Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

665 results about "Liquid air" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid air is air that has been cooled to very low temperatures (cryogenic temperatures), so that it has condensed into a pale blue mobile liquid. To thermally insulate it from room temperature, it is stored in specialized containers (Vacuum insulated flasks are often used). Liquid air can absorb heat rapidly and revert to its gaseous state. It is often used for condensing other substances into liquid and/or solidifying them, and as an industrial source of nitrogen, oxygen, argon, and other inert gases through a process called air separation.

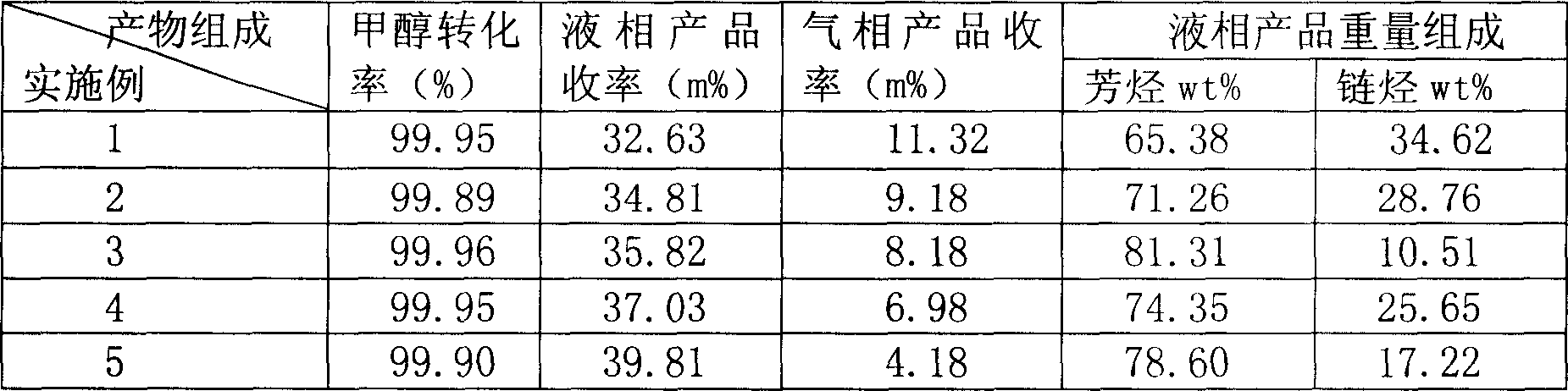

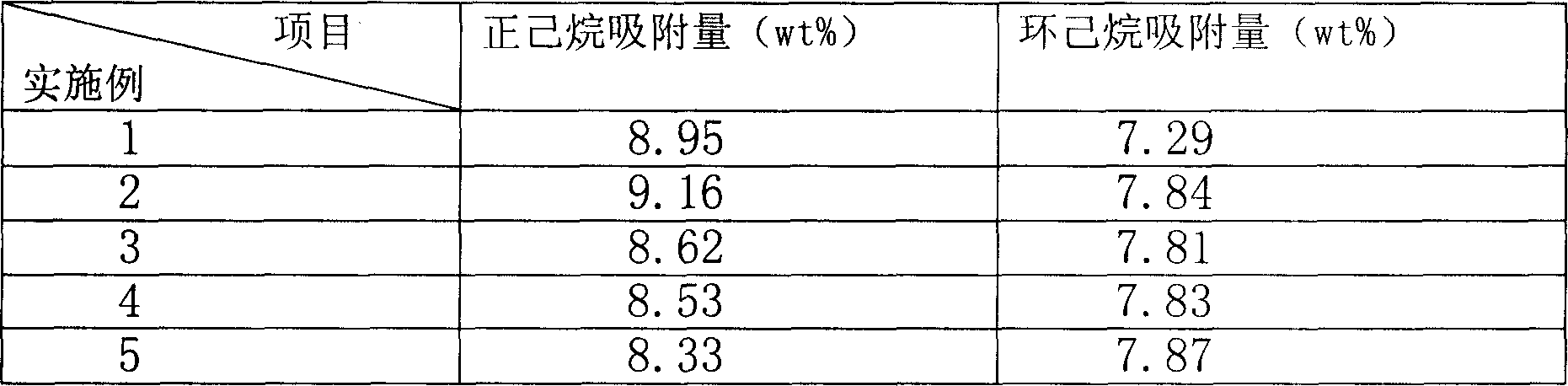

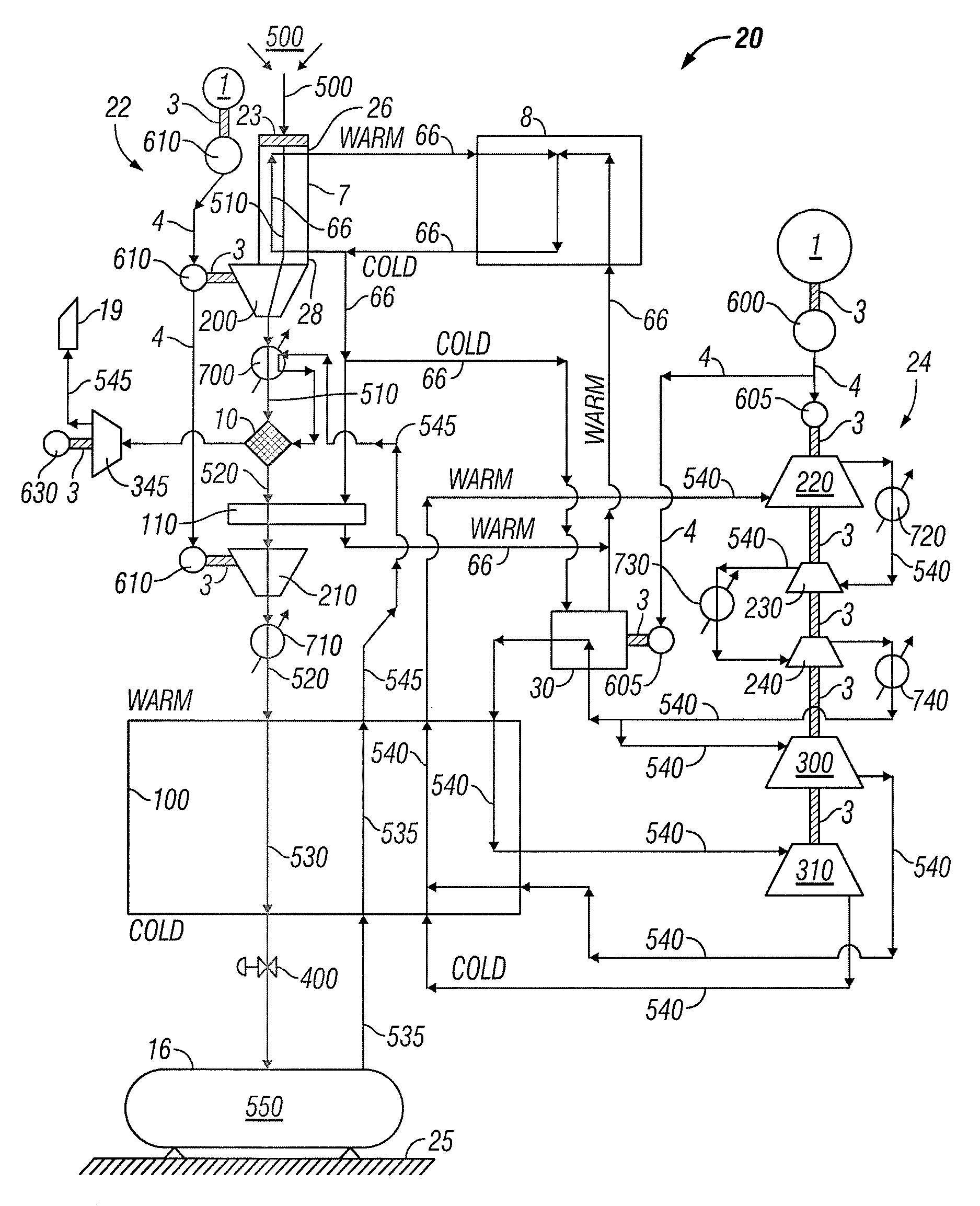

Process of methanol conversion for preparing arene and catalyst and catalyst preparation method

InactiveCN1880288AHigh selectivityHigh flexibility in process operationMolecular sieve catalystsHydrocarbonsGas phaseAromatic hydrocarbon

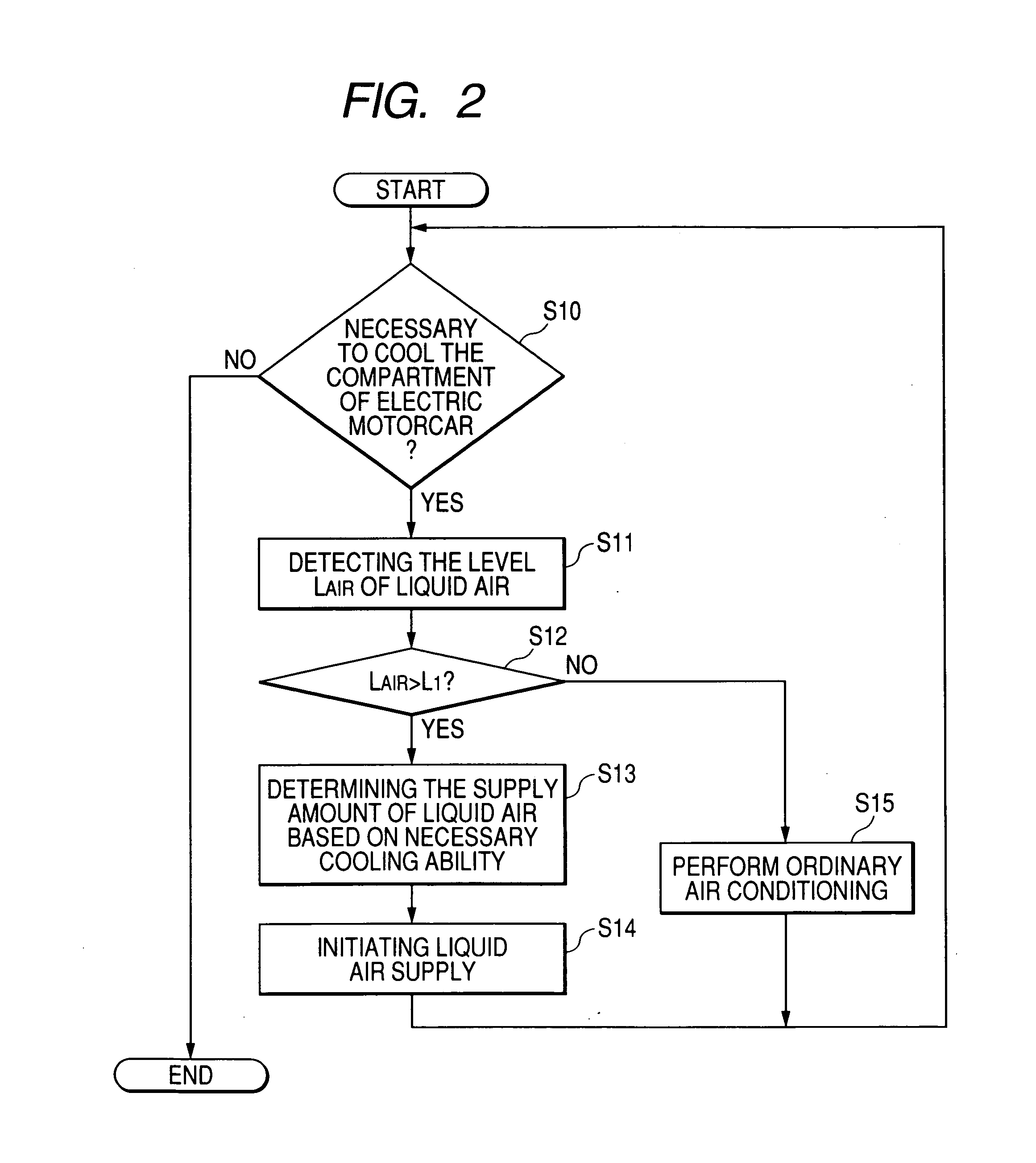

This invention relates to a process for transforming methanol to aromatic hydrocarbons, comprising: use methanol as raw material, with modified ZSM-5 molecular sieve as catalyst, under conditions of operation pressure 0.1-5.0Mpa, operation temperature 300-460Deg C, raw material liquid air speed 0.1-6.0h-1, transformed to products with aromatic hydrocarbons as main components; separate the gas-phase products lower carbon hydrocarbons from the liquid-phase C5+ hydrocarbons by cooling separation; the liquid-phase C5+ hydrocarbons then can be separated to be aromatic hydrocarbons and non-aromatic hydrocarbons by extracting separation. This invention is characterized of high total selectivity of aromatic hydrocarbons and flexible process operation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

