Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

635 results about "Colloidal Silicon Dioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the pharmaceutical industry, silicon dioxide (also known as colloidal silicon dioxide) has many uses in tablet-making: some include as an anti-caking agent, adsorbent, disintegrant, or glidant to allow powder to flow freely when tablets are processed. These compounds appear to be biologically inert.

Pharmaceutical excipient having improved compressibility

InactiveUS6103219AImprove compression performanceReduce the amount requiredCosmetic preparationsPowder deliverySilica particleColloid

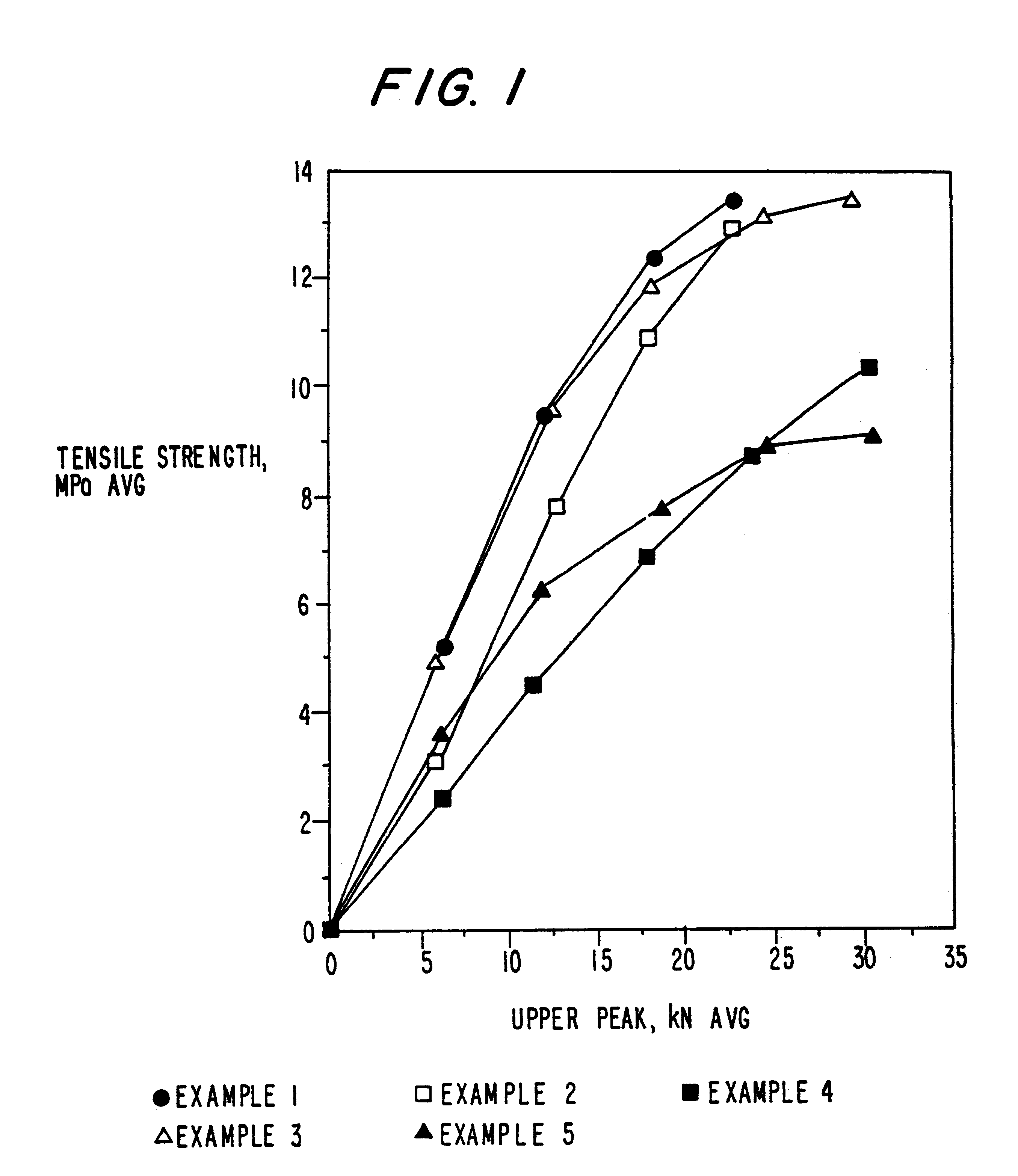

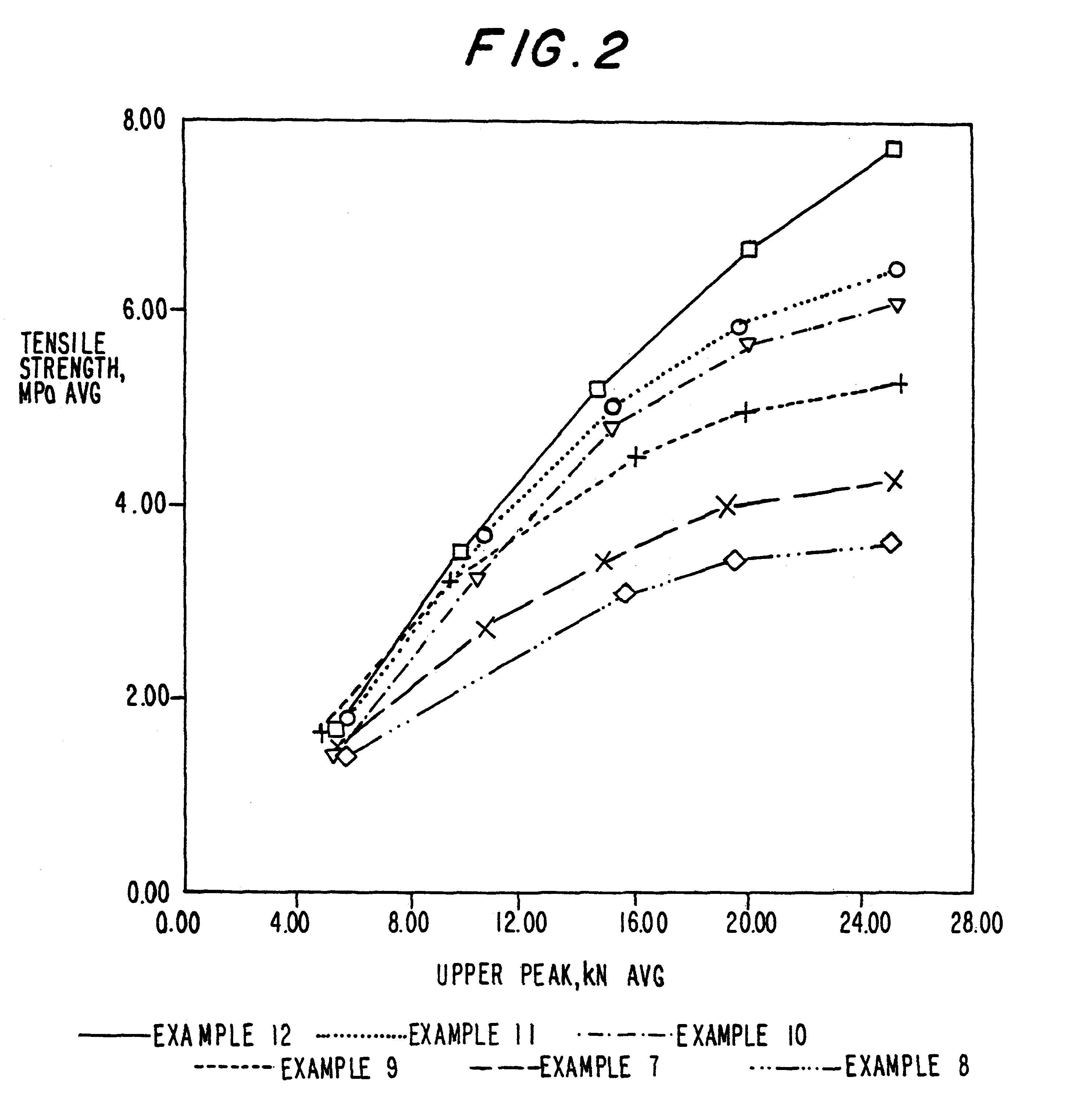

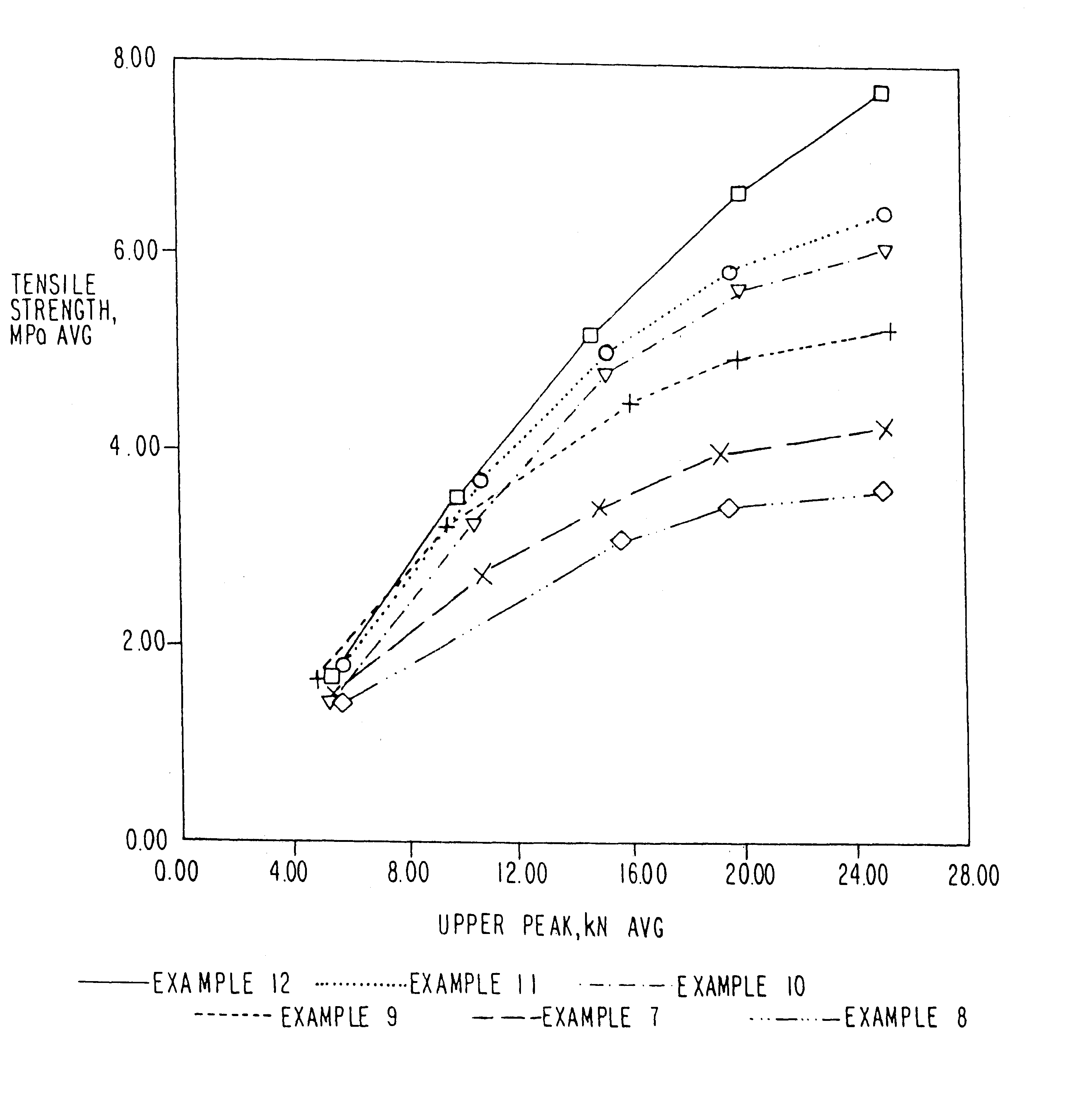

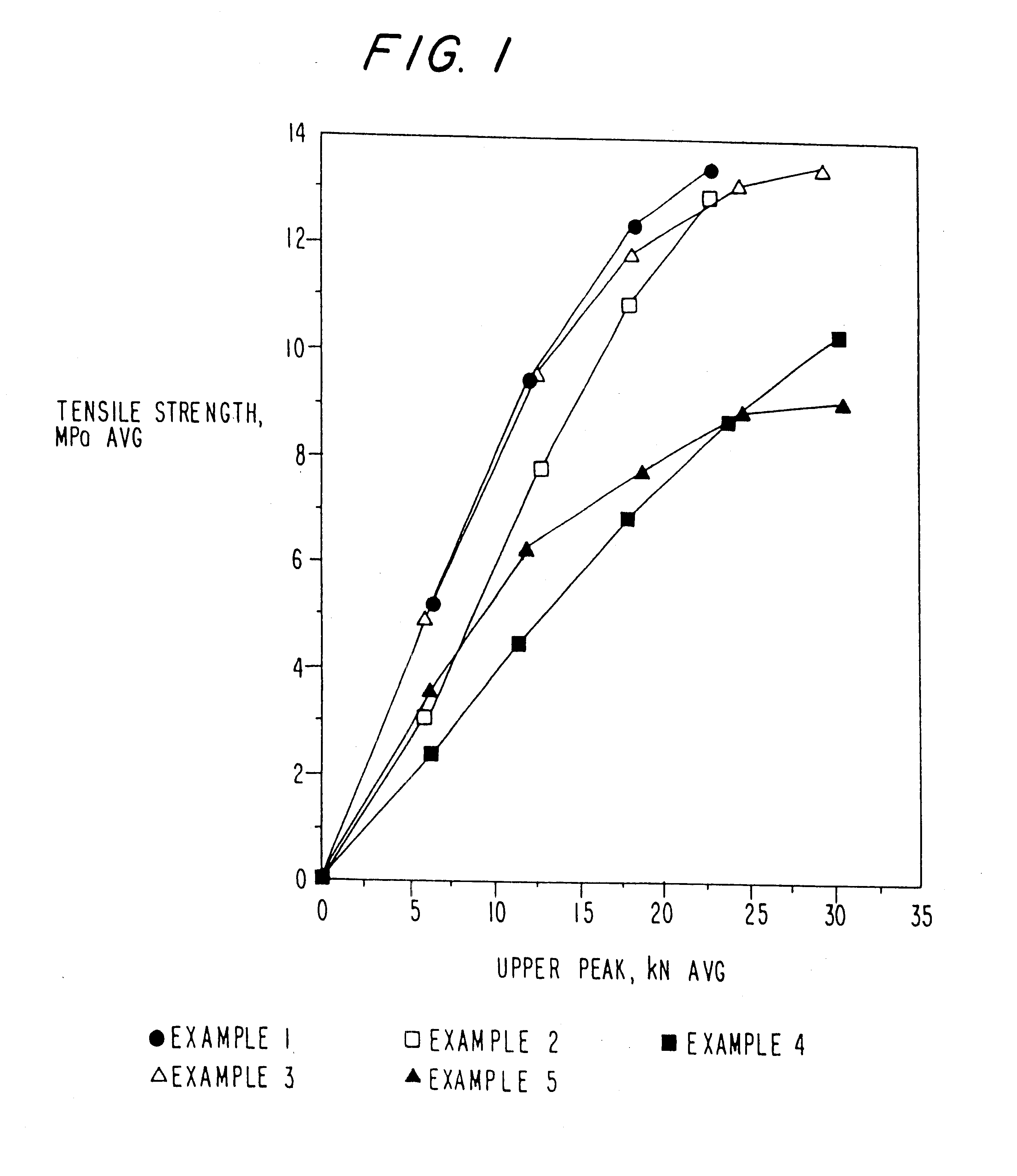

A microcrystalline cellulose-based excipient having improved compressibility, whether utilized in direct compression, dry granulation or wet granulation formulations, is disclosed. The excipient is an agglomerate of microcrystalline cellulose particles and from about 0.1% to about 20% silicon dioxide particles, by weight of the microcrystalline cellulose, wherein the microcrystalline cellulose and silicon dioxide are in intimate association with each other. The silicon dioxide utilized in the novel excipient has a particle size from about 1 nanometer to about 100 microns. Most preferably, the silicon dioxide is a grade of colloidal silicon dioxide.

Owner:J RETTENMAIER & SOEHNE GMBH CO KG ROSENBERG

Pharmaceutical excipient having improved compressibility

InactiveUS6217909B1Improve compression performanceReduce the amount requiredInorganic/elemental detergent compounding agentsPowder deliverySilica particleSilicon dioxide

Owner:J RETTENMAIER & SOEHNE GMBH CO KG ROSENBERG

Thermal protective coating for ceramic surfaces

ActiveUS20050051057A1Extend working lifeReduce surface temperatureFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

Composition and method for polishing a sapphire surface

InactiveUS20060196849A1Simple compositionImprove methodOther chemical processesDecorative surface effectsColloidal silicaSlurry

An improved composition and method for polishing a sapphire surface is disclosed. The method comprises abrading a sapphire surface, such as a C-plane or R-plane surface of a sapphire wafer, with a polishing slurry comprising an abrasive amount of an inorganic abrasive material such as colloidal silica suspended in an aqueous medium having a salt compound dissolved therein. The aqueous medium has a basic pH and includes the salt compound in an amount sufficient to enhance the sapphire removal rate relative to the rate achievable under the same polishing conditions using a the same inorganic abrasive in the absence of the salt compound.

Owner:CABOT MICROELECTRONICS CORP

Pharmaceutical excipient having improved compressibility

InactiveUS6471994B1Improve compression performanceGood disintegrationPowder deliveryNanotechSilica particleCompressibility

