Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

210 results about "Zinc molybdate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc molybdate is an inorganic compound with the formula ZnMoO₄). It is a white pigment, which is also a corrosion inhibitor. A related pigment is sodium zinc molybdate, Na₂Zn(MoO₄)₂. The material has also been investigated as an electrode material.

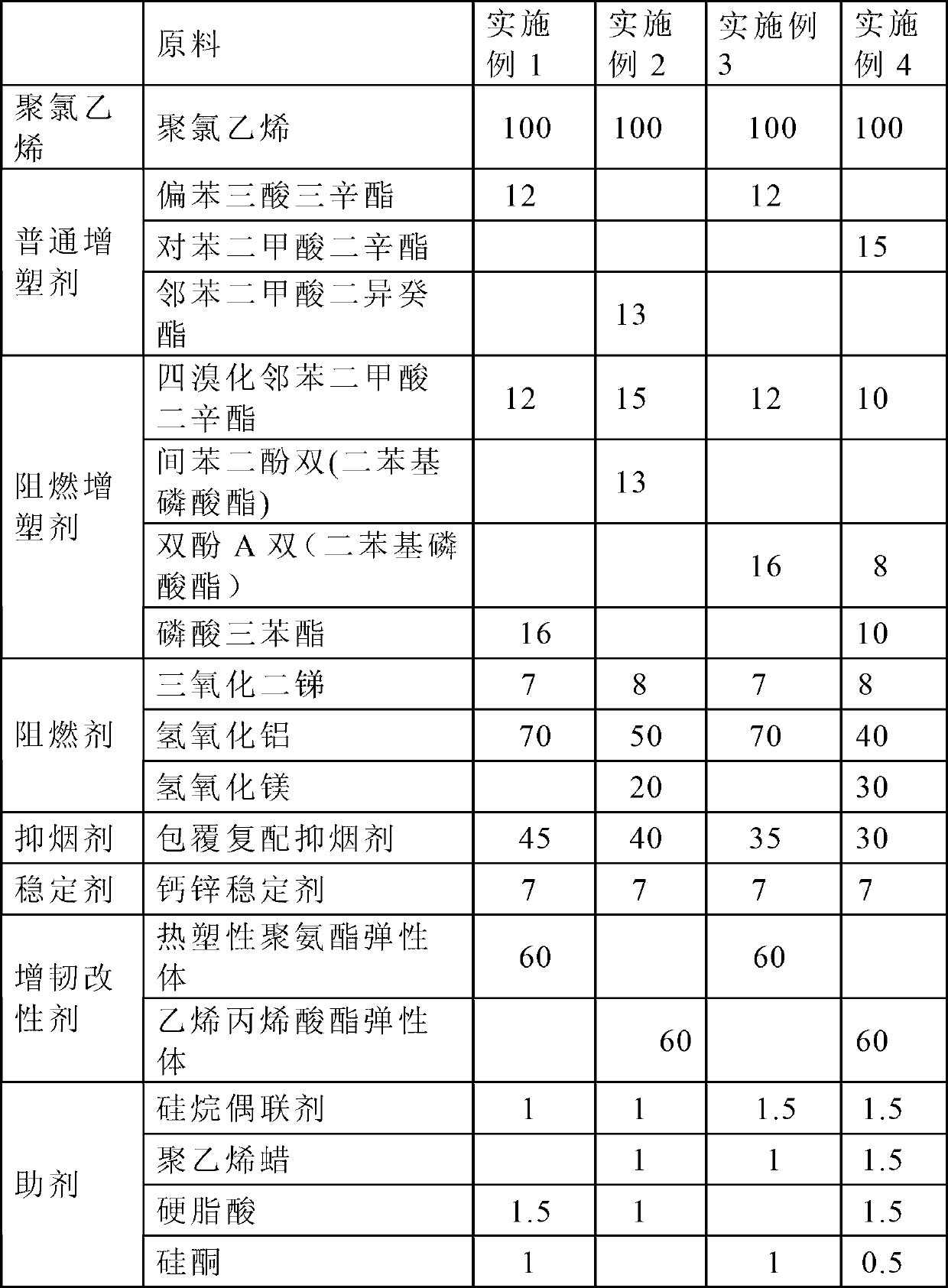

Corrugated metal pipe (CMP) grade flame-retardant smoke-suppressing polyvinyl chloride cable sheath material and preparation method thereof

ActiveCN102993602AReasonable cooperationImprove flame retardant and smoke suppression performanceInsulated cablesInsulated conductorsAluminium hydroxidePolyvinyl chloride

The invention provides a corrugated metal pipe (CMP) grade flame-retardant smoke-suppressing polyvinyl chloride cable sheath material and a preparation method thereof and belongs to the technical field of material. The invention solves the problem that in the prior art, the flame-retardant and smoke-suppressing effects and the mechanical property and the physical property of the cable sheath material are all good. The raw materials thereof comprise the following components in parts by weight: 100 parts of polyvinyl chloride, 5-15 parts of common plasticizer, 20-50 parts of flame-retardant plasticizer, 40-100 parts of fire retardant, 20-50 parts of smoke-suppressing agent, 5-10 parts of stabilizer, 40-80 parts of toughening modification agent and 1-5 parts of promoter; wherein the smoke-suppressing agent comprises ammonium octamolybdate, zinc molybdate and zinc borate which are compounded according to the proportion of 1:1 to 3:1 to 3 and coated by aluminium hydroxide the grain size of which is 1-5mu m according to the proportion of 1:1 to 3. The CMP grade flame-retardant smoke-suppressing polyvinyl chloride cable sheath material has the advantages of good flame-retardant and smoke-suppressing effect, mechanical property and physical property.

Owner:江西一舟数据技术有限公司

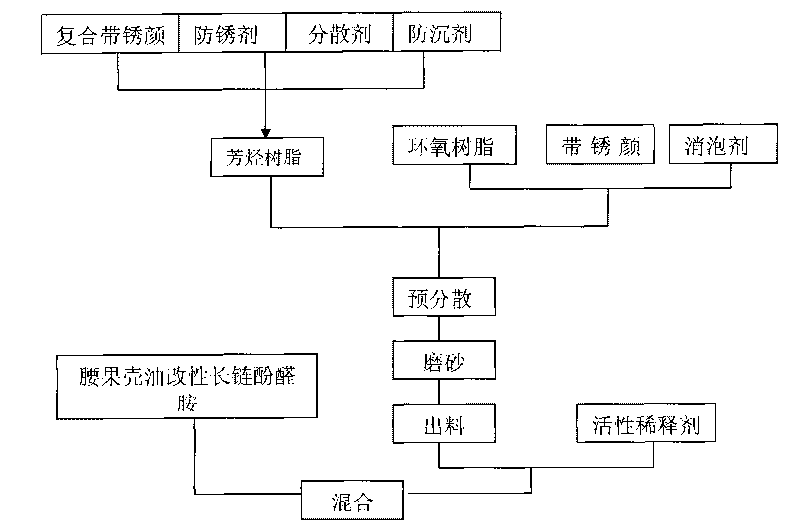

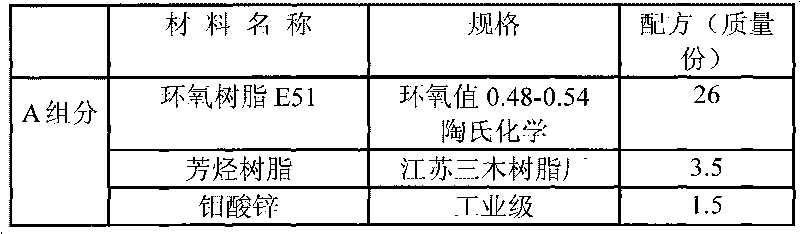

Environment-friendly solvent-free humidified and rusted anticorrosive paint

InactiveCN101747825AEasy pretreatmentConvenient anti-corrosion solutionAnti-corrosive paintsEpoxy resin coatingsOrganic filmSolvent free

The invention relates to a paint material with formed organic film, in particular to an epoxy solvent-free anticorrosive paint applied to low surface treatment steel structure. The anticorrosive paint is prepared by efficiently compounding rusted coating pigments such as zinc molybdate, zinc phosphate, aluminium trippolyhosphate, iron oxide red and the like, using cashew nut oil modified long-chain amine phenolic aldehyde as, alicyclic glycidyl ether as active diluent, thus overcoming the problems that surface treatment technique in coating construction costs high and heavy anticorrosive paint with high solvent content pollutes the environment, having easy preparation and construction, low cost, fast solidification at high temperature, good mechanical and anticorrosive performance, solvent-free and environment-friendly properties, and being applicable to heavy anticorrosive projects of steel structures such as ship, train, bridge and the like.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Water -borne anticorrosion paint and method for preparing same

ActiveCN102746766AImprove adhesionImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyZinc phosphate

The invention provides a water -borne anticorrosion paint and a method for preparing the same, and belongs to the paint technical field. The paint comprises, by weight, 10% to 45% of water-borne epoxy resins, 5% to 20% of silica sol, 5% to 15% of anticorrosion pigments, 20% to 40% of pigment fillers, 0.5% to 5% of additives and 10% to 15% of water. The anticorrosion pigments are selected from one of zinc phosphate, modified zinc phosphate and zinc molybdate or a mixture formed by any of the three in any proportion; and the additives are a mixture formed by wetting agents, dispersing agents, film forming additives, pH modifiers, antifoaming agents and rheological additives in any proportion. The water -borne anticorrosion paint has a good adhesive force with metals, and excellent anticorrosion performance, rigidity and chemical resistant performances, and the salt mist resistant performance is more than1000 hours.

