Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94 results about "Azane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Azanes /ˌæzeɪns/ are acyclic, saturated hydronitrogens, which means that they consist only of hydrogen and nitrogen atoms and all bonds are single bonds. They are therefore pnictogen hydrides. Because cyclic hydronitrogens are excluded by definition, the azanes comprise a homologous series of inorganic compounds with the general chemical formula NₙHₙ₊₂.

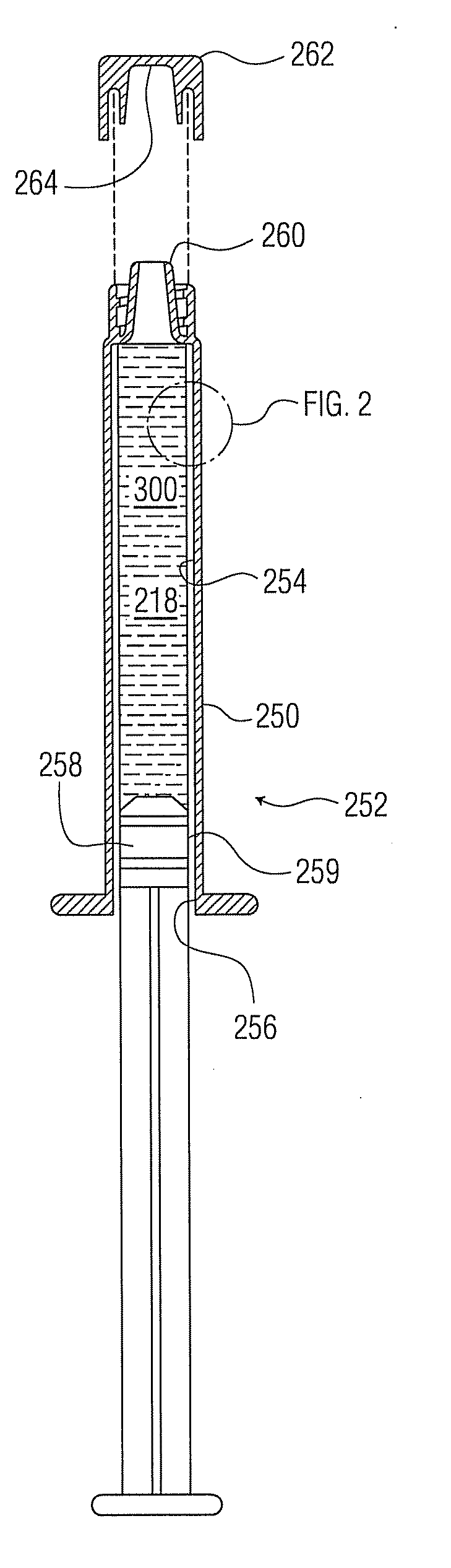

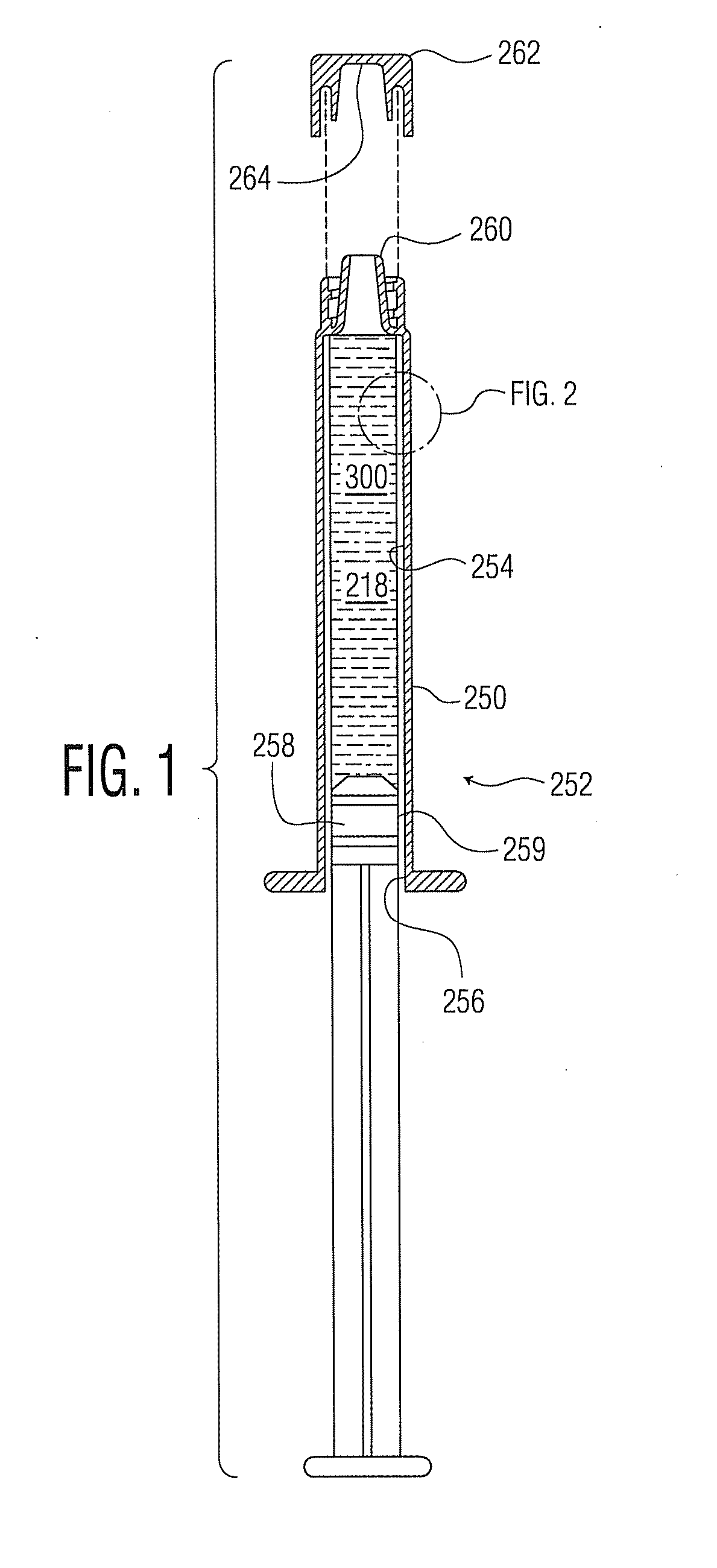

Plasma or CVD pre-treatment for lubricated pharmaceutical package, coating process and apparatus

ActiveUS20140249484A1Improve the lubrication effectReduce sliding frictionInfusion syringesSurgeryPolymer sciencePre treatment

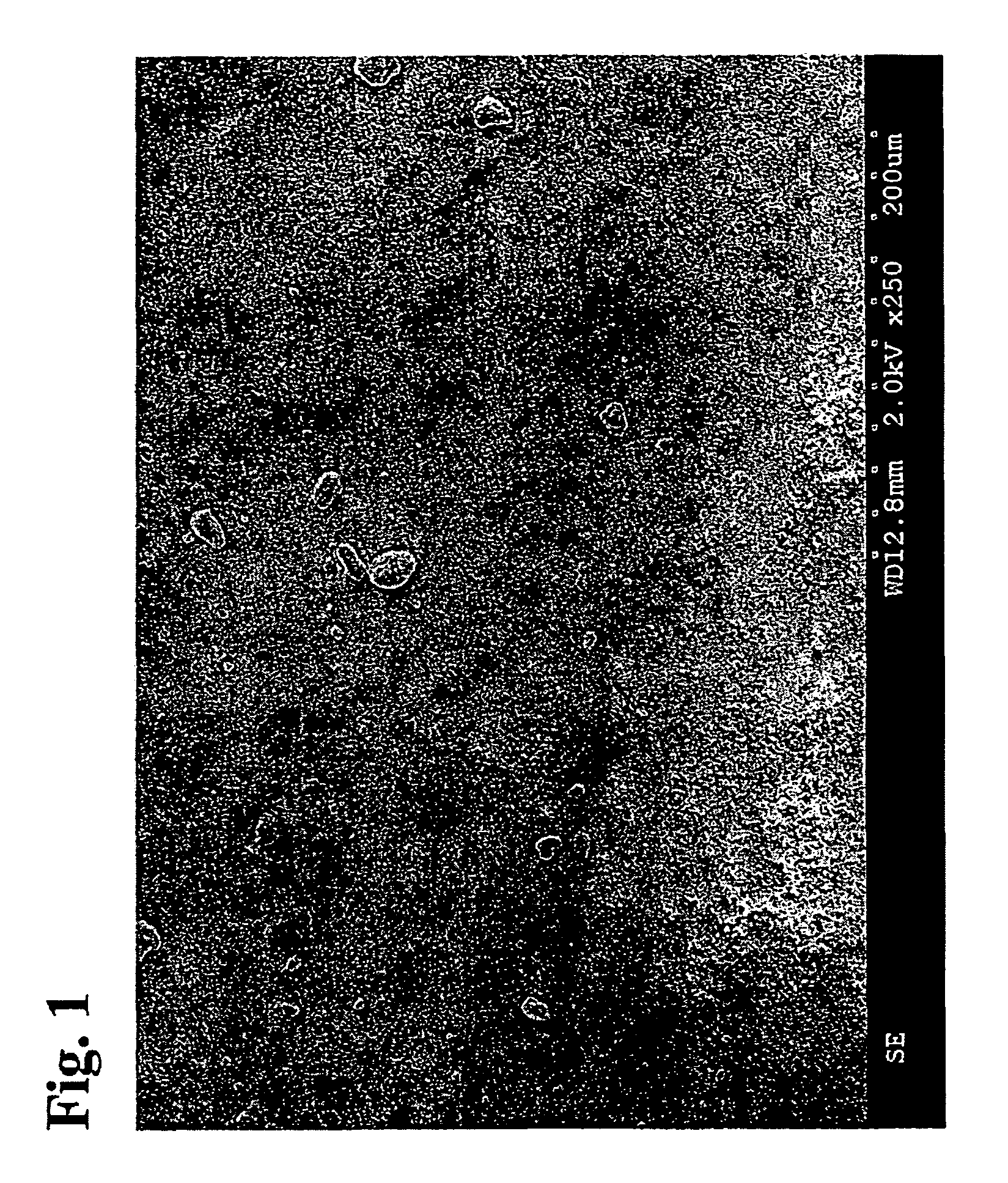

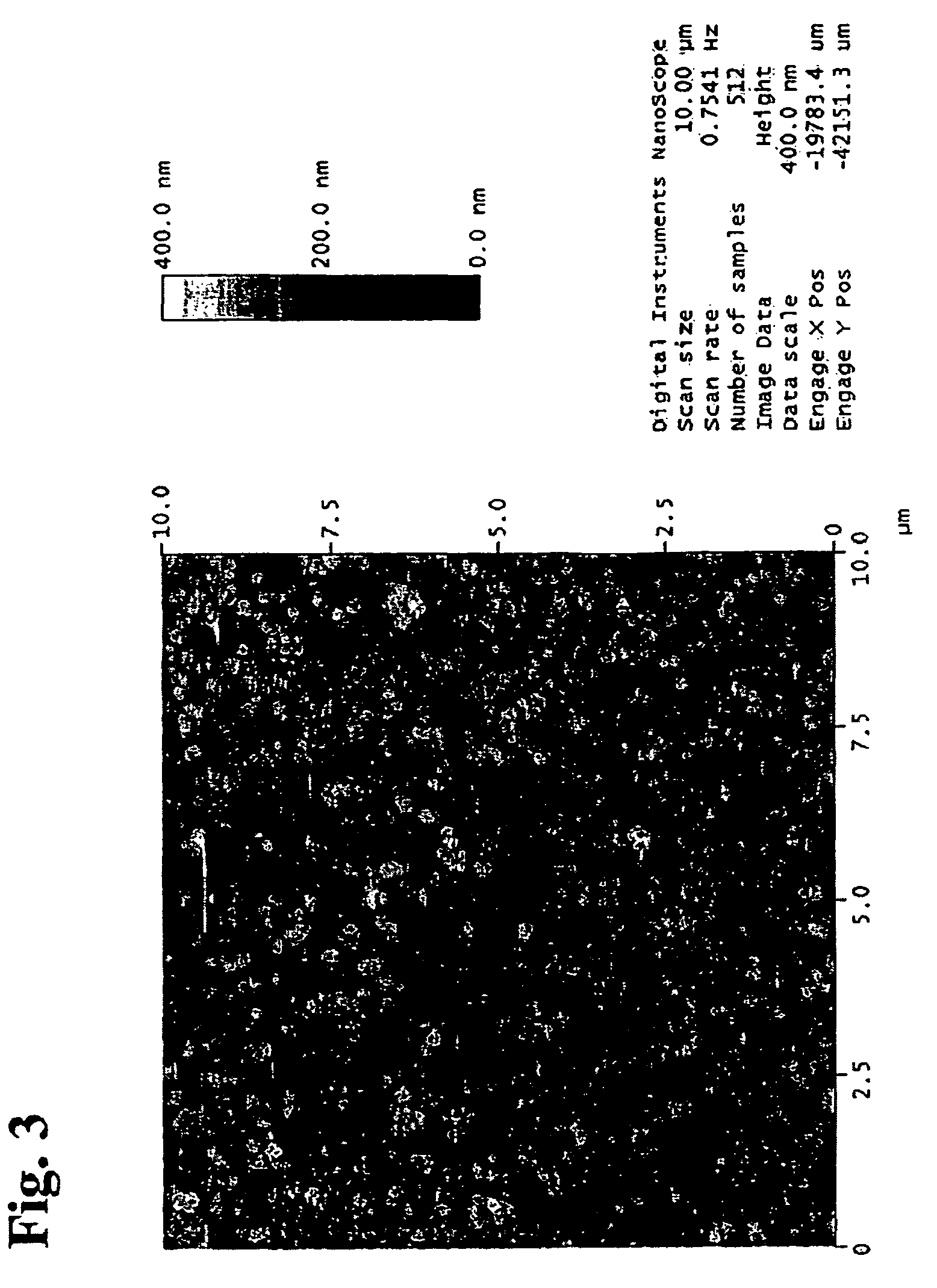

An article is described including an article surface, a primer coating or layer of SiOx, SiOxCy or SiNxCy applied to the article surface, and a deposit of lubricant applied to the primer coating or layer. The primer coating or layer of SiOx, SiOxCy or SiNxCy is applied by chemical vapor deposition of a polysiloxane or polysilazane precursor in the presence of oxygen. A first deposit of lubricant is applied to the primer coating or layer. The primer coating or layer improves the adhesion or wetting of the lubricant on the surface to be lubricated. Examples of such an article are a prefilled syringe having a barrel with a lubricated interior portion and a plunger tip that slides along it. Another example of such an article is a vial having a lubricated opening to receive a septum. Another aspect of the invention is a method of making such an article.

Owner:SI02 MEDICAL PRODS

Process for producing hydrophobic silica powder

InactiveUS20060112860A1Good dispersionSimple equipmentMaterial nanotechnologyPigmenting treatmentColloidal silicaAzane

A process for producing a hydrophobic silica powder, comprises the steps for hydrophobic treatment of: adding to an aqueous silica sol containing hydrophilic colloidal silica having a specific surface area of 5.5 to 550 m2 / g, a disilazane compound represented by formula (1) (R13Si)2NH (1) wherein each R1 is C1-6alkyl group or phenyl group that is selected independently of one another, in an amount of 0.1 to 10 mmol per surface area 100 m2 of the hydrophilic colloidal silica, to obtain a first mixture of the aqueous silica sol and the disilazane compound; and heating the mixture at a temperature of 50 to 100° C. for aging it to obtain a slurry as dispersion of hydrophobic treated colloidal silica. The process provides a hydrophobic silica powder through a simple hydrophobic treatment step.