A microcrystalline cellulose-based excipient having improved compressibility, whether utilized in direct compression, dry granulation or wet granulation formulations, is disclosed. The excipient is an agglomerate of microcrystalline cellulose particles and from about 0.1% to about 20% silicon dioxide particles, by weight of microcrystalline cellulose, wherein the microcrystalline cellulose and silicon dioxide are in intimate association with each other. The silicon dioxide utilized in the novel excipient has a particle size from about 1 nanometer to about 100 microns. Most preferably, the silicon dioxide is a grade of colloidal silicon dioxide. An extra low moisture excipient is provided which exhibits improved compressibility as compared to conventional microcrystalline cellulose, while providing a moisture content of from about 0.5 to 2.5% LOD, preferably between about 0.5 and about 1.8%, more preferably between 0.8 and 1.5%, and most preferably between about 0.8 and about 1.2 %.

Owner:J RETTENMAIER & SOEHNE GMBH CO KG ROSENBERG

Polishing liquid

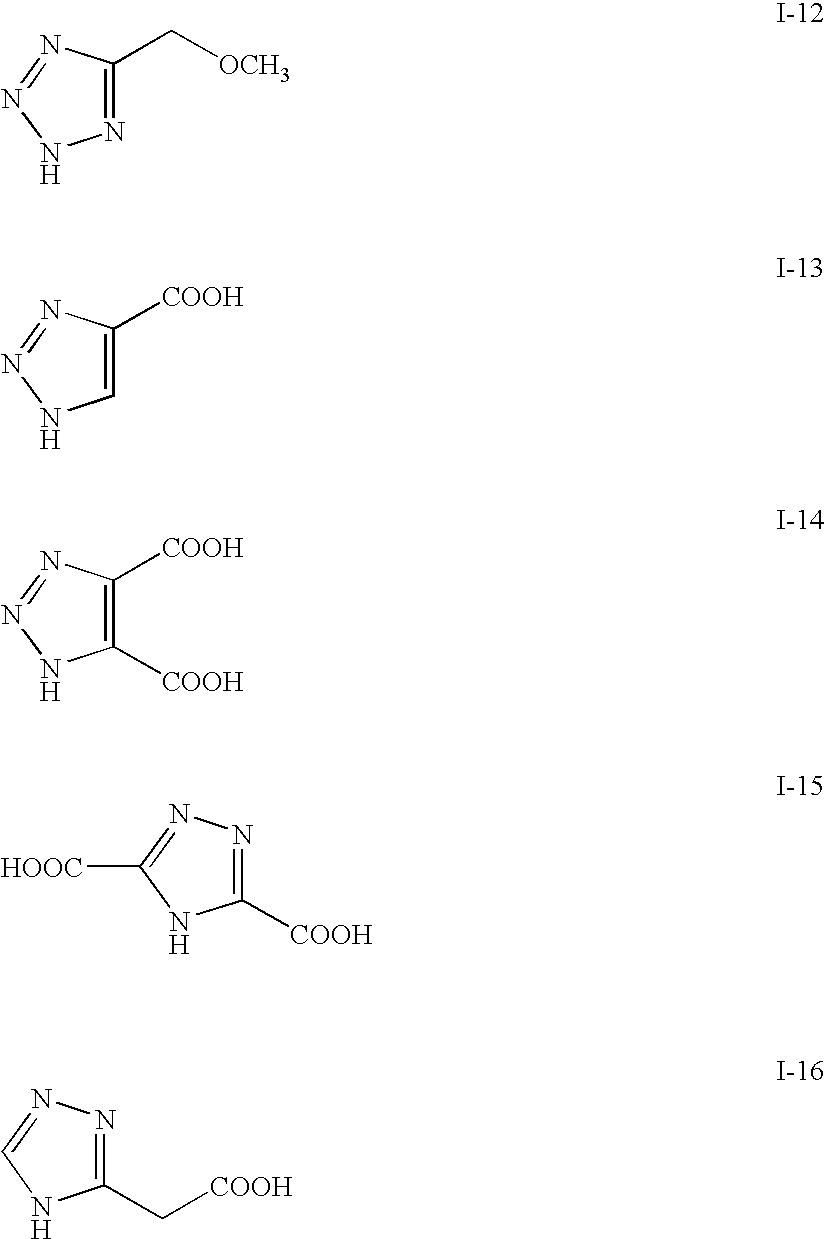

ActiveUS20100167547A1InhibitionHigh rateOther chemical processesDecorative surface effectsColloidal silicaDevice material

A polishing liquid for a chemical mechanical polishing of a semiconductor device includes (a) a carboxylic acid compound having one or more carboxy groups, (b) colloidal silica particles having a ζ potential of −10 mV to −35 mV when used in the polishing liquid, (c) a benzotriazole derivative, (d) an anionic surfactant, and (e) an oxidizing agent, and the polishing liquid has a pH of from 5.0 to 8.0.

Owner:FUJIFILM CORP

Polishing composition and polishing method

InactiveUS20050205837A1Suitable for useOther chemical processesDecorative surface effectsColloidal silicaTetramethylammonium hydroxide

A polishing composition includes silicon dioxide, an alkaline compound, an anionic surfactant, and water. The silicon dioxide is, for example, colloidal silica, fumed silica, or precipitated silica. The alkaline compound is, for example, potassium hydroxide, sodium hydroxide, ammonia, tetramethylammonium hydroxide, piperazine anhydride, or piperazine hexahydrate. The anionic surfactant is at least one selected from a sulfonic acid surfactant, a carboxylic acid surfactant, and a sulfuric acid ester surfactant. The polishing composition can be suitably used in applications for polishing a silicon wafer.

Owner:FUJIMI INCORPORATED

Water-based coating

A water-based coating is described comprising colloidal silica and lamellar materials such as glass flakes or mica admixed with a water-based film-forming polymeric carrier such as an epoxy. The water-based epoxy coating can be directly applied to unset, set, cured or uncured concrete and exhibits a water vapor permeance of about 0.14 perms by ASTM F-1869-04. A method for using the coating is also disclosed.

Owner:CORRO SHIELD INT

Metal-polishing composition and chemical-mechanical polishing method

InactiveUS20080057716A1Other chemical processesSemiconductor/solid-state device manufacturingColloidal silicaSilicon dioxide

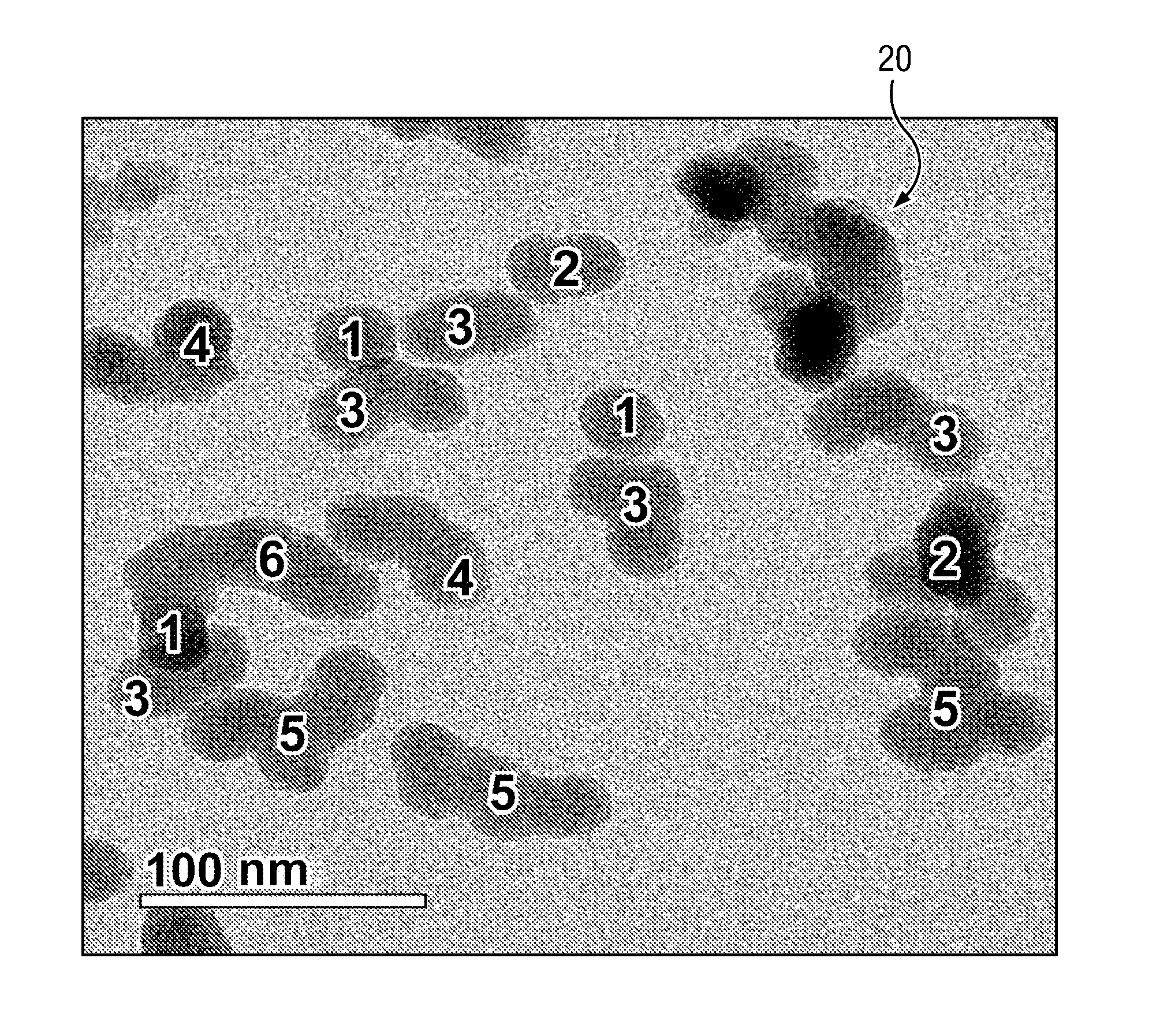

A metal-polishing composition includes colloidal silica particles, which has a ratio of minor axis / major axis of 0.2 to 0.8 and a surface at least partially covered with aluminum atoms, comprises in an amount of 50% or more with respect to total abrasives. The metal-polishing composition preferably includes an oxidizing agent, an organic acid or the like. The colloidal silica constituting the colloidal silica particles is preferably formed by hydrolysis of alkoxysilane. The major axis of the colloidal silica particles is preferably in a range of 20 nm to 100 nm.

