Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

259 results about "Ball clay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ball clays are kaolinitic sedimentary clays that commonly consist of 20–80% kaolinite, 10–25% mica, 6–65% quartz. Localized seams in the same deposit have variations in composition, including the quantity of the major minerals, accessory minerals and carbonaceous materials such as lignite. They are fine-grained and plastic in nature, and, unlike most earthenware clays, produce a fine quality white-coloured pottery body when fired, which is the key to their popularity with potters.

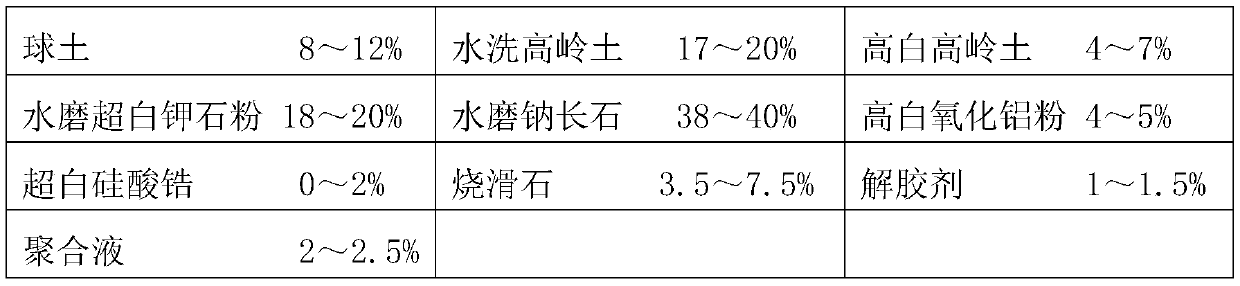

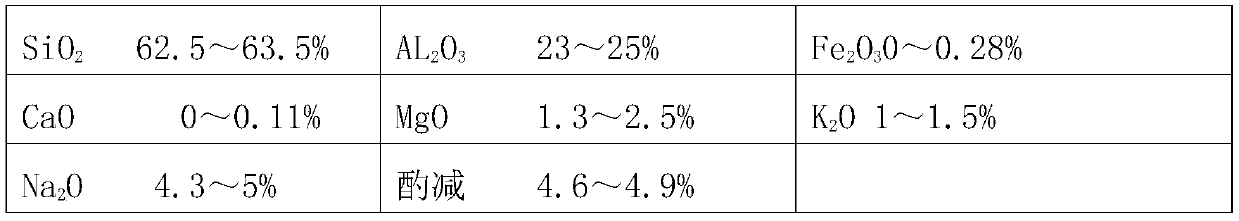

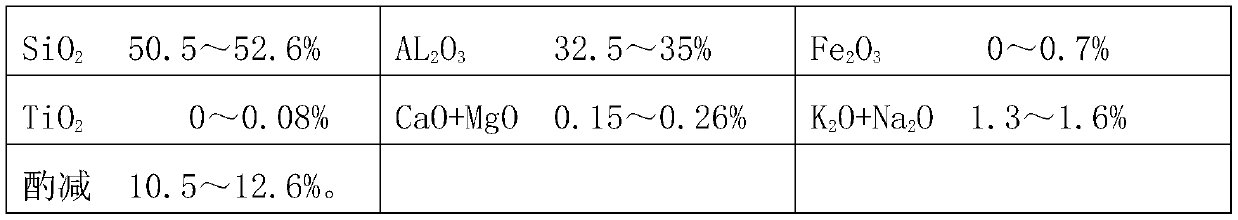

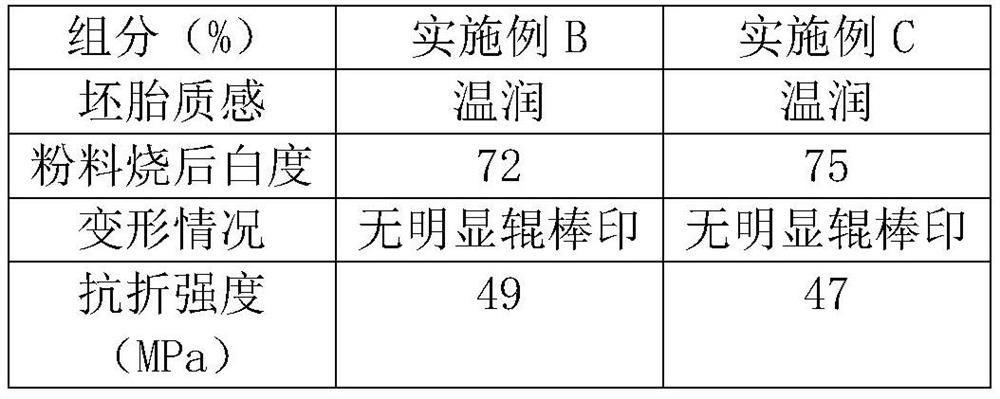

Thin ceramic rock plate and preparation method thereof

The invention relates to a preparation method of a thin ceramic rock plate. A thin ceramic rock plate blank is composed of the following components in percentage by weight: 8-12% of ball clay; 17-20%of washed kaolin; 4-7% of high-whiteness kaolin; 18-20% of water-milled ultra-white potash stone powder; 38 to 40% of water milled albite; 4-5% of high-whiteness aluminum oxide powder; 0-2% of ultra-white zirconium silicate; 3.5%-7.5% of calcined talc; 1 to 1.5% of a dispergator; and 2-2.5% of a polymerization liquid. The preparation method of the thin ceramic rock plate comprises the following steps: preparing a green body, processing a blank, spray-drying to prepare powder, dry-pressing to form, brushing the green body to remove ash, printing ground coat on a roller, decorating patterns, decorating a pattern protective layer, firing, polishing and edging.

Owner:JIANGXI HEMEI CERAMICS +3

Fine-pottery sanitary ceramic body and manufacturing method thereof

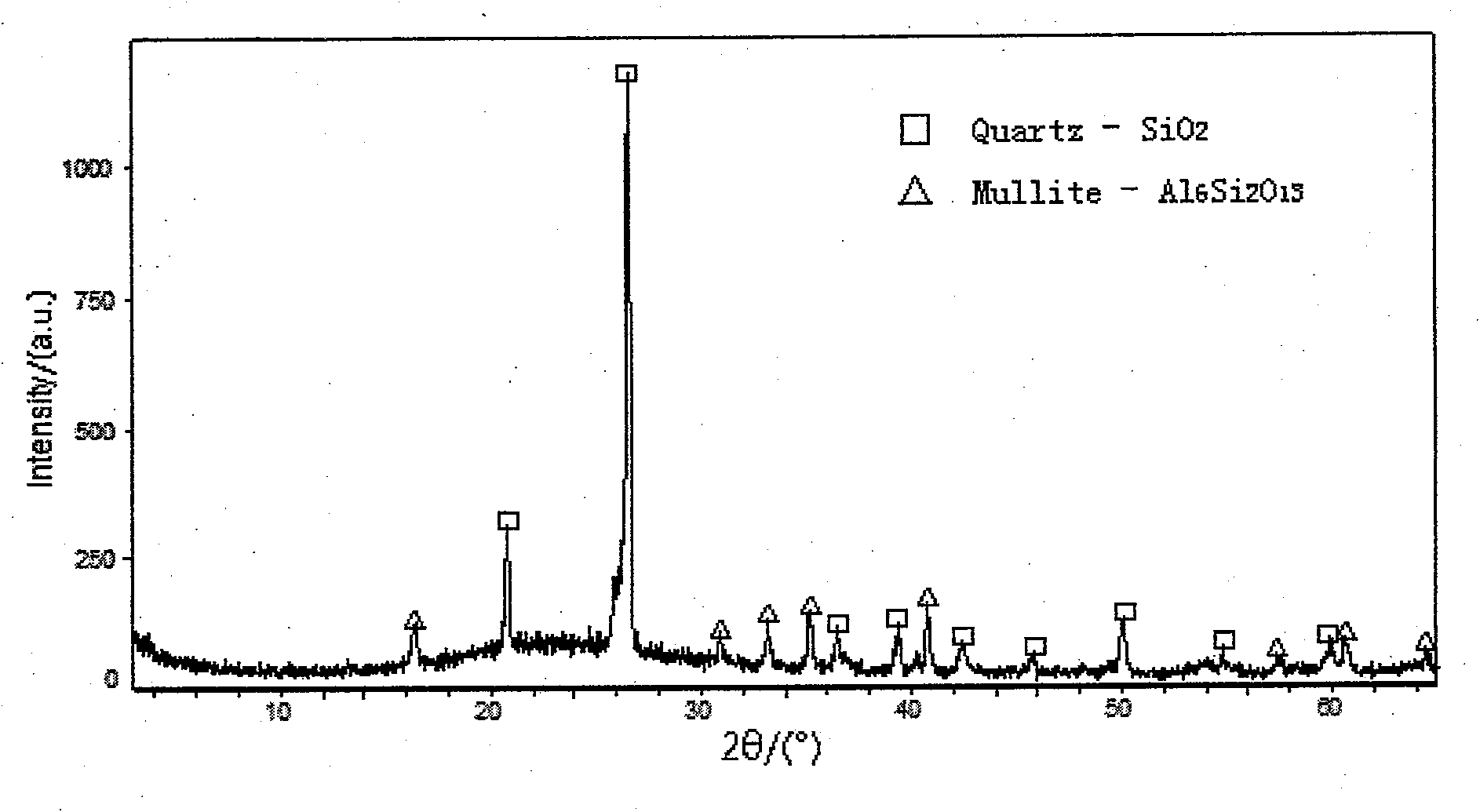

ActiveCN101811858AReduce hygroscopic swellingHigh coefficient of thermal expansionClaywaresGranularityMullite

