Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2639results about "Sealing arrangement for pumps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

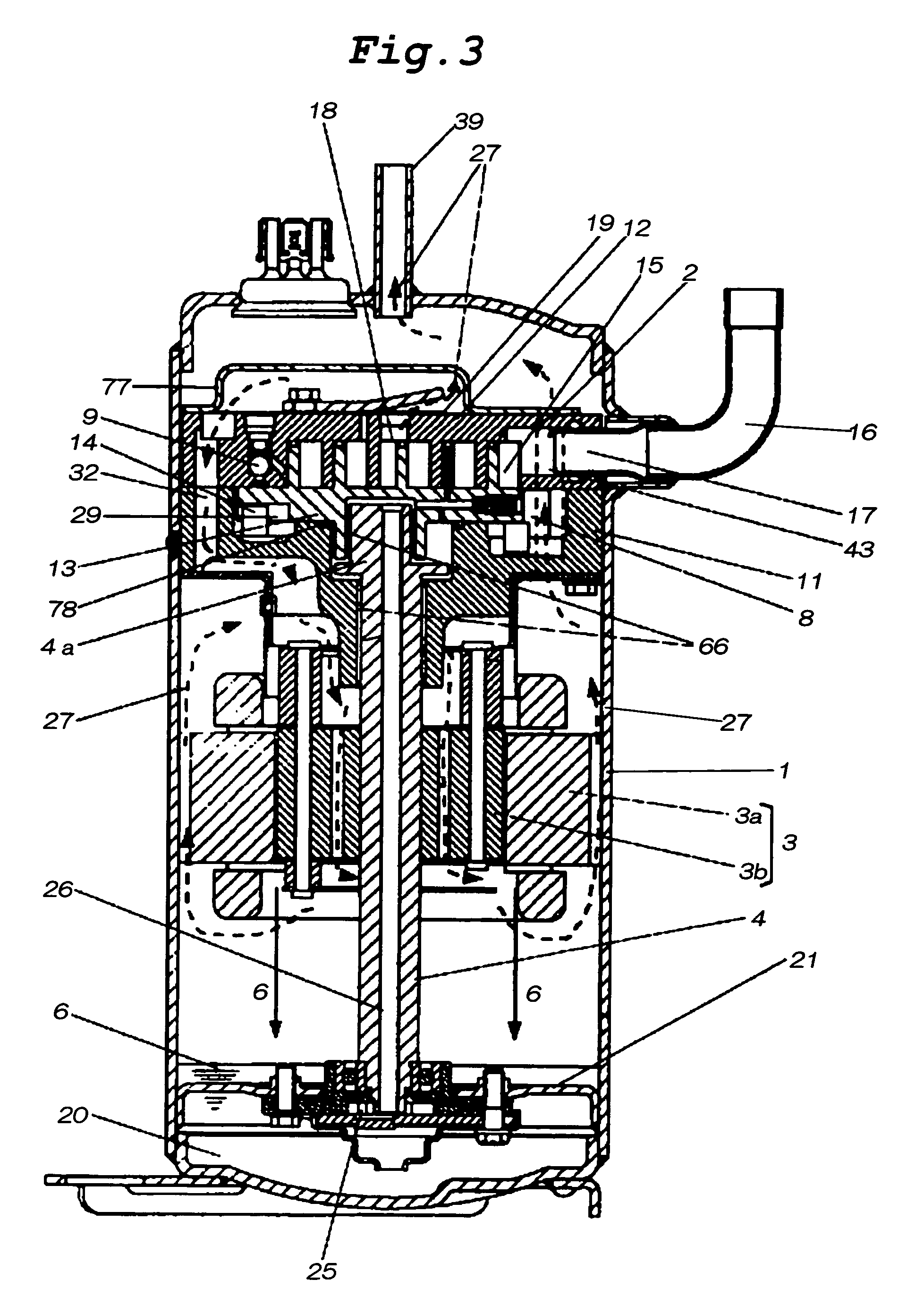

Compressor

ActiveUS6960070B2Easy to fixPrecise alignmentRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeDrive shaftEngineering

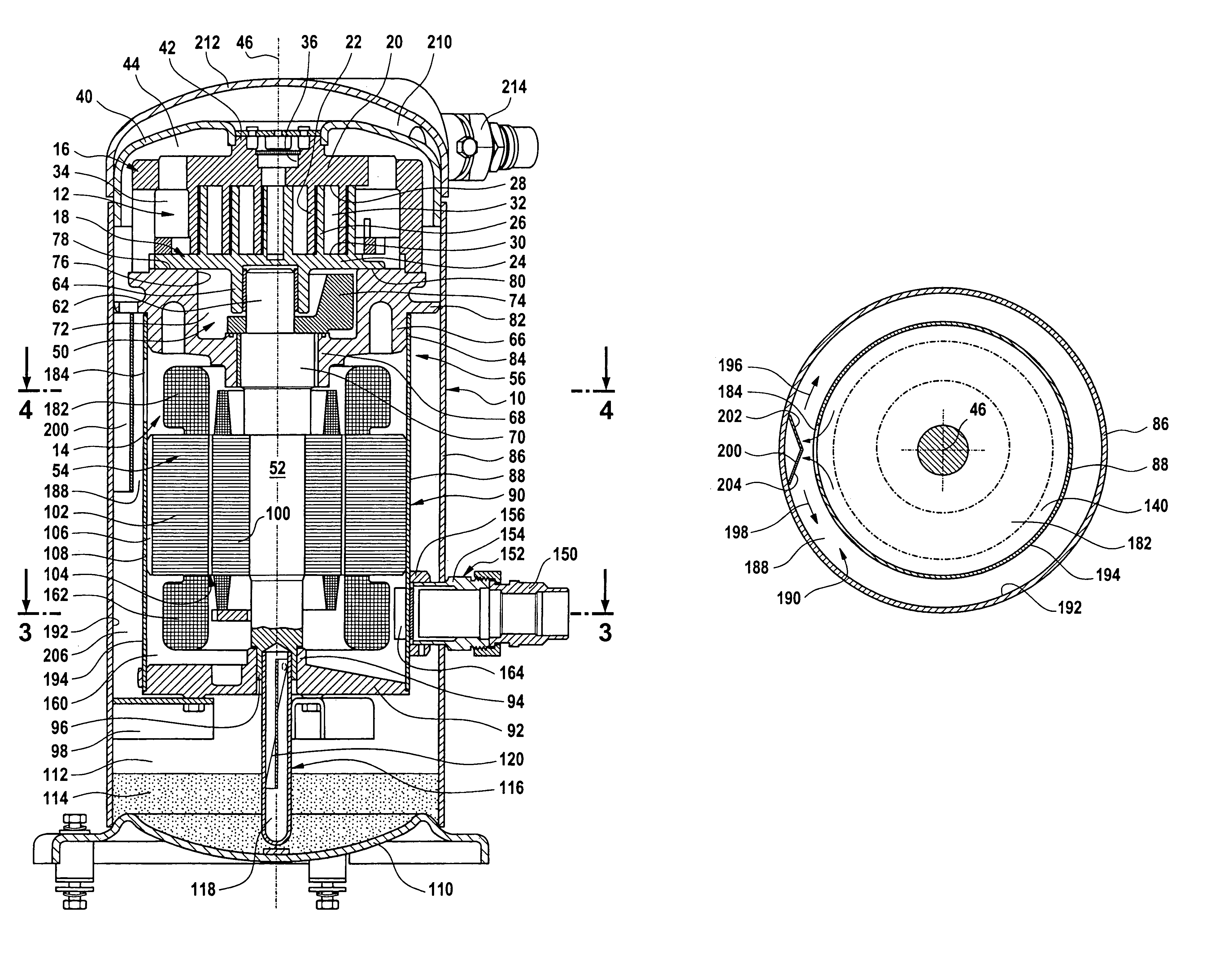

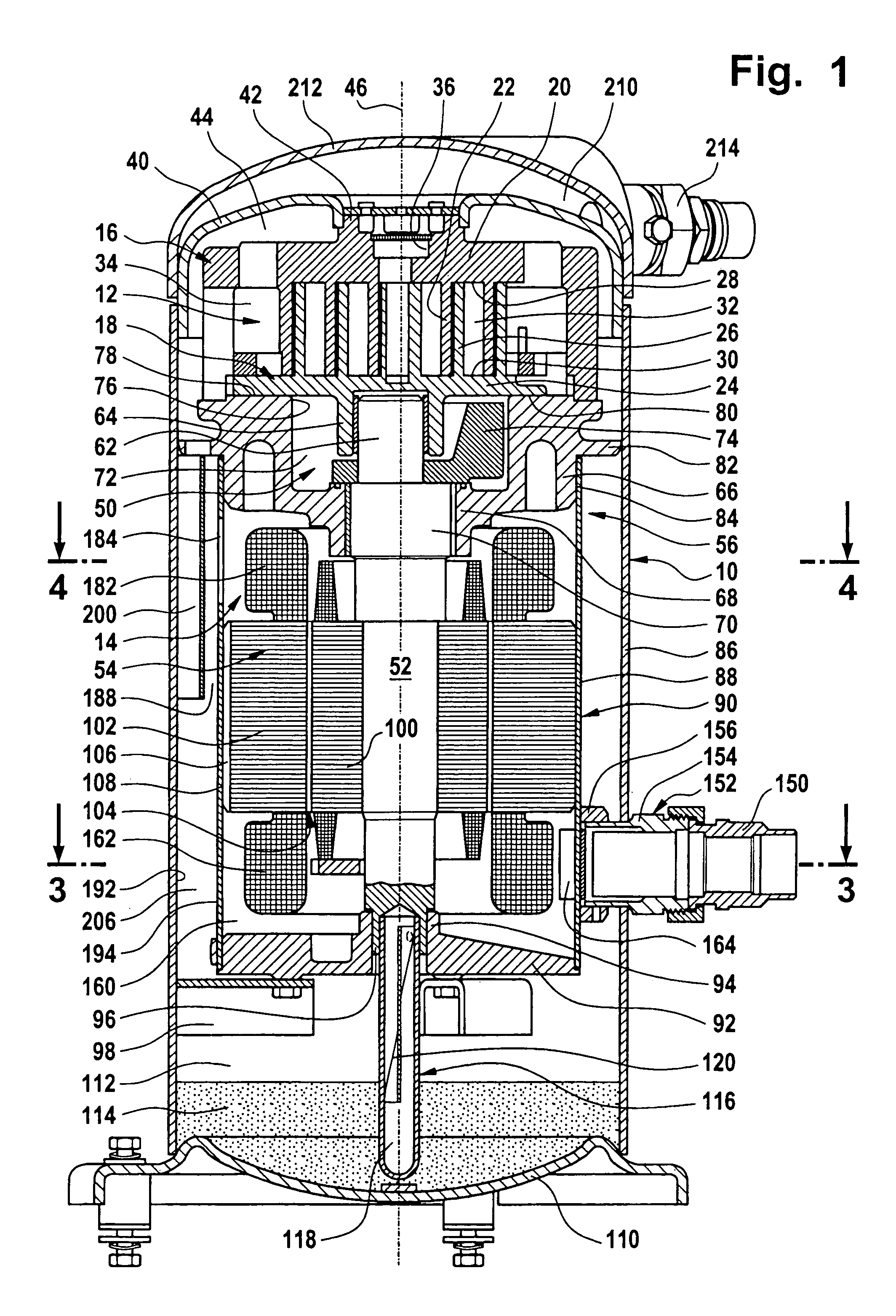

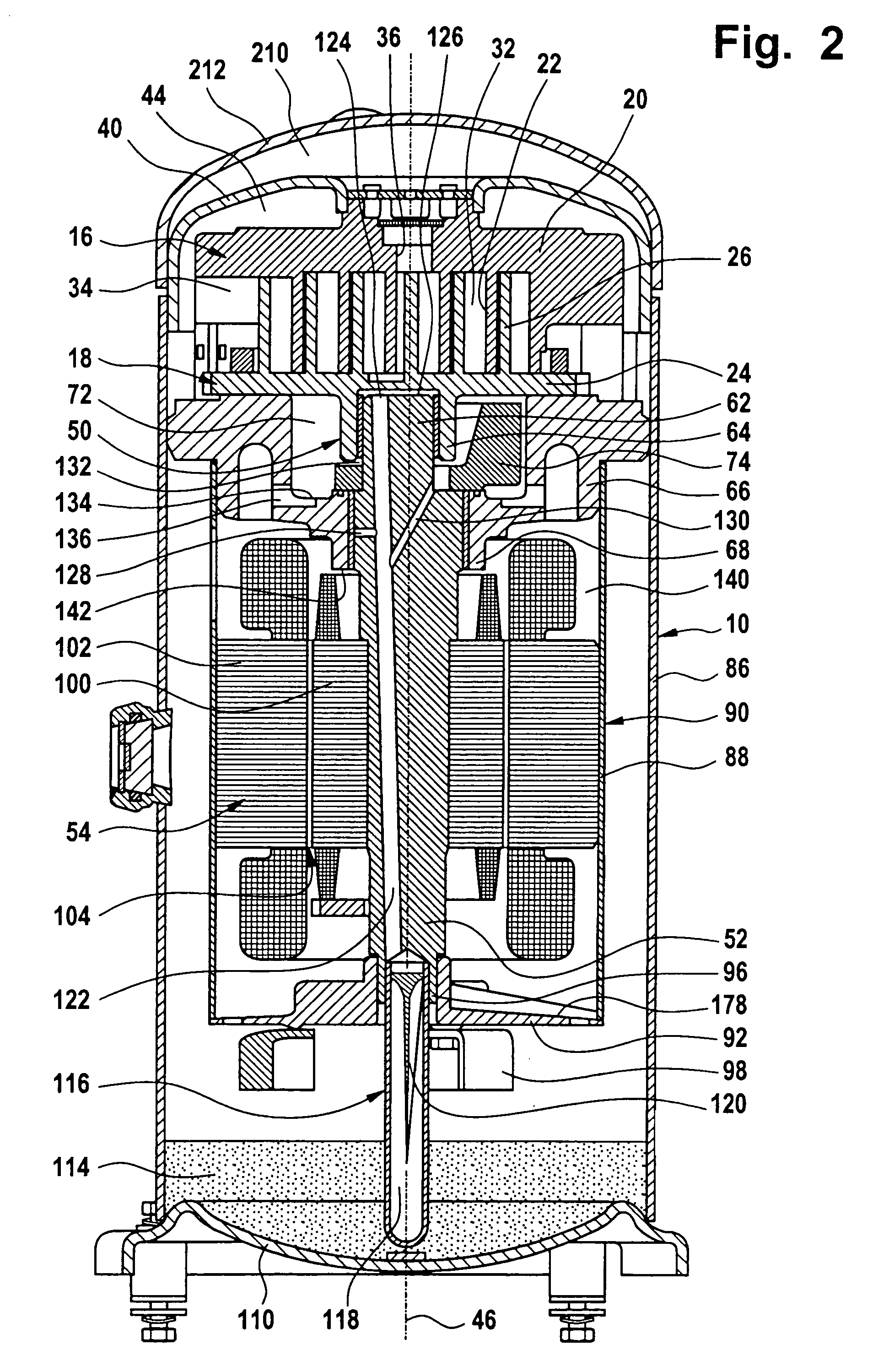

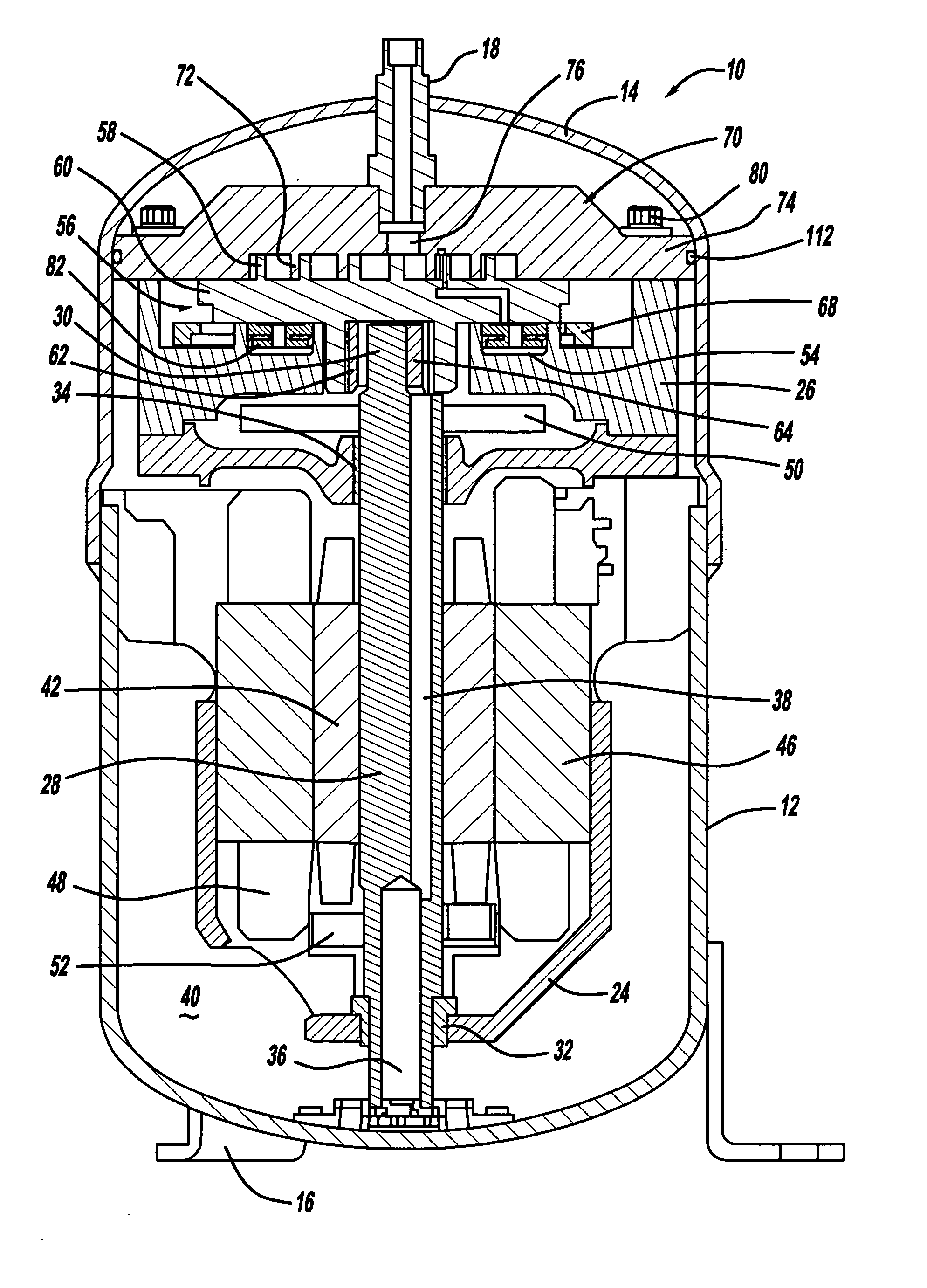

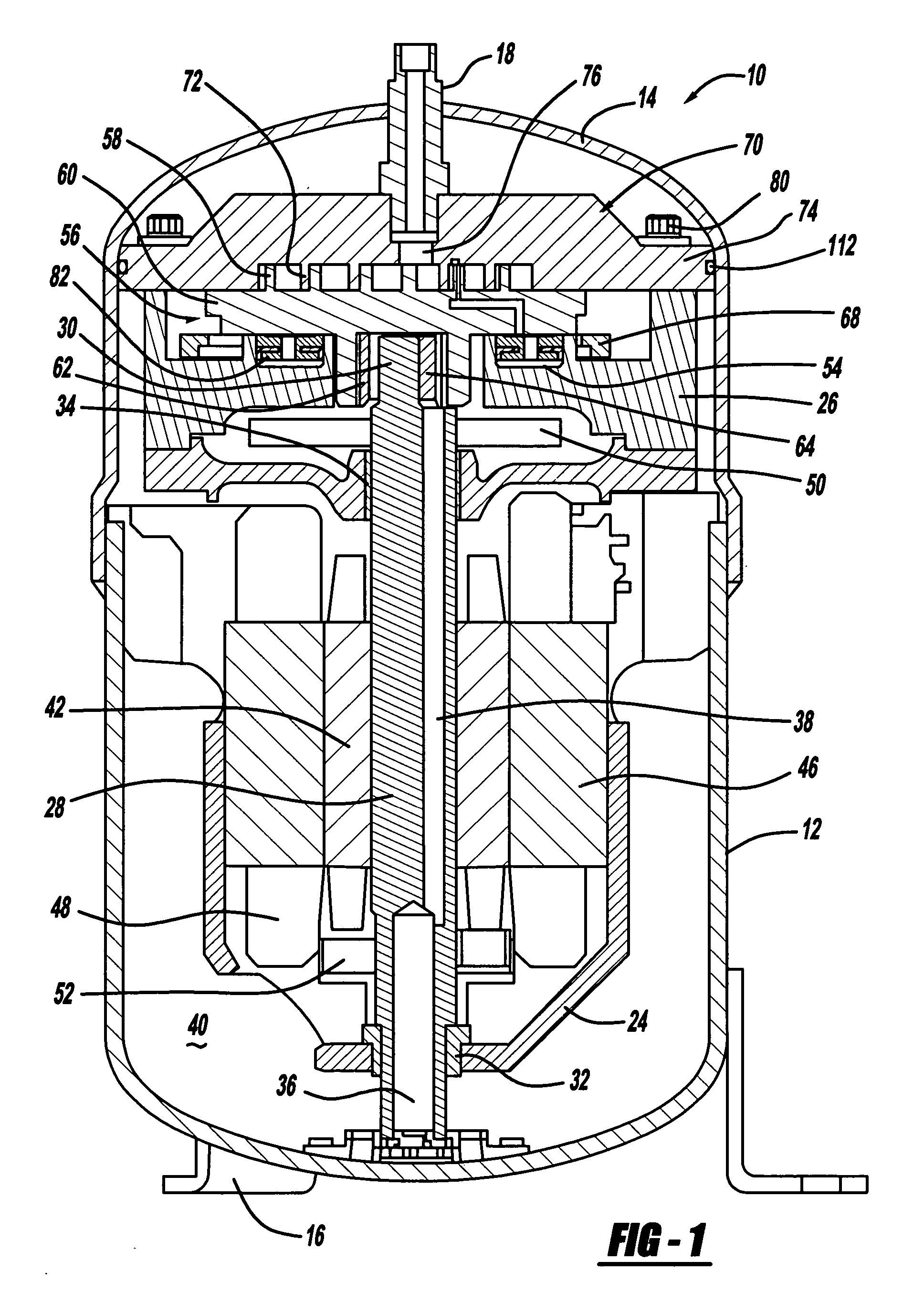

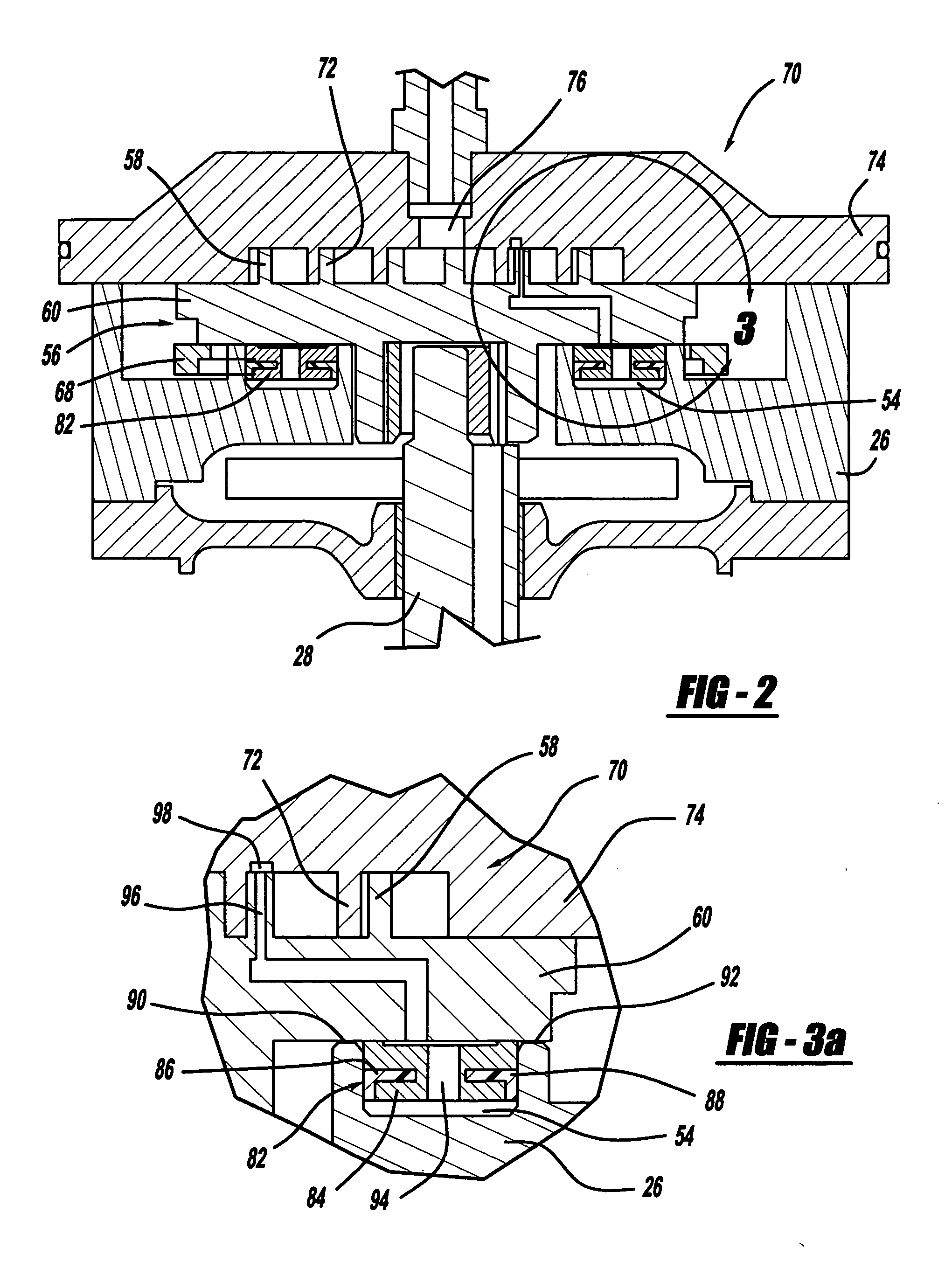

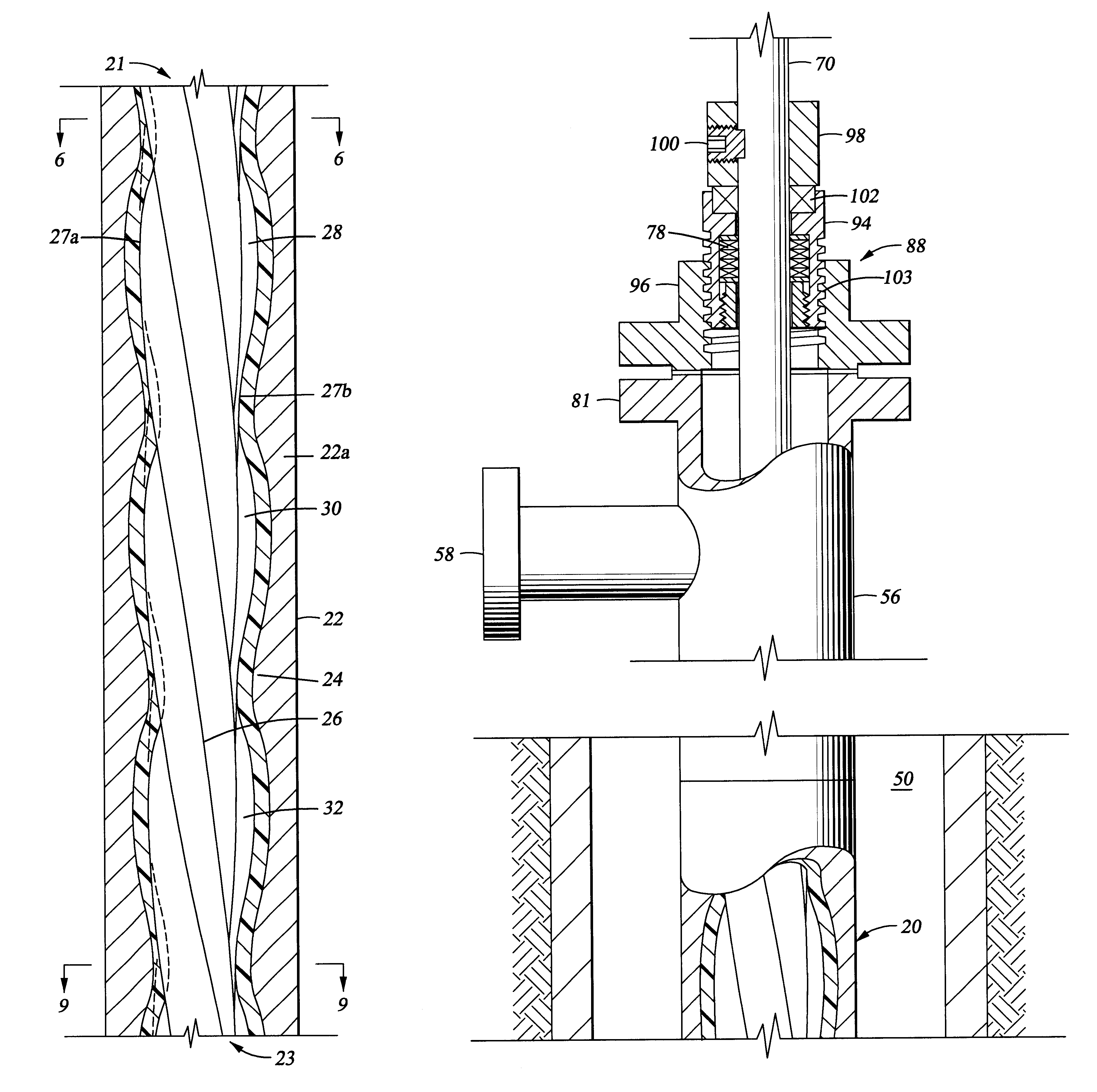

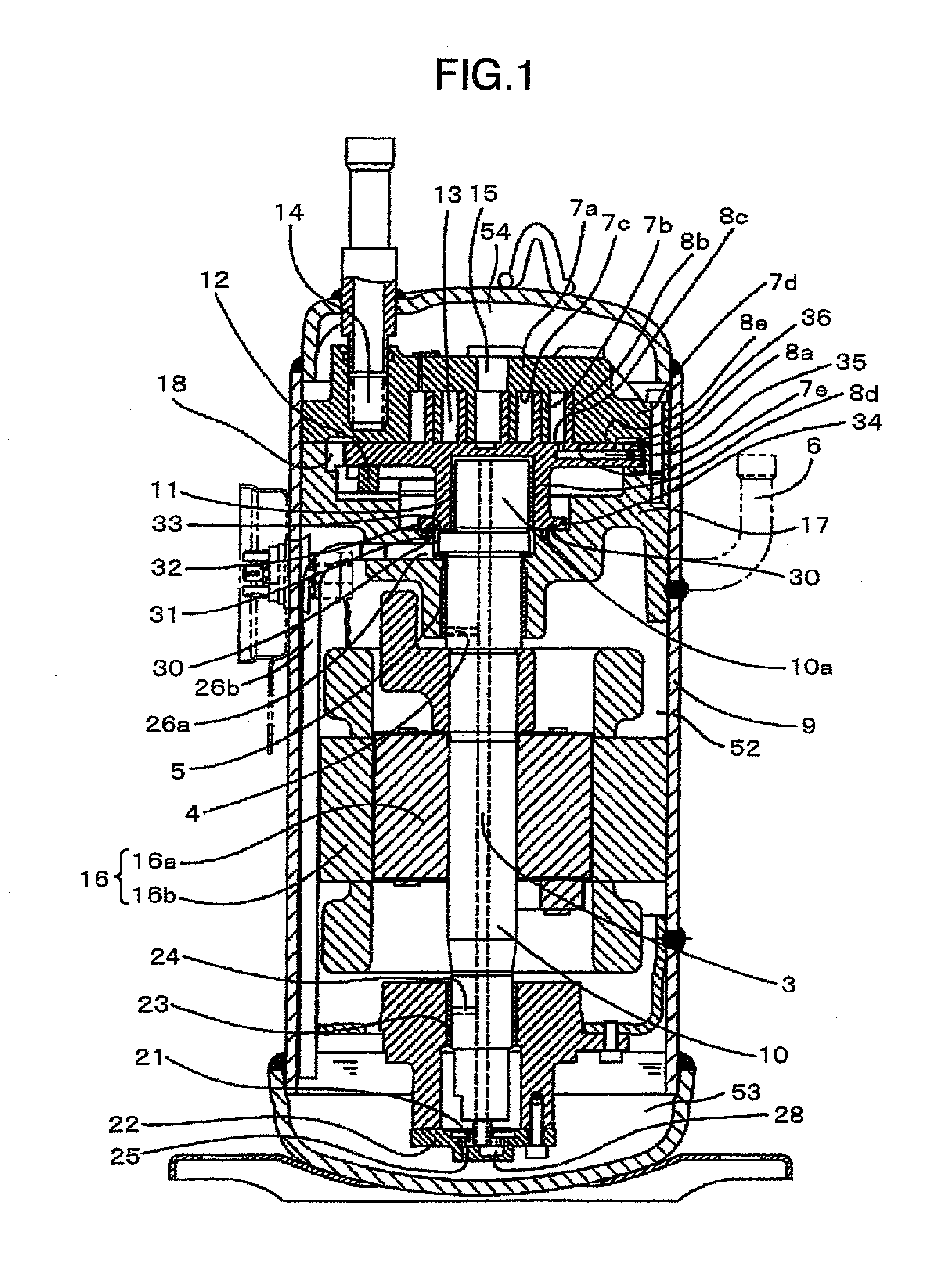

In order to improve a compressor for refrigerant, comprising an outer housing, a scroll compressor arranged in the outer housing and having a first compressor member arranged stationarily in the outer housing and a second compressor member which is movable relative to the first compressor member, the compressor members each having a base and first and second scroll ribs, respectively, which rise above the respective base and engage in one another such that the second compressor member is movable relative to the first compressor member on an orbital path about a central axis for the purpose of compressing the refrigerant, a drive unit for the second compressor member having an eccentric drive, a drive shaft, a drive motor arranged in a motor housing and having drawn-in refrigerant flowing around it as well as a bearing unit for the drive shaft which comprises a first bearing member connected to the outer housing, in such a manner that the refrigerant drawn in by the scroll compressor is free from lubricating oil to as great an extent as possible it is suggested that the refrigerant flow through an oil separator, which is arranged in the outer housing between this and the drive unit, after flowing around the drive motor and prior to entering the scroll compressor.

