Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

317 results about "Multistage compressor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

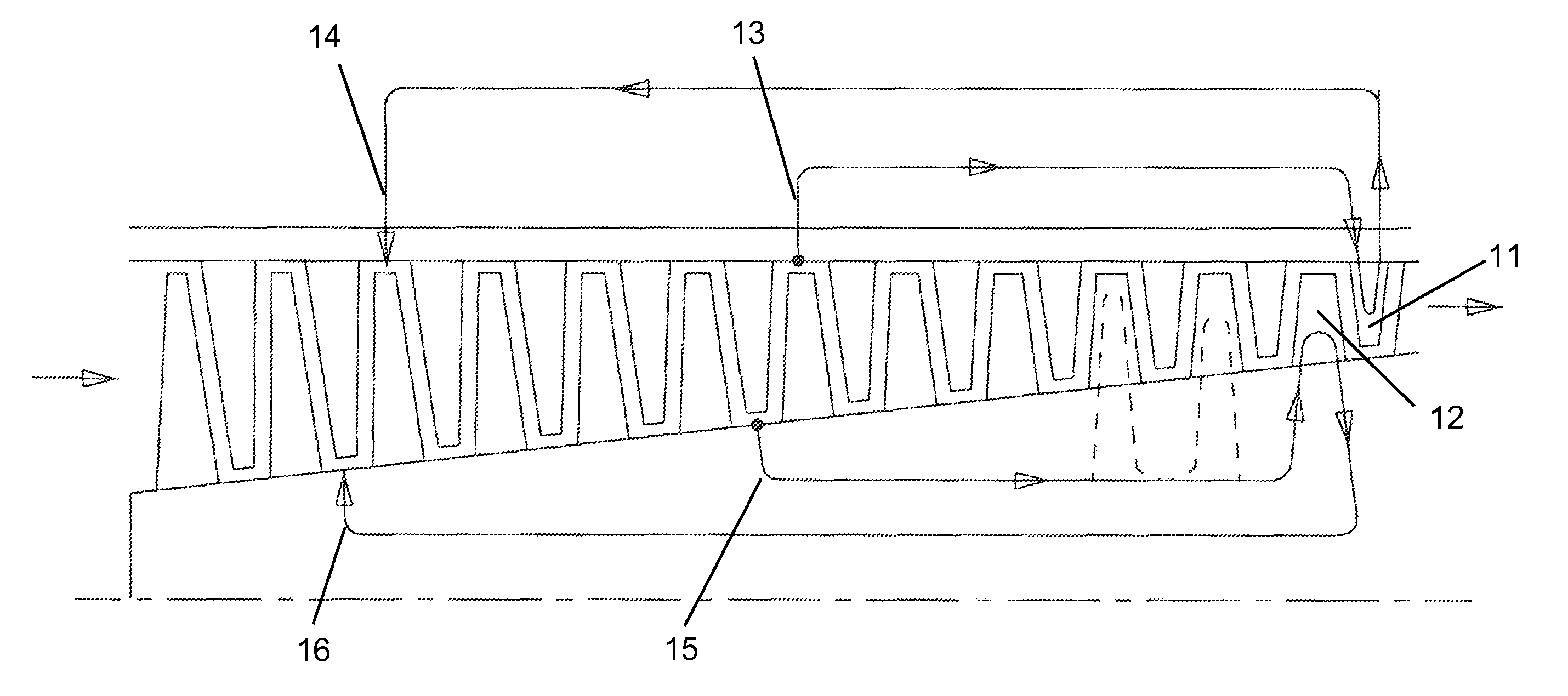

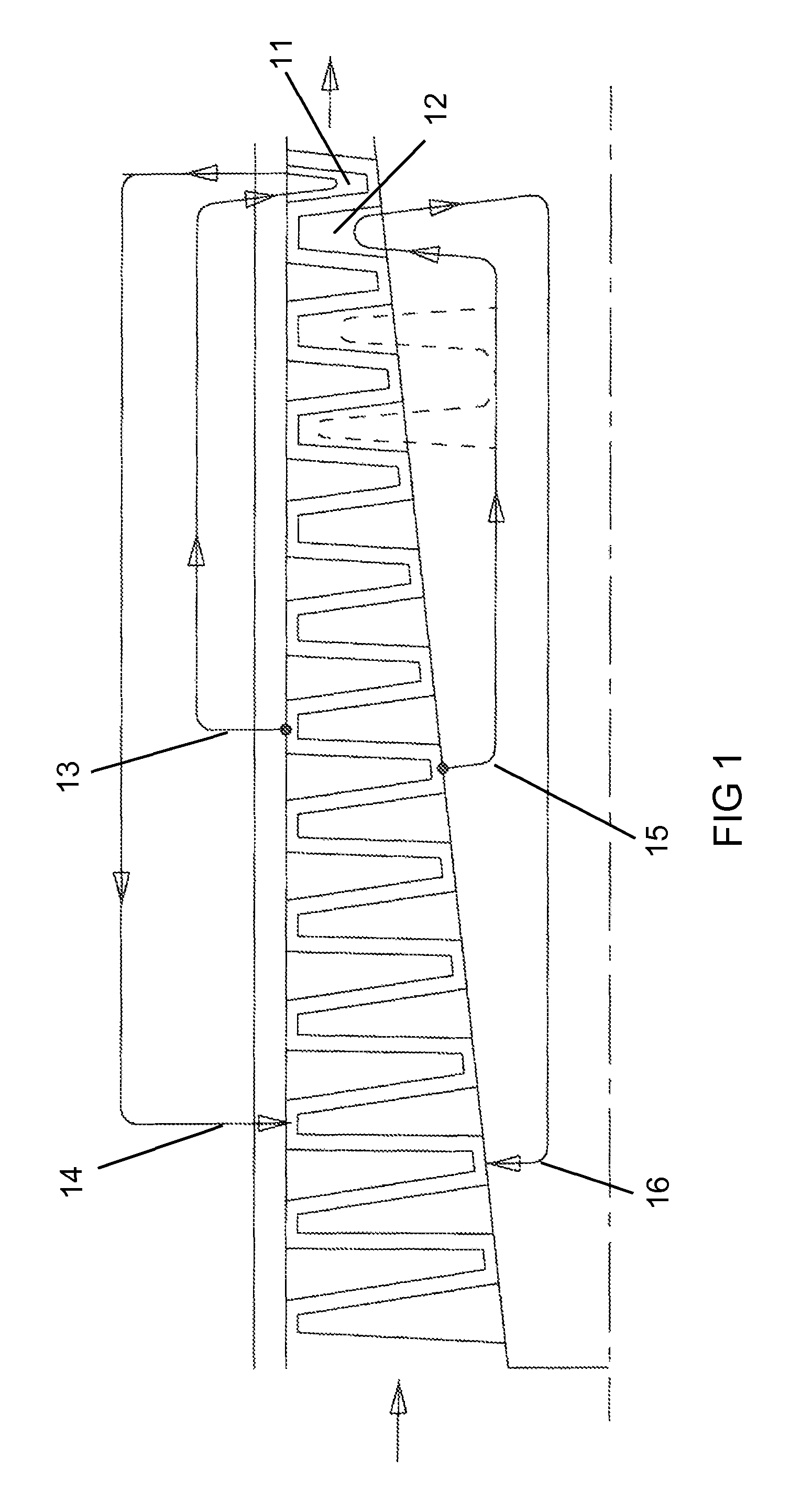

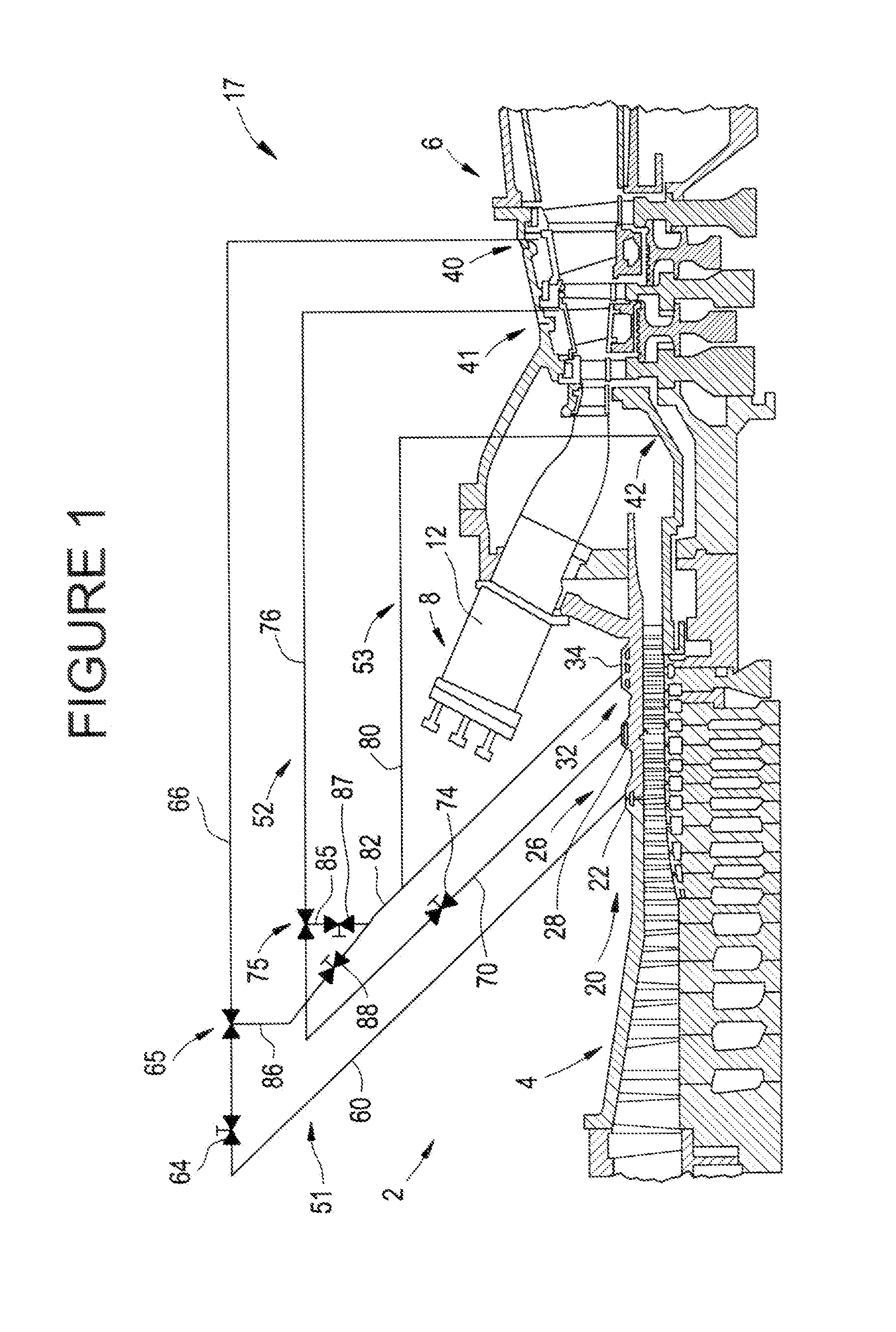

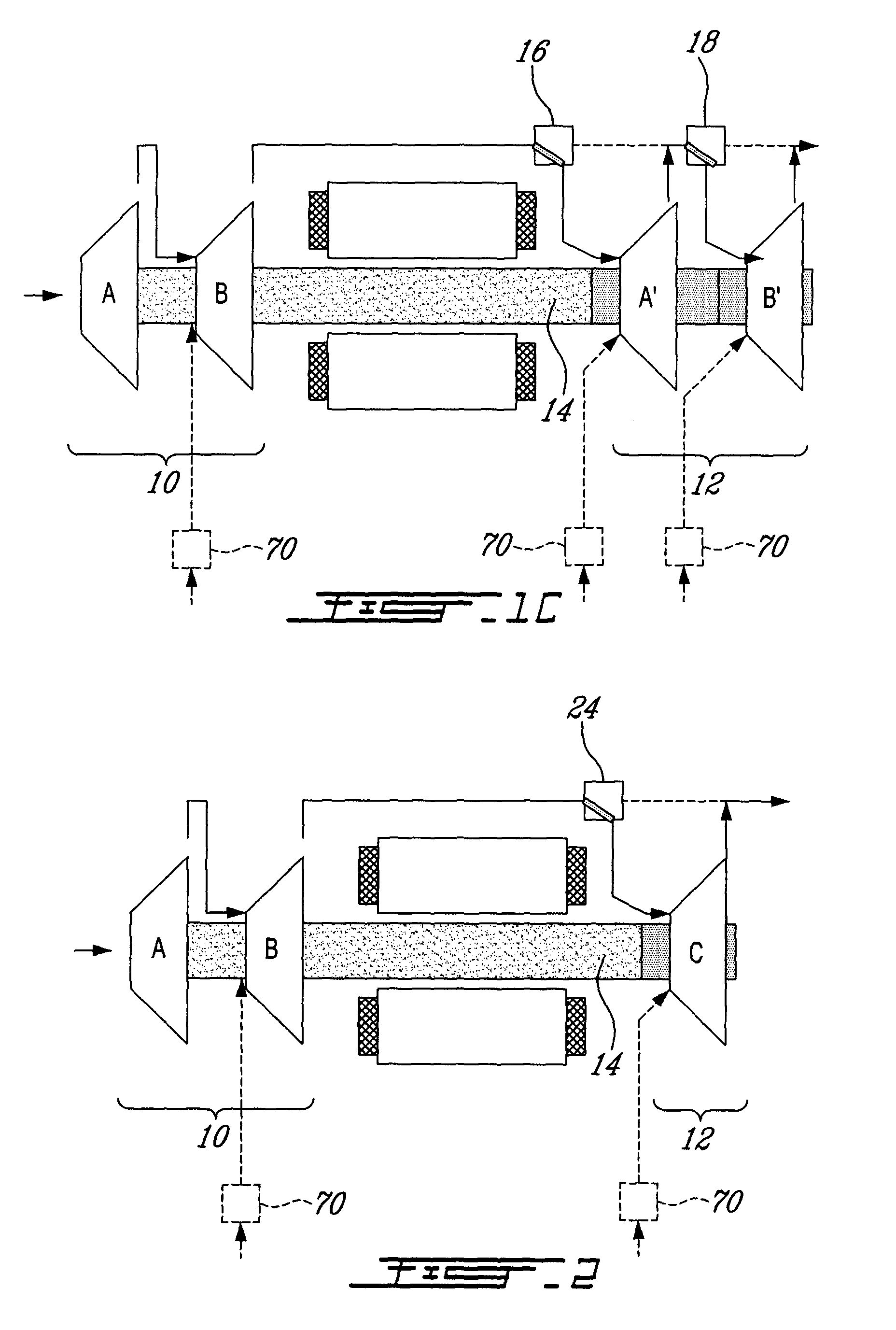

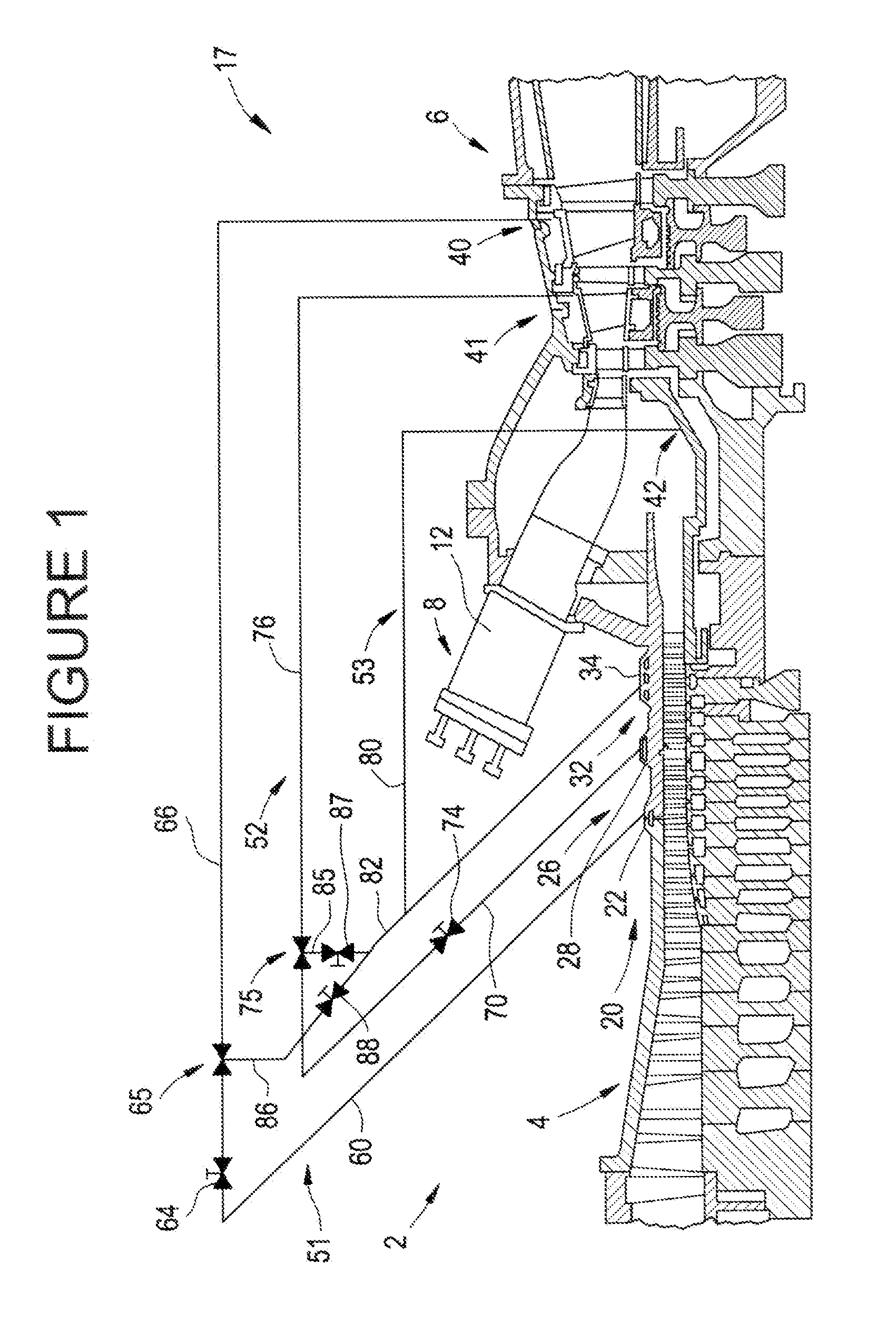

Multiple staged compressor with last stage airfoil cooling

An industrial gas turbine engine in which a compressor includes later stage airfoils that are cooled using a coolant from an external closed loop cooling circuit or from a heat recovery steam generator. Cooling air compressed by a compressor external to the IGT engine can be used for cooling of the main compressor airfoils with a heat exchanger to preheat a fuel used in the combustor. Or, water and steam from a heat recover steam generator can be used to cool the compressor airfoils in which steam can be bled off from the steam generator for cooling and then reintroduced into the HRSG at a downstream stage. Steam is used to cool the rotor blades while water is used to cool the stator vanes.

Owner:FLORIDA TURBINE TECH

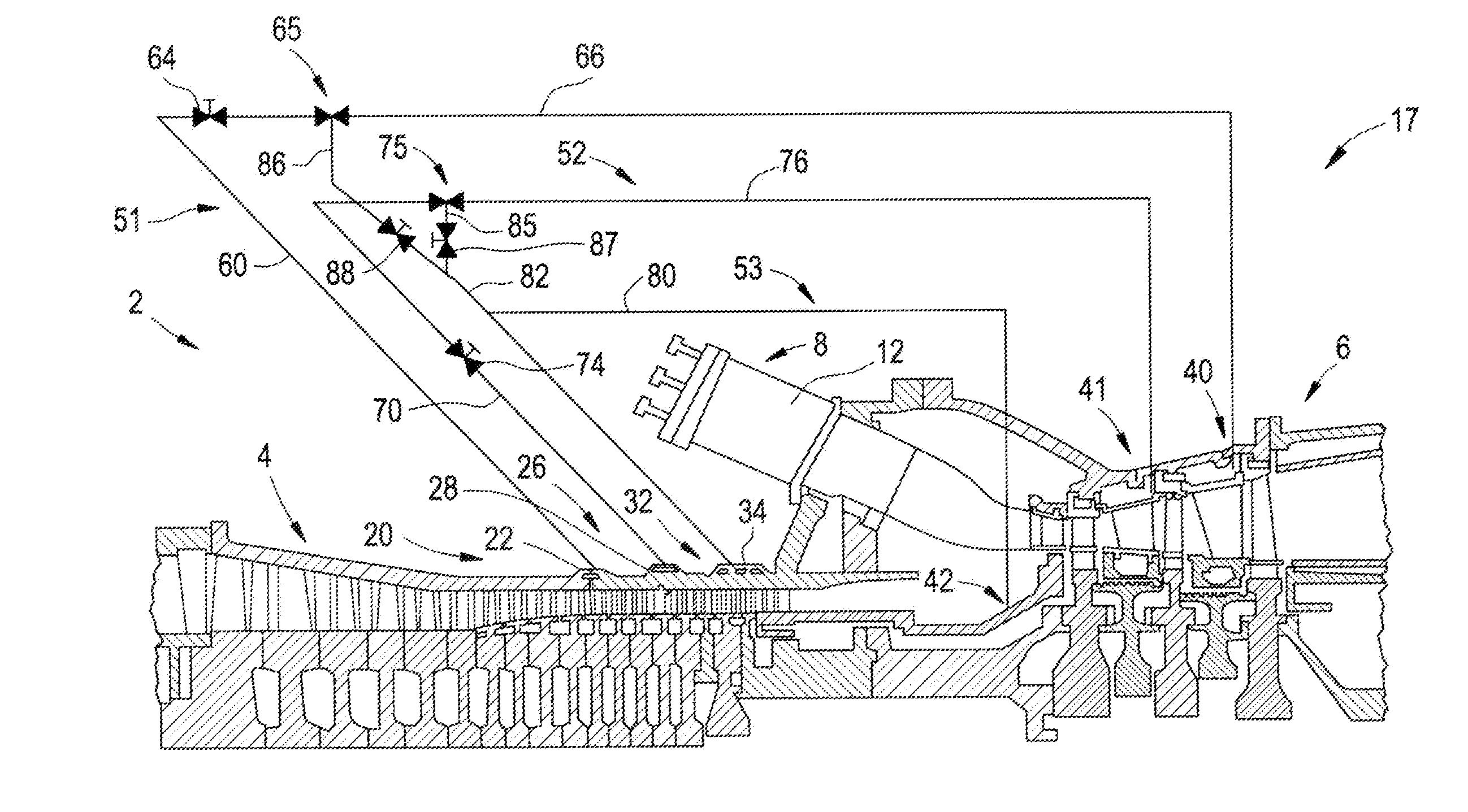

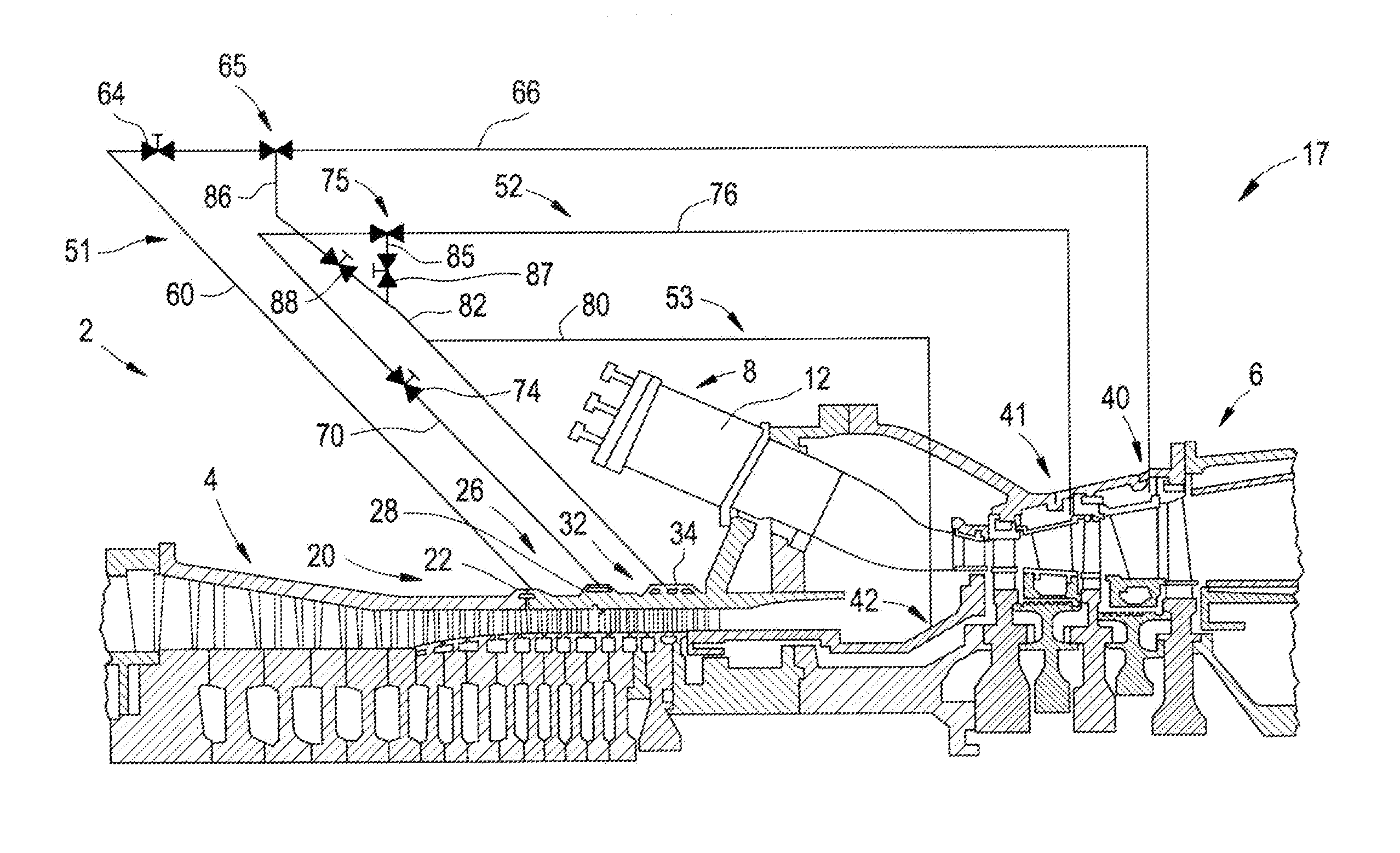

Triple circuit turbine cooling

A turbofan engine includes in serial flow communication a first fan, second fan, multistage compressor, combustor, first turbine, second turbine, and third turbine. The first turbine is joined to the compressor by a first shaft. The second turbine is joined to the second fan by a second shaft. And, the third turbine is joined to the first fan by a third shaft. First, second, and third cooling circuits are joined to different stages of the compressor for cooling the forward and aft sides and center bore of the first turbine with different pressure air.

Owner:GENERAL ELECTRIC CO

Turbocharger system to inhibit surge in a multi-stage compressor

A turbocharger system for an internal combustion engine is provided with at least one rotatable shaft and a multi-stage compressor. The multi-stage compressor includes a first compressor wheel carried by a corresponding shaft, an axially extending first inlet associated with the first compressor wheel, a radially extending first outlet associated with the first compressor wheel, a second compressor wheel carried by a corresponding shaft, an axially extending second inlet associated with the second compressor wheel, and a radially extending second outlet associated with the second compressor wheel. An interstage duct fluidly interconnects in series the first outlet associated with the first compressor wheel with the second inlet associated with the second compressor wheel. At least one bypass duct is provided, with each bypass duct fluidly interconnecting the first outlet with the first inlet; the first outlet with an ambient environment; and / or the second outlet with the first outlet. At least one valve is provided, each valve being positioned within a corresponding bypass duct. A controller is coupled with each valve and selectively actuates each valve.

