Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Guaranteed section size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

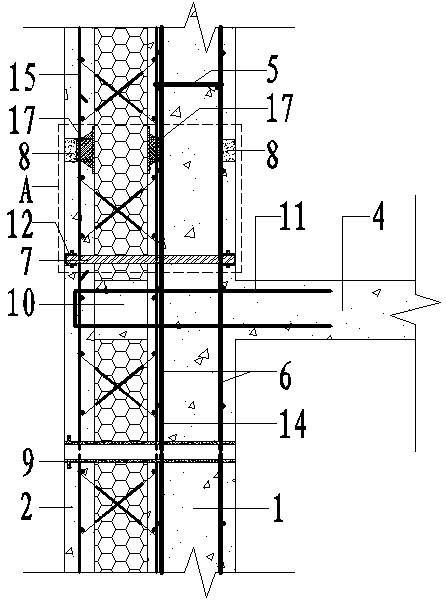

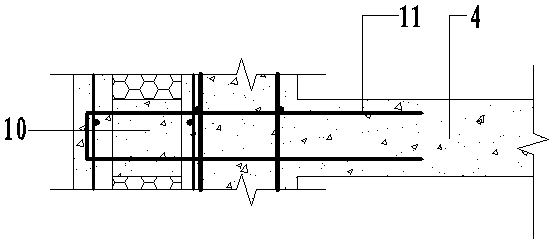

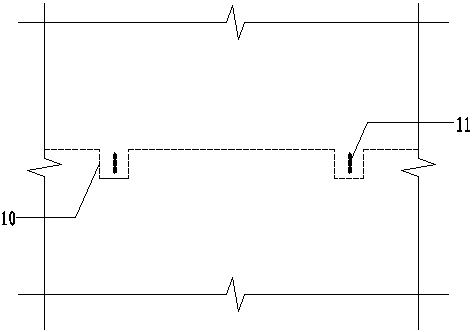

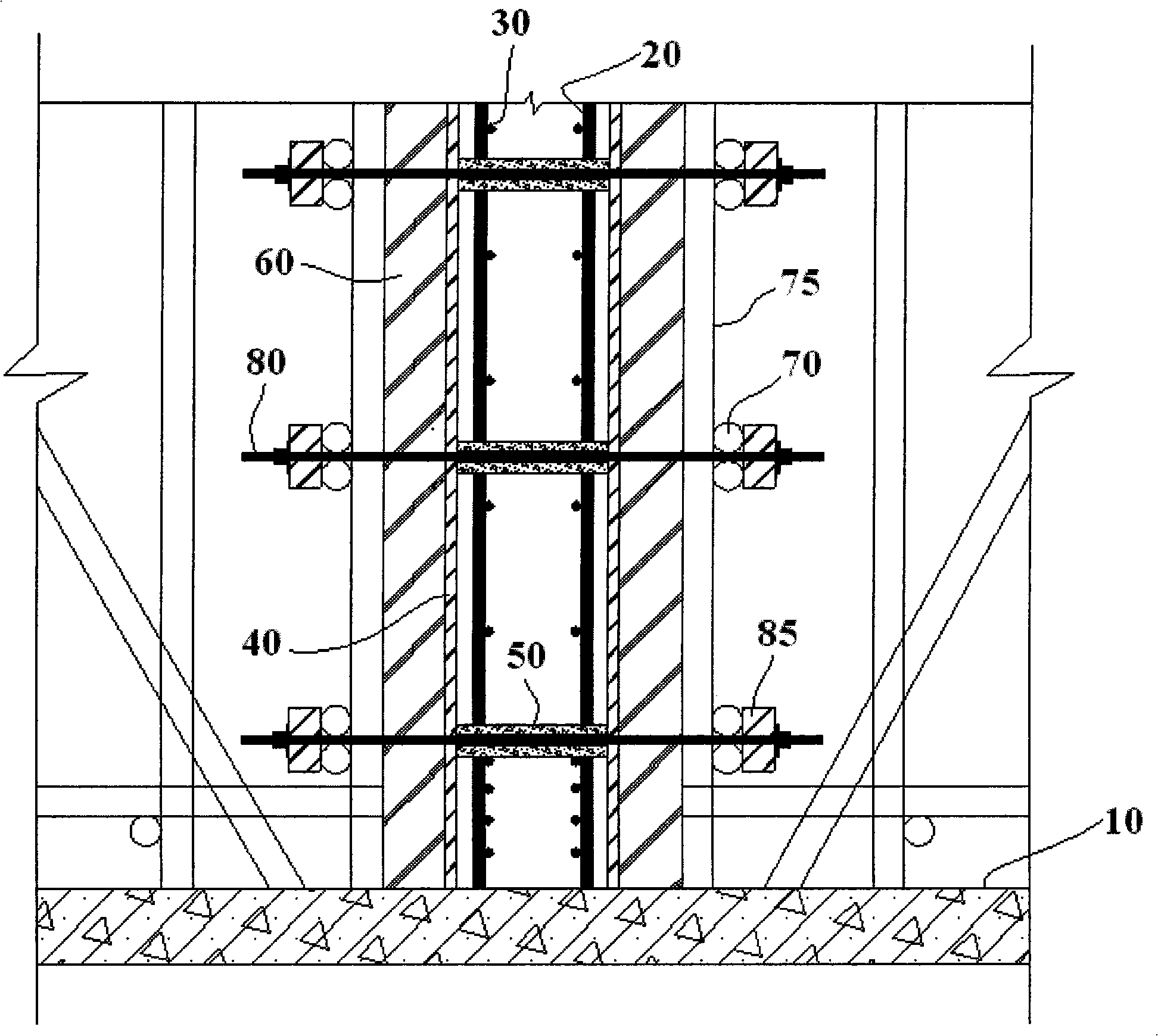

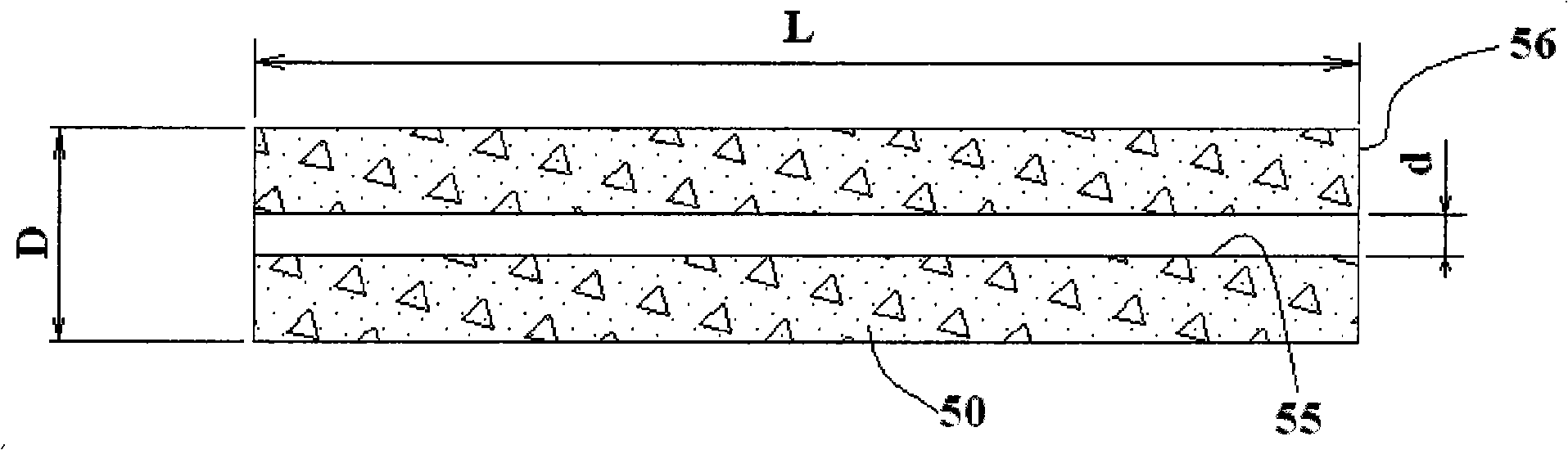

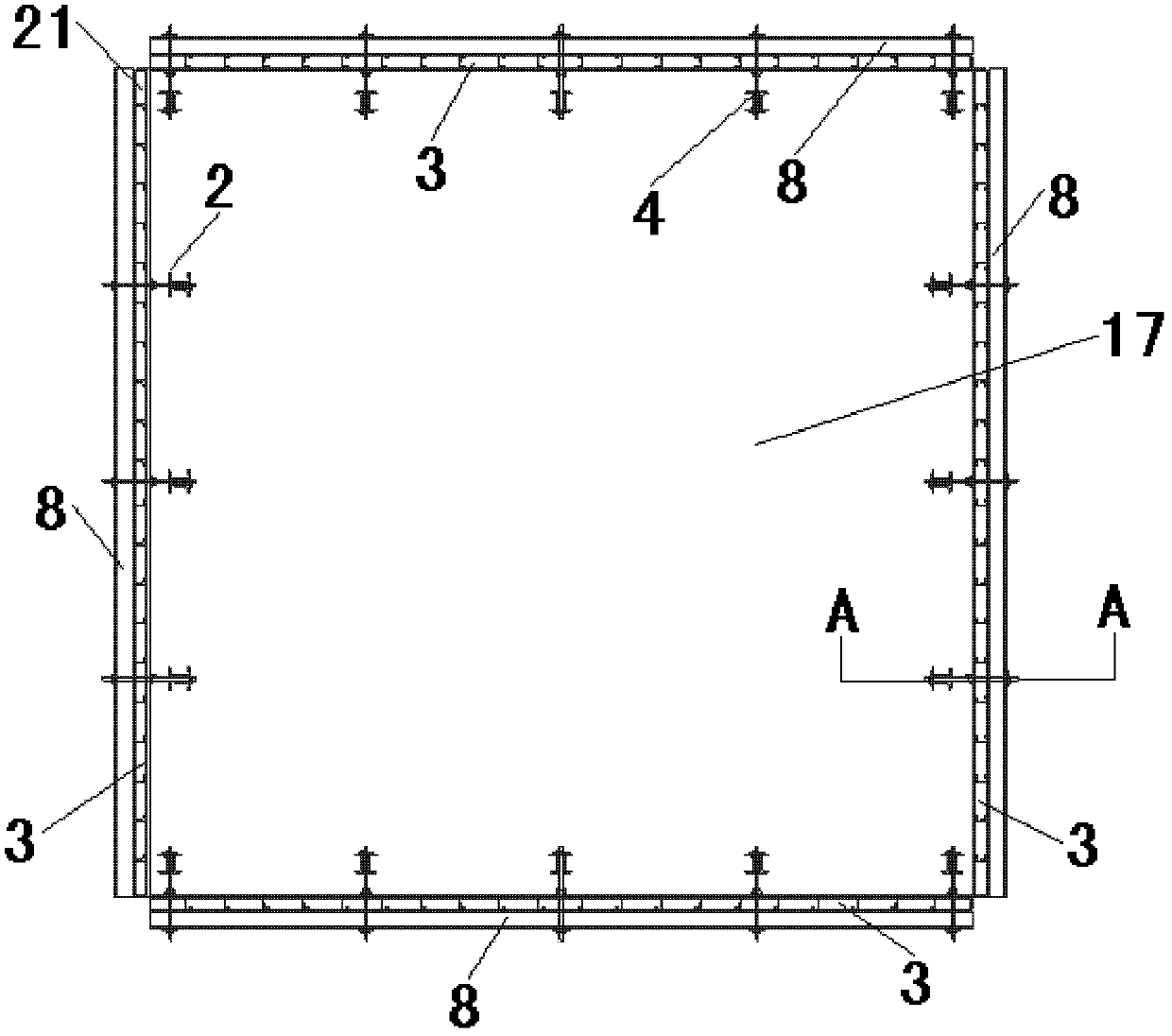

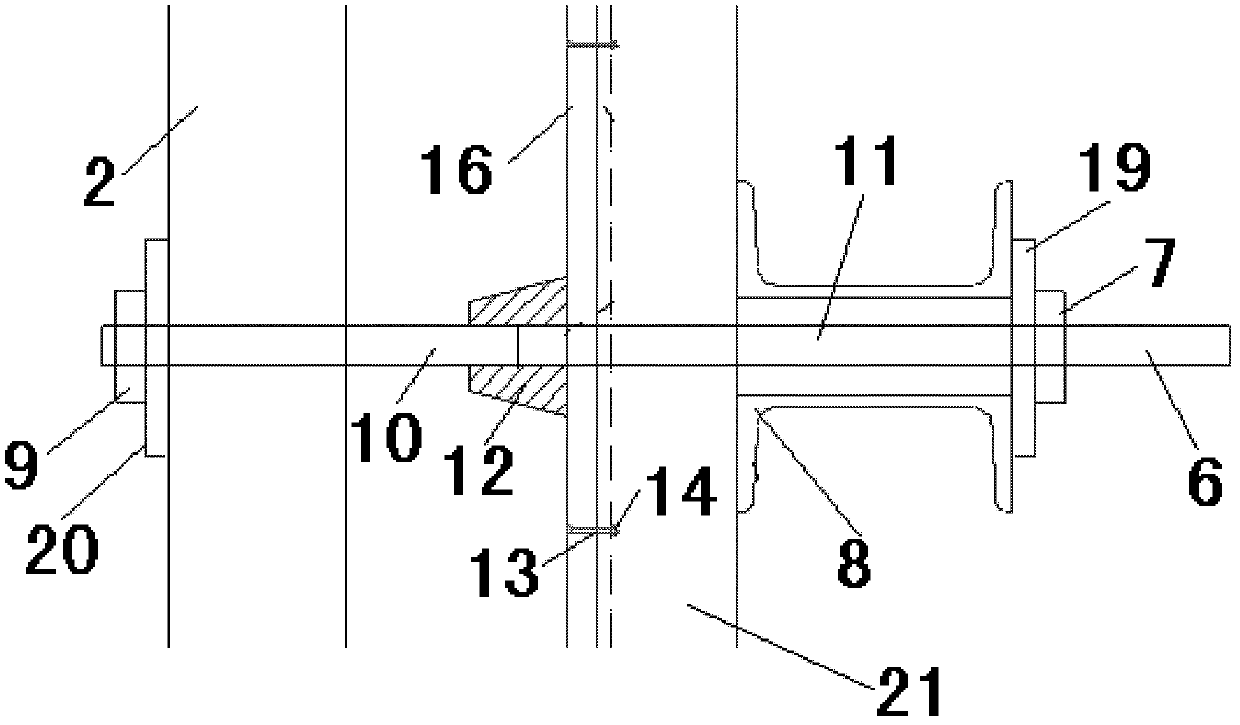

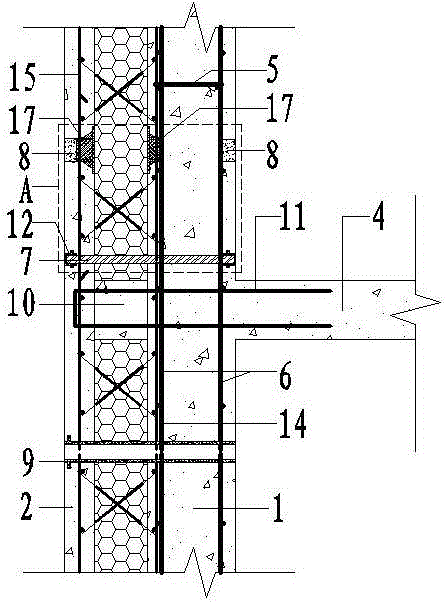

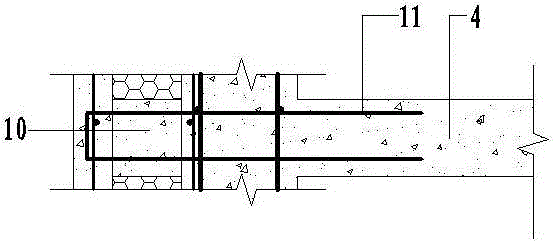

Structure and construction method of cast-in-site style welded steel frame composite concrete shear wall

ActiveCN103195193AGuaranteed section sizeSolving Linear Thermal Bridge ProblemsWallsBuilding material handlingFloor slabSandwich board

The invention relates to a structure and a construction method of a cast-in-style welded steel frame composite concrete shear wall. The structure comprises an indoor concrete layer, an outdoor concrete layer and a wire frame insulation sandwich board. The wire frane insulation sandwich board is coated between the indoor concrete layer and the outdoor concrete layer. At least two rectangular and groove-typed cantilever holes are arranged at the top of the sandwich board, and each cantilever hole is provided with a U-shaped cantilever anchor bar which penetrates through the sandwich board and a floor slab to be fixedly connected with the floor slab. The construction method includes site preparation work, binding of load-bearing steel bars of a wall body and edge member steel bars, custom processing of the sandwich boards, installation of the sandwich boards, pavement of template positioning pieces and wall bushings, fixation of water and electric pipes inside the wall body, binding of ordinary blocks on both sides of the wall body steel bars, erecting of the templates, pouring of the concrete, removing of the templates and concrete curing. Since a series of composite wall construction methods are adopted, problems existing in the prior art are solved, and a composite heat preservation technology is improved.

Owner:石家庄晶达建筑体系有限公司

Aluminum alloy pipe bend forming method

InactiveCN103861912AAdjustable melting point temperatureModerate plasticityInternal pressureUltimate tensile strength

The invention discloses an aluminum alloy pipe bend forming method and belongs to the technical field of machining. According to the method, low-melting-point alloy is used as a filler to achieve internal pressure supporting, and bend forming with controlled section deformation is achieved. The method has the advantages that the low-melting-point alloy is used as the filler so that strength and hardness of a pipe are improved, problems of sectional serious deformation, such as deboss and embossment after bend forming of an aluminum alloy pipe are solved, the sectional dimension of an aluminum alloy pipe bent piece can meet design requirements, and machining efficiency and qualified rate of the aluminum alloy pipe bent piece are increased. Besides, low-melting-point alloy is adjustable in melting point temperature, alloy composition can be adjusted according to machining requirements, the plasticity of the low-melting-point alloy is moderate and not prone to break during machining, and bend forming with low-melting-point alloy as the filler is advantageous.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

