Synthesis of vinyl polysilazane and application of vinyl polysilazane in anti-doodling coating

A technology of vinyl polysilazane and methyl vinyl dichlorosilane, applied in the field of chemical coatings, can solve the problems of low vinyl activity and preparation into light-curing coatings, etc., and achieve the effect of safety and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

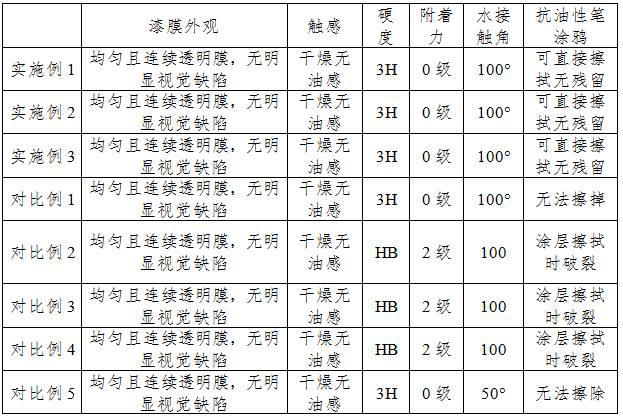

Examples

Embodiment 1

[0018] (1) Synthesis of vinyl polysilazane.

[0019] 1) In the benzene solution of methylvinyldichlorosilane, under stirring conditions, pass dry and high-purity ammonia gas, keep the reaction at 300 °C for 4 hours, and filter out the precipitate to obtain small molecular methylvinylsilicon. Azane Vi-PZ Liquid.

[0020] 2) Preparation of polysilazane polymer PSZ: co-ammonolysis of dimethyldichlorosilane and methyldichlorohydrogen-containing silane in a molar ratio of 1.5:1 to obtain a low-molecular-weight intermediate, and then under nitrogen protection with 5 The ℃ / min heating rate was slowly raised to 300 ℃, and the reaction was kept for 4 hours. After the reaction, the low-molecular polymer PSZ was removed by vacuum distillation.

[0021] 3) After mixing the products obtained in step 1) and step 2) according to the instruction ratio of 5:1, the solvent was evaporated under nitrogen protection, and then the reaction was kept at 200 °C for 24 h to obtain vinyl polysilazane V...

Embodiment 2

[0025] (1) Synthesis of vinyl polysilazane.

[0026] 1) Pour dry and high-purity ammonia gas into the benzene solution of methylvinyldichlorosilane while stirring, keep the reaction at 300 °C for 4 hours, filter out the precipitate to obtain small molecular methylvinylsilazane Vi-PZ liquid.

[0027] 2) Preparation of polysilazane polymer PSZ, the specific preparation method is as follows: co-ammonolysis of dimethyldichlorosilane and methyldichlorohydrogen-containing silane in a molar ratio of 1.5:0.5 to obtain a low molecular intermediate, and then in Under nitrogen protection, the temperature was slowly raised to 300 °C at a heating rate of 5 °C / min, and the reaction was kept for 4 h. After the reaction, the low molecular weight polymer PSZ was removed by vacuum distillation.

[0028] 3) After mixing the products obtained in step 1) and step 2) according to the instruction ratio of 5:2, the solvent was evaporated under nitrogen protection, and then the reaction was kept at 2...

Embodiment 3

[0032] (1) Synthesis of vinyl polysilazane.

[0033] 1) Pour dry and high-purity ammonia gas into the benzene solution of methylvinyldichlorosilane while stirring, keep the reaction at 300 °C for 4 hours, filter out the precipitate to obtain small molecular methylvinylsilazane Vi-PZ liquid.

[0034] 2) Preparation of polysilazane polymer PSZ, the specific preparation method is as follows: co-ammonolysis of dimethyldichlorosilane and methyldichlorohydrogen-containing silane according to a molar ratio of 1:1 to obtain a low molecular intermediate, and then in Under nitrogen protection, the temperature was slowly raised to 300 °C at a heating rate of 5 °C / min, and the reaction was kept for 4 h. After the reaction, the low molecular weight polymer PSZ was removed by vacuum distillation.

[0035] 3) After mixing the products obtained in step 1) and step 2) according to the instruction ratio of 5:1.5, the solvent was evaporated under nitrogen protection, and then the reaction was k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com