Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

140results about "Engines with oscillating pistons" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

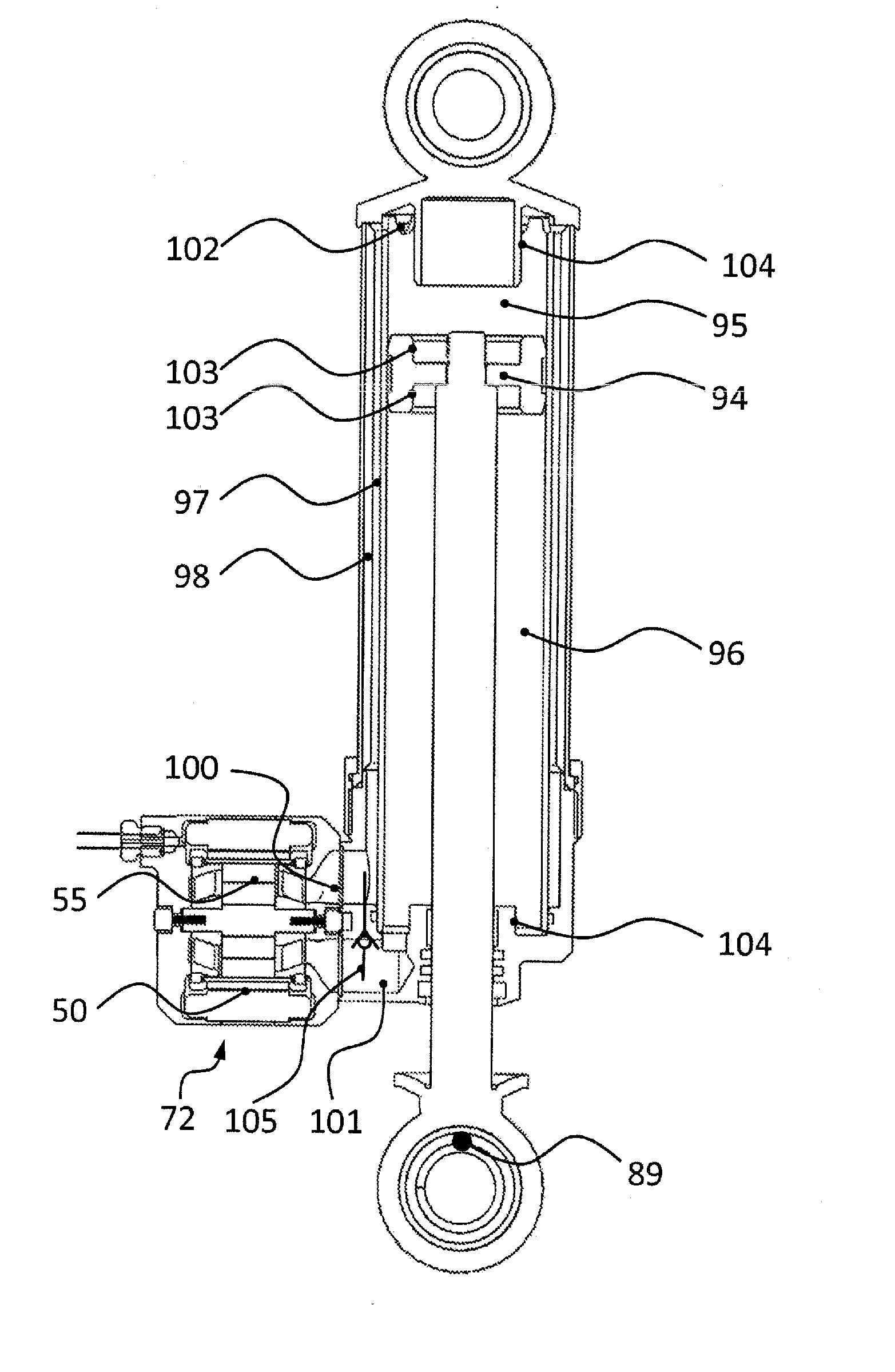

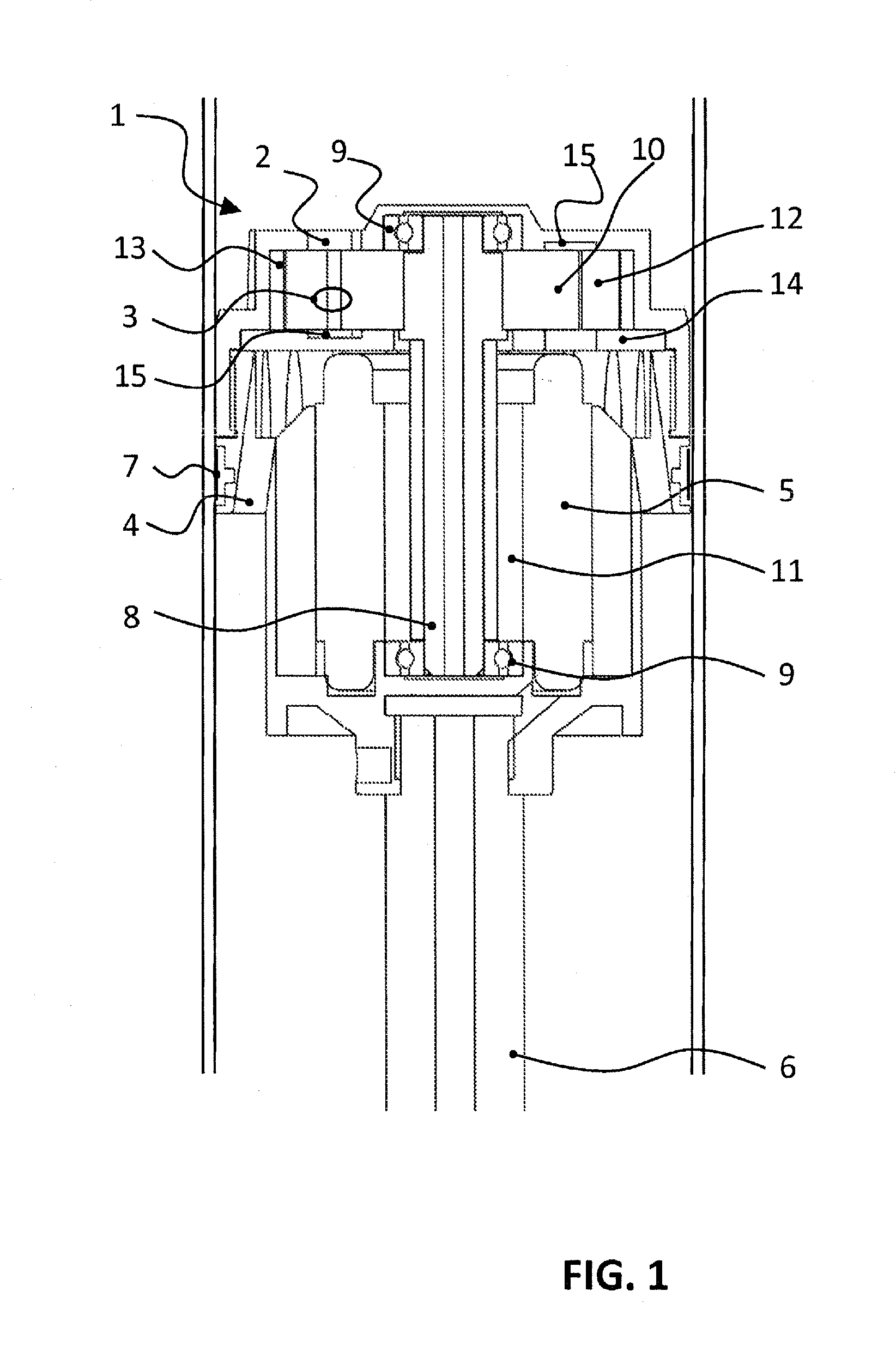

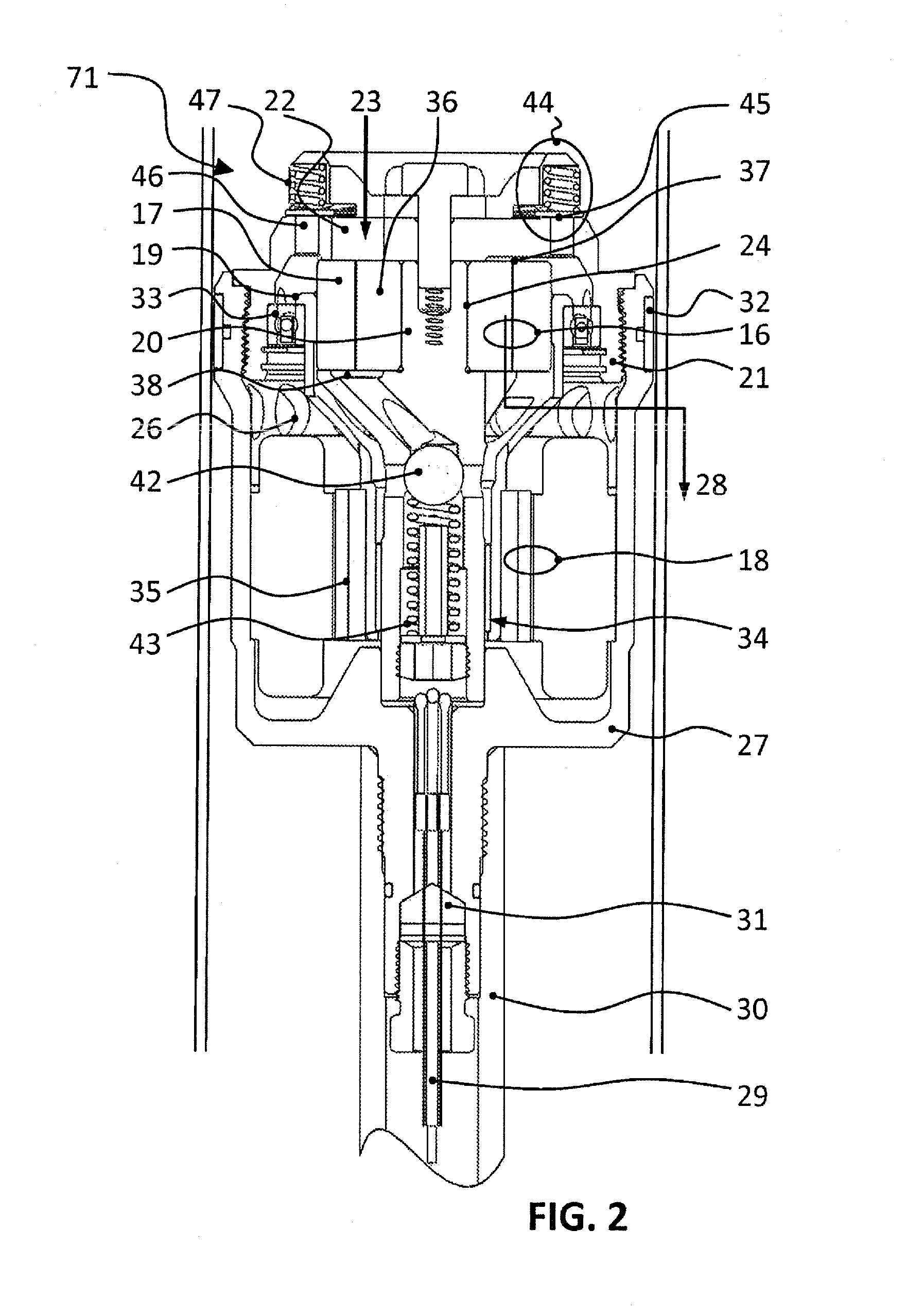

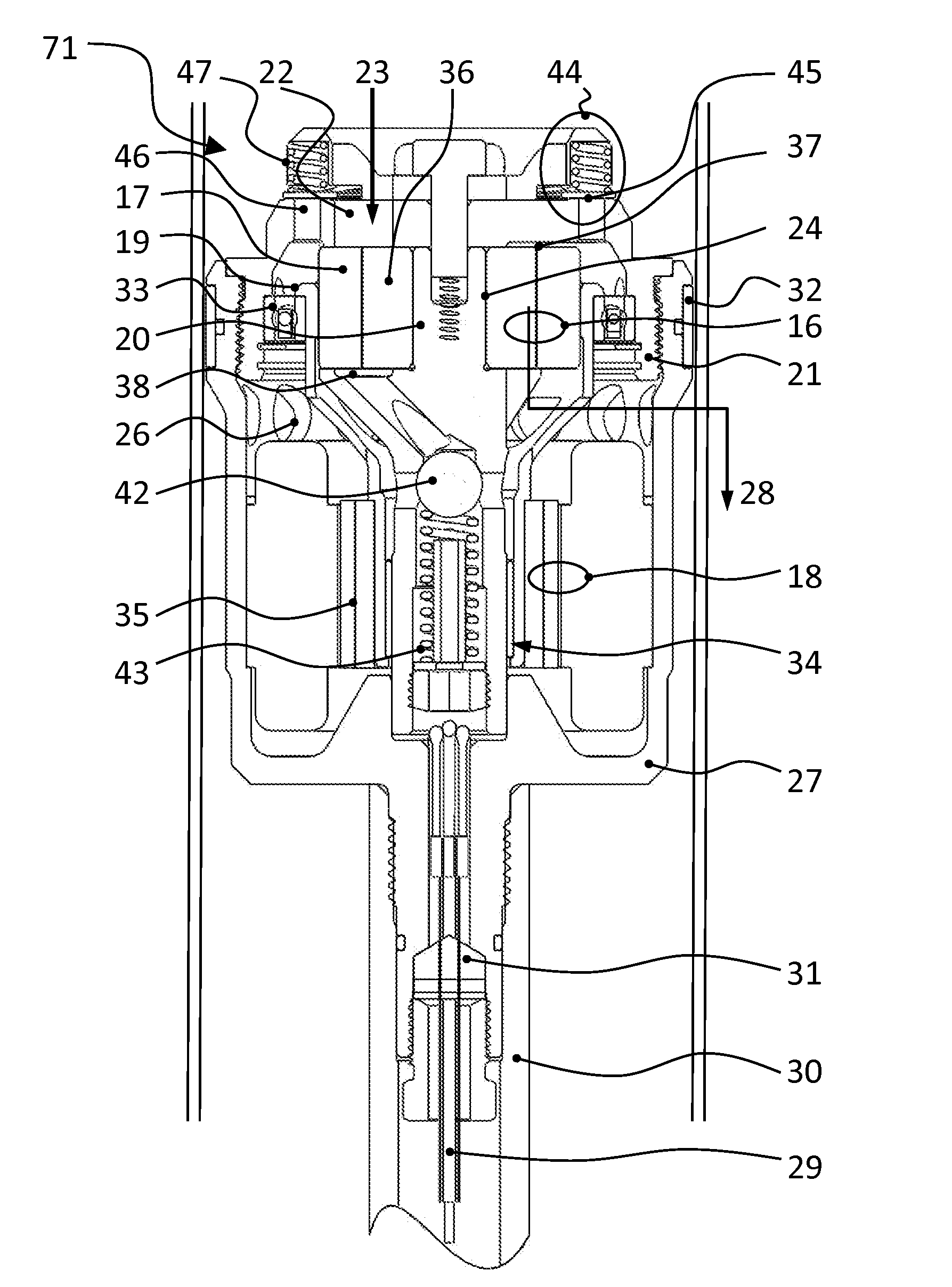

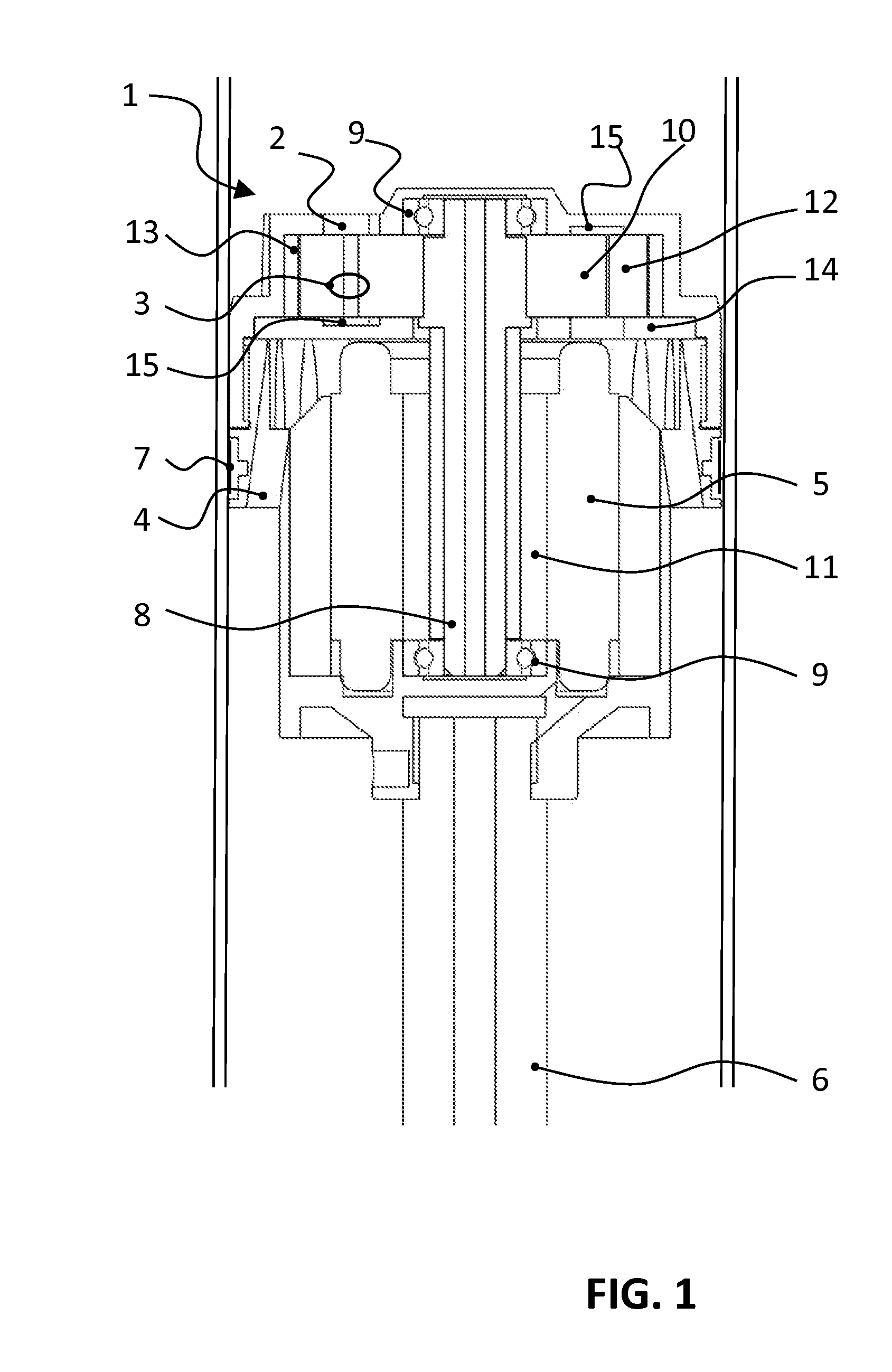

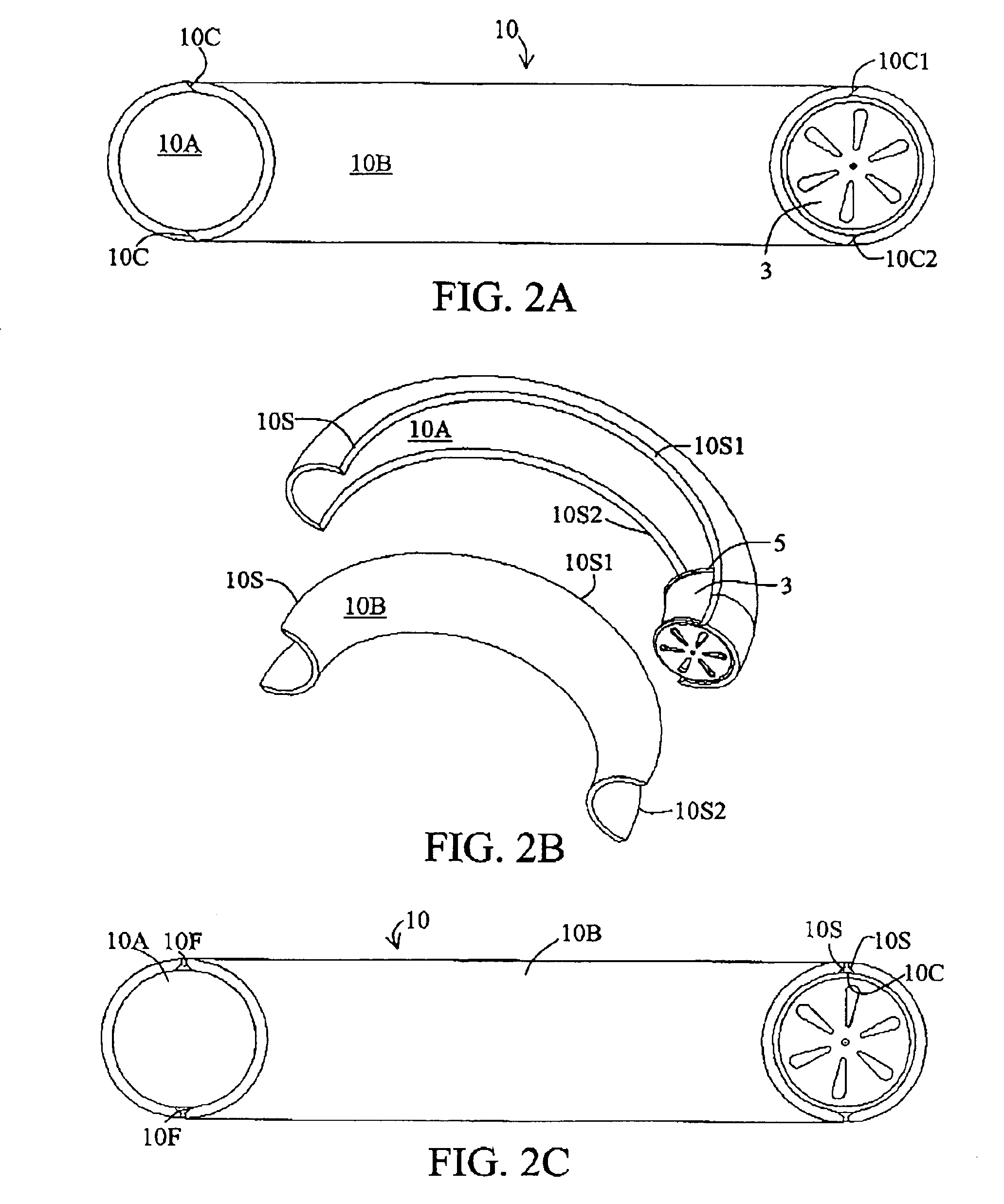

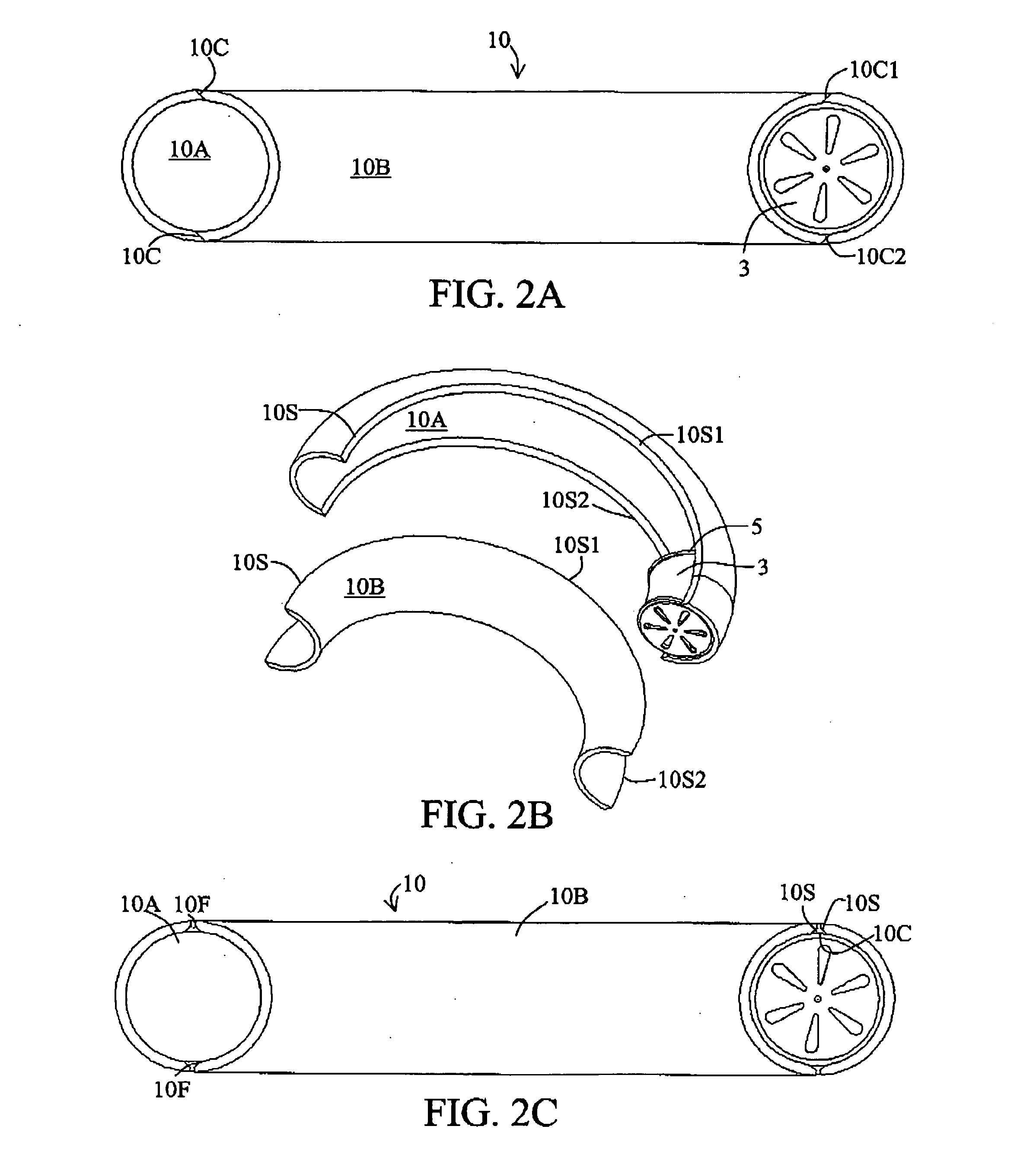

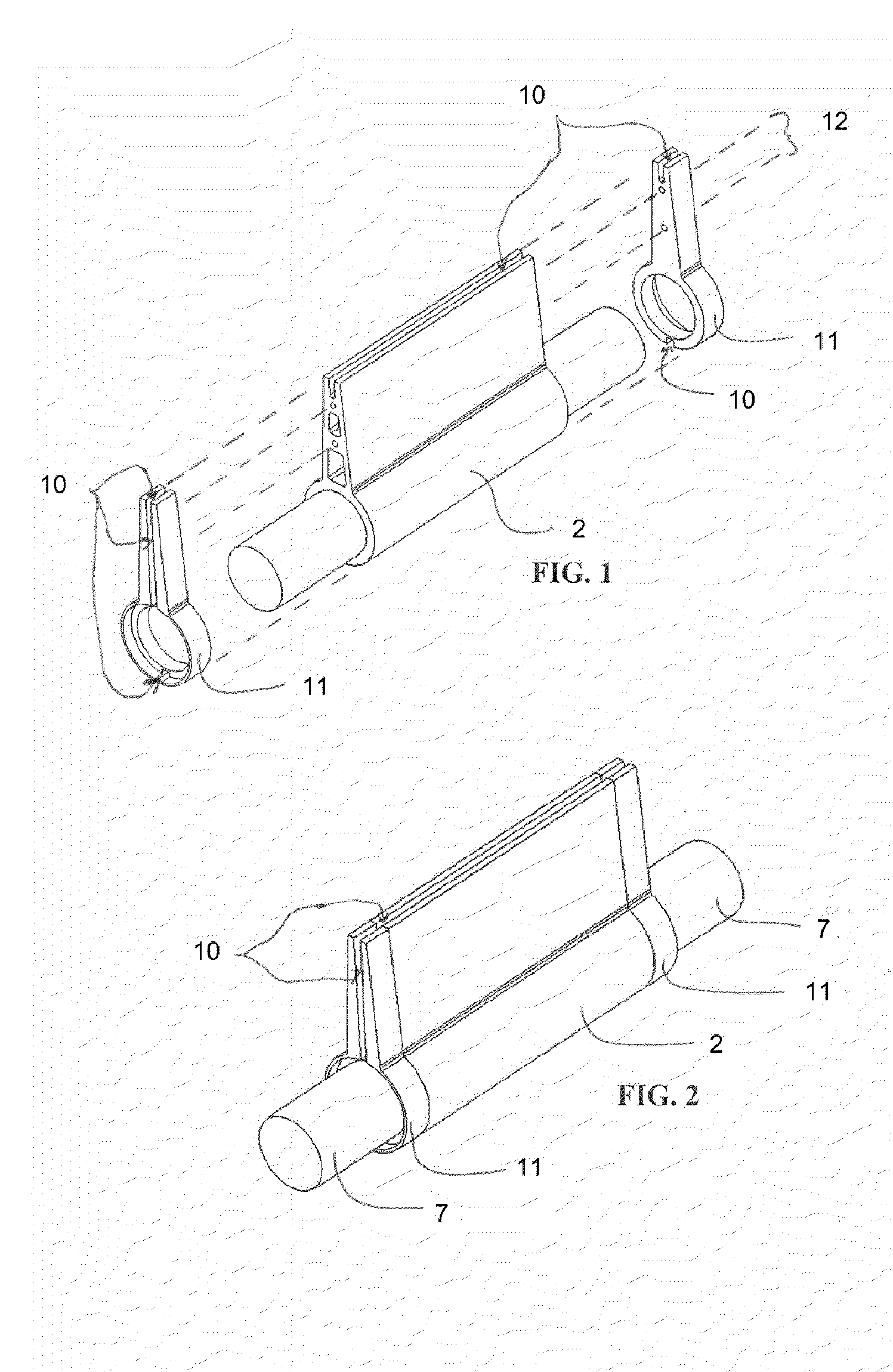

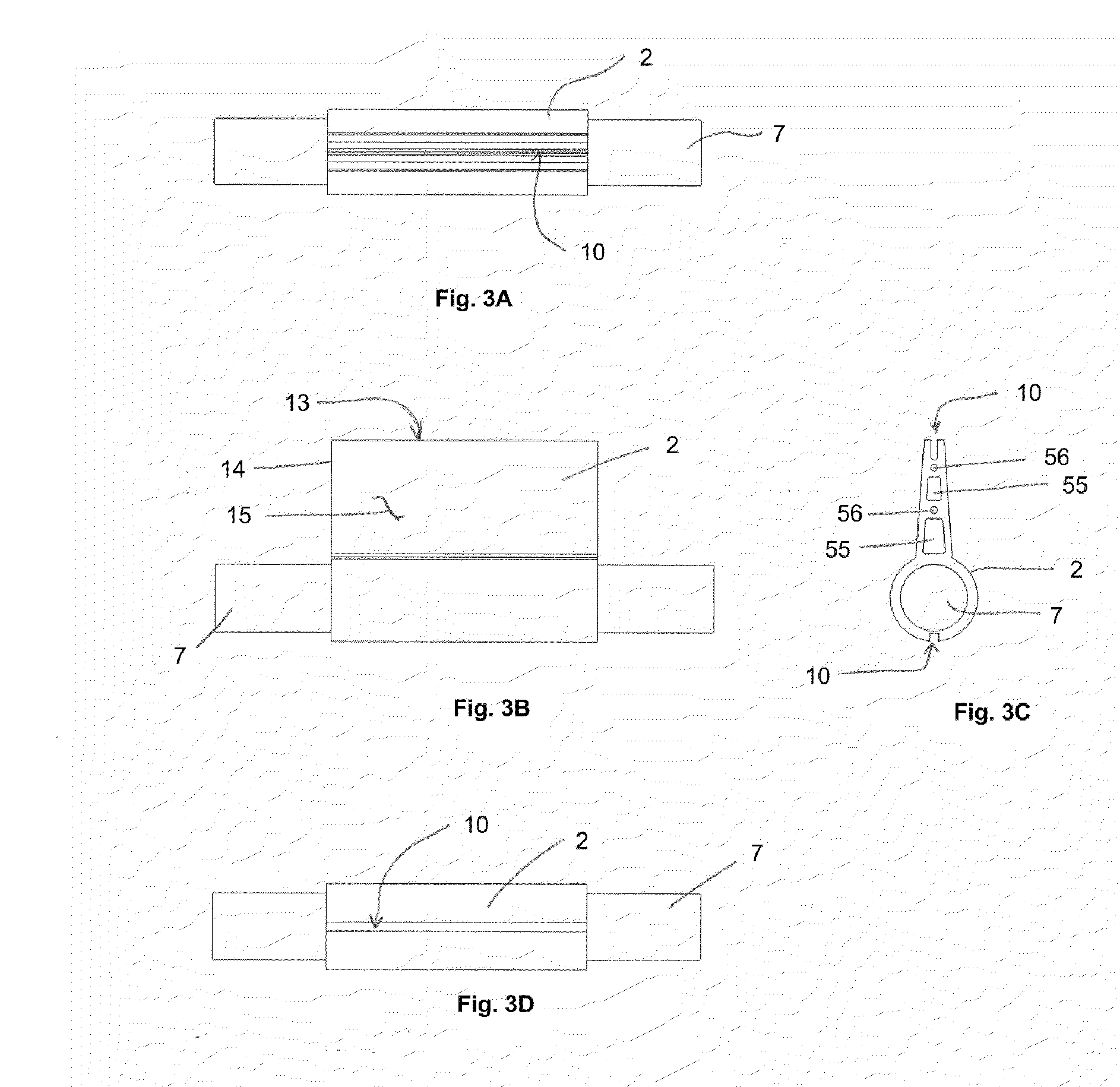

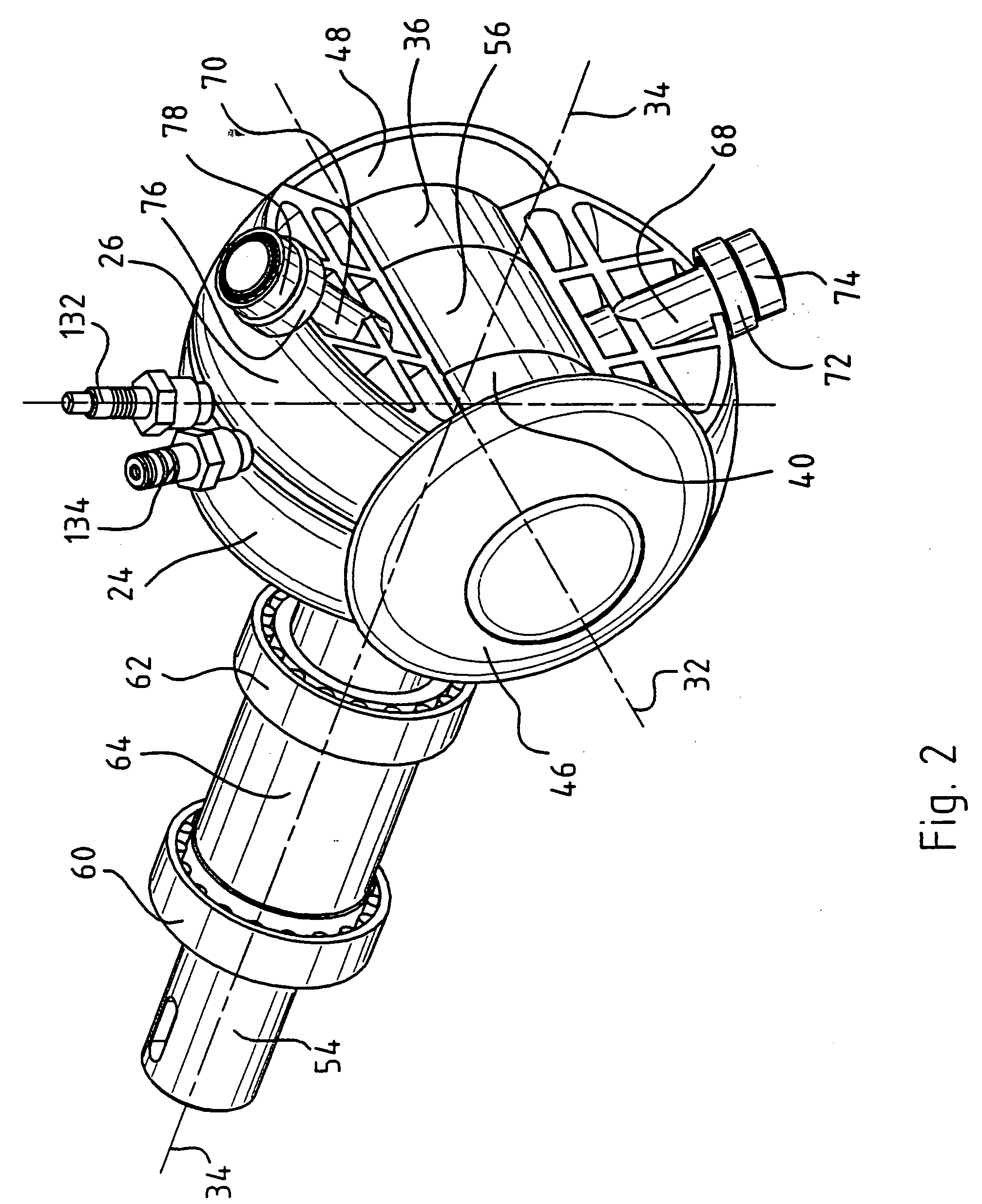

Integrated energy generating damper

A linear energy harvesting device that includes a housing and a piston that moves at least partially through the housing when it is compressed or extended from a rest position. When the piston moves, hydraulic fluid is pressurized and drives a hydraulic motor. The hydraulic motor drives an electric generator that produces electricity. Both the motor and generator are central to the device housing. Exemplary configurations are disclosed such as monotube, twin-tube, tri-tube and rotary based designs that each incorporates an integrated energy harvesting apparatus. By varying the electrical characteristics on an internal generator, the kinematic characteristics of to the energy harvesting apparatus can be dynamically altered. In another mode, the apparatus can be used as an actuator to create linear movement. Applications include vehicle suspension systems (to act as the primary damper component), railcar bogie dampers, or industrial applications such as machinery dampers and wave energy harvesters, and electro-hydraulic actuators.

