Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2294 results about "Glycidyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Allyl glycidyl ether is an organic compound used in adhesives and sealants and as a monomer for polymerization reactions. It is formally the condensation product of allyl alcohol and glycidol via an ether linkage. Because it contains both an alkene and an epoxide group, either group can be reacted...

Photosensitive compositions based on polycyclic polymers for low stress, high temperature films

InactiveUS20060020068A1Increase variabilityFilm/foil adhesivesSemiconductor/solid-state device manufacturingAddition polymerNorbornene

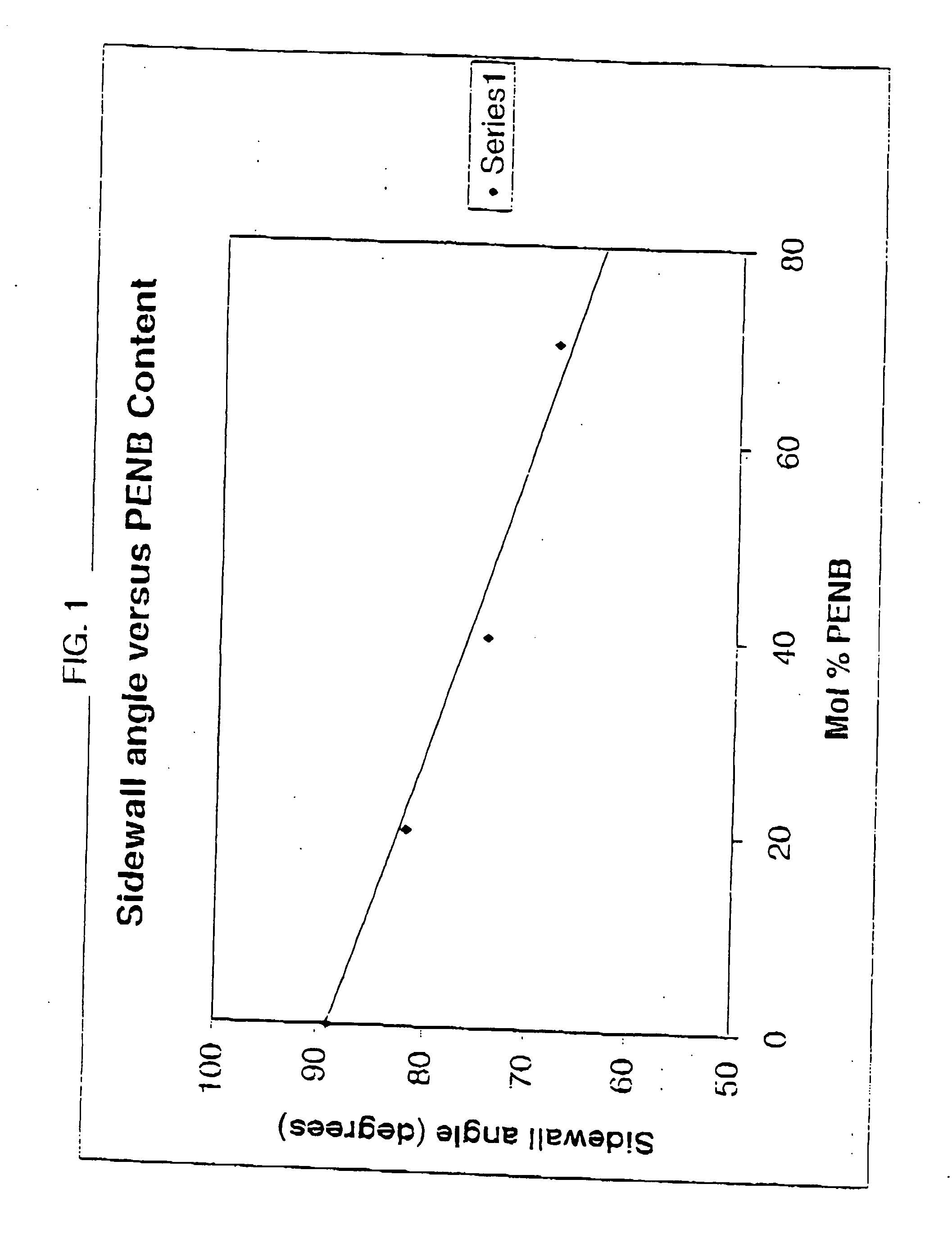

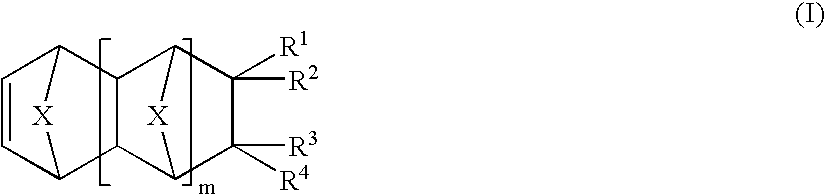

Vinyl addition polymer compositions, methods for forming such compositions, methods for using such compositions to form microelectronic and optoelectronic devices are provided. The vinyl addition polymer encompassed by such compositions has a polymer backbone having two or more distinct types of repeat units derived from norbornene-type monomers independently selected from monomers of Formula I: wherein each of X, m, R1, R2, R3, and R4 is as defined herein and wherein a first type of repeat unit is derived from a glycidyl ether substituted norbornene monomer and a second type of repeat unit is derived from an aralkyl substituted norbornene monomer.

Owner:PROMERUS LLC

Biodegradable polyester resin composition, preparation method therefor, and foamed article and molded article produced therefrom

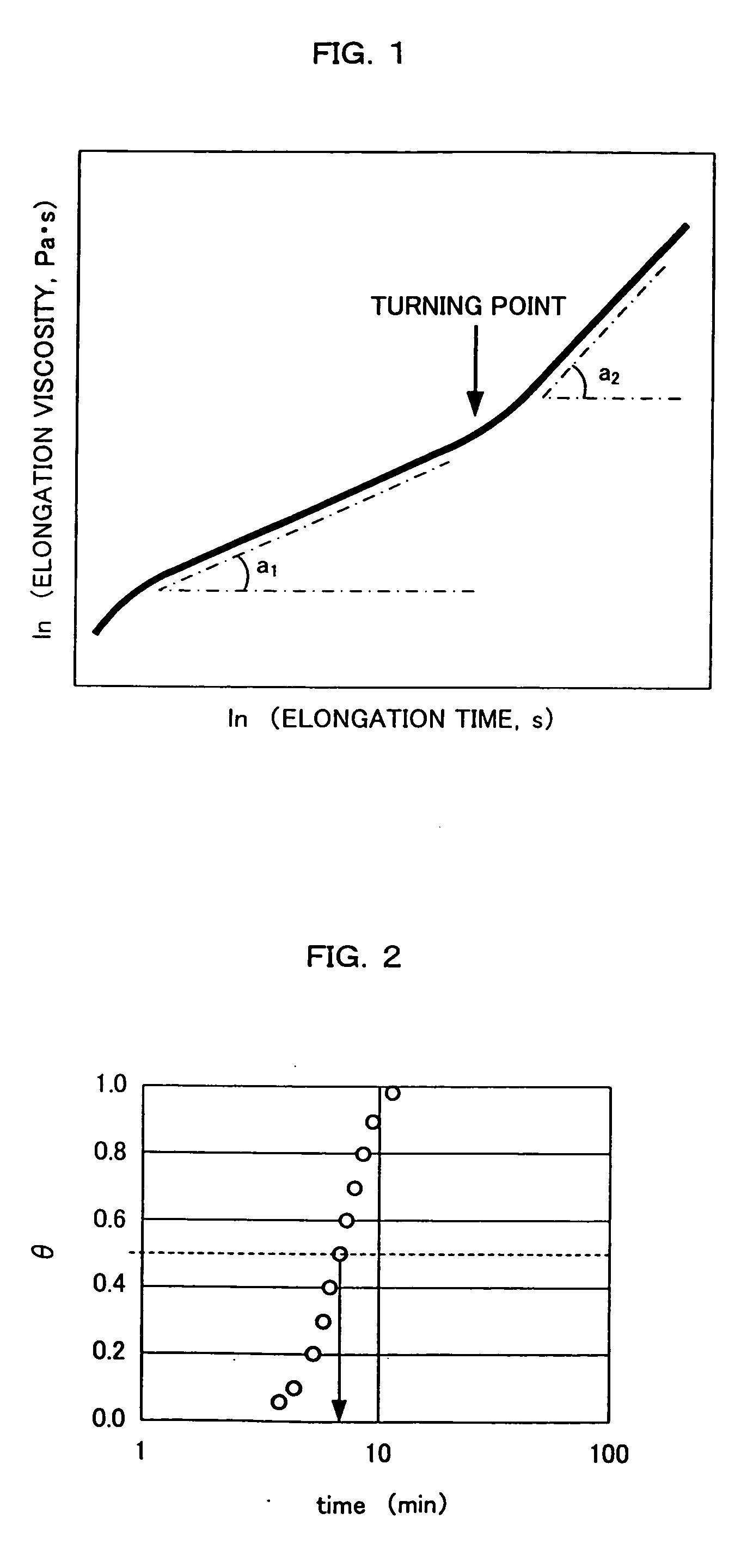

A biodegradable polyester resin composition which comprises a thermoplastic polymer comprising 100 parts by mass of an aliphatic polyester (A) and 0.01 to 5 parts by mass of a (meth)acrylic ester (B1) and / or a glycidyl ether (B2, and has a gelation index (1) of not lower than 0.1% and a gelation index (2) of not higher than 0.5%.

Owner:UNITIKA LTD

Shape Memory Epoxy Copolymer

ActiveUS20080269420A1Harden and quickly and repetitivelySoften quickly and repetitivelyHydrogenGlass transition

The shape memory polymers disclosed are a reaction product of at least one reagent containing two active amino-hydrogen or two active phenolic-hydrogen with at least one multifunctional cross linking reagent which contains at least three or more active amino- or phenolic-hydrogen or is a reagent containing at least three glycidyl ether moieties which is then further mixed with at least one diglycidyl ether reagent whereupon the resulting mixture is cured and has a glass transition temperature higher than 00C. This reaction creates crosslinking between the monomers and polymers such that during polymerization they form a crosslinked thermoset network.

Owner:CORNERSTONE RES GROUP

Mixed gel of polylactic acid microspheres and cross-linked hyaluronic acid for injection and preparation method of mixed gel

The invention relates to a mixed gel of polylactic acid microspheres and cross-linked hyaluronic acid for injection and a preparation method of the mixed gel. The polylactic acid microspheres have the molecular weight of 15000-120000 and the average particle size of 10-150mu m, and the mass fraction of the polylactic acid microspheres in the mixed gel is 5-25%; a salt solution of the cross-linked hyaluronic acid gel is obtained by swelling and balancing the cross-linked hyaluronic acid gel in a sodium chloride solution or a phosphate buffer solution with the osmotic pressure of 250-350mOsmol / L and the pH value of 6.5-7.5; the cross-linked hyaluronic acid gel is a hyaluronic acid gel cross-linked by divinyl sulfone or glycidyl ether. A mixed gel product of polylactic acid and cross-linked hyaluronic acid, obtained by directly mixing the polylactic acid microspheres with the cross-linked hyaluronic acid gel obtained by swelling and balancing in the salt solution is uniform, fine, long in partial retention time, good in plasticity and few in side effects, has an obvious effect on eliminating wrinkles, and has few operation steps and stable product quality.

Owner:河北善远科技有限公司

Stereolithographic resins with high temperature and high impact resistance

InactiveUS6989225B2High modulusHigh elongation at breakAdditive manufacturing apparatusImpression capsMeth-Cationic polymerization

A liquid radiation-curable composition that comprises(A) at least one polymerizing organic substance comprising a mixture of(1) at least one alicyclic epoxide having at least two epoxy groups; and(2) at least one difunctional or higher functional glycidylether of a polyhydric compound;(B) at least one free-radical polymerizing organic substance comprising a mixture of(1) optionally, at least one trifunctional or higher functional (meth)acrylate compound; and(2) at least one aromatic di(meth)acrylate compound;(C) at least one cationic polymerization initiator;(D) at least one free-radical polymerization initiator;(E) optionally, at least one hydroxyl-functional aliphatic compound; and(F) at least one hydroxyl-functional aromatic compound;wherein the concentration of hydroxyl groups in the radiation-curable composition is at least about 1.1 equivalent OH groups per kilogram;wherein the concentration of epoxy groups in the radiation-curable composition is at least about 5.5 equivalent epoxy groups per kilogram; andwherein the amount of trifunctional or higher functional (meth)acrylate compound (B)(1) is from 0% to about 3% of the composition and the amount of aromatic di(meth)acrylate compound (B)(2) is at least 10% of the composition.

Owner:3D SYST INC

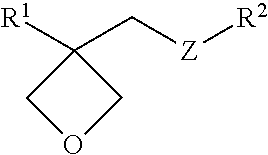

Low-viscosity liquid radiation curable dental aligner mold resin compositions for additive manufacturing

Liquid radiation curable resin compositions for additive manufacturing comprising: from about 5 to about 30 wt % of an oxetane; a (meth)acrylate component; a cationic photoinitiator; a free-radical photoinitiator; and from about 50 to about 80 wt % of an epoxy, which further comprises a cycloaliphatic epoxy component, and an epoxy component having an aromatic glycidyl ether group, wherein the majority of the epoxy is the cycloaliphatic epoxy component are described and claimed. Also described and claimed is a process for using the liquid radiation curable resins for additive manufacturing to create molds for dental aligners, and the three-dimensional molds made from the liquid radiation curable resins for additive manufacturing.

Owner:STRATSYS INC

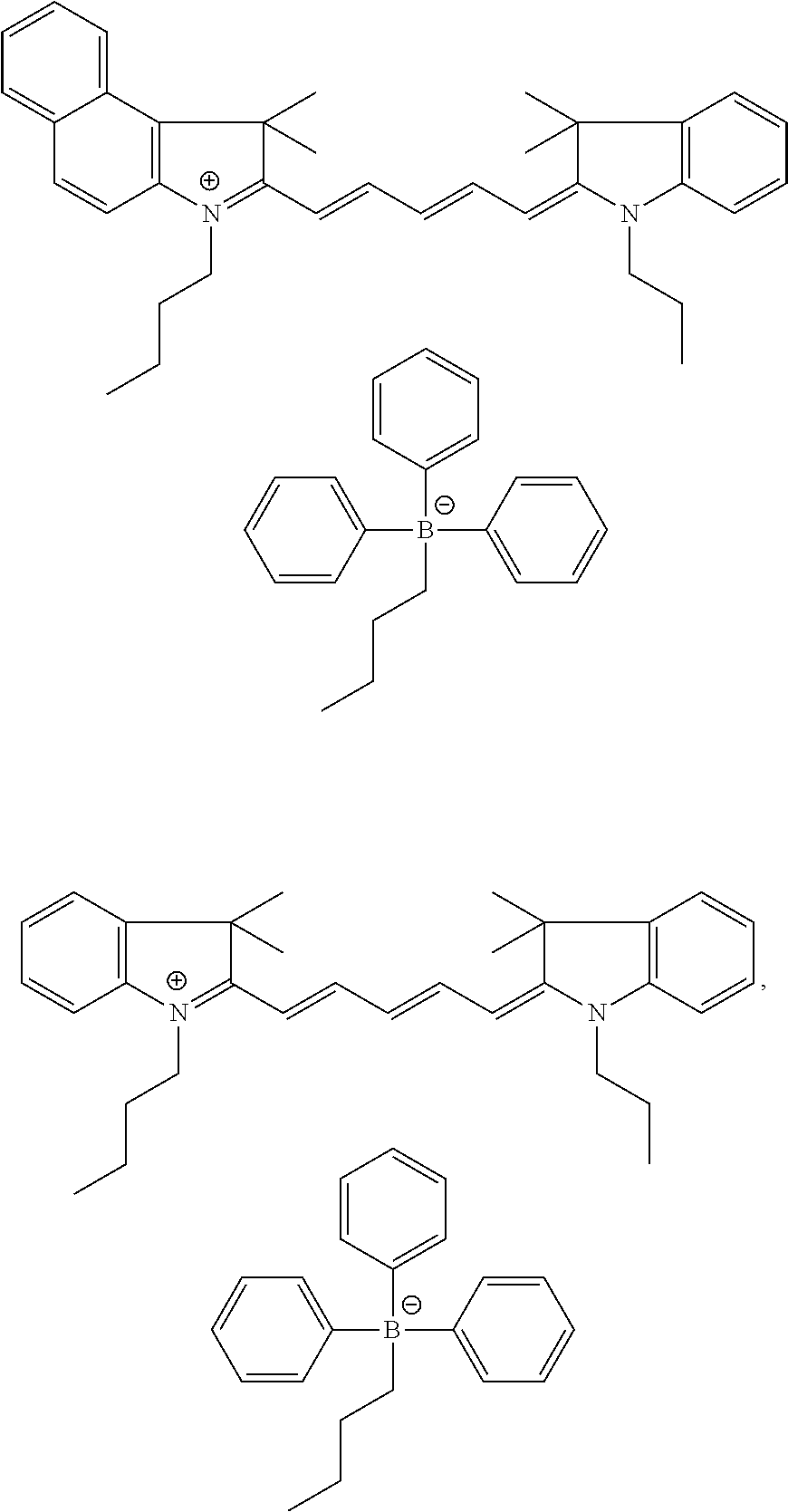

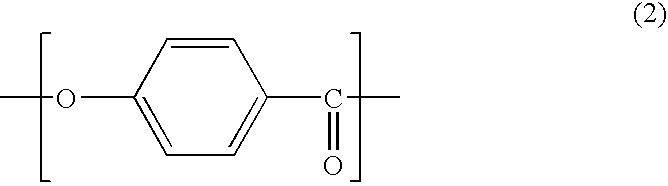

Dry toner for developing electrostatic images

A dry toner for developing electrostatic images, including a colorant and a binder resin which comprises a copolymer resin having (A) a polyol resin moiety having a main chain of polyoxyalkylene and obtained by reaction of (a) an epoxy resin, (b) a dihydric phenol, and (c) an alkylene oxide adduct of a dihydric phenol or a glycidyl ether thereof; and (B) a polyester resin moiety obtained by reacting an alkylene oxide adduct of a dihydric phenol or a glycidyl ether thereof with a polycarboxylic acid, wherein the weight ratio of the epoxy resin of the polyol resin moiety (A) to the polyester resin moiety (B) is 95:5 to 60:40, wherein the epoxy resin includes at least two kinds of bisphenol epoxy resins having different number-average molecular weights, and wherein the binder resin has an acid value of not greater than 5.