Owner:CATERPILLAR INC

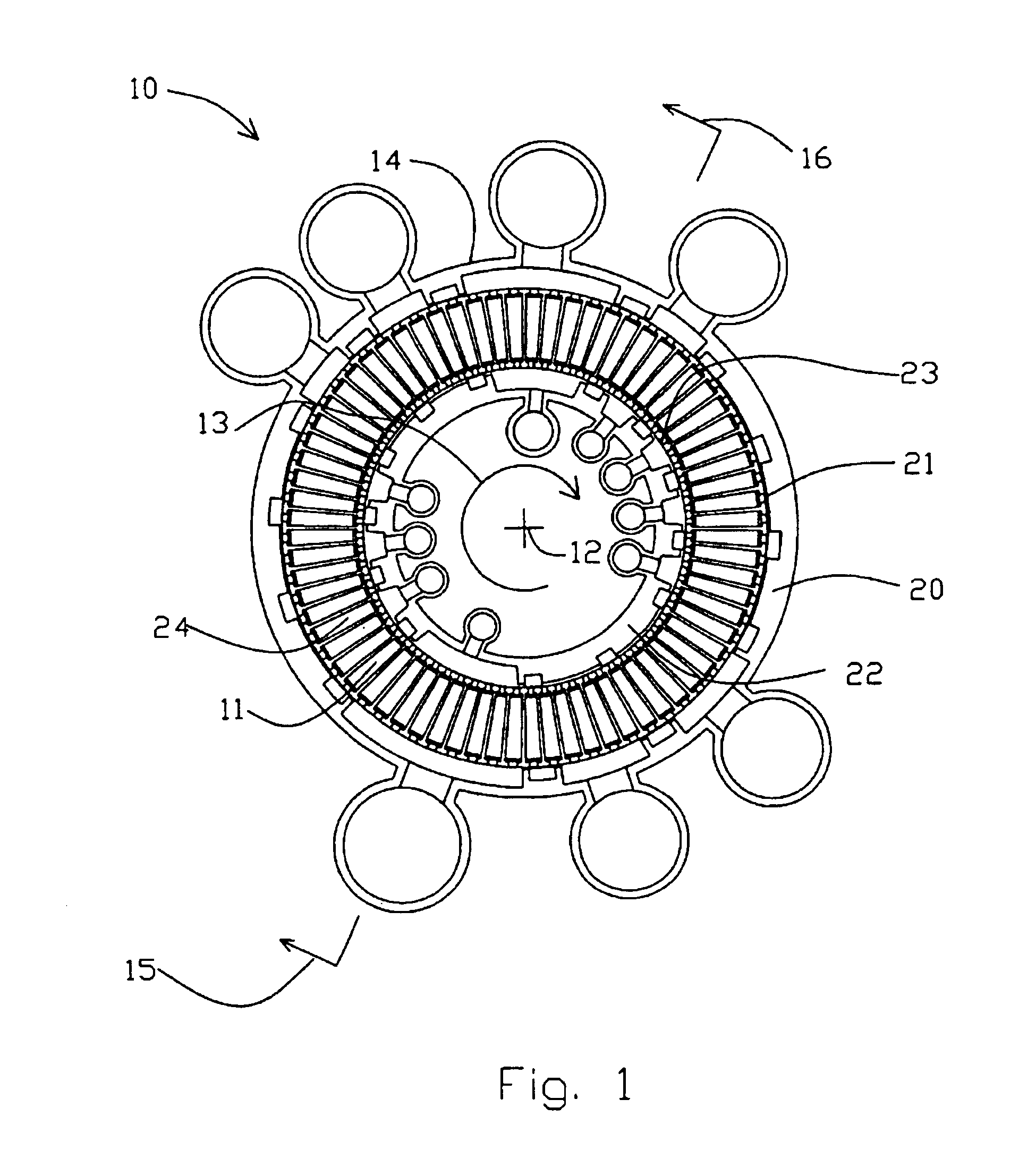

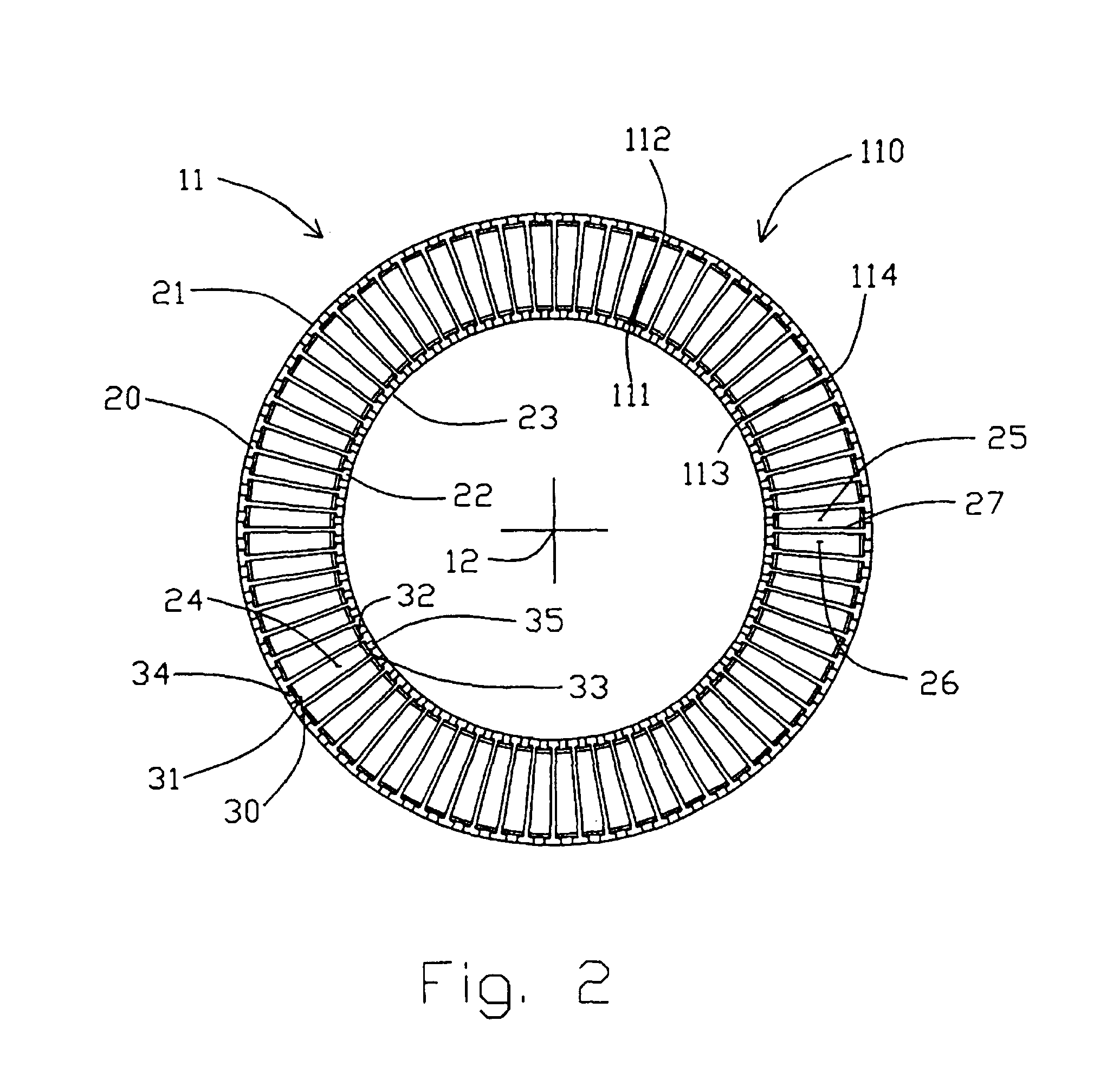

Surge absorber flow regulation for modular pressure swing adsorption

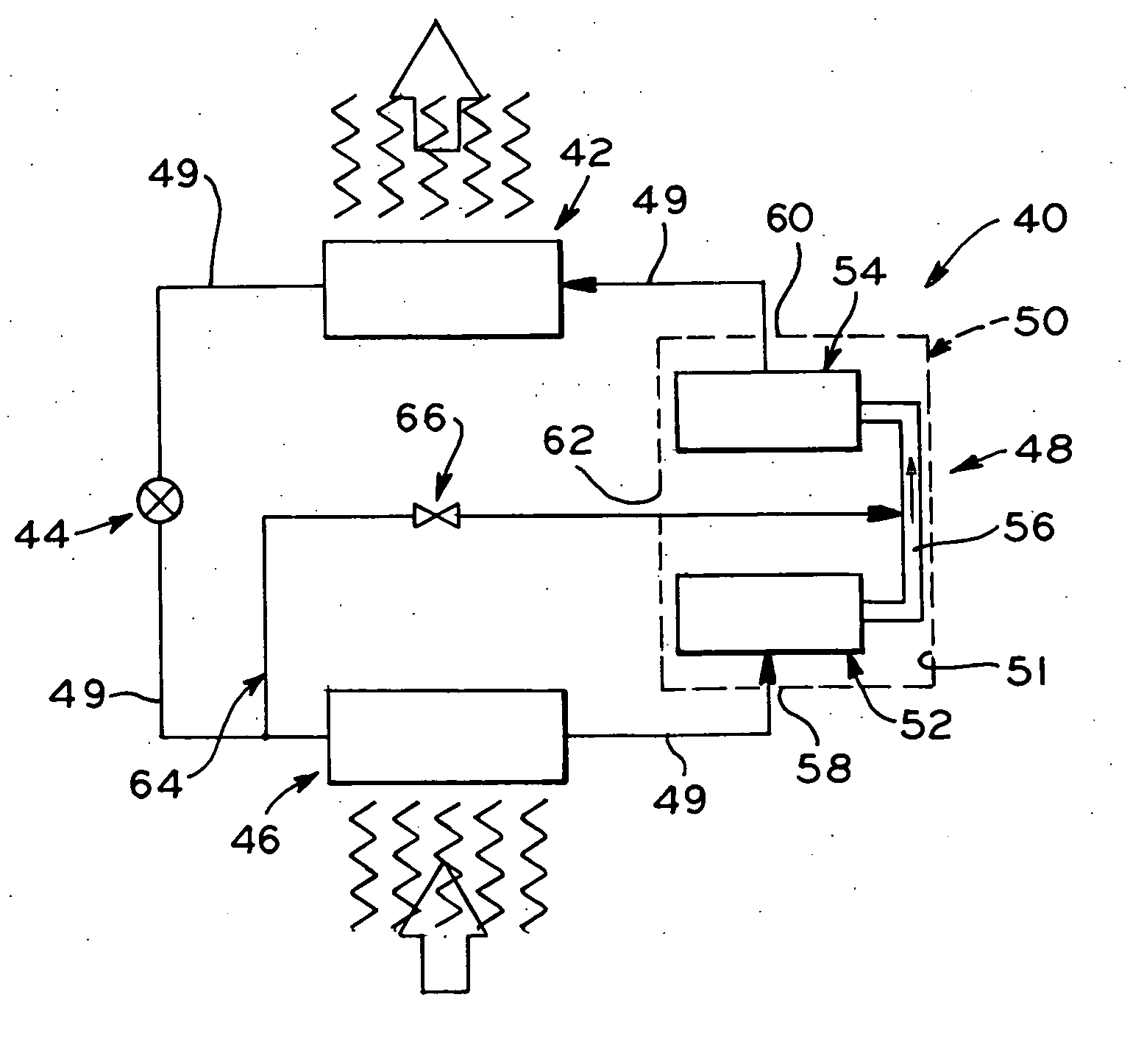

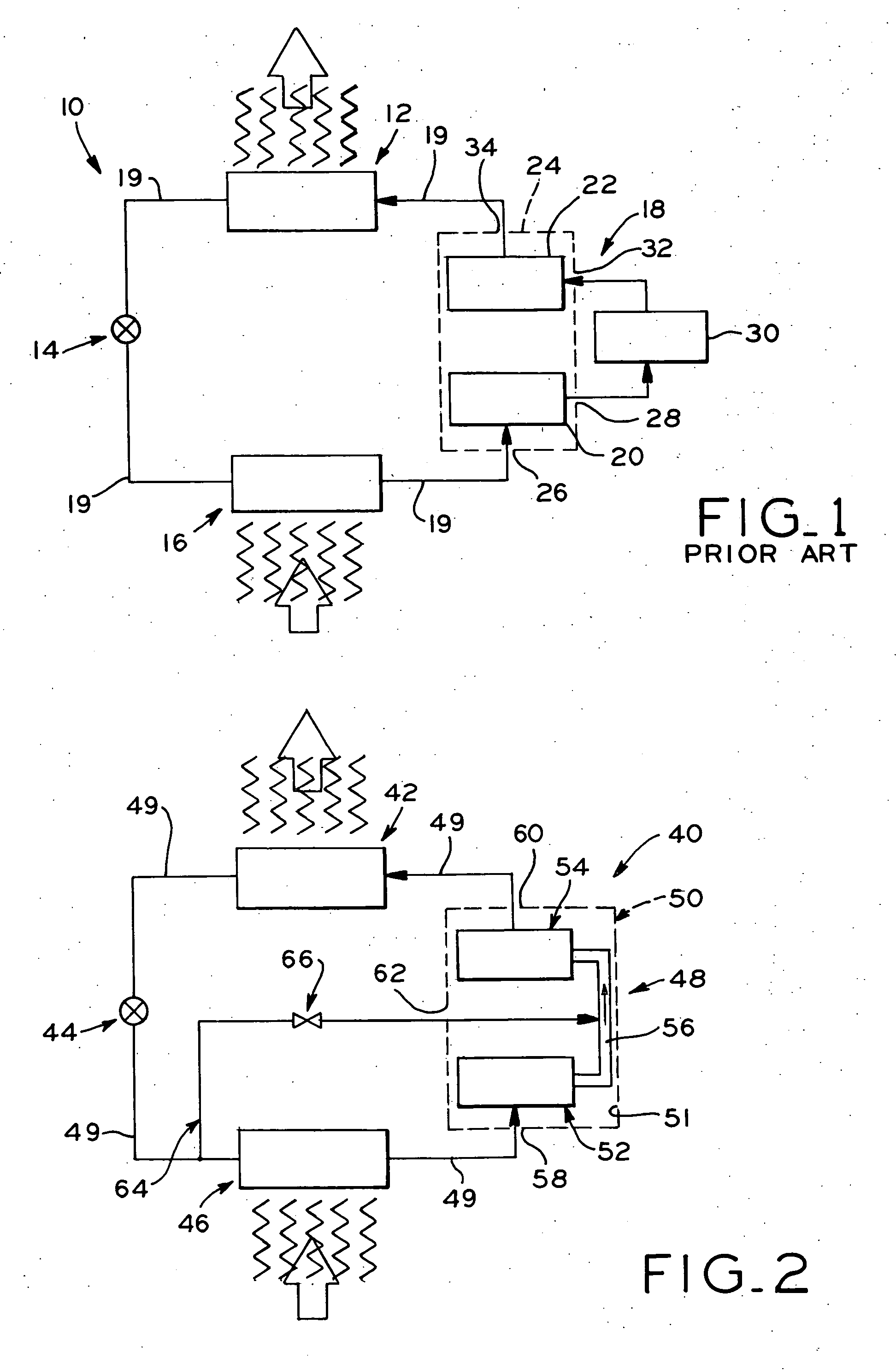

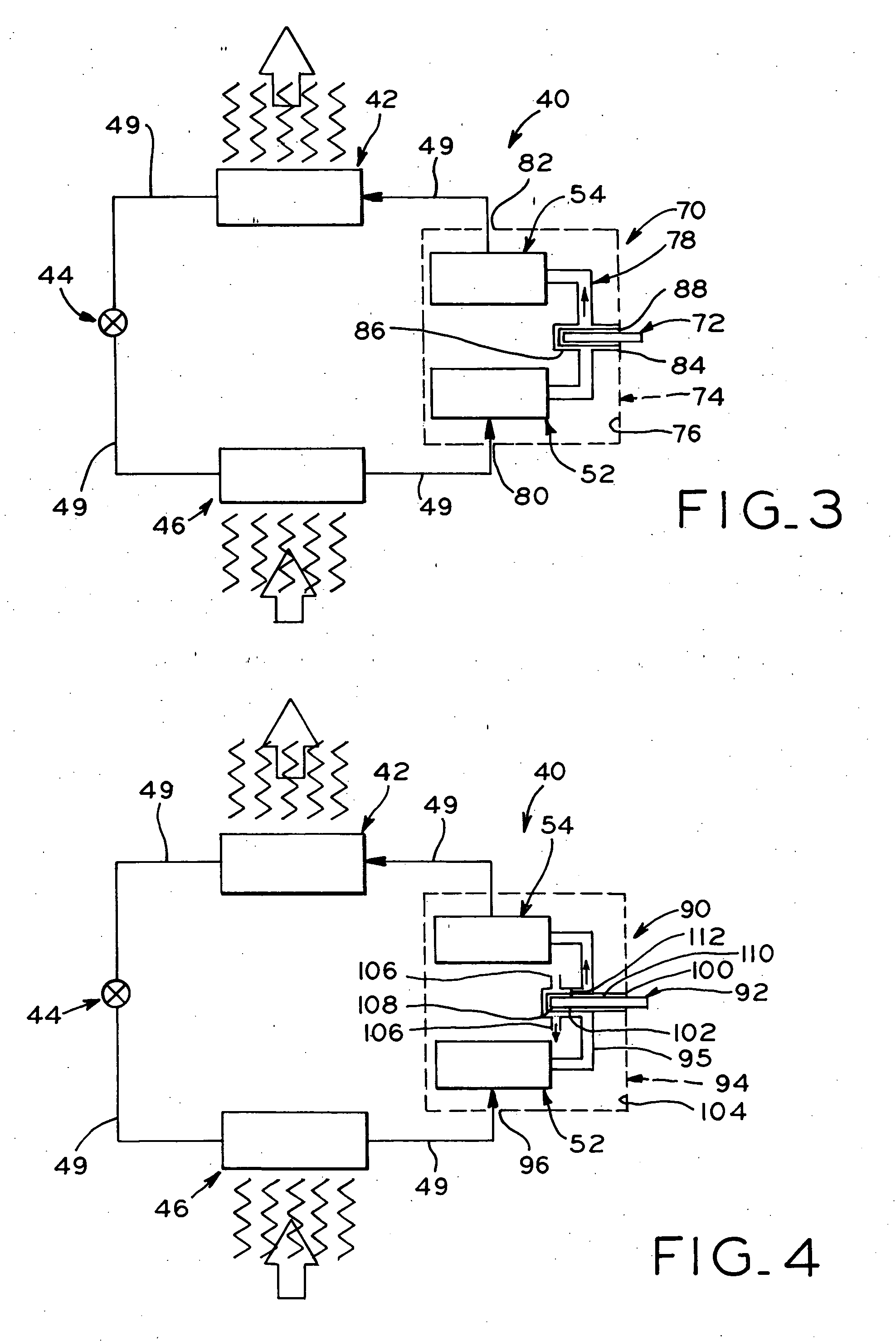

InactiveUS6840985B2Contribute to dead volumeReduce dead volumeGas treatmentIsotope separationEngineeringStreamflow

A gas separation system includes a stator, and a rotor rotatably coupled to the stator, and at least one surge absorber in communication with the stator. The stator includes a stator valve surface and a plurality of function compartments opening into the stator valve surface. The rotor includes a rotor valve surface in communication with the stator valve surface, and a plurality of flow paths for receiving adsorbent material therein. The rotor also includes a plurality of apertures provided in the rotor valve surface and in communication with the flow paths for cyclically exposing the flow paths to the function compartments. The surge absorbers are configured to reduce pressure variations in the function compartments and to maintain each function compartment at one of a plurality of discrete pressure levels. In this manner, substantially uniform gas flow can be maintained through the function compartments and the flow paths without recourse to multistage compression machinery.

Owner:AIR PROD & CHEM INC

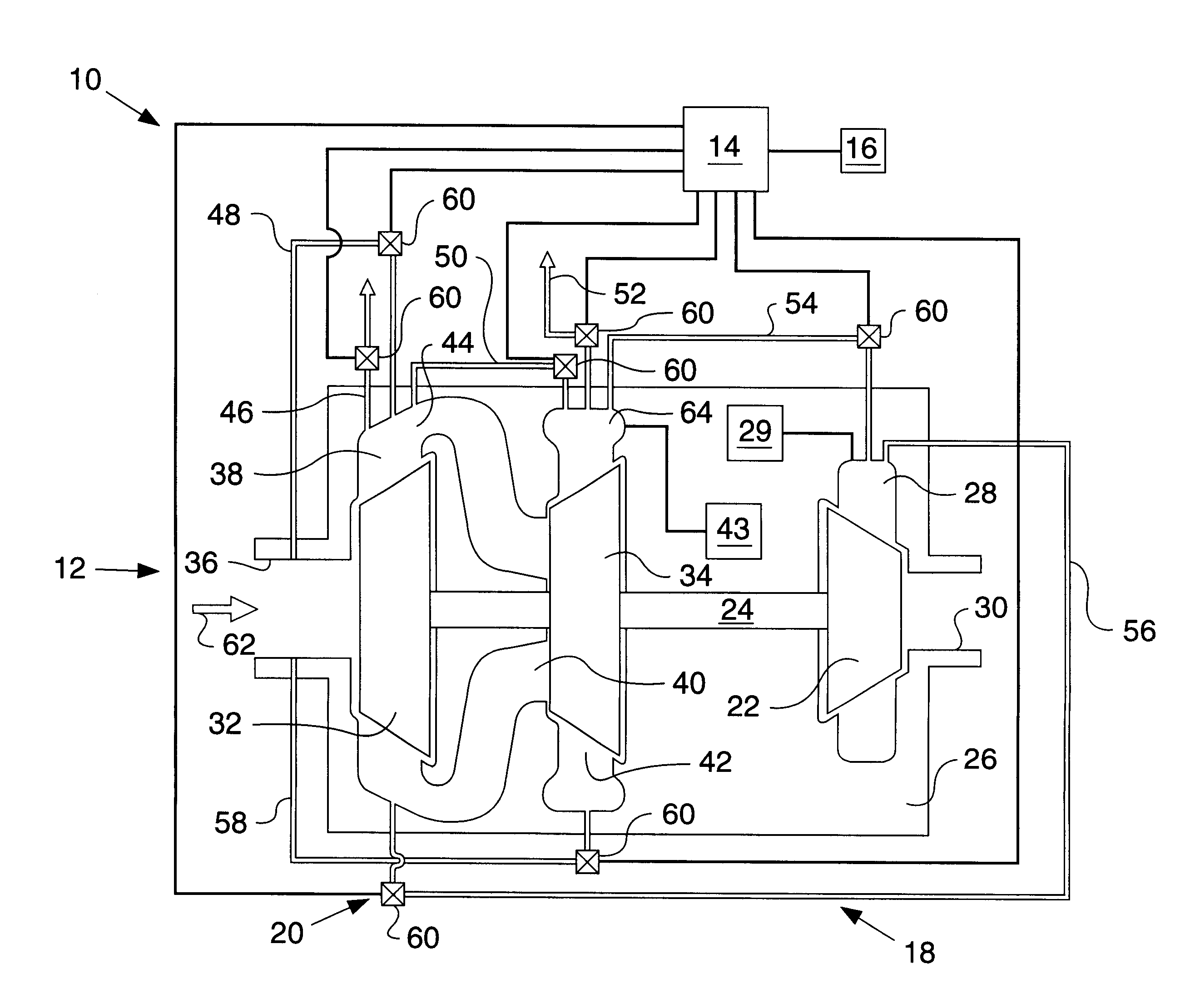

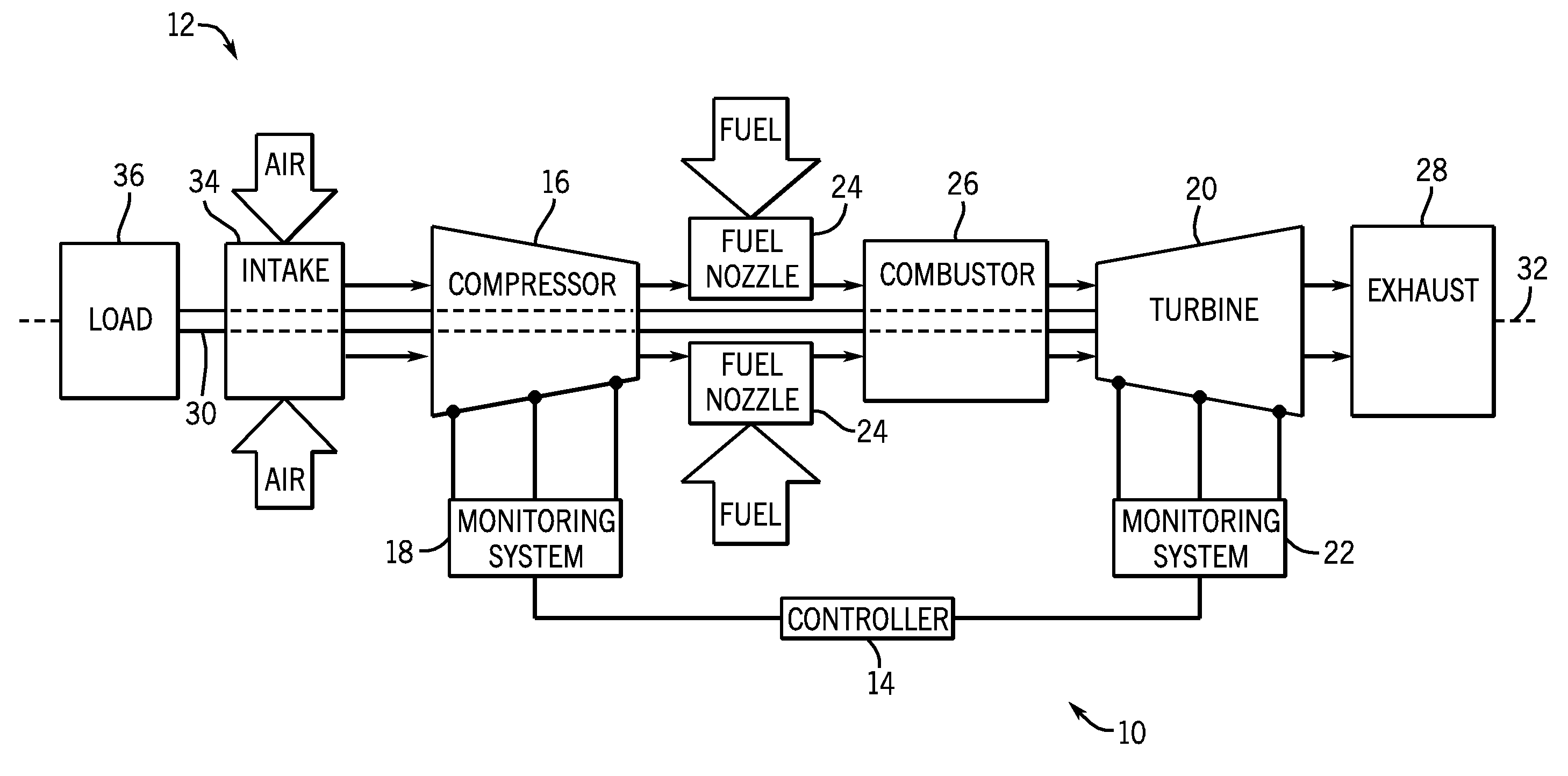

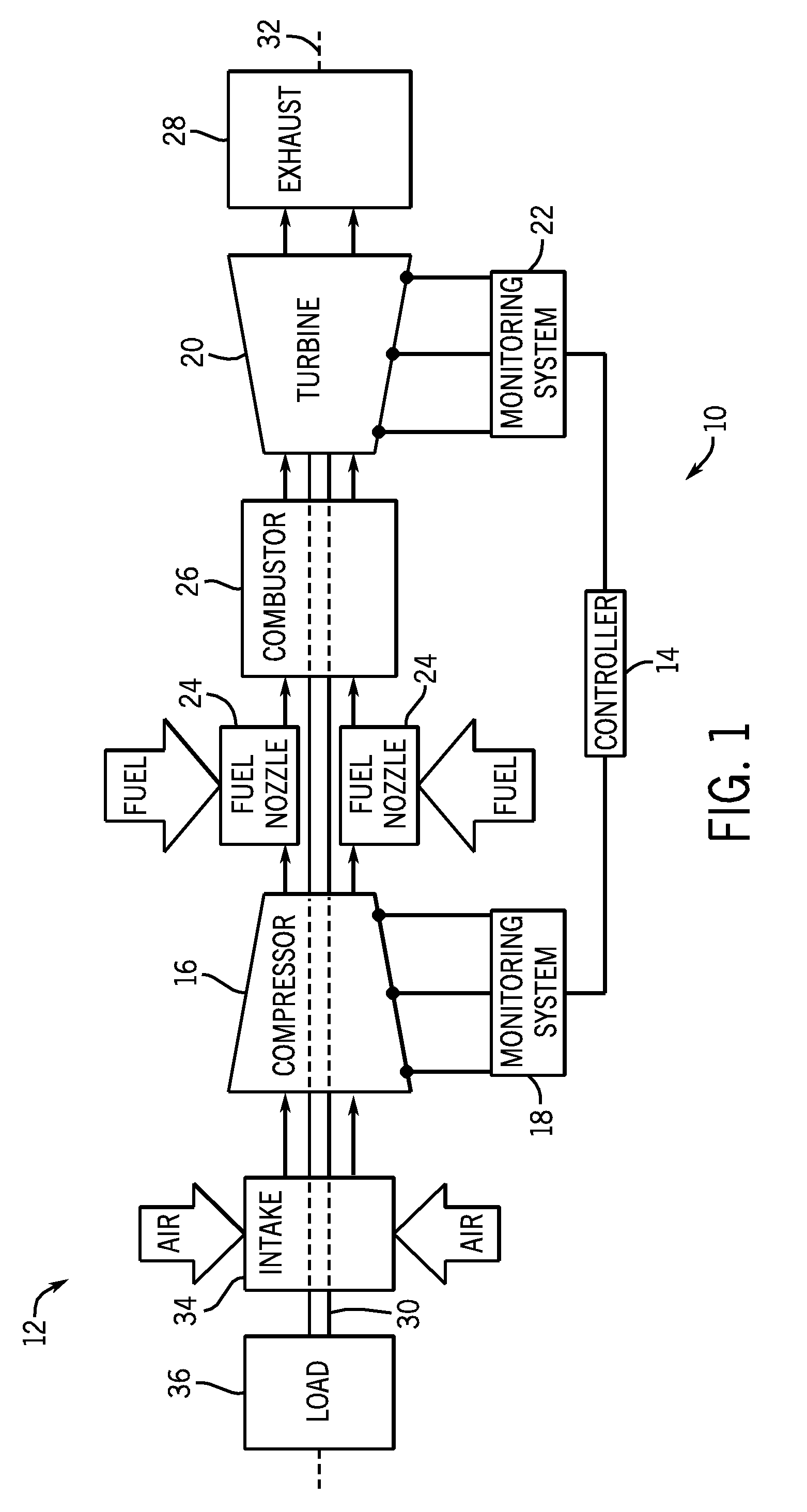

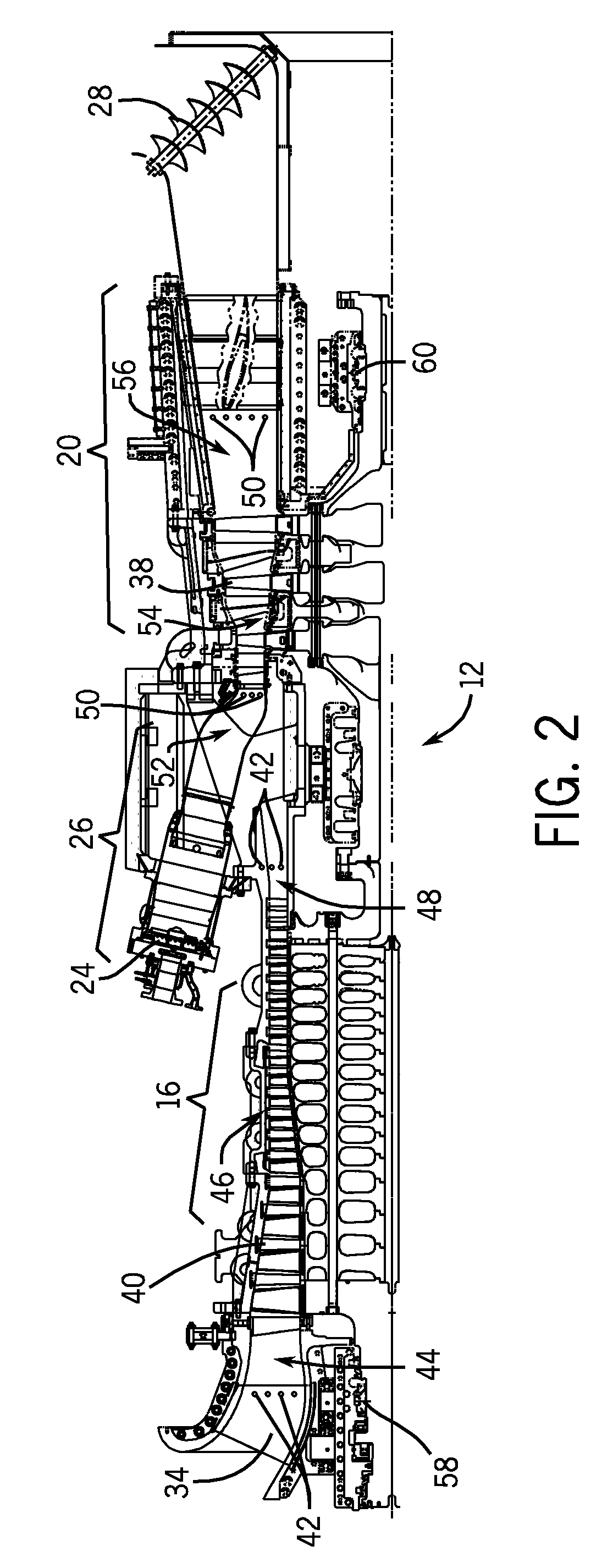

System for delivering air from a multi-stage compressor to a turbine portion of a gas turbine engine

ActiveUS20090104020A1Lower fuel bum rateReduce outputPump componentsWind motor controlHigh pressureTurbine

A system for providing air from a multi-stage to a turbine includes a turbine having a high pressure input port and a low pressure input port. The system also includes a compressor having at least one high pressure extraction air output and at least one low pressure extraction air output. A valve is fluidly connected to the at least one high pressure extraction air output, at least one low pressure extraction air output and low pressure input port of the turbine. The valve is selectively operated to fluidly connect the at least one low pressure extraction air output with the low pressure input port during normal operating conditions and fluidly connect the at least one high pressure extraction air output and the low pressure input port during a turn down condition or below design temperature operation to enhance turbine engine performance.