Owner:BITZER KUEHLMASCHINENBAU GMBH

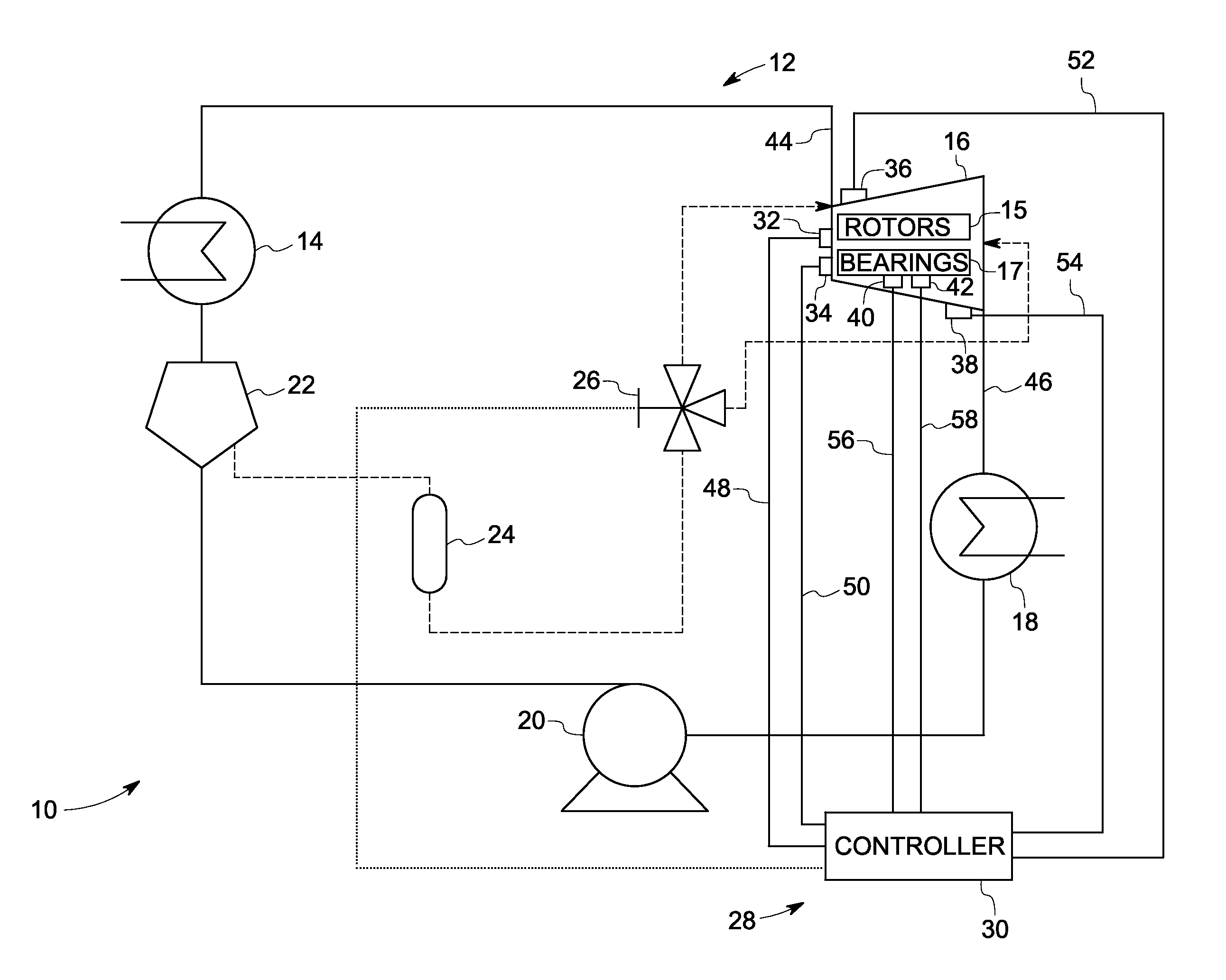

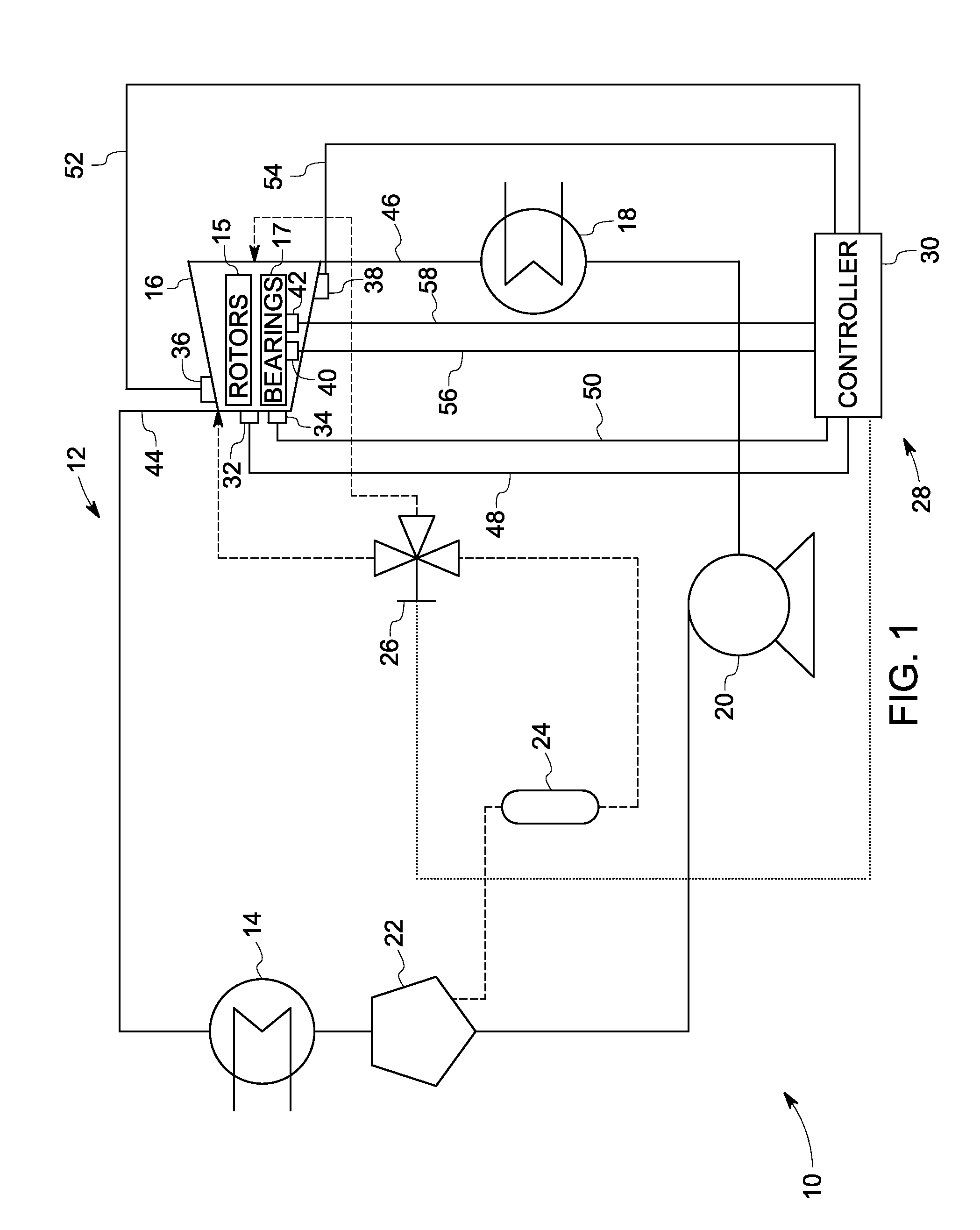

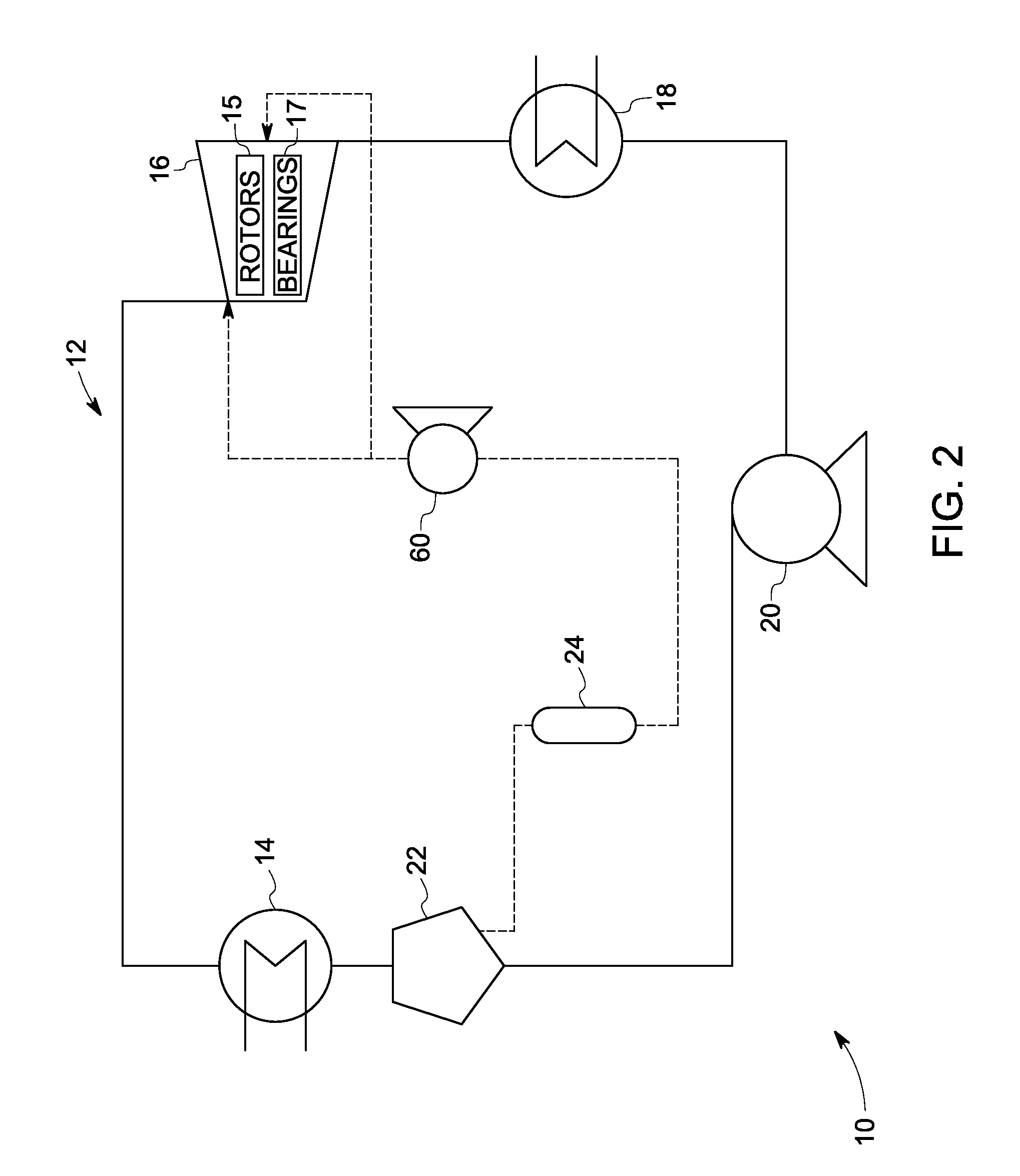

Method for lubricating screw expanders and system for controlling lubrication

A method for lubricating a screw expander includes condensing a mixture of working fluid and lubricant fed from the screw expander, through a condenser. At least a portion of the mixture of working fluid and lubricant fed from the condenser is pressurized from a first pressure to a second pressure through a pump. The method also includes separating the lubricant from the condensed working fluid of the at least portion of the mixture via a separator and feeding the lubricant to the screw expander; or separating the lubricant from the working fluid of the at least portion of the mixture via an evaporator and feeding the lubricant to the screw expander; or feeding the at least portion of the mixture of condensed working fluid and lubricant to the screw expander; or combinations thereof.

Owner:GENERAL ELECTRIC CO

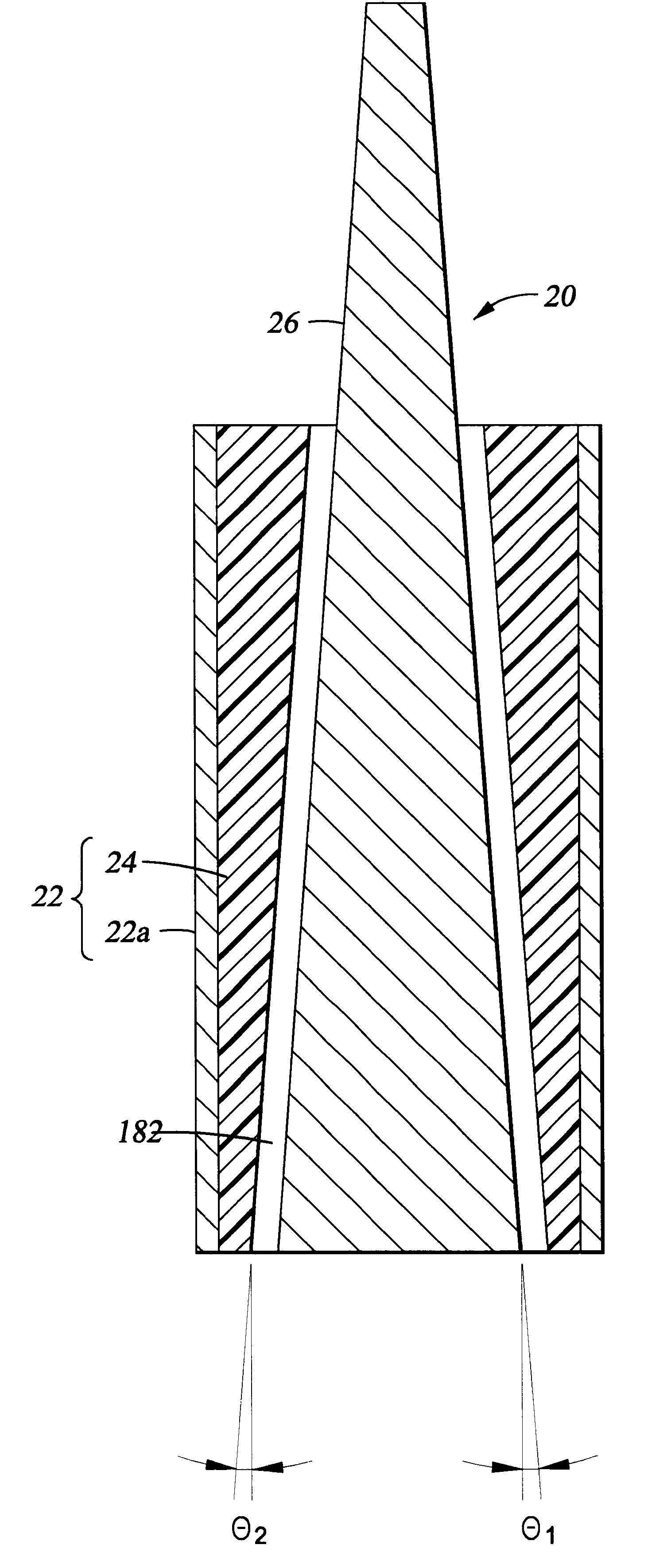

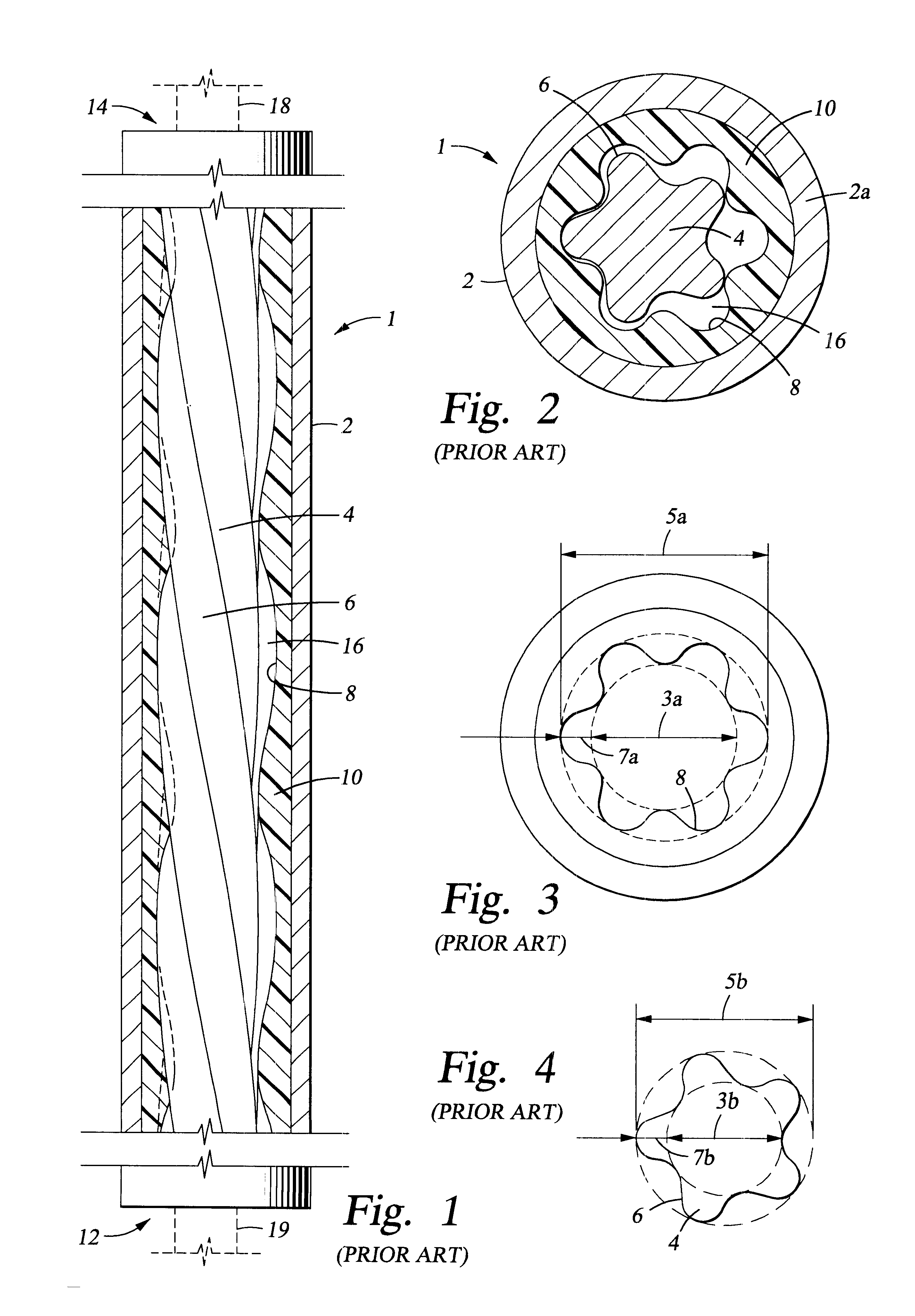

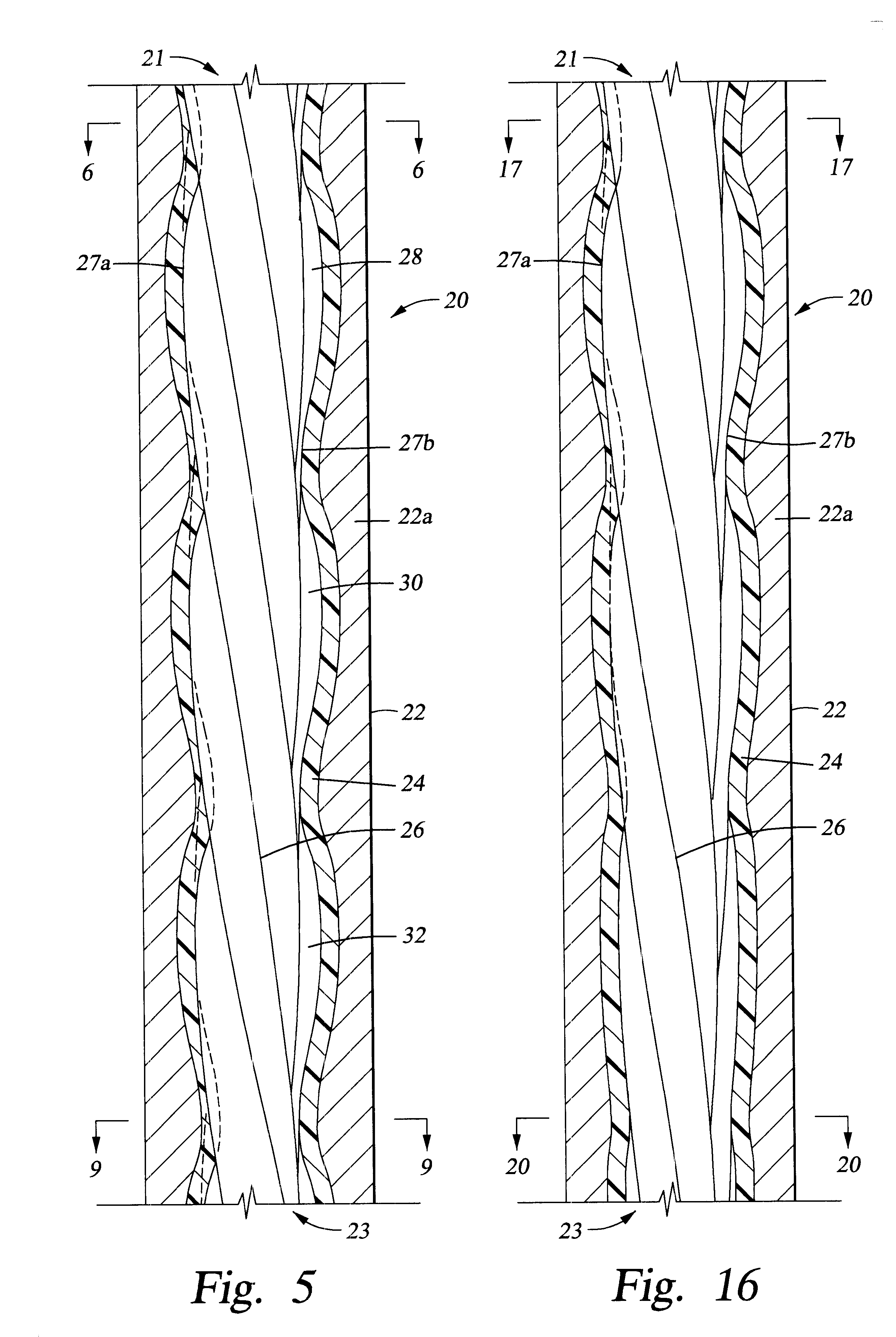

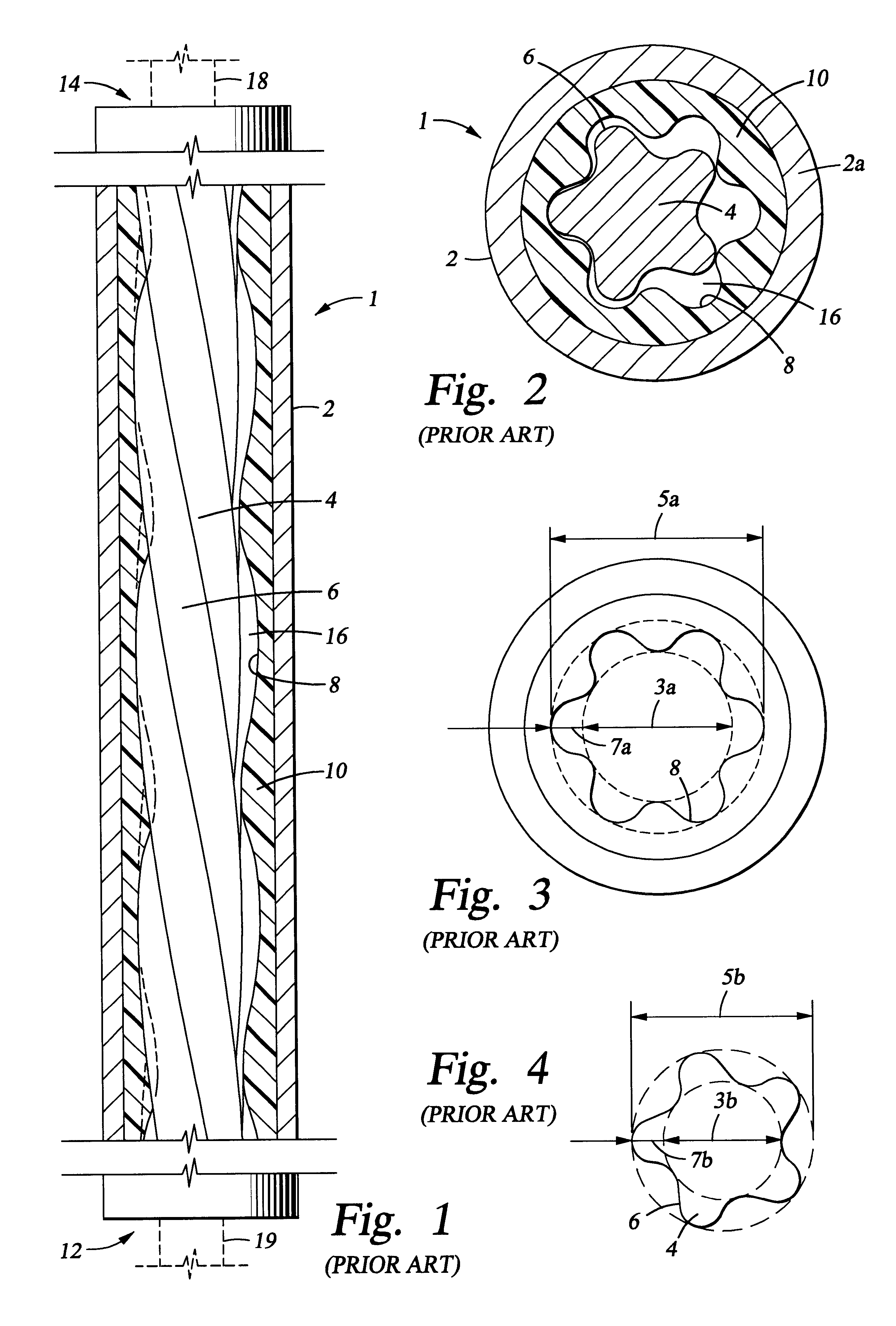

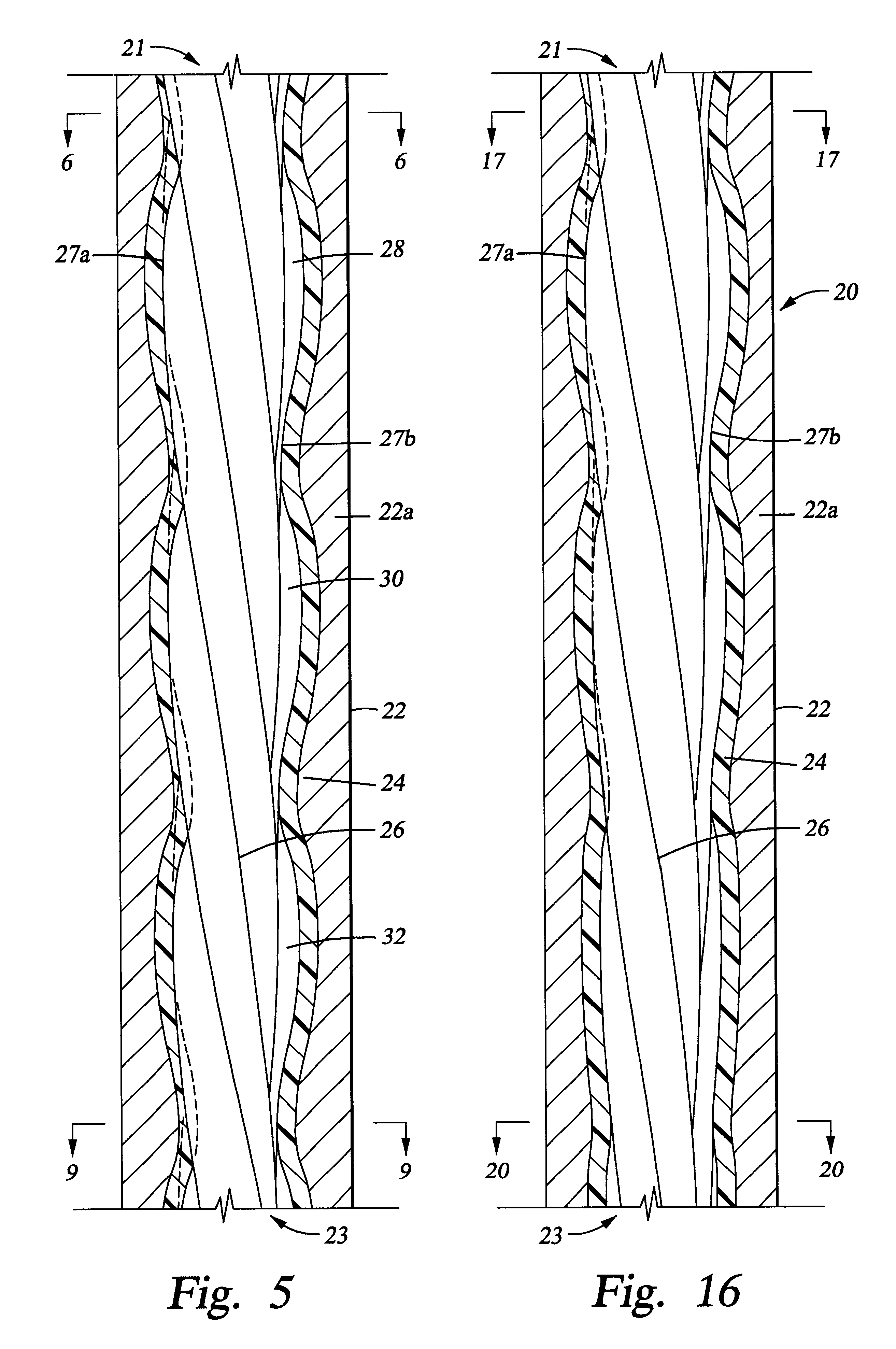

Self compensating adjustable fit progressing cavity pump for oil-well applications with varying temperatures

The present invention provides an adjustable rotor and / or stator, so that the interference fit and / or clearance can be adjusted. The rotor and / or stator are tapered to provide a difference in fit between the rotor and stator by longitudinal adjustment of their relative position. The relative longitudinal adjustment is achieved in response to a change in temperature and is matched to the taper angle of the stator / rotor to maintain a desired interference fit.

Owner:WEATHERFORDLAMB

Pump with conveying chamber formed in outer rotor surface

ActiveUS7674100B2Avoid flowEngine of arcuate-engagement typeRotary piston pumpsMechanical engineeringMedical treatment

Owner:QUANTEX ARC LTD

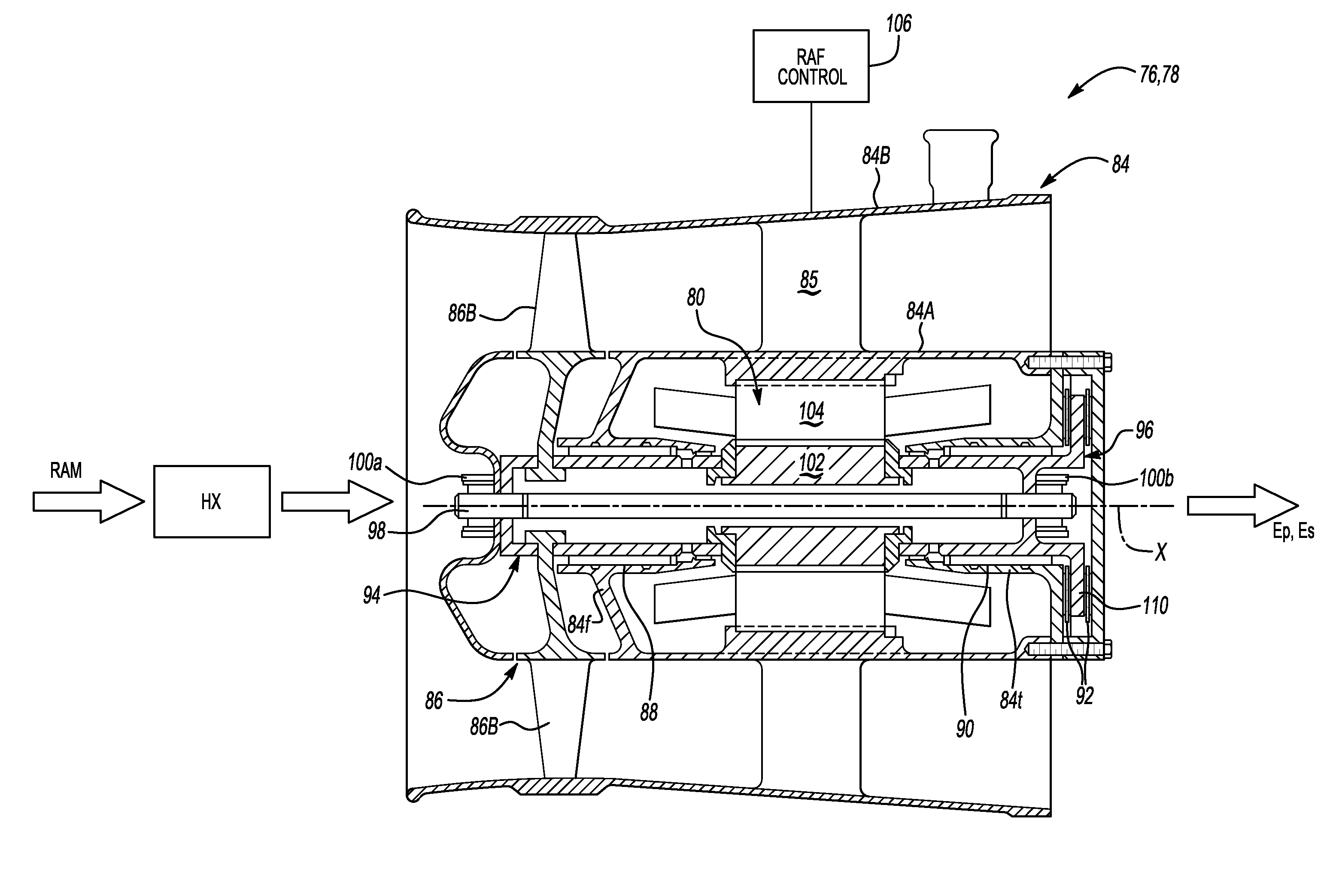

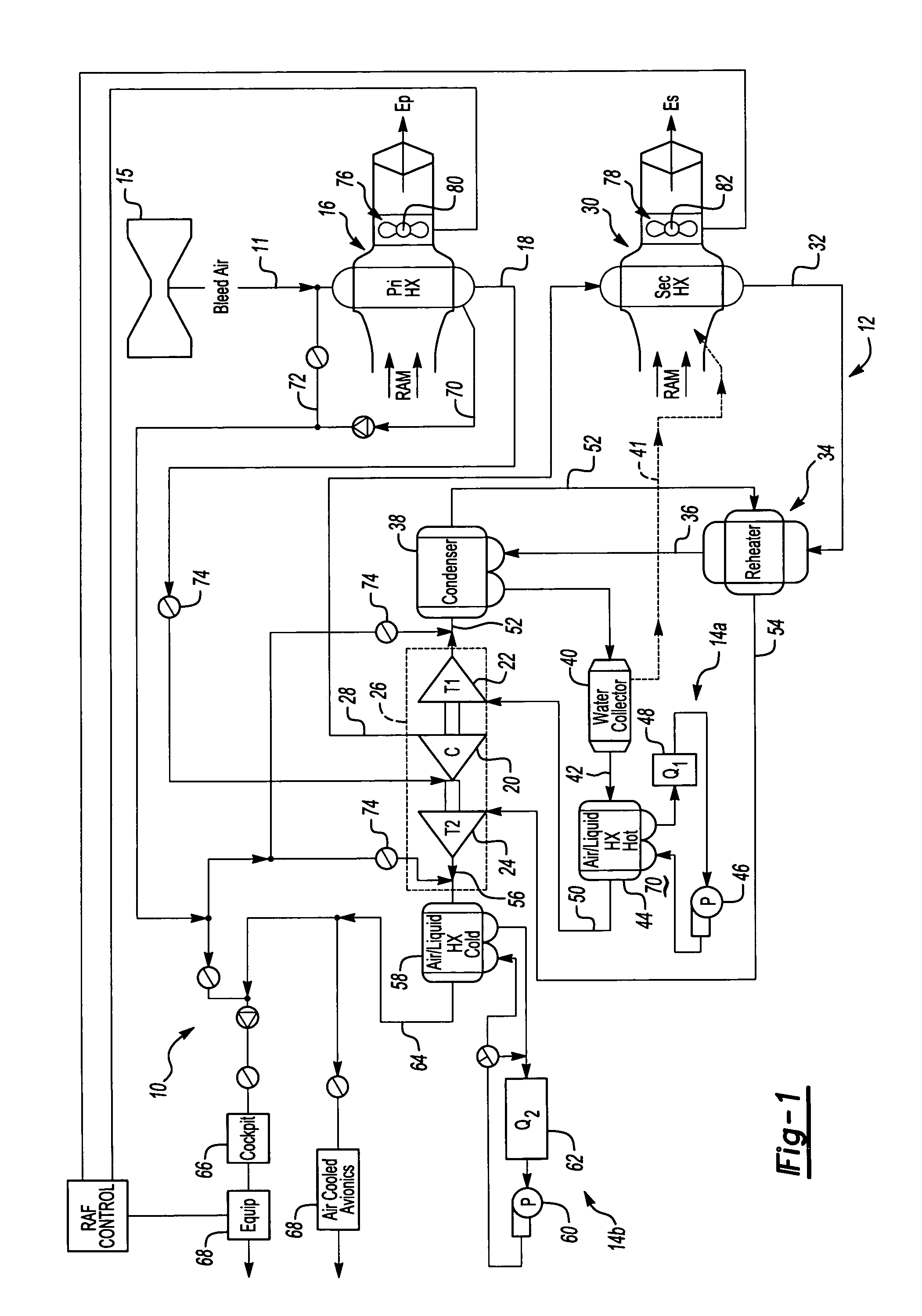

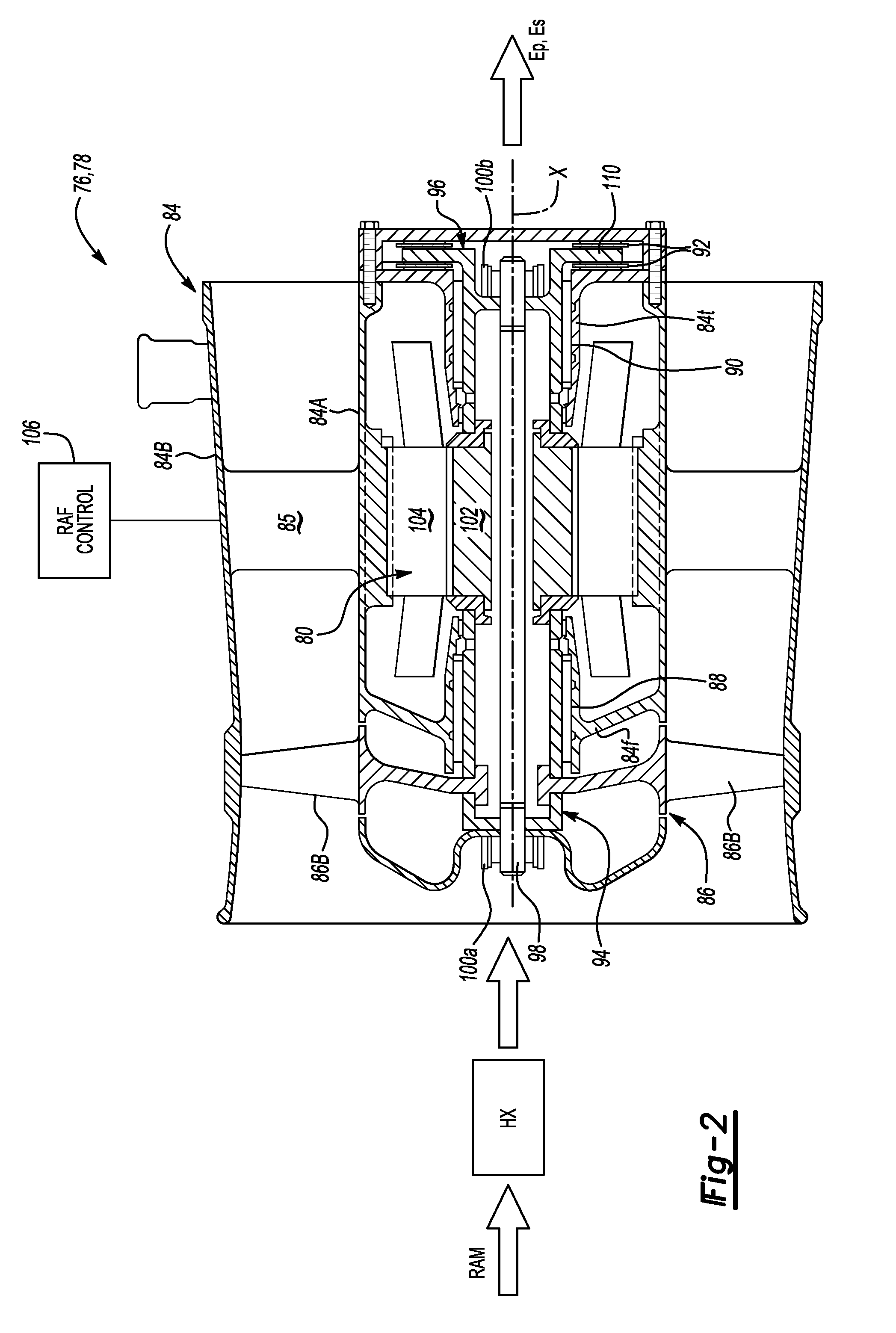

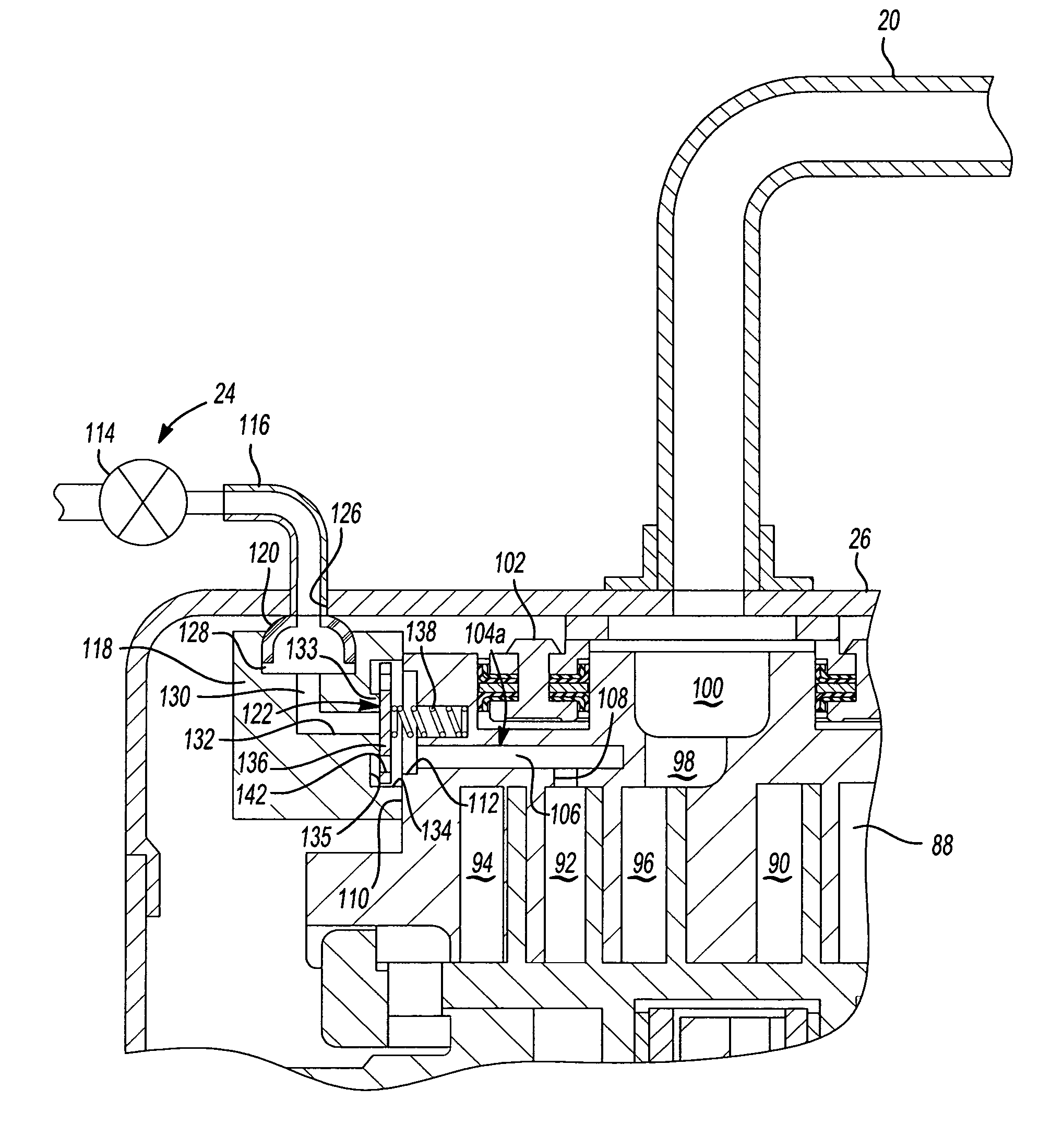

RAM fan system for an aircraft environmental control system

InactiveUS7757502B2Reduce noiseEasy to operateDomestic cooling apparatusSteam/vapor condensersAir cycle machineControl system

An environmental control system includes a RAM air fan system downstream of a respective heat exchanger in the relatively high temperature RAM exhaust. The RAM air fan includes a RAM air fan electric motor such that the RAM air fan is driven at a speed independent of an air cycle machine. A fan rotor is completely supported by hydrodynamic foil journal and thrust bearings. As the RAM air fan is driven by the RAM air fan electric motor the RAM air fan is installed in the environmental control system as a self-contained system.

