Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

258results about "Oscillating piston pumps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

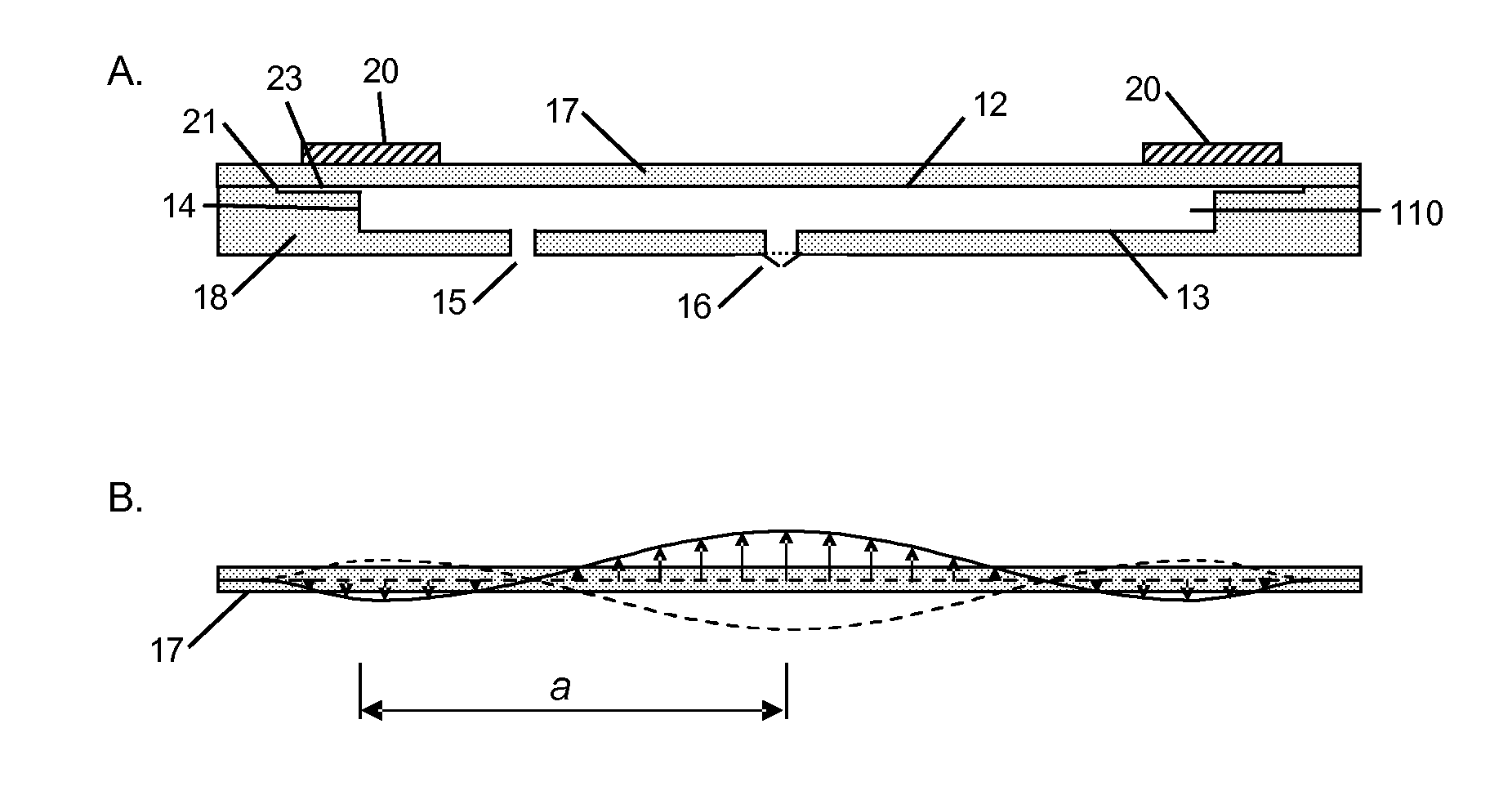

Fluidic Energy Transfer Devices

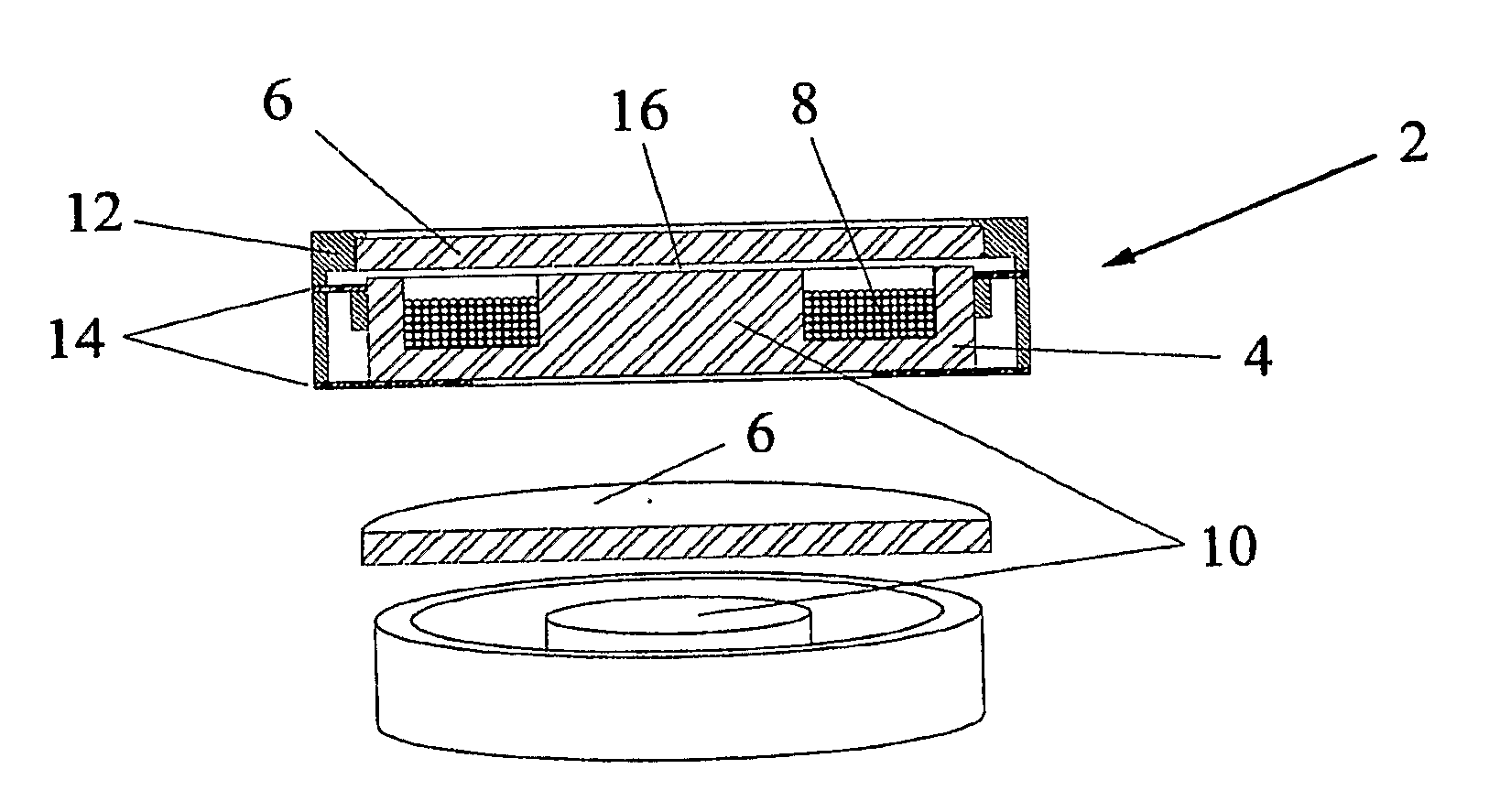

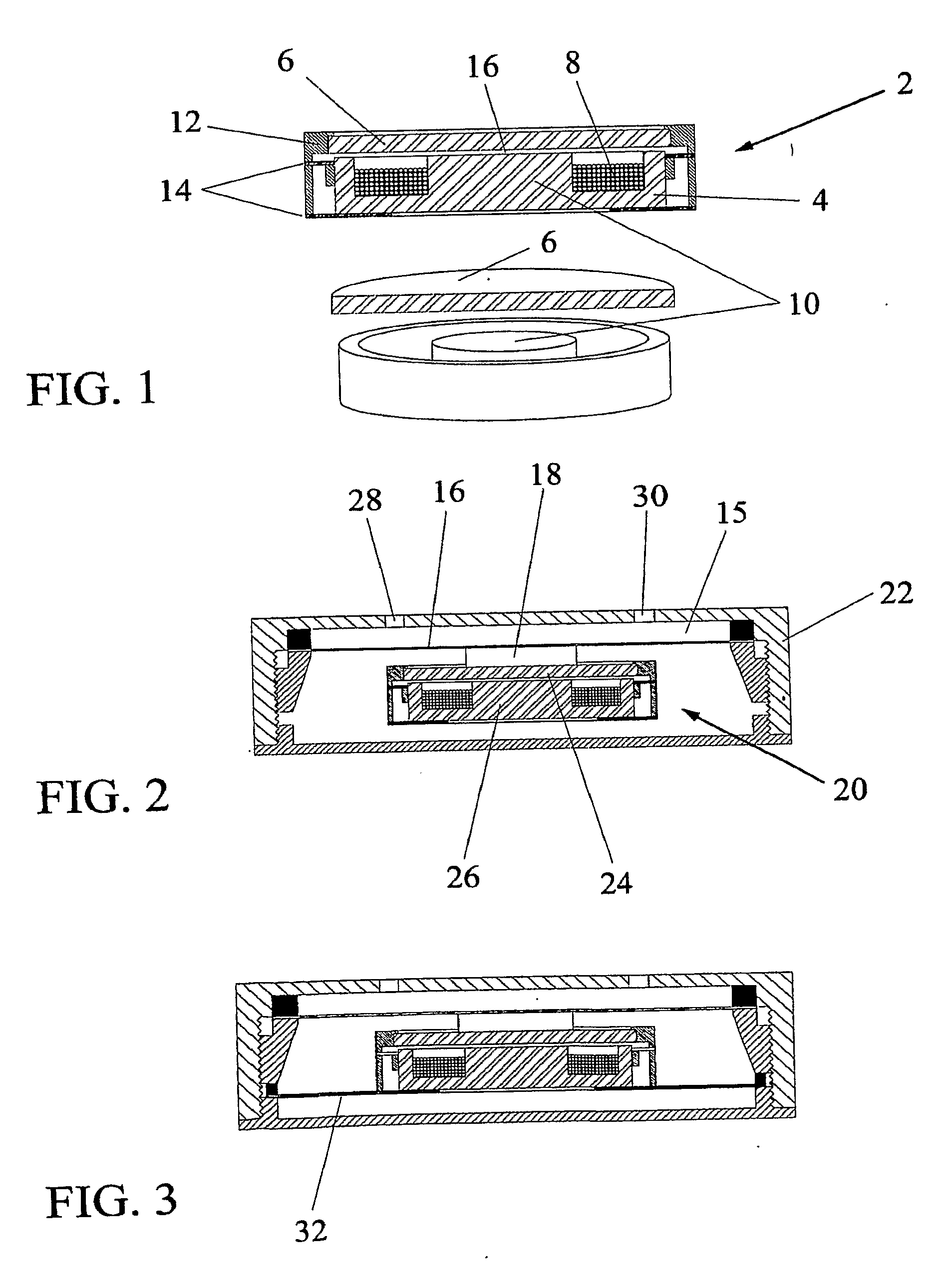

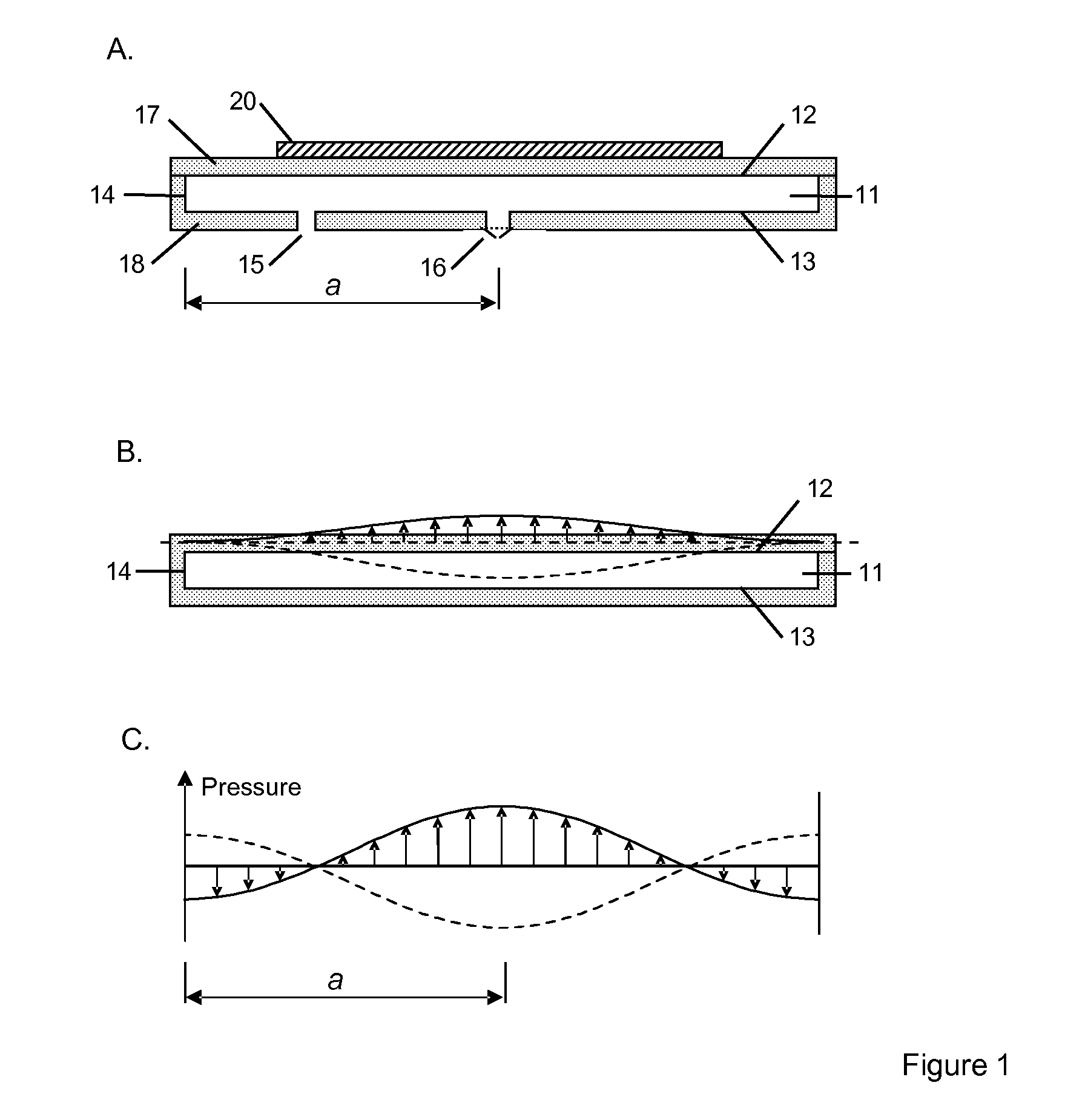

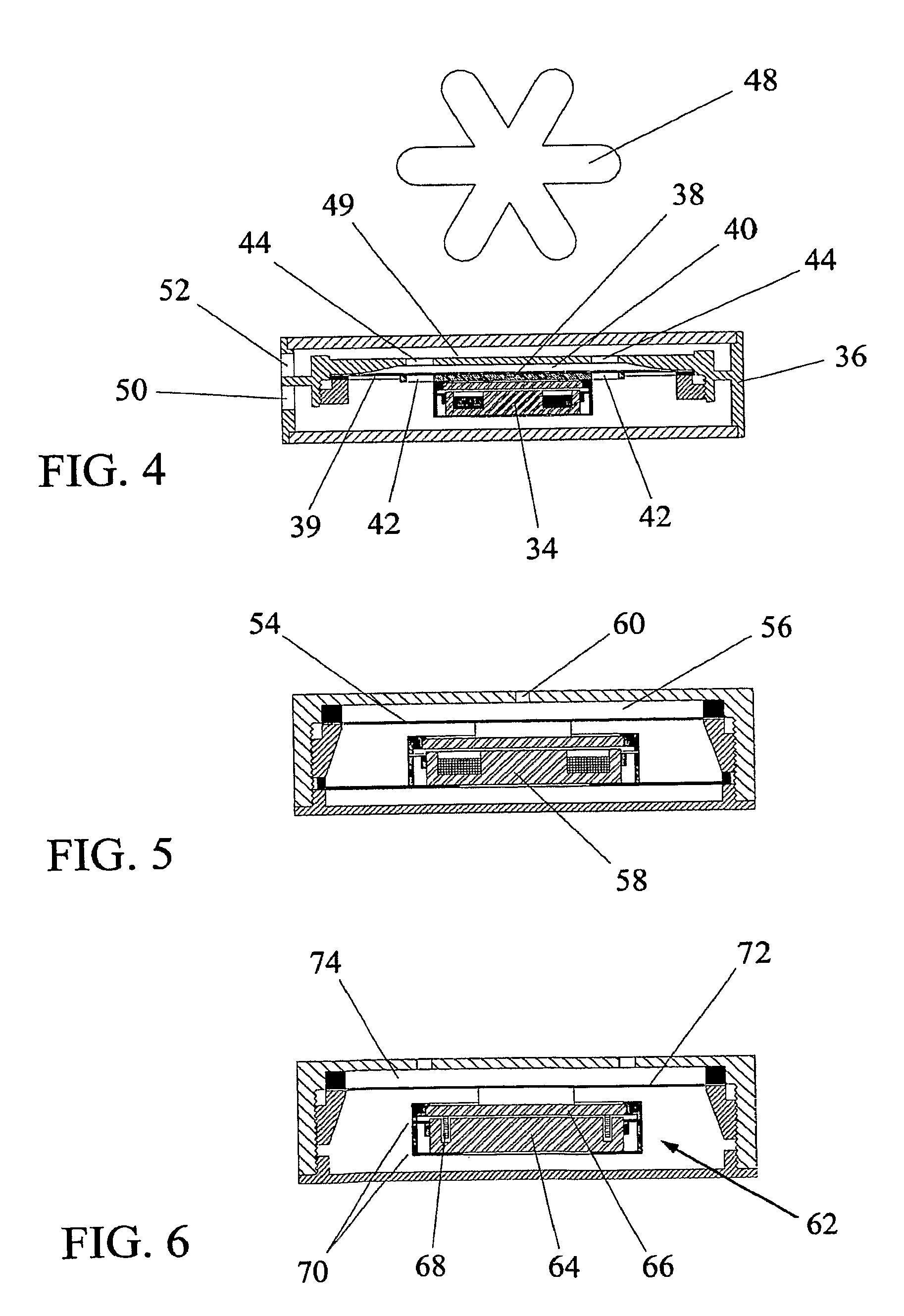

ActiveUS20090148320A1Increase volume of chamberReduce chamber volumeFlexible wall reciprocating enginesOscillating piston pumpsEngineeringActuator

A fluid energy transfer device, including a chamber for receiving a fluid, at least a portion of the chamber comprising a movable portion relative to another portion of the chamber, the movable portion being adapted to change the volume of the chamber from a first volume to a second volume by movement of the movable portion. The device further includes an actuator attached to the movable portion, wherein the displacements of the movable portion can be larger than the displacement of the actuator.

