Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

641results about How to "Reduce sliding friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

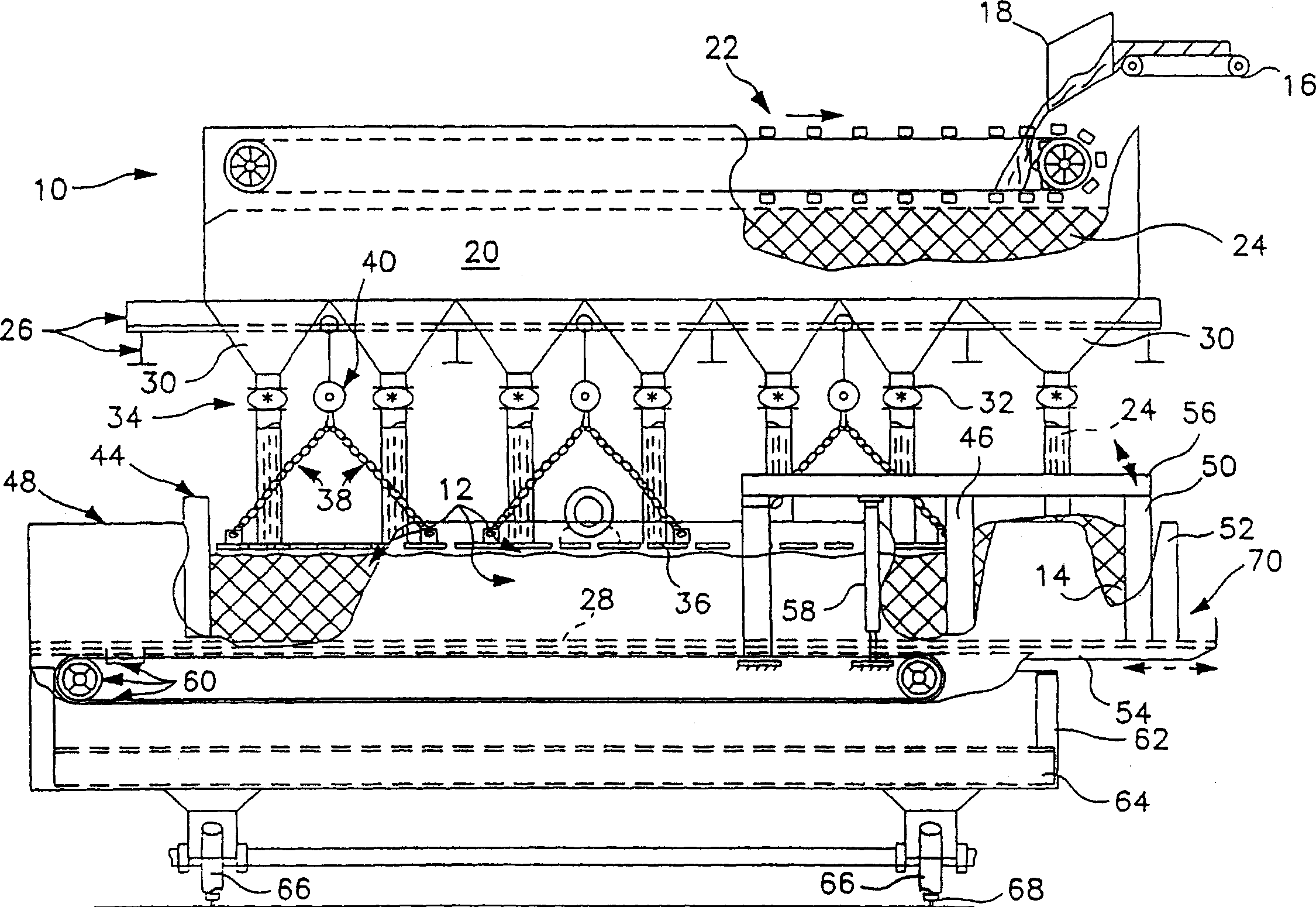

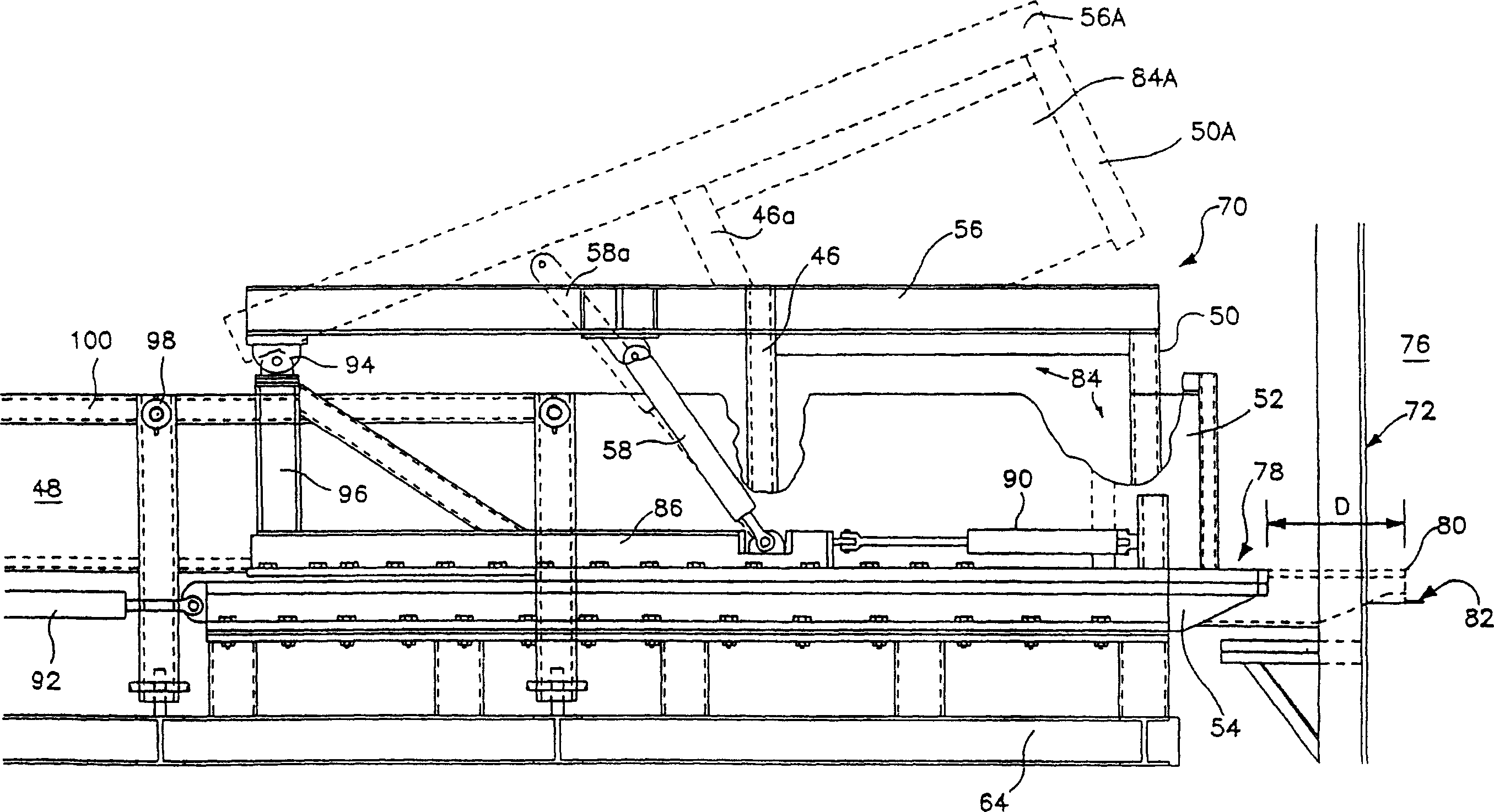

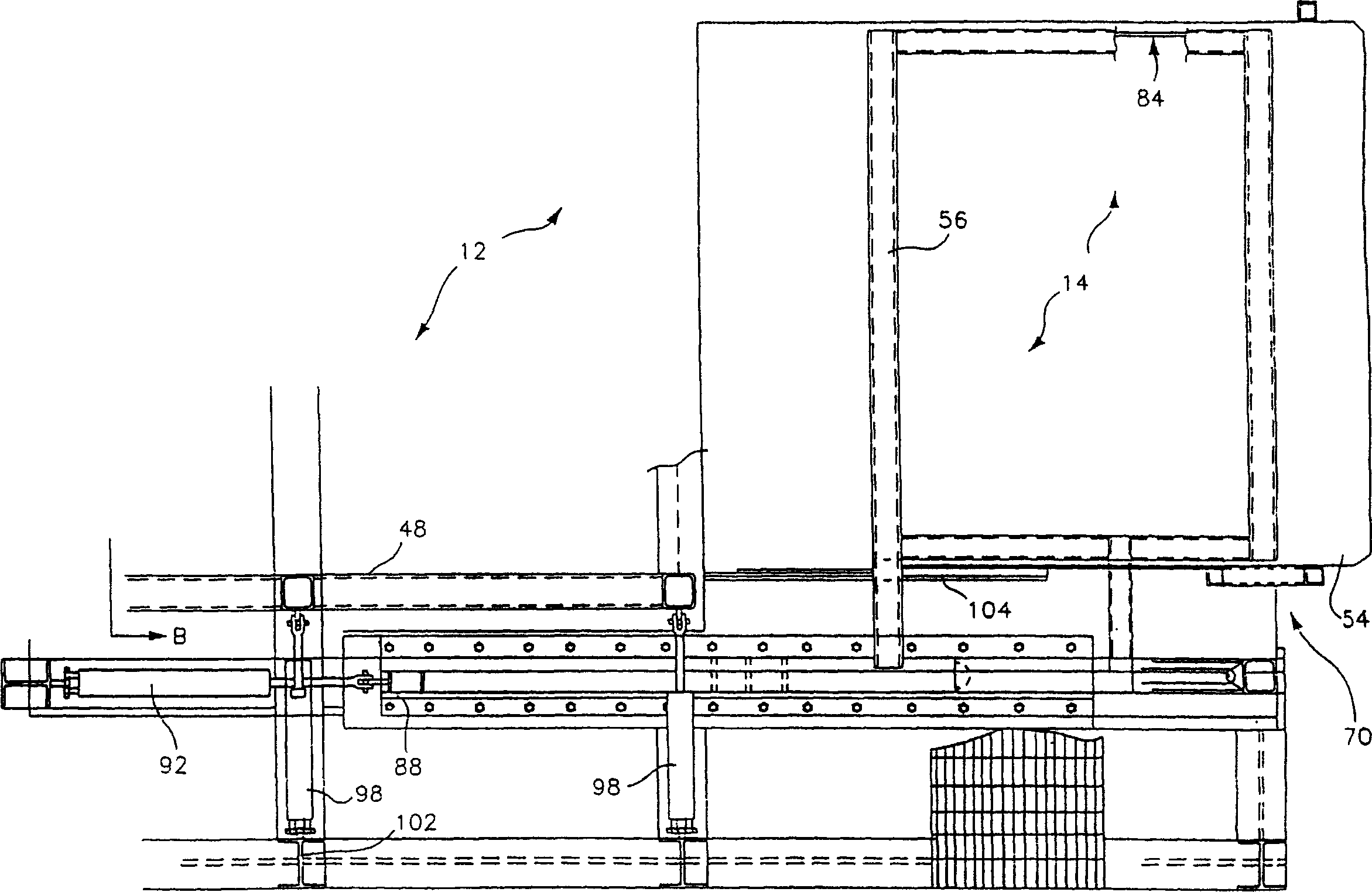

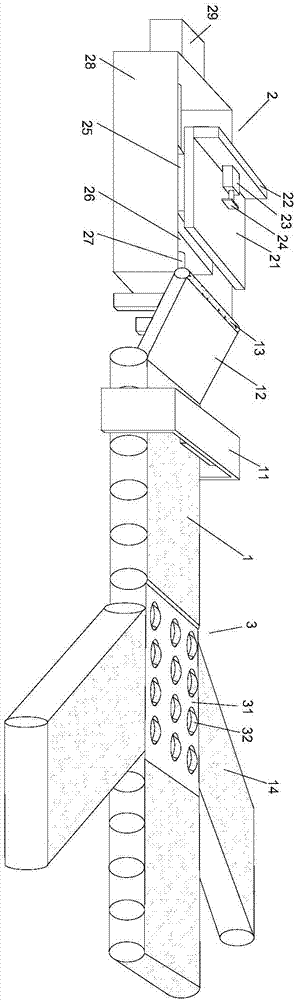

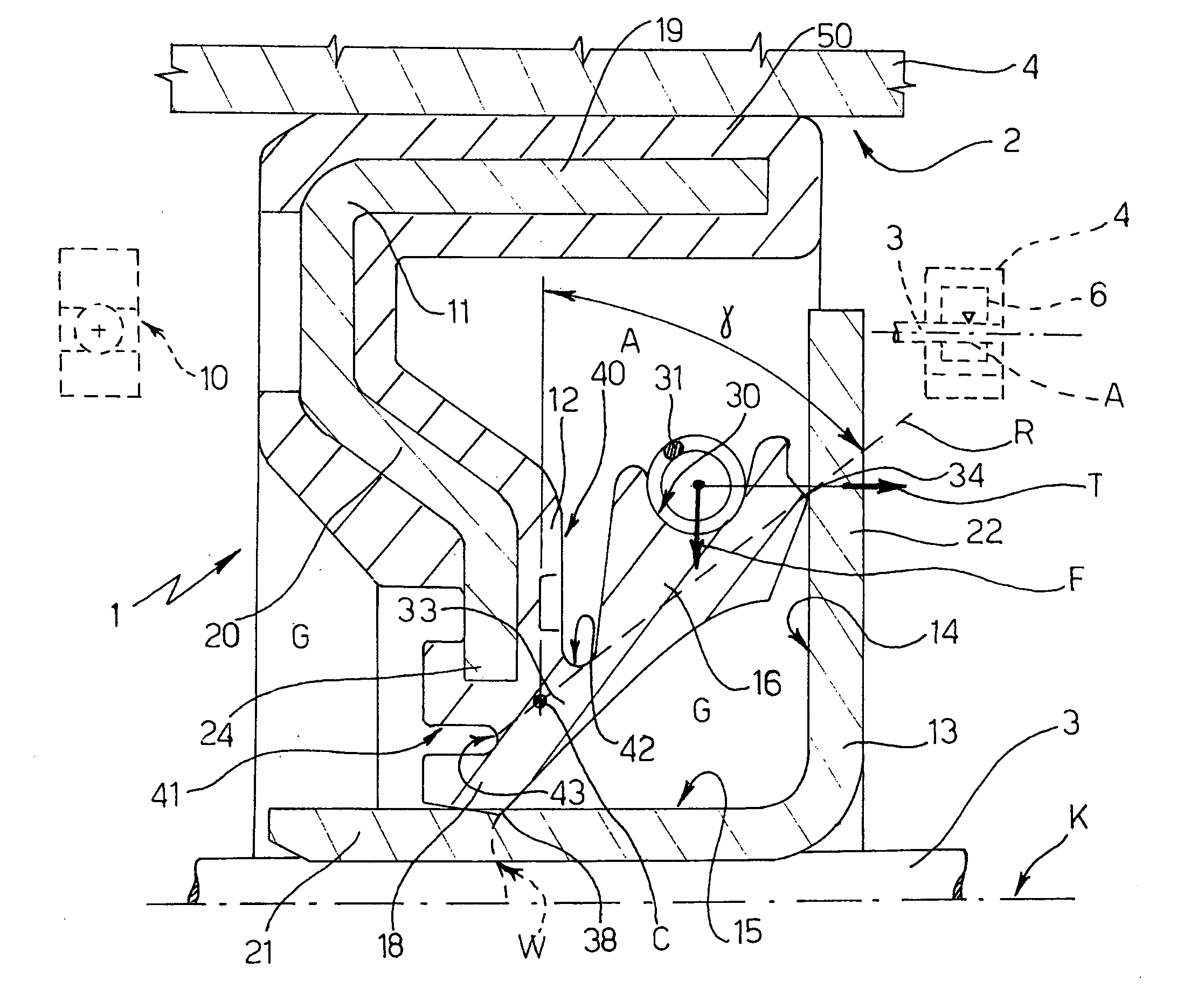

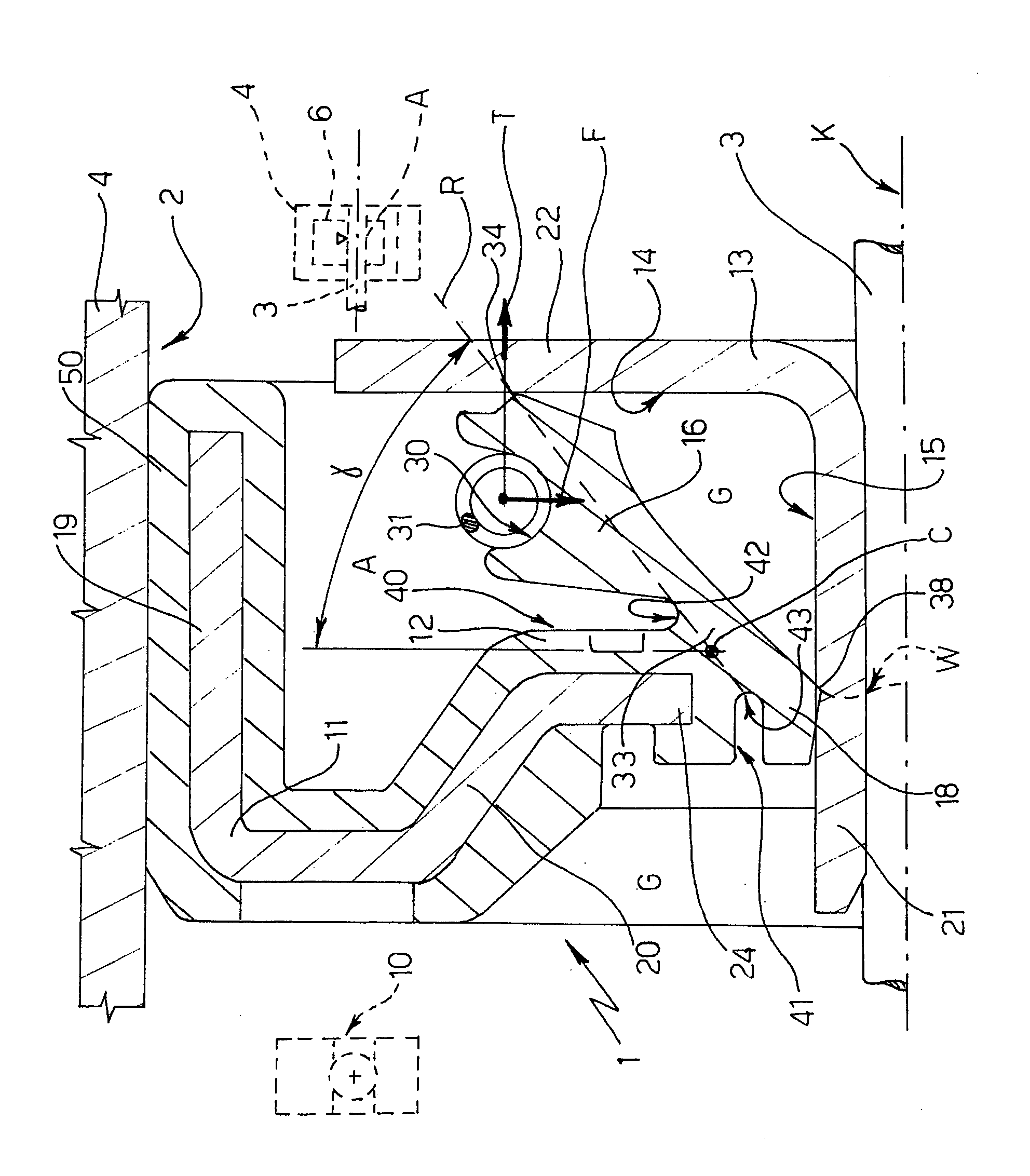

Method and apparatus for coal coking

InactiveCN1468364AReduce warpageReduce sliding frictionCharge manipulationCharging devicesEngineeringCoke oven

The invention provides a coke oven charging machine including a mobile frame and a coke oven feed device on the mobile frame. The coke oven feed device includes a movable, elongate charging plate having a first end and a second end, retractable side-walls adjacent the charging plate, first and second end walls adjacent the first and second ends of the charging plate and a shuttle section adjacent the first end of the charging plate for spanning an area between the first end of the charging plate and an entrance to the oven. The shuttle section has opposed shuttle side walls and a shuttle end wall. A charging plate moving device is provided for moving the charging plate into and out of the oven. The charging machine apparatus provides a means for quickly charging coking ovens with a compacted coal charge so that lower quality coals may be used to make metallurgical coke.

Owner:桑科克技术和发展有限责任公司

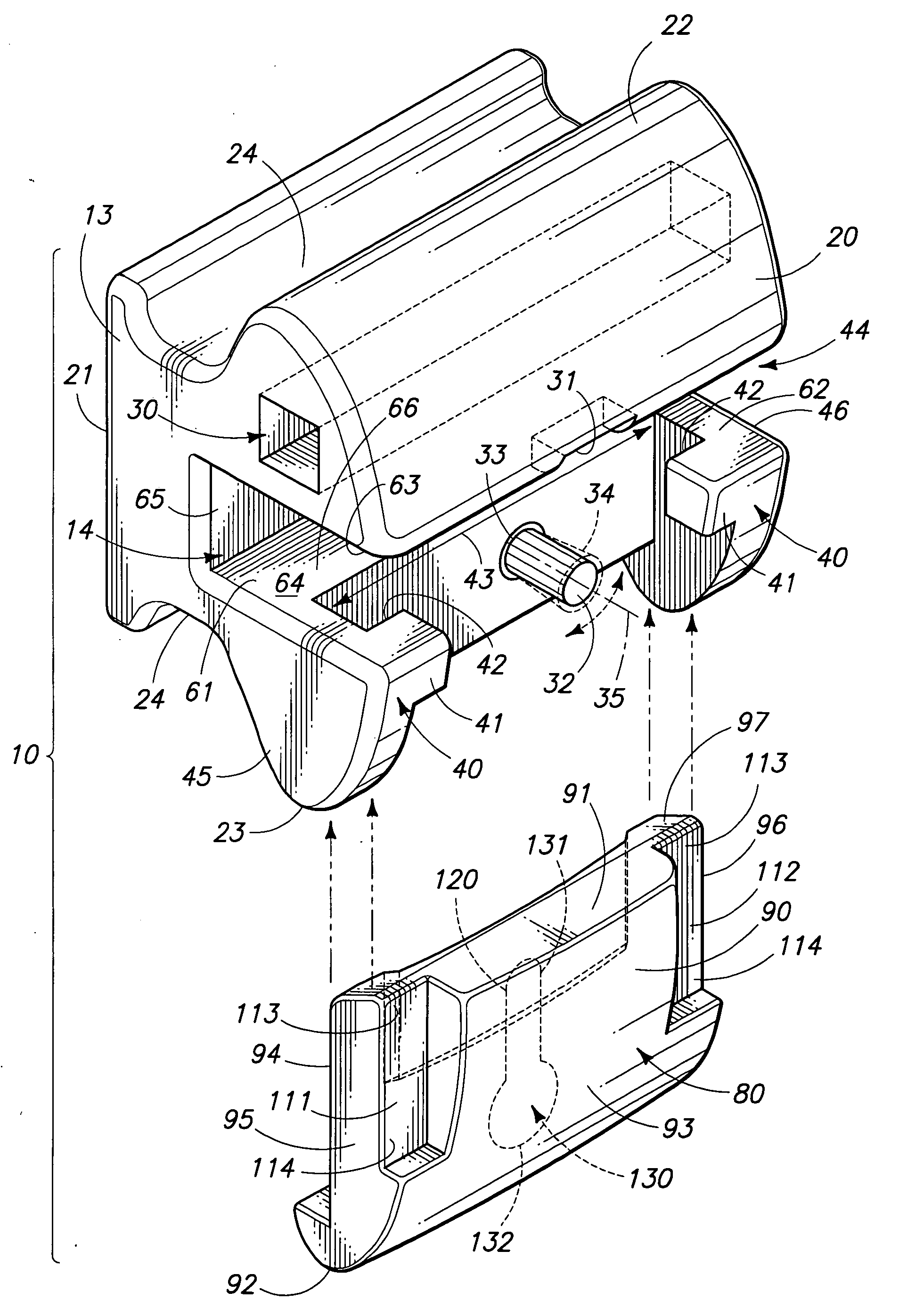

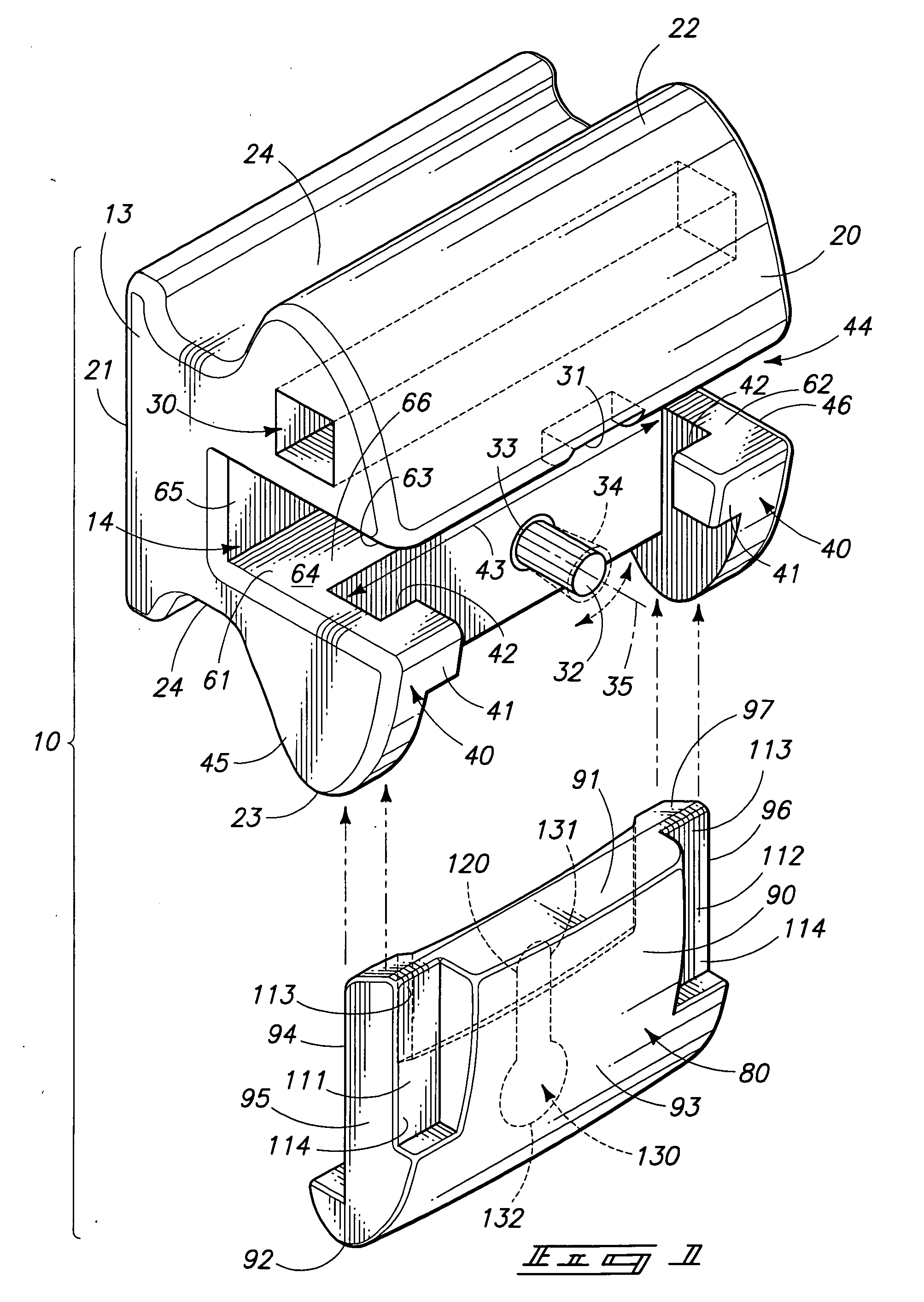

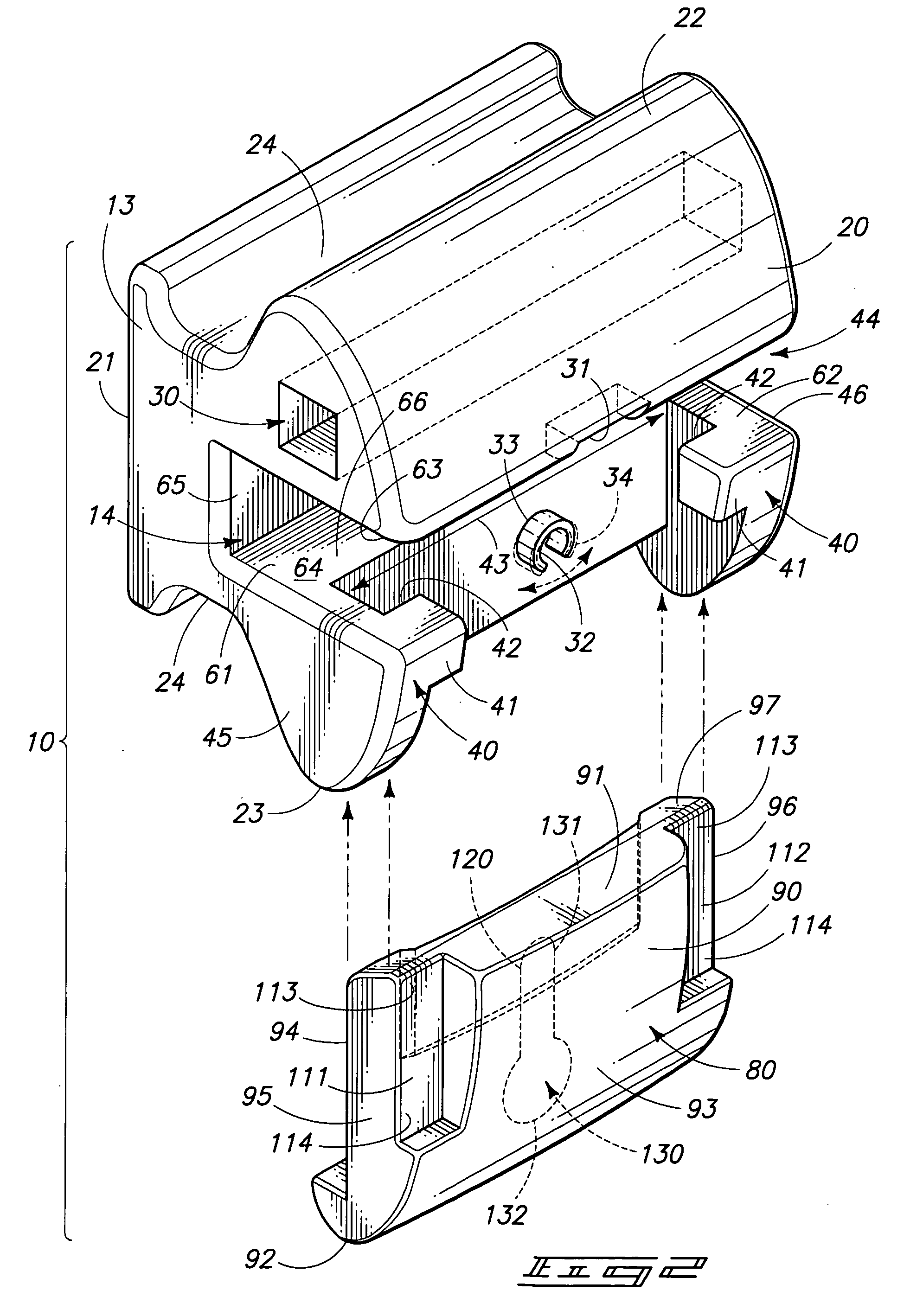

Orthodontic bracket

InactiveUS20090155734A1Minimizing frictional engagementImprove rotationArch wiresBracketsOrthodontic bracketsEngineering

Owner:ORMCO CORP

Syringe

InactiveUS20060200084A1Increase sliding frictionAvoid it happening againInfusion syringesIntravenous devicesDrugs solutionMedicine

A syringe coated with a lubricant containing a silicone oil and a fine silica powder on the inner surface of the barrel of the syringe can be used for injection of a surface-active drug solution without oil droplet formation on the inner surface while preventing an increase of the gasket sliding friction.