Owner:RICOH KK

Injection amphiphilic-microsphere-containing hyaluronic acid mixed gel and preparation method thereof

The invention relates to injection amphiphilic-microsphere-containing hyaluronic acid mixed gel and a preparation method thereof. The microsphere material relates to amphiphilic materials of PLLA-PEG, PLGA, PLGA-PEG and the like. The molecular weight of PLLA or PLGA is 10,000-500,000, the molecular weight of PEG is 1,000-10,000, and in PLGA, LA / GA=90 / 10-10 / 90. The average grain diameter of the microsphere is 1-200 [mu[m, and the mass percent of the microsphere in the gel is 1-50%; the gel is made from hyaluronic acid, divinyl sulphone crosslinked hyaluronic acid, or glycidyl ether crosslinked hyaluronic acid, the molecular weight of the hyaluronic acid is 100,000-3,000,000, and the mass percent of the hyaluronic acid is 1-50%. The gel can be also made from animal-derived collagen, chitosan, amino acid cellulose and sodium alginate. The microsphere mixed gel is prepared in a sodium chloride solution or a phosphate buffered solution with the osmotic pressure of 250-350 mOsm / L and pH of 6.5-7.5. According to the invention, the amphiphilic microsphere is directly mixed with hyaluronic acid gel, can be uniformly distributed in the gel easily, and is unlikely to aggregate into blocks in the water environment of a human body after being injected.

Owner:IMEIK TECH DEV CO LTD

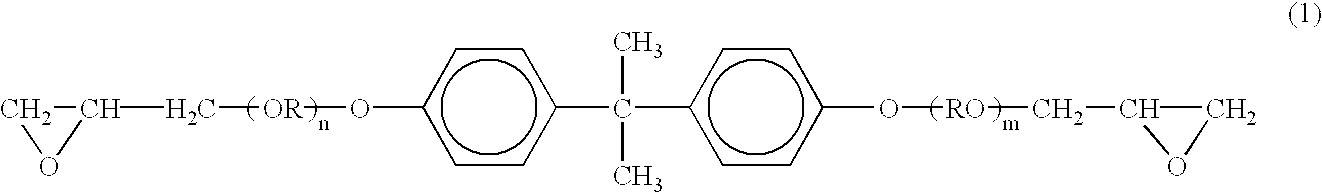

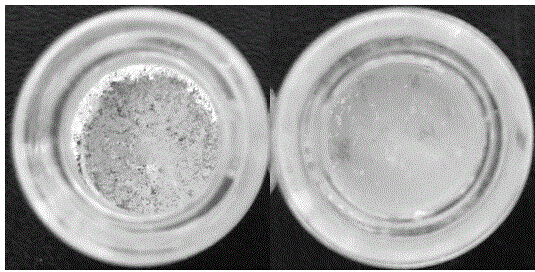

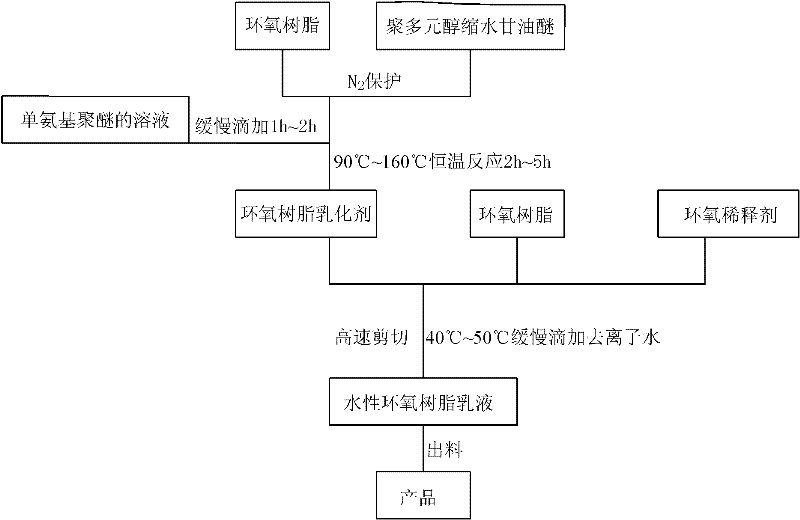

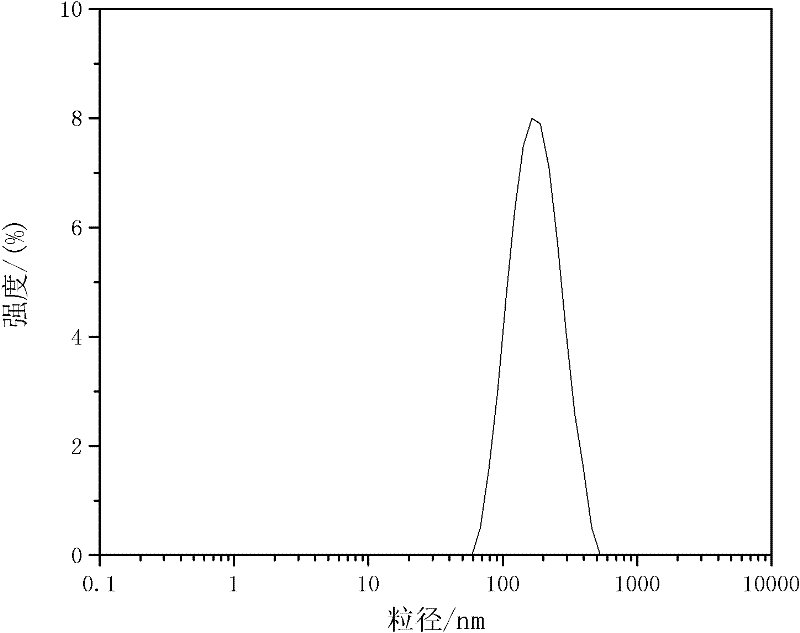

Non-ionic aqueous epoxy resin emulsion and its preparation method

The invention relates to the technical field of chemical painting, specifically to a non-ionic aqueous epoxy resin emulsion and its preparation method. The preparation method of the non-ionic aqueous epoxy resin emulsion provided by the invention comprises the following steps of: firstly, slowly adding dropwisely mono-aminopolyether dissolved by an organic solvent into a mixture of epoxy resin and polyalcohol glycidyl ether to react at the temperature of 90-160 DEG C so as to generate an epoxy-terminated intermediate product, namely an epoxy resin emulsifier; and secondly, mixing the epoxy resin, an epoxy diluent and the epoxy resin emulsifier at the temperature of 40-50 DEG C, slowly adding dropwisely deionized water under high-speed shearing, followed by phase inversion to produce the stable aqueous epoxy resin emulsion. The epoxy resin emulsion provided by the invention has small particle size and high stability; in addition, the solidified film performance of the emulsion is excellent and the production process flow is simple. The aqueous epoxy emulsion provided by the invention can be applied in aqueous paintings and aqueous binders, such as terrace paintings, industrial protection paintings and the like.

Owner:湖南松井先进表面处理与功能涂层研究院有限公司

Solar cell packaging EVA adhesive film capable of resisting heat, humidity, ultraviolet light and aging

InactiveCN101626039AIncrease crosslink densityModerate reaction temperatureElectrical equipmentGlass/slag layered productsAntioxidantPhosphate

The invention relates to a solar cell packaging EVA adhesive film capable of resisting heat, humidity, ultraviolet light and aging, which comprises the following materials by weight portions: 100 portions of copolymer of ethylene vinyl acetate, 0.8-1.4 portions of crosslink curing agent, 0.05-0.15 portion of crosslink curing accelerator, 0.2-0.6 portion of tackifier, 0.1-0.5 portion of antioxidant, 0.05-0.25 portion of ultraviolet light stabilizer and 0.1-0.3 portion of ultraviolet light absorbent, wherein the crosslink curing agent is tert butyl peroxy 2-ethyl hexyl carbonate; the crosslink curing accelerator is triallyl isocyanurate; the tackifier is r-glycidyl ether oxy-propylltrimethoxysilane; the antioxidant is one or two selected from the group consisting of bis(2,4-dicumylphenyl)pentaerythritol diphosphite, distearyl pentaerythritol diphosphite, tris(nonyl phenyl)phosphate and tris(2,4-butylphenyl)phosphate; and ultraviolet light absorbent is gas phase silicon dioxide. The solar cell packaging EVA adhesive film can resist high temperature of 85 DEG C, humidity of 85 percent, ultraviolet light and thermal oxidative aging.

Owner:苏州爱康商务咨询服务有限公司

Non-ionic self-emulsifying aqueous epoxy hardener and preparation method and application thereof

InactiveCN101624385AGood self-emulsifying performanceGood flexibilityOrganic compound preparationEpoxy resin adhesivesEpoxyNitrogen

The invention relates to an epoxy hardener, in particular to a non-ionic self-emulsifying aqueous epoxy hardener. The hardener is prepared according to the following steps: adopting hydrophobic alkylamine and hydrophilic diglycidol ether with low molecular weight for reaction so as to obtain a diepoxy compound which has epoxy groups at two ends and a middle nitrogen atom linked with a long hydrophobic alkyl side chain; and adopting alicyclic amine for reaction for purpose of sealing the ends or respectively using the alicyclic amine and hydrophilic amine to seal the two ends, and finally obtaining the amino-terminated non-ionic self-emulsifying aqueous epoxy hardener similar to the structure of surfactant. The hardener can be further mixed with deionized water so that a light-yellow aqueous epoxy resin hardener with 50-60 percent of solids content can be obtained. The hardener has good self-emulsifying effect, is well compatible with epoxy resin and has high stability and good flexibility and surface activating function. The hardener can be widely applied in materials such as aqueous epoxy resin paint, epoxy resin binding agent, aqueous epoxy grouting materials, and the like.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

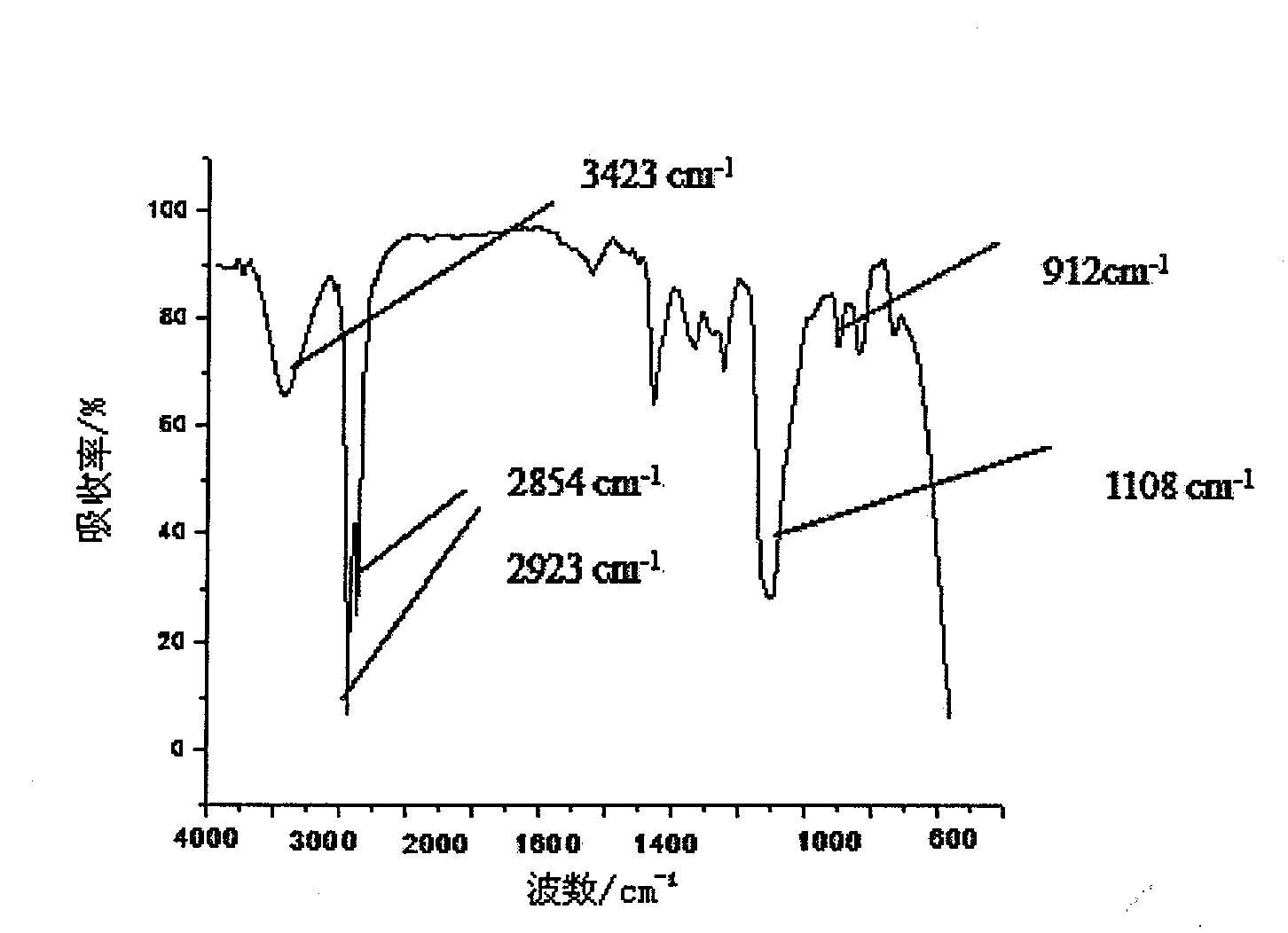

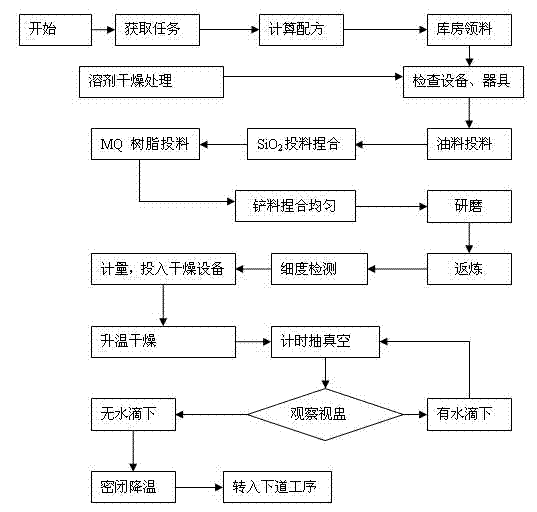

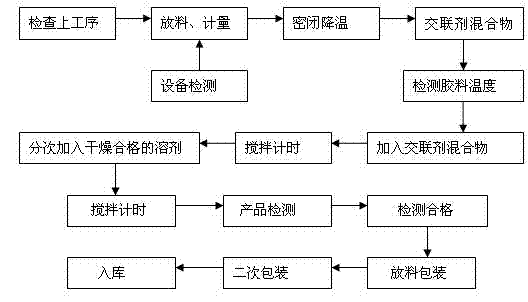

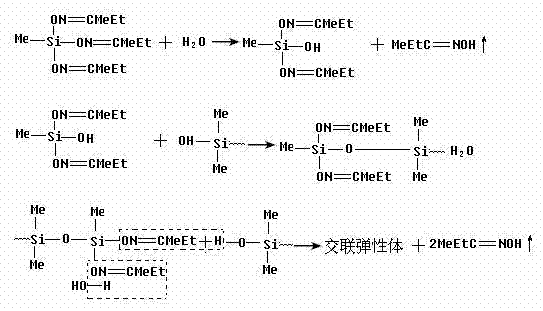

Organosilicon coating and preparation method thereof

The invention belongs to the field of organosilicon, and particularly relates to an organosilicon coating and a preparation method thereof. The organosilicon coating is characterized in that the organosilicon coating comprises 90 to 120 parts of Alpha, Omega-dihydroxy polydimethylpolysiloxane, 10 to 30 parts of MQ resin, 10 to 30 parts of white carbon black, 0.3 to 1 part of vulcanization accelerators, 2 to 3 parts of methyl-tri-(butanone-oxime) silane, 2 to 3 parts of vinyl tributanoximo silane, 1 to 3 parts of propylamino triethoxy silane, 1 to 2 parts of 3-glycidyl ether oxypropyl trimethoxysilane and 70 to 90 parts of solvent. The preparation method comprises the steps of raw material selection, raw material weighing, rubber compound drying, rubber compound preparation, and the like. The organosilicon elastic coating disclosed by the invention has low viscosity and high fluidity, can be rapidly self-leveled and filled after being coated, has a high curing speed at room temperature, needs short surface drying time and curing time, has excellent electric insulation performance, high strength, low hardness, high elasticity and good toughness after being cured, has self-repairing performance and an elongation percentage reaching 200 to 500 percent, has good bonding performance, has shear strength of 2 to 5MPa over aluminum, has little odor, cannot corrode a matrix, adopts solvent oil as the solvent, can effectively insulate and protect the surfaces of printed circuit boards (PCB) and electronic devices, and can also used as other elastic coatings needing insulation performance and anticorrosion performance.