Owner:NISSAN CHEM IND LTD

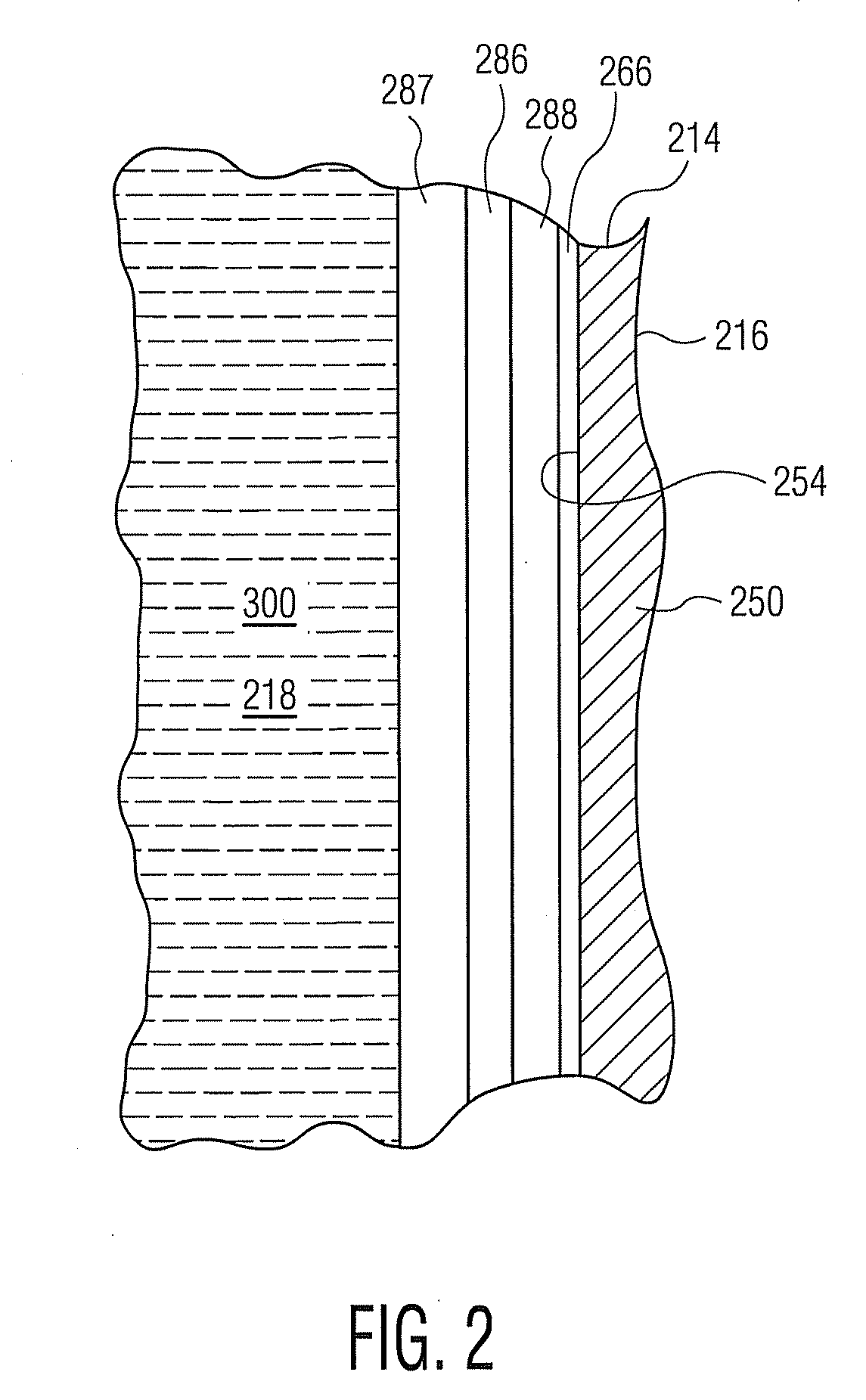

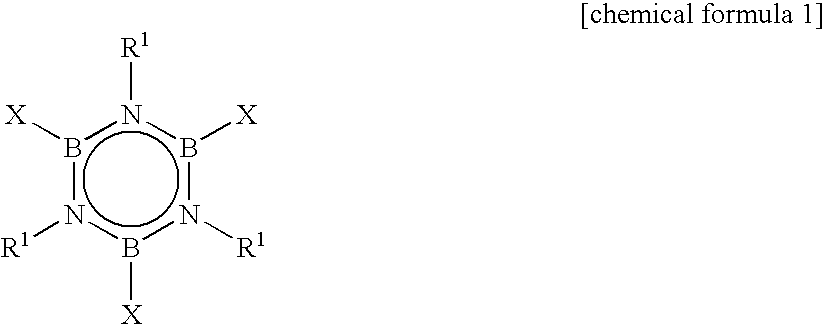

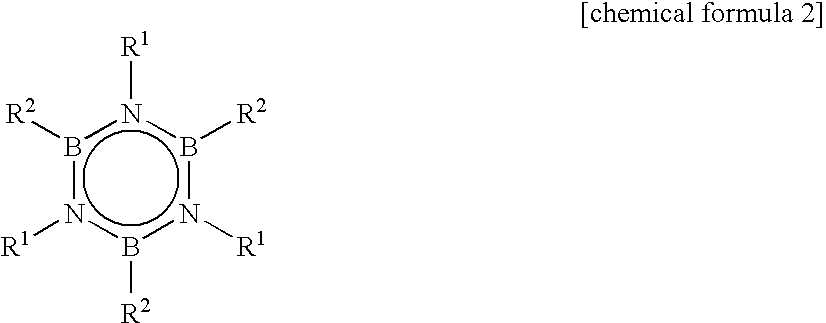

Alkylborazine compound and production method for the same

InactiveUS20050177002A1Boiling pointImprove flammabilitySilicon organic compoundsGroup 3/13 element organic compoundsHalogenDistillation

In the process of synthesizing alkylborazine compound represented by the chemical formula 2, by a reaction of a halogenated borazine compound represented by the chemical formula 1 with a Grignard reagent, thus synthesized alkylborazine compound is washed with water, or subjected to sublimation purification or distillation purification at least three times, and / or subjected to distillation purification at least twice. In the formulas, R1 independently represents alkyl group; R2 independently represents alkyl group; and X represents halogen atom.

Owner:NIPPON SHOKUBAI CO LTD

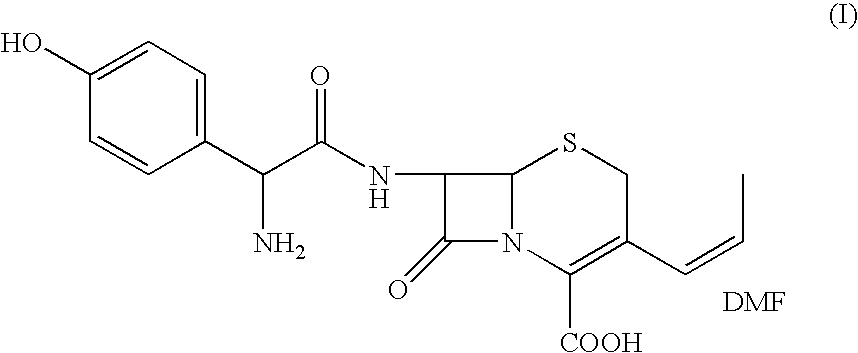

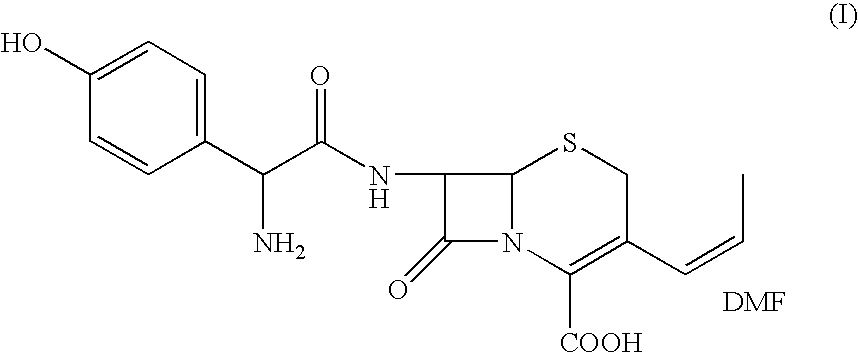

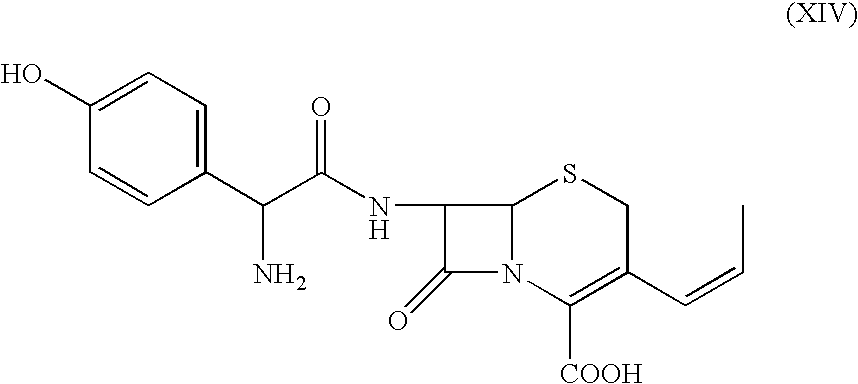

Process for the preparation of 3-propenyl cephalosporin DMF solvate

InactiveUS6903211B2High purityHigh yieldAntibacterial agentsOrganic chemistryEnzymatic hydrolysisBis(trimethylsilyl)amine

The present invention relates to an improved process for the preparation of cefprozil DMF solvate of formula (I), which is useful for the preparation of cefprozil, comprising:i) reacting a compound of formula (VIII) with acetaldehyde to produce a compound of formula (IX),ii) deesterifying the carboxy protecting group of the compound of formula (IX) using an acid to yield a compound of formula (X),iii) converting the compound of formula (X) to a compound of formula (XI),iv) neutralizing the compound of formula (XI) followed by enzymatic hydrolysis to produce an APCA of formula (V),v) silylating the APCA using a mixture of trimethylsilylchloride and hexamethyldisilazane to produce silylated APCA of formula (XII), andvi) condensing the silylated APCA with a mixed anhydride to produce the DMF solvate compound of formula (I).

Owner:ORCHID CHEM & PHARM LTD

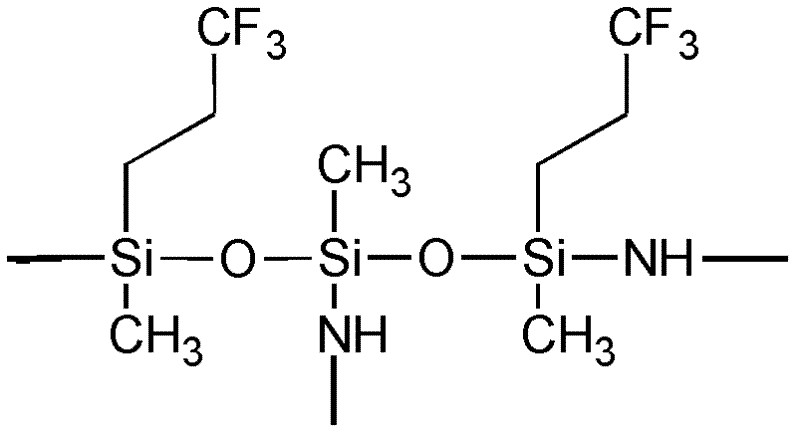

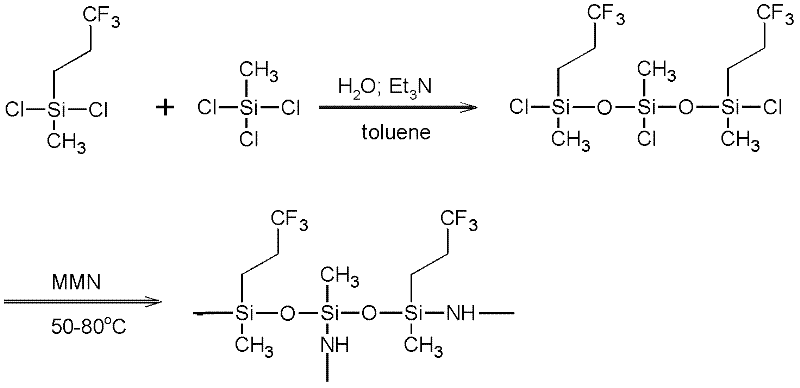

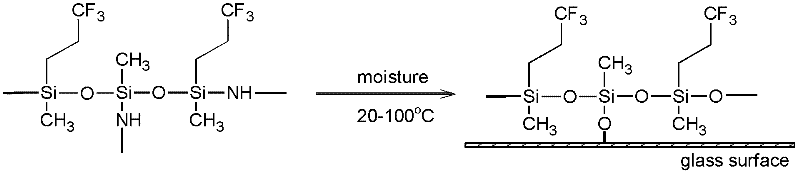

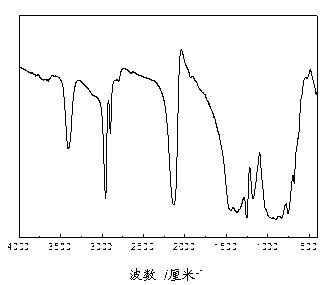

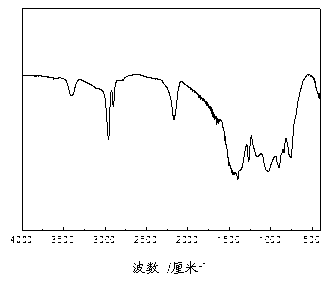

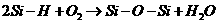

Ceramic precursor resin applicable to rainproof and self-cleaning coating of glass

InactiveCN102391514AImprove bindingOvercoming the limitations of poor adhesionCoatingsElastomerChemical Linkage

The invention discloses a synthesis method of fluoride-containing polysilazane-polysiloxane resin and a method for preparing durable rainproof agent coating applied on the surface of glass. The method comprises the following steps of: carrying out partial hydrolysis on fluoride-containing chlorosilane monomer mixture to form polysiloxane prepolymer, and then carrying out amido exchange reaction with hexamethyldisilazide to prepare fluoride-containing polysilazane-polysiloxane polymer. The polysilazane and polysiloxane are combined together with the surface of glass to form a firmly-combined protecting film by chemical bonds. The fluoride-containing polysiloxane elastomer coating formed by hydrolysis in the air has the advantages of hydrophobicity performance, high / low temperature resistance and scribing resistance, and also has the functions of being rainproof, anti-fog and self-cleaning.

Owner:BEIHANG UNIV

Process for producing hydrophobic silica powder

ActiveUS20070003701A1Efficient productionGood dispersionMaterial nanotechnologyPigmenting treatmentColloidal silicaAzane

A process for producing a hydrophobic silica powder, comprises the steps for hydrophobic treatment of: adding to a silica sol in mixed solvent having a silica concentration of 5 to 50 mass % obtained by mixing an aqueous silica sol containing hydrophilic colloidal silica having a specific surface area of 5.5 to 550 m2 / g with a hydrophilic organic solvent in a mass ratio of 0.12 to 2.5 based on water in the aqueous silica sol, a disilazane compound of formula (1) (R13Si)2NH (1) wherein each R1 is C1-6alkyl group or phenyl group that is selected independently of one another, in an amount of 0.1 to 20 mmol per surface area 100 m2 of the hydrophilic colloidal silica, to obtain a mixture of the silica sol in mixed solvent and the disilazane compound; and heating the mixture at a temperature of 50 to 100° C. for aging it to obtain a slurry dispersion of hydrophobic treated colloidal silica. The process provides a hydrophobic silica powder through a simple hydrophobic treatment step.