Owner:AAVID THERMALLOY LLV

Pump

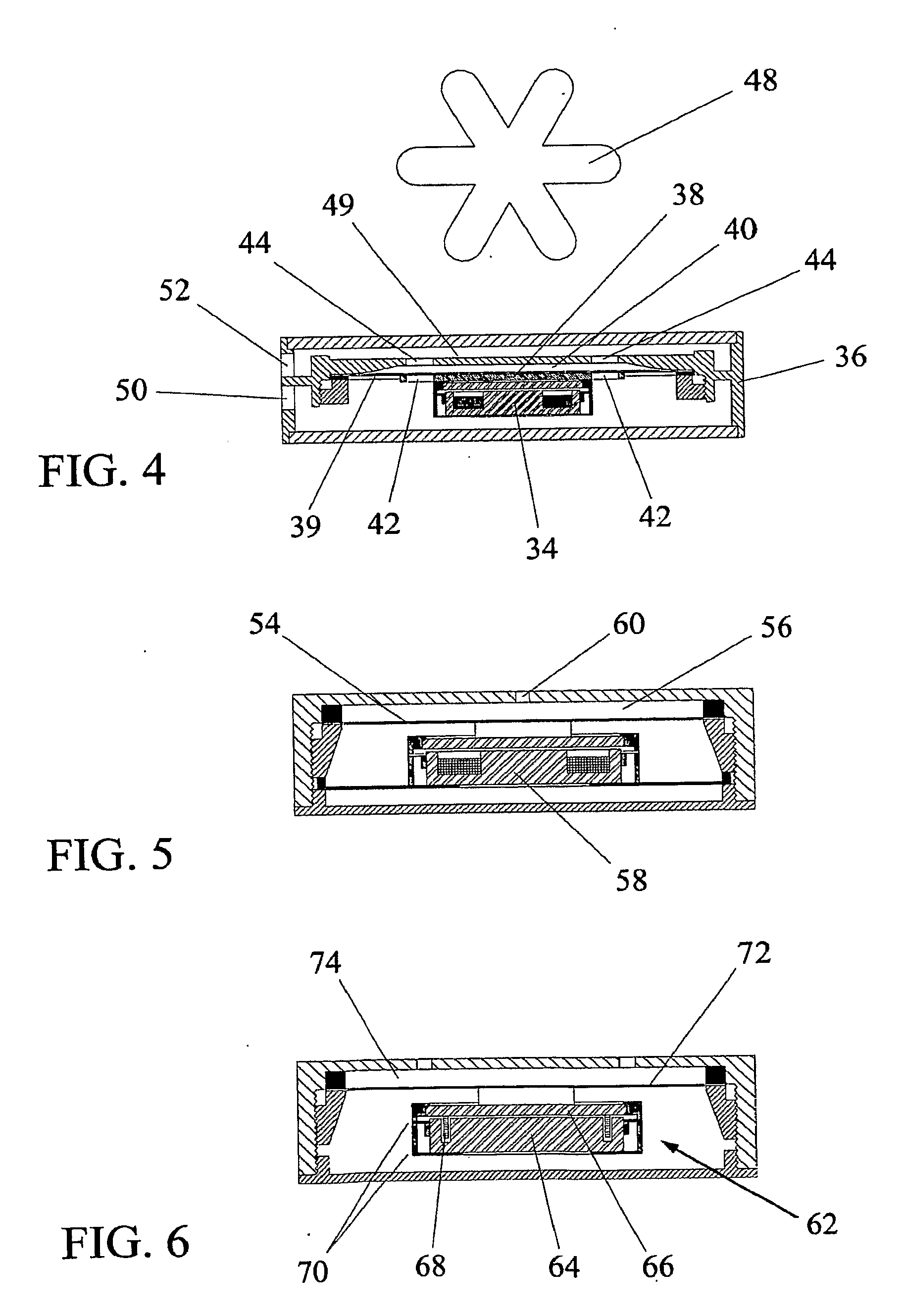

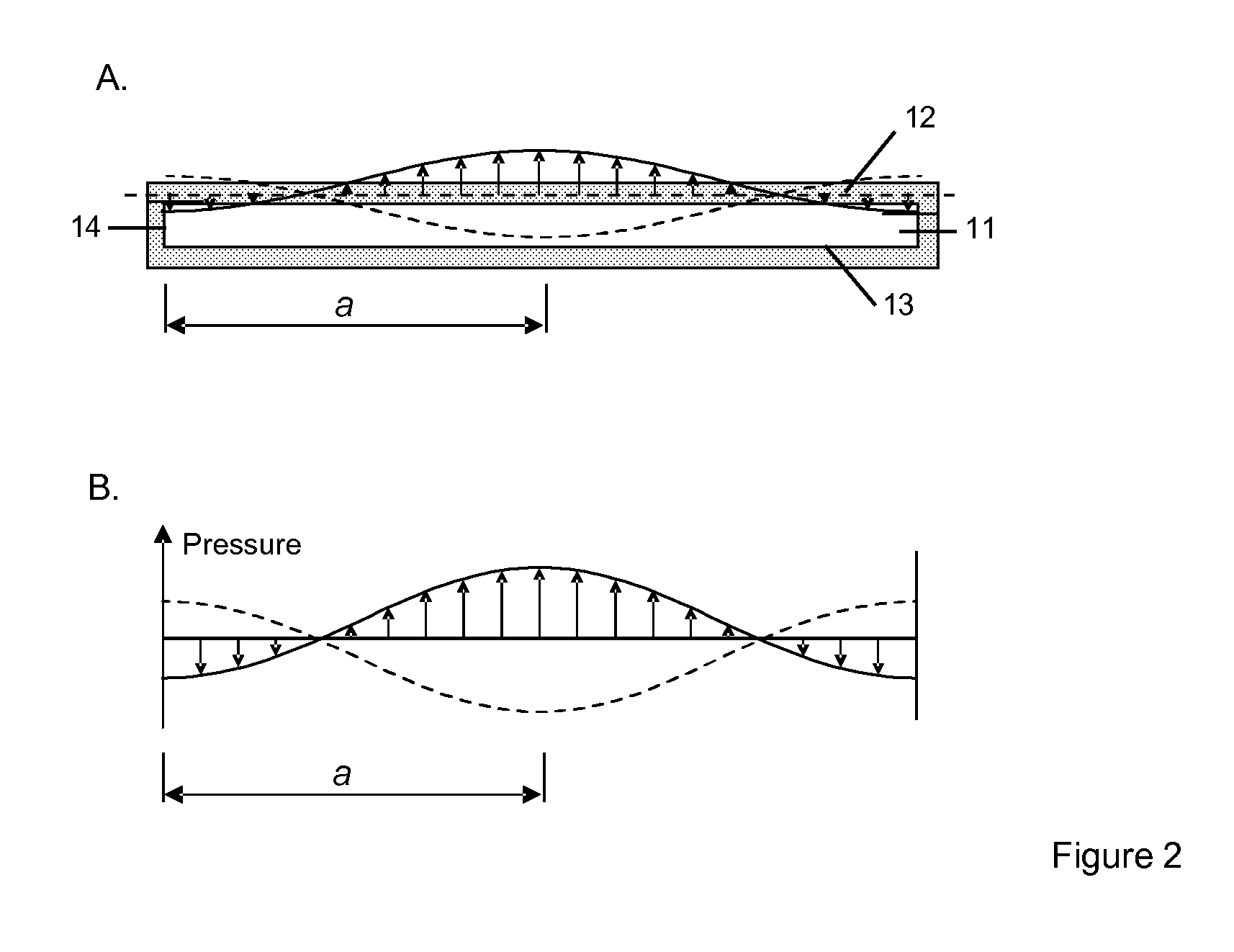

ActiveUS20110081267A1Large outer diameterIncrease volumeOscillating piston pumpsFlexible member pumpsEngineeringActuator

A fluid pump comprising a chamber which, in use, contains a fluid to be pumped, the chamber including a main cavity having a substantially cylindrical shape bounded by first and second end walls and a side wall and a secondary cavity extending radially outwards of the main cavity, one or more actuators which, in use, cause oscillatory motion of the first end wall in a direction substantially perpendicular to the plane of the first end wall, and whereby, in use, the axial oscillations of the end walls drive radial oscillations of the fluid pressure in the main cavity, and wherein the secondary cavity spaces the side wall from the first end wall such that the first end wall can move relative to the side wall when the actuator is activated.

Owner:TTP VENTUS LTD

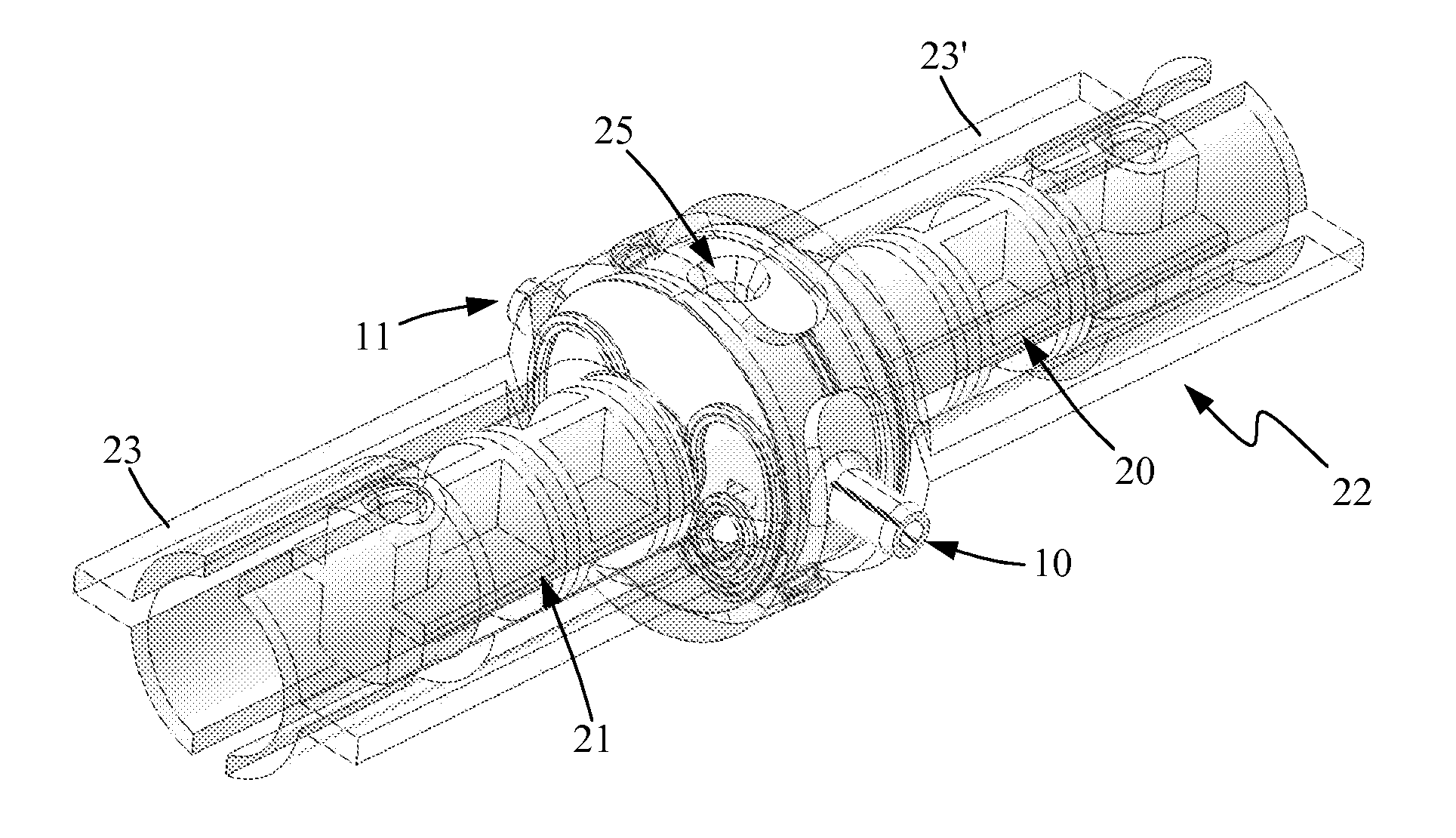

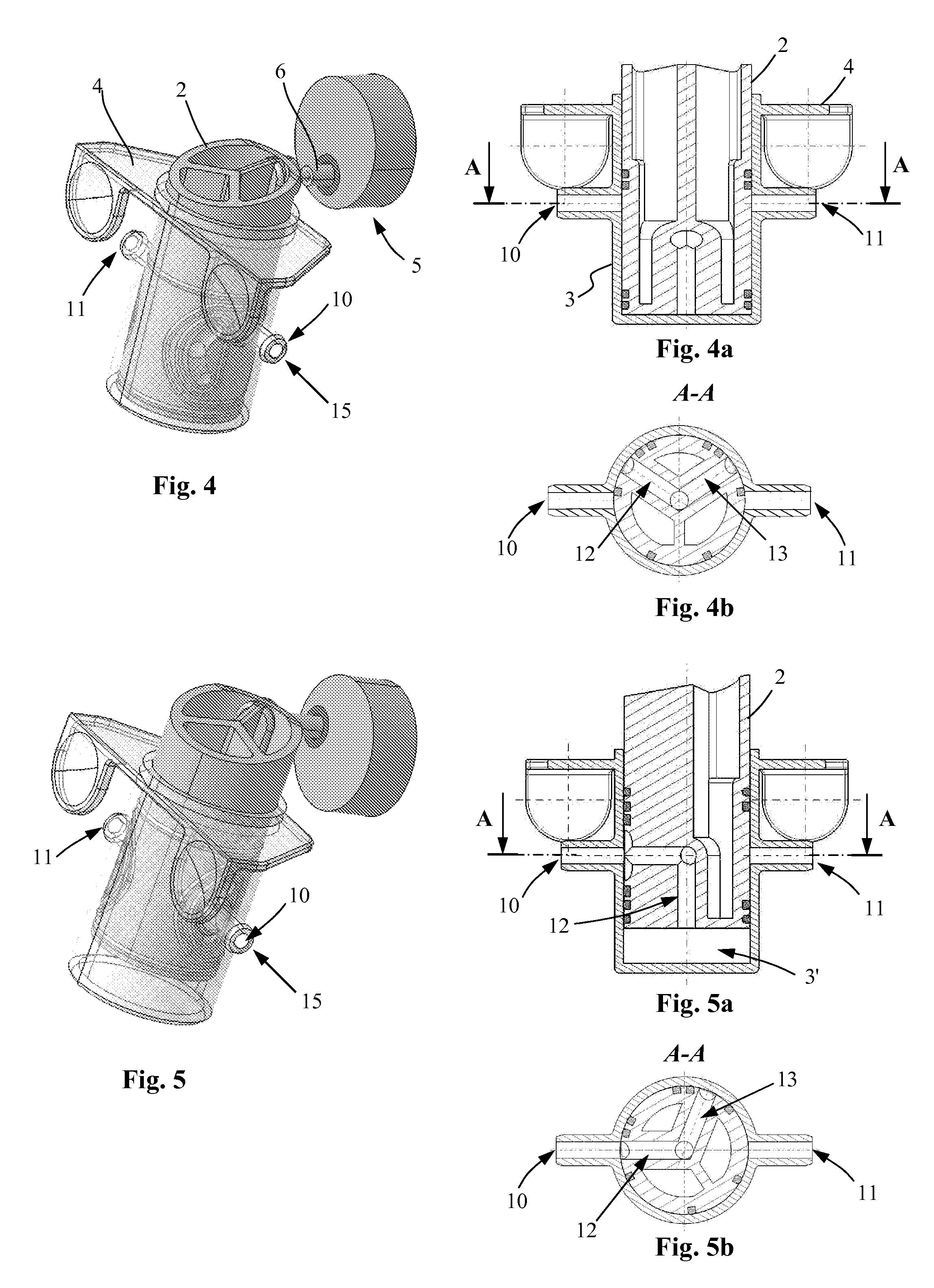

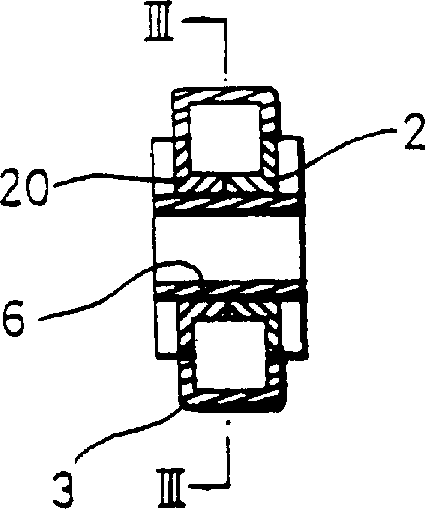

Volumetric pump with reciprocated and rotated piston

InactiveUS7887308B2Increase costIncrease in costOscillating piston pumpsPositive displacement pump componentsEngineeringMechanical engineering

A volumetric pump (1) comprising a piston (2) and a cylindrical chamber (3), contains an inlet port (10) and an outlet port (11). The piston (2) is actuated by a rotor (5) bearing an eccentric shaft (6). The shaft (6), being connected to the piston (2), causes the piston to slide back and forth inside the cylinder chamber (3) while having a bidirectional angular movement. The instroke of the piston (2) sucks a fluid (15) from the inlet port (10) through a first channel (12) into the pump chamber (3), the fluid being propelled through a second channel (13) to the outlet port (11) during the outstroke of the piston (2). The inlet (10) and outlet port (11) are opened and closed alternatively by the bidirectional angular movement of the piston (2) which acts as a valve for the inlet and outlet ports (10, 11).