Owner:JIANGSU HUAXIA PAINT MAKING

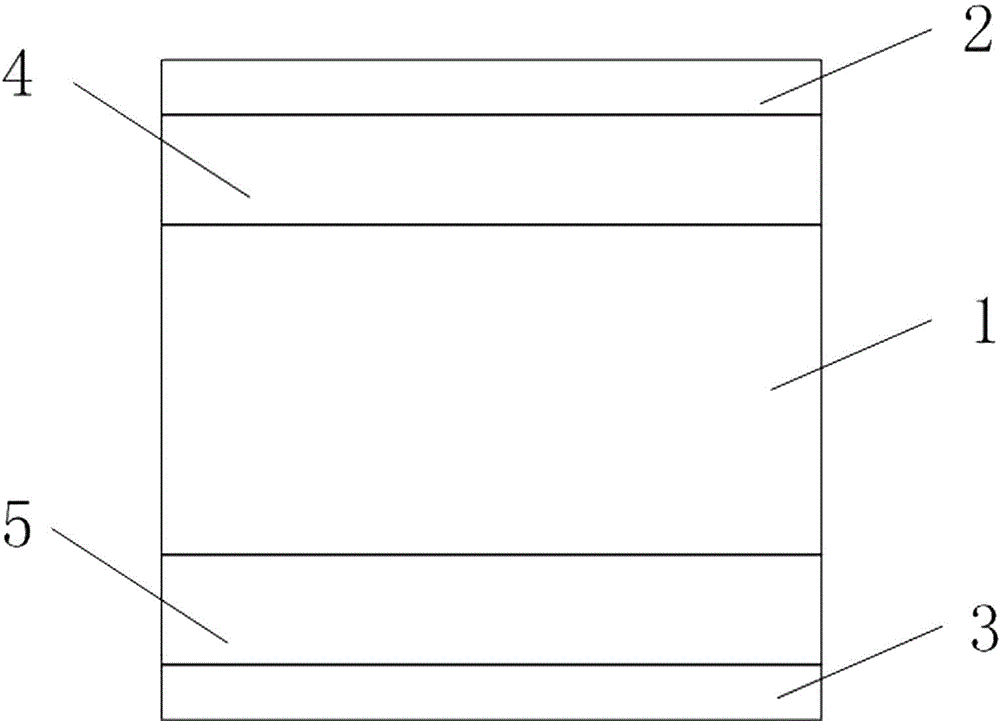

Manufacturing method of grade-A2 fireproof aluminum composite plate

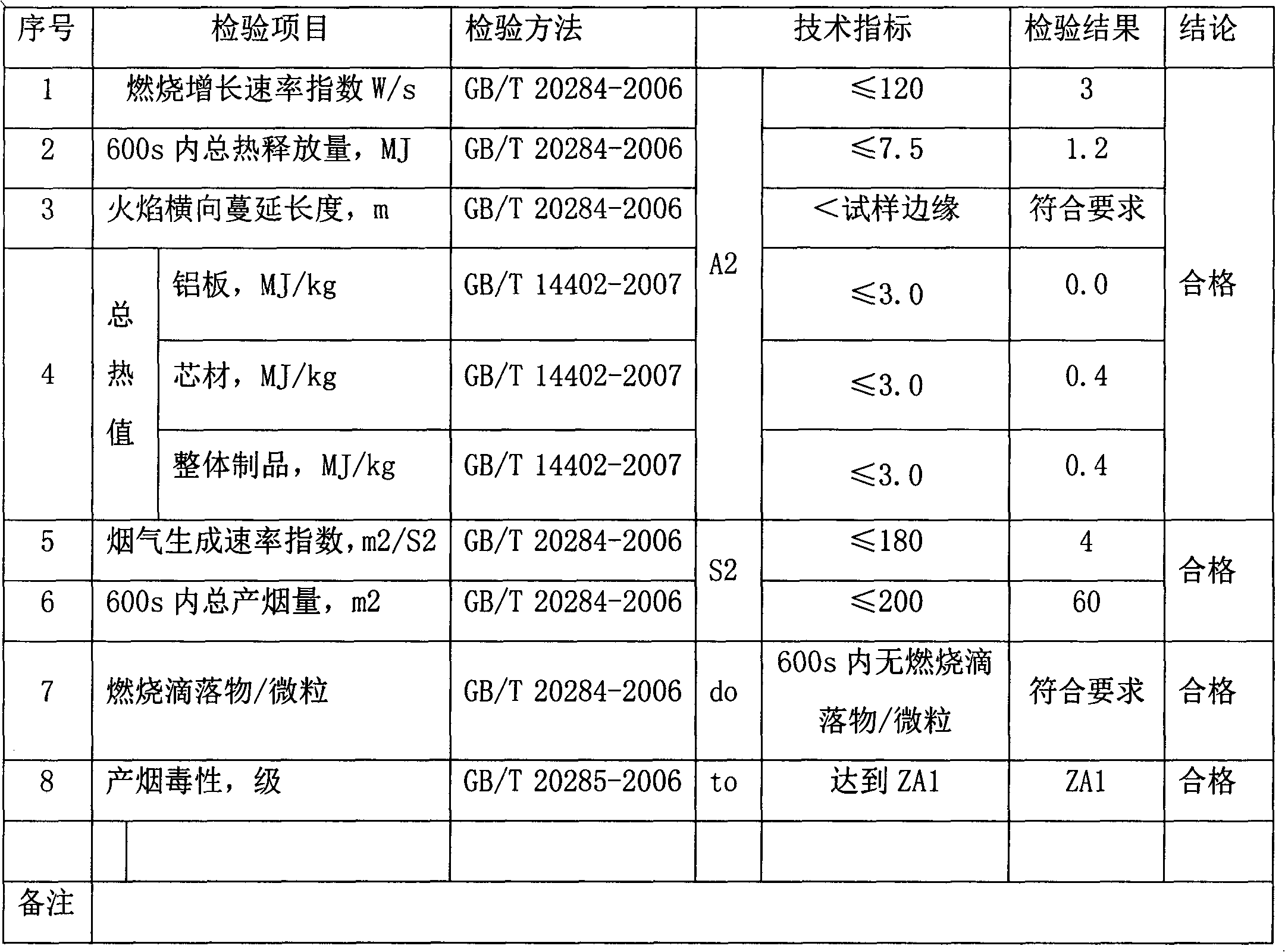

The invention discloses a manufacturing method of a grade-A2 fireproof aluminum composite plate. The grade-A2 fireproof aluminum composite plate is manufactured from 83kg-93kg of calcium carbonate, 130kg-142kg of silicon micro-powder, 87kg-97kg of quartz sand, 10kg-15kg of pearlite, 7kg-12kg of polypropylene staple fiber, 40kg-50kg of silicon dioxide, 58kg-67kg of aluminium hydroxide, 12kg-27kg of zinc molybdate and 135kg-145kg of acrylic based emulsion. The method comprises the following steps of: 1, preparing materials; 2, discharging and pasting non-woven fabrics; 3, roasting, stripping the non-woven fabrics and rolling; 4, cooling, grinding, gluing and roasting; and 5, adhering, cooling and shearing. By adopting the manufacturing method of the fireproof aluminum composite plate, liquid materials are roasted into a solid state to form the core materials through roasting for eight times by an oven and rolling by a rolling mill, and the core materials and the aluminum plate are difficult to delaminate under the high-temperature condition, and the fireproof intensity is improved.

Owner:JIANGSU XIECHENG SCI & TECH DEV +1

Laminboard of level A fireproof plastic-aluminum plate and method for producing the same

The invention discloses a coreboard of an A-level fire-proof aluminium-plastic board and the preparation method thereof. Calculating according to a boil of raw material slurry, the coreboard consists of calcium carbonate of 85 to 95 kilograms, silicon fine powder of 128 to 140 kilograms, quartz sand of 85 to 95 kilograms, perlite of 10 to 20 kilograms, polypropylene short fibre of 6 to 15 kilograms, Sio2 of 45 to 55 kilograms, aluminium hydroxide of 55 to 65 kilogram, zinc molybdate of 10 to 25 kilograms and acrylic latex of 130 to 140 kilograms. The method comprises the step as follows: preparing the feed slurry; balancing the ingredients according to the weight requirement and then pouring into a stirring mill with a revolution of 80 to 150 per minute to stir for 3 to 5 minutes; making the feed slurry out of the pot; heating and pressing the aluminum after casting the feed slurry into the mold pressing cavity with the traditional method; after that, the A-level fire-proof aluminium-plastic board is made. The invention takes the acrylic latex as the resin acceptor, the aluminium hydroxide as the flame retardant, the zinc molybdate as the antismoke agent, and the polypropylene fibre as the strengthening and toughing agent; the racking strength of the made A-level fire-proof aluminium-plastic board exceeds the standard; the indexes such as the water-proof index, the fire-proof index and the breaking resisting index and so on all accord with the national standard of GB8642-1997A level.

Owner:JIANGSU XIECHENG SCI & TECH DEV

Epoxy organosilicon anticorrosion paint and preparing method thereof

InactiveCN101033370AImprove basic physical propertiesImprove corrosion resistanceAnti-corrosive paintsPolyamide coatingsTalcPhysical property