Owner:NISSAN CHEM IND LTD

Process for producing hydrophobic silica powder

ActiveUS7186440B2Efficient productionGood dispersionMaterial nanotechnologyPigmenting treatmentAzaneSilazane

A process for producing a hydrophobic silica powder, comprises the steps for hydrophobic treatment of: adding to a silica sol in mixed solvent having a silica concentration of 5 to 50 mass % obtained by mixing an aqueous silica sol containing hydrophilic colloidal silica having a specific surface area of 5.5 to 550 m2 / g with a hydrophilic organic solvent in a mass ratio of 0.12 to 2.5 based on water in the aqueous silica sol, a disilazane compound of formula (1)(R13Si)2NH (1)wherein each R1 is C1-6alkyl group or phenyl group that is selected independently of one another, in an amount of 0.1 to 20 mmol per surface area 100 m2 of the hydrophilic colloidal silica, to obtain a mixture of the silica sol in mixed solvent and the disilazane compound; and heating the mixture at a temperature of 50 to 100° C. for aging it to obtain a slurry dispersion of hydrophobic treated colloidal silica. The process provides a hydrophobic silica powder through a simple hydrophobic treatment step.

Owner:NISSAN CHEM IND LTD

Process for preparing fatty polyester

The method for preparing high molecular weight fatty polyester whose number-average molecular weight is 28000-40000 and weight-average molecular weight is 6000-13000 by adopting two-stage process is characterized by that it utilizes binary acid, dibasic alcohol and (or) hydroxy acid to make polycondensation reaction to prepare terminal hydroxyl polyester performed polymer, then adopts organic silicon azane compound as chain extender to make chain expansion reaction, the mole ratio of terminal hydroxyl polyester performed polymer and organic silicon azane chain extender is 1:0.8-2.0, and the Chain expansion reaction temp. is at 90-200 deg.C. It is simple in preparation process, non-toxic, high-effective, moderate in reaction condition, and suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH

Chemical vapor crosslinking method for polyborosilazane fiber

ActiveCN103074706AHigh reactivityCross-linkingSynthetic polymer filament chemical after-treatmentFiberPtru catalyst

The invention discloses a chemical vapor crosslinking method for a polyborosilazane fiber, which comprises the following operation steps of (1) placing a polyborosilazane fibril in a chemical vapor crosslinking system, vacuumizing, displacing system gas with high-purity nitrogen or high-purity argon to a normal pressure, and repeating for three times, (2) introducing boron hydride compound gas to the normal pressure after vacuumizing, (3) conducting temperature programming to 50-100 DEG C for reaction for 0.5-25h, and (4) conducting temperature programming to 350-500 DEG C, keeping warm for 0.5-12h, and cooling to a room temperature. The method has the following advantages that (1) no catalyst is needed, no oxygen is needed, and a dehydrogenation coupled reaction can be conducted at a temperature below a melting point of polyborosilazane, so that crosslinking of the polyborosilazane fiber is realized; (2) no equipment change on the existing chemical vapor crosslinking system is needed; and (3) the method is simple in technology and is suitable for large-scale production.

Owner:NAT UNIV OF DEFENSE TECH

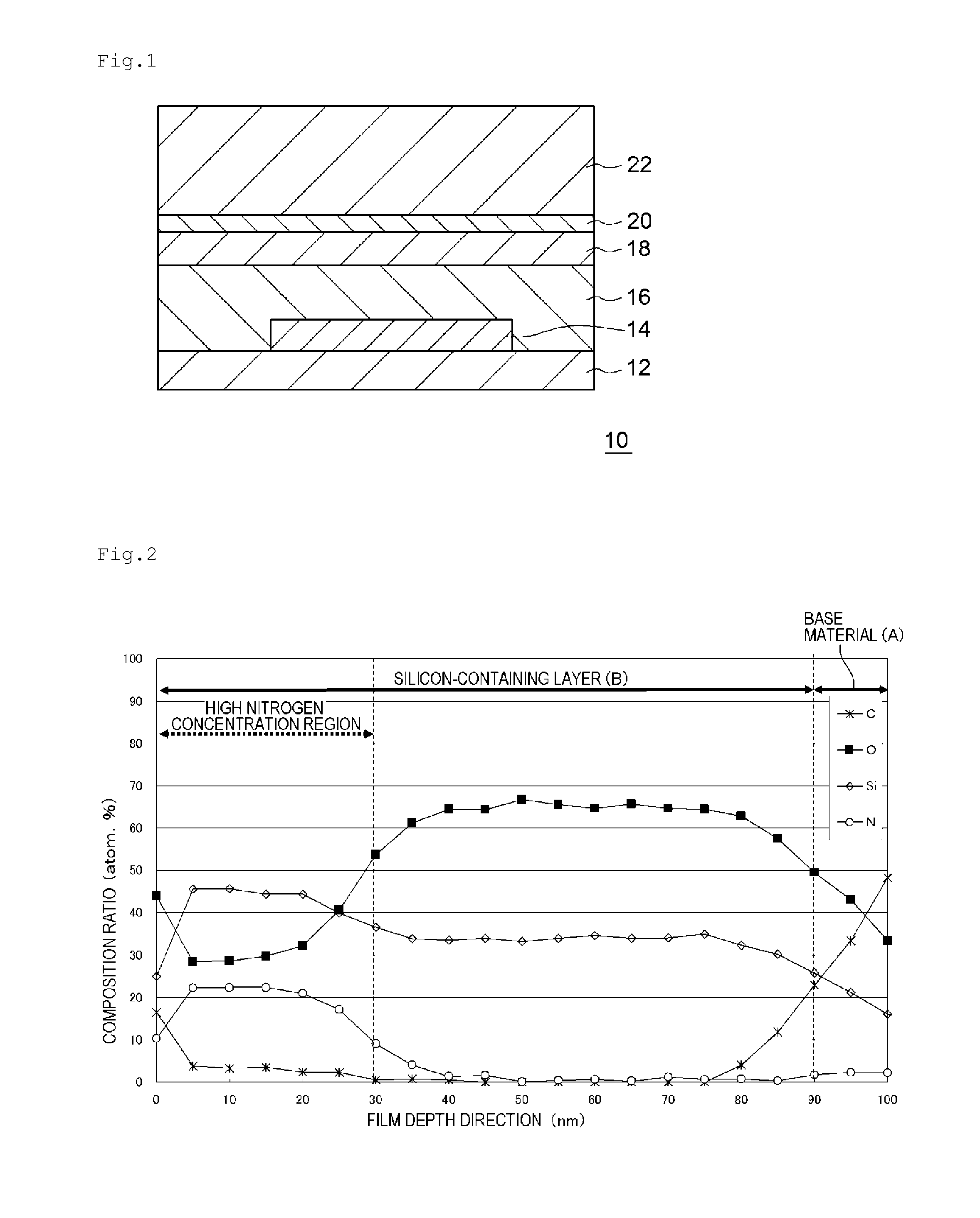

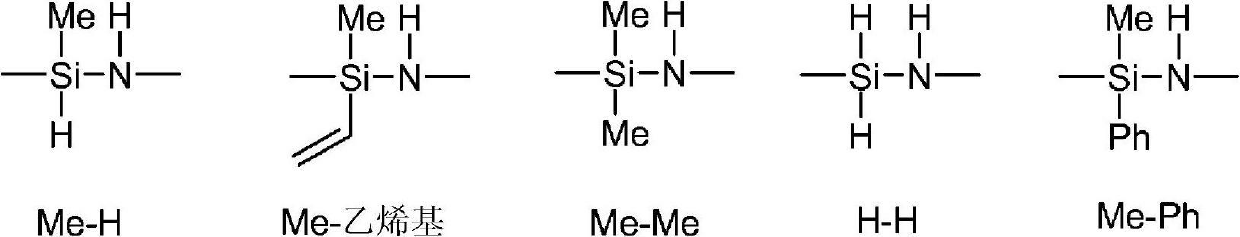

Laminate

InactiveUS20150166751A1Excellent gas barrier performanceImprove water vapor barrier performanceLayered product treatmentSynthetic resin layered productsOrganic acidNitrogen

The laminate according to the invention is comprised of a base material (A), a silicon-containing layer (B) and a polymer layer (C) obtained from an organic acid metallic salt having a polymerizable group. The silicon-containing layer (B) and the polymer layer (C) are sequentially laminated over at least one surface of the base material (A), the silicon-containing layer (B) includes a high nitrogen concentration region comprised of silicon atoms and nitrogen atoms, silicon atoms and nitrogen atoms and oxygen atoms, or silicon atoms and nitrogen atoms and oxygen atoms and carbon atoms. The high nitrogen concentration region is formed by irradiating energy ray onto a polysilazane film formed over the base material (A) under an oxygen concentration equal to or lower than 5% and / or a relative humidity at room temperature (23° C.) equal to or lower than 30% so as to denature at least a part of the film.