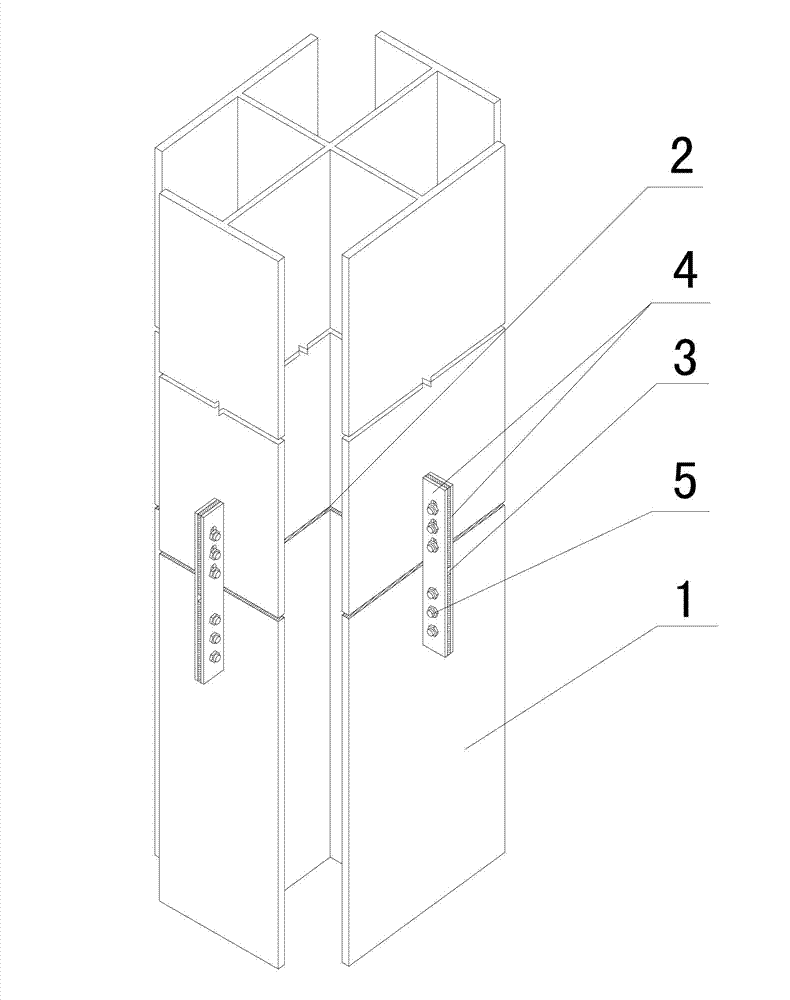

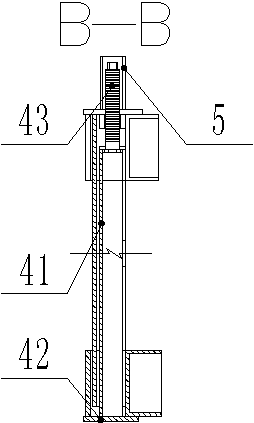

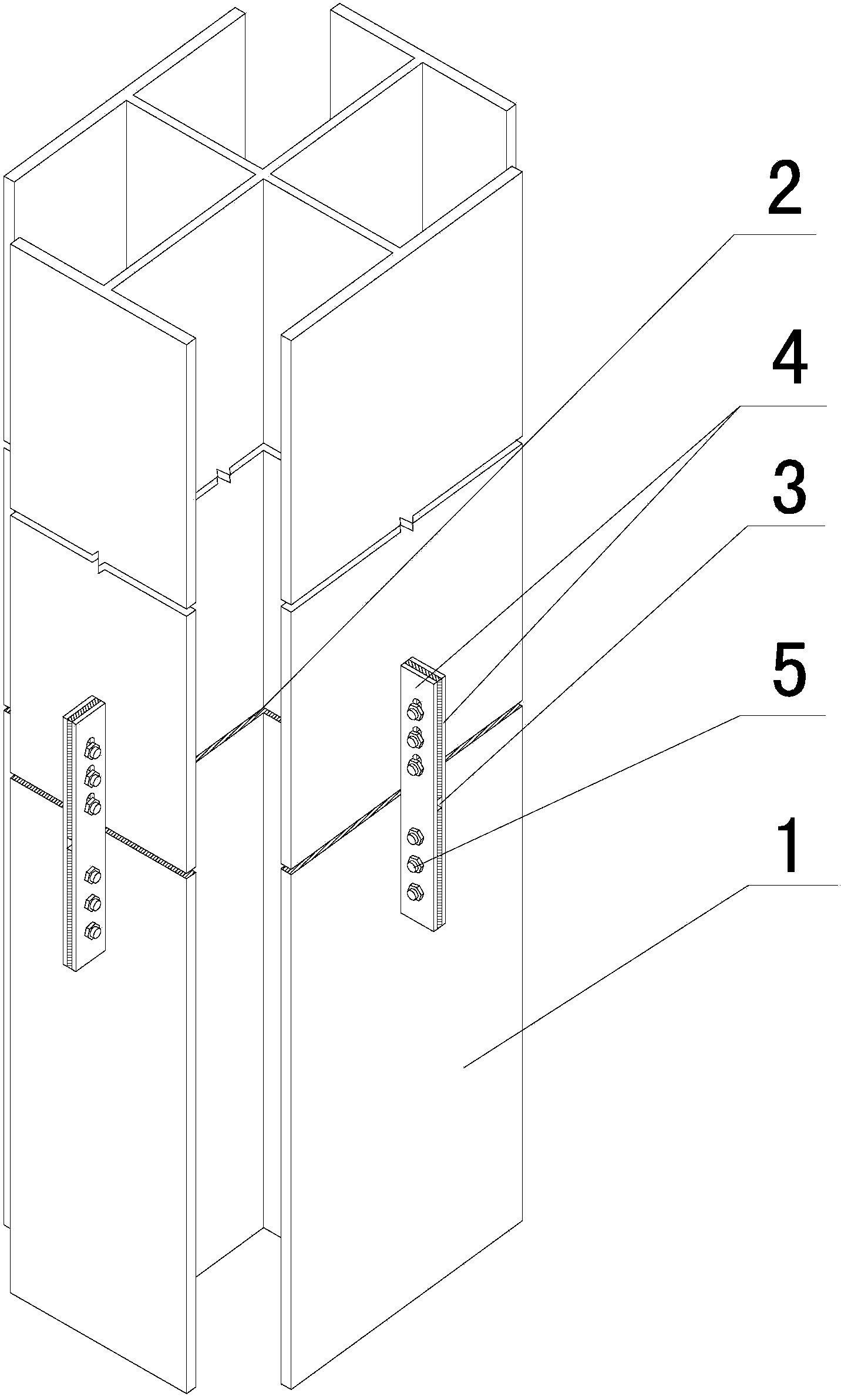

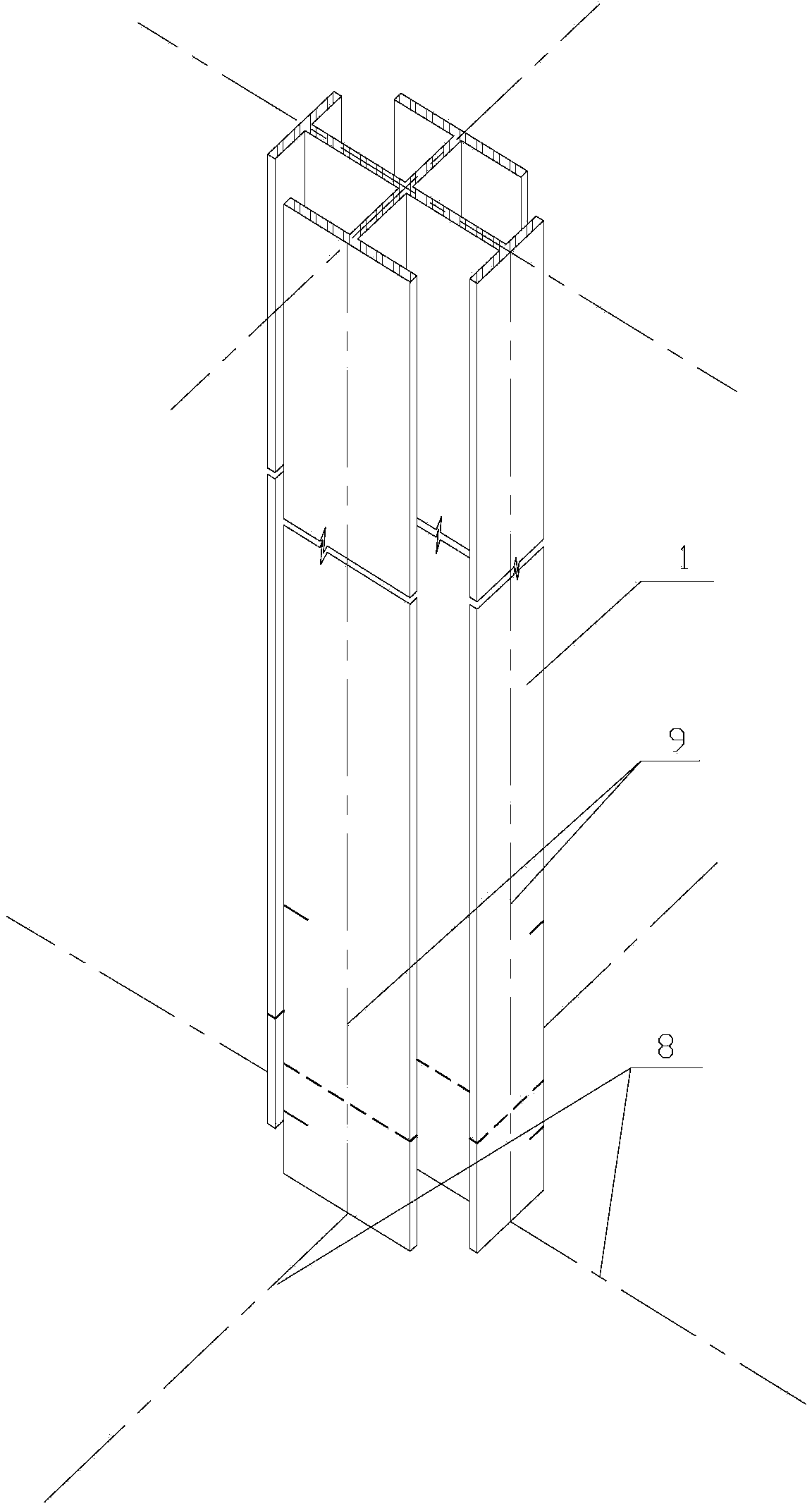

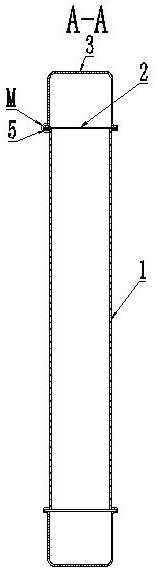

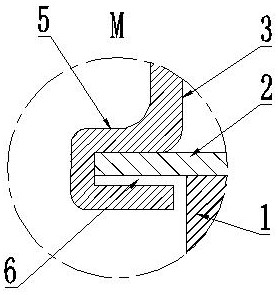

Section steel column for high-rise building section steel concrete combination structure, and construction method thereof

ActiveCN102733545AGuaranteed section sizeGuaranteed lengthStrutsBuilding material handlingConnection typeEngineering

The present invention discloses a section steel column for a high-rise building section steel concrete combination structure, and a construction method thereof. The section steel column comprises a plurality of column sections, wherein the column sections are sequentially connected from bottom to top, an interface position of two optionally adjacent column sections is provided with an inner sleeve interface, and an outer side wall of a connection position of the two adjacent column sections is provided with a buckle fixation type assembly. The construction method comprises that: the insert-connection type initial positioning of the two adjacent column sections is achieved through the inner sleeve interface; the cross extending line and the buckle fixation type assembly are combined to carry out positioning correction on the column; a scale measurement method is adopted to carry out column scale height adjustment; and the cross extending line and the buckle fixation type assembly are combined to carry out verticality correction on the full length of the column sections. With the section steel column of the present invention, the model of one construction interface in each floor of the traditional section steel column can be increased to the model of one construction interface in every two floors or three floors, such that more than half of the construction interfaces of the section steel column can be saved, the probability of deviation error due to construction interface operation can be greatly reduced, and the guarantee degree of installation quality can be improved.

Owner:广东中城建设集团有限公司 +1

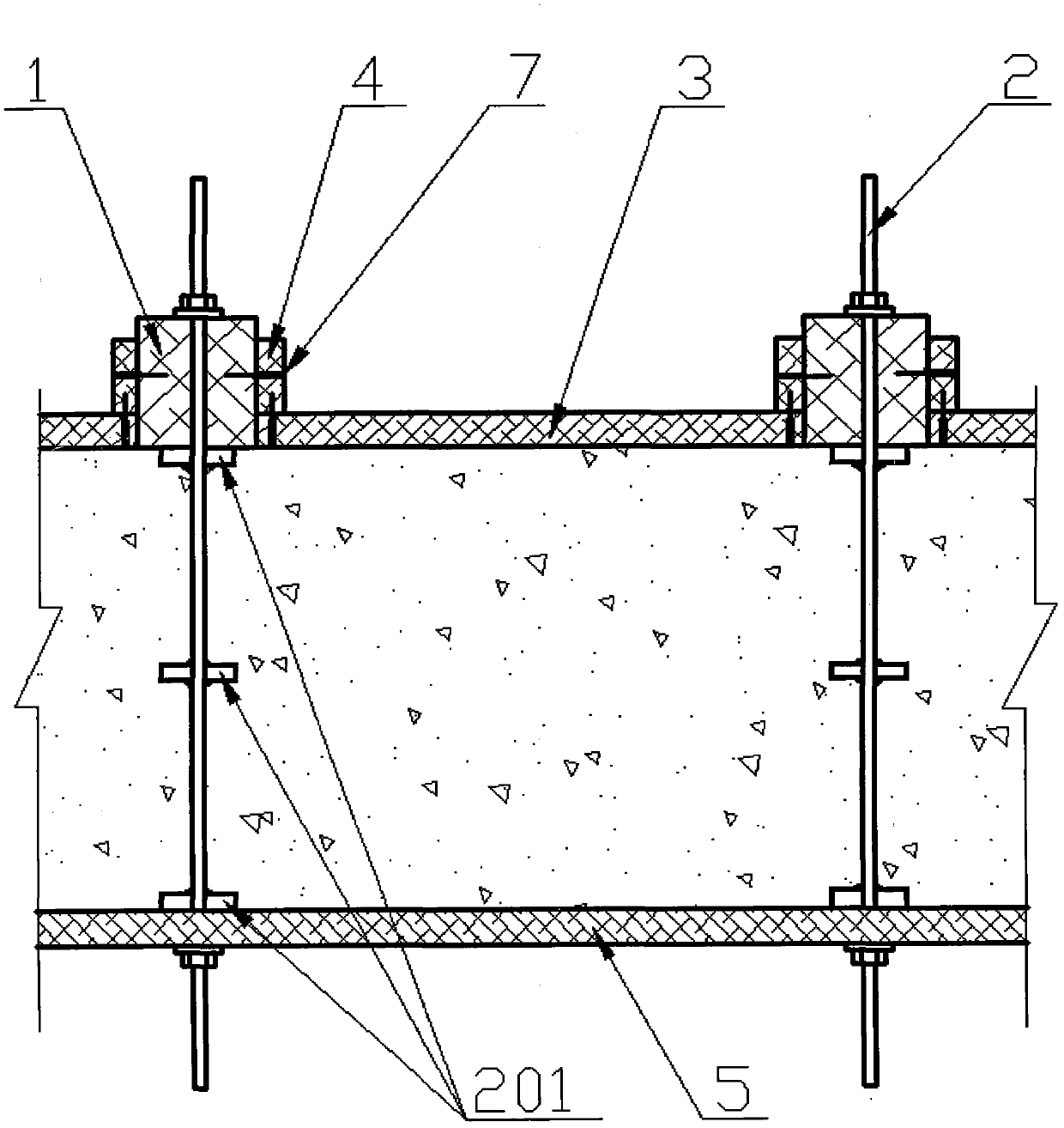

Construction technology of wall body

InactiveCN101525917AGuaranteed section sizeCounteract the pullWallsAuxillary members of forms/shuttering/falseworksRebarShear wall

A construction technology of a wall body is characterized in that a concrete hollow supporting body is arranged between position-limiting templates which are arranged on two sides for limiting the thickness of the wall body for ensuring the thickness of a protective layer of the concrete of a shear wall, controlling the width of the cross section of the wall body and being used as a sleeve of a tying bolt, the hollow supporting body comprises steel wires or small short steel bars which are shaped like hollow rods; supporting surfaces for supporting the templates are arranged on two ends of the hollow supporting body, a through hole for being penetrated by the tying bolt is arranged at the center along the longitudinal direction; the length of the hollow supporting body is less than the thickness of the wall body to be constructed by 1.5-2.5mm, the width and the height of the end surfaces are 45-85mm, and the diameter of the through hole is greater than the diameter of the tying bolt by 3-7mm. The hollow supporting body integrates a pad of the protective layer of the concrete of the shear wall, a jack for controlling the cross section of the wall body and the sleeve of the tying bolt into a whole body, thereby not only saving a great number of steel bars or PVC sleeves, but also reducing the construction cost and improving the construction efficiency.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU

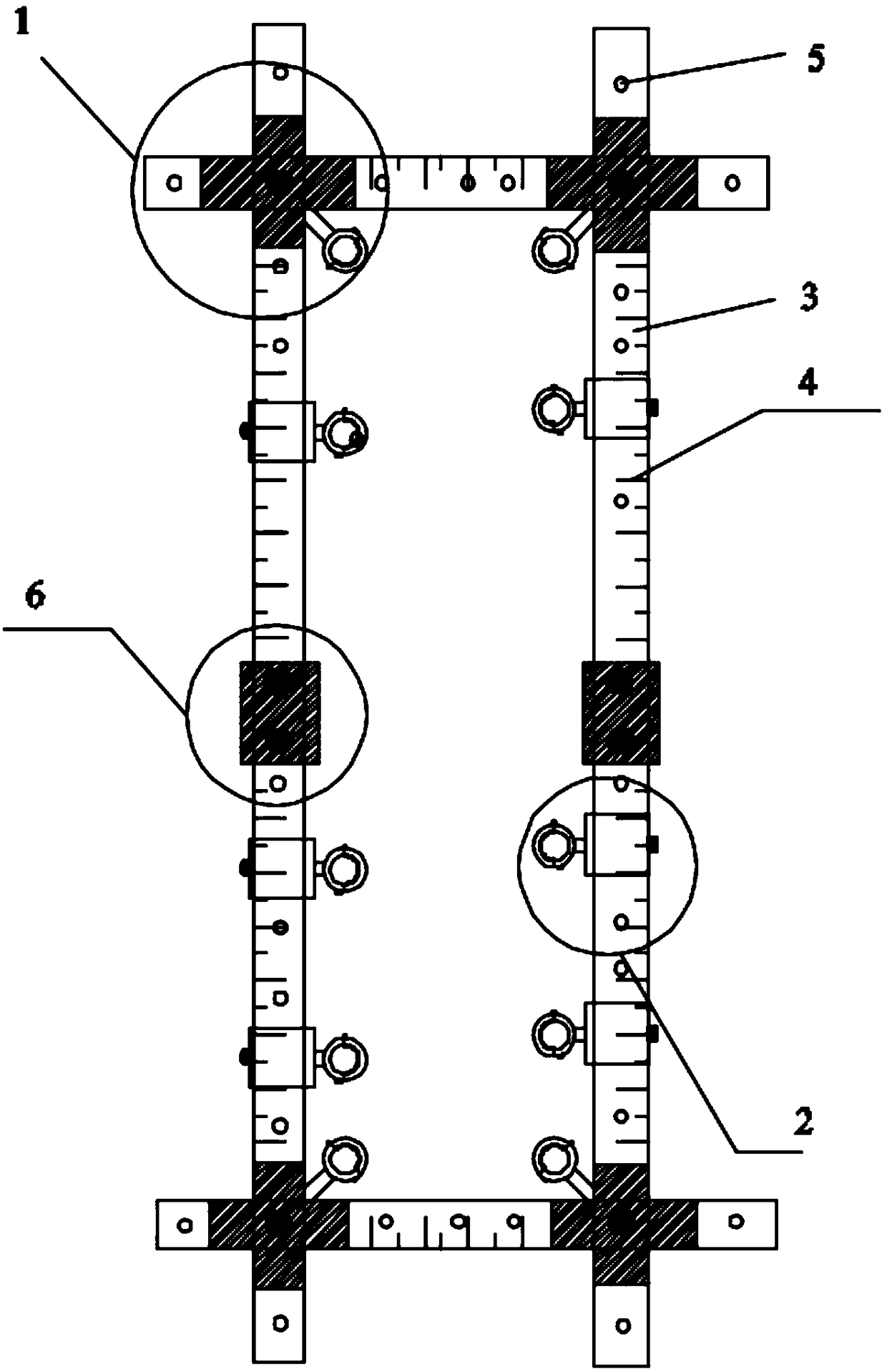

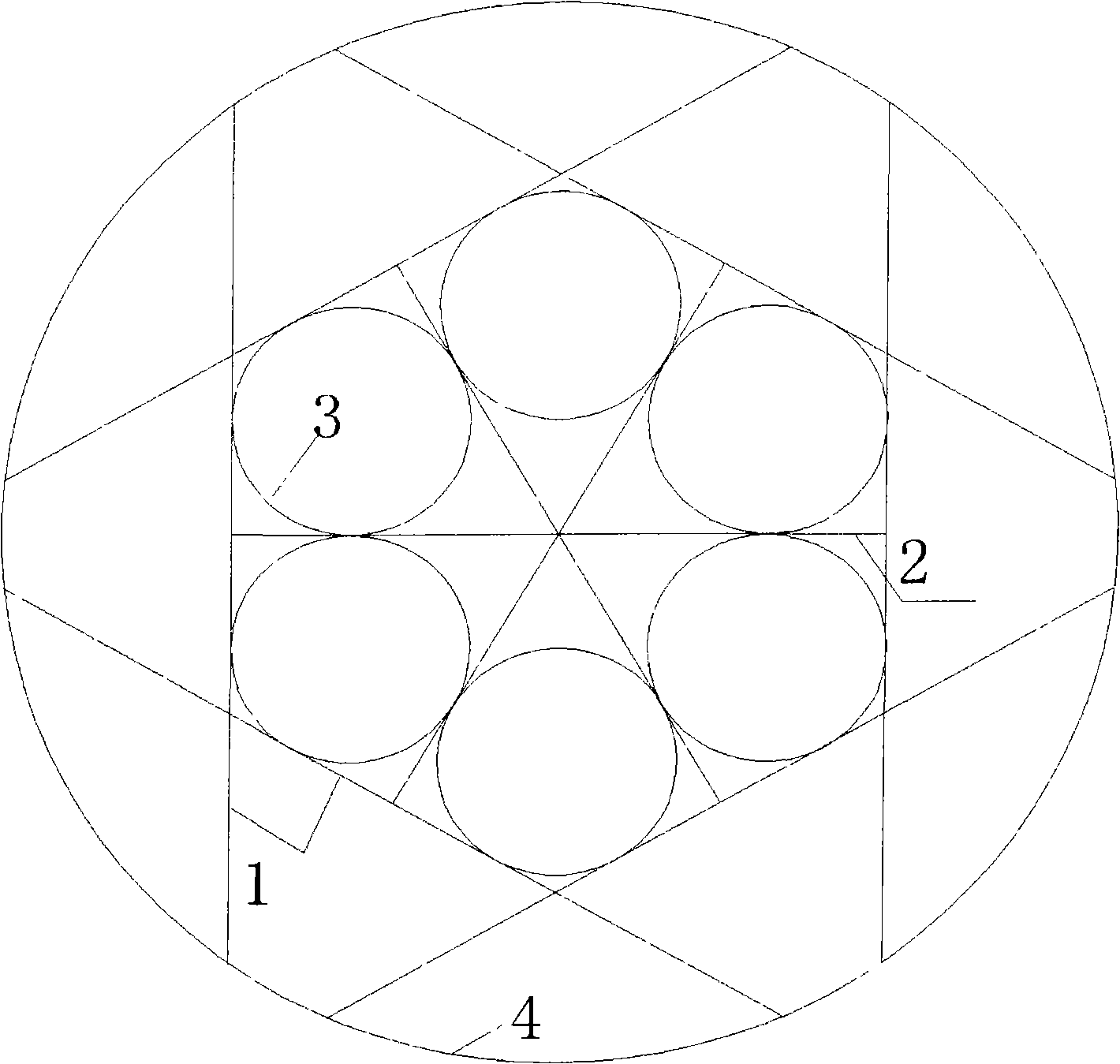

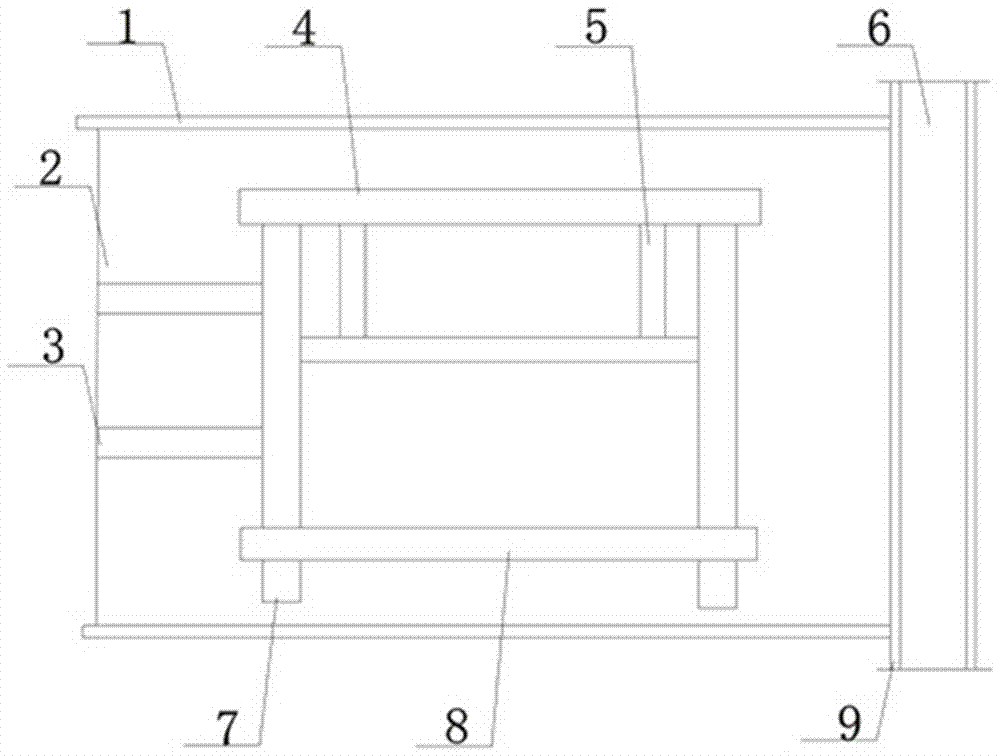

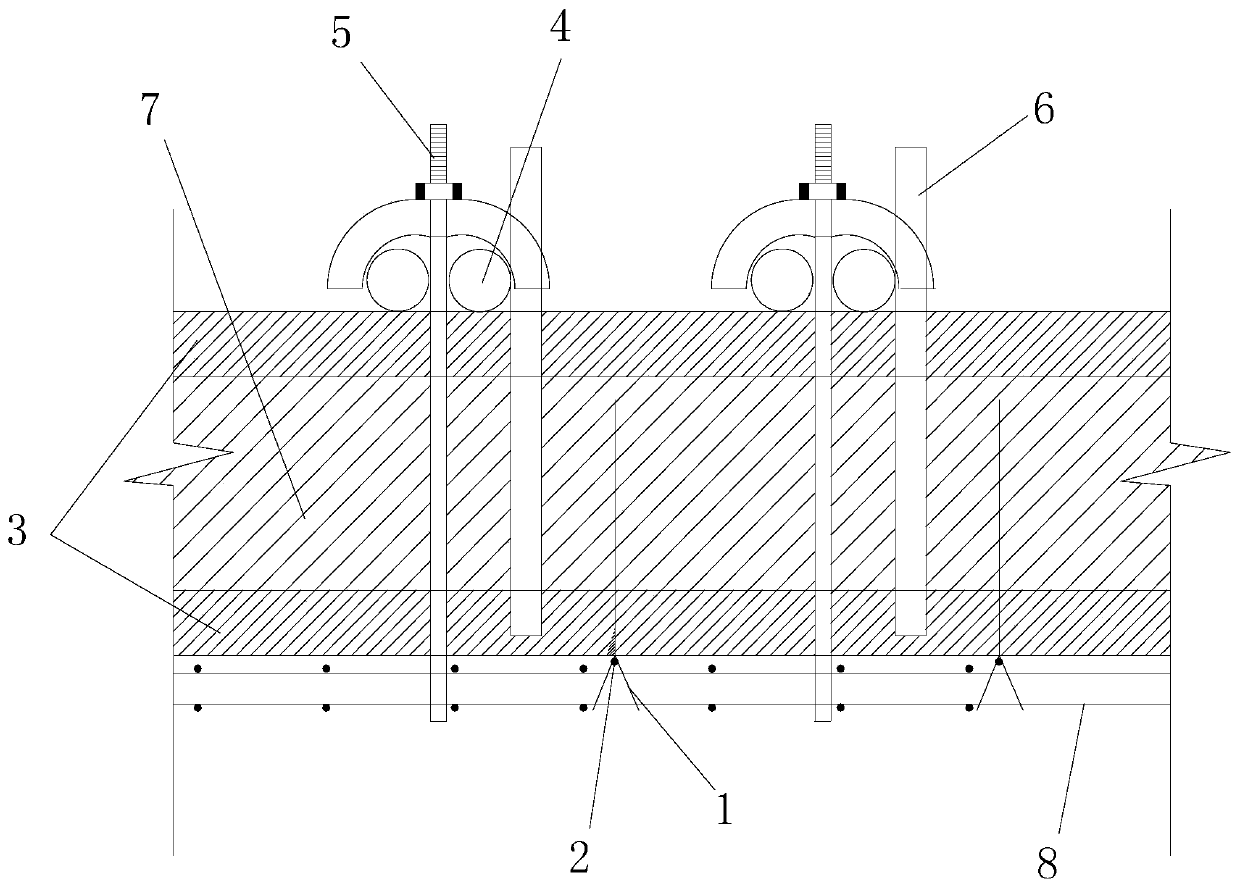

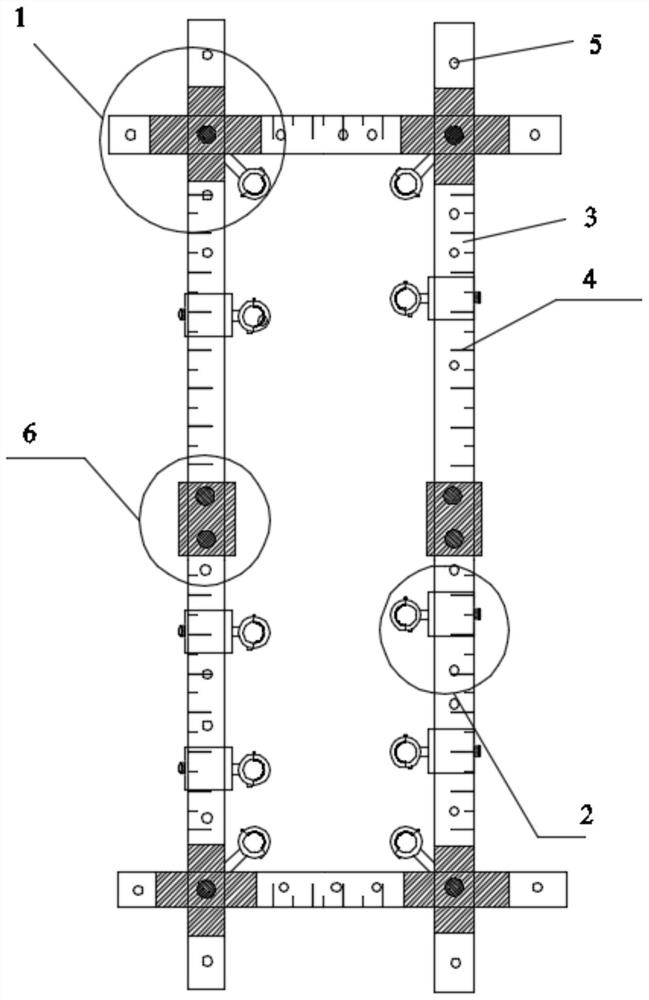

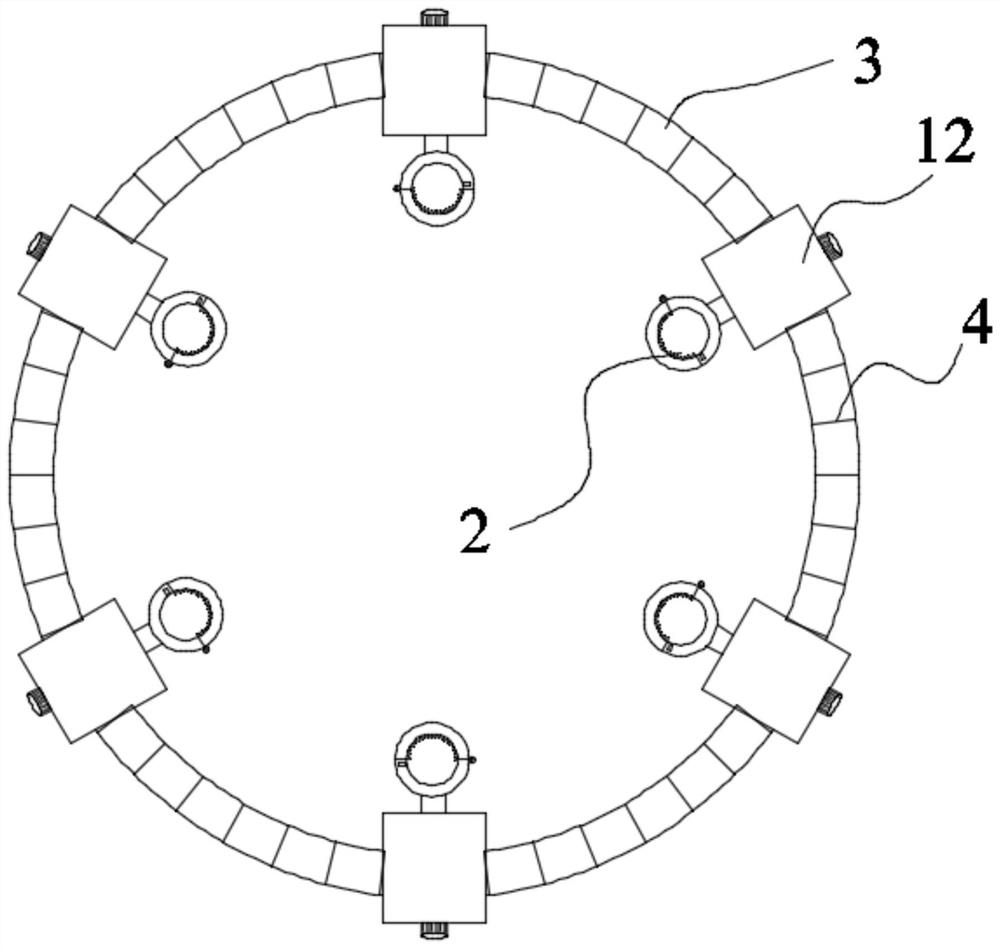

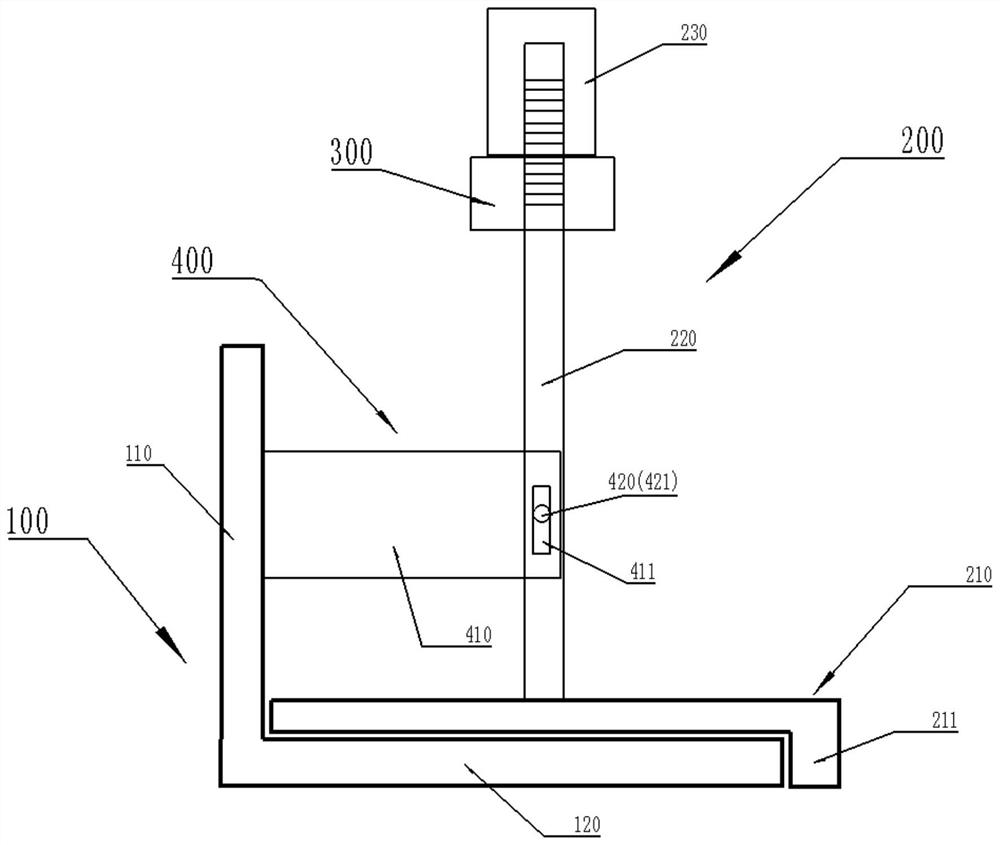

Temporary positioning device for steel bar framework

ActiveCN108756077AReliable connectionEasy to assemble and disassembleBuilding reinforcementsSteel bar

The invention discloses a temporary positioning device for a steel bar framework. The temporary positioning device for the steel bar framework comprises fixed buckles and a supporting frame, wherein the shape of the supporting frame is matched with the cross-sectional shape of the steel bar framework. The fixed buckles are installed on the supporting frame and the number of the fixed buckles is matched with the number of longitudinal steel bars of the steel bar framework. The fix buckles comprise upper rings and lower rings, one ends of the upper rings and one ends of the low rings are connected in a hinged mode through pin shafts, and the other ends of the upper rings and the other ends of the low rings are detachably connected through locking devices, so that the upper rings and the lower rings are combined into a circular fixing ring for temporarily fixing steel bars, anti-skid rubber pads are arranged on the inner walls of the upper rings and the inner walls of the lower rings, andthe lower rings are mounted on the supporting frame through connecting pieces. The fixed buckles are mounted on four side rods of a rectangular frame through sliding bases, and a sliding device comprises the sliding bases, wherein sliding holes formed in the four side rods of the rectangular frame in a sleeving mode are formed in the sliding bases. The temporary positioning device for the steel bar framework is simple, efficient and high-practical and in a rectangular or strip shape, has the functions of fixing the spacing and position of the steel bars in a steel bar cage and preventing thesteel bars from shifting.

Owner:CHINA FIRST METALLURGICAL GROUP

Construction method for special structure layer of cone bottom wheat-immersion

InactiveCN101294420AGuaranteed StrengthGuaranteed stabilitySpecial buildingExtraordinary structuresFalseworkShaped beam

Owner:CHINA CONSTR SIXTH ENG DIV CORP +1

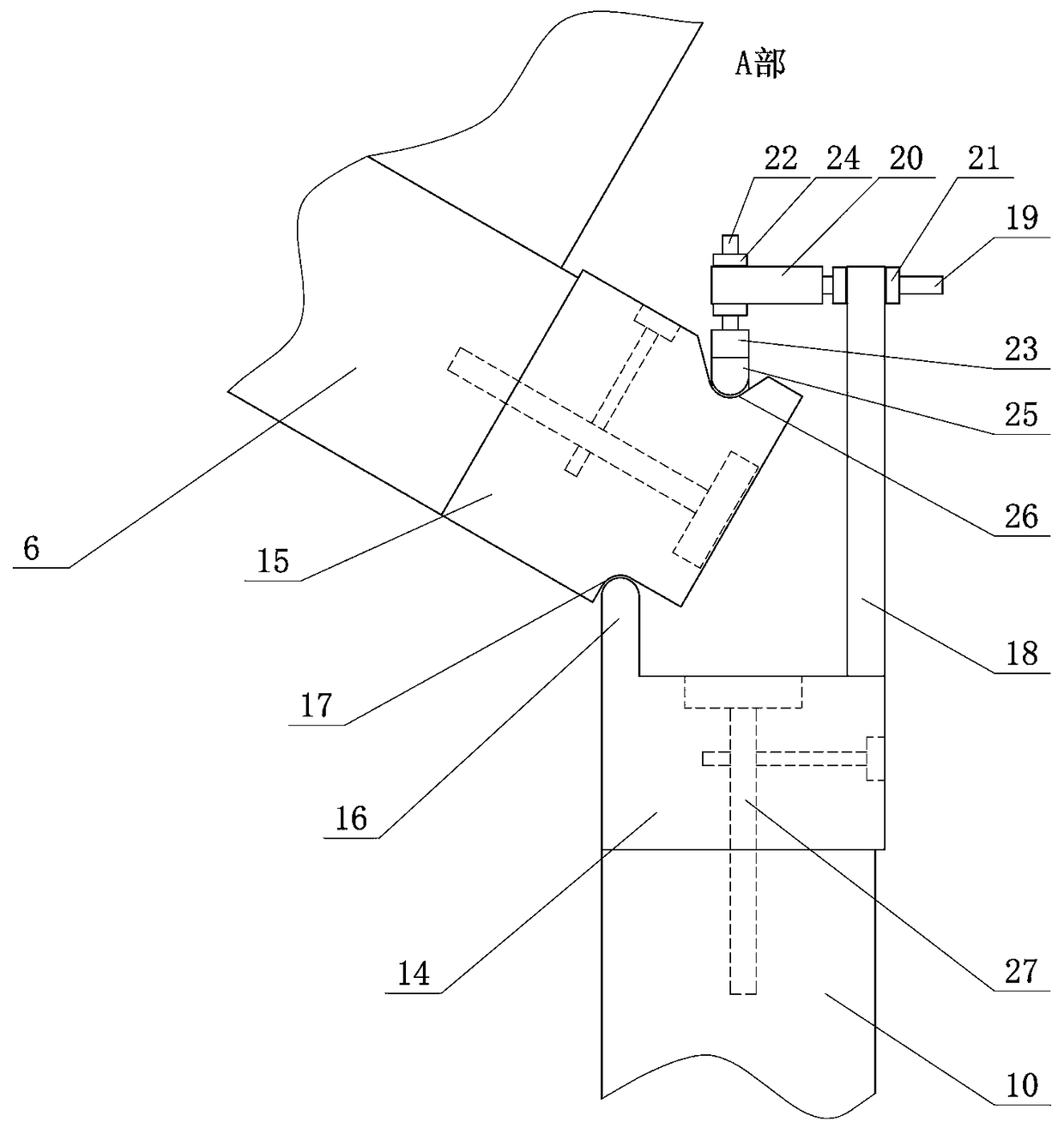

Surface layer template connecting structure of cast-in-place concrete sloping roof

InactiveCN102168487AEnsure concrete section size and appearance qualityEnsure compactness requirementsRoof covering using sealantsForms/shuttering/falseworksWood plankSurface layer

The invention discloses a surface layer template connecting structure of a cast-in-place concrete sloping roof, which a compact sloping roof structure suitable for building a slope between 30 degrees and 60 degrees. The surface layer template connecting structure of the cast-in-place concrete sloping roof comprises a bottom layer template, a surface layer template, a water stopping bolt, a plurality of vertical keels and a plurality of side keels, wherein the bottom layer template is positioned on a bottom surface; the vertical keels are distributed in parallel above the bottom layer template; length directions of the vertical keels are consistent with the direction from a slope bottom to a slope top; one end of the water stopping bolt is connected with the bottom layer template while the other end of the water stopping bolt is connected with the vertical keels; side surfaces of the side keels are connected with side surfaces of the vertical keels; the surface layer template is a stripped wood plate with length adaptive to a distance between the adjacent vertical keels; and two ends of the surface layer template are connected with the side keels. In the invention, because the surface layer template connecting structure located by the vertical keels and limited by the water stopping bolt is adopted, the thickness of the sloping roof structure is controlled, the foundation is laid for mounting the surface layer template, a compactness requirement on the concrete structure is assured, and the construction difficulty of the structure leakage is fundamentally solved.

