Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

354 results about "Power stroke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Power Stroke is a name used by a family of diesel engines for trucks produced by Ford Motor Company since 1994. Along with its use in the Ford F-Series (including the Ford Super Duty trucks), applications include the Ford E-Series, Ford Excursion, and Ford LCF commercial truck; the name was also used for a diesel engine used in South American production of the Ford Ranger.

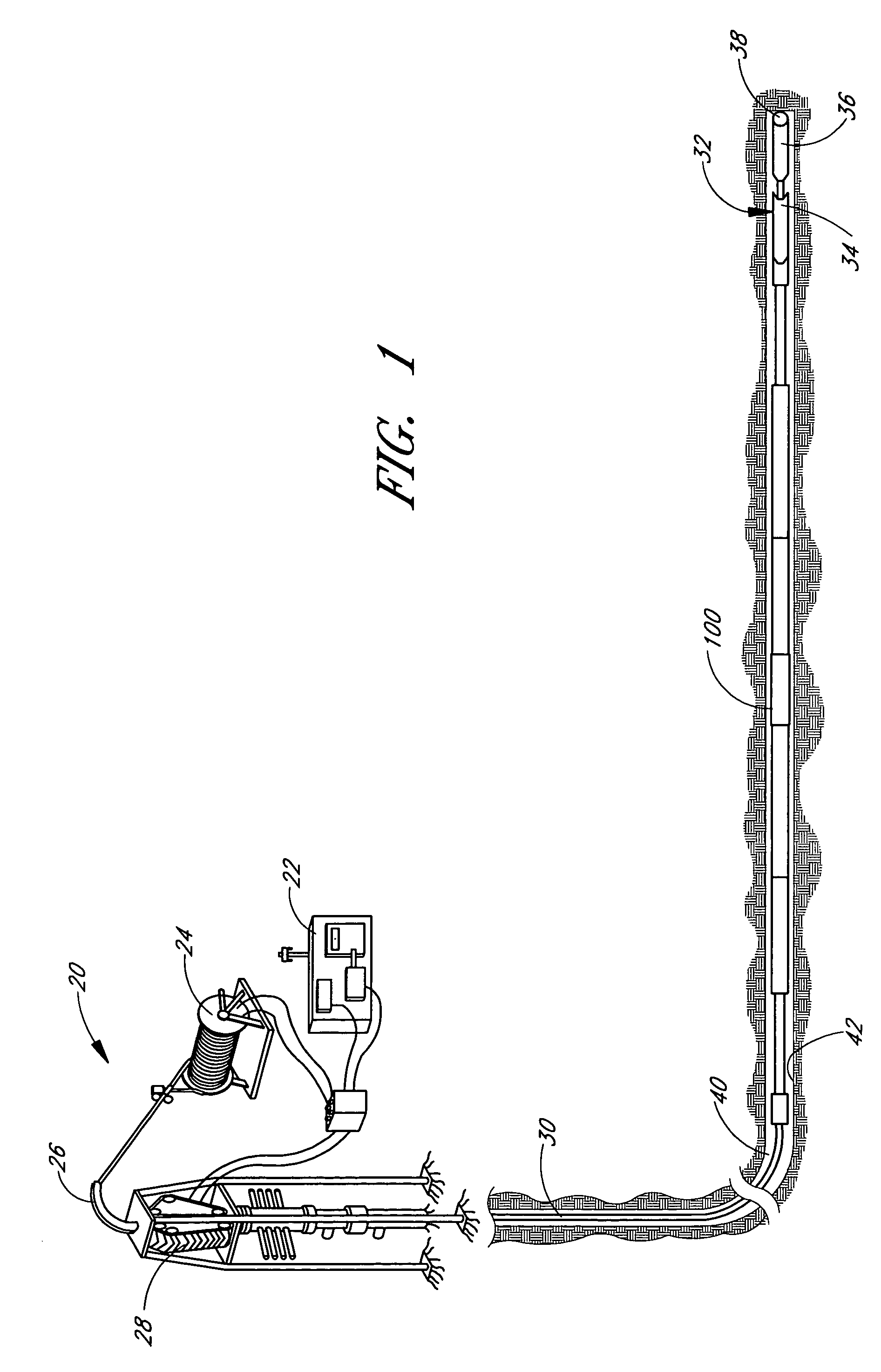

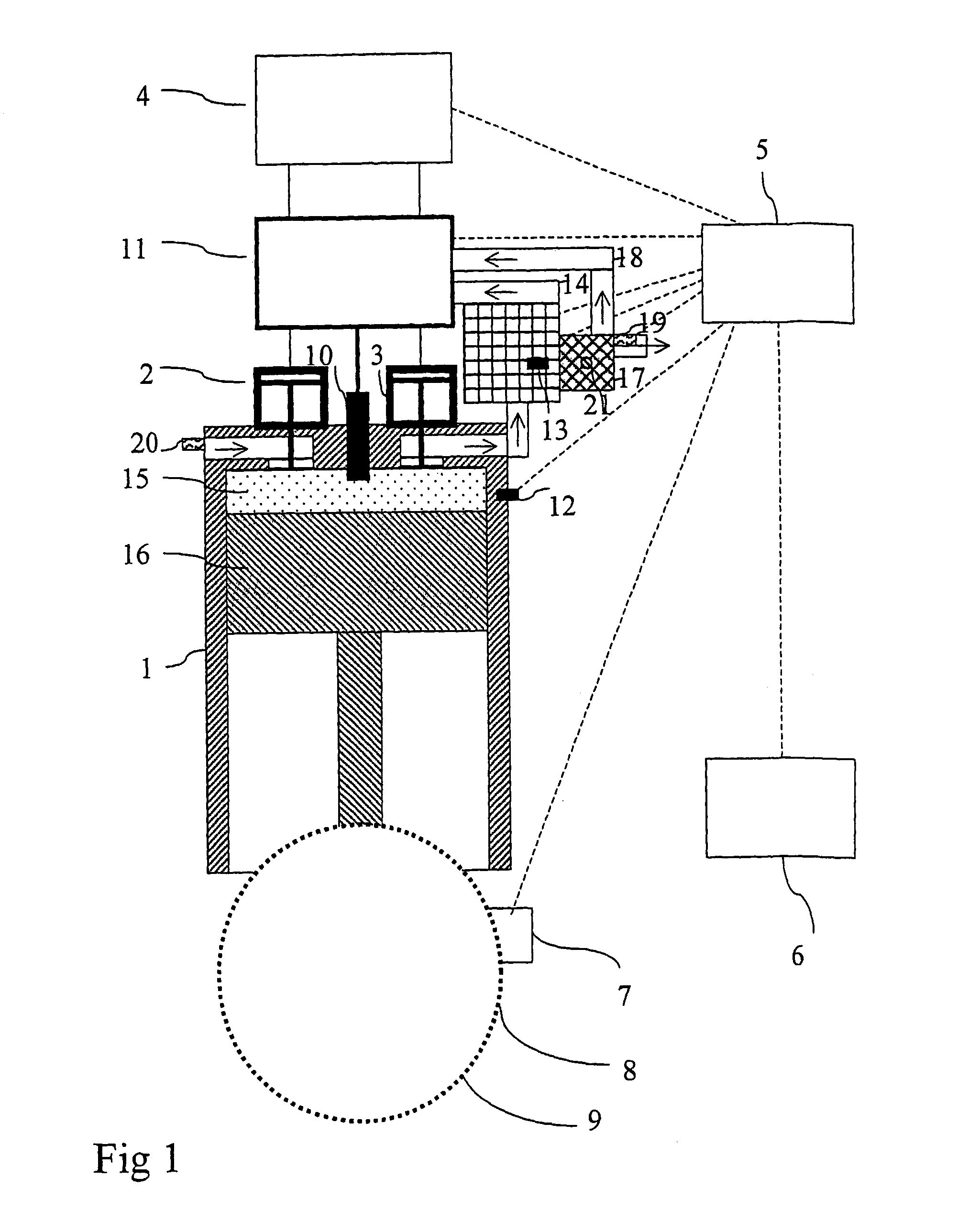

Tractor system

A tractor system has been invented which, in certain embodiments, includes a body connected to the item, first setting means on the body for selectively and releasably anchoring the system in a bore, first movement means having a top and a bottom, the first movement means on the body for moving the body and the item, the first movement means having a first power stroke, and the tractor system for moving the item through the bore at a speed of at least 10 feet per minute.

Owner:EXPRO AMERICAS +1

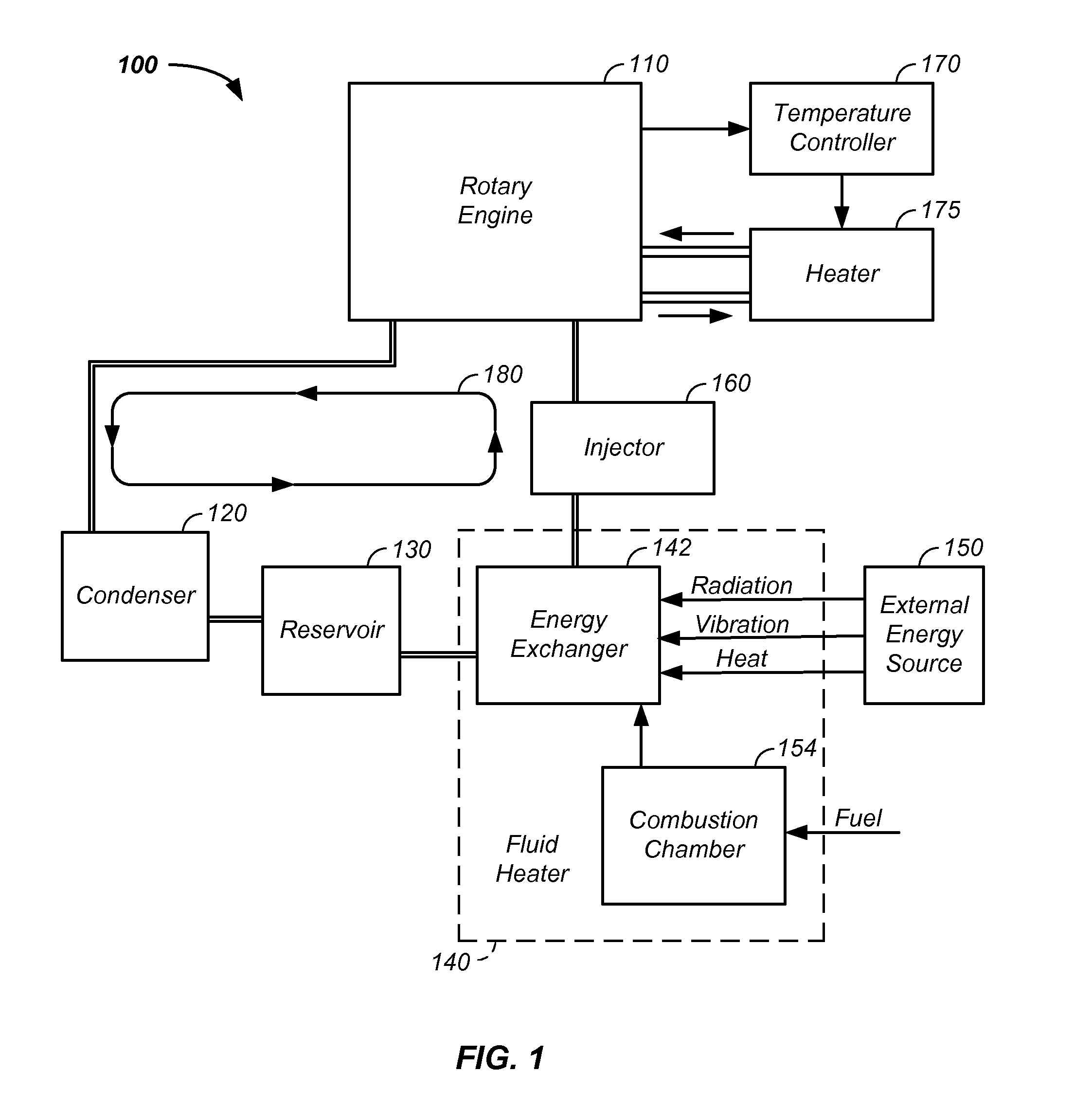

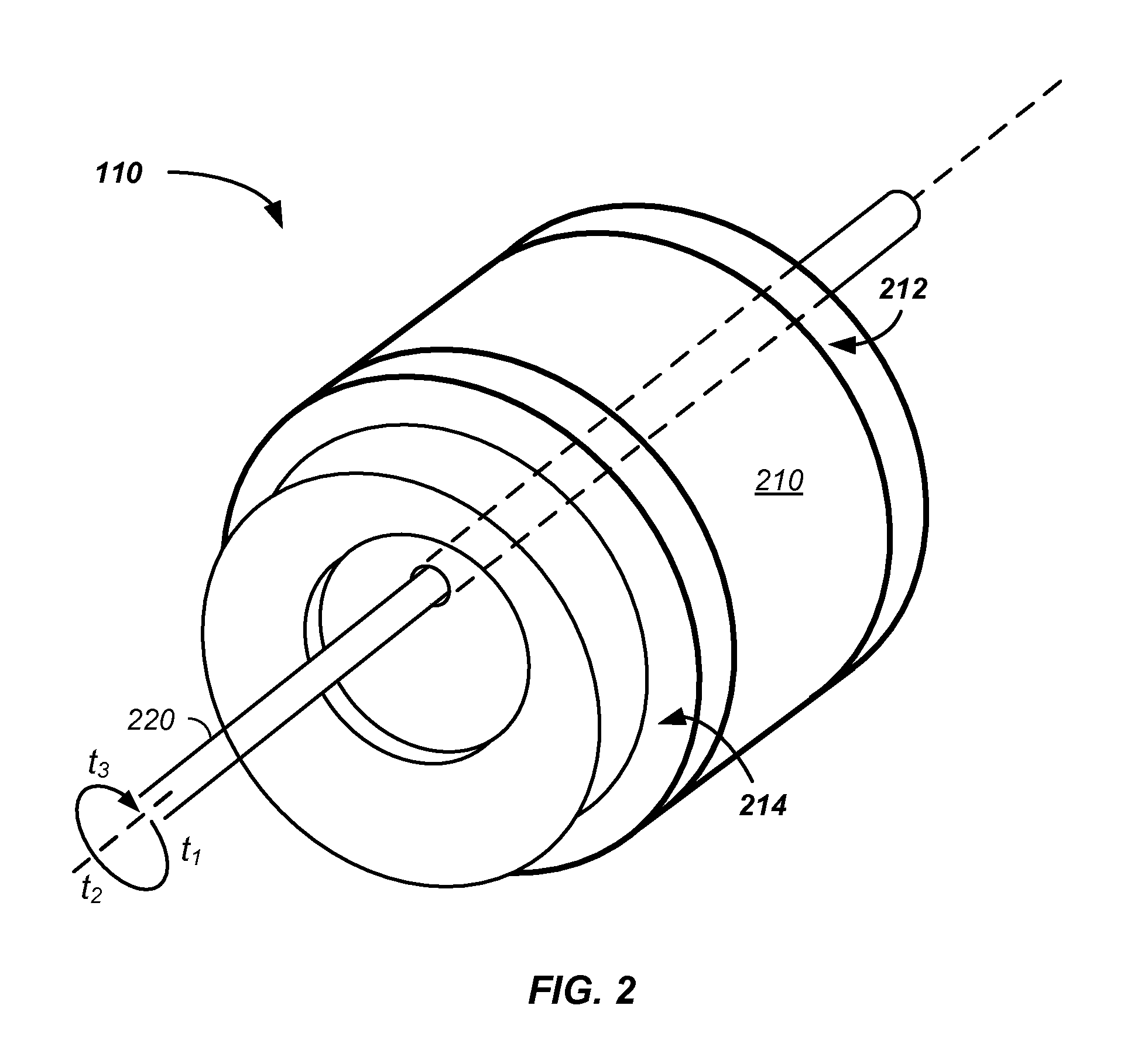

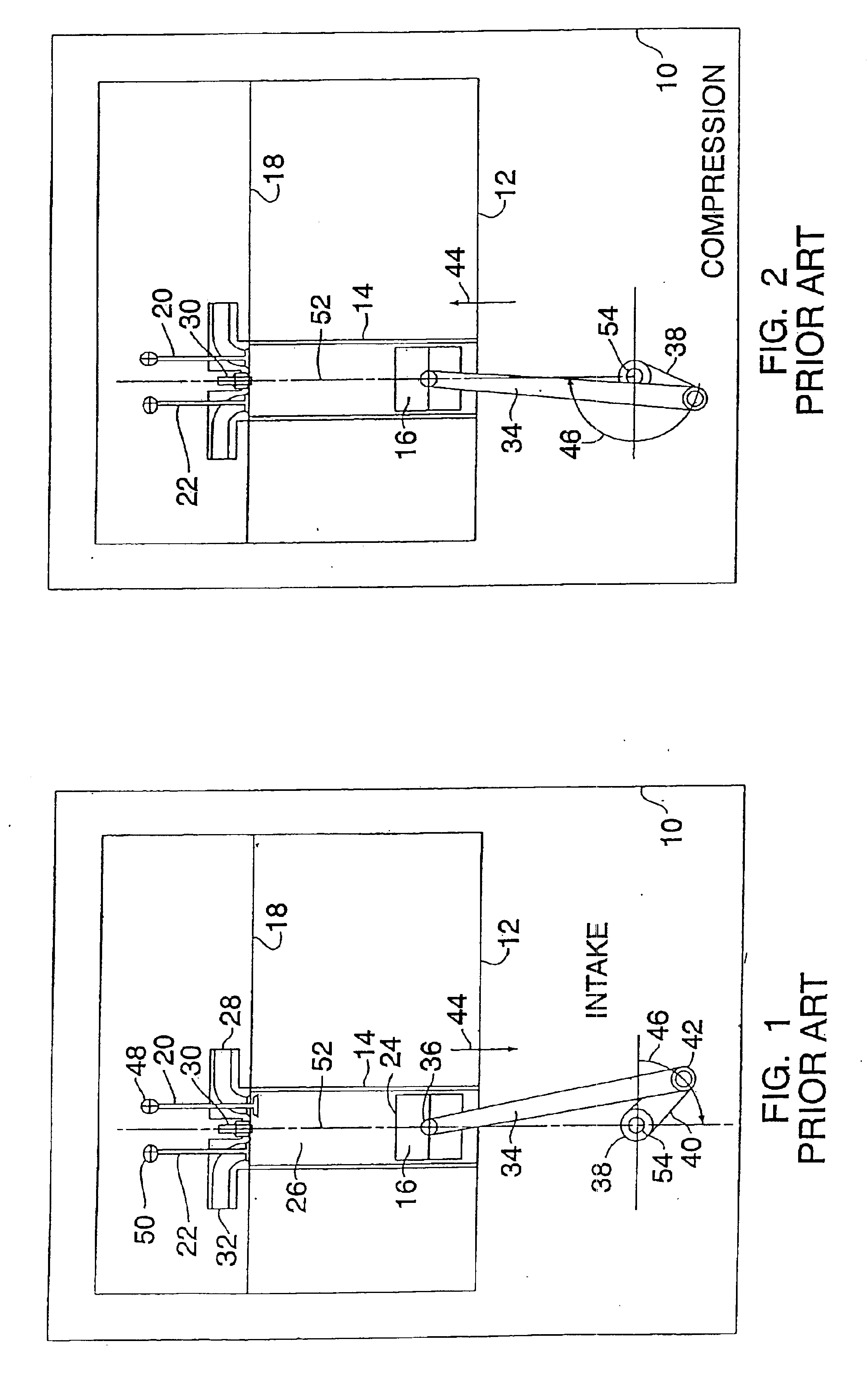

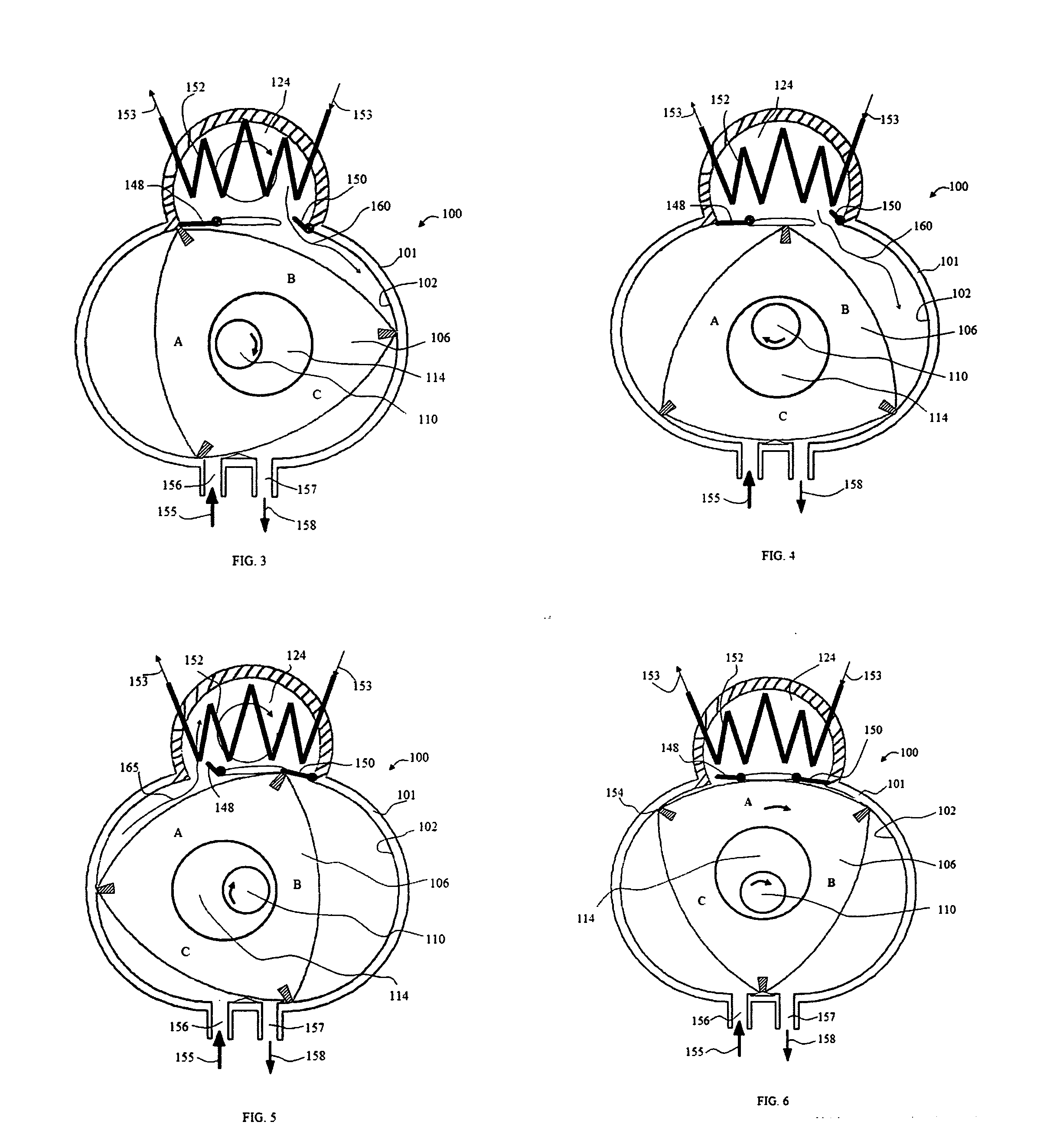

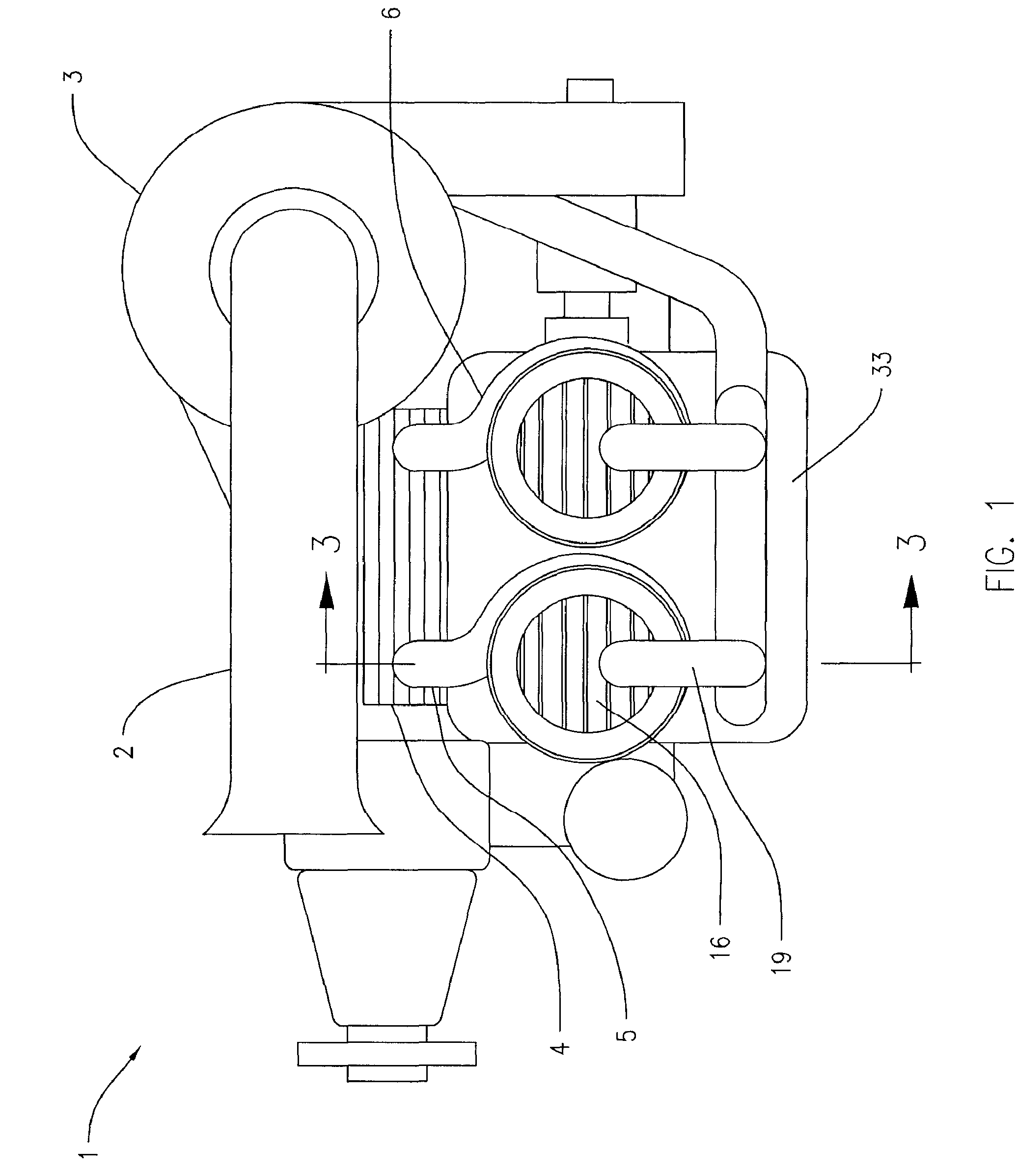

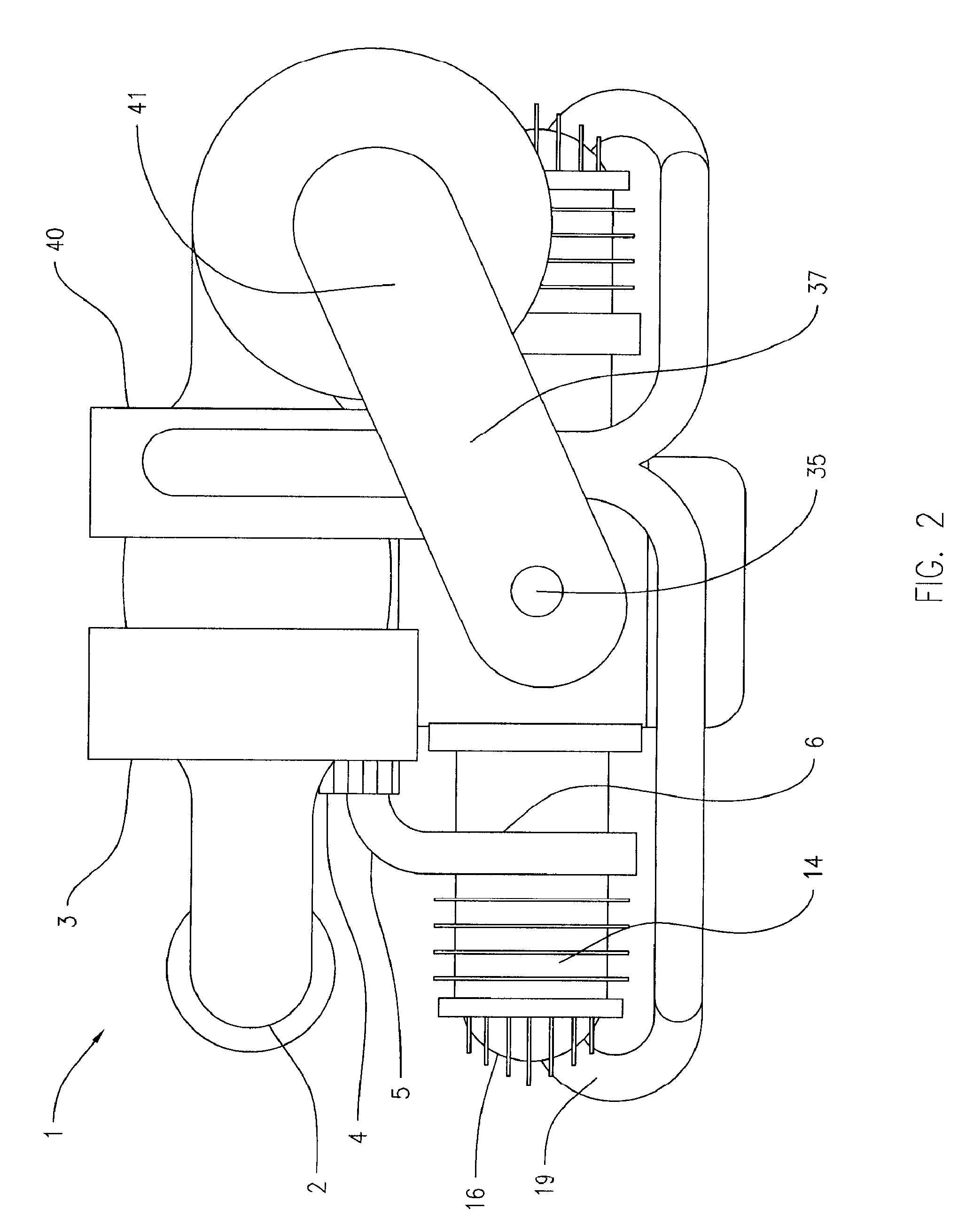

Rotary engine expansion chamber apparatus and method of operation therefor

ActiveUS8523547B2Internal combustion piston enginesOscillating piston enginesRotary engineExpansion chamber

Owner:PEKRUL MERTON W

Internal combustion engine

InactiveUS6880501B2Easy to implementLower emission levelsCombustion enginesEngineeringInternal combustion engine