Owner:MITSUI CHEM INC +1

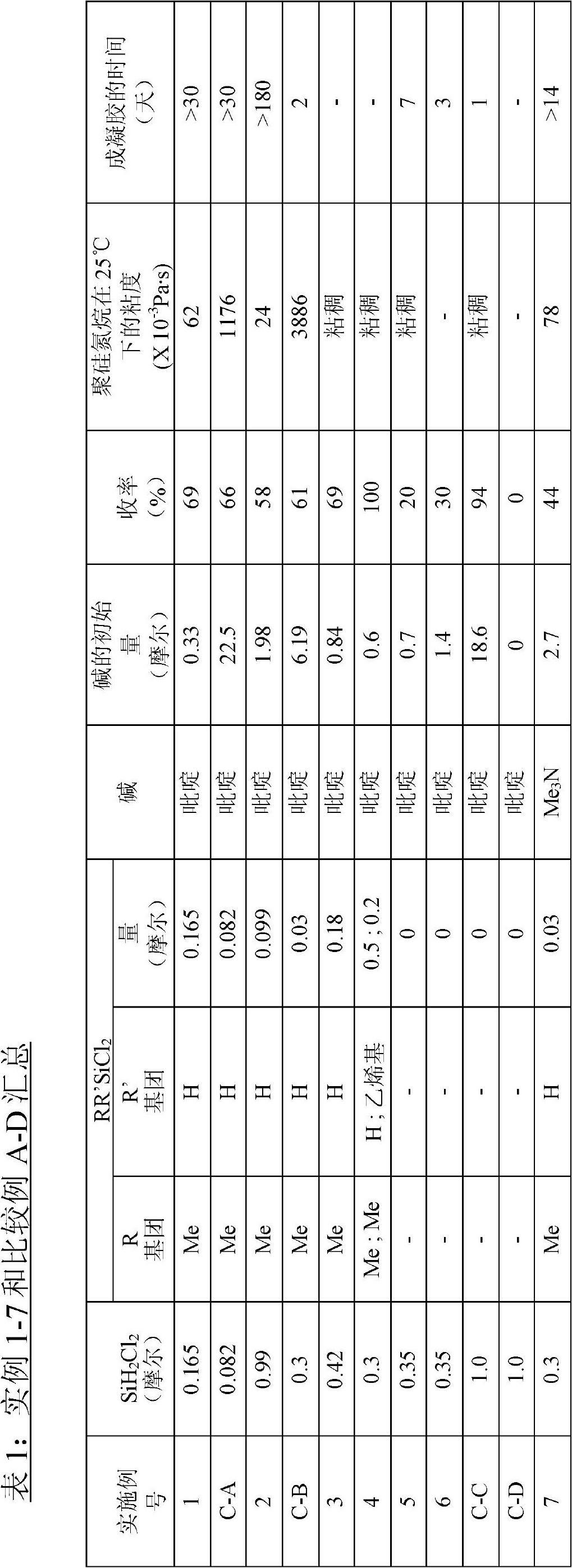

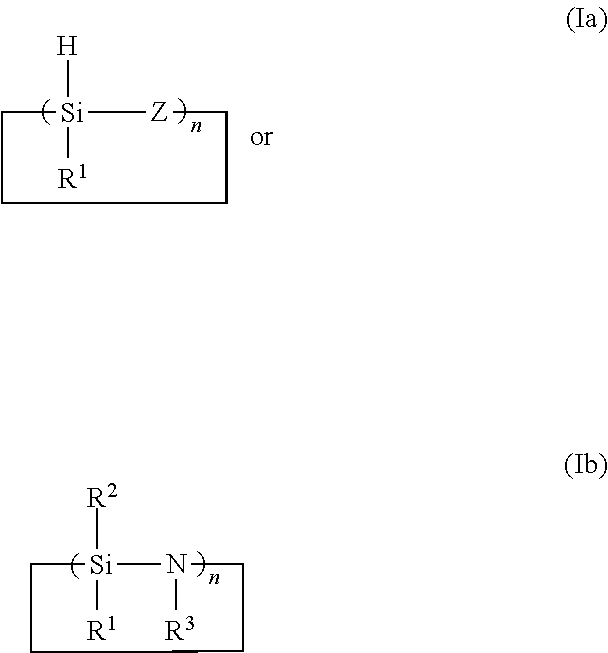

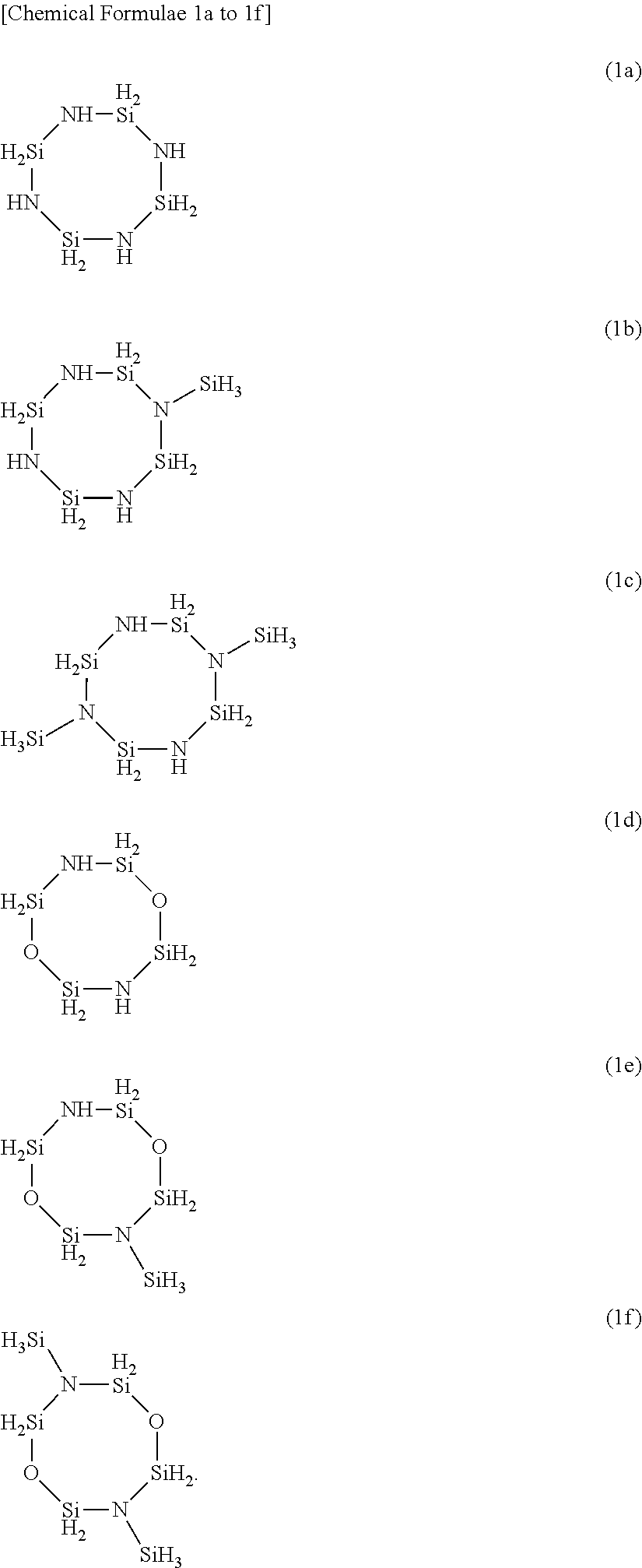

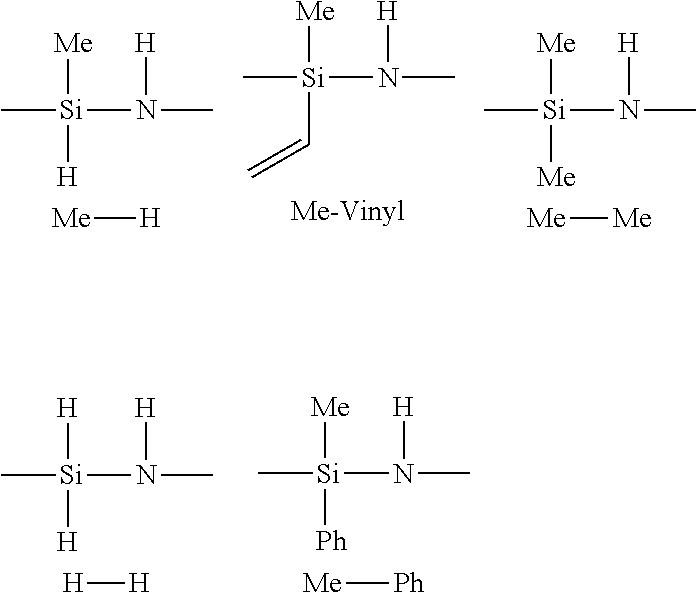

Process for preparing shelf-stable curable polysilazanes, and polysilazanes prepared thereby

A process for preparing curable oligomeric and / or polymeric polysilazanes comprises (a) forming at least one dihalosilane-base adduct by reacting at least one dihalosilane with at least one base; (b) optionally, combining at least one dihalosilane-base adduct and at least one organodihalosilane; and (c) carrying out ammonolysis of at least one dihalosilane-base adduct or of the resulting combination of at least one dihalosilane-base adduct and at least one organodihalosilane; with the proviso that the base (1) is used for the dihalosilane-base adduct formation in a limited amount that is less than or equal to twice the stoichiometric amount of silicon-halogen bonds in the dihalosilane or (2) is used for the dihalosilane-base adduct formation in excess of this limited amount and, prior to the ammonolysis, the total amount of the resulting reacted and unreacted base is reduced to no more than this limited amount.

Owner:3M INNOVATIVE PROPERTIES CO

Method for making functionalized polymer

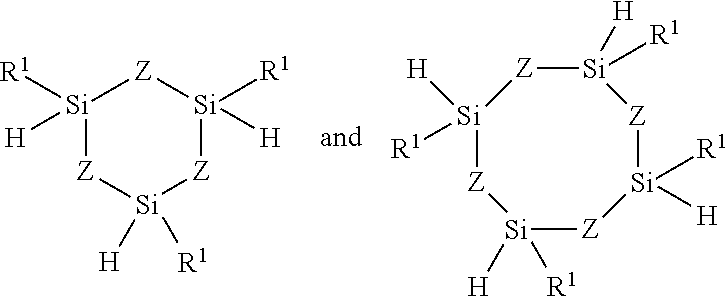

A macromolecule includes at least one polymer chain and terminal functionality. The terminal functionality includes a ring-opened radical of a cyclosilazane or cyclic hydrosiloxane. The polymer can include unsaturated mer units and can be provided via anionic polymerization techniques. The macromolecule can be used as a component of a composition that also includes particulate fillers, with the composition being useful for the production of vulcanizates.

Owner:BRIDGESTONE CORP

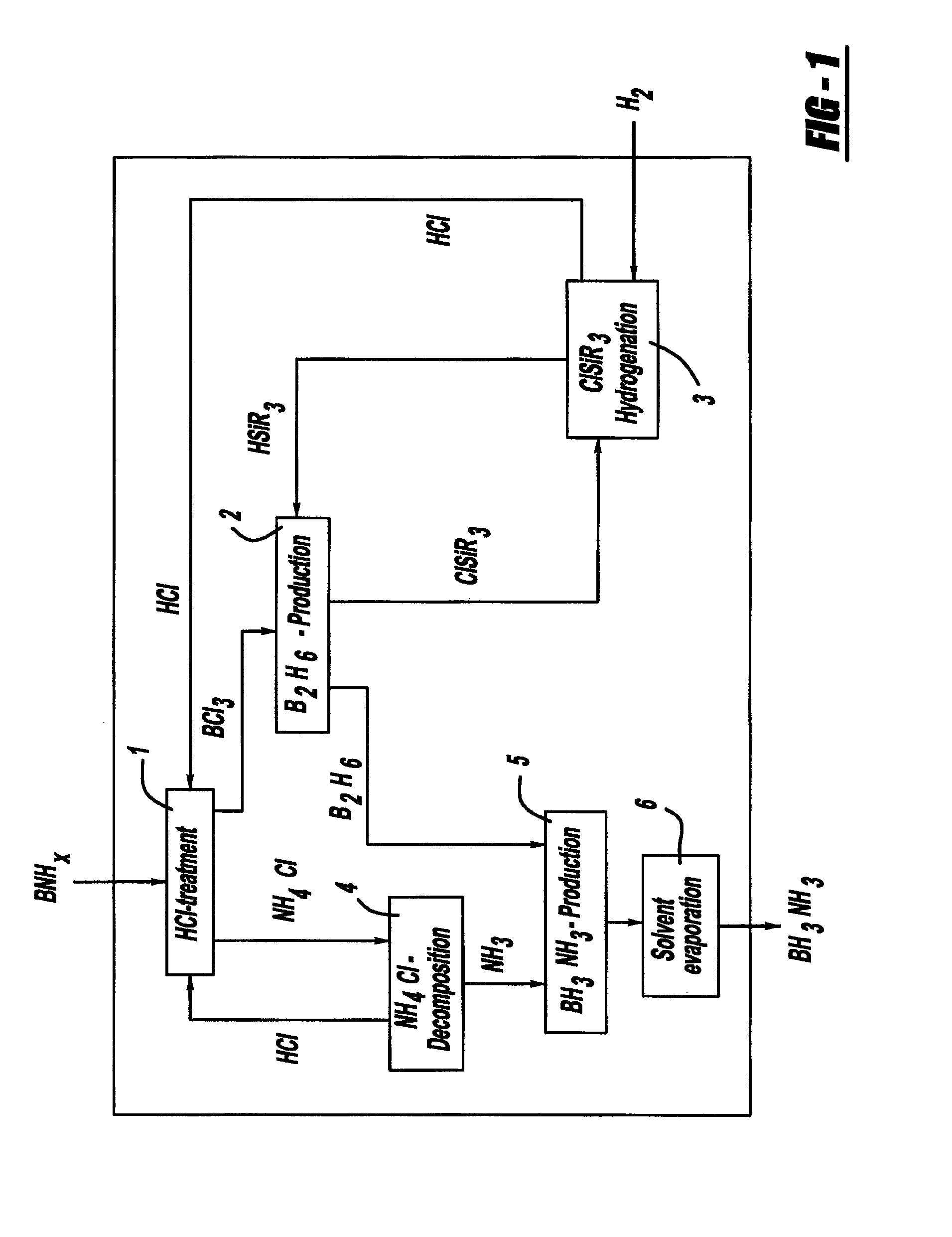

Procedure for the hydrogenation of bnh-containing compounds

InactiveUS20080193356A1Improve energy efficiencyNitrogen compoundsOther chemical processesHydrogen halideCompound a

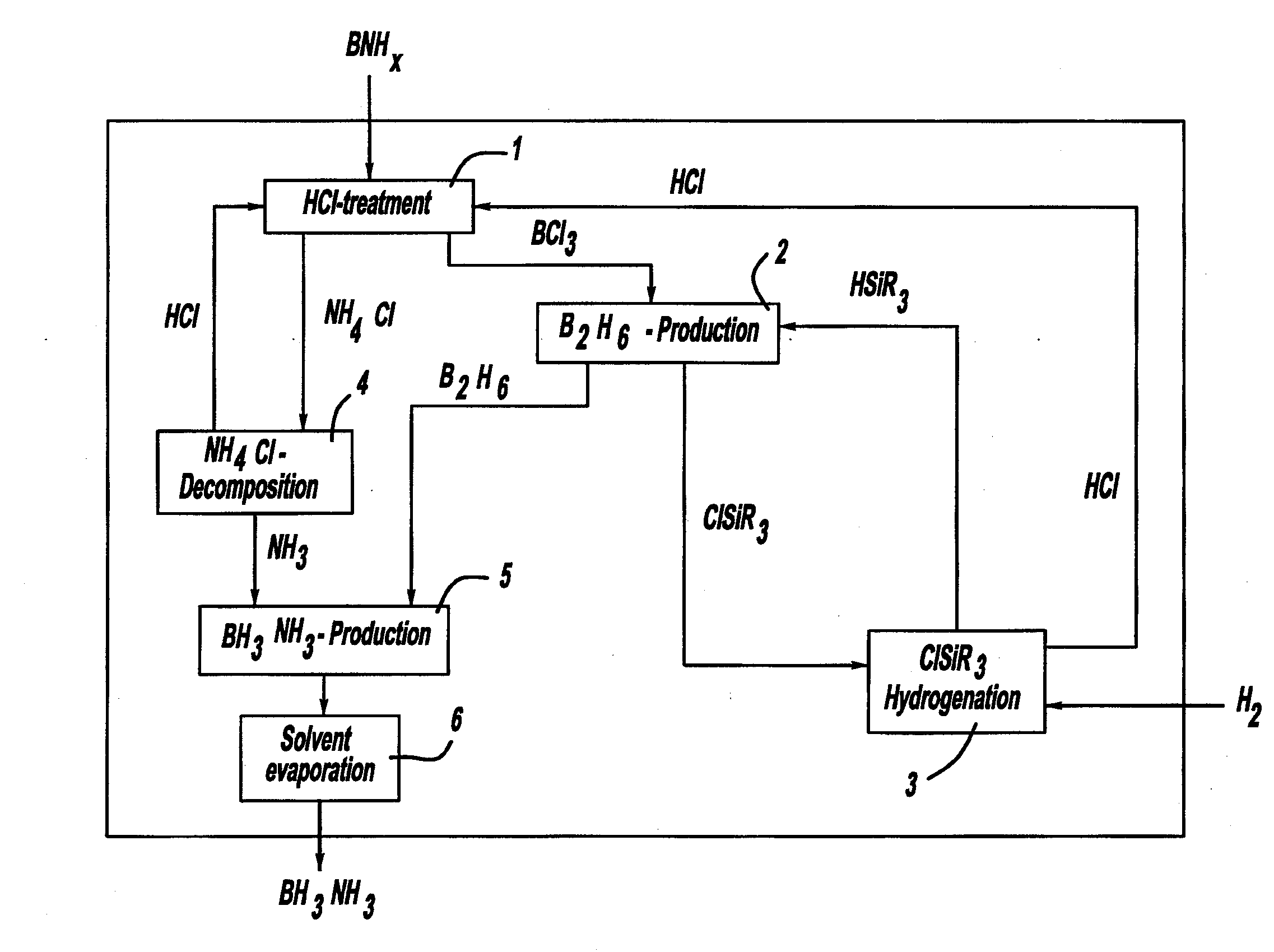

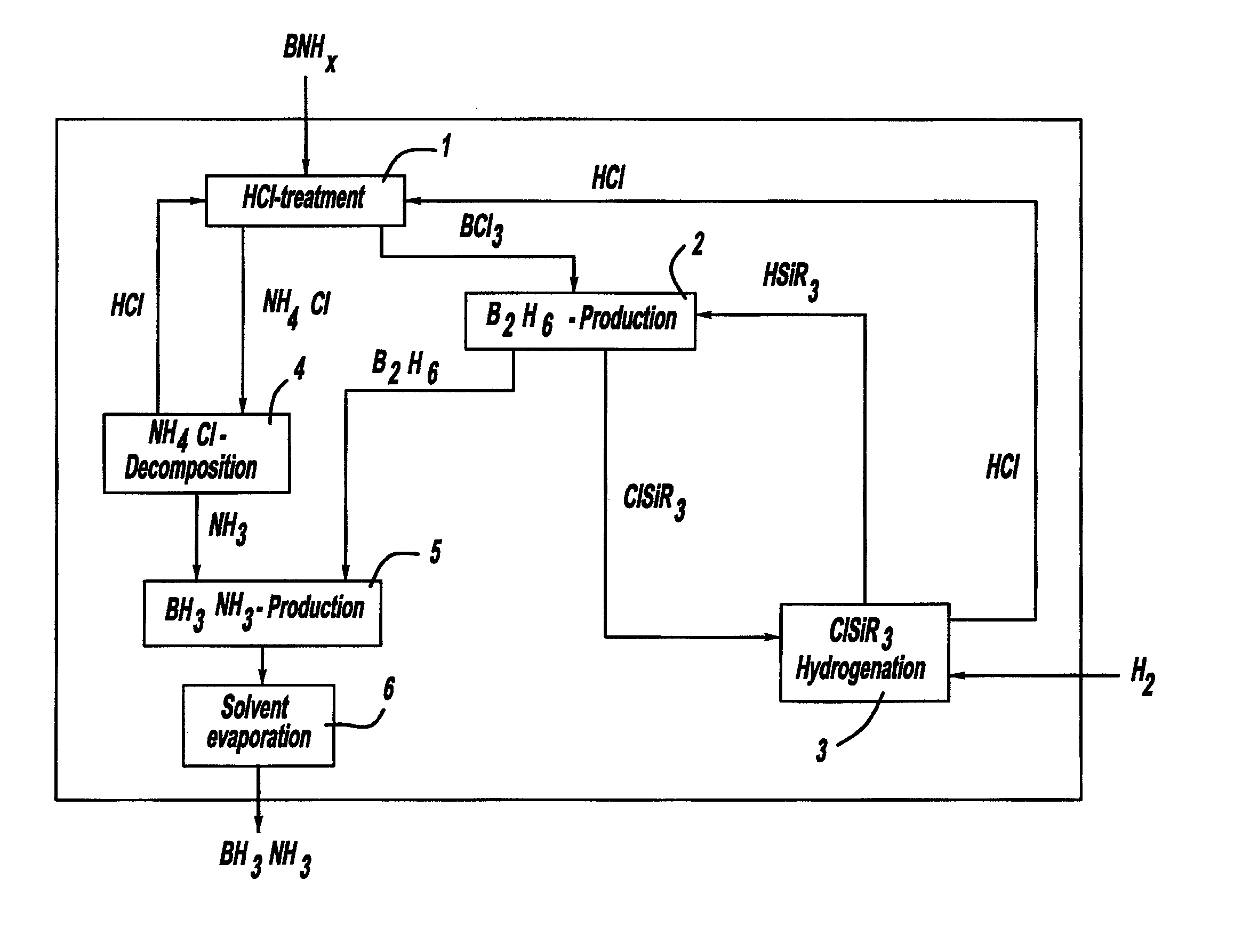

A process for producing borazane from boron-nitrogen and boron-nitrogen-hydrogen containing BNH-waste products. The process includes reacting the BNH-waste products with a hydrogen halide, having the formula HX, wherein X is selected from the group consisting of F, Cl, Br, I, and combinations thereof, to form any of the following: a boron trihalide, having the formula BX3, an ammonium halide, having the formula NH4X, and hydrogen. The boron trihalide is then reacted with the hydrogen to form diborane, having the formula B2H6, and hydrogen halide. The ammonium halide is then converted to ammonia, having the formula NH3, and hydrogen halide. The diborane is then reacted with the ammonia to form borazane, having the formula BH3NH3.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Procedure for the hydrogenation of BNH-containing compounds