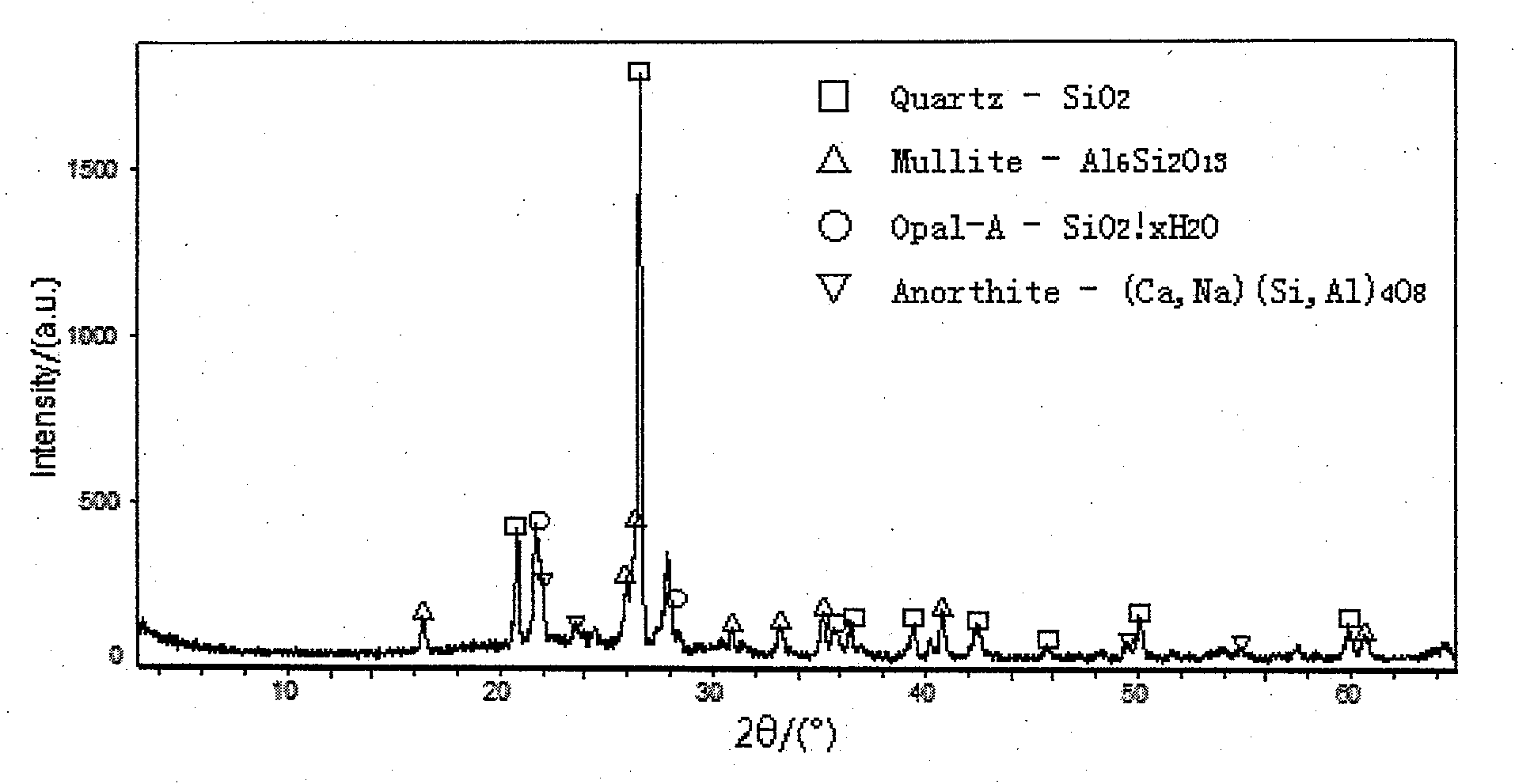

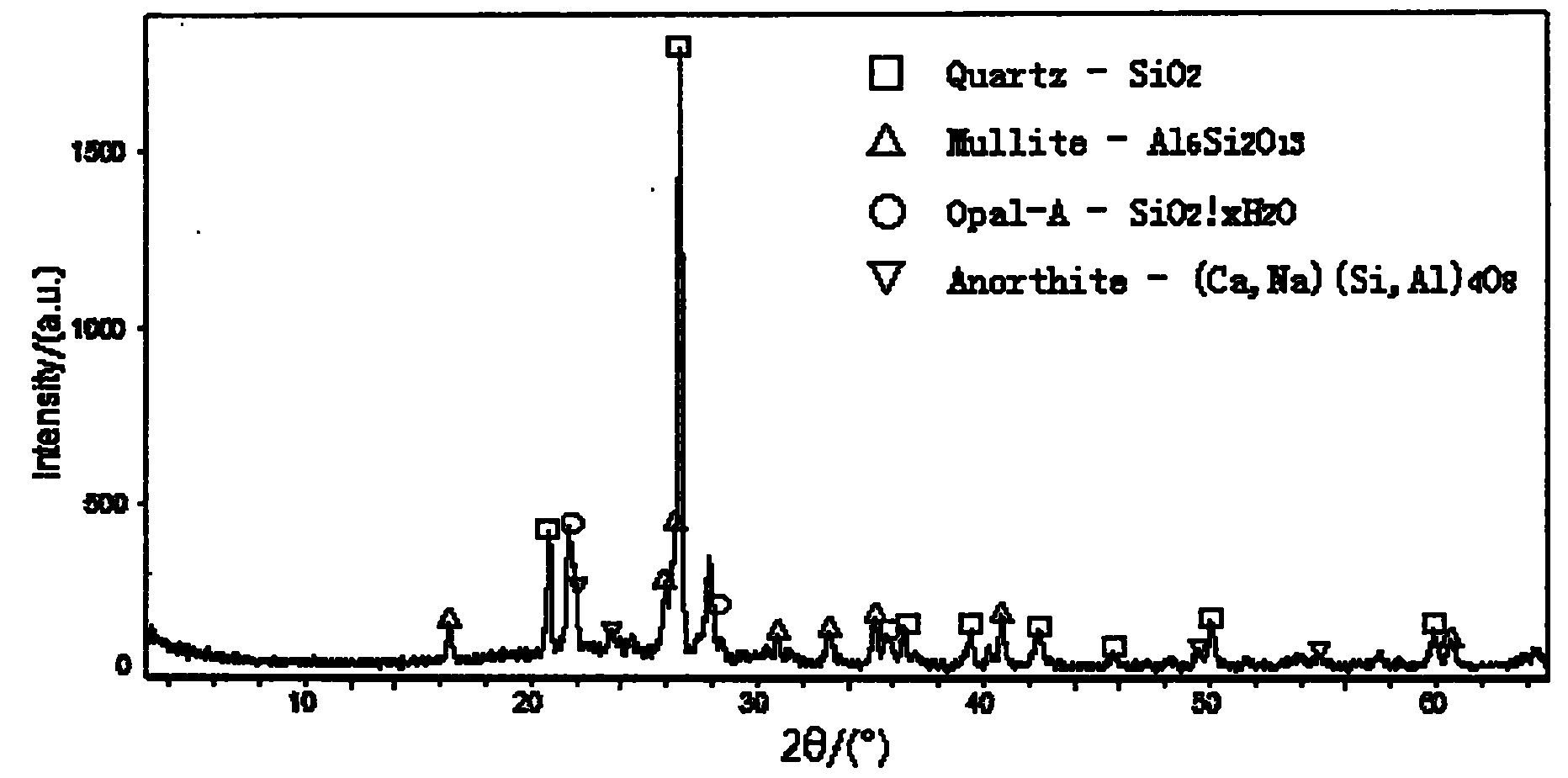

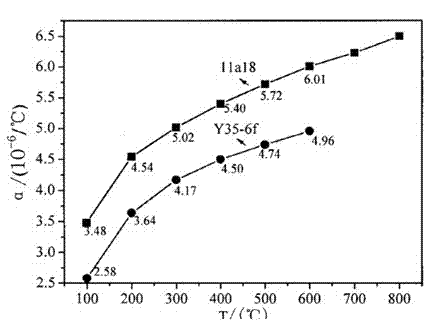

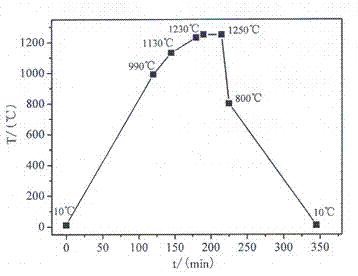

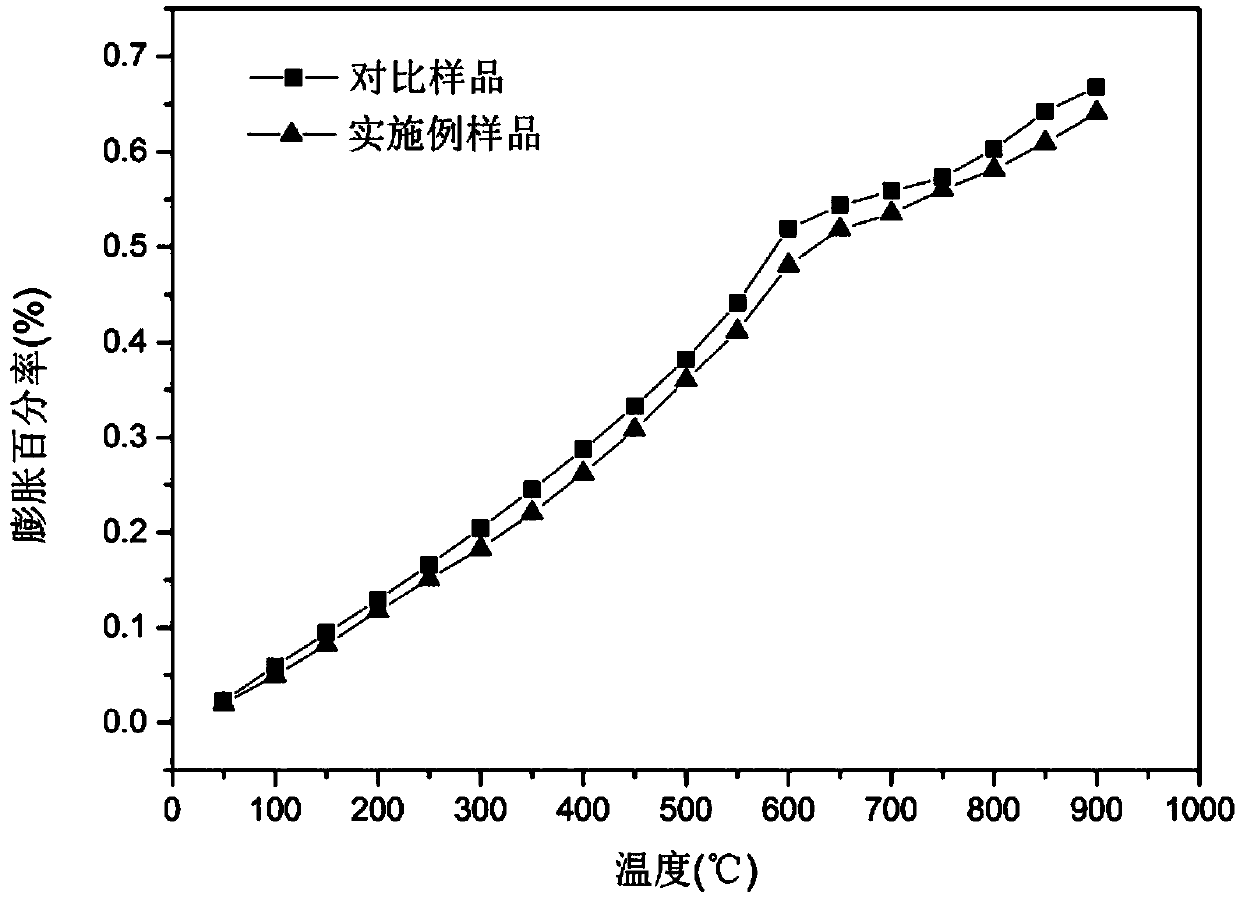

The invention relates to a fine-pottery sanitary ceramic body and a manufacturing method thereof and belongs to the technical field of ceramic products, which is used for reducing the deformation of a sanitary ceramic product and improving the quality of glaze. The fine-pottery sanitary ceramic body is characterized in that a body raw material comprises the following components in part by mass: 10 to 30 parts of ball clay, 30 to 60 parts of kaoline, 5 to 15 parts of porcelain clay, 5 to 15 parts of quartz and 5 to 15 parts of wollastonite, wherein the kaoline comprises 10 to 25 calcined kaoline. In the manufacturing method, the raw materials and the adding proportion of the fine-pottery body are preferably selected, the crystal phase content of mullite, quartz and the like is controlled, and the glass phase content and the high-temperature plastic deformation are reduced so as to fulfill the aim of reducing the deformation of fine-pottery sanitary ceramics; while reducing the hygroscopic expansion of the body, the manufacturing method improve thermal expansion coefficient of the body at the temperature of 200 DEG C to make the glaze bear high compressive stress, thereby improving the anti-cracking performance of products and ensuring enough long service life. Through the refinement of slurry granularity, the method remarkably reduces the occurrence of disadvantage of glaze pinholes, does not need to reduce the pinholes by using engobe, simplifies a production process, and improves the production efficiency and the qualification rate of the products.

Owner:HUIDA SANITARY WARE

Magnesian ceramic blank, magnesian ceramic and preparation method thereof

ActiveCN102786298ASmall coefficient of thermal expansionImprove thermal stabilitySodium BentoniteBall clay

The invention provides novel magnesian ceramic blank. The novel magnesian ceramic blank comprises, by weight percent, 60-70% of talcum, 20-25% of clay, 5-10% of feldspar, and 5-10% of alumina. The talcum is mixture of raw talcum and burnt talcum. The clay is mixture of kaolin, ball clay and bentonite. The invention further provides a preparation method of magnesian ceramic, and the magnesian ceramic prepared by the preparation method. The magnesian ceramic prepared by the magnesian ceramic blank, glaze and the preparation method is low in thermal expansion coefficient, and has improved thermal stability and formability. In addition, sintering range is wide, sintering temperature is low, and the risk of ceramic burst is lowered greatly.

