Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6045results about How to "Good molding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

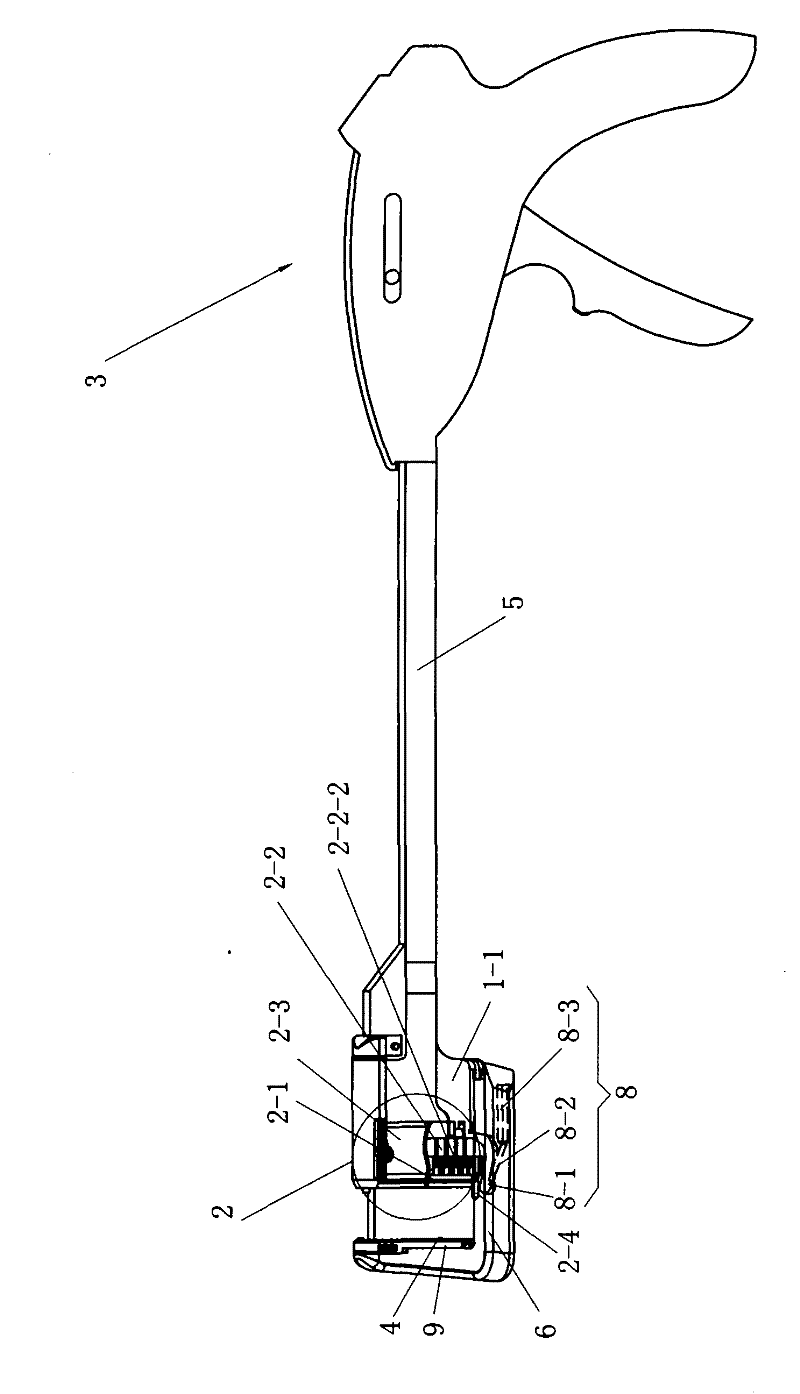

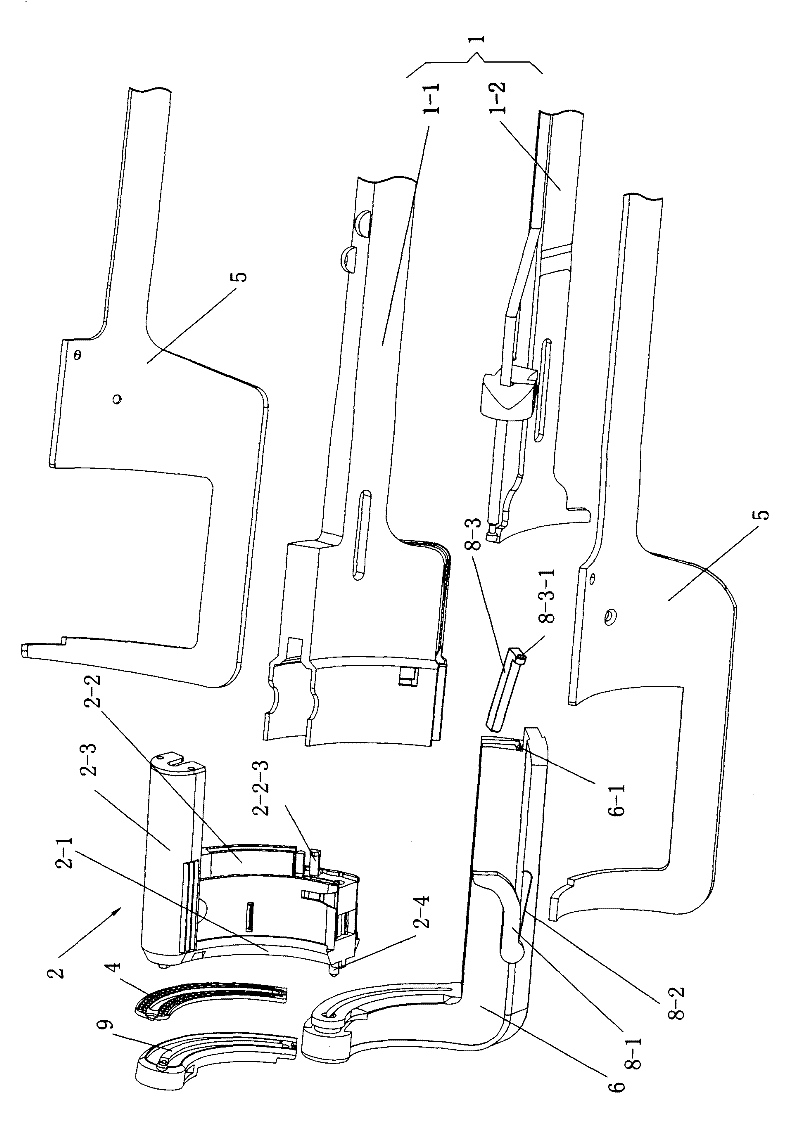

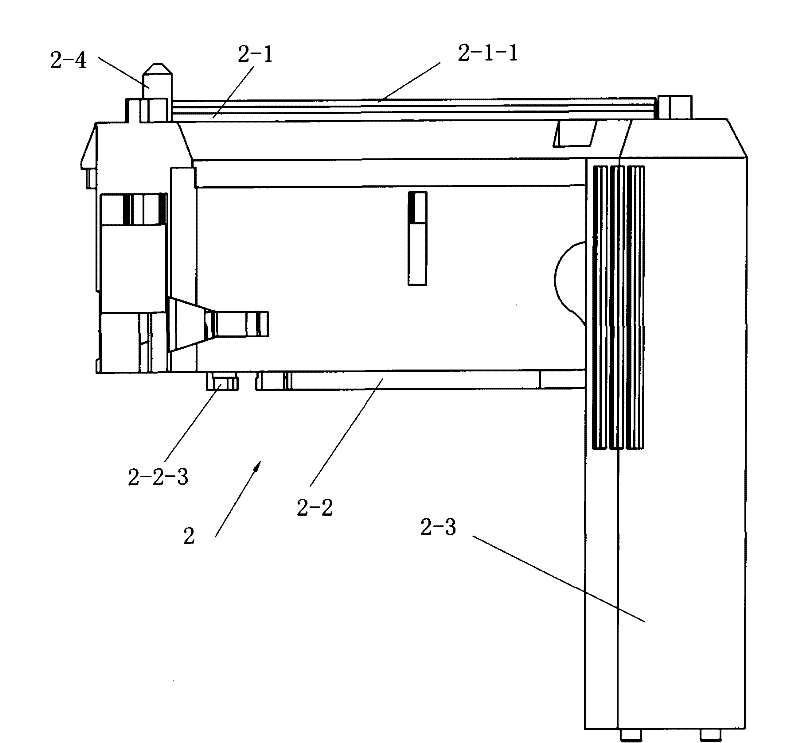

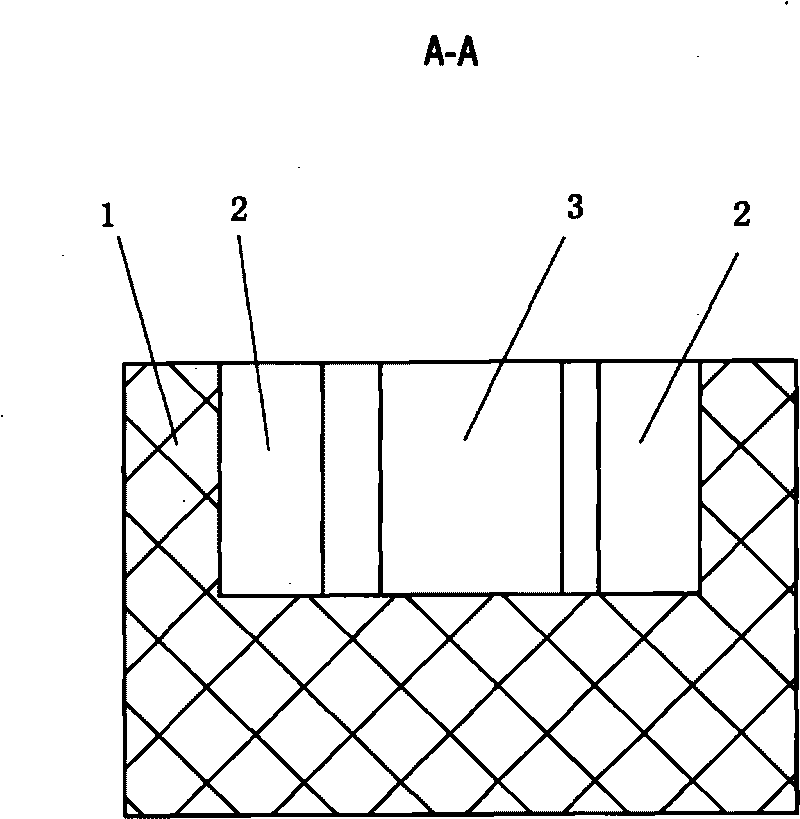

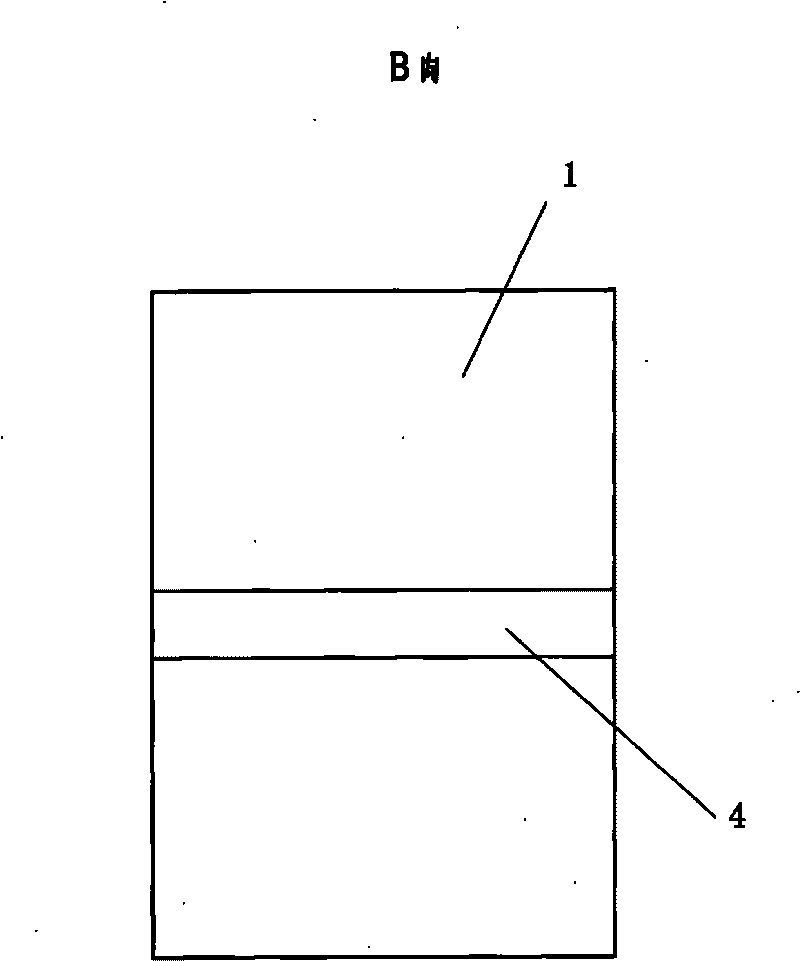

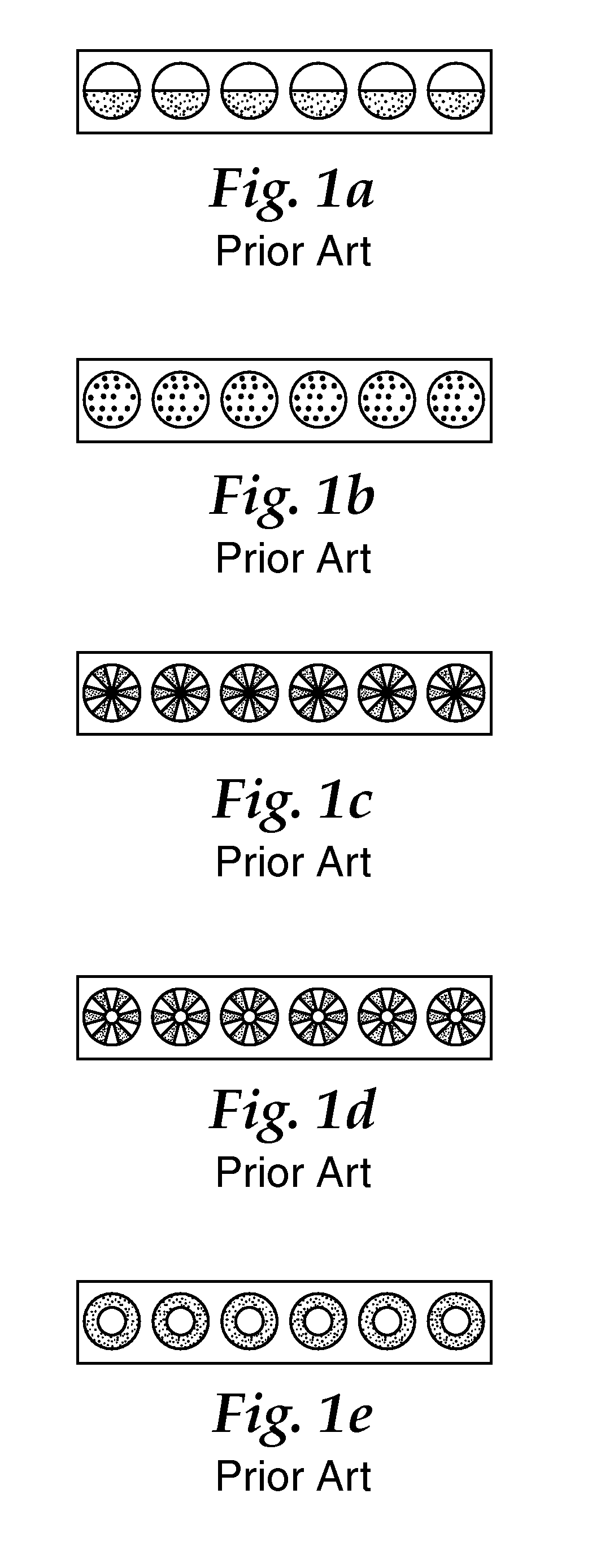

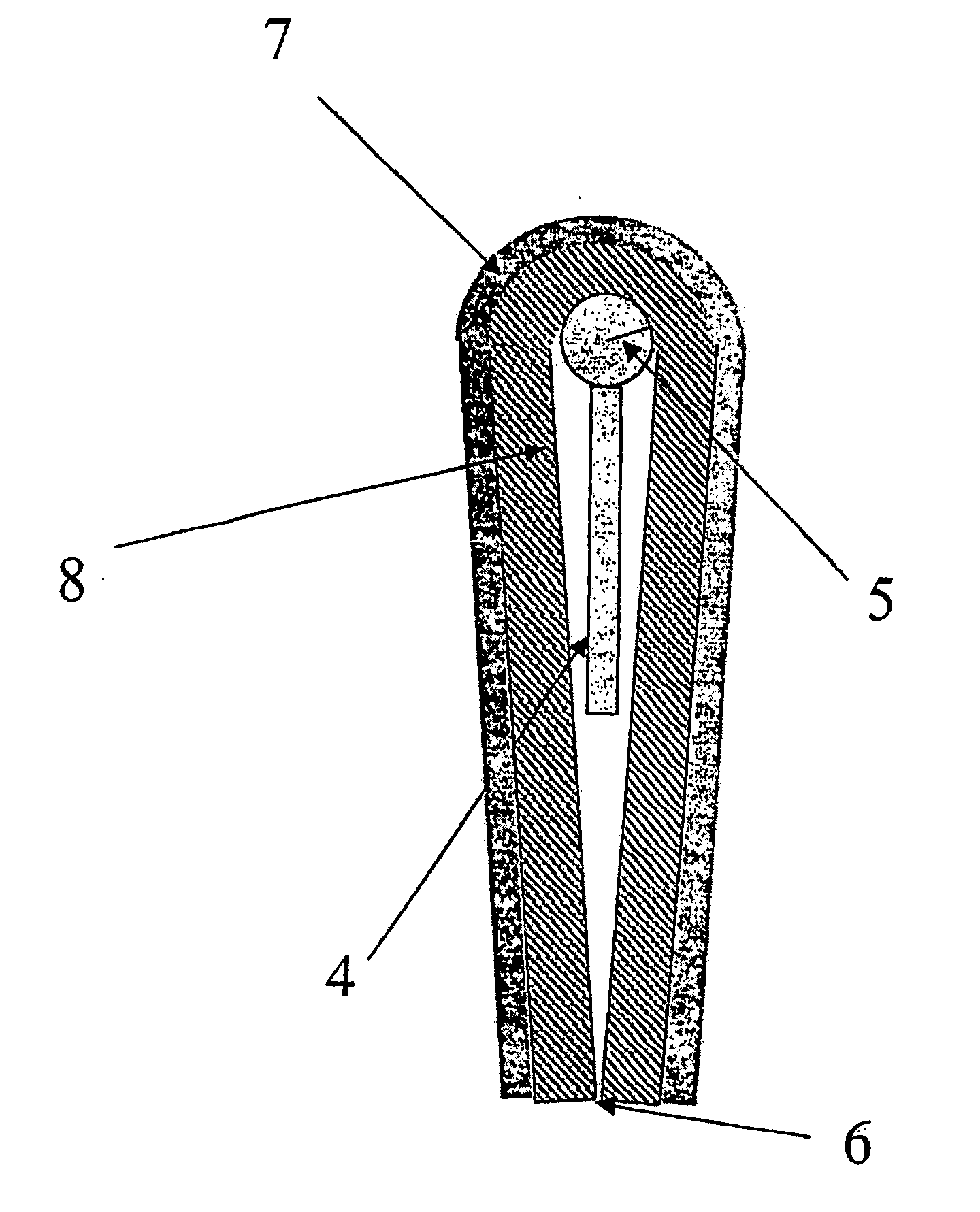

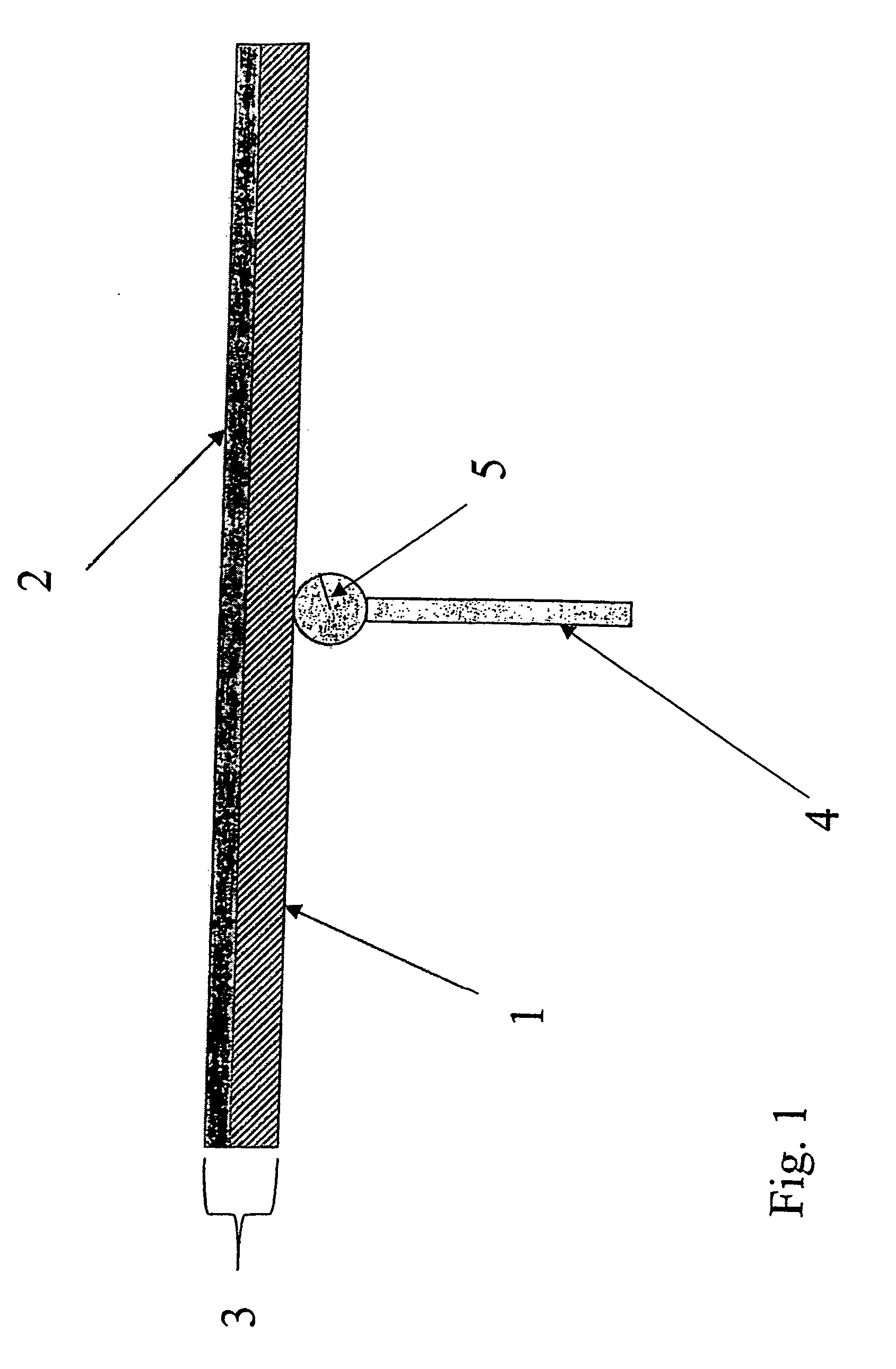

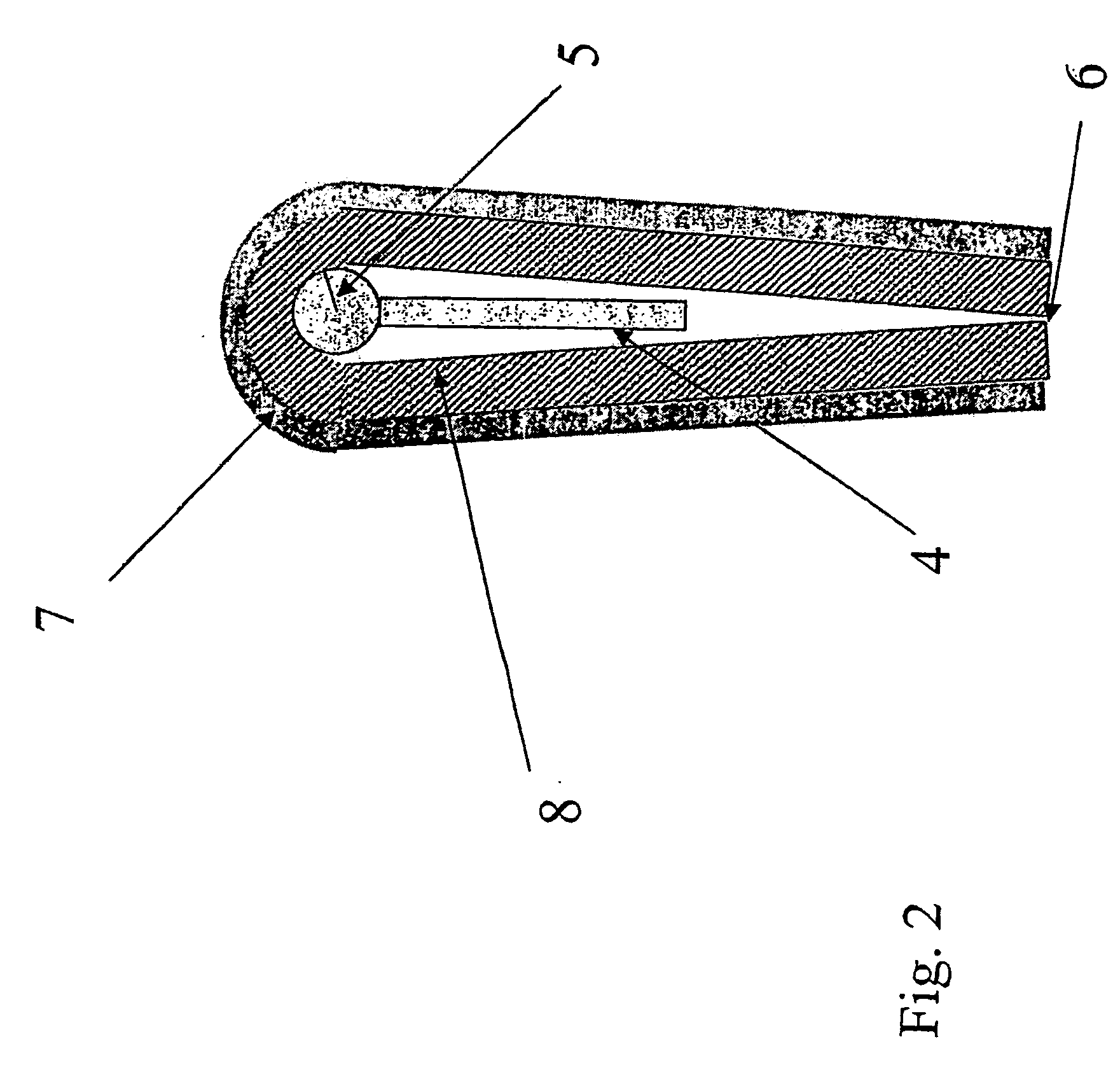

Arc-shaped cutting anastomat

The invention relates to an arc-shaped cutting anastomat comprising an anastomosis nail shaping mechanism, a nail pushing assembly, a trigger handle, a nail supporting seat, a base of the nail supporting seat, a knife cushioning ring and two splints, wherein the nail pushing assembly comprises a cutting knife, a nail pushing sheet, a nail bin and a guide post; the end of the nail pushing sheet and both sides of the cutting knife are respectively provided with a plurality of inner nail pushing dental sheets which are near the cutting knife and a plurality of outer nail pushing dental sheets which are far away from the cutting knife; the cutting knife and the nail pushing sheet are injected and molded at a time to be fixed together; the outer side of the each outer nail pushing dental sheeton the nail pushing sheet is provided with a reinforcing rib; the inner side of each nail pushing dental sheet on the nail pushing sheet is provided with a reinforcing rib; both ends of the first guide surfaces of the nail pushing dental sheets are respectively connected with the first contact surfaces and the second contact surfaces of the nail pushing dental sheets through concave arc-shaped connecting surfaces, and both ends of the second guide surfaces thereof are respectively connected with the first contact surfaces and the second contact surfaces through the concave arc-shaped connecting surfaces; and the first contact surfaces and the second contact surfaces are respectively in contact with the inner walls of the nail pushing dental sheet holes of the nail bin. The invention has the advantages of good trigger anastomosis shaping effect and high safety.

Owner:CHANGZHOU JIANRUIBAO MEDICAL DEVICES

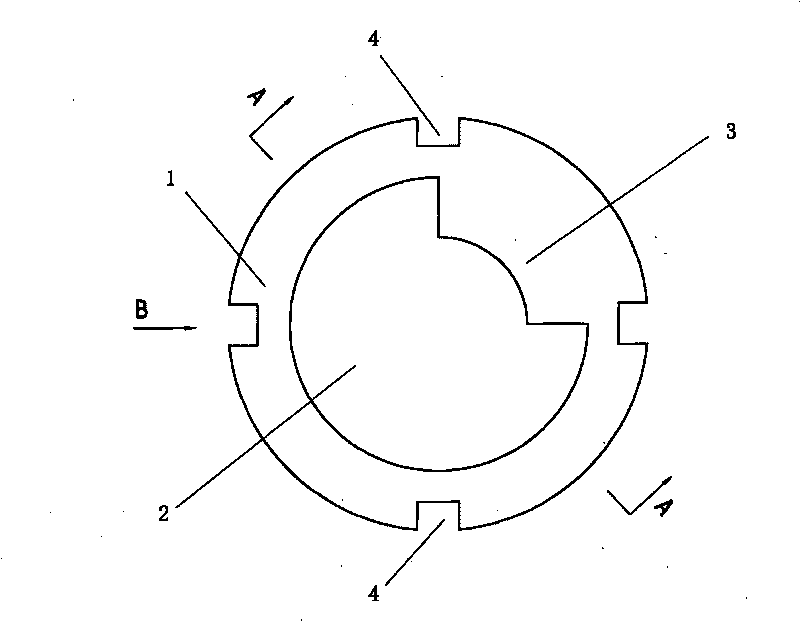

Nut cap of tubular anastomat

InactiveCN101716090AImprove use reliabilityExtended service lifeMetal-working hand toolsSurgical staplesEngineering

The invention discloses a nut cap of a tubular anastomat, belonging to a medical appliance. A sinking cavity is arranged in the inner end of a cap body and is internally provided with a backstop which is a bulge extending radially from the peripheral wall of the sinking cavity or a bulge extending axially from the bottom surface of the sinking cavity. The nut cap of the tubular anastomat is difficult to fall off from the rear end of an adjusting handle of the tubular anastomat and can improve the use reliability of the tubular anastomat.