Owner:NIPRO CORP

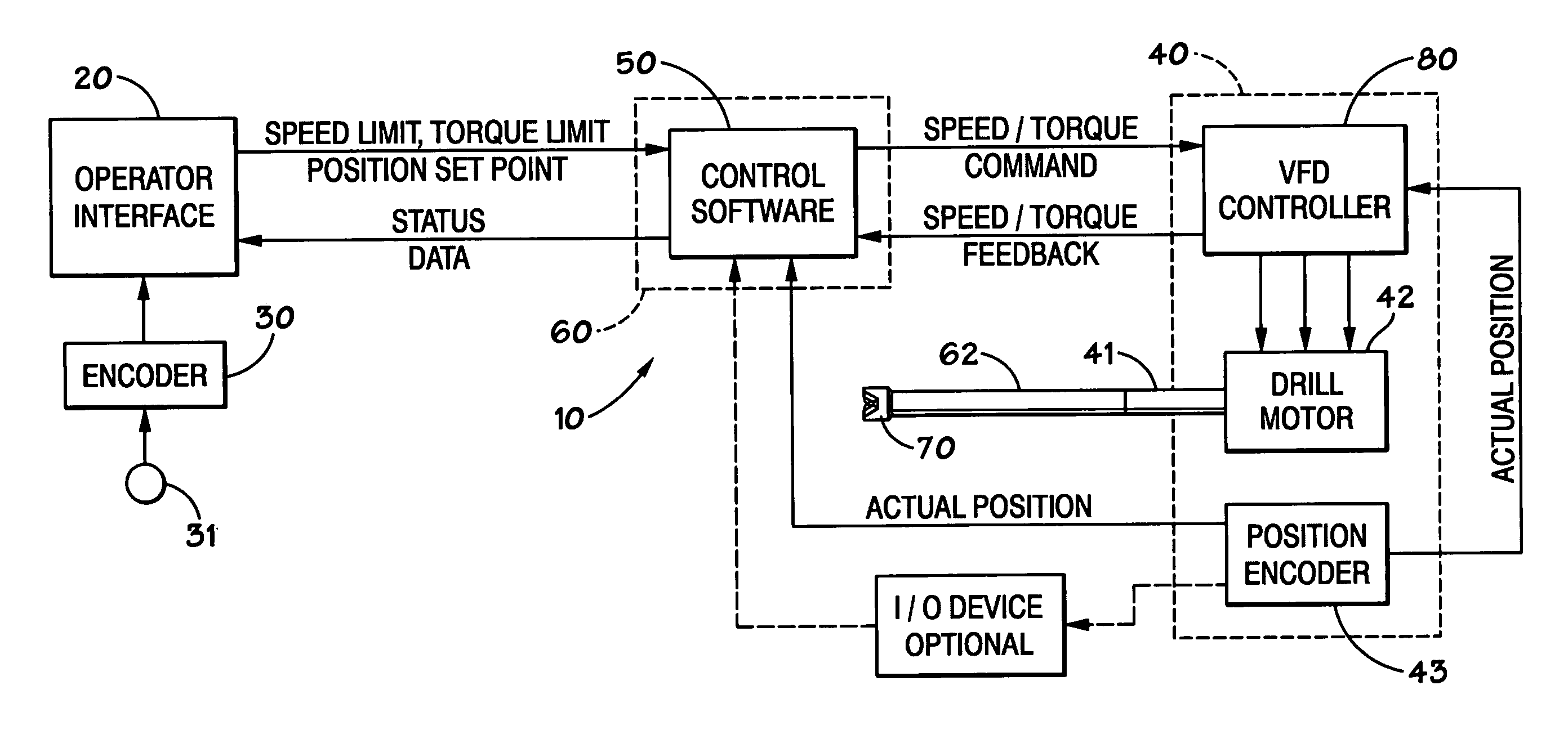

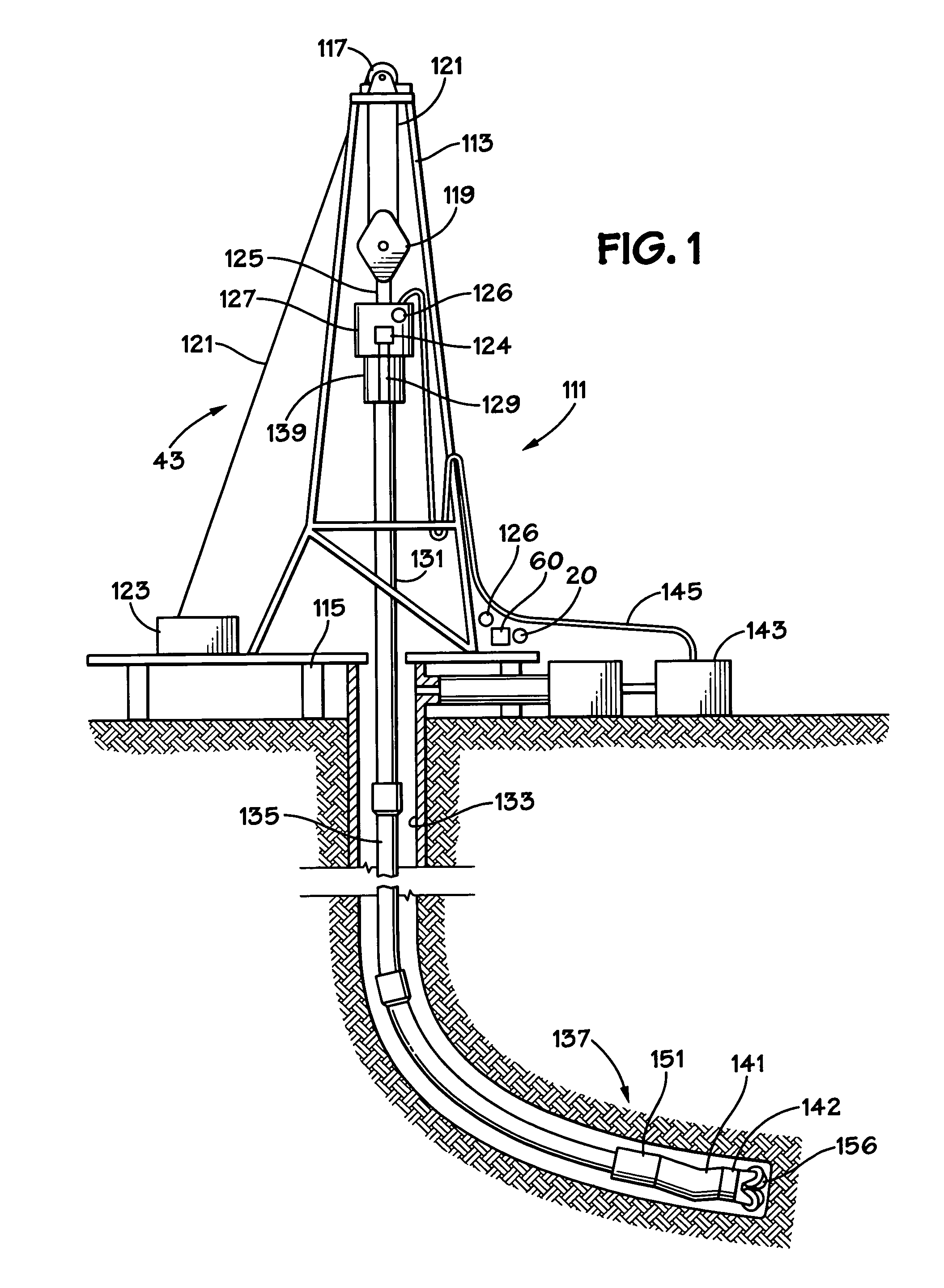

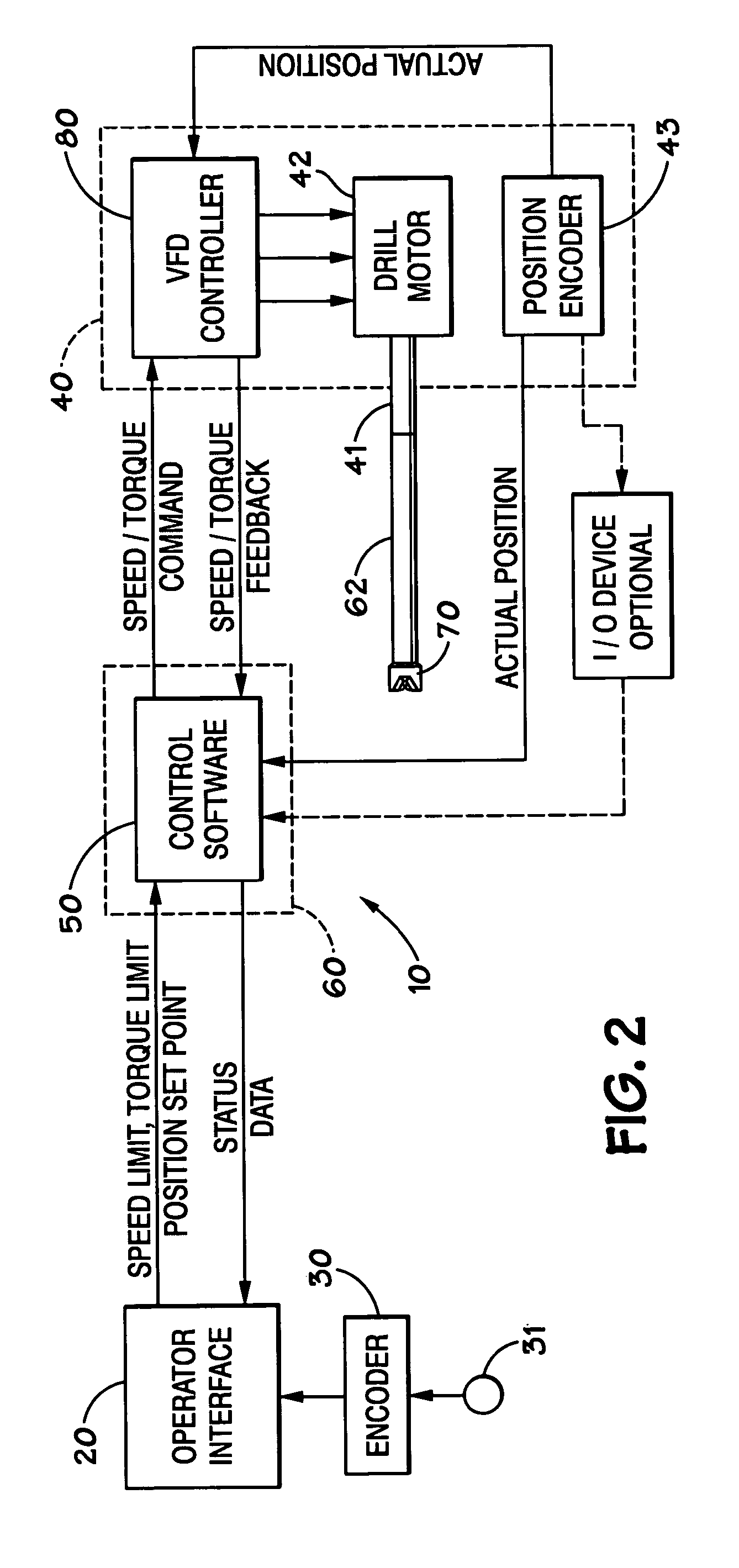

Directional drilling control

ActiveUS7461705B2Reduce sliding frictionReduce frictionConstructionsFluid removalEngineeringDirectional drilling

Owner:VARCO I P INC

Seal ring

InactiveUS7341256B2Easily vomitedReduce pressureEngine sealsPiston ringsEngineeringMechanical engineering

Owner:NOK CORP

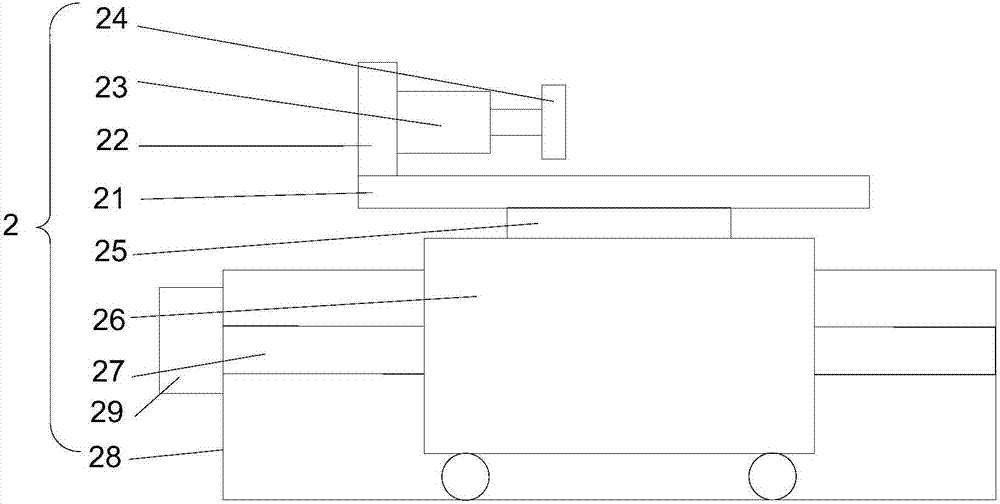

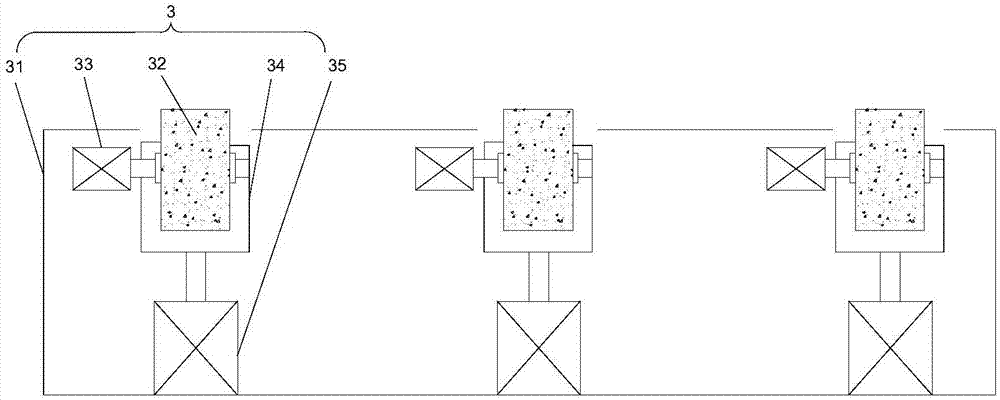

Logistics sorting device

The invention discloses a logistics sorting device. The logistics sorting device comprises a controlling system, a main conveyor belt, code scanning devices, an auxiliary conveyor belt, a weighing mechanism and a sorting mechanism; the code scanning devices are arranged above the main conveyor belt and are fixed on ground on the front side and rear side of the main conveyor belt; an inclined slideway is fixedly connected with the left side of the main conveyor belt, and a convey assisting roller is fixedly connected to the top end of the inclined slideway; the weighing mechanism is arranged on the left side of the convey assisting roller; the weighing mechanism comprises a tray, an air cylinder supporting seat, an air cylinder, a pushing plate, a weight sensor, a sliding block, a lead screw, a weighing mechanism casing and a first motor; the sorting mechanism is arranged on the right side of the main conveyor belt; and the sorting mechanism comprises a sorting mechanism casing, guiding wheels, a second motor, a guiding wheel supporting seat and a third motor. According to the logistics sorting device, input of labor cost can be reduced, sorting and transporting of logistics can be accurately achieved through a controlling system, efficiency is high, and error is not easy to occur.

Owner:XIAN INT UNIV

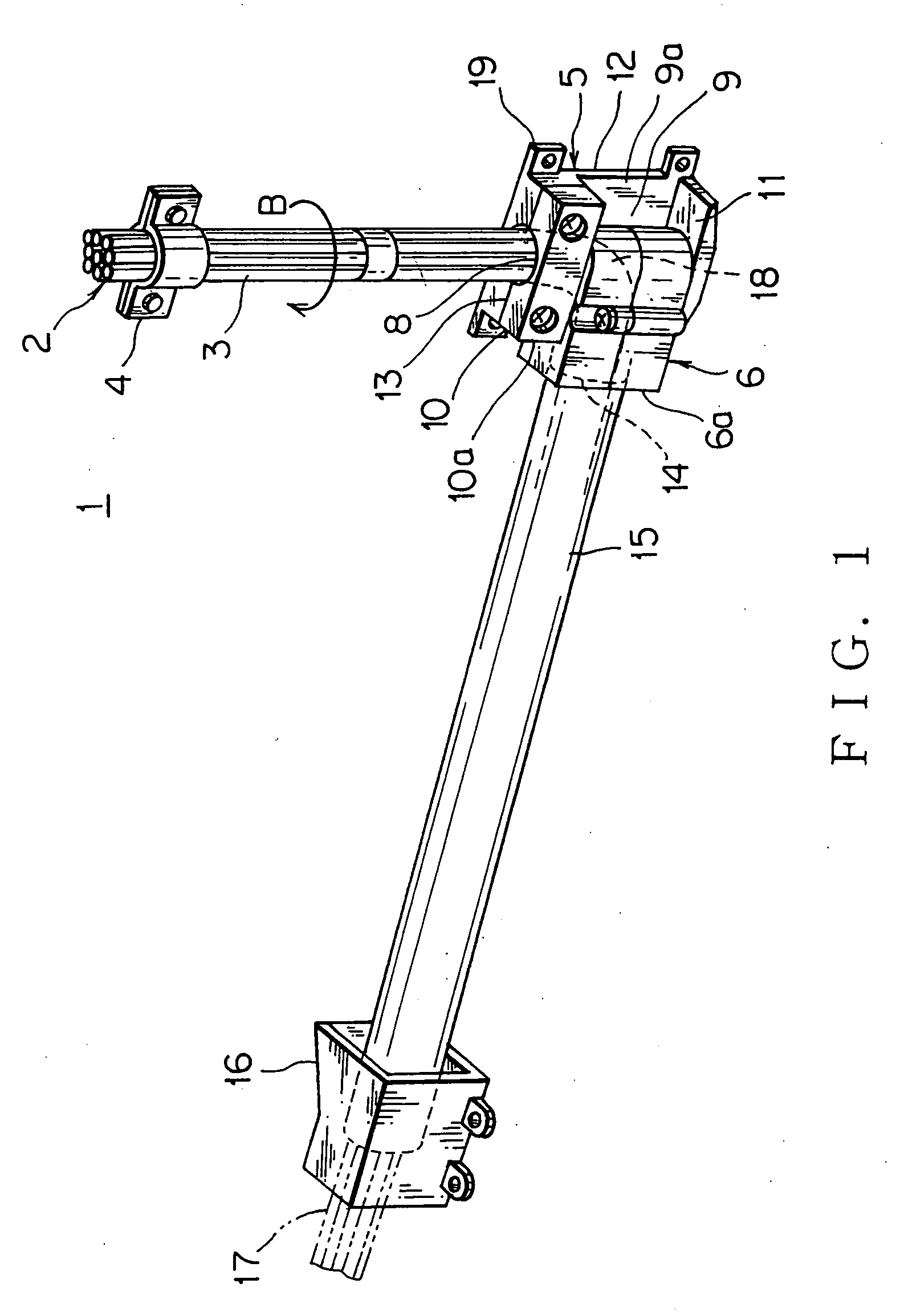

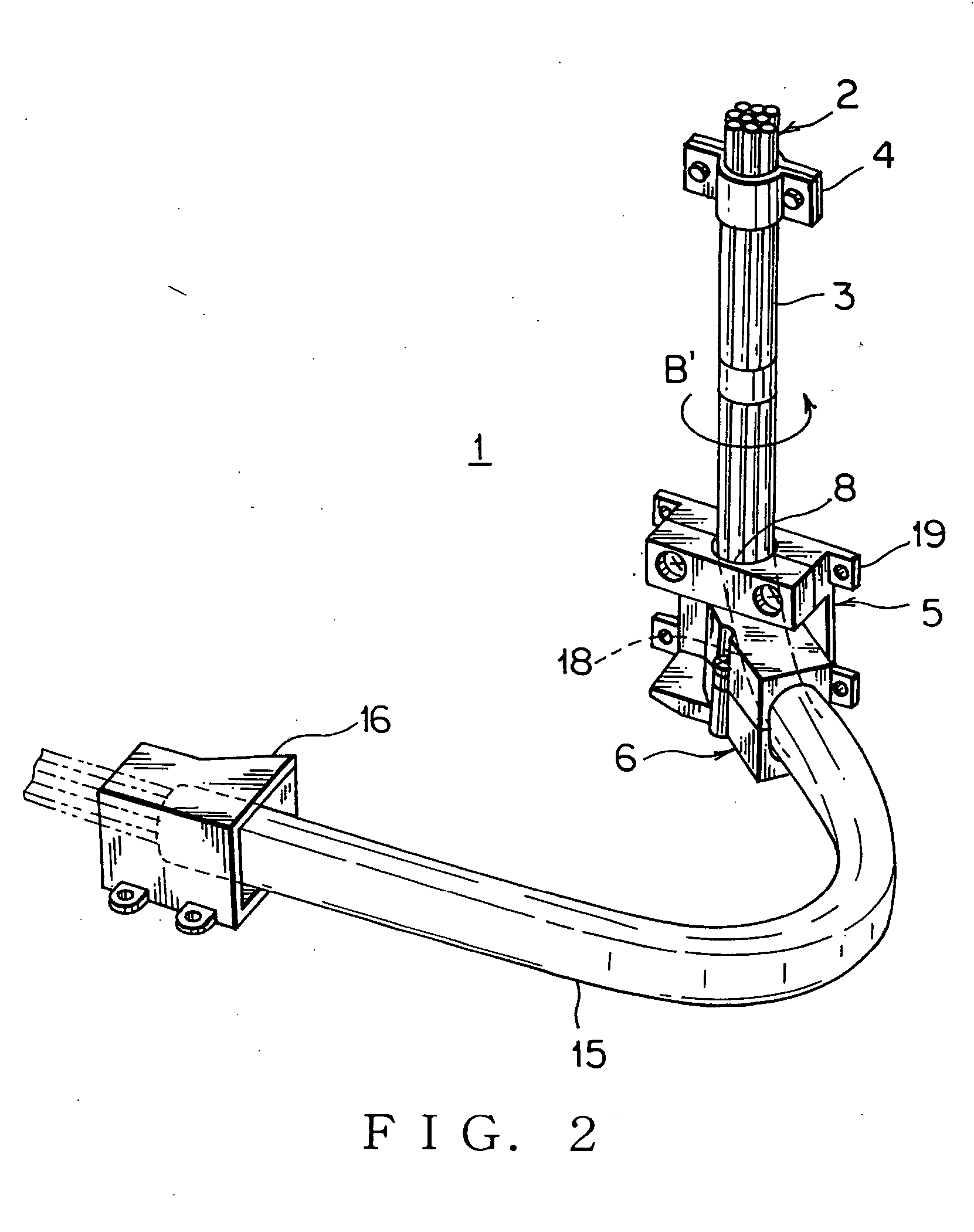

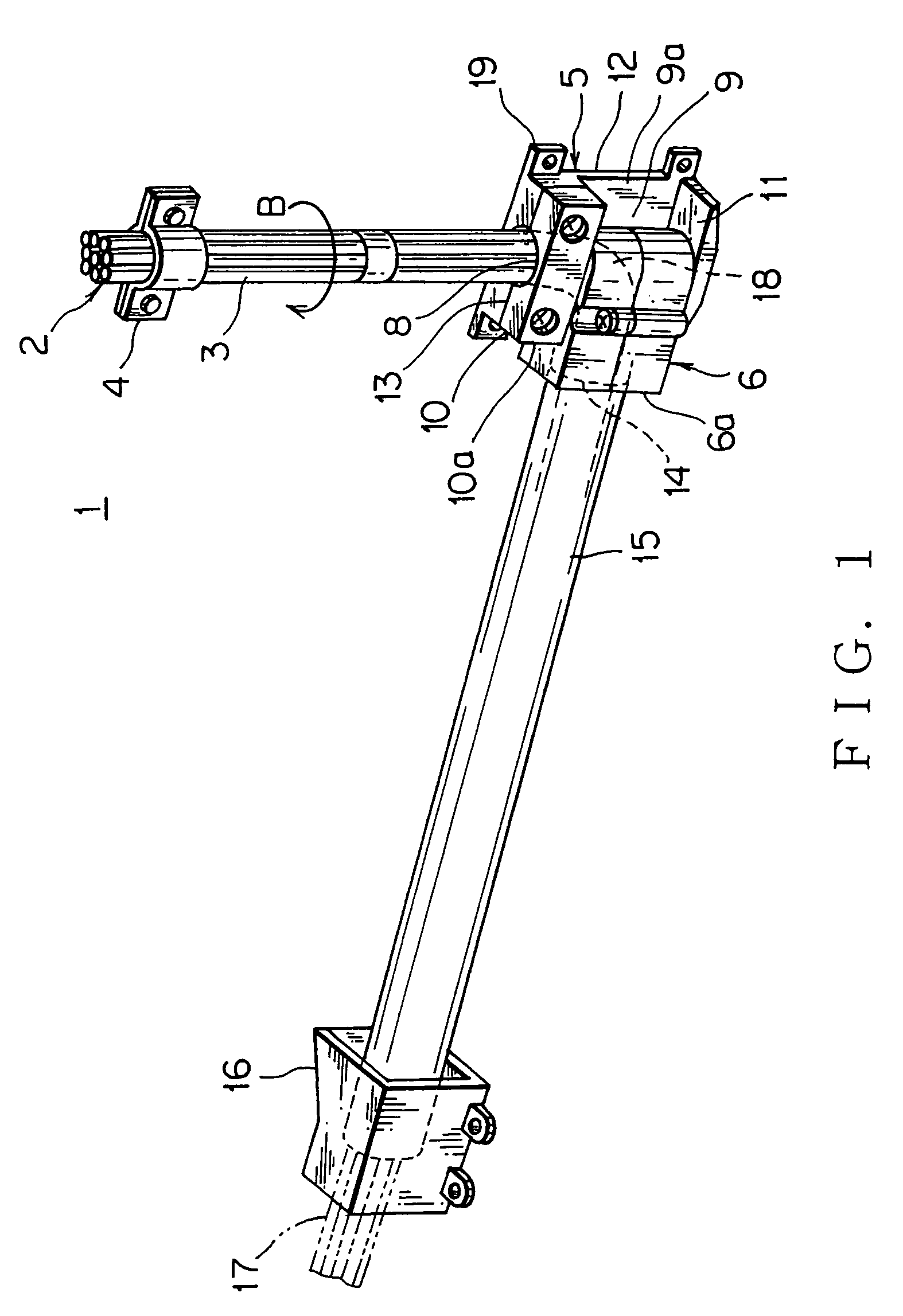

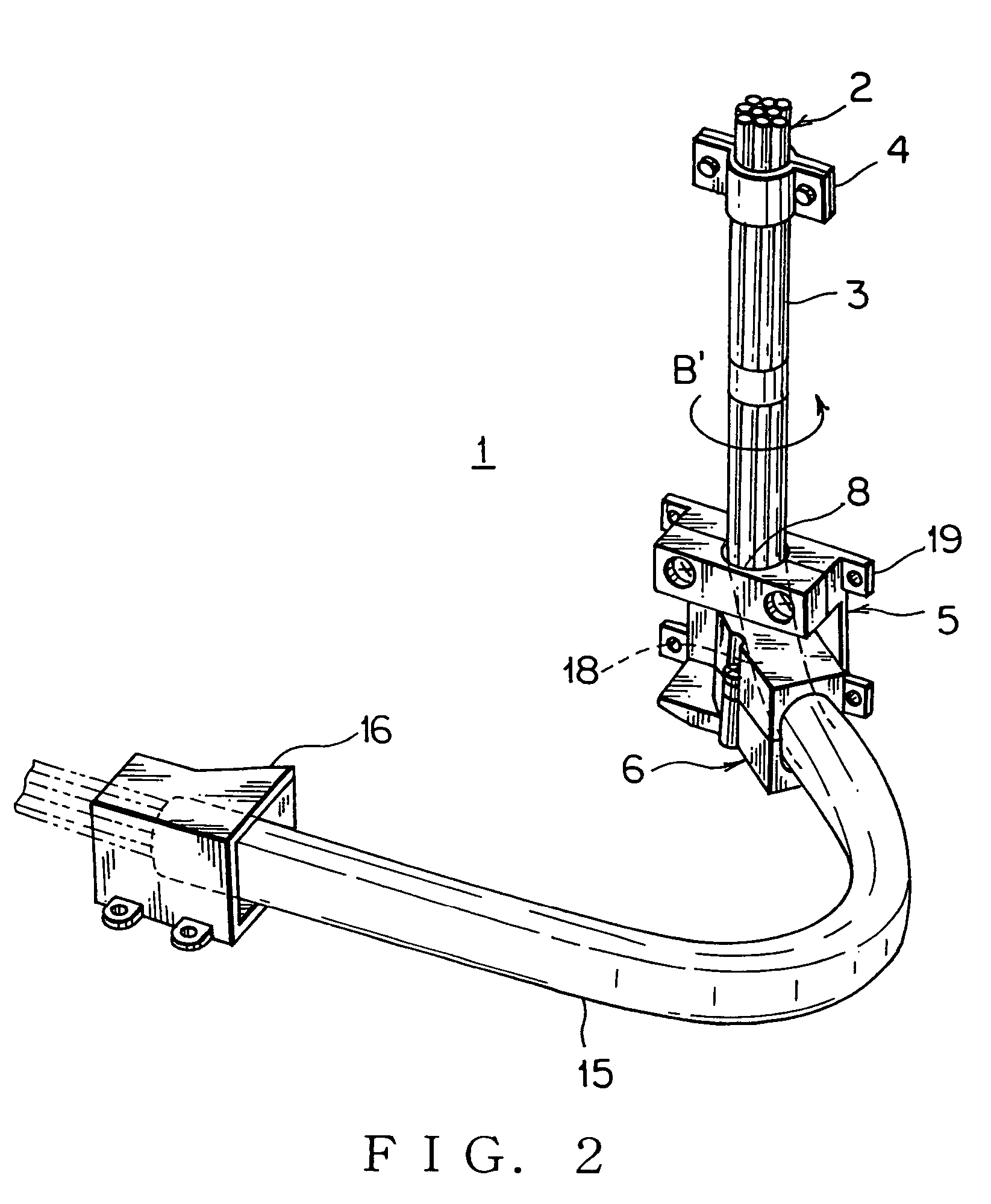

Power supply apparatus for sliding structure

ActiveUS20070084619A1Vertical path portion can be shortenedSmall structure sizeCoupling device connectionsElectric discharge tubesCable harnessElectrical and Electronics engineering

Providing a power supply apparatus for a sliding structure, which can be arranged in a small space in the sliding structure, the power supply apparatus includes a wiring harness having a vertical path portion; a harness fixing member for fixing one end of the vertical path portion of the wiring harness on the sliding structure; a fixed base fixed on the sliding structure for holding the other end of the vertical path portion; and a swing member mounted on the fixed base to swing freely in a horizontal plane for allowing the vertical path portion to be twisted along a circumferential direction of itself and leading a part of the wiring harness continued to the vertical path portion toward a fixed structure. Instead of the fixed base, a movable base 5′, and a guide rail to be engaged with the movable base can be applied.