Owner:HUNAN XIANFENG CERAMIC IND

Multiphase nitride combined silicon carbide ceramic foam filter and preparation method thereof

The invention relates to a multiphase nitride combined silicon carbide ceramic foam filter and a preparation method thereof, and belongs to the technical field of refractory materials. The preparation method is realized in a way as follows: preparing slurry from silicon, silicon carbide, silicon dioxide, ball clay, admixtures and water; soaking the slurry by using soft polyurethane foam as the carrier to prepare a blank; and drying, and sintering at 1400-1500 DEG C in the nitrogen atmosphere to obtain the multiphase nitride combined silicon carbide ceramic foam filter. The ceramic foam filter of the invention has favorable high temperature stability in ferric and copper solutions, does not pollute alloys, has the open-cell rate of 80-90%, has favorable filtration and adsorption capacities on oxide inclusions and flux inclusions, and has the advantages of high filter capacity, favorable filtration and purifying effect, small hot melt and high thermal shock stability; the compression strength at normal temperature is not lower than 2.3 MPa; the ceramic foam filter can be cooled by water at 1100-20 DEG C for more than 23 times, and does not need preheating in use; and the highest service temperature is 1550 DEG C.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Ceramic tile capable of generating negative ions and effectively improving indoor air quality, and production method thereof

The invention provides a ceramic tile having air purifying and harmful gas removing effects, extremely beneficial for the health of human bodies, and capable of generating negative ions and effectively improving the indoor air quality, and a production method thereof. The ceramic tile capable of generating negative ions and effectively improving the indoor air quality comprises potash feldspar powder, albite powder, ball clay, zeolite, diatom ooze, medical stone, tourmalinite and germanite. According to the invention, natural mineral raw materials having an adsorption effect and releasing negative ions are added in the technological formula of the ceramic tile, so the ceramic tile can generate negative ions, has the air purifying and harmful gas removing effects, and is extremely beneficial for the health of the human bodies.

Owner:李心红

Thin porcelain brick and production method thereof

The invention relates to a thin porcelain brick and a production method thereof, wherein the production method comprises the following steps: 1. mixing blank raw materials comprising 4.5 to 5 percent of ball clay, 5 to 6 percent of black mud, 6 to 8 percent of Yichun kaolin, 6 to 10 percent of Beihai kaolin, 6 to 13 percent of Dehua pyrophyllite, 4 to 10 percent of Paishan pyrophyllite, 12 to 16 percent of sodium-potassium feldspar powder, 12 to 15 percent of weathered potassium feldspar, 8 to 15 percent of superfine pottery stone, 8 to 16 percent of sodium-potassium feldspar, 5.5 to 6 percent of Zhuji porcelain sand and 0.8 to 1.3 percent of lignin and lignin derivative; 2. adding water accounting for 50 to 60 percent of the weight of a powder material, 0 to 0.1 percent of polymethyl cellulose sodium (CMC) and 0.1 to 1 percent of sodium tripolyphosphate (STPP), putting into a ball mill, and controlling the ball milling fineness to have 0.5 to 1 percent of sieve residue through a 325-mesh sieve; 3. preparing the powder material containing 5 to 7 percent of water through iron removal, sieving and spray drying of the obtained mud; 4. ageing the powder material for 24 hours, then molding through pressing, and drying at the temperature of 150 to 200 DEG C to enable the water content of a blank to be below 0.3 percent; and 5. placing into a kiln for sintering, wherein the early period time of sintering is 6 to 15 minutes, the high temperature time is 15 to 30 minutes ,and the cooling time is 5 to 10 minutes. In the invention, the thin porcelain brick can be produced under the condition of traditional process equipment, and each item of performance index reaches or exceeds a porcelain brick standard GB / T4100-2006.

Owner:DEQING NABEL CERAMIC

Super-white polished brick

This invention relates to a ultrawhite polishing brick. According to weight shares the raw materials includes: calcined alumina 5 to 10 shares, burning talcum 10 to 40, ultrawhite ball clay 18 to 25, water washing kaolin 5 to 12, low temperature feldspar 13 to 25, middle and high temperature porcelain sand 10 to 18 shares. The process includes: ball milling, spraying and corning, shaping by quenching, adobe drying and kiln burning. This invention has high whiteness, good thermostability, and avoid zirconium silicate radioactive problem.

Owner:霍镰泉

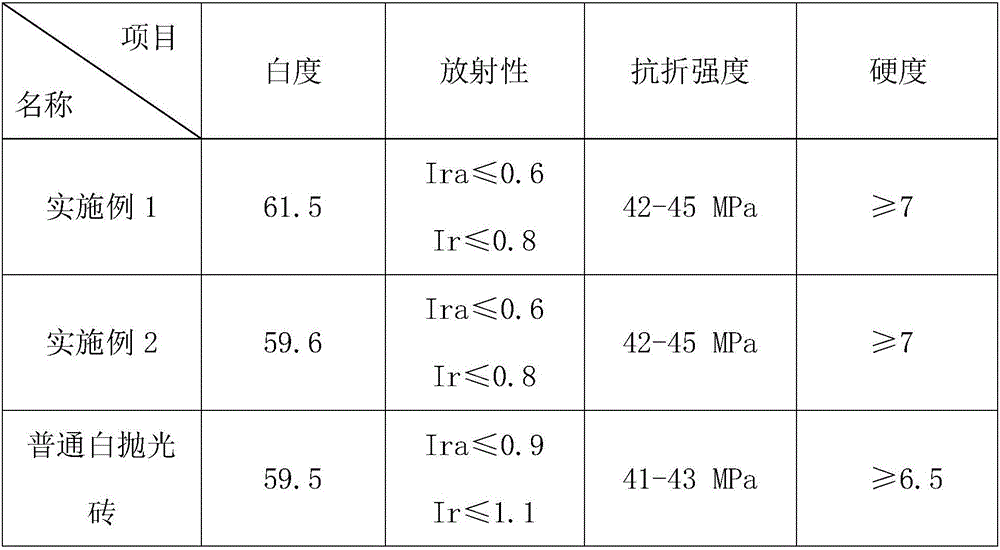

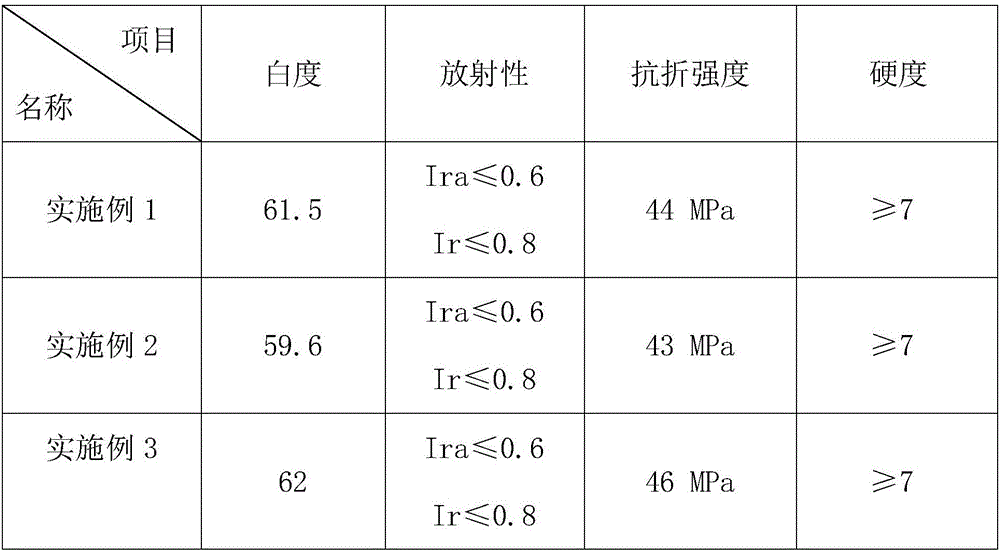

Pure white polished tile and production method thereof

The invention discloses a pure white polished tile and a production method thereof. The chemical components of raw material components of the tile comprise, by mass, 65-74% of SiO2, 16-21% of Al2O3, 5-8% of alkali metal oxide and / or alkali earth oxide, 0.25% or less of Fe2O3 and 0.1% or less of TiO2, and has an ignition loss of 3-5%. In the invention, desiliconized aluminum powder is fully used to substitute previous zirconium silicate and other zirconium-containing materials, and the polished brick is directly whitened by the selected raw material without adding the zirconium-containing materials, so the whiteness of the polished tile is greatly improved through the desiliconized aluminum powder, whiteness technology requirements are met, and the radioactivity standard exceeding problem of present polished tiles is solved; and high-viscosity bentonite is introduced to substitute parts of ball clay / clay (called mud for short) to increase the whiteness, and the whiteness of the produced polished tile is 60-62 DEG and is suitable for market demands in the ceramic industry. The production method has the advantages of simplicity in operation, easily available raw materials, low cost, strong technology controllability, and realization of production of the 60 DEG pure white polished tile.