Owner:CHENGDU TALY TECH CO LTD

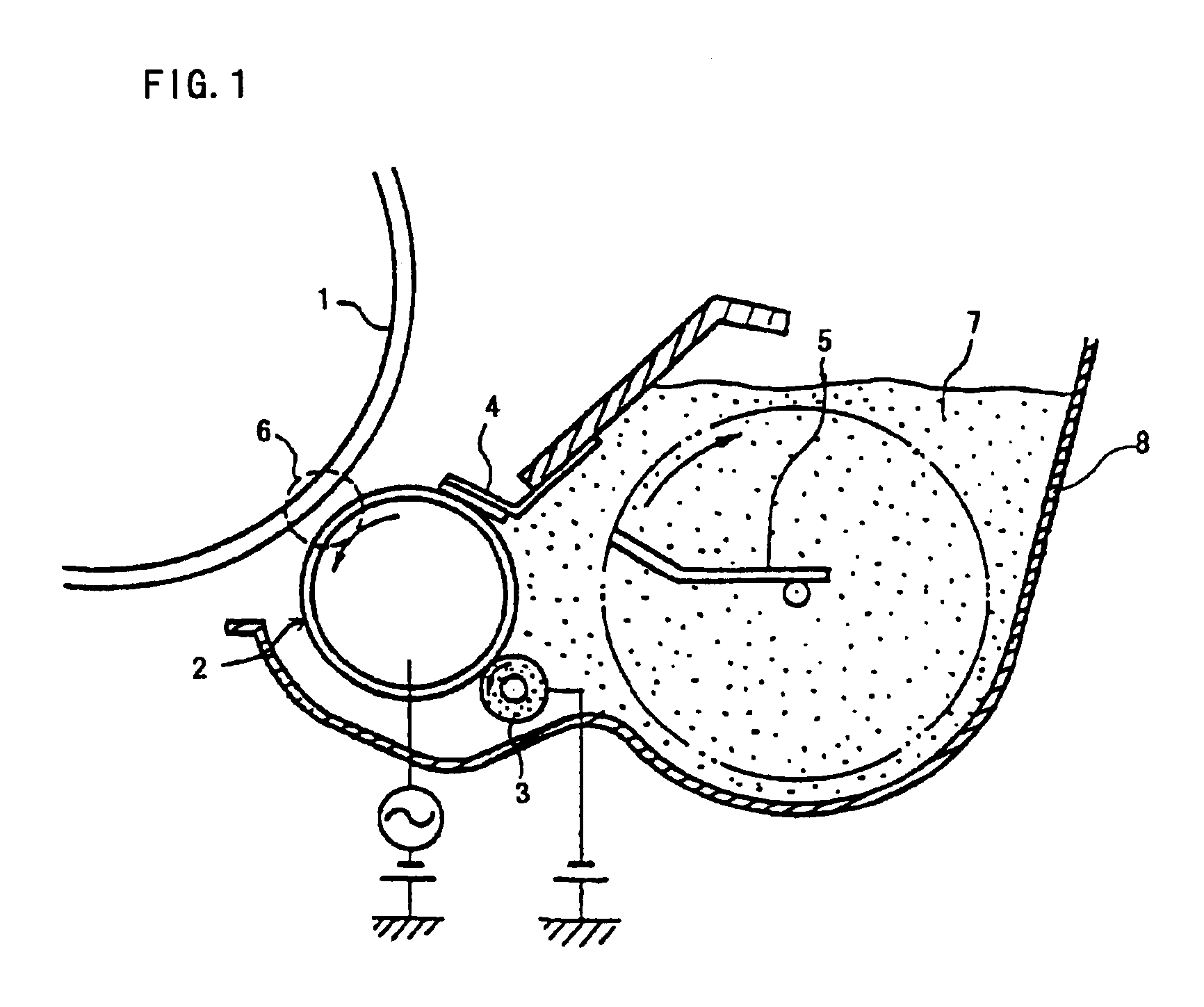

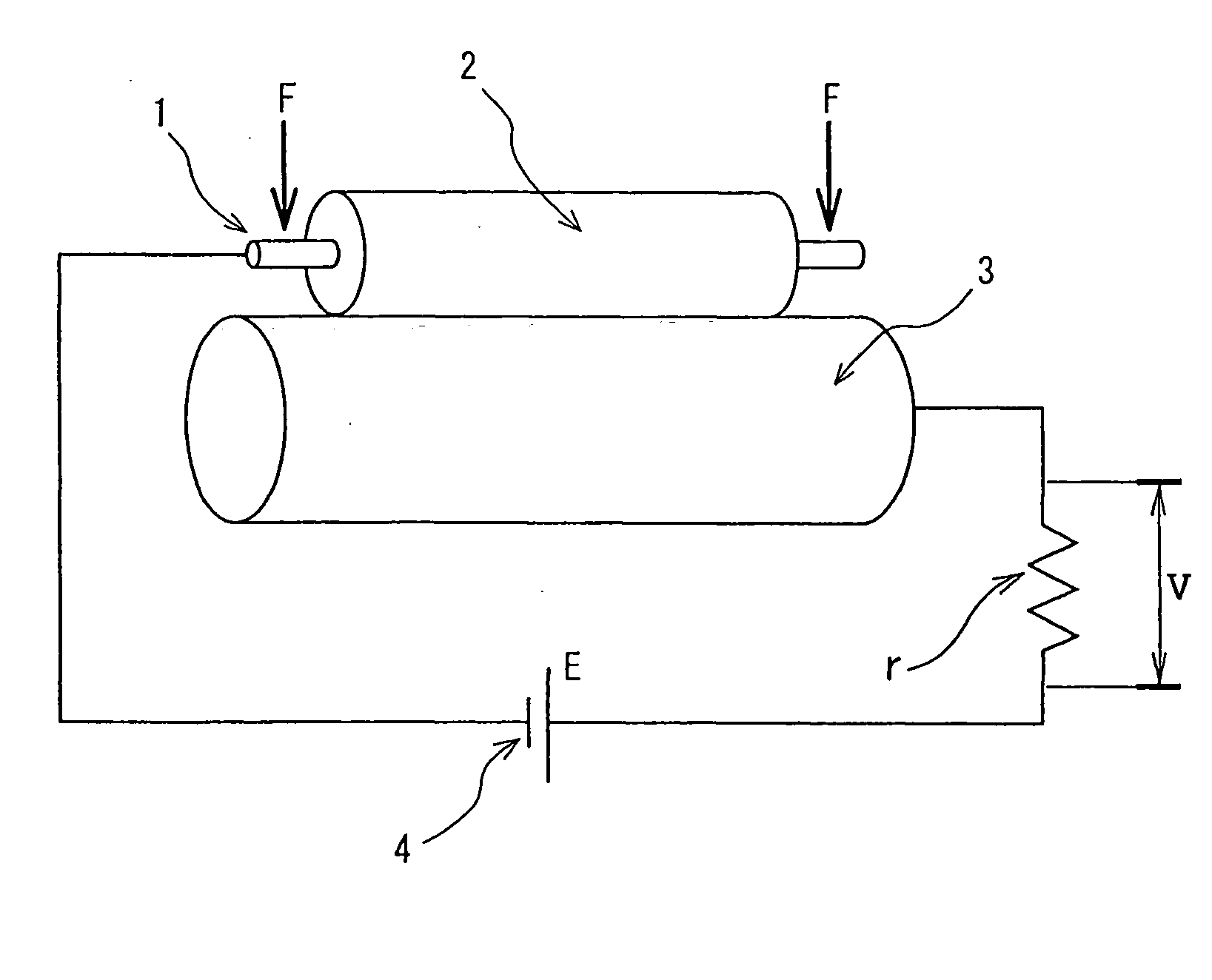

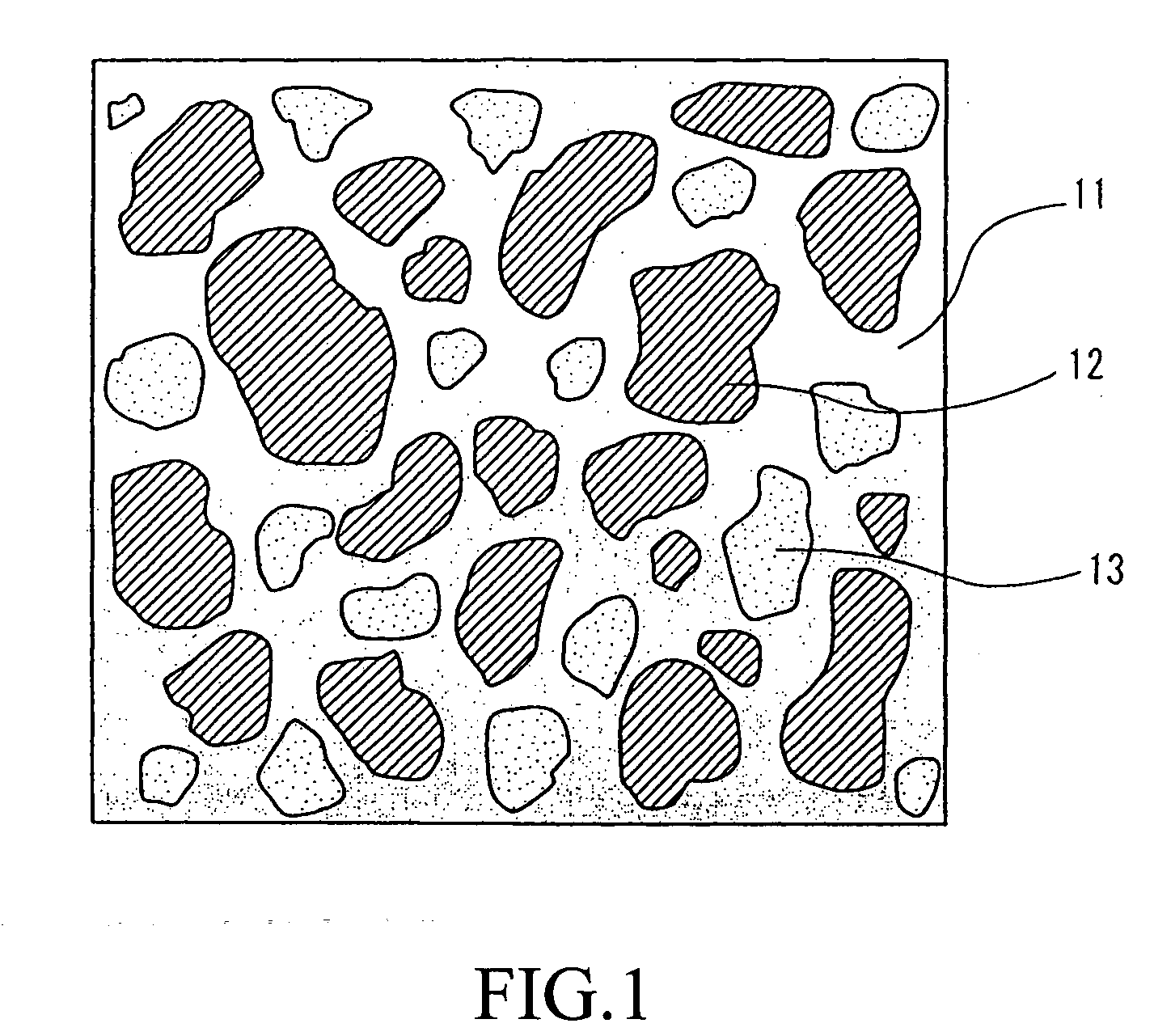

Method for producing conductive thermoplastic elastomer composition and conductive roller composed of same

InactiveUS20080315159A1Low compression setDecreasing variation of electric resistanceShaft and bearingsConductive materialElastomerPolymer science

A conductive thermoplastic elastomer composition including a continuous phase and first and second uncontinuous phases. The continuous phase and the first and second uncontinuous phases form a sea-island structure; and the first and second uncontinuous phases independently forming island structures. In this structure, the continuous phase contains a composition (A) which is a mixture of a thermoplastic elastomer and a thermoplastic resin; the first continuous phase contains a rubber component (B) containing at least one of diene rubber and ethylene-propylene-diene rubber; and the second continuous phase contains an ethylene oxide-propylene oxide-allyl glycidyl ether copolymer containing an anion-containing salt having a fluoro group and a sulfonyl group (component (C)).

Owner:SUMITOMO RUBBER IND LTD

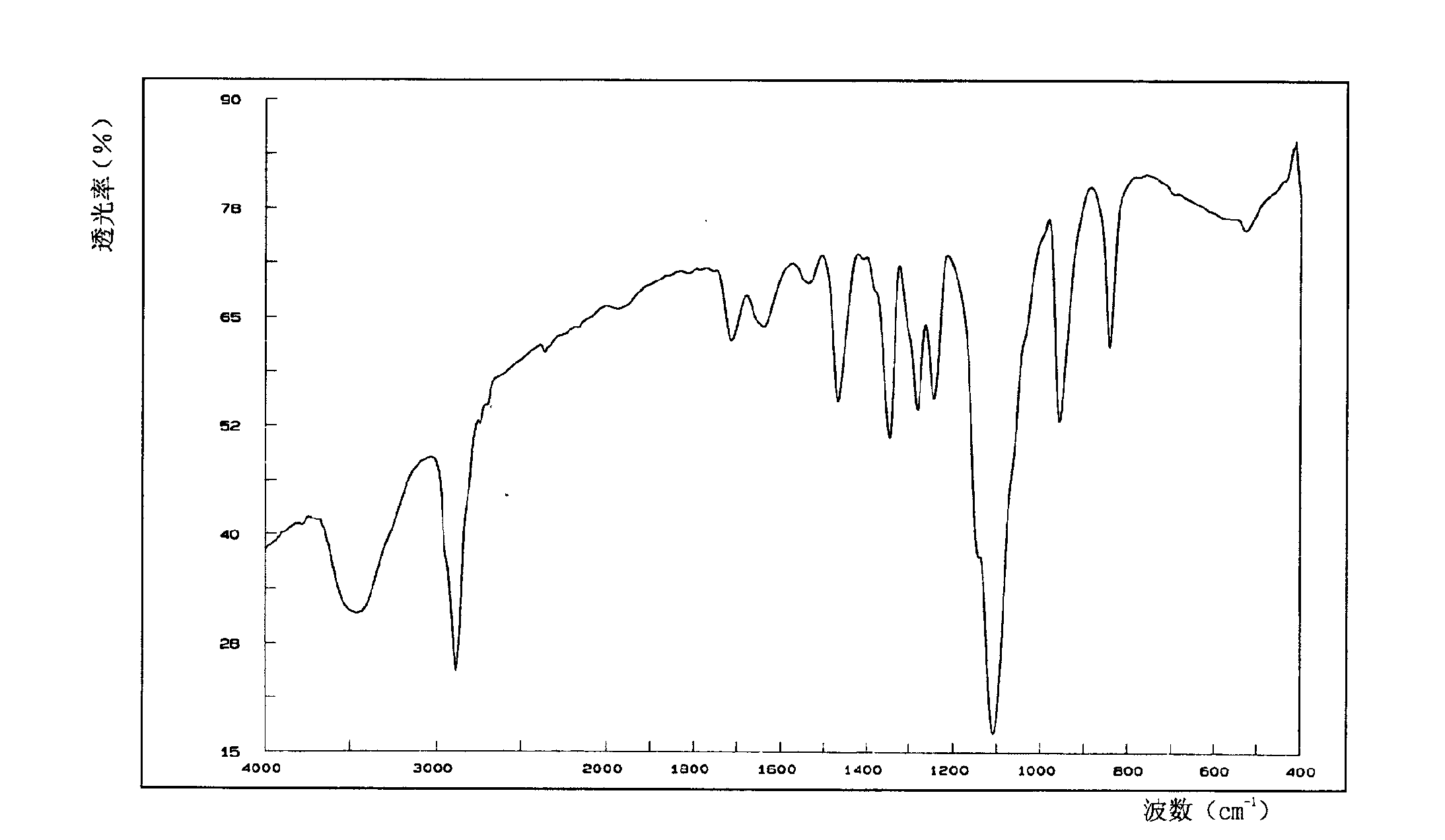

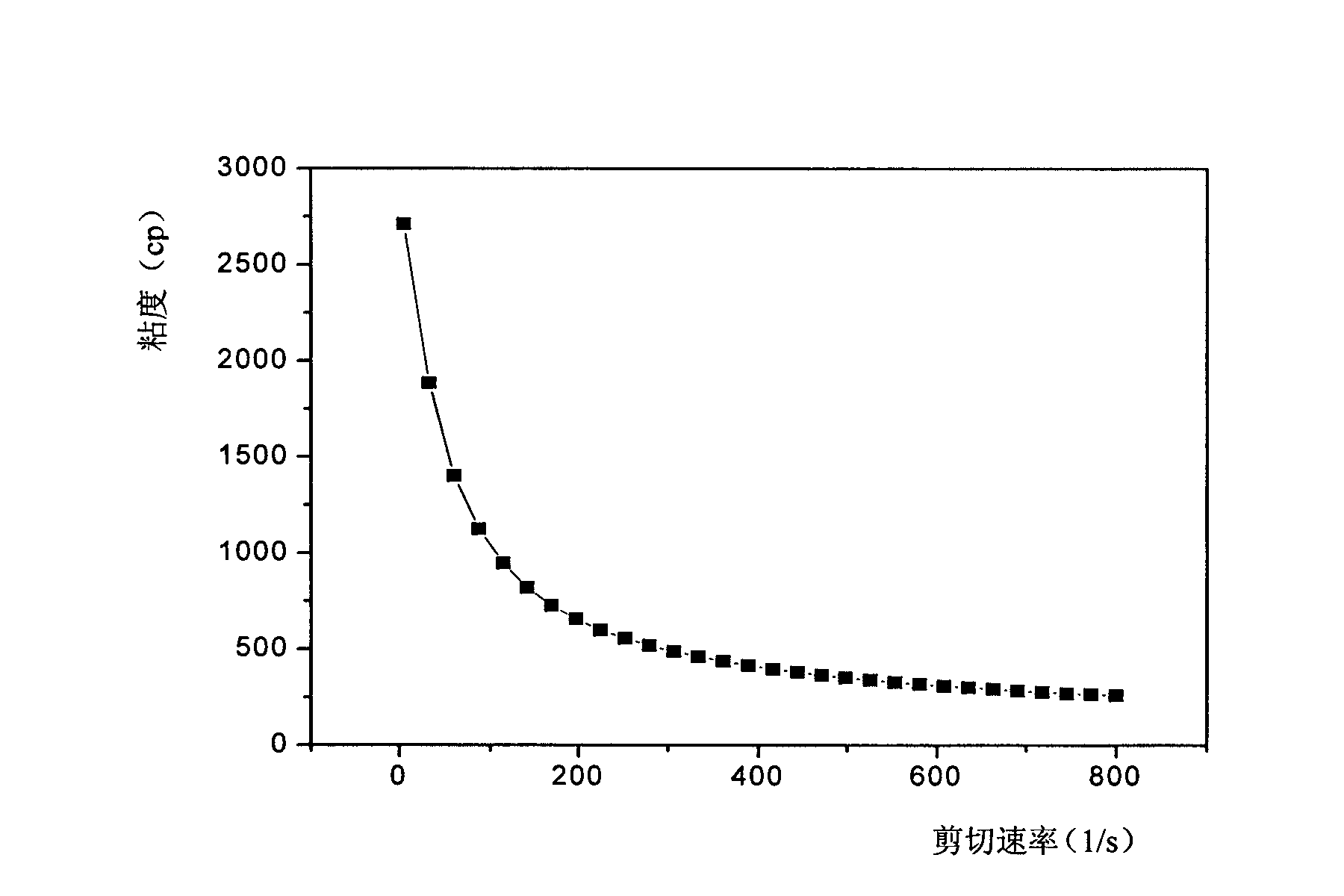

Comb polyurethane associated thickener and preparation method and application thereof

