Process for magnesium alloy surface micro-arc oxidation

A technology of micro-arc oxidation and magnesium alloy, which is applied in anodic oxidation and other directions, can solve the problems of uneven micro-arc oxidation ceramic film, poor corrosion resistance and wear resistance, small specific heat capacity of electrolyte, etc., and achieve low production cost and corrosion resistance Strong resistance to abrasion and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

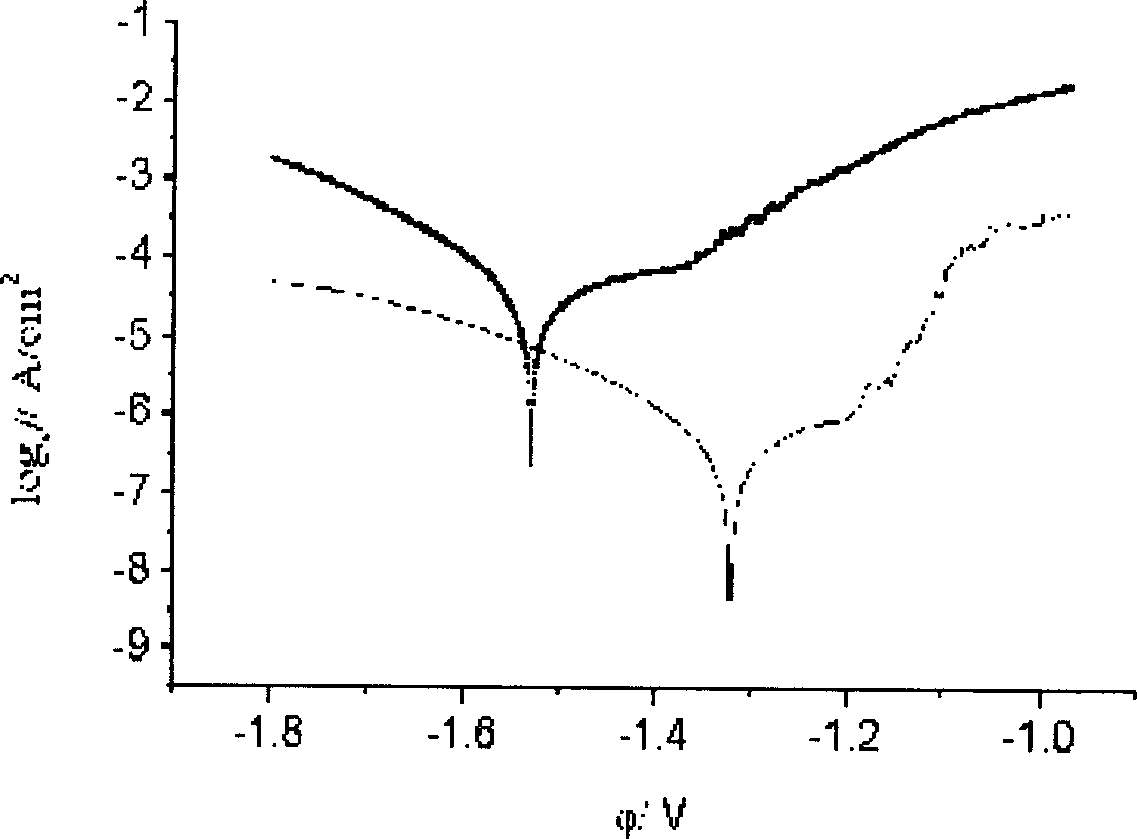

Image

Examples

specific Embodiment approach 1

[0007] Specific embodiment one: this embodiment is carried out through the following steps: (one) magnesium alloy is carried out pretreatment; (two) preparation alkaline electrolyte: a. preparation alkaline silicate electrolyte: add 4 -30g silicate, 2-10g potassium fluoride, sodium fluoride, sodium silicofluoride or potassium silicofluoride, 1-10g potassium hydroxide or sodium hydroxide, 5-30mL ethylene glycol or glycerol; b. Preparation Alkaline aluminate electrolyte: add 4-30g aluminate, 2-10g potassium fluoride, sodium fluoride, sodium fluorosilicide or potassium fluorosilicide to 1L deionized water; (3) Put the pretreated magnesium alloy in Micro-arc oxidation in alkaline silicate electrolyte or alkaline aluminate electrolyte: direct current is applied, the voltage keeps rising, constant current, and the current density is 1-15A / dm 2 , The power-on time is 5-90min, and the electrolyte temperature is always kept below 40°C.

specific Embodiment approach 2

[0008] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step (1), magnesium alloy is put into the pickling solution that forms by the volume ratio of acid and deionized water 1: 2-1: 10 Pickling for 30s-3min.

specific Embodiment approach 3

[0009] Specific embodiment three: the difference between this embodiment and specific embodiment one is: in step (1), magnesium alloy is put into sulfuric acid pickling solution successively (concentration is that the sulfuric acid of 98% and deionized water volume ratio are 1: 3 ) and alkaline degreasing liquid for pretreatment, in which the soaking time for pickling is 30s-3min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com