Owner:SWISSINNOV PROD SARL

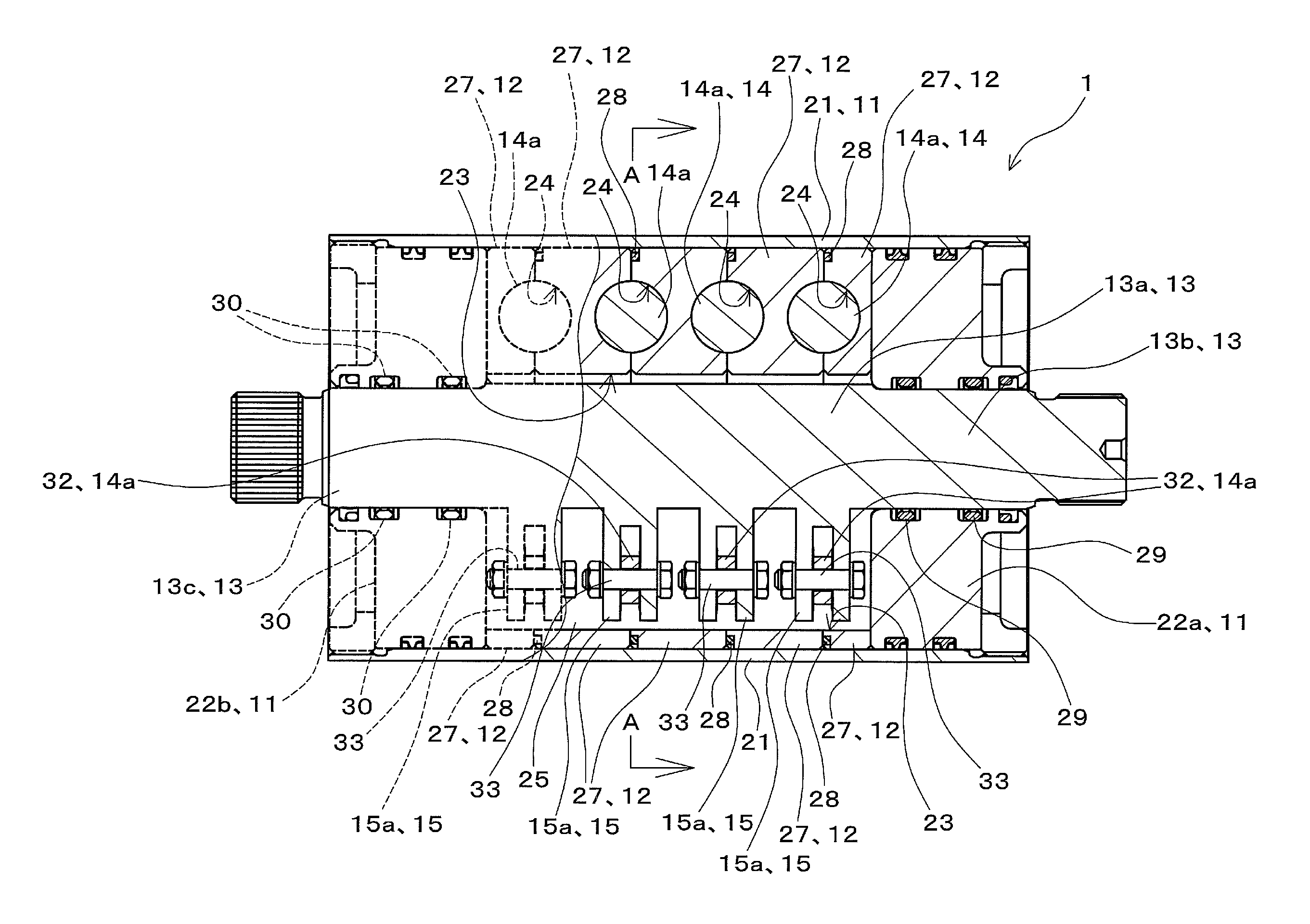

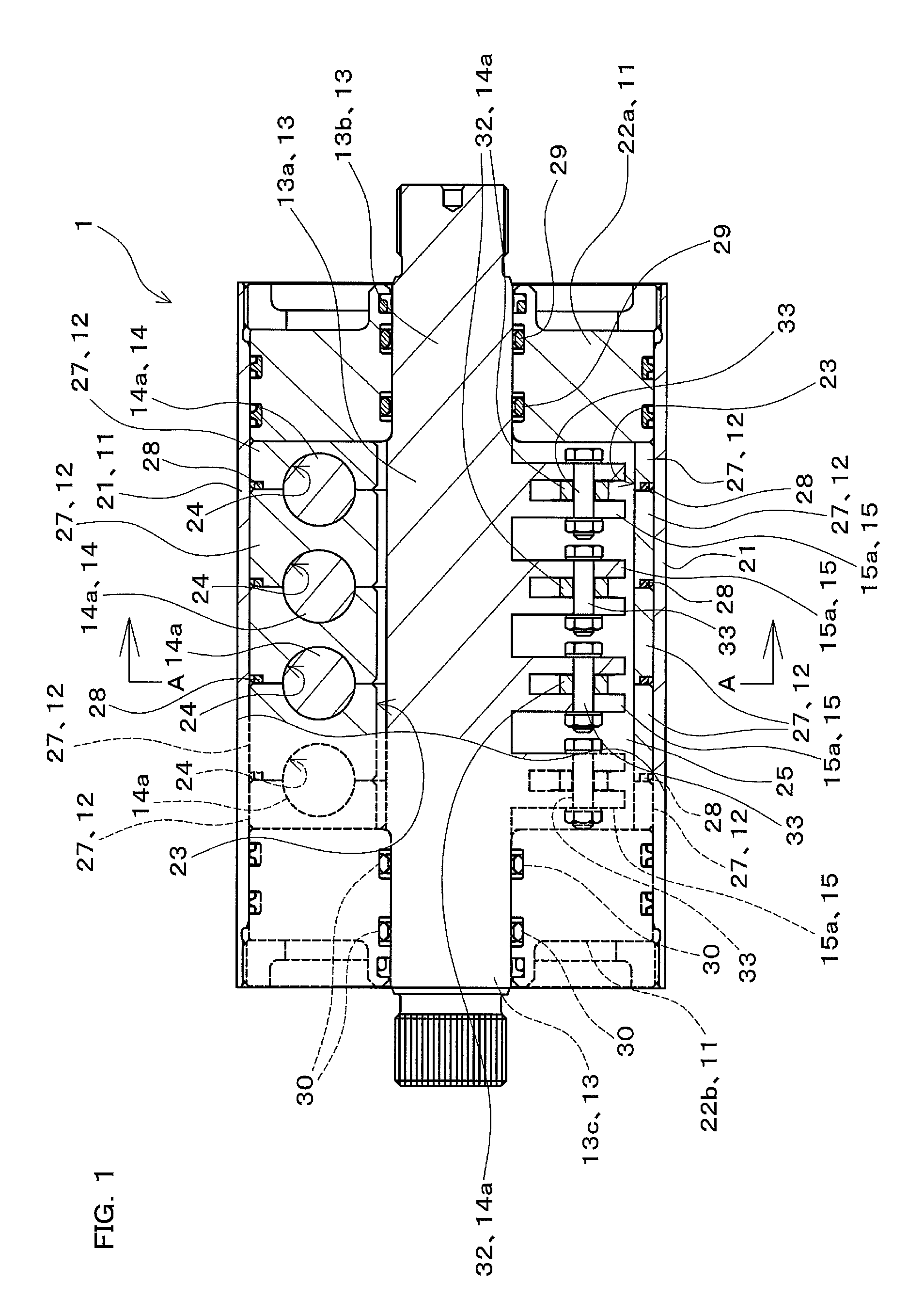

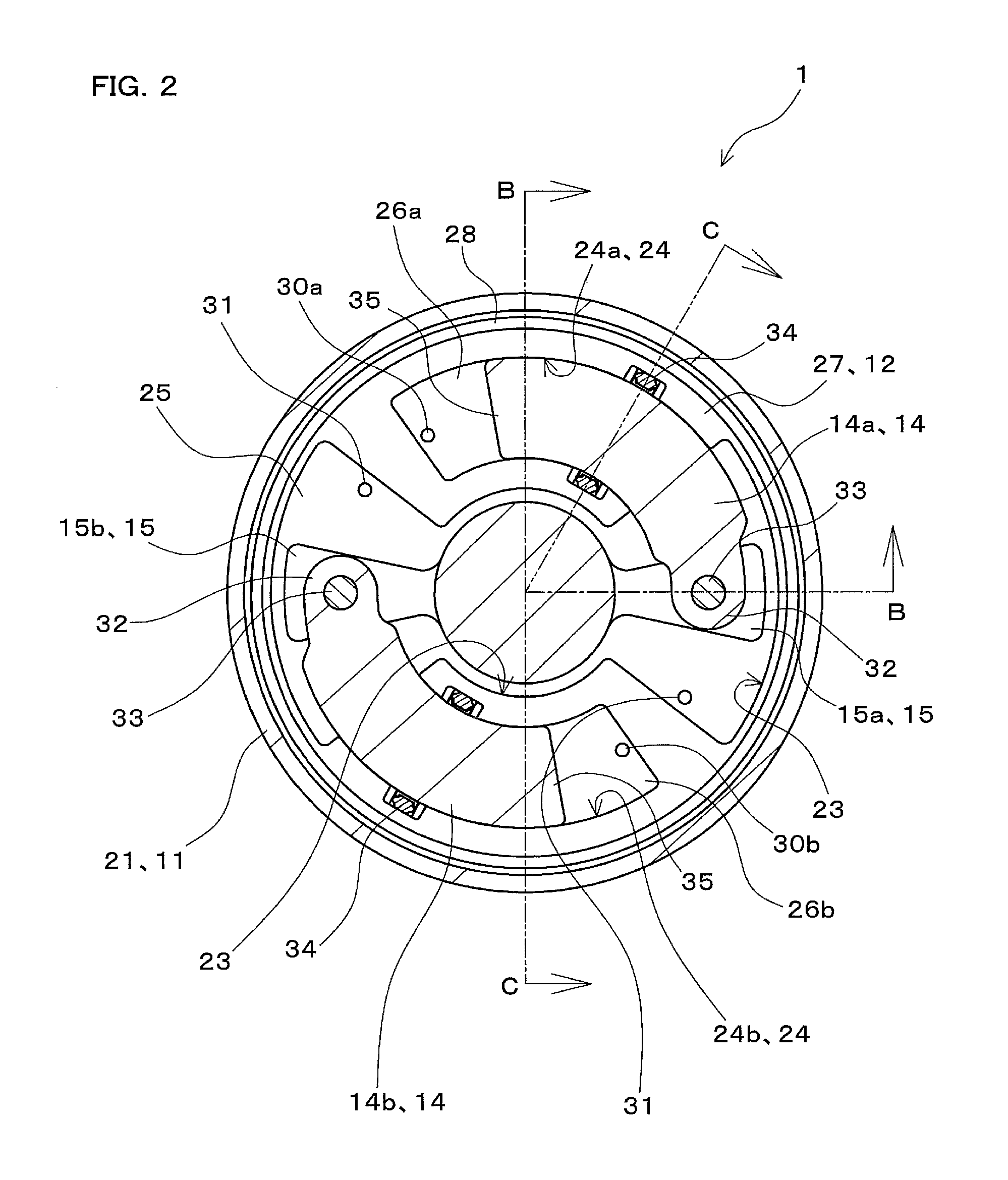

Rotary actuator

ActiveUS20130133513A1Reduce in quantityReduce internal leakageOscillating piston pumpsCombination enginesEngineeringRotary actuator

A cylinder is installed within a case, and an output shaft and an arm that is integrated thereto and extends in a radial direction are installed within the cylinder. A piston extending in an arc slides and is displaced in a circumferential direction of the cylinder within the cylinder. One end portion of the piston is rotatably connected to the arm. The cylinder is internally provided with a first pressure chamber in which the arm is housed and a second pressure chamber in which the other end portion of the arm is slidably installed. A pressure medium is fed into one of the first and second pressure chambers and discharged from the other, and the output shaft pivots in a rotational direction.

Owner:NABLESCO CORP

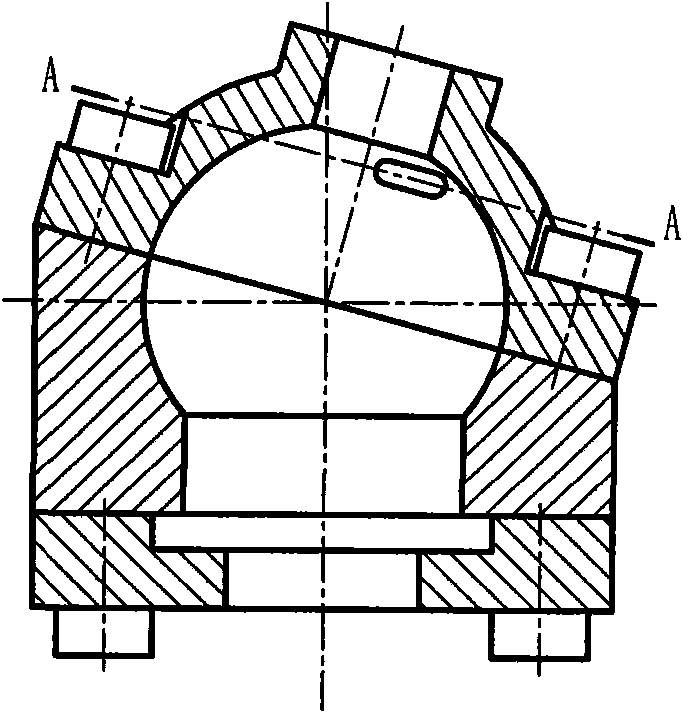

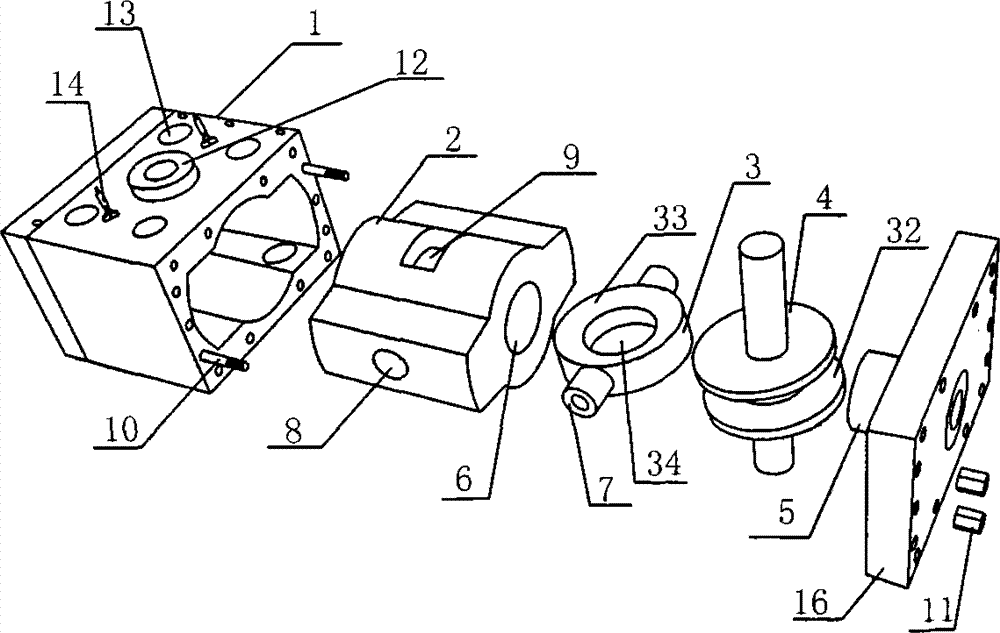

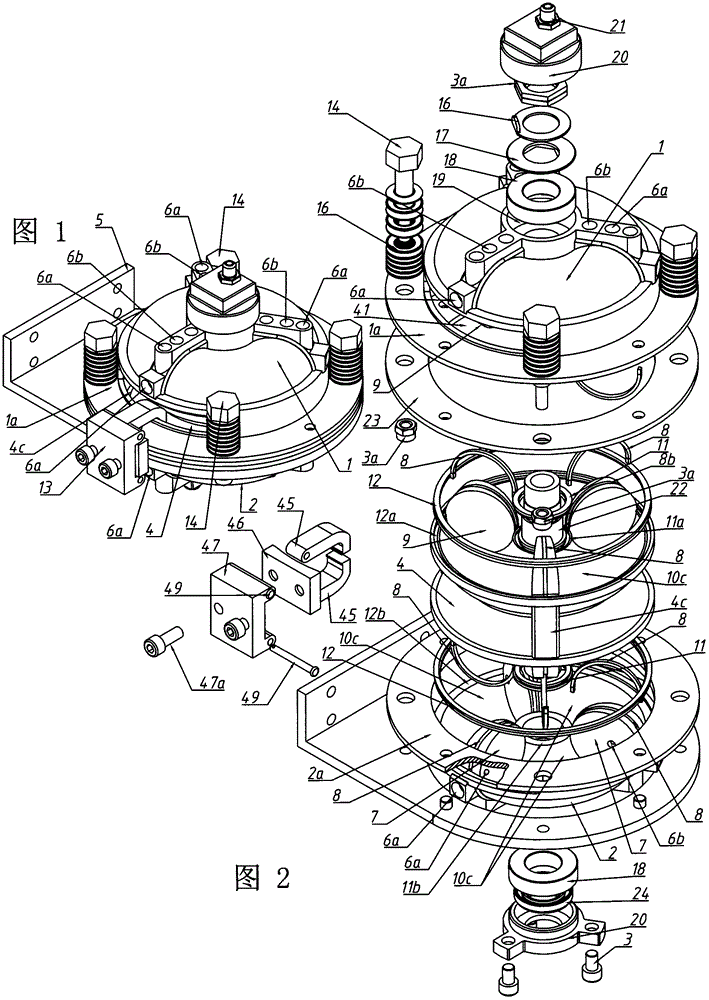

Ball-shape compressor and expansion compressor capable of realizing multi-stage compression

ActiveCN1932293AImprove sealingWell lubricated surfaceOscillating piston pumpsOscillating piston liquid enginesGas compressorEngineering

The present invention relates to a kind of compressor and expansion compressor capable of implementing multi-stage compression. Said compressor is characterized by that several working chambers are set in a ball cylinder, the air channel is set on the piston and piston hinge support, intake and exhaust channel is set on the cylinder body and cylinder cover, when the piston is rotated to all the working chamber and has need of intaking air and exhausting air, the correspondent air channel is communicated with intake and exhaust channel so as to implement multi-stage compression and expansion.

Owner:XIAN ZHENGAN ENVIRONMENTAL TECH

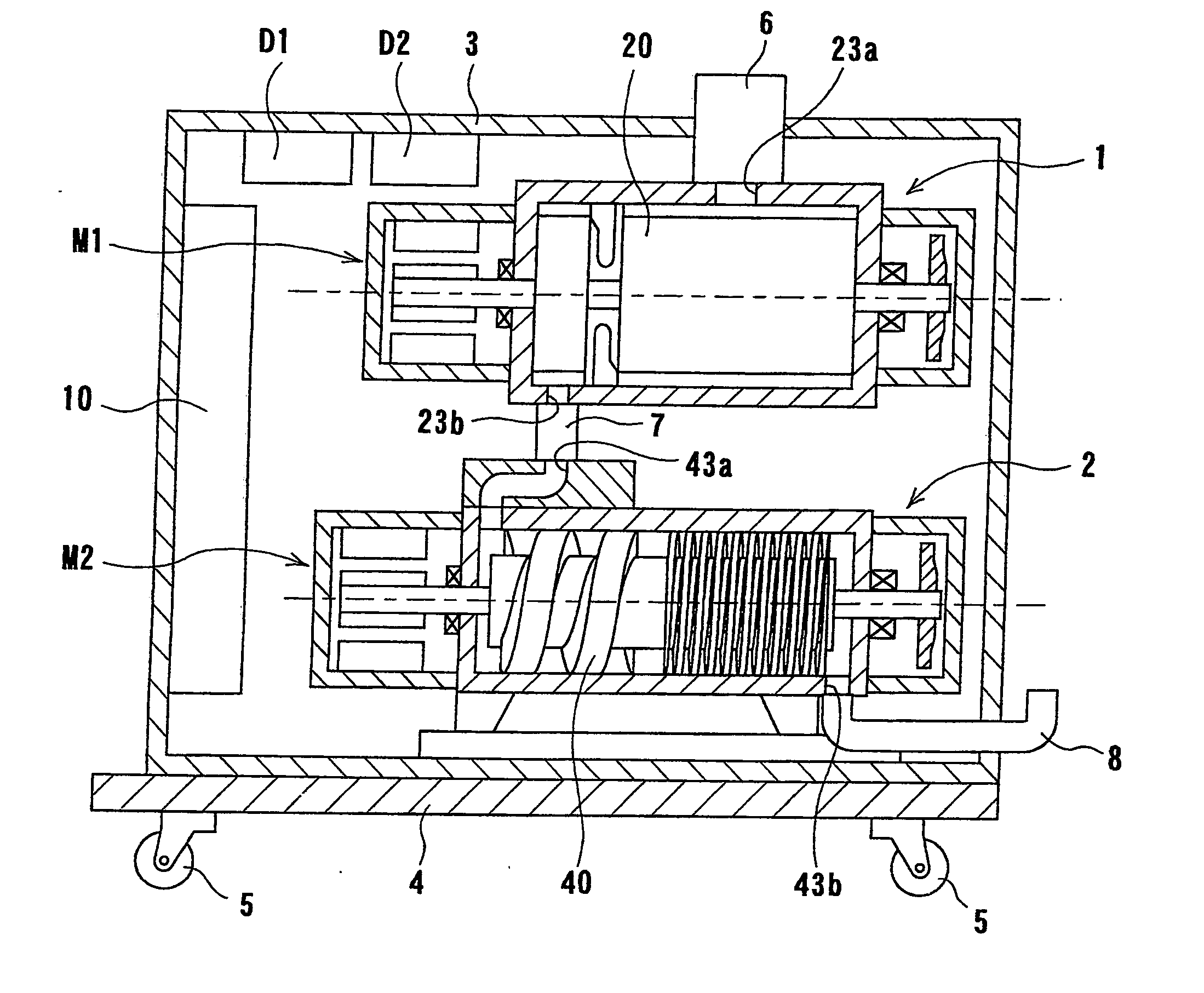

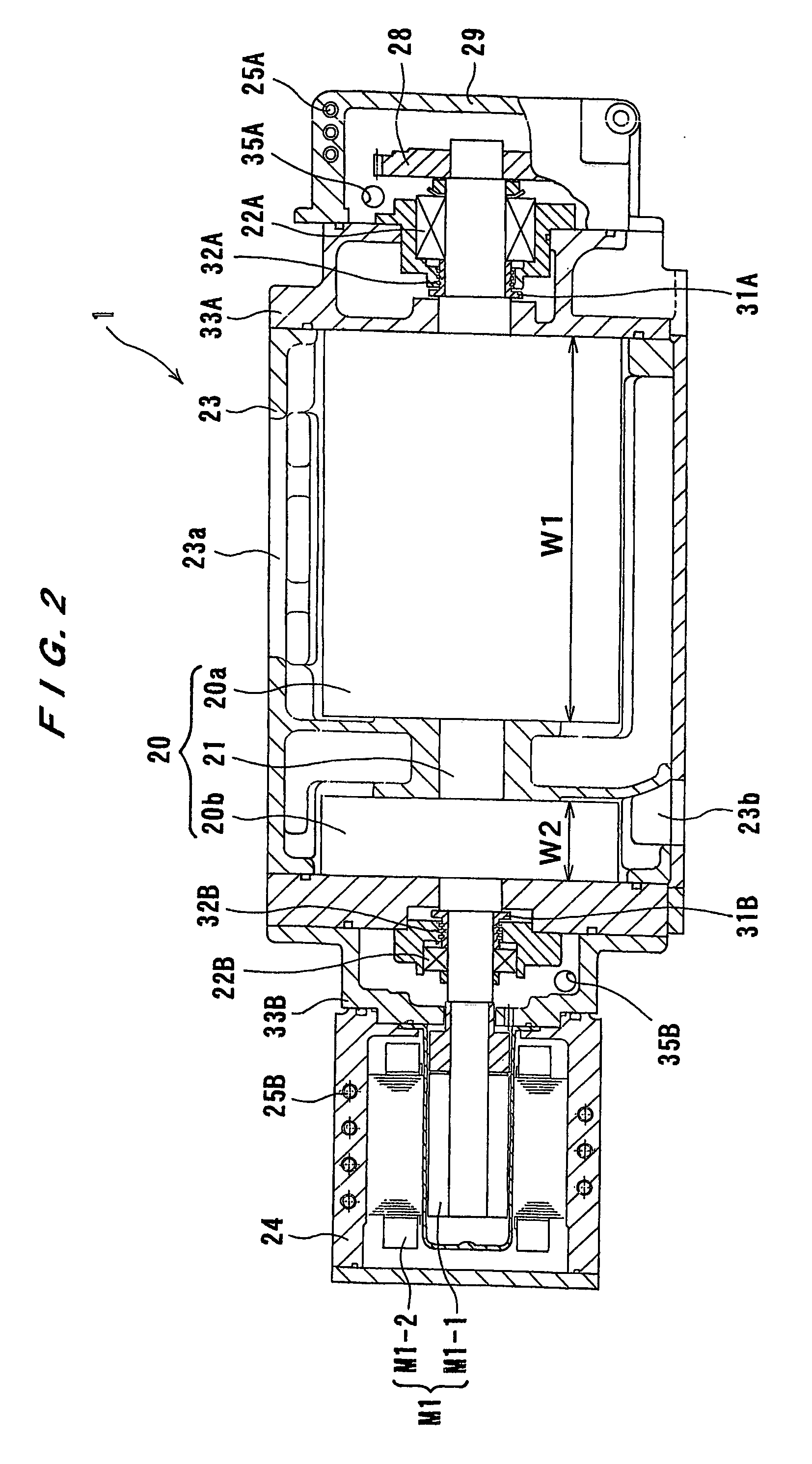

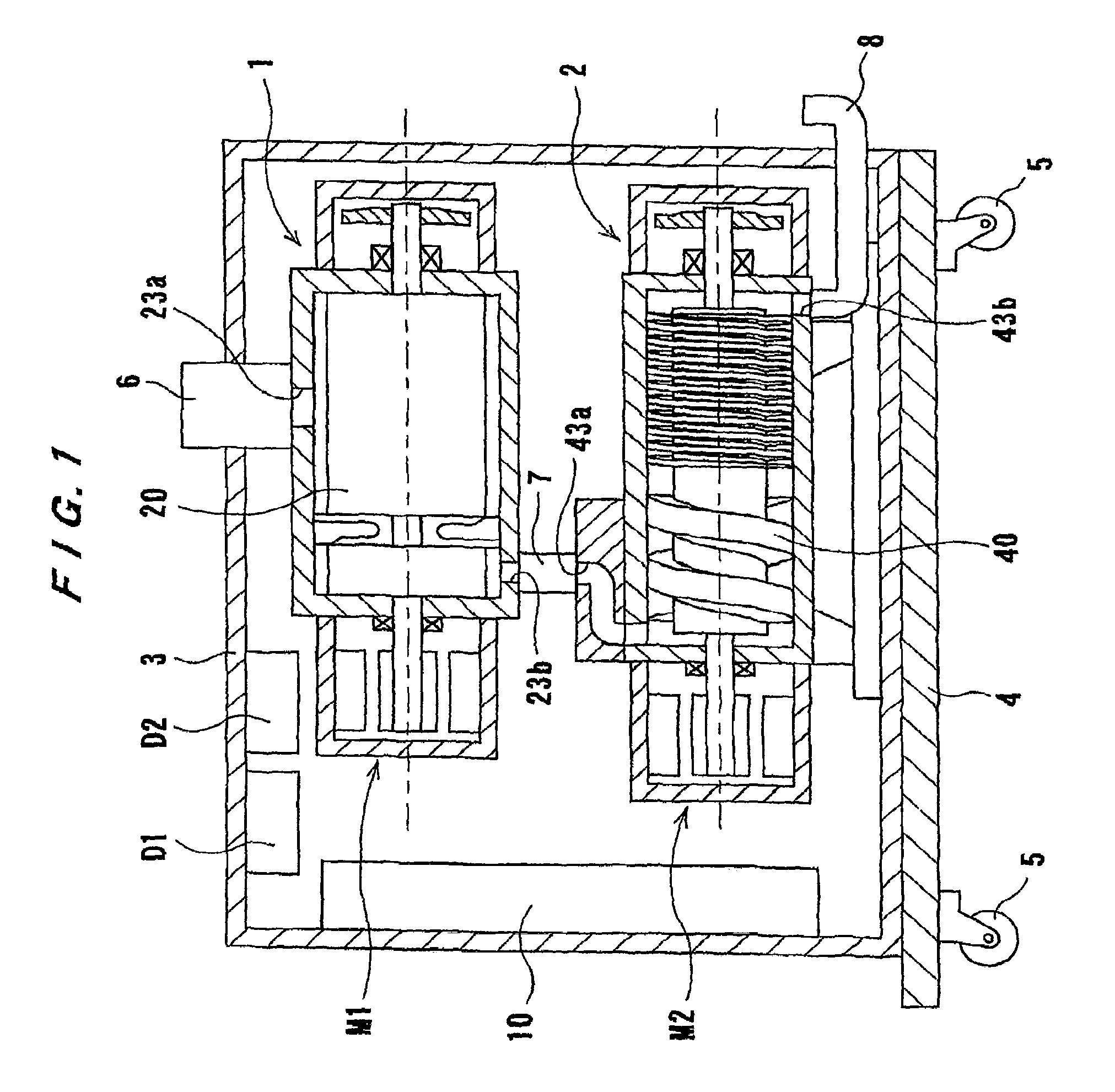

Evacuation apparatus

ActiveUS20070104587A1Prevent overloadAvoid small quantitiesRotary/oscillating piston combinations for elastic fluidsOscillating piston pumpsVacuum chamberVacuum pump

The present invention relates to an evacuation apparatus for evacuating a vacuum chamber of a substrate processing apparatus for processing a substrate such as a semiconductor wafer or liquid crystal panel. An evacuation apparatus according to the present invention includes a first vacuum pump connected to a vacuum chamber, and a second vacuum pump connected to the first vacuum pump. The first vacuum pump has a pair of multistage pump rotors.

