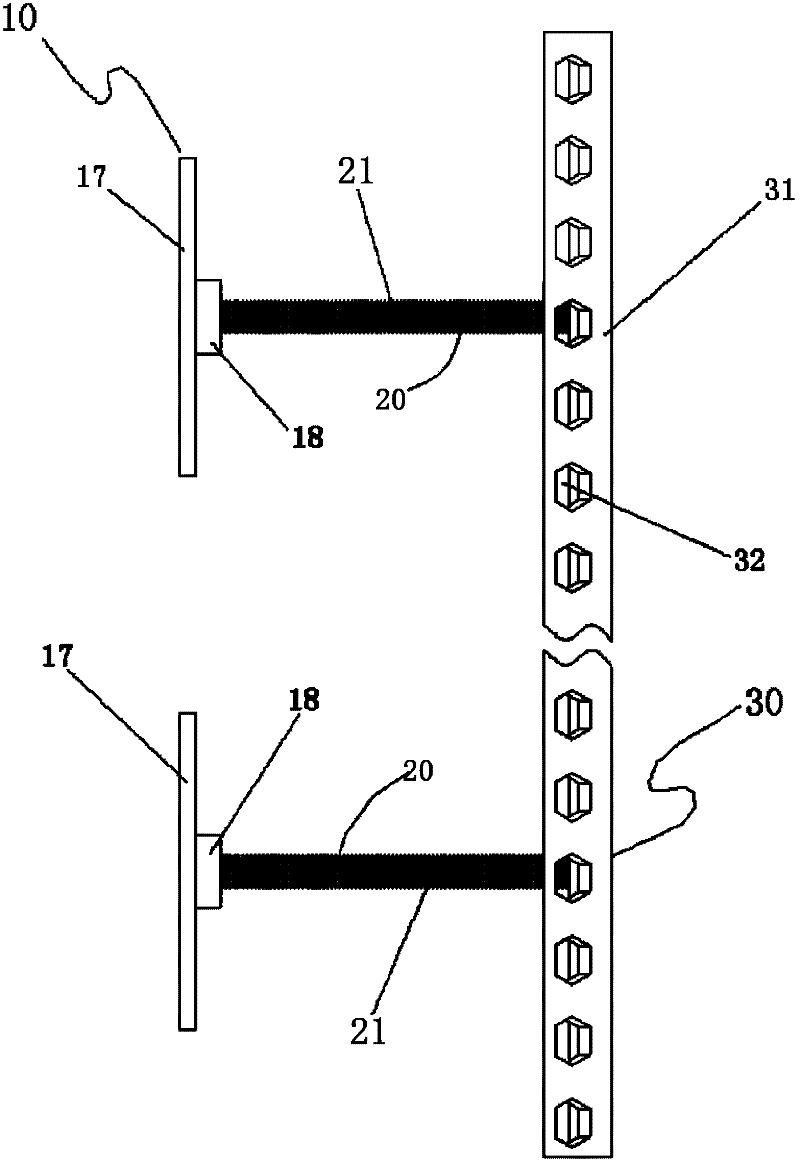

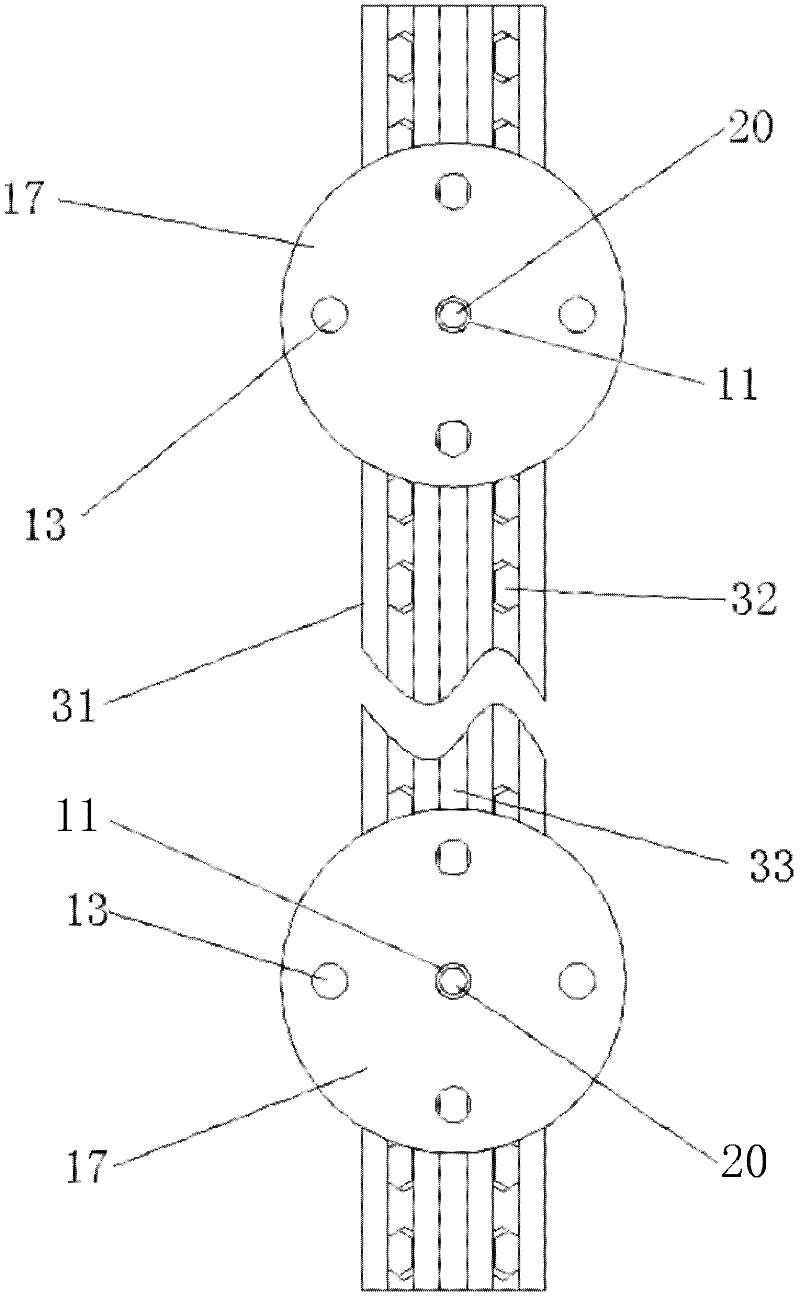

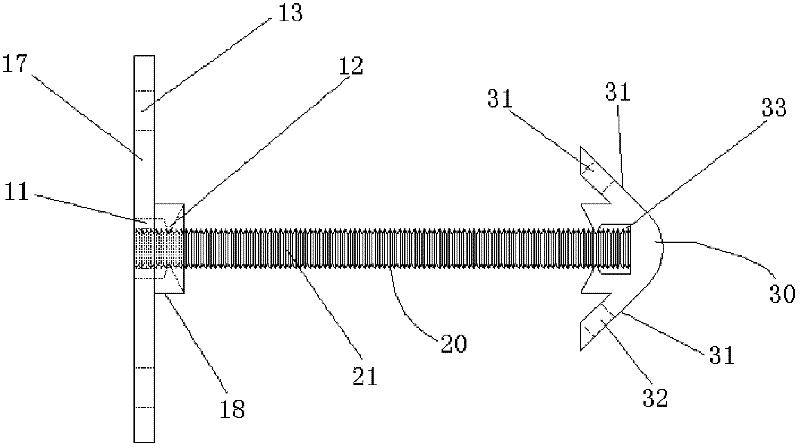

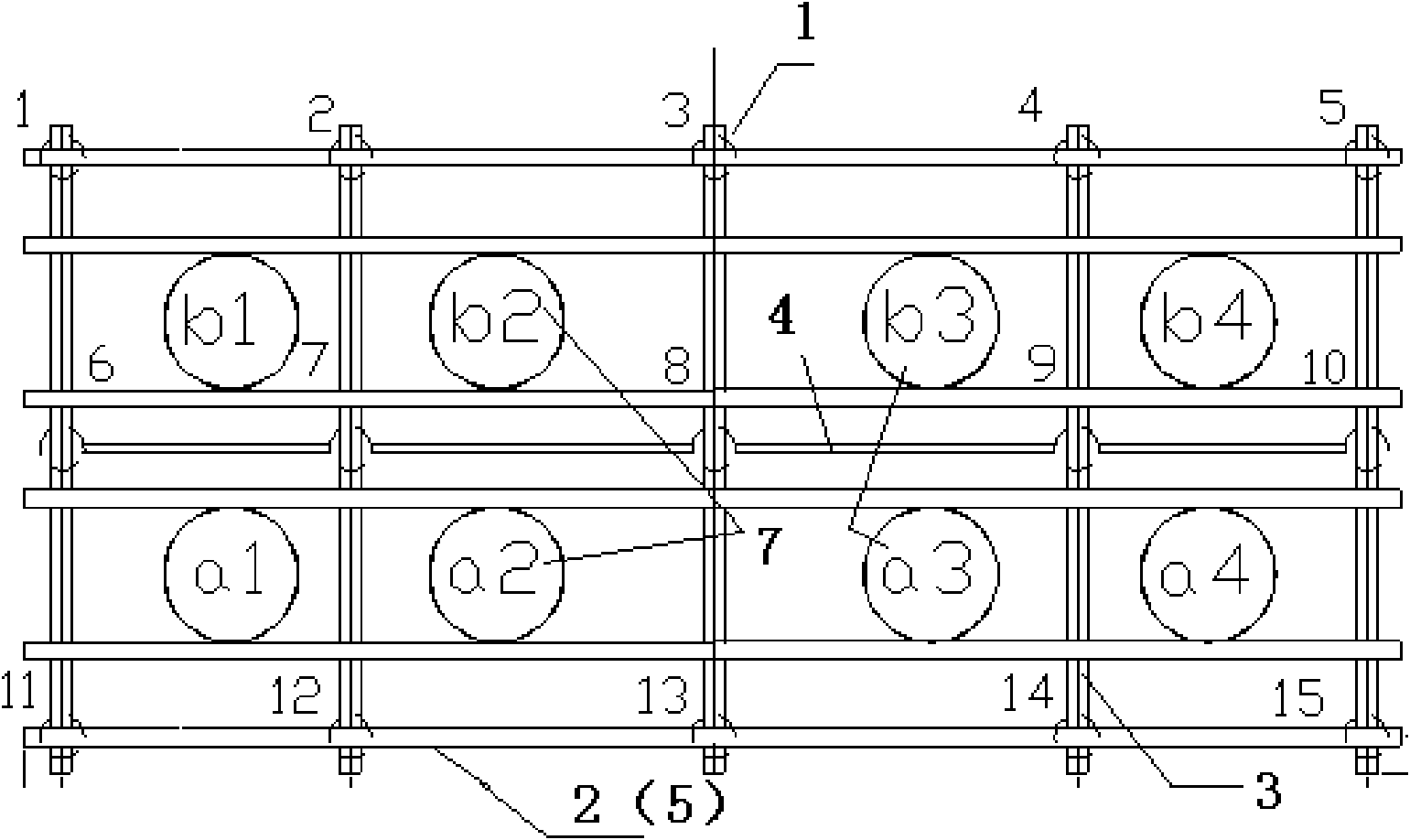

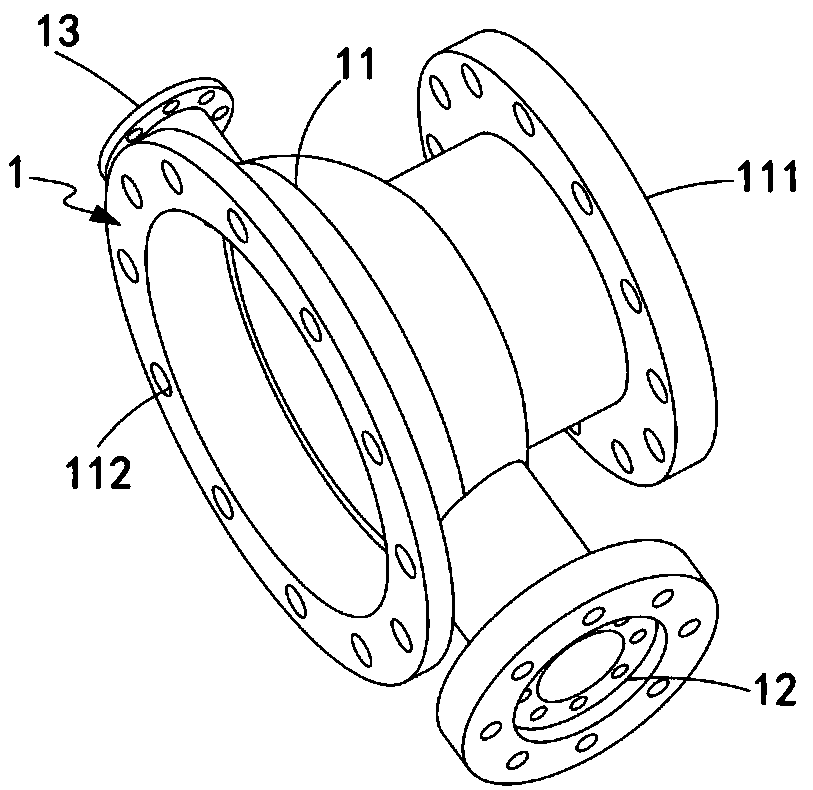

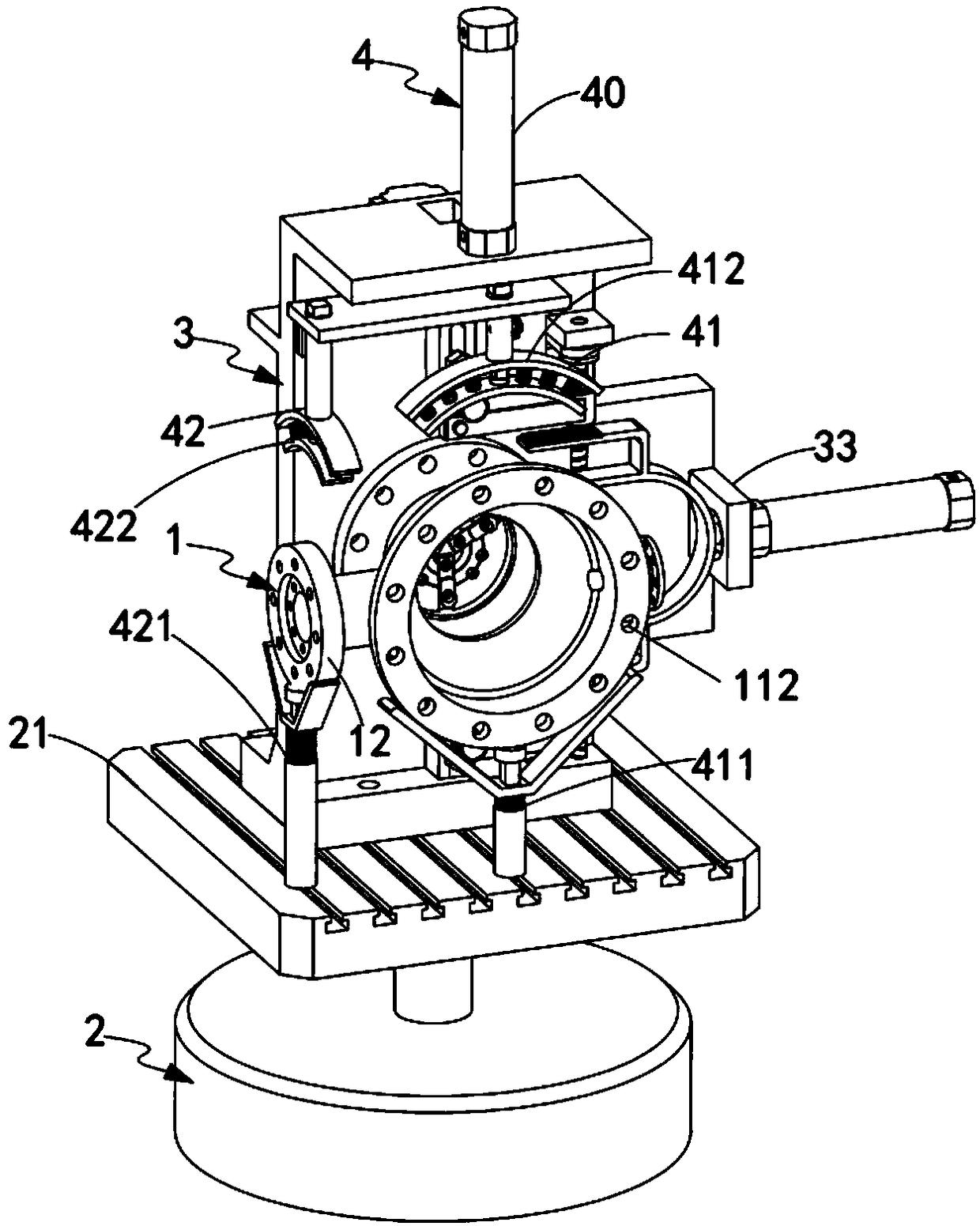

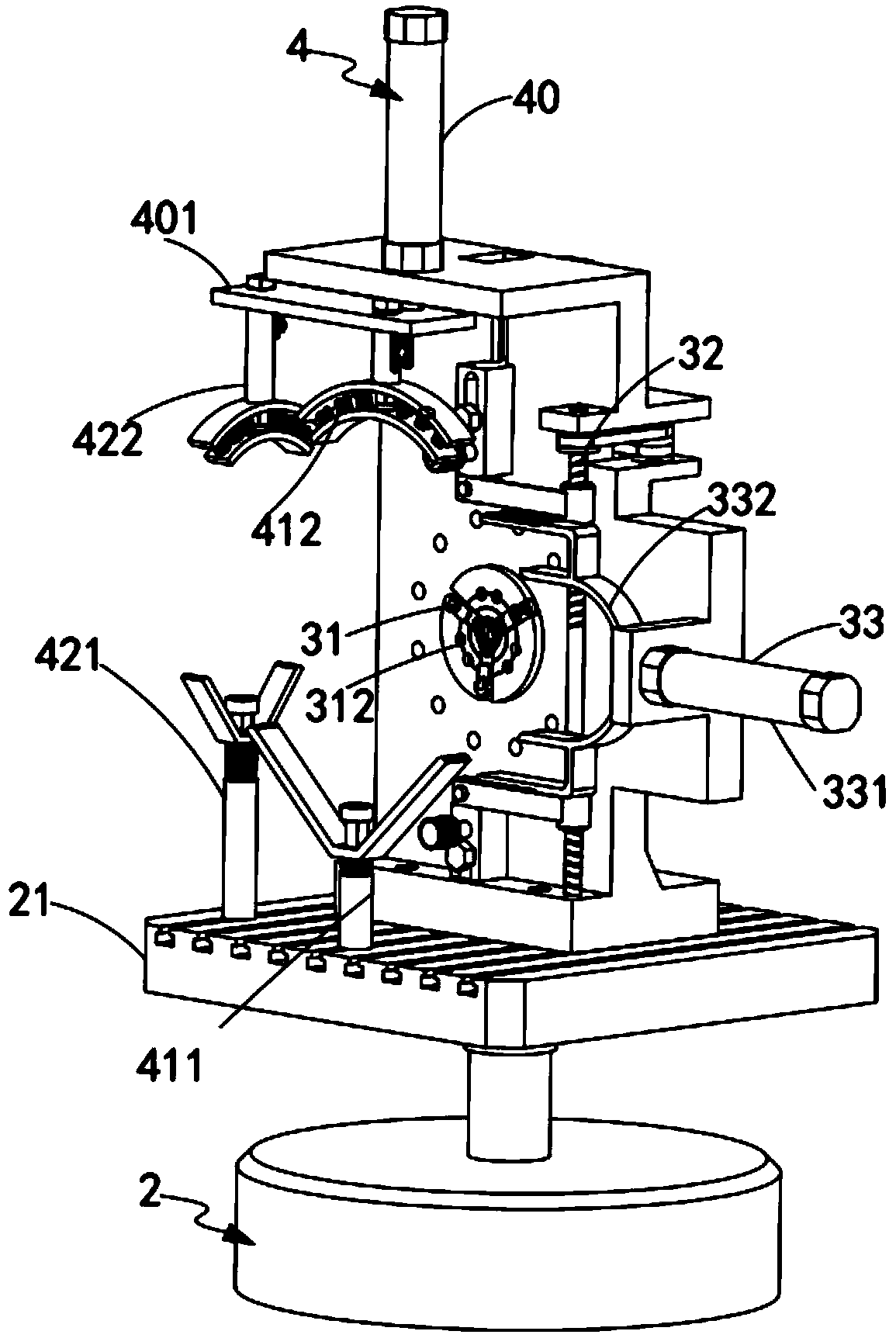

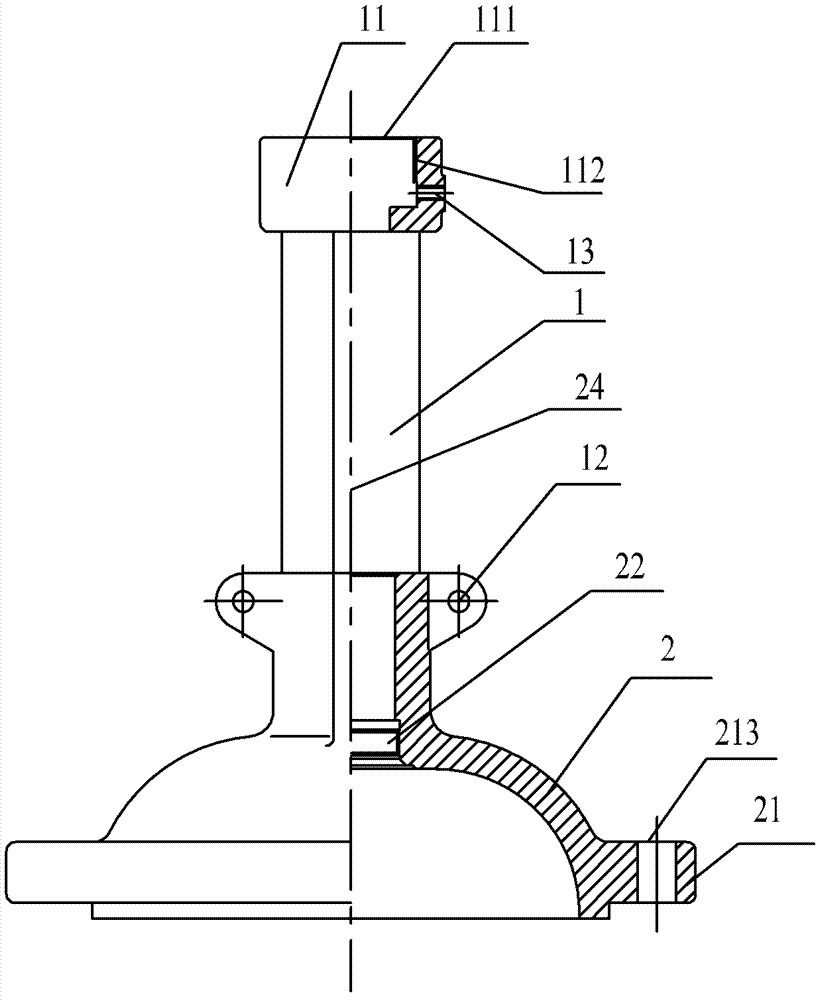

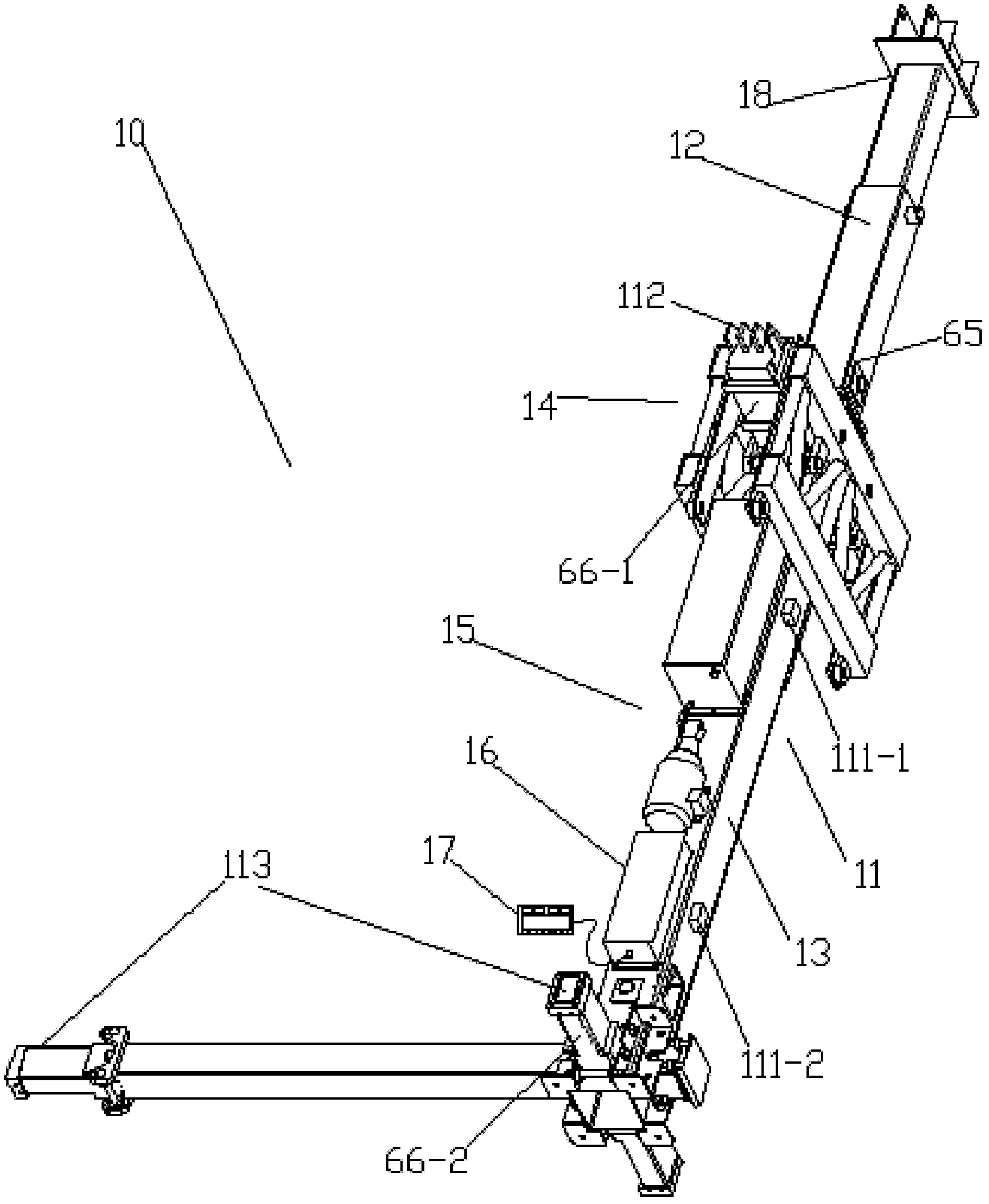

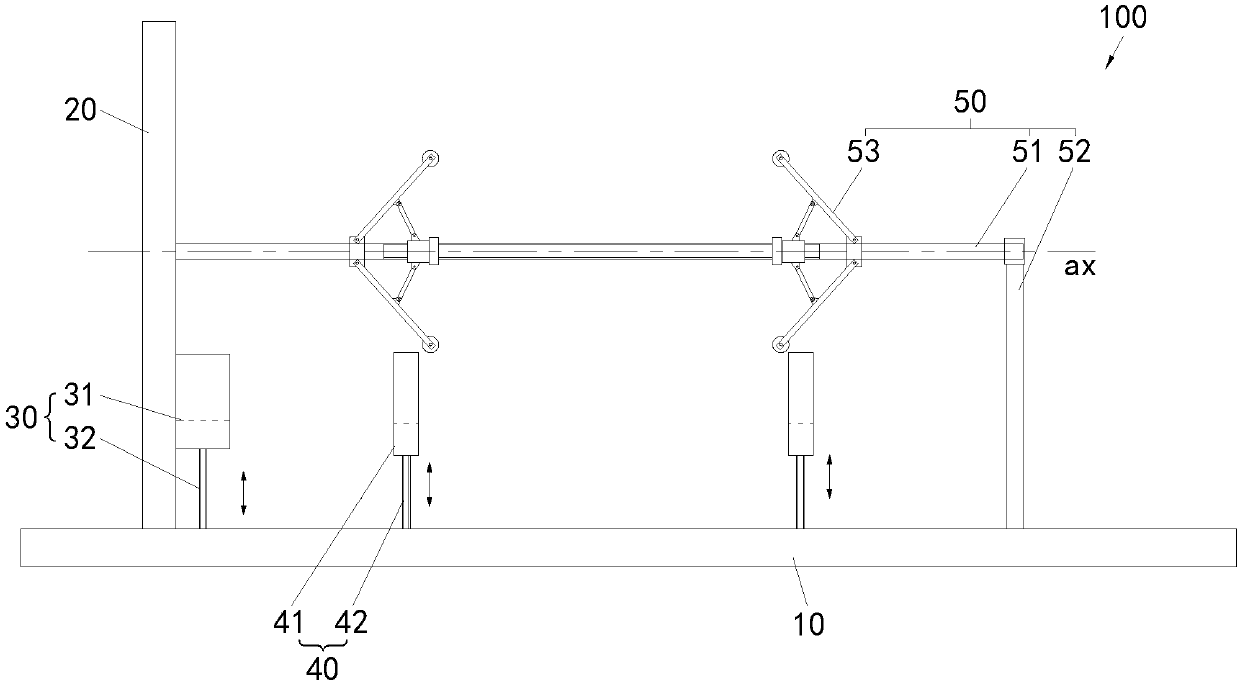

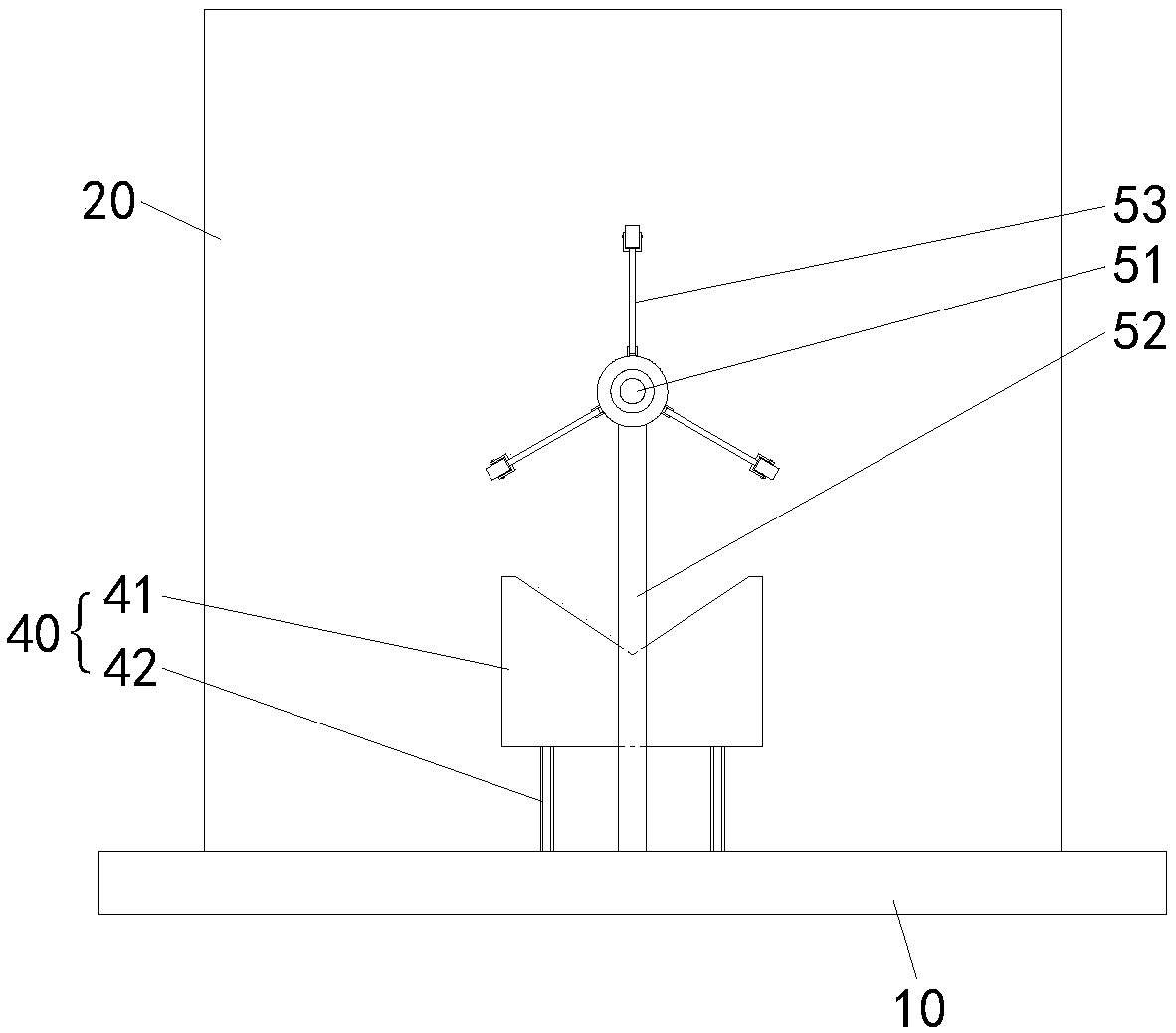

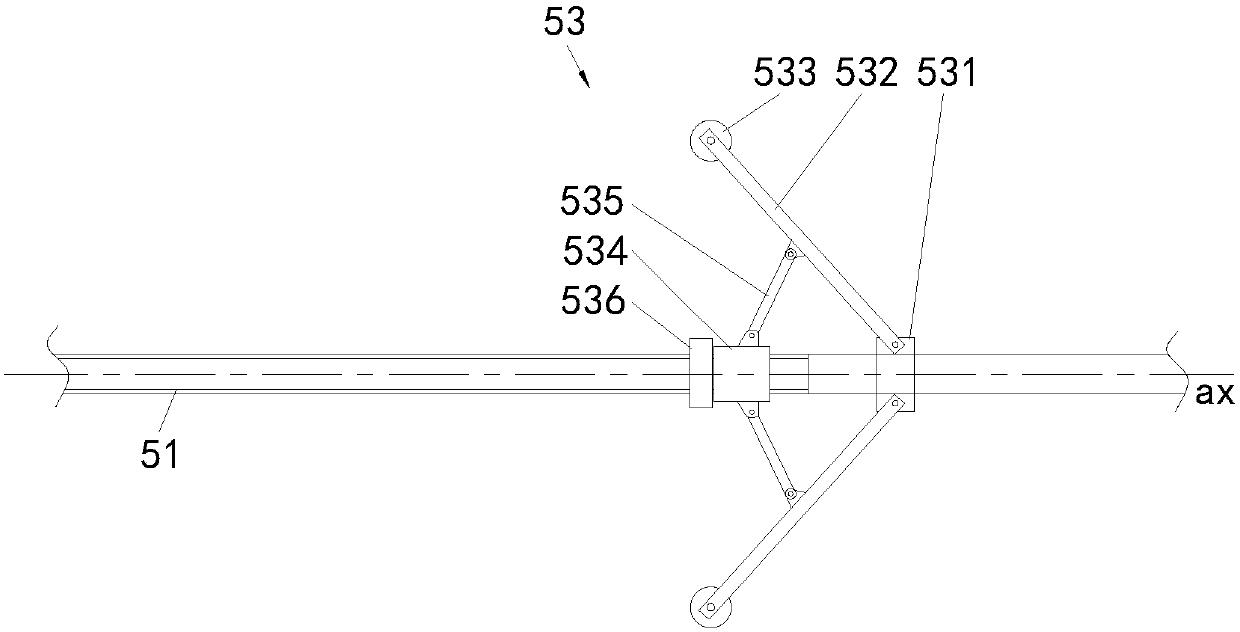

