Automatical compensation mechanism for sealing clearance of hinges used for spherical compressor

A spherical compressor and automatic compensation technology, which is applied to the sealing device of the engine, the sealing device of the machine/engine, and the piston pump, etc., can solve the problems of increased mechanical friction, poor force bearing capacity, and affecting sealing efficiency, etc. Effects of Manufacturing Difficulty and Manufacturing Cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

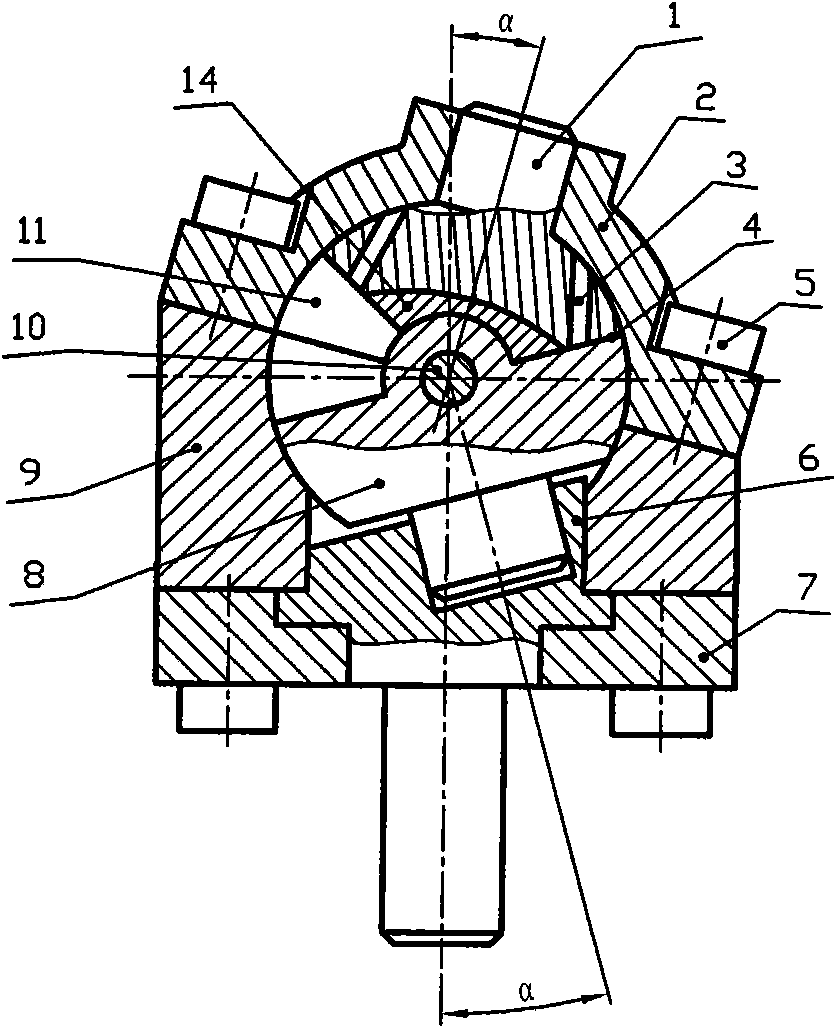

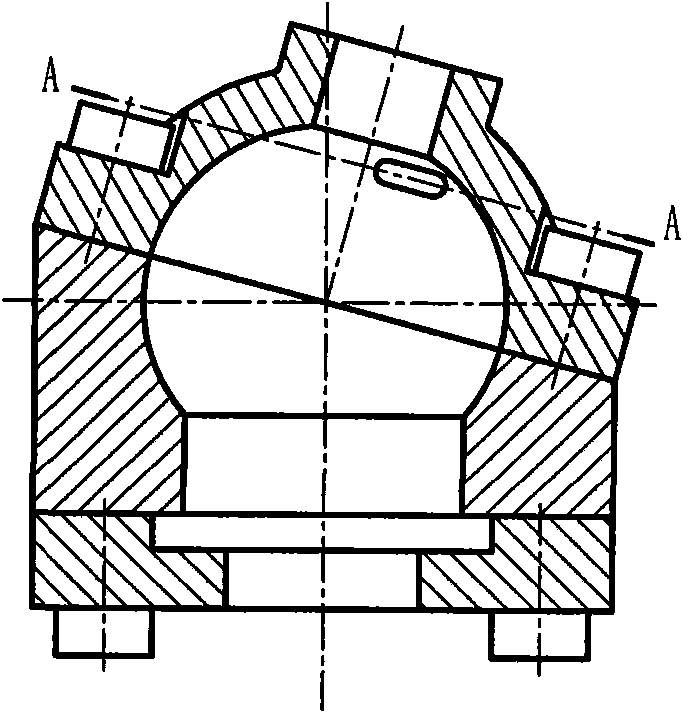

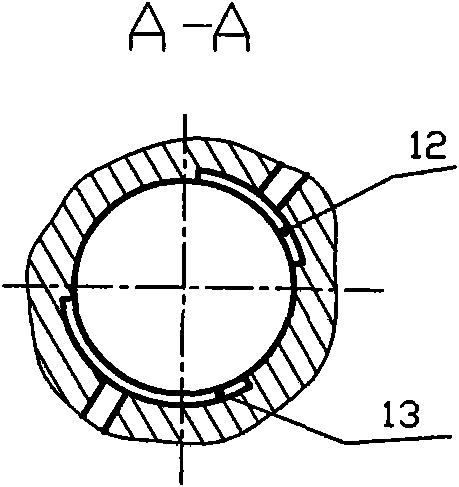

[0031] figure 1 It is a structural sectional view of an embodiment of a spherical compressor of the present invention, the spherical compressor includes a cylinder 9, a cylinder head 2, a piston 1, an insert 14, a turntable 8, a main shaft 6, a main shaft support 7 and a central pin 10, and the cylinder 9 It is connected with the cylinder head 2 through the connecting screw 5 to form a spherical inner cavity; as Figure 9 , Figure 10 As shown, the piston 1 has a spherical top surface, a piston shaft extending from the center of the spherical top surface, two side surfaces at a certain angle, an air passage 3 and a piston pin seat formed at the lower part of the two sides of the piston 1, the piston pin seat is half Cylindrical structure, with a groove in the middle of the semi-cylindrical, and a through pin hole in the axial direction; the cylinder head 2 is provided with a shaft hole matching the piston shaft, and the piston 1 can rotate freely in the shaft hole around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com