Owner:GENERAL ELECTRIC CO

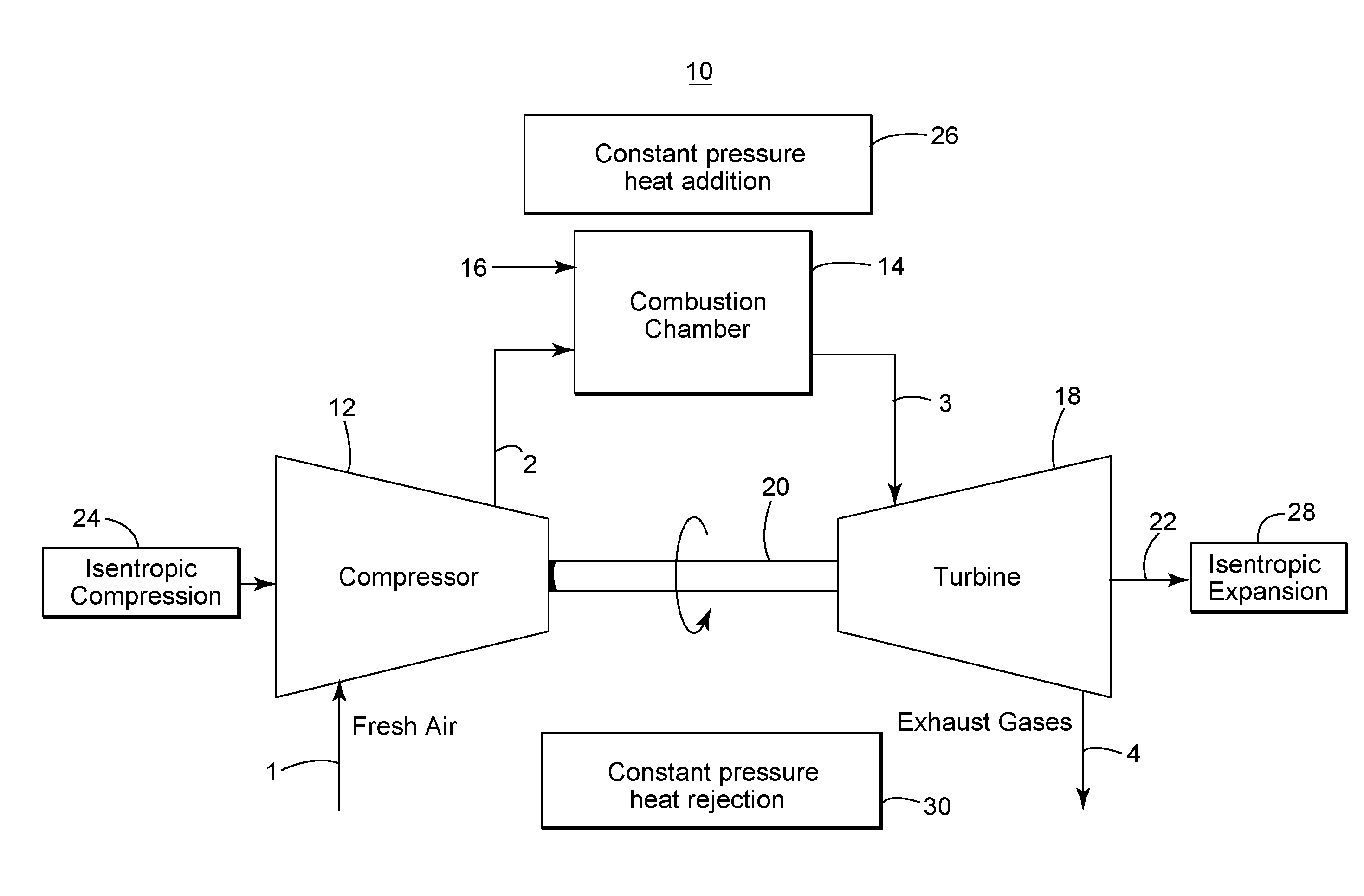

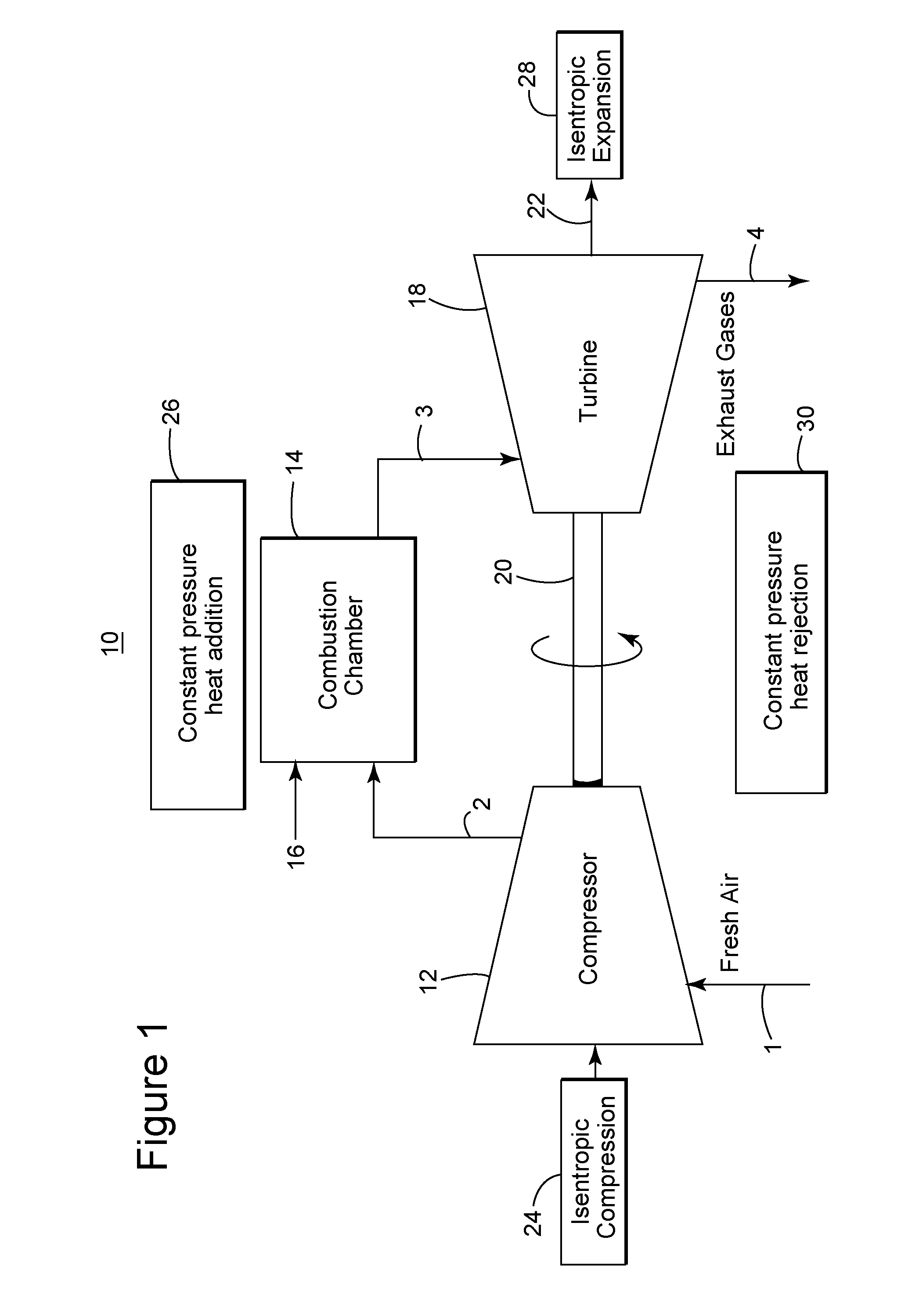

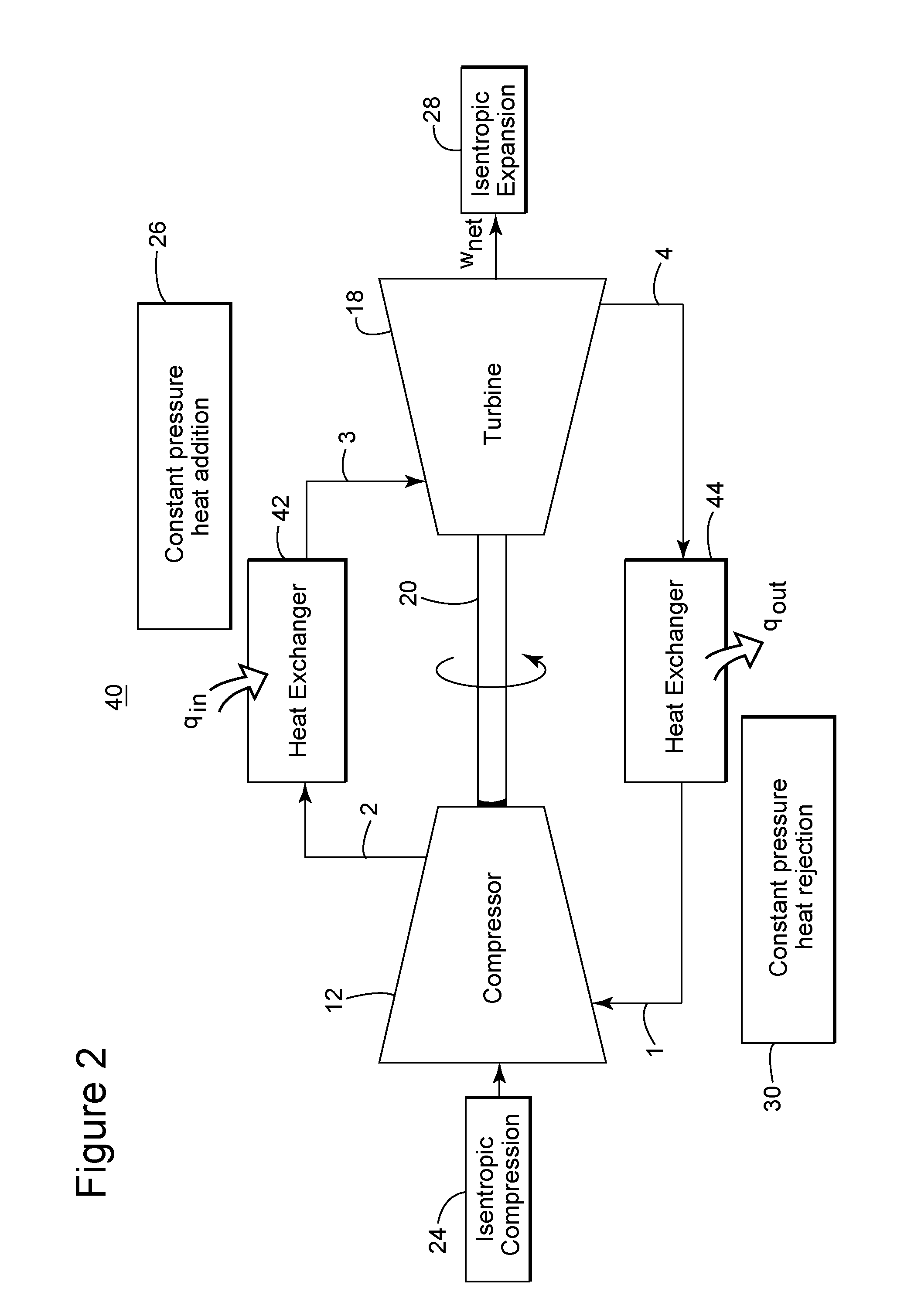

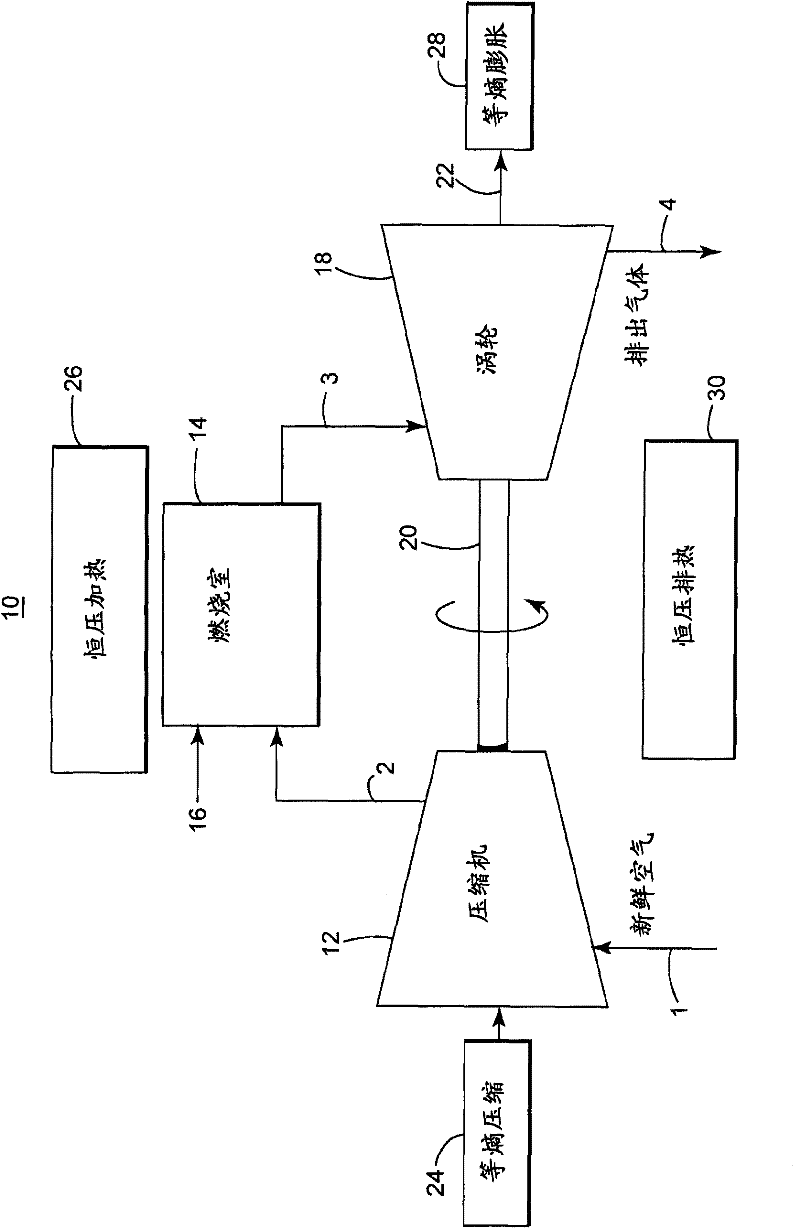

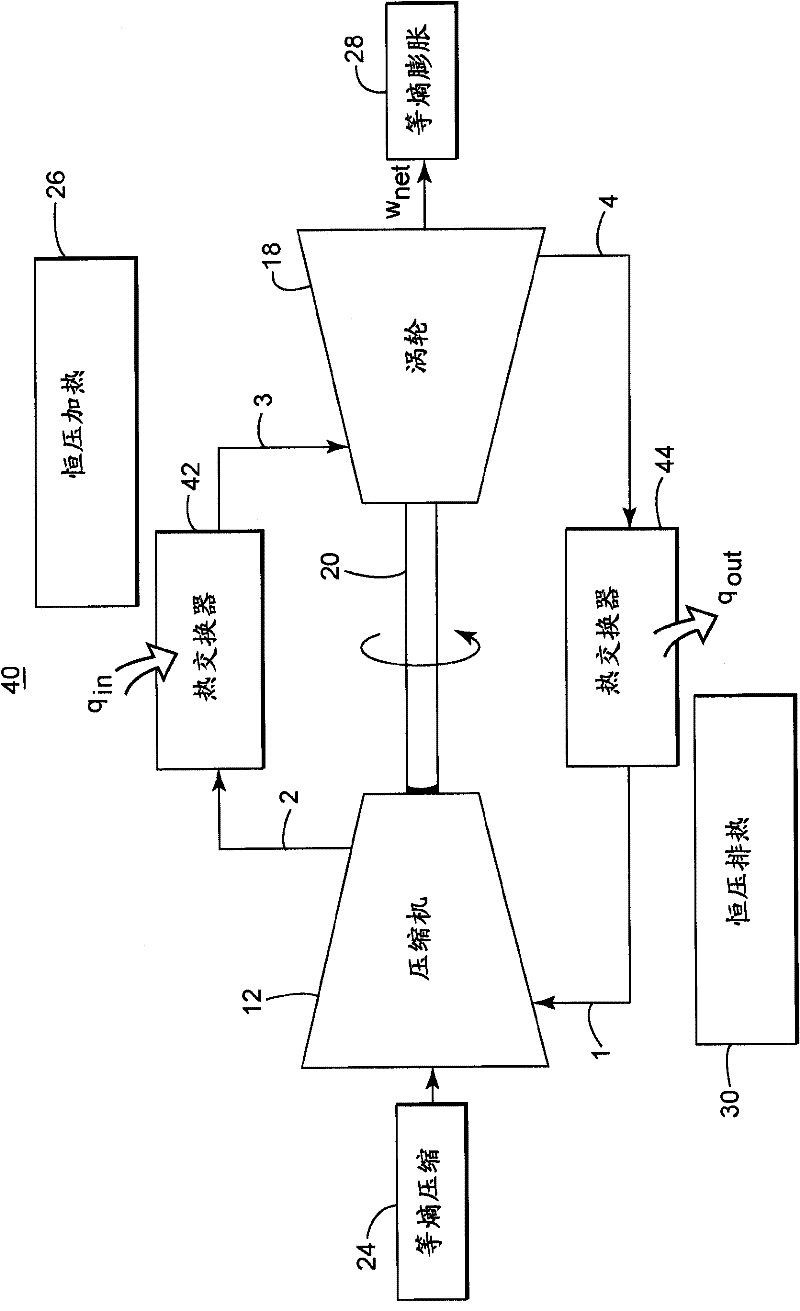

Closed Cycle Brayton Cycle System and Method

Method and unit for generating energy with improved efficiency. A Brayton cycle unit includes a multistage compressor configured to compress a flowing medium; a first heat exchanger fluidly connected to the multistage compressor and configured to transfer heat from a working medium passing the first heat exchanger to the compressed flowing medium; an expander fluidly connected to the first heat exchanger and configured to expand the heated compressed flowing medium for producing a rotation of a shaft of the expander; and a second heat exchanger fluidly connected between the expander and the compressor and configured to remove heat from the expanded flowing medium. A path of the flowing medium through the unit is closed. At least one inter-cooler mechanism between first and second stages of the multistage compressor is configured to cool the flowing medium to a predetermined temperature.

Owner:NUOVO PIGNONE SPA

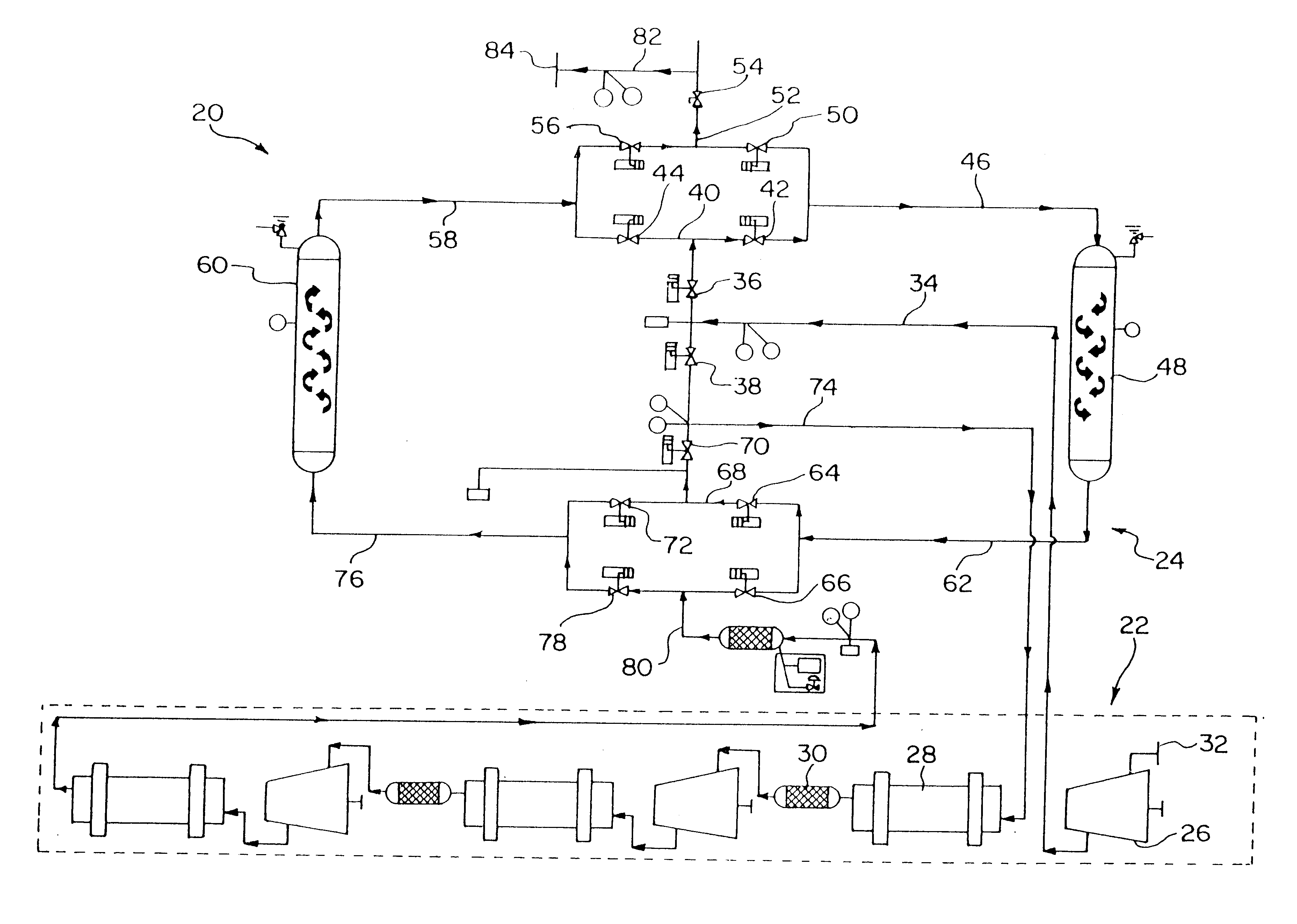

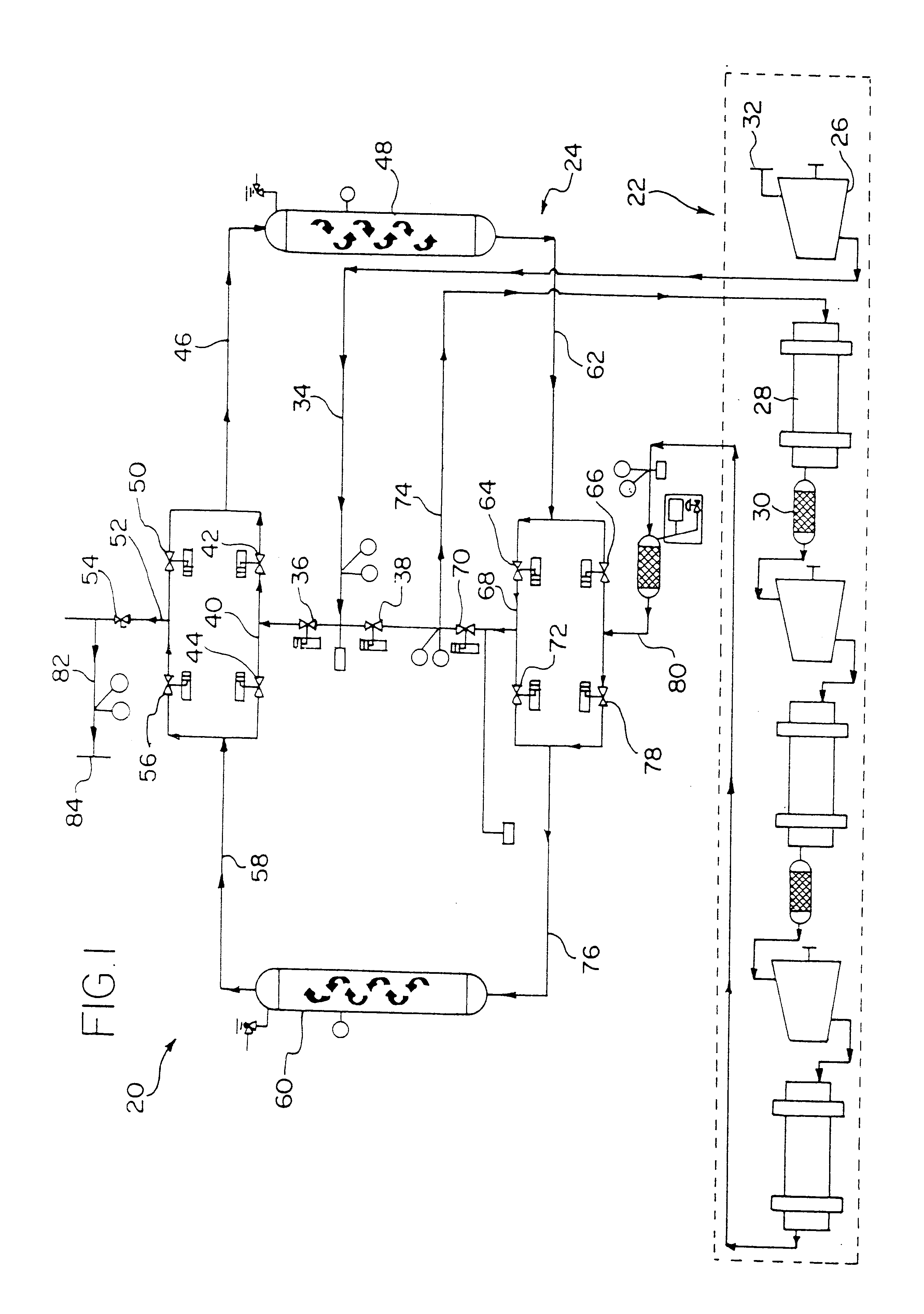

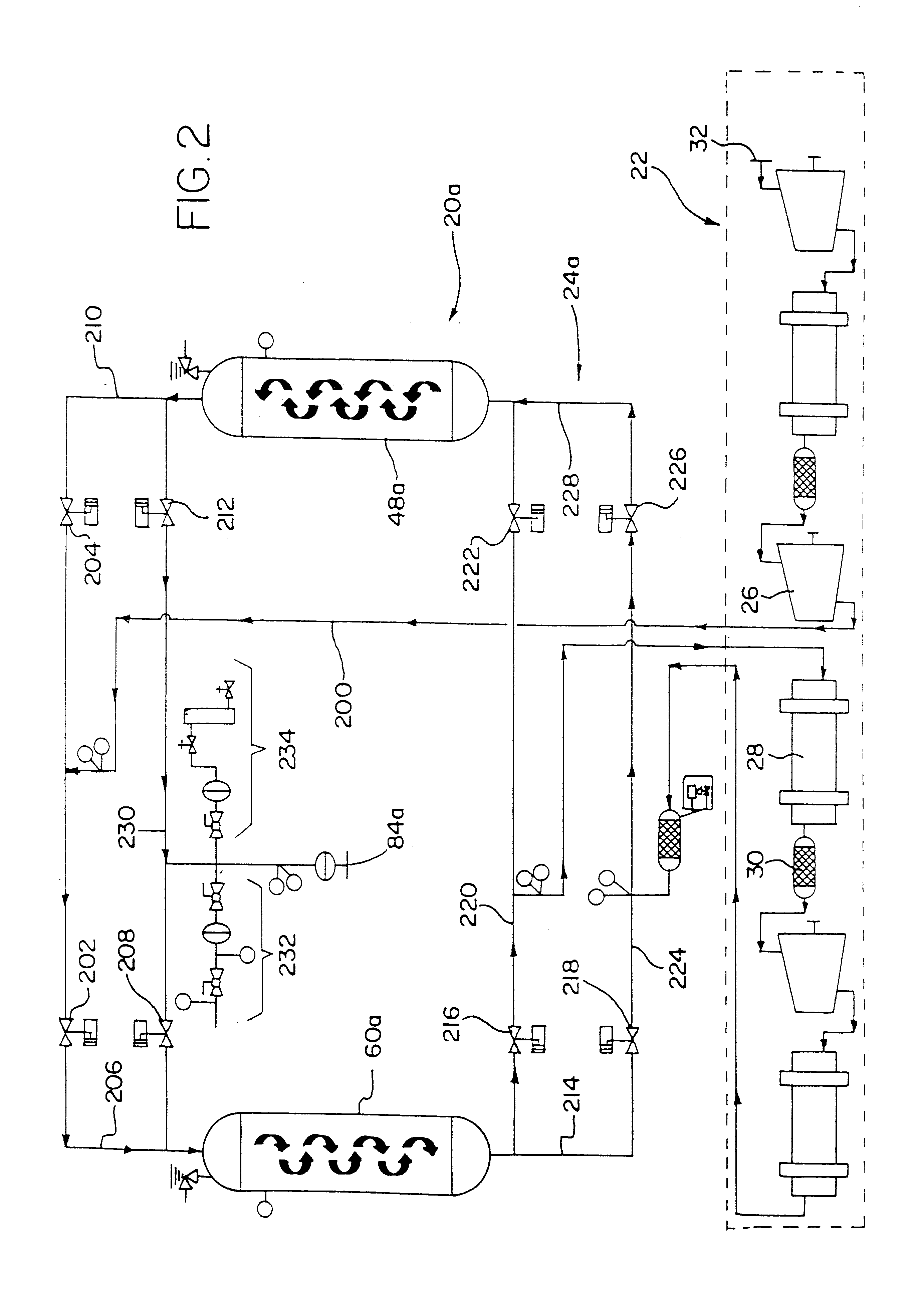

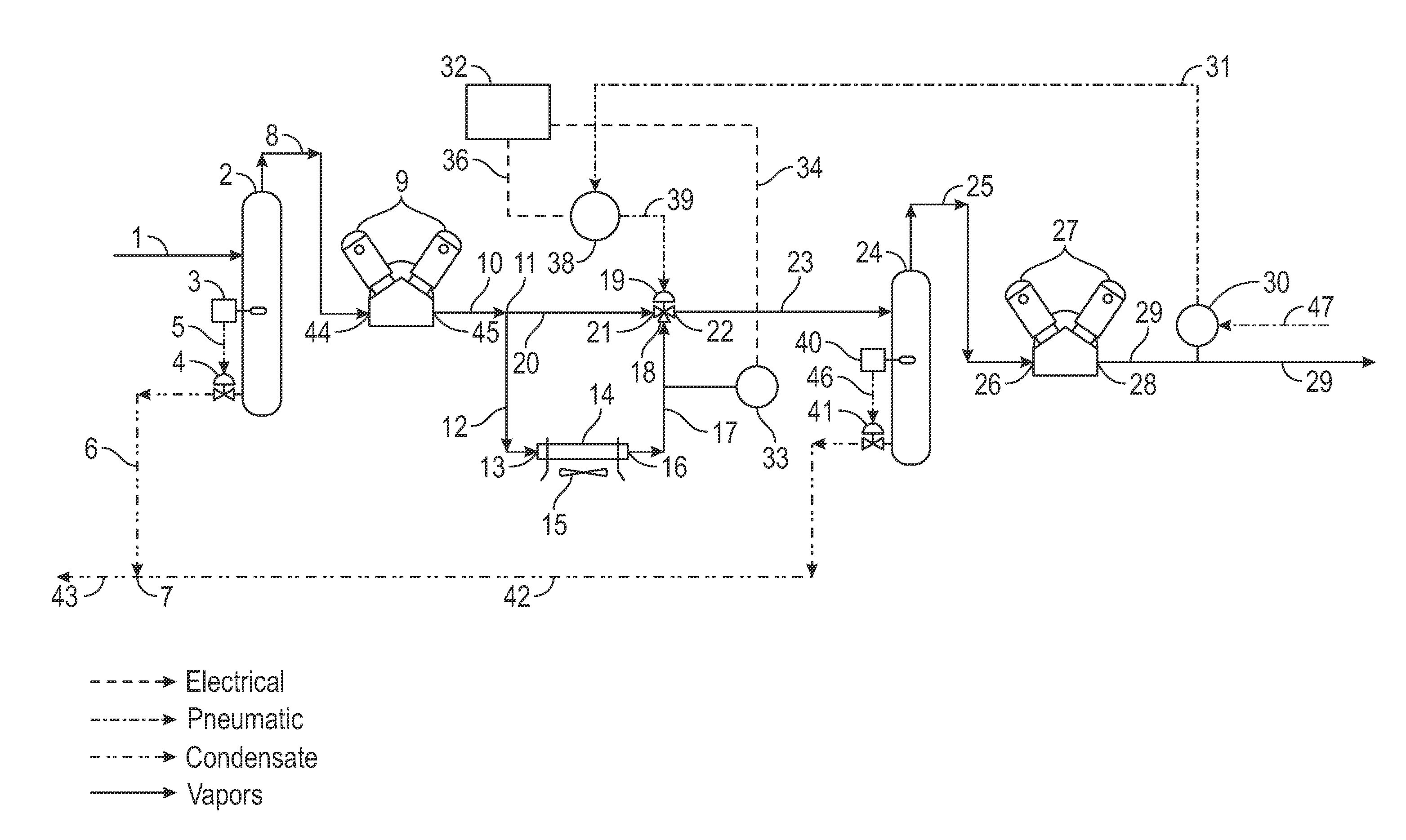

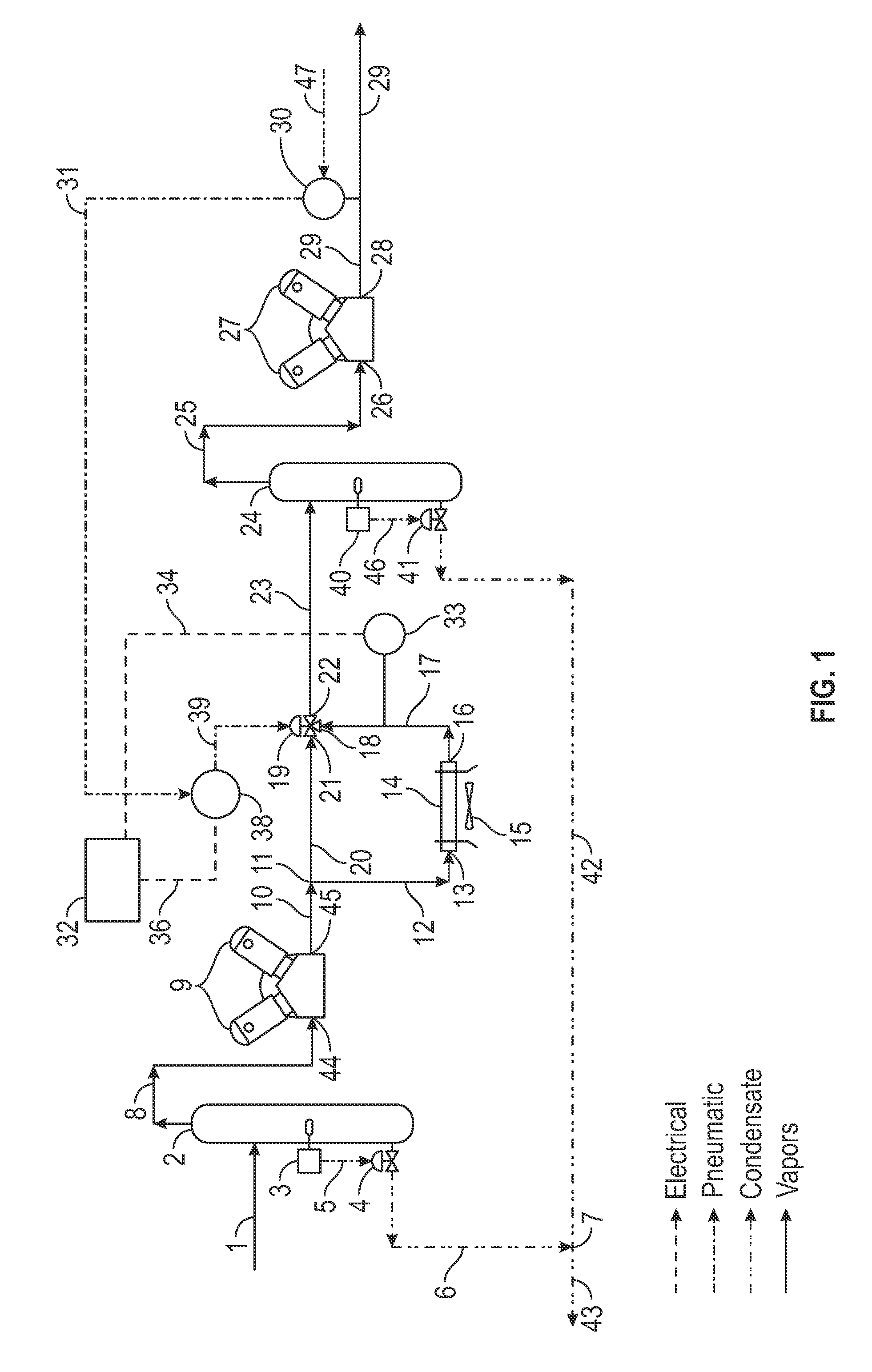

Regenerative compressed air/gas dryer

A system for drying a gas, such as air, includes a source of gas to be dried, a multi-stage compressor having an inlet connected to the source, and a dryer connected interstage to the compressor and to the outlet of the compressor. The dryer is connected interstage to the compressor between a compression stage and a heat exchanger of one of the compressor stages for regenerating a first desiccant filled tower. The dryer is also connected to the outlet of the compressor for drying the gas using a second desiccant filled tower. A communication structure can be activated to connect the first tower to the outlet of the compressor for drying the gas using the first tower, and to connect the second tower interstage to the compressor for regeneration of the second tower.

Owner:HENDERSON ENG CO INC

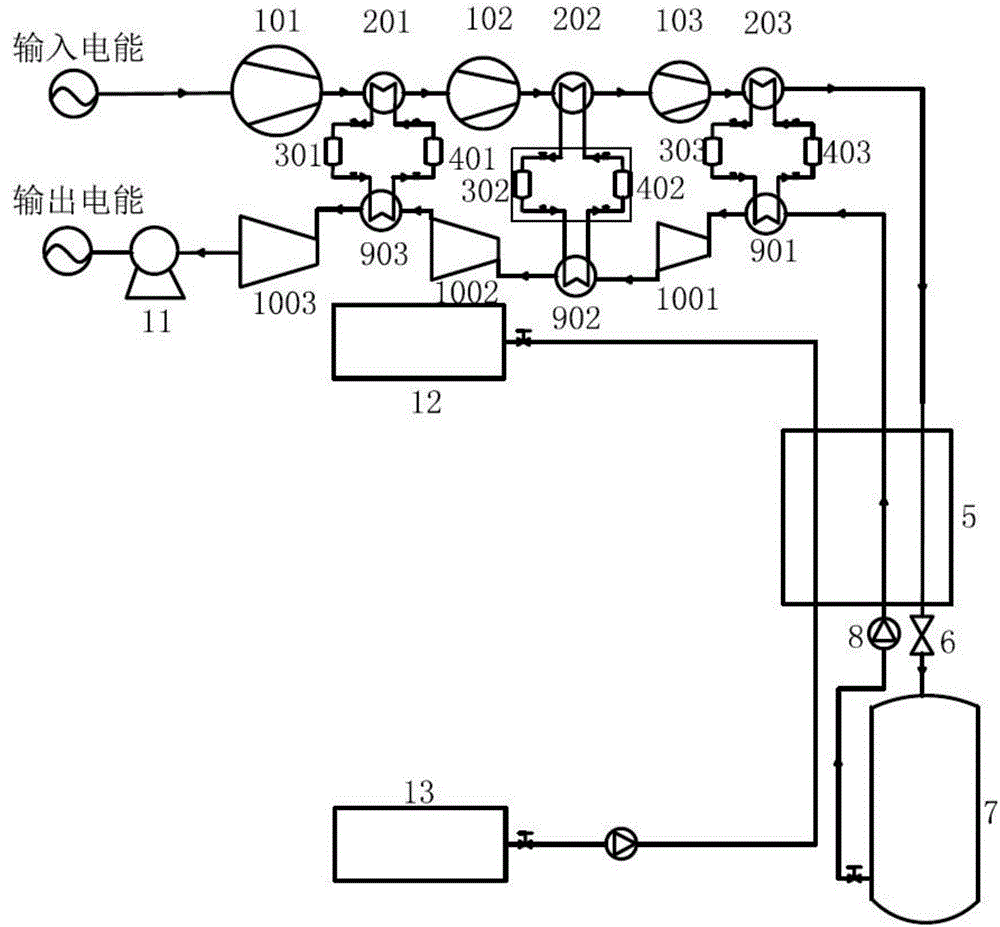

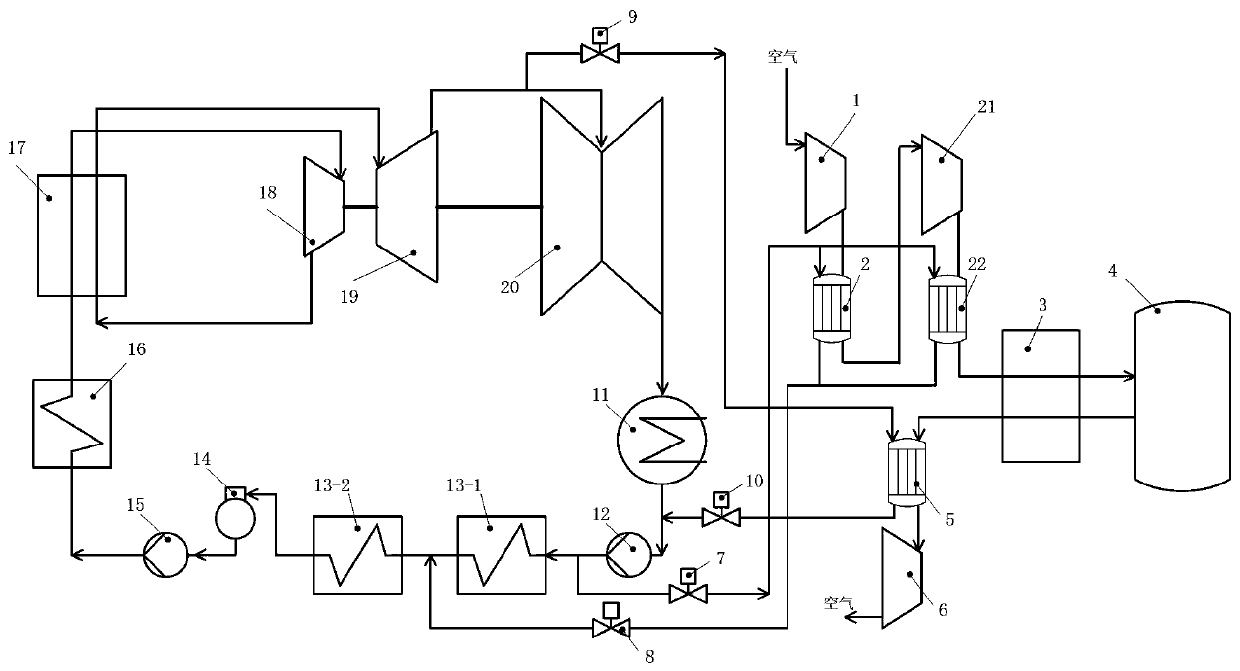

Liquefied compressed air energy storage system with cold-storage liquid media

ActiveCN105043147AHigh energy storage densityLow costHeat storage plantsMachines/enginesLiquid mediumThermal energy storage

The invention relates to a liquefied compressed air energy storage system with cold-storage liquid media. The liquefied compressed air energy storage system comprises compressor systems, a cold storage system, a heat storage system, a liquefying system and a turbine power generation system. During energy storage, the multistage compressor system is driven by renewable energy sources, so that compressed air is supercharged to exchange heat with a room-temperature cold-storage liquid medium, the cold quantity stored in the liquid medium is lowered to liquefying temperature, and the compressed air is liquefied through throttling; during energy releasing, the liquid air is supercharged to exchange heat with a high-temperature cold-storage liquid medium, the medium recycles cold energy to give to the liquefying process, and the air is warmed to be vaporized; room-temperature high-pressure air is input into a multi-stage turbine expander for acting, and a power generator is driven to output electric energy; the heat storage system reduces the power consumption of the next stage of compressor, and the stored heat is heated step by step before expansion to raise the intake air temperature; a cold-storage medium with a low freezing point and a high / low boiling point recycles the cold energy of the liquid air, the specific heat capacity of the liquid media is large, and the large-temperature-span heat exchange is realized. The liquefied compressed air energy storage system has the advantages of being simple in structure and stable in performance, can realize integration of energy storage and power generation, and can realize the large-scale grid-connection of renewable energy generation, therefore improving the capacity of a power grid accepting new energy power generation.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Compressor inter-stage temperature control

InactiveUS20120261092A1Mechanical apparatusCompression machines with non-reversible cycleTemperature controlGas compressor

A method, system and apparatus for providing temperature control of compressed gases between stages of a multiple-stage compressor, by selectively manipulating a valve which can cause at least a portion of the compressed gases to flow through an air-cooled heat exchanger.