Owner:李东瑞

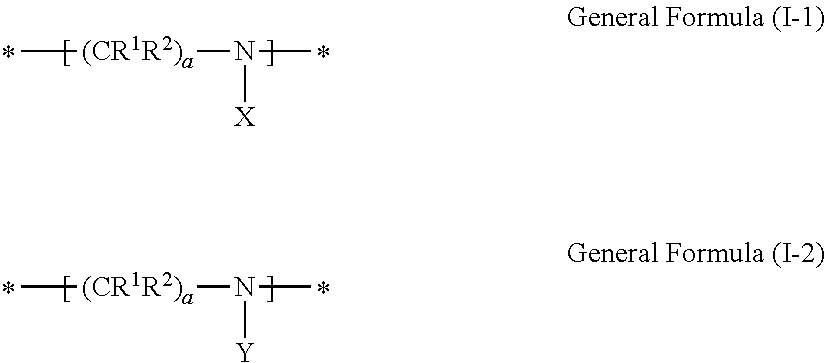

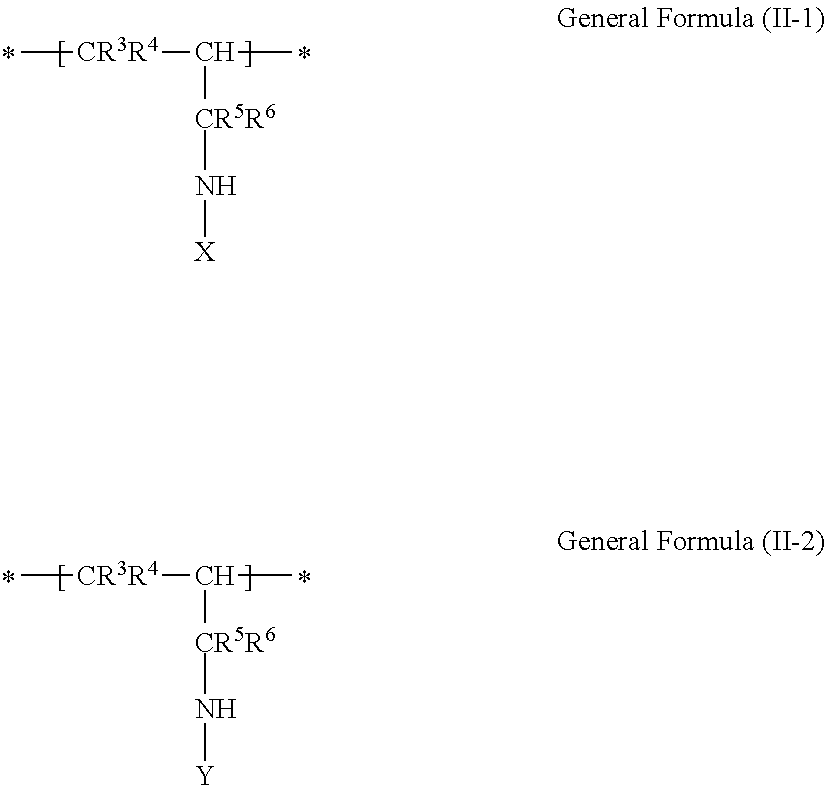

Resin, pigment dispersion, colored curable composition, color filter produced using the same, and method for producing the same

ActiveUS20110003241A1High color purityIncrease contrastPhotosensitive materialsOptical filtersOligomerBackbone chain

A resin including (i) a main chain portion containing a nitrogen atom, (ii) a group X that has a functional group having a pKa of 14 or less and is bonded to a nitrogen atom present in the main chain portion, and (iii) an oligomer chain or polymer chain Y having a number average molecular weight of from 500 to 1,000,000 in a side chain.

Owner:FUJIFILM CORP

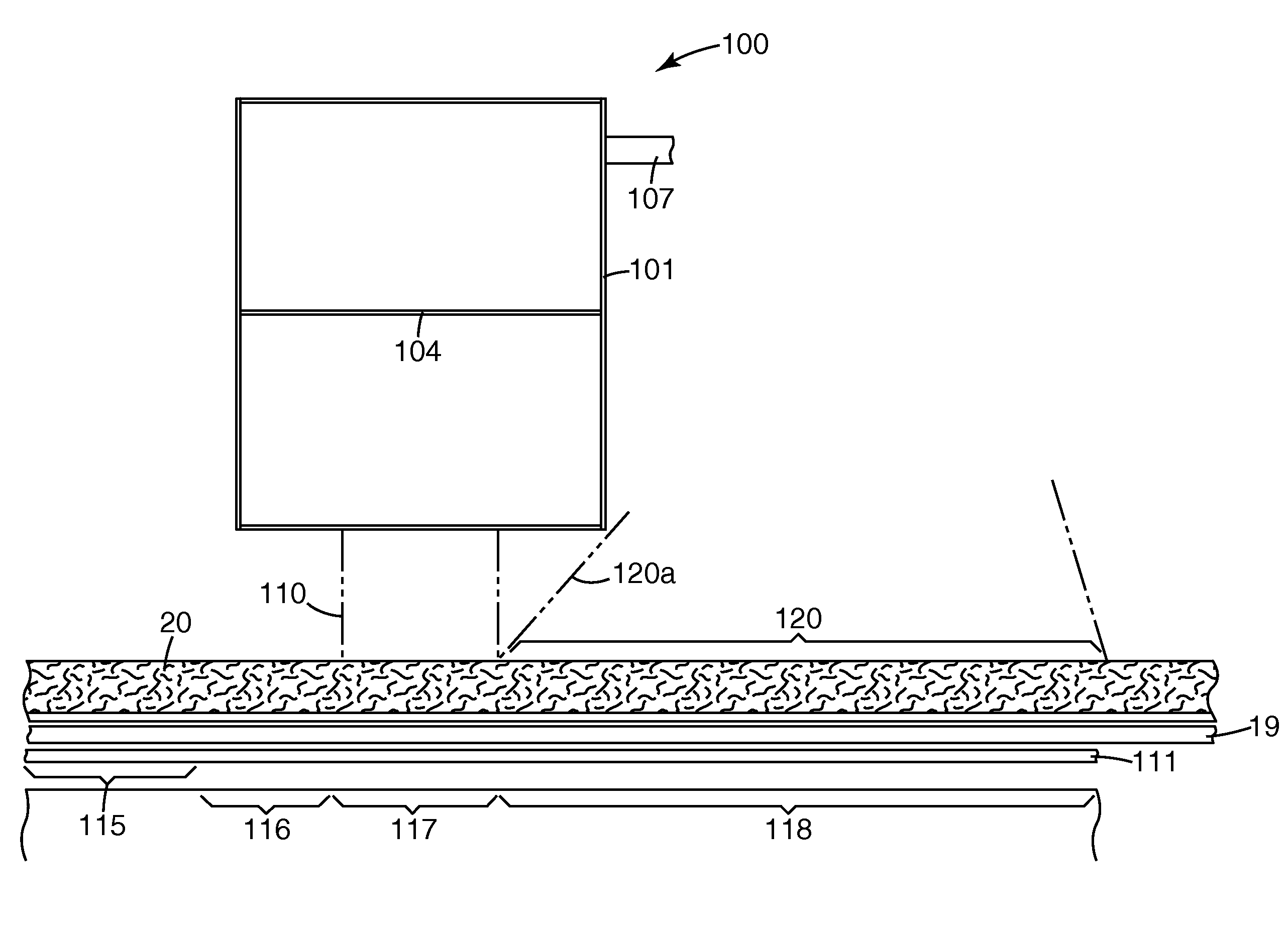

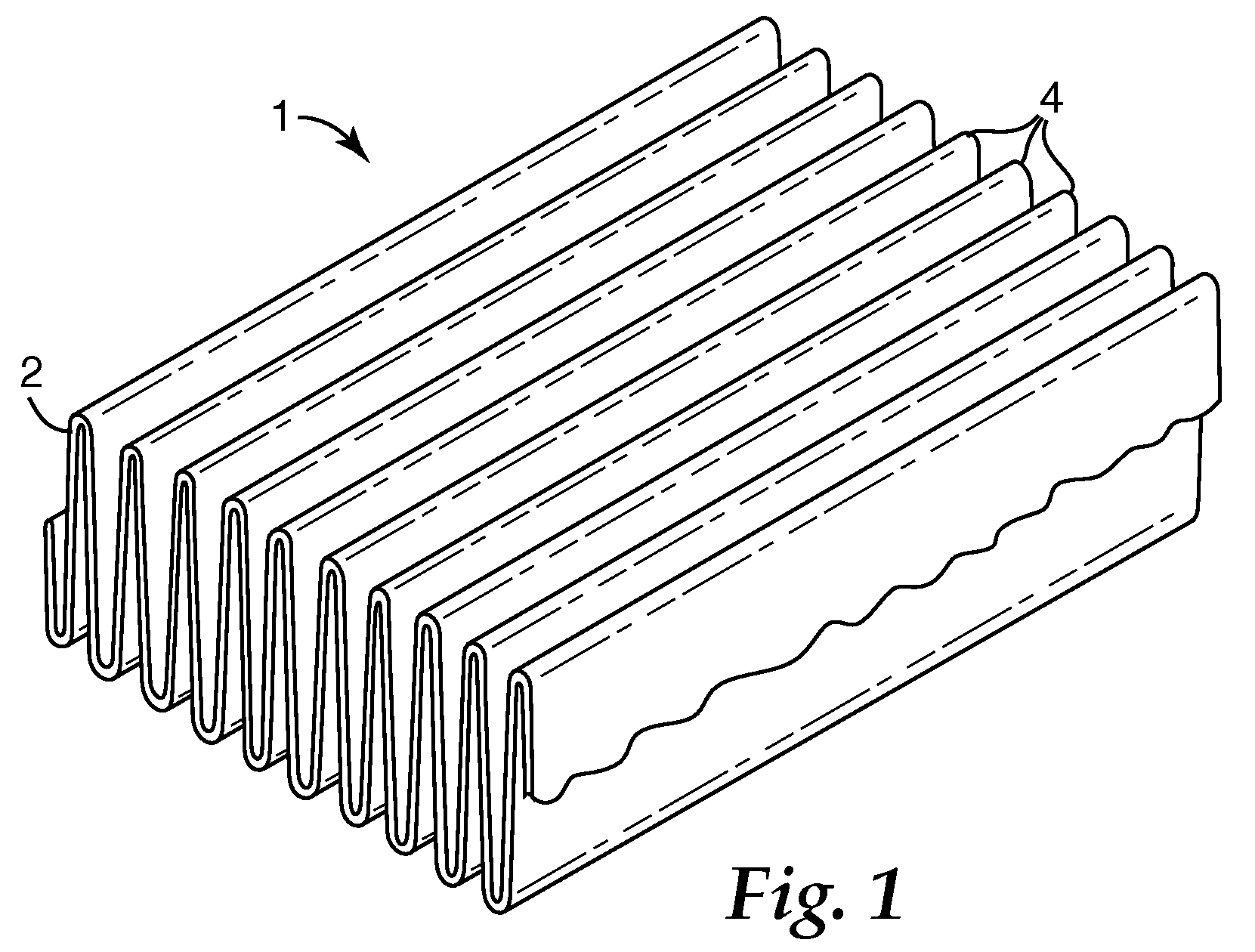

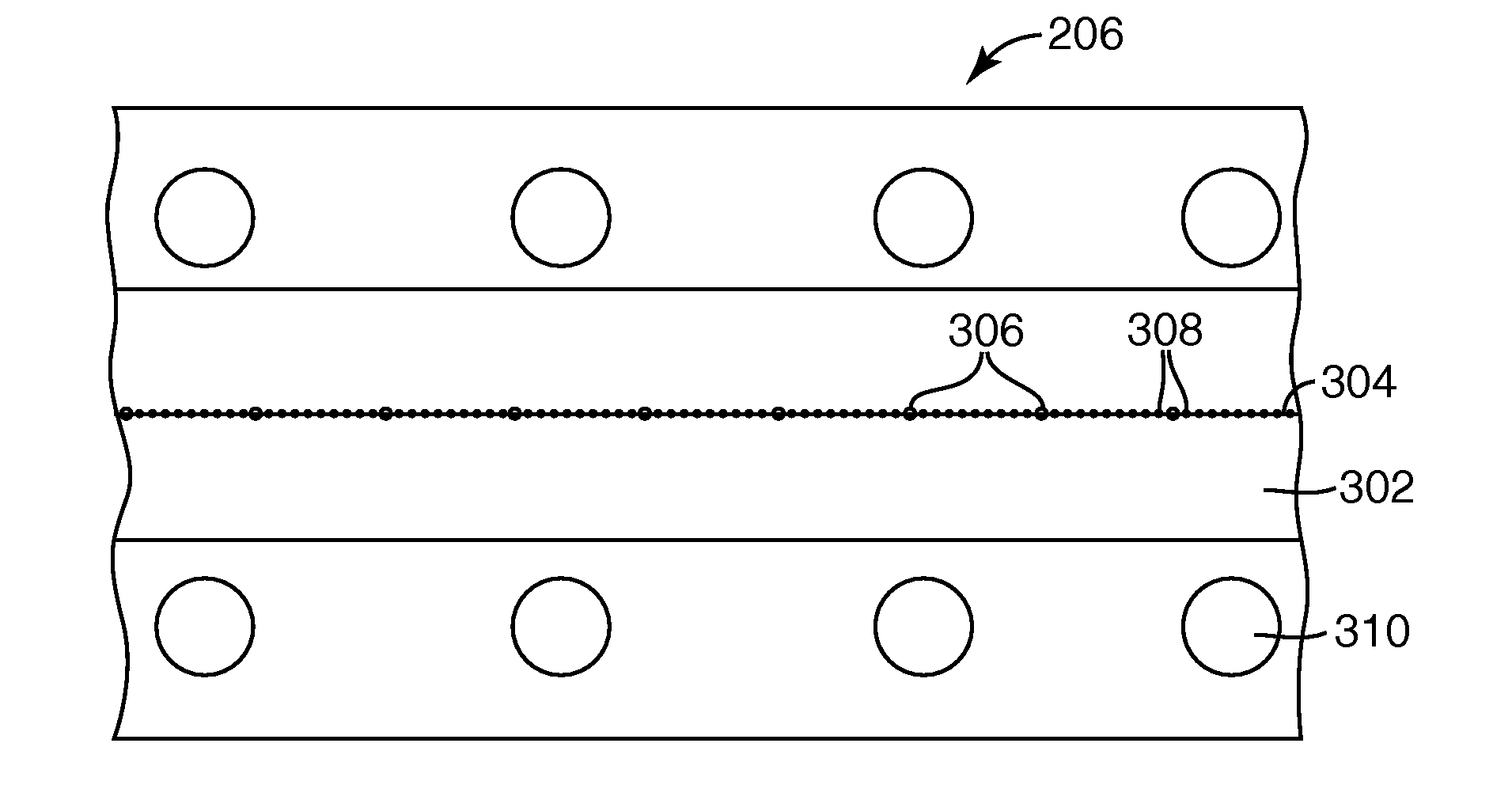

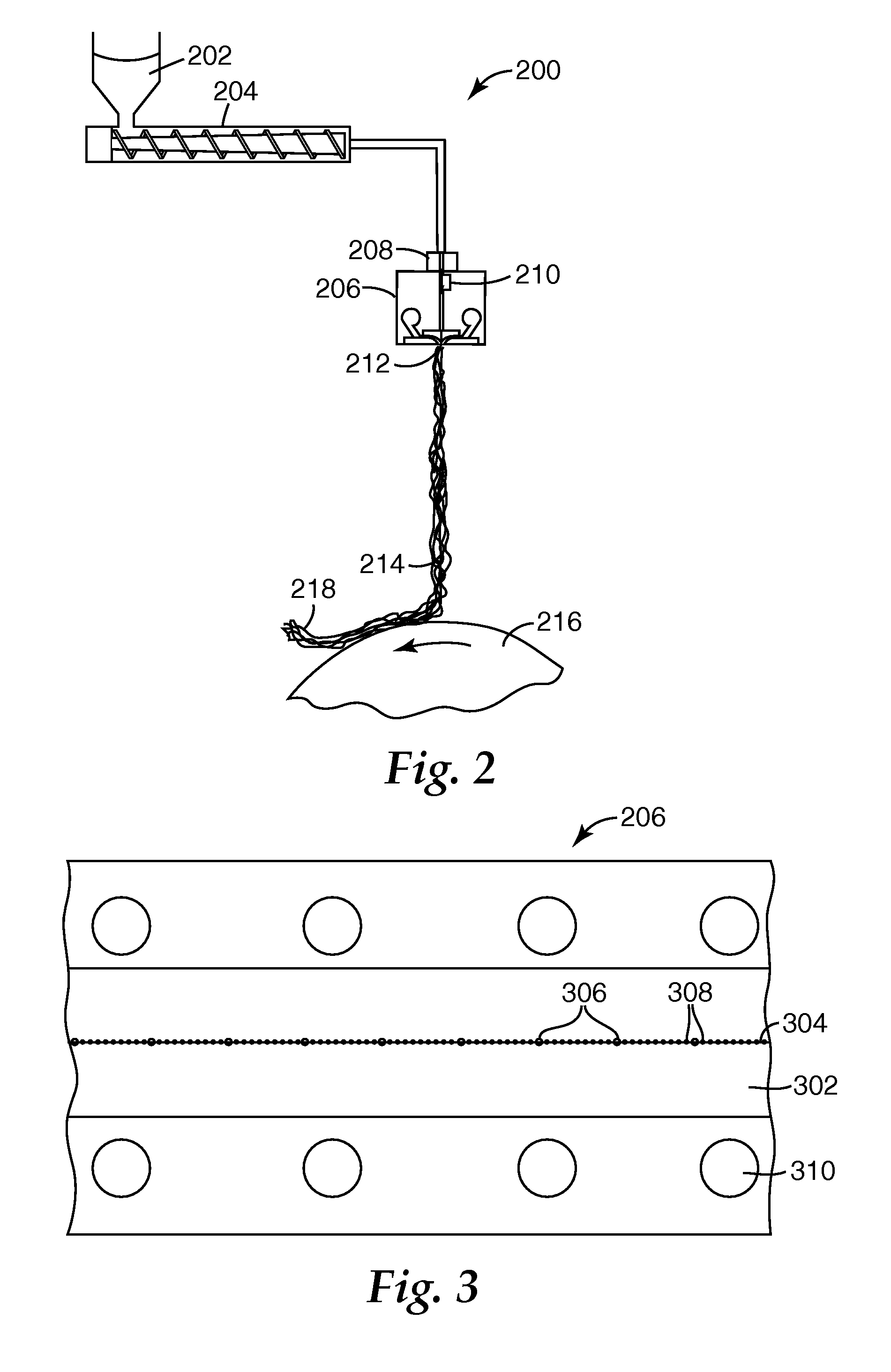

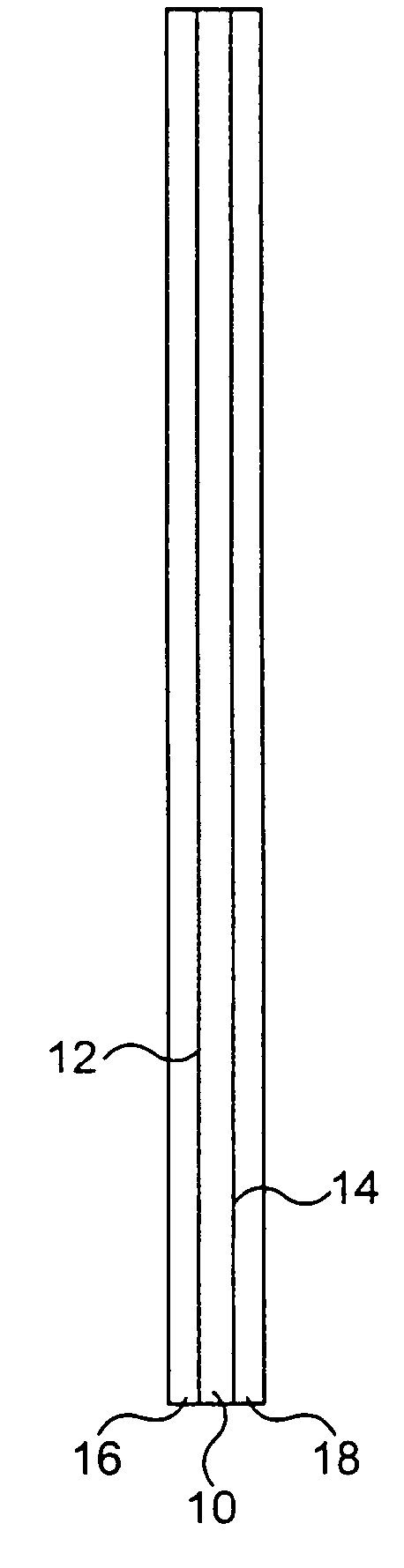

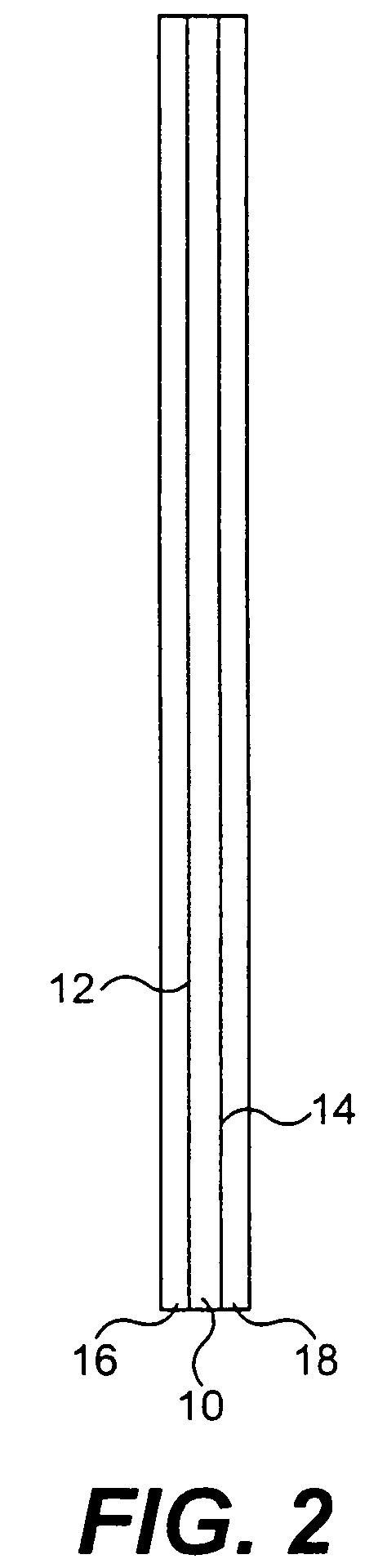

Pleated filter with monolayer monocomponent meltspun media

ActiveUS7947142B2Lower overall pressure dropEfficient captureDispersed particle filtrationLaminationFilter mediaEngineering

A pleated filter is made from a monocomponent monolayer nonwoven web of continuous monocomponent meltspun partially crystalline and partially amorphous oriented fibers of the same polymeric composition that are bonded to form a coherent and handleable web having a Gurley Stiffness of at least 100 mg and which further may be softened while retaining orientation and fiber structure. Rows of pleats are formed in the nonwoven web, and the web is cut to a desired size and shape to provide a pleated filter element containing a self-supporting porous monocomponent monolayer matrix of fibers bonded to one another at least some points of fiber intersection and having an average initial submicron efficiency of at least 15% at a 1.52 meters / sec face velocity. The filter element is deformation resistant without requiring stiffening layers, bicomponent fibers, adhesive or other reinforcement in the filter media layer.

Owner:3M INNOVATIVE PROPERTIES CO

Novel aerogel multifunctional material and preparation method thereof

InactiveCN106928908AGood material uniformityGood formabilityHeat-exchange elementsAerogel preparationWeather resistanceChemistry

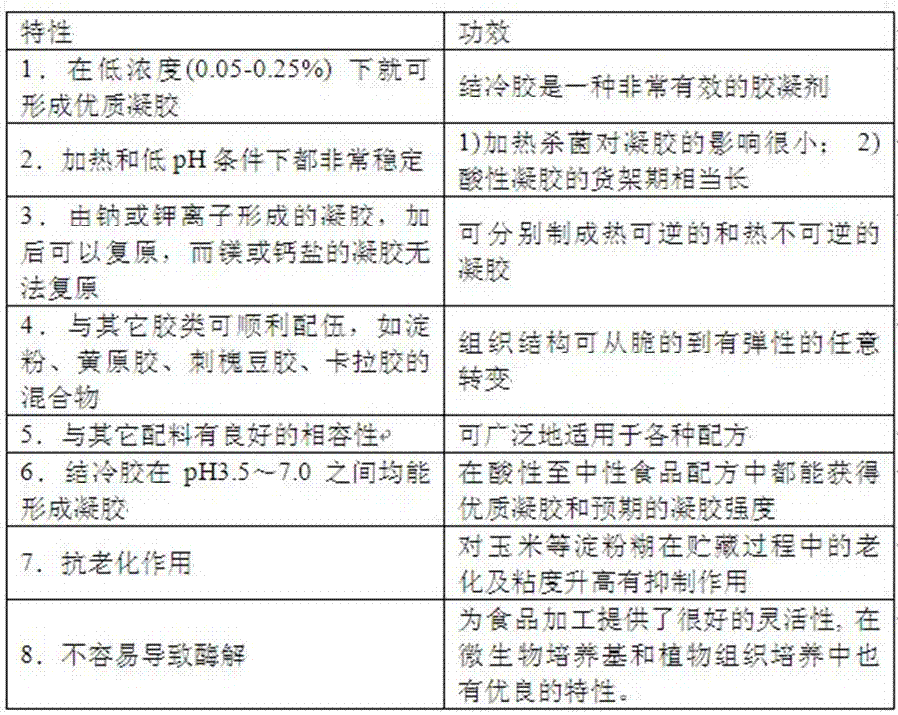

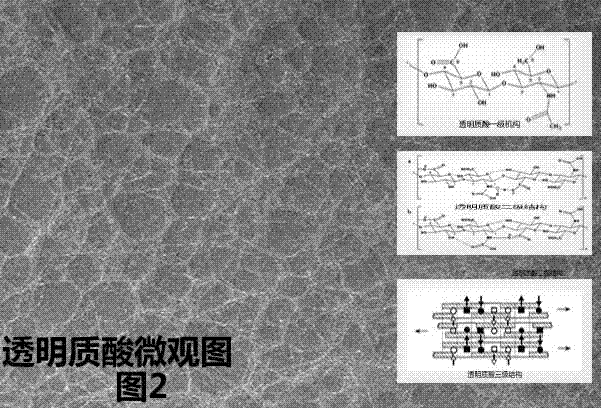

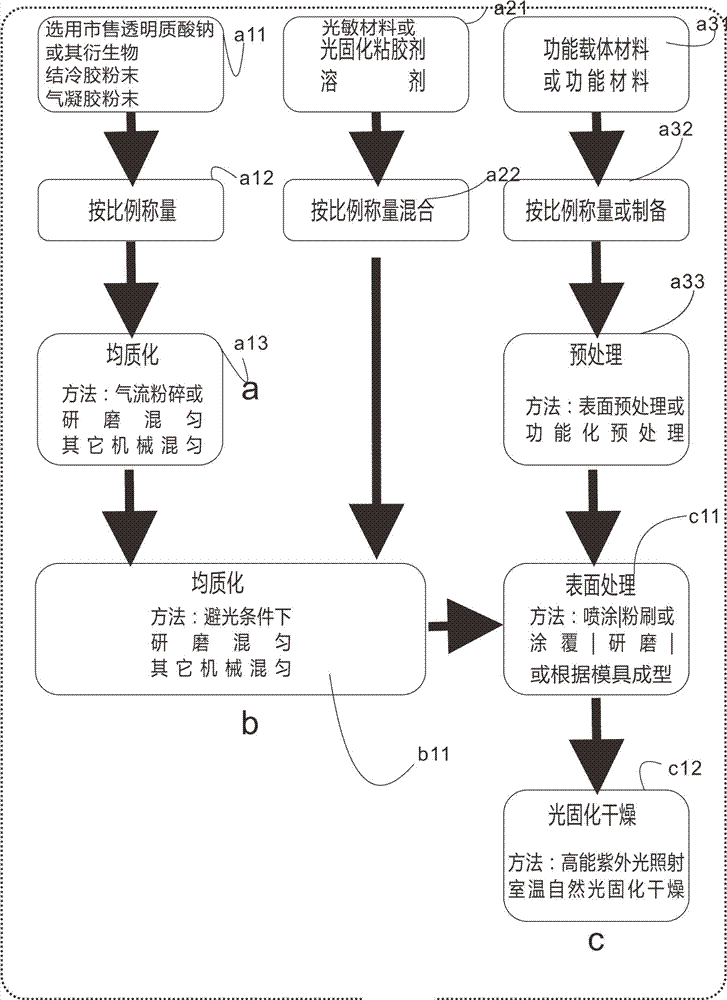

The invention provides a novel aerogel multifunctional material and a preparation method thereof. The multifunctional aerogel composite is prepared from gellan gum, hyaluronic acid as well as derivatives or mixture of the gellan gum and the hyaluronic acid, aerogel, a novel light-sensitive material, a novel solvent or novel ionic liquid or a novel mixed solvent formred by the above solvents or essential oil and the like by a high-energy photocuring method. The composite material has the characteristics of low density, low heat-conducting coefficient, high weather resistance, environmental friendliness and the like. A functional carrier or a functional material coated with the composite material has high heat-isolating, heat-insulating, cold-accumulating, moisturizing, moisture-proof, moisture-retaining and anti-haze characteristics, and the characteristics and the use range of the materials can be improved. The multifunctional material is extremely widely applied, and can be widely applied in the fields of haze prevention and control, disease diagnosis and treatment, medicine, military industry, chemical industry, spaceflight, navigation, aviation, high-speed train, paper making, printing, water treatment, agriculture and animal husbandry, a cold chain system, food and cosmetic safety.