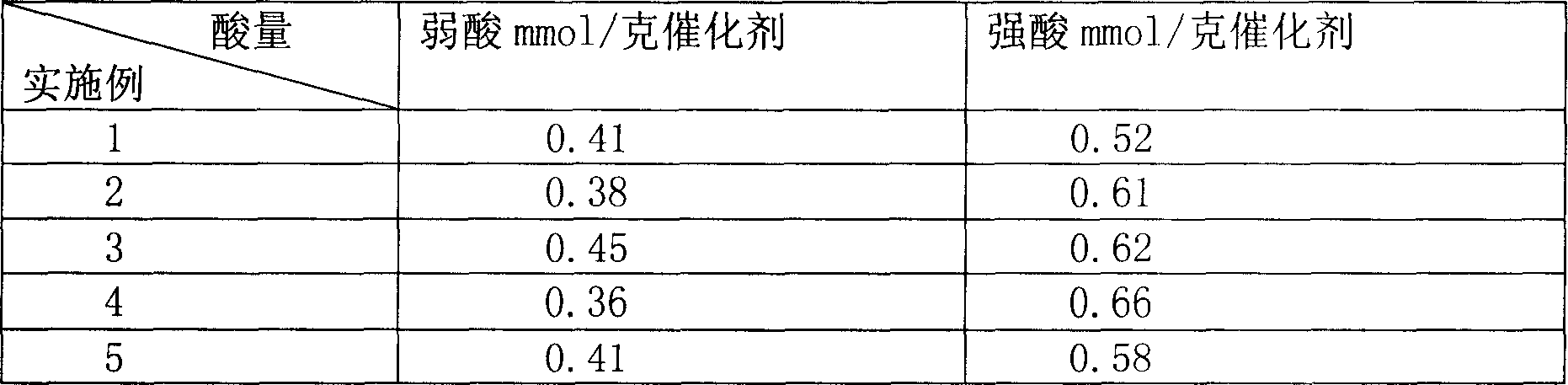

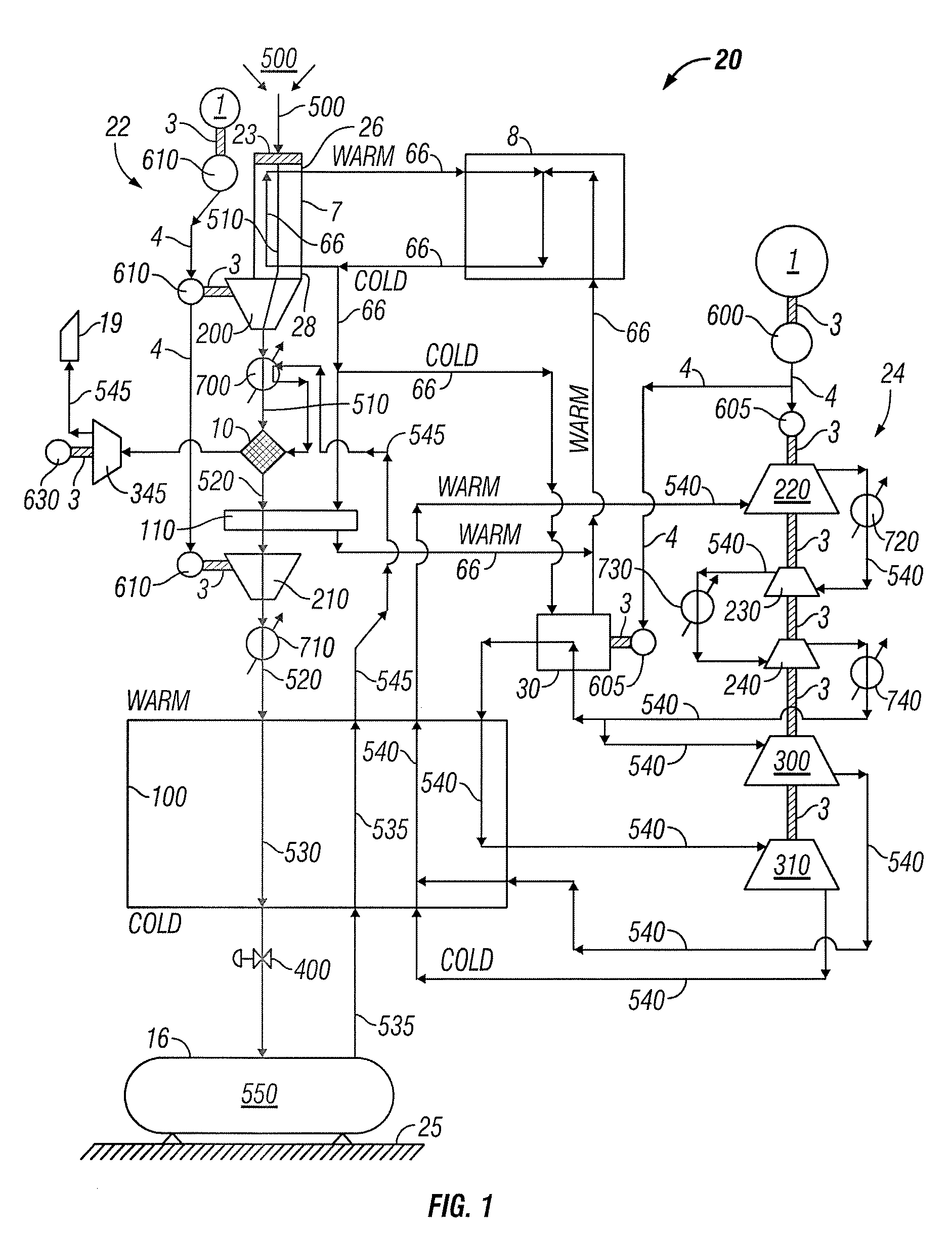

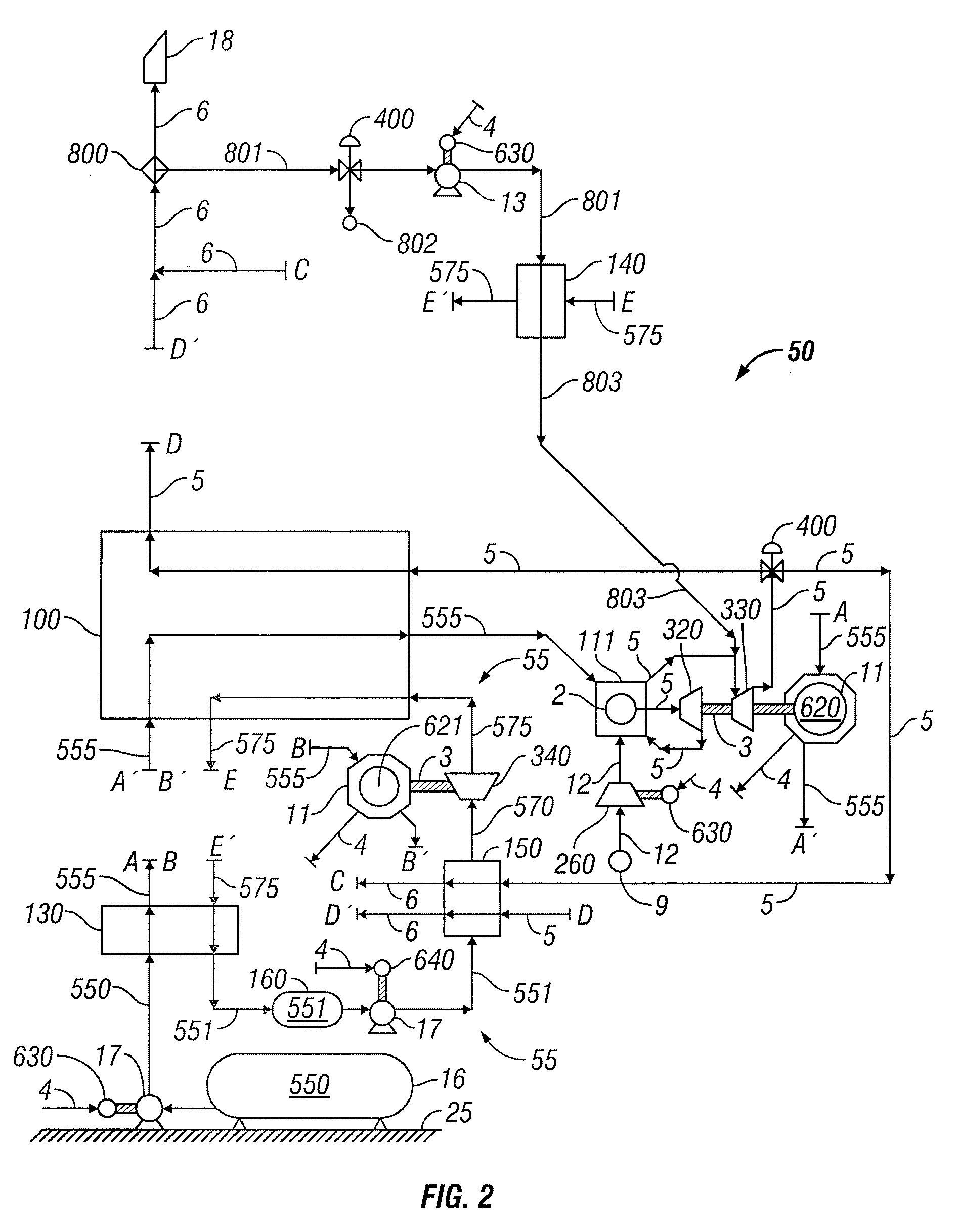

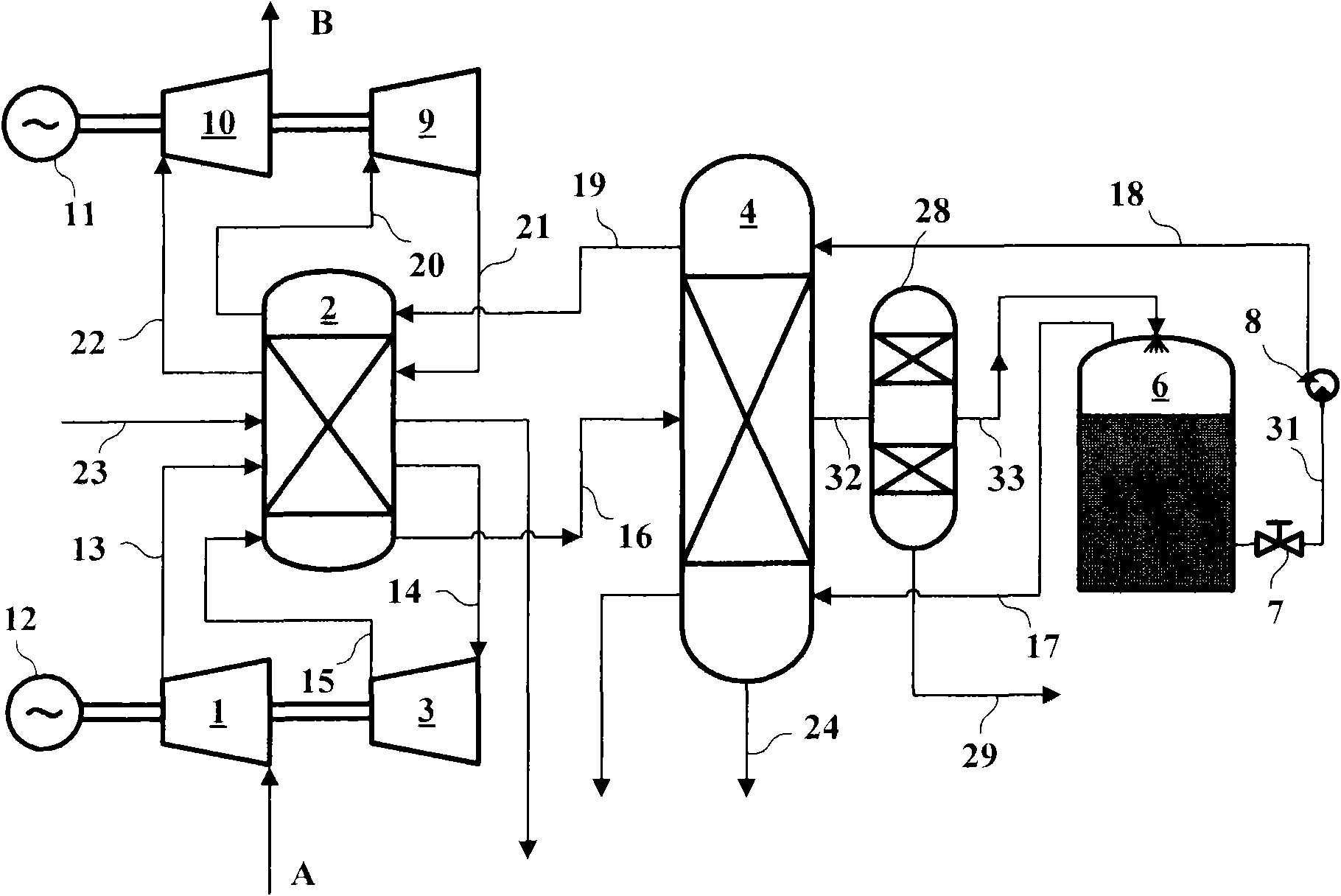

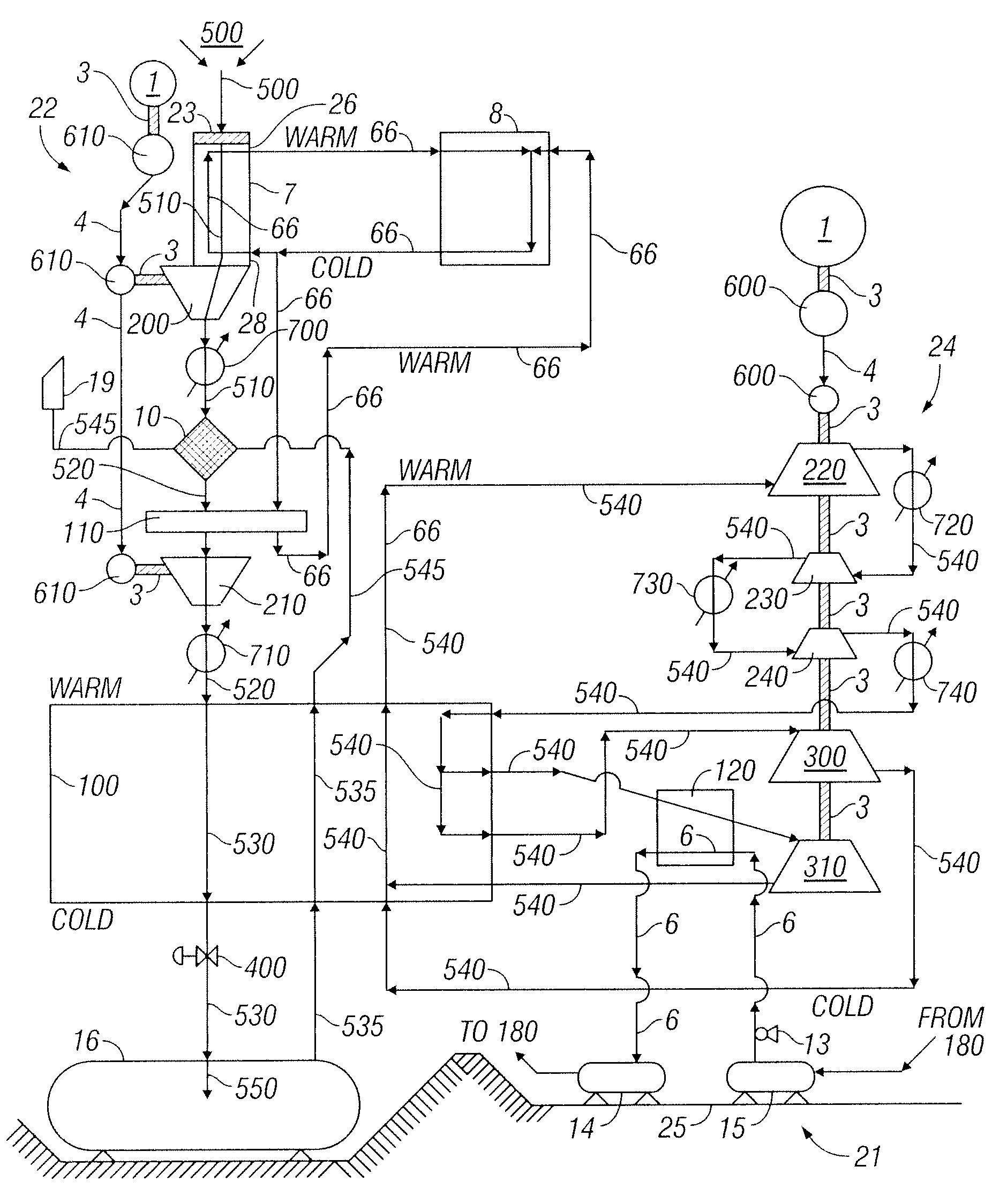

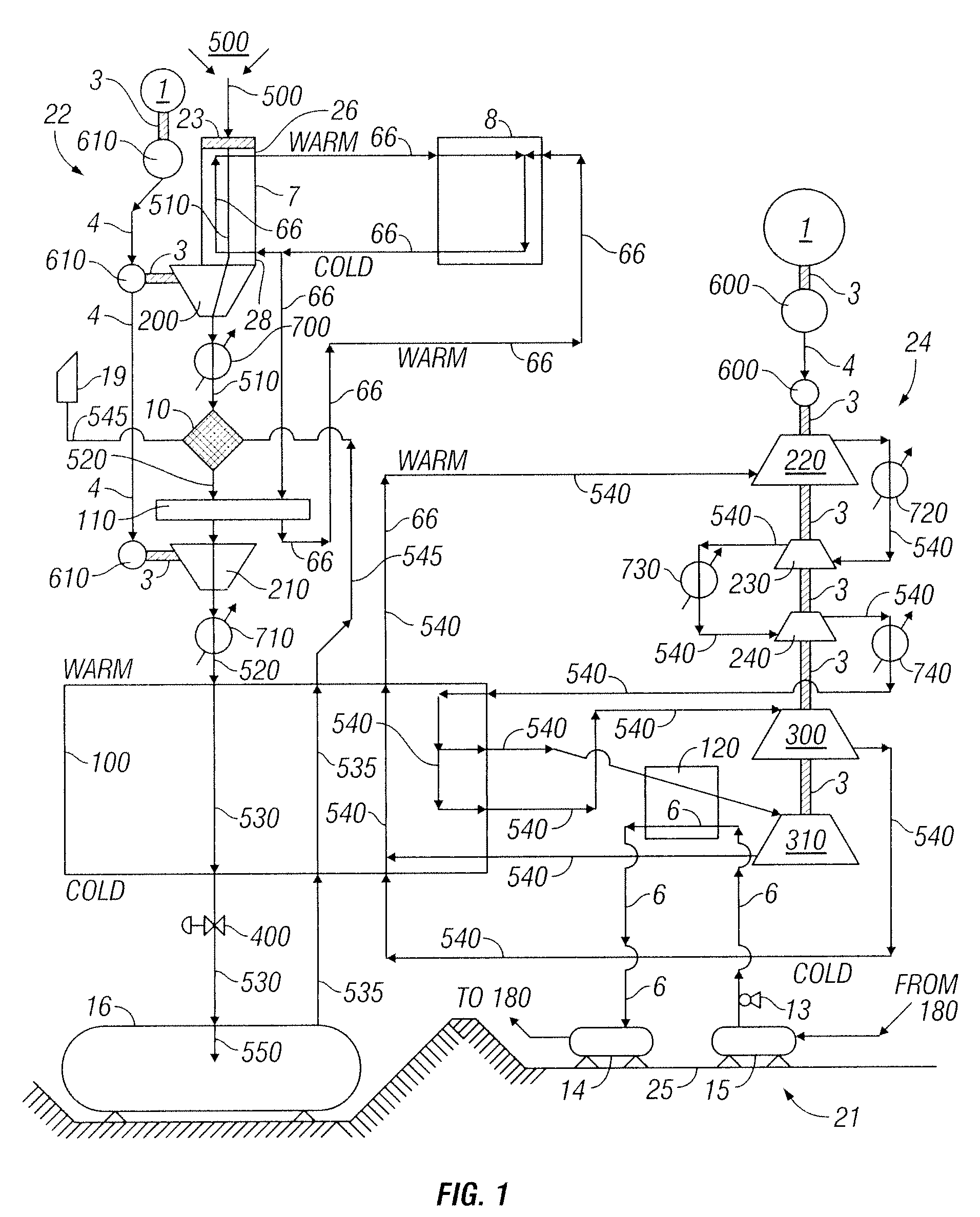

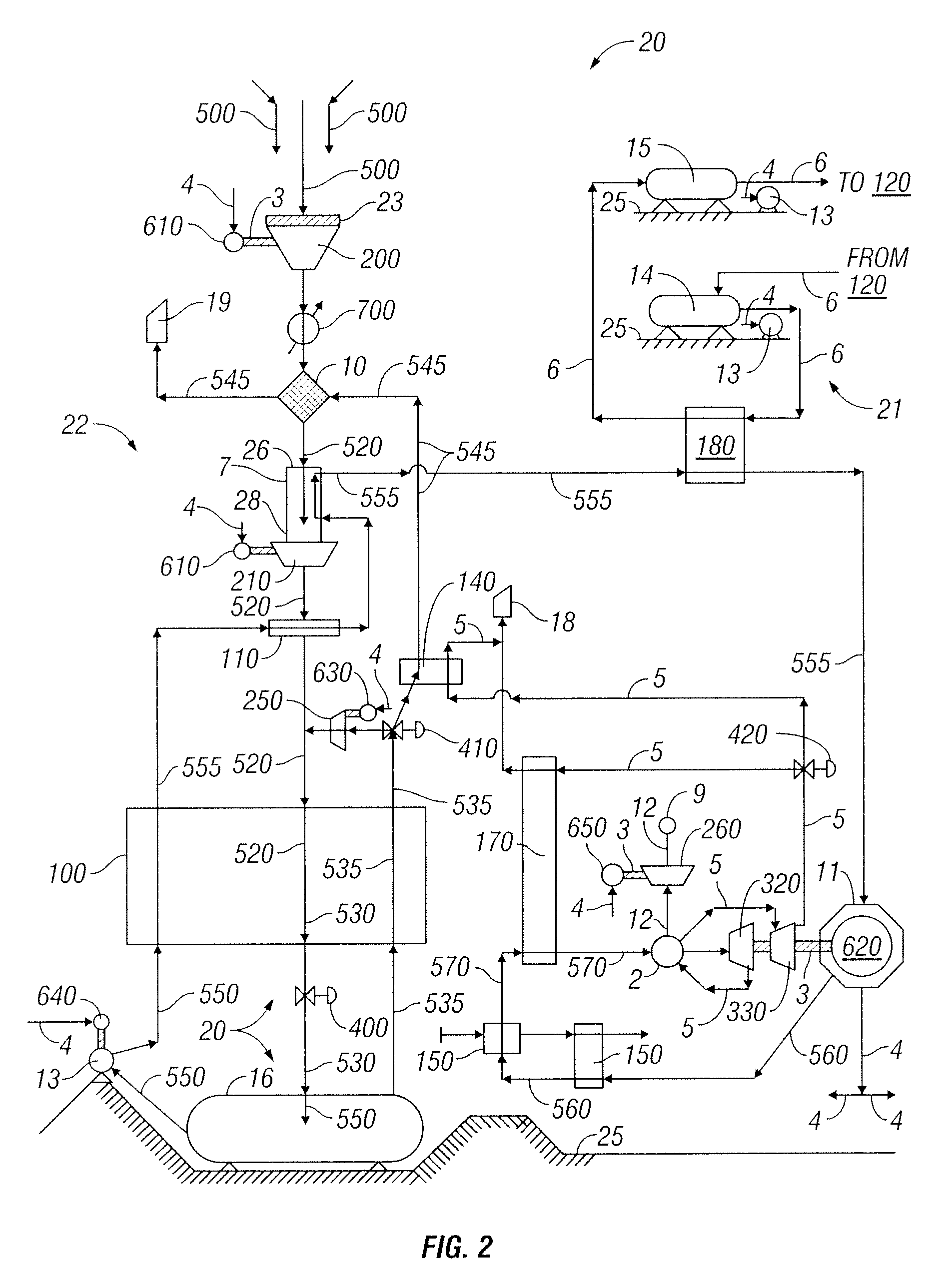

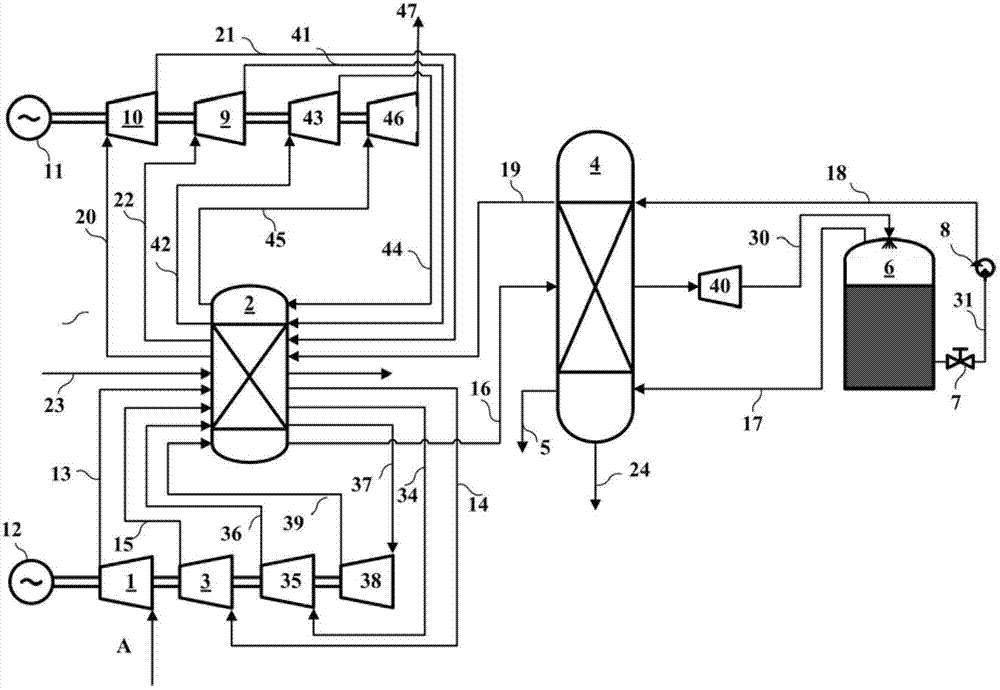

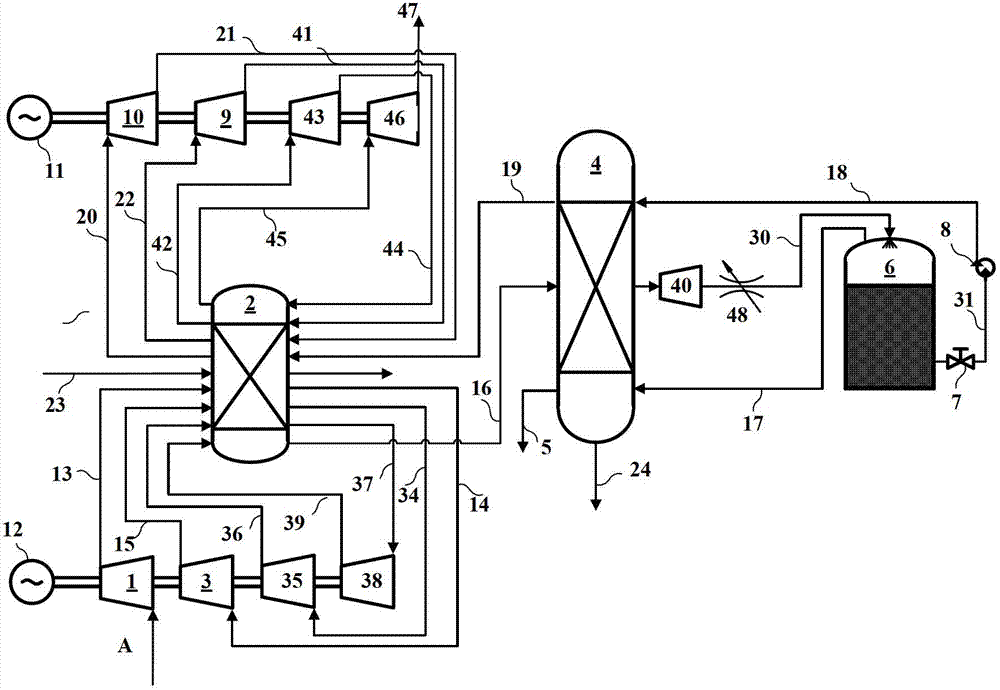

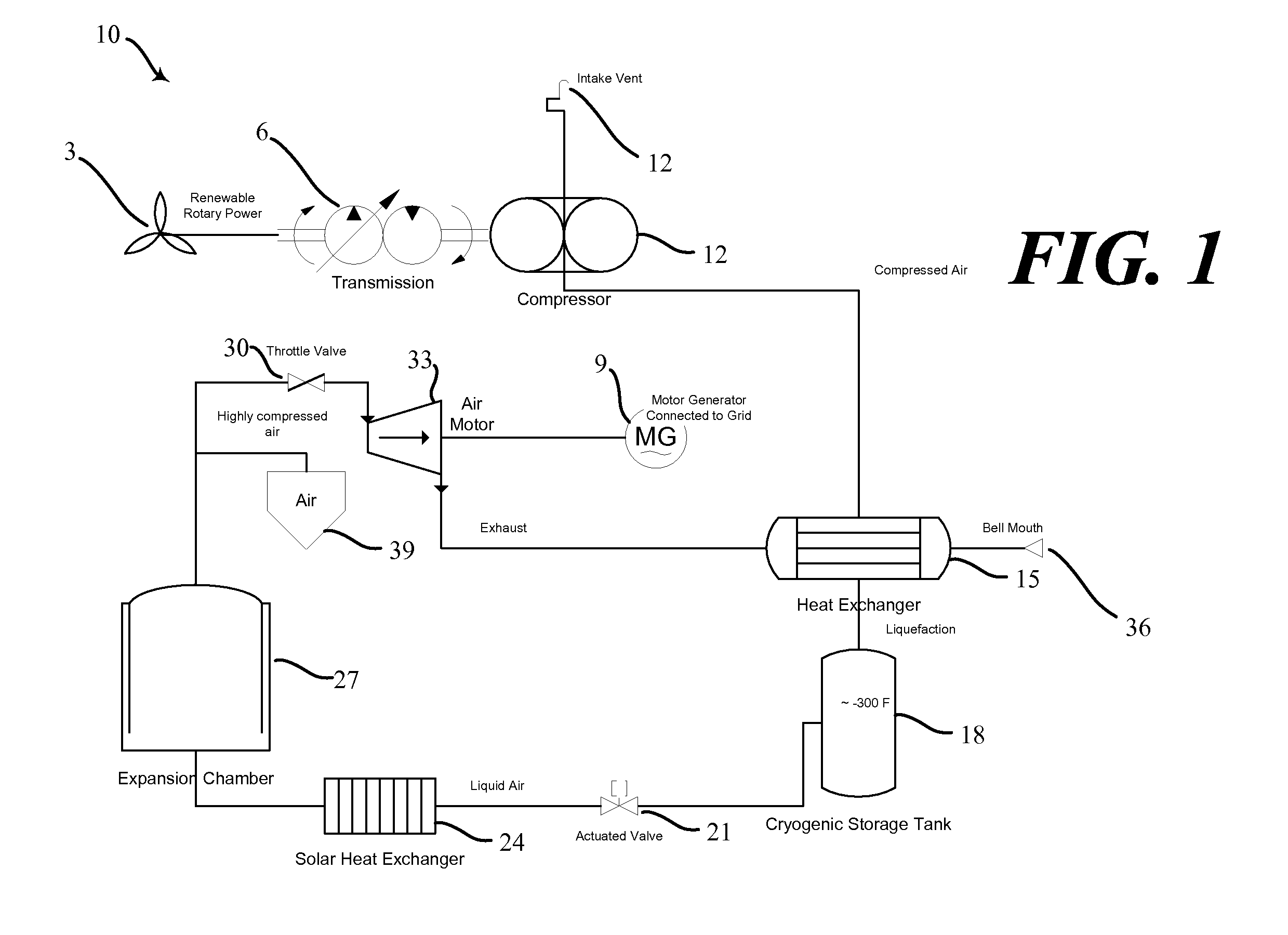

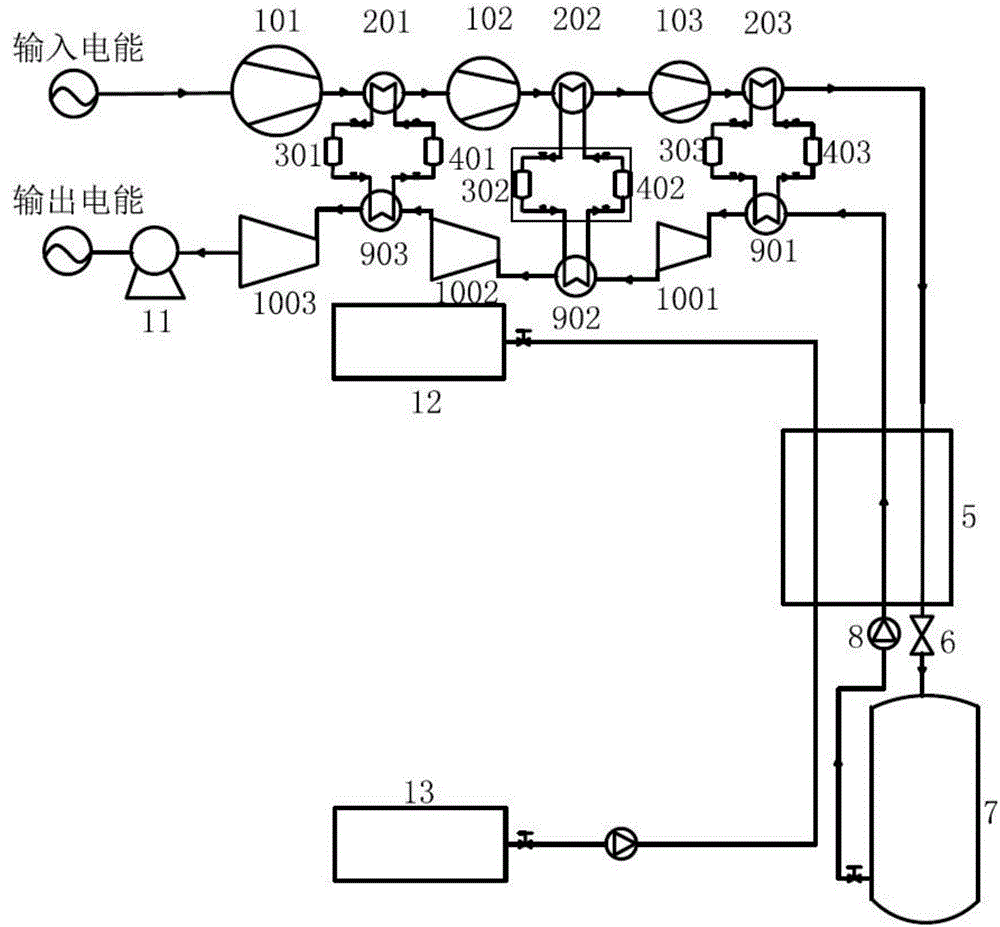

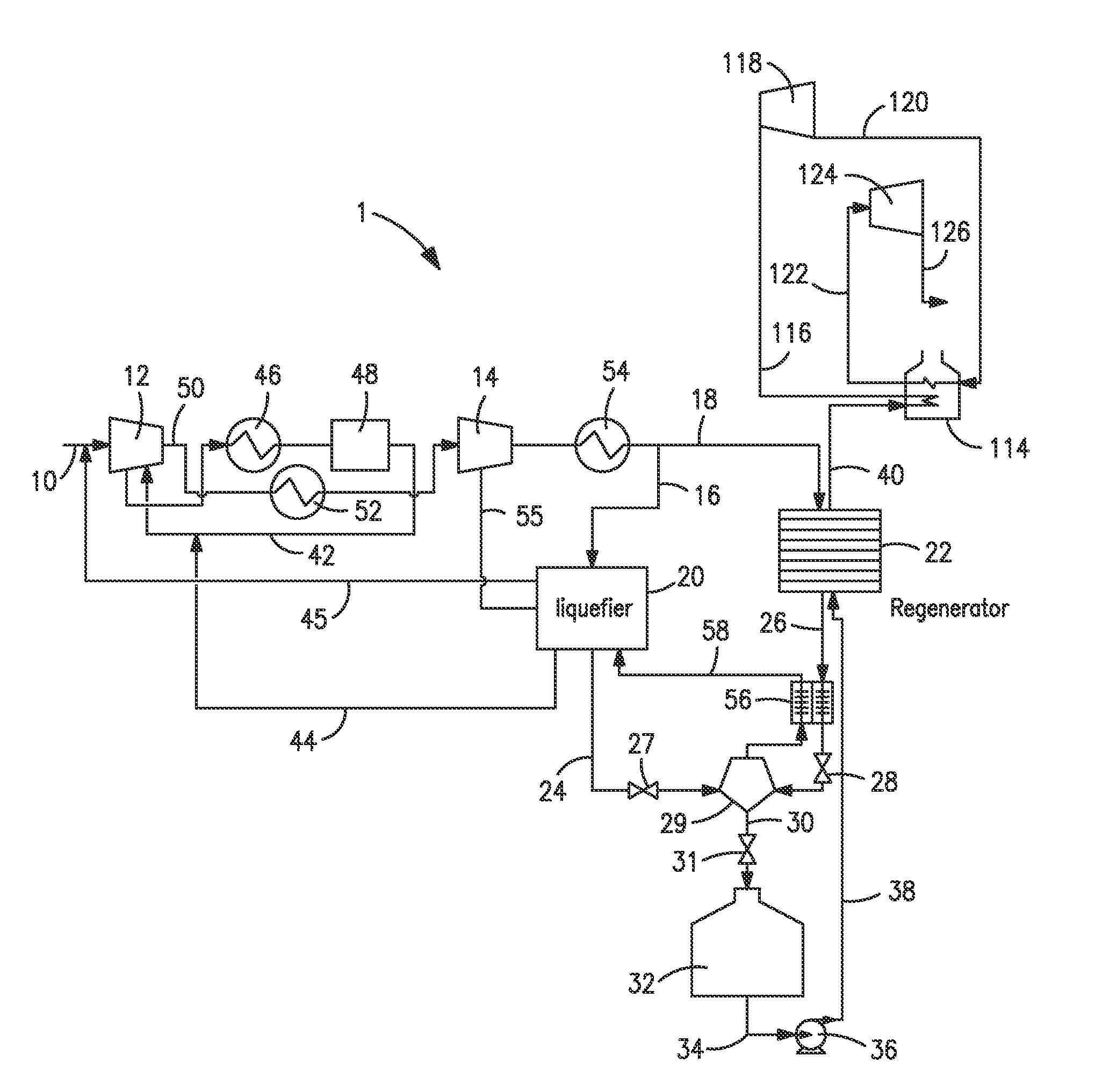

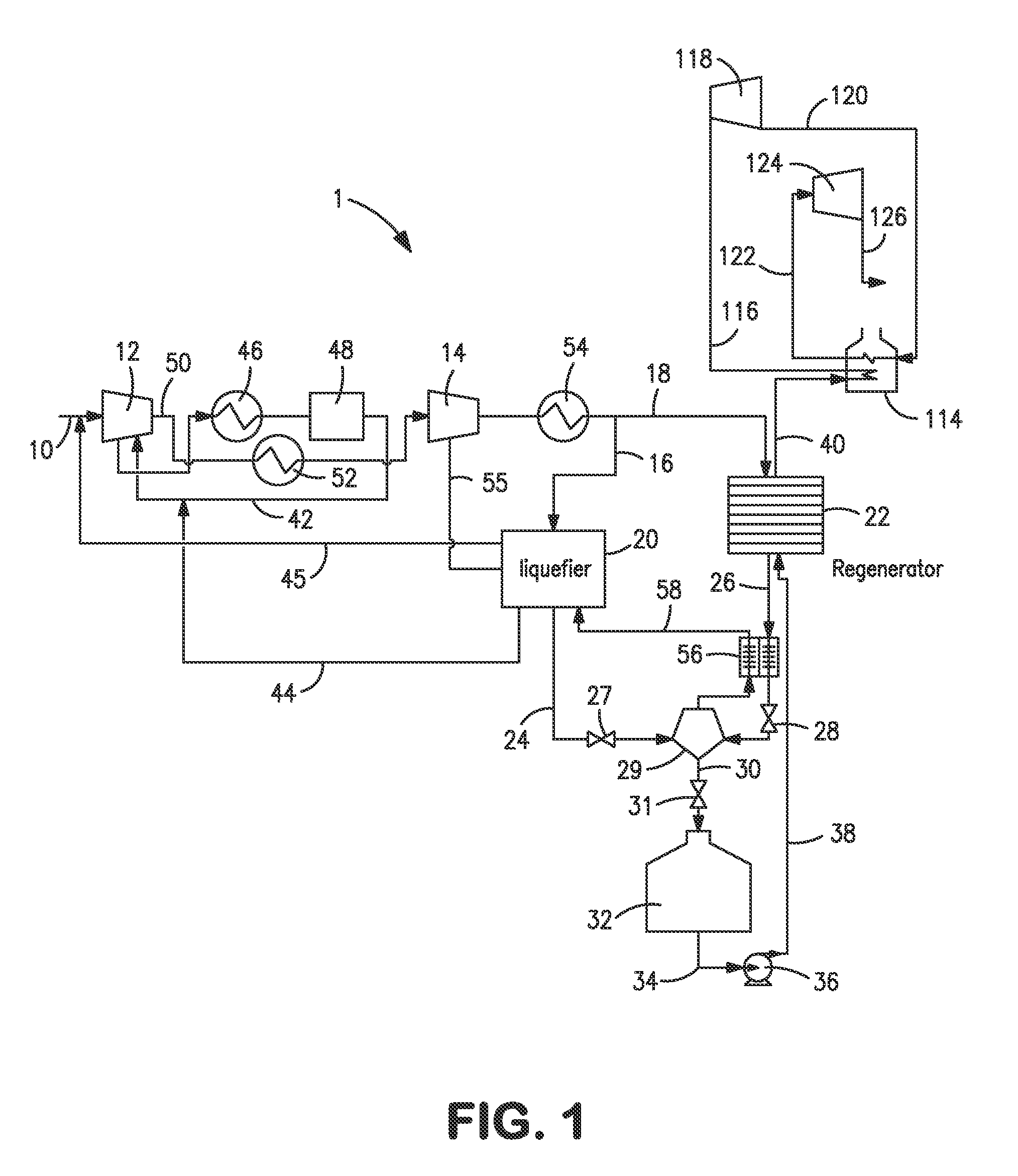

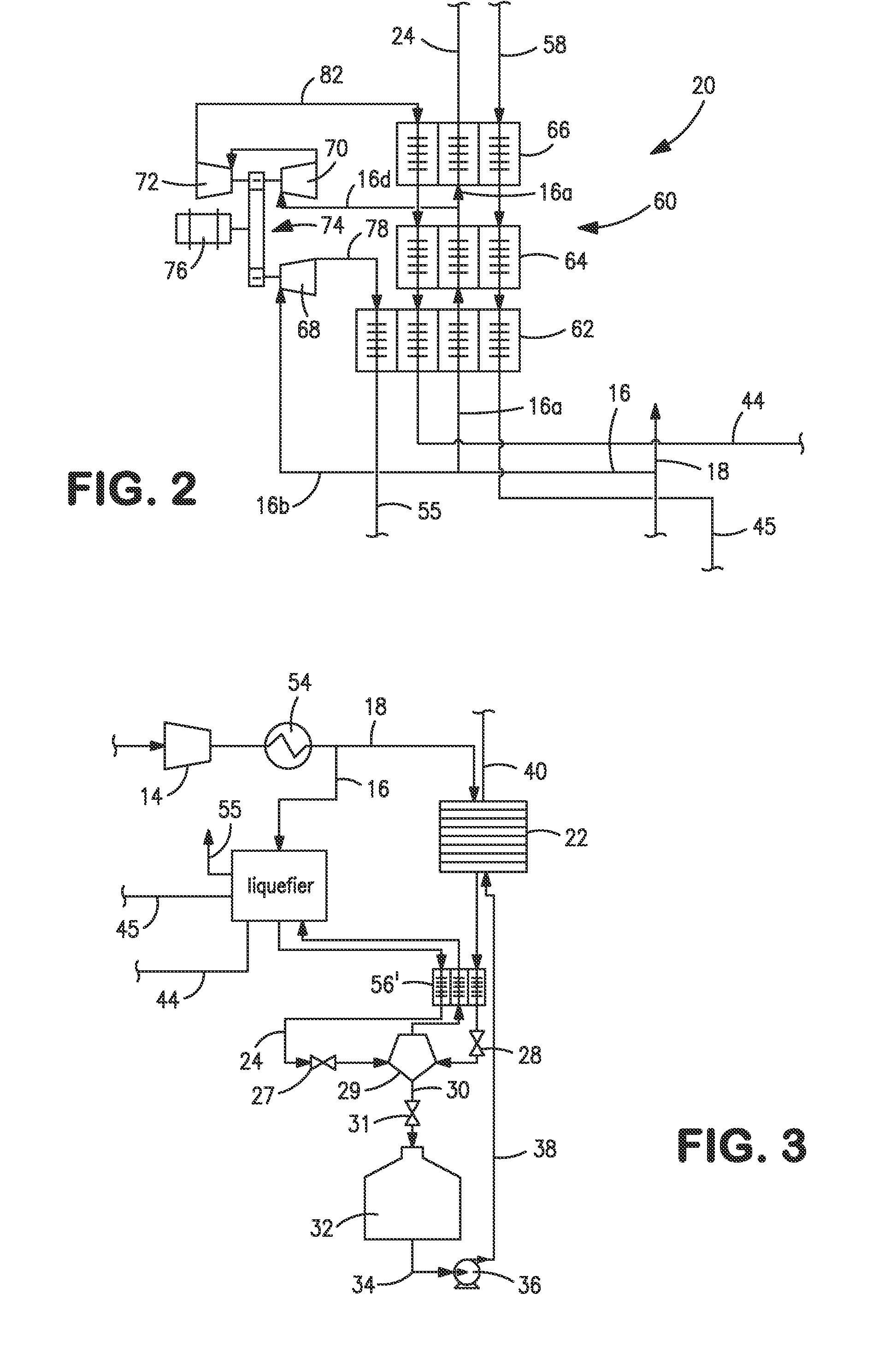

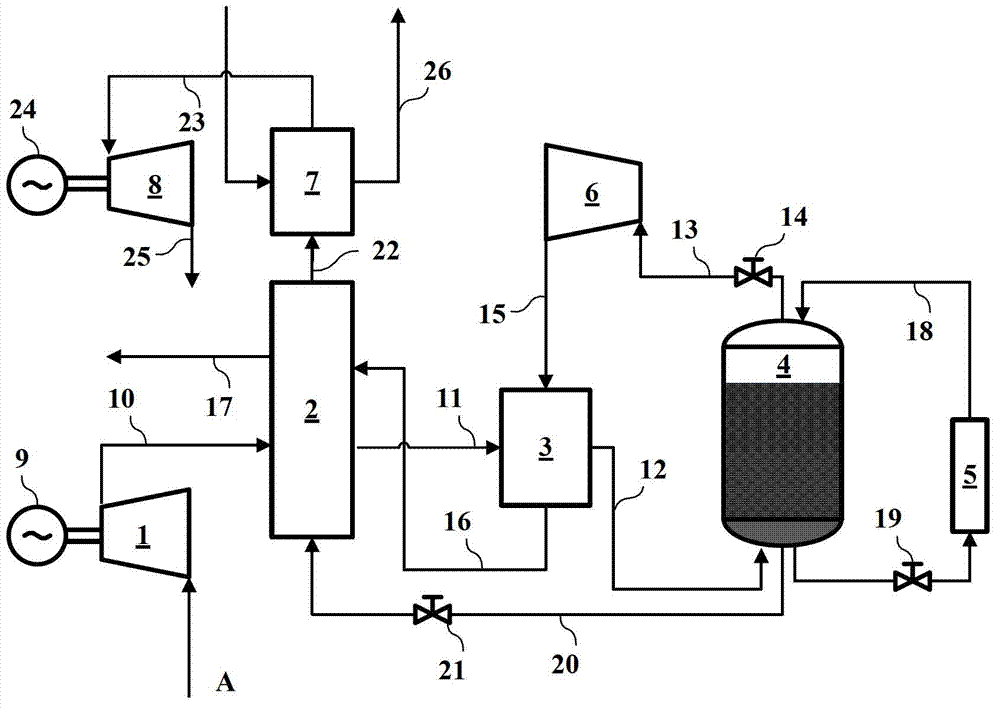

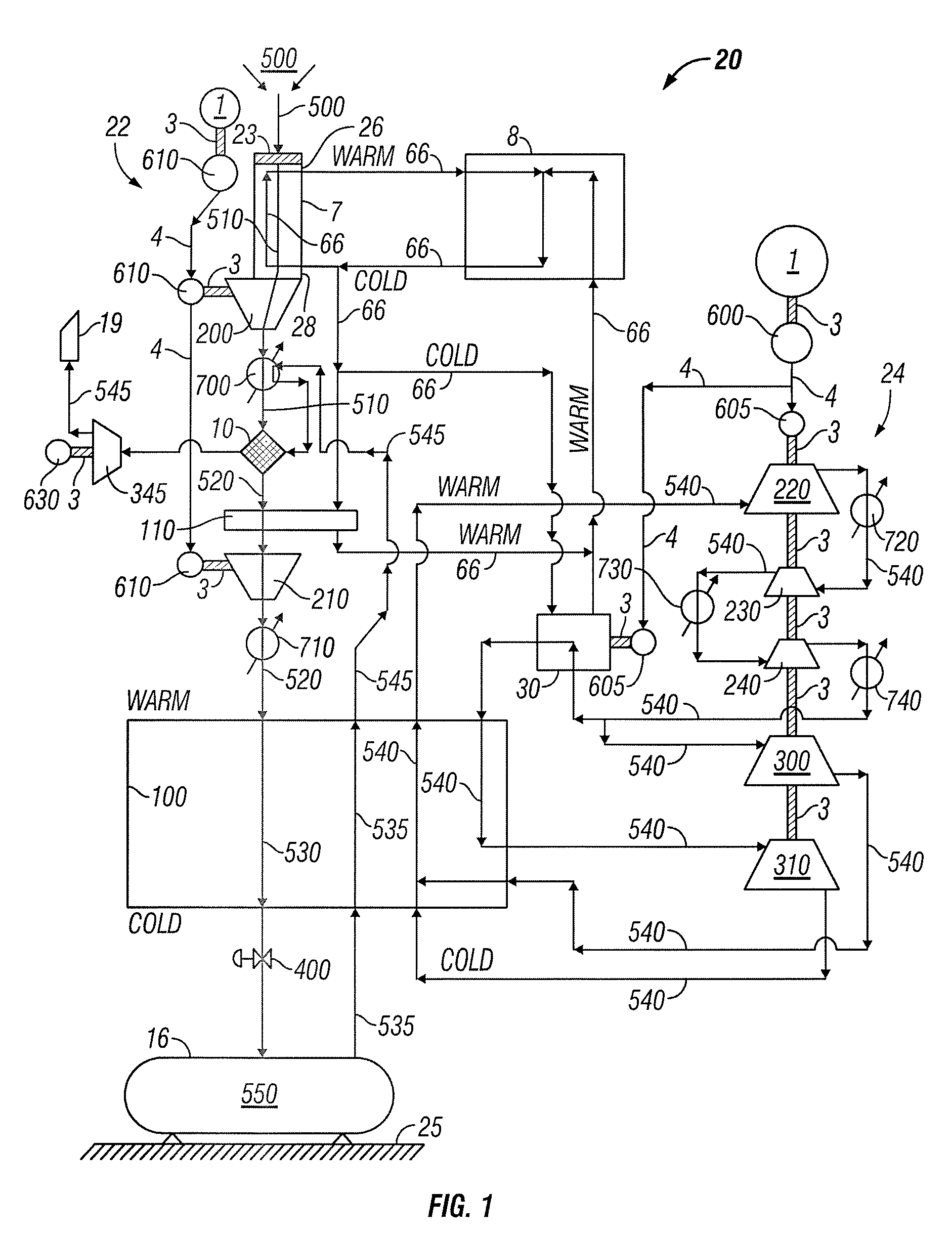

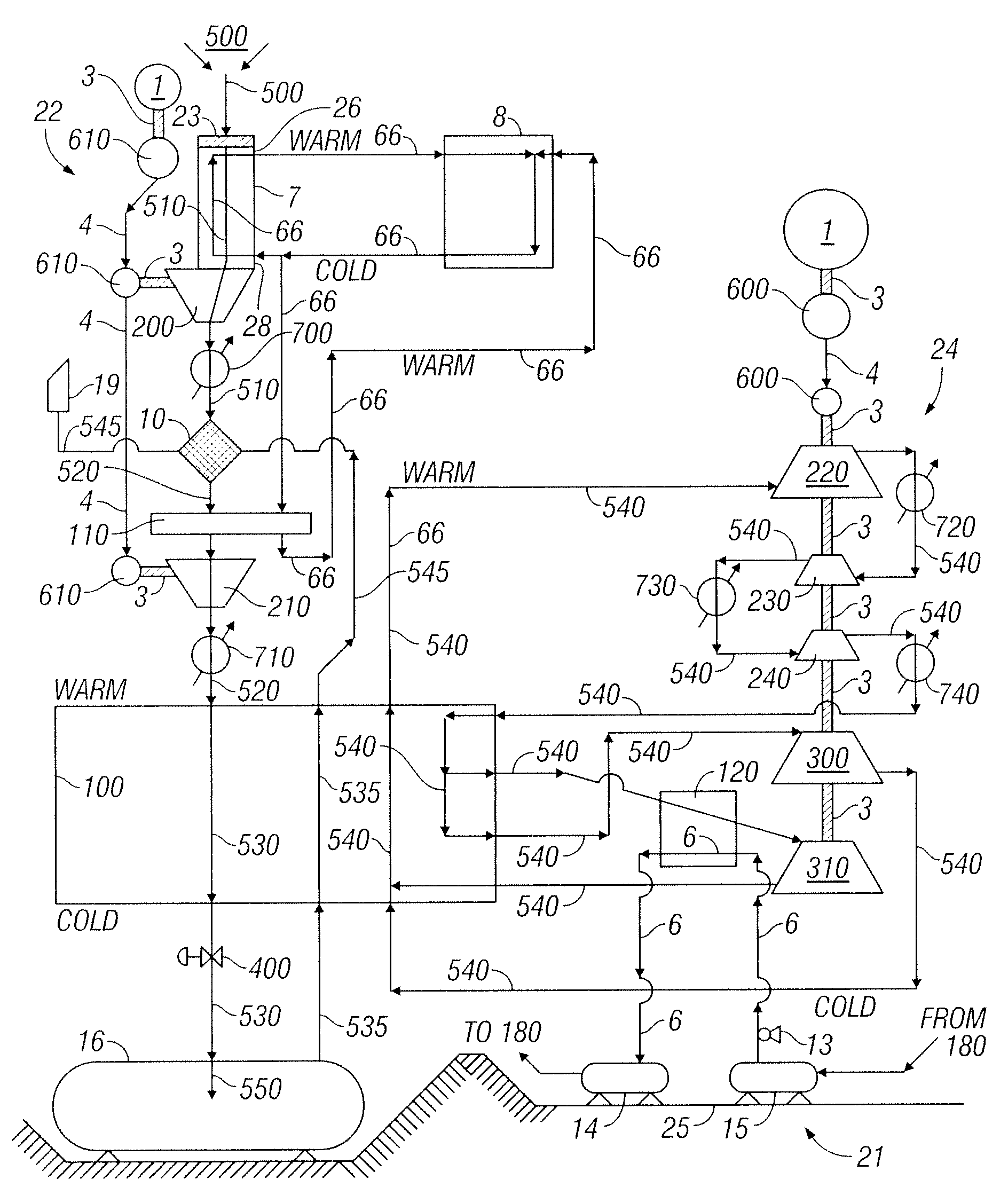

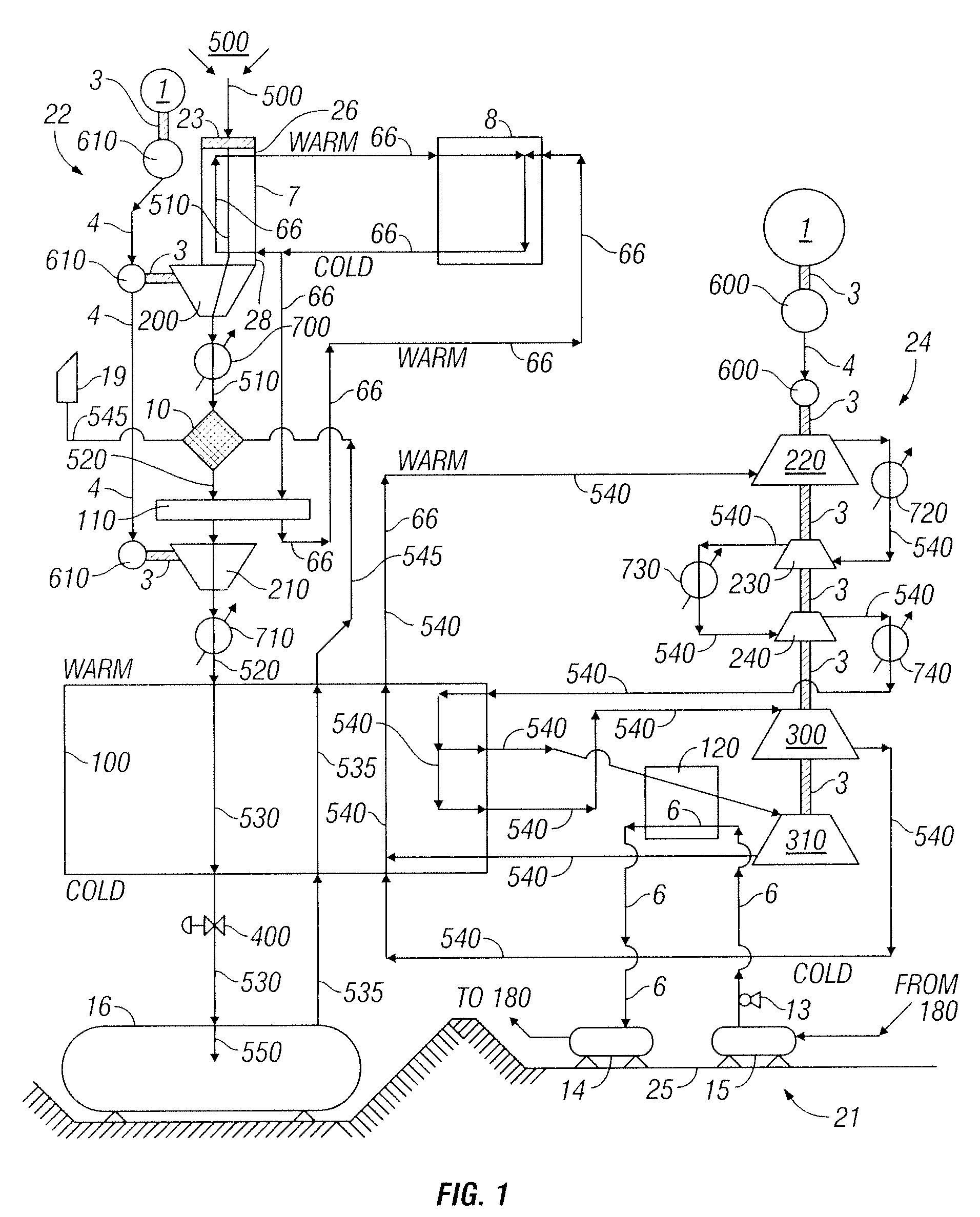

System and method for liquid air production, power storage and power release

InactiveUS20090293503A1Great energy outputEnergy efficiencySolidificationLiquefactionCombustion chamberEngineering