Owner:HEATH RODNEY T +2

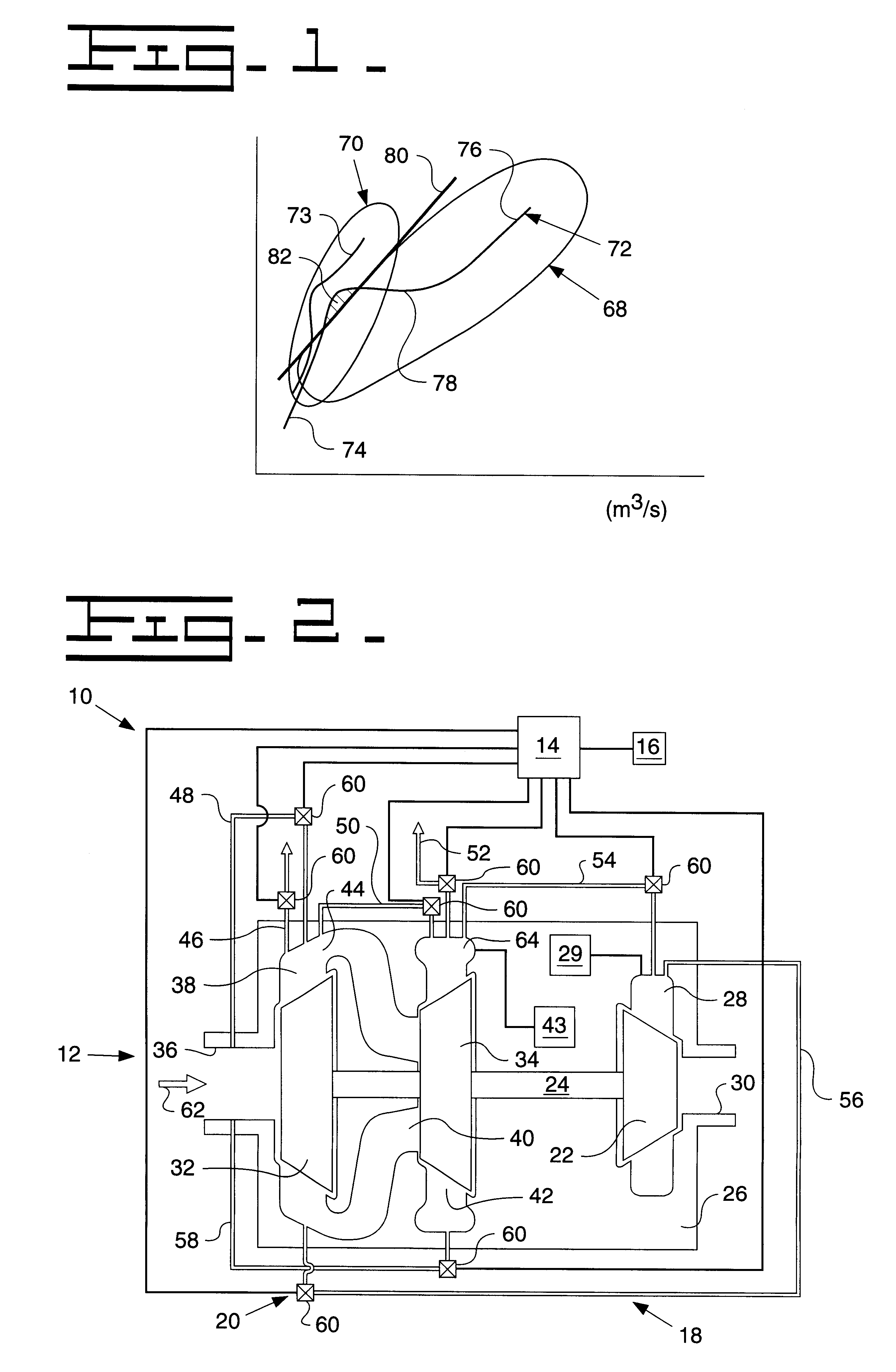

Multi-stage compressor

InactiveUS20110038737A1Increase capacityReduce capacityPump componentsFlexible member pumpsGas compressorEngineering

A system and a method for adding and subtracting stages of compression to a compressor as and when the compressor requires them. If the compressor needs only a low pressure ratio, then the system and method allow the compressor to operate with only a primary pumping circuit spinning, while available additional stages, forming a secondary pumping circuit, and which may be required at other times when the needed pressure ratios increase, are decoupled from the rotating shaft, so that the compressor pumps at its most efficient and flexible point. Further, a system and method for adding and subtracting stages of compression to a compressor in order to increase and decrease the pumping capacity as and when required to satisfy a given load requirement.

Owner:DANFOSS AS

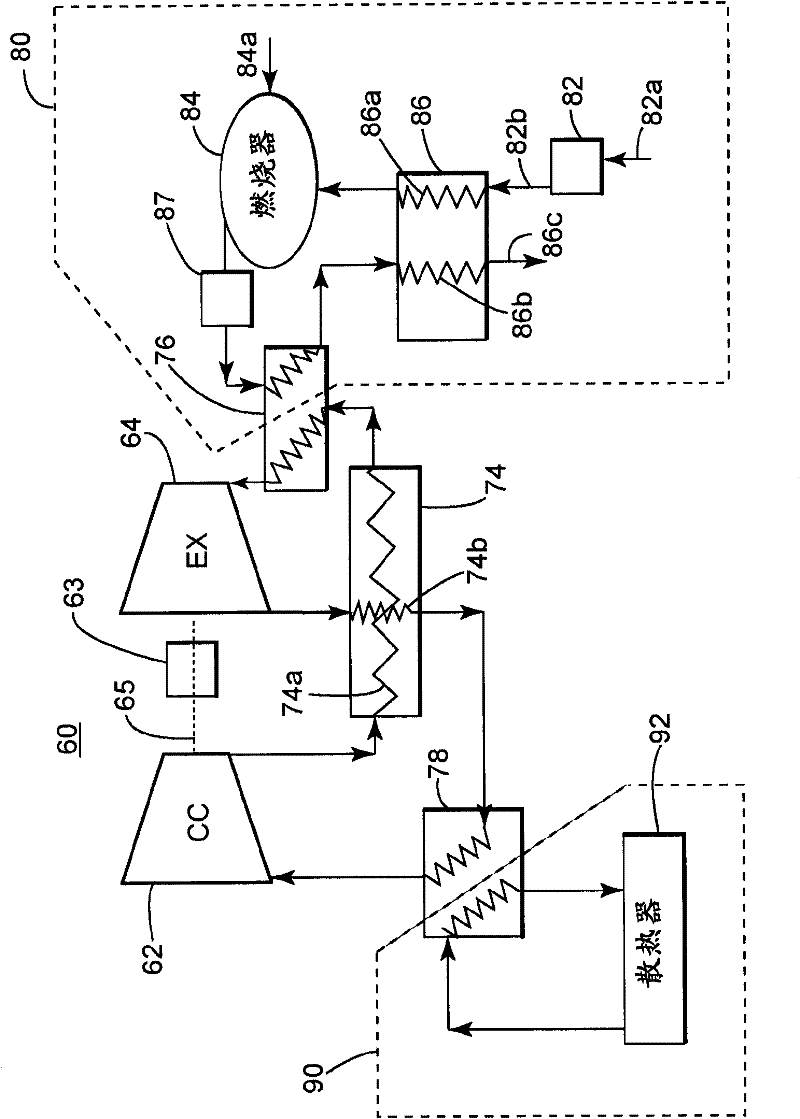

Hybrid microturbine for generating electricity

ActiveUS7574867B2Reduce weightEmission reductionPump componentsGas turbine plantsElectricityCombustor

Owner:TEETAB JOSEPH MICHAEL +1

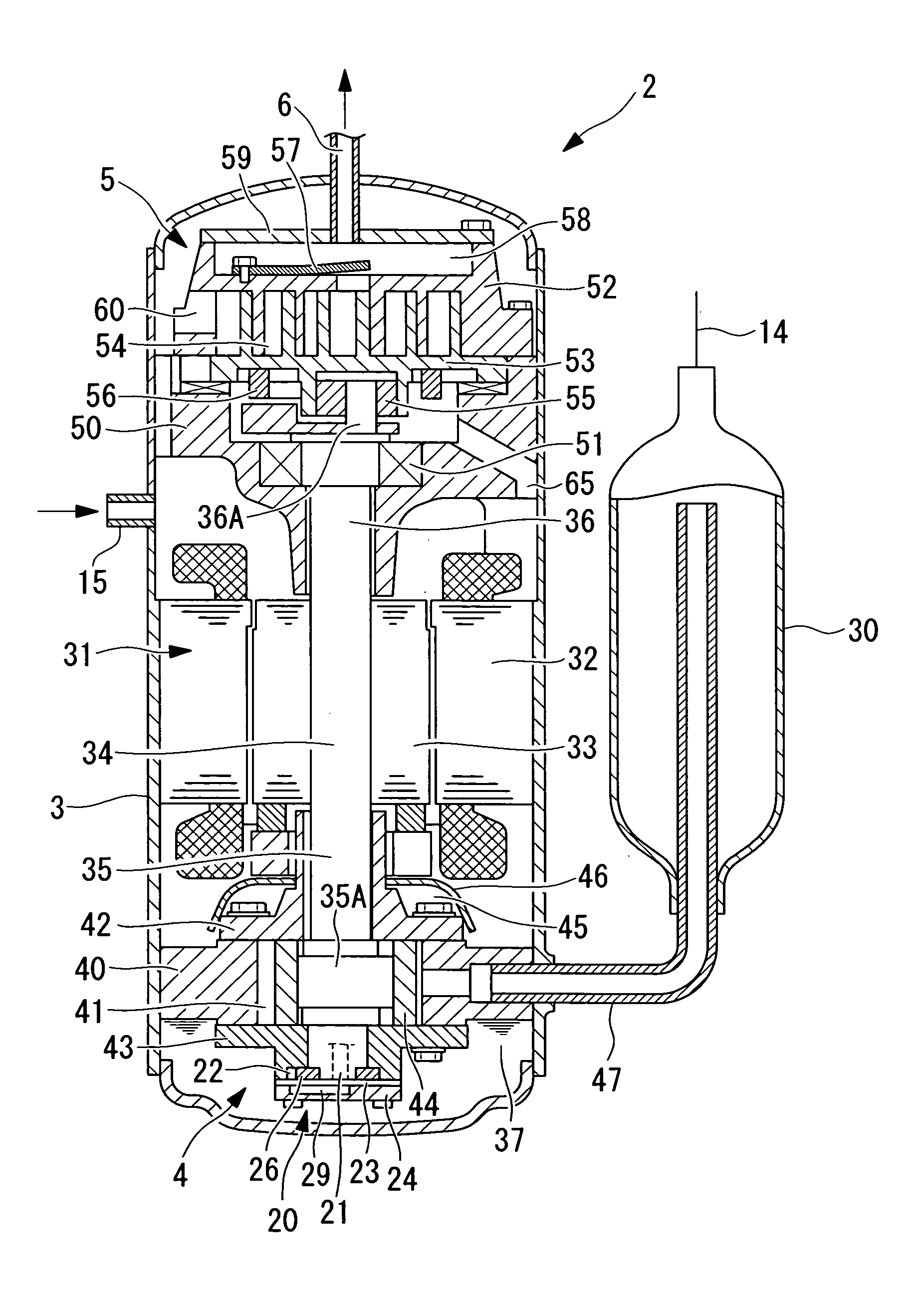

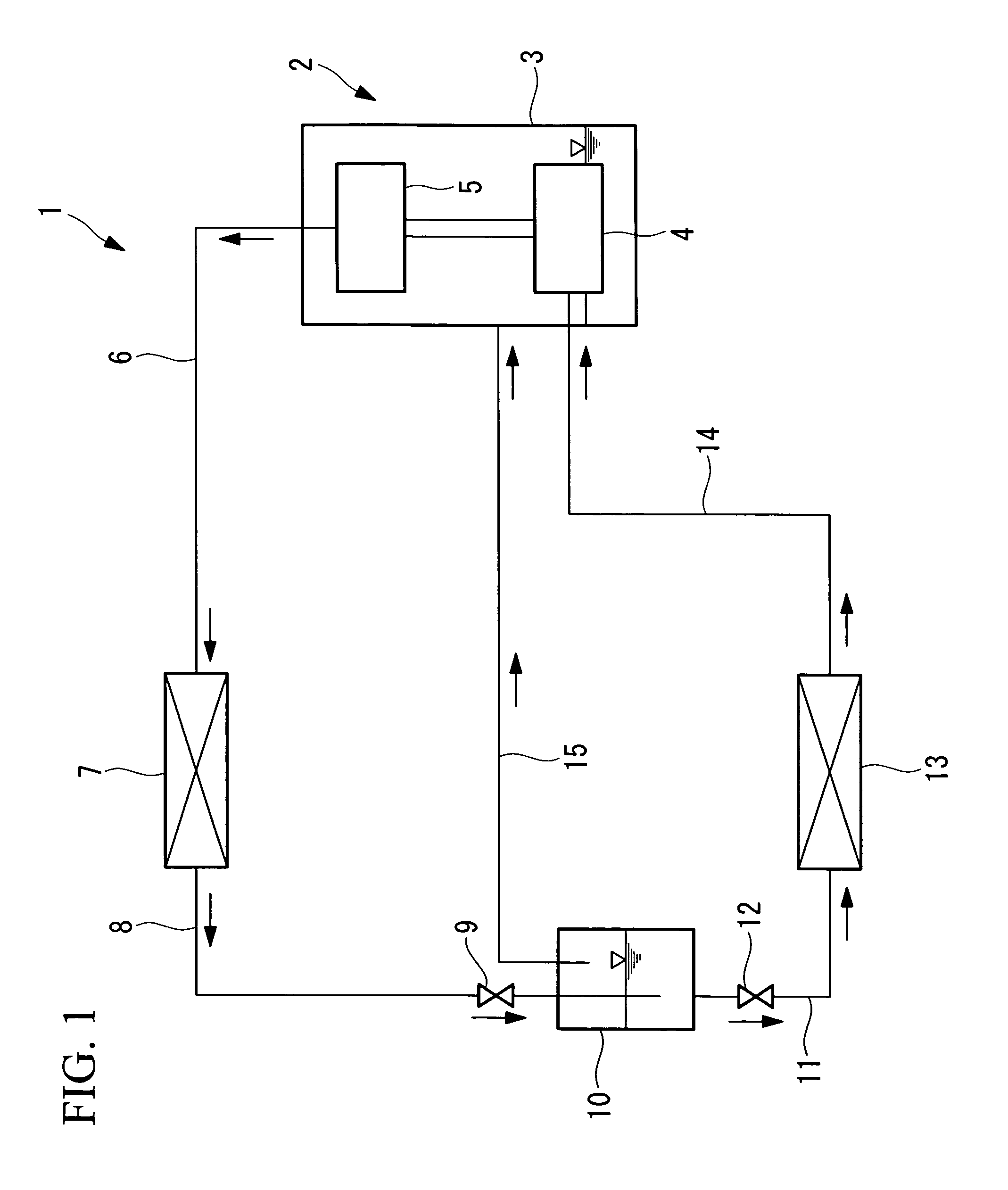

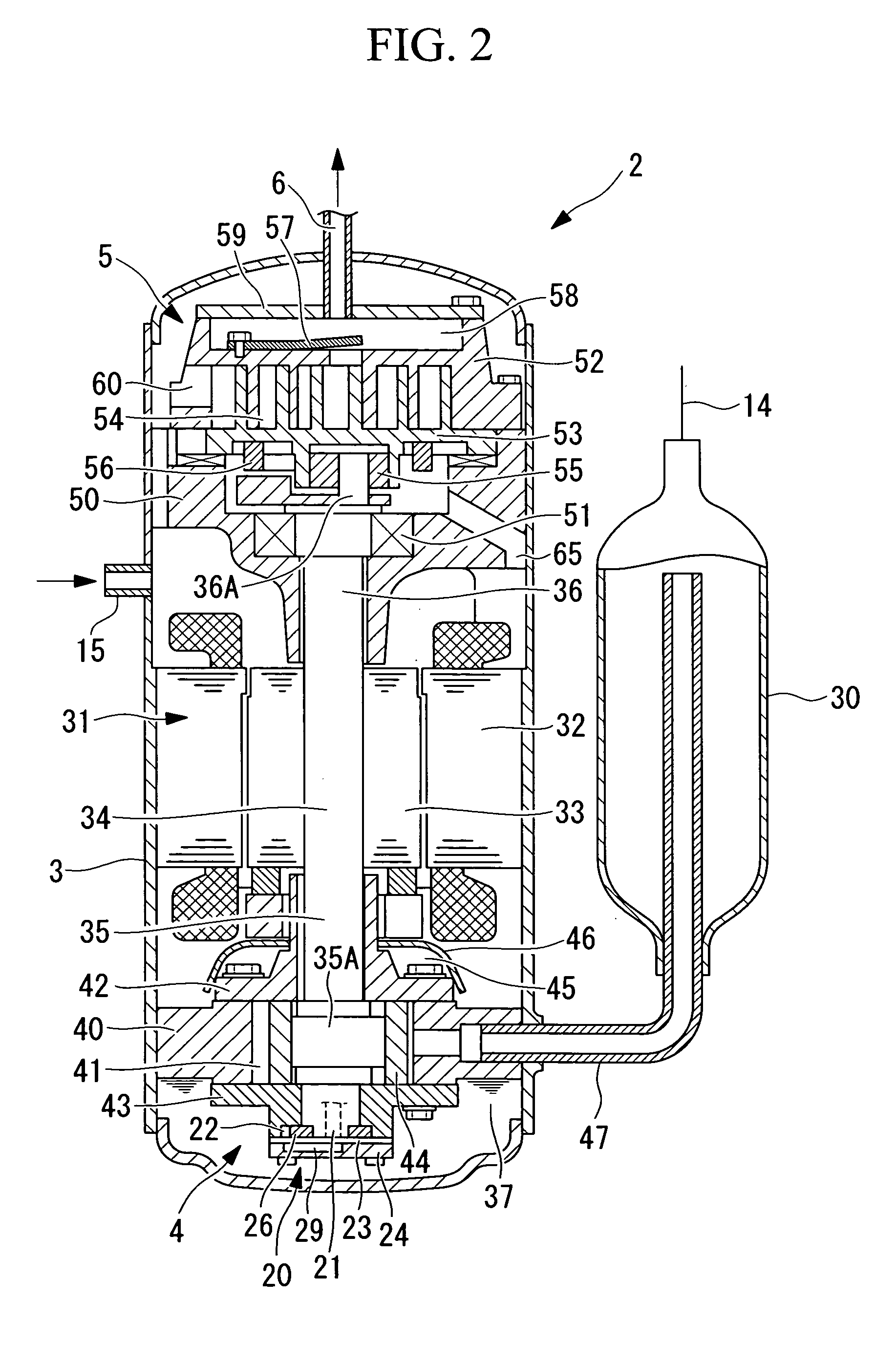

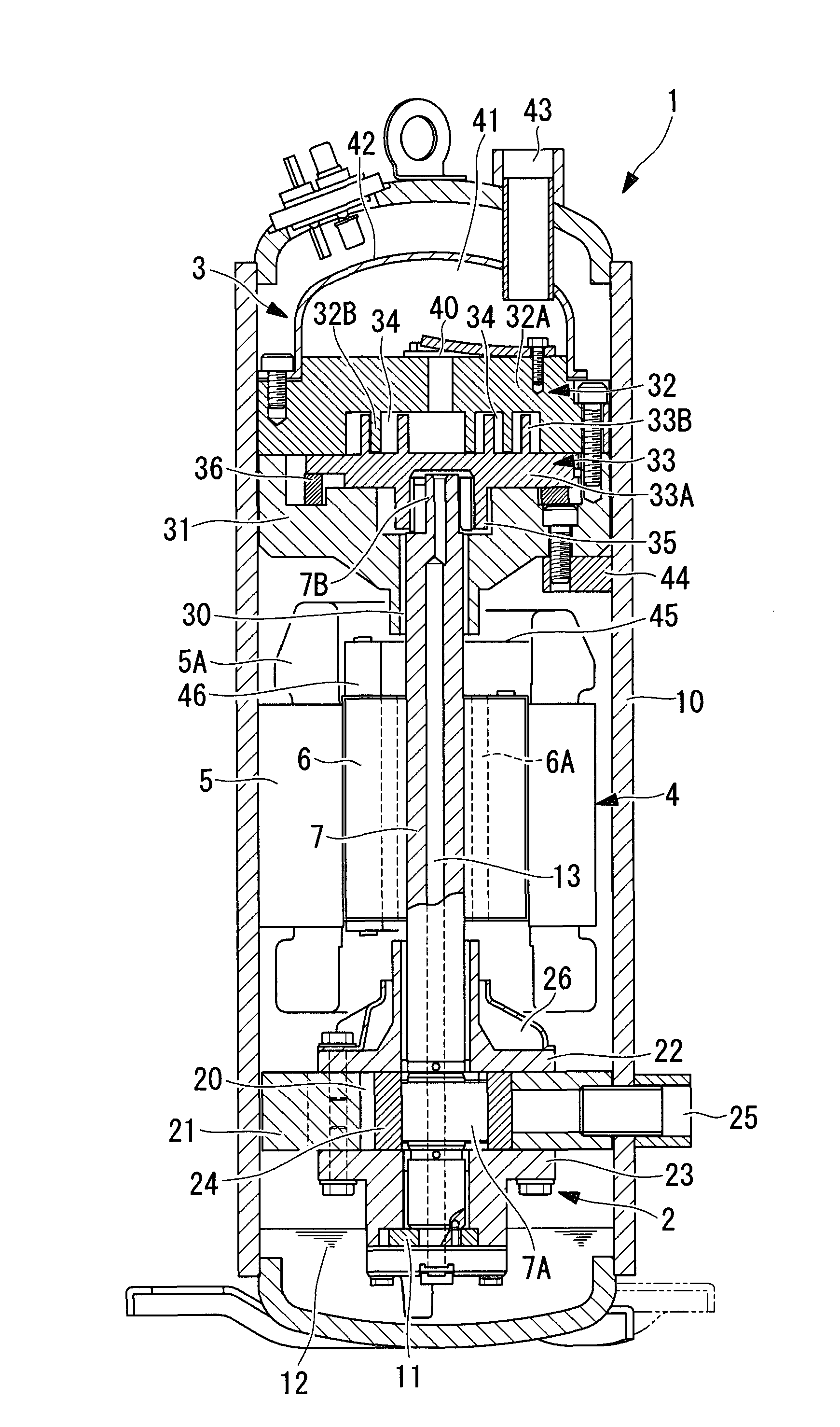

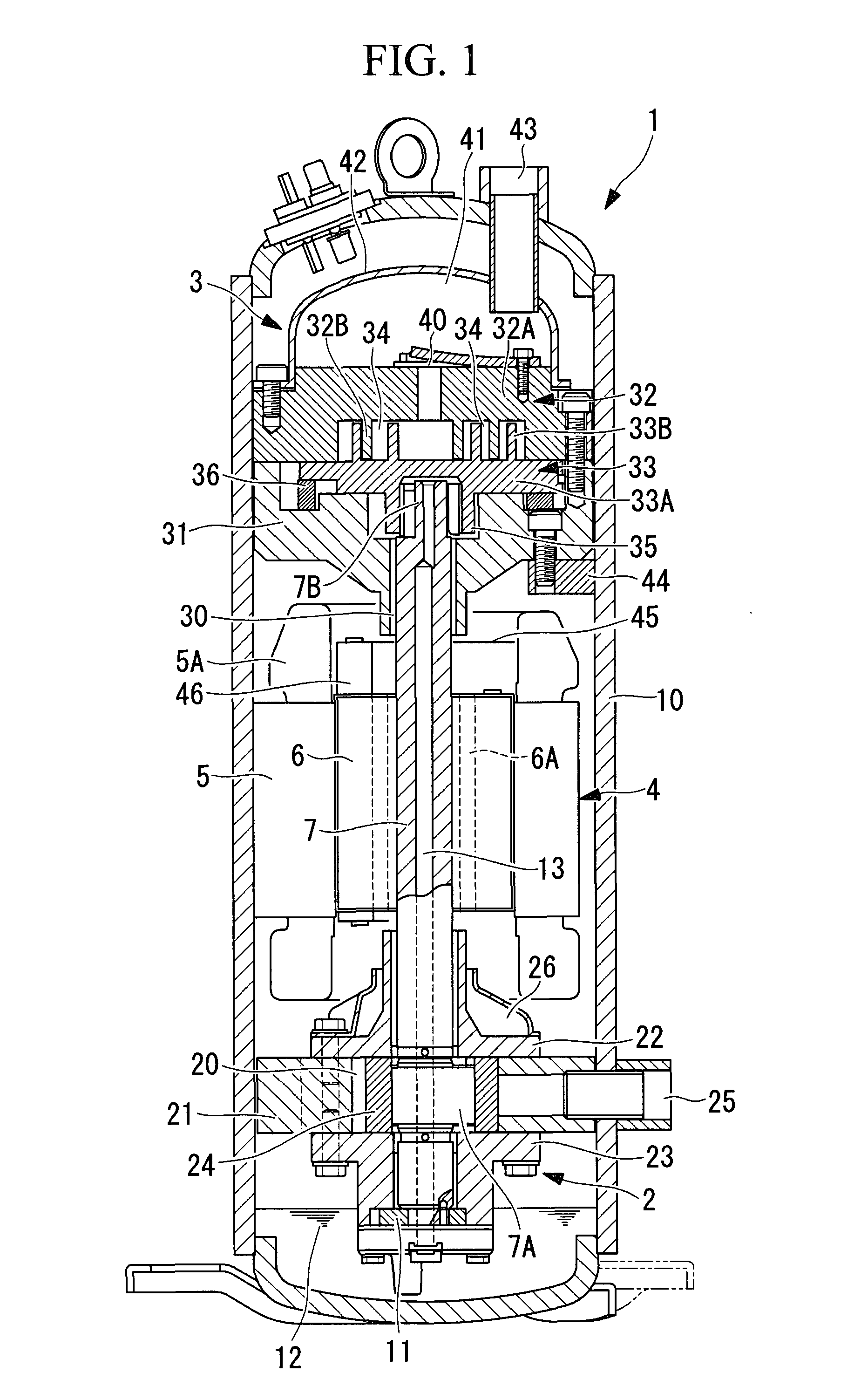

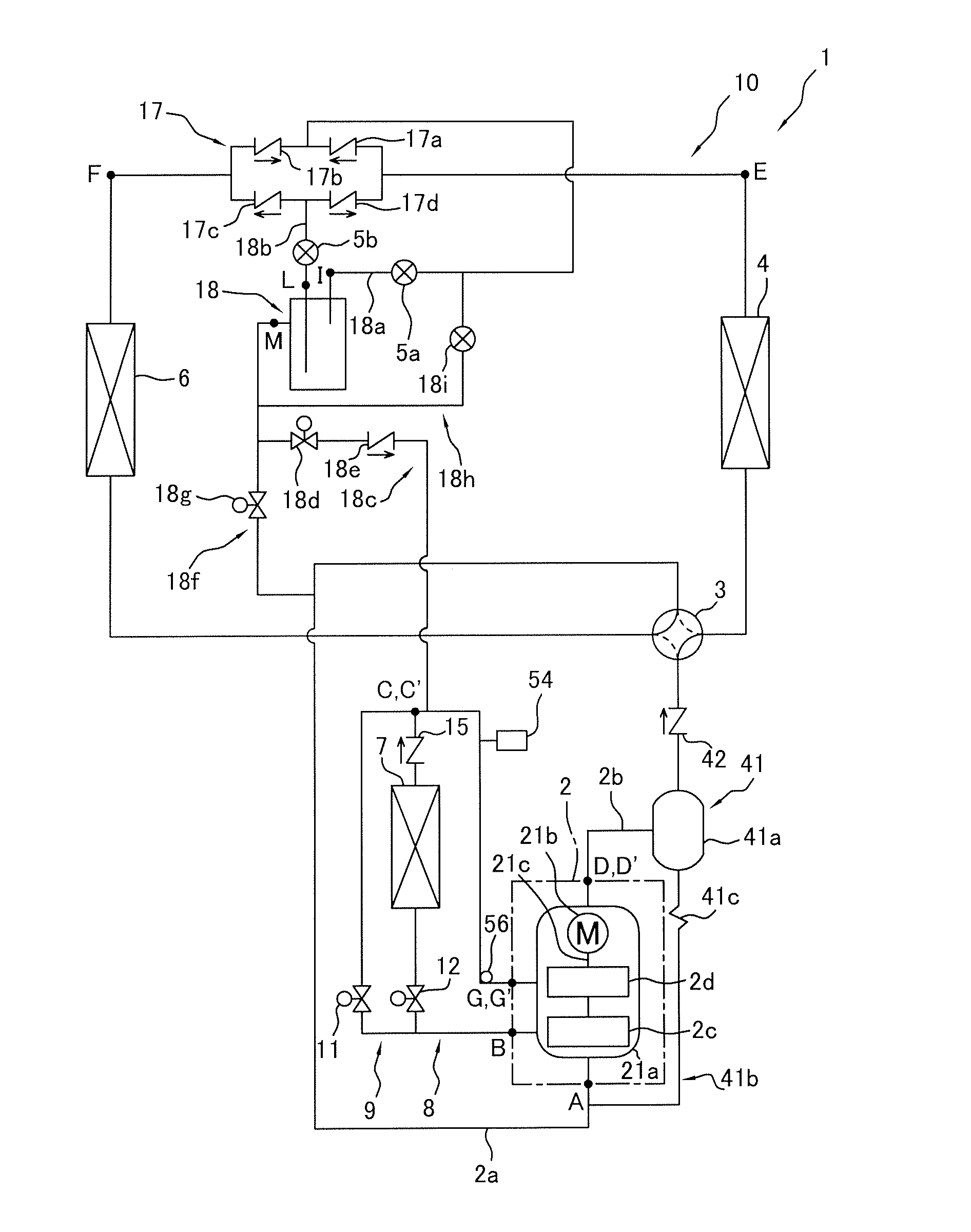

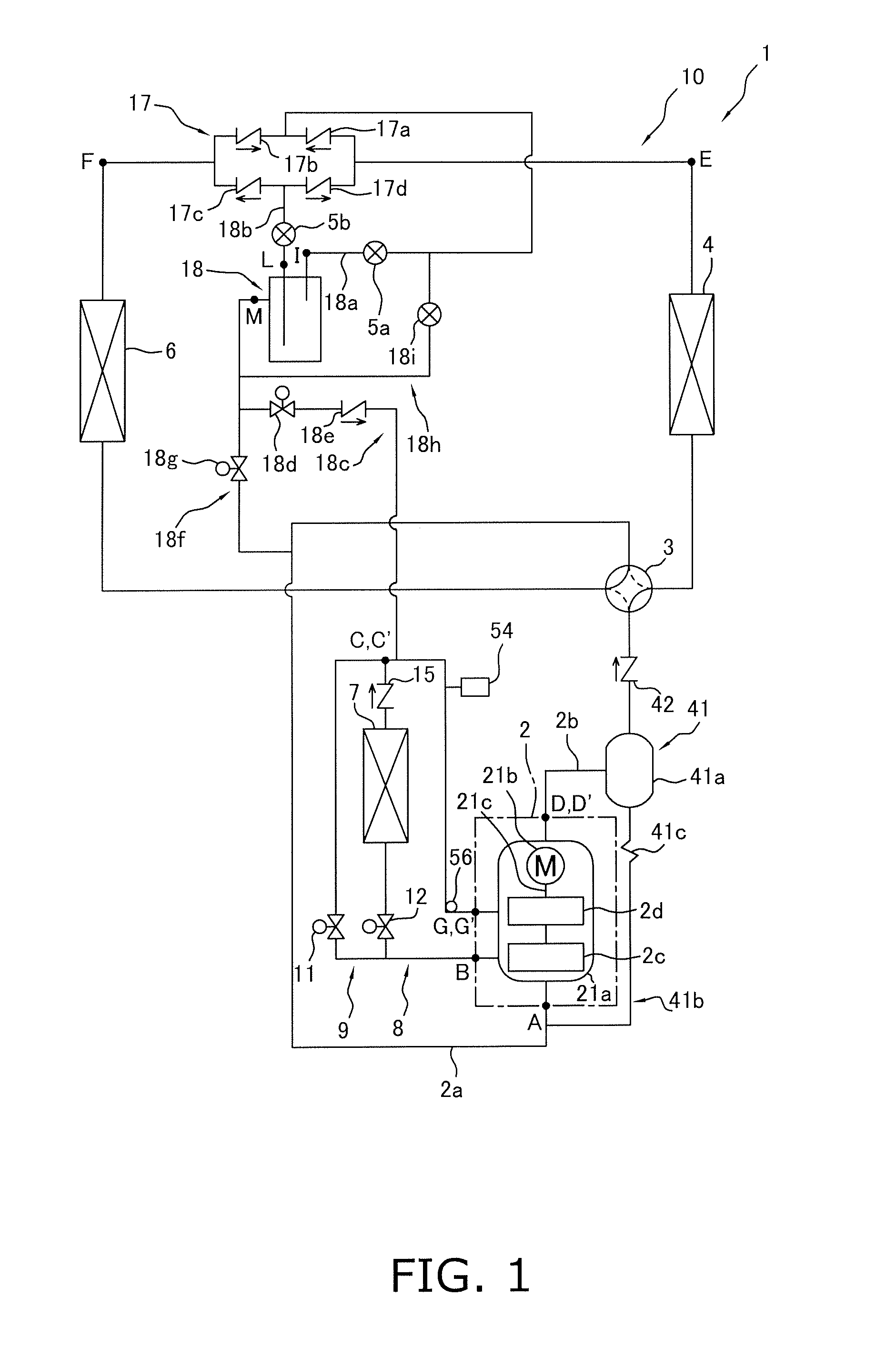

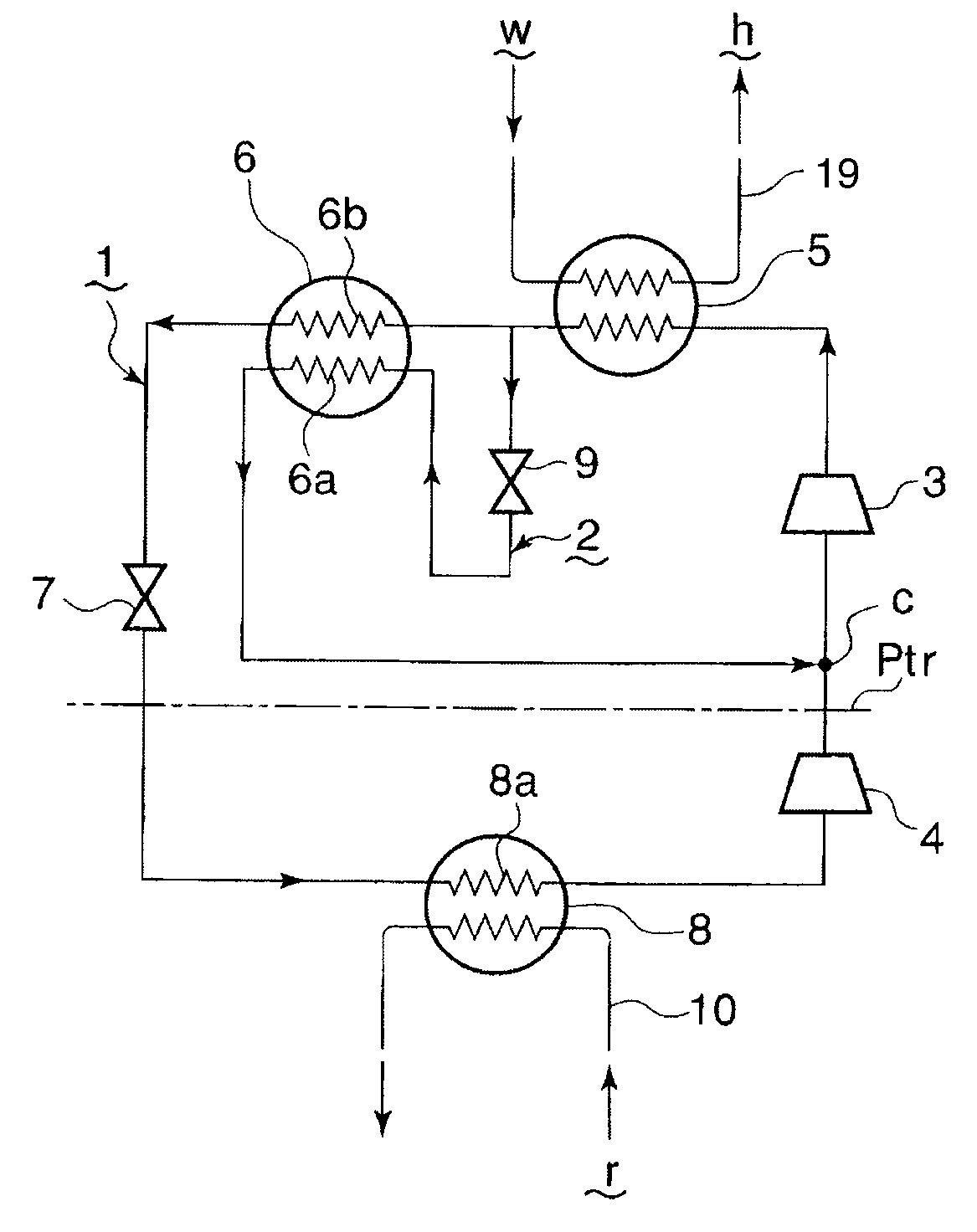

Multistage Compressor

ActiveUS20100143172A1Improve motor efficiencyImprove performanceRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringRefrigerant

A multistage compressor employing a gas injection system for CO2 cycle that attains enhancements of compression efficiency and compression performance. The multistage compressor is multistage compressor (2) for CO2 cycle (1) adapted to carry out two-stage compression involving emitting the CO2 refrigerant gas compressed by inferior-stage side rotary compression means (4) into sealed housing (3) and having the intermediate-pressure refrigerant gas within the sealed housing (3) suctioned by superior-stage side scroll compression means (5), wherein to the sealed housing (3), there is connected gas injection circuit (15) capable of injection of intermediate-pressure CO2 refrigerant gas extracted from a refrigerant circuit into the sealed housing (3), and wherein the inferior-stage side rotary compression means (4) and the superior-stage side scroll compression means (5) are approximately identical with each other in pressure ratio and approximately equivalent with each other in displacement ratio.

