Environment-friendly solvent-free humidified and rusted anticorrosive paint

An anti-corrosion coating, solvent-free technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of high price, high solvent content of heavy anti-corrosion coatings and pollute the environment, to ensure anti-corrosion quality and optimize anti-corrosion solutions , The effect of simplifying the pretreatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

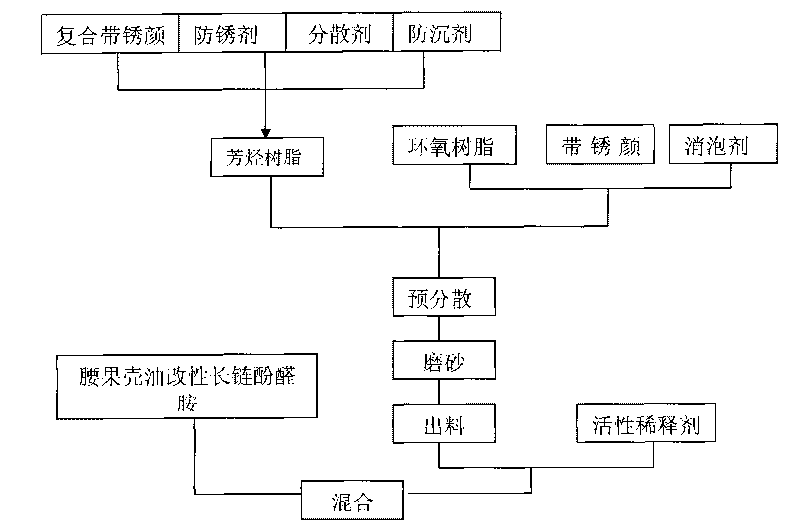

Method used

Image

Examples

Embodiment 1

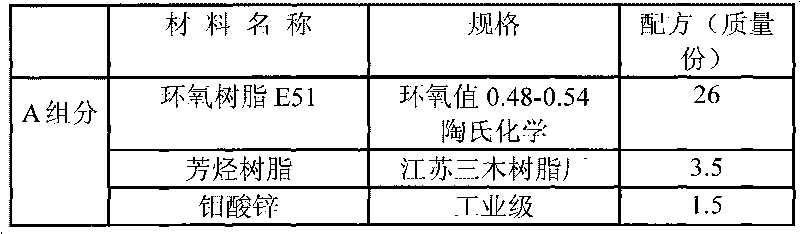

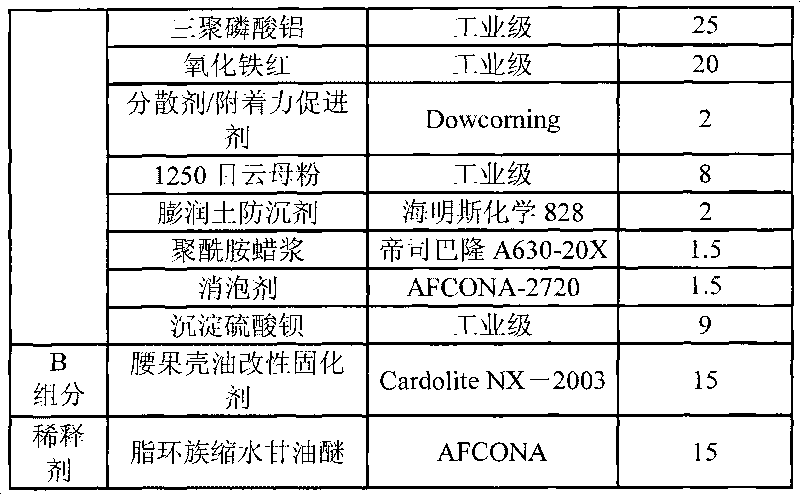

[0043] Table 2 Example 1 formula

[0044]

[0045]

[0046] According to the mass ratio in Table 2, add the rust pigment prepared with zinc molybdate and aluminum tripolyphosphate, mica powder antirust agent, dispersant, bentonite, polyamide wax paste anti-settling agent to aromatic hydrocarbon resin, and pre-mix with a high-speed mixer . Add iron oxide red, precipitated barium sulfate inert pigment and defoamer to epoxy resin for pre-grinding, with a fineness of 50 μm. Mix and grind the two preparatory materials, the fineness is 30μm, mix with a certain amount of curing agent before painting, and add active diluent to adjust the viscosity.

[0047] The data of the present invention aspect performance are listed in table 3

[0048] Table 3 Embodiment 1 coating properties

[0049] project

[0050] Note: The above test coatings are all applied to the steel structure with a rust layer thickness of 60-80 μm and covered with a water film

Embodiment 2

[0052] Table 4 Example 2 formula

[0053]

[0054]

[0055] With the band rust pigment of zinc molybdate, zinc phosphate and aluminum tripolyphosphate configuration and mica powder antirust agent, dispersant, bentonite, nanometer SiO by the mass proportion of table 4 2 The anti-settling agent is added to the aromatic resin and pre-mixed with a high-speed mixer. Then add the precipitated barium sulfate inert pigment and defoamer to the epoxy resin for pre-grinding, with a fineness of 50 μm. Mix and grind the two preparatory materials, the fineness is 30μm, mix with a certain amount of curing agent before painting, and add active diluent to adjust the viscosity.

[0056] Table 5 Embodiment 2 coating properties

[0057] project

[0058] project

[0059] Note: The above test coatings are all applied to the steel structure with a rust layer thickness of 60-80 μm and covered with a water film

Embodiment 3

[0061] Table 6 Embodiment 3 coating formula

[0062]

[0063]

[0064] According to the mass ratio in Table 6, the rusty pigment and mica powder antirust agent, dispersant, and polyamide wax slurry antisettling agent prepared with zinc molybdate, zinc phosphate, and aluminum tripolyphosphate are added to the aromatic hydrocarbon resin, and pre-treated with a high-speed mixer. mix. Add iron oxide red, precipitated barium sulfate inert pigment and defoamer to epoxy resin for pre-grinding, with a fineness of 50 μm. Mix and grind the two preparatory materials, the fineness is 30μm, mix with a certain amount of curing agent before painting, and add active diluent to adjust the viscosity.

[0065] The data of the present invention aspect performance are listed in table 7

[0066] Table 7 embodiment 3 coating properties

[0067] project

[0068] Note: The above test coatings are all applied to the steel structure with a rust layer thickness of 60-80μm and covered w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com