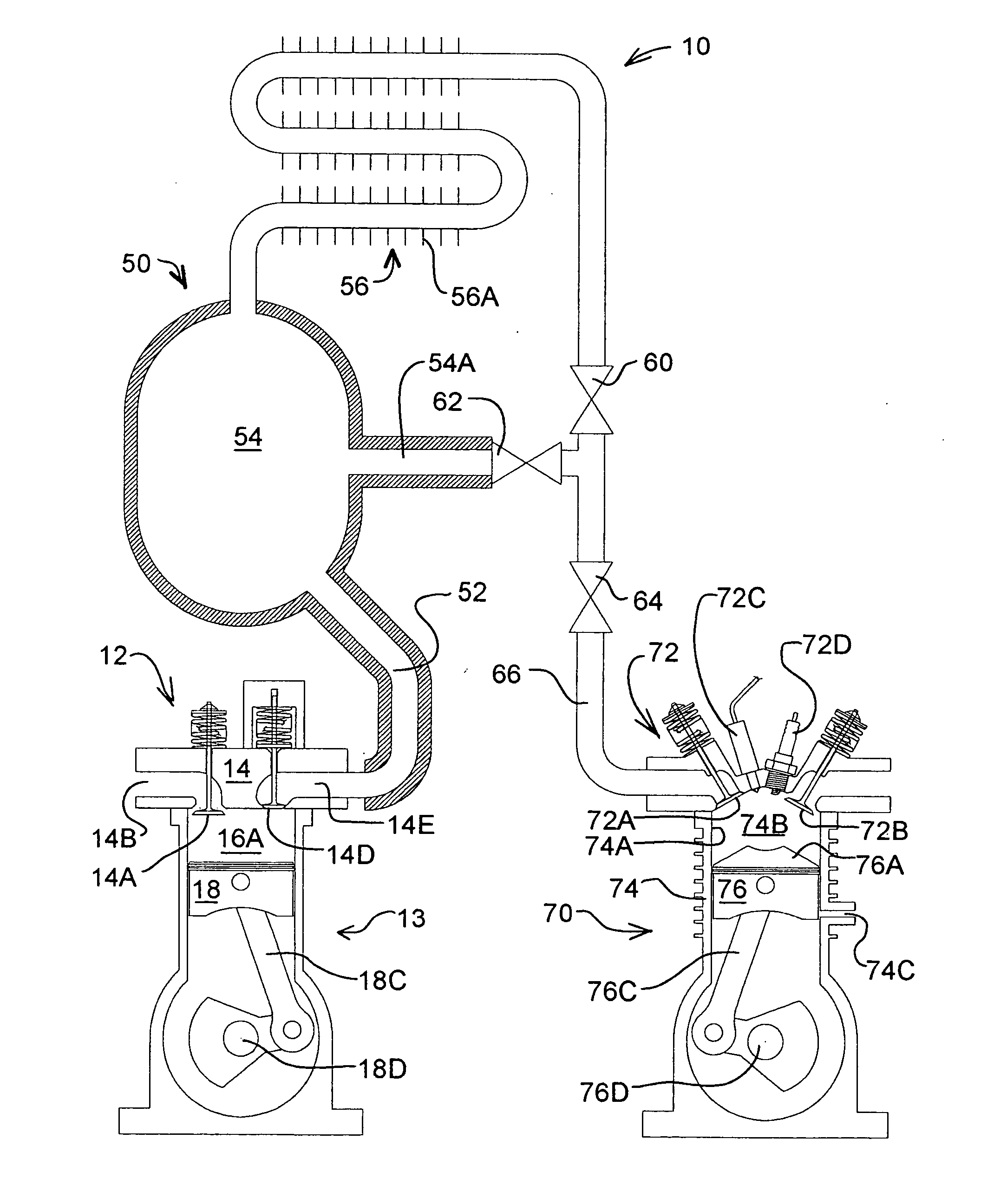

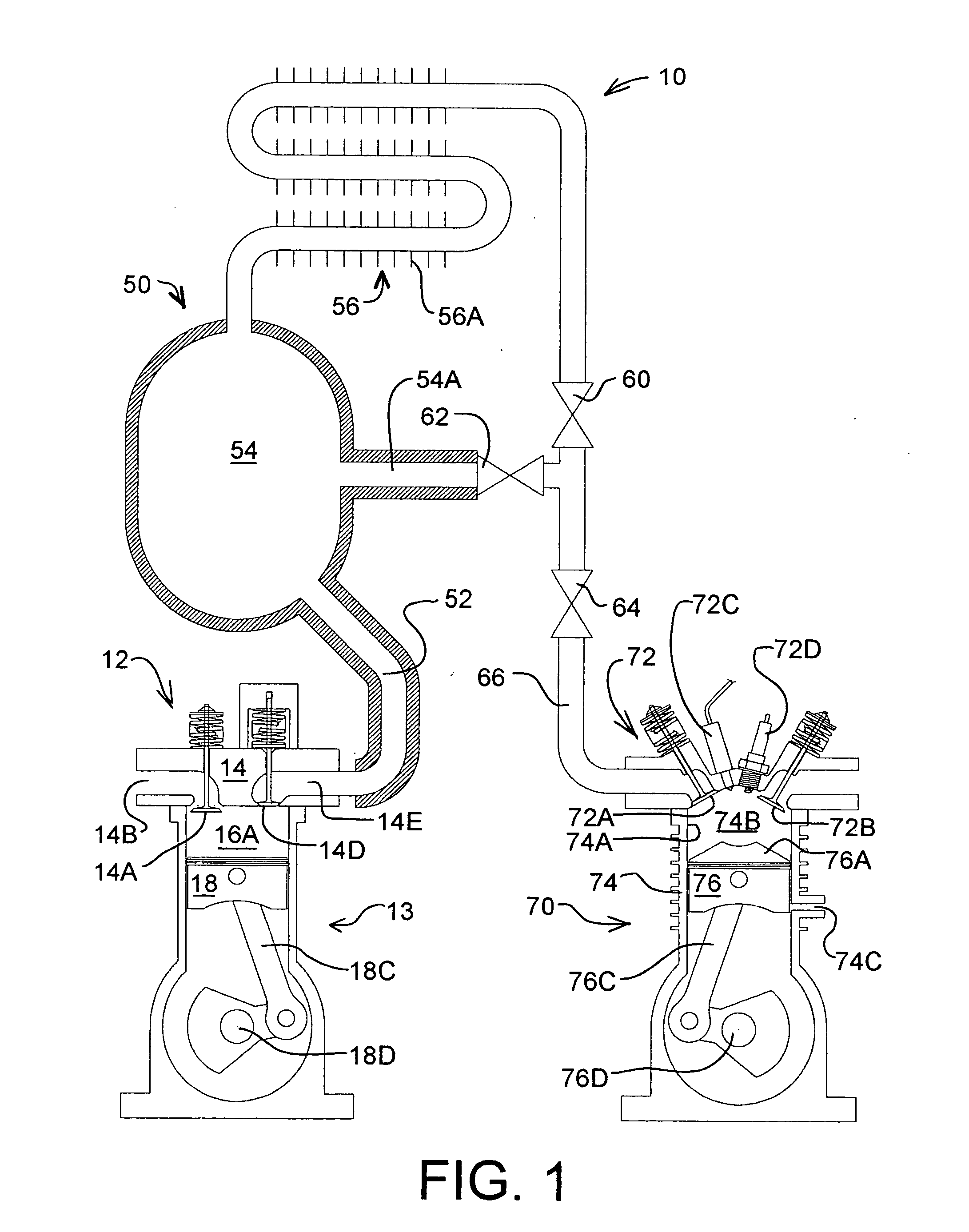

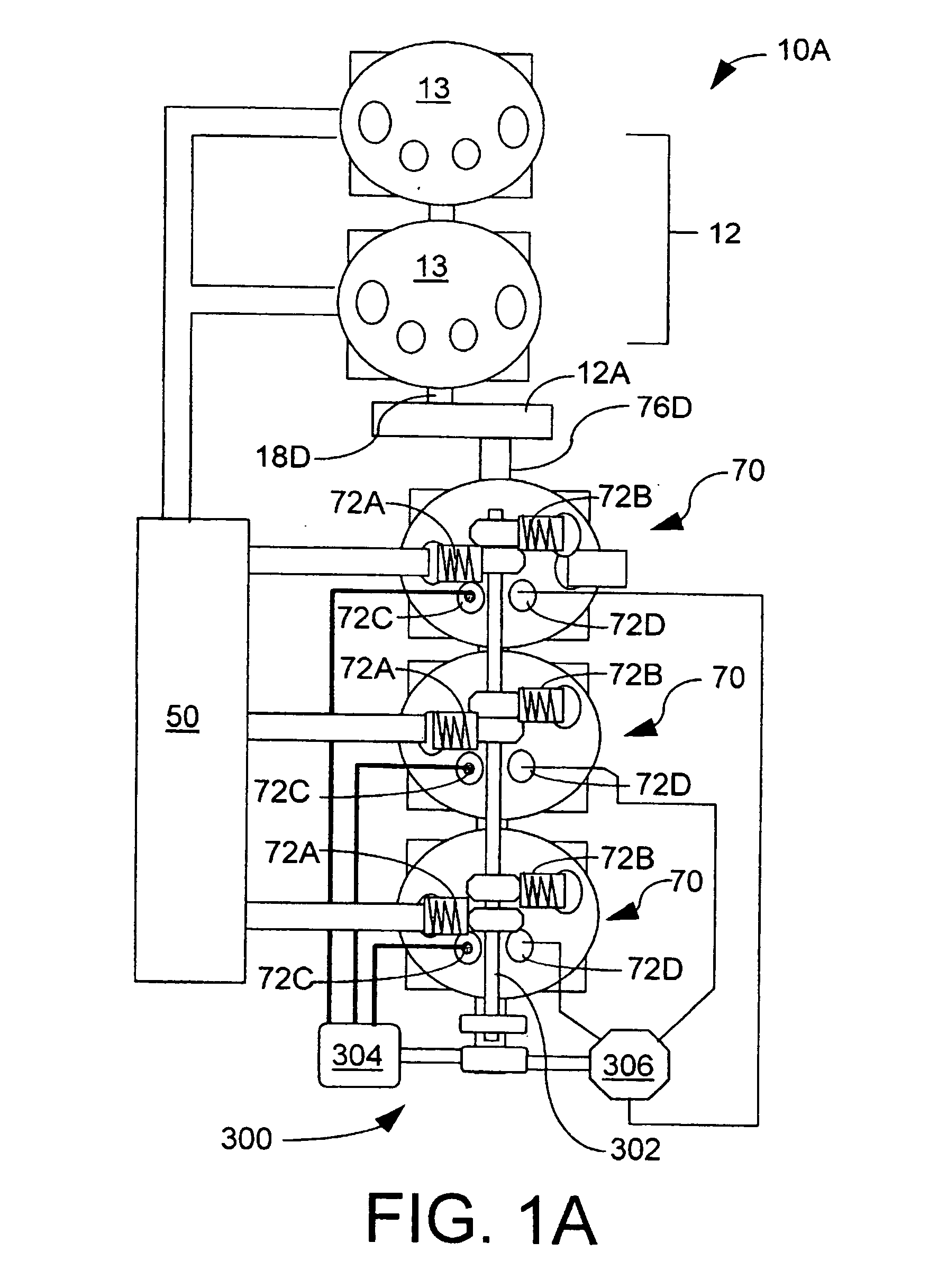

An internal combustion engine that has a pair of cylinders each having a reciprocating piston connected to a crank shaft by a connecting rod. One of the cylinders is adapted for an air and fuel intake and a compression strokes only, and the other of the cylinders adapted for at least power and exhaust strokes. A conduit exists for transfer of gases from the one into the other cylinder after the compression stroke. The conduit has means for isolating gases in the conduit intermediate the compression and power strokes. Furthermore, the conduit is designed to prevent the transfer of liquefied fuel from the one cylinder to the other.

Owner:MASSACHUSETTS INST OF TECH

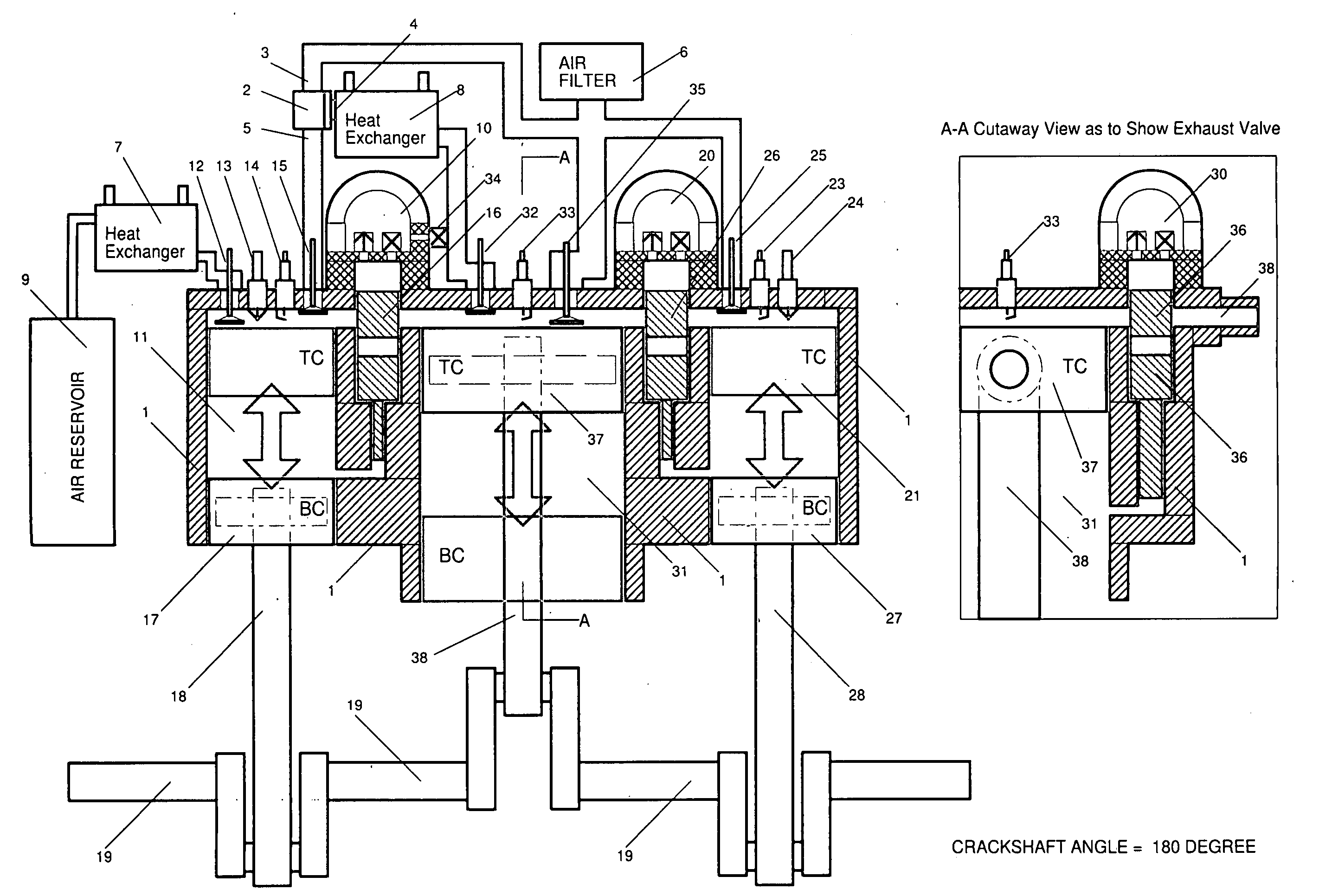

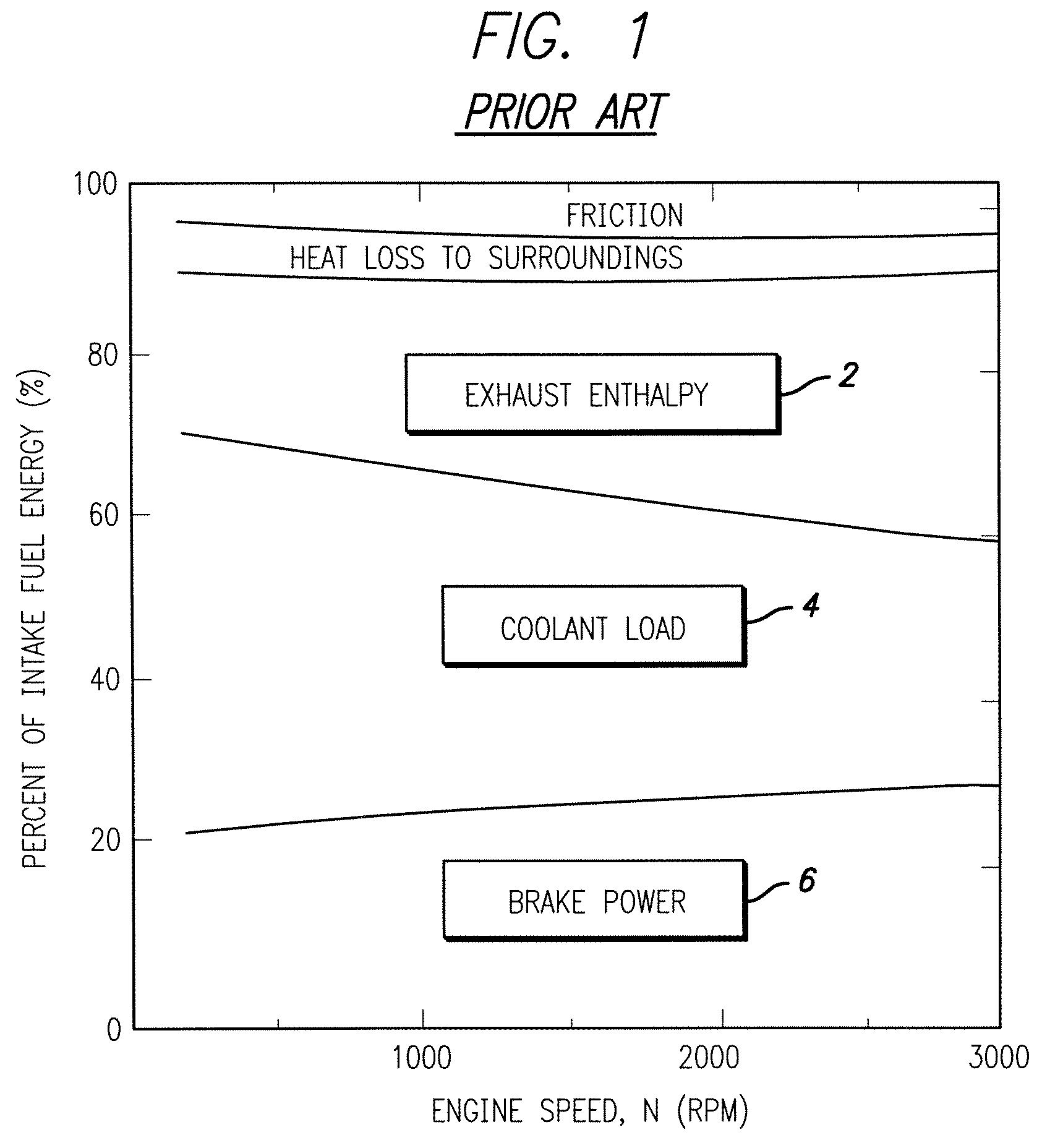

High efficiency integrated heat engine (HEIHE)

InactiveUS20090056331A1Reduce heat lossEfficient heatingInternal combustion piston enginesSteam engine plantsWork periodWorking fluid

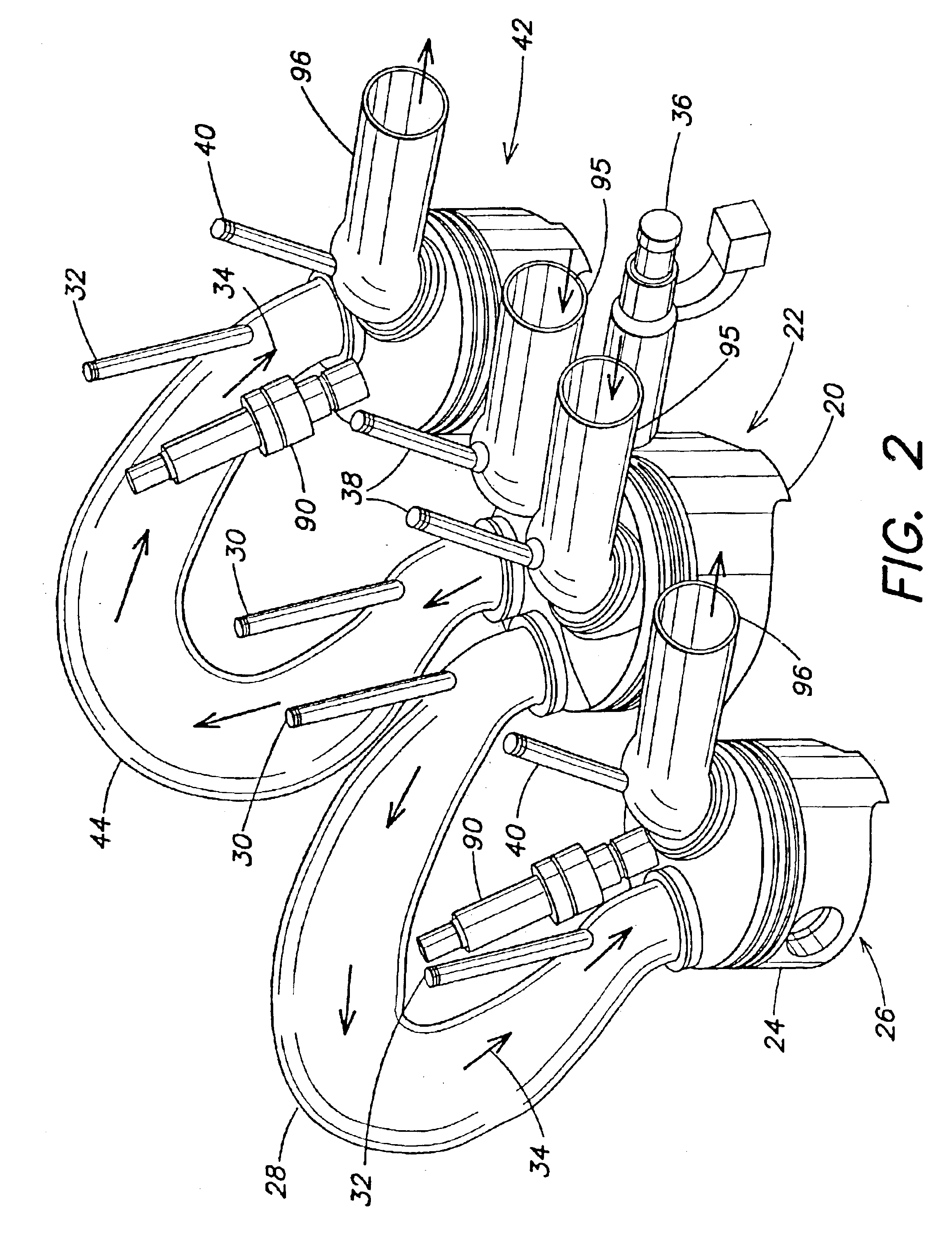

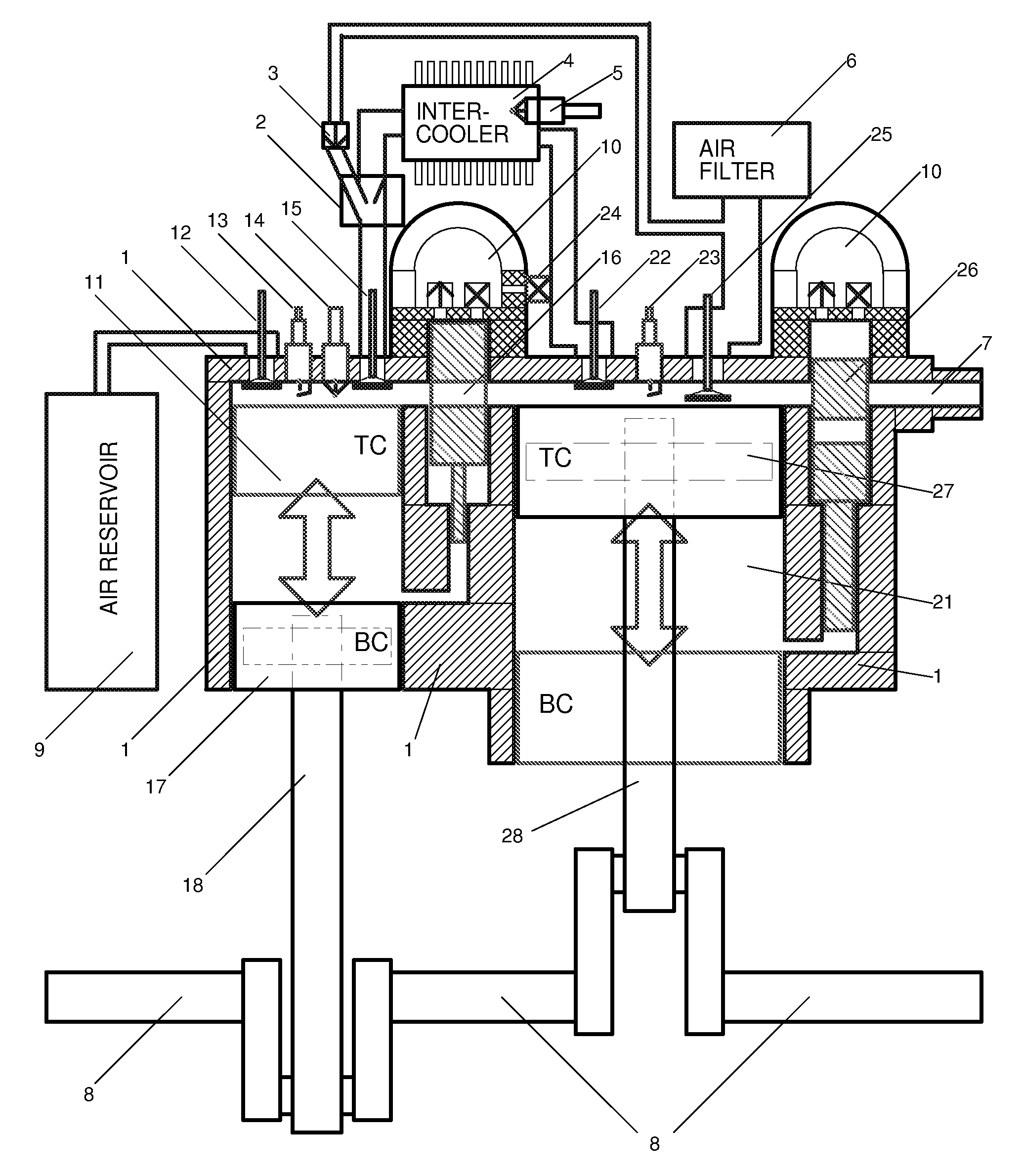

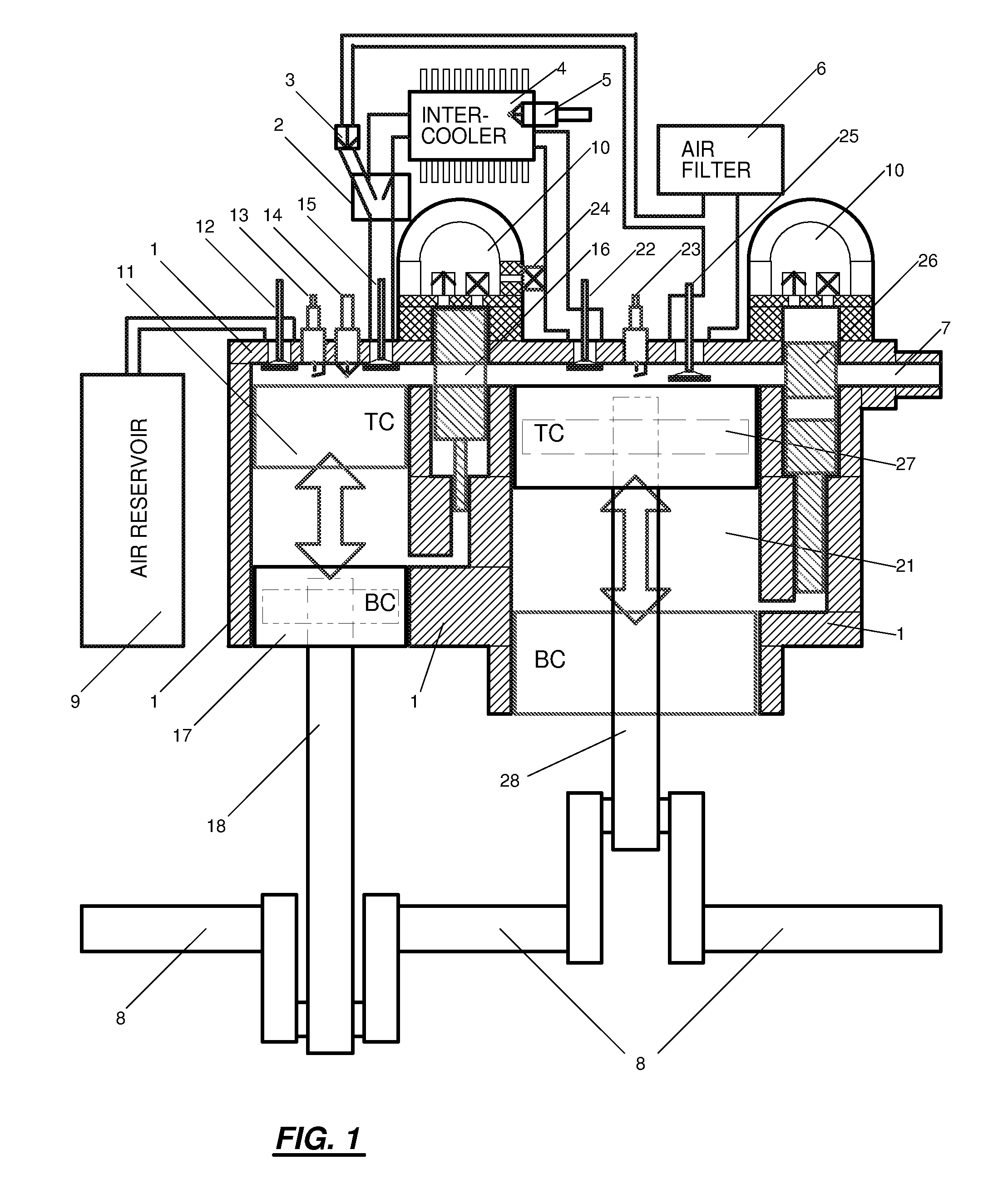

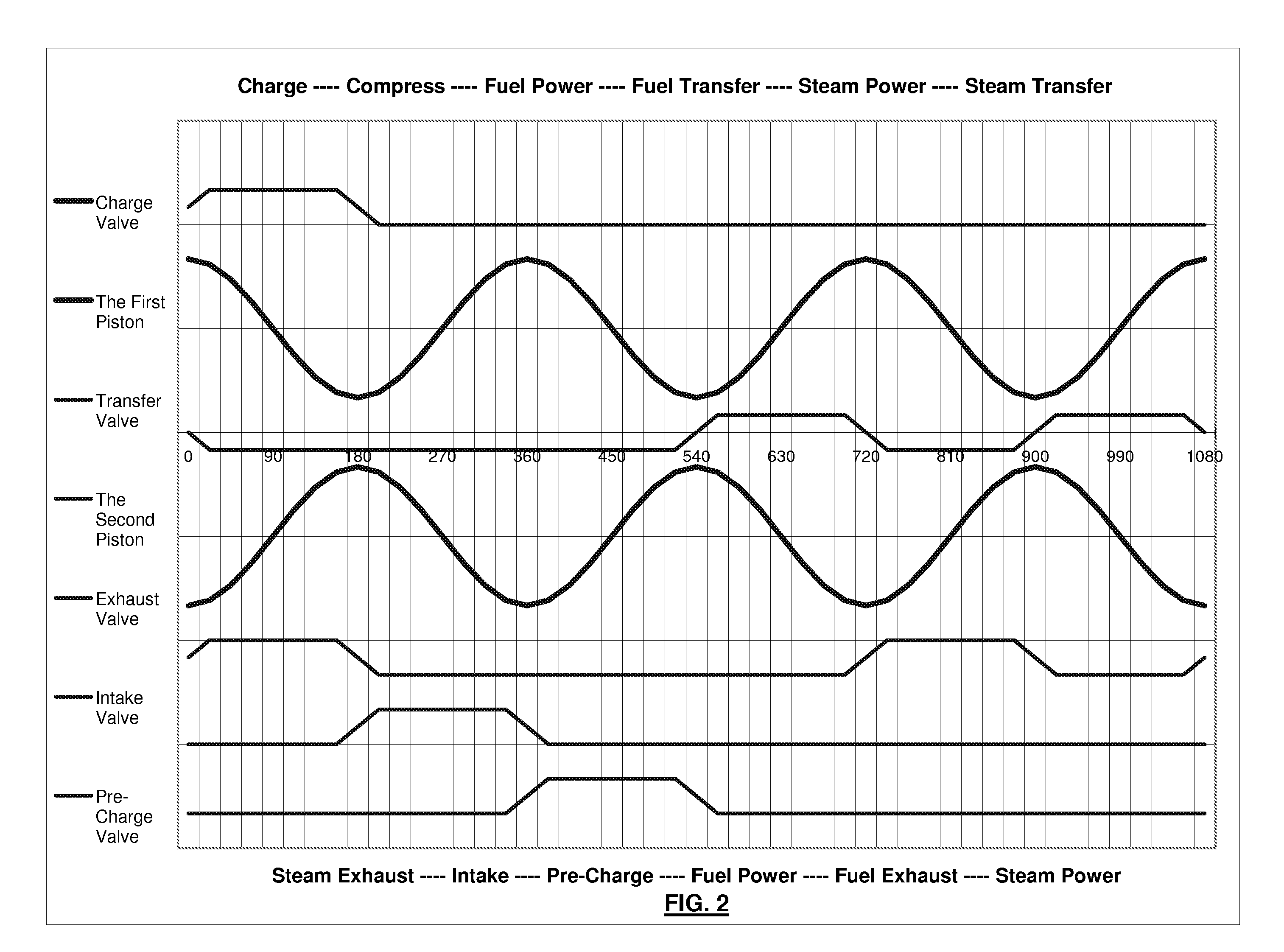

The present invention is a High Efficient Integrated Heat Engine, or HEIHE for short. HEIHE is a reciprocal combustion engine integrated with both compound cycle and combined cycle. HEIHE comprises twin compound cylinder structure, with the first cylinder being the primary combustion and / or expansion cylinder; the second cylinder being the secondary combustion and / or expansion cylinder. Power strokes driven by expansions of different working fluids such as air-fuel combustion products, steam and compressed air, are integrated into one engine block. Twin cylinder structure provides compound expansions of three (3) different fluids as to recover the energies that would be lost with the exhaust fluids or during braking. All of these make HEIHE work around six (6) periods with twelve (12) operation strokes. Among six (6) working periods involved, four (4) periods contain four (4) different power strokes but only one of the power strokes consumes the fuel. Thus the fuel conversion efficiency could be greatly increased, or even be doubled comparing with the conventional internal combustion engine (ICE).