InactiveUS7695704B2Improve energy efficiencyNitrogen compoundsOther chemical processesHydrogen halideCompound a

A process for producing borazane from boron-nitrogen and boron-nitrogen-hydrogen containing BNH-waste products. The process includes reacting the BNH-waste products with a hydrogen halide, having the formula HX, wherein X is selected from the group consisting of F, Cl, Br, I, and combinations thereof, to form any of the following: a boron trihalide, having the formula BX3, an ammonium halide, having the formula NH4X, and hydrogen. The boron trihalide is then reacted with the hydrogen to form diborane, having the formula B2H6, and hydrogen halide. The ammonium halide is then converted to ammonia, having the formula NH3, and hydrogen halide. The diborane is then reacted with the ammonia to form borazane, having the formula BH3NH3.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Process for preparing shelf-stable curable polysilazanes, and polysilazanes prepared thereby

A process for preparing curable oligomeric and / or polymeric polysilazanes comprises (a) forming at least one dihalosilane-base adduct by reacting at least one dihalosilane with at least one base; (b) optionally, combining at least one dihalosilane-base adduct and at least one organodihalosilane; and (c) carrying out ammonolysis of at least one dihalosilane-base adduct or of the resulting combination of at least one dihalosilane-base adduct and at least one organodihalosilane; with the proviso that the base (1) is used for the dihalosilane-base adduct formation in a limited amount that is less than or equal to twice the stoichiometric amount of silicon-halogen bonds in the dihalosilane or (2) is used for the dihalosilane-base adduct formation in excess of this limited amount and, prior to the ammonolysis, the total amount of the resulting reacted and unreacted base is reduced to no more than this limited amount.

Owner:3M INNOVATIVE PROPERTIES CO

Processing compositions and method of forming the same

ActiveUS8034173B2Increased durabilityImprove conditionsPigmenting treatmentSilicaSilica particleProcess composition

Owner:EVONIK OPERATIONS GMBH

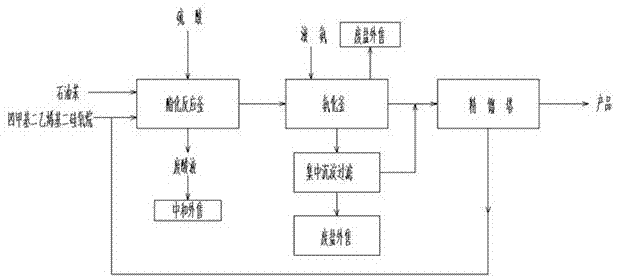

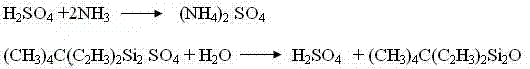

Process for preparing tetramethyldivinyldisilazane by conversion of divinyl tetramethyl disiloxane

The invention discloses a process for preparing tetramethyldivinyldisilazane by conversion of divinyl tetramethyl disiloxane. The process comprises steps of: (1) esterification reaction: first adding concentrated sulfuric acid into a dropping tank, and then adding thedivinyl tetramethyl disiloxane and petroleum benzene into a stirring kettle; then dropwise adding concentrated sulfuric acid into the stirring kettle, stopping stirring after reaction, releasing dilute sulfuric acid at the bottom upper, and introducing upper crude product into an ammoniation reactor; (2) ammoniation: opening a circulating water pump and mixing, opening an ammonia inlet valve, and introducing ammonia slowly; and (3) distillation: adding clear liquid into a rectification tower kettle, recovering petroleum benzene and intermediate distillate intermittently for recycling, and then recovering tetramethyldivinyldisilazane, so as to finally leave the target product of tetramethyldivinyldisilazane in the tower kettle. The process of the invention adopts a compressor recovery unit to carry out secondary amination synthesis and usage of ammonia, and avoids ammonia waste caused by the reaction pressure requirement.

Owner:XINYAQIANG SILICON CHEM JIANGSU

Preparation method for boron nitride ceramics fibre precursor

The invention relates to a method for preparing boron nitride ceramic fiber precursor polymer, the method comprises the following steps: the anhydrous toluene solution of cyclic trichloroboron azane is cooled to 80 DEG C below zero-70 DEG C below zero, anhydrous toluene solution of methylamine is dripped, and the reaction endures 1-10 hours under -40 DEG C below zero -0 DEG C, and then endures 10-20 hours under room temperature, and is subsequently filtered; the boron trichloride is condensed in anhydrous toluene solution of methylamine (40 DEG C below zero - 80 DEG C below zero), stirred for reaction for 1-10hr, and then stirred for 5-20hr under room temperature, and then filtered; the filtrates are combined, stirred for 2-4hr under 10 DEG C below zero -0 DEG C, stirred for 5-10hr under room temperature, and then filtered; the filtrates react for 10-60min under 50-100 DEG C, the toluene is evaporated out under 100-120 DEG C, and then react for 5-20hr under 160-170 DEG C. The precursor polymer synthesized by the method has a proper linear shape and a mesh structure, and has sound spinnability and wave-penetrating performance.

Owner:DONGHUA UNIV

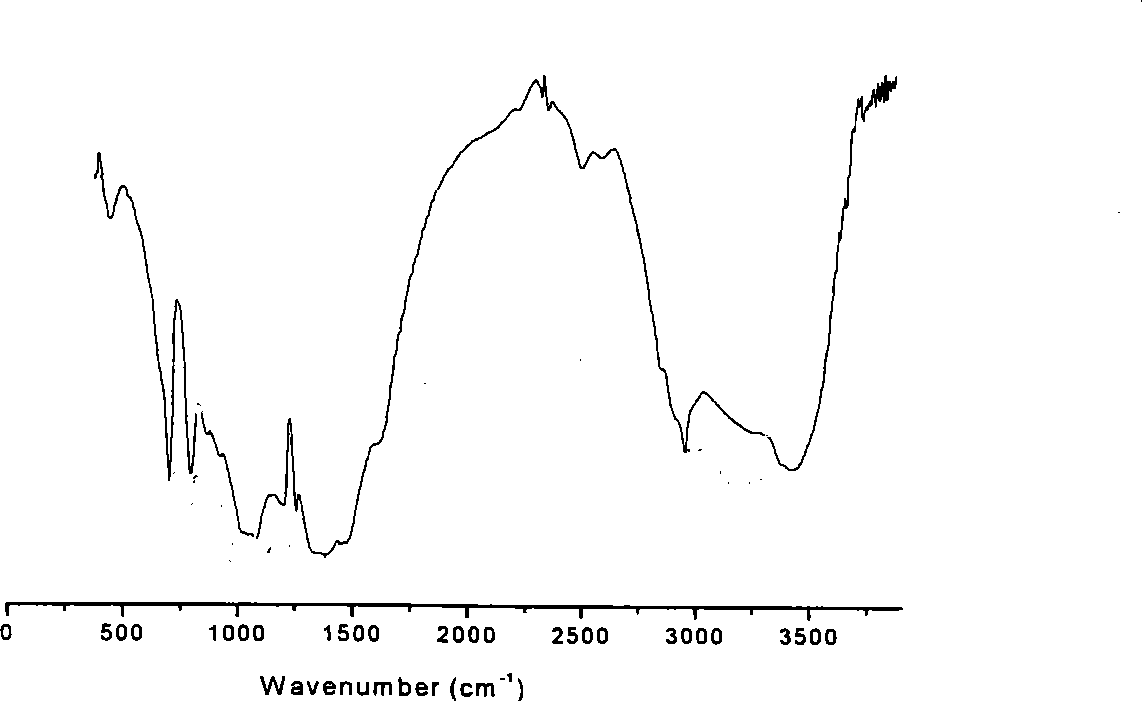

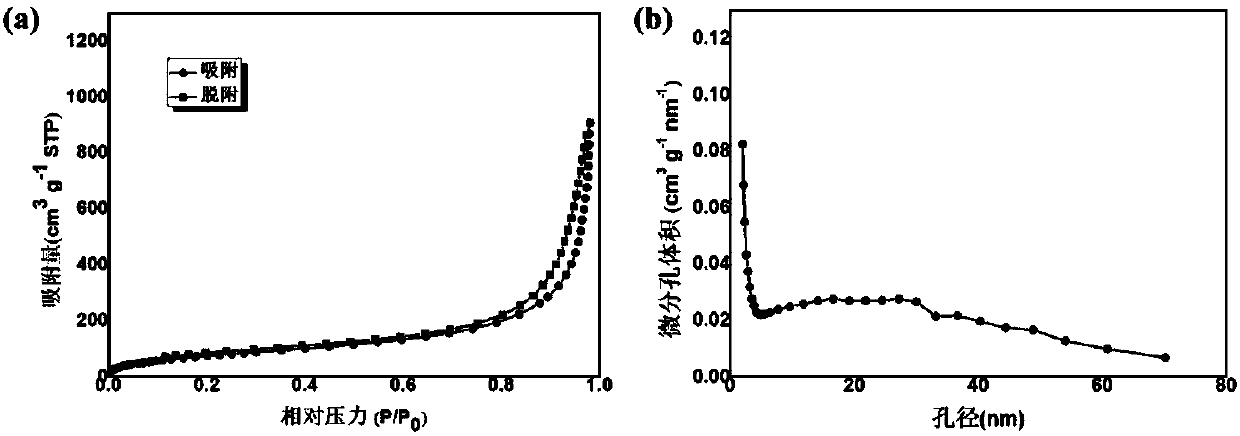

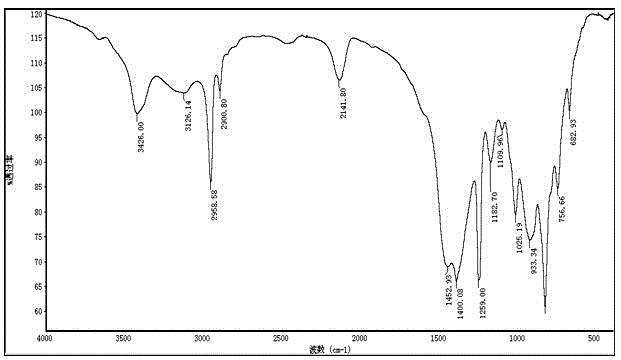

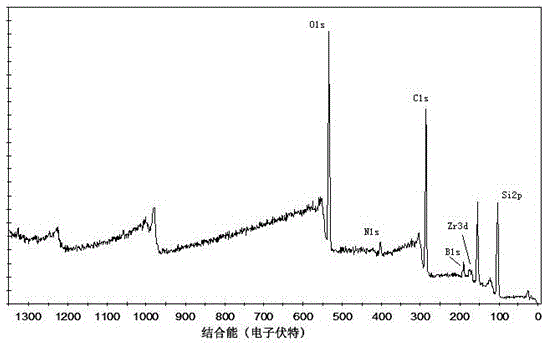

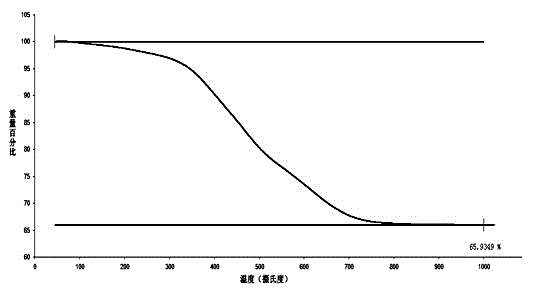

Polysilazane-zirconium dioxide composite aerogel material as well as preparation method and application thereof

InactiveCN107778875AHigh porosityLarge specific surface areaBulk chemical productionSupercritical dryingRoom temperature

The invention discloses a polysilazane-zirconium dioxide composite aerogel material as well as a preparation method and application thereof. The preparation method comprises the following steps: dispersing a polysilazane precursor in methylbenzene, successively adding zirconium n-butoxide and divinyl benzene, rapidly and uniformly stirring, obtaining a mixed dilute solution, transferring the mixeddilute solution into a hydrothermal reaction kettle, sealing the hydrothermal reaction kettle, placing the reaction kettle with the mixed dilute solution in a drying box, performing the reaction, cooling to room temperature to obtain wet gel, and standing the wet gel in a beaker with the methylbenzene; and transferring a product of the step 1 into a carbon dioxide supercritical extraction apparatus, soaking in liquid carbon dioxide, supercritically drying, and obtaining the polysilazane-zirconium dioxide composite aerogel material. The polysilazane-zirconium dioxide composite aerogel materialis a novel nano porous composite material, has high porosity, high specific surface area and low density; and the preparation condition is mild, and the process is simple and controllable.