Owner:CLEARMOTION INC

Integrated energy generating damper

A linear energy harvesting device that includes a housing and a piston that moves at least partially through the housing when it is compressed or extended from a rest position. When the piston moves, hydraulic fluid is pressurized and drives a hydraulic motor. The hydraulic motor drives an electric generator that produces electricity. Both the motor and generator are central to the device housing. Exemplary configurations are disclosed such as monotube, twin-tube, tri-tube and rotary based designs that each incorporates an integrated energy harvesting apparatus. By varying the electrical characteristics on an internal generator, the kinematic characteristics of the energy harvesting apparatus can be dynamically altered. In another mode, the apparatus can be used as an actuator to create linear movement. Applications include vehicle suspension systems (to act as the primary damper component), railcar bogie dampers, or industrial applications such as machinery dampers and wave energy harvesters, and electro-hydraulic actuators.

Owner:CLEARMOTION INC

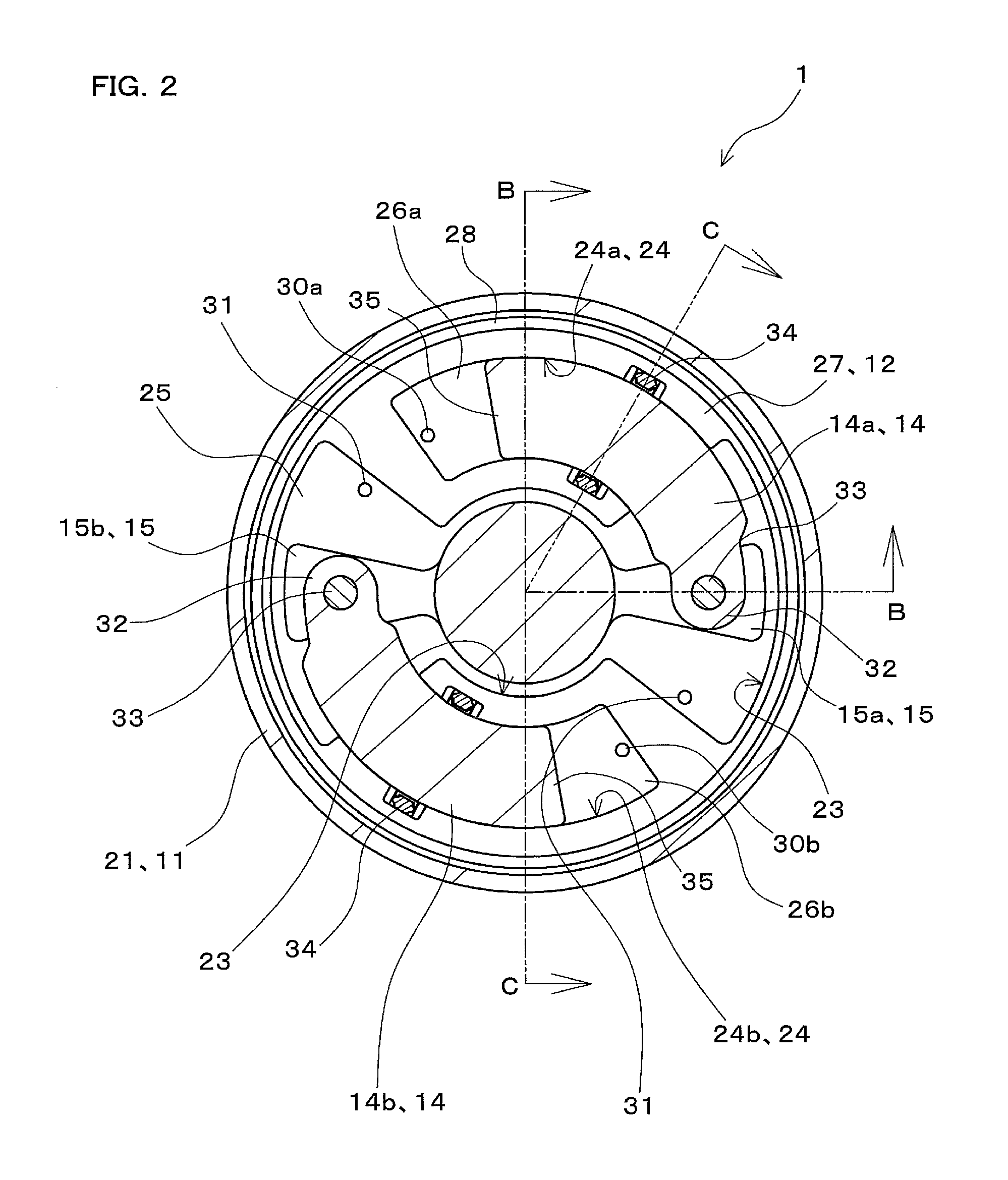

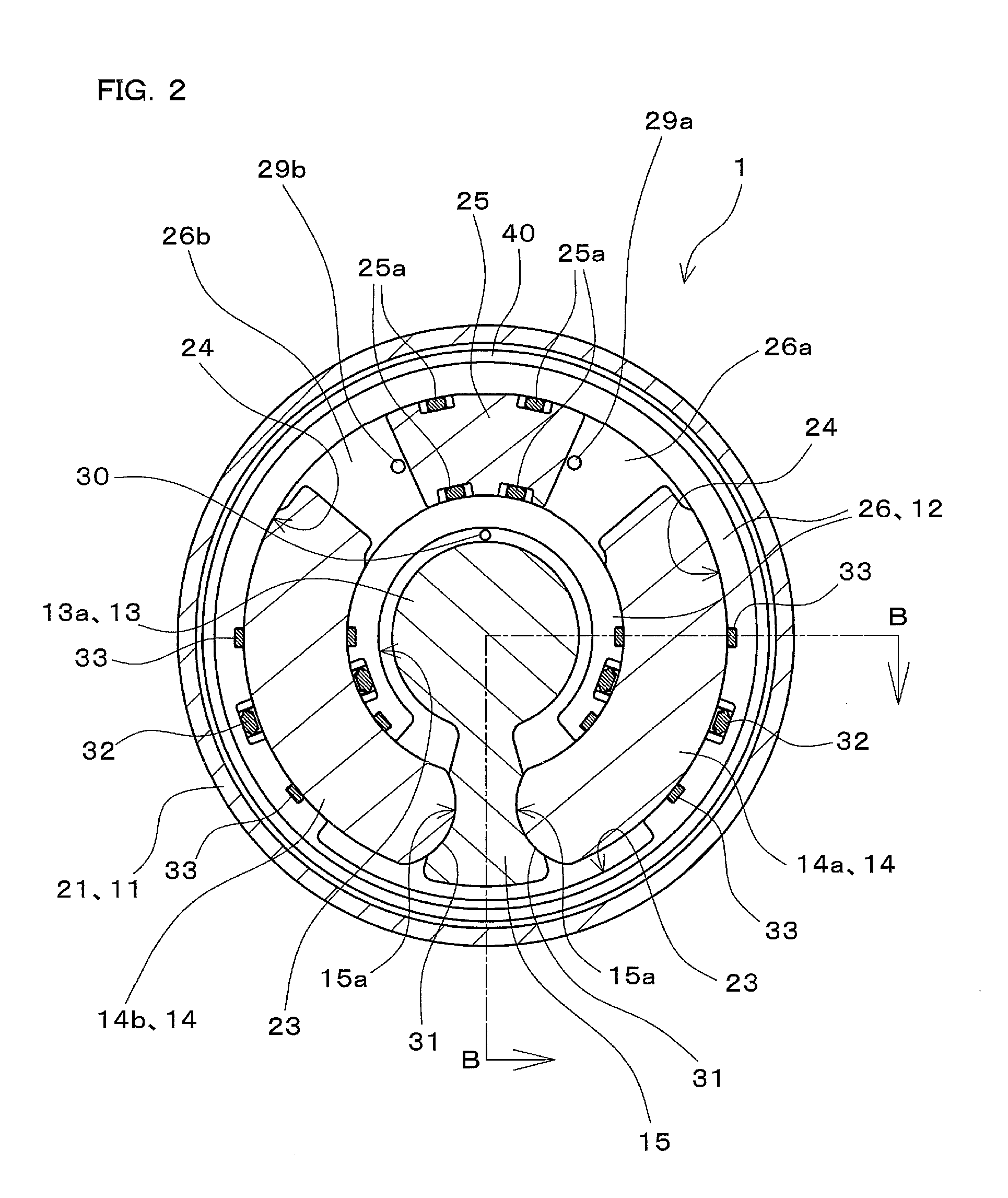

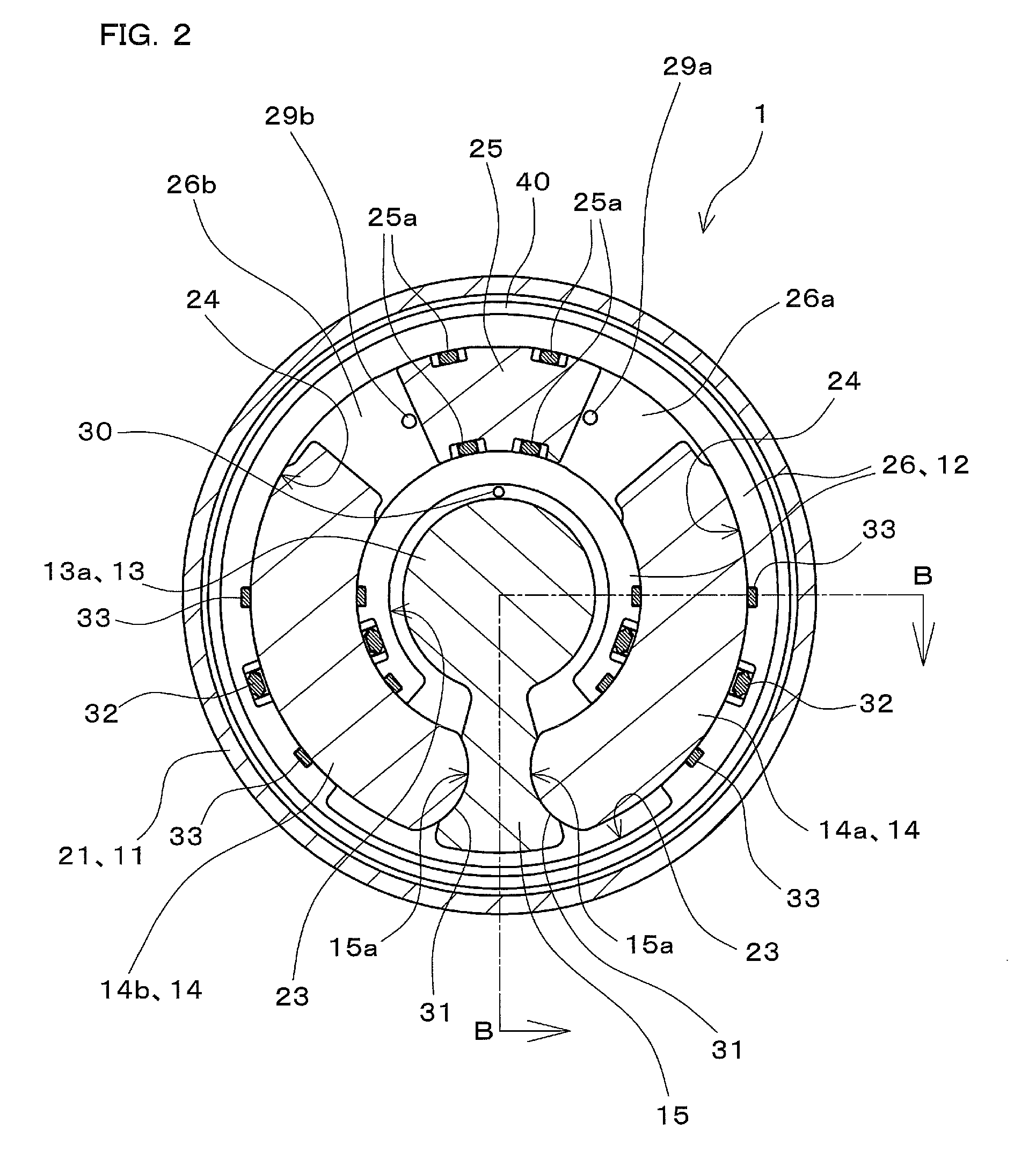

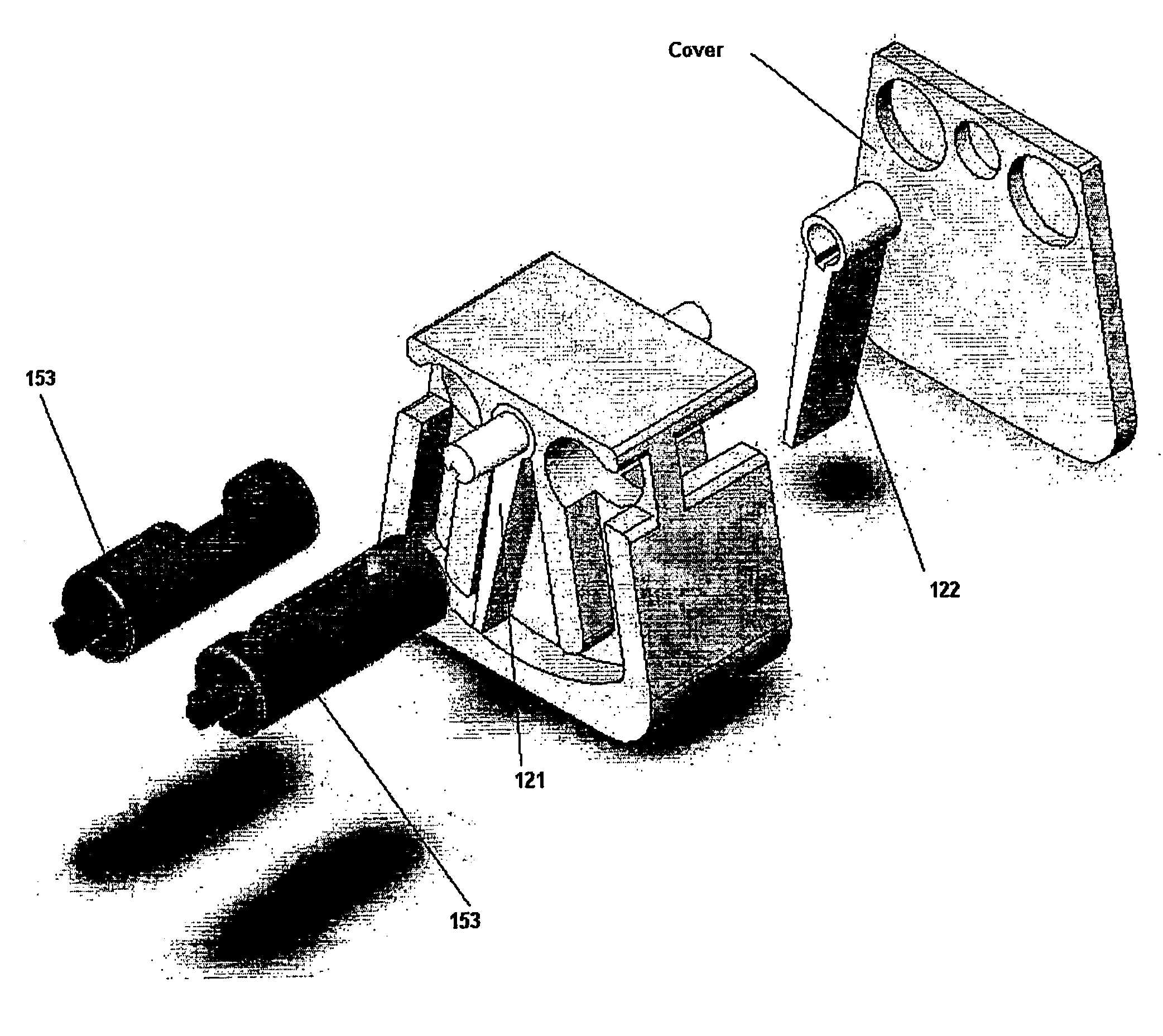

Rotary actuator

ActiveUS20130133513A1Reduce in quantityReduce internal leakageOscillating piston pumpsCombination enginesEngineeringRotary actuator

A cylinder is installed within a case, and an output shaft and an arm that is integrated thereto and extends in a radial direction are installed within the cylinder. A piston extending in an arc slides and is displaced in a circumferential direction of the cylinder within the cylinder. One end portion of the piston is rotatably connected to the arm. The cylinder is internally provided with a first pressure chamber in which the arm is housed and a second pressure chamber in which the other end portion of the arm is slidably installed. A pressure medium is fed into one of the first and second pressure chambers and discharged from the other, and the output shaft pivots in a rotational direction.