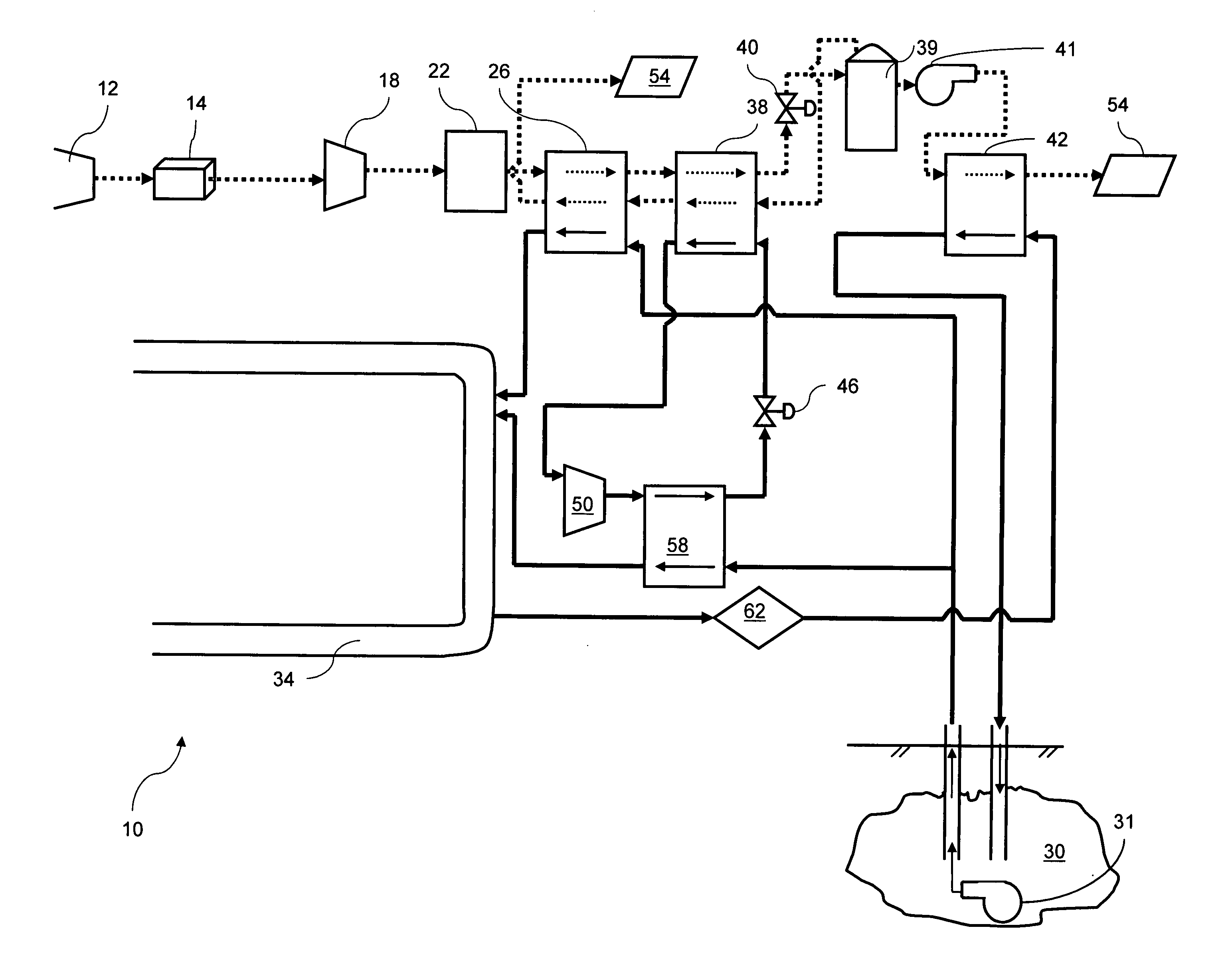

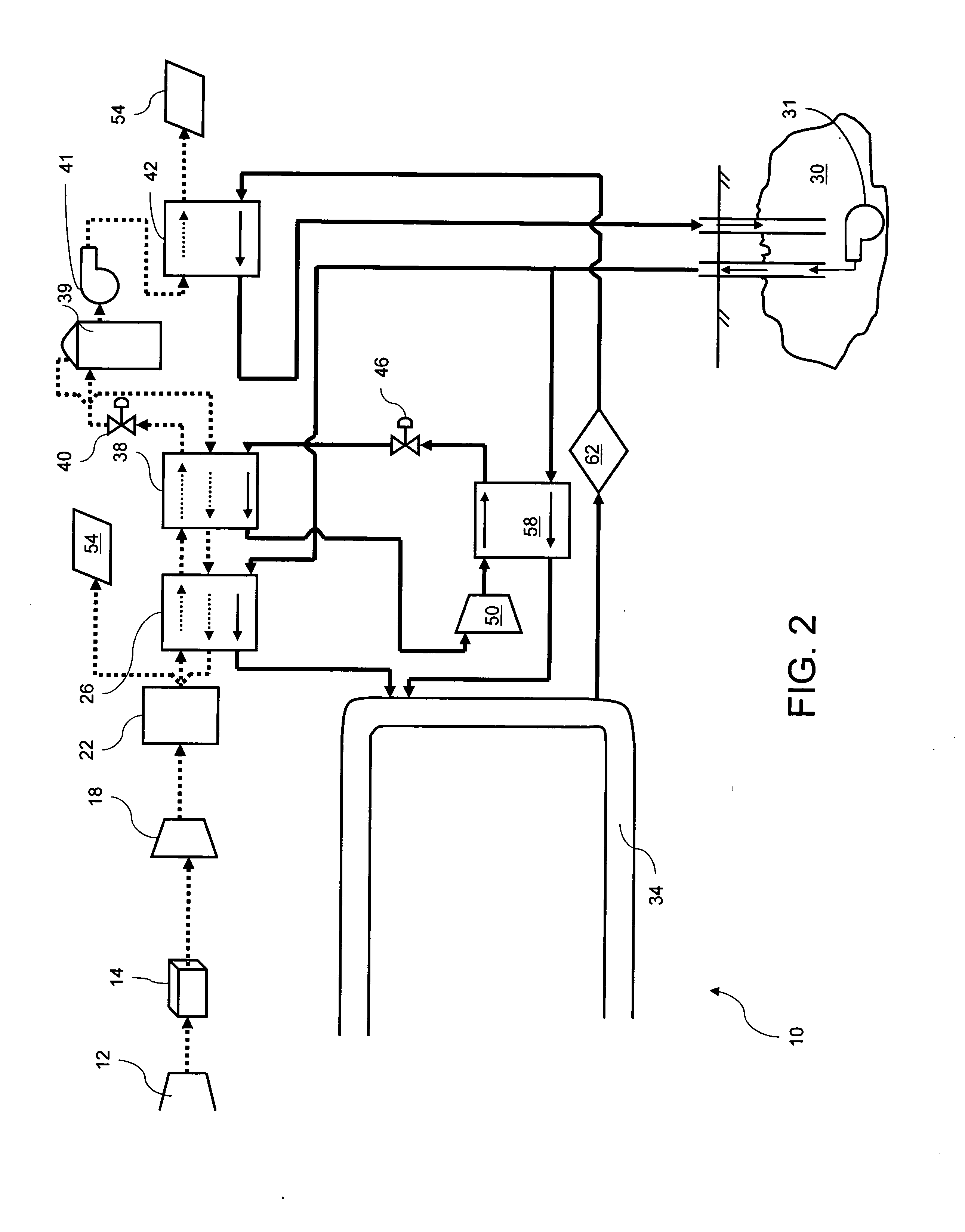

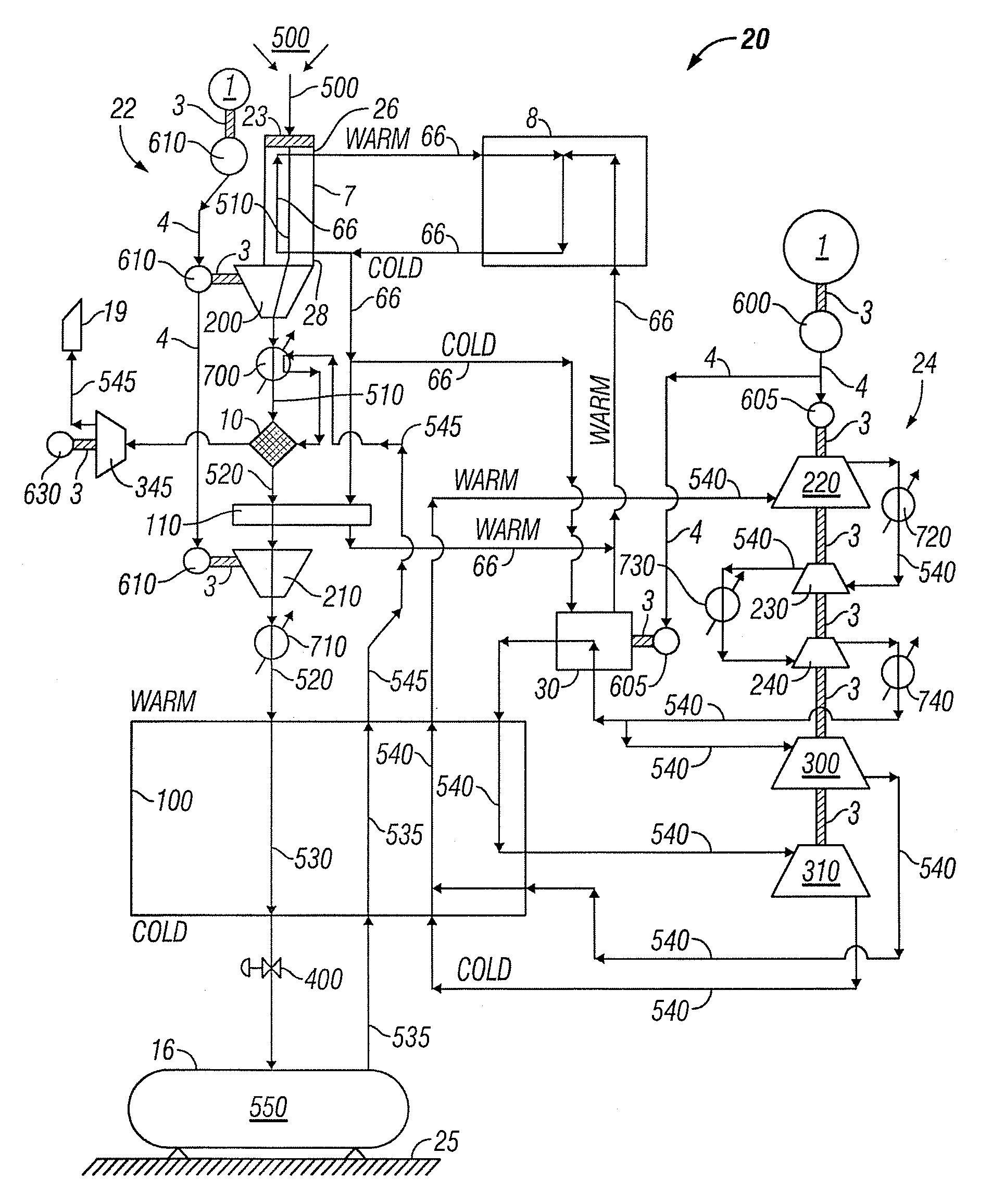

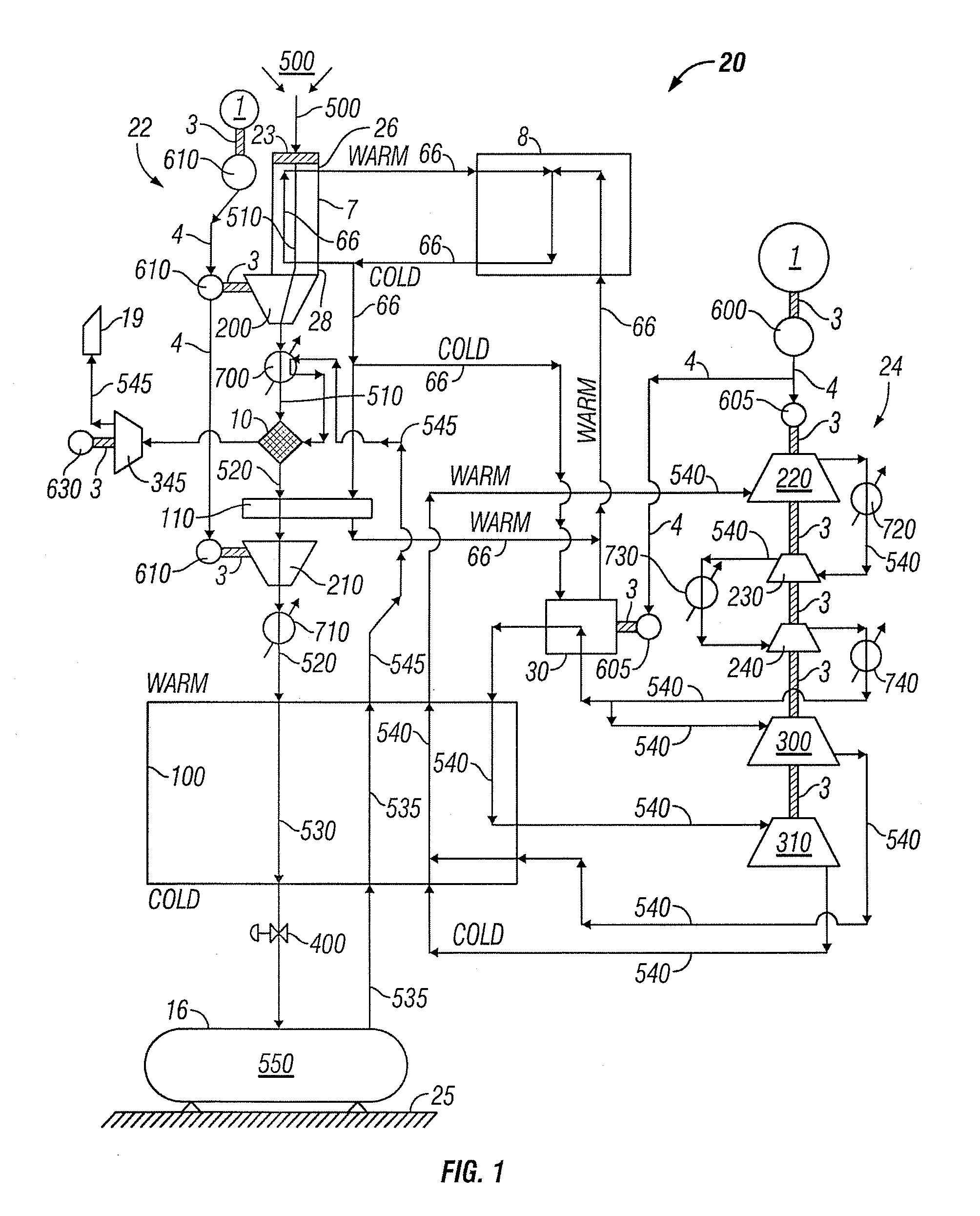

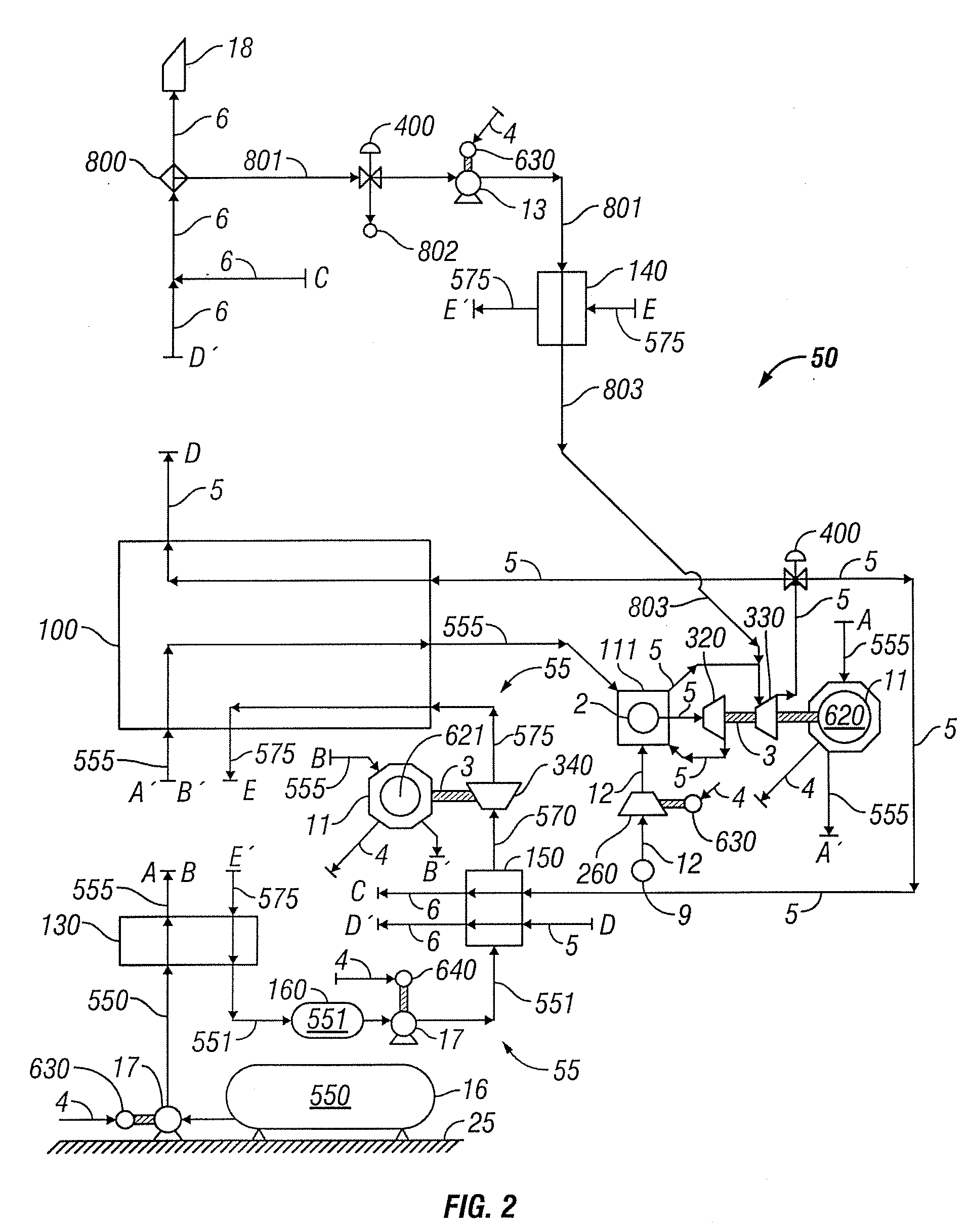

Systems and methods for storing and releasing energy comprising directing inlet air into a vertical cold flue assembly having an air inlet at or near its top into which inlet air is directed and an exit at or near its bottom. The air is cooled within the cold flue assembly and a portion of moisture is removed from the air within the cold flue assembly. The air is directed out the exit of the cold flue assembly and compressed. The remaining moisture is substantially removed and the carbon dioxide is removed from the air by adsorption. The air is cooled in a main heat exchanger such that it is substantially liquefied using refrigerant loop air, the refrigerant loop air generated by a refrigerant loop process. The substantially liquefied air is directed to a storage apparatus. The refrigerant loop air is cooled by a mechanical chiller and by a plurality of refrigerant loop air expanders. In energy release mode, working loop air warms the released liquid air such that the released liquid air is substantially vaporized, and the released liquid air cools the working loop air such that the working loop air is substantially liquefied. A portion of the released liquid air is directed to the at least one generator and used as bearing air for the at least one generator. The substantially vaporized air is directed to a combustion chamber and combusted with a fuel stream. Combustion gas may be directed from the combustion chamber to at least one expander and expanded in the expander, the expanded combustion gas split into a first portion and a second portion, the first portion being relatively larger than the second portion. The first portion may be directed to a first heat exchanger, and the second portion may be directed to a second heat exchanger such that the second portion heats and substantially vaporizes the released liquid air.

Owner:EXPANSION ENERGY

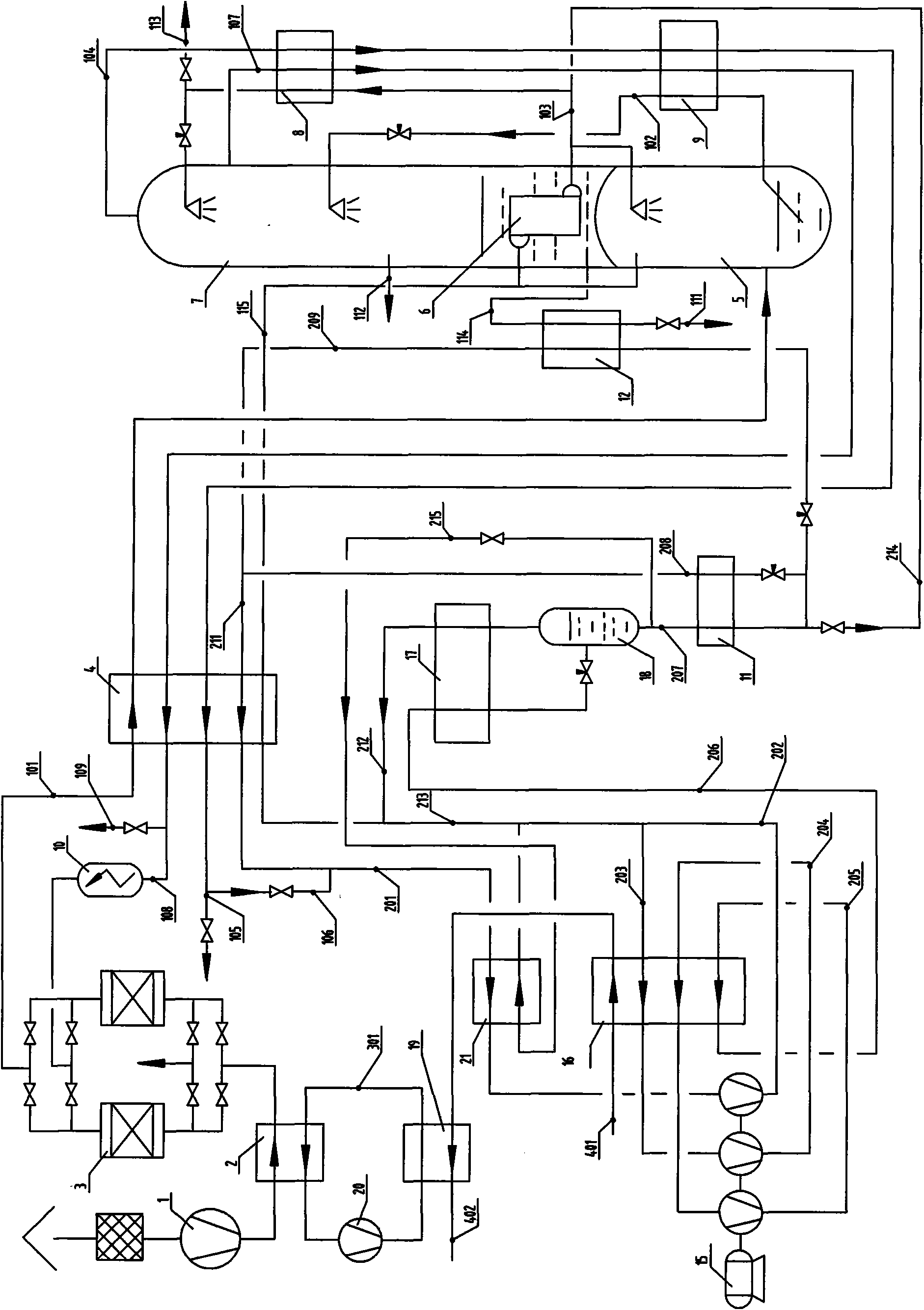

Supercritical air energy storage system

ActiveCN102052256AImprove efficiencyIncrease energy densitySolidificationLiquefactionHigh energyThermal energy storage

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

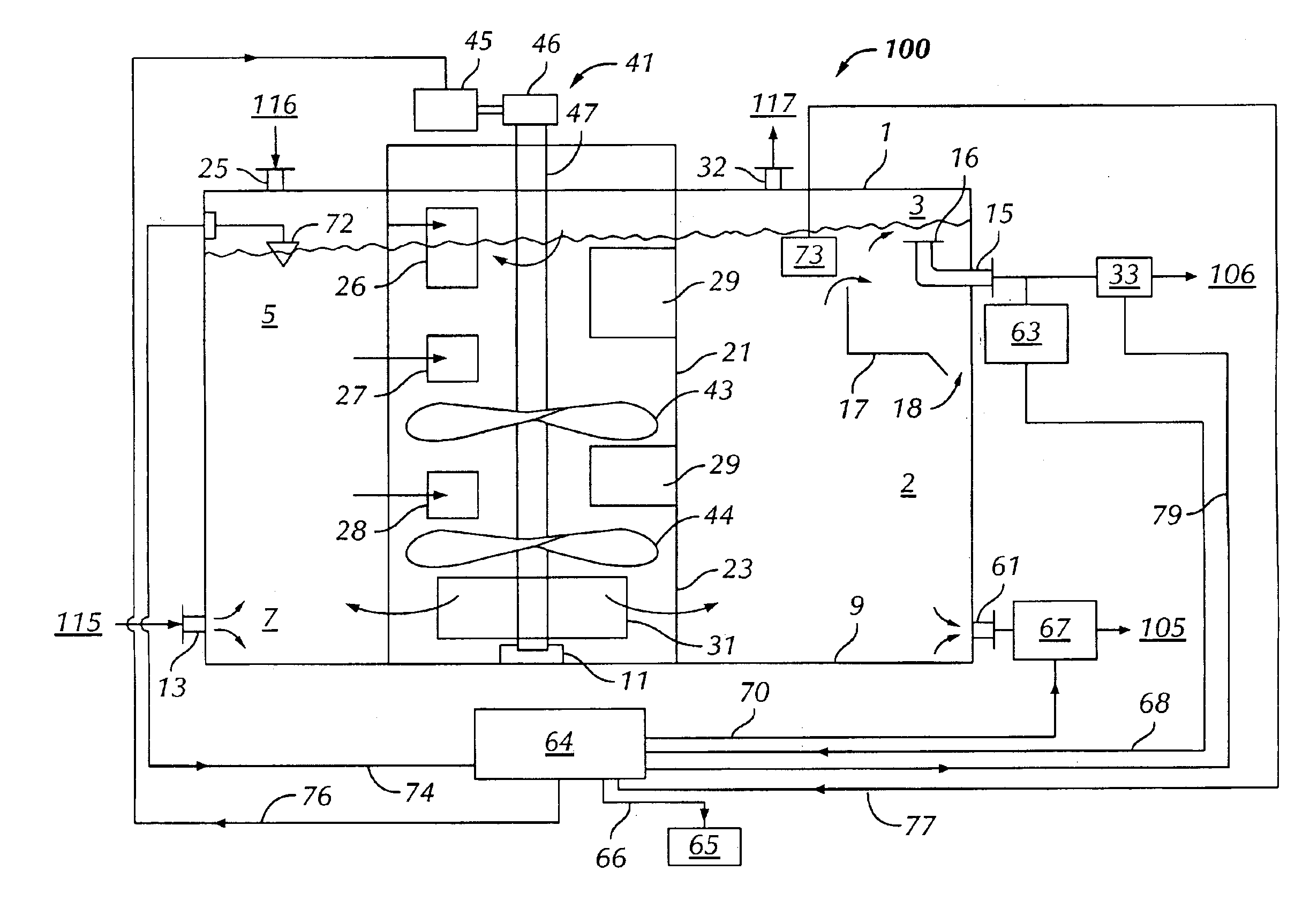

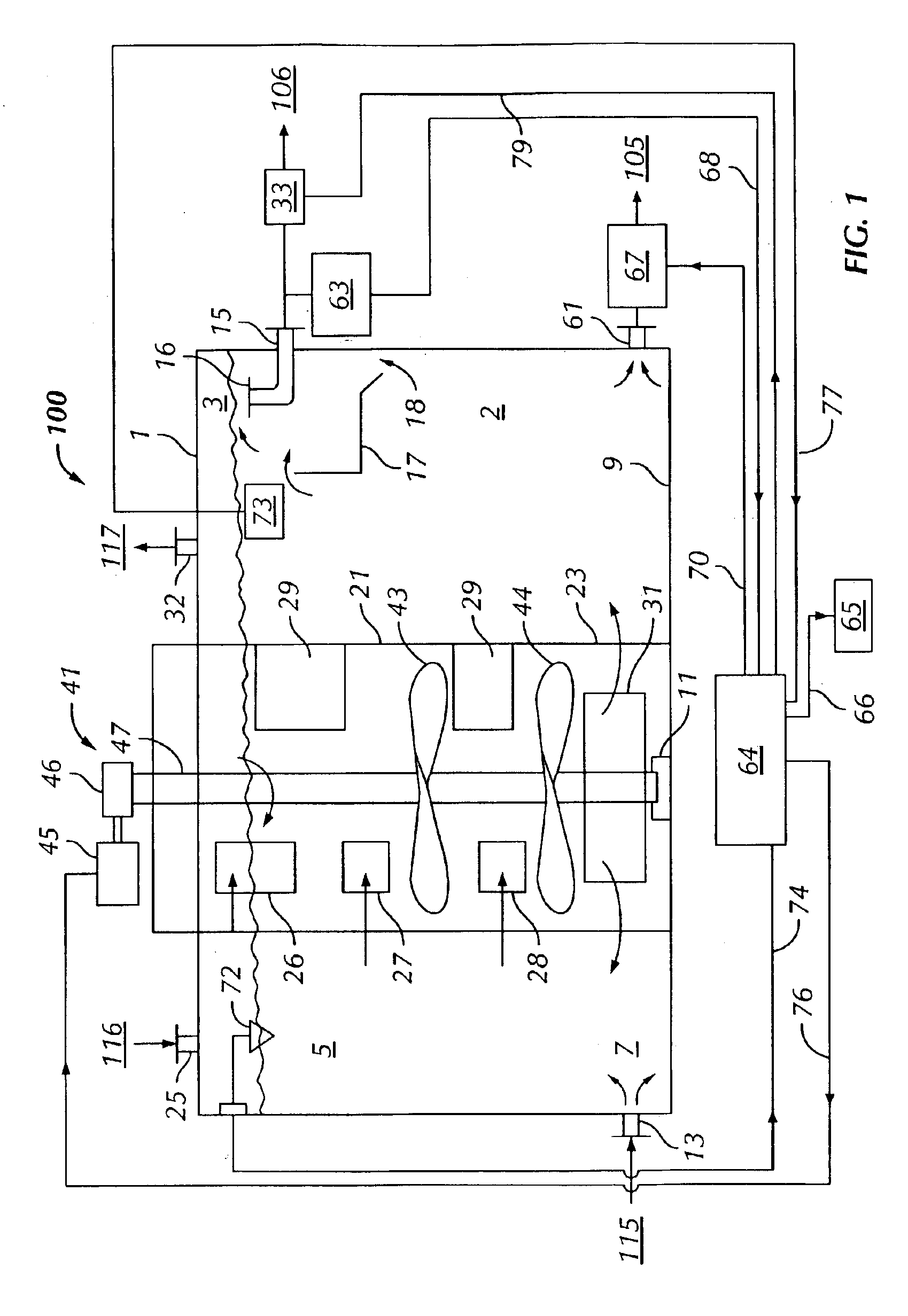

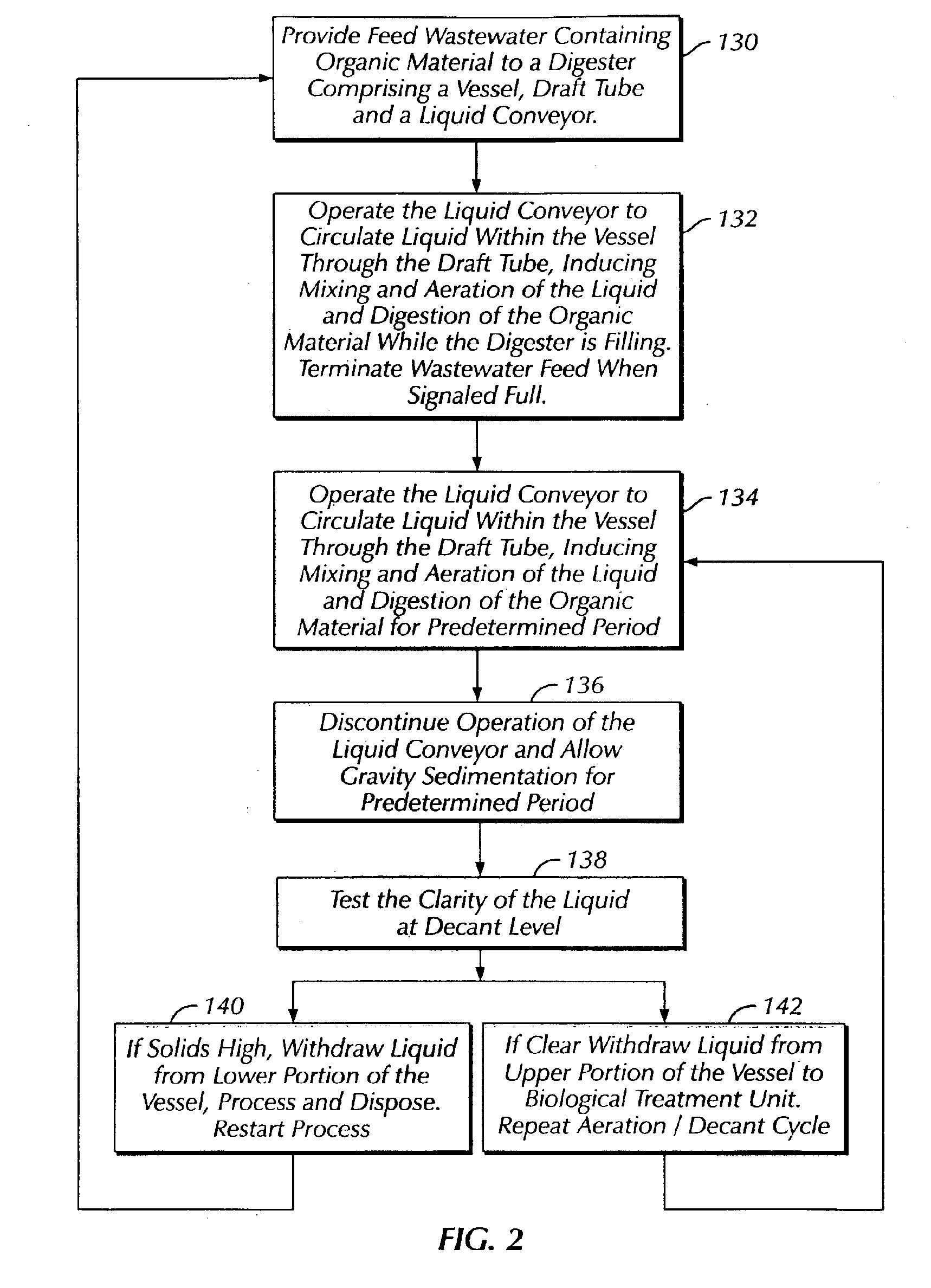

Sludge digestion methods and apparatus

InactiveUS6869534B2Large depthPrevent exitWater treatment parameter controlTreatment using aerobic processesWater treatment systemSludge

The invention relates to an aerobic wastewater digestion unit useful for degrading organic material dissolved or suspended in a wastewater stream. The wastewater is fed to a vessel, wherein it is circulated by a liquid conveyor between the vessel and a downwardly-directed tube. Expulsion of fluid from the tube into the lower portion of the vessel agitates the liquid in the vessel and disperses into the liquid air that has been entrained in the liquid in the tube. The digester can be operated using varying liquid levels, and is amenable to batch, semi-batch, and continuous operation. The digester is suitable for use in combination with other components of wastewater treatment systems, and can be included as a module in modular wastewater treatment systems.

Owner:BRENTWOOD INDS

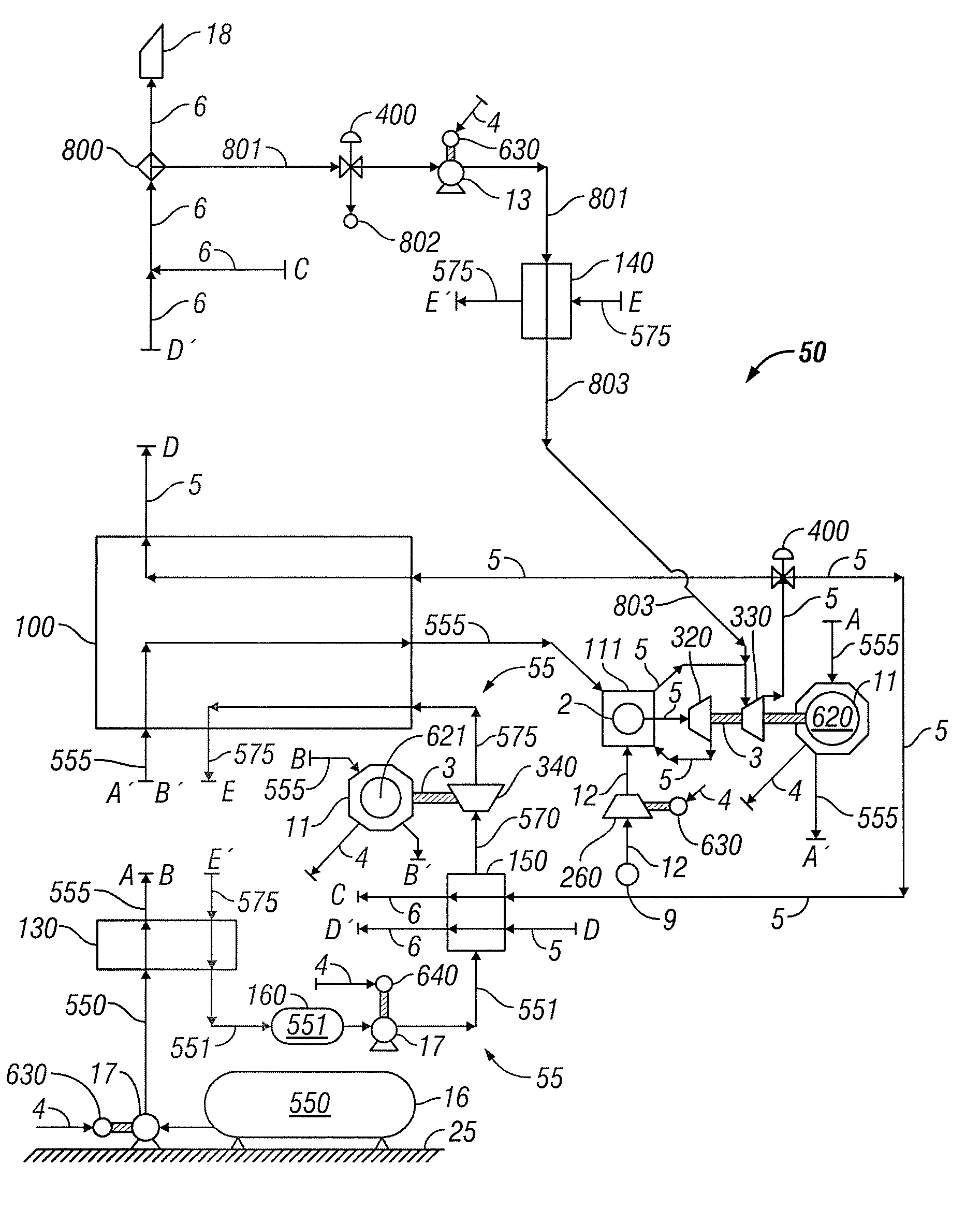

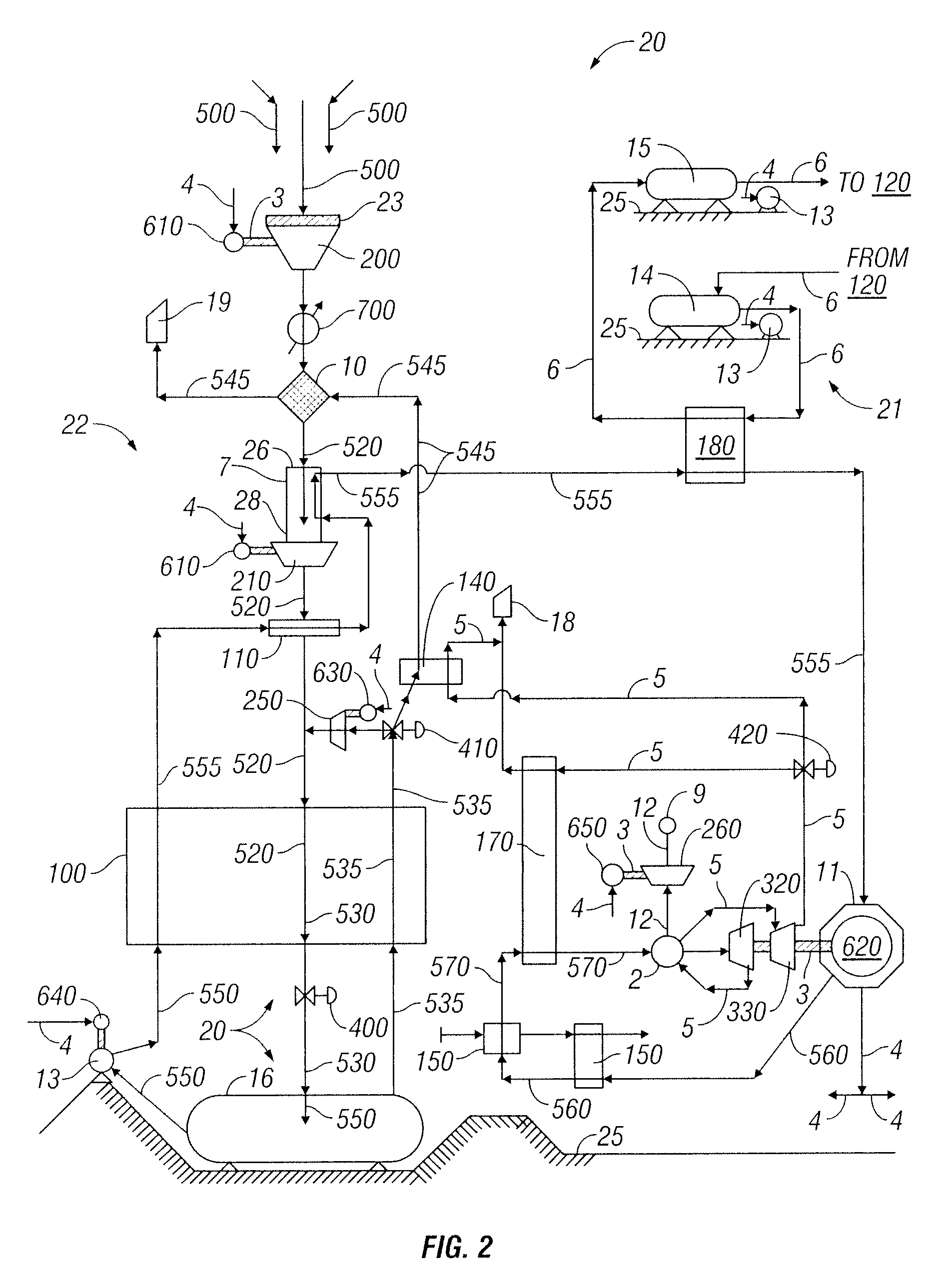

System and method for liquid air production power storage and power release

InactiveUS20090293502A1Reduce maintenance costsEliminate needSolidificationLiquefactionStored energyElectricity

Systems and methods for releasing and replacing stored energy comprise capturing inlet air from the ambient environment so the inlet air flows in a first general direction. Released liquid air flows in a second general direction, the second general direction being substantially opposite to the first general direction. The released liquid air is pumped to pressure, and the released liquid air and inlet air flow past each other such that heat exchange occurs. The inlet air warms the released liquid air such that the released liquid air is substantially vaporized, and the released liquid air cools the inlet air. Moisture and carbon dioxide are removed from the inlet air, and the inlet air is compressed and cooled such that the inlet air is substantially liquefied. The substantially liquefied air replaces a portion of the released liquid air; and the substantially vaporized released liquid air is combusted with fuel to produce electricity.