Owner:TIANJIN CHENGJIAN UNIV

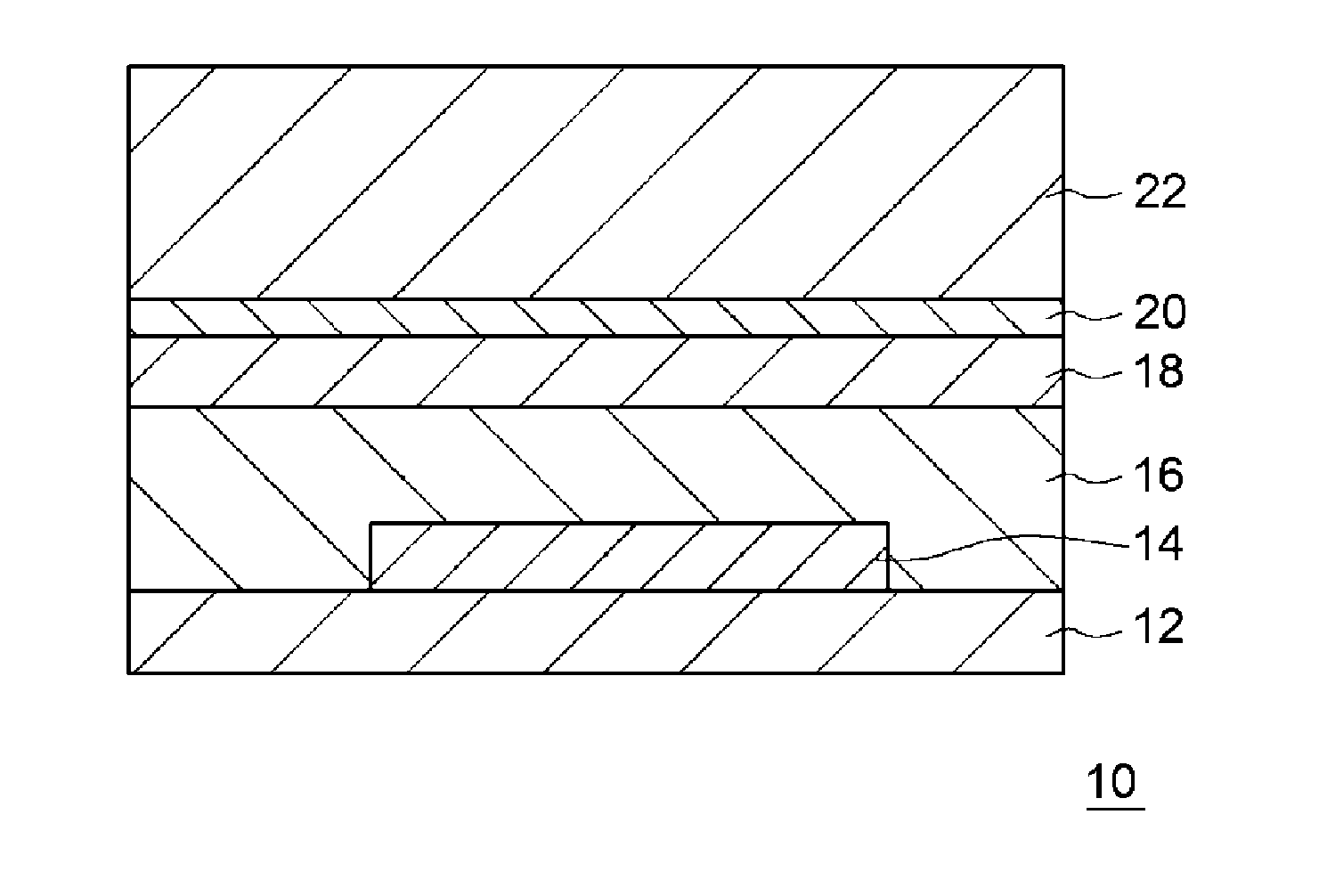

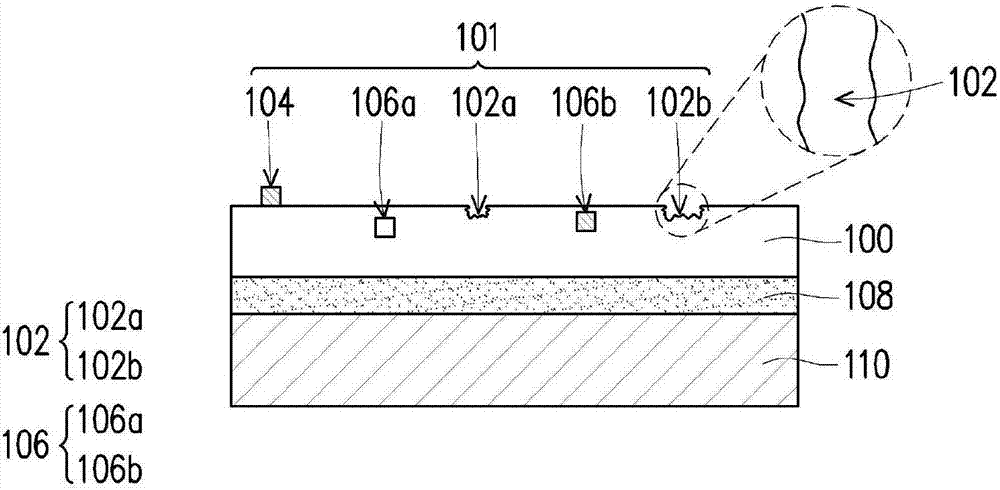

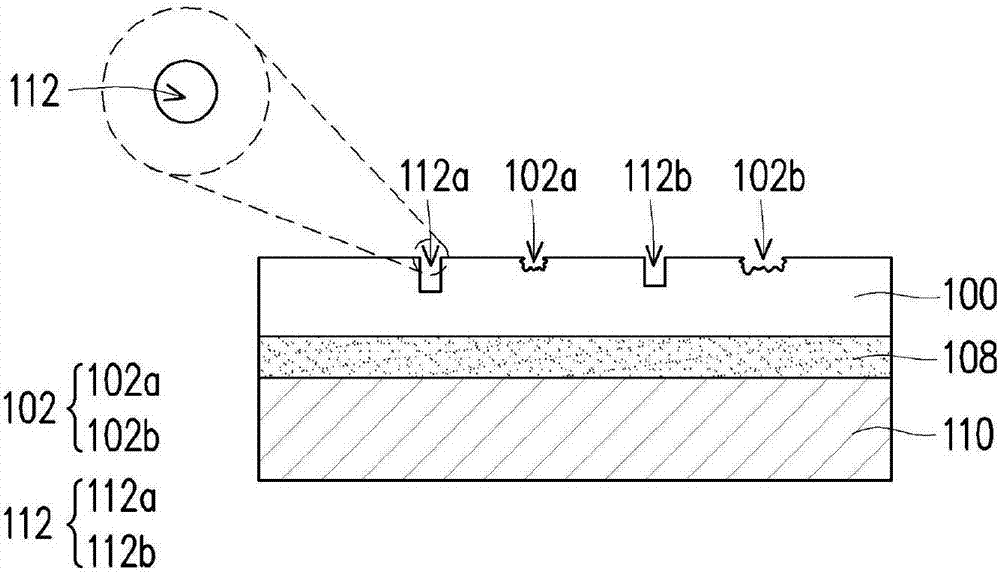

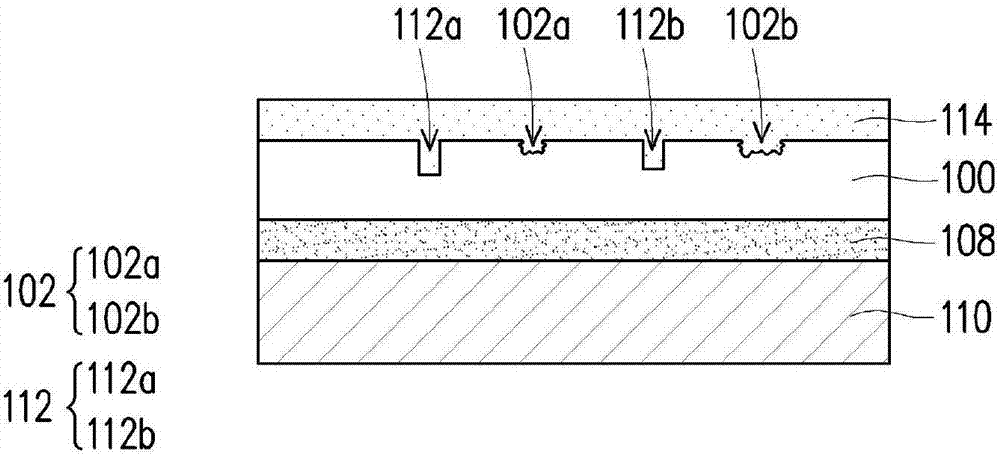

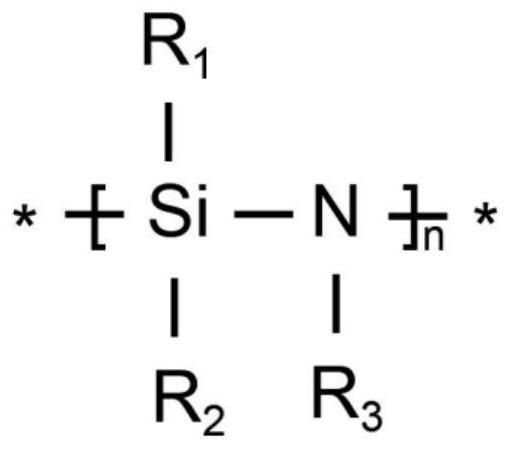

Flexible substrate repair structure, manufacturing method, and detection and repairing method

ActiveCN106997845AAvoid delaminationImprove adhesionCircuit bendability/stretchabilitySemiconductor/solid-state device detailsCarbon numberAzane

The invention provides a flexible substrate repair structure, a manufacturing method, and a detection and repairing method. The flexible substrate repair structure includes a flexible substrate and at least one repairing layer, regular sunken parts formed on the flexible substrate. The repairing layer is located on the flexible substrate and fills the regular sunken parts. The material of the at least one repairing layer includes a polysilazane compound, which is represented as the chemical formula (I), wherein Rx, Ry, and Rz are repsectively hydrogen atoms, substituted alkyl groups, non-substituted alkyl groups, alkenyl groups, or aromatic groups, carbon number being 1 to 10. The repairing layer can avoid or reduce problems of cracks or ruptures on a film layer on the flexible substrate.

Owner:HANNSTAR DISPLAY CORPORATION

Delay coking high temperature defoaming agent and its application

ActiveCN103768833AFacilitate cross-linkingHighly regular structureThermal non-catalytic crackingFoam dispersion/preventionAzaneSilazane

The invention relates to a delay coking high temperature defoaming agent and its application, the defoaming agent is prepared by compounding ultra-high-viscosity linear polydimethylsiloxane, glycerin-type dendritic polyether, high carbon alcohol, vinyl-containing polysilazane and a solvent under certain conditions. A preparation method of the defoaming agent is as follows: dispersing required specifications of the ultra-high-viscosity linear polydimethylsiloxane, the glycerin-type dendritic polyether and the high carbon alcohol in the solvent at a constant temperature of 60-100 DEG C, then cooling to room temperature, mixing, simultaneously adding the vinyl-containing polysilazane, and then filtering away non-homogeneous impurities to obtain the defoaming agent finished product. The efficient multi-active-component defoaming agent used in the delay coking process has good defoaming and anti-foaming properties at a high use temperature, also can maintain the high chemical stability, and is not easy to generate low-boilnig-point silicon-containing small molecules cyclized compounds, and the adverse influence of the defoaming agent on the subsequent processing process can be avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

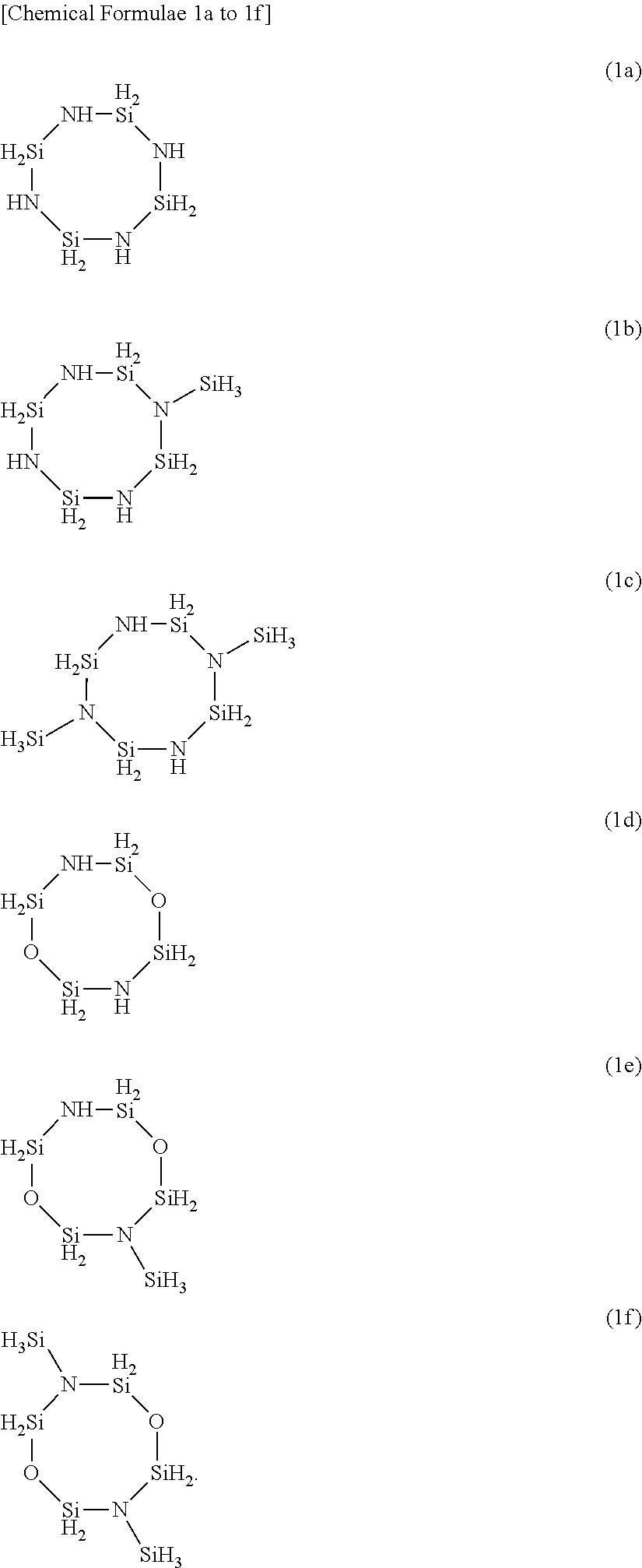

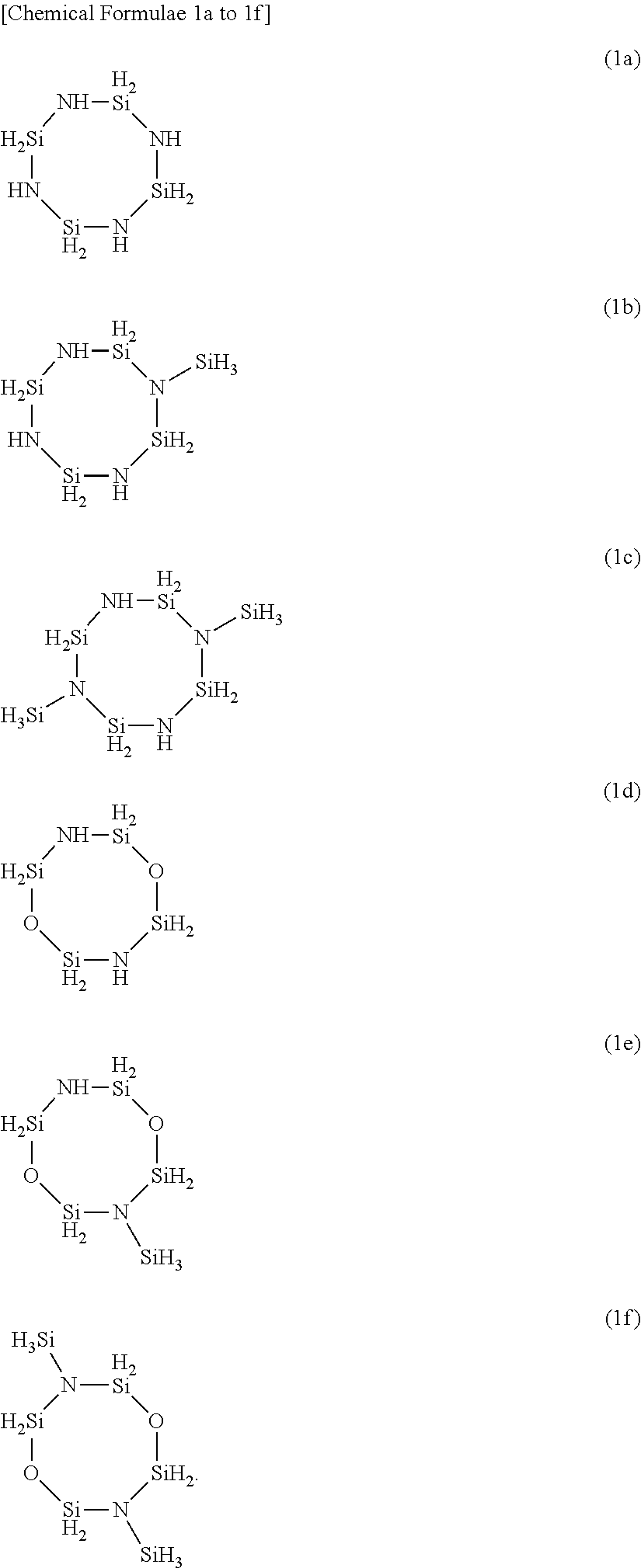

Composition for forming silica-based insulating layer, method for preparing composition for forming silica-based insulating layer, silica-based insulating layer, and method for manufacturing silica-based insulating layer

ActiveUS20150274980A1Improve thickness uniformityReduce generationSilicaPlastic/resin/waxes insulatorsInsulation layerAzane

Disclosed is a composition for a silica-based insulation layer including hydrogenated polysilazane or hydrogenated polysiloxzane, wherein a concentration of a cyclic compound having a weight average molecular weight of less than 400 is less than or equal to 1,200 ppm. The composition for a silica-based insulation layer may reduce a thickness distribution during formation of a silica-based insulation layer, and thereby film defects after chemical mechanical polishing (CMP) during a semiconductor manufacturing process may be reduced.