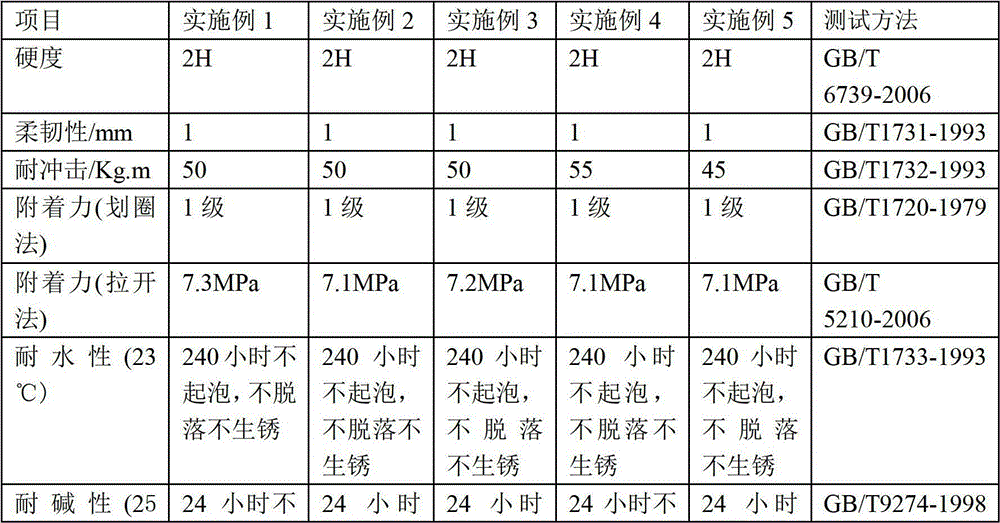

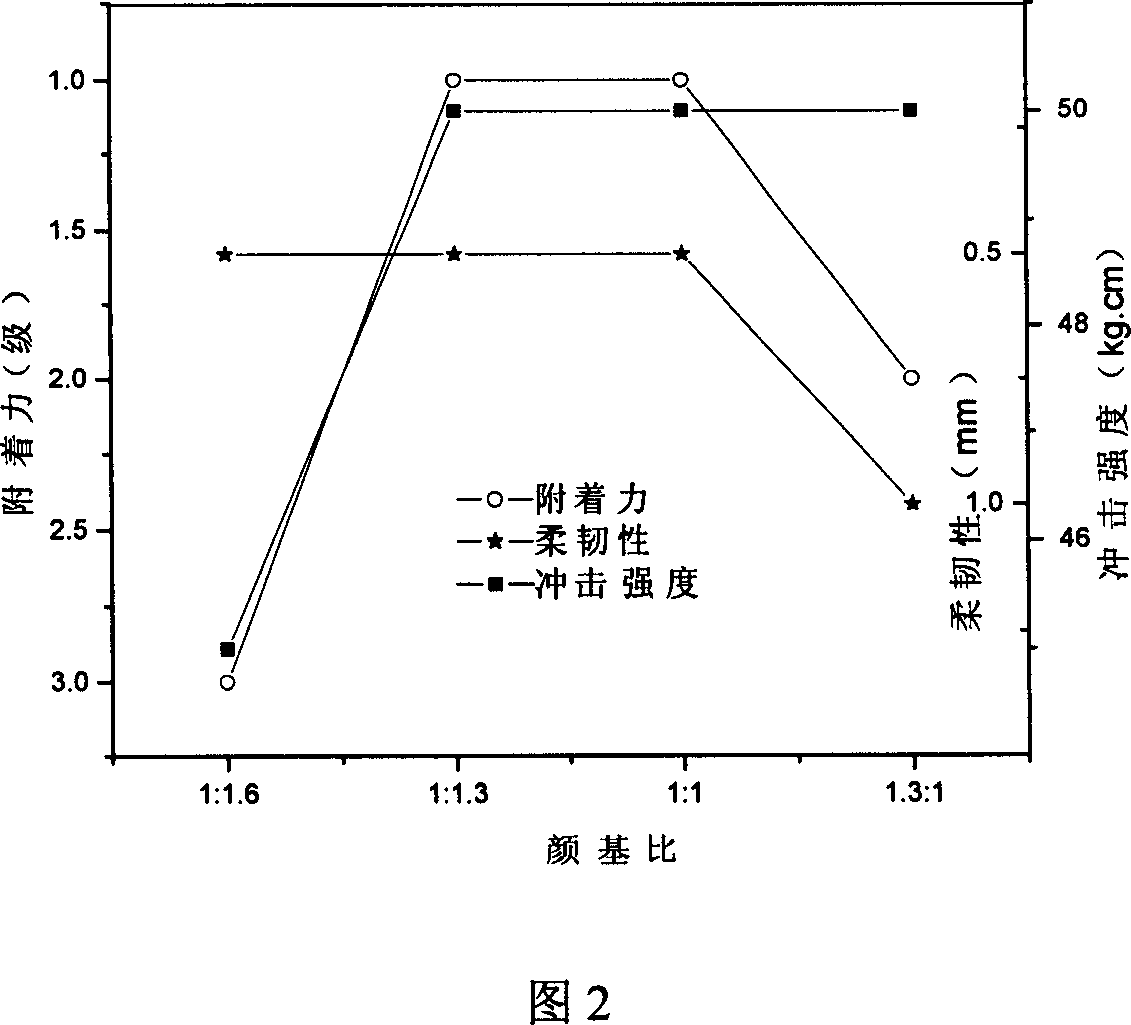

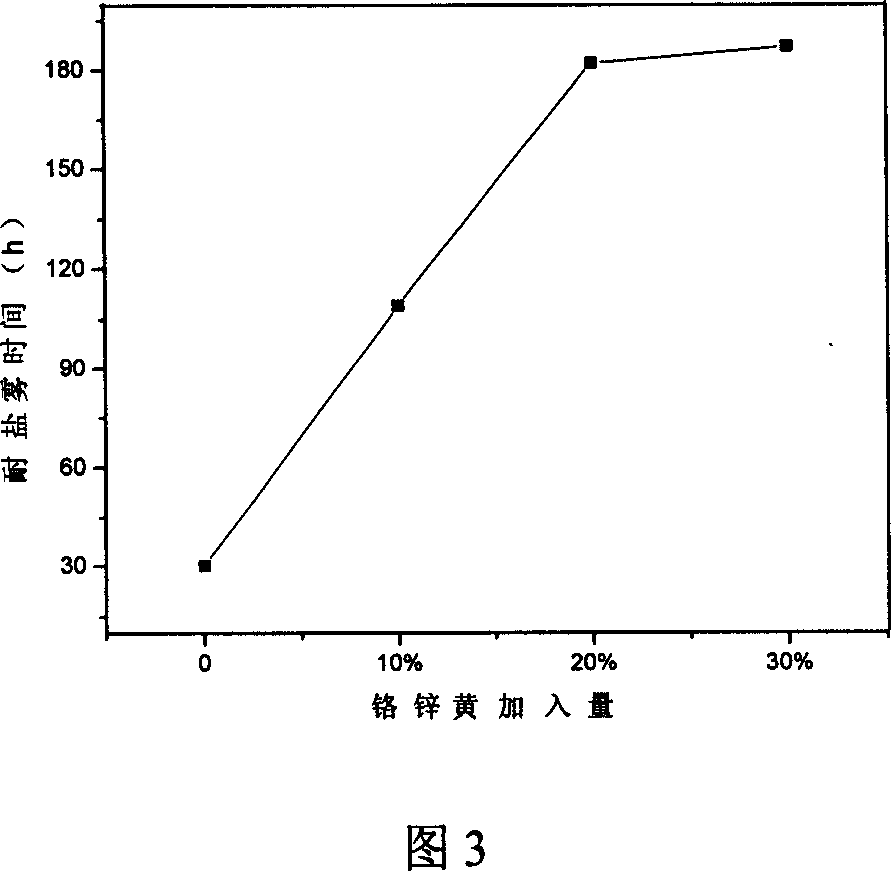

The invention relates to a kind of anti-corrosion epoxy-silicone resin coating and its preparation. In the invention, it takes the anti-corrosion epoxy-silicone resin ES-06 as material for the film, and polyamide 650 as curing agent, and it also includes anti-rust paint chrome yellow zinc, chromium and molybdenum acid strontium zinc, titanium dioxide pigments physique, mica, talc, defoamer 550, dispersant TM-950 and the solvent system of xylene and n-butyl alcohol. The advantage of the matiral is that the coating can be cured at room temperature, meanwhile, it has the properties such as the maximum adhesion of one class, a flexible of 0.5mm, a impact strength of 50kg.cm, a salt spray cumulative maximum time a 360 hours, and the coating has a good basic physical property and excellent corrosion resistance.