Owner:FUJIFILM CORP

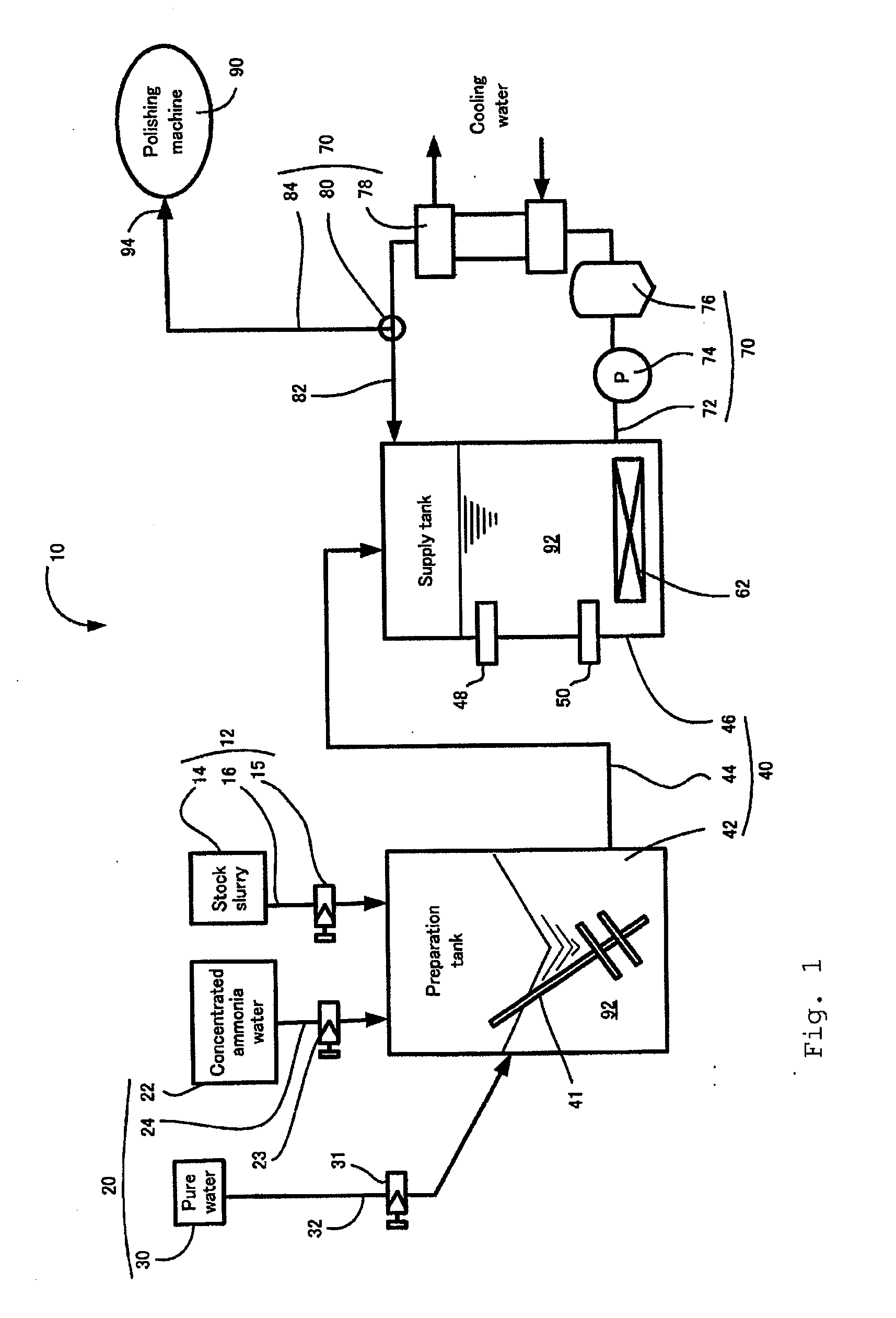

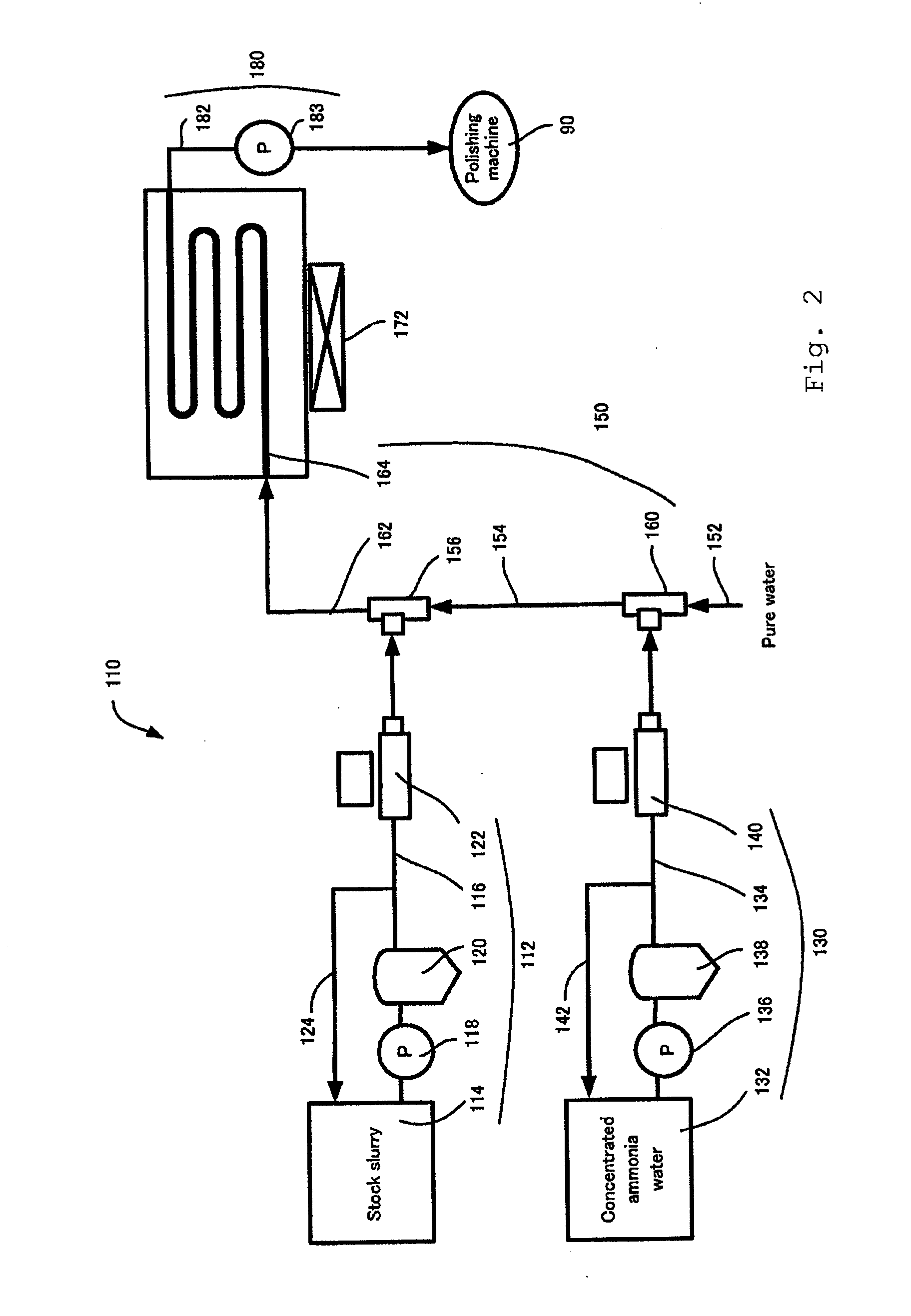

Slurry supplying apparatus and method of polishing semiconductor wafer utilizing same

ActiveUS20090298393A1Semiconductor/solid-state device manufacturingLapping machinesColloidal silicaDiluent

A diluted slurry supplying apparatus utilized in a polishing apparatus for finishing a semiconductor wafer with a slurry containing colloidal silica and water-soluble polymer is provided. The polishing method comprises: a slurry supplier capable of supplying the slurry containing the colloidal silica and the water-soluble polymer; a diluent supplier capable of supplying a diluent containing an aggregation preventing agent to dilute the slurry; a mixer capable of receiving the slurry and the diluent having been supplied from the slurry supplier and the diluent supplier, respectively, the mixer forming a diluted slurry with a pH value of at least 9; and an ultrasonic vibrator capable of applying an ultrasonic vibration to the diluted slurry staying in the mixer or being fed out from the mixer. Here, the diluent supplying apparatus can change a dilution proportion of the diluted slurry.

Owner:SUMCO TECHXIV

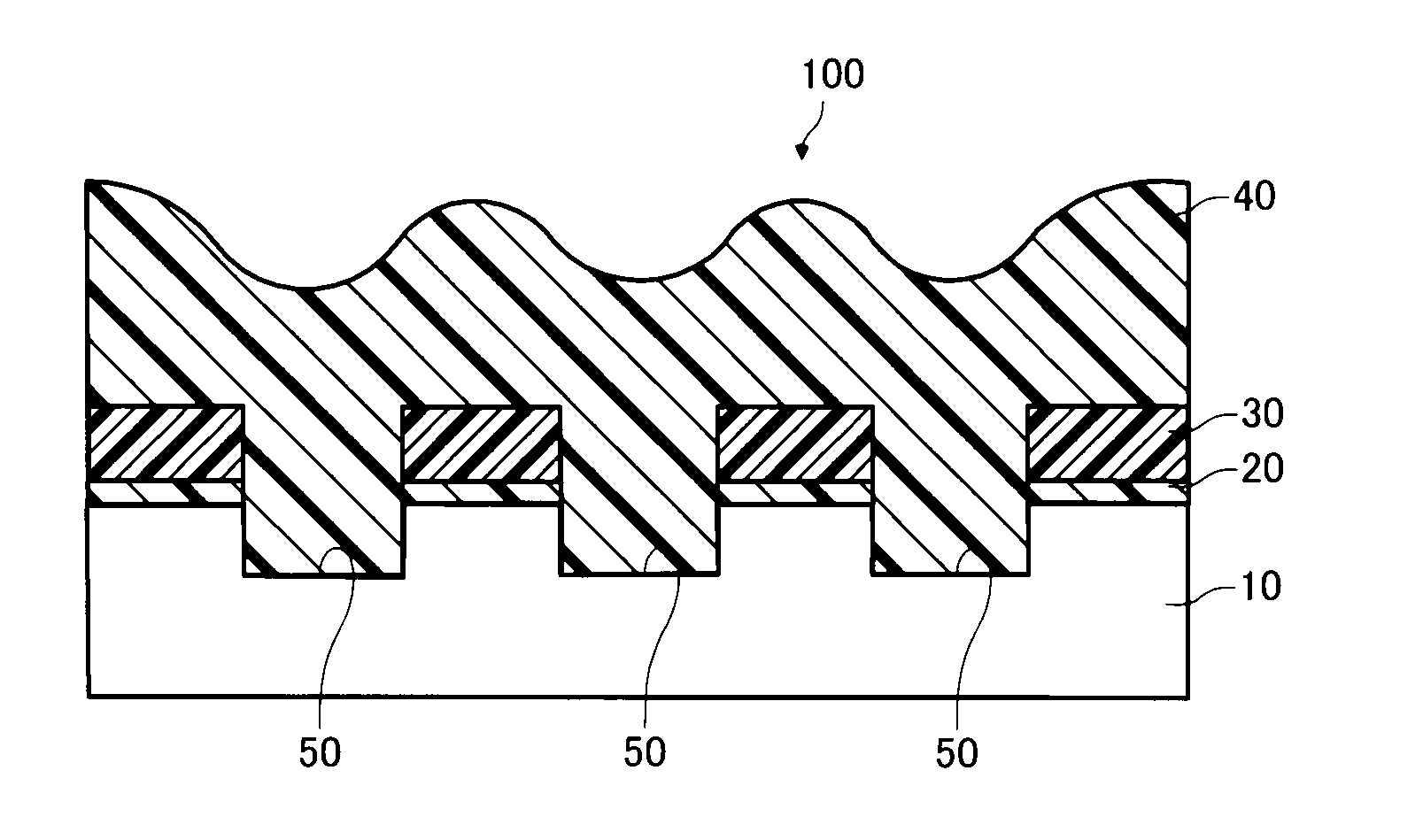

Method of making a photovoltaic device with antireflective coating containing porous silica and resulting product

InactiveUS20080185041A1Low densityReasonable durabilityPretreated surfacesCoatingsColloidal silicaAnti-reflective coating

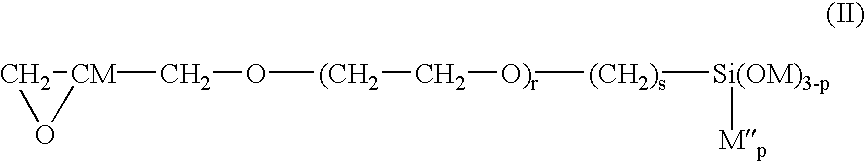

A method of making an anti-reflection coating using a sol-gel process, for use in a photovoltaic device or the like. The method may include the following steps in certain example embodiments: forming a polymeric component of silica by mixing glycycloxypropyltrimethoxysilane (or other suitable silane) with one or more of a first solvent, a catalyst, and water; forming a silica sol gel by mixing the polymeric component with a colloidal silica, optionally a second solvent, and at least one organic additive; casting the mixture by spin coating to form a porous silica based layer on a substrate; and curing and / or heat treating the layer. This layer may make up all or only part of an anti-reflection coating.