Owner:EXPANSION ENERGY

Multi-mode multi-propellant liquid rocket engine

InactiveUS6619031B1Cosmonautic vehiclesCosmonautic propulsion system apparatusCombustion chamberLiquid fluorine

A multi-mode multi-propellant rocket engine capable of operating in a plurality of selected modes.Propellant components may include liquid hydrogen, liquid hydrocarbon, liquid oxygen, liquid fluorine, and liquid air. The liquid oxygen and the liquid air are stored in separate tanks are mixed in a dedicated mixer prior to their injection into the combustion chamber.

Owner:MSE TECH APPL

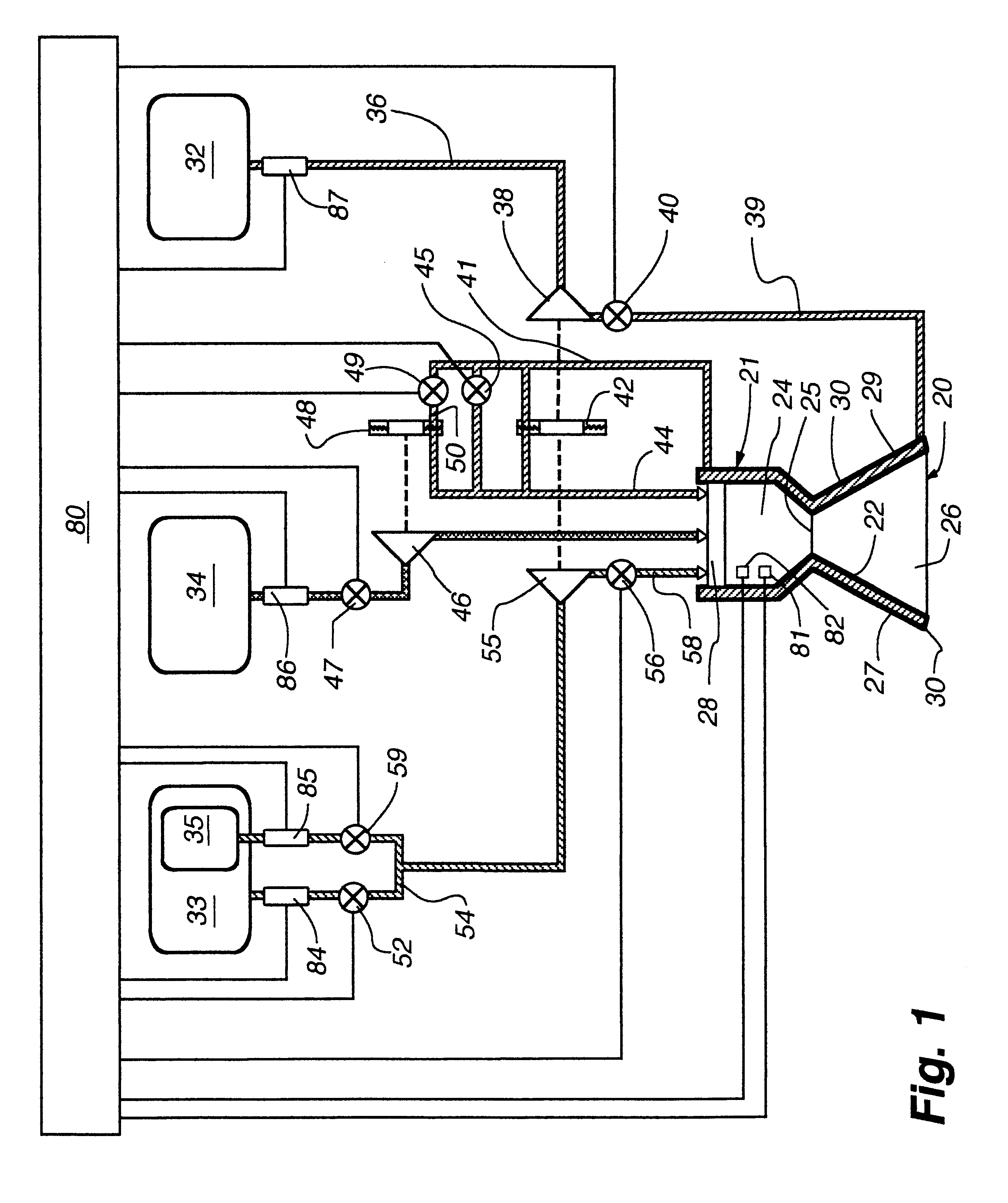

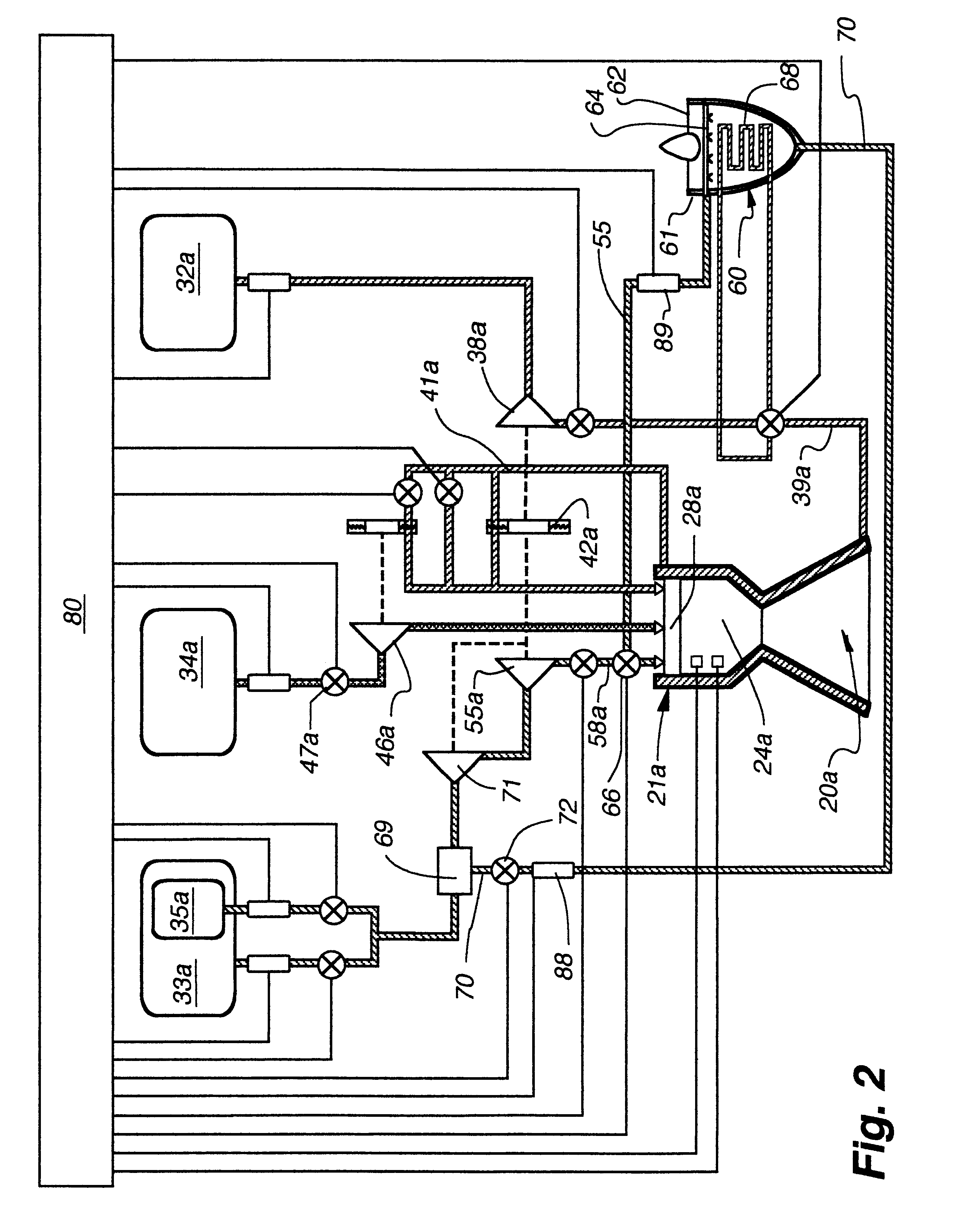

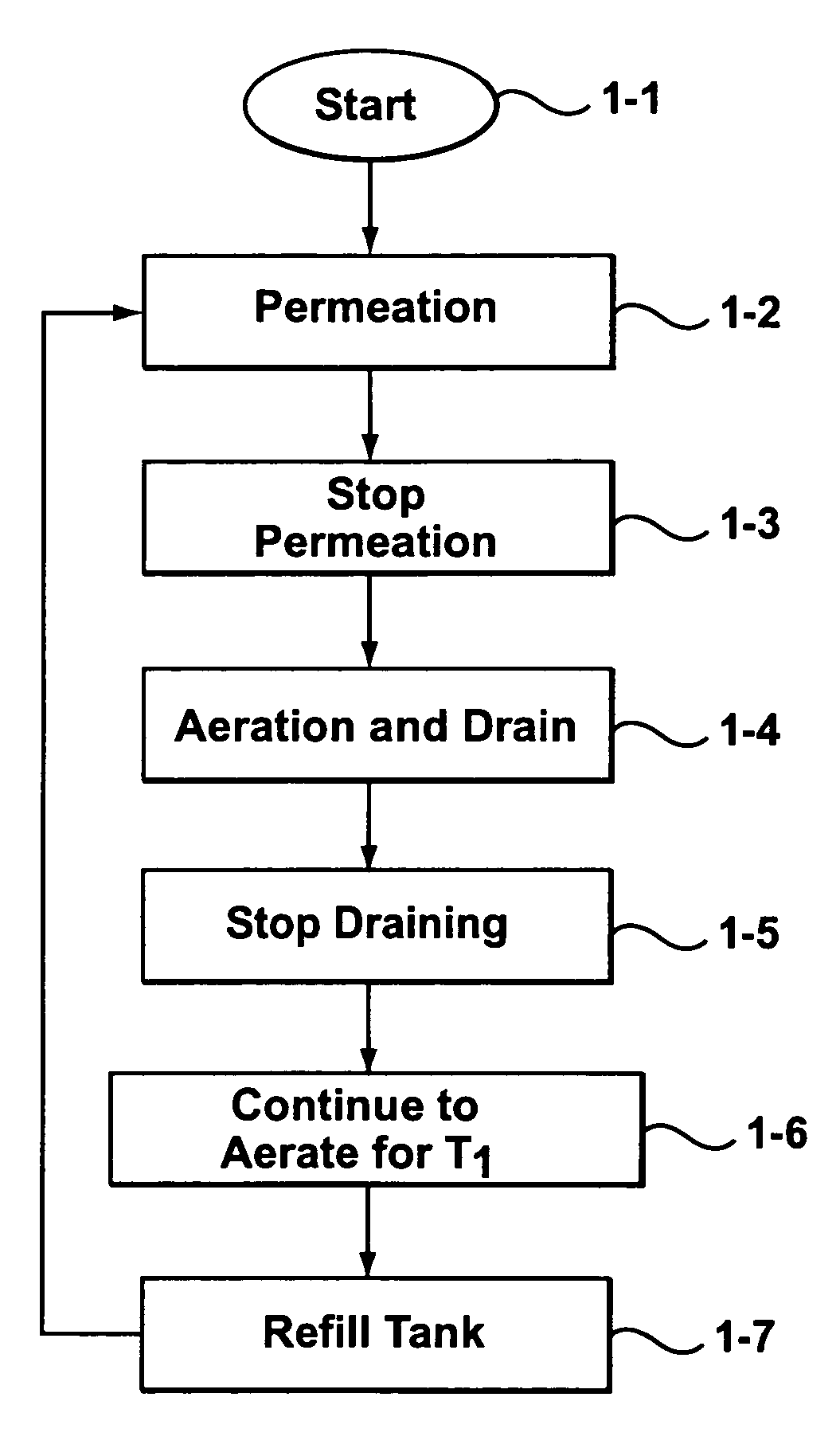

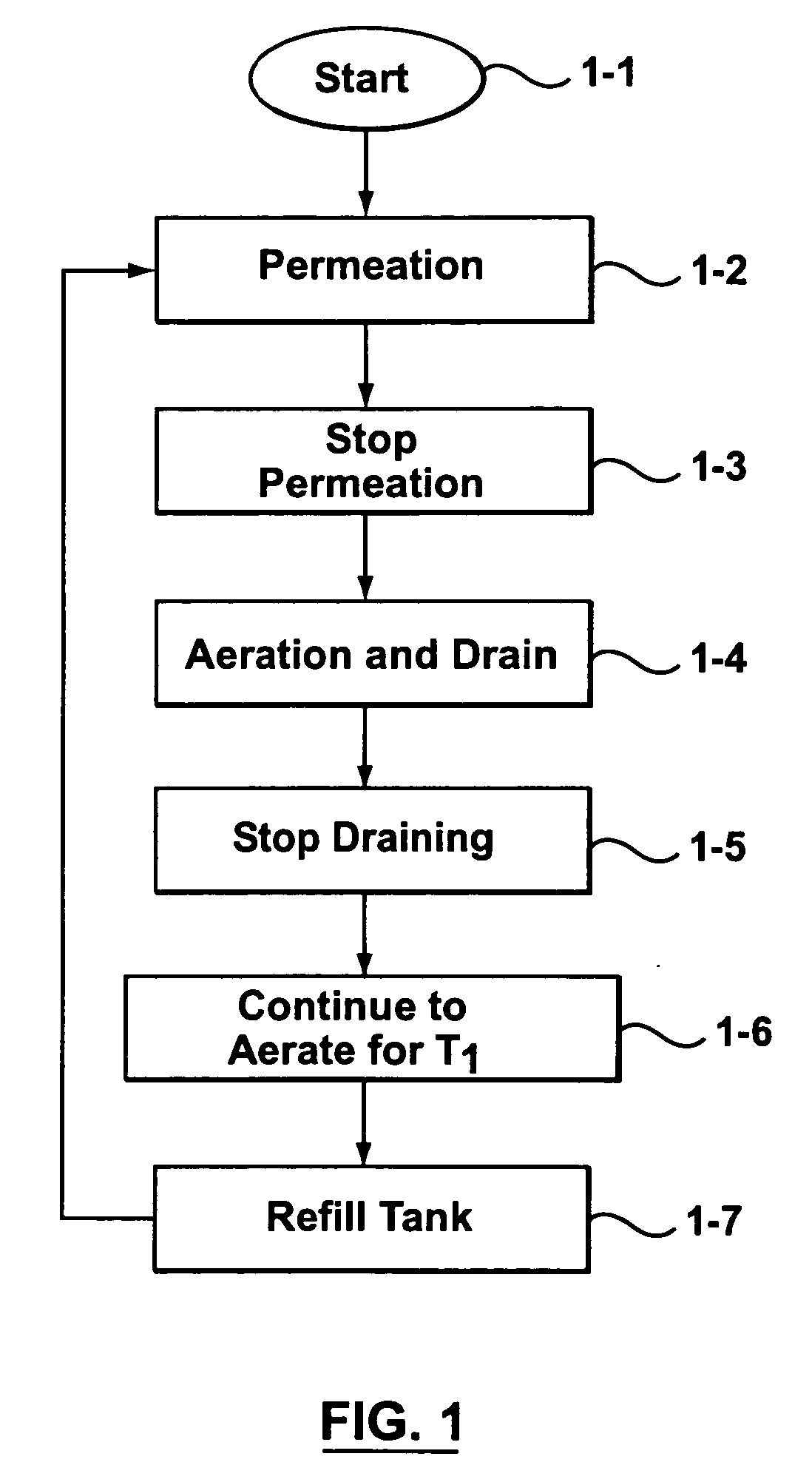

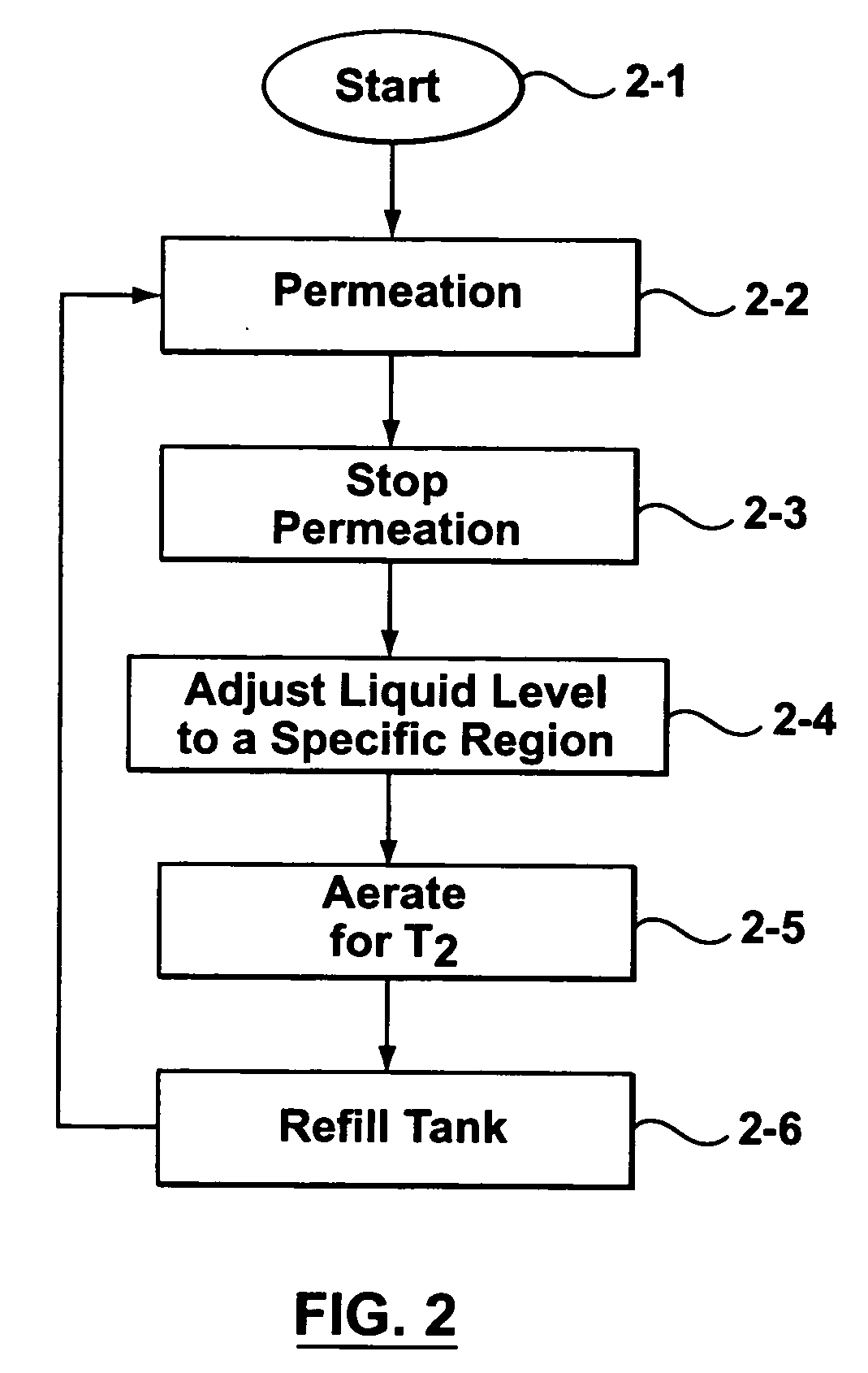

Membrane filter cleansing process

InactiveUS20060065596A1Reduce accumulationLower the liquid levelMembranesSemi-permeable membranesFiberHollow fibre membrane

Immersed hollow-fiber membrane filtration systems sometimes encounter process problems as a result of solids accumulation in and around the hollow fibers. The solids can accumulate to the point where they begin to dewater and form a mud like substance known as sludge. In some embodiments of the invention there is provided a process for substantially preventing the accumulation of sludge build-up on membrane fibers and / or cleansing membrane fibers that have been fouled by a substantial sludge build-up. Many of these embodiments involve aerating a membrane tank in which the membrane fibers are immersed after the water level has been reduced to near the level of solids accumulation. In some embodiments of the invention, the energy released by bursting bubbles at the liquid-air interface is employed to prevent fouling of membrane fibers and / or cleanse fouled membrane fibers.

Owner:ZENON TECH PARTNERSHIP

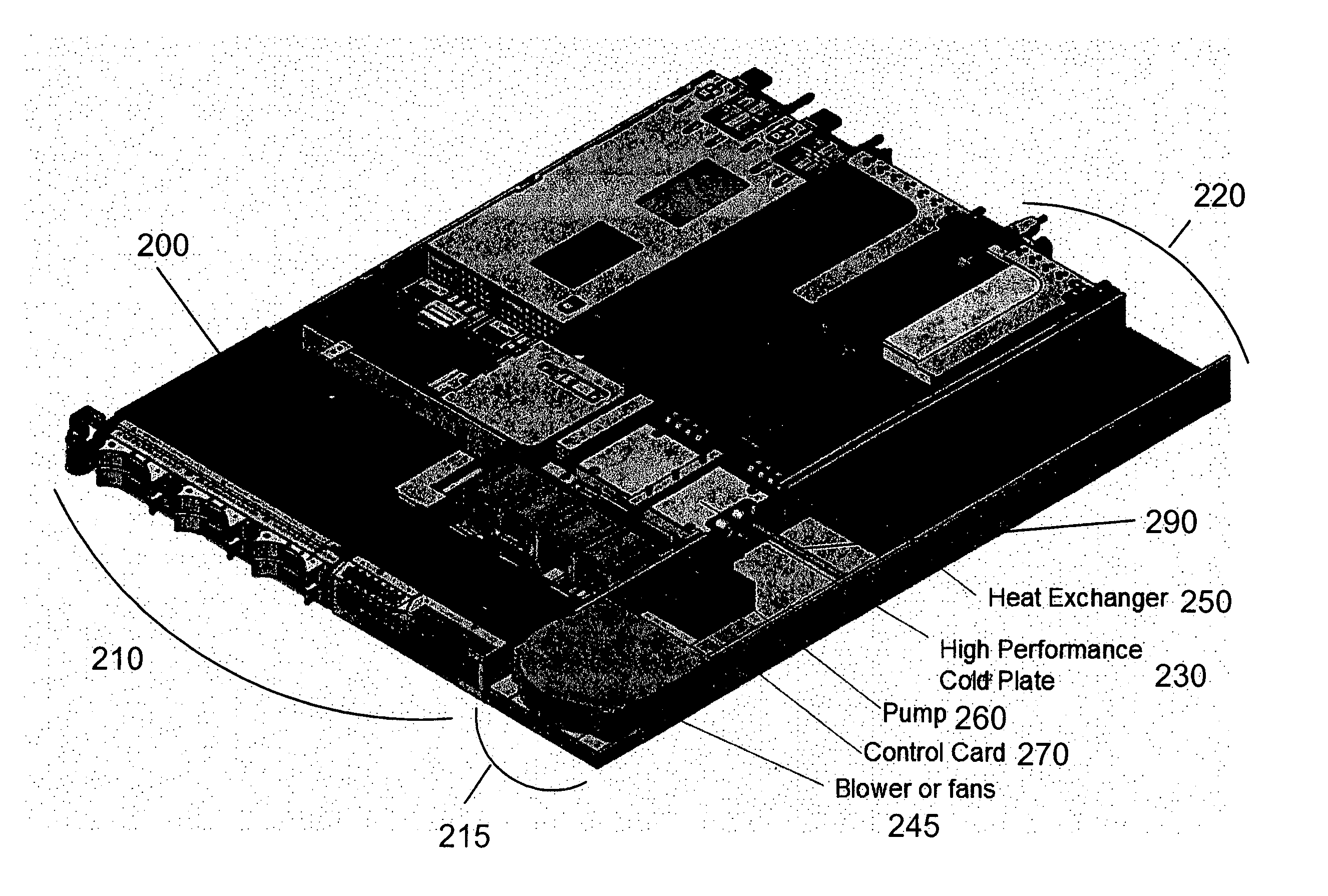

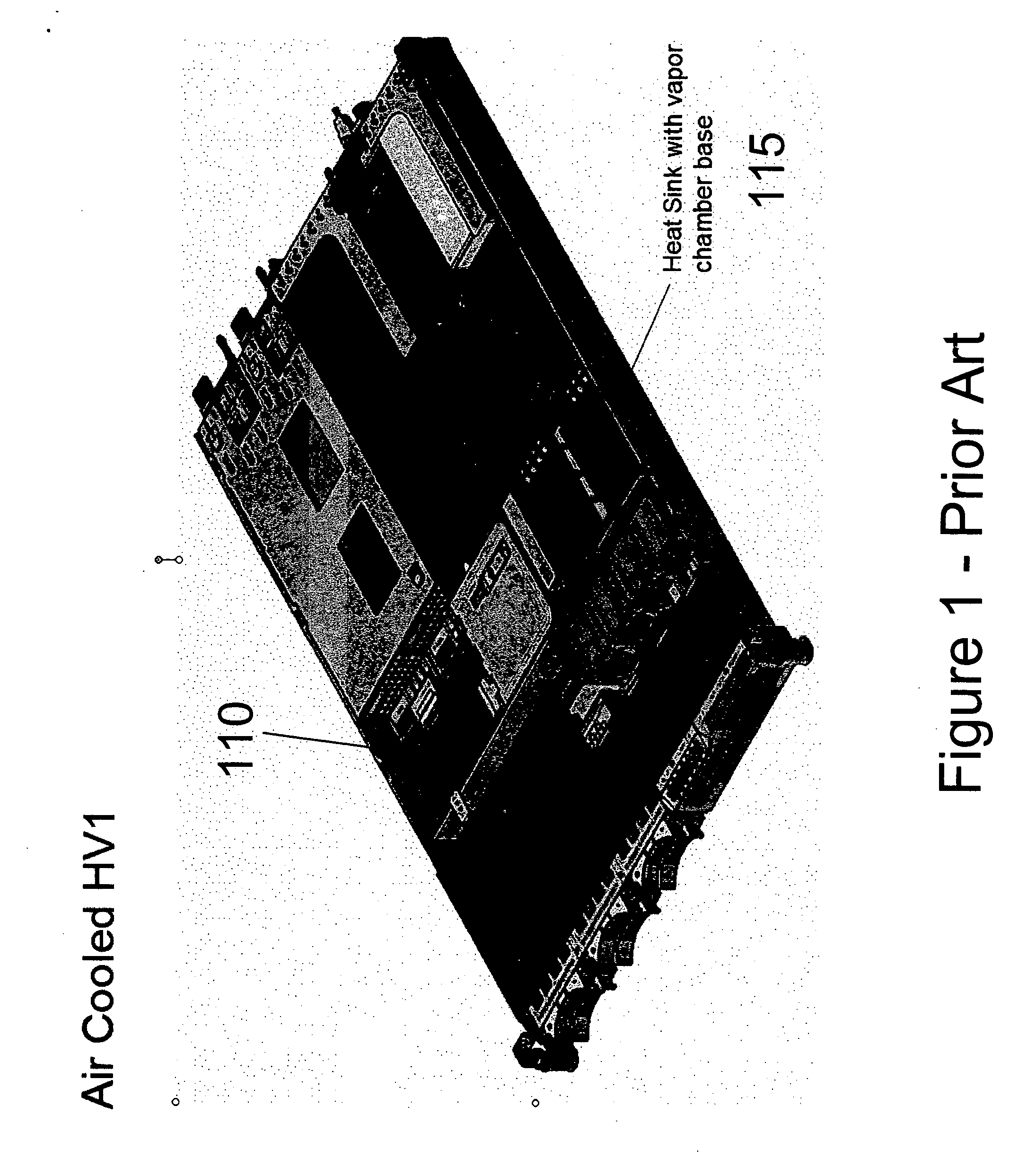

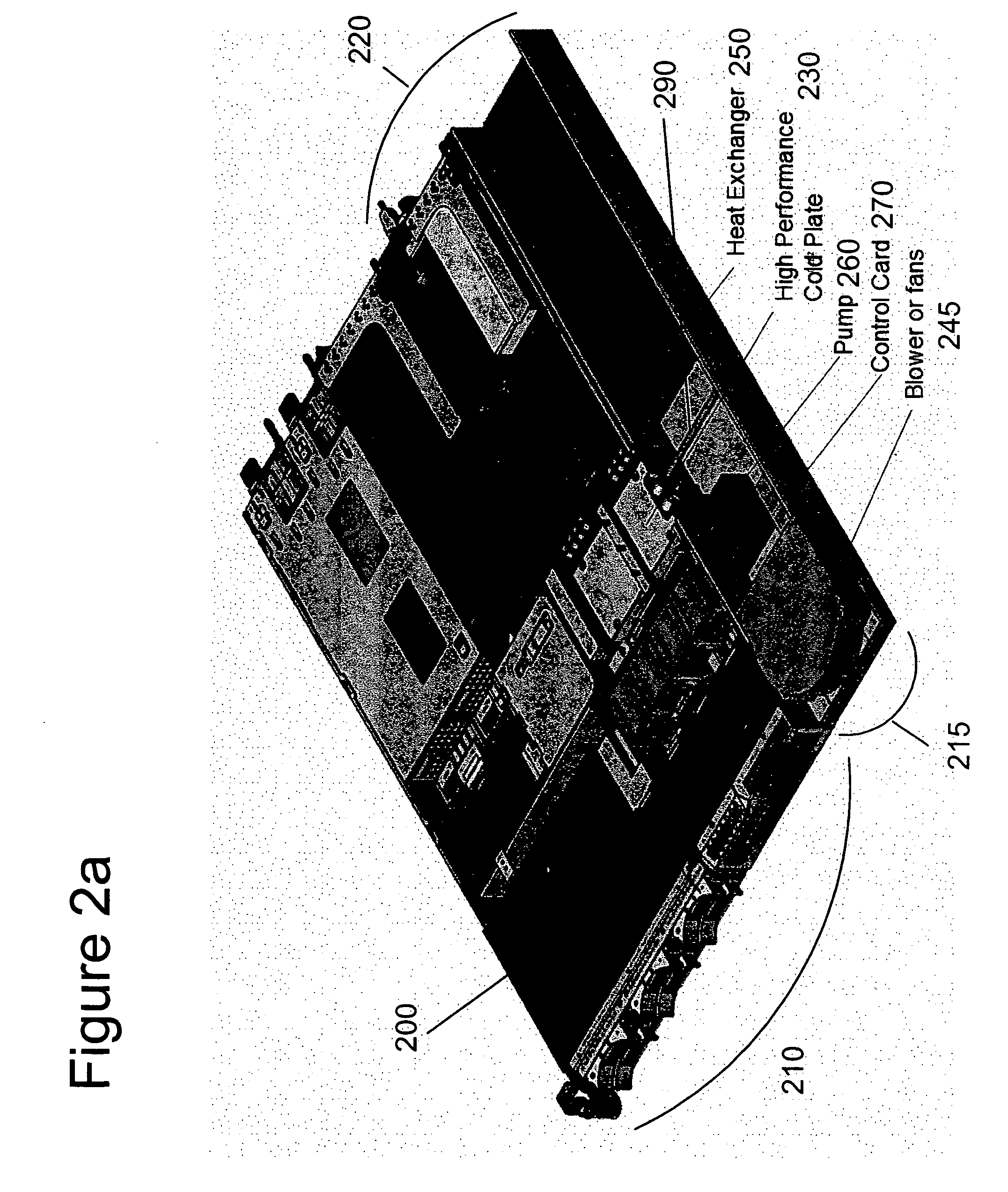

Hybrid liquid-air cooled module

InactiveUS20070121295A1Overcomes shortcomingEnhanced advantageDigital data processing detailsCooling/ventilation/heating modificationsNuclear engineeringClosed loop

A method and incorporated hybrid air and liquid cooled module for cooling electronic components of a computing system is disclosed. The module is used for cooling electronic components and comprise a closed loop liquid cooled assembly in thermal communication with an air cooled assembly, such that the air cooled assembly is at least partially included in the liquid cooled assembly.

