Construction technology of wall body

A wall and process technology, applied in building structures, walls, buildings, etc., can solve the problems of adverse effects on construction work efficiency, high consumption of steel bars 52 or PVC pipes 51, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

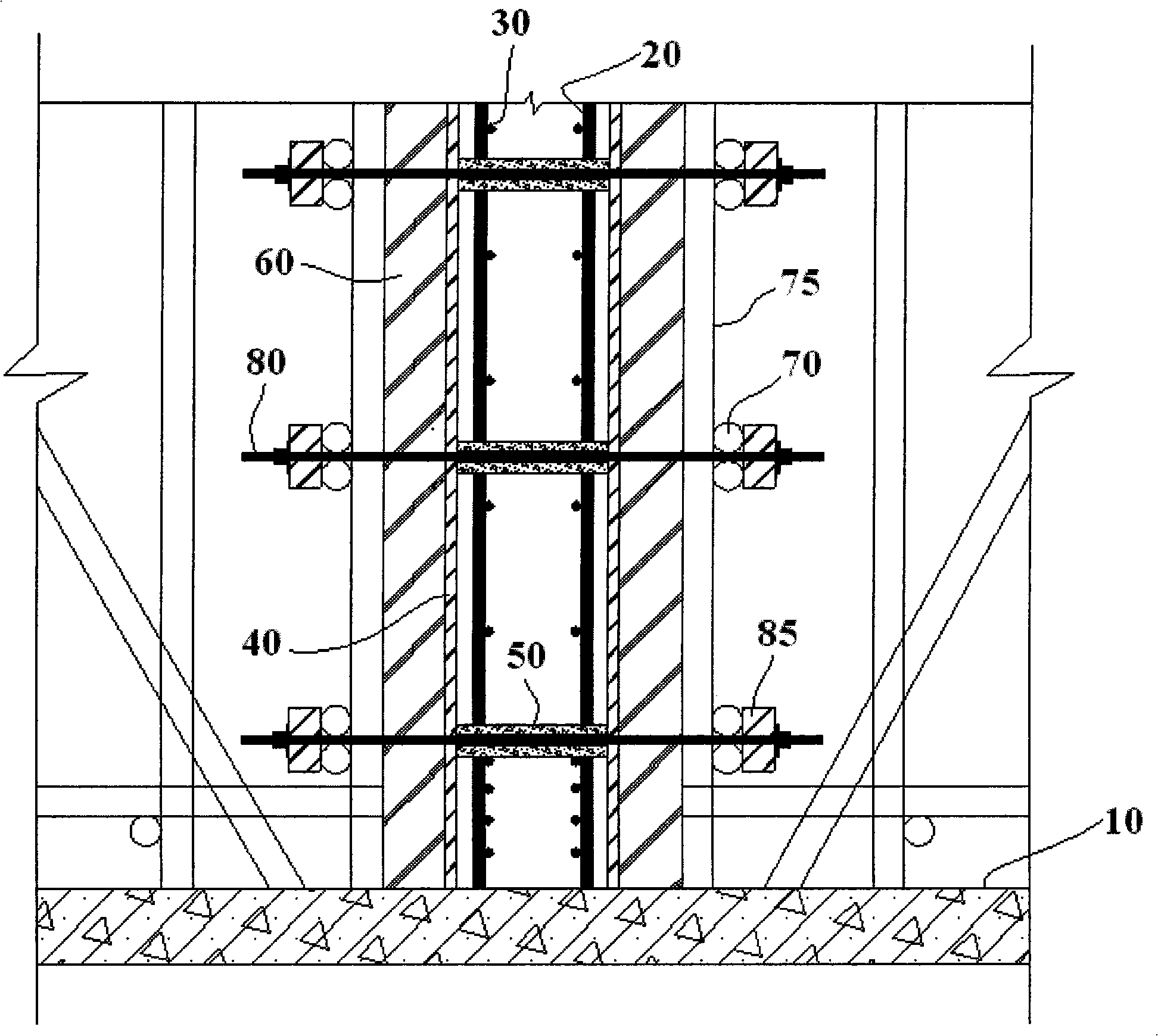

[0016] Such as figure 1 As shown, according to the prior art, when building a shear wall on the basis of the floor 1, firstly, the vertical reinforcement 2 and the transverse reinforcement 3 of the wall are supported and bound; The limit templates 4 and 4 on both sides that limit the width W of the wall body; the wooden beams 6 are arranged outside the limit templates 4 and 4 on both sides; the vertical steel pipe supports 72 for the shear wall are supported outside the wooden beams 6; The outer side of the vertical steel pipe support 72 of the force wall is provided with the horizontal steel pipe support 71 of the shear wall; through the locking nut 82 of the shear wall tension bolt 81, the shear wall tension bolt 81 can be used to prevent the limit templates 4 and 4 on both sides from moving away from each other role. Then, concrete is poured between the limit templates 4 and 4 on both sides to form a body of wall.

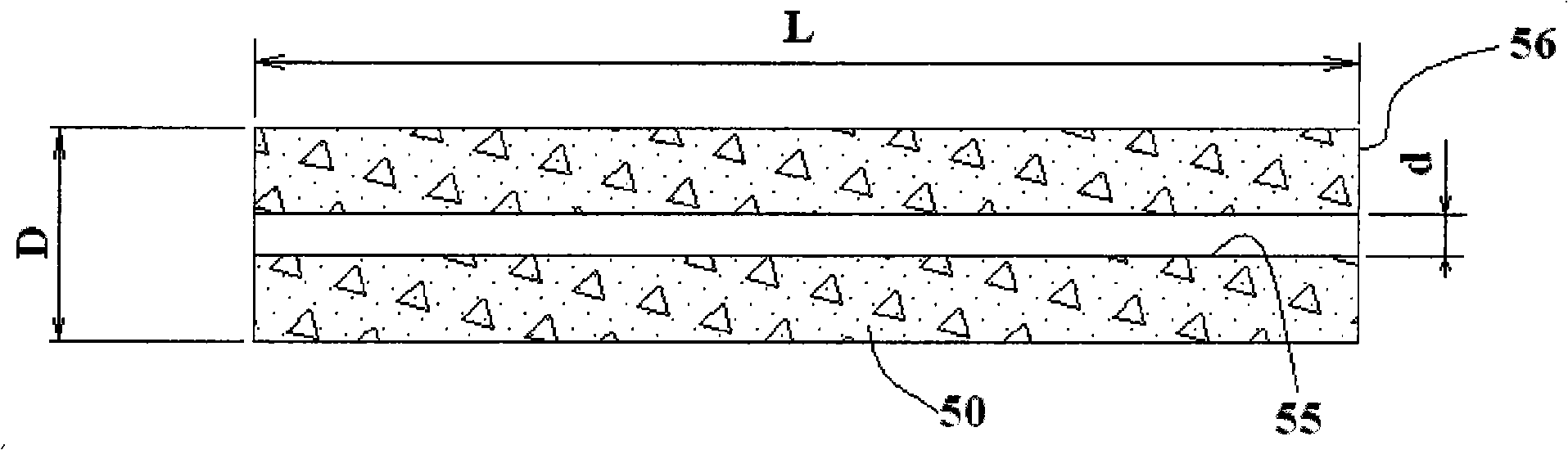

[0017] Among them, the prefabricated parts used include ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross section | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com