Section steel column for high-rise building section steel concrete combination structure, and construction method thereof

A technology for high-rise buildings and composite structures, applied in building construction, processing of building materials, construction, etc., can solve the problem of lack of safe, effective and precise adjustment components and adjustment methods for the positioning of steel columns, the inability to effectively ensure the accuracy of elevation, The problem of low positioning accuracy of the steel column can be solved, so as to achieve the effect of saving turnover materials, saving interface materials, and improving the degree of assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

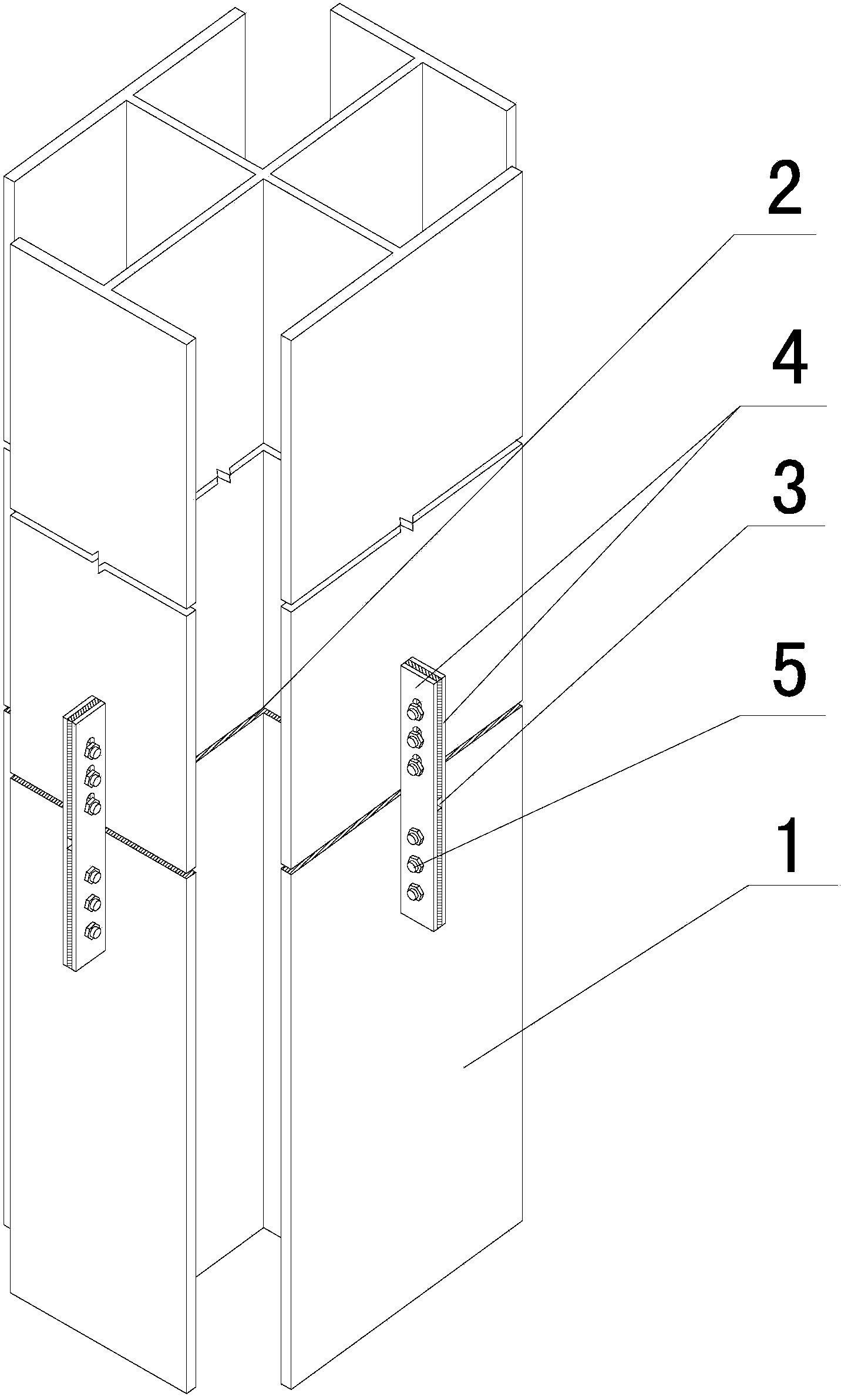

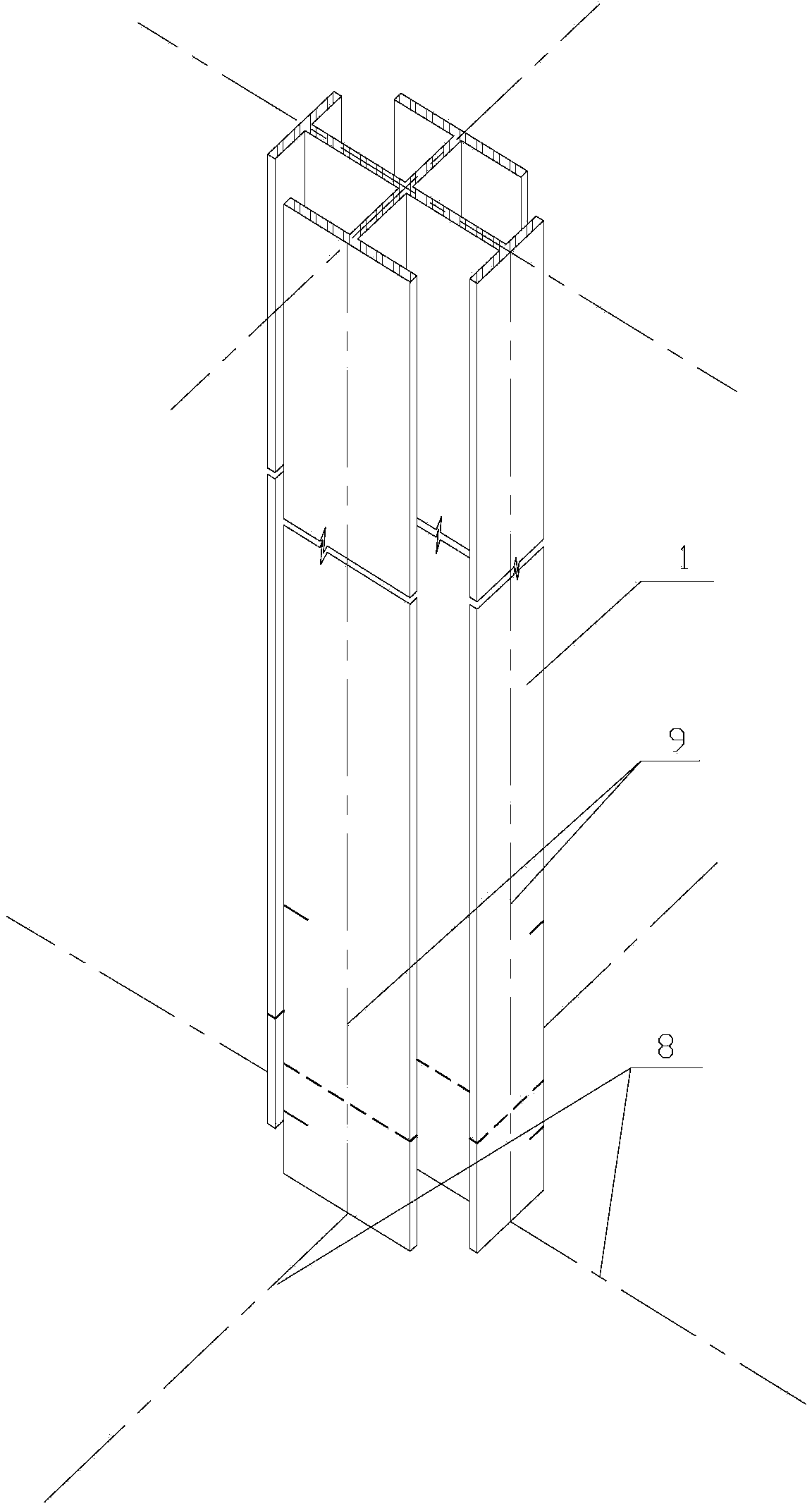

[0045] A kind of section steel column that present embodiment steel-concrete composite structure of high-rise building is used, and its structure is as follows figure 1 As shown, it includes a plurality of column sections 1 sequentially connected from bottom to top, an inner socket 2 is provided at the interface of any two adjacent column sections, and a fastening type is provided on the outer wall of the connection of two adjacent column sections. components.

[0046] Fastening components include steel plate base material 3, fastening steel plate 4 and locking bolts 5; among the two adjacent column sections, each column section is welded and fixed with steel plate base material 3 on the outer side wall of the joint respectively, and the steel plate base material Fastening steel plates 4 are respectively arranged on both sides of the material, and the fastening steel plates 4 are fixedly connected with the steel plate base material 3 through locking bolts 5 .

[0047] There a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com