Owner:ZHAO YUANPING +1

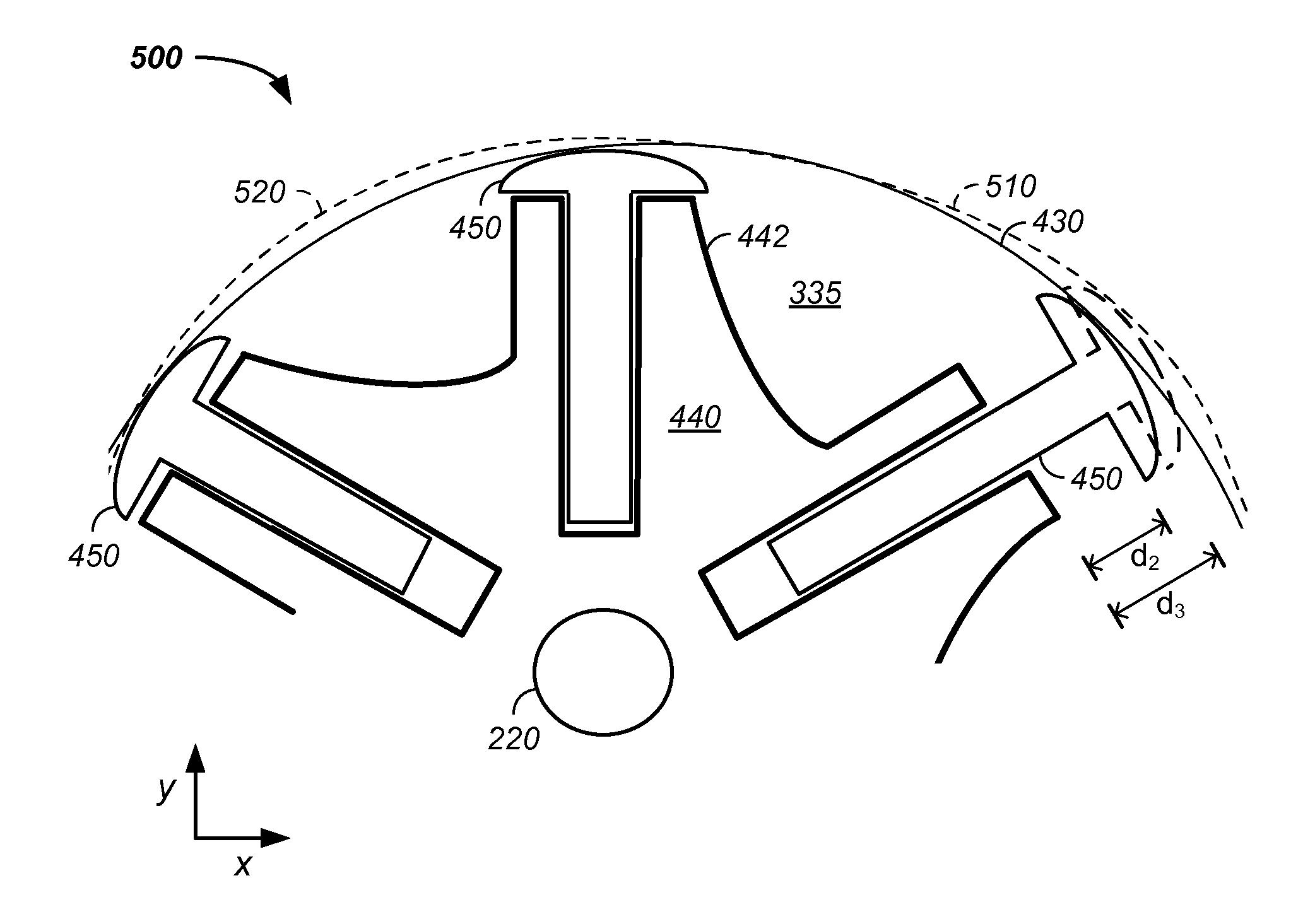

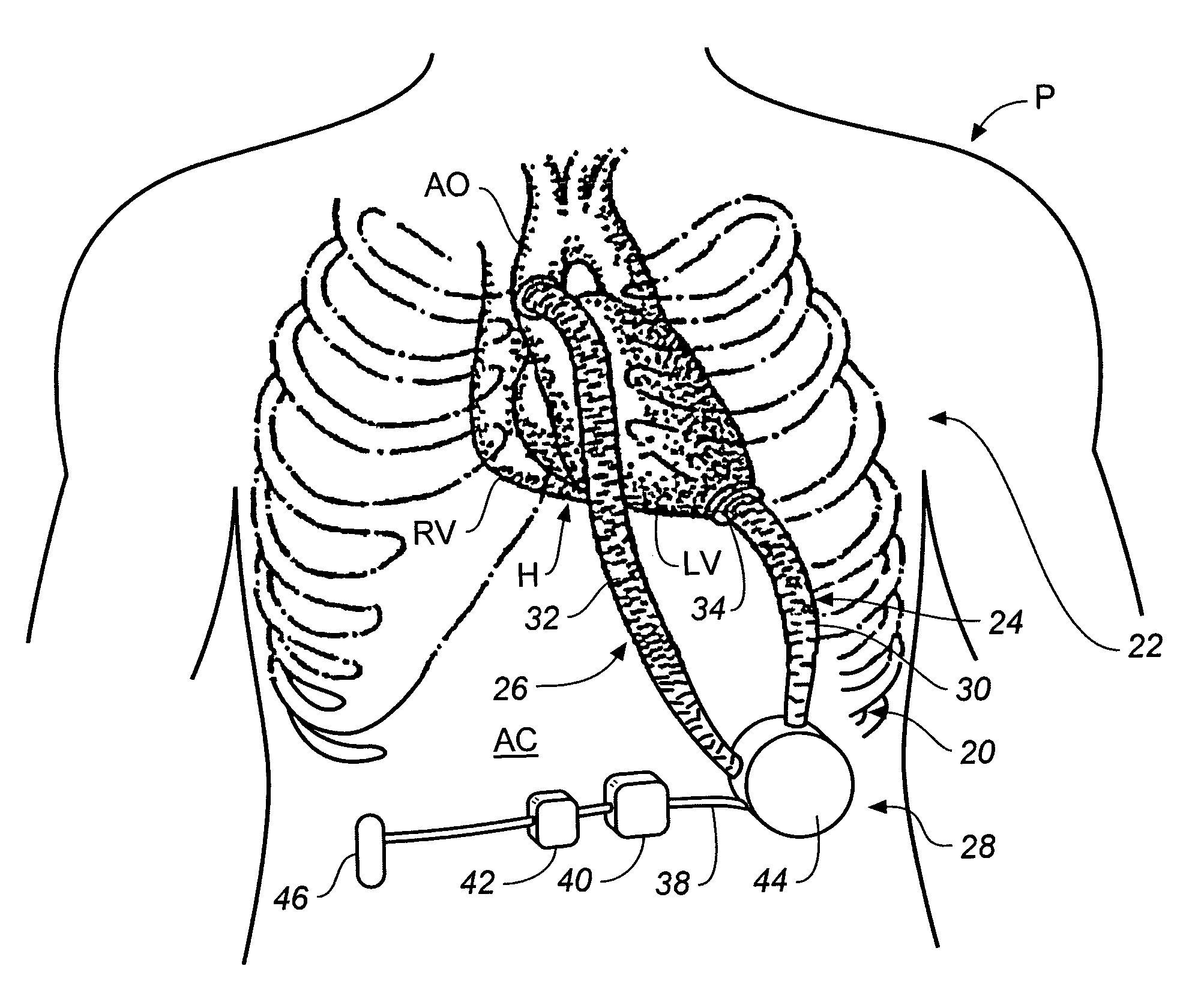

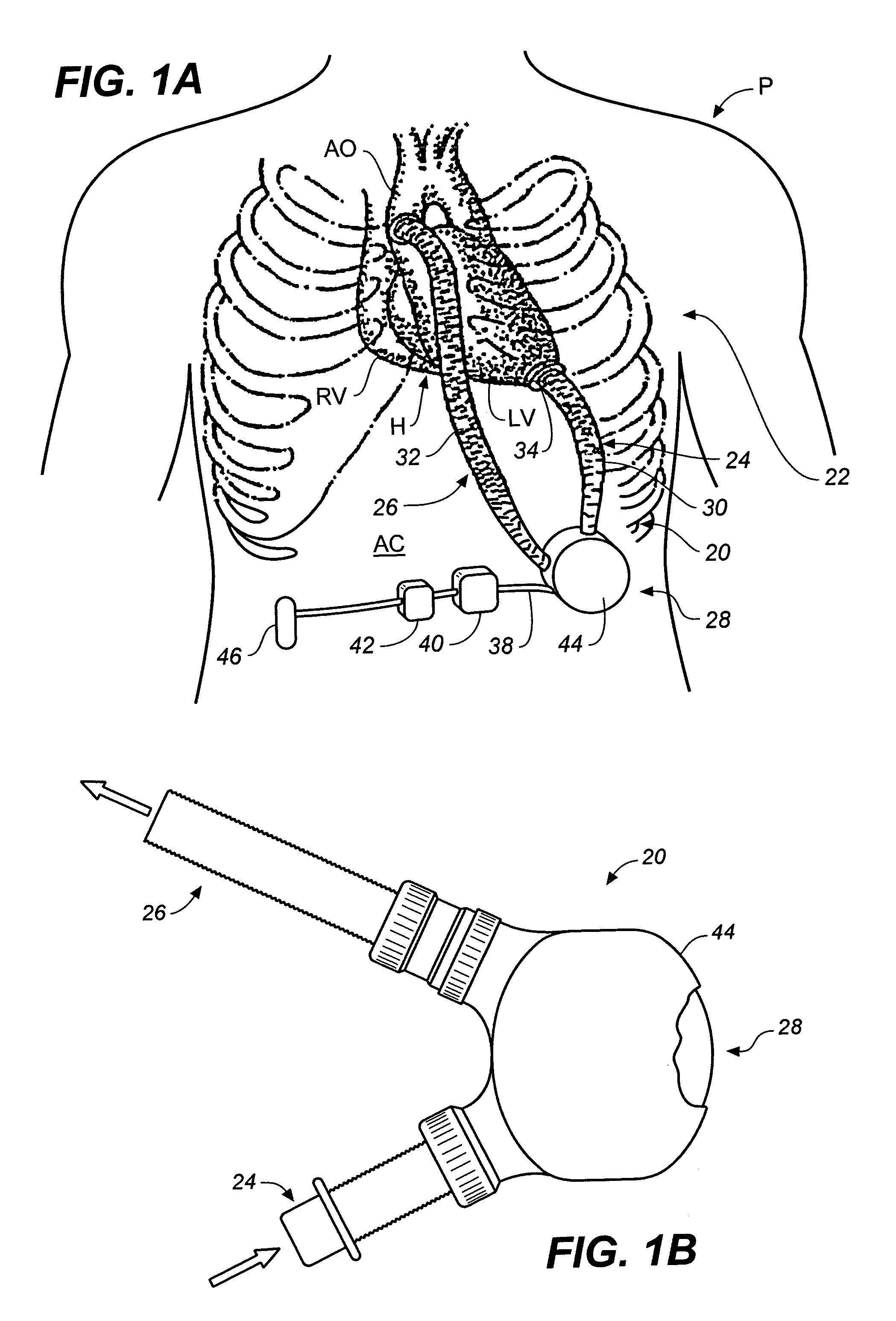

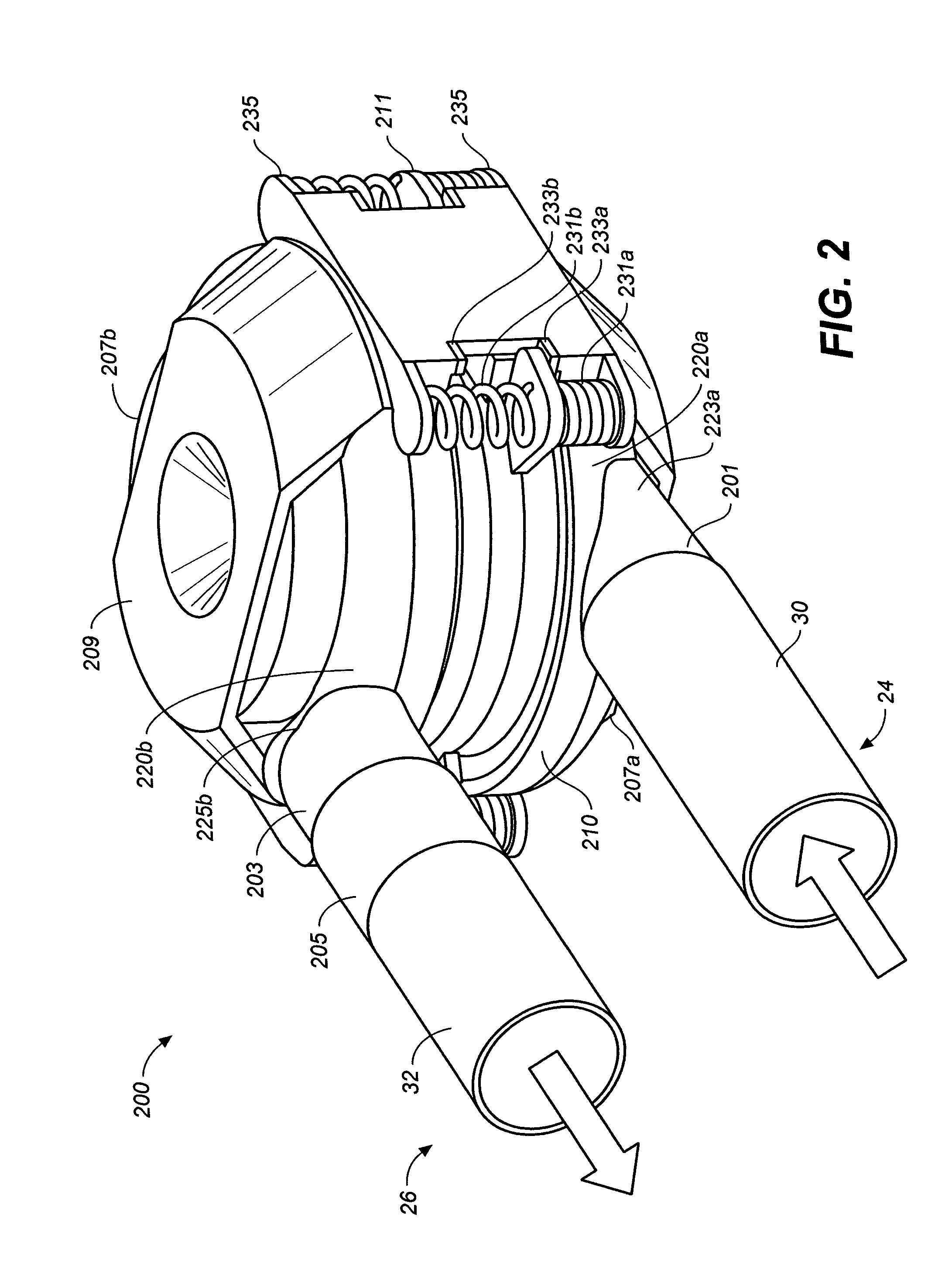

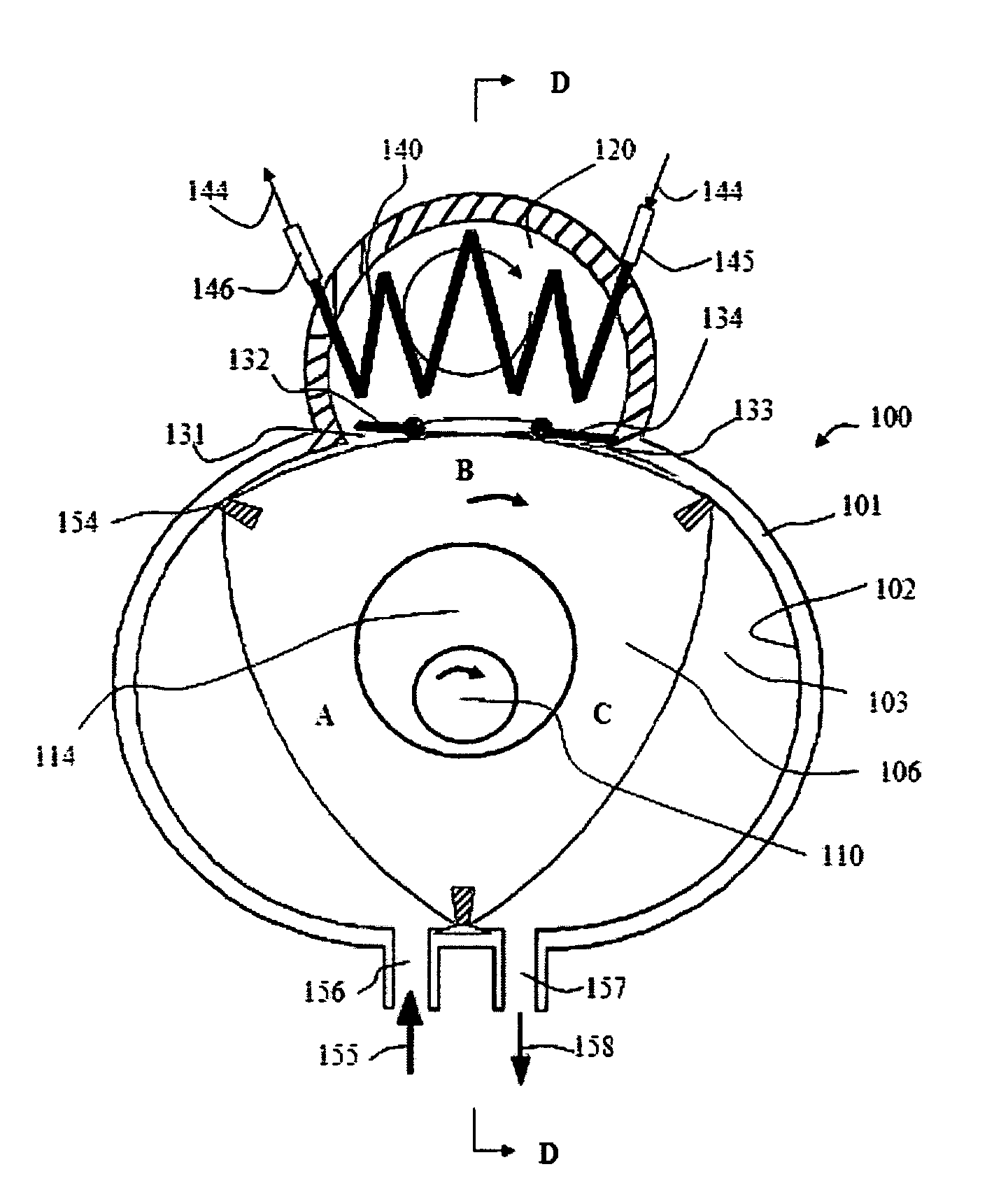

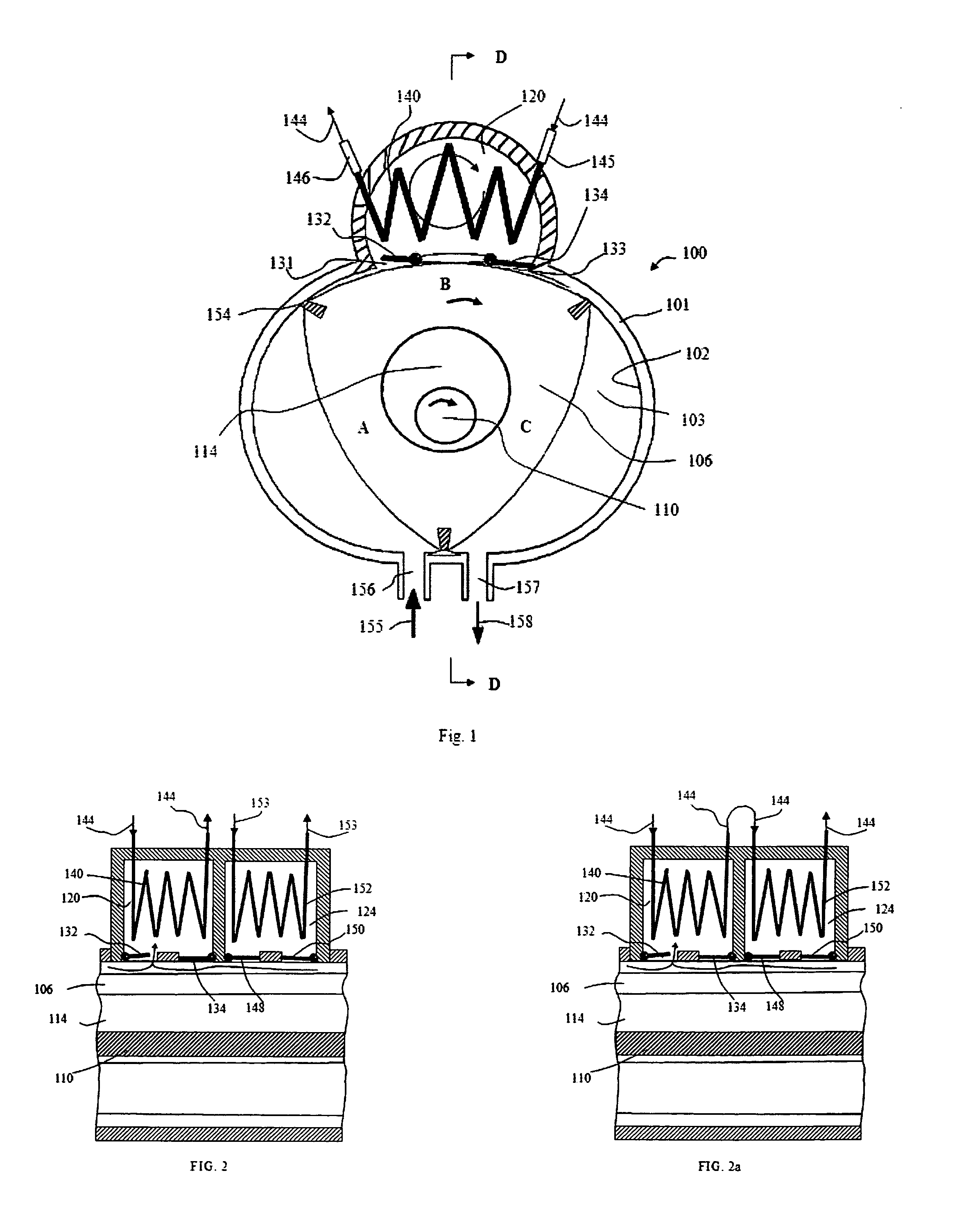

Miniature, pulsatile implantable ventricular assist devices and methods of controlling ventricular assist devices

ActiveUS6969345B2Small sizeSmall and efficient and atraumatic and fully implantableControl devicesBlood pumpsSystoleEngineering

A pumping system for assisting either or both ventricles of the heart. In one embodiment, separate devices are provided for each ventricle. In another embodiment, one device provides both right and left pumping. The pumping system is small, efficient, atraumatic, and fully implantable. In addition, the pumping system can provide pulsatile flow during systole. The ventricular assist device includes an actuator plate between a pair of serially connected pumping chambers that operate in a two-stroke mode, specifically a power stroke and a transfer stroke. The ventricular assist device also includes an electromagnetic drive system that provides adjustment to the pump pressure according to the current through an electromagnet. For the pumping system, springs provide a “spring force” on the actuator plate that is towards the high-pressure pump chamber. The bias force allows the springs to store and deliver energy from the electromagnetic drive system to provide better utilization of the pump components, and to reduce the pump size and consumption of electricity.