Owner:CHINA CONSTR SEVENTH ENG BUREAU THE SECOND CO LTD

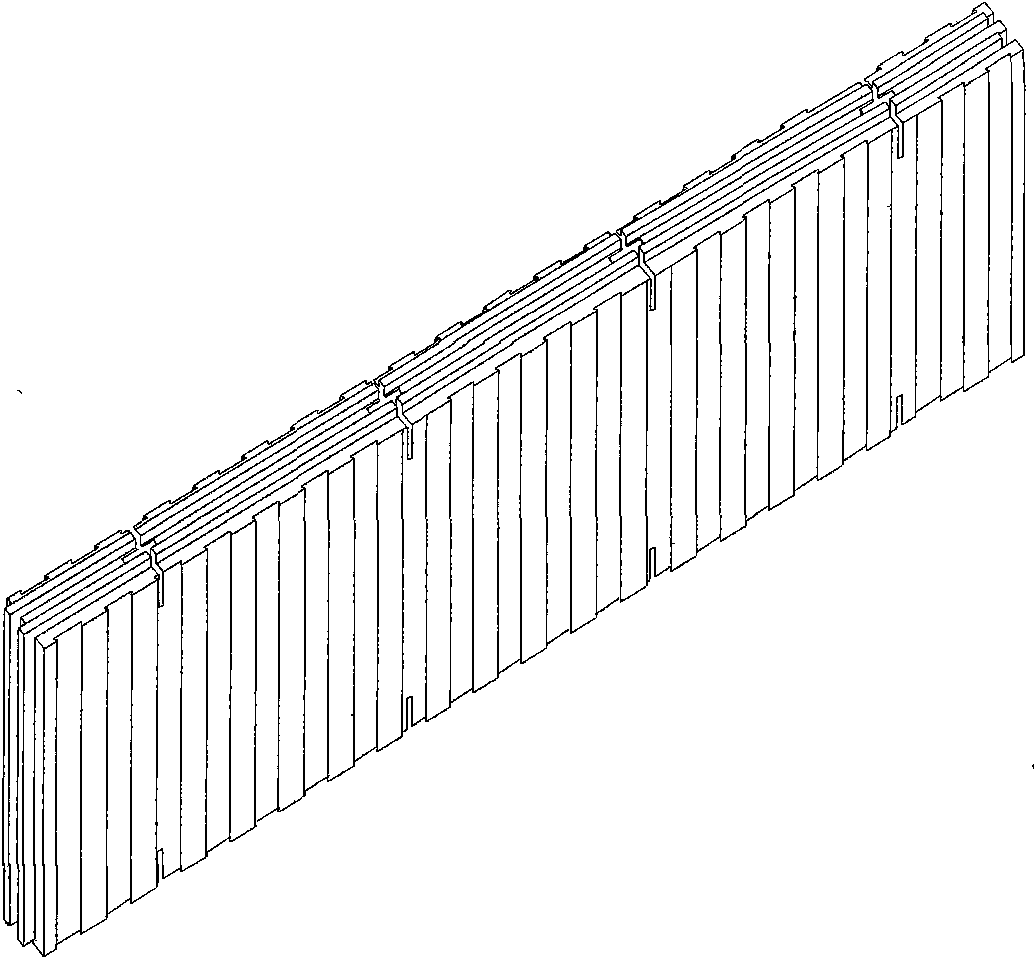

Module connected combined type energy conservation and heat preservation moulding board for wall body construction

InactiveCN101571005AGuaranteed section sizeSection size is accurateForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksWire gauzeComputer module

The invention provides a module connected combined type energy conservation and heat preservation moulding board for wall body construction, comprising an exterior moulding board, an interior moulding board and a connecting piece connected between the exterior moulding board and the interior moulding board, wherein the exterior moulding board is formed by the mutual insertion of energy conservation and heat preservation modules, the connecting piece comprises a connecting plate and connectors which are positioned at both ends of the connecting plate and are respectively matched with the exterior and the interior moulding boards, and the connector matched with the exterior moulding board comprises a projecting end plate and a flashboard, or a projecting end plate and a chuck plate, or the projecting end plate, the flashboard and the chuck plate. The moulding board can ensure the sectional dimension of the wall body and can realize the fixed installation of steel wire gauzes, and high construction speed and stable installation can ensure the sectional dimension of the wall body to be accurate. The moulding board has the advantages of accurate positioning, convenient construction and low cost.

Owner:HARBIN HONGSHENG ROOM ENERGY SAVING SYST RES CENT

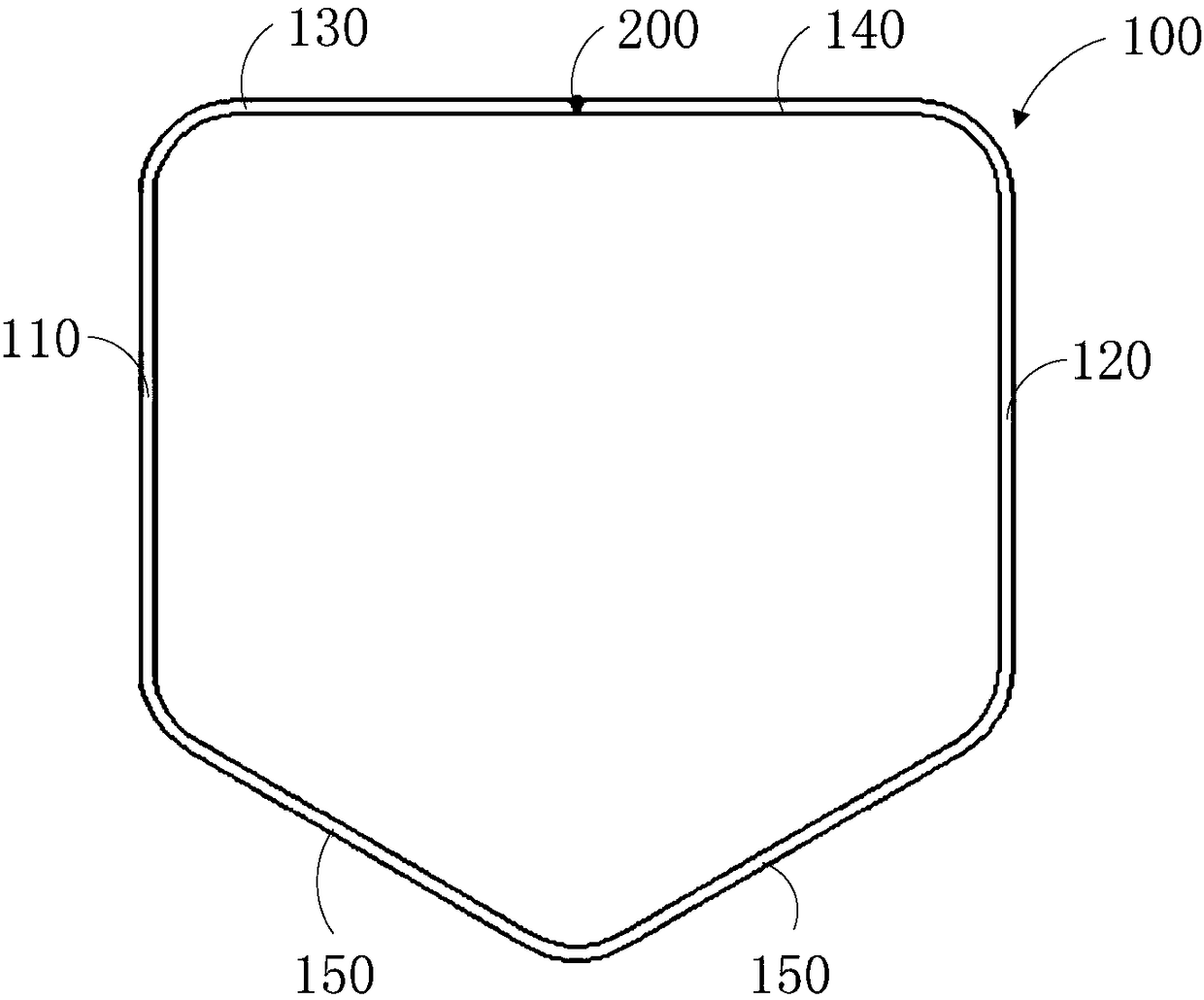

Pentagonal arm frame, wet spraying machine, and manufacturing method of polygonal arm frame

The invention provides a pentagonal arm frame, a wet spraying machine, and a manufacturing method of a polygonal arm frame, and relates to the technical field of engineering machines. The pentagonal arm frame comprises an arm frame body which is formed by bending of a plate, the two ends of the bent plate are connected in a welded mode, and a welded joint formed by welding is located on a top plate of the arm frame body. According to the pentagonal arm frame, the technical problems that in the prior art, the section size of the pentagonal arm frame is difficult to ensure due to the fact that welding heat input is large, and consequently, the two side faces are prone to shrinkage deformation are relieved.

Owner:HUNAN PENGXIANG XINGTONG AUTOMOBILE CO LTD

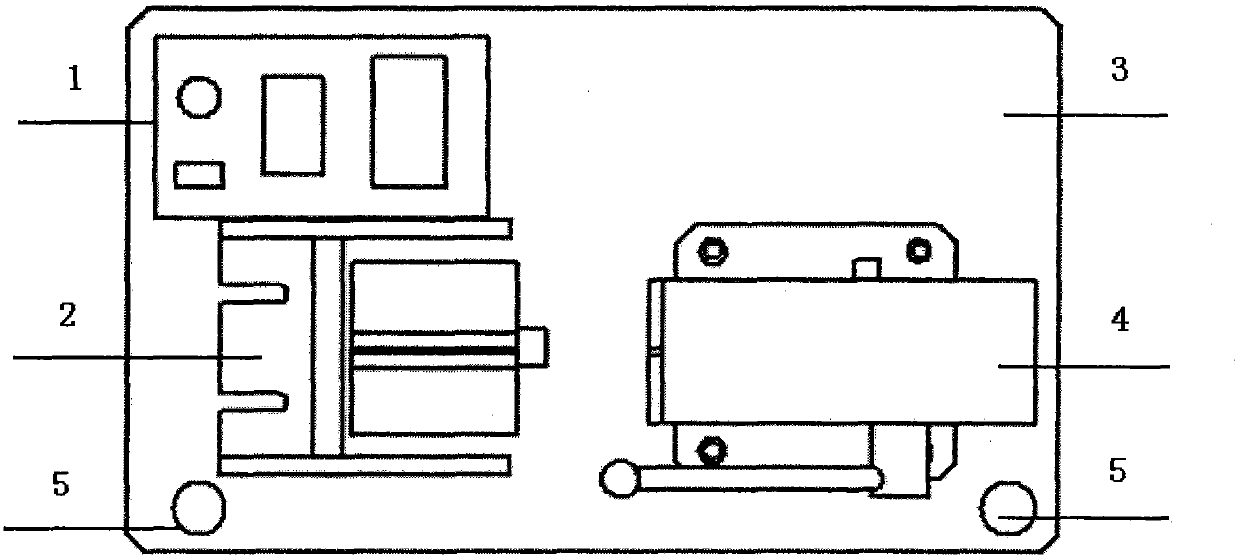

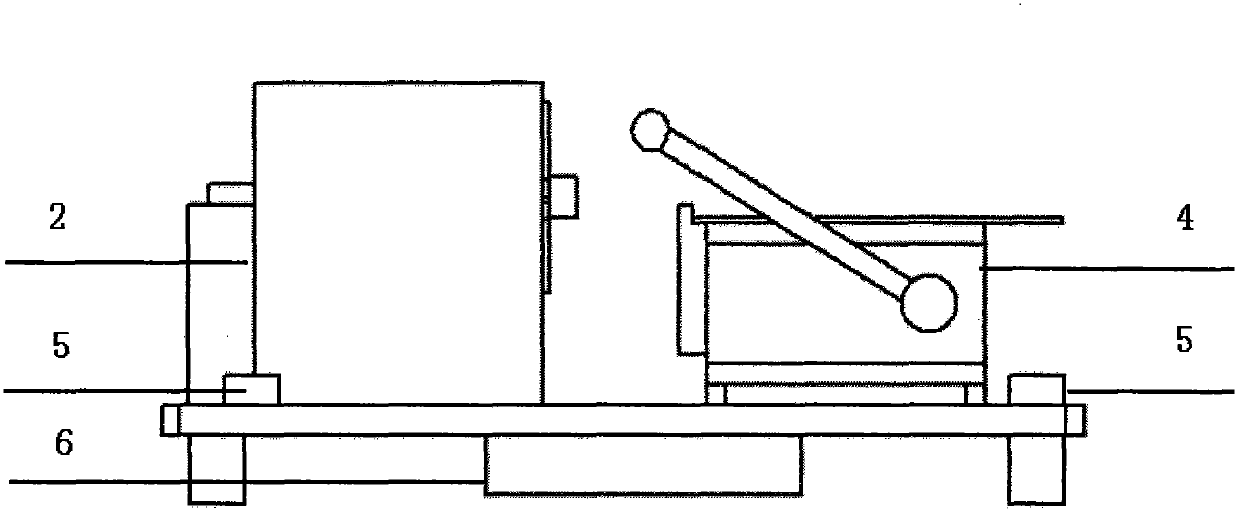

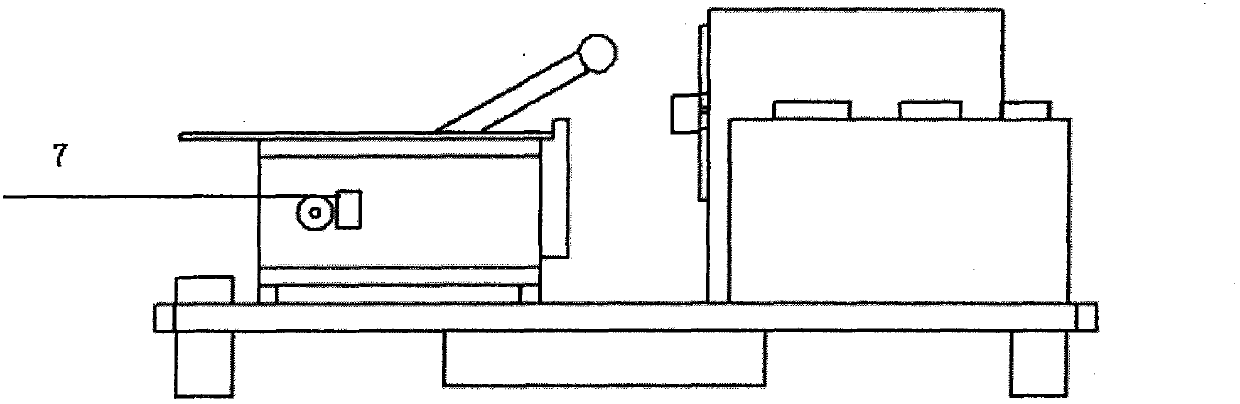

Horizontal pneumatic pressing machine and press-fit method for cable assembly

ActiveCN102882098AImprove efficiencyQuality improvementLine/current collector detailsAutomatic controlProgrammable logic controller

The invention provides a horizontal pneumatic pressing machine and a press-fit method for a cable assembly. The pressing machine adopts the structure that an electromagnetic valve is mounted below a table board; a pressure mechanism, a positioning mechanism, a PLC (Programmable Logic Controller) electrical control mechanism and two start switches are mounted on the table board; a sensing mechanism is mounted on the side of the positioning mechanism; a power supply is connected when the sensing mechanism induces a signal that a wrench is pulled downwards to a 90-degree position; and two start switches are pressed by two hands at the same time so as to automatically control the action of the pressure mechanism to carry out press-fit. According to the invention, a mechanical and sensing combined positioning way, a manual pre-positioning and self-control press-in combined mode, and modularized mechanism design are adopted, and the PLC electrical control mechanism is utilized to directly input pre-arranged parameters so as to realize the horizontal press-fit of the cable assembly. During the press-fit period, manual support is not required, working burden is reduced, and the safety is ensured. According to the invention, the automatic press-fit problem of the larger-diameter semi-flexible rigid cable assembly is solved, and both the press-fit efficiency and the press-fit quality are greatly improved.

Owner:陕西华达通讯技术有限公司

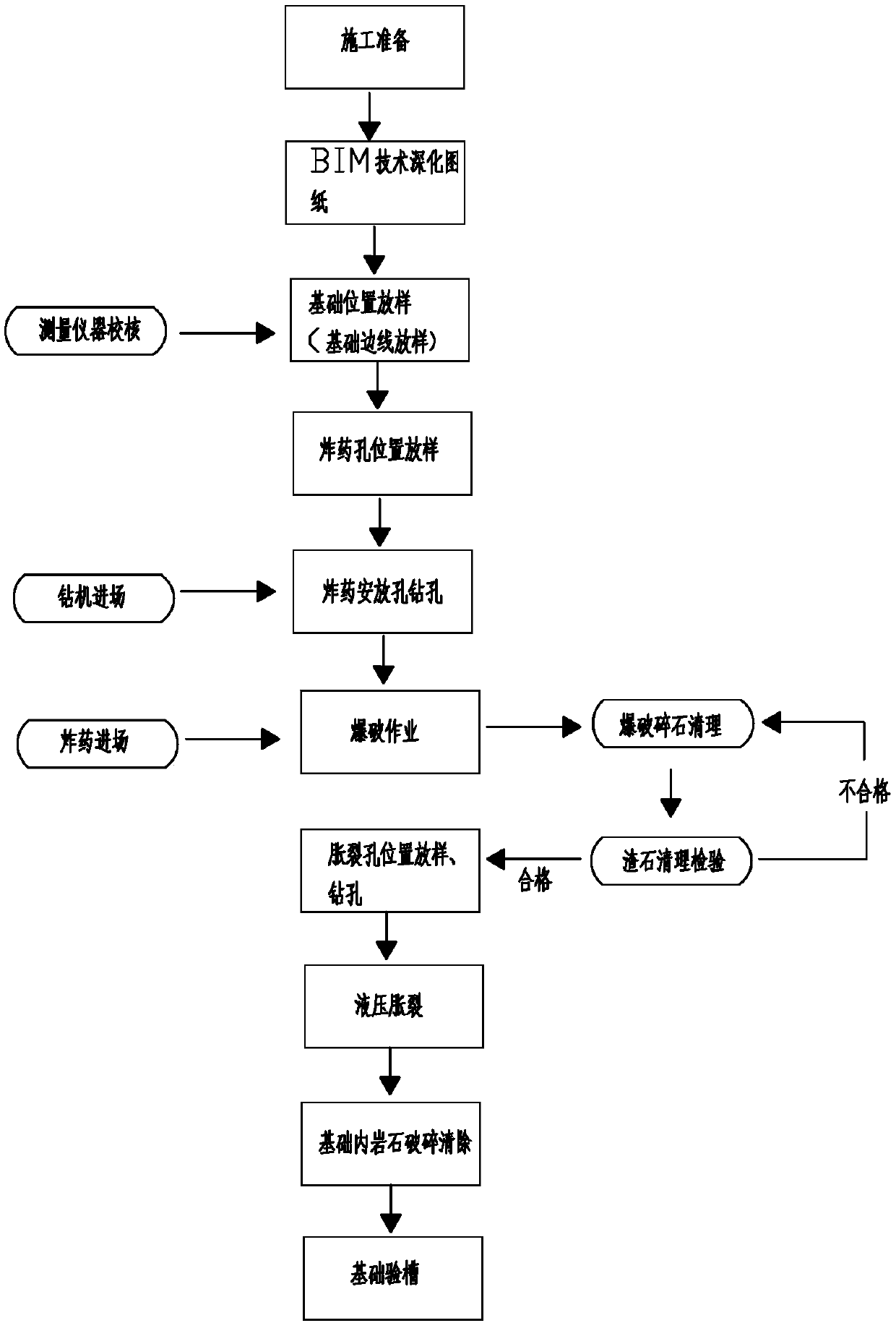

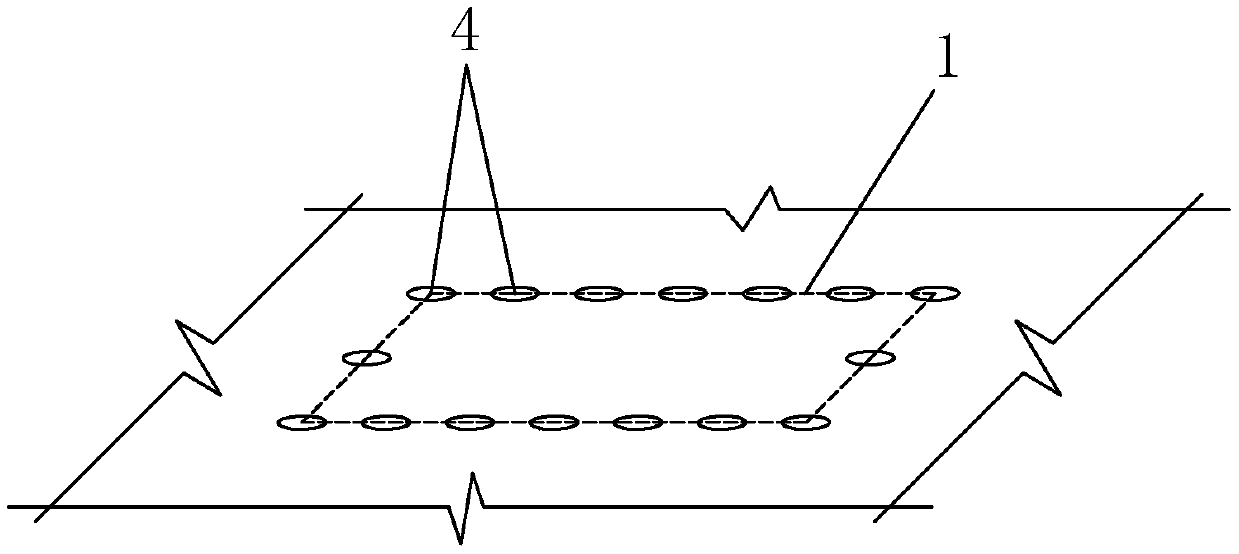

Solid rock foundation positioning and blasting and hydraulic spalling combined excavation construction method

The invention provides a solid rock foundation positioning and blasting and hydraulic spalling combined excavation construction method which comprises the following steps of A construction preparation; B, drawing deepening based on a BIM technology; C, foundation position lofting; D, explosive mounting hole lofting; E, explosive mounting hole drilling; F, foundation middle position blasting; G, blasted gravel cleaning; H, spalling hole position lofting and spalling hole drilling; I, hydraulic spalling; J, crushing and cleaning of rocks in a foundation; and K, qualified foundation subsoil inspecting to complete excavation construction of the foundation. The invention provides the solid rock foundation positioning and blasting and hydraulic spalling combined excavation construction method which is a novel construction method, not only can improve the excavation speed of the solid rock foundation but also can ensure the excavation size of the solid rock foundation well, and is efficient,environmentally-friendly and energy-saving in the construction process.