Owner:YAZAKI CORP +1

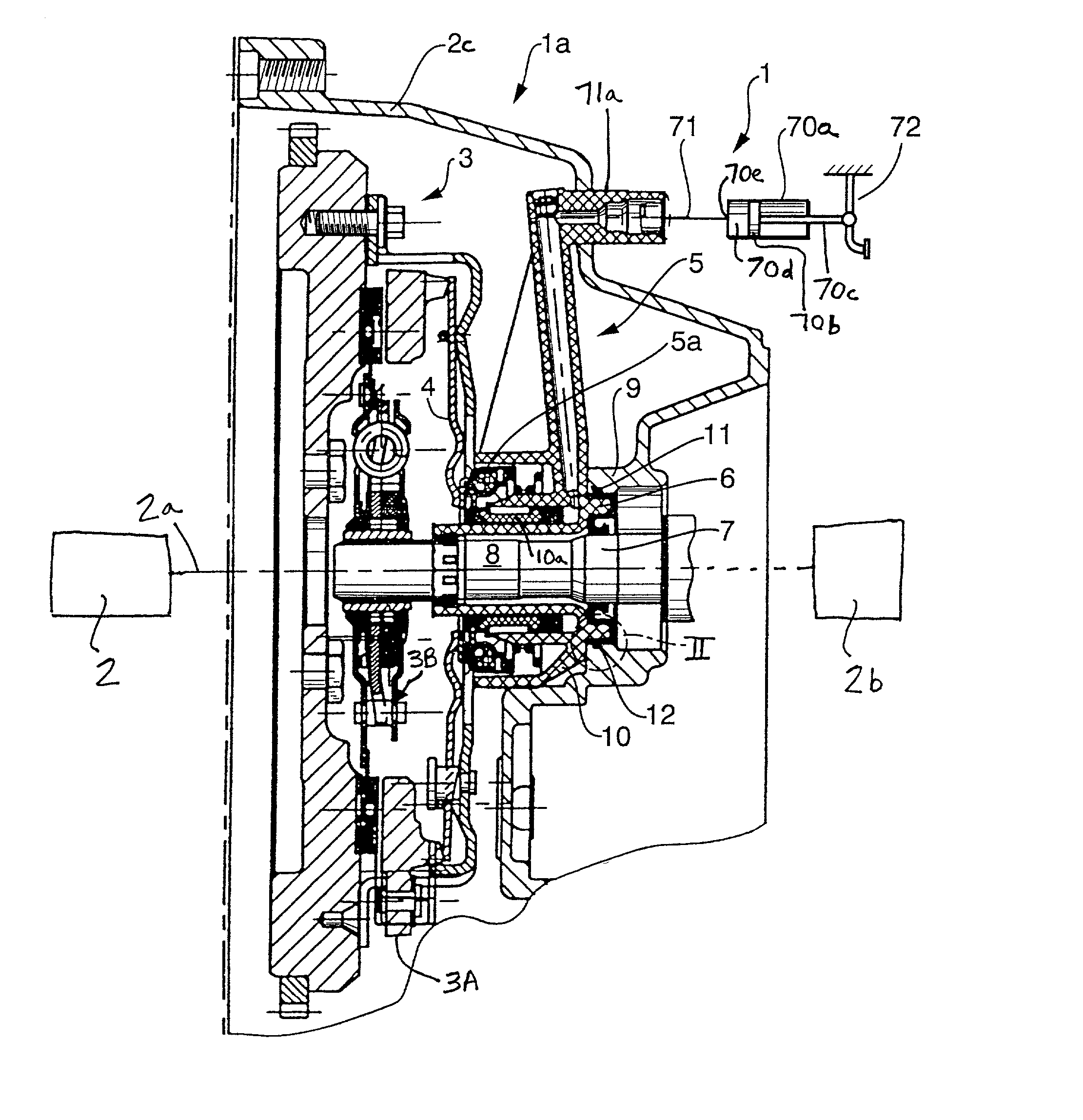

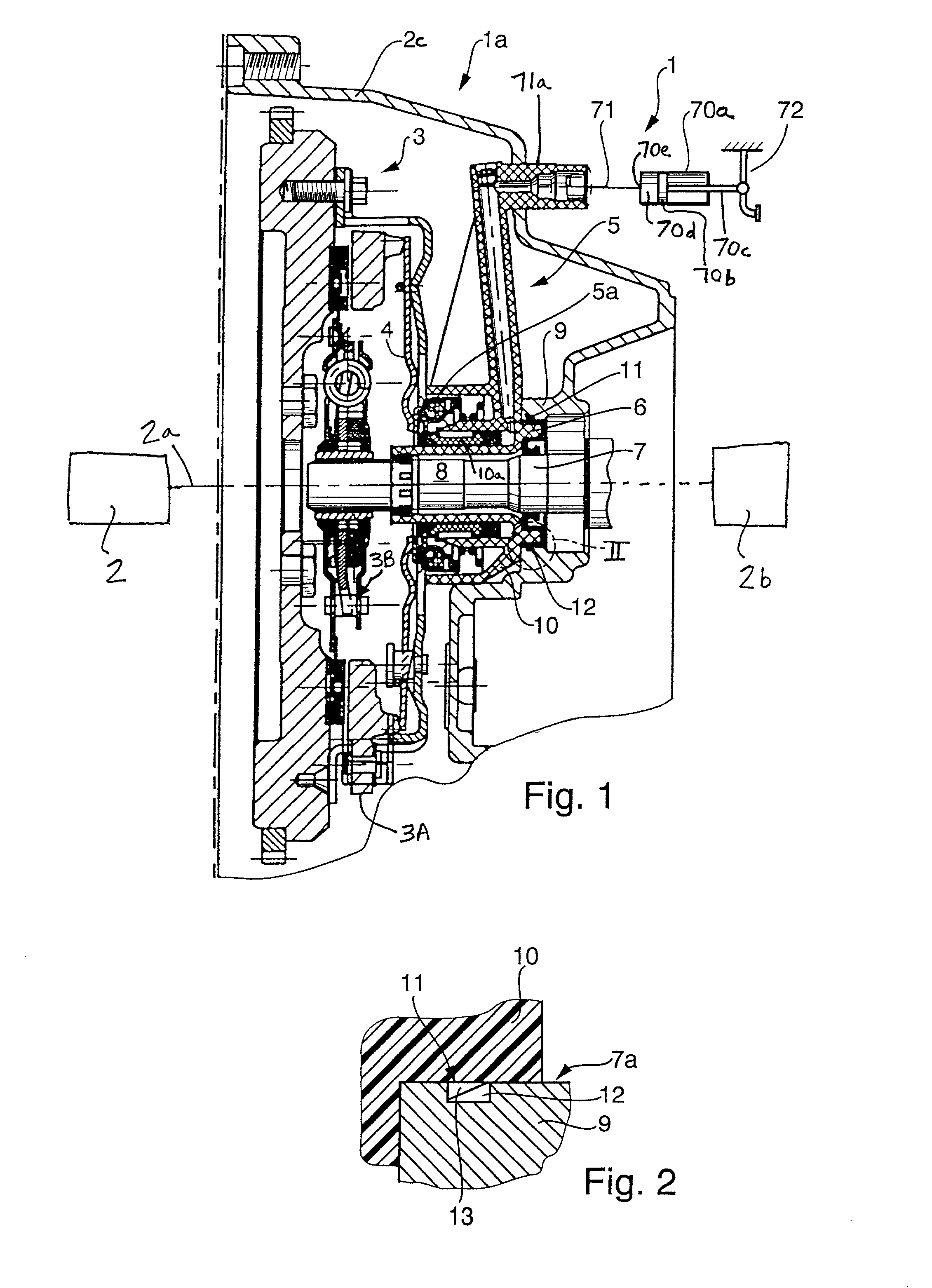

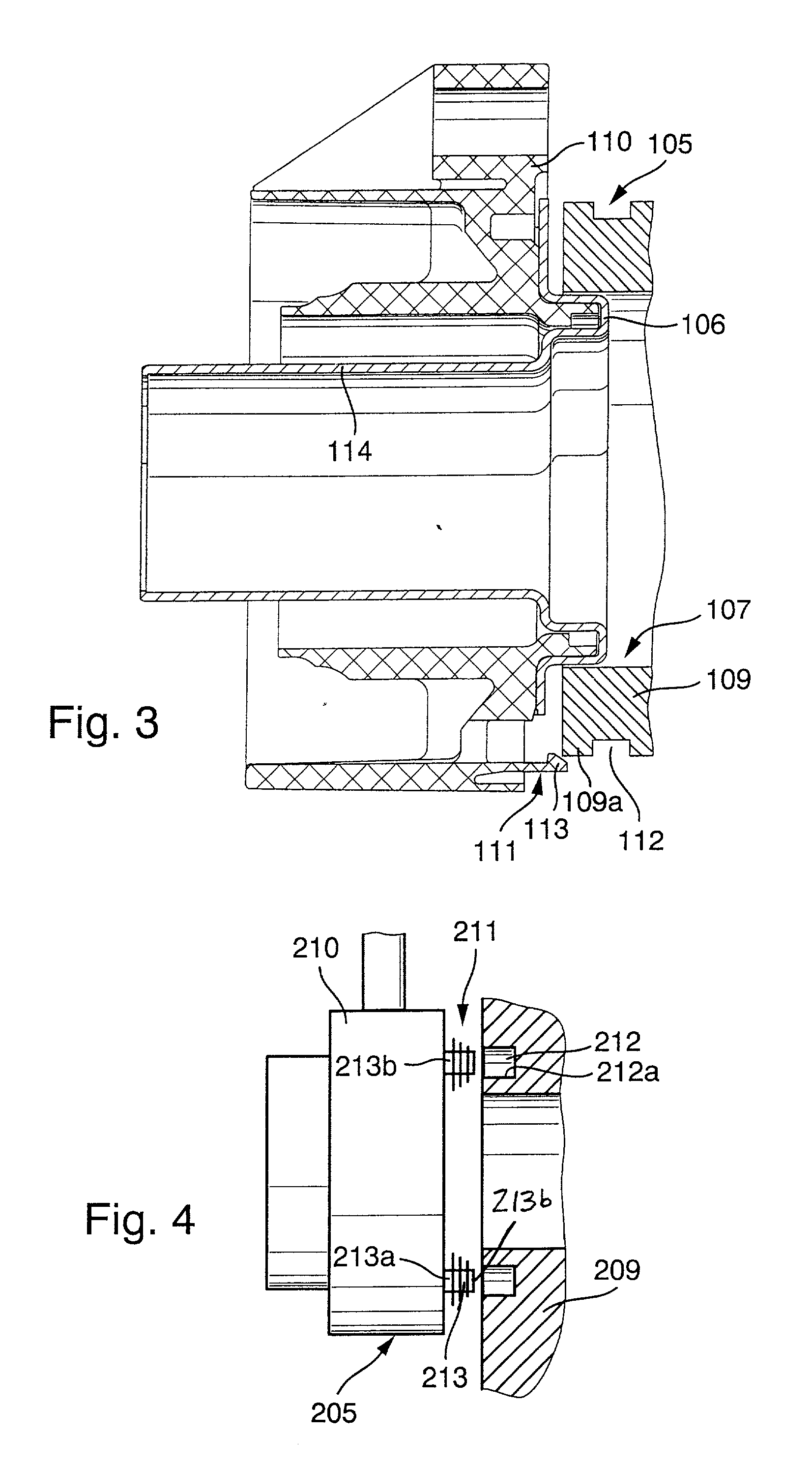

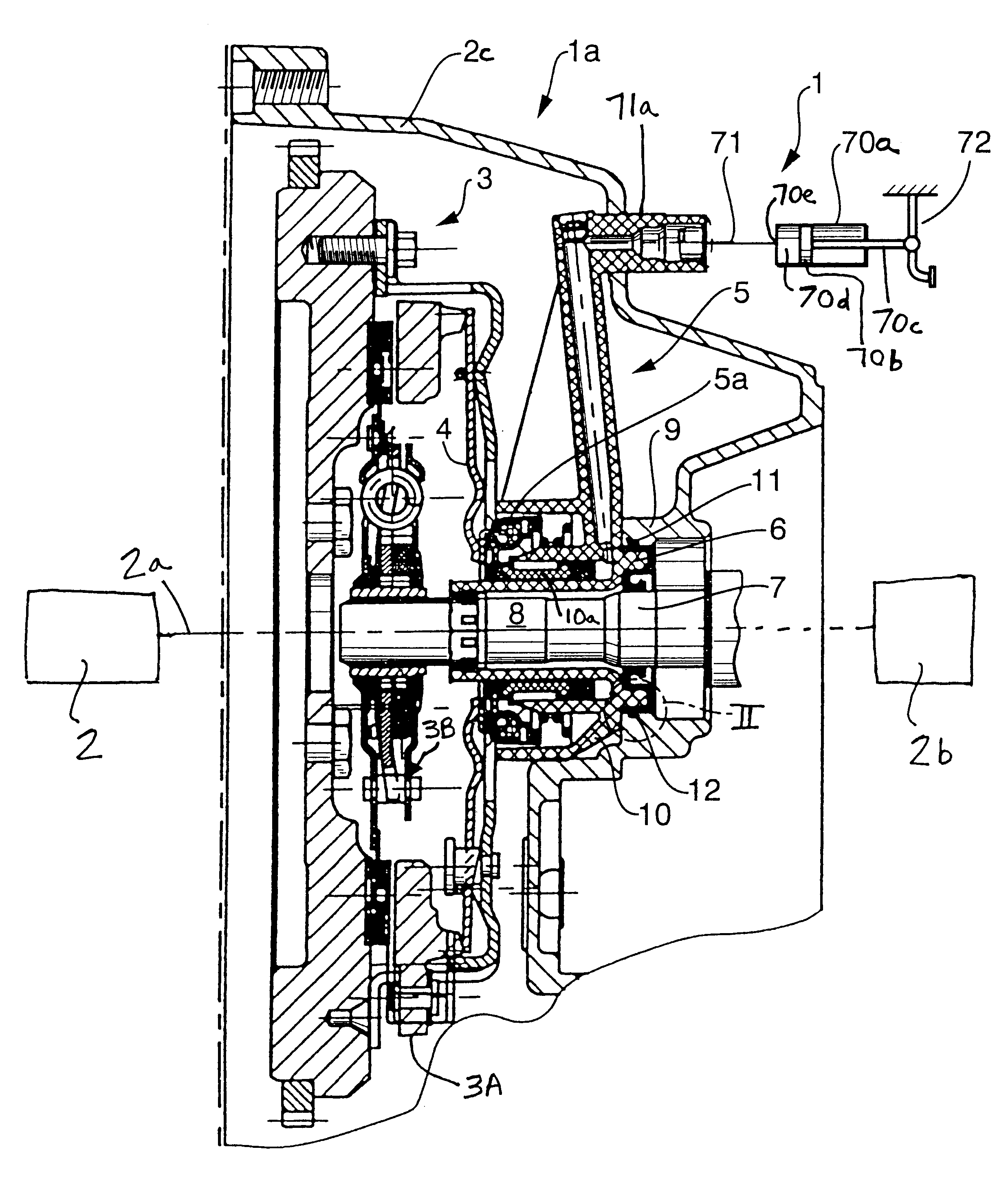

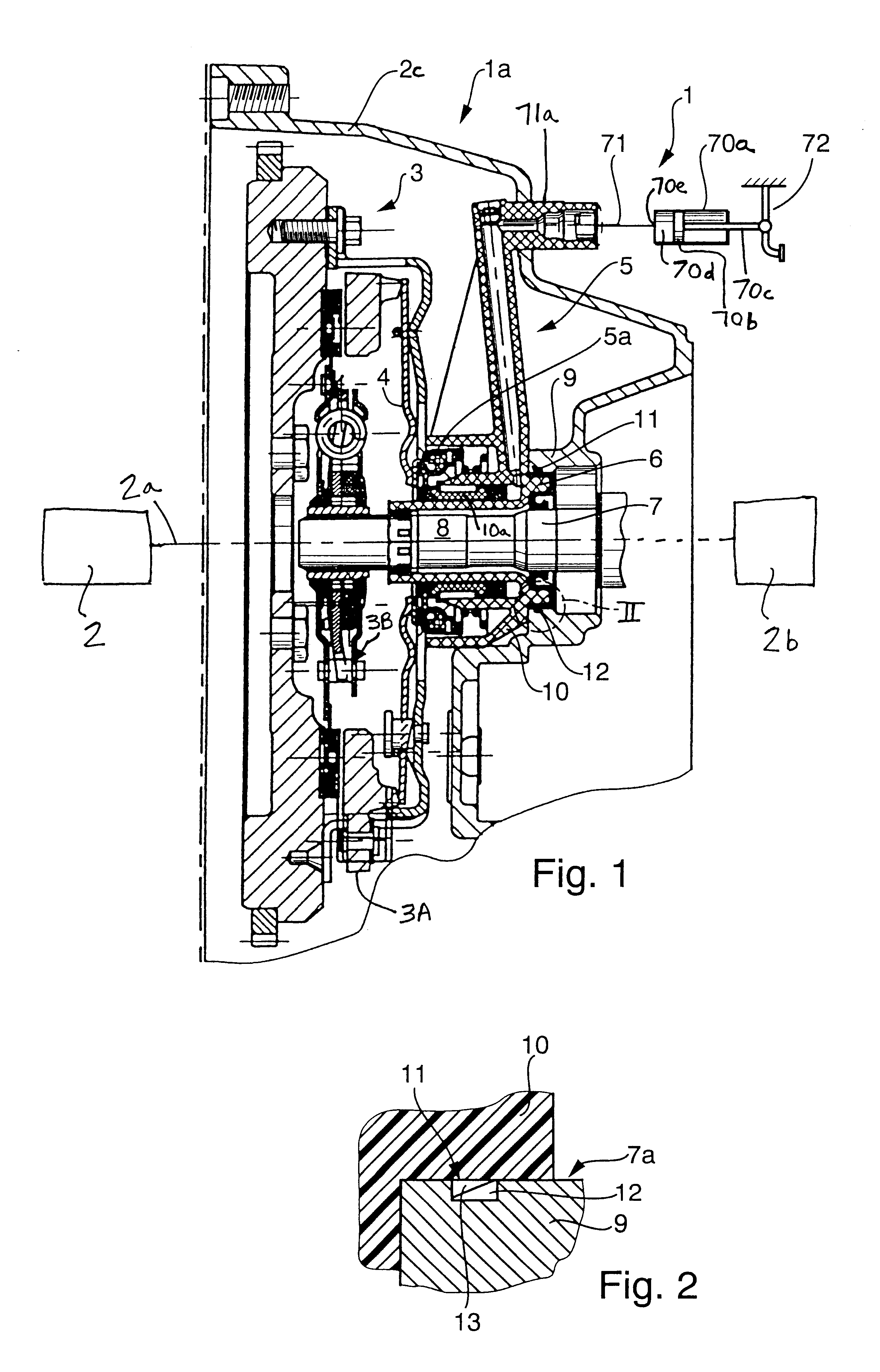

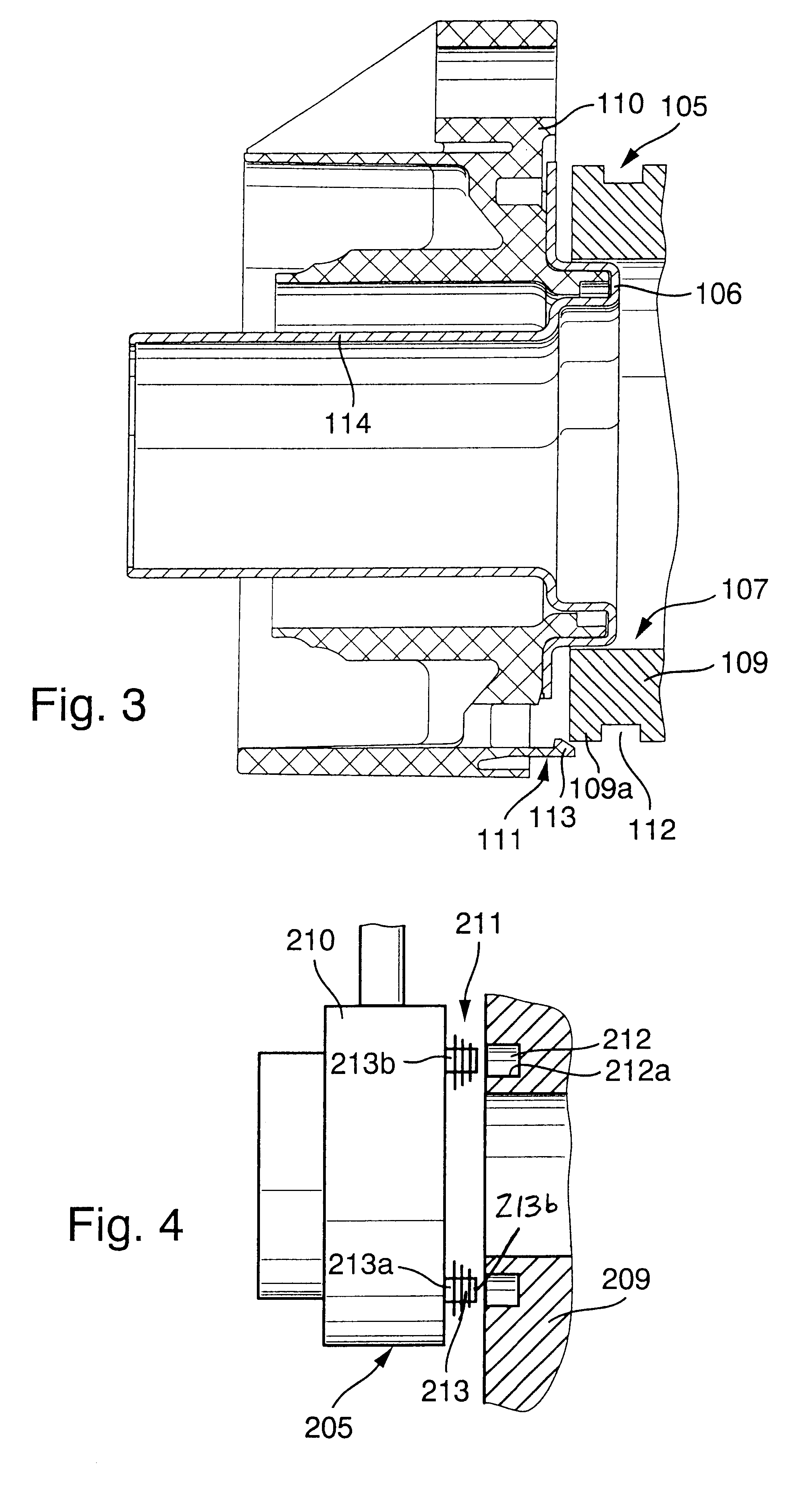

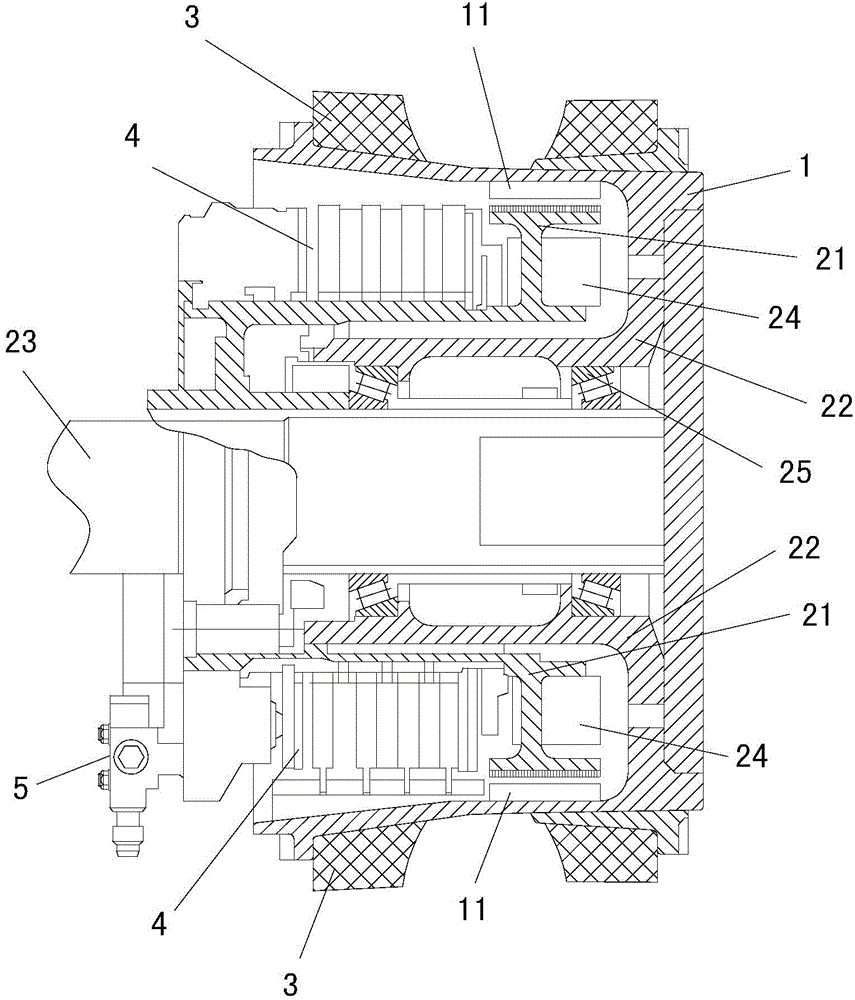

Hydraulic operating arrangement for clutches and the like

InactiveUS20030029692A1Minimal maintenanceLong useful lifeGearboxesFluid actuated clutchesMaster cylinderPlastic materials

The friction clutch between the prime mover and the change-speed transmission in the power train of a motor vehicle is actuatable by a slave cylinder cooperating with a master cylinder wherein the piston is movable by a clutch pedal or by an electric actuator. The casing of the slave cylinder is made, at least in part, of a plastic material and defines a plenum chamber arranged to receive pressurized fluid from the master cylinder by way of a conduit extending through a bell which contains the clutch and the slave cylinder. The annular piston of the slave cylinder surrounds the input shaft of the transmission. The plastic material of the casing of the slave cylinder can contain one or more additives which enhance its strength and / or influence its frictional engagement with the adjacent surfaces of the piston or of a lip seal which reciprocates with the piston. The piston and / or the lip seal can be installed in the casing to contact one or two metallic or plastic guide sleeves which are connected to or form part of the casing.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

Hydraulic operating arrangement for clutches and the like

InactiveUS6719115B2Minimal maintenanceLong useful lifeFluid actuated clutchesCylindersMaster cylinderPlastic materials

The friction clutch between the prime mover and the change-speed transmission in the power train of a motor vehicle is actuatable by a slave cylinder cooperating with a master cylinder wherein the piston is movable by a clutch pedal or by an electric actuator. The casing of the slave cylinder is made, at least in part, of a plastic material and defines a plenum chamber arranged to receive pressurized fluid from the master cylinder by way of a conduit extending through a bell which contains the clutch and the slave cylinder. The annular piston of the slave cylinder surrounds the input shaft of the transmission. The plastic material of the casing of the slave cylinder can contain one or more additives which enhance its strength and / or influence its frictional engagement with the adjacent surfaces of the piston or of a lip seal which reciprocates with the piston. The piston and / or the lip seal can be installed in the casing to contact one or two metallic or plastic guide sleeves which are connected to or form part of the casing.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