InactiveCN101633718AReduce application viscosityHigh viscosityCosmetic preparationsCoatings with pigmentsPolymer scienceEmulsion

The invention discloses a comb polyurethane associated thickener and a preparation method and an application thereof and the preparation method comprises the following steps: adopting primary amine and diglycidyl ether to react, obtaining hydrophobic diol; then adopting polyether diol, catalyst, diisocyanate, hydrophobic diol and alkanol to react, using precipitate for precipitation after finishing the reaction, drying the precipitation and obtaining the comb polyurethane associated thickener. More than two hydrophobic groups (long chain alkyl) in the molecules of the comb polyurethane associated thickener so that the consistency of the emulsion paint can be greatly improved, the emulsion paint has not only high viscosity under low shear but also low applicable viscosity under high shear, and the quality of the emulsion paint is increased. The polyurethane associated thickener is applicable to thickening the water-containing system and can be used in emulsion paint, varnish, adhesive, leather, papermaking, dyeing and printing, ink, cosmetics and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Lubricating oil composition for refrigerators

ActiveUS20100133463A1Improve compatibilityLow global warming potentialHeat-exchange elementsAdditivesPhosphorous acidScavenger

A lubricating oil composition for refrigerators including (A) a base oil containing as a main component a polyol ester compound obtained from a polyhydric alcohol selected from among pentaerythritol, dipentaerythritol, trimethylolpropane and neopentyl glycol and a C4 to C20 aliphatic monocarboxylic acid, (B) a phosphorus-based additive comprised of a phosphoric acid triester and / or a phosphorous acid triester, and (C) at least one acid scavenger selected from among glycidyl esters, glycidyl ethers and α-olefin oxides.The lubricating oil composition is applicable to such refrigerators that use a refrigerant having a specific structure, such as an unsaturated fluorinated hydrocarbon compound, and being usable in current car air conditioner systems, and has excellent compatibility with the refrigerant, good sealing properties, capability of imparting a low coefficient of friction to sliding members and, yet, excellent stability.

Owner:IDEMITSU KOSAN CO LTD

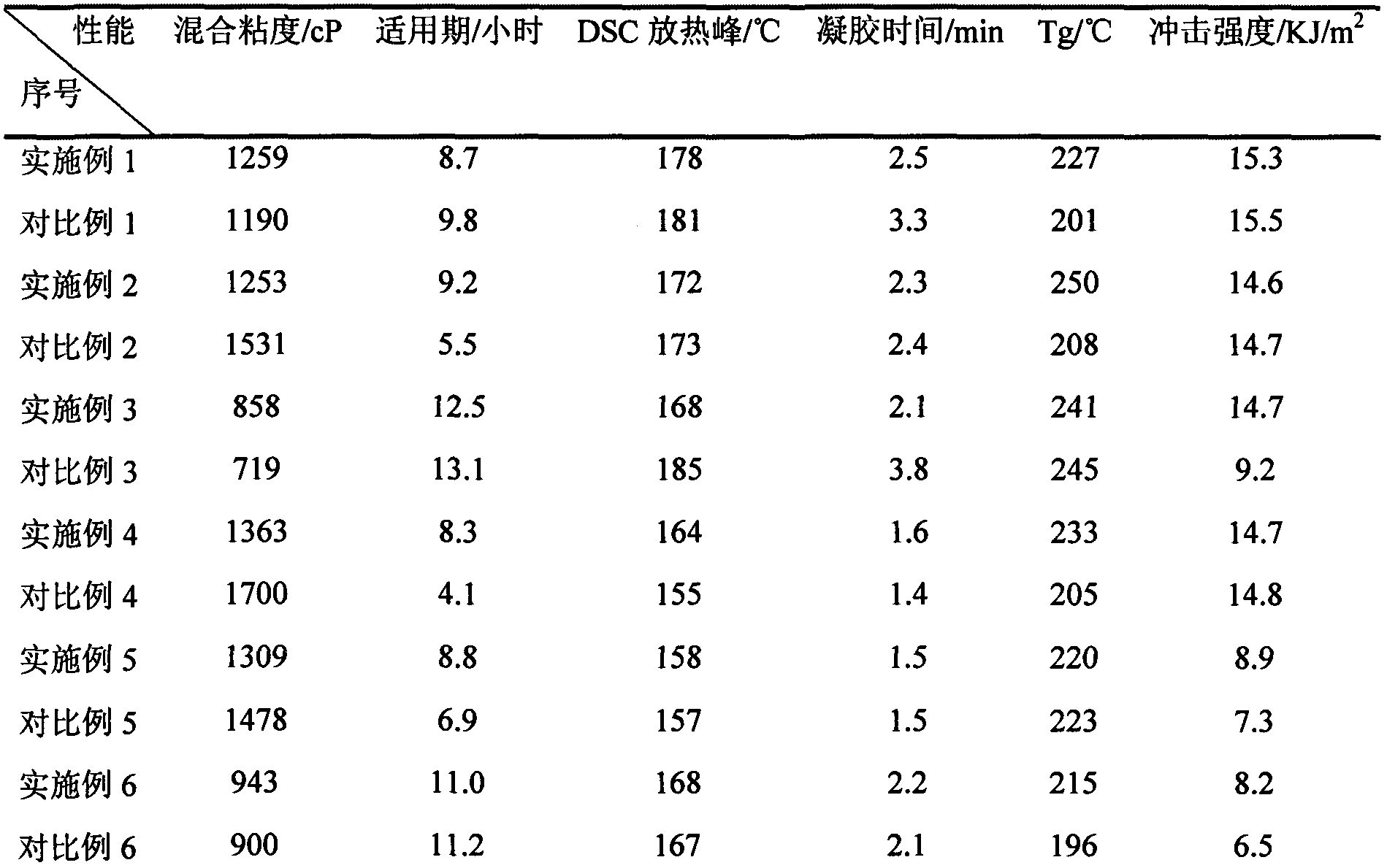

High temperature-resistant epoxy resin composition for pultrusion and preparation method

The invention provides a high temperature-resistant epoxy resin composition for pultrusion and a preparation method. The high temperature-resistant epoxy resin composition for pultrusion comprises A and B components, wherein the A component comprises glycidyl ether epoxy resin, cycloaliphatic epoxy resin and an epoxy resin active diluents, the B component comprises cycloaliphatic anhydride, aromatic hydrocarbon polyanhydride, a thermoplastic phenolic resin curing agent, a maleic anhydride grafted rubber toughening agent, a polysiloxane toughening modifier, and an epoxy resin curing accelerator, and the ratio of the A component to the B component, by weight of the components, is 100:50-250. The composition of the invention has excellent high temperature resistance, and also maintains balance between processing properties, impact toughness and comprehensive performance. The prepared products can be used for a long time in rigorous wild high temperature environment.