Owner:IBM CORP +1

Ultra-supercritical air energy storage/release system

ActiveCN102758689AImprove efficiencyImprove energy storage efficiencyGas turbine plantsElectricityPower station

The invention discloses an ultra-supercritical air energy storage / release system, which is a novel large-scale energy storage system and relates to an energy storage technology, namely, air is compressed into an ultra-supercritical state by using off-peak electricity of a power station, heat is compression is stored simultaneously, air is cooled by using an expansion engine and simultaneously expansion work is recovered to improve the efficiency, and the ultra-supercritical air is cooled, liquefied and stored by using stored cold energy; and liquid air is pressurized and absorbs heat to reach an ultra-supercritical state at the power utilization peak and further absorb heat of compression for power generation by a turbo-generator. The ultra-supercritical air energy storage / release system disclosed by the invention has the advantages of high energy density, high efficiency, no limitation by energy storage cycle and geological conditions, suitability for various power stations, environmental friendliness, capability of recovering intermediate-temperature and low-temperature waste heat and the like.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

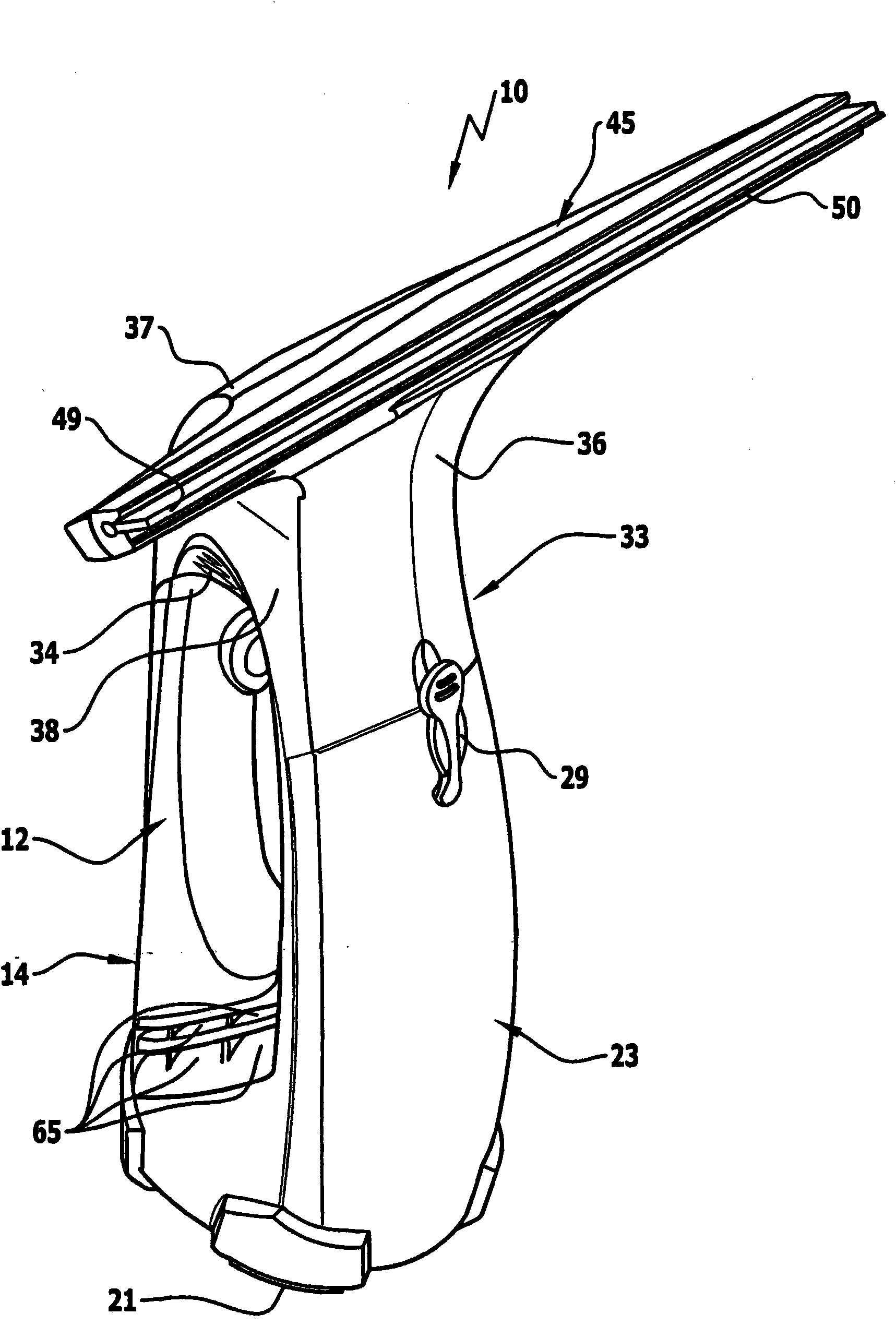

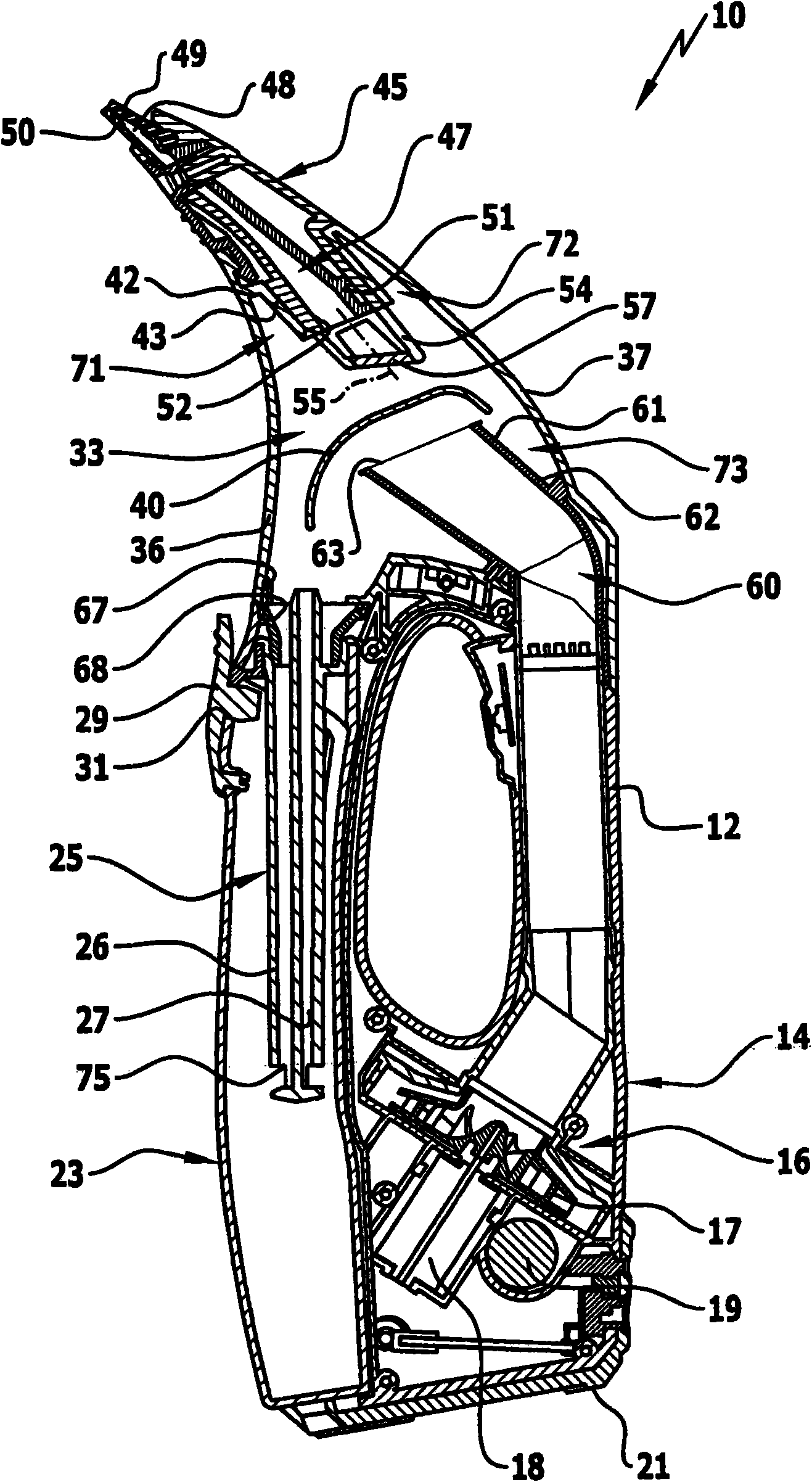

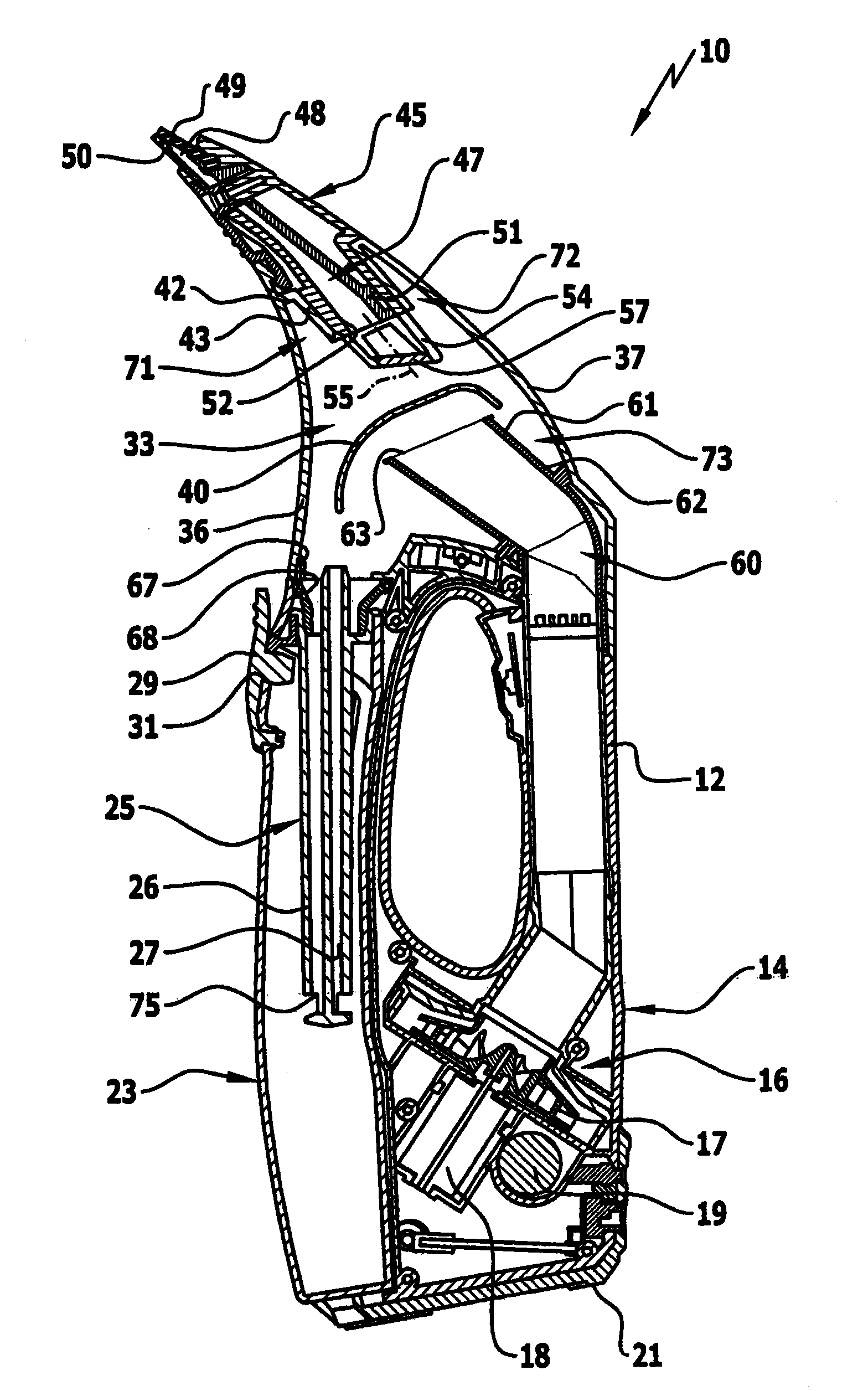

Portable hard surface vacuum

InactiveCN101909499AEasy to separateReduce flow lossCarpet cleanersFloor cleanersLiquid tankLow stress

The invention relates to a portable hard surface vacuum (10) comprising a suction nozzle (45) and a suction unit (16), which is in fluid connection with the suction nozzle, for vacuuming a liquid-air mixture from a hard surface, and comprising a separating device (40, 57) for separating liquid from the liquid-air mixture and comprising a waste liquid tank (23) for receiving the separated liquid. In order to refine the hard surface vacuum in such a way that a constant suction flow is provided, regardless of the fill level of the waste liquid tank, and such that operation in an arbitrary orientation in relation to the vertical position can be carried out, a separating chamber (33) is arranged between the suction nozzle and the suction unit, said chamber housing the separating unit and being in fluid connection via a suction line (47) to the suction port (48) of the suction nozzle and in fluid connection to the suction unit via a suction line (60), and said chamber being connected via an outlet opening (67) to the waste liquid tank, wherein the port regions (51, 61) of the suction (47) and vacuum line within the separating chamber are surrounded at least partially by intermediate storage regions (71, 72, 73) for separated liquid in the circumferential direction.

Owner:ALFRED KARCHER GMBH & CO KG

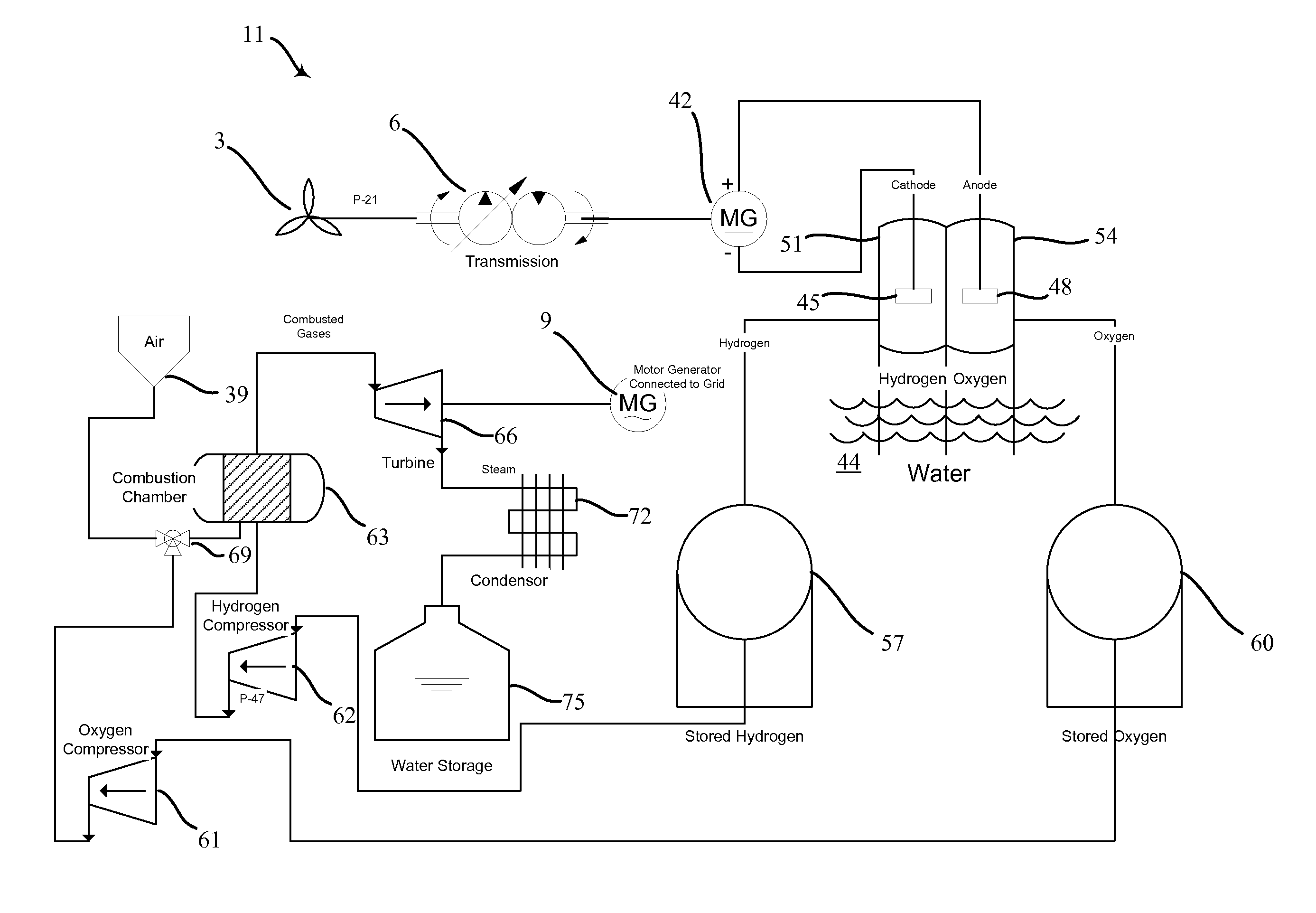

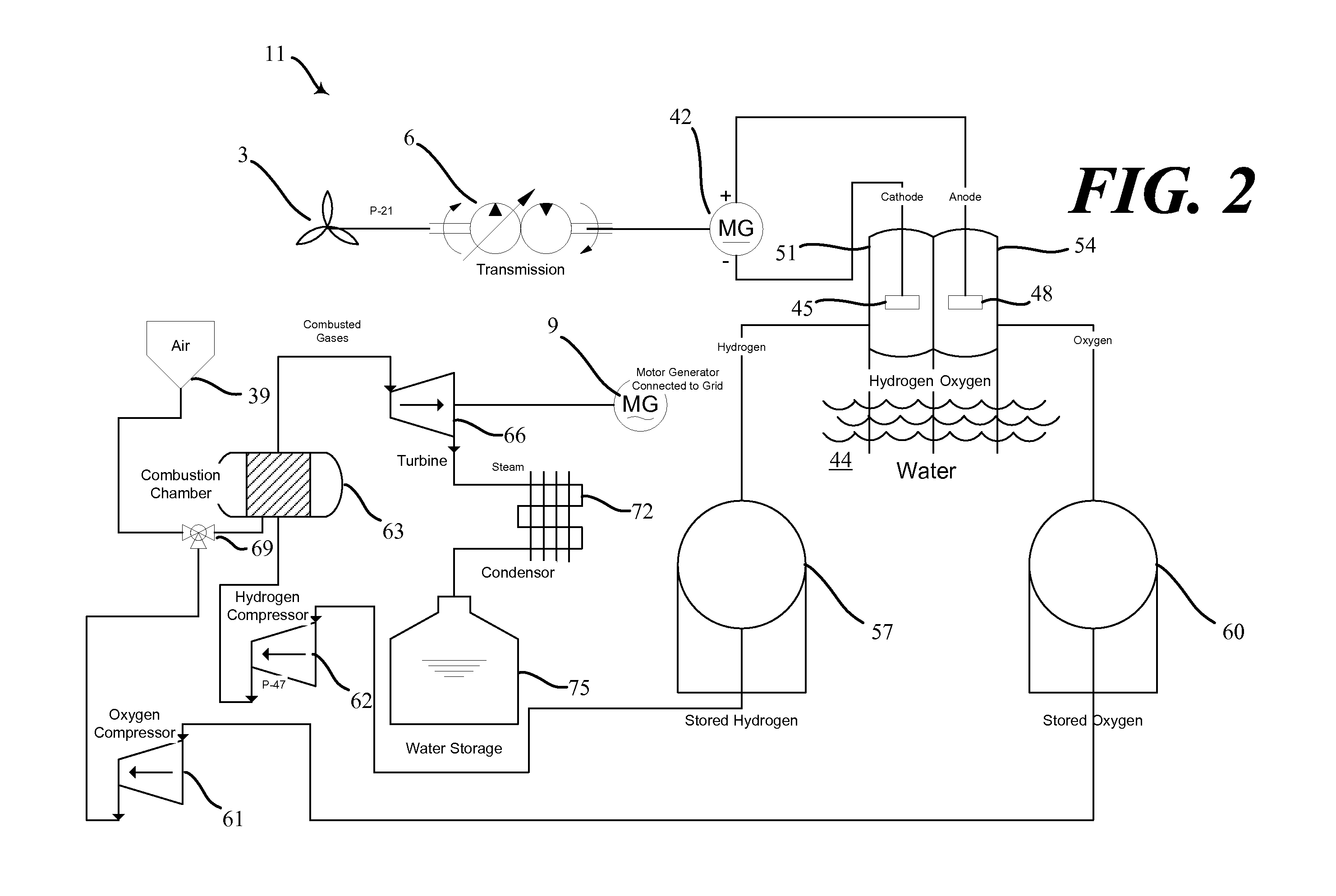

Managed storage and use of generated energy

InactiveUS20080163618A1Wind motor with solar radiationSteam generation heating methodsElectrolysisEngineering

An apparatus for driving a turbine connected to a generator for generating power to supply to a grid the power derived from a rotating shaft includes a transmission for selectably driving either of a compressor or a direct current motor generator. The compressor compresses ambient air changing phase to liquid air. The direct current motor generator generates a current at a constant voltage for water electrolysis. A first bell containing a cathode collects elemental hydrogen; a second bell containing an anode collects elemental oxygen. The elemental hydrogen burns in the presence of the elemental oxygen to produce a highly energetic exhaust. A valve selectably admits either of the highly compressed air or the highly energetic exhaust into the turbine to drive the turbine thereby energizing the generator to supply the grid.

Owner:PAUL MARIUS ANGELO

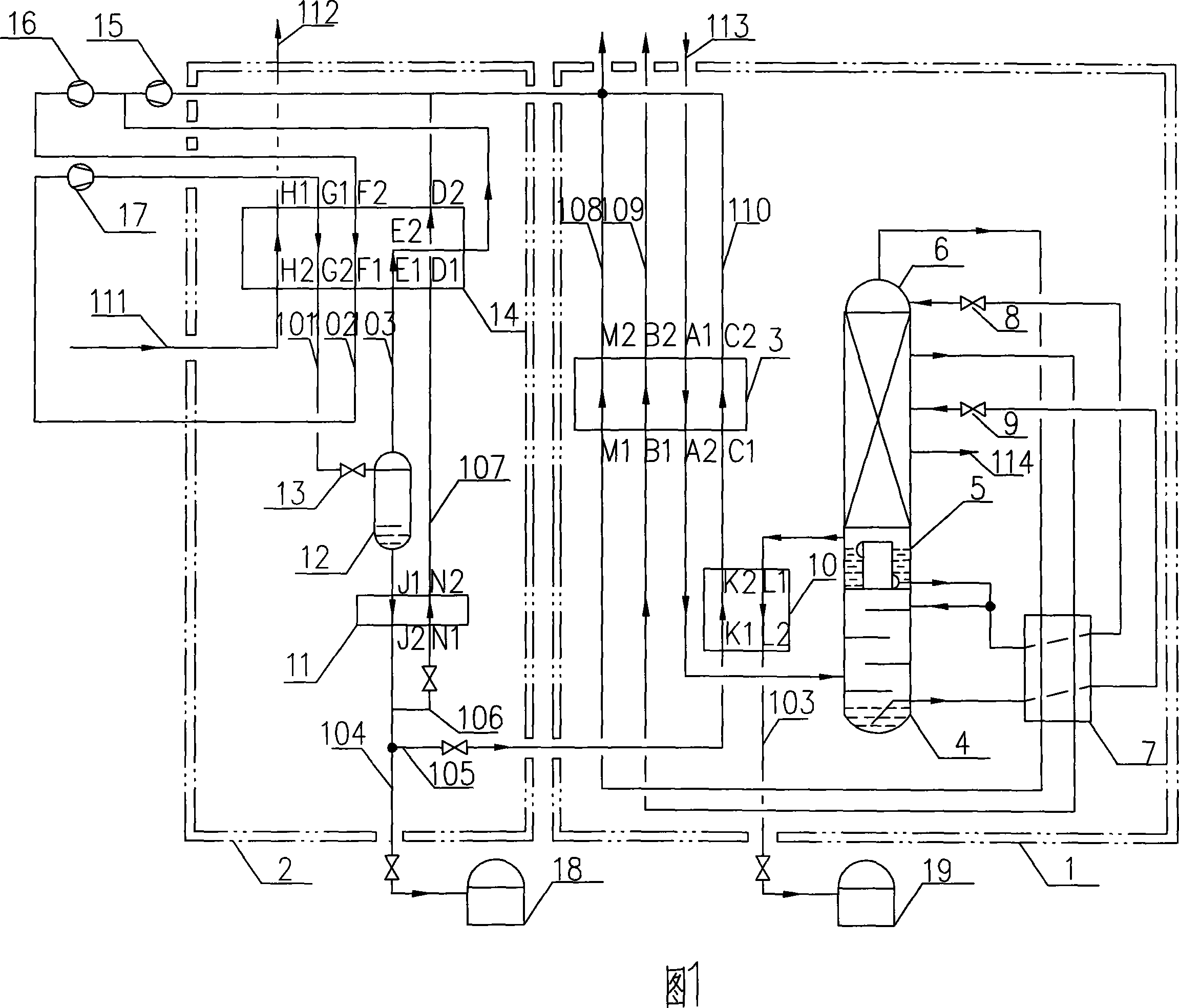

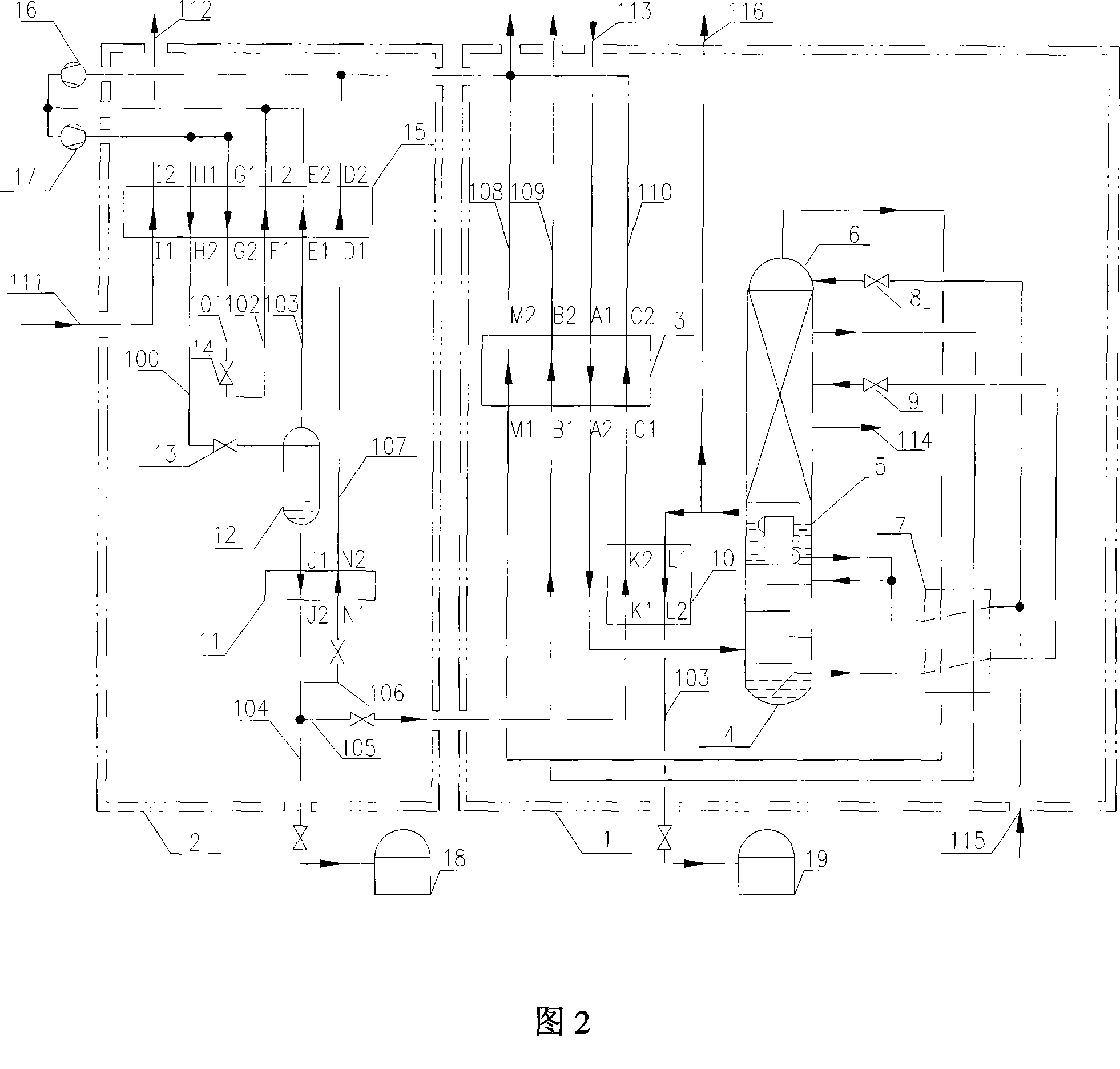

Liquefied compressed air energy storage system with cold-storage liquid media

ActiveCN105043147AHigh energy storage densityLow costHeat storage plantsMachines/enginesLiquid mediumThermal energy storage

The invention relates to a liquefied compressed air energy storage system with cold-storage liquid media. The liquefied compressed air energy storage system comprises compressor systems, a cold storage system, a heat storage system, a liquefying system and a turbine power generation system. During energy storage, the multistage compressor system is driven by renewable energy sources, so that compressed air is supercharged to exchange heat with a room-temperature cold-storage liquid medium, the cold quantity stored in the liquid medium is lowered to liquefying temperature, and the compressed air is liquefied through throttling; during energy releasing, the liquid air is supercharged to exchange heat with a high-temperature cold-storage liquid medium, the medium recycles cold energy to give to the liquefying process, and the air is warmed to be vaporized; room-temperature high-pressure air is input into a multi-stage turbine expander for acting, and a power generator is driven to output electric energy; the heat storage system reduces the power consumption of the next stage of compressor, and the stored heat is heated step by step before expansion to raise the intake air temperature; a cold-storage medium with a low freezing point and a high / low boiling point recycles the cold energy of the liquid air, the specific heat capacity of the liquid media is large, and the large-temperature-span heat exchange is realized. The liquefied compressed air energy storage system has the advantages of being simple in structure and stable in performance, can realize integration of energy storage and power generation, and can realize the large-scale grid-connection of renewable energy generation, therefore improving the capacity of a power grid accepting new energy power generation.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

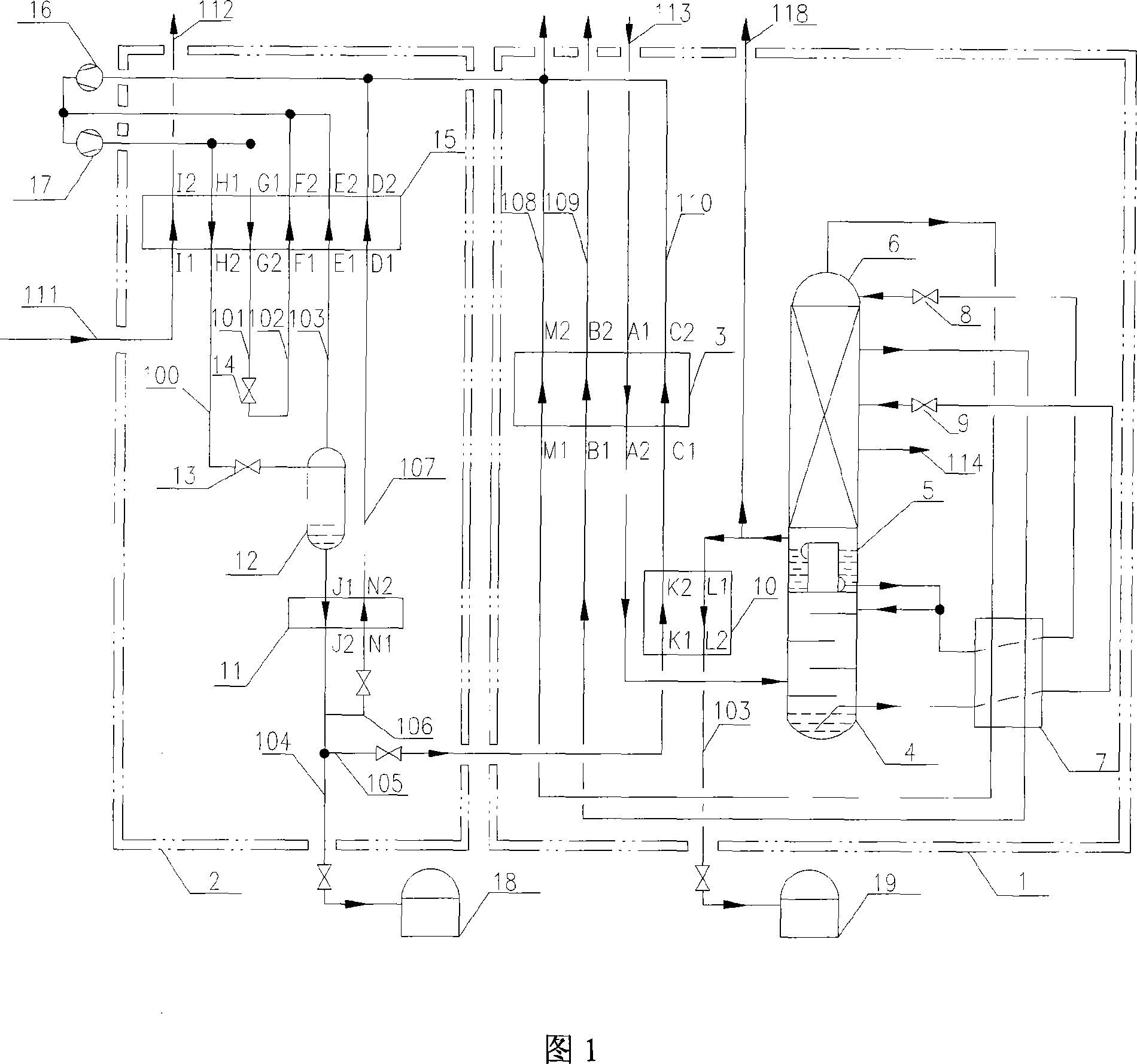

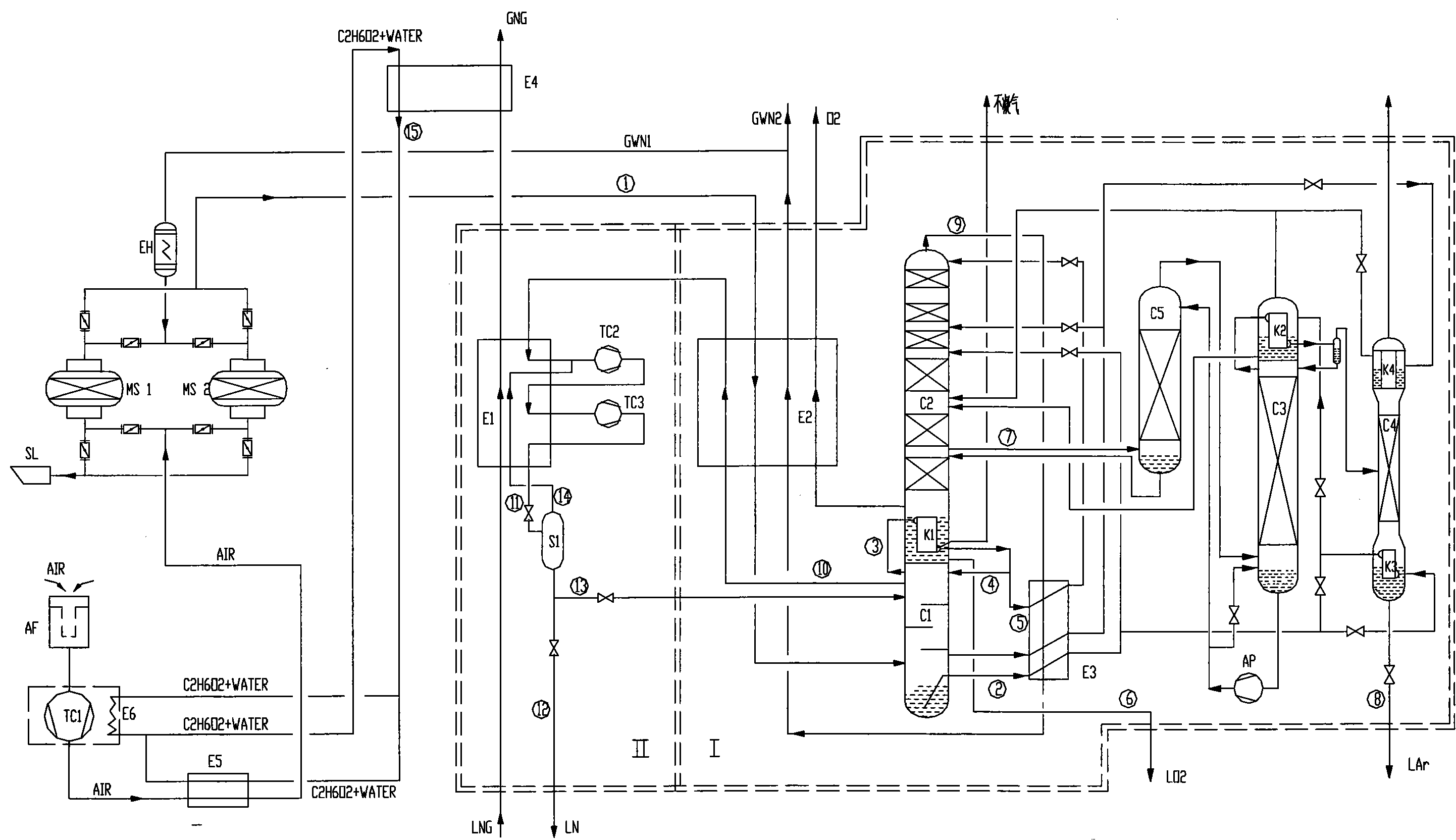

Air separation system for generating liquid oxygen and liquid nitrogen

This kind of air separation system obtaining liquid oxygen and liquid nitrogen at least includes an air separator mainly consisting of a fractionating tower and at least includes an equipment for recovering cold energy of liquefied natural gas mainly consisting of an liquefied natural gas heat exchanger, which still includes main heat exchanger, liquid-oxygen heat exchanger and liquid-nitrogen liquid air subcooler; oxygen is drawn out from the underpart of the upper column on the fractionating tower, and cools and liquefied in the liquid-oxygen heat exchanger as the liquid oxygen products; after nitrogen from the top of the upper column passes through a liquid-nitrogen liquid air subcooler and is reheated by main heat exchanger, some nitrogen enters into liquefied-natural-gas heat exchanger to recool and exchange heat to become high pressure nitrogen through primary compression and pressurization at least. And through throttling expansion and air-liquid separator, nitrogen and liquid nitrogen participate in recycling and other nitrogen as liquid-nitrogen products; energy consumption is reduced notably after using actually, power consumption which produces liquid oxygen of 1kg is 0.39kwh, while the power consumption of the traditional equal air separator is 1.0 to 1.25kwh, which is 2.4 to 3 times than the separator. And it is easy to popularize and apply.