Owner:EBARA CORP

Fluidic energy transfer devices

ActiveUS8272851B2Increase volumeLower the volumeOscillating piston pumpsFlexible wall reciprocating enginesEnergy transferEngineering

A fluid energy transfer device, including a chamber for receiving a fluid, at least a portion of the chamber comprising a movable portion relative to another portion of the chamber, the movable portion being adapted to change the volume of the chamber from a first volume to a second volume by movement of the movable portion. The device further includes an actuator attached to the movable portion, wherein the displacements of the movable portion can be larger than the displacement of the actuator.

Owner:AAVID THERMALLOY LLV

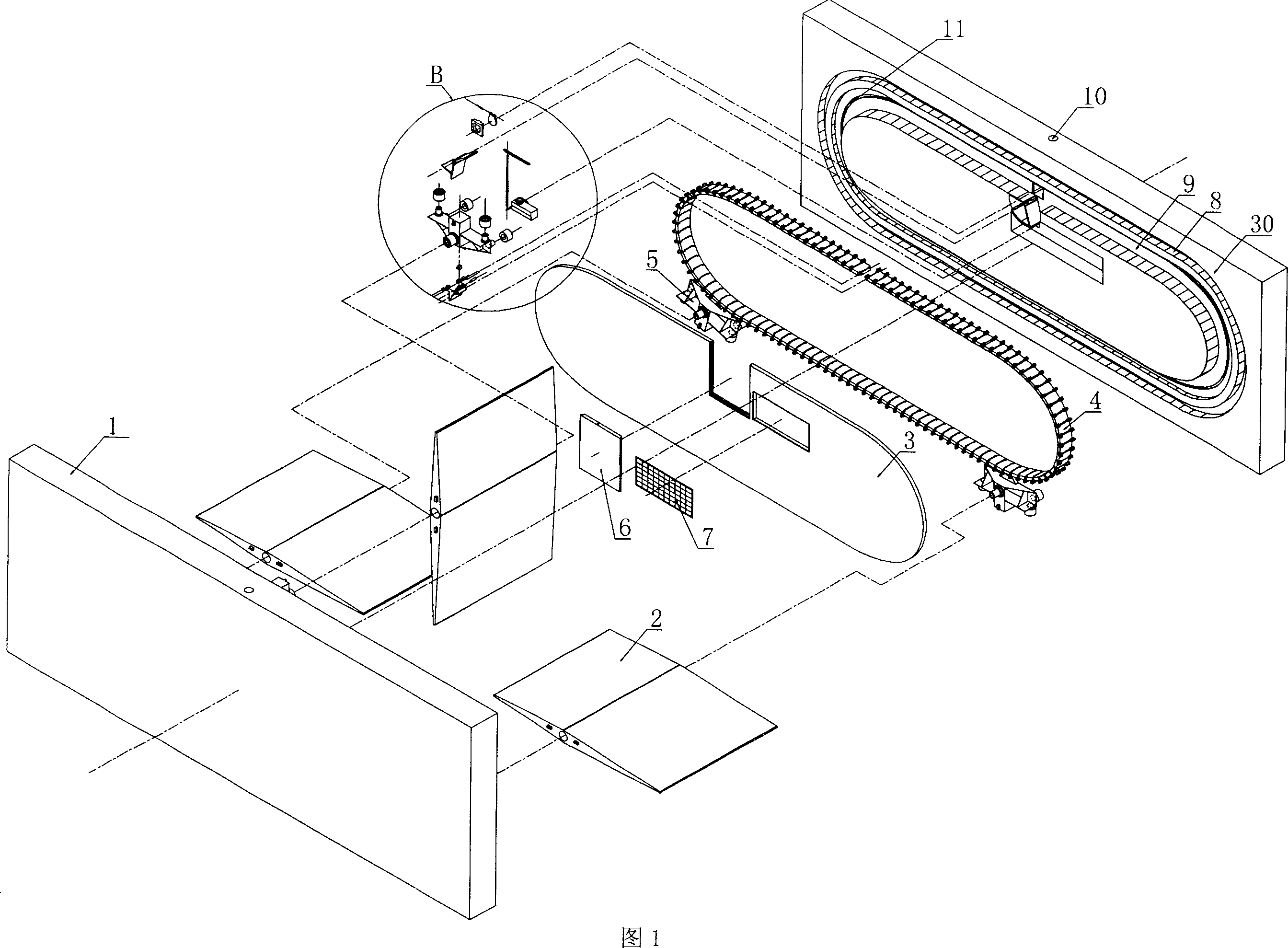

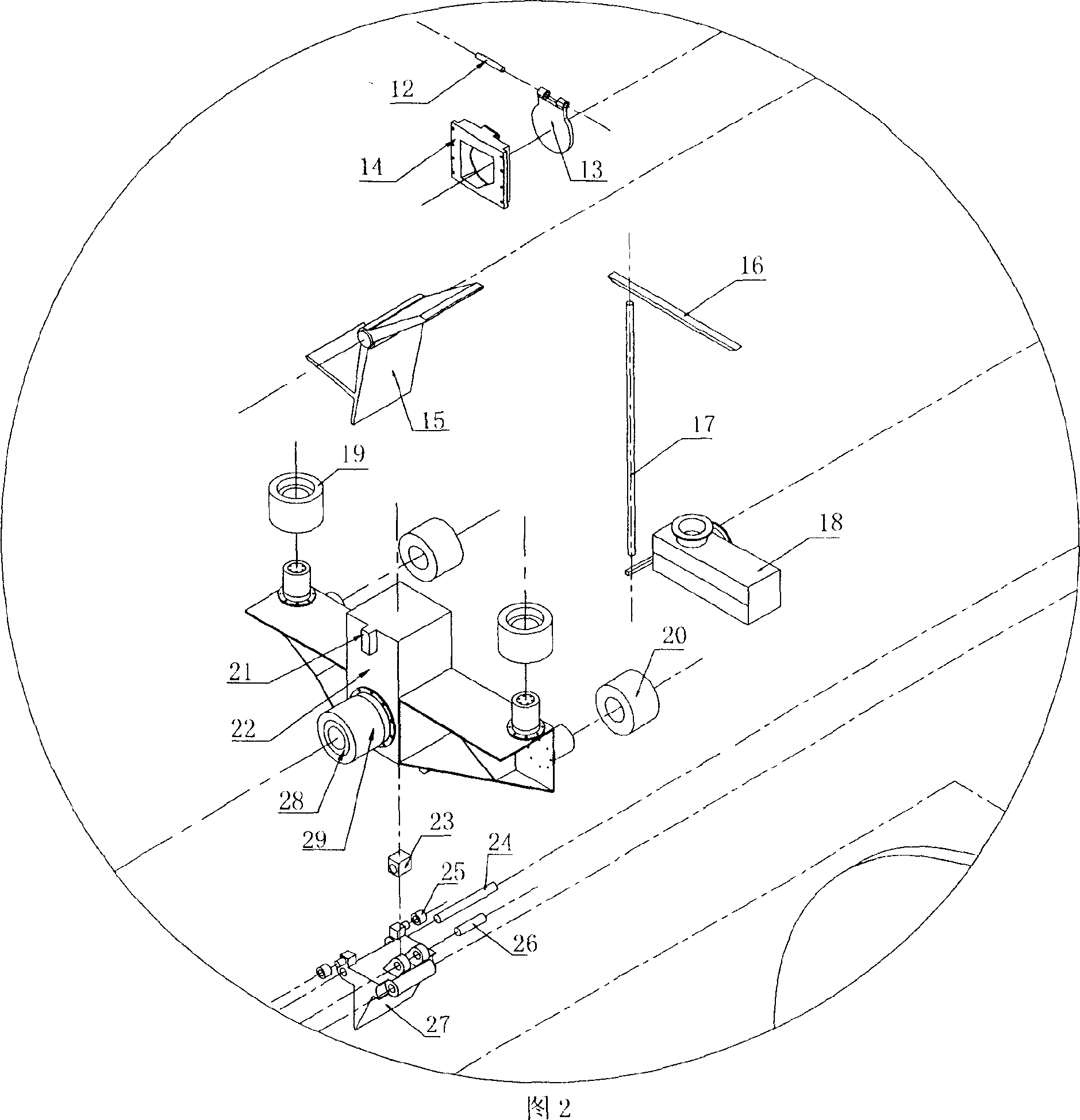

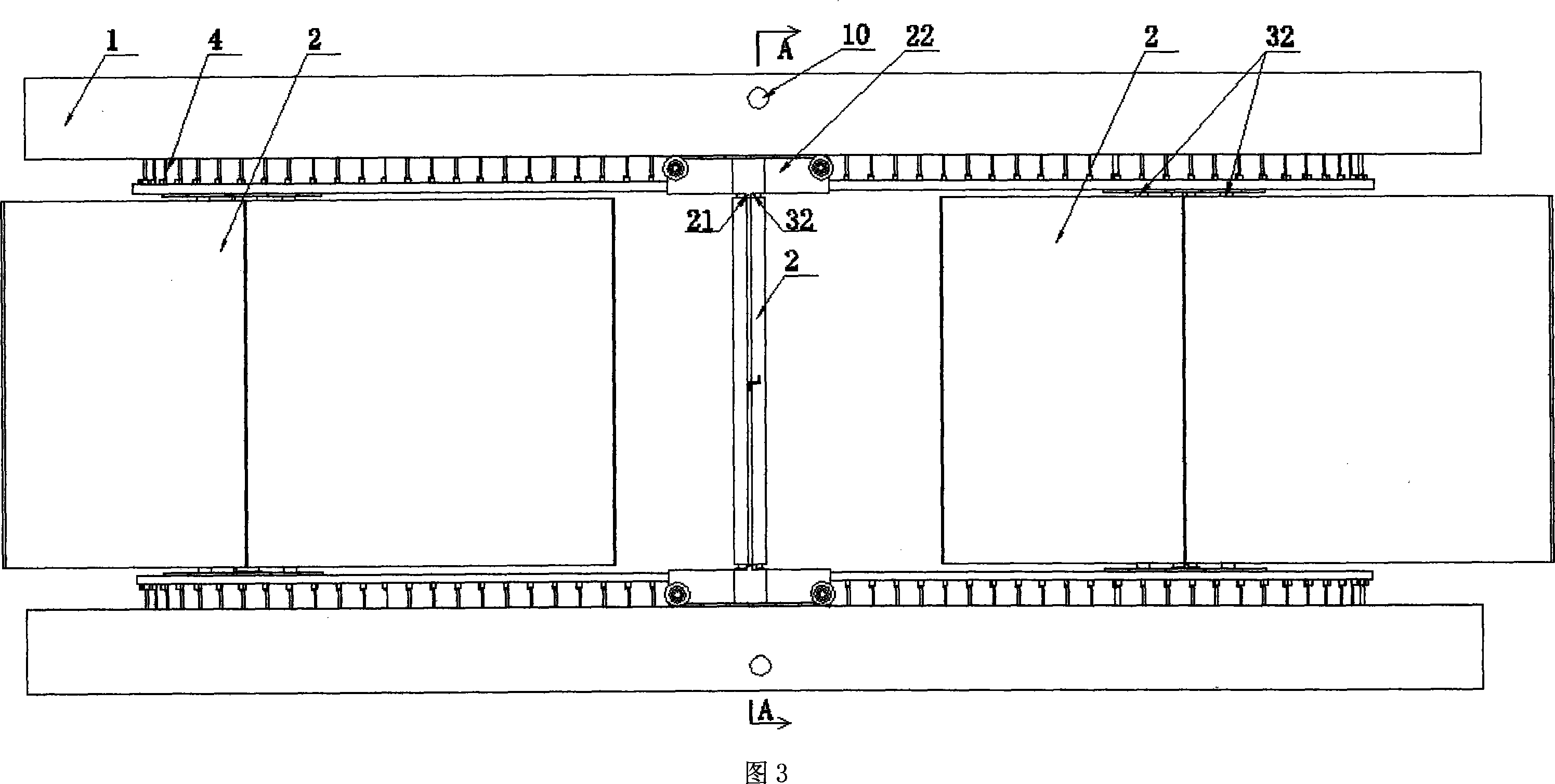

Rotating blade vehicle type fluid machine

InactiveCN101100974AWide range of wind speedImprove efficiencyOscillating piston pumpsWind motor combinationsEngineeringElectric generator

This invention is rotating blade car type fluid power generator. The chain connects to three groups of rotating blade cars. Rotating blades are evenly distributed on circulate track. Two straight tracks and two half circular arc tracks are connected to form circulating track. Under the effect of fluid, rotating blade of rotating blade car is vertical to fluid flowing direction at the straight segment of track. Thus, fluid active force is strong. At another straight segment, under the effect of fluid, rotating blade of rotating blade car is parallel to fluid flowing direction. Thus, fluid active force is little. The three groups of rotating blade cars and rotating blades undertake circulating operation along track. The chain transfers power to power generator through driving train. The flow power driving train, which is applied underground, is composed of chain pump, pipe, accumulator and water turbine. It makes power generator can be assembled on water surface. The resistance type wind power machine is driven by chain.

Owner:陈崟

Scroll compressor with captured thrust washer

InactiveUS20130251574A1Rotary/oscillating piston combinations for elastic fluidsOscillating piston pumpsScroll compressorAerospace engineering

A load transmittal apparatus transfers an axial load to a thrust surface during operation of a scroll compressor.