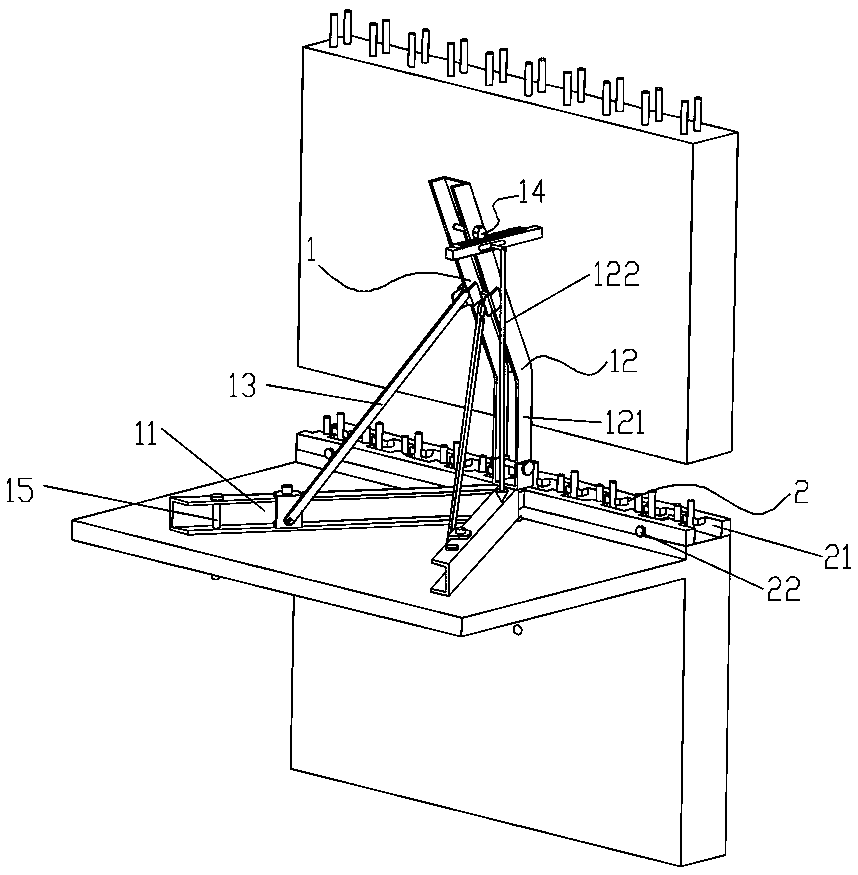

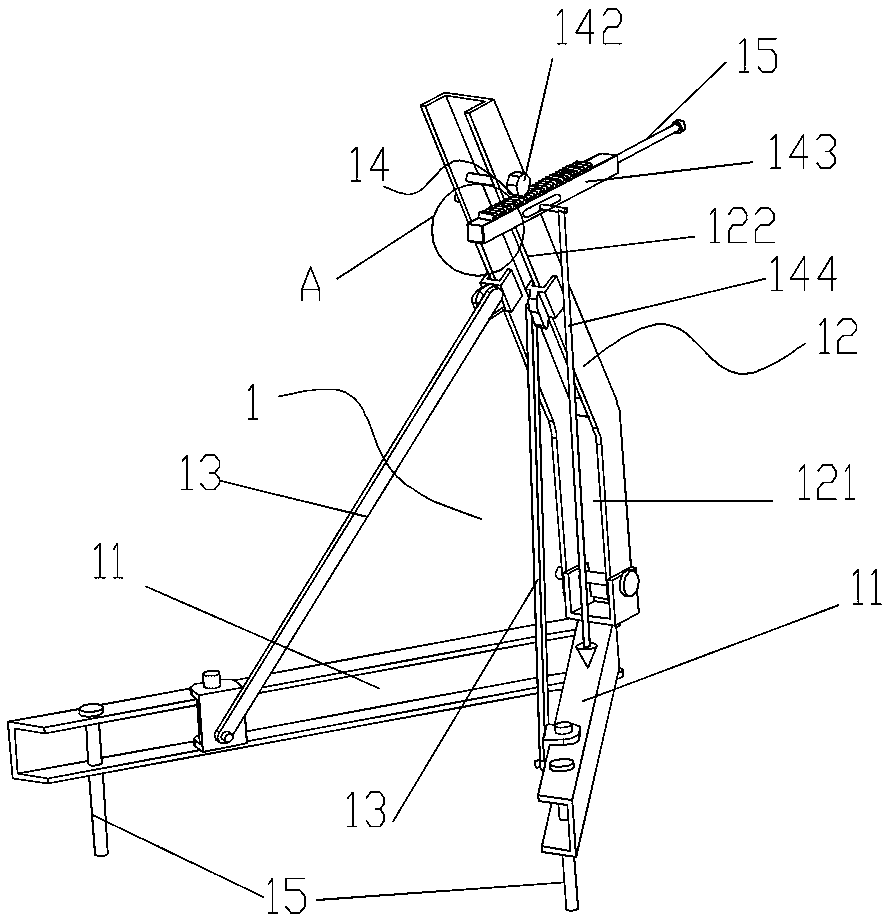

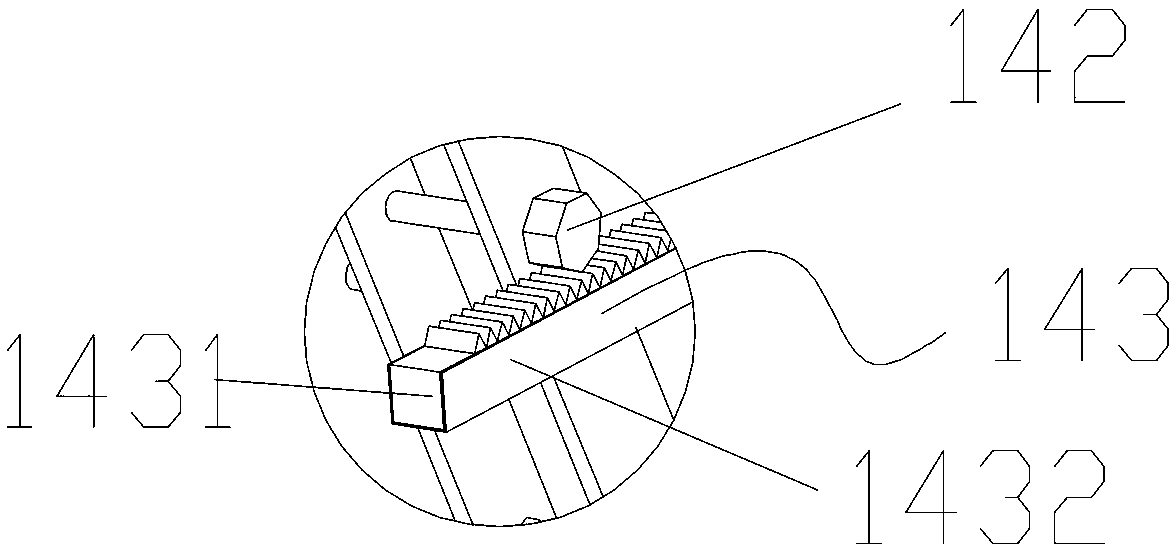

Prefabrication platform and prefabrication method for jacketed pipe

PendingCN107855721AEasy to penetrate and installGuaranteed verticalityWelding/cutting auxillary devicesAuxillary welding devicesFiberCompound (substance)

The invention discloses a prefabrication platform and a prefabrication method for a jacket pipe and relates to the technical field of petrochemical engineering and chemical fiber equipment installation. The prefabrication platform and the prefabrication method for the jacketed pipe are provided to solve the problems that according to existing prefabrication construction for a straight pipe sectionof a major-diameter jacketed pipe, operation is relatively complex, and the working efficiency is low. The prefabrication platform is composed of a flange plate positioning frame, an inner pipe positioning assembly and a plurality of outer pipe positioning assemblies. A first adjusting rod arranged on the bottom of a positioning base can adjust the height of a flange plate. The inner pipe positioning assembly is composed of a center rod perpendicularly fixed to a back plate, an extensible and retractable guide wheel supporting frame arranged on the center rod in a sleeving manner and a supporting frame connected to the other end of the center rod, wherein the extensible and retractable guide wheel supporting frame is composed of a fixing casing pipe arranged on the center rod in a sleeving manner, supporting rods which are evenly distributed in the radial direction of the axis of the center rod and hinged to the fixing casing pipe and extensible and retractable supports, one end of each extensible and retractable support is hinged to the corresponding supporting rod, the other end of each extensible and retractable support is hinged to the center rod, and the other end of each supporting rod is provided with a guide wheel. The outer pipe positioning assembly comprises an outer pipe support and a second adjusting rod which are detachably connected.

