Magnesian ceramic blank, magnesian ceramic and preparation method thereof

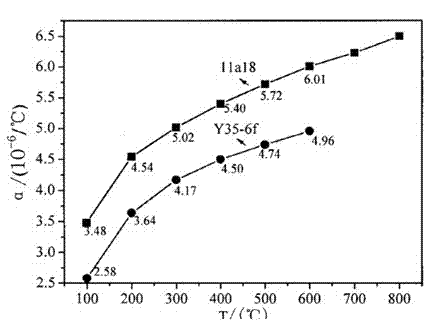

A magnesia porcelain and blank technology, applied in the field of ceramics, can solve the problems of reducing the risk of frying porcelain, small thermal expansion coefficient, poor forming performance, etc., and achieve the effect of reducing the risk of frying porcelain, small thermal expansion coefficient and solving poor forming performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides a preparation method of magnesia porcelain, comprising the following steps:

[0027] S1. Green body preparation: ball mill the green body, sieve it, and roll it after aging to obtain the green body;

[0028] S2, glazing: immerse the green body obtained in step S1 into the glaze slurry, and then put it out, and attach a glaze layer on the surface of the green body to obtain a glazed green body;

[0029] S3. Sintering: drying the glazed green body obtained in step S2, transferring it to a kiln with an oxidizing atmosphere for sintering, and obtaining the magnesia porcelain after cooling;

[0030] Wherein, the blank is the magnesia porcelain blank provided by the present invention.

[0031] According to the preparation method of the present invention, the raw materials are first weighed according to the proportion, and then the raw materials are mixed. In order to ensure that the raw materials are mixed evenly, the hard raw materials s...

Embodiment 1

[0056] (1) Blank A1: raw talc 37.6wt%, burnt talc 25wt%, alumina 8.9wt%, kaolin 10.7wt%, ball clay 7.1wt%, bentonite 3.6wt%, potassium feldspar 7.1wt%.

[0057] (2) Add 0.1% dextrin, 0.025% CMC, and 0.3% sodium humate to the blank A1, then ball mill, sieve, dehydrate, smelt, and shape to obtain the blank A10.

[0058] After testing, the chemical composition of the green body A10 is 57.53wt% SiO 2 , 18.2wt%Al 2 o 3 , 1.61wt%CaO, 20.68wt%MgO, 1.33wt%K 2 O, 0.43wt%Na 2 O, 0.18wt%Fe 2 o 3 , 0.04wt%TiO 2 ; Among them, the amount of crystal phase accounts for 85wt%, and the main crystal phase is original enstatite and cordierite, and feldspar glass accounts for 18wt%.

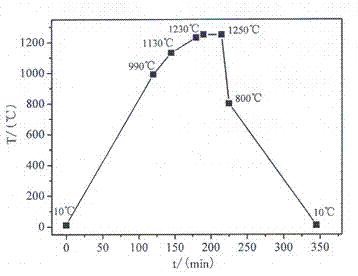

[0059] (3) Immerse the green body A10 in the glaze slurry B10, quickly form a 0.3mm glaze layer on the surface of the green body A10, dry it until the moisture content is less than 2wt%, and then put it into the kiln for sintering. The sintering curve is as follows: figure 2 shown;

[0060] Glaze B10 is pre...

Embodiment 2

[0063] Magnesia porcelain S20 was prepared by the same preparation method as in Example 1, the difference being:

[0064] In step (1), use blank A2 to replace A1, and the composition of blank A2 is: raw talc 35wt%, burnt talc 25wt%, alumina 10wt%, kaolin 10wt%, ball clay 6.7wt%, bentonite 3.3wt%, potassium feldspar 10wt%;

[0065] In step (2), the chemical composition of the obtained green body A20 is 59.4wt% SiO 2 , 19.8wt%Al 2 O3, 1.5wt%CaO, 18.1wt%MgO, 0.8wt%K 2 O, 0.4wt%Na 2 O; the amount of crystal phase accounts for 80wt%, the main crystal phase is enstatite and cordierite, and feldspar glass accounts for 15wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com