Owner:CHEIL IND INC

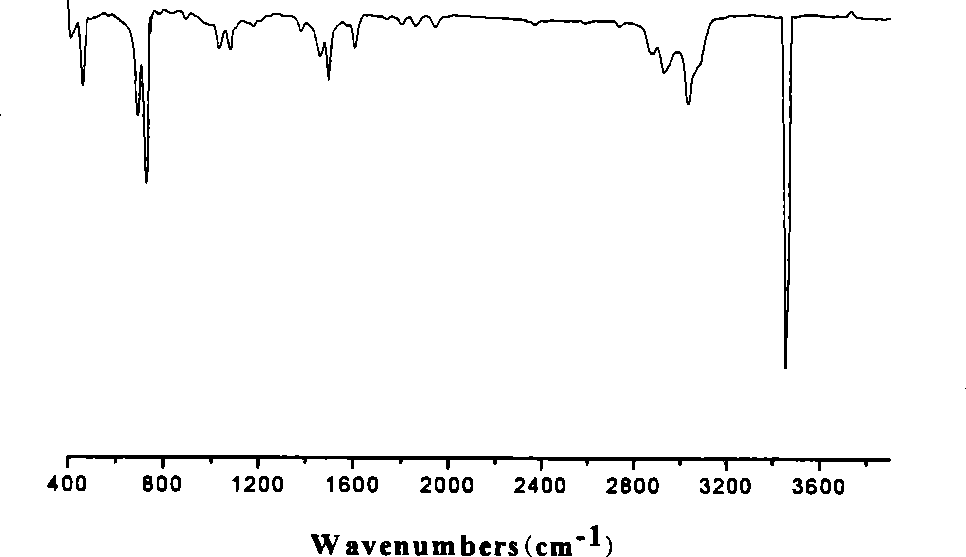

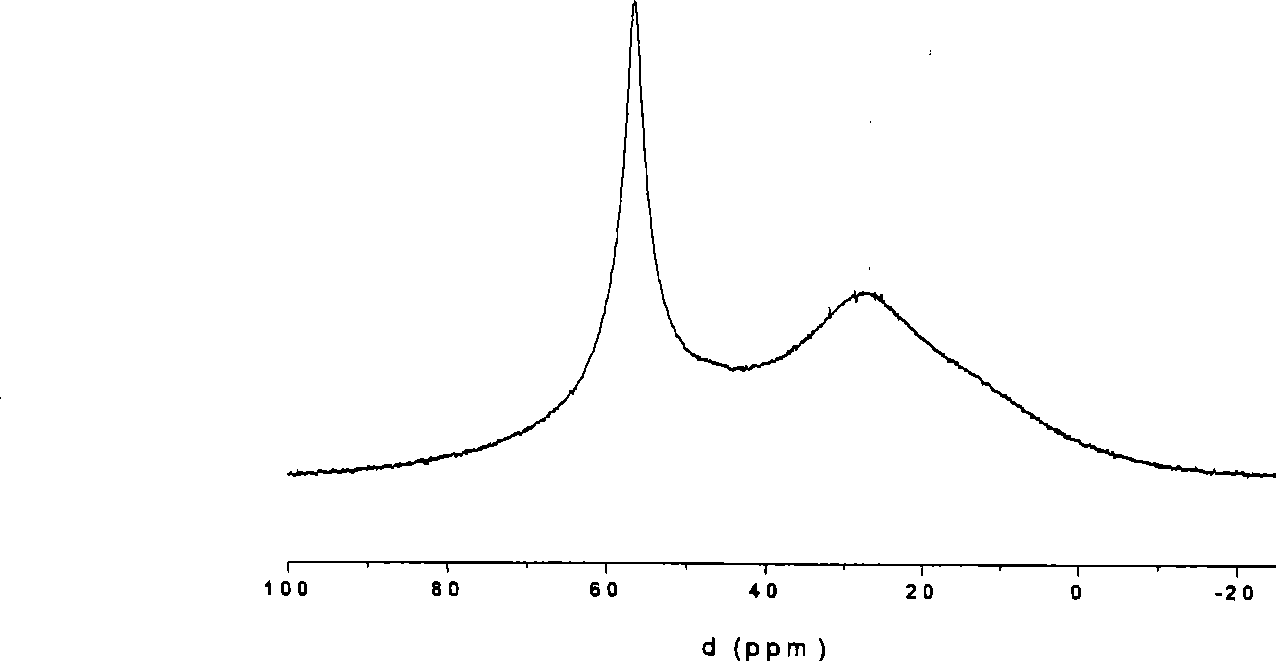

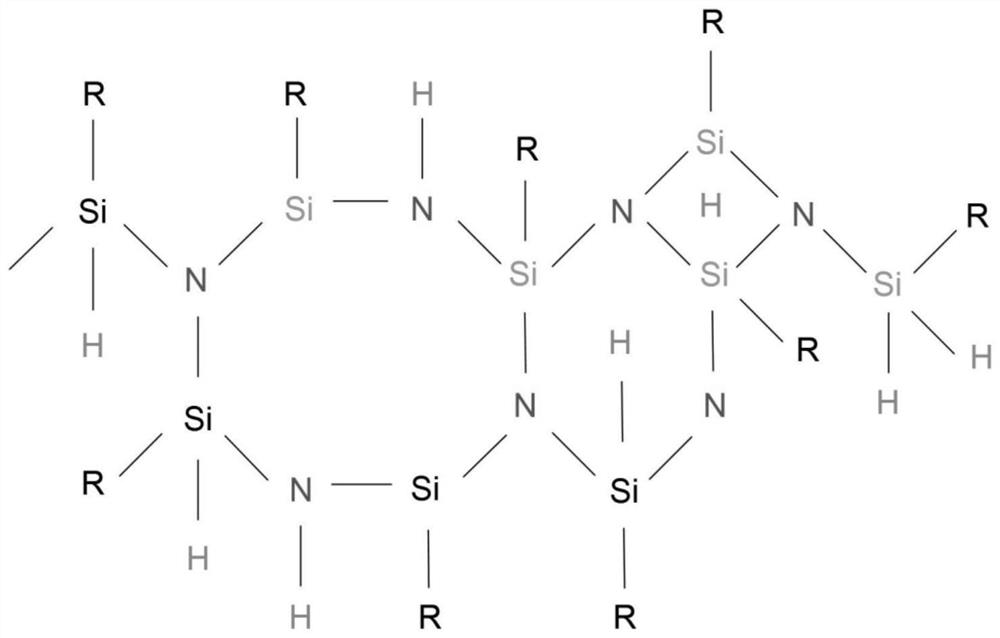

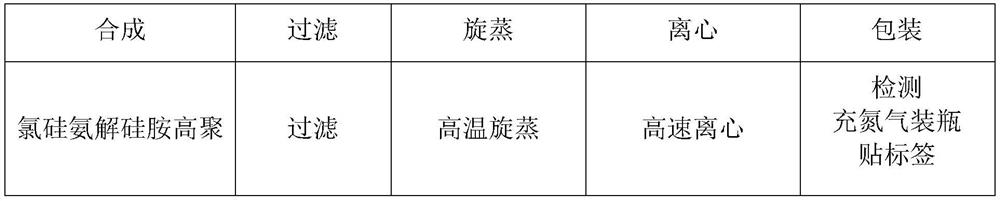

Methyl polysilazane resin and preparation method thereof

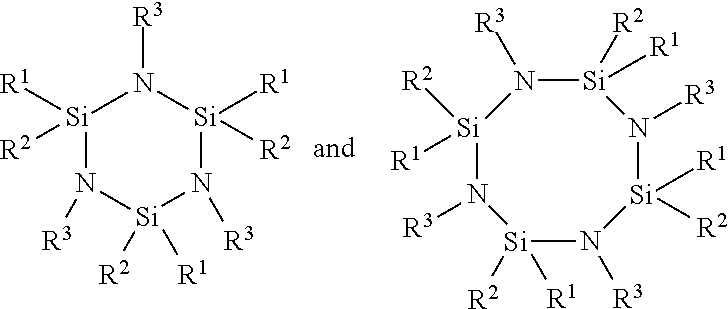

The invention discloses methyl polysilazane resin and a preparation method thereof, the methyl polysilazane resin controls the raw material input amount of methyldichlorosilane and trichlorosilane inammonolysis raw materials, and six-membered and eight-membered ring-shaped and linear methyl polysilazane mixtures with Si-N and methyl double chains on side chains are synthesized; the addition amount of the raw materials of the methyl polysilazane resin is as follows: the mass ratio of methyl dichlorosilane to trichlorosilane is 1: (0.8-1.2); the mass ratio of the proton inert solvent to the nitrogen silane is 7-12: 1; the molar ratio of the introduction amount of the ammonia gas to the chlorosilane is (5-12): 1, and the total amount of the chlorosilane is the sum of methyl dichlorosilane and trichlorosilane. The invention relates to a brand-new preparation method of methyl polysilazane resin, the methyl polysilazane resin has strong adhesive force, high temperature resistance, corrosionresistance, weather resistance, hydrophobicity, antifouling property and other comprehensive properties, and compared with the preparation method of foreign similar products, the preparation method is simpler and more convenient to operate and less in environmental pollution.

Owner:库贝化学(上海)有限公司

High-temperature-resistant wear-resistant brake pad

InactiveCN106009497AImprove wear performanceImprove mechanical propertiesOther chemical processesFriction liningInsulation layerWear resistant

The invention discloses a high-temperature-resistant wear-resistant brake pad which comprises a steel plate, a heat-insulation layer and a friction block. The friction block is prepared from a phenolic resin, biphenyl polyimide powder, superfine total vulcanized powder rubber, octaanilino POSS (polyhedral oligomeric silsesquioxane), polyurethane powder, an epoxy resin, silicon carbide whiskers, high silica fibers, potassium titanate whiskers, aluminum borate whiskers, basic magnesium sulfate whiskers, nano paligorskite, barium carbonate, aluminum nitride powder, calcined coke, zinc sulfide, titanium carbide, vermiculite, mica, molybdenum disulfide, natural graphite, zirconium dioxide microspheres, multi-wall carbon nanotubes, polyboron azane, boron carbide and epoxy soybean oil. The high-temperature-resistant wear-resistant brake pad disclosed by the invention has the advantages of excellent high temperature resistance, excellent wear resistance, excellent heat stability, favorable braking property and long service life.

Owner:WUHU DONGZHENG AUTOMOTIVE IND

Preparation method of poly-zirconium-boron-silazane precursor

A preparation method of a poly-zirconium-boron-silazane precursor comprises the following steps: 1, weighing an organic zirconium compound, boron haloalkane, halogenosilane and micromolecular disilazane at the molar ratio of 1:(0.1-10):(0.1-10):(3-30); 2, respectively dissolving the boron haloalkane and the halogenosilane in organic solvents; 3, adding the organic zirconium compound to a reaction vessel, vacuumizing, filling dry nitrogen gas and precooling the reaction vessel; 4, adding the organic solvent of the boron haloalkane adn the organic solvent of the halogenosilane to the reaction vessel, and dripping the micromolecular disilazane in the reaction vessel; 5, after the dripping is finished, heating the reaction vessel to 150-500 DEG C, and preserving heat for 2-30 hours; 6, cooling the reaction vessel to 120-350 DEG C, distilling under reduced pressure and cooling to the room temperature. The poly-zirconium-boron-silazane precursor prepared according to the method is especially suitable for preparing ultra-high temperature ceramic materials.

Owner:NAT UNIV OF DEFENSE TECH

Process for preparing shelf-stable curable polysilazanes, and polysilazanes prepared thereby

A process for preparing curable oligomeric and / or polymeric polysilazanes comprises (a) forming at least one dihalosilane-base adduct by reacting at least one dihalosilane with at least one base; (b) optionally, combining at least one dihalosilane-base adduct and at least one organodihalosilane; and (c) carrying out ammonolysis of at least one dihalosilane-base adduct or of the resulting combination of at least one dihalosilane-base adduct and at least one organodihalosilane; with the proviso that the base (1) is used for the dihalosilane-base adduct formation in a limited amount that is less than or equal to twice the stoichiometric amount of silicon-halogen bonds in the dihalosilane or (2) is used for the dihalosilane-base adduct formation in excess of this limited amount and, prior to the ammonolysis, the total amount of the resulting reacted and unreacted base is reduced to no more than this limited amount.

Owner:3M INNOVATIVE PROPERTIES CO

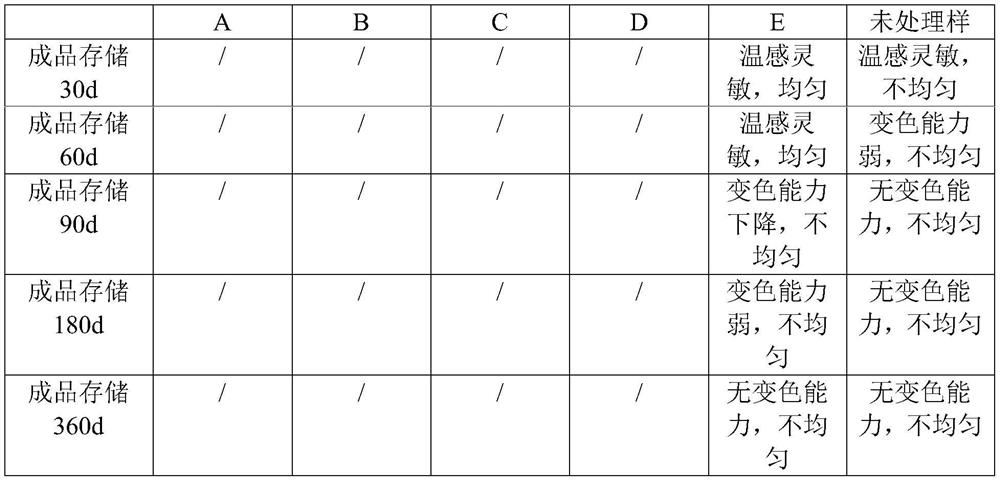

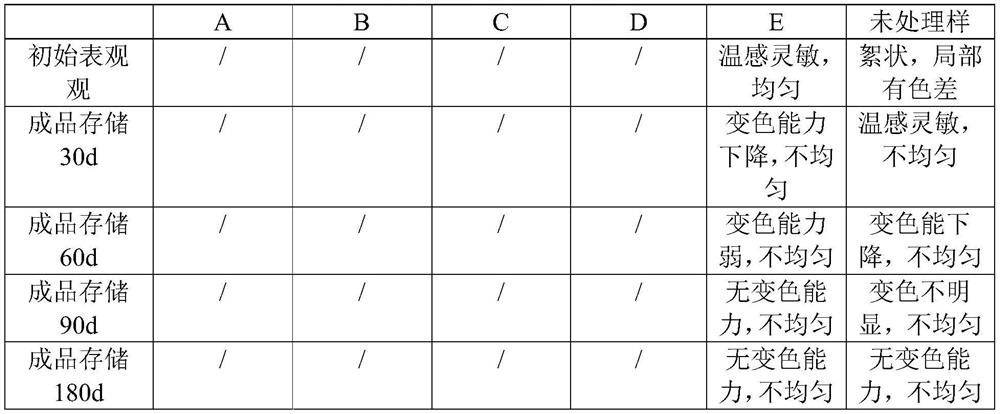

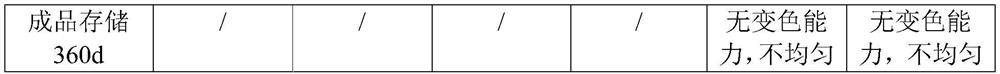

Temperature-sensitive color-changing agent as well as preparation method and application thereof

The invention relates to a temperature-sensitive color-changing agent and a preparation method and application thereof, and belongs to the field of fine chemical engineering technology and functional material preparation. The temperature-sensitive color-changing agent comprises temperature-sensitive color-changing powder and a modifier; the modifying agent is nitrogen-containing silane or chlorine-containing silane; the mass ratio of the thermochromic powder to the modifier is 1: (0.05-0.15). The temperature-sensing color-changing agent is subjected to surface treatment through hexamethyldisilazane or dimethyldichlorosilane, so that the capsule shell is more stable and more resistant to chemical corrosion and mechanical extrusion, and on the other hand, capsule powder obtained after surface treatment is more easily dispersed into silica gel. And if not treated, the color change function is lost in the product storage process or along with the increase of the use time.