Owner:NABLESCO CORP

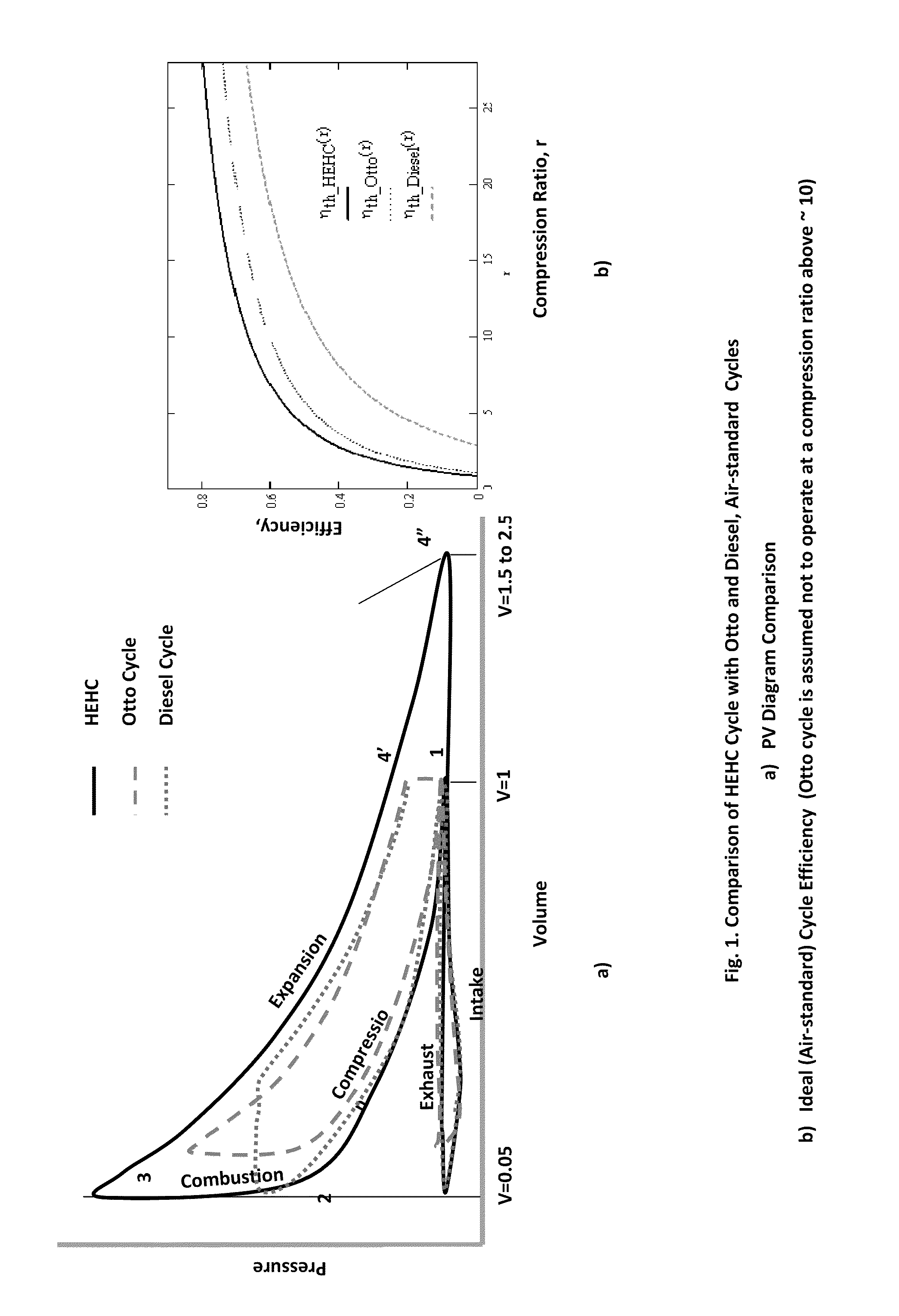

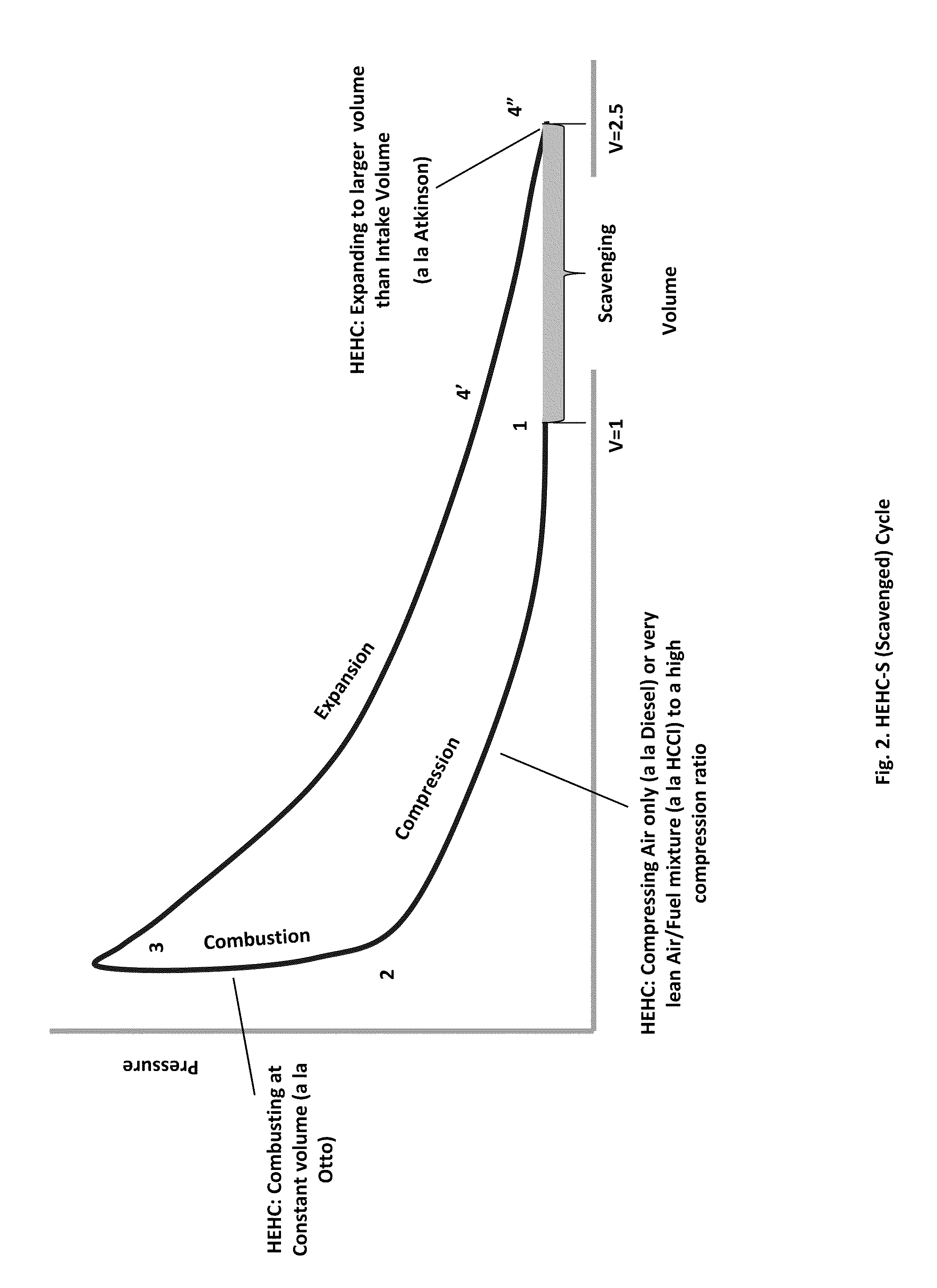

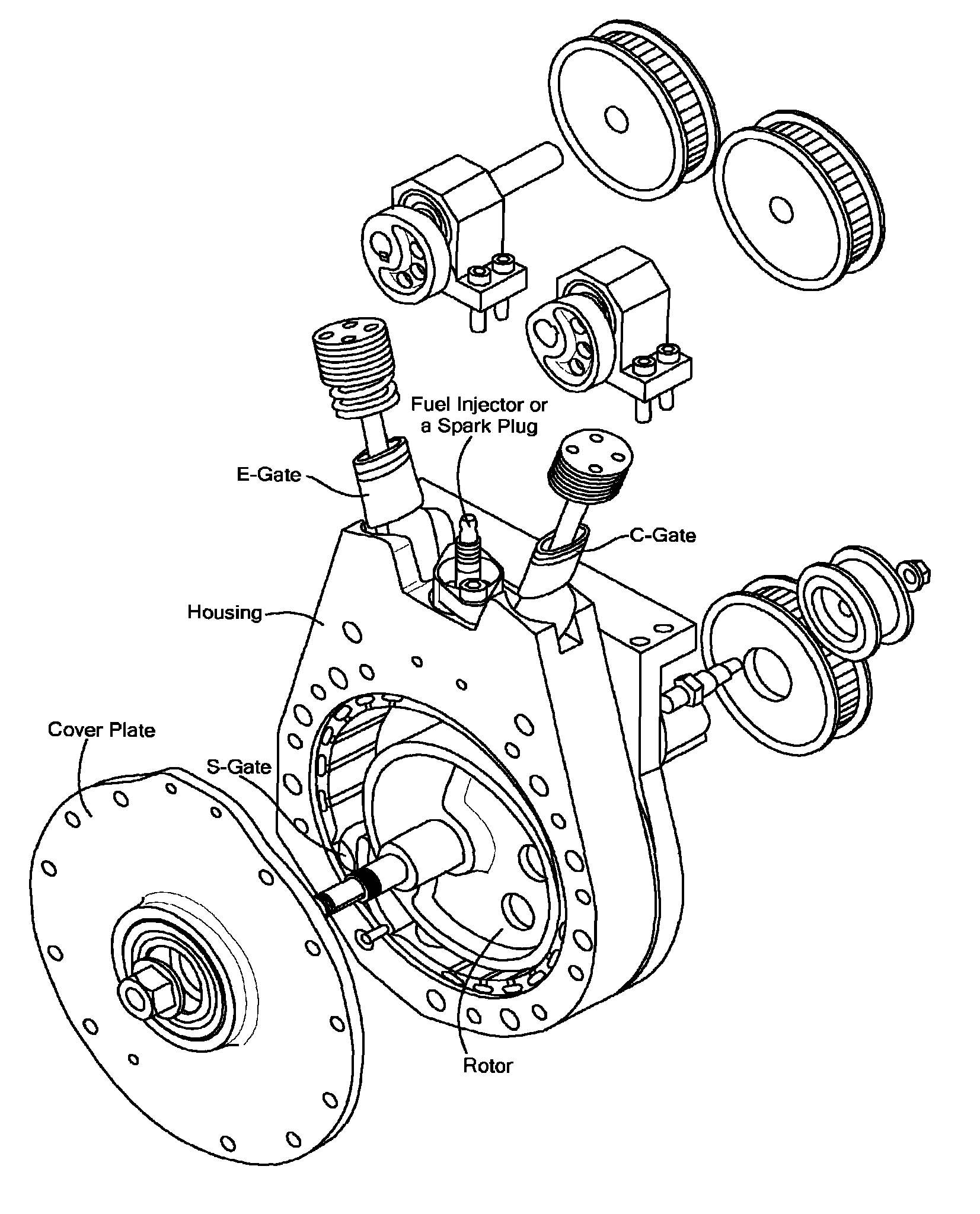

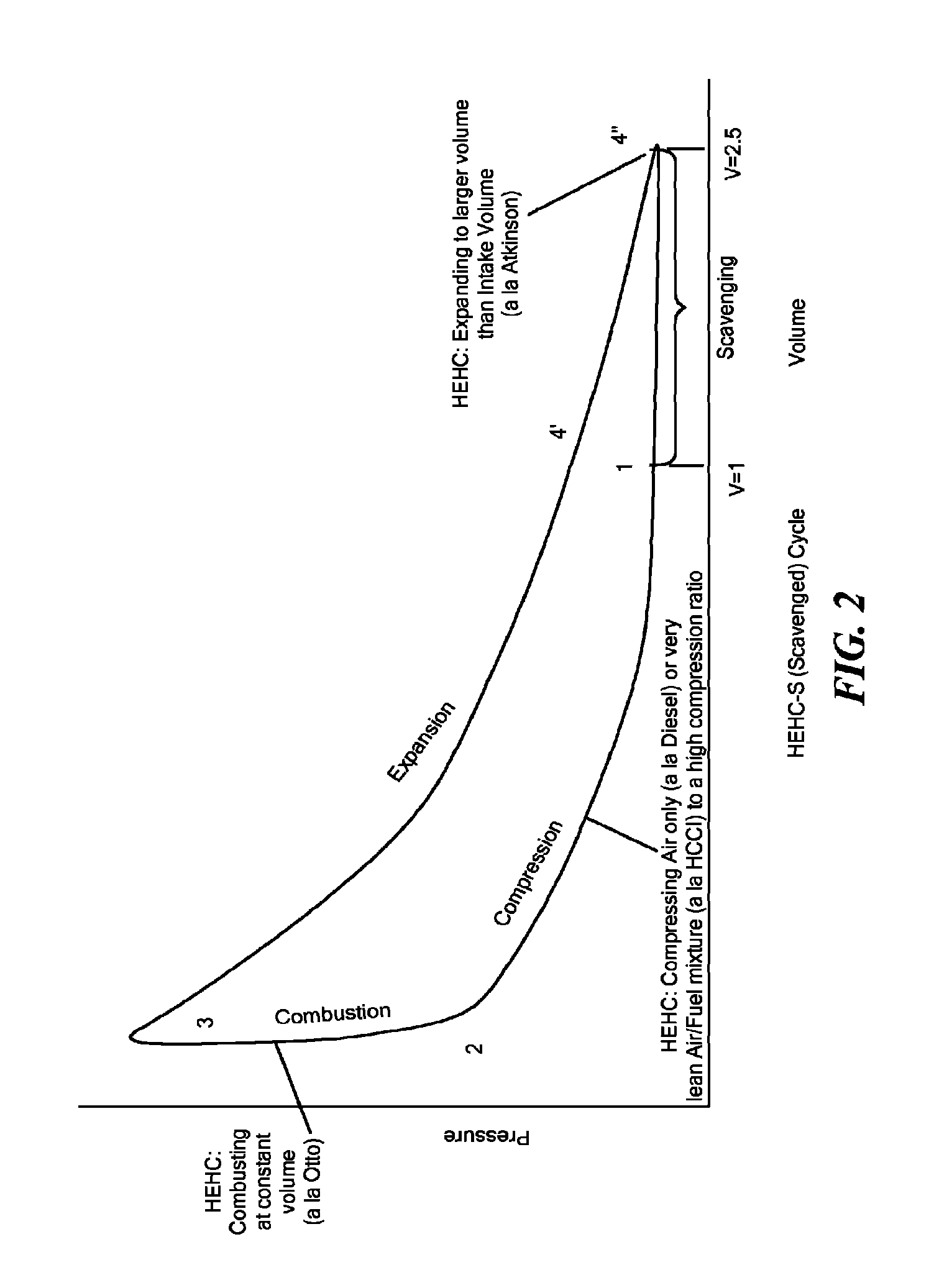

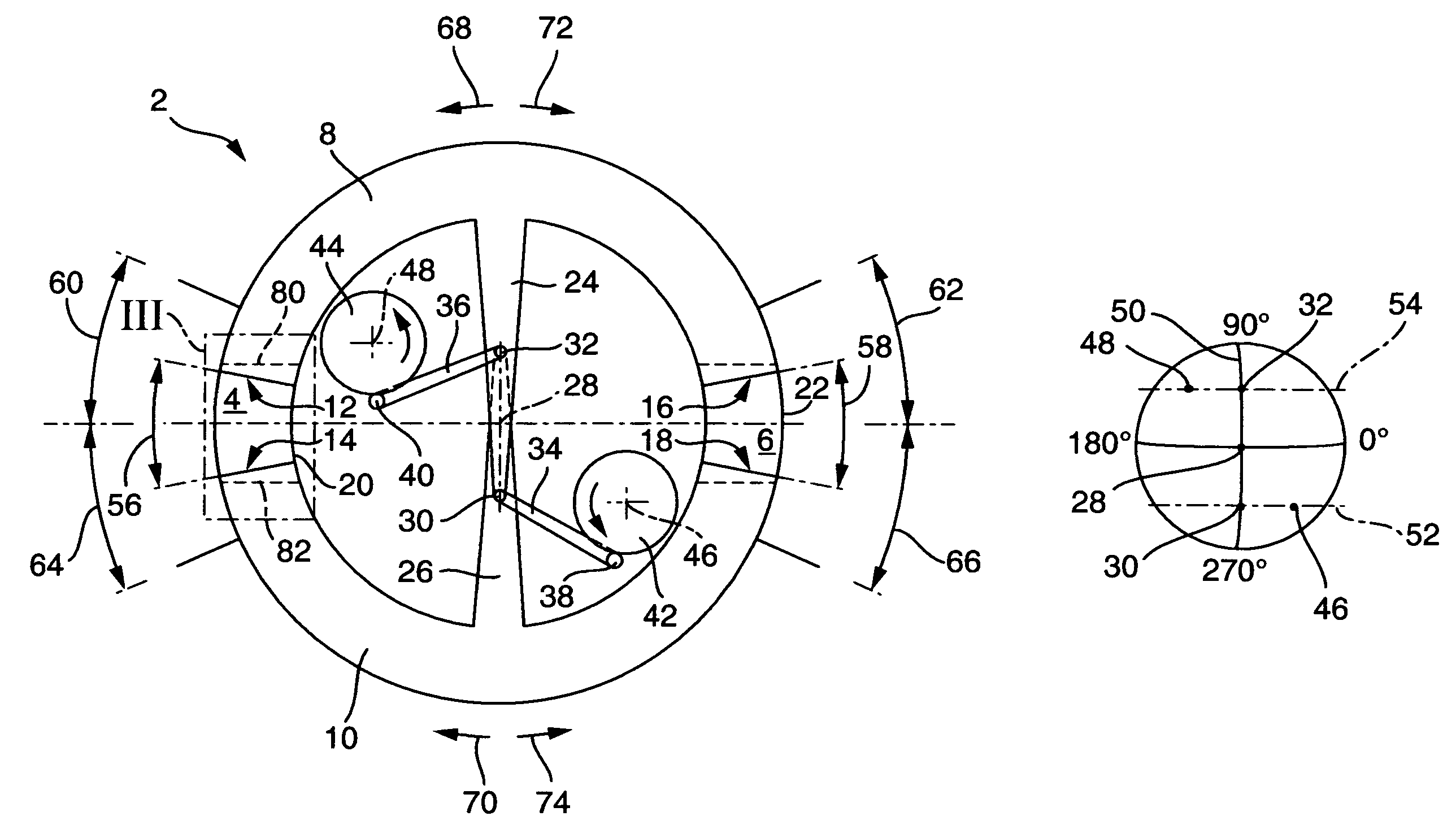

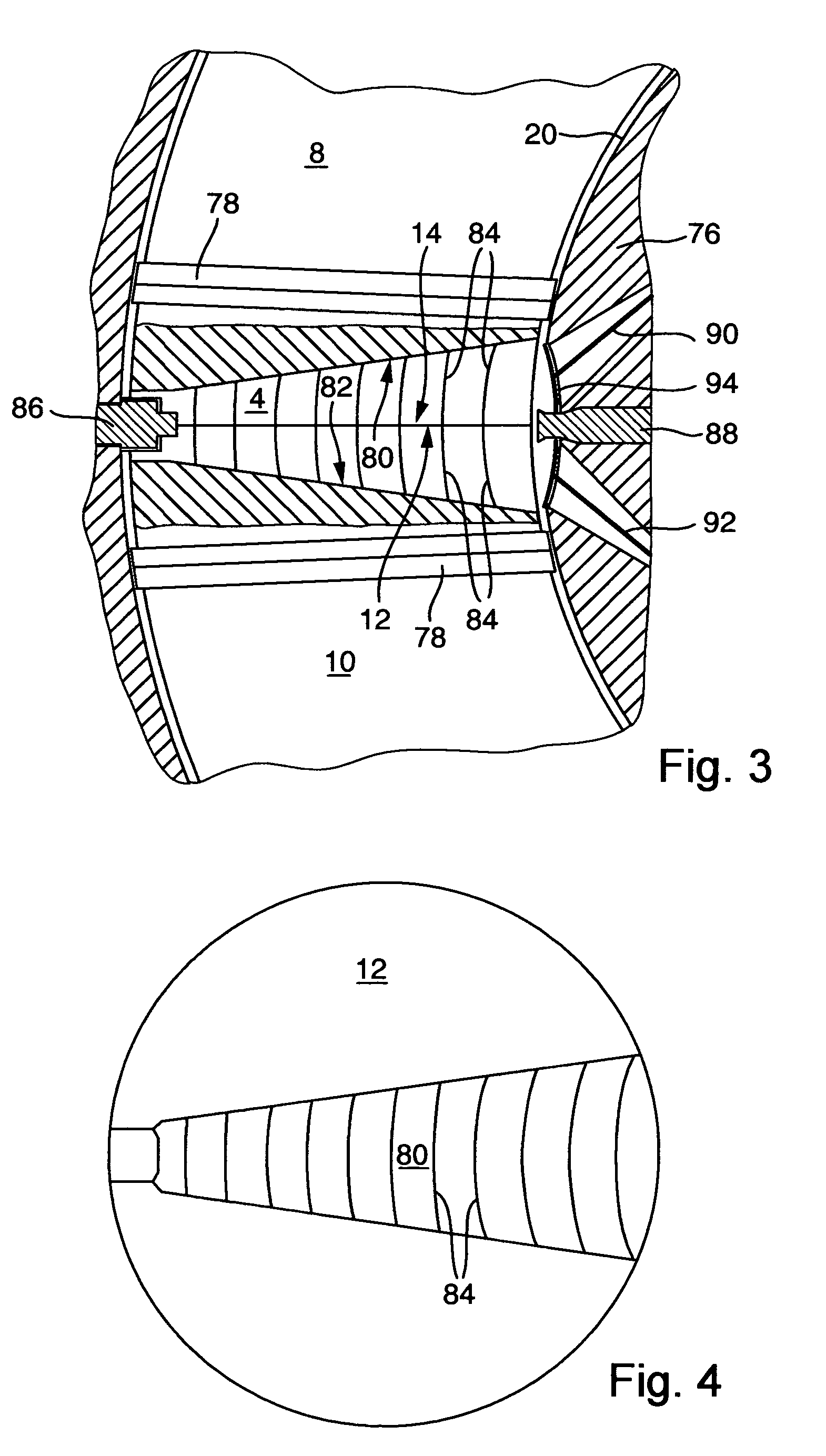

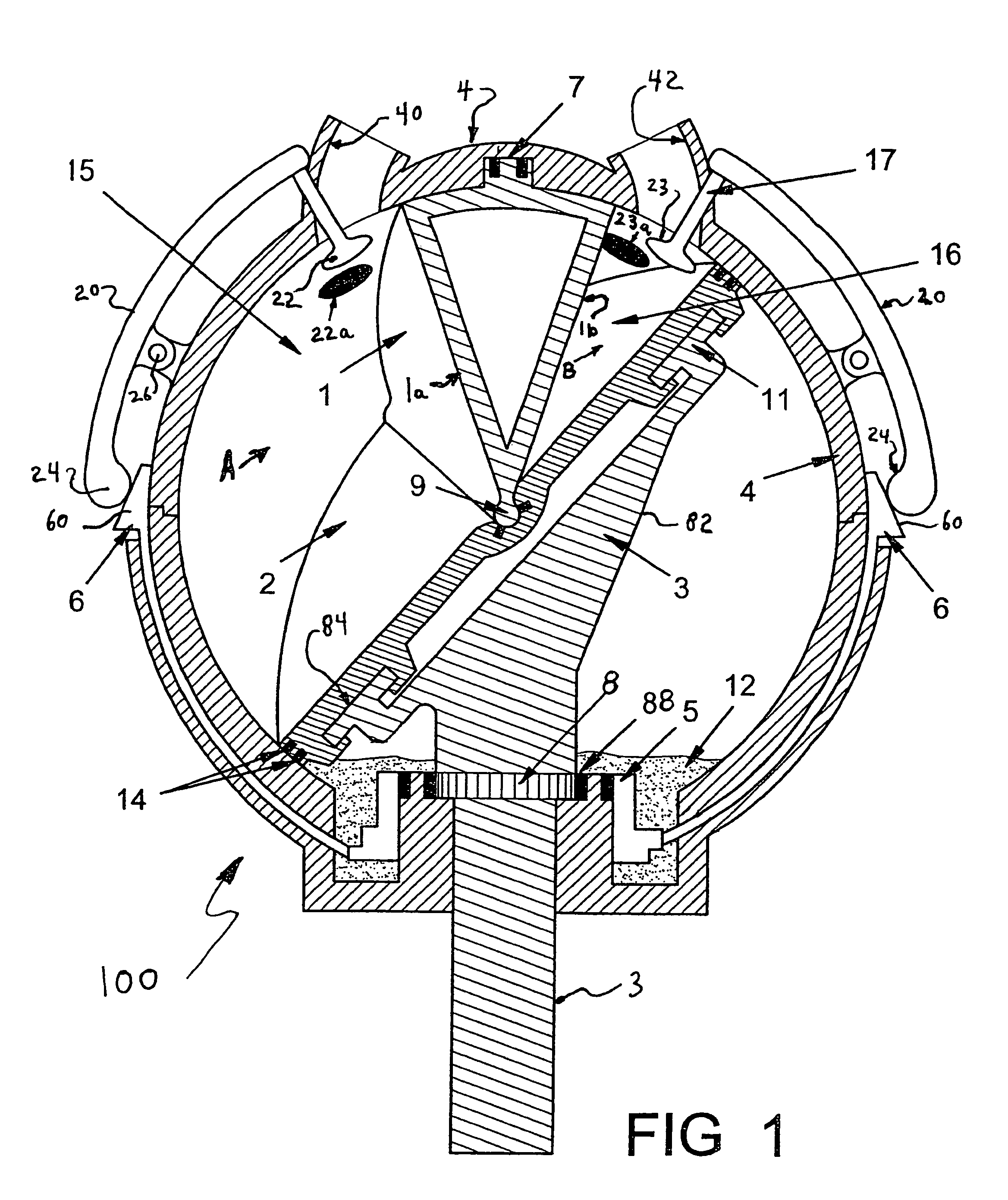

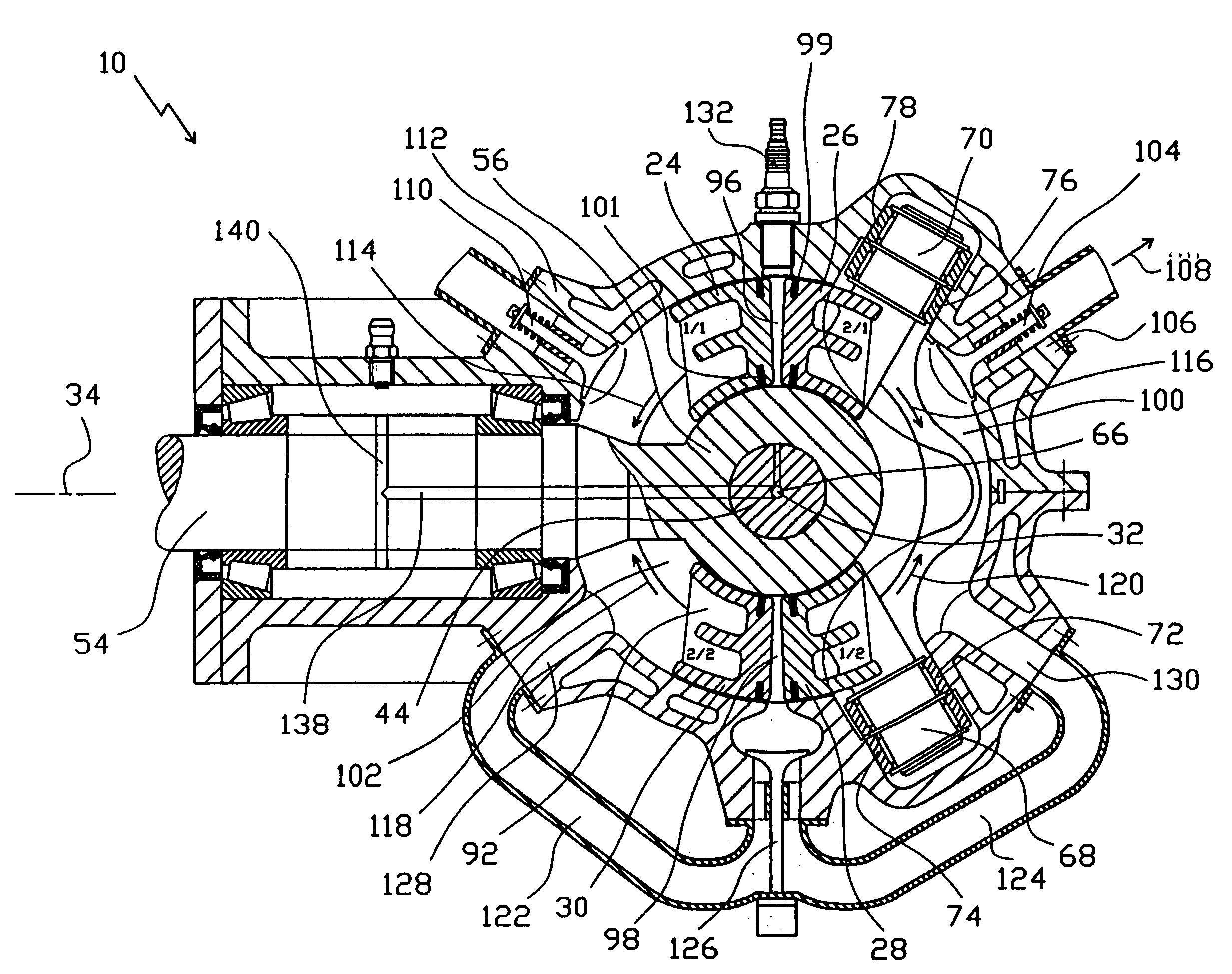

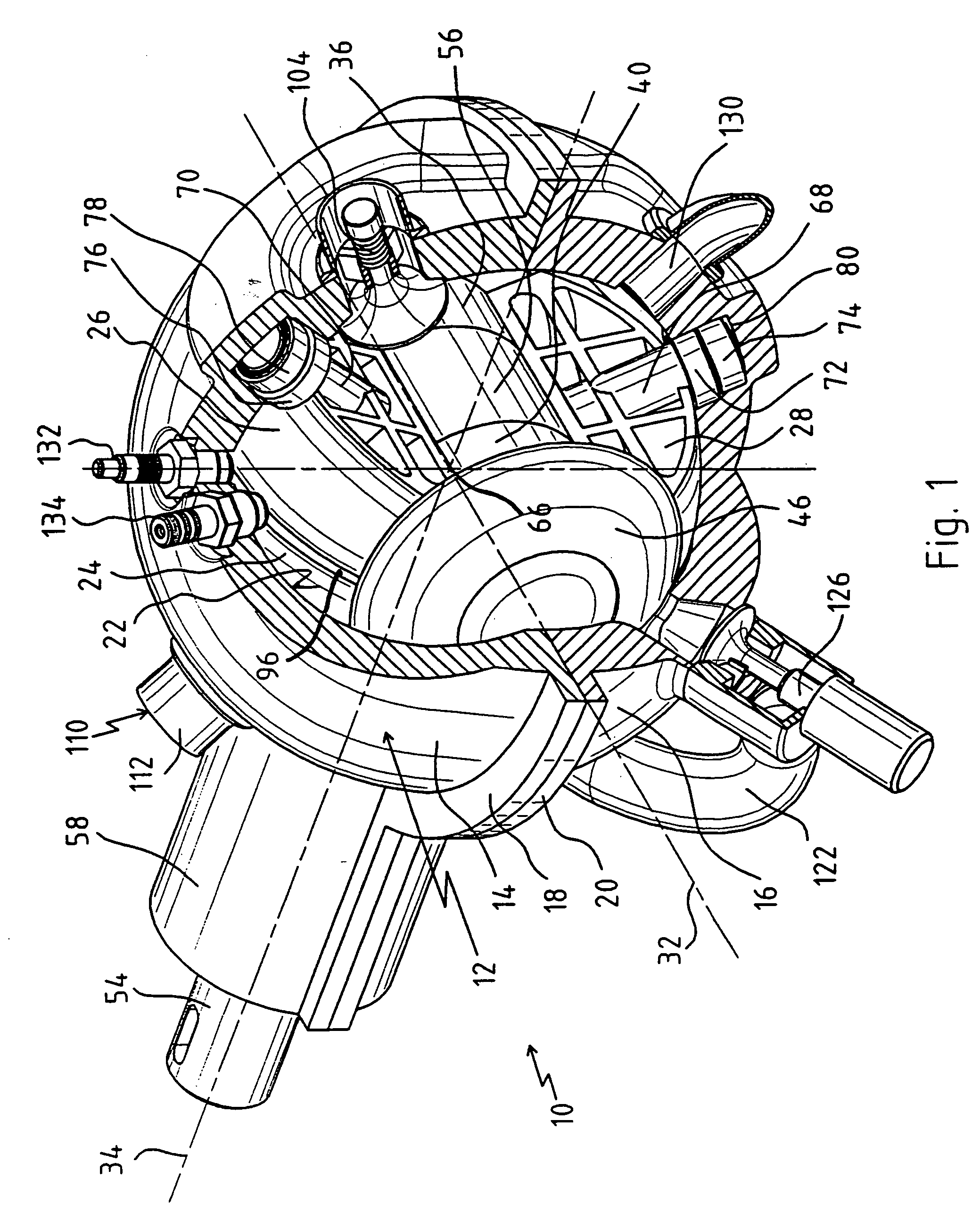

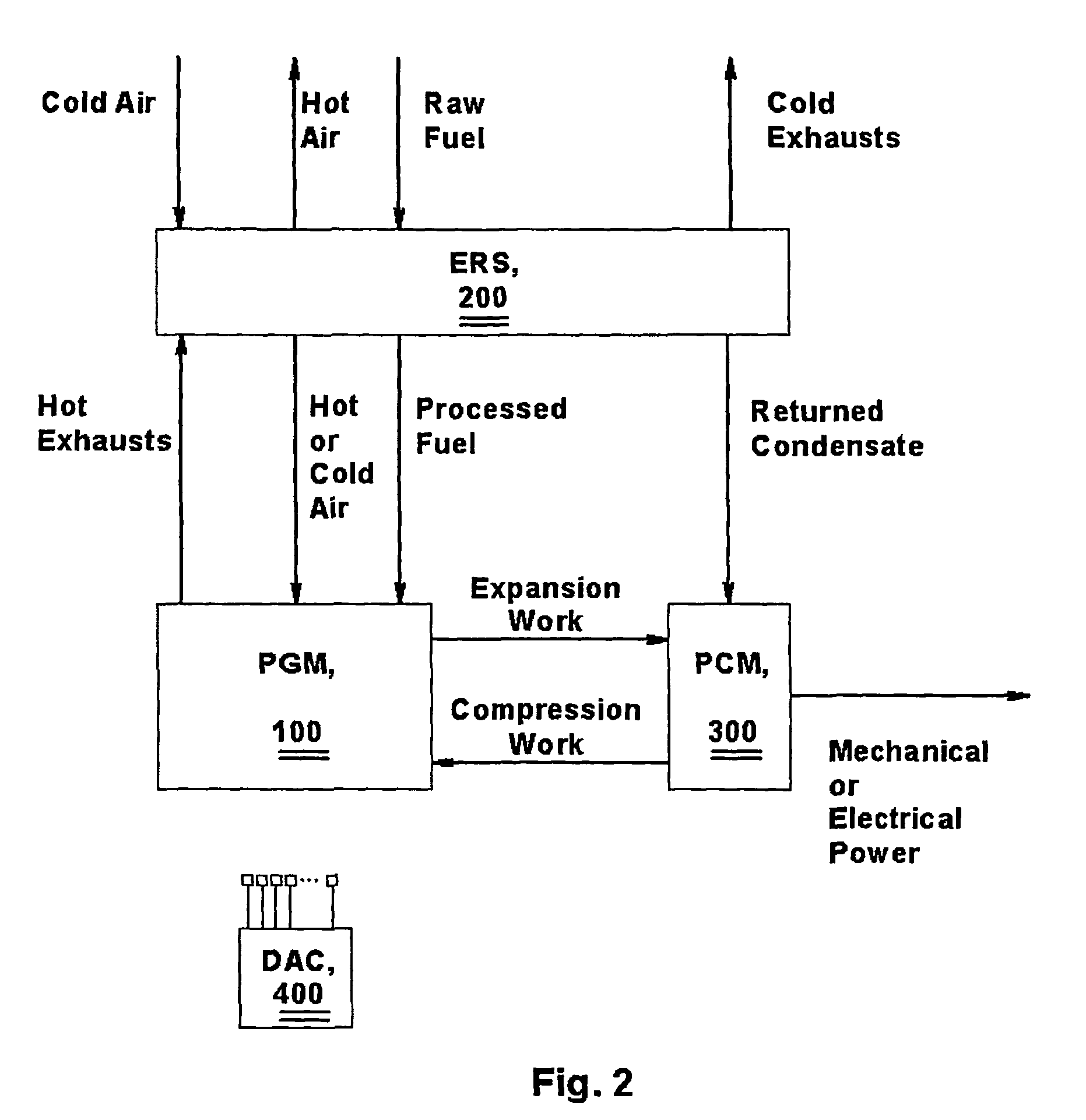

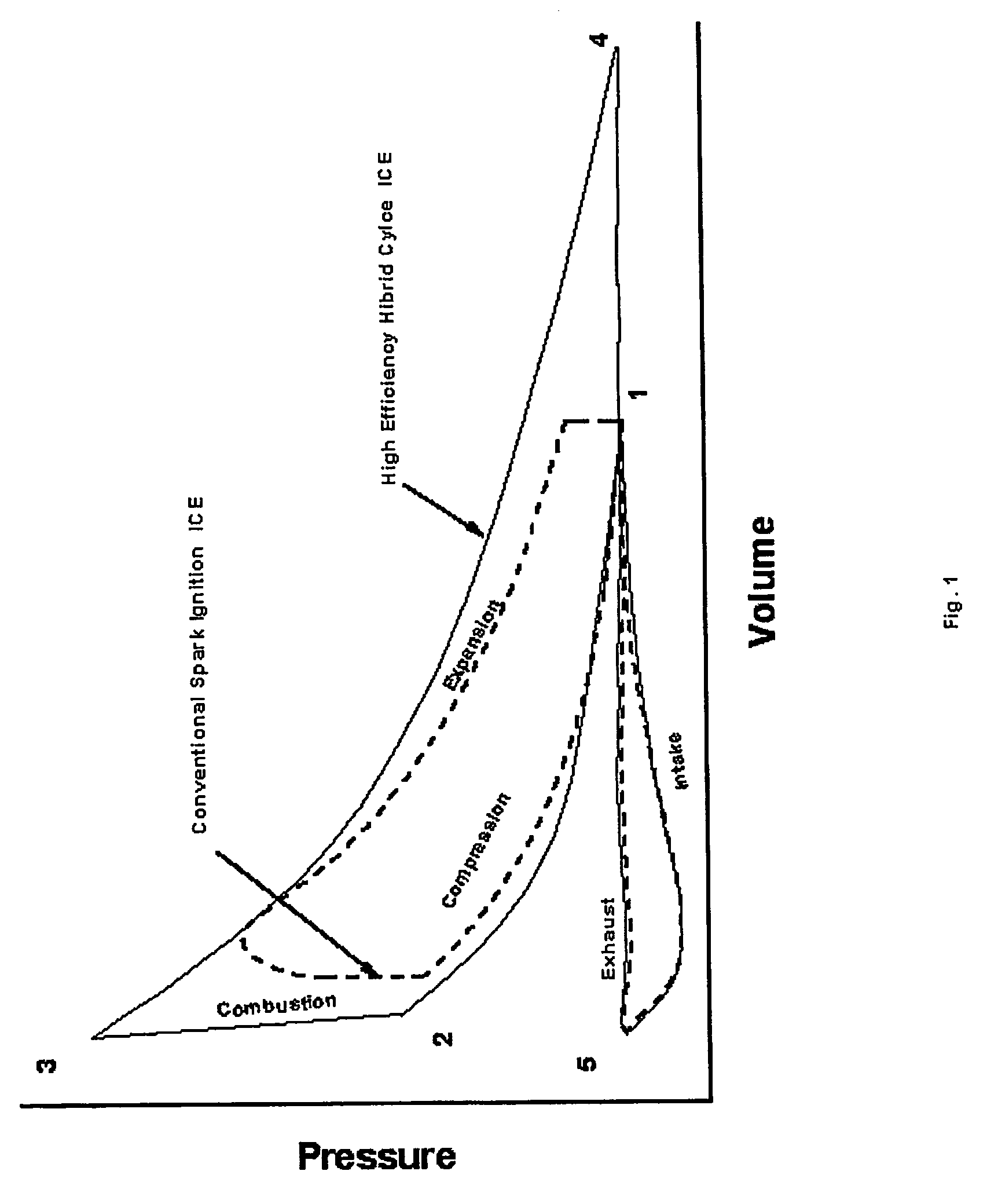

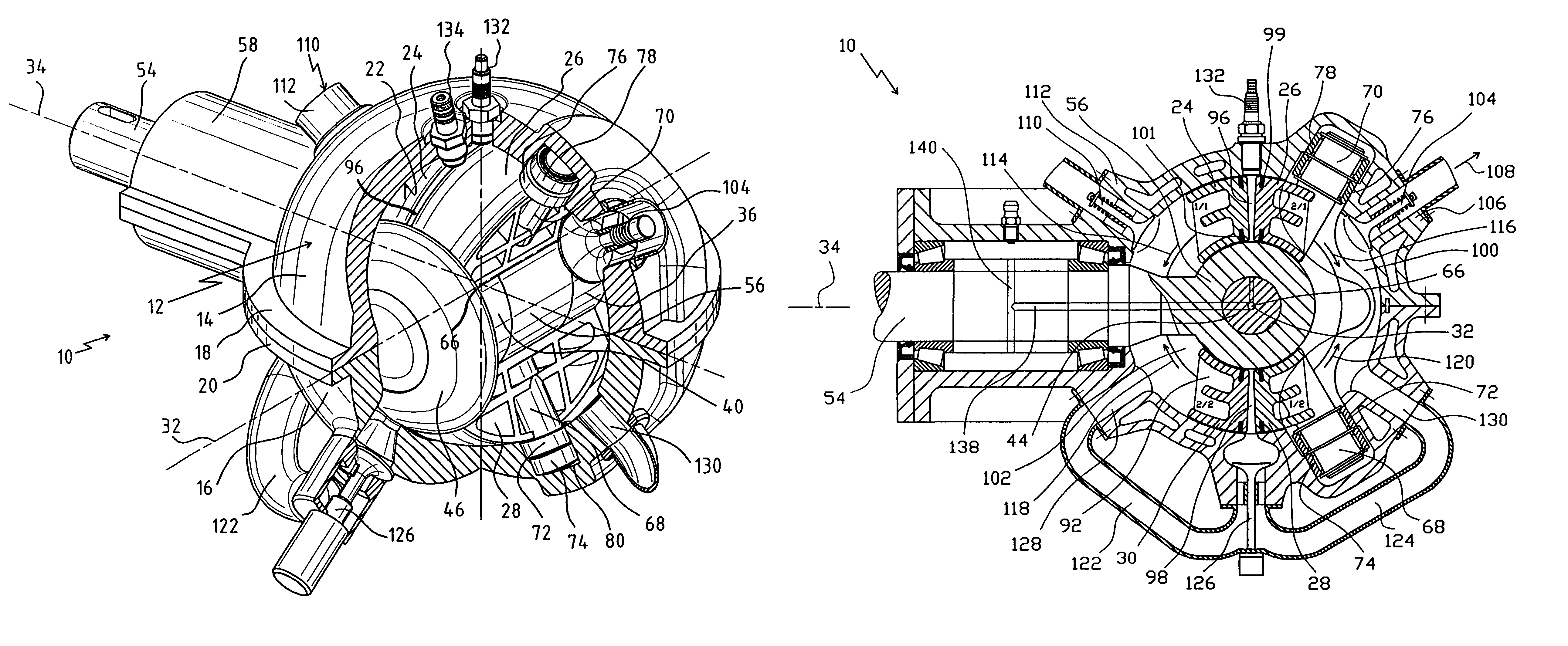

Isochoric Heat Addition Engines and Methods

ActiveUS20110023814A1Improve sealingReduce tangential flow of fluidInternal combustion piston enginesFuel-injection pumpsProcess engineeringHigh-efficiency hybrid cycle

Engines and methods execute a high efficiency hybrid cycle, which is implemented in a volume within an engine. The cycle includes isochoric heat addition and over-expansion of the volume within the engine, wherein the volume is reduced in a compression portion of the cycle from a first quantity to a second quantity, the volume is held substantially constant at the second quantity during a heat addition portion of the cycle, and the volume is increased in an expansion portion of the cycle to a third quantity, the third quantity being larger than the first quantity.

Owner:LIQUIDPISTON INC

Toroidal internal combustion engine

InactiveUS6880494B2Improve performanceEmission reductionInternal combustion piston enginesEngine of arcuate-engagement typeExhaust valveInlet valve

Toroidal internal combustion engine comprising two concentric engine rings. Intake valves are assembled in two faces of one set of pistons and exhaust valves in two faces of the second set of pistons. The intake-valve pistons are fixedly attached to one of the engine rings and the exhaust-valve pistons to the other engine ring. The face of one intake-valve piston and the face of one adjacent exhaust-valve piston form boundaries of an engine chamber. Combustion forces on the piston faces force the two concentric engine rings to counter-rotate. The intake-valve piston and the adjacent exhaust-valve piston sweep the same chamber volume at different strokes of the engine cycle. The engine is constructed of CRC material and mounted on a central shaft, with the intake manifold and the exhaust manifold mounted on each side of the engine, providing a lightweight, self-lubricating, highly fuel efficient, and dynamically balanced engine.

Owner:APPLIED THERMAL SCI

Rotary valveless internal combustion engine

InactiveUS7222601B1Quickly and efficiently and economically convertSave materialInternal combustion piston enginesEngine of arcuate-engagement typeWork cycleEngineering

A rotatably alternating air or water cooled two-stroke internal combustion engine comprising a cylindrical casing, and a rotor comprising two radially extending vanes affixed to a shaft rotatably mounted within the casing upon two end plates. Two longitudinally extending walls affixed to the casing. Sealing strips provided between said walls, the shaft, the vanes, the casing and the end plates respectively. The casing and / or the end plates equipped with plurality of ports which communicate with interior chambers formed between the vanes and the walls, allowing for intake of combustible air-fuel mixture and exhaust thereafter. Ignition means delivering a spark at the end of each working cycle. An extendable and adjustable connecting rod assembly converting the oscillating bi-directional rotary motion of the output shaft into a continuous unidirectional motion of the main shaft. A self lubricating mechanism incorporated into the engine.