Owner:江苏绿材谷新材料科技发展有限公司

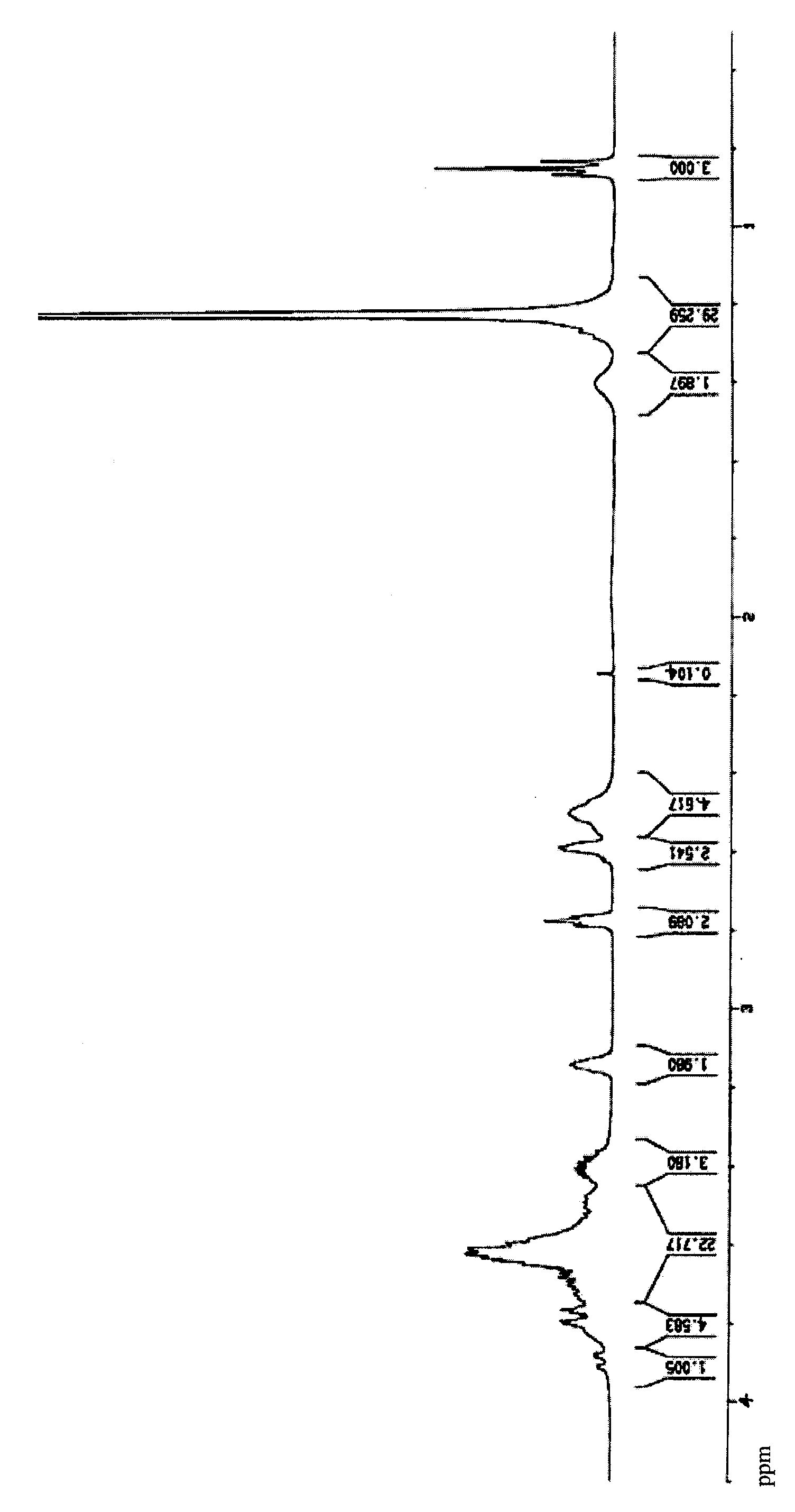

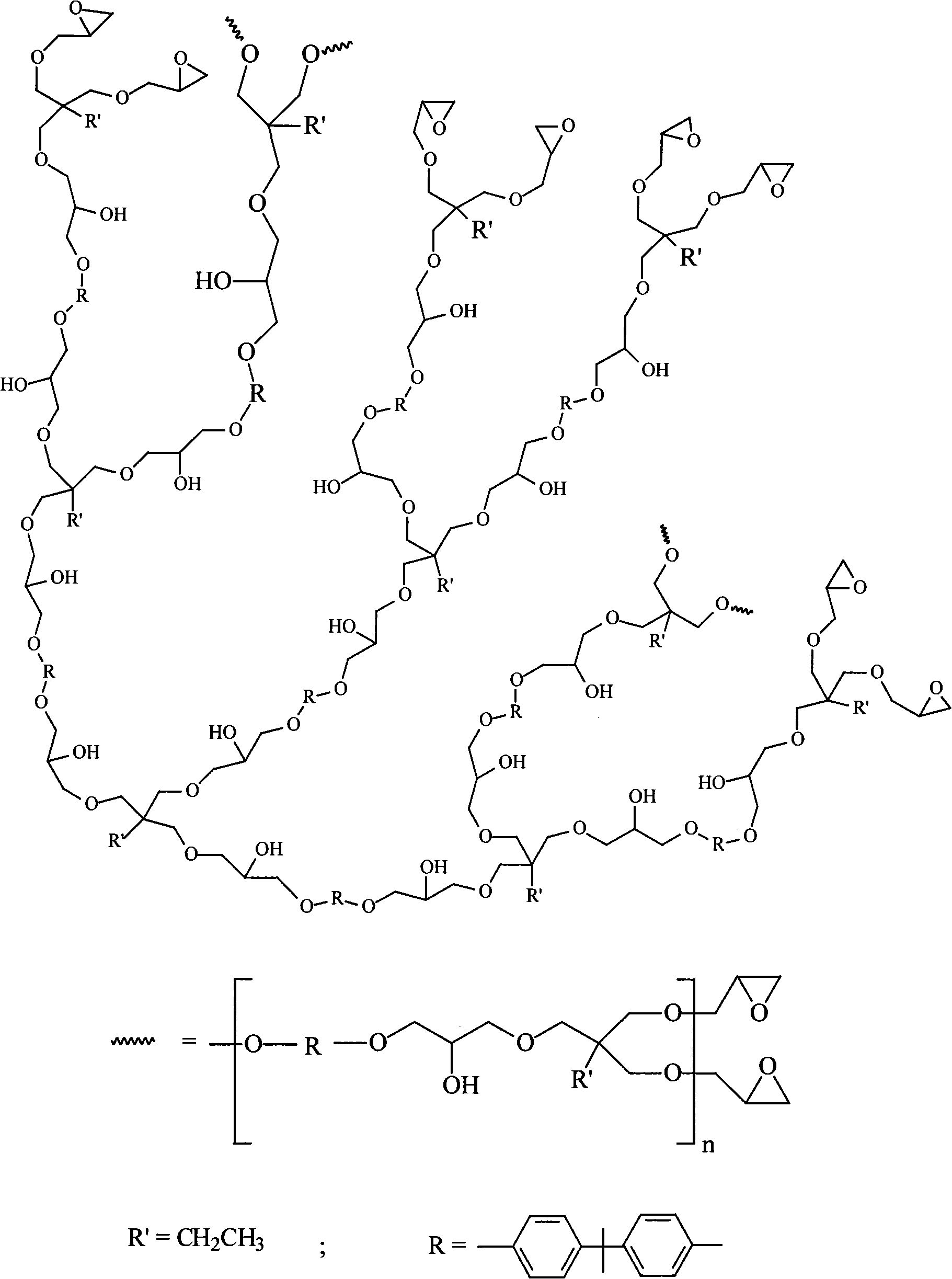

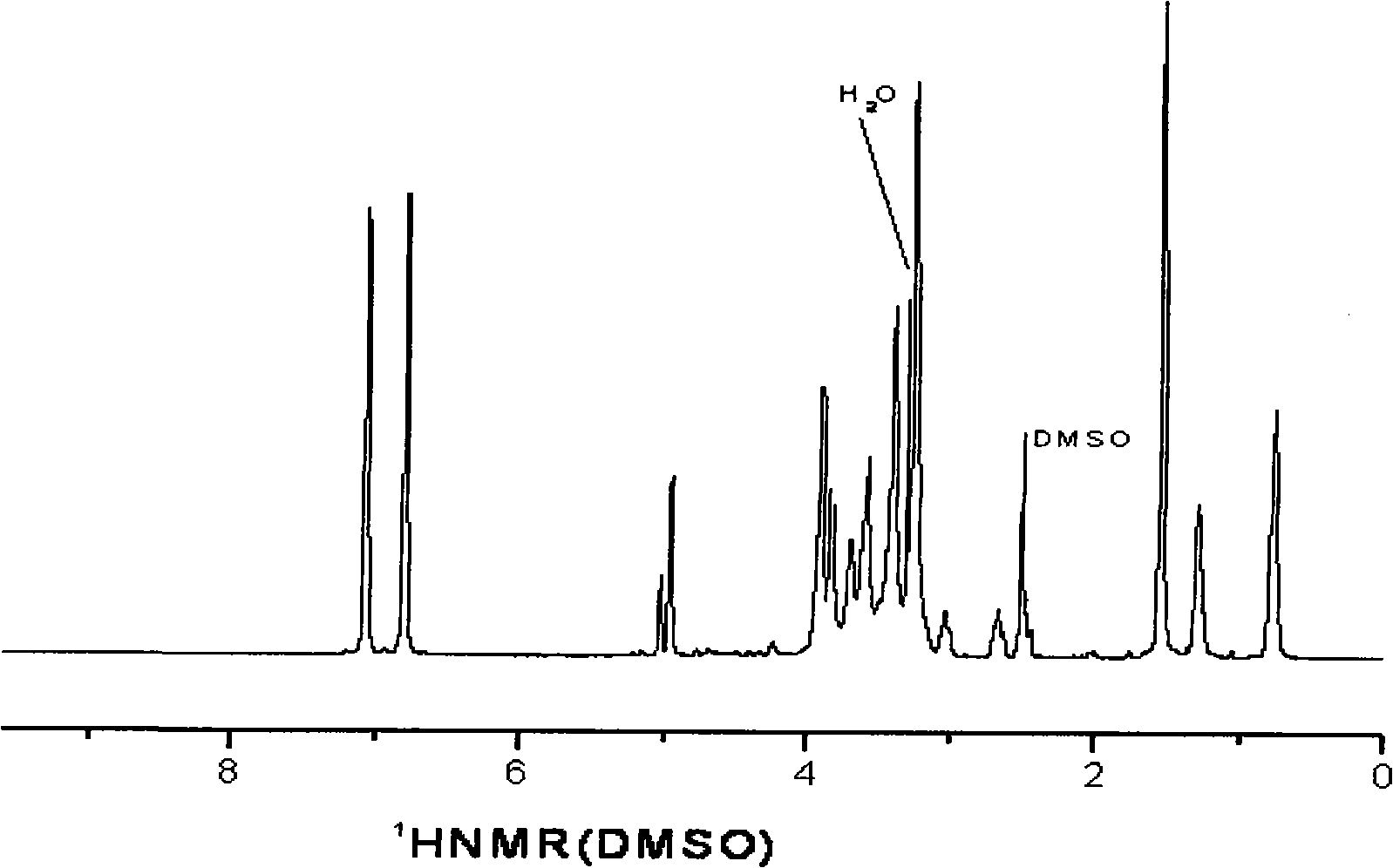

Polyether type hyperbranched epoxy resin and preparation method thereof

ActiveCN101570592AAddresses issues such as inherent brittlenessSolve problems such as brittlenessNitrogen gasSolvent

The invention relates to polyether type hyperbranched epoxy resin and a preparation method thereof. The preparation method is as follows: the polyether type hyperbranched epoxy resin is synthesized by taking commercial dihydric phenol and polylol glycidyl ether as raw materials through a proton translocation reaction under the protection of nitrogen. All reactants are added to a reaction unit once during reaction, and in the reaction process, the hyperbranched epoxy resin is obtained according to the following steps in sequence: catalyst catalyzes the epoxy groups of a plurality of epoxy monomers to open epoxy rings, a phenolic hydroxyl group and secondary oxygen anion are processed by proton transfer and phenoxy oxygen anion is processed by electrophilic substitution. The hyperbranched epoxy polymer can be used in the fields of modification of environment-friendly bond with less solvent or no solvent, painting, traditional epoxy resin, and the like.

Owner:BEIJING UNIV OF CHEM TECH

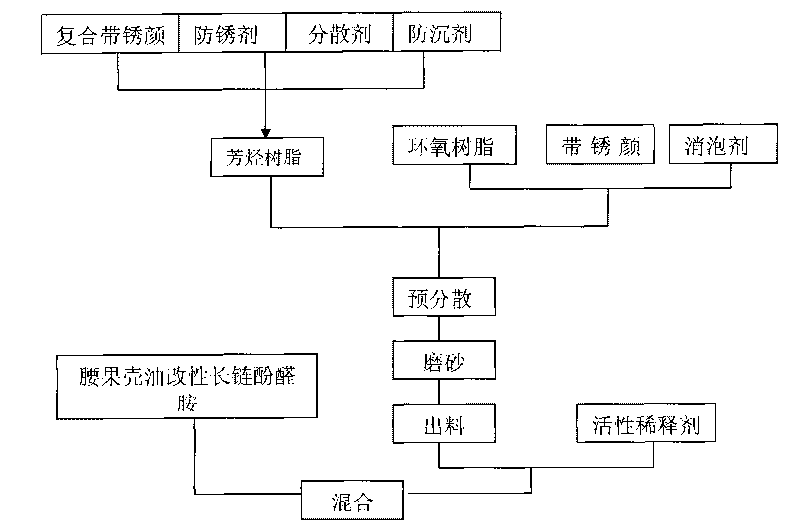

Environment-friendly solvent-free humidified and rusted anticorrosive paint

InactiveCN101747825AEasy pretreatmentConvenient anti-corrosion solutionAnti-corrosive paintsEpoxy resin coatingsOrganic filmSolvent free

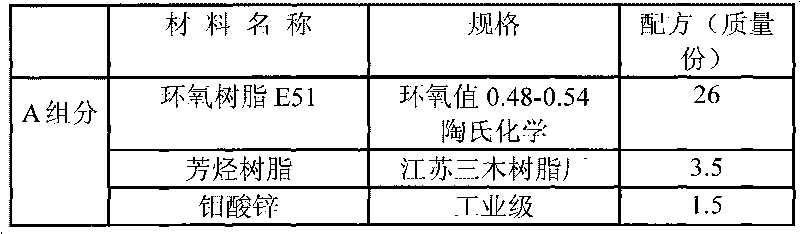

The invention relates to a paint material with formed organic film, in particular to an epoxy solvent-free anticorrosive paint applied to low surface treatment steel structure. The anticorrosive paint is prepared by efficiently compounding rusted coating pigments such as zinc molybdate, zinc phosphate, aluminium trippolyhosphate, iron oxide red and the like, using cashew nut oil modified long-chain amine phenolic aldehyde as, alicyclic glycidyl ether as active diluent, thus overcoming the problems that surface treatment technique in coating construction costs high and heavy anticorrosive paint with high solvent content pollutes the environment, having easy preparation and construction, low cost, fast solidification at high temperature, good mechanical and anticorrosive performance, solvent-free and environment-friendly properties, and being applicable to heavy anticorrosive projects of steel structures such as ship, train, bridge and the like.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Low temp. solidifeed resin emulion used for cathode electrolytic coating

InactiveCN1483772AImprove the decorative effectImprove the level ofPaints for electrolytic applicationsEpoxy resin coatingsChemical reactionPolyamine

The present invention relates to a low-temp. soldified resin emulsion for cathodic electrophoretic coating. It is made of 20-70% of modified epoxy resin, 5-50% of polyamine and 10-30% of closed polyisocyanate which can completely declosed at 120-140 deg.C, through the processes of chemical reaction, mixing, neutralizing with organic acid and dispersing in water, in which the modified epoxy resin is made up by using epoxy compound and polyhydroxylated compound and adopting epoxy resin synthesis method under the action of catalyst, its molecular weight is 300-3000, and the pure solid weight ratio of epoxy compound and polyhydroxylated compound is 5-8 / 2-5. The described epoxy compound is bisphenol A diglycidyl ether and glicidyl ether containing flexible chain or glycidyl ester, and the polyhydroxylated compound is bisphenol A and polyhydroxylated compound containing flexible chain.

Owner:CNOOC CHANGZHOU EP COATING

Ultraviolet laser solidification rapid-prototyping photosensitive resin and manufacture method thereof

InactiveCN102385250AIncrease photosensitivityHigh precisionPhotosensitive materials for photomechanical apparatusMass ratioUltraviolet

The invention discloses an ultraviolet laser solidification rapid-prototyping photosensitive resin and a manufacture method thereof. The ultraviolet laser solidification rapid-prototyping photosensitive resin comprises the following components in mass ratio: 5-80% of epoxy resin, 0-65% of oxetane compound, 1-12% of cationic initiator, 1-40% of hydroxy organic compound, 0-55% of unsaturated oligmer containing C-C double bonds, 0-35% of unsaturated monomer containing C-C double bonds, 0-20% of glycidyl ether or epoxy diluent with low molecular weight and 0-10% of free redical type photopolymerization initiator. The manufacture method comprises the following steps: mixing the raw materials in the mass ratio, heating at 20-80DEG C, and stirring for 5-120 minutes to obtain transparent faint yellow uniform liquid. The photosensitive resin disclosed by the invention has good photosensitiveness, and the critical exposure Ec is less than 15mJ / cm<2>; a formed part has high precision; the camber factor CF(6) of the formed part is between-0.01 and 0.01; and the camber factor CF (11) is between -0.03 and 0.03. The photosensitive resin disclosed by the invention can be directly manufactured into any part with complex shape, high precision and low cost.

Owner:NANCHANG UNIV

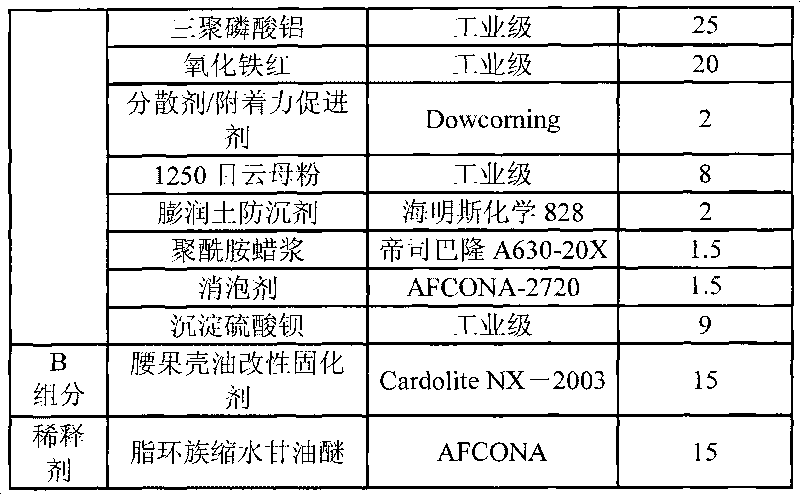

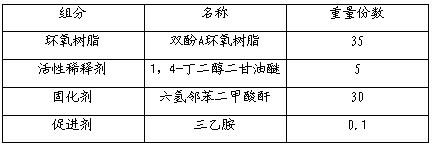

Epoxy solvent-free impregnating resin with low viscosity and preparation method thereof

InactiveCN102304217AImprove craftsmanshipMeet environmental protection requirementsRoom temperatureSolvent free

The invention relates to an epoxy solvent-free impregnating resin with a low viscosity and a preparation method thereof. The epoxy solvent-free impregnating resin comprises the following components in parts by weight: 35-55 parts of epoxy resin, 5-15 parts of active diluent, 0.1-10 parts of accelerator and 30-55 parts of curing agent. The preparation method comprises the following steps of: adding the epoxy resin into a reactor, raising the temperature to 60-100 DEG C while agitating, adding the active diluent, uniformly mixing and agitating, cooling to a room temperature, adding the curing agent and the accelerator, agitating for 30-40 minutes, vacuumizing for 10-40 minutes, controlling the vacuum degree between -0.06MPa and -0.1MPa, and finally obtaining the epoxy solvent-free impregnating resin with a low viscosity. Non-toxic or low-toxic glycidyl ether with mono-functionality or poly-functionality is utilized to reduce the viscosity of the impregnating resin and improve the technical properties of the impregnating resin, and meanwhile, extremely low volatile content meets the requirements of environment friendliness.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

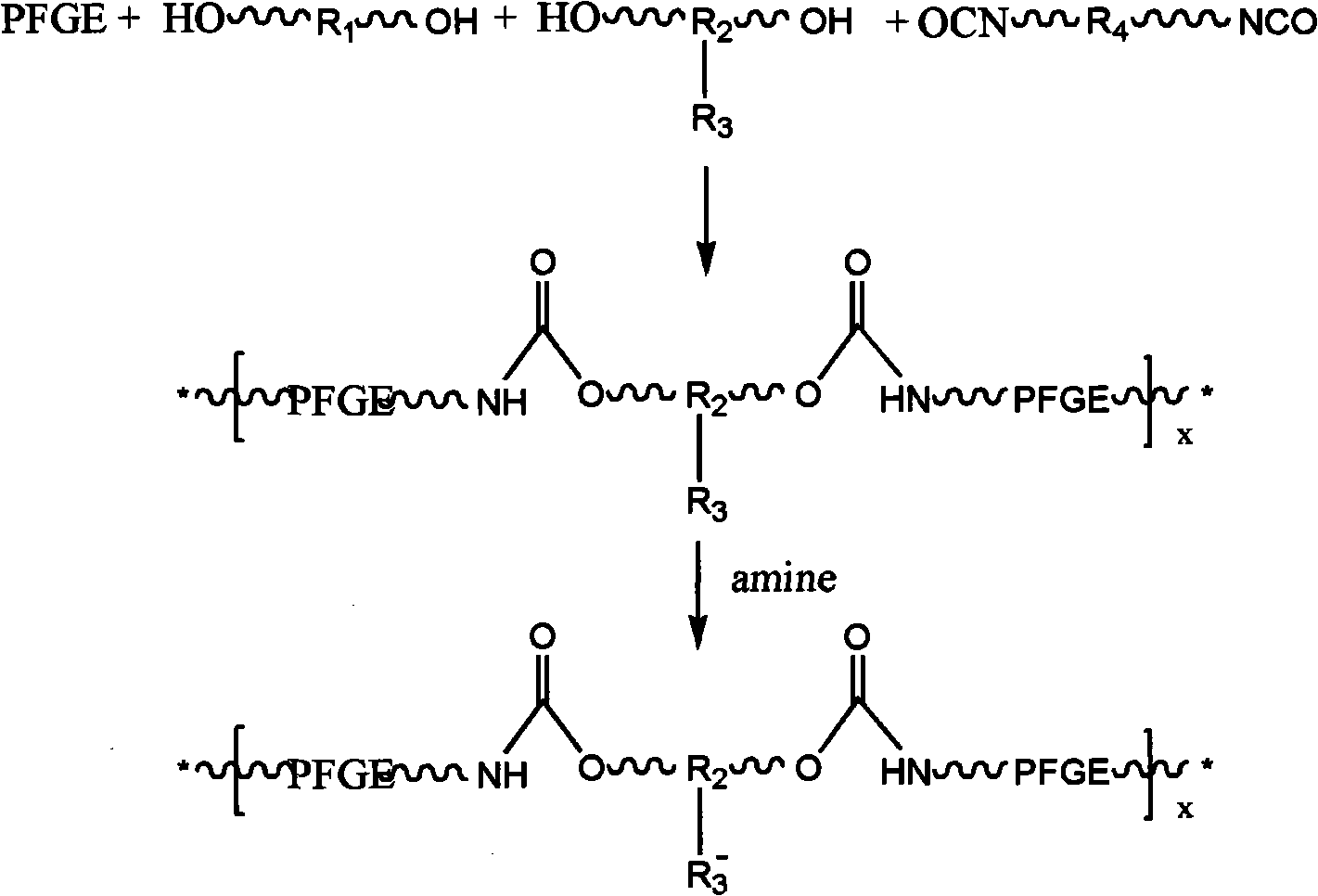

Preparation method of soft segment lateral chain fluorine-containing waterborne polyurethane

The invention discloses a preparation method of soft segment lateral chain fluorine-containing waterborne polyurethane, which comprises the following preparation steps: (1) synthesizing fluorine-containing glycidyl ether; (2) synthesizing lateral chain fluorine-containing polyether glycol; and (3) preparing the soft segment lateral chain fluorine-containing waterborne polyurethane. The invention is mainly characterized in that fluorine elements are introduced on the lateral chain of the waterborne polyurethane, so the surface performance of the waterborne polyurethane is improved, and the waterborne polyurethane has the waterproof performance, oil resistance performance, stain resistance performance and excellent chemical stability.