Owner:广西建工第五建筑工程集团有限公司

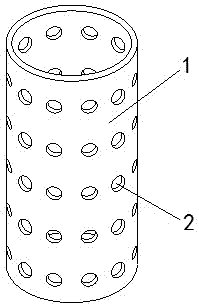

Ultra-high performance concrete and common concrete combined pile and construction method thereof

InactiveCN104762961ASimple structureGood mechanical propertiesBulkheads/pilesEconomic benefitsMechanical property

The invention relates to an ultra-high performance concrete and common concrete combined pile and a construction method thereof. The combined pile comprises an ultra-high performance concrete prefabricated barrel, a plurality of holes are formed in the side wall of the ultra-high performance concrete prefabricated barrel, the ultra-high performance concrete prefabricated barrel is placed in a pile hole, the center line of the ultra-high performance concrete prefabricated barrel coincides with that of the pile hole, common concrete is poured in the ultra-high performance concrete prefabricated barrel to form a common concrete inner core, the common concrete flows out of the holes in the outer wall of the ultra-high performance concrete prefabricated barrel from inside to outside to form a common concrete bonding outer layer, and the common concrete bonding outer layer is located between the outer wall of the ultra-high performance concrete prefabricated barrel and the inner wall of the pile hole. The ultra-high performance concrete and common concrete combined pile is simple in structure construction, novel in material and good in mechanical property, the pile diameter can be reduced, manufacturing cost can be saved, the problems happening to pile foundation construction are effectively solved, the quality and durability of the pile are improved, the good mechanical property and economic benefits are achieved, and the quite wide application prospect is achieved.

Owner:FUZHOU UNIV

Concrete small-cross section special-shaped column mould box method construction method

InactiveCN109653434ASimplified reinforcement construction processFast constructionStrutsForms/shuttering/falseworksEngineeringRebar

The invention discloses a concrete small-cross section special-shaped column mould box method construction method. The concrete small-cross section special-shaped column mould box method constructionmethod comprises the following steps: S1, performing deepening design, and determining the types, the numbers and the cross sections of the mould boxes required to be added for changing a special-shaped column into a rectangular column; S2, manufacturing the mould boxes; S3, performing lofting on side lines of a small-cross section concrete special-shaped column and a rectangular contour line; S4,mounting reinforcing steel bars of the small-cross section concrete special-shaped column; S5, mounting mould plates of the small-cross section concrete special-shaped column; and S6, pouring, vibrating, curing, checking and accepting concrete of the small-cross section concrete special-shaped column. According to the construction method, the special-shaped column is changed into the rectangularcolumn through rectangular mould plate boxes, so that the mould supporting reinforcing construction process is simplified; the construction speed is high; the efficiency is high; the safety of a reinforcing system is ensured; the waste caused by cutting a large mould plate into small mould plates and cutting a steel pipe can be avoided; standardized and sized rectangular template boxes can be prefabricated in a factory directly and spliced on site; and the mould plate boxes, and the mould supporting and reinforcing materials can be used repeatedly, so that the construction energy consumption is reduced, and the construction cost is reduced.

Owner:广西建工第五建筑工程集团有限公司

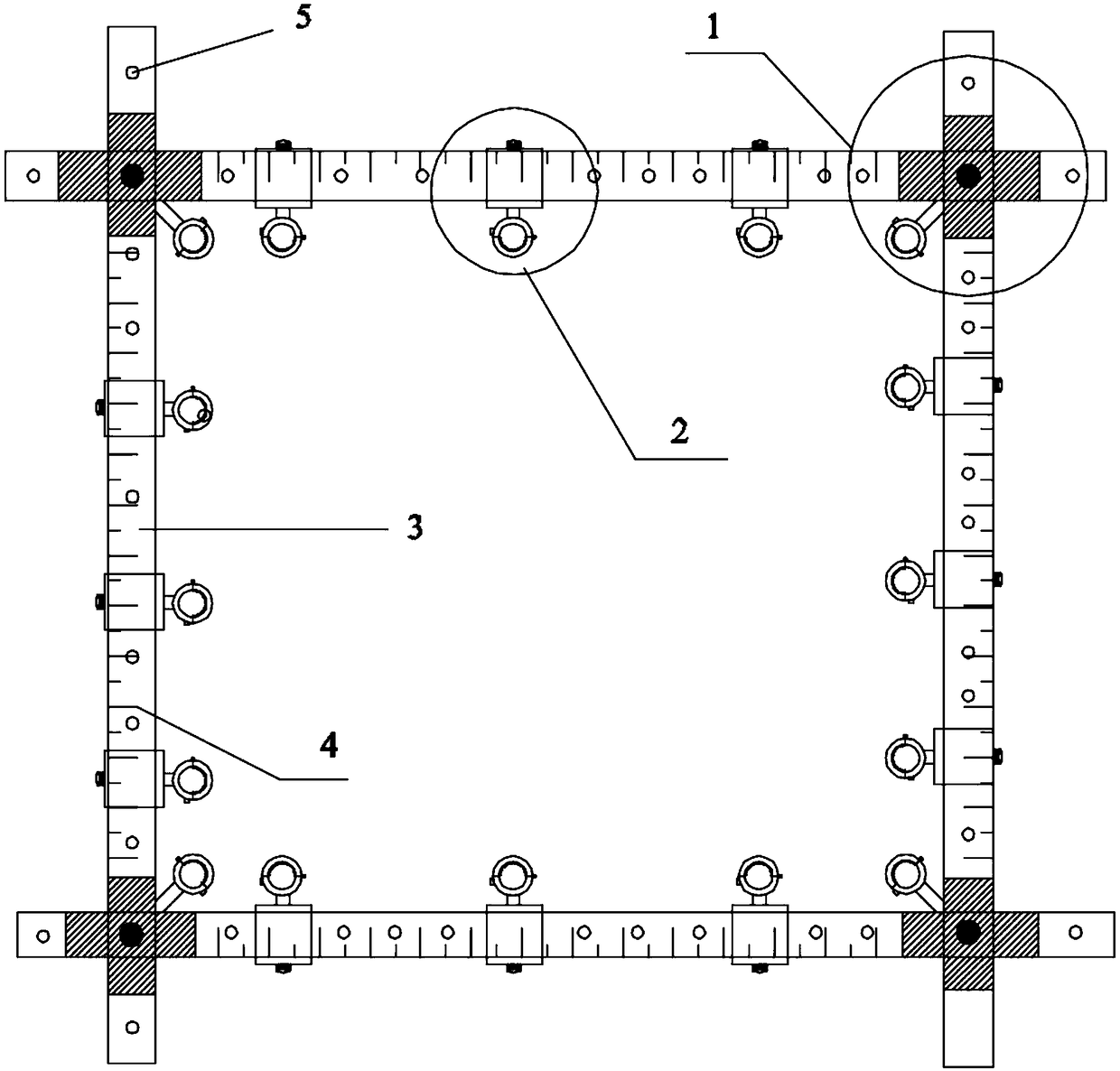

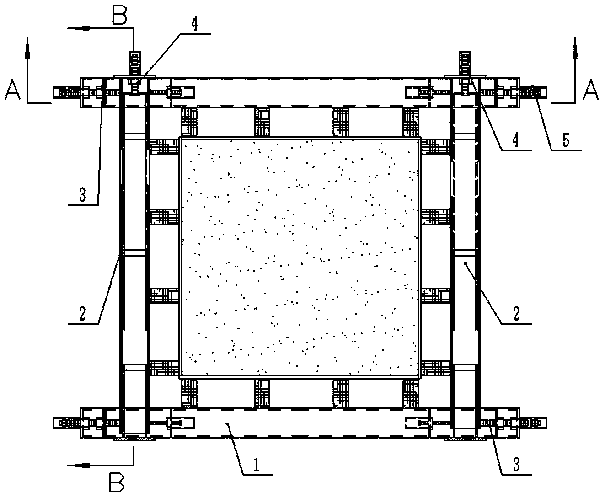

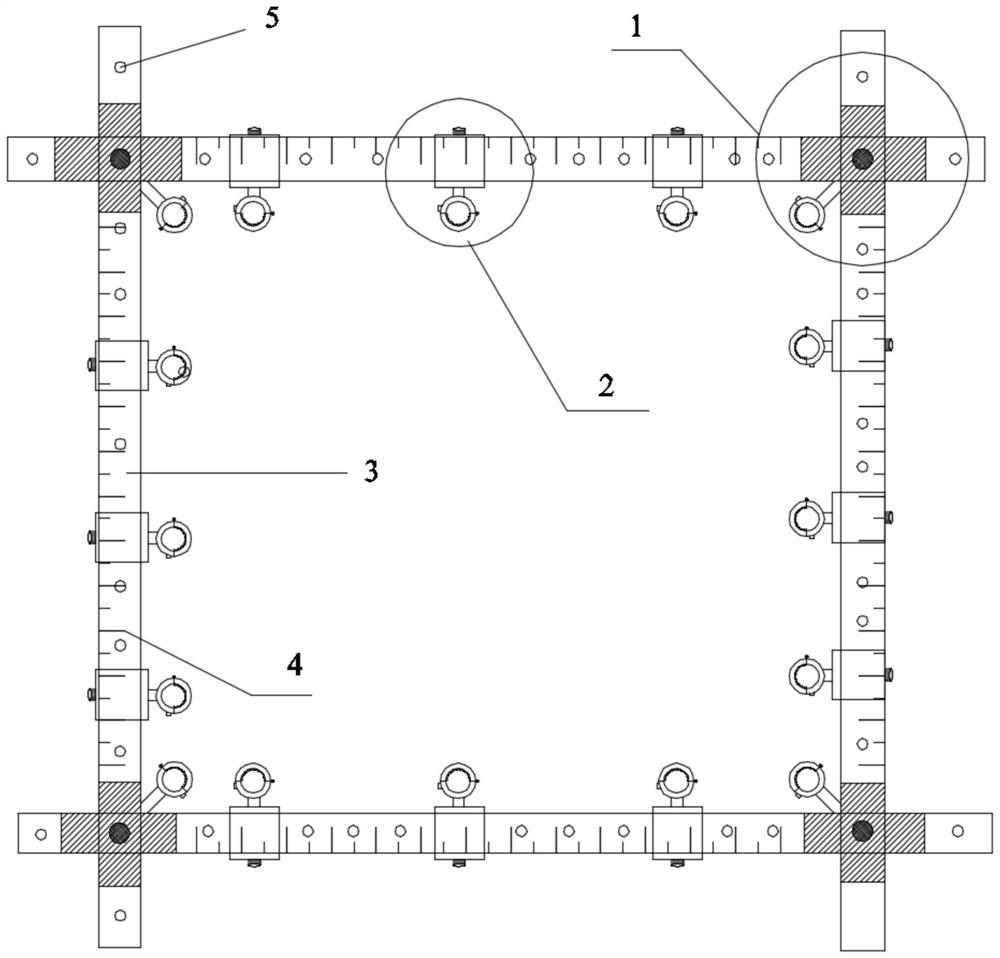

Novel tool type rectangular column mold reinforcing device

InactiveCN103912120APrecise distance controlGuaranteed section sizeForms/shuttering/falseworksEngineeringUtilization rate

The invention belongs to the field of rectangular column mold pouring, particularly discloses a novel tool type rectangular column mold reinforcing device, and aims to solve the technical problem of providing a novel tool type rectangular column mold reinforcing device which is simple in structure, convenient to use, adjustable in section and recyclable. The novel tool type rectangular column mold reinforcing device comprises two I-shaped rod pieces and two II-shaped rod pieces, each of two end portions of each I-shaped rod piece is provided with a first limiting and adjusting device, second limiting and adjusting devices are arranged on the II-shaped rod pieces, the two I-shaped rod pieces are parallelly arranged on two sides of a rectangular column mold, the first limiting and adjusting devices on the same sides of the two I-shaped rod pieces are connected via the II-shaped rod pieces and used for adjusting distance between the II-shaped rod pieces, and the second limiting and adjusting devices are used for adjusting the length of the II-shaped rod pieces and the distance between the two I-shaped rod pieces. The novel tool type rectangular column mold reinforcing device is simple to manufacture, convenient to use and recyclable while serving as a tool type product to be applied to rectangular column mold reinforcing, so that capital investment can be reduced and a utilization rate of materials is increased.

Owner:SHANXI HONGTU CONSTR GRP

Shear wall strengthening structure

InactiveCN107448007AReinforcement structure construction is convenientStable structureBuilding repairsSheet steelWall plate

The invention discloses a shear wall reinforcement structure, which comprises two concrete wall panels, the two concrete wall panels are arranged in parallel, one end of the two concrete wall panels is connected to an inner filling steel plate wall, and the inner filling steel plate wall Clamping parts are installed on the outside, and the clamping parts are connected with the inner filling steel plate wall through the clamping structure. There is a concrete wall between the two concrete wall panels, and one end of the concrete wall is fixed on the inner filling steel plate wall. There is a frame, one end of the frame is fixed on the inner side of the concrete wall, the other end is connected with a steel structure column, there are two steel structure columns, and a partition is installed on the top of the two steel structure columns. The shear wall reinforcement structure is convenient in construction, firm in structure, free to adjust and lock, can effectively ensure the cross-sectional size, flatness and verticality of the shear wall, can effectively improve the bearing level of the steel structure column, and plays a role of reinforcement, avoiding In order to avoid the phenomenon of grout leakage or mold explosion caused by fracture during pouring shear walls.

Owner:DONGGUAN ZHIPEI ELECTROMECHANICAL TECH CO LTD

Independent foundation closed type formwork structure and process

ActiveCN108661066AGuaranteed section sizeImprove performanceFoundation engineeringButt jointEngineering

The invention discloses an independent foundation closed type formwork structure and process. The independent foundation closed type formwork structure comprises templates, square timber, steel pipes,rebars and split bolts. Inclined binding bars are pre-embedded in a concrete cushion. The upper sides of the left and right side face templates are each connected with one side face template throughseal butt joint structures. Meanwhile the diagonal split bolts are perpendicularly installed on all the slope templates. All the diagonal split bolts and the corresponding pre-embedded binding bars are fixed together. The independent concrete cushion serves as the foundation, the area formed by all the side face templates and the slope templates in a surrounded mode serves as a closed pouring area, and thus a closed type formwork supporting purpose can be achieved. The overall performance of an independent foundation template system is improved, the binding bars are pre-embedded in the independent foundation cushion and are welded to split wires, the split wires are connected with the slope templates to resist buoyancy of concrete to the slope templates, and thus the independent foundationtemplate system is firm and stable.