Owner:KAMENOV KAMEN GEORGE

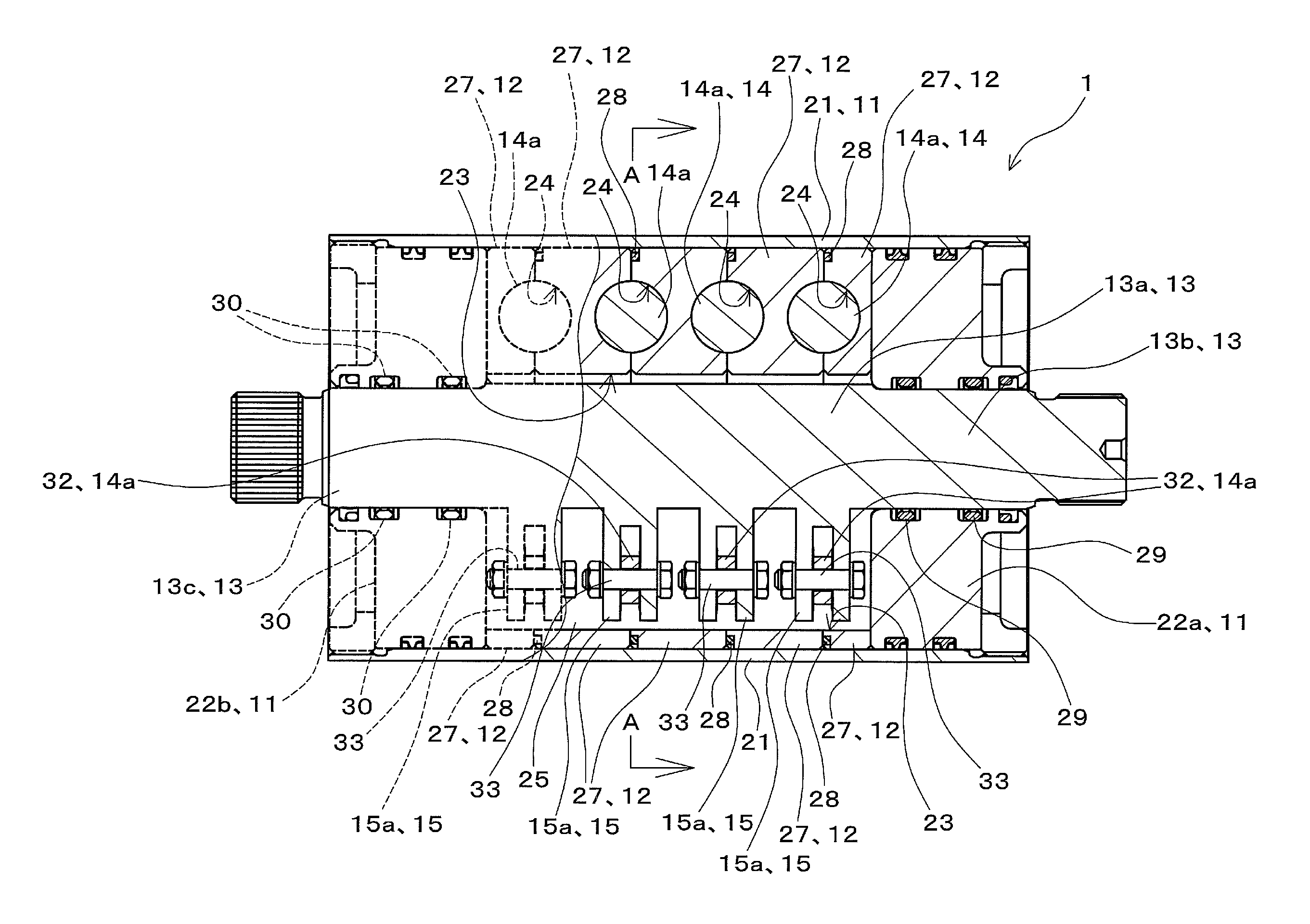

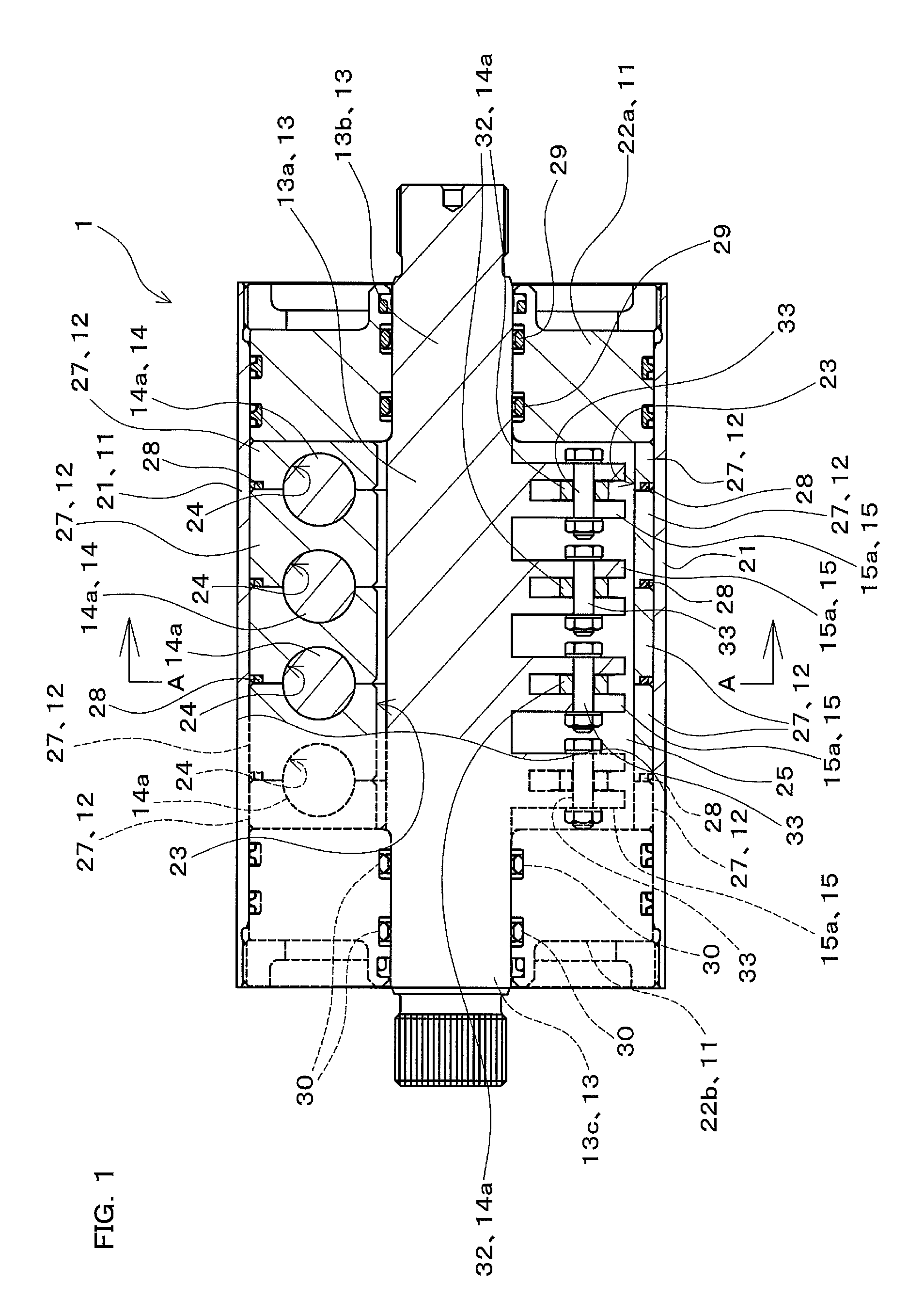

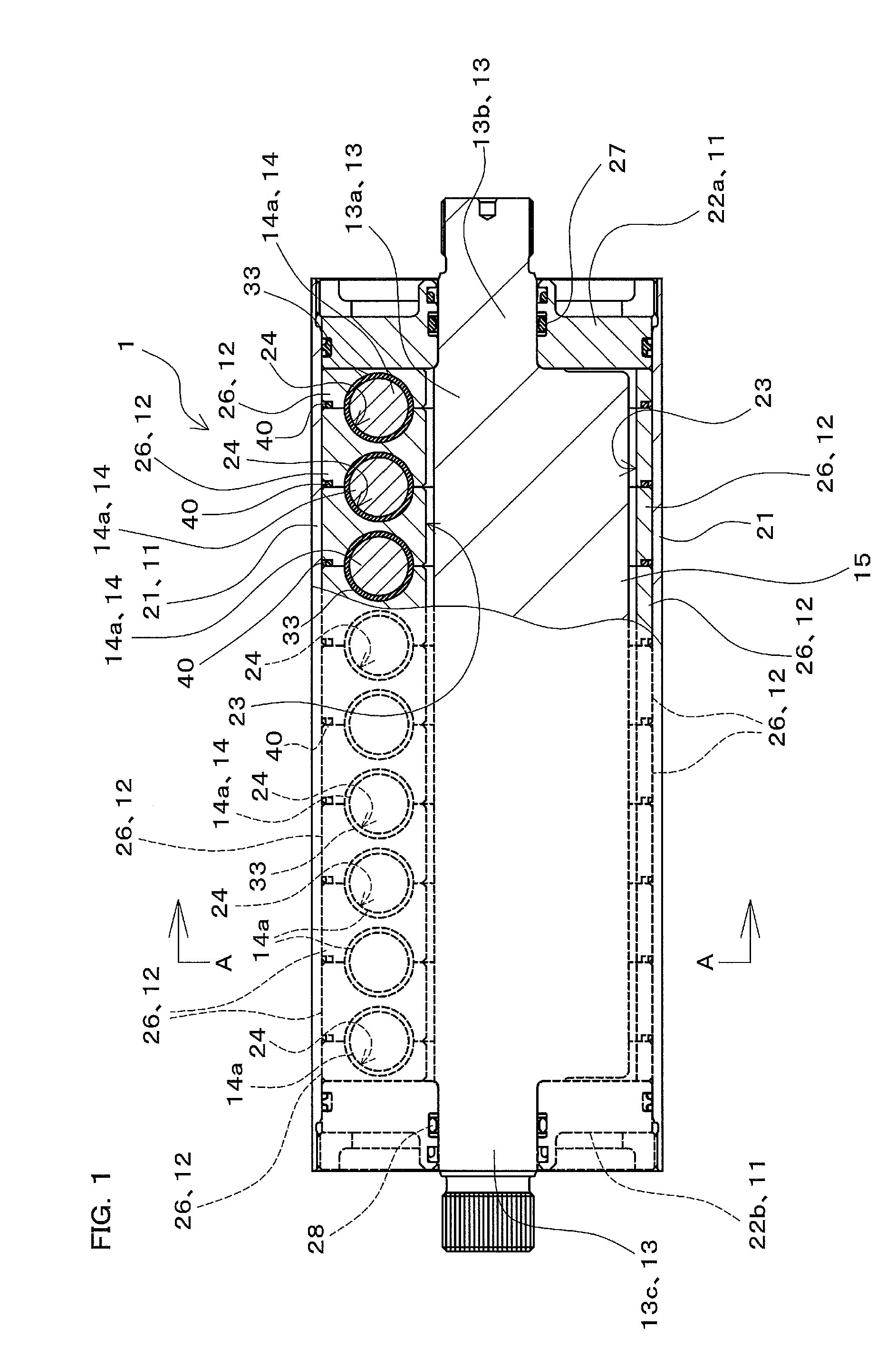

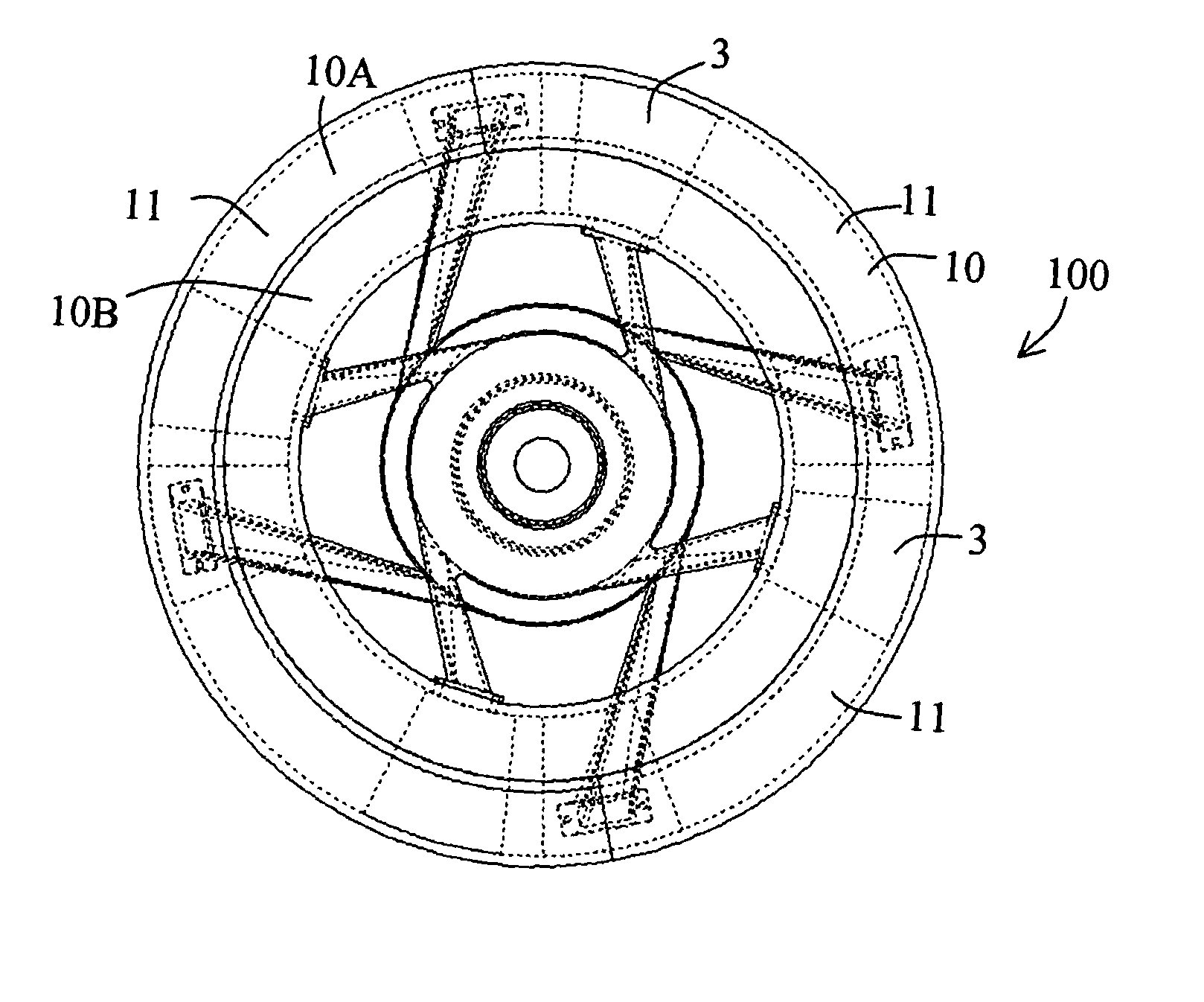

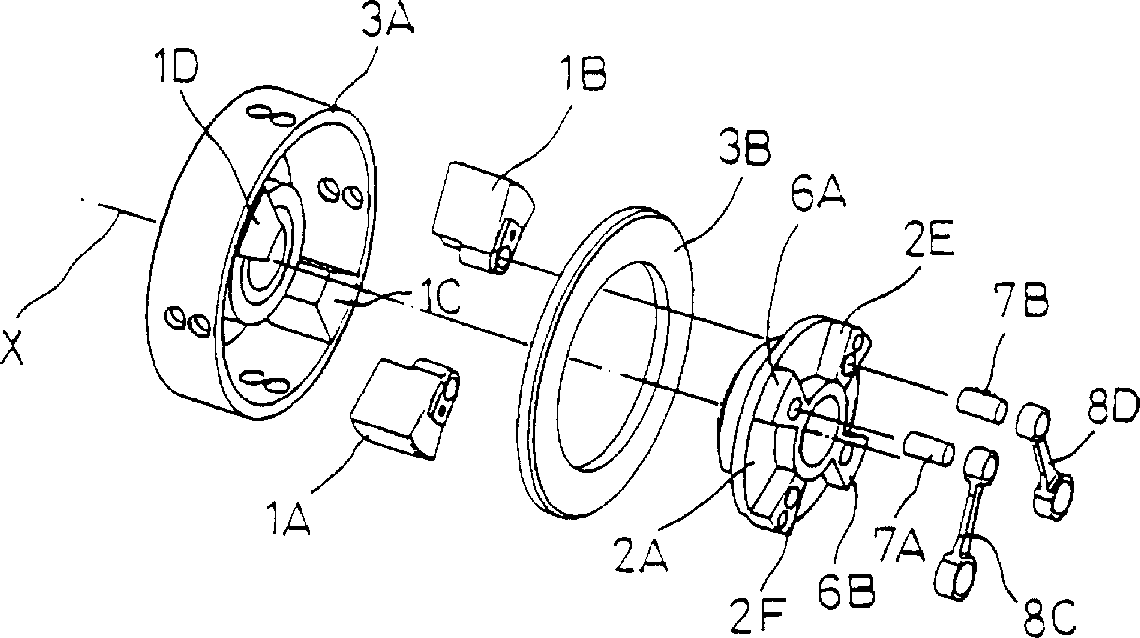

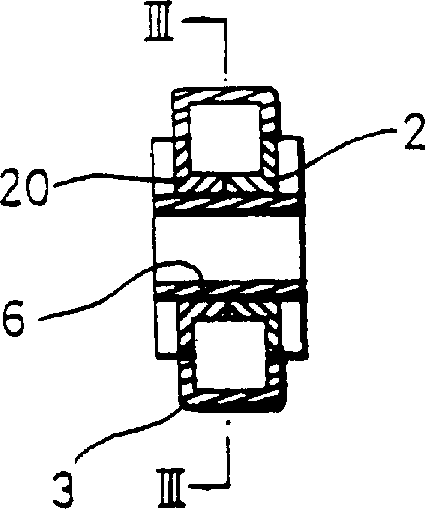

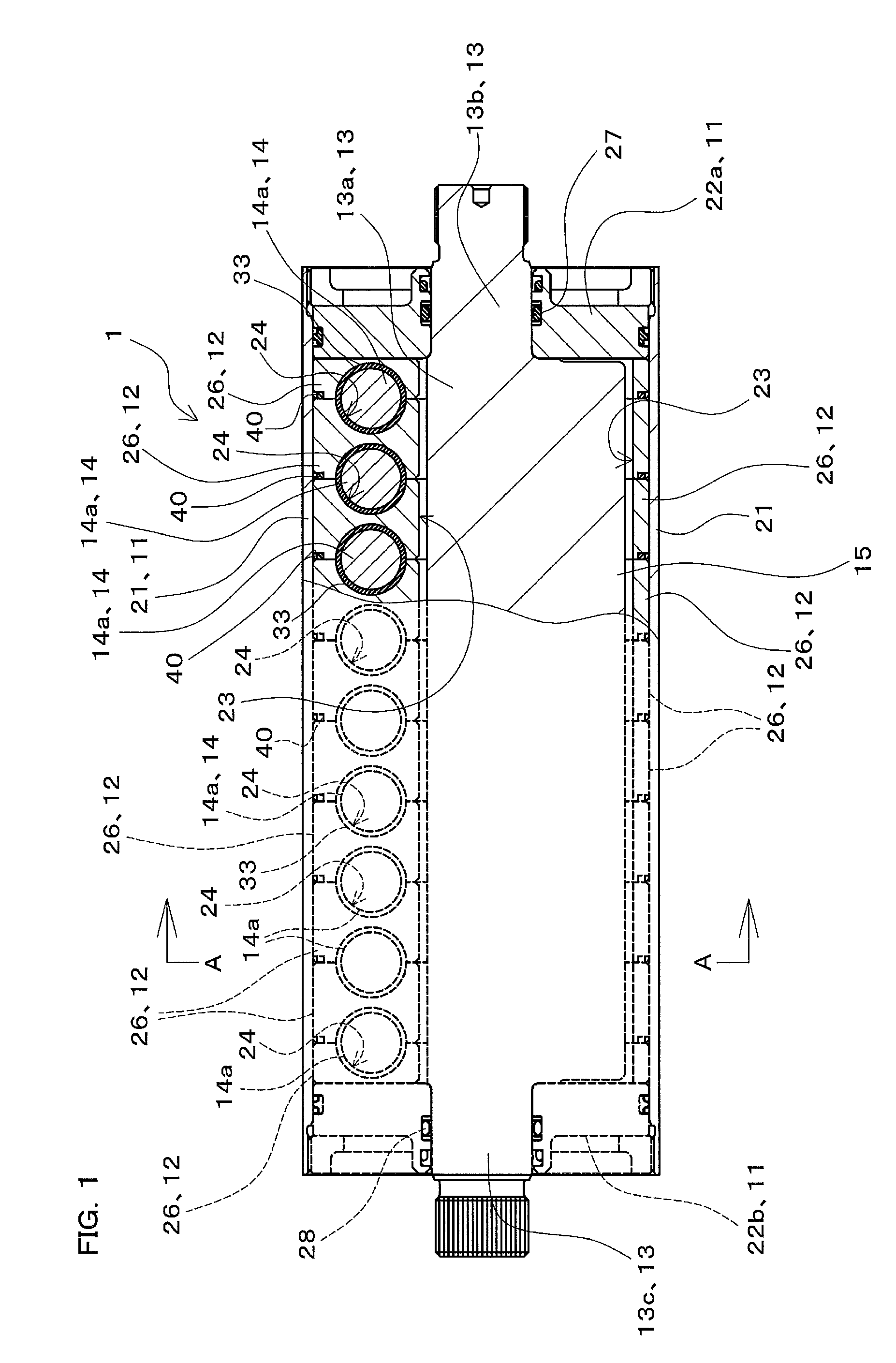

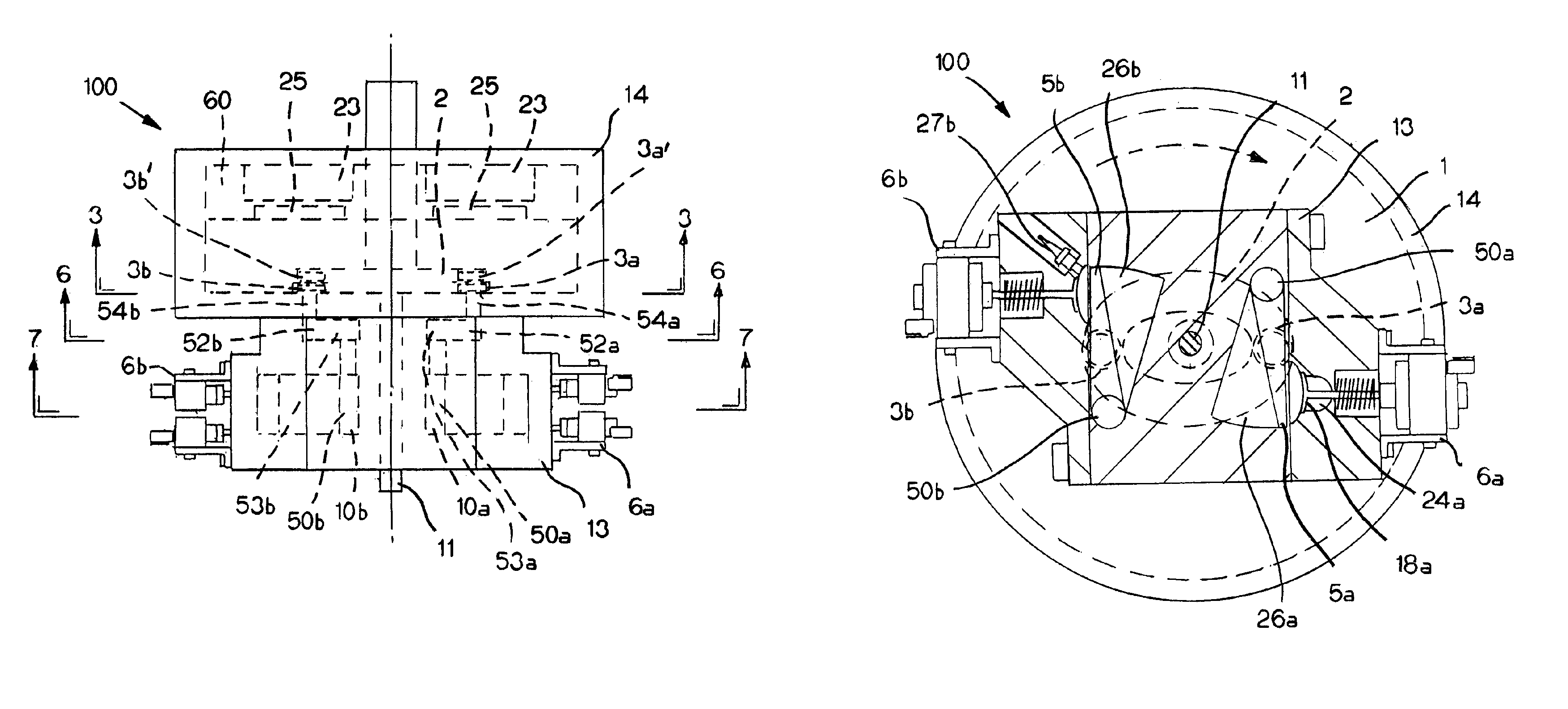

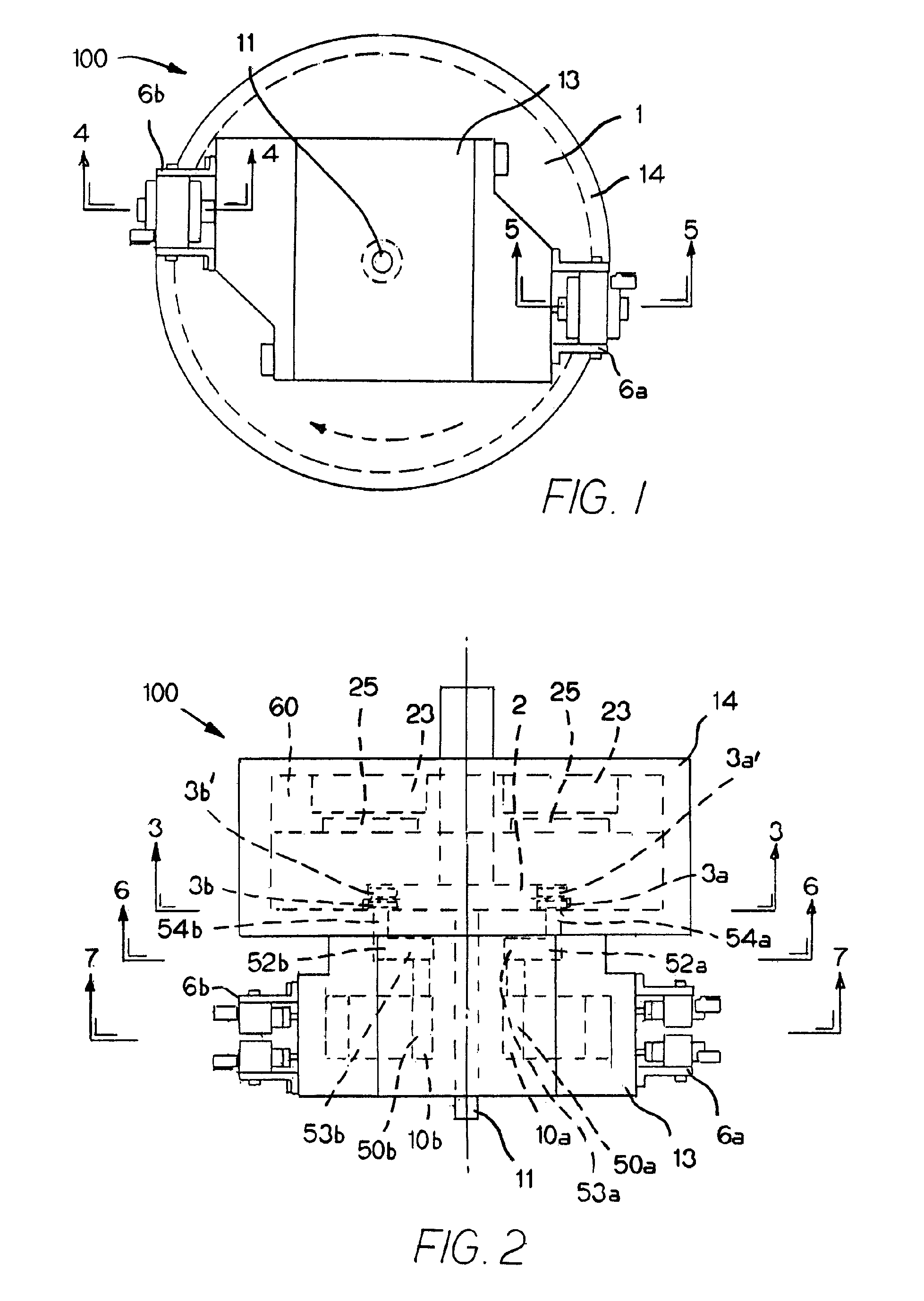

Rotary actuator

ActiveUS20130104729A1Reduce internal leakageThe implementation process is simpleGearingFluid-pressure actuatorsControl theoryRotary actuator

A cylinder is installed within a case. An output shaft is installed in a hollow space within the cylinder. A pair of pistons extend in an arc, and is supported so as to be able to slide and be displaced along a circumferential direction of the cylinder within the cylinder. The pair of pistons is able to urge an arm integrated with the output shaft from two sides of the arm. Pressure chambers into which a pressure medium is introduced are defined between the cylinder and each piston in the pair of pistons. The pressure medium is fed to one of the pressure chambers and drained from the other, and thus the arm is displaced, and the output shaft pivots in a rotational direction.

Owner:NABLESCO CORP

Isochoric heat addition engines and methods

ActiveUS8863724B2Reduce gapImprove sealingNon-fuel substance addition to fuelInternal combustion piston enginesProcess engineeringHigh-efficiency hybrid cycle

Engines and methods execute a high efficiency hybrid cycle, which is implemented in a volume within an engine. The cycle includes isochoric heat addition and over-expansion of the volume within the engine, wherein the volume is reduced in a compression portion of the cycle from a first quantity to a second quantity, the volume is held substantially constant at the second quantity during a heat addition portion of the cycle, and the volume is increased in an expansion portion of the cycle to a third quantity, the third quantity being larger than the first quantity.

Owner:LIQUIDPISTON INC

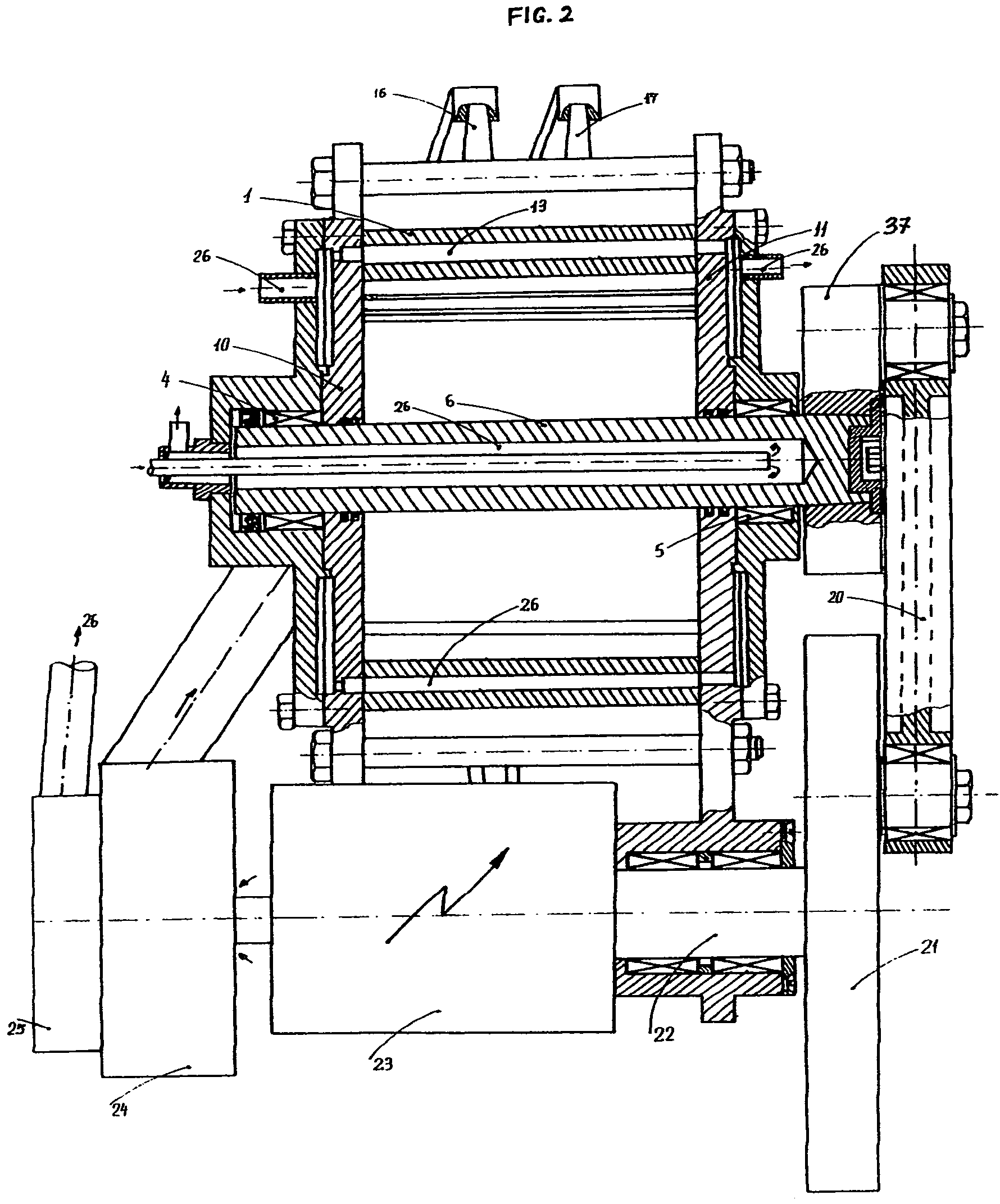

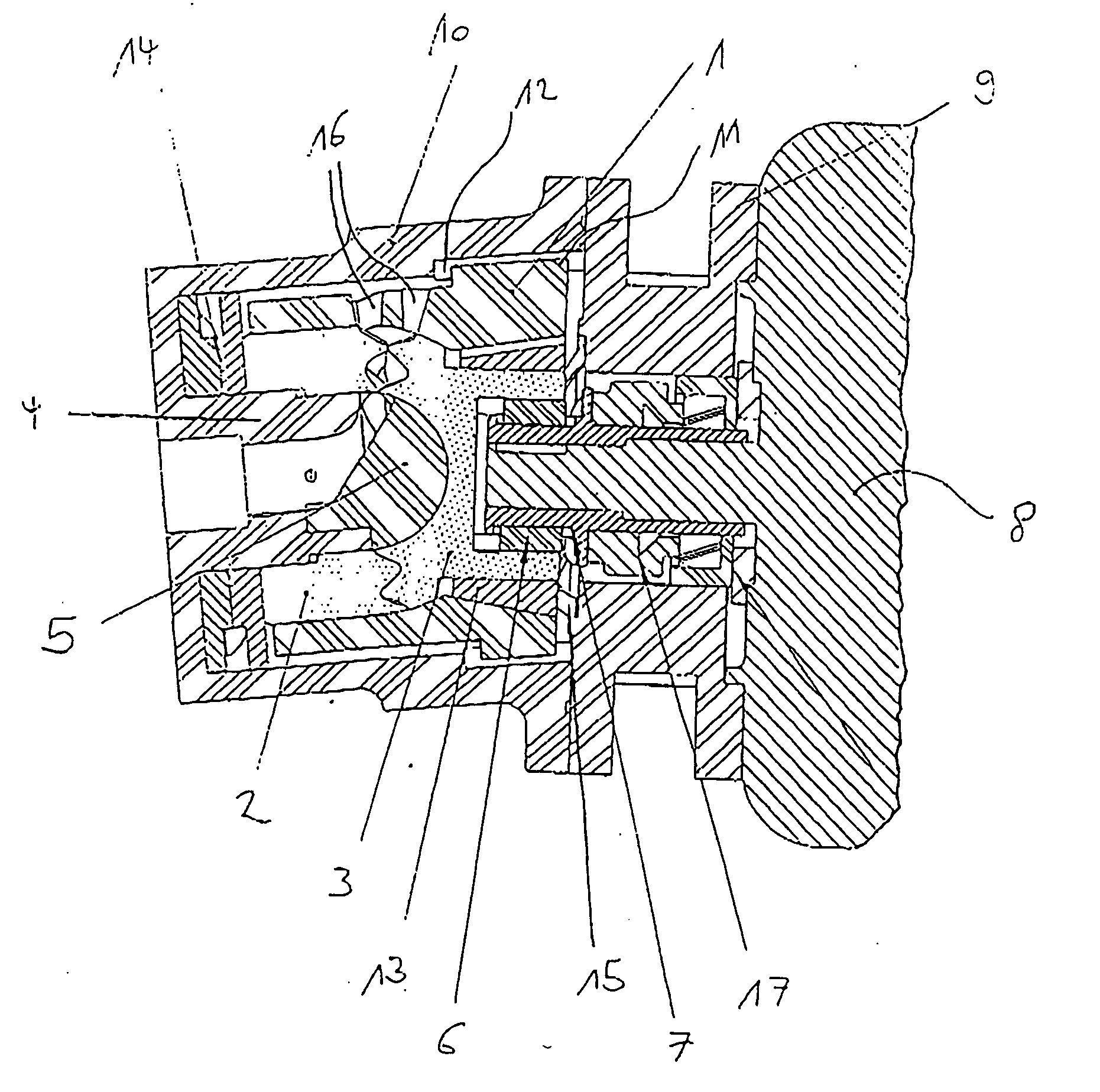

Internal combustion engine

ActiveUS7415962B2Improve engine efficiencyReduce fuel consumptionInternal combustion piston enginesExhaust apparatusCombustion chamberEngineering

An internal-combustion engine comprises an engine housing having a first wall delimiting a first combustion chamber, a first piston also delimiting said first combustion chamber and with a first piston head, a first crankshaft, a second piston also delimiting said first combustion chamber and with a second piston head, a second crankshaft, and a second connecting rod connected between said second piston and said second crankshaft, said first wail defining at least a section of a torus, said pistons being guided along a curved path defined by said section of a torus.