Owner:广州市芯检康生物科技有限公司

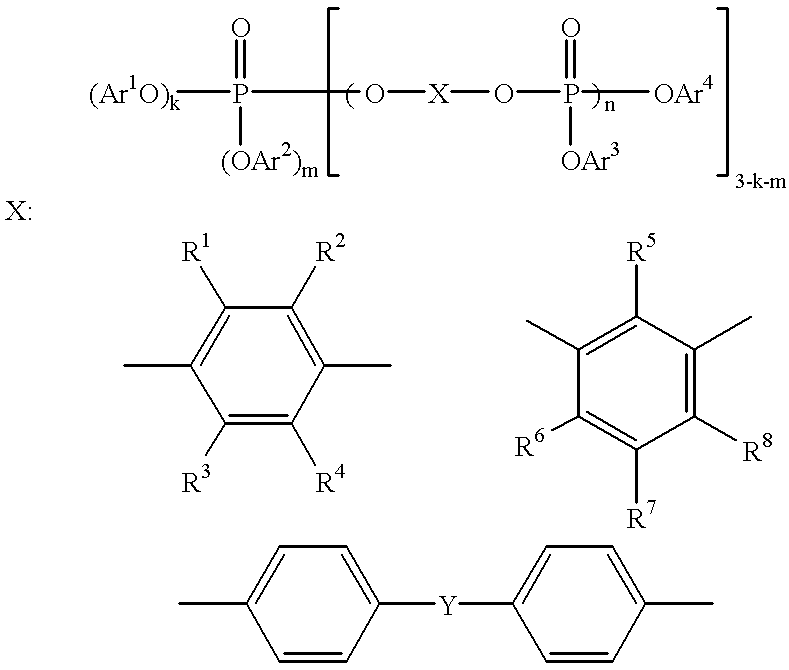

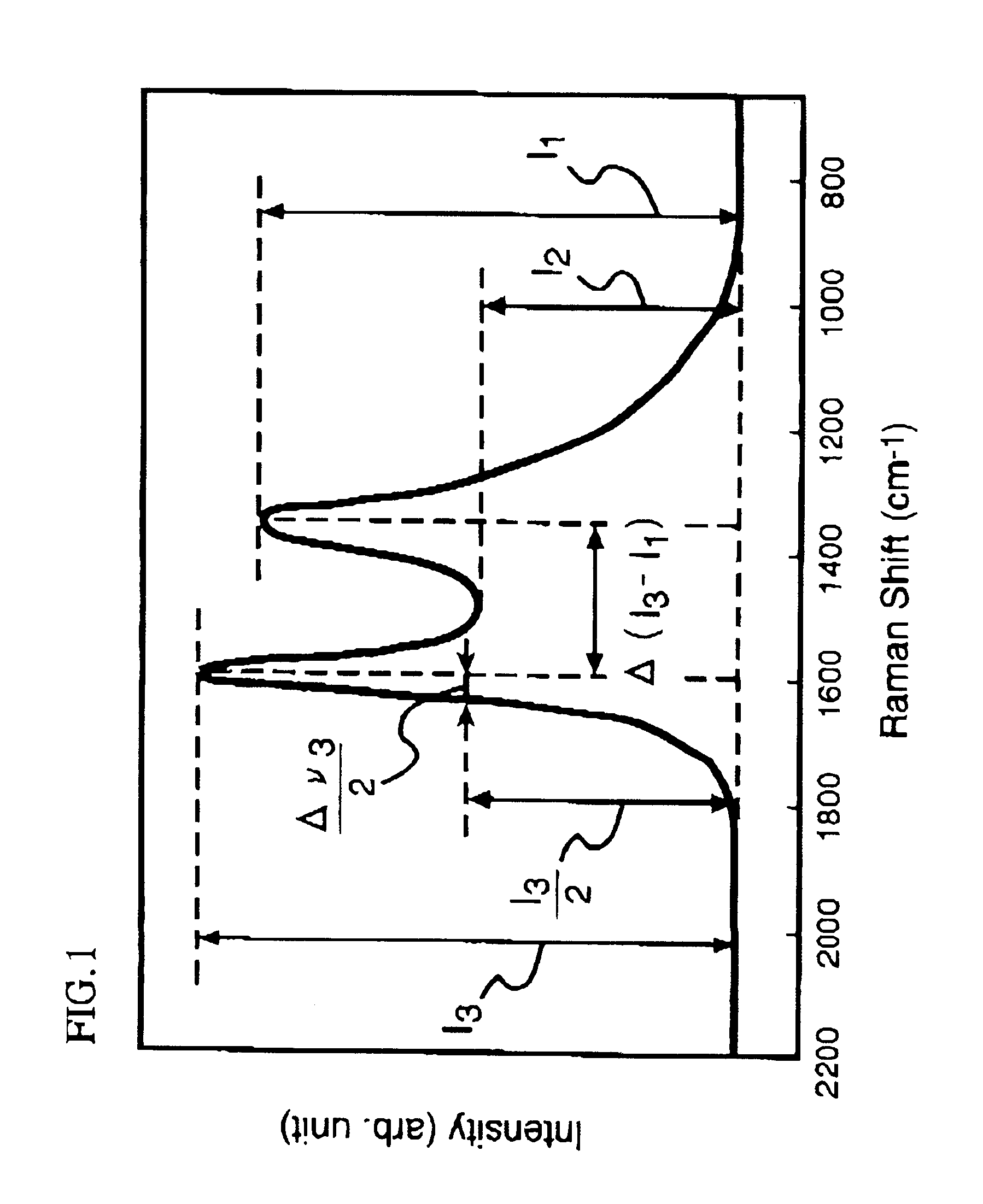

Thermoplastic resin composition, molding material, and molded article thereof

A thermoplastic resin composition capable of providing a thin walled molded article whose flame retardancy with a thickness of 1.6 mm ({fraction (1 / 16)} inch) in accordance with an UL 94 standard is V-0 or better, and which comprises the following components [A], [B] and [C], wherein the component [B] satisfies the following conditions (B1) and / or (B2):[A]: an electrically conductive fiber;[B]: a carbon powder;[C]: a thermoplastic resin;(B1): Raman scattering intensity ratio I2 / I1 is 0.55-0.8;(B2): Raman scattering intensity ratio I2 / I3 is 0.54-0.8; whereI1: local maximum value of Raman scattering intensity appearing near a Raman shift of 1360 cm-1;I2: local minimum value of the Raman scattering intensity appearing near a Raman shift of 1480 cm-1;I3: local maximum value of the Raman scattering intensity appearing neat a Raman shift of 1600 cm-1.

Owner:TORAY IND INC

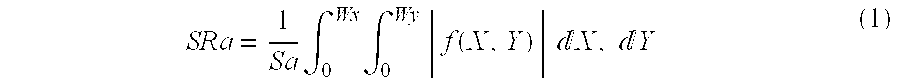

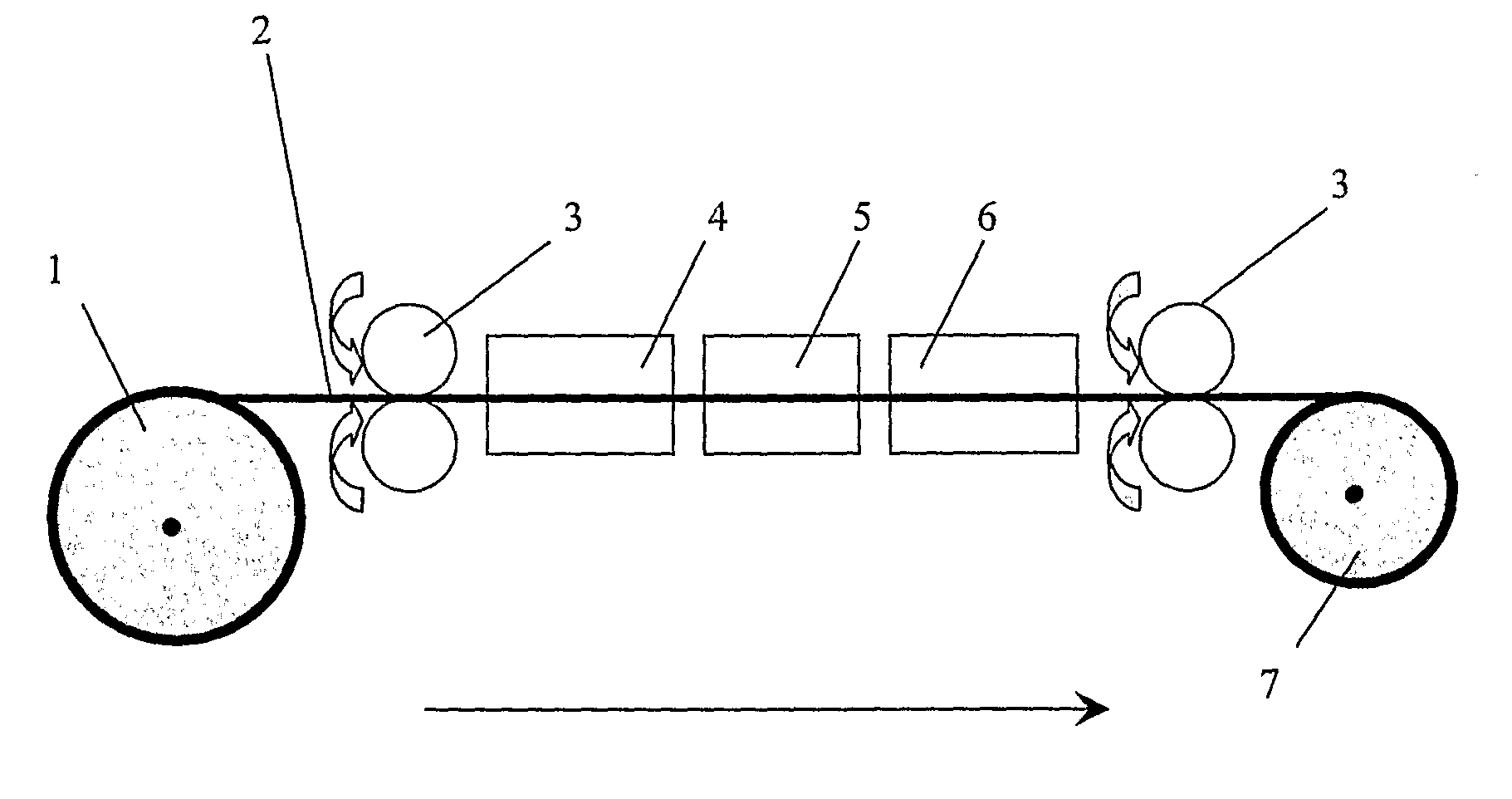

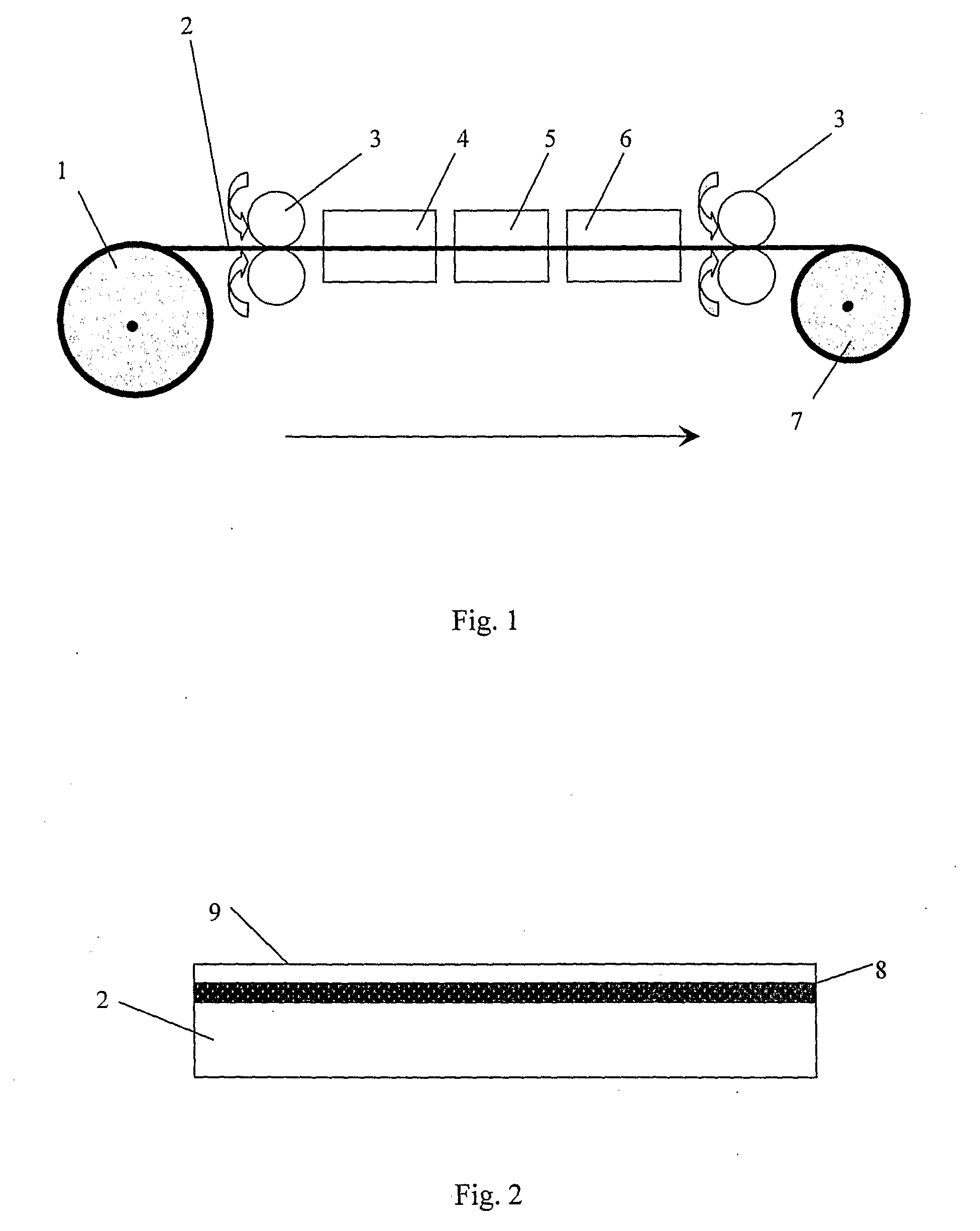

Nonwoven fabric for separator of non-aqueous electrolyte battery and non-aqueous electrolyte battery using the same

InactiveUS6200706B1Uniform and efficient productionImprove various performanceOrganic electrolyte cellsPaper/cardboardSurface roughnessEngineering

The object of the present invention is to provide a nonwoven fabric for separators of non-aqueous electrolyte batteries which is superior in adhesion to electrodes, causes no breakage of the separator and neither slippage nor space between electrode and the separator at the time of fabrication of battery, provides superior battery processability such as rollability with electrodes, causes no internal short-circuit due to contact between electrodes caused by shrinking or burning of the nonwoven fabric even when electrodes generate heat owing to external short-circuit, whereby ignition of the battery can be inhibited, has no pin holes and is superior in retention of electrolyte and penetration of electrolyte, and which can give non-aqueous electrolyte batteries superior in capacity, battery characteristics and battery storage characteristics. Specifically, the nonwoven fabric for separators of non-aqueous electrolyte batteries according to the present invention has a thickness non-uniformity index (Rpy) of 1000 mV or less or a center surface average roughness SRa of 6 mum or less in whole wavelength region as measured using a tracer method three-dimensional surface roughness meter.

Owner:MITSUBISHI PAPER MILLS LTD

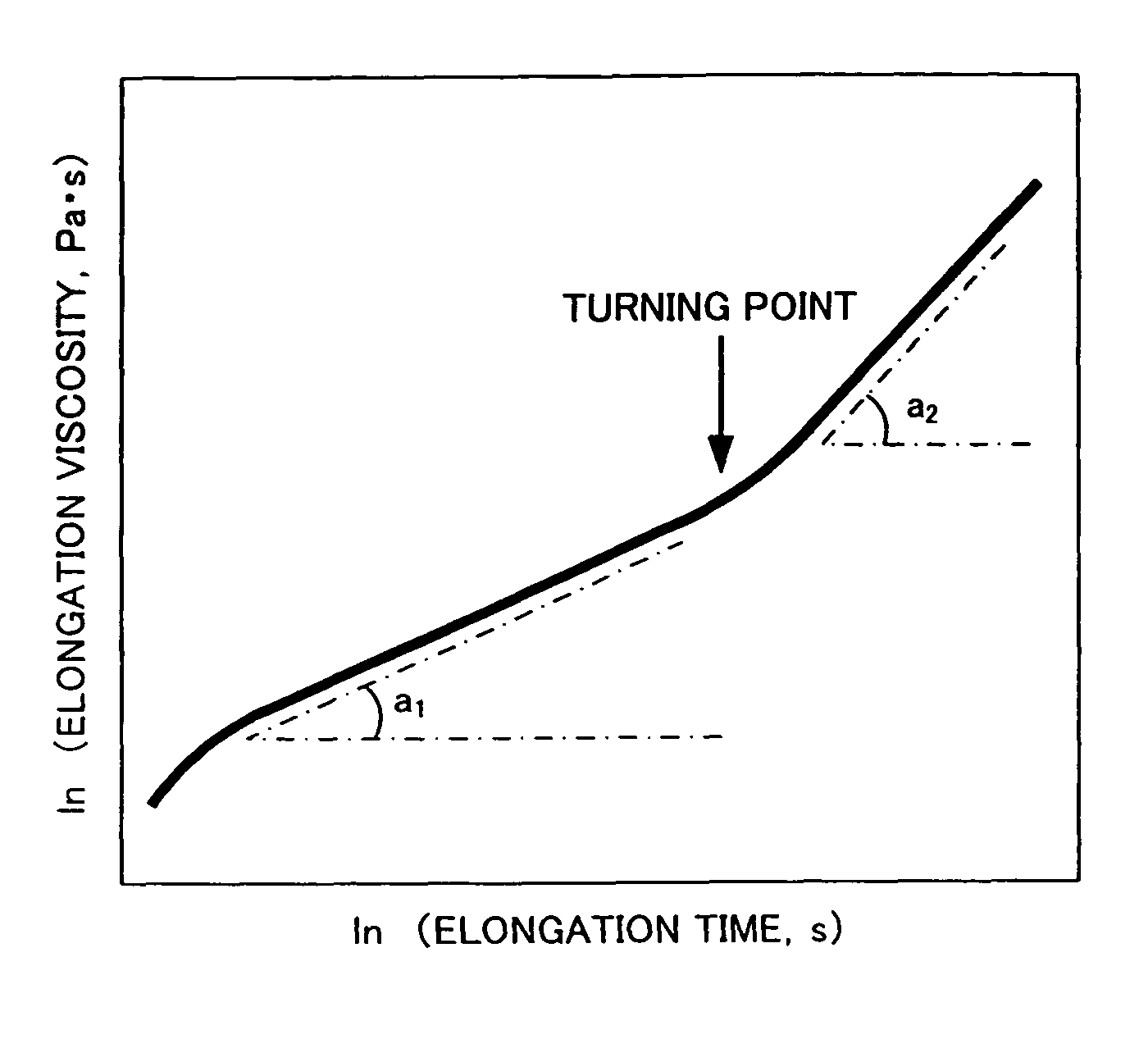

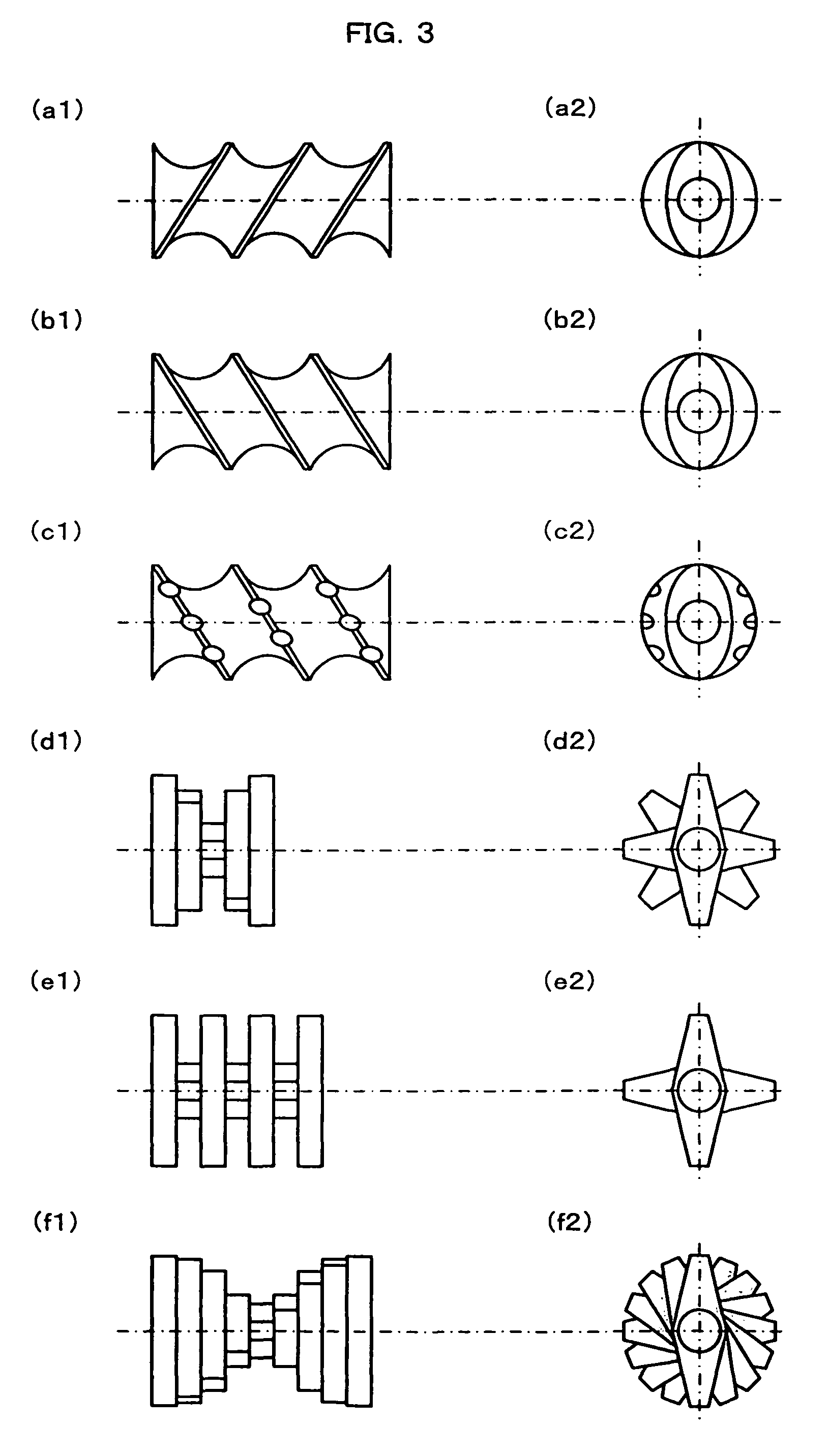

Biodegradable polyester resin composition, preparation method therefor, and foamed article and molded article produced therefrom

A biodegradable polyester resin composition which comprises a thermoplastic polymer comprising 100 parts by mass of an aliphatic polyester (A) and 0.01 to 5 parts by mass of a (meth)acrylic ester (B1) and / or a glycidyl ether (B2, and has a gelation index (1) of not lower than 0.1% and a gelation index (2) of not higher than 0.5%.

Owner:UNITIKA LTD

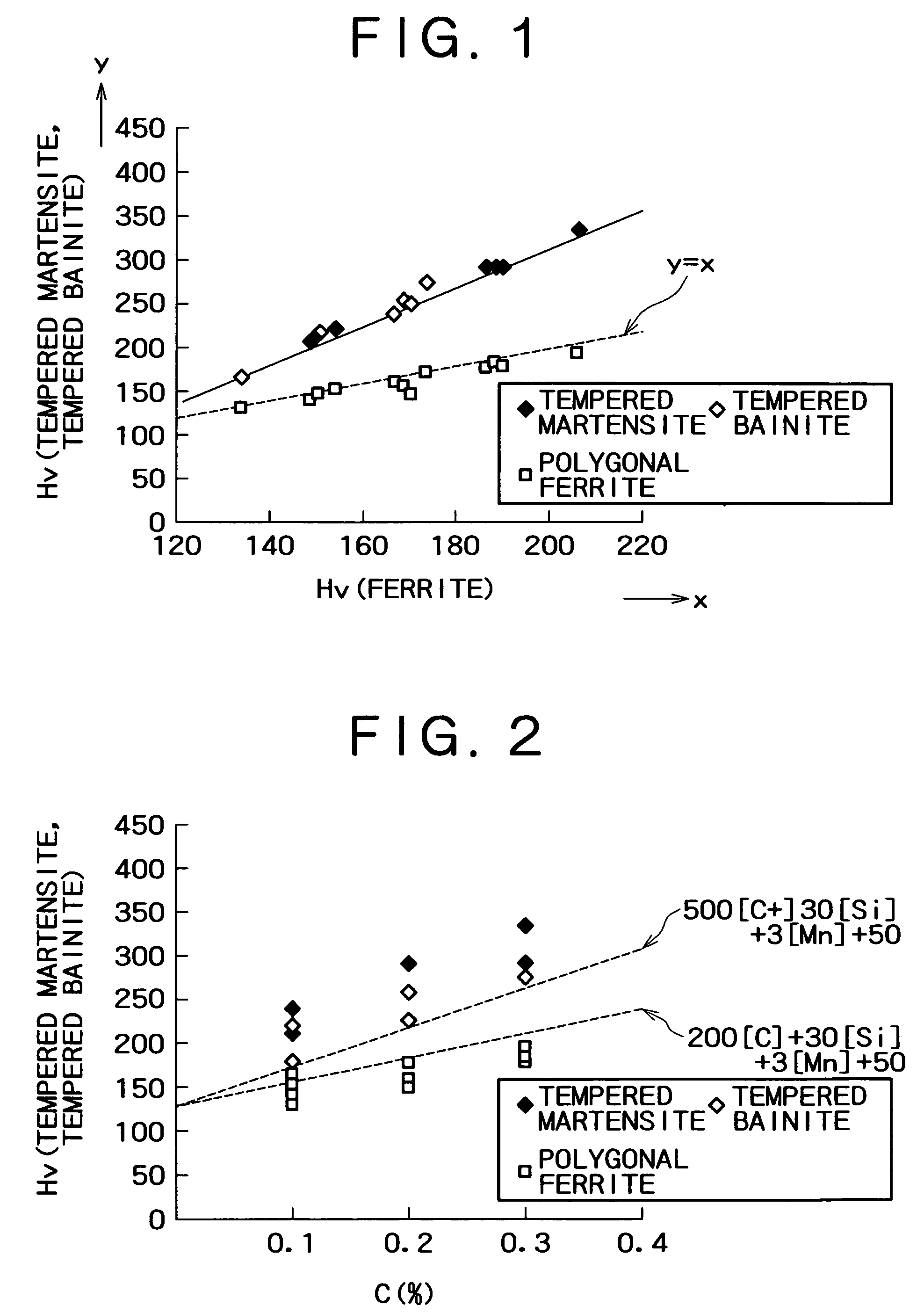

High strength steel sheet having excellent formability and method for production thereof

InactiveUS7090731B2Good molding effectHigh strengthHot-dipping/immersion processesFurnace typesHigh intensityHardness

A high strength steel sheet having (2-1) a base phase structure, the base phase structure being tempered martensite or tempered bainite and accounting for 50% or more in terms of a space factor relative to the whole structure, or the base phase structure comprising tempered martensite or tempered bainite which accounts for 15% or more in terms of a space factor relative to the whole structure and further comprising ferrite, the tempered martensite or the tempered bainite having a hardness which satisfies the relation of Vickers hardness (Hv)≧500[C]+30[Si]+3[Mn]+50 where [ ] represents the content (mass %) of each element, and (2-2) a second phase structure comprising retained austenite which accounts for 3 to 30% in terms of a space factor relative to the whole structure and optionally further comprising bainite and / or martensite, the retained austenite having a C concentration (CγR) of 0.8% or more.

Owner:KOBE STEEL LTD

Bonding wire for semiconductor device

ActiveUS20090188696A1Economical in material costSuperior in ball bondability bondabilityNon-insulated conductorsSolid-state devicesConcentration gradientControllability

The present invention provides a bonding wire improved in formability of a ball part, improved in bondability, good in loop controllability, improved in bonding strength of a wedge connection, securing industrial production ability as well, and mainly comprised of copper which is more inexpensive than gold wire, that is, provides a bonding wire for a semiconductor device comprised of a bonding wire having a core material having copper as its main ingredient and a surface covering layer over the core material and of a conductive metal of a composition different from the core material, characterized in that the surface covering layer has as its main ingredients two or more types of metals selected from gold, palladium, platinum, rhodium, silver, and nickel and the surface covering layer has a concentration gradient of one or both of a main ingredient metal or copper in the wire radial direction.

Owner:NIPPON STEEL CHEMICAL CO LTD

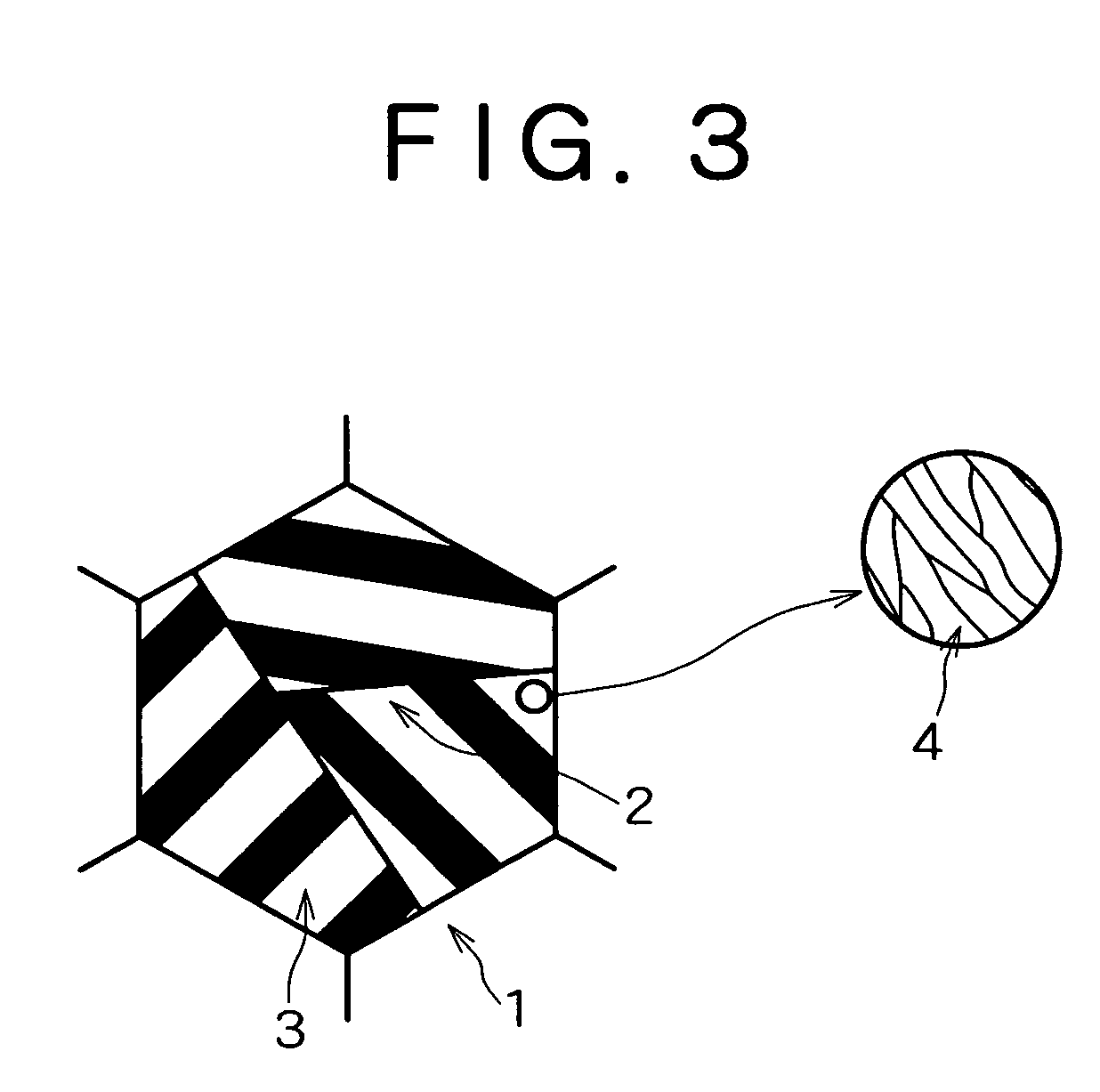

Metal Product, Method of Manufacturing a Metal Product and Use Thereof

InactiveUS20080038579A1Good molding effectVacuum evaporation coatingSputtering coatingFiberMetal alloy

A metal product having a metallic substrate in the form of a tube, strip, foil wire, fibre or bar has a decorative coating consisting of at least two different layers. One layer is based on a metal or metal alloy and one layer is based on a transparent oxide. The product is produced with the aid of PVD in a continuous process and is used in various customer-related products, such as household equipment, mobile phones, or buttons and zippers in clothing.