Owner:WORLD HEART

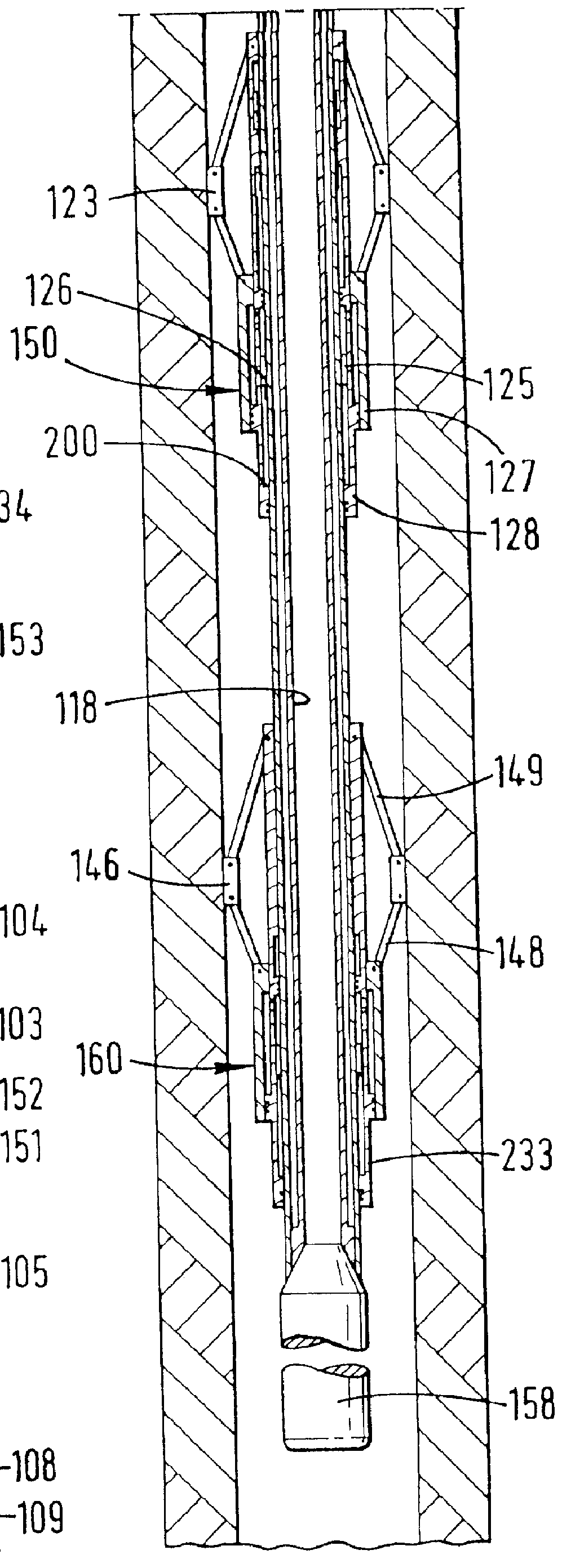

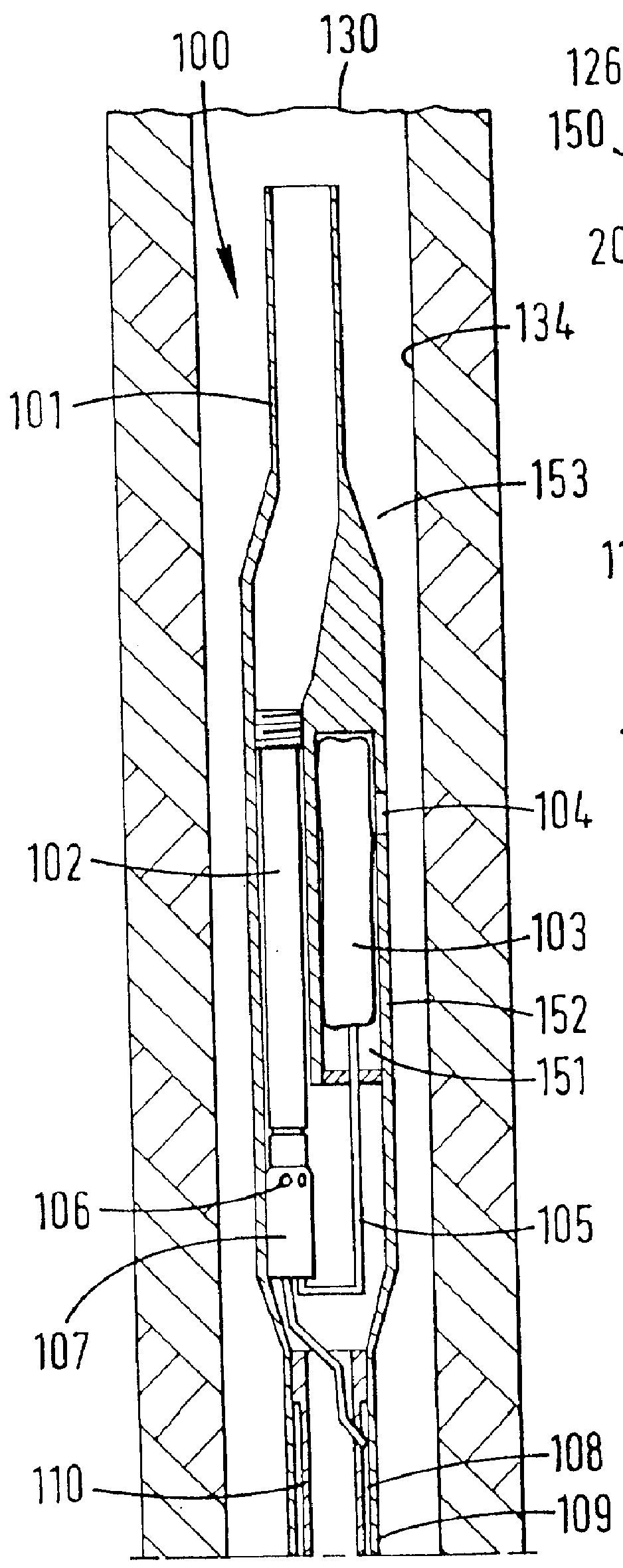

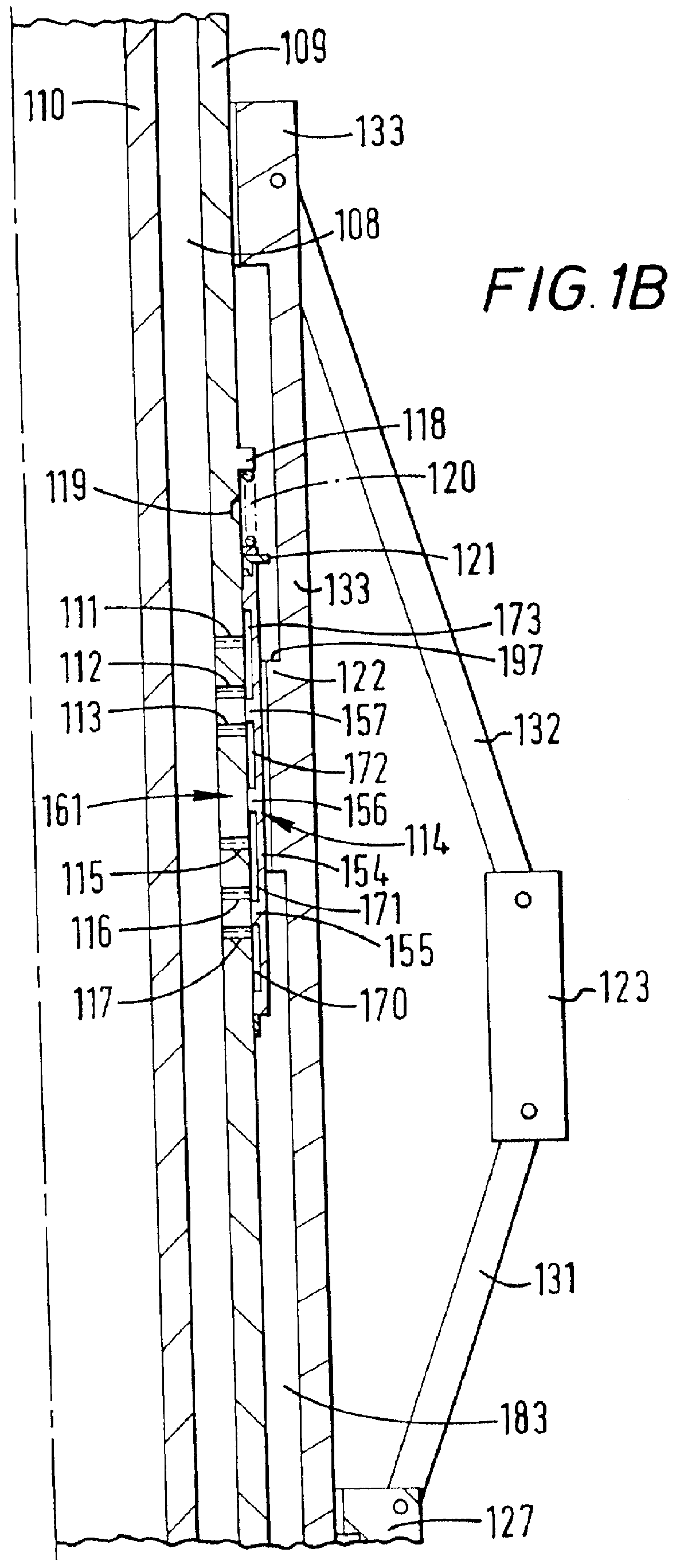

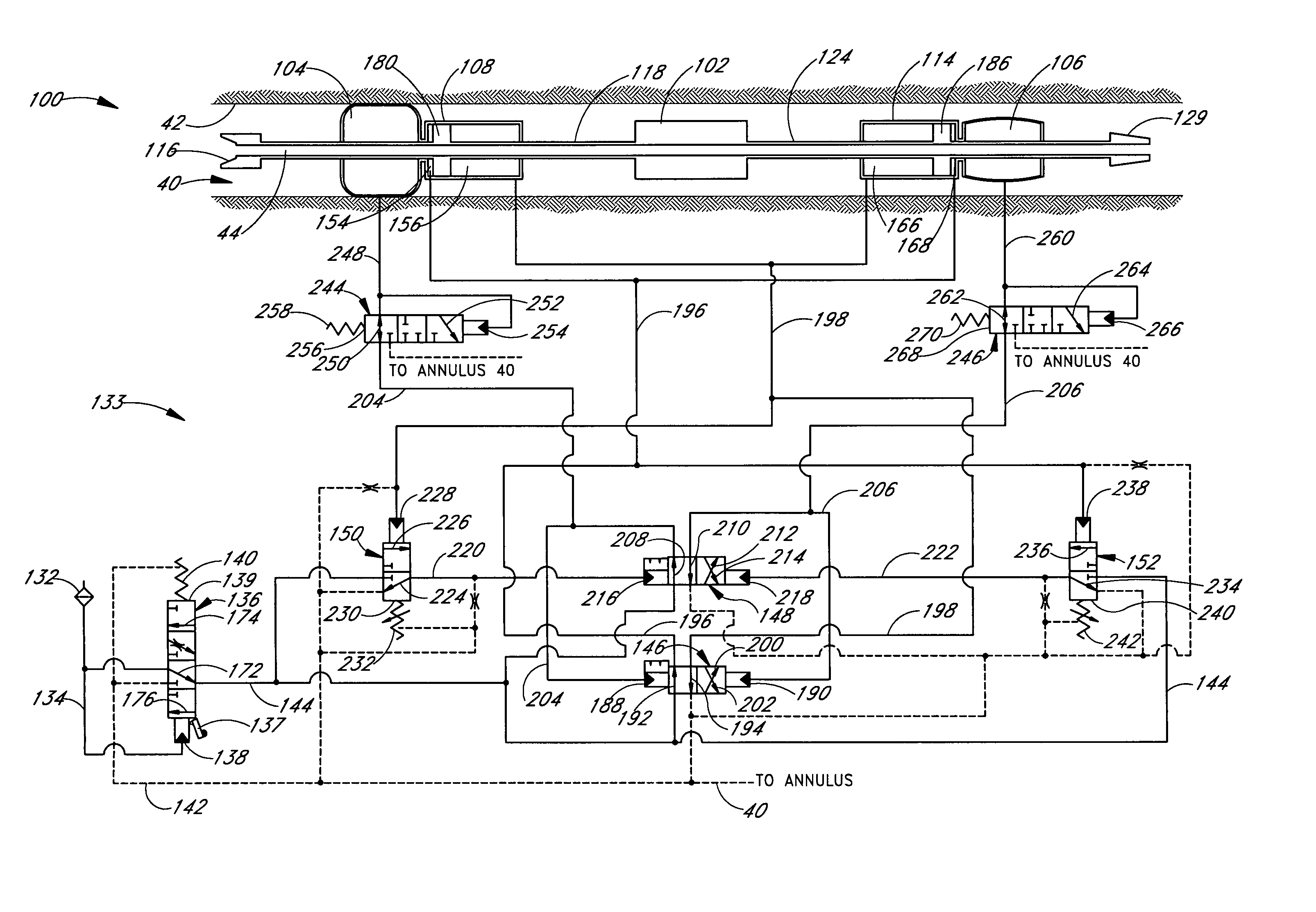

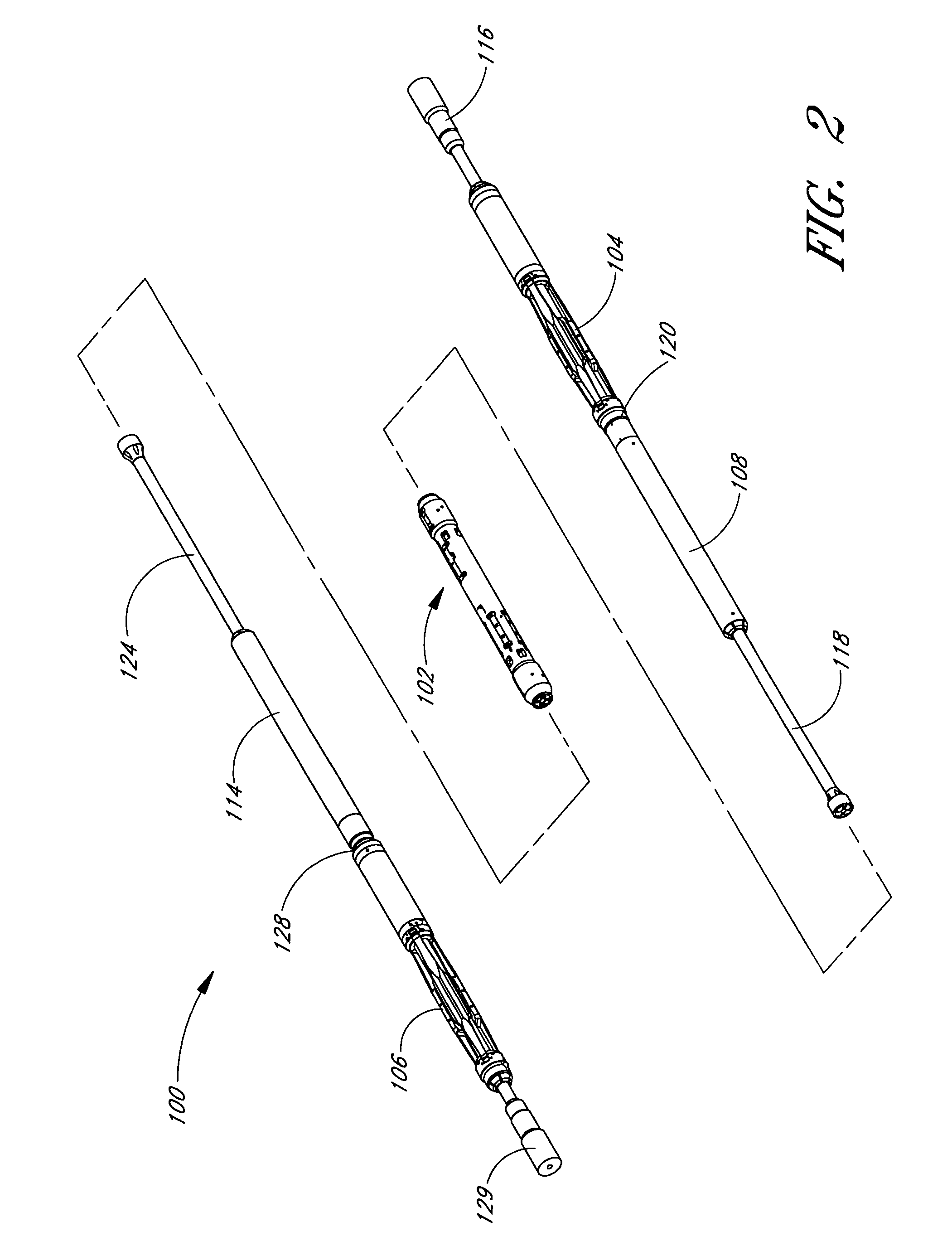

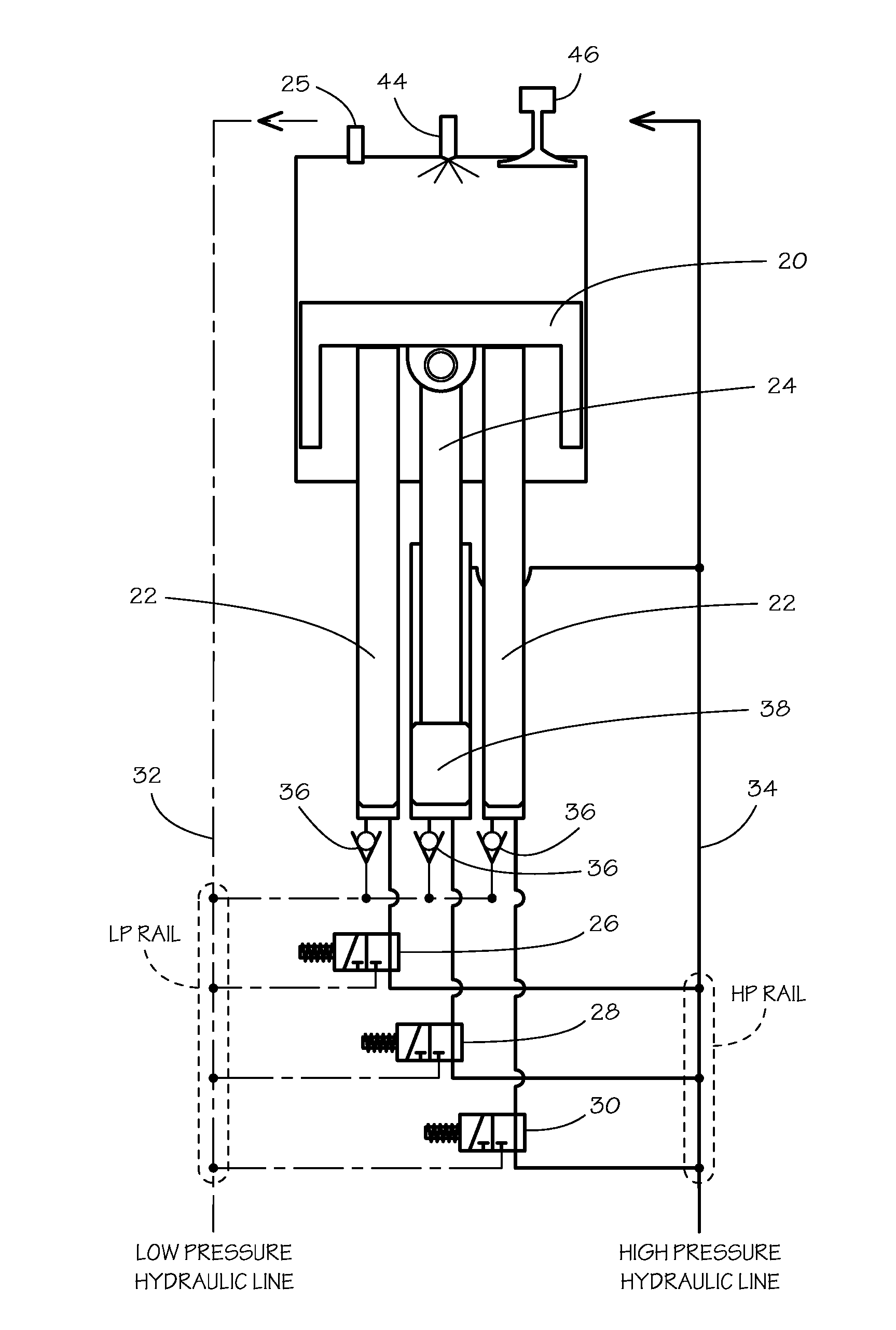

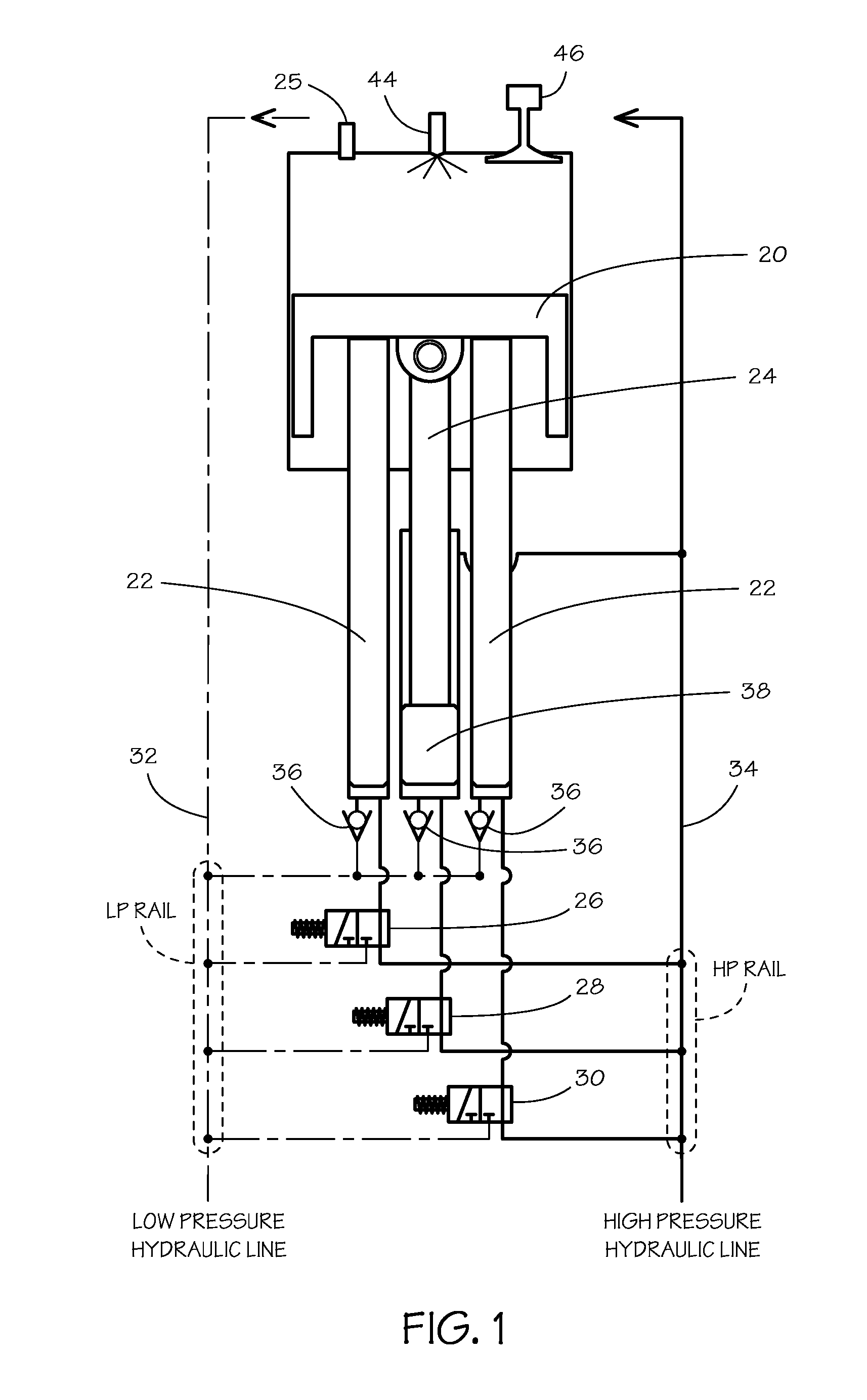

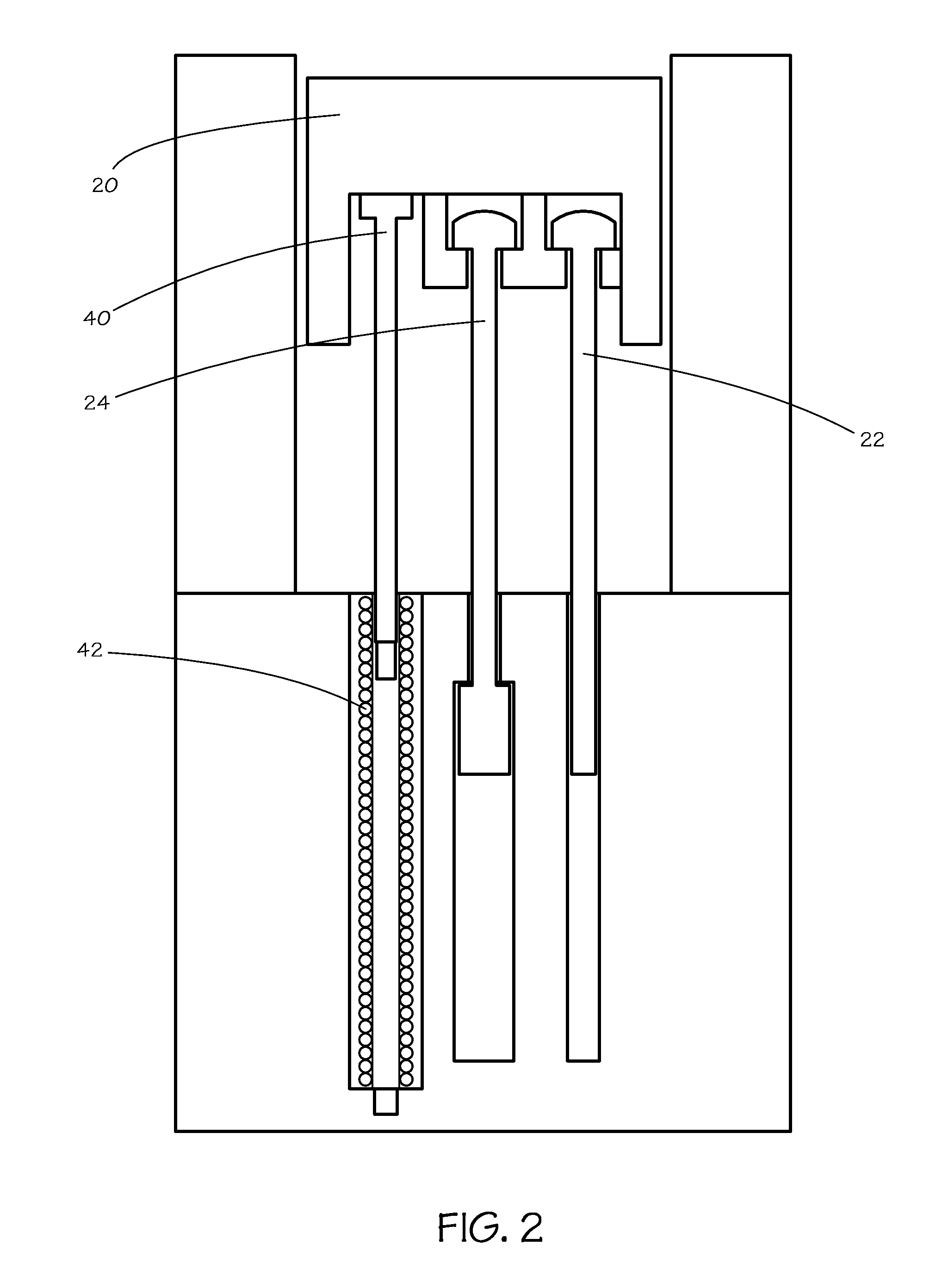

Tractor with improved valve system

InactiveUS7080700B2Long time lagBetter shiftingDrilling rodsReciprocating drilling machinesWorking fluidDetent

A hydraulically powered tractor includes an elongated body, two gripper assemblies, at least one pair of aft and forward propulsion cylinders and pistons, and a valve system. The valve system comprises an inlet control valve, a two-position propulsion control valve, a two-position gripper control valve, two cycle valves, and two pressure reduction valves. The inlet control valve spool includes a hydraulically controlled deactivation cam that locks the valve in a closed position, rendering the tractor non-operational. The propulsion control valve is piloted on both ends by fluid pressure in the gripper assemblies. The propulsion control valve controls the distribution of operating fluid to and from the propulsion cylinders, such that one cylinder performs a power stroke while the other cylinder performs a reset stroke. Each end of the gripper control valve is piloted by a source of high-pressure fluid selectively admitted by one of the cycle valves. The gripper control valve controls the distribution of operating fluid to and from the gripper assemblies. The cycle valves are spring-biased and piloted by fluid pressure in the propulsion cylinders, so that the gripper control valve shifts only after the cylinders complete their strokes. The pressure reduction valves limit the pressure within the gripper assemblies. These valves are spring-biased and piloted by the pressure of fluid flowing into the gripper assemblies. Some or all of the valves include centering grooves on the landings of the spools, which reduce leakage and produce more efficient operation. The propulsion control and gripper control valves include spring-assisted detents to prevent inadvertent shifting.

Owner:WWT NORTH AMERICA HLDG

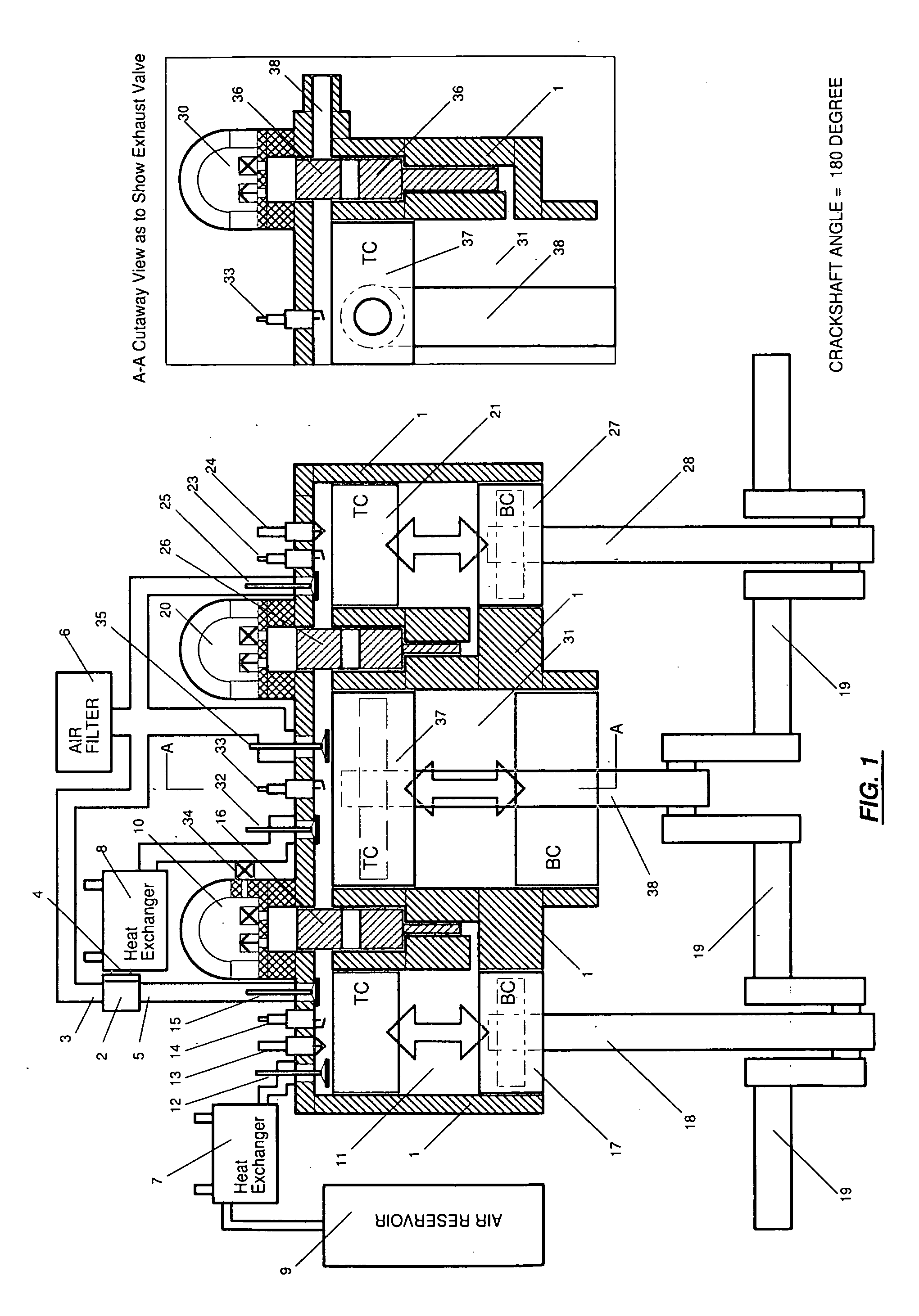

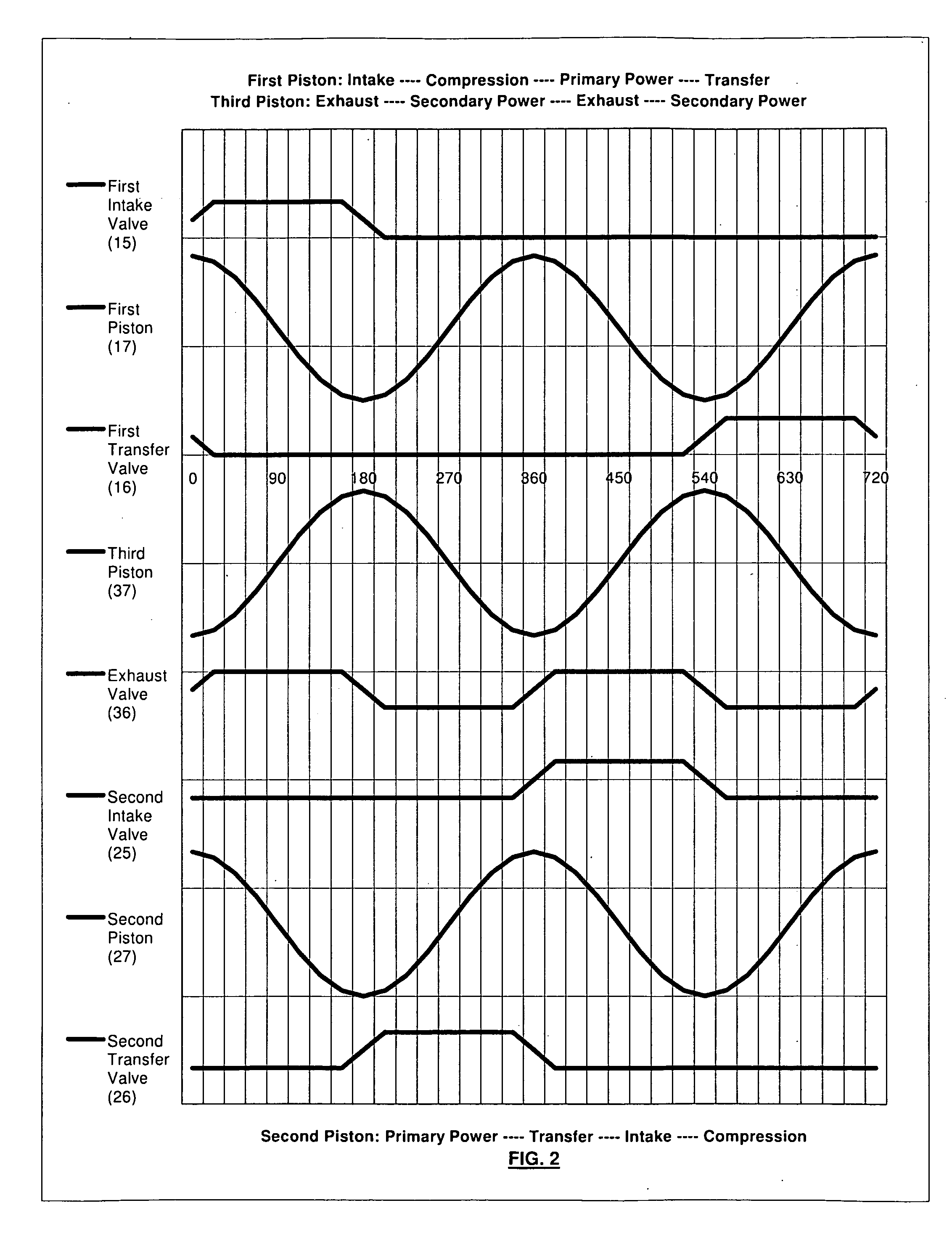

High efficiency integrated heat engine-2 (heihe-2)

InactiveUS20090056670A1Improve efficiencyImprove conversion efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelWork periodWorking fluid

The present invention is a second kind of High Efficiency Integrated Heat Engine, or HEIHE-2 for short. HEIHE-2 is a reciprocal combustion engine integrated with both compound cycle and combined cycle. HEIHE-2 comprises triple compound cylinder structure, with the first cylinder and the second cylinder being the primary combustion and / or expansion cylinders; and the third cylinder being the secondary combustion and / or expansion cylinder. Power strokes driven by expansions of different working fluids such as air-fuel combustion products, steam and compressed air, are integrated into one engine block. Triple cylinder structure provides compound expansions of three (3) different fluids as to recover the energies that would be lost with the exhaust fluids or during braking. All of these make HEIHE-2 work around four (4) periods with six (6) different operation strokes. All four (4) working periods contain four (4) different power strokes but only two (2) of them consume the fuel. Thus the fuel conversion efficiency could be greatly increased, or even be doubled comparing with the conventional internal combustion engine (ICE).

Owner:ZHAO YUANPING +1

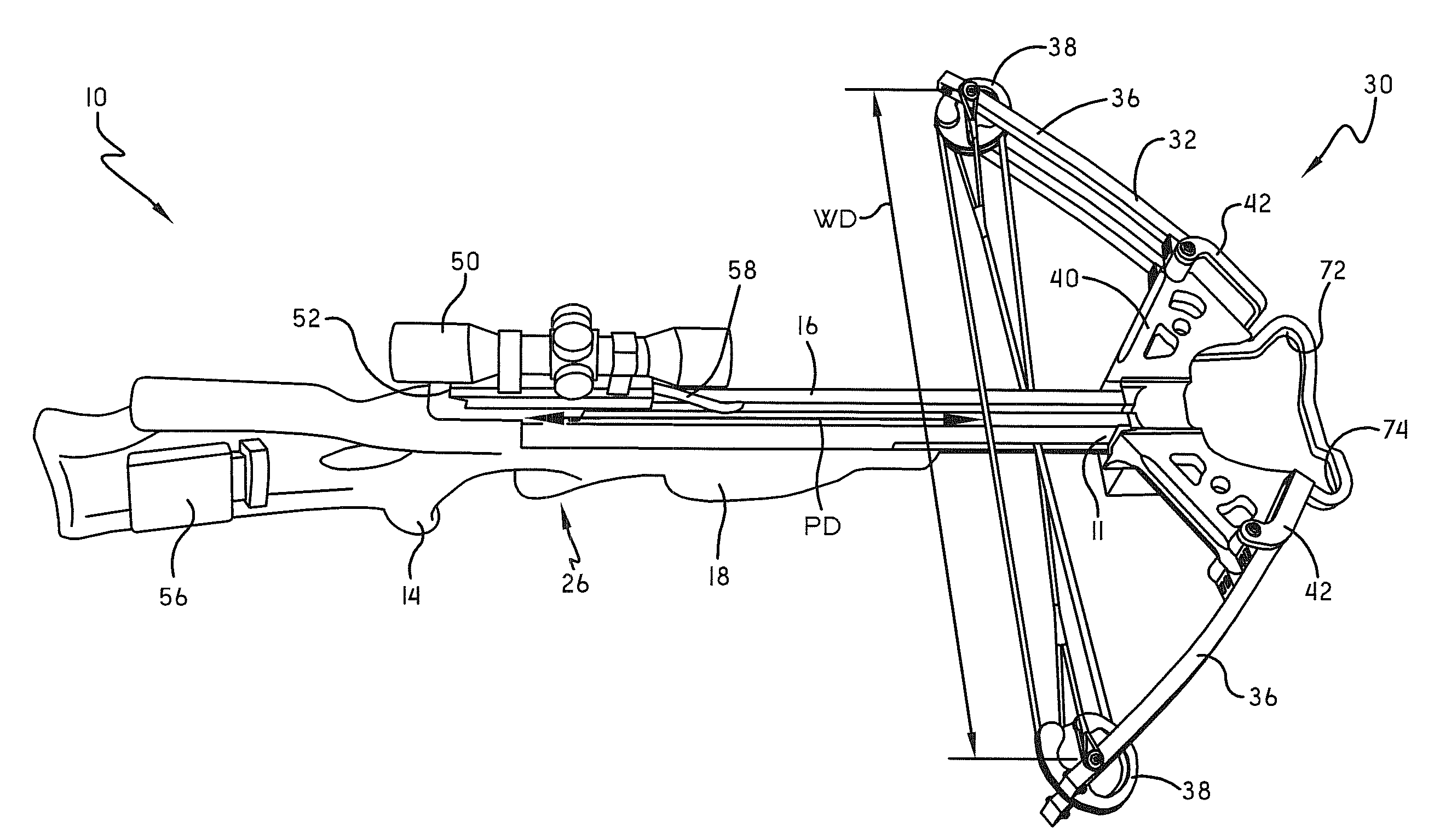

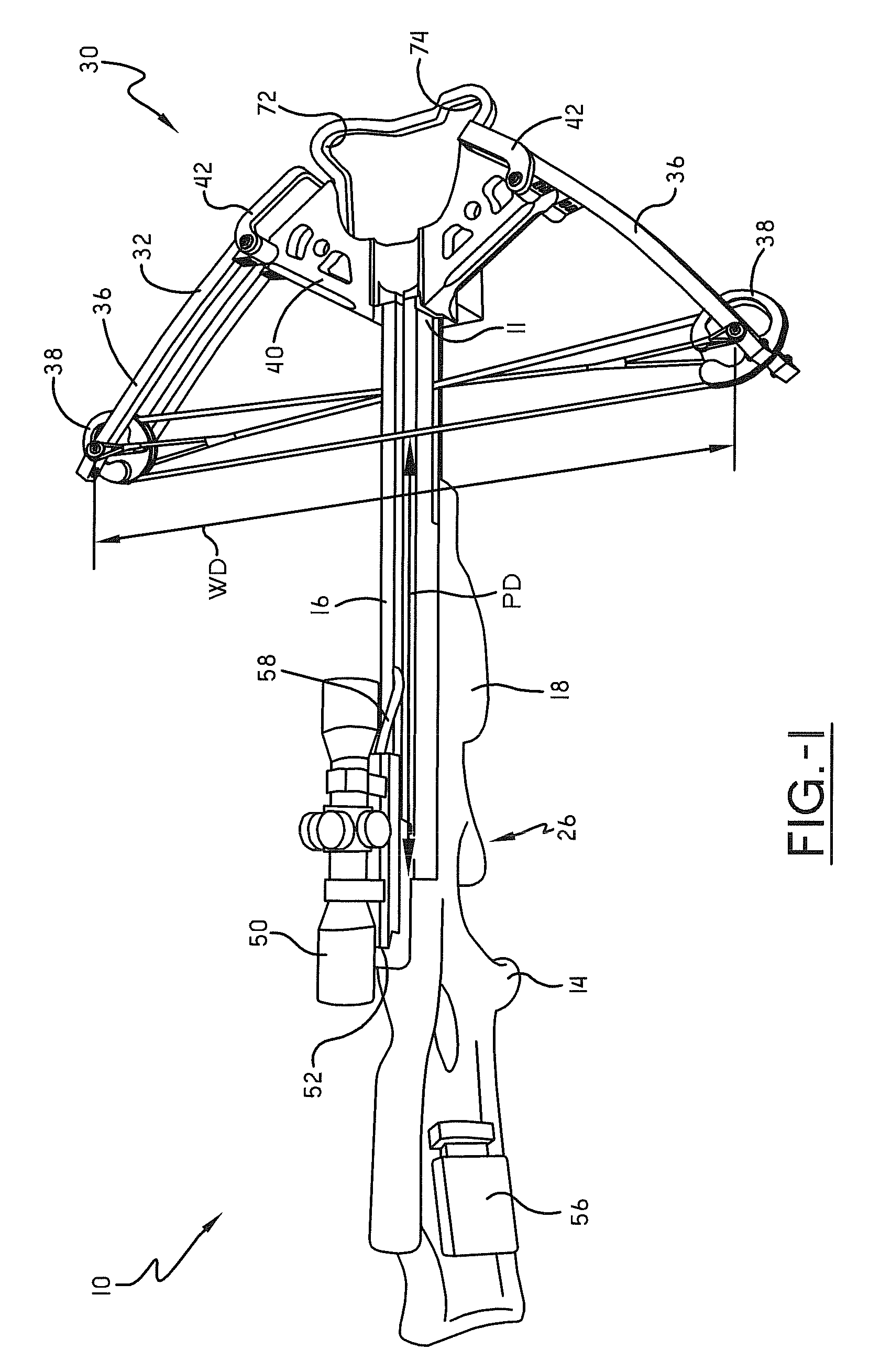

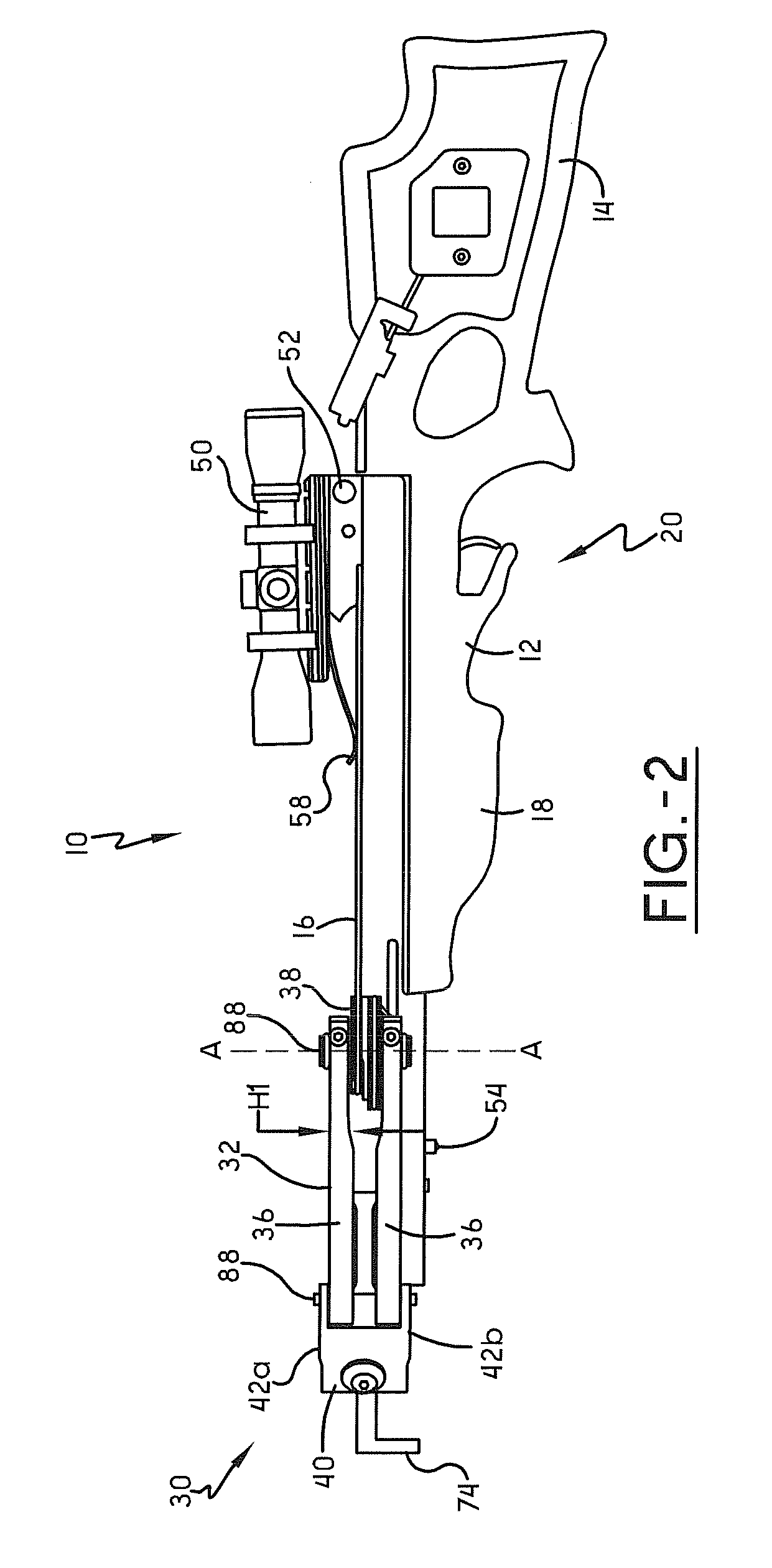

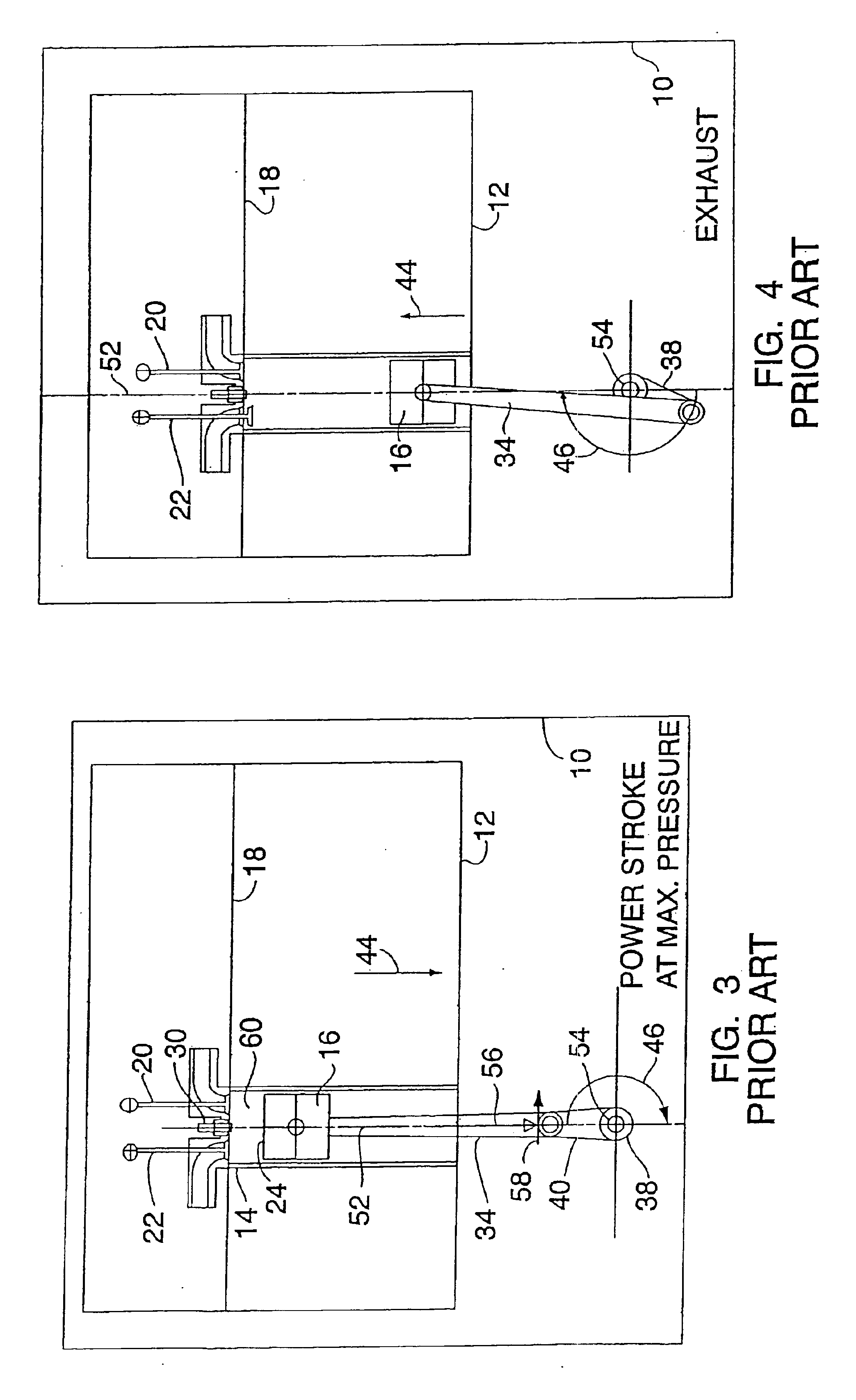

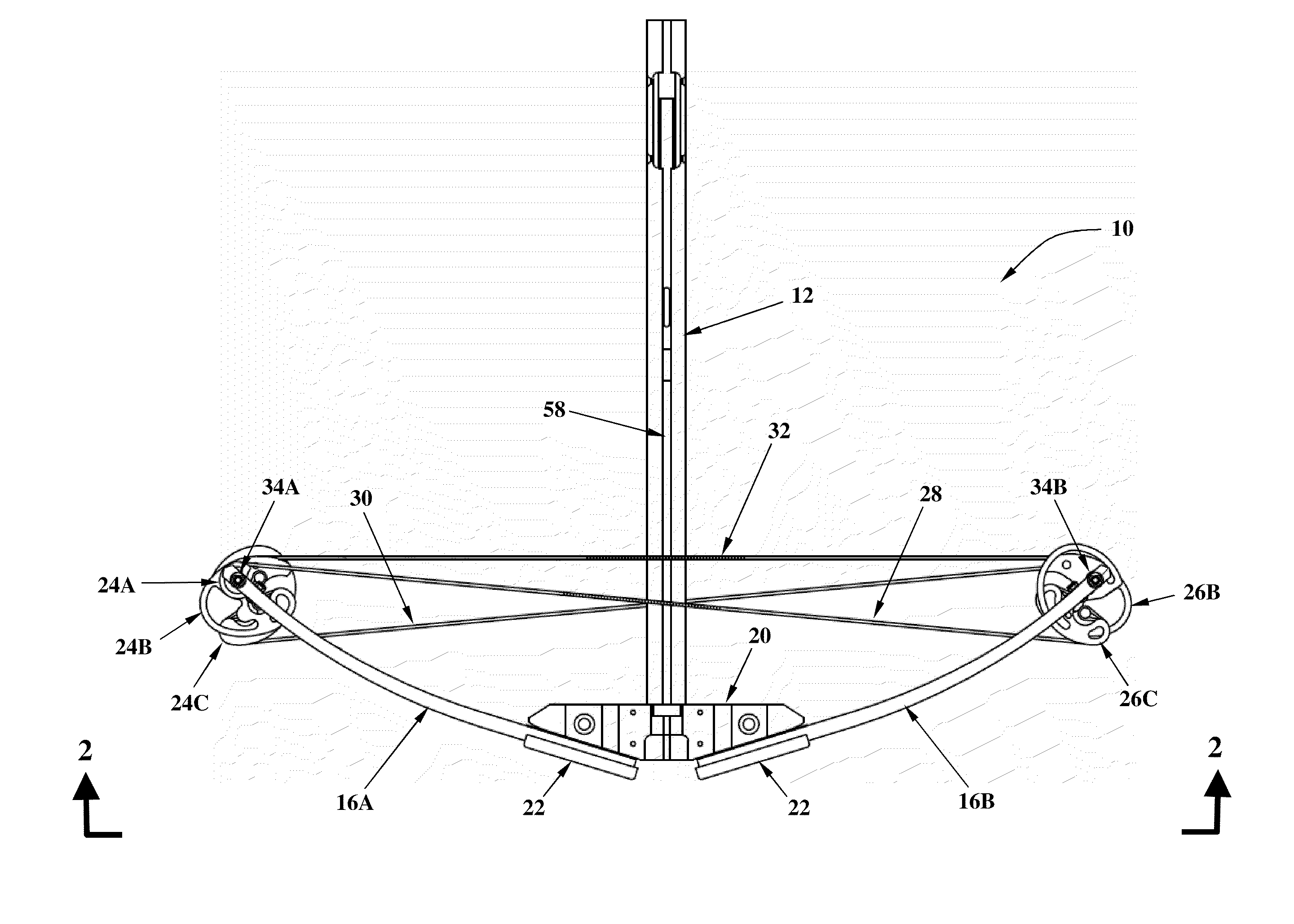

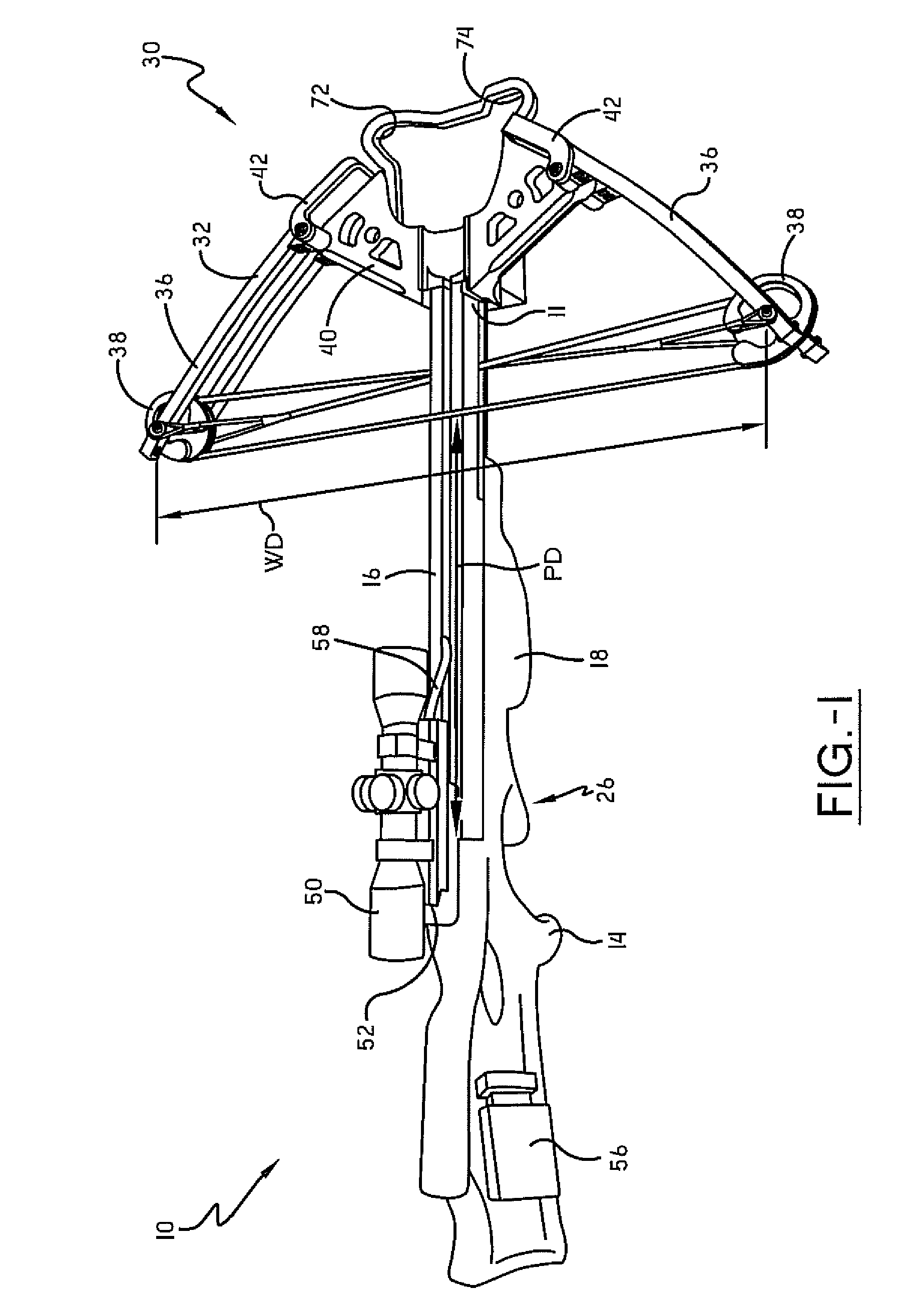

Narrow Crossbow With Large Power Stroke

ActiveUS20110203561A1Large power strokeEasy to manually cockSpring gunsBows/crossbowsMechanical engineeringPower stroke

A crossbow may include a main beam; a compound bow assembly mounted to the main beam; and, a trigger mechanism mounted to the main beam for use in holding a bowstring in a cocked position. The crossbow may include wheels at opposite ends of the bow that operatively receive the bowstring. The wheels may be separated by a wheel distance (WD) when the crossbow is in an un-cocked position. The crossbow may also have a power stroke distance (PD) and the ratio WD / PD may be less than 2.0.

Owner:HUNTERS MFG CO INC

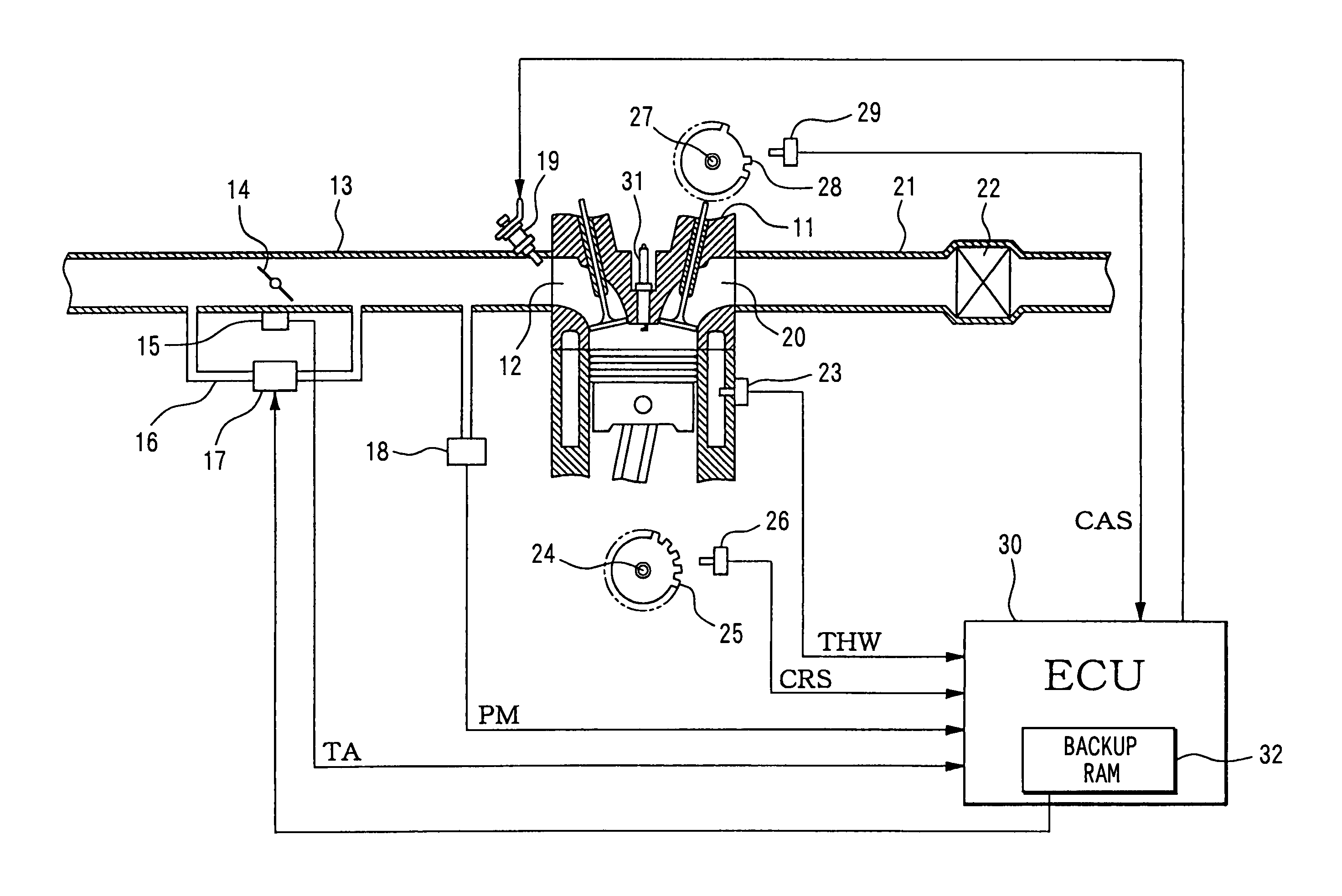

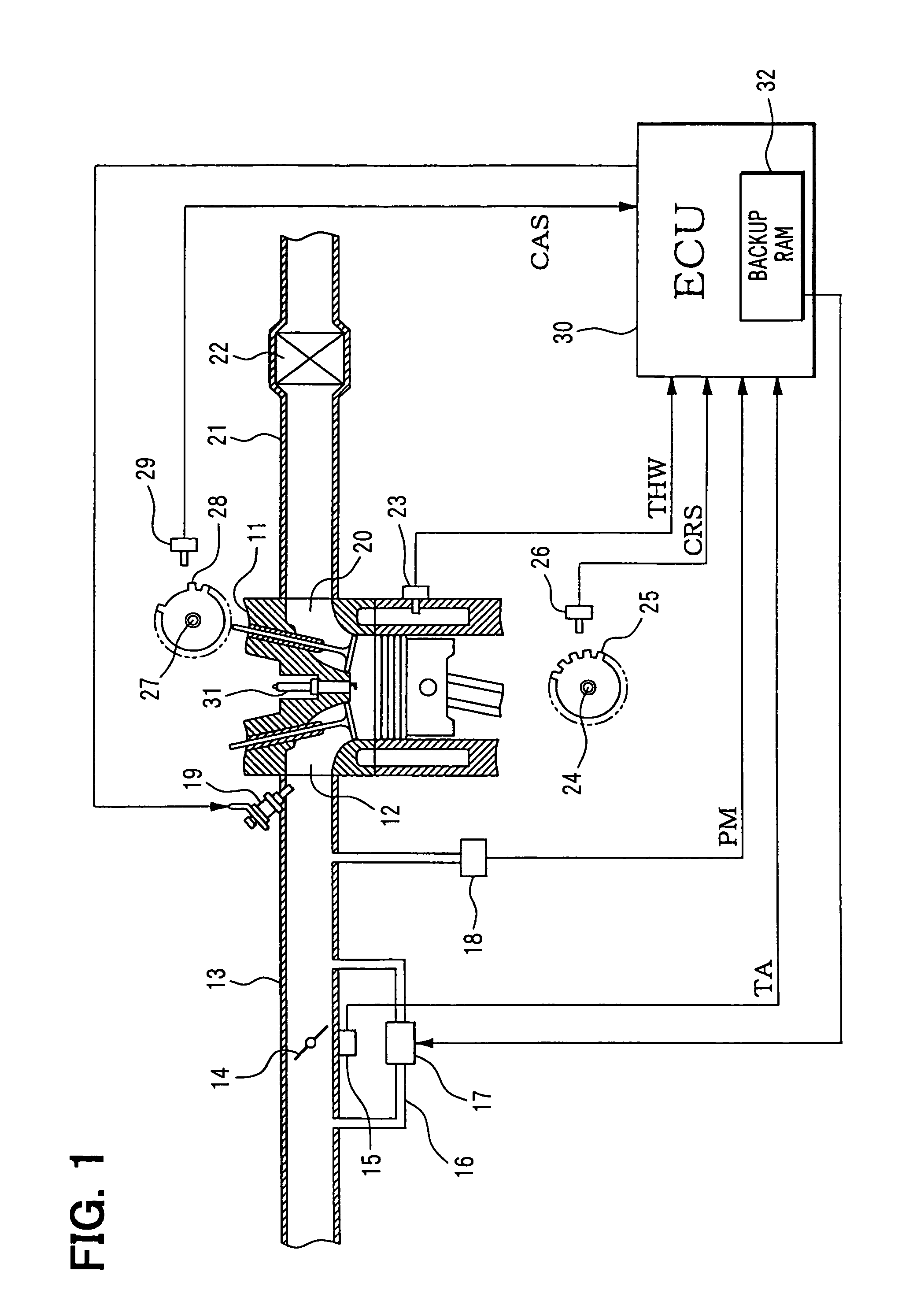

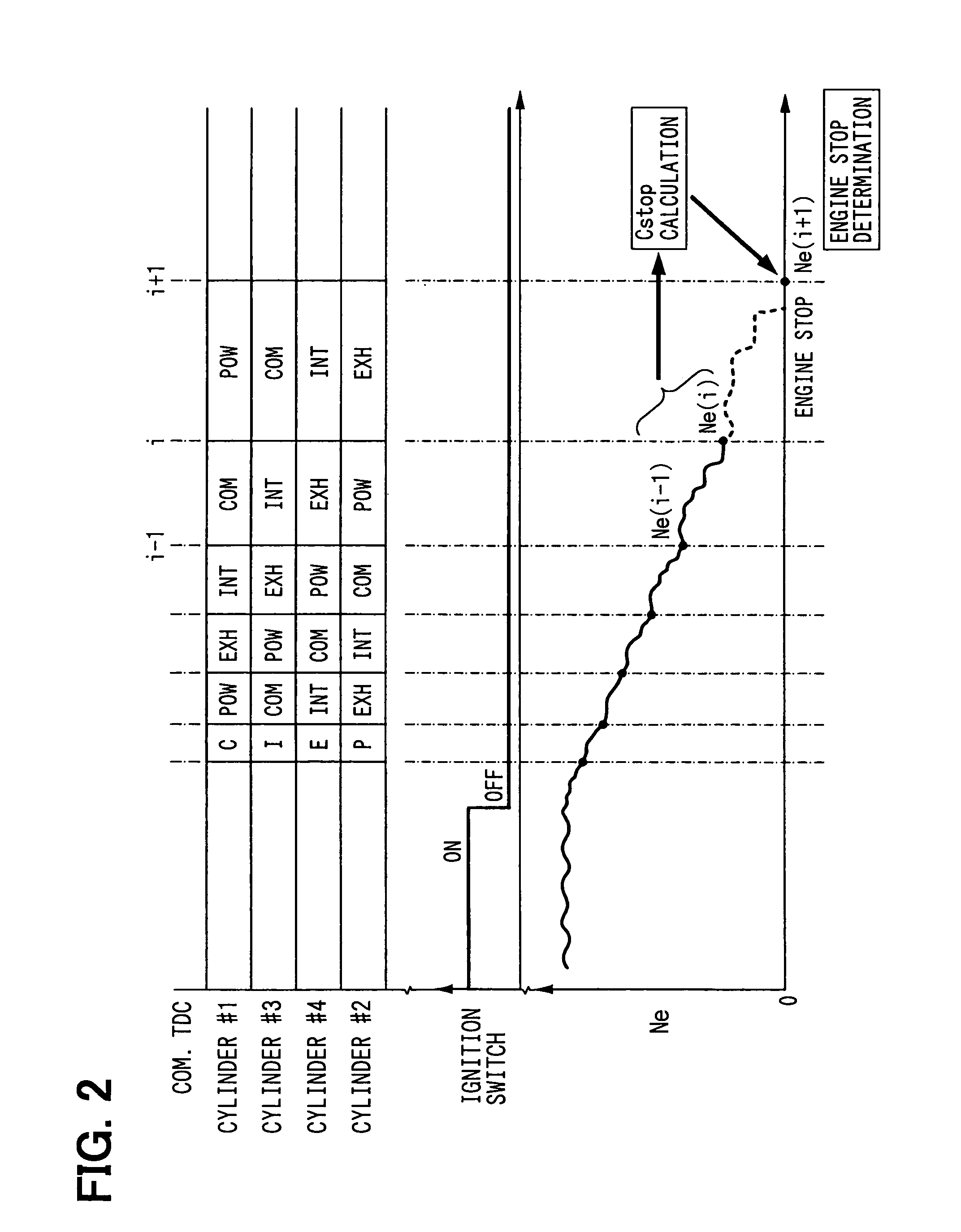

Engine controller for starting and stopping engine

InactiveUS7066128B2Low costQuick stopAnalogue computers for vehiclesElectrical controlIdle speedIgnition timing

During a shut-down period of an engine based on an idle stop control, a computer estimates a power stroke cylinder and a compression stroke cylinder when the engine is stopped. A fuel is injected into the power stroke cylinder and the compression stroke cylinder in an intake stroke just before the engine is stopped. An air-fuel mixture is hold in each cylinder with the engine stopped. When an auto start is required while the engine is stopped, a spark ignition is performed in the power stroke cylinder to start cranking of the engine by combustion energy. At nest ignition timing, a spark ignition is performed in the compression stroke cylinder to start the engine without an aid of a starter.

Owner:DENSO CORP

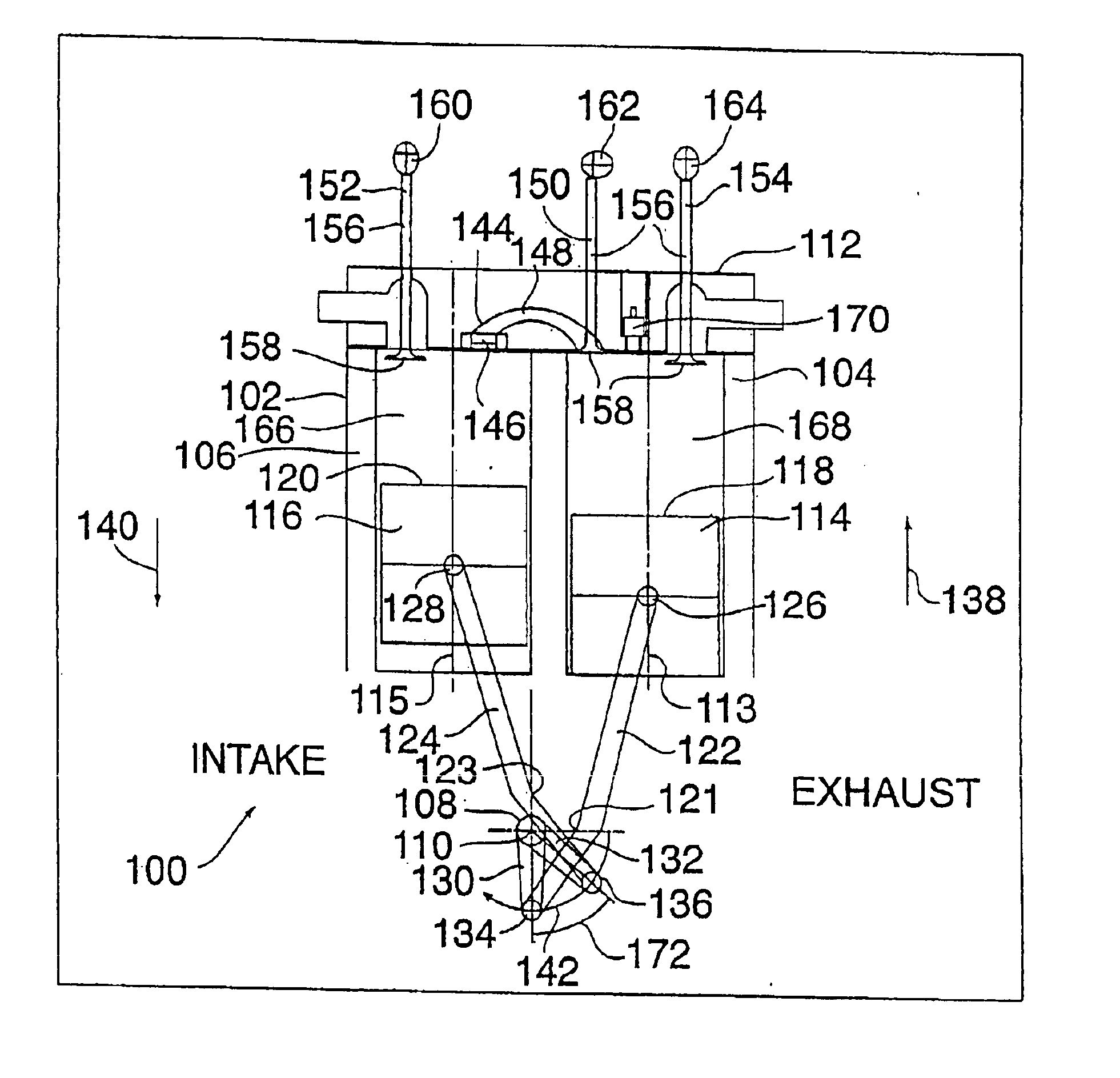

Split four stroke engine

InactiveUS6880502B2Improve efficiencyIncrease the compression ratioCasingsInternal combustion piston enginesPhase shiftedReciprocating motion

An engine includes a crankshaft, rotating about a crankshaft axis of the engine. A power piston is slidably received within a first cylinder and is operatively connected to the crankshaft via first linkage system. The power piston reciprocates through a power stroke and an exhaust stroke of a four stroke cycle during a single rotation of the crankshaft. A compression piston is slidably received within a second cylinder and operatively connected to the crankshaft via second linkage system. The first and second linkage systems share no common mechanical link. The compression piston reciprocates through an intake stroke and a compression stroke of the same four stroke cycle during the same revolution of the crankshaft. The power piston leads the compression piston by a phase shift angle that is substantially equal to or greater than zero degrees and less than 30 degrees.

Owner:SKADERI GRUP LLC

Compound archery crossbow

InactiveUS20110030666A1Extending power strokeImprove performanceSpring gunsBows/crossbowsPower cablePower stroke

The invention is directed to a compound archery crossbow wherein the power cables and the bowstring remain substantially parallel allowing the bowstring to be positioned for increased power and accuracy of an arrow and / or wherein the power stroke has been extended by positioning the bowstring farther from the string catch.

Owner:DARLINGTON REX FRLIN

Air injection engine

InactiveUS7007639B1Improve power densityHigh expansion rateInternal combustion piston enginesOutput powerCombustionExternal combustion engine

An internal combustion engine of the present invention features separate compression and expansion cycles. The engine includes a separate compressor device which pressurizes air by a ratio greater than 15 to 1, at least one two stroke combustion cylinder and a compressed air conduit for transferring compressed air from the compressor to the at least one combustion cylinder. An air injection valve injects the compressed air into the combustion cylinder during the second half portion of the return stroke of the combustion cylinder. The compressed air is mixed with fuel and combusted for expansion during a power stroke. In this engine compression occurs only to a minor degree in the combustion cylinder. Accordingly, the compression ratio of the present engine may be significantly higher or lower than the volumetric expansion ratio of the combustion cylinder thus resulting in corresponding increases in either power density or thermodynamic efficiency respectively.

Owner:D J ENG

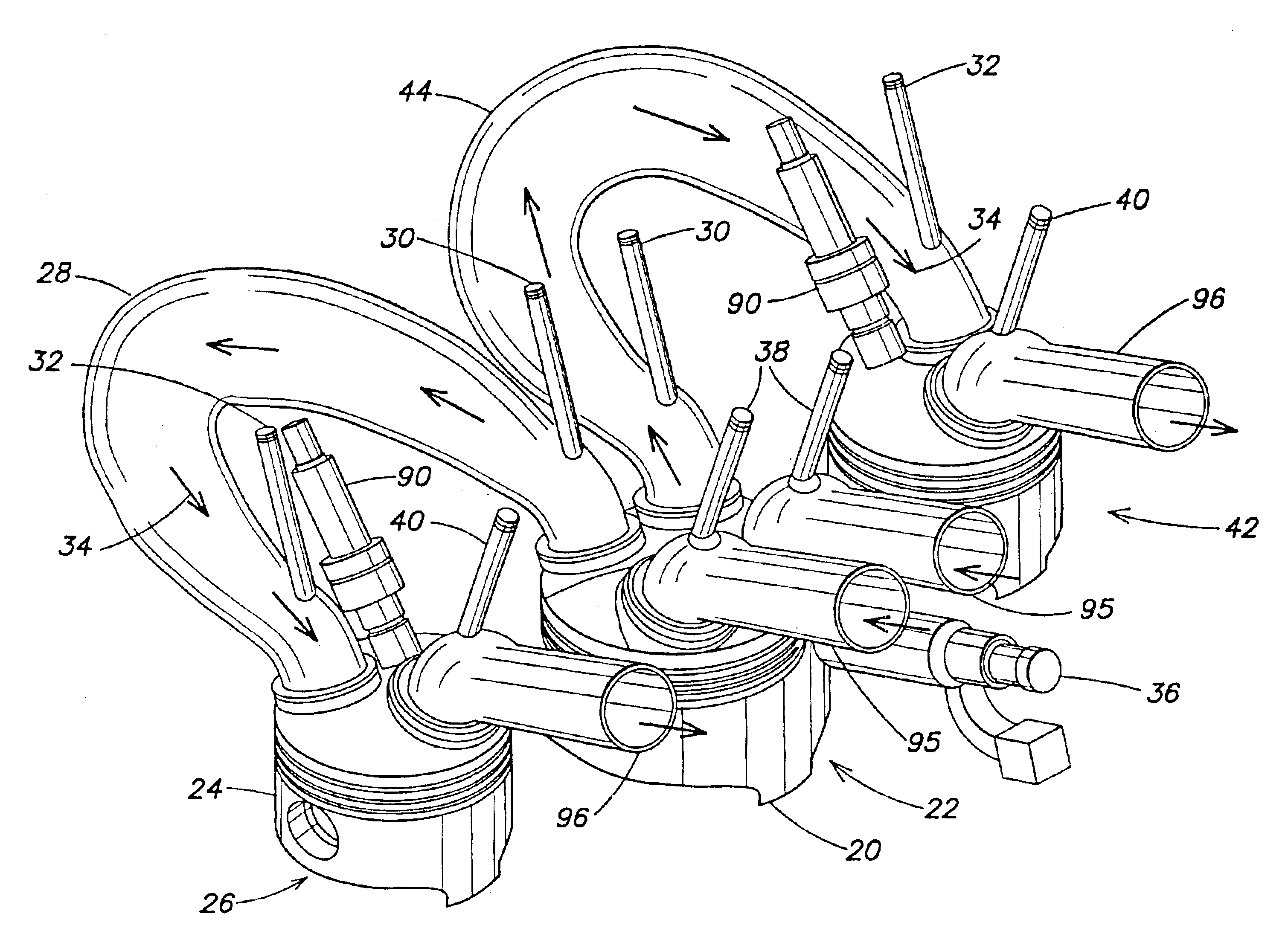

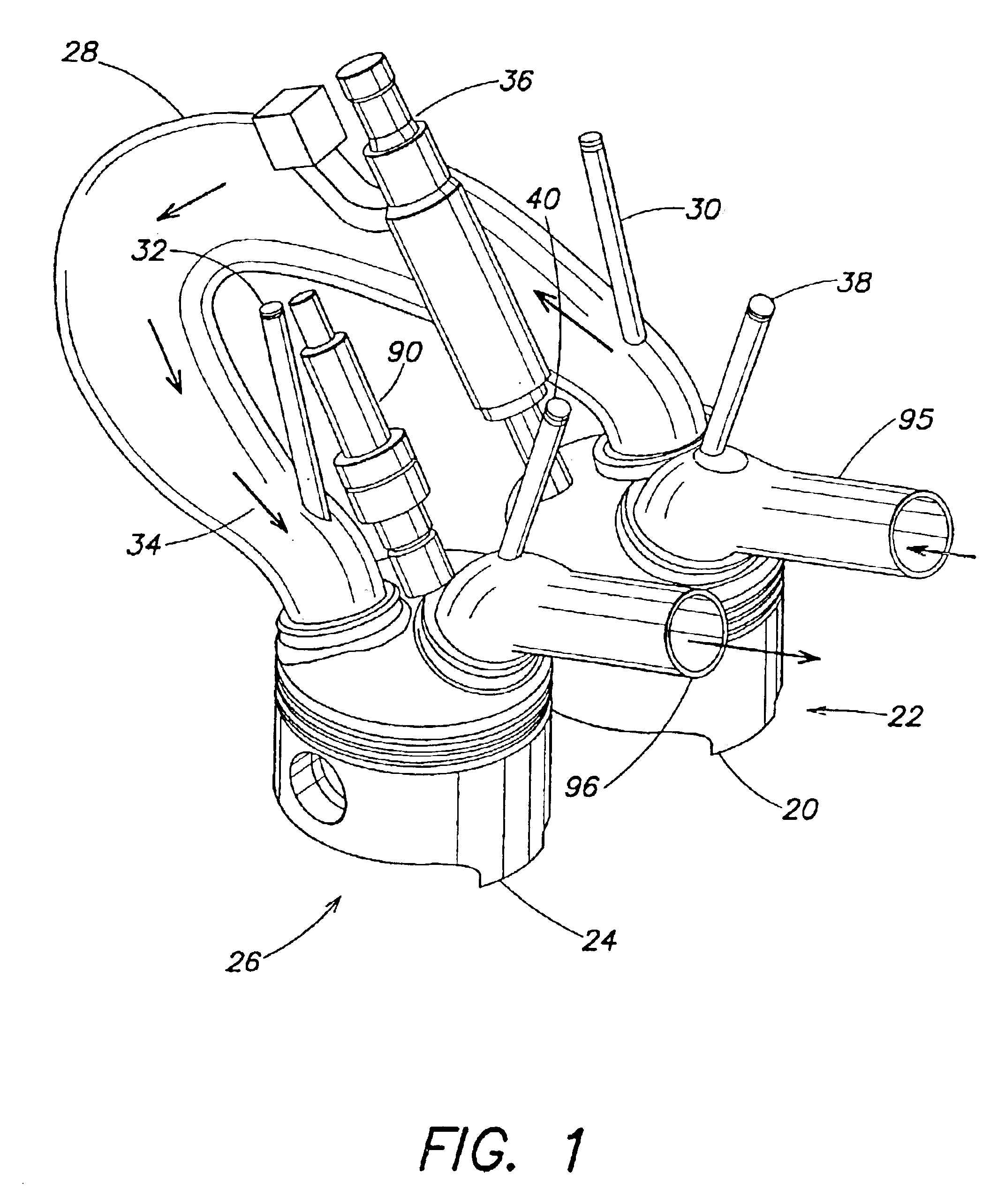

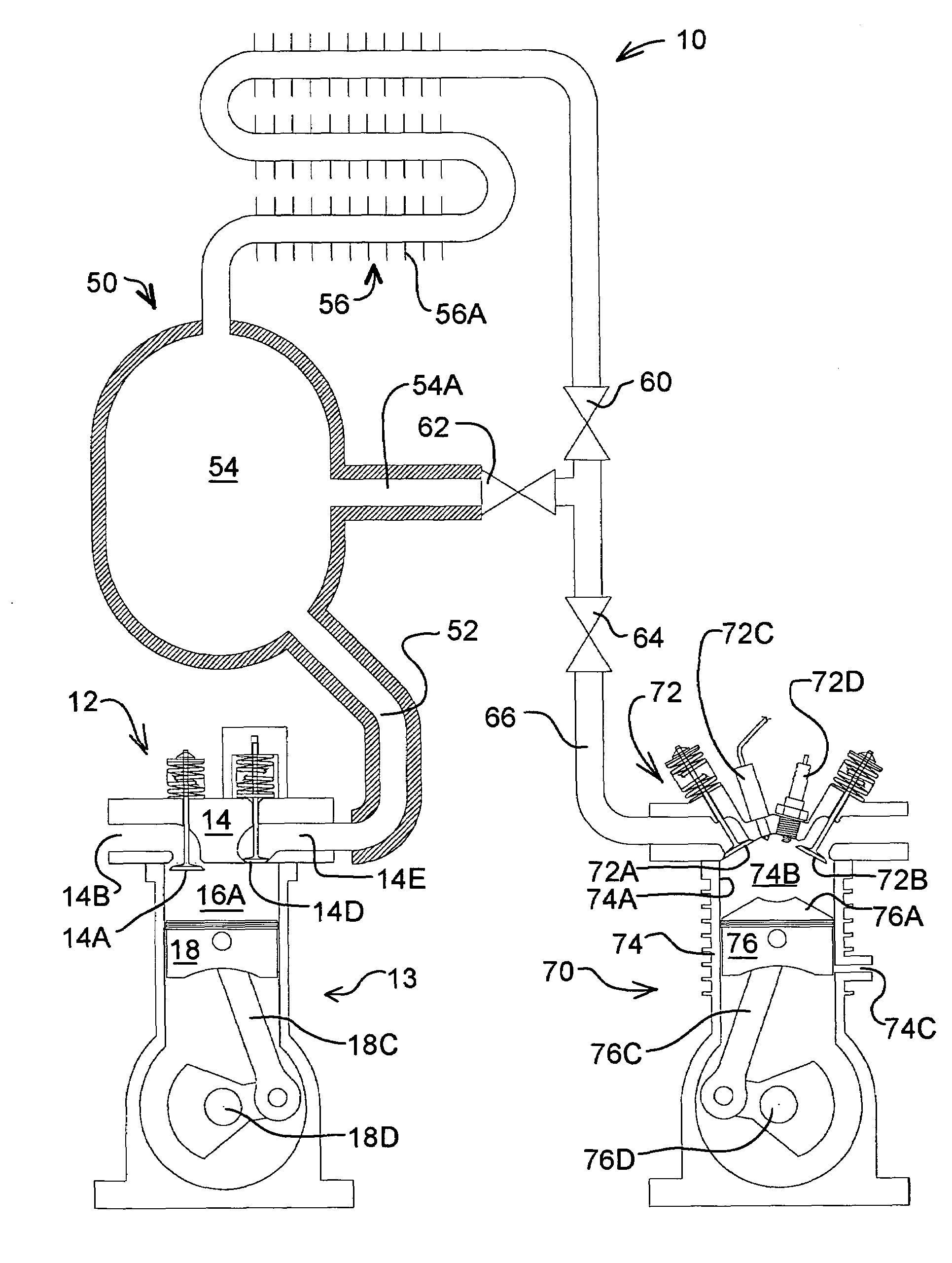

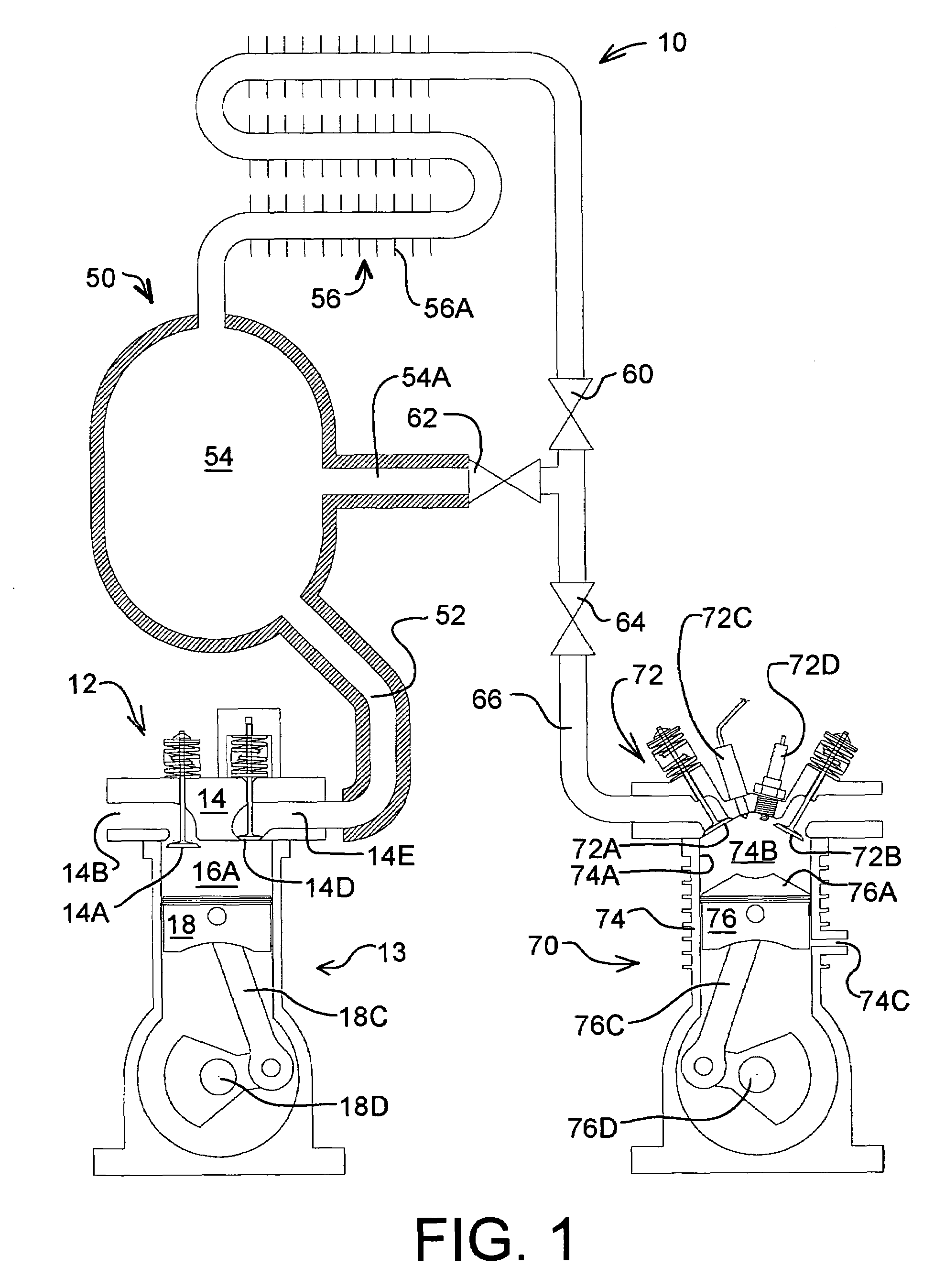

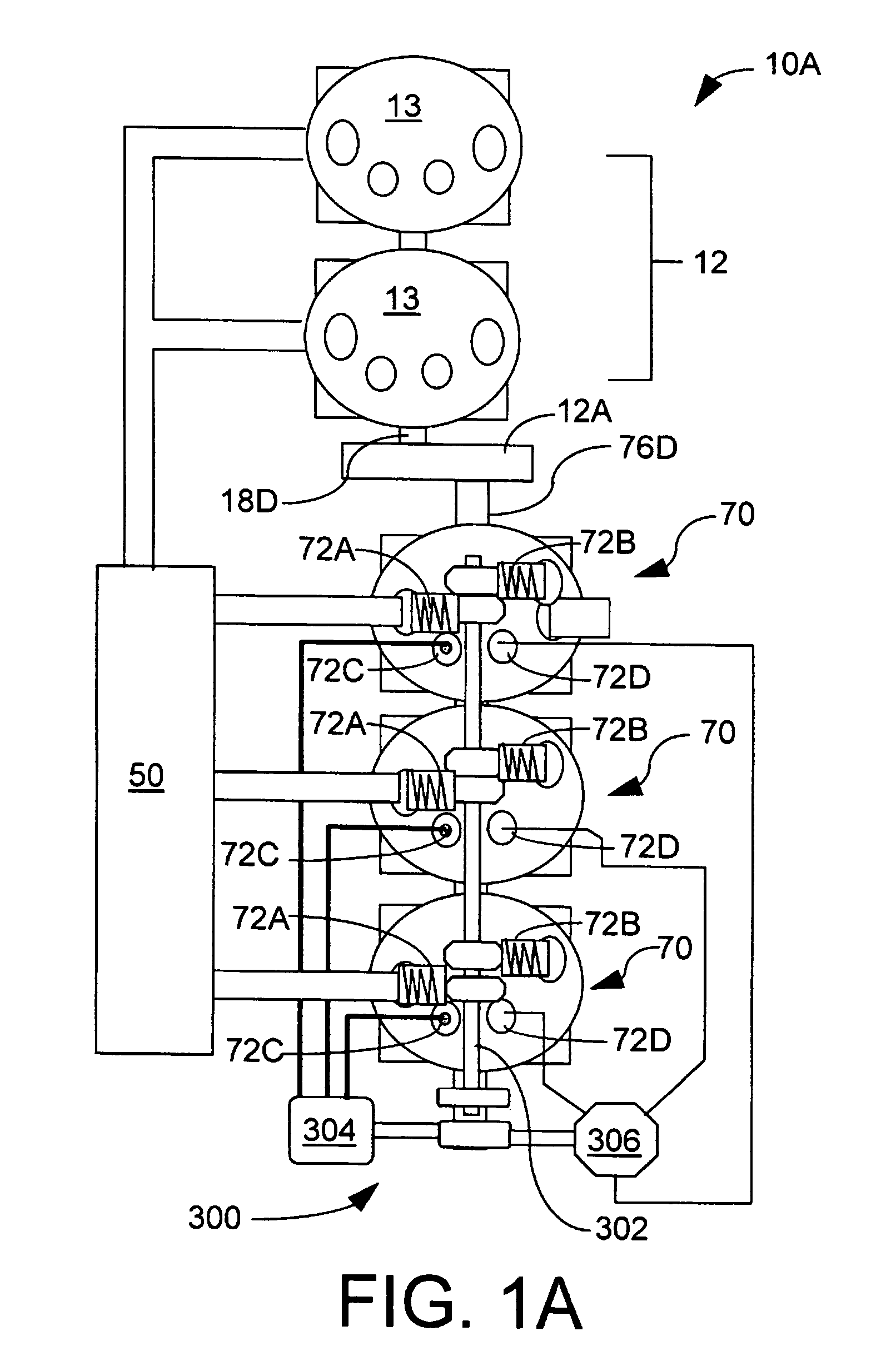

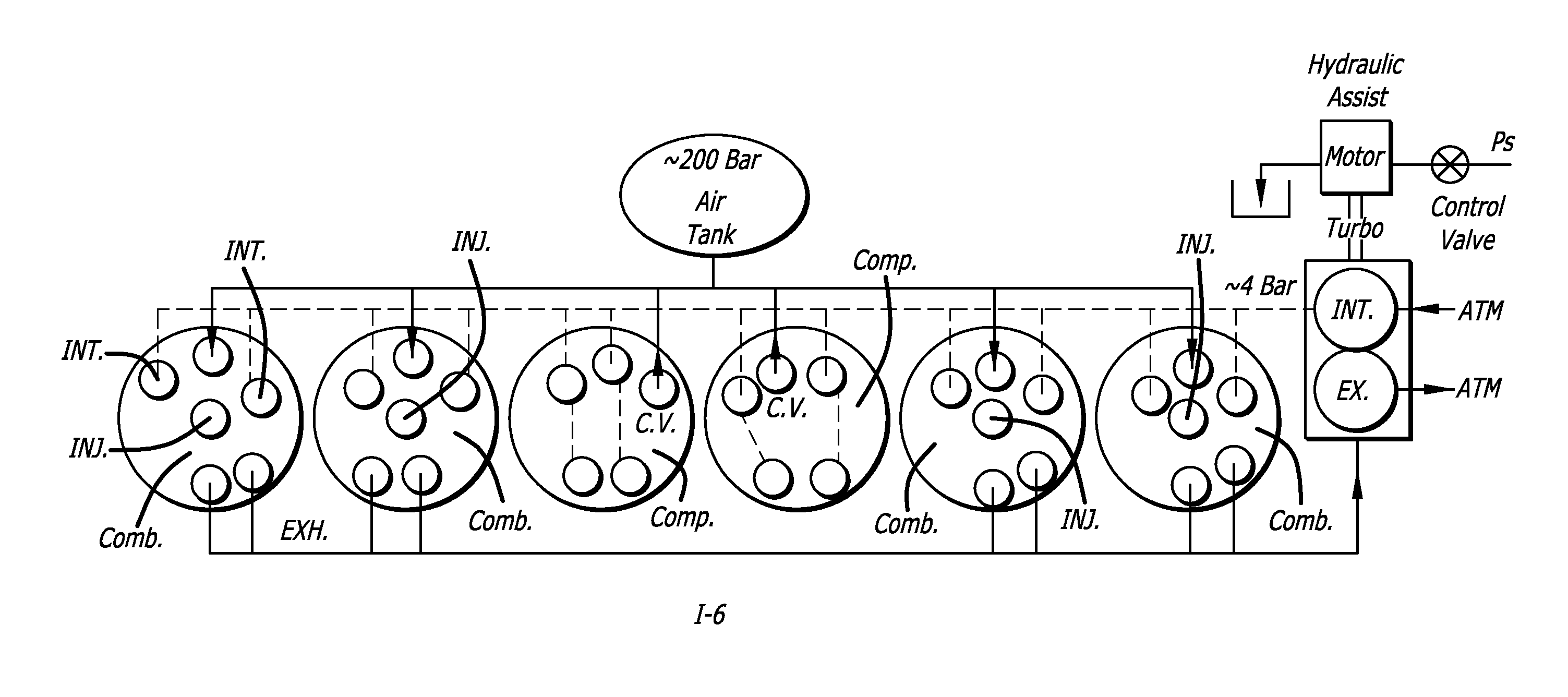

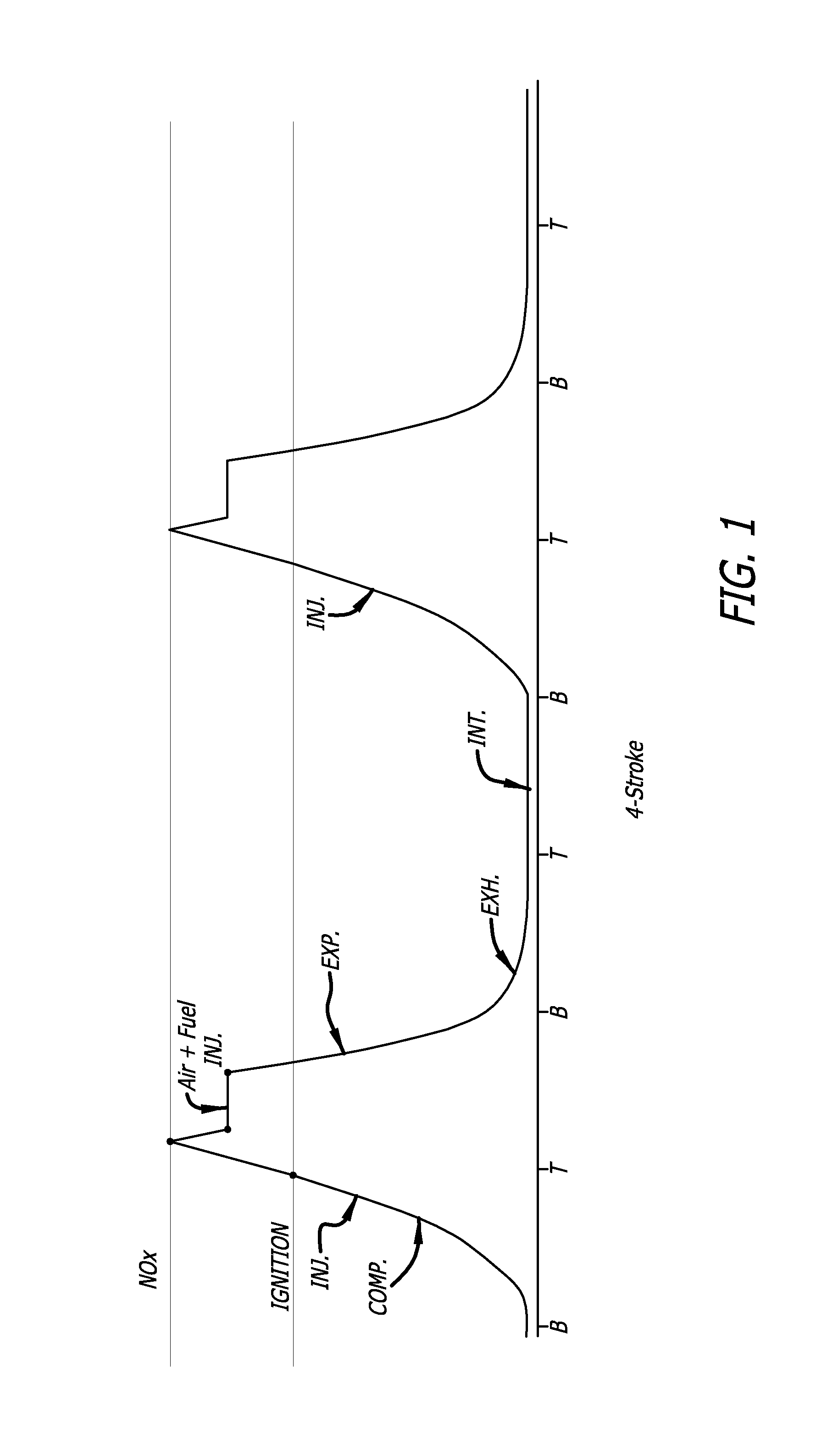

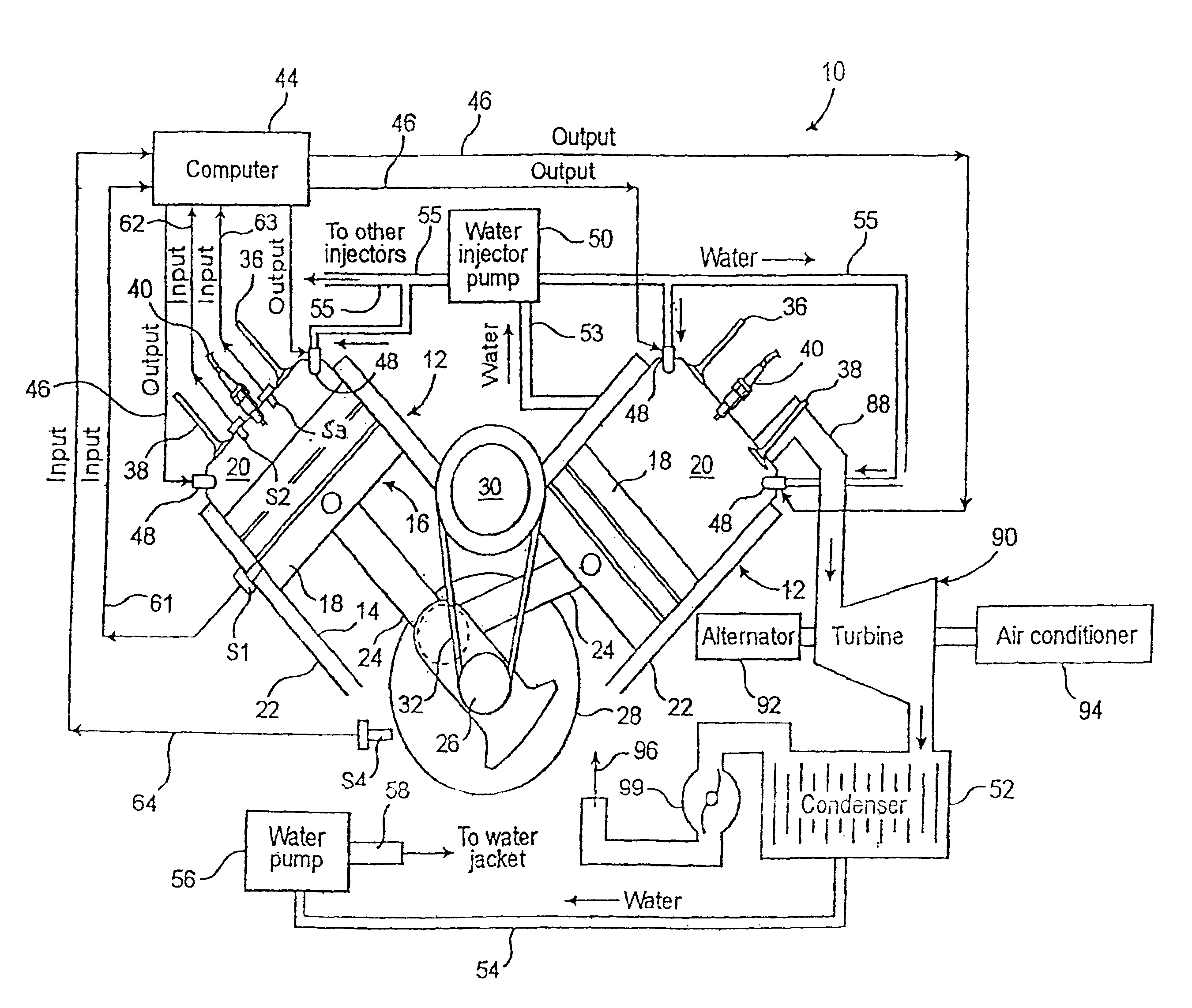

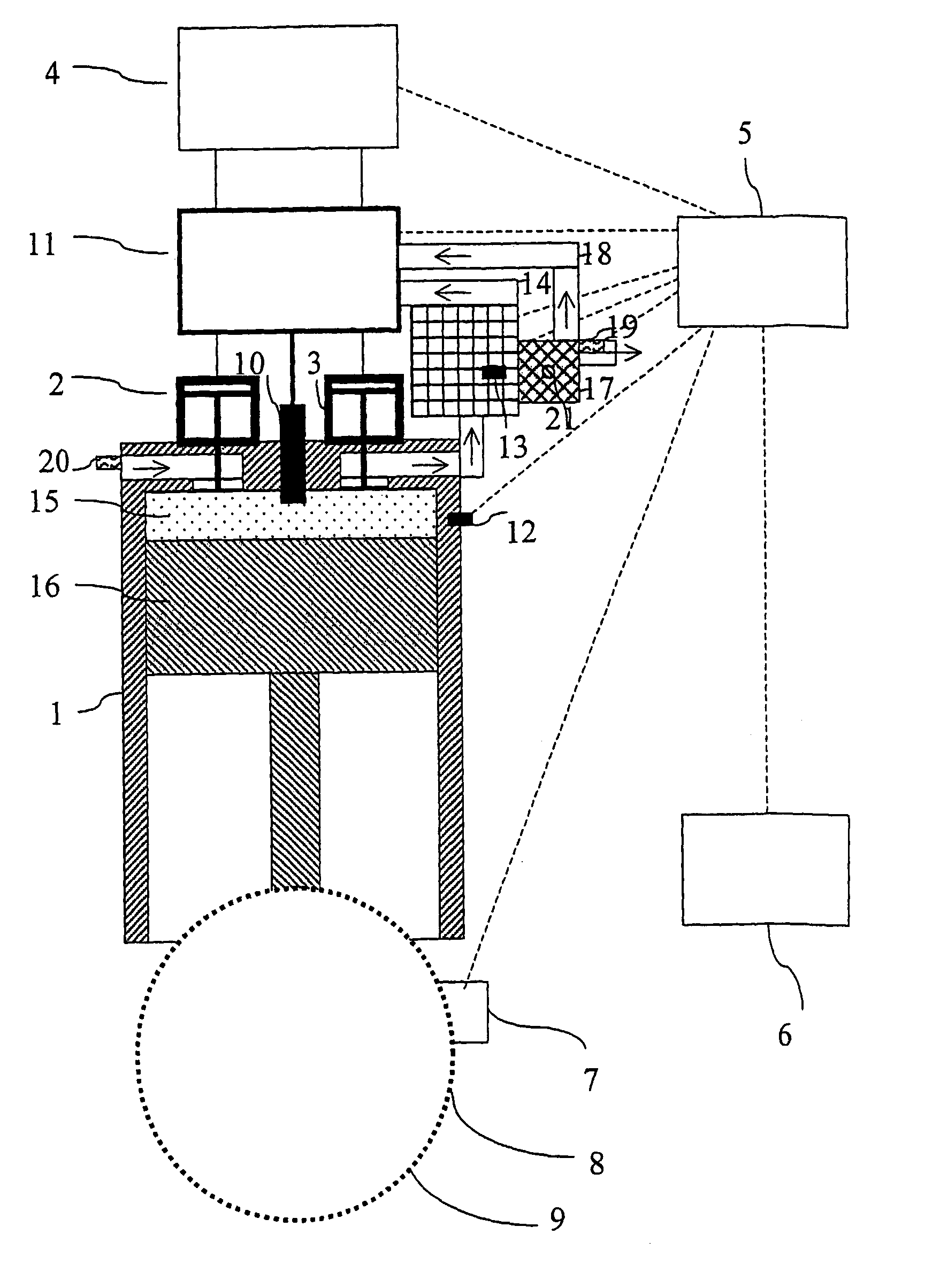

High performance, low emission engines, multiple cylinder engines and operating methods

ActiveUS7954472B1Electrical controlInternal combustion piston enginesCombustion chamberExhaust valve

High performance, low emission engines, multiple cylinder engines and operating methods based on compression ignition of a combustion chamber charge. In accordance with the methods, fuel is injected into the combustion chamber after the exhaust valve closes, and air is injected into the combustion cylinder before the end of the compression stroke in an amount to limit the temperature after ignition to less than the temperature at which NOX forms. After ignition and during the power stroke, more air is injected into the combustion chamber to sustain combustion until all fuel is consumed, the air being injected so as to again limit the combustion temperatures to less than the temperature at which NOX forms. The air injected during the compression stroke is injected at substantially the same combustion chamber pressure as the air injected during the power stroke, so that air may efficiently be injected from the same pressurized source. The fuel injected into the combustion chamber may be all the fuel needed, or additional fuel may be injected during the power stoke.

Owner:STURMAN DIGITAL SYST

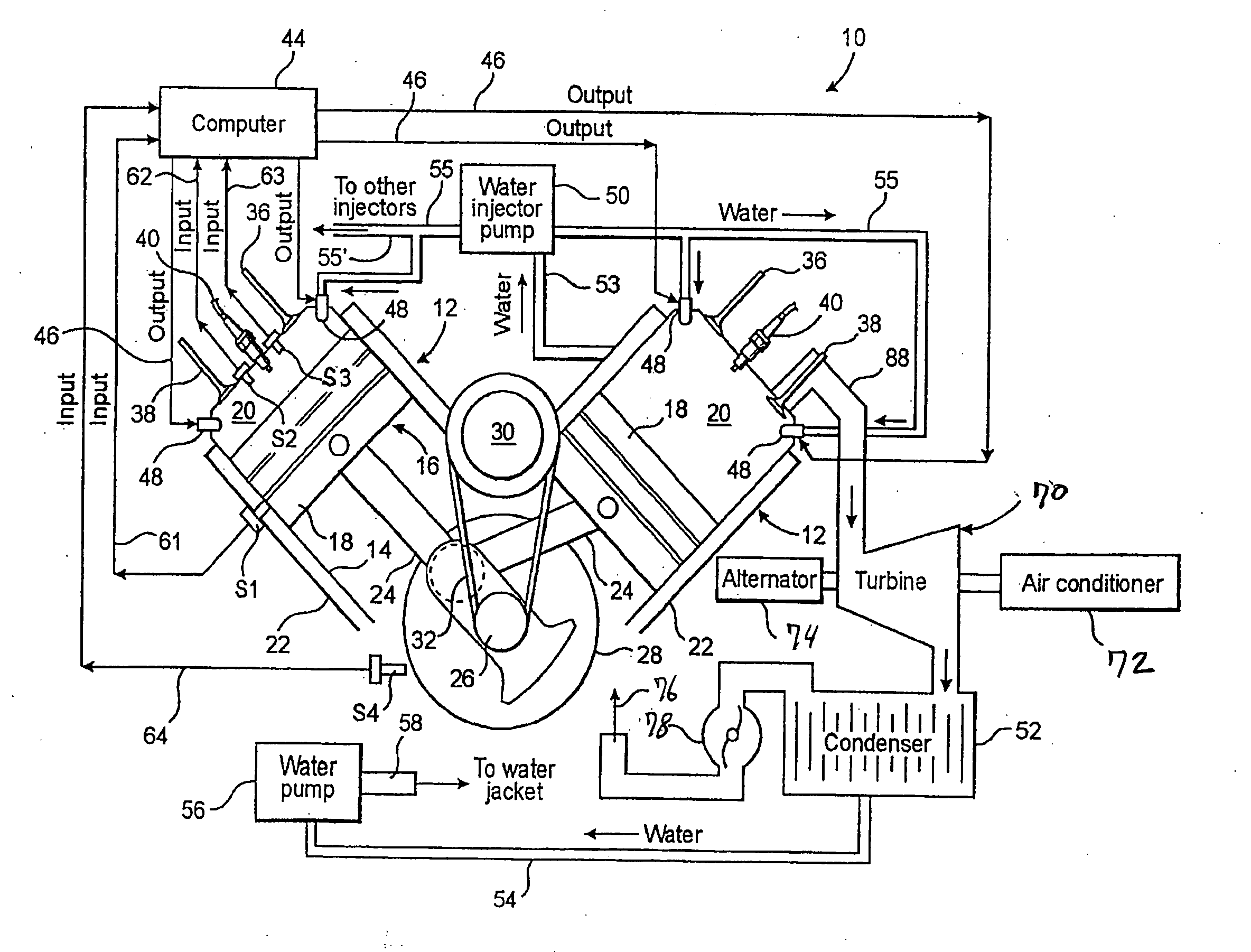

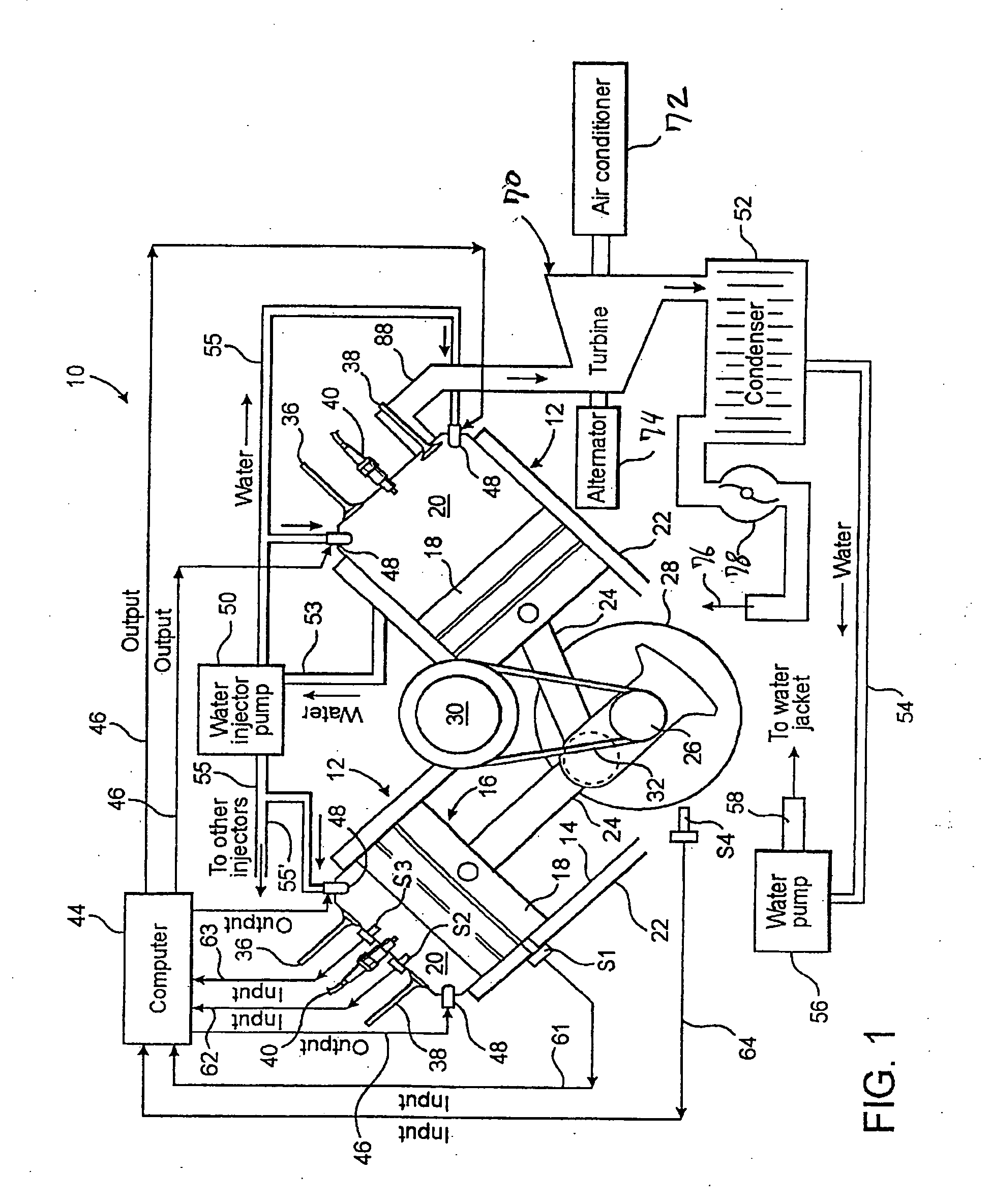

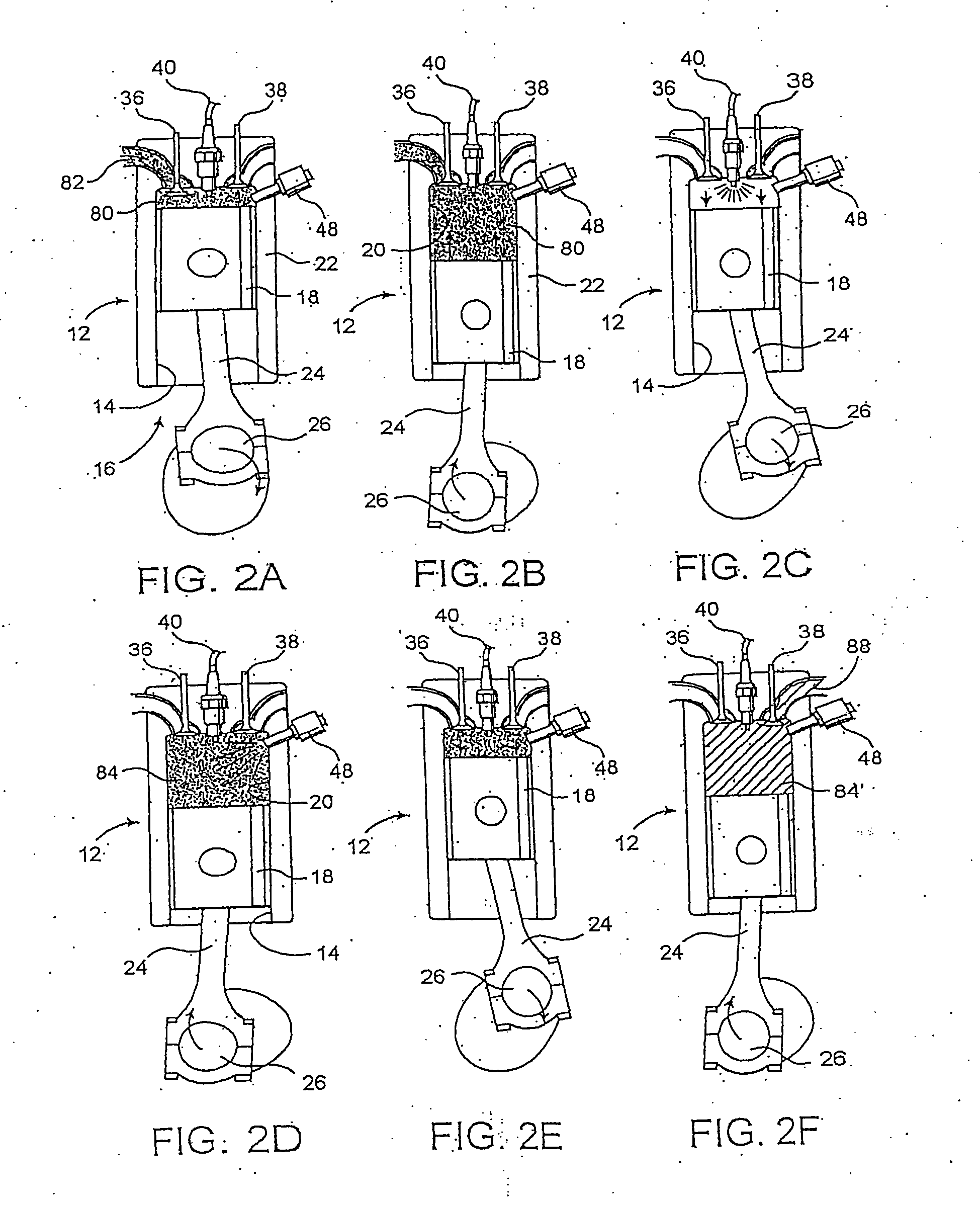

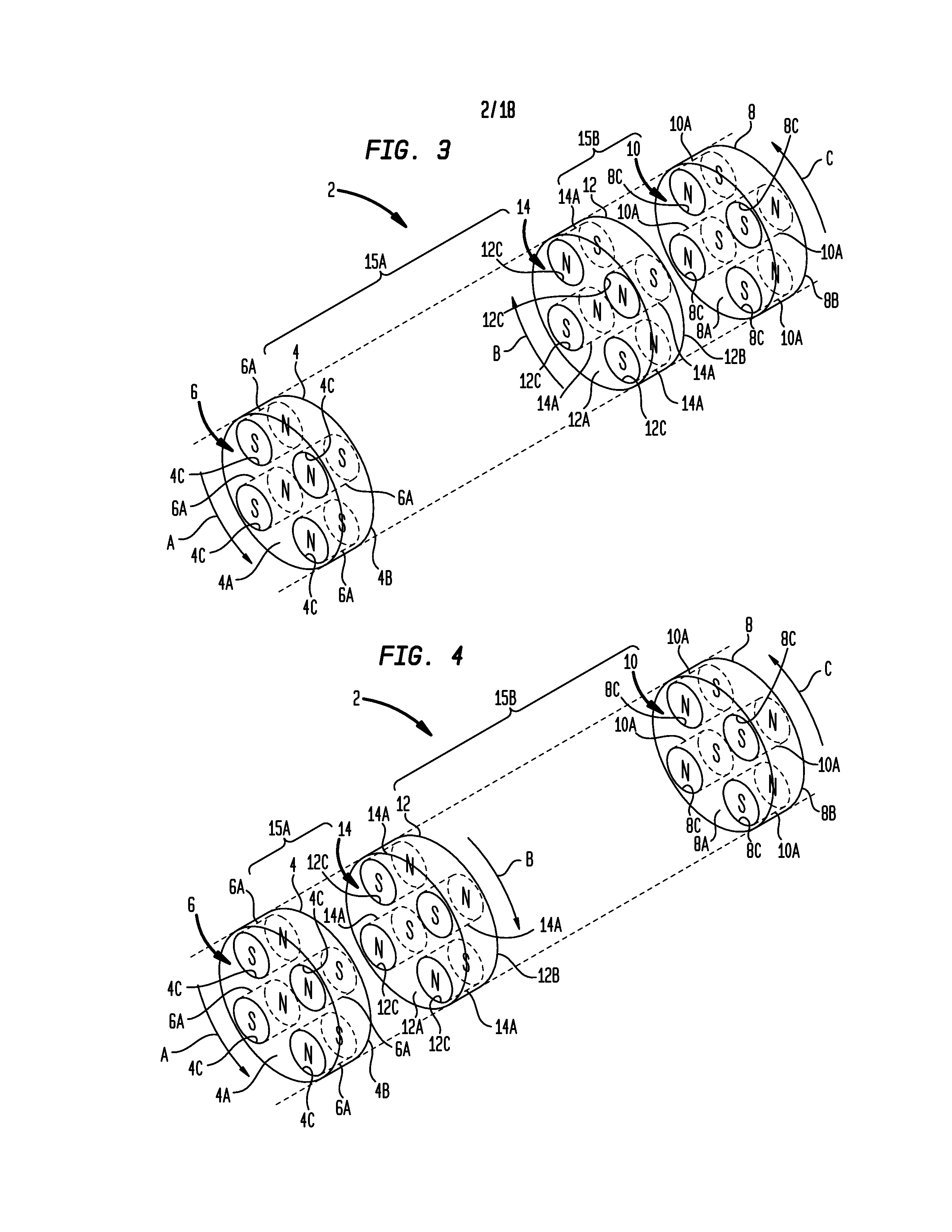

Method and apparatus for operating an internal combustion engine

InactiveUS20070022977A1Improve engine efficiencyIncrease powerNon-fuel substance addition to fuelInternal combustion piston enginesCombustion chamberSystem requirements

An internal combustion engine and method of operation employing timed injection of water into the combustion chamber for one or a combination of recapturing waste heat, cooling the engine, and lowering Nox emissions of the engine. The water injection subsequent to the power stroke of the engine employs residual heat and heat conducted from surfaces of the combustion chamber, to form steam to drive a second power stroke. The water injection can also be employed to pre-cool the combustion chamber to avoid formation of Nox gases during fuel combustion and by recapturing residual and conductive heat from the combustion chamber the engine is cooled thereby minimizing or eliminating exterior cooling system requirements.

Owner:CROWER H BRUCE

Injector-ignition for an internal combustion engine

InactiveUS7546826B2Reduce heat lossImprove powerLiquid surface applicatorsInternal combustion piston enginesExternal combustion engineInternal combustion engine

The present invention provides a heated catalyzed fuel injector that dispenses fuel substantially exclusively during the power stroke of an internal combustion engine, wherein ignition occurs in a fast burn zone at high fuel density such that a leading surface of the fuel is completely burned within several microseconds. In operation, the fuel injector precisely meters instantly igniting fuel at a predetermined crank angle for optimal power stroke production. Specifically, the fuel is metered into the fuel injector, such that the fuel injector heats, vaporizes, compresses and mildly oxidizes the fuel, and then dispenses the fuel as a relatively low pressure gas column into a combustion chamber of the engine.

Owner:ECOMOTORS

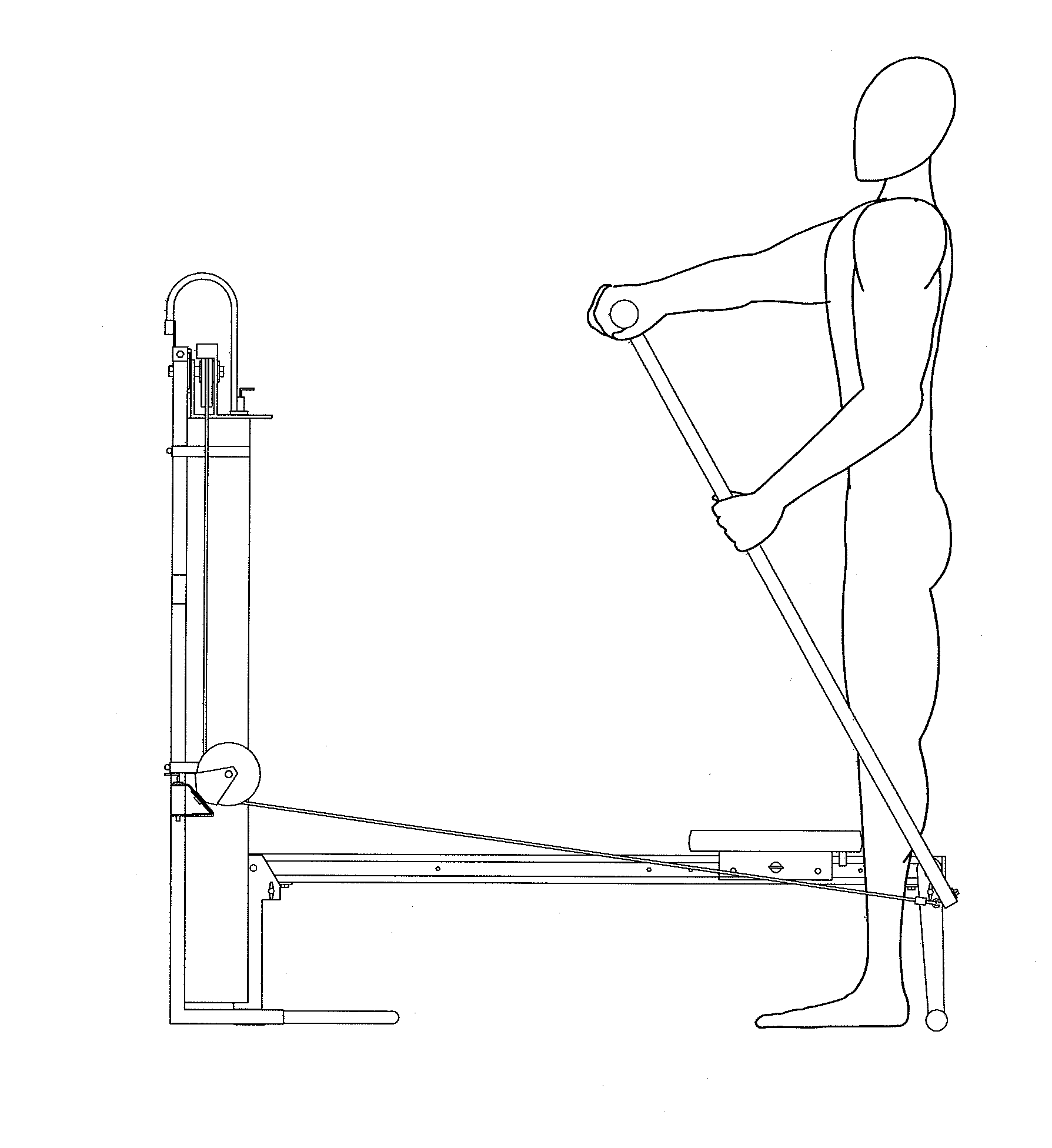

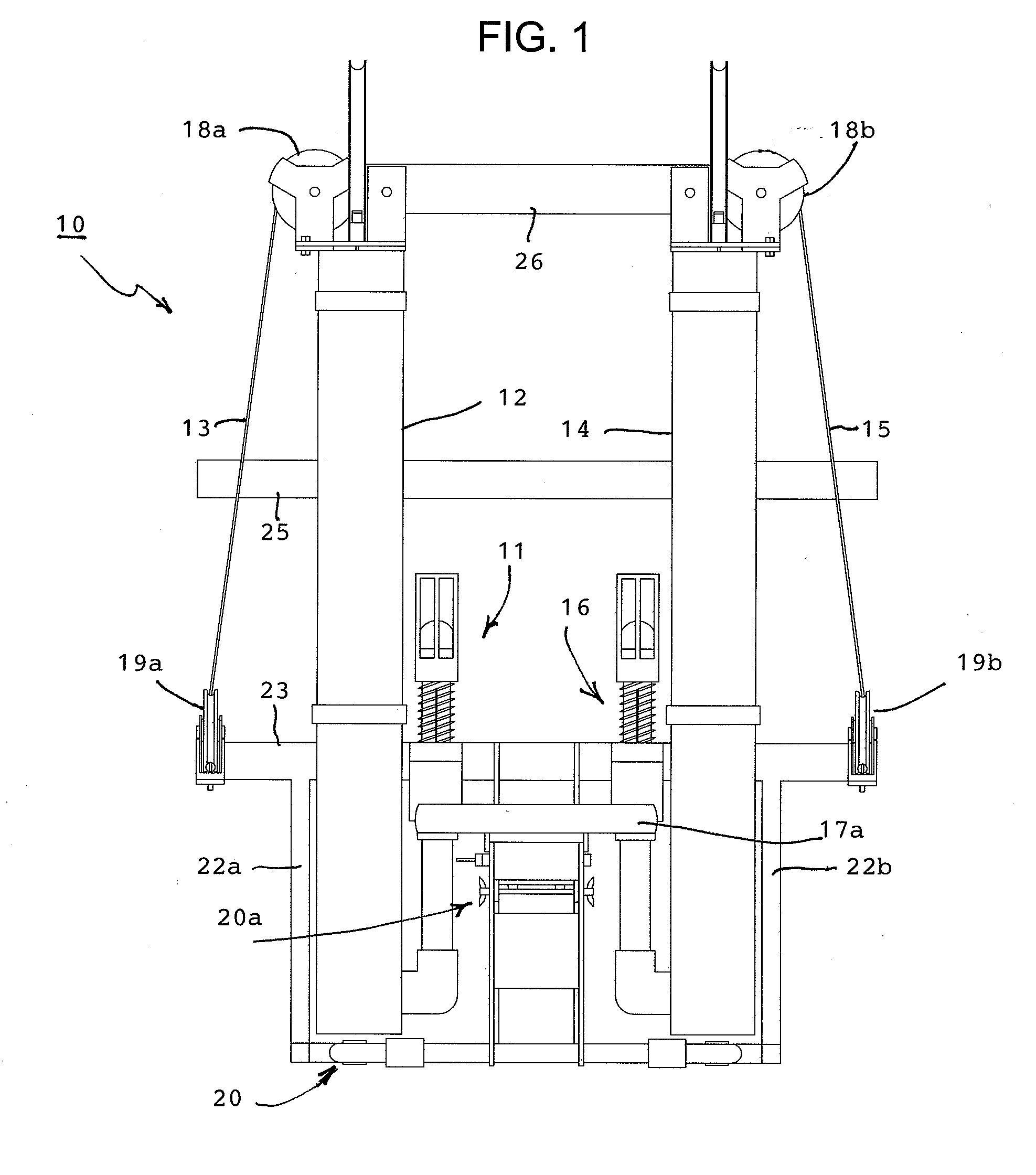

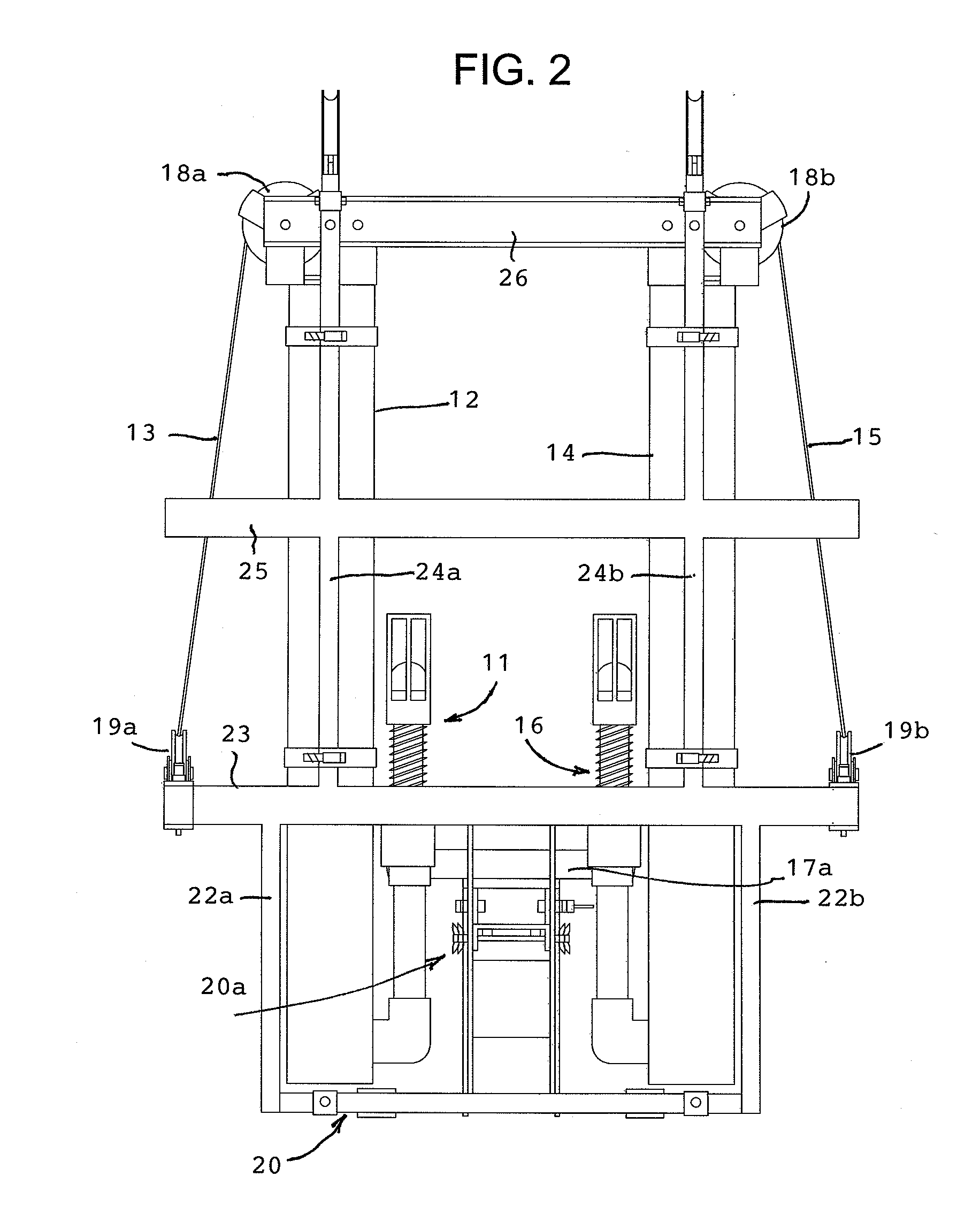

Exercise machine for training watersports athletes

InactiveUS20110275489A1Save equipmentSave spaceSwimming detailsSpace saving gamesAir movementReciprocating motion

An exercise machine adapted for training watersports athletes has a pair of spaced-apart vertical columns each with hollow tubular body with a weighted plunger attached to a cable for vertical reciprocation while a user performs power and return stroke movements on an instrument attached to the other end of the cable. The plunger is hydraulically coupled to an air channel fed by an air-through valve sized to control air movement into the air channel by the rising plunger during a power stroke to approximate water resistance to an oar, paddle or arm in the water. The air channel has a release opening for releasing air balanced against the weight of the falling plunger to approximate lifting an oar, paddle, or arm out of the water on a return stroke. The exercise machine can be used to practice a wide range of watersports training exercises for swimming, paddleboarding, canoe paddling, rowing, etc.

Owner:APAU MICHAEL

Human-powered, ride-on vehicle

A human-powered, ride-on vehicle, includes a main longitudinal frame member having a steering / drive mechanism mounted thereon for oscillating movement; a driven rear wheel having an axle, a rear sprocket operatively fixed to the rear wheel for coastable engagement therewith; a pair of spaced apart, steerable front wheel located adjacent the other end of the main longitudinal frame member and operatively connected to the steering / drive mechanism; wherein, the steering / drive mechanism include: a teeter arm mounted to the main longitudinal frame member intermediate the ends thereof for pivoting movement in a fore direction and an aft direction; a drive mechanism including first and second drive linkages, wherein the first drive linkage provides a motive force to the driven rear wheel during a first power stroke and the second drive linkage provides a motive force to the driven rear wheel during a second power stroke, and wherein, for equal movement of the teeter arm in the for and aft directions, the motive force of the first powers strokes is between about one to three times that of the second power stroke.

Owner:COLUMBIA INLAND CORP

Hydraulic Internal Combustion Engines

ActiveUS20110083643A1Free piston enginesEngines without rotary main shaftHydraulic equipmentHydraulic fluid

Hydraulic internal combustion engines having at least one combustion piston not mechanically connected to a crankshaft or any other combustion piston, but instead acting on hydraulic plungers through valving that is electronically controlled to control the piston position and velocity, typically through an intake stroke, a compression stroke, a combustion or power stroke and an exhaust stroke. Electronically controlled fuel injection and electronically controlled engine valves provided great flexibility in the operating cycles that may be used, with the engine pumping hydraulic fluid to a high pressure accumulator for use in hydraulic motors or other hydraulic equipment. Embodiments using high pressure air injection to sustain combustion are also disclosed.

Owner:STURMAN DIGITAL SYST

Narrow crossbow with large power stroke

ActiveUS20080127956A1Large power strokeEasy to manually cockSpring gunsBows/crossbowsBowstringMechanical engineering

A crossbow may include a main beam; a compound bow assembly mounted to the main beam; and, a trigger mechanism mounted to the main beam for use in holding a bowstring in a cocked position. The crossbow may include wheels at opposite ends of the bow that operatively receive the bowstring. The wheels may be separated by a wheel distance (WD) when the crossbow is in an un-cocked position. The crossbow may also have a power stroke distance (PD) and the ratio WD / PD may be less than 2.0.

Owner:HUNTERS MFG CO INC

Cao heat engine and refrigerator

InactiveUS20100089062A1Increase the number ofExtended durationAuxillary drivesInternal combustion piston enginesThermal energyAir cycle machine

Owner:CAO YIDING

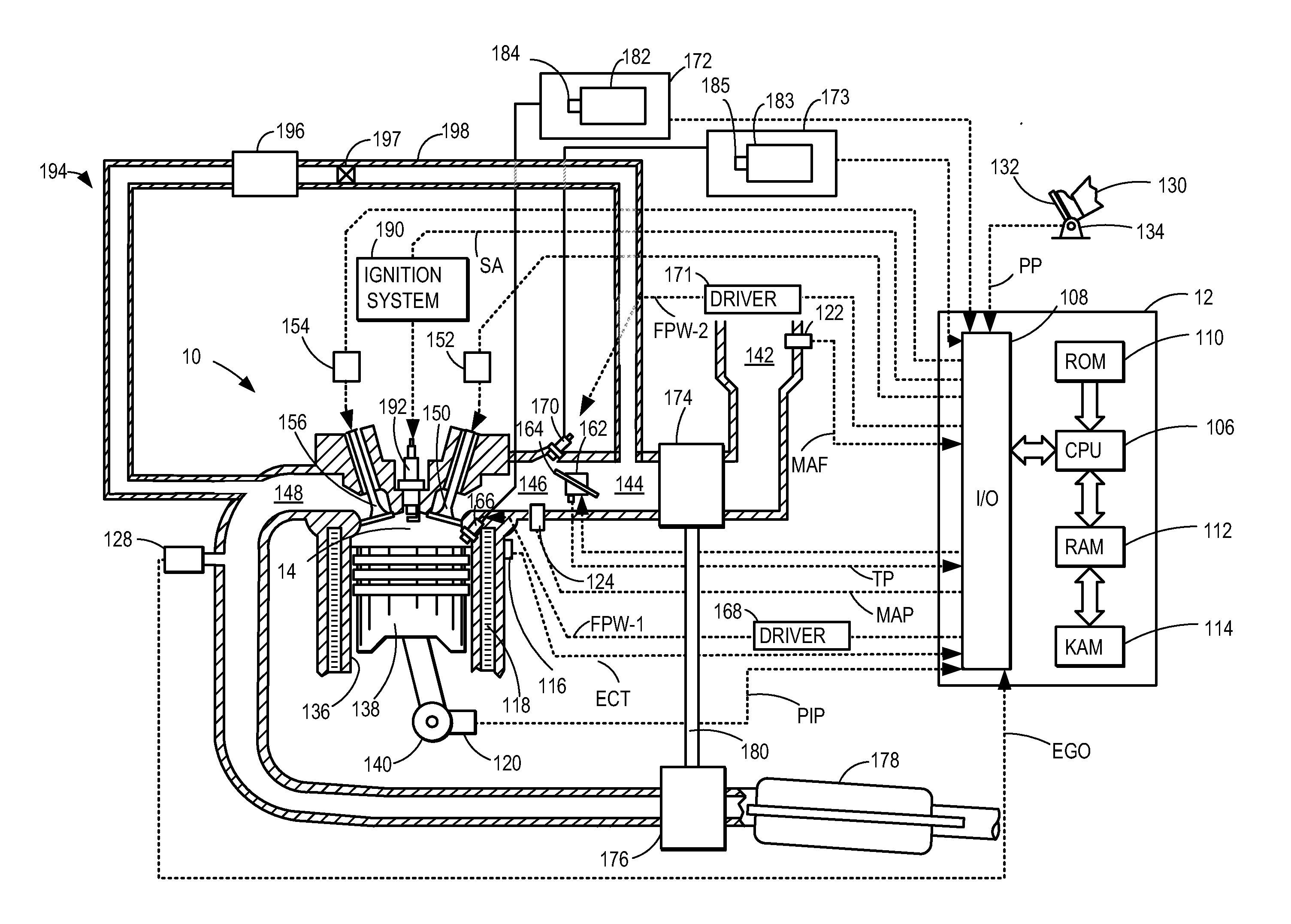

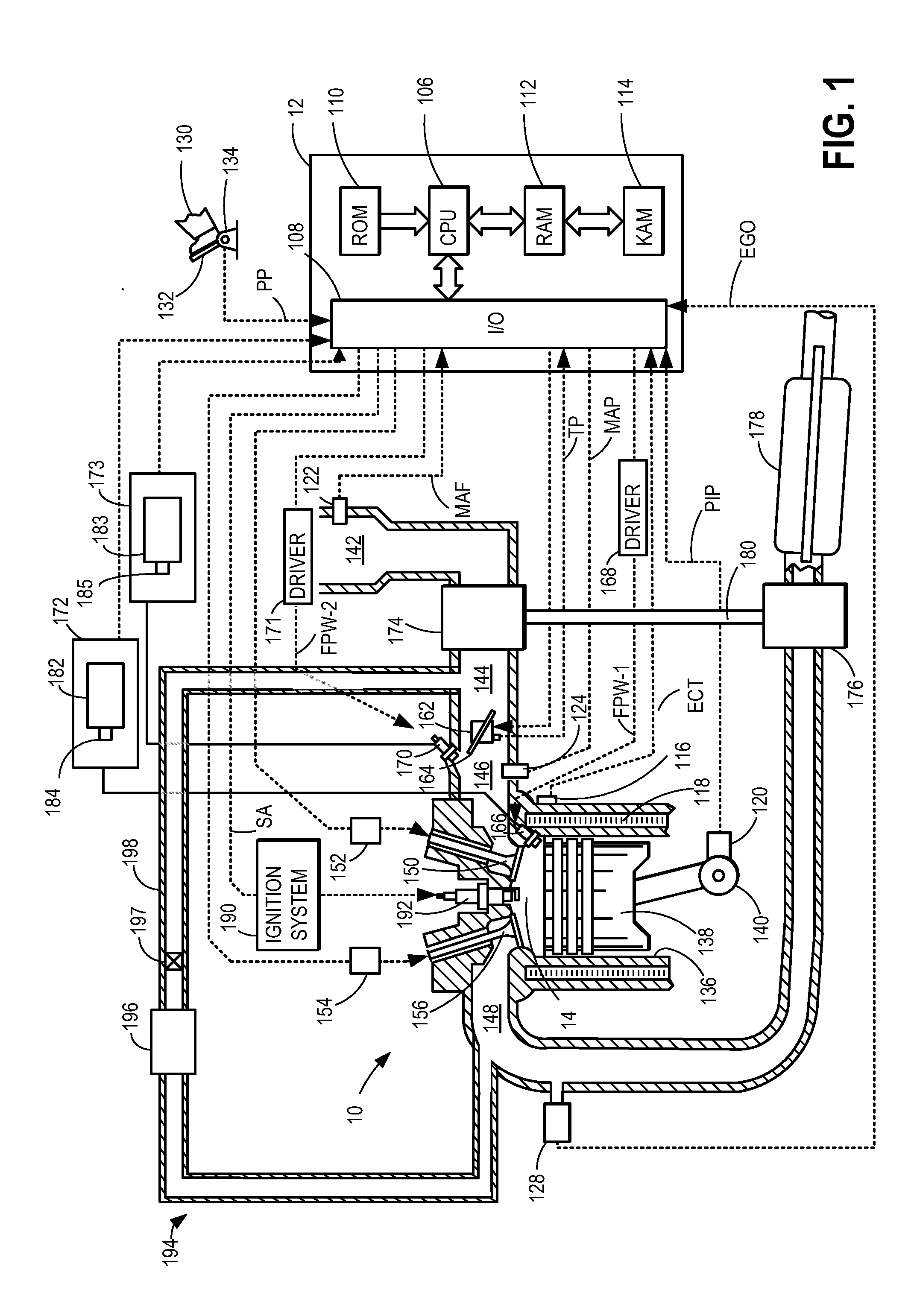

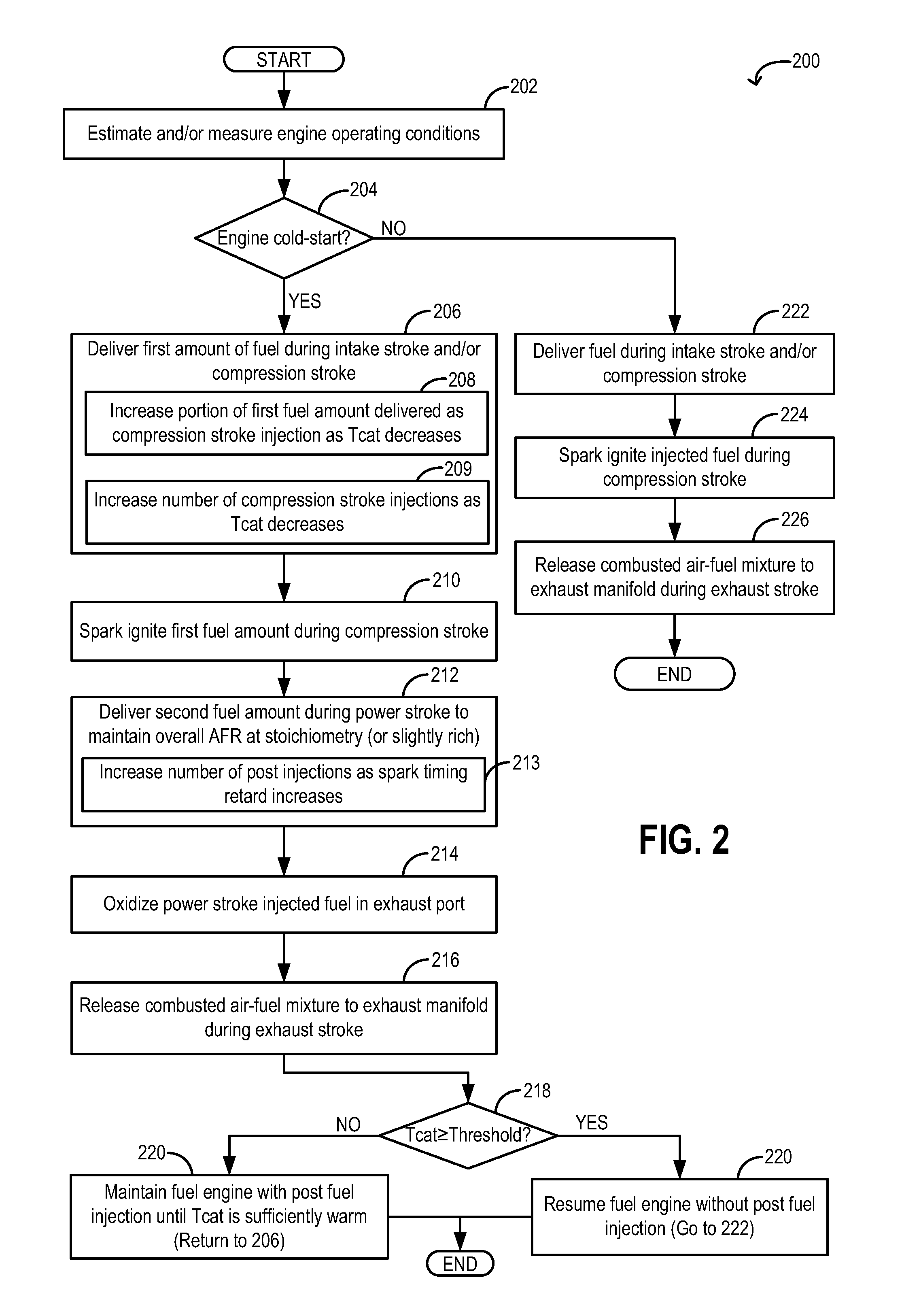

Post fuel injection of gaseous fuel to reduce exhaust emissions

InactiveUS20150167576A1Improve fuel efficiencyImprove cooling effectElectrical controlInternal combustion piston enginesExhaust fumesFuel injection

Methods and systems are provided for delivering gaseous fuel as multiple fuel injections split between an intake stroke, a compression stroke, and / or a power stroke to expedite exhaust catalyst heating during an engine cold-start. Fuel injected in the intake and compression stroke is ignited and combusted. The power stroke fuel injections are combusted in the exhaust port to increase exhaust temperature and pressure for faster catalyst light-off.

Owner:FORD GLOBAL TECH LLC

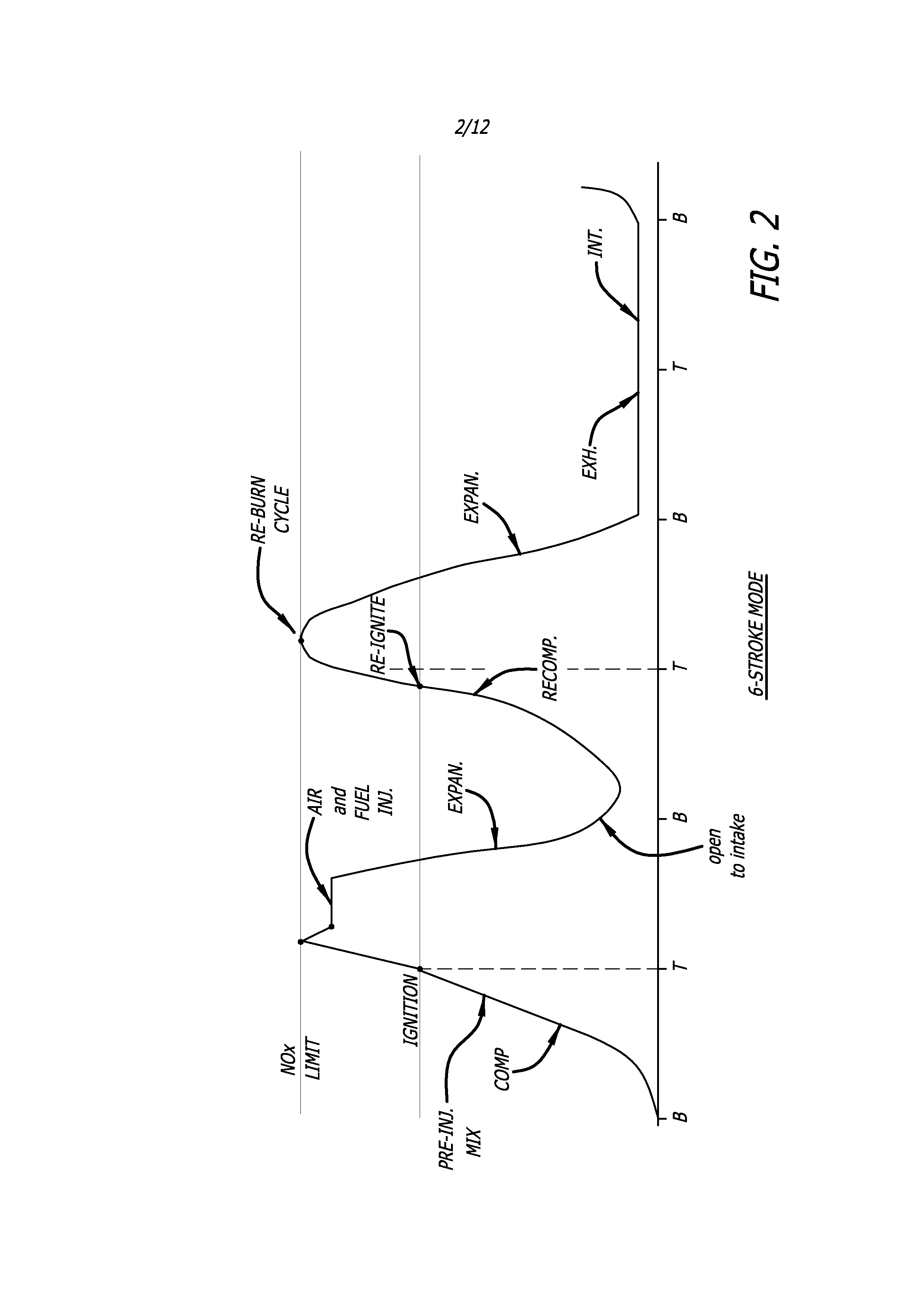

System and method for recovering wasted energy from an internal combustion engine

InactiveUS20060124079A1Efficient powerReduce compressionNon-fuel substance addition to fuelInternal combustion piston enginesExhaust fumesRisk stroke

An internal combustion engine and its method of operation including at least one embodiment operating on a six-stroke cycle and including at least one piston and cylinder assembly. The six-stroke cycle includes two power strokes, the latter of which is the result of a water to steam conversion process utilizing the heat of the exhaust gas from the first power stroke. A second embodiment comprises a hybrid power generating assembly incorporating alternative, first and second power sources respectively comprising an internal combustion engine and a water injection engine, the latter of which operates on the water to steam conversion process, wherein the required heat therefore is derived from the exhaust gas of the internal combustion engine. Another preferred embodiment comprises the utilization of different normally wasted heat sources from an IC engine for the generation of sufficient work energy to drive a power take-off, such as hybrid drive assembly.

Owner:SINGH SATNARINE

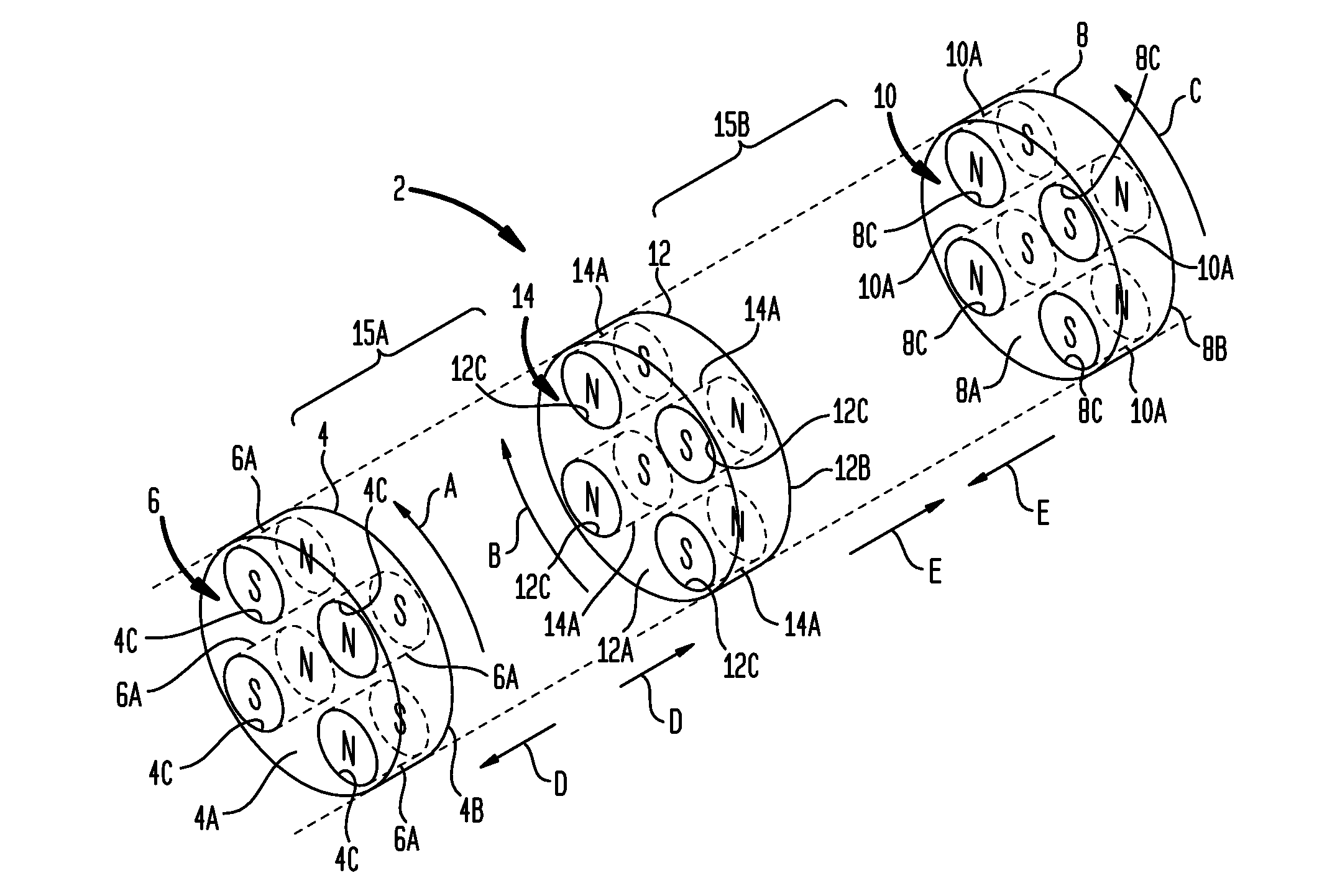

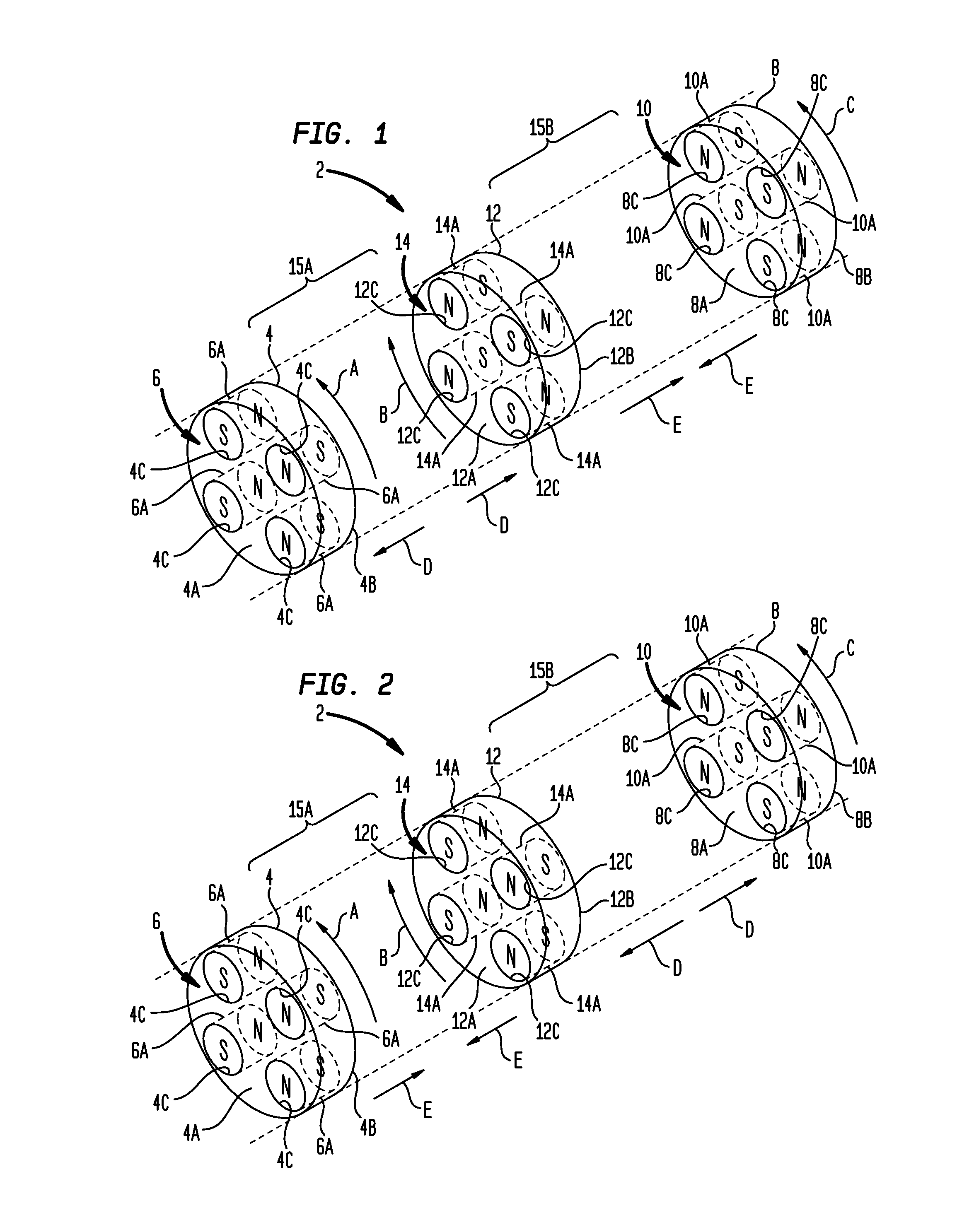

Permanent magnet drive apparatus and operational method

InactiveUS8487484B1Magnetic circuitPermanent-magnet clutches/brakesMagnetic tension forcePush and pull

A magnetic drive apparatus includes first and second magnet carriers carrying first and second permanent magnet arrangements. An intermediate magnet carrier disposed between the first and second magnet carriers carries a third permanent magnet arrangement. The magnet carriers are arranged for rotation relative to each other such that the magnet arrangements produce magnetic interactions that result in power stroke forces causing the magnet carriers to undergo relative reciprocation in first and second stroke directions during power zone portions of the relative rotation. The magnetic interactions impart substantially no power stroke forces during dead zone portions of the relative rotation. The dead zones include magnet carrier relative rotation positions wherein opposing magnetic poles are mutually coaxially aligned but produce a substantially equal balance of push and pull magnetic forces. The apparatus may be synchronized so that the dead zones coincide with top dead center and bottom dead center relative reciprocation positions.

Owner:COLSON ANDREW E JR MR

Computer controlled multi-stroke cycle power generating assembly and method of operation

InactiveUS7021272B2Reciprocating combination enginesInternal combustion piston enginesInternal combustion enginePower take-off

An internal combustion engine and its method of operation including at least one embodiment operating on a six-stroke cycle and including at least one piston and cylinder assembly. The six-stroke cycle includes two power strokes, the latter of which is the result of a water to steam conversion process utilizing the heat of the exhaust gas from the first power stroke. A second embodiment comprises a hybrid power generating assembly incorporating alternative, first and second power sources respectively comprising an internal combustion engine and a water injection engine, the latter of which operates on the water to steam conversion process, wherein the required heat therefore is derived from the exhaust gas of the internal combustion engine. The second power source drives a source of electric energy which powers an electric motor, wherein the electric motor and the internal combustion engine are both connected in driving relation to a power take-off.

Owner:SINGH SATNARINE

Air injection engine

InactiveUS20060124085A1Ratio of compression can be significantly higher or lowerHigh expansion rateInternal combustion piston enginesOutput powerInjection airCylinder (engine)

An internal combustion engine of the present invention features separate compression and expansion cycles. The engine includes a separate compressor device which pressurizes air by a ratio greater than 15 to 1, at least one two stroke combustion cylinder and a compressed air conduit for transferring compressed air from the compressor to the at least one combustion cylinder. An air injection valve injects the compressed air into the combustion cylinder during the second half portion of the return stroke of the combustion cylinder. The compressed air is mixed with fuel and combusted for expansion during a power stroke. In this engine compression occurs only to a minor degree in the combustion cylinder. Accordingly, the compression ratio of the present engine may be significantly higher or lower than the volumetric expansion ratio of the combustion cylinder thus resulting in corresponding increases in either power density or thermodynamic efficiency respectively.

Owner:D J ENG

Internal combustion engine with steam expansion stroke

InactiveUS6986252B2Need can be quite largeEfficiency advantageElectrical controlInternal combustion piston enginesCombustion chamberControl system

Owner:CARGINE ENG AB

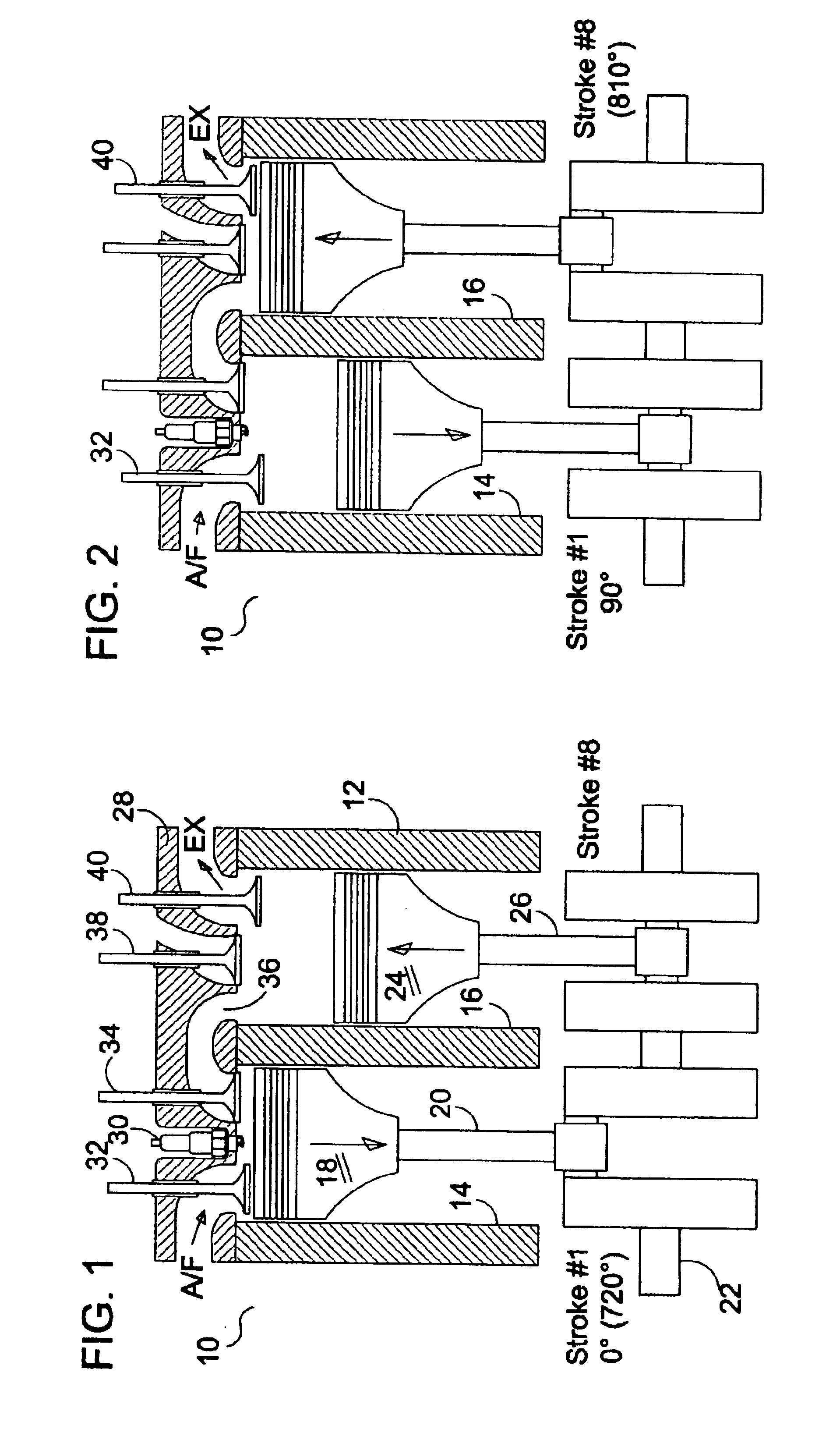

Eight-stroke internal combustion engine utilizing a slave cylinder

InactiveUS6918358B2Improve fuel efficiencyLess pollutionReciprocating combination enginesInternal combustion piston enginesAtmospheric airMaster cylinder

By the utilizing of a slave cylinder working in coordination with a master cylinder, the slave cylinder both receives cool atmospheric air and receives hot, partially un-burnt exhaust gases from the master cylinder to create a second power-stroke in the slave cylinder. With the two coordinating cylinders, the entire working process is from 0 to 810 degrees of revolution crankshaft. The master cylinder cycles work from 0 to 720 degrees of revolution and slave cylinder cycles work from 90 to 810 degrees of revolution. The master cylinder begins to intake air and fuel at 0 degree of revolution and slave cylinder begins to intake air at 90 degrees of revolution. There is an angle of 60-120 degrees differences between master and slave cylinder, where the slave cylinder is trailing the master.

Owner:HU LUNG TAN

Human powered vehicle drive system

The present invention provides a human powered vehicle drive system that includes a vehicle frame, a power system including a pivotable drive lever and a one-way clutch, a neutral shifting system, and a braking system. The drive lever may be coupled to a tension member that is associated with the drive lever and a drive spool, so that power is transmitted from the drive lever to the drive spool via the tension member, and from the drive spool to a driven wheel via the one-way clutch. A drive-ratio shifting control allows a user to vary a drive ratio by translating the attachment point of the tension member to the drive lever up or down the drive lever. A neutral shifting control allows the user to engage and disengage the one-way clutch. The braking system includes a flexible brake linkage routed along the drive lever. The drive-ratio shifting, neutral shifting, and braking controls may all be situated proximate to a drive lever handle adjustably coupled to the drive lever. Additionally, the drive lever is biased in the forward direction by power-stroke assisting springs, which store energy applied in recovery strokes applied to the drive levers, then releasing the energy to assist in forward power strokes. An assembly including the power system, neutral shifting system and brake system integrated with each driven wheel may be released from the chair by a quick release mechanism.

Owner:CHAIR FORCE ONE

Two-stroke uniflow turbo-compound internal combustion engine

InactiveUS8051830B2Increased turbulenceRapid, well defined, stratified charge combustionInternal combustion piston enginesExhaust apparatusCombustionCylinder head

A reciprocating two-stroke uniflow internal combustion (IC) cylinder and multiple cylinder engine, the cylinder having a cylinder wall and a cylinder head, the cylinder head having an exhaust port, a fuel injector, and a spark means disposed through the cylinder head, a piston reciprocally mounted in the cylinder for movement alternately through compression and power strokes, and a scroll plenum extending unidirectional around the outside of the cylinder wall and having an inlet and a plurality of swirl ports disposed through the cylinder wall providing fluid communication from the scroll plenum into the cylinder chamber, wherein the plurality of swirl ports enter the cylinder chamber tangentially with respect to the axial centerline of the cylinder, and wherein the plurality of swirl ports are subject to opening and closing in response to movement of said piston.

Owner:TAYLOR PATENT HLDG CO LLC

Control method and apparatus for gaseous fuelled internal combustion engine

InactiveUS20050257769A1Increase the cross-sectional areaPrevent exitElectrical controlInternal combustion piston enginesCombustion chamberTop dead center

A method and apparatus create an environment within a combustion chamber of an internal combustion engine suitable for auto-ignition and combustion of a fuel that will not otherwise auto-ignite. Under high-load conditions, a pilot quantity of the fuel is injected in the combustion chamber of an internal combustion engine during the compression stroke of the piston. The quantity and timing of the fuel are chosen to heat an intake charge within the combustion chamber to a temperature at or above the auto-ignition temperature of the fuel by the time required for a main injection of the fuel to drive the piston during the power stroke. Generally, auto-ignition temperatures should be reached at or near top dead center of the piston. An injector design delivers fuel in manner carried out by the method.

Owner:WESTPORT POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com