Owner:REISSER HEINZ GUSTAV A

Toroidal internal combustion Engine

InactiveUS20050016493A1Improve performanceEmission reductionInternal combustion piston enginesRotary piston pumpsExhaust valveEngineering

Toroidal internal combustion engine comprising two concentric engine rings. Intake valves are assembled in two faces of one set of pistons and exhaust valves in two faces of the second set of pistons. The intake-valve pistons are fixedly attached to one of the engine rings and the exhaust-valve pistons to the other engine ring. The face of one intake-valve piston and the face of one adjacent exhaust-valve piston form boundaries of an engine chamber. Combustion forces on the piston faces force the two concentric engine rings to counter-rotate. The intake-valve piston and the adjacent exhaust-valve piston sweep the same chamber volume at different strokes of the engine cycle. The engine is constructed of CRC material and mounted on a central shaft, with the intake manifold and the exhaust manifold mounted on each side of the engine, providing a lightweight, self-lubricating, highly fuel efficient, and dynamically balanced engine.

Owner:APPLIED THERMAL SCI

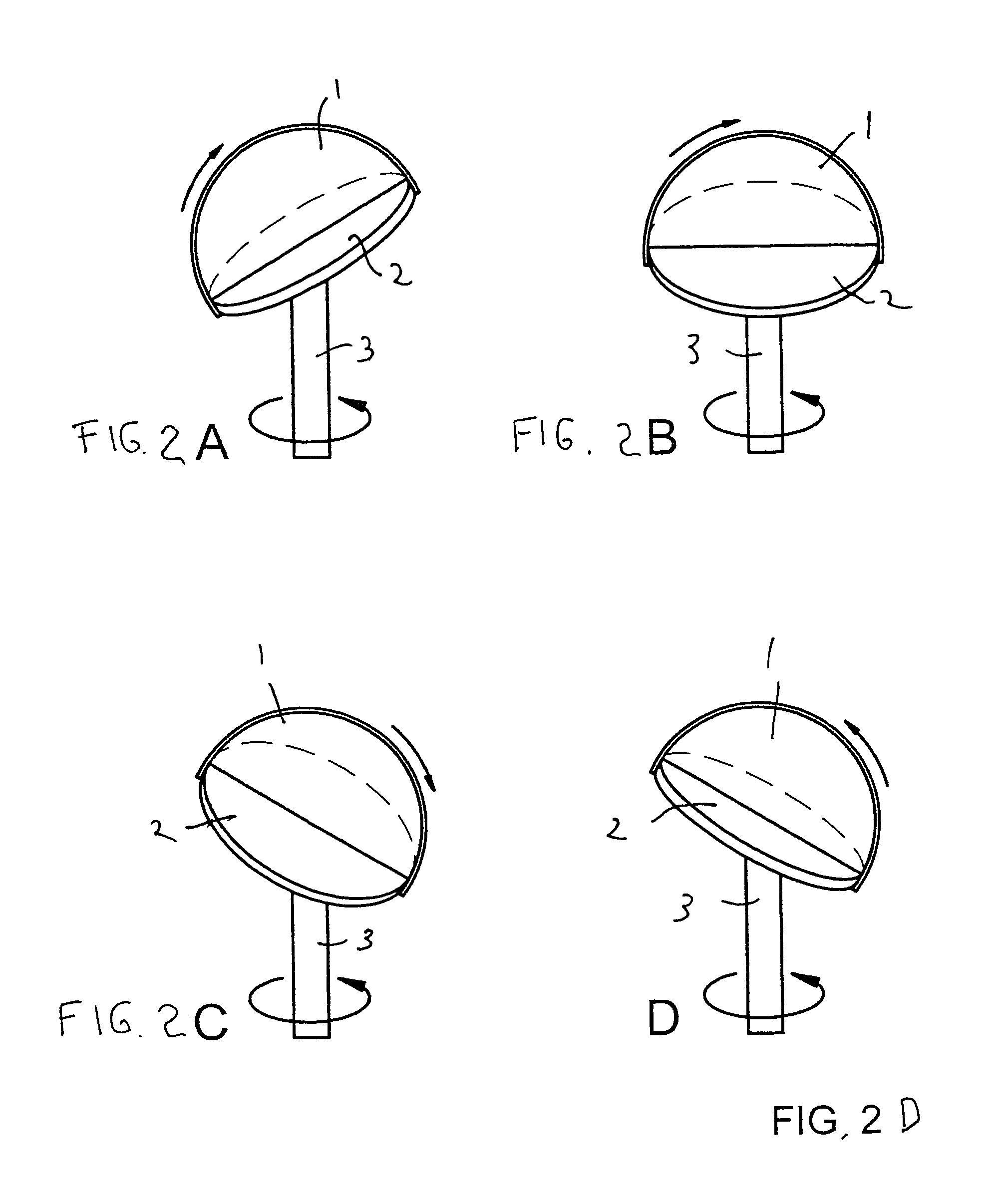

VAL rotary engine

InactiveUS6941900B1Compact designProlong lifeInternal combustion piston enginesEngine of arcuate-engagement typeCombustion chamberRotary engine

A rotary engine has a spherical enclosure serving as a combustion chamber, a first baffle inside the combustion chamber slideable along a groove formed in the spherical enclosure, and a second baffle disposed in the combustion chamber which is in sealing engagement with the internal spherical surface of the combustion chamber. The second baffle is carried by a rotatable shaft, the shaft extending into the spherical combustion chamber. The first baffle rests against the second baffle, and separates the interior of the combustion chamber into a first part and a second part. A first valve in a first opening is disposed to communicate with the first part of the combustion chamber, and a second valve in a second opening is disposed to communicate with the second part of the combustion chamber.

Owner:MALINOV VALENTIN

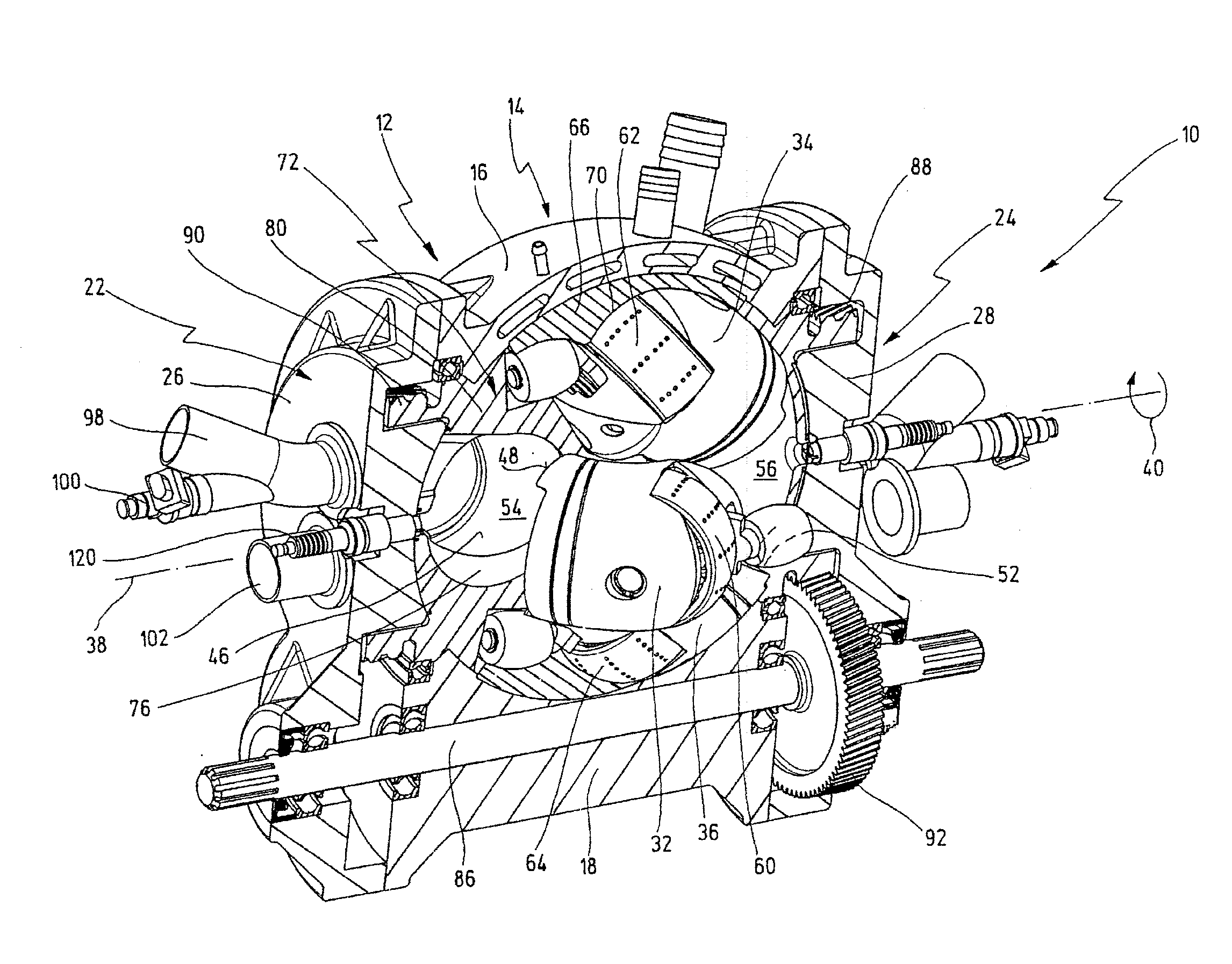

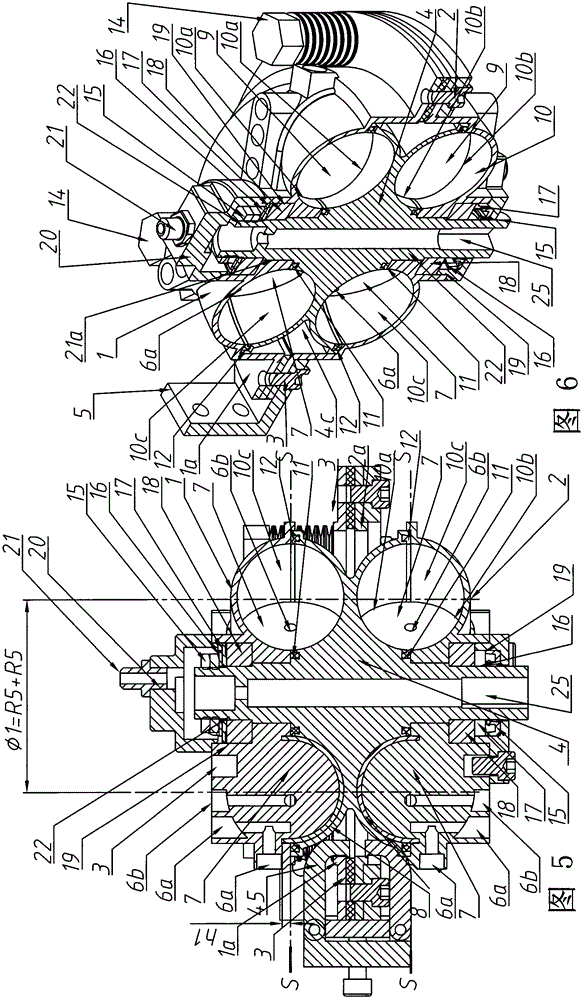

Rotary-piston engine and vehicle comprising an engine of this type

InactiveUS7469673B2Easy constructionReduce frictionInternal combustion piston enginesEngine of arcuate-engagement typeRotational axisPiston

A rotary-piston engine includes at least two rotary pistons, which are located in an essentially spherical housing and which rotate in common about a rotational axis running through the center of the housing, each of the rotary pistons comprising two pistons that are interconnected in a fixed manner, lie diametrically opposite the center of the housing and execute pivoting displacements back and forth in opposite directions about a pivoting axis running perpendicular to the rotational axis, during their rotation. To control the pivoting displacements, the engine is provided with loose spherical or ellipsoidal rotational bodies, which are rotatably mounted in the sliding surfaces of the pistons in respective guide sockets that are hemispherical or ellipsoidal and which engage in at least one guide groove that is configured in the housing. The groove has an essentially hemispherical or ellipsoidal profile.

Owner:PERAVES

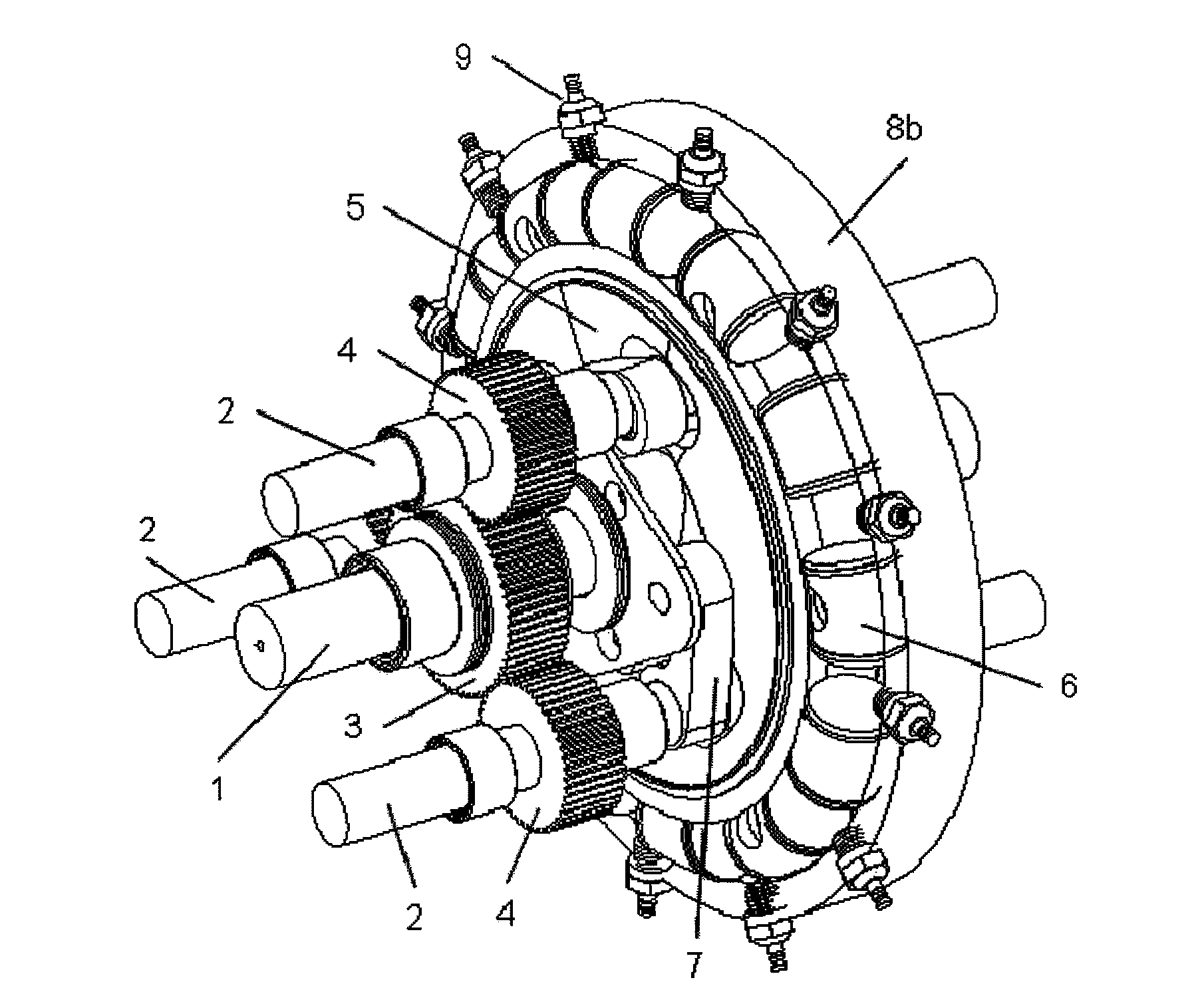

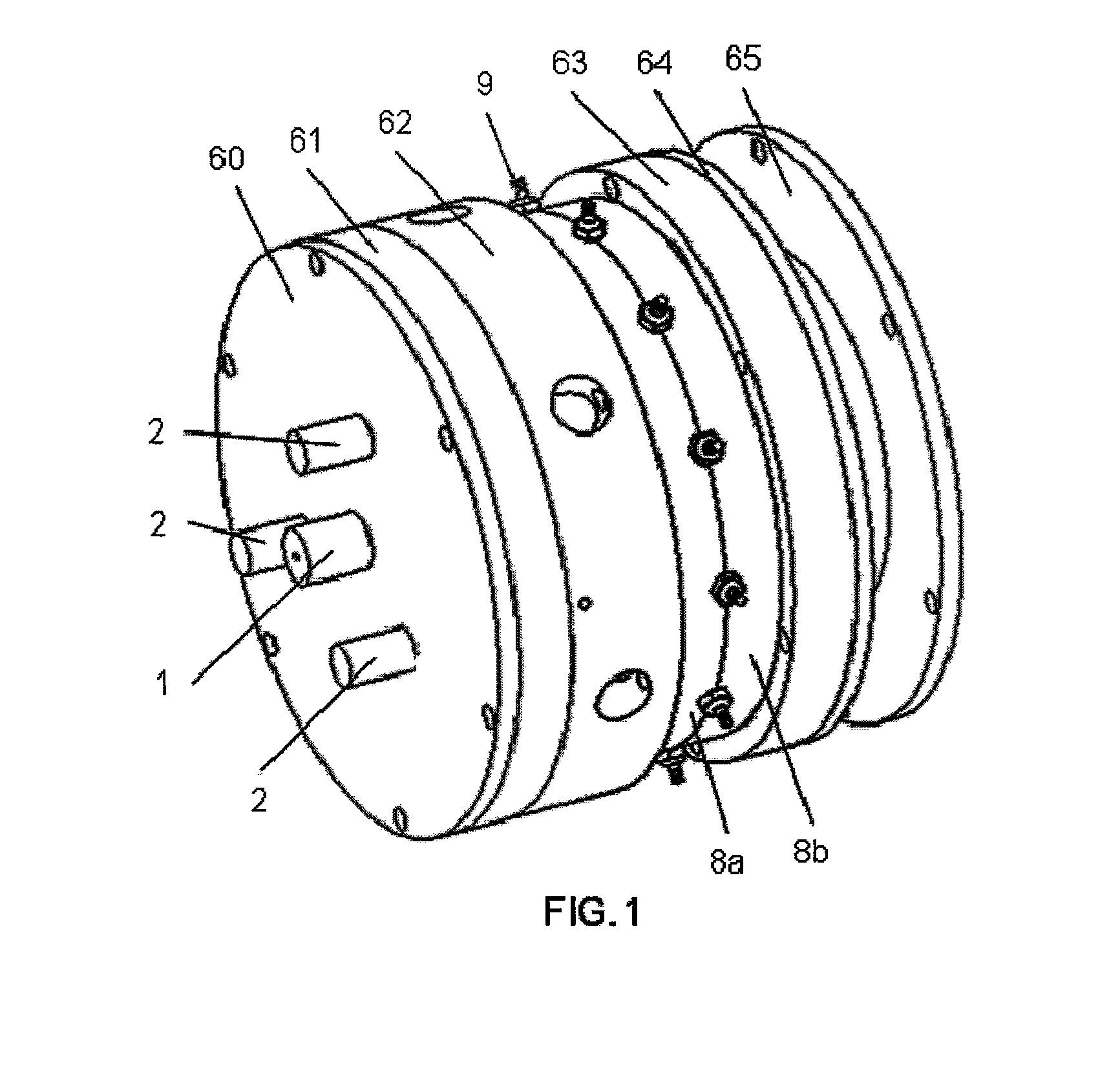

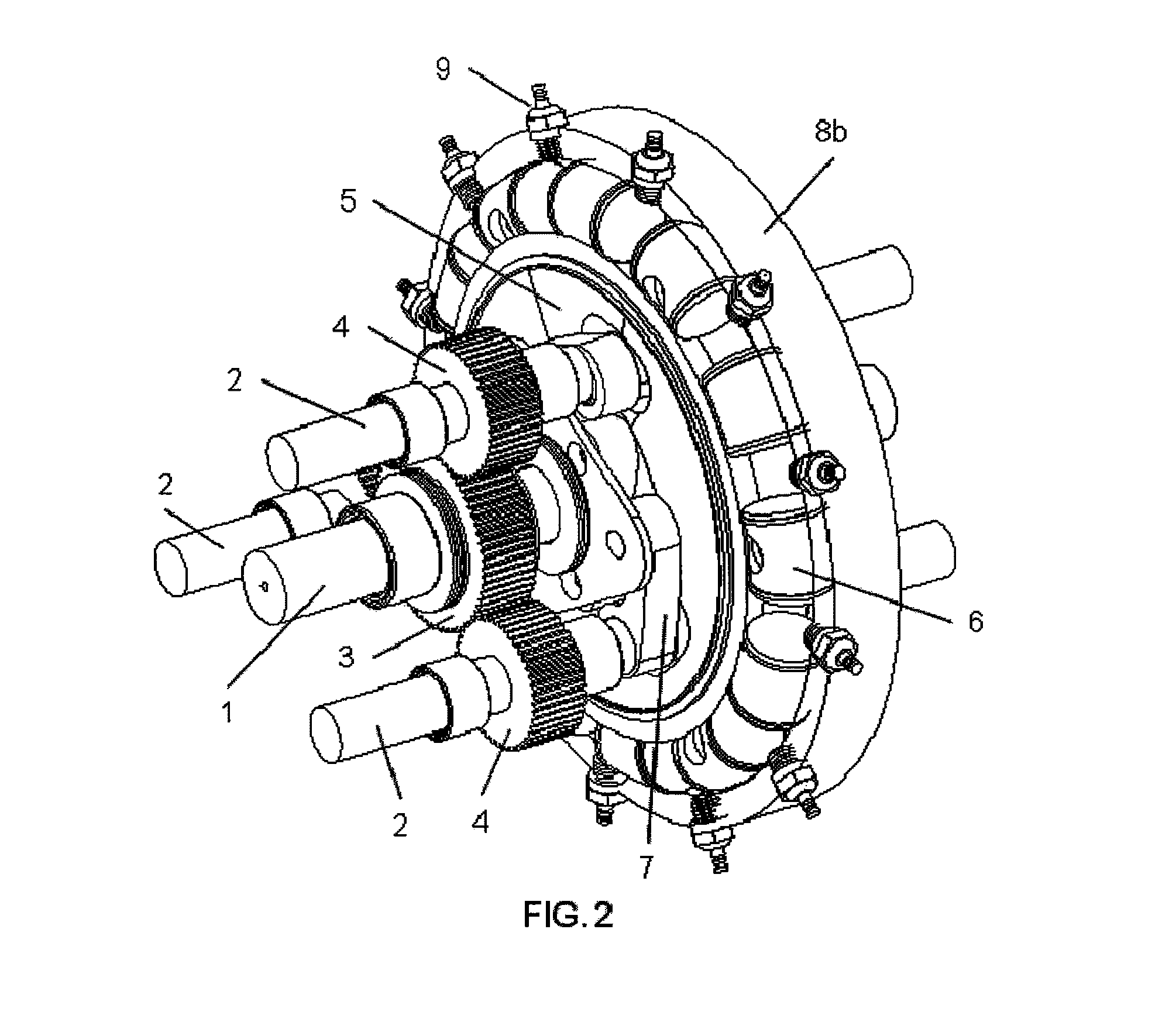

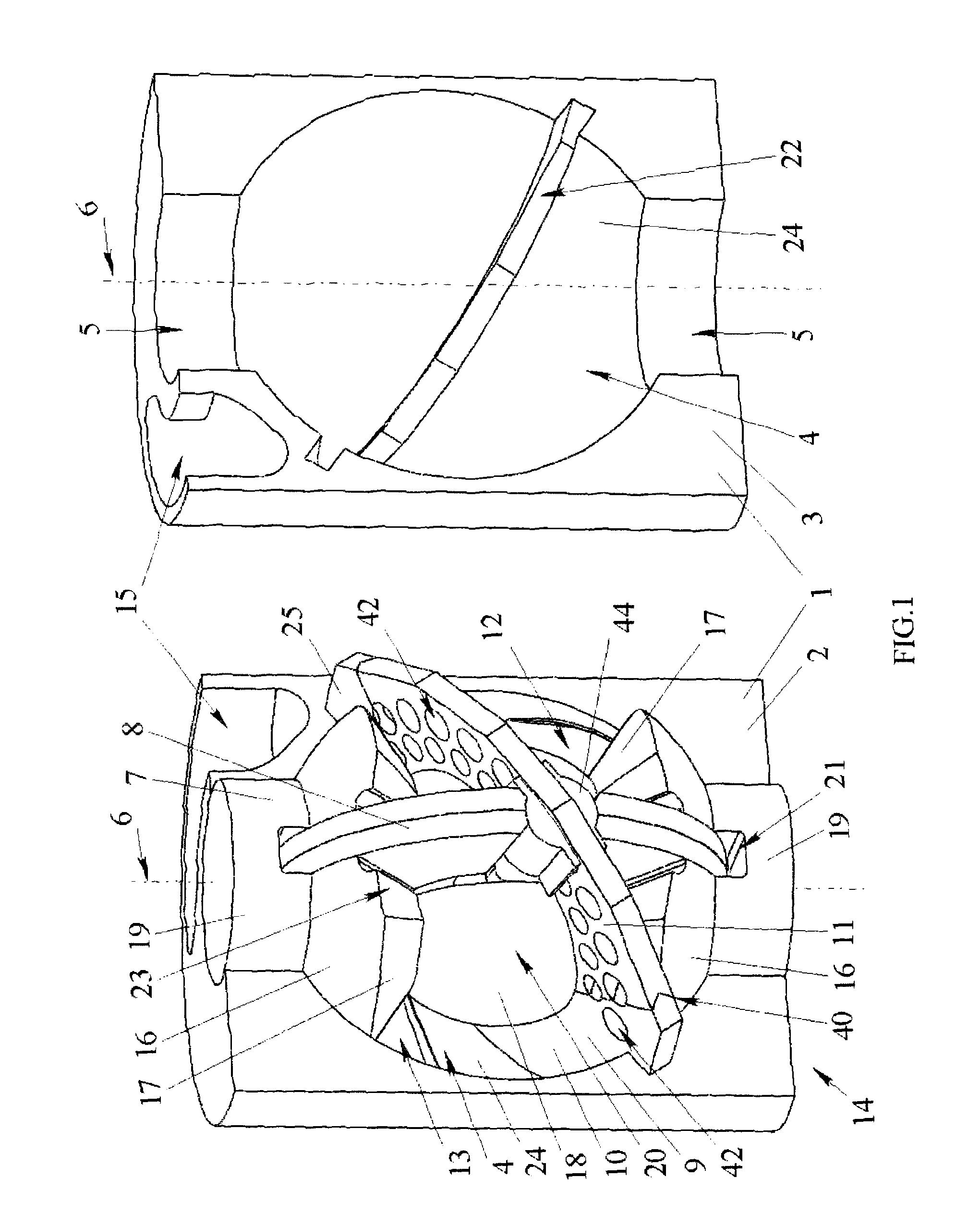

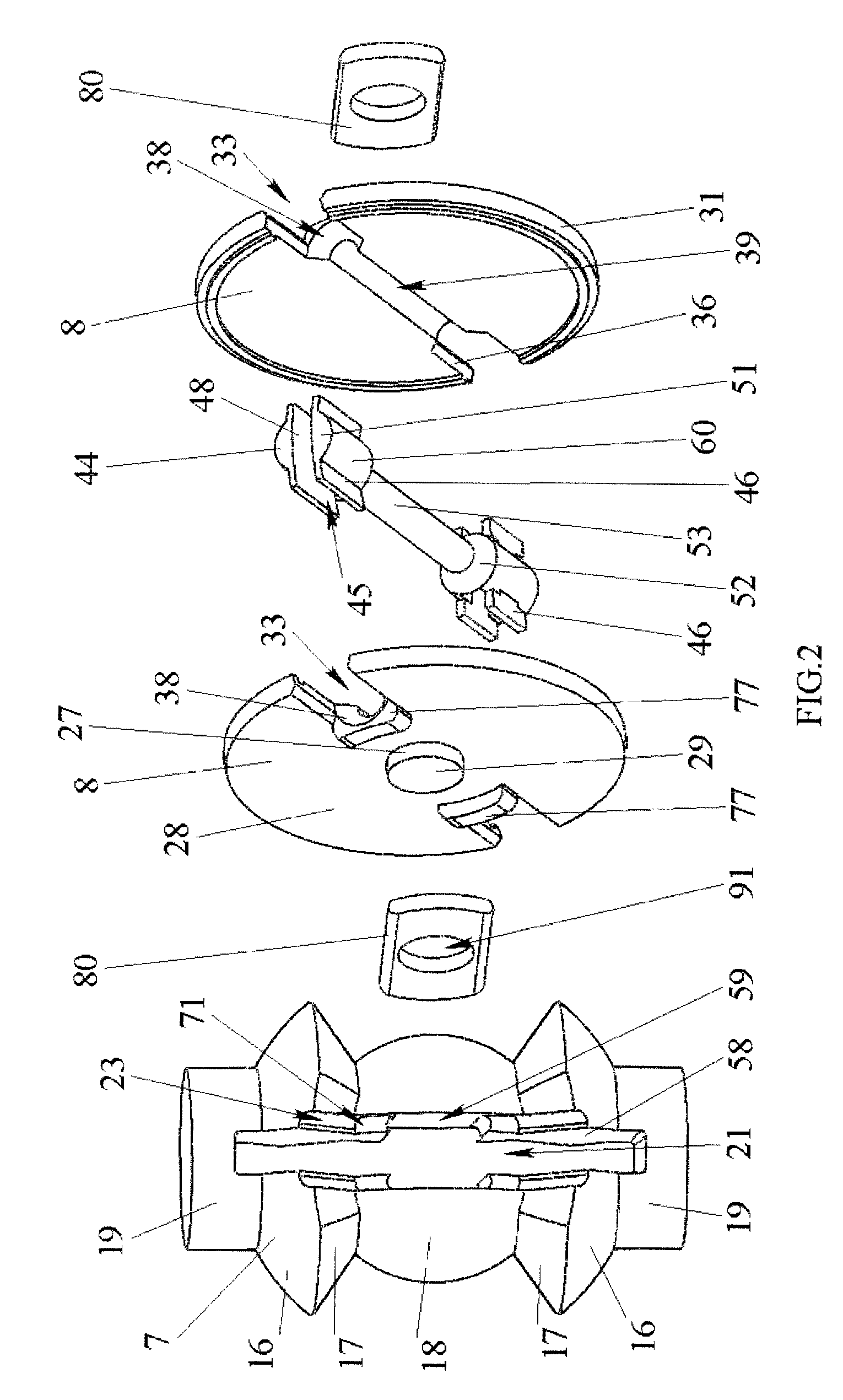

Oscillating piston engine

InactiveUS20110239981A1Increase torqueReduce the total massInternal combustion piston enginesEngine componentsExternal combustion engineGasoline

An engine configuration that places multiple pistons on one or two oscillating discs. The engine can be configured to operate as an internal combustion engine that uses diesel fuel, gasoline, or natural gas, or it can be configured as an expander to convert high pressure high temperature gas to rotary power. For any given set of choices of numbers of pistons and sizes of pistons, disks, and gears, there are disclosed dimensional constraints useful for more efficient functioning of the engine. This engine is especially suited as a driver for electrical power generation as it delivers high torque at low engine speeds, among other uses. Its compact design results in high power to weight ratios.

Owner:CUNNINGHAM STEPHEN LEE +1

Peripherally pivoted oscillating vane machine

InactiveUS20090081061A1Increase pressureIncrease speedOscillating piston pumpsRotary piston pumpsEngineeringMechanical engineering

The present invention is directed to a peripherally pivoted oscillating vane machine (OVM). The OVM has been optimized for performance and efficiency. This has been accomplished by reducing loads on the drive mechanism and by employing de-phased motion of the peripherally pivoted vanes in conjunction with improved porting configurations as well as valve actuation and manufacture.