Owner:COSCO KANSAI PAINT & CHEM TIANJIN

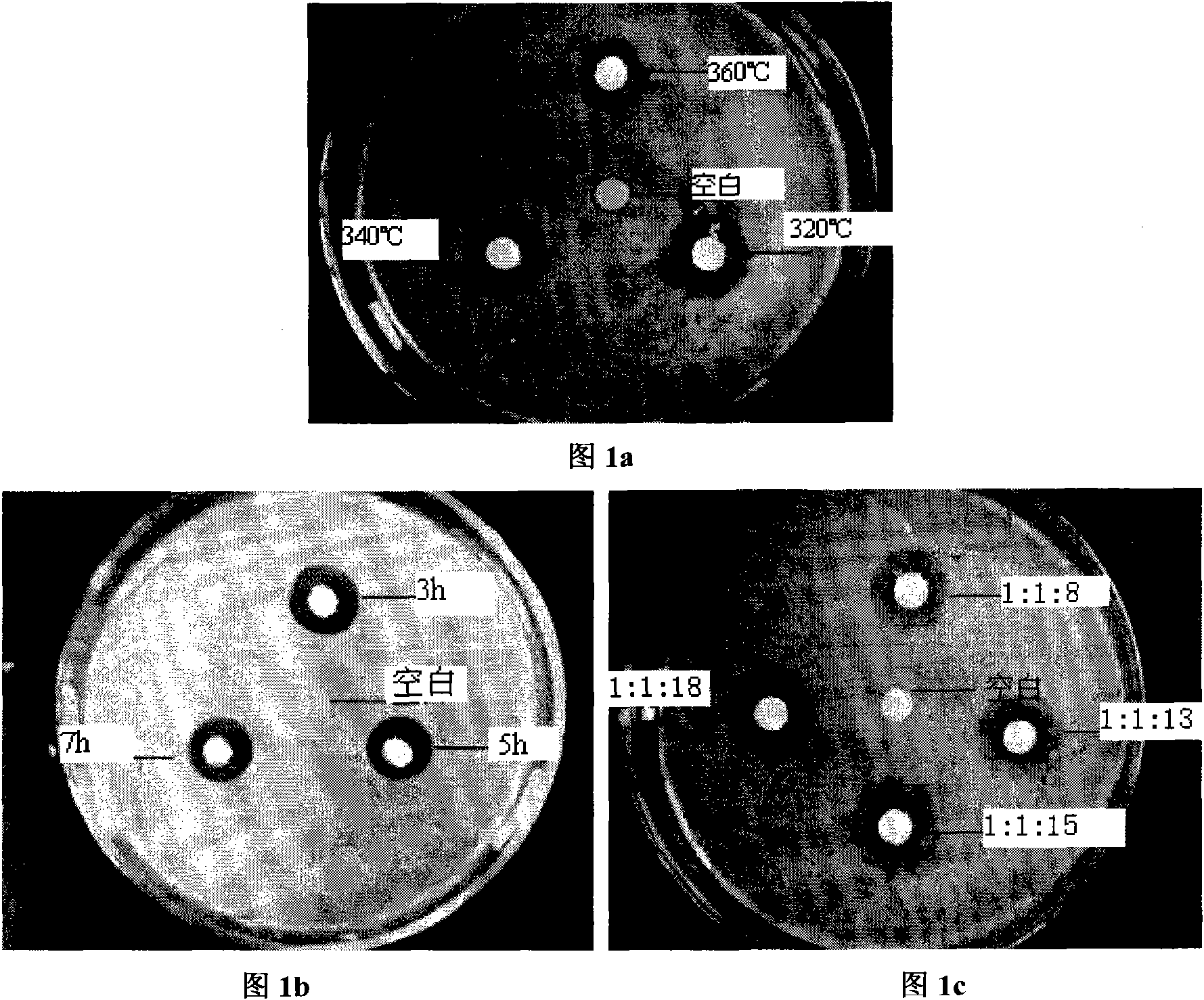

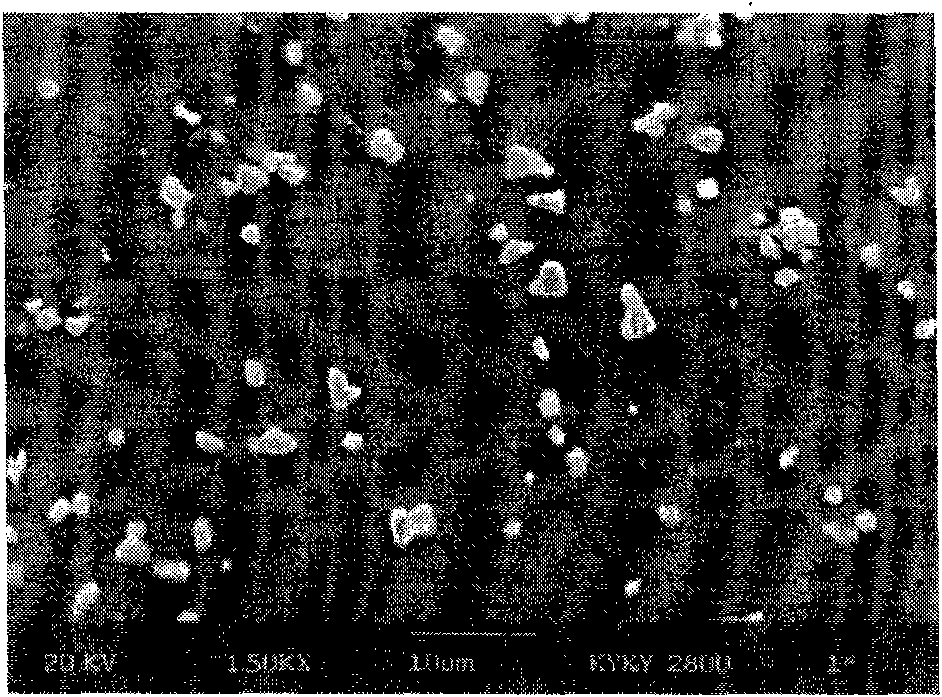

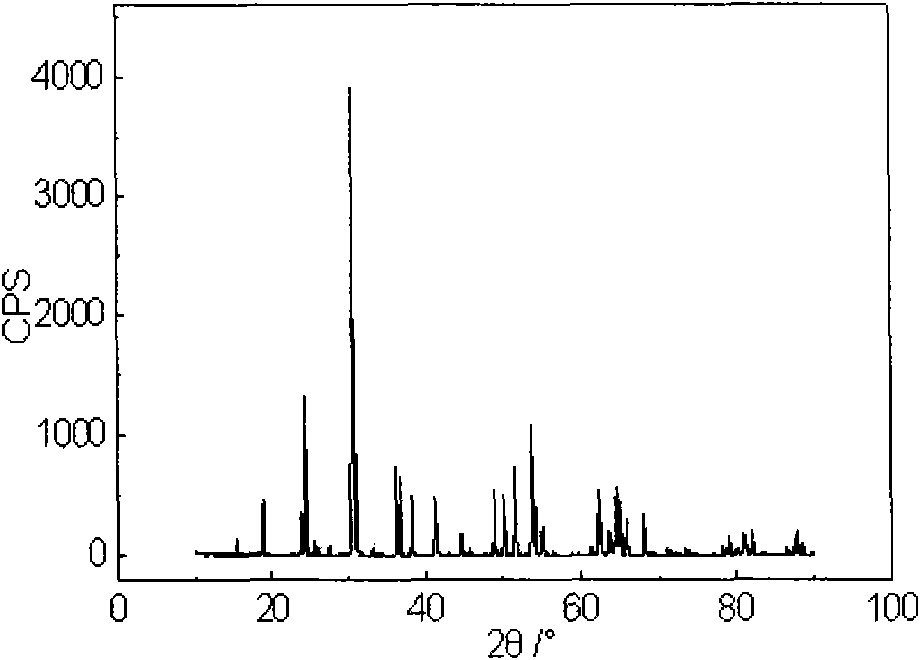

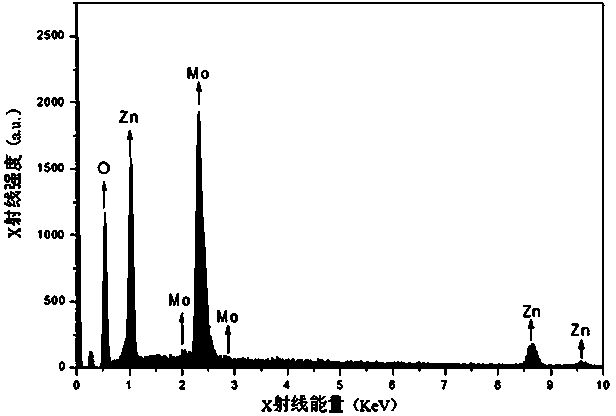

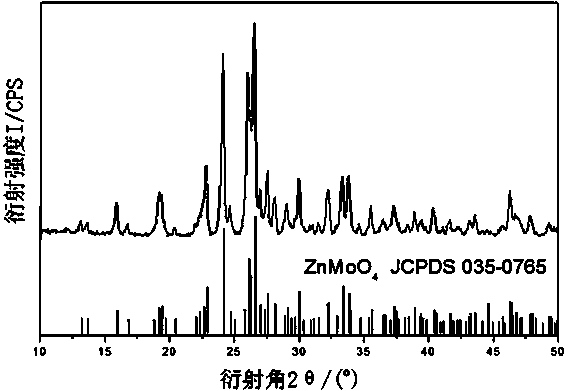

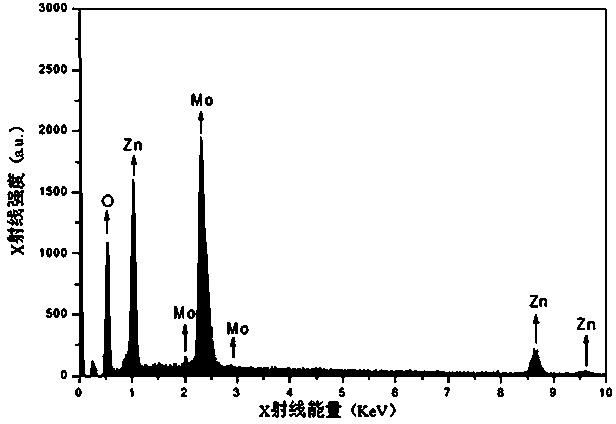

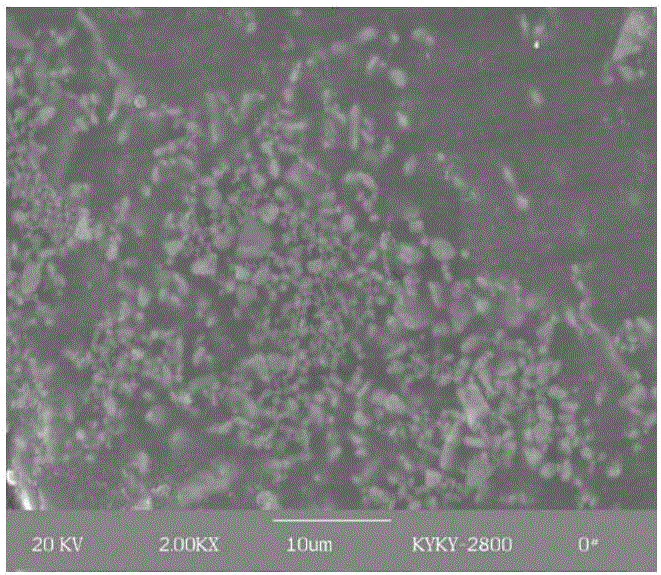

Method for preparing zinc molybdate ultrafine anti-bacterial powder by adopting molten-salt growth method

InactiveCN101891252AImprove antibacterial propertiesOptimize synthesis conditionsBiocideMolybdeum compoundsZinc nitrateColor changes

The invention relates to a method for preparing zinc molybdate ultrafine anti-bacterial powder by adopting a molten-salt growth method. The method comprises the following steps that: sodium molybdate and zinc nitrate serving as raw materials and sodium nitrate serving as a salt material are mixed in a mortar in the proportion of 1:1:8-18; a proper amount of absolute alcohol is added in the mortar to grind for 1 to 2 hours to ensure that the raw materials and the salt material are mixed sufficiently and uniformly; the mixture is dried for 2 to 4 hours at 90 DEG C in a crucible, and is melted and calcined for 3 to 7 hours in an electric furnace at the temperature of between 320 and 360 DEG C; and the calcined curing product is sufficiently soaked and washed with distilled water, is filtered and dried to remove residual fused salt to obtain the ultrafine zinc molybdate powder. Researches prove that the ultrafine zinc molybdate anti-bacterial powder prepared by the molten-salt growth method has bacteria resistance superior to the anti-bacterial powder synthesized by a chemical precipitation method under the same testing condition, and avoids the problems of high cost and color change by using a silver antibacterial agent. The method can be widely applied in the fields of plastics, ceramics, paints and the like.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Flame retardant composite board and manufacture method thereof

InactiveCN104552488AHigh mechanical strengthGood nail gripWood veneer joiningDomestic articlesBruciteComposite plate

The invention provides a flame retardant composite board. The flame retardant composite board comprises a homogeneous naked panel and a facing layer arranged on at least one surface of the homogeneous naked panel, wherein the homogeneous naked panel is prepared from raw materials of, based on weight parts, 65-98.5 parts of plant straw particles, 3-10 parts of binder and 3-10 parts of fire retardant, wherein the fire retardant is prepared from raw materials of magnesium oxide, calcium sulfate, aluminum hydroxide, brucite, zinc molybdate and zinc borate. The flame retardant composite board has good chemical properties of fire retarding, water prevention, insect prevention and the like, and good physical and mechanical properties, can replace wood artificial boards, and is used in various fields. The invention further provides a manufacture method of the flame retardant composite board. The manufacture method of the flame retardant composite board mainly adopts a normal temperature cold press molding technology to solidify and shape the raw materials of the naked panel, not only greatly saves energy, but also improves product performance, enables the flame retardant composite board to have water prevention and fire prevention functions, and simultaneously can substantially reduce equipment cost, achieves a whole green production process, and does not cause pollution during the whole production process.

Owner:信阳美丽真好秸秆新材科技有限公司

Glass oil paint

ActiveCN103897564AEconomical to makeStrong adhesionShellac coatingsPolyester coatingsLacquerOil paint

The invention relates to an glass oil paint which comprises the following components in parts by weight: 20-27 parts of modified dry oil, 12-17 parts of hydroxyethyl cellulose, 3-6 parts of butyl stearate, 12-15 parts of water-soluble resin, 5-8 parts of lac resin, 3-6 parts of lacquer resin, 12-15 parts of zinc phosphate, 4-6 parts of zinc molybdate, 11-16 parts of mica powder, 1-4 parts of citric acid, 2-4 parts of antiseptic antirust emulsion and 5-8 parts of thinners. According to the glass oil paint, raw materials are common in the market, so that the production cost is low, and the glass oil paint has strong adhesive force, acid and alkali resistance and water resistance, can effectively remove and prevent iron rust due to addition of the antiseptic antirust emulsion, and can be smeared on glass, so as to meet the demands of people.

Owner:SHANGHAI DABAO CHEM PROD

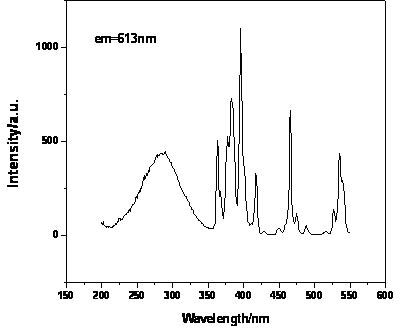

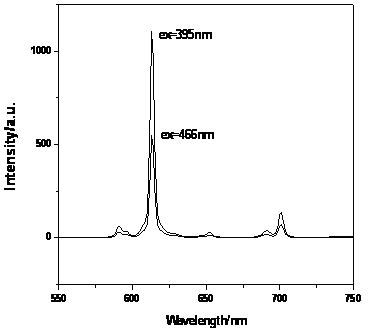

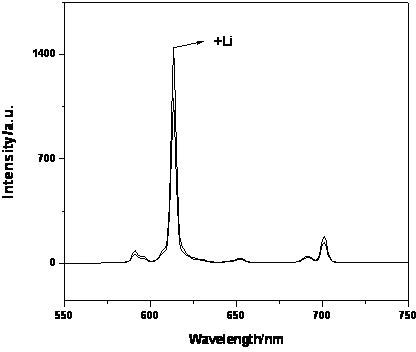

Europium-doped hydrated zinc molybdate high-efficient red fluorescent powder and preparation method thereof

InactiveCN102277162APromote absorptionImprove luminous brightnessGas discharge lamp usageLuminescent compositionsMolybdateRare earth ions

The invention relates to europium-doped hydrated zinc molybdate high-efficient red fluorescent powder and a preparation method thereof. The main crystalline phase of the fluorescent powder is zinc dimolybdate pentahydrate (or calcium, gadolinium and other alkaline earth or rare earth metal replacing parts of zinc); and during synthesizing, batching is carried out according to a general formula of A1-x-yMoO4:EuxBy. The preparation method comprises the following steps of: reacting the prepared zinc-containing and zinc-substituted ionized calcium and rare earth ion solution with an alkali metal or ammonium molybdate under appropriate conditions; regulating PH (Potential of Hydrogen) to completely precipitate; filtering directly or filtering after aging for a period of time, and washing the precipitate; and drying at a normal temperature to finish the preparation. According to the invention, the preparation method is simple and easy to operate; moreover, the red fluorescent powder has a good luminous effect and stable physical and chemical properties, can be well matched with near-ultraviolet and blue-light LED (Light Emitting Diode) chips, and can be used as red fluorescent powder of a novel high-efficient white-light LED.