Owner:SCHUISKY MIKAEL +1

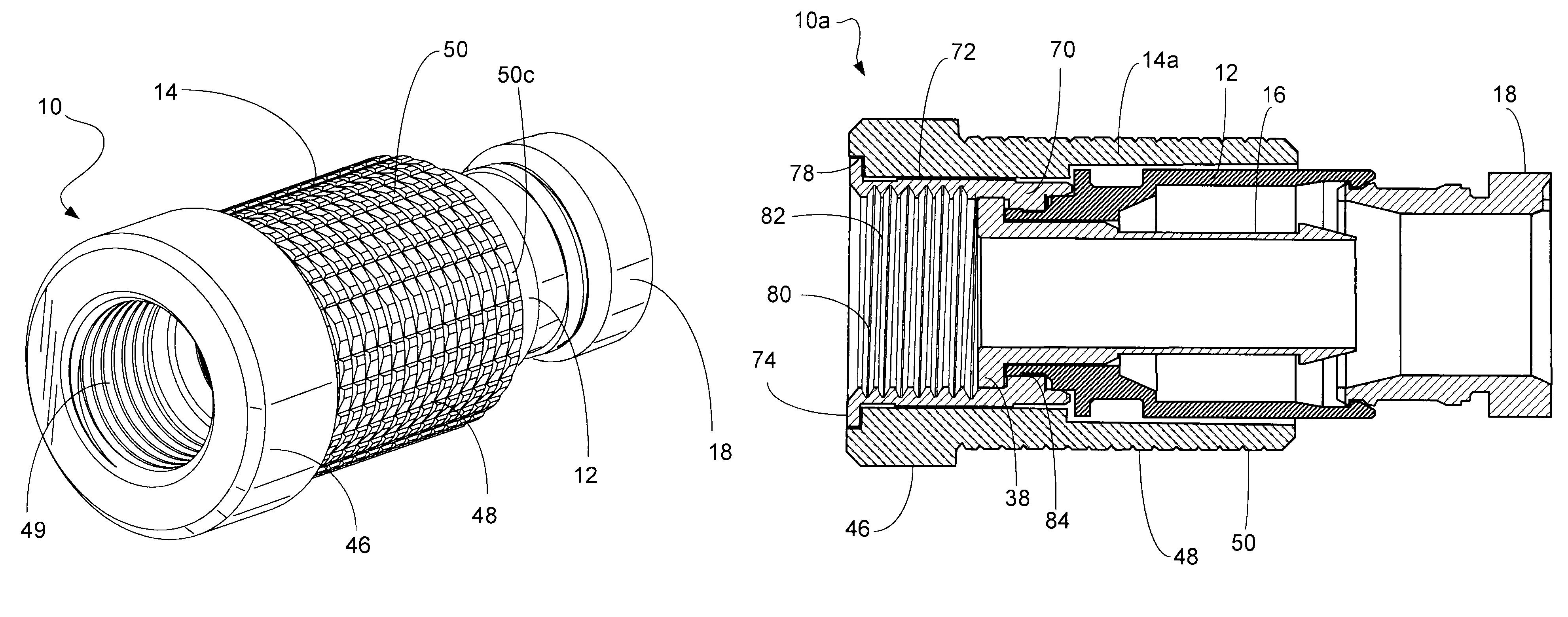

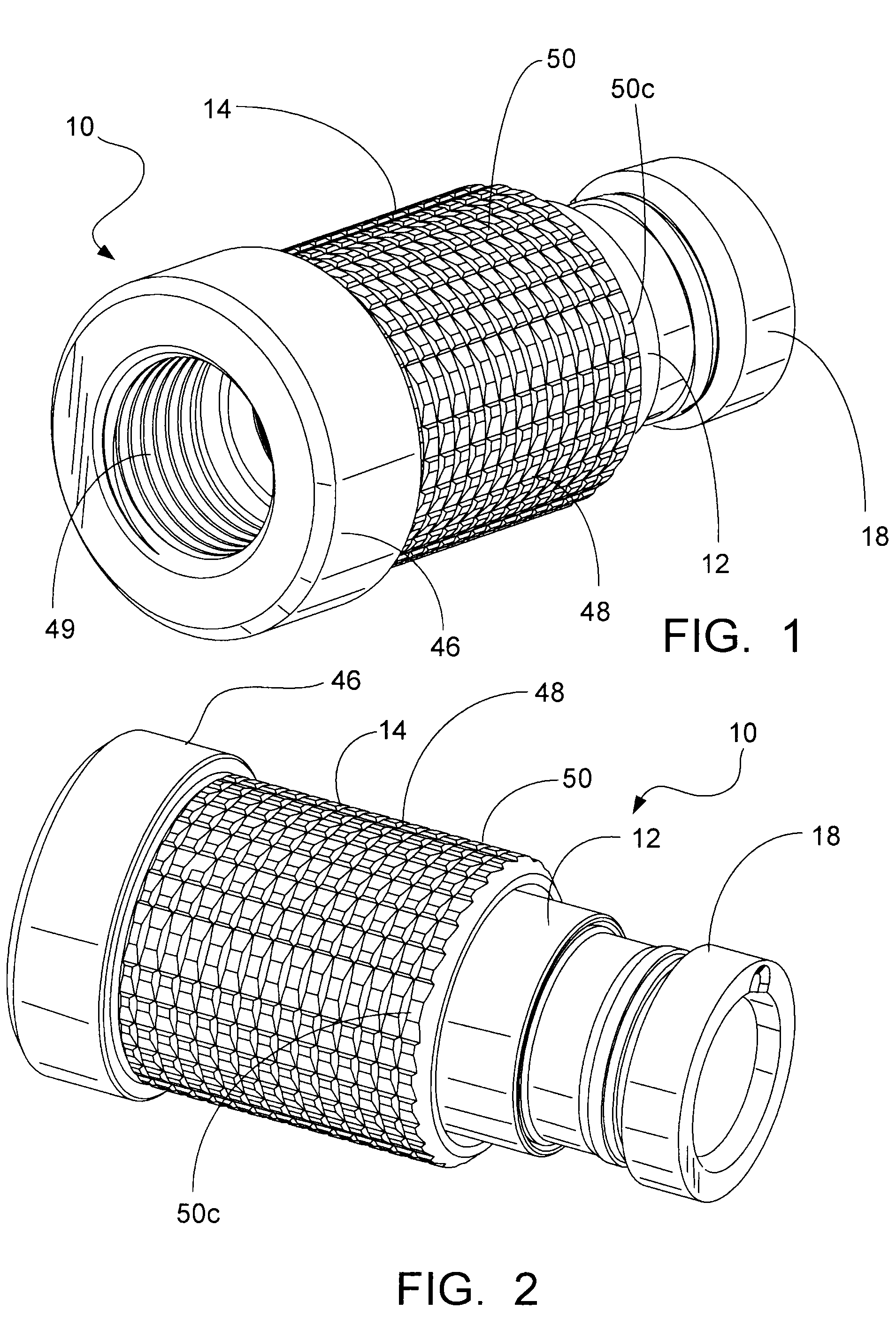

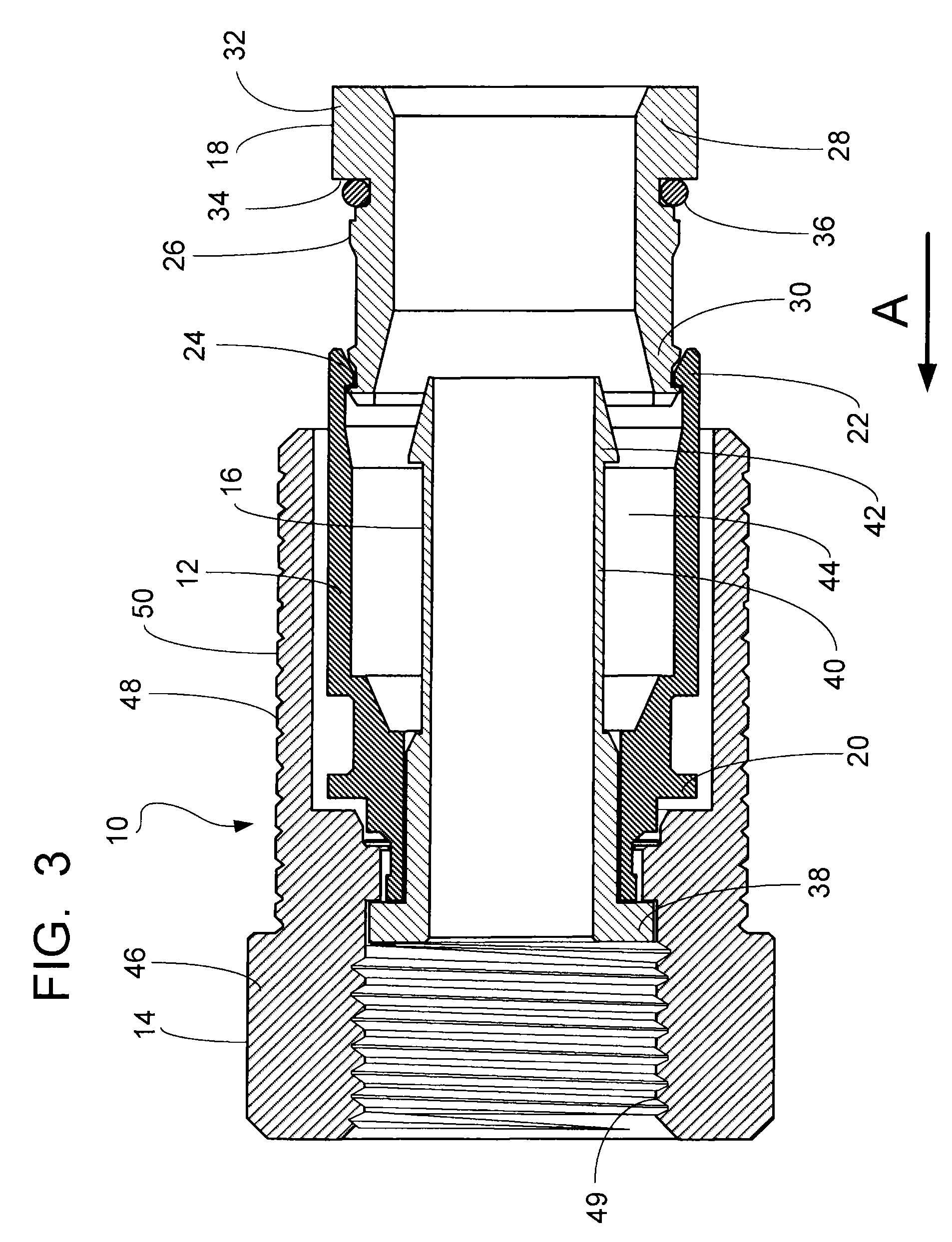

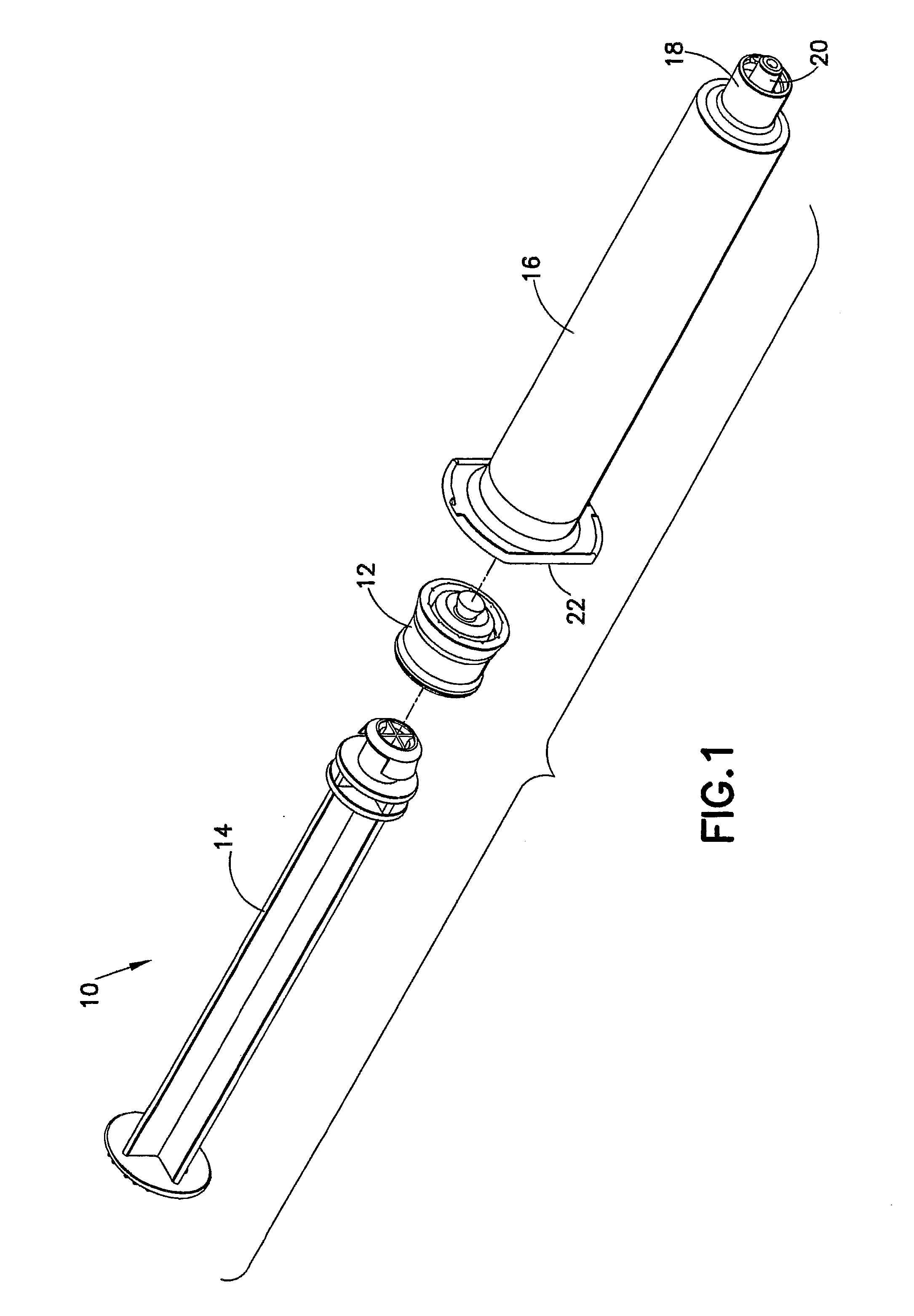

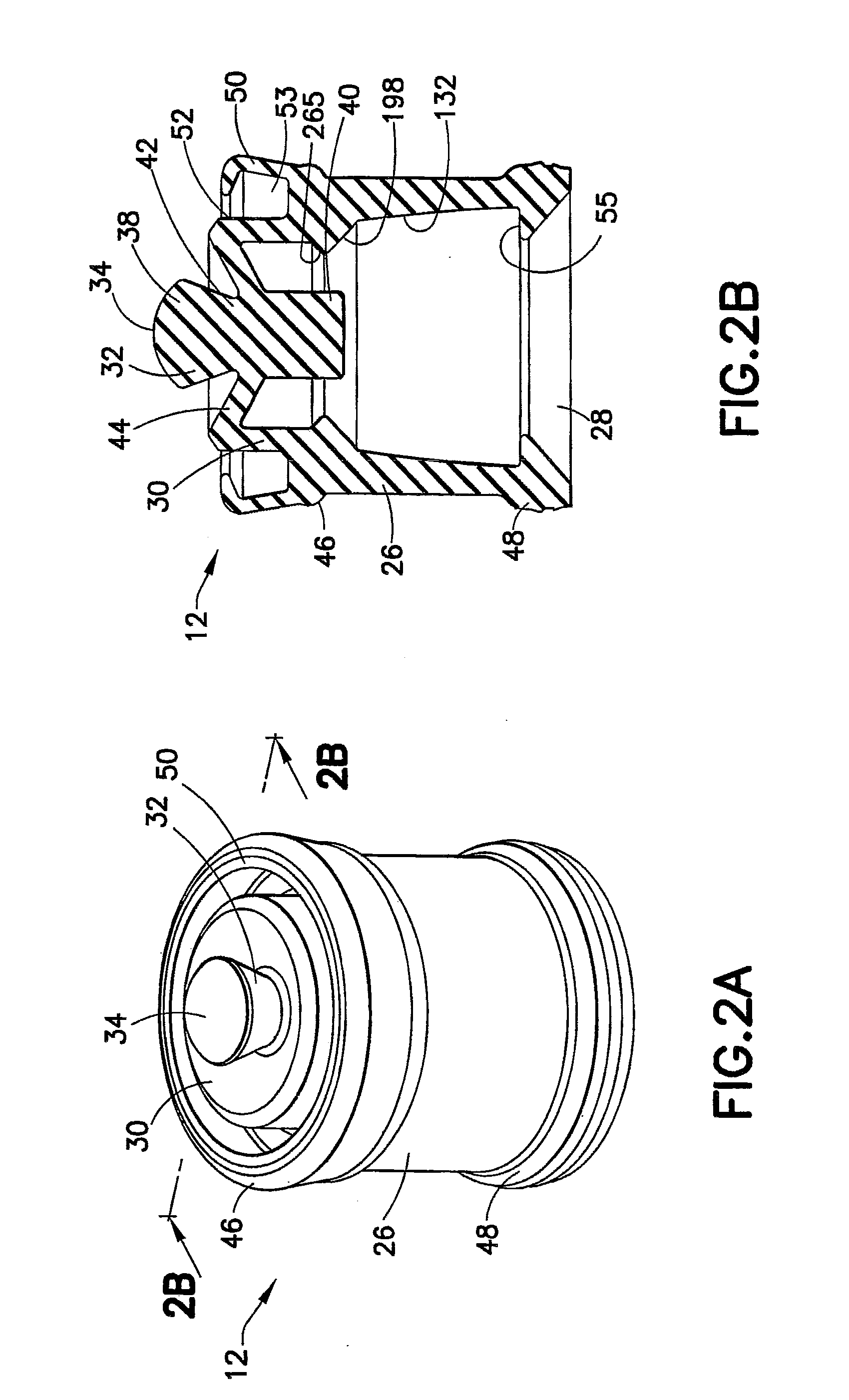

Hand tightenable coaxial cable connector

ActiveUS8029316B2Enhance hand-tighteningMinimizing cost and complexityElectrically conductive connectionsCoupling device detailsCoaxial cableEngineering

A coaxial cable connector includes a connector body having a forward end and a rearward cable receiving end for receiving a cable and a nut rotatably coupled to the forward end of the connector body. The nut includes a flanged head portion at its forward end and a tubular body portion extending rearwardly from the head portion over the connector body and terminating adjacent the rearward cable receiving end of the connector body. The flanged head portion is radially enlarged, having an outer diameter greater than a maximum outer diameter of the tubular body portion, and the tubular body portion preferably surrounds more than half the length of the connector body.

Owner:PPC BROADBAND INC

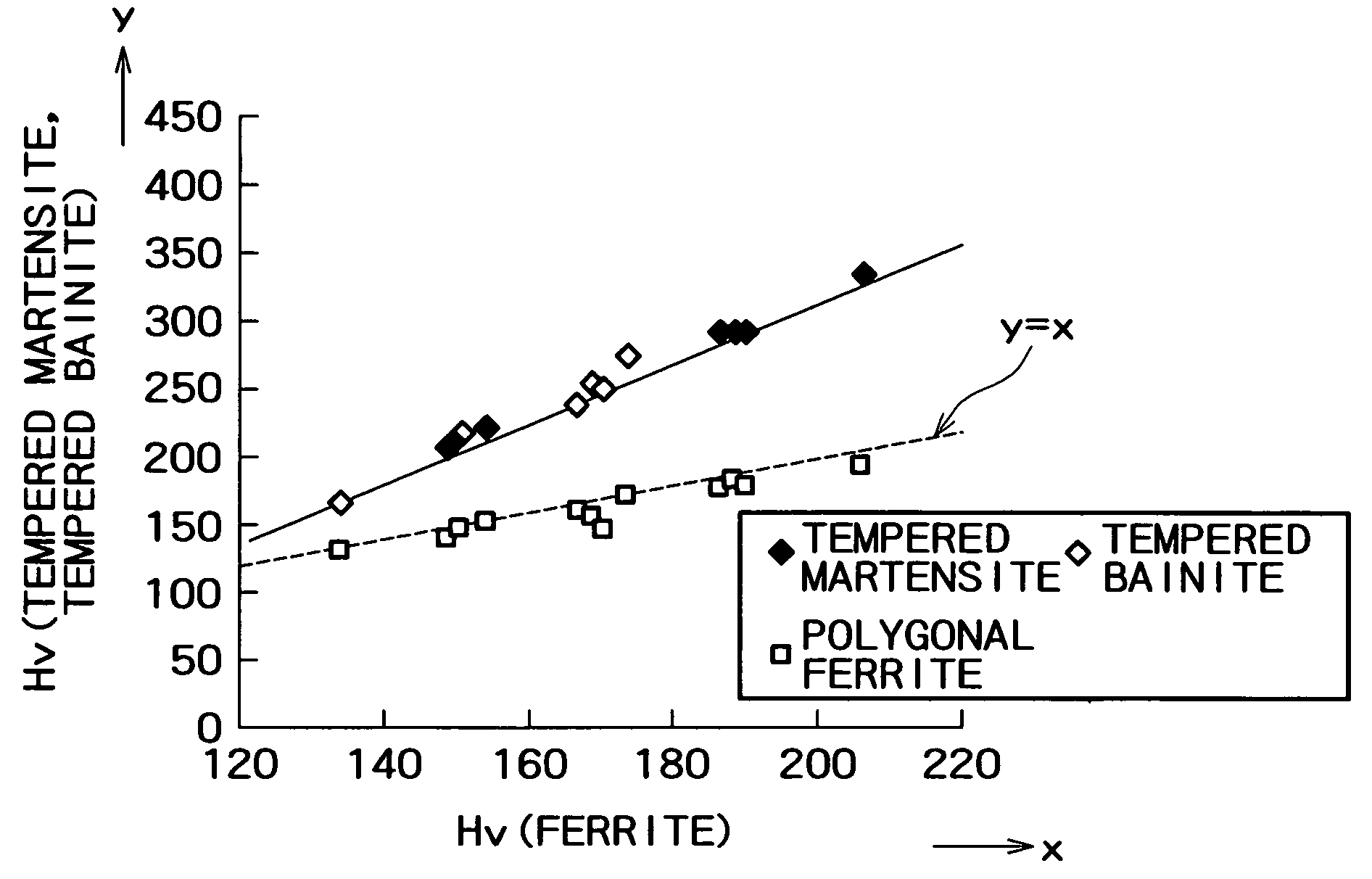

Absorbent material of water absorbent polymer, thermoplastic polymer, and water and method for making same

InactiveUS20030065296A1High tensile strengthPromote absorptionInsulated cablesBaby linensFiberPolymer science

An absorbent material is disclosed, containing at least about 30 weight percent of a superabsorbent polymer, a thermoplastic polymer binder resin, and about 0.1 to about 10 weight percent water. The absorbent material absorbs deionized water to at least about 70 percent of maximum capacity within about 20 minutes after exposure to the deionized water. The method of making the absorbent material includes combining binder resin and absorbent polymer in a twin screw extrusion mechanism, compounding and driving the composition toward exit openings, extruding the composition through the exit openings, and preferably rapidly cooling the extrudate with non-liquid quenching means. The quenched or non-quenched extrudate may be made in the form of a pellet, film, or fibrous strand.

Owner:STOCKHAUSEN GMBH & CO KG DEGUSSA-HUELS AKTIENGESE

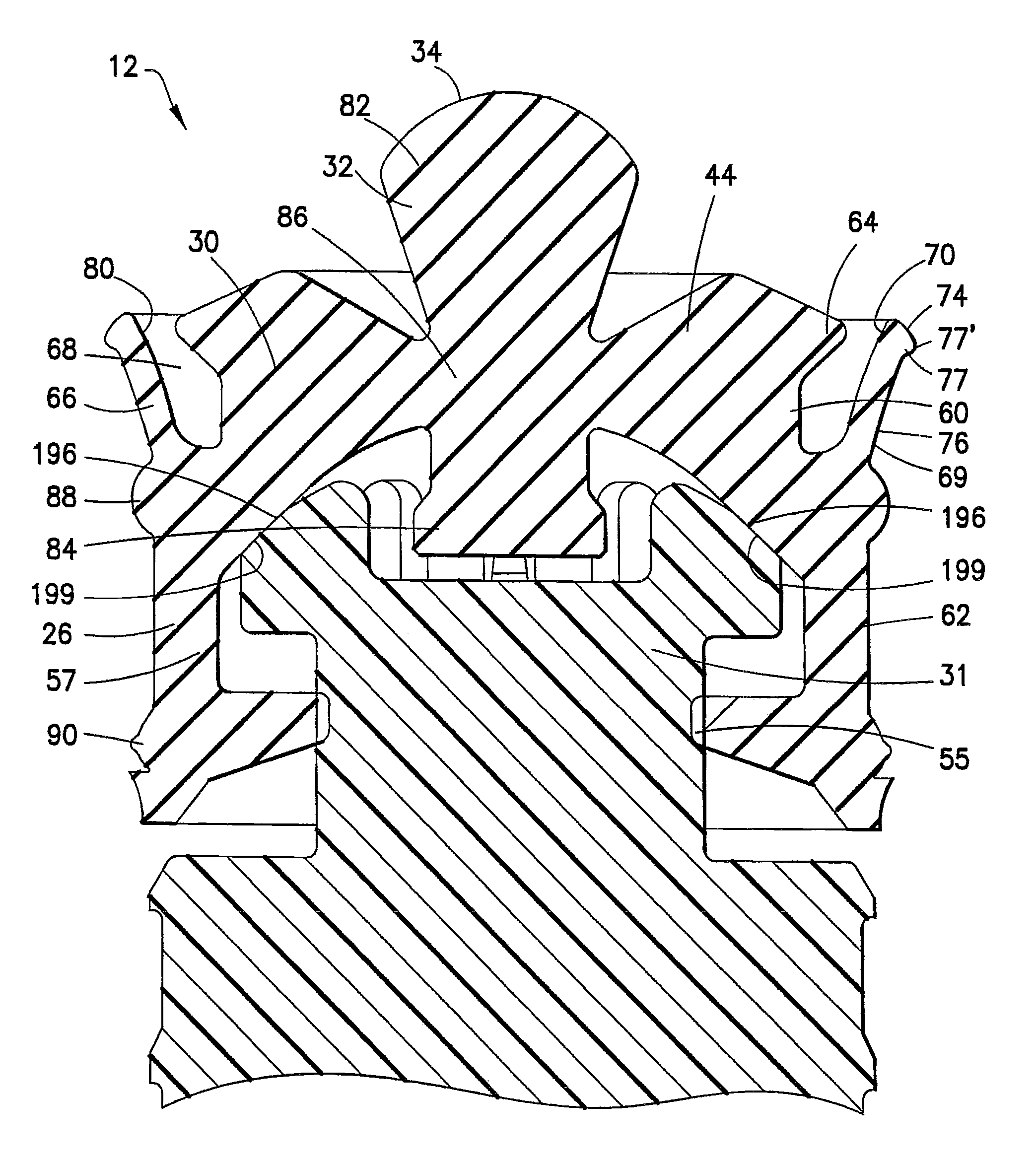

Stoppers Used in Pre-filled Syringes

ActiveUS20110034882A1Simple moldingIncrease contact pressureInfusion syringesIntravenous devicesEngineeringPrefilled Syringe

A stopper adapted for attachment with a plunger rod for use within a syringe barrel is disclosed. The stopper includes a main body defining an open rearward end and a closed front end. The open rearward end is adapted to receive a front forward end attachment portion of the plunger rod. The stopper also includes a core member integrally formed with the main body adjacent the closed front end. The core member includes a nose portion having a conical tip configured for entering an outlet opening of the syringe barrel. The closed front end of the stopper has a profile configured to cooperate with an internal surface of the syringe barrel wall to prevent reflux and reduce dead space within the barrel.