Owner:MITSUBISHI HEAVY IND LTD

Closed cycle brayton cycle system and method

The invention relates to a closed cycle brayton cycle system and a method. Specifically, the invention provides a method and a unit for generating energy with improved efficiency. A Brayton cycle unit includes a multistage compressor configured to compress a flowing medium; a first heat exchanger fluidly connected to the multistage compressor and configured to transfer heat from a working medium passing the first heat exchanger to the compressed flowing medium; an expander fluidly connected to the first heat exchanger and configured to expand the heated compressed flowing medium for producing a rotation of a shaft of the expander; and a second heat exchanger fluidly connected between the expander and the compressor and configured to remove heat from the expanded flowing medium. A path of the flowing medium through the unit is closed. At least one inter-cooler mechanism between first and second stages of the multistage compressor is configured to cool the flowing medium to a predetermined temperature.

Owner:NUOVO PIGNONE SPA

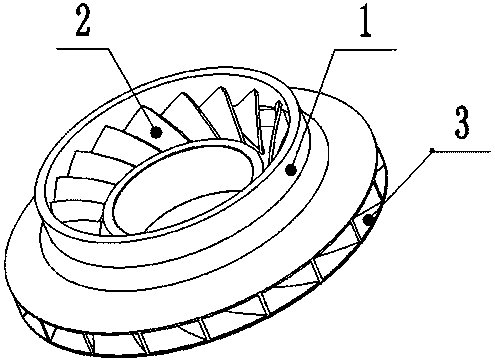

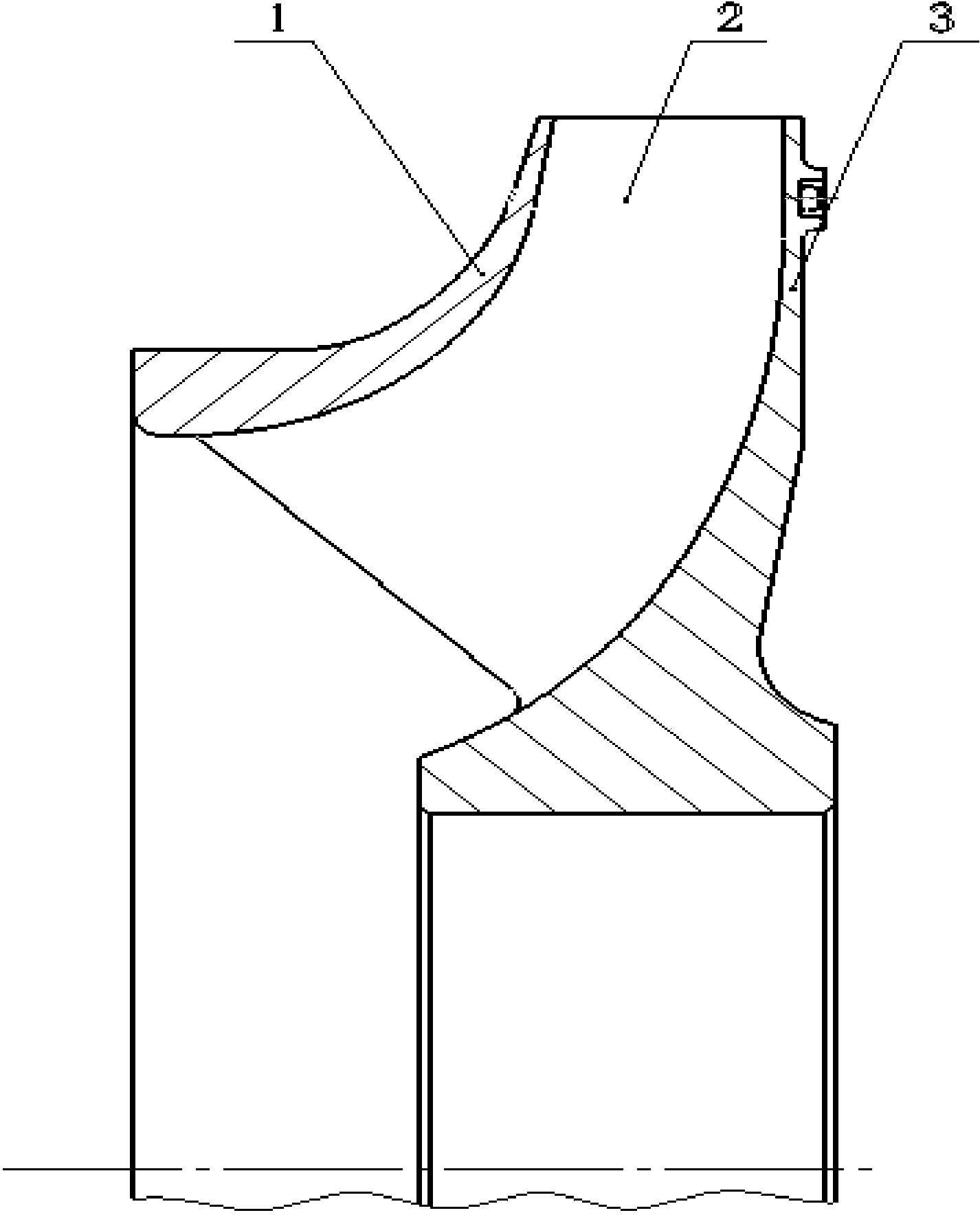

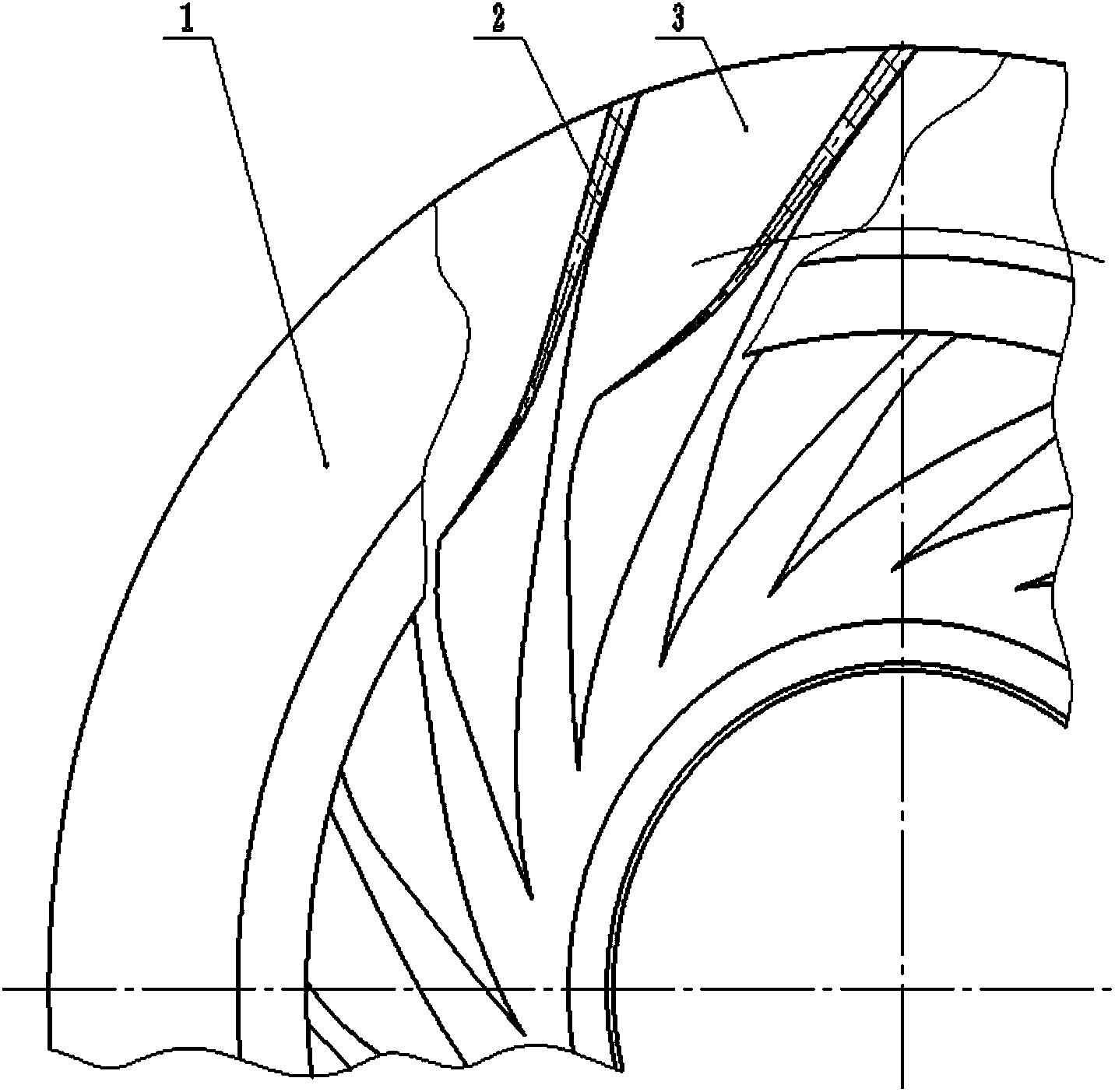

Enclosed impeller of centrifugal compressor

InactiveCN103807209AImprove performance indicatorsHigh pressure ratioPump componentsPumpsAutomatic controlPerformance index

The invention discloses an enclosed impeller of a centrifugal compressor. The enclosed impeller of the centrifugal compressor comprises blades, hubs and a wheel disc. The enclosed impeller of the centrifugal compressor is characterized in that the blades are of a backward-bending type constant strength structure; the blades and the hubs are integrated, and the blades and the hubs are connected with the wheel disc through a welding structure. The blades are of the constant strength structure, and circumferential thicknesses of the blades are increased gradually from blade tips to blade roots; the hubs and the wheel disc are connected through the welding structure, and the welding structure is completed by adopting the robot automatic control argon arc welding process. In the process of designing the multi-stage compressor, deflection angles between blade faces of the corresponding blades of a front impeller and a back impeller range from minus 5 degrees to minus 15 degrees. The invention further provides an optimum design method for the enclosed impeller of the centrifugal compressor. According to the method, the manufacturing process of the impeller can be automatically completed and controlled through a computer. According to the enclosed impeller, the high pressure ratio and the high efficiency of airflow inside the compressor can be achieved, the eddy loss inside a channel is reduced, and performance indexes of the centrifugal compressor are obviously improved.

Owner:SHENYANG SITE MACHINERY MFG

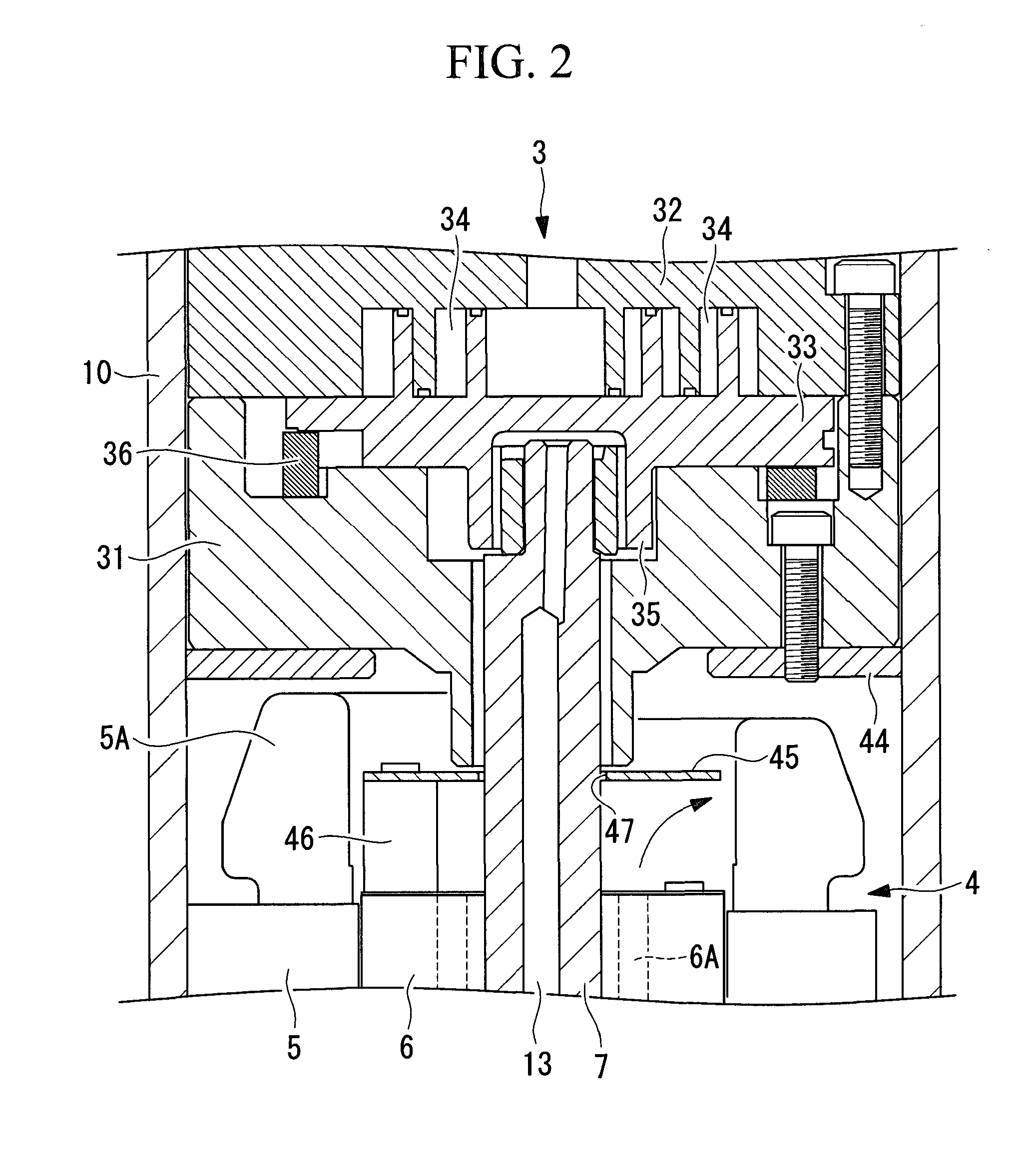

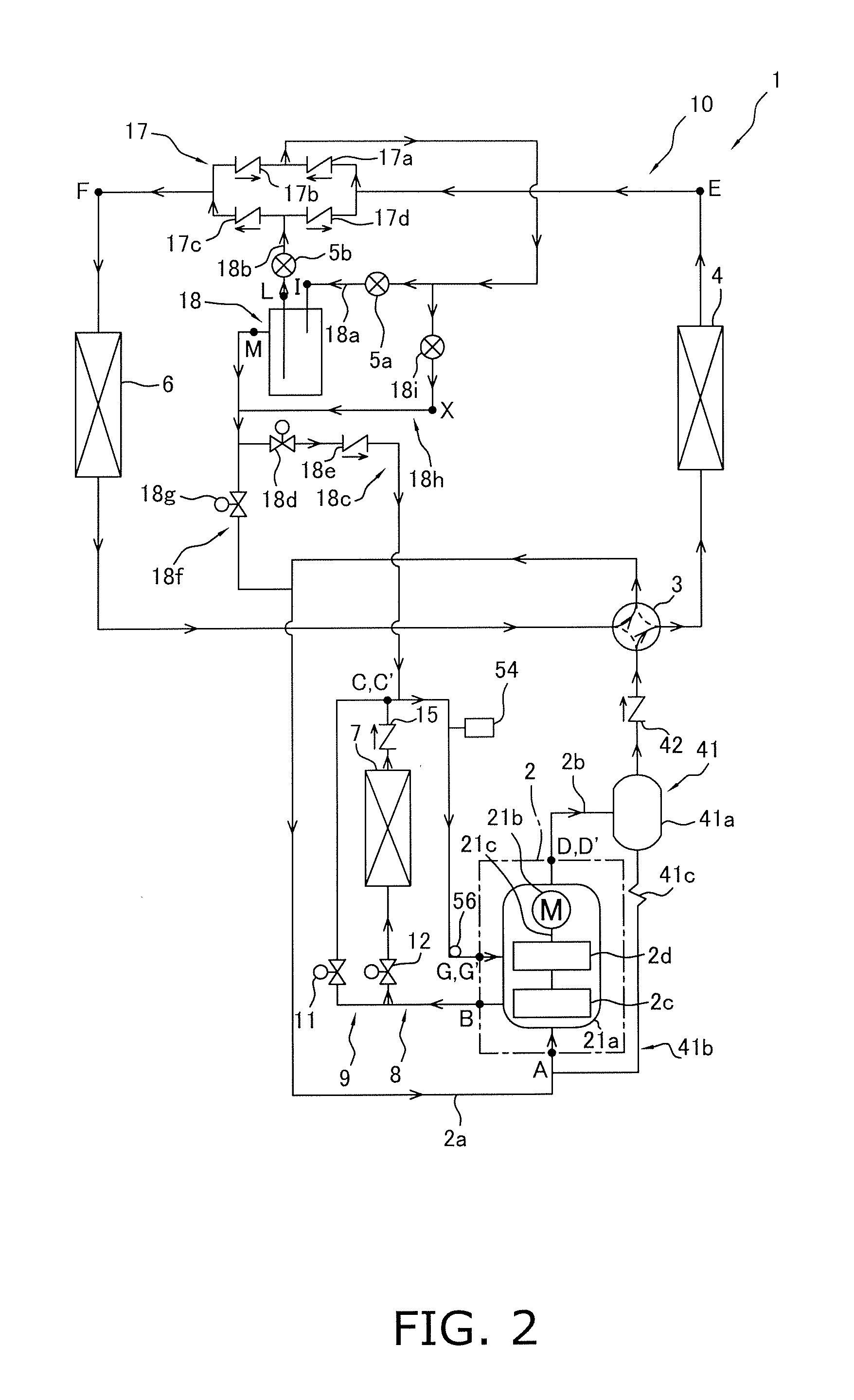

Multistage compressor

ActiveUS20100083690A1Improve system efficiencyReduce oil circulationRotary/oscillating piston combinations for elastic fluidsCombination enginesProduct gasEngineering

A multistage compressor is provided, which can reduce an oil circulation ratio by reducing the amount of lubricating oil to be taken in by a high-stage compression mechanism to improve the system efficiency and prevent a shortage of lubricating oil. A low-stage compression mechanism and a high-stage compression mechanism are disposed below and above to flank an electric motor, respectively, intermediate-pressure refrigerant gas compressed by the low-stage compression mechanism is discharged into a sealed housing, and the intermediate-pressure refrigerant gas is taken in by the high-stage compression mechanism so as to be compressed in two stages, an oil separator plate that centrifugally separates lubricating oil contained in the intermediate-pressure refrigerant gas, which is taken in by the high-stage compression mechanism after passing through the electric motor, is provided at one end of a rotor of the electric motor such that a rotary shaft extends through the oil separator plate.

Owner:MITSUBISHI HEAVY IND LTD

Fuel cell compressor system

The invention provides a fuel cell compressor system that comprises a motor, including a motor shaft driven by the motor; a drive housing at least partially surrounding the motor shaft; a first gear set driven by the motor shaft; a carrier torque tube driven by the first gear set; and an impeller. The impeller includes an impeller shaft driven by the second gear set, so that the impeller shaft is configured to rotate at a speed greater than motor speed. Embodiments of the invention may also be used with a multi-stage compressor that allows, for example, first and second impellers to rotate at different speeds. Embodiments of the invention may also include removal of a gear set driving the carrier torque tube or the impeller shaft, so that the impeller shaft speed is divided between one or more bearings supporting the carrier torque tube and one or more bearings supporting the impeller shaft.

Owner:EATON CORP

Compressor and hermetic housing with minimal housing ports

InactiveUS20060083626A1Easy to manufactureEliminate the problemCompression machines with non-reversible cycleMulti-stage pumpsWorking fluidEngineering

A vapor compression system having a multi-stage compressor with a minimal number of ports located in the hermetically sealed compressor housing. A working fluid at suction pressure enters the compressor housing through a first port and is compressed to an intermediate pressure. The intermediate pressure refrigerant flows from the first stage compressor mechanism to the second stage compressor mechanism where it is compressed to a discharge pressure and discharged through a second port. The intermediate pressure refrigerant is in thermal communication with a heat exchange medium which is introduced into the compressor housing through a third port in the housing.

Owner:TECUMSEH PROD CO

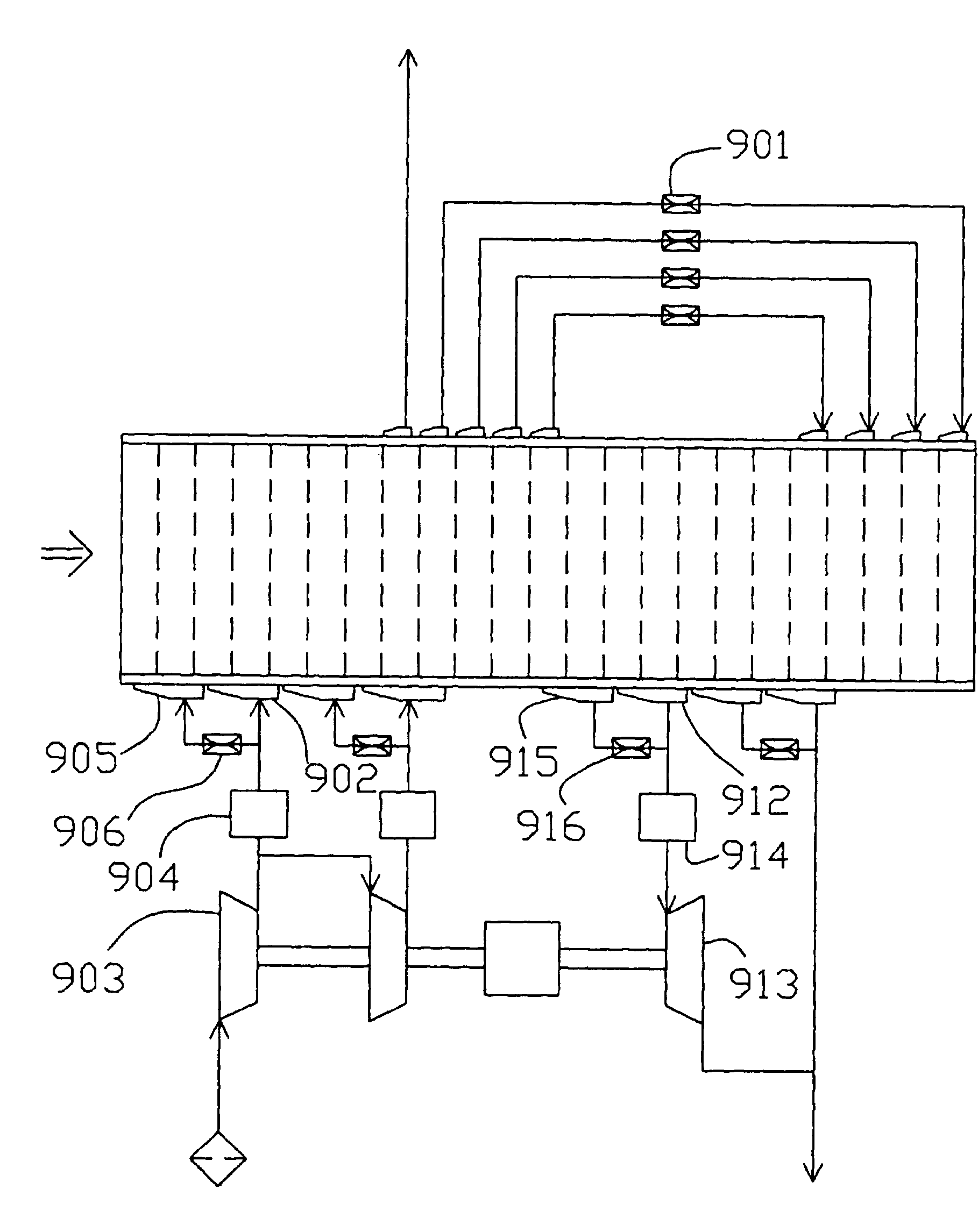

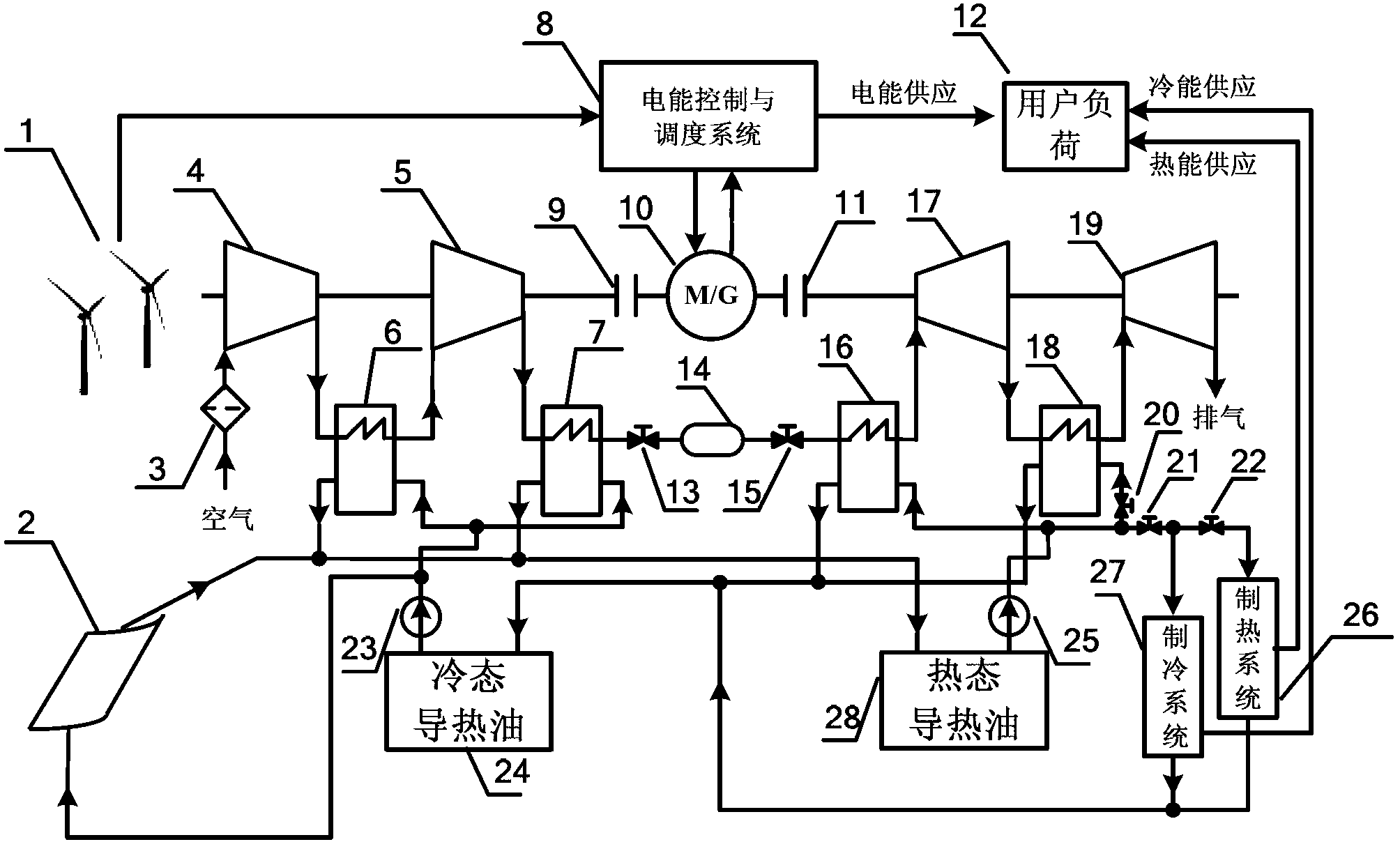

Wind-light-storage island-type combined cooling, heating and power system based on solar light-heat utilization

InactiveCN103291557AImprove consumption structureImprove utilization efficiencySolar heat devicesMachines/enginesThermal energyThermal state

The invention provides a wind-light-storage island-type combined cooling, heating and power system based on solar light-heat utilization. The system comprises a wind energy conversion system, a solar heat collecting system, a micro compressed air energy-storage system and a heat storage system. When wind speed is high, surplus electric energy drives a multistage compressor to compress air from a level of atmospheric pressure to a higher level of pressure to be stored into a compressed air storage pipeline, and heat in the process of compressing is recovered into the heat storage system, at the moment, supplying of cold energy and heat energy is realized after pumped thermal-state heat conducting oil is shunted and enters an absorption-type refrigerating system and a heating system. When the wind speed is low, after absorbing heat from the heat storage system, compressed air enters a turbine to expand for doing work so as to fill a demand gap of electric energy, so that demands of a user on cold energy and heat energy are met through the thermal-state heat conducting oil.

Owner:XI AN JIAOTONG UNIV

Multi-stage compressor fault detection and protection

In certain embodiments, a system includes a controller configured to obtain an inter-stage pressure measurement between stages of a multi-stage compressor. The controller is also configured to identify actual damage in the multi-stage compressor based at least in part on the inter-stage pressure measurement.