Owner:FOSHAN SHIWAN HOPO CERAMICS CO LTD

Large-size porcelain thin plate and production method thereof

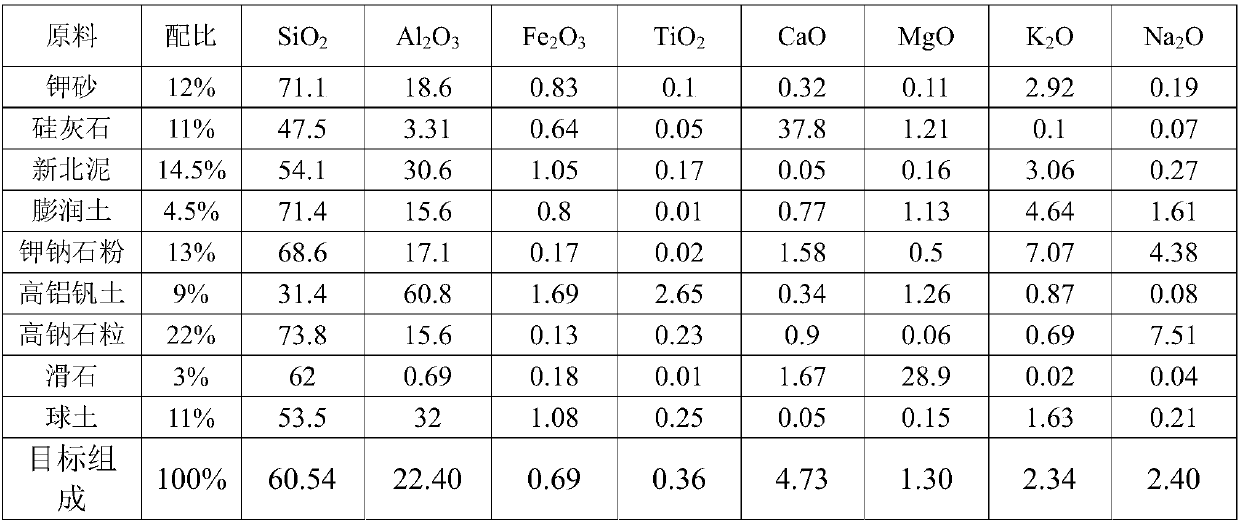

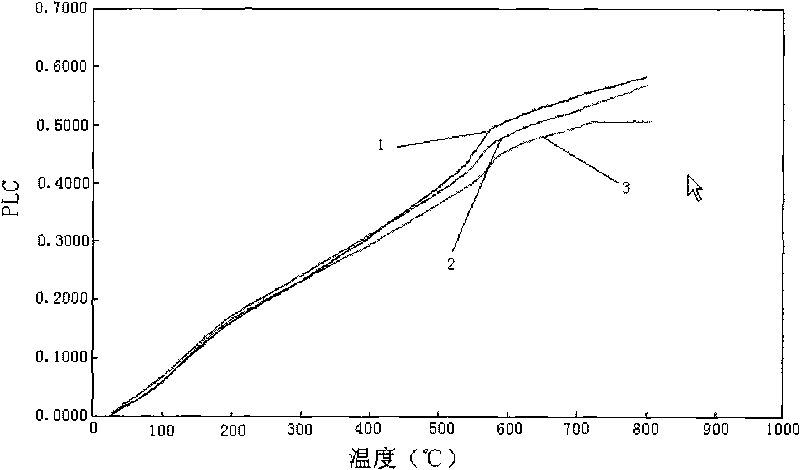

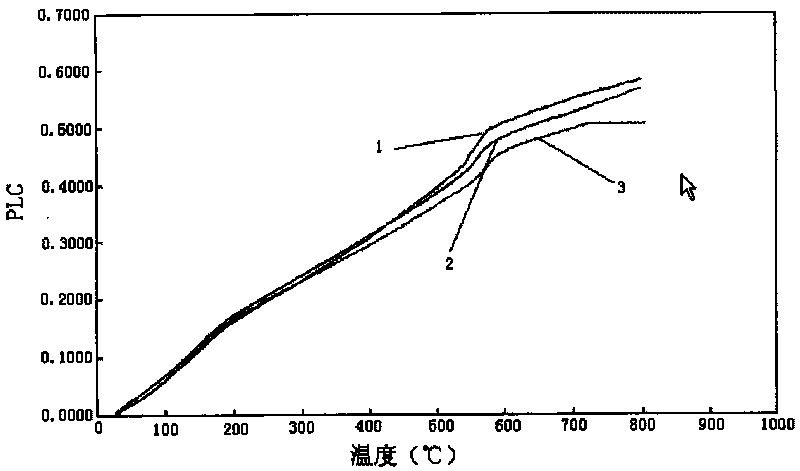

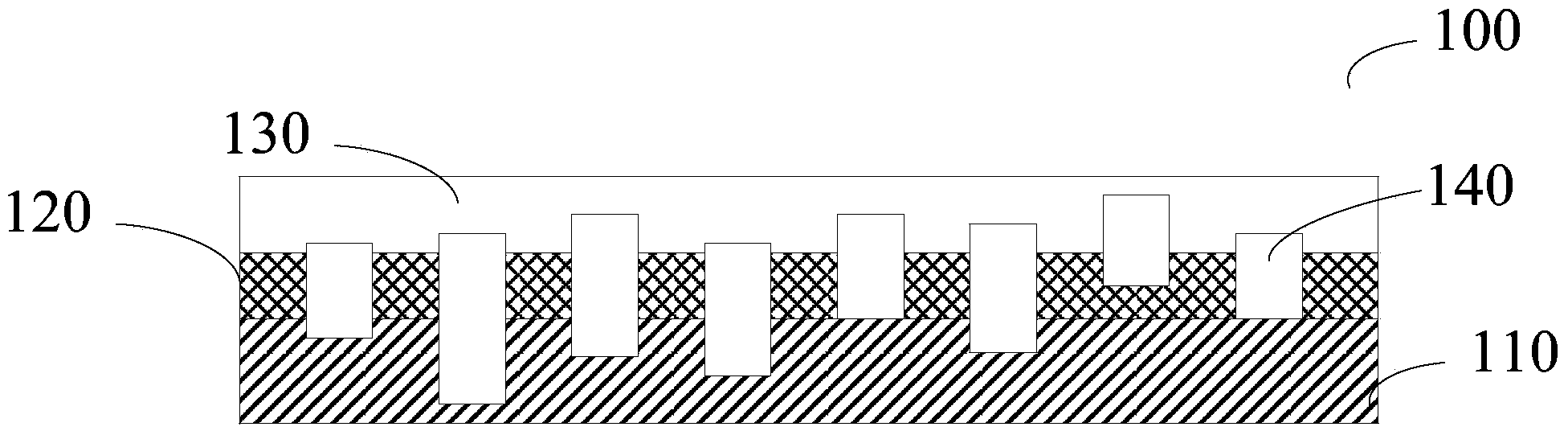

The invention discloses a large-size porcelain thin plate and a production method thereof, wherein the large-size porcelain thin plate has an upper surface area of 1.62-2.88 m<2> and a thickness of 3.5-5.5 mm, and comprises the following raw materials by weight: 10-12% of potassium sand, 10-11% of wollastonite, 14.5-17.5% of Xinbei mud, 4-4.5% of bentonite, 12-13% of potassium sodium stone powder,7-9% of high bauxite, 21-22% of high sodium stone particles, 3-4% of talc, and 11-13% of ball clay. According to the present invention, by reducing the SiO2 content, the residual stress caused by thevolume change due to the quartz crystal form transformation during the firing cooling stage is reduced, and the content of the SiO2 glass phase is reduced, such that the product structure stability is good, the residual stress is low, no corner-chipping is generated during the machining, and the processing performance is significantly improved.

Owner:佛山市高明贝斯特陶瓷有限公司 +3

Blank body of fine porcelain ceramic, preparation method and application thereof

The invention relates to a blank body of fine porcelain ceramic, a preparation method and an application thereof. The raw materials of the blank body comprise the following components in the percentage by weight: 30-50% of calcined kaolin with high aluminum, low contraction and low thermal expansion, 10-20% of porcelain waste powder, 10-20% of quartz sand and 20-40% of ball clay. The invention also further discloses fine porcelain ceramic and a preparation method thereof. The fine porcelain ceramic can be used for casting a product with the size greater than 1,000 mm, and the product is flat, straight and regular and is not easy to deform.

Owner:LIXIL AS SANITARY MFG (SHANGHAI) CO LTD

Method for preparing travertine ceramic tile with three-dimensional holes formed in part of travertine ceramic tile

The embodiment of the invention provides a method for preparing a travertine ceramic tile with three-dimensional holes formed in part of the travertine ceramic tile. The method includes the steps of preparing a hole forming material, preparing a surface material, preparing a backing material, preparing a glaze material, distributing the material, performing drying, applying the glaze and performing firing forming. The prepared hole forming material comprises, by mass, 5% to 10 % of ball clay, 10% to 20% of low-temperature frit powder, 10% to 20% of graphite powder, 10% to 15% of sodium carbonate, 20 percent to 30 percent of calcium carbonate powder and 5% to 10% of polishing waste residue. Powder material is formed through polishing, spraying and drying. When the surface material is prepared, the hole forming material is added into a conventional surface material according to the ratio of 15% to 25% as foaming material. According to the method for preparing the travertine ceramic tile with three-dimensional holes formed in part of the travertine ceramic tile, the prepared artificial travertine ceramic tile solves the problems that holes of an existing artificial holeless travertine ceramic tile are too flat, rigid and unnatural, and the abrasion resistance, the dryness and humidity, the coldness and heat of the whole surface of the ceramic tile are not uniform, and the service life of the holeless travertine ceramic tile is greatly prolonged; because the surface of the ceramic tile is provided with certain holes or gullies, the water absorbing and anti-skid performance can be achieved, the ceramic tile can have a very good anti-skid effect in the plum rain season, and the ceramic tile has very good application prospects in wide areas of the south.

Owner:FOSHAN DONGPENG CERAMIC +2

Ceramic tile with antifouling glaze

The invention discloses a ceramic tile with antifouling glaze. The surface of the ceramic tile is spray-coated with surface glaze. The surface glaze is prepared from 30 to 45 portions by weight of albite powder, 3 to 8 portions by weight of quartz powder, 2 to 6 portions by weight of calcite, 5 to 10 portions by weight of talc powder, 10 to 16 portions by weight of calcined kaolin, 3 to 7 portions by weight of a solvent, 6 to 10 portions by weight of zirconium white frit, 5 to 9 portions by weight of washing ball clay, 3 to 8 portions by weight of a hyperdispersant, 8 to 16 portions by weight of alumina powder, 14 to 20 portions by weight of zirconium silicate, 2 to 7 portions by weight of praseodymium yellow, 1 to 3 portions by weight of zirconium iron pink, 0.1 to 0.6 portions by weight of methylcellulose and 0.3 to 0.6 portions by weight of sodium tripolyphosphate. The preparation method of the surface glaze comprises adding raw materials into a ball mill according to the above ratio, adding 0.3 to 0.5 times water into the raw materials on the basis of the mass of the raw materials and carrying out ball milling until glaze slurry fineness of 250-500 meshes. The glaze can effectively prevent the quality problem caused by the color difference.

Owner:佛山市石湾裕龙陶瓷有限公司

Natural stone imitation ceramic tile and preparation method thereof

The invention relates to a ceramic tile of artificially natural stone. The weight percentages of main materials are as follows: 10-15 percent of low-temperature porcelain stone powder, 10-20 percent of medium-temperature porcelain sand soil, 9-18 percent of high-temperature porcelain sand, 10-15 percent of washed black mud, 10-15 percent of sodium stone powder, 5-10 percent of high-alumina porcelain sand, 10-20 percent of sodium porcelain sand, 5-18 percent of ball clay, 0.5-1 percent of decondensation agent and 0.5-1.5 percent of pigment; the preparation method includes the following: proportioning, ball milling, slurry color washing, spraying and drying, material mixing of each pigment by proportion, one-time prilling, suppressing with a compressor, adobe drying, curlicue seeping, sintering and polishing; the preparation method also includes the following steps: (1) second enwrapped prilling is carried out with an enwrapping granulator after the one-time prilling; (2) second lamellar prilling is carried out with a lamellar granulator after the second enwrapped prilling. The ceramic tile of artificially natural stone adopts a secondary granulation process to cause density of green body to be improved by 60 percent; the ceramic tile of artificially natural stone is well antifouling and anti-aging and is easy to be cleaned and maintained, as well as corrosion resistant.

Owner:广东能强陶瓷有限公司

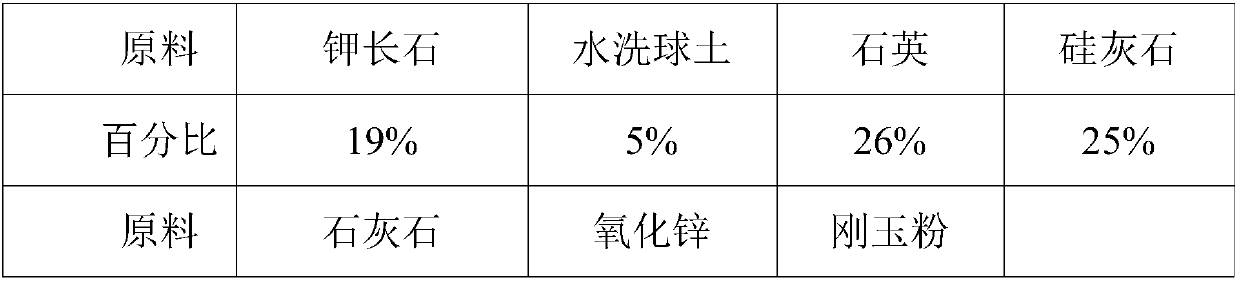

Novel printing glaze material and production method thereof

The invention provides a novel printing glaze material and a production method thereof. The novel printing glaze material consistent with standards is produced by putting the following components into a ball mill for grinding, wherein the components are as follows in percentage by weight: 32% to 42% of albite, 8% to 12% of nepheline orthoclase, 3% to 5% of wollastonite, 3% to 5% of kaolin, 1.5% to 2.5% of ball clay, 3% to 5% of quartz, 3% to 5% of aluminium oxide, 5% to 8% of corundum, 7% to 9% of calcium carbonate, 4% to 7% of zinc oxide, 1% to 2% of talc, 3% to 5% of dolomite, 1% to 2% of barium carbonate, 4% to 8% of clinker, and 6% to 15% of zirconium silicate. The produced novel printing glaze material has the advantages that color development of the ink is better, a problem of color system variation does not exist, the definition of ink figures and the flatness of glaze surfaces can be guaranteed, and a defect of printing ink gloss variation is overcome through controlling a molten softening point.