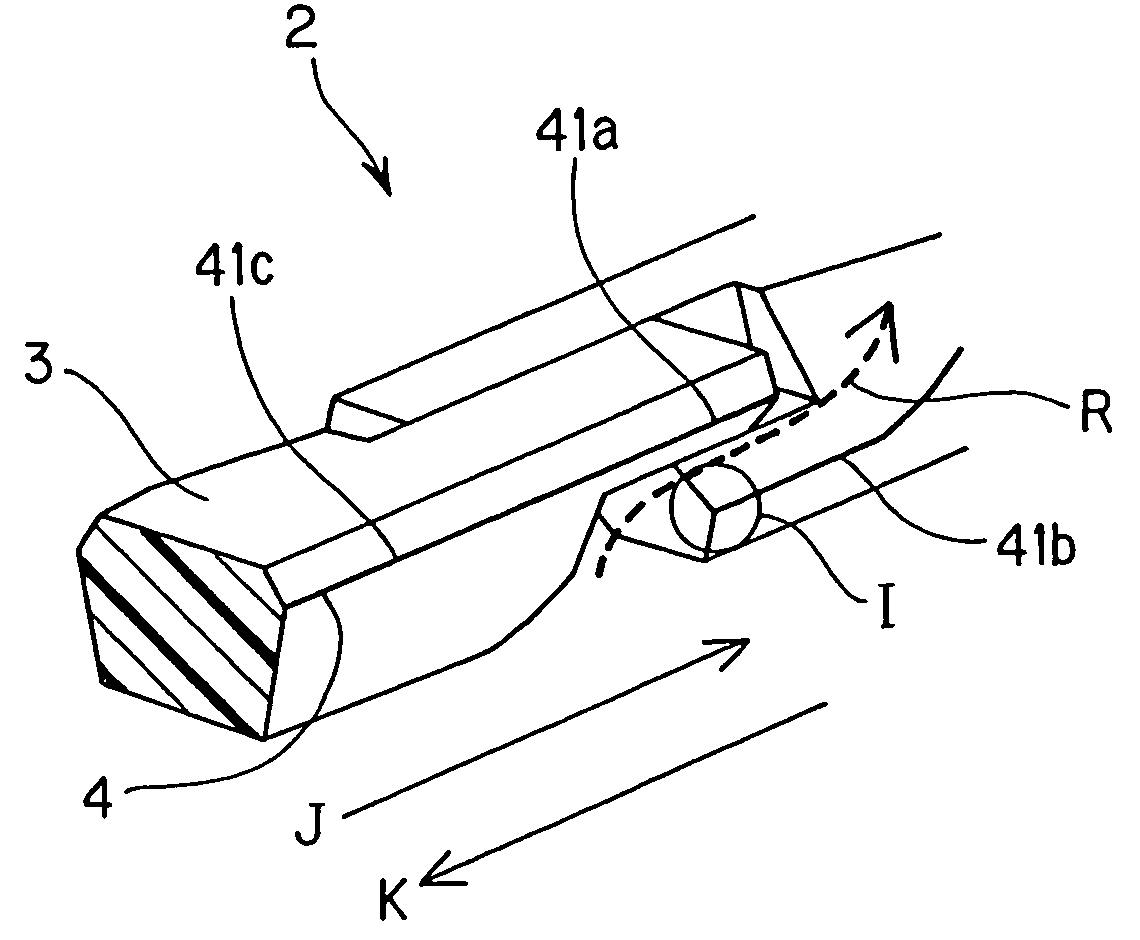

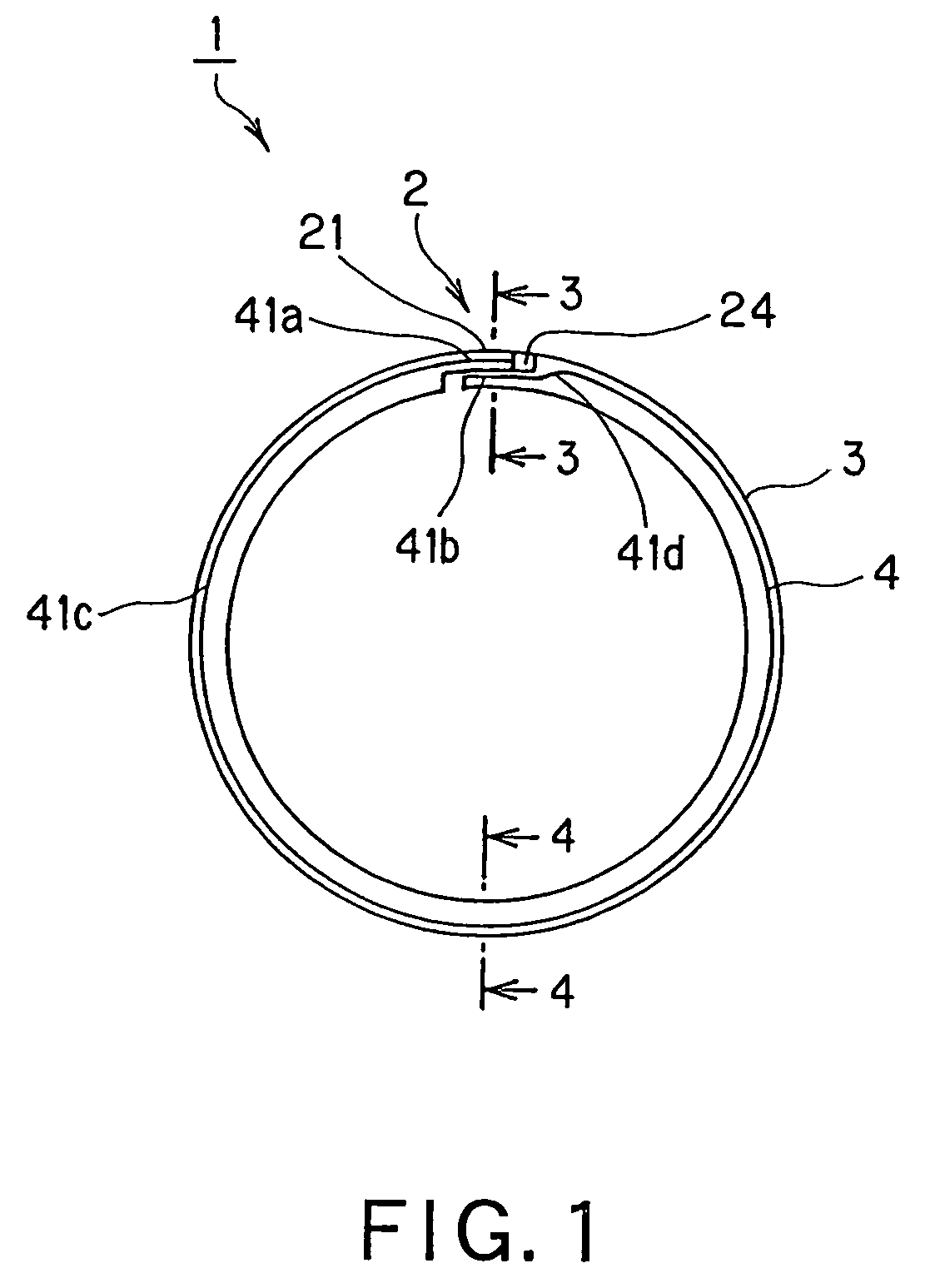

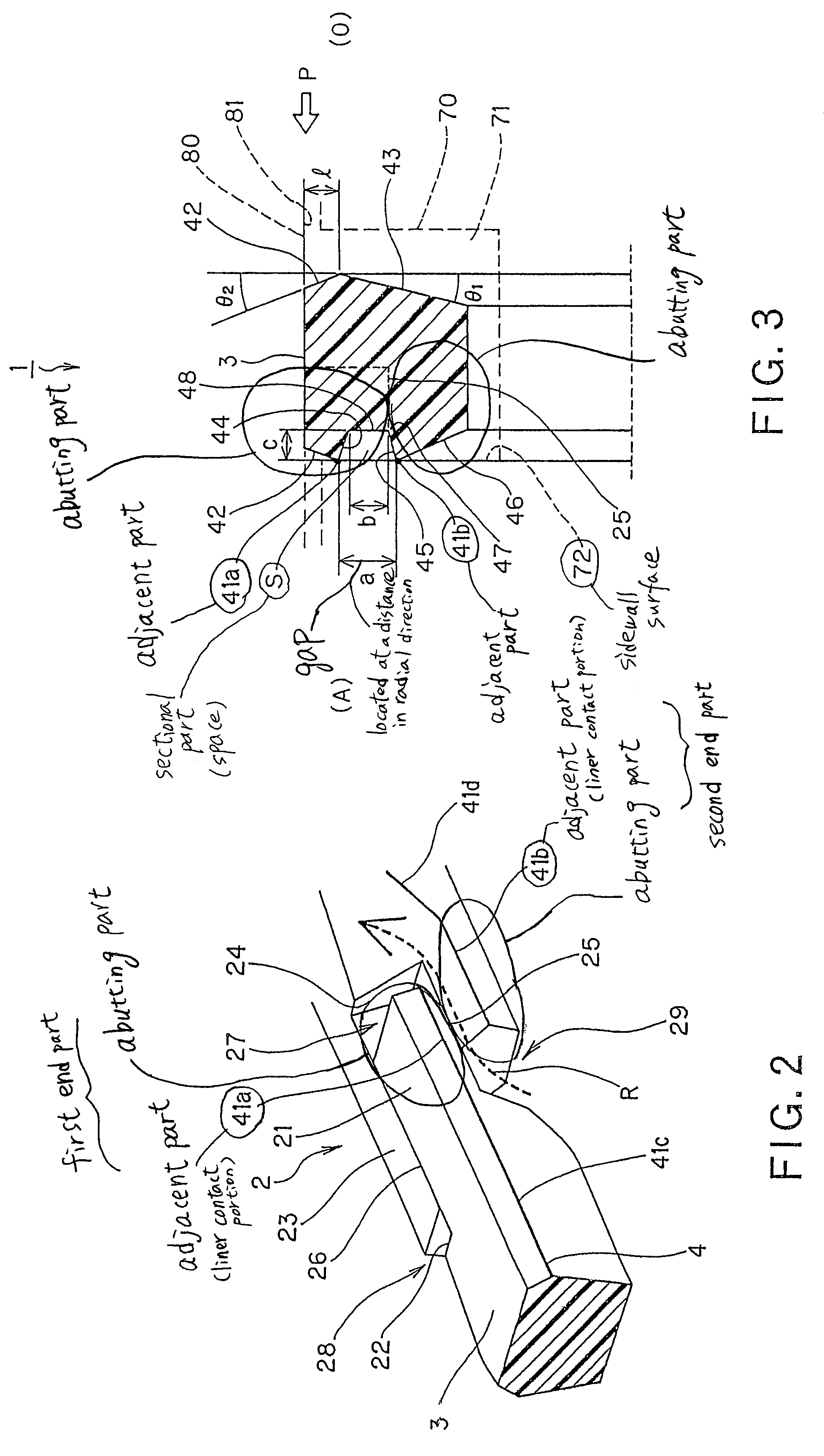

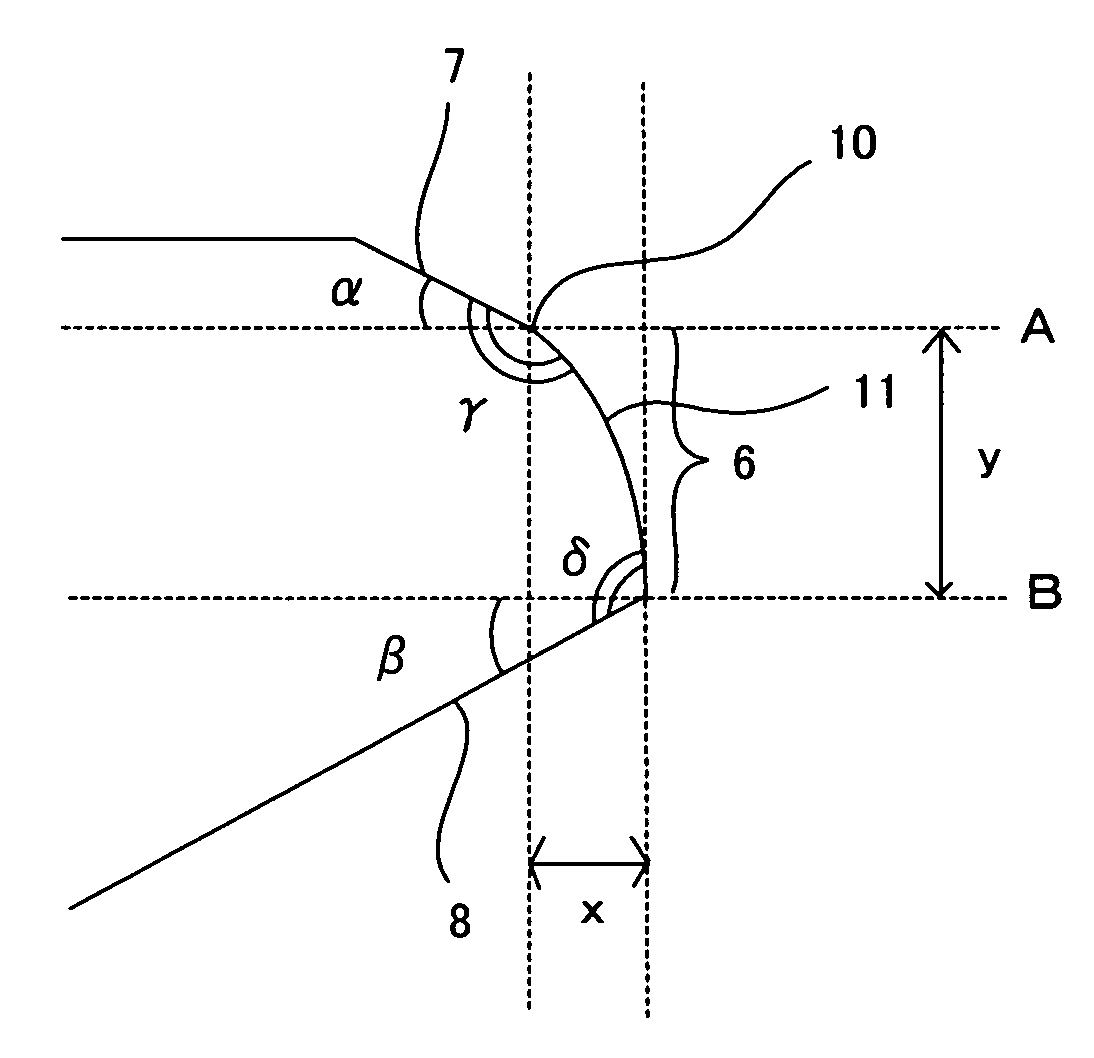

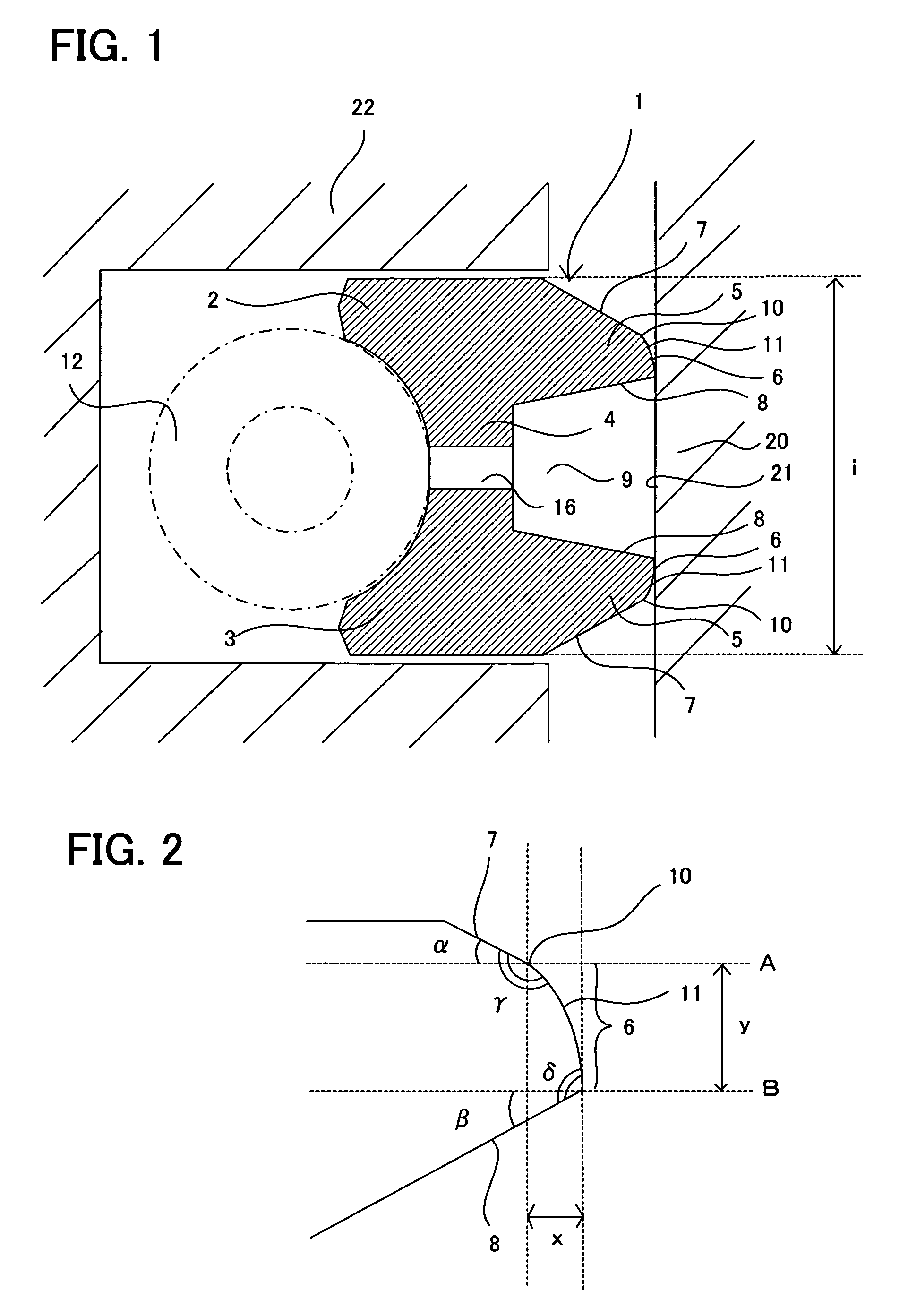

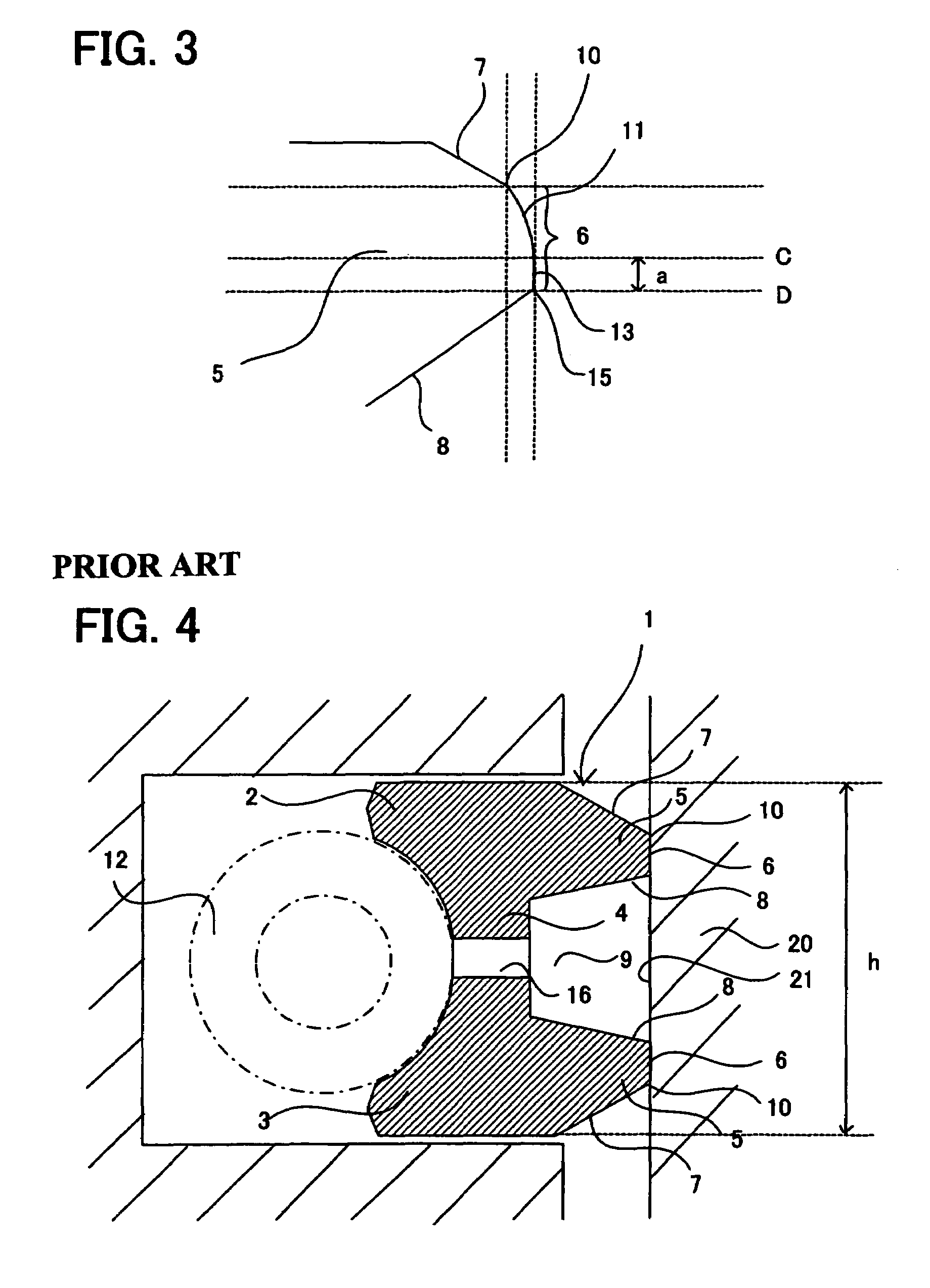

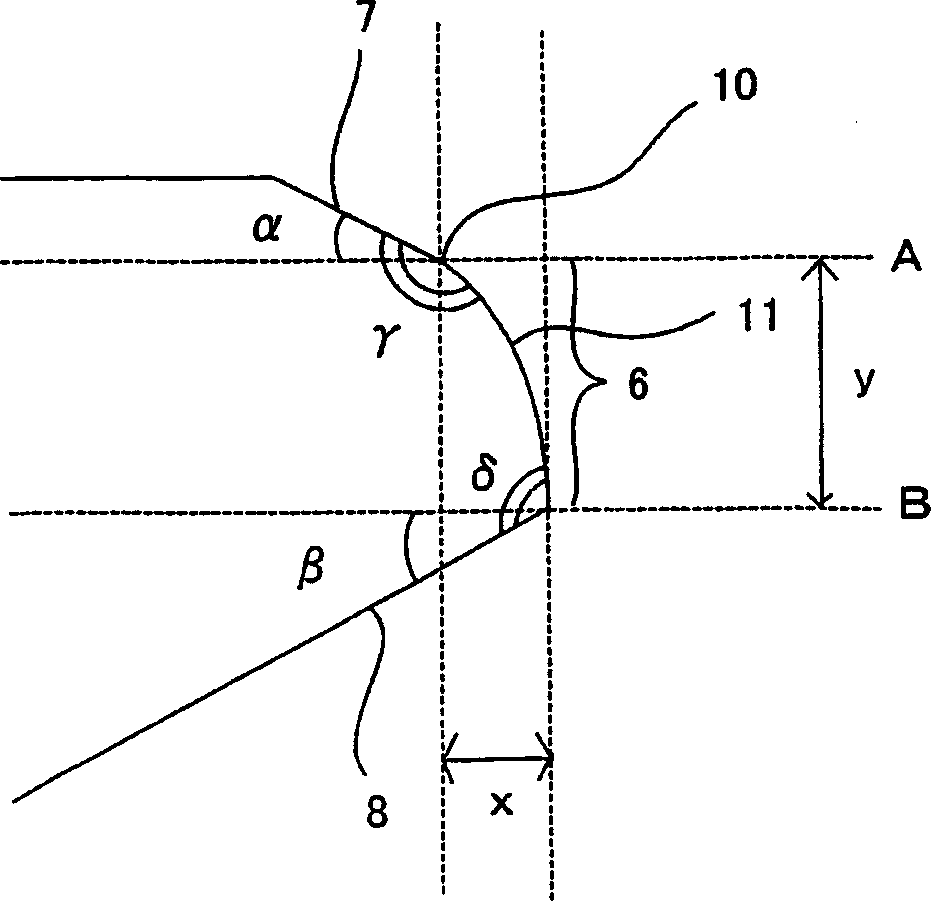

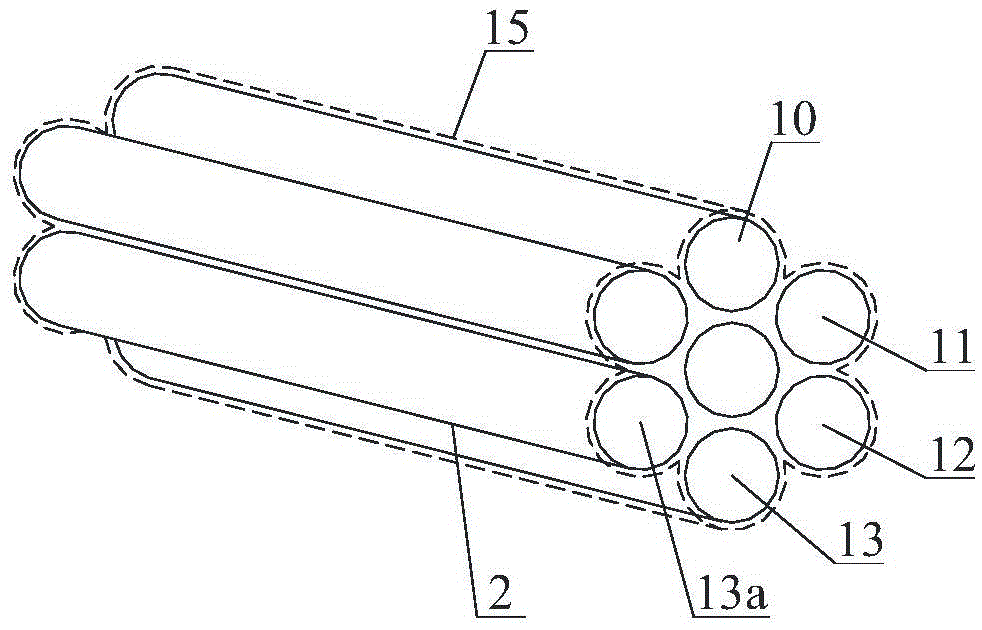

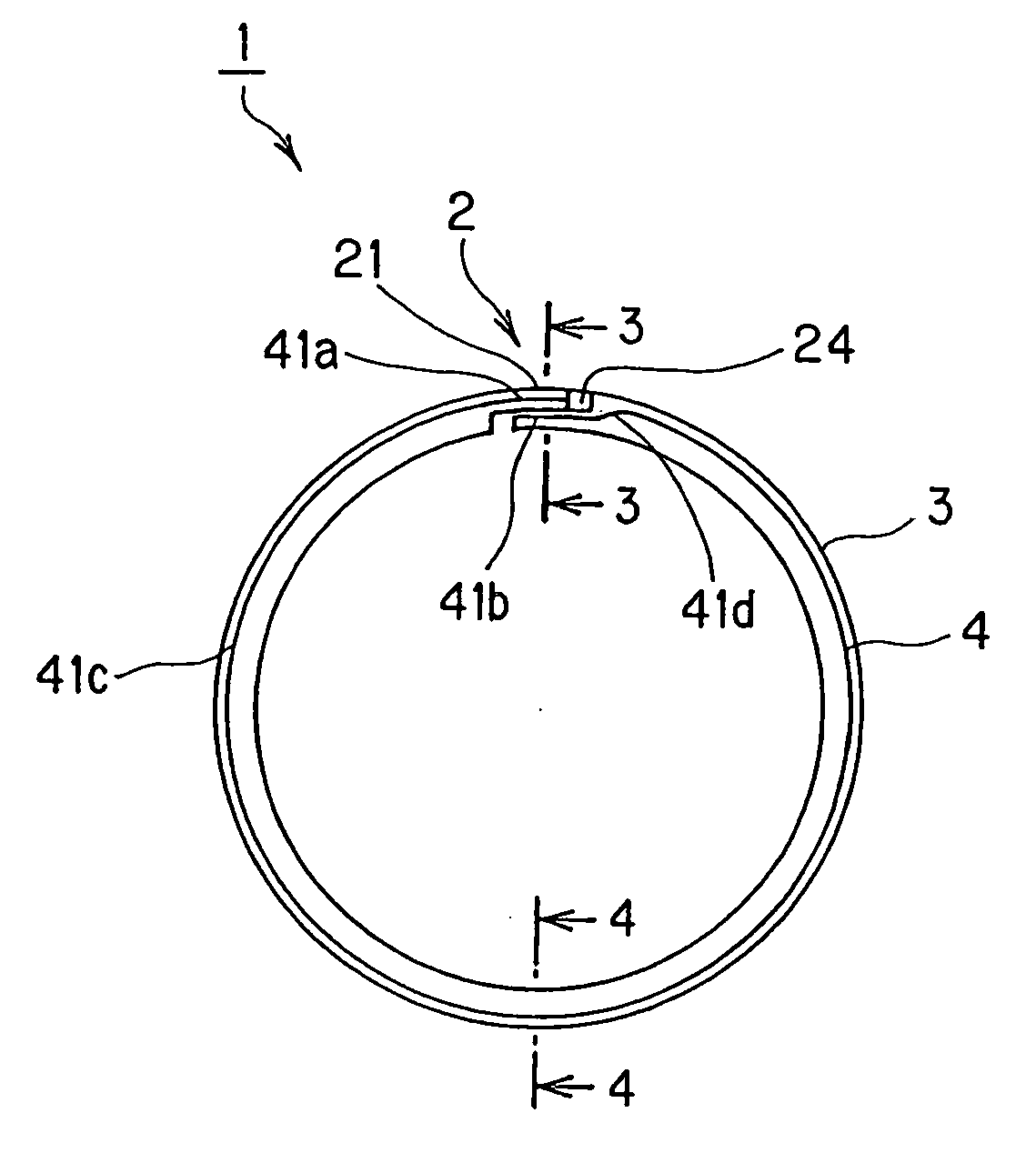

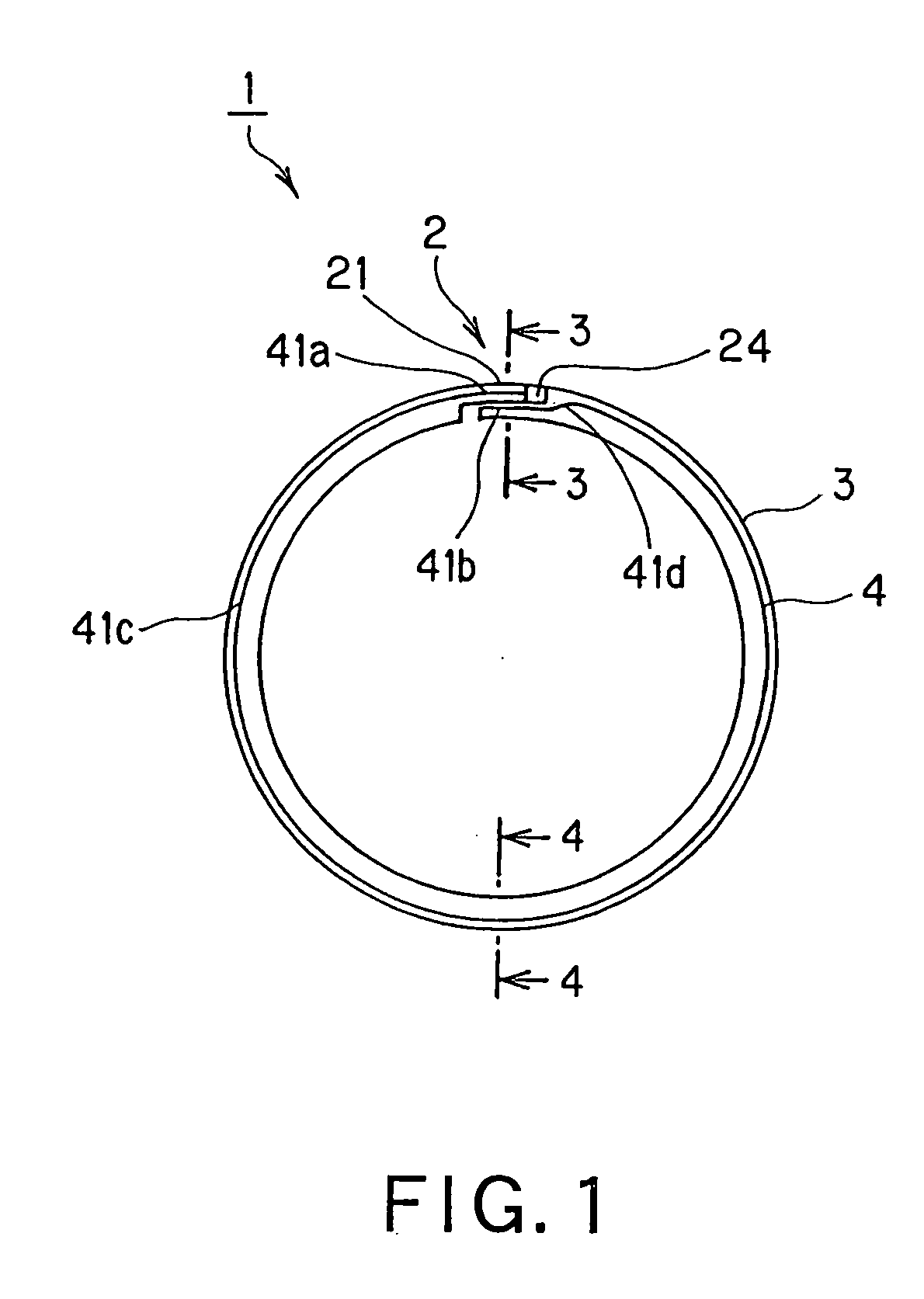

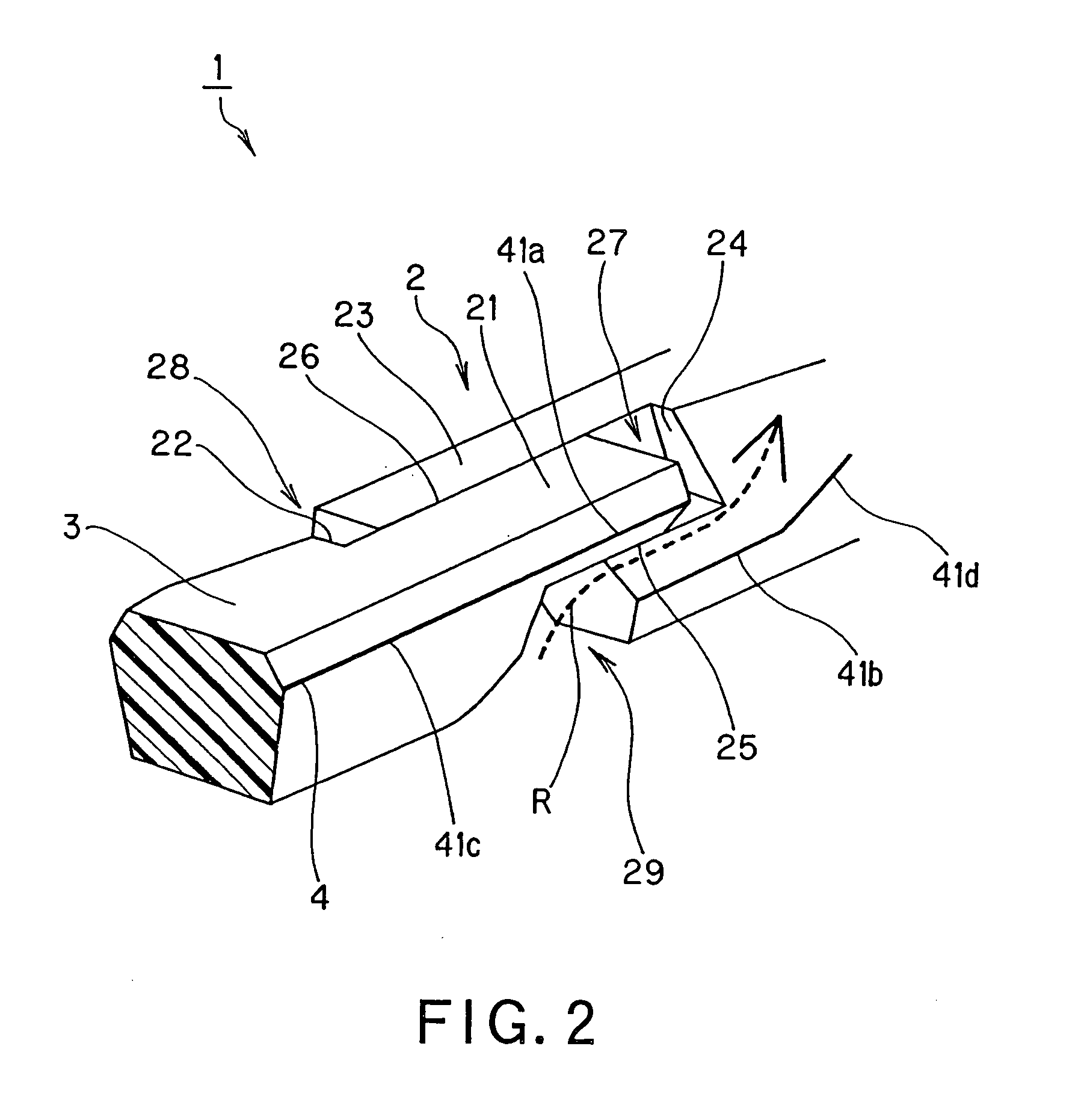

Oil ring

InactiveUS7354045B2Increase fuel consumptionSimple working processPiston ringsBraking action transmissionMechanical engineeringPiston

It is a main object of the present invention to provide an oil ring which is capable of reducing sliding friction even in a high speed revolution region of a piston, and capable of reducing the consumption of oil. To achieve the object, the present invention provides an oil ring which is formed into cross-section substantially of an I-shape that two rails are connected at a columnar portion thereof, wherein a sliding projection formed in each of the two rails comprises an outer side surface of sliding projection which forms an outer portion of the sliding projection, a inner side surface of sliding projection which forms an inner portion of the sliding projection, and a sliding surface which slides on a cylinder inner wall and forms a tip end of the sliding projection;wherein a taper angle of the outer side surface of sliding projection is in a range of 10° to 60°; andwherein the outer edge portion, where the outer side surface of sliding projection and the sliding surface are joined to each other, is formed into the curved surface, and the sliding surface has the curved surface sliding portion which is joined to the outer side surface of sliding projection and formed into a gently curved surface.