Owner:SHANGHAI INSTALLATION ENG GRP

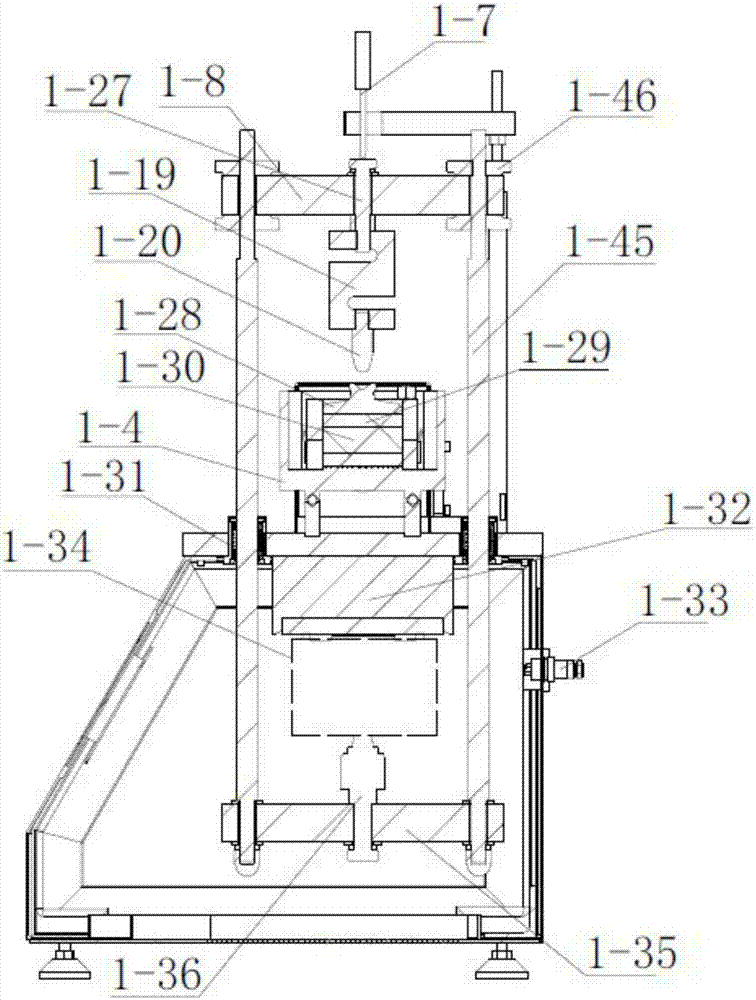

Automatic rheological direct-shear apparatus and experimental operation method thereof

PendingCN106940274AHigh control precisionVersatileMaterial strength using steady shearing forcesMechanical pressure/force controlDirect shear testRelaxation test

The invention discloses an automatic rheological direct-shear apparatus and an operation method thereof. The automatic rheological direct-shear apparatus comprises a rheological direct-shear instrument (1) and a computer (2). The rheological direct-shear instrument (1) is under servo closed-loop control, a vertical load sensor (1-19) in a vertical servo loading system is employed for adjusting and controlling axial stress applied on a sample (1-30), and meanwhile, a first horizontal load sensor (1-3) arranged in a horizontal shear driving system and connected with a horizontal shear driving device is used for applying a constant a horizontal shear force on the sample (1-30), so direct-shear creep test of soil is realized; and at the same time, a horizontal displacement sensor (1-16) is employed for accurate control of the horizontal shear amount of the sample (1-30), so direct-shear strain relaxation test of soil is realized. The automatic rheological direct-shear apparatus provided by the invention can carry out both conventional direct-shear test and rheological direct-shear test on soil, has high stability and can realize accurate control of testing and whole-process automation of acquisition.