Owner:BITZER KUEHLMASCHINENBAU GMBH

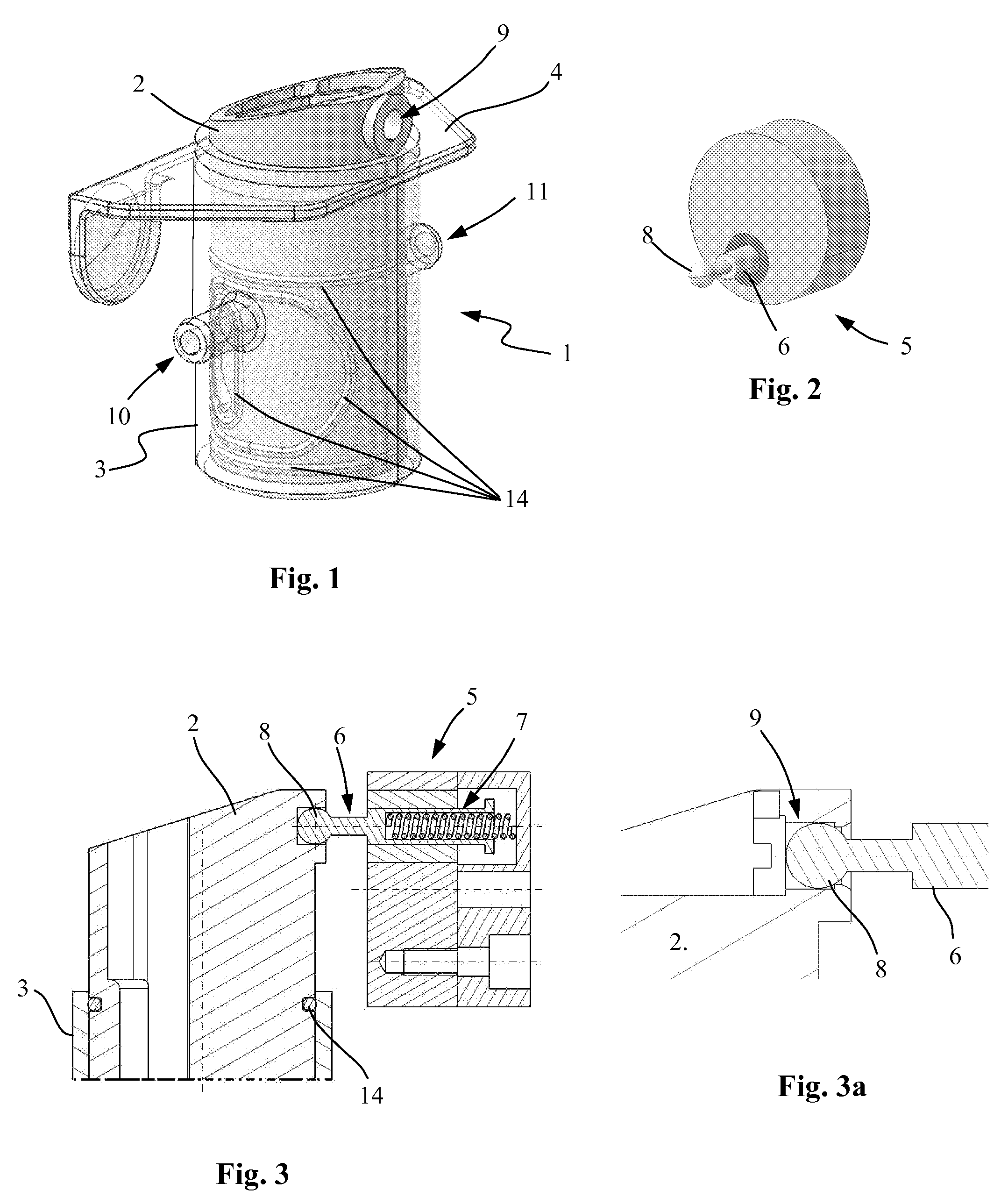

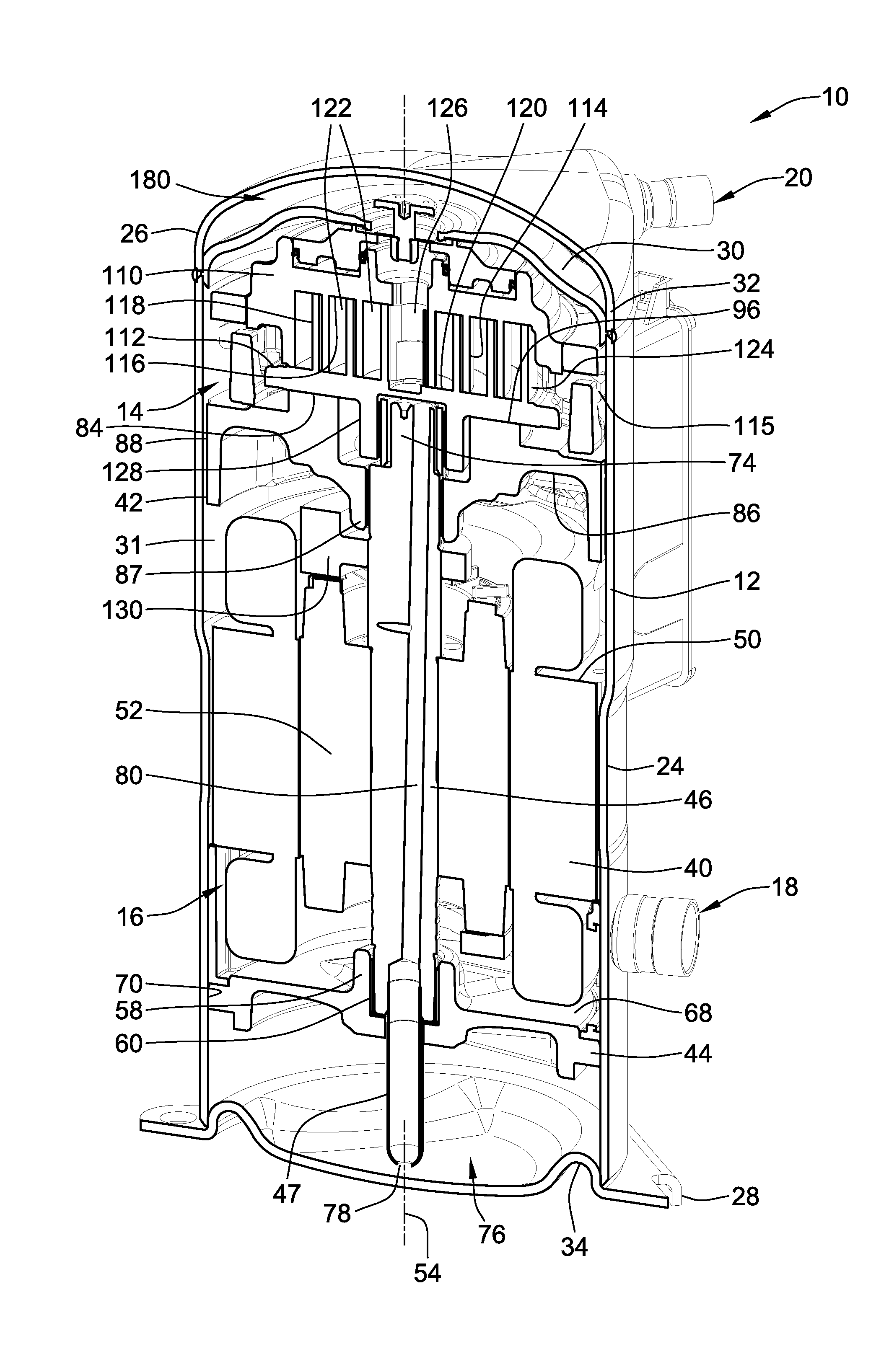

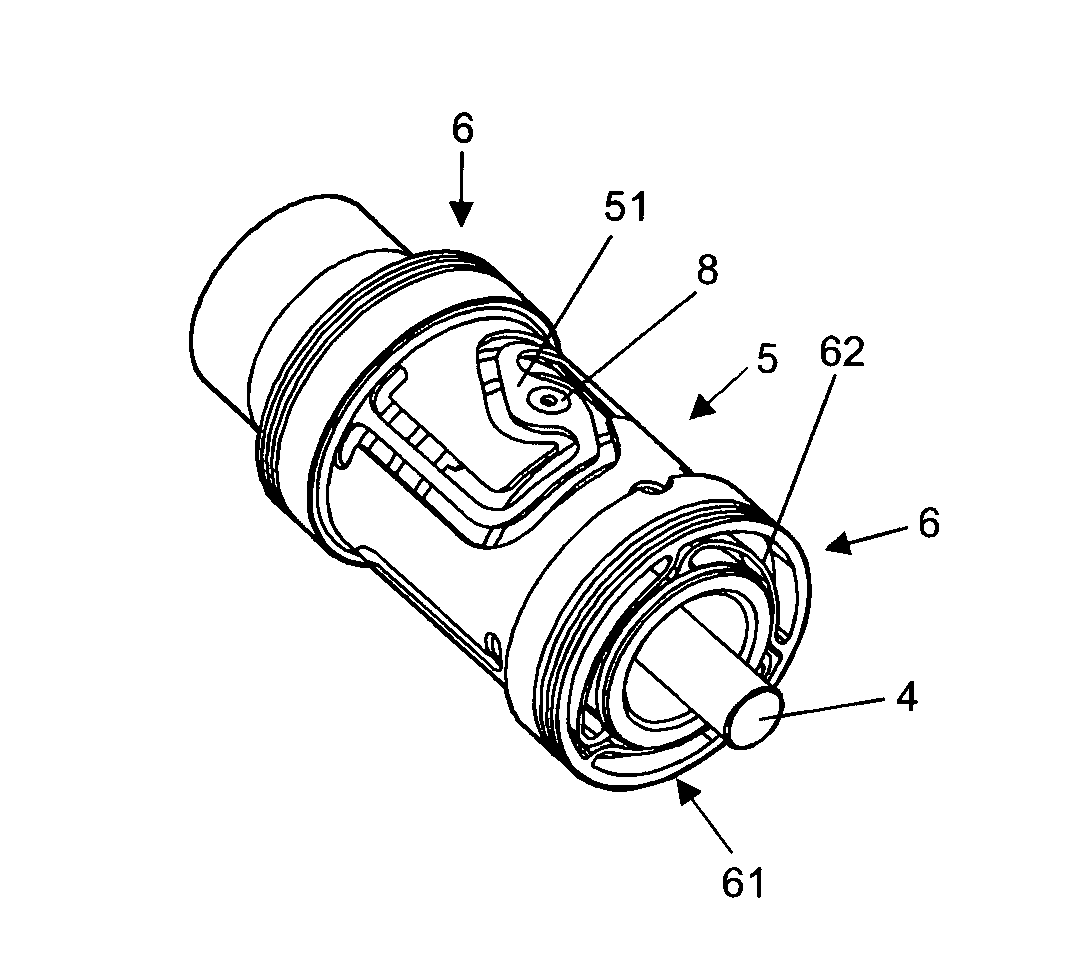

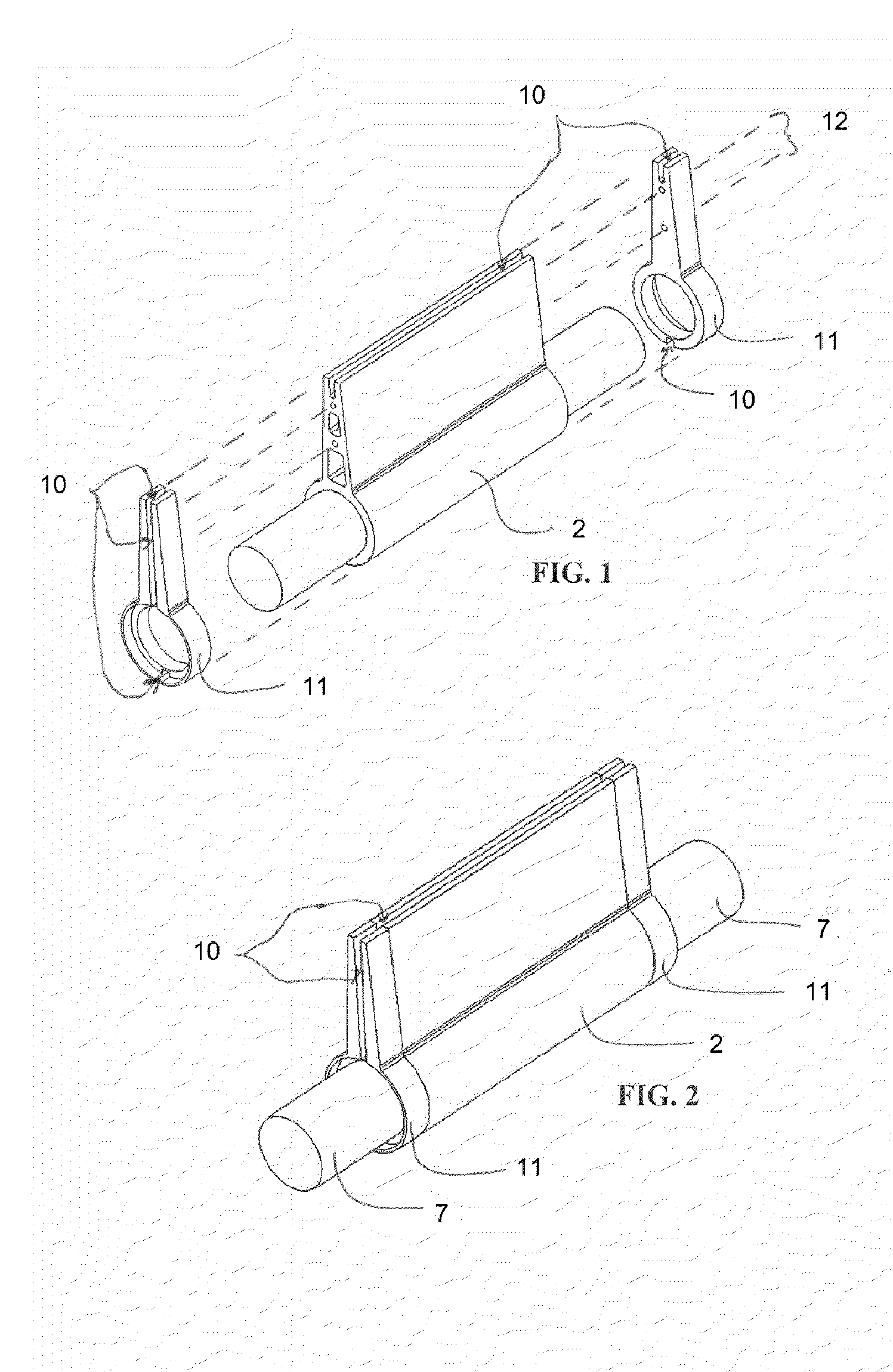

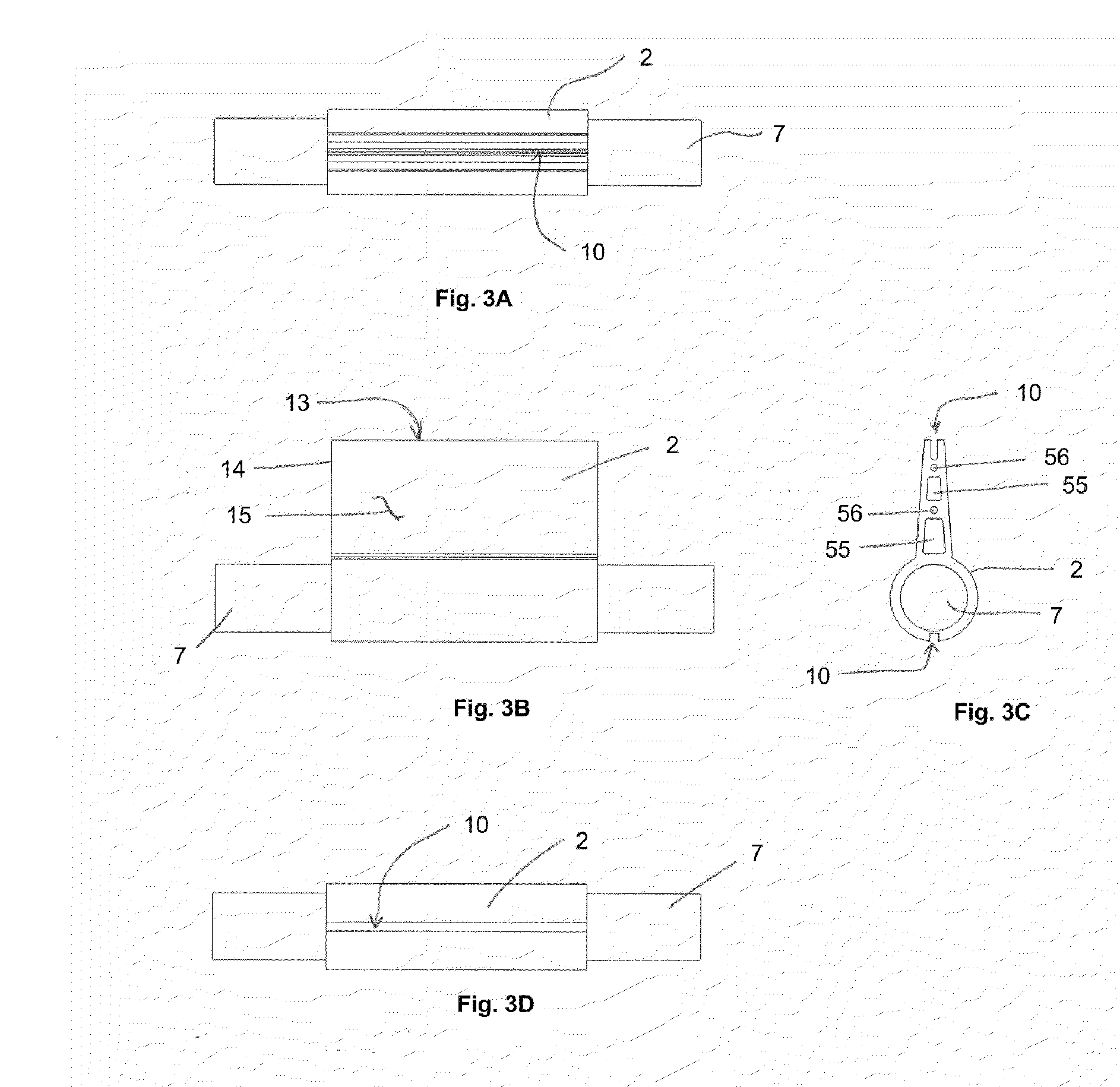

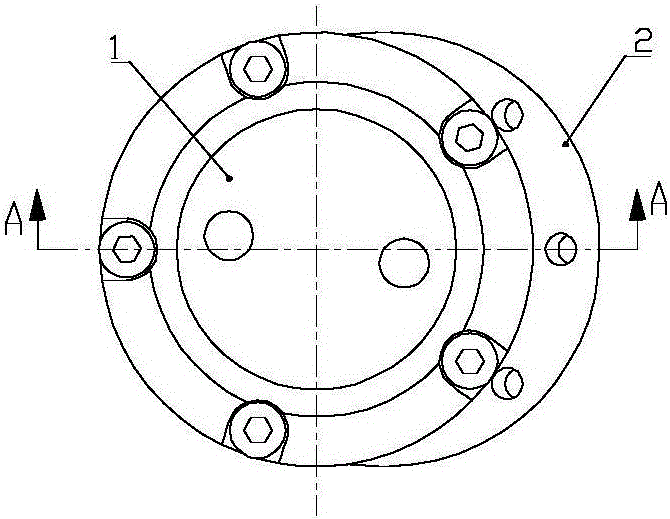

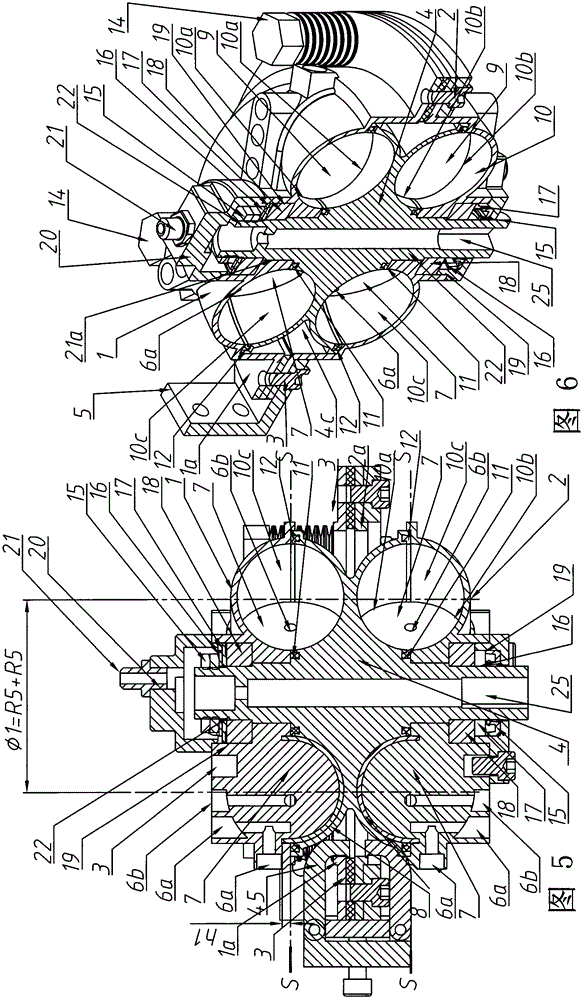

Arrangement of components of a linear compressor

InactiveUS20140234145A1Reduce vibration levelsLow variabilityOscillating piston pumpsPositive displacement pump componentsLinear compressorMagnet

The present invention refers to the arrangement of components comprised in a linear compressor (1), which is fundamentally composed by at least one resonant oscillating mechanism comprising at least one resonant spring (2) which defines at least one neutral point (21), at least one magnet (3) and at least one piston (4); at least one intermediate element (5) which defines an axially flexible surface (51); at least one flat spring (6) which defines at least one binding structure (62); at least one shell (7); and at least one attaching means (8).

Owner:EMBRACO IND DE COMPRESSORES E SOLUCOES EM REFRIGERACAO LTDA

Vane type continuous rotating cylinder

InactiveCN101586474ASolve the leakage loss problem of linear sealSolve the problem of unstable outputOscillating piston pumpsRotary piston pumpsEngineeringCylinder block

A vane type continuous rotating cylinder comprises a cylinder body (1), a rotor (2), a spacer (3), a working substance inlet (4), a working substance outlet (5) and a vane (7). The rotor is arranged in the cylinder body to form a ring chamber with the cylinder body. The spacer separates the continuous chamber of the ring chamber. The working substance inlet (4) and working substance outlet (5) are located respectively on both sides of the spacer. The vane type continuous rotating cylinder further comprises a cam (6) which guides the vane passing through the spacer.

Owner:周华

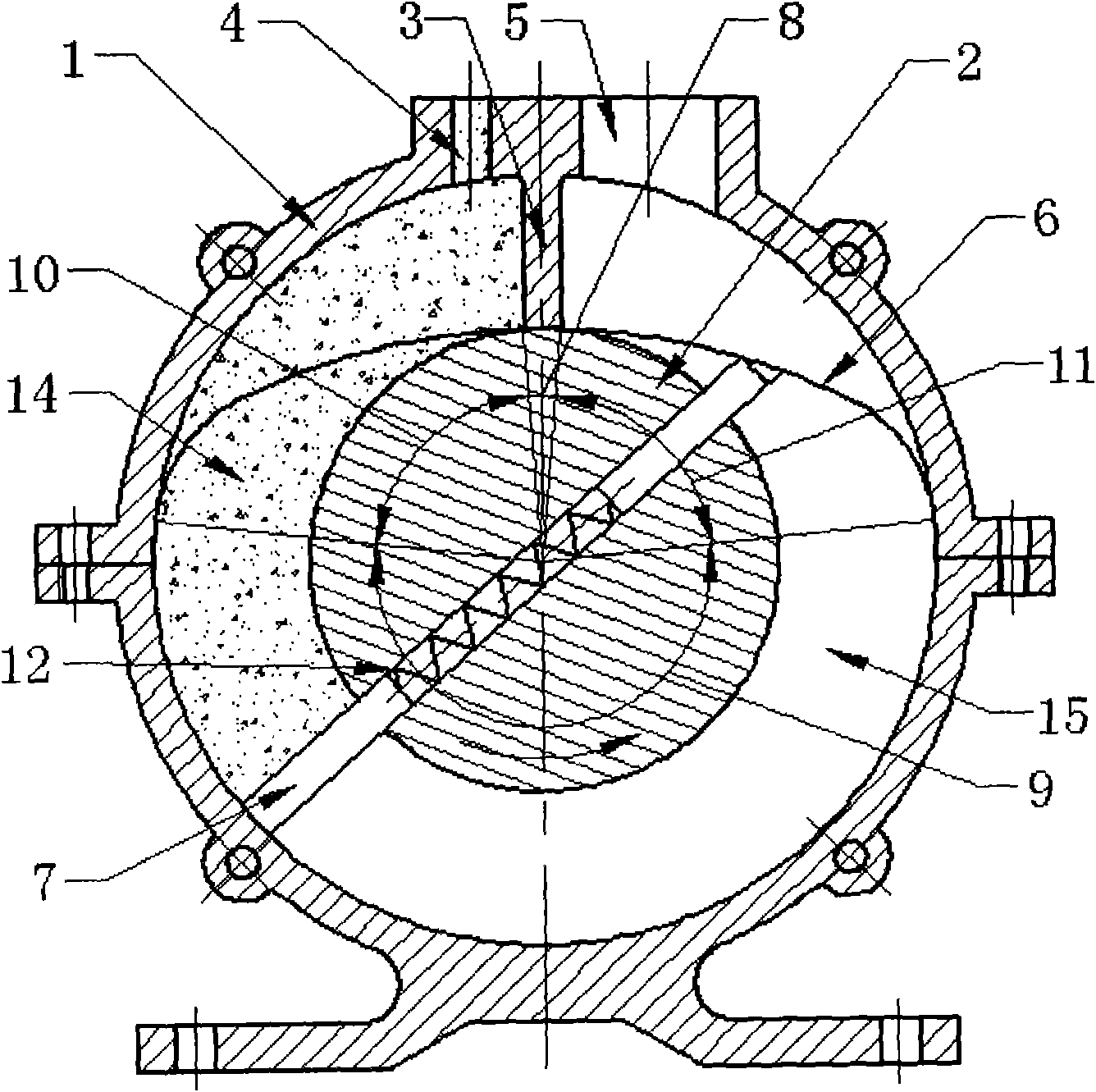

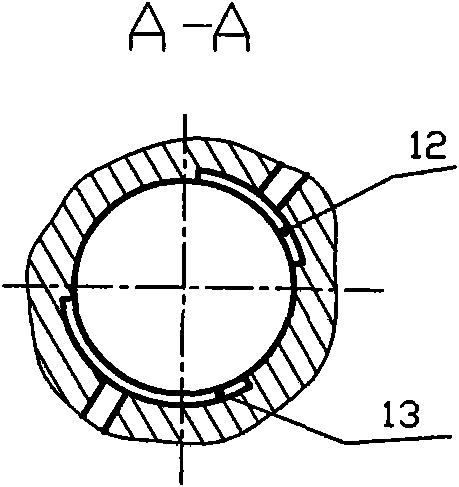

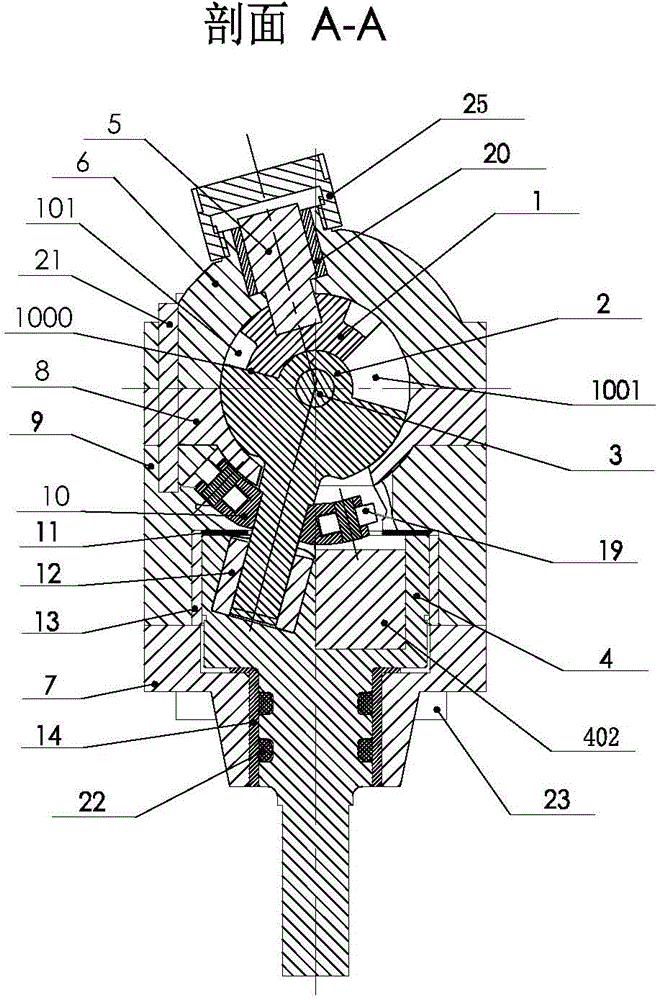

Automatical compensation mechanism for sealing clearance of hinges used for spherical compressor

ActiveCN101929463AImprove sealingGuaranteed feasibilityOscillating piston pumpsSealing arrangement for pumpsEngineeringHigh pressure

The invention designs an automatical compensation mechanism with a novel hinge sealing structure used for a spherical compressor based on the Chinese patent ZL03114505.1, wherein a cylindrical surface hinge is formed among a centrepin, a turntable pin boss and a wrist pin boss of the spherical compressor; an embedded lump is arranged in a groove on the pin boss for forming the cylindrical surface hinge; the embedded lump is in a sector block structure in which the two sides are thick and the middle part is thin; the embedded lump is arranged at the bottom of the groove; the embedded lump has a shape adaptive to that of the groove and that of an external cylindrical surface of a semicylinder lug on the pin boss for forming the cylindrical surface hinge and respectively forms seal movable fit with the groove and the semicylinder lug; and when one of the working chambers which are used for alternative compression and are formed at the two sides of the cylindrical surface hinge is in a high pressure state, the embedded lump is pressed at the side surface of the working chamber so as to enable the embedded lump to have slightly relative movement toward the low pressure side, thus the clearances close to the high pressure side between the embedded lump and the groove bottom surface as well as the cylindrical surface of the semicylinder lug are reduced, and the larger the pressure is, and the smaller the clearances are.