Owner:GUANGDONG YINYANG ENVIRONMENT FRIENDLY NEW MATERIALS CO LTD

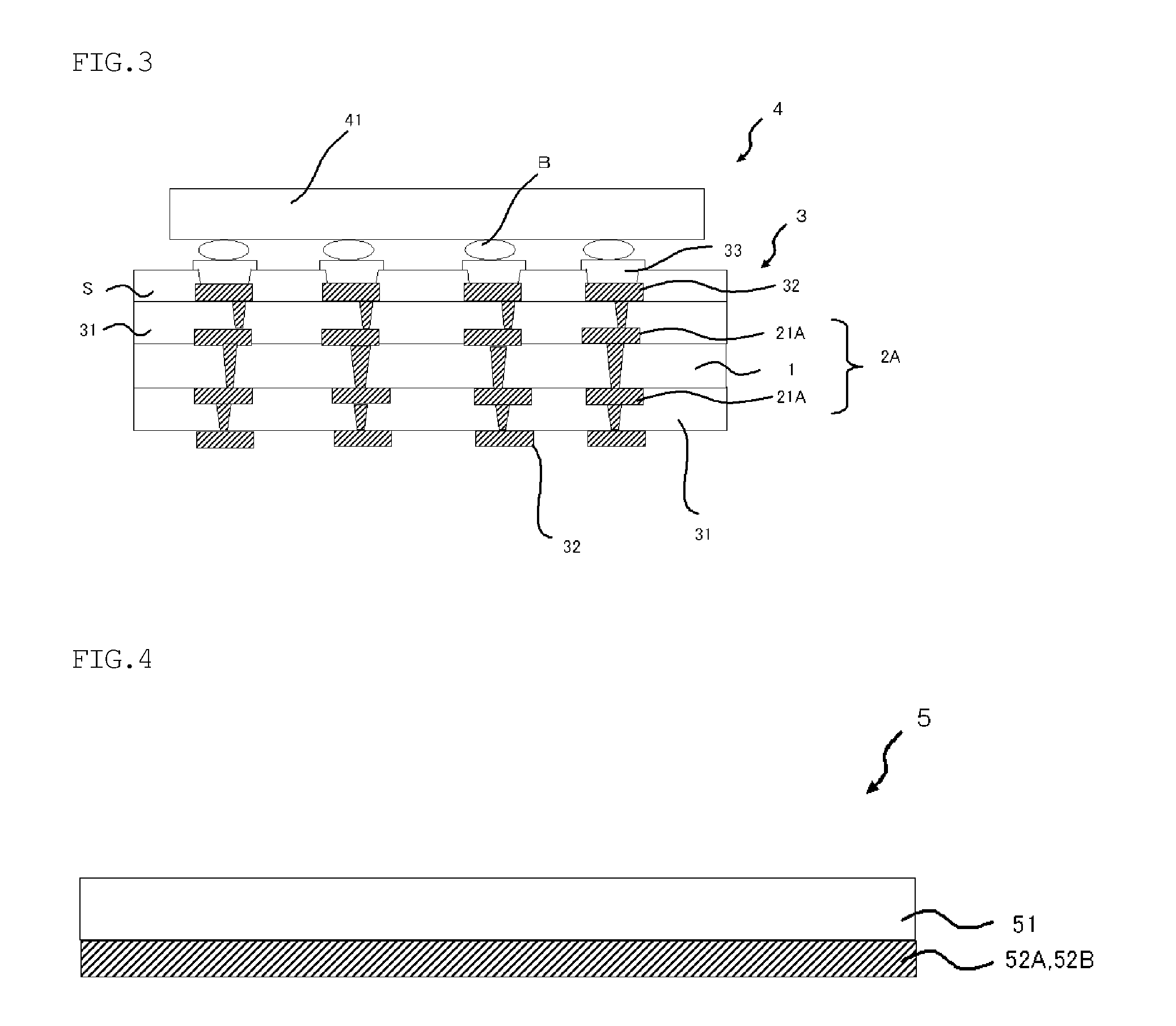

Metal-coated resin molded article and production method therefor

InactiveUS20070190346A1Improve adhesionExcellent circuit adhesionPrinted circuit aspectsCoatingsPolyesterLiquid crystalline

A metal-coated resin molded article is provided, which has improved adhesion between a metal layer and a substrate of a resin composition as well as excellent moldability, heat resistance, electronic and mechanical properties. The resin composition comprises a liquid-crystalline polyester and an epoxy-group containing ethylene copolymer. The ethylene copolymer contains 50 to 99.9 wt % of an ethylene unit and 0.1 to 30 wt % of at least one of an unsaturated carboxylic acid glycidyl ester unit and an unsaturated glycidyl ether unit in the molecule thereof. A content of the ethylene copolymer is in a range of 0.1 to 25 parts by weight with respect to 100 parts by weight of the liquid-crystalline polyester.

Owner:MATSUSHITA ELECTRIC WORKS LTD +1

Biodegradable polyester resin composition, preparation method therefor, and foamed article and molded article produced therefrom

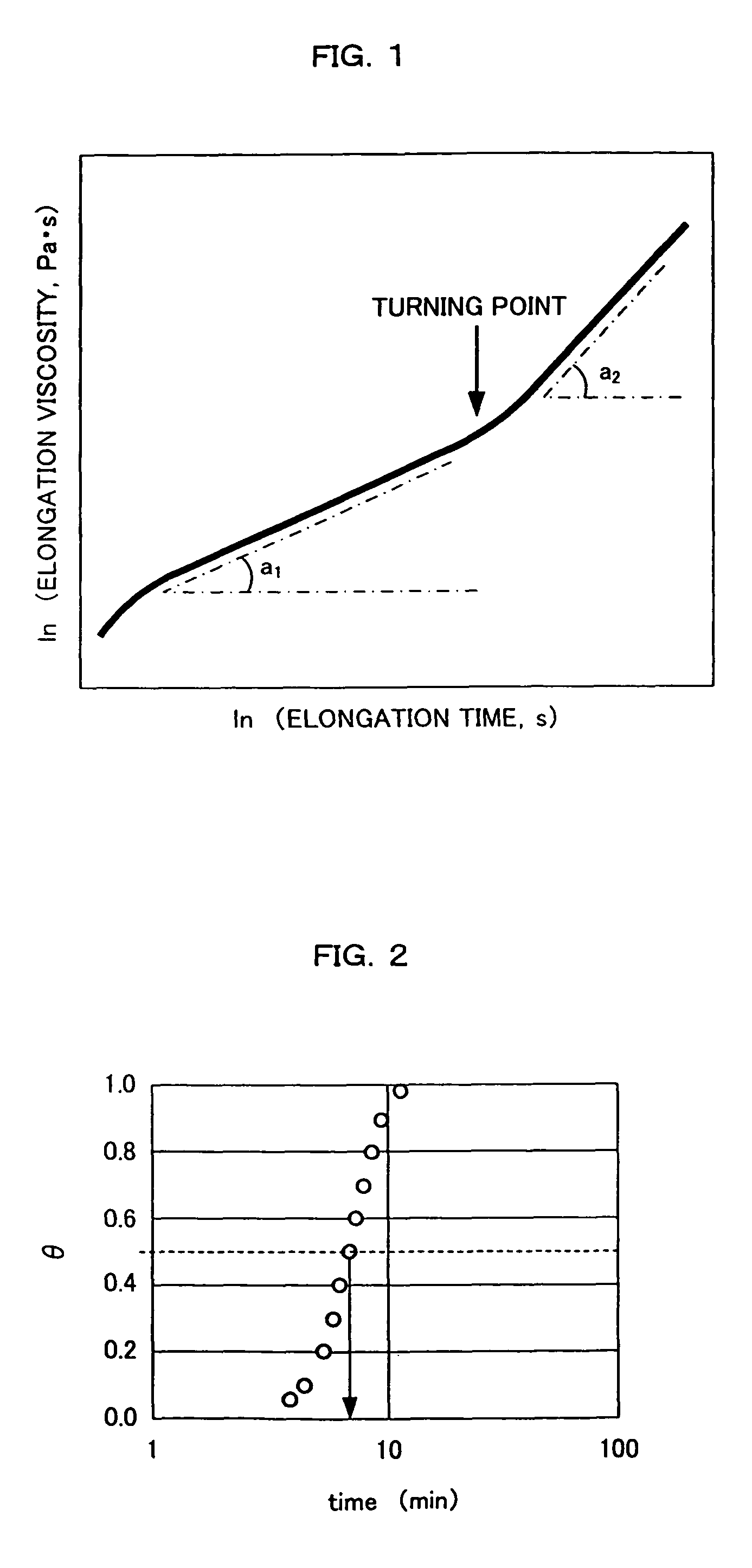

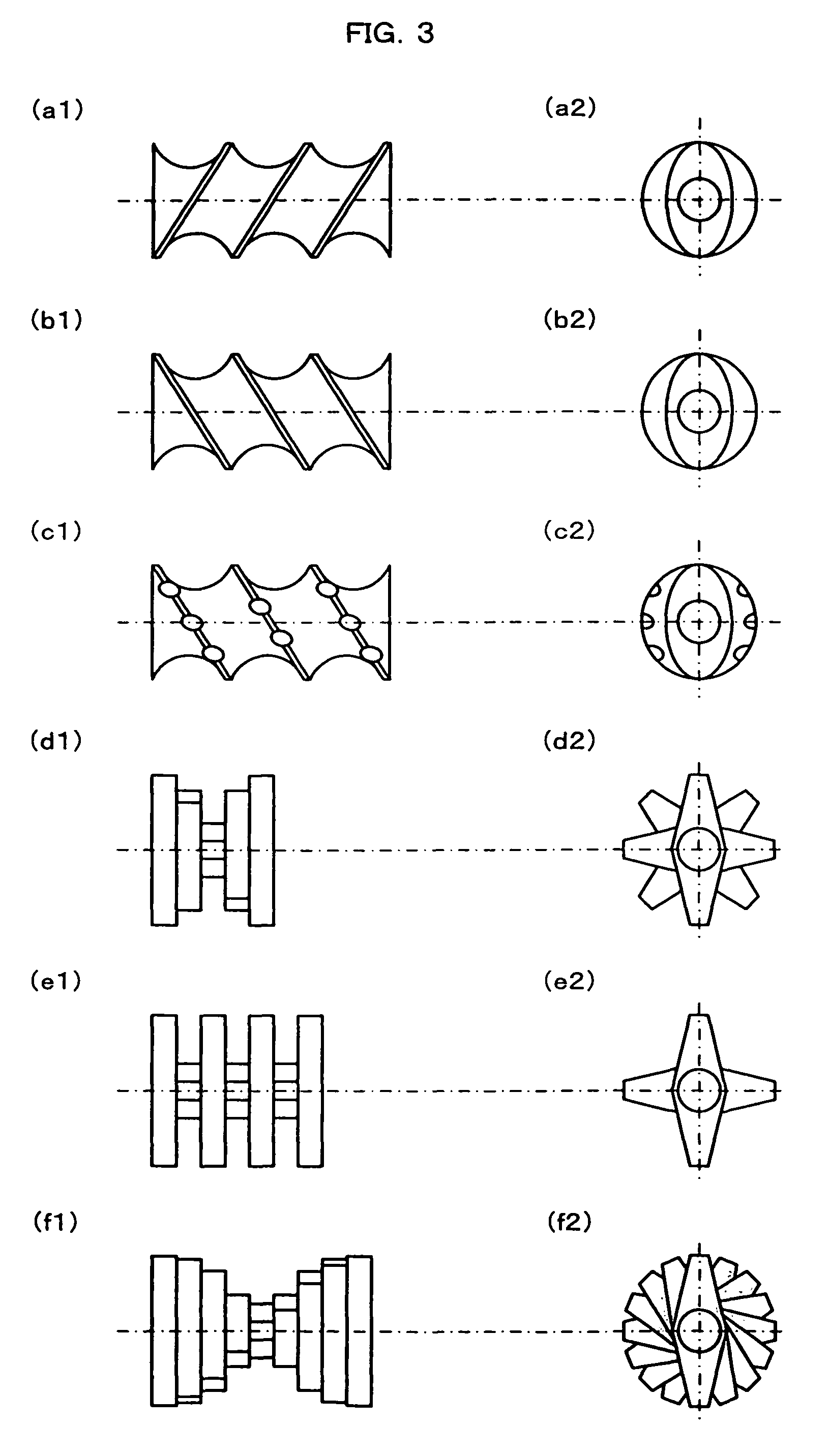

InactiveUS20070179253A1Low gel contentImprove heat resistanceSynthetic resin layered productsMeth-Polyester resin

A biodegradable polyester resin composition which comprises a thermoplastic polymer comprising 100 parts by mass of an aliphatic polyester (A) and 0.01 to 5 parts by mass of a (meth)acrylic ester (B1) and / or a glycidyl ether (B2), and has a gelation index (1) of not lower than 0.1% and a gelation index (2) of not higher than 0.5%.

Owner:UNITIKA LTD

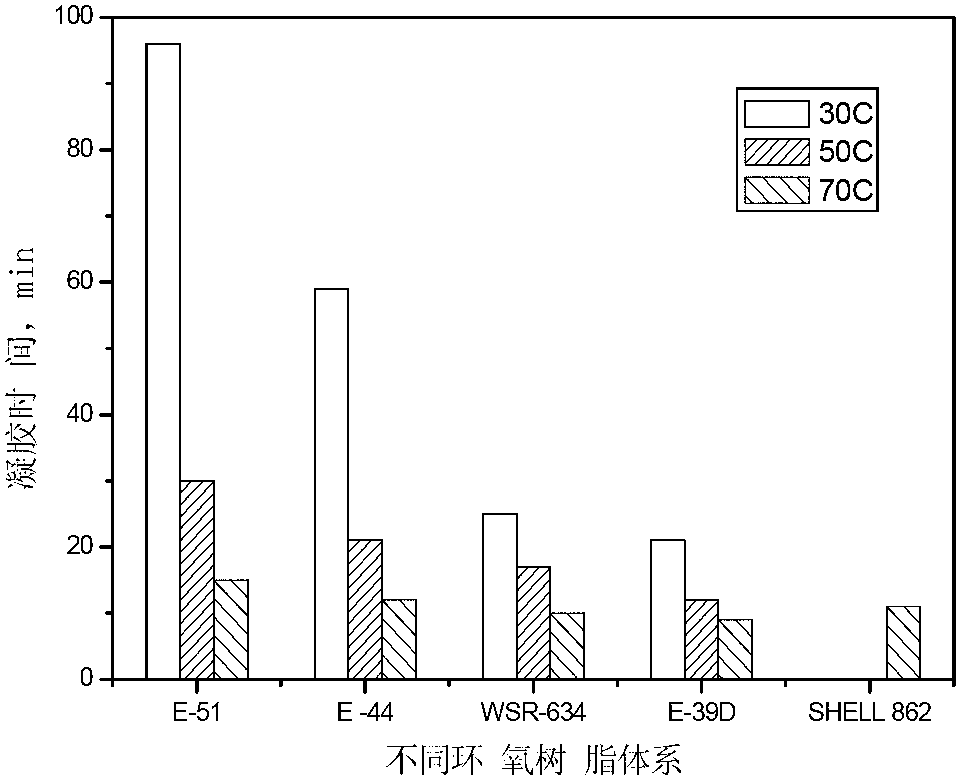

Crack pouring adhesive for concrete cracks and application of crack pouring adhesive

The invention discloses a crack pouring adhesive for concrete cracks and an application of the crack pouring adhesive. The crack pouring adhesive for the concrete cracks consists of a component I and a component II which are independently packaged, and the mass ratio of the component I to the component II is (5-2):1; the component I consists of raw materials in parts by mass as follows: 70 parts of an E-51 bisphenol A liquid epoxy resin, 30 parts of a 6002 bisphenol A liquid epoxy resin, 15-30 parts of a toughening agent,5-15 parts of benzyl glycidyl ether and 5-15 parts of benzyl alcohol; and the component II consists of 30-65 parts of a curing agent, 5-10 parts of diluent and 0.5 part of a sticking accelerating agent; the curing agent consists of 30-50 parts of a polyether amine curing agent and 0-15 parts of a phenolic amine epoxy curing agent; and the diluent is benzyl alcohol. The crack pouring adhesive for the concrete cracks is a solvent-free double-component low-viscosity crack pouring adhesive and can be used for filling the concrete cracks to seal the concrete cracks.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

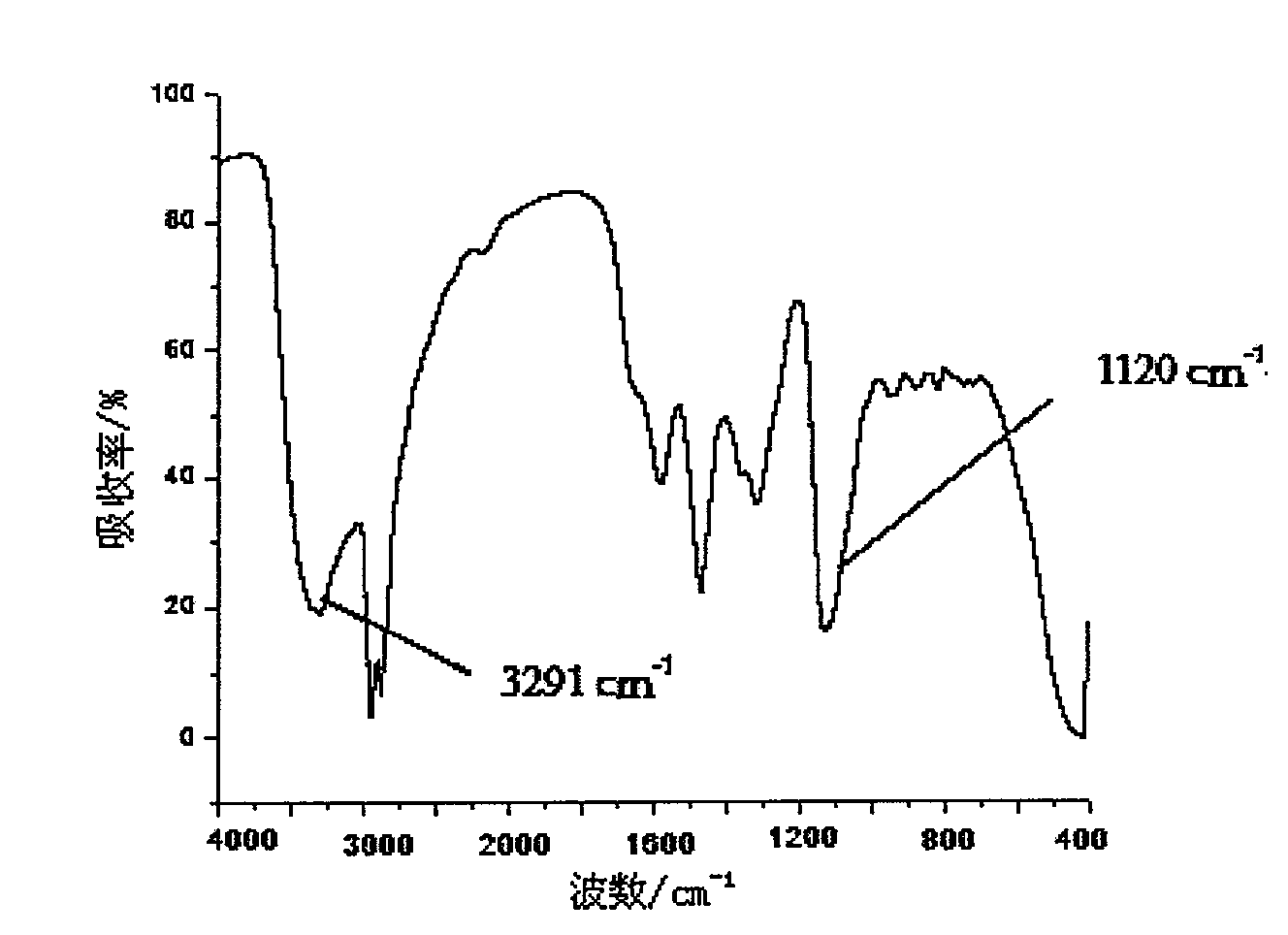

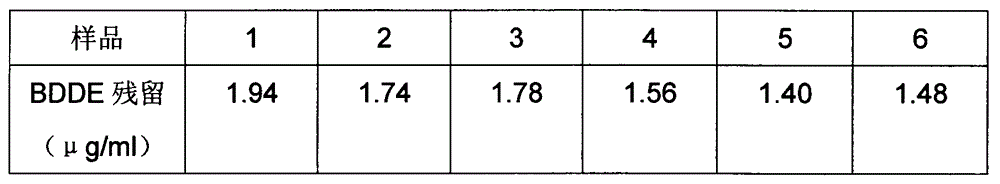

Preparation method of low-temperature secondary cross-linked sodium hyaluronate gel