Owner:南京泰克奥科技有限公司

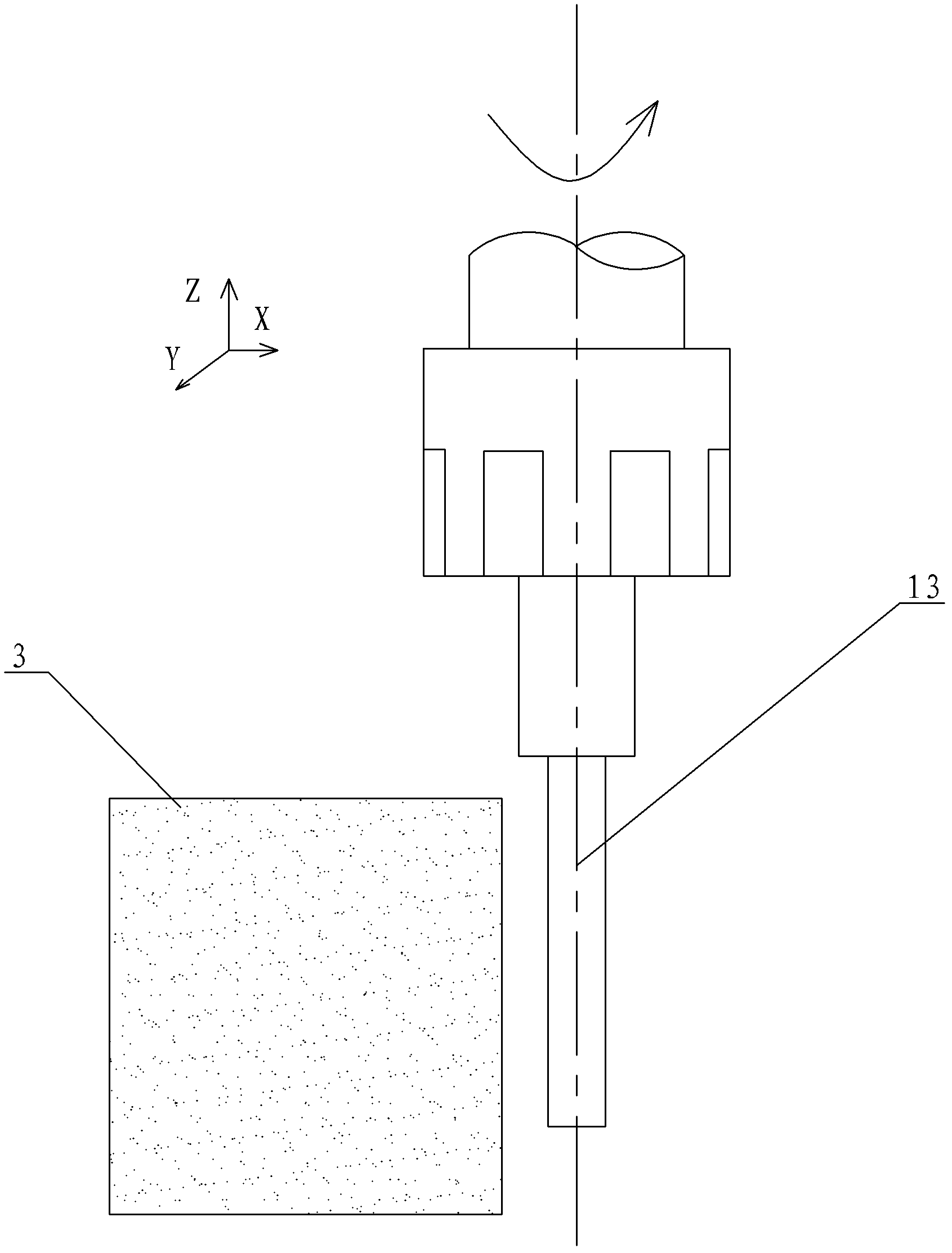

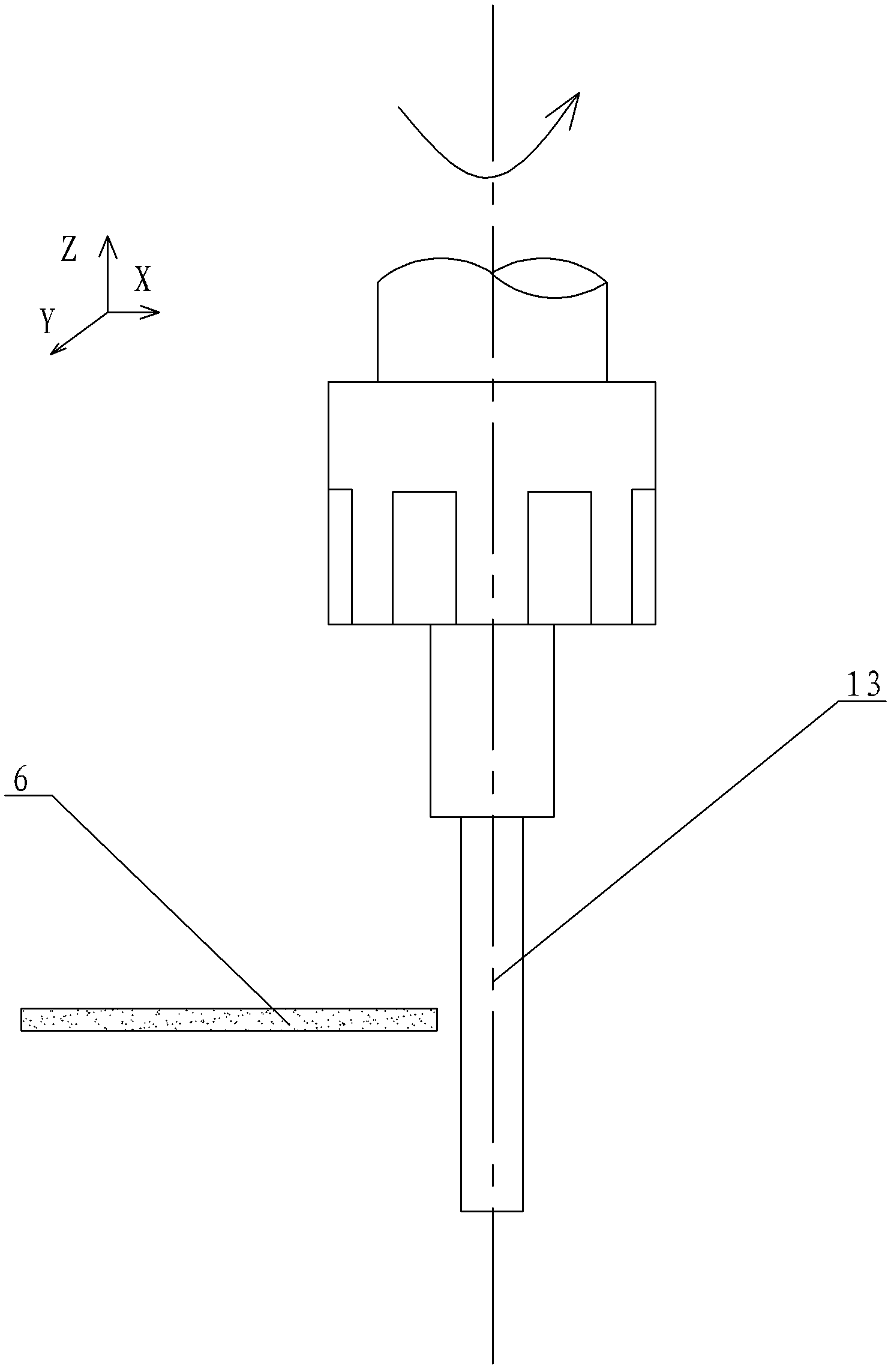

Electric spark and electrochemical composite machining method of micro-electrode

The invention provides an electric spark and electrochemical composite machining method of a micro-electrode, relates to an electric spark and electrochemical composite machining method, and belongs to the field of special machining. The electric spark and electrochemical composite machining method of the micro-electrode is provided in order to solve the problems that: the traditional electric spark grinding method of a block electrode has machining taper error, poor quality of an electrode surface, and a micro-electrolytic grinding method of an edge electrode has low machining efficiency. The method comprises the following: step 1. a machine tool is initialized, and tools and electrodes are clamped; step 2. a block electrode of an electrode (13) is subjected to electric spark grinding machining; step 3. the electrode (13) is subjected to electrolytic grinding finish machining; and step 4. the electrode (13) after being subjected to the electrolytic grinding finish machining is tested. The electric spark and electrochemical composite machining method is particularly applicable to the machining of micro cylindrical electrodes.

Owner:HARBIN INST OF TECH

Welding method and equipment for multifunctional threaded fastener

ActiveCN105880895AImprove welding efficiencyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStud welding

The invention discloses a welding method and equipment for a multifunctional threaded fastener. The welding method comprises MAG welding, TIG welding, MIG welding, stud welding and MIG brazing. The threaded fastener and a workpiece are positioned by a positioning mechanism of the equipment, a welding gun is clamped by a clamping mechanism, a pressing force is transmitted to a pressing mechanism by a power component, the threaded fastener and the workpiece are pressed by the pressing mechanism, the welding gun is driven to move downwards at the same time, and the threaded fastener and the workpiece are welded by a welding mechanism. Compared with existing arc welding equipment for welding the threaded fastener, the method and the equipment have the advantages that the efficiency is improved by 2 to 4 times; moreover, the problems of poor stability of conventional resistance projection welding of the threaded fastener, incapability in welding medium- and high-carbon steel, alloy steel, dissimilar metals and dissimilar materials, incapability of welding on the sidewall of a U-shaped sheet metal part, various hollow and solid pipe fittings and thick plates, incapability of abreast welding of the threaded fastener and the workpiece and the like are solved. In addition, the invention further provides MIG-brazed and flame-brazed fastener and a workpiece used for welding a threaded fastener and positioned by a light beam.

Owner:何强

Processing method for high-precision thin step shaft and grinding chuck for processing method

ActiveCN104227345ASolving Grinding DifficultiesGuaranteed verticalityGrinding work supportsMaterials scienceHeat treated

The invention provides a processing method for a high-precision thin step shaft and a grinding chuck for the processing method. The processing method mainly comprises the following steps: (1) preparing materials; (2) performing heat treatment; (3) performing end face and excircle turning and center drilling; (4) performing the heat treatment; (5) performing surface treatment; (6) performing abrasive machining on center holes in both ends of the thin step shaft; (7) grinding a step excircle and a step end face; (8) performing precision grinding; the grinding chuck comprises a clamping disk and a deflector rod arranged on the clamping disk; a chuck hole is formed in the middle part of the clamping disk; three inclined holes are evenly distributed, along the peripheral direction of the chuck hole, in the clamping disk; a lifting pin is arranged in each oblique hole, and is locked through an inner hexagon cone point set screw. According to the processing method and the grinding chuck provided by the invention, the thin step shaft is clamped through the grinding chuck to perform grinding on the excircle and the end face, and the processing quality is stable; meanwhile, traditional processes for cutting the thin step shaft into two pieces, performing abrasive cut-off on a rear end face and removing burrs are reduced in the processing technology of the processing method provided by the invention, so that the raw materials are greatly saved, and meanwhile, the processing efficiency is improved.