Owner:NANCHANG UNIV

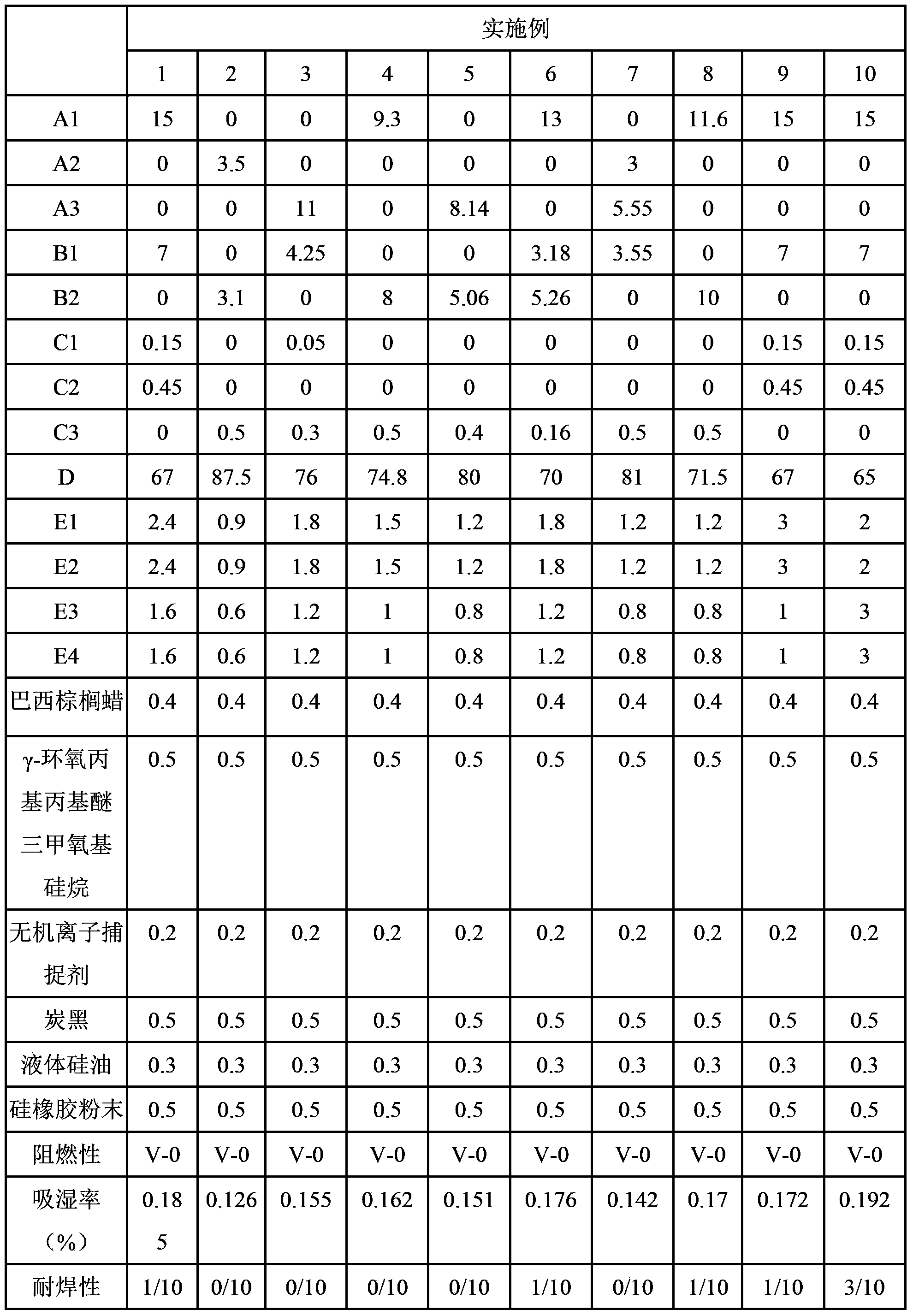

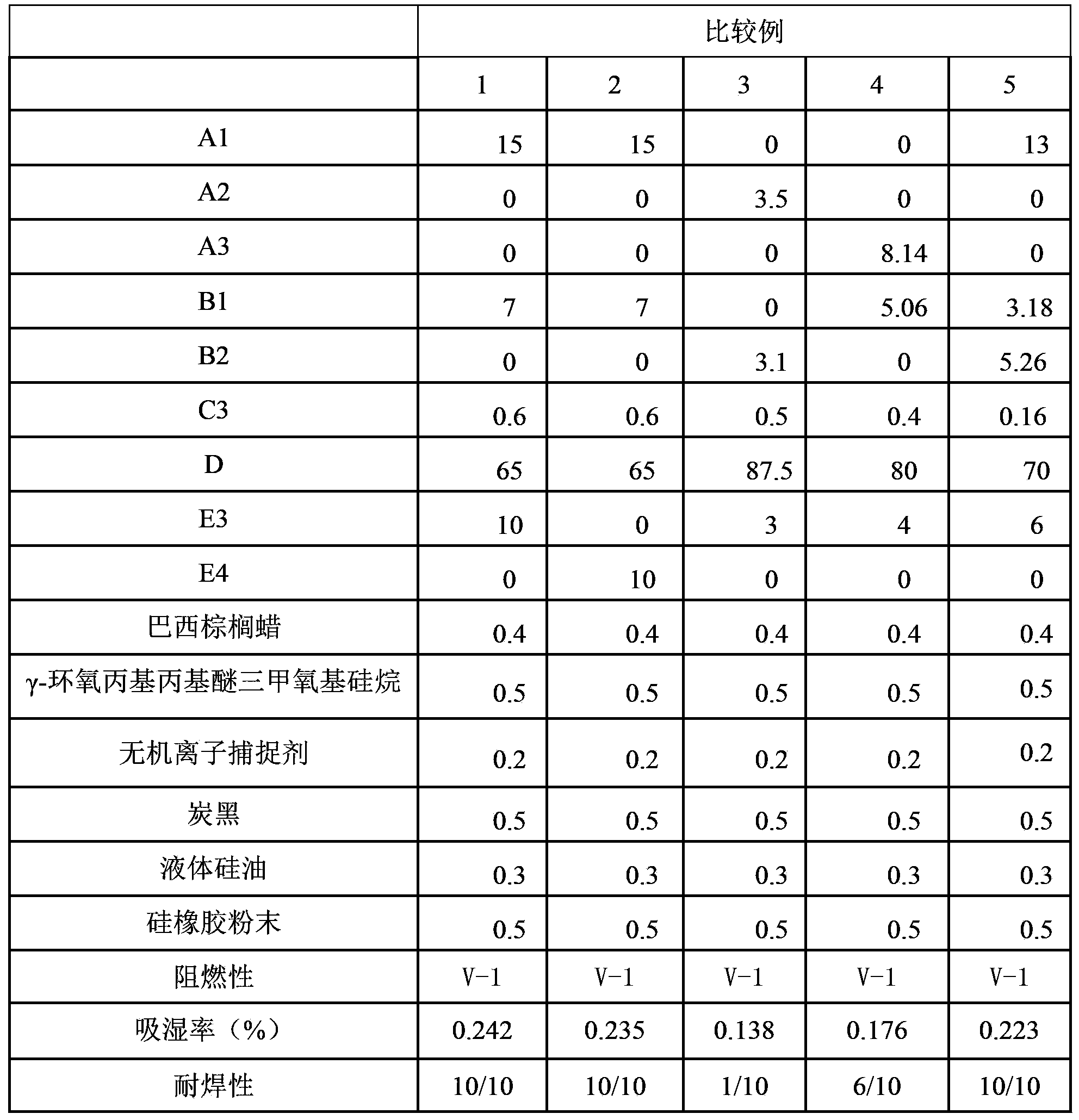

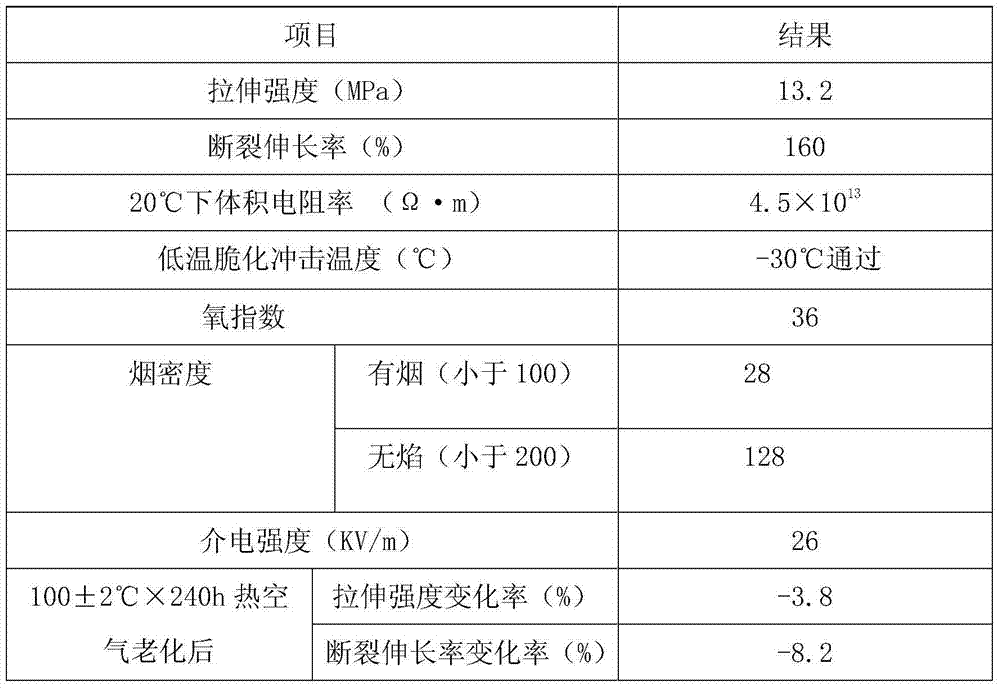

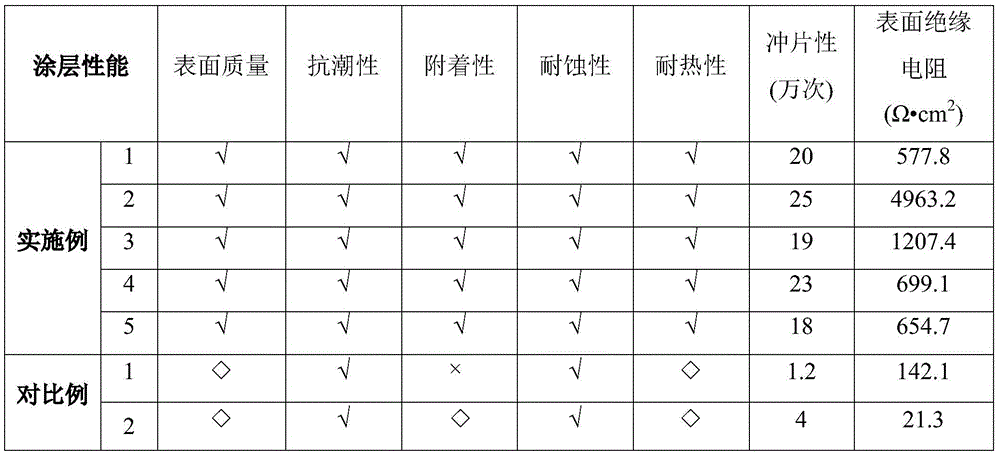

Epoxy resin composition containing composite flame retardant

InactiveCN104277417AImprove solder resistanceLiquiditySemiconductor/solid-state device detailsSolid-state devicesEpoxyZinc borate

The invention relates to a resin for semiconductor packaging, and particularly relates to an epoxy resin composition which contains a composite flame retardant and can improve soldering resistance of an epoxy resin composition molded material. The epoxy resin composition comprises the main components and contents: 3.5-15 wt% of epoxy resin, 3.1-10 wt% of phenolic resin, 65-87.5 wt% of a filler, and 2-10 wt% of the composite flame retardant (containing zinc molybdate, zinc borate, magnesium hydroxide and aluminum hydroxide). The epoxy resin composition containing the composite flame retardant is a semiconductor packaging material with excellent soldering resistance, and moreover, also has necessary liquidity, moldability, flame retardance and mechanical properties.

Owner:BEIJING SHOUKEHUA MICRO ELECTRONICS +1

Modified antirust paint for egg turning rack of incubator

InactiveCN106118273AImprove thermal shock resistanceImprove stabilityAnti-corrosive paintsEpoxy resin coatingsEpoxyThermal shock

The invention relates to the field of antirust paint, in particular to modified antirust paint for an egg turning rack of an incubator. The modified antirust paint is prepared from the following raw materials in parts by weight: 36 to 40 parts of a styrene-acrylic emulsion, 14 to 20 parts of an epoxy resin emulsion, 3 to 5 parts of inositol hexaphosphate, 3 to 5 parts of tourmaline powder, 4 to 6 parts of a silane coupling agent, 1 to 2 parts of tris(2-ethylhexyl)acetyl citrate, 2 to 4 parts of bamboo charcoal fiber, 3 to 6 parts of basic calcium-zinc molybdate, 0.5 to 1 part of butylene terephthalate, 0.5 to 1 part of 2-n-octyl-4-isothiazolin-3-one, 1 to 2 parts of oxyethylene polyoxypropylene ether and 4 to 8 parts of modified nano graphene. The antirust paint is good in thermal shock resistance, can tolerate frequent change of temperature, is strong in adhesion to metal, free of cracking and spalling, and resistant to acid-alkali, salt spray and bacterium erosion, can also emit far infrared rays, has certain benefits on hatching eggs, is good in stability, very low in volatilization rate and non-toxic, and cannot cause influence on the hatching eggs.

Owner:BENGBU JIAAI ELECTRONICS

Low-smoke halogen-free flame-retardant cable material

InactiveCN103571009AImprove flame retardant performanceExcellent non-flammabilityInsulated cablesInsulatorsUltraviolet lightsStearic acid

The invention provides a low-smoke halogen-free flame-retardant cable material. The low-smoke halogen-free flame-retardant cable material is prepared from the following raw materials in parts by weight: 30-40 parts of polyethylene, 20-30 parts of EVA (ethylene-vinyl acetate), 40-60 parts of magnesium hydroxide, 5-6 parts of nanometer silicon carbide, 0.2-0.4 part of nanometer nitriding aluminum powder, 4-6 parts of hydrotalcite, 2-3 parts of zinc molybdate, 2-4 parts of ethylene-octene copolymer grafted maleic anhydride, 0.1-1 part of tricresyl phosphate, 1-2 parts of calcium stearate, 0.5-1.0 part of stearic acid, 0.2-0.4 part of ultraviolet absorbent UV-531 and 8-10 parts of modified filler. The cable material provided by the invention has excellent flame resistance and incombustibility, generates little smoke during burning, does not generate poisonous gases and corrosive gases and meanwhile has good low temperature resistance, oil resistance and ultraviolet light resistance.

