Blast furnace taphole filled aluminum stemming and preparation method thereof

A blast furnace iron and aluminum technology, which is applied in the field of high-temperature metallurgical refractory materials, can solve problems such as poor high-temperature strength of blast furnace mud, environmental pollution, and poor high-temperature toughness, so as to improve the service life of blast furnaces, protect furnace walls, and suppress circulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

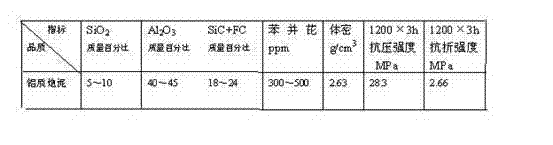

Image

Examples

Embodiment 1

[0017] According to the 2200m of a blast furnace in Baotou 3 Blast furnace parameters, according to the formula standard to prepare aluminum gun clay, which is composed of powder and modified liquid tar, in which the components in the powder are: corundum 40%, silicon carbide 30%, Al 2 o 3 Micropowder 4%, ball clay 8%, plasticizer 2%, graphite 2%, expansion agent aluminum silicate 4%, metal silicon powder 3%, titanium corundum 4%, modified asphalt powder 3%; modified liquid tar The mass percentage is 15%

[0018] Prepare a kind of blast furnace taphole filling aluminum gun clay according to the following steps: be 40% corundum by mass percentage, 30% silicon carbide, 4% micropowder, 8% ball clay, 2% plasticizer, 2% of graphite, 4% of expansion agent aluminum silicate, 3% of metal silicon powder, 4% of titanium corundum, 3% of modified asphalt powder, the fine powder is premixed for later use, and the critical particle size of the above fine powder is 3mm , the bone meal rat...

Embodiment 2

[0020] According to the 1780m of a steel factory in Jiangxi 3 Blast furnace parameters, according to the formula standard, the aluminum gun clay is prepared, which is composed of powder and modified liquid tar. The components in the powder are: corundum 45%, silicon carbide 18%, Al 2 o 3 Micro powder 3%, ball clay 10%, plasticizer 3%, graphite 4%, expansion agent aluminum silicate 5%, metal silicon powder 5%, titanium corundum 3%, modified asphalt powder 4%; modified liquid tar The mass percentage is 18%.

[0021] Prepare a kind of blast furnace taphole filling aluminum matter gun mud according to the following steps: be 45% corundum by mass percentage, 18% silicon carbide, 3% Si. 2 Micropowder, 10% ball clay, 3% plasticizer, 4% graphite, 5% expansion agent aluminum silicate, 5% metal silicon powder, 3% titanium corundum, 4% modified asphalt powder, The fine powder is pre-mixed for later use. The critical particle size of the above-mentioned fine powder is 3mm, and the bone...

Embodiment 3

[0023] According to a blast furnace in Anshan 3200m 3 Blast furnace parameters, according to the formula standard, the aluminum gun clay is prepared, which is composed of powder and modified liquid tar. The components in the powder are: corundum 50%, silicon carbide 12%, Al 2 o 3 Micropowder 5%, ball clay 12%, plasticizer 1%, graphite 3%, expansion agent aluminum silicate 3%, metal aluminum powder 4%, titanium corundum 5%, modified asphalt powder 5%; modified liquid tar The mass percentage is 20%

[0024] According to the following steps, a kind of blast furnace tap hole is prepared to fill aluminum gun clay: the corundum that the mass percentage is 50%, the silicon carbide of 12%, the Al of 5% 2 o 3 Micropowder, 12% ball clay, 1% plasticizer, 3% graphite, 3% expansion agent aluminum silicate, 4% metal silicon powder, 5% titanium corundum, 5% modified asphalt powder, The fine powder is pre-mixed for later use. The critical particle size of the above-mentioned fine powder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com