Owner:ZHENGZHOU NO 1 CONSTR ENG GRP

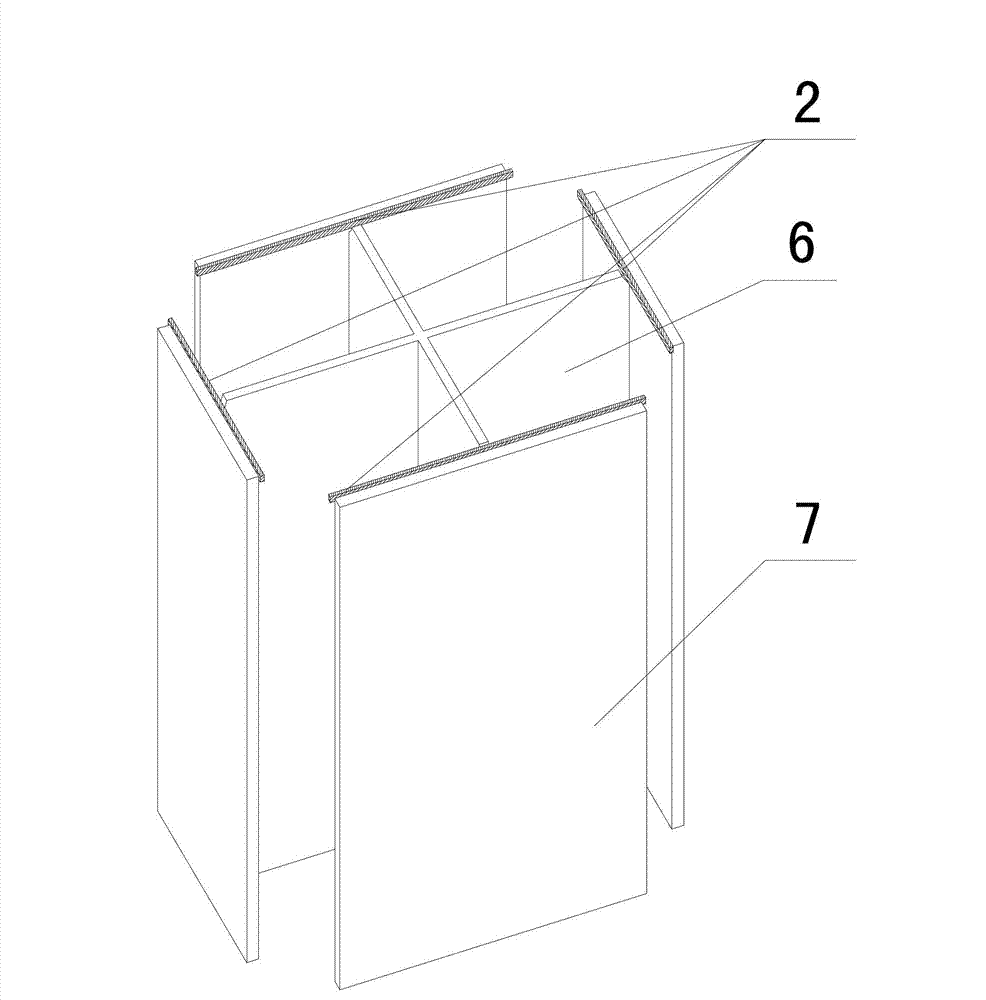

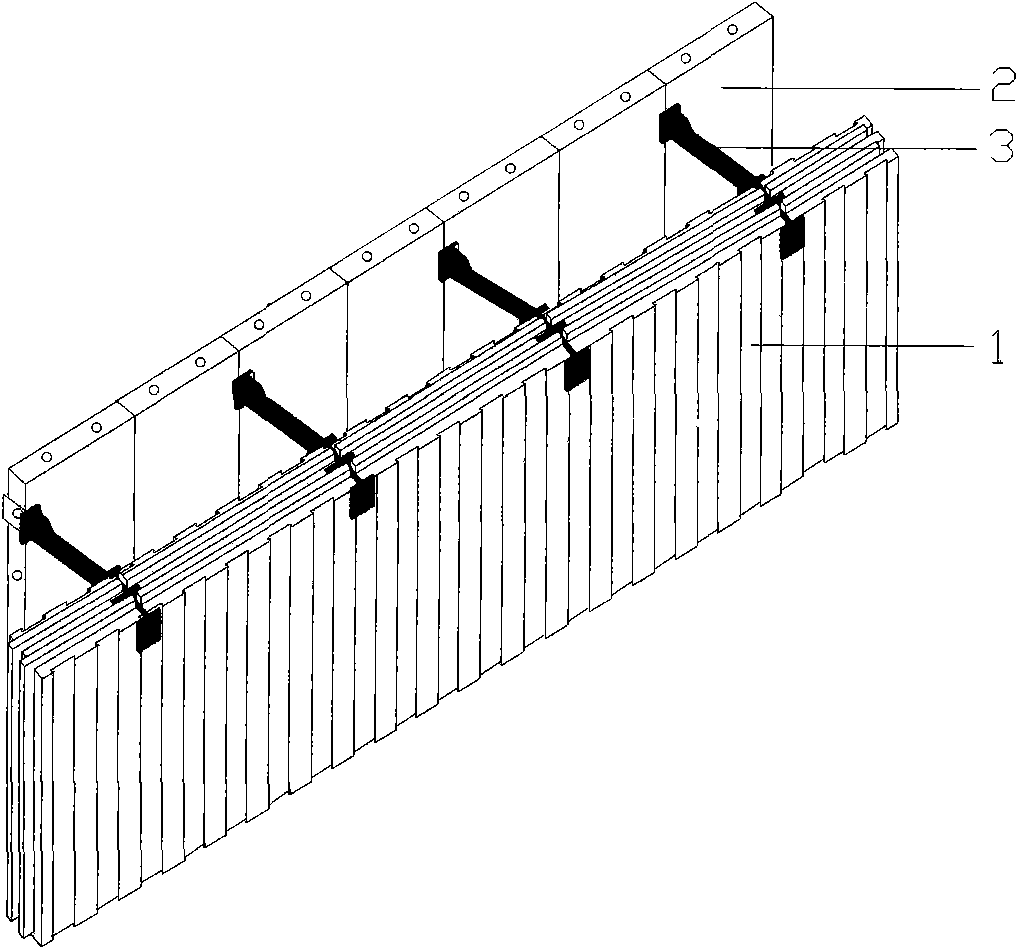

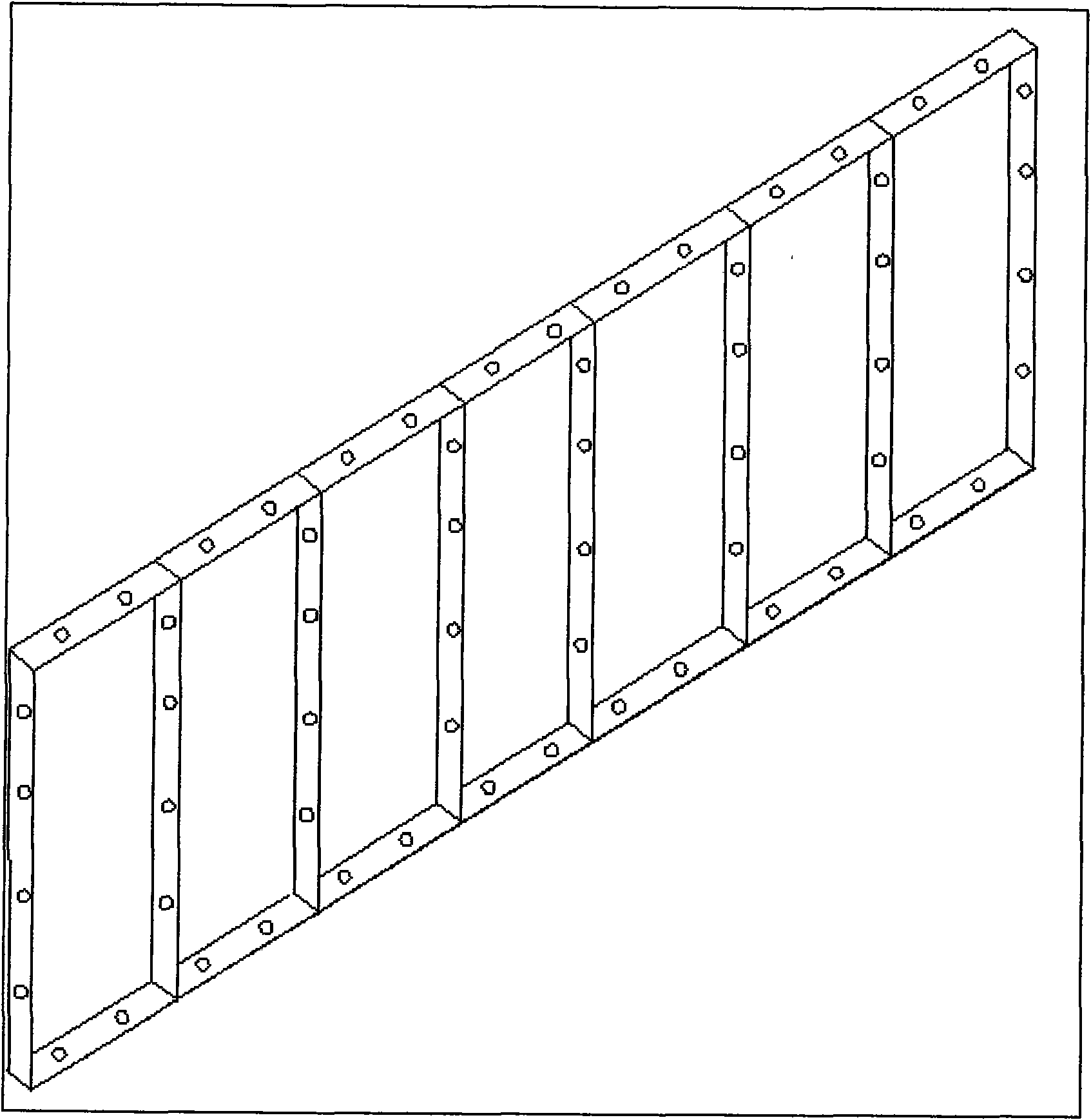

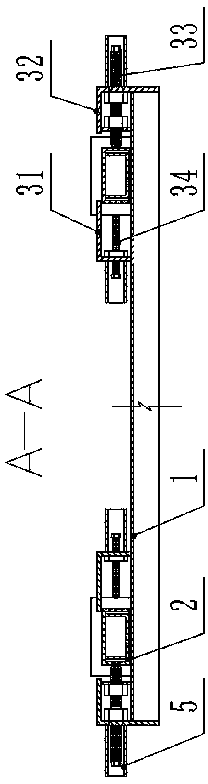

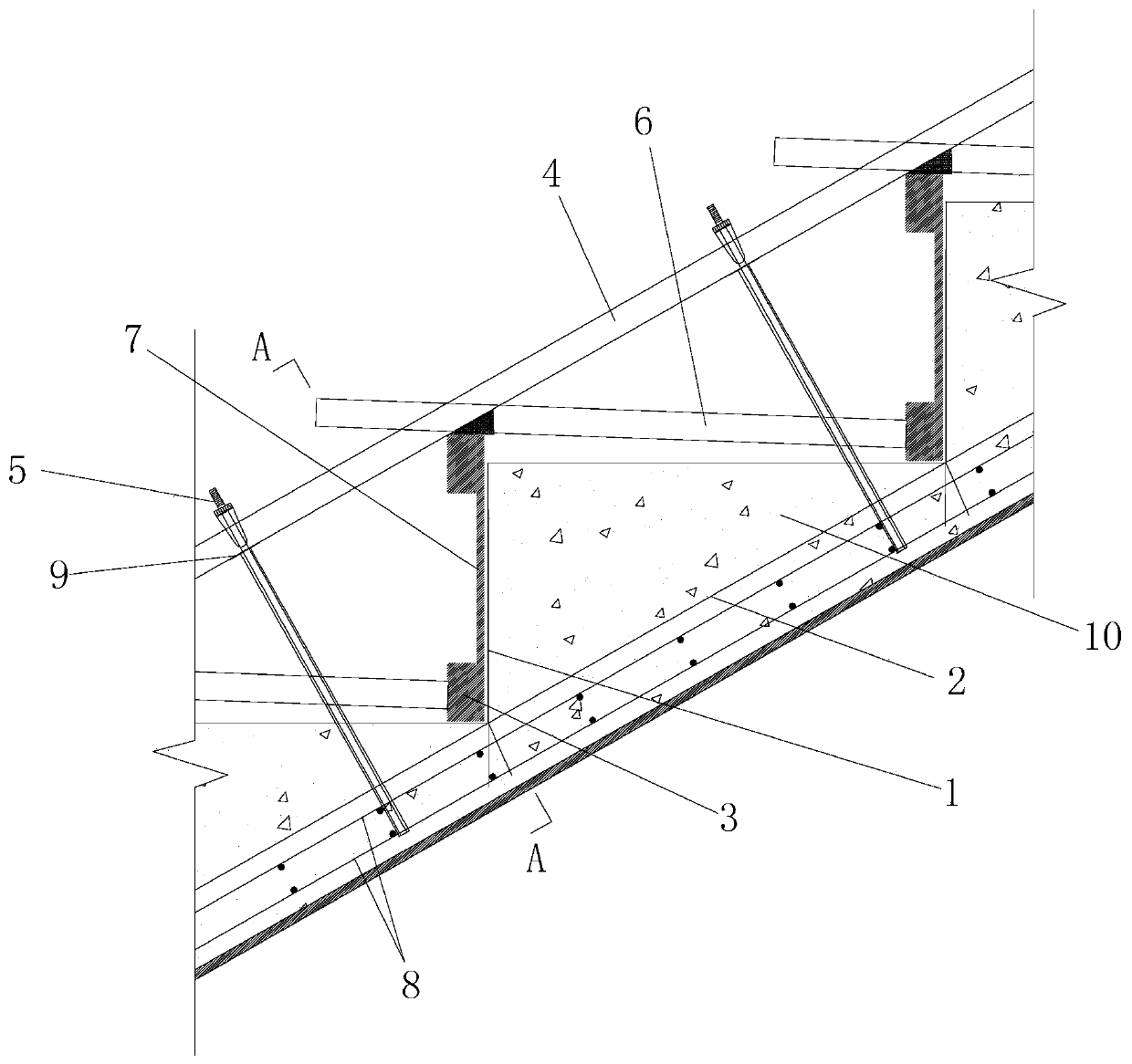

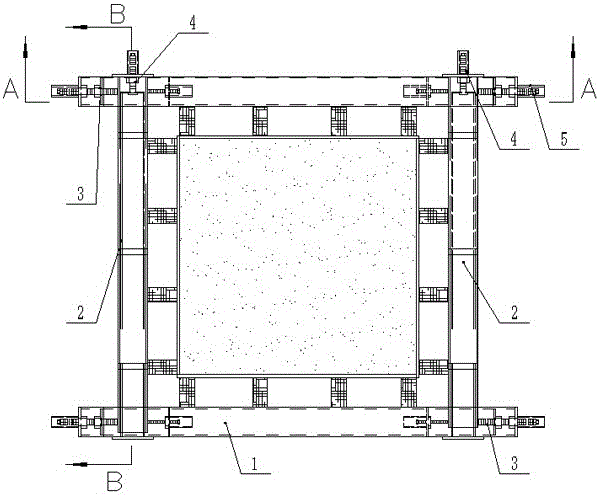

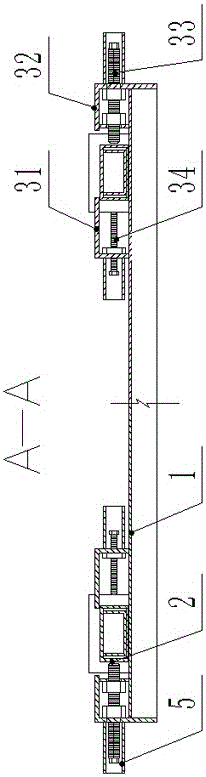

Template for large-volume concrete casting

ActiveCN102505837BIncrease stiffnessImprove stabilityAuxillary members of forms/shuttering/falseworksForming/stuttering elementsMass concreteCasting

The invention provides a template for concrete casting, and particularly provides a template applied to the field of large-volume concrete casting. An embedded part (1) of a casting template is buried on the ground; a plurality of vertical rods (2) are arranged at intervals and form a frame structure on the ground; each vertical rod (2) is fixedly connected with the embedded part (1); a plurality of panels (3) are respectively connected with each side face of the frame structure consisting of the vertical rods (2); and each panel (3) is respectively and moveably connected with the vertical rods (2) close to the panel (3) through connecting pieces (4). The structure of the casting template has the advantages of high rigidity and stability, small deformation amount and the like, and the requirement on cross section size can be met during large-volume concrete casting; and because a Wisa plate serves as a concrete panel and has a certain water-absorption and exhaustion effect, the glossiness and the flatness of the surface of the cast concrete can be improved, and the casting quality of concrete is greatly improved.

Owner:CCCC SECOND HARBOR ENG

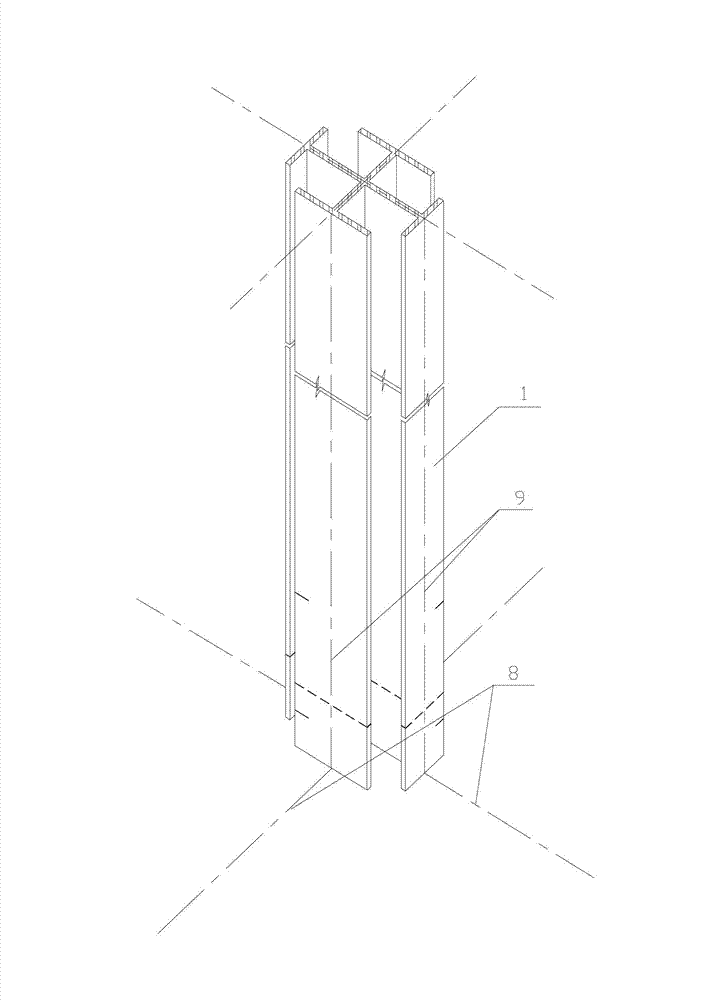

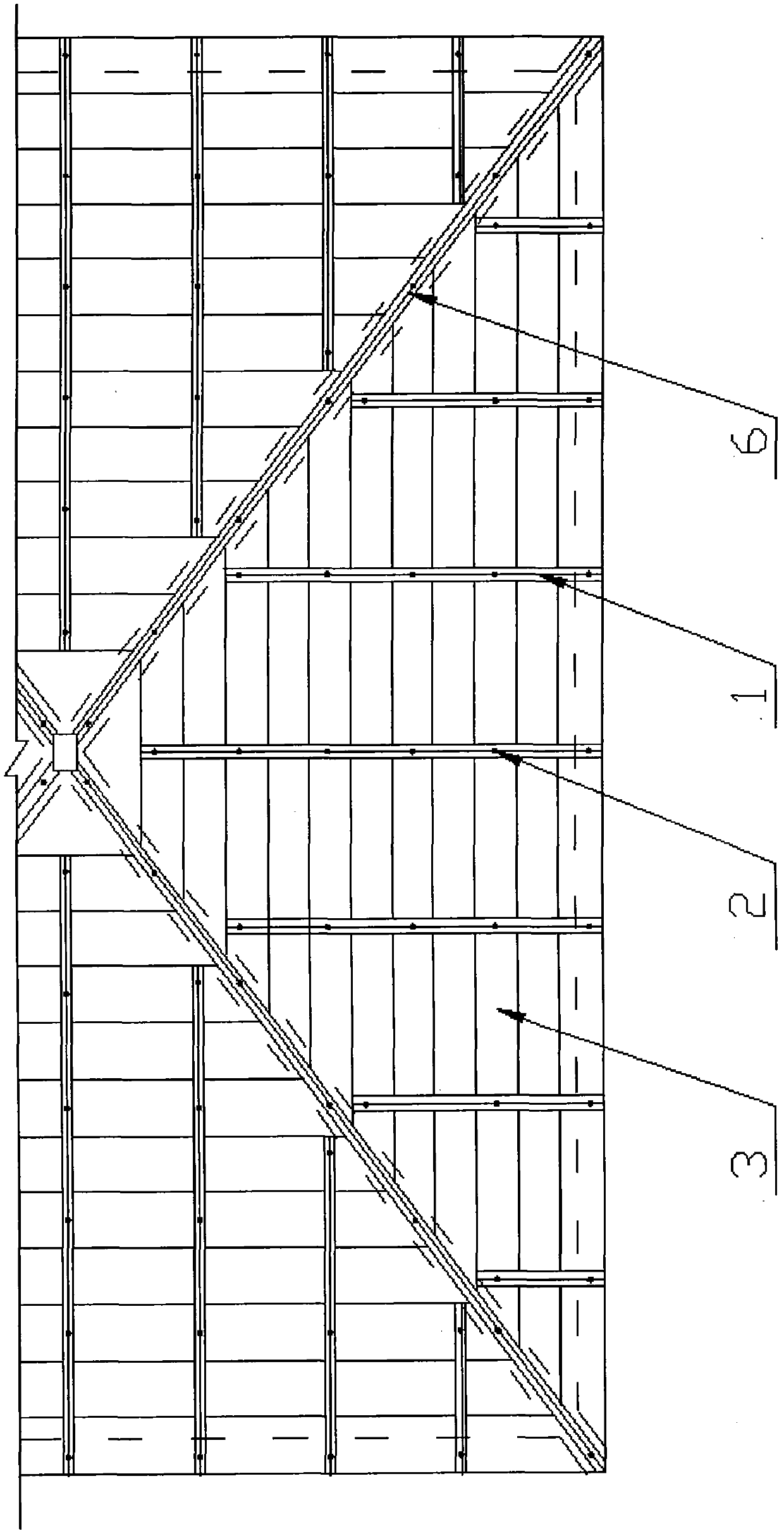

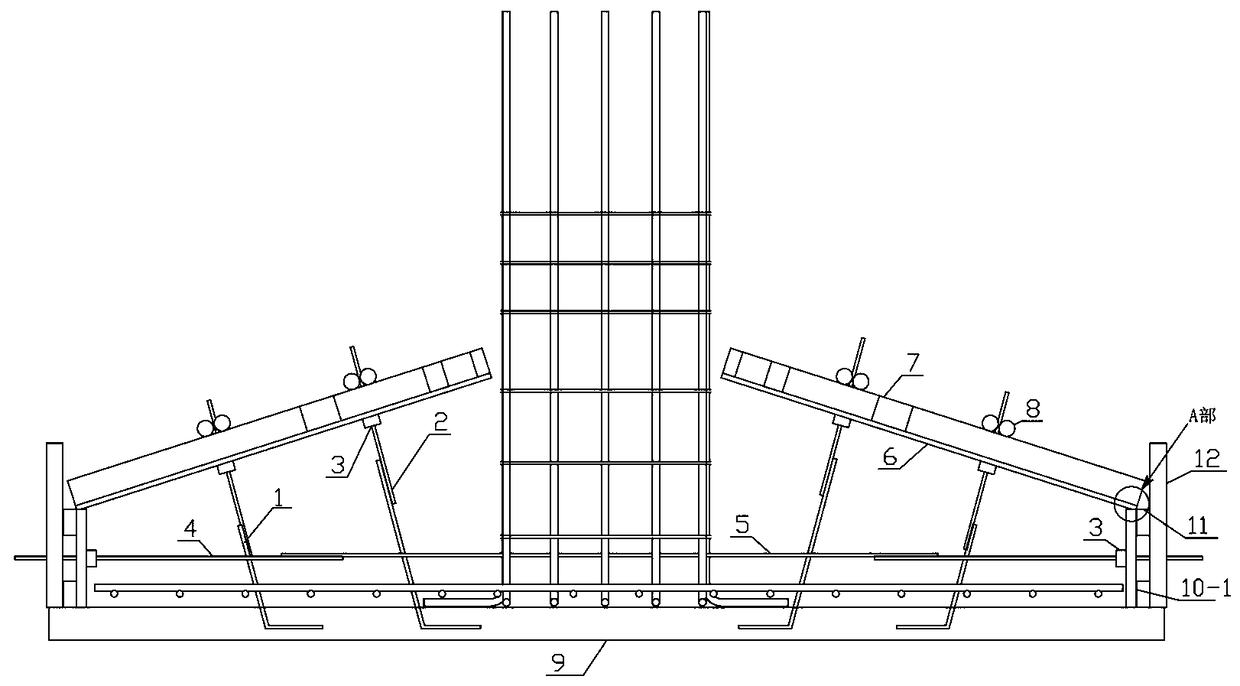

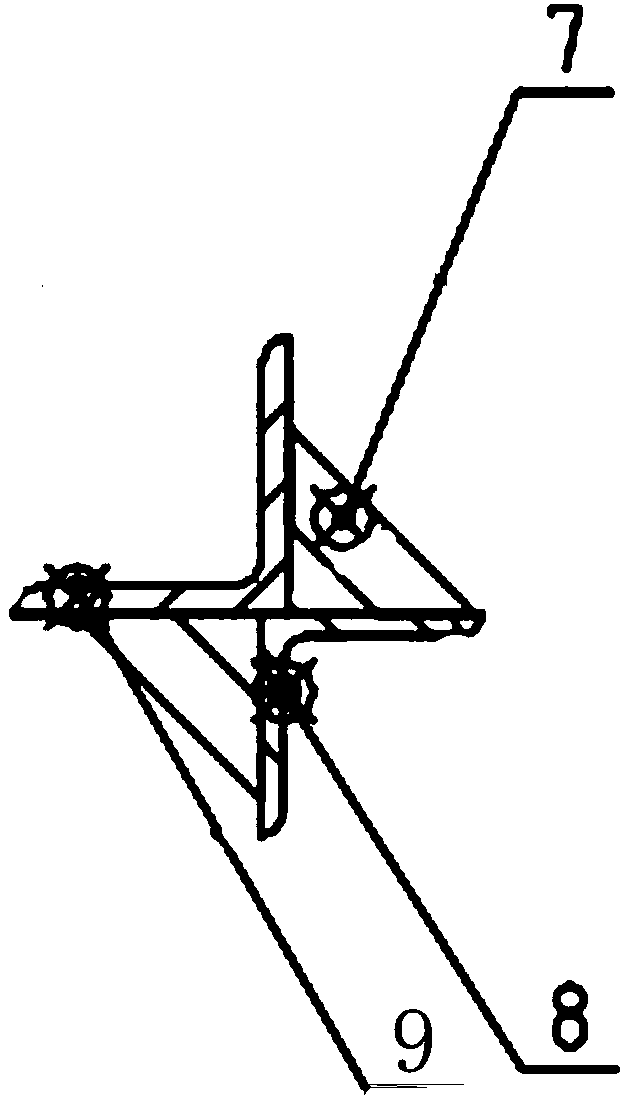

Stair inclined plate type stadium stand template reinforcement system and construction method thereof