Owner:湖南科森高分子材料科技有限公司

A preparing method of an environmental friendly flame-retardant polycarbonate composite material

InactiveCN105348763AChange surface propertiesGood compatibilityPotassium perfluorobutanesulfonatePhosphate

A preparing method of an environmental friendly flame-retardant polycarbonate composite material is disclosed. The method includes mixing nanometer zinc oxide, nanometer titanium dioxide, nanometer aluminium hydroxide, glass fibre, kaolin, nanometer zinc stannate, ferrocene, zinc molybdate, basic sodium aluminium carbonate, calcium stearate, zinc stearate and a silane coupling agent KH-540 to obtain a modified filler; melting and extruding polyvinyl butyral, polyvinylidene fluoride, octafluoro-diphenyl diglycidylether, styrene-acrylonitrile copolymer, melamine resin and the modified filler in a twin-screw extruder to obtain dispersed master batch; adding polycarbonate, the dispersed master batch, tris(2,4-diisobutyl) phosphate, hexaphenoxycyclotriphosphazatriene, potassium perfluorobutanesulfonate, bisphenol A bisphthalonitrile, a plasticizer and an oxidant into a twin-screw extruder, melting and extruding. The composite material prepared by the method is good in heat resistance and excellent in flame retardance.

Owner:ANHUI GUANGYUAN TECH DEV

Non-toxic environmentally-friendly oriented electrical steel insulation coating and preparation method thereof

InactiveCN105566970AImprove the problem of moisture absorption and stickinessImprove heat resistanceAnti-corrosive paintsPhosphateMoisture absorption

The present invention provides an oriented electrical steel insulation coating and a preparation method thereof, and the coating is prepared from the following ingredients by mass: 35 to 50 % of a metal dihydric phosphate, 16 to 25 % of zinc molybdate, 4 to 10% of boric acid, 5 to 10% of colloidal silicon dioxide, 2 to 5% of nano oxide powder, 2 to 13% of organic resin, 0.01-0.08% of a nonionic surfactant and the balance of water. The oriented electrical steel insulation coating is free from chromium elements, non-toxic and environmentally-friendly, has good insulating property, adhesion property and blanking property, can ensure the coating uniformity, corrosion resistance, and heat resistance, is low in moisture absorption tendency to tacky, can be saved stably for long term, is simple in preparation method and low in requirements on equipment, and industrialization is easy to realize.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +3

Method for preparing zinc molybdate by using cationic membrane electrolysis method

The invention discloses a method for preparing zinc molybdate by using a cationic membrane electrolysis method. The method comprises the following steps: by taking a zinc piece as a positive electrode, an inert electrode as a negative electrode, a sodium molybdate solution as anolyte, and an acid solution, an alkali solution or a salt solution as catholyte, electrolyzing the sodium molybdate solution at a temperature between the room temperature and 90 DEG C in a double-chamber electrolysis bath with a cationic membrane as a diaphragm in a constant-current electrolysis or constant-voltage electrolysis mode till Na+ ions are completely transferred to a negative electrode chamber; after the electrolysis is completed, washing the obtained product with deionized water and filtering at the same time; drying the obtained filter cake, heating to 450-600 DEG C at the heating rate of 2.5-10 DEG C / min in an air atmosphere, performing high-temperature roasting for 1-5 hours; and naturally cooling to room temperature, thus obtaining zinc molybdate which is high in purity and free of impurity phases. According to the method, the electrolysis function of a cationic membrane is adopted, and Na+ is transferred to the negative electrode chamber, so that the influence of Na+ is eliminated and the reaction time is shortened.

Owner:SHANGHAI INST OF TECH

Method of producing organosilicon heat-resistant coating

The invention relates to a method for producing heat-resisting organic silicon dope, which is characterized in the preparation of the component A, the component B, zinc powder and zinc molybdate. The component A is composed of the following substances in mass share: tetraethoxysilane 100, isobutanol 50, isopropanol 25, water 17 and hydrochloric acid 0.1 and the component B is composed of methyltriethoxysilane 100, isobutanol 60, isopropanol 76, tap water 16 and hydrochloric acid 0.1. The heat-resisting organic silicon dope is prepared in the following proportion in mass percentage: component A 50, component B 30, zinc powder 15 and zinc molybdate 5. The product can be used for doping heat-resisting boiler, heating apparatuses and engine lining etc. and heat-resisting and anti-corrosion apparatuses.

Owner:王瑞明

Laser carving powder applied to laser marking and preparation process thereof

The invention discloses laser carving powder applied to laser marking. The laser carving powder comprises the following raw materials in parts by weight: polypropylene resin, C5 petroleum resin, barium sulfate, a nucleating agent, an antioxidant, toner, a lubricant, silicon oxide, titanium dioxide, zinc sulfide, chromium sesquioxide, neodymium oxide, bismuth oxide, tin oxide, zinc molybdate, ammonium molybdate, basic copper phosphate, copper oxide, copper chromite black, copper carbonate, copper sulfate, copper chloride, copper chromite, copper thiocyanate, spinel, tin dioxide, tin ash, sodiumstannate, potassium stannate, zinc sulfate, antimony trioxide, antimony pentoxide, sodium antimonate, potassium carbonate, syndiotactic polystyrene and polyhexamethylene adipamide; according to the preparation process of the laser carving powder applied to laser marking, the laser carving powder applied to laser marking is prepared, and the preparation process comprises the following steps: S1, grinding; S2, performing crushing; S3, performing mixing; S4, adding a chemical agent; S5, drying; and S6, crushing.

Owner:东莞市烁康新材料科技有限公司

Semiconductor encapsulating epoxy resin compositions, and semiconductor devices encapsulated therewith

InactiveUS6518332B2Improve flame retardant performanceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesPolymer scienceDevice material

Semiconductor encapsulating epoxy resin compositions comprising an epoxy resin, a phenolic resin curing agent, a fire retardant comprising zinc molybdate carried on spherical silica having a mean particle diameter of 0.2-20 mum and a specific surface of 1-20 m2 / g, and an inorganic filler are able to provide cured products having excellent fire retardance. The compositions have good flow and curing properties and excellent reliability and do not pose a hazard to human health or the environment.

Owner:SHIN ETSU CHEM CO LTD

Antibacterial sanitary ceramic glaze and preparation method

The invention belongs to the technical field of ceramics, and relates to an antibacterial sanitary ceramic glaze and a preparation method. The antibacterial sanitary ceramic glaze is prepared from the following raw materials: potash feldspar, sandstone, dolomite, limestone, zircon powder, frit, aluminum oxide, zinc oxide, Suzhou clay, zirconium iron pink, praseodymium yellow, cellulose and compound antibacterial powder; the composite antibacterial powder is prepared from the following raw materials in percentage by mass: 15 to 20 percent of silver molybdate, 60 to 65 percent of zinc molybdate and 20 to 25 percent of titanium dioxide. The preparation method of the antibacterial sanitary ceramic glaze comprises the following steps of A, preparation of the composite antibacterial powder; B, preparation of glaze slip; C, preparation of the antibacterial sanitary ceramic glaze. The preparation method provided by the invention is simple and is easy to operate; the antibacterial sanitary ceramic glaze is resistant to a high temperature, does not discolor, and is excellent in antibacterial property.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

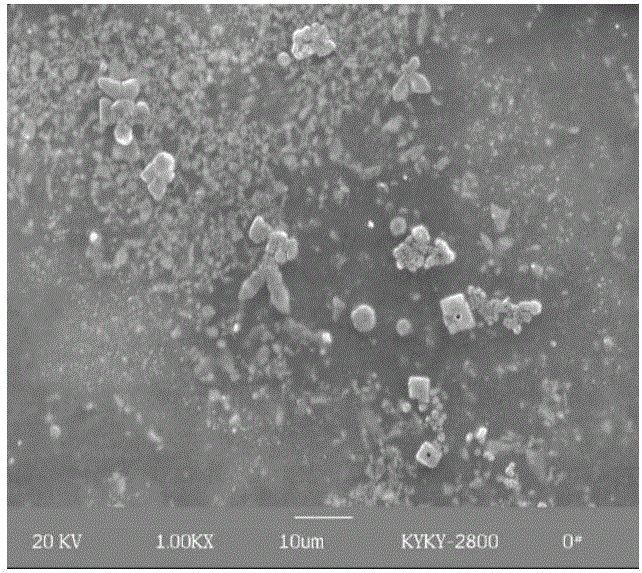

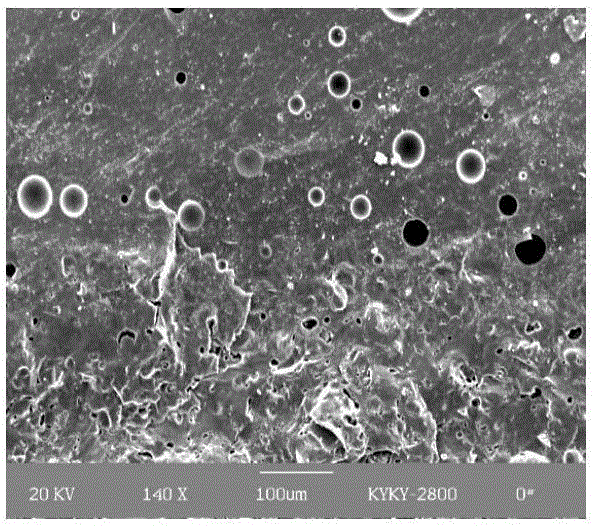

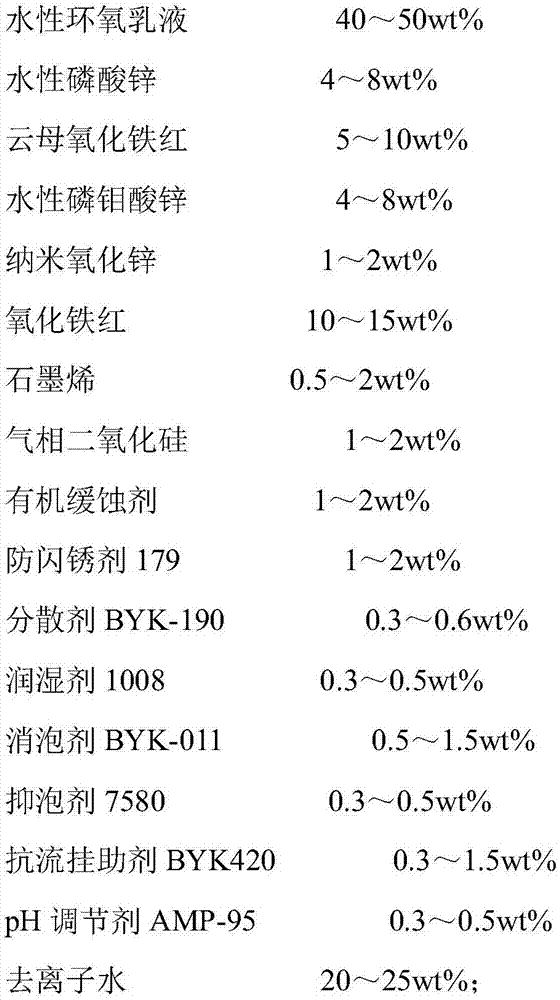

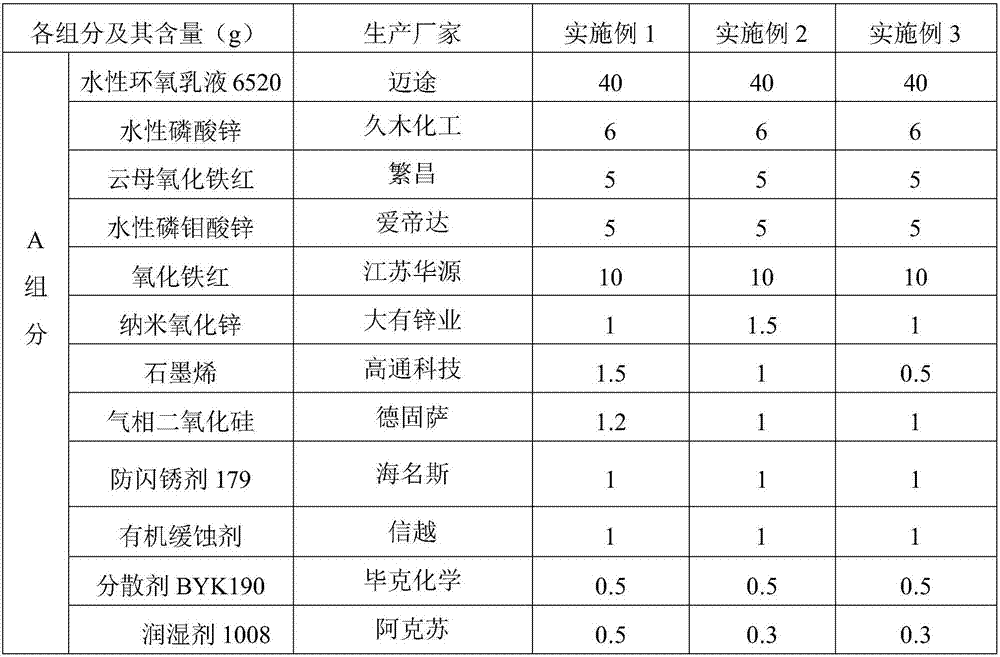

Graphene modified aqueous epoxy heavy anti-corrosion coating and detection method thereof