Owner:HAMILTON SUNDSTRAND CORP

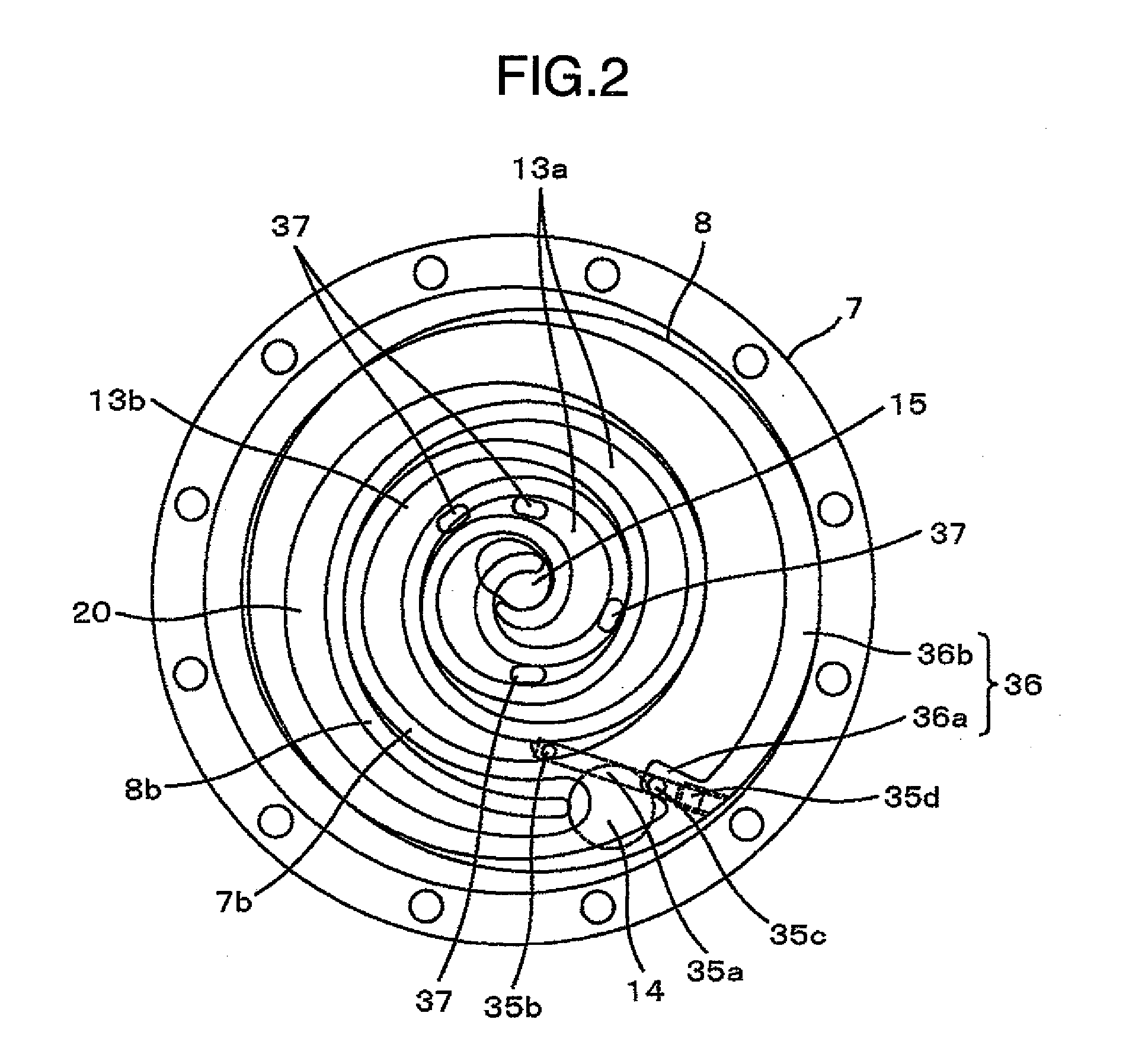

Scroll compressor having an annular recess located outside an annular seal portion and another recess communicating with suction port of fixed scroll

ActiveUS7229261B2Reduce back pressureSliding loss can be reducedEngine of arcuate-engagement typeOscillating piston enginesEngineeringSliding contact

A surface of a fixed scroll which is opposed to a end plate of an orbiting scroll existing outside of a lap of the fixed scroll is formed with: a substantially annular seal portion which extends such as to have an outer wall surface of the fixed scroll outwardly extending from an inner wall surface of outermost periphery of the lap substantially along the inner wall surface, and which comes into slide contact with the end plate of the orbiting scroll; a substantially annular recess located outside of the substantially annular seal portion; and a recess which is brought into communication with an intake port of the fixed scroll independently from the substantially annular recess. With this, back pressure of the orbiting scroll is increased, and turning-over phenomenon of the orbiting scroll can be suppressed.

Owner:PANASONIC CORP

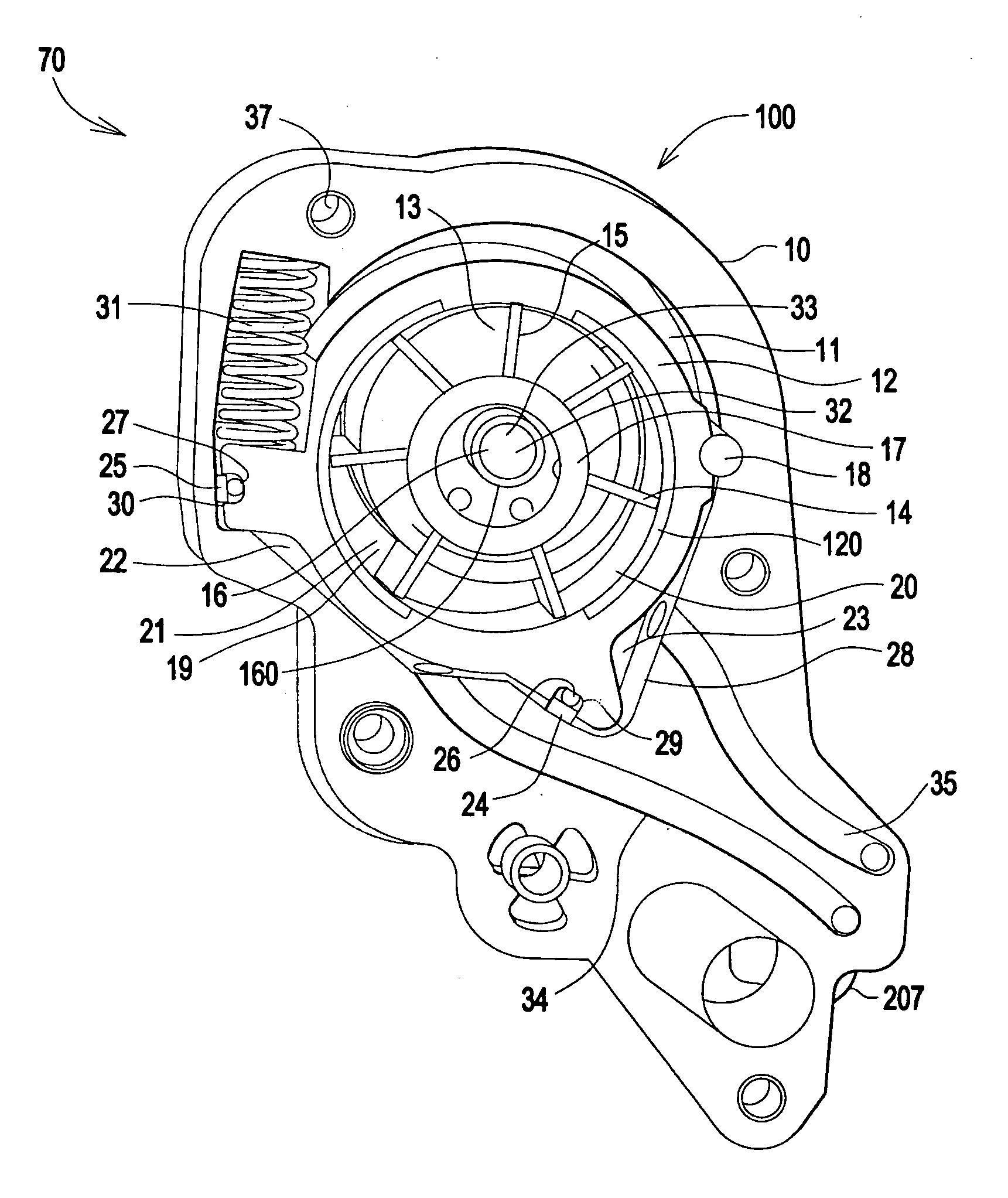

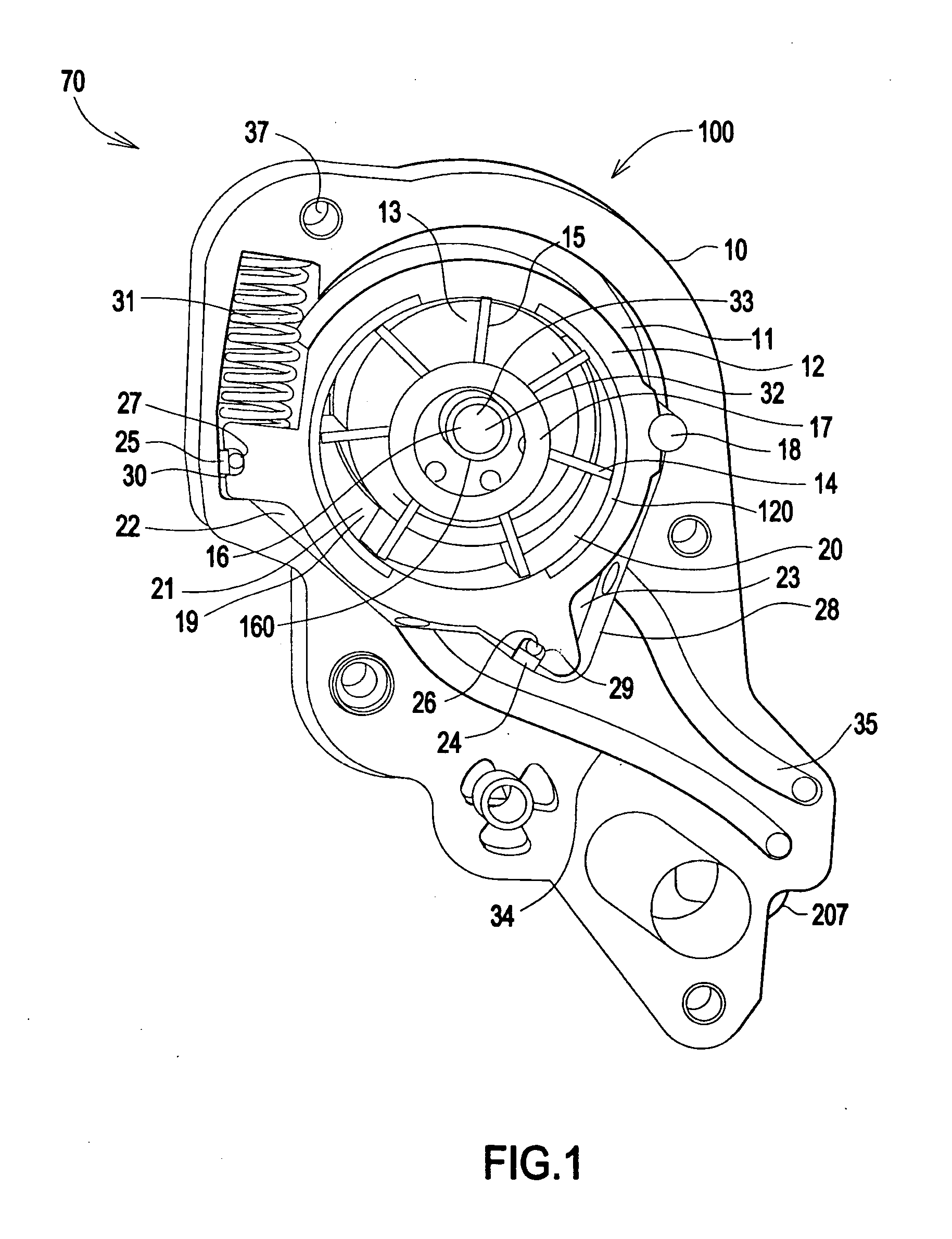

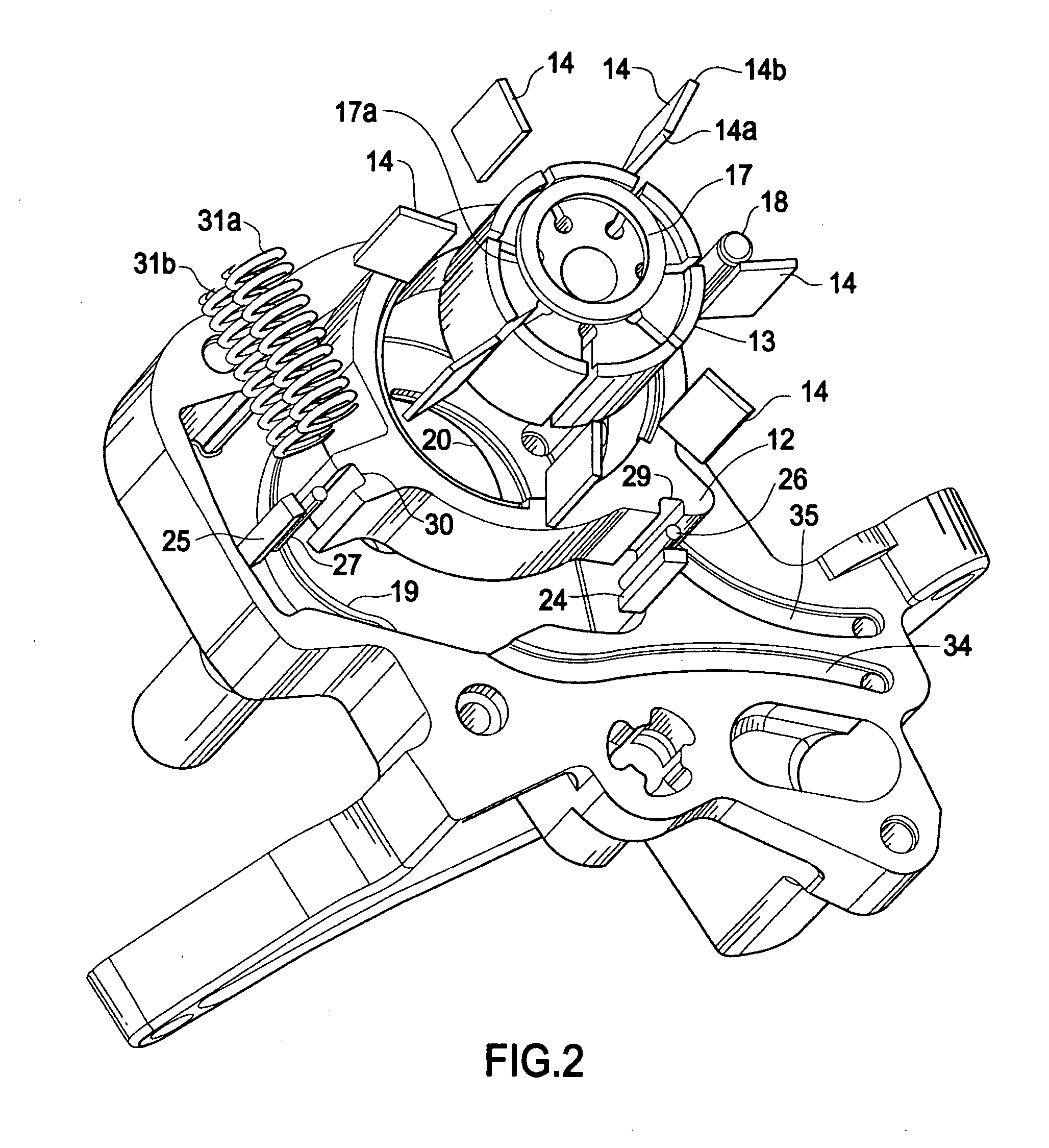

Load-regulating device for scroll type compressors

InactiveUS6913448B2Quickly build up pressurePrevent leakageEngine of arcuate-engagement typeOscillating piston enginesEngineeringLoad regulation

A load-regulating device for scroll type compressors comprising a compressor housing, a bracket body, a partition block, a gliding block, a pair of scrolls and a plurality of air chambers, wherein the gliding block being coupled with the pair of scrolls for defining a plurality of air chambers on the scrolls, the pressure variation in the air chambers is then utilized for causing the motion of the gliding block, enabling the compressor to cause the gliding block by means of the pressure variation to motion upwardly as the compressor is actuated, and preventing the fluid in the high-pressure chamber from leaking towards the low-pressure chamber, thus allowing the compressors to quickly build up the pressure; the gliding block is caused by the pressure variation to motion downwardly at times when the compression ratio is excessively high, so as to relieve part of the load, thus improving the performance and reliability of the compressors.

Owner:IND TECH RES INST

Scroll compressor

InactiveUS20070092390A1Improve sealingImprove efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringScroll compressor

A scroll compressor has a fluid pressure biasing system for both the orbiting scroll member and the non-orbiting scroll member. The biasing system can utilize a pressurized gas from the pocket of the scroll compressor or it can utilize an external pressurized oil source. In an additional embodiment, a hydrostatic bearing is located between the orbiting scroll member and the non-orbiting scroll member.

Owner:EMERSON CLIMATE TECH INC

Adjustable fit progressive cavity pump/motor apparatus and method

InactiveUS6358027B1Oscillating piston enginesSealing arrangement for pumpsInterference fitEngineering

The present invention provides an adjustable rotor and / or stator, so that the interference fit and / or clearance can be adjusted. The rotor and / or stator are tapered to provide a difference in fit between the rotor and stator by longitudinal adjustment of their relative position. In one embodiment, the adjustment may occur while the PCP in mounted downhole in a wellbore. In another embodiment, the adjustment may occur automatically depending on sensor input of operating conditions of the PCP.

Owner:WEATHERFORDLAMB

Scroll compressor

InactiveUS20100111741A1Improve performanceImprove reliabilityRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringBack pressure

A scroll compressor comprises a fixed scroll, an orbiting scroll engaged with the fixed scroll to form a compression chamber therebetween, a back pressure chamber arranged at a back side of an end plate of the orbiting scroll, a back pressure hole formed in the end plate of the orbiting scroll to form a fluidal communication between the compression chamber and the back pressure chamber, and a release valve mechanism for discharging the fluid from the compression chamber to the discharge space when a pressure in the compression chamber is higher than the pressure in the discharge space, wherein the back pressure hole and the release flow path are arranged to prevent both of the fluidal communication and the another fluidal communication from being formed simultaneously.

Owner:HITACHI APPLIANCES INC

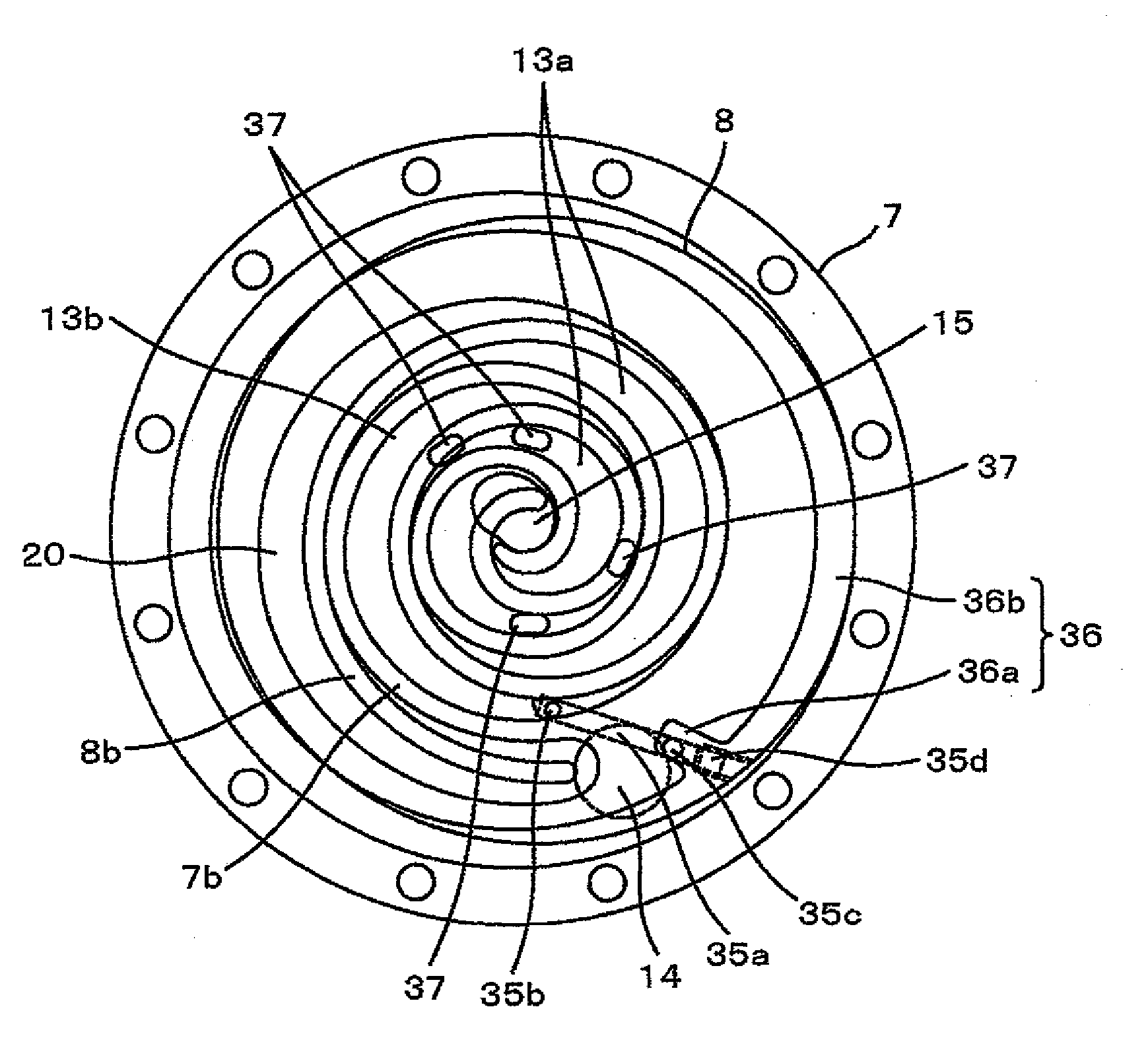

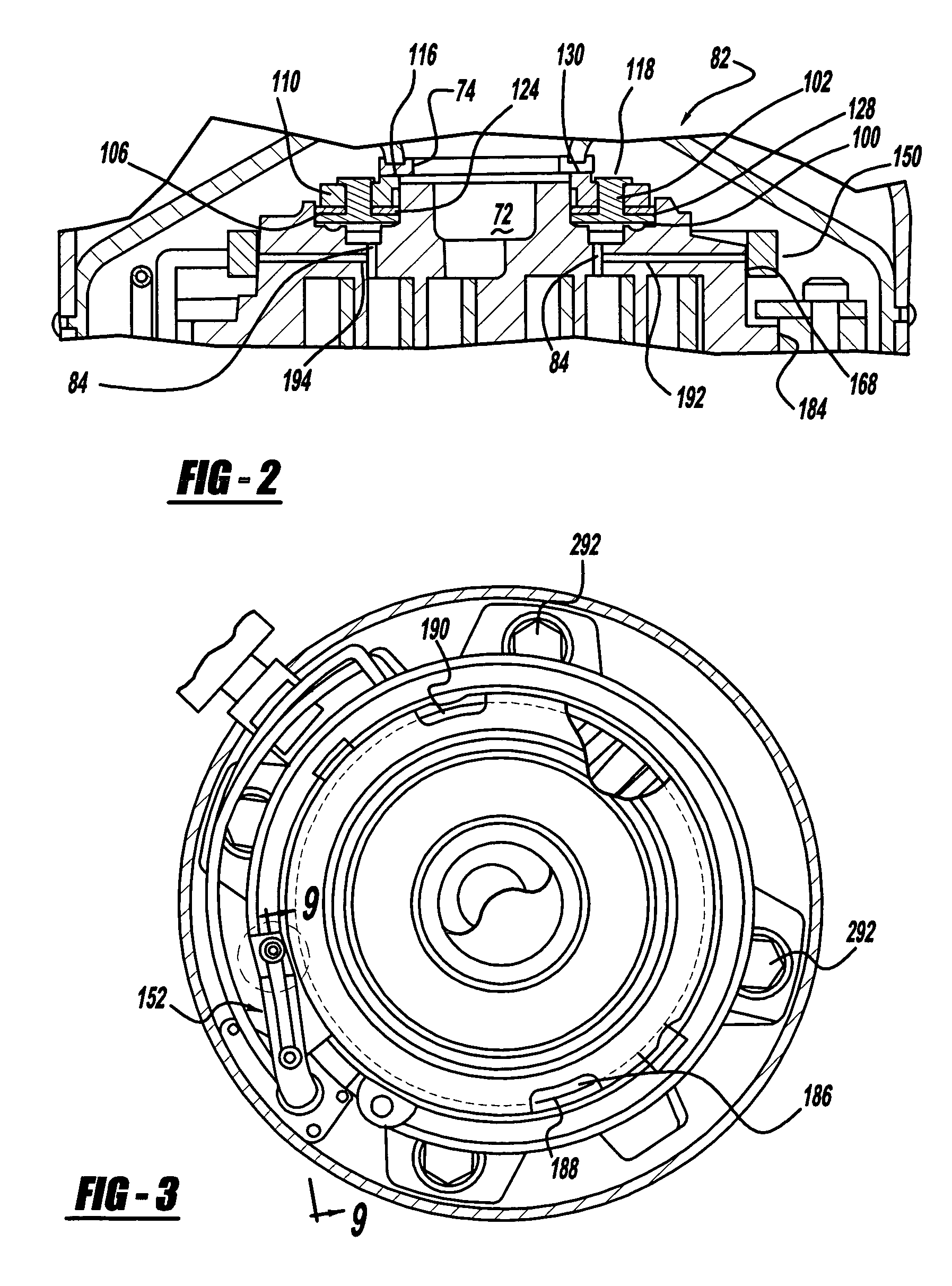

Capacity modulated scroll compressor

InactiveUS20070036661A1Reduce compressionCapacity modulationRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsElectrical and Electronics engineeringScroll compressor

A scroll compressor has a biasing chamber which contains a pressurized fluid. The pressurized fluid within the chamber biases the two scroll members together. A rotatable ring is attached to one of the scroll members to open and close a passage leading to this biasing chamber. When the ring opens the passage in one embodiment, this releases the pressurized fluid to remove the load, biasing the two scroll members together. When the biasing load is removed, the two scroll members separate, creating a leakage path between discharge and suction to reduce the capacity of the scroll compressor. When the ring opens the passage in another embodiment, a delayed suction passage is opened to reduce the capacity of the compressor.

Owner:EMERSON CLIMATE TECH INC

Variable displacement sliding vane pump

InactiveUS20070224067A1Oscillating piston enginesSealing arrangement for pumpsDrive shaftEngineering

A variable displacement sliding vane pump comprising a pump body, inlet and outlet ports formed in said pump body, a drive shaft rotatably mounted in said pump body, a rotor driven by said drive shaft and co-axially aligned therewith, a plurality of radially extending vanes slidably disposed in said rotor, a pivot disposed in said pump body, a slide pivotally disposed on said pivot in said pump body and having a central axis eccentric to the axis of said rotor, a plurality of fluid chambers defined by said rotor, said vanes, and said slide that are successively connected to said inlet and outlet ports, a spring acting on said slide to urge said slide in one direction, a first chamber and a second chamber, each suitable for receiving a fluid pressure and each disposed between said pump body and an outer surface of said slide, the first chamber in fluid communication with a pump outlet discharge pressure, and a valve operable to selectively pressurize and depressurize the second chamber.

Owner:STACKPOLE POWERTRAIN INT ULC

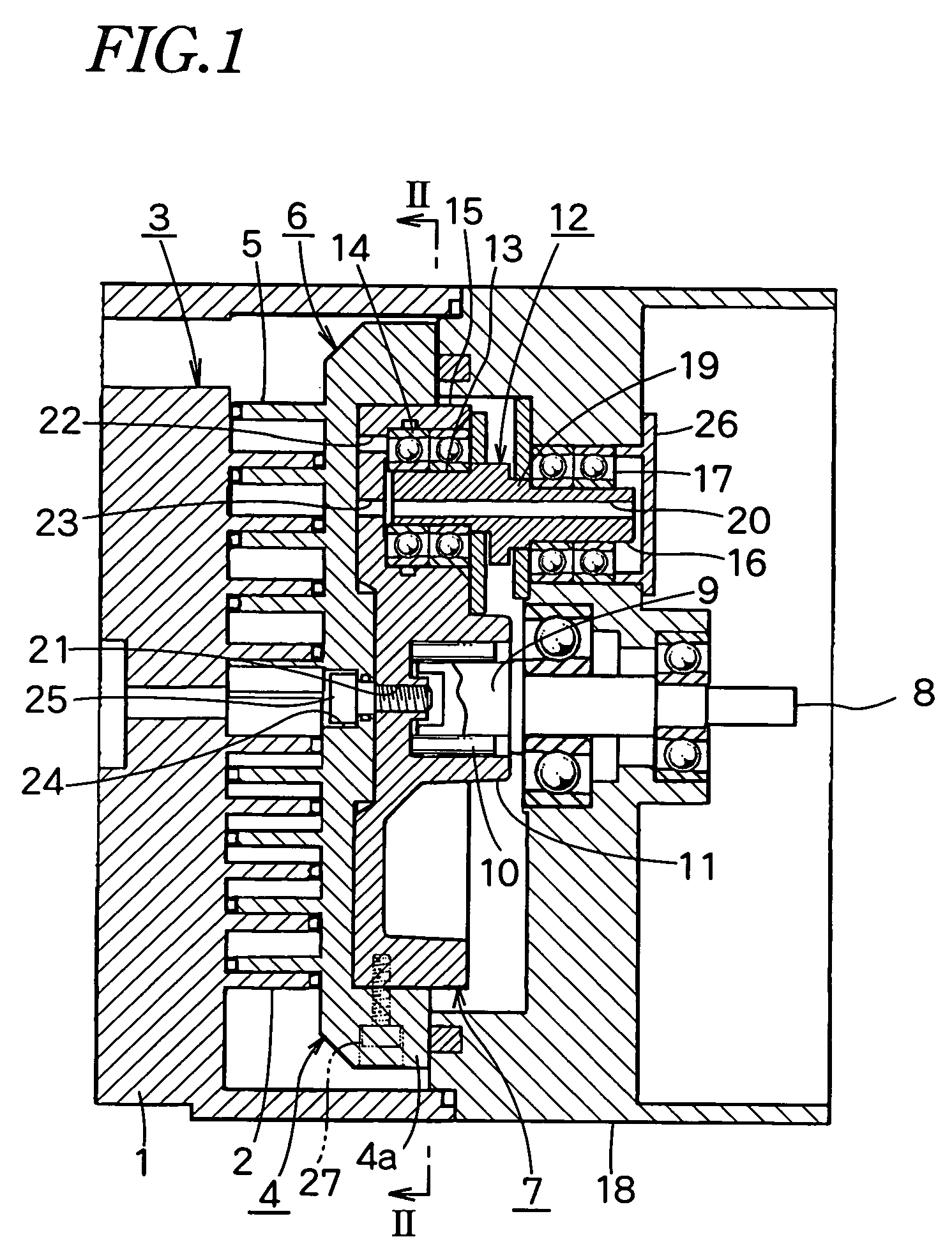

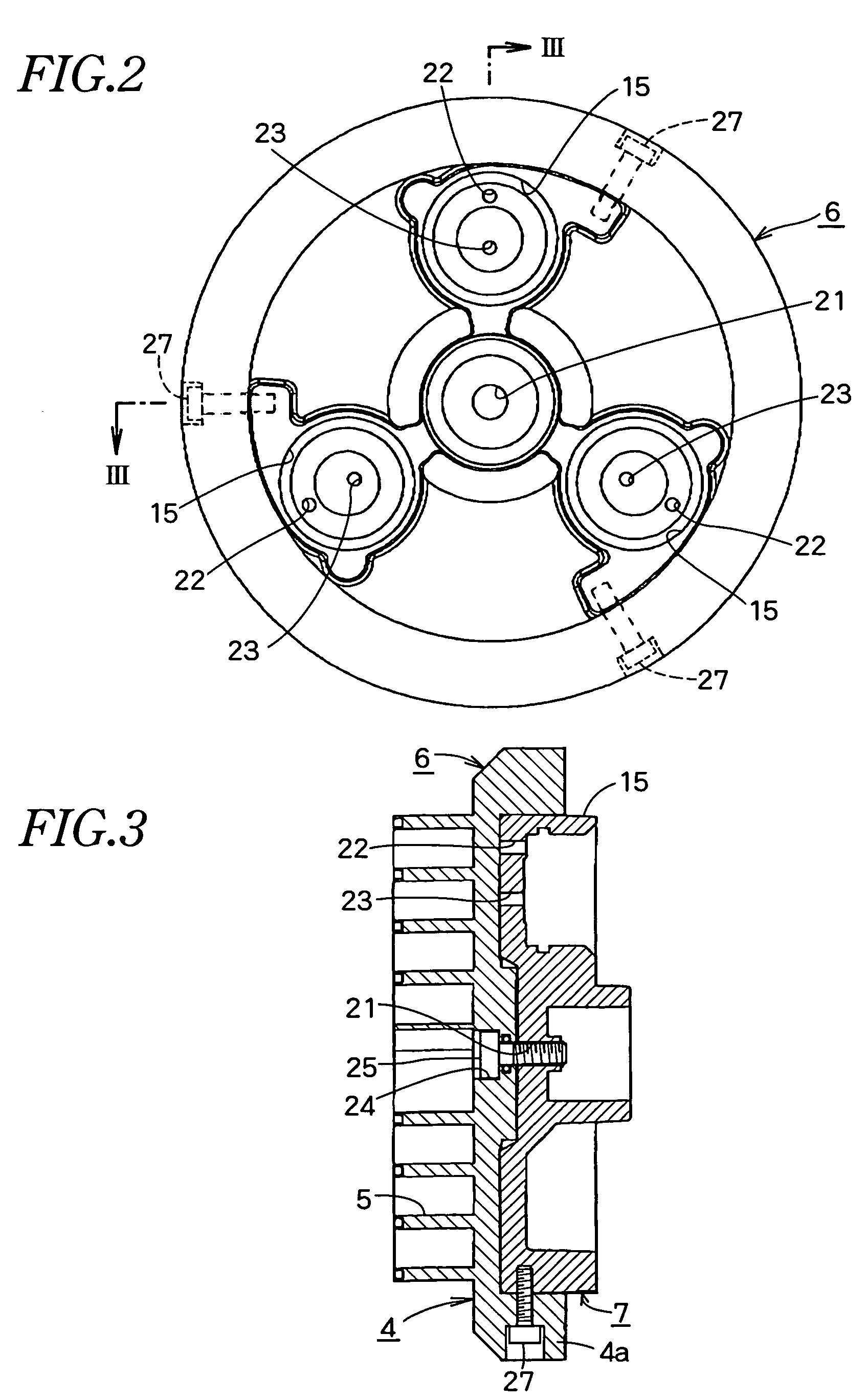

Scroll fluid machine having oil-supply holes being formed through a reinforcement bearing plate on a rear surface of the orbiting scroll

InactiveUS7404706B2Increase supplyEngine of arcuate-engagement typeOscillating piston enginesEngineeringOil supply

A scroll fluid machine comprises a fixed scroll, an orbiting scroll and a plurality of self-rotation preventing device for preventing the orbiting scroll from rotating on its own axis. On the rear surface of the orbiting scroll, a reinforcement bearing plate is fixed with a central bolt and an outer circumferential bolt. A follower of the self-rotation preventing device is provided in the reinforcement bearing plate. An oil-supply hole is formed through the reinforcement bearing plate to supply oil to the follower.