Owner:GUARDIAN GLASS LLC

Pharmaceutical excipient having improved compressibility

InactiveUS6746693B2Improve compression performanceReduce the amount requiredPowder deliveryNanotechSilica particleCompressibility

Owner:J RETTENMAIER & SOEHNE GMBH CO KG ROSENBERG

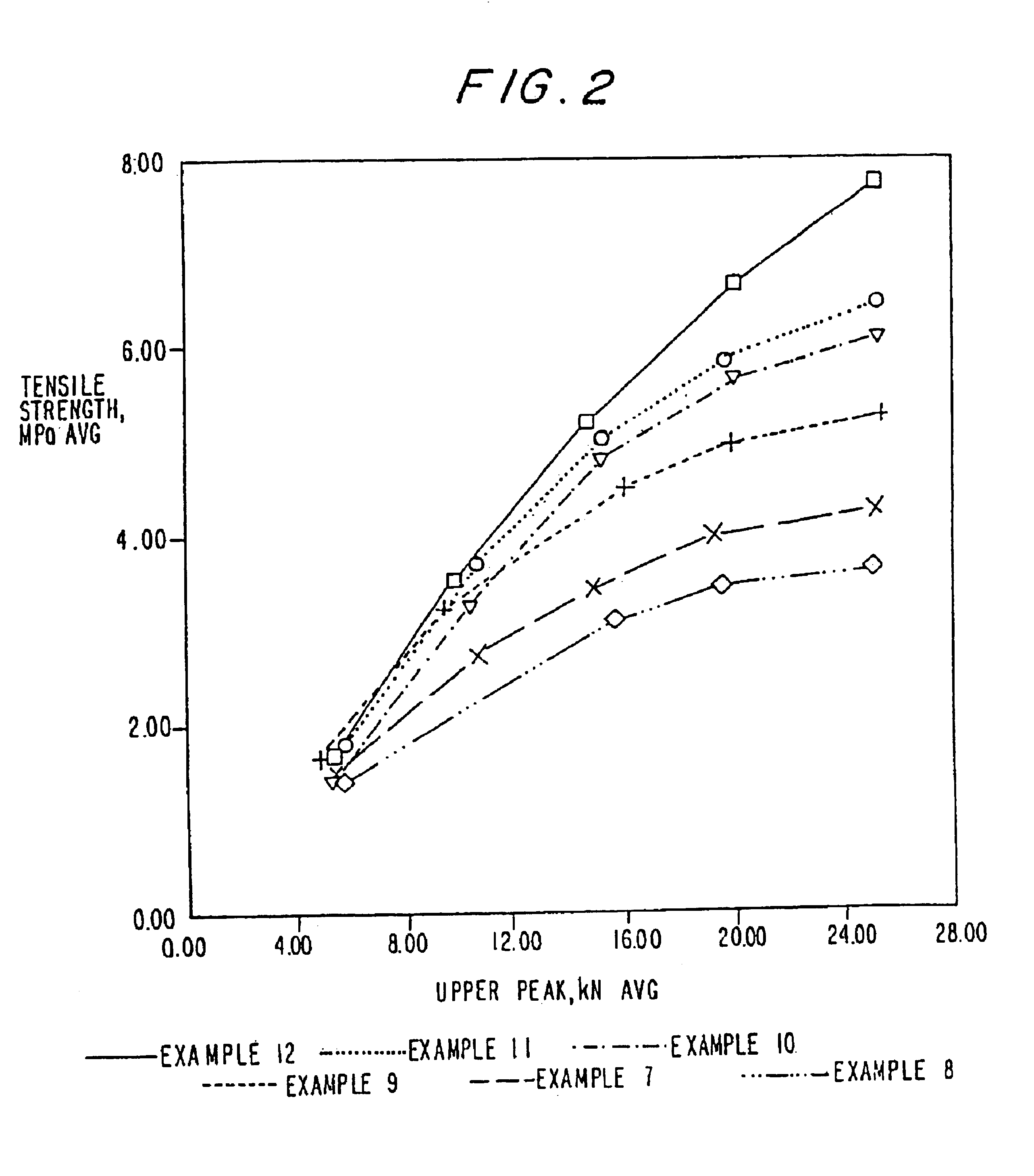

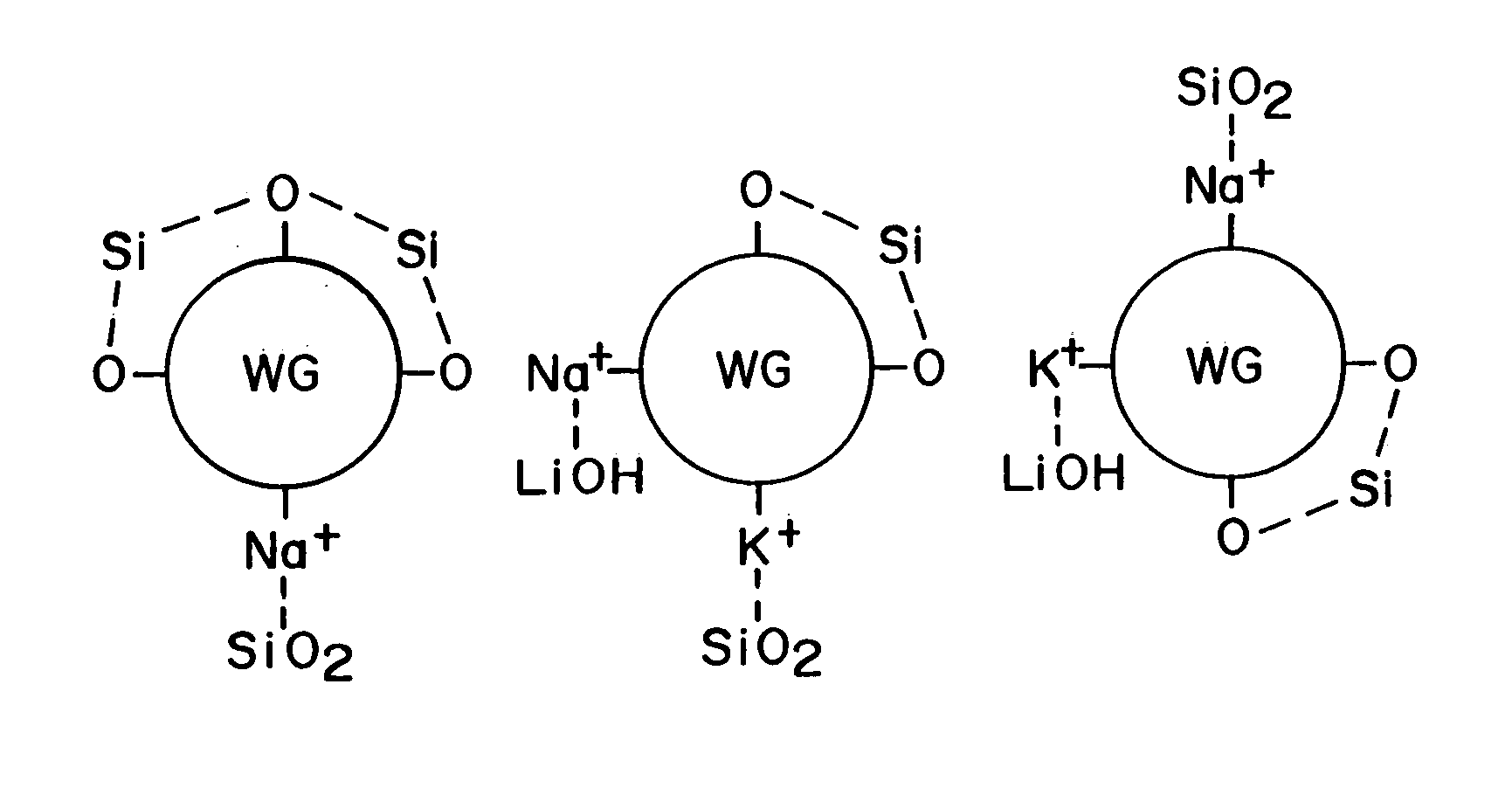

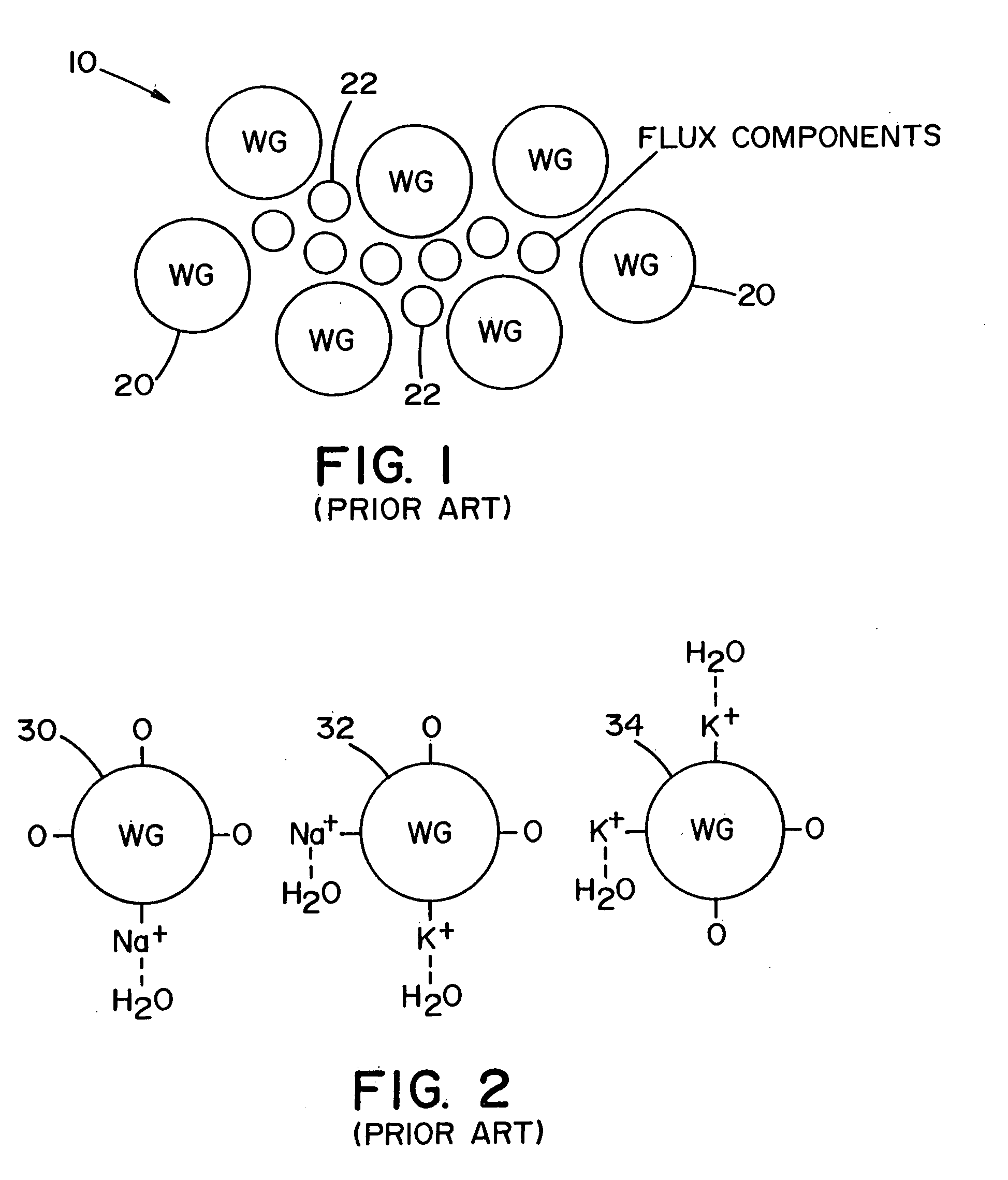

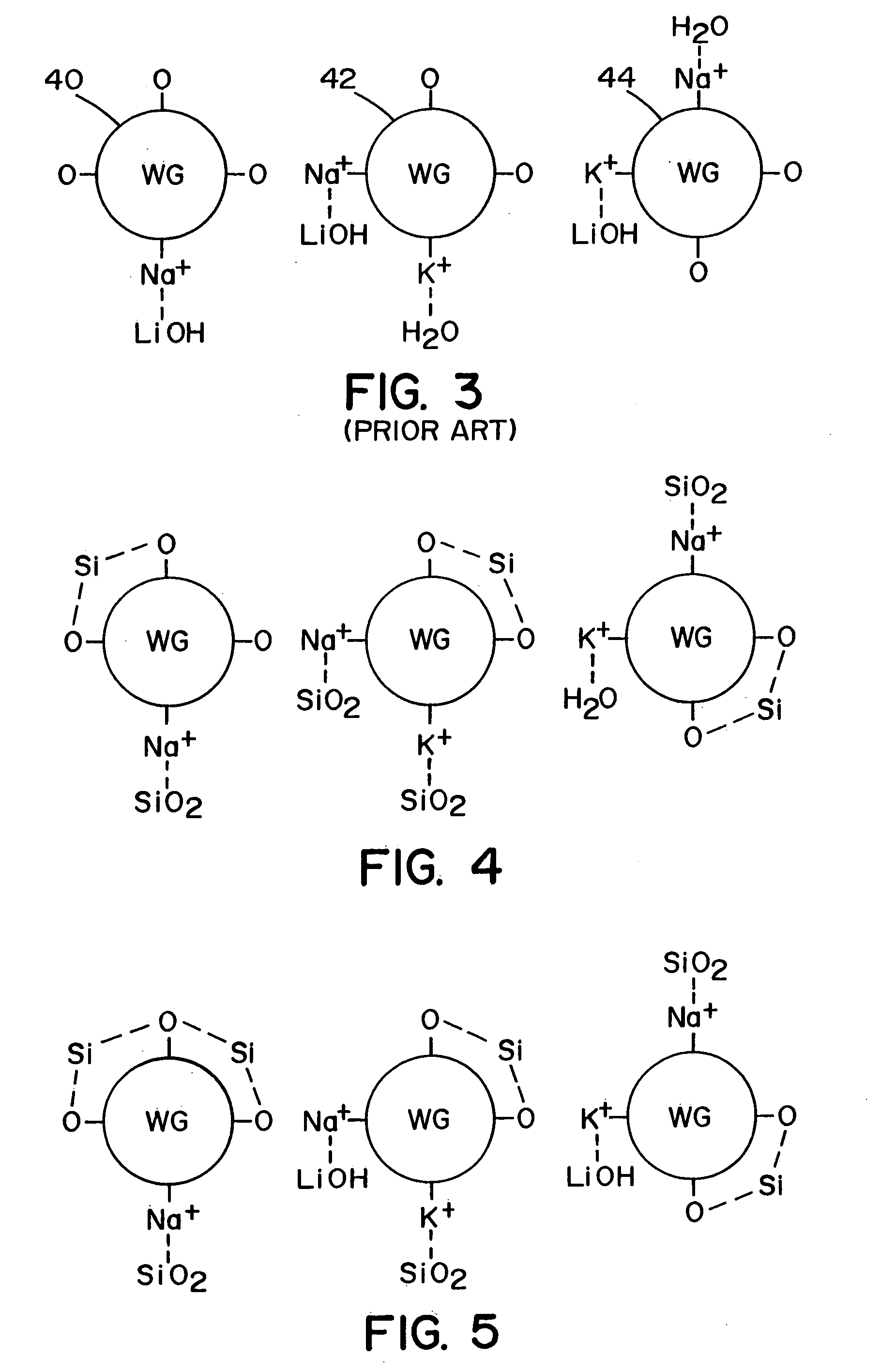

Colloidal silica binder system

InactiveUS20050121110A1Hygroscopic property is decreasedReduce dryingWelding/cutting media/materialsSoldering mediaColloidal silicaHydrogen