Owner:CARLOBBIA GLAZE KUNSHAN

Ball clay as raw materials of superwhite polished tile and method for making same

The invention provides a ball clay as raw materials of superwhite polished tile and method for preparation, wherein the ball clay is made from porcelain clay, secondary clay, water, thinning agent and flocculating agent. The preparation comprises which comprises the steps of grout melting, removing sand, sieving, flocculating and filter-pressing..

Owner:XINHUI GILFAIR CERAMIC MINERAL

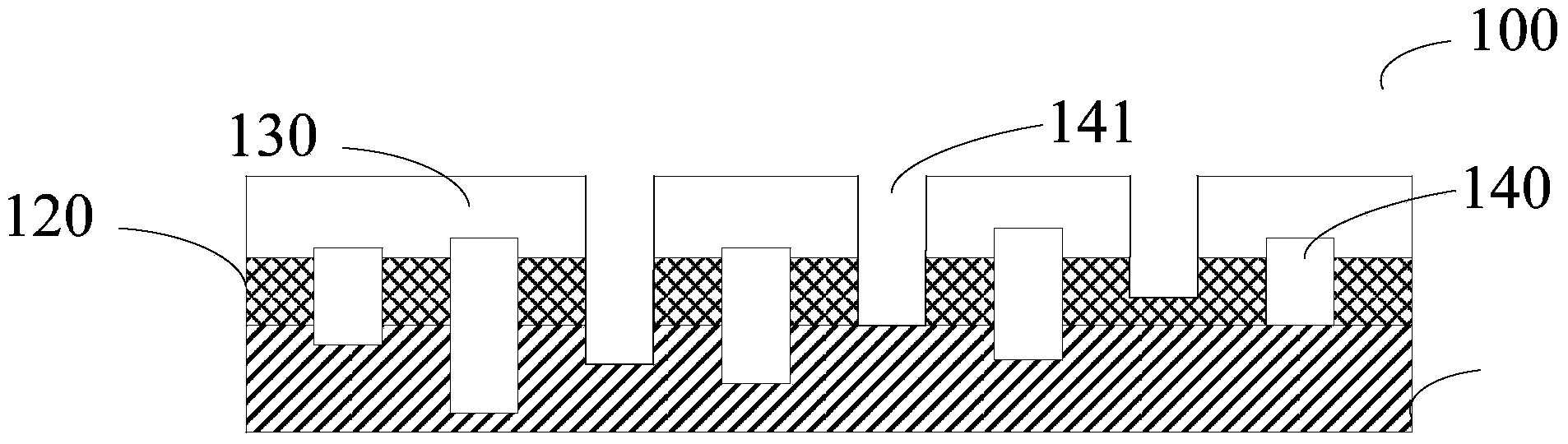

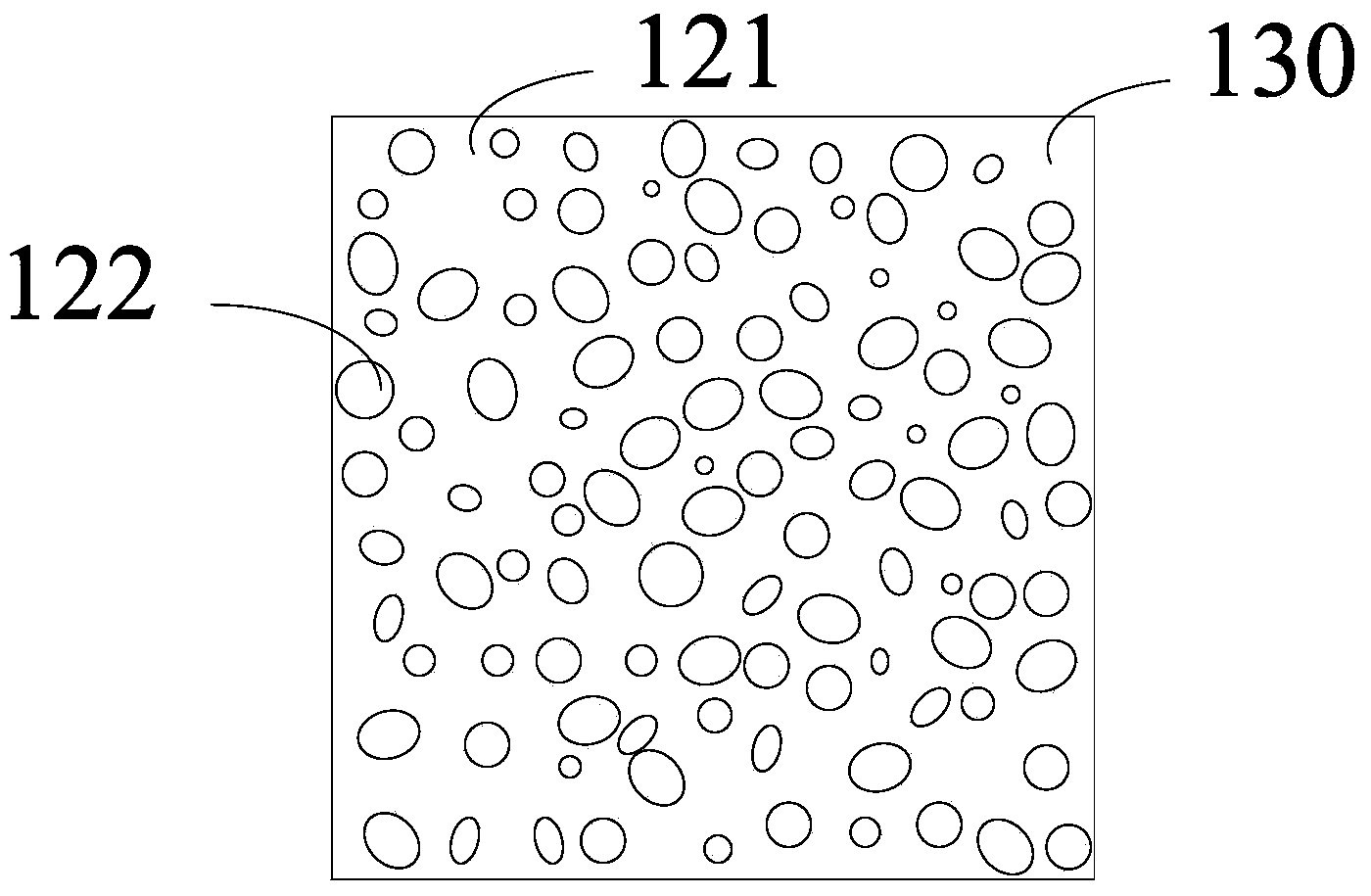

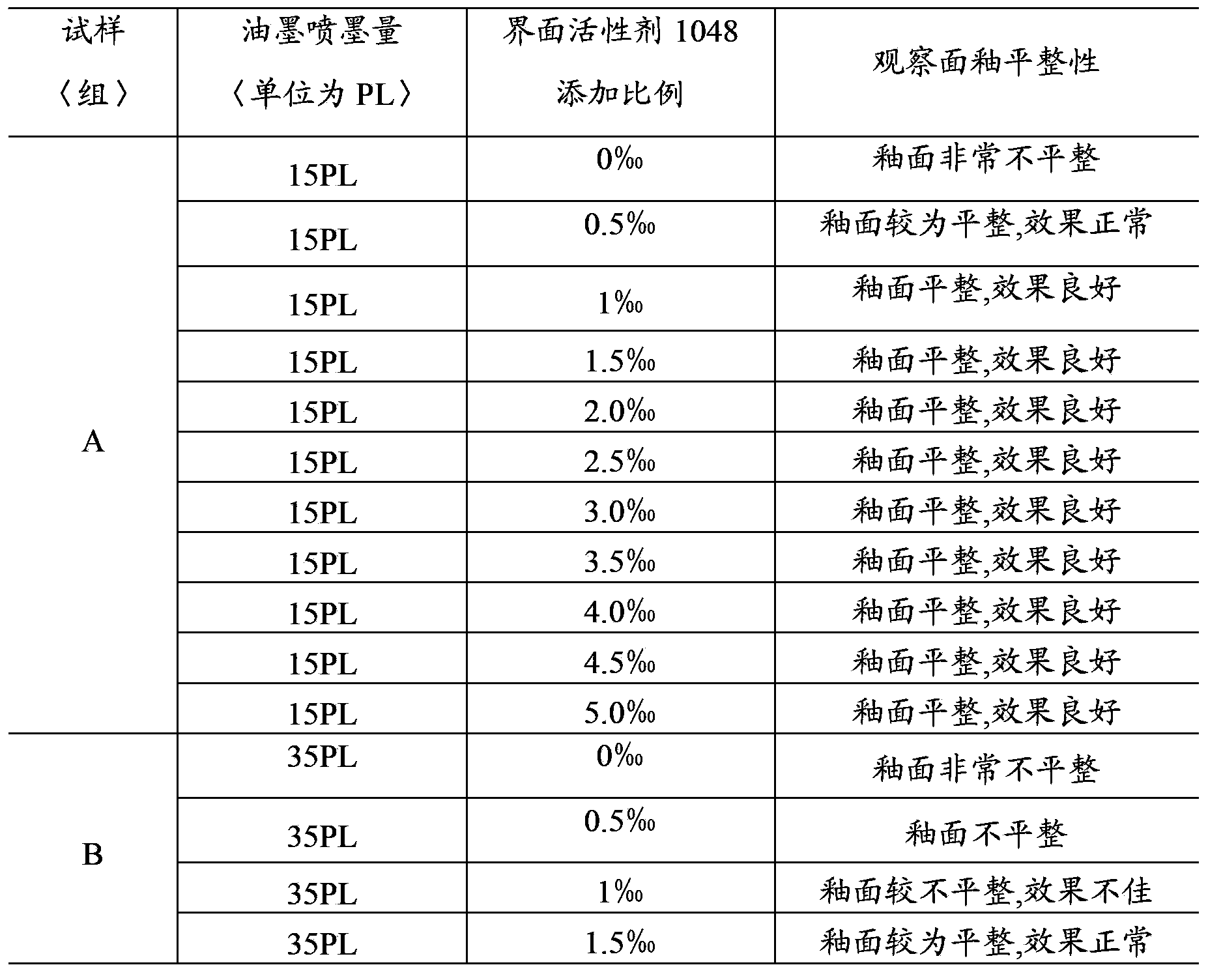

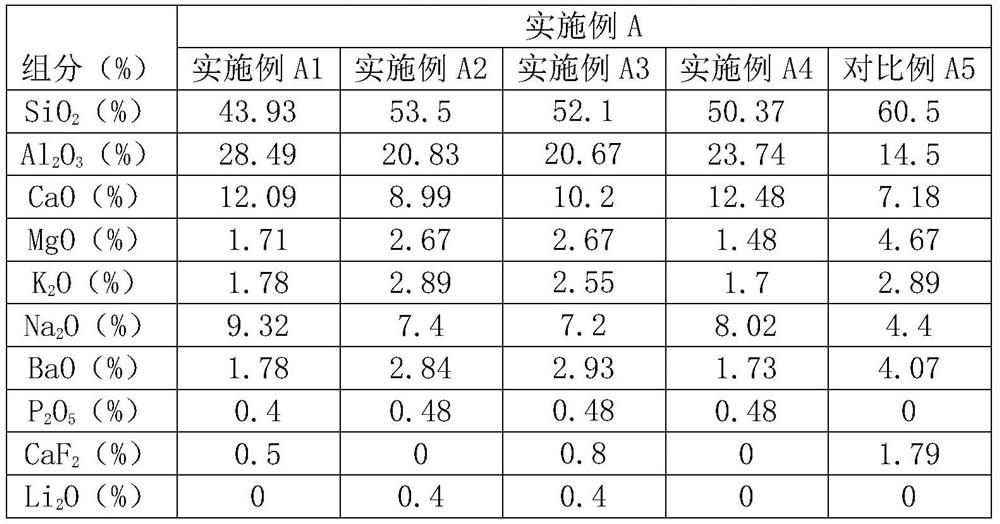

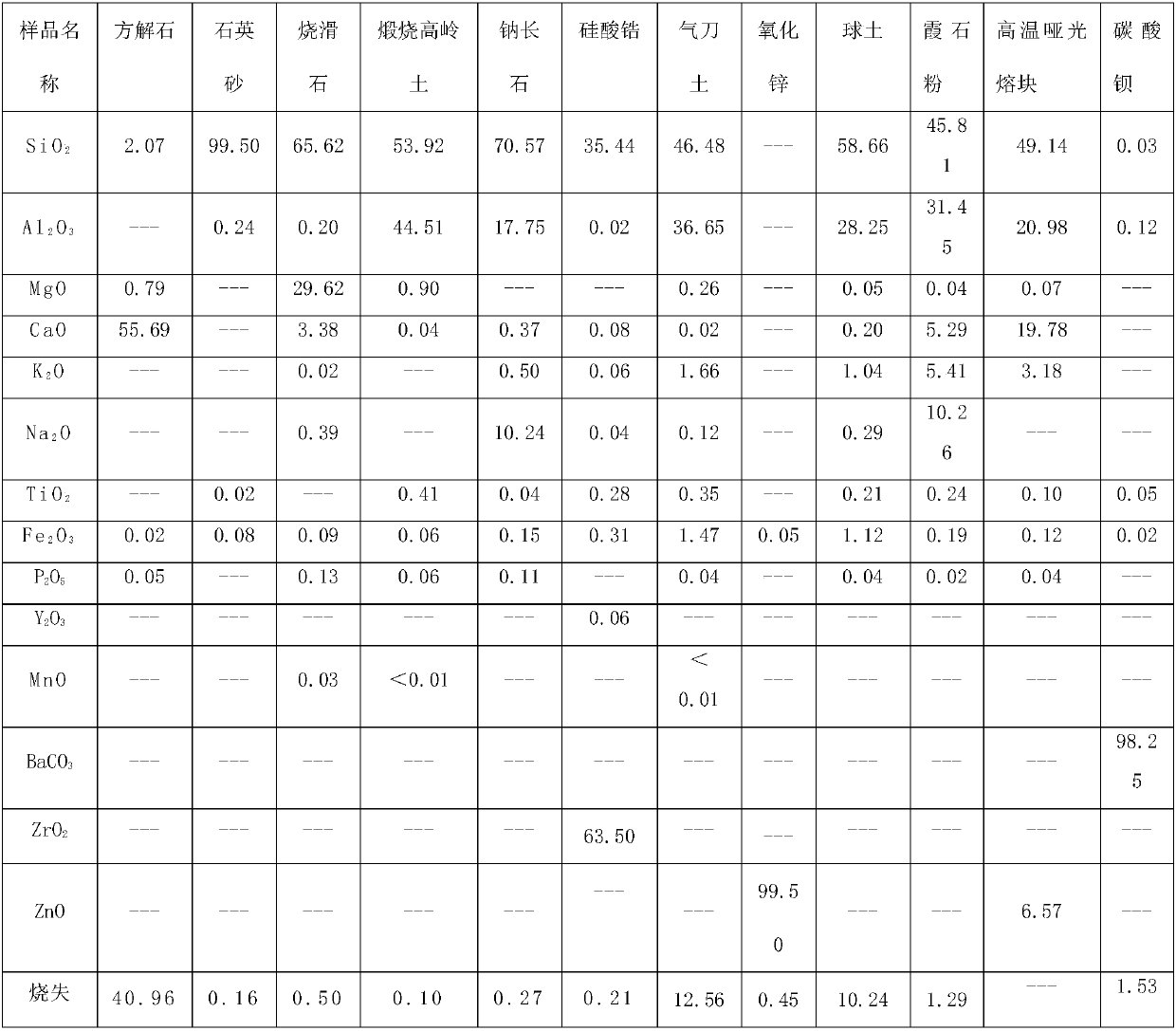

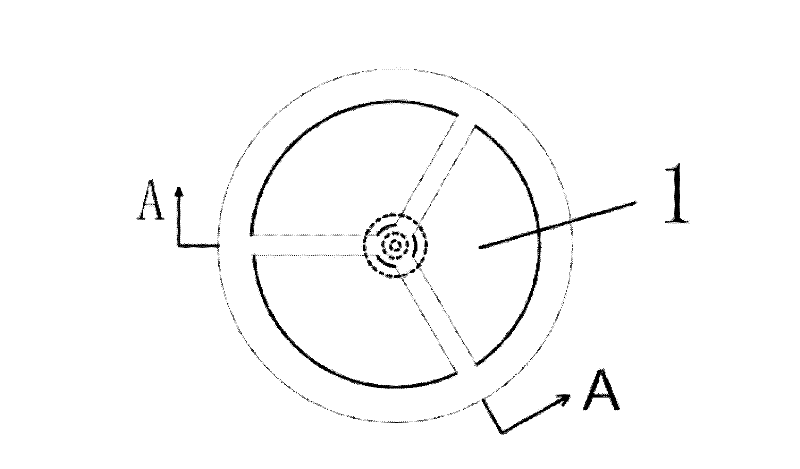

Crystallization frit, jade light-transmitting brick and preparation method of jade light-transmitting brick

The invention relates to a crystallization frit, a jade light-transmitting brick and a preparation method of the jade light-transmitting brick. The crystallization frit comprises the following components by mass: 40-55% of SiO2, 20-32% of Al2O3, 8-15% of CaO, 1-3% of MgO, 1-3% of K2O, 7-10% of Na2O, 1.4-3.5% of BaO, 0-1.0% of Li2O, 0.01-1.5% of P2O5 and 0-1.5% of CaF2; the jade light-transmittingbrick comprises ultra-white kaolin, ball clay, high-white bentonite, ultra-white quartz powder, high-white potassium feldspar, wollastonite, calcined talc and crystallization frit. According to the preparation method of the jade light-transmitting brick, the jade light-transmitting brick is prepared through the step (1) to (4). When the crystallization frit is used for a brick body, the brick bodyhas the pure white texture of natural jade, the whole brick body is transparent, warm and moist and has the texture of grease, and the problem that roller marks appear when the brick body is sinteredat high temperature is solved.

Owner:GUANGDONG TRIBECA BUILDING MATERIALS TECH CO LTD

Subdued light glaze for thin ceramic plate

The invention discloses a subdued light glaze for a thin ceramic plate. The subdued light glaze comprises a surface glaze and a ground glaze, wherein the surface glaze comprises the following effective constitution components in percentage by weight: 18-22% of high-temperature matte frit, 8-12% of Qidao clay, 14-18% of calcite, 19-23% of albite, 9-12% of calcined talc, 5-9% of zirconium silicate,3-6% of zinc oxide and 9-12% of barium carbonate; and the ground glaze comprises the following effective constitution components in percentage by weight: 22-26% of quartz sand, 8-11% of Qidao clay, 5-8% of ball clay, 7-11% of calcined talc, 13-16% of albite, 10-14% of nepheline powder, 8-12% of zirconium silicate and 11-15% of