InactiveCN107400442AChemically stableFirm textureAnti-corrosive paintsEpoxy resin coatingsGas phaseWear resistant

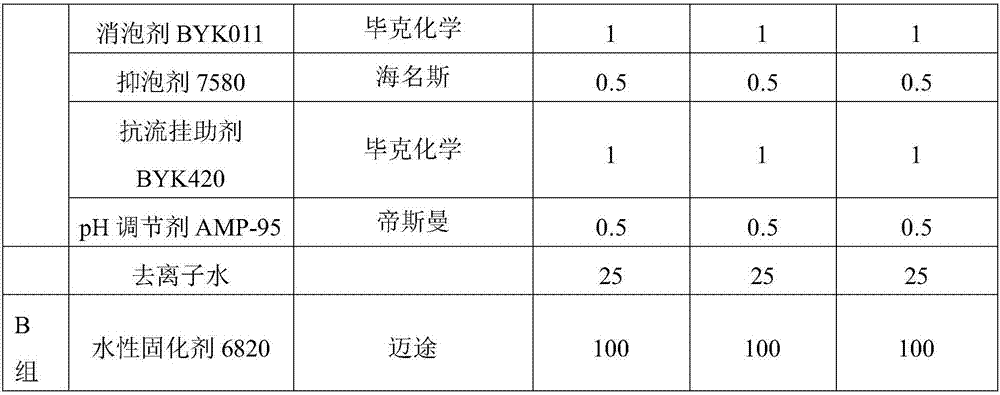

The invention discloses a graphene modified aqueous epoxy heavy anti-corrosion coating which is prepared by mixing a component A and a component B in a weight ratio of 4:1, wherein the component A comprises 40-50 parts of a bisphenol A aqueous epoxy emulsion, 0.5-2 parts of graphene, 4-8 parts of aqueous zinc phosphate, 4-8 parts of aqueous zinc molybdate, 10-15 parts of iron oxide red, 1-2 parts of fumed silica, 1-2 parts of nano zinc oxide, 5-10 parts of mica iron oxide red, 1-2 parts of an organic corrosion inhibitor, 1-2 parts of a 179 anti-flash rust agent, 0.3-0.6 part of a 190 dispersant, 0.3-0.5 part of a 1008 wetting agent, 0.5-1.5 parts of a BYK-011 defoamer, 0.3-0.5 part of a 7580 foam inhibitor, 0.1-1.5 parts of a BYK420 anti-sagging auxiliary agent, 0.3-0.5 part of an AMP-95 pH regulator and some deionized water; the component B is a polyamine addition product aqueous epoxy curing agent. The coating disclosed by the invention has excellent physical property and excellent chemical resistance, in particular salt fog resistance; a film with the coating is firm and tenacious and wear-resistant, is high in adhesive force and construction adaptability and has very good environment-friendliness.

Owner:江苏纽克莱涂料有限公司

High-impact-resistant polypropylene composite material for bumpers of automobiles and method for manufacturing polypropylene composite material

The invention discloses a high-impact-resistant polyethylene composite material for bumpers of automobiles and a method for manufacturing the high-impact-resistant polyethylene composite material. The high-impact-resistant polyethylene composite material comprises, by weight, 90-110 parts of polyethylene, 15-25 parts of polyethylene glycol terephthalate-1, 4-cyclohexanedimethanol terephthalate, 5-7 parts of bi-12-carbon alcohol ester, 7-9 parts of liquid nitrile rubber, 3-5 parts of graphene, 4-6 parts of zirconium boride, 2-3 parts of lead sulfate tribasic, 6-10 parts of zinc stearate, 6-8 parts of dipropyl maleate, 5-8 parts of thermoplastic polyurethane elastomers, 4-6 parts of rosin glycerin ester, 6-9 parts of Chinese insect wax, 9-11 parts of epoxidized soybean oil, 8-10 parts of glass fibers, 10-14 parts of gypsum whiskers, 6-9 parts of stronWiNTC, 4-6 parts of zinc molybdate, 7-9 parts of antimony trioxide and 13-15 parts of nanometer diamond. The high-impact-resistant polyethylene composite material and the method have the advantages that the high-impact-resistant polyethylene composite material manufactured by the aid of the method is excellent in impact-resistant performance and high in tensile strength and impact strength.

Owner:李子健

Aluminium zinc phosphomolybdate compounded rustproof pigment and production method thereof

ActiveCN101864214ANon-toxicEnvironmentally friendly and efficientAnti-corrosive paintsPhosphorus compoundsPhosphomolybdic acidZinc phosphate

The invention provides an aluminium zinc phosphomolybdate compounded rustproof pigment which takes aluminium zinc phosphate, zinc molybdate, aluminium phosphate and the like as main raw materials to synthesise aluminium zinc phosphomolybdate compounded rustproof pigment. The rustproof pigment is prepared from the following raw materials in parts by weight: 50-75 parts of aluminium zinc phosphomolybdate, 10-20 parts of aluminium phosphate, 3-10 parts of zinc oxide, 1-8 parts of barium sulphate, 0.5-5 parts of zinc molybdate and 0.1-0.5 part of accessory ingredient. The preparation method comprises the following steps: (1) after a certain quantity of water is added into an agitated reactor, successively adding the aluminium zinc phosphate, aluminium phosphate and zinc molybdate into an agitated reactor under the condition of stirring, stirring at the temperature of 50-100 DEG C; (2) fully stirring the materials with barium sulfate and zinc oxide, and carrying out modified treatment; (3) cooling the materials to be below 50 DEG C, and adding the accessory ingredient to carry out surface treatment; and (4) carrying out centrifugal dehydration, drying, smashing, weighting and packaging into products. The invention has the characteristics of no toxin, environment protection and high efficiency of the rustproof pigment and can completely replace the traditional toxic heavy metal rustproof pigment, such as red lead, zinc chrome and the like in the industrial pigment.

Owner:GUANGXI XINJING TECH

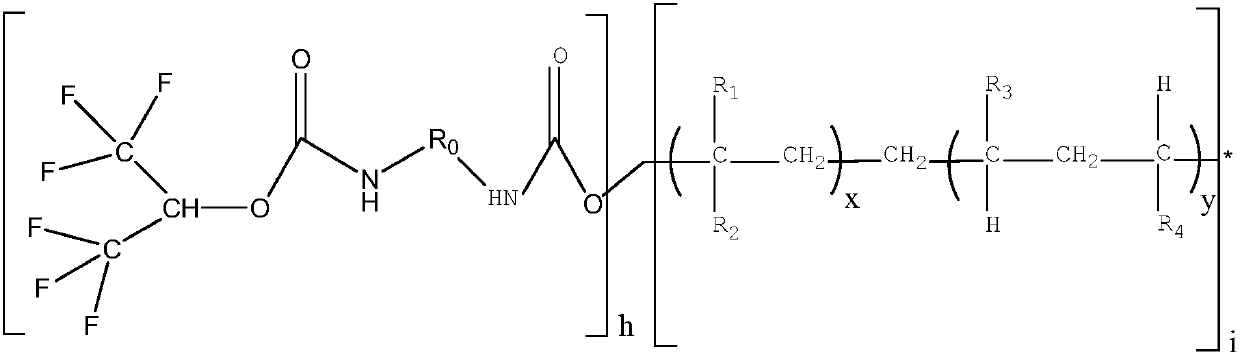

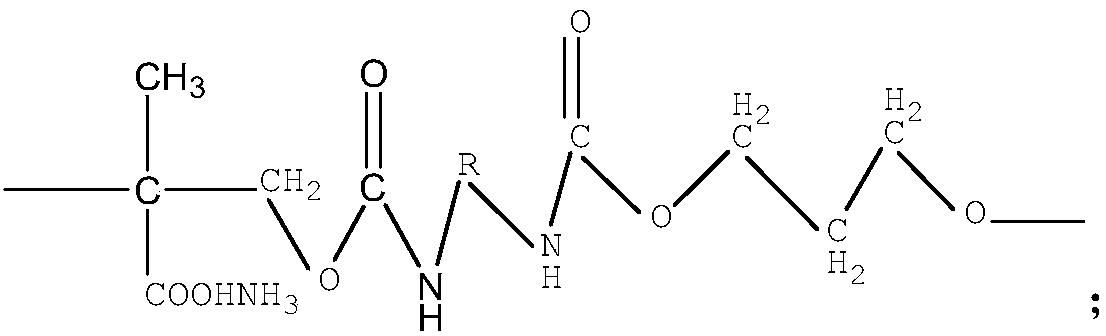

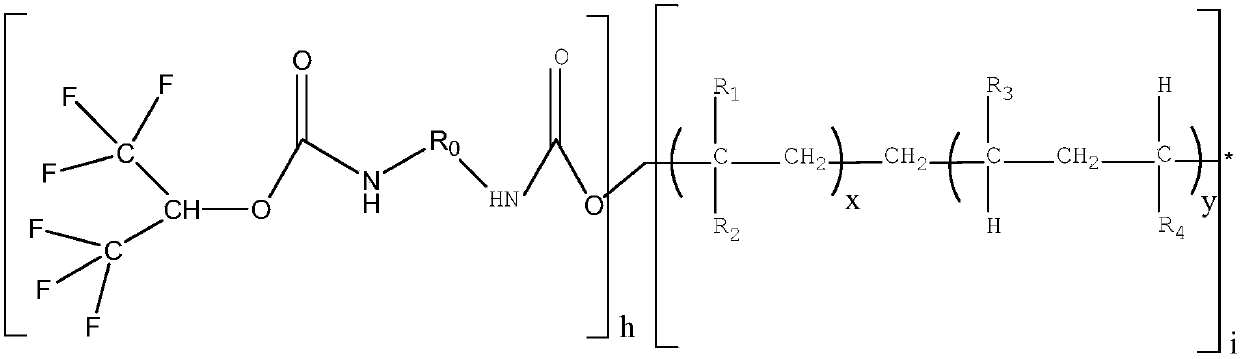

Fluoropolymer water-based anticorrosive paint

ActiveCN107779036AGood flexibilityImprove thermal stabilityFireproof paintsAntifouling/underwater paintsWater basedPolymer science

The invention relates to fluoropolymer water-based anticorrosive paint. The fluoropolymer water-based anticorrosive paint comprises fluoropolymer water-based resin, zinc dinitrobenzoate, zinc phosphate, zinc molybdate, zinc aluminum phosphate hydrate, cosolvent, anti-flash-rust agent, assistants and deionized water. The fluoropolymer water-based resin is obtained through reaction among polyisocyanate, polyalcohol, hexafluoroisopropanol, oligomer polyalcohol, dimethylolpropionic acid, hydroxyethyl acrylate, acrylic acid type soft-hard monomers and neutralizers. Since the obtained fluoropolymerwater-based anticorrosive paint comprises low-surface-free-energy F-C chains, coatings have high flexibility, heat stability, ageing resistance, chemical inertness, hydrophobicity and corrosion resistance; the fluoropolymer water-based anticorrosive paint is widely applied to water, contamination and corrosion resistance of surfaces of steel structures and concrete in the fields of buildings, chemical engineering, petroleum, electricity, metallurgy, ships, transportation, spaceflight and the like.