Owner:NIPPON PISTONRING CO LTD +1

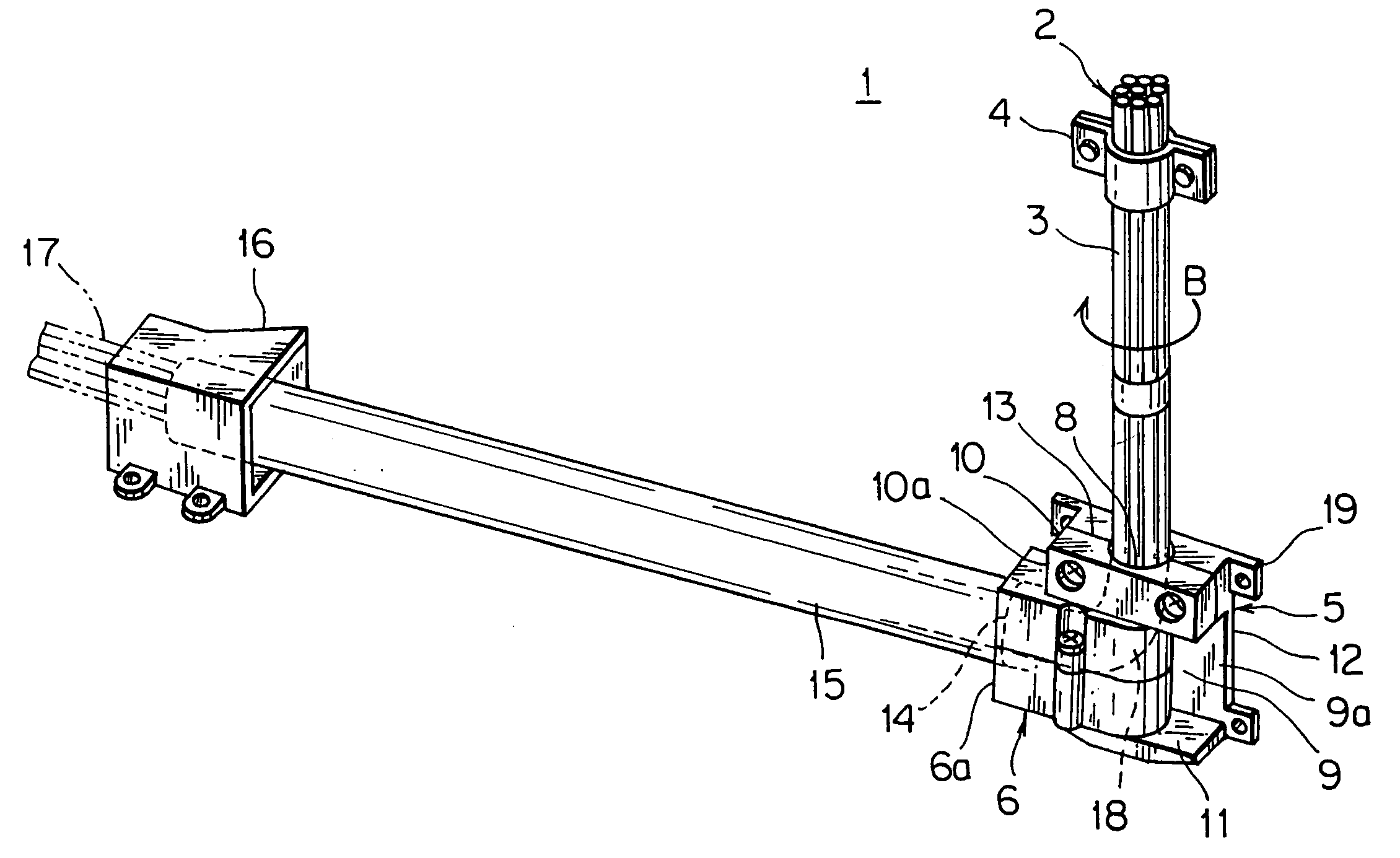

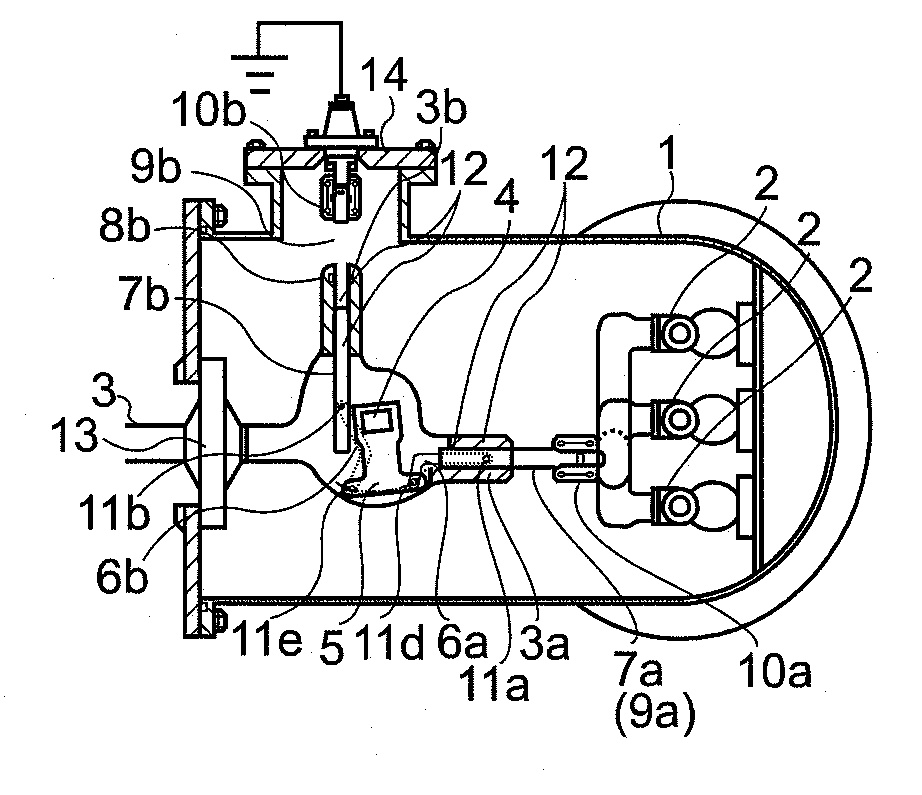

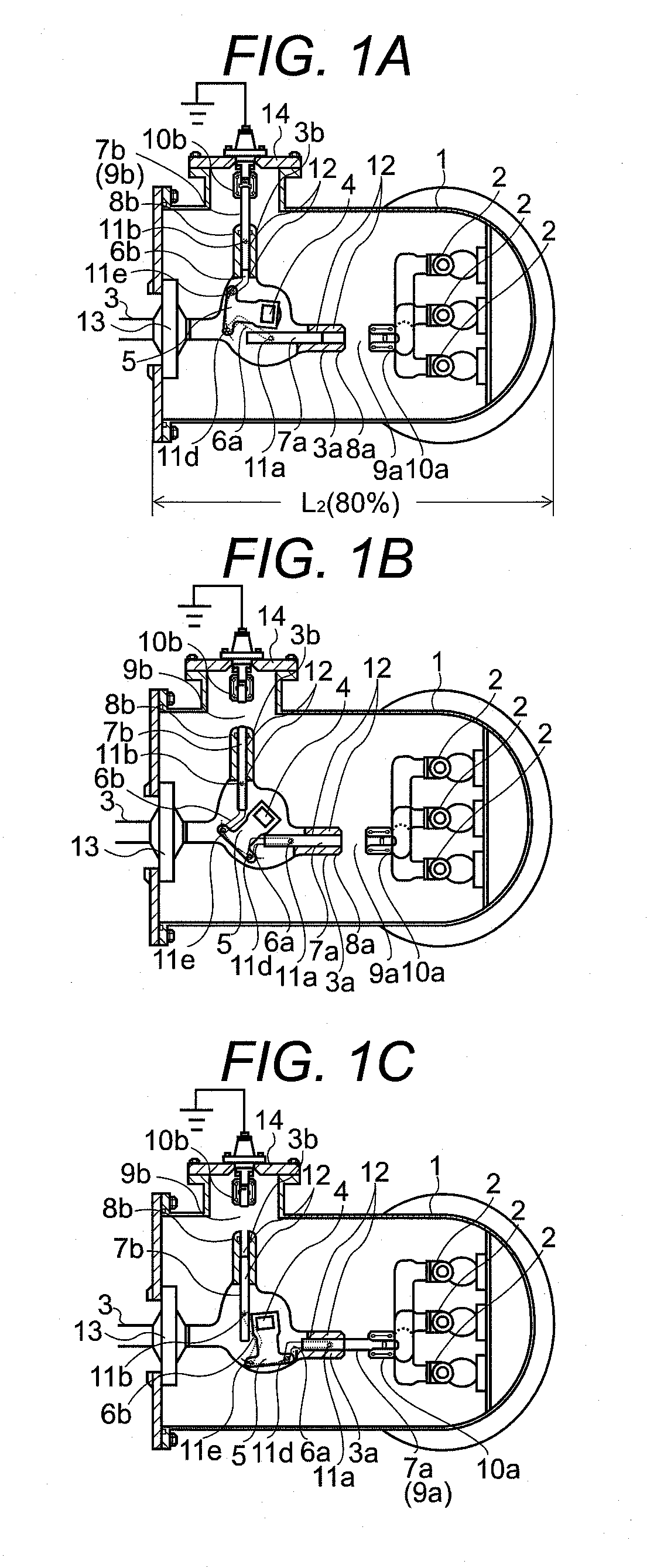

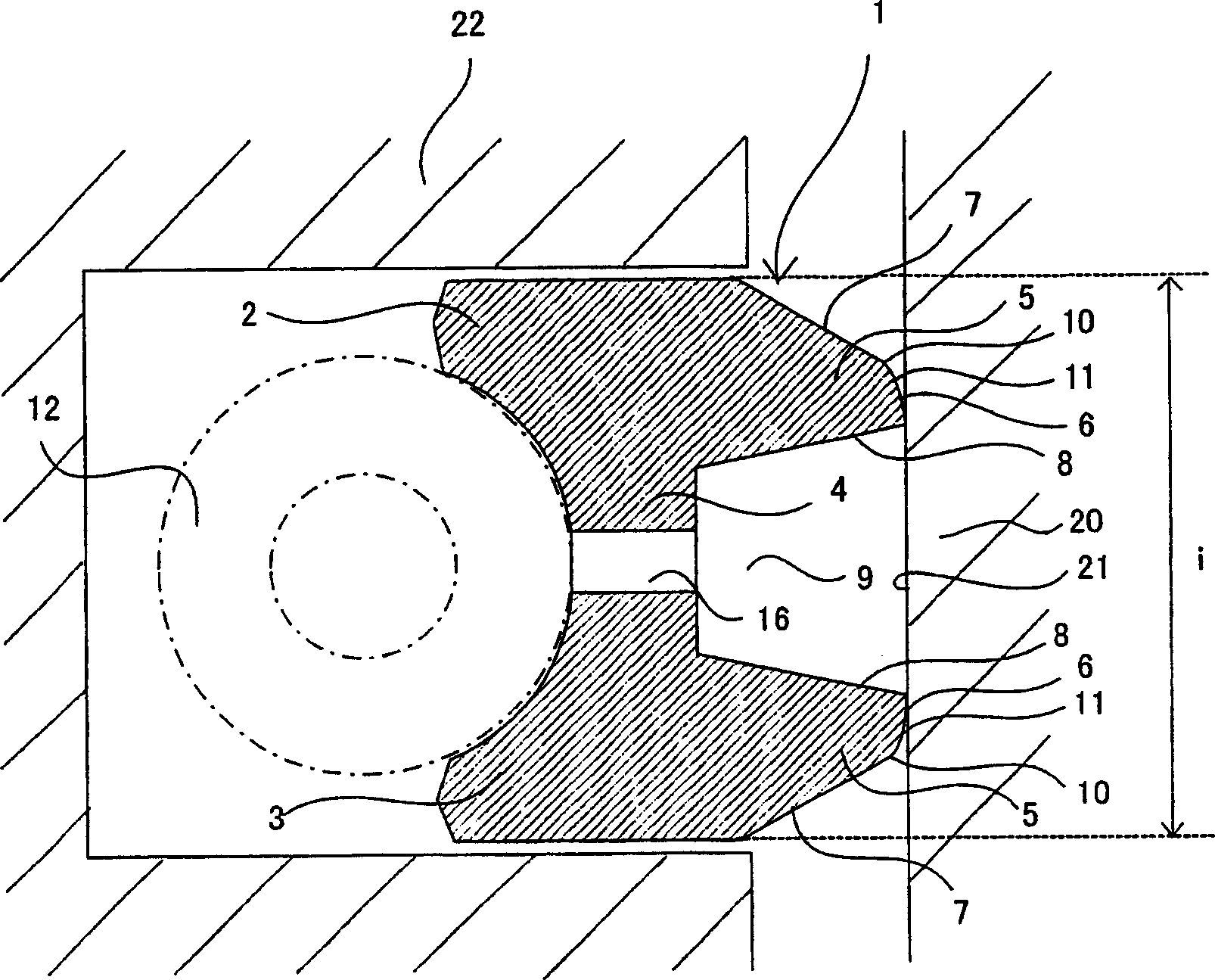

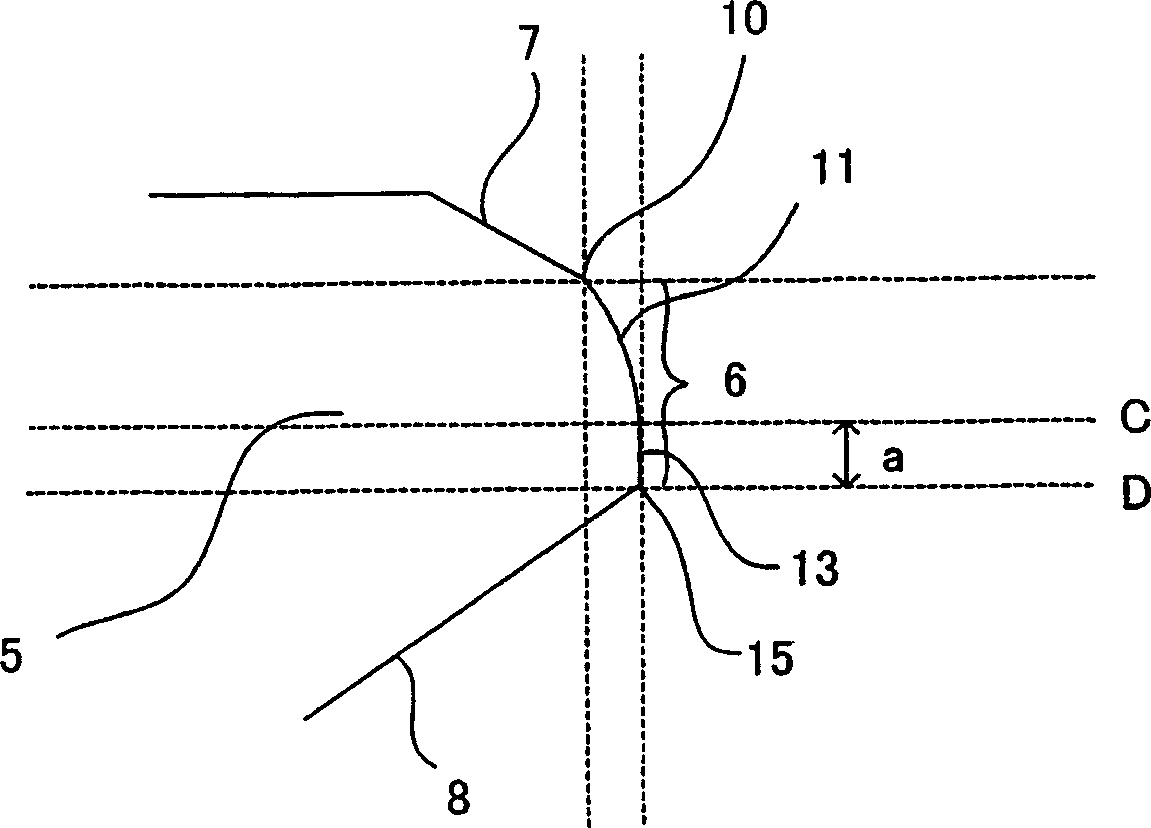

Disconnecting switch with earthing switch

ActiveUS20120012449A1Reduce frictionSmall sizeContact driving mechanismsSwitches with movable electrical contactsControl theoryClosed state

Operating shaft 4 allows disconnecting switch-side and earthing switch-side moving contacts 7a and 7b to linearly reciprocate with the rotation of operating shaft 4. Operating shaft 4 has two-hole lever 5 allow an arc motion. Each one end of two curved links 6a and 6b is connected to two-hole lever 5 and the other end of two curved links 6a and 6b is respectively connected to the disconnecting switch-side moving contact or the earthing switch-side moving contact. When the two connecting points are axisymmetric with respect to the bisector, both the disconnecting switch and the earthing switch are in an open state; when two-hole lever 5 moves at a predetermined angle to the disconnecting switch-side, the disconnecting switch is in a closed state; and when two-hole lever 5 moves at a predetermined angle to the earthing switch-side, the earthing switch is in a closed state.

Owner:HITACHI LTD

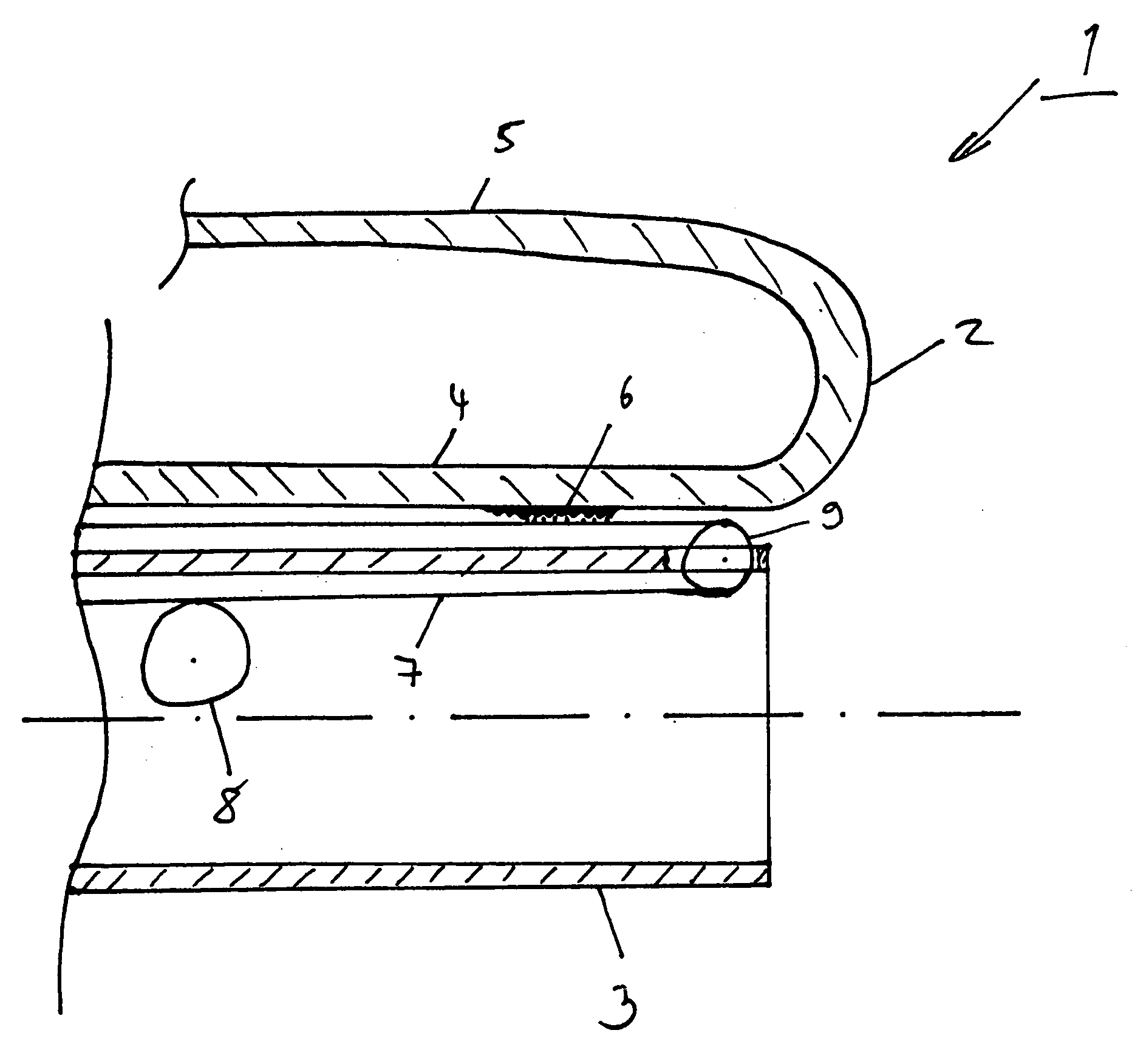

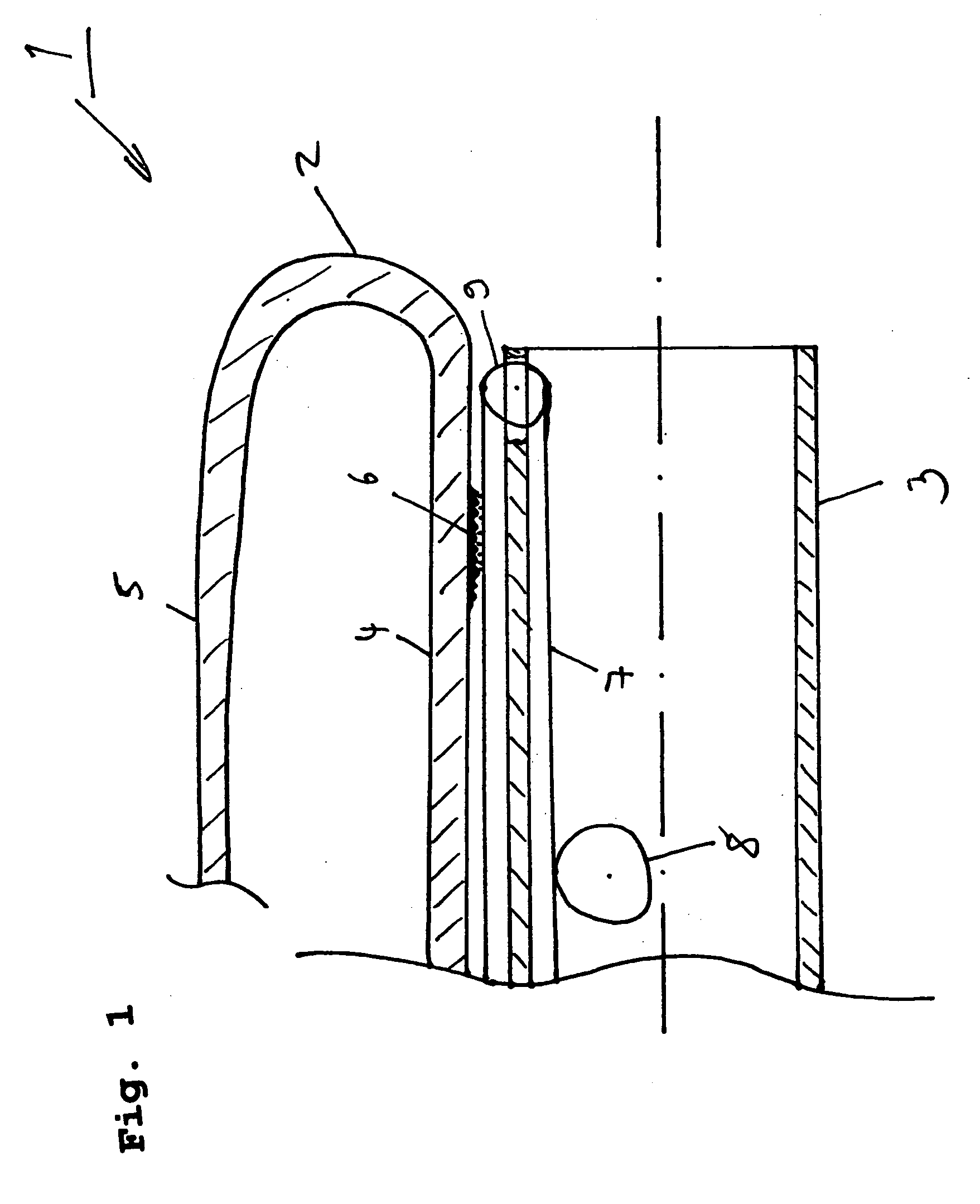

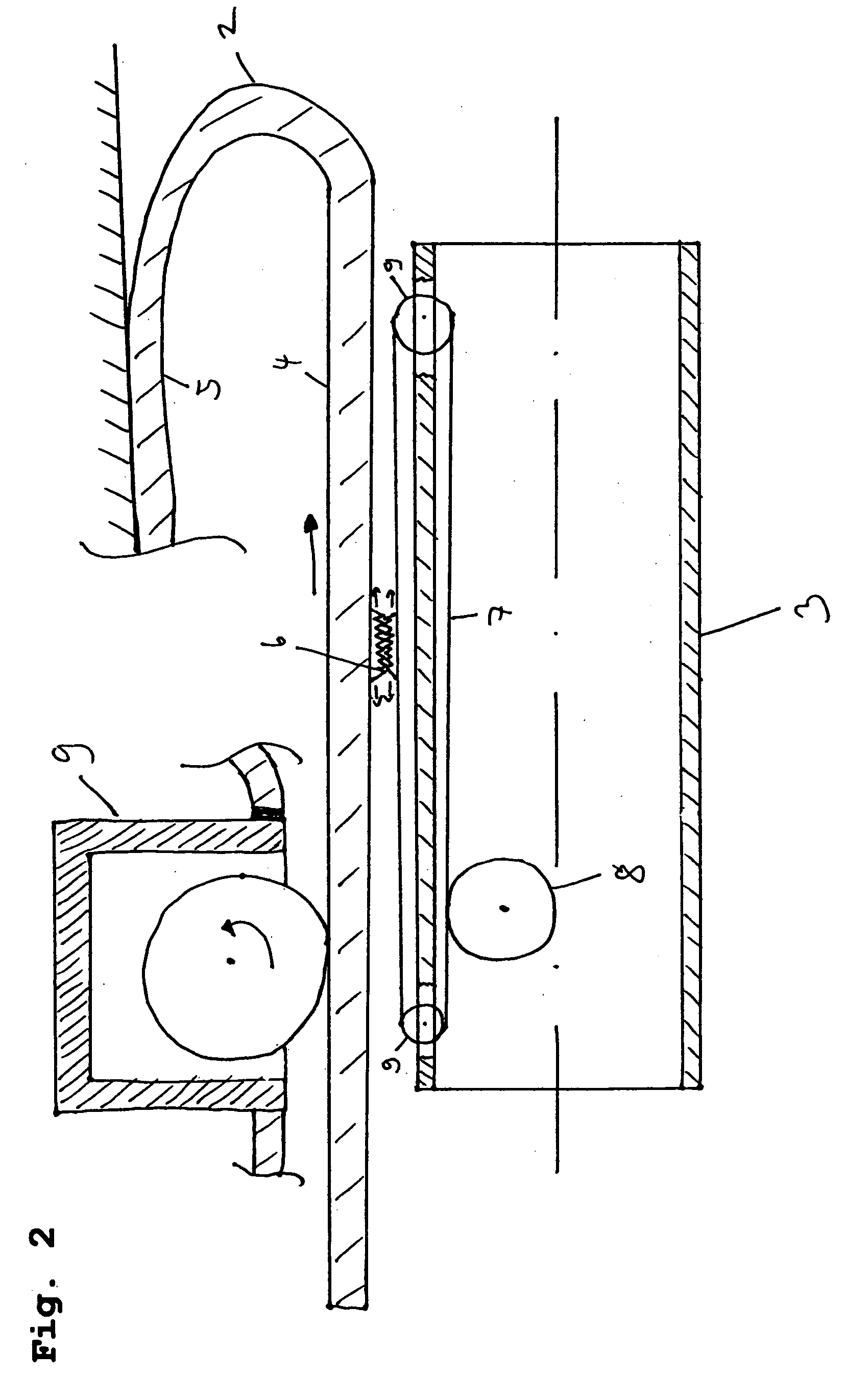

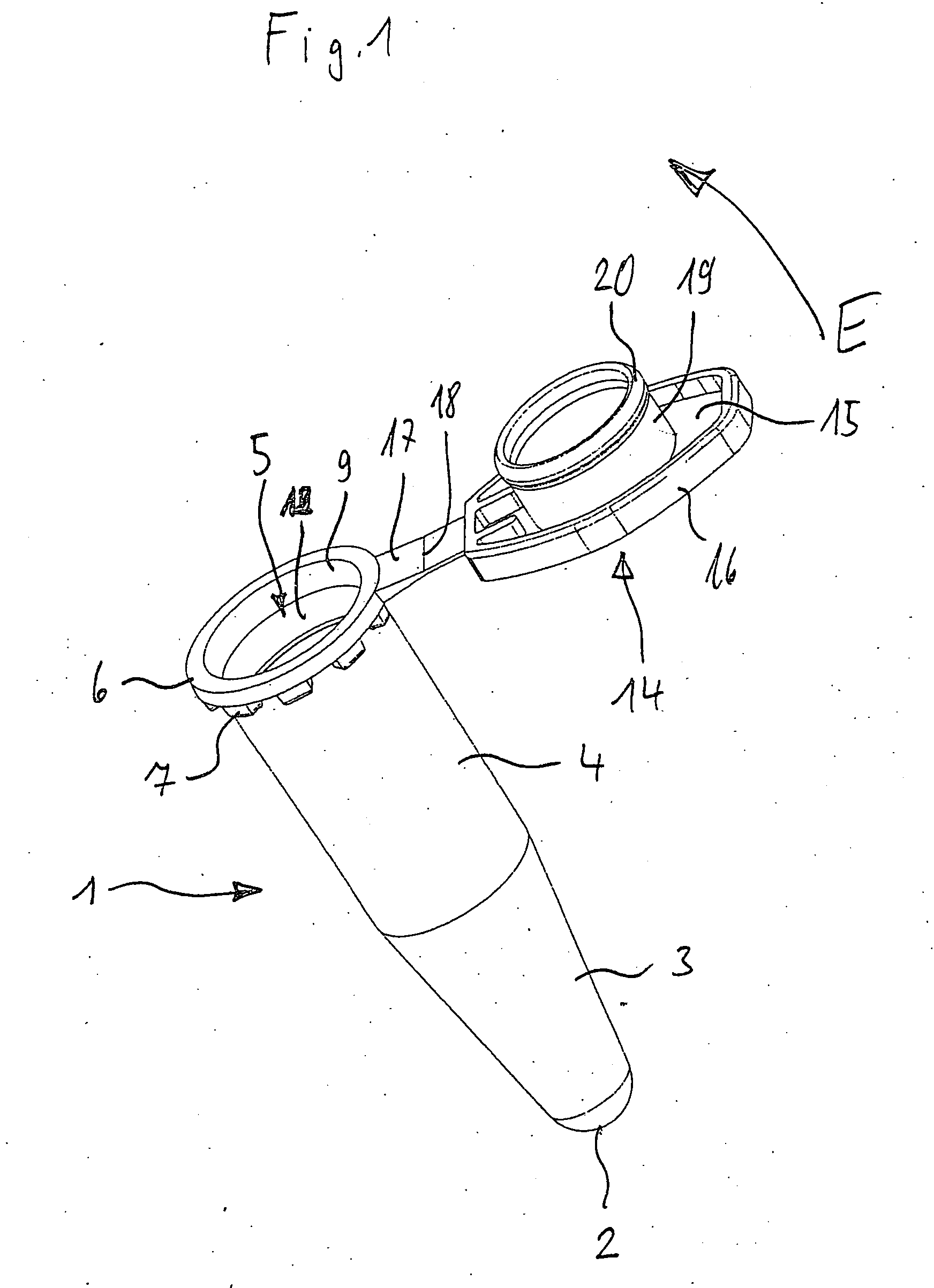

Endoscope comprising a longitudinally guided everting tube

The present invention deals with an endoscope comprising an everting tube including a radially outer portion and a radially inner portion. The everting tube surrounds at least partly an endoscope shaft. Longitudinal guiding means which are engaged with each other are formed at each of the endoscope shaft and the everting tube. One of the longitudinal guiding means can be designed such that it forms an undercut, whereas the other is correspondingly shaped so that both longitudinal guiding means are in sliding engagement with each other. Moreover, the longitudinal guiding means can be, on the one hand, in the form of a continuous conveyor disposed at the endoscope shaft and, on the other hand, in the form of an engaging means disposed at the everting tube, which are engaged with each other.