calcined kaolin. The sintering temperature of the subdued light glaze for the thin ceramic plate is 1180-1200 DEG C, the sintering cycle is 60-65 minutes, and the heat preservation time is 15 minutes. The subdued light glaze has relatively gentle glossiness, the glossiness of the subdued light glaze is generally within 30-60 degrees, and the glossiness relatively well meets a comfortable human view range. Due to the subdued light glaze disclosed by the invention on the thin ceramic plate blank, the surface of the thin ceramic plate blank can be smooth and fine, very gentle and free of light pollution, and a very good decoration effect is achieved.

Owner:GAOAN CERAMIC ENG CENT

Novel printing glaze material and production method thereof

The invention provides a novel printing glaze material and a production method thereof. The novel printing glaze material consistent with standards is produced by putting the following components into a ball mill for grinding, wherein the components are as follows in percentage by weight: 36% to 42% of albite, 8% to 10% of nepheline orthoclase, 6% to 8% of wollastonite, 4% to 8% of kaolin, 2% to 5% of ball clay, 4% to 7% of quartz, 3% to 5% of aluminium oxide, 5% to 8% of corundum, 8% to 10% of calcium carbonate, 1% to 2% of barium carbonate, 4% to 10% of clinker and 6% to 10% of fluxing agent. The produced novel printing glaze material solves the problems of needle hole, poor permeability, poor sewage suction performance, poor abrasive resistance and poor warping degree.

Owner:CARLOBBIA GLAZE KUNSHAN

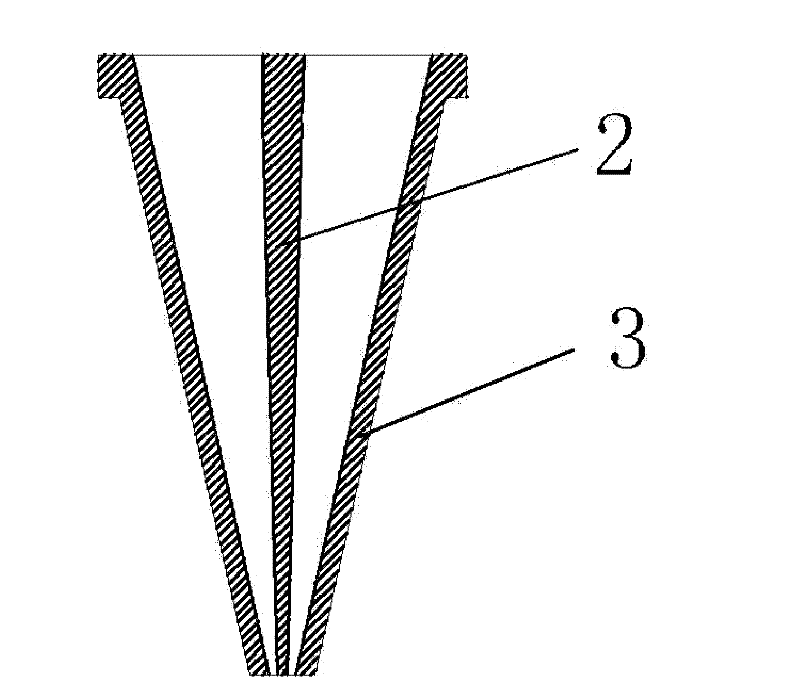

Hollow fiber ceramic membrane and preparation method thereof

The invention belongs to the technical field of material preparation, and provides a hollow fiber ceramic membrane with high filtering flux and a preparation method thereof. The hollow fiber ceramic membrane comprises the following components in parts by weight: 40-80 parts of powdery aluminum hydrate, 10-20 parts of powdery soft refractory ball clay, 1-10 parts of powdery albite, 1-10 parts of powdery dolomite, 6-10 parts of powdery borosilicate glass powder, 1-7 parts of carboxymethyl cellulose and 1-3 parts of glycerin, and is prepared through burdening, ball milling, mud squeezing and dehydration, vacuum pressing, extrusion molding and sintering. Preferably, the outer diameter of the hollow fiber ceramic membrane with high filtering flux is 3-6 millimeters, the inner diameter is 1-2 millimeters, and the length is 100-1,000 millimeters; and the porosity factor is 50-56 percent, the pure water flux is 10,000-12,500 L / m<2>.h.Mpa, and the bending strength is 35-85 MPa, which are 3-5 times that of an ordinary hollow fiber ceramic membrane.