Owner:HANGZHOU HANGYANG

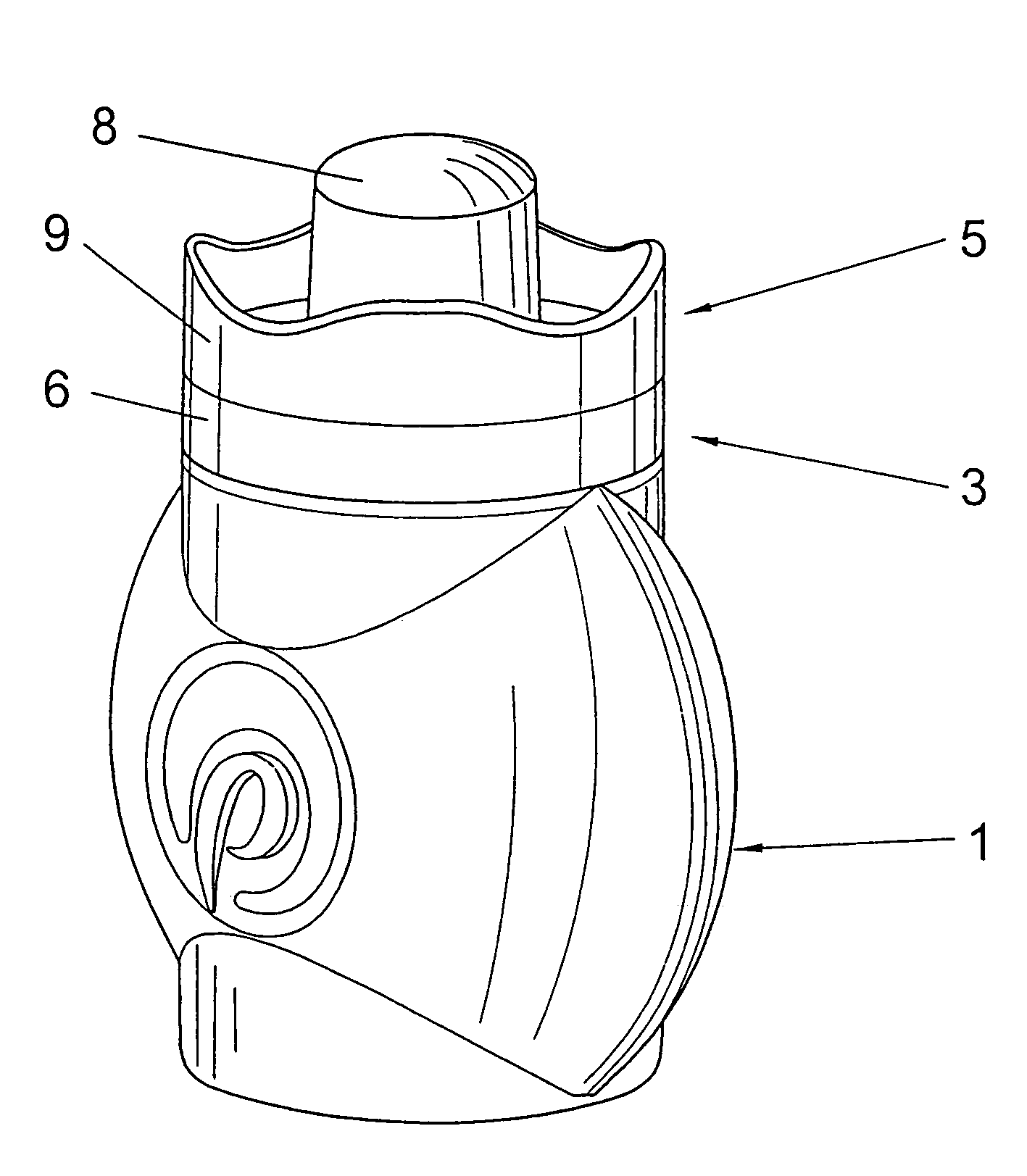

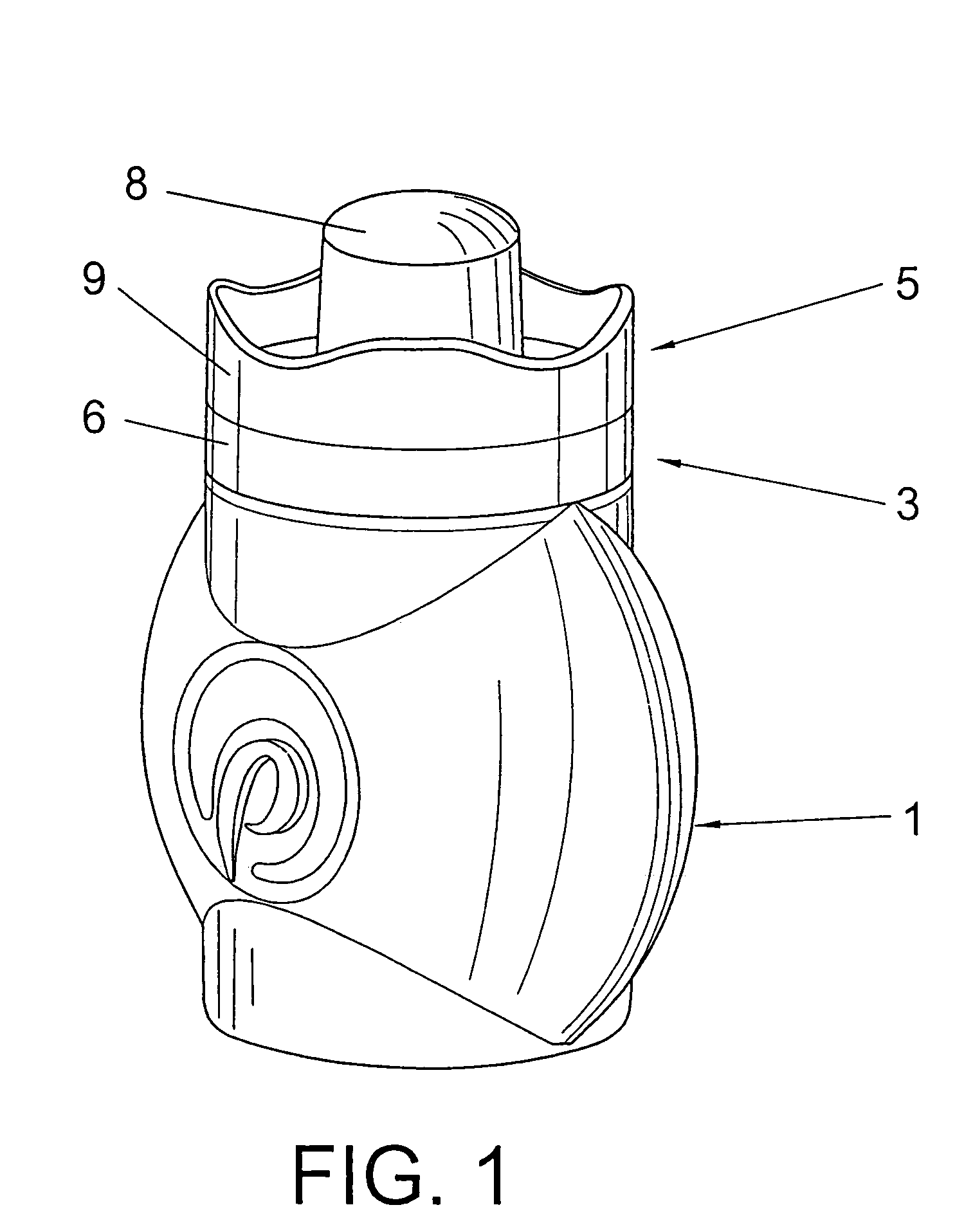

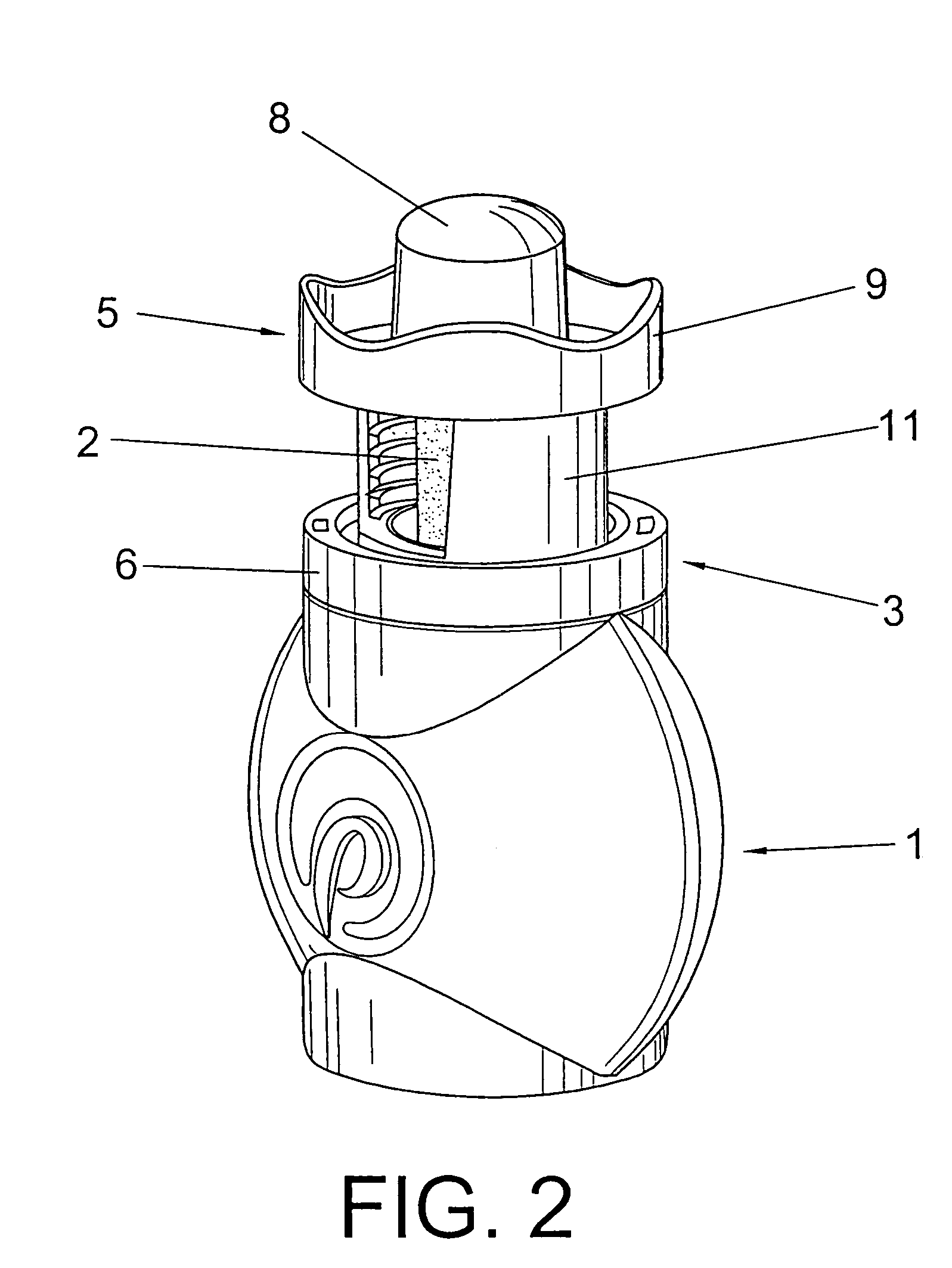

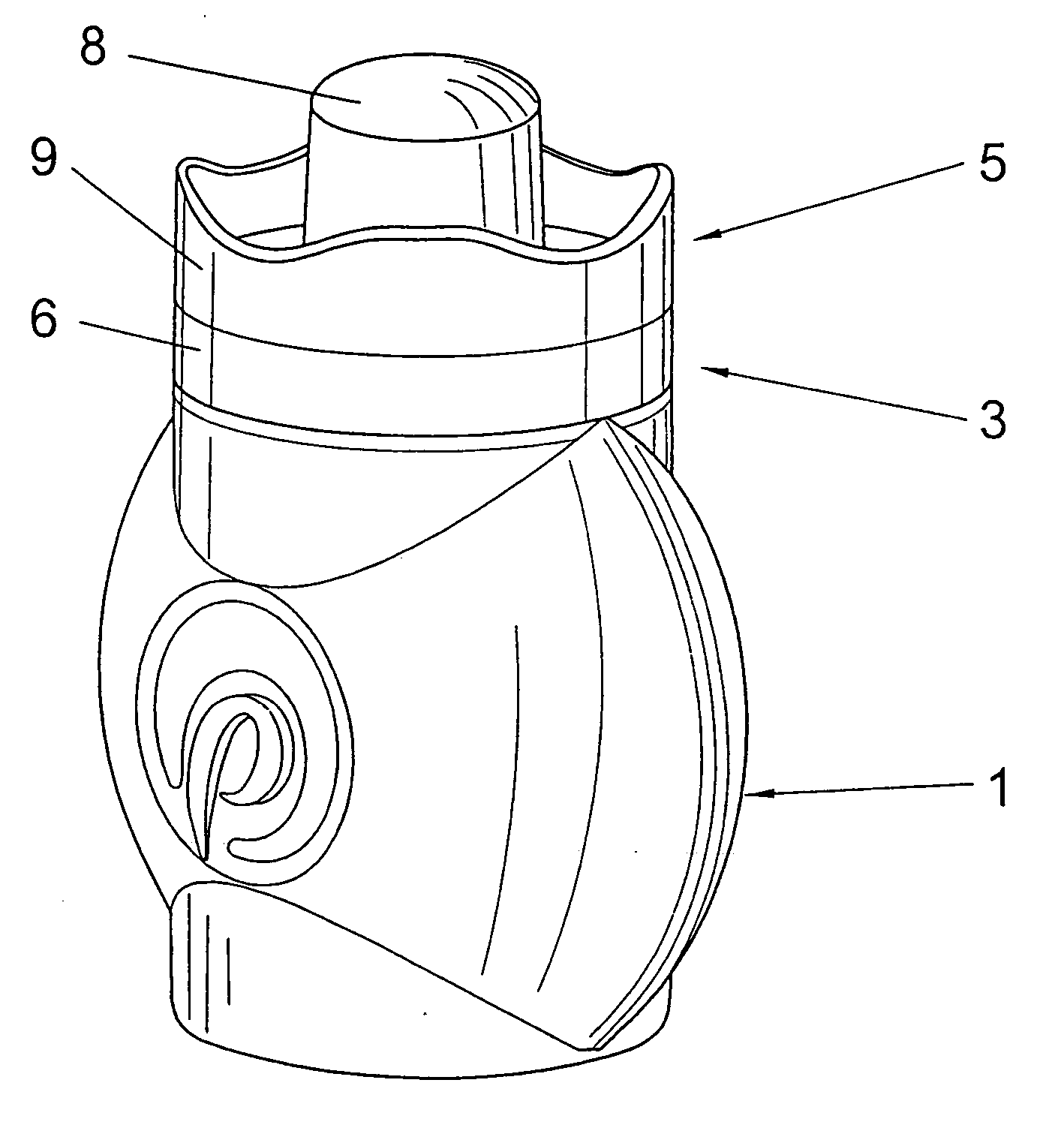

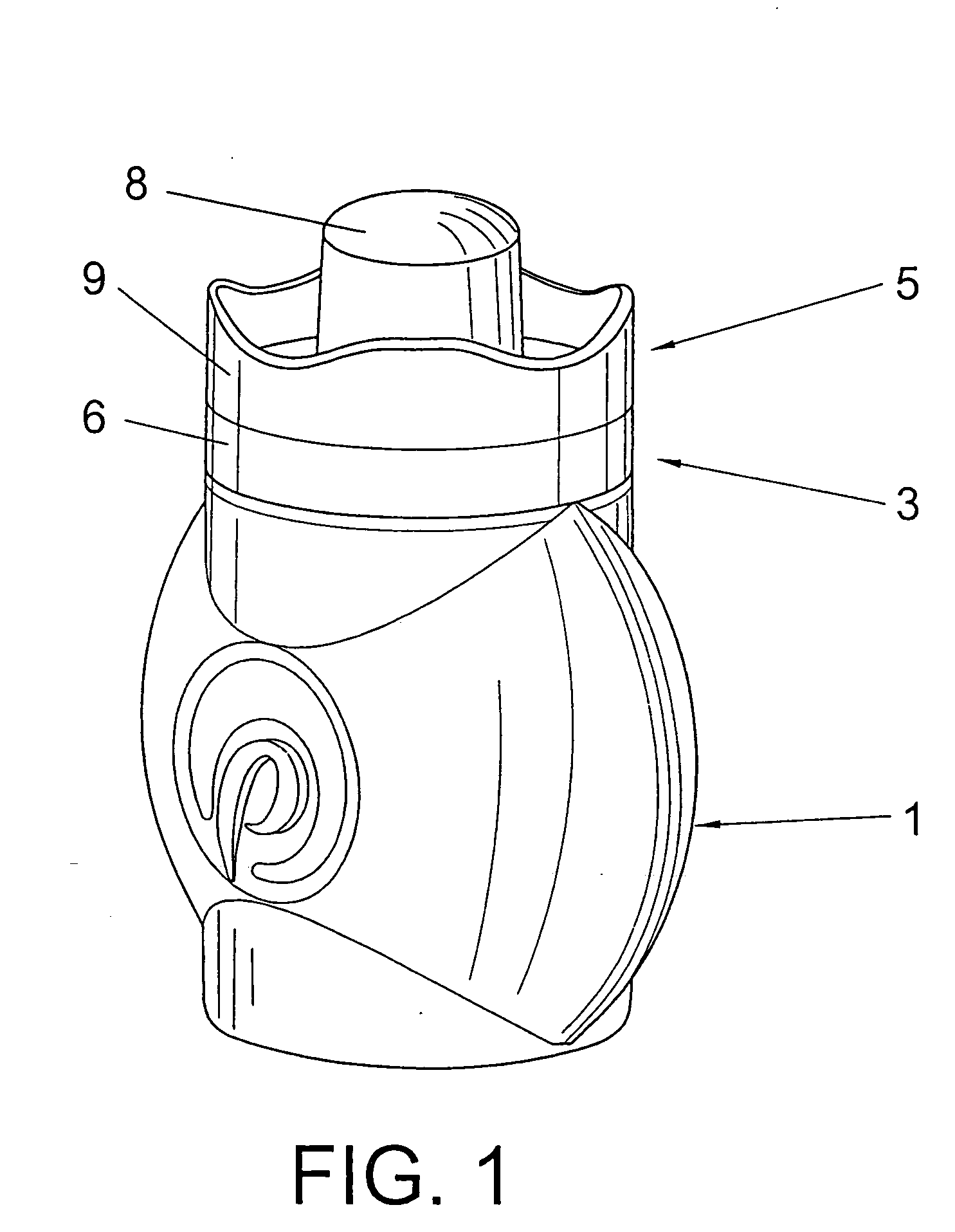

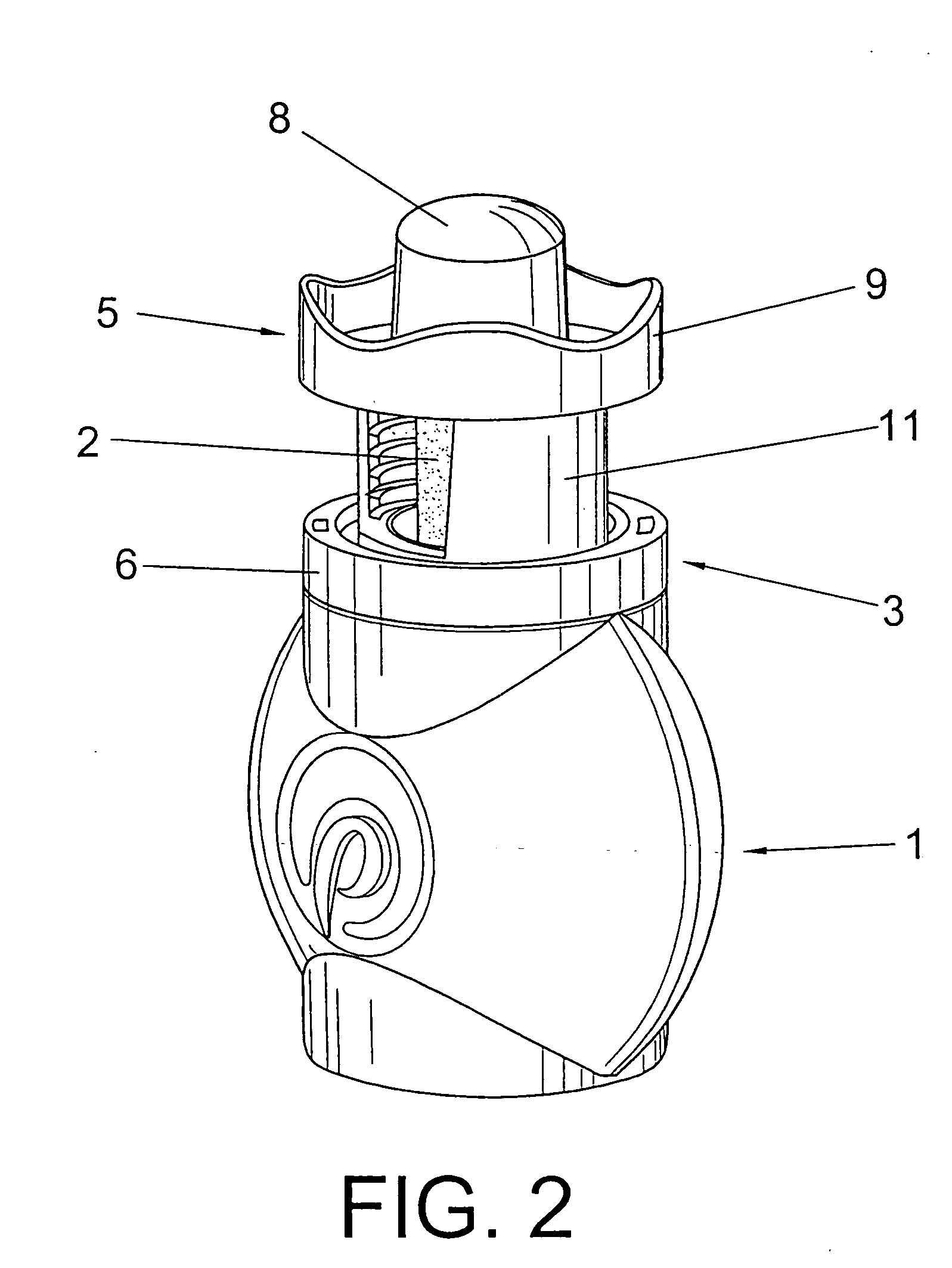

Adjustable non-electric liquid air freshener device

InactiveUS7243859B2Avoid separationPrevent extractionTobacco devicesGaseous substancesEvaporationBiomedical engineering

Comprises a vessel (1) containing scented liquid, a wick (2) partially submerged in the liquid, a stopper (3) coupled on the mouth (7) of the vessel (1) and a cap (5) that covers the stopper (3) and has a lower tubular portion (11) provided with two windows (15) and an inner threaded segment that unscrews from a central threaded tubular portion (13) of the stopper (3) as the cap (5) is turned, raising it and gradually revealing the windows (15) so that the wick (2) is exposed to the exterior, facilitating the adjustable evaporation of the scented liquid, the cap (5) being provided with flexible stops (16) that are prolonged externally from the base of its lower tubular portion (11) and as they rise meet a trapezoidal inner peripheral flange (17) defined in a cylindrical body (14) of the stopper (3) to prevent the exit of the cap (5).

Owner:ZOBELE ESPANA

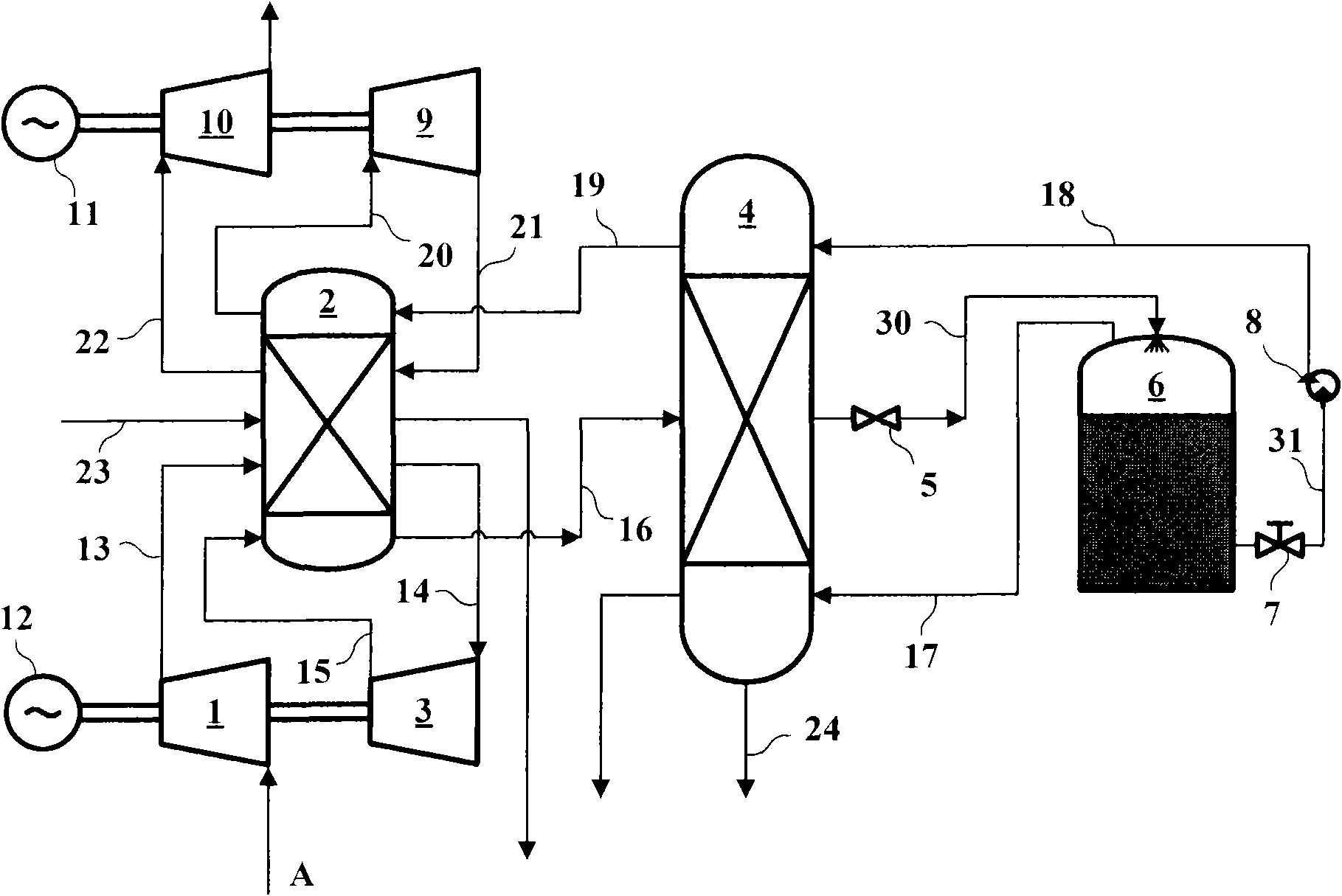

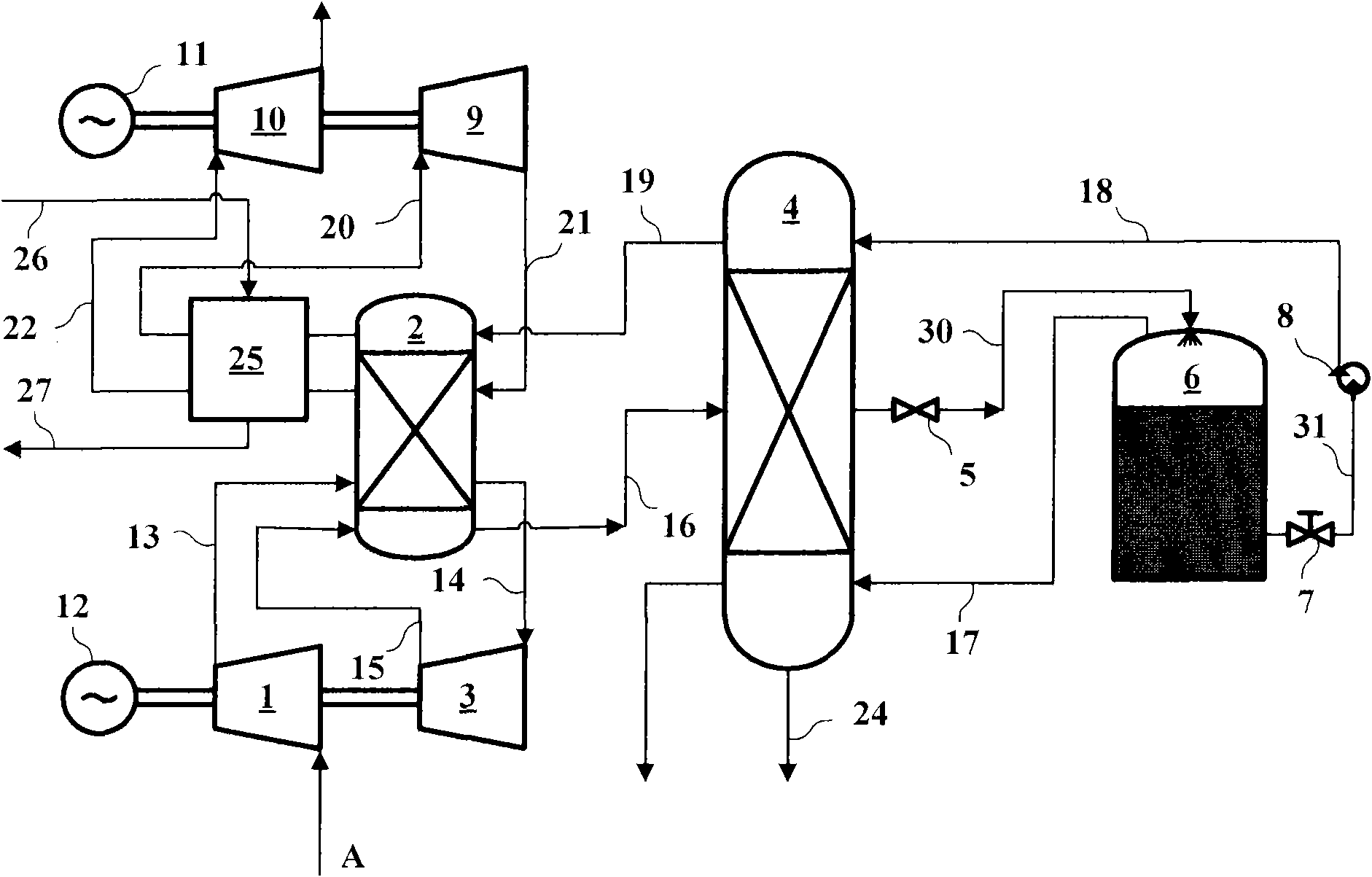

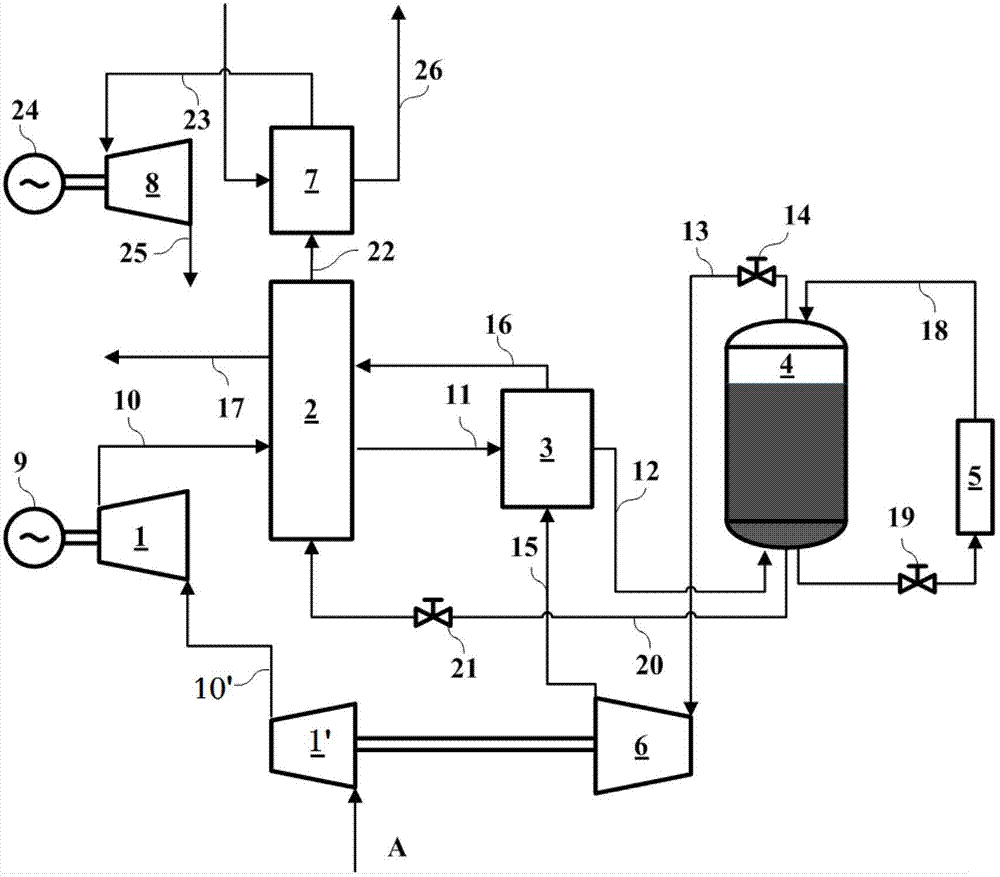

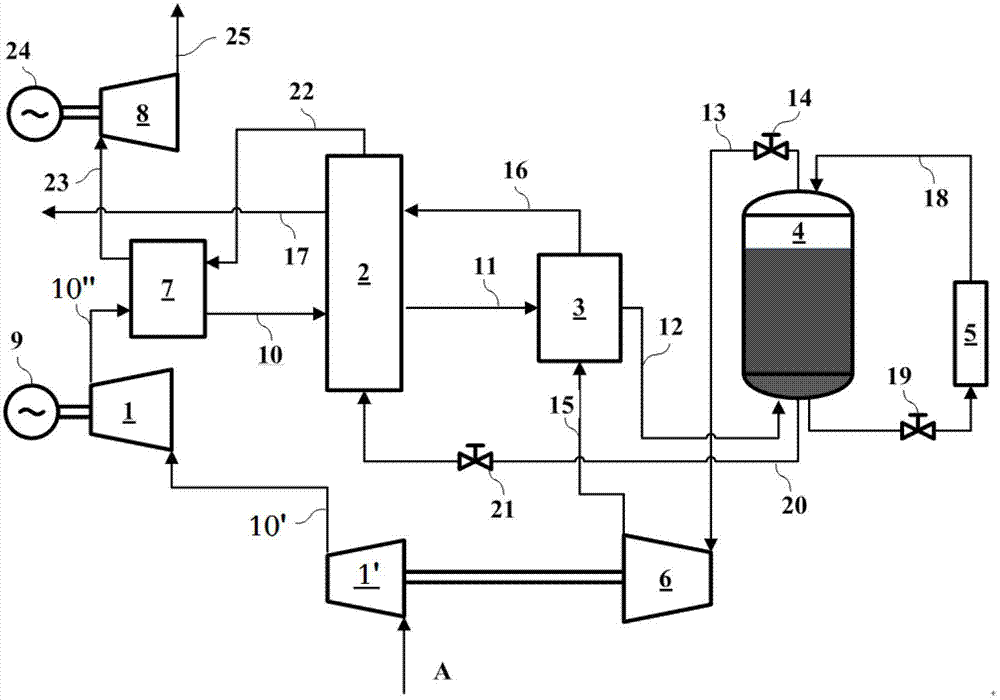

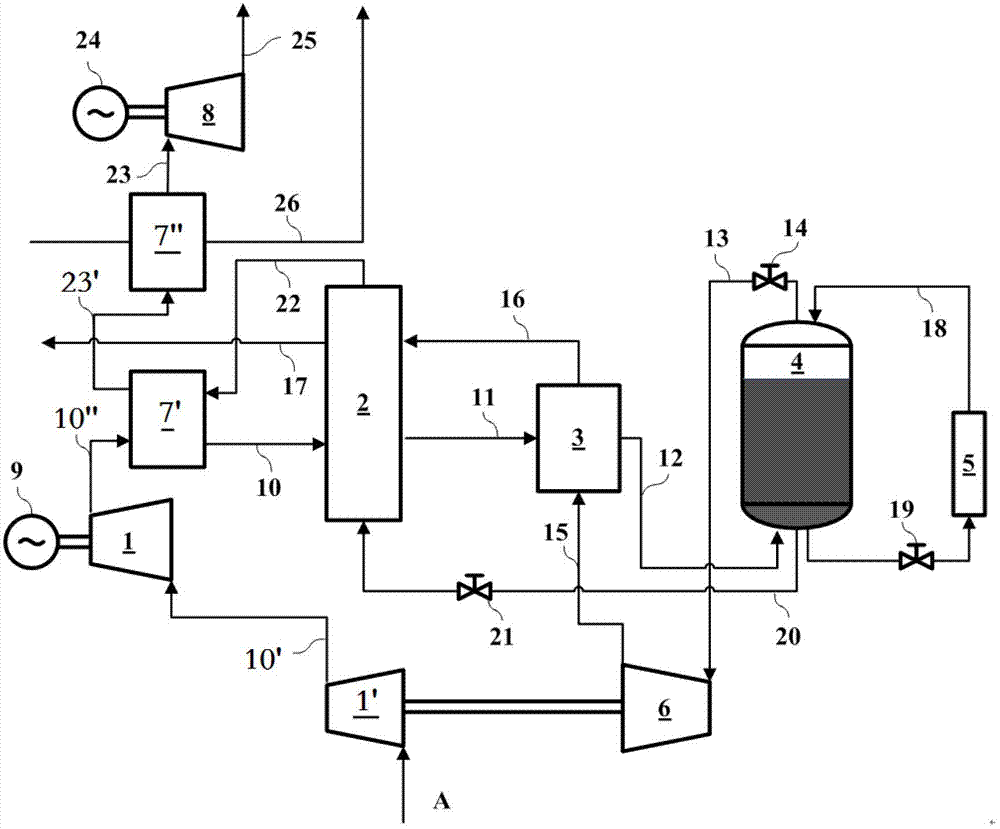

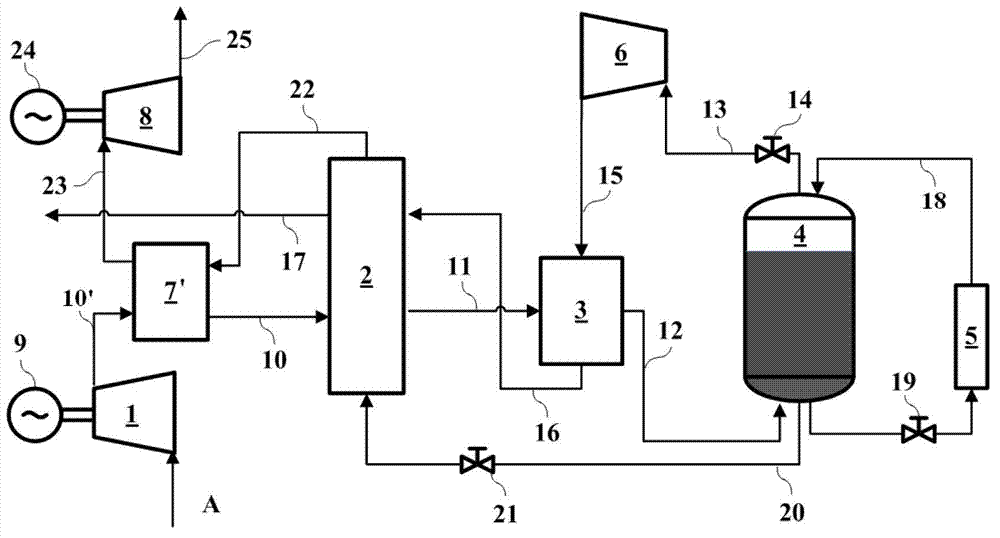

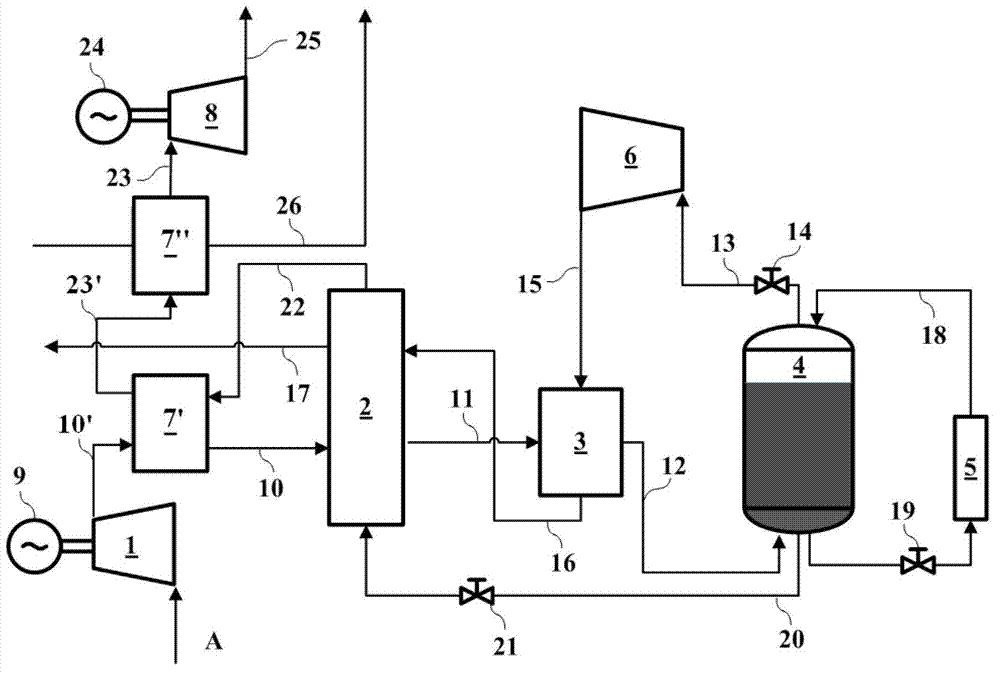

Efficient high-pressure liquid air energy storage/release system

ActiveCN102758690AIncrease energy densityImprove efficiencyGas turbine plantsPower stationHigh energy