Owner:GUANGZHOU JOINTAS CHEM

Zinc phosphomolybdate flame retarding and smoke suppressing PVC sheet material

InactiveCN107286494APromote cross-linking into charReduce generationPhosphorus compoundsPlasticizerPhosphate

The invention discloses a zinc phosphomolybdate flame retarding and smoke suppressing PVC sheet material which is prepared from the following components in parts by weight: 100 parts of PVC resin, 4 to 5 parts of a heat stabilizer, 5 to 20 parts of a plasticizer, 3 to 7 parts of a flame retarding and smoke suppressing agent, 0.5 to 3 parts of a phosphate coupling agent and 0.4 to 0.6 part of PE wax. According to the PVC sheet material, by the flame retarding action of phosphorus and the smoke suppressing action of molybdenum and zinc, the synergistic effect of phosphorus, molybdenum and zinc can effectively improve the flame retarding and smoke suppressing performance of the PVC sheet material.

Special fertilizer for planting of high-quality broccoli

InactiveCN105949007ARich in nutrientsPromote growth and developmentMagnesium fertilisersAnimal corpse fertilisersEcological environmentManganese

The invention discloses a special fertilizer for planting of high-quality broccoli. The special fertilizer is prepared from the following materials: celery leaves, radish peels, fern roots, fungi residues, cow manure, chicken manure, radix patriniae heterophylla, mint leaves, rhizoma atractylodis, turtle shells, modified corncobs, urea, boric acid, fulvic acid potassium, sodium selenite, ammonium phosphate, ammonium chloride, ferrous sulfate, magnesium sulfate, manganese sulfate, sodium molybdate and zinc molybdate. All compositions of the fertilizer cooperate with one another and have a synergistic effect, so that rich and reasonable nutrient substances are provided for the growth of the broccoli, and the ecological environment of soil is improved and protected; meanwhile, common wastes are efficiently reutilized; finally, the yield of the finally-cultivated broccoli is improved by above 30 percent, the content of flavonoids in the cultivated broccoli is improved by 70-80 percent, the content of iron and magnesium elements is improved by 20-25 percent, and the content of iodine and zinc elements is improved by 15-20 percent, therefore, the special fertilizer has a good edible value.

Owner:固镇县华丰蔬菜专业合作社

Passivation antibacterium treatment technology for surface of grinding roll of corn flour mill

InactiveCN105887070AImprove compactnessImprove physical and chemical propertiesMetallic material coating processesPhytic acidDimethyl siloxane

The invention discloses a passivation antibacterium treatment technology for the surface of a grinding roll of a corn flour mill. The passivation antibacterium treatment technology comprises the steps of (1) surface polishing; (2) deoiling treatment; (3) cleaning treatment; (4) passivation treatment; and (5) cleaning and drying. According to the passivation antibacterium treatment technology, under the action of a film coalescing aid composed of hydroxypropyl methyl cellulose, tributyl phosphate, calcium glycerophosphate, methacrylate modified 1,2-polybutadiene resin, polydimethylsiloxane and triethanolamine borate, phytic acid, citric acid, tartaric acid, potassium molybdate, zinc molybdate, calcium molybdate, nano silica and modified nano diatomite react with iron on the surface of the grinding roll while exerting a chelating connection function, and a uniform and compact meshy composite molecular film is formed, so that the hardness, toughness, abrasion resistance and corrosion resistance of the grinding roll are improved, the grinding roll has relatively high insect resistance and antibacterial performance, and the safety of food processing is guaranteed; and through the auxiliary function of ultrasonic, the service life of the finally prepared grinding roll is prolonged by 3 to 4 times.

Owner:WUHE HUANGHUAI GRAIN & OIL MACHINERY CO LTD

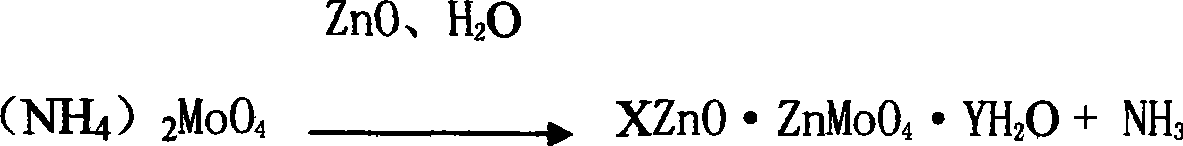

Method for synthesis of zinc molybdate or alkali type zinc molybdate

ActiveCN101367553AThe synthesis method is simpleNo side effectsMolybdeum compoundsReaction temperatureAmmonia gas

The invention provides method for synthesizing the zinc molybdate or the basic zinc molybdate adopting the industrial zinc oxide and the ammonium molybdate as the raw materials through controlling different mole ratio between the zinc and the molybdenum. When the mole ratio between the zinc and the molybdenum is 0 to 1: 1, zinc molybdate can be obtained through the method; when the mol ratio of Zn / Mo more than 1:1, the basic zinc molybdate is obtained; the reaction temperature is 40 to 100 DEG C, and the reaction time is 0.5 to 12 hours, and the ammonia gas that is generated in the reaction is absorbed by the water for use; the mother solution that is centrifugally separated is used as the reacted zinc molybdate solution to be cycled for use. The content of the zinc molybdate that is synthesized with the method can reach 99 percent, and the content of the basic zinc molybdate can be more than 95 percent.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

Rare earth cerium-containing metal treatment fluid and production method thereof

InactiveCN102433559AHigh activityImprove bindingMetallic material coating processesRare-earth elementSilanes

The invention discloses a rare earth cerium-containing metal treatment fluid and a production method thereof. The rare earth cerium-containing metal treatment fluid is characterized by consisting of 0.5 to 2 parts of fluorozirconic acid, 1.5 to 3.5 parts of zinc molybdate, 0.2 to 1 part of sodium nitrate, 0.04 to 0.06 part of ethylene diamine tetraacetic acid, 0.4 to 0.6 part of sodium fluoride, 0.2 to 0.8 part of lanthanum nitrate and 100 parts of water. A ceramic technology is adopted, and after the metal surface treatment fluid is coated, sprayed or deposited on the surface of metal, a zirconium oxide ceramic film can be formed on the surface of the metal, and the activity of the zirconium oxide ceramic film formed on the surface of the metal is greatly improved under the action of a rare earth element of cerous nitrate; compared with the similar ceramic technology, the production method has the advantages that: the surface of the zirconium oxide ceramic film has higher activity, and the formed zirconium oxide ceramic film can be well bonded with the surface of the metal and also can be well bonded with a subsequent film required to be coated; and compared with a silane technology, the production method has a wider application range and high adaptability.

Owner:宁波科苑鑫泰表面处理新技术有限公司

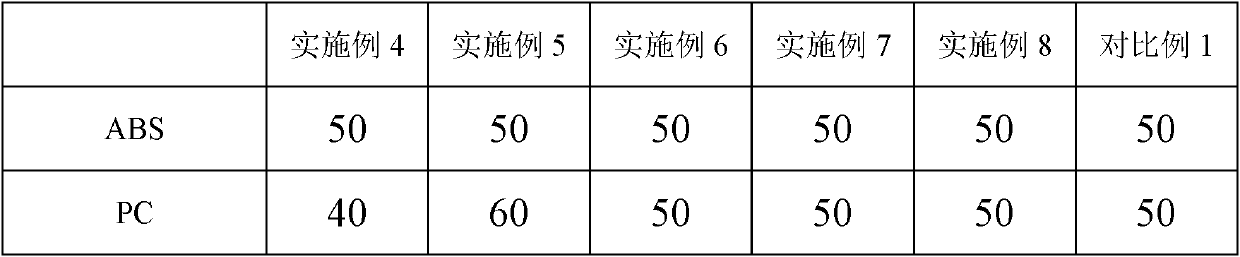

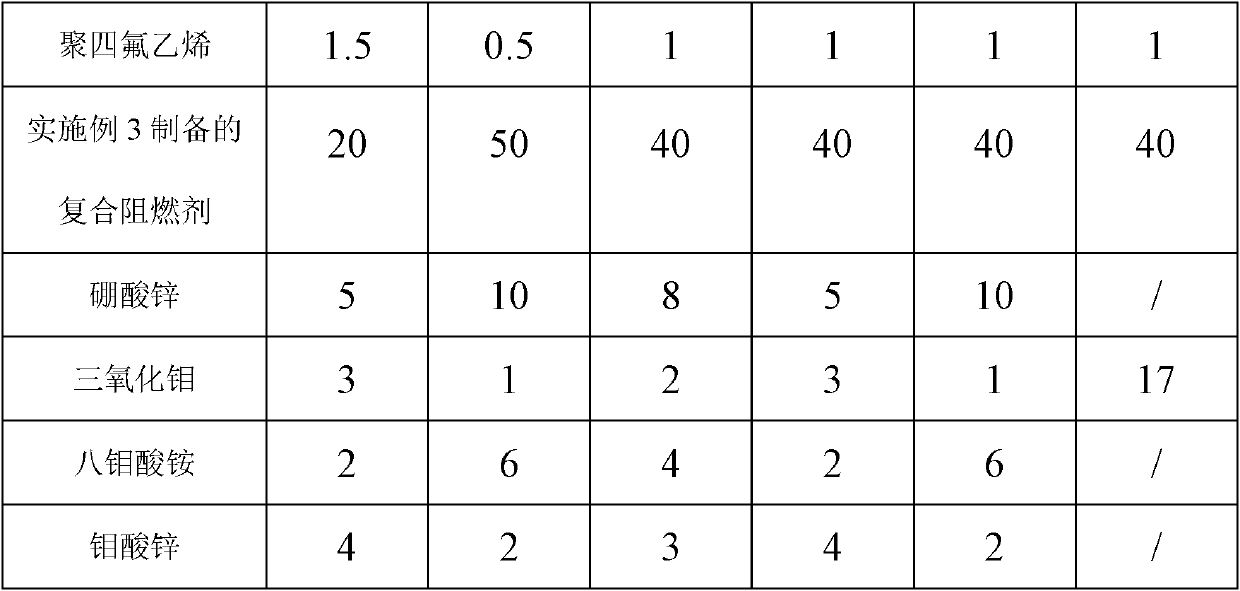

Low-smoke-density PC/ABS (Poly Carbonate/Acrylonitrile Butadiene Styrene) plastic for automobile interior and preparation method thereof

The invention discloses low-smoke-density PC / ABS (Poly Carbonate / Acrylonitrile Butadiene Styrene) plastic for an automobile interior and a preparation method thereof. The low-smoke-density PC / ABS plastic for the automobile interior comprises the following components in parts by weight: 50 parts of ABS resin, 40-60 parts of PC resin, 0.5-1.5 parts of polyfluortetraethylene, 5-10 parts of zinc borate, 1-3 parts of molybdenum trioxide, 2-6 parts of ammonium octamolybdate and 2-4 parts of zinc molybdate. The low-smoke-density PC / ABS plastic has excellent flame retardancy, particularly has lower smoke density, is used for suppressing smoke efficiently, and has excellent comprehensive performance. The low-smoke-density PC / ABS plastic for the automobile interior disclosed by the invention is particularly suitable for being molded into various automobile interiors by injecting.

Owner:扬州诚森塑胶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com