Owner:BECTON DICKINSON & CO

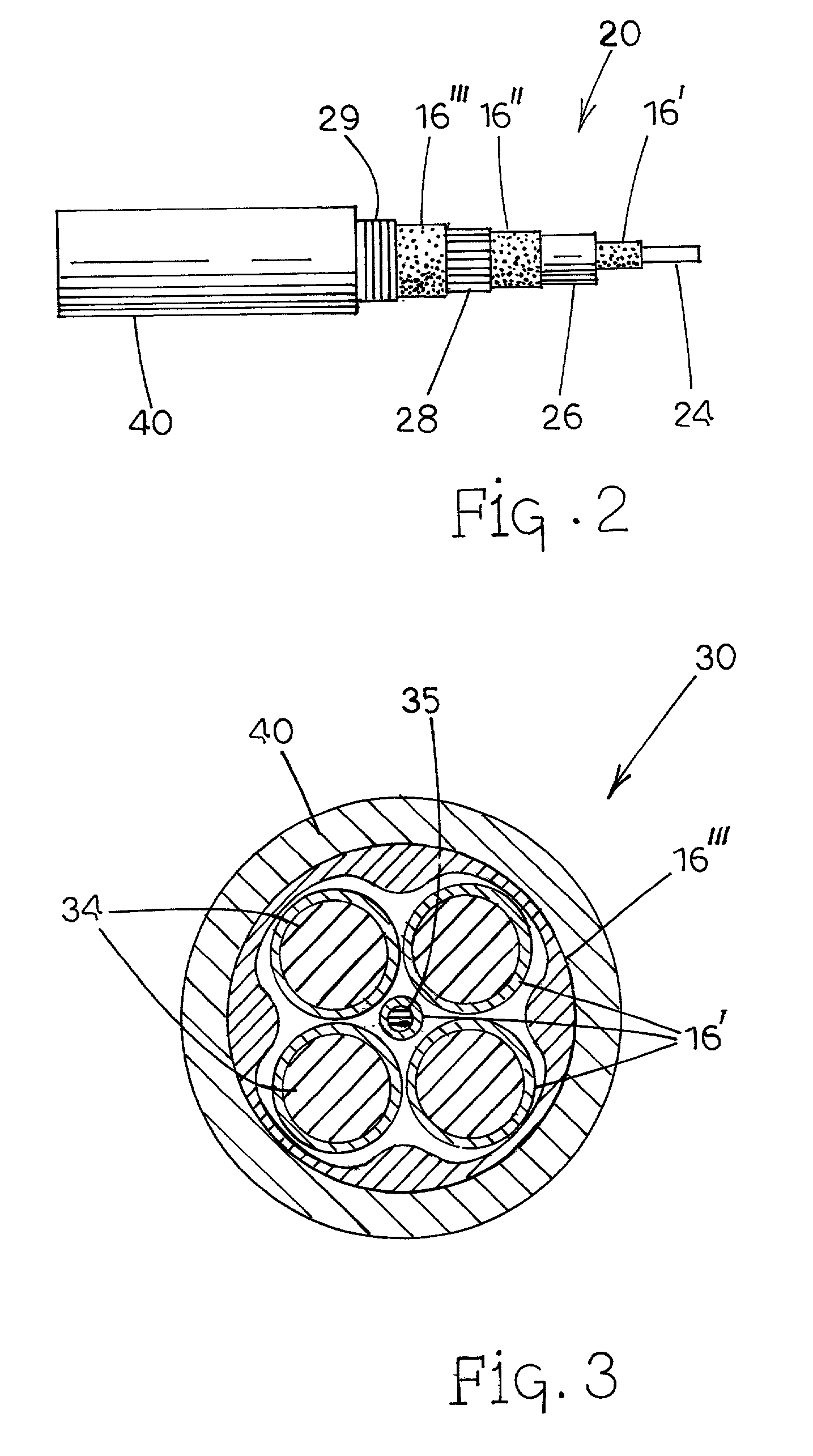

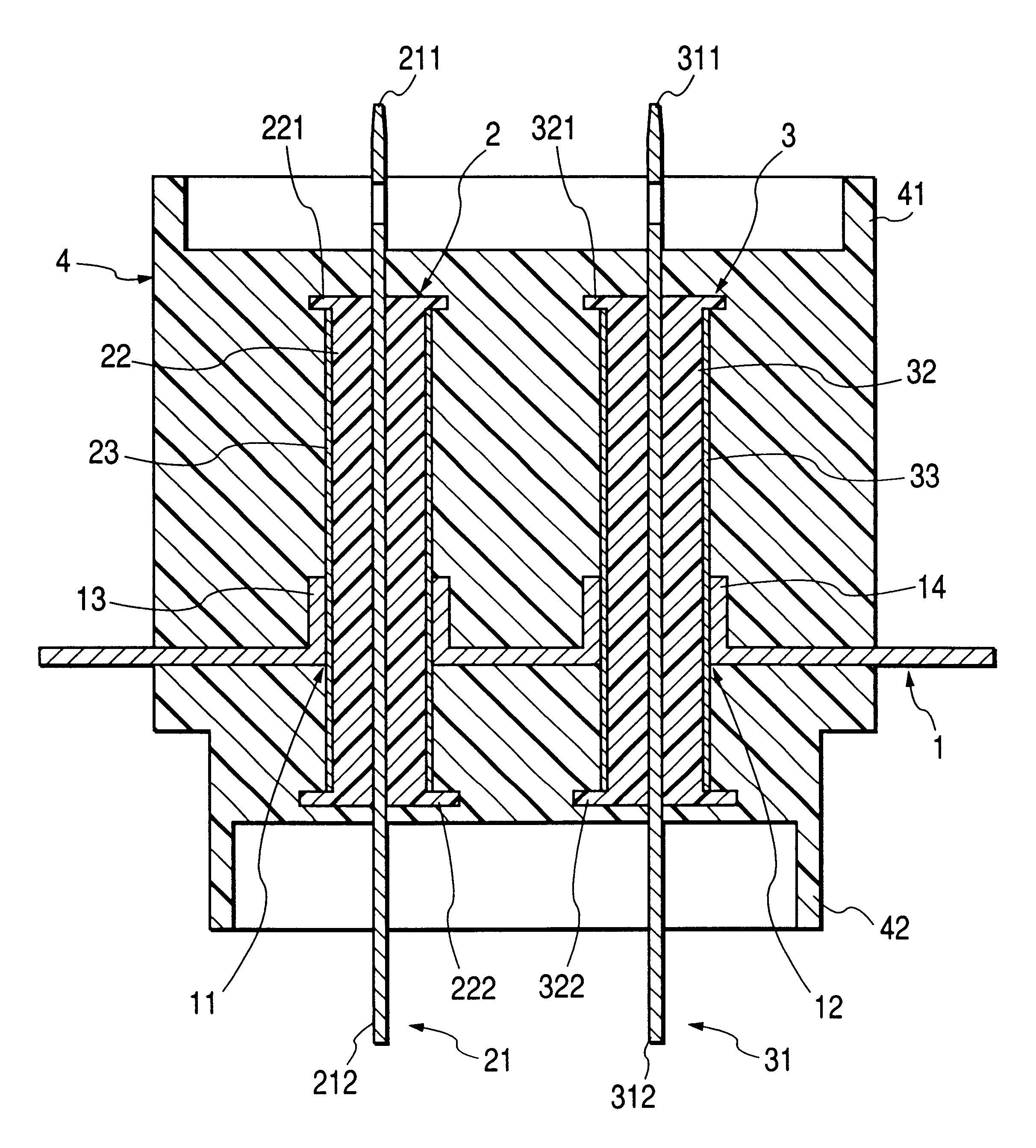

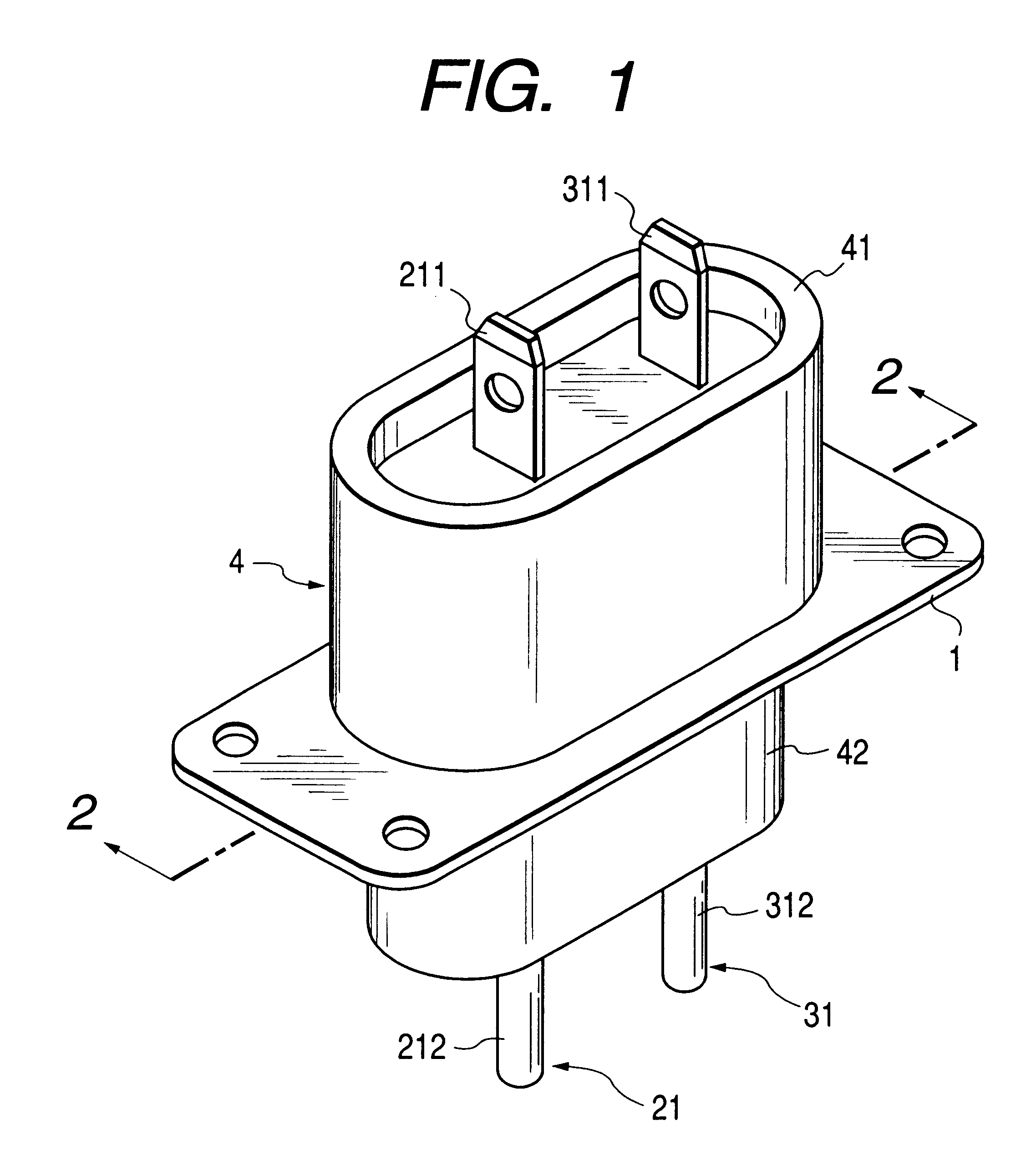

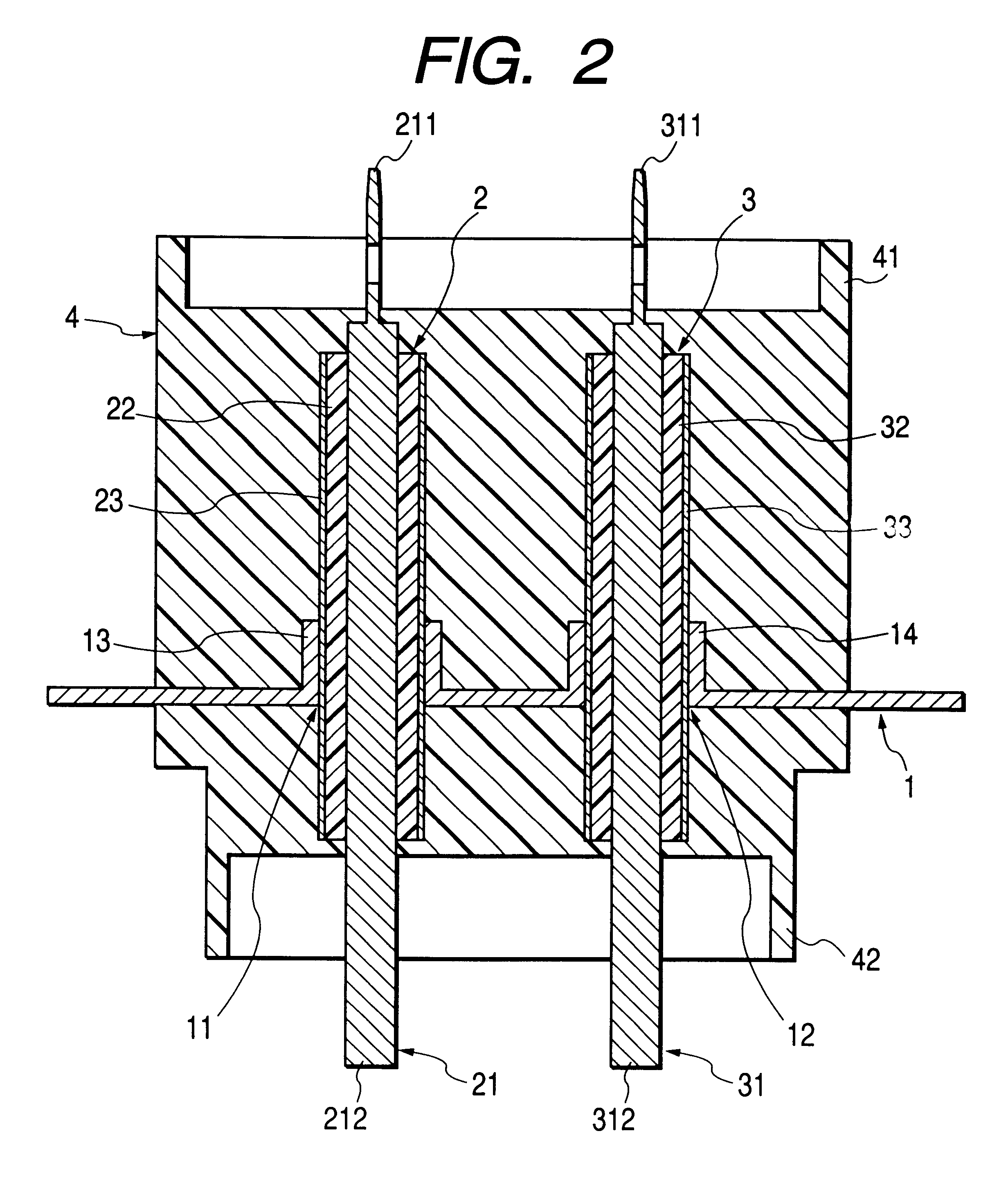

High-voltage feedthrough capacitor

InactiveUS6510038B1Increase capacitanceImprove filtering effectAnti-noise capacitorsTransit-tube leading-in arrangementsElectrical conductorEngineering

In a high-voltage feedthrough capacitor, a grounding member has two through-holes spaced away from each other. Feedthrough capacitors each has one central conductor, a dielectric layer, and an electrode. The periphery of the central conductor is respectively covered with the dielectric layer, and the surface of the dielectric layer is respectively covered with the electrode. The feedthrough capacitor extends respectively through the through-hole, and has been fitted to the grounding member. The electrode has been bonded to the grounding member. An armoring insulator covers the peripheries of the feedthrough capacitors and the periphery of the grounding member.

Owner:TDK CORPARATION

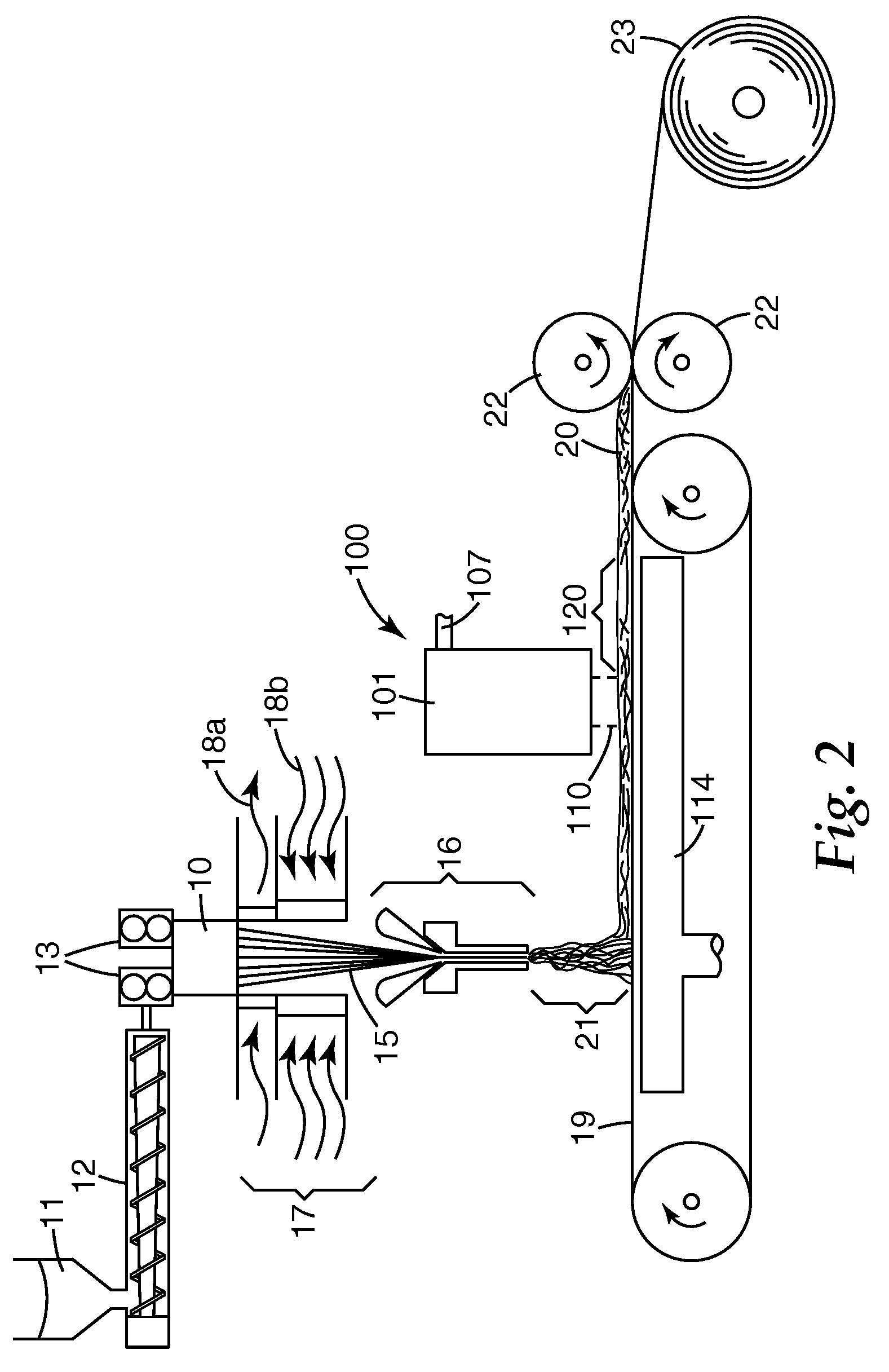

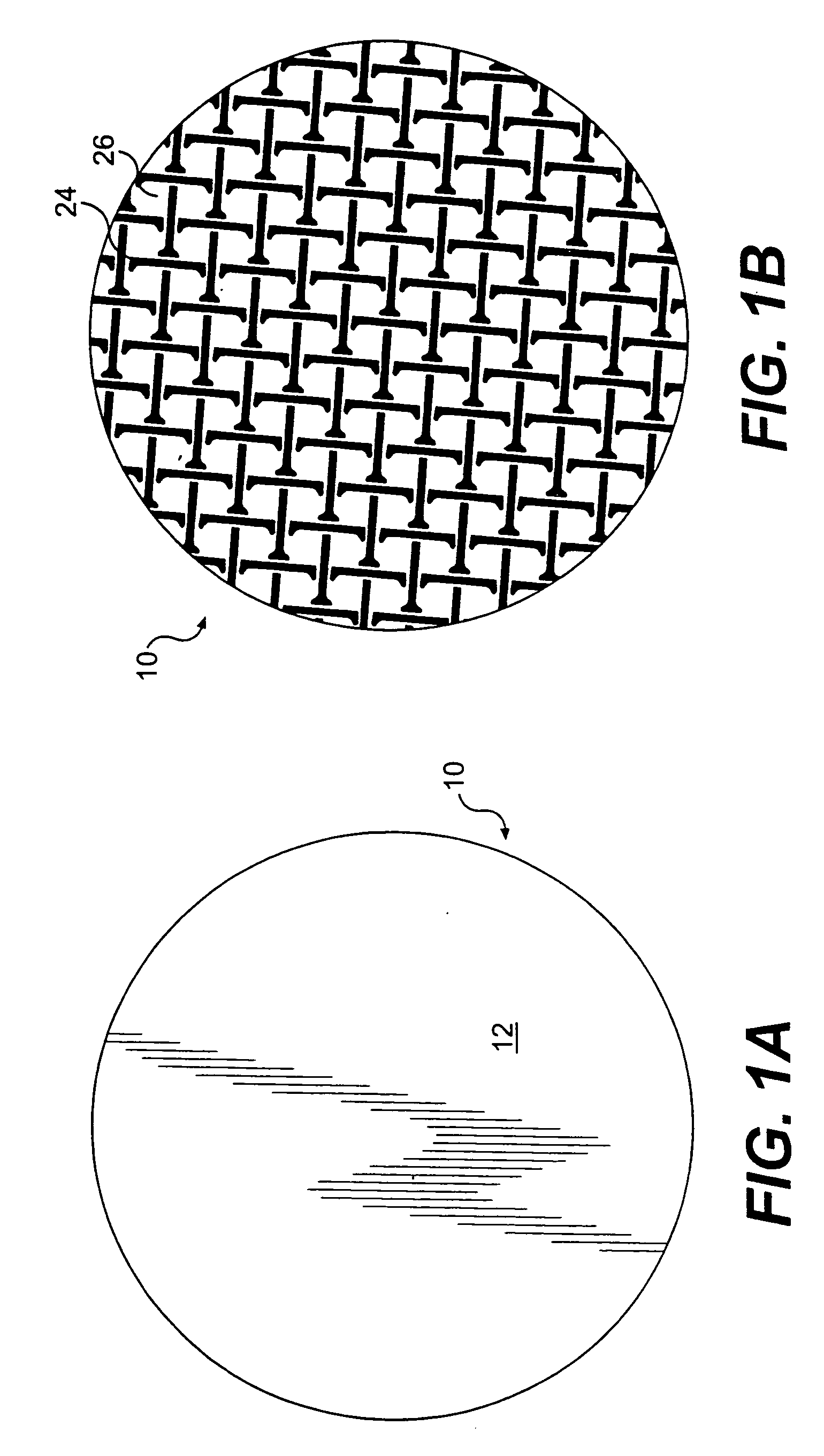

Monocomponent monolayer meltblown web and meltblowing apparatus

ActiveUS7902096B2Narrow distributionReduced service lifeDispersed particle filtrationFilament/thread formingPolymer scienceAir filter

A porous monocomponent nonwoven web contains a bimodal mass fraction / fiber size mixture of intermingled continuous microfibers and larger size fibers of the same polymeric composition. There are at least five times as many microfibers as larger size fibers, and a histogram of the mass fraction of fibers vs. fiber size exhibits a larger size fiber mode greater than 10 μm. The web may be made by flowing fiber-forming material through a die cavity having larger size orifices and at least five times as many smaller size orifices to form filaments, attenuating the filaments into fibers and collecting the attenuated fibers to form the nonwoven web. The web is especially well suited to the manufacture of self-supporting three dimensional articles such as molded cup-shaped respirators and pleated air filters.

Owner:3M INNOVATIVE PROPERTIES CO

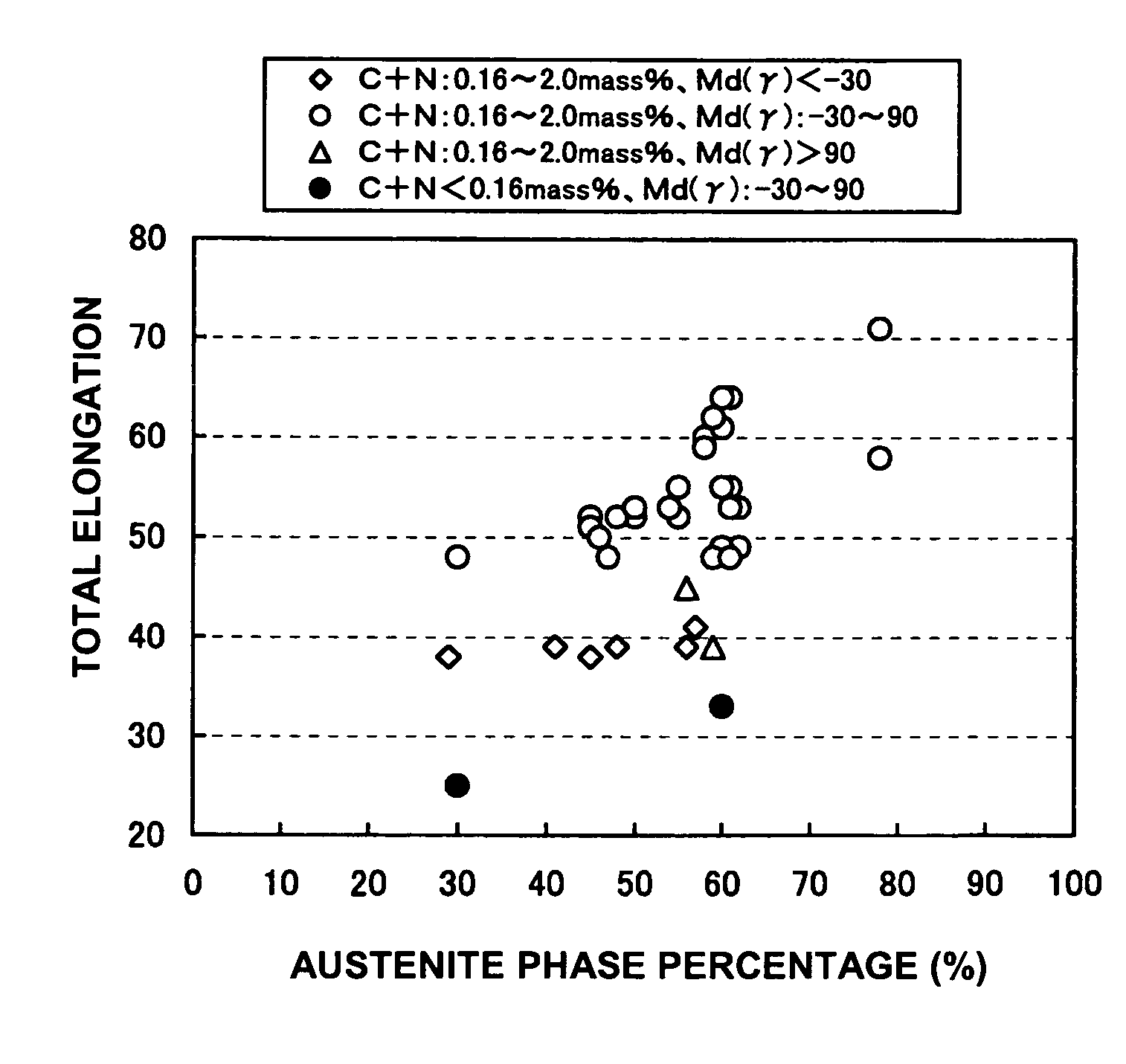

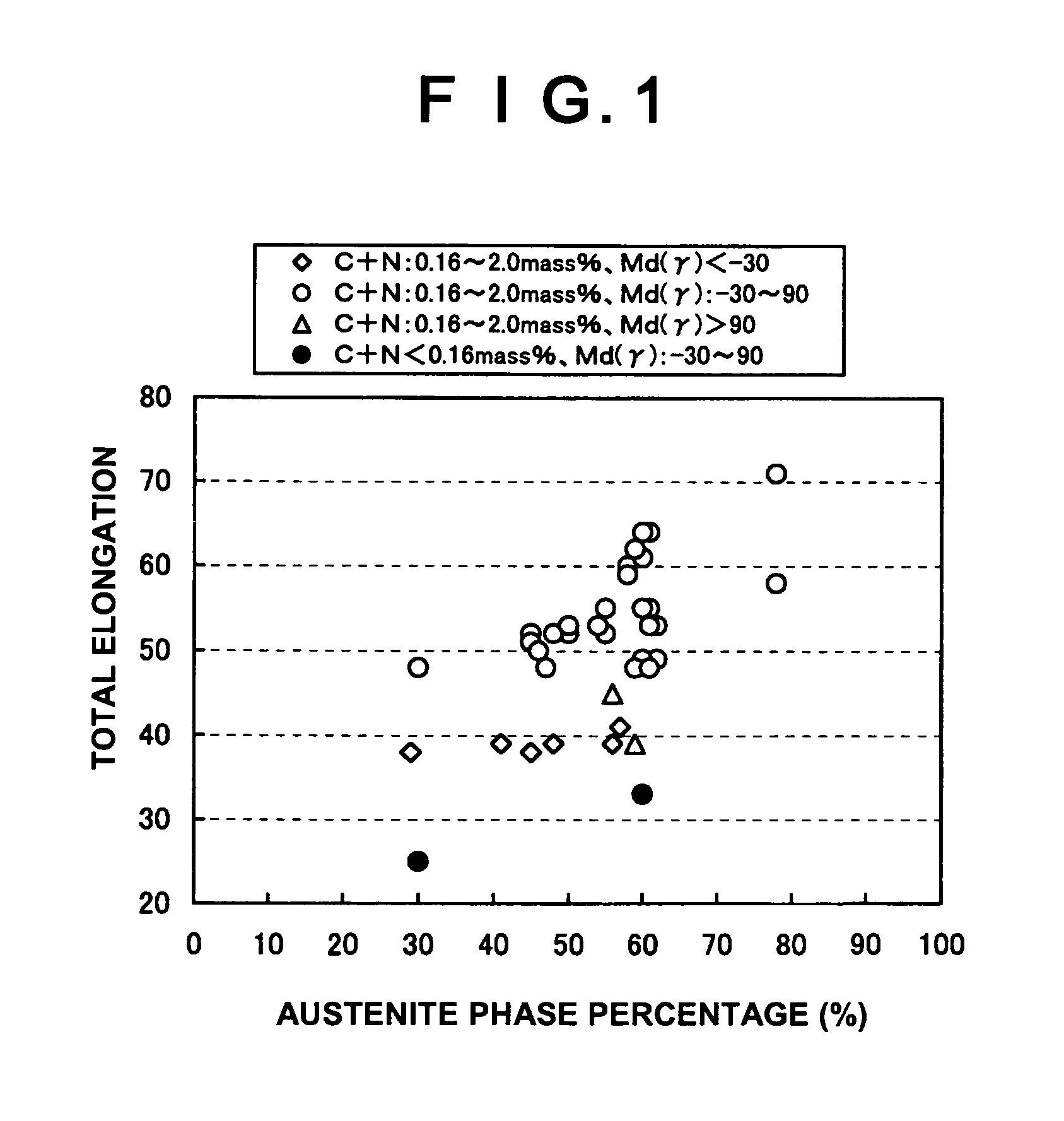

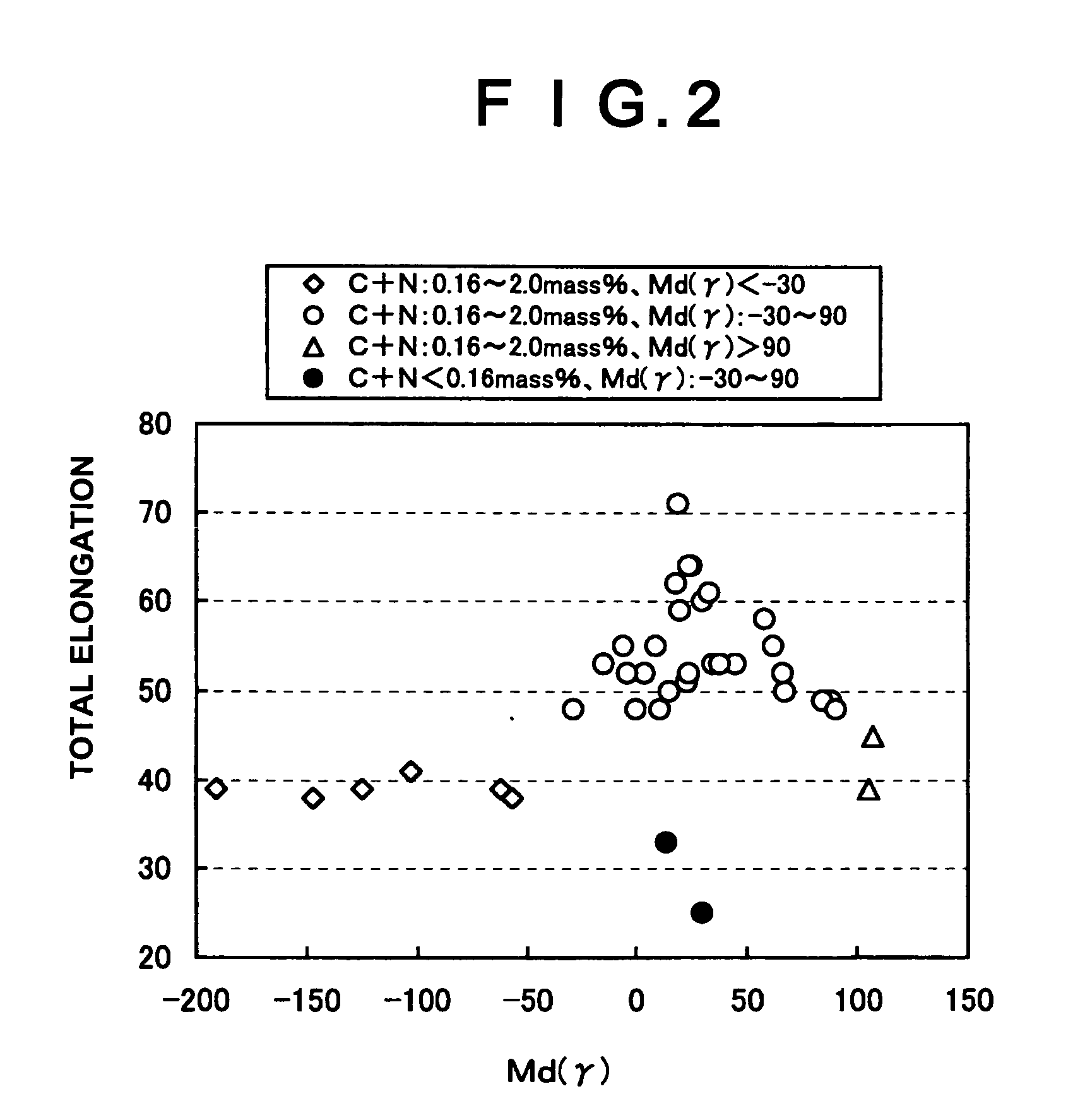

Austenitic-ferritic stainless steel

A low Ni and high N austenitic-ferritic stainless steel is disclosed. It includes an austenitic-ferritic stainless steel having high formability and punch stretchability, crevice corrosion resistance, corrosion resistance at welded part, or excellent intergranular corrosion resistance, from a stainless steel structured by mainly austenite phase and ferrite phase, and consisting essentially of 0.2% or less C, 4% or less Si, 12% or less Mn, 0.1% or less P, 0.03% or less S, 15 to 35% Cr, 3% or less Ni, and 0.05 to 0.6% N, by mass, by adjusting the percentage of the austenite phase in a range from 10 to 85%, by volume. Furthermore, it includes an austenitic-ferritic stainless steel having higher formability by adjusting the amount of (C+N) in the austenite phase to a range from 0.16 to 2% by mass.