Owner:INVENDO MEDICAL GMBH

Power supply apparatus for sliding structure

ActiveUS7482538B2Vertical path portion can be shortenedReduce power levelCoupling device connectionsElectric discharge tubesCable harnessElectrical and Electronics engineering

A power supply apparatus for a sliding structure, which can be arranged in a small space in the sliding structure, the power supply apparatus including a wiring harness having a vertical path portion; a harness fixing member for fixing one end of the vertical path portion of the wiring harness on the sliding structure; a fixed base fixed on the sliding structure for holding the other end of the vertical path portion; and a swing member mounted on the fixed base to swing freely in a horizontal plane for allowing the vertical path portion to be twisted along a circumferential direction of itself and leading a part of the wiring harness continued to the vertical path portion toward a fixed structure. Instead of the fixed base, a movable base 5′, and a guide rail to be engaged with the movable base can be applied.

Owner:YAZAKI CORP +1

Oil ring

The present invention provides an oil ring capable of reducing sliding friction even in a high-speed operation region of a piston, thereby reducing lubricating oil consumption. In order to achieve the above object, the oil ring of the present invention is an oil ring that connects two ring rails with a column and has an I-shaped cross section. The sliding part protrusion formed by the above two ring rails has: Part of the outer surface of the protrusion of the sliding part, the inner surface of the protrusion of the sliding part forming the inner part of the protrusion of the sliding part, and the sliding surface that slides with the inner wall of the cylinder and forms the front end part of the protrusion of the sliding part, is characterized in that the sliding part The inclination angle of the outer surface of the protrusion is in the range of 10° to 60°; the outer edge portion of the outer surface of the protrusion of the sliding part that is joined to the sliding surface is formed in a curved shape, and the sliding surface has a protrusion that is connected to the sliding part. The outer surfaces are joined and formed as a curved sliding portion in the shape of a gentle slope curved surface.

Owner:TOYOTA JIDOSHA KK +1

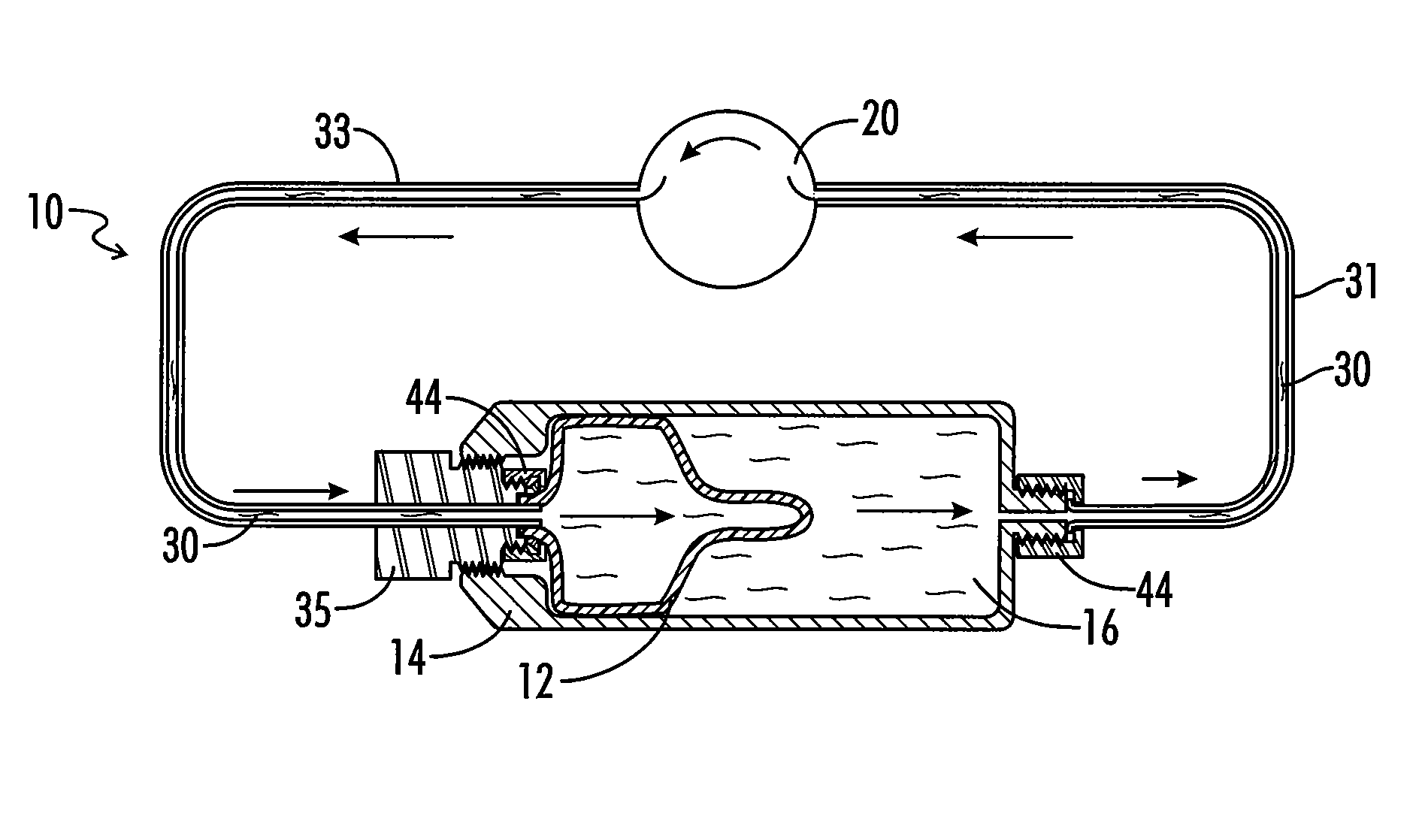

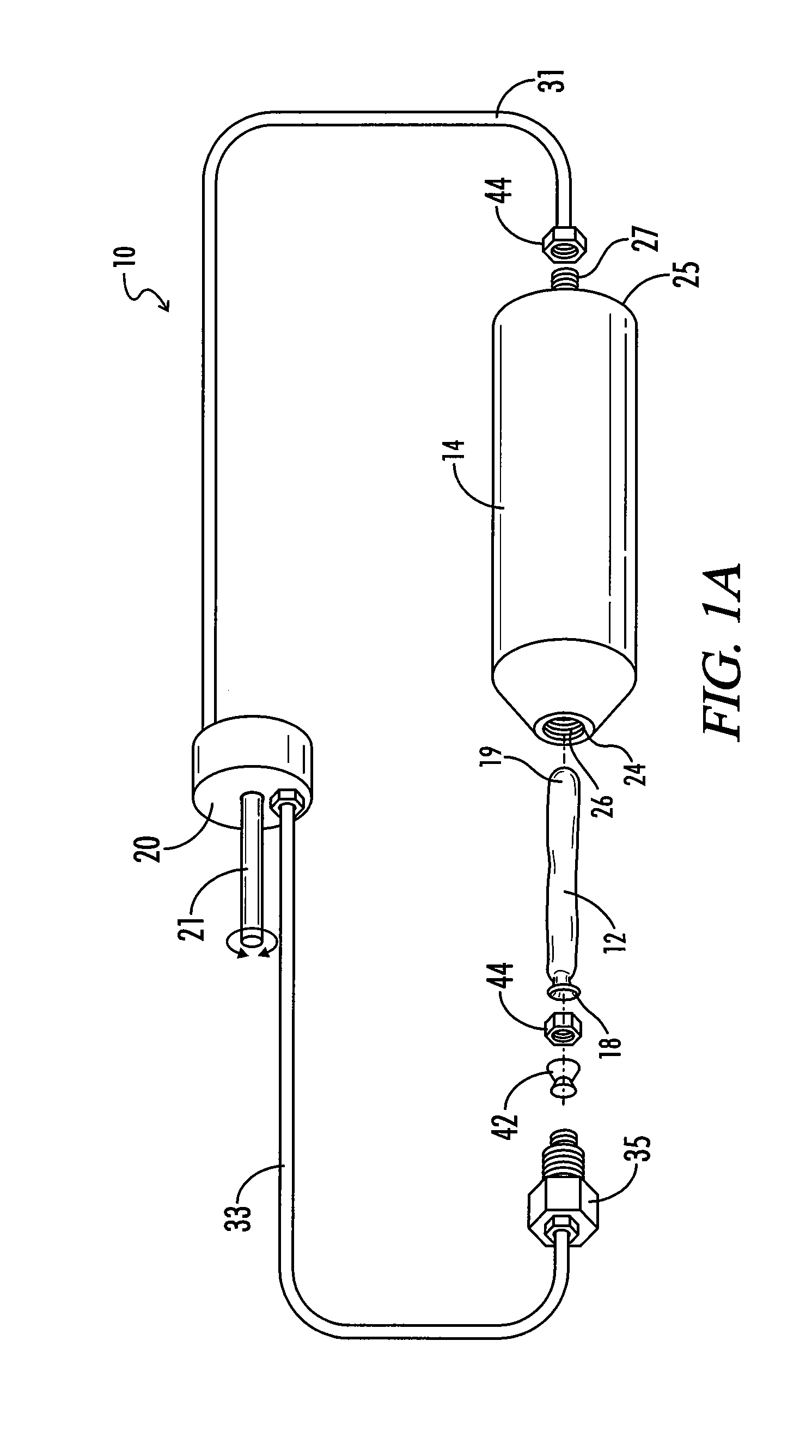

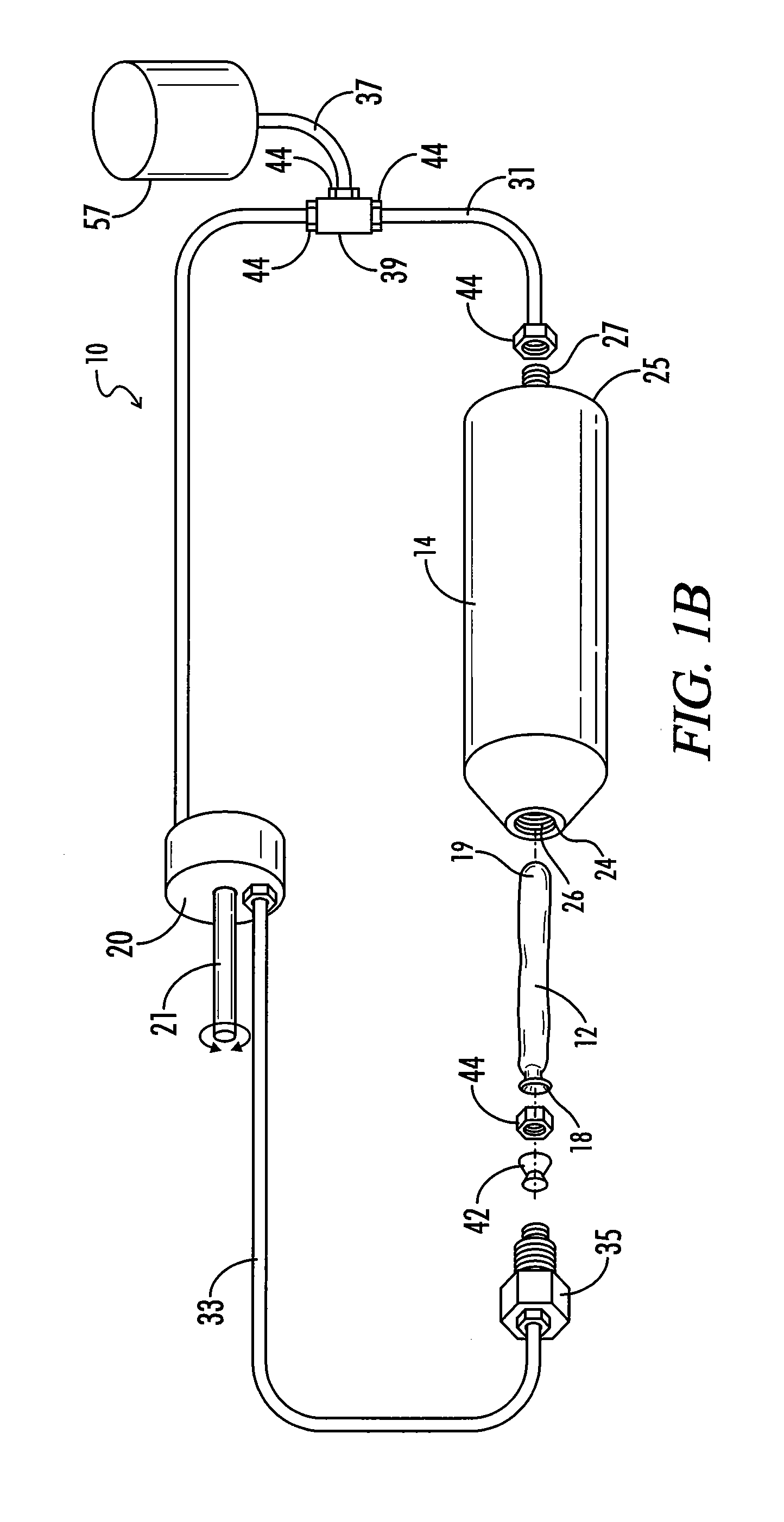

Elastic hydraulic accumulator/reservoir system

ActiveUS8434524B2Less spaceLight weightFlexible wall reciprocating enginesPump assembliesStored energyEngineering

The invention is a combination accumulator and reservoir which stores energy when the accumulator deforms from its original shape in response to the flow of a pressurized fluid from the reservoir. The stored energy is returned when the fluid flow is reversed and the accumulator discharges the fluid and returns to its original shape. At least one part of the novelty of the invention is that the accumulator and the fluid reservoir reside in the same housing such that the volume of each varies inversely. Accordingly, the invention is more compact and weighs less than conventional accumulators. Another feature of the invention is that fluid is located around the bladder accumulator to lubricate contact between the bladder and sides of the reservoir.

Owner:VANDERBILT UNIV

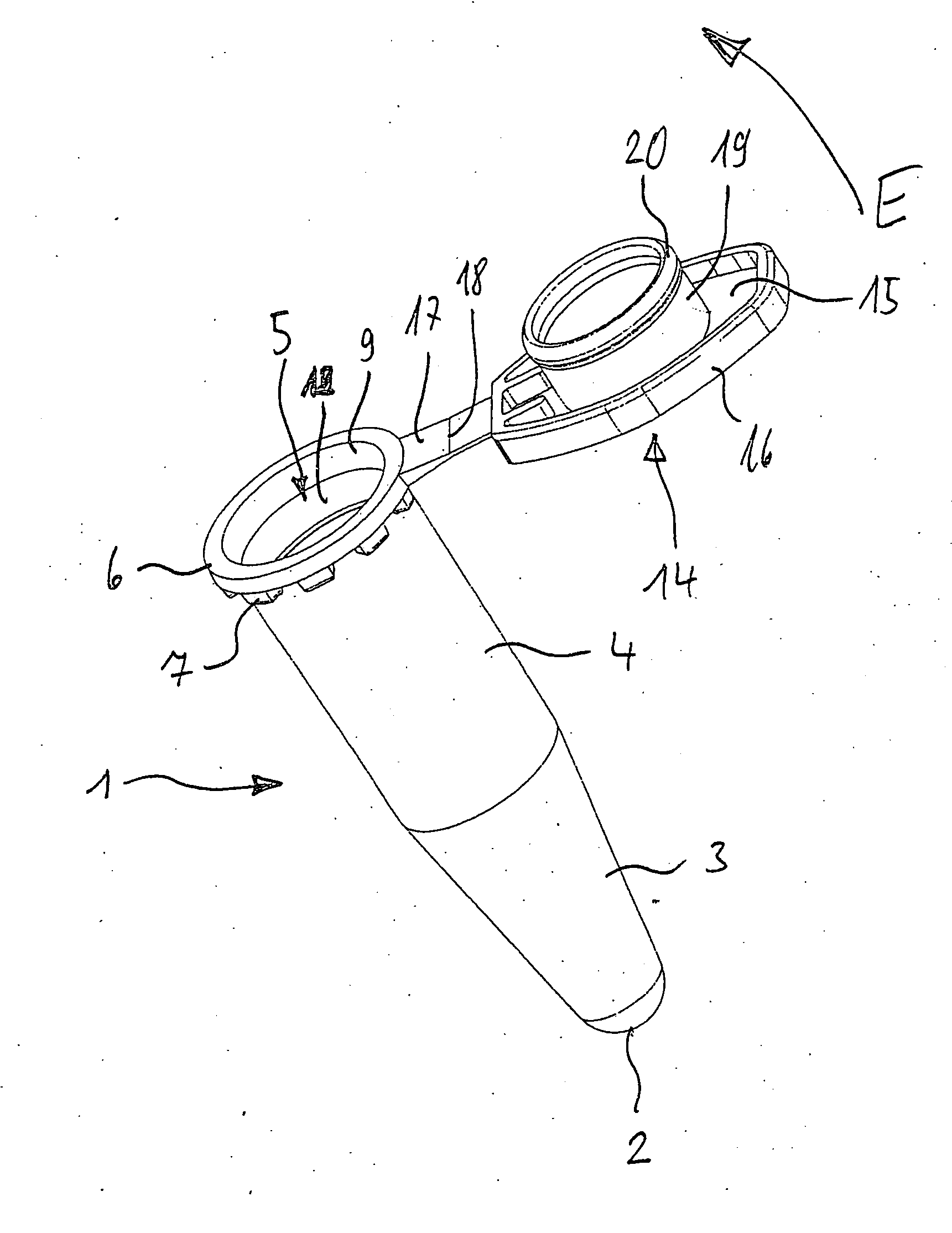

Lidded vessel

InactiveUS20070128080A1Reduce wall thicknessReduction factorAnalysis using chemical indicatorsLaboratory glasswaresEngineeringBung

Lidded vessel made from resilient plastics for laboratory use with a tubular vessel which has a vessel base at one end, a vessel opening at the other end, a retaining region on the inner wall of the vessel and an insertion region between the vessel opening and the retaining region, a lid which has a lid base and a stopper on one side of the lid base and which may be inserted through the vessel opening into a sealing position in the vessel, in which a sealing region of the stopper is placed on a sealing seat on the inner wall of the vessel, and a sliding ring and a retaining ring on the periphery of the stopper, the sliding ring having a lower coefficient of sliding friction relative to the insertion region than the retaining ring has relative to the retaining region and, when mounted, slides over the insertion region and is placed in the sealed position of the retaining ring on the retaining region.

Owner:EPPENDORF AG

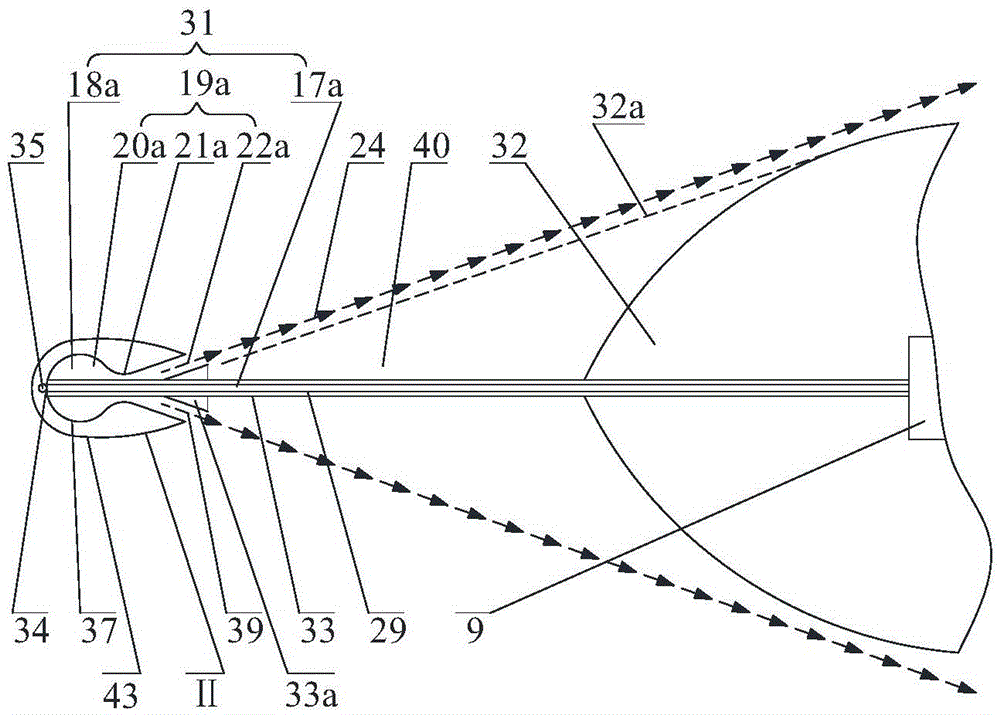

System taking compressed air as force applying source, operation method for system and airplane

ActiveCN105649775ASimple structureLow costWorking fluid for enginesJet type power plantsAviationShortest distance

The invention provides a system taking compressed air as a force applying source. The system comprises a compressed air jet engine (14) which takes high-pressure and ultrahigh-pressure compressed air as a jet working medium, a compressed air production and supply device (48) for greatly producing, storing and supplying high-pressure and ultrahigh-pressure compressed air in an economic and environment-friendly manner and a controller, wherein the compressed air jet engine (14) is arranged on aviation, aerospace and navigation equipment such as airplanes, rockets, submarines, trains and the like as well as moving carriers which travel on the ground; the compressed air jet engine (14) comprises an air tank (9) used for storing the compressed air and a jet engine (16) used for generating power; the jet engine (16) comprises a primary jet engine (14) for generating thrust and a plurality of secondary jet engines for reducing air (or seawater) resistance as well as air (or seawater) sliding friction force generated in travelling of the moving carriers, so as to be beneficial for increasing the speed and saving energy, as well as increasing lifting force of wings of the airplane, so as to be beneficial for short-distance or vertical take-off, landing and the like of the airplane.

Owner:王力丰

Seal ring

ActiveUS20060038355A1Inhibit wearEasily vomitedEngine sealsPiston ringsEngineeringMechanical engineering

Owner:NOK CORP

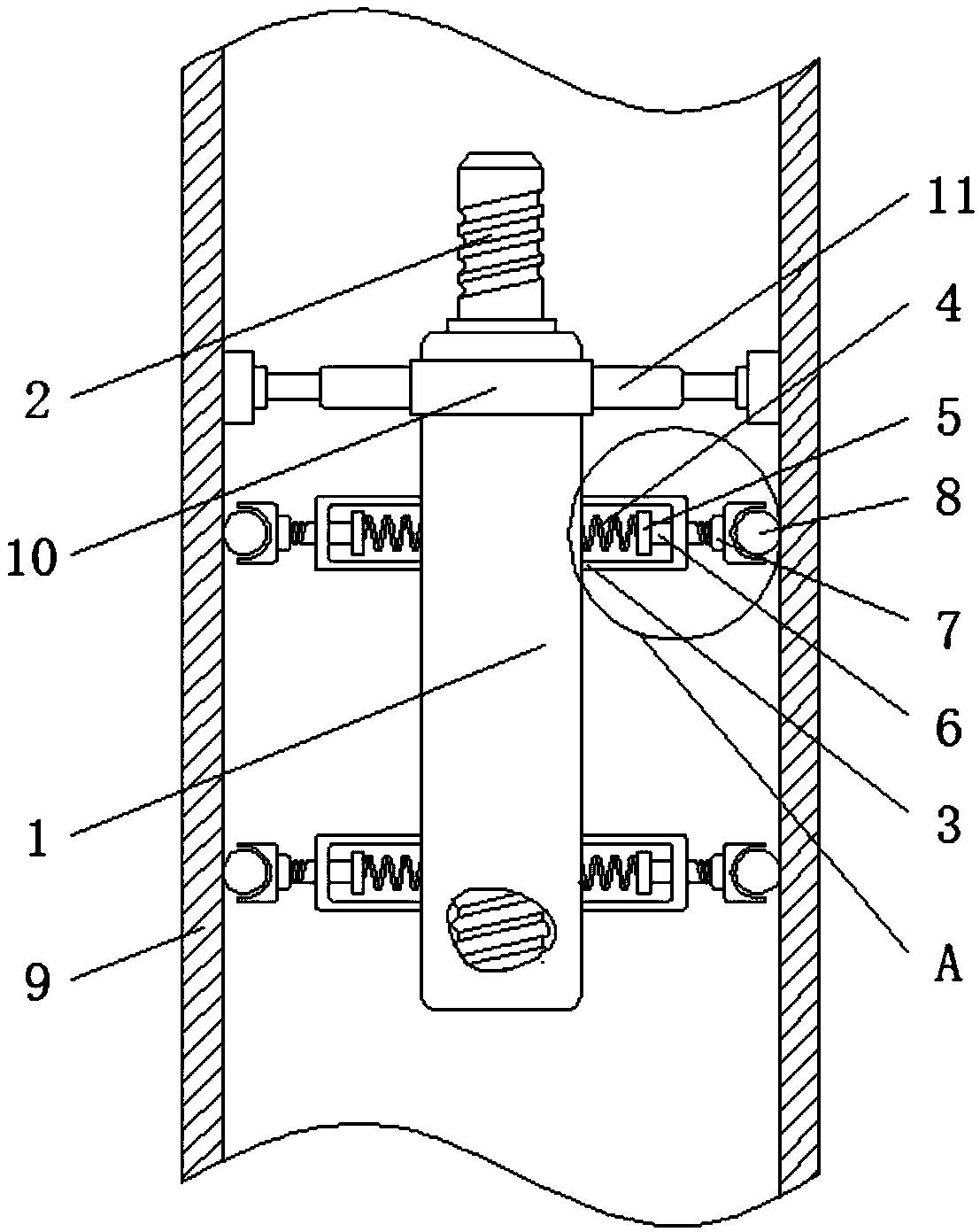

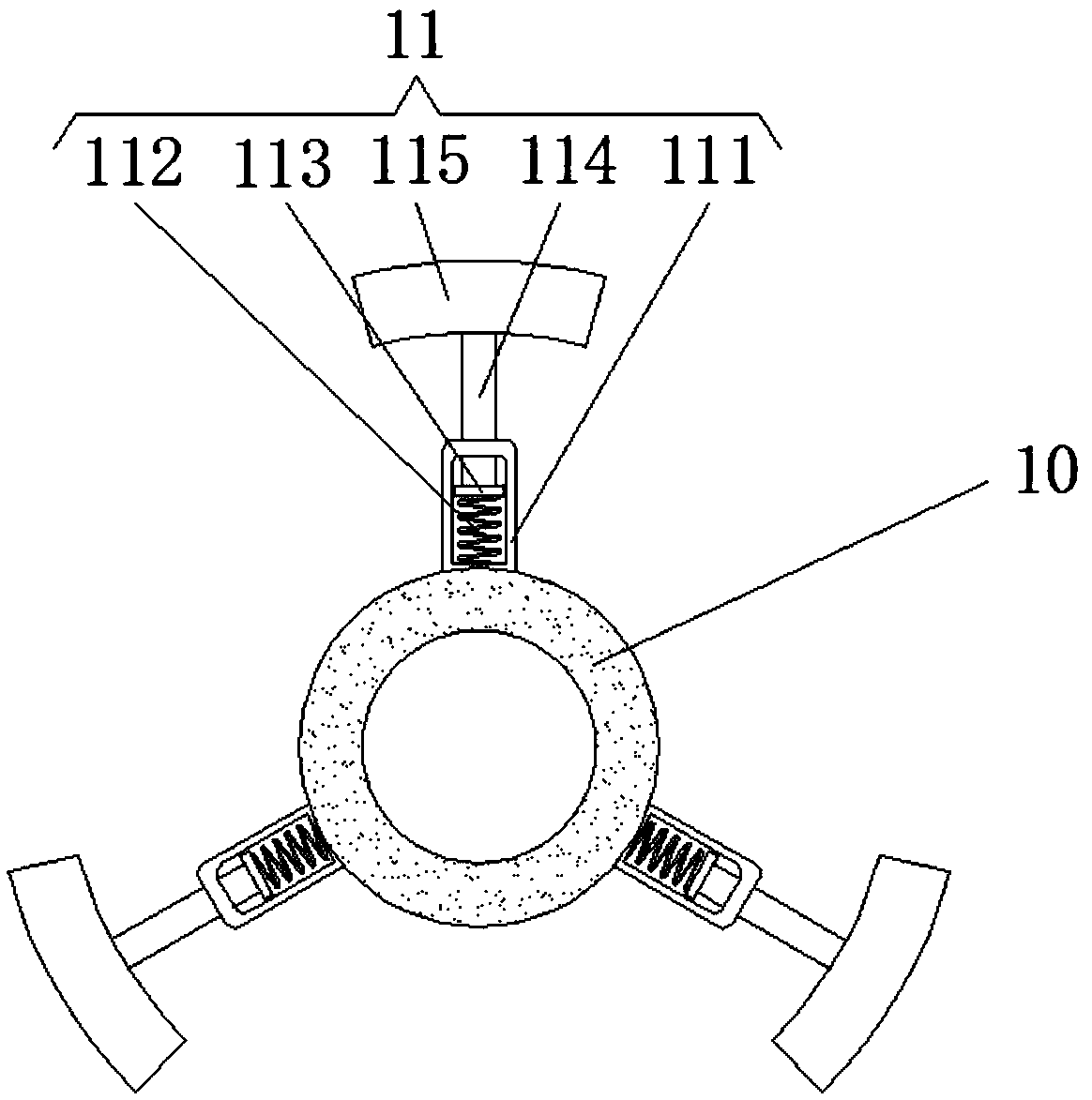

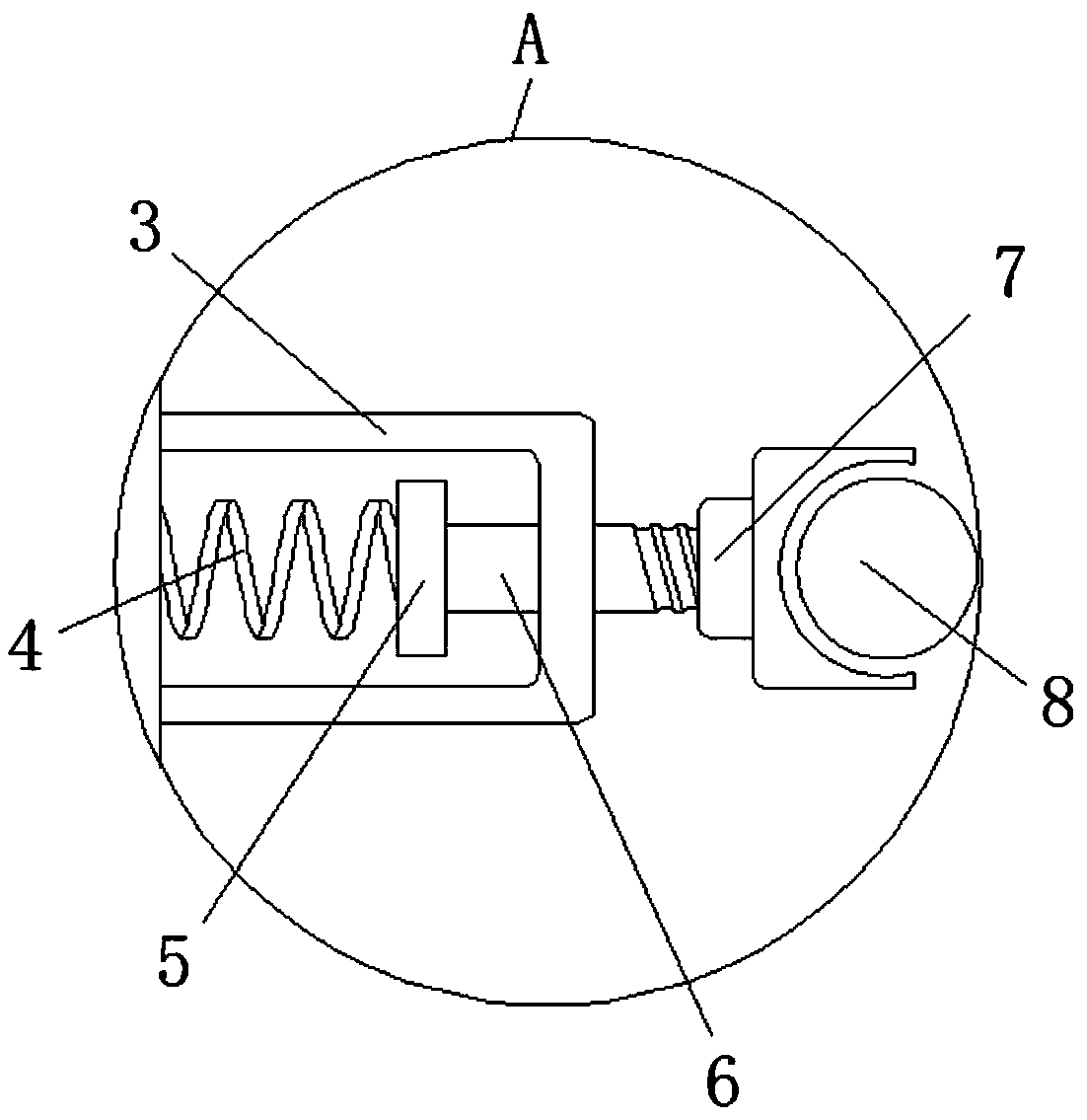

Elastic oil sucker rod centralizer for oil fields

ActiveCN108756775AExtended service lifeReduce maintenance costsDrilling rodsCleaning apparatusIdler-wheelSucker rod

The invention relates to the technical field of oil extraction equipment, and discloses an elastic oil sucker rod centralizer for oil fields. The elastic oil sucker rod centralizer for oil fields comprises a centralizer body. The top end of the centralizer body is fixedly connected with one end of a fixing screw rod. The top portion of one side of the centralizer body is fixedly connected with onesides of regulating sleeves, one sides of inner cavities of the regulating sleeves are fixedly connected with one ends of adjusting springs, and the other ends of the adjusting springs are fixedly connected with one sides, arranged in the inner cavities of the regulating sleeves, of adjusting plates. The other sides of the adjusting plates are fixedly connected with one ends of regulating link rods. According to the elastic oil sucker rod centralizer for oil fields, by arranging ball type clamp blocks and balls, the sliding friction between the balls and the inner wall of an oil tube can be effectively reduced, and the service life of idler wheels is prolonged. Meanwhile, the ball type clamp blocks are in threaded connection with the regulating link rods, the problem that an existing one-piece structure cannot replace the wornout idler wheels is avoided, and the maintenance cost of the elastic oil sucker rod centralizer for oil fields is reduced.