Owner:GENERAL ELECTRIC CO

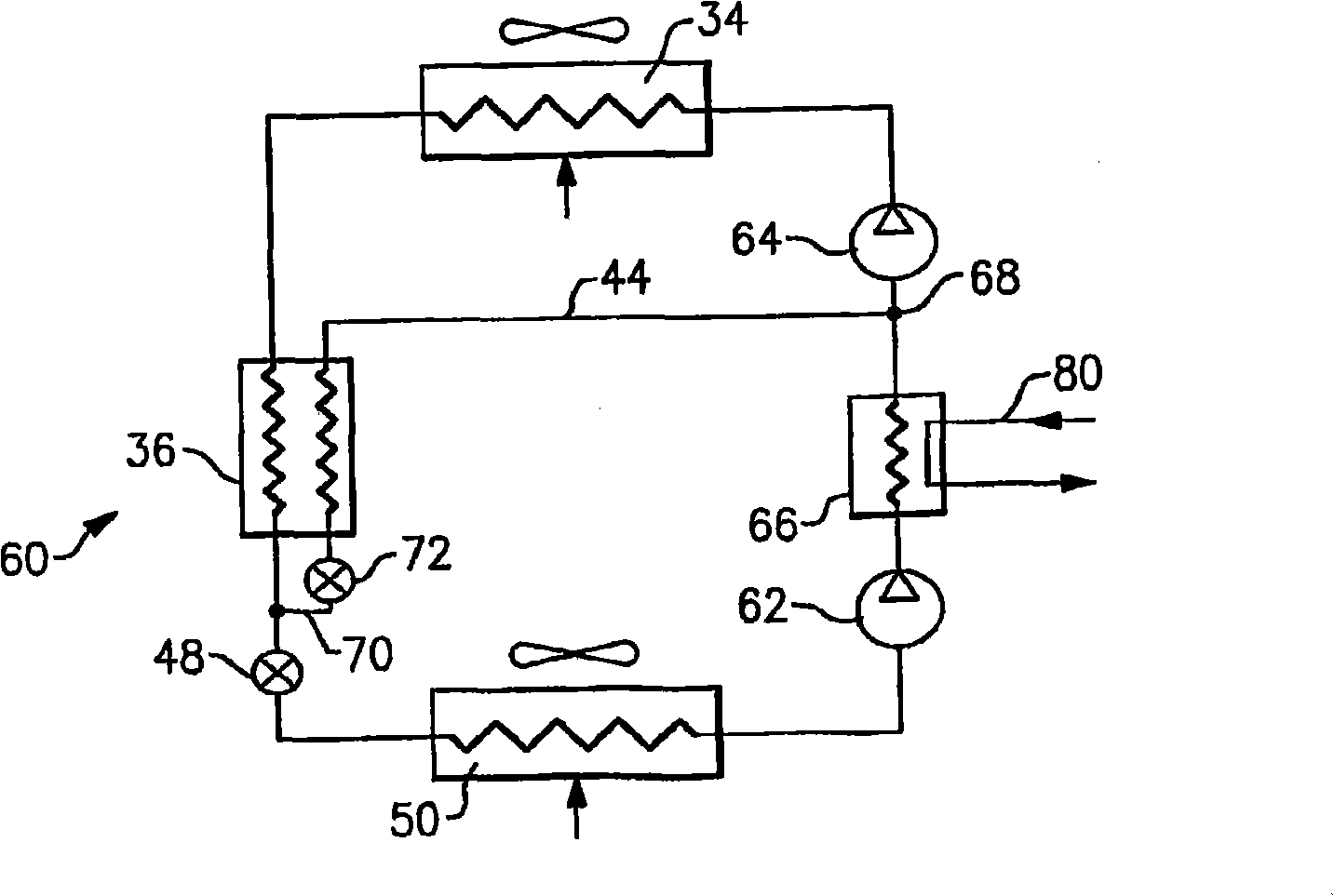

Coaxial economizer assembly and method

ActiveUS20090205361A1Improve fluid flowImprove performanceCompressorMechanical apparatusLiquid stateFlash-gas

A coaxial economizer for use in a chiller system comprising an inner housing and an outer housing having a common longitudinal axis. The outer housing has an inlet for receiving a fluid from a upstream compressor stage of a multistage compressor and an outlet for conveying a fluid to a downstream compressor stage of a multistage compressor. A flow chamber forms a fluid flow path about the inner housing. A flash chamber is coterminous with the flow chamber and flashes fluid in a liquid state to a gas state. A flow passage between said flash chamber and the flow chamber for conveying a flashed gas from the flash chamber to the flow chamber; wherein the flashed gas conveyed from the flash chamber and the fluid received from the inlet of the outer housing mix along the fluid flow path toward the outlet of the outer housing.

Owner:TRANE INT INC

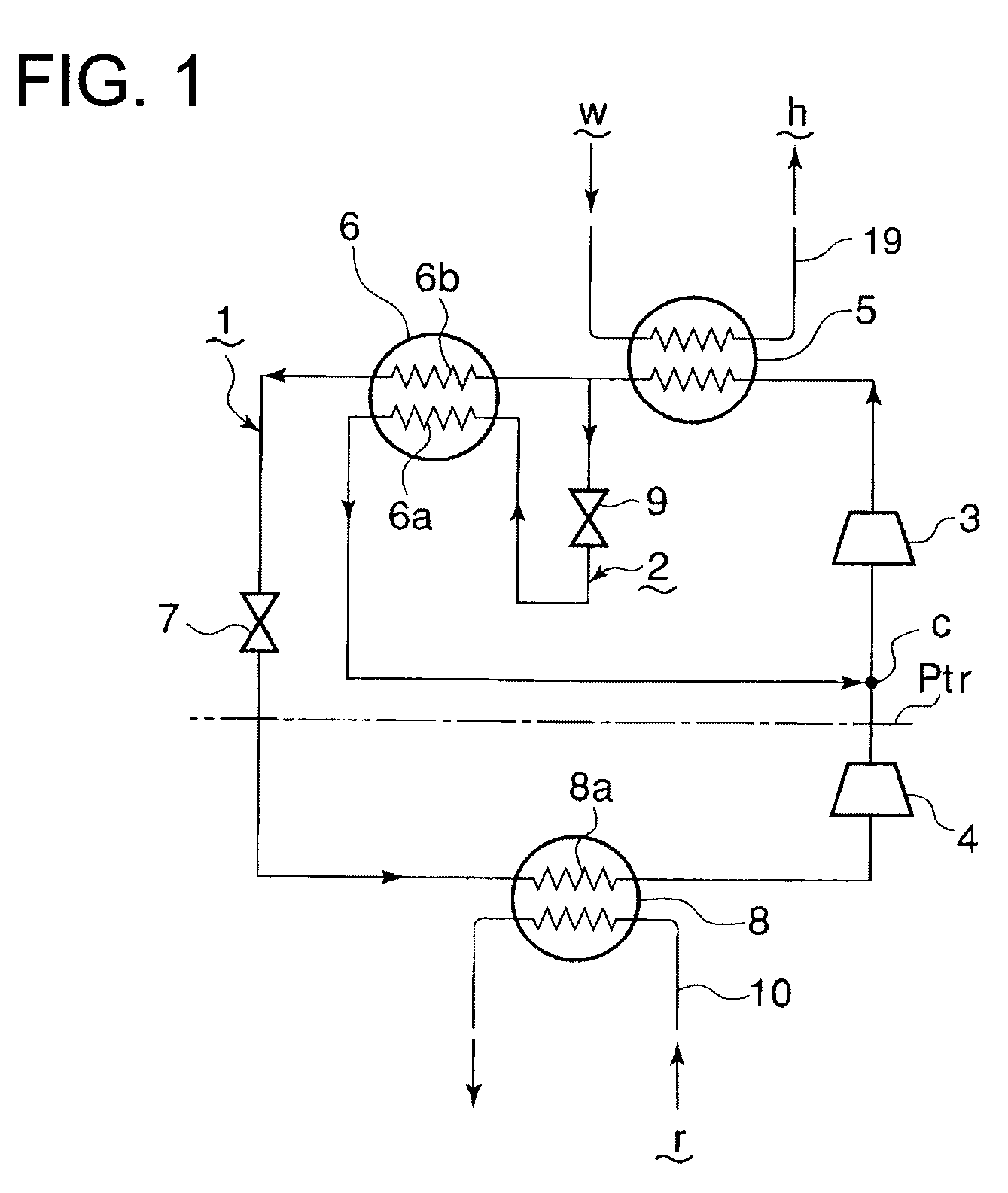

Refrigeration apparatus

ActiveUS20110048055A1Raise the ratioReduce power consumptionCompression machines with non-reversible cycleFluid circulation arrangementIntermediate heat exchangerEngineering

A refrigeration apparatus includes a multi-stage compression mechanism, heat source-side and usage side heat exchangers each operable as a radiator / evaporator, a switching mechanism switchable between cooling and heating operation states, a second-stage injection tube, an intermediate heat exchanger and an intermediate heat exchanger bypass tube. The intermediate heat exchanger bypass tube ensures that refrigerant discharged from the first-stage compression element and drawn into the second-stage compression element is not cooled by the intermediate heat exchanger during a heating operation. Injection rate optimization controls a flow rate of refrigerant returned to the second-stage compression element through the second-stage injection tube so that an injection ratio is greater during the heating operation than during a cooling operation. The injection ratio is a ratio of flow rate of the refrigerant returned to the second-stage compression element through the second-stage injection tube relative to flow rate of the refrigerant discharged from the compression mechanism.

Owner:DAIKIN IND LTD +1

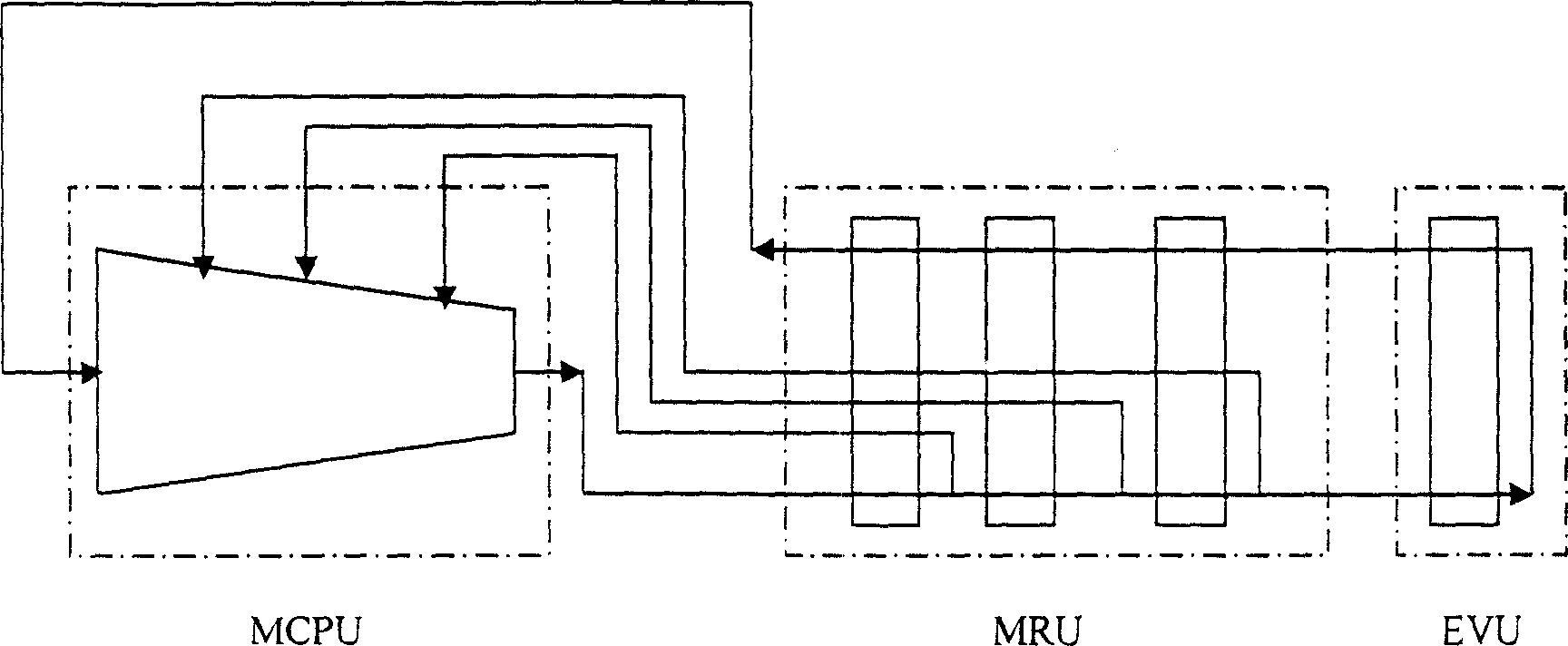

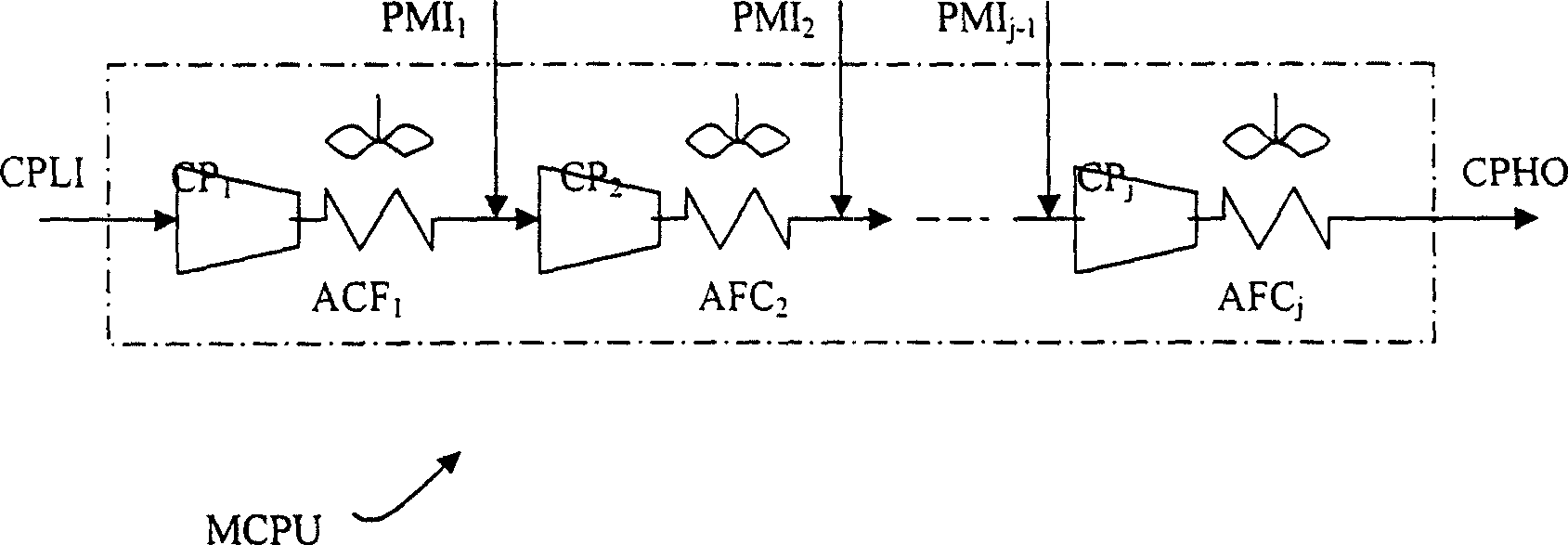

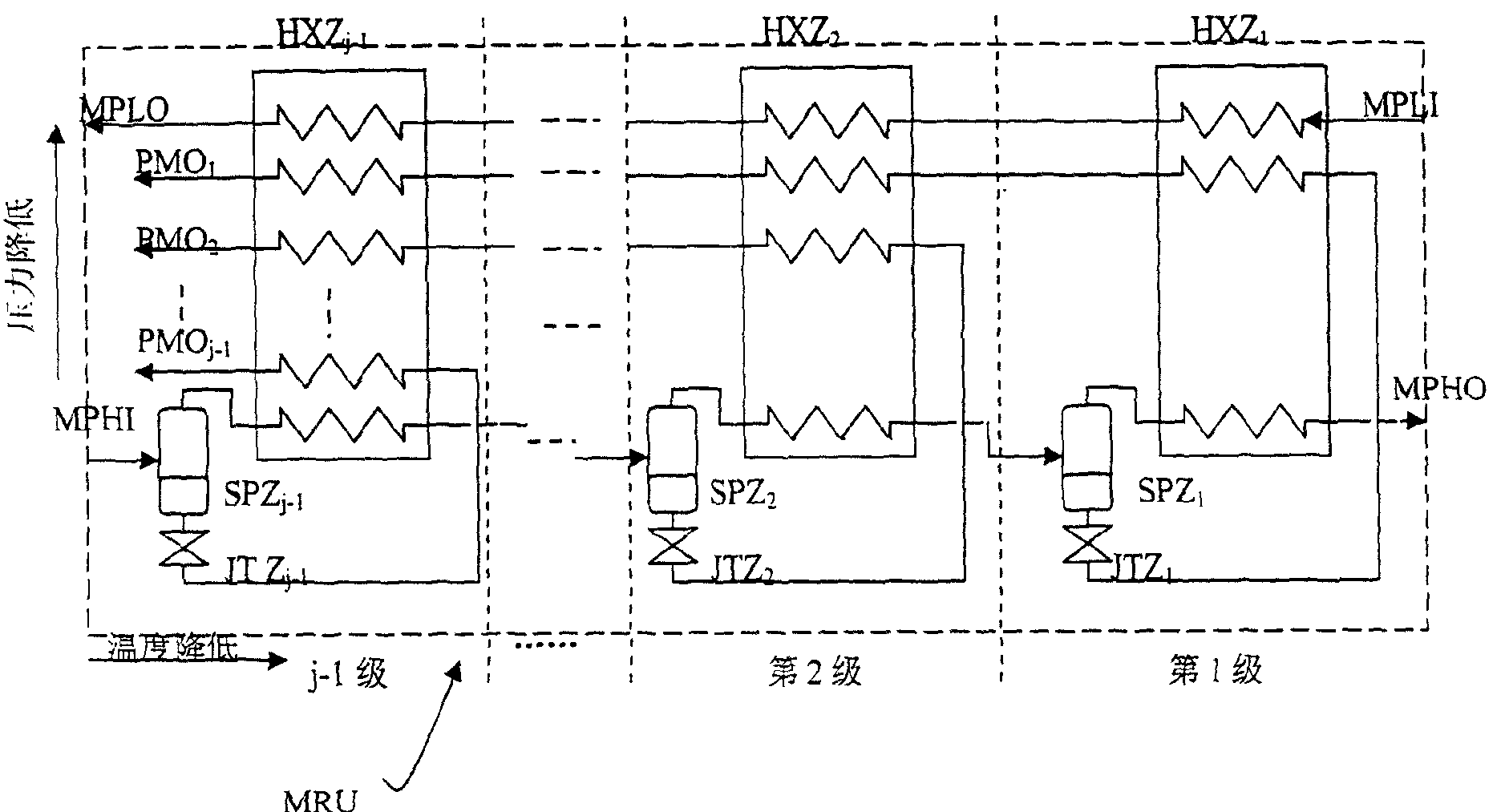

Multiple pressure grade mixed working medium cryogenic throttling refrigeration system

ActiveCN1683844AHigh thermal efficiencyGood throttling effectSolidificationLiquefactionProduct gasEngineering

The multiple pressure stage mixed work medium cryogenic throttling refrigeration system consists of several stages of compressor set unit MCPU, back heating pre-cooling unit MRU and evaporator unit EVU. The connection mode includes connecting the high pressure outlet of MCPU to the high pressure inlet of MRU, connecting the low pressure inlet of MCPU to the low pressure outlet one MRU, connecting the high pressure outlet operate MRU to the inlet of EVU, and connecting the outlet of EVU to the low pressure inlet of MRU. The present invention adopts high efficiency multiple-element mixed work medium. The refrigeration system has lowered irreversible loss of compression and back heating process thermodynamically, reduced loss in the practical flow and heat exchange process, and thus high thermodynamic efficiency, and is especially suitable for large and middle scale low temperature refrigerating and gas liquefying fields.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

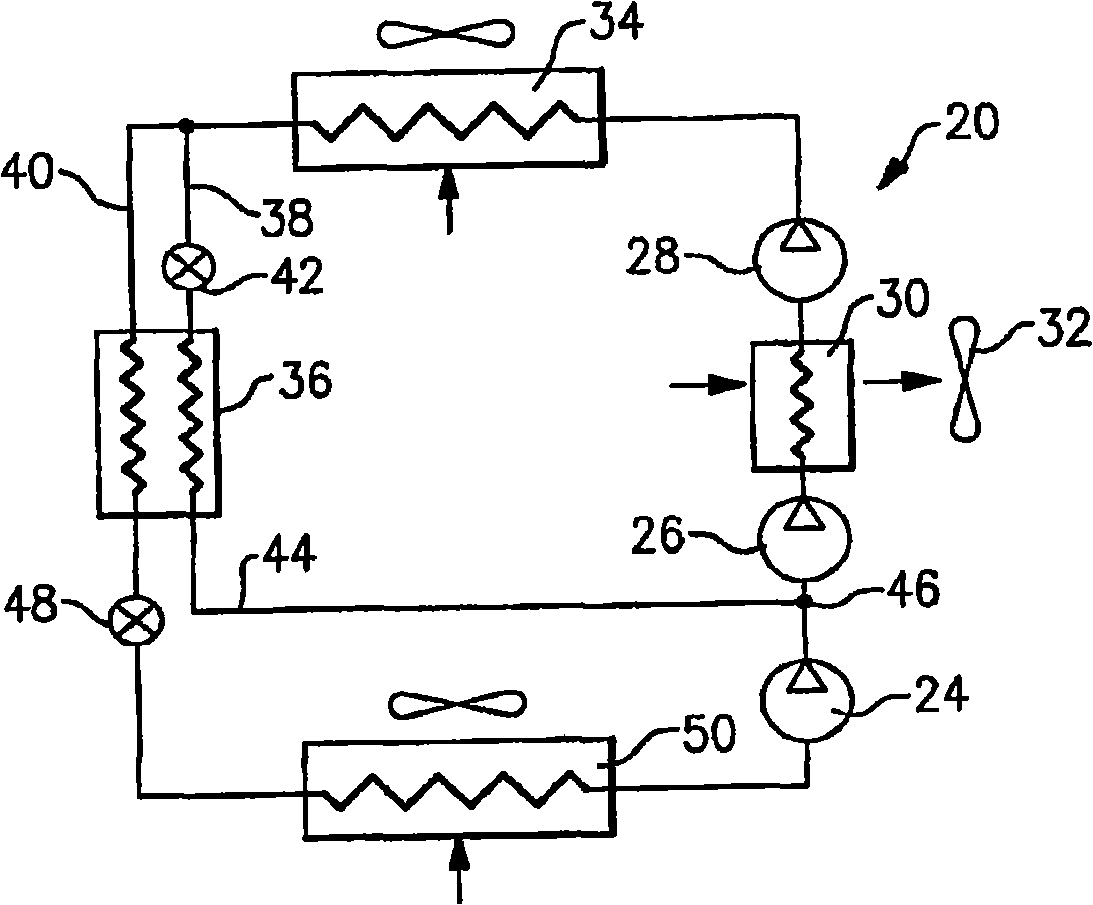

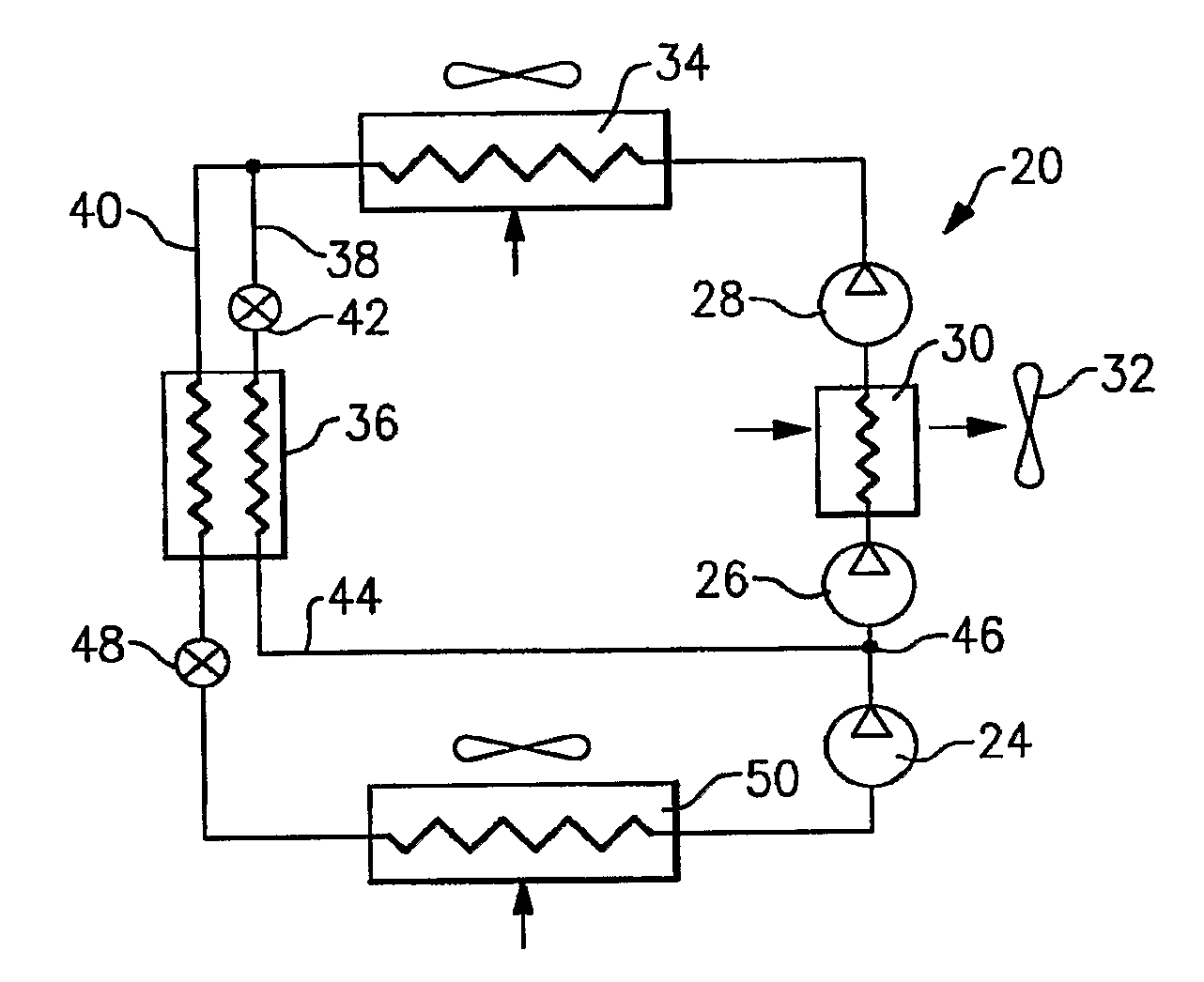

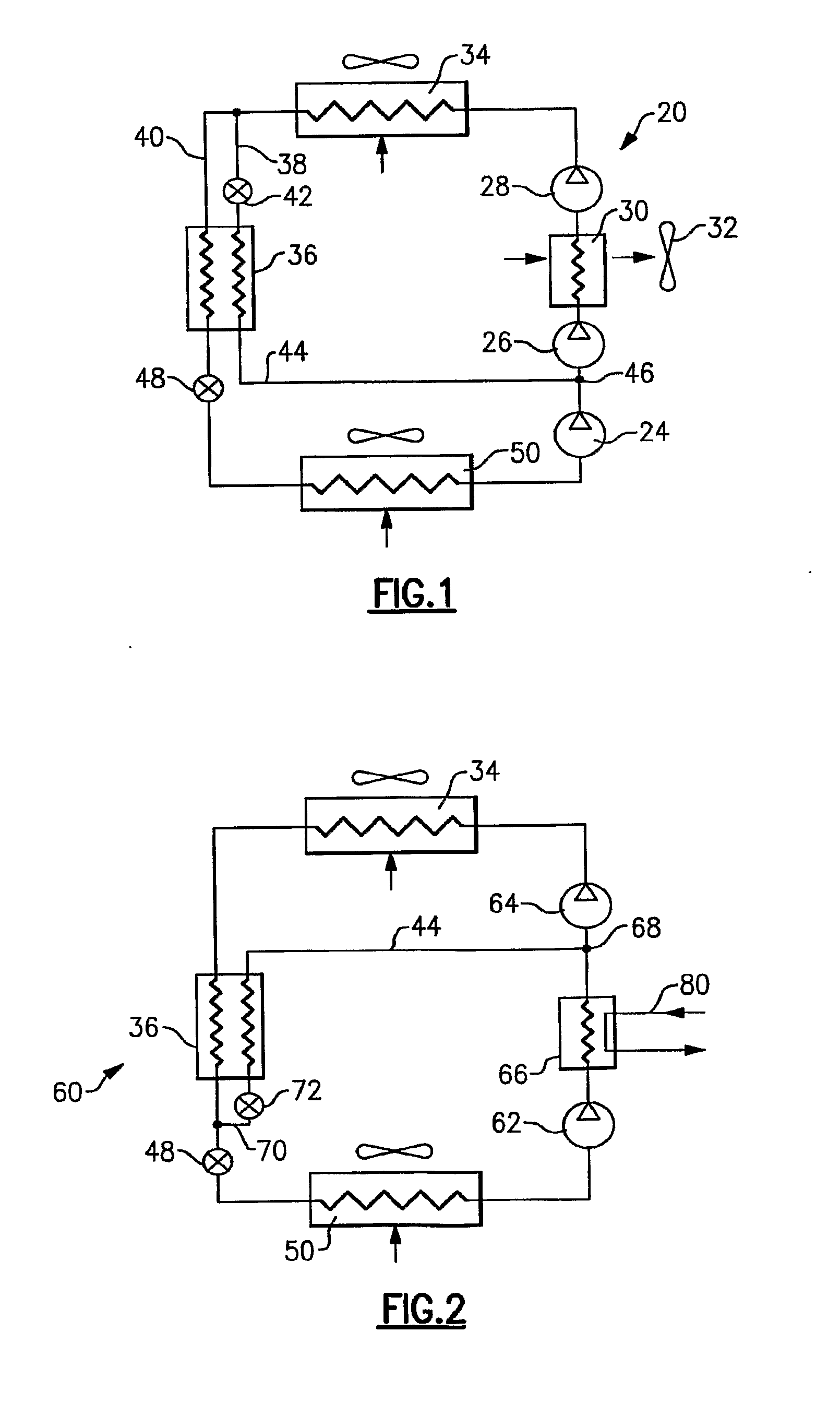

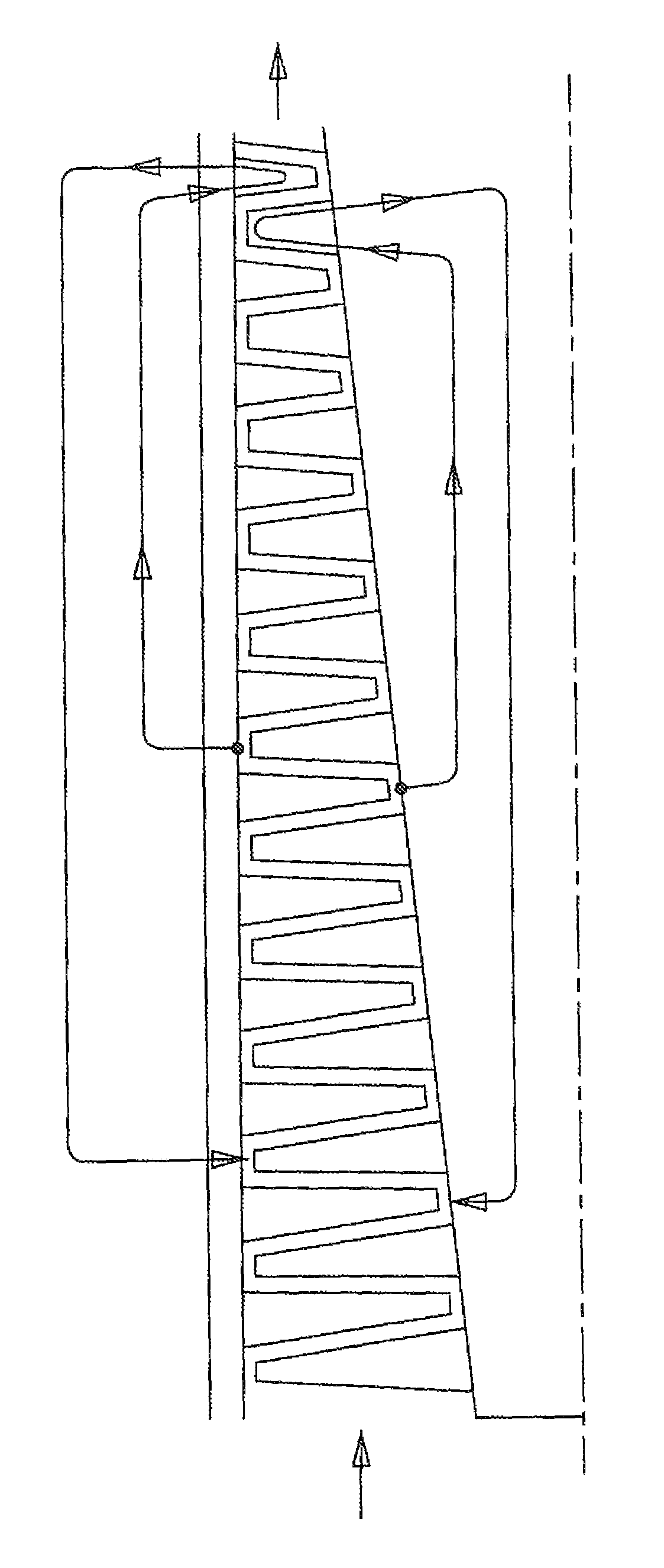

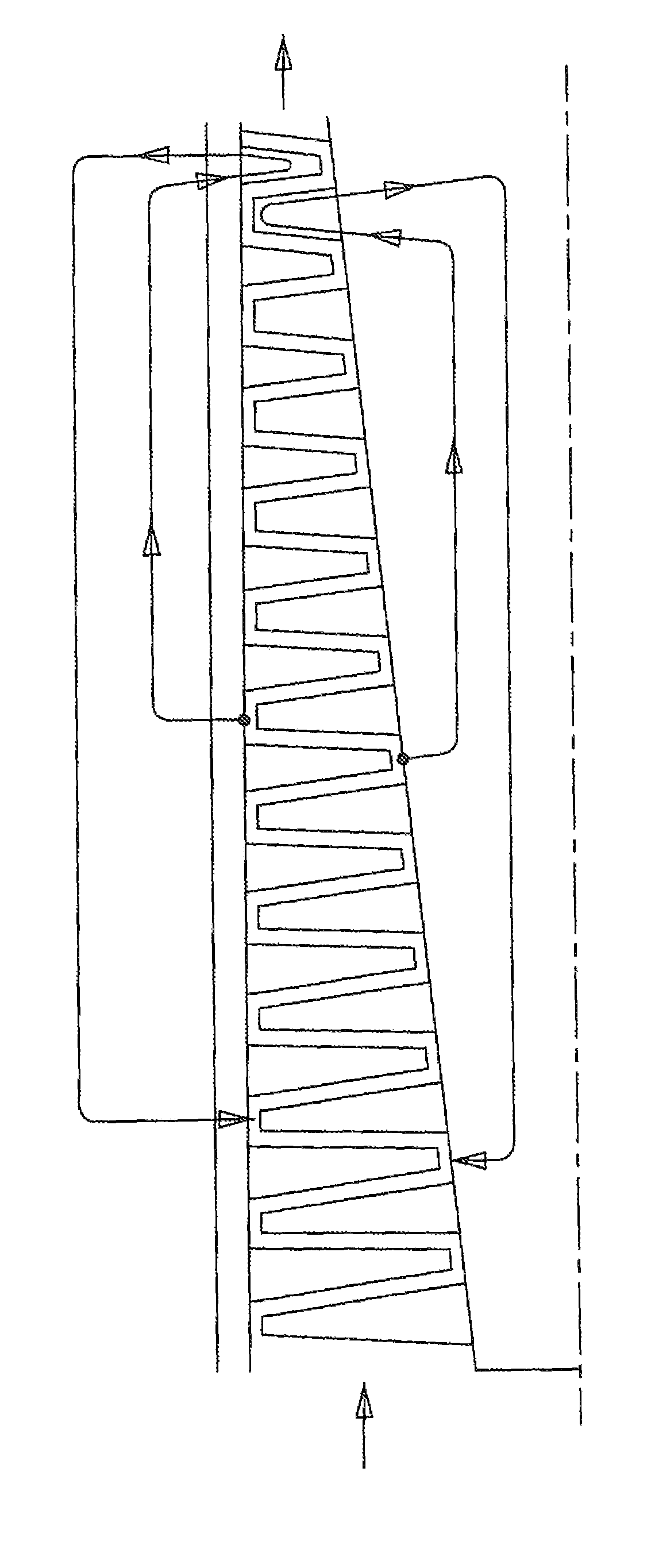

Refrigerant system with economizer, intercooler and multi-stage compressor

InactiveCN101568769AImprove dehumidification effectHigh cooling potentialCompression machines with non-reversible cycleRefrigeration componentsIntercoolerEngineering

A refrigerant system is provided with a multi-stage compression system. An intercooler is positioned between at least two compression stages to cool a refrigerant, by heat transfer interaction with a secondary fluid, after it has been compressed in the lower compression stages to some intermediate pressure. The intercooler enhances refrigerant system performance, improves compressor reliability, and extends operational envelope. Further, at least one economizer circuit is incorporated into the refrigerant system that returns the economized refrigerant flow at the location between at least two compression stages.