Owner:ANEST IWATA CORP

Reduced rotor assembly diameter vane pump

InactiveUS7997882B2Reduce the overall diameterReduce radial sizeOscillating piston enginesSealing arrangement for pumpsWorking fluidDrive shaft

A vane pump with a reduced rotor diameter is provided. The reduced rotor diameter allows a reduction in the overall size of the pump which allows the pump to be used in circumstances wherein sufficient packaging volume does not exist for conventional vane pumps. Further, the reduced rotor diameter permits operation of the pump at a higher speed, in comparison to conventional vane pumps, for a given working fluid and pump rate. The rotor includes an integrally formed drive shaft and a cylindrical rotor head. Both fixed displacement and variable displacement embodiments are shown.

Owner:MAGNA POWERTRIAN INC (US)

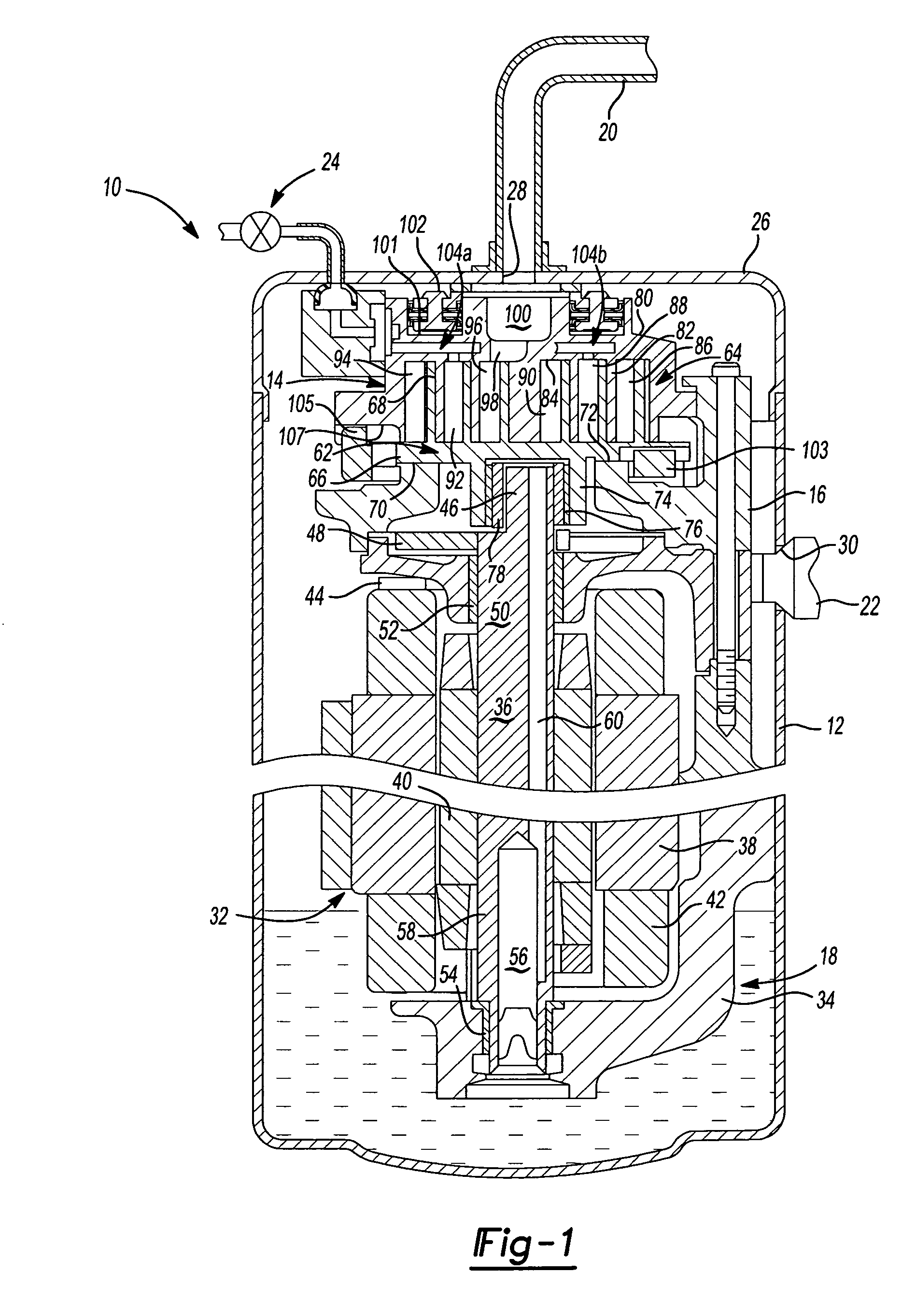

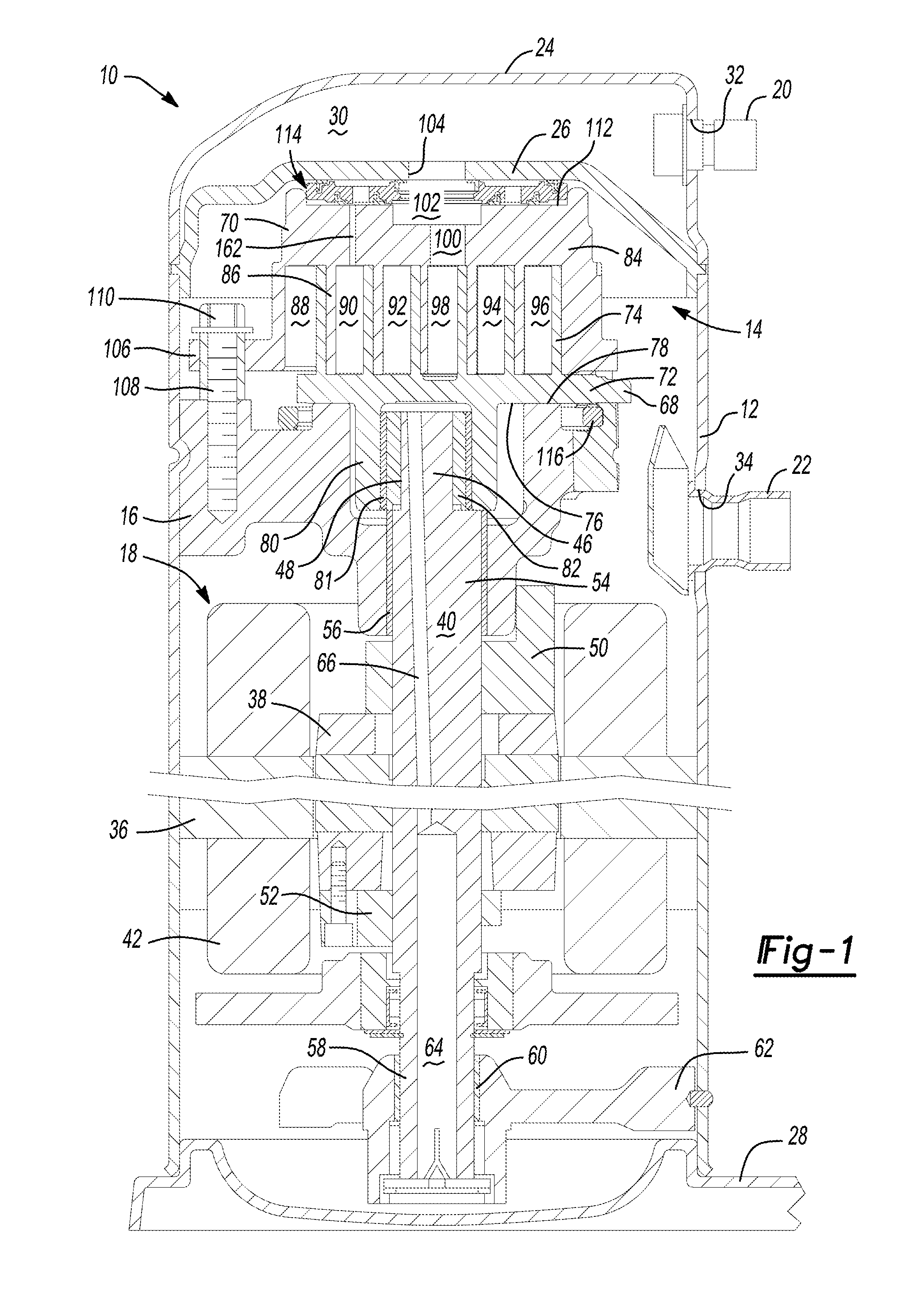

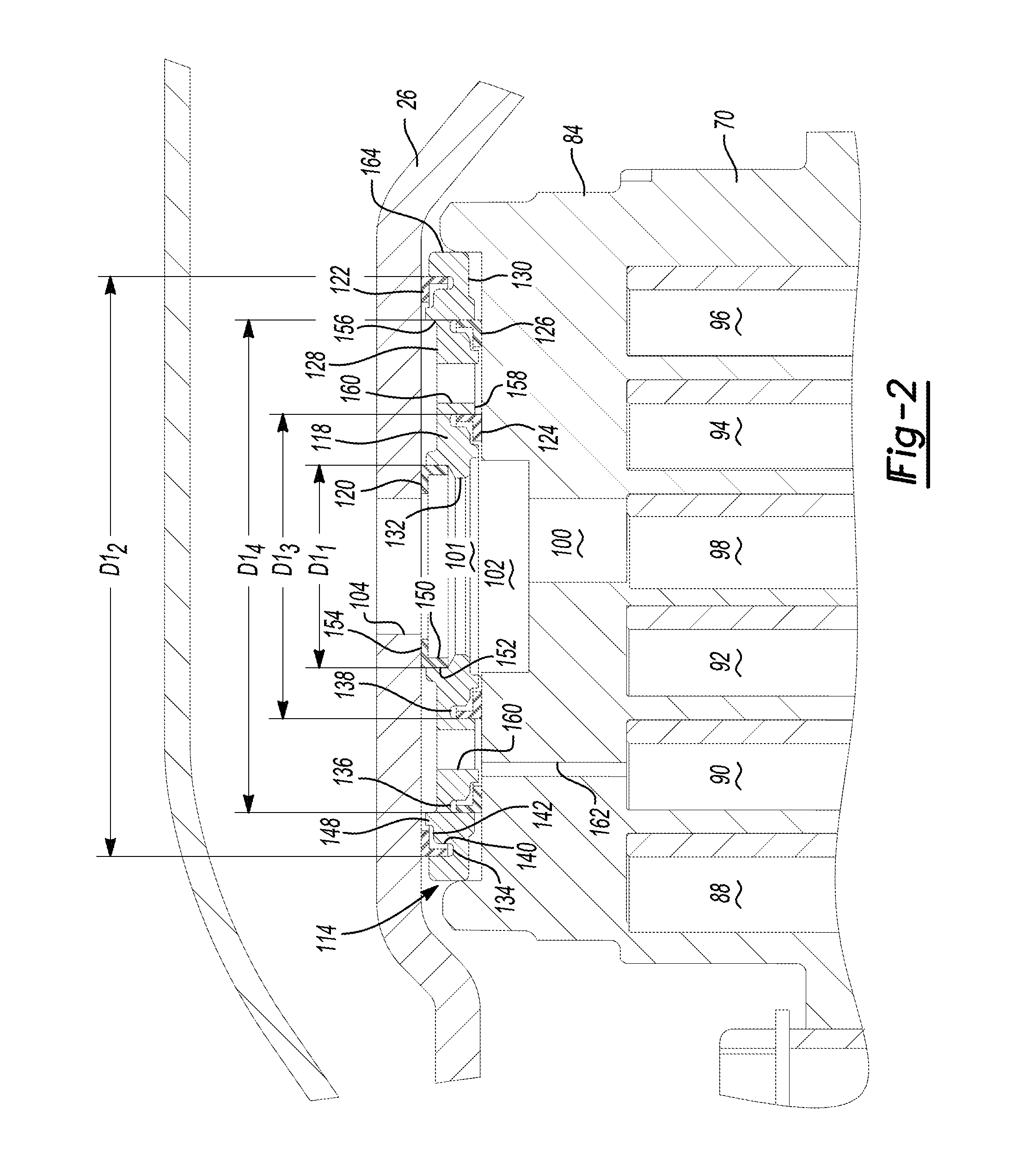

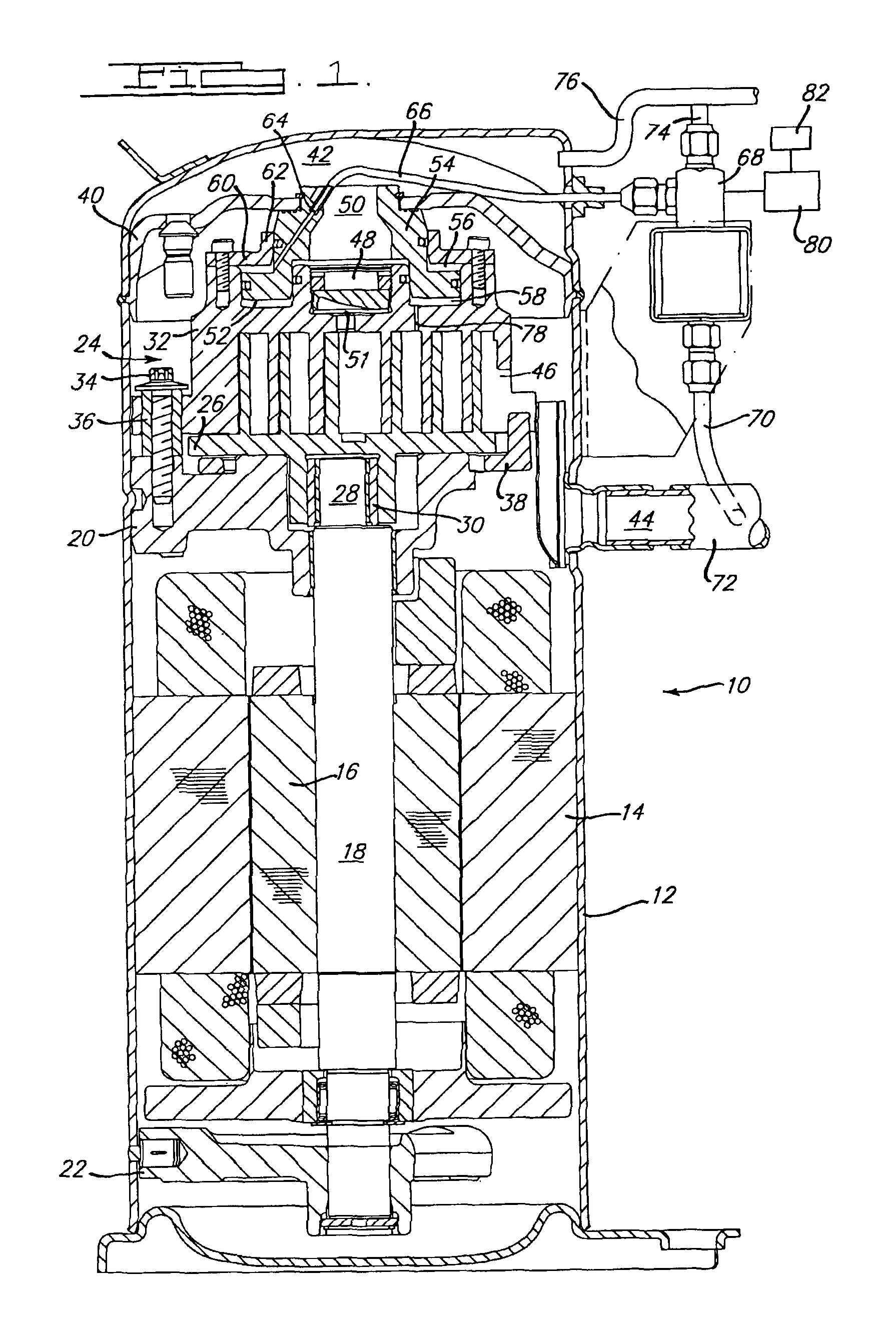

Vapor injection system for a scroll compressor

ActiveUS7771178B2Increase capacityImprove efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeInjection deviceScroll compressor

A compressor may include a shell, a compression mechanism, a motor, and a vapor injection system. The compression mechanism may be contained within in the shell and include a non-orbiting scroll axially displaceably mounted to the shell. The non-orbiting scroll may have an exterior portion, an interior portion, and a vapor injection passage extending therethrough from the exterior portion to the interior portion. The motor may be contained within the shell and may be drivingly coupled to the compression mechanism. The vapor injection system may include a vapor injection device, a vapor injection fitting, and a vapor injection valve. The vapor injection fitting may be in communication with the vapor injection device and the vapor injection passage. The vapor injection valve may be disposed between the shell and the interior of the non-orbiting scroll.