The invention discloses an efficient high-pressure liquid air energy storage / release system, which comprises an energy storage subsystem and an energy release subsystem; in the energy storage subsystem, a low-pressure compressor set (1'), a high-pressure compressor set (1), a cold accumulator (2), a low-temperature heat exchanger (3), a high-pressure low-temperature storage tank (4), a low-temperature expansion machine set (6) and a low-temperature heat exchanger (3) are communicated in sequence; a driving unit (9) drives the high-pressure compressor set (1), and the low-temperature expansion machine set (6) drives the low-pressure compressor set (1'); the energy release subsystem comprises a self-pressurization unit (5) and an acting unit; and the high-pressure and low-temperature storage tank (4), the cold accumulator (2), a heat accumulator / heat exchanger (7) and a main expansion machine set (8) are connected in sequence, and the main expansion machine set (8) drives a power generator (24). The energy storage system disclosed by the invention has the advantages of high energy density, high efficiency, no power consumption in the power generation stage, suitability for various power stations, no greenhouse gas generation, capability of recovering intermediate-temperature and low-temperature waste heat and the like.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

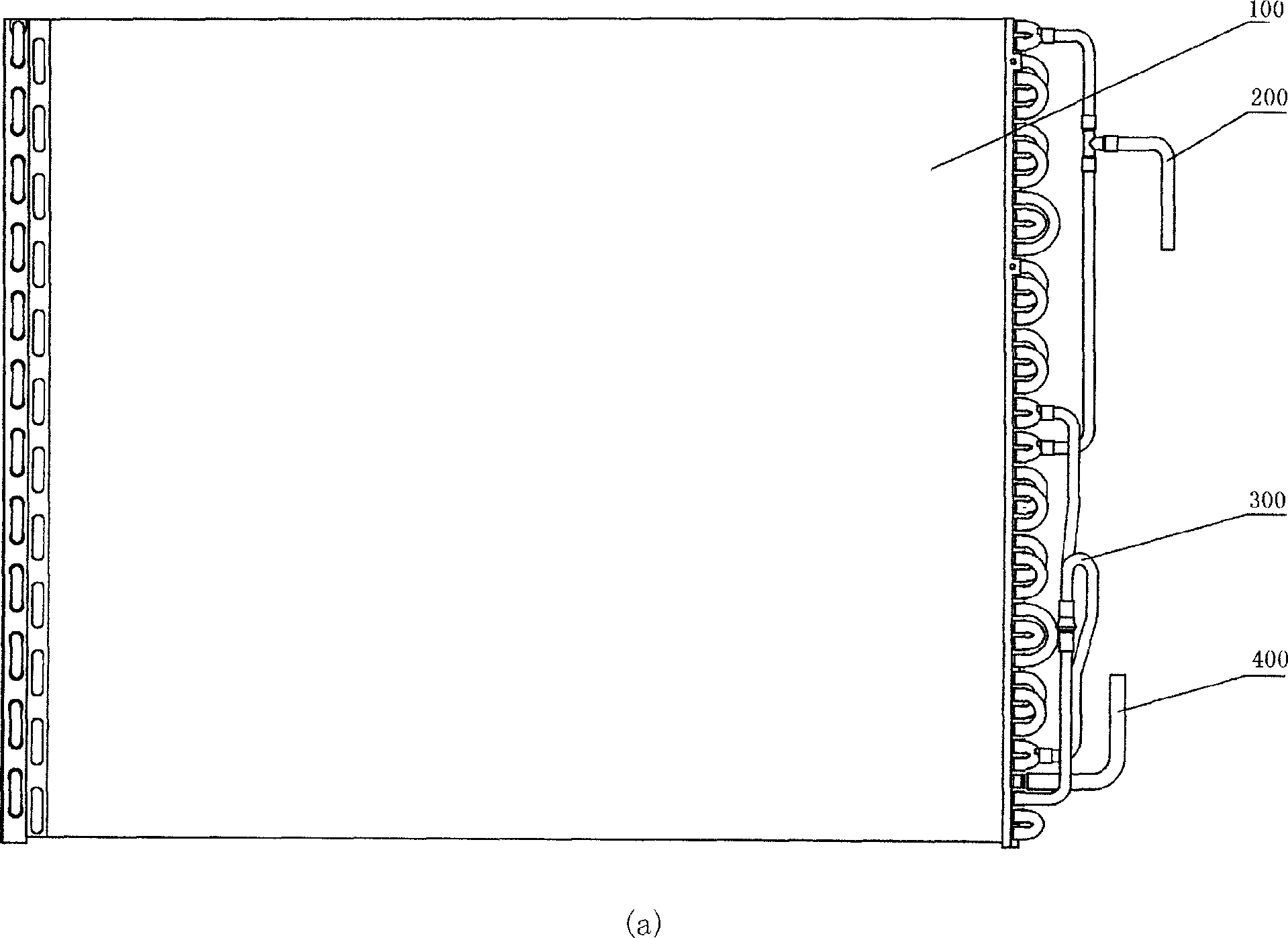

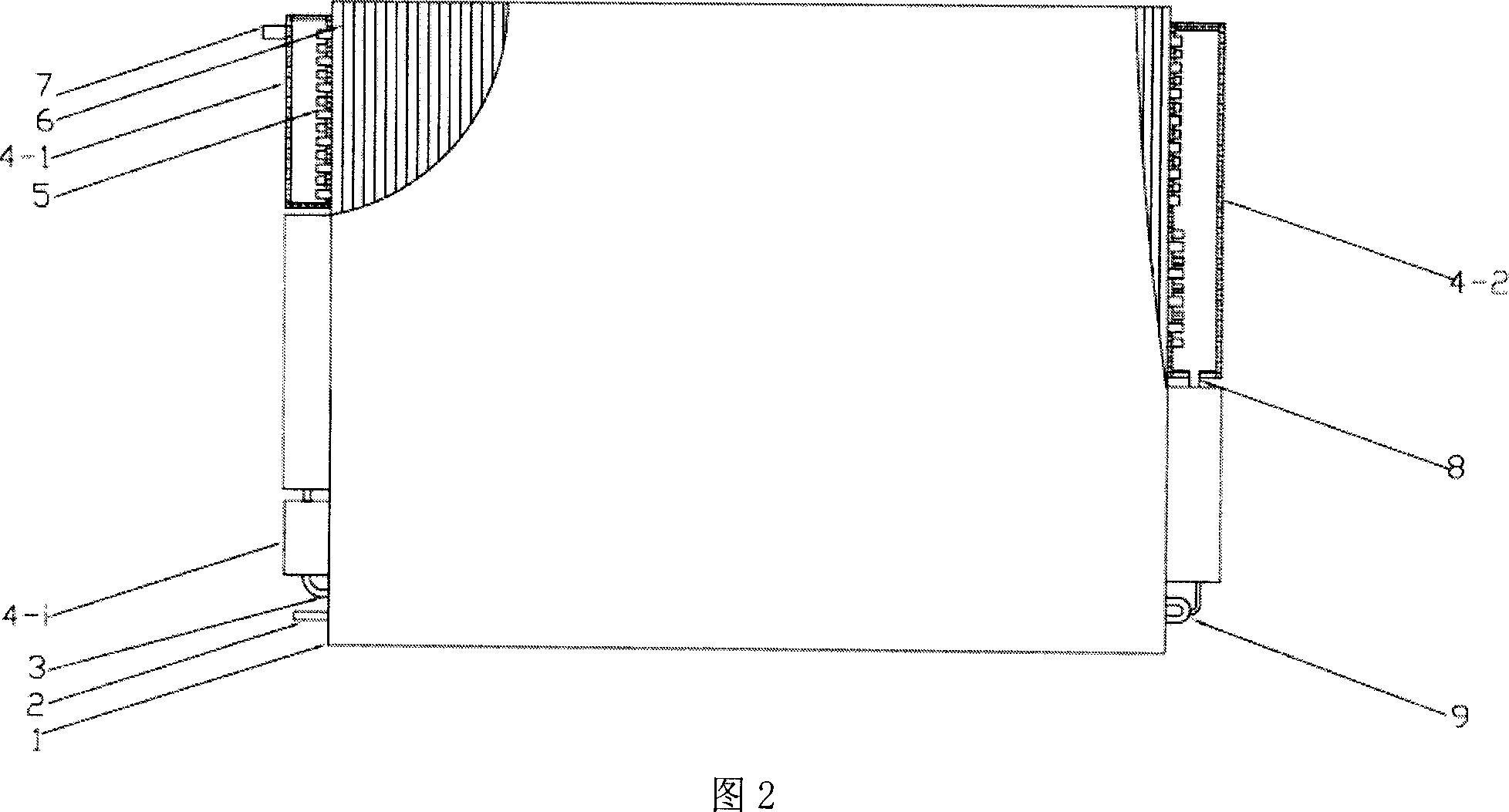

Liquid separating air condenser

InactiveCN1975311ANo steam leakage or short circuitReduce thicknessEvaporators/condensersSteam/vapor condensersCondensation processSuper cooling

A liquid-air-condenser belongs to thermal equipment technical fields. comprising steam inlet, heat exchange tube, fin, j cascade box, discharge pipe, three-limb tube, condensate outlet, single-pass pipe, shell; Steam from the steam inlet enter into the first cascade box and condense through the first group heat exchange tube, the vapor-liquid mixture flows into the second cascade box, vapor and liquid are separated: the liquid is ejected into the next cascade box by discharge pipes between cascade boxes , while steam enter into the next heat exchange tube group; collected by three-limb tube in the end and flow out through condensate outlet. The invention condense with stepped steam, separate by middle automatic vapor-liquid and drain fluid associate with super-cooling technology by the condensate concentrations, guarantee that each tube pass is entered with pure steam and cooled, effectively reduce the thickness of the liquid film in condensation process and eliminate the adverse biphasic flow pattern; compared with traditional condenser, save 30% material and reduce the condenser production and operation cost, and simple in production.

Owner:TSINGHUA UNIV

Liquid air method and apparatus

A method and apparatus in which air is liquefied and stored for later energy recovery during which the liquid air is pumped to high pressure, heated and then expanded to recover the energy. During the recovery of energy, the pumped liquid air is heated within a regenerator that stores the refrigeration within the liquid air. During the liquefaction of the air, part of the refrigeration required is obtained from the refrigeration stored in the regenerator.

Owner:PRAXAIR TECH INC

System integrating air separation with cool capacity recovery of liquefied natural gas

ActiveCN101033910AReduce energy consumptionGuaranteed safe operationSolidificationLiquefactionNitrogen gasCooling capacity

This kind of system separating air and recovering cold energy of liquefied natural gas at least includes an air separator mainly consisting of a fractionating tower and at least includes an equipment for recovering cold energy of liquefied natural gas mainly consisting of an liquefied natural gas heat exchanger, which still includes main heat exchanger, liquid-oxygen heat exchanger and liquid-nitrogen liquid air subcooler; nitrogen drawing out from the underpart of the upper column on the fractionating tower passes through liquid-nitrogen liquid air subcooler and reheated by main heat exchanger, and enters into liquefied-natural-gas heat exchanger to precool and exchange heat; the equipment recovering cold energy of liquefied natural gas at least includes air-liquid separator and liquid nitrogen subcooler, which is placed in a single ice chest II; while main heat exchanger, liquid-oxygen heat exchanger, liquid-nitrogen liquid air subcooler and fractionator consisting of the lower column, the upper column and main evaporator are placed in an ice chest I; it fully utilizes high-grade cooling capacity of liquefied natural gas, and makes energy consumption of air separator reduce notably and ensures it operate safely, and can get the great society and economy benefits.

Owner:HANGZHOU HANGYANG

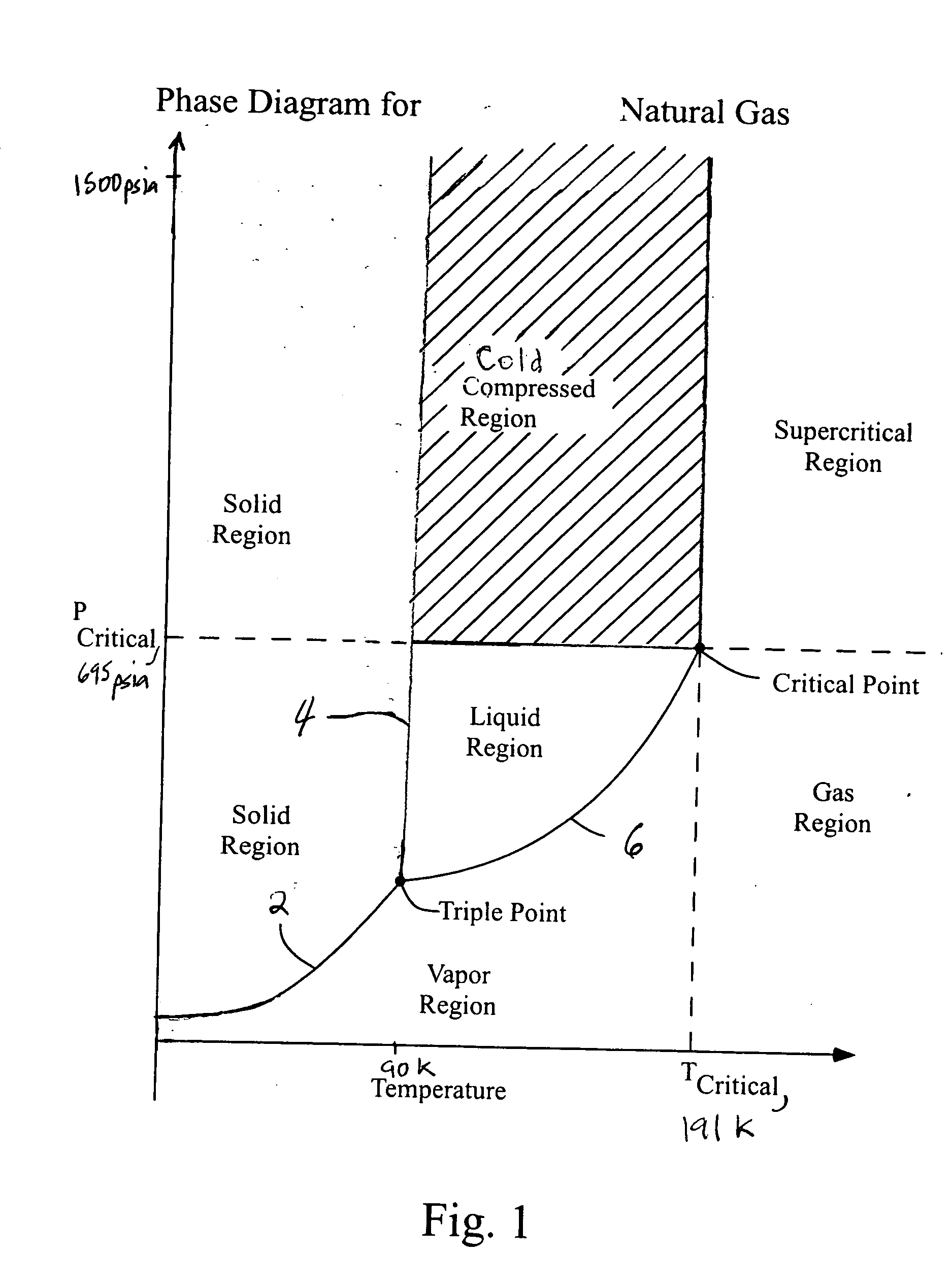

System and method for cold recovery

A method of cold recovery in a cold compressed natural gas cycle, the method comprising: compressing air; drying air; heat exchanging air with cold compressed natural gas from a storage vessel, in a first heat exchanger, thereby forming cooled air; heat exchanging the cooled air with liquid methane, in a second heat exchanger, such that the cooled air becomes liquid air and the liquid methane becomes methane; heat exchanging the liquid air with natural gas from a pipeline, in a third heat exchanger, such that the natural gas cools to a cold compressed natural gas and the liquid air becomes air in a gaseous state; discharging the air in a gaseous state. A system of cold recovery comprising: an air dryer; an air compressor in fluid communication with the air dryer; a first heat exchanger in fluid communication with the air compressor; a second heat exchanger in fluid communication with the first heat exchanger; a third heat exchanger in fluid communication with the second heat exchanger; a methane expander valve in fluid communication with the second heat exchanger; a fourth heat exchanger in fluid communication with the methane expansion valve; a methane compressor in fluid communication with the second heat exchanger and with the fourth heat exchanger; a natural gas scrubber in fluid communication with a third heat exchanger; a natural gas pipeline in fluid communication with the first heat exchanger; the fourth heat exchanger, and the natural gas scrubber; and a storage vessel in fluid communication with the first heat exchanger, the third heat exchanger, and the fourth heat exchanger.

Owner:EXPANSION ENERGY

Adjustable non-electric liquid air freshener device

InactiveUS20060016904A1Avoid separationPrevent extractionTobacco devicesGaseous substancesEvaporationBiomedical engineering

Comprises a vessel (1) containing scented liquid, a wick (2) partially submerged in the liquid, a stopper (3) coupled on the mouth (7) of the vessel (1) and a cap (5) that covers the stopper (3) and has a lower tubular portion (11) provided with two windows (15) and an inner threaded segment that unscrews from a central threaded tubular portion (13) of the stopper (3) as the cap (5) is turned, raising it and gradually revealing the windows (15) so that the wick (2) is exposed to the exterior, facilitating the adjustable evaporation of the scented liquid, the cap (5) being provided with flexible stops (16) that are prolonged externally from the base of its lower tubular portion (11) and as they rise meet a trapezoidal inner peripheral flange (17) defined in a cylindrical body (14) of the stopper (3) to prevent the exit of the cap (5).

Owner:ZOBELE ESPANA

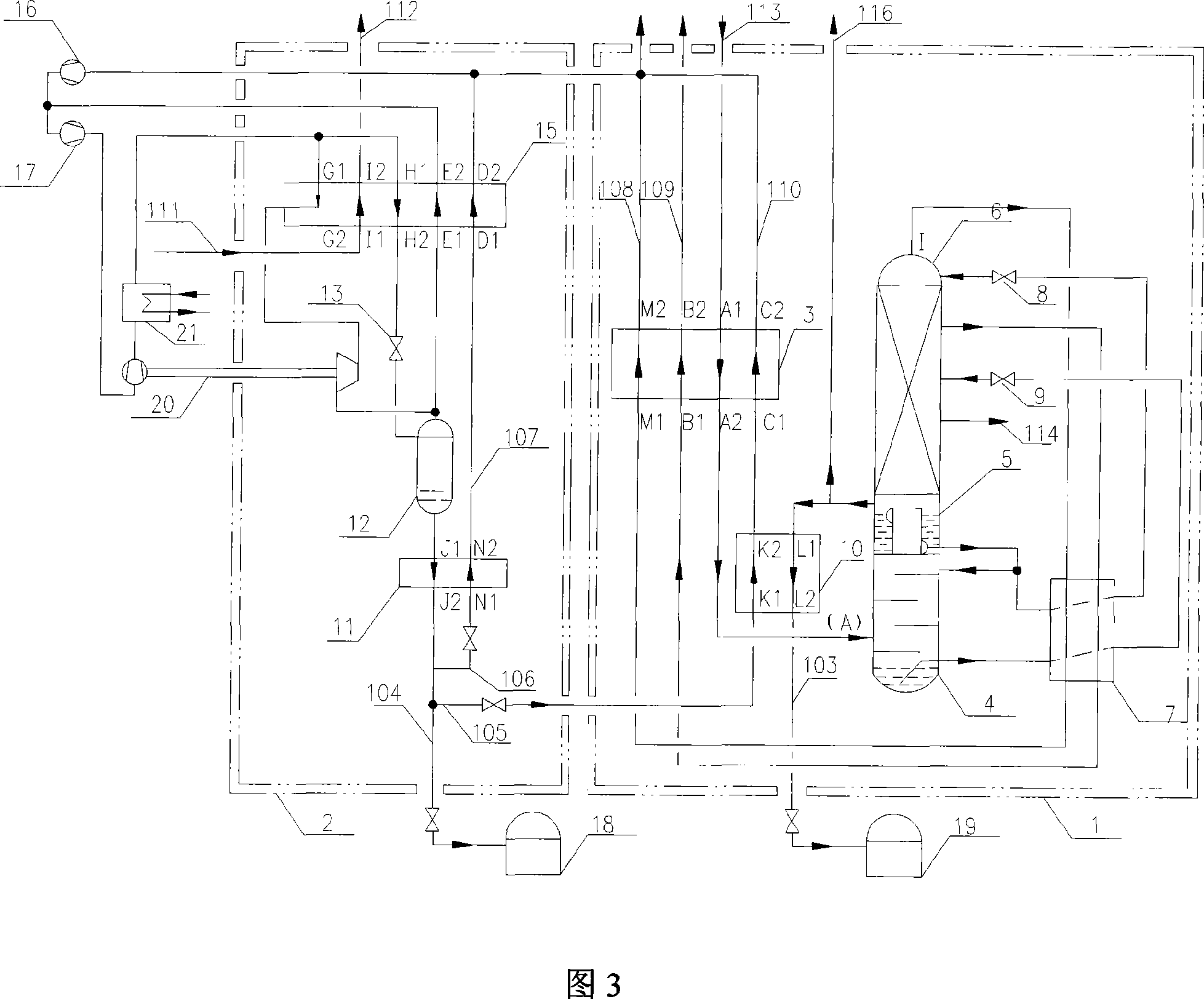

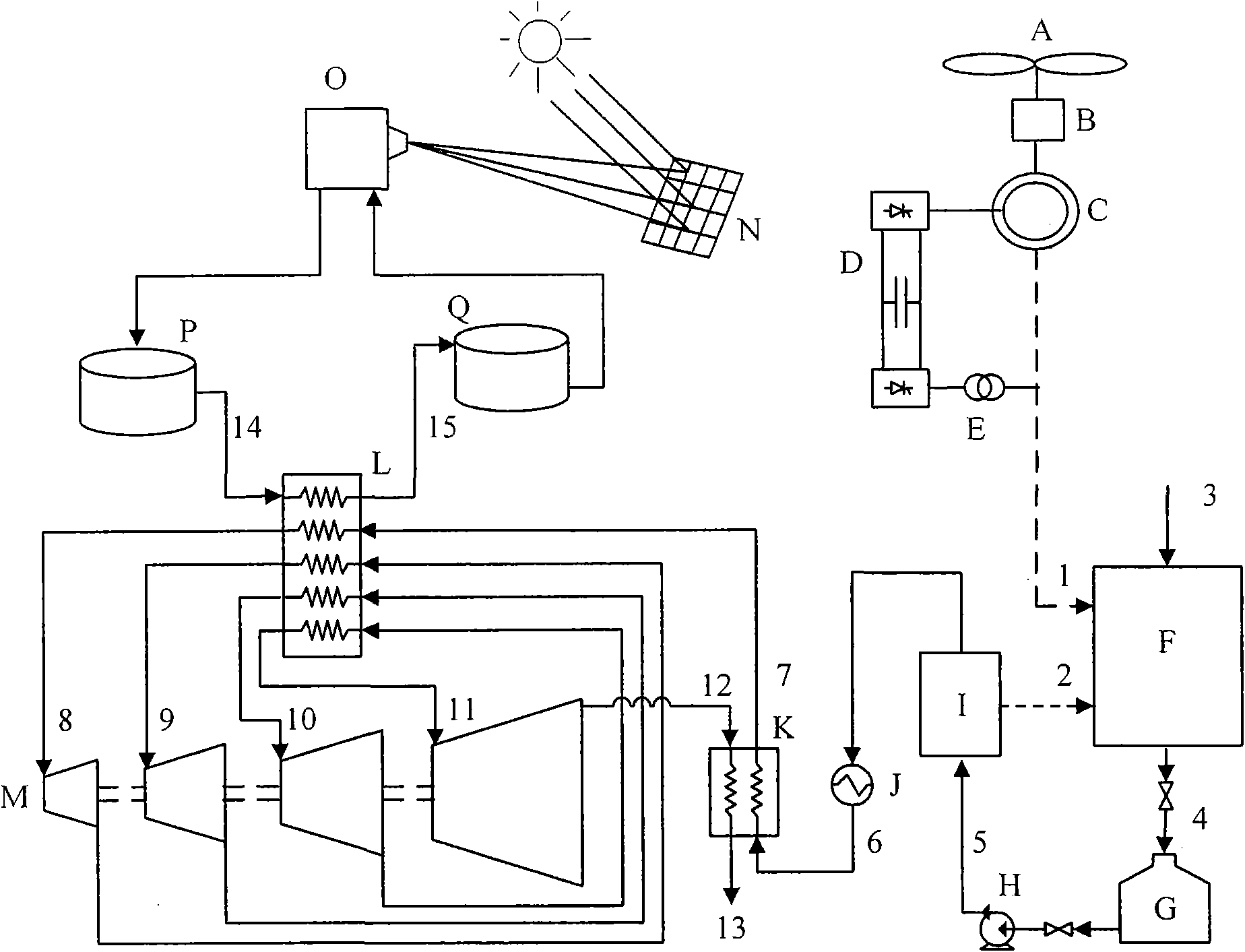

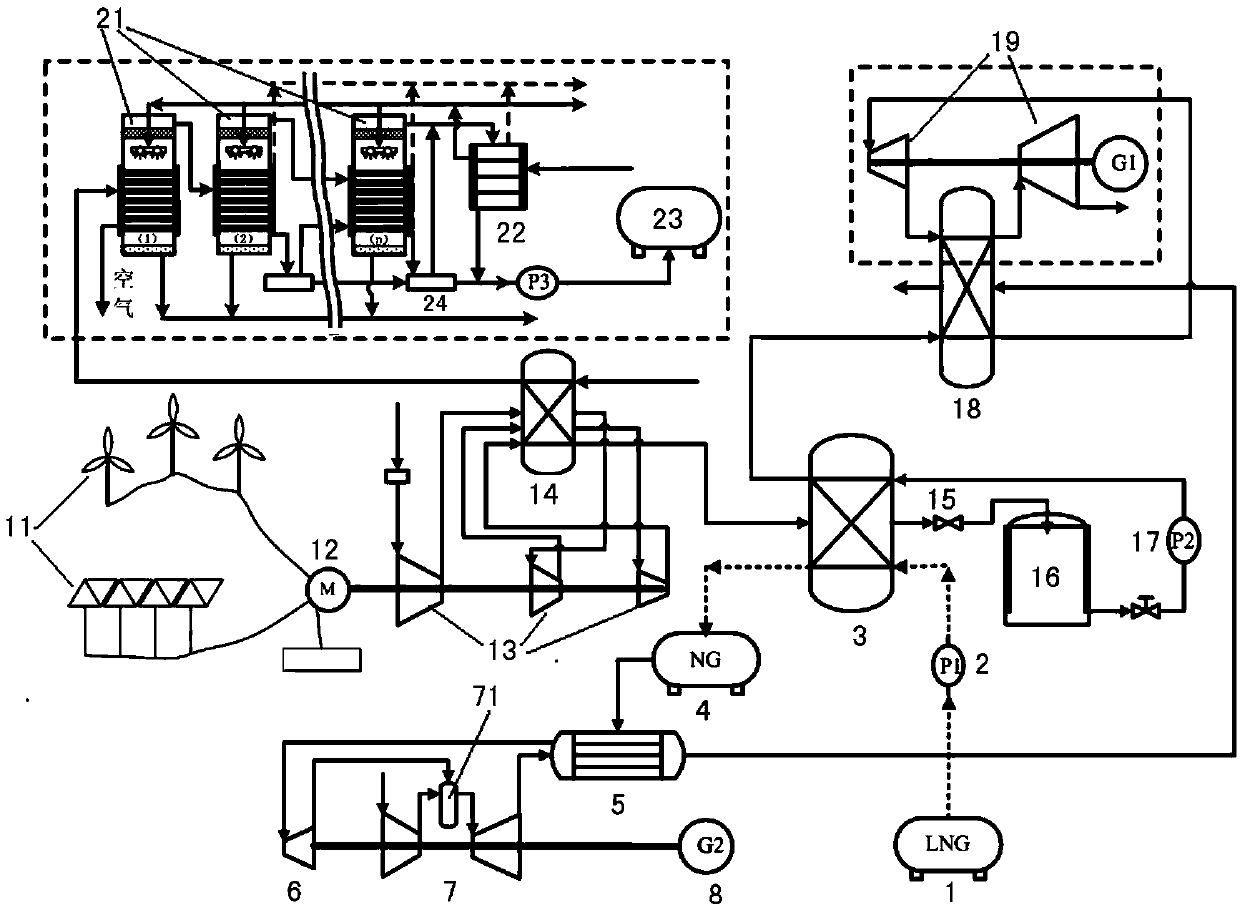

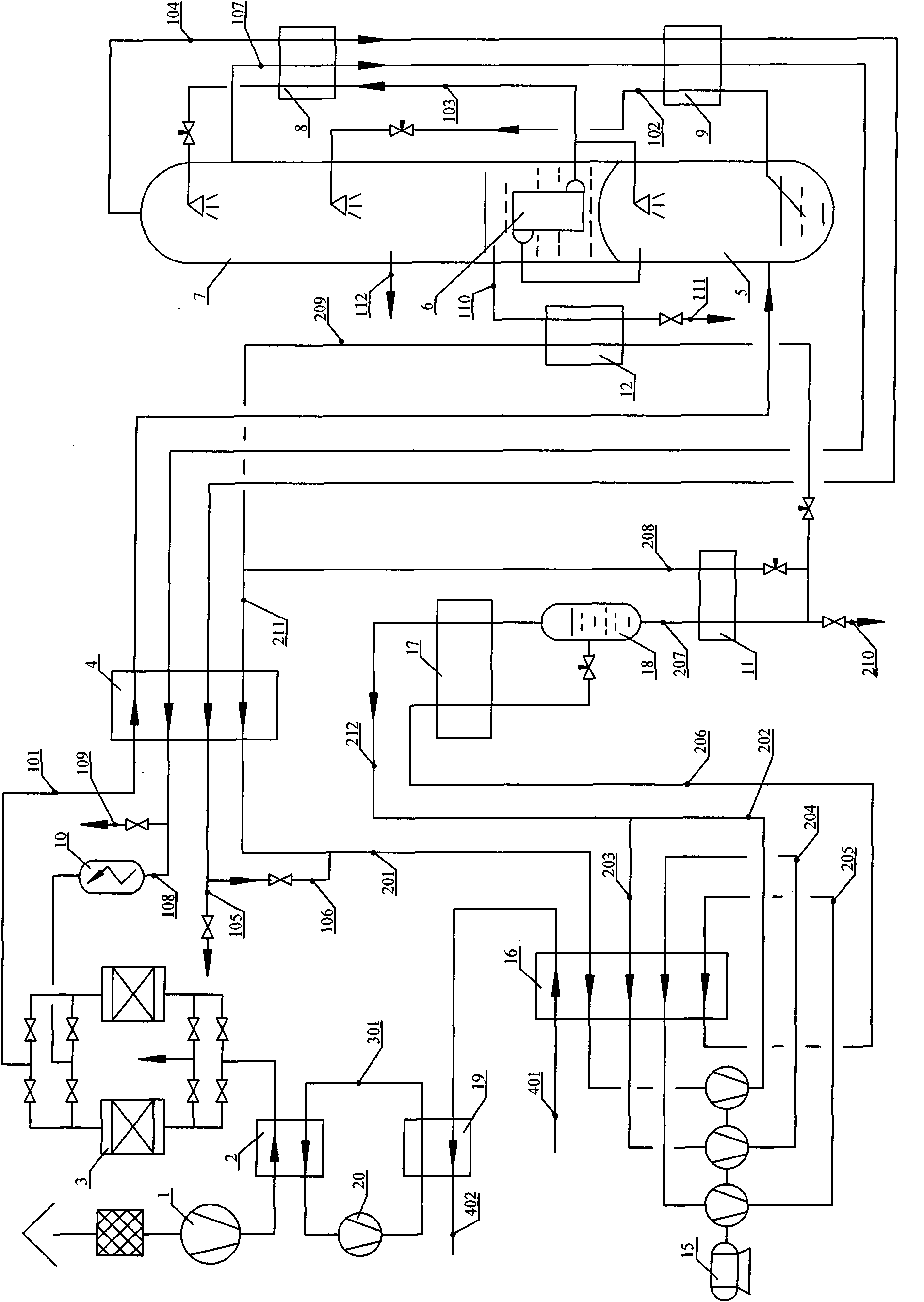

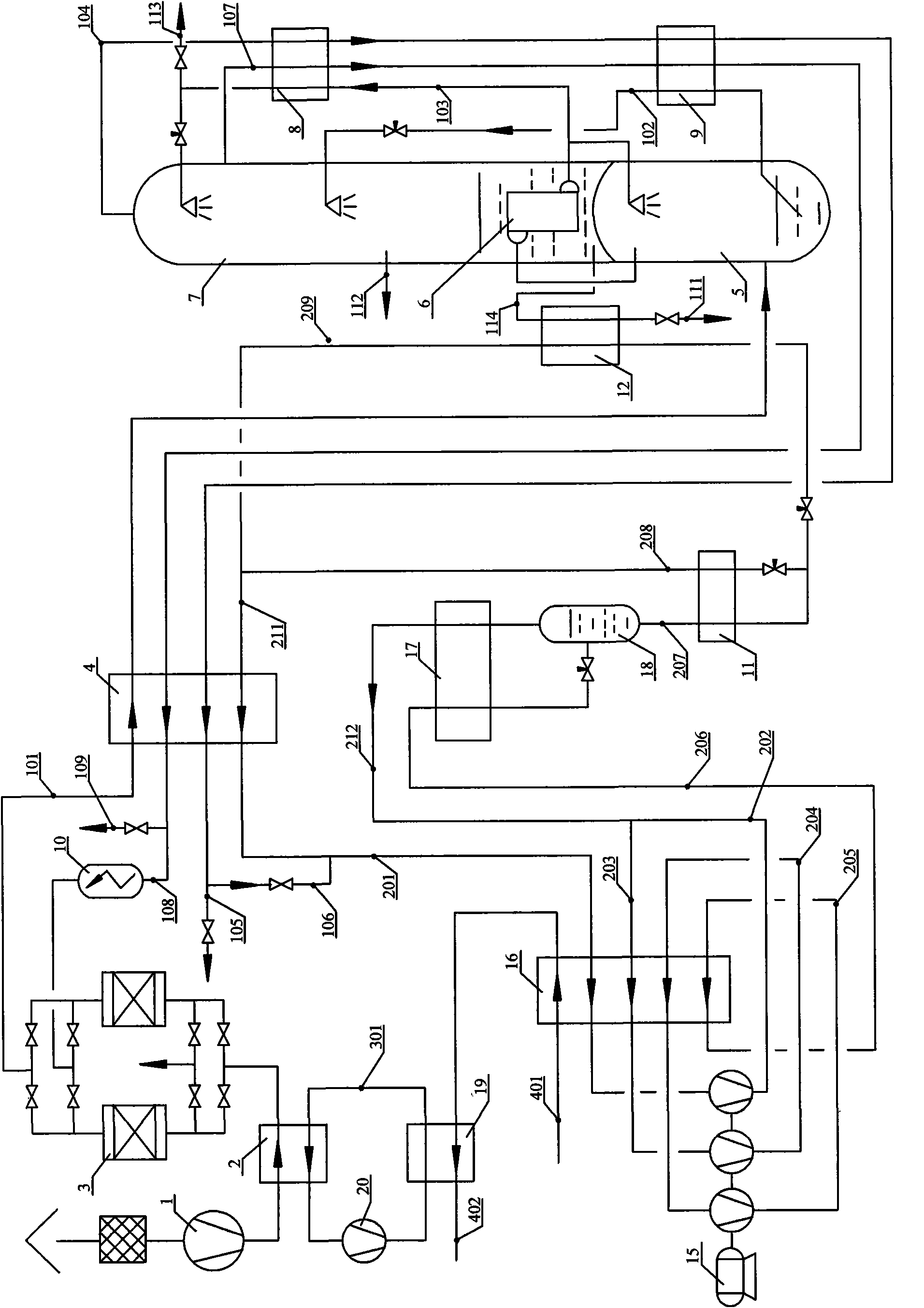

Wind and solar hybrid energy storage and power generation integration system and process

ActiveCN102062052ATo achieve complementary useImprove working abilitySolidificationLiquefactionThermal energyCollector device

The invention discloses a wind and solar hybrid energy storage and power generation integration system and process. The system comprises a wind power generation subsystem, a solar energy storage subsystem, a liquefied air subsystem and a power subsystem. The process comprises the following steps: solar energy is gathered by a thermal collector to obtain heat energy, the heat energy is stored in heat storge medium; wind energy is converted to electric energy, the wind power is used to liquefy air and stored in the liquefied air; and when electricity is required, the liquefied air is pressurized to recycle cold energy for the air liquefying process, then the air is heated by the high temperature heat storge medium which stores solar energy to obtain high temperature and high pressure air, and finally the air is sent to a multistage reheating turbine to expand and do work. The system of the invention recycles the cold energy of the liquefied air to reduce the wasted work for air liquefying; a pump is used to increase the pressure of the working medium, thus reducing the wasted work for compressing the working medium; the turbine utilizes recycled heat for exhaustm, thus effectively utilizing heat energy; solar energy is utilized to heat the working medium at the inlet of the turbine, thus increasing the expansion efficiency of the turbine; and wind energy and solar energy can be utilized for complementation, energy storage and power generation can be integrated and the system of the invention has wide application prospect.