Owner:HUNAN AEROSPACE SANFENG SCI & TECH CO LTD

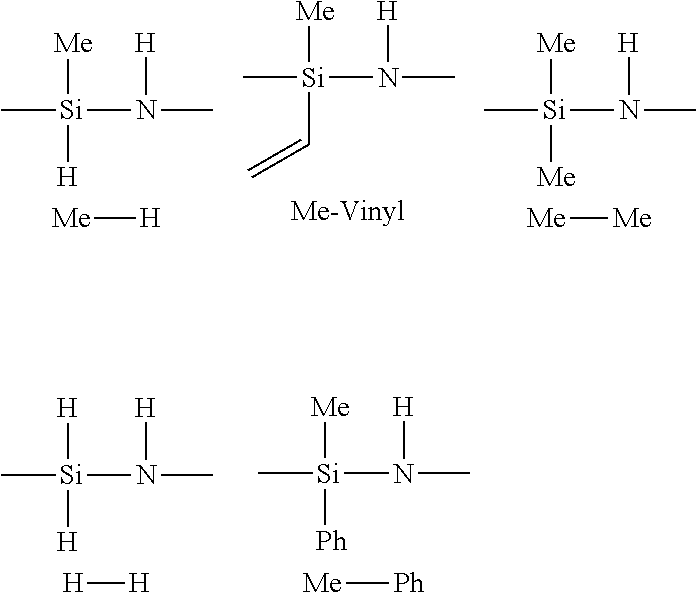

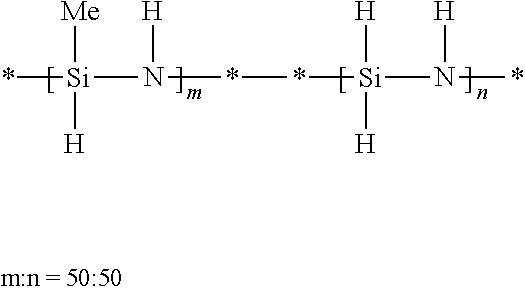

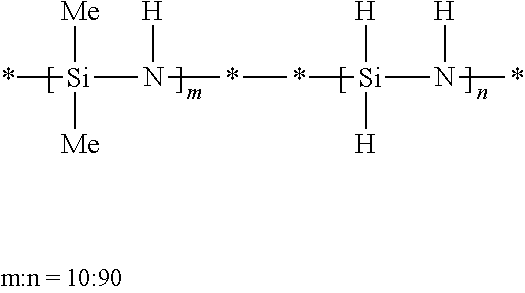

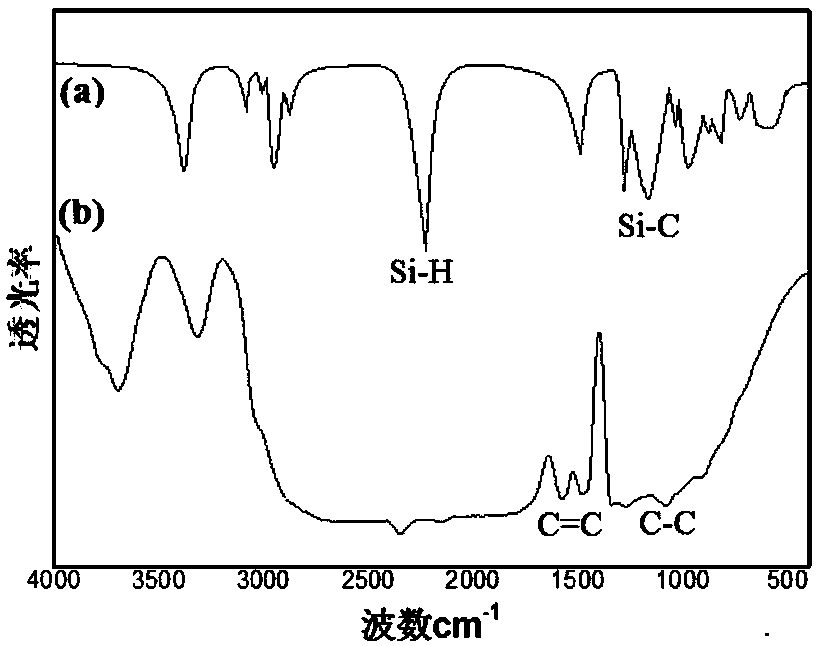

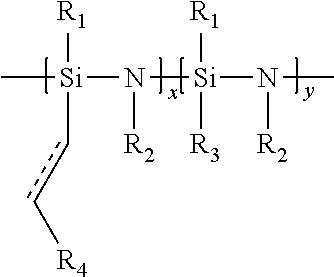

Formulations for 3D printing of hydrosilylation-modified polysilazanes

Some variations provide a preceramic resin precursor formulation comprising: first molecules comprising at least one Si—C bond and / or at least one Si—N bond, wherein the first molecules include at least one silyl hydride group (Si—H) available for hydrosilylation; and second molecules with at least one unsaturated carbon-carbon bond attached to a UV-active functional group. The first molecules and second molecules may be reacted, via hydrosilylation with a homogeneous or heterogeneous metal-containing catalyst, to produce third molecules comprising a hydrosilylation-modified polysilazane that contains the UV-active functional group. Many possible starting formulations are described, and methods are disclosed for carrying out the chemical reactions to generate the hydrosilylation-modified polysilazanes. The hydrosilylation-modified polysilazanes may then be 3D-printed and thermally treating to fabricate a ceramic material.

Owner:HRL LAB

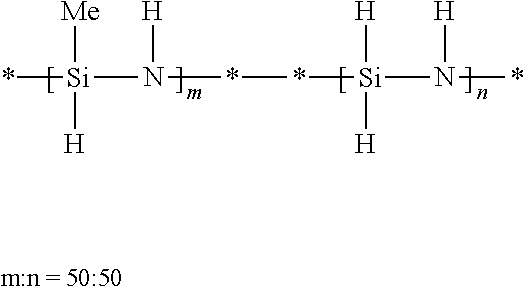

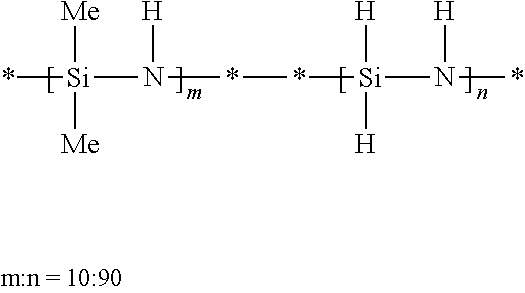

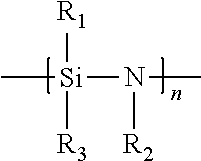

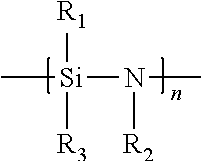

Transparent coating film forming composition

ActiveUS20200199406A1Improve machinabilityImprove securityPaints for electrolytic applicationsPolymer sciencePtru catalyst

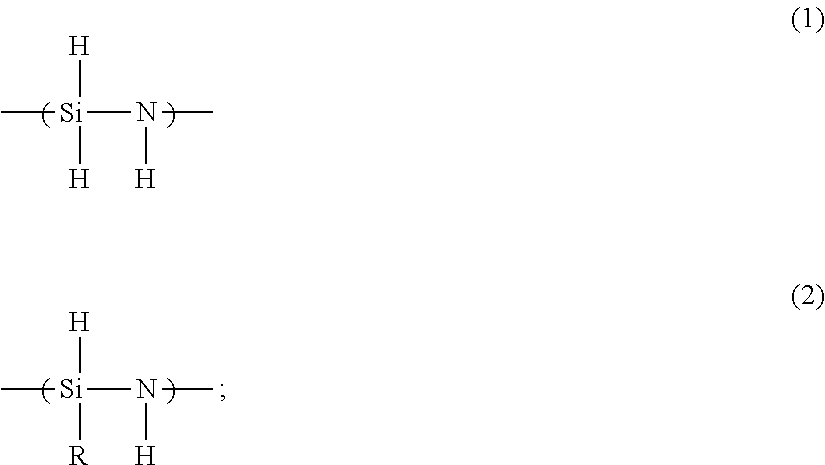

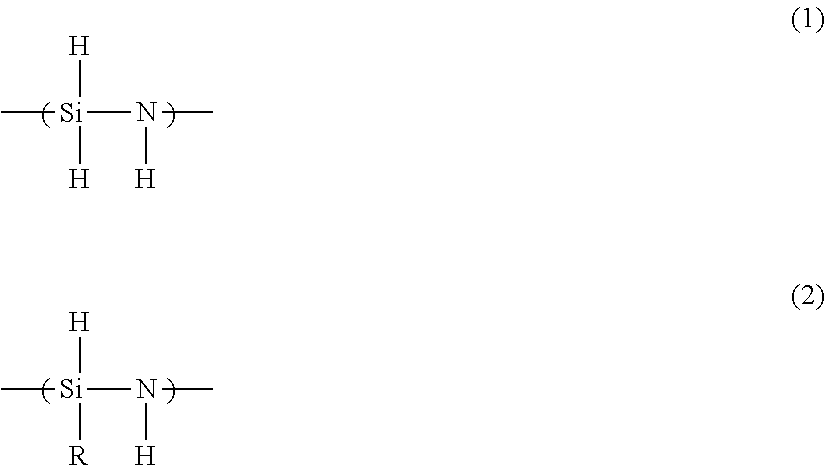

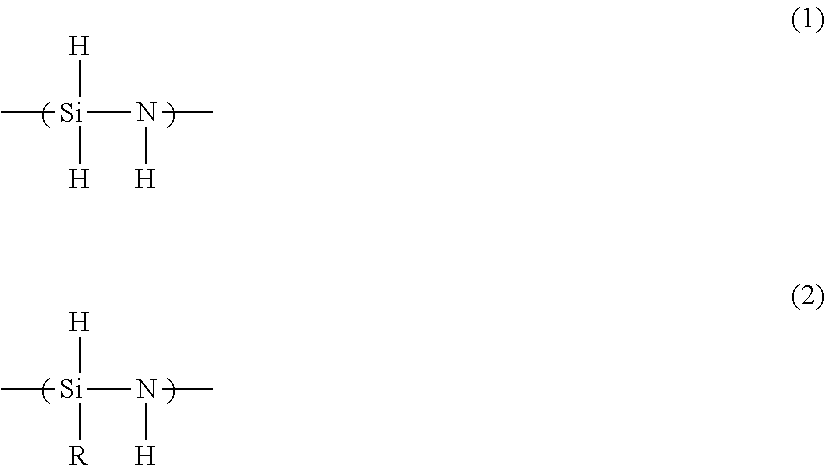

A transparent coating film forming composition contains: (A) a polysilazane having units represented by the following formulae (1) and (2), and having predetermined modification rate and weight average molecular weight,(B) an organic solvent containing (B-1) and (B-2), (B-1) an organic solvent having a dielectric constant of 2.1 to 15.0 on average and a higher boiling point under atmospheric pressure (1013 hPa) than that of an organic solvent contained as the component (B-2), and (B-2) a saturated aliphatic hydrocarbon organic solvent; and (C) a predetermined curing catalyst. The mixing ratio of the component (A) and the component (B) satisfies a predetermined range. This provides a transparent coating film forming composition using an organic solvent having high polysilazane solubility, volatility at an appropriate speed during application, high safety and workability, the composition enabling formation of a coating film that is uniform and has high transparency and hardness after curing.

Owner:SHIN ETSU CHEM IND CO LTD

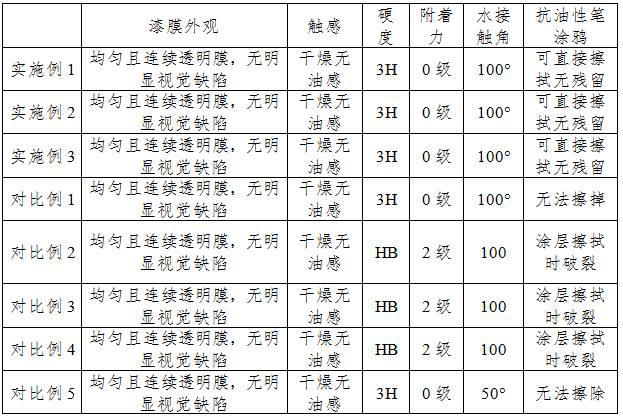

Synthesis of vinyl polysilazane and application of vinyl polysilazane in anti-doodling coating

The invention relates to synthesis of vinyl polysilazane and application of vinyl polysilazane in an anti-doodling coating, and the synthesis comprises the following steps: 1) in a benzene solution of methyl vinyl dichlorosilane, stirring, introducing ammonia gas, reacting at 300 DEG C for more than or equal to 4 hours, filtering, and carrying out reduced pressure suction filtration to obtain micromolecular methyl vinyl silazane; (2) carrying out ammonolysis on dimethyldichlorosilane and methyl dichloro hydrogen-containing silane to obtain an intermediate, carrying out nitrogen protection, slowly heating to 300 DEG C, carrying out heat preservation reaction for more than or equal to 4 hours, and carrying out reduced pressure distillation to remove a low-molecular polymer, so as to obtain a polysilazane polymer; and (3) mixing the products in the steps (1) and (2) according to a mass ratio of 5: (1-10), evaporating to remove the solvent under the protection of nitrogen, and reacting at 200 DEG C for 24 hours to obtain vinyl polysilazane. The preparation method comprises the following steps: uniformly mixing vinyl polysilazane, high-activity UV resin, a cross-linking agent, a catalyst, a photoinitiator, a solvent and an anti-pollution additive, spraying, and curing by ultraviolet irradiation. The preparation method is safe in reaction temperature and high in repeatability, and can be used for preparing the fast-curing anti-fouling easy-to-clean vinyl polysilazane coating.

Owner:JIANGXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com