InactiveCN103146003AImprove cross-linking efficiencyAvoid the disadvantages of yellowingProsthesisHigh concentrationCross linker

The invention relates to a preparation method of 1,4-butanediol diglycidyl ether cross-linked sodium hyaluronate gel. The method comprises the steps of: by taking high-concentration sodium hyaluronate solution as reaction matrix, performing first cross-linking for a longer time under the low-temperature condition by adding less cross-linking agent, then performing secondary deep cross-linking under high-temperature condition, and finally processing and pelleting through short-time dialysis technique, thereby obtaining the sodium hyaluronate gel product. With the method, the cross-linking condition of the high-concentration cross-linking agent under the traditional high-temperature condition can be eliminated, milder secondary depth cross-linking condition is adopted, the reaction efficiency of the less cross-linking agent can be greatly improved, the residual cross-linking agent is more easily removed, and the excellent biocompatibility of the cross-linked sodium hyaluronate gel can be ensured. The method is simple in preparation technique, excellent in controllability and easier to practically produce on large scale.

Owner:SHANGHAI QISHENG BIOLOGICAL PREPARATION CO LTD

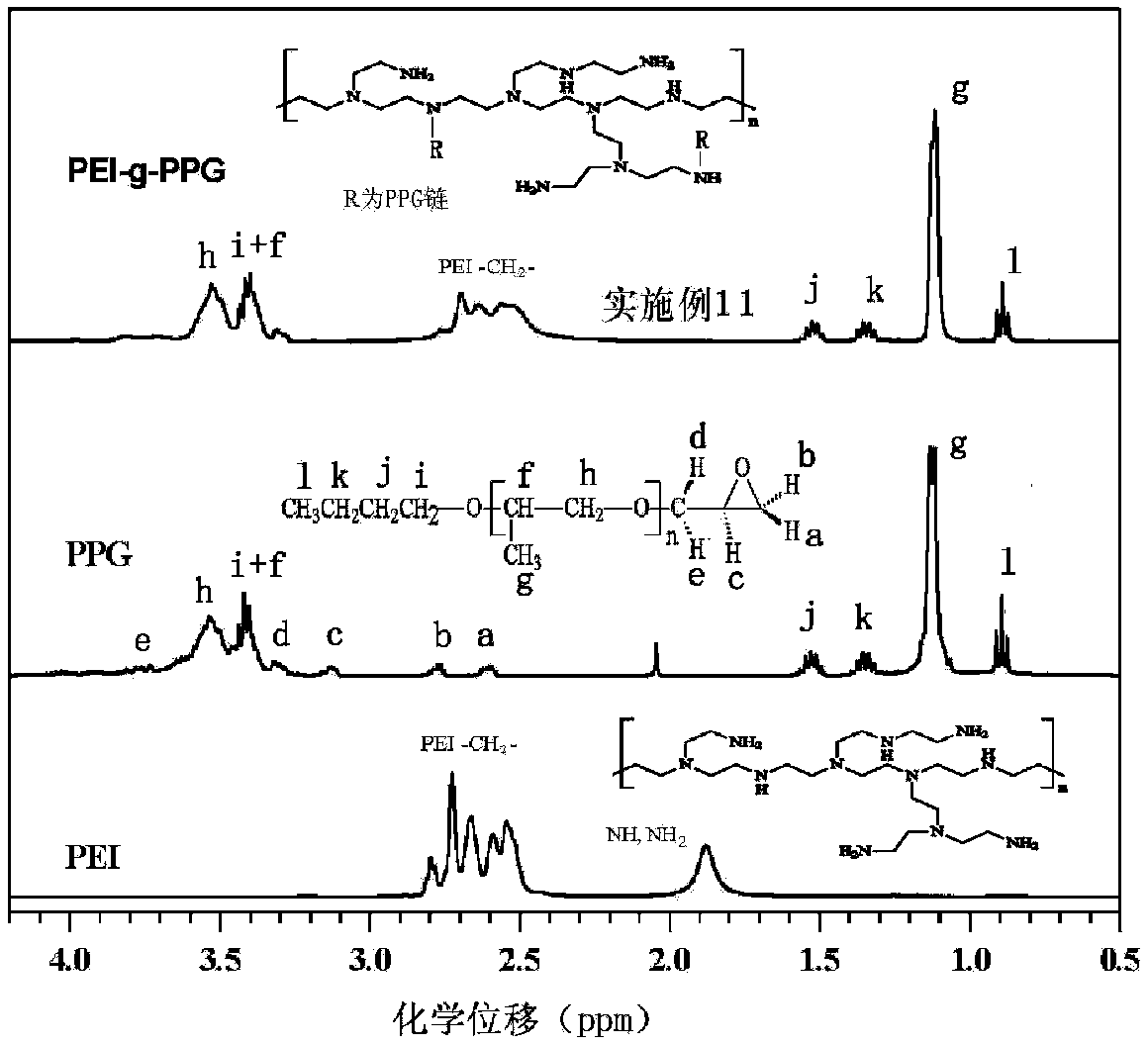

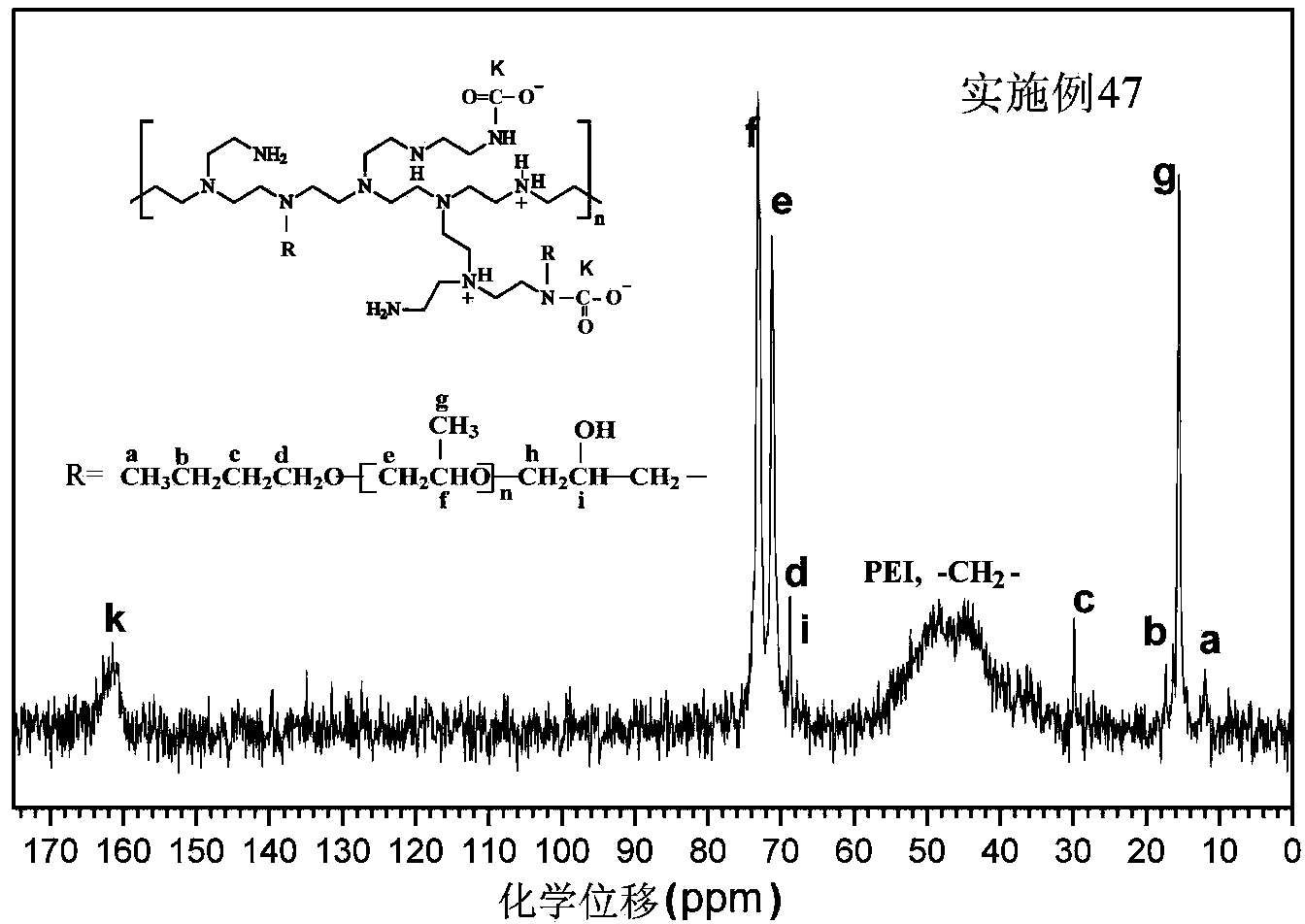

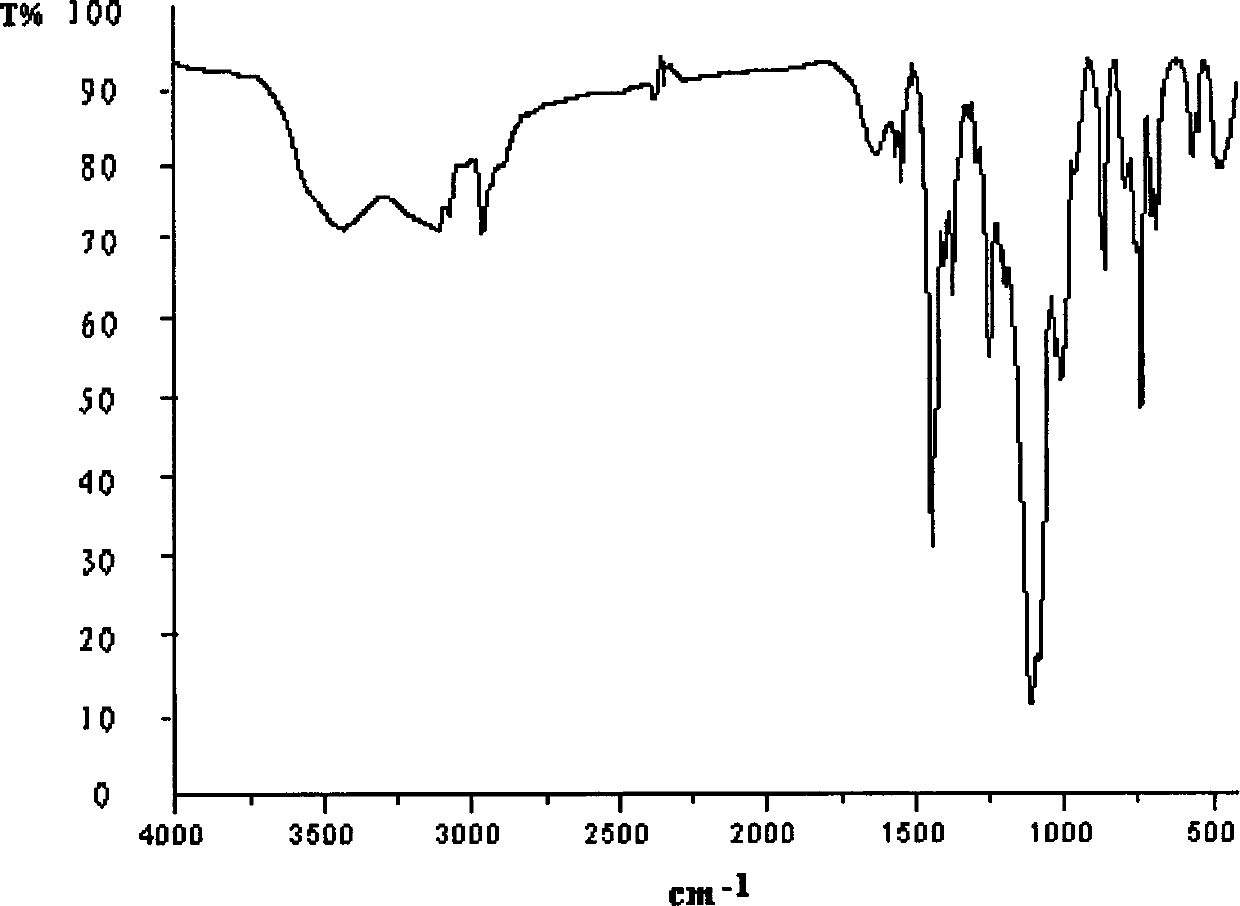

Hydrophobically-modified polyethyleneimine foaming agent capable of releasing carbon dioxide, and application thereof

The invention discloses a hydrophobically-modified polyethyleneimine foaming agent capable of releasing carbon dioxide. The hydrophobically-modified polyethyleneimine foaming agent is prepared by reacting polyethyleneimine subjected to hydrophobic modification by a glycidyl ether compound or an alkyl carboxylic compound or a halogenated alkane compound with 0-31% of distilled water at the pressure of 0.1-1 MPa in carbon dioxide at the room temperature for 1-3 days; a 5-40.4 mol% hydrophobic chain is grafted on N atoms in a polyethyleneimine molecular chain of the foaming agent, and a carbamic acid anion (-NCOO-) characteristic absorption peak or a bicarbonate (HCO3-) characteristic absorption peak exists at the range of 159-165 ppm of a C Nuclear magnetic resonance of the foaming agent, and the foaming agent can release carbon dioxide CO2 at the temperature of 50-150 to prepare a polyurethane foam material. The foaming agent provided by the invention can be uniformly dispersed in a preparation raw material of hydrophobic polyurethane foam, can solve a series of problems caused by the fact that non-modified polyethyleneimine is used as a foaming agent, and is climate-friendly.

Owner:SICHUAN UNIV

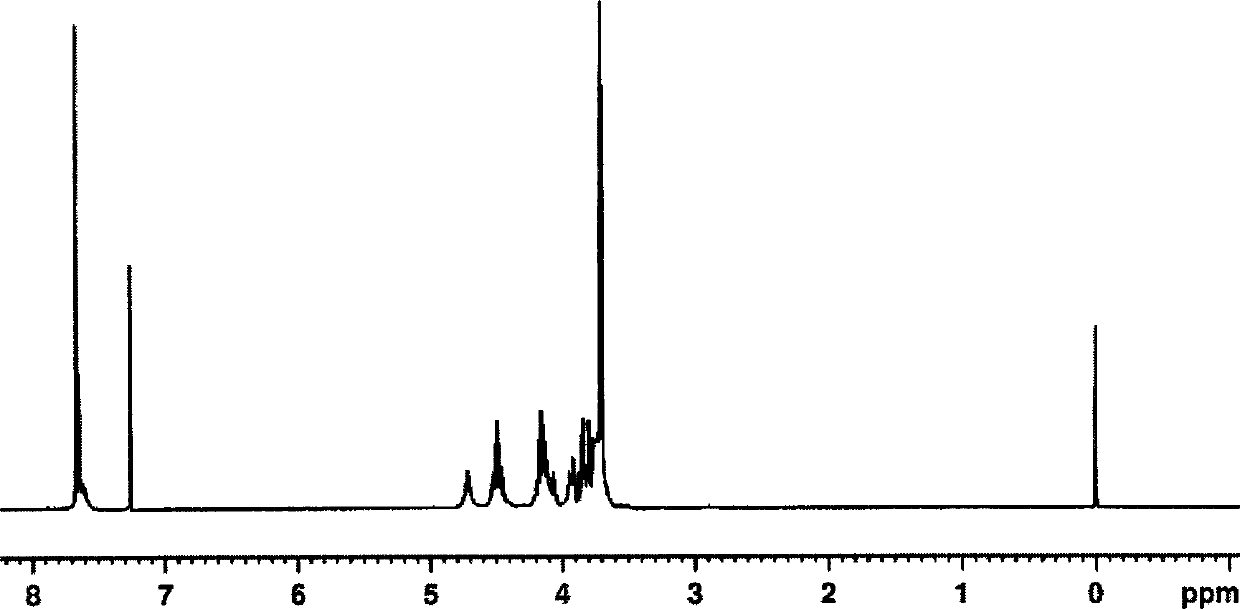

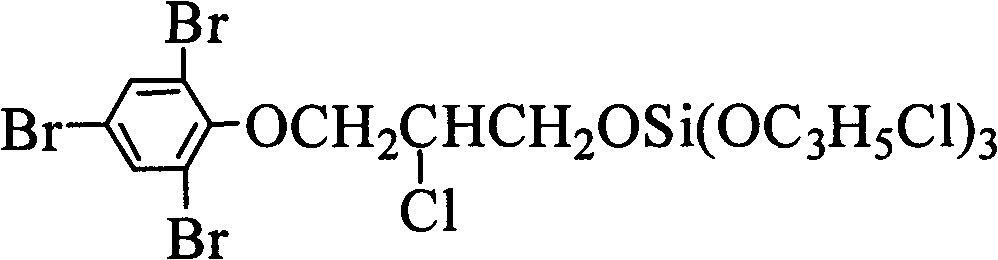

Tris(dichloropropyl) tribromophenoxy chloropropyl silicate compound and preparation method thereof

ActiveCN102731553AGood symmetryPhysicochemically stableSilicon organic compoundsOrganic solventHalogen

The invention relates to a tris(dichloropropyl) tribromophenoxy chloropropyl silicate compound which is a silicon-halogen synergistic fire retardant, and a preparation method of the compound. The compound has a structure shown in a formula described in the specification; and in the formula, OC3H5Cl2 is OCH2CHClCH2Cl or OCH (CH2Cl) 2. The preparation method of the compound comprises the following steps: reacting tribromophenyl glycidyl ether and silicon tetrachloride according to the same molar ratio in an organic solvent for 4-6h at 60-80 DEG C; then dropwise adding dichloropropanol according to a certain molar ratio, reacting for 4-8h at 50-100 DEG C; and finally purifying to obtain faint yellow liquid which is the tris(dichloropropyl) tribromophenoxy chloropropyl silicate. The compound is applicable to fire retardants for polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and other materials; and the production process is simple, low in equipment investment and cost, and suitable for industrial production.