Owner:COPELAND LP

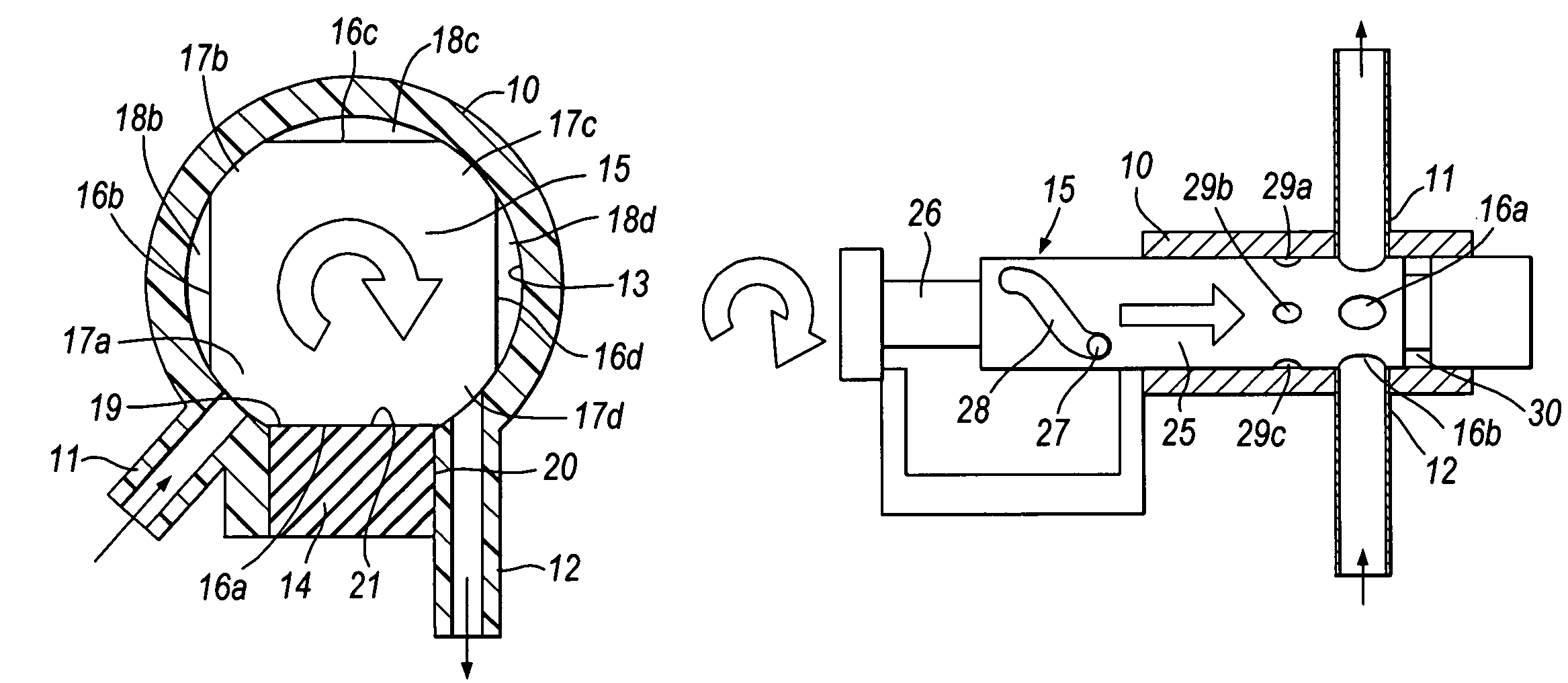

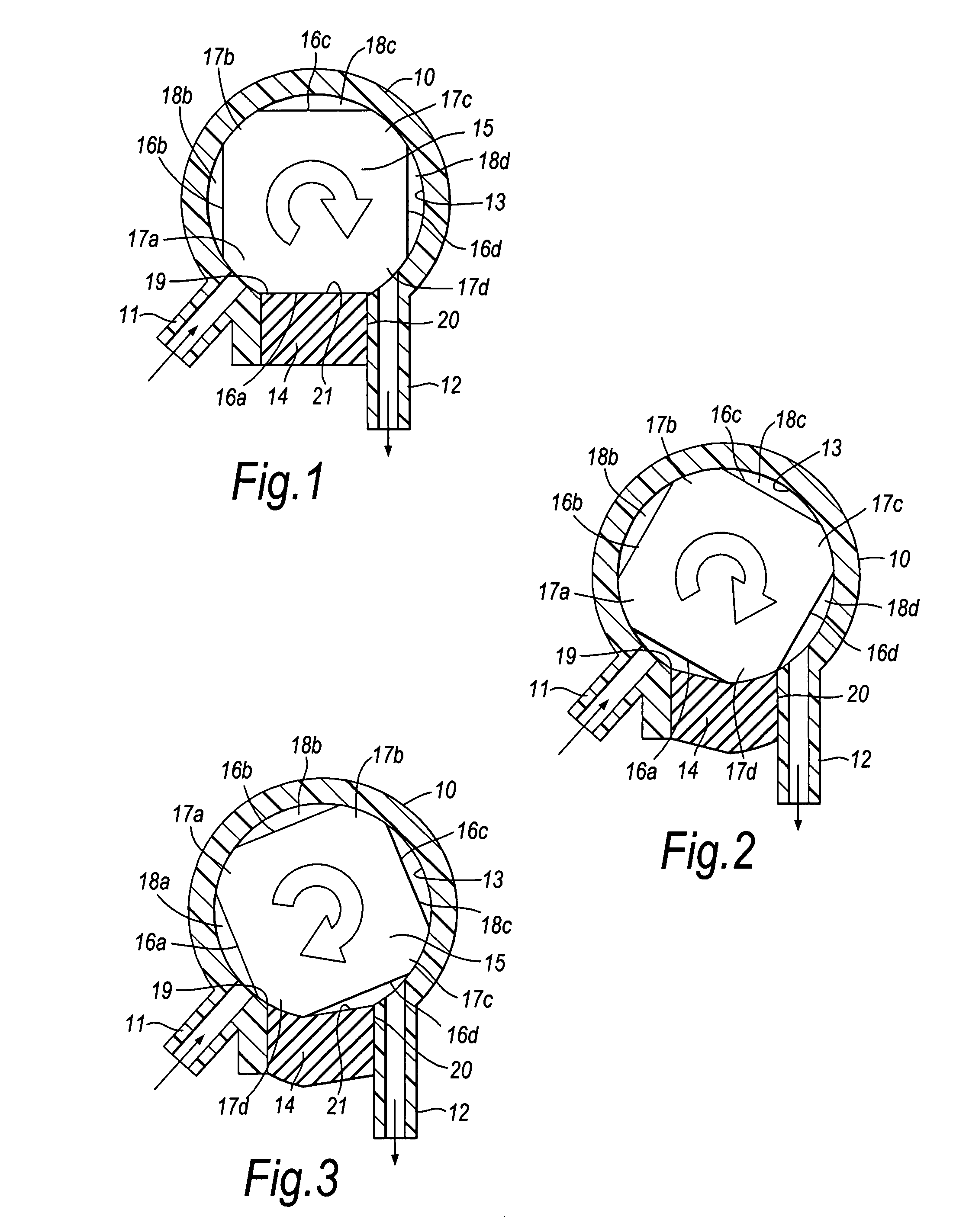

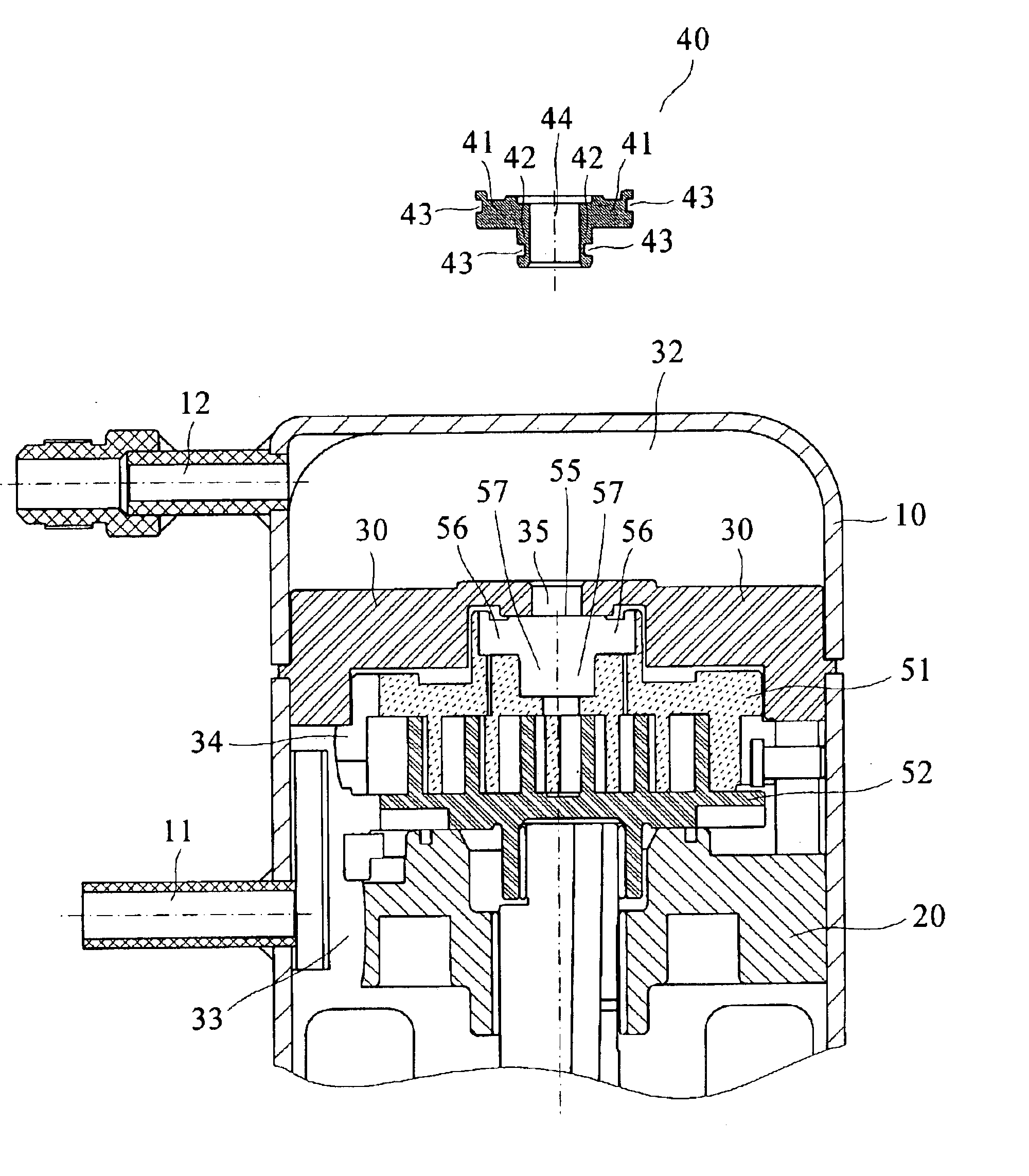

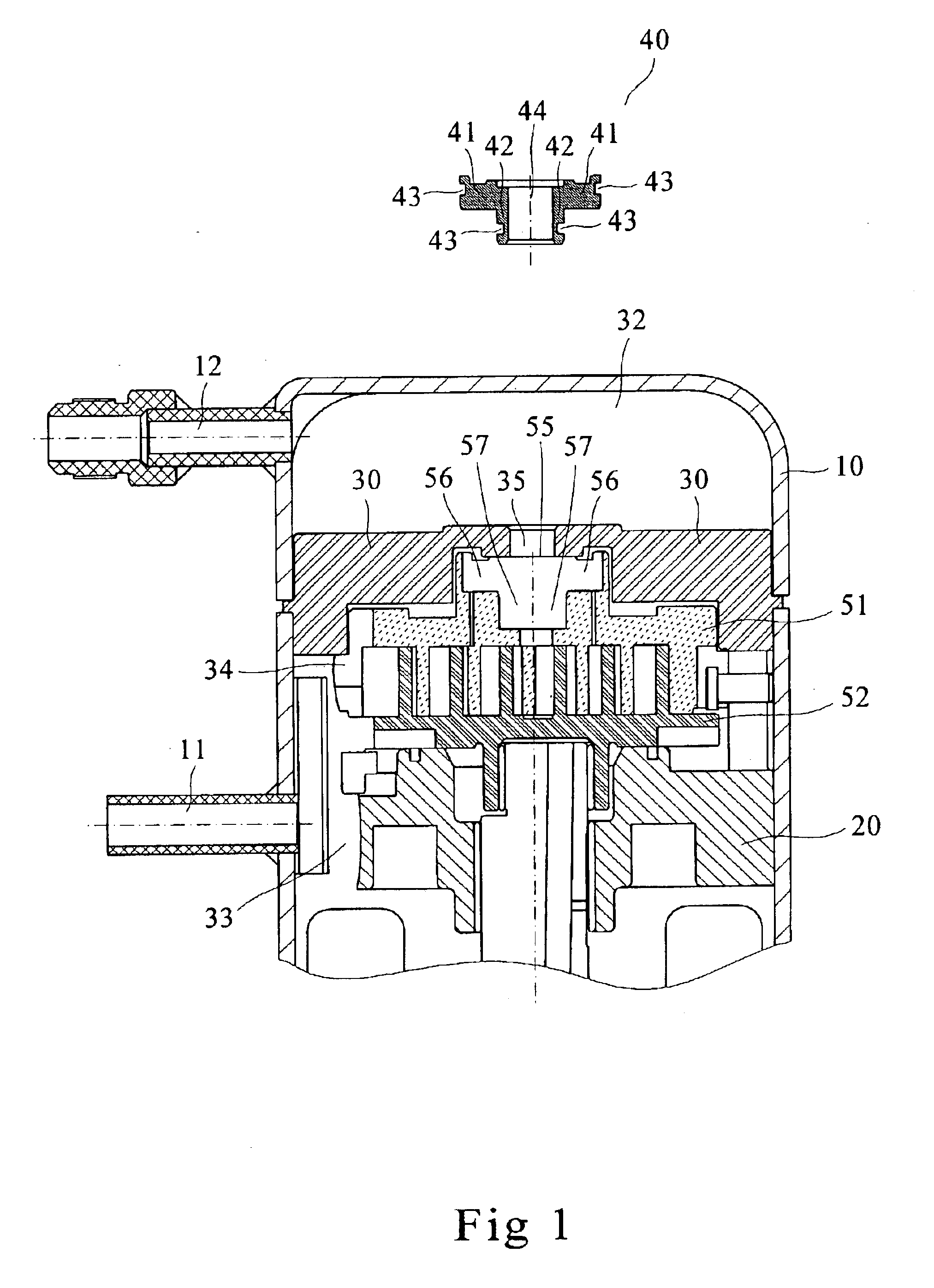

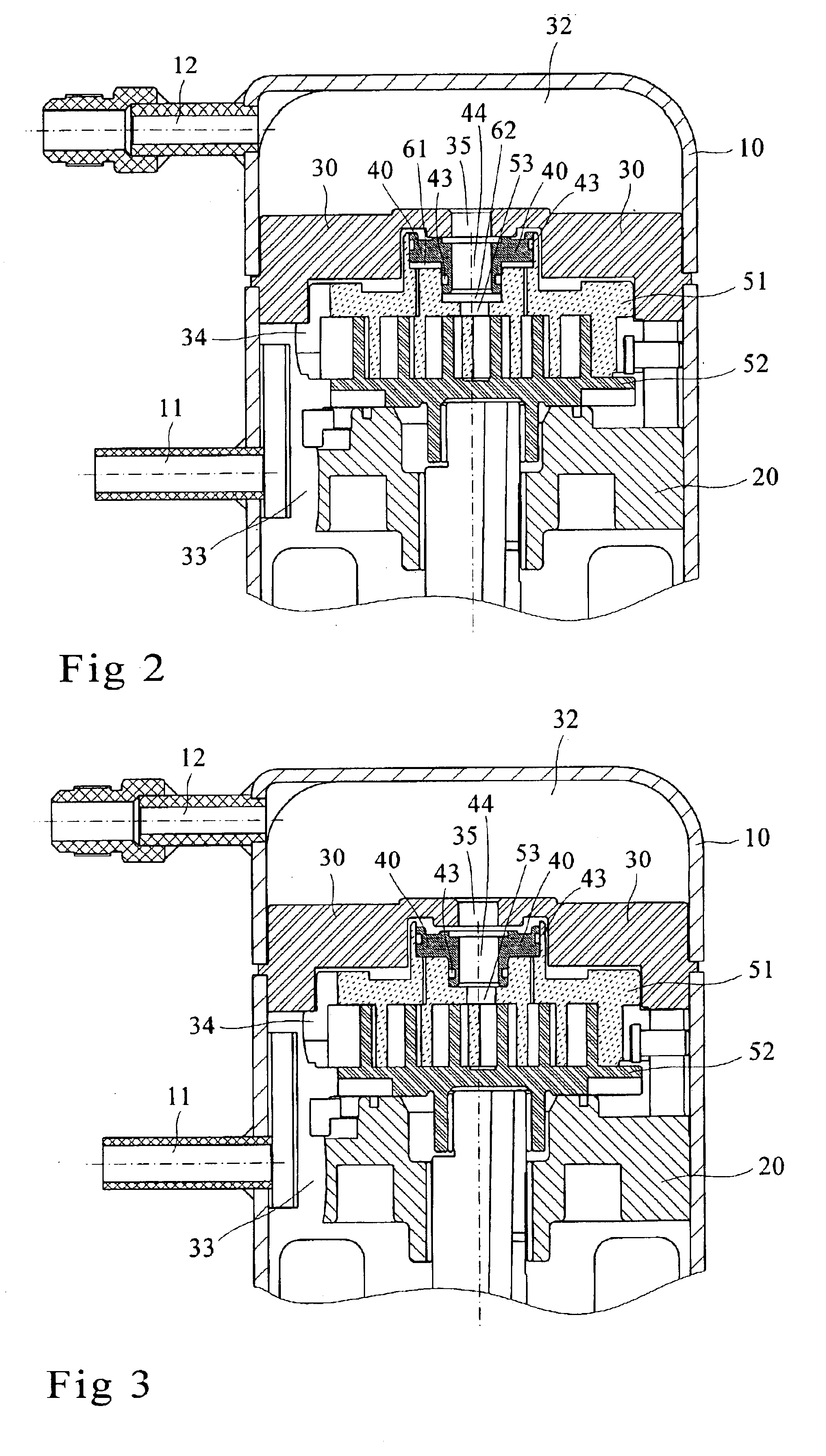

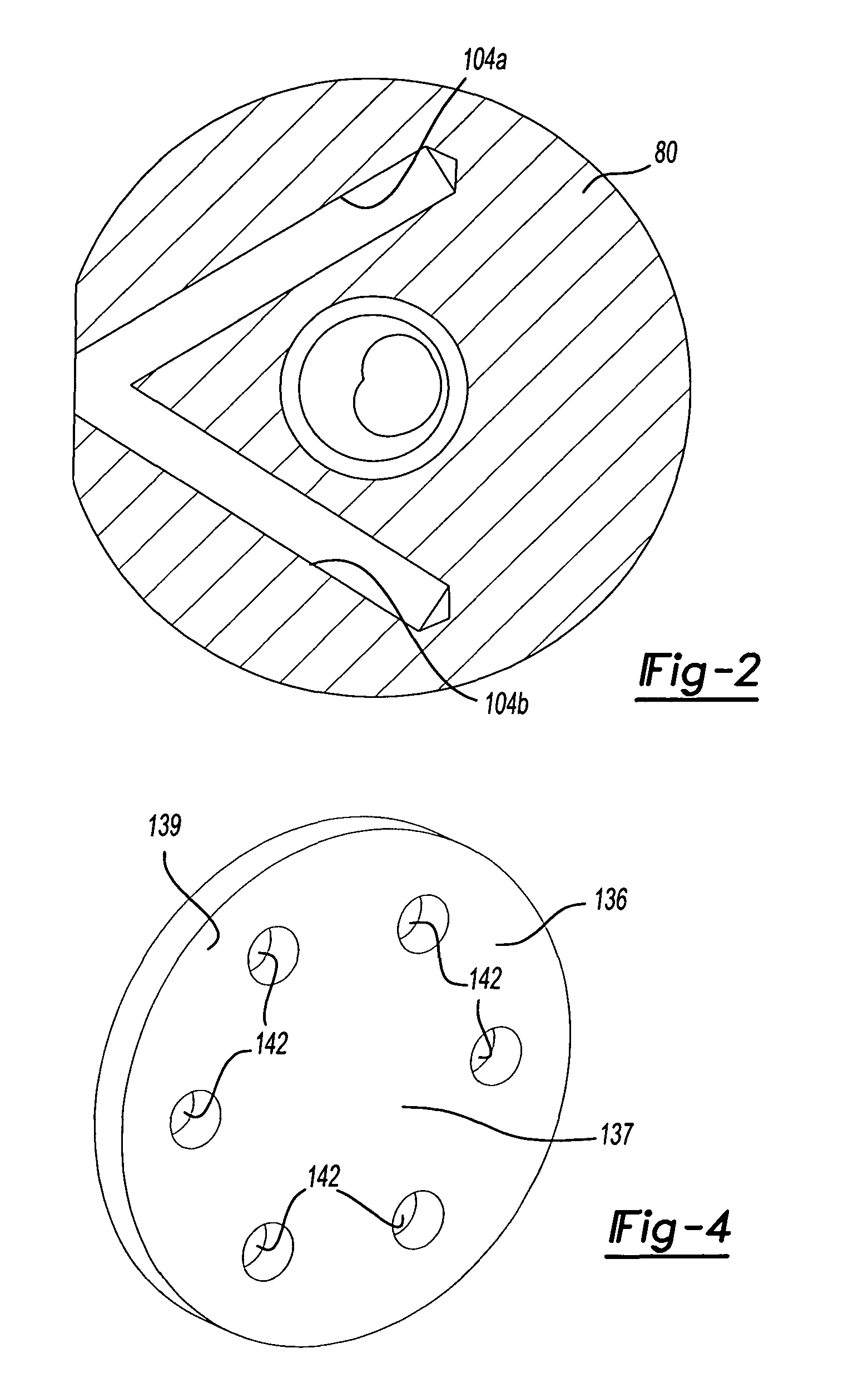

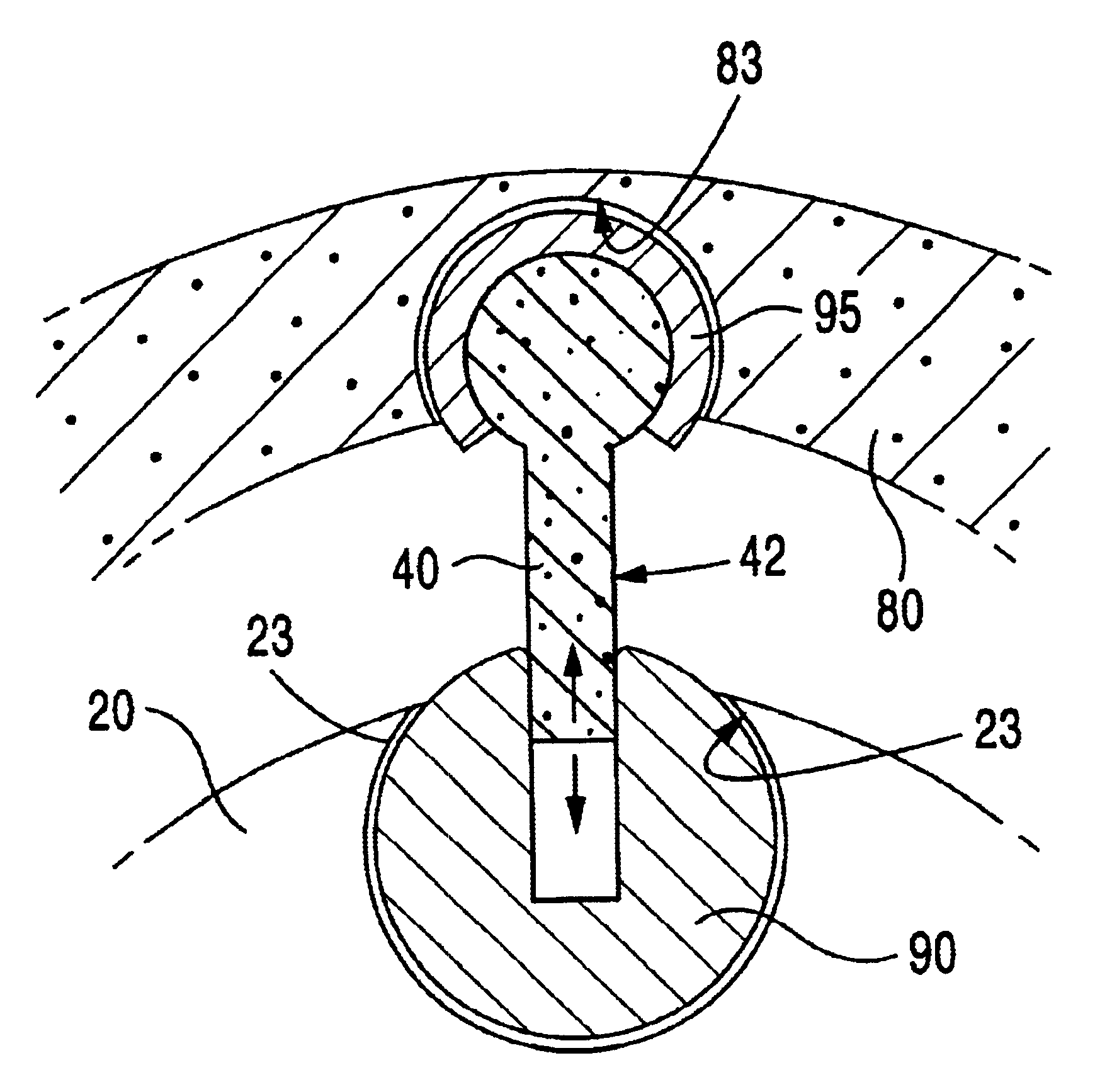

Rotary pump

InactiveUS6666671B1Shorten speedReduce wear rateOscillating piston enginesSealing arrangement for pumpsRotary pumpFree rotation

A rotary pump for pumping compressible fluid comprising an eccentrically mounted rotor 20 and a stator 10. The stator 10 comprises a stator inner liner 80 that is free to rotate, driven directly or in response to rotation of the rotor 20 such that the relative velocity between the outer surface of the rotor 20 and the inner surface of the stator 10 is reduced. The vanes 40 are held at each end by sockets 90, 95 in the rotor 20 and stator 10. The vane 40 and socket 90, 95 coupling provides fluid sealing without liquid lubricant. Opposing solid lubricant and hard surfaces are used on contact surfaces between the elements.

Owner:IC INNOVATIONS

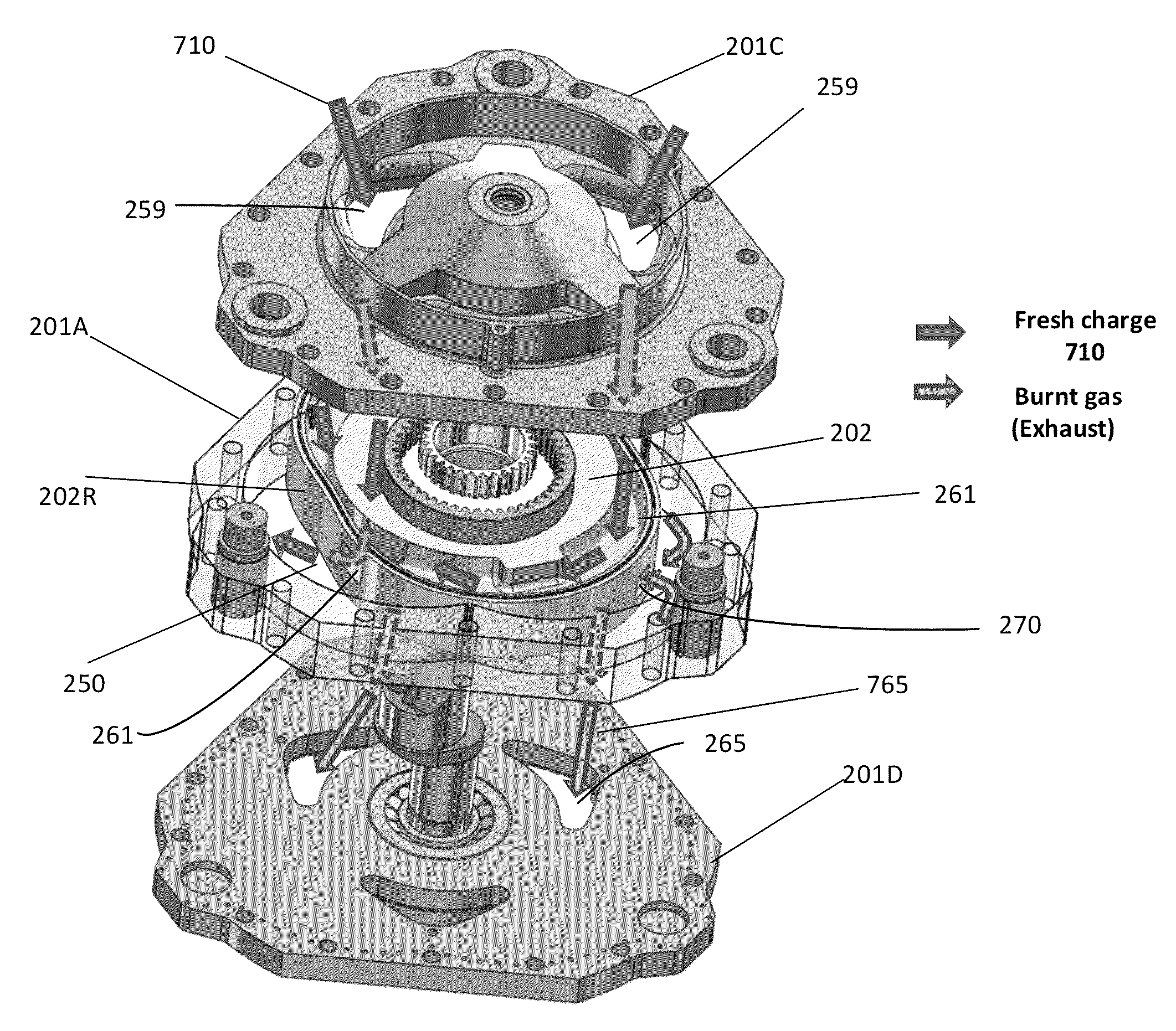

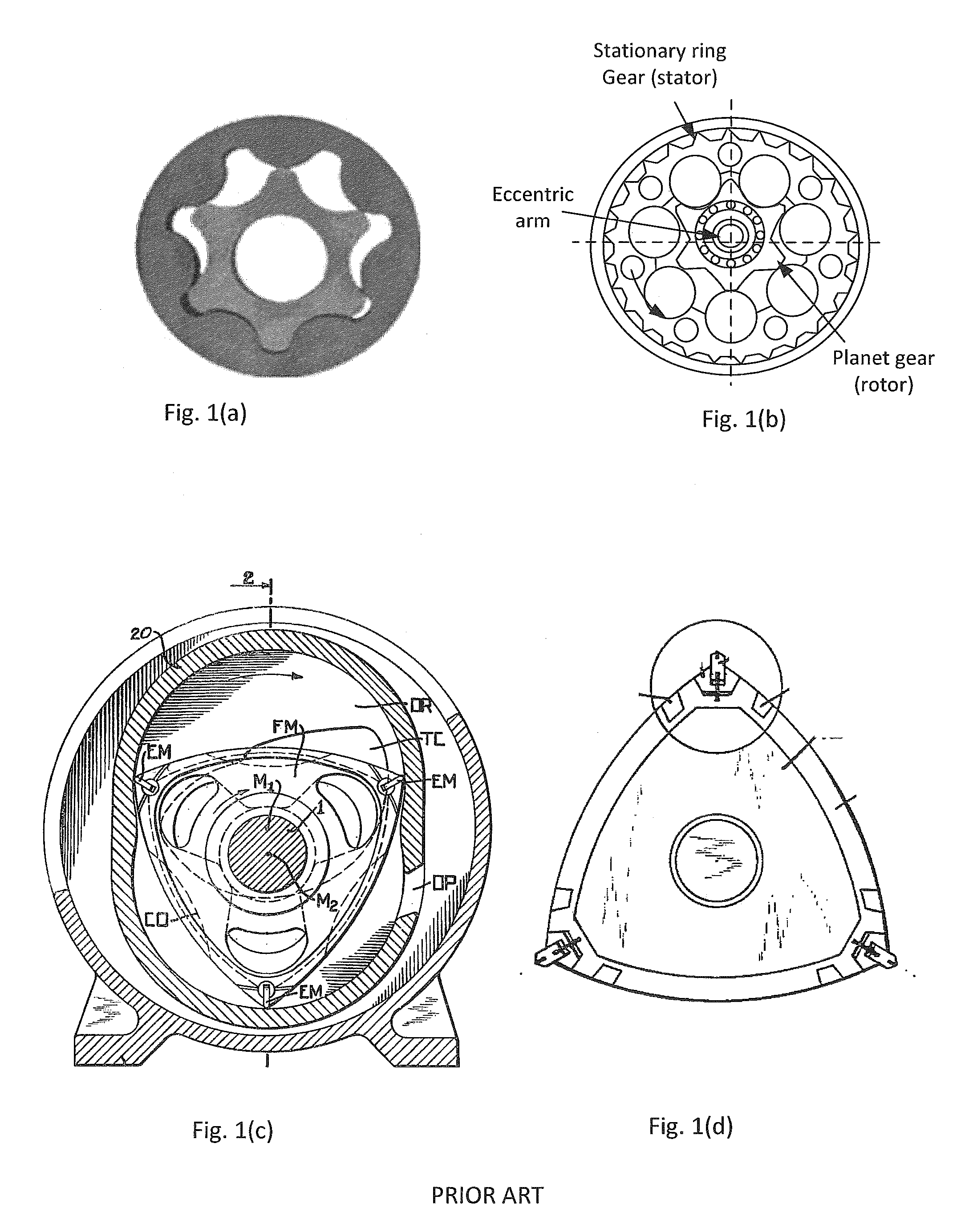

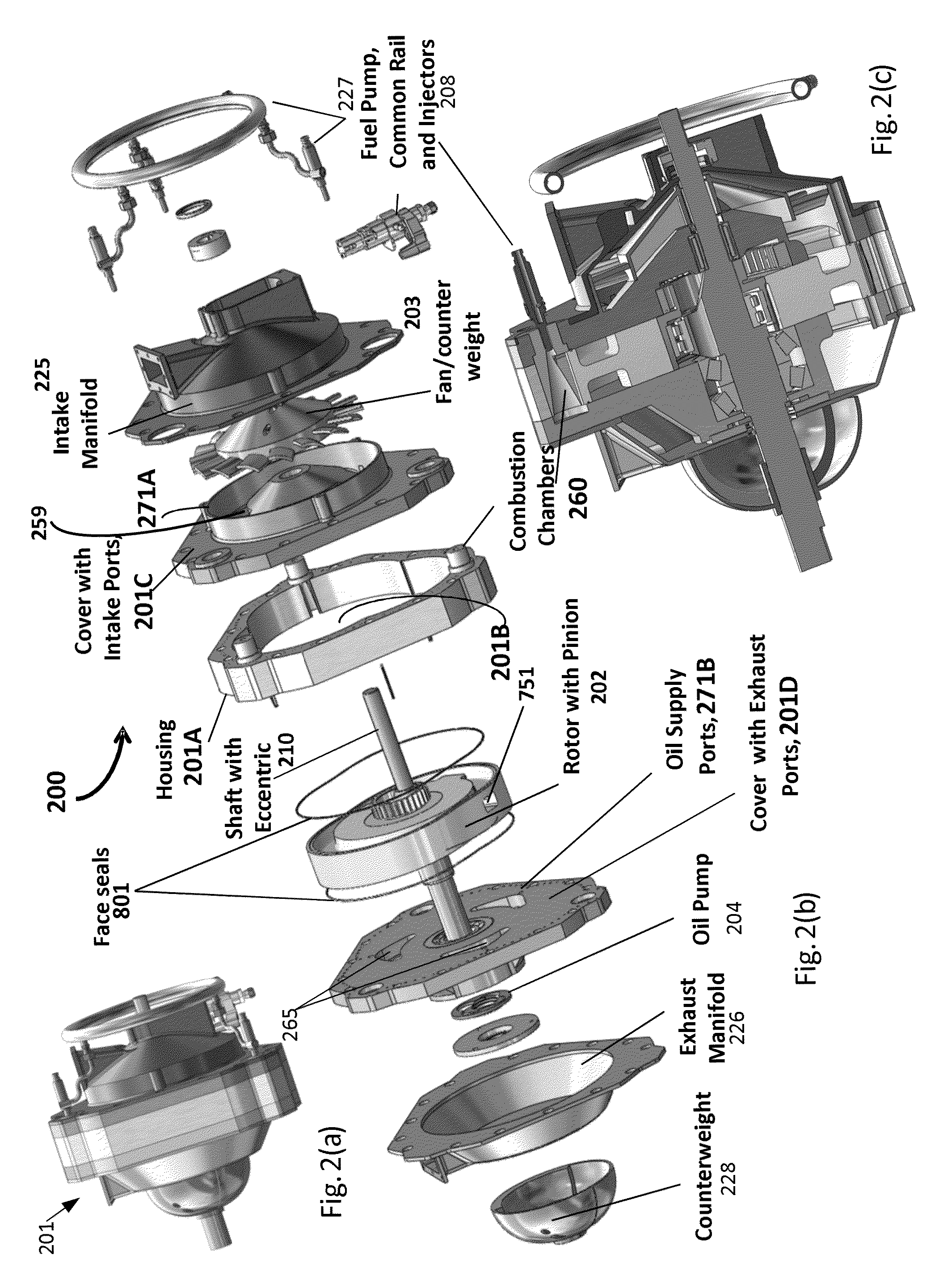

Cycloid rotor engine

ActiveUS8523546B2Internal combustion piston enginesEngine of arcuate-engagement typeRotary engineEngineering

Owner:LIQUIDPISTON INC

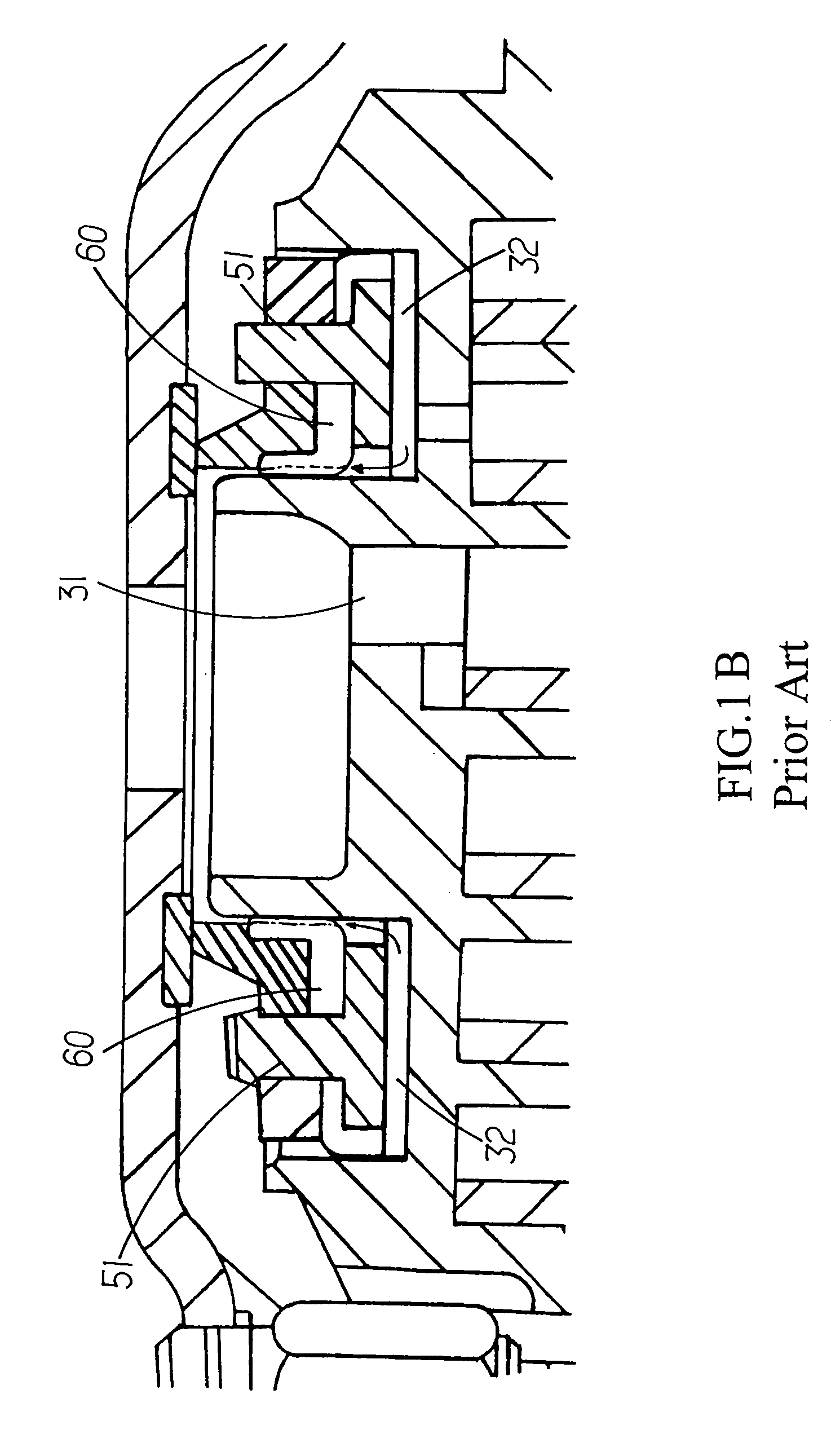

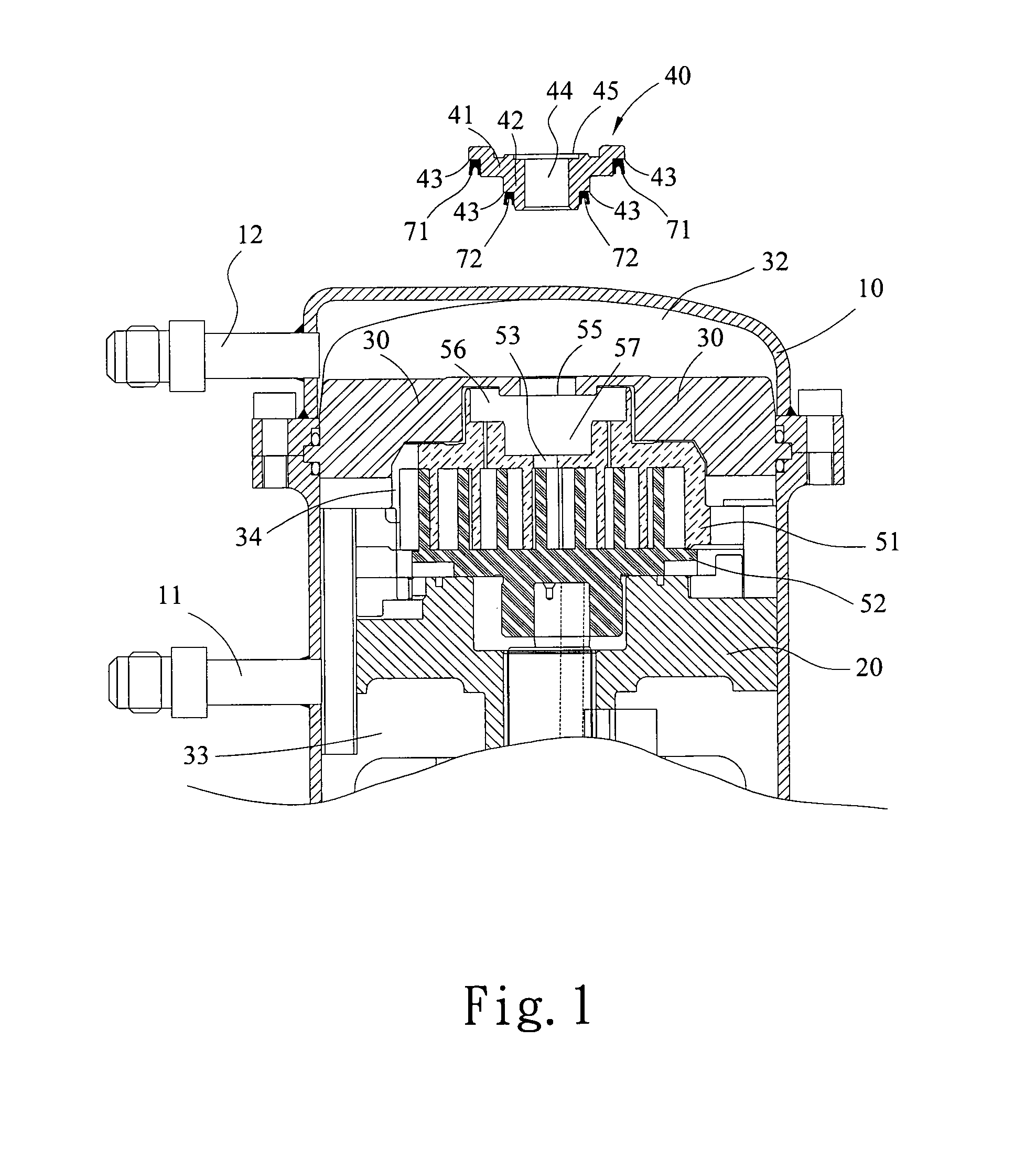

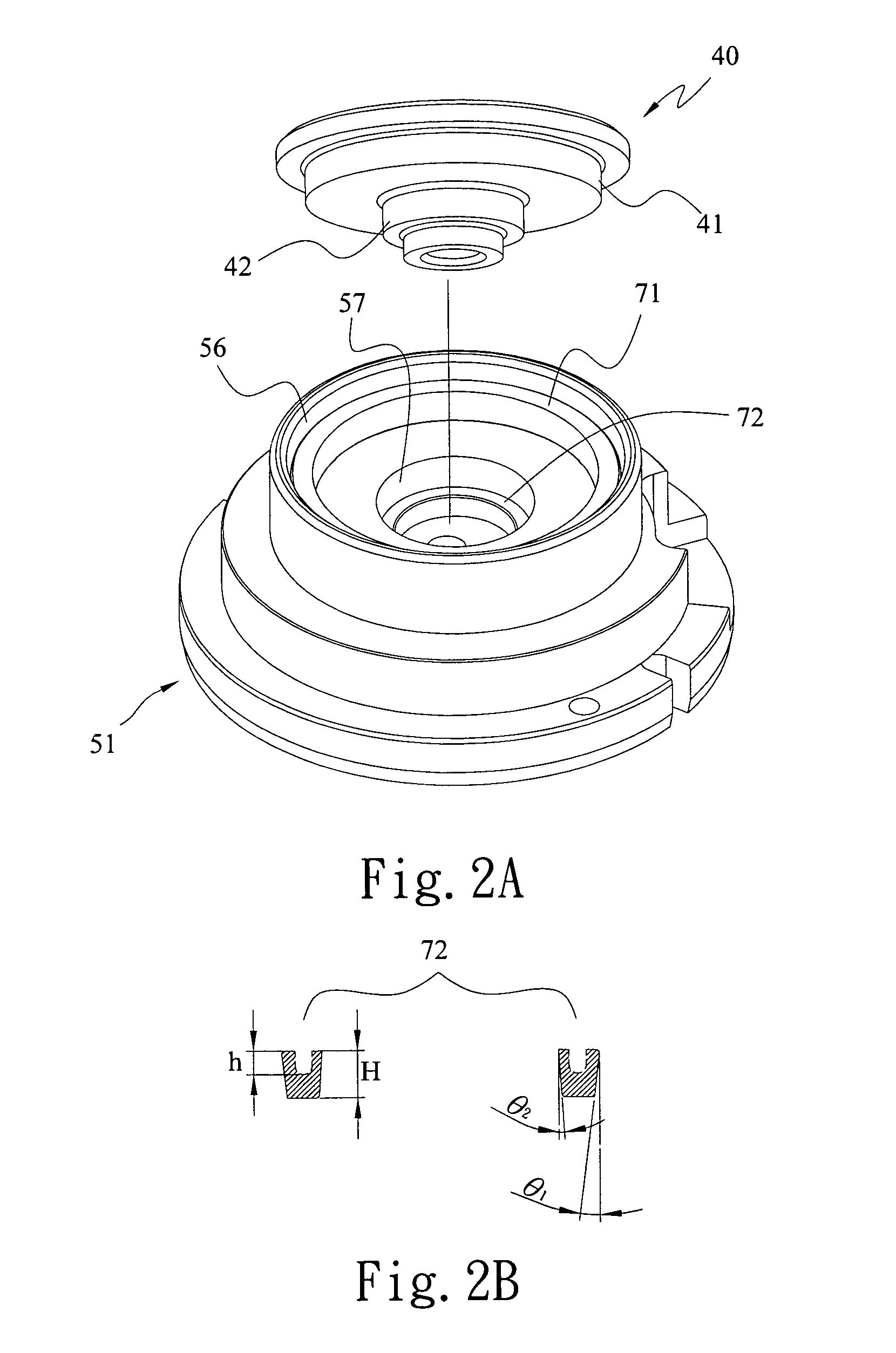

Backpressure mechanism of scroll type compressor

InactiveUS7029251B2Improve operational efficiencySimple structureEngine of arcuate-engagement typeOscillating piston enginesHigh pressureMedium pressure

A backpressure mechanism for a scroll type compressor to effectively prevent leakage of coolant; a recessed seat being provided at the top of a coolant passage at the center of a fixed scroll; a ring groove being disposed on the outer circumference of the recessed seat; a high-pressure sealing assembly comprised of a high-pressure ring, a sealing device and a high pressure ring seat and a medium-pressure sealing assembly comprised of a medium-pressure ring, a sealing device and a medium-pressure ring seat being respectively provided to the recessed seat and the ring groove; pressure from the compressed coolant causing an axially compromising vacuum unloading function to float the both sealing assemblies.