Owner:葛洲坝中科储能技术有限公司

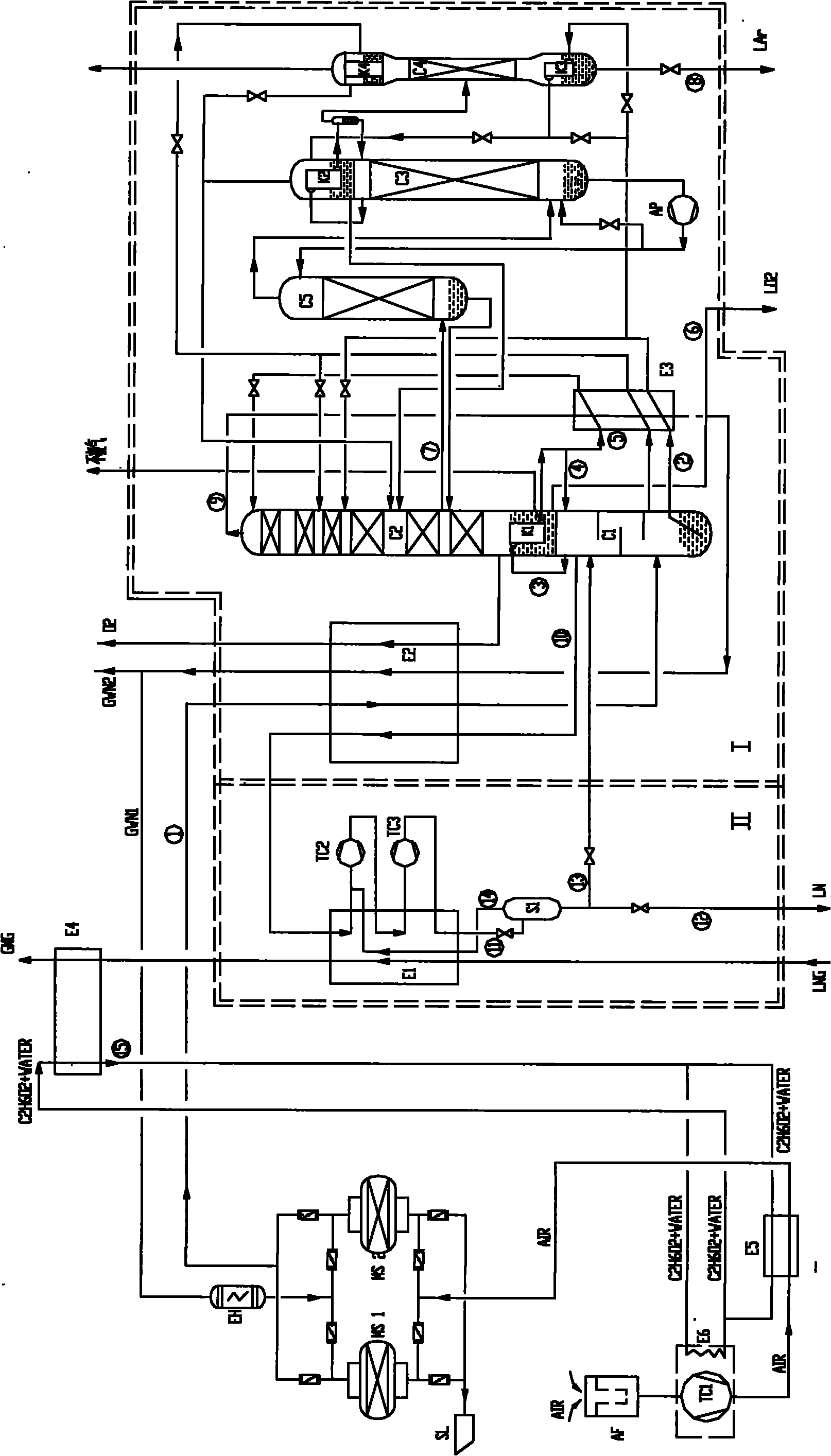

Full-liquid air separation device using cold energy of liquefied natural gas (LNG)

InactiveCN101846436ACompact structureImprove heat transfer efficiencySolidificationLiquefactionComing outAir cleaning

The invention disclose a full-liquid air separation device using the cold energy of the liquefied natural gas (LNG), comprising an air compressing and pre-cooling system, an air purifying system, an air separating system and a nitrogen circulating system capable of recycling the cold energy of the LNG which has the pressure of 8.0MPa or higher. The nitrogen circulating system capable of recycling the cold energy of the LNG comprises a nitrogen compressor, a wound tube heat exchanger and a gas-liquid separator; the gaseous nitrogen coming out of the gas separating system is made to enter the wound tube heat exchanger to exchange heat with the LNG and then is compressed by the nitrogen compressor to have higher pressure; the liquid nitrogen coming out of the wound tube heat exchanger is separated into gaseous nitrogen and liquid hydrogen; the liquid nitrogen coming out of the gas-liquid separator is separated into two branches, wherein one branch of the liquid nitrogen is fed in the air separating system to be used as the return liquid of a lower tower to involve in the rectification of the lower tower and to be made to carry the cold energy in the air separating system, and the other branch of the liquid nitrogen is discharged as the liquid nitrogen product; the gaseous nitrogen coming out of the gas-liquid separator is made to enter the wound tube heat exchanger and reheated to the temperature of the inlet of the nitrogen compressor and then made to enter the nitrogen compressor to circulate. Compared with the prior air separation device of the same scale, the full-liquid air separation device can save the electric energy of more than 50 percent and the consumed water of more than 90 percent.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Island energy supply system with cold energy

ActiveCN103993920AImprove energy utilizationImprove economyFrom solar energyGeneral water supply conservationCombustion chamberDistillation

The invention relates to an island energy supply system with cold energy. The island energy supply system comprises an LNG power generation system unit, a renewable energy power generation and energy storage unit and a low-temperature multi-effect distillation seawater desalination system. The island energy supply system is a combination island energy supply system formed by power generation and energy storage systems in a combination mode based on an LNG power generator and unstable renewable energy such as wind energy, solar energy and wave energy. System waste heat is used as a heat source for a seawater desalination unit. During an energy storage process, stored LNG is converted into high-pressure natural gas (NG) by cold accumulation gasifying, the NG enters an NG storage tank and a pipe network system for storage and standby application, then air is subjected to compression, indirect cooling and cold accumulation, cold energy is recycled, and after throttling, liquidation storage is carried out. During a power using process, after high-pressure NG absorbs heat and is heated, the high-pressure NG enters a turbine expansion machine for working, then the NG enters a small gas turbine combustion chamber and burns with compressed air to drive a gas turbine to work, and liquid air is subjected to cold accumulation and gradual heat absorption temperature raising and then enters the turbine expansion machine for working. According to the energy supply system, on-island electricity energy and fresh water can be supplied at the same time, unstable renewable resources are converted into stable controllable generated power to be output, system efficiency is improved, power using cost is lowered, and compared with traditional island energy supply system, the island energy supply system has the great advantages.

Owner:鄂尔多斯大规模储能技术研究所 +1

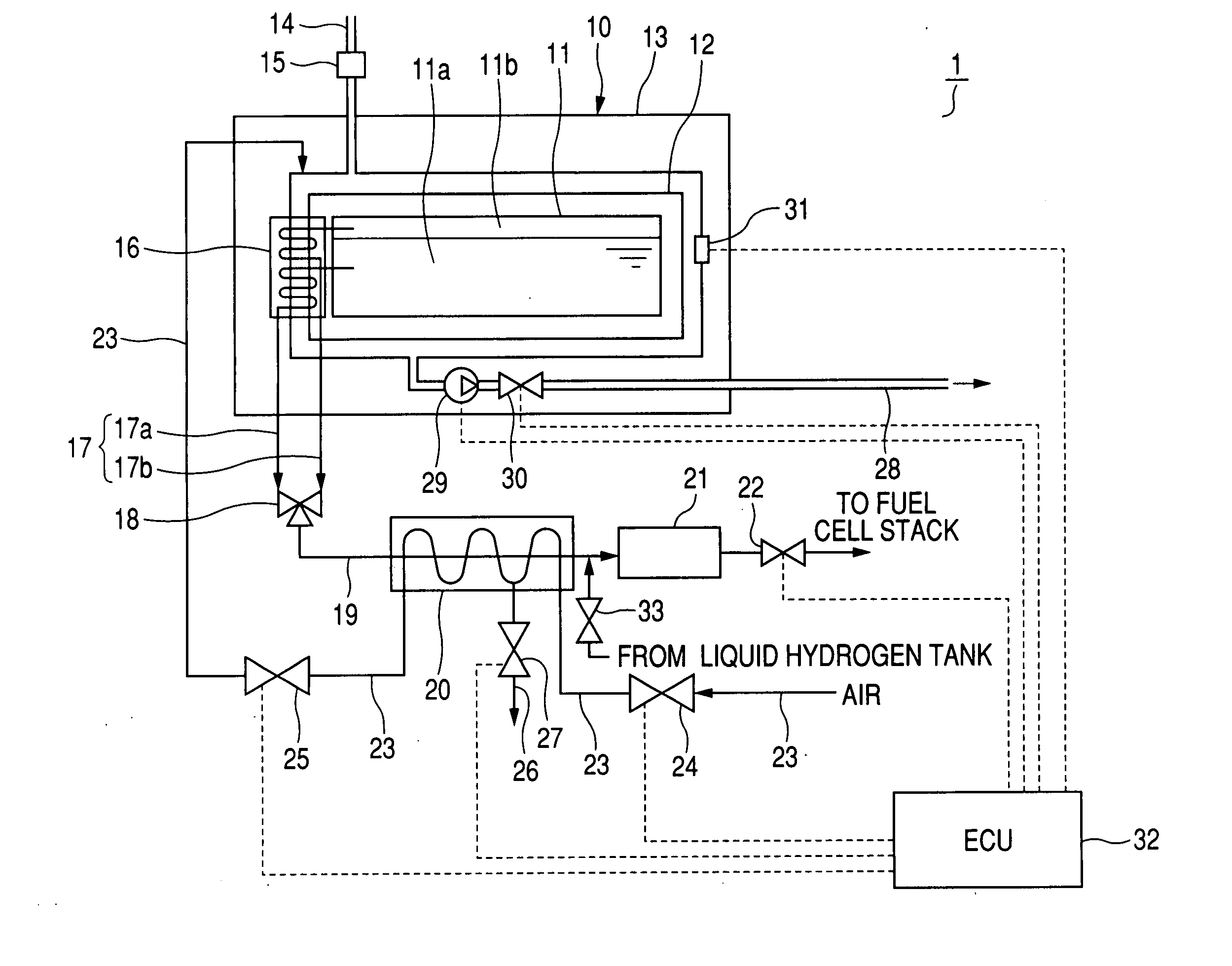

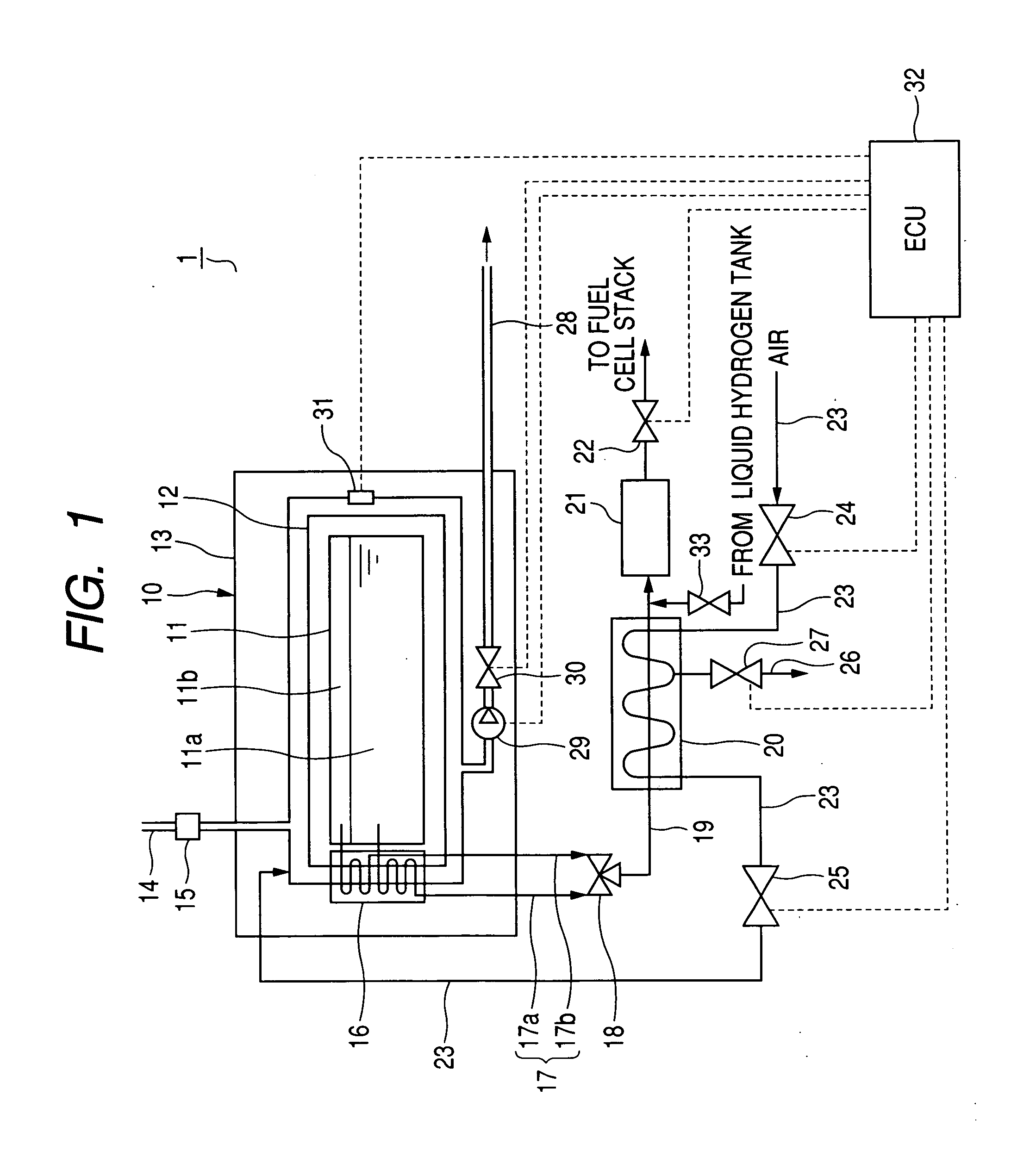

Liquid fuel storage system

Owner:DENSO CORP

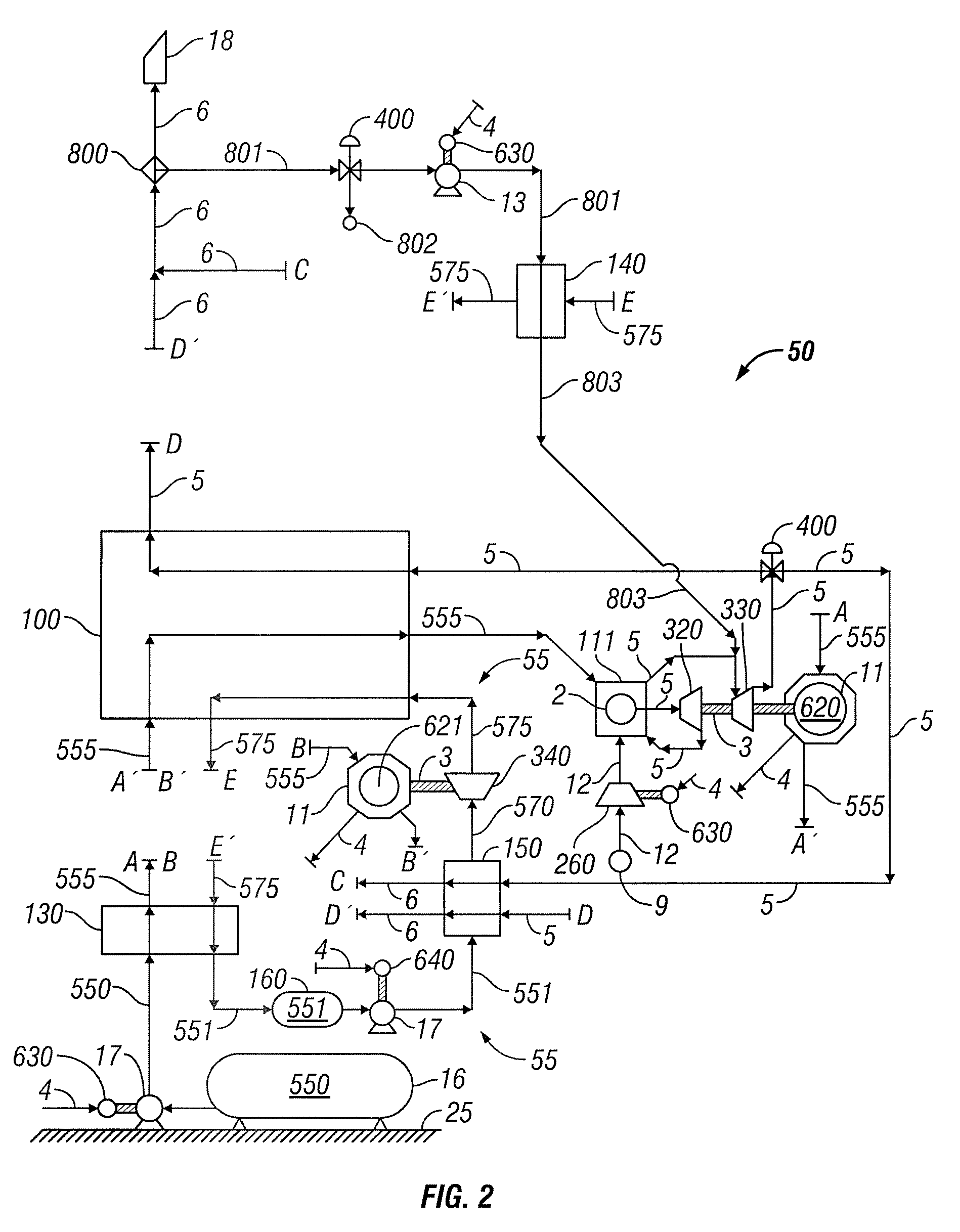

System and method for liquid air production, power storage and power release

ActiveUS20110030332A1Great energy outputEnergy efficiencySolidificationLiquefactionCombustion chamberLiquid state

Systems and methods for storing and releasing energy comprising directing inlet air into a vertical cold flue assembly, a portion of moisture being removed from the air within the cold flue assembly. The air is directed out of the cold flue assembly and compressed. The remaining moisture is substantially removed and the carbon dioxide is removed from the air by adsorption. The air is cooled in a main heat exchanger such that it is substantially liquefied using refrigerant loop air. The substantially liquefied air is directed to a storage apparatus. The refrigerant loop air is cooled by a mechanical chiller and by a plurality of refrigerant loop air expanders. In energy release mode, working loop fluid warms the released liquid air such that the released liquid air is substantially vaporized, and the released liquid air cools the working loop fluid such that the working loop fluid is substantially liquefied. A portion of the released liquid air is directed to the at least one generator and used as bearing air for the at least one generator. The substantially vaporized air is directed to a combustion chamber and combusted with a fuel stream. Combustion gas may be directed from the combustion chamber to at least one expander and expanded in the expander, the expanded combustion gas split into a first portion and a second portion, the first portion being relatively larger than the second portion. The first portion may be directed to a first heat exchanger, and the second portion may be directed to a second heat exchanger such that the second portion heats and substantially vaporizes the released liquid air.

Owner:EXPANSION ENERGY

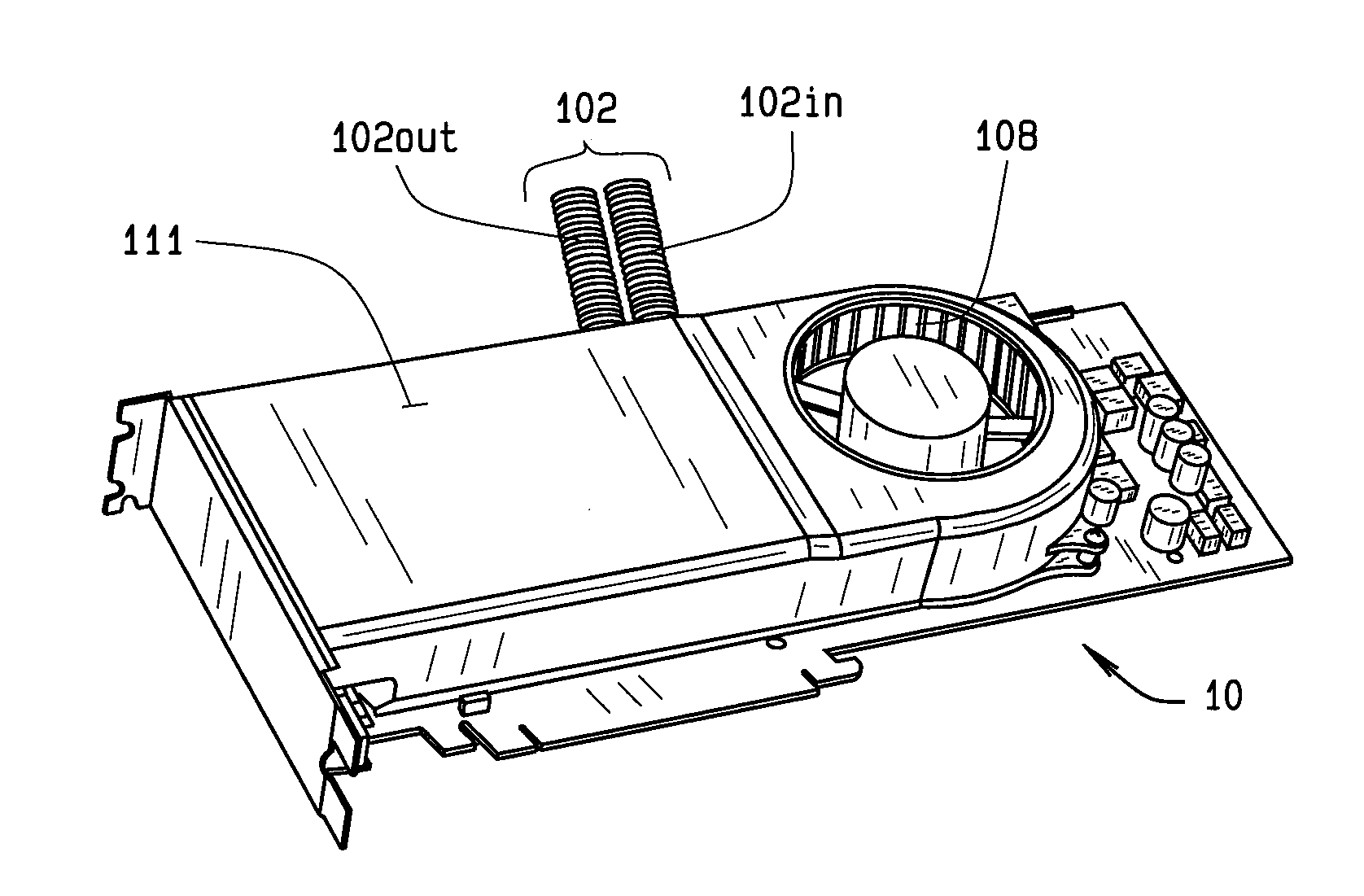

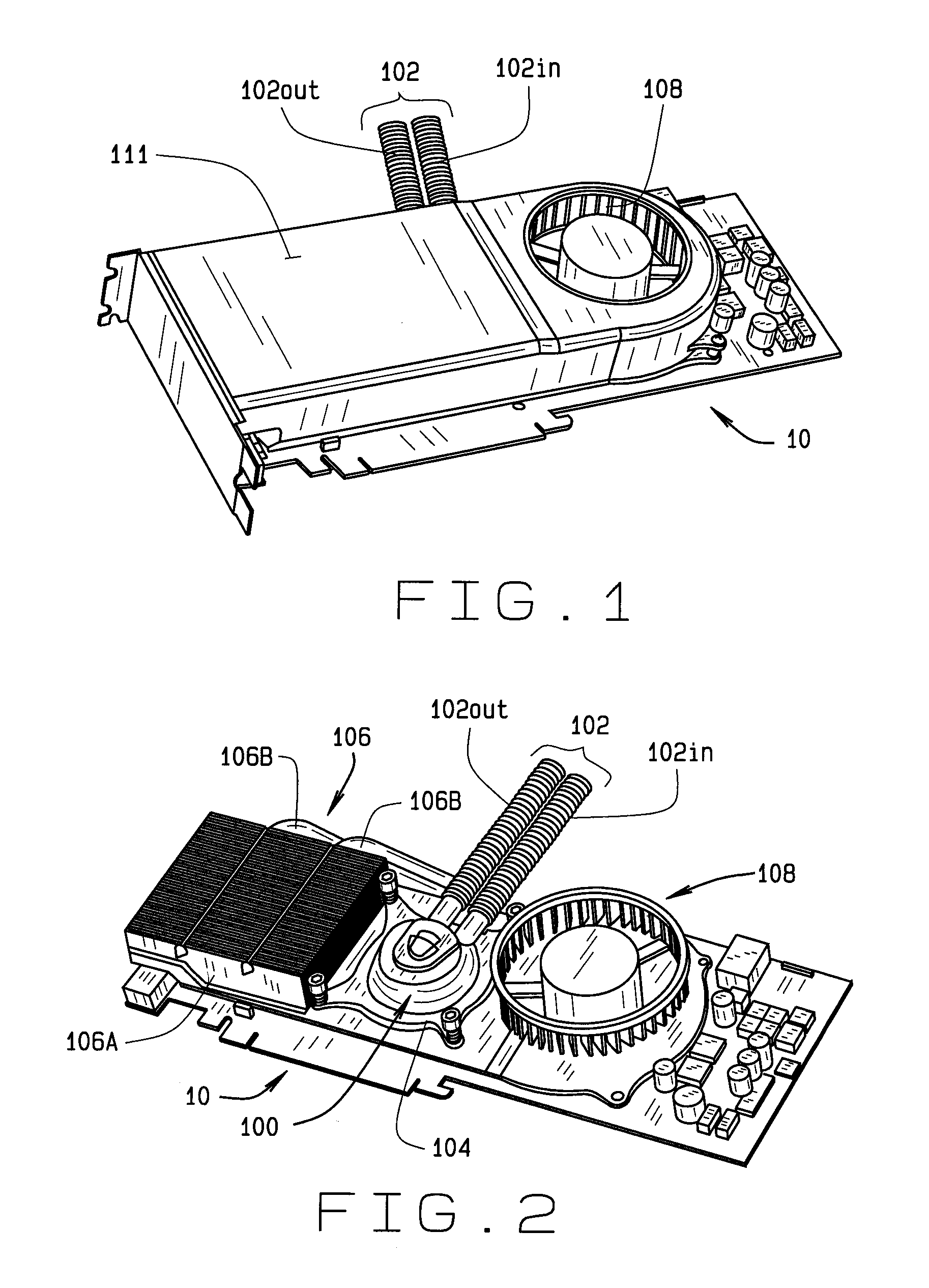

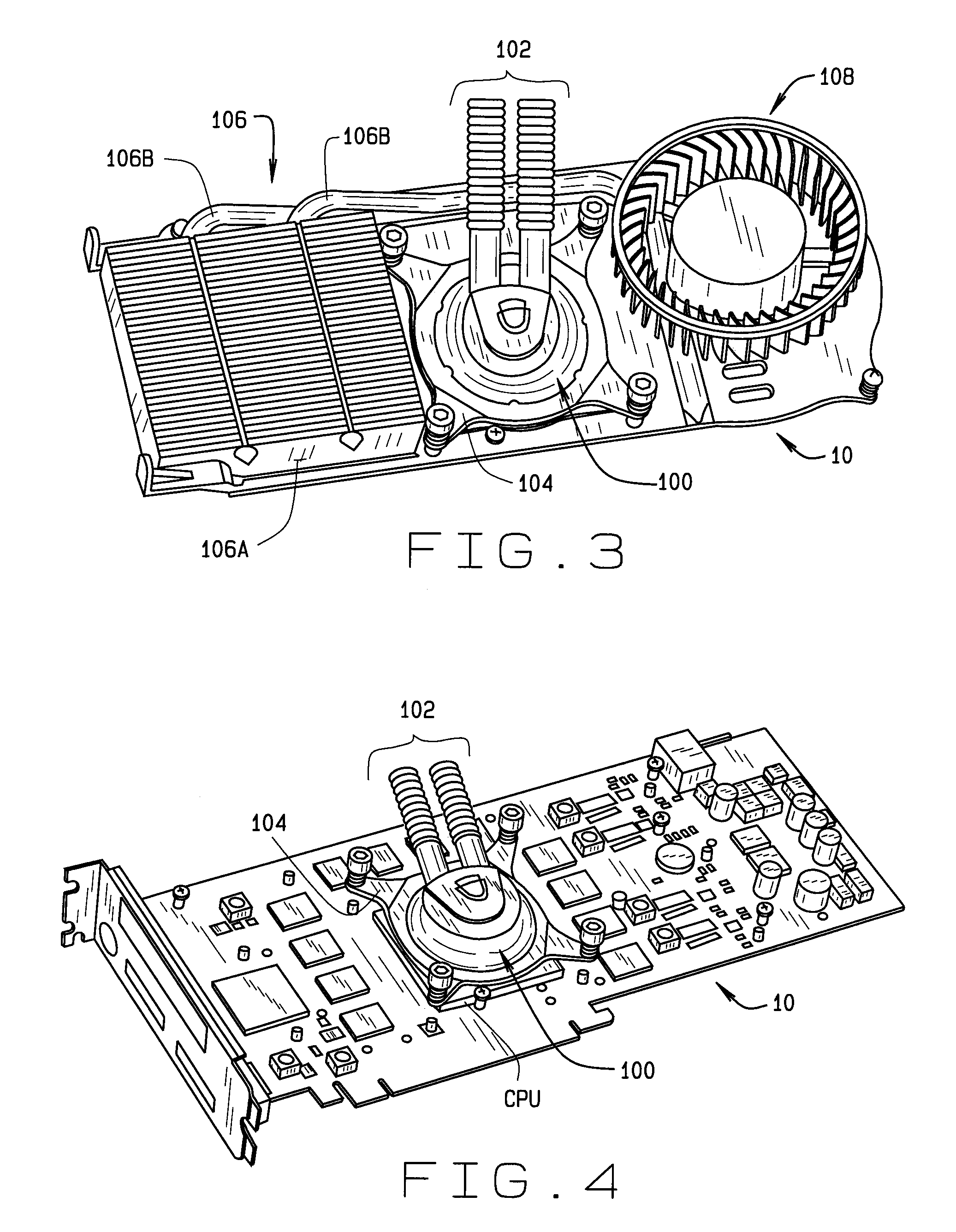

Hybrid liquid-air cooled graphics display adapter

InactiveUS20100128431A1Easy to adaptEasy to moveDigital data processing detailsSemiconductor/solid-state device detailsGraphicsLiquid cooling system

A hybrid liquid-air cooling system which may be easily adapted to provide a liquid cooling mechanism for use with a wide range of heat sources on components or adapter boards (10) in a personal computer system, and which functions cooperatively with an air cooling system (106). The liquid cooling mechanism includes a cold plate component (100) adapted for use with a wide range of applications, and Is secured in place by an exchangeable mounting clip (104) which eliminates the need to breach the liquid cooling system flow pathways (102) to insert, remove, or replace heat source components. The cold plate component (100) functions cooperatively with an air cooling structure (106) consisting generally of an aluminum heat sink, cooling fins (106a), heat pipes (106b), and a cooling fan (106c).

Owner:ASETEK

High-pressure liquid air energy storage/release system

ActiveCN102758748AIncrease energy densityImprove efficiencyMachines/enginesMechanical power devicesHigh energyEngineering

The invention discloses a high-pressure liquid air energy storage / release system, which comprises an energy storage subsystem and an energy release subsystem; in the energy storage subsystem, a compressor set (1), a cold accumulator (2), a low-temperature heat exchanger (3), a high-pressure low-temperature storage tank (4), a low-temperature expansion machine set (6) and a low-temperature heat exchanger (3) are communicated in sequence; the energy release subsystem comprises a self-pressurization unit (5) and an acting unit; and the high-pressure and low-temperature storage tank (4), the cold accumulator (2), a heat accumulator / heat exchanger (7) and a main expansion machine set (8) are connected in sequence, and the main expansion machine set (8) drives a power generator (24). The high-pressure liquid air energy storage system disclosed by the invention has the advantages of high energy density, high efficiency, no power consumption in the power generation stage, suitability for various power stations, no greenhouse gas generation, capability of recovering intermediate-temperature and low-temperature waste heat and the like.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Air separation method utilizing liquefied natural gas cold energy

ActiveCN101571340AReduce unit power consumptionConform to energy savingSolidificationLiquefactionLiquefied natural gasSocial benefits

The invention discloses an air separation method utilizing liquefied natural gas cold energy, comprising an air separation unit, an LNG cold energy utilization unit providing refrigeration energy for the LNG cold energy utilization unit and a glycol water solution circulation unit utilizing NG high temperature cold energy. In the invention, low temperature cold energy of the LNG is applied to the air separation system, thus unit power consumption of a liquid air separation product can be reduced to about 0.30kwh / m, which is one third of the unit power consumption of a liquid air separation product in conventional process production; and unit power consumption of the internal compressed gas product also can be greatly reduced, and meanwhile a large number of cooling water can be saved, thus being in accordance with the trend of energy saving, consumption reduction and circular economy developing and having obvious social benefit and economic benefit.

Owner:CHINA NAT OFFSHORE OIL CORP +3

System and method for liquid air production, power storage and power release

InactiveUS7821158B2High outputEnergy efficiencySolidificationLiquefactionCombustion chamberEngineering

Systems and methods for storing and releasing energy comprising directing inlet air into a vertical cold flue assembly, a portion of moisture being removed from the air within the cold flue assembly. The air is directed out of the cold flue assembly and compressed. The remaining moisture is substantially removed and the carbon dioxide is removed from the air by adsorption. The air is cooled in a main heat exchanger such that it is substantially liquefied using refrigerant loop air, The substantially liquefied air is directed to a storage apparatus. The refrigerant loop air is cooled by a mechanical chiller and by a plurality of refrigerant loop air expanders. In energy release mode, working loop air warms the released liquid air such that the released liquid air is substantially vaporized, and the released liquid air cools the working loop air such that the working loop air is substantially liquefied. A portion of the released liquid air is directed to the at least one generator and used as bearing air for the at least one generator. The substantially vaporized air is directed to a combustion chamber and combusted with a fuel stream. Combustion gas may be directed from the combustion chamber to at least one expander, the expanded combustion gas split into two portions. The first portion may be directed to a first heat exchanger, and the second portion may be directed to a second heat exchanger such that the second portion heats and substantially vaporizes the released liquid air.

Owner:EXPANSION ENERGY

System and method for liquid air production, power storage and power release

InactiveUS7870746B2Energy efficiencyReduce disadvantagesSolidificationLiquefactionStored energyElectricity

Systems and methods for releasing and replacing stored energy comprise capturing inlet air from the ambient environment so the inlet air flows in a first general direction. Released liquid air flows in a second general direction, the second general direction being substantially opposite to the first general direction. The released liquid air is pumped to pressure, and the released liquid air and inlet air flow past each other such that heat exchange occurs. The inlet air warms the released liquid air such that the released liquid air is substantially vaporized, and the released liquid air cools the inlet air. Moisture and carbon dioxide are removed from the inlet air, and the inlet air is compressed and cooled such that the inlet air is substantially liquefied. The substantially liquefied air replaces a portion of the released liquid air; and the substantially vaporized released liquid air is combusted with fuel to produce electricity.

Owner:EXPANSION ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com