Owner:张家港市乐余科创园投资发展有限公司

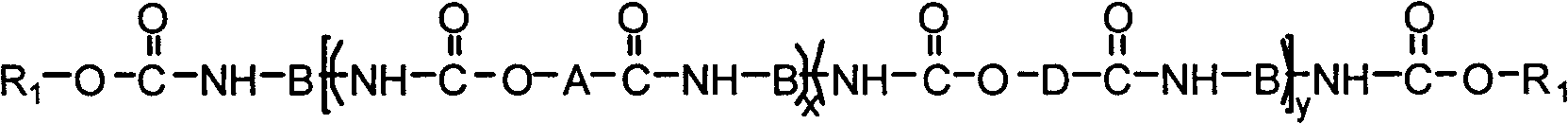

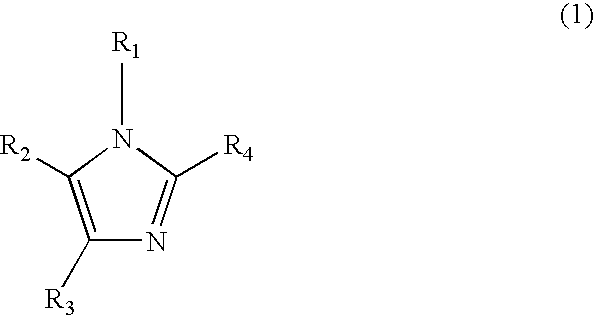

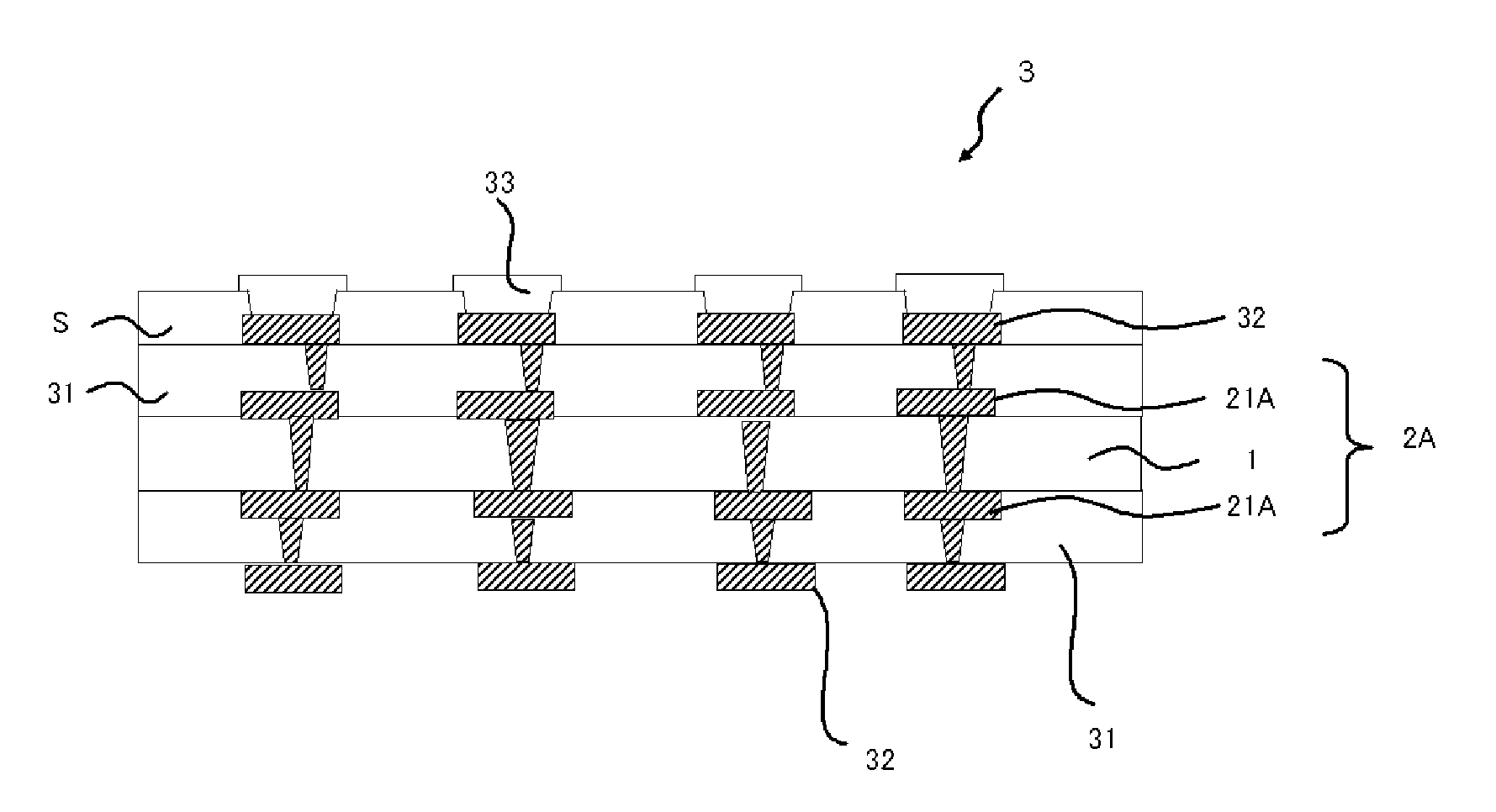

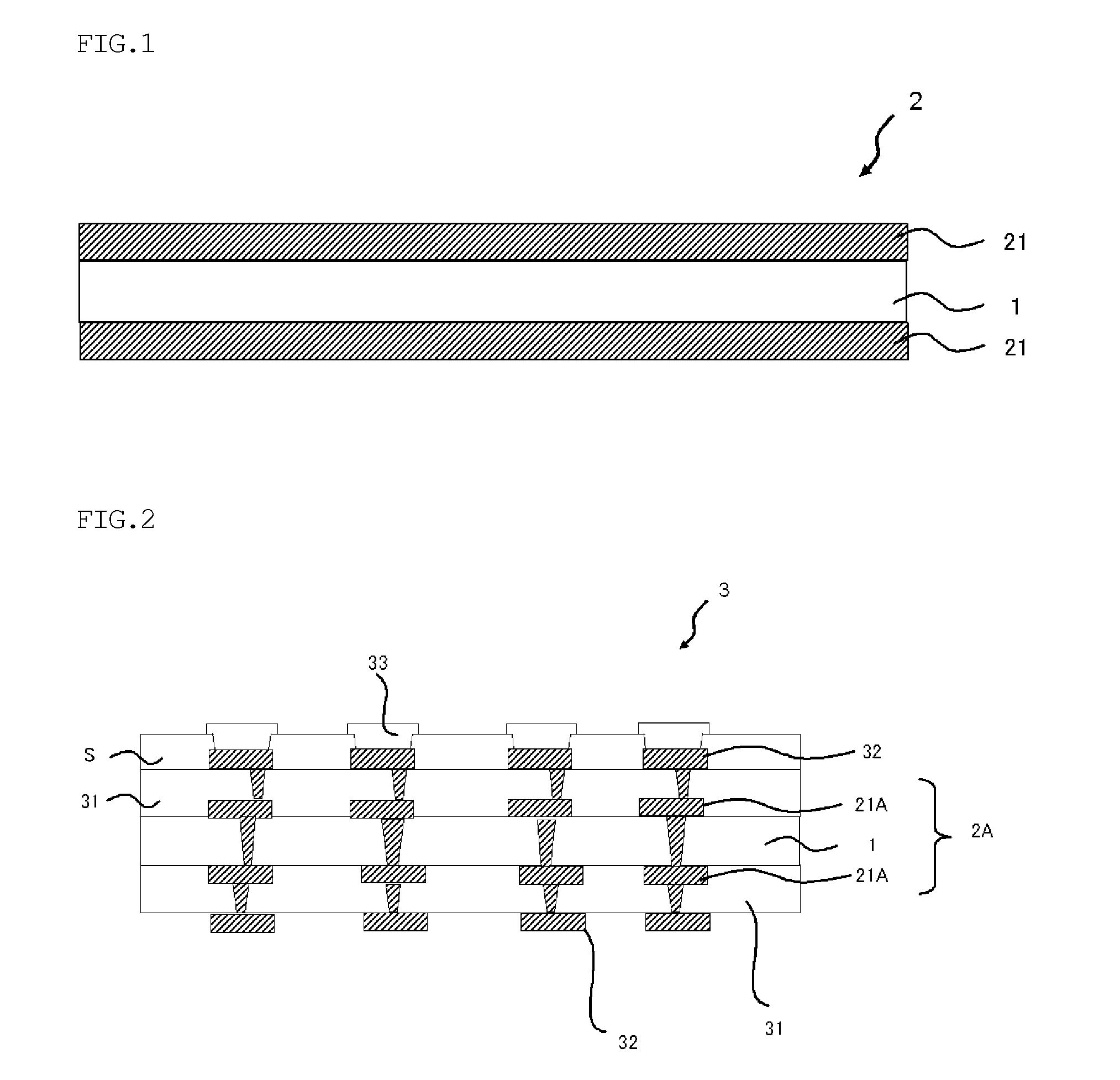

Epoxy resin composition, prepreg, laminate board, multilayer printed wiring board, semiconductor device, insulating resin sheet, and process for manufacturing multilayer printed wiring board

InactiveUS20100227170A1Reduction factorPreventing defect in appearanceSynthetic resin layered productsPrinted circuit aspectsHydrogenEthyl group

Disclosed is an epoxy resin composition essentially containing (A) an epoxy resin having a structure represented by the general formula (1), (B) a curing agent, (C) an inorganic filler and (D) a cyanate resin and / or a prepolymer thereof, wherein Ar represents a fused aromatic hydrocarbon group; r is an integer of 1 or more; X is a hydrogen or an epoxy group (glycidyl ether group); R1 represents one selected from the group consisting of a hydrogen, a methyl group, an ethyl group, a propyl group, a butyl group, a phenyl group and a benzyl group; n is an integer of 1 or more; p and q are an integer of 1 or more; and p's and q's in respective repeating units may be the same as or different from one another.

Owner:SUMITOMO BAKELITE CO LTD

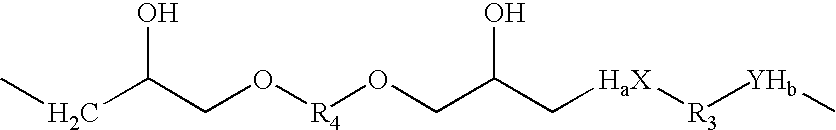

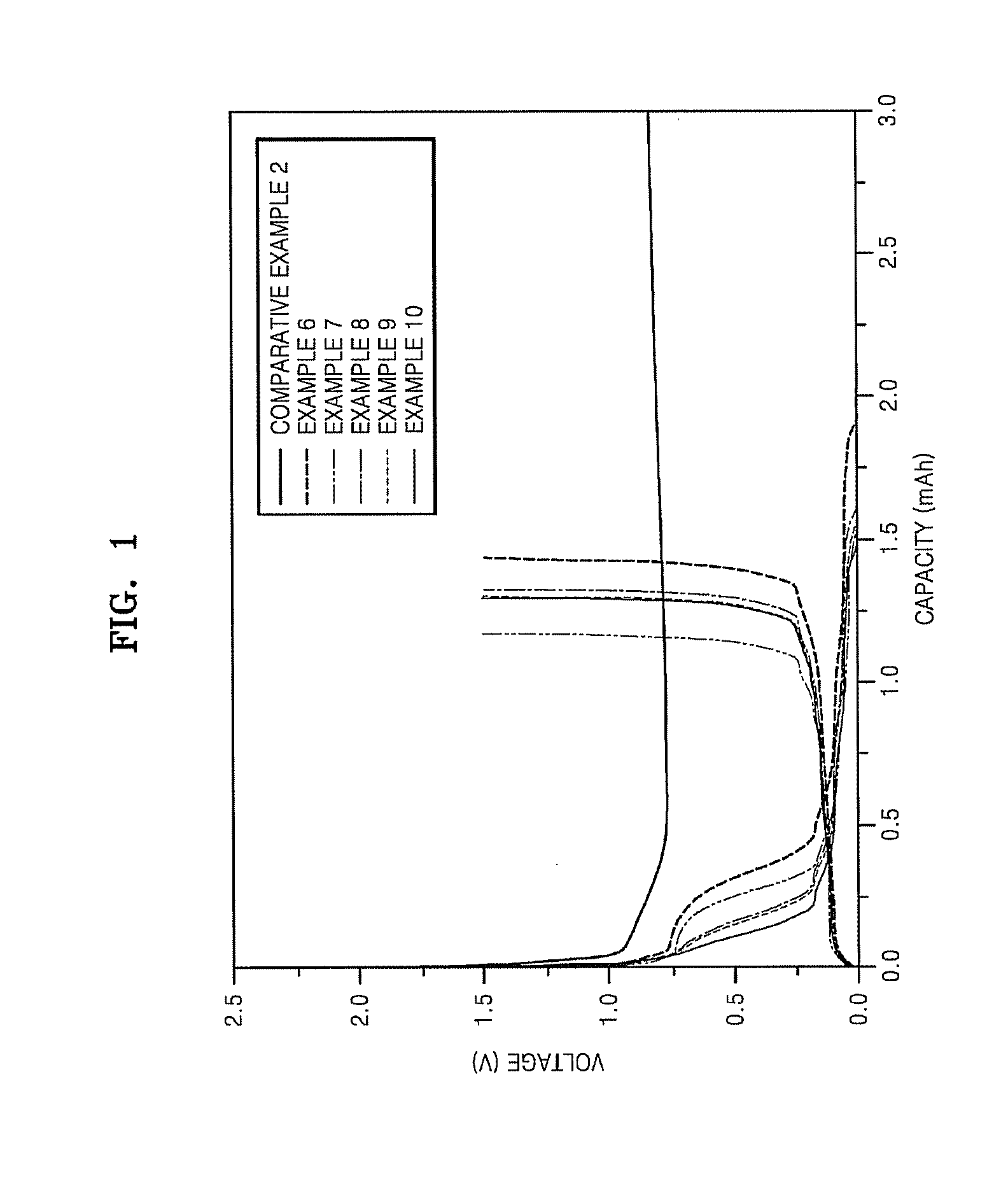

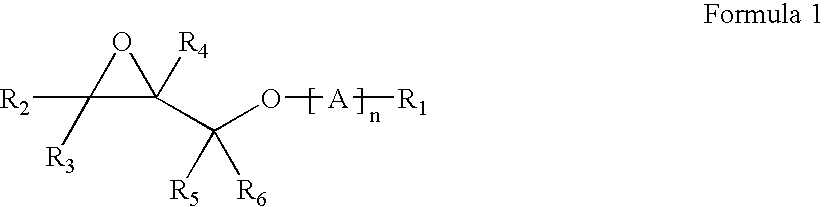

Organic electrolytic solution comprising glycidyl ether compund and lithium battery employing the same

InactiveUS20090035656A1Reduce conductivityExcellent charge and discharge characteristicsAlkaline accumulatorsLead-acid accumulatorsDischarge efficiencyOrganic solvent

An organic electrolytic solution includes a lithium salt; an organic solvent containing a high dielectric constant solvent and / or a low boiling point solvent; and a glycidyl ether compound represented by Formula 1:where, n, R1, R2, R3, R4, R5, R6 and A are described in the detailed description. In conventional organic electrolytic solutions, irreversible capacity is increased due to decomposition of a polar solvent. A lithium battery employing the organic electrolytic solution has excellent charge / discharge characteristics by inhibiting cracks of a negative electrode active material which occur during charging and discharging of the battery. Therefore, the lithium battery can have high stability, reliability and charge / discharge efficiency.

Owner:SAMSUNG SDI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com