A welding flux that includes a flux agent, water glass and colloidal compound formed from small particles of silicon dioxide. The welding flux has a very low hygroscopicity, thus is well suited from low hydrogen electrodes.

Owner:LINCOLN GLOBAL INC

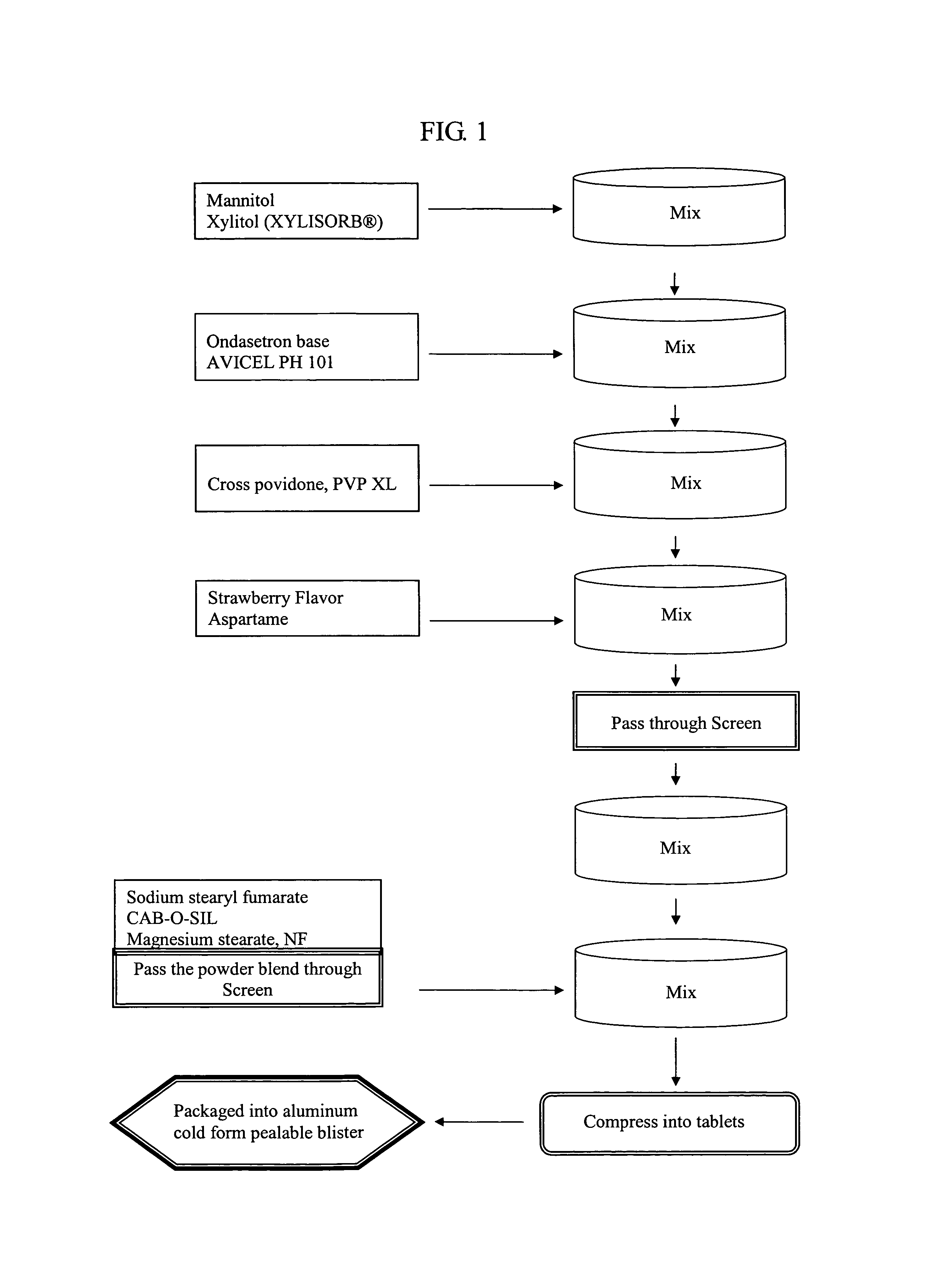

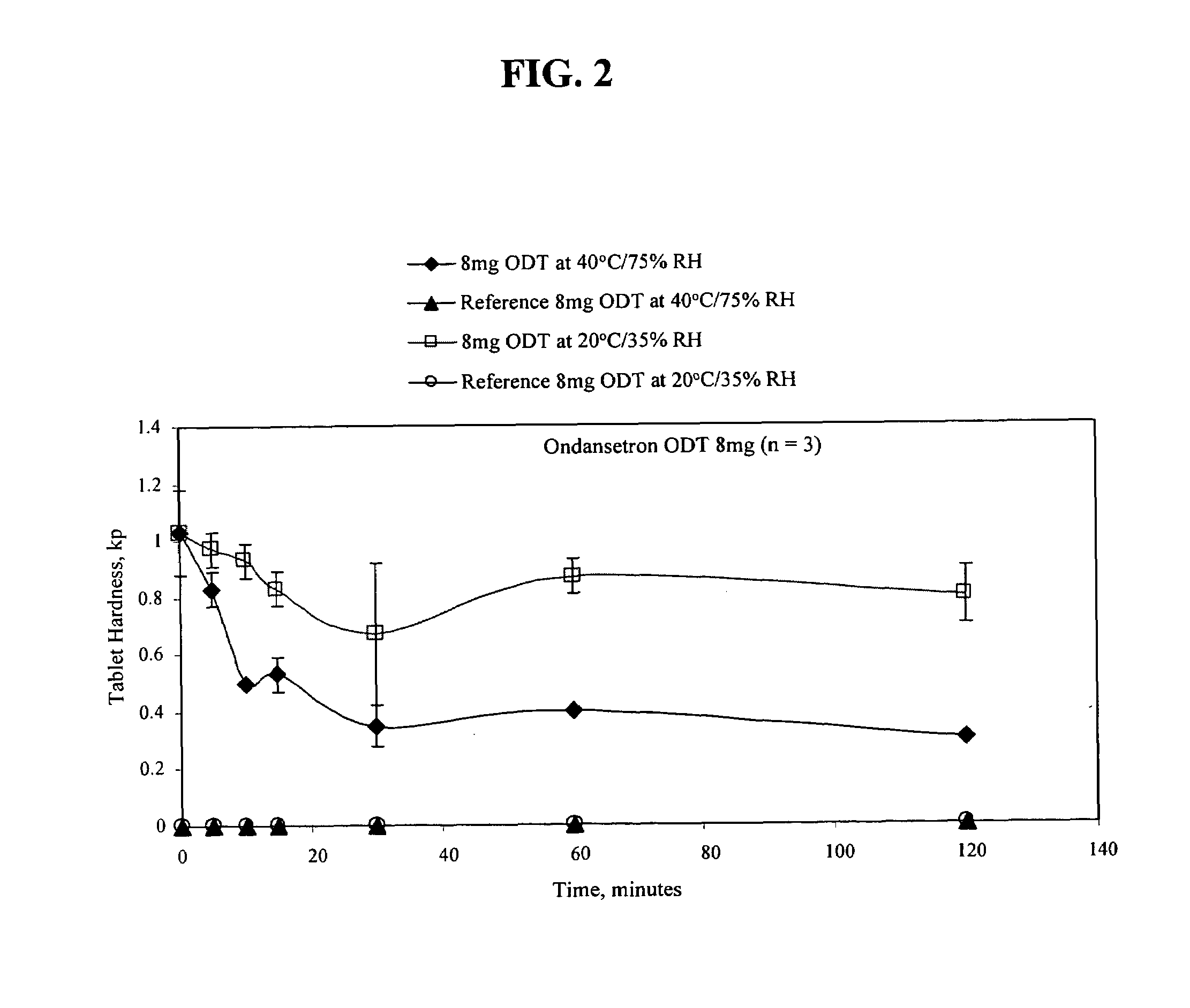

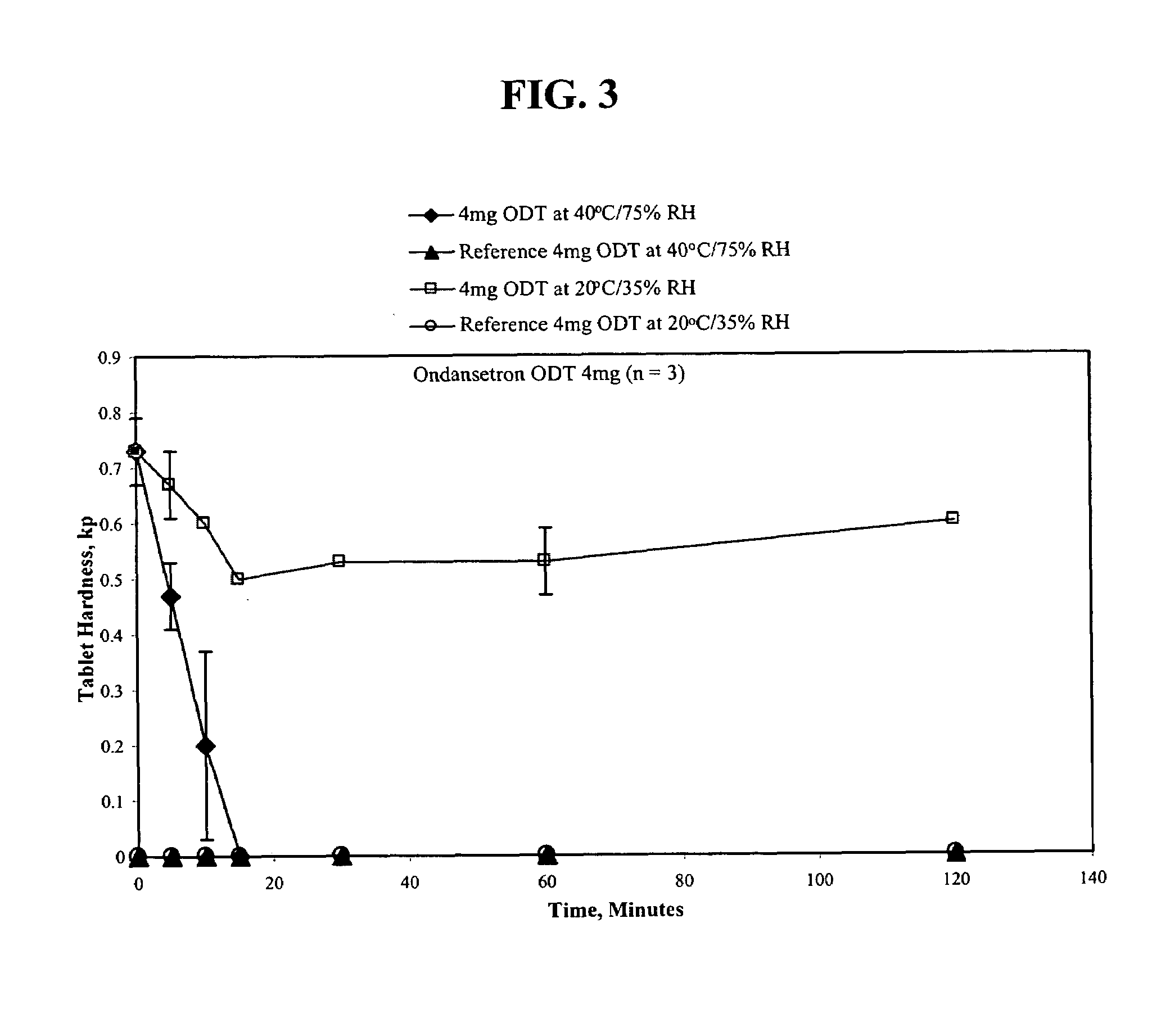

Ondansetron orally disintegrating tablets

InactiveUS7390503B1Safe and effective absorptionImprove bioavailabilityPowder deliveryPill deliveryWater dispersibleOrally disintegrating tablet