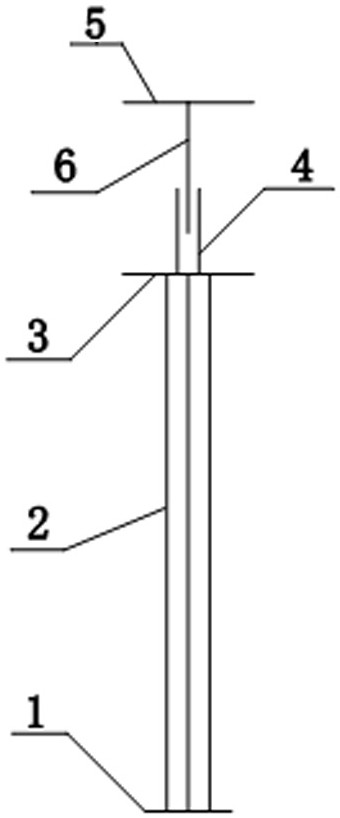

PendingCN110259118AMake sure not to slipThe installation position is accurate and firmForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksTriangular systemsEngineering

The invention discloses a stair inclined plate type stadium stand template reinforcement system and a construction method thereof. The stair inclined plate type stadium stand template reinforcement system includes horse stool reinforcement (1), positioning reinforcement (2), square wood (3), double steel tubes (4), water stopping screw rods (5) and a short steel tube (6), two short supporting legs at the bottom of the horse stool reinforcement (1) and main reinforcement of a rebar mesh piece (8) are welded to form a triangular bracket structure, the positioning reinforcement and the horse stool reinforcement are welded and fixed, side dies (7) are bound to the positioning reinforcement, the transversely spliced side dies are overlapped through the square wood, the double steel tubes are arranged above the side dies and tied with the water stopping screw rods, the water stopping screw rods are welded to the rebar mesh piece, and the short steel tube is welded to the double steel tubes and supports the square wood located at the lower end of the upper step side die. According to the stair inclined plate type stadium stand template reinforcement system and the construction method thereof, a rebar mesh of an inclined plate of a stand is fixed by pulling the upper part and supporting the lower part, it is ensured that the rebar mesh piece does not slide downward, the positioning reinforcement at a step template lower opening is fixed, the upper opening transverse double steel tubes and the short steel tube form a firm triangular system with the side dies, and stability of the template system is guaranteed.

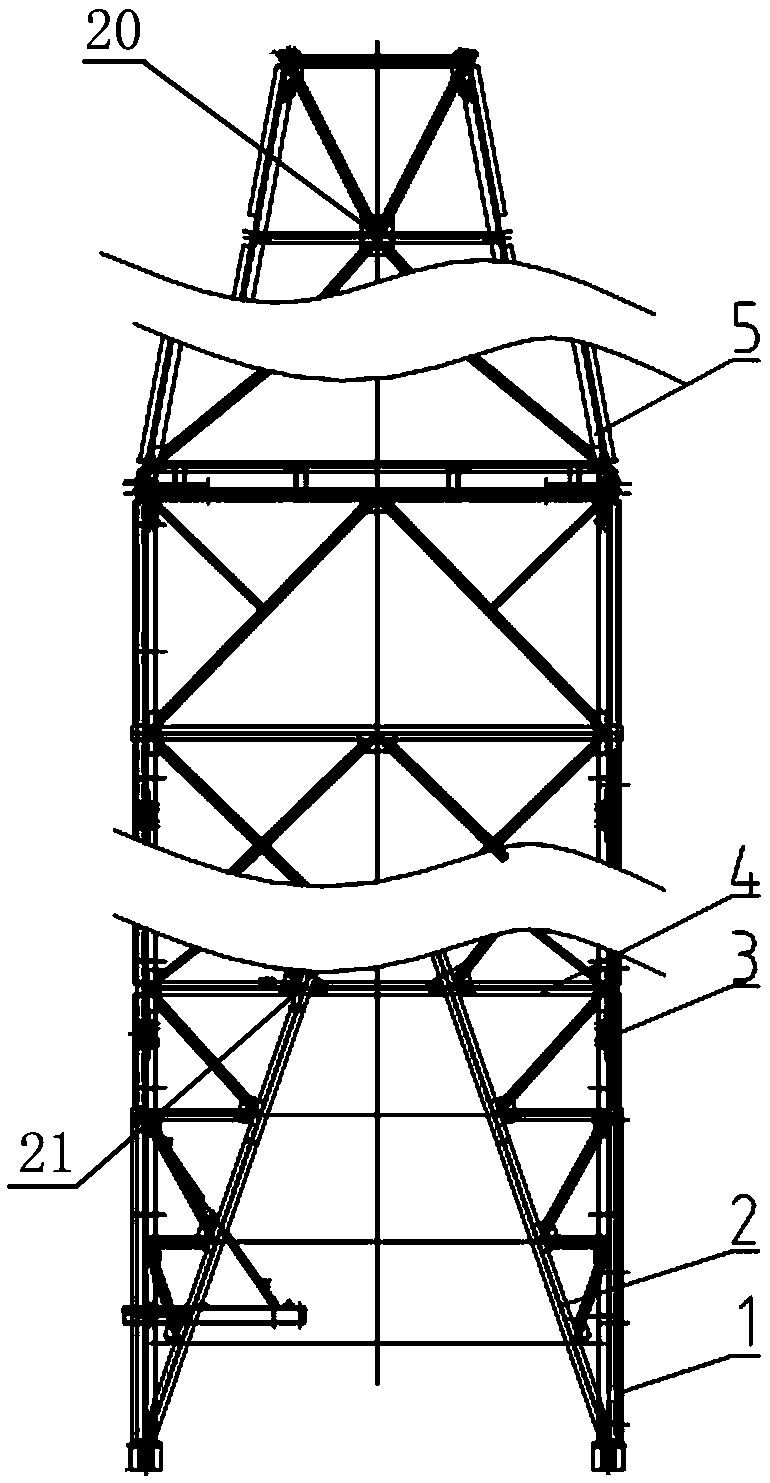

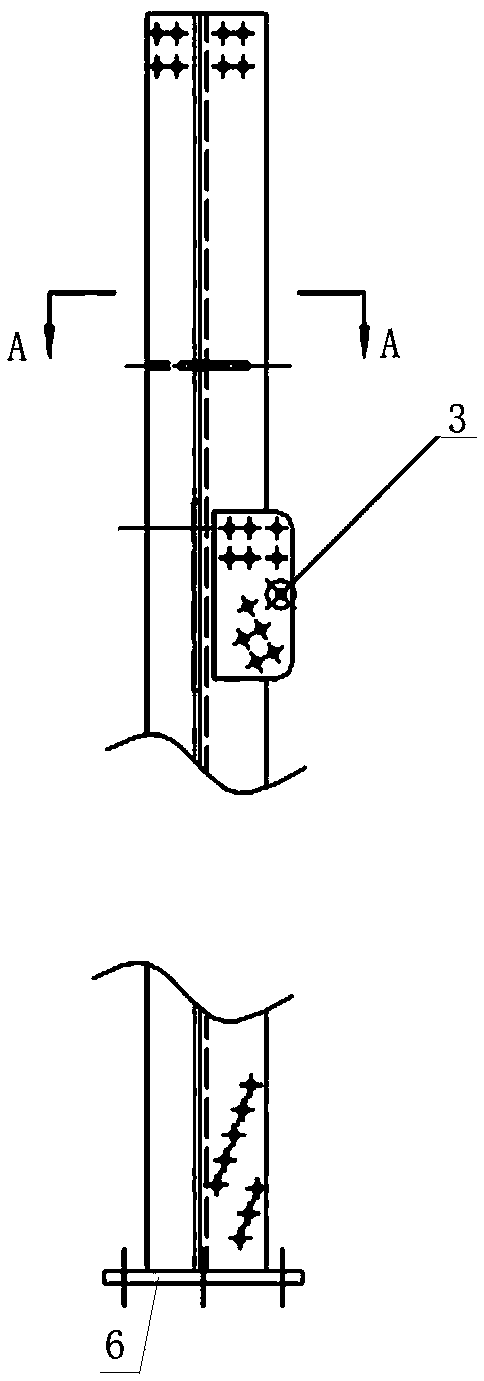

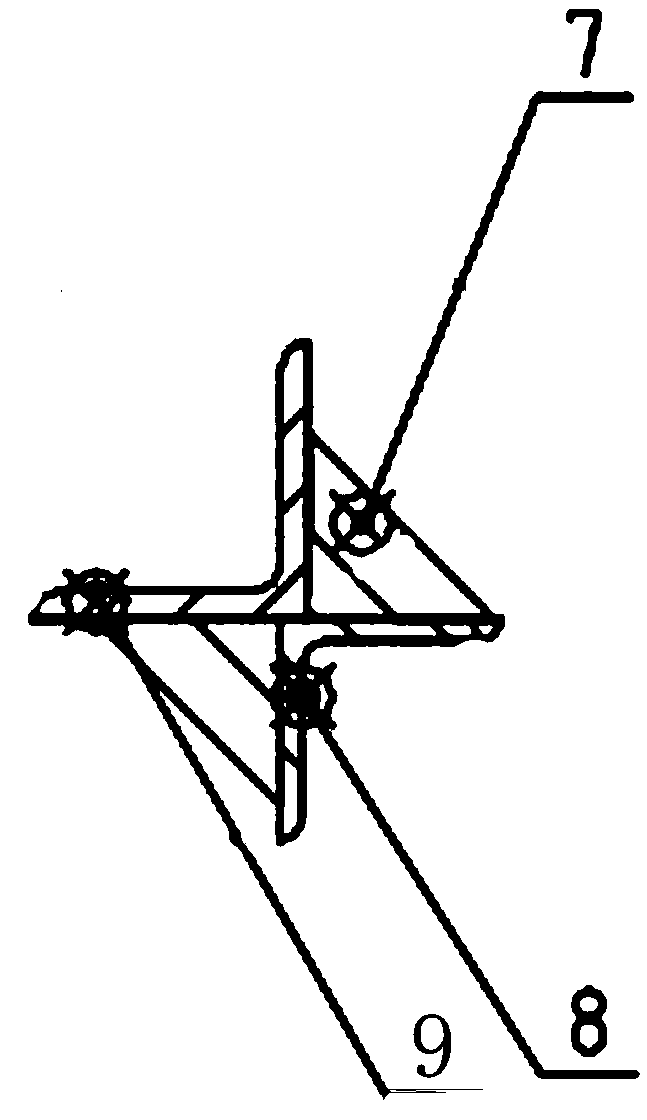

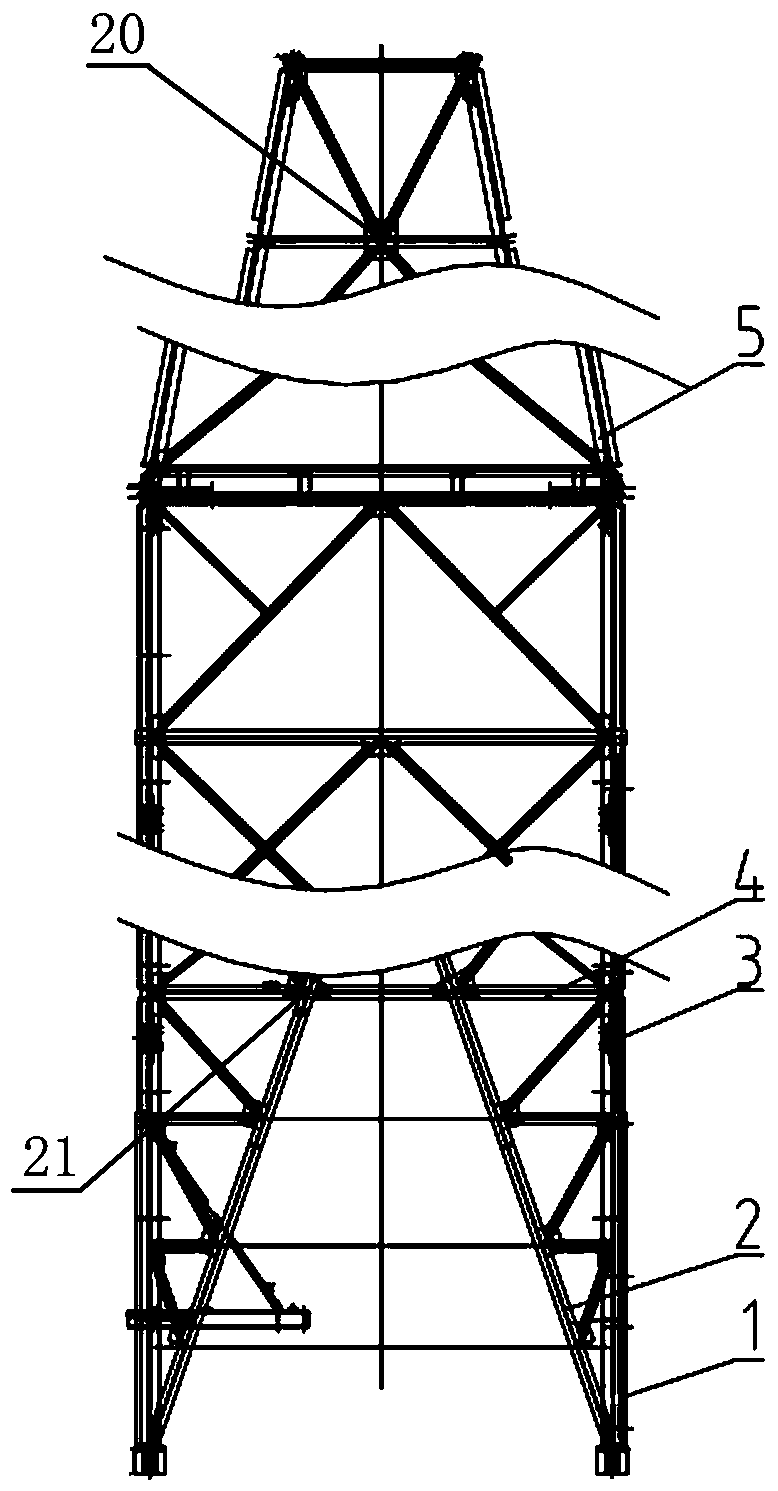

Novel ocean bottleneck type tower-shaped derrick and manufacturing method thereof

ActiveCN105370215ATotal light weightGuaranteed assembly qualityDerricks/mastsTowerUltimate tensile strength

The invention discloses a novel ocean bottleneck type tower-shaped derrick and a manufacturing method thereof. The derrick is obtained through combining, welding and manufacturing by a structural steel assembly welding tool and integral connection by bolts, the assembly welding tool enables cross splice welding structural members of upright angle iron to be located and clamped fast, advanced manufacturing and welding processes are adopted for a clamping tool, and welding and fast machining of connection devices are completed. Compared with the prior art, the derrick is purely formed by assembling and welding structural steel and is simple in structure, light in total weight, high in strength and good in rigidity; the combination quality of the derrick is guaranteed, and the problems that assembly of work-pieces is difficult, the welding quality is poor, welding deformation occurs and positioning deviation of connection holes occurs in the manufacturing process are solved.

Owner:RG PETRO MACHINERY GROUP

A marine bottleneck tower derrick and its manufacturing method

ActiveCN105370215BQuick disassemblyGuaranteed assembly qualityDerricks/mastsTowerUltimate tensile strength

The invention discloses a novel ocean bottleneck type tower-shaped derrick and a manufacturing method thereof. The derrick is obtained through combining, welding and manufacturing by a structural steel assembly welding tool and integral connection by bolts, the assembly welding tool enables cross splice welding structural members of upright angle iron to be located and clamped fast, advanced manufacturing and welding processes are adopted for a clamping tool, and welding and fast machining of connection devices are completed. Compared with the prior art, the derrick is purely formed by assembling and welding structural steel and is simple in structure, light in total weight, high in strength and good in rigidity; the combination quality of the derrick is guaranteed, and the problems that assembly of work-pieces is difficult, the welding quality is poor, welding deformation occurs and positioning deviation of connection holes occurs in the manufacturing process are solved.

Owner:RG PETRO MACHINERY GROUP

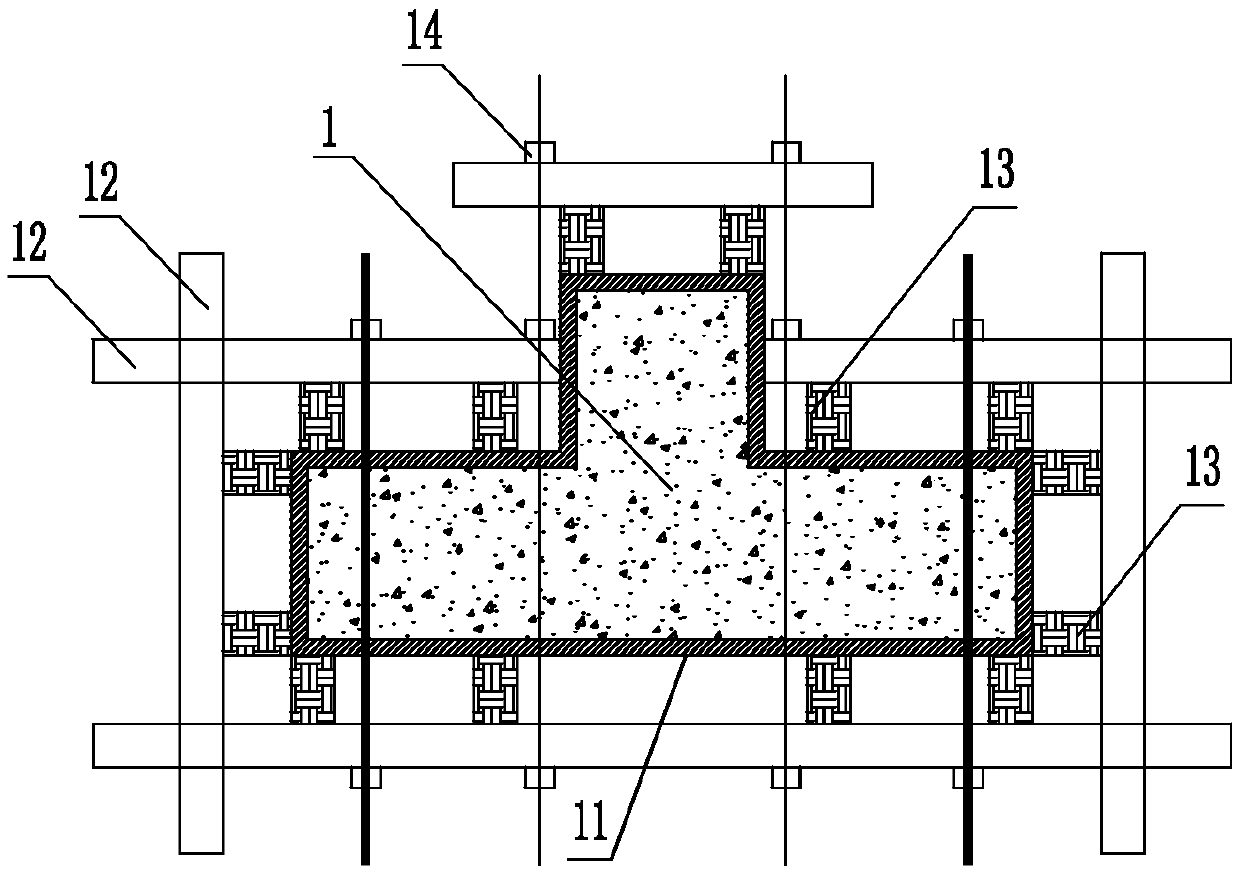

Temporary positioning device for steel frame

The invention discloses a temporary positioning device for a steel bar framework. The temporary positioning device for the steel bar framework comprises fixed buckles and a supporting frame, wherein the shape of the supporting frame is matched with the cross-sectional shape of the steel bar framework. The fixed buckles are installed on the supporting frame and the number of the fixed buckles is matched with the number of longitudinal steel bars of the steel bar framework. The fix buckles comprise upper rings and lower rings, one ends of the upper rings and one ends of the low rings are connected in a hinged mode through pin shafts, and the other ends of the upper rings and the other ends of the low rings are detachably connected through locking devices, so that the upper rings and the lower rings are combined into a circular fixing ring for temporarily fixing steel bars, anti-skid rubber pads are arranged on the inner walls of the upper rings and the inner walls of the lower rings, andthe lower rings are mounted on the supporting frame through connecting pieces. The fixed buckles are mounted on four side rods of a rectangular frame through sliding bases, and a sliding device comprises the sliding bases, wherein sliding holes formed in the four side rods of the rectangular frame in a sleeving mode are formed in the sliding bases. The temporary positioning device for the steel bar framework is simple, efficient and high-practical and in a rectangular or strip shape, has the functions of fixing the spacing and position of the steel bars in a steel bar cage and preventing thesteel bars from shifting.