Owner:RECHI PRECISION

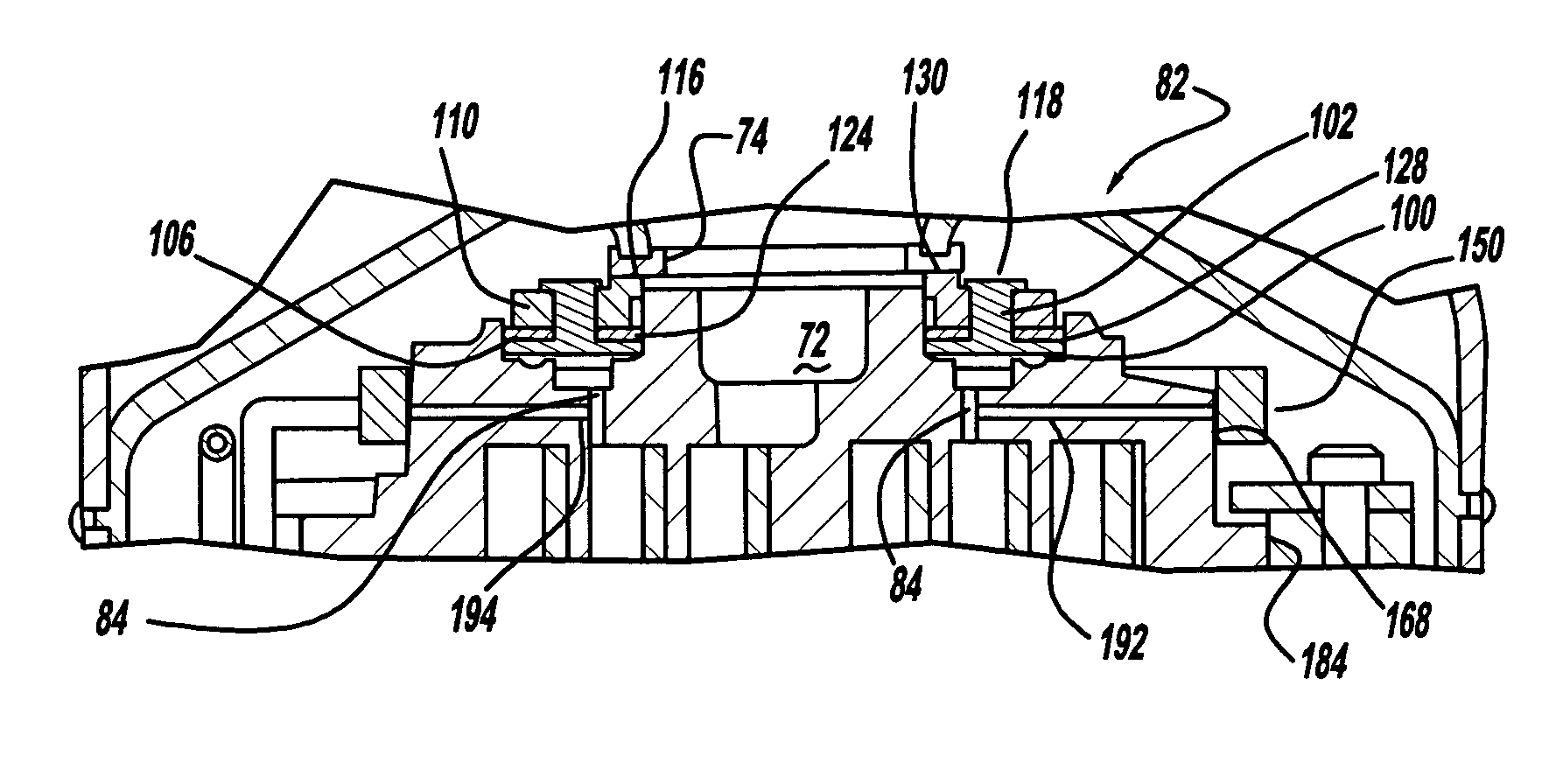

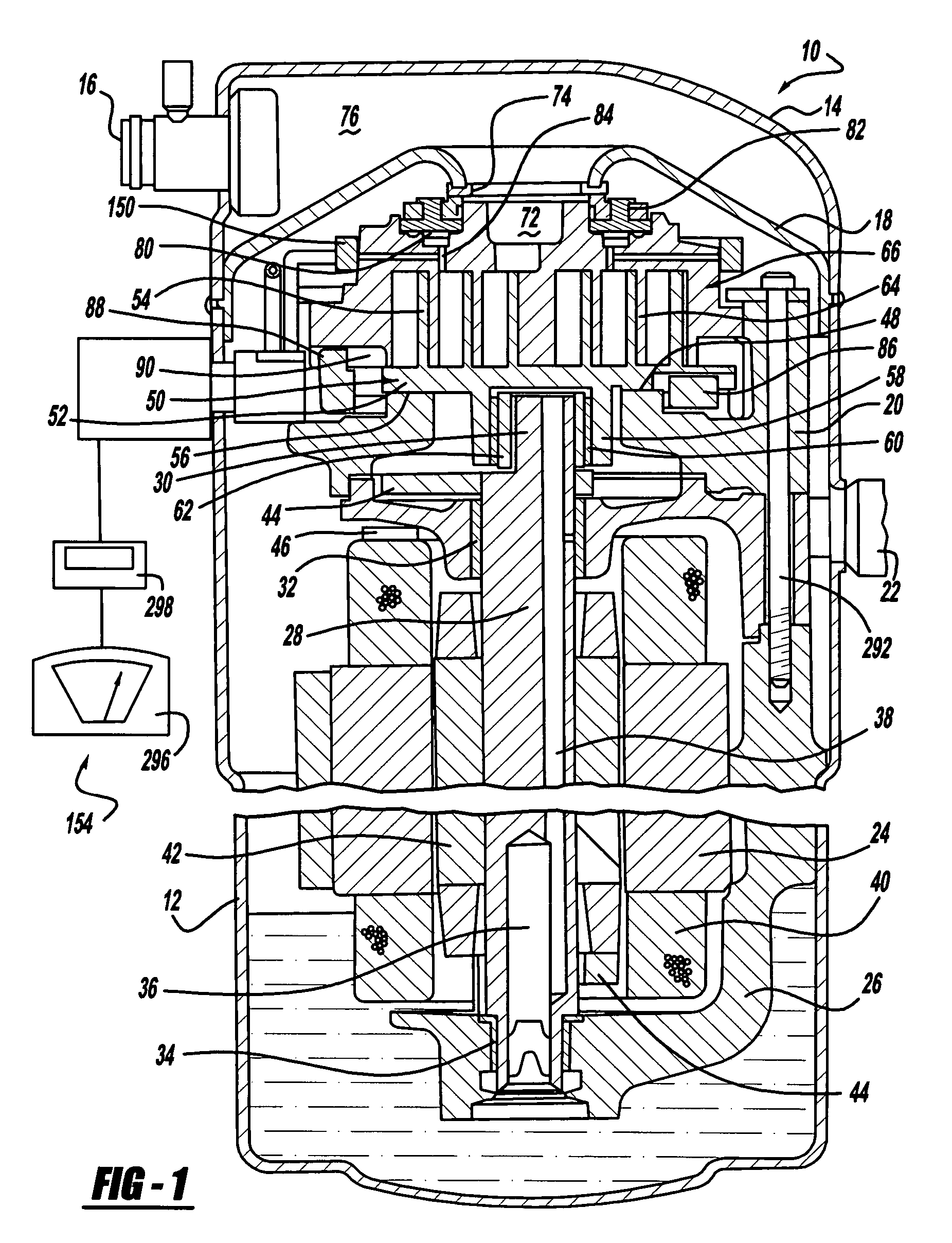

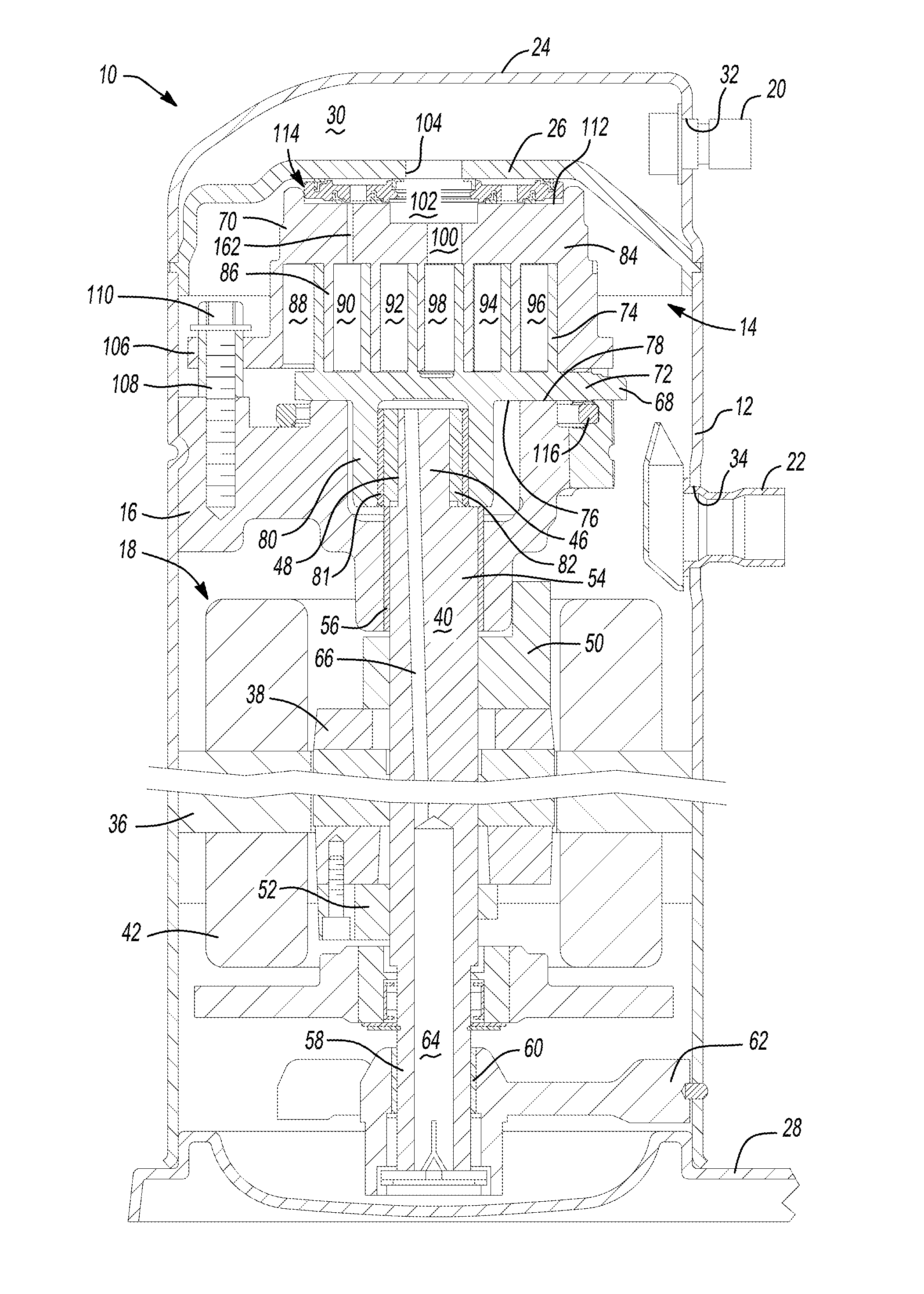

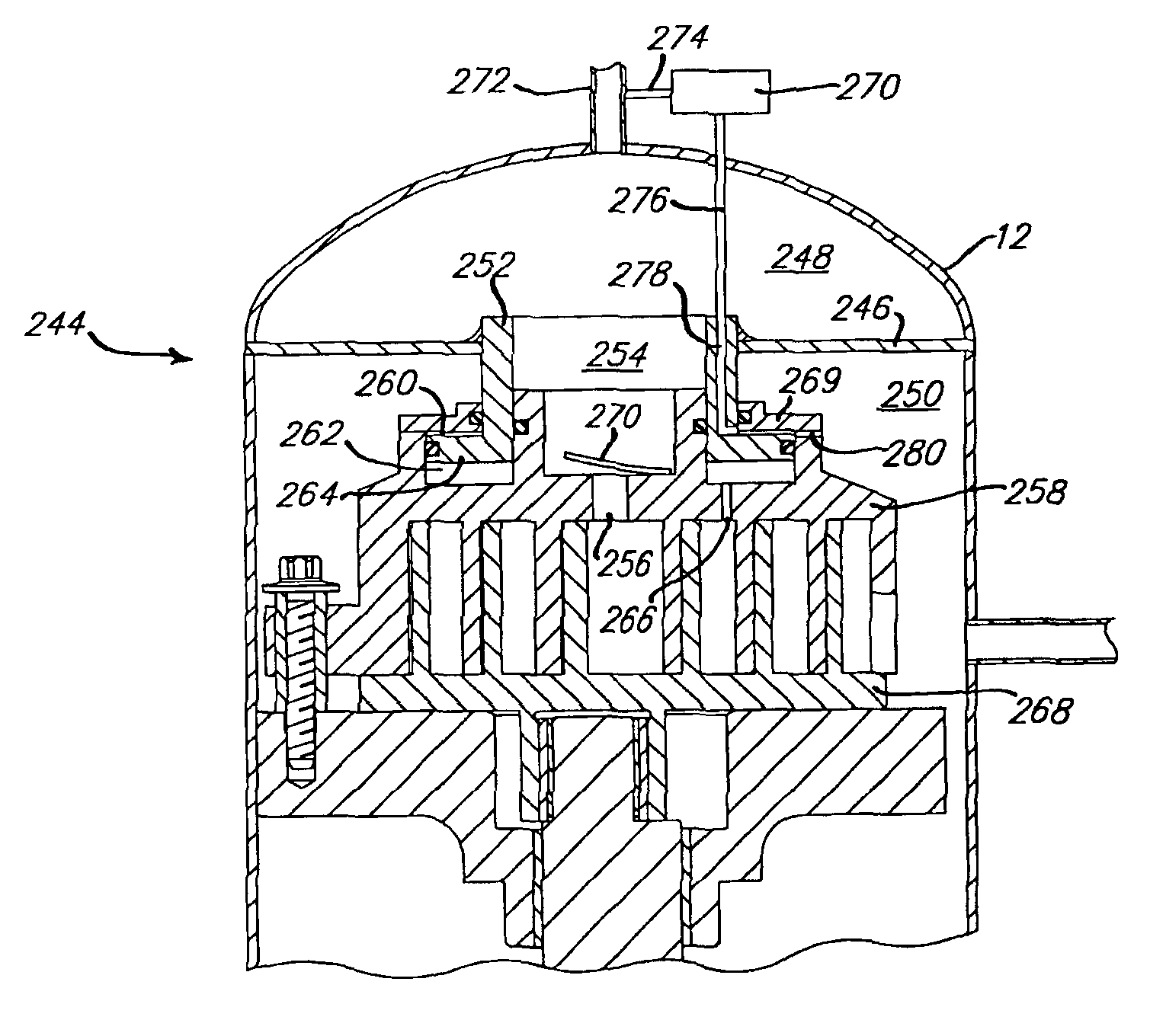

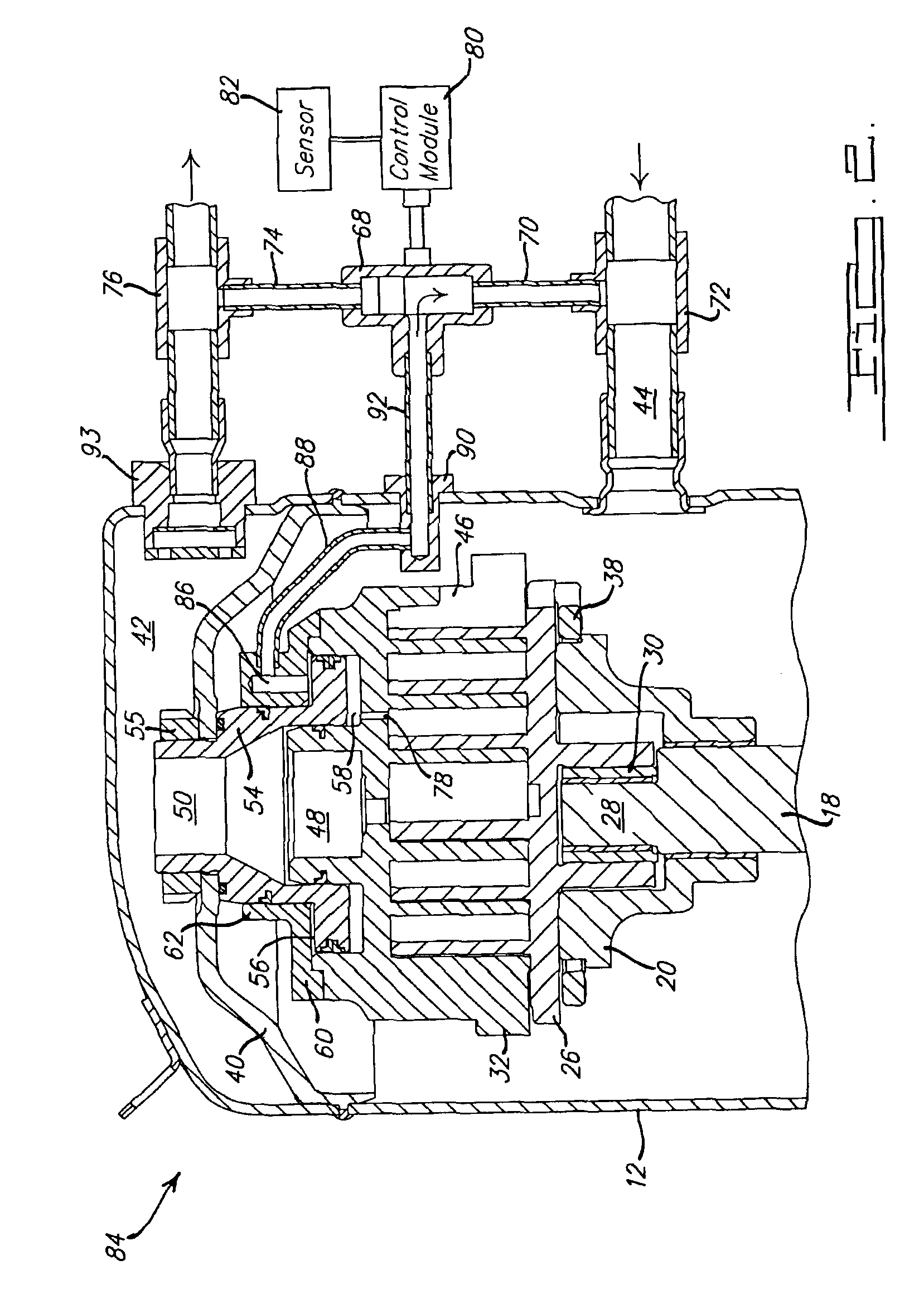

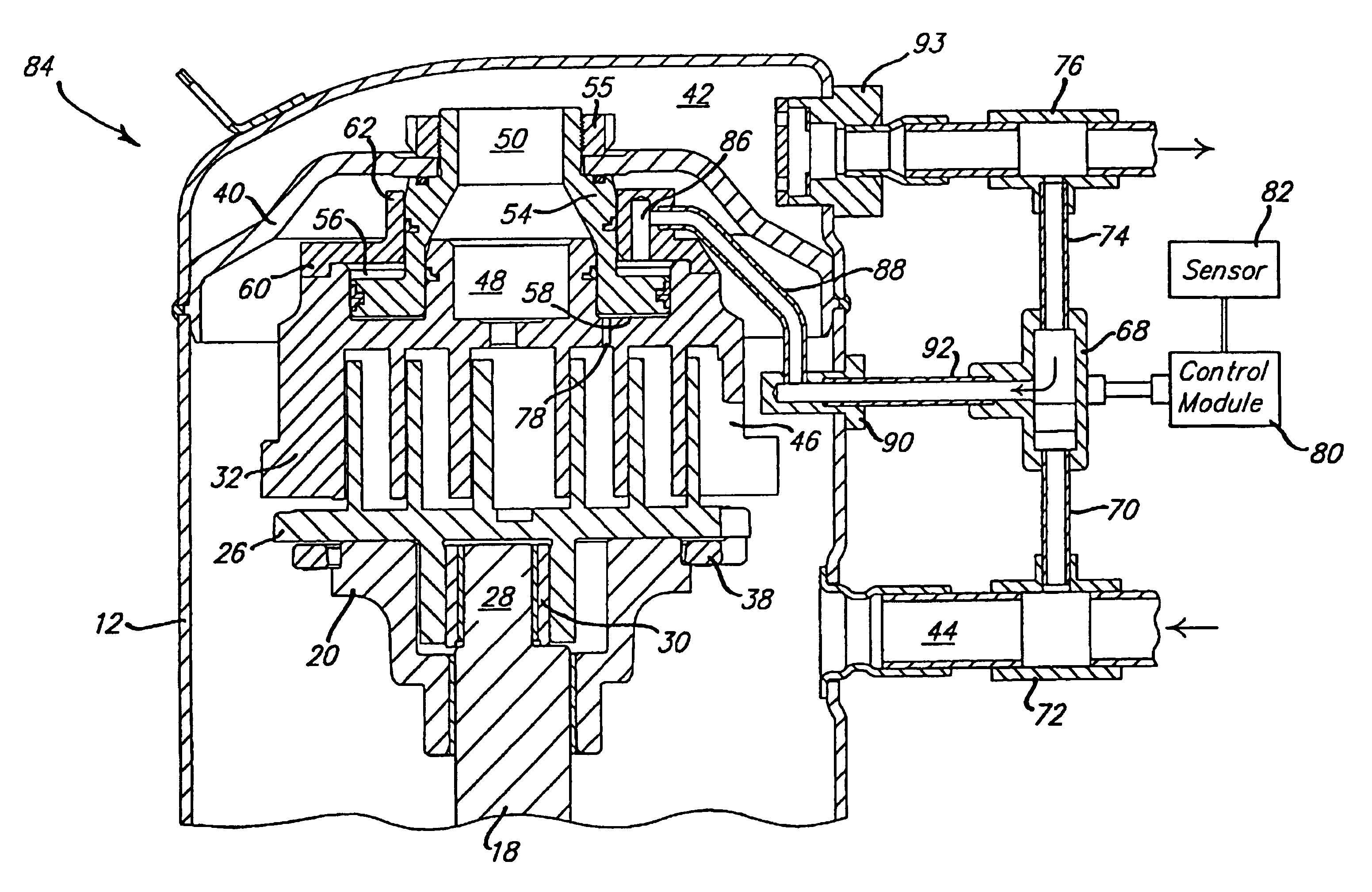

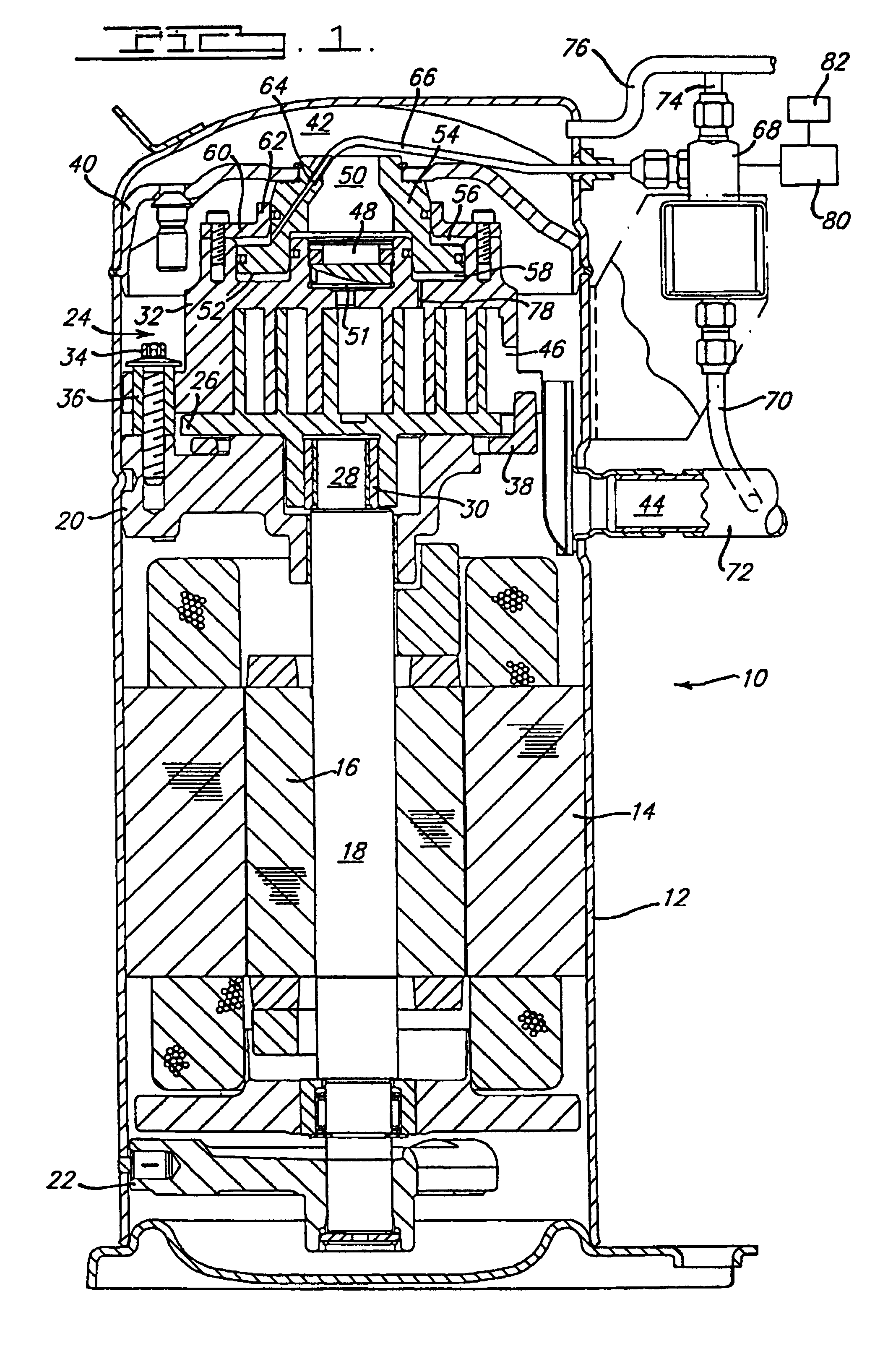

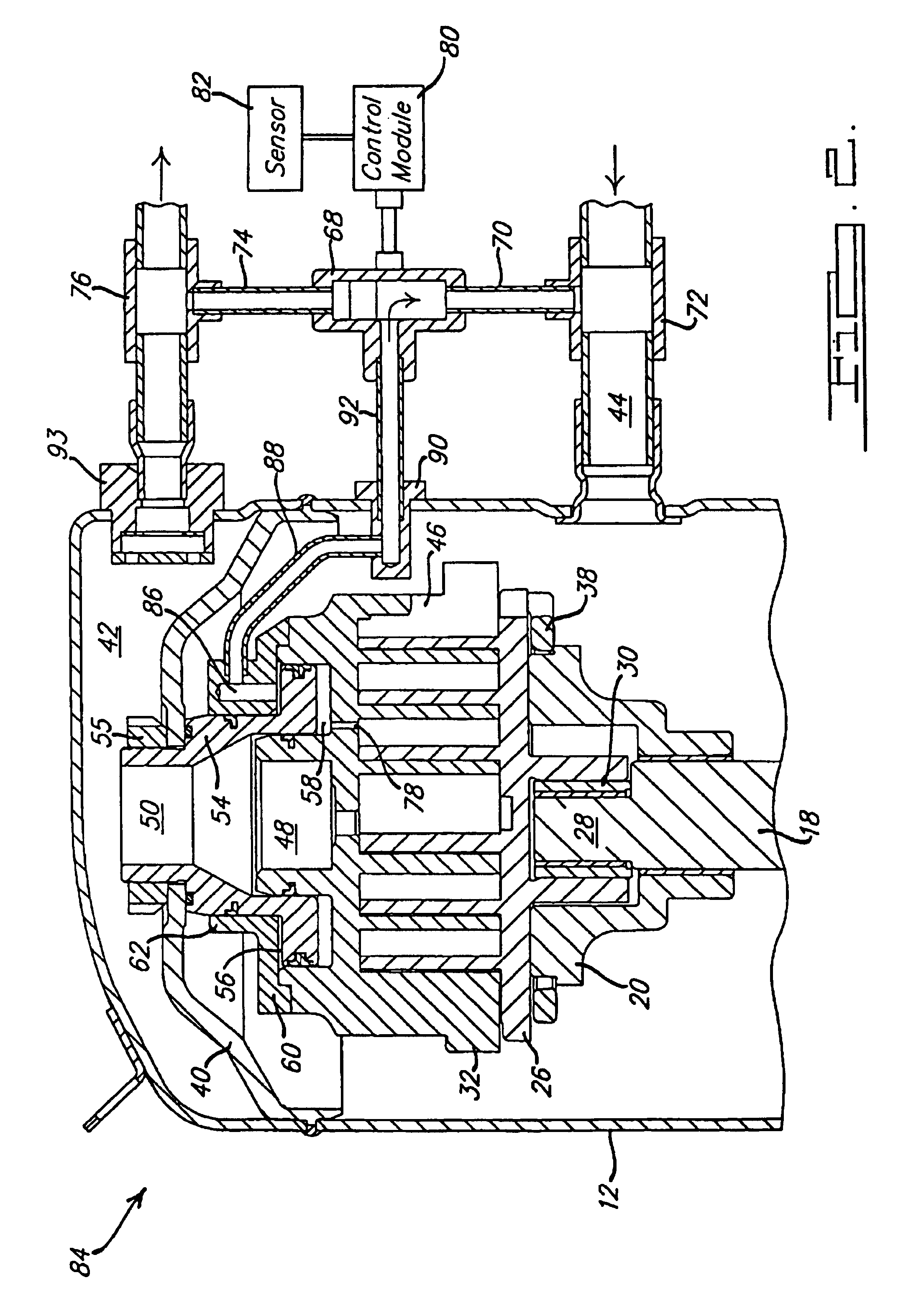

Scroll machine

ActiveUS20110293456A1Rotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringDischarge pressure

A compressor includes a shell, a compression mechanism, and an axial biasing system. The shell defines a first passage forming a first discharge passage. The compression mechanism includes first and second scroll members meshingly engaged with one another and forming a series of compression pockets. The first scroll member includes a second discharge passage. The axial biasing system includes a biasing member having first and second surfaces generally opposite one another. The first surface includes a first radial surface area exposed to an intermediate pressure from one of the compression pockets and a second radial surface area exposed to a discharge pressure. The second surface includes a third radial surface area exposed to the intermediate pressure. The biasing member is axially displaceable between first and second positions. The biasing member axially engages the first scroll member when in the first position.

Owner:COPELAND LP

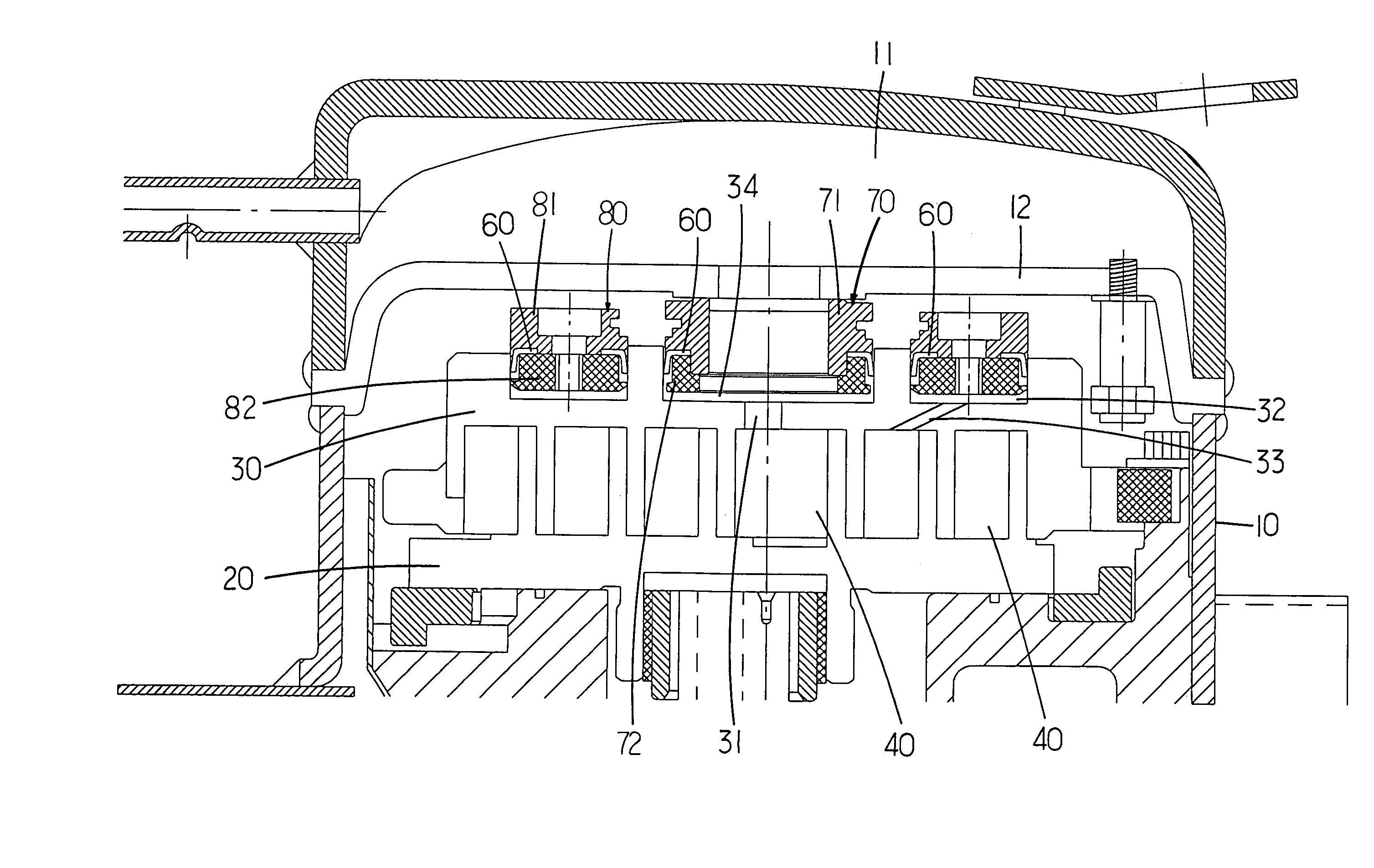

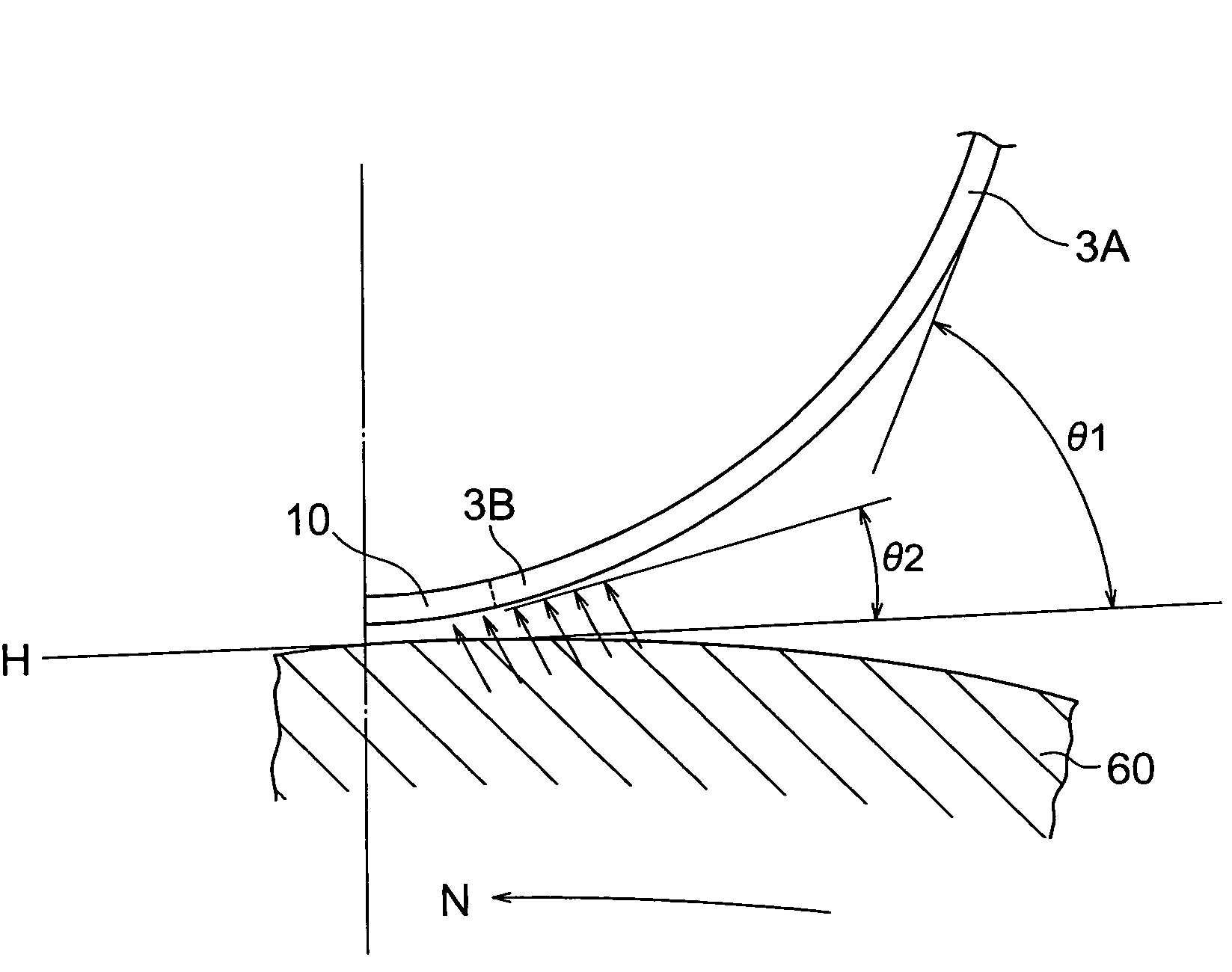

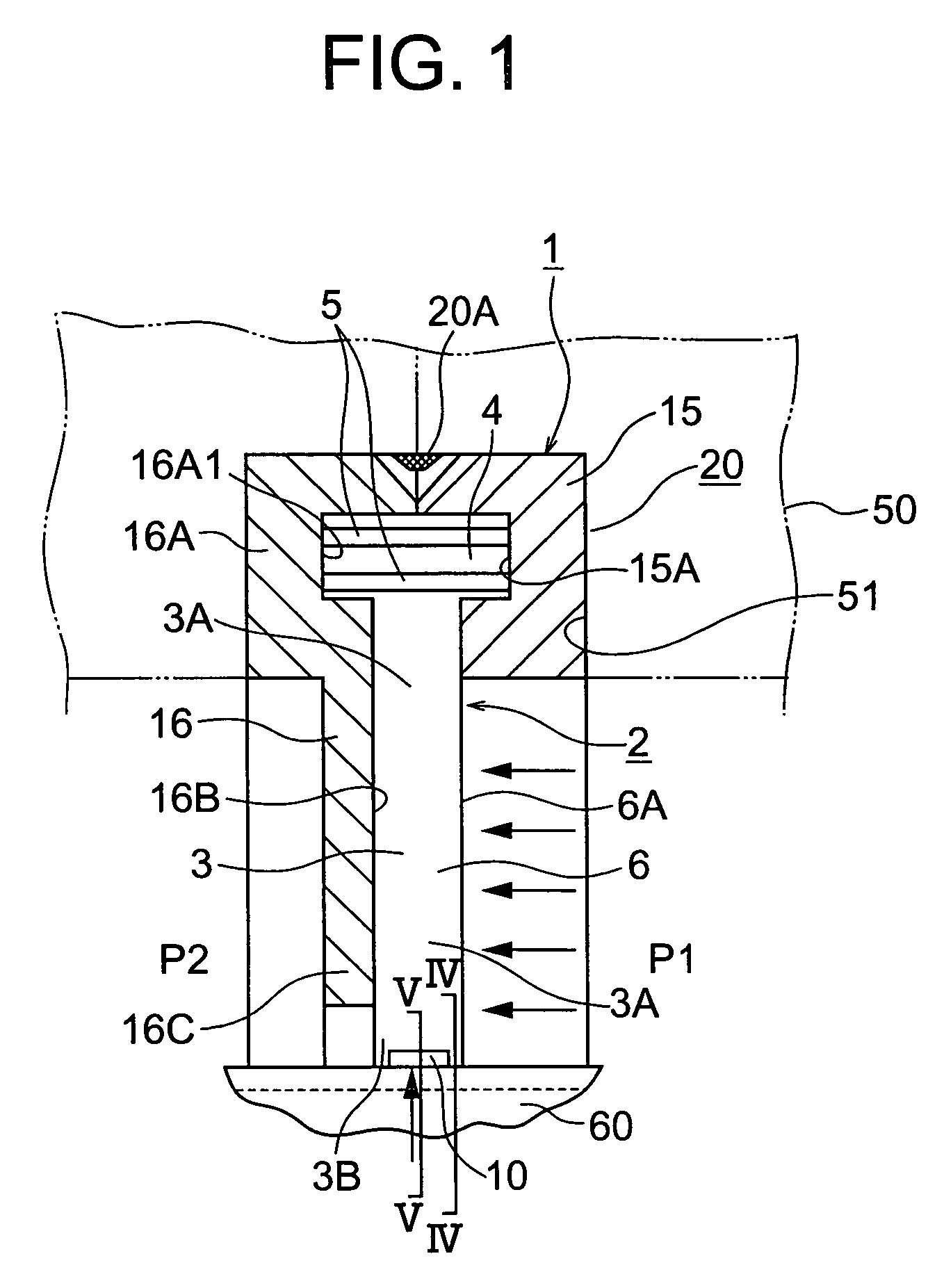

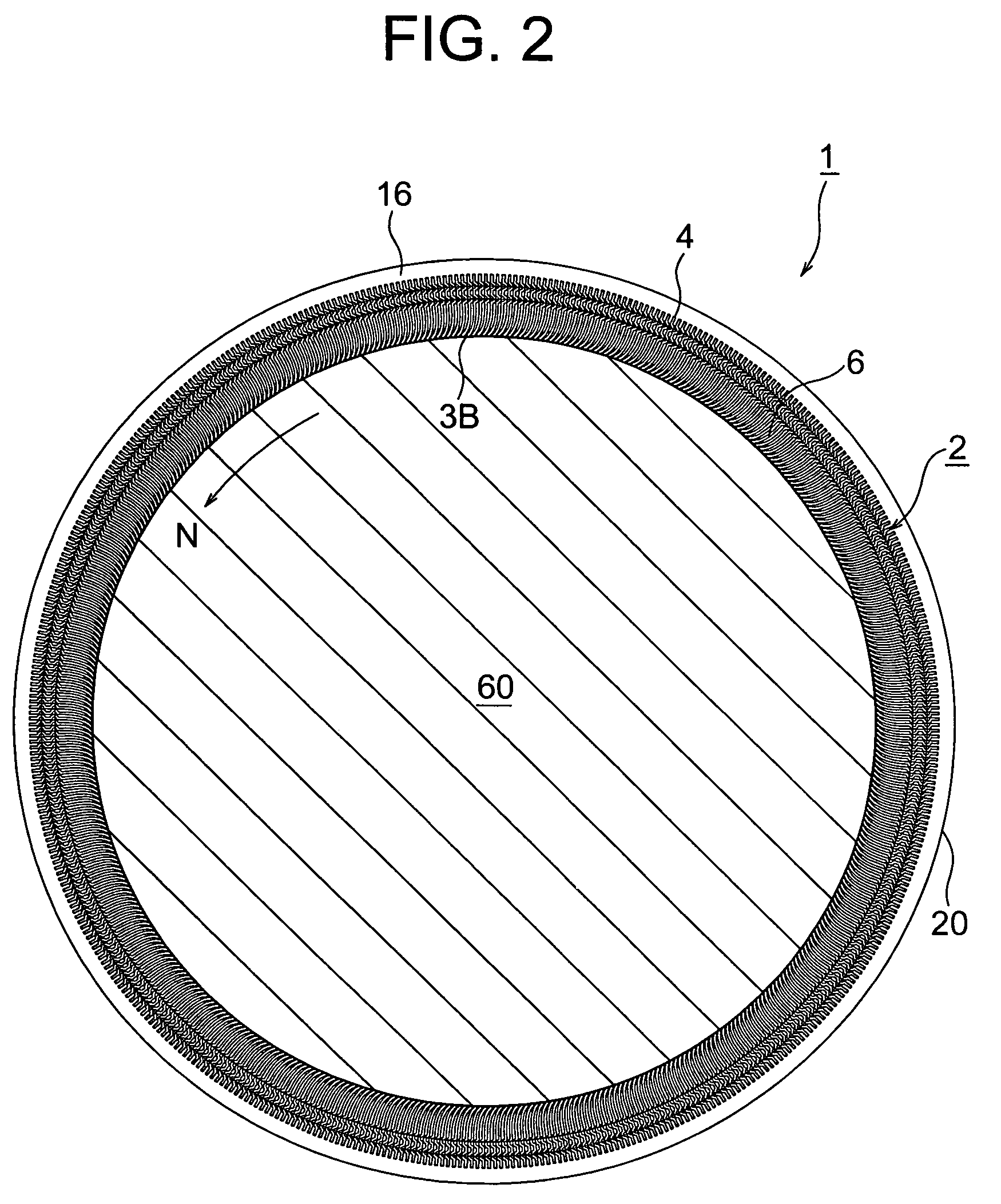

Strip brush seal

ActiveUS7201378B2Inhibit wearImprove sealingEngine sealsSealing arrangement for pumpsBand shapeMechanical engineering

A primary technical goal of this strip brush seal device is to prevent friction of a lifting portion of a seal portion against the circumference of a rotary shaft and to improve the seal capability thereof. In the strip brush seal device, each seal strip in a seal portion forms a stoppage portion in the radially outward portion thereof and a lifting strip in the radially inward portion thereof wherein the lifting strip is inflected toward the rotational direction of the rotary shaft at a second angle (θ) to the tangential direction of the circumference of the rotary shaft and the second angle (θ) is in the range of from 0 to 40 degrees.