An ondansetron solid orally disintegrating dosage form for oral administration having at least one first water-dispersible component or water-insoluble cellulose derivative, a component having a —CHOH functional group, a disintegrating agent and at least one lubricant is provided. The dosage form can comprise ondansetron, a hydrophilic polymer such as microcrystalline cellulose, a component having a —CHOH functional group such as mannitol or xylitol and a disintegrating agent such as crospovidone. The lubricant may be a mixture of magnesium stearate, sodium stearyl fumarate and colloidal silicon dioxide. The present invention provides a non-effervescent tablet comprising the ondansetron dosage form. Another aspect of the invention is the treatment of emesis such as nausea and vomiting caused by cancer chemotherapy and radiation by the administration of the ondansetron formulation of the present composition. Finally, a process of forming an ondansetron disintegrating tablet using the ondansetron dosage form is disclosed.

Owner:BARR LAB

Underfill composition and packaged solid state device

ActiveUS7279223B2Synthetic resin layered productsSemiconductor/solid-state device manufacturingEpoxyColloidal silica

Owner:GENERAL ELECTRIC CO

Composition for providing a non-wettable coating, articles coated therewith, and methods for preparing the same

A heat-settable composition for a coating which is hydrophobic, oleophobic and resistant to abrasion, wherein the coating contains a hydrolyzate obtained from a solution of:one or more epoxidized alkoxysilane having alkoxy groups which are directly linked to the silicon atom;a hydrolyzable, non-epoxidized silane;colloidal silica;a catalyst which promotes cleavage of an epoxy bond; andat least one fluorinated hydrolyzable alkylsilane; and the use of the heat-settable composition in the preparation of a coated substrate of organic glass or mineral glass material, coated with a coating obtained from the heat-settable composition, with the substrate preferably being a pane (comprised of glass or a polymeric material) or an ophthalmic lens.

Owner:SAINT-GOBAIN GLASS FRANCE

Process for producing hydrophobic silica powder

InactiveUS20060112860A1Good dispersionSimple equipmentMaterial nanotechnologyPigmenting treatmentColloidal silicaAzane

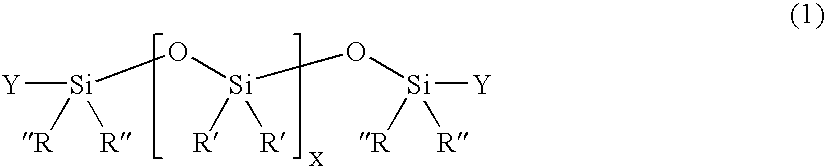

A process for producing a hydrophobic silica powder, comprises the steps for hydrophobic treatment of: adding to an aqueous silica sol containing hydrophilic colloidal silica having a specific surface area of 5.5 to 550 m2 / g, a disilazane compound represented by formula (1) (R13Si)2NH (1) wherein each R1 is C1-6alkyl group or phenyl group that is selected independently of one another, in an amount of 0.1 to 10 mmol per surface area 100 m2 of the hydrophilic colloidal silica, to obtain a first mixture of the aqueous silica sol and the disilazane compound; and heating the mixture at a temperature of 50 to 100° C. for aging it to obtain a slurry as dispersion of hydrophobic treated colloidal silica. The process provides a hydrophobic silica powder through a simple hydrophobic treatment step.

Owner:NISSAN CHEM IND LTD

Tungsten chemical-mechanical polishing composition

ActiveUS20150376462A1Other chemical processesSemiconductor/solid-state device manufacturingColloidal silicaChemical compound

A chemical-mechanical polishing composition includes colloidal silica abrasive particles having a chemical compound incorporated therein. The chemical compound may include a nitrogen-containing compound such as an aminosilane or a phosphorus-containing compound. Methods for employing such compositions include applying the composition to a semiconductor substrate to remove at least a portion of a layer.

Owner:CMC MATERIALS INC

Nano cerium oxide polishing liquid composition

The invention provides a cerium oxide polishing liquid suitable for polishing rock crystals, photomask quartz glass, semiconductor devices and glass-prepared hard disks and polishing low-dielectric-constant materials for interlayer insulating films of semiconductor devices of siloxane and the like. The polishing liquid contains surface modified nano cerium oxide, silicon dioxide, a dispersing agent, an oxidizing agent, an alkaline compound, an alcohol compound and water. Preferably, stearic acid treated nano cerium oxide is selected, the particle size is preferably 10-100 nm, and the mass content is 1-10%; preferably, the particle size of the colloidal silicon dioxide is 40-100 nm, and the mass content is 0.1-5%; preferably, the polishing liquid contains 0.01-5% of the high-molecular dispersing agent, 1-10% of the hydrogen peroxide oxidizing agent, and the balance an alcohol-water mixture, wherein the pH value of a slurry is 8-10. The nano cerium oxide polishing liquid selects the surface modified nano cerium oxide, has addition of a proper amount of the silicon dioxide, thereby reducing the grinding trigger time and improving the processing stability.