Owner:THE THIRD XIANGYA HOSPITAL OF CENT SOUTH UNIV

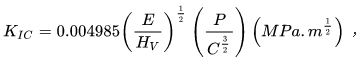

Composition for high-strength and high-toughness rock plate blank and application of composition

ActiveCN112979273AReduce brittlenessImprove toughnessCeramic materials productionClaywaresPyrophylliteKaolin clay

The invention discloses a composition for a high-strength and high-toughness rock plate blank and application of the composition. The composition comprises feldspar powder, high-alumina clay, calcined talc, pyrophyllite, potassium-sodium feldspar, high-sodium feldspar, ball clay, kaolin, diopside, high-alumina clay, ceramic waste and white carbon black. The white carbon black with the characteristics of serious surface coordination insufficiency, large specific surface area, surface oxygen deficiency and the like is used in the composition for the high-strength and high-toughness rock plate blank, so that the binding force between materials is improved, and the strength, toughness, ductility and tear resistance of the blank material are greatly improved. The rock plate blank body prepared by the method has relatively high breaking strength, relatively high toughness and relatively high stress resistance, and the situation of cutting cracks of the prepared rock plate is greatly reduced.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +1

Preparation method of ball clay for high-grade sanitary appliance

InactiveCN101844913AWhiteness stabilityHigh strengthCeramic materials productionClaywaresSocial benefitsLower grade

The invention relates to a preparation method of ball clay for high-grade sanitary appliance, which is characterized in that blackmud, plaster and kaolin are used as raw materials for preparing ball clay used by the high-grade sanitary appliance; the size comprises according to the percentage by volume: 10-60% of blackmud, 10-20% of plaster and 20-80% of kaolin; the preparation method overcomes the defect which is brought about by changeable raw material components caused by organic impurity and sand contents of low-grade ball clay; the formed ball clay has stable whiteness, intensity and stickiness and good slip-casting mobility, can be widely applied to high-grade ceramic industries and is the vanguard and demonstration in the process of national ceramic raw material standardizing, and has obvious economic benefic and social benefit.

Owner:广州市花都区梯面金鹏高岭土原料厂 +1

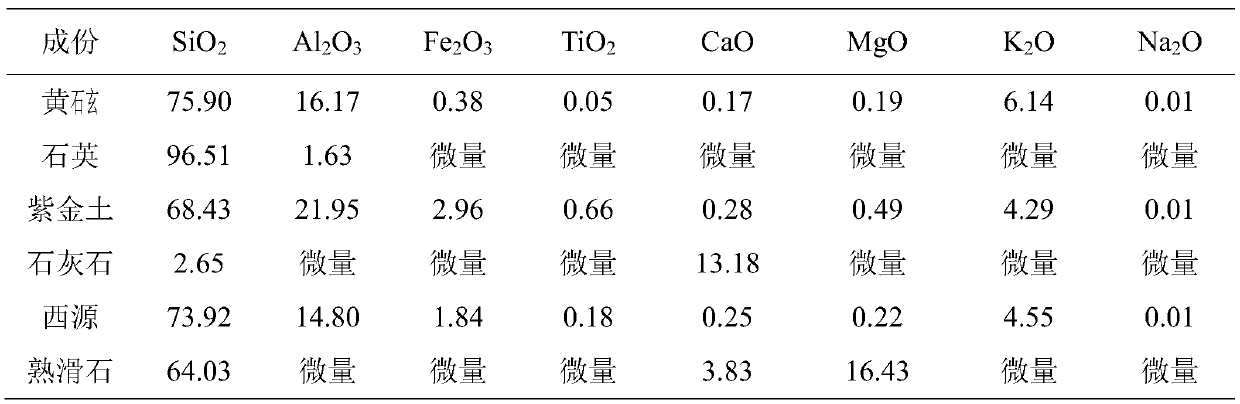

Method for preparing medium-temperature high-alumina high-strength domestic ceramics

The invention discloses a method for preparing medium-temperature high-alumina high-strength domestic ceramics. The method comprises the following production steps: 1, preparing a blank, namely by taking corundum, potassium feldspar, kaolin, ball clay, talc, zinc oxide and zirconia as raw materials, performing wet milling, removing iron, performing filter pressing, pugging, and preparing an ejection material for later use; 2, preparing a glaze, namely taking potassium feldspar, quartz, talc, kaolin, stalactite, zinc oxide and corundum as raw materials of the glaze, mixing the materials, and performing ball milling; removing iron from ball-milled material through an iron removal machine, passing the material through a 325-mesh screen, and preparing a finished glaze for later use; and 3, performing a product manufacturing process comprising molding, fettling, glazing and firing, thereby preparing the medium-temperature high-alumina high-strength domestic ceramic product. The domestic ceramic product prepared by the method is high in yield, regular in appearance and flat in glaze surface; the thermal shock resistant test proves that the domestic ceramic product of 200 DEG C is not cracked when added into water at the temperature of 20 DEG C for performing heat exchange once; the Vickers microhardness of the glaze surface is higher than 6.0GPa; and the shock strength is higher than 1.5J / cm<2>.

Owner:CHAOZHOU LIANJUN CERAMICS CO LTD

High efficiency ceramic blank casting slip and processing method thereof

The invention relates to a high efficiency ceramic blank casting slip. The ceramic blank casting slip comprises the following raw materials, by weight, 8-9 parts of Zhangcun soil, 6-7 parts of Zhangwu clay, 8-9 parts of Tangshan knag, 9-10 parts of Shanxi knag, 13-14 parts of Qinyang soil, 2-3.5 parts of Guangdong ball clay, 0.7-1.3 parts of Guangdong black mud, 1.4-1.7 parts of dolomite, 5-6 parts of Weichang clay, 9-10 parts of Fengrun sandstone, 14-15 parts of Luanxian feldspar, 3-4 parts of porcelain powder, 1-2.5 parts of Zhanjiang porcelain clay B, 7-8.5 parts of Xuanhua porcelain stone, 3-4 parts of northeast black mud, and 1.5-3 parts of Zhanjiang porcelain clay A, wherein dolomite in the raw materials is ground into a dolomite slurry, and the dolomite slurry and other raw materials, which are mixed, are ground in a ball mill according to a raw materials: balls: water ratio of 1:1.8:0.4. The raw materials of the casting slip are easy to obtain, a large ceramic product is subjected to slip casting twice each day, the slip suction speed is fast, the ceramic product production efficiency is improved, and the output is increased, so the ceramic blank casting slip is suitable for the large scale production.

Owner:TANGSHAN HUALI CERAMICS CO LTD

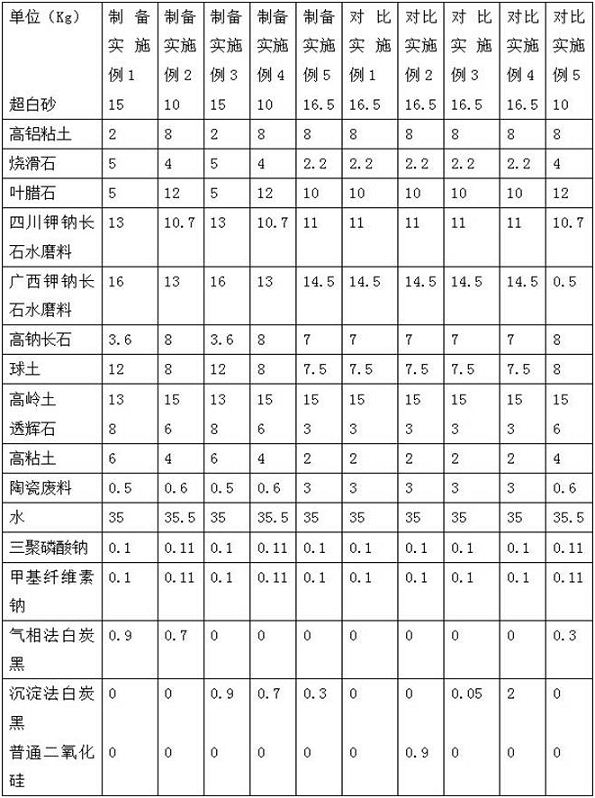

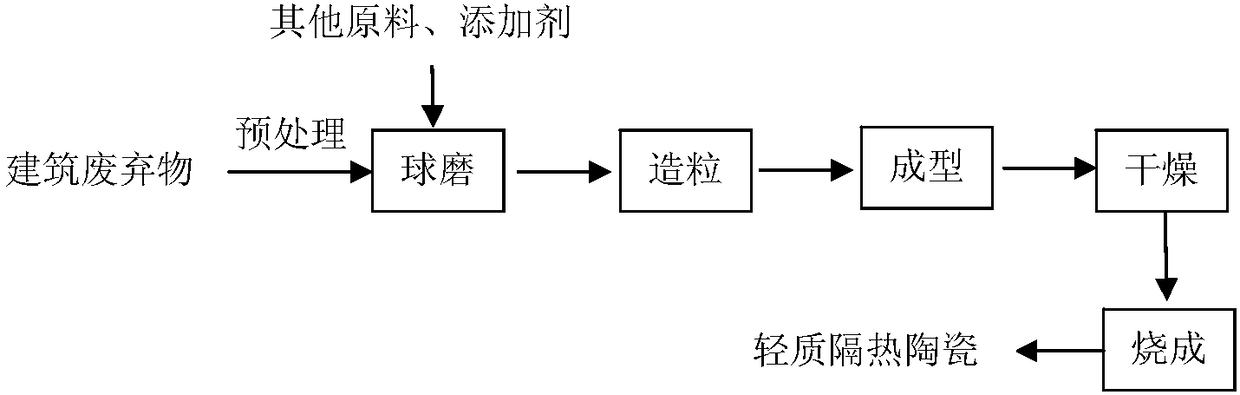

Low-temperature preparation method for lightweight heat-insulation ceramics

InactiveCN108129131ALow costReduce consumptionCeramic materials productionCeramicwareChemical industryEcological environment

The invention discloses a low-temperature preparation method for lightweight heat-insulation ceramics. Raw materials used in the preparation method comprise construction waste, ceramic polishing slag,fly ash, talc, feldspar, ball clay, diatomite and a foaming agent, wherein the amount of the solid waste is 60% or more. Pre-treated construction waste and other raw materials are subjected to ball milling mixing, and then subject to granulation, compaction molding, drying and low temperature sintering (700-1200 DEG C) to prepare the environmentally friendly lightweight heat-insulation ceramics.The method is simple in process, low in production cost and suitable for industrialized production. The prepared lightweight heat-insulation ceramics have the advantages of low density, controllable pore size, low heat conductivity, excellent mechanical properties and the like, and can be widely applied in heat preservation and heat insulation in the fields of architecture, chemical industry and the like. While achieving low temperature sintering, energy saving and emission reduction, the method can promote high-efficiency resource utilization of the solid waste, and is of great significance to the ecological environment.