Owner:MITSUBISHI HEAVY IND LTD

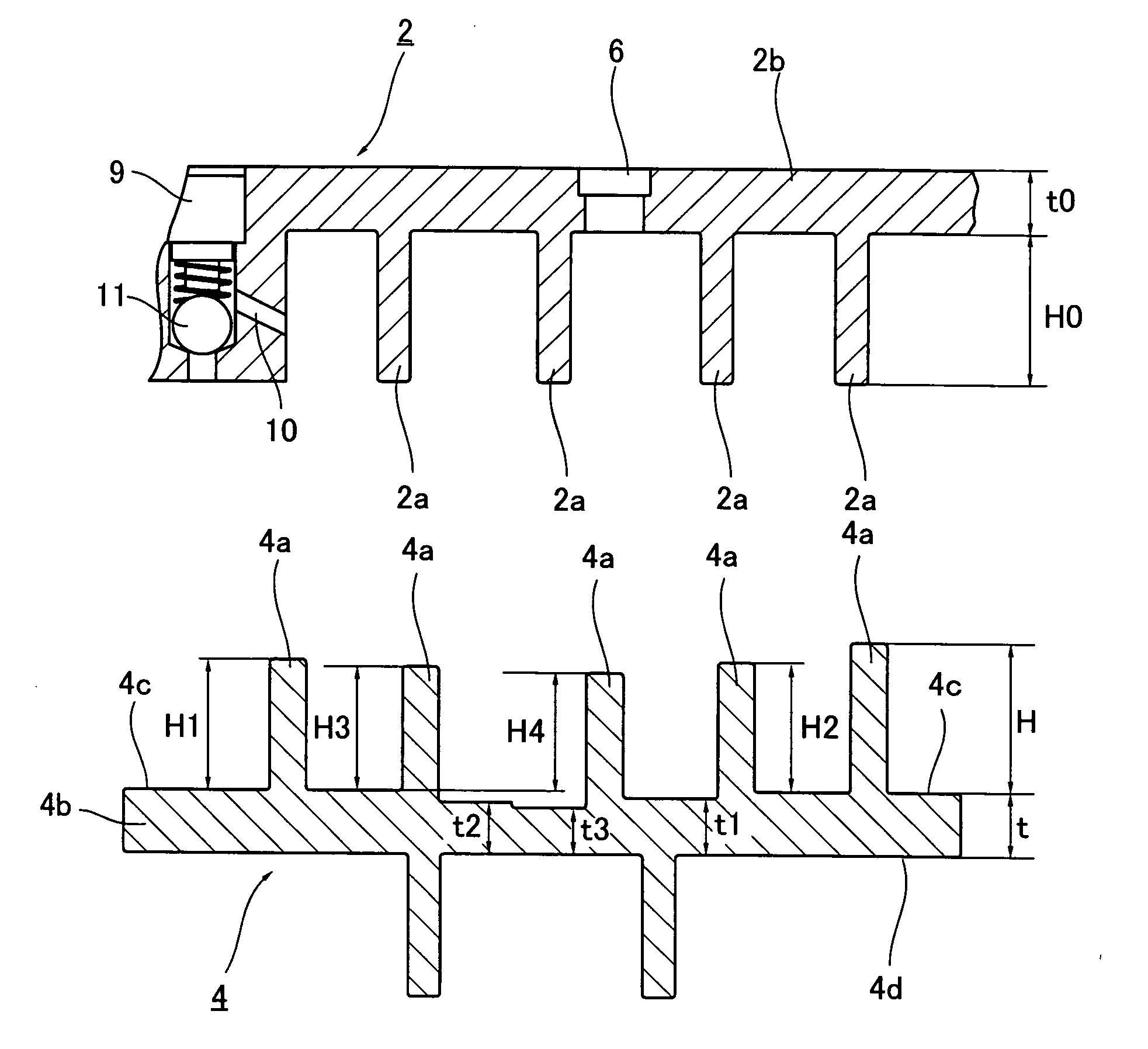

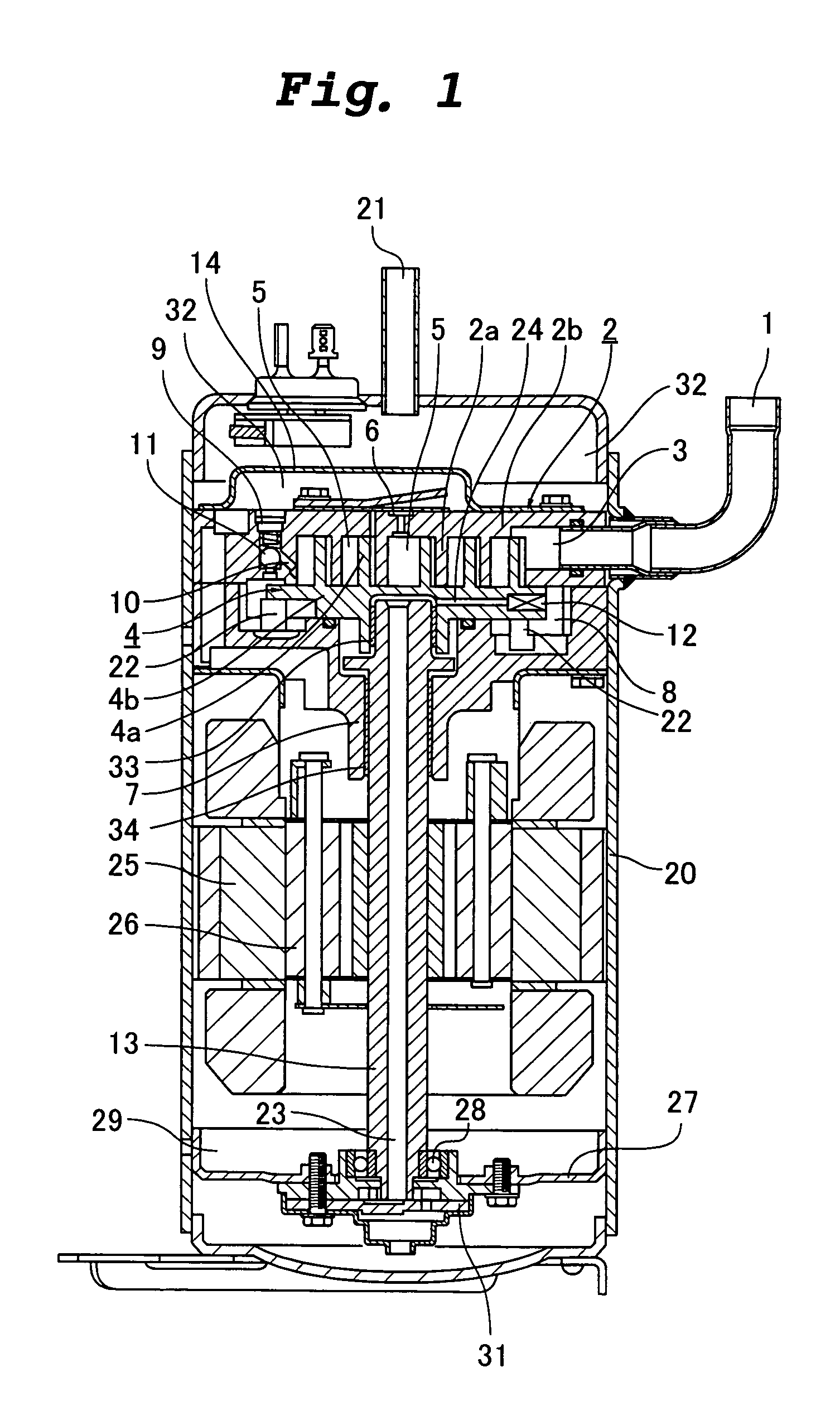

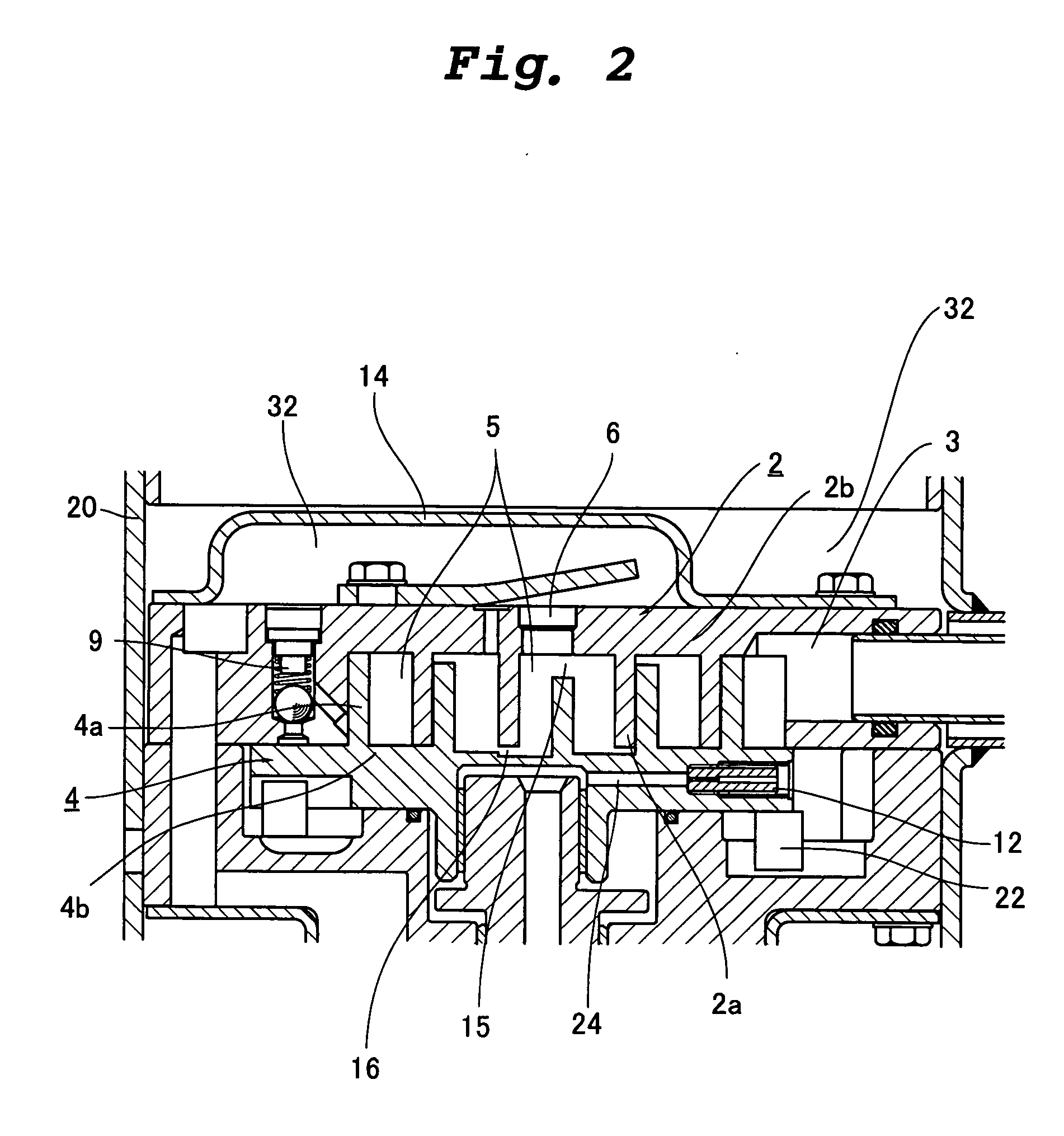

Scroll compressor

InactiveUS20070178002A1Avoid abnormal wearReliable scroll compressorEngine of arcuate-engagement typeOscillating piston enginesContact pressureScroll compressor

a First gap 15 in a thrust direction between teeth bottoms of a fixed mirror plate 2b and teeth tips of an orbiting lap 4a, and a second gap 16 in the thrust direction between teeth bottoms of an orbiting mirror plate 4b and teeth tips of a fixed lap 2a are formed such as to gradually increase from an outer peripheral side to an inner peripheral side of a scroll compressor, the first gap 15 is made greater than the second gap 16. Contact surface pressures of the laps 2a and 4a are kept low with respect to pressure deformation, contact pressure of the teeth tips of the fixed scroll part 2 and the teeth bottoms of the orbiting scroll part 4 are equally maintained. With this loads applied to the scroll parts 2 and 4 are equally received by a thrust surface.

Owner:PANASONIC CORP

Capacity modulated scroll machine

InactiveUSRE40400E1Easy to operateImprove efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringMotor control

A scroll-type machine is disclosed which is particularly well suited for use as a compressor in refrigeration and air conditioning systems and incorporates a unique arrangement for modulating the capacity thereof. In one group of embodiments the capacity of the scroll-type machine is modulated by relative axial movement between the scroll members so as to form a leakage path across the wrap tips and opposed end plates. In another group of embodiments, modulation is achieved by reducing the orbital radius of one of the scroll members to thereby form a leakage path across the flank surfaces of the wraps. Both types of scroll separation may be accomplished in a time pulsed manner to thereby enable a full range of modulation with the duration of the loading and unloading periods being selected to maximize the efficiency of the overall system. A motor control arrangement is also disclosed which may be used with either of the modulation methods mentioned above to increase the efficiency of the motor during periods of reduced load. Additionally, either of the modulation arrangements mentioned above may be combined with a delayed suction form of capacity modulation with or without the motor control feature to thereby achieve better operating efficiency under certain conditions.

Owner:EMERSON CLIMATE TECH INC

Fluid pump mechanism for use in existing helical gearsets

A fluid pump cowling for attachment to at least a pair of helical drivetrain gears having teeth and lands. The cowling has a pair of sidewalls adapted to extend at least partially over the lands of a first of the pair of drivetrain gears and a curved sump wall extending between the sidewalls that corresponds generally to the outermost circumference of the first gear. A sump channel is defined between the sidewalls on the sump wall adjacent a distal end of the sump wall. The sump channel has a generally frustoconical shape and leads to a fluid outlet opening defined in one of the sidewalls. The cowling is positioned such that the teeth of the pair of helical gears mesh in an area in fluid communication with the sump channel to create an area of high fluid pressure upon rotational movement of the gears with a fluid.

Owner:FORD GLOBAL TECH LLC

Capacity modulated scroll machine having one or more pin members movably disposed for restricting the radius of the orbiting scroll member

InactiveUSRE40554E1Maximize efficiencyEasy to operateRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeMotor controlAir conditioning

Owner:EMERSON CLIMATE TECH INC

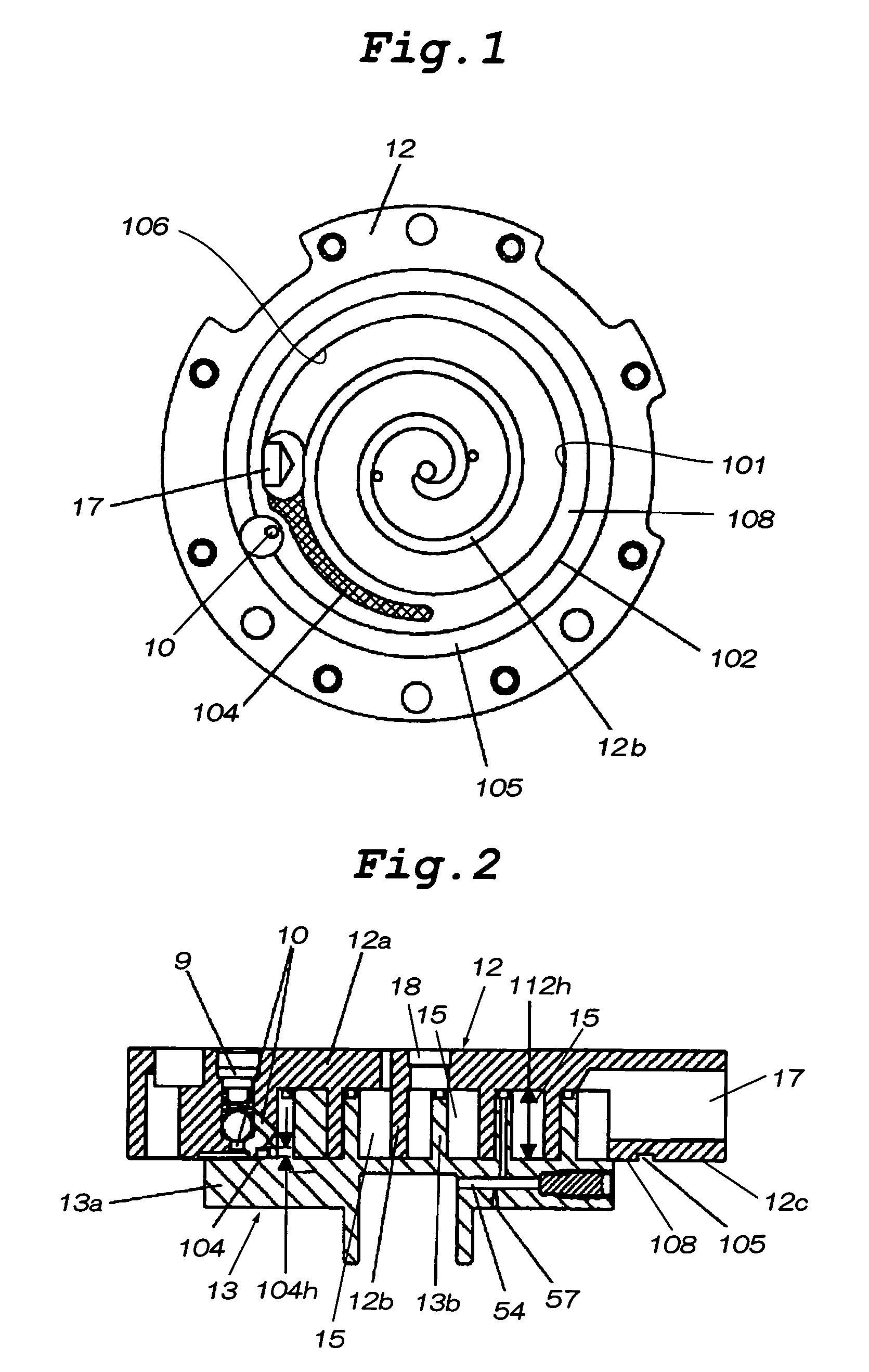

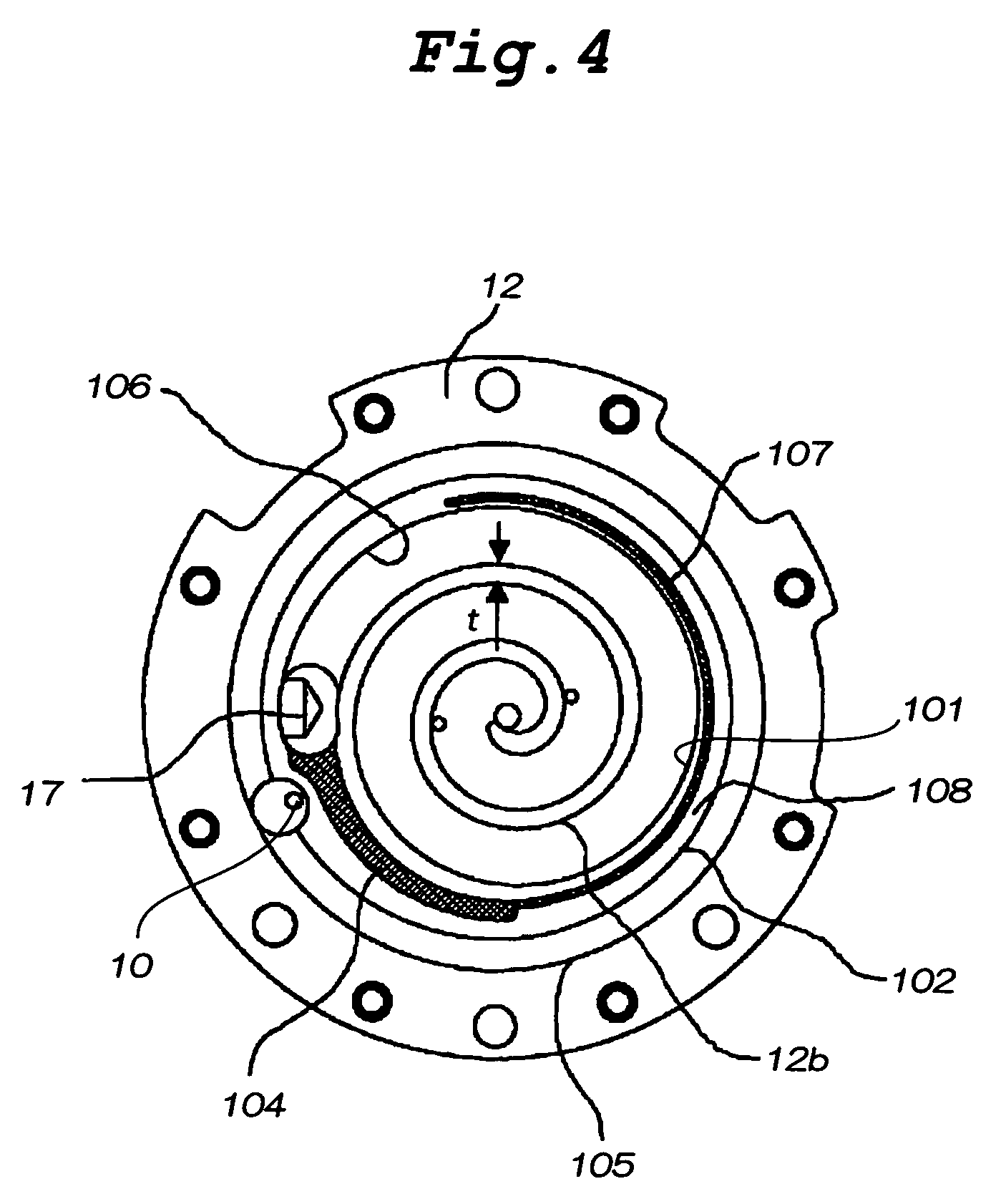

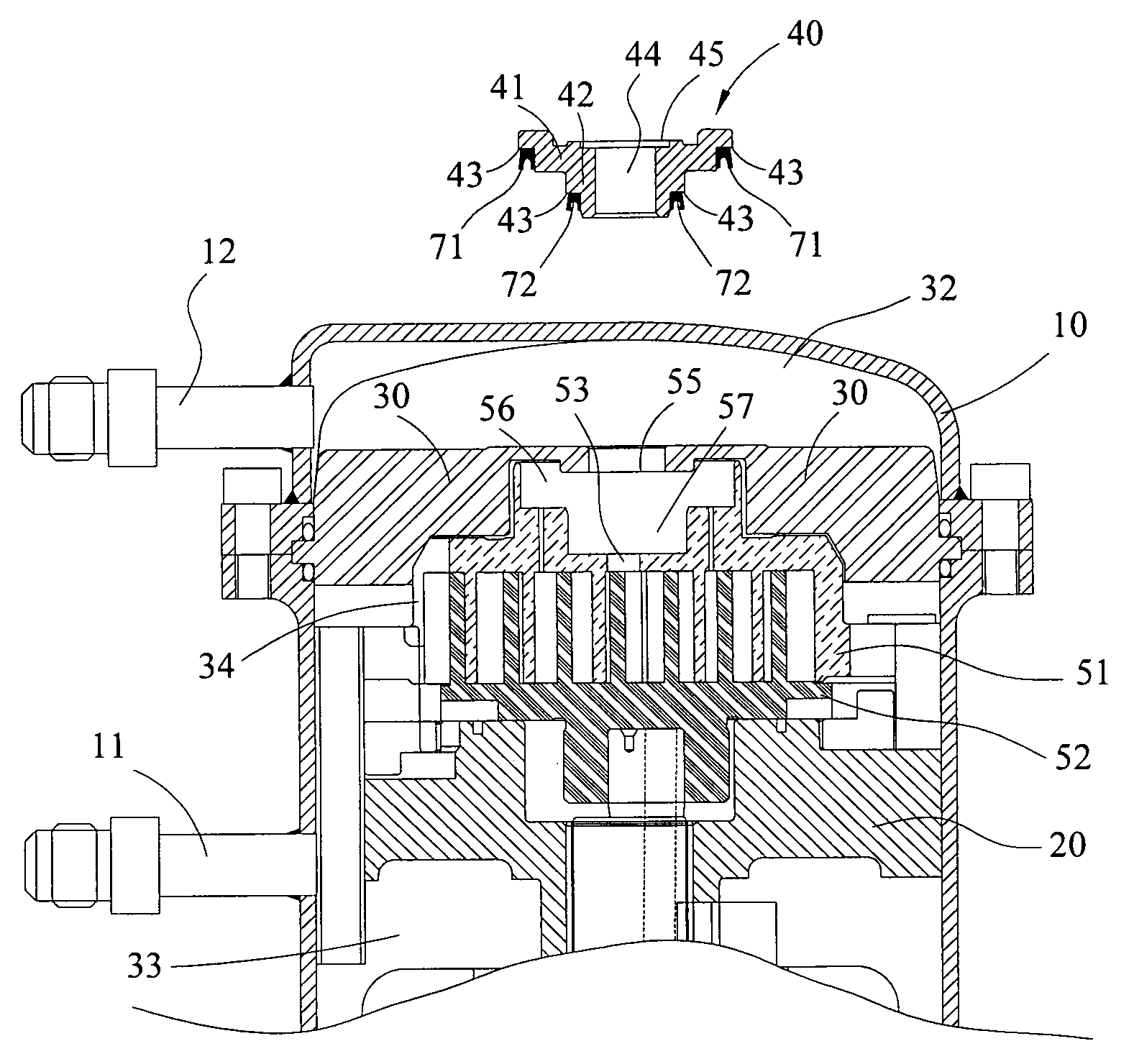

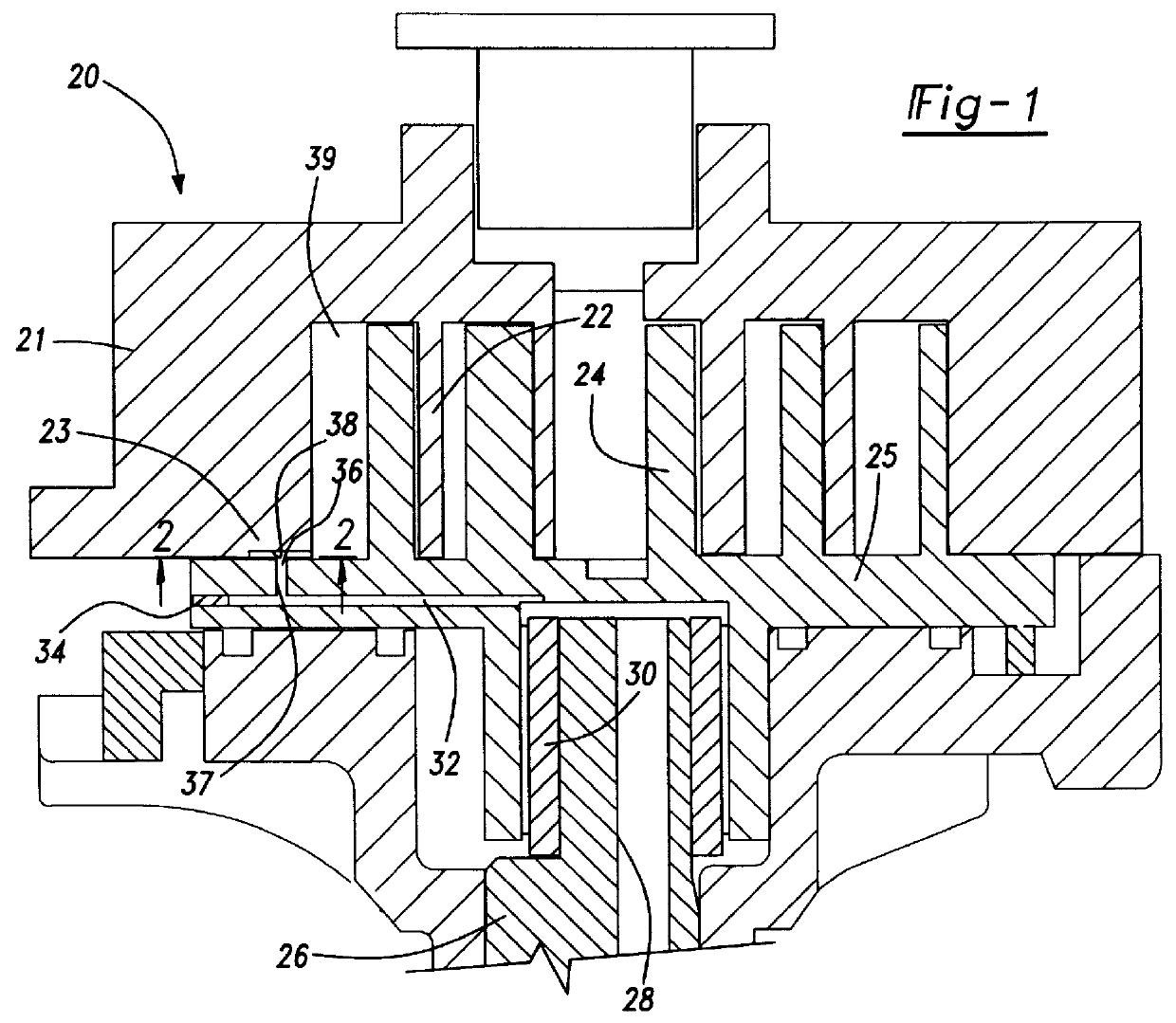

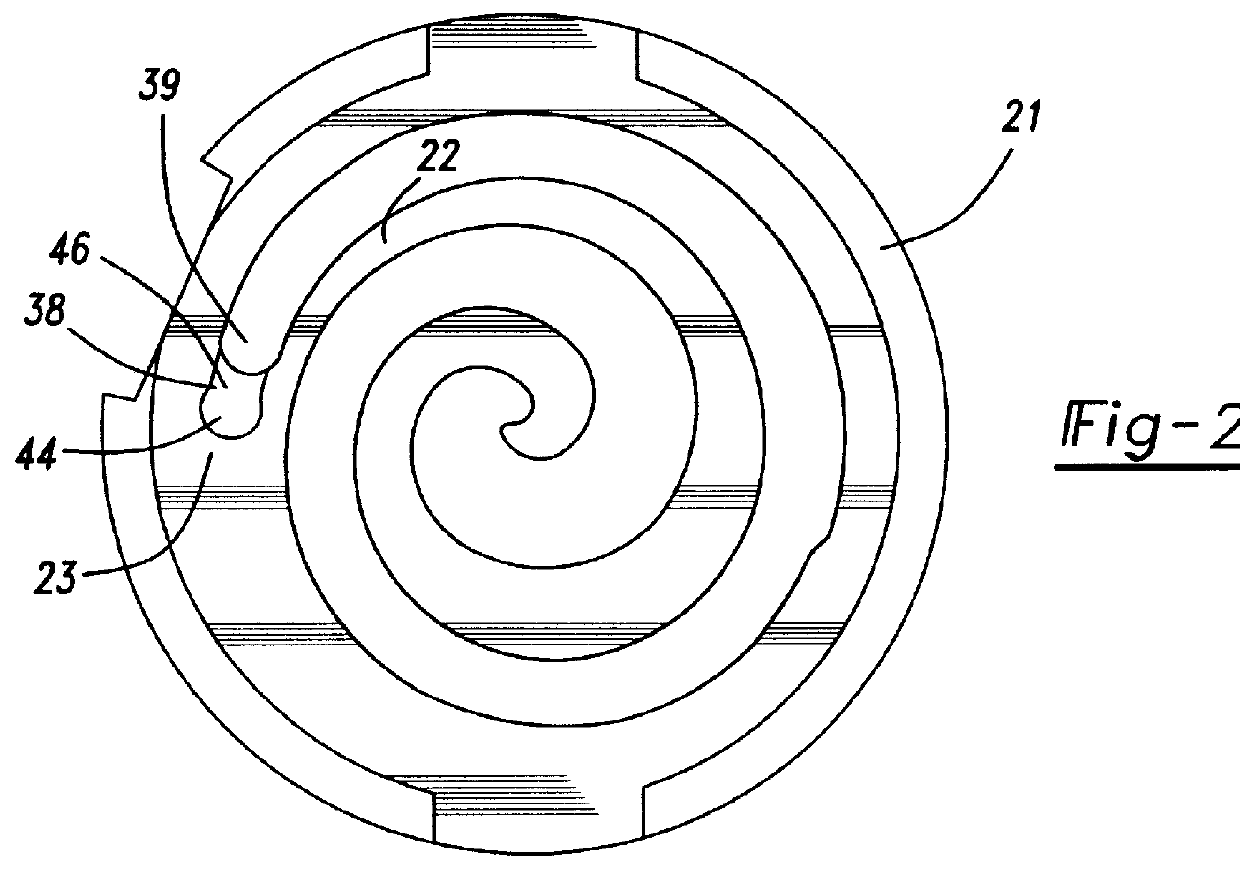

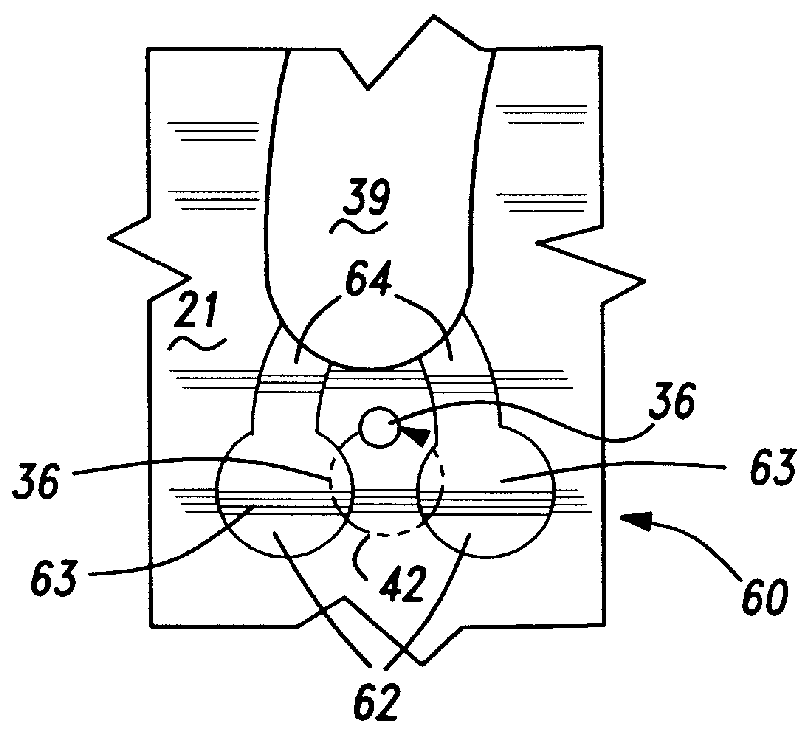

Scroll type compressor with an enhanced sealing arrangement

ActiveUS7364416B2Easy to assembleImprove sealingEngine of arcuate-engagement typeOscillating piston enginesEngineeringMechanical engineering

A scroll type compressor with an enhanced sealing arrangement includes two sealing rings, mounted one between a first part of a gliding block and a first chamber of a fixed scroll and another one between a second part of the gliding block and a second chamber of the fixed scroll, respectively. The sealing ring has a U-shape cross section characterized in having a center depth smaller than half of a total height of the cross section. By providing such sealing rings, damage in mounting the sealing rings can be reduced to a minimum, possible leakage from the damage can be avoided, the assembly process in producing the compressor can be improved, and the compressor can be successfully merchandized.