Owner:JFE STEEL CORP

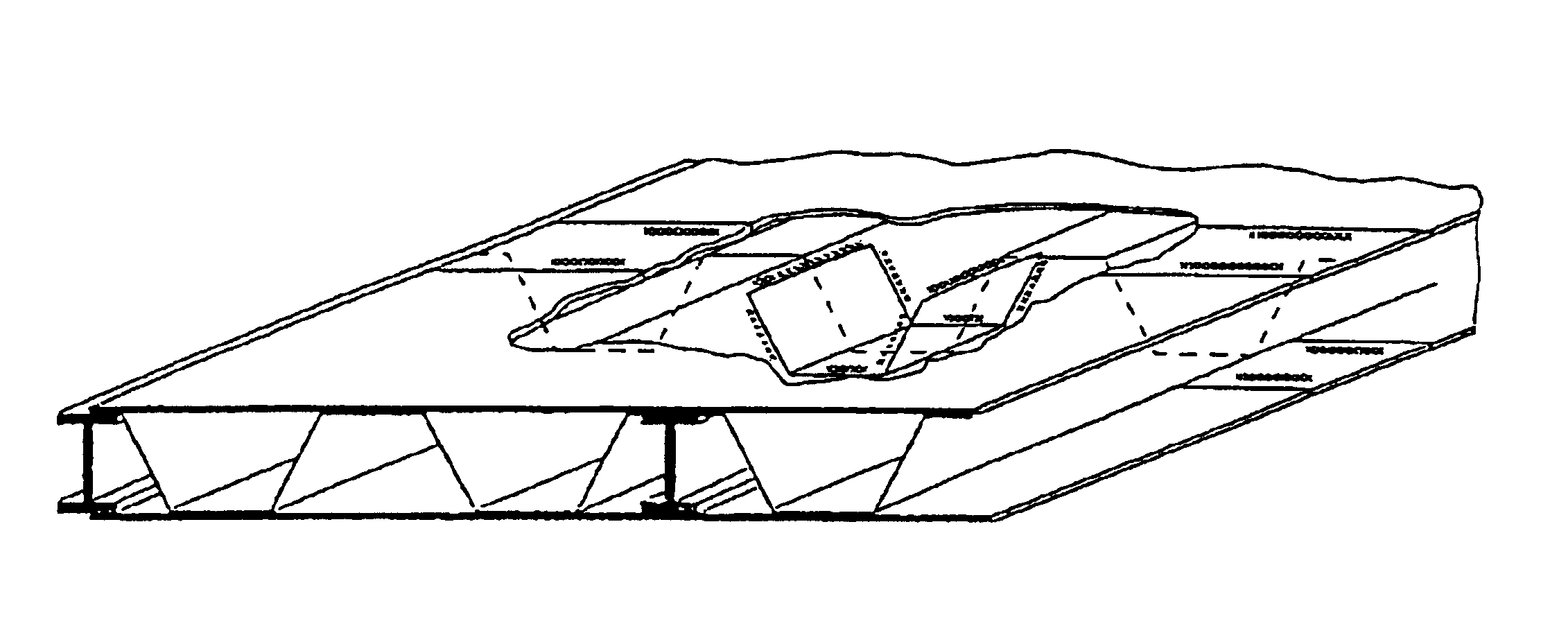

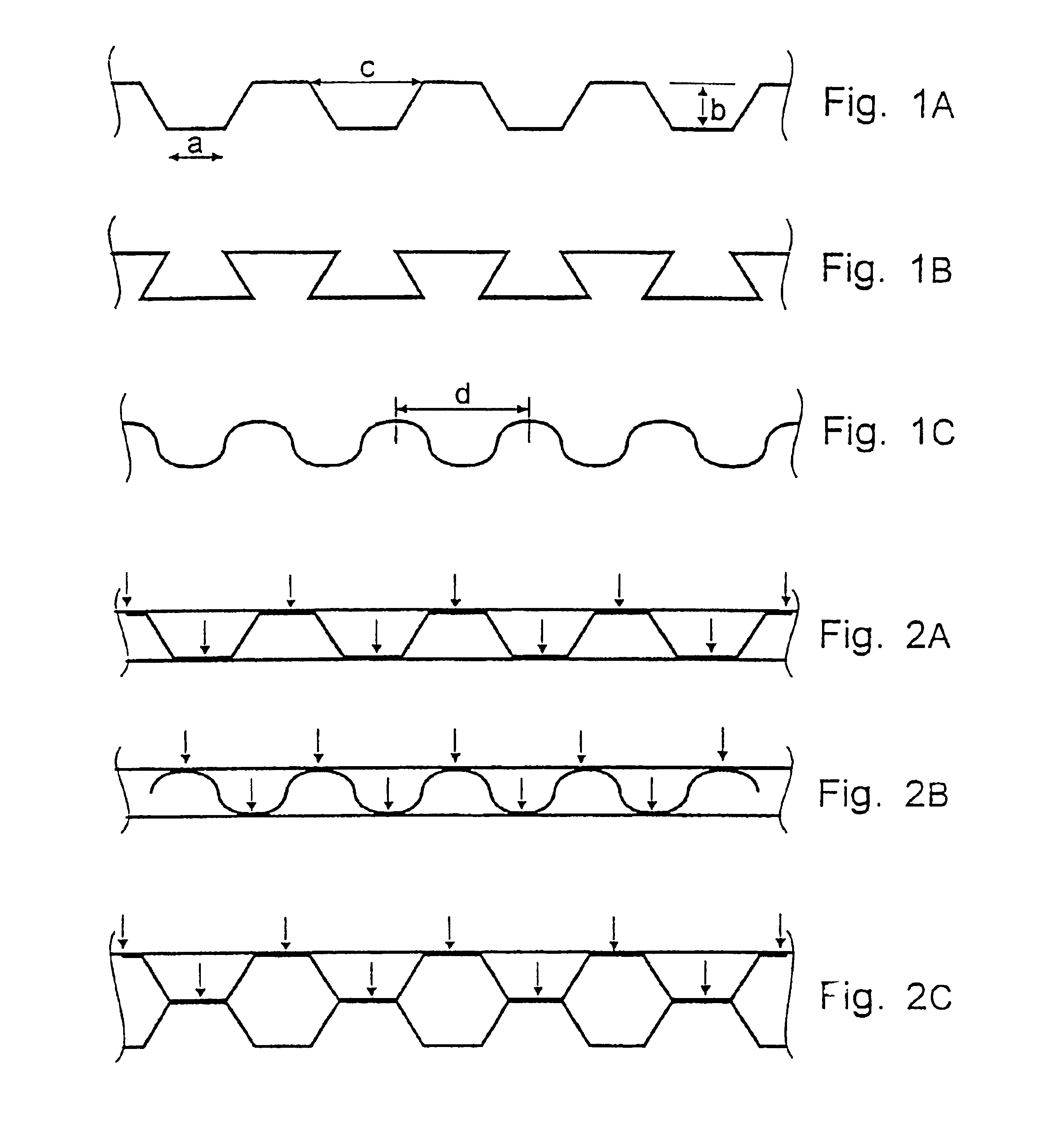

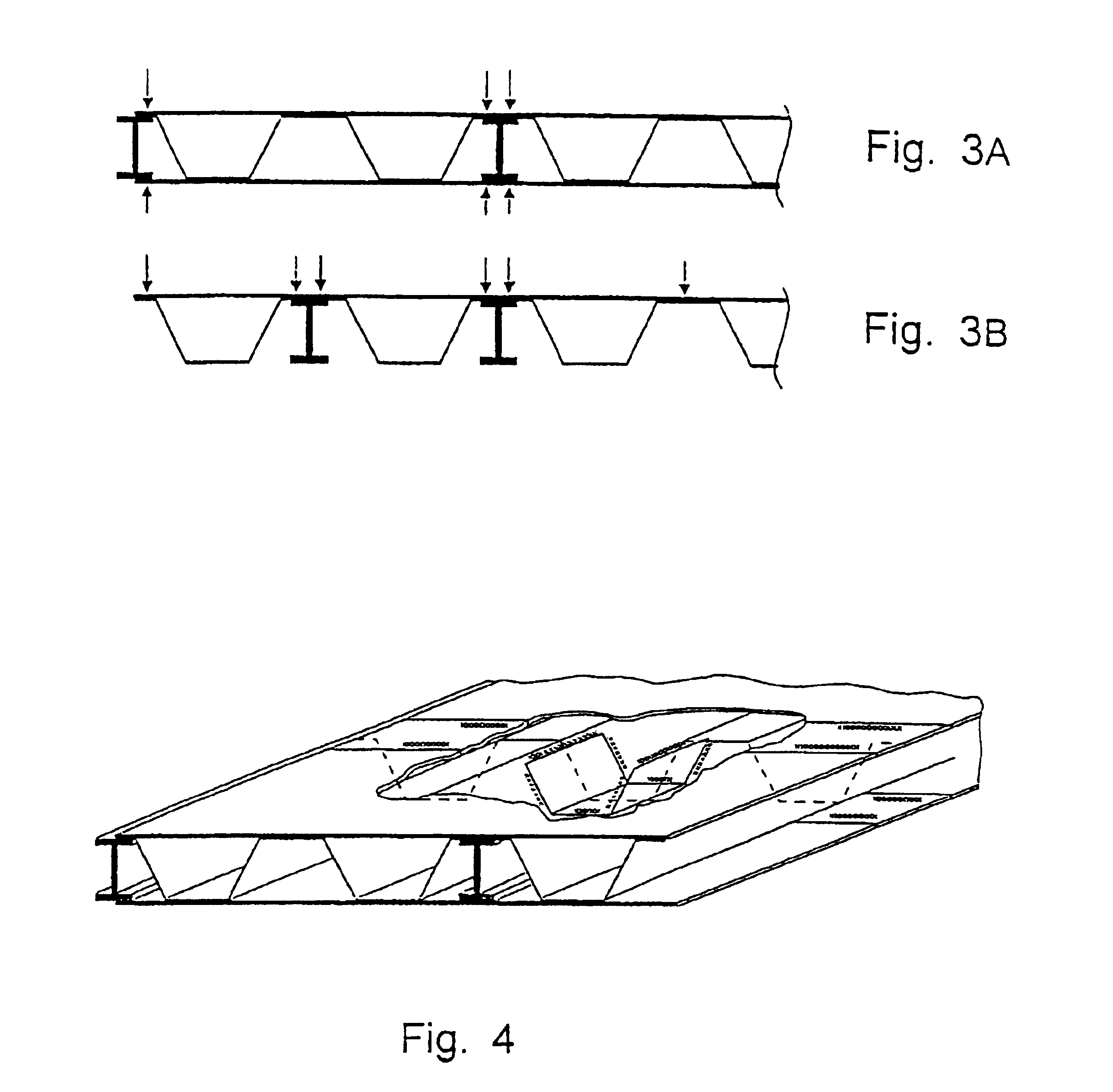

Composite aluminium panel

InactiveUS6848233B1Improve corrosion resistanceReliable and easy to manufactureNon-magnetic metal hullsLayered product treatmentParallel plateMaterials science

A composite aluminium panel comprising two parallel plates and / or sheets secured to the peaks and troughs of a corrugated aluminium stiffener sheet between the parallel plates and / or sheets, wherein the corrugated aluminium stiffener sheet is made from an aluminium alloy rolled sheet of composition (in weight percent): Mg 1.5-6.0, Mn 0.3-1.4, Zn 0.4-5.0, Fe up to 0.5, Si up to 0.5, Zr up to 0.30; optionally one or more of Cr 0.05-0.3, Ti 0.01-0.20, V 0.05-0.25, Ag 0.05-0.40, and Cu up to 0.40; and other elements up to 0.05 each, 0.15 total, with a balance of Al; and having in an H-condition or in an O-condition a ratio of PS / UTS in the range of 0.4 to 0.9 and having good roll formability.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

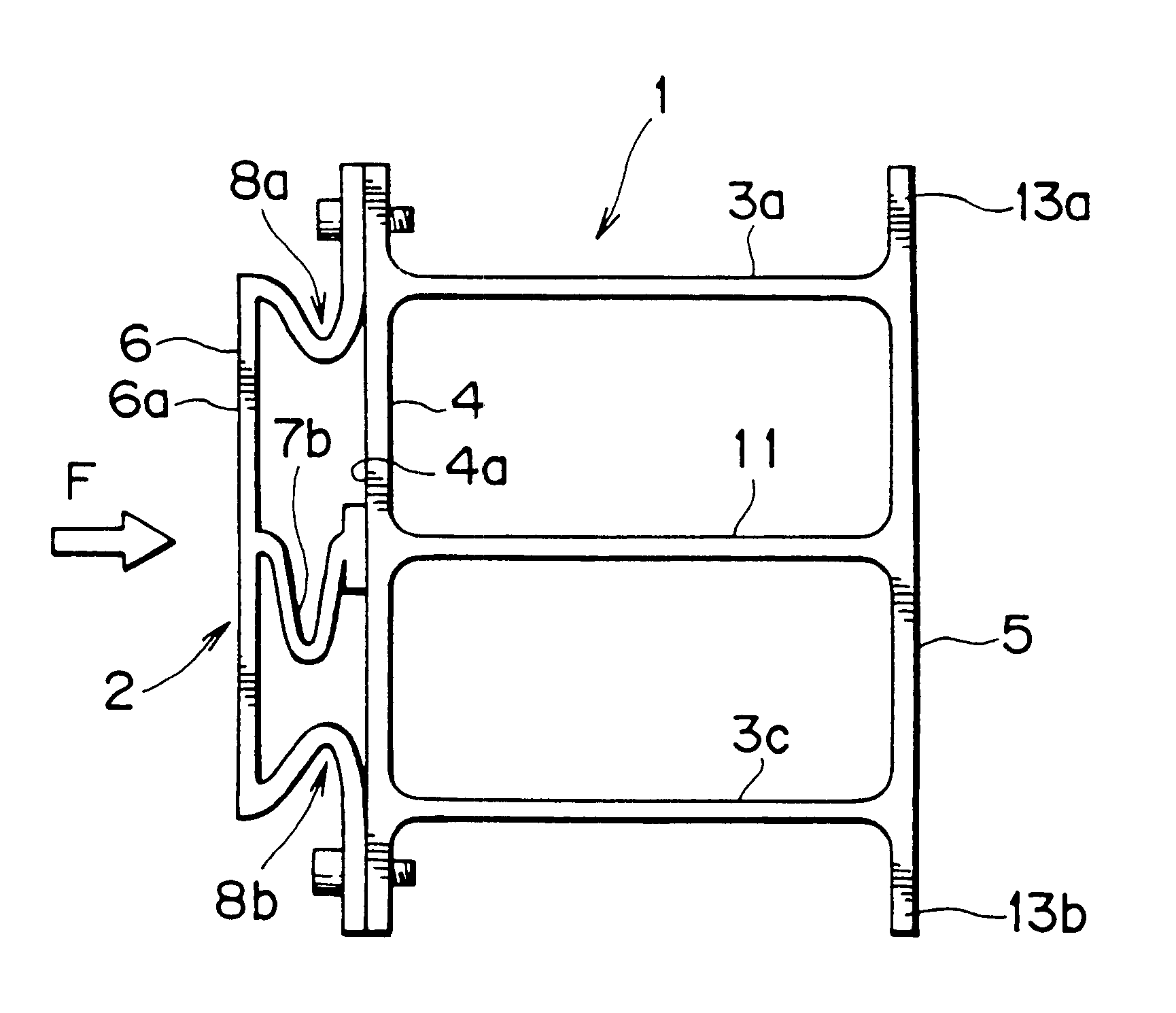

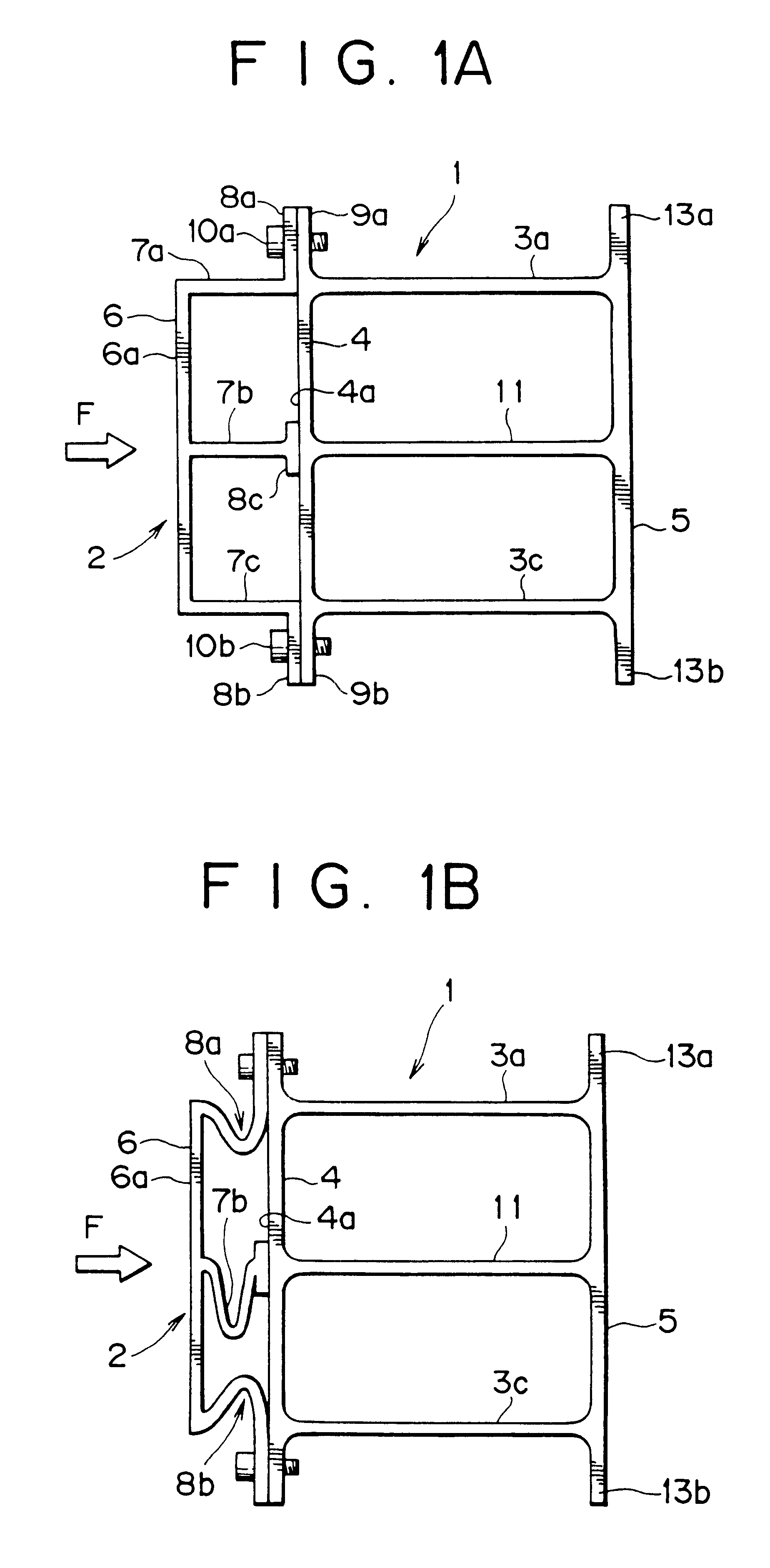

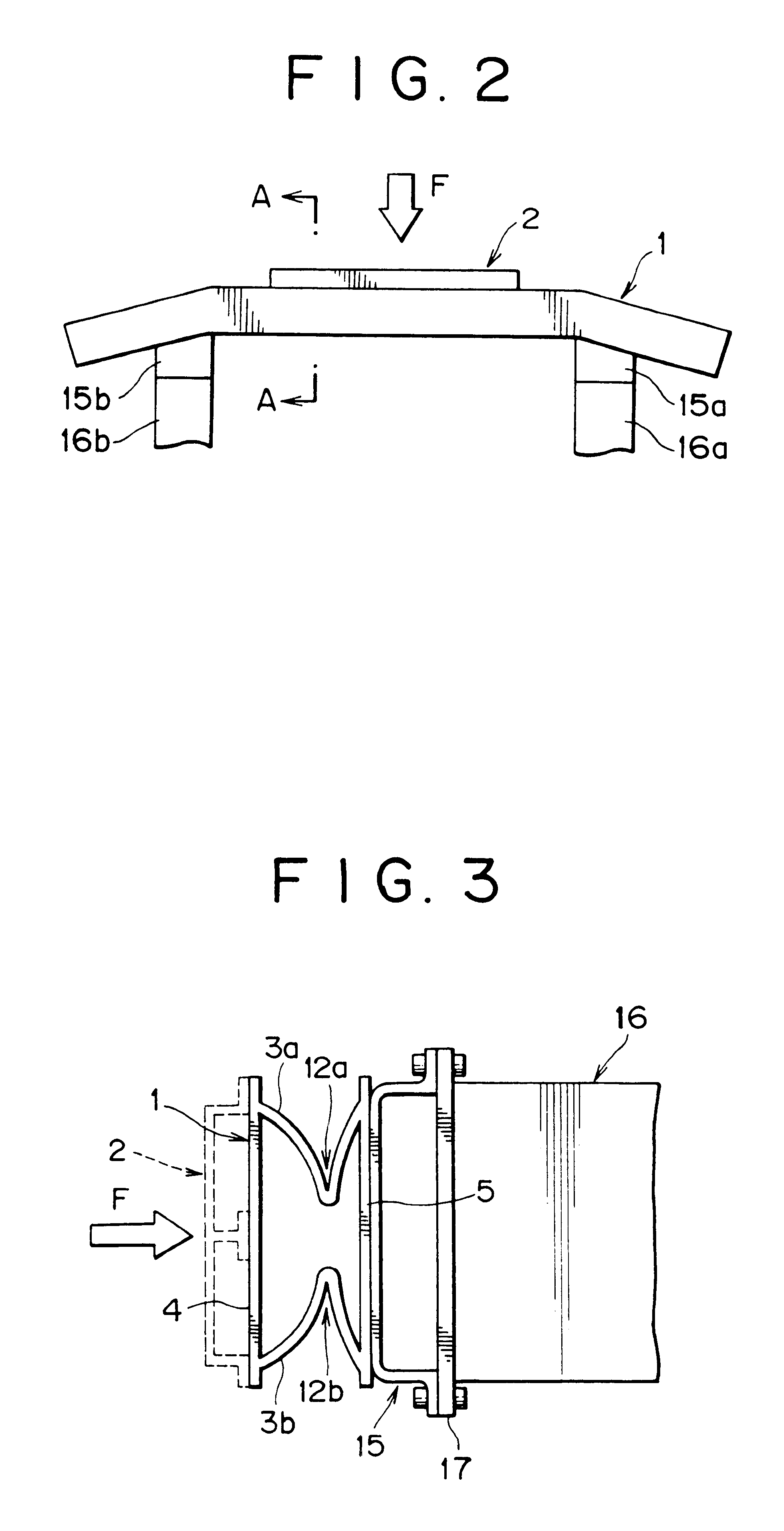

Car body energy absorber and bumper stay

InactiveUS6481690B2Reduce weightWeight increaseVehicle seatsEngine sealsHigh energyMaterials science

A lightweight car body energy absorber made of Al alloy which provides a high energy absorption performance. The car body energy absorber comprises a hollow shape with a rectangular sectional profile and a reinforcing shape attached to the front face of the collision plane of the hollow shape, where the hollow shape and the reinforcing shape are aluminum alloy extruded shapes. The reinforcing shape has a hat-shaped open sectional profile, which is composed of a collision wall almost parallel to the collision plane of the hollow shape, plural mutually parallel horizontal ribs which support the collision wall, and vertical flanges provided at the tips of these ribs. The reinforcing shape is joined to the collision plane of the hollow shape through the vertical flanges.

