Aluminum alloy pipe bend forming method

A bending forming, aluminum alloy technology, applied in the field of mechanical processing, can solve problems such as depression, protrusion, distortion, etc., achieve the effect of enhancing strength and hardness, moderate plasticity, improving processing efficiency and pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

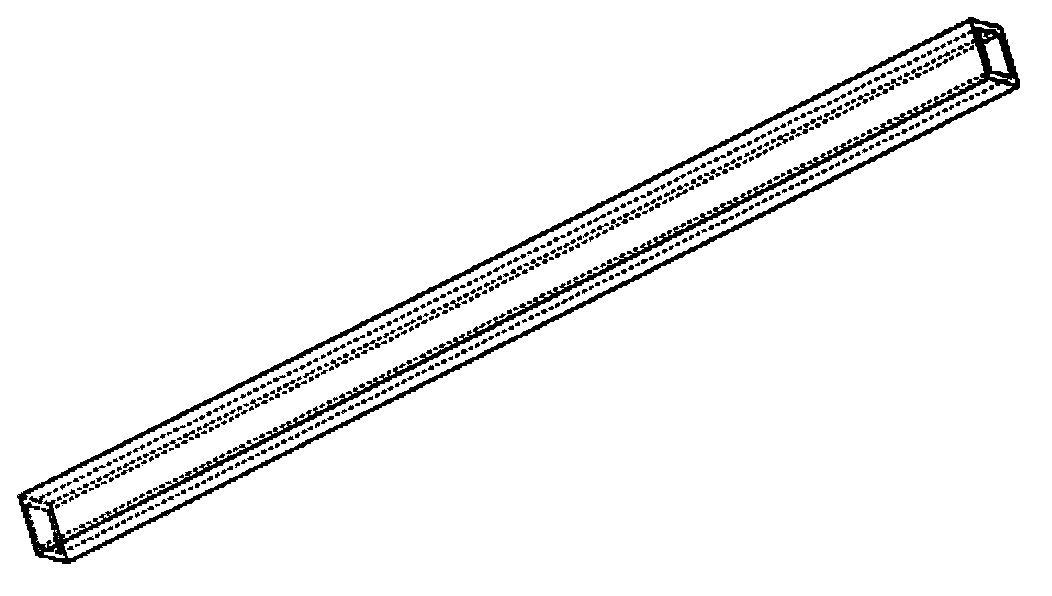

[0019] The material used in bending forming in this embodiment is an aluminum alloy rectangular pipe with a cross-sectional size of 14.1 mm*12.1 mm, a wall thickness of 1.4 mm, and a length of 1.5 m, such as figure 1 shown. The mass percentage of each element in the low melting point alloy is 6% cadmium, 17% lead, 23% tin, 3% zinc, 51% bismuth, and the melting point is 72 degrees. The specific steps of bending forming are as follows:

[0020] 1.1 Preparation of low-melting point alloys, the specific method is as follows: open the resistance furnace for smelting, place the prepared metal raw materials (purity above 99.9%) in the crucible of the resistance furnace, sprinkle diboron trioxide as a covering agent, and put the resistance Adjust the temperature of the furnace to 400°C-500°C. After the metal in the crucible is completely melted, stir the melt for 1-2 minutes, remove the scum on the surface of the melt and sprinkle with boron trioxide covering agent again, let it stan...

Embodiment 2

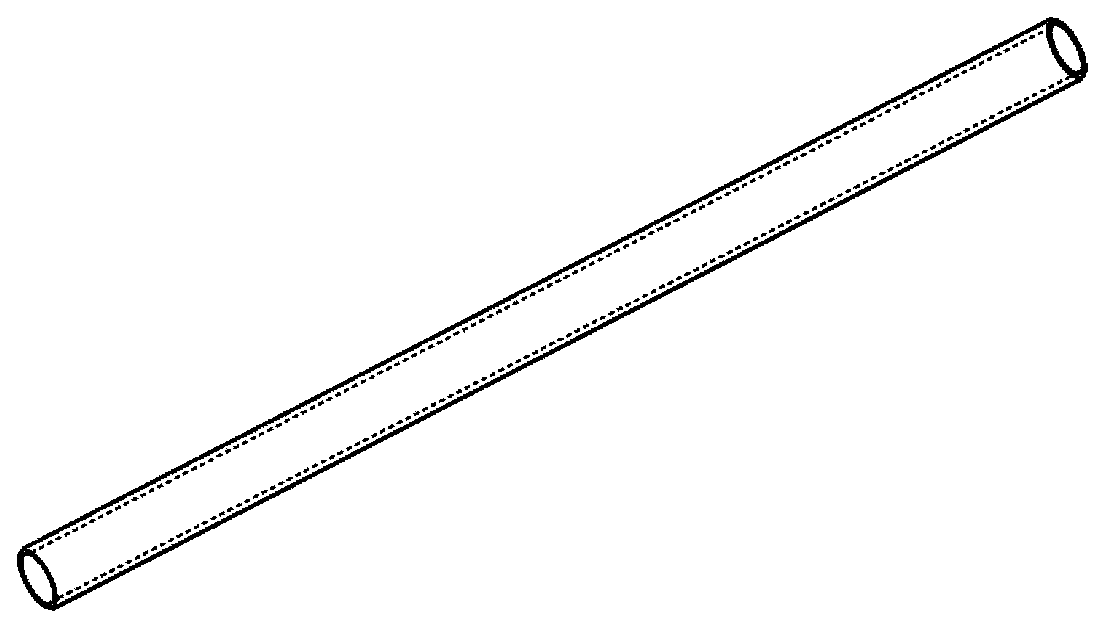

[0024] The material used in bending forming in this embodiment is an aluminum alloy circular pipe with a diameter of 13.6 mm, a wall thickness of 1 mm, and a length of 1.5 m, such as figure 2 shown. The composition of the low melting point alloy is 8% cadmium, 18% lead, 24% tin, 50% bismuth, and the melting point is 70 degrees. The specific steps of bending forming are as follows:

[0025] 2.1 Preparation of low-melting point alloys, the specific method is as follows: open the resistance furnace for smelting, place the prepared metal raw materials (purity above 99.9%) in the crucible of the resistance furnace, sprinkle diboron trioxide as a covering agent, and put the resistance Adjust the temperature of the furnace to 400°C-500°C. After the metal in the crucible is completely melted, stir the melt for 1-2 minutes, remove the scum on the surface of the melt and sprinkle with boron trioxide covering agent again, let it stand for 2-3 minutes and then remove it. The slag is ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com