Owner:天津西美半导体材料有限公司

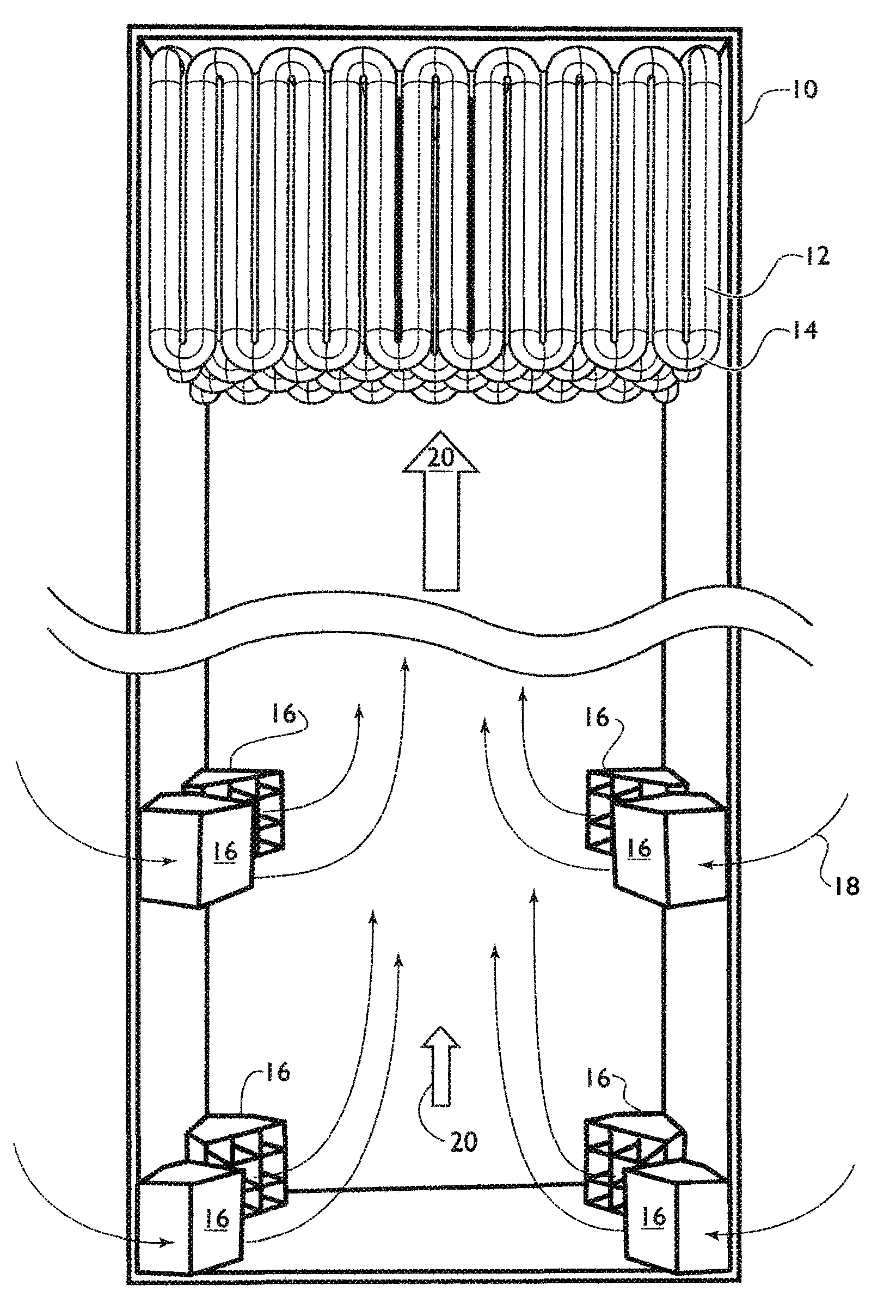

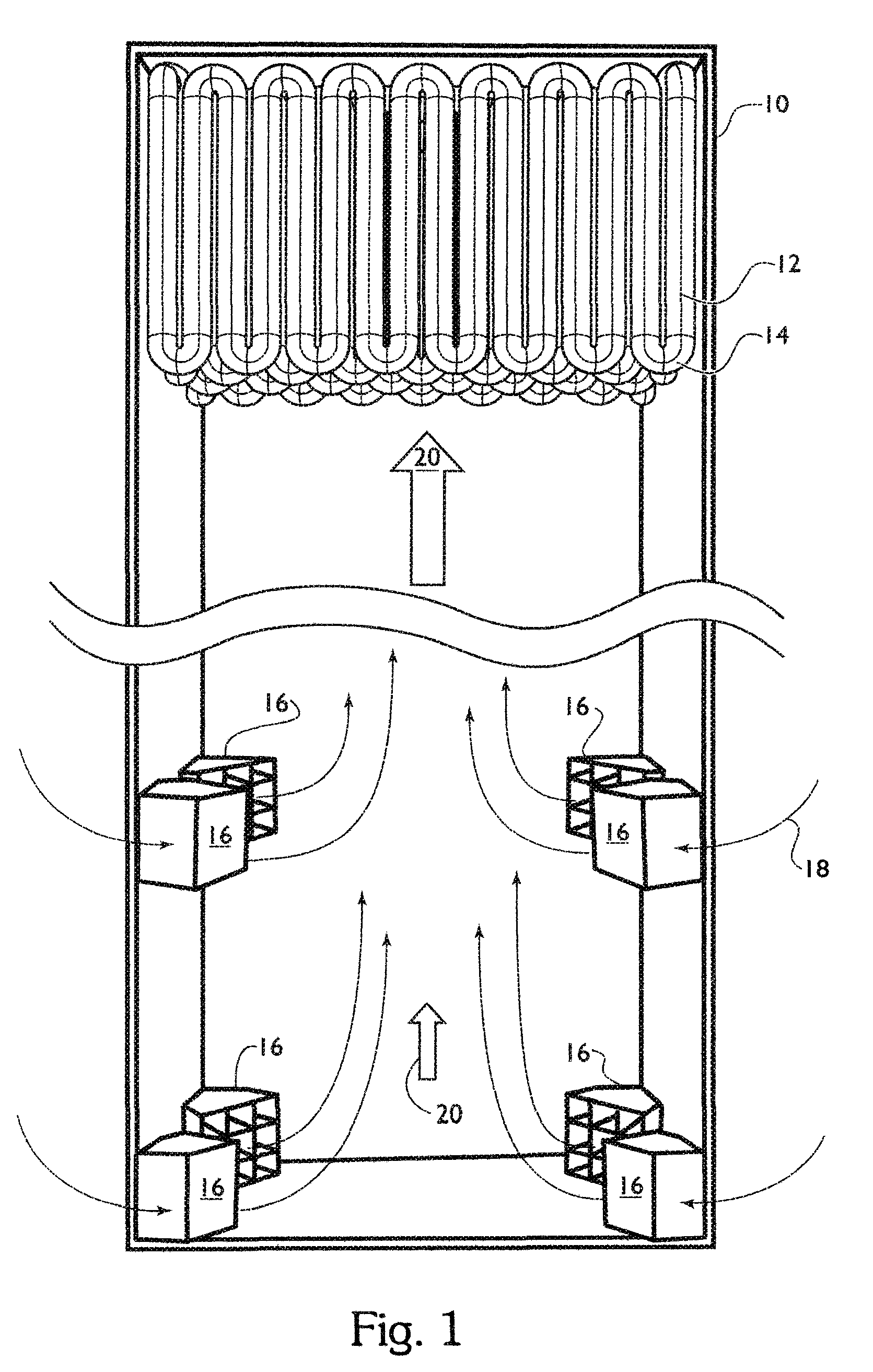

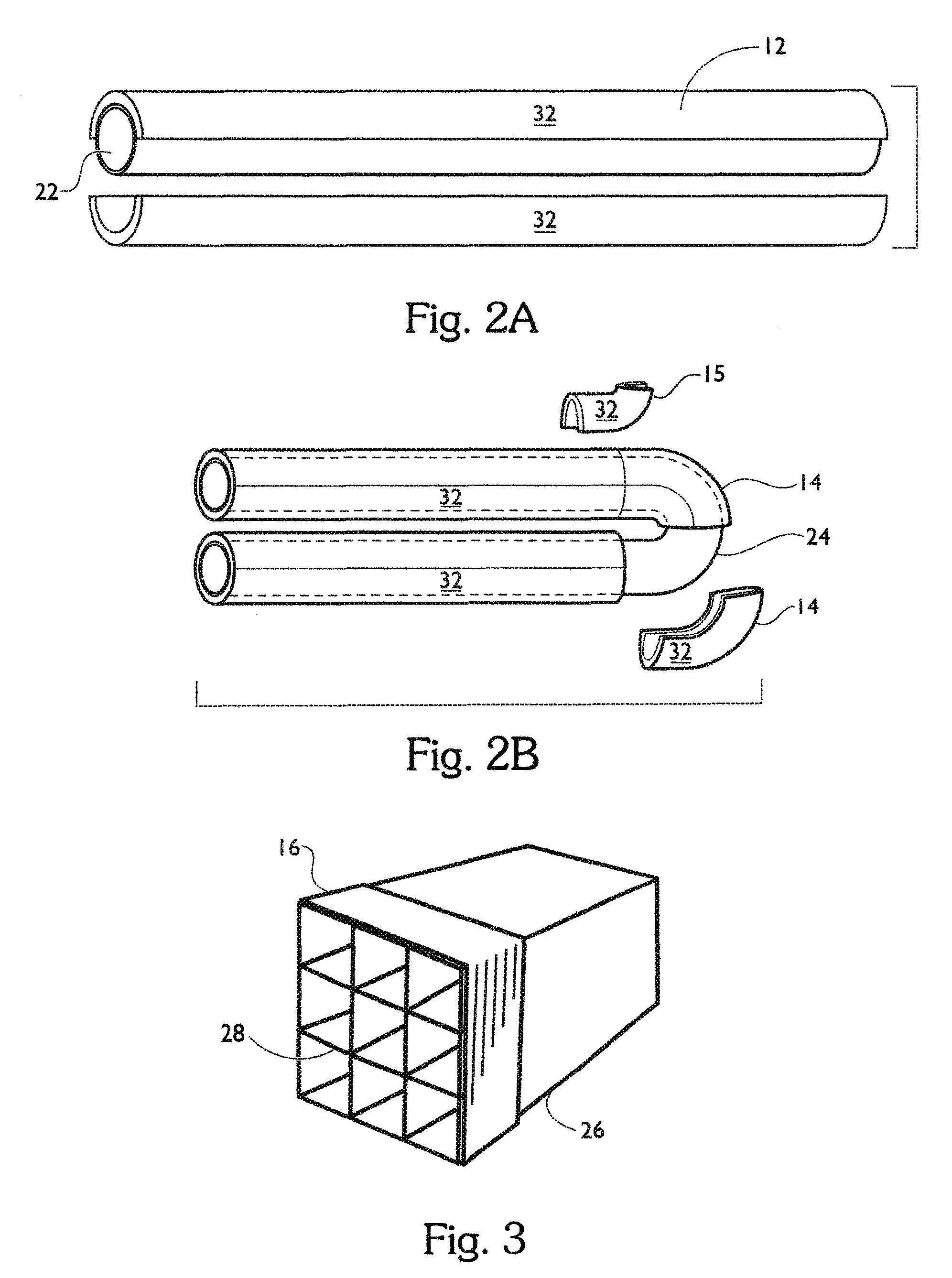

Tube shields having a thermal protective layer

InactiveUS20100038061A1Extend effective repair and replacement cycleReduce use costMetal-working apparatusCorrosion preventionColloidal silicaEmissivity

A tube shield, and method of manufacturing the tube shield, having a support structure with an external surface, an internal surface, and an edge, and a thermal protective layer on at least one surface of the shield support structure. The thermal protective layer is composed of a filler, one or more emissivity agent, and either an inorganic adhesive or a binder that is colloidal silica, colloidal alumina, or combinations thereof. A colorant, a surfactant, and / or a stabilizer may be incorporated into the thermal protective layer.

Owner:WESSEX

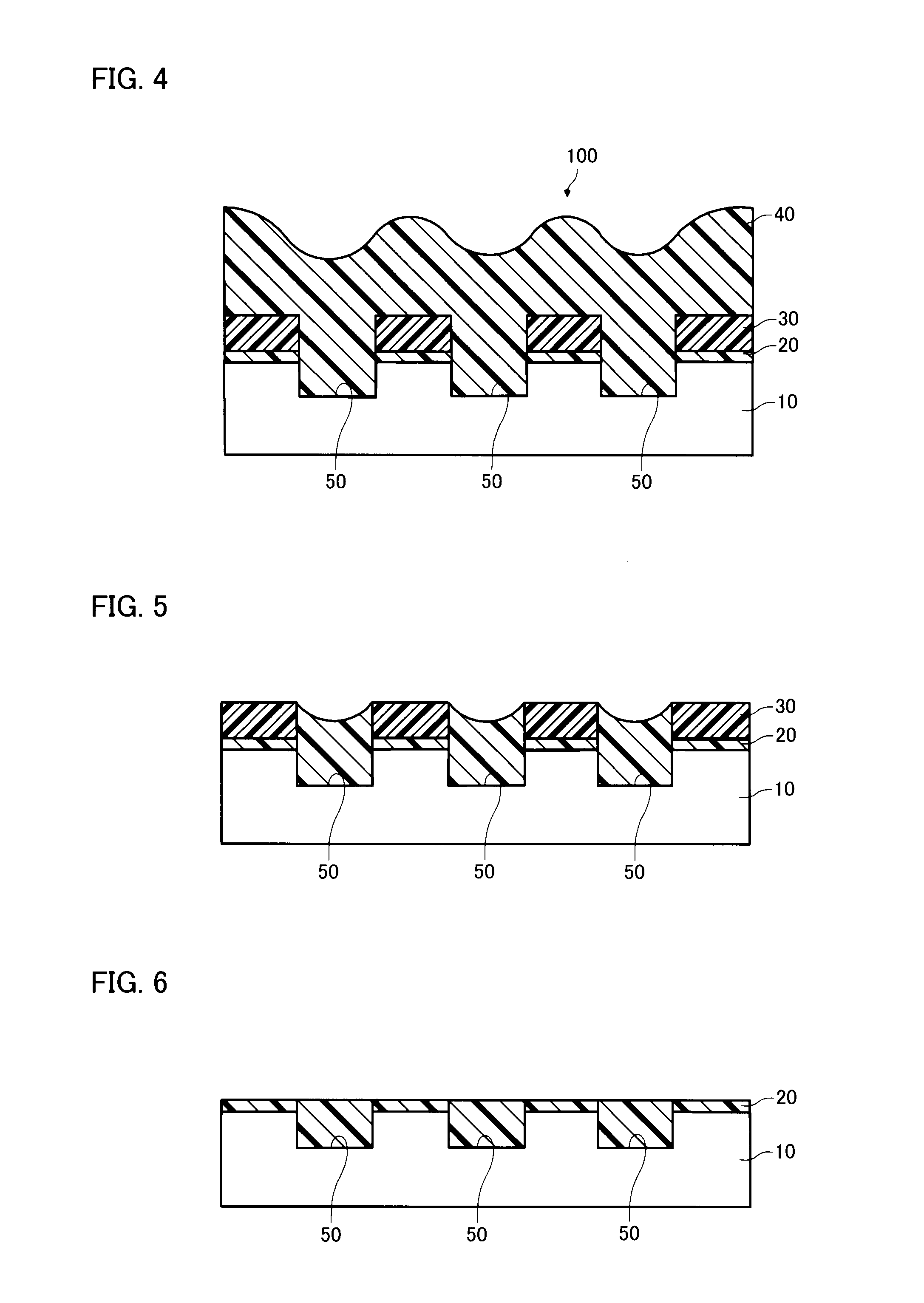

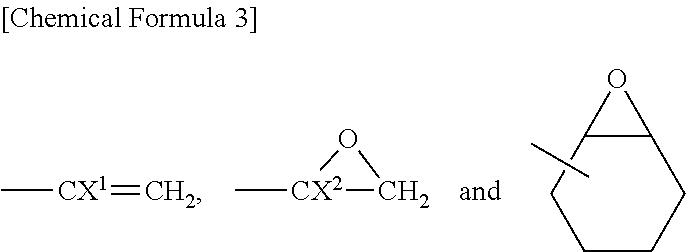

Laminate

InactiveUS20090104447A1Excellent abrasion resistanceGood weather resistanceSilicaSynthetic resin layered productsColloidal silicaAcrylic resin

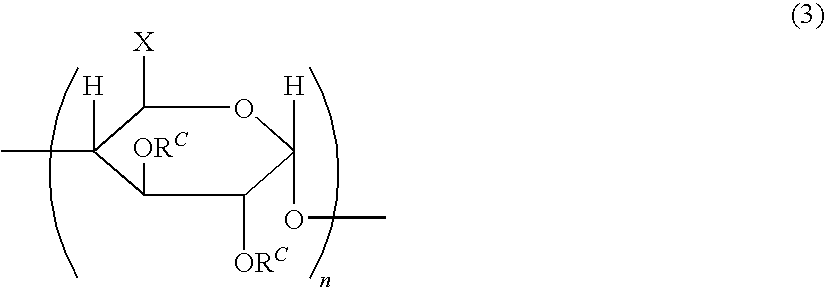

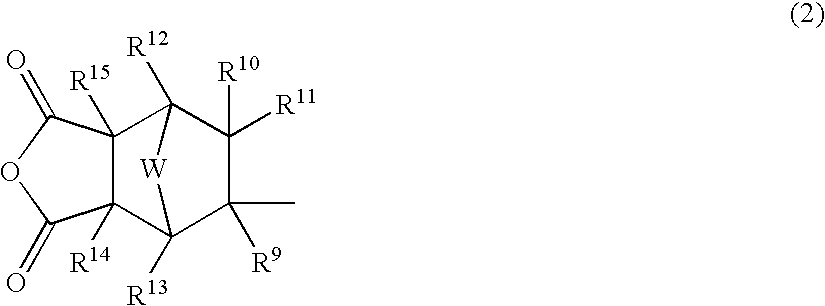

It is an object of the present invention to provide a laminate having excellent weatherability and abrasion resistance as well as adhesion.The present invention relates to a laminate comprising a base, a first layer formed by thermally curing an acrylic resin composition and a second layer formed by thermally curing an organosiloxane resin composition, all of which are formed in the mentioned order, whereinthe acrylic resin composition comprises:(A) an acrylic copolymer which contains at least 70 mol % of a recurring unit represented by the following formula (A):wherein X is a hydrogen atom or methyl group, and Y is a methyl group, ethyl group, cycloalkyl group, hydroxyalkyl group having 2 to 5 carbon atoms or triazine-based ultraviolet absorber residue;(B) a blocked polyisocyanate compound;(C) a curing catalyst; and(D) a triazine-based ultraviolet absorber, andthe organosiloxane resin composition comprises:(E) colloidal silica and (F) a hydrolysis condensate of an alkoxysilane.

Owner:TEIJIN KASEK KK

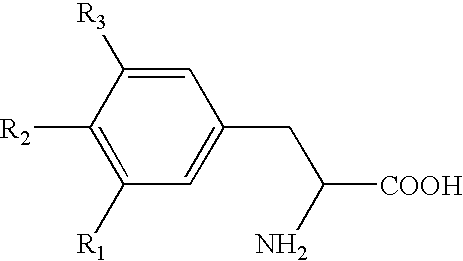

Aqueous dispersion for chemical mechanical polishng and chemical mechanical polishing method for semiconductor device

ActiveUS20100099260A1Improve polishing rateHigh rateOther chemical processesDecorative surface effectsColloidal silicaAmmonium compounds

A chemical mechanical polishing aqueous dispersion includes (A) colloidal silica having an average particle size calculated from the specific surface area determined by the BET method of 10 to 60 nm, (B) an organic acid having two or more carboxyl groups and one or more hydroxyl groups in one molecule, and (C) a quaternary ammonium compound shown by the following general formula (1),wherein R1 to R4 individually represent hydrocarbon groups, and M− represents an anion, the chemical mechanical polishing aqueous dispersion having a pH of 3 to 5.