Owner:CARRIER CORP

Refrigerant system with economizer, intercooler and multi-stage compressor

InactiveUS20100058781A1Large temperature differenceImprove performanceCompression machines with non-reversible cycleCompression machines with cascade operationEngineeringIntercooler

A refrigerant system is provided with a multi-stage compression system. An intercooler is positioned between at least two compression stages to cool a refrigerant, by heat transfer interaction with a secondary fluid, after it has been compressed in the lower compression stages to some intermediate pressure. The intercooler enhances refrigerant system performance, improves compressor reliability, and extends operational envelope. Further, at least one economizer circuit is incorporated into the refrigerant system that returns the economized refrigerant flow at the location between at least two compression stages.

Owner:CARRIER CORP

Multiple staged compressor with last stage airfoil cooling

A high compression ratio compressor having multiple stages of airfoils to produce the high pressure rations, where the last stage airfoils are cooled by passing cooling air through the airfoils without discharging film cooling air. The cooling air for the airfoils is bled off from an upstream stage of the compressor, passed through the airfoil to provide for the cooling, and then discharged back into the compressor at a stage upstream of where the bleed off air was extracted and where the pressure is lower. Because of the high pressure rations, the air temperature in the compressor is at such a high temperature that the last stage airfoils must be cooled to prevent thermal damage.