Owner:SOUTH CHINA UNIV OF TECH

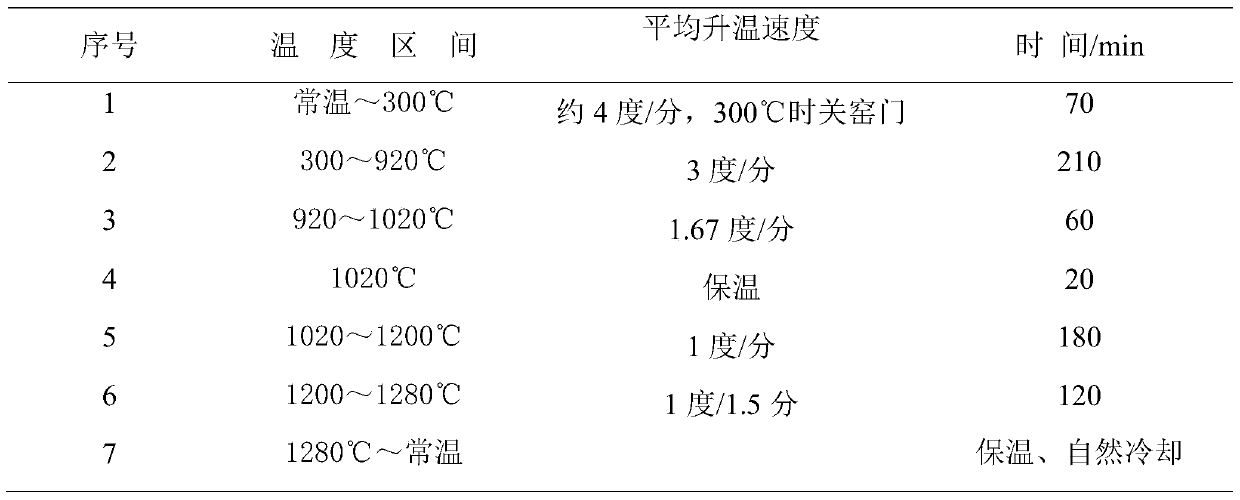

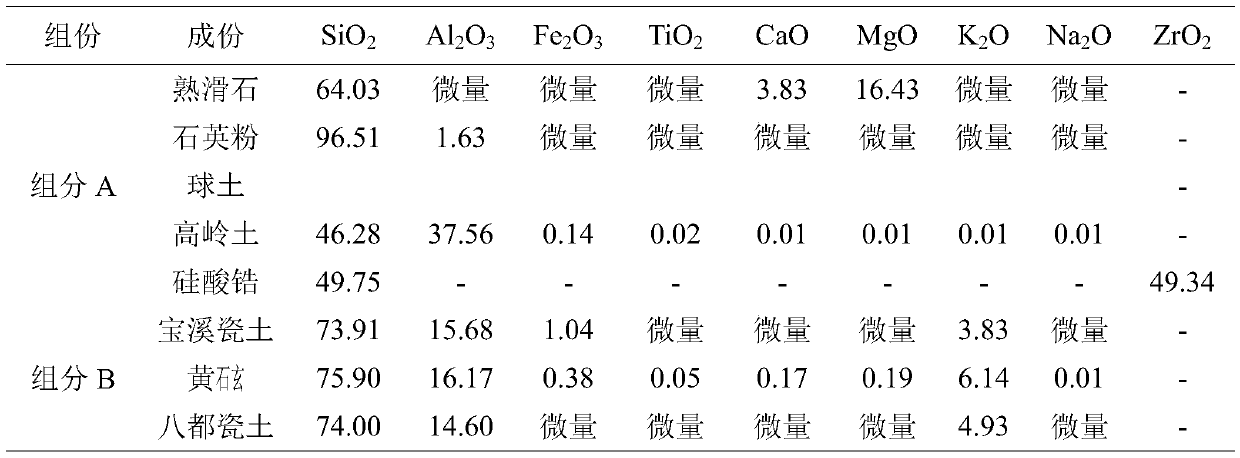

Preparation method of high-strength magnesium Longquan celadon billet, glaze and product

The invention relates to a production method of a high-strength magnesium Longquan celadon billet, glaze and product and a preparation method of slurry in the production method. The high-strength billet for the high-strength magnesium Longquan celadon product is prepared from a component A and a component B. The component A is composed of the following ingredients in percentage by weight: 20-35% of cured talcum, 43-52% of quartz powder, 4-15% of ball clay, 5-18% of kaolin and 1-5% of zirconium silicate. The component B is composed of the following ingredients in percentage by weight: 35-55% of Baoxi porcelain clay, 13-27% of Huangshixuan and 25-45% of Badu porcelain clay. On the basis of ensuring the aesthetical effect on the traditional Longquan celadon, the strength of the Longquan celadon product is improved.

Owner:LONGQUAN JINHONG PORCELAIN

Stripping glaze, stripping-glaze marble ceramic tile without glaze defects and preparation process of marble ceramic tile

Owner:FOSHAN DONGPENG CERAMIC +2

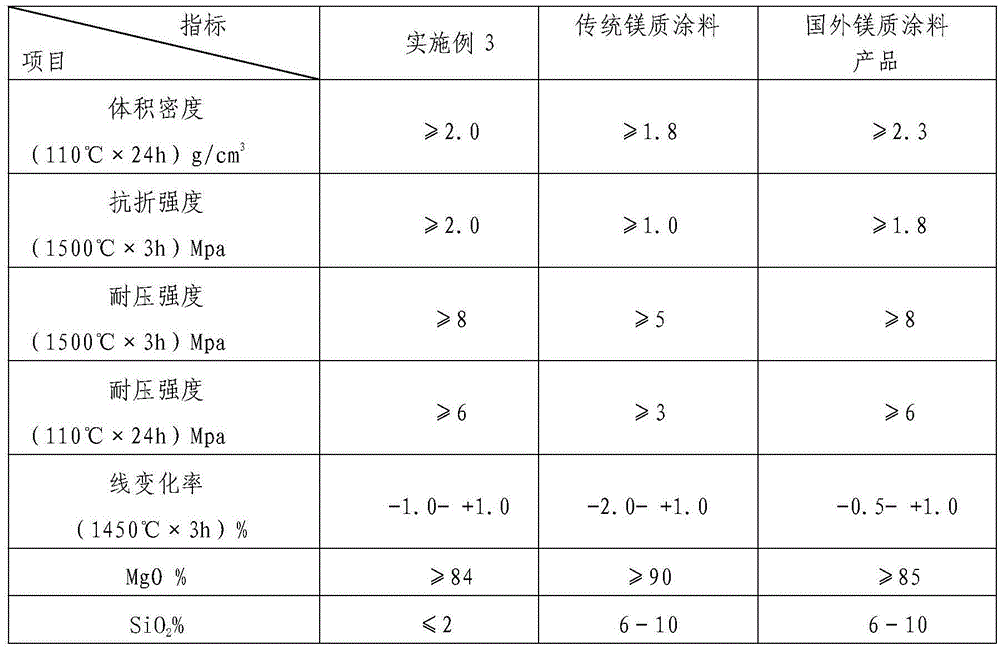

Tundish ultralow-silicon magnesium coating and preparation method thereof

The invention discloses a tundish ultralow-silicon magnesium coating which comprises the following raw materials in parts by weight: 250-300 parts of 95 magnesite, 500-700 parts of 97 magnesite, 20-40 parts of clay, 10-30 parts of bentonite, 20-40 parts of alpha-Al2O3, 10-20 parts of paper fiber, 1-2 parts of lignin, 0-3 parts of sodium tripolyphosphate, 0.1-0.5 part of metallic aluminum, 0.01-0.15 part of sodium dodecyl sulfate and 0.5-2 parts of polyvinyl alcohol. The tundish ultralow-silicon magnesium coating disclosed by the invention can achieve good plasticity (spreading property) when a small quantity of gel materials are added by using the polyvinyl alcohol as a film-forming agent and can achieve good construction property by substituting superfine nanoscale high-viscosity ball clays for silicon micropowder, Guangxi mud and kaolin which are contained in the traditional coating and being matched with the film-forming agent PVA (Polyvinyl Alcohol). As for the same coating spreading property, the tundish ultralow-silicon magnesium coating disclosed by the invention only needs to add the superfine nanoscale high-viscosity ball clay (2%), and the traditional magnesium coating needs to add the silicon micropowder (4%-6%) and ordinary clay (1%-2%), so that the problem of carrying of free SiO2 contained in the silicon micropowder is solved.

Owner:HUZHOU MINGDE REFRACTORY MATERIAL

Environment-friendly cordierite-mullite kiln furniture and preparation method thereof

Environment-friendly cordierite-mullite kiln furniture is prepared from the following raw materials in parts by weight: 25 to 35 parts of waste ceramics, 12 to 22 parts of cordierite-mullite clinker,30 to 45 parts of washing ball clay, 10 to 15 parts of andalusite, 8 to 13 parts of talcum powder, 5 to 15 parts of kyanite, 5 to 12 parts of industrial-alpha-alumina powder. According to the environment-friendly cordierite-mullite kiln furniture disclosed by the invention, a solid matter of a composite material of the environment-friendly cordierite-mullite kiln furniture is prepared by taking the waste ceramics, the cordierite-mullite clinker and the andalusite as aggregates and introducing the washing ball clay, the talcum powder, the kyanite and the industrial-alpha-alumina powder as matrix materials, so that the utilization rate of the waste ceramics is up to 25 to 35 percent, waste of resources is reduced, and the production cost of kiln furniture materials is also reduced; a prepared environment-friendly cordierite-mullite kiln furniture product has the advantages of low density, light weight, high bending strength under a normal temperature, high apparent porosity, good thermalshock stability and good energy-saving performance.

Owner:福建省德化县创捷窑具有限公司

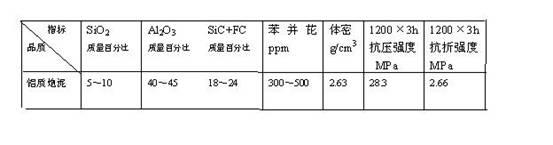

Blast furnace taphole filled aluminum stemming and preparation method thereof

The invention relates to blast furnace taphole filled aluminum stemming and a preparation method thereof and belongs to the field of high-temperature metallurgical fireproof materials. The preparation method comprises the following steps of: premixing 40 to 50 mass percent of corundum, 12 to 30 mass percent of silicon carbide, 3 to 5 mass percent of micropowder, 8 to 12 mass percent of ball clay,1 to 3 mass percent of plasticizer, 2 to 4 mass percent of graphite, 3 to 5 mass percent of expanding agent aluminium silicate, 3 to 5 mass percent of metal powder, 3 to 5 mass percent of titanium corundum and 3 to 5 mass percent of modified asphalt powder for later use; adding the mixture into a wheel roller, and pre-rolling for 5 minutes; adding 15 to 20 mass percent of modified liquid tar; performing high-speed wheel rolling for 30 to 35 minutes, so that the Marshall value is 4 to 16 MPa; and measuring the Marshall value again after 3 days, wherein if the Marshall value is 8 to 24 MPa, theproduct is qualified. By the blast furnace taphole filled aluminum stemming and the preparation method thereof, problems of low high-temperature strength, low high-temperature toughness and environmental pollution of the stemming are solved; and problems of shallow iron notch, broken iron notch and spattering are solved at the same time.

Owner:XUZHOU SUPAI HIGH TEMPERATURE NEW MATERIAL CO LTD

Broadband infrared ceramic material with anti-aging function at normal temperature and preparation method thereof

The invention discloses a broadband infrared ceramic material with an anti-aging function at normal temperature and a preparation method thereof. The preparation method is characterized by comprising the following steps of: crushing non-metallic minerals taking magnesium-rich silicate ore, spodumene and Guibao stone as main components, composite rare earth oxides taking praseodymium and neodymiumoxides as main components and reduced alloy iron powder; mixing the crushed powder with auxiliary materials for pulping; spraying and granulating; pressing; and sintering to obtain the broadband infrared ceramic material. The raw materials include the following components in percentage by weight: 8-60% of magnesium-rich silicate ore, 2-10% of spodumene, 5-15% of Guibao stone, 2-10% of reduced alloy iron powder and 2-8% of praseodymium and neodymium oxides; and the auxiliary materials include the following components in percentage by weight: 10-46% of ball clay and 1-8% of bonding agent. The broadband infrared ceramic material can continuously release infrared light beneficial to the human health at the normal temperature lower than 45 DEG C so as to generate a non-thermal biological resonance effect, thereby effectively improving the energy required by cell self-replication and an information transfer mechanism, enhancing activity functions such as organism metabolism and immunity andthe like, improving the disease resistance of human bodies, achieving the purposes of preventing and treating diseases and resisting ageing, and saving energy sources.

Owner:SHANGHAI YISHOUKANG MEDICAL APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com