Owner:MECHANOLOGY INC

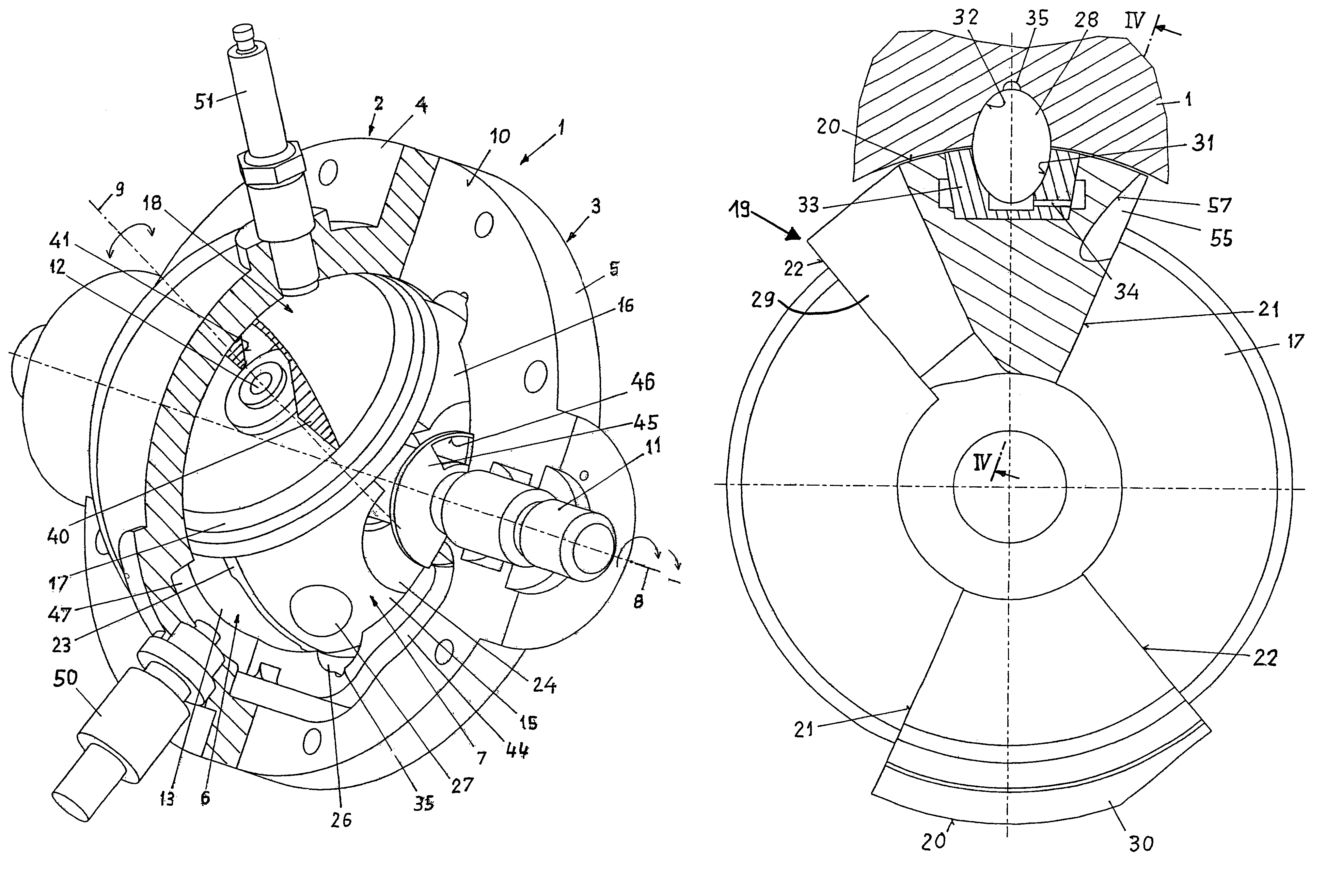

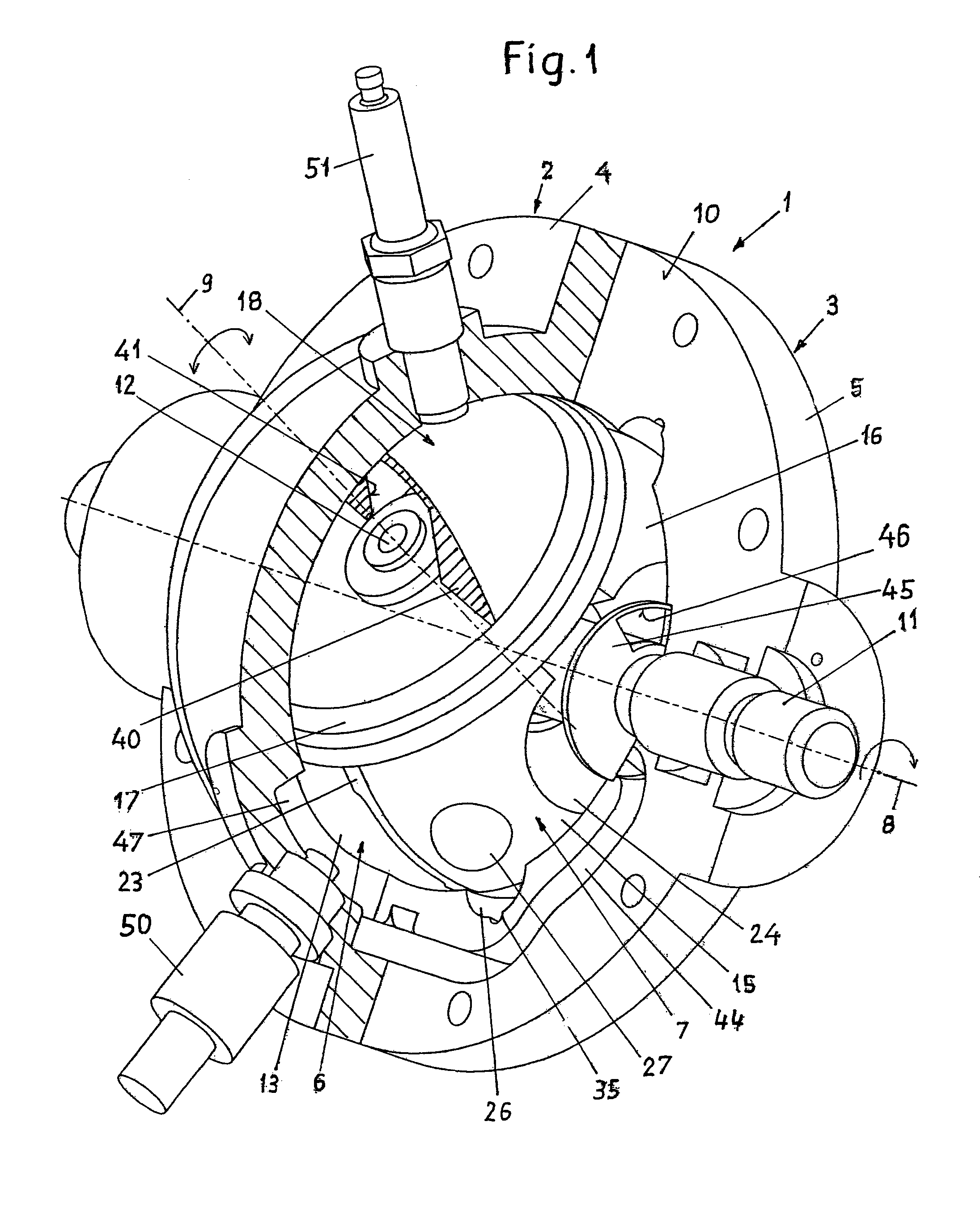

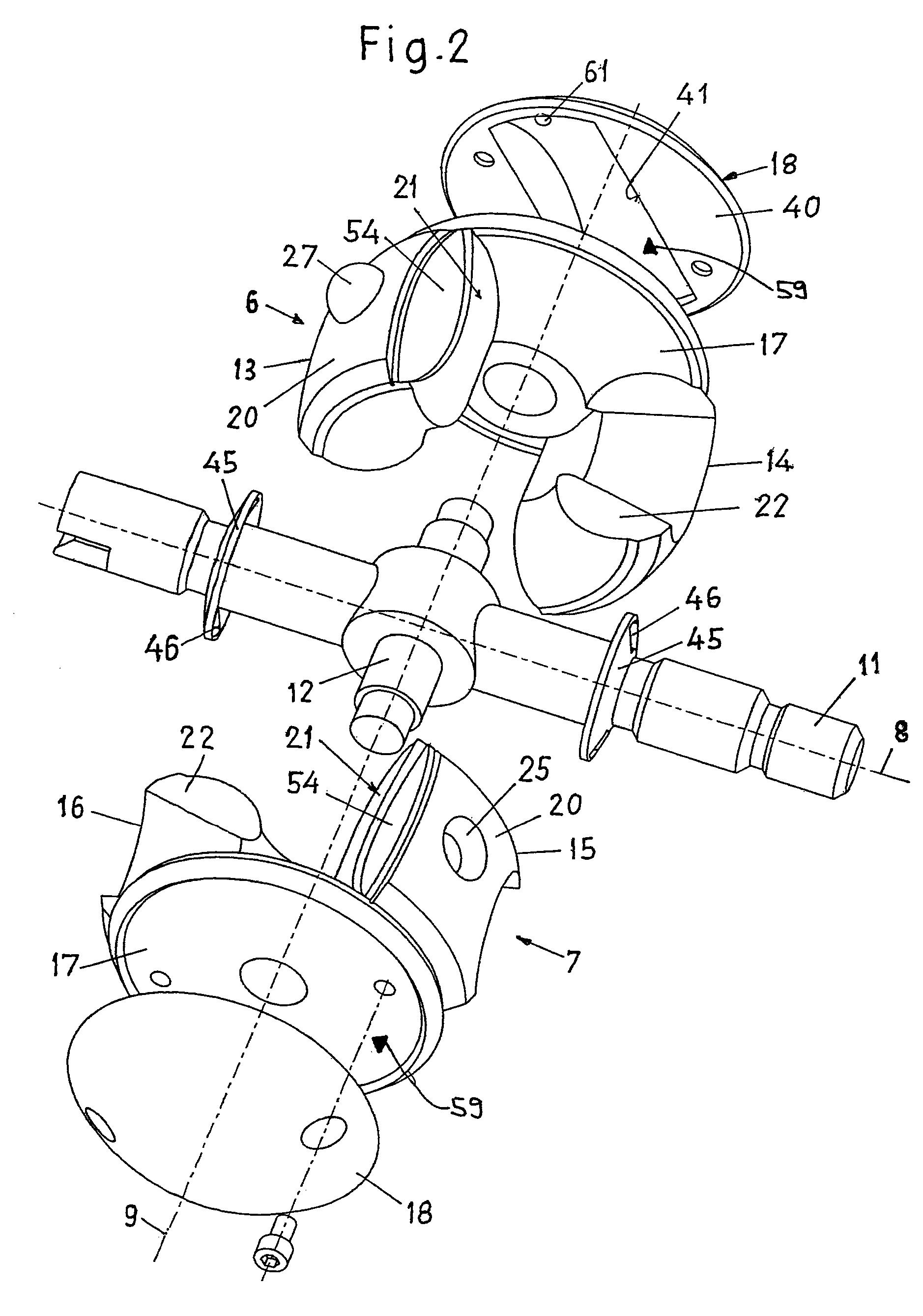

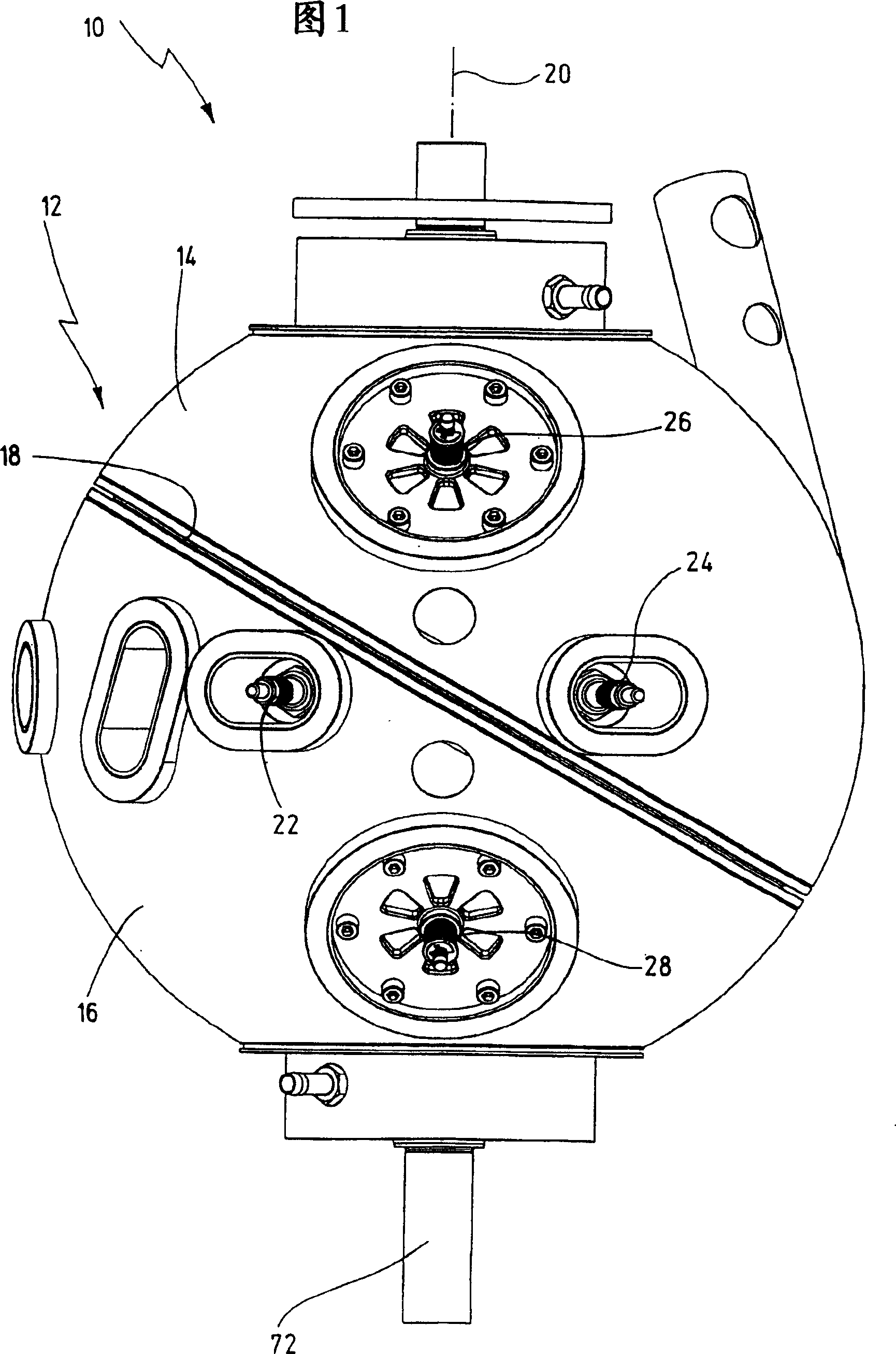

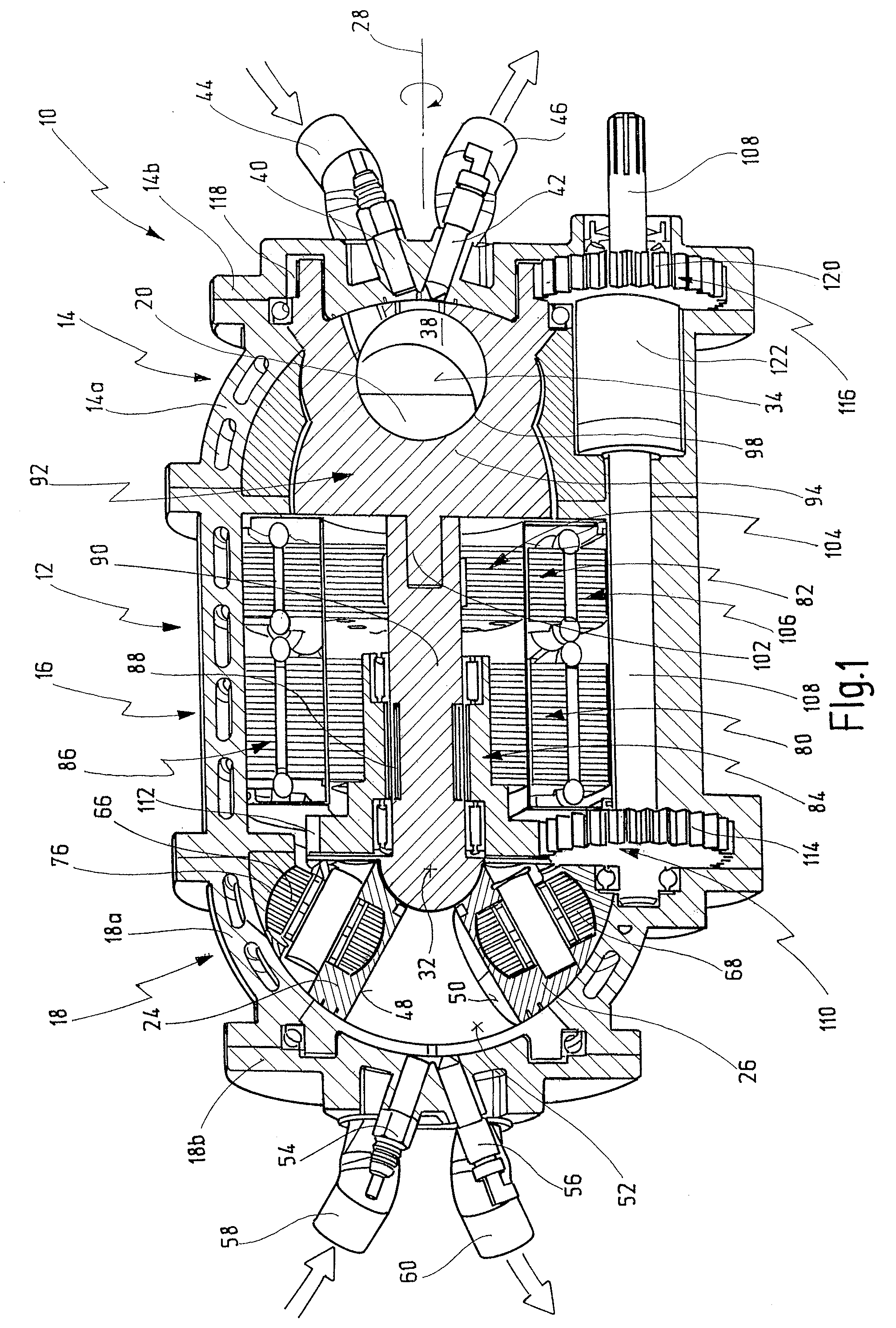

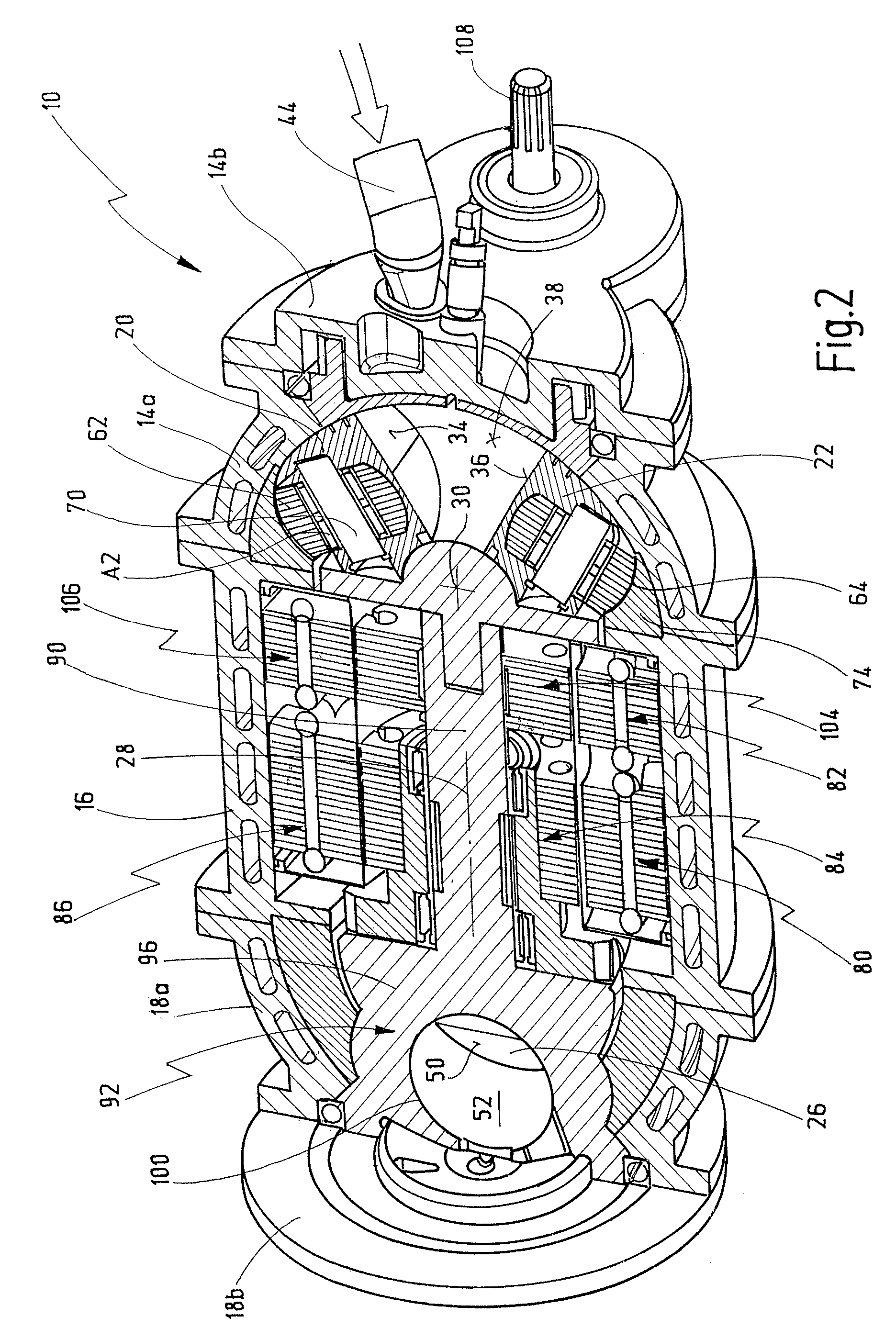

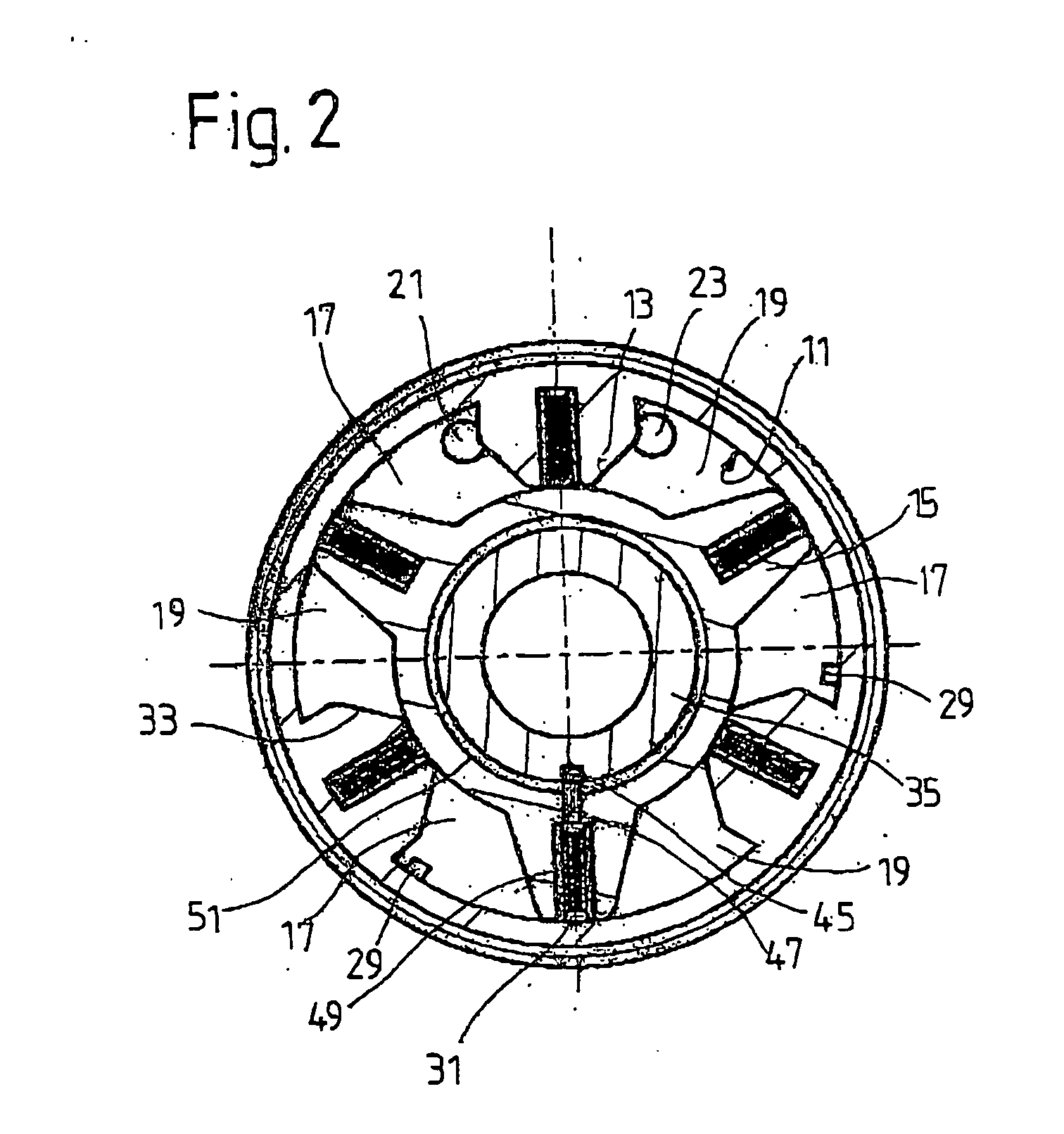

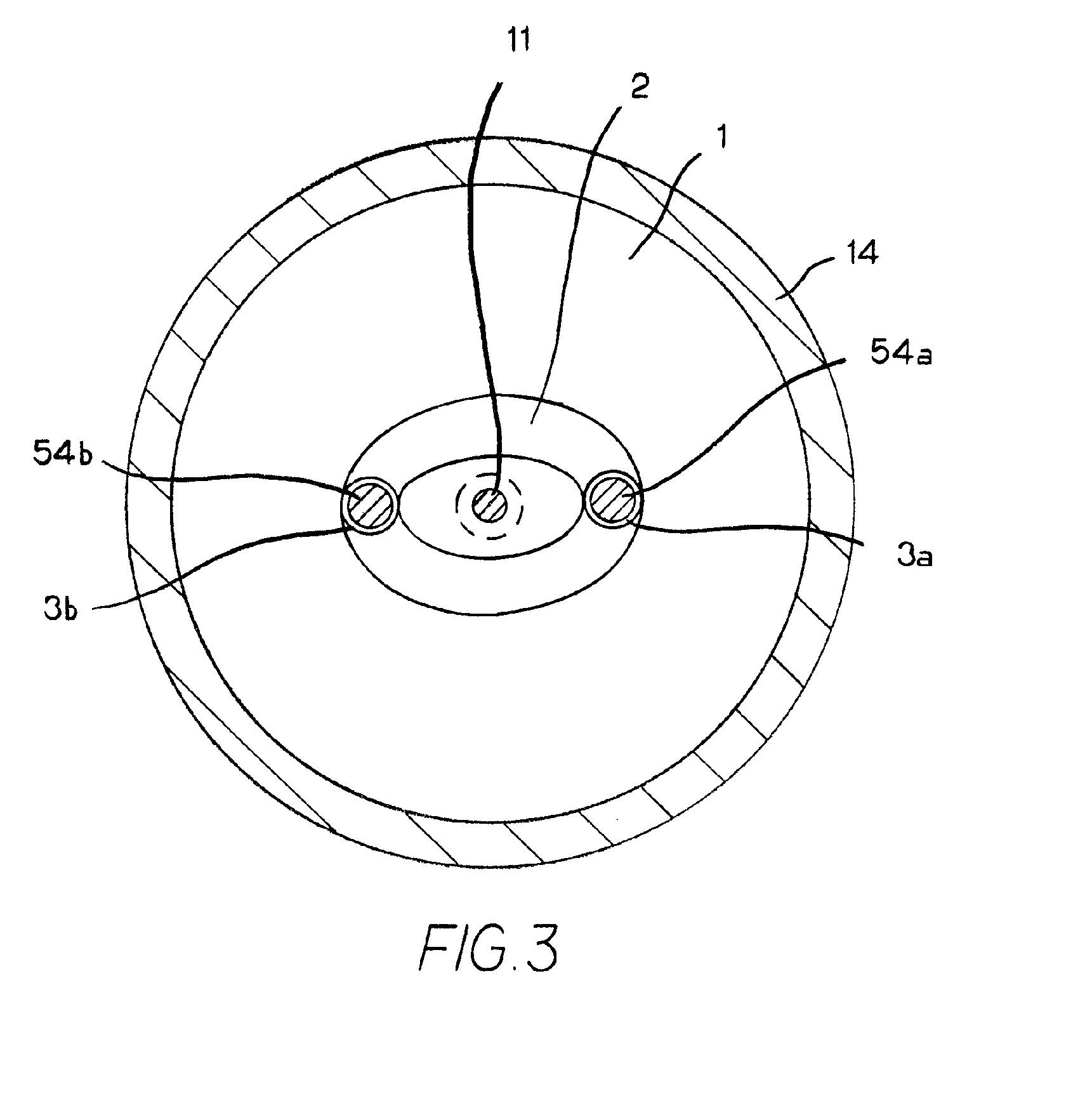

Oscillating piston machine

InactiveUS20050008515A1Enhanced interactionQuieter runningOscillating piston pumpsInternal combustion piston enginesEngineeringPiston

An oscillating piston machine comprises a plurality of pistons which are arranged in a housing, rotate together in the housing about an axis of rotation which is essentially central in the housing and is fixed to the housing, and execute reciprocating oscillating movements about a respective oscillation axis as they rotate in the housing, in each case two adjacent pistons executing oscillating movements in opposite directions. The housing is of spherical construction on the inside, the oscillation axes of the pistons being formed by a common oscillation axis which run essentially through the center of the housing.

Owner:HUTTLIN HERBERT

Valveless rotary internal combustion engine

InactiveUS7931006B1Quickly and efficiently and economically convertLow costInternal combustion piston enginesEngine of arcuate-engagement typeWork cycleEngineering

A rotatably alternating air or water cooled two-stroke internal combustion engine comprising a cylindrical casing, and a rotor comprising two radially extending vanes affixed to a shaft rotatably mounted within the casing upon two end plates. Two longitudinally extending walls affixed to the casing. Sealing strips provided between said walls, the shaft, the vanes, the casing and the end plates respectively. Working and supercharging interior chambers between the vanes and the walls. The casing and / or the end plates equipped with ports which communicate with the interior chambers, allowing for intake of combustible air-fuel mixture and exhaust thereafter. Ignition means delivering a spark at the end of each working cycle. An extendable and adjustable connecting rod assembly converting the oscillating bi-directional rotary motion of the output shaft into a continuous unidirectional motion of the main shaft. A self lubricating mechanism incorporated into the engine.

Owner:KAMENOV KAMEN GEORGE

Pivoting piston engine

InactiveCN1637233AImprove efficiencyFirmly connectedEngine componentsEngines with oscillating pistonsRotational axisEngineering

The invention relates to an oscillating piston machine, the casing (12) of which has a spherical inner wall, and four pistons (32-38) are arranged in the casing, and they jointly rotate around a rotation axis (40), and each of the four pistons Two pistons diametrically opposed to the center of the housing form a rigid pair of pistons (32 / 36, 34 / 38) which can pivot about a common axis of oscillation perpendicular to the axis of rotation (40) ( 42) Swing back and forth in reverse, the two piston pairs are arranged through the cross joint relative to the swing axis, so that the two pistons of the two piston pairs face each other with their working surfaces, so as to form a working surface between the working surfaces. Cavities (48, 50), each pair of pistons has a supporting section (52, 56) for supporting the pair of pistons on the swing axis, and each of the two pistons of the pair of pistons has a side wall section (54) for forming them respectively A lateral boundary of a working chamber. The support section and the side wall section are designed in one piece and are arranged on the same side of the respective piston pair.