Owner:KOBE STEEL LTD

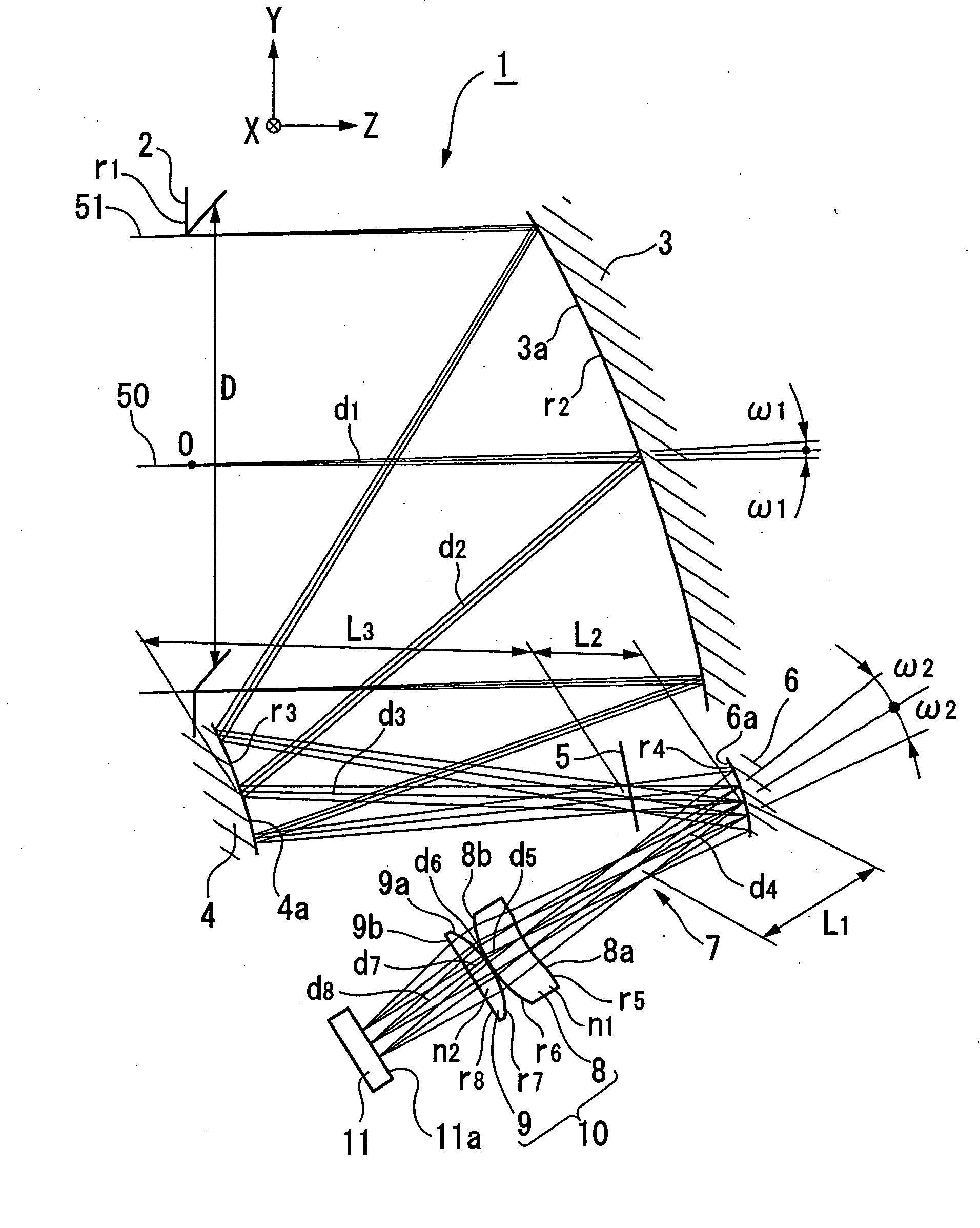

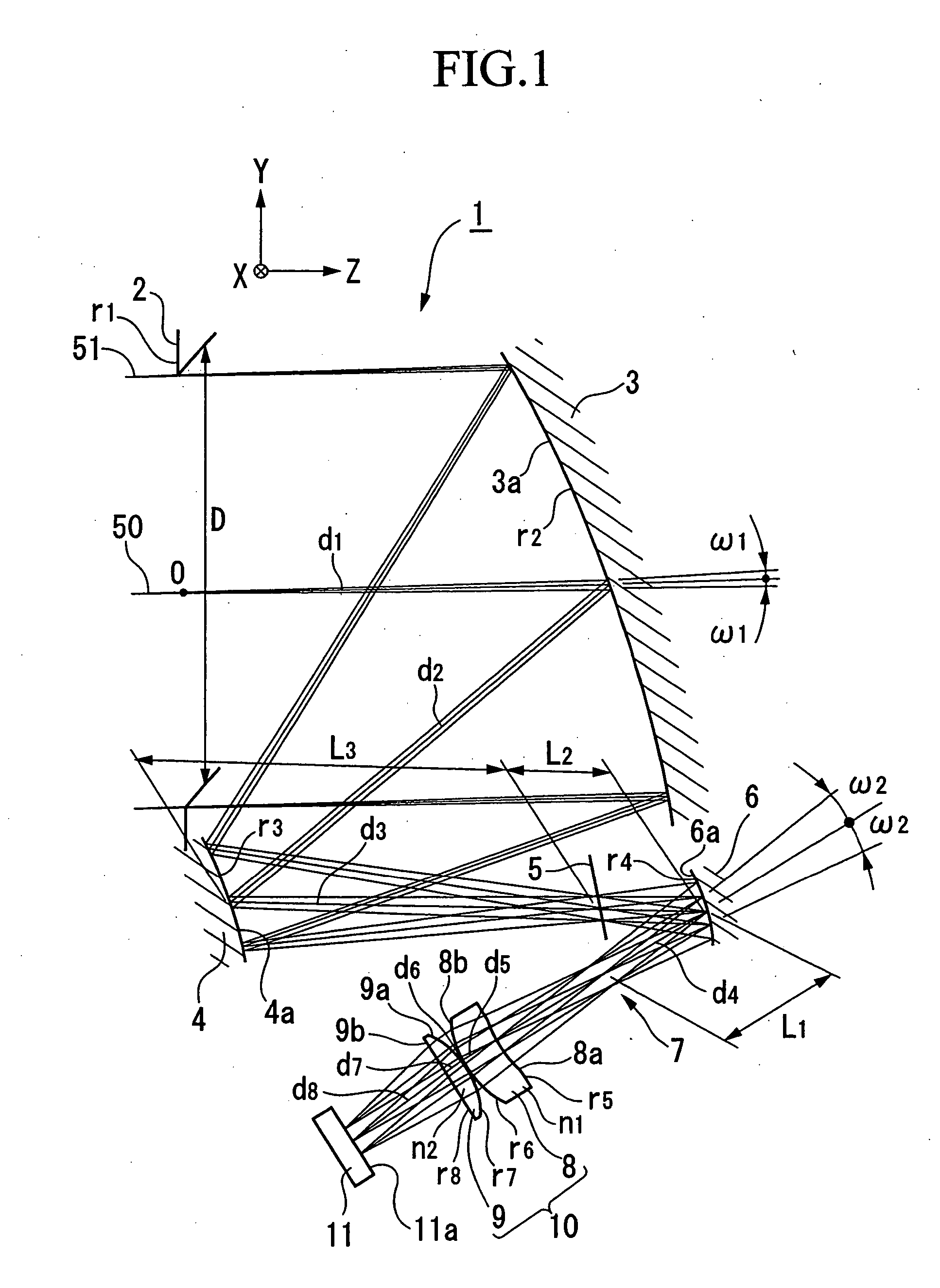

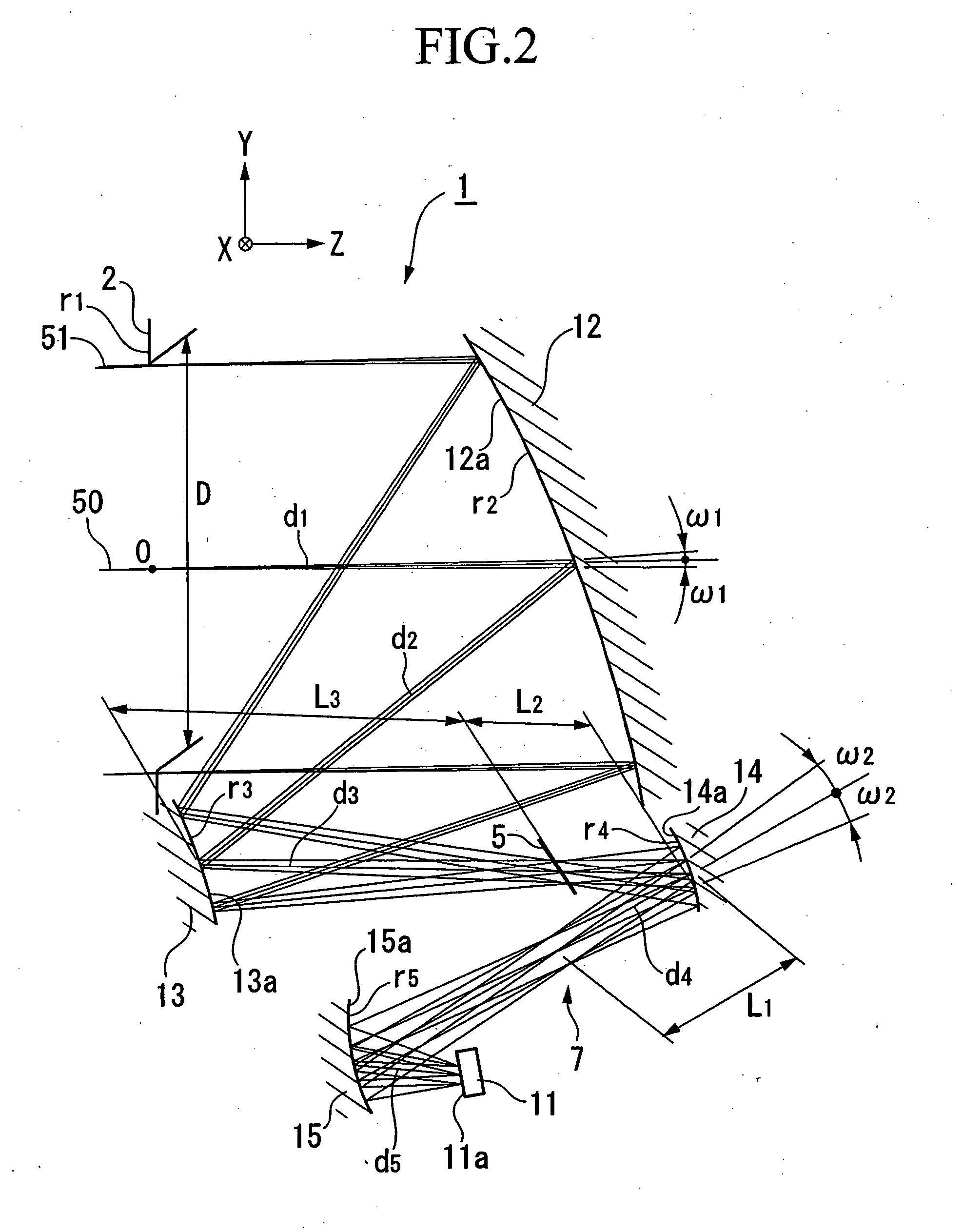

Decentered optical system, light transmitting device, light receiving device, and optical system

The decentered optical system is configured by a first, a second and a third reflecting mirror disposed decentered, a focusing device, and a light receiver. The optical path is folded by the first, second, and third reflecting mirrors, aberration correction is carried out by a rotationally asymmetric reflecting surface, and an intermediate image is formed between the second and third reflecting mirrors and another reflecting mirror. The reflected light of the third reflecting mirror is made to form a substantially parallel light beam that forms an exit pupil. An image is formed on the light receiving surface by the focusing device. This decentered optical system is used in a light transmitting device, a light receiving device, and a light transmitting and receiving system, and carries out light tracking by detecting the position of the received light image.

Owner:OLYMPUS CORP

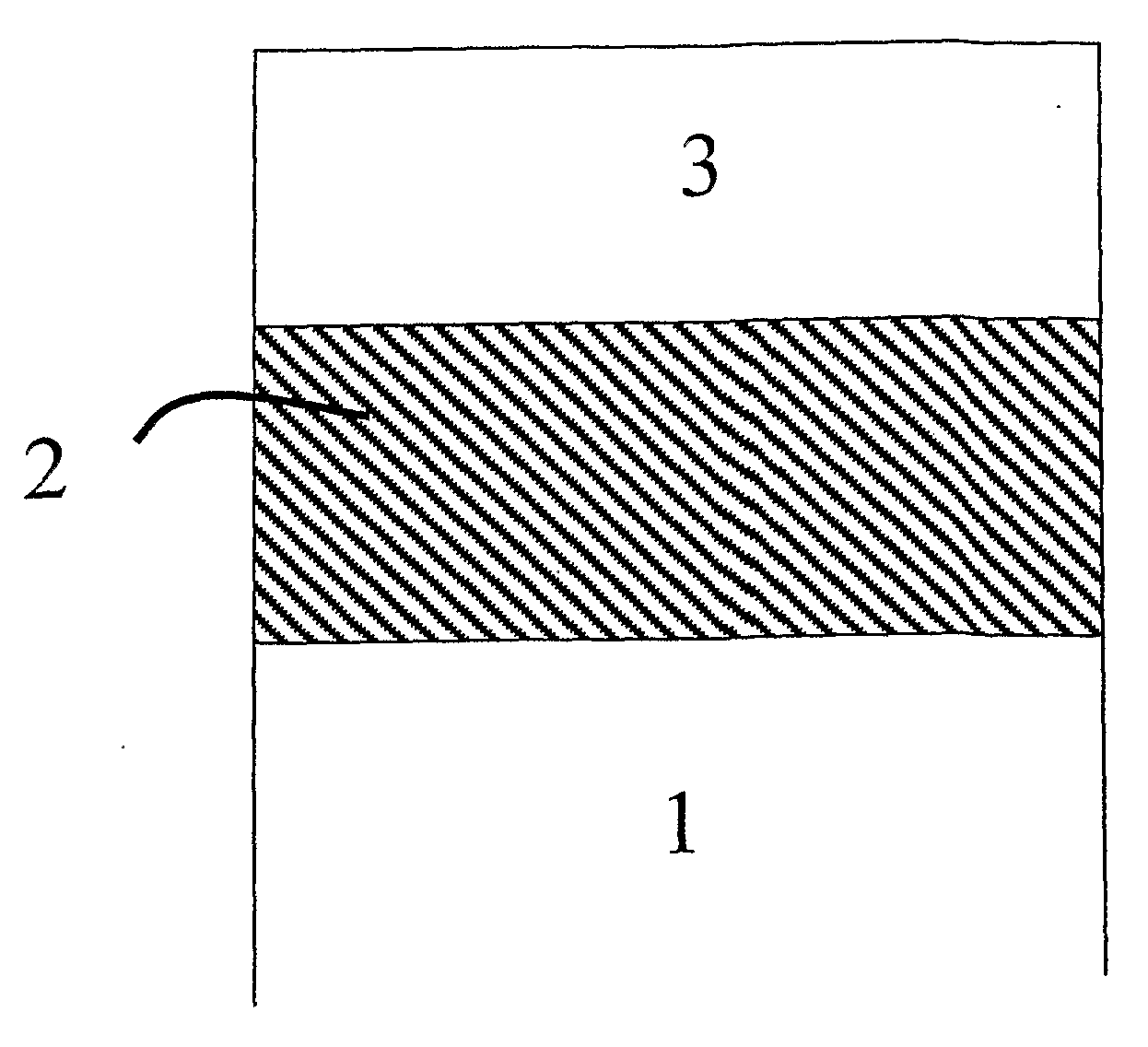

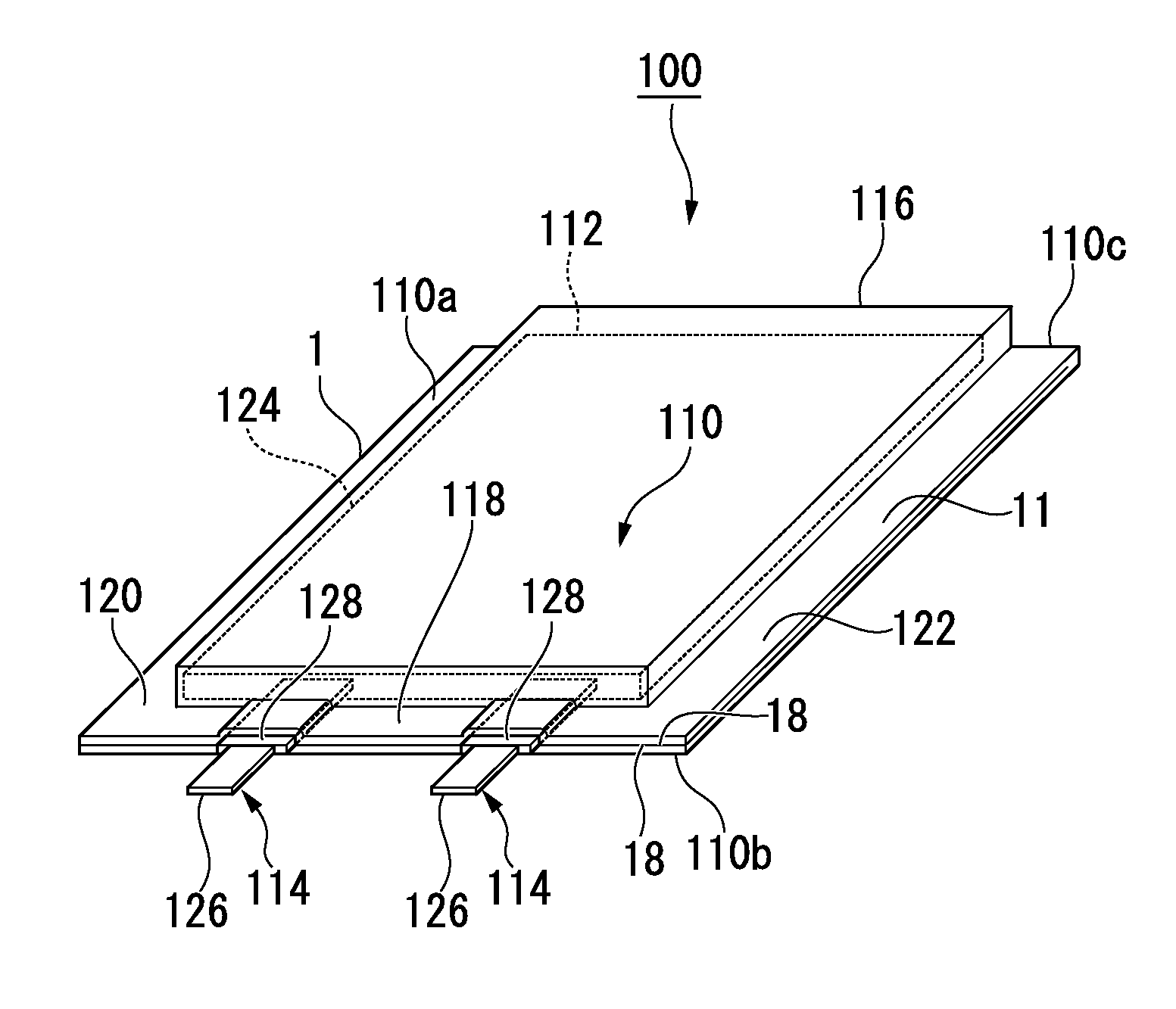

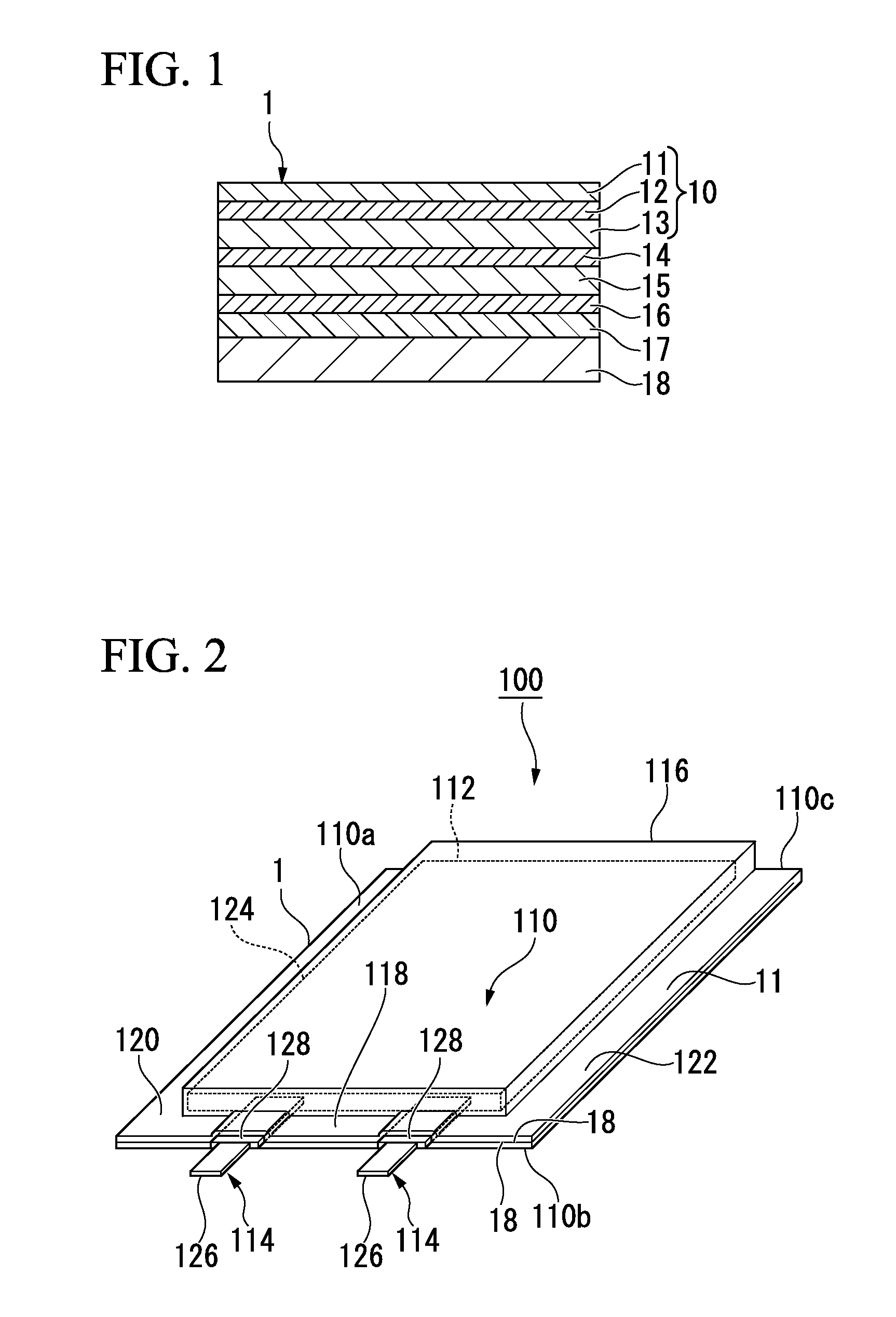

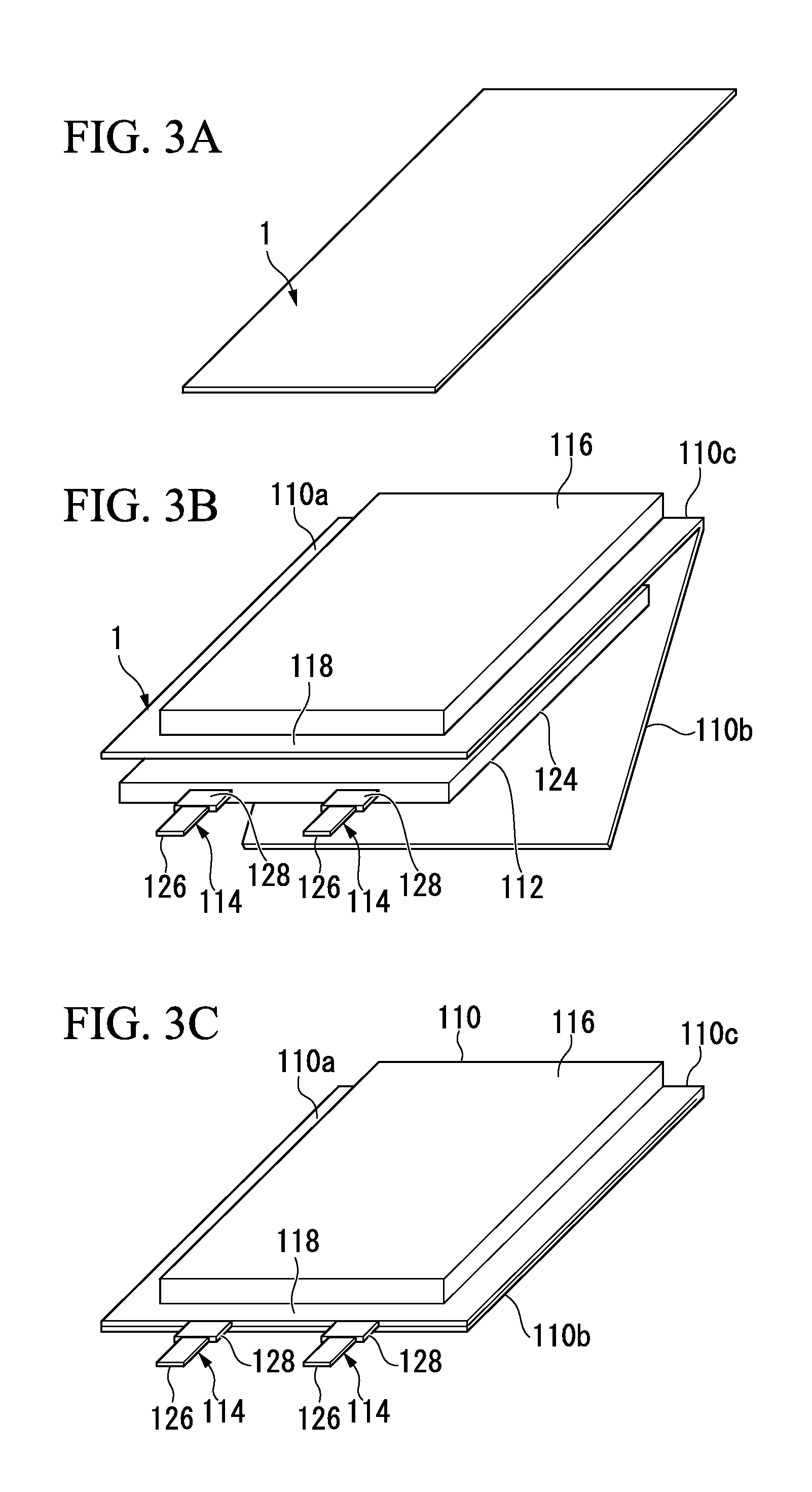

Packaging material for lithium ion battery, lithium ion battery, and method for manufacturing lithium ion battery

ActiveUS20140072864A1Good molding effectStay in shapeFinal product manufactureElectrode carriers/collectorsMetal foilPack material

A packaging material for a lithium ion battery includes: a base material layer that is formed from a film obtained by biaxially stretching a multi-layered coextruded film including a first thermoplastic resin layer having rigidity and chemical resistance and being disposed at an outer side thereof, a second thermoplastic resin layer having a capability of propagating stress and adhesiveness, and a third thermoplastic resin layer having toughness; a metal foil layer that is laminated on one surface of the base material layer; an anti-corrosion-treated layer that is laminated on the metal foil layer; an inner adhesive layer that is laminated on the anti-corrosion-treated layer; and a sealant layer that is laminated on the inner adhesive layer.

Owner:TOPPAN PRINTING CO LTD

Coated paperboards and paperboard containers having improved tactile and bulk insulation properties

InactiveUS20060057365A1Improve insulation performanceIncrease stiffnessNon-fibrous pulp additionWrappersMicrospherePaperboard

An improved paperboard has been bulk enhanced by retaining a substantial portion microspheres in a suitable distribution within the paperboard. As in one embodiment, the high retention of the bulk enhancing additives is believed to result from the incorporation of suitable retention aids. The paperboard is able to be formed into suitable paperboard containers without loss of integrity. The resulting containers have increased hold times when they contain hot or cold food or drink.

Owner:DIXIE CONSUMER PROD

Magnesium-based alloy

ActiveUS20100161031A1Improve plasticityImprove corrosion resistanceSuture equipmentsStentsInsertion stentHeat resistance

The present invention relates to compositions and structure of deformable alloys on the basis of magnesium with an optimum combination of mechanical properties (strength, plasticity) and a resistance to corrosion, including in vivo. Alloys of the new group possess an excellent formability at room temperature, high corrosion stability in sodium chloride solution, excellent heat resistance and can be used in various technical applications, particularly in vivo as a structural material for stents.

Owner:ACROSTAK CORP

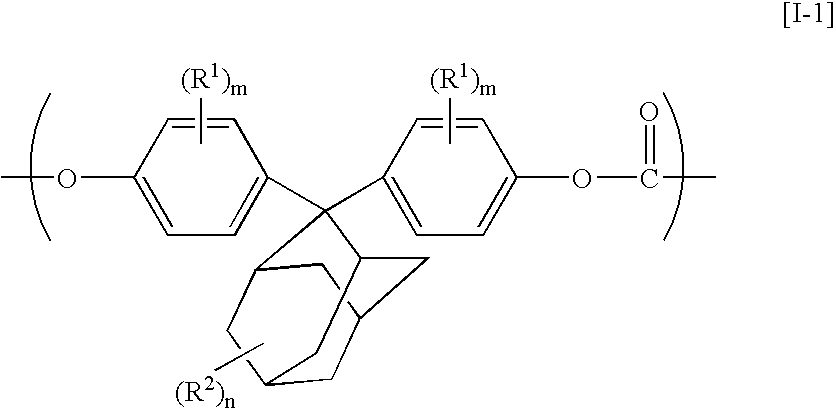

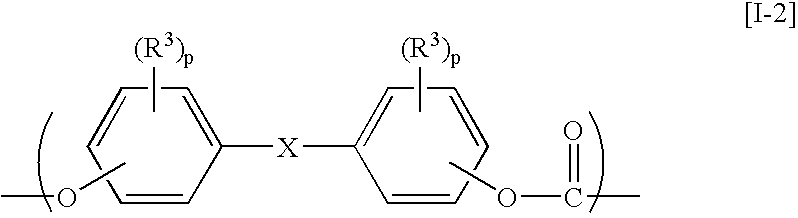

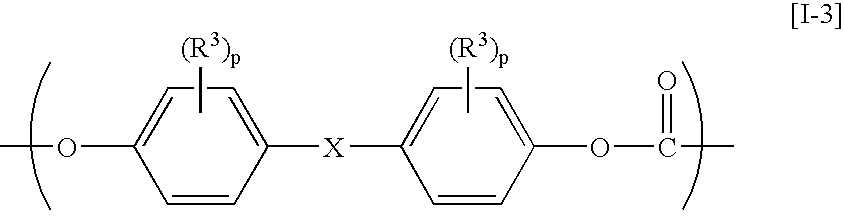

Aromatic polycarbonate resin, process for producing the same, optical-part molding material, and optical part

InactiveUS7112644B2Increase resistanceHigh transparencyOrganic chemistryRecord information storageHeat resistancePolycarbonate

The present invention relates to an aromatic polycarbonate resin which comprises repetitive units originating in residual groups of a 2,2-bis(4-hydroxyphenyl)adamantane compound and a 1,3-bis(4-hydroxyphenyl)adamantane compound having a substituent on an aromatic ring and which is excellent in a transparency, a heat resistance and a mechanical strength and has a good moldability and a production process for the aromatic polycarbonate resin described above in which the adamantane compounds described above are reacted with a carbonic ester-forming compound. Further, it relates to an aromatic polycarbonate resin which is excellent in an optical characteristic and an optical part prepared by molding the same.