Owner:贵州凯星液力传动机械有限公司

Assembled wall auxiliary mounting device and using method

Owner:北京市住宅产业化集团股份有限公司

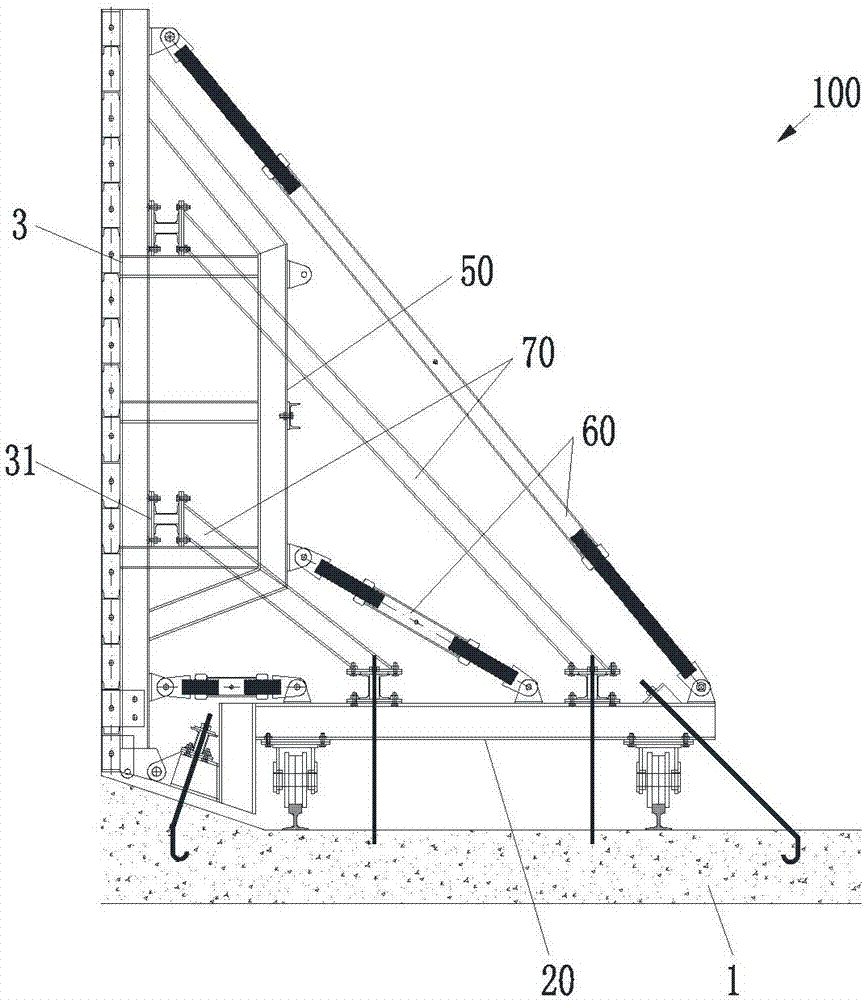

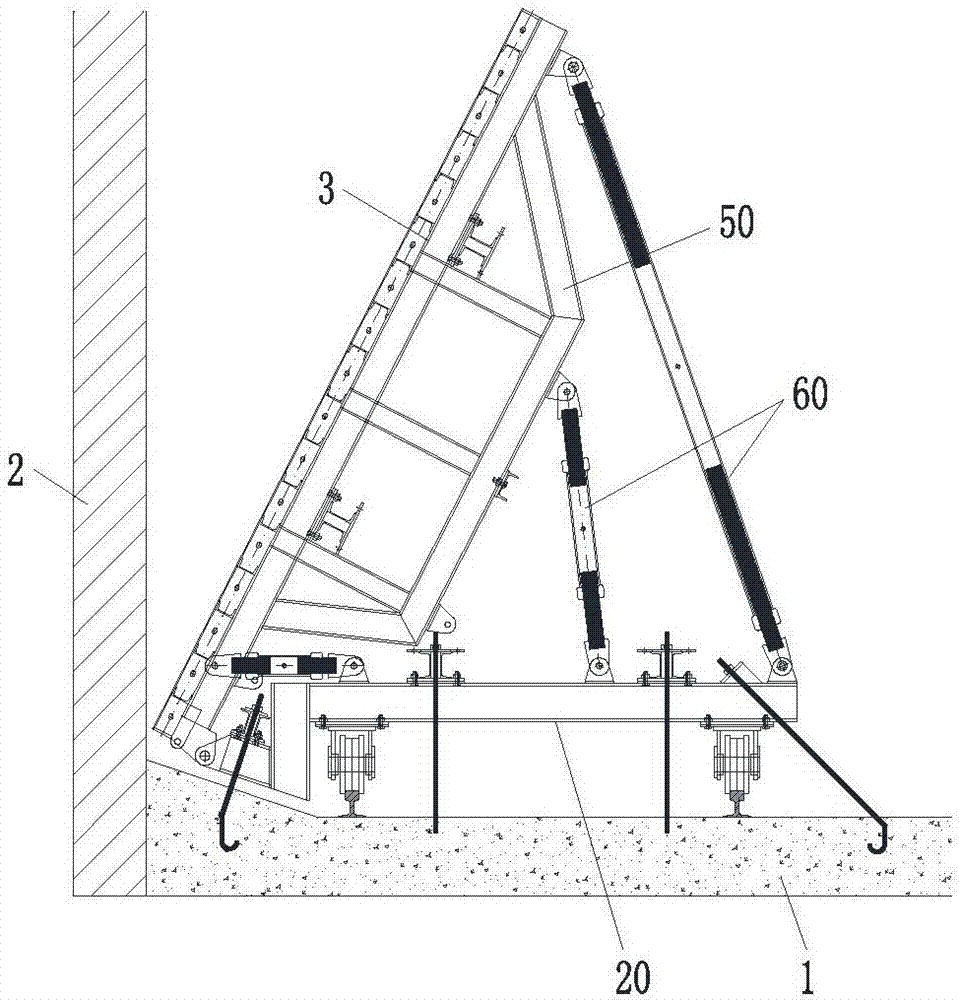

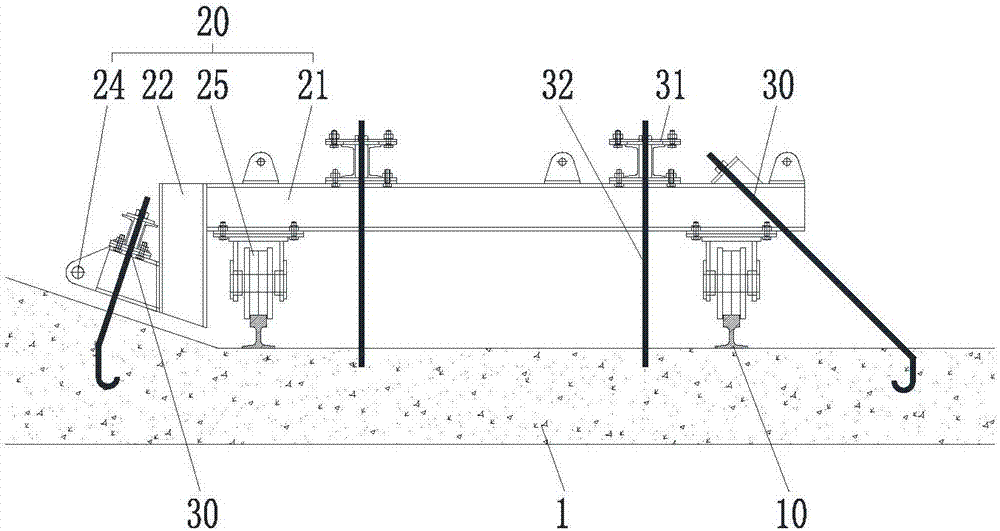

Basement outer wall single-side steel formwork supporting system and construction method thereof

PendingCN107313589AVerticality is easy to controlGuaranteed verticalityAuxillary members of forms/shuttering/falseworksBuilding material handlingSupporting systemArchitectural engineering

The invention provides a basement outer wall single-side steel formwork supporting system and a construction method thereof, and relates to the technical filed of constructional engineering equipment. Aiming at the problems that the labor intensity of construction personnel is high and formwork supporting work efficiency is low existing in the available supporting system, the basement outer wall single-side steel formwork supporting system and the construction method thereof are provided. The basement outer wall single-side steel formwork supporting system comprises a pair of tracks, bases, and a plurality of supporting trusses, wherein the pair of tracks is laid at a foundation slab and parallel to an outer wall steel formwork, the bases are arranged on the tracks and can slide along the tracks, and the multiple supporting trusses are vertically arranged at intervals and are connected with the outer wall steel formwork; and bottom parts of the supporting trusses are hinged to the bases, and the supporting trusses are detachably connected with top ends of the bases through a plurality of adjusting rod pieces. The construction method comprises the steps that the steel formwork supporting system is spliced and fixed, after outer wall concrete is poured, a ground anchor assembly and a diagonal bracing are disassembled, an adjusting rod piece is retracted, so that the demoulded outer wall steel formwork are made to be supported on the base, and the next working section is started to continue pouring construction of outer wall concrete.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

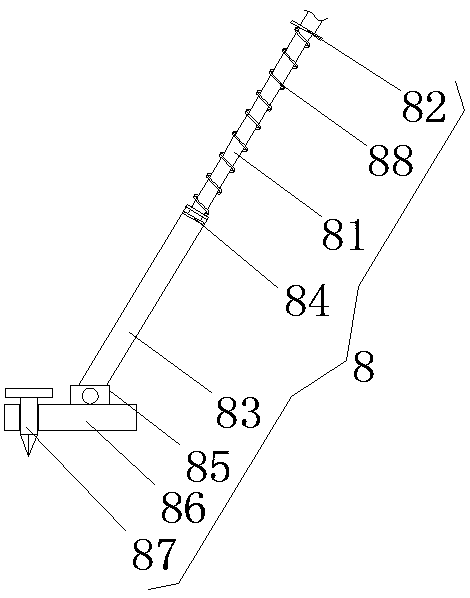

Soil obtaining device special for construction soil detection

InactiveCN108398292AGuaranteed verticalityWon't tiltWithdrawing sample devicesThreaded pipeEngineering

The invention relates to the technical field of soil detection equipment, and discloses a soil obtaining device special for construction soil detection. The soil obtaining device comprises a rigid supporting sleeve, a connecting disc sleeves the middle of the rigid supporting sleeve through threads, and a threaded pipe sleeve is fixedly connected to the top of the connecting disc; an adjusting handle is arranged on one side of the top of the threaded pipe sleeve, and a soil sampling probe located below the rigid supporting sleeve is fixedly connected to the bottom of the connecting disc; evenly distributed soil obtaining grooves are formed in the periphery and the top of the soil sampling probe respectively. According to the soil obtaining device special for construction soil detection, three groups of auxiliary supporting devices and positioning devices are in pin connection with the ground at the same time, so that it is guaranteed that the upper end and the lower end of the whole device is fixed at the same time in the soil obtaining process, when drilling is carried out, the device cannot incline, the perpendicularity of a drill rod moving downwards is guaranteed, then soil indifferent soil layers can be conveniently taken out, the soil obtaining uniformity is improved, and accurate measurement data can be obtained conveniently.

Owner:诸暨市开翎工业设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com