Owner:SHENZHEN SPHERICAL POWER TECH CO LTD

Peripherally pivoted oscillating vane machine

InactiveUS20090081061A1Increase pressureIncrease speedOscillating piston pumpsRotary piston pumpsEngineeringMechanical engineering

The present invention is directed to a peripherally pivoted oscillating vane machine (OVM). The OVM has been optimized for performance and efficiency. This has been accomplished by reducing loads on the drive mechanism and by employing de-phased motion of the peripherally pivoted vanes in conjunction with improved porting configurations as well as valve actuation and manufacture.

Owner:MECHANOLOGY INC

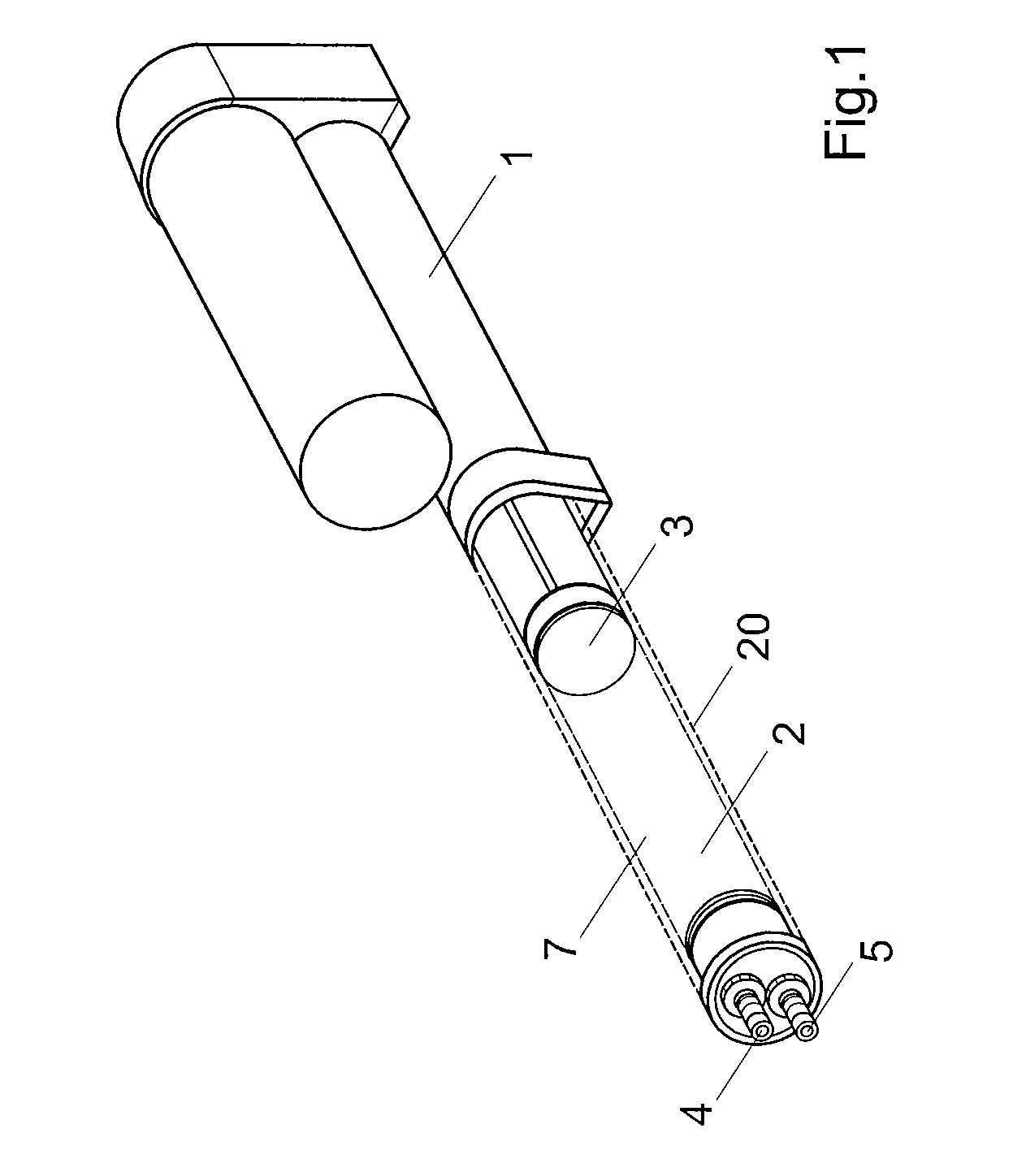

Pump

ActiveUS8734131B2Large diameterIncrease volumeOscillating piston pumpsFlexible member pumpsEngineeringActuator

A fluid pump comprising a chamber which, in use, contains a fluid to be pumped, the chamber including a main cavity having a substantially cylindrical shape bounded by first and second end walls and a side wall and a secondary cavity extending radially outwards of the main cavity, one or more actuators which, in use, cause oscillatory motion of the first end wall in a direction substantially perpendicular to the plane of the first end wall, and whereby, in use, the axial oscillations of the end walls drive radial oscillations of the fluid pressure in the main cavity, and wherein the secondary cavity spaces the side wall from the first end wall such that the first end wall can move relative to the side wall when the actuator is activated.

Owner:TTP VENTUS LTD

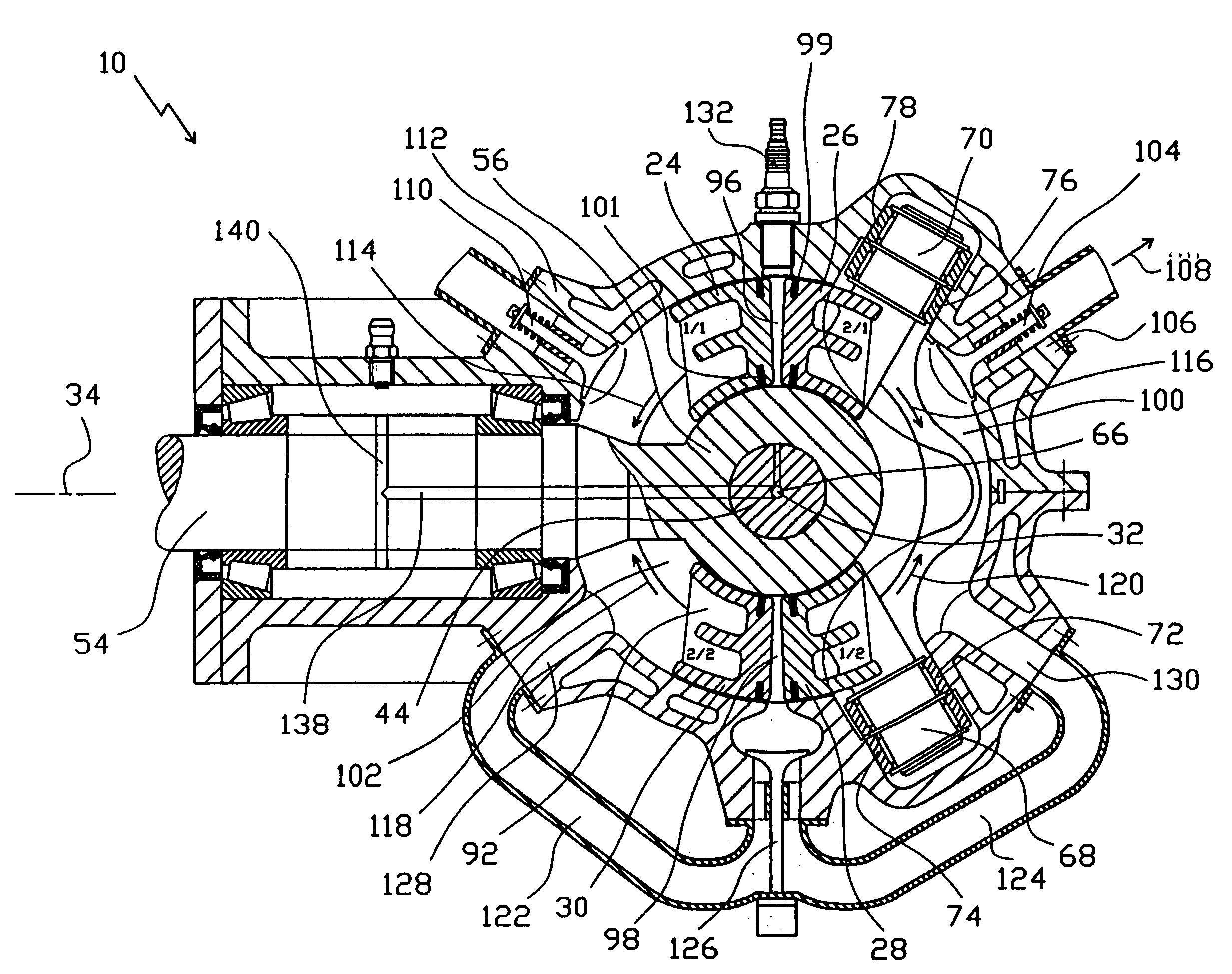

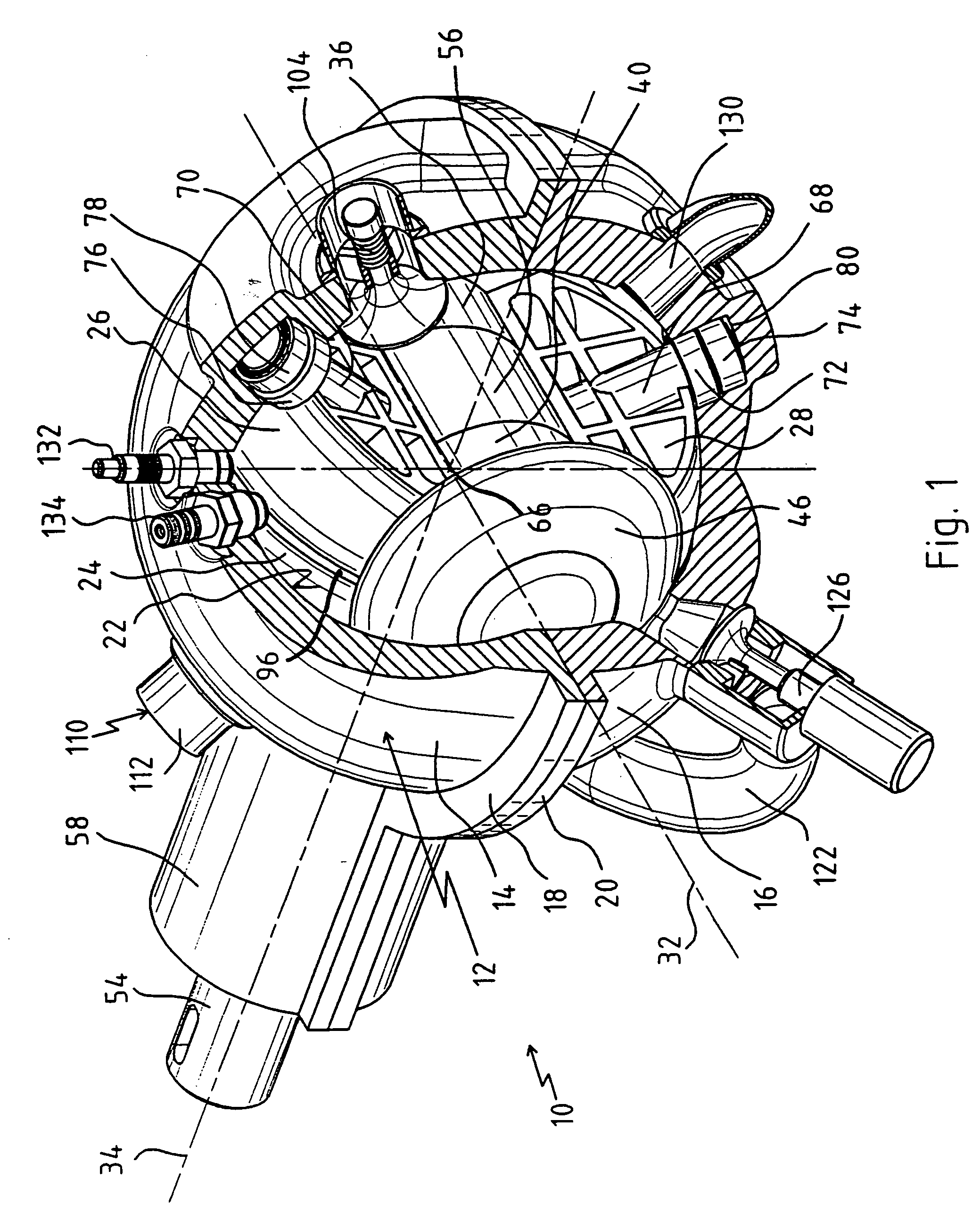

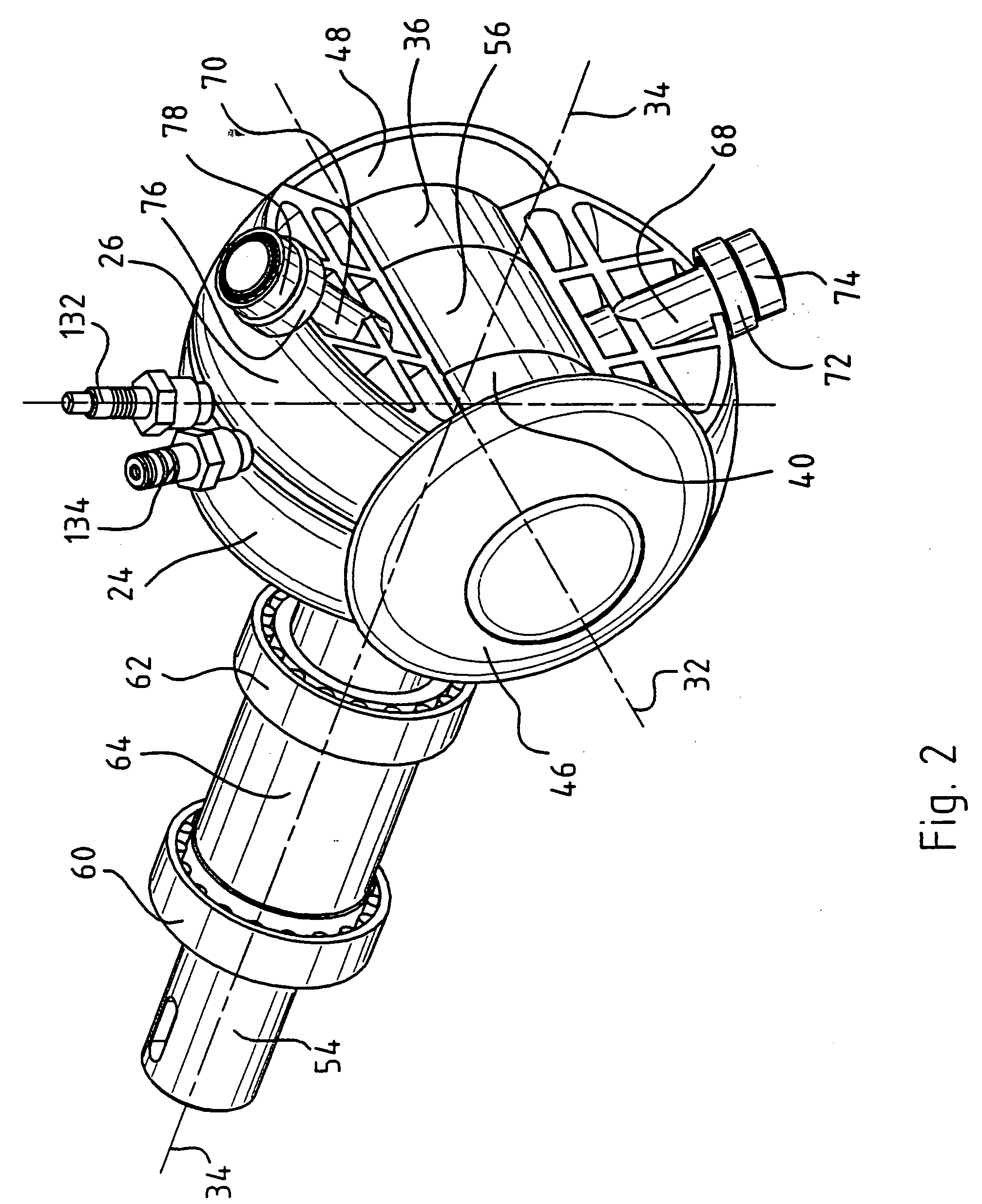

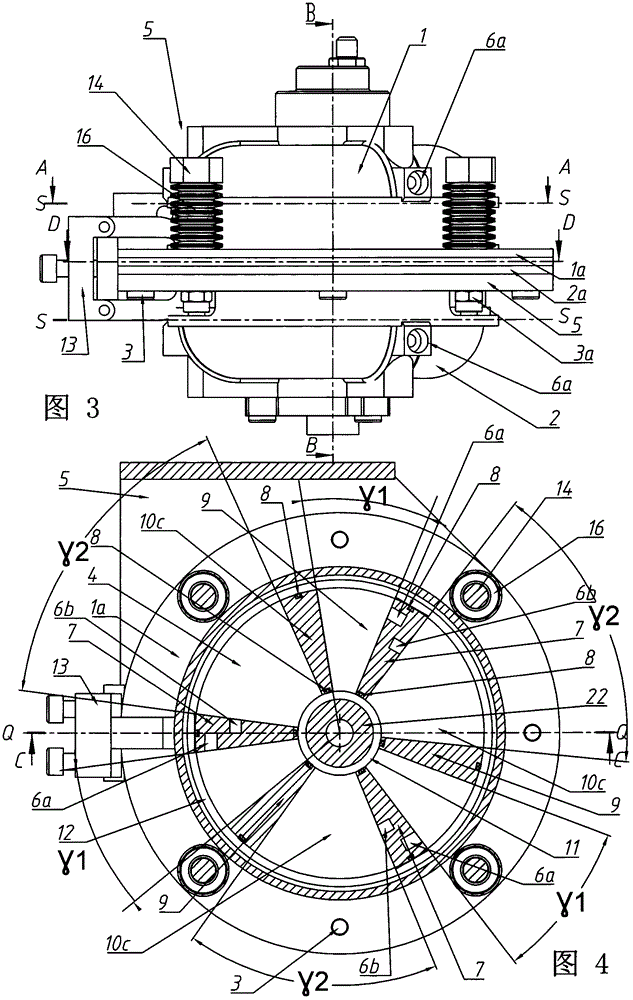

Oscillating piston machine

InactiveUS20050008515A1Enhanced interactionQuieter runningOscillating piston pumpsInternal combustion piston enginesEngineeringPiston

An oscillating piston machine comprises a plurality of pistons which are arranged in a housing, rotate together in the housing about an axis of rotation which is essentially central in the housing and is fixed to the housing, and execute reciprocating oscillating movements about a respective oscillation axis as they rotate in the housing, in each case two adjacent pistons executing oscillating movements in opposite directions. The housing is of spherical construction on the inside, the oscillation axes of the pistons being formed by a common oscillation axis which run essentially through the center of the housing.

Owner:HUTTLIN HERBERT

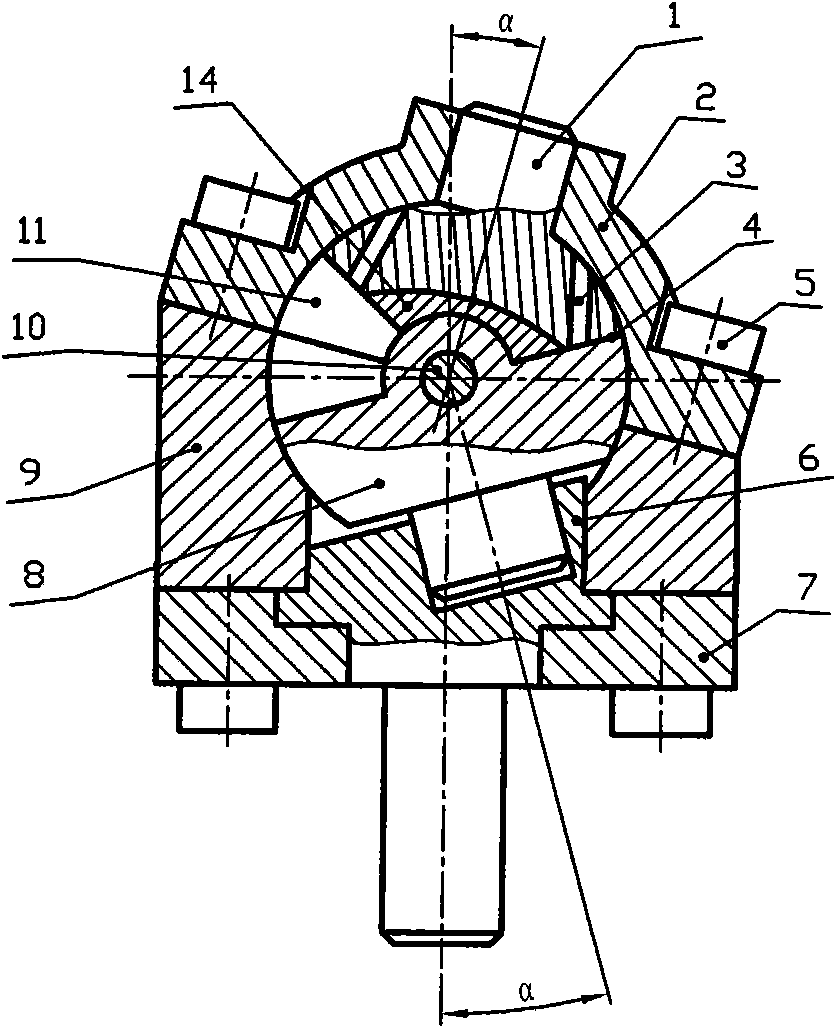

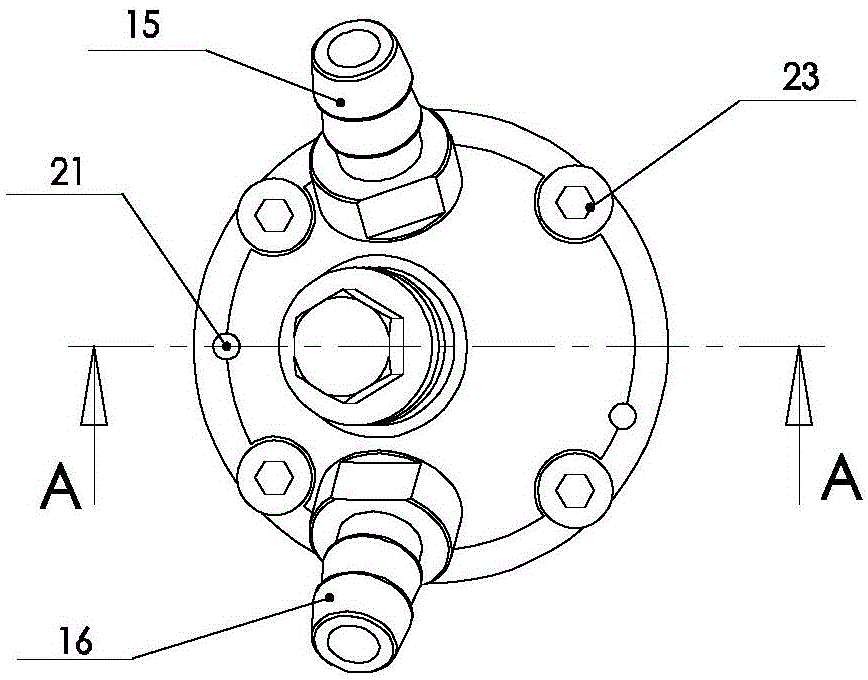

Anti-blocking power mechanism of spherical compressor

ActiveCN104314808ASolve the dead point problemImprove work efficiencyOscillating piston pumpsRotary piston pumpsHigh pressurePiston

The invention discloses an anti-blocking power mechanism of a spherical compressor. A rotating plate synchronous power mechanism consisting of a power handle (10) and a track limiting surface (24) is arranged between a cylinder body (8) and a cylinder body seat (9), the power handle (10) is of a dumbbell structure with two symmetric ends, is fixed on a rotating plate shaft (203) and rotates along with a rotating plate (2), when the rotating plate (2) rotates to a position at which the axis of the rotating plate is overlapped with the axis of a piston, the rotating plate (2) is driven by the rotation of a main shaft (4), the rotating plate synchronous power mechanism can produce power enabling the rotating plate (2) to rotate continuously around the axis, so that a rotor continuously rotates and crosses a dead point; the rotating plate is provided with a backpressure support, so that the local imbalance pressure produced by a rotating plate spherical surface on the spherical surface of the cylinder body due to the working high pressure can be reduced, the mechanism can operate firmly and reliably, and the blocking problem of the rotor of the spherical compressor can be thoroughly solved.