Owner:JSR CORPORATIOON

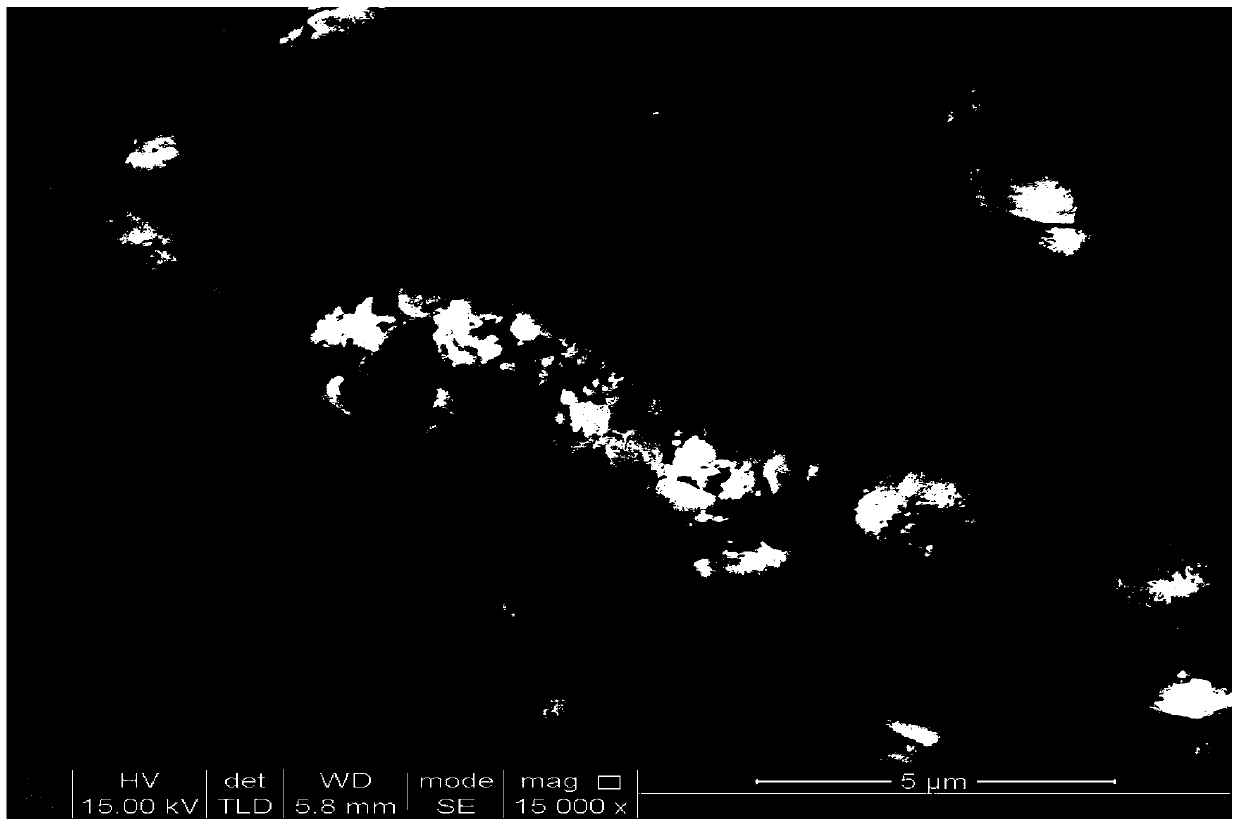

Silica sols with controlled minimum particle size and preparation thereof

InactiveUS20070034116A1Increase feed rateInhibition of nucleationPigmenting treatmentSilicaColloidal silicaSilica particle

Colloidal silica having an increased particle size and narrow particle size distribution is disclosed. A method for continuously producing the desired colloidal composition is disclosed comprising the steps of providing preformed silica particles having a surface area which controls the particle size of the colloidal silica product, adding a feed silica comprising an alkaline solution and silicate at a feed rate which is less than a nucleation rate, and increasing the feed rate as the feed silica is added wherein the feed rate is less than the nucleation rate.

Owner:NALCO CO

Polishing solution containing ceric oxide powder/colloid silicon dioxide mixed abrasive and preparing process thereof

ActiveCN103992743AImprove removal rateImprove surface qualityPolishing compositions with abrasivesSilica particleCerium(IV) oxide

The invention relates to a chemically mechanical polishing solution and a preparation process thereof, and particularly to a polishing solution containing a ceric oxide powder / colloid silicon dioxide mixed abrasive and a preparing process thereof. The polishing solution containing the mixed abrasive is simple in preparing process, practical and prone to production. Raw materials of the polishing solution comprise 3-10% of ceric oxide powder having a particle size of 100-2000 nm, 5-50% of colloid silicon dioxide having a particle size of 10-200 nm, and 0.001-0.5% of a dispersing agent, with the balance being water. The polishing solution is prepared by selecting a container, adding the colloid silicon dioxide solution, adding the ceric oxide powder, stirring uniformly, adding the dispersing agent and the water to the required volume, and stirring uniformly. The ceric oxide powder and the colloid silicon dioxide of different particle sizes are adopted as the abrasive. In the polishing solution, the smaller silicon dioxide particles decrease scratches, pits, and other defects so as to improve the surface quality, and the larger ceric oxide particles obtain a high removing rate.

Owner:杰明纳微电子股份有限公司 +1

Method of preparing a surface of a semiconductor wafer to make it epiready

InactiveUS20050020084A1Semiconductor/solid-state device manufacturingLapping machinesColloidal silicaSilica particle

The invention concerns a method of preparing the surface of a semiconductor wafer intended for microelectronics and / or optoelectronics applications. In particular, a method of preparing a SiC surface of a semiconductor wafer to make it epiready is described. The technique includes annealing the wafer in an oxidizing atmosphere, and polishing a surface of the wafer with an abrasive based on particles of colloidal silica to make the SiC wafer surface suitable for homoepitaxy or heteroepitaxy.

Owner:SOITEC SA

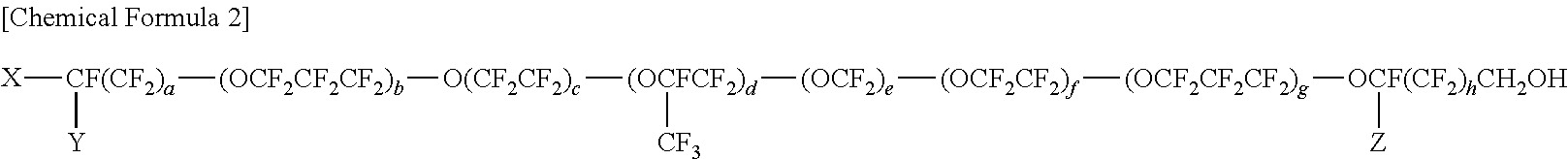

High energy ray-curable composition

ActiveUS20110135905A1Good storage stabilityHigh hardnessImpression capsAnimal housingColloidal silicaPolymer science

Disclosed is a high energy ray-curable composition which is excellent in storage stability before curing and enables to form a cured coating film which is excellent in hardness, property of preventing adhesion of fats and oils, property of wiping off fats and oils, abrasion resistance, transparency, water repellency, adhesion, smoothness and uniformity. Specifically disclosed is a high energy ray-curable composition containing the following components (A)-(D). (A) 100 parts by weight of a polyfunctional acrylate (B) 1-30 parts by weight of an organoalkoxysilane having an aliphatic unsaturated bond (C) 1-100 parts by weight of colloidal silica (D) 0.2-20 parts by weight of a fluorine compound having an aliphatic unsaturated bond.

Owner:DAIKIN IND LTD

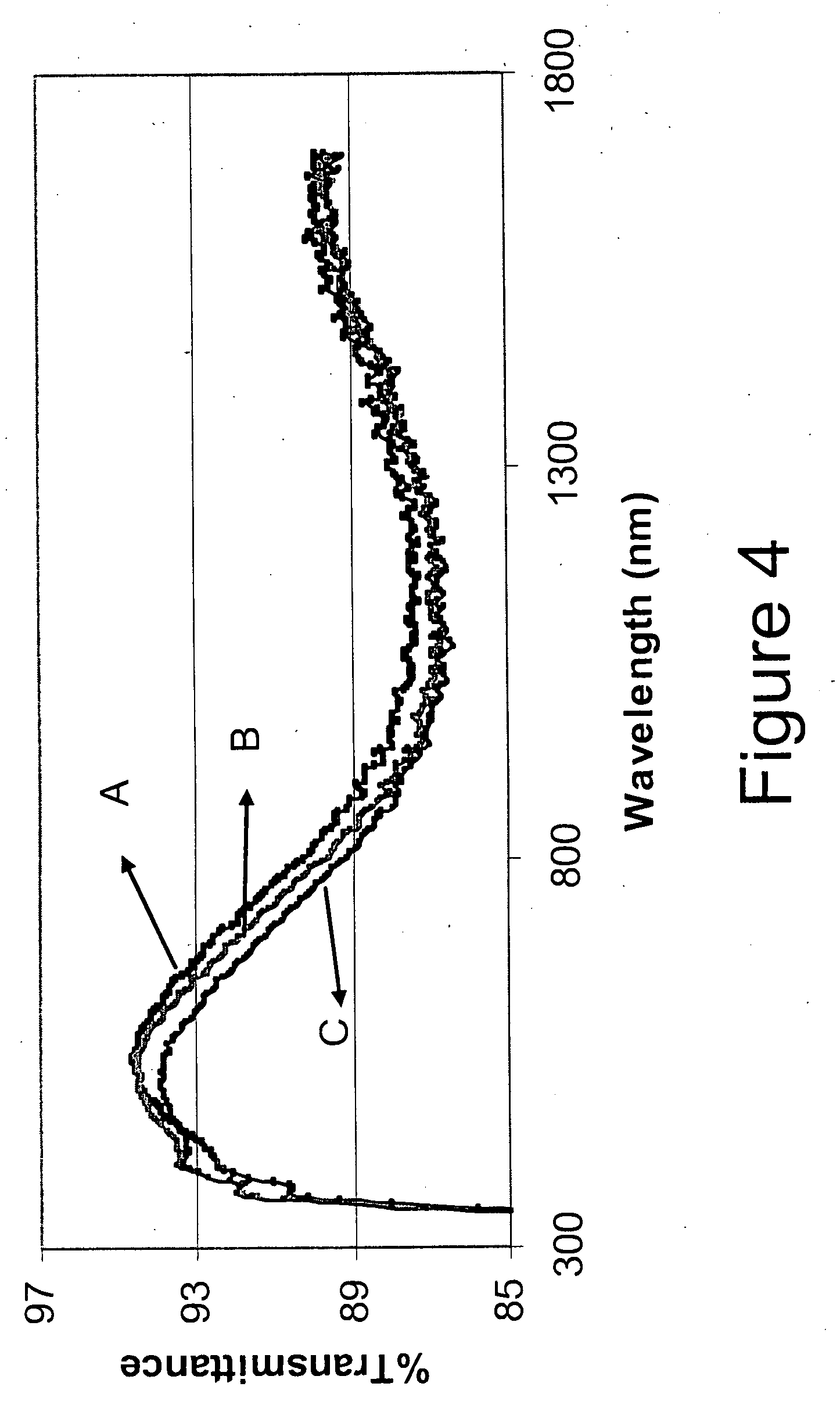

Thick crack-free silica film by colloidal silica incorporation

The invention relates to low temperature curable spin-on glass materials which are useful for electronic applications, such as optical devices, in particular for flat panel displays. A substantially crack-free silicon polymer film is produced by (a) preparing a composition comprising at least one silicon containing pre-polymer, colloidal silica, an optional catalyst, and optional water; (b) coating a substrate with the composition to form a film on the substrate, (c) crosslinking the composition by heating to produce a substantially crack-free silicon polymer film, having a thickness of from about 700 Å to about 20,000 Å, and a transparency to light in the range of about 400 nm to about 800 nm of about 90% or more.

Owner:HONEYWELL INT INC

Storage stable thyroxine active drug formulations and methods for their production

InactiveUS6936274B2Improve stabilityPrevents decrease in effective dosagePowder deliveryBiocideSucroseMagnesium stearate

This invention provides a storage-stable dosage form of a thyroxine active drug composition which exhibits an improved stability. The formulation contains a thyroxine active drug substance, an alditol, and a saccharide, and, optionally, additional pharmaceutically accepted excipients. Levothyroxine sodium is the preferred active drug substance, mannitol is the preferred alditol, and sucrose is the preferred saccharide. Additional preferred excipients include, for example, microcrystalline cellulose, crospovidone, magnesium stearate, colloidal silicon dioxide, and sodium lauryl sulfate.

Owner:MYLAN PHARMA INC

Dental paste glass ionomer cement composition

InactiveUS20070072957A1High affinityIncrease physical strengthImpression capsSpecial tyresColloidal silicaGlass ionomers

To give high mechanical strength, particularly compression strength, and excellent operationality in a two-paste system, a dental paste glass ionomer cement composition comprises a first paste comprising an α-β unsaturated carboxylic acid polymer, a filler that is not reacted with the α-β unsaturated carboxylic acid polymer and is not in a monodisperse state in water, a silica aqueous sol containing colloidal silica having an average particle diameter of 1 to 100 nm dispersed in a monodisperse state in water to an SiO2 concentration of 1 to 50% by weight, and water, in prescribed amounts respectively, and a second paste containing fluoroalumino silicate glass powder in a prescribed amount, where the second paste sometimes contains a thickening agent comprising a water soluble polymer material and water, or a polymerizable monomer having no acid group.

Owner:GC CORP

Method for controling uniformity of colloidal silica particle size

InactiveUS6906109B2Uniform shapeUniform sizeMaterial nanotechnologyMembranesSilica particleColloidal silica

A system and method are disclosed for producing uniform size silica particles by the steps of providing preformed colloidal silica particles having a surface area, adding an alkali metal silicate and a cation exchange resin to produce a quantity of feed silica at a feed rate which is less than a nucleation rate, and increasing the feed rate as the feed silica is added wherein the feed rate is less than the nucleation rate.

Owner:CHEM PROD CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com