Owner:DAQING DANNUO PETROLEUM TECH DEV

Syringe

InactiveUS7648487B2Increase sliding frictionAvoid it happening againInfusion syringesIntravenous devicesDrugs solutionMedicine

Owner:NIPRO CORP

Annular seal assembly for insertion between two relatively rotatable members, in particular a tub and a rotating shaft of the drum of a washing machine

ActiveUS20080272557A1Improve performanceSlight frictionEngine sealsOther washing machinesRotational axisRadial plane

A seal assembly including a first rigid shield having an annular sealing member of elastomeric material, and a second rigid shield mounted facing the first and having respective sliding surfaces for a first and second annular sealing lip of the annular sealing member, which extend towards the second rigid shield to exert axial sealing pressure and radial sealing pressure, respectively; wherein the first annular sealing lip has a radial seat facing the opposite way to the second annular sealing lip and housing a toroidal spring, which exerts a radial thrust on the first annular sealing lip eccentrically with respect to an elastic hinge defined by a root portion common to the first and second annular sealing lip, and having a centre of rotation located along a line extending through a V-shaped sealing edge of the first annular sealing lip and forming a 20° to 60° angle with a radial plane; the root portion being defined between two opposite annular recesses of the annular sealing member, which have a U-shaped radial section and bottom walls facing each other and substantially aligned along the aforementioned line; and the second annular sealing lip having a V-shaped sealing edge defined by an undulated, circumferential groove.

Owner:AB SKF

Aircraft wheel and landing-assisting method

ActiveCN104608921AReduce decelerationLittle deflection momentElectrodynamic brake systemsAircraft braking arrangementsFixed frameEngineering

The invention discloses an aircraft wheel and a landing-assisting method. The aircraft wheel comprises a tire, an outer hub and a core part, wherein the tire is arranged on the outer hub in a sleeving manner; the core part is arranged in a cavity of the outer hub; a plurality of pieces of permanent magnet steel are arranged on the inner surface of the outer hub; the core part comprises a plurality of coil groups, a brake resistor, a controller and a wheel shaft; the plurality of coil groups are distributed in the outer edge area of the core part and correspond to the plurality of pieces of permanent magnet steel; the controller is electrically connected with the plurality of coil groups and the brake resistor respectively; the wheel shaft is located on the central axis of the core part; the outer hub is arranged on the wheel shaft in a sleeving manner; the core part further comprises a stator iron core and a fixed frame, the stator iron core is arranged on the fixed frame in a sleeving manner, the plurality of coil groups are arranged on the stator iron core, and the wheel shaft is arranged at the center of the fixed frame. The aircraft wheel is capable of effectively reducing the slide friction force and the deflection torque stressed by contacting to earth when an aircraft lands, thus greatly improving the safety.

Owner:GUANGZHOU INST OF RAILWAY TECH

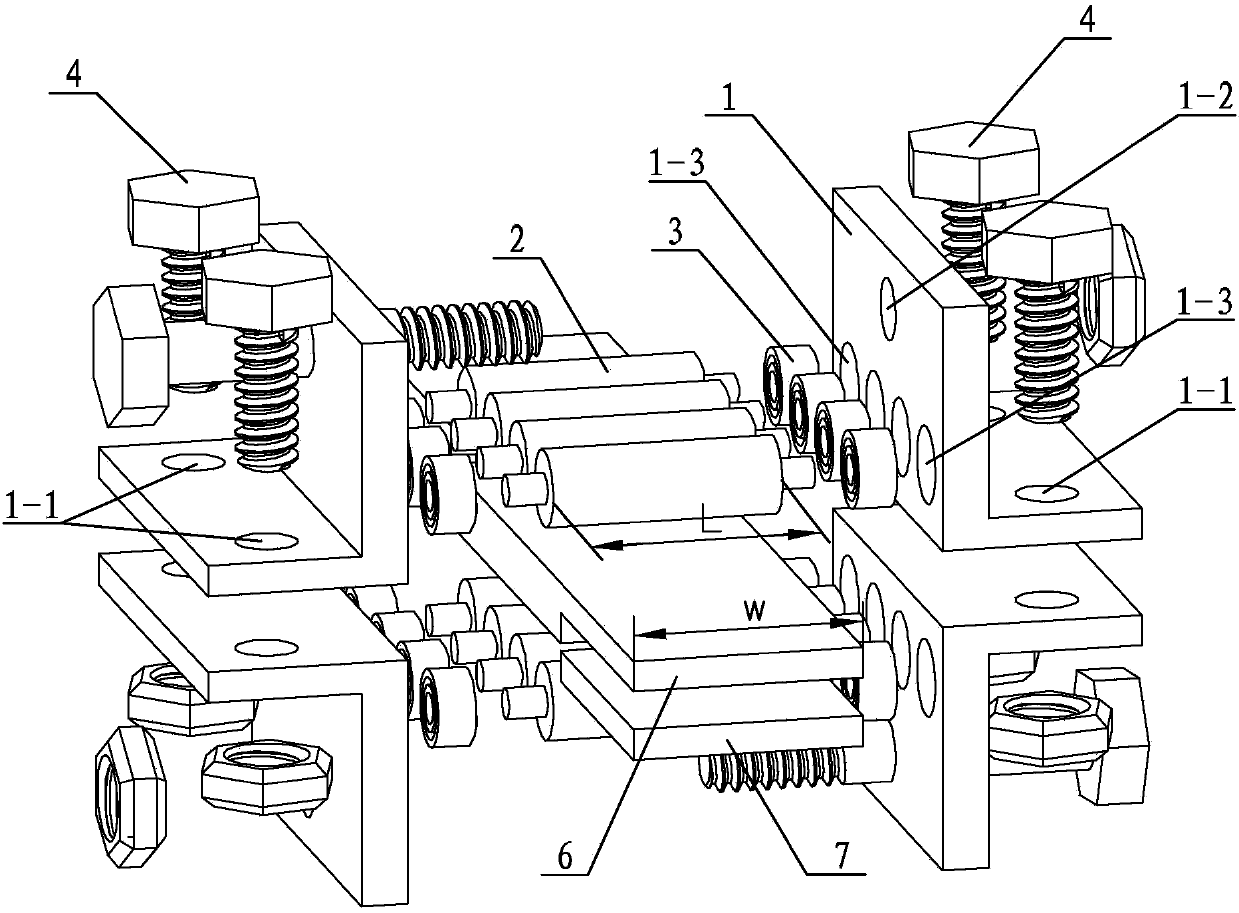

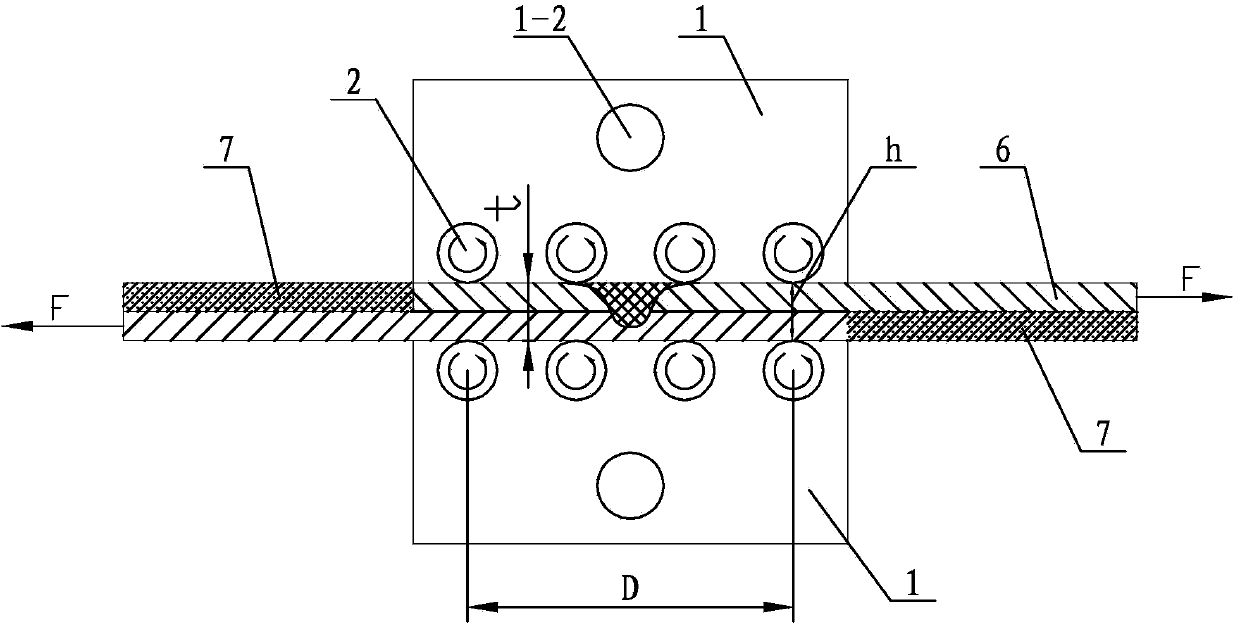

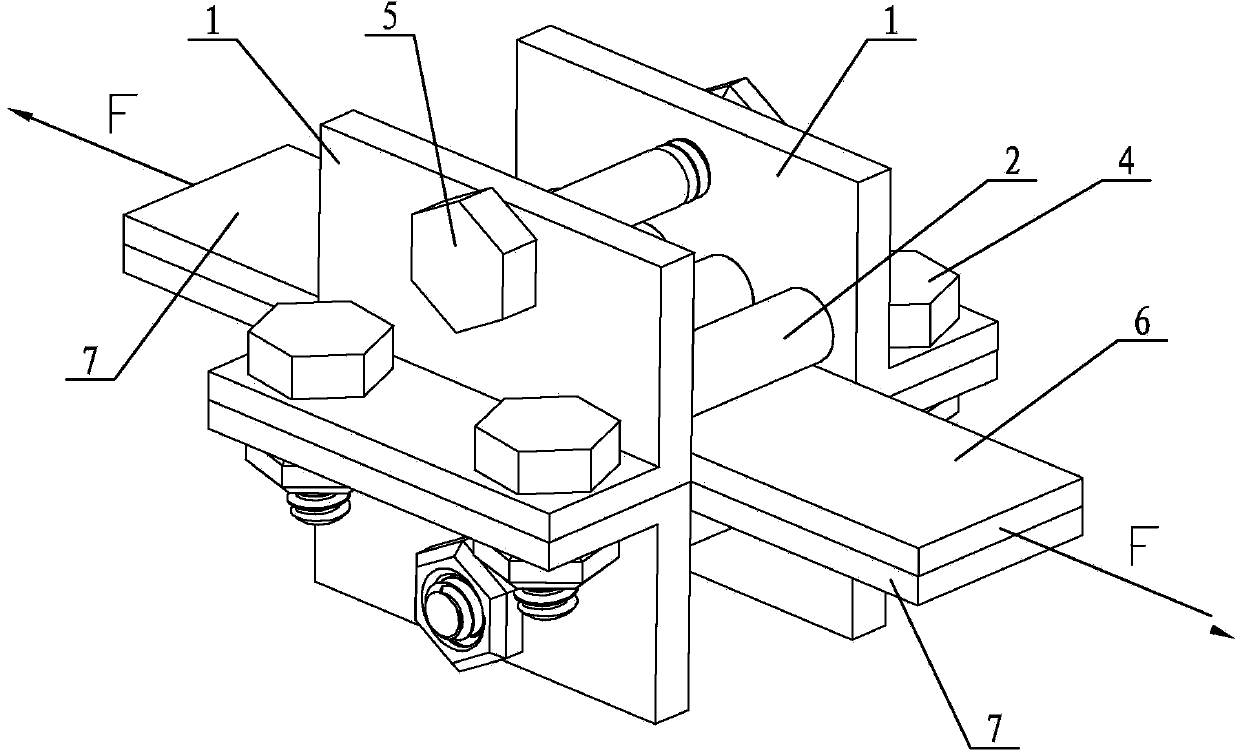

Fixture and method for measuring maximum tensile and shearing force of lap joint of friction stir welding

ActiveCN103592181AGuaranteed pure tensile shear failureEliminate additional bending momentsMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesFriction weldingLap joint

The invention provides a fixture and a method for measuring the maximum tensile and shearing force of a lap joint of friction stir welding to overcome the problem that additional bending moment influences measurement results of the maximum tensile and shearing force of a lap joint of friction stir welding in a traditional tensile and shearing test. According to the fixture, four bearing installing holes are arranged along a same horizontal line; eight rollers are arranged in two layers, each layer consisting of four parallely arranged rollers; the end parts of each roller is mounted in a corresponding bearing installing hole through a positioning bearing. The method comprises the following steps: 1, allowing the distance between axle centers of two rollers located at two outermost sides of each layer of rollers to be 10 to 20 times thickness of the lap part of a test piece for tensile and shearing testing; 2, placing the test piece for tensile and shearing testing between the upper layer of rollers and the lower layer of rollers; and 3, clamping the assembled test piece for tensile and shearing testing, the fixture and cushion blocks on a tensile and shearing testing machine, carrying out tensile and shearing testing on the test piece for tensile and shearing testing at a loading speed of 0.5 to 1.5 mm / min and recording a maximum tensile and shearing test load F. The fixture and the method provided by the invention are used for measuring the maximum tensile and shearing force of the lap joint of friction stir welding.

Owner:HARBIN INST OF TECH

Medical examination table with pullout step

ActiveUS7386899B2Easy to moveReduce sliding frictionOperating tablesBed-tablesEngineeringMedical treatment

Owner:MIDMARK

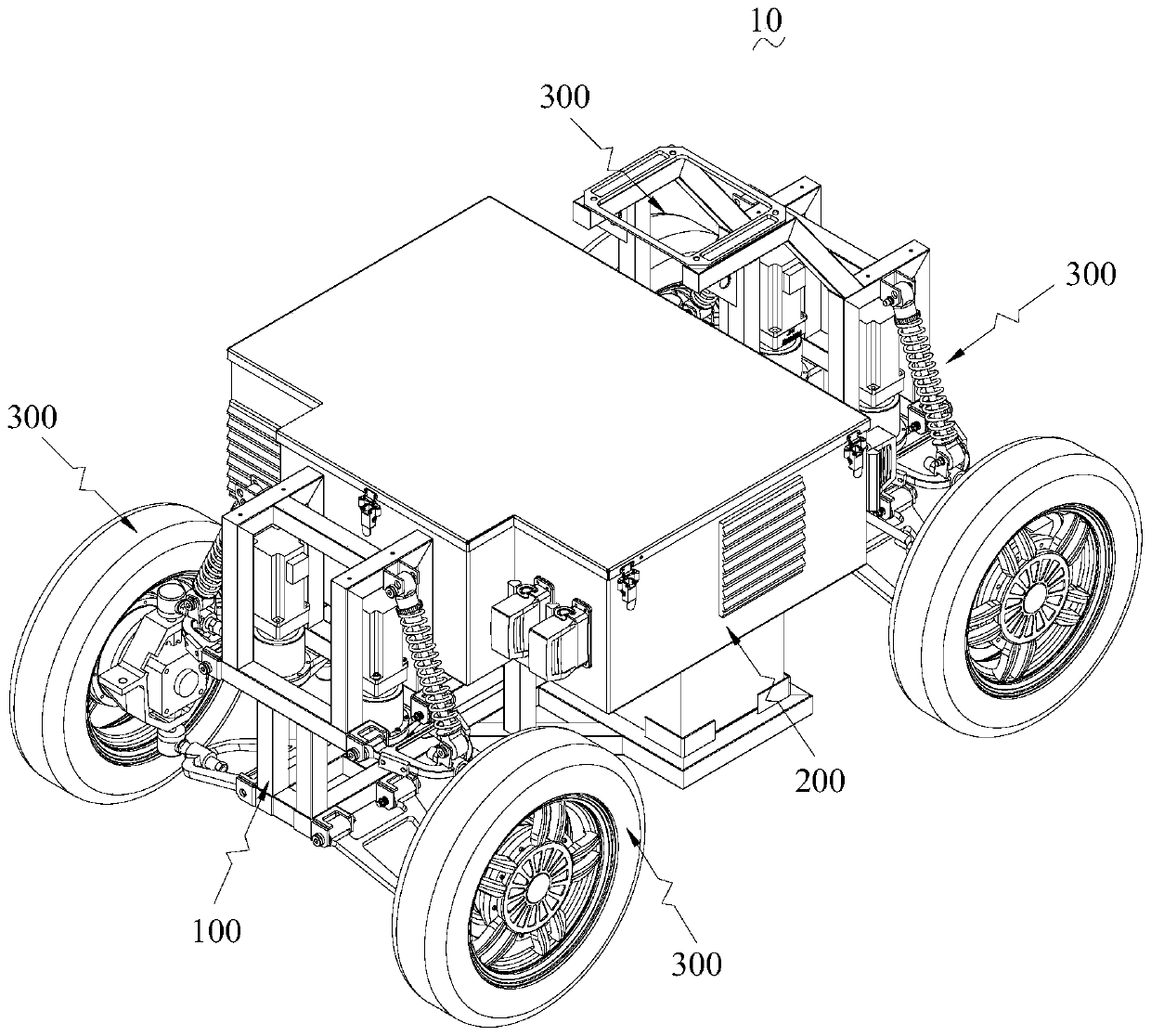

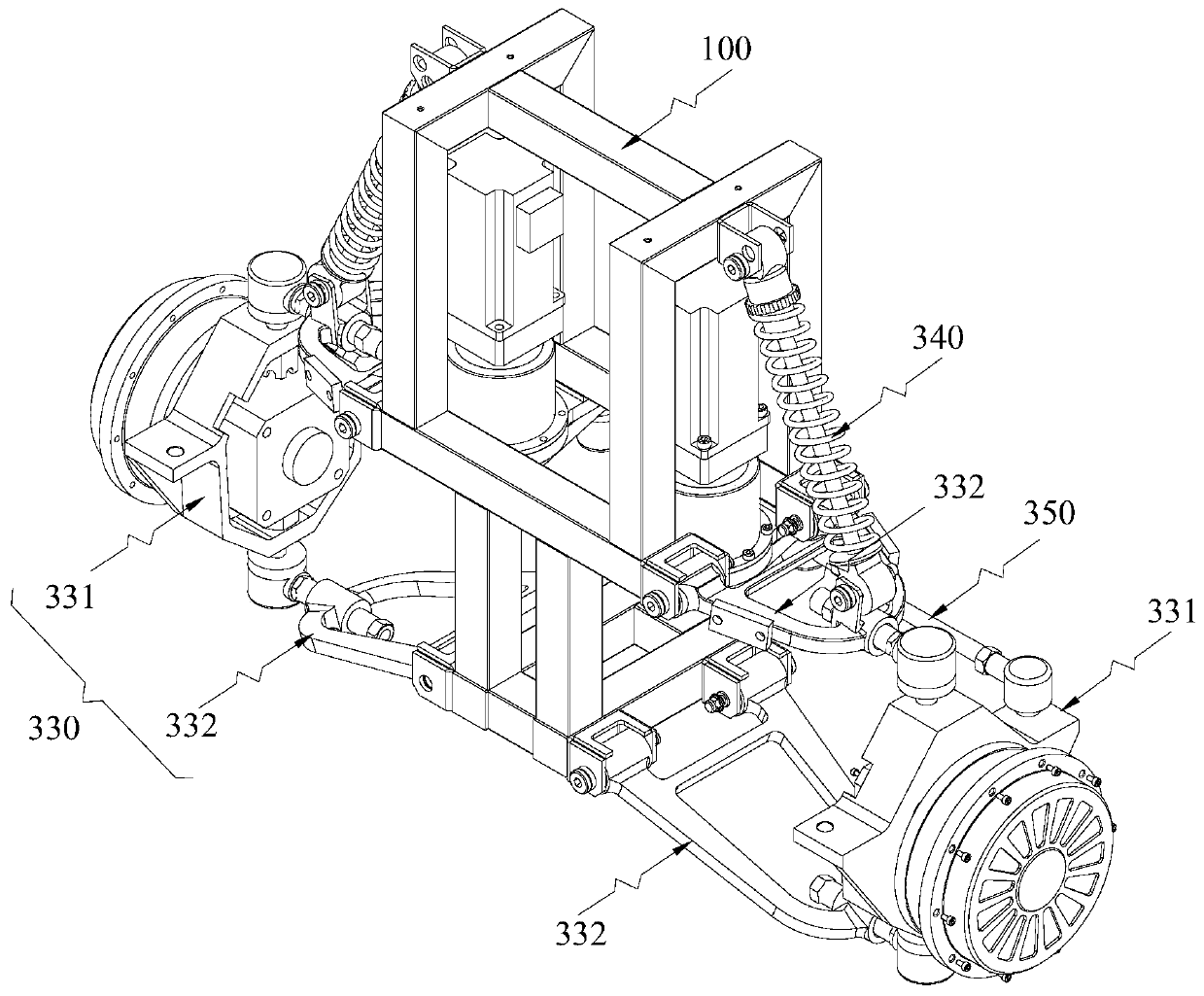

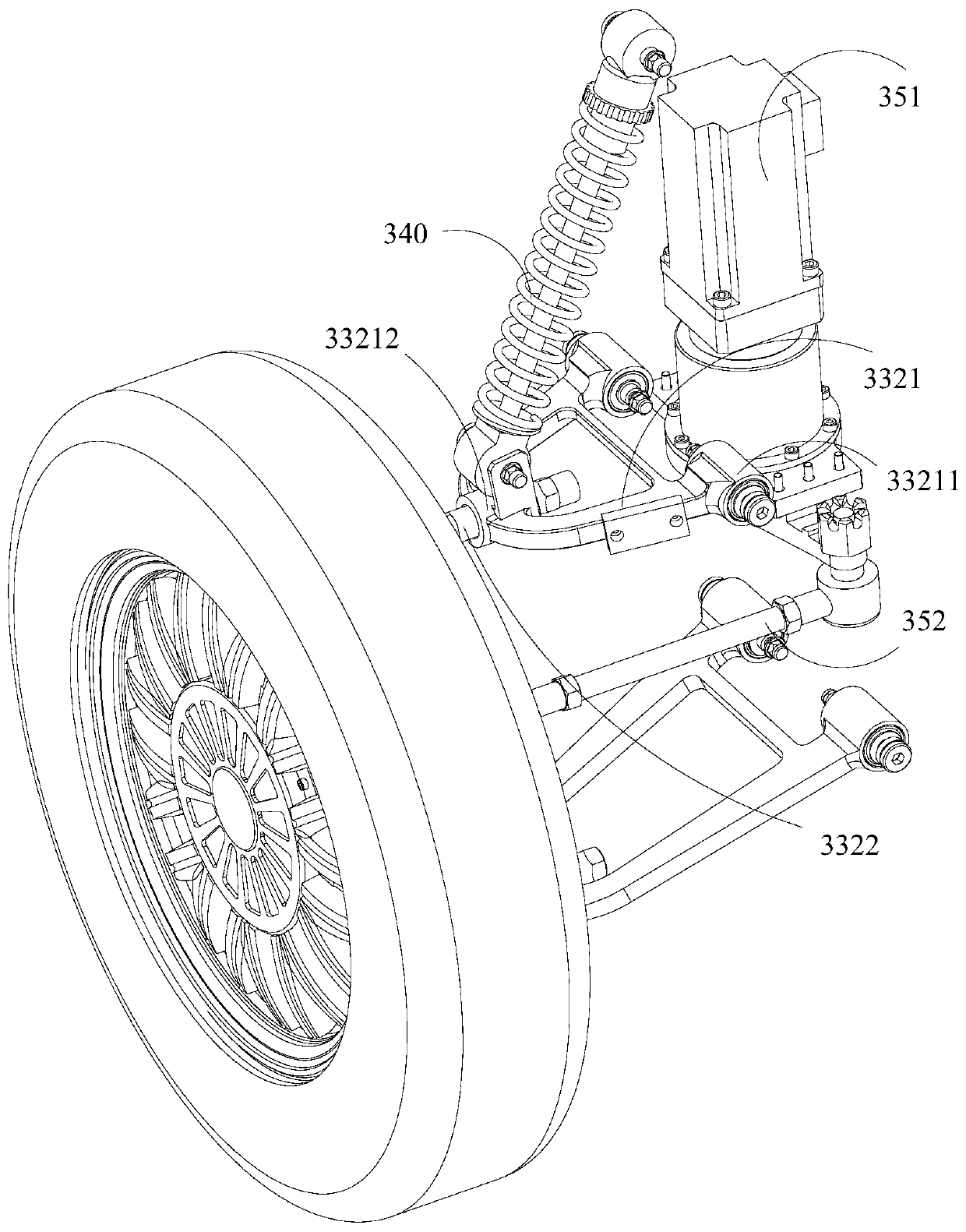

Chassis system and robot

PendingCN110239336AImprove adaptabilityImprove movement stabilityElectrical steeringMotor depositionCushioningDrive wheel

The invention provides a chassis system and a robot. The robot includes the chassis system, the chassis system includes a chassis frame, an electrically controlled module arranged on the chassis frame and at least four driving modules movably connected to the chassis frame, and the driving modules are mutually independent; in any driving module, hub motors are arranged in tyres, thus the tyres are all driving wheels, the tires are independently connected to suspension assemblies with the cushioning and damping function correspondingly, thus the tyres cannot affect mutually on the uneven road surface, the chassis system has the excellent road surface adaptability and motion stability, users can independently control the rotating direction and the rotating speed of the tyres through steering assemblies, it can be ensured that wheel axes of the tyres meet at one point during steering, thus the tyres are not prone to slipping, the sliding friction between the tyres and the ground is greatly reduced, thus the turning radius of the chassis system is small, and then the power consumption of the hub motors is reduced.

Owner:深圳市安泽智能机器人有限公司

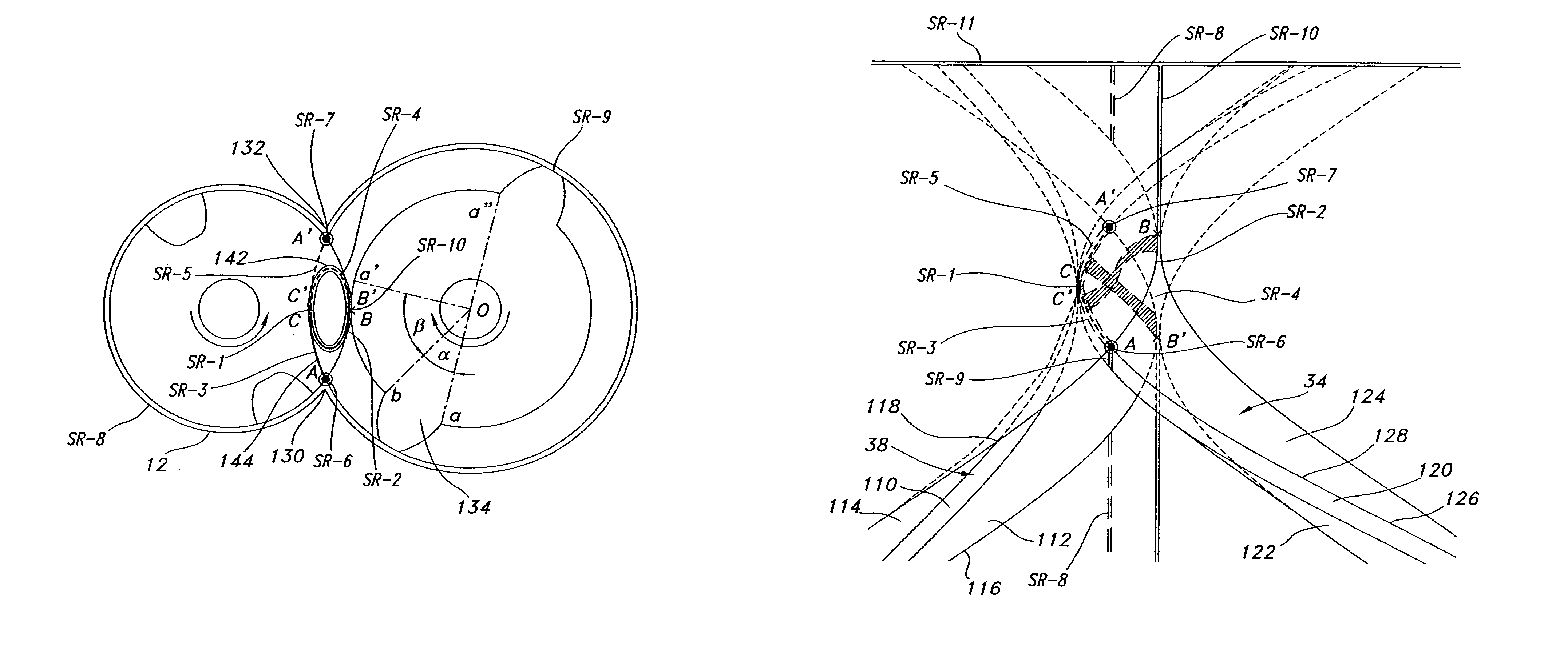

Gapless screw rotor device

InactiveUS7008201B2Maximize thermodynamic efficiency and volumetric efficiencyReduce manufacturing costOscillating piston enginesSealing arrangement for pumpsScrew threadHelix

A screw rotor device has a housing with an inlet port and an outlet port, a male rotor with helical threads, and a female rotor with helical grooves. The helical threads and helical grooves are designed to eliminate the blow hole leak pathway for multiple-pitch screw rotor devices as well as single-pitch screw rotor devices. The male rotor has a pair of helical threads with a phase-offset aspect, and the female rotor has a corresponding pair of helical grooves. The female rotor counter-rotates with respect to the male rotor and each of the helical grooves respectively intermeshes in phase with each of the helical threads. The phase-offset aspect of the helical threads is formed by a pair of teeth bounding a toothless sector.