Owner:XIAN ZHENGAN ENVIRONMENTAL TECH

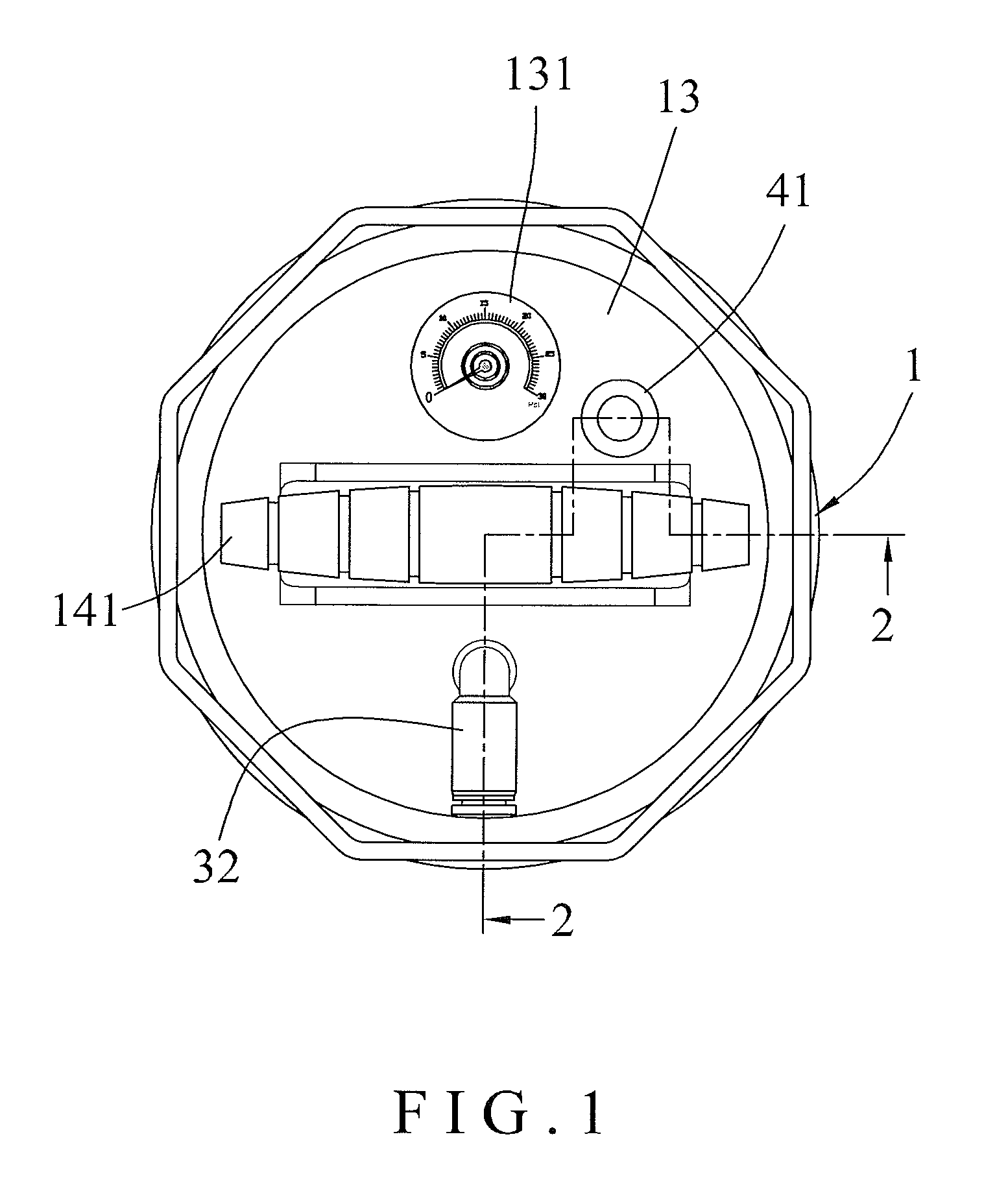

Pumping device having a pressure adjustable function

ActiveUS8419377B2Operational securityEnsure safe operationOscillating piston pumpsLiquid fillingEngineeringCheck valve

Owner:CRAFTS & CARRIERS TAIWAN

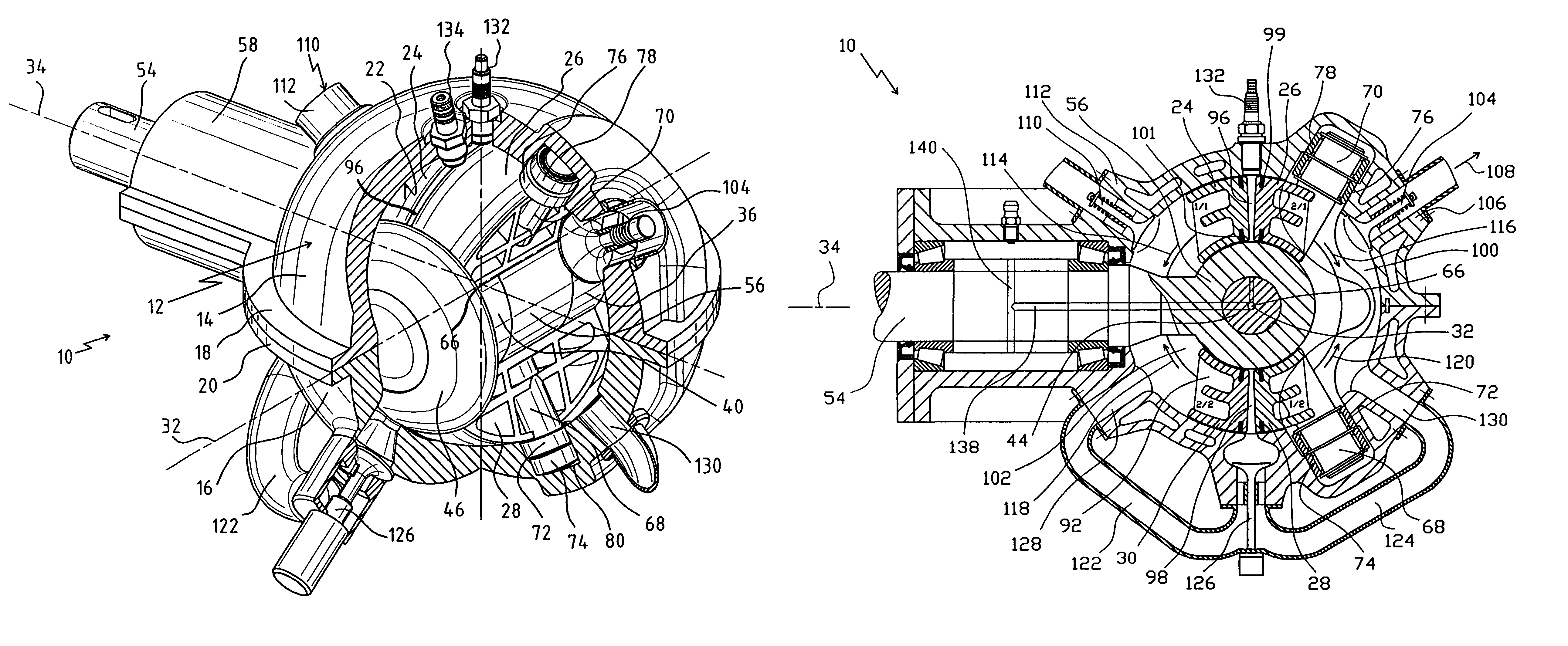

Adjustable fail-safe rotary spring operator with a retaining band

ActiveUS20130004358A1Eliminate inadvertentImprove security featuresOscillating piston pumpsEqualizing valvesEngineeringActuator

A rotary spring-return actuator operator is provided with a multi-slot shaft and a clock type spring retained by a retaining band which encircles the spring in such a manner as to insure that the potential energy within the spring is safely contained during all operations requiring disassembly of the actuator assembly, and wherein the retaining band facilitates the in-field reversal of the spring direction or the adjustment of the spring preload by securing the spring to one or more of the slots on the multi-slot shaft.

Owner:CONTROLS INT

Swing piston power machine

InactiveCN104775899ASimple structureFew moving partsOscillating piston pumpsInternal combustion piston enginesInternal combustion enginePiston

The invention discloses a swing piston internal combustion engine structure, and relates to the field of power machines. A swing piston power machine is mainly composed of the components such as an air cylinder, a swing piston, a swinging plate, a main shaft, a swash plate, a spark plug and an intake and exhaust system; the swing piston is mounted in the air cylinder, and is mutually matched with the inner surface of the air cylinder to form four working chambers; along with the swing of the swing piston, the volumes of the working chambers change periodically, and the four strokes of air suction, compression, acting and air exhaust are completed; the swing piston is connected with the main shaft through the swash plate, and mutual conversion between the swing of the piston and the rotation of the main shaft is completed. The swing piston power machine has the advantages of simple and compact structure, large power density, small friction, high operational reliability and efficiency and the like.

Owner:石喆

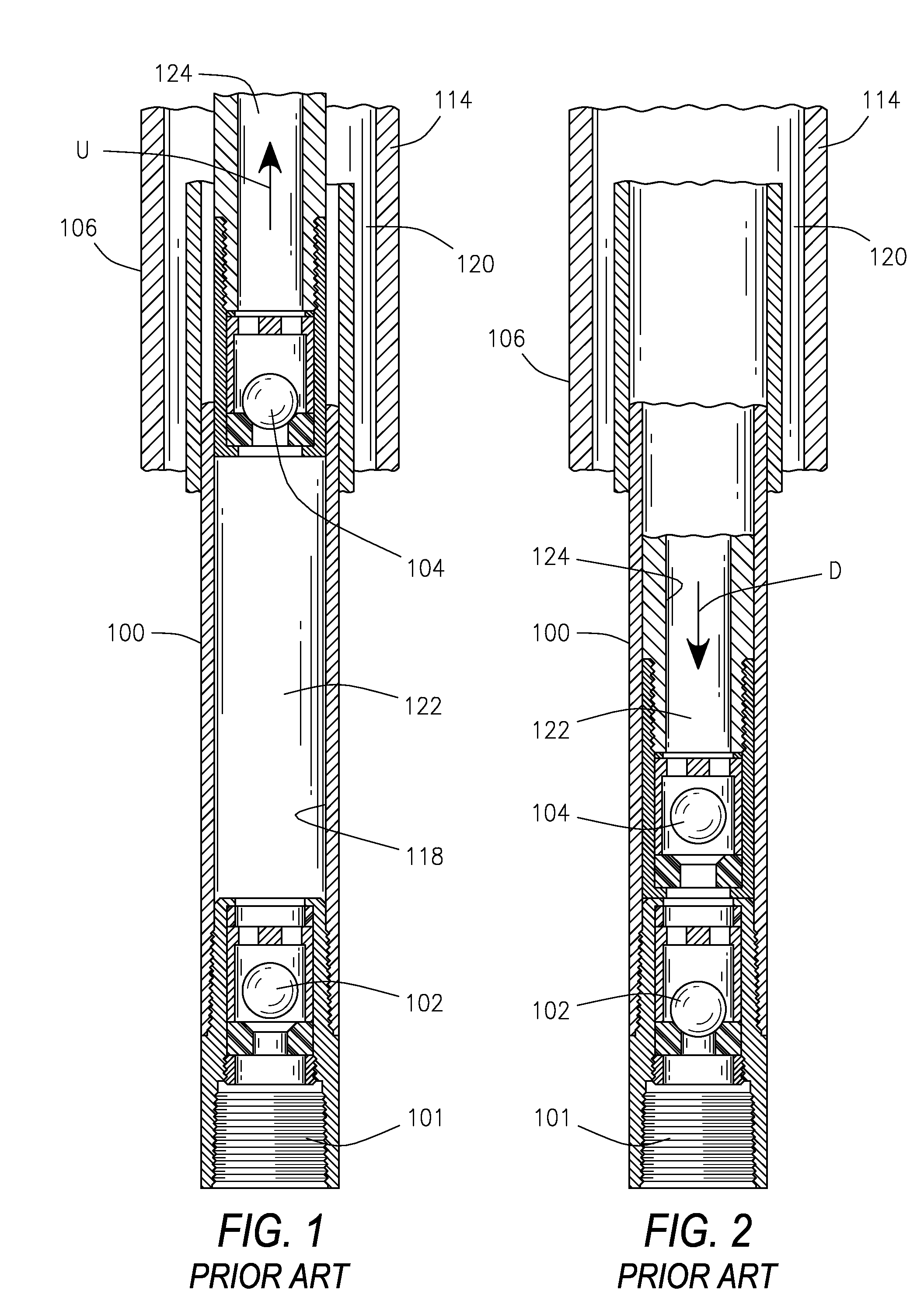

Double standing valve sucker rod pump

A sucker rod pump with no travelling valve consisting of, from the bottom: hold down with pump inlet, lower standing valve, hollow coupling, upper standing valve suspended within the coupling, relief valve, hollow pump housing, solid piston within the housing, and barrel to clean and retain the piston in the housing. The piston attaches to and reciprocating with the rod string. Peripheral channels in the relief valve communicate between the coupling and the housing. A central channel in the relief valve communicates between the upper standing valve and the pump's outlets. The upstroke pulls fluid from the bottom of the well upward through the open lower standing valve, around the closed upper standing valve and into the housing chamber. The down stroke pushes fluid from the housing chamber past the closed lower standing valve and through the open upper standing valve to the pump's exit into the tubing.

Owner:THOMPSON PUMP

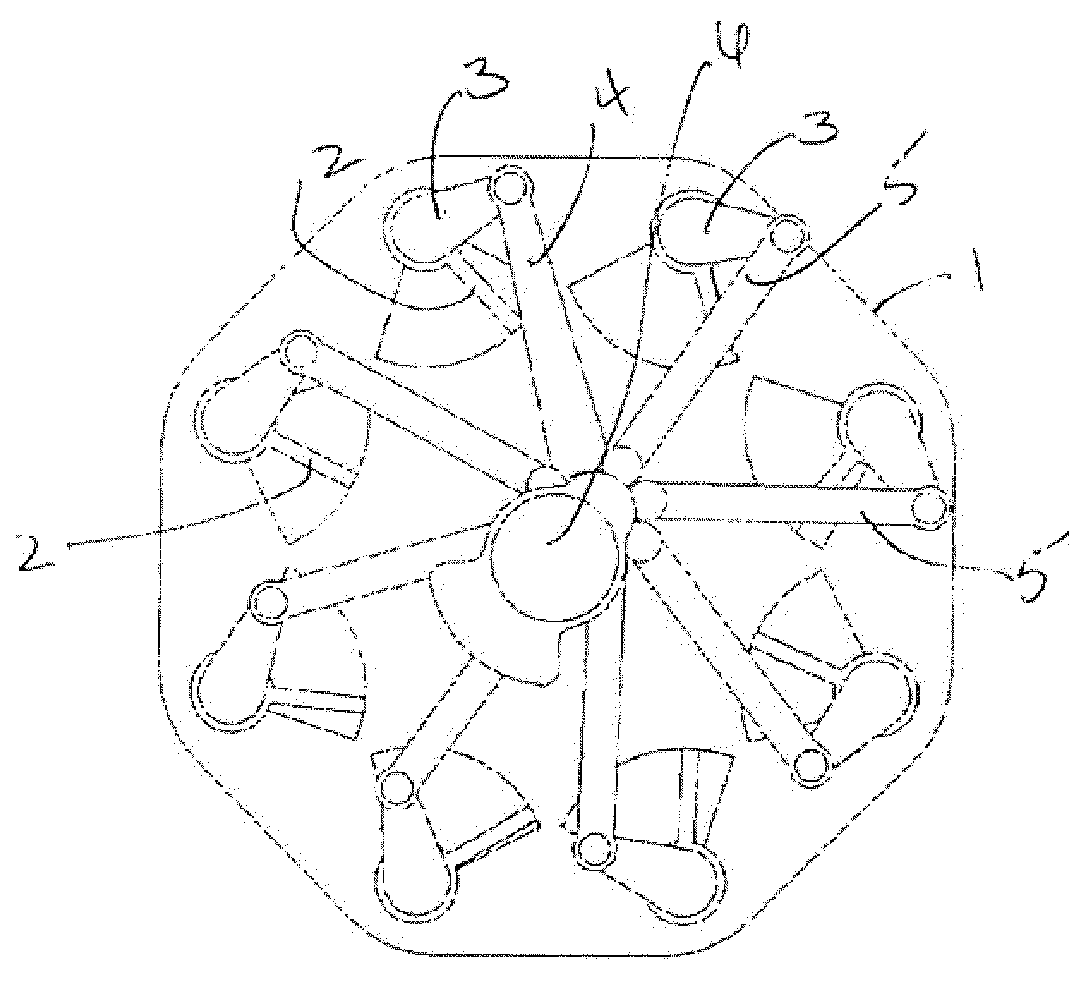

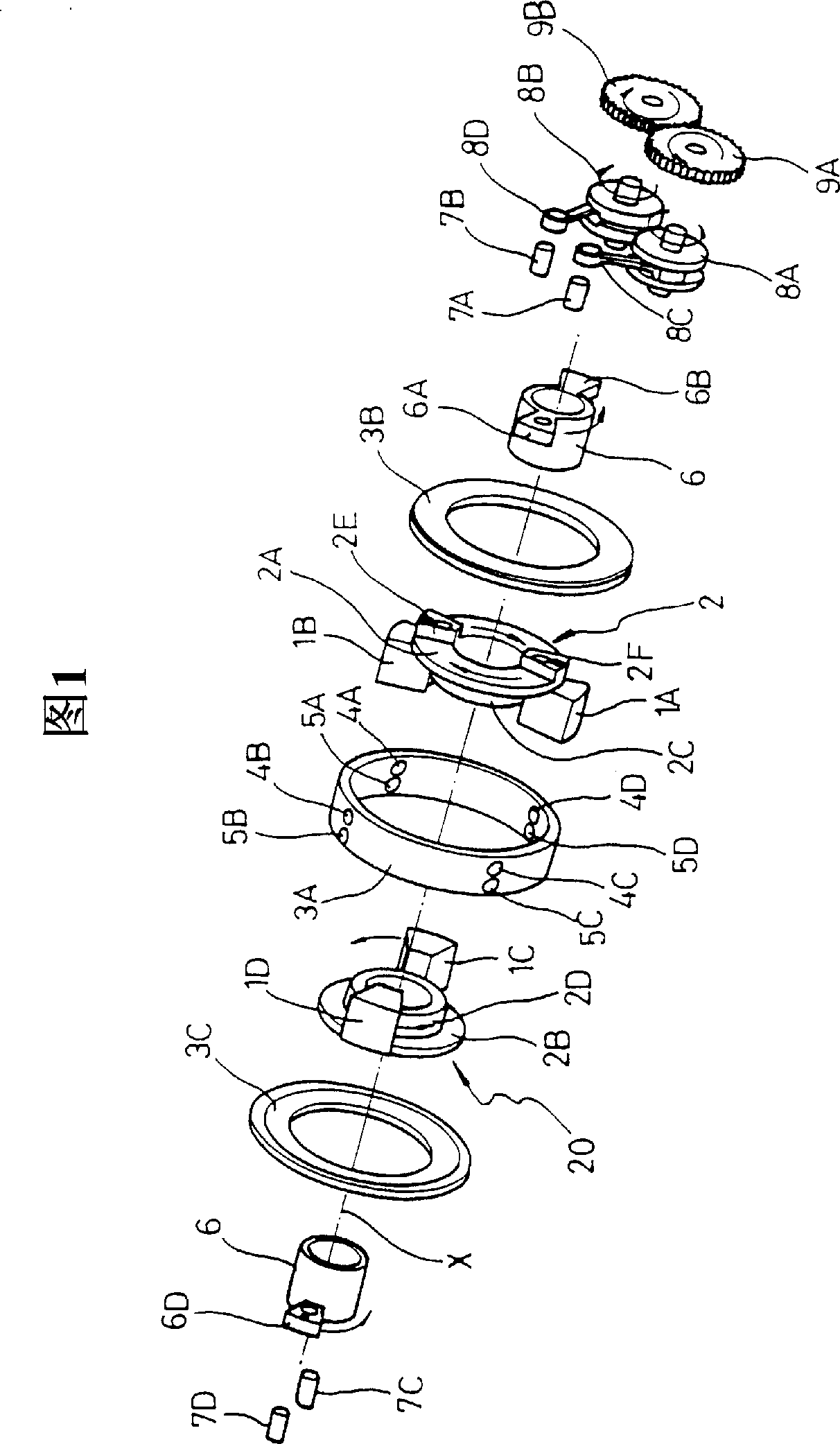

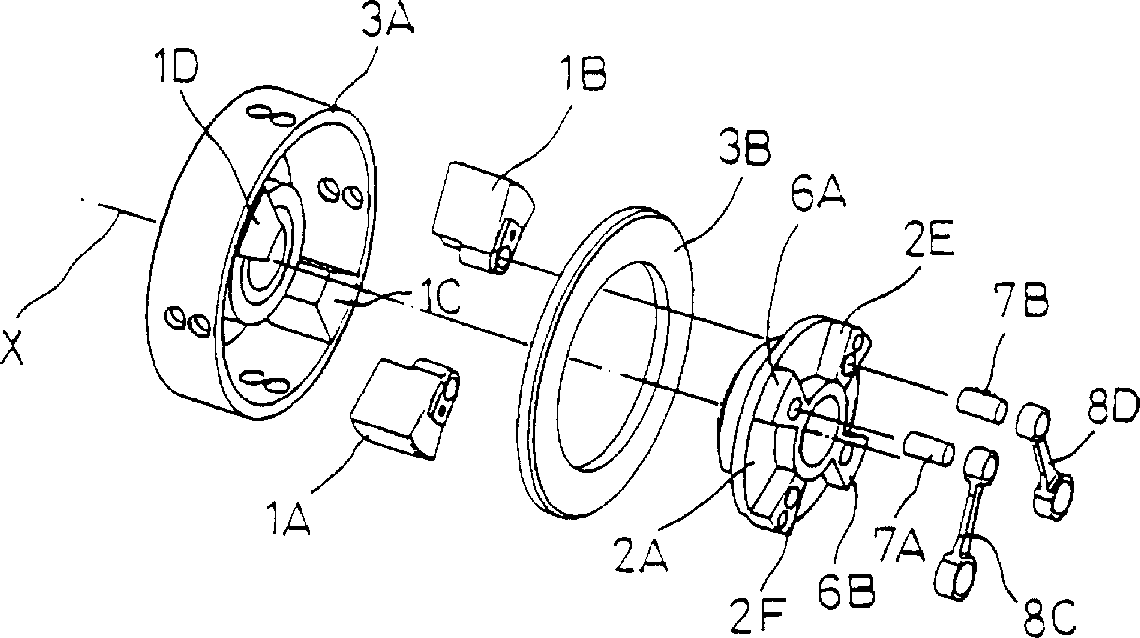

Reciprocating rotary piston system and pressure pump and IC engine using same

InactiveCN1281527AExtend your lifeReduce vibrationValve arrangementsOscillating piston pumpsExhaust valveReciprocating motion