Owner:CHINA FIRST METALLURGICAL GROUP

Section steel column for high-rise building section steel concrete combination structure, and construction method thereof

ActiveCN102733545BGuaranteed section sizeGuaranteed lengthStrutsBuilding material handlingConnection typeEngineering

The present invention discloses a construction method of a section steel column for a high-rise building section steel concrete combination structure. The section steel column comprises a plurality of column sections, wherein the column sections are sequentially connected from bottom to top, an interface position of two optionally adjacent column sections is provided with an inner sleeve interface, and an outer side wall of a connection position of the two adjacent column sections is provided with a buckle fixation type assembly. The construction method comprises that: the insert-connection type initial positioning of the two adjacent column sections is achieved through the inner sleeve interface; the cross extending line and the buckle fixation type assembly are combined to carry out positioning correction on the column; a scale measurement method is adopted to carry out column scale height adjustment; and the cross extending line and the buckle fixation type assembly are combined to carry out verticality correction on the full length of the column sections. With the section steel column of the present invention, the model of one construction interface in each floor of the traditional section steel column can be increased to the model of one construction interface in every two floors or three floors, such that more than half of the construction interfaces of the section steel column can be saved, the probability of deviation error due to construction interface operation can be greatly reduced, and the guarantee degree of installation quality can be improved.

Owner:广东中城建设集团有限公司 +1

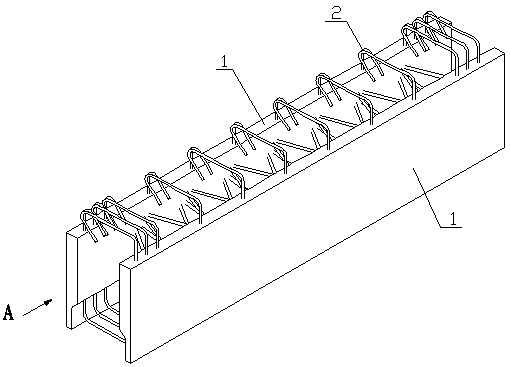

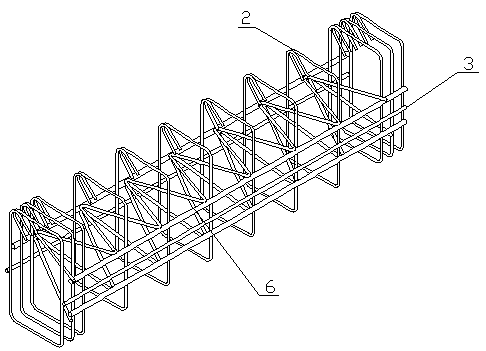

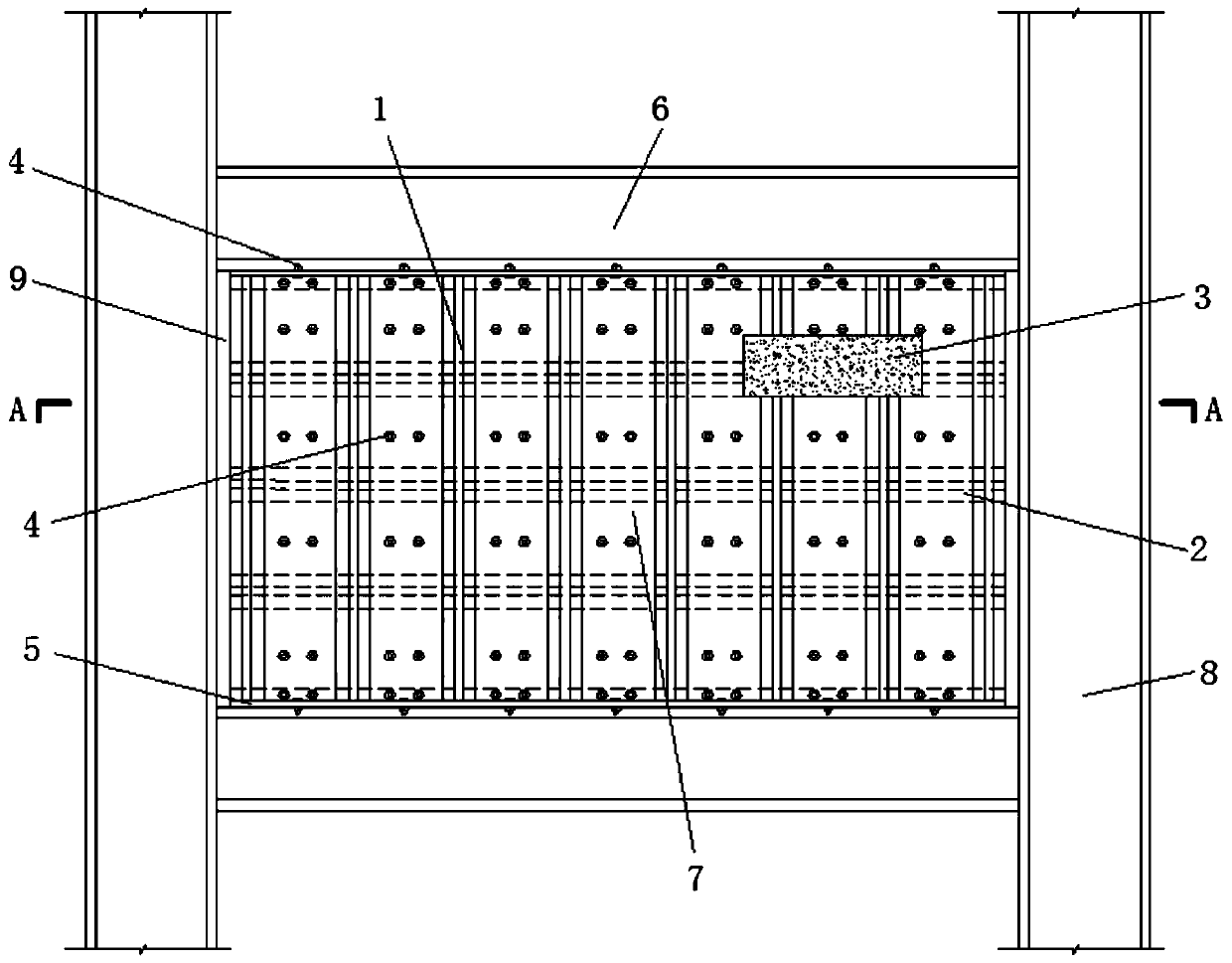

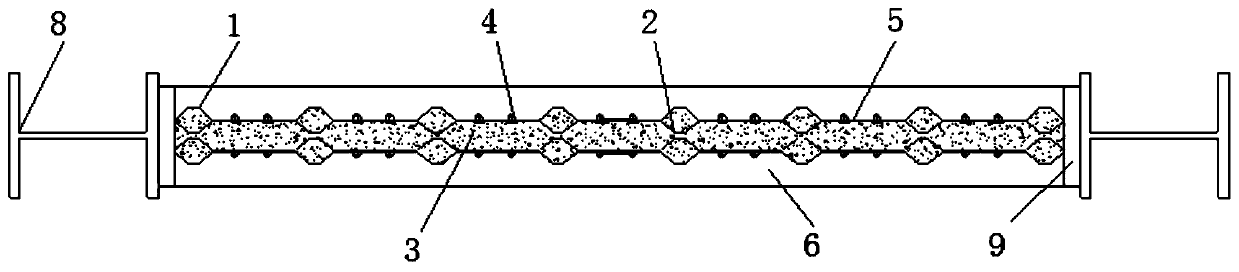

Double-sided composite beam and its construction method

ActiveCN105569264BDoes not affect lashingLess consumablesGirdersJoistsArchitectural engineeringSteel bar

The invention relates to a double-faced superposed beam and a construction method thereof. At the present stage, the state energetically develops housing industrialization, but in an existing prefabricated building mode, a prefabricated beam is limited by the beam length, a production environment, transportation and installation conditions and the like. The double-faced superposed beam comprises a steel bar framework (6) and prefabricated concrete slabs (1), the prefabricated concrete slabs are poured on the two vertical sides of the steel bar framework, the steel bar framework comprises truss bars (4), a set of beam stirrups (2) are installed in the truss bars, the two vertical sides of the one set of beam stirrups are fixed with the truss bars, the two vertical sides of the one set of beam stirrups are fixed with a set of constructional steel bars (3), beam main bars (5) are arranged at the circular arc positions of four corners of the one set of beam stirrups in a penetrating mode respectively, and the inner sides of the prefabricated concrete slabs are provided with smoothly-reduced cross sections.

Owner:黑龙江中晟绿色建筑产业发展有限公司

A New Tool-Type Rectangular Column Formwork Reinforcing Device

InactiveCN103912120BPrecise distance controlGuaranteed section sizeForms/shuttering/falseworksEngineeringUtilization rate

The invention belongs to the field of rectangular column mold pouring, particularly discloses a novel tool type rectangular column mold reinforcing device, and aims to solve the technical problem of providing a novel tool type rectangular column mold reinforcing device which is simple in structure, convenient to use, adjustable in section and recyclable. The novel tool type rectangular column mold reinforcing device comprises two I-shaped rod pieces and two II-shaped rod pieces, each of two end portions of each I-shaped rod piece is provided with a first limiting and adjusting device, second limiting and adjusting devices are arranged on the II-shaped rod pieces, the two I-shaped rod pieces are parallelly arranged on two sides of a rectangular column mold, the first limiting and adjusting devices on the same sides of the two I-shaped rod pieces are connected via the II-shaped rod pieces and used for adjusting distance between the II-shaped rod pieces, and the second limiting and adjusting devices are used for adjusting the length of the II-shaped rod pieces and the distance between the two I-shaped rod pieces. The novel tool type rectangular column mold reinforcing device is simple to manufacture, convenient to use and recyclable while serving as a tool type product to be applied to rectangular column mold reinforcing, so that capital investment can be reduced and a utilization rate of materials is increased.

Owner:SHANXI HONGTU CONSTR GRP

Structure and construction method of cast-in-site style welded steel frame composite concrete shear wall

ActiveCN103195193BGuaranteed section sizeSolving Linear Thermal Bridge ProblemsWallsBuilding material handlingFloor slabSandwich board

The invention relates to a structure and a construction method of a cast-in-style welded steel frame composite concrete shear wall. The structure comprises an indoor concrete layer, an outdoor concrete layer and a wire frame insulation sandwich board. The wire frane insulation sandwich board is coated between the indoor concrete layer and the outdoor concrete layer. At least two rectangular and groove-typed cantilever holes are arranged at the top of the sandwich board, and each cantilever hole is provided with a U-shaped cantilever anchor bar which penetrates through the sandwich board and a floor slab to be fixedly connected with the floor slab. The construction method includes site preparation work, binding of load-bearing steel bars of a wall body and edge member steel bars, custom processing of the sandwich boards, installation of the sandwich boards, pavement of template positioning pieces and wall bushings, fixation of water and electric pipes inside the wall body, binding of ordinary blocks on both sides of the wall body steel bars, erecting of the templates, pouring of the concrete, removing of the templates and concrete curing. Since a series of composite wall construction methods are adopted, problems existing in the prior art are solved, and a composite heat preservation technology is improved.

Owner:石家庄晶达建筑体系有限公司

A processing technology of internal combustion engine radiator

ActiveCN111168335BGuaranteed section sizeGuaranteed adaptabilitySoldering apparatusMachines/enginesProcess engineeringInternal combustion engine

The invention discloses a machining process of an internal combustion engine radiator. The machining process comprises the following steps that S1, materials are selected; S2, blanking is carried out,and a water chamber and a clamping part at the lower end are integrally extruded and formed; S3, a core body is assembled; S4, the core body and the water chamber are assembled; S5, the core body andthe water chamber are compressed, and the clamping part and a main sheet in the clamping part are compressed through an extrusion device; S6, an end plate of the water chamber is assembled; S7, a reinforcing plate is assembled; and S8, brazing forming is carried out. According to the machining process of the internal combustion engine radiator, the welding quality can be improved, the water testing and pressing qualification rate is increased, and the one-time pressing qualification rate reaches 98% or above; the assembling efficiency of the aluminum water chamber and the main sheet is improved, and the forming period of the radiator is shortened; the automation level is improved, manual operation is reduced, and the yield of radiator finished products is not limited by argon arc weldingworkers; and compared with other processes, the appearance of the product is more attractive.

Owner:WEIFANG TIANXIN RADIATOR

Two-side-slotted deformed stainless steel stiffening rib profiled steel sheet-recycled concrete shear wall

InactiveCN110173064AReduce construction proceduresImprove stabilityWallsSheet steelMaterials science

The invention discloses a two-side-slotted deformed stainless steel stiffening rib profiled steel sheet-recycled concrete shear wall. The two-side-slotted deformed stainless steel stiffening rib profiled steel sheet-recycled concrete shear wall comprises two profiled steel sheets, wherein an interval between the two profiled steel sheets is filled with recycled concrete, a deformed stainless steelstiffening rib is arranged on the outer side of each profiled steel sheet, the bent shape of each deformed stainless steel stiffening rib is as same as the shape of each profiled steel sheet, each deformed stainless steel stiffening rib is installed on each profiled steel sheet in crest-crest opposite mode so as to form a cellular cavity, and the recycled concrete is poured in the cellular cavity. The shear wall is installed between a frame beam and a frame pillar, and a gap is left between the shear wall and the frame pillar. Two sides of the shear wall are slotted, and therefore interactionbetween the shear wall and the frame pillar is avoided. By arranging the deformed stainless steel stiffening ribs, shear resistance of the shear wall is enhanced. Furthermore, the problems that a traditional shear wall is cumbersome and complex in construction procedure, generates residual stress and the like are solved, a construction period is greatly shortened, and cost is saved.

Owner:CHANGZHOU INST OF TECH

Device capable of increasing laying quality of external wall insulation boards and construction method

InactiveCN112523404AGuaranteed flatnessImprove appearance qualityWallsHeat proofingArchitectural engineeringEngineering

The invention relates to a device capable of increasing the laying quality of external wall insulation boards. The device is characterized in that a cross stiffening rod is arranged on an inner wall support plate, an insulation board inner baffle is arranged on the cross stiffening rod, a connecting rod guide pipe is arranged on the insulation board inner baffle, and a connecting rod is inserted into the connecting rod guide pipe; adjusting screws are connected to both sides of the insulation board inner baffle, an insulation board outer baffle is arranged on the adjusting screws, and nuts areinstalled on the ends of the adjusting screws; the distance between the insulation board inner baffle and the insulation board outer baffle is equal to the thickness of an insulation board; the distance between the inner wall support plate and the insulation board inner baffle is equal to the thickness of a shear wall; and the lengths of the two adjusting screws which extend out of the insulationboard outer baffle are equal. A construction method comprises the steps of placing the device on a to-be-poured wall; inserting the connecting rod into the connecting rod guide pipe; installing two insulation boards; pouring concrete; removing the insulation board outer baffle and the connecting rod; repeating the steps till the pouring of a shear wall body is finished; and cutting the exposed adjusting screws. According to the device and the construction method, the problems of flatness and no damage to the abutted seam of the insulation boards can be solved, and the section size of the shear wall is guaranteed.

Owner:CHINA FIRST METALLURGICAL GROUP

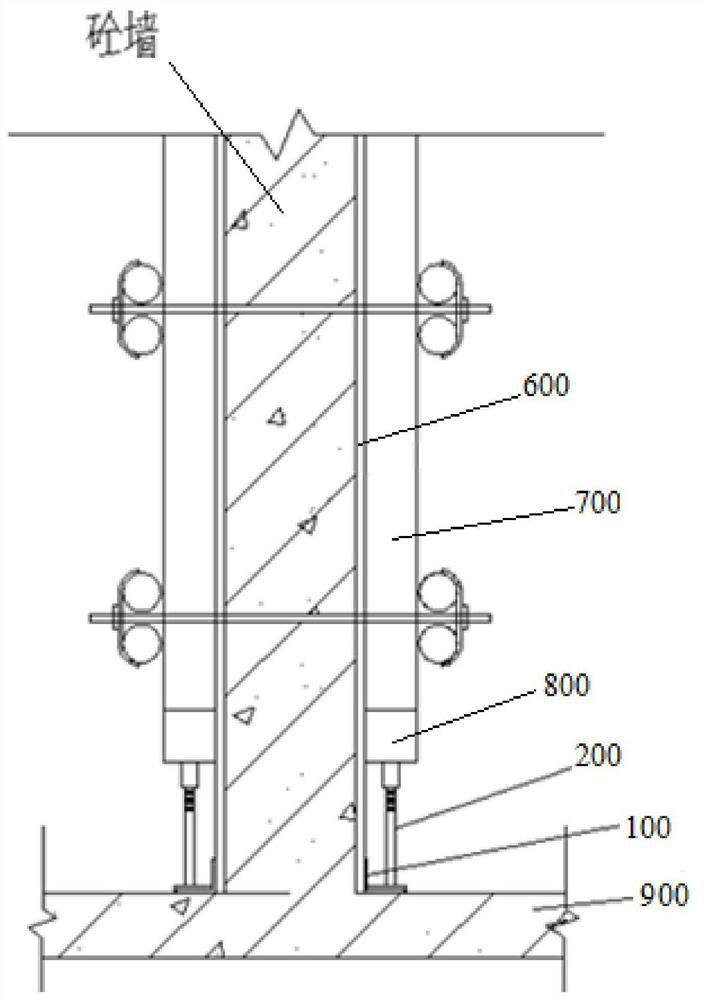

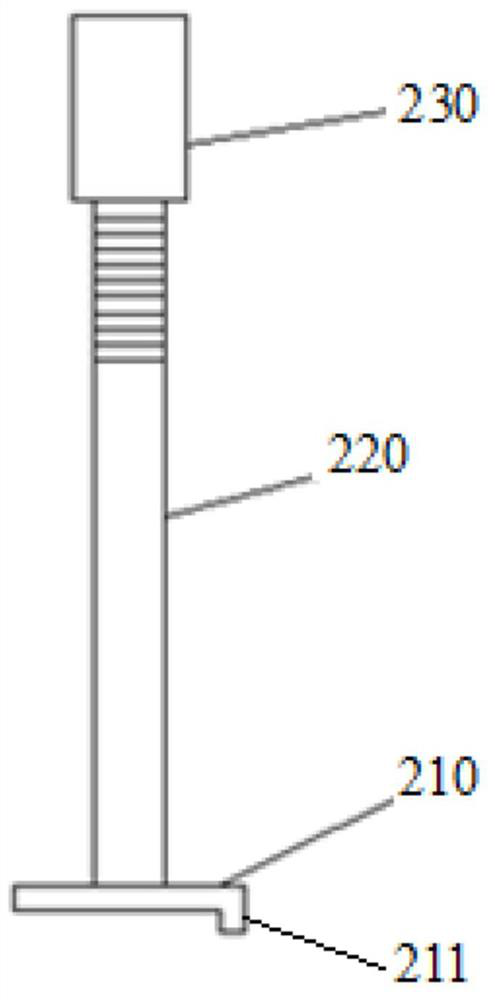

Wall column formwork plugging and leveling device and its construction method

ActiveCN110485707BGuaranteed section sizeTo achieve the purpose of fixing the position of the blocking memberForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringStructural engineering

Owner:CHINA HUAYE GROUP +1

Structural steel two-stage heating hardening and tempering process method

InactiveCN110714113AGuaranteed hardenabilityEnsure organizational transformationTemperature controlTempering

The invention discloses a structural steel two-stage heating hardening and tempering process method. The structural steel two-stage heating hardening and tempering process method comprises the following steps that S1, one-stage heating is carried out, specifically, a structural steel workpiece is overall heated, and the first-stage heating temperature is controlled to be the lower limit of the normal quenching temperature of the structural steel workpiece. The structural steel two-stage heating hardening and tempering process method is suitable for the workpiece with the diameter or thicknesslarger than the material hardenability critical diameter or with the large section size change, the first-stage heating temperature selects the lower limit of the normal quenching temperature of steel, grains can be refined, the internal stress is reduced, the probability of cracks is greatly reduced, and deformation and decarburization are reduced; the second-stage heating temperature selects theupper limit of the quenching temperature, the hardenability effect of the large part of the section size of the workpiece is guaranteed, and the situation that the temperature of the small part of the section size is reduced too low in the process of transferring from a heating chamber to a cooling chamber is prevented; the first-stage long-time heating is carried out, and the overall structure transformation of the workpiece is guaranteed; and the second-stage short-time heating is carried out, and the situation that the section size of the workpiece is small or the temperature of the changing part is too high, and consequently defects are generated is prevented.

Owner:JIANGSU JUYUAN ELECTRICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com