Owner:赫伯特·许特林

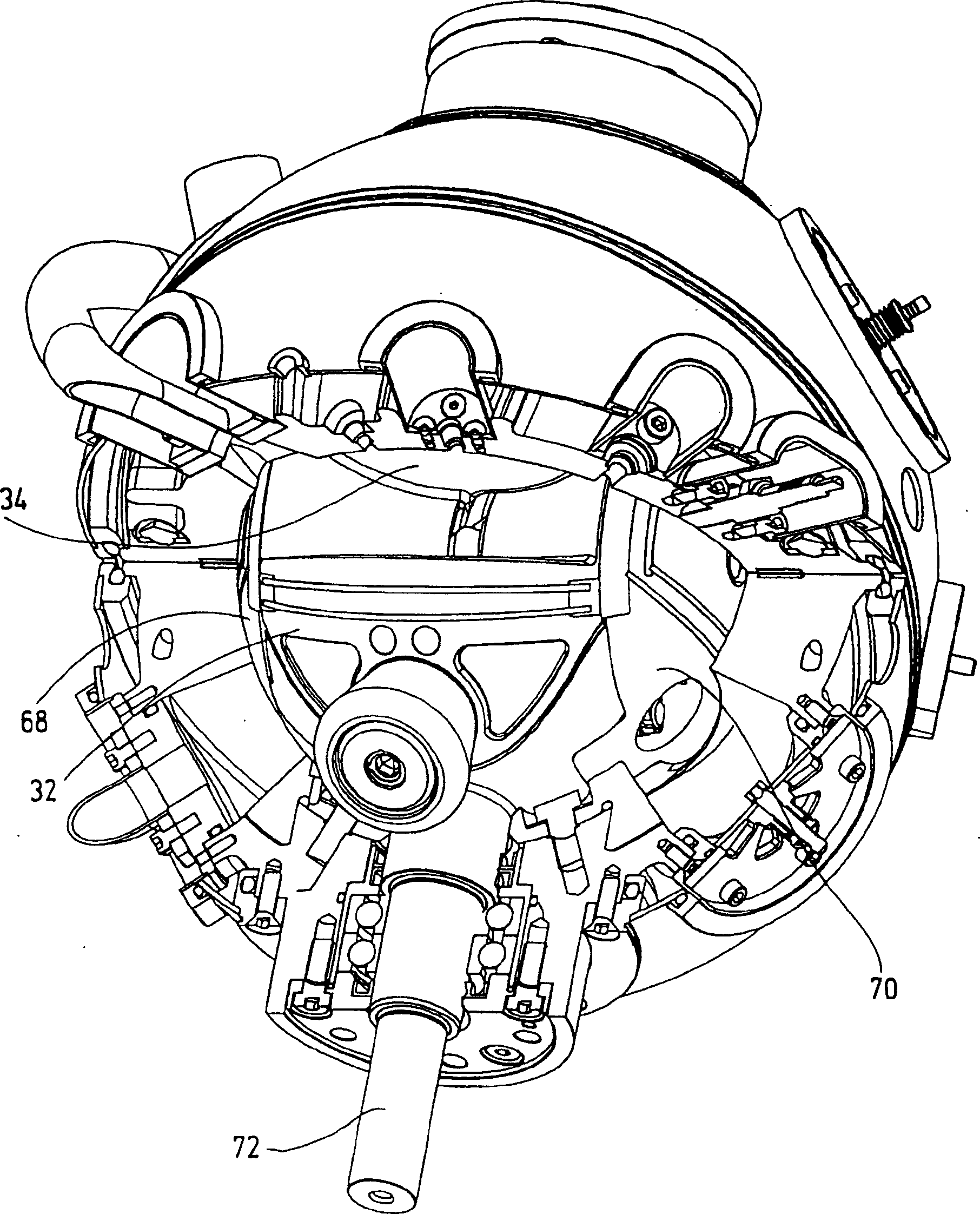

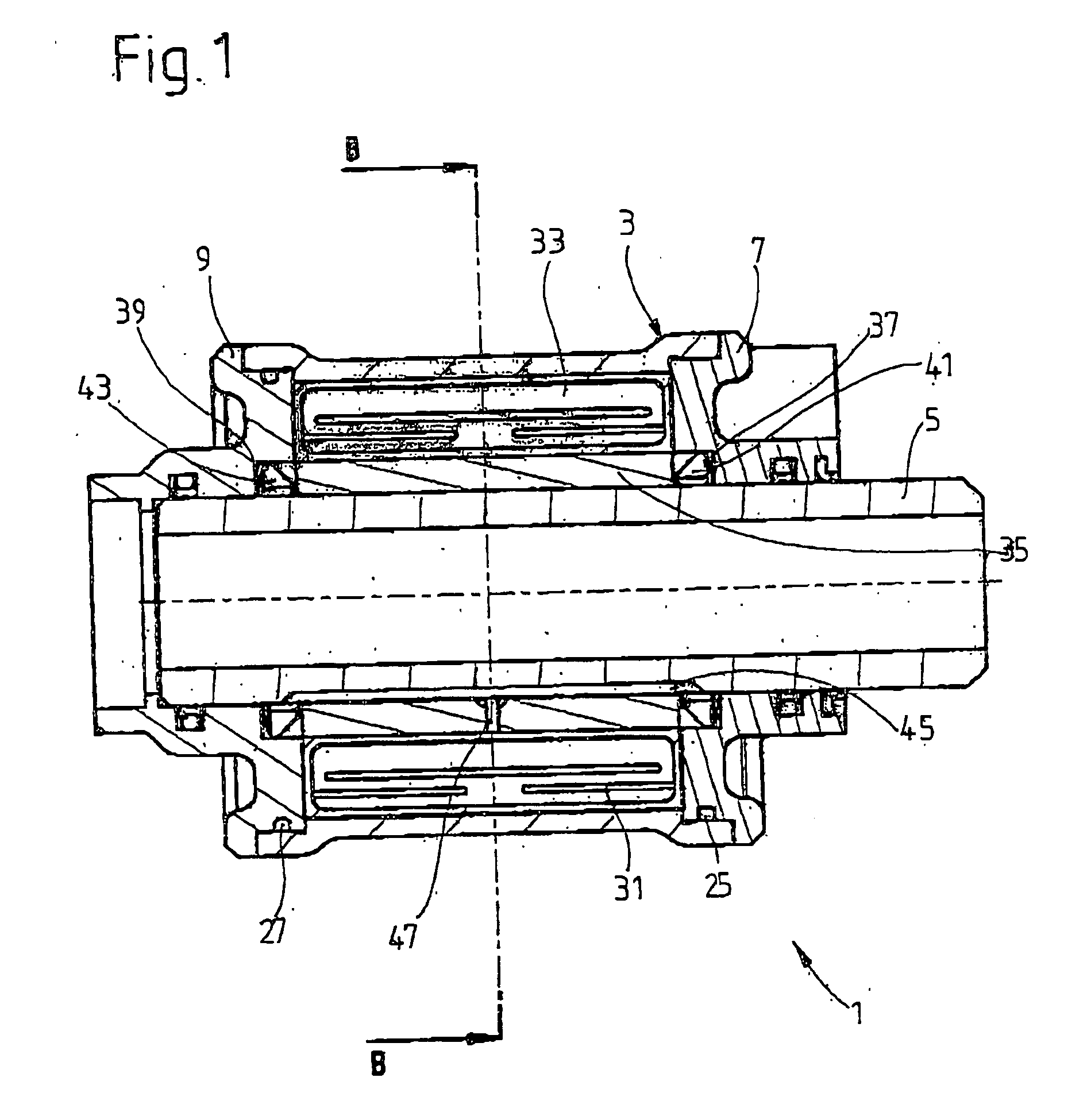

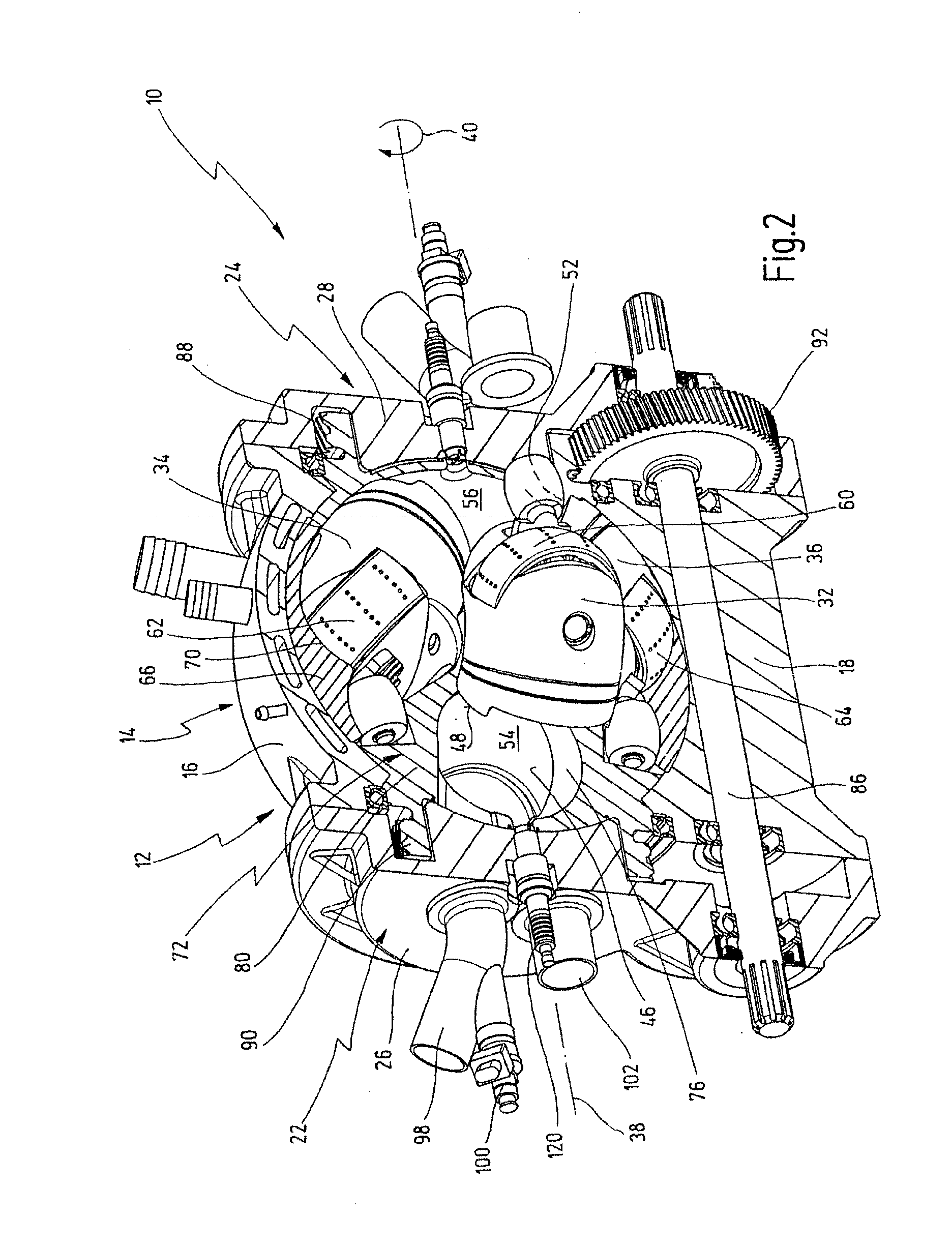

Oscillating Piston Engine

InactiveUS20080245345A1Internal combustion piston enginesCombination enginesExternal combustion engineEngineering

An oscillating piston engine comprises an internal combustion engine part having a housing part in which there are arranged a first and at least a second piston which can jointly revolve in the housing part about an axis of rotation fixed in relation to the housing and which, when revolving about the axis of rotation, perform reciprocating oscillating movements in opposition to one another about an axis of oscillation extending perpendicularly to the axis of rotation. The first piston has a first end face and the at least second piston has a second end face facing the first end face, the end faces delimiting a working chamber in the direction of oscillation of the pistons. The internal combustion engine part is adjoined in the direction of the axis of rotation by an electromotive part having at least one rotor which is arranged concentrically with the axis of rotation and which is arranged in a housing part adjoining the housing part of the internal combustion engine part.

Owner:HUETTLIN HERBERT

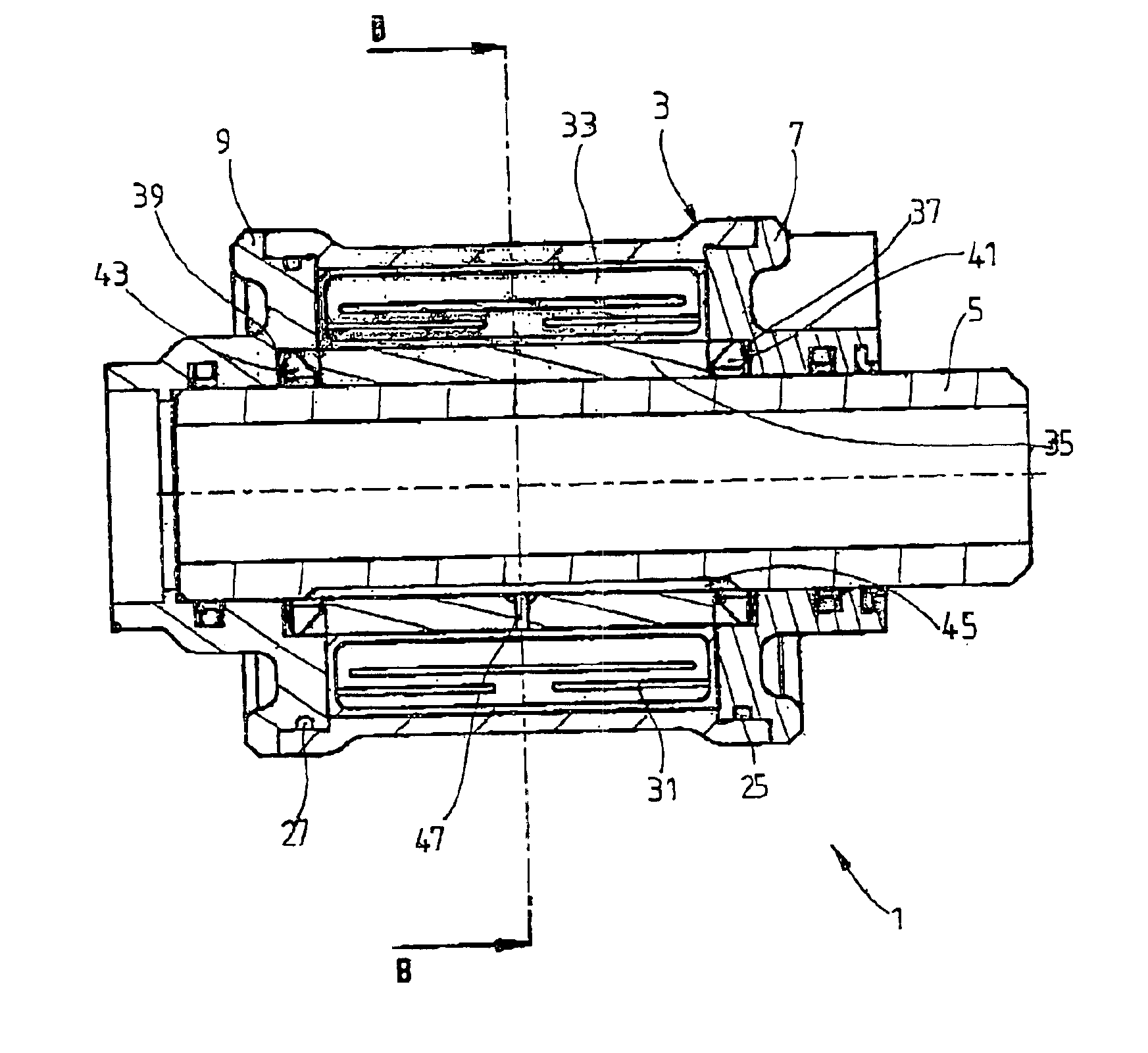

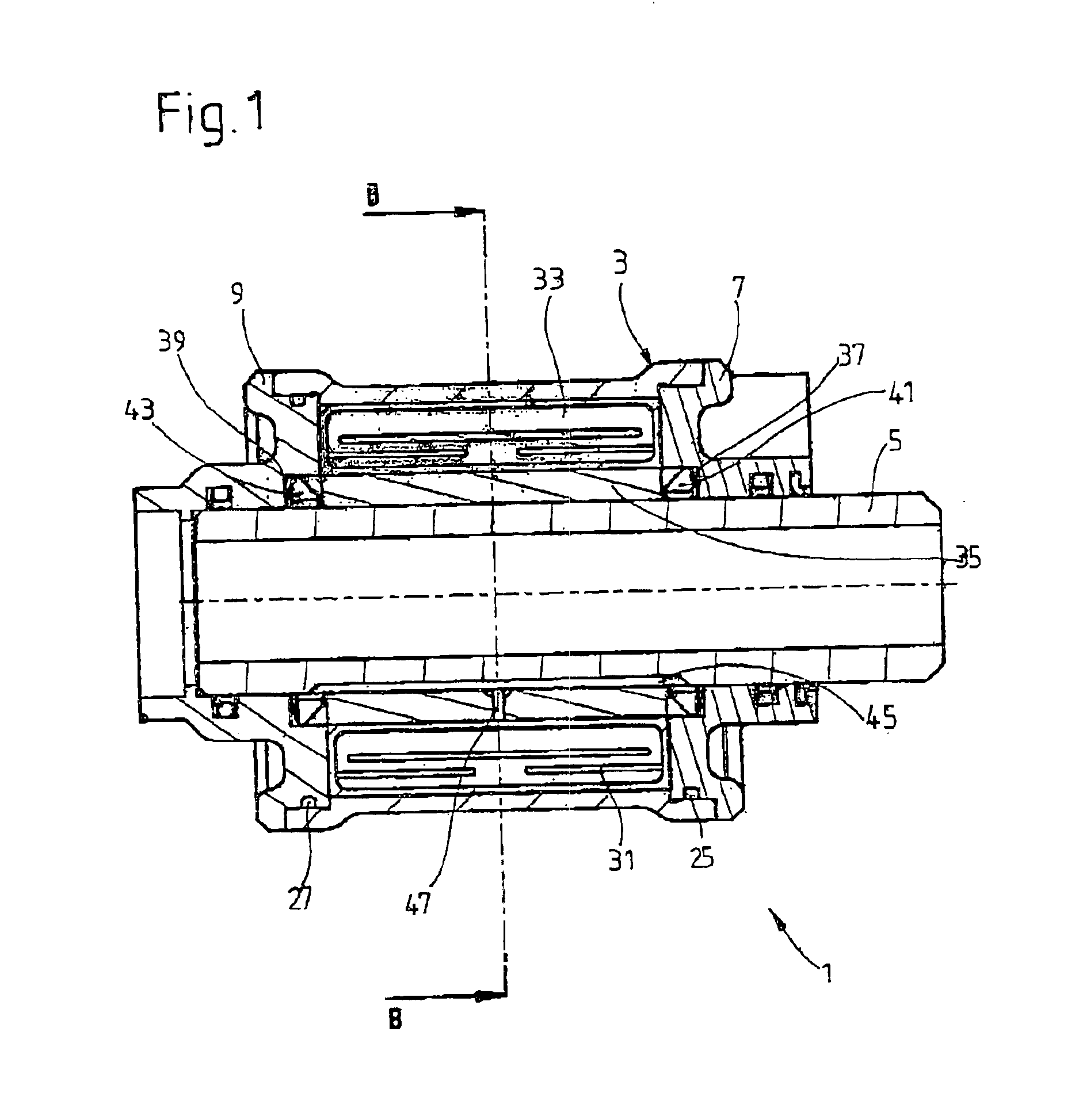

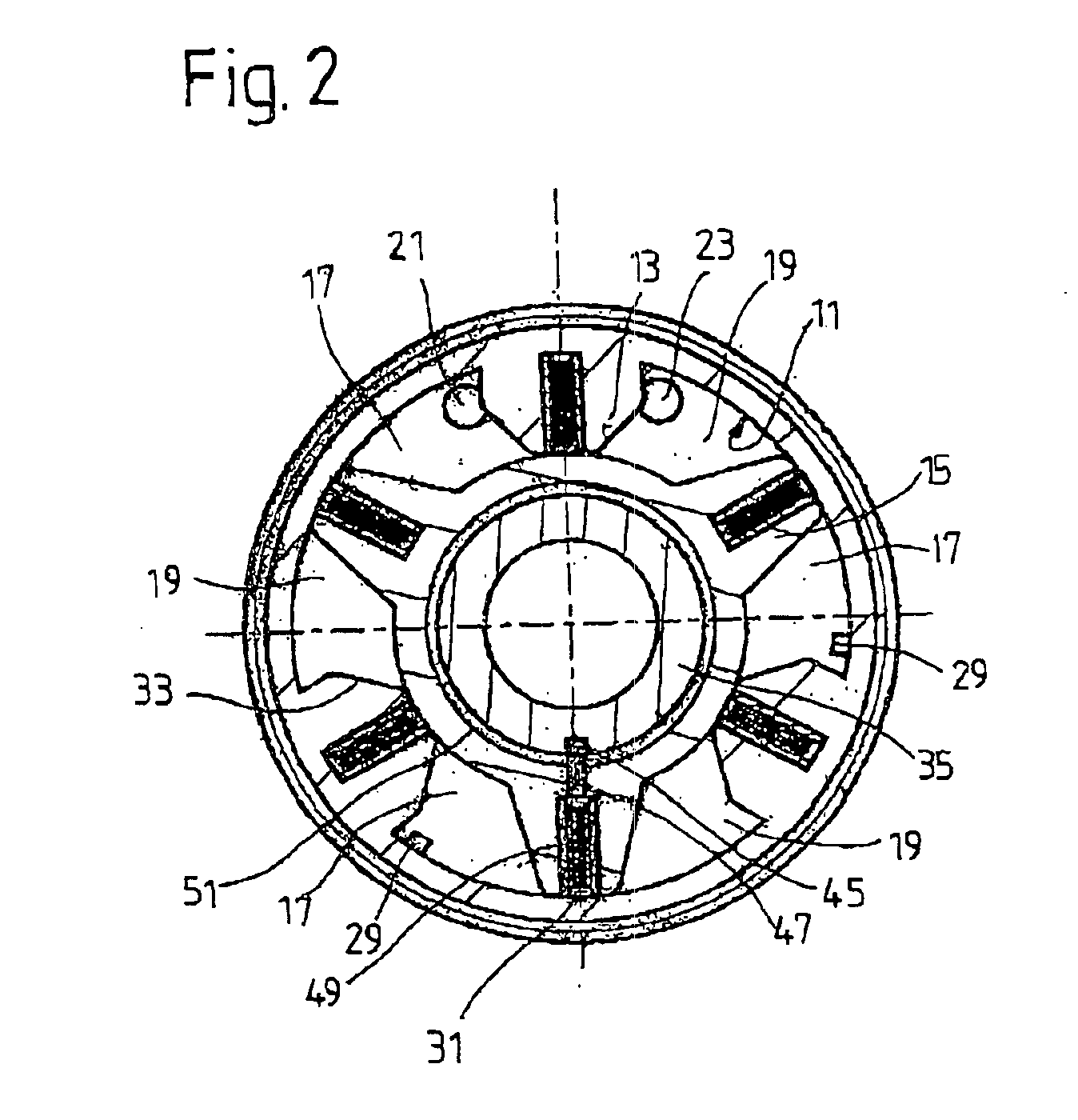

Oscillating motor

InactiveUS20040134345A1Pressure equalization channel can be produced much more easilyEasy to produceSealing arrangements for enginesFluid-pressure actuatorsEngineeringEqualization

An oscillating motor includes a cylinder which is filled with hydraulic medium and which has at least one rib on its inside wall, whereby a motor shaft with at least one vane is supported inside the cylinder with freedom to oscillate, a sleeve concentric to the motor shaft, and a pressure-preloaded sealing arrangement inside each of at least two ring-shaped spaces between the cylinder and the motor shaft, which sealing arrangements seal the working chambers formed by the cylinder and its rib, the motor shaft, and the vane together with the cylinder covers at the ends. The ring-shaped spaces are connected to each other by a pressure equalization channel, and an axial groove, which forms the pressure equalization channel, is present in the contact area between the motor shaft and the sleeve.

Owner:ZF SACHS AG

Rotary piston machines comprising a displaceable inner housing

ActiveUS20050175493A1Reducing gap lossPrevent rotationInternal combustion piston enginesSealing arrangement for pumpsEngineeringMechanical engineering

Owner:ROBERT BOSCH GMBH

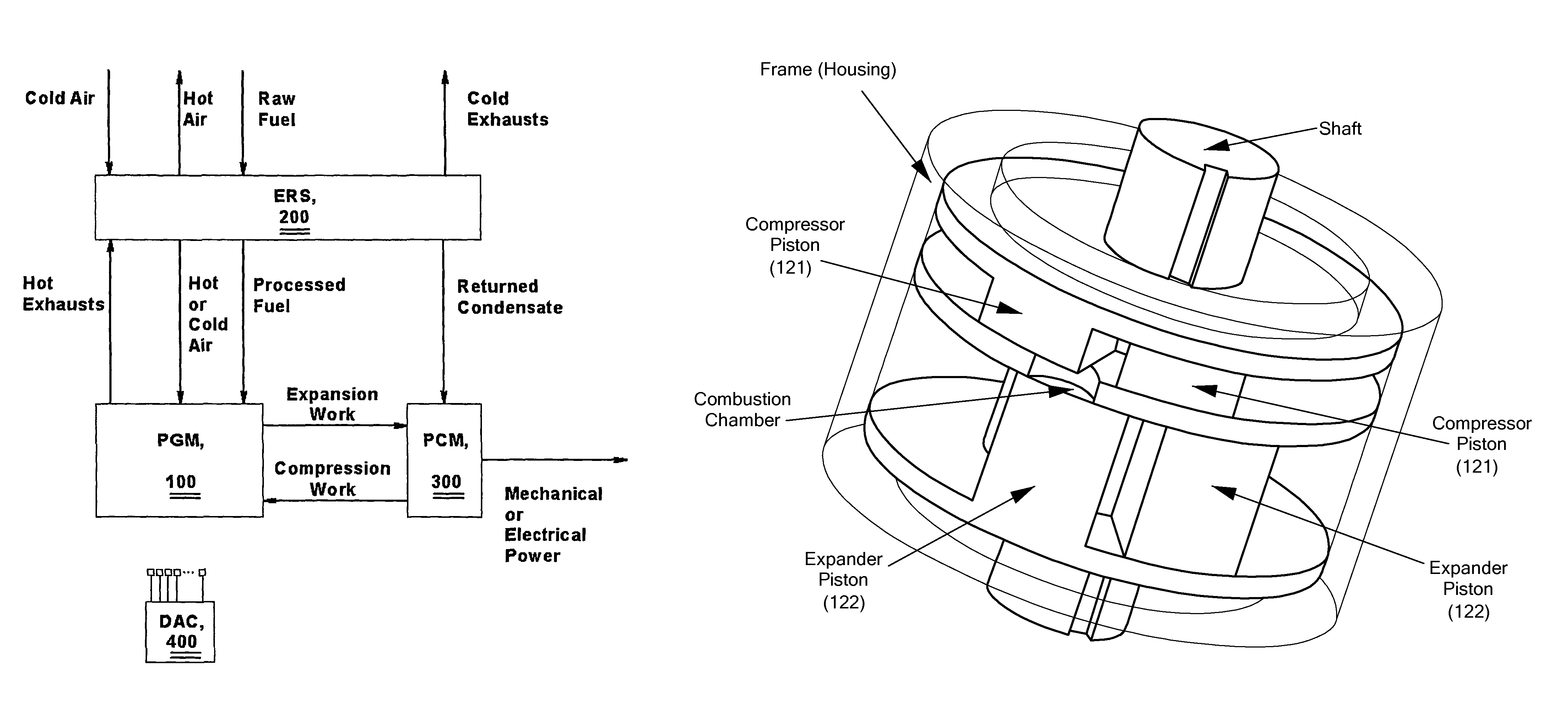

Hybrid cycle combustion engine and methods

ActiveUS8365698B2Reduce workloadIncrease volumeReciprocating combination enginesNon-fuel substance addition to fuelEngineeringInternal combustion engine

An improved internal combustion engine of the four-stroke variable volume type operates by refraining from introducing substantial fuel into the working medium during the compression stroke until substantially maximum pressure of the working medium has been reached and utilizing at least one of the following processes: (a) causing combustion of fuel under substantially constant volume conditions; and (b) causing the power stroke to provide a larger volume to combustion products than the compression stroke provides to the working medium. Related methods are also provided.