Owner:FLORIDA TURBINE TECH

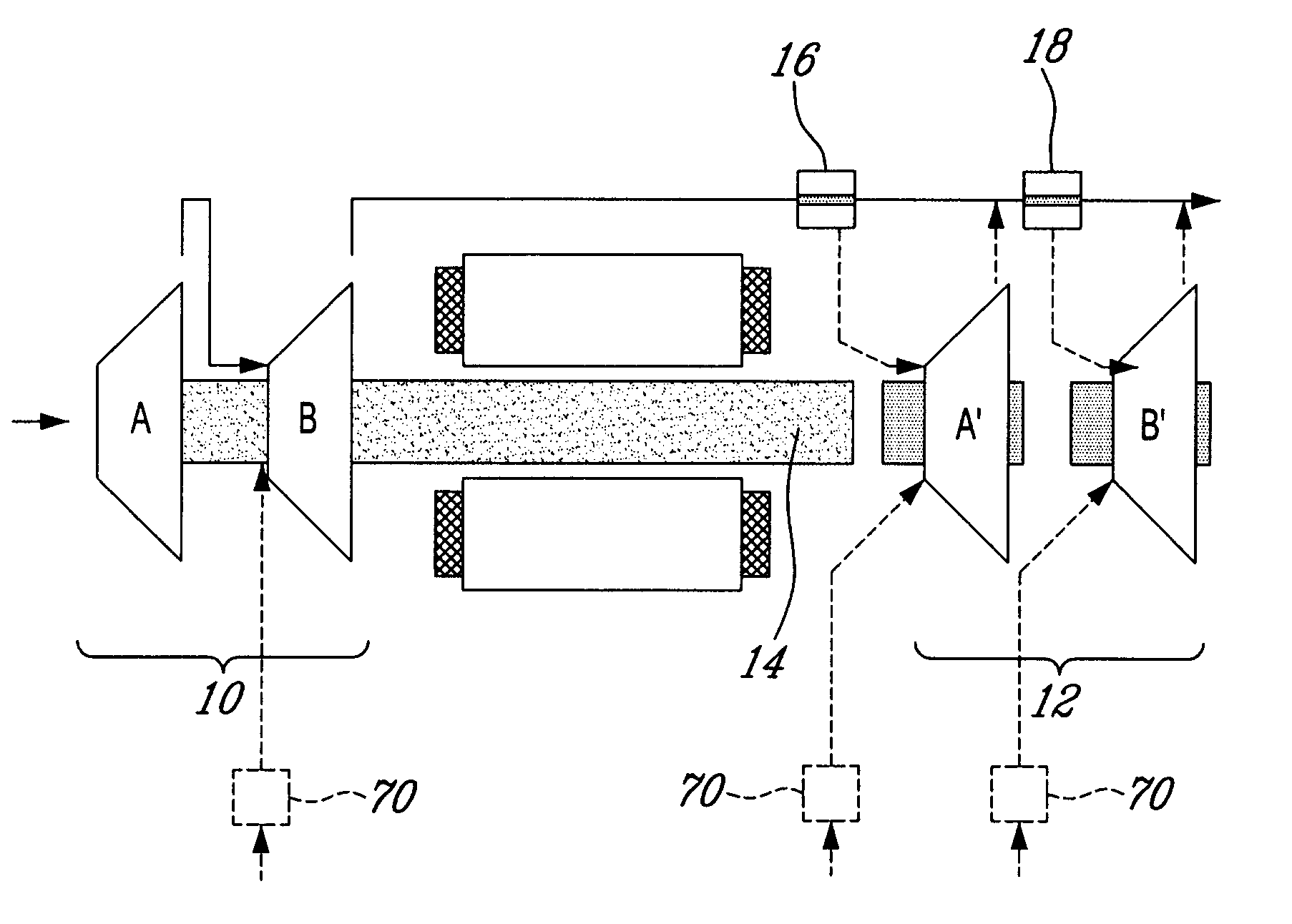

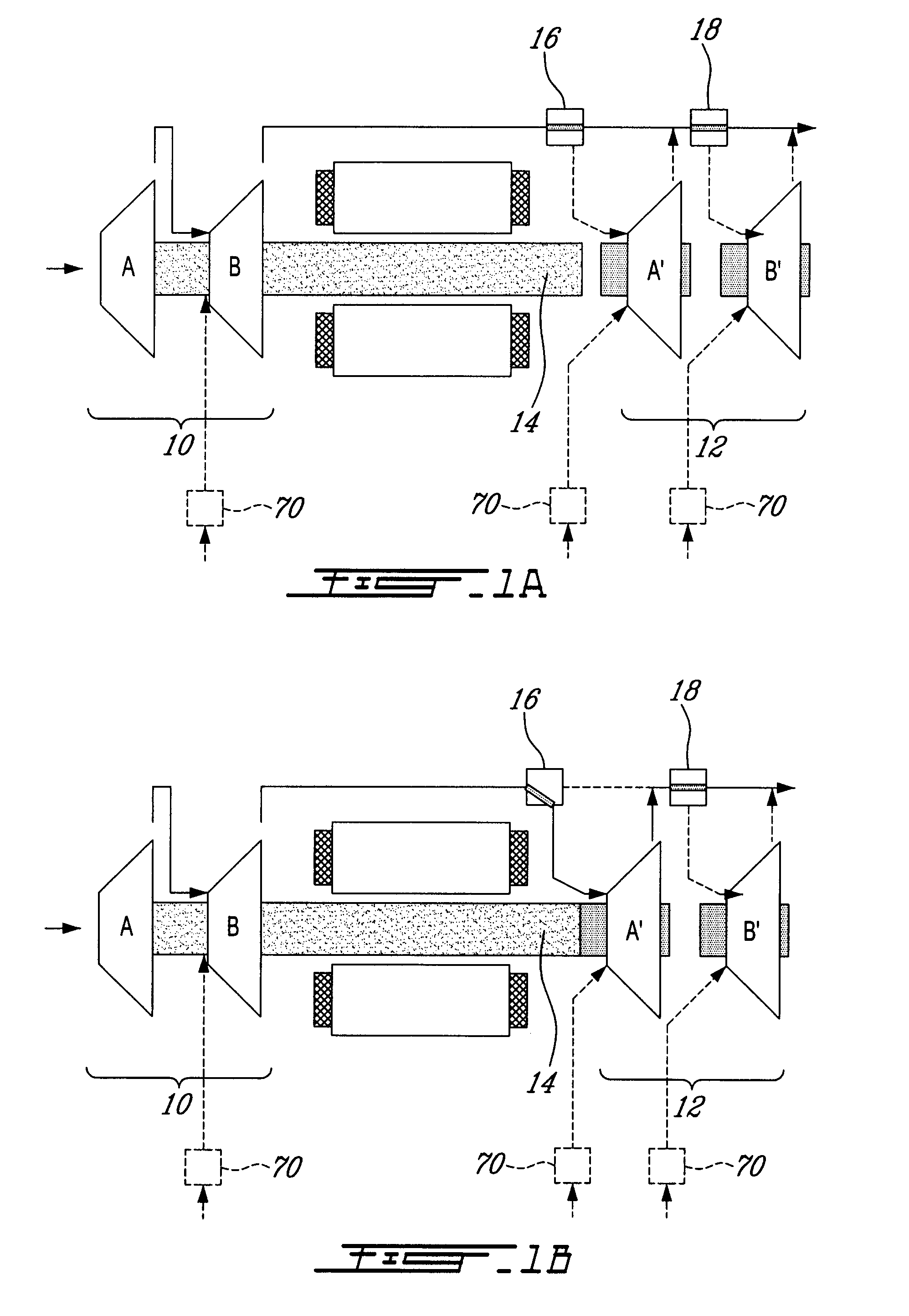

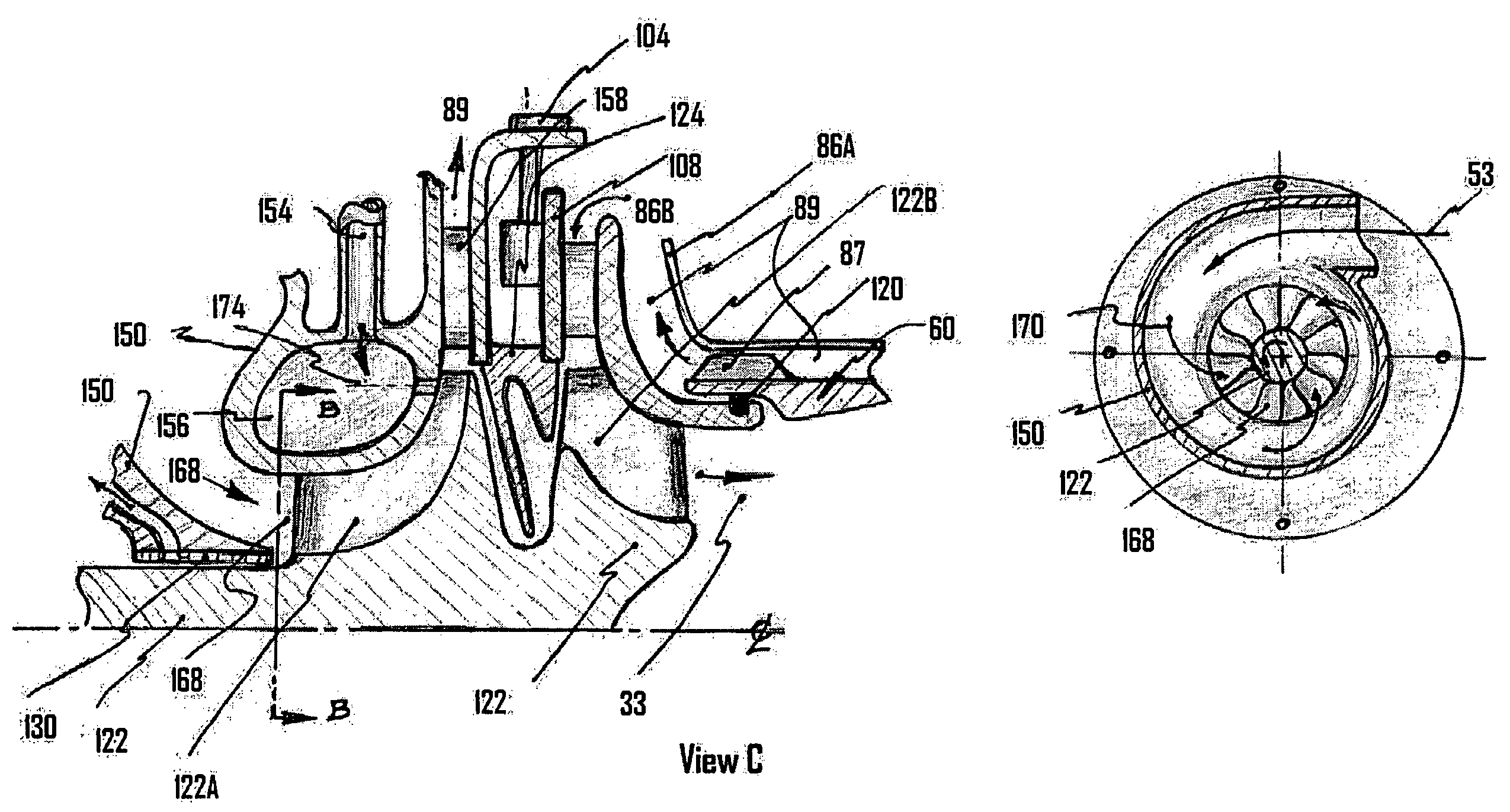

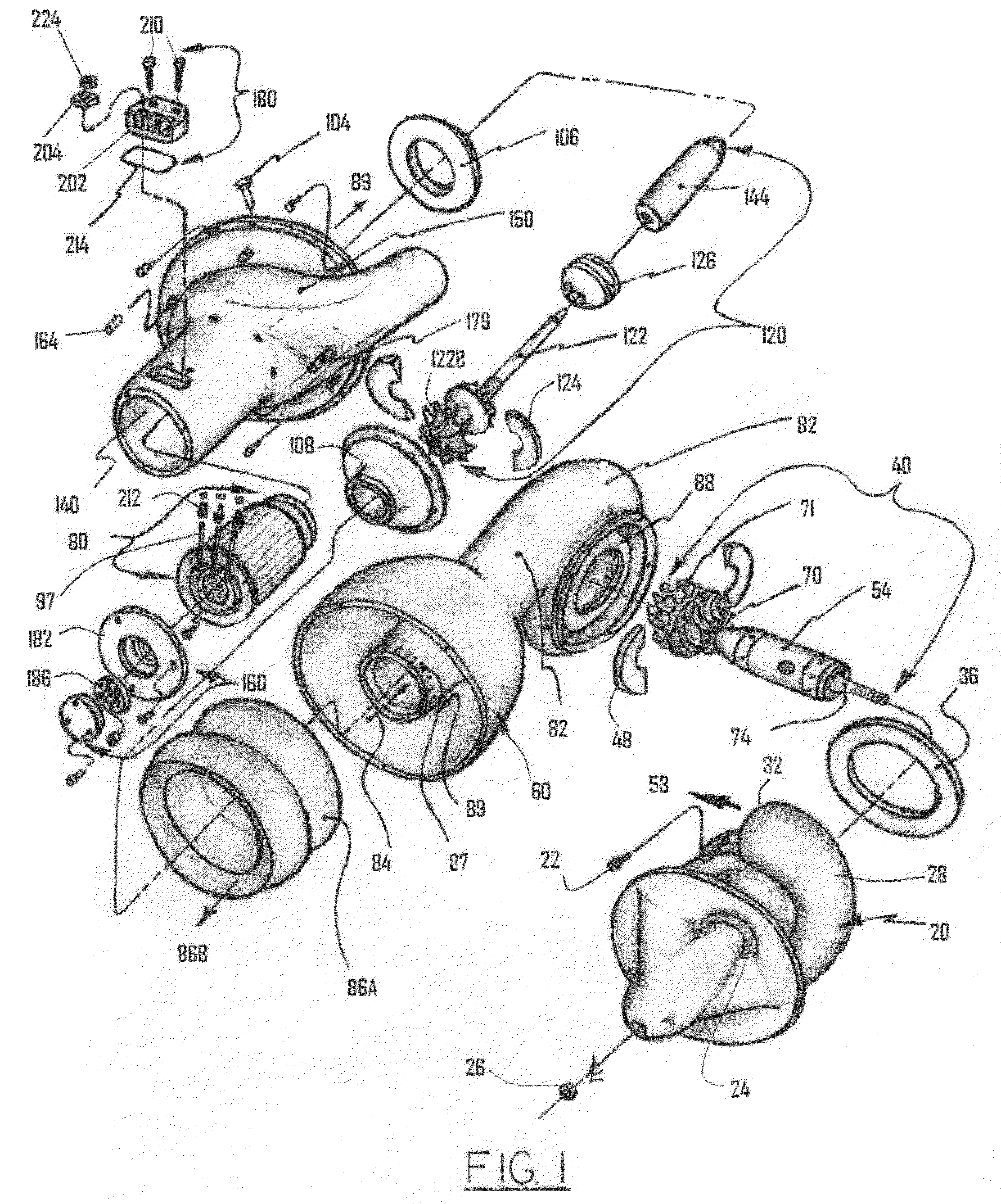

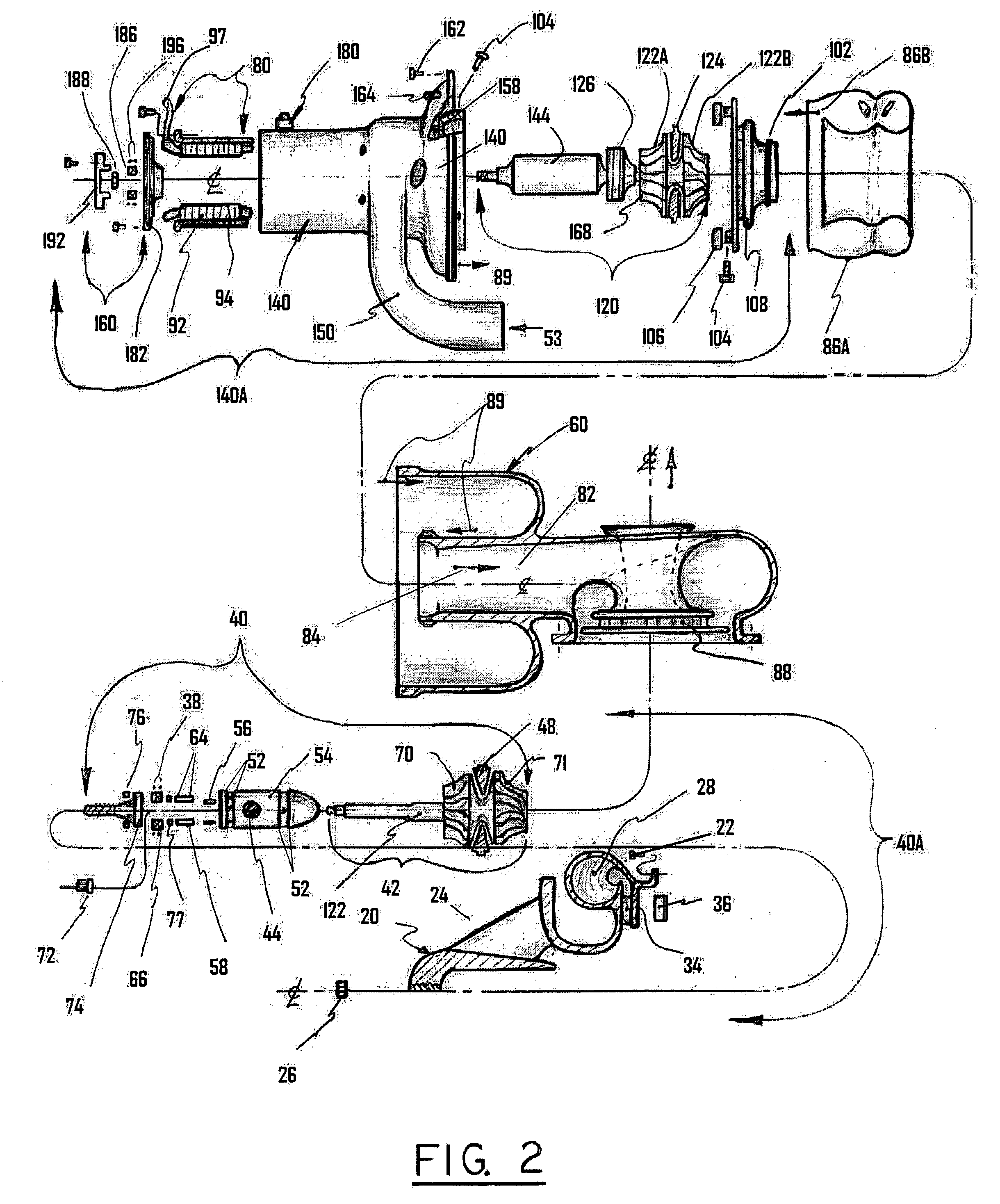

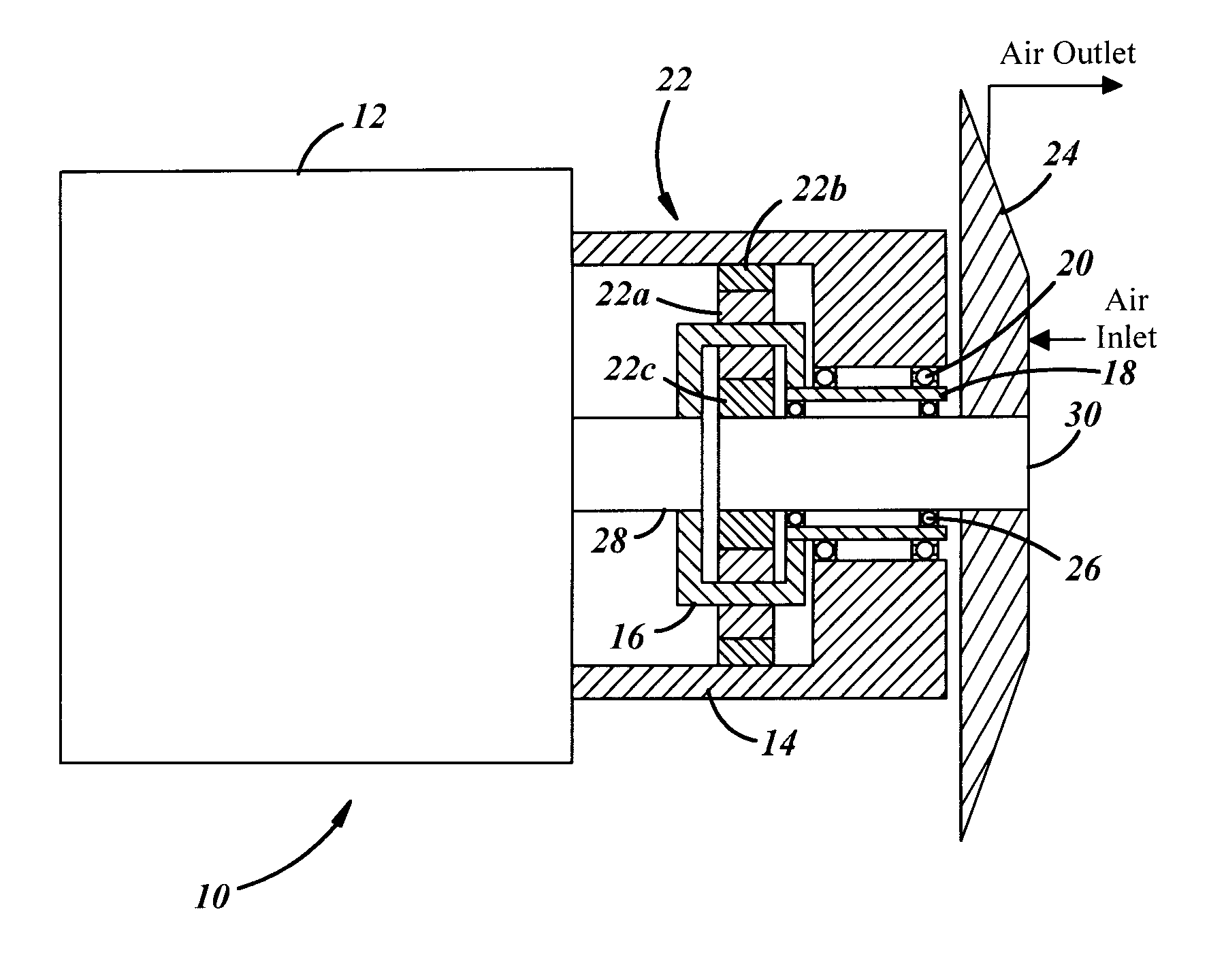

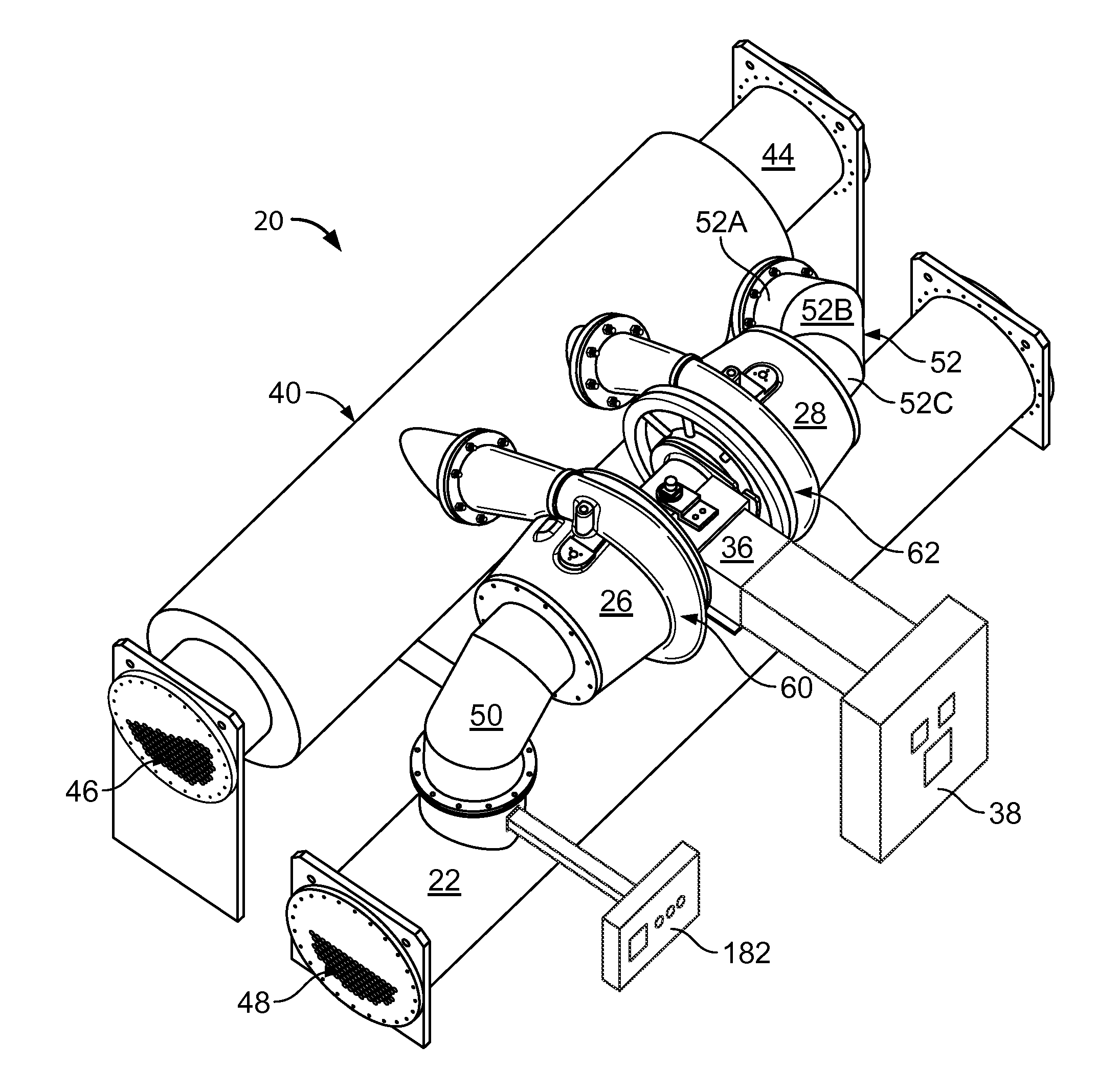

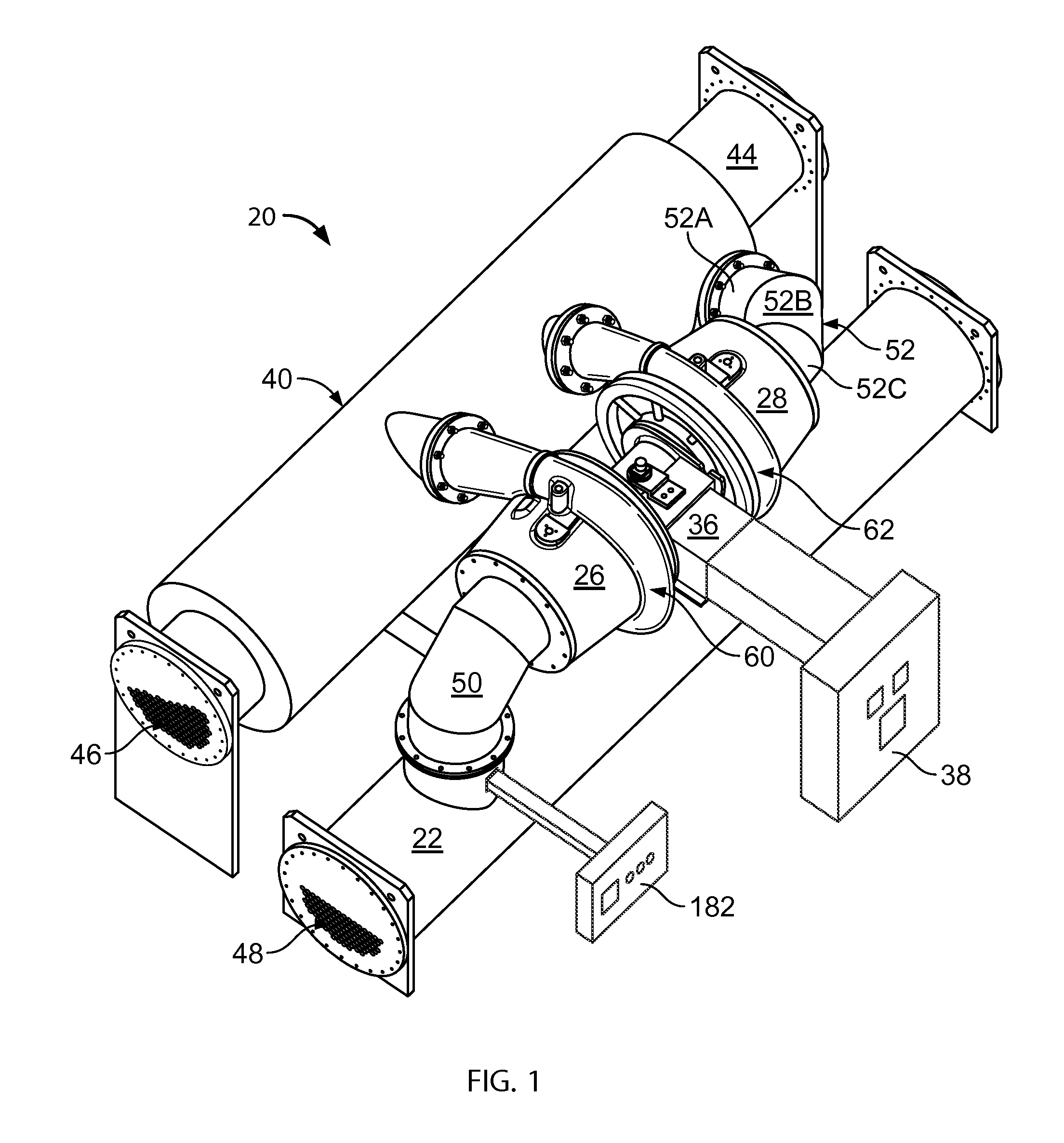

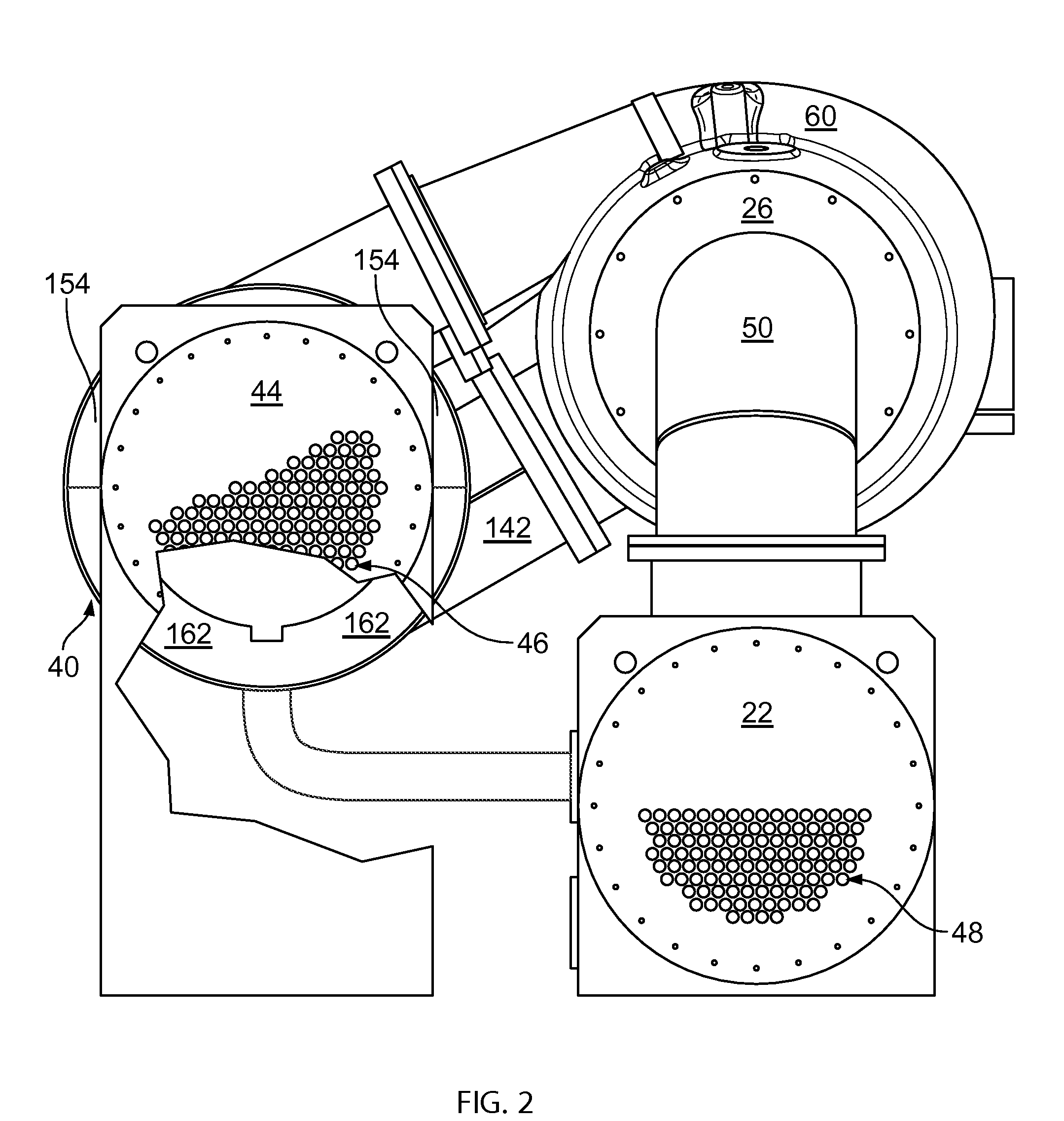

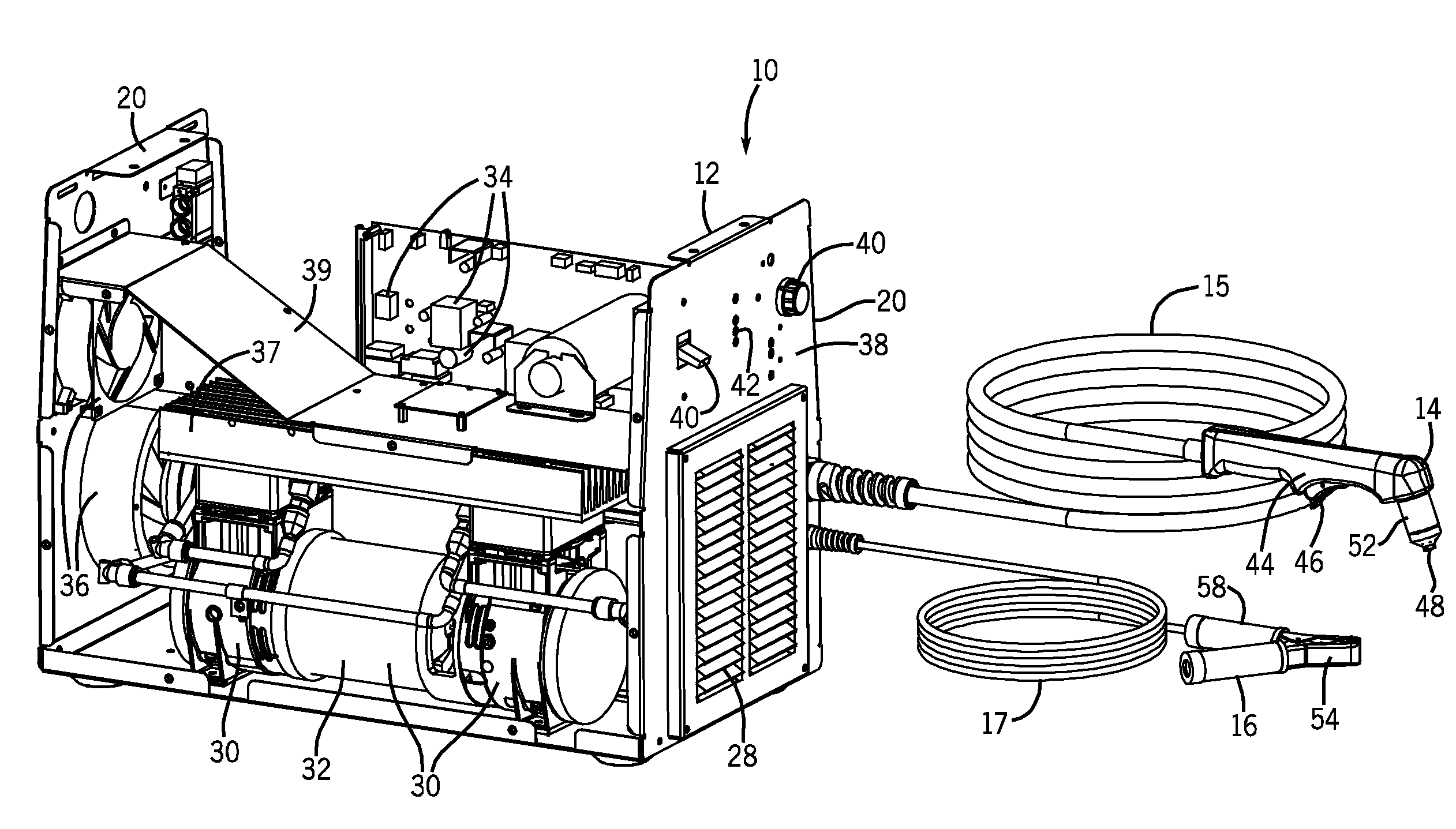

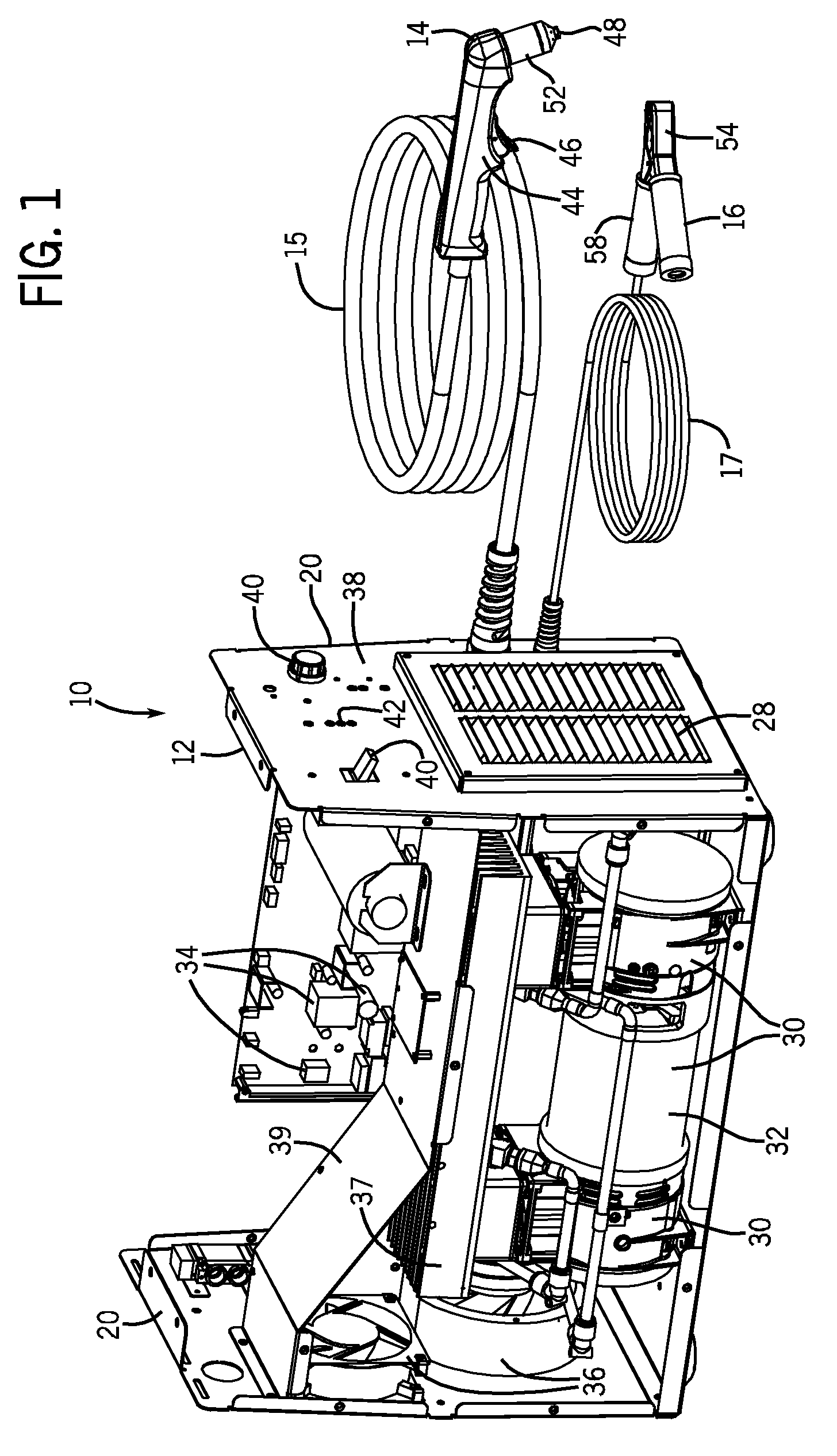

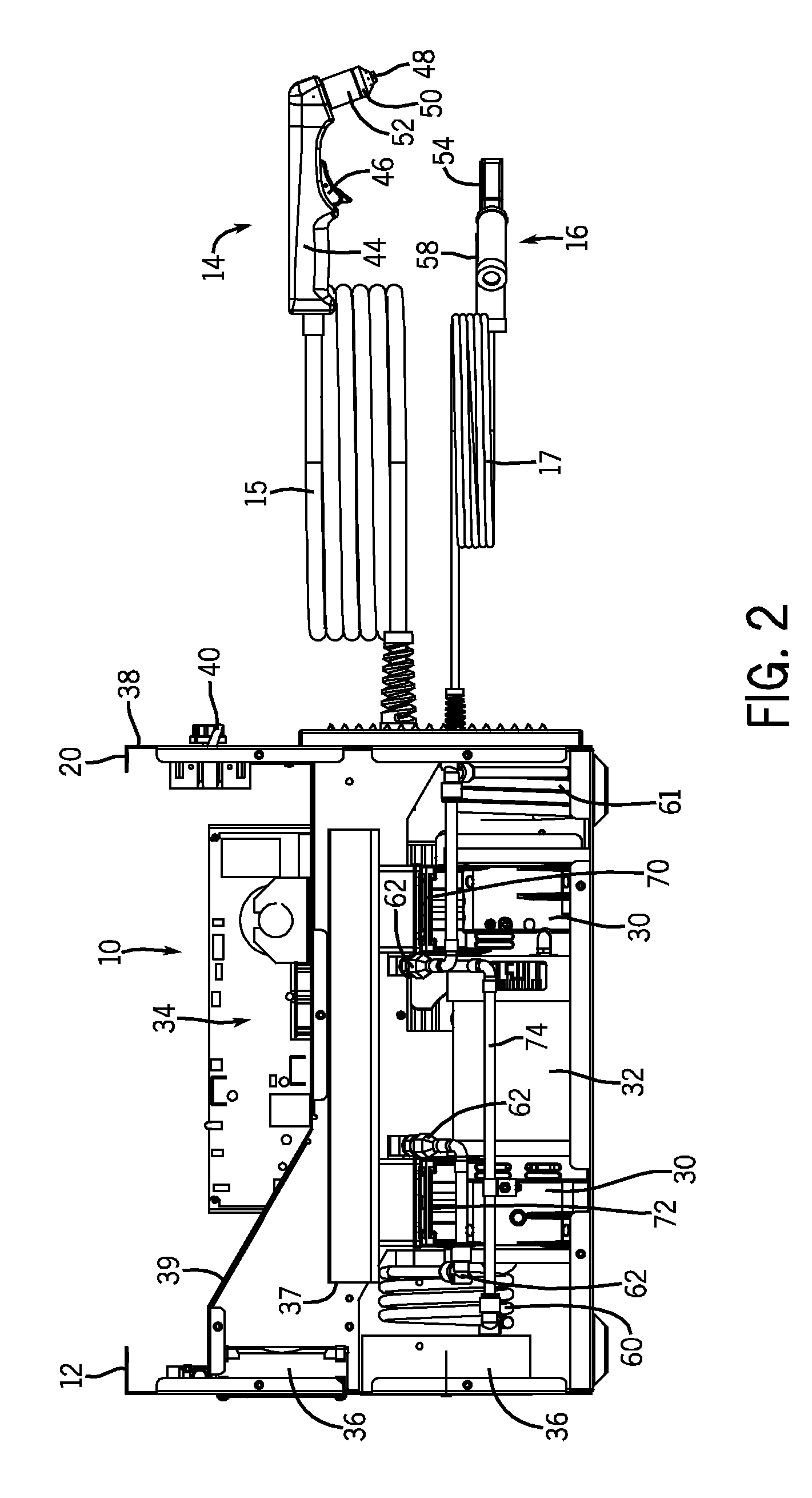

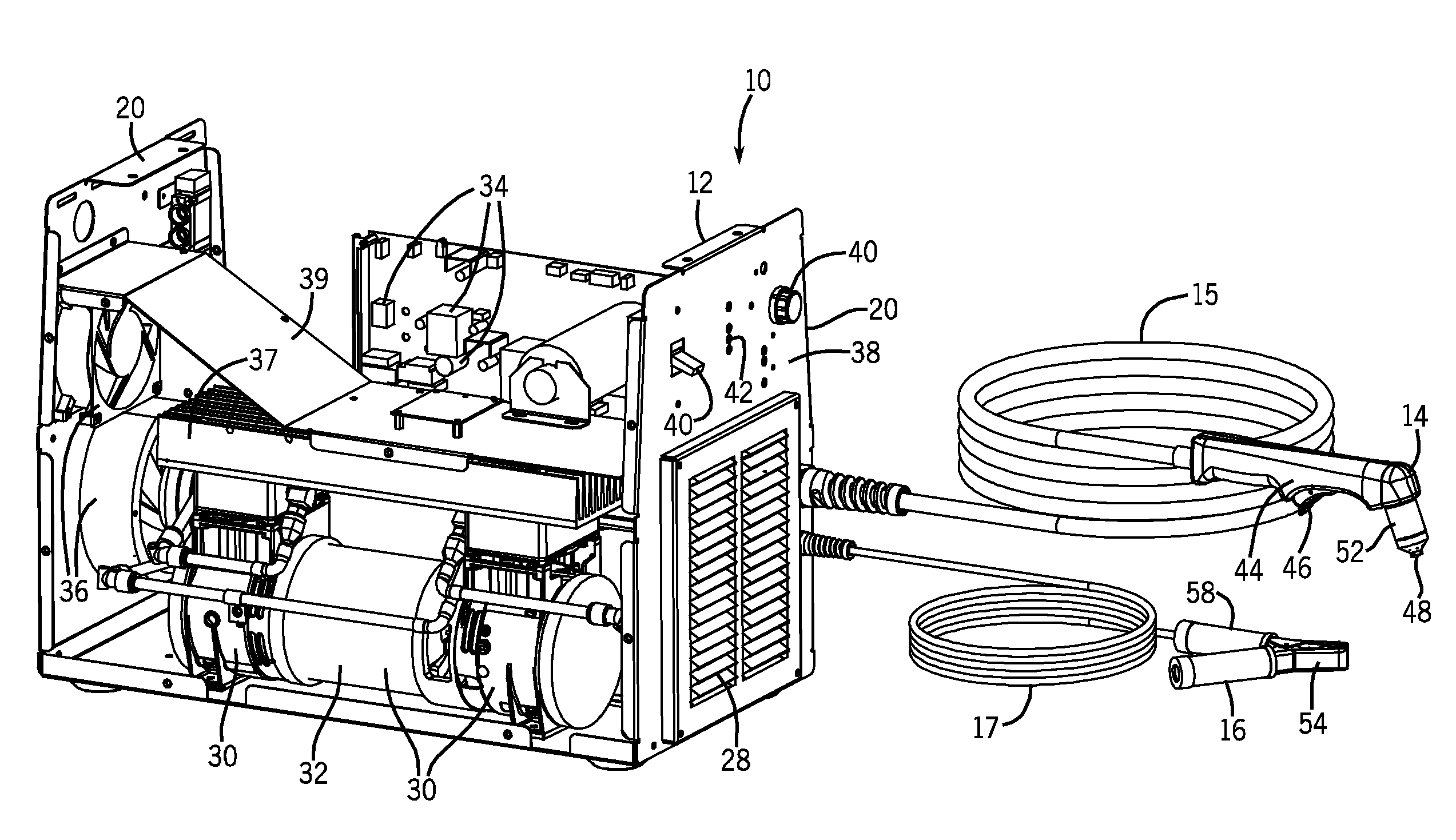

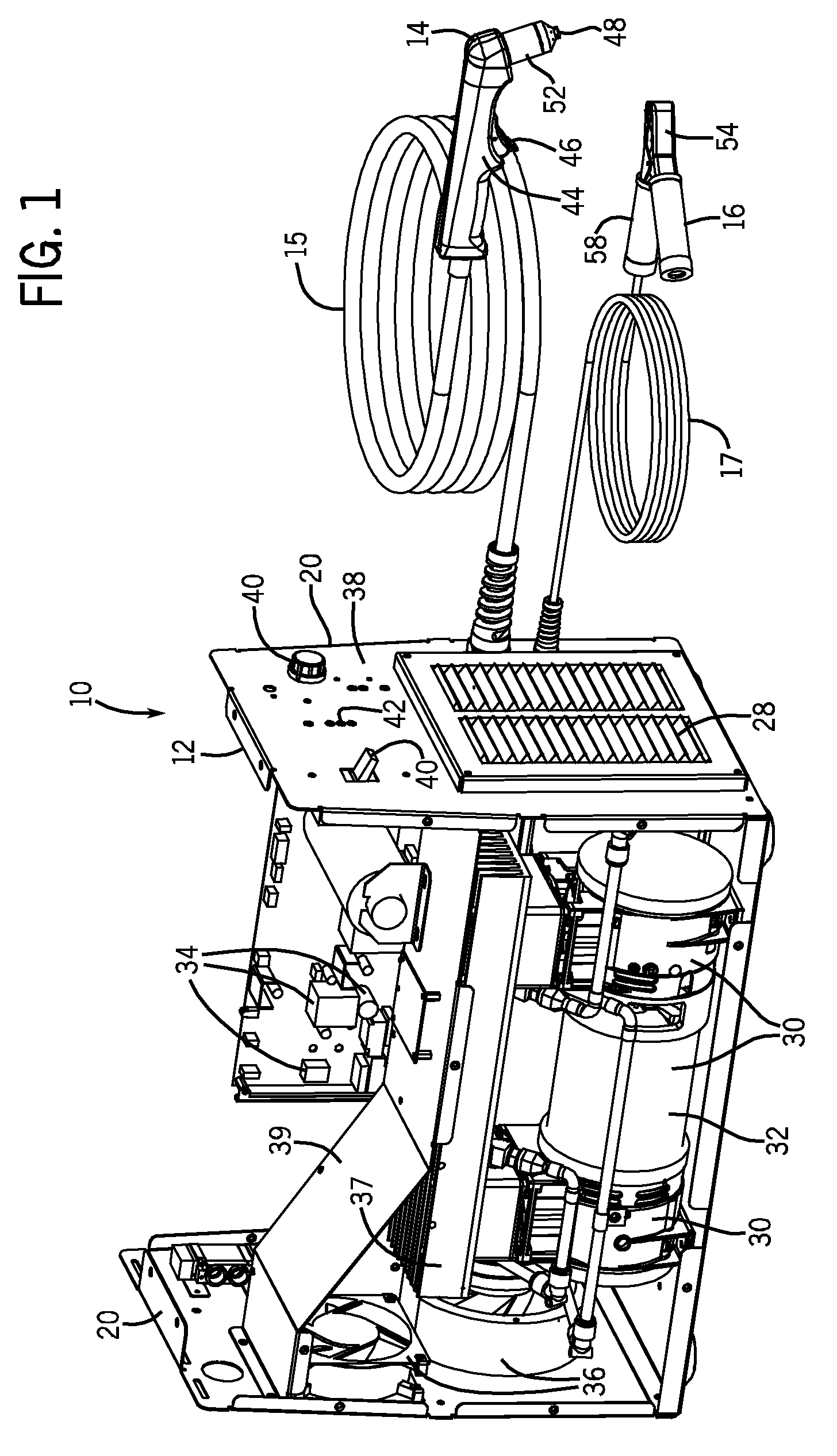

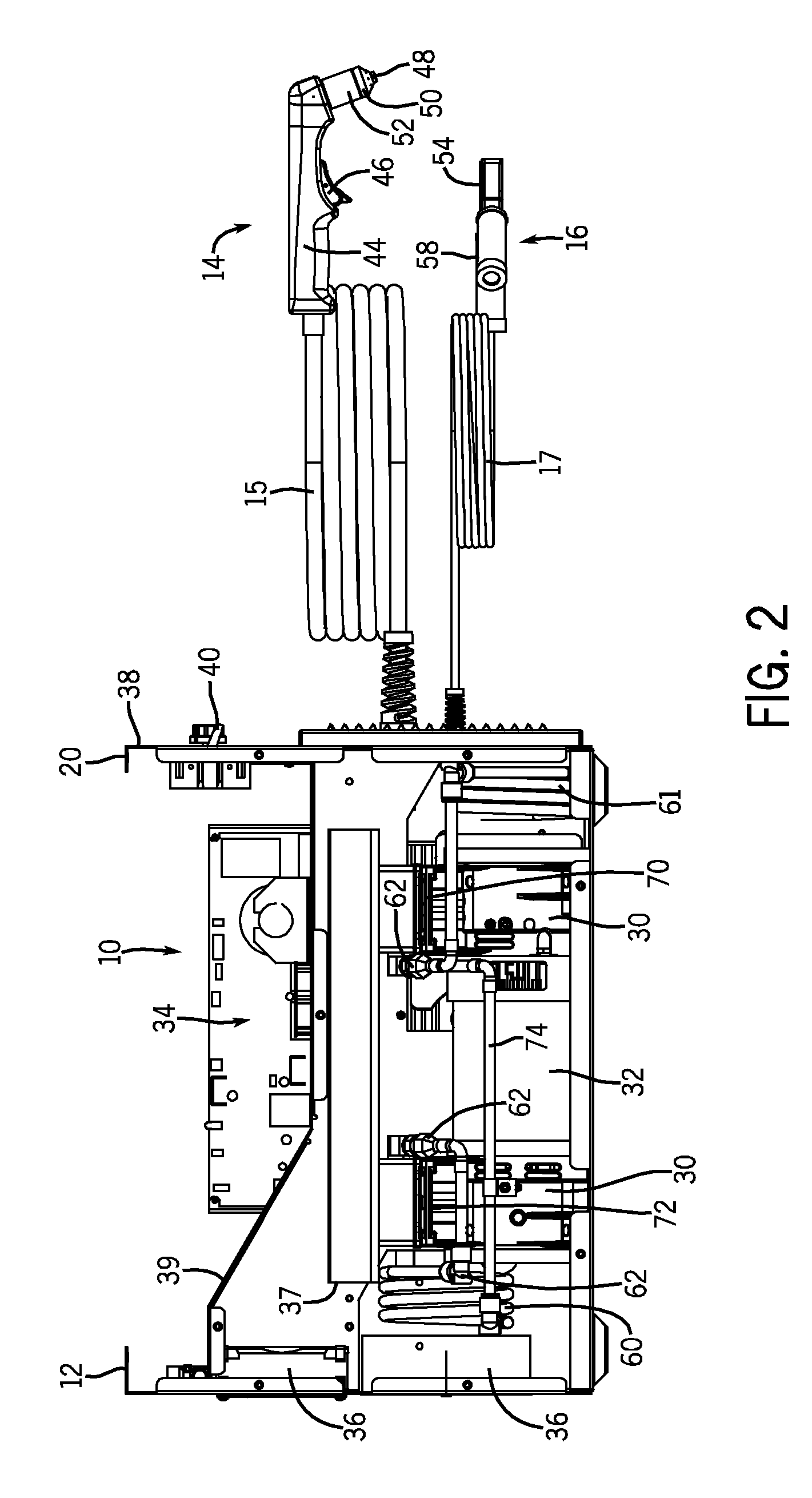

Multi-Stage Compressor in a Plasma Cutter

Systems and methods are provided for a torch power system using a multi-stage compressor. In one embodiment, a system includes a torch power unit that includes a compressor having multiple compression stages. A method of operation is provided that includes compressing a gas via a multi-stage compressor in a torch power unit. A method of manufacturing a torch power unit is provided that includes providing a multi-stage compressor for a torch power unit and mounting the multi-stage compressor inside an enclosure of the torch power unit. Another system is provided that includes a plasma cutting circuit, a multi-stage compressor, a motor coupled to the compressor, and a compressor controller.

Owner:ILLINOIS TOOL WORKS INC

Multi-stage compressor in a plasma cutter

Owner:ILLINOIS TOOL WORKS INC

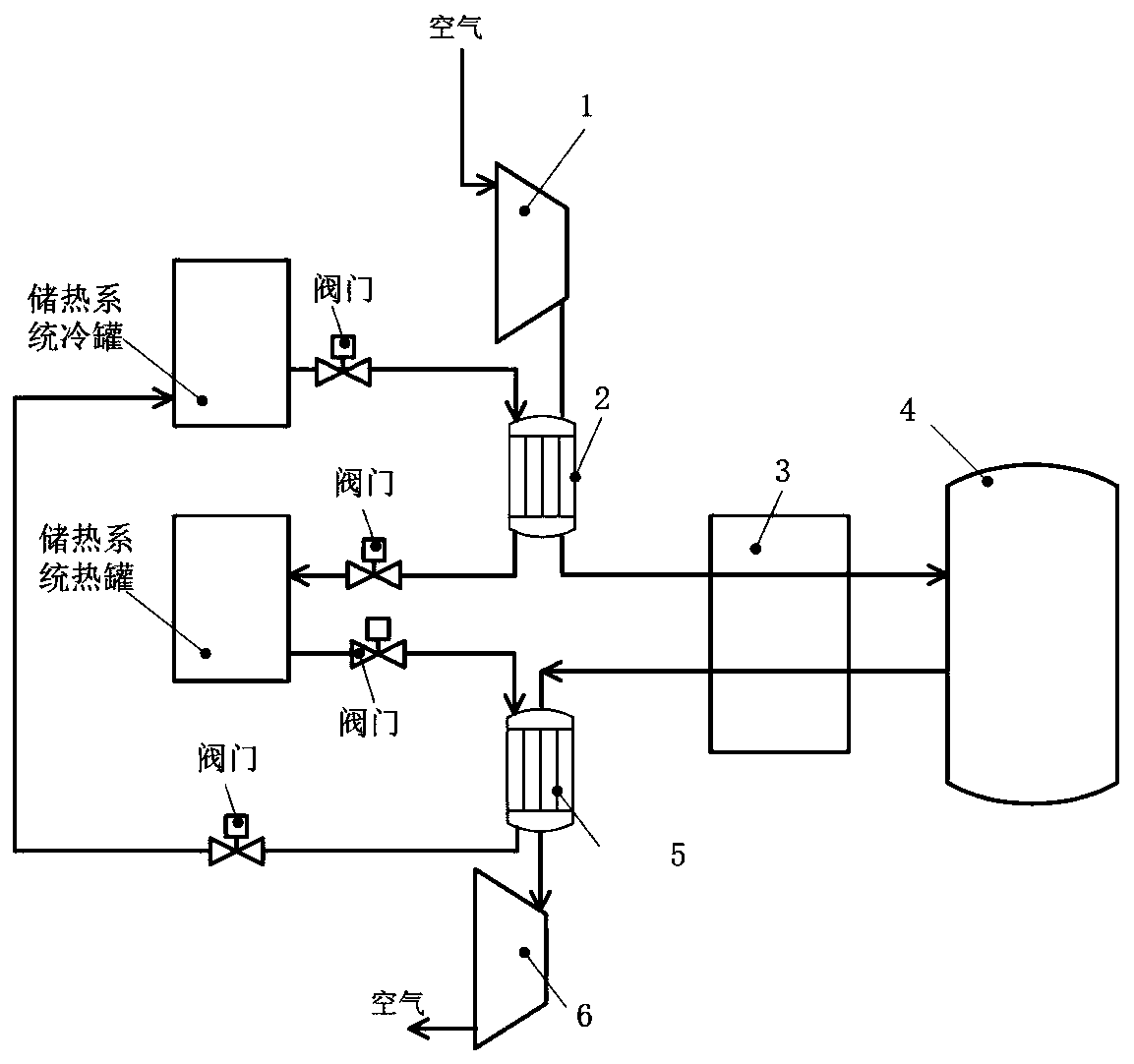

Flexible peak regulation system and method for air energy storage of power plant

PendingCN111305919AAvoid mismatchIncrease flexibilityPositive displacement pump componentsSteam engine plantsHigh energyThermal energy storage system

The invention discloses a flexible peak regulation system and method for air energy storage of a power plant. The system comprises a liquid compressed air energy storage system and a coal-fired unit power generation system. The operation modes of the system comprise an energy storage mode and an energy release mode. The energy storage mode is started when the power utilization load of a power gridis low and residual electric energy exists, and the residual electric energy is used for driving a multi-stage compressor to compress air. The energy release mode is started when the power utilization peak of the power grid is short of electric energy supply, and low-temperature air is heated by utilizing steam extraction of a coal-fired unit to push an expansion machine to generate power and output electric energy to the outside. According to the invention, the efficiency of the energy storage system can be improved, and meanwhile, the problems of high energy consumption, short service lifeand the like when a high-pressure compressor is used are avoided; according to the invention, a heat storage system in a traditional liquid compressed air energy storage system is omitted, the investment of the energy storage system is reduced, and meanwhile, the problem of mismatching of heat in the energy storage process and the energy release process is solved.

Owner:XIAN XIRE ENERGY SAVING TECH +1

System for delivering air from a multi-stage compressor to a turbine portion of a gas turbine engine

ActiveUS8057157B2Improve performanceLow turn downPropellersWind motor controlGas compressorHigh pressure

A system for providing air from a multi-stage to a turbine includes a turbine having a high pressure input port and a low pressure input port. The system also includes a compressor having at least one high pressure extraction air output and at least one low pressure extraction air output. A valve is fluidly connected to the at least one high pressure extraction air output, at least one low pressure extraction air output and low pressure input port of the turbine. The valve is selectively operated to fluidly connect the at least one low pressure extraction air output with the low pressure input port during normal operating conditions and fluidly connect the at least one high pressure extraction air output and the low pressure input port during a turn down condition or below design temperature operation to enhance turbine engine performance.

Owner:GENERAL ELECTRIC CO

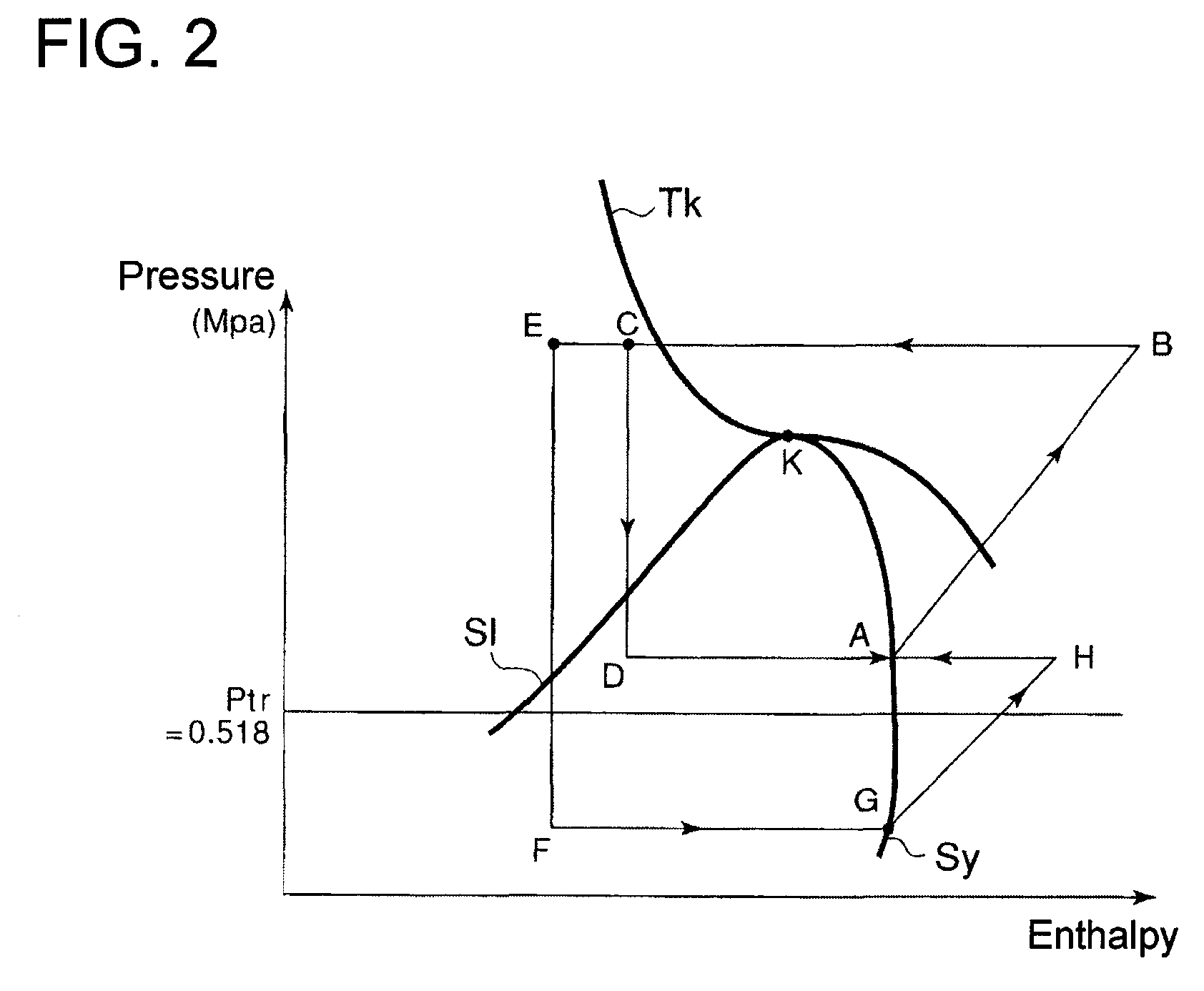

Co2 cooling and heating apparatus and method having multiple refrigerating cycle circuits

InactiveUS20080245505A1High temperature heat sourceReduce decreaseCompression machines with non-reversible cycleEvaporators/condensersTriple pointEvaporation

A CO2 cooling and heating apparatus and method permit simultaneous production of high-temperature heat source and low-temperature heat source having a temperature difference therebetween. The apparatus / method uses CO2 (carbon dioxide) as a refrigerant, and has a first refrigerating cycle circuit where the refrigerant is compressed to a supercritical zone and then decompressed via an expansion device to a pressure / temperature level of the CO2 triple point or below to thereby attain evaporation. The apparatus can include multistage compressors, intermediate cooler disposed in a first refrigerant flow path between a condenser and the expansion device. A second refrigerating cycle circuit having a second refrigerant flow path, which can branch off from the first refrigerant flow path or provided in an independent closed circuit, can be provided to carry out absorption of evaporation latent heat with the first refrigerant flow path to thereby maintain the pressure / temperature level of the CO2 triple point (Ptr) or above. A third refrigerating cycle circuit having a third refrigerant flow path also can be provided to carry out heat exchange with the second refrigerant flow path.

Owner:MAYEKAWA MFG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com