A reciprocating rotary piston system includes a cylinder having an annular and hollow interior; a plurality of pistons (1A to 1D) of which first and second parties are formed to be disposed alternately on the same inner circumference of the cylinder, the first and second parties of the pistons reciprocating along a given arc at the same speed and in the opposite direction with respect to each other; a plurality of intake valves (4A to 4D) mounted at each point of the cylinder where the two adjacent pistons meet for controlling flow of a fluid introduced thereinto from the outside; and a plurality of exhaust valves (5A to 5D) mounted at each point of the cylinder where the two adjacent pistons meet for controlling flow of a fluid forced out from the inside. The piston system is used for a hydraulic / pneumatic pump, a vacuum pump and an internal combustion engine.

Owner:金昌钧 +1

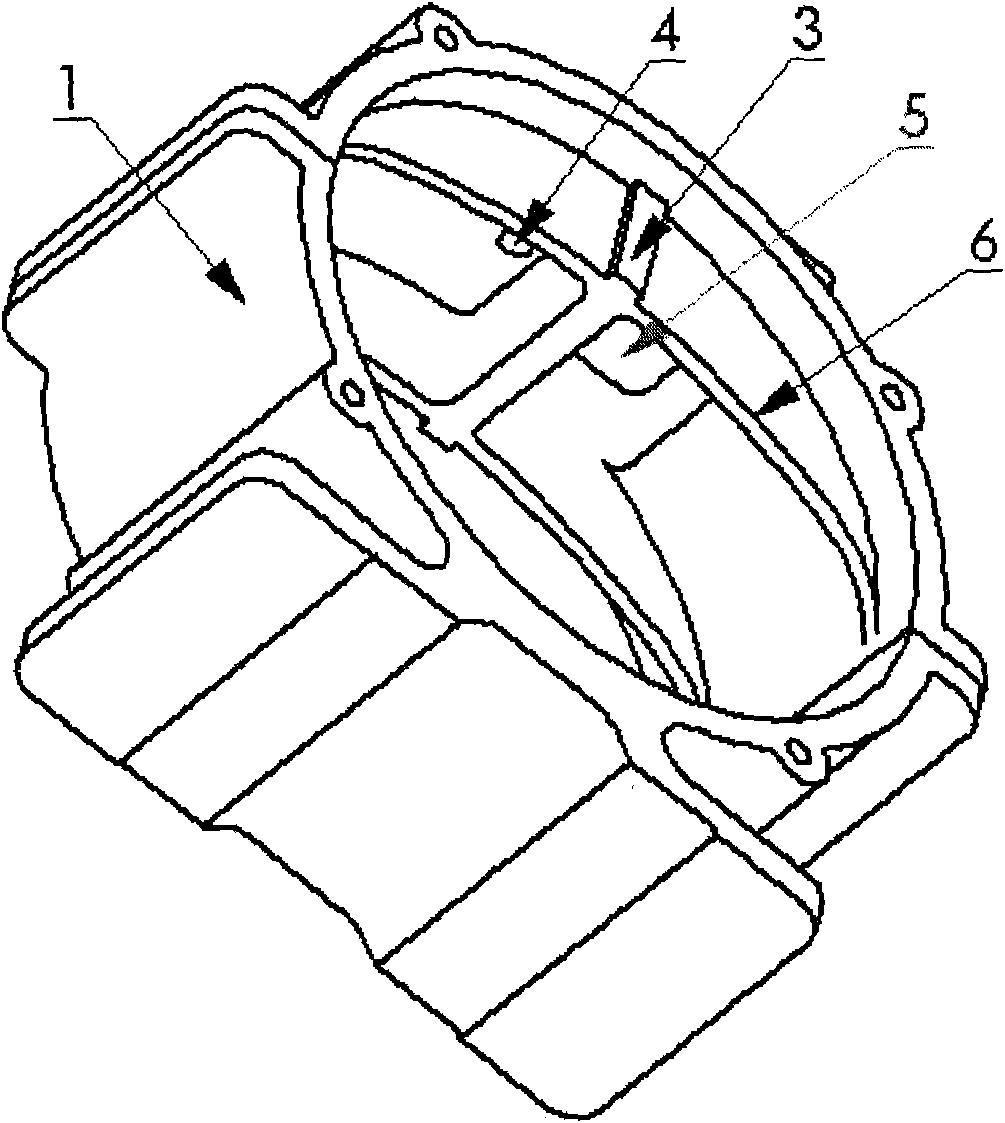

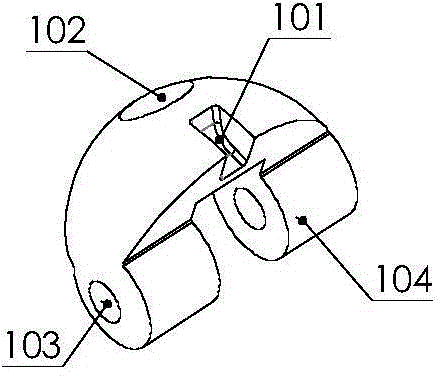

Spherical compressor

ActiveCN105756932ASimple structureReduce machining accuracyOscillating piston pumpsOscillating piston liquid enginesVolume variationCylinder block

The invention discloses a spherical compressor.A cylinder body (2) and a cylinder cover (1) are combined to form a spherical inner cavity, and a slide groove swing mechanism is arranged between a piston shaft (301) and a piston shaft hole (105) or between a rotating plate shaft (501) and a rotating plate shaft hole (201).The rotating plate shaft (501) is driven to rotate to enable a piston (3) to swing relative to the axis of the piston shaft hole (105) along a slide groove of the slide groove swing mechanism between the piston shaft (301) and the piston shaft hole (105) or swing relative to the axis of the rotating plate shaft hole (201) along a slide groove of the slide groove swing mechanism between the rotating plate shaft (501) and the rotating plate shaft hole (201), and consequently an operation chamber V1 (1001) and an operation chamber V2 (1002) in alternate volume variation are formed in the spherical inner cavity.The spherical compressor has the advantages of small quantity of parts, freeness of dead points in mechanism movement and high operation efficiency.

Owner:深圳市球形动力科技有限公司

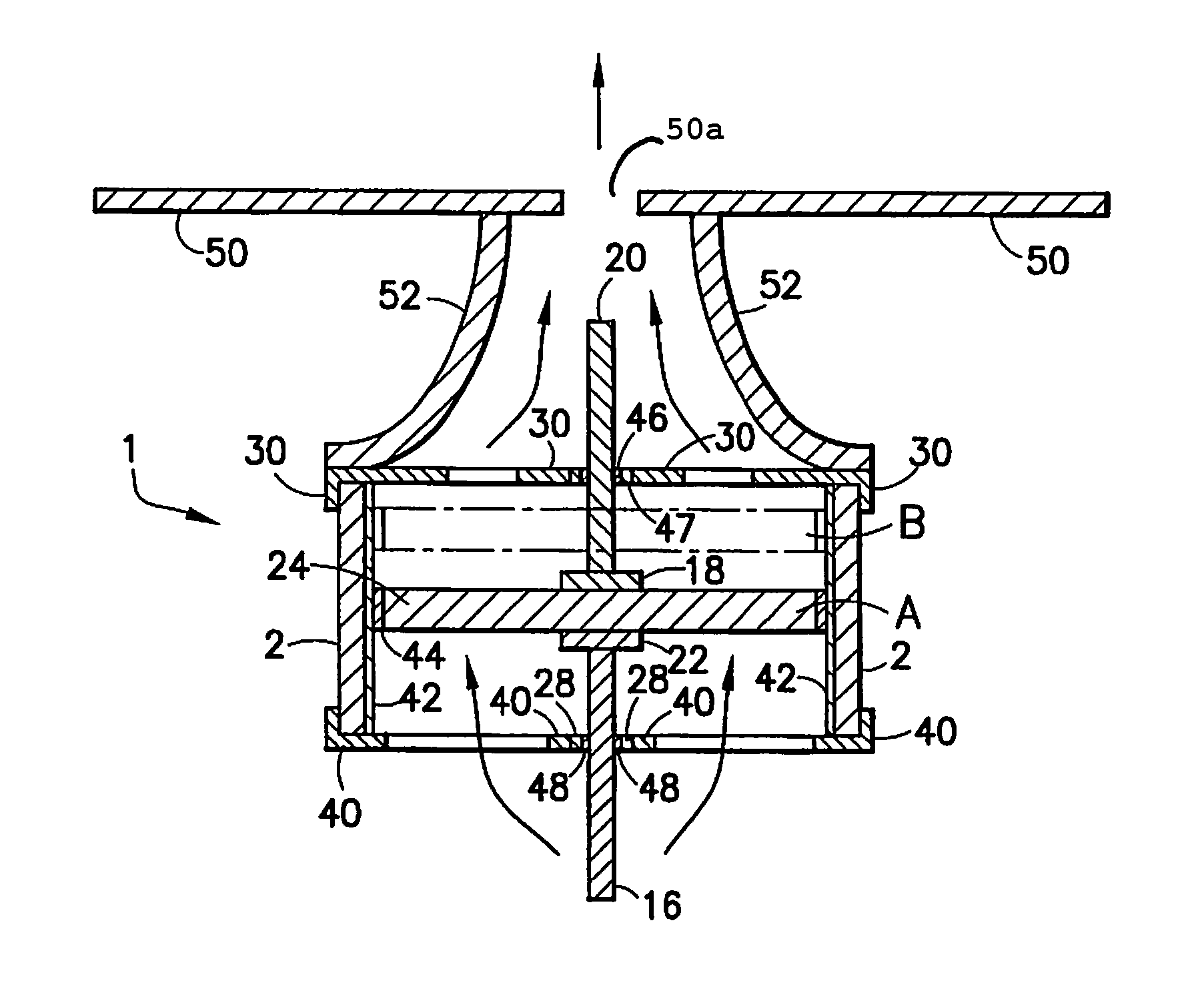

Heating pump for liquids

ActiveUS20100272582A1Fast heatingFast transferOscillating piston pumpsPositive displacement pump componentsInlet valveEngineering

Liquid pump comprising:a cylinder (2);an inlet valve (4) for feeding the liquid into the cylinder;a discharge valve (5) for discharging the liquid out of the cylinder;a piston (3) sliding in said cylinder so as to draw said liquid into said cylinder and to expel the same outside the cylinder;an electric circuit (7) for heating the cylinder, with at least one resistor (70, 71) for electrically heating the liquid in the cylinder.The resistor (70, 71) is made in the form of an electrically conducting thin track deposited on or in the wall (20) of the cylinder (2). The heating is initiated before the introduction of the liquid into the cylinder, and interrupted before the full discharge of the liquid out of the cylinder.

Owner:GOTEC

Ultra-low friction air pump for creating oscillatory or pulsed jets

InactiveUS7980516B2Improve performanceSmall sizeOscillating piston pumpsPositive displacement pump componentsFluid controlEngineering

An air pump positioned within a hollow space in an aerodynamic structure for controlling the flow over an aerodynamic surface thereof, includes a movable member linearly displaced by a very low friction piston mechanism and a compression chamber open to the exterior of the aerodynamic surface through an orifice. Reciprocal displacement of the very low friction movable member changes the volume of the compression chamber to alternately expel fluid (e.g., air) from and pull fluid into the compression chamber through the orifice. The movable member includes a piston oscillating within a piston housing each having an ultra-low friction coating for improved thermal performance and reduced maintenance. Fluid intake to the compression chamber may be increased through the use of a one-way valve located either in the aerodynamic surface, or in the piston. Multiple flapper valves may surround the orifice in the aerodynamic surface for increased fluid control.

Owner:THE BOEING CO

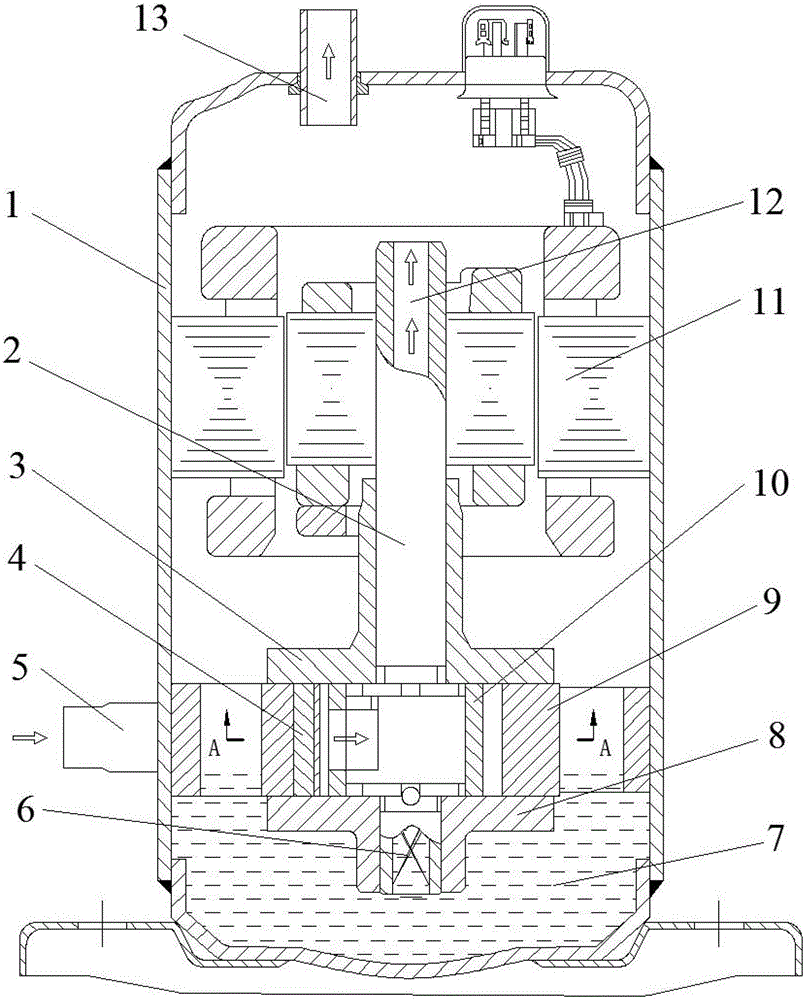

Butt clamp swing tray piston swing driver

ActiveCN104912600AImprove sealing propertiesExtend your lifeOscillating piston pumpsOscillating piston liquid enginesForce generationCrusher

The invention relates to a butt clamp swing tray piston swing driver; the angular travel swing thereof is in a range of 0-330 degrees, or is continuous one-way rotation; the butt clamp swing tray piston swing driver is specifically suitable for such angular travel type valves as a ball valve, or replaces a motor to drive such revolving machines as a crusher, and is also suitable for pumping a fluid; and the fluid of a pressure feed piston of the driver driving a mechanical load to work or the fluid of mechanically driving a piston pressure feed load to work can be gas or liquid. The driver comprises a butt clamp swing tray piston swing actuation device, a fluid intake / drain channel system, a cooling system and a driving force generation system; a gas channel of the fluid intake / drain channel system is communicated with a working cavity; the cooling system is a forced cooling and / or natural cooling mechanism; the driving force generation system is a system of the fluid pressure driving the piston to act on the mechanical load or a system of mechanically driving the piston to act on the fluid load; and the butt clamp swing tray piston swing actuation device comprises trays of k not fewer than 3, a piston piece, a connecting mechanism, a power intake / discharge bonding structure, a lubricating system and a sealing structure.

Owner:桐乡市诺客信息科技有限公司

Rotating compressor low in exhaust oil content

ActiveCN105889069AImprove reliabilityStable oil quantityOscillating piston pumpsOscillating piston liquid enginesEngineeringCentrifugal force

A rotating compressor low in exhaust oil content comprises a shell, a crankshaft, an upper end cover, a guide rail, a lower end cover, a cylinder, a swing rotor and a motor. The crankshaft comprises a main shaft, an eccentric wheel and an auxiliary shaft. The eccentric wheel is sleeved with the swing rotor. A gas inlet hole is formed in the cylinder. The swing rotor is provided with an exhaust hole. An axial gas way is formed in the center of the main shaft. An axial oil way is formed in the center of the auxiliary shaft. An exhaust cavity and an oil return groove are formed in the eccentric wheel. The exhaust cavity communicates with the axial gas way. One end of the oil return groove communicates with the exhaust cavity. The other end of the oil return groove communicates with an upper oil cavity jointly formed by the upper end cover, the swing rotor and the crankshaft. According to the compressor, compressed gas enters the exhaust cavity through the exhaust hole, and oil and gas separation is performed under the effect of the centrifugal force. Separated lubricating oil returns to an oil pond in the shell, and separated gas enters the shell through the axial gas way and then is discharged. The compressor is high in system energy efficiency and good in reliability and speed changing characteristic.

Owner:GUANGXI UNIV

Evacuation apparatus

InactiveUS20100209259A1Prevent overloadAvoid small quantitiesRotary/oscillating piston combinations for elastic fluidsOscillating piston pumpsEngineeringVacuum chamber

Owner:EBARA CORP

Press-Fit Bearing Housing With Large Gas Passages

ActiveUS20130251573A1Rotary/oscillating piston combinations for elastic fluidsOscillating piston pumpsDrive shaftEngineering

A scroll compressor that includes a housing and scroll compressor bodies disposed in the housing. A motor is disposed within the housing and operably connected to a drive shaft for driving one of the scroll compressor bodies. The drive shaft is rotationally supported at one end by a crankcase which includes a bearing housing and a bearing. The crankcase includes a plurality of openings or gas passages passing through the crankcase, as well as a plurality of generally cylindrical sections positioned respectively between adjacent openings. The cylindrical sections define contact regions which can engage an inner periphery of the housing when the crankcase is mounted therein.

Owner:BITZER KUEHLMASCHINENBAU GMBH

Tray piston type swing driving machine capable of mechanically driving a piston to act on fluid load

ActiveCN104847952AExtend your lifeReduce machining accuracyOperating means/releasing devices for valvesOscillating piston pumpsForce generationEngineering

The invention relates to a tray piston type swing driving mechanism capable of mechanically driving a piston to act on a fluid load. The angular stroke swing range of the machine is from 0 degree to 330 degrees or continuous rotate in a single-way manner, and the machine is particularly suitable for pumping fluid. The fluid of the driving machine pressure feeding piston driving machine load work or the fluid of mechanical driving piston pressure feeding load work can be gas or liquid. The driving machine comprises a tray piston type swing execution device, a fluid inlet and draining channel system, a cooling system and a driving force generation system. The fluid inlet and exhaust channel system comprises a fluid channel, a pipe opening and a valve, and the fluid channel is communicated with a working cavity; the cooling system carries out forced cooling and / or natural heat dissipation on an element of the driving machine; the driving force generation system is a system capable of enabling the mechanical driving piston to act on the fluid load; and the tray piston type swing execution device comprises two trays, a piston piece, a connecting mechanism, a power inlet and outlet bonding structure, a lubricating system and a sealing structure.

Owner:桐乡市中元建材科技有限公司

Oscillating piston machine

InactiveUS7563086B2Reduce frictionMore compactOscillating piston pumpsInternal combustion piston enginesEngineeringPiston

Owner:HUTTLIN HERBERT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com