Owner:IND TECH RES INST

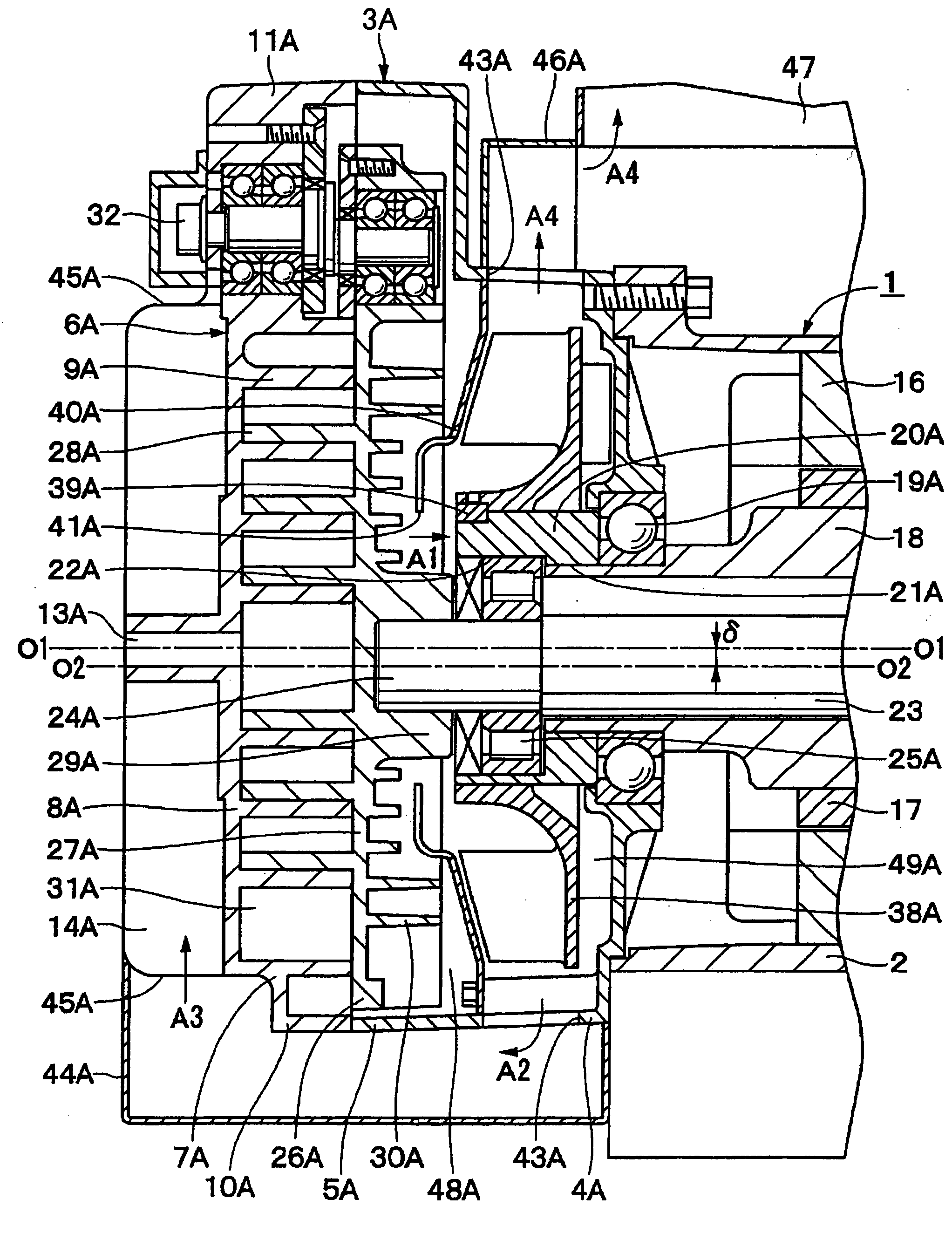

Scroll type fluid machinery

InactiveUS20050169788A1Simple cooling structureSmall sizeRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeMechanical engineeringEngineering

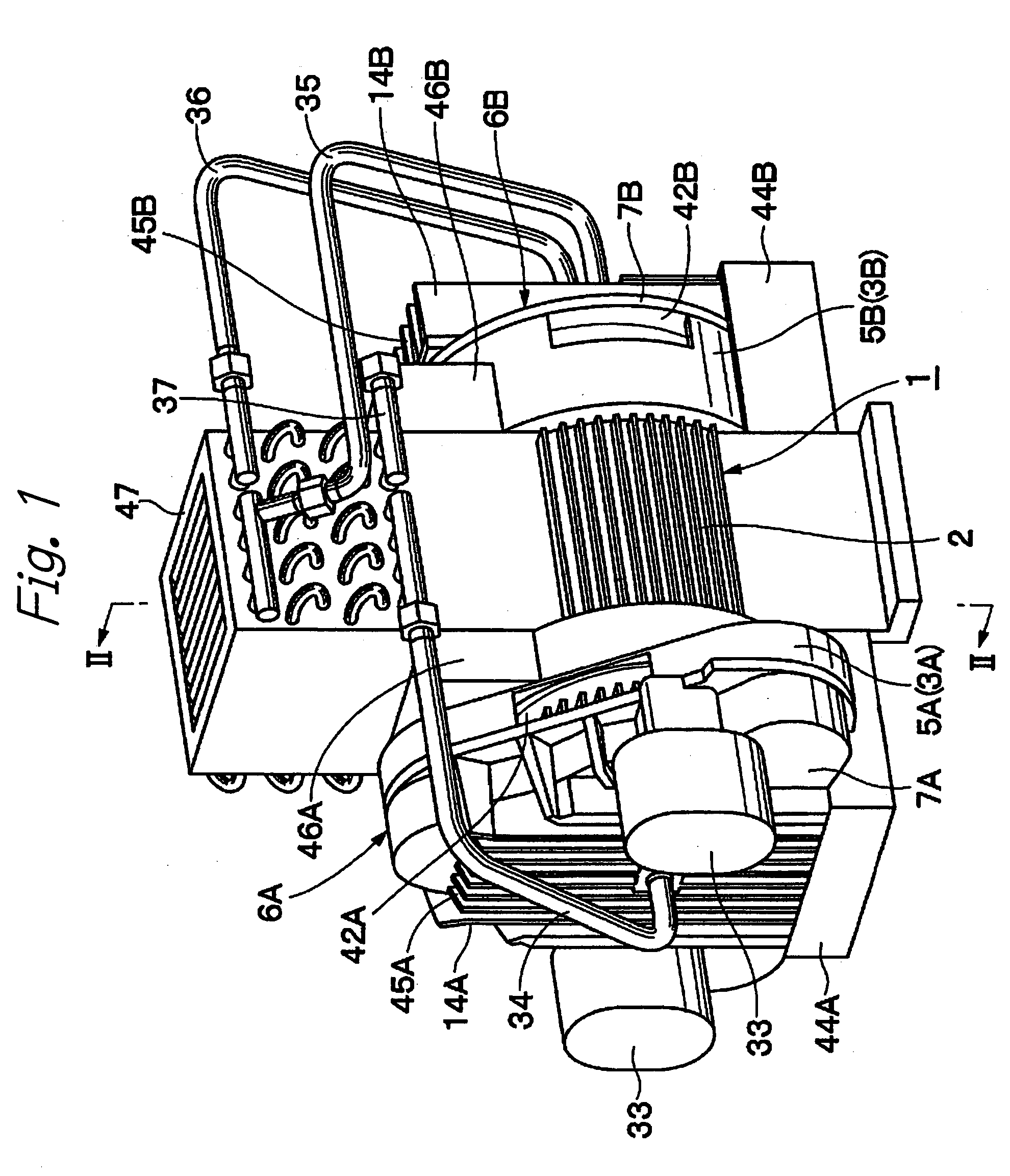

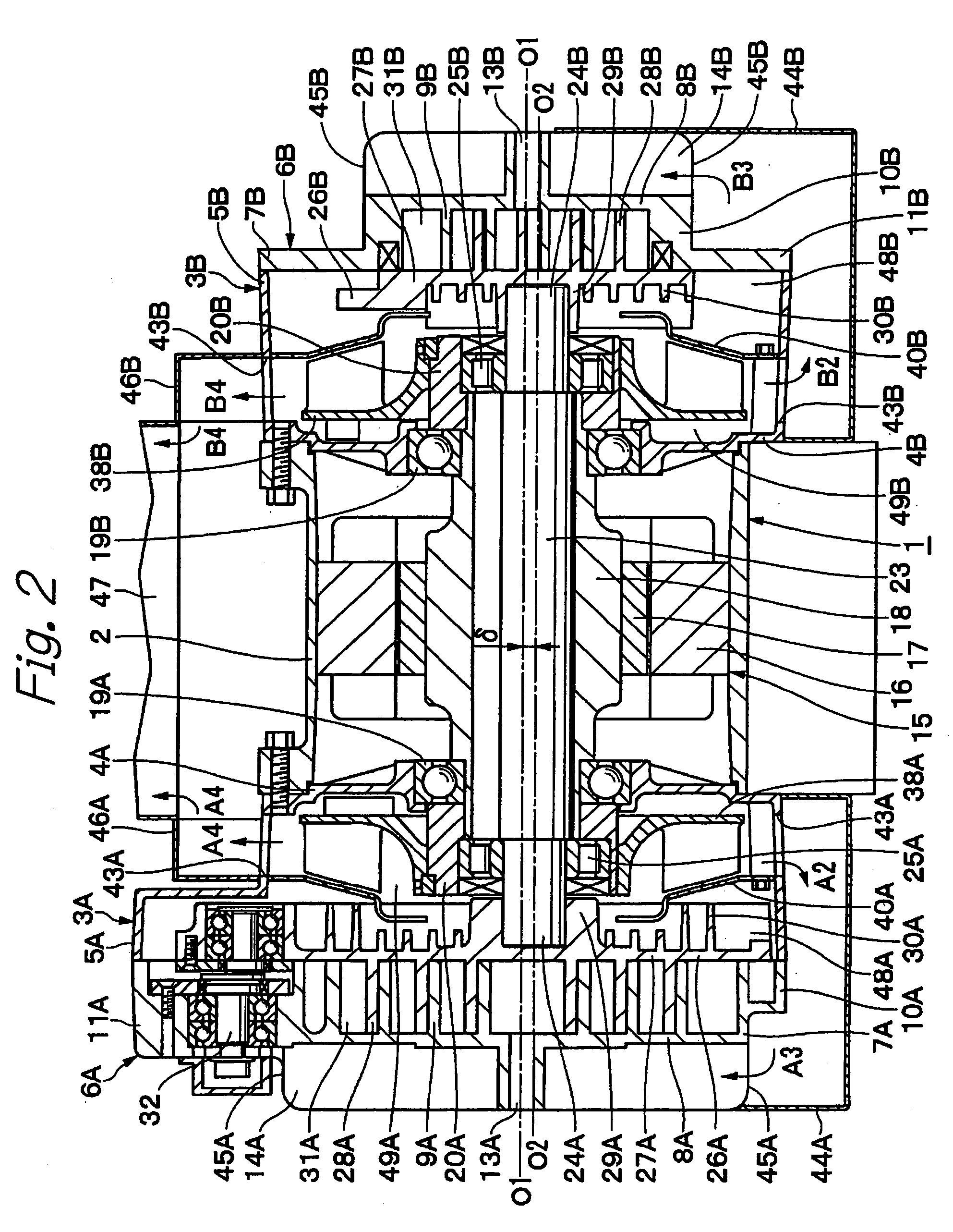

The present invention provides a scroll type fluid machine which enables both of a fixed scroll and an orbiting scroll to be cooled by means of a cooling fan, and which enables an overall size of the machine to be compact. Cooling fans 38A and 38B are connected to a rotary shaft 18 between an electric motor 15 and orbiting scrolls 26A and 26B. Outer cases 3A and 3B are provided with flow inlet openings 42A and 42B, flow outlet openings 43A and 43B, scroll ducts 44A and 44B and cooling device ducts 46A and 46B. Compression portions 6A and 6B are operated by rotatably driving the rotary shaft 18 using the electric motor 15. In this instance, the cooling fans 38A and 38B are rotated with the rotary shaft. Therefore, with a simple structure having no electric fans, the fixed scrolls 7A and 7B, the orbiting scrolls 26A and 26B and the cooling device 47 can be efficiently cooled, and a compressor having a compact size and a high cooling performance can be formed.

Owner:HITACHI LTD

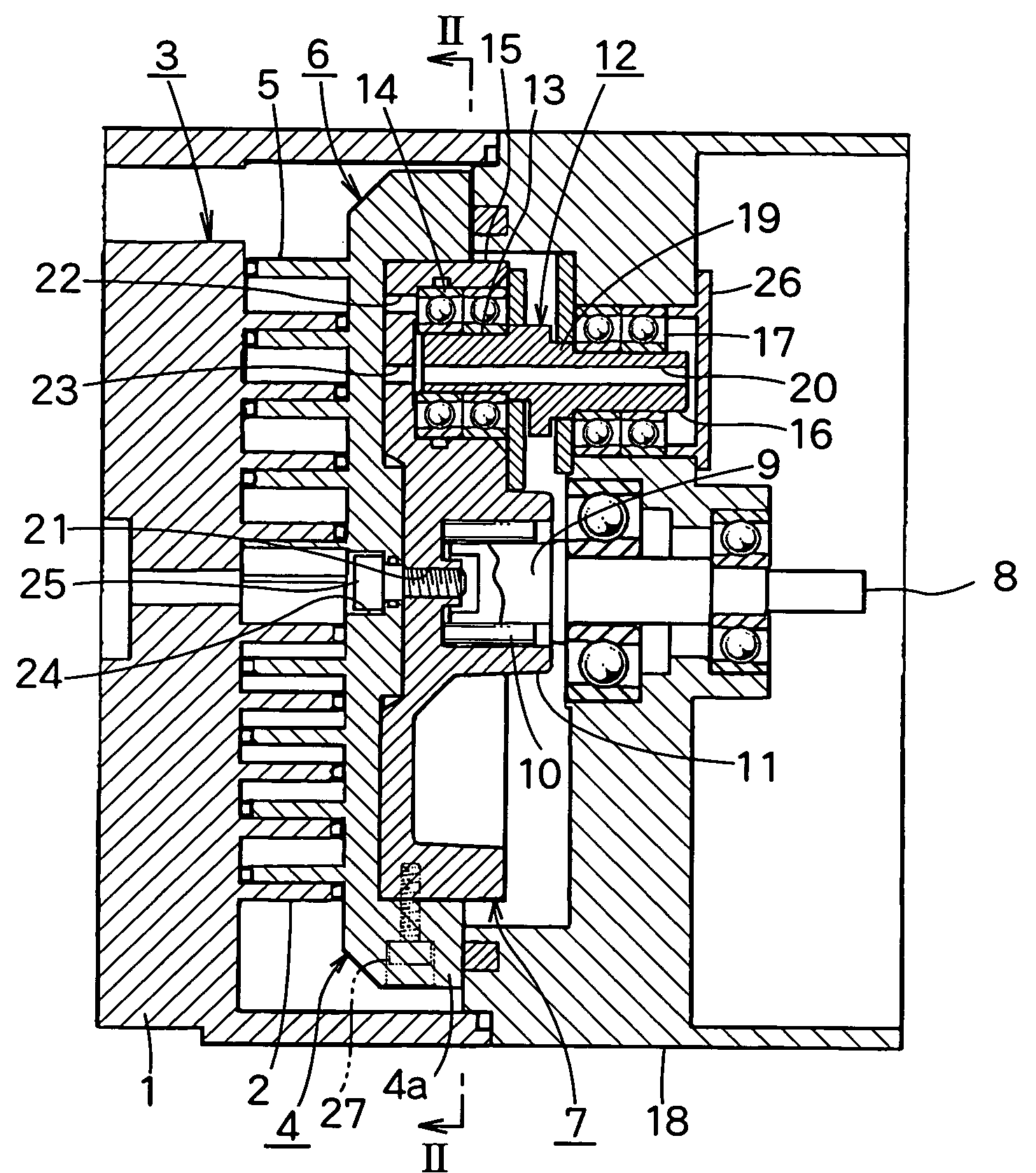

CO2 compressor

InactiveUS6129532ASmall sizeStable, reliable lubricant supply unitRotary/oscillating piston combinations for elastic fluidsCompressorForeign matterDifferential pressure

A CO2 compressor is disclosed for forcing and moving a lubricant under discharge pressure. If the oil path is reduced in size or a pressure reducing part is inserted to handle the large differential pressure caused between the discharge pressure and the intake pressure, the oil path would become liable to be easily clogged by foreign matter. In view of this, an intermittent oil supply mechanism is formed in the oil path using the sliding contact portion between a fixed member of the compressor body and a movable member. Thus, the substantial lubrication time period is shortened and the amount of oil supplied is limited.

Owner:DENSO CORP

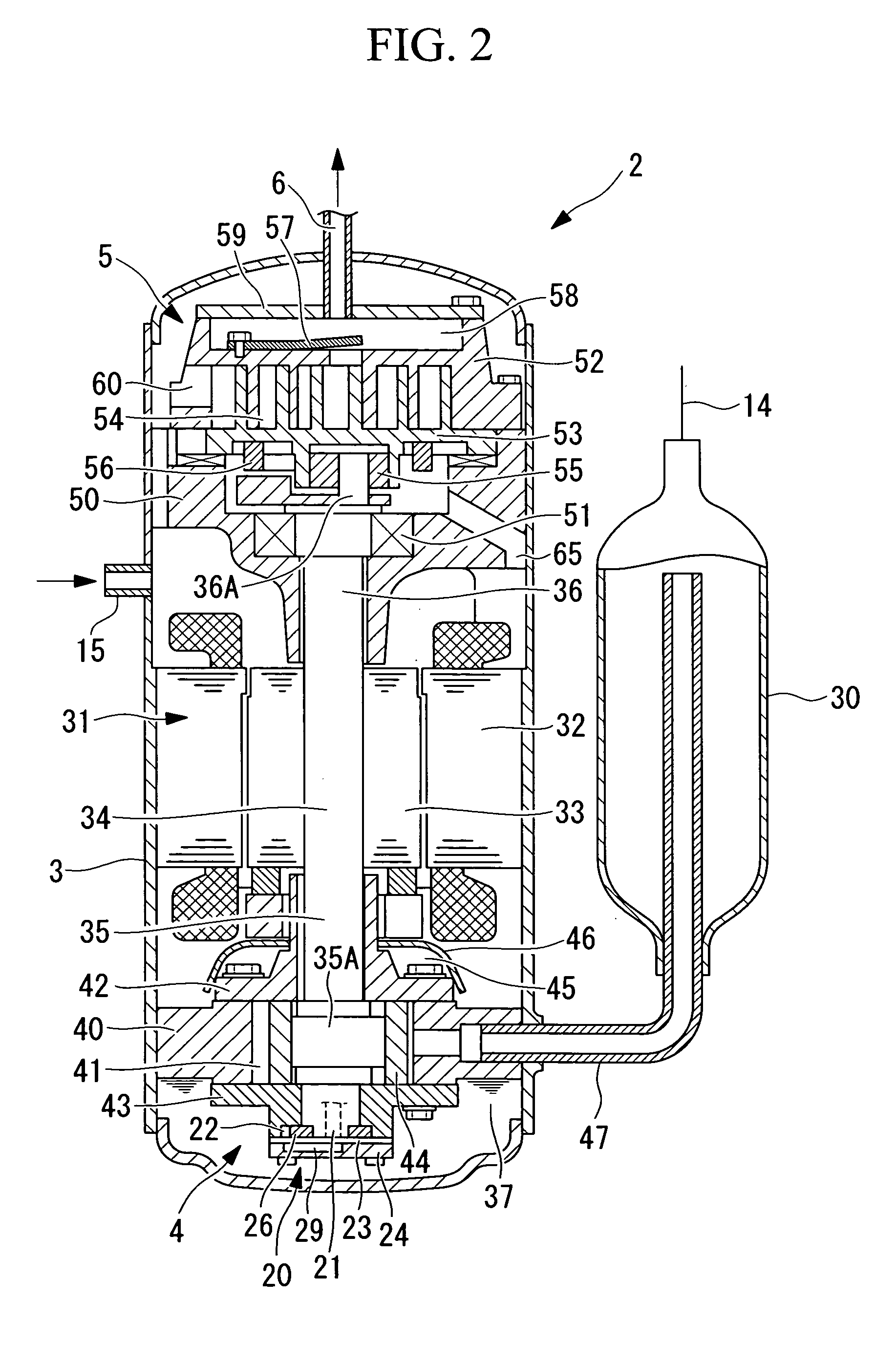

Multistage Compressor

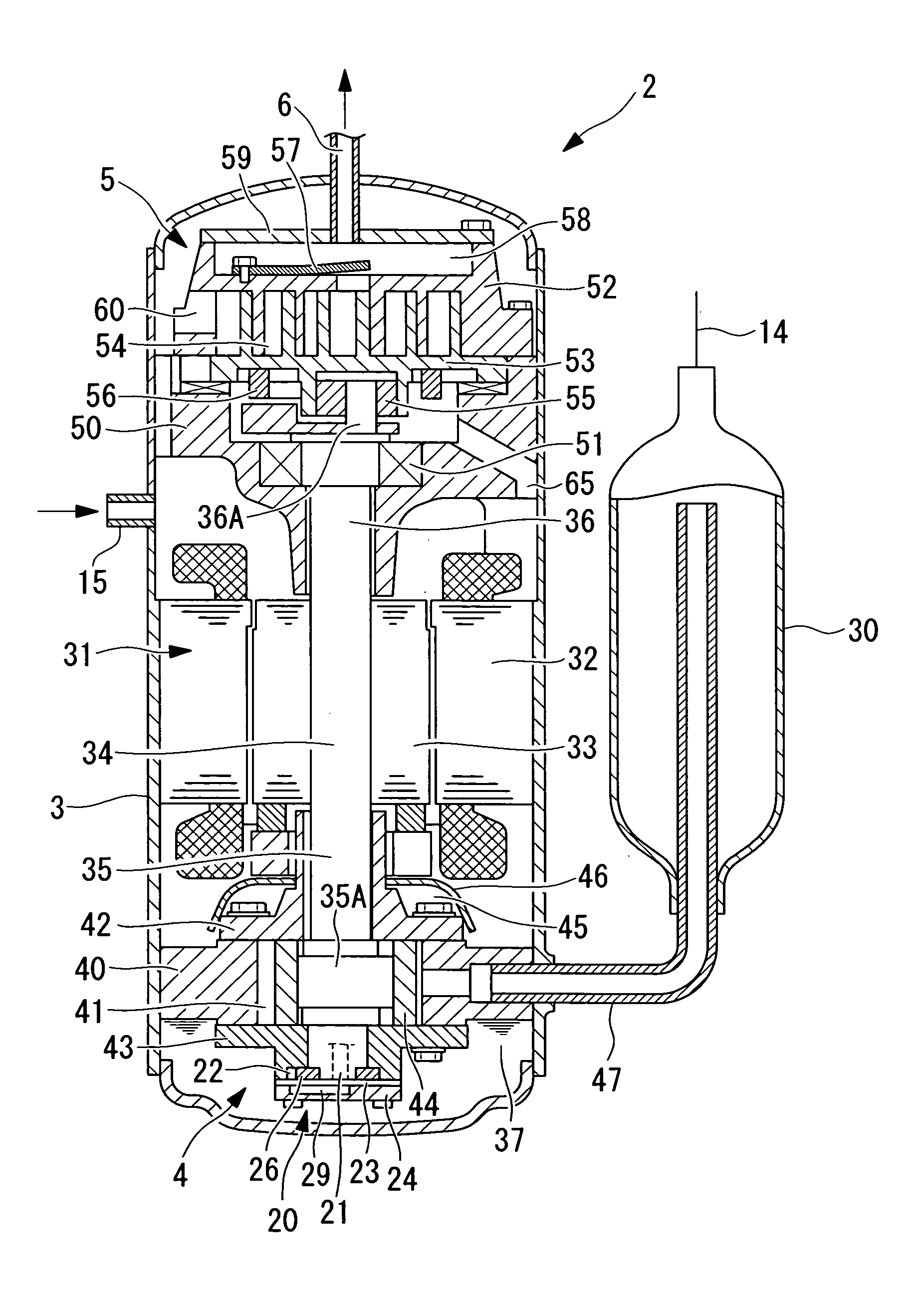

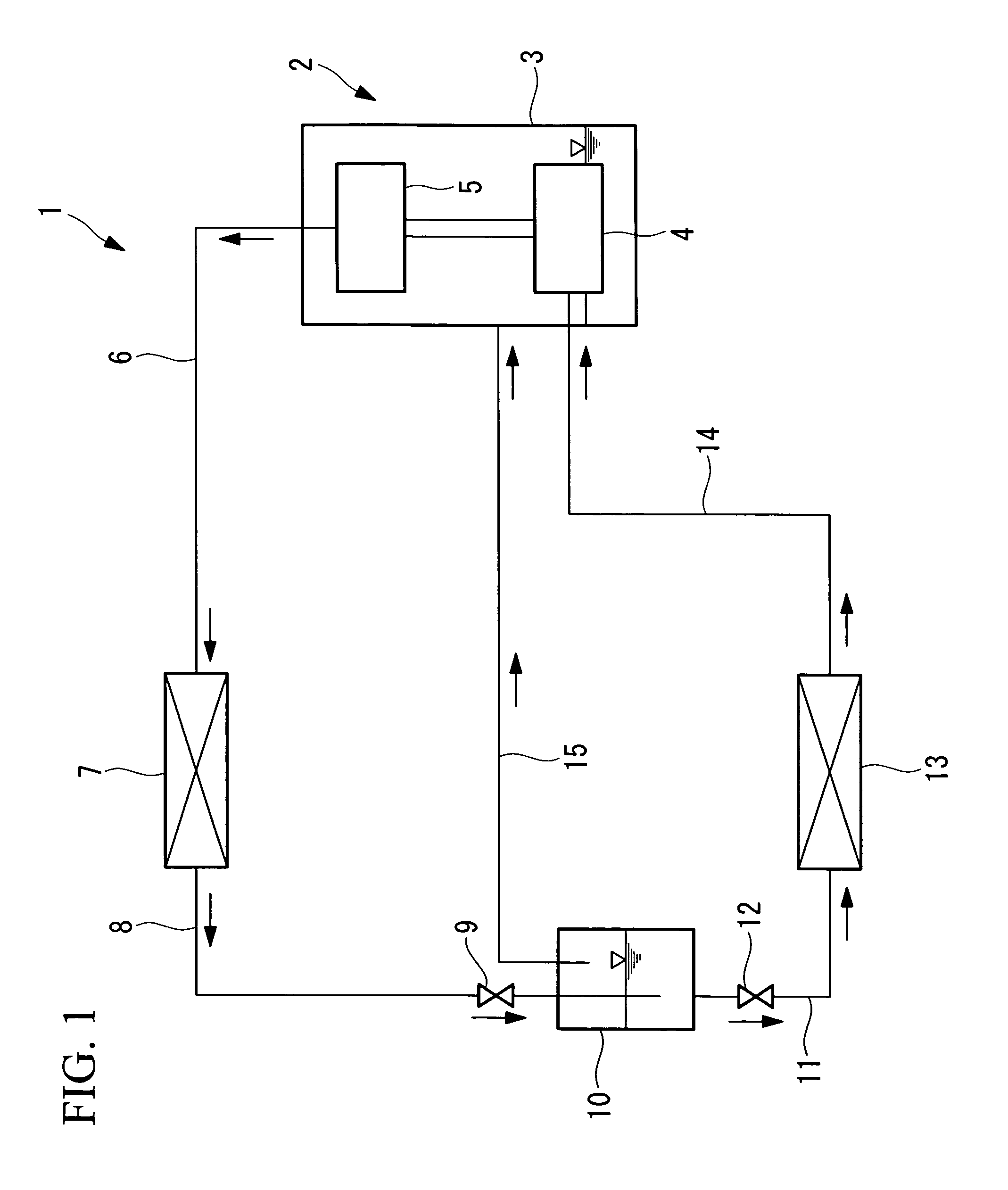

ActiveUS20100143172A1Improve motor efficiencyImprove performanceRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringRefrigerant

A multistage compressor employing a gas injection system for CO2 cycle that attains enhancements of compression efficiency and compression performance. The multistage compressor is multistage compressor (2) for CO2 cycle (1) adapted to carry out two-stage compression involving emitting the CO2 refrigerant gas compressed by inferior-stage side rotary compression means (4) into sealed housing (3) and having the intermediate-pressure refrigerant gas within the sealed housing (3) suctioned by superior-stage side scroll compression means (5), wherein to the sealed housing (3), there is connected gas injection circuit (15) capable of injection of intermediate-pressure CO2 refrigerant gas extracted from a refrigerant circuit into the sealed housing (3), and wherein the inferior-stage side rotary compression means (4) and the superior-stage side scroll compression means (5) are approximately identical with each other in pressure ratio and approximately equivalent with each other in displacement ratio.

Owner:MITSUBISHI HEAVY IND LTD

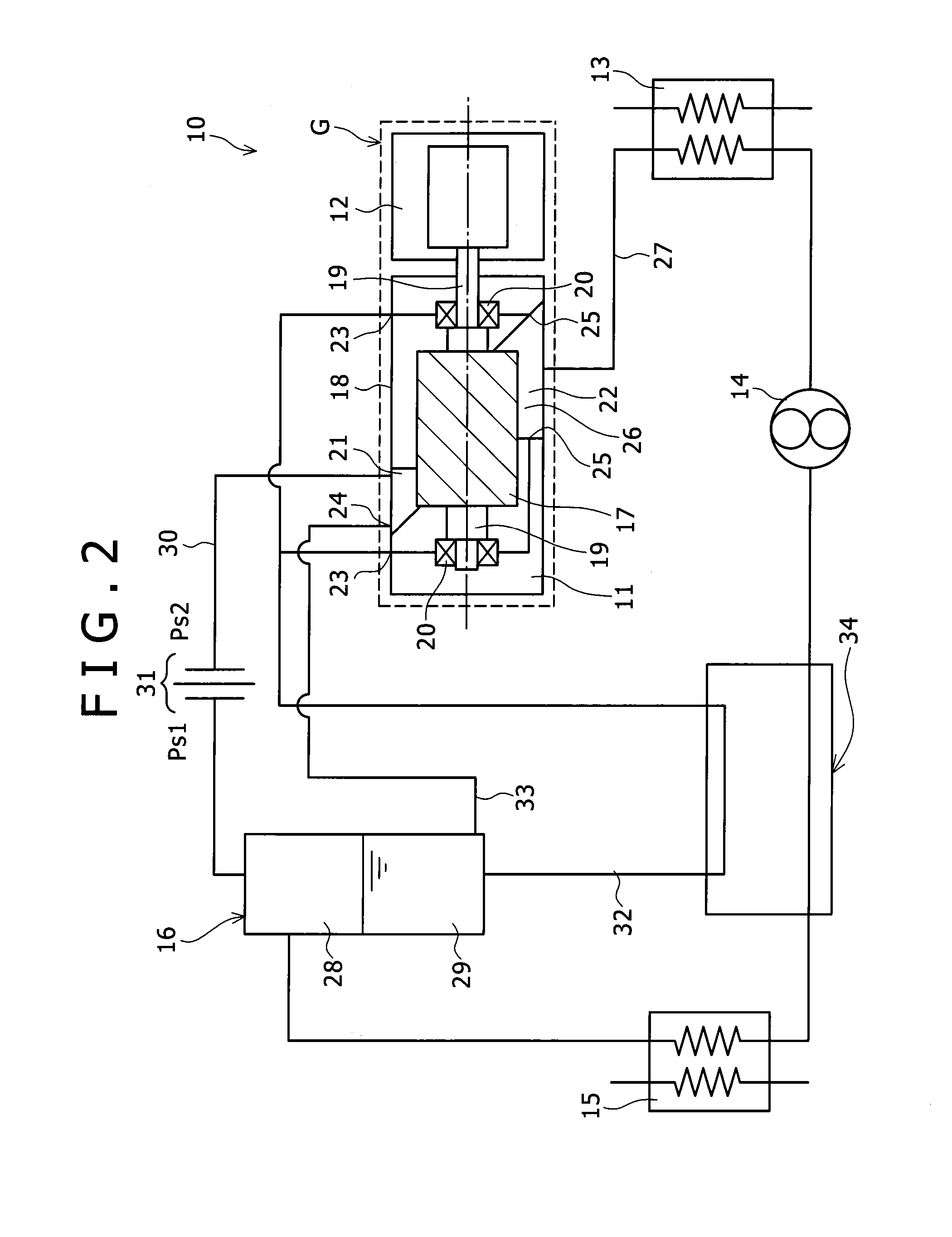

Screw expander system

InactiveUS20120237382A1Reduce device sizeLoss of mechanical powerOscillating piston enginesSealing arrangement for pumpsPetroleum engineeringEvaporator

A screw expander system includes a screw expander provided with an expansion space for expanding an operating medium, an operating medium inlet, an operating medium outlet, oil inlets, and oil outlets, a condenser which condenses a mixture, sent from the screw expander, of oil and the operating medium, a pump which pressure-feeds the mixture sent from the condenser, and an evaporator which evaporates the operating medium contained in the mixture. The screw expander system circulates and supplies the operating medium sent from the evaporator, to the operating medium inlet, and circulates and supplies the oil sent from the evaporator, to the oil inlets. An oil separating tank which separates the mixture into the operating medium and the oil is disposed between the evaporator and the screw expander, and an oil containing section of the oil separating tank and the oil inlets of the screw expander are connected.

Owner:KOBE STEEL LTD

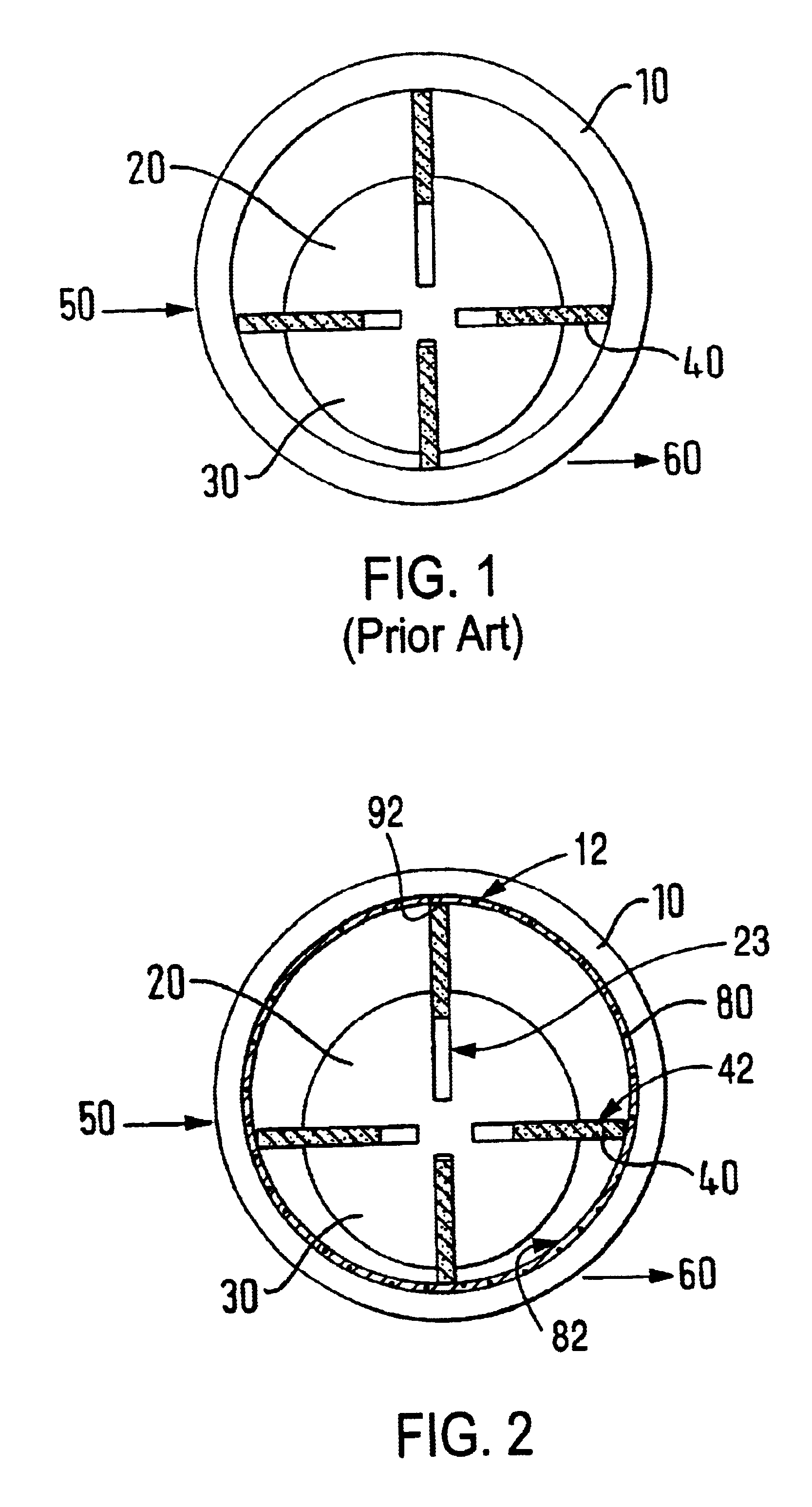

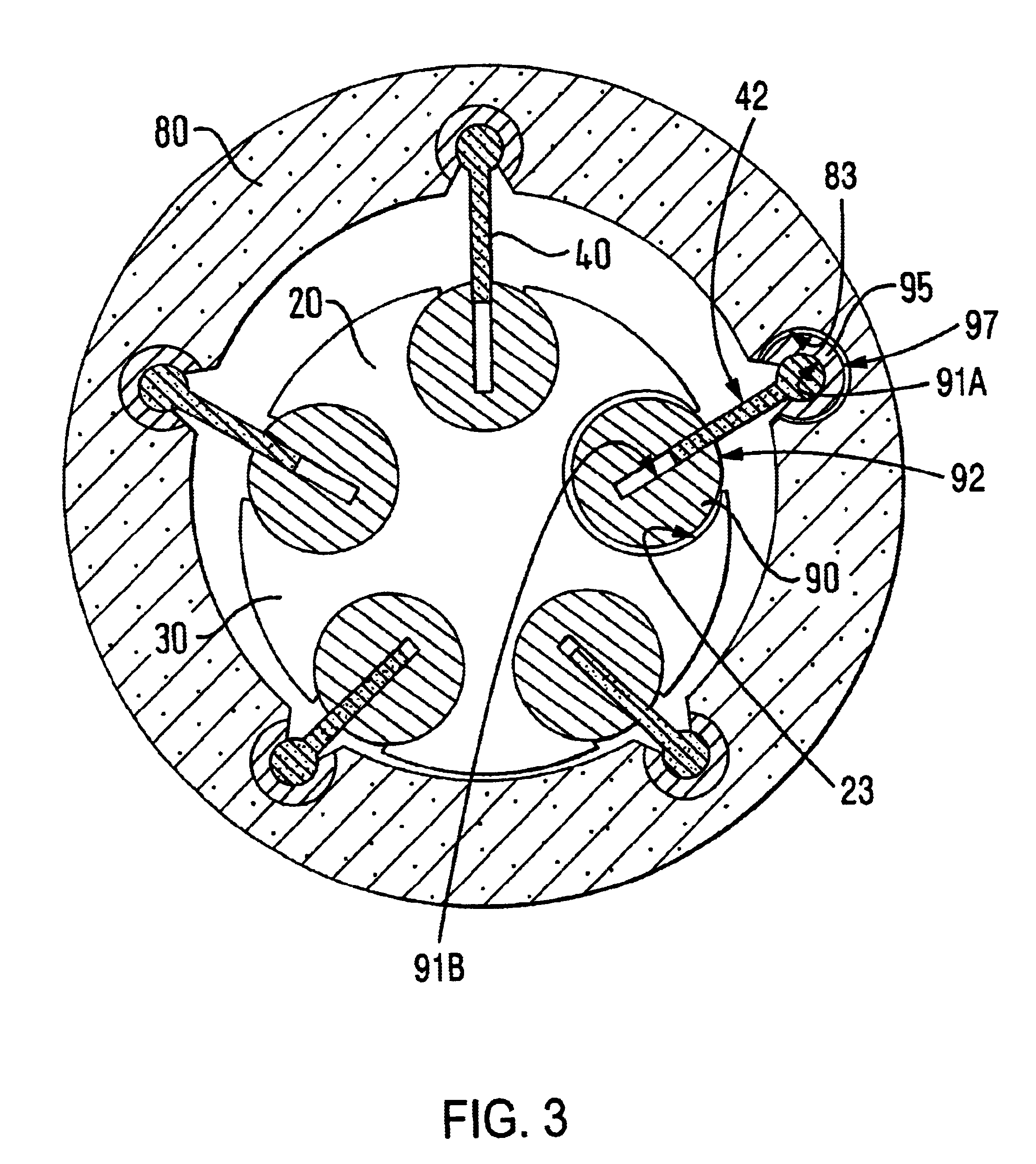

Lubrication systems for scroll compressors

An improved scroll compressor lubrication system includes a number of embodiments wherein a lubricant port in the orbiting scroll supplies lubricant to the compression chambers throughout its entire orbiting cycle. The lubricant port is aligned with a recess in a flange of the fixed scroll throughout its entire orbiting cycle. In a further embodiment, the lubricant port is exposed to the compression chamber throughout its entire cycle. In other embodiments, the fixed scroll is provided with recesses spaced from each other by approximately 180 DEG . The lubricant port moves sequentially into and out of communication with these spaced recesses to supply lubricant to the compression chambers.

Owner:CARRIER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com