Owner:LIQUIDPISTON INC

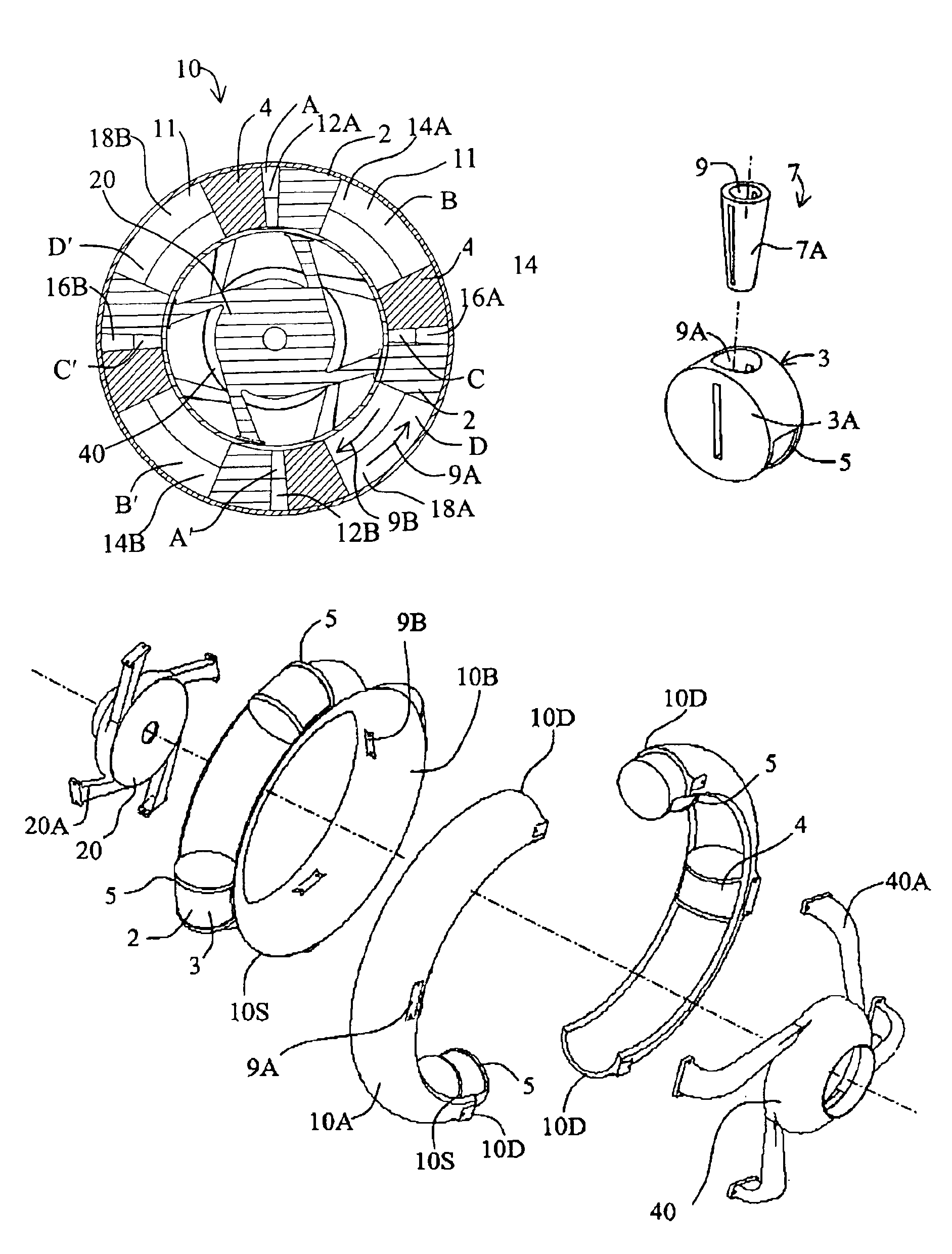

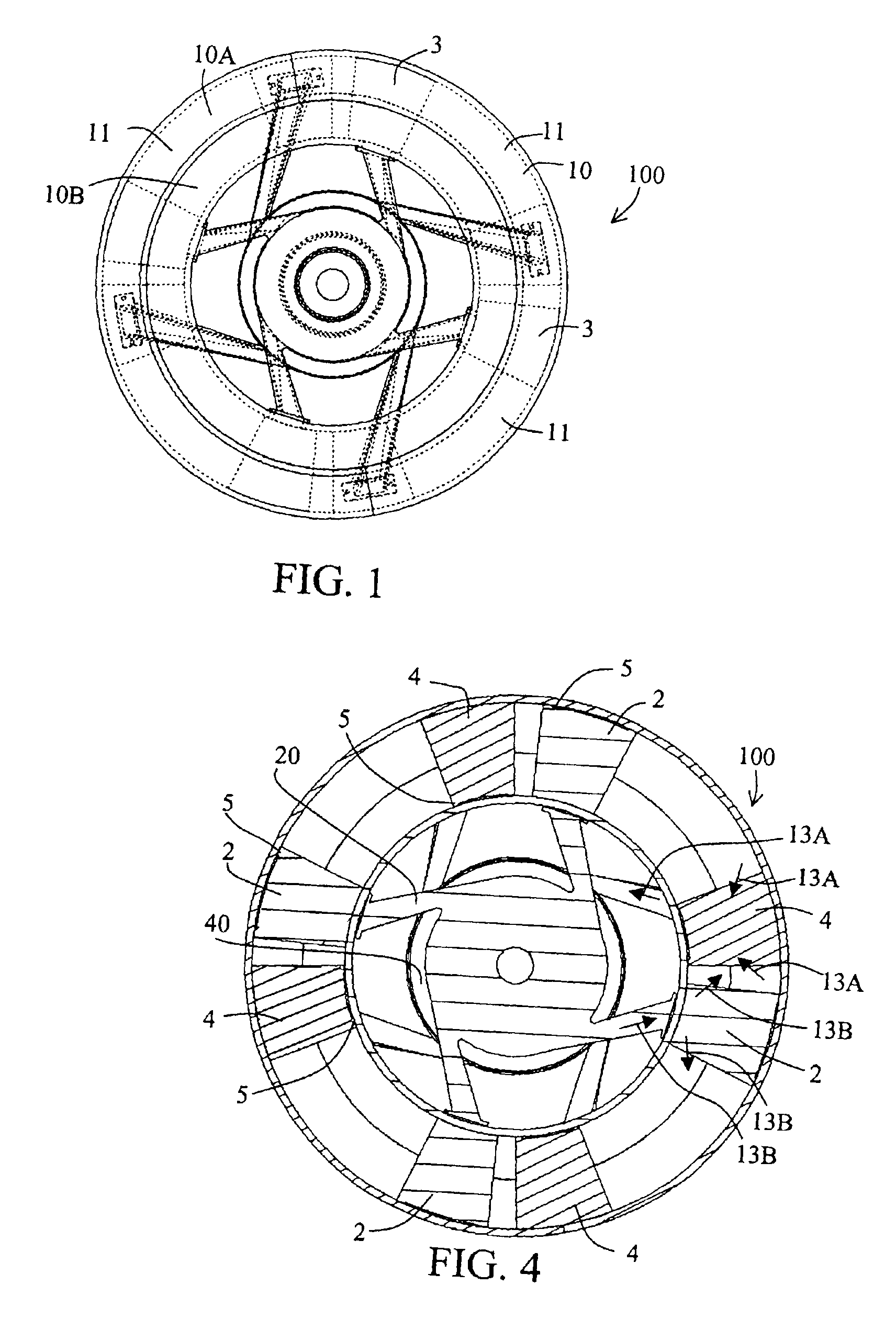

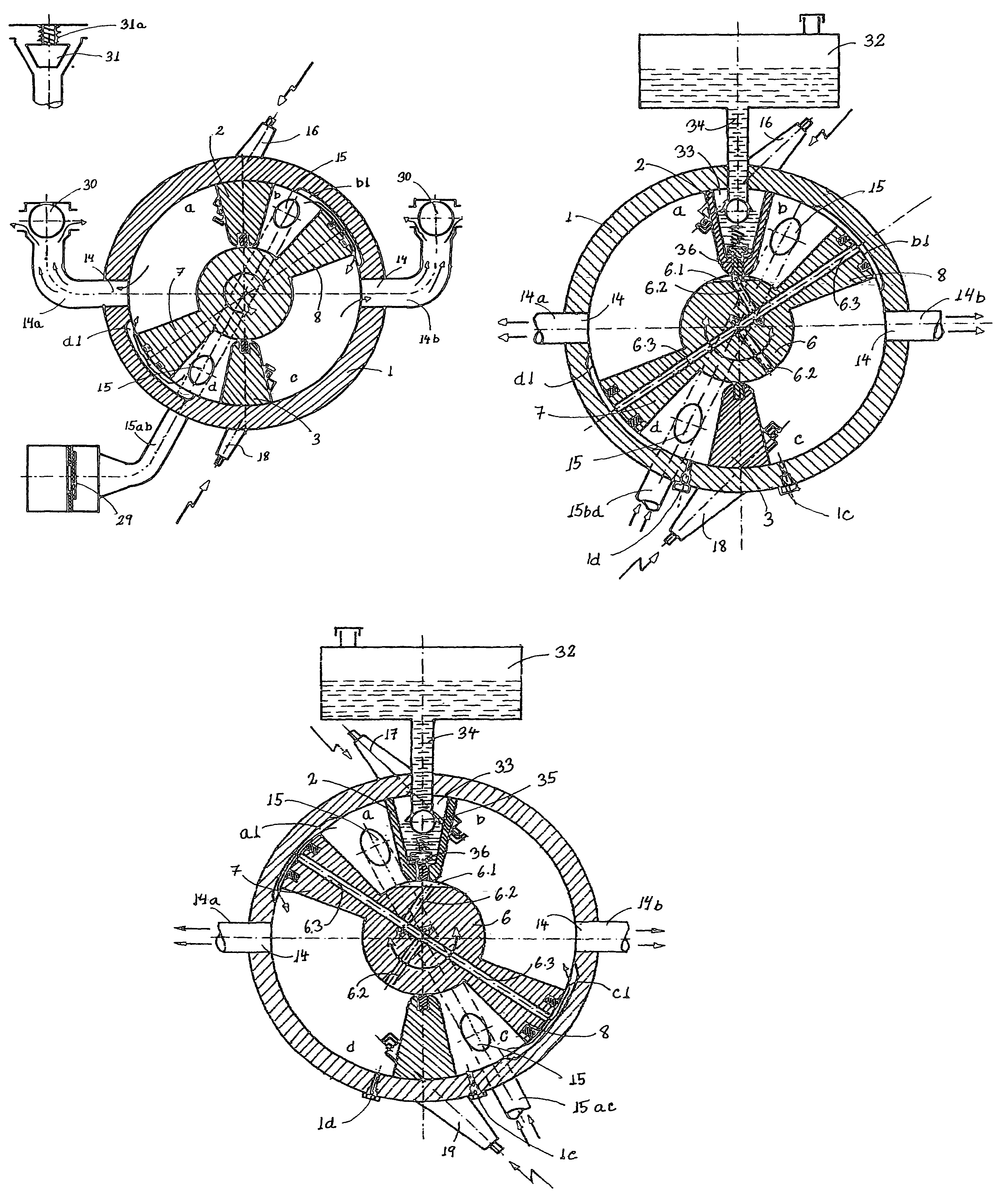

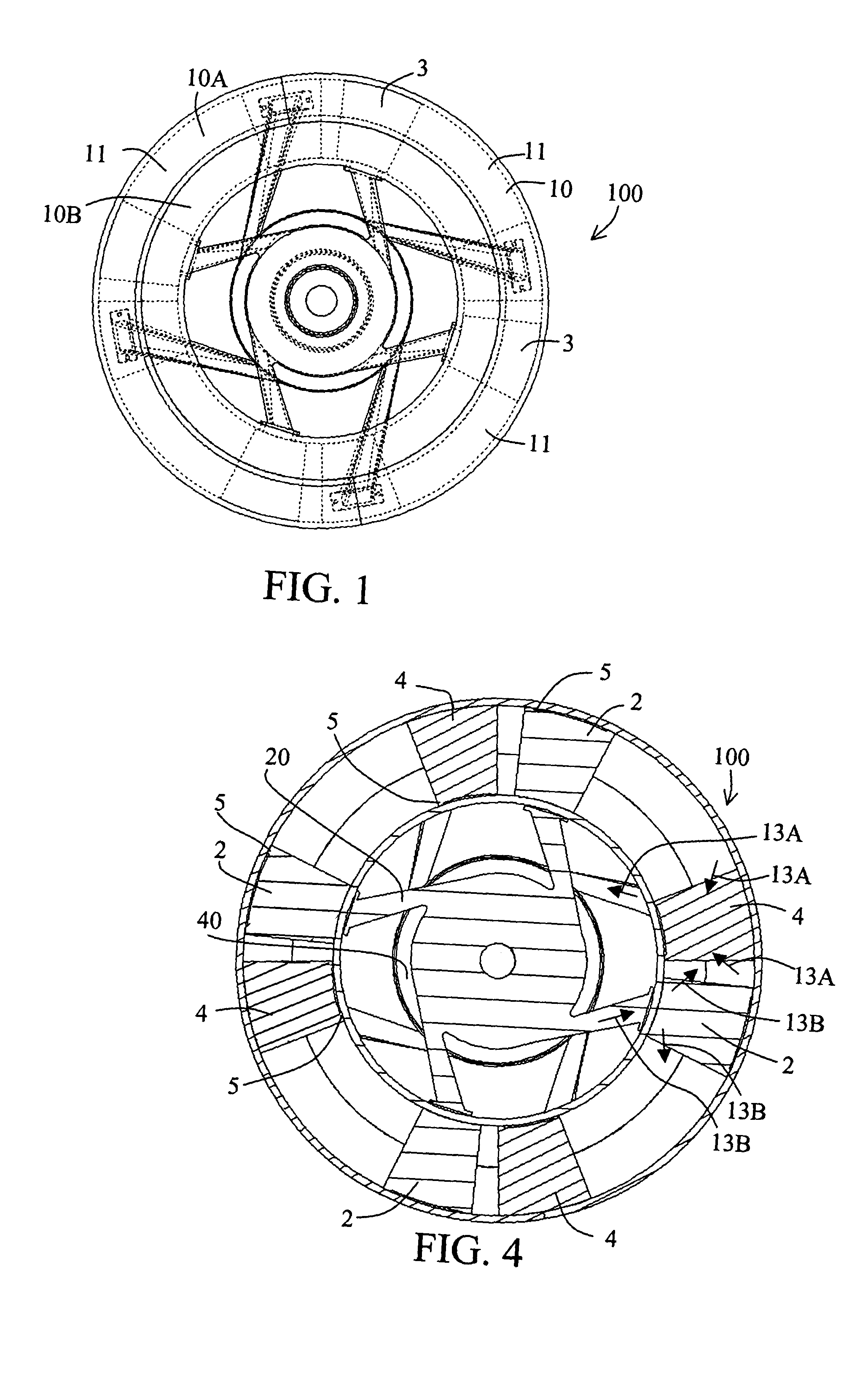

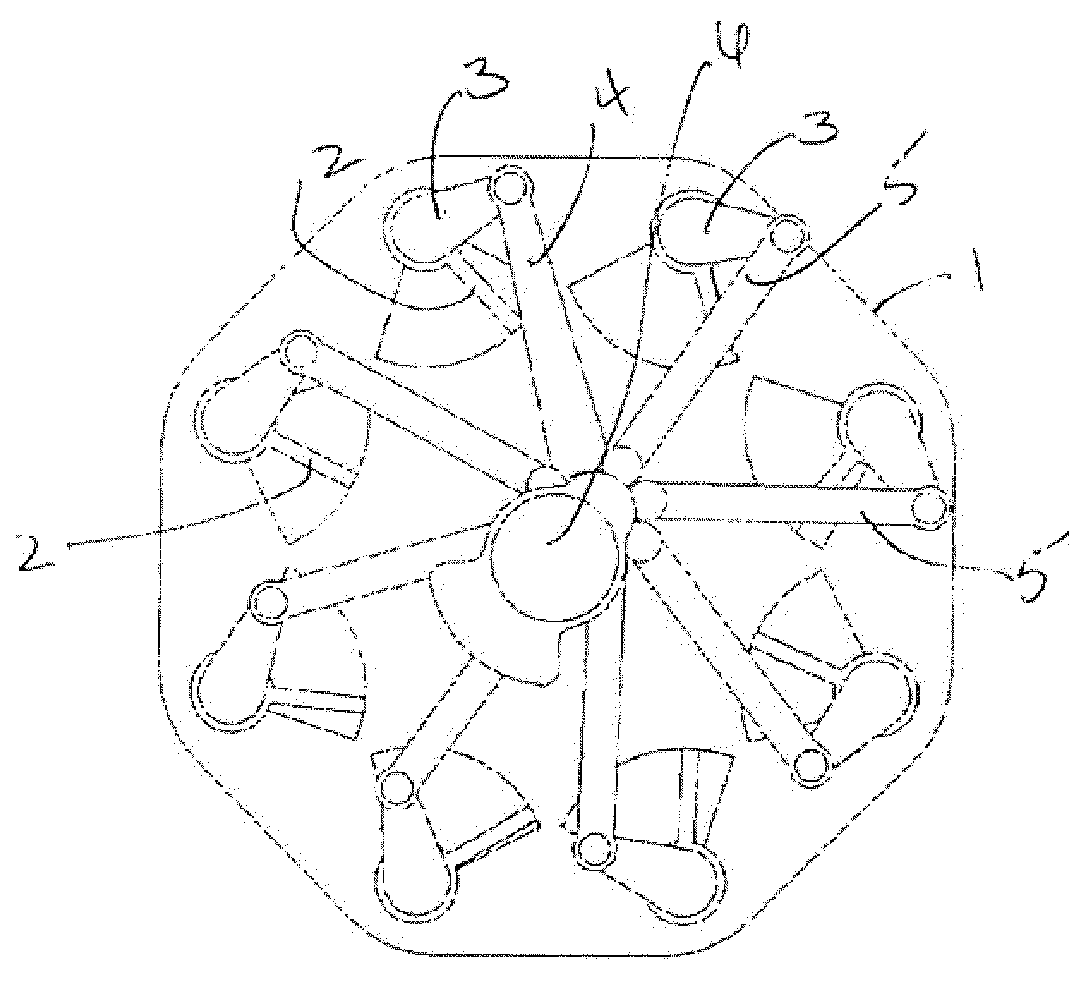

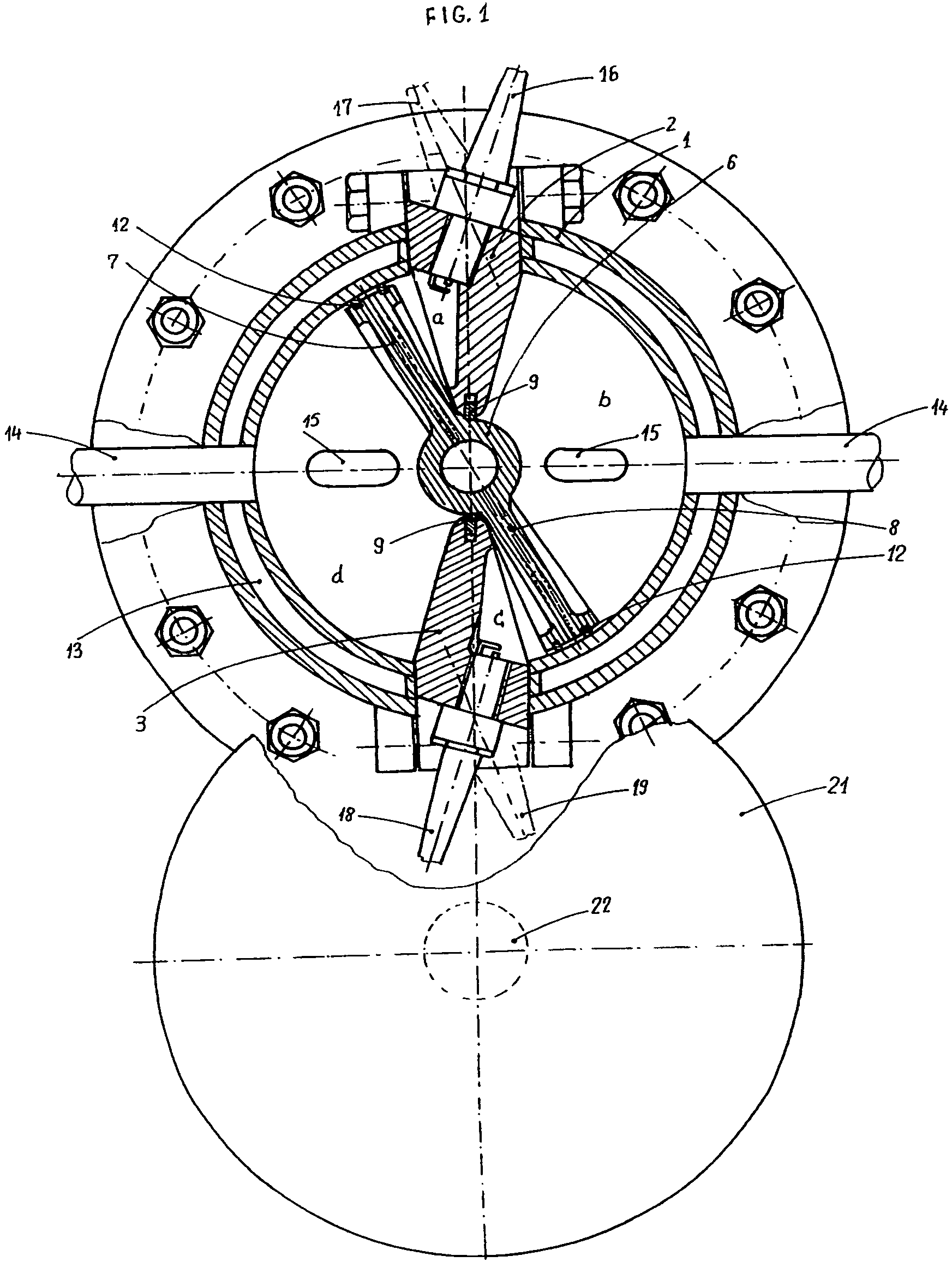

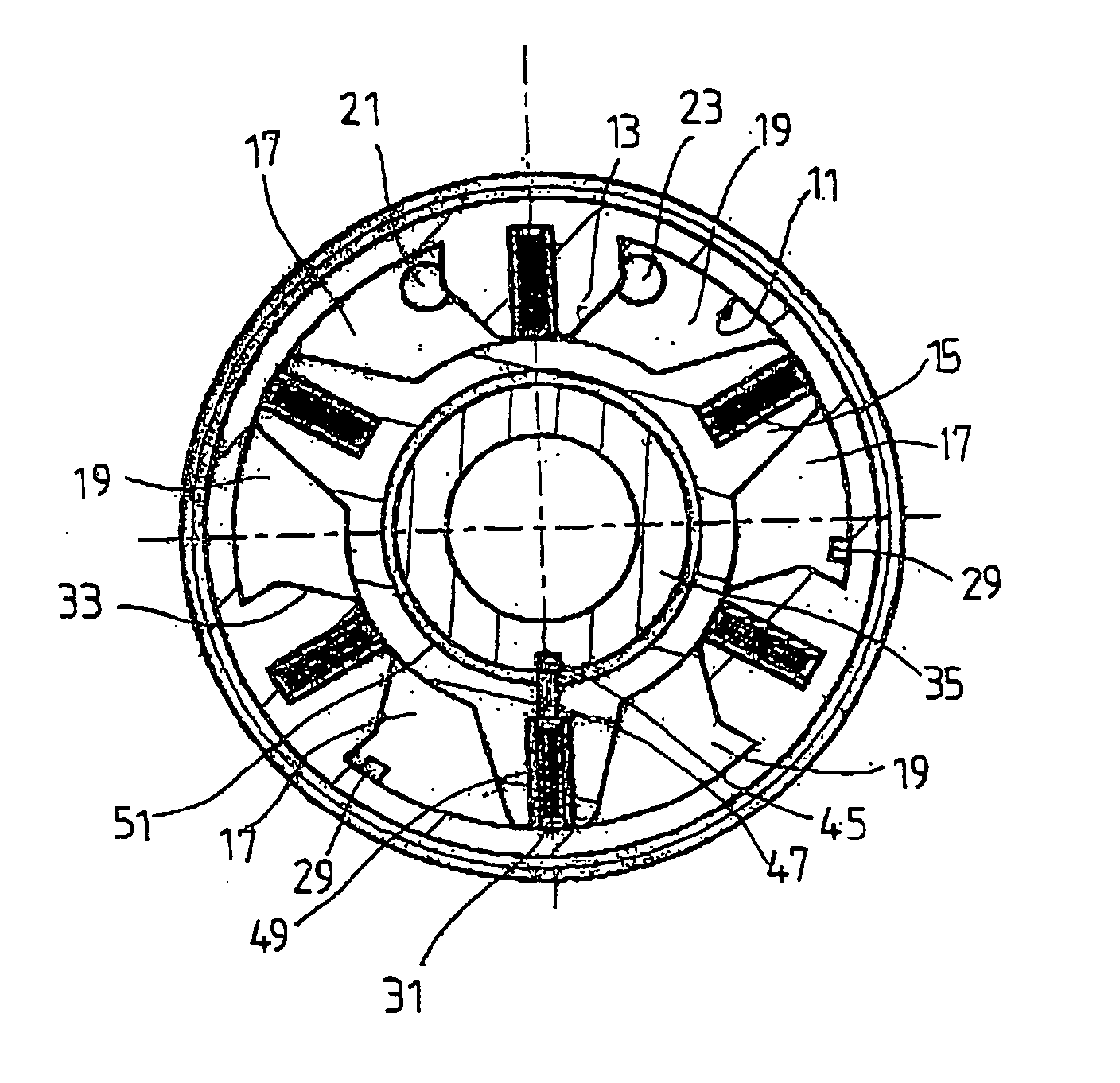

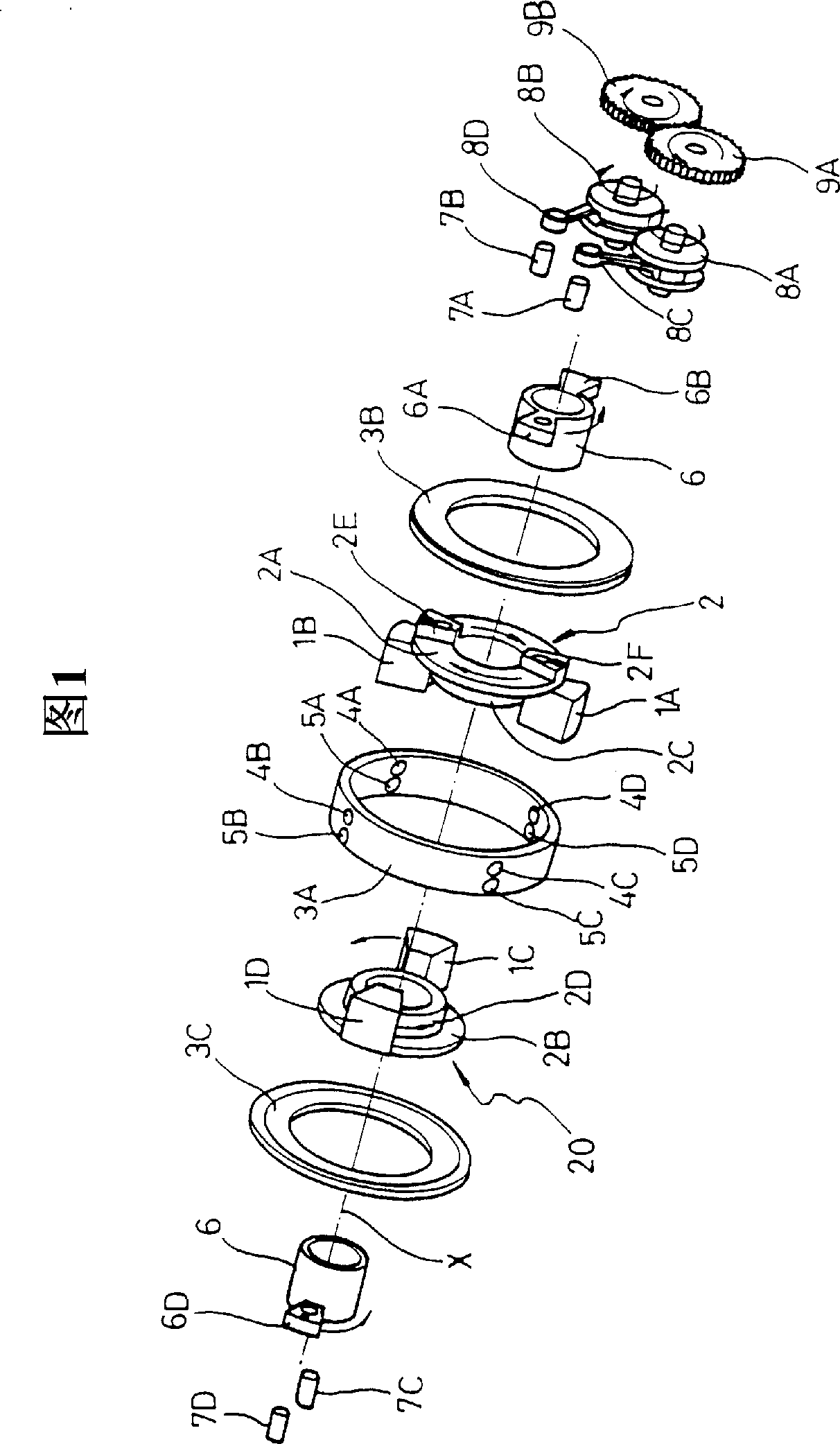

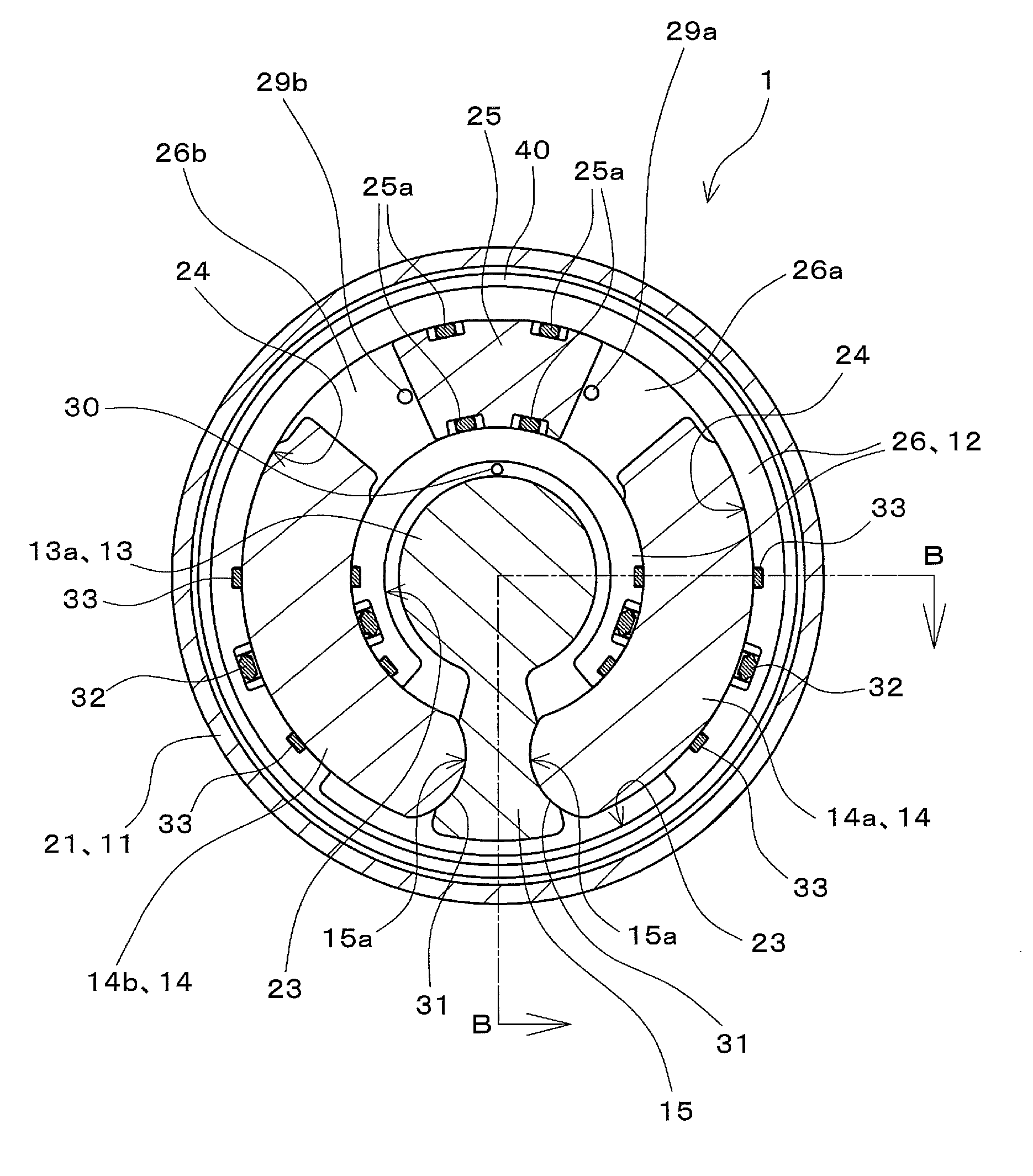

Reciprocating rotary piston system and pressure pump and IC engine using same

InactiveCN1281527AExtend your lifeReduce vibrationValve arrangementsOscillating piston pumpsExhaust valveReciprocating motion

A reciprocating rotary piston system includes a cylinder having an annular and hollow interior; a plurality of pistons (1A to 1D) of which first and second parties are formed to be disposed alternately on the same inner circumference of the cylinder, the first and second parties of the pistons reciprocating along a given arc at the same speed and in the opposite direction with respect to each other; a plurality of intake valves (4A to 4D) mounted at each point of the cylinder where the two adjacent pistons meet for controlling flow of a fluid introduced thereinto from the outside; and a plurality of exhaust valves (5A to 5D) mounted at each point of the cylinder where the two adjacent pistons meet for controlling flow of a fluid forced out from the inside. The piston system is used for a hydraulic / pneumatic pump, a vacuum pump and an internal combustion engine.

Owner:金昌钧 +1

Oscillating motor

InactiveUS6880451B2Pressure equalization channel can be produced much more easilyEasy to produceSealing arrangements for enginesFluid-pressure actuatorsEngineeringPressure balance

An oscillating motor includes a cylinder which is filled with hydraulic medium and which has at least one rib on its inside wall, whereby a motor shaft with at least one vane is supported inside the cylinder with freedom to oscillate, a sleeve concentric to the motor shaft, and a pressure-preloaded sealing arrangement inside each of at least two ring-shaped spaces between the cylinder and the motor shaft, which sealing arrangements seal the working chambers formed by the cylinder and its rib, the motor shaft, and the vane together with the cylinder covers at the ends. The ring-shaped spaces are connected to each other by a pressure equalization channel, and an axial groove, which forms the pressure equalization channel, is present in the contact area between the motor shaft and the sleeve.

Owner:ZF SACHS AG

Method of operation of a spherical positive displacement rotary machine and devices for carrying out said method

InactiveUS8152504B2Rotary/oscillating piston combinations for elastic fluidsInternal combustion piston enginesMechanical engineeringSpherical form

A positive displacement rotary machine with a body having an internal spherical working surface divided into bypass and propulsion areas, a rotor with a working rotational surface, a ring working cavity formed by the working surfaces of the body and rotor, and a C-shaped separator mounted in part of the cavity at an angle to a plane of the rotor rotation. The cavity is partitioned by the separator at the bypass area, and the working medium openings are located from opposite sides of the separator. The working surface of the rotor has at least one slot. In each slot is mounted a piston capable of sealing the working cavity, and performing rotational oscillations in a slot plane. The piston is at least in the form of a part of a disk and has at least one through-cutout for the separator passage, and can seal the through-cutout at the propulsion area.

Owner:DIDIN ALEXANDR VLADIMIROVICH +1

Oscillating Piston Engine

InactiveUS20090038581A1Internal combustion piston enginesEngine of arcuate-engagement typeRotational axisEngineering

The invention relates to an oscillating piston engine comprising a housing that contains a first and at least a second piston, both of which can rotate about a fixed rotational axis in the housing and which when rotating about said axis execute counter-rotating displacements back and forth about a pivoting axis that runs perpendicular to the rotational axis through the centre of the housing. A working chamber is situated between opposing end faces of the first and at least second piston. The housing is provided with at least one gas exchange opening for admitting or discharging a gas into or from the working chamber. The pistons are arranged in such a way that the rotational axis runs through the working chamber. The pistons are mounted to slide in a piston cage, which is located in the housing, is concentric with the rotational axis, and rotates together with the pistons about said axis. The gas exchange opening is arranged eccentrically in relation to the rotational axis, on one end face of the housing.

Owner:HUETTLIN HERBERT

Rotary actuator

ActiveUS9133923B2Reduce internal leakageThe implementation process is simpleGearingFluid-pressure actuatorsRotary actuatorControl theory

A cylinder is installed within a case. An output shaft is installed in a hollow space within the cylinder. A pair of pistons extend in an arc, and is supported so as to be able to slide and be displaced along a circumferential direction of the cylinder within the cylinder. The pair of pistons is able to urge an arm integrated with the output shaft from two sides of the arm. Pressure chambers into which a pressure medium is introduced are defined between the cylinder and each piston in the pair of pistons. The pressure medium is fed to one of the pressure chambers and drained from the other, and thus the arm is displaced, and the output shaft pivots in a rotational direction.

Owner:NABLESCO CORP

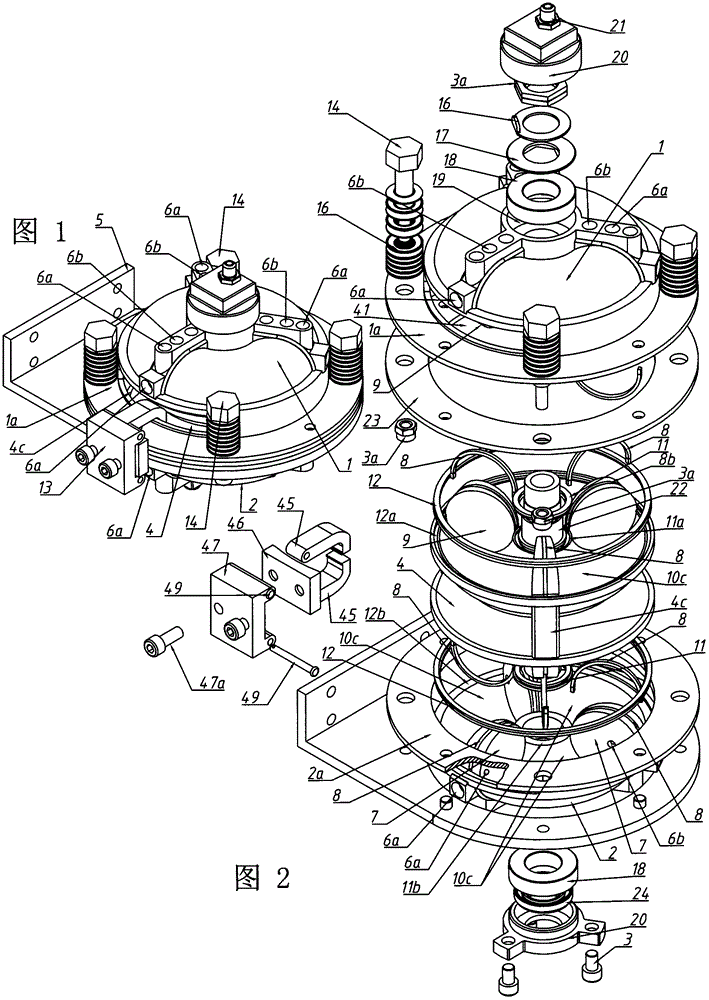

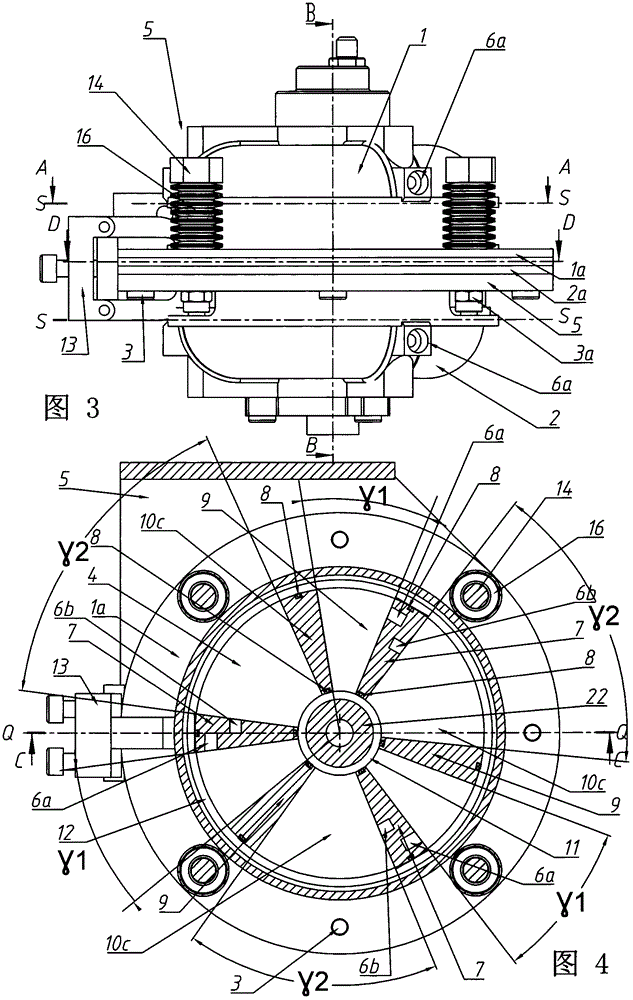

Butt clamp swing tray piston swing driver

ActiveCN104912600AImprove sealing propertiesExtend your lifeOscillating piston pumpsOscillating piston liquid enginesForce generationCrusher

The invention relates to a butt clamp swing tray piston swing driver; the angular travel swing thereof is in a range of 0-330 degrees, or is continuous one-way rotation; the butt clamp swing tray piston swing driver is specifically suitable for such angular travel type valves as a ball valve, or replaces a motor to drive such revolving machines as a crusher, and is also suitable for pumping a fluid; and the fluid of a pressure feed piston of the driver driving a mechanical load to work or the fluid of mechanically driving a piston pressure feed load to work can be gas or liquid. The driver comprises a butt clamp swing tray piston swing actuation device, a fluid intake / drain channel system, a cooling system and a driving force generation system; a gas channel of the fluid intake / drain channel system is communicated with a working cavity; the cooling system is a forced cooling and / or natural cooling mechanism; the driving force generation system is a system of the fluid pressure driving the piston to act on the mechanical load or a system of mechanically driving the piston to act on the fluid load; and the butt clamp swing tray piston swing actuation device comprises trays of k not fewer than 3, a piston piece, a connecting mechanism, a power intake / discharge bonding structure, a lubricating system and a sealing structure.

Owner:桐乡市诺客信息科技有限公司

Internal combustion engine

InactiveUS7500462B2Volume maximizationMinimized volumeInternal combustion piston enginesEngine componentsFour-stroke engineInternal combustion engine

An internal combustion engine operates on a four-stroke cycle and includes a housing defining: one or more generally wedge-shaped combustion chambers, and an internal cavity in which a wheel is mounted for rotation on a crankshaft. Arranged inside each combustion chamber is a gate, with each gate having a corresponding gate control assembly including a control shaft. Each control shaft is supported by bearings that engage and ride in a generally elliptical cam-cutout defined in the surface of the wheel. Movement of the gate control assemblies within and with respect to the elliptical cam-cutout controls the movement and operation of the gates, such that, as the wheel rotates, a fuel / air mixture is drawn into a combustion chamber; compressed by the rotating movement of a gate; and ignited, imparting a force on the gate, with the gate then rotating to expel combustion gases through an exhaust port.

Owner:KARNES DYNO REV ENGINE

Hybrid Cycle Combustion Engine and Methods

ActiveUS20080202486A1Increase volumeReduce workloadReciprocating combination enginesInternal combustion piston enginesEngineeringInternal combustion engine

An improved internal combustion engine of the four-stroke variable volume type operates by refraining from introducing substantial fuel into the working medium during the compression stroke until substantially maximum pressure of the working medium has been reached and utilizing at least one of the following processes: (a) causing combustion of fuel under substantially constant volume conditions; and (b) causing the power stroke to provide a larger volume to combustion products than the compression stroke provides to the working medium. Related methods are also provided.

Owner:LIQUIDPISTON INC

Oscillating piston machine

InactiveUS7563086B2Reduce frictionMore compactOscillating piston pumpsInternal combustion piston enginesEngineeringPiston

Owner:HUTTLIN HERBERT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com