Owner:IDEMITSU KOSAN CO LTD

Coated Metal Product, Method to Produce It and Use of the Method

InactiveUS20090181262A1High quality finishResistant to damageDecorative surface effectsPretreated surfacesLacquerMetallic substrate

Owner:SANDVIK INTELLECTUAL PROPERTY AB

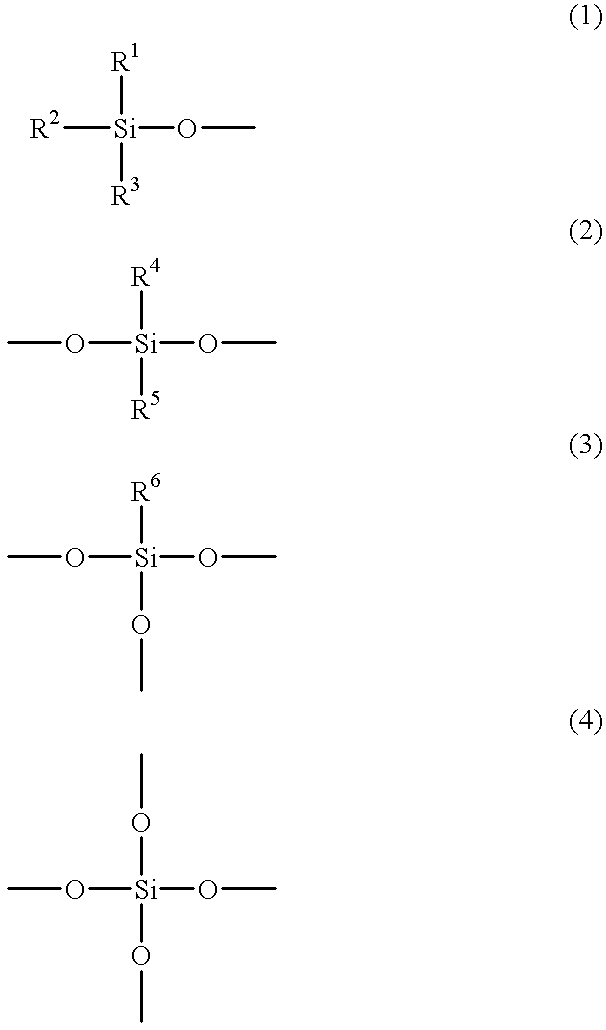

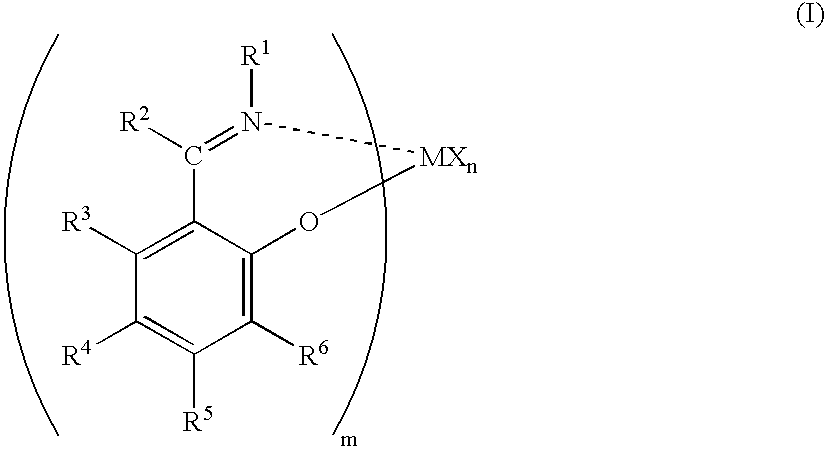

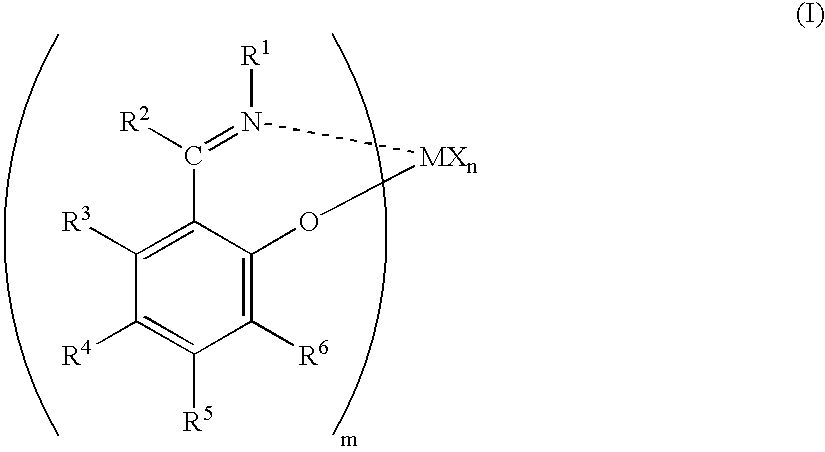

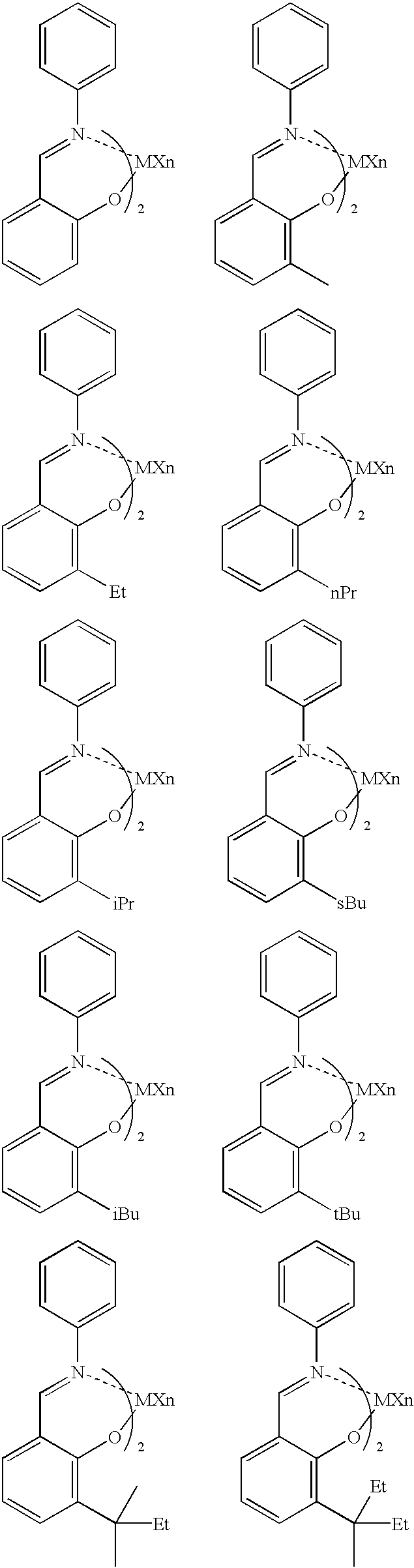

Catalyst for olefin polymerization, method for producing olefin polymer, method for producing propylene-based copolymer, propylene polymer, propylene-based polymer composition, and use of those

ActiveUS20080220193A1High molecular weightHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsBottlesMethyl groupAluminium

A catalyst for olefin polymerization, comprising:(A-1) a bridged metallocene compound represented by the following Formula [1-1], and (b) at least one compound selected from: (b-1) an organoaluminum oxy compound, (b-2) a compound which forms an ion pair, and (b-3) an organoaluminum compound:wherein in Formula [1-1], R1, R2, R3, R4, R5, R8, R9, and R12 are each selected from a hydrogen, a hydrocarbon group and a silicon-containing group; the four groups of R6, R7, R10, and R11 are not hydrogen atoms, and are each selected from a hydrocarbon group or a silicon-containing group; R13 and R14 are each a hydrocarbon group or the like, excluding a hydrogen atom and a methyl group; M is Ti, Zr or the like; Y is carbon or the like; Q is a halogen or the like; and j is an integer from 1

Owner:MITSUI CHEM INC

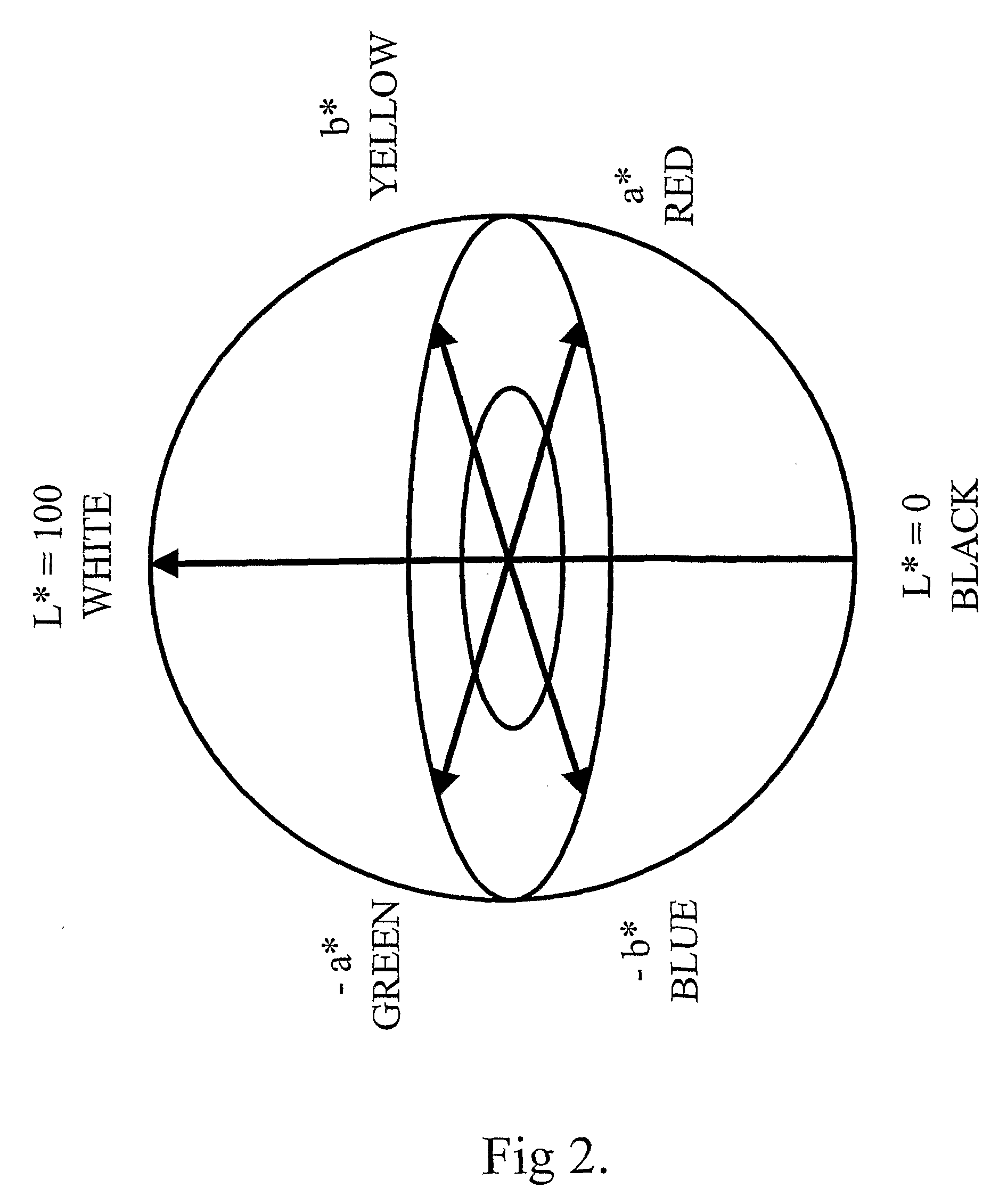

Stainless Steel Strip Coated With A Decorative Layer

InactiveUS20070275264A1Improve adhesionImprove corrosion resistanceLayered productsVacuum evaporation coatingMetallurgyLayer thickness

The invention relates to a coated stainless steel strip product with an evenly distributed layer on one side or both sides of said strip. Said layer has a decorative appearance, the thickness of said layer is maximally 10 μm, the tolerance of said layer is maximally + / −30% of the layer thickness, the parameter value of L*, a*, b* is respectively 0<L*<95, −66<a*<64, −90<b*<70, the tolerance of said decorative appearance as expressed in terms of ΔE is maximally 15 and the layer has such a good adhesion so that the coated steel strip when tested in soft-annealed condition can be bent more than 90° over a radius maximally equal to 5*t, where t is the thickness of said strip, without showing any tendency to flaking or the like.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Powdery alloy processing material in site by movable laser smelt-coating process

A movable field processing alloy powder material for the laser melting is to reinforce the nickel-base alloy using the below elements: Cr, W, Mo, Al, Ti, Co; also it can be added with the Co, C, N, Nb, Cu, B, Si and the minim rare-earth metal which can be the Ce, Y and the Hf. The invention has the high hardness, the strength and the low melting point, high wearing resistance. It has improved the cracking resistance, moldability, the stability and the uniformity of the laser melting layer. So it can repair the high temperature alloy, the carbon steel, the structural steel and the stainless steel by the laser melting.

Owner:SHENYANG DALU LASER TECH

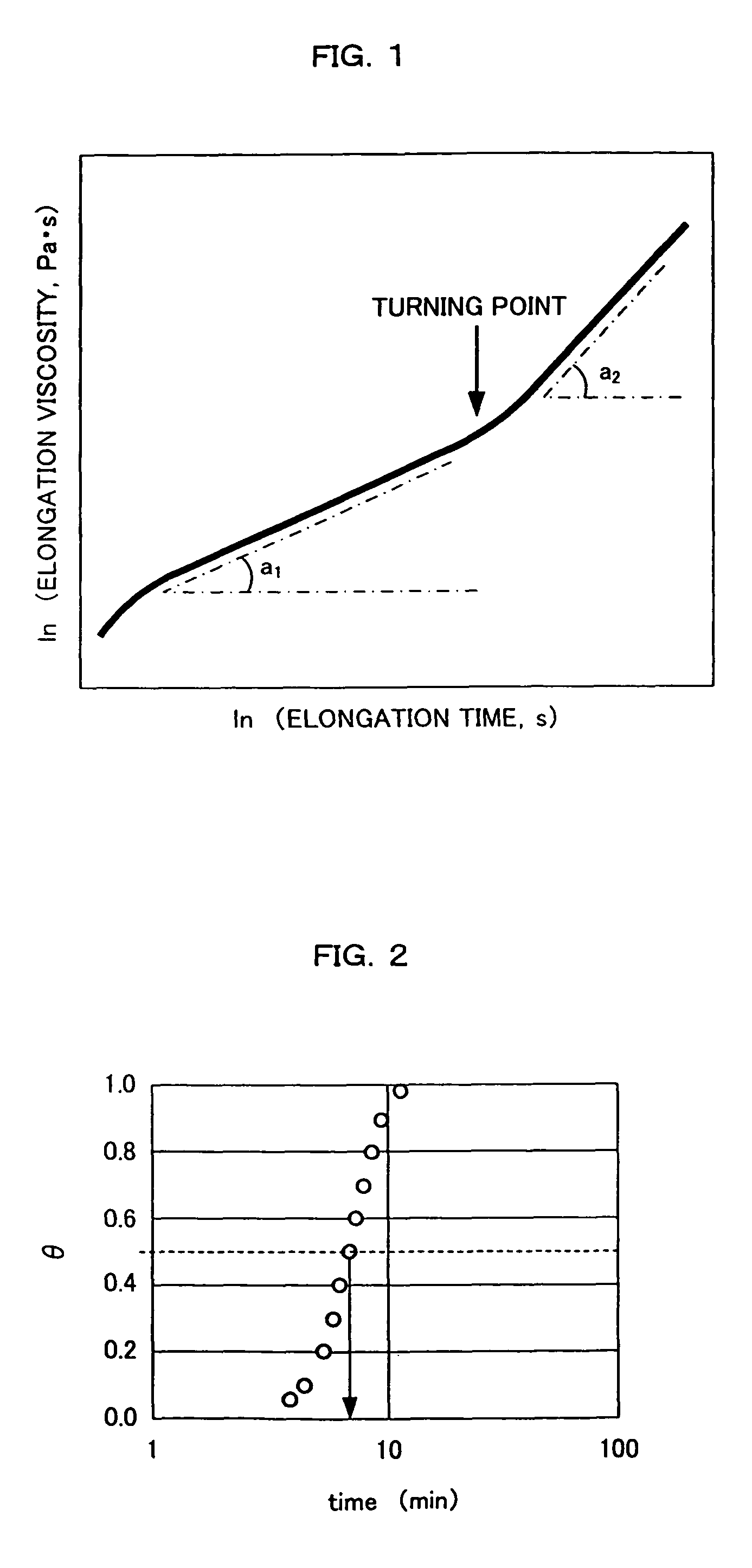

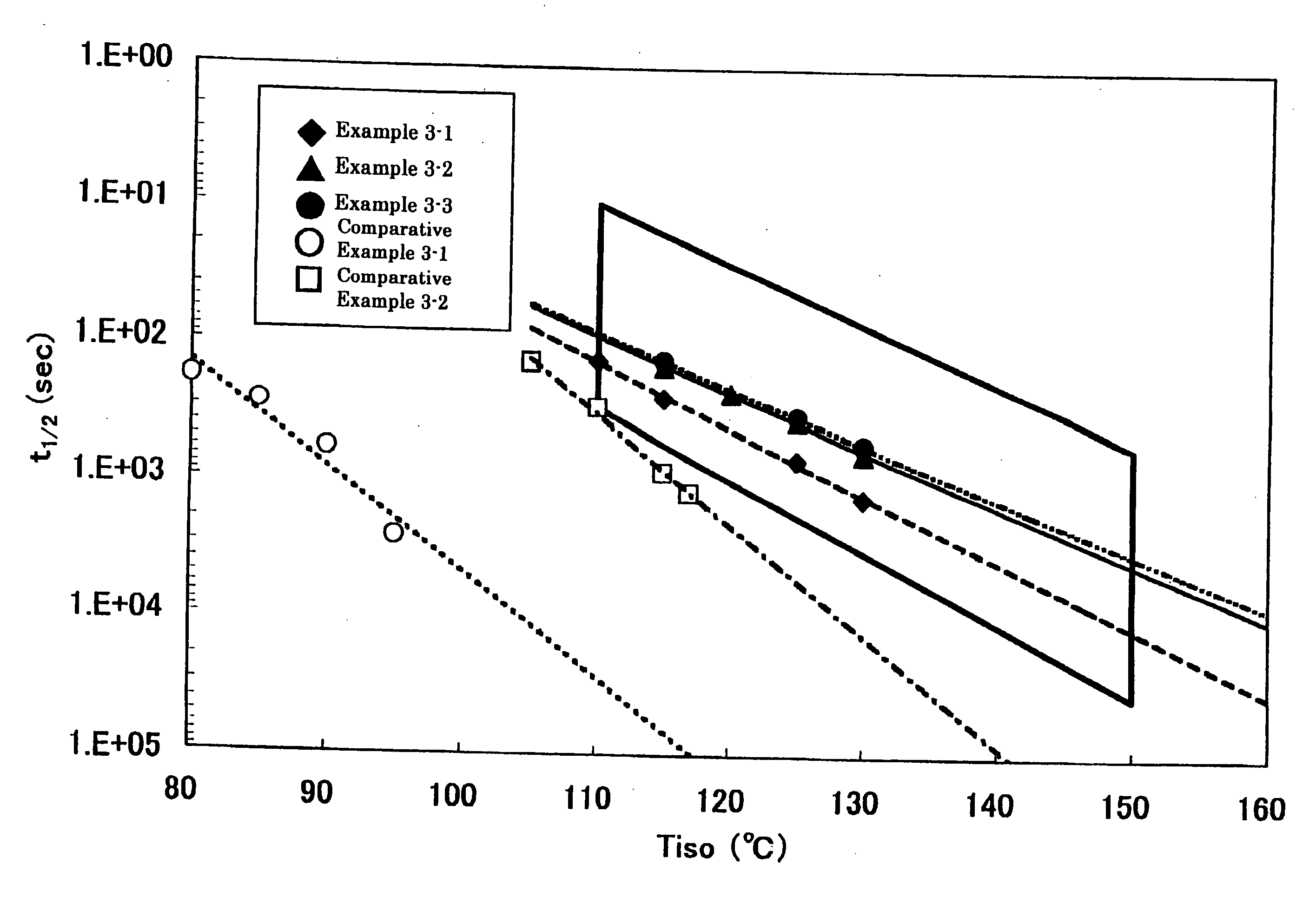

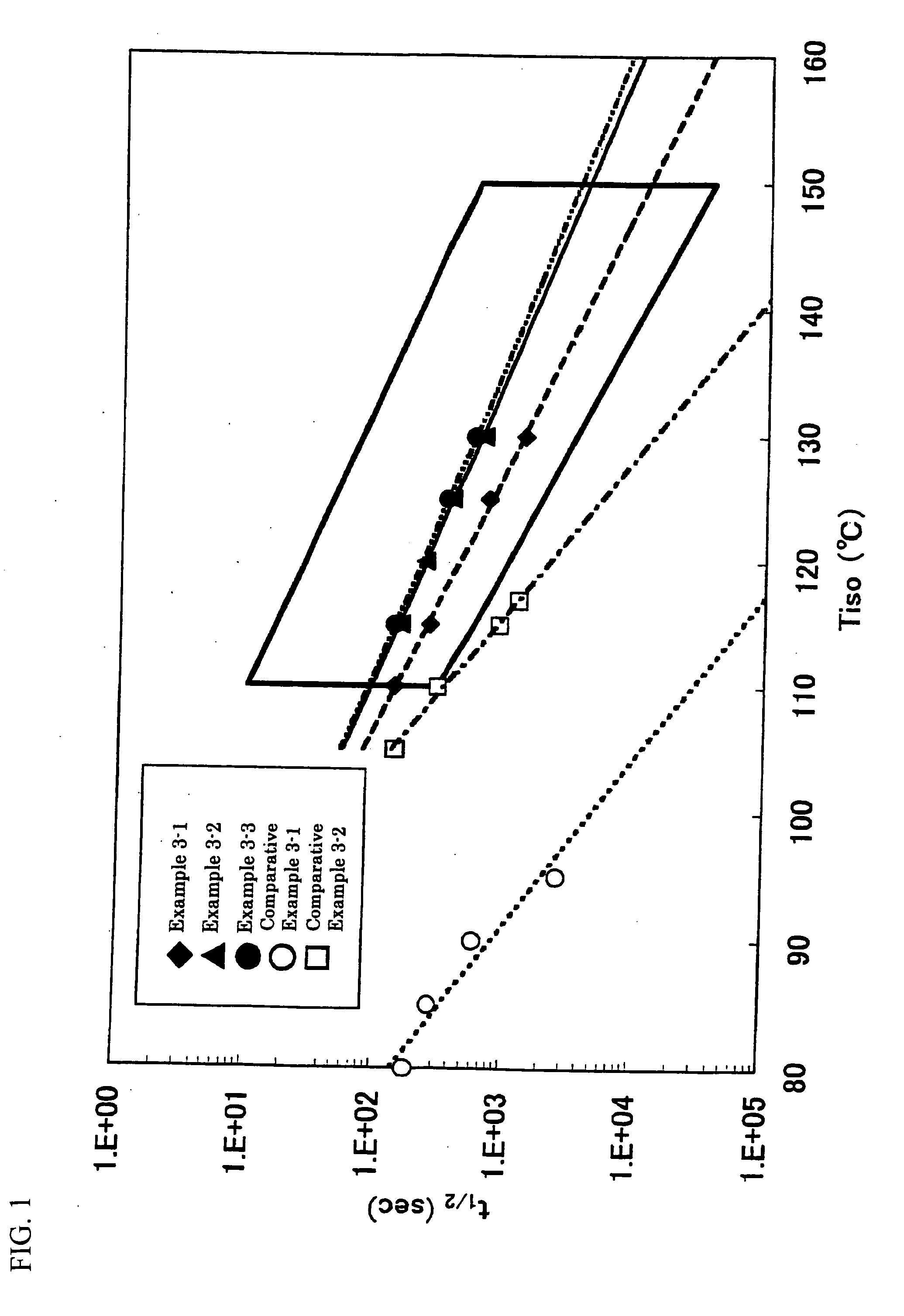

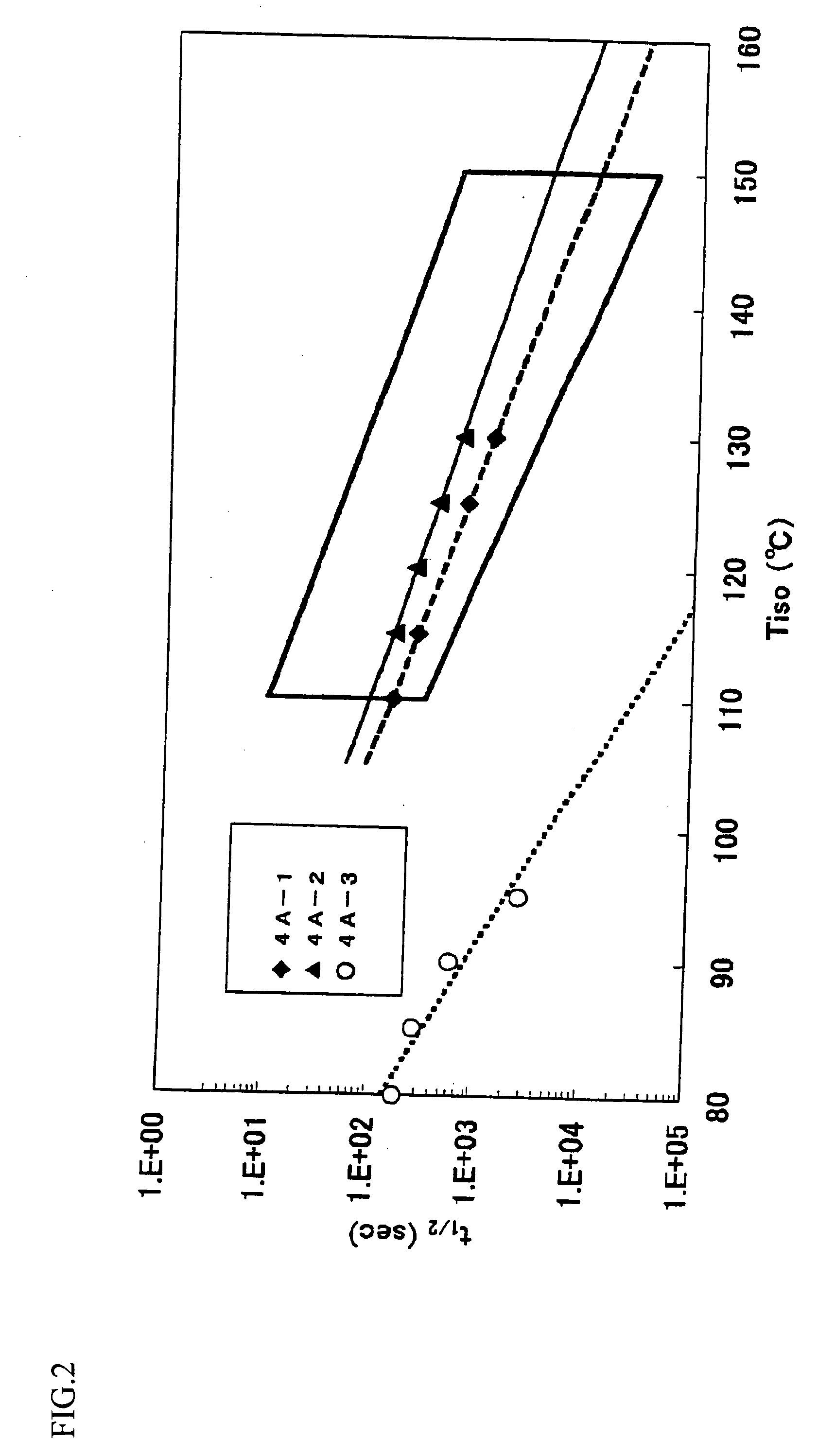

Ethylene copolymer and process for producing the same, resin composition containing the copolymer, and uses of these

InactiveUS6462136B1High tear strengthUniform processElectric/magnetic detectionAcoustic wave reradiationPolymer scienceActivation energy

The present invention is intended to provide an ethylene copolymer having excellent mechanical properties and moldability, a process for preparing the copolymer, a resin composition containing the copolymer and uses thereof. The ethylene copolymer has the following properties: the copolymer comprises 90 to 99% by mol of ethylene constituent units and 1 to 60% by mol of C3-20 alpha-olefin constituent units; the ratio (Mz / Mw) of a Z average molecular weight (Mz) to a weight-average molecular weight (Mw), each molecular weight being measured by GPC, is in the range of 10 to 30, and said ratio (Mz / Mw) and the ratio (Mw / Mn) of a weight-average molecular weight (Mw) to a number-average molecular weight (Mn), each molecular weight being measured by GPC, satisfy the relation (Mz / Mw)>(Mw / Mn); the intrinsic viscosity is in the range of 0.5 to 9 dl / g; the ratio (n*0.01 / n*8) of a melt viscosity (eta*0.01) at a shear rate of 0.01 rad / sec, as measured at 190° C., to a melt viscosity (eta*8) at a shear rate of 8 rad / sec, as measured at 190° C., and the intrinsic viscosity (eta) satisfy the relation (eta*0.01 / eta*8)>=0.893x(eta)+1.0; and the absolute value of an activation energy (Ea) of a shift factor of melt viscoelasticity is not more than 4x104 J / mol.K.

Owner:MITSUI CHEM INC

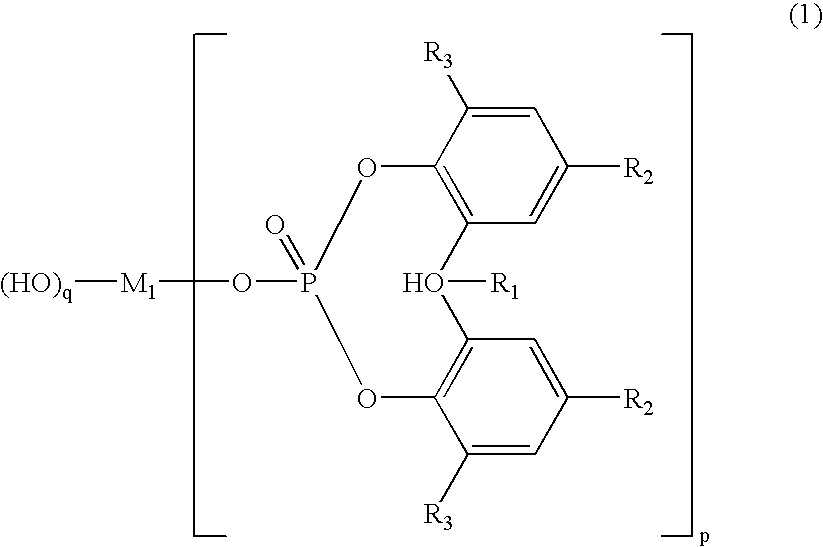

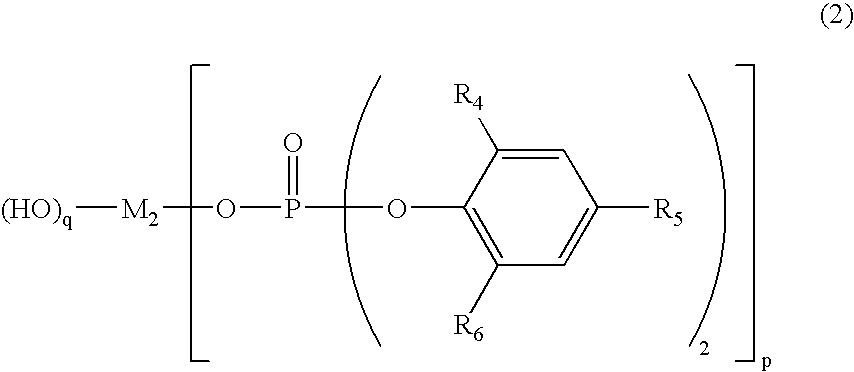

Polylactic acid-based resin compositions, molded articles and process for producing the same

A polylactic acid-based resin composition is provided from which molded articles with a high heat resistance and high impact strength can be molded with improved moldability. Also provided is a heat-resistant polylactic acid-based resin molded article manufactured from the polylactic acid-based resin composition, as well as a process for manufacturing such a heat-resistant molded article. A polylactic acid-based resin composition comprising 0.01 to 5.0 parts by weight of a metal phosphate and 0.01 to 5.0 parts by weight of a basic inorganic aluminum compound, each serving as a nucleating agent, with respect to 100 parts by weight of a polylactic acid-based polymer. The polylactic acid-based resin composition is melted and filled a mold of a molding machine set in a temperature range of not more than the crystallization-initiating point nor less than the glass transition point, as measured by a differential scanning calorimeter (DSC), to be molded the composition under crystallizing.

Owner:ADEKA CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com