Owner:IMPERIAL RES

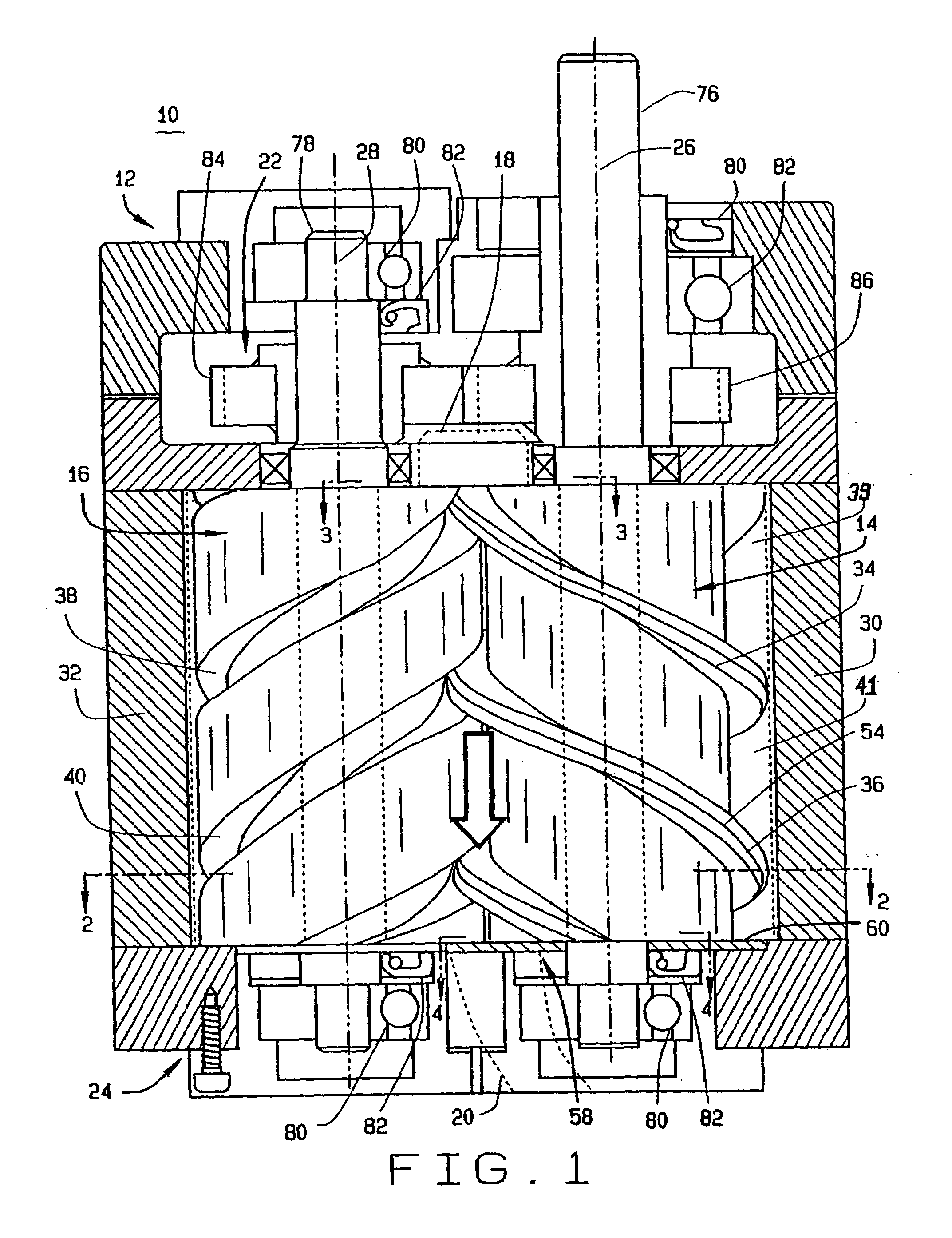

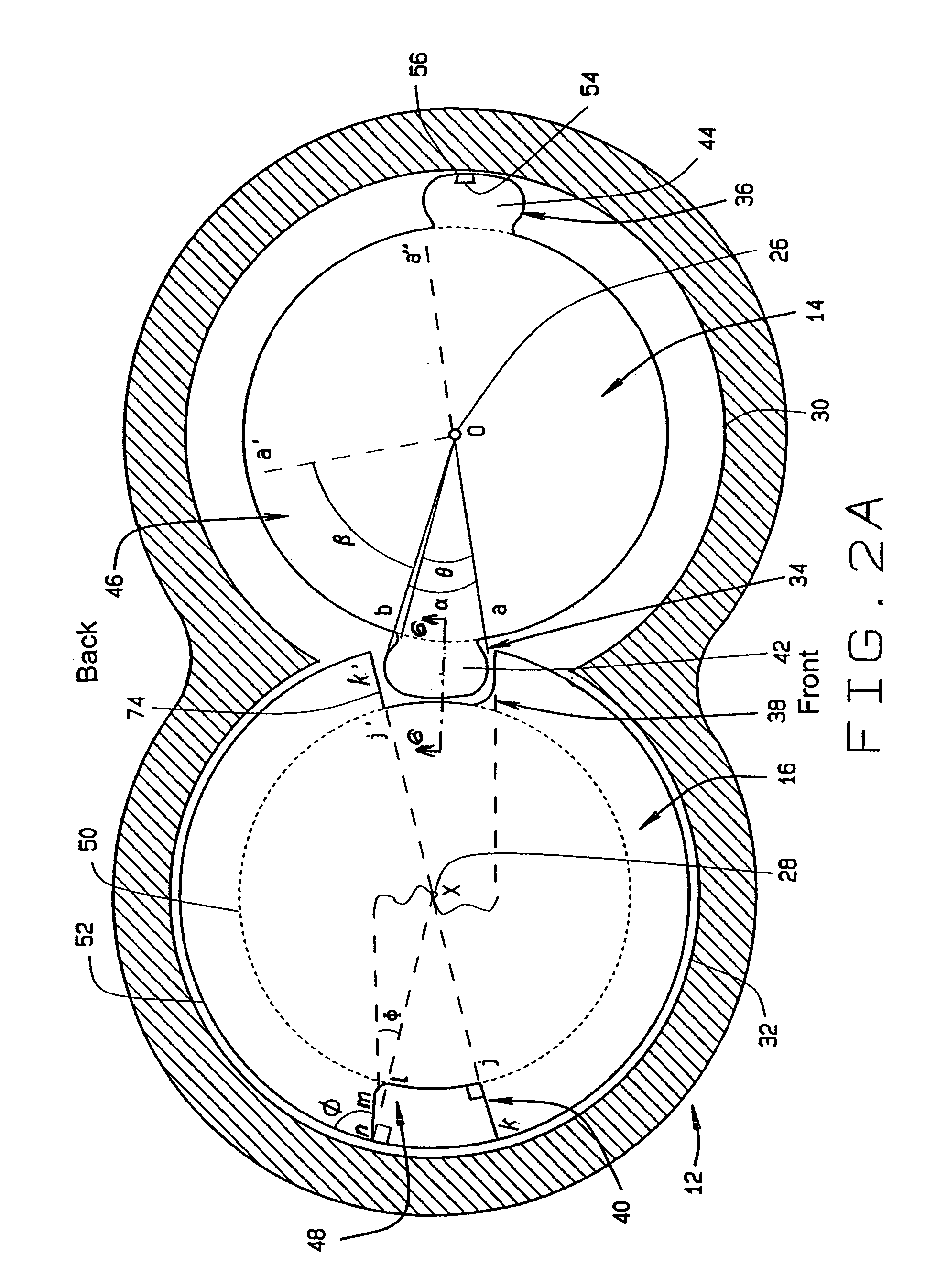

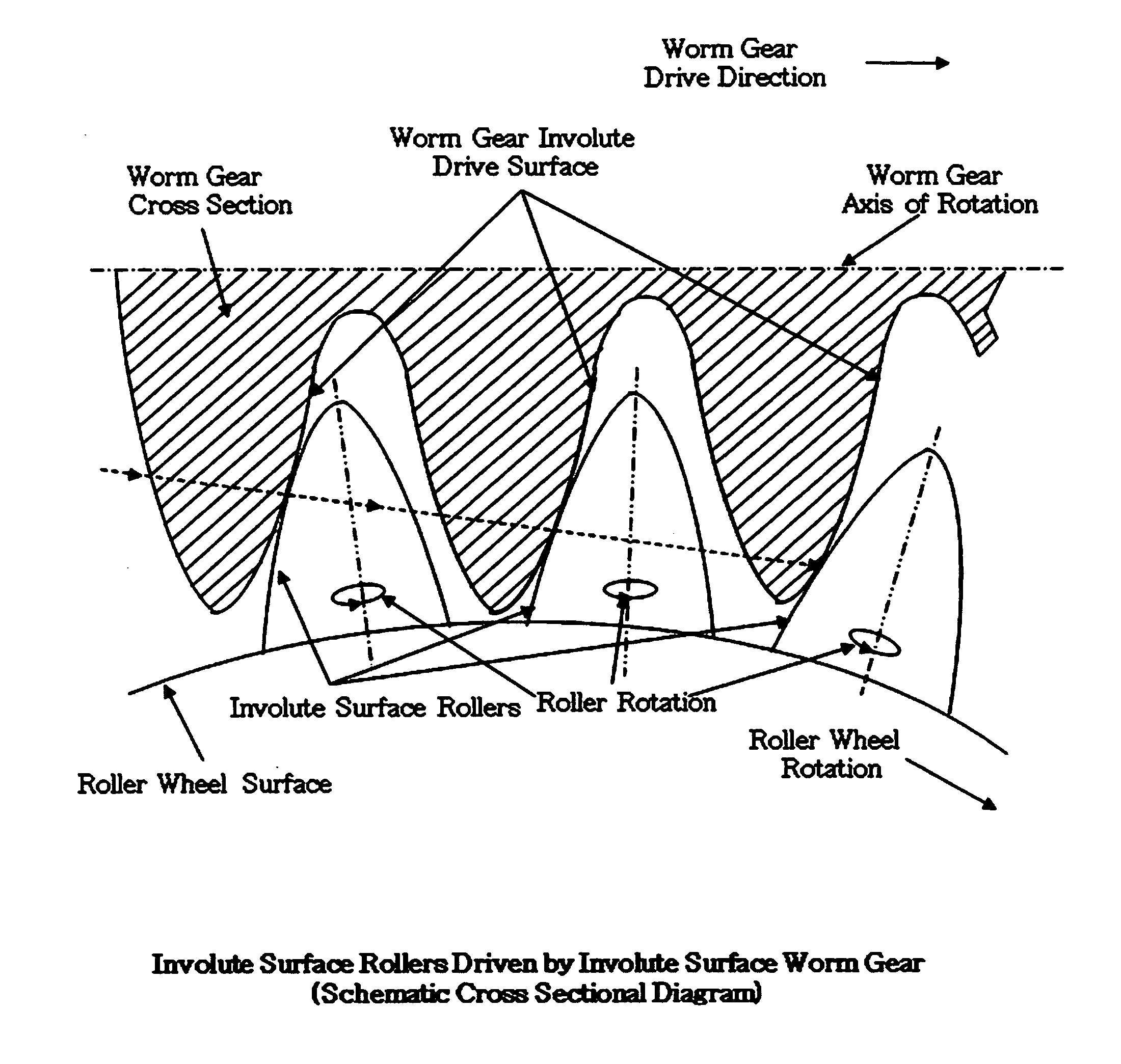

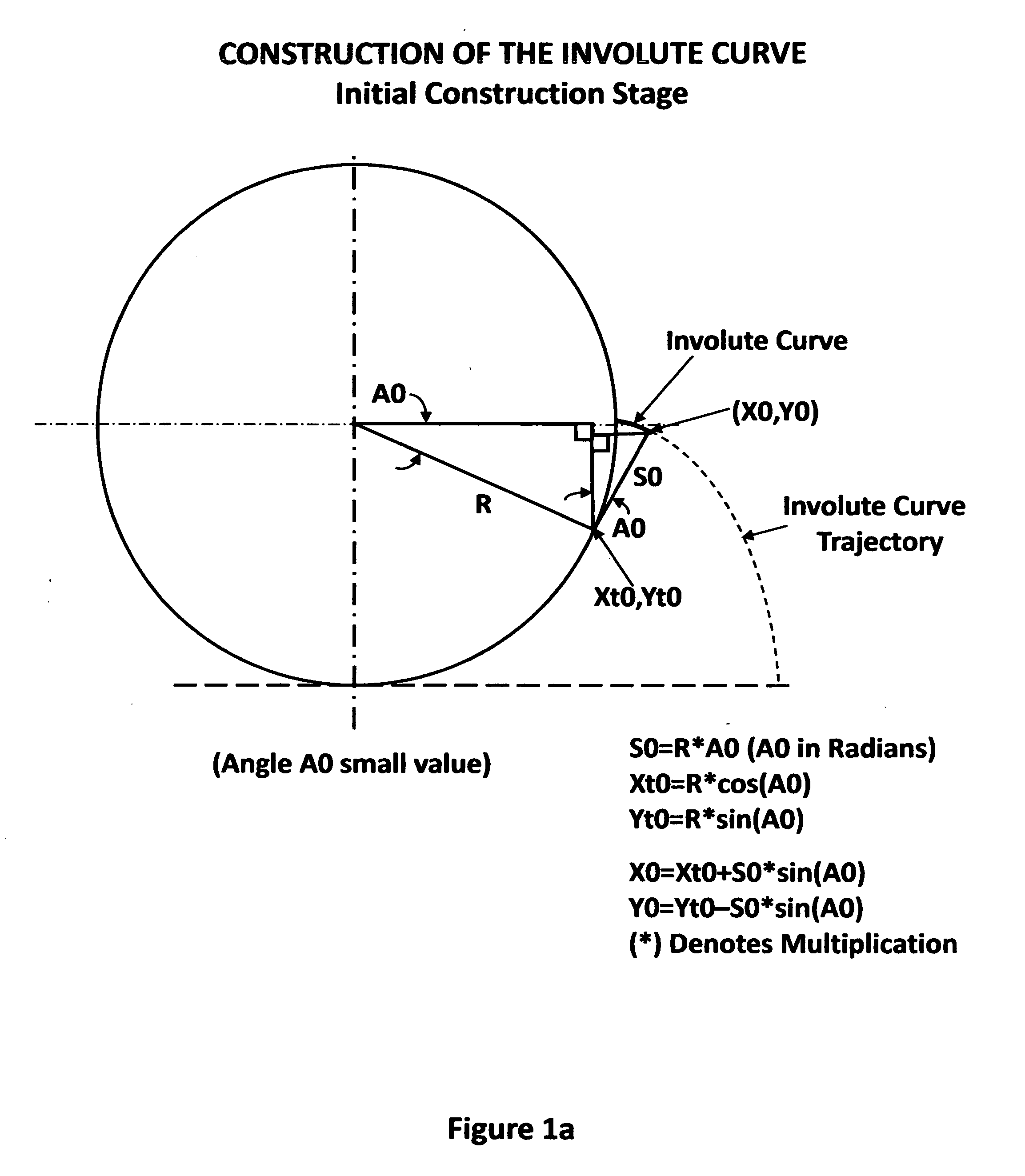

Conjugate roller drive

InactiveUS20100212444A1Readily apparentEfficient energy transferPortable liftingToothed gearingsEnergy lossWorm drive

This invention provides improvements to worm drives for mechanical power transmission and roller wheels and the worm screws for use in such drives. The principal innovation is utilizing conjugate mesh between the worm screw and the roller wheel by shaping both the surfaces of the threads of the worm screw and the driven surfaces of the roller tips so that they become conjugate surfaces that accomplish the most efficient energy transfer.Previous worm drive approaches have emphasized conforming shapes for the roller tips and the worm screw as well as certain other techniques in an attempt to compensate certain inherent limitations to energy transfer between driving and driven surfaces. This has caused greater energy losses in the gearing mechanism with corresponding decreased power transfer efficiency. The use of conjugate shapes for the roller tips and the driving worm gear surface represents a significant improvement to the concept.

Owner:SMITH THOMAS DAVID

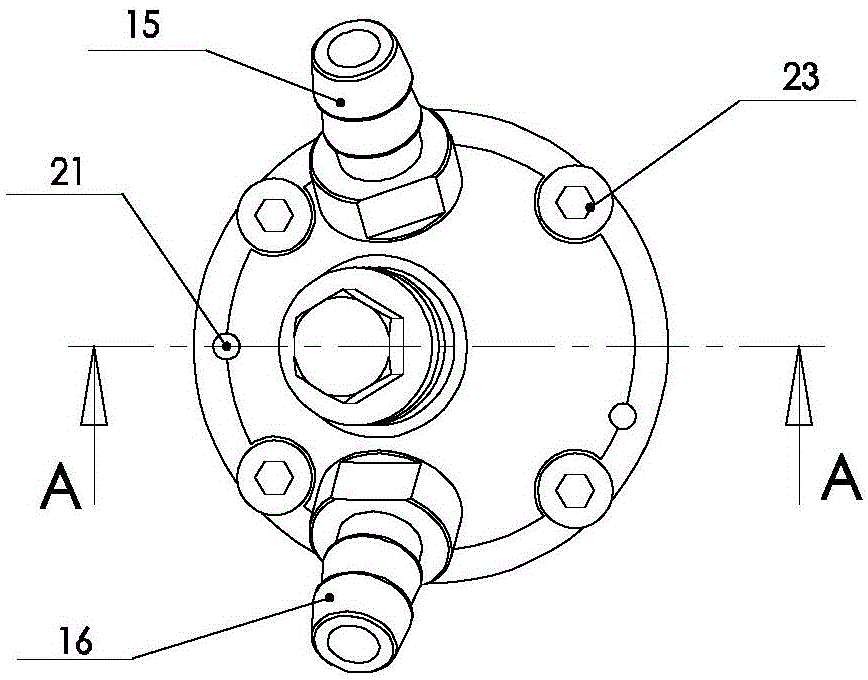

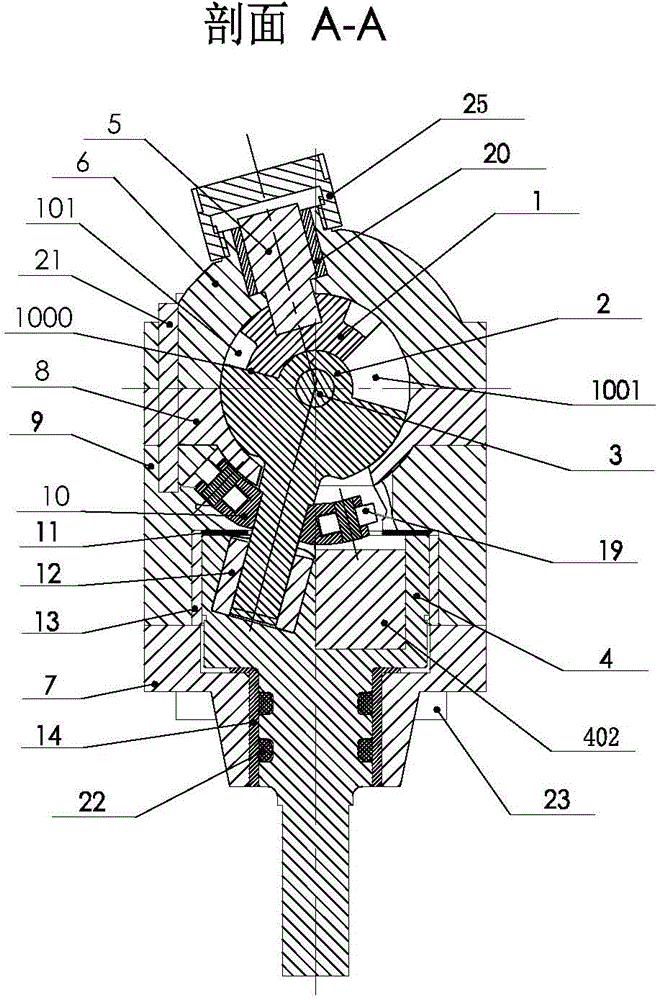

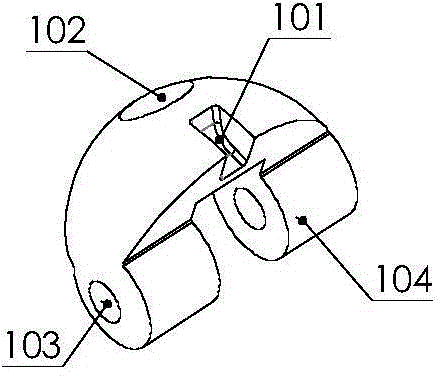

Anti-blocking power mechanism of spherical compressor

ActiveCN104314808ASolve the dead point problemImprove work efficiencyOscillating piston pumpsRotary piston pumpsHigh pressurePiston

The invention discloses an anti-blocking power mechanism of a spherical compressor. A rotating plate synchronous power mechanism consisting of a power handle (10) and a track limiting surface (24) is arranged between a cylinder body (8) and a cylinder body seat (9), the power handle (10) is of a dumbbell structure with two symmetric ends, is fixed on a rotating plate shaft (203) and rotates along with a rotating plate (2), when the rotating plate (2) rotates to a position at which the axis of the rotating plate is overlapped with the axis of a piston, the rotating plate (2) is driven by the rotation of a main shaft (4), the rotating plate synchronous power mechanism can produce power enabling the rotating plate (2) to rotate continuously around the axis, so that a rotor continuously rotates and crosses a dead point; the rotating plate is provided with a backpressure support, so that the local imbalance pressure produced by a rotating plate spherical surface on the spherical surface of the cylinder body due to the working high pressure can be reduced, the mechanism can operate firmly and reliably, and the blocking problem of the rotor of the spherical compressor can be thoroughly solved.

Owner:XIAN ZHENGAN ENVIRONMENTAL TECH

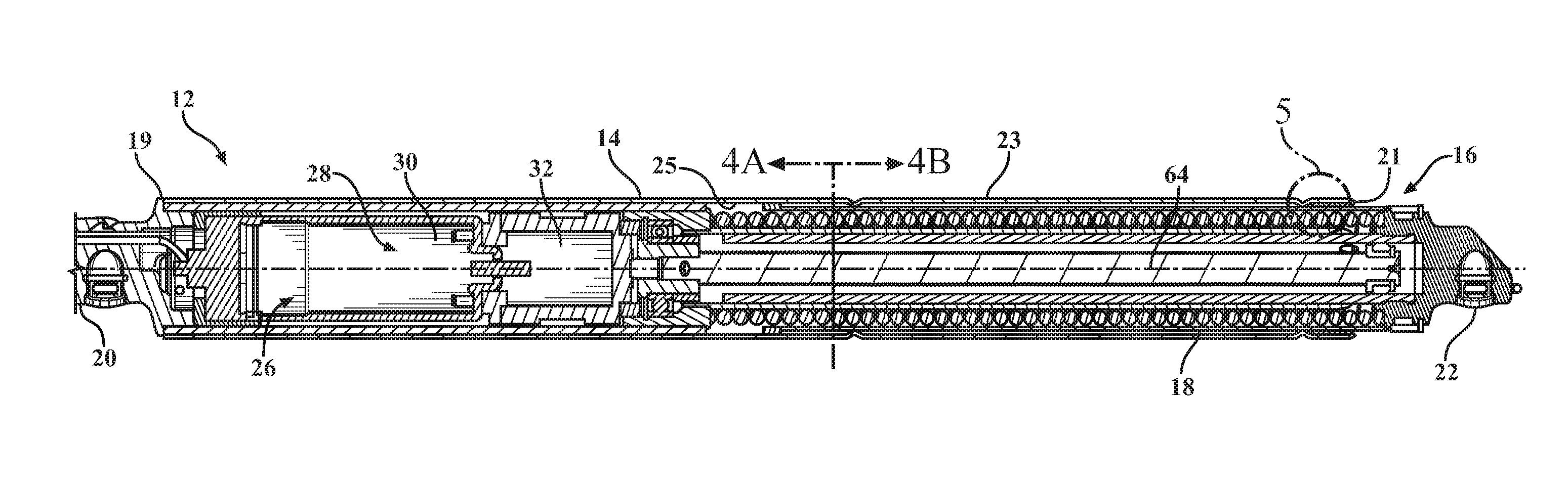

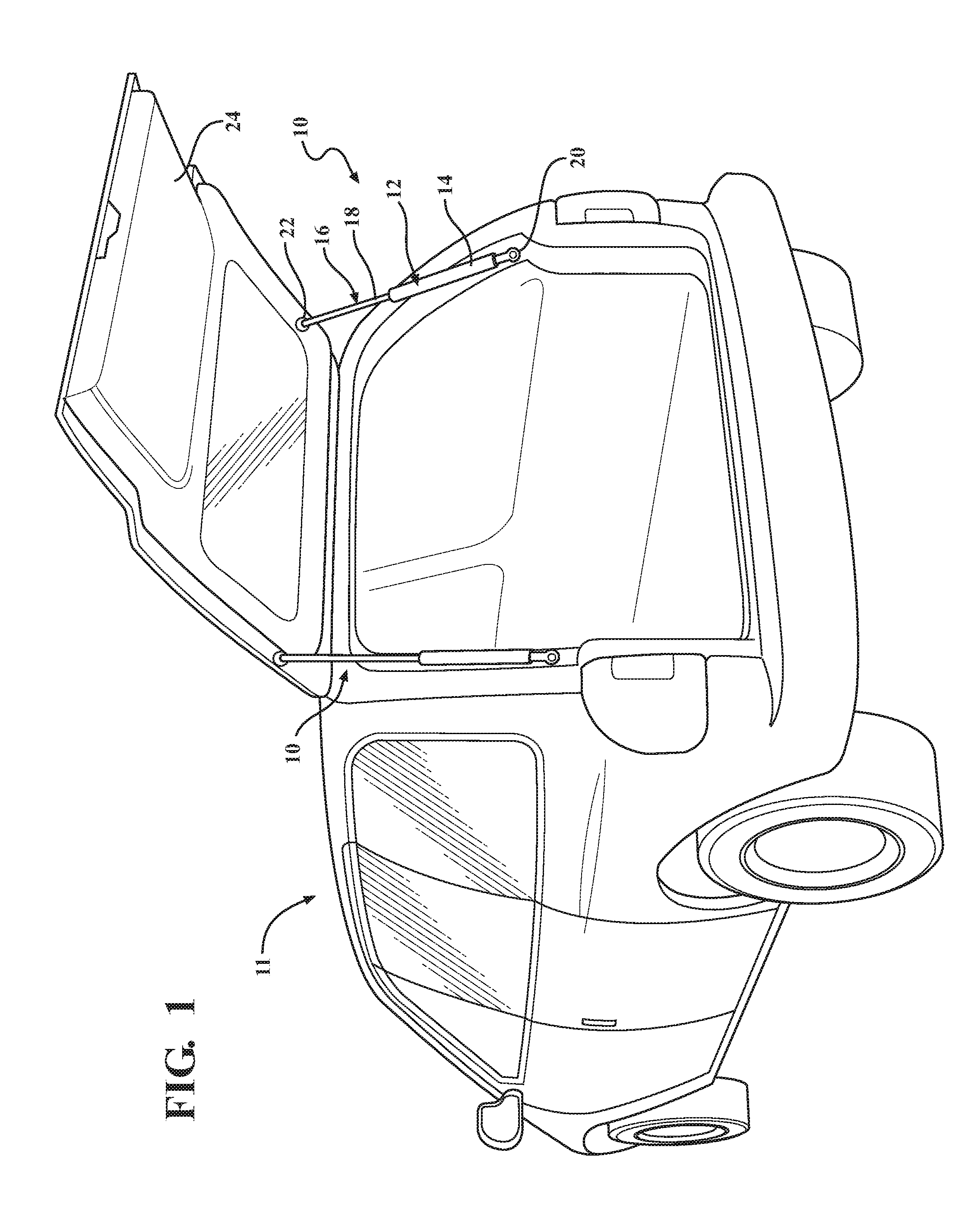

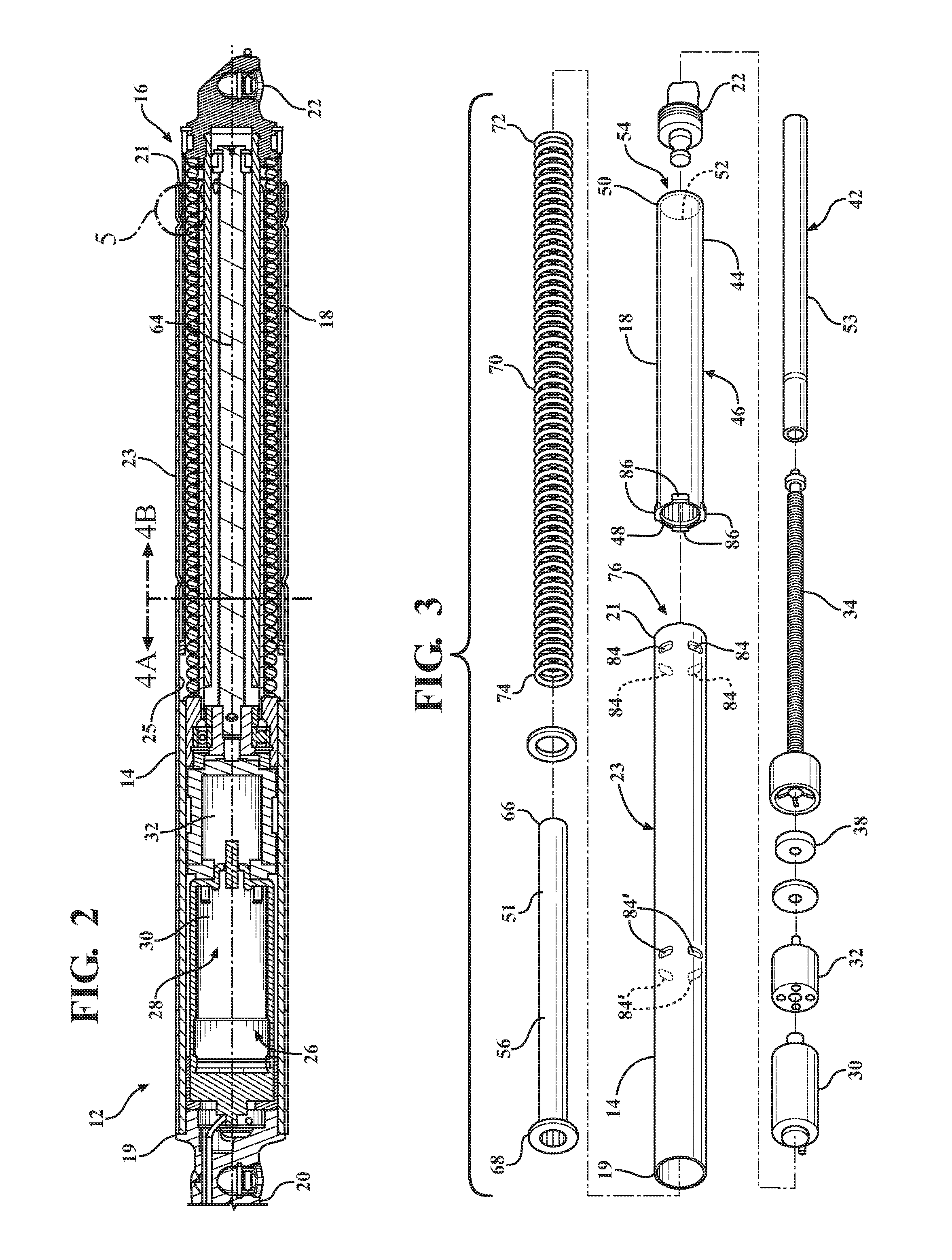

Electromechanical strut with lateral support feature

ActiveUS20170044814A1Minimizing lateral playReduce sliding frictionPower-operated mechanismMechanical energy handlingLinear motionEngineering

An electromechanical strut for moving a closure member between open and closed positions relative to a vehicle body includes a housing having an inner surface bounding a cavity extending along a central axis between opposite first and second ends. A power screw is disposed in the cavity in operable communication with a motor, with a gear assembly operably connecting the motor to the power screw. An extensible member has an outer cover tube received in the housing cavity and a drive mechanism for converting rotary motion of the power screw into linear motion of the extensible member. An annular gap extends between the inner surface of the housing and an outer surface of the outer cover tube. An annular bushing is disposed within the annular gap to minimize laterally play between the housing and the outer cover tube.

Owner:MAGNA CLOSURES INC

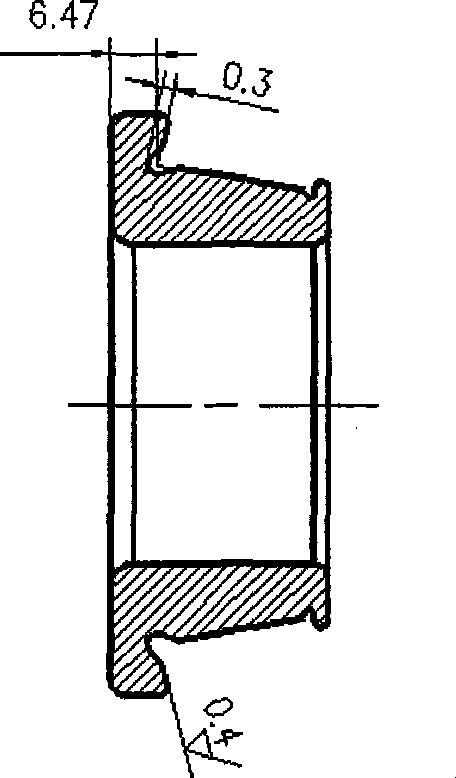

Tapered roller bearing with high strength and low friction torque

The invention relates to a tapered roller bearing with high strength and low friction torque, comprising an outer ring, an inner ring, a plurality of rollers and a cage, wherein the rollers are clamped between the outer ring and the inner ring and used for supporting and realizing relatively rotating; and the cage is used for guiding the rollers to move; a big rib of the inner ring is a convex curved rib; the root part width of the big rib of the inner ring is larger than 6.47 mm, and the axial depth of an oil groove is smaller than 0.5 mm; the raceway buses and the roller buses of the inner ring and the outer ring are in a logarithm curve convexity shape; the number of the rollers is less than 16, the length of the rollers is smaller than 24 mm, and the convex diameter of a raceway is small; the sphere base surface diameter of the rollers is smaller than 136 mm, and the diameter of the rollers is larger than 21.671 mm. The invention has long service life, saves the energy and reduces the energy consumption.